Susceptor for epitaxial layer forming apparatus, epitaxial layer forming apparatus, epitaxial wafer, and method of manufacturing epitaxial wafer

A technology of epitaxial wafers and epitaxial films, applied in chemical instruments and methods, semiconductor/solid-state device manufacturing, crystal growth, etc., can solve the problems of increased thickness deviation of epitaxial wafers, achieve the effect of small thickness deviation and improve flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Embodiments of the present invention will be described below with reference to the drawings. The drawings referred to in the following description are for explaining the configuration of the epitaxial film forming apparatus and the like according to the present embodiment, and the size, thickness, and dimension of each part in the illustration may differ from the dimensional relationship of the actual apparatus and the like.

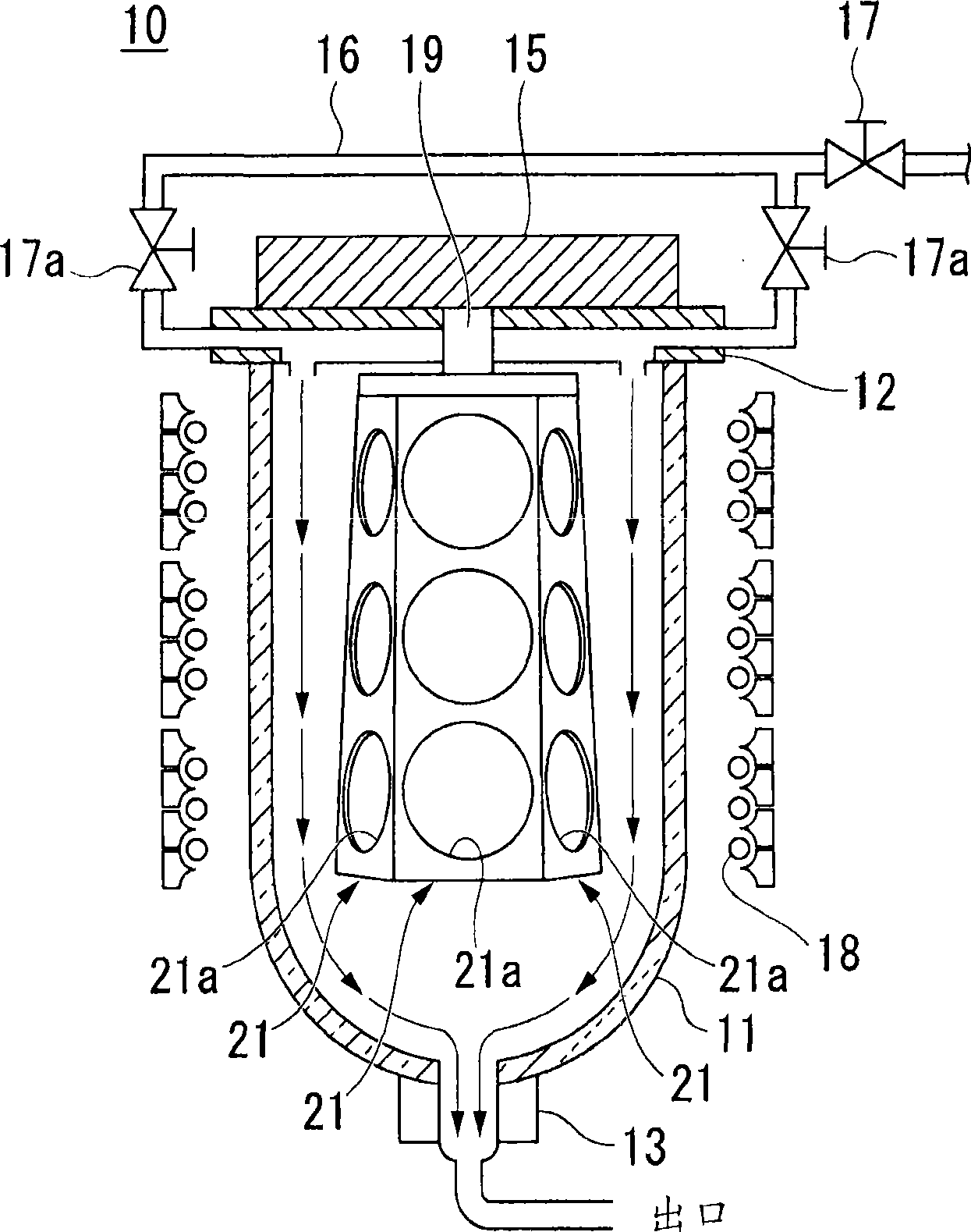

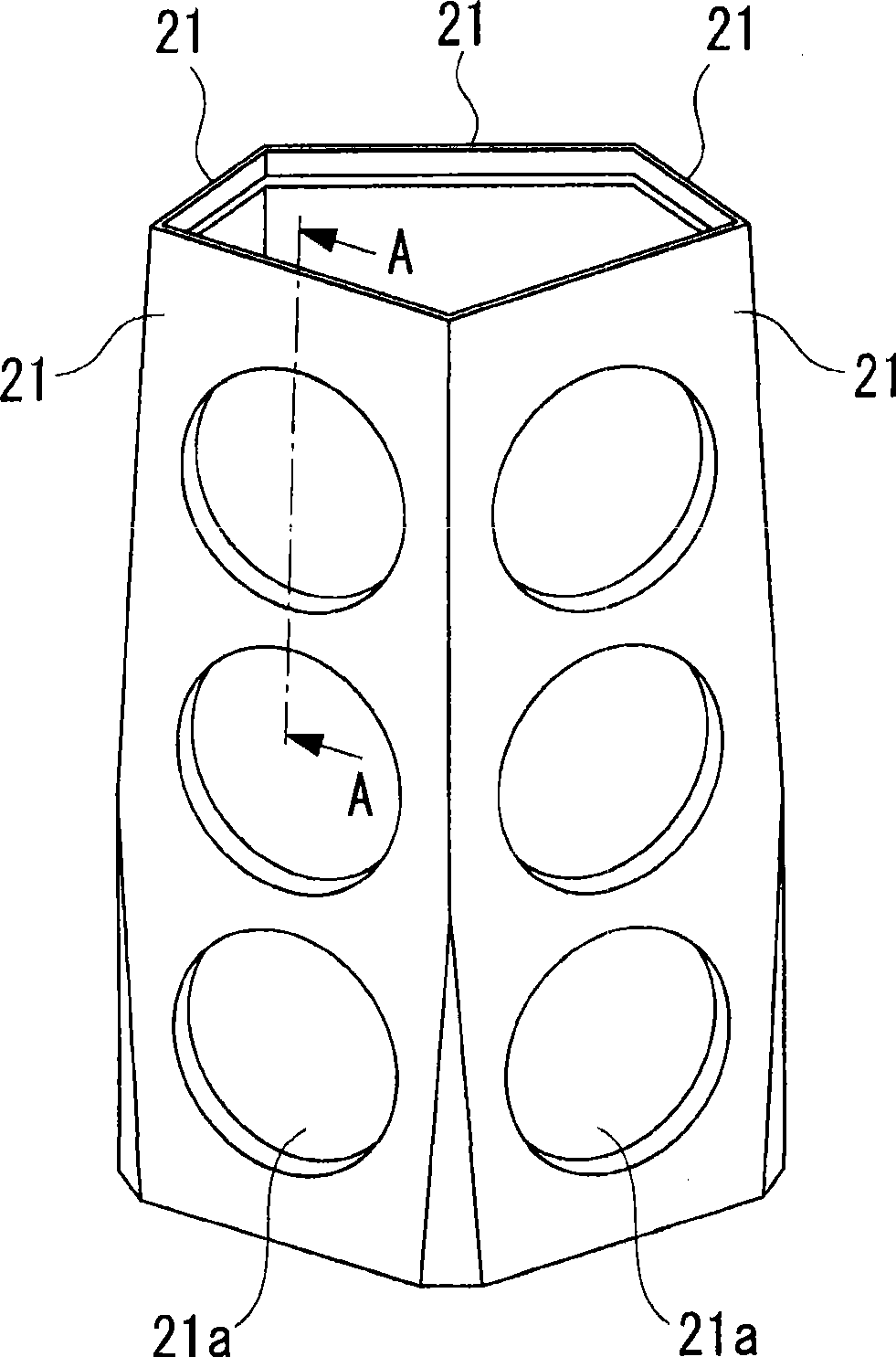

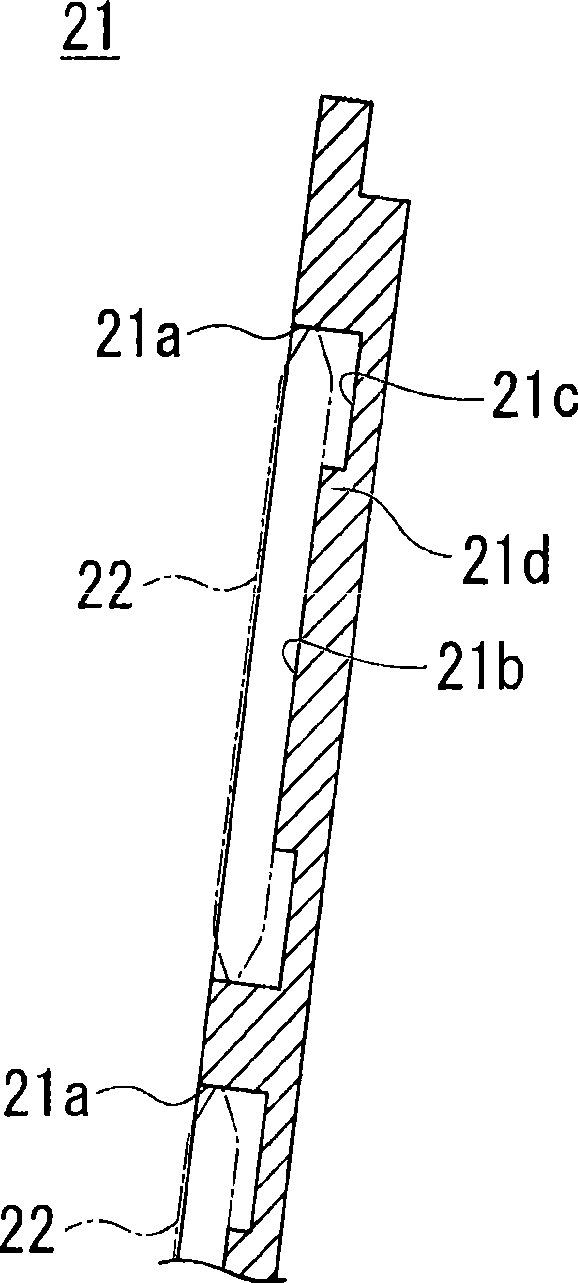

[0039] Below, refer to Figure 1 ~ Figure 4 , an example of the epitaxial film forming apparatus of this embodiment will be described. figure 1 is a cross-sectional view showing an example of the epitaxial film forming apparatus of this embodiment, figure 2 It is a perspective view showing a susceptor included in the epitaxial film forming apparatus. and image 3 With figure 2 The partial sectional view corresponding to the line A-A' of Figure 4 yes means figure 2 An enlarged cross-sectional view of the main part of the pedestal. Such a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com