Negative electrode active material for lithium secondary battery, preparation method of the same, and lithium secondary battery containing the same

A cathode active material, lithium secondary battery technology, applied in the direction of active material electrodes, secondary batteries, secondary battery components, etc., can solve problems such as the inability to achieve high electrode density, and the inability to fully meet the characteristics of high capacity and cycle capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

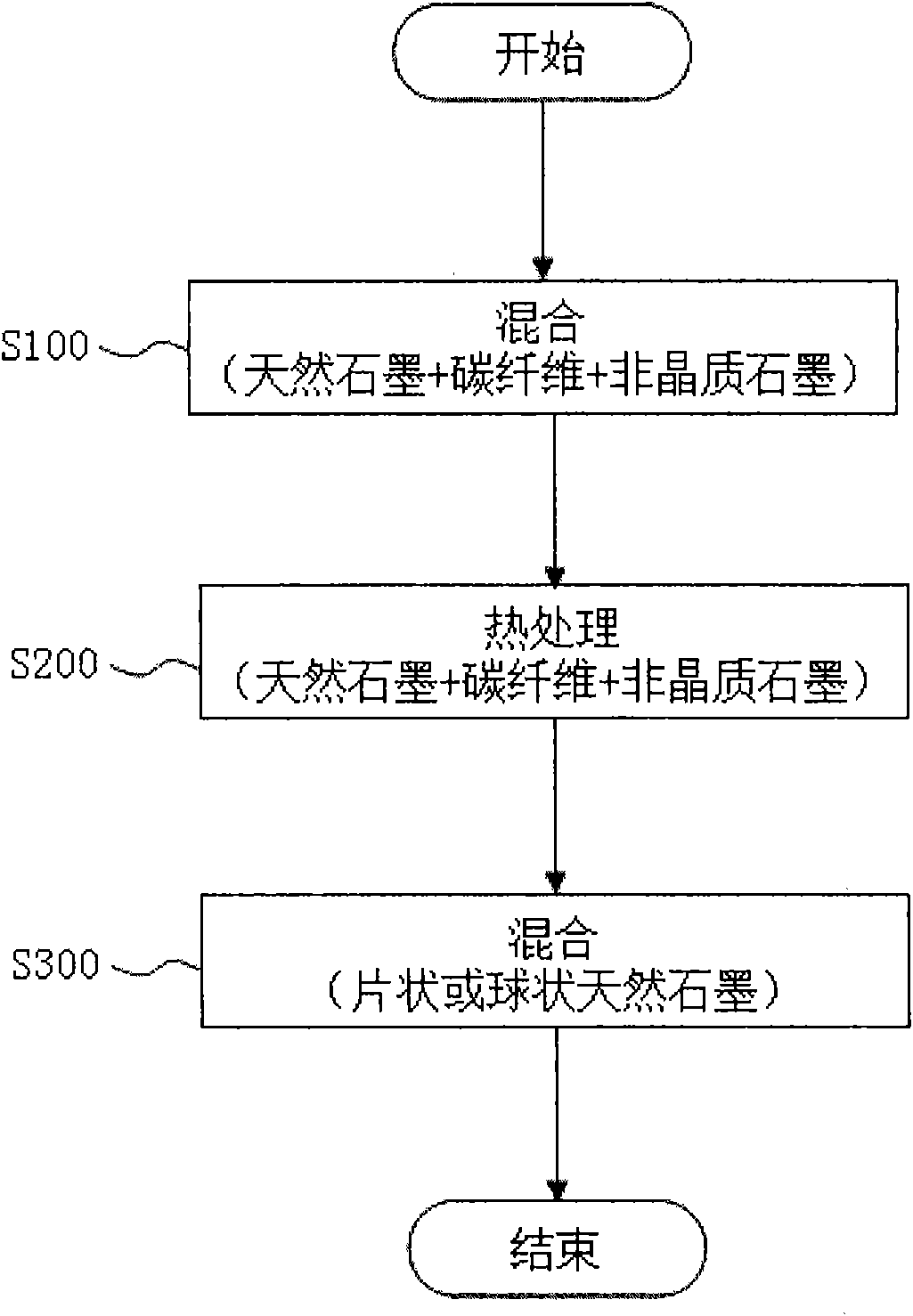

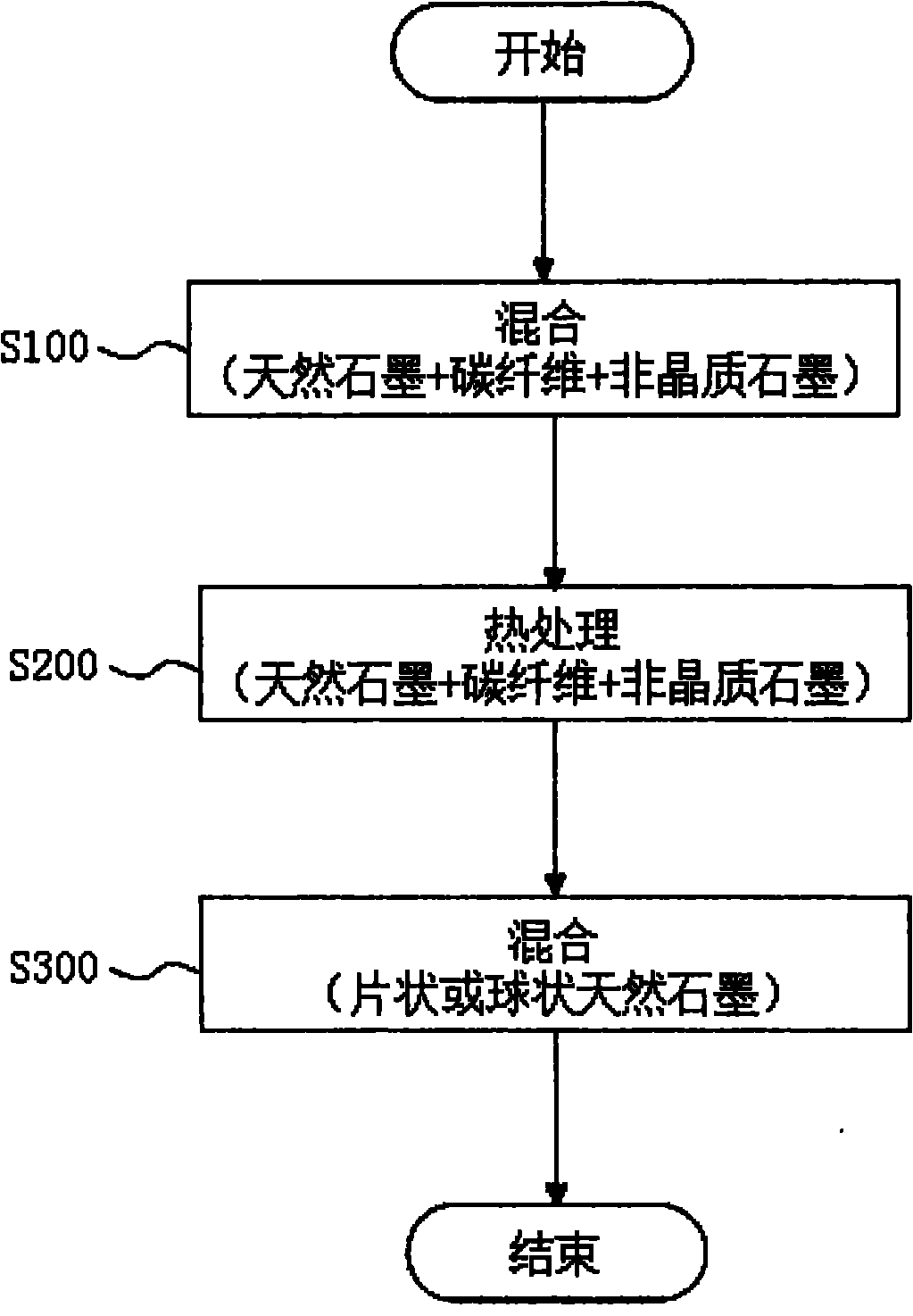

Method used

Image

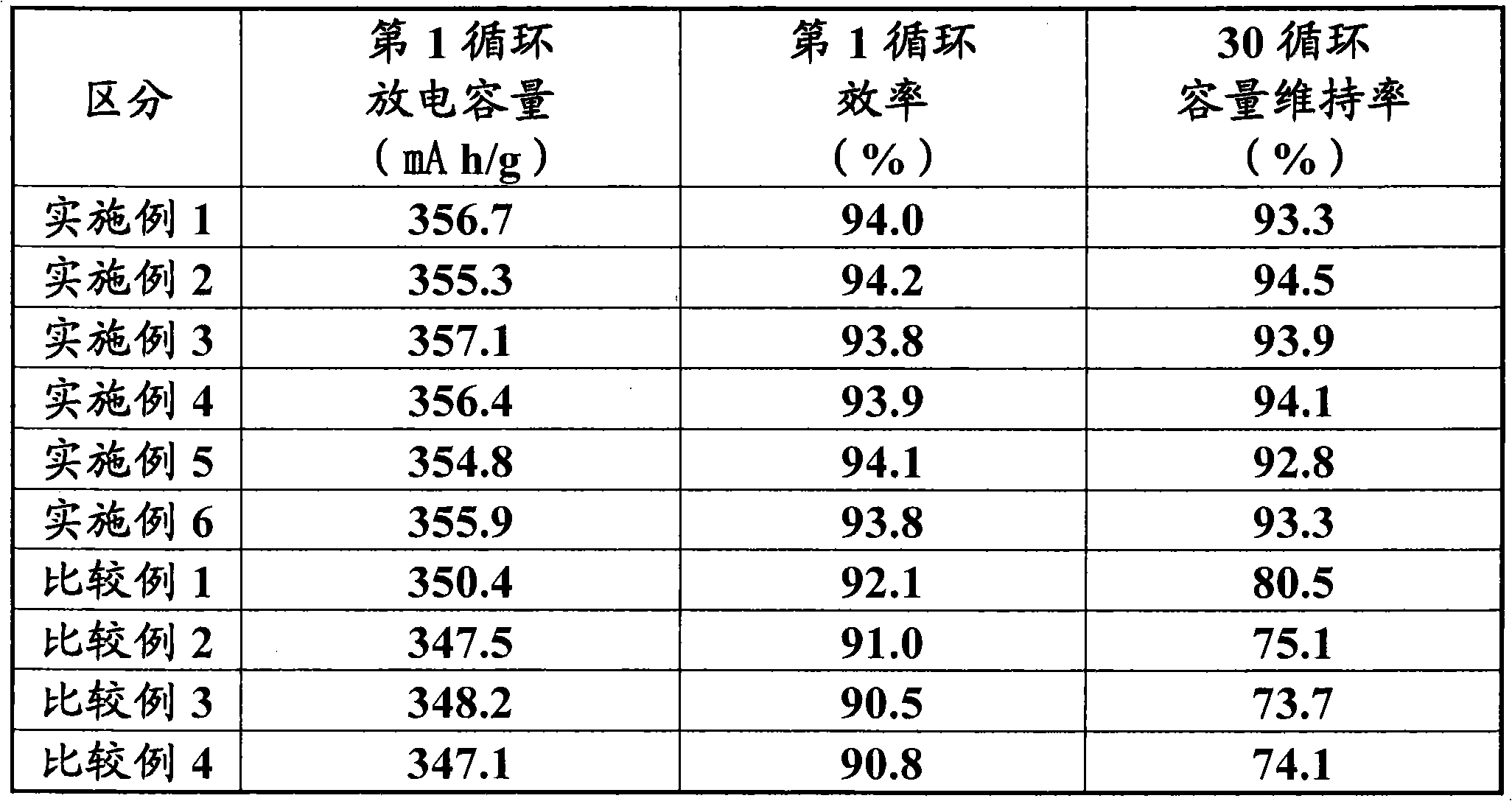

Examples

Embodiment 1

[0041] In spherical natural graphite, a mixture was prepared by dry mixing 5% by weight of pitch and 2% by weight of carbon fiber (VaporGrowth Carbon Fiber, VGCF) at high speed for about 10 minutes. The 1st and 2nd firings were carried out at the same temperature for 1 hour, respectively. Next, fine powder is classified and removed, thereby producing a carbon material uniformly coated with pitch and carbon fibers.

[0042] Uncoated spherical natural graphite was added to the carbon material produced above, and uniformly mixed with a rotary mixer at a mixing ratio of 50%. The cathode active material prepared in this way of 100g is put into 500ml reactor, and after dropping into carboxymethylcellulose (CMC) aqueous solution and styrene-butadiene rubber (SBR) aqueous dispersion, utilize mixer to mix, And coated on the copper foil with a thickness of about 100μm. Afterwards, the product is dried and shaped by rolling. The bulk density of the manufactured electrode is 1.7g / cm 3...

Embodiment 2

[0044] The cathode active material was prepared in the same manner as in Example 1 above, except that the spherical natural graphite coated with amorphous graphite in whole or in part was mixed in a mixing ratio of 50%.

Embodiment 3

[0046] Except for mixing 20% uncoated flake-shaped natural graphite, the cathode active material was prepared in the same manner as in Example 1 above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com