Patents

Literature

62 results about "Vapor growth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

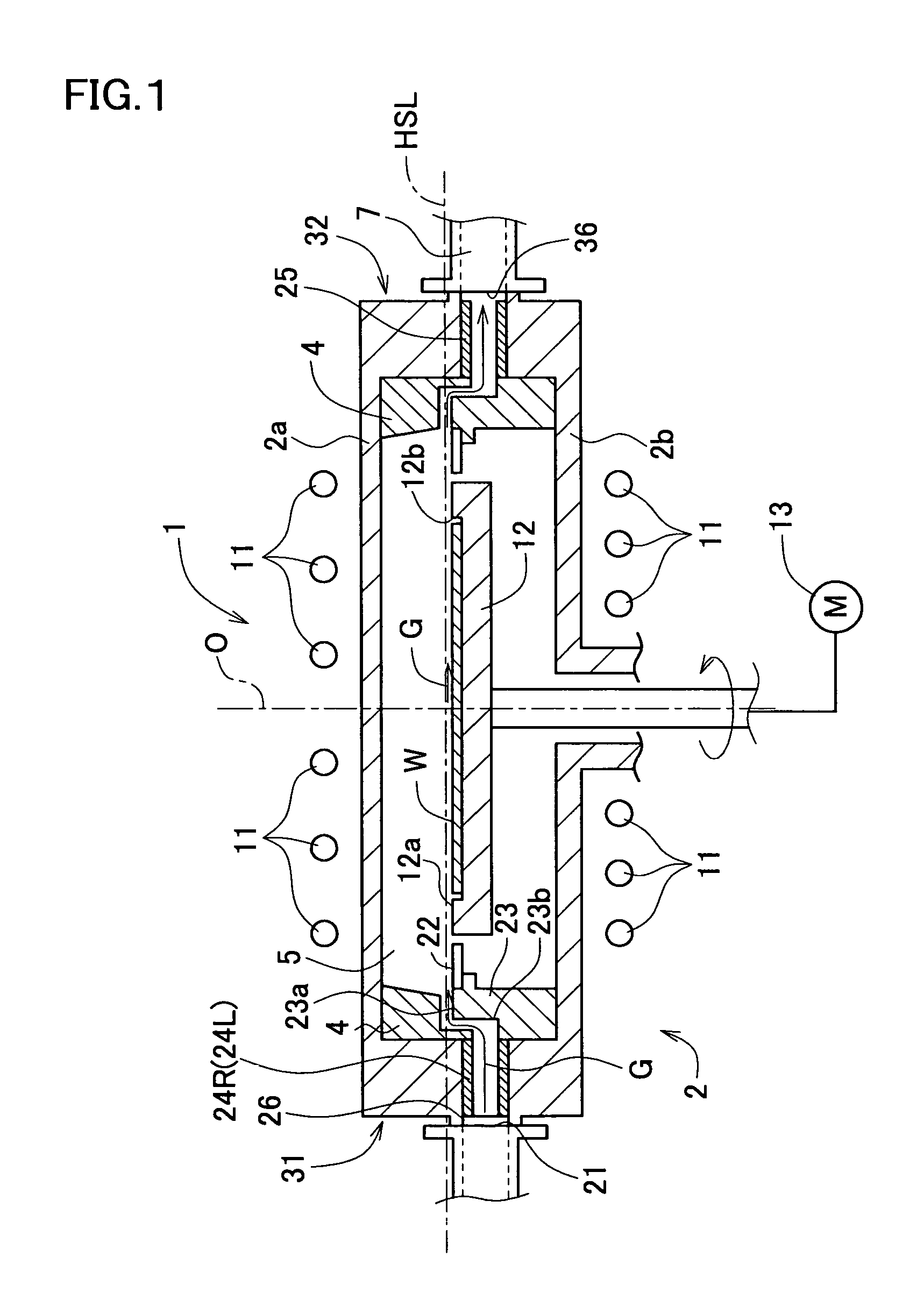

Epitaxial growth film formation method

ActiveUS8404044B2Avoid stickingAvoid formingAfter-treatment apparatusPolycrystalline material growthEngineeringVapor growth

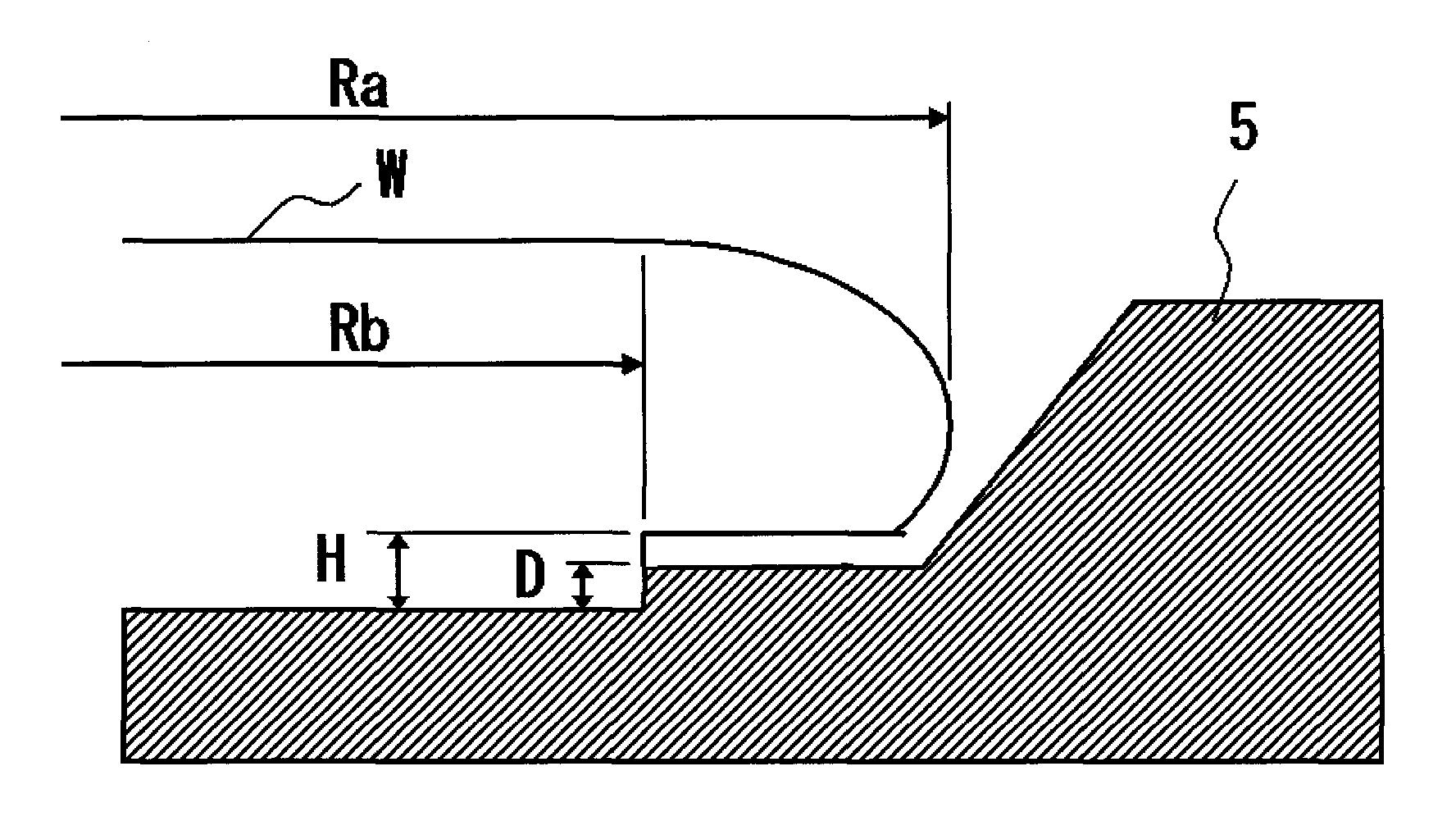

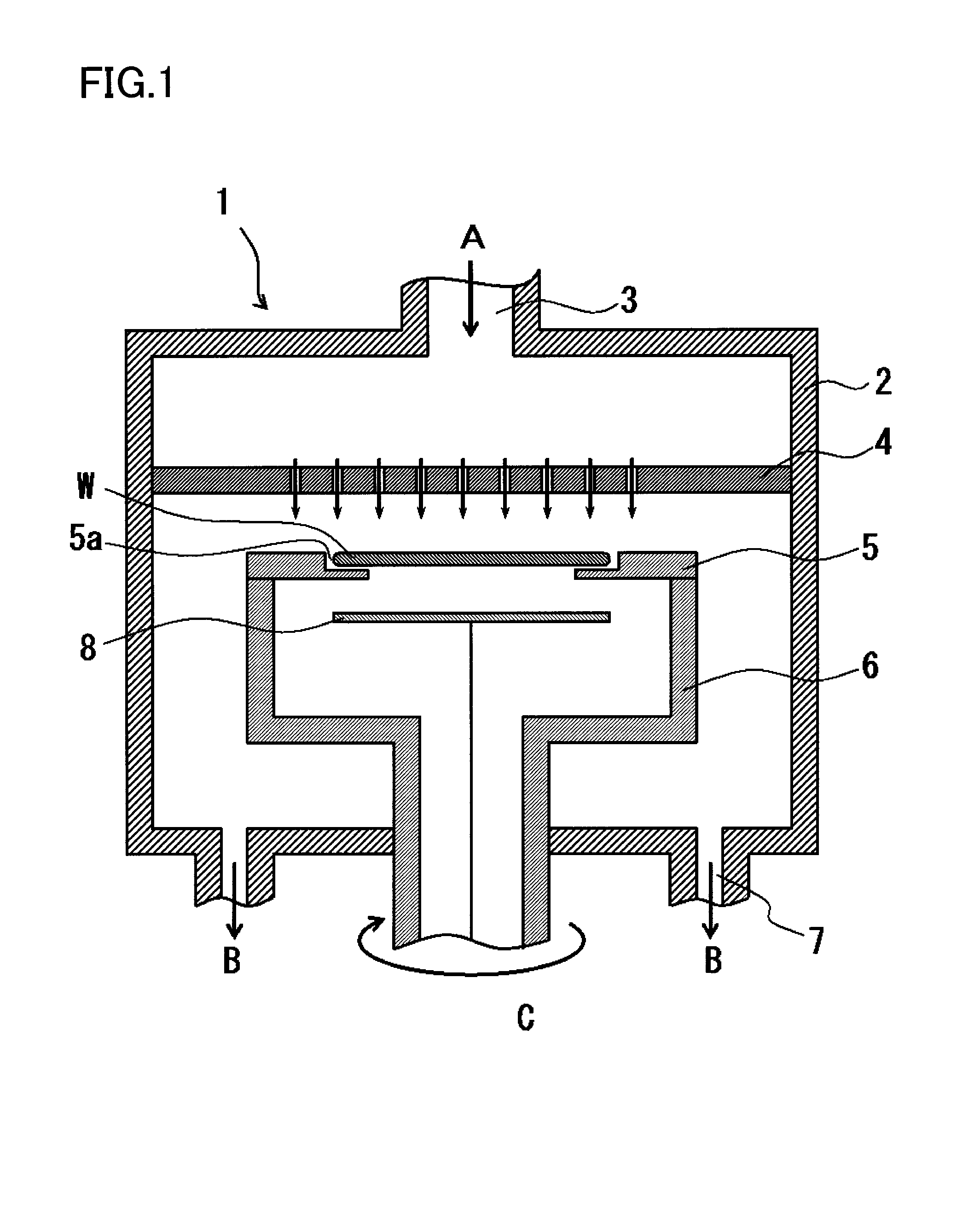

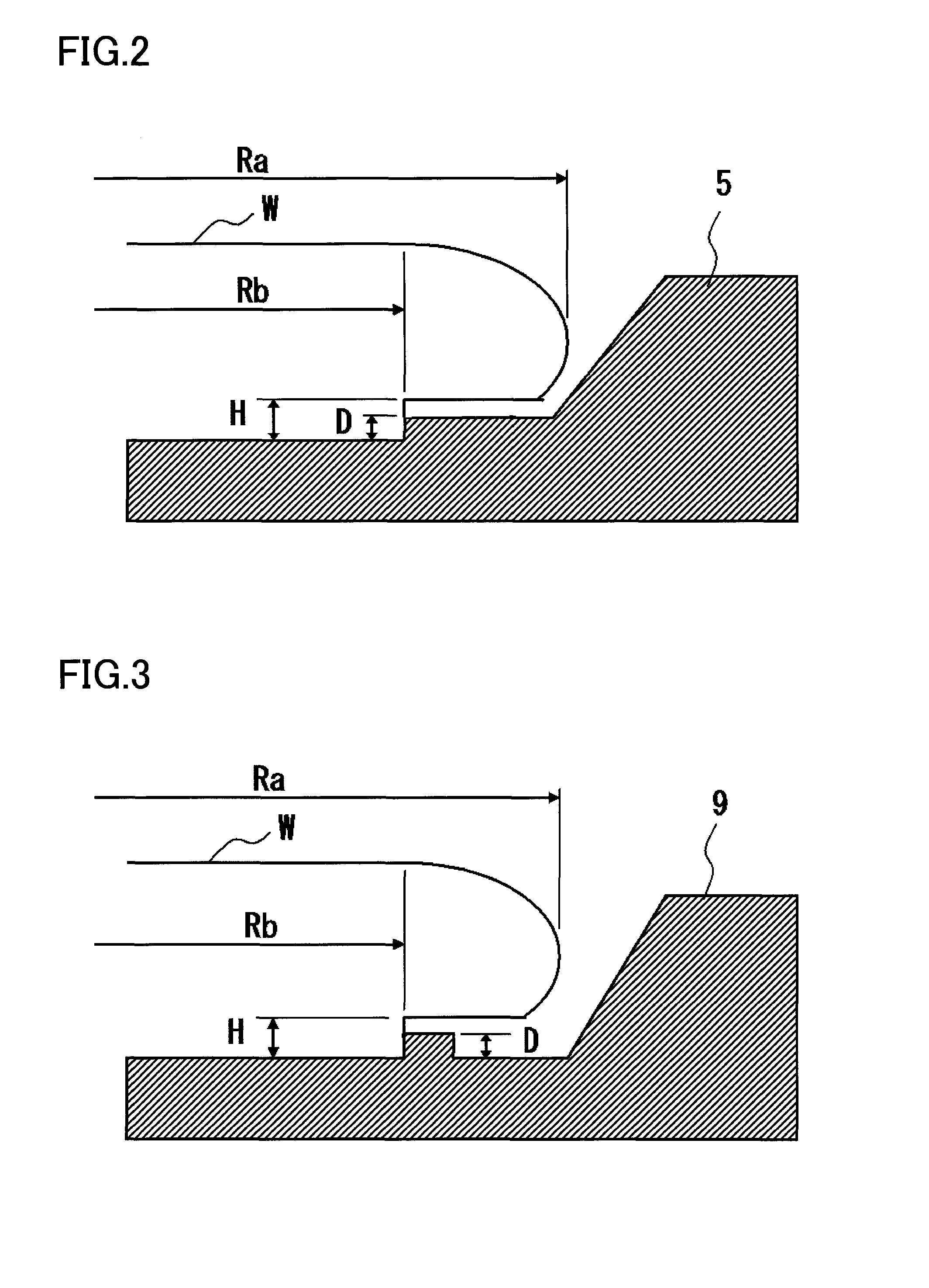

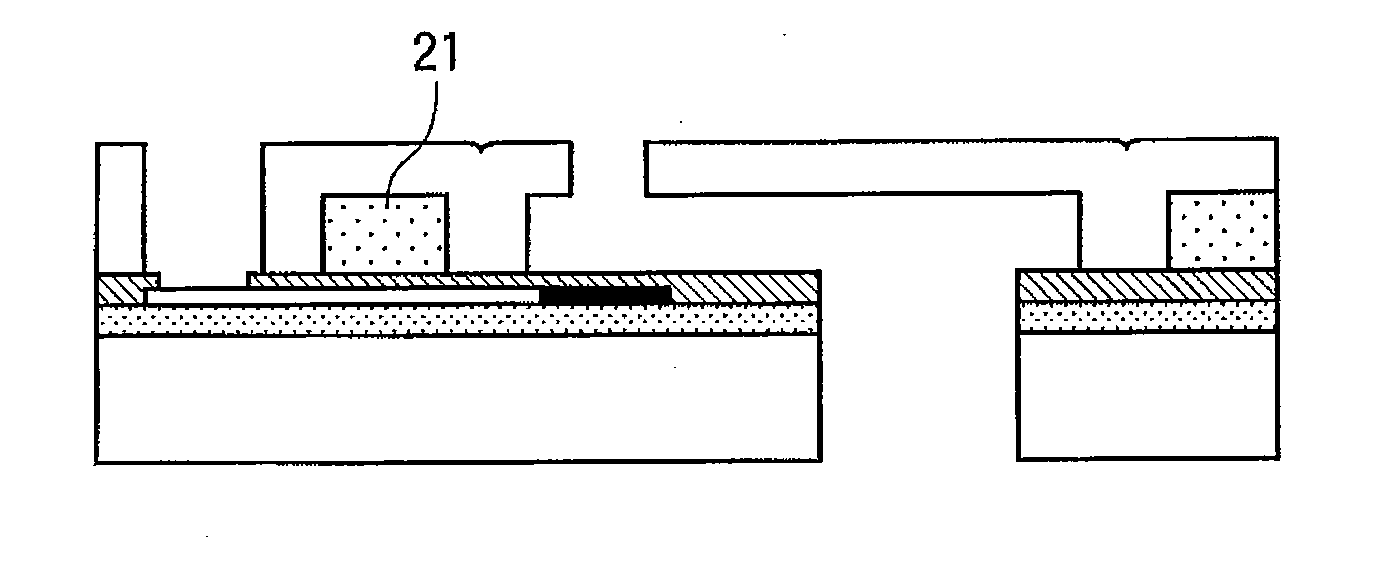

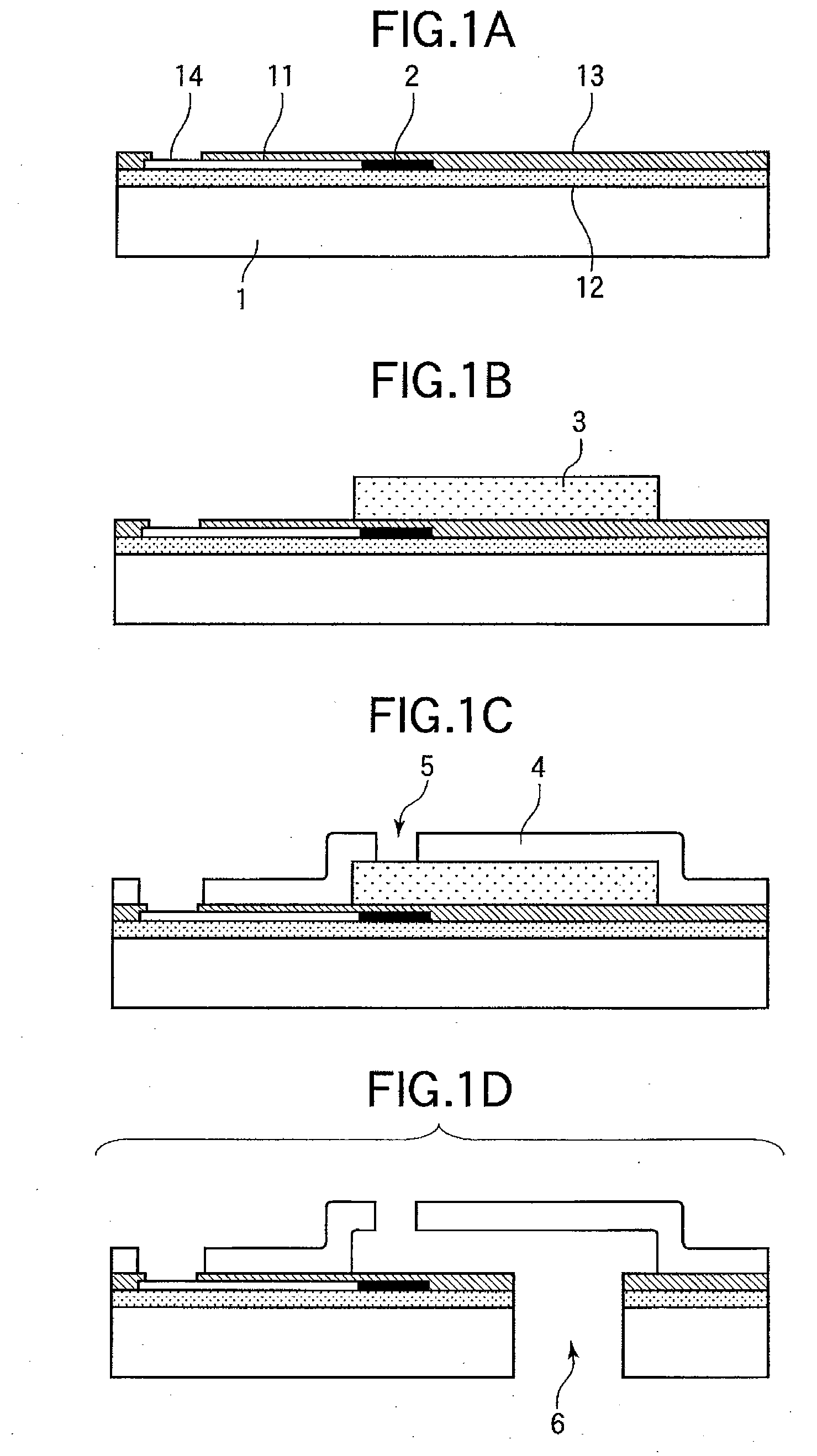

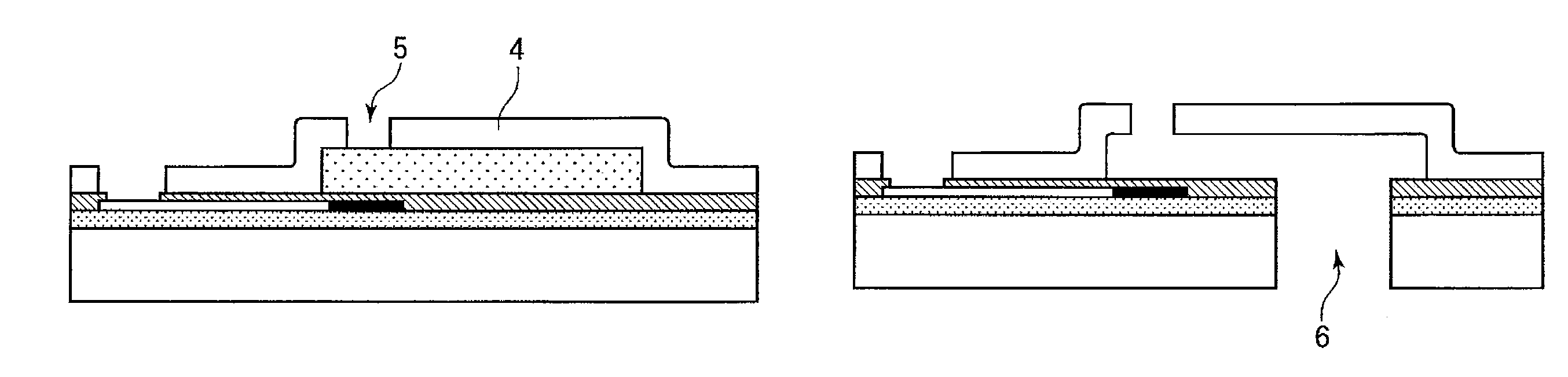

An epitaxial growth film formation method allowing to adequately prevent the sticking phenomenon spreading over both a wafer and a susceptor when a horizontal disc-like susceptor is used to form an epitaxial growth film is provided. The epitaxial growth film formation method is a method of forming a vapor growth film on the wafer by placing the wafer having a diameter smaller than that of the susceptor approximately horizontally in substantially a center section on the horizontal disc-like susceptor, wherein the vapor growth film is formed on the wafer by bringing a circumferential recess step adjacent to a bottom inside from an edge part of the wafer and a convex step provided on a circumference of an upper surface inside from the edge part of the susceptor into contact.

Owner:NUFLARE TECH INC

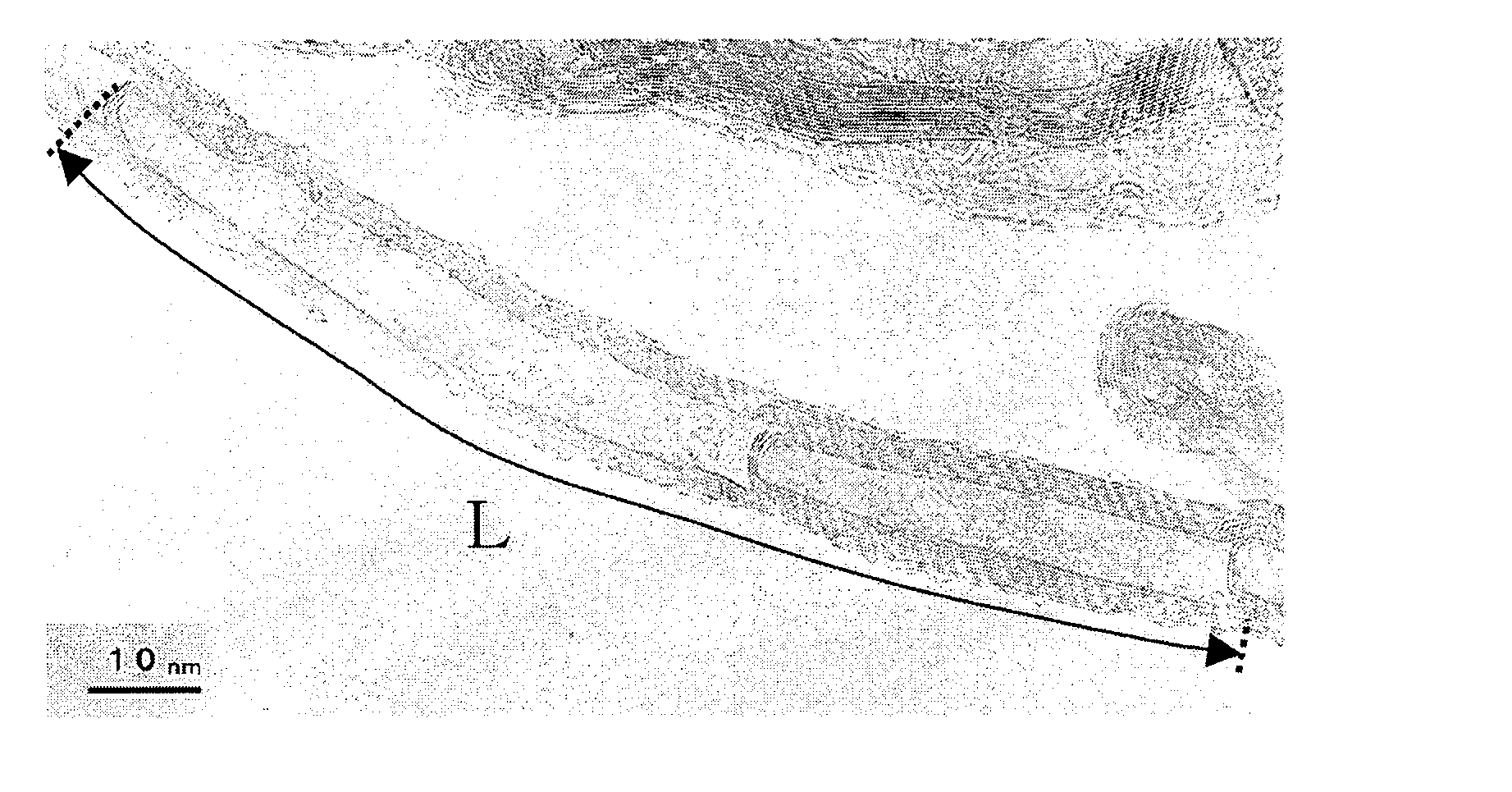

Expanded carbon fiber product and composite using the same

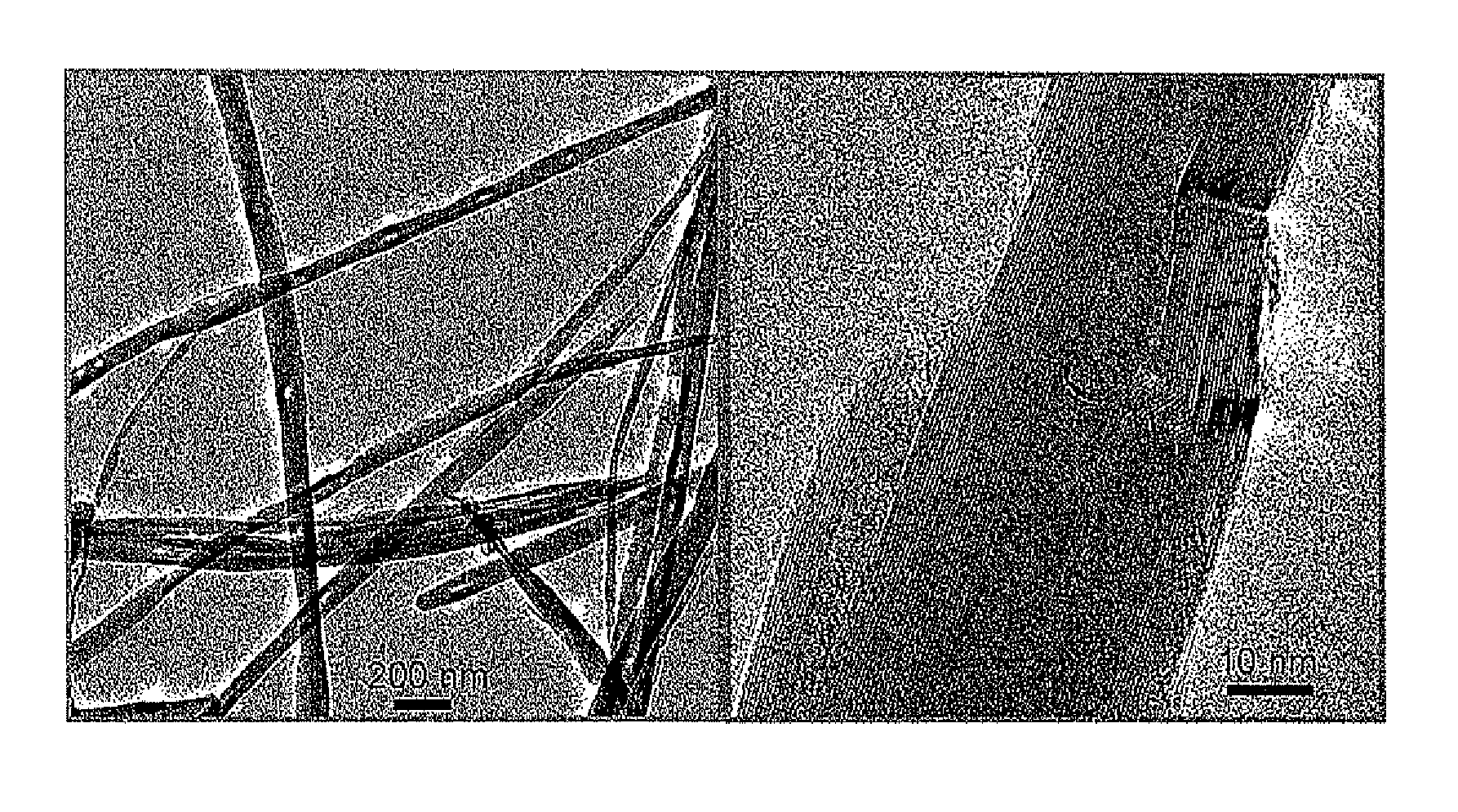

InactiveUS7018600B2High activityHigh affinityMaterial nanotechnologyPigmenting treatmentFiberCarbon layer

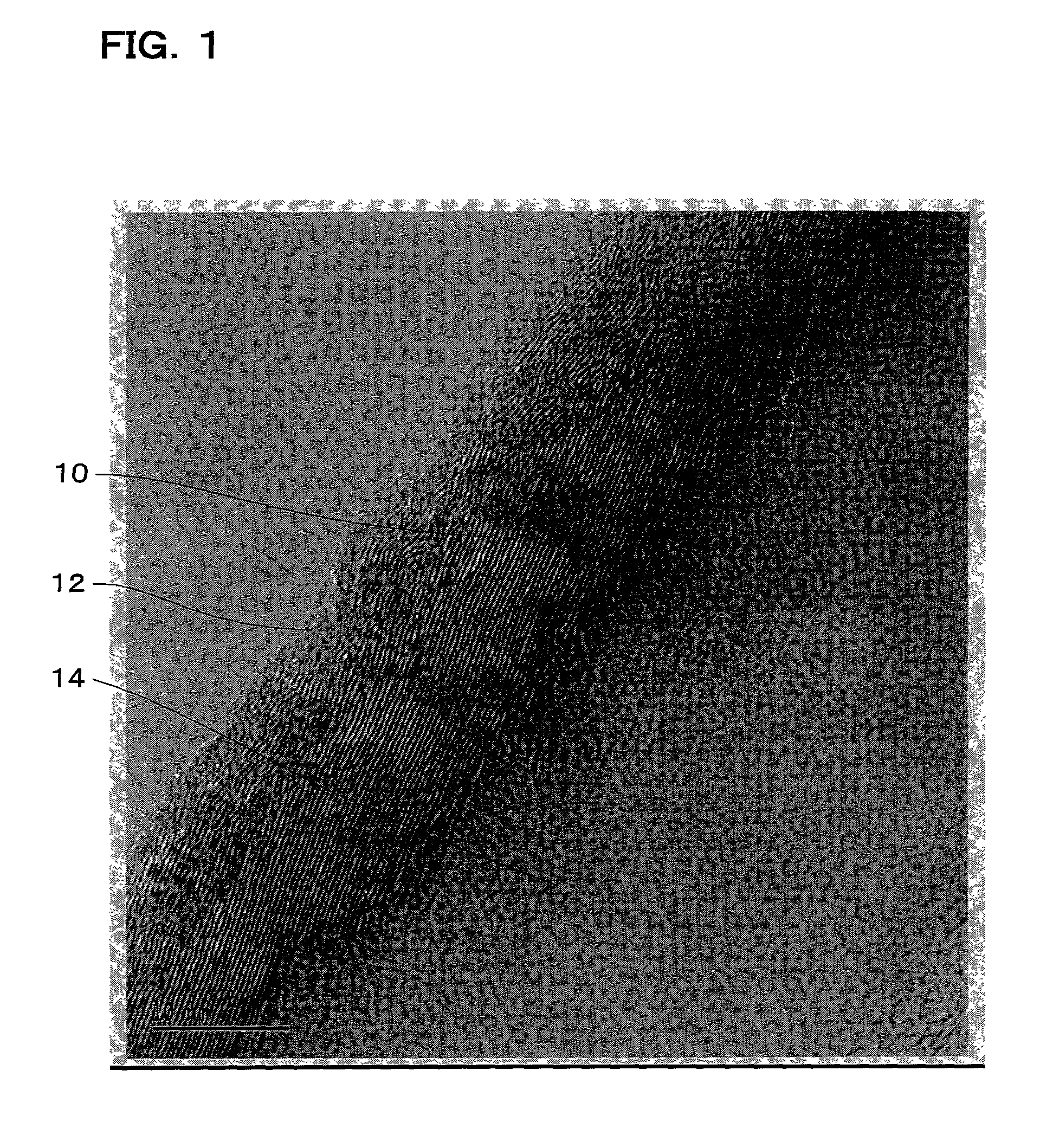

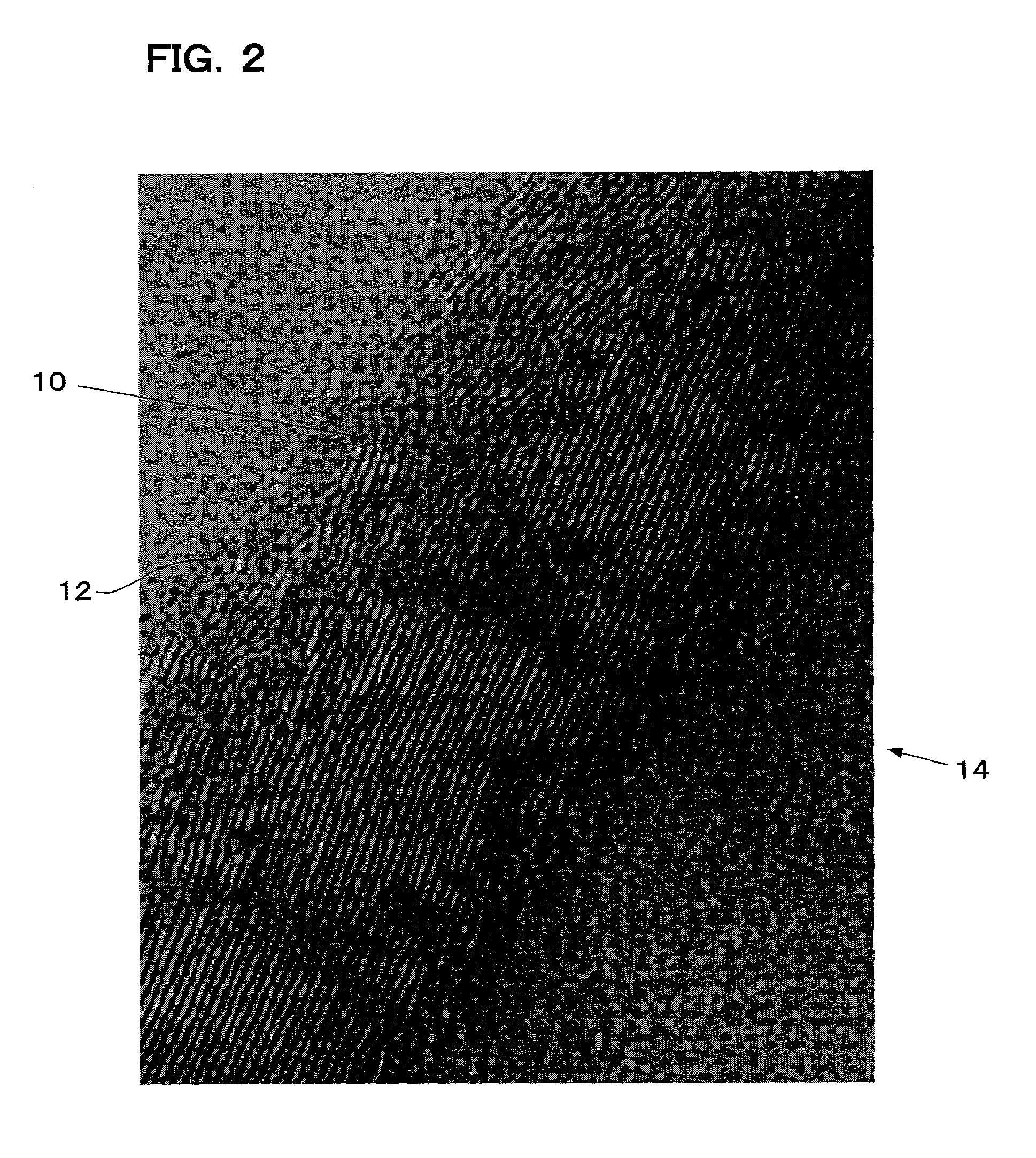

In an expanded carbon fiber product according to the present invention, a number of hexagonal carbon layers in the shape of a cup having no bottom are stacked. At least part of edges of the hexagonal carbon layers is exposed at an outer surface or inner surface of the expanded carbon fiber product. At least part of gaps between the hexagonal carbon layers is larger than the gaps between the hexagonal carbon layers at the time of vapor growth.

Owner:GSI CREOS CORP +1

Fine carbon fiber mixture and composition thereof

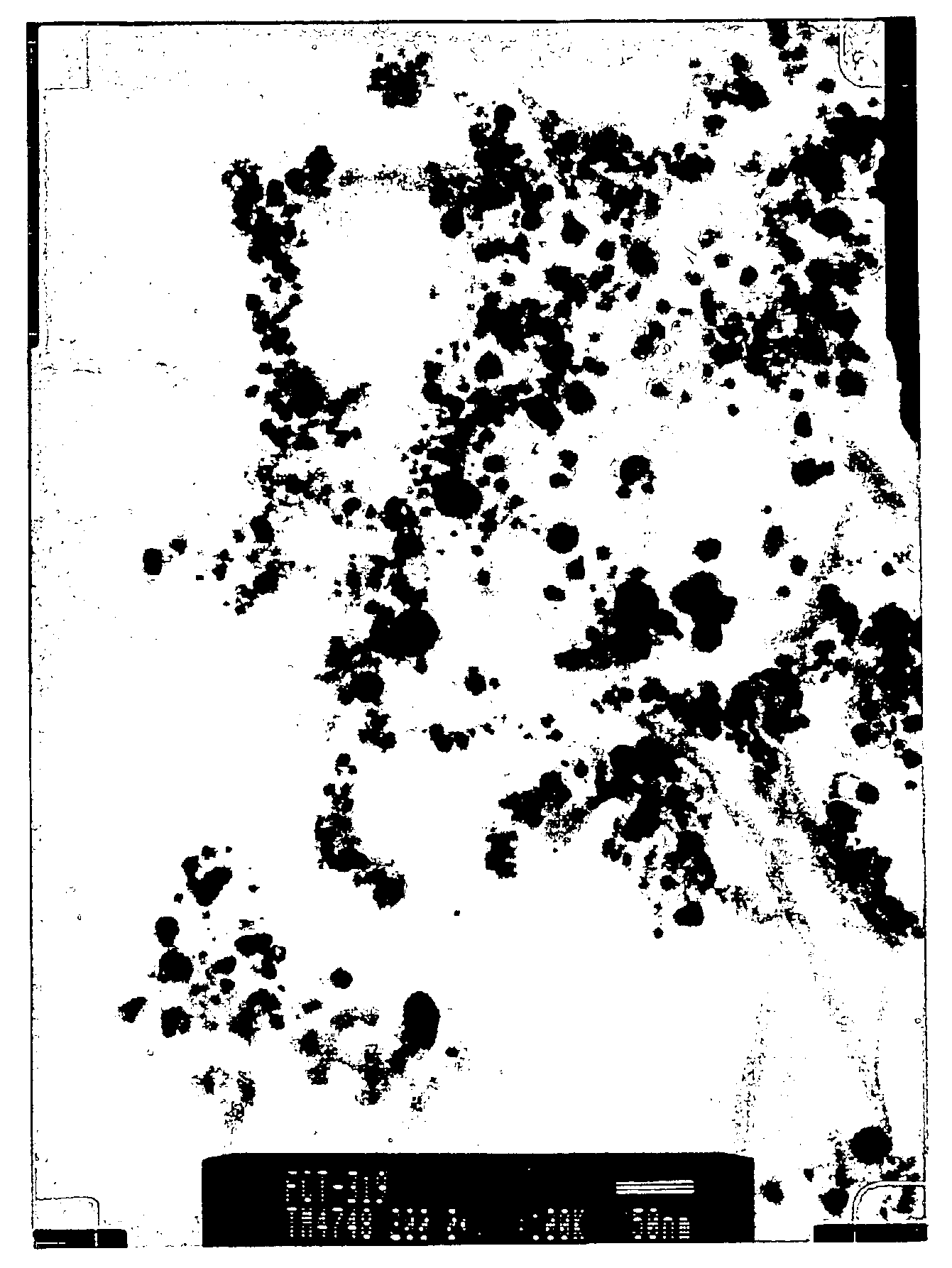

A fine carbon fiber mixture produced through a vapor-growth process, which comprises fine carbon fiber, each fiber filament of the fiber having an outer diameter of 1 to 500 nm and an aspect ratio of 10 to 15,000 and comprising a hollow space extending along its center axis and a multi-layer sheath structure consisting of a plurality of carbon layers; and non-fibrous carbon such as flake-like carbon, granular carbon, or sheet-like carbon. A composition comprising a resin or a rubber and a fine carbon fiber mixture as above contained therein. An electrically conductive article or a sliding article comprising the composition.

Owner:SHOWA DENKO KK +1

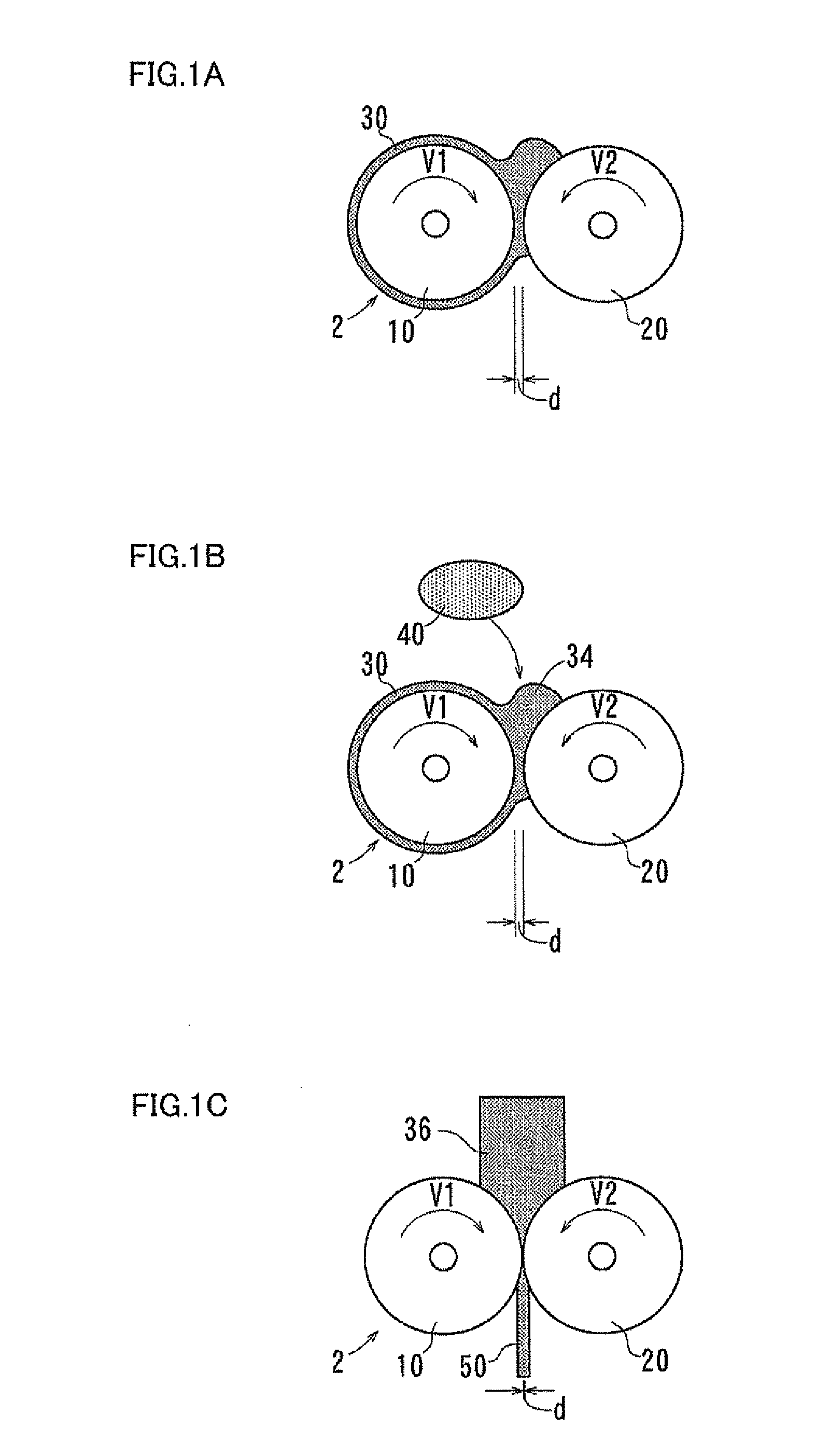

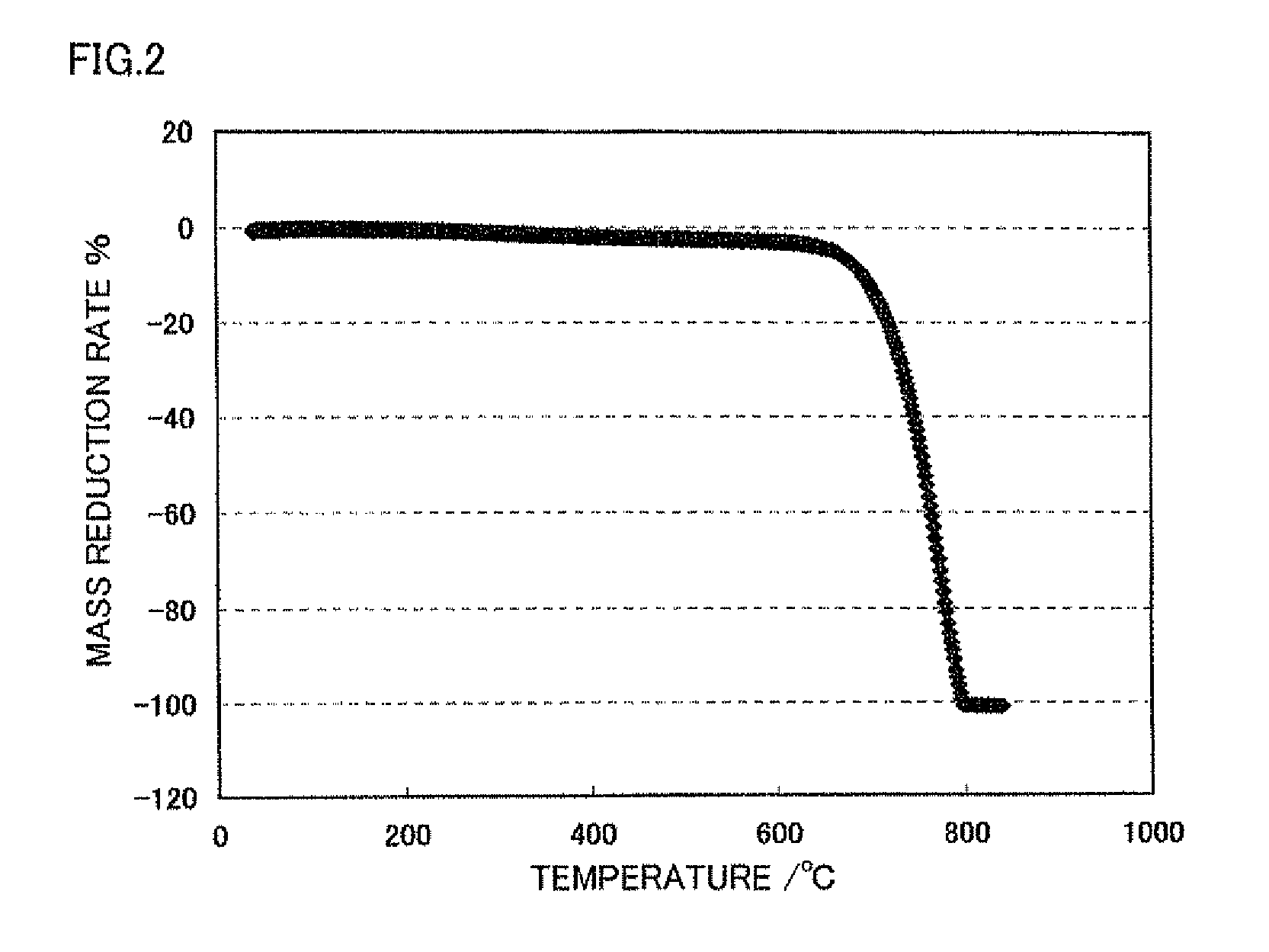

Carbon nanofiber, method for production thereof, method for production of carbon fiber composite material using carbon nanofiber, and carbon fiber composite material

ActiveUS20110060087A1Improve surface reactivityImprove wettabilityMaterial nanotechnologySpecial tyresElastomerFiber

A method of producing a carbon fiber composite material includes a first step and a second step. The first step includes oxidizing first carbon nanofibers produced by a vapor growth method to obtain second carbon nanofibers having an oxidized surface. The second step includes mixing the second carbon nanofibers into an elastomer, and uniformly dispersing the carbon nanofibers in the elastomer by applying a shear force to obtain the carbon fiber composite material. The second carbon nanofibers obtained by the first step have a surface oxygen concentration measured by X-ray photoelectron spectroscopy (XPS) of 2.6 to 4.6 atm %.

Owner:HITACHI ASTEMO LTD +1

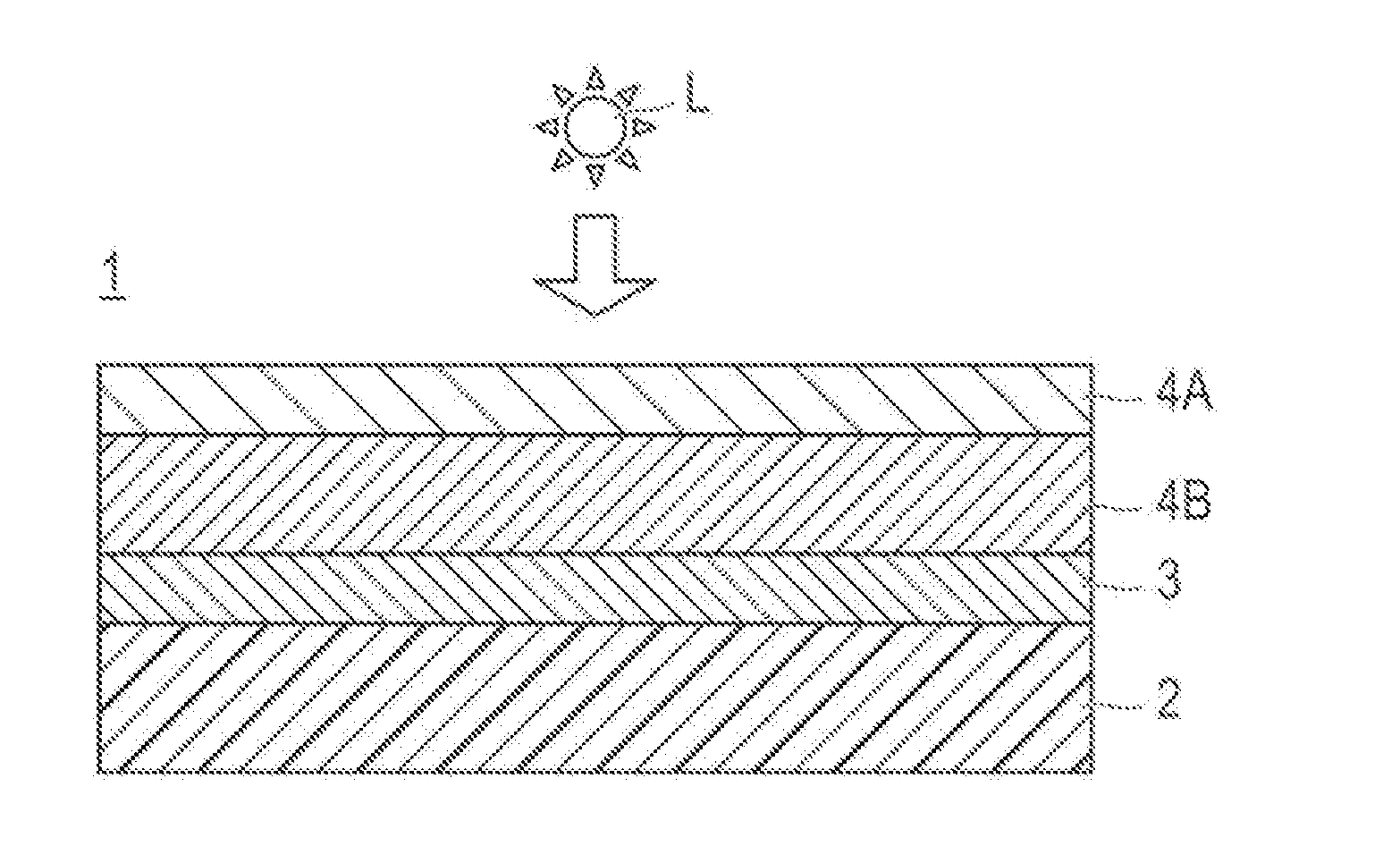

Gas barrier film, manufacturing method for gas barrier film, and electronic device

InactiveUS20150125679A1Improve barrier propertiesImprove bending resistanceLayered productsFinal product manufactureGas phaseSilicon

The present invention is to provide a gas barrier film which has a high barrier property, excellent bending resistance and smoothness and suitability for cutting process, a manufacturing method for the same, and an electronic device using the gas barrier film.A gas barrier film having a base, a first barrier layer formed on the surface of the base by a vapor growth method, a second barrier layer formed by a conversion treatment of a coating film formed by coating the surface of the first barrier layer with a first silicon compound, and a protective layer having no barrier property which is formed by a conversion treatment of a coating film formed by coating the surface of the second barrier layer with a second silicon compound.

Owner:KONICA MINOLTA INC

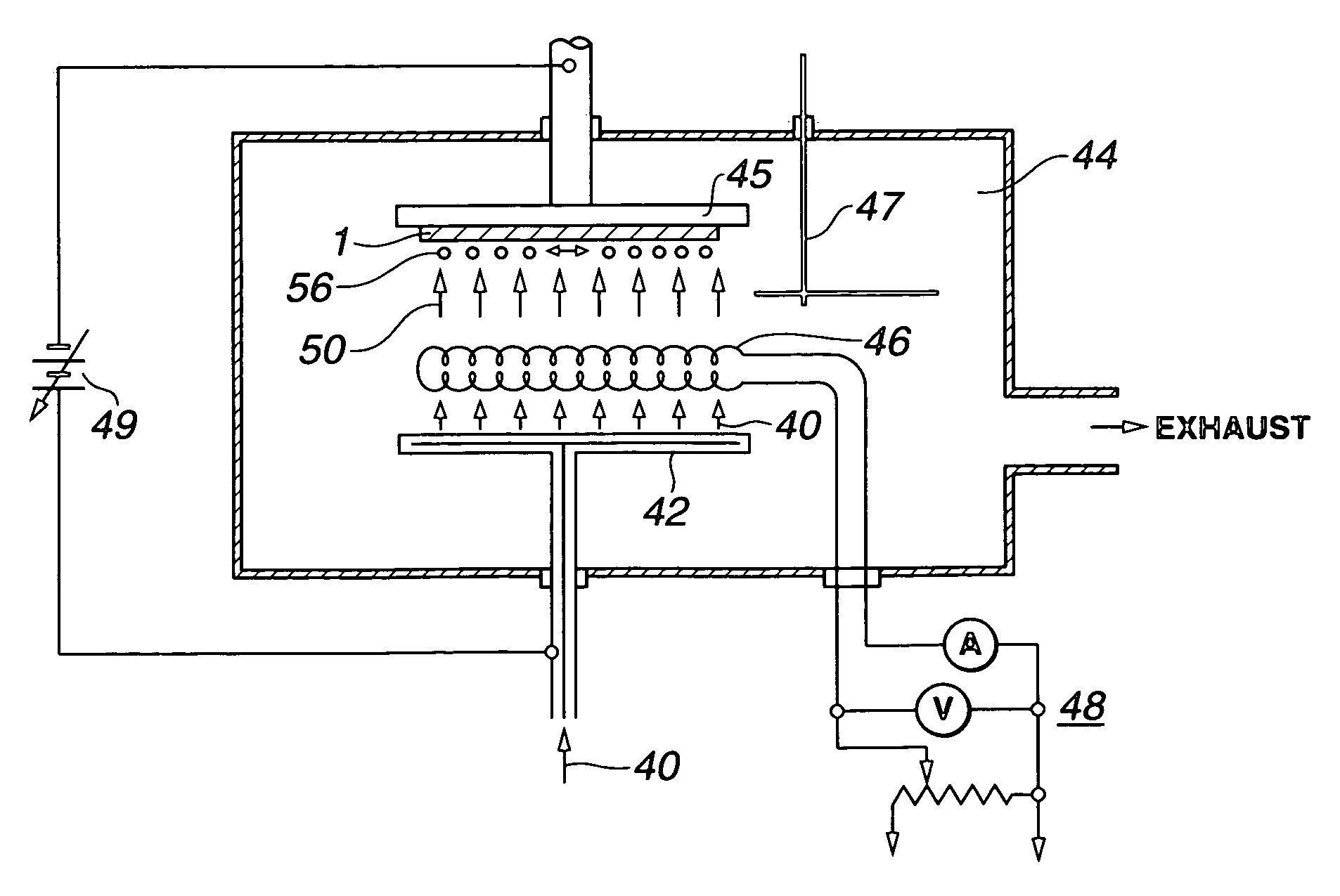

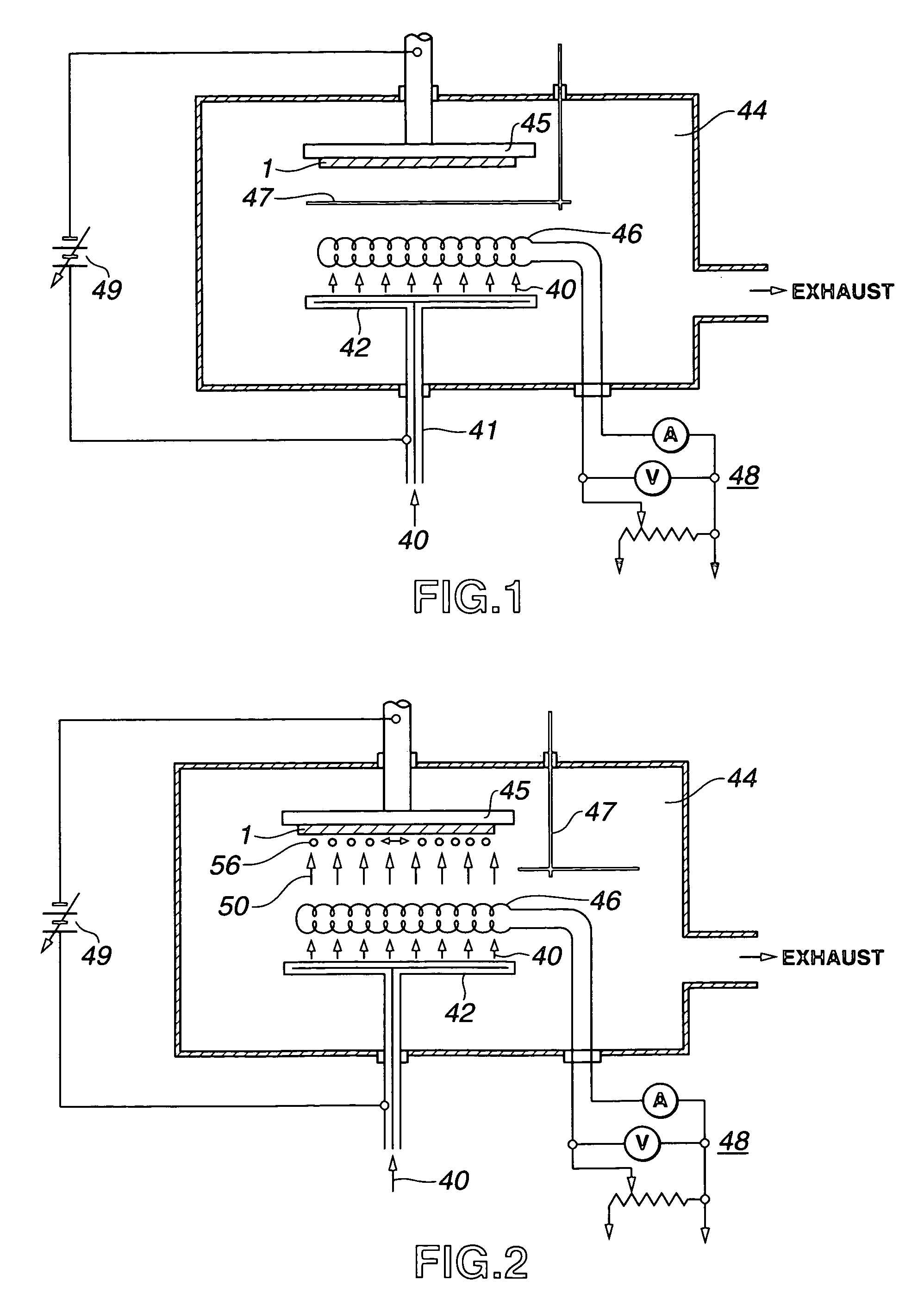

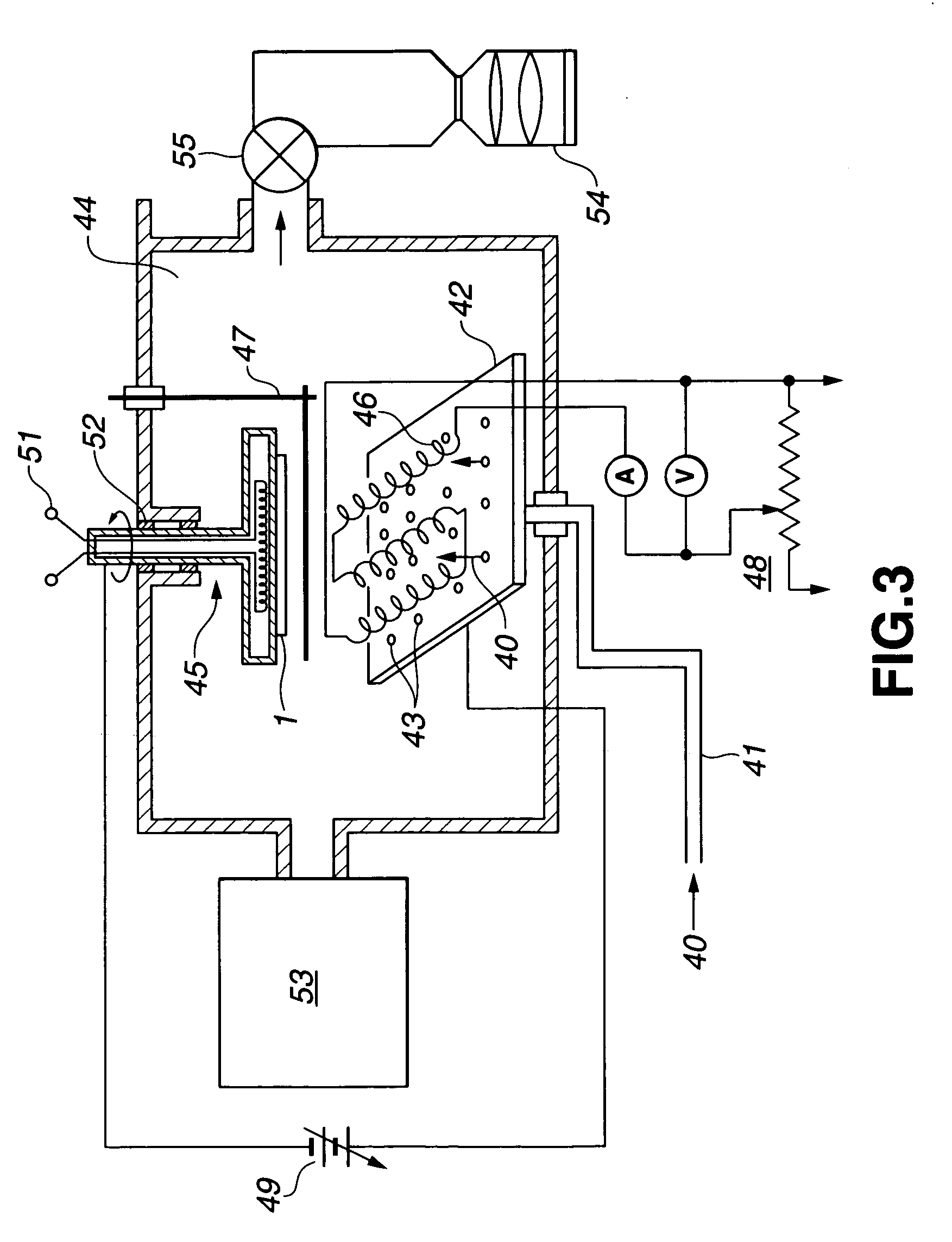

Method and apparatus for film deposition

InactiveUS7011866B1Increase contactHigh densitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingHydrogenSilanes

A reaction gas made of a hydrogen-based carrier gas and a silane gas or the like is brought in contact with a heated catalyzer of tungsten or the like, and a DC voltage not higher than a glow discharge starting voltage or a voltage produced by superimposing an AV voltage or an RF voltage on the DC voltage is applied on the produced reactive species, so as to provide kinetic energy and carry out vapor growth of a predetermined film on a substrate, thereby providing a film of high quality.

Owner:SONY CORP

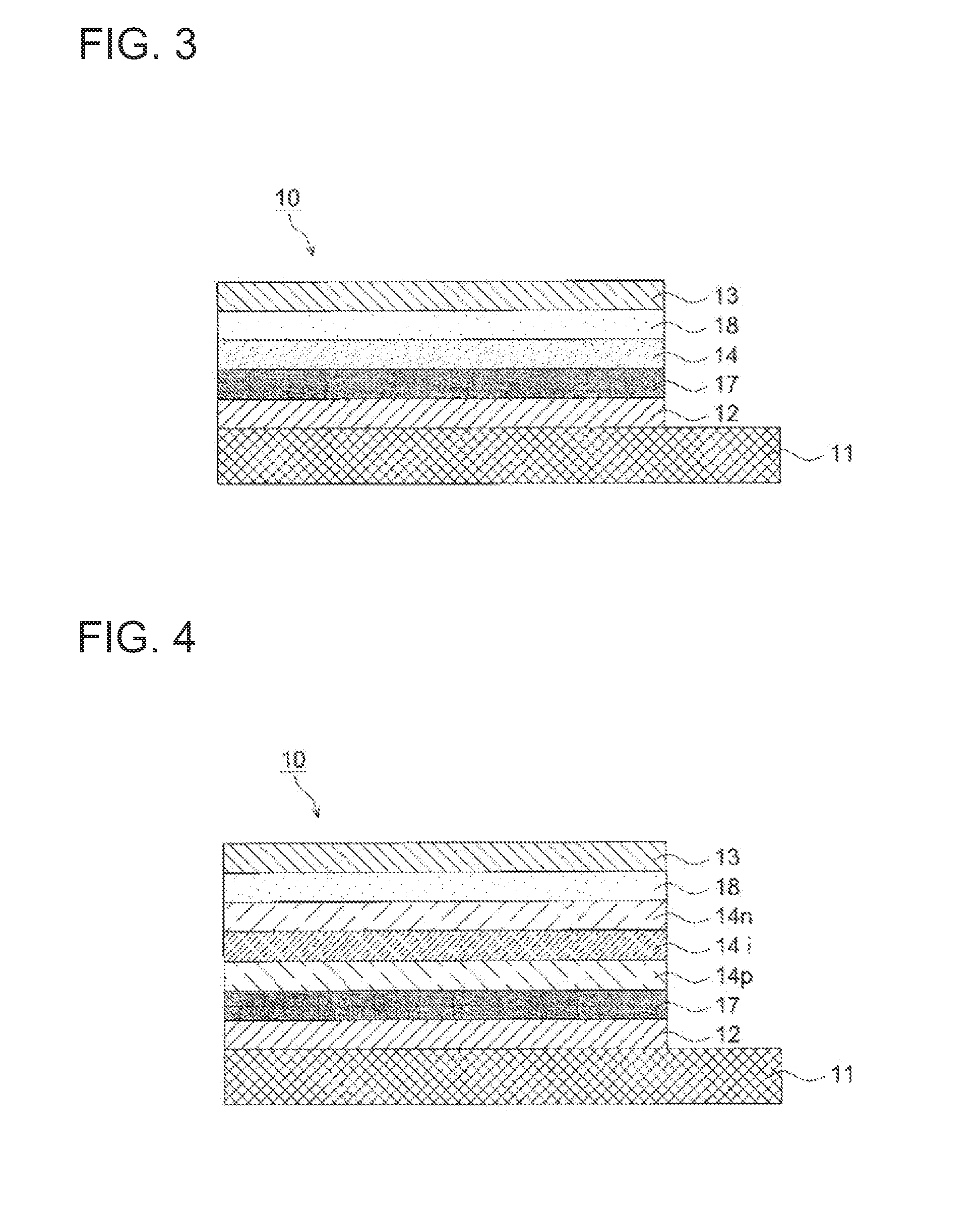

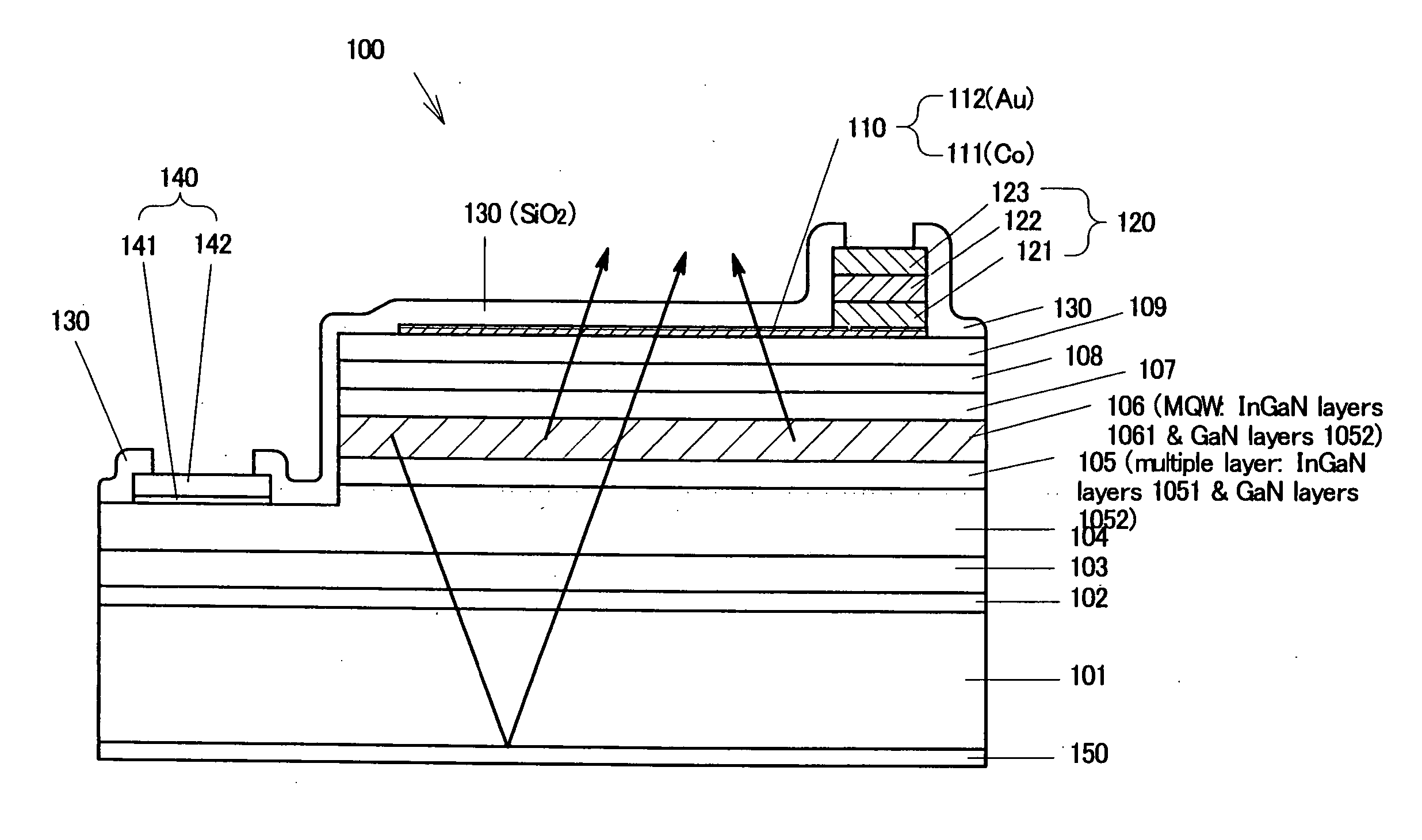

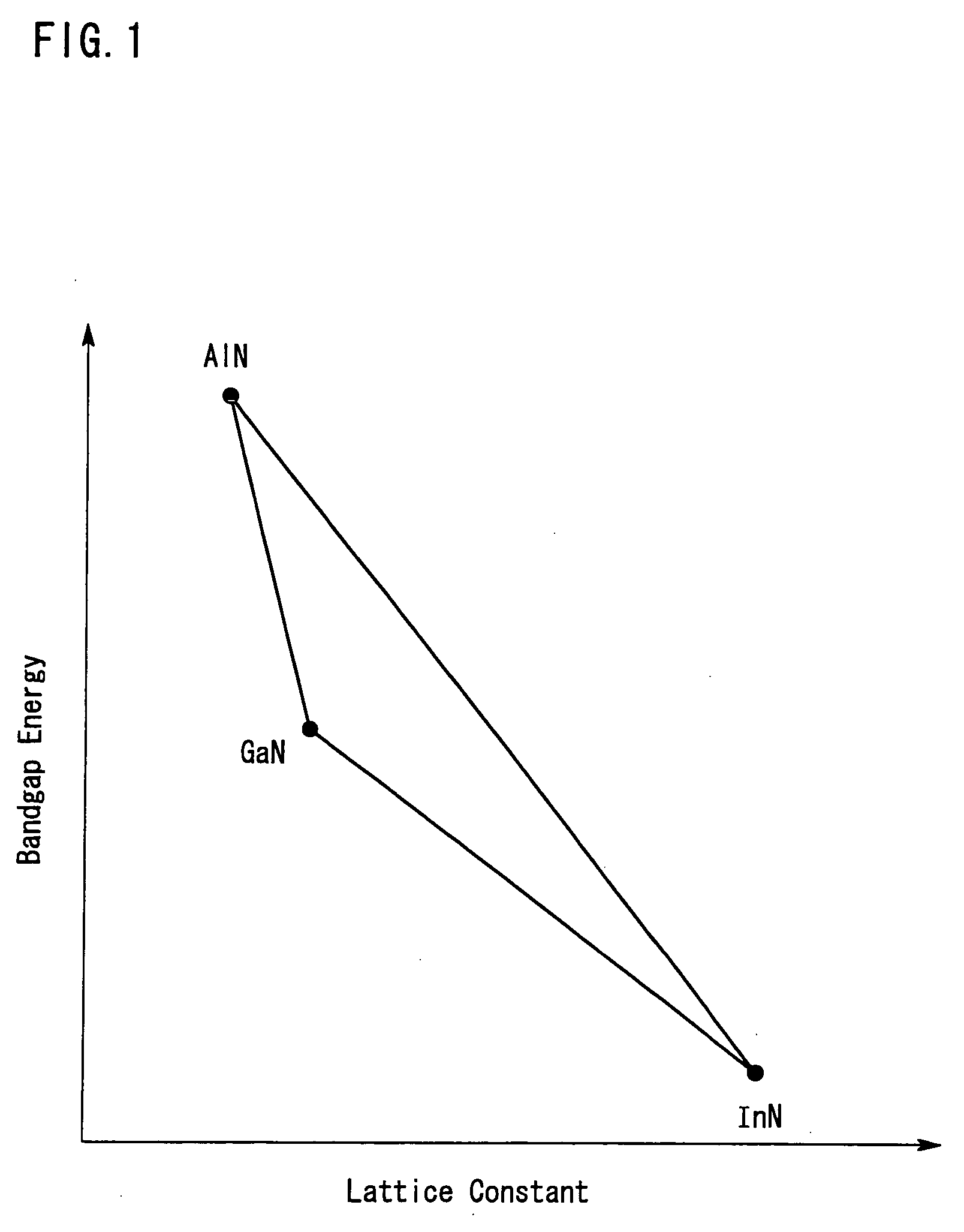

Group III nitride-based compound semiconductor light-emitting device and method for producing the same

ActiveUS20060169990A1Avoid it happening againHigh crystallinitySolid-state devicesNanoopticsIndiumCompound (substance)

The invention relates to a Group III nitride-based compound semiconductor light-emitting device having a well layer, a first layer formed on one surface of the well layer, a second layer formed on the other surface of the well layer, a first region provided in the vicinity of the interface between the first layer and the well layer, and a second region provided in the vicinity of the interface between the second layer and the well layer, wherein the first and second regions are formed such that the lattice constants of the first and second layers approach the lattice constant of the well layer. The invention also relates to a method for producing a Group III nitride-based compound semiconductor light-emitting device having a light-emitting layer of a single or multiple quantum well structure including at least an indium (In)-containing well layer, wherein, during formation of the well layer through vapor growth, an In source is fed through a procedure including: initiating feeding of the In source at a minimum feed rate; subsequently, elevating the In source feed rate to a target feed rate; maintaining the feed rate at the target feed rate; and subsequently, lowering the feed rate from the target feed rate to the minimum feed rate, and a Group III source other than the In source is fed at a constant feed rate from initiation of feeding of the In source to termination of the feeding.

Owner:TOYODA GOSEI CO LTD

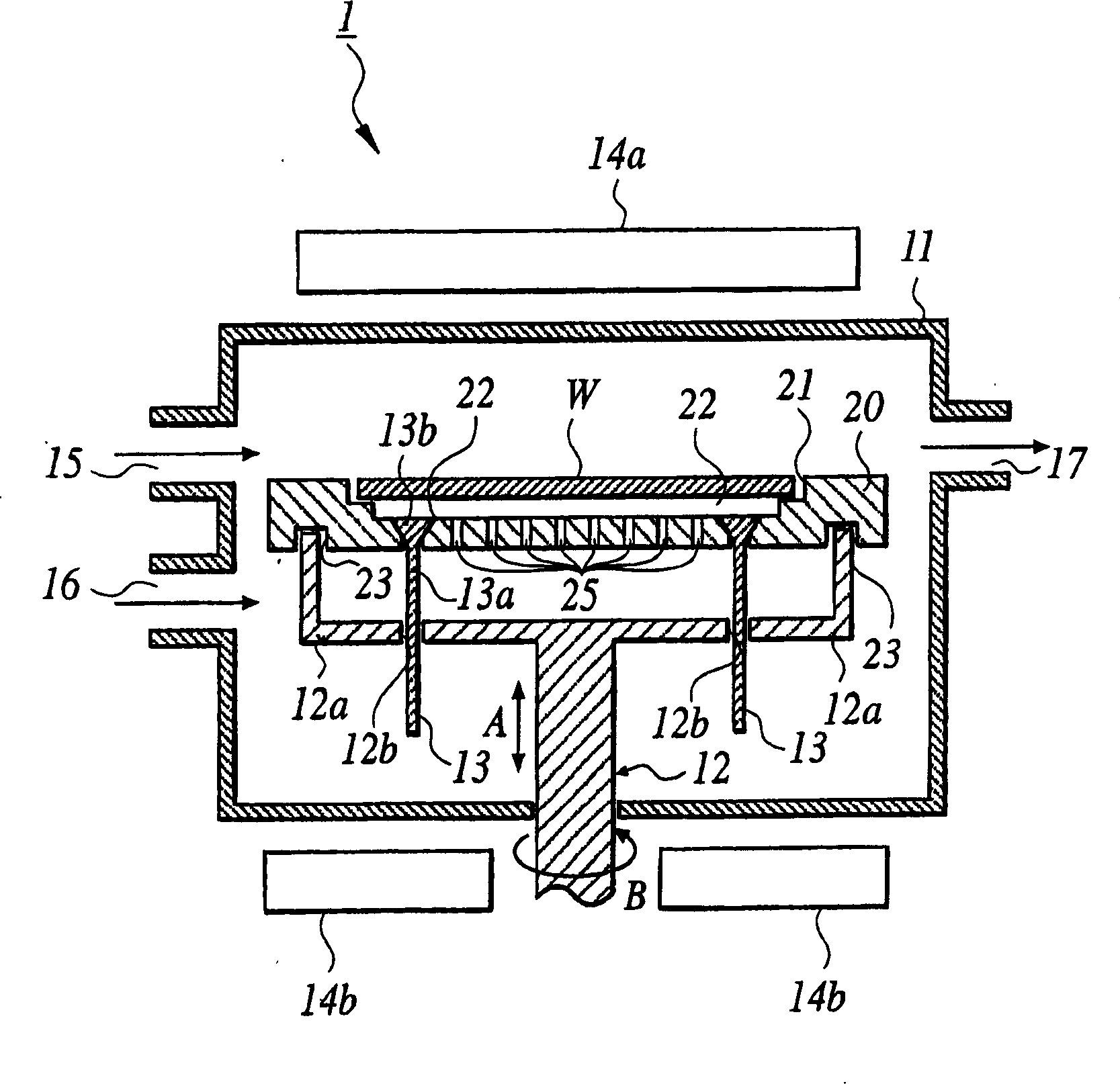

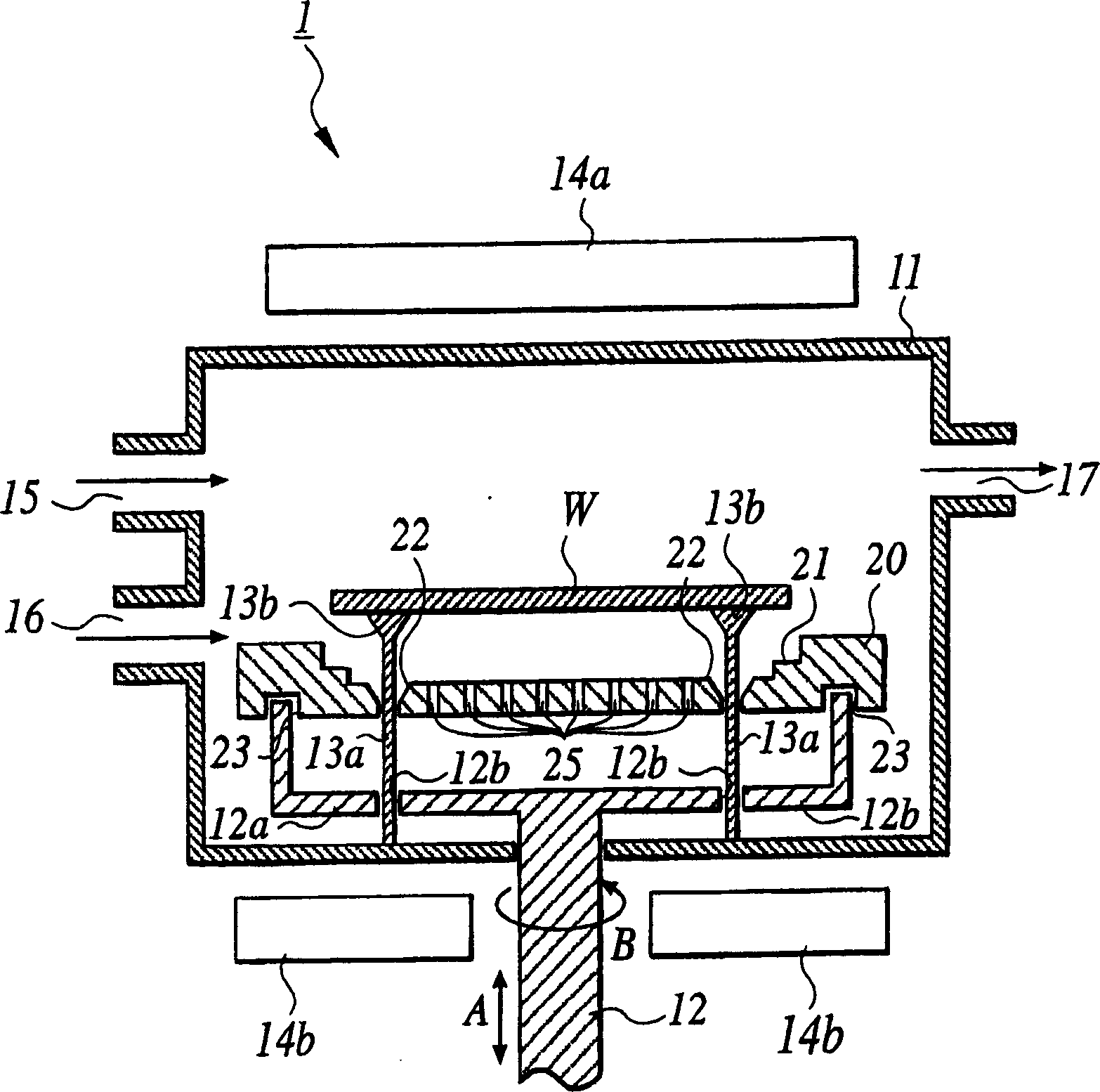

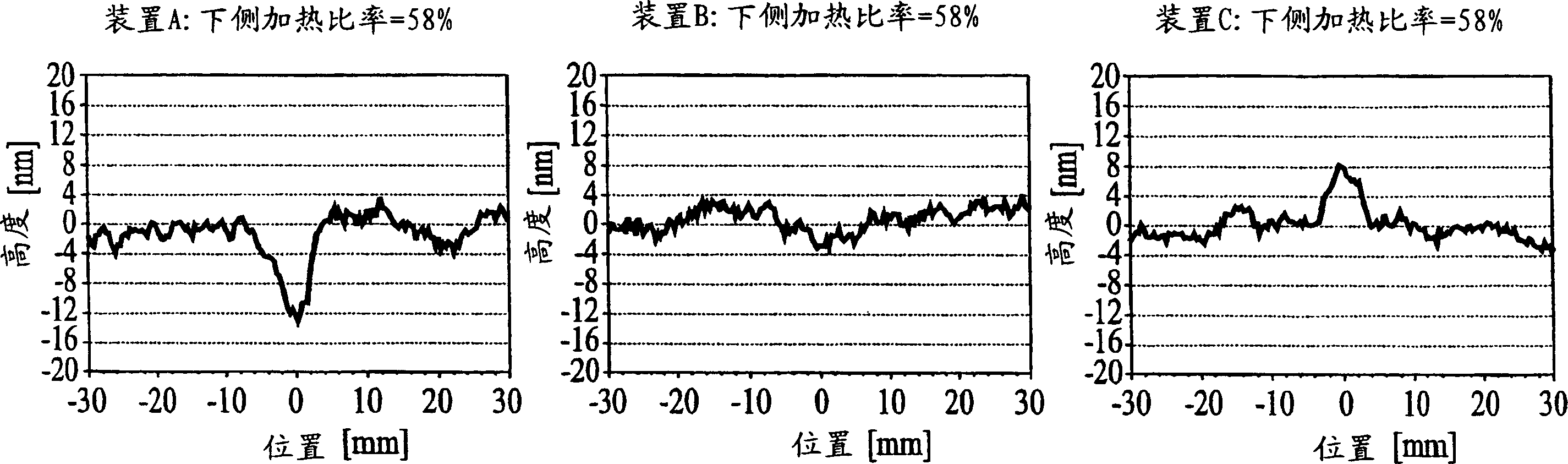

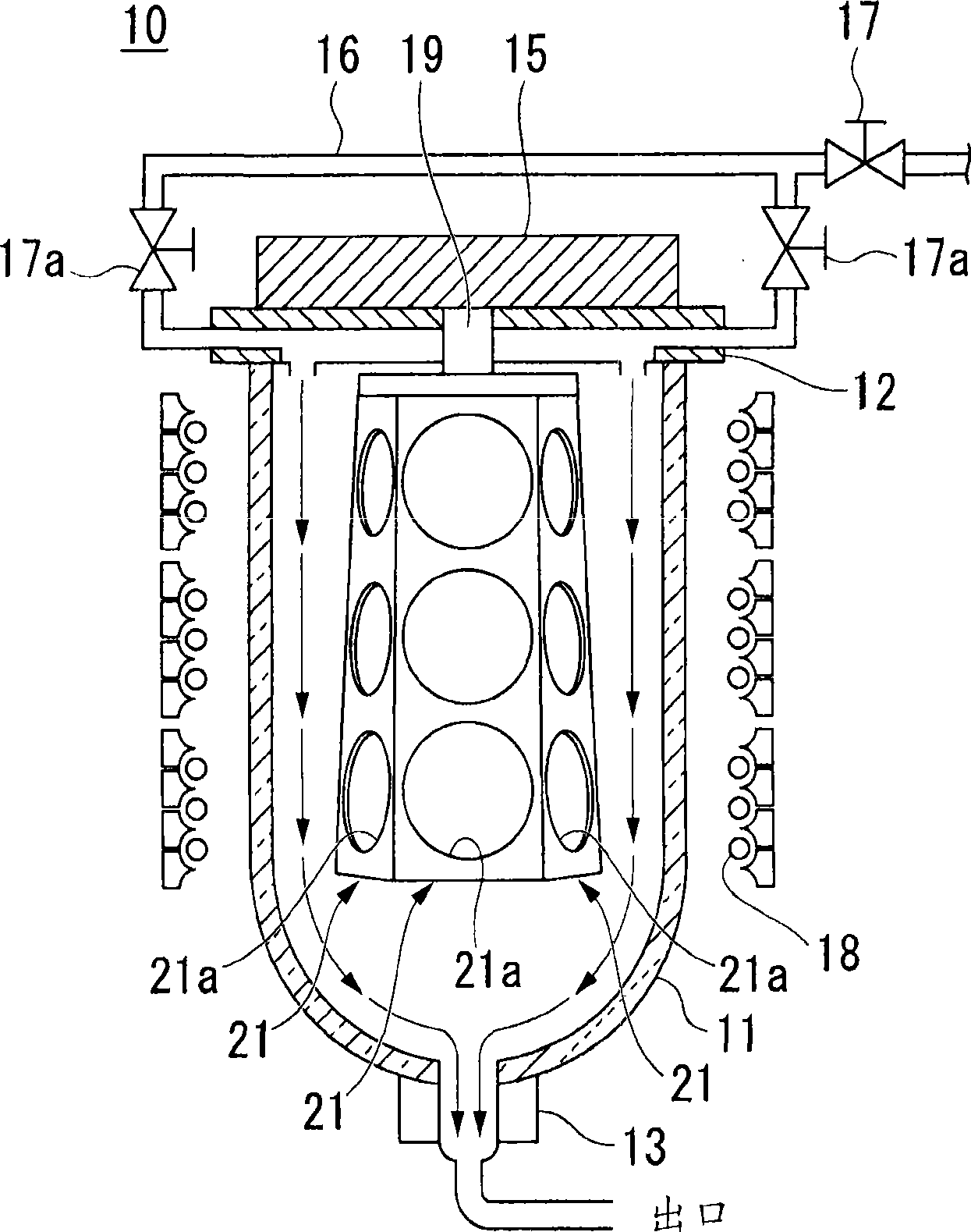

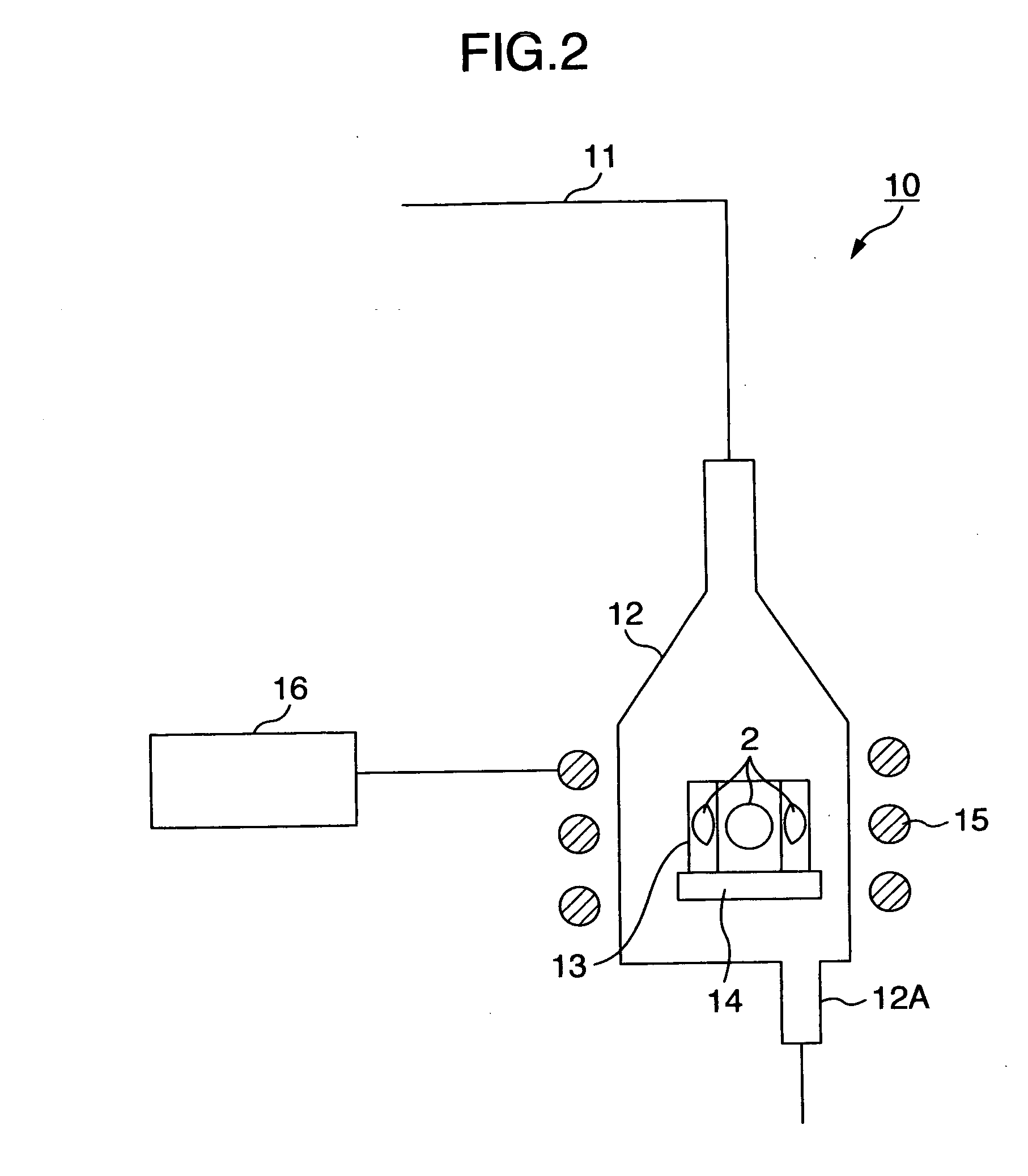

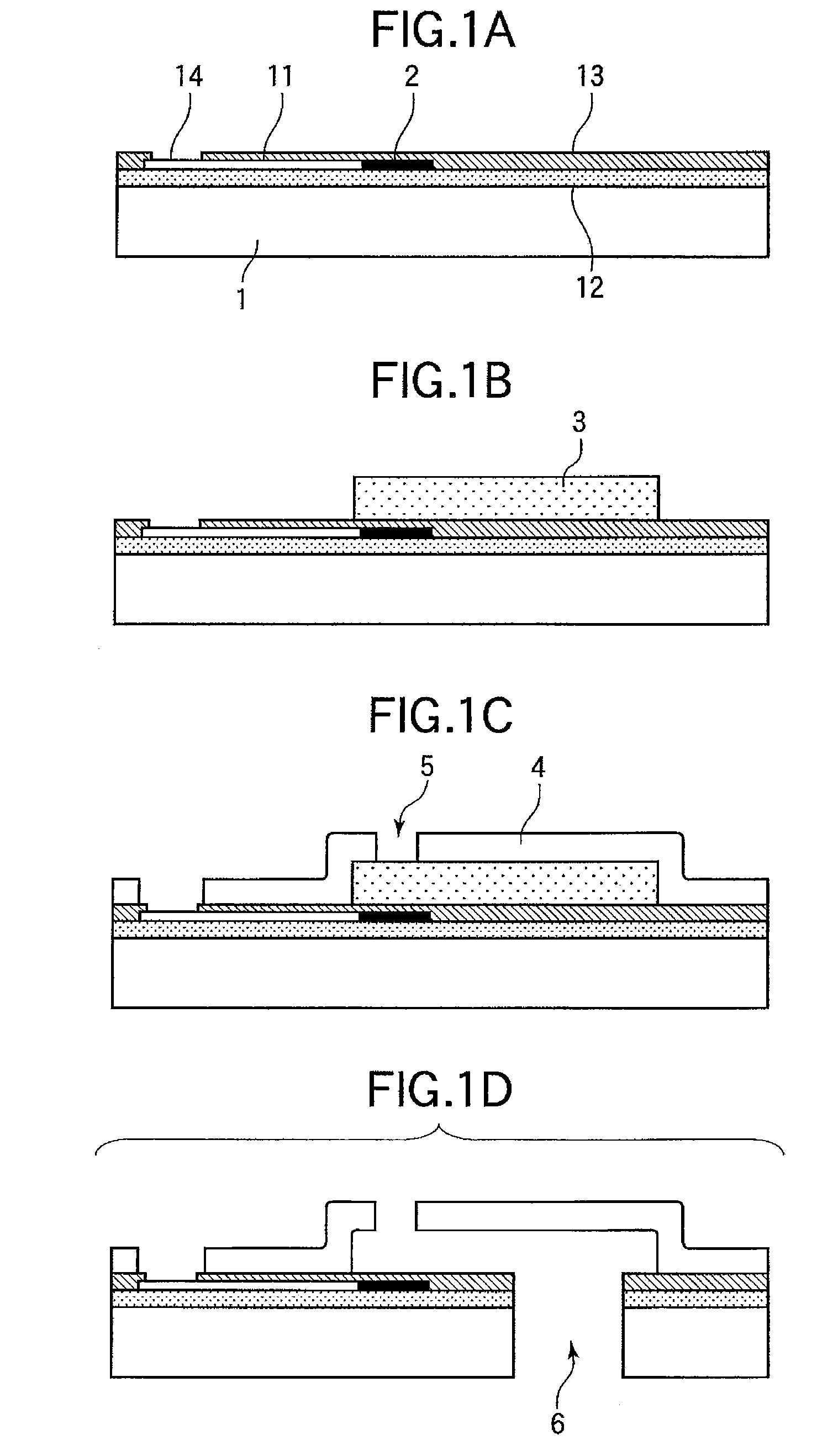

Production method for silicon epitaxial wafer, and silicon epitaxial wafer

InactiveCN1864245ASuppresses the problem that the thickness of the film is thinner than other parts near the ejector pinImprove flatnessPolycrystalline material growthSemiconductor/solid-state device manufacturingSusceptorGas phase

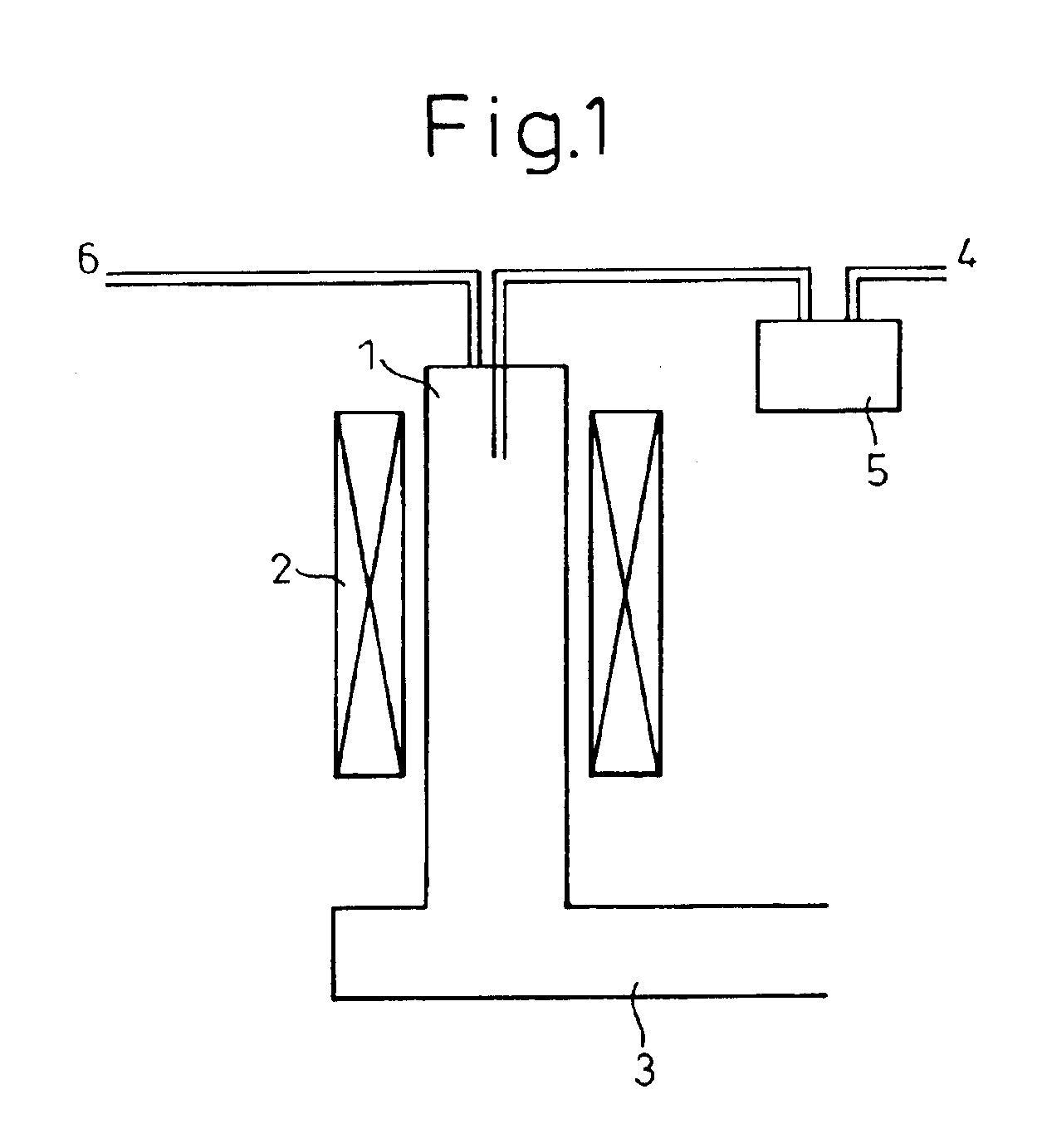

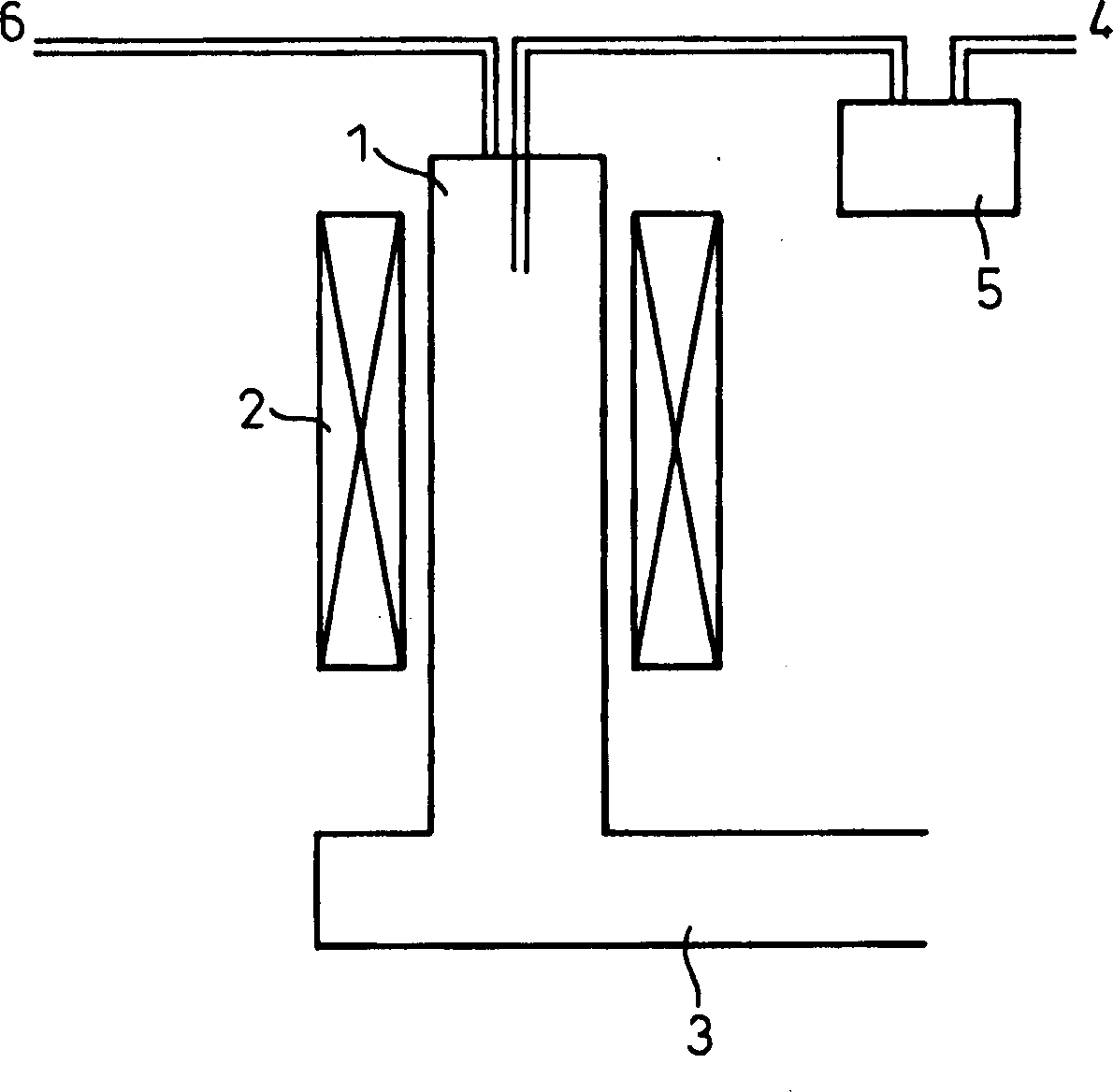

A vapor growth device comprising a reaction container (11), a susceptor (20), a lift pin (13), an upper-side heating device (14a), and a lower-side heating device (14b), a heating ratio between the upper-side heating device and the lower-side heating device being regulated. The surface shape of a silicon epitaxial layer formed near the lift pin and the shape of an uneven portion formed on the rear surface of a silicon epitaxial wafer can be controlled.

Owner:SHIN-ETSU HANDOTAI CO LTD

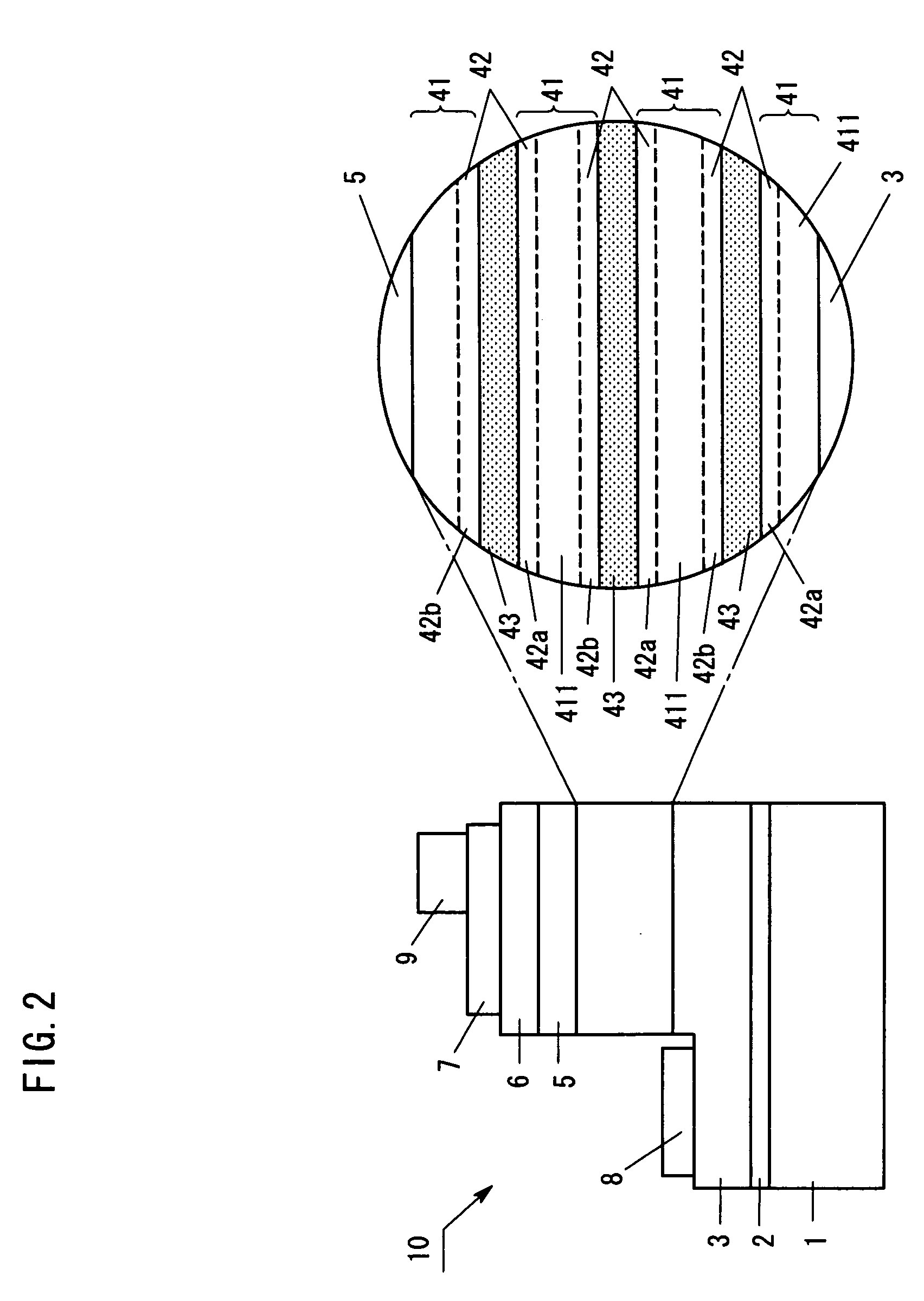

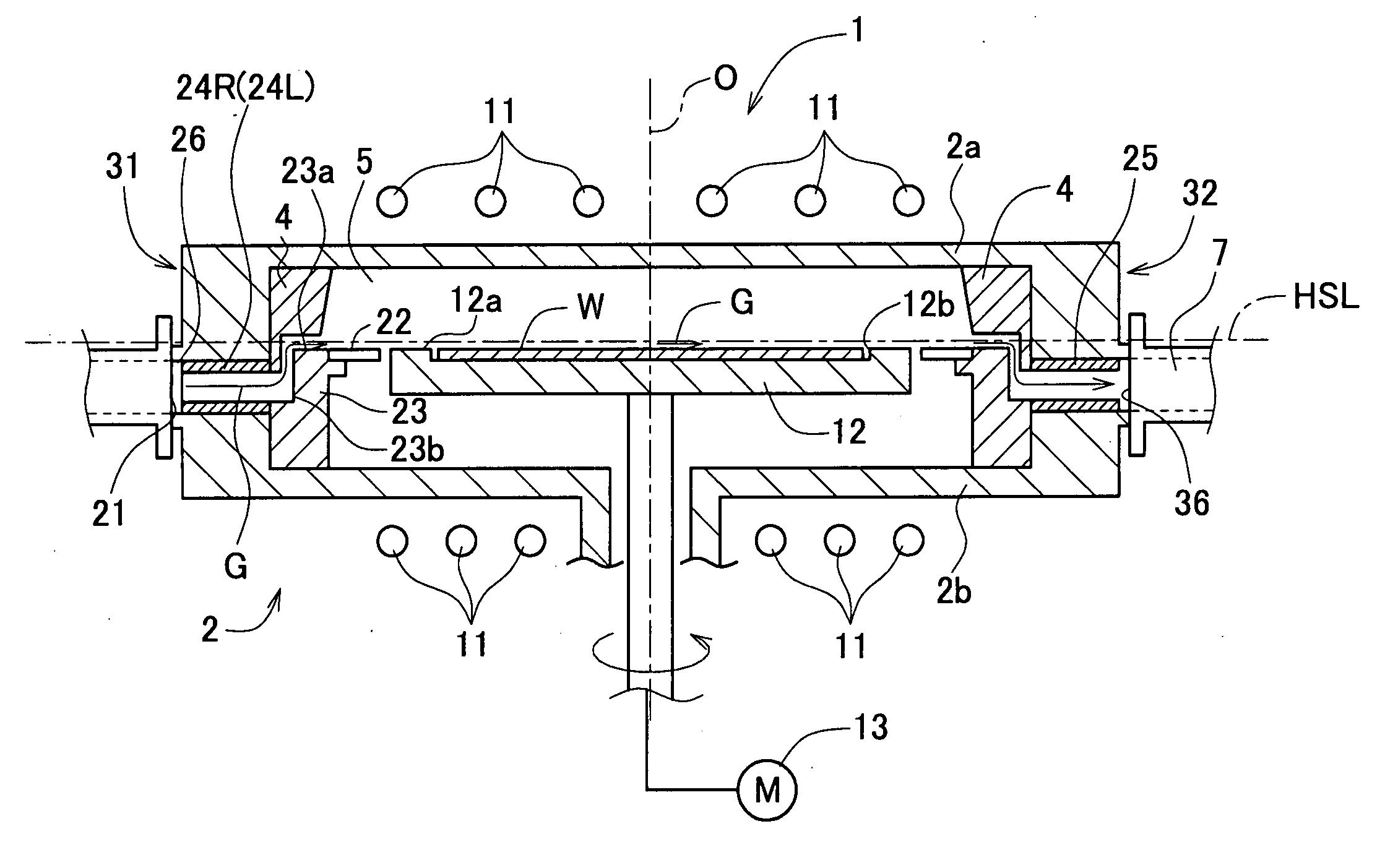

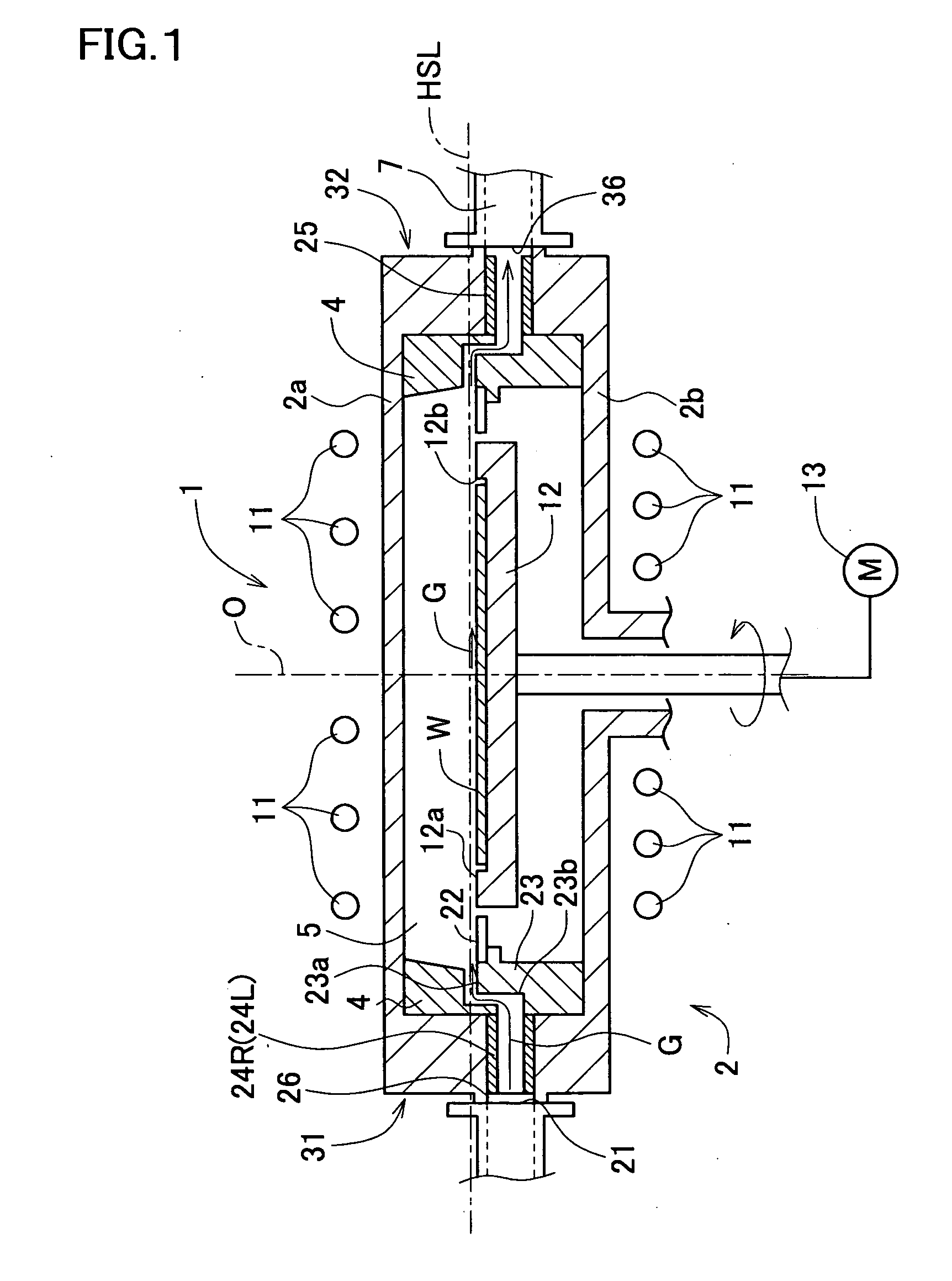

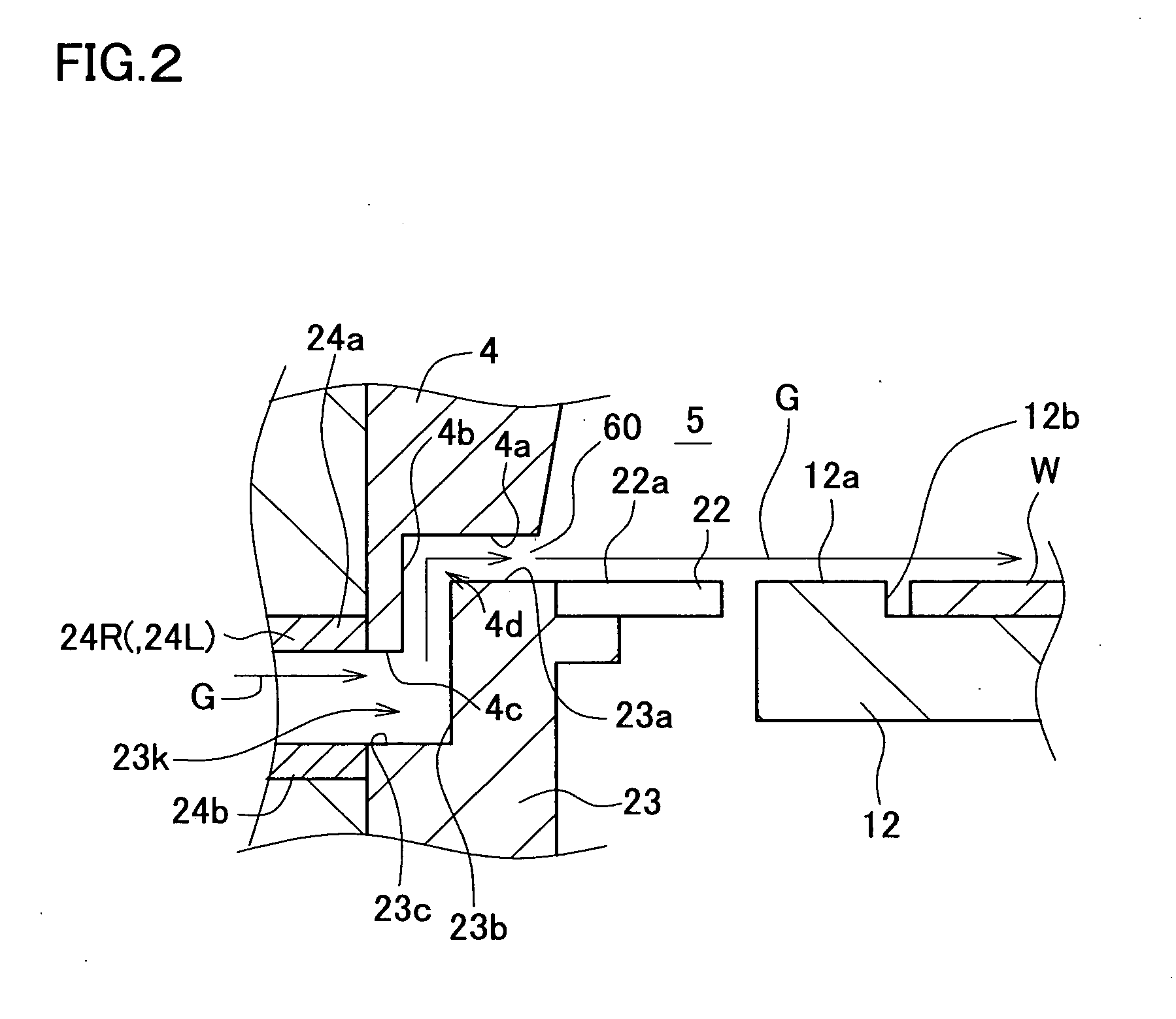

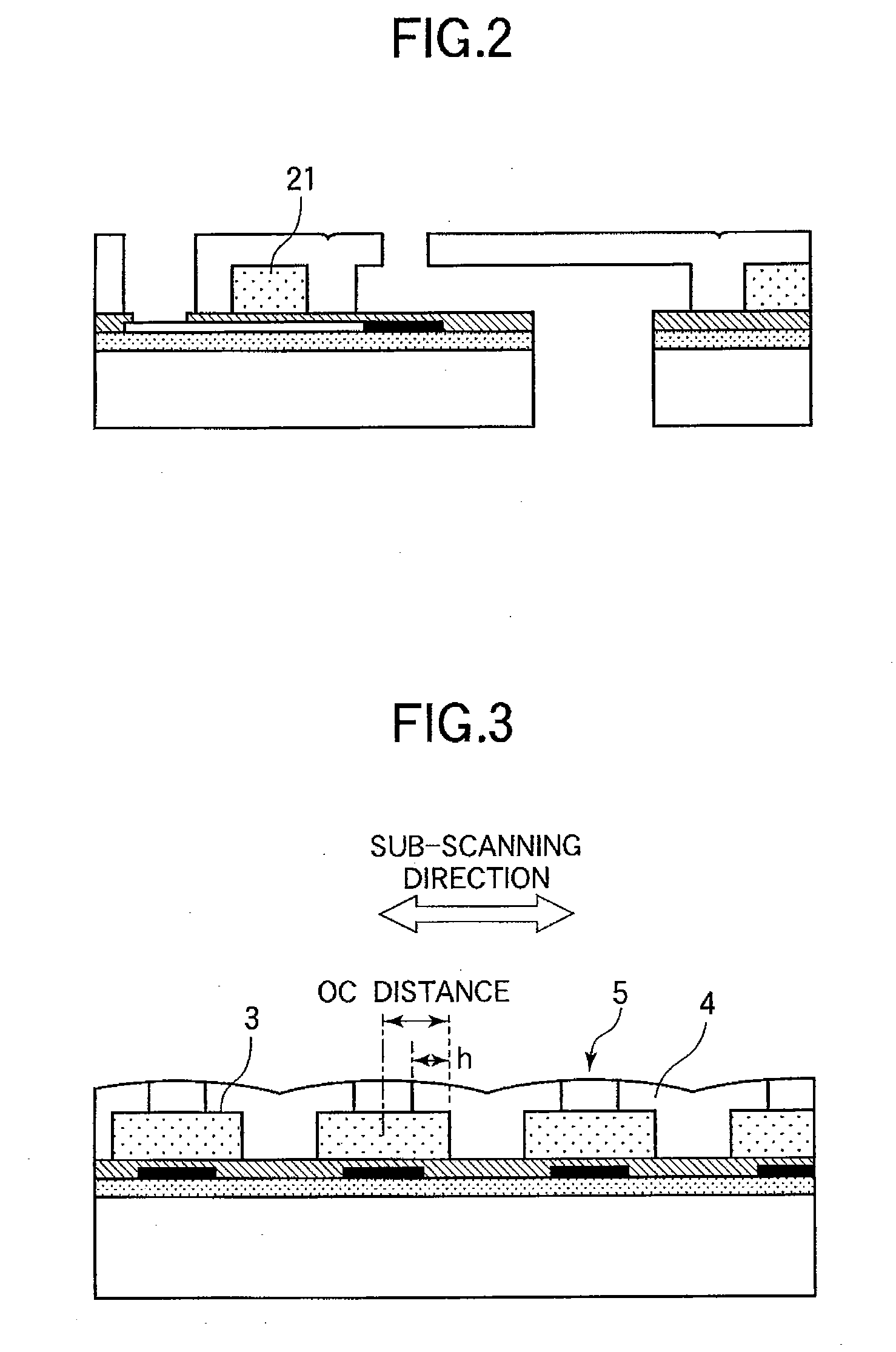

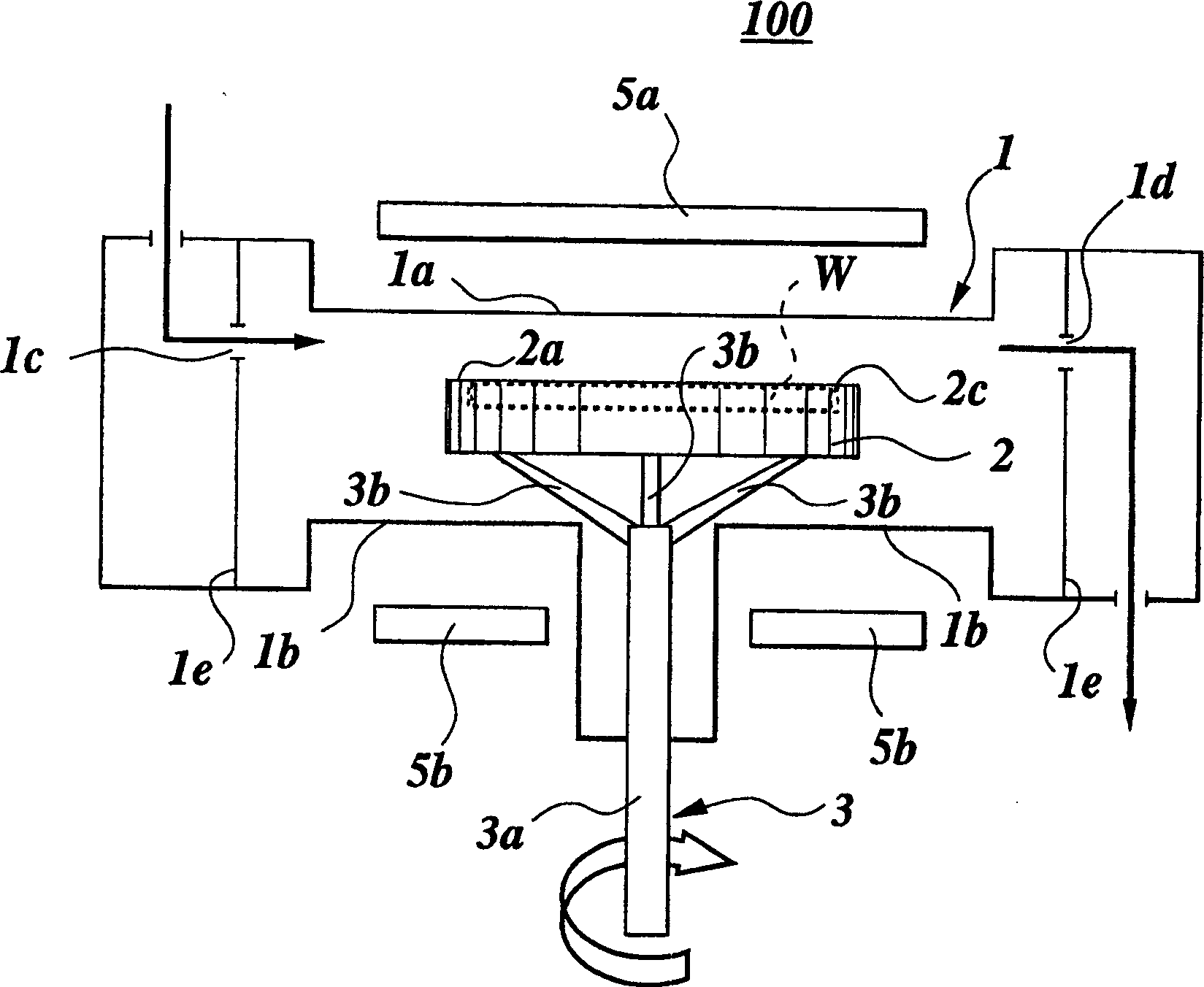

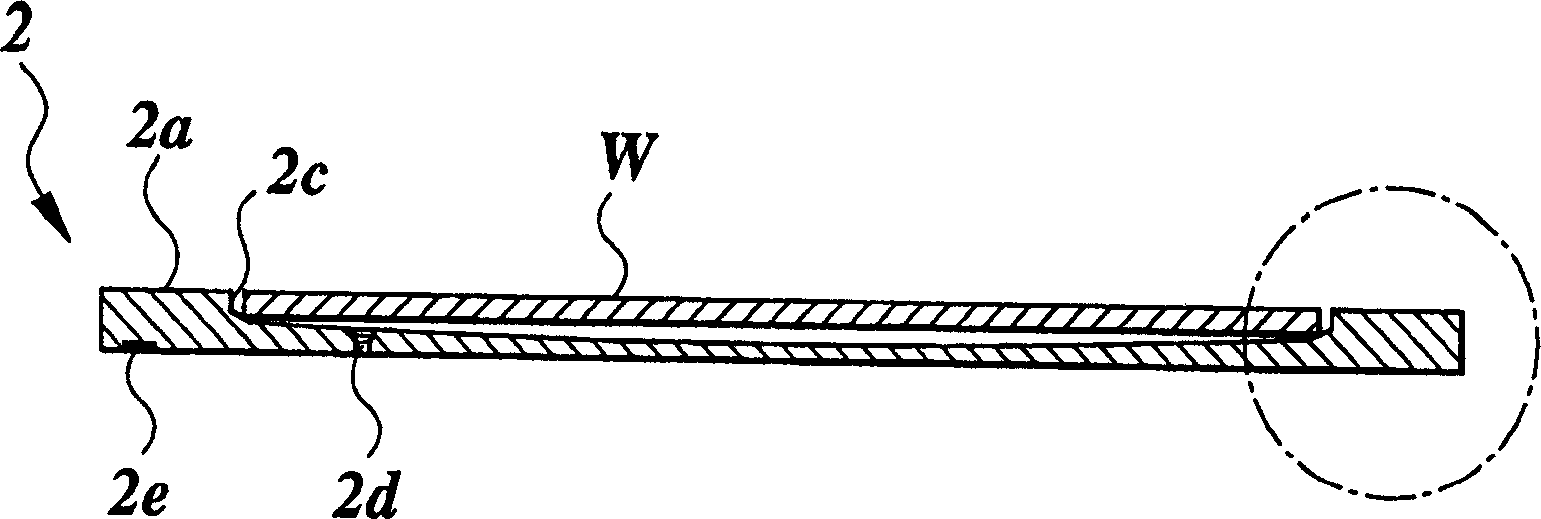

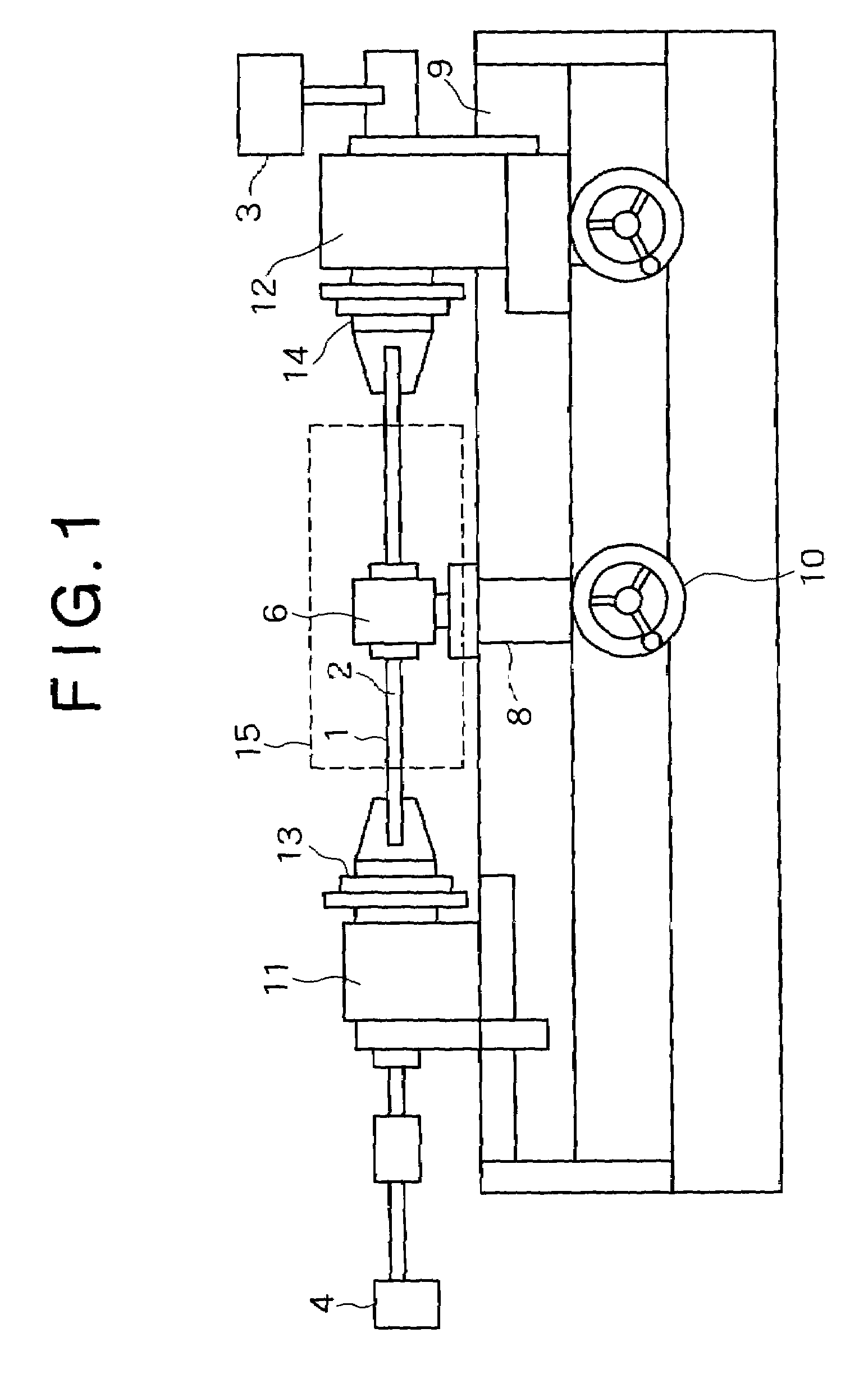

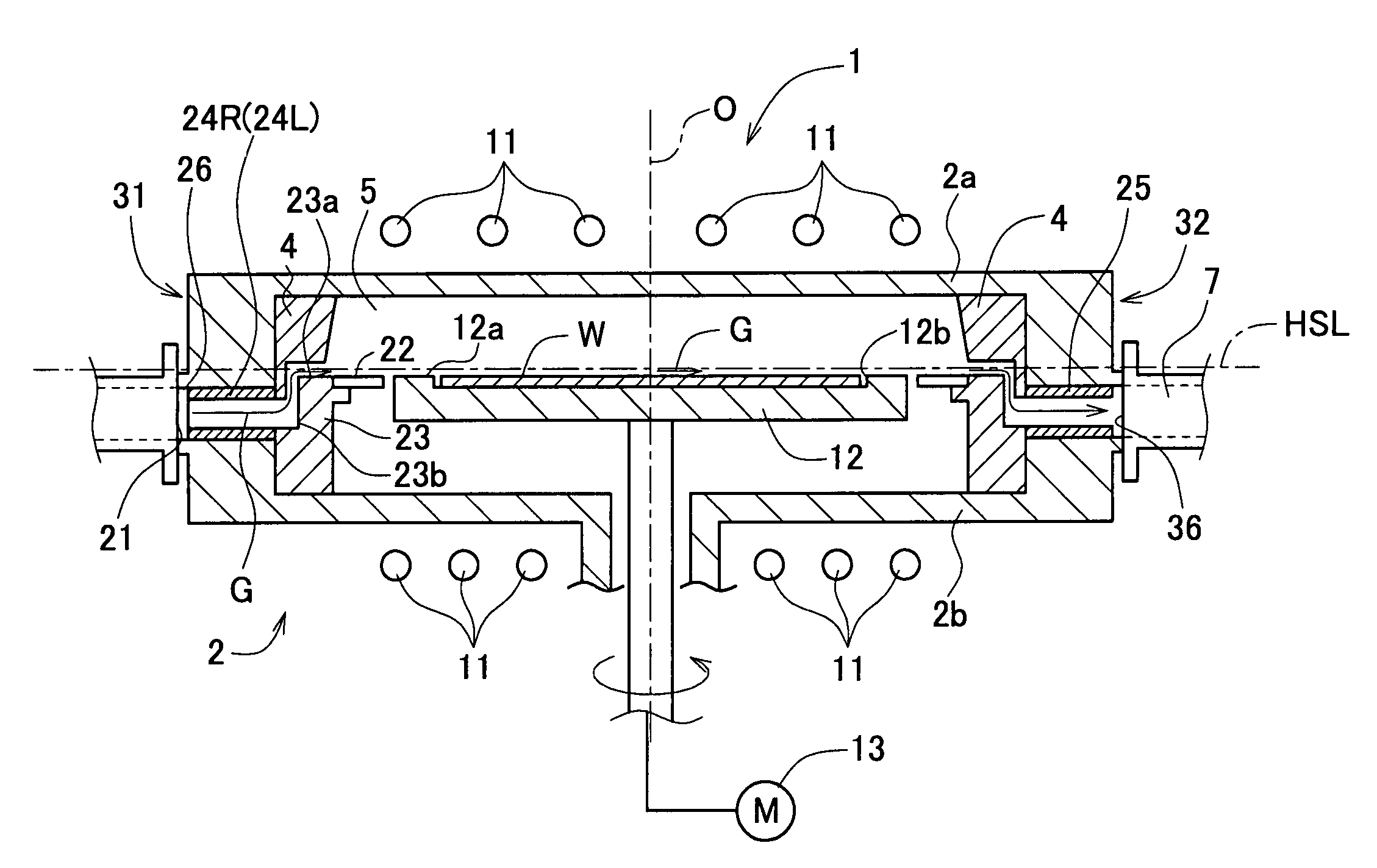

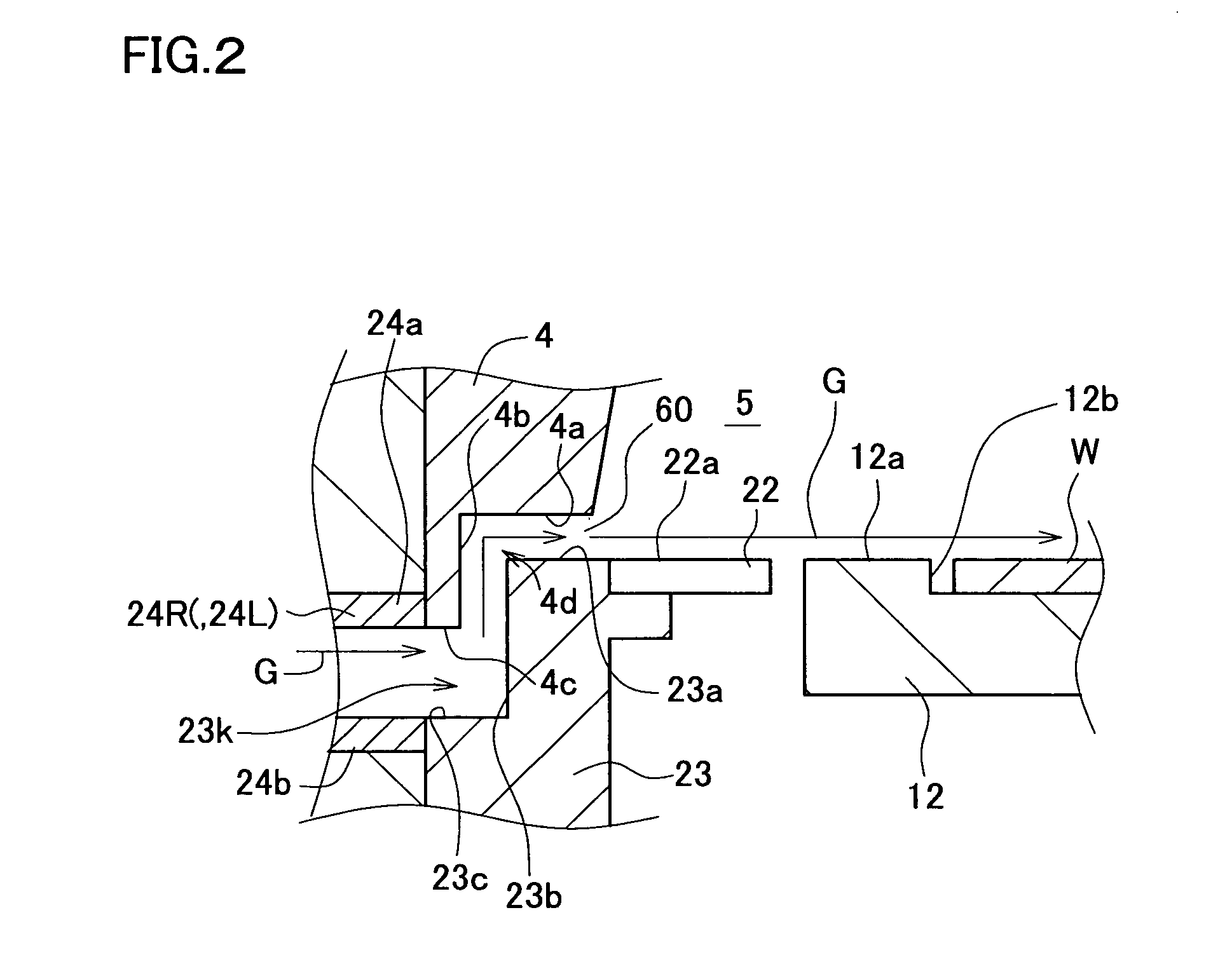

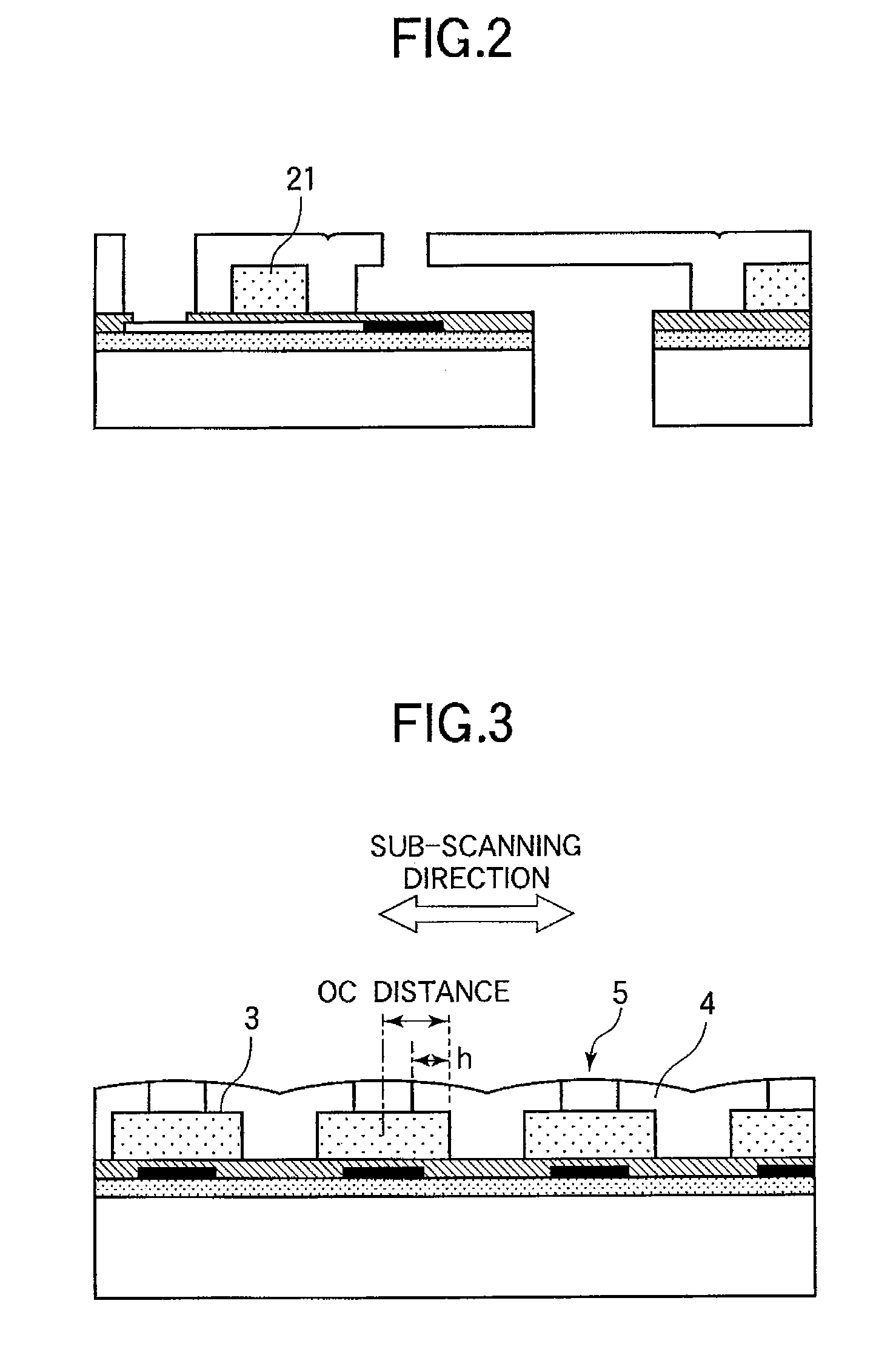

Vapor phase growth apparatus and method of fabricating epitaxial wafer

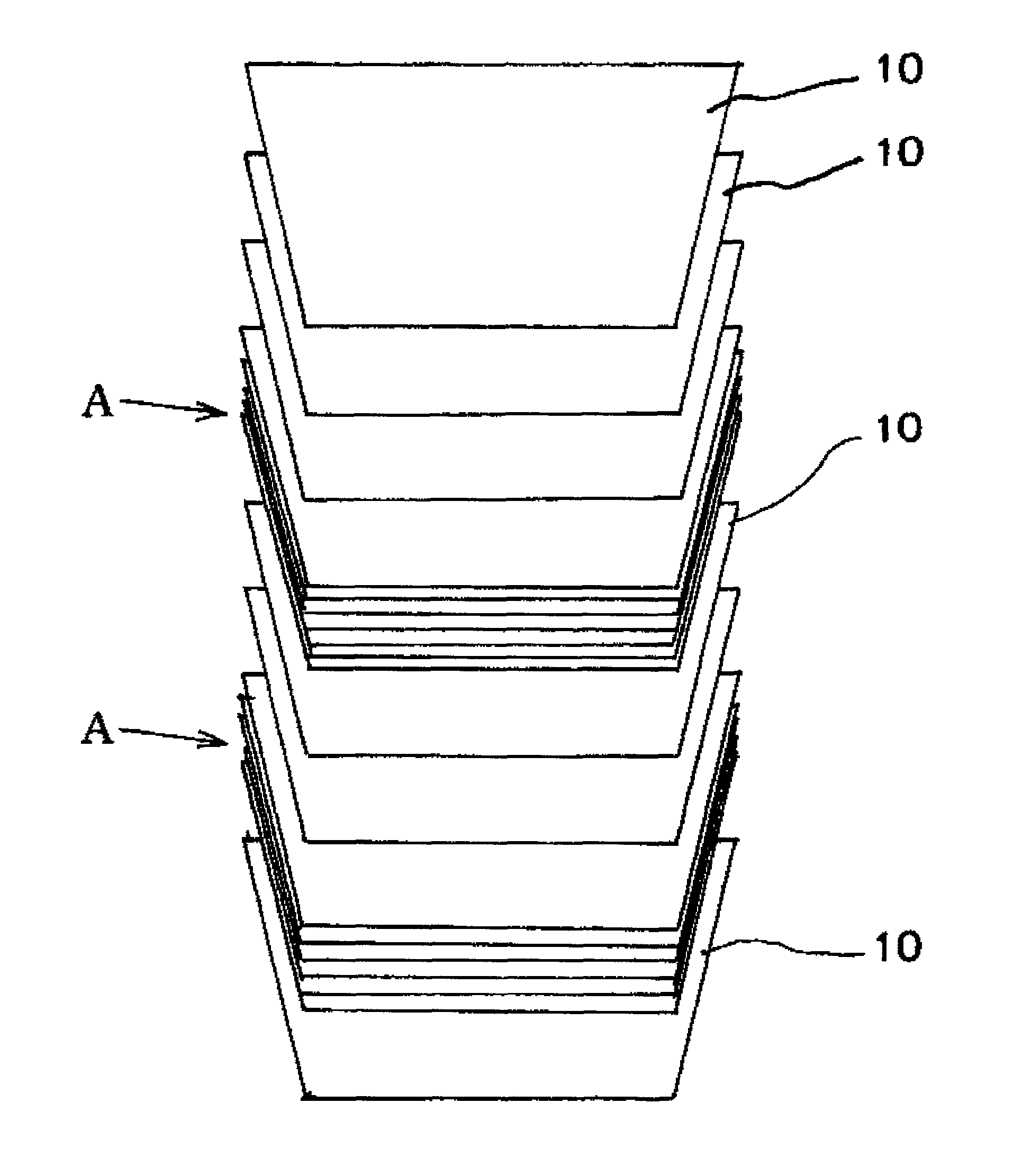

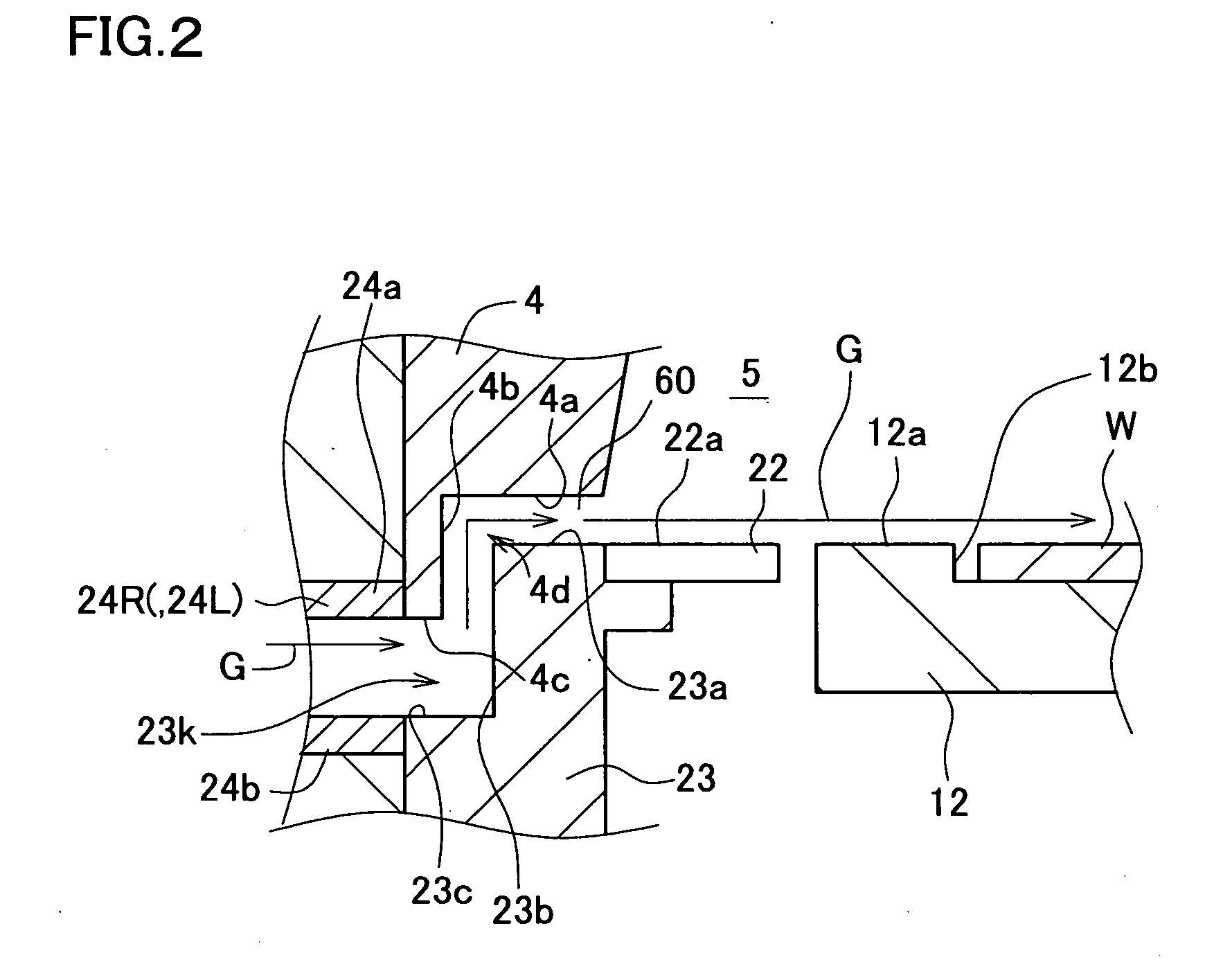

ActiveUS20070107653A1Shorten the lengthMinimize frictional resistanceAfter-treatment apparatusPolycrystalline material growthSusceptorGas phase

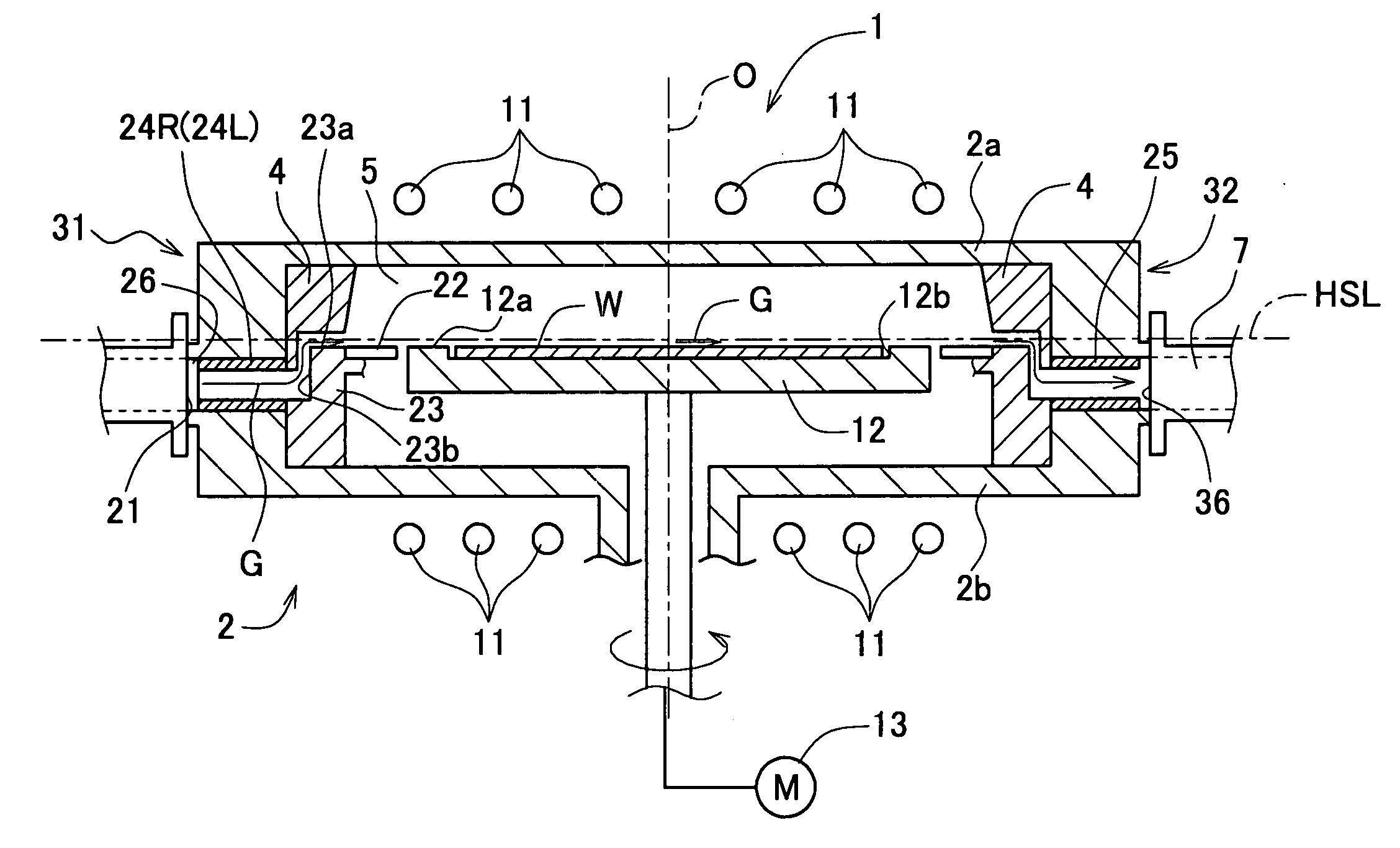

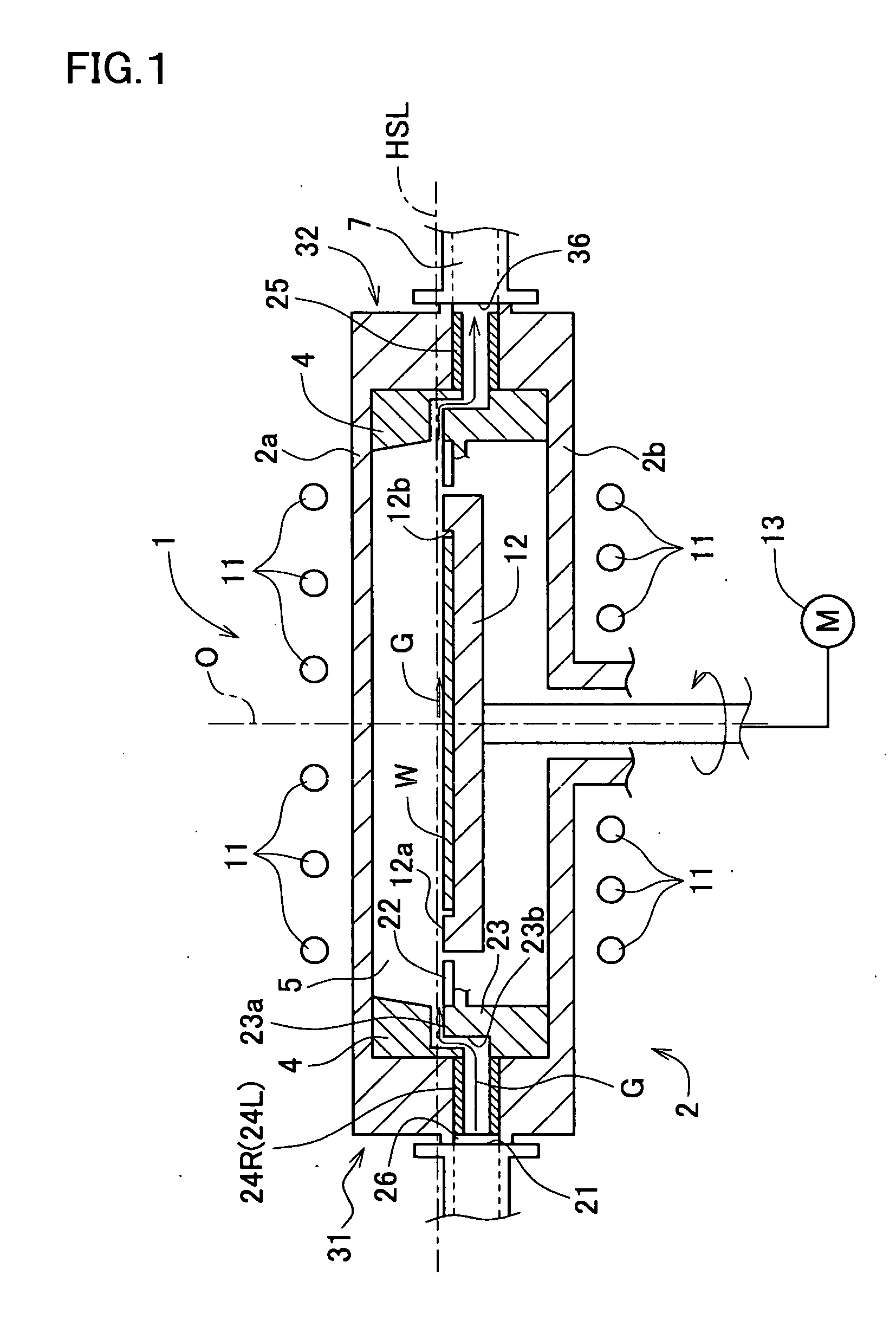

Material gas hits the outer peripheral surface of a dam member and rides on the upper surface side, and then is allowed to flow along the main surface of a silicon single-crystal substrate placed on a susceptor. An upper lining member is disposed above the dam member so as to face the dam member. A gas introducing clearance is formed between the dam member and the upper lining member. In a vapor growth device, the upper lining member is regulated in size so that the length, formed in a direction along the horizontal reference line, of the gas introducing clearance gradually decreases as it is away from the horizontal reference line or is kept constant at any position. A vapor growth device capable of making more uniform the flowing route of a material gas flowing on the silicon single-crystal substrate, and a production method for an epitaxial wafer are provided.

Owner:SHIN-ETSU HANDOTAI CO LTD

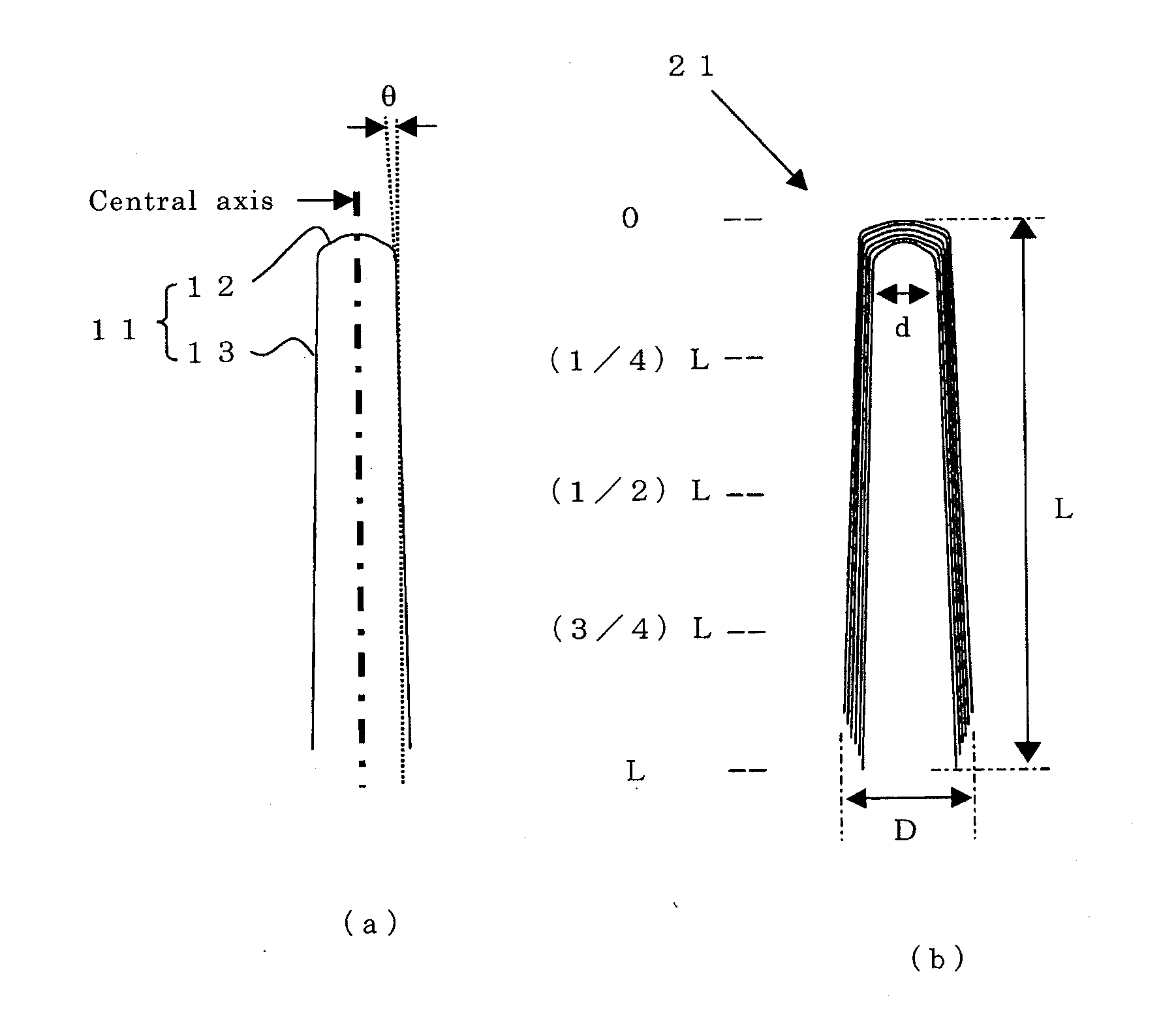

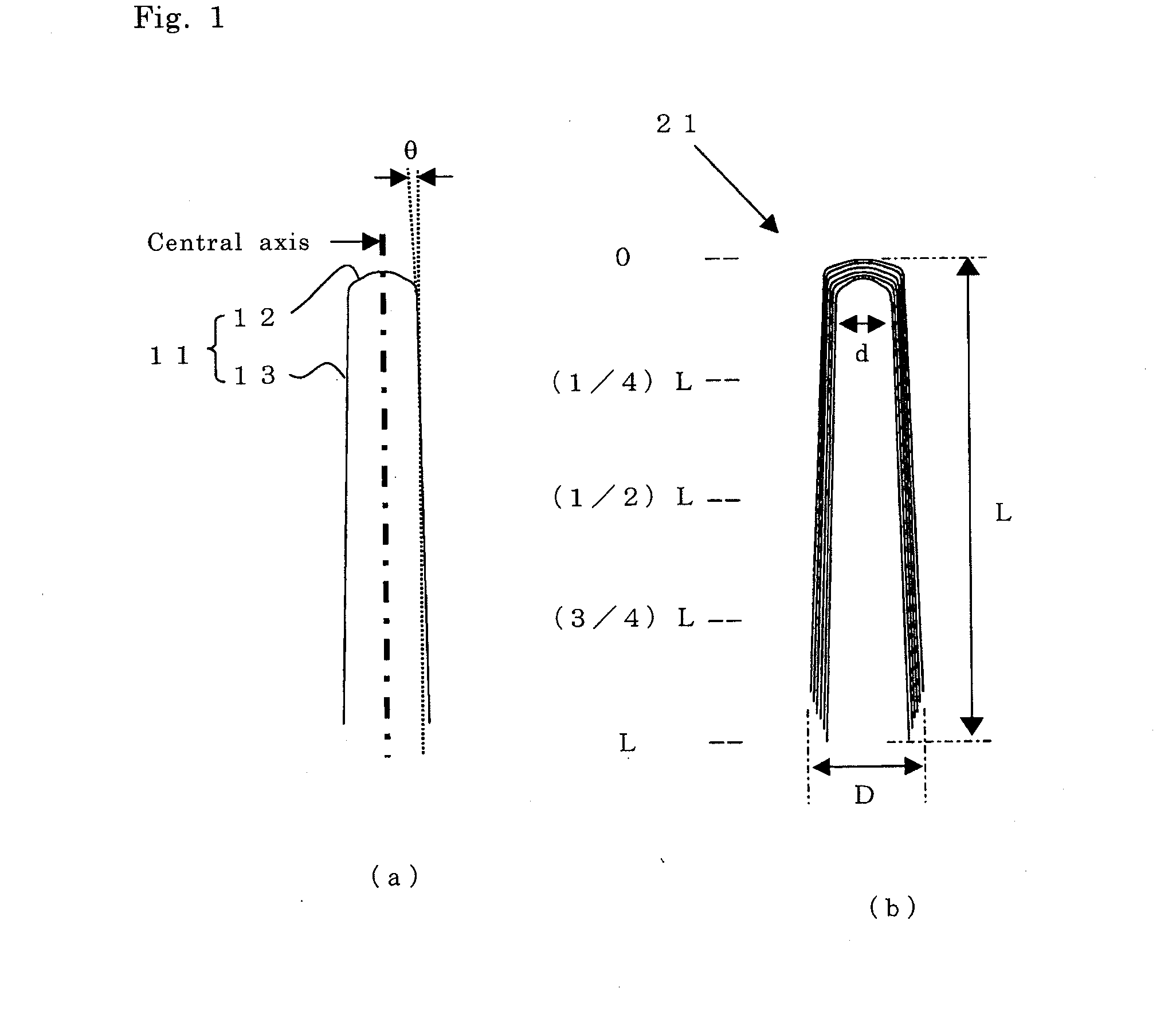

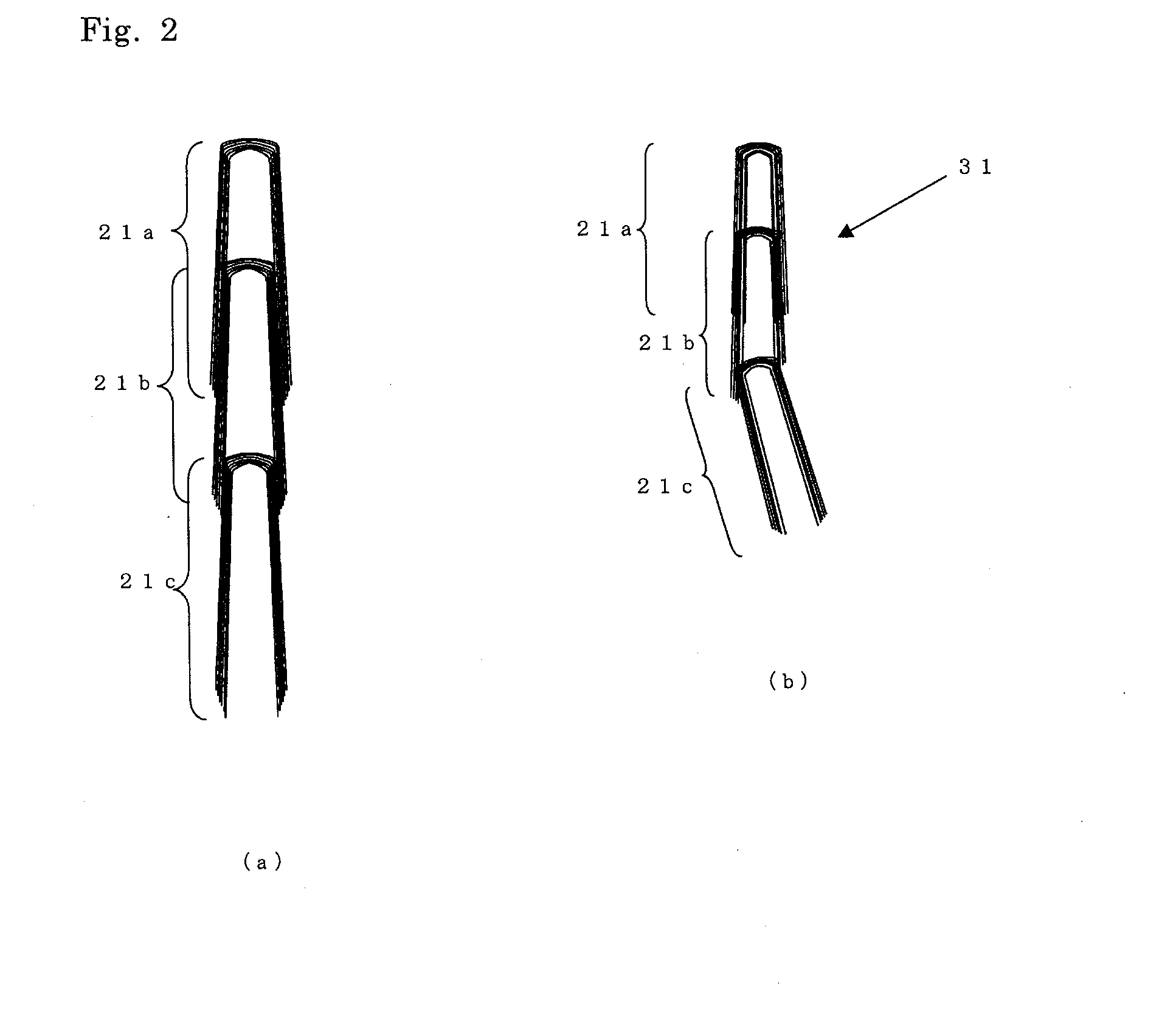

Fine carbon fiber, fine short carbon fiber, and manufacturing method for said fibers

InactiveUS20110003151A1Improve conductivityHigh bonding strengthMaterial nanotechnologyLayered productsFiberCarbon fibers

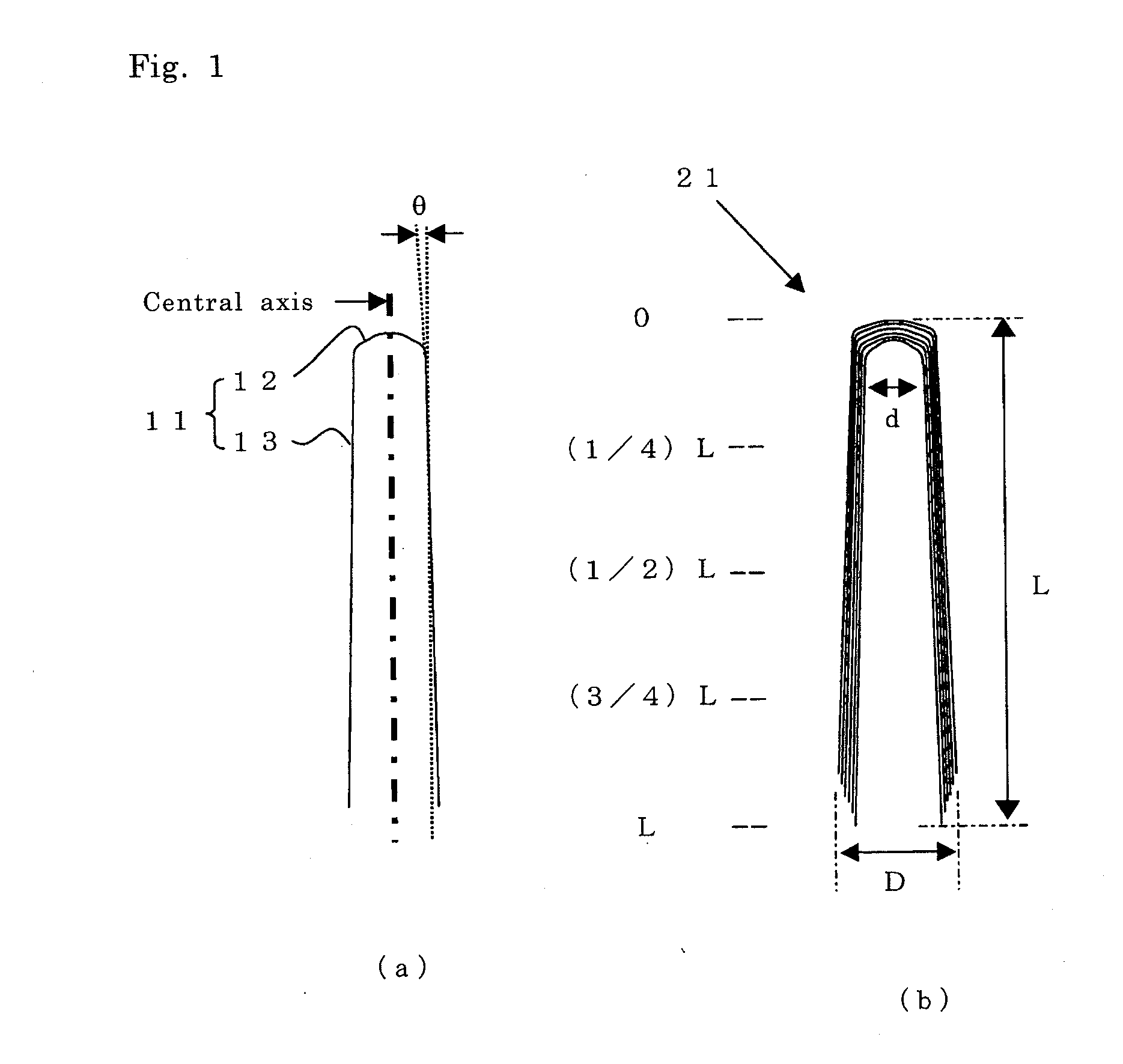

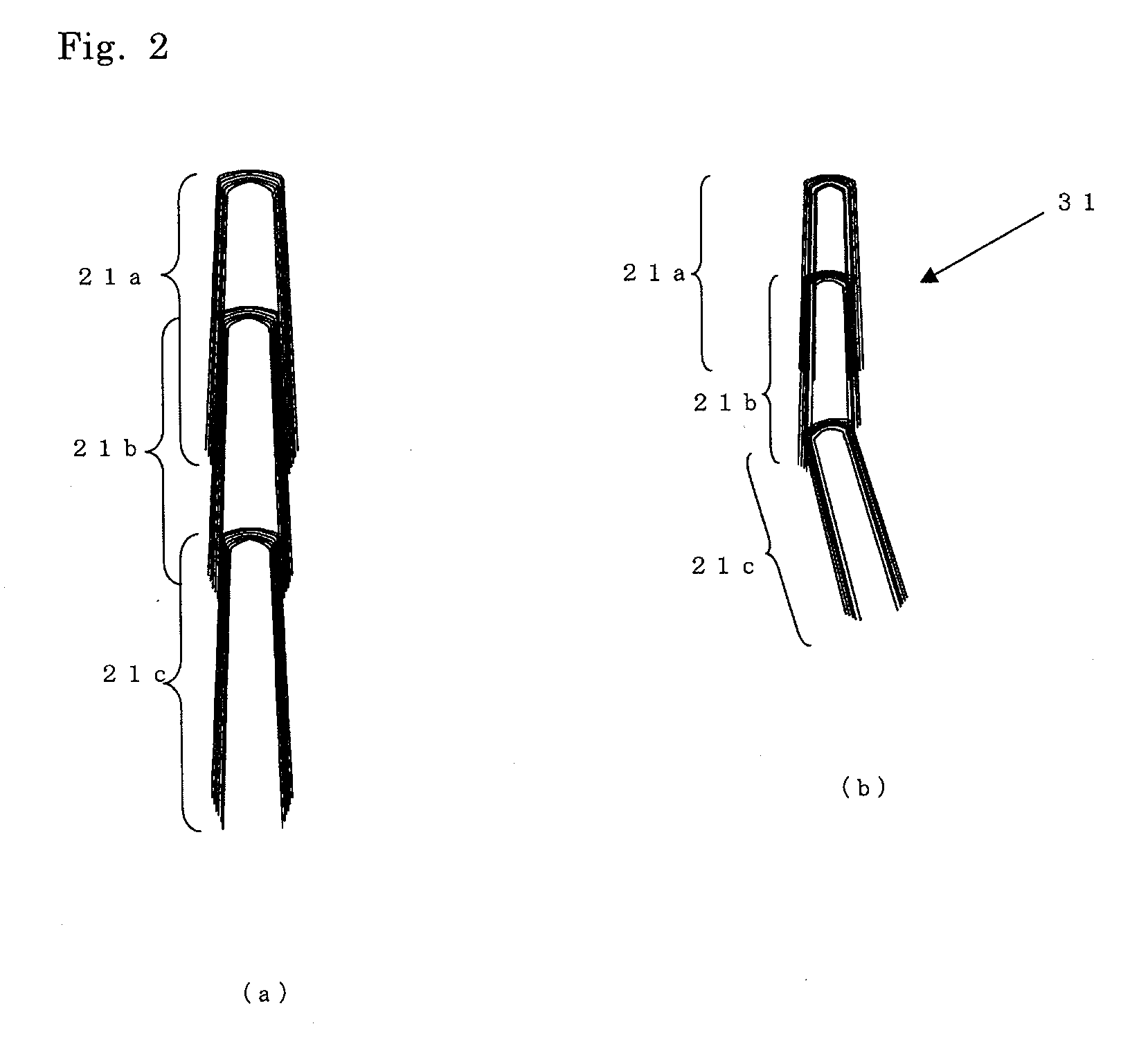

A novel fine carbon fiber is produced by vapor growth, in which a graphite-net plane consisting of carbon atoms alone forms a temple-bell-shaped structural unit comprising closed head-top part and body-part with open lower-end, where an angle θ formed by a generatrix of the body-part and a fiber axis is less than 15°, 2 to 30 of the temple-bell-shaped structural units are stacked sharing a central axis to form an aggregate, and the aggregates are connected in head-to-tail style with a distance, thereby forming a fiber. Furthermore, a fine short carbon fibers with excellent dispersibility can be obtained by shortening the fine carbon fiber.

Owner:UBE IND LTD

Vapor phase growth apparatus and method of fabricating epitaxial wafer

InactiveUS20070122323A1Uniform film thickness distributionDegree of reductionPolycrystalline material growthBacterial antigen ingredientsSusceptorGas phase

A vapor growth device which is constituted as a single-wafer type and has a gas introducing port through which a material gas is led into a reaction vessel. A dam member is disposed around a susceptor, and the material gas from the gas introducing port hits the outer peripheral surface of the dam ring and rides on an upper surface side, and then is allowed to flow along the main surface of a silicon single-crystal substrate placed on the susceptor. Guide plates for dividing the flow in the width direction of the material gas are disposed on the upper surface of the dam member. Accordingly, a vapor growth device capable of controlling the flow rate of material gas flowing on a silicon single-crystal substrate, and a production method for an epitaxial wafer using it are provided.

Owner:SHIN-ETSU HANDOTAI CO LTD

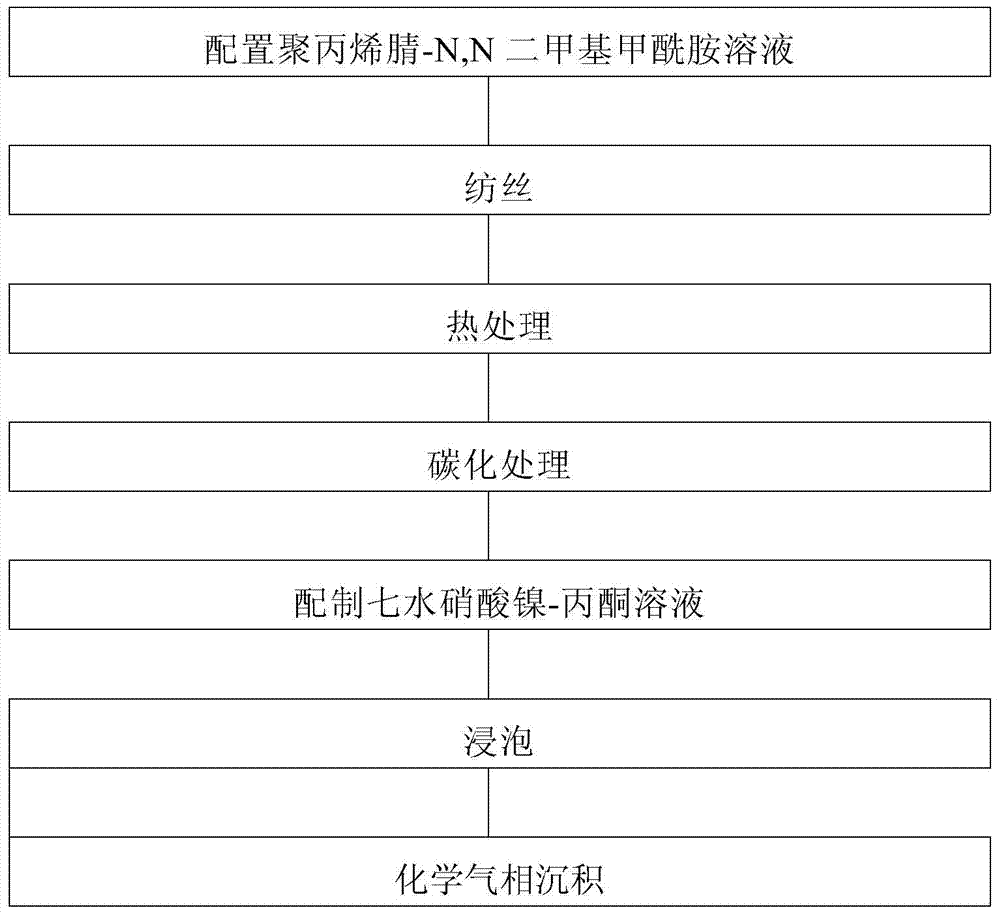

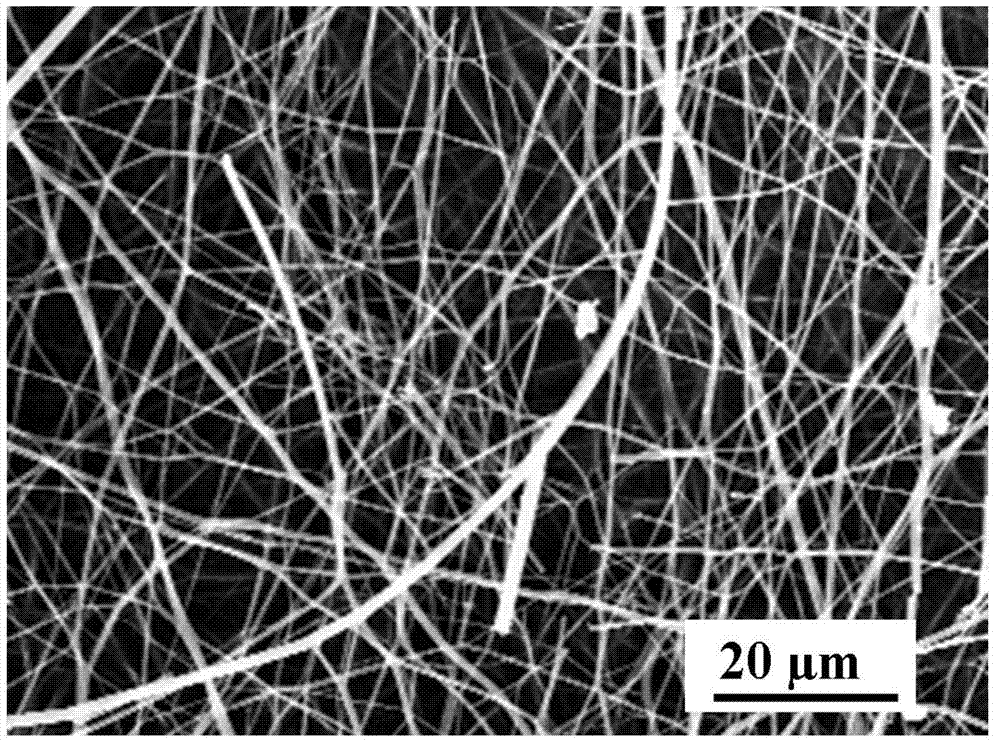

Preparation method of carbon nano-fiber film

ActiveCN103696239AHigh strengthHigh temperature carbonization produces good flexibility and flexibilityCarbon fibresFilament/thread formingIn planeGas phase

The invention discloses a preparation method of a carbon nano-fiber film, and particularly discloses a method for preparing a high-strength polyacrylonitrile-based carbon nano-fiber film by using electrostatic spinning-high temperature carbonization in combination with a catalytic chemical vapor deposition process. The method comprises the following steps: preparing a polyacrylonitrile-based carbon nano-fiber porous reinforcement with high flexibility but low strength by using electrostatic spinning and high temperature carbonization; and further filling vapor growth carbon nano-fibers into the polyacrylonitrile-based carbon nano-fiber porous reinforcement by using a chemical vapor deposition technology to obtain the carbon nano-fiber film with high flexibility and high strength. Compared with a polyacrylonitrile-based carbon nano-fiber film prepared by merely using an "electrostatic spinning-high temperature carbonization" technology, the carbon nano-fiber film prepared with the method disclosed by the invention has the advantage that the in-plane tensile strength is increased by 80-120 percent.

Owner:XIAN AVIATION BRAKE TECH

Lithium-ferrous disulfide battery and manufacturing method thereof

ActiveCN102751499AImprove discharge performanceImprove low temperature discharge performanceCell electrodesFinal product manufactureFiberCarbon fibers

The invention relates to a lithium-ferrous disulfide battery. The lithium-ferrous disulfide battery comprises a housing, an anode, a cathode, an isolating membrane for isolating the anode from the cathode, and an electrolytic solution, wherein the anode and the cathode are arranged in the housing, the anode contains 80-95% of ferrous disulfide (FeS2) by mass ratio, the cathode is a lithium tablet, solvents for the electrolytic solution comprise 1,3-dioxolane and glycol dimethyl ether, and electrolyte for the electrolytic solution comprises lithium iodide. A manufacturing method for the lithium-ferrous disulfide battery is as follows: adding a proper amount of carbon nanotube, vapor growth carbon fibers, conductive graphite and / or super conductive carbon into the anode, and adding a proper amount of additives such as N,N-dimethyl trifluoroacetamide and the like into the electrolytic solution. The lithium-ferrous disulfide battery manufactured by the manufacturing method is good in discharge performance in wider high and low temperature environments.

Owner:EVE ENERGY CO LTD

Method of manufacturing ink jet recording head

InactiveUS20070058001A1High densityImprove accuracyRecording apparatusPiezoelectric/electrostrictive device manufacture/assemblyEngineeringVolumetric Mass Density

Provided is a method capable of manufacturing an ink jet recording head with a high degree of accuracy even though the density of an ink passage pattern is increased. The method of manufacturing an ink jet recording head according to the present invention comprises the steps of forming an ink passage pattern on a substrate formed therein with ink discharge pressure generating elements from dissoluble resin; depositing an organic material on the substrate formed thereon with the ink passage pattern from the dissoluble resin by a vapor growth process at a temperature at which the dissolubility of the dissoluble resin is not lost, so as to form a coated resin layer; forming ink discharge ports in the coated resin layer in parts located above the ink discharge pressure generating elements; and eluting the dissoluble resin.

Owner:CANON KK

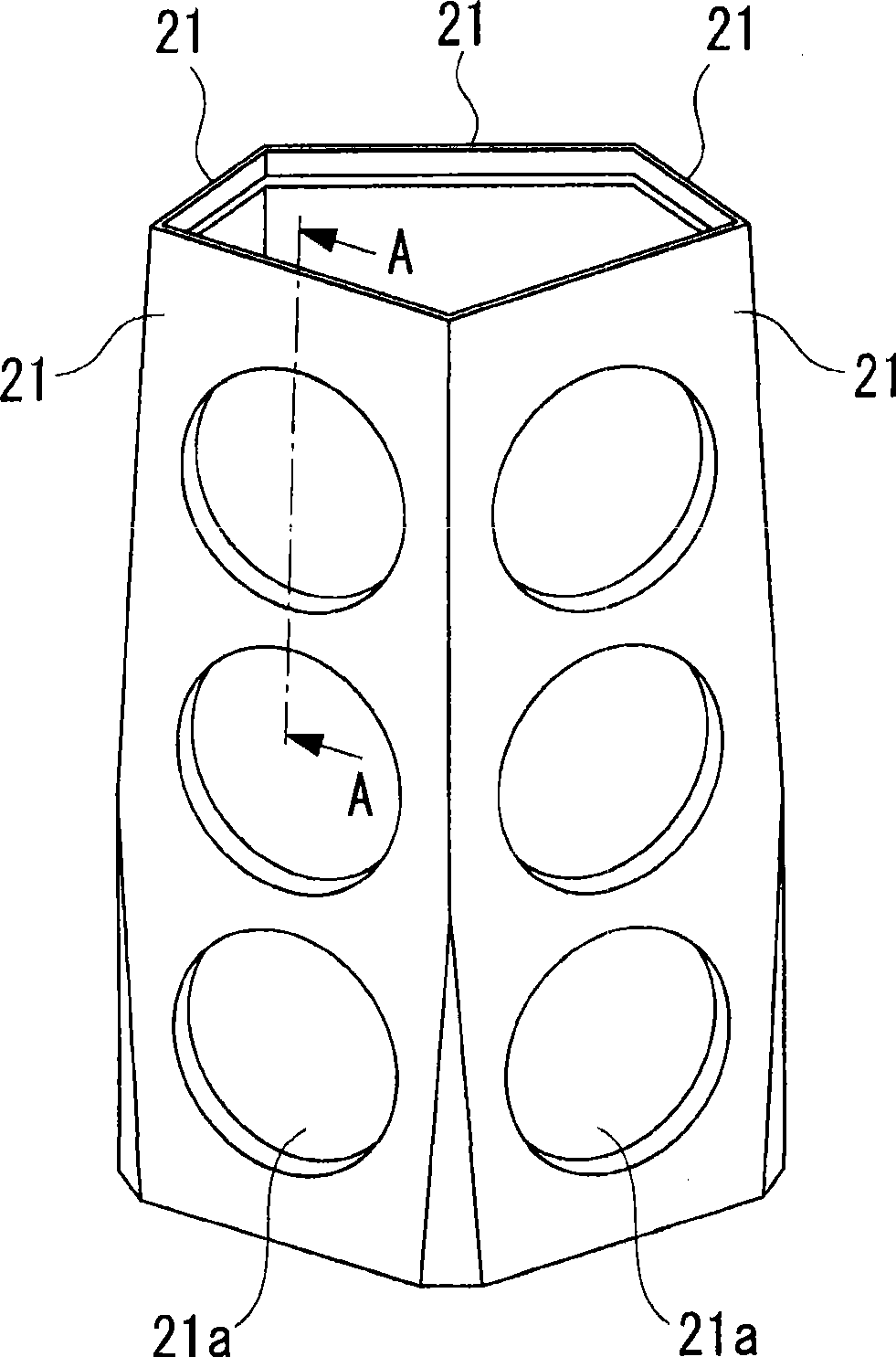

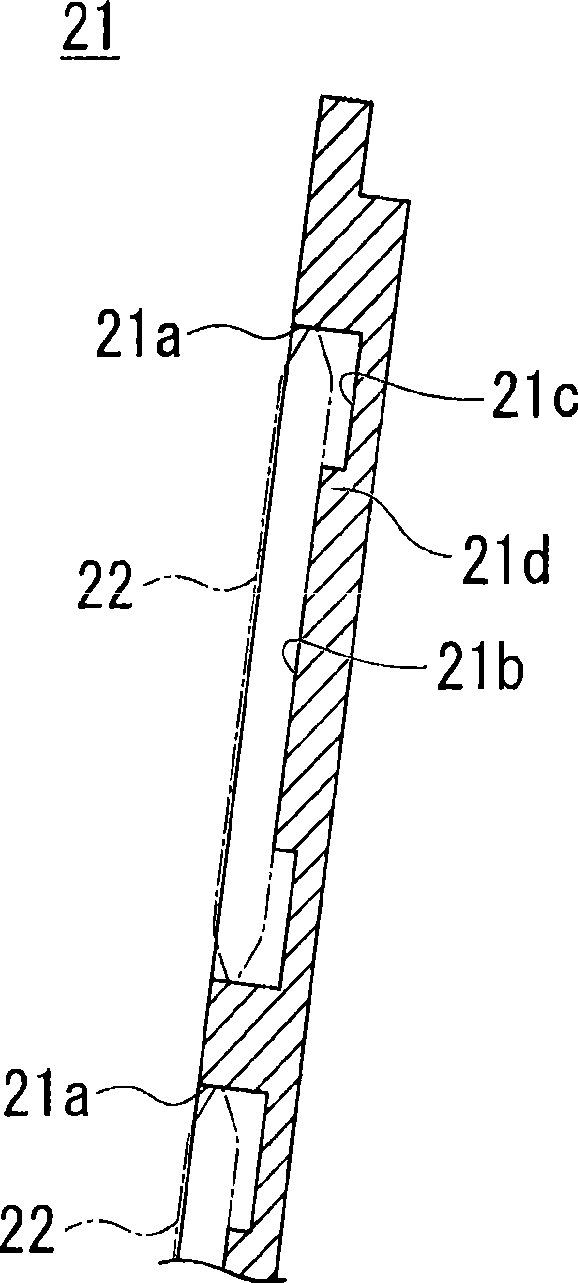

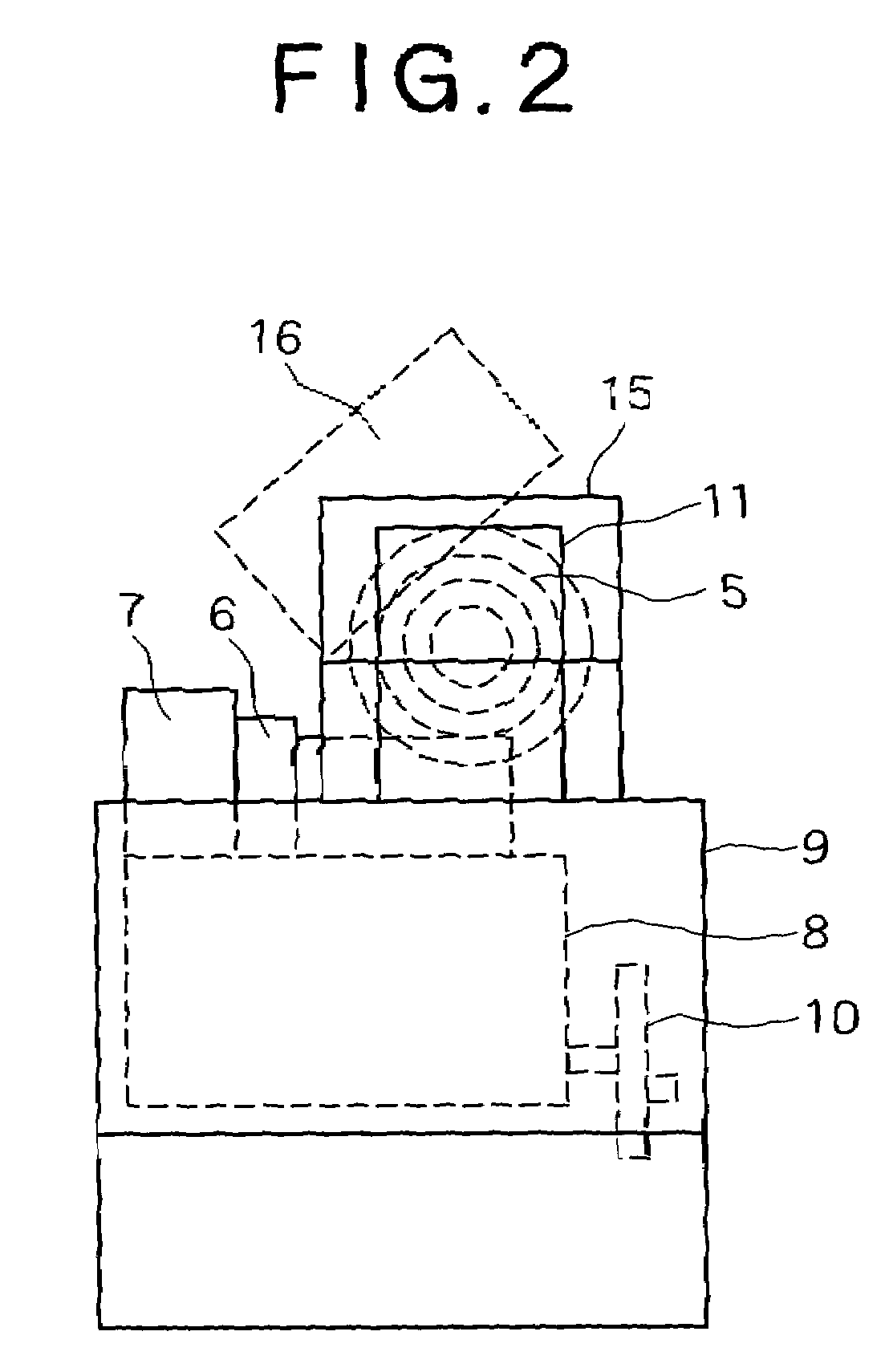

Susceptor for epitaxial layer forming apparatus, epitaxial layer forming apparatus, epitaxial wafer, and method of manufacturing epitaxial wafer

ActiveCN101423977AReduce flatness deviationSemiconductor/solid-state device manufacturingFrom chemically reactive gasesWaferingSusceptor

The present invention provides a base used by an epitaxial film forming device. The base is installed in the film forming chamber of epitaxial film forming device and is provided with a dent which is used for containing a semiconductor chip and is approximately circular in overhead view. The dent is installed with a projection which supports the semiconductor chip and is approximately circular in overhead view. The diameter of projection is smaller than that of the dent. Furthermore the diameter of projection is set to a size that the reacting gas for vapor growth reaction can wholly circulate at the interface between the projection and the semiconductor chip when the semiconductor chip is loaded on the dent.

Owner:SUMCO CORP

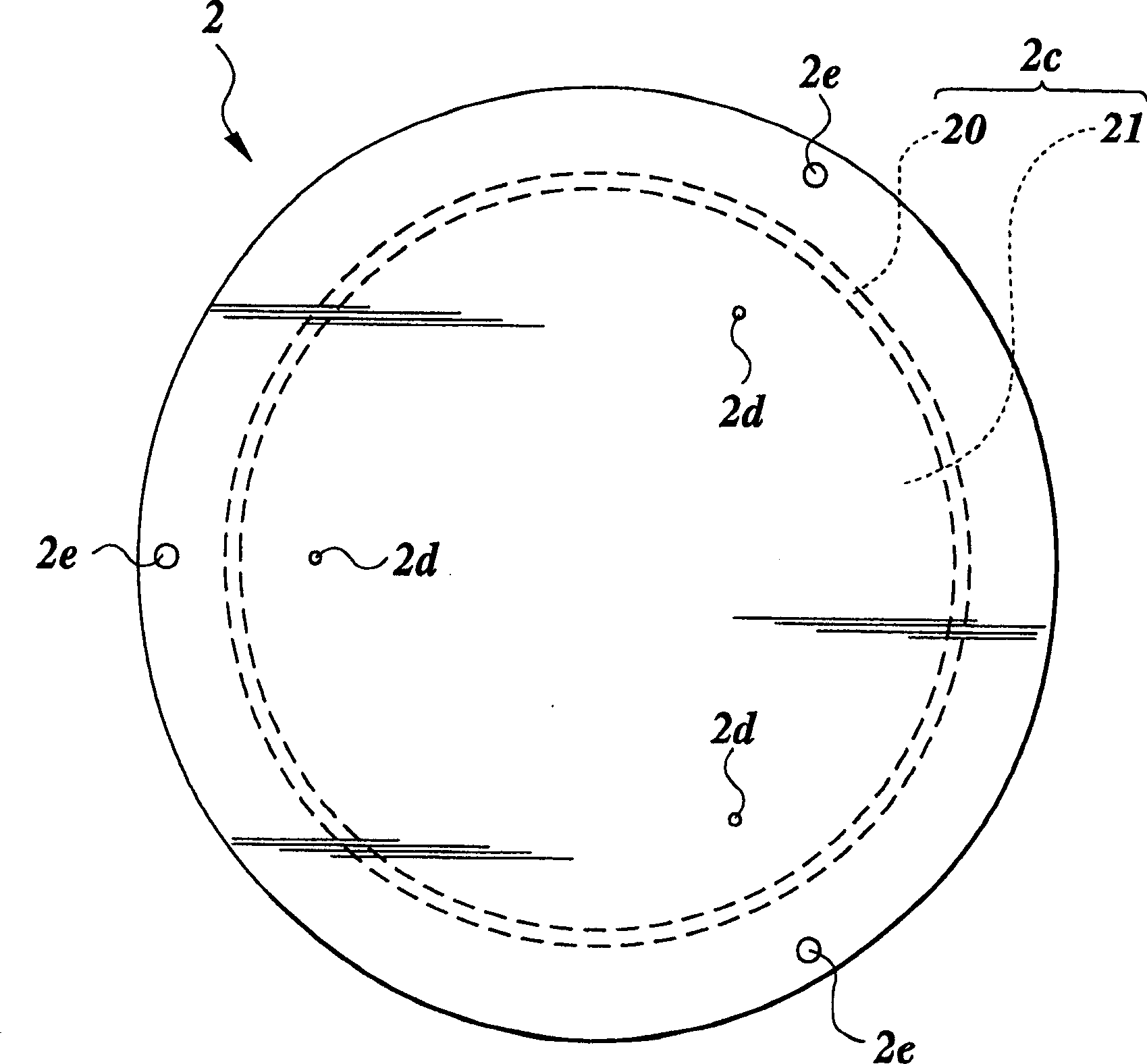

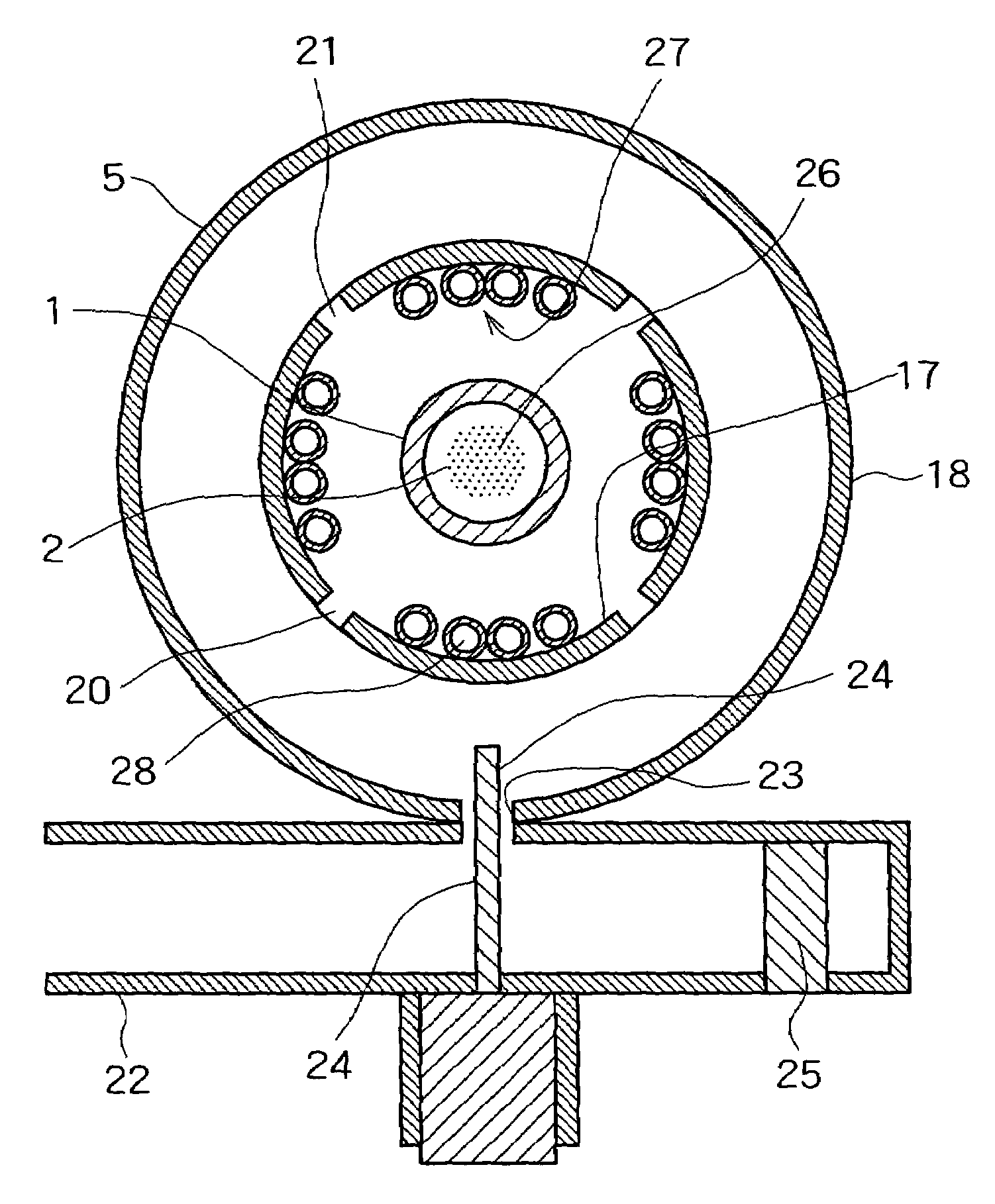

Susceptor and vapor growth device

ActiveCN1774794ASemiconductor/solid-state device manufacturingFrom chemically reactive gasesSusceptorEngineering

A susceptor (2), wherein the semiconductor substrate (W) is supported approximately horizontally in a recess (2c) when performing vapor phase growth of a single crystal thin film on the front surface of the semiconductor substrate (W), and the recess (2c ) includes an outer peripheral recess (20) for supporting a semiconductor substrate (W) and a central recess (21) formed inside the outer peripheral recess (20) and recessed from the outer peripheral recess (20), wherein The outer peripheral side recess (20) includes a substrate supporting surface (20a) inclined downward relative to a horizontal surface from the outer peripheral side toward the central side of the recess (2c), and at least The area outside the inner peripheral edge supports a part of the back surface of the semiconductor substrate (W) located inside the outer peripheral edge of the semiconductor substrate (W).

Owner:SHIN-ETSU HANDOTAI CO LTD

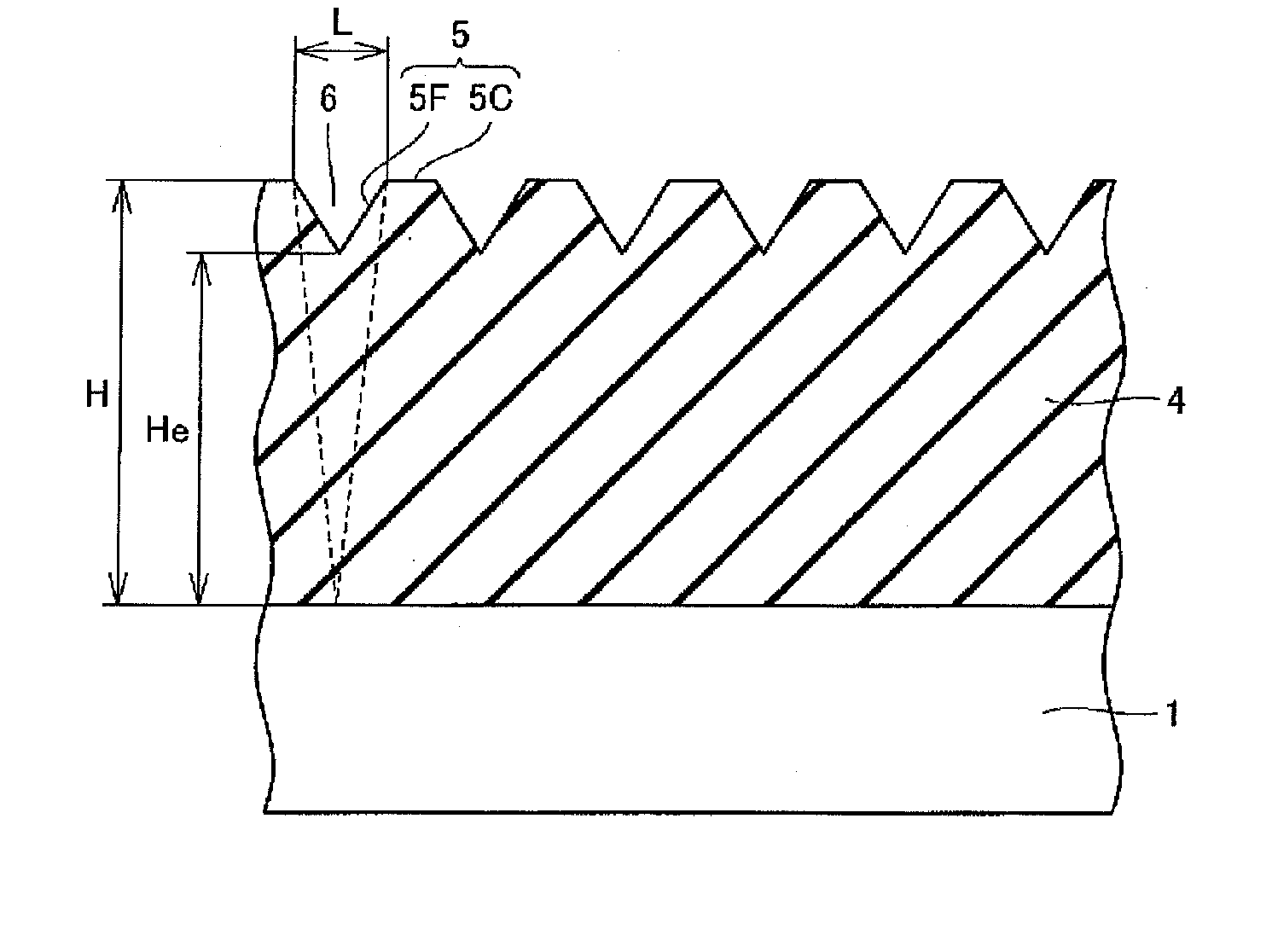

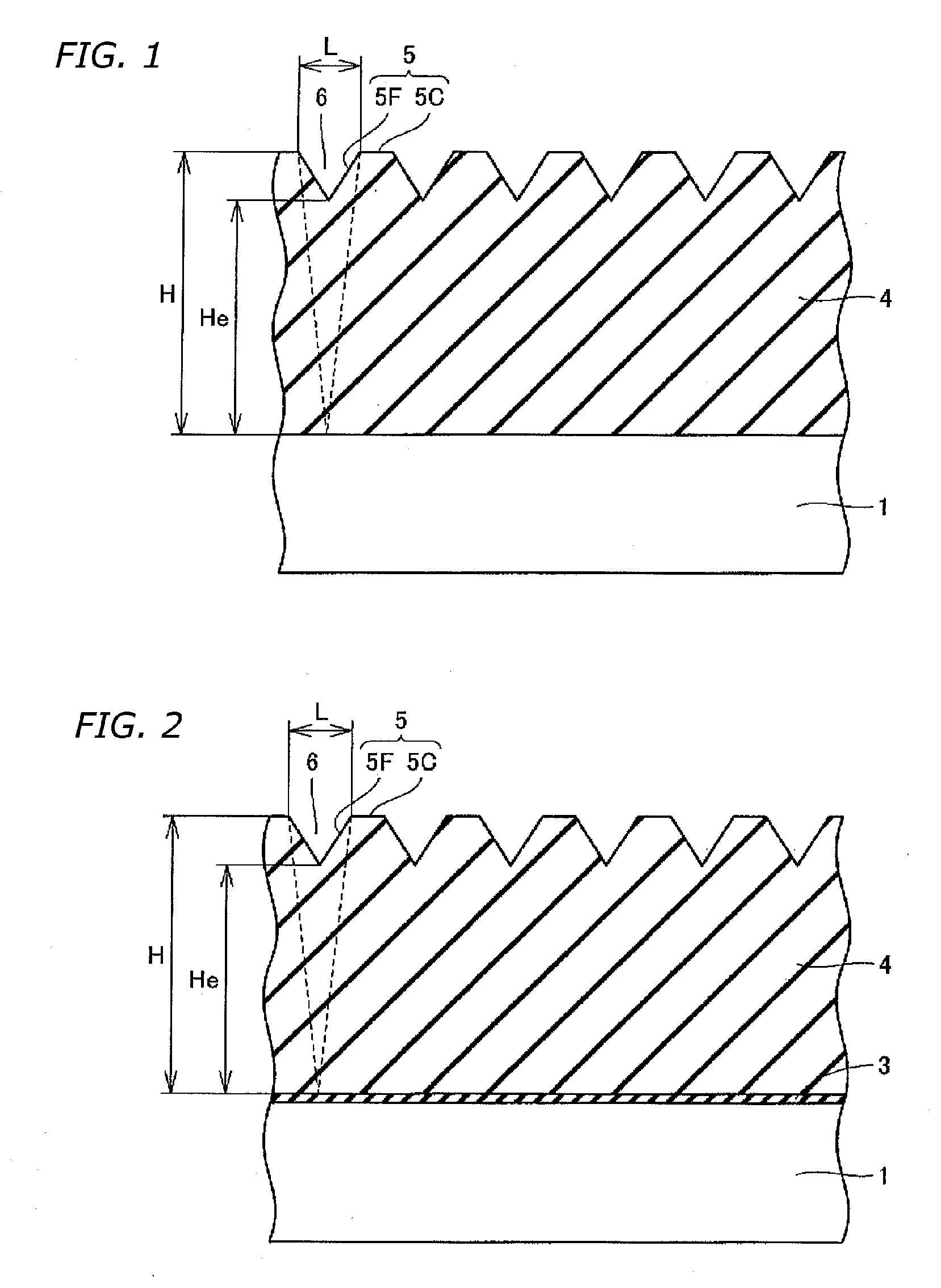

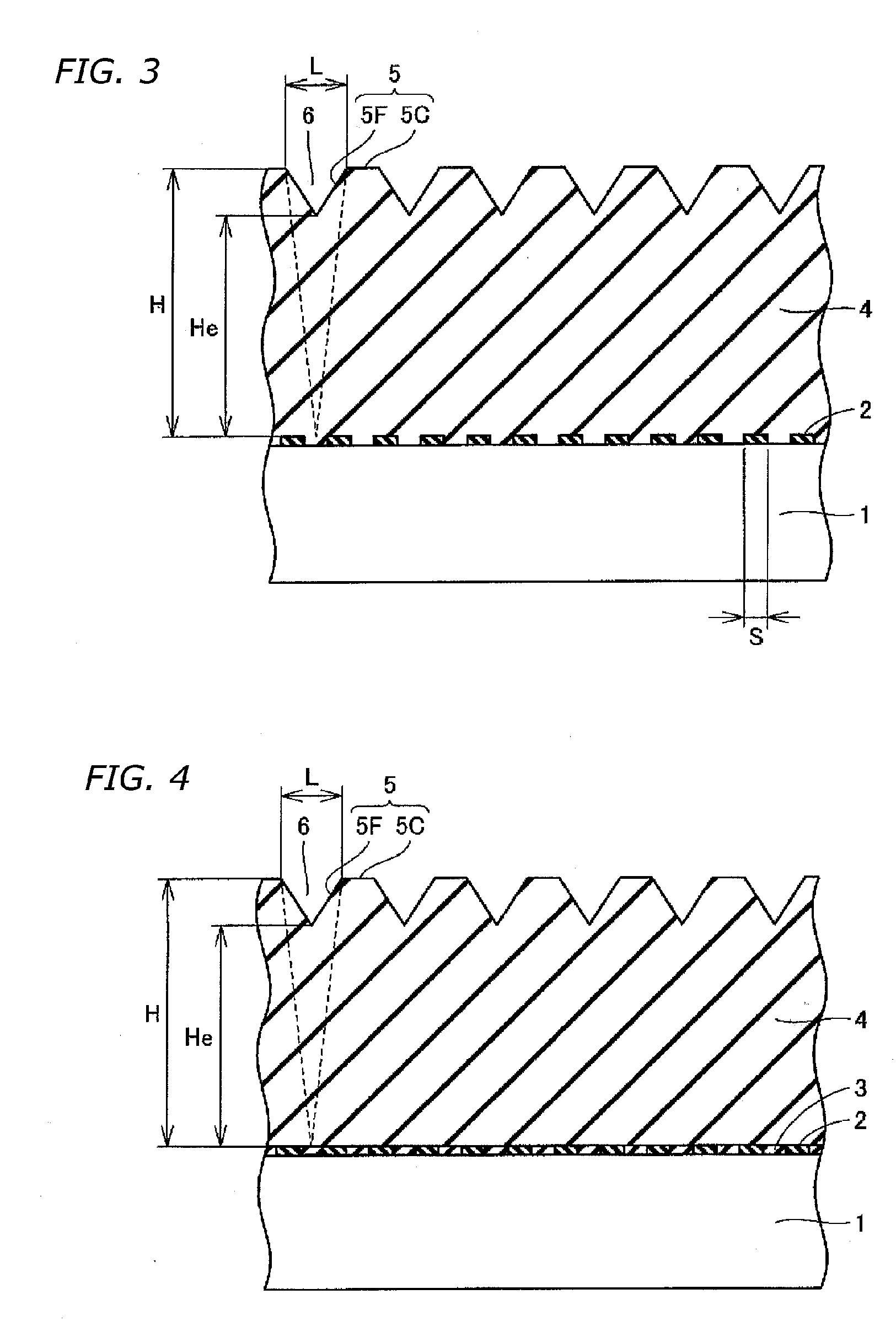

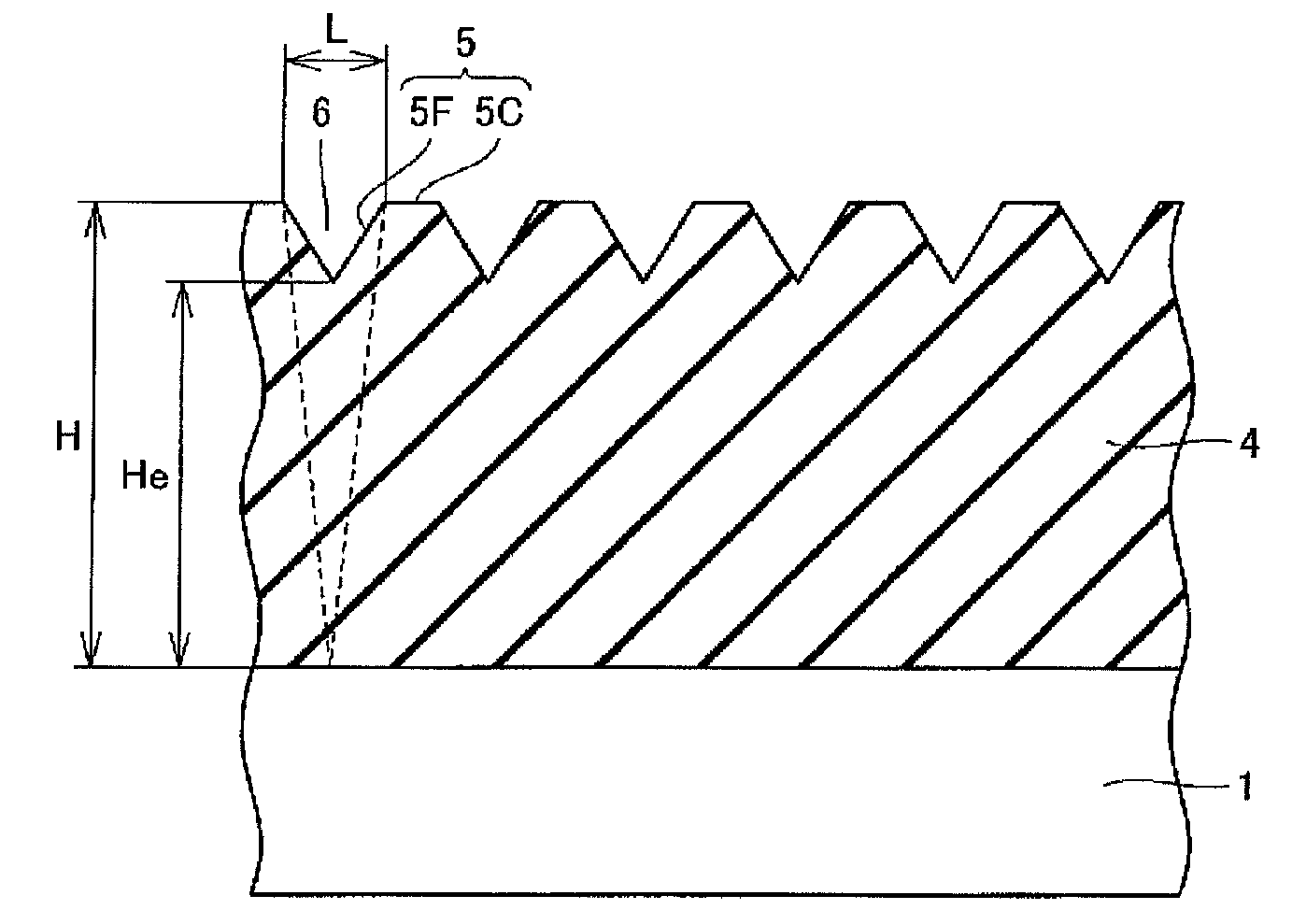

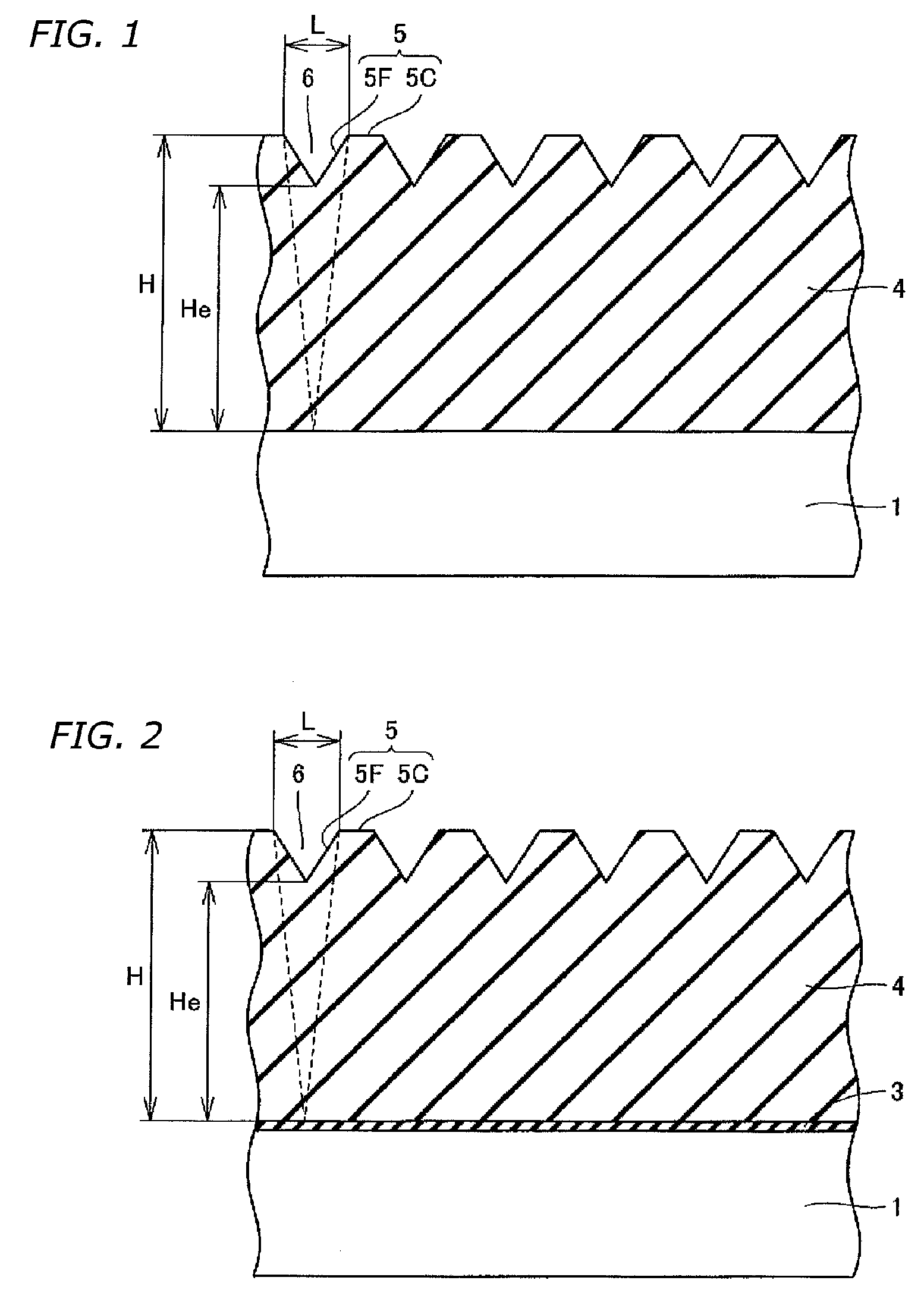

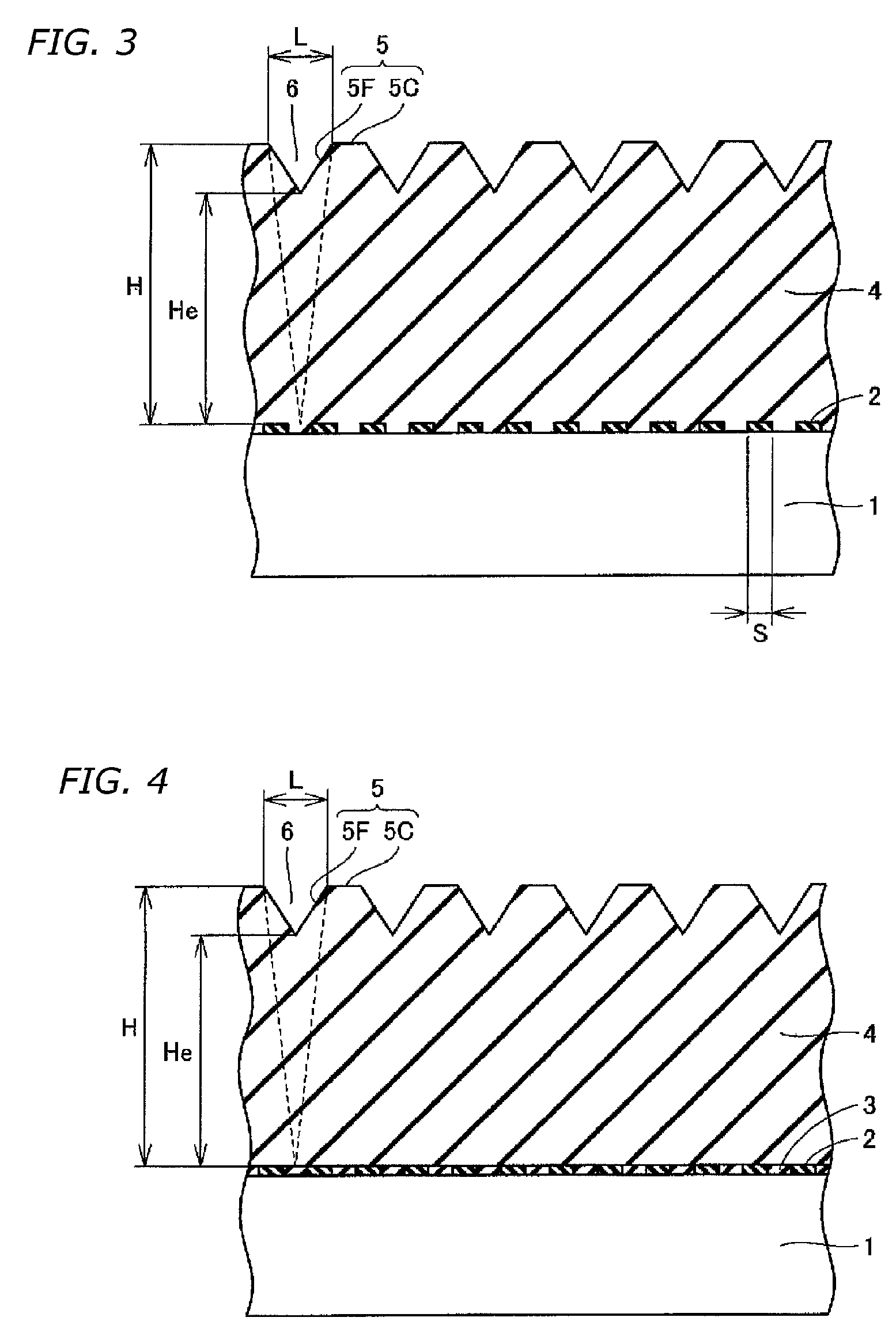

Method of Manufacturing GaN Crystal Substrate

InactiveUS20050155544A1Increase chanceIncrease in sizePolycrystalline material growthSolid-state devicesSize increaseGas phase

Affords a method of manufacturing GaN crystal substrate in which enlargement of pit size in the growing of GaN crystal is inhibited to enable GaN crystal substrate with a high substrate-acquisition rate to be produced. The method of manufacturing GaN crystal substrate includes a step of growing GaN crystal (4) by a vapor growth technique onto a growth substrate (1), the GaN-crystal-substrate manufacturing method being characterized in that in the step of growing the GaN crystal (4), pits (6) that define facet planes (5F) are formed in the crystal-growth surface, and being characterized by having the pit-size increase factor of the pits (6) be 20% or less.

Owner:SUMITOMO ELECTRIC IND LTD

Radiation image conversion panel

ActiveUS20110017925A1Excellent in luminanceImprove sharpnessElectrical apparatusElectroluminescent light sourcesGas phasePhosphor

A radiation image conversion panel which is excellent in luminance and sharpness is disclosed, comprising a phosphor layer formed on a support by a process of vapor growth, and the support comprising a resin and exhibiting a linear thermal expansion coefficient of 20 to 70 ppm / ° C.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

Method of manufacturing GaN crystal substrate

InactiveUS7481881B2Efficient yieldIncrease in sizePolycrystalline material growthSolid-state devicesSize increaseGas phase

Owner:SUMITOMO ELECTRIC IND LTD

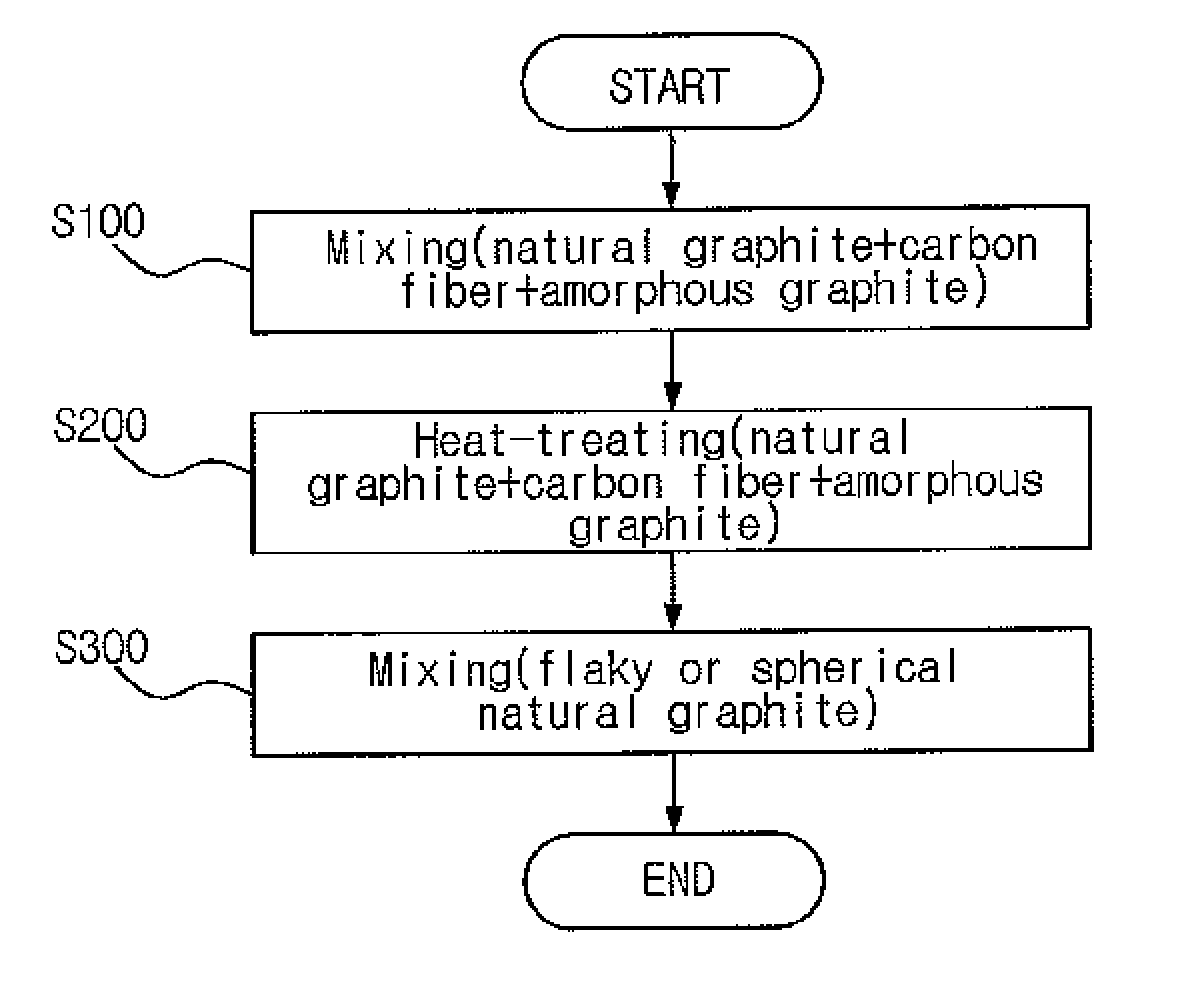

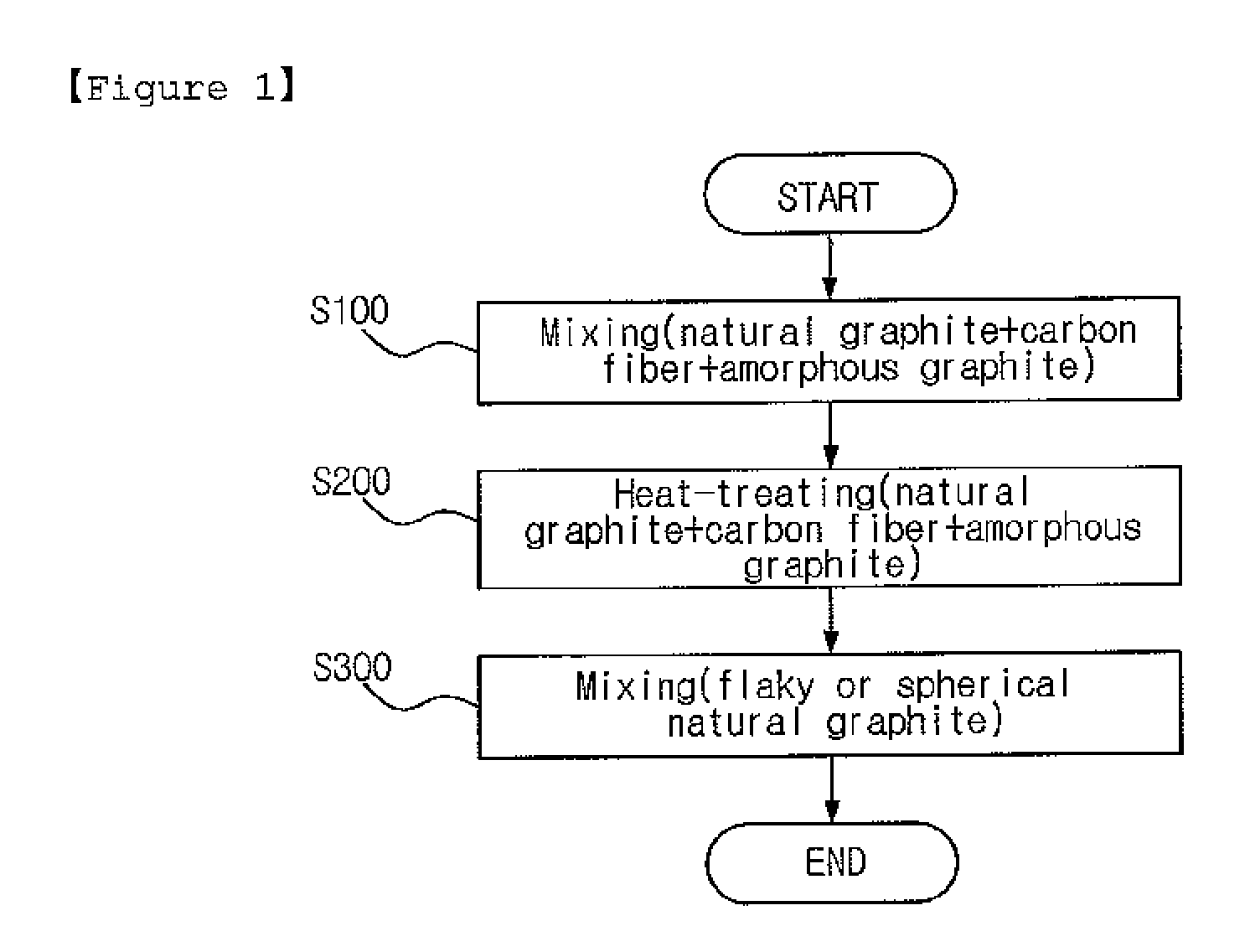

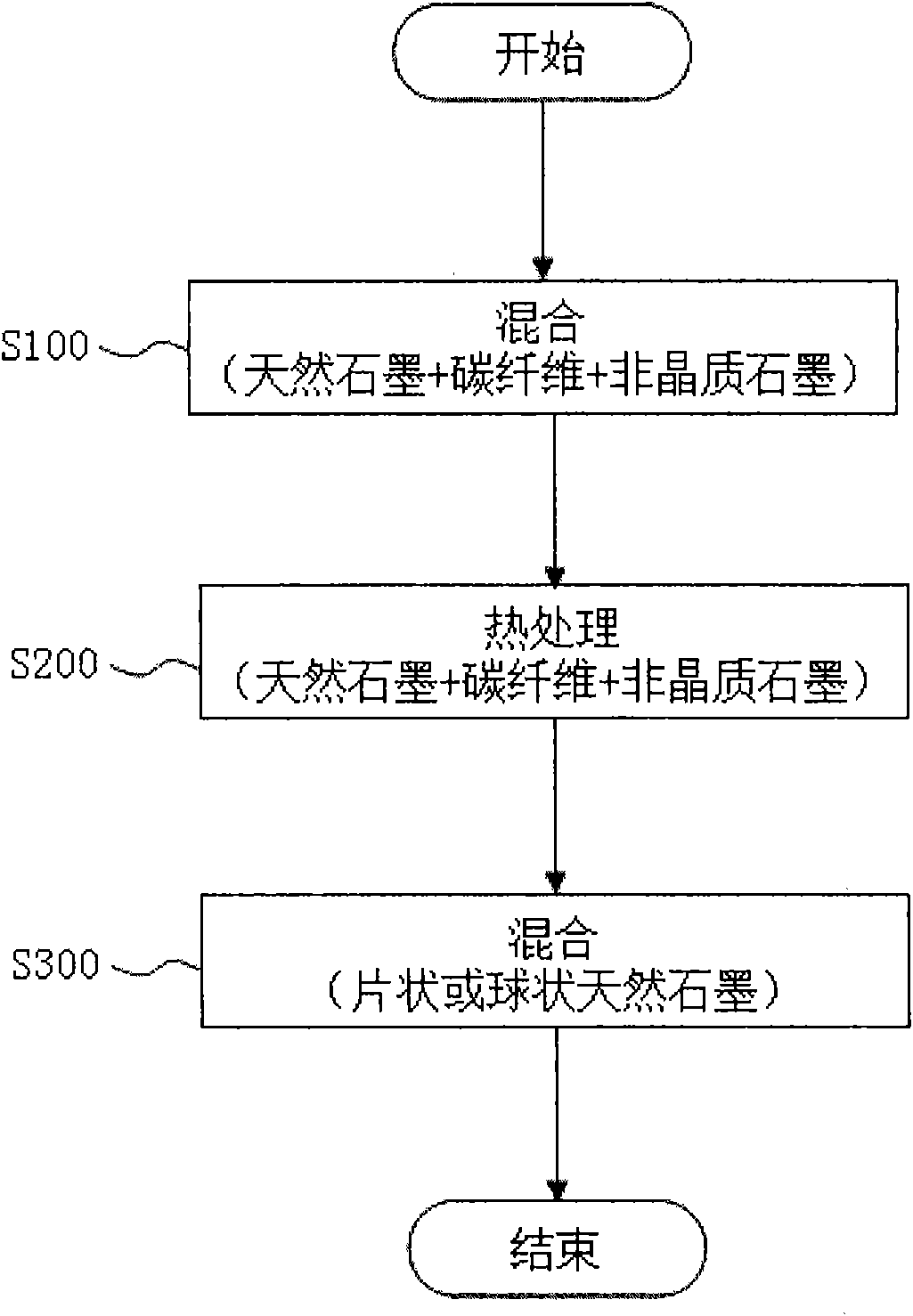

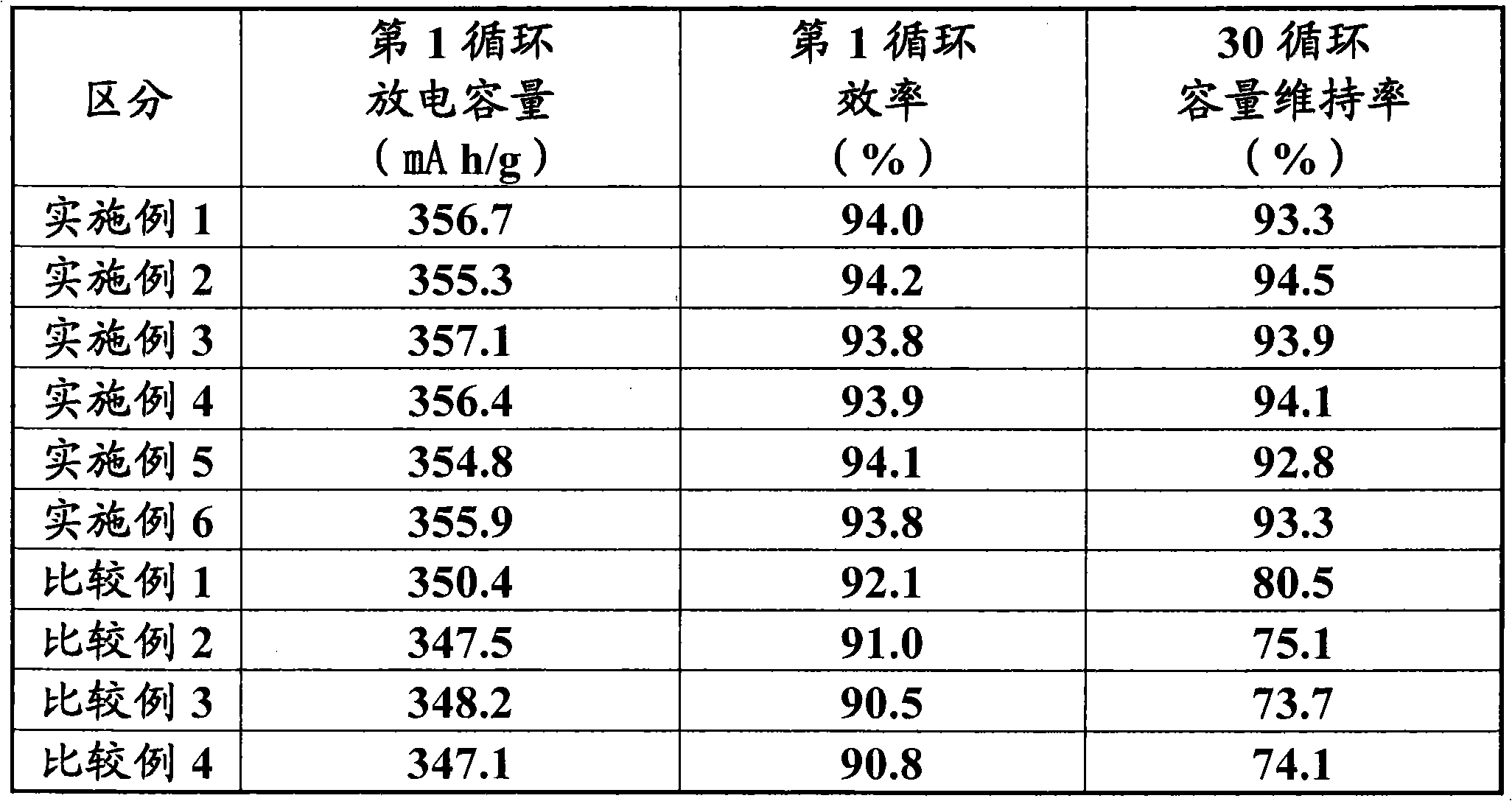

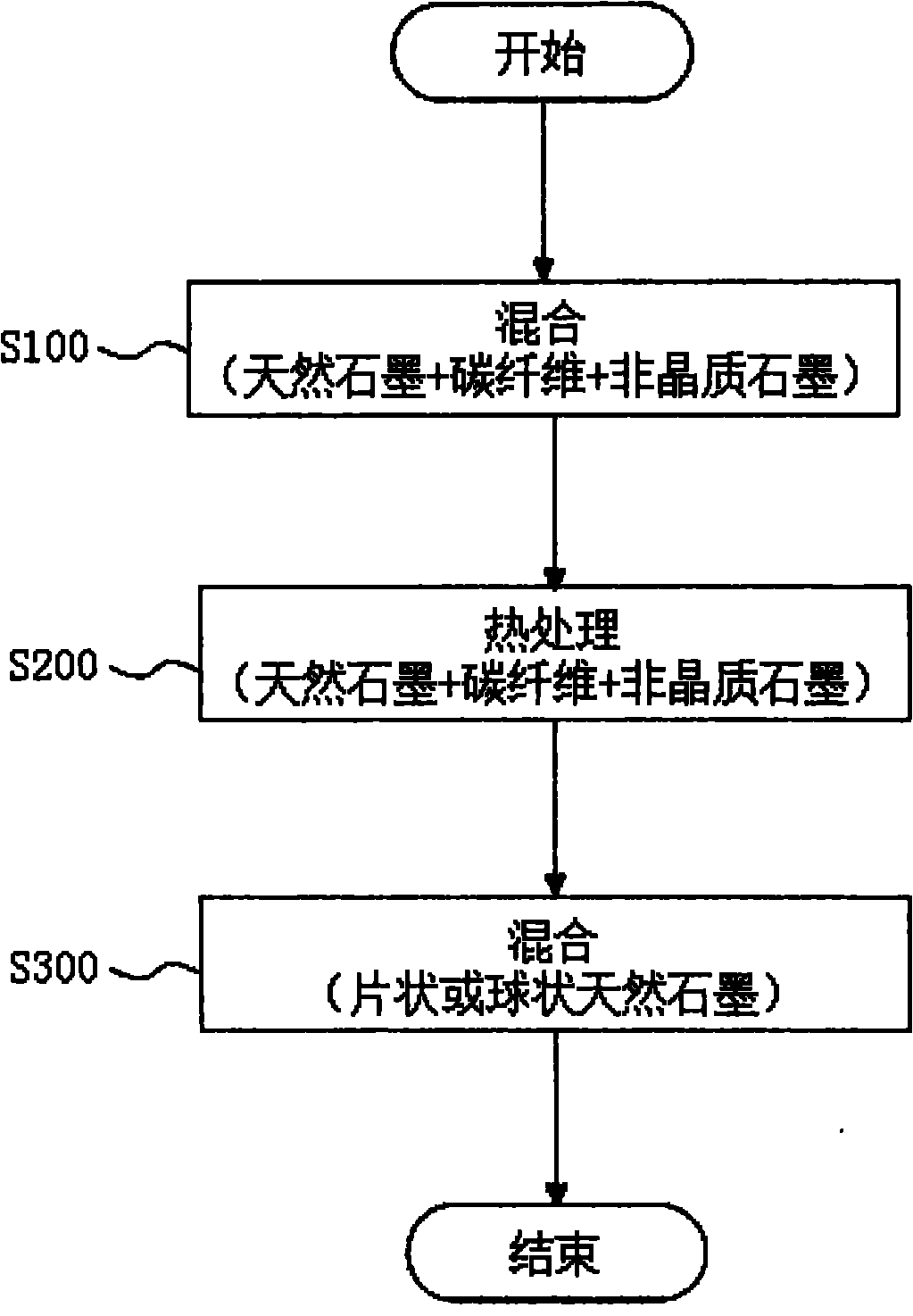

Negative electrode active material for lithium secondary battery, preparation method of the same, and lithium secondary battery containing the same

InactiveUS20110262812A1Good electrochemical propertiesMaterial nanotechnologyConductive materialFiberDischarge efficiency

The present invention relates to a negative electrode active material for a lithium secondary battery, a preparation method thereof, and a lithium secondary battery containing the negative electrode active material. The negative electrode active material for the lithium secondary battery according to the present invention is formed by mixing: a carbon material coated with vapor growth carbon fiber (VGCF) and amorphous graphite; and one or more kinds of other carbon material selected from natural graphite, artificial graphite, amorphous-coated graphite, resin-coated graphite and amorphous carbon. According to the present invention, when the negative electrode active material is prepared, the carbon fiber is uniformly dispersed throughout the carbon material, and the carbon material is coated with the amorphous graphite and then mixed with other carbon materials, and thus, a high electrode density can be achieved. Accordingly, even with high electrode density, the invention can provide the negative electrode active material with excellent electrochemical properties such as charge / discharge efficiency and cycle characteristics.

Owner:LS MTRON LTD +1

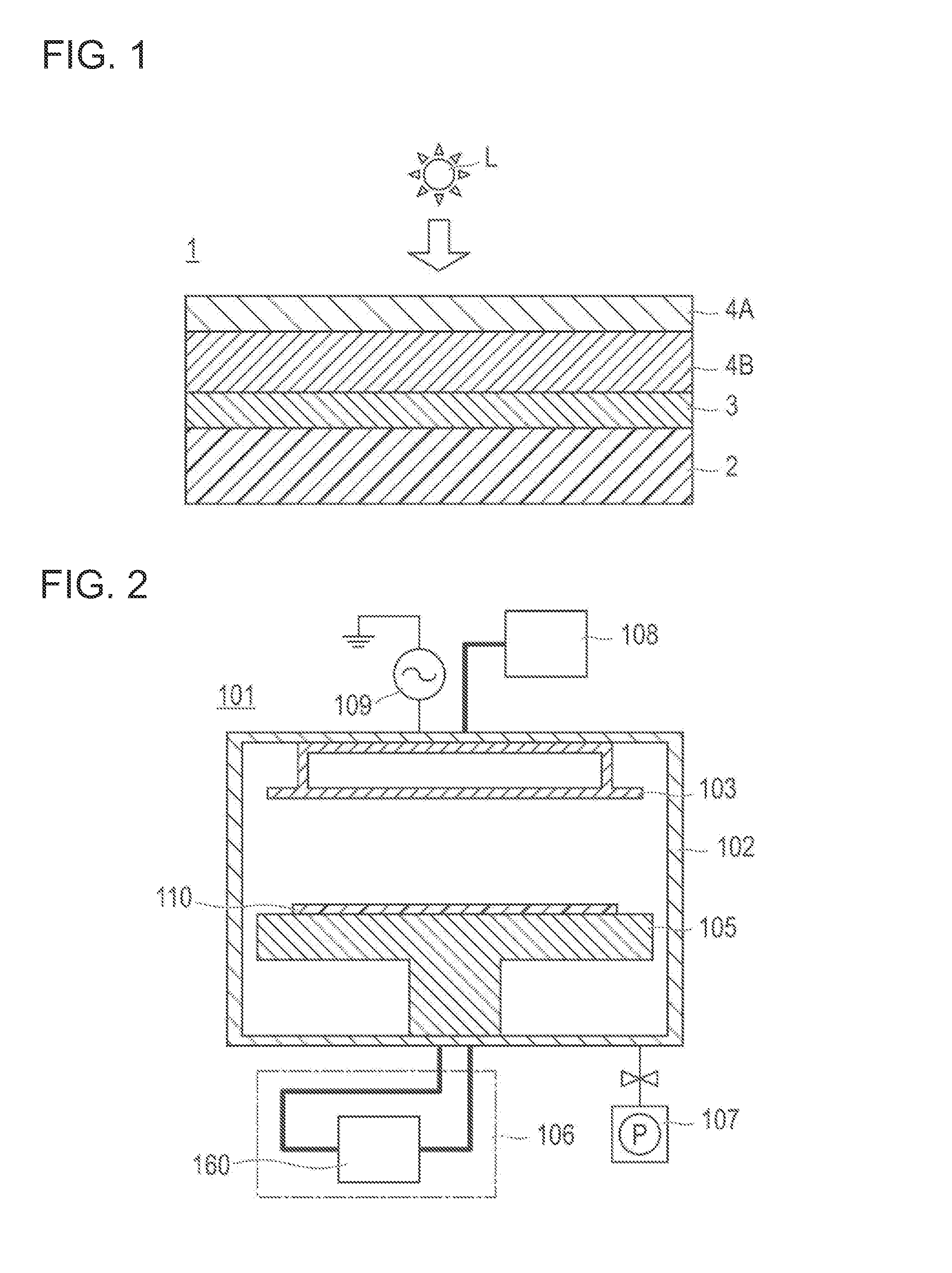

Plasma CVD apparatus

InactiveUS7156046B2Avoid overall overheatingReduced Radiation EfficiencyGlass making apparatusElectric discharge tubesGas phaseMicrowave power

A plasma CVD apparatus in which microwave power is supplied into a reaction chamber provided inside an annular waveguide through an antenna provided on the inner peripheral part of the waveguide to produce a plasma inside the reaction chamber and to form a film by a vapor growth synthesizing method. A cooler is disposed between the annular waveguide and the reaction chamber to maintain the low temperature of the annular waveguide.

Owner:KOBE STEEL LTD

Vapor phase growth apparatus and method of fabricating epitaxial wafer

ActiveUS8926753B2Shorten the lengthFriction minimizationAfter-treatment apparatusPolycrystalline material growthSusceptorGas phase

Material gas hits the outer peripheral surface of a dam member and rides on the upper surface side, and then is allowed to flow along the main surface of a silicon single-crystal substrate placed on a susceptor. An upper lining member is disposed above the dam member so as to face the dam member. A gas introducing clearance is formed between the dam member and the upper lining member. In a vapor growth device, the upper lining member is regulated in size so that the length, formed in a direction along the horizontal reference line, of the gas introducing clearance gradually decreases as it is away from the horizontal reference line or is kept constant at any position. A vapor growth device capable of making more uniform the flowing route of a material gas flowing on the silicon single-crystal substrate, and a production method for an epitaxial wafer are provided.

Owner:SHIN-ETSU HANDOTAI CO LTD

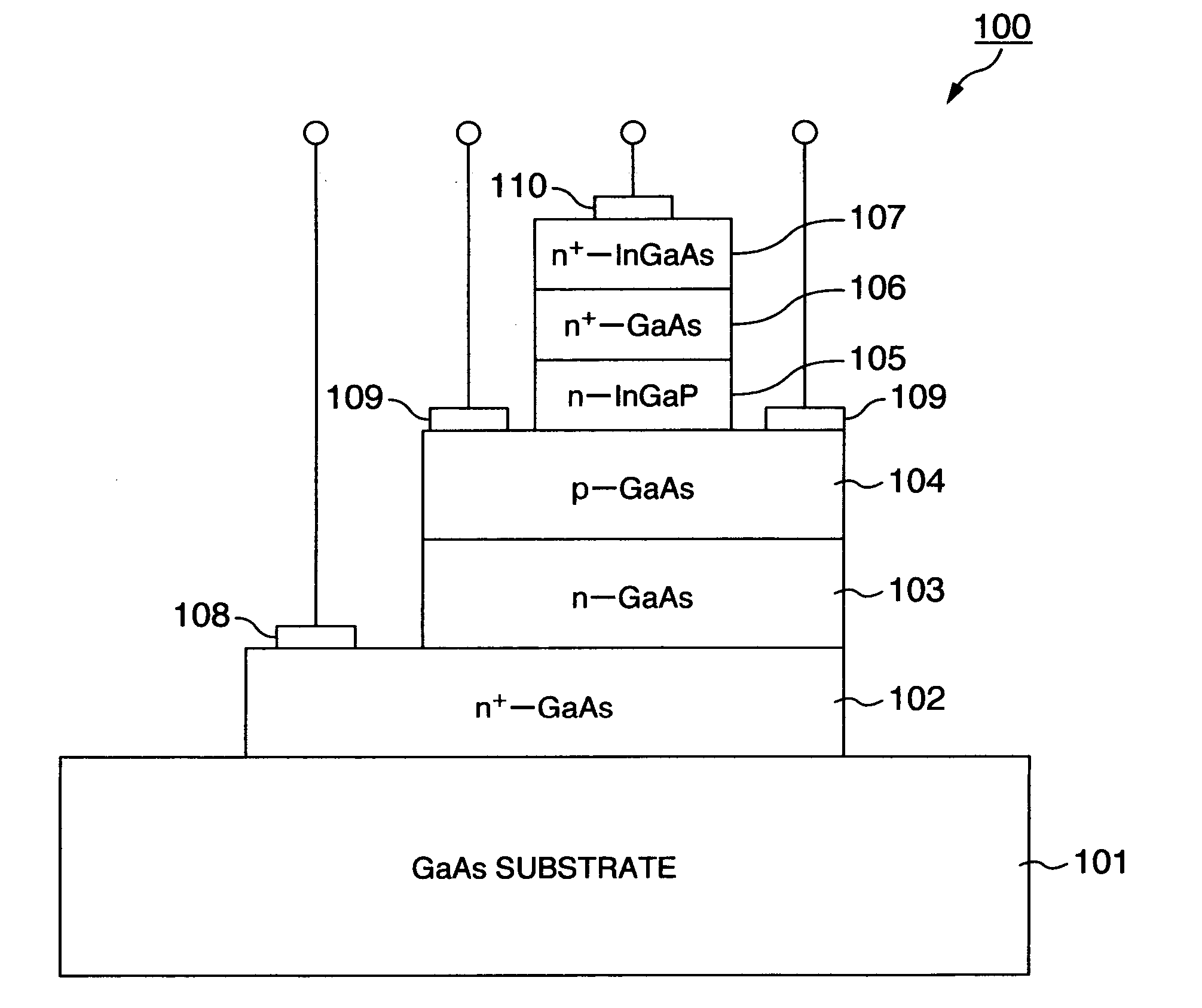

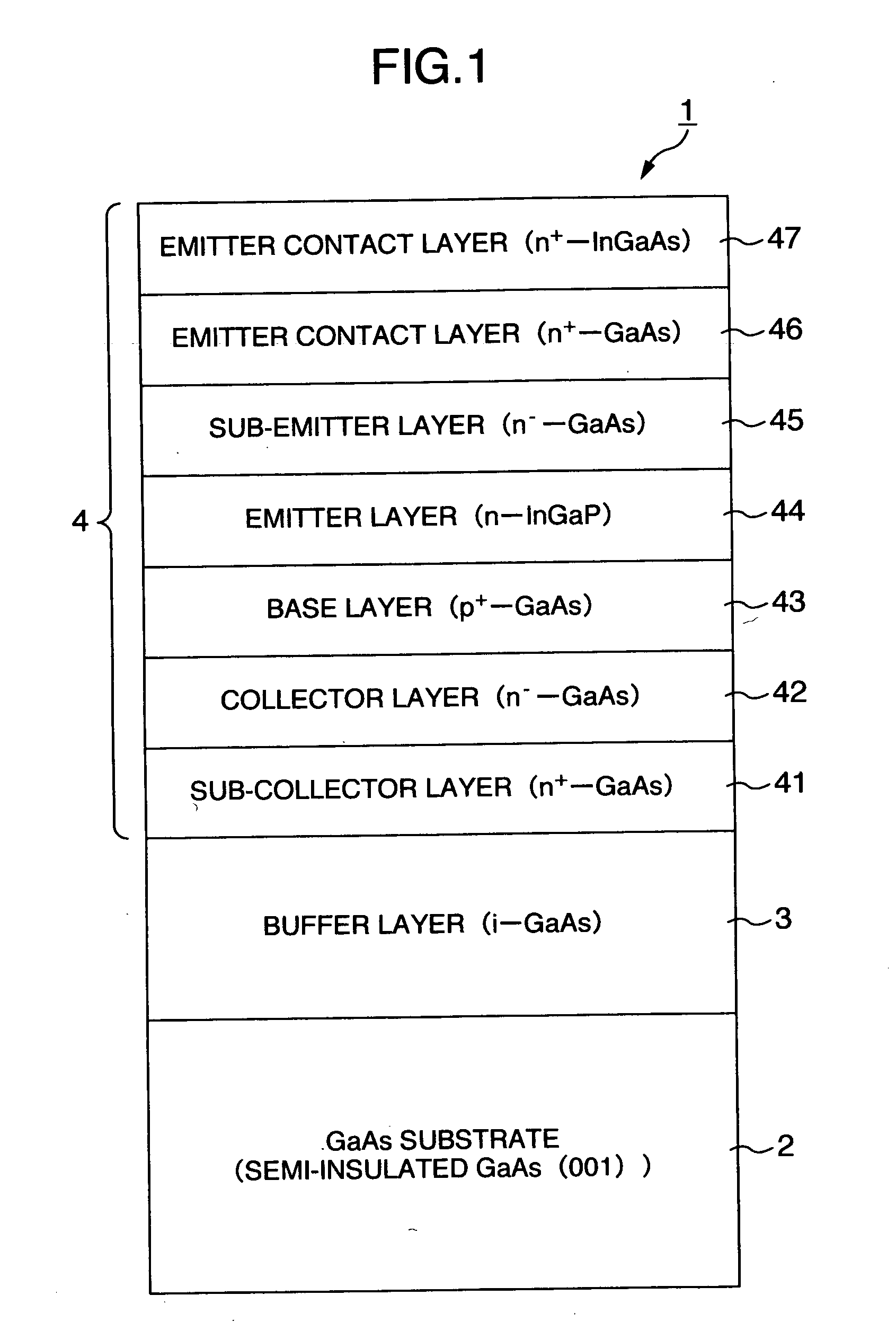

Method for manufacturing compound semiconductor wafer and compound semiconductor device

InactiveUS20060001044A1Solve problemsHigh crystallinityThyristorSemiconductor/solid-state device manufacturingCompound (substance)Compound semiconductor

A method for producing a compound semiconductor wafer used for production of HBT by vapor growth of a sub-collector layer, a collector layer, a base layer and an emitter layer in this turn on a compound semiconductor substrate using MOCVD method wherein the base layer is grown as a p-type compound semiconductor thin film layer containing at least one of Ga, Al and In as a Group III element and As as a Group V element under such growth conditions that the growth rate gives a growth determined by a Group V gas flow rate-feed.

Owner:SUMITOMO CHEM CO LTD +1

Fine carbon fiber, fine short carbon fiber, and manufacturing method for said fibers

InactiveUS20140329093A1High bonding strengthImprove conductivityMaterial nanotechnologySynthetic resin layered productsFiberCarbon fibers

A novel fine carbon fiber produced by vapor growth, in which a graphite-net plane consisting of carbon atoms alone forms a temple-bell-shaped structural unit including a closed head-top part and a body-part with an open lower-end, in which an angle θ formed by a generatrix of the body-part and a fiber axis is less than 15°, 2 to 30 of the temple-bell-shaped structural units are stacked sharing a central axis to form an aggregate, and the aggregates are connected head-to-tail with a distance to form a fiber. Fine short carbon fibers with excellent dispersibility can be obtained by shortening the fine carbon fiber.

Owner:UBE IND LTD

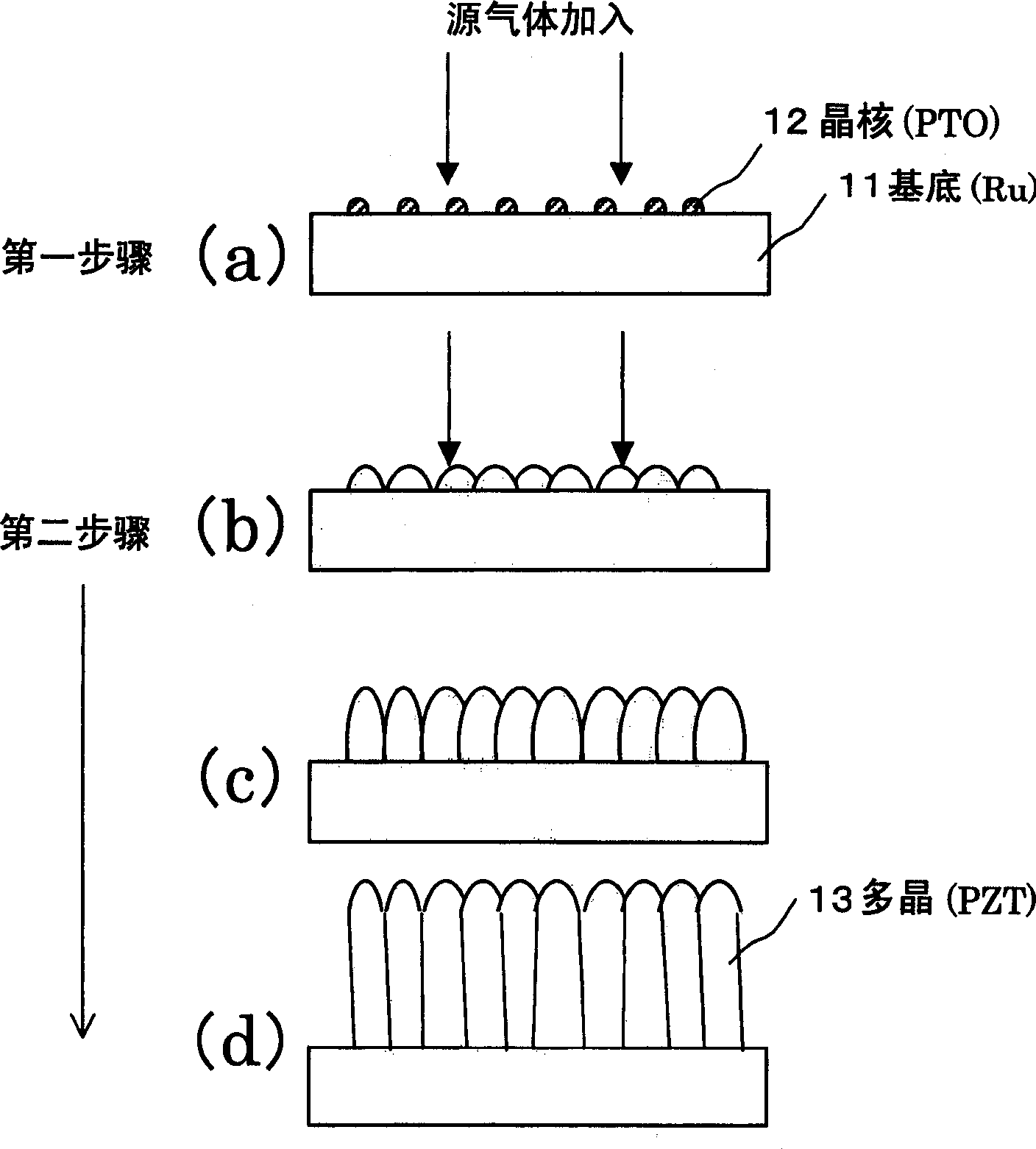

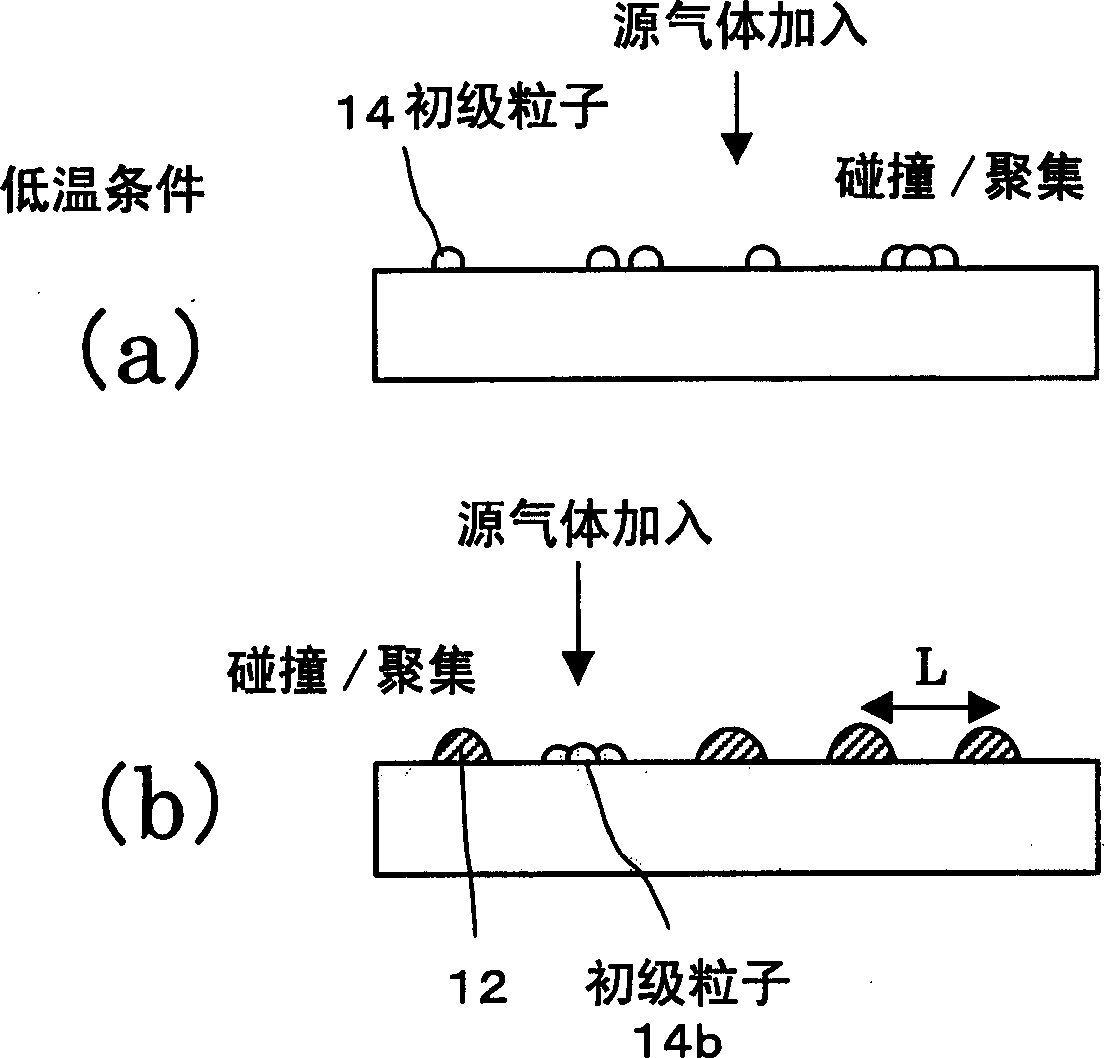

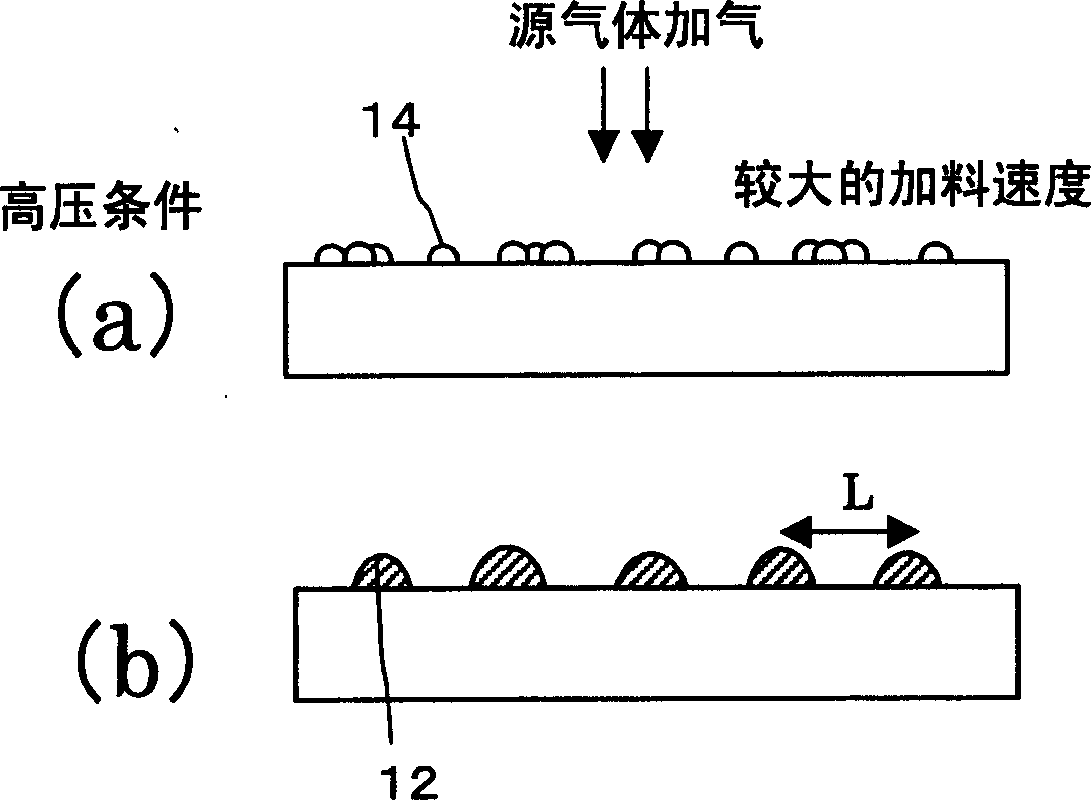

Vapor growth method for metal oxide dielectric film and PZT film

For forming a metal-oxide dielectric film having a perovskite type of crystal structure represented by ABO3 on a base conductor material using organometallic source gases, initial perovskite crystal nuclei or an initial amorphous layer having an amorphous structure are formed on the base conductor material under the first deposition conditions; and a film having a perovskite crystal structure is further grown on the initial crystal nuclei or the initial amorphous layer under the second deposition conditions. In the process, the first deposition conditions meet at least one of the requirements: (a) a lower substrate temperature than that in the second deposition conditions; and (b) a higher source gas pressure than that in the second deposition conditions. This process can be used to deposit a film such as PZT exhibiting a reduced leak current.

Owner:NEC CORP

Method of manufacturing ink jet recording head

InactiveUS7637013B2High densityImprove accuracyRecording apparatusPiezoelectric/electrostrictive device manufacture/assemblyGas phaseEngineering

A method, which is capable of manufacturing an ink jet recording head with a high degree of accuracy even though the density of an ink passage pattern is increased, includes the steps of forming an ink passage pattern on a substrate formed therein with an ink discharge pressure generating element from dissoluble resin; depositing an organic material on the substrate formed thereon with the ink passage pattern from the dissoluble resin by a vapor growth process at a temperature at which the dissolubility of the dissoluble resin is not lost, so as to form a coated resin layer; forming an ink discharge port in the coated resin layer in parts located above the ink discharge pressure generating element; and eluting the dissoluble resin.

Owner:CANON KK

Negative electrode active material for lithium secondary battery, preparation method of the same, and lithium secondary battery containing the same

InactiveCN102077398AGood electrochemical propertiesActive material electrodesLi-accumulatorsFiberDischarge efficiency

The present invention relates to a negative electrode active material for a lithium secondary battery, a preparation method thereof, and a lithium secondary battery containing the negative electrode active material. The negative electrode active material for the lithium secondary battery according to the present invention is formed by mixing: a carbon material coated with vapor growth carbon fiber (VGCF) and amorphous graphite; and at least one kind of other carbon material selected from natural graphite, artificial graphite, amorphous-coated graphite, resin-coated graphite and amorphous carbon. According to the present invention, when the negative electrode active material is prepared, the carbon fiber is uniformly dispersed throughout the carbon material, and the carbon material is coated with the amorphous graphite and then mixed with other carbon materials, and thus high electrode density can be achieved. Accordingly, even with high electrode density, the invention can provide the negative electrode active material with excellent electrochemical properties such as charge / discharge efficiency and cycle characteristics.

Owner:POSCO CHEMTECH CO LTD +1

Carbon nanofiber, method for production thereof, method for production of carbon fiber composite material using carbon nanofiber, and carbon fiber composite material

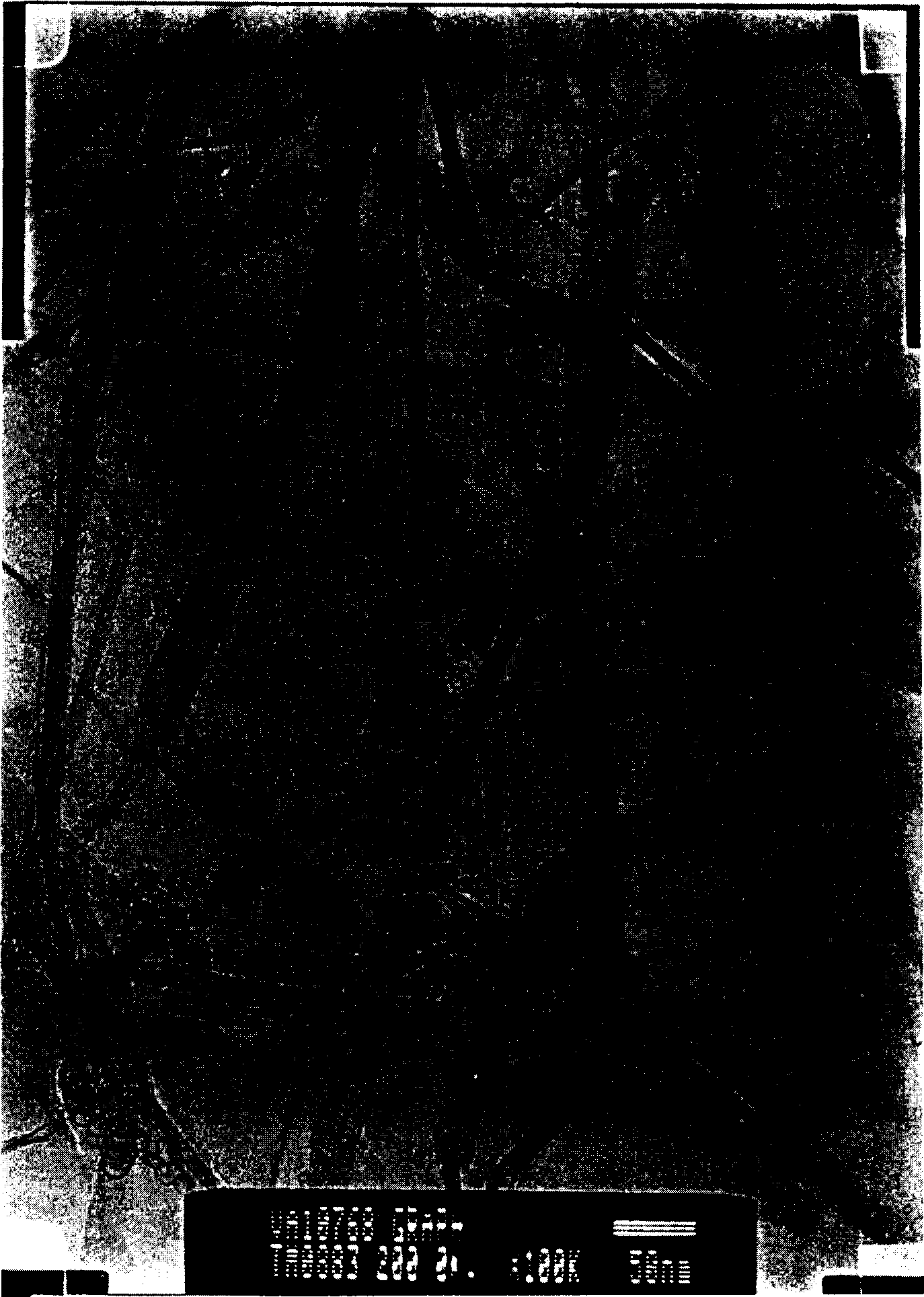

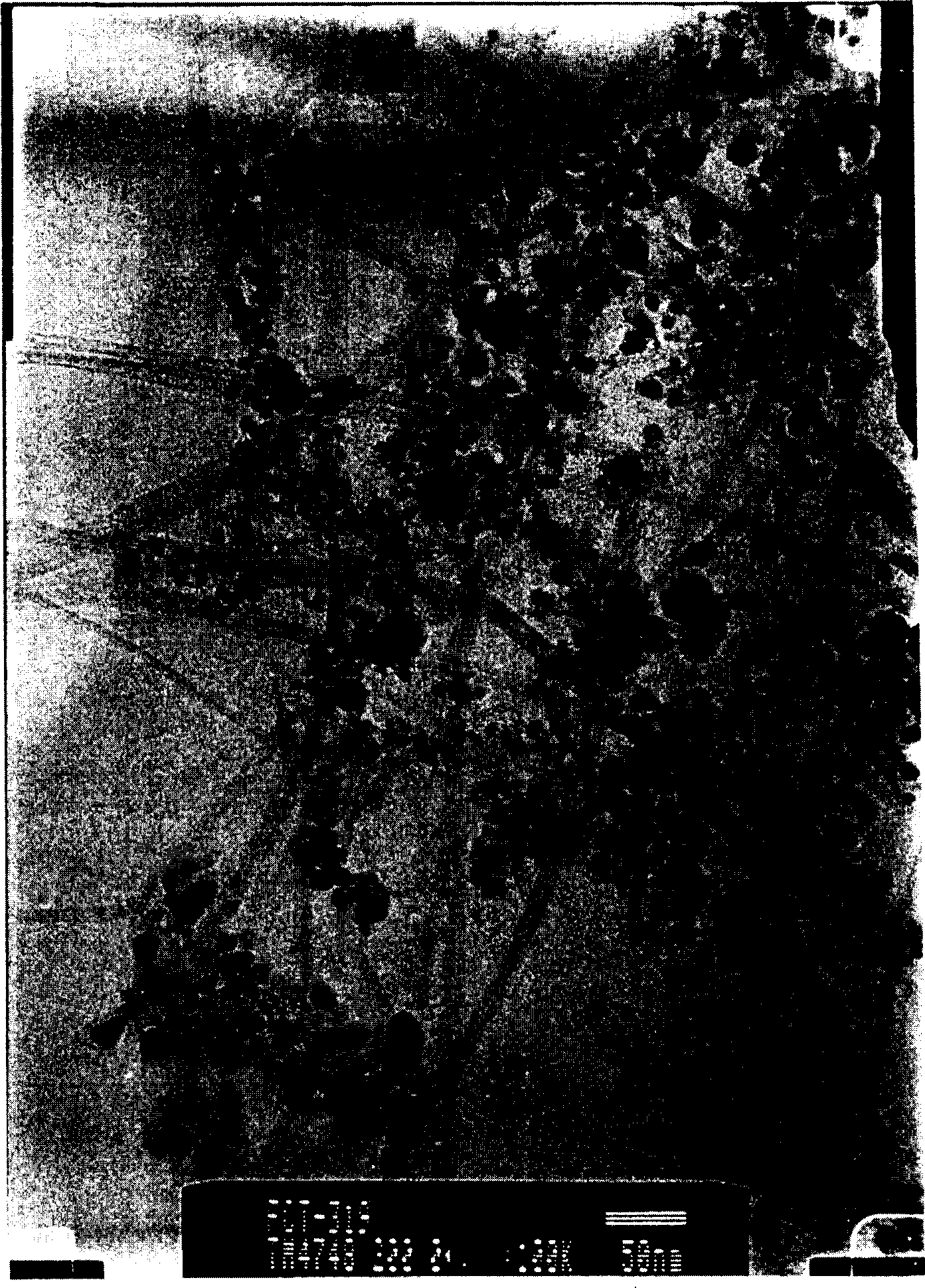

ActiveUS8263698B2Improve surface reactivityImprove wettabilityMaterial nanotechnologySpecial tyresElastomerCarbon nanofiber

A method of producing a carbon fiber composite material includes a first step and a second step. The first step includes oxidizing first carbon nanofibers produced by a vapor growth method to obtain second carbon nanofibers having an oxidized surface. The second step includes mixing the second carbon nanofibers into an elastomer, and uniformly dispersing the carbon nanofibers in the elastomer by applying a shear force to obtain the carbon fiber composite material. The second carbon nanofibers obtained by the first step have a surface oxygen concentration measured by X-ray photoelectron spectroscopy (XPS) of 2.6 to 4.6 atm %.

Owner:HITACHI ASTEMO LTD +1

Fine carbon fiber mixture and composition thereof

A fine carbon fiber mixture produced through a vapor-growth process, which comprises fine carbon fiber, each fiber filament of the fiber having an outer diameter of 1 to 500 nm and an aspect ratio of 10 to 15,000 and comprising a hollow space extending along its center axis and a multi-layer sheath structure consisting of a plurality of carbon layers; and non-fibrous carbon such as flake-like carbon, granular carbon, or sheet-like carbon. A composition comprising a resin or a rubber and a fine carbon fiber mixture as above contained therein. An electrically conductive article or a sliding article comprising the composition.

Owner:SHOWA DENKO KK +1

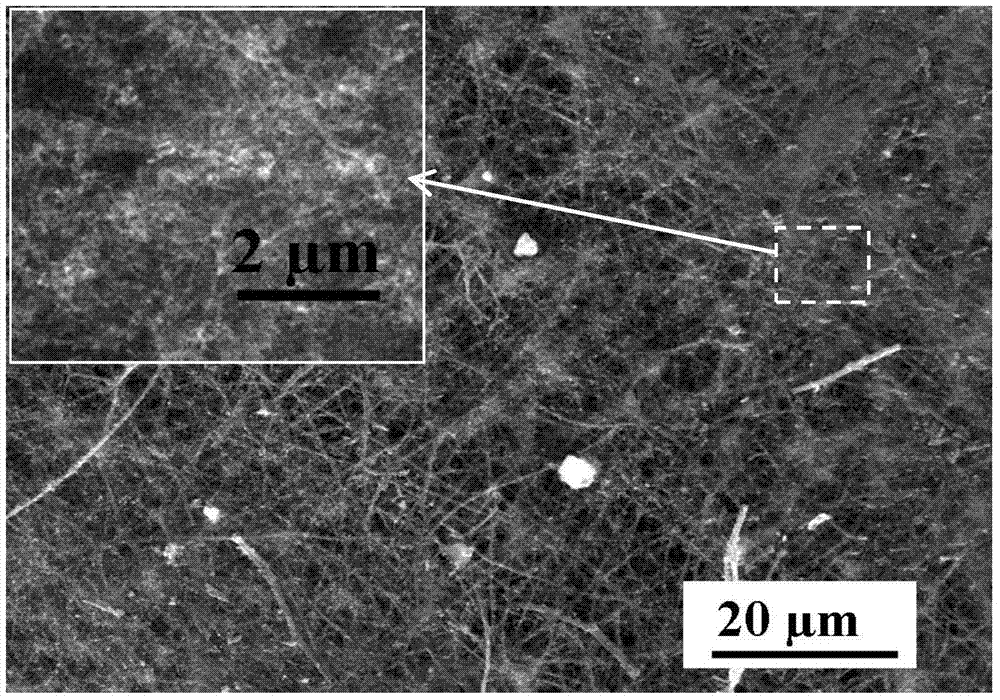

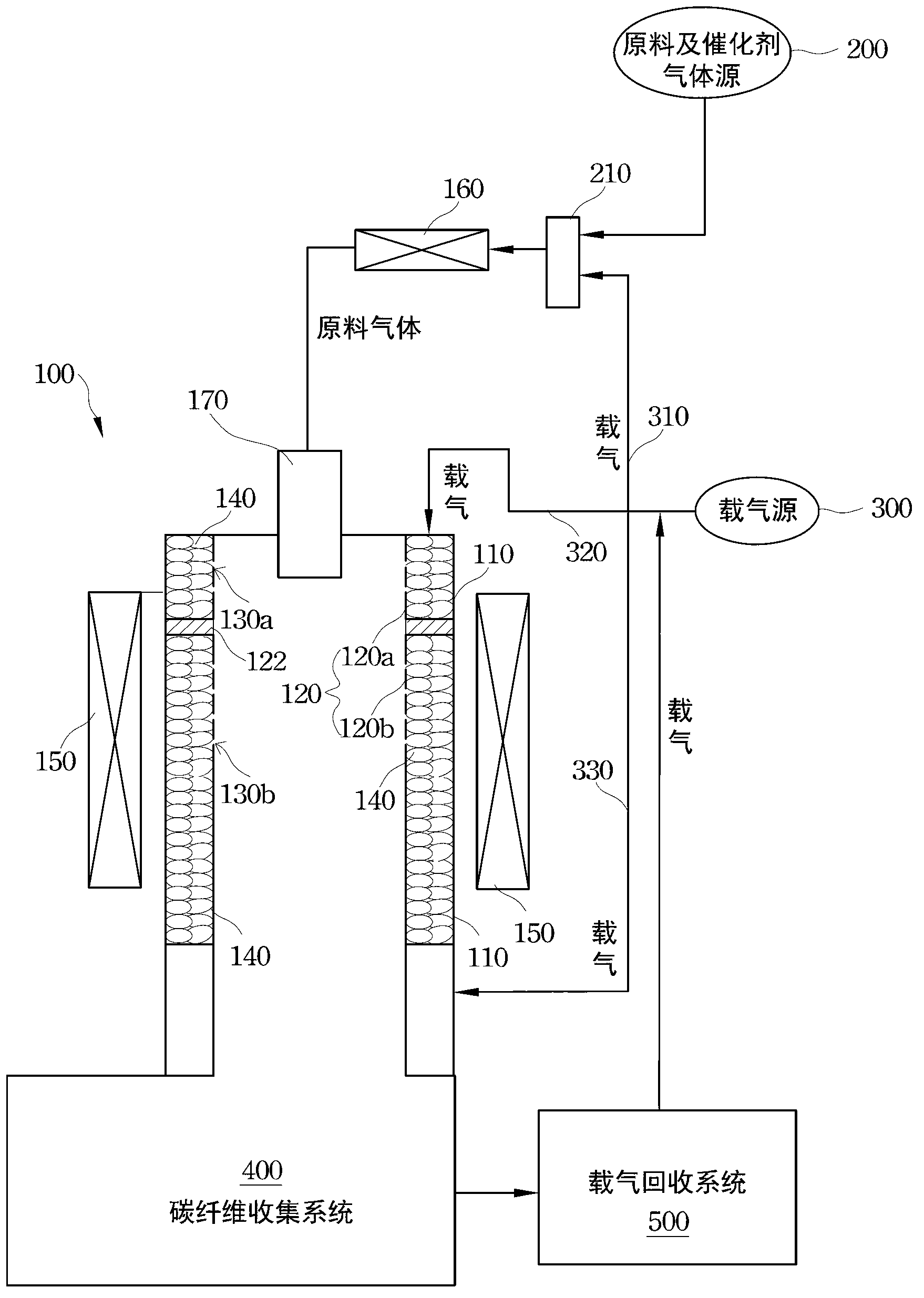

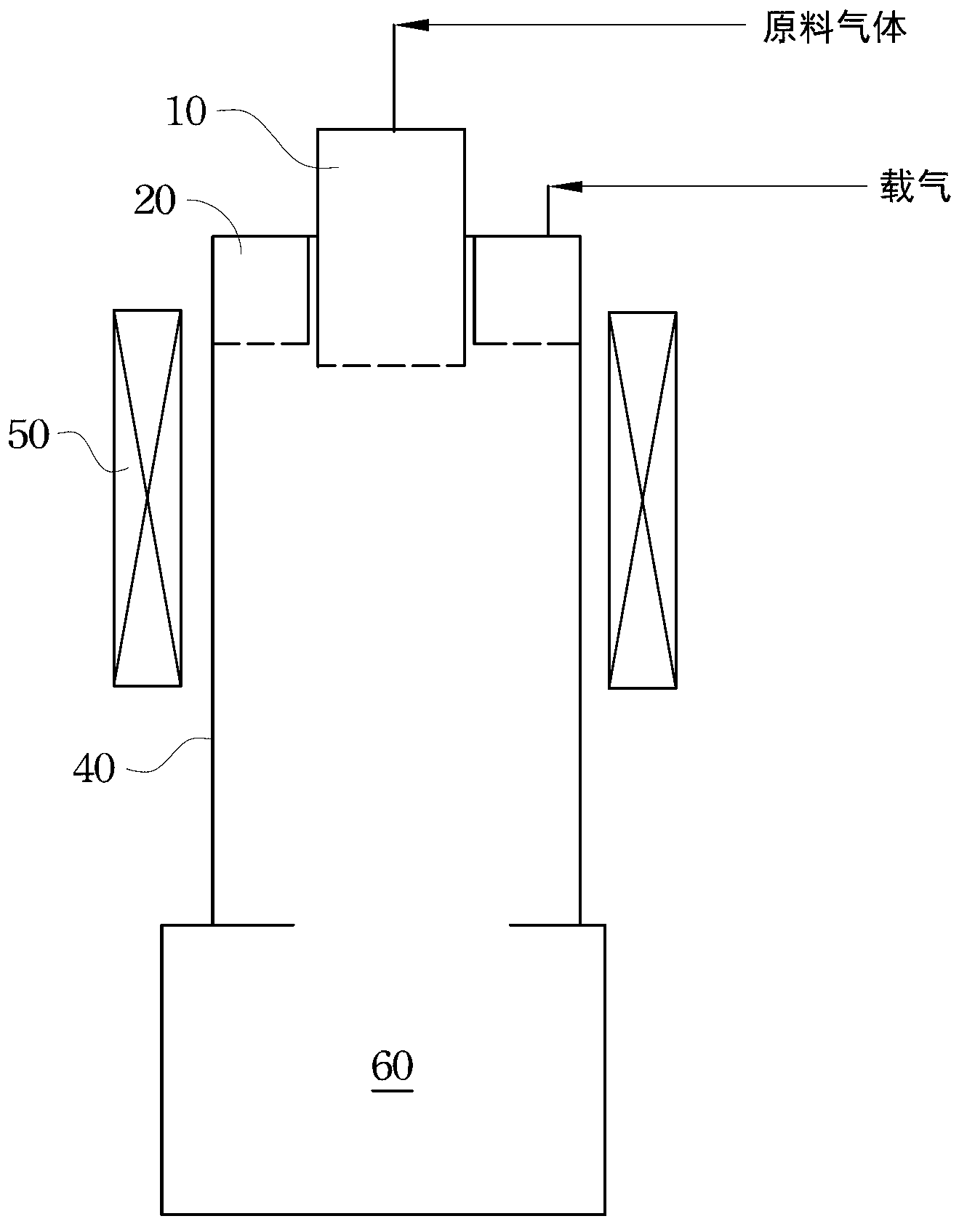

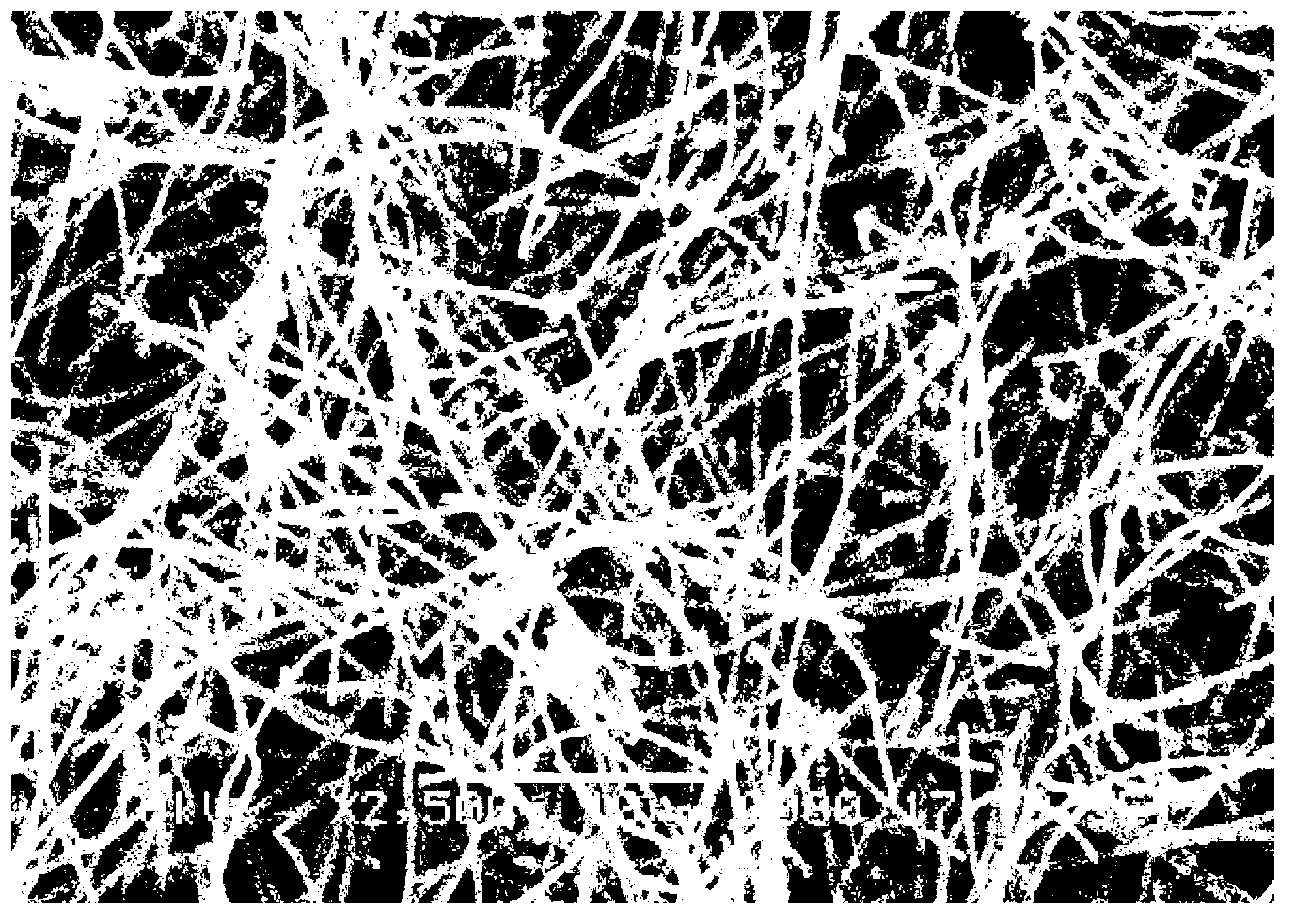

Vapor growth graphite fiber composition, its mixture and application

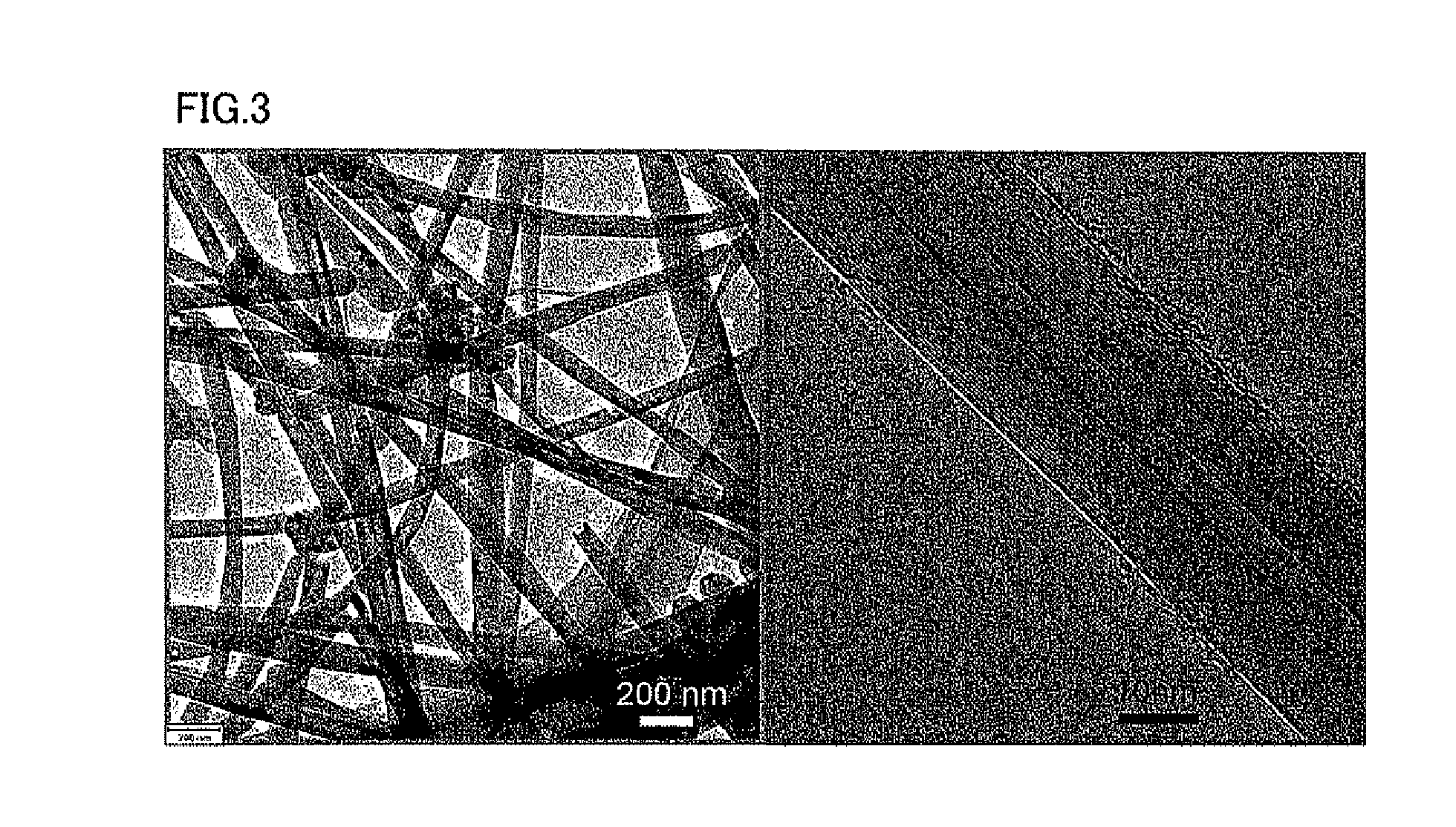

ActiveCN102795618AIncrease the number ofImprove conductivityMaterial nanotechnologyGrapheneGas phaseScanning electron microscope

The invention relates to a vapor growth graphite fiber composition, its mixture and an application. The VGGF composition comprises a carbon component with content of at least 99.9 weight percentage, the graphitization degree of the carbon component is at least 75%, the carbon component comprises non fibrous carbon and fibrous VGGF, wherein the area ratio of the non fibrous carbon to the fibrous VGGF measured by a scanning electron microscope is less than or equal to 5%. The fibrous VGGF also comprises the graphite fiber in a three-dimensional crosslinked structure, wherein the content of the graphite fiber which is measured by the scanning electron microscope in the three-dimensional crosslinked structure is between 5 area percentages and 50 area percentages in the fibrous VGGF. The VGGF composition and its mixture can be used in the composite materials for increasing the strength, conductive property, heat conduction property and the like of the composite material.

Owner:YONGYU APPLIED TECH MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com