Heteroatom doped graphene coated composite electrode material and preparation method thereof

A graphene-coated, composite electrode technology, applied in electrode manufacturing, battery electrodes, circuits, etc., can solve problems such as difficulty in greatly improving battery electrochemical performance, cumbersome preparation process, and limited battery performance improvement, and achieve protection from corrosion. , the effect of enhancing interaction and improving wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

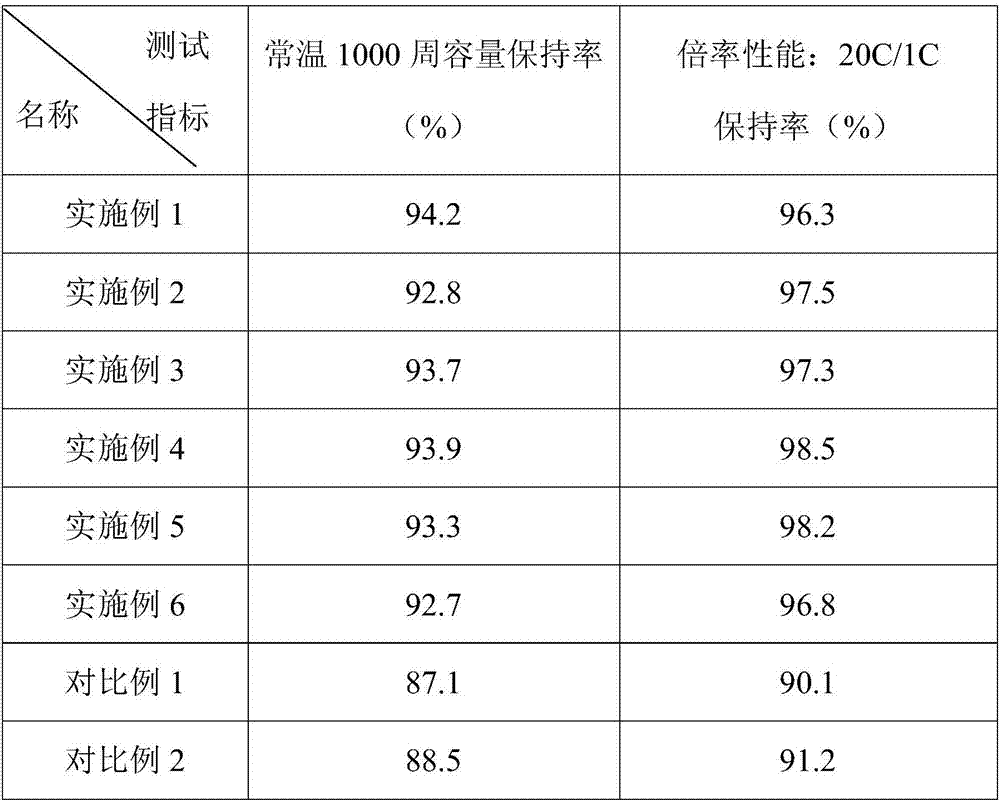

Examples

Embodiment 1

[0056] This embodiment provides a composite positive electrode material coated with boron-doped graphene, the composite positive electrode material includes a positive electrode material and boron-doped graphene coated on the surface of the positive electrode material;

[0057] Among them, the positive electrode material is lithium iron phosphate;

[0058] In boron-doped graphene, the doping amount of boron is 1mol%;

[0059] In the composite positive electrode material, the percentage of boron-doped graphene in the total mass of the composite positive electrode material is 2wt%.

[0060] Preparation:

[0061] (1) Put lithium iron phosphate and platinum into a three-dimensional mixer, perform three-dimensional mixing, and the mixing time is 4 hours to obtain a mixed precursor, wherein the mass of platinum accounts for 1 wt% of the total mass of the mixed precursor;

[0062] (2) Place the mixed precursor in the rotary furnace, feed high-purity argon gas, and remove the air in...

Embodiment 2

[0065] This embodiment provides a composite positive electrode material coated with boron-doped graphene, the composite positive electrode material includes a positive electrode material and boron-doped graphene coated on the surface of the positive electrode material;

[0066] Among them, the positive electrode material is lithium manganese phosphate;

[0067] In boron-doped graphene, the doping amount of boron is 1mol%;

[0068] In the composite positive electrode material, the percentage of boron-doped graphene in the total mass of the composite positive electrode material is 5 wt%.

[0069] Preparation:

[0070](1) Put lithium manganese phosphate and copper into a ball mill tank and perform ball milling for 6 hours to obtain a mixed precursor, wherein the mass of copper accounts for 0.5wt% of the total mass of the mixed precursor;

[0071] (2) Place the mixed precursor in the rotary furnace, feed high-purity nitrogen, and get rid of the air in the rotary furnace;

[007...

Embodiment 3

[0074] This embodiment provides a composite positive electrode material coated with phosphorus-doped graphene, the composite positive electrode material includes a positive electrode material and phosphorus-doped graphene coated on the surface of the positive electrode material;

[0075] Among them, the positive electrode material is lithium manganese iron phosphate;

[0076] In phosphorus-doped graphene, the doping amount of phosphorus is 1mol%;

[0077] In the composite positive electrode material, the percentage of phosphorus-doped graphene to the total mass of the composite positive electrode material is 5 wt%.

[0078] Preparation:

[0079] (1) Put lithium manganese iron phosphate and nickel into a three-dimensional mixer, perform three-dimensional mixing, and the mixing time is 2 hours to obtain a mixed precursor, wherein the mass of nickel accounts for 0.7wt% of the total mass of the mixed precursor;

[0080] (2) Place the mixed precursor in the rotary furnace, feed h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com