Process for preparing carbon nano tube and carbon onion by Ni/Al catalyst chemical gas phase deposition

A chemical vapor deposition, carbon nanotube technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., to achieve clean inner core, uniform particle size, and simple preparation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is further described below in conjunction with examples, and these examples are only for illustrating the present invention, do not limit the present invention. The weight ratio of Ni / Al catalyst precursor in the present invention refers to the weight ratio of nickel and aluminum in the catalyst precursor.

[0022] Raw materials used: nickel nitrate hexahydrate, commercially available, purity>96%; aluminum powder, commercially available, 400 mesh.

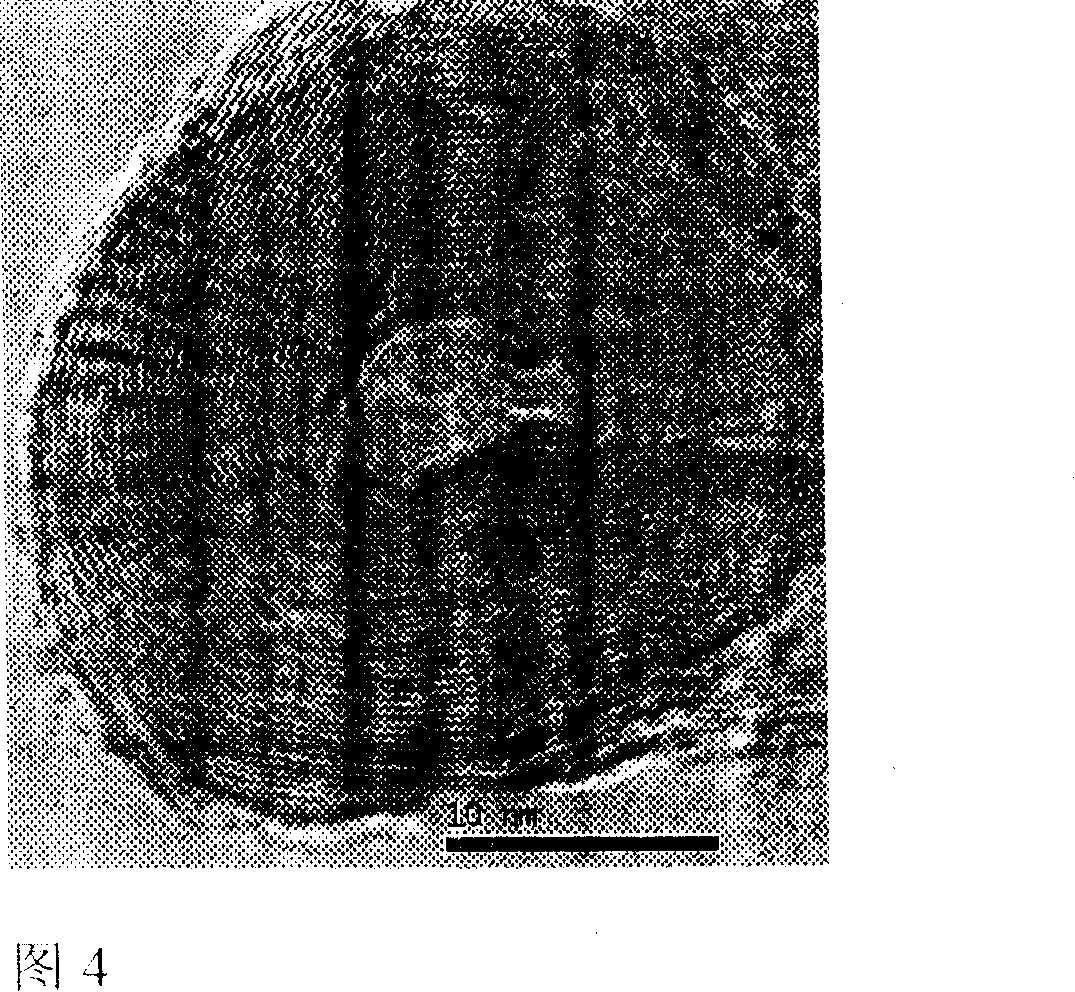

[0023] Take 800 mg of the Ni / Al catalyst precursor prepared by the method of the present invention, and after one hour of catalytic cracking reaction, the obtained product and its increased weight are shown in the following table. The purity of the carbon nanotube and the carbon onion is as high as 96% and 93% respectively, the diameter of the carbon tube is 10-30nm, the length is 1-15μm, and the particle size of the carbon onion is 5-50nm.

[0024] example

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com