Electrostatic chuck, thin film manufacturing apparatus having the same, thin film manufacturing method, and substrate surface treatment method

An electrostatic chuck and substrate technology, which can be used in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., and can solve problems such as increased maintenance load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

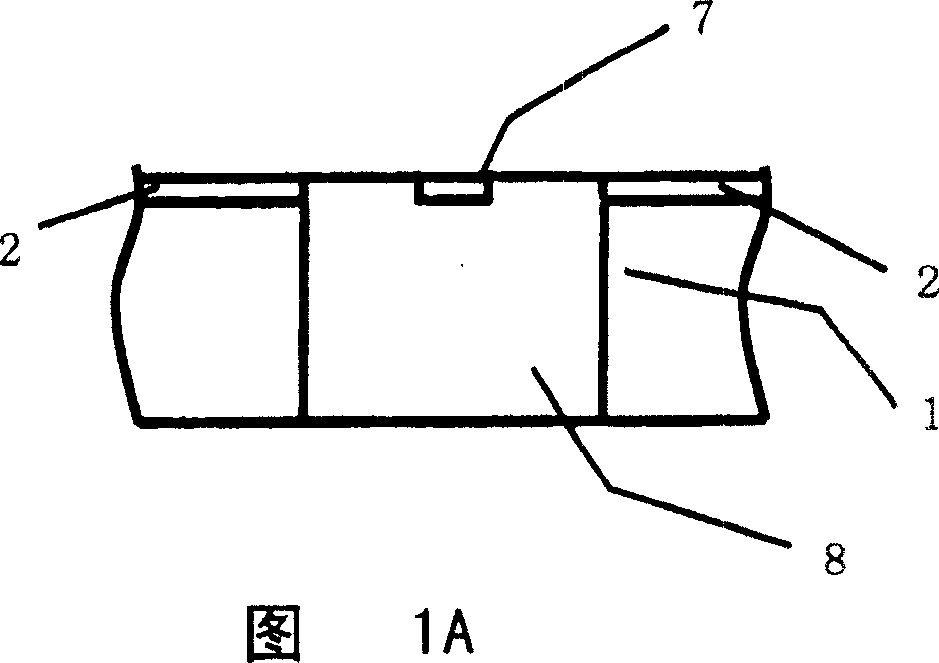

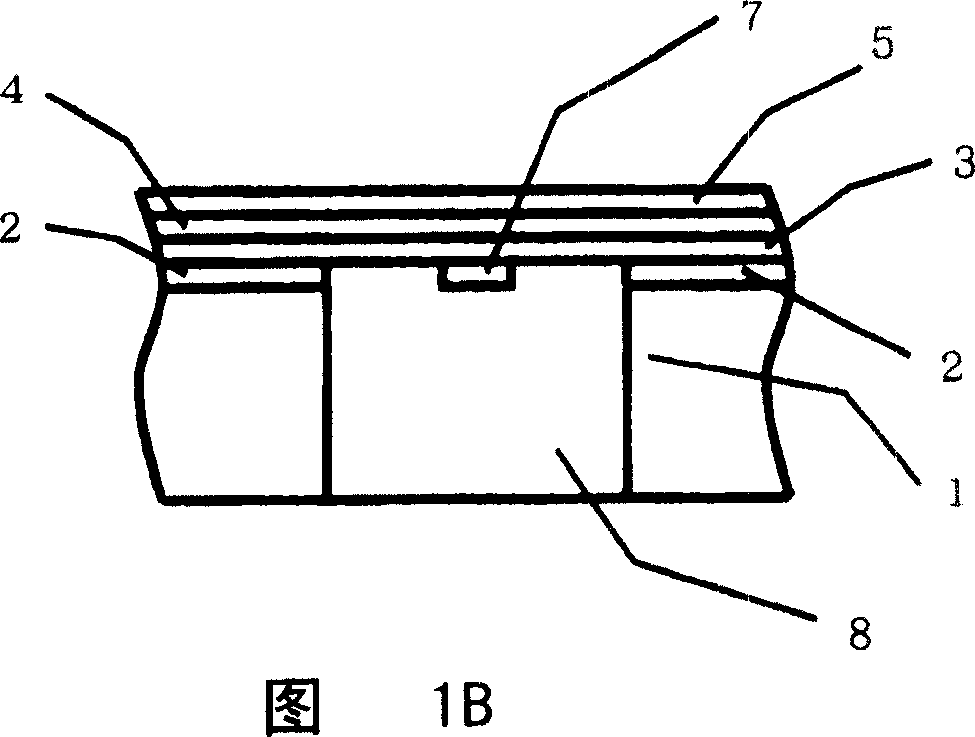

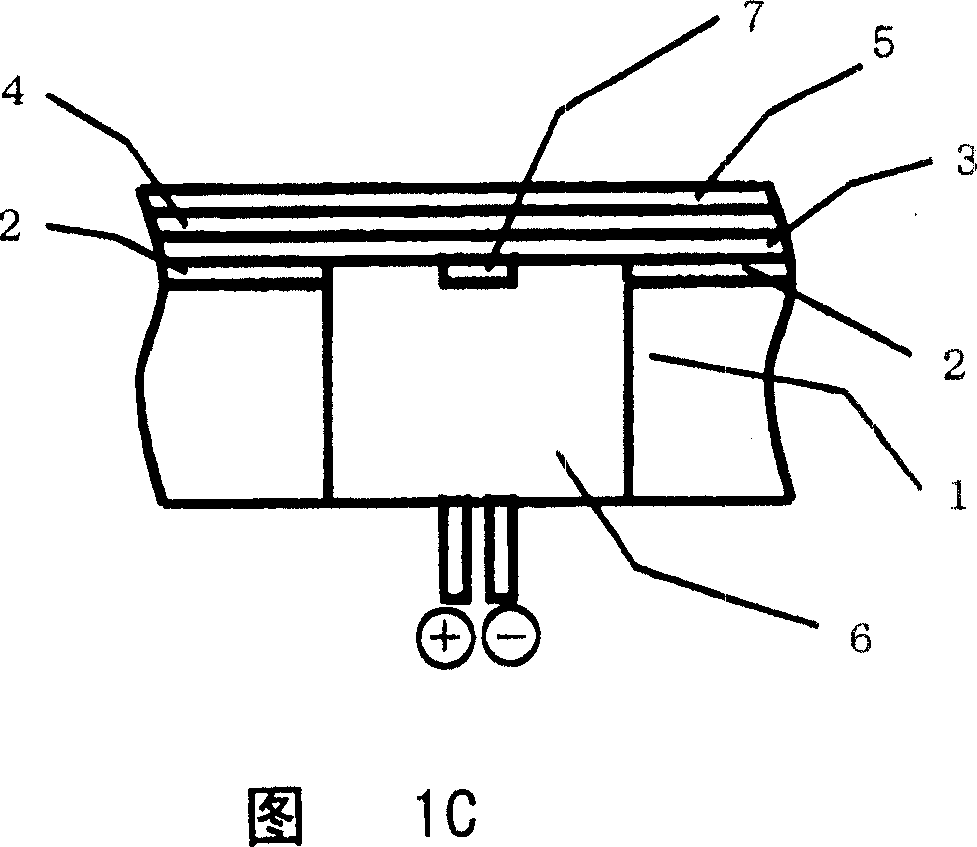

[0023] An electrostatic chuck of an embodiment of the present invention is described using FIGS. 1A to 1C. A first dielectric layer 2 including alumina was thermally sprayed onto an aluminum substrate 1 having a cavity in the central portion, and then an electrode 7 as a conductor was placed in the cavity in the central portion together with a jig 8 ( FIG. 1A ). Then, an internal electrode 3 made of tungsten is thermally sprayed thereon for electrical connection between the electrode 7 and the internal electrode 3 , after which aluminum oxide is thermally sprayed for the second dielectric layer 4 . Although aluminum oxide is used here for the second dielectric layer, magnesium oxide may be used. Further, a silicon nitride film is formed as an insulating film 5 on the second dielectric layer 4 by a chemical vapor deposition process (FIG. 1B). In addition to the silicon nitride film, a film containing silicon nitride or silicon oxide may also be used for the insulating film 5 ....

Embodiment 2

[0029] When using the electrostatic chuck 14 described in example 1 in the catalysis chemical vapor deposition equipment, the electrostatic chuck 14 is set in the catalysis chemical vapor deposition equipment, then by the catalysis chemical vapor deposition equipment can be on the second dielectric A silicon nitride film is deposited on layer 4. In addition, although the adsorption capacity of the electrostatic chuck 14 gradually decreases when the chuck is used for a considerable period of time, when the adsorption capacity decreases, silicon nitride is re-deposited on the surface of the electrostatic chuck 14 by catalytic chemical vapor deposition equipment. membrane, whereby the adsorption capacity can be easily restored. Since the adsorption capacity can be easily restored without removing the electrostatic chuck having reduced adsorption capacity for repolishing, there is an advantage produced by the embodiments of the present invention that an electrostatic chuck with ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com