Patents

Literature

42results about How to "Uniform film thickness distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

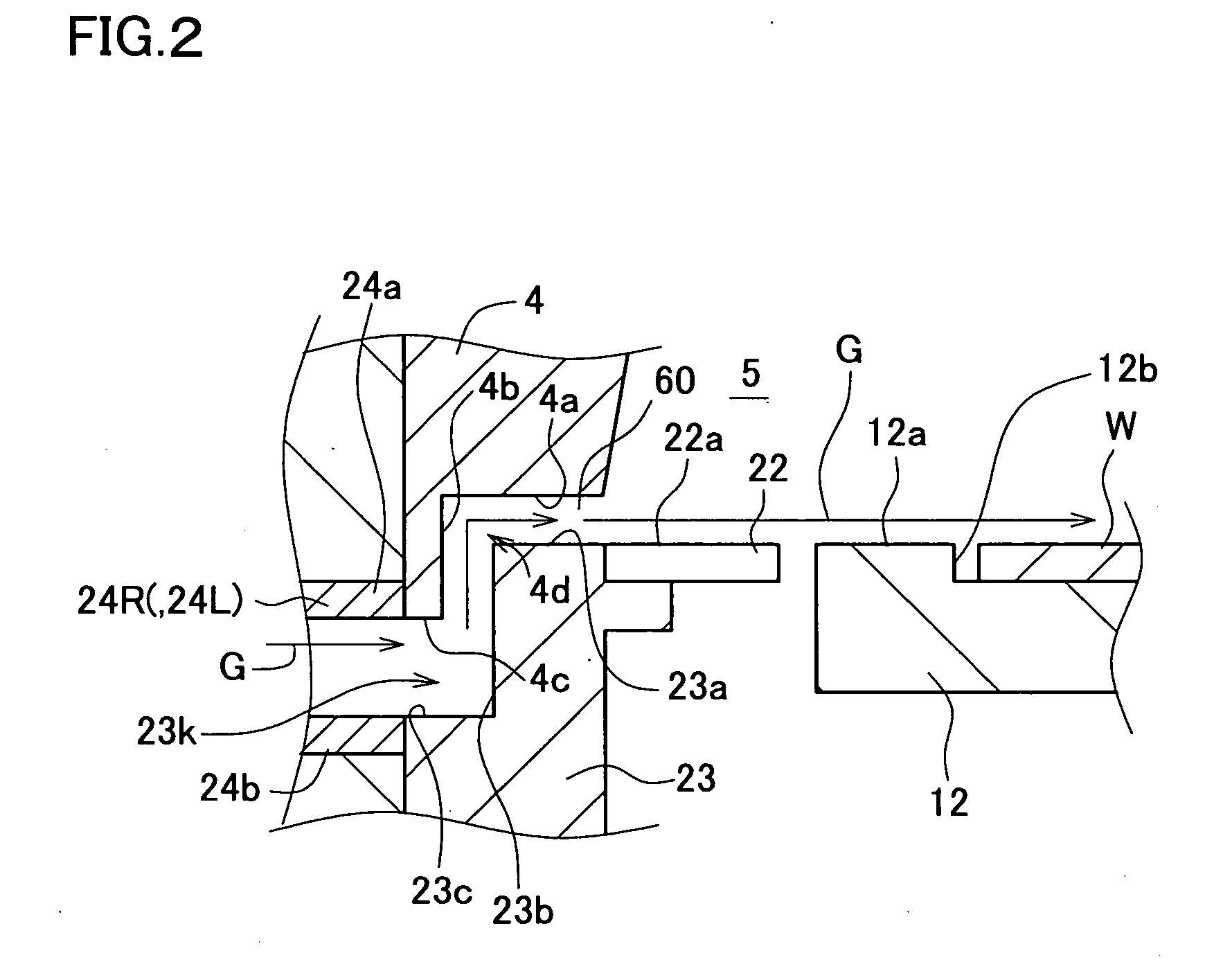

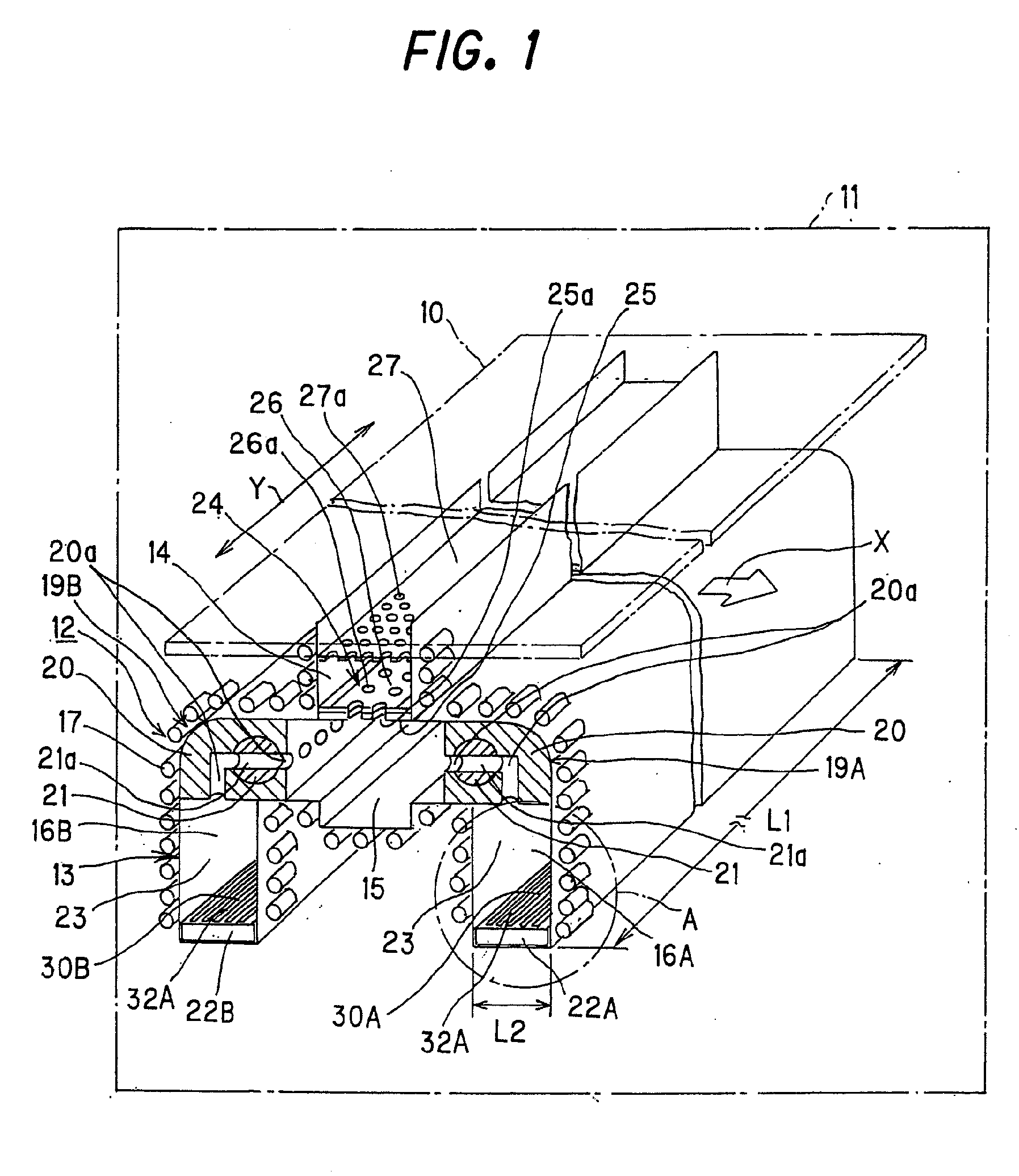

Vacuum vapor deposition apparatus

InactiveUS20060162662A1Prevent unevenness in vaporizationEasy to handleBrushesVacuum evaporation coatingCrucibleEvaporation

A crucible is a monolithic structure extending over an entire area of a vaporizing chamber and has at least one slit groove provided in the upper surface thereof. The at least one slit groove has a length from one end of the upper surface of the crucible to other end thereof. The at least one slit groove is used as a portion for containing the evaporation material (dopant material or the like). Alternatively, a crucible is a monolithic structure extending over the entire area of the vaporizing chamber and has a plurality of holes provided in the upper surface thereof. The holes are used as portions for containing the evaporation material. Further, the crucible is divided into a plurality of regions, and individual electric heaters are provided under the lower surface of the crucible for the respective regions, whereby temperature can be individually controlled for the respective regions by the electric heaters.

Owner:MITSUBISHI HEAVY IND LTD

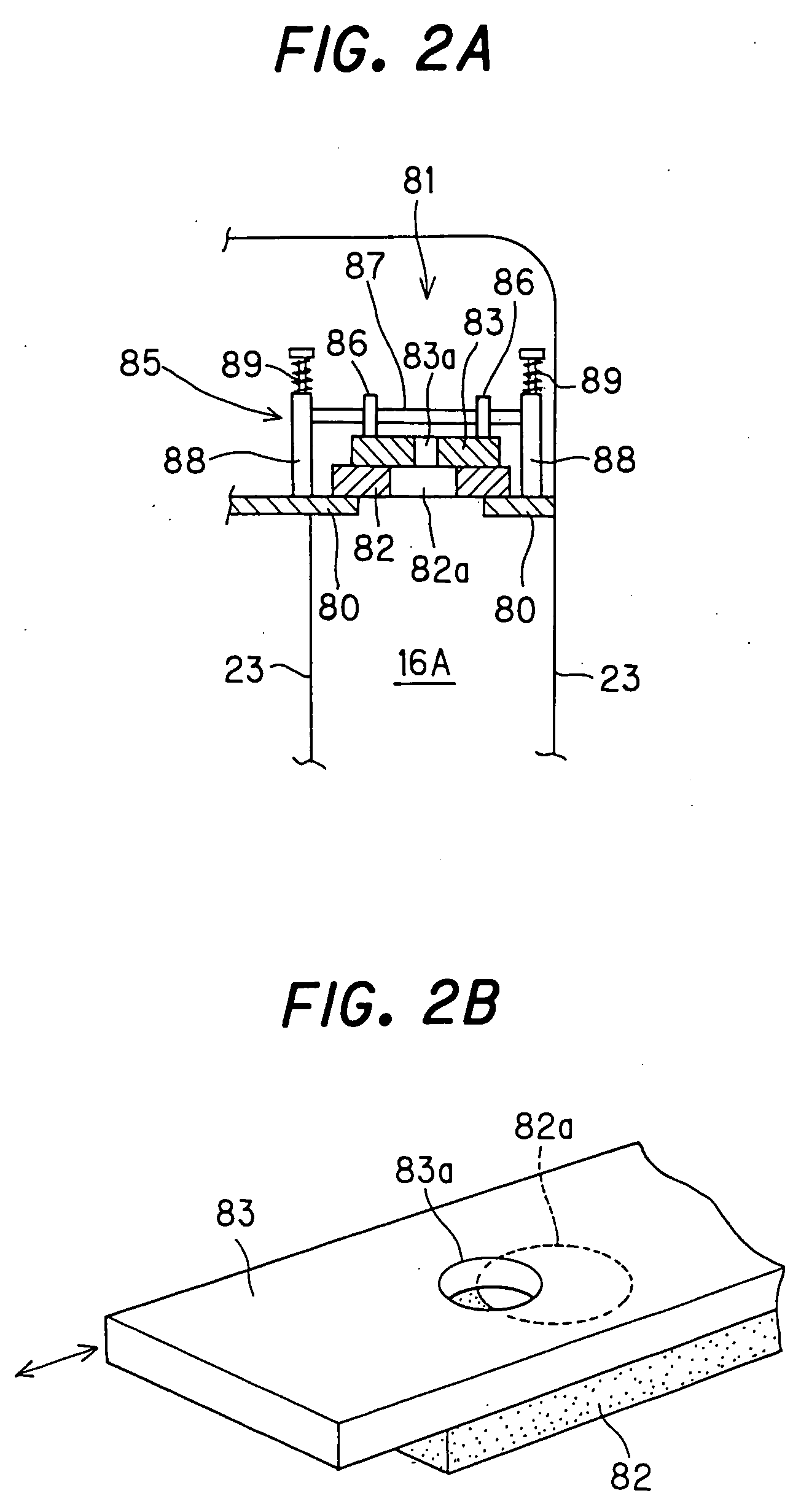

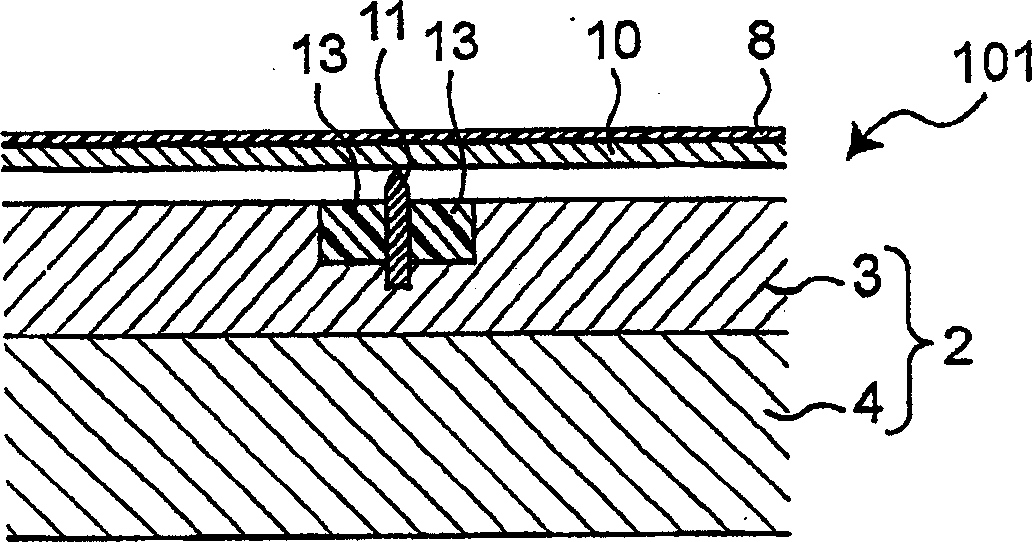

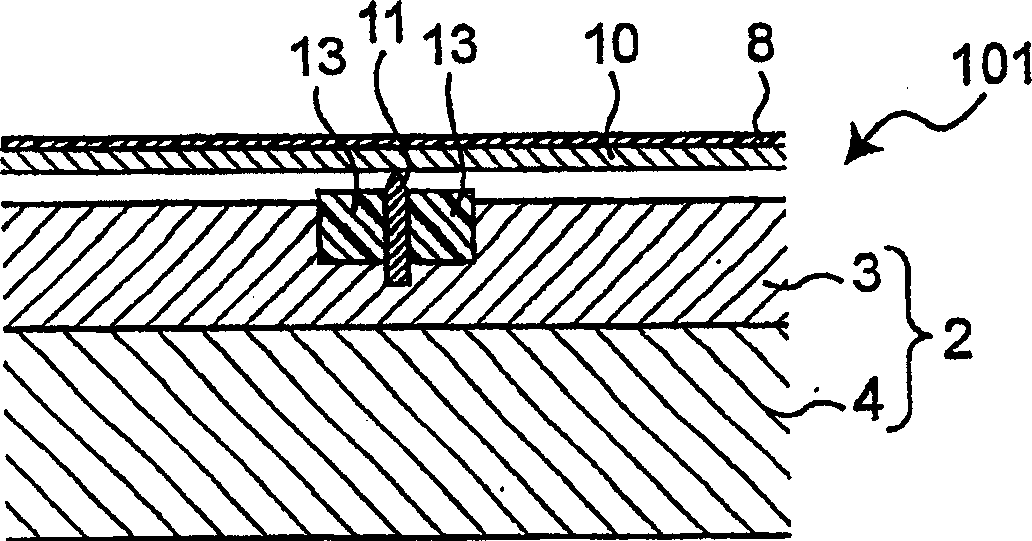

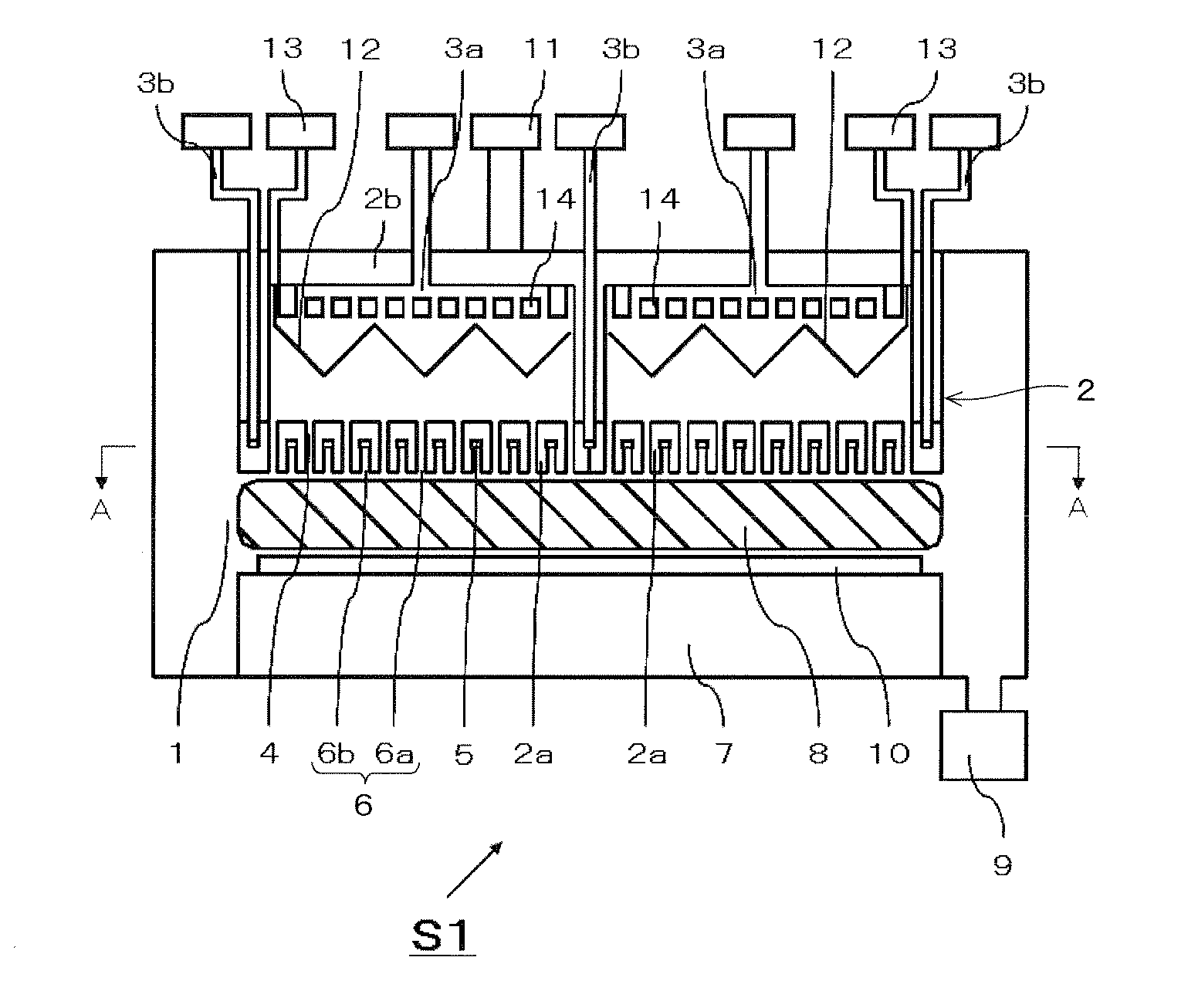

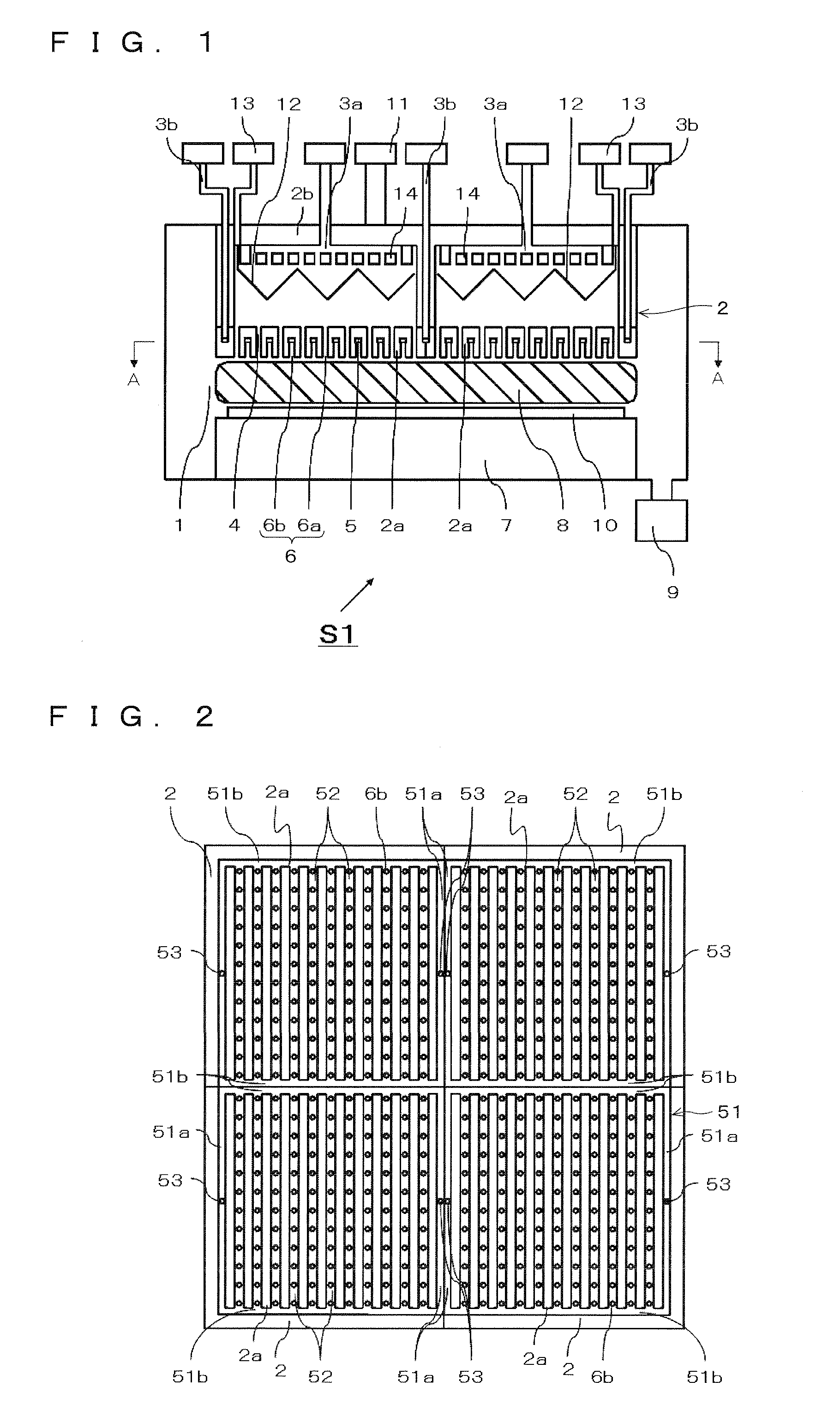

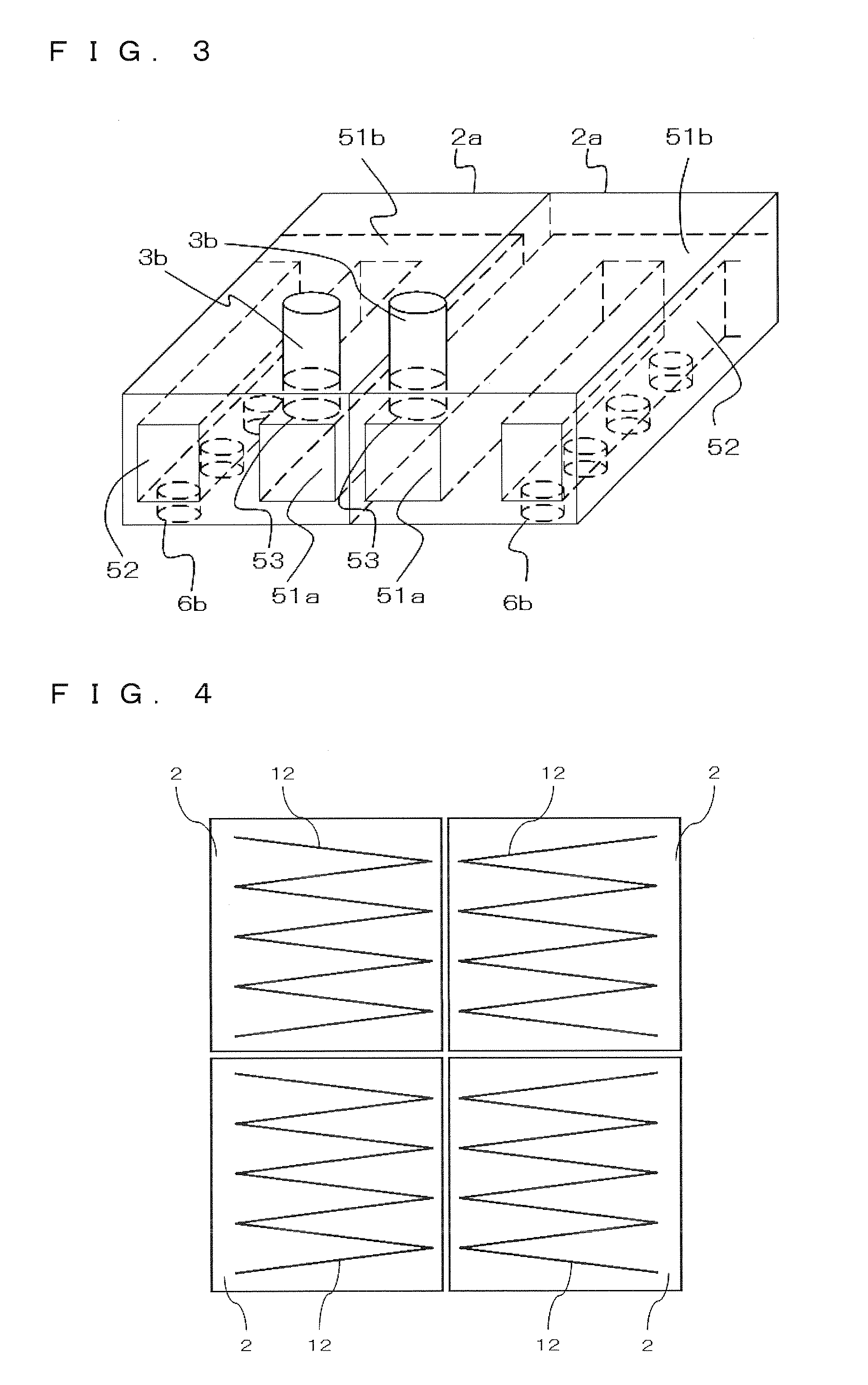

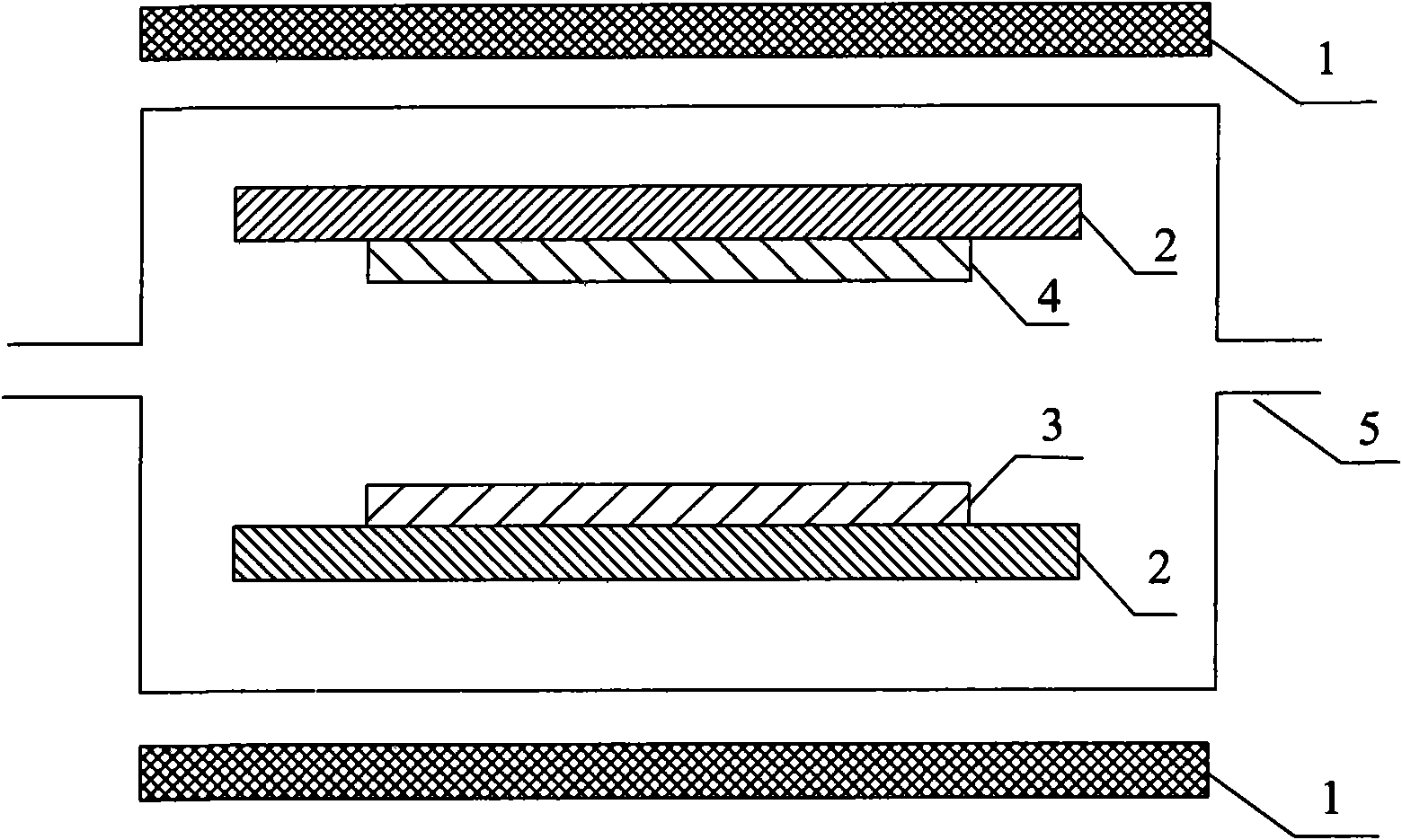

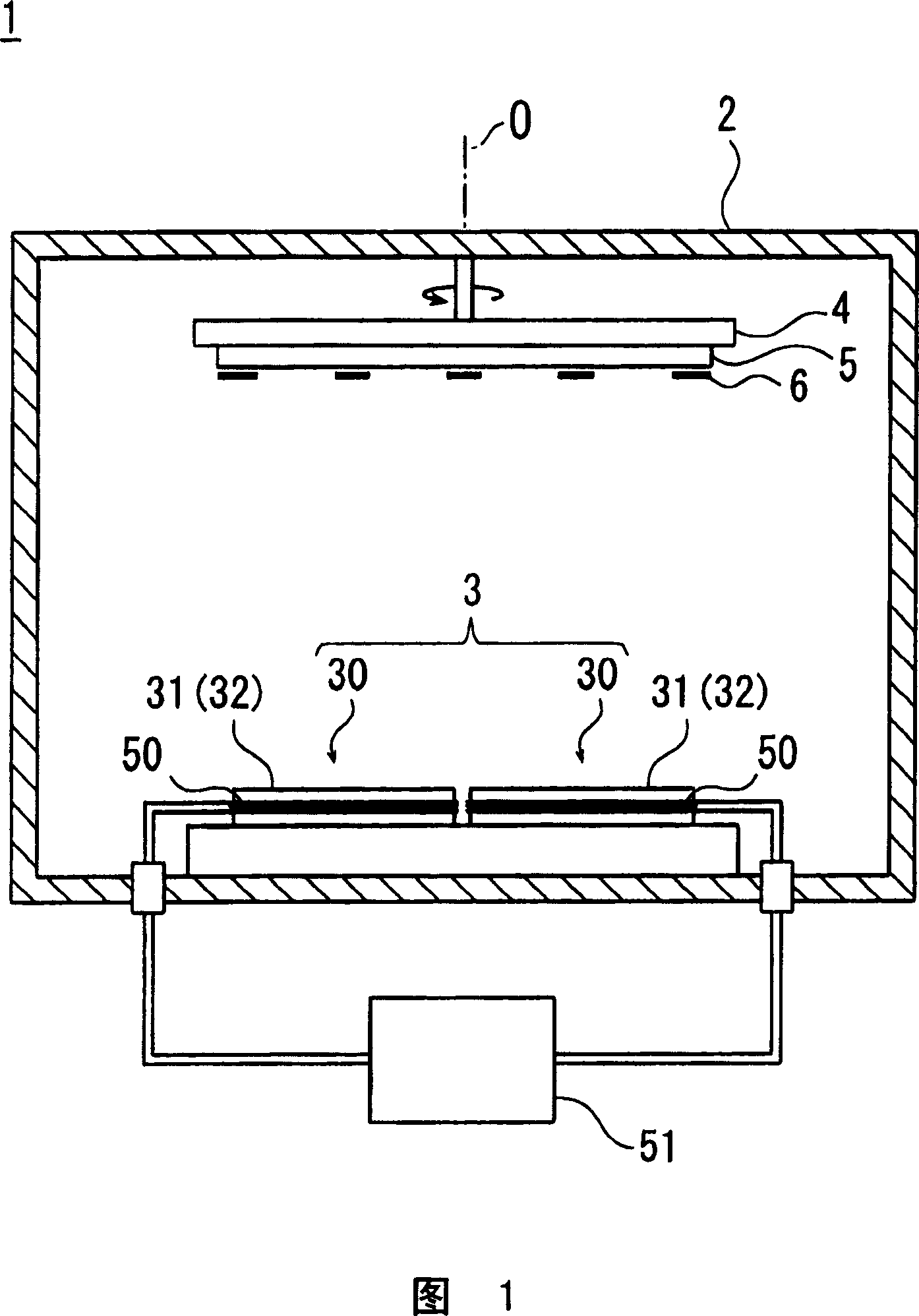

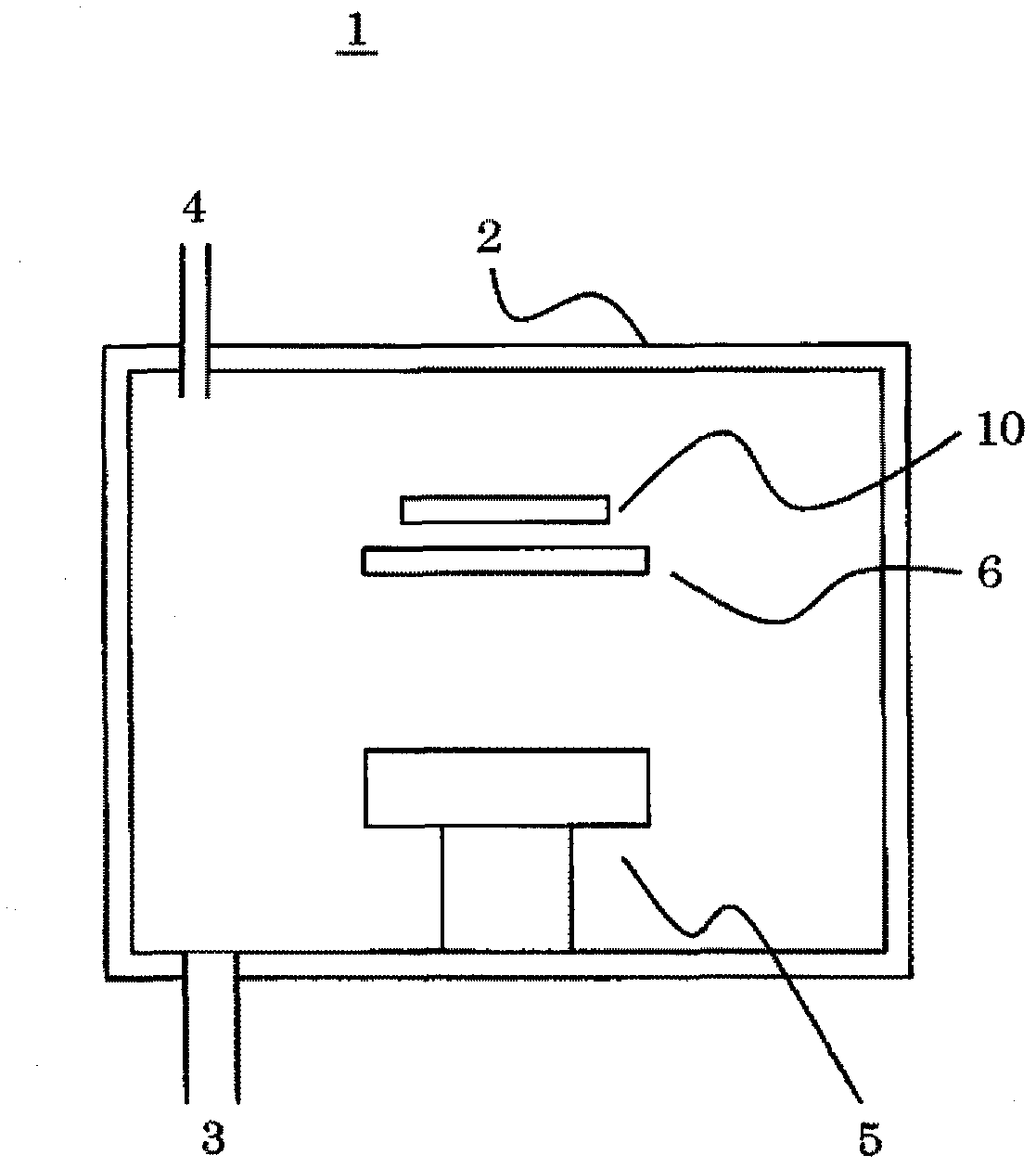

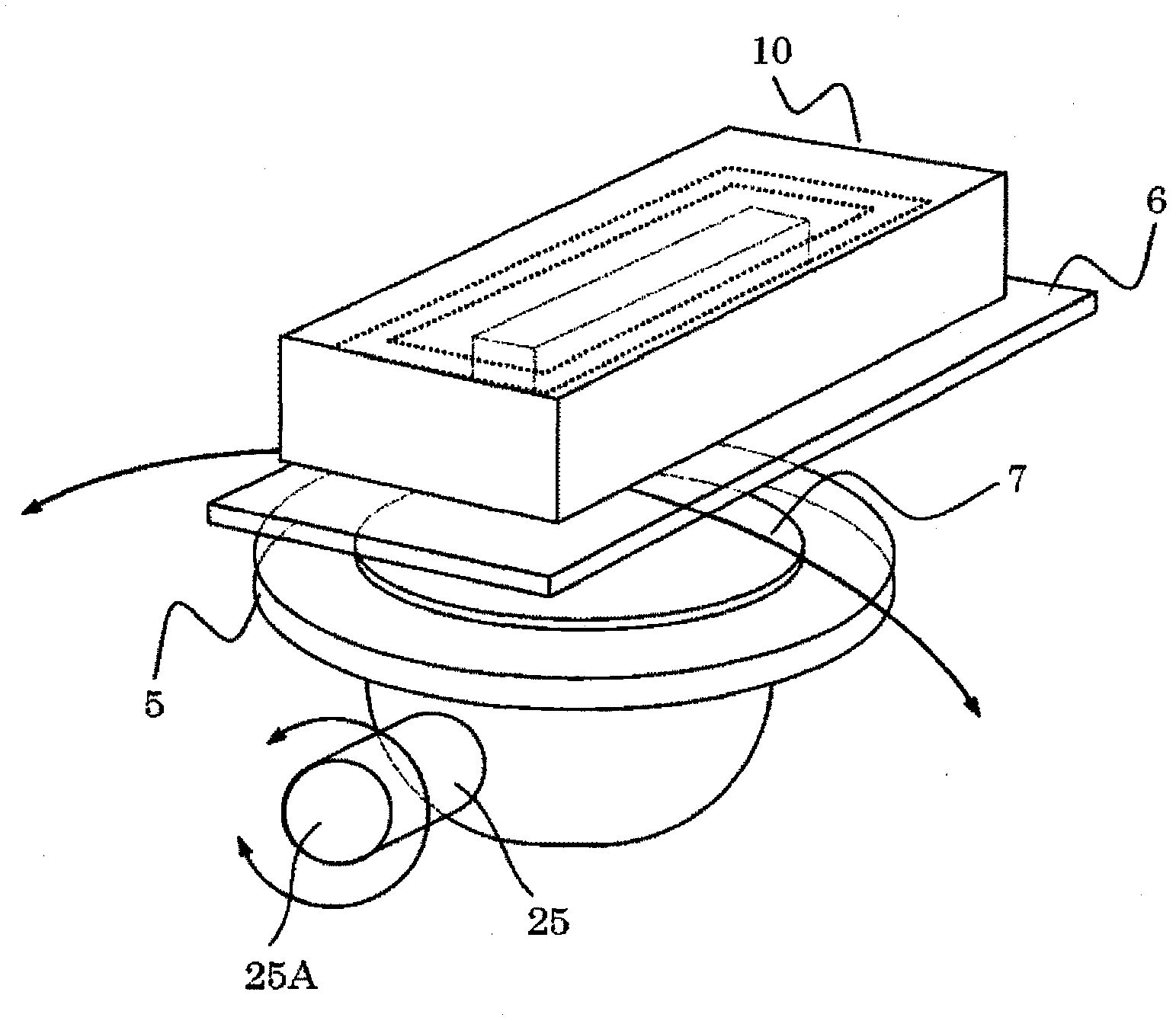

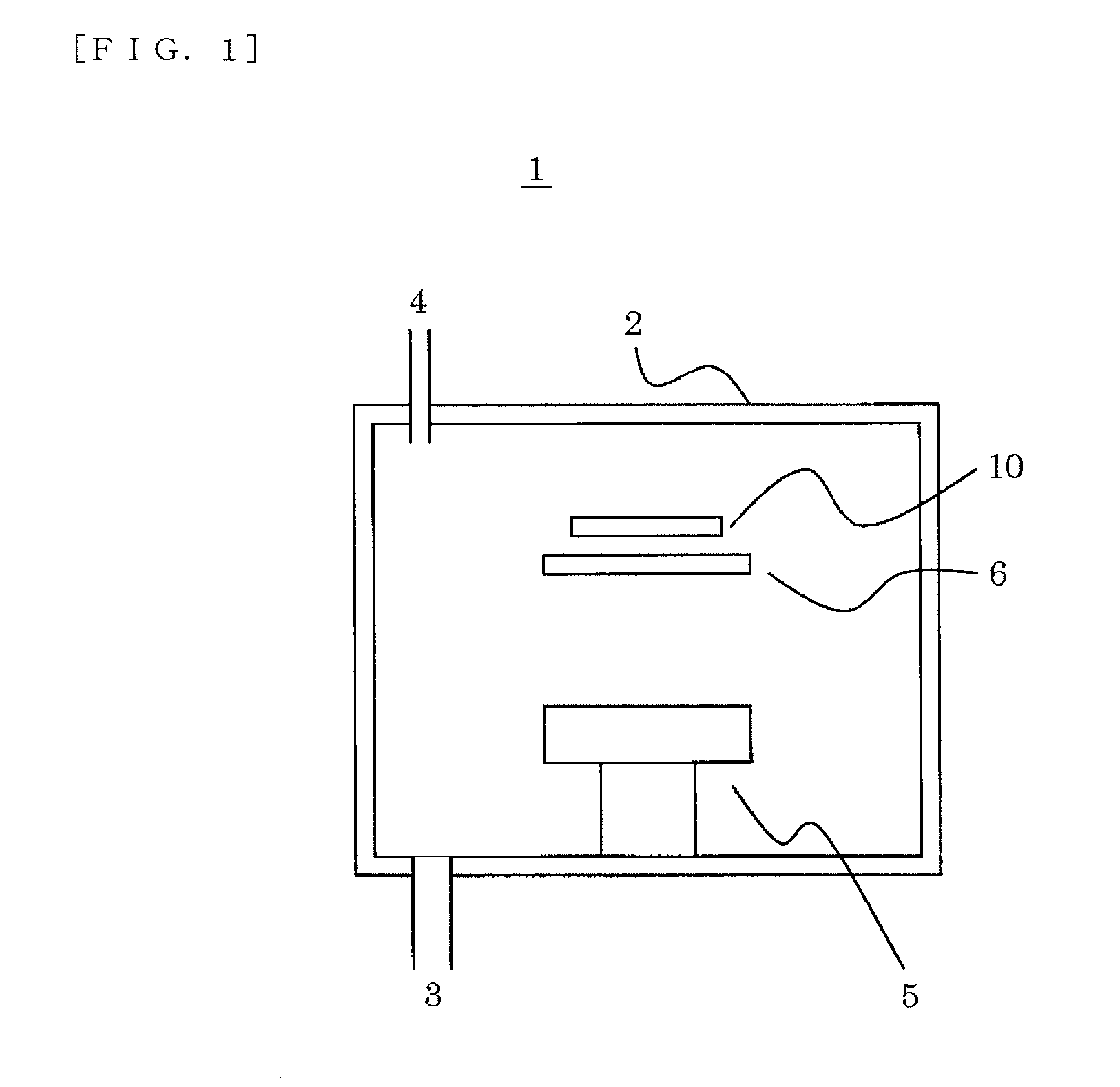

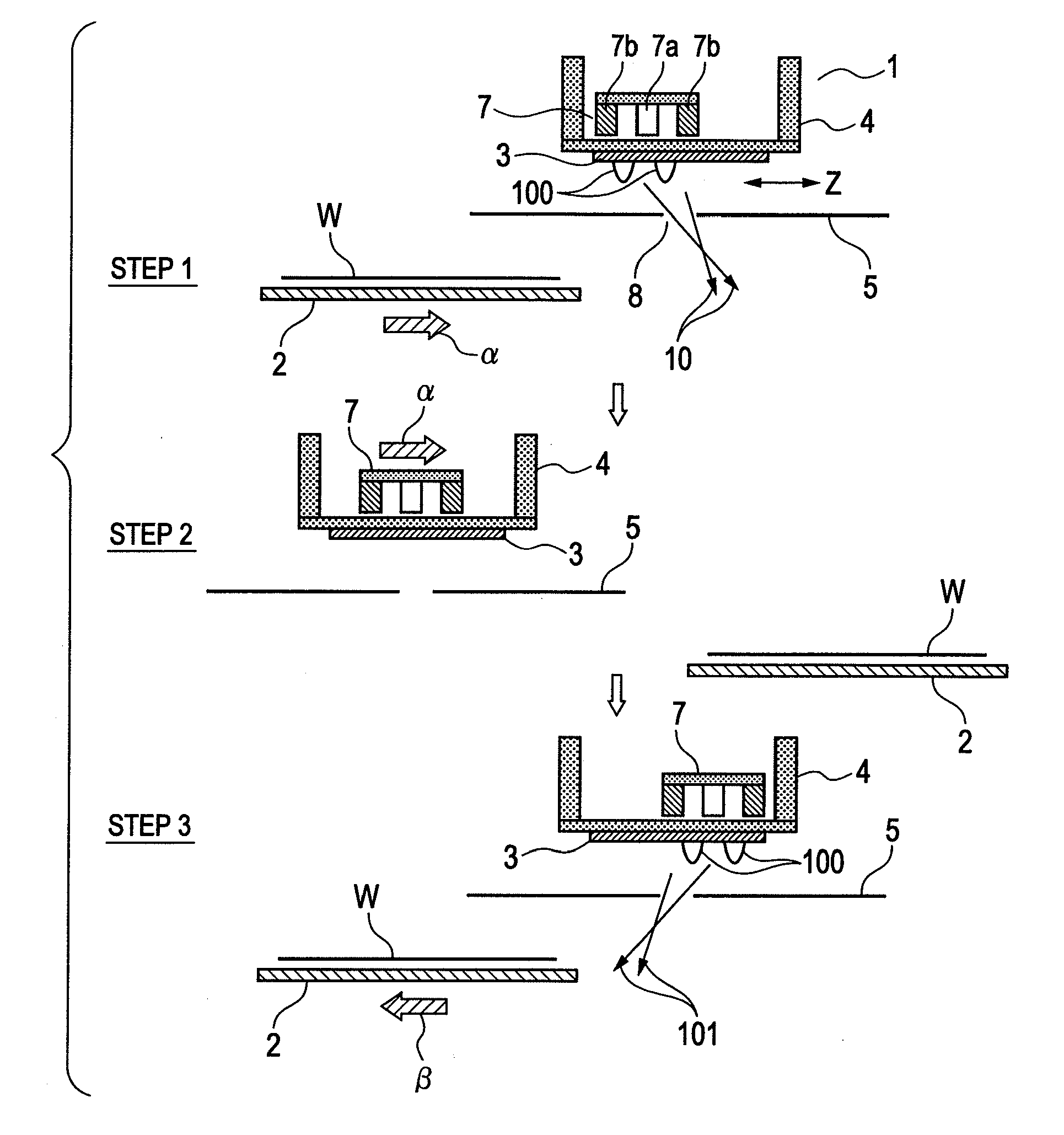

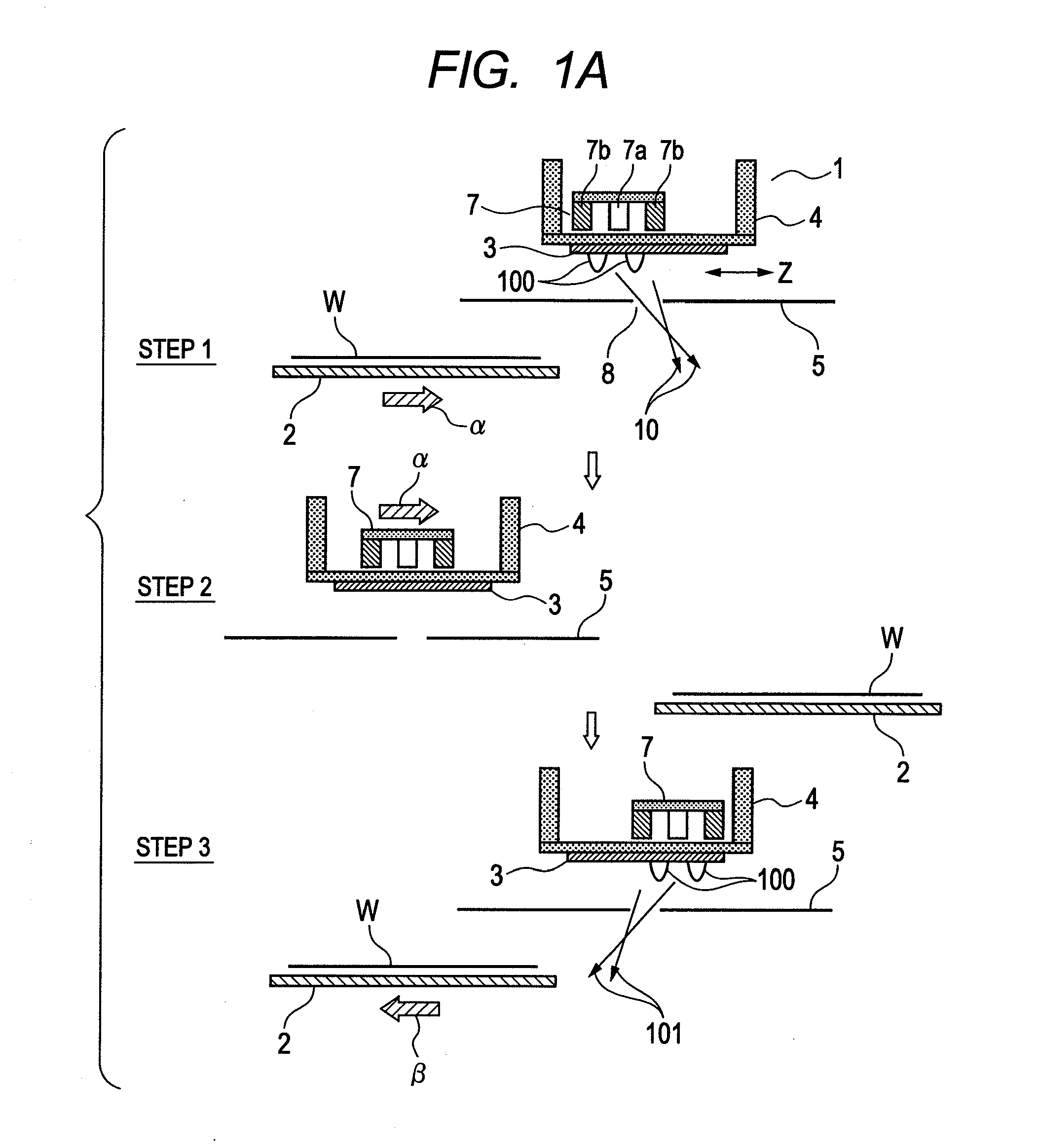

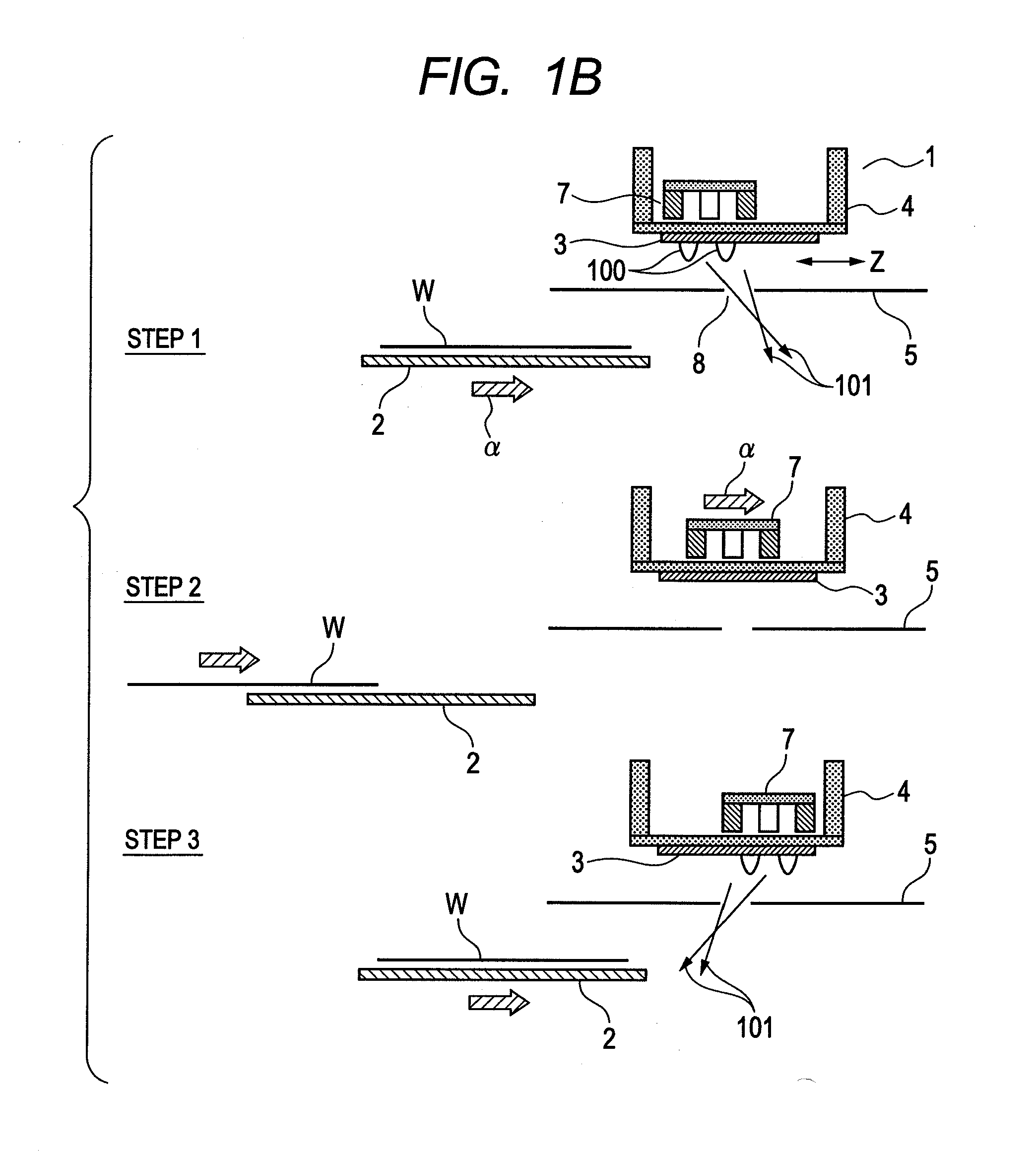

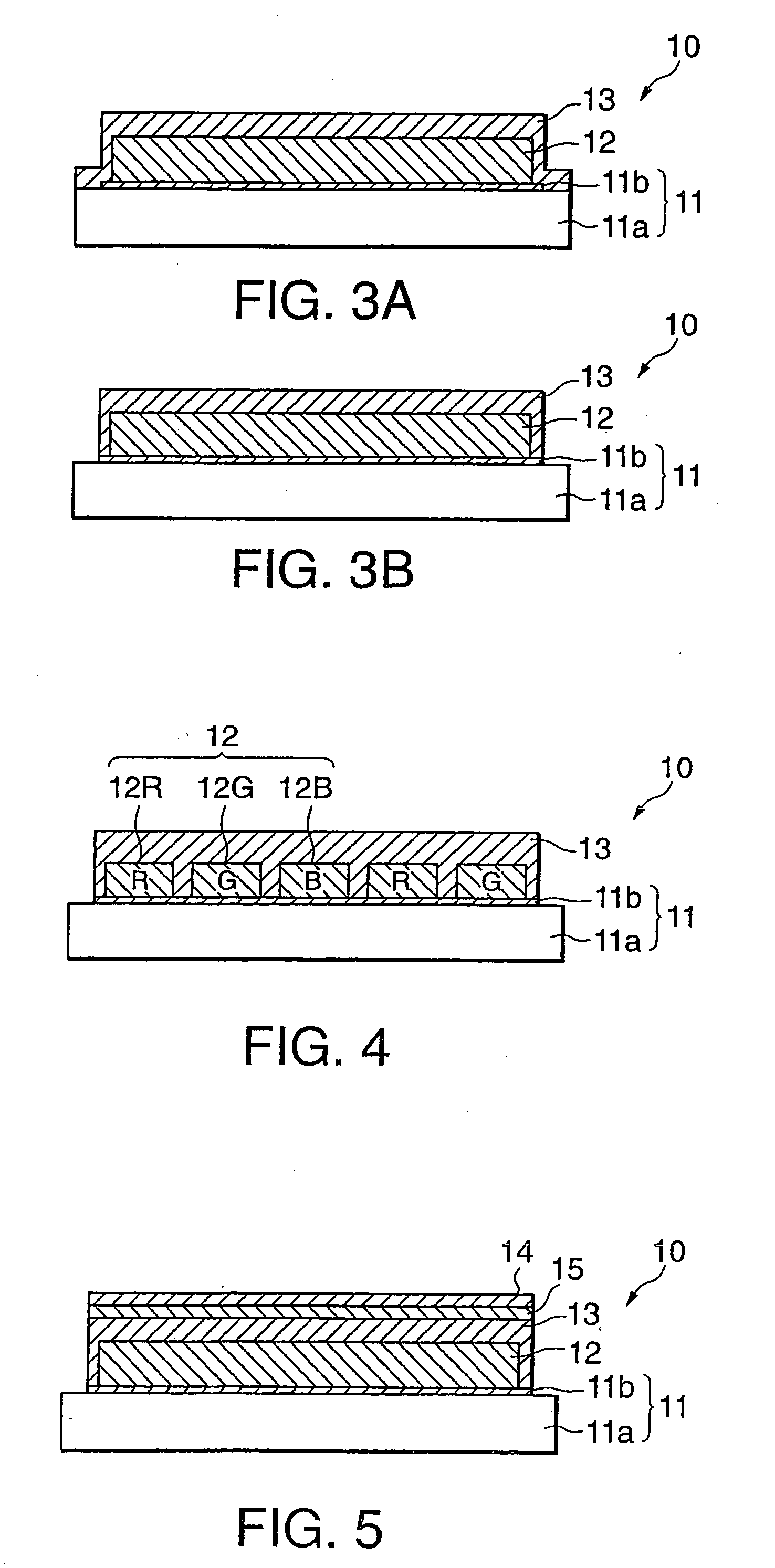

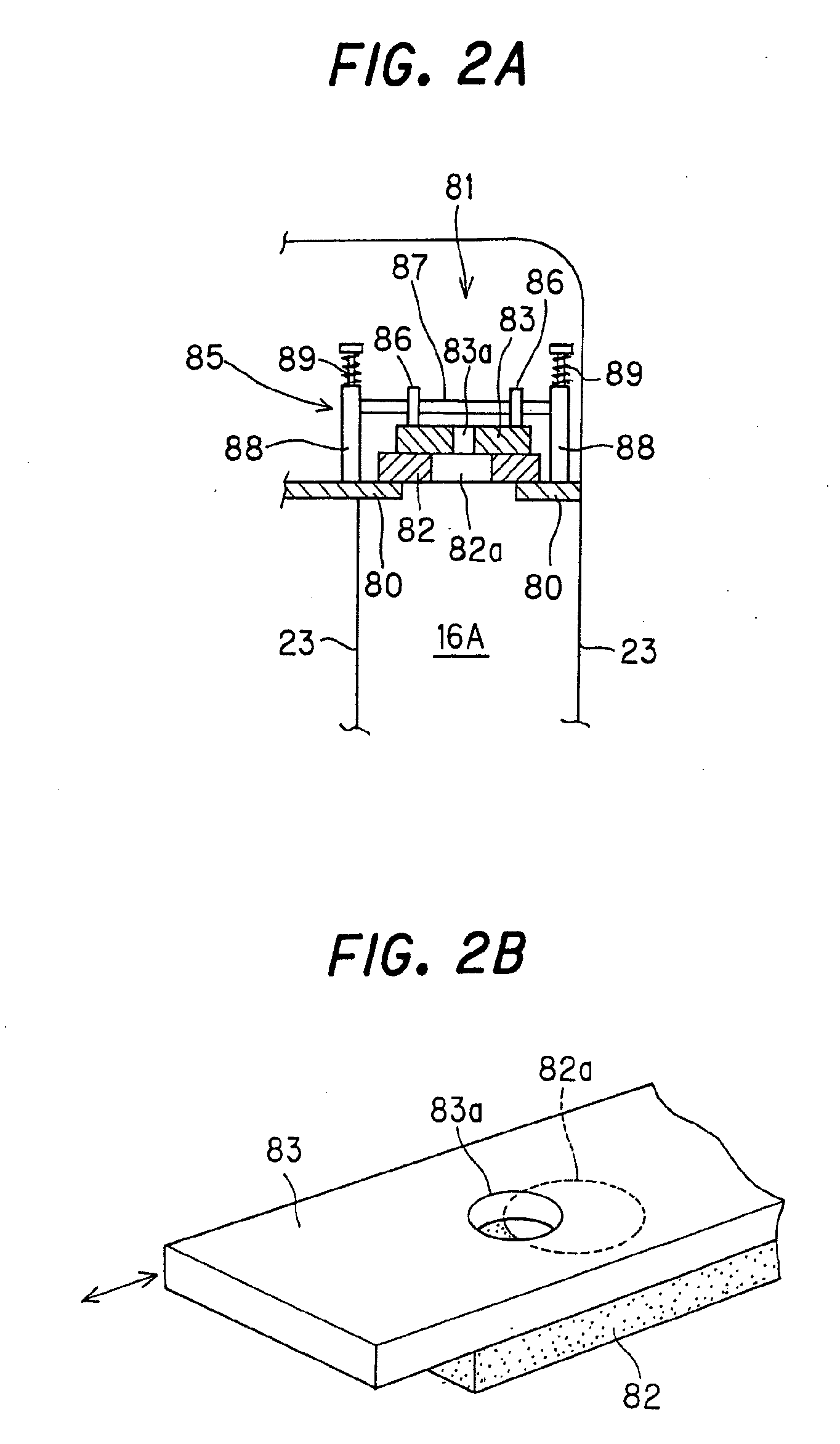

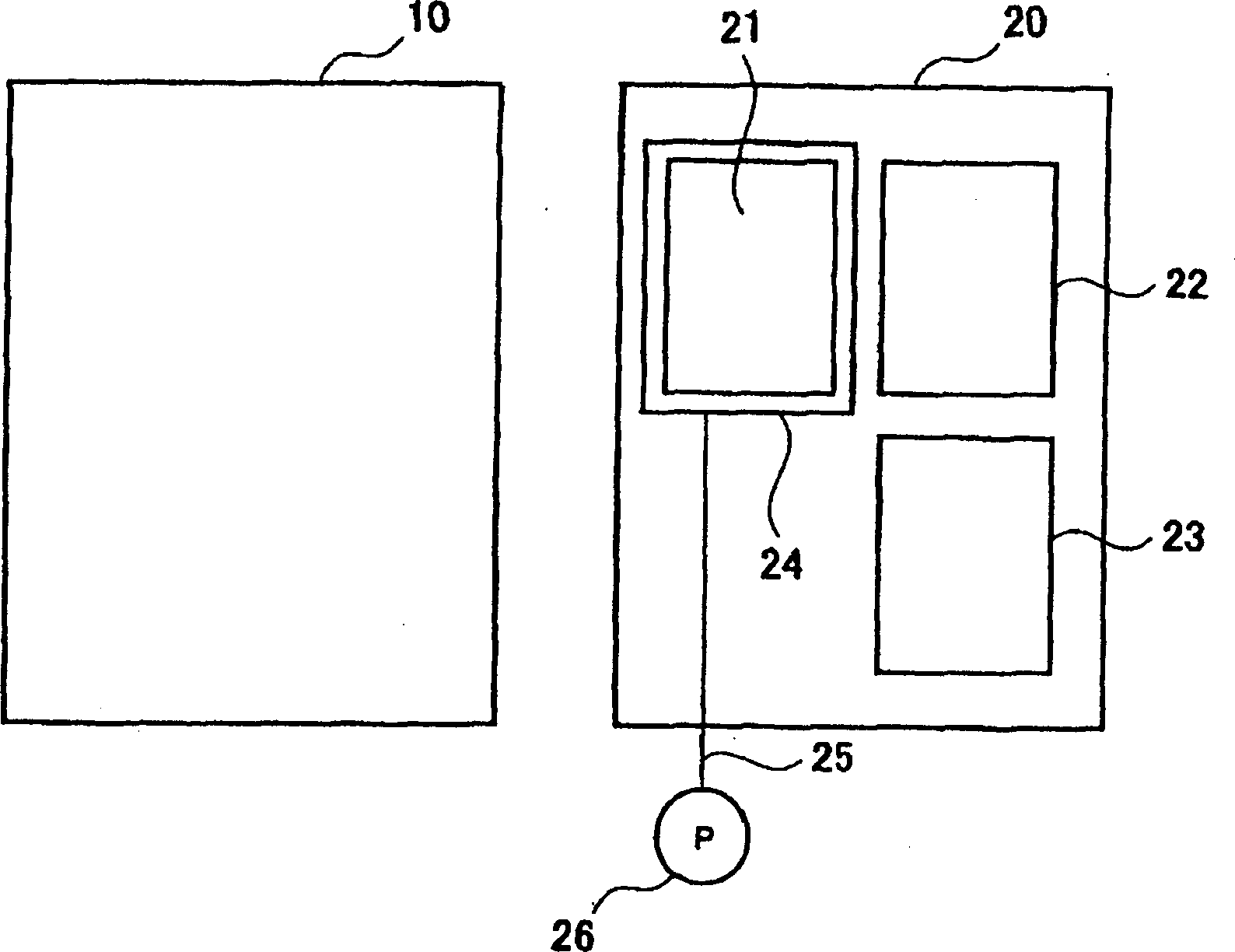

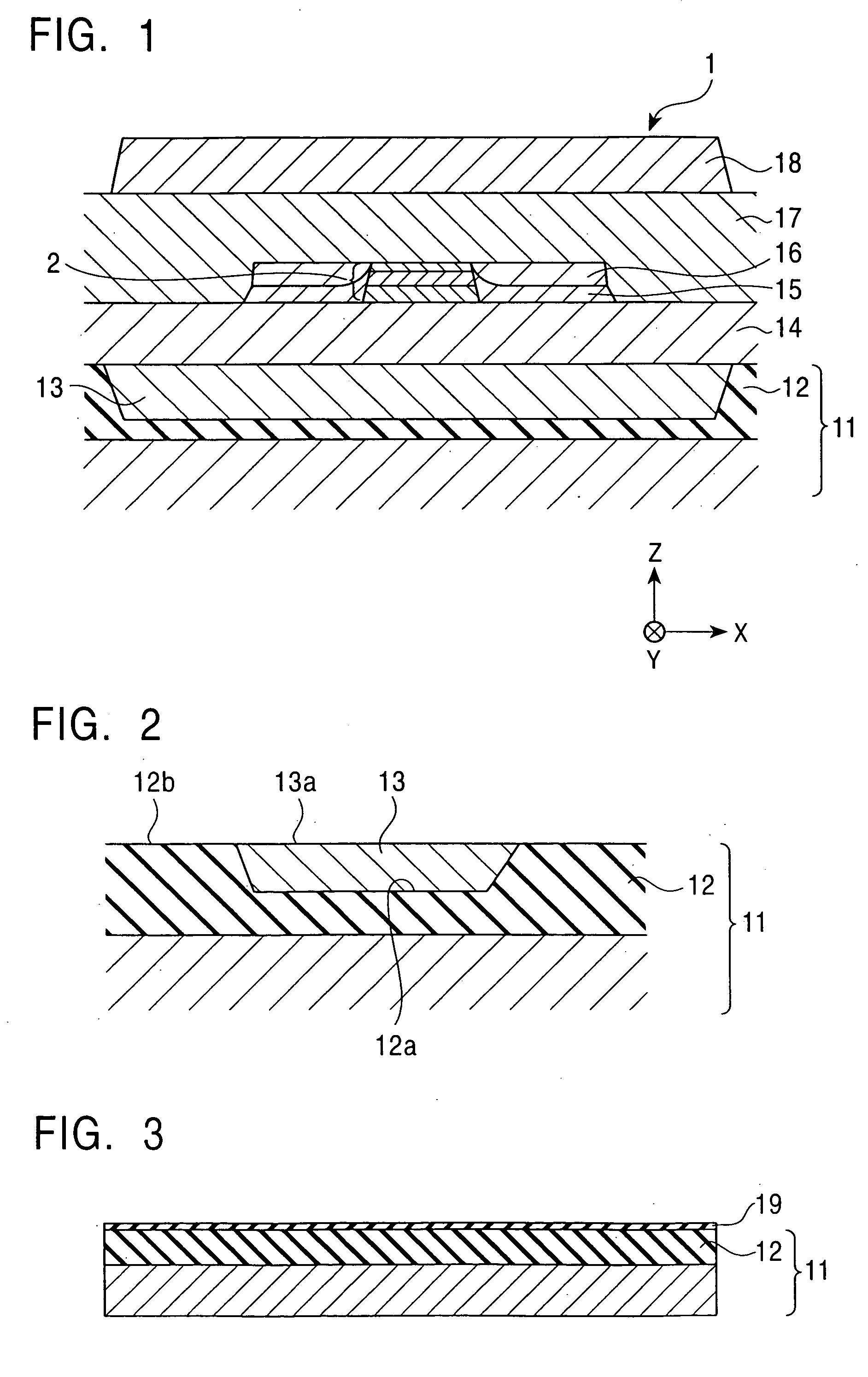

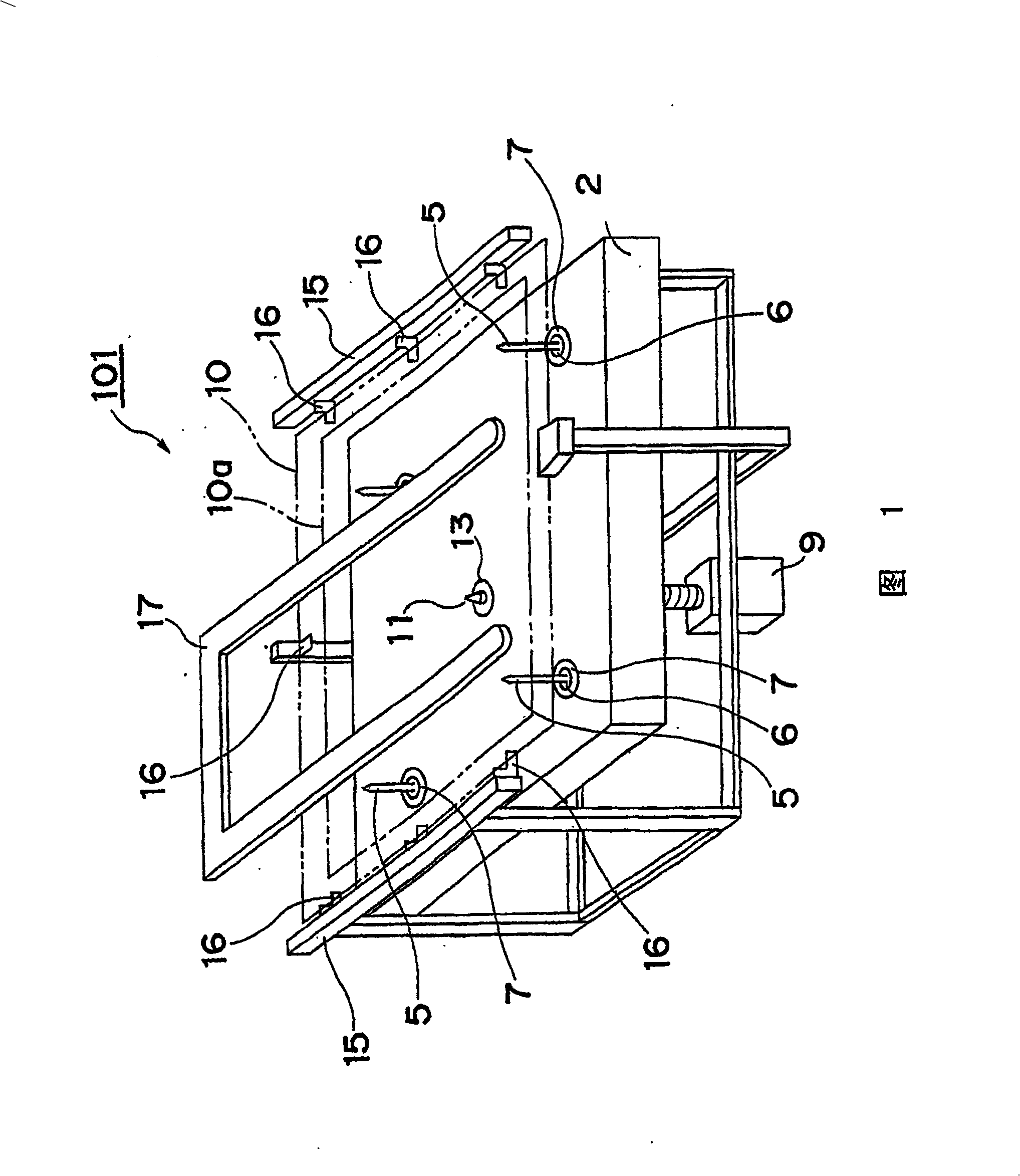

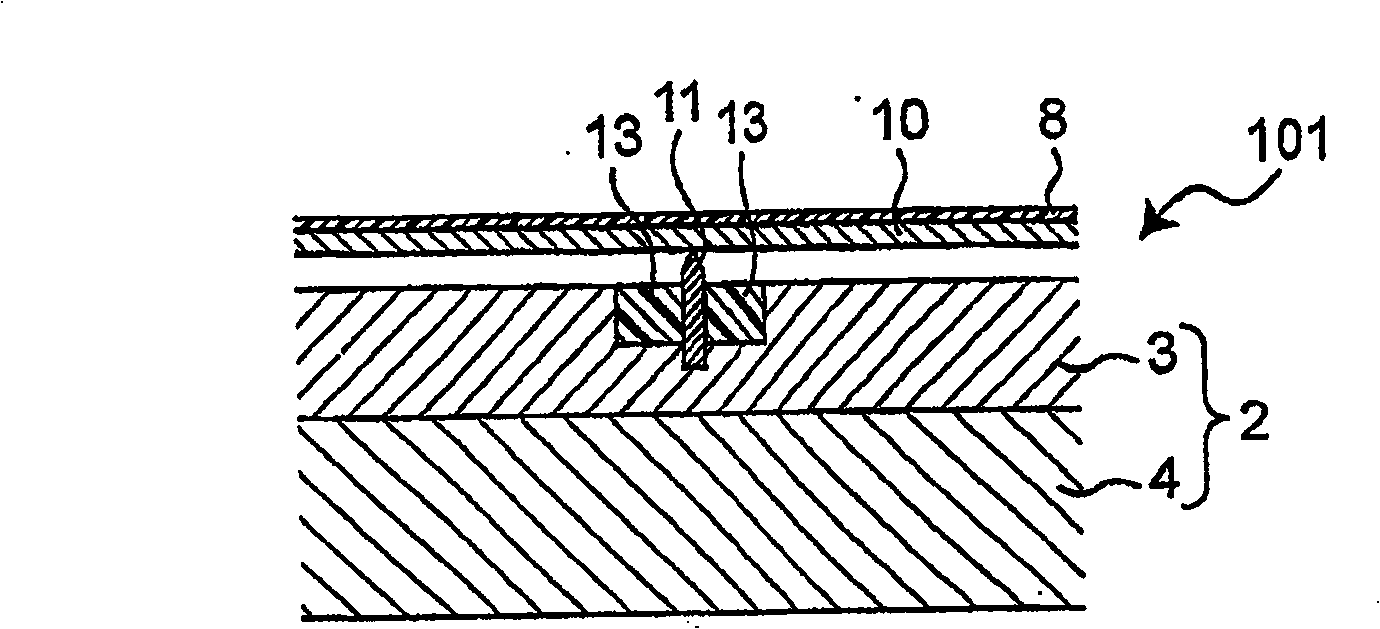

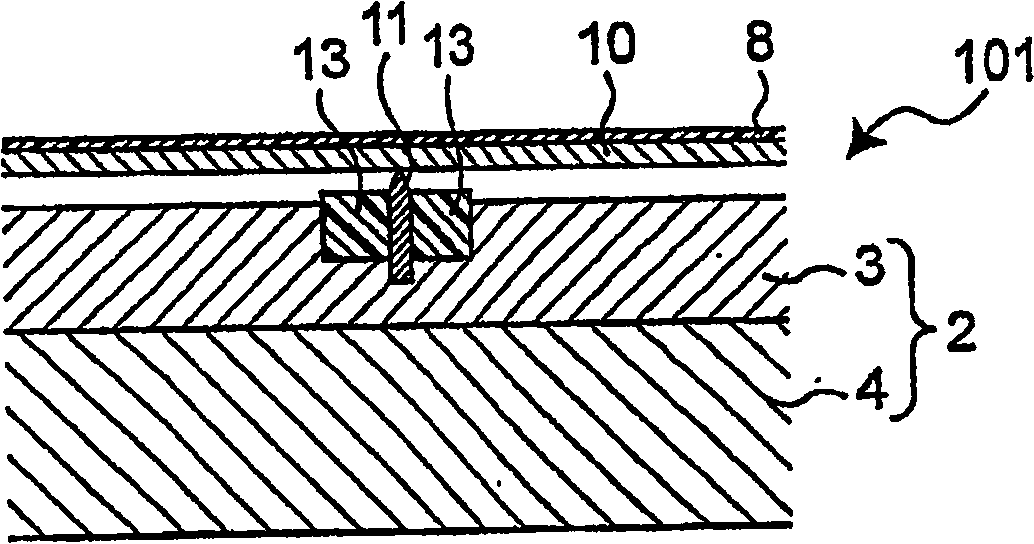

Heating apparatus

InactiveCN1745332AHeating evenlyAchieve homogenizationSemiconductor/solid-state device manufacturingHot plates heating arrangementsRadiant heatRadiant heating

A heating apparatus (101), comprising a hot plate (2) heating a heated substrate (10) by radiation, lift pins (5) liftably disposed in through-holes (6) formed in the hot plate and lifting the heated substrate, and a proximity pin (11) fixed to the hot plate and holding the heated substrate so as to be separated from the hot plate while the heated substrate is heated. Heat reducing parts (13, 7) reducing radiant heat are installed in the hot plate around the proximity pin or around the through-holes.

Owner:NISSHA PRINTING COMPANY

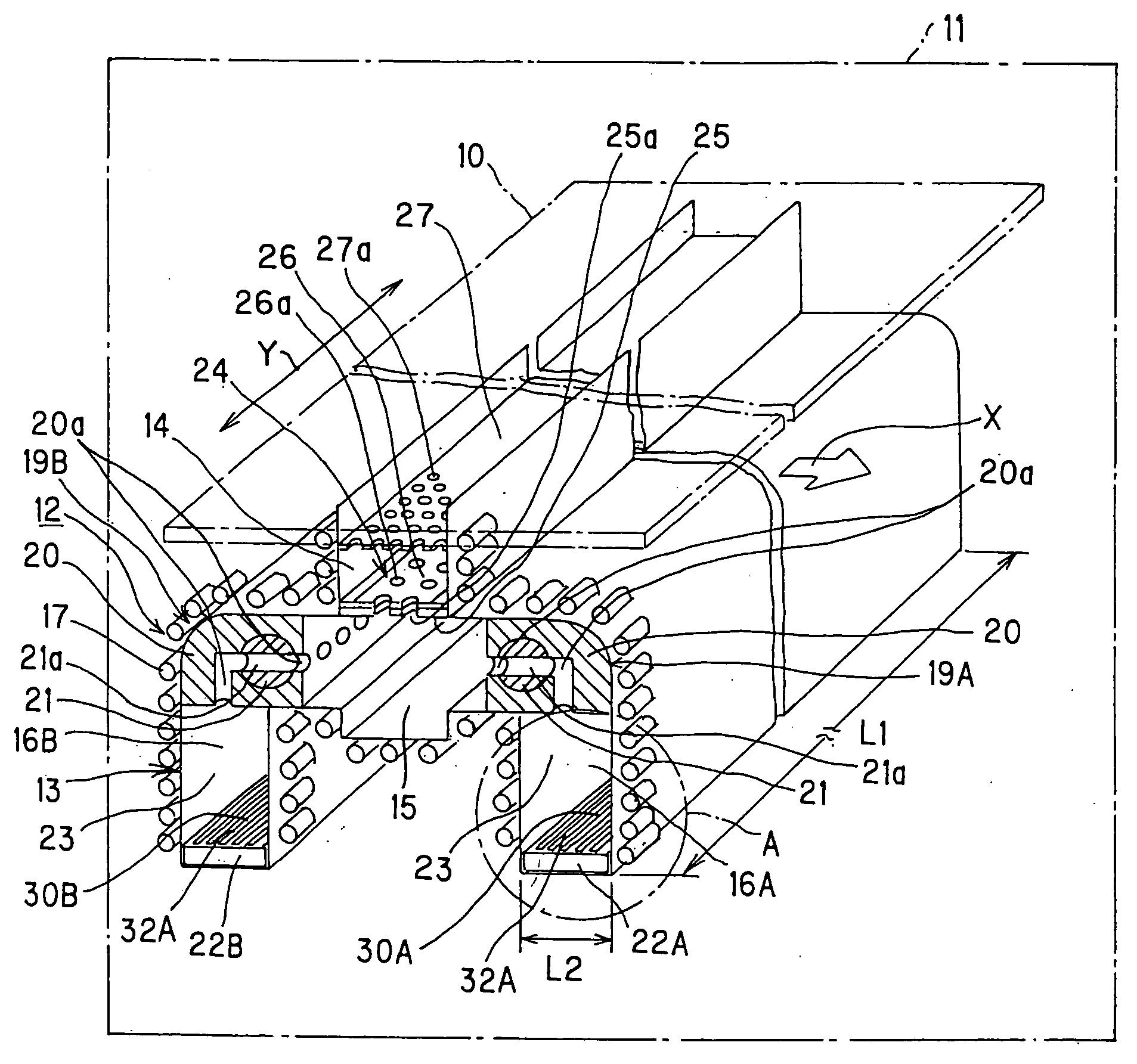

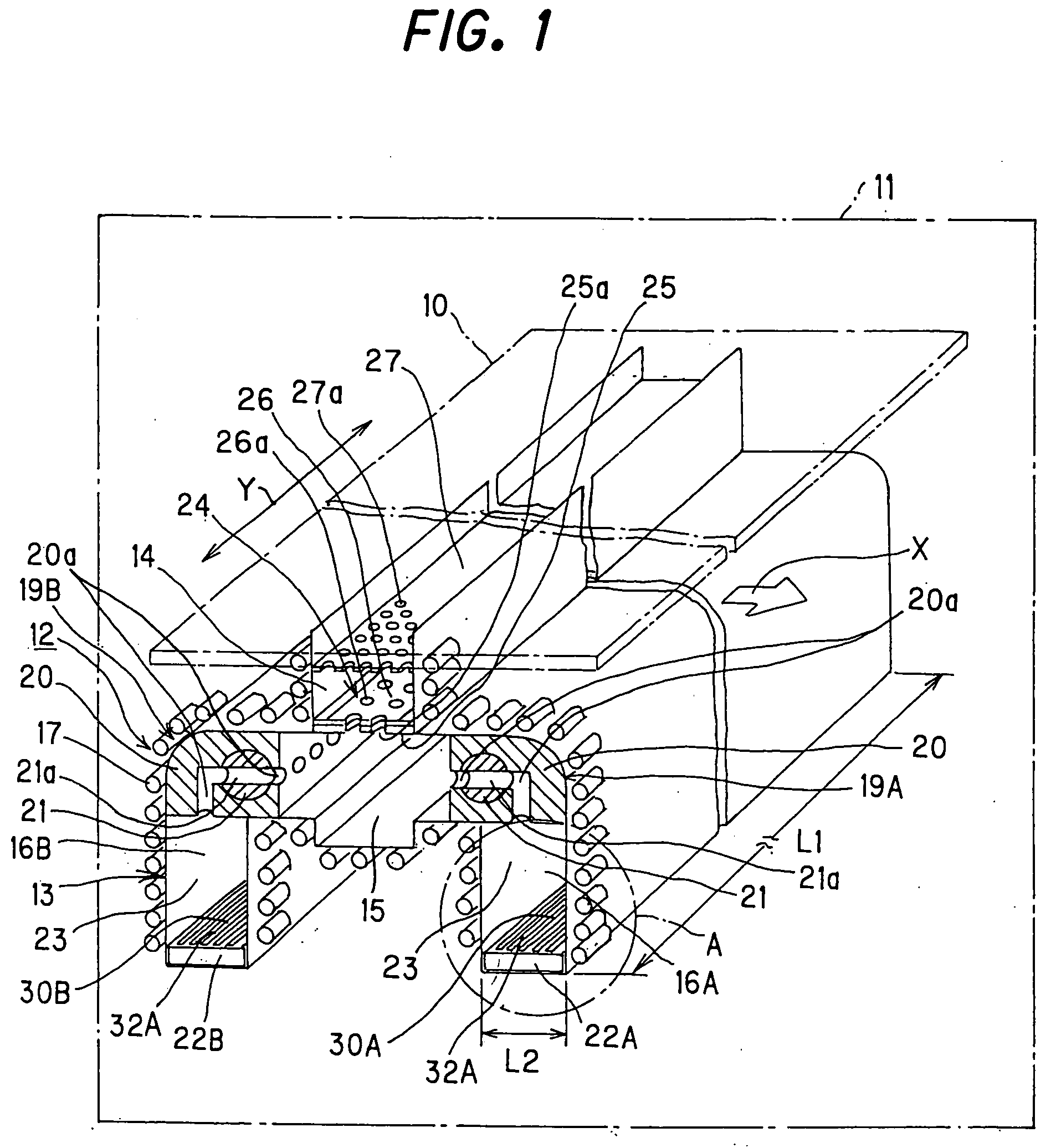

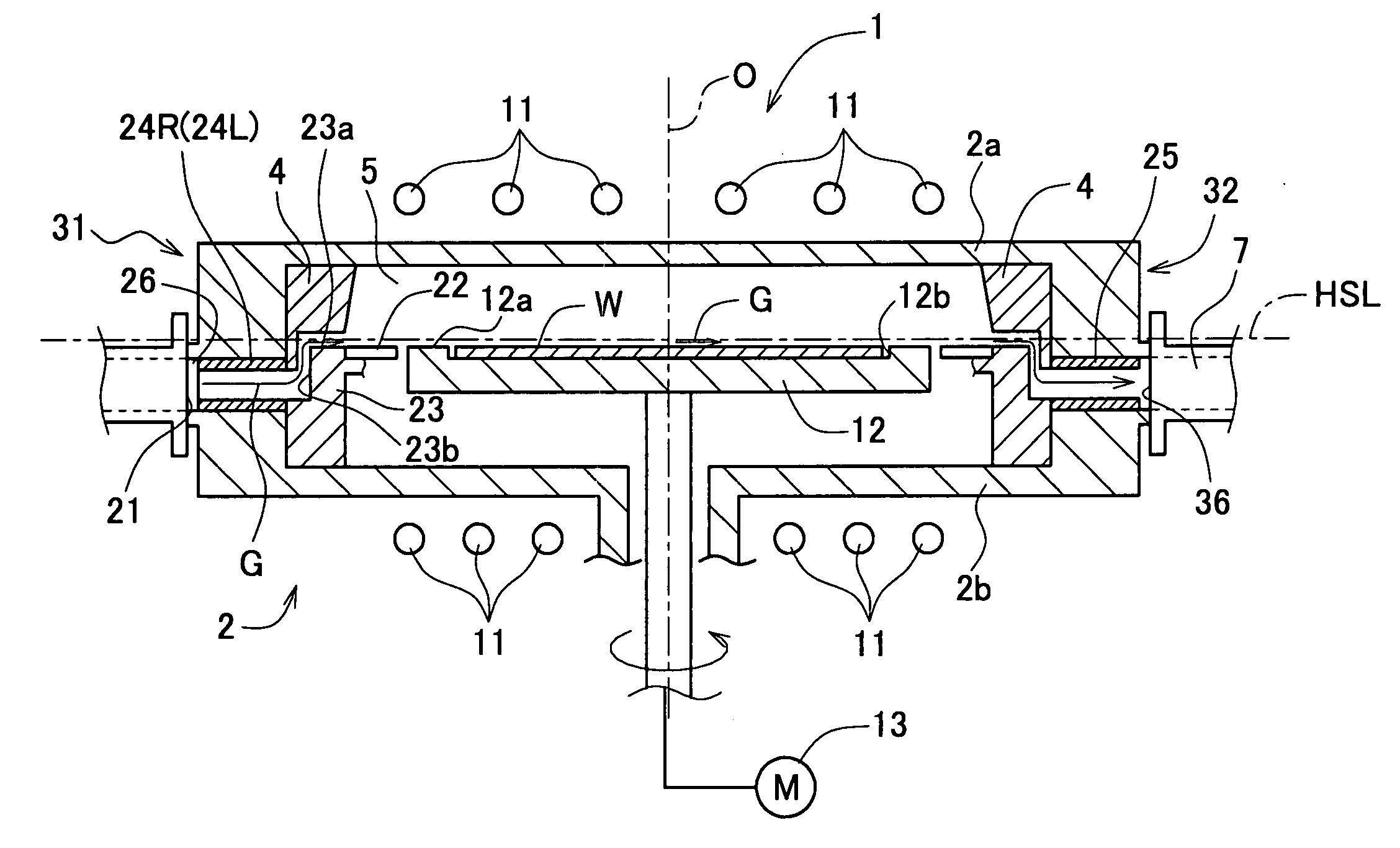

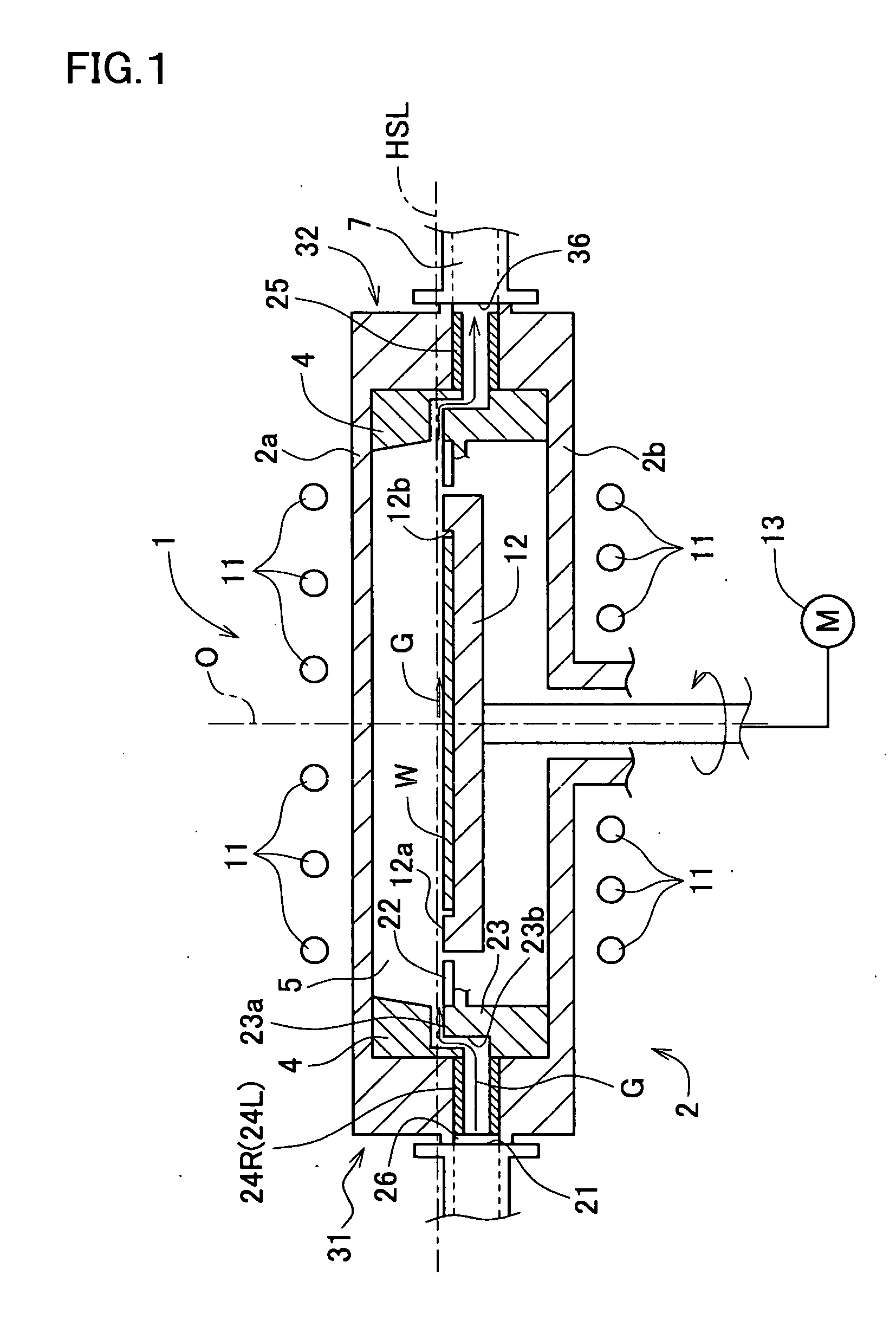

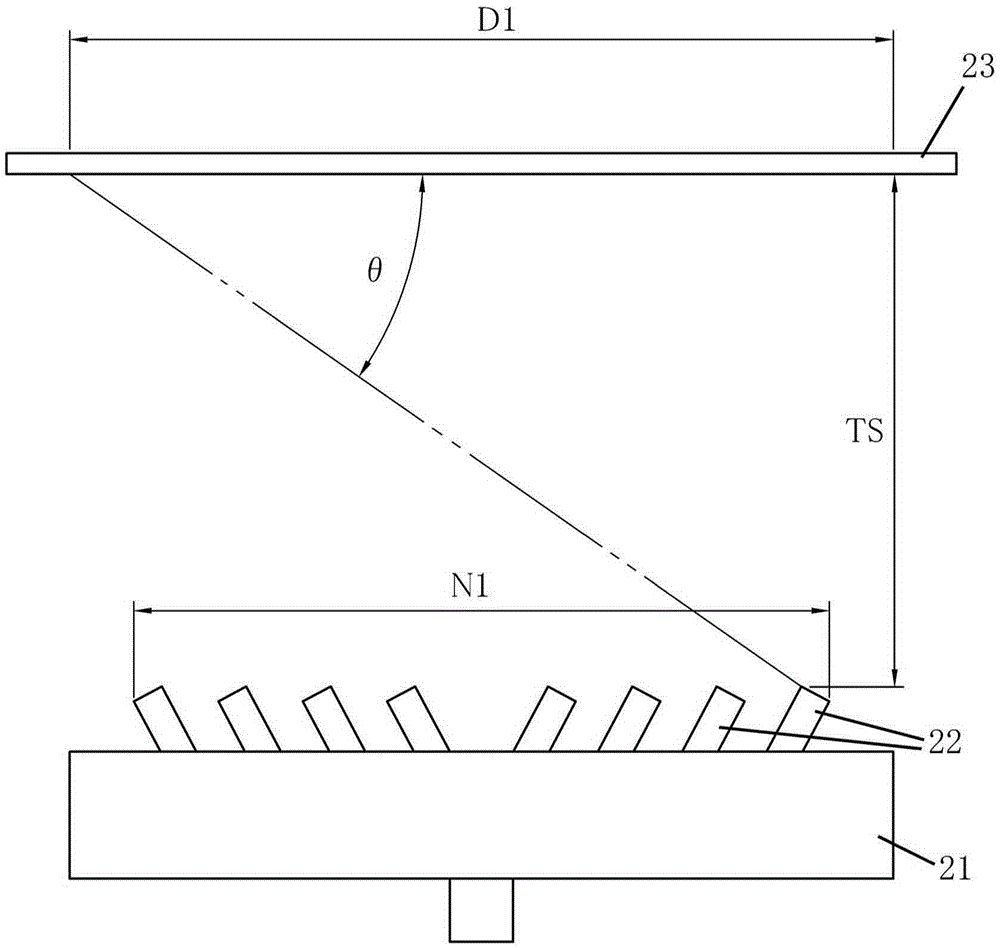

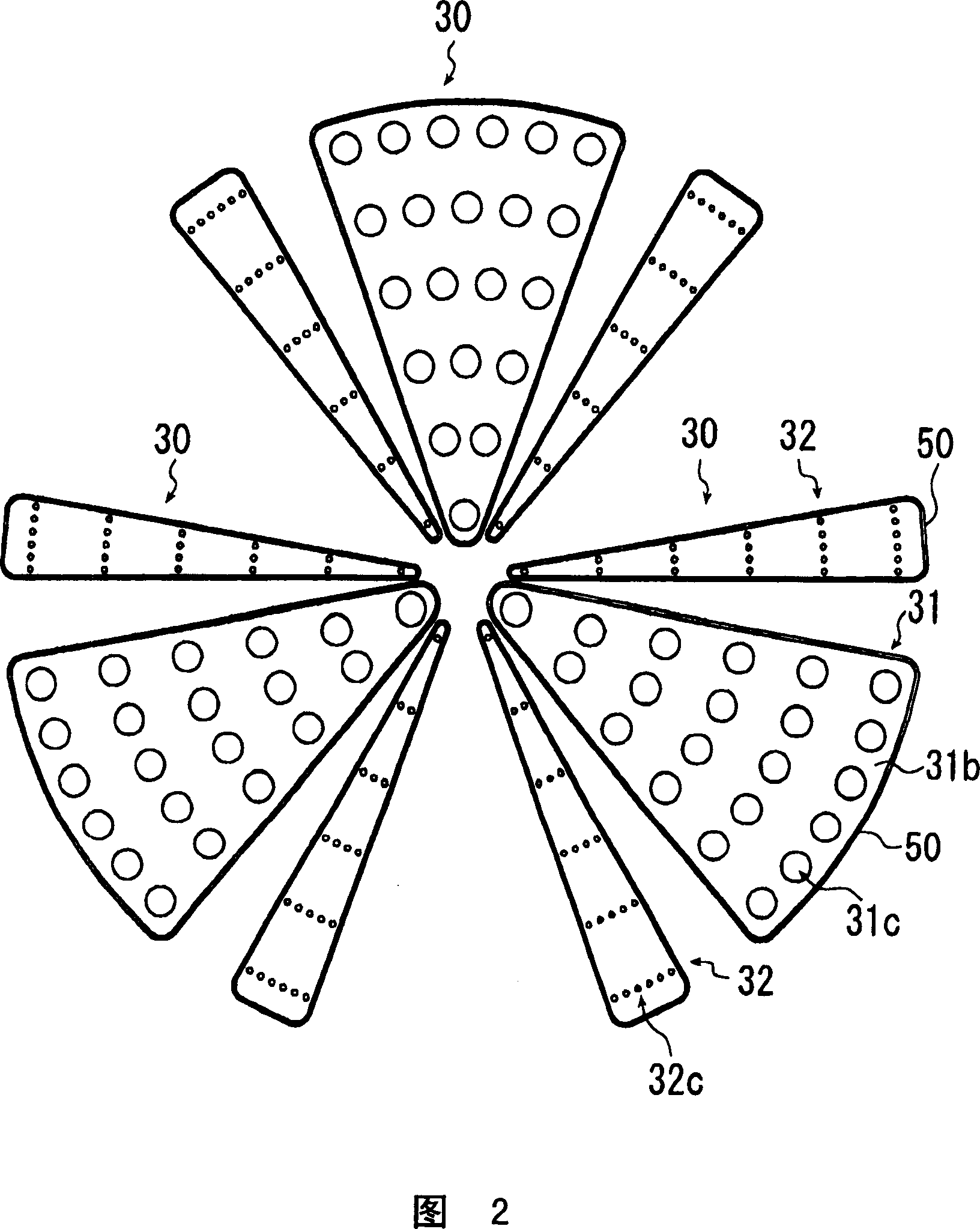

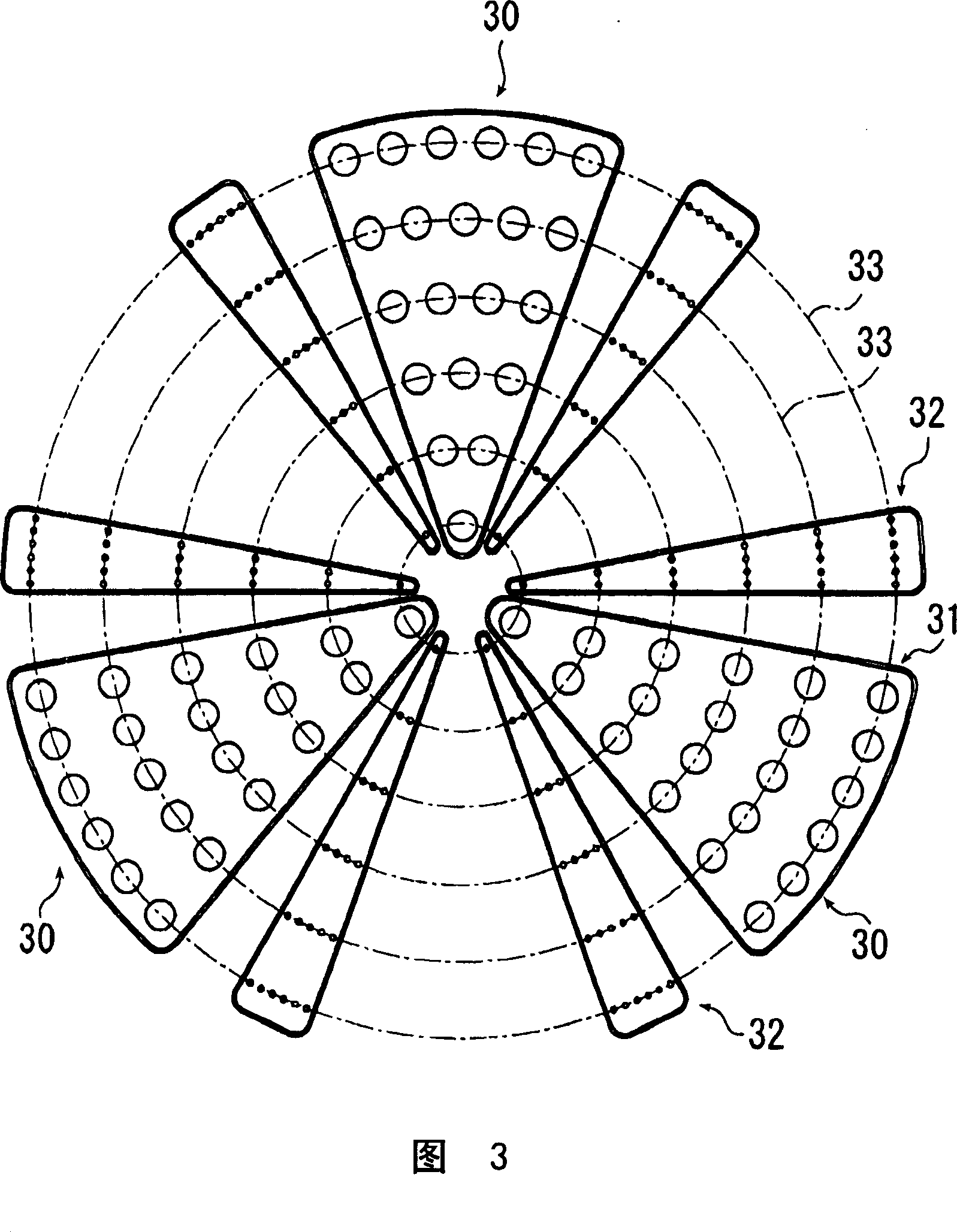

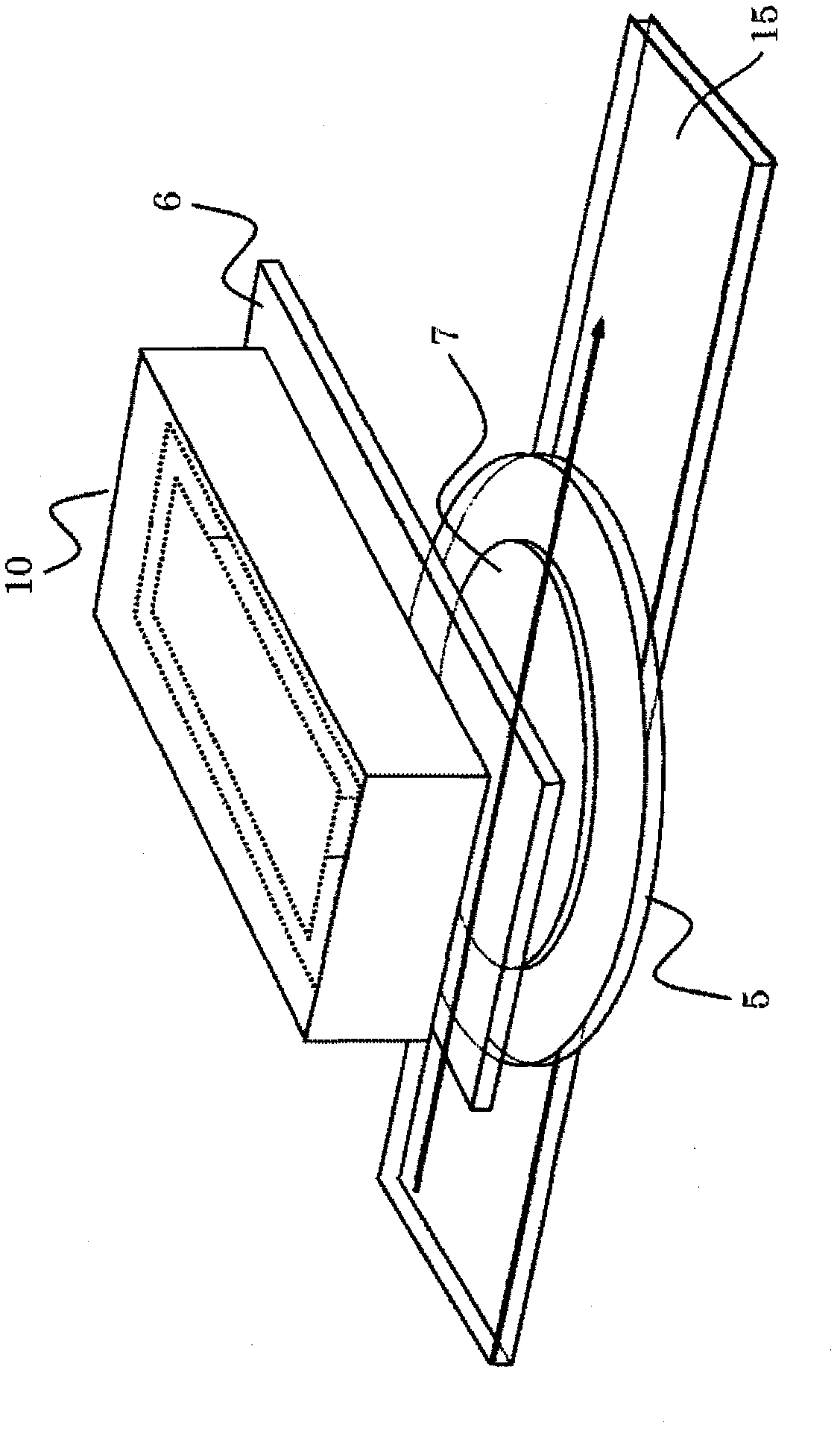

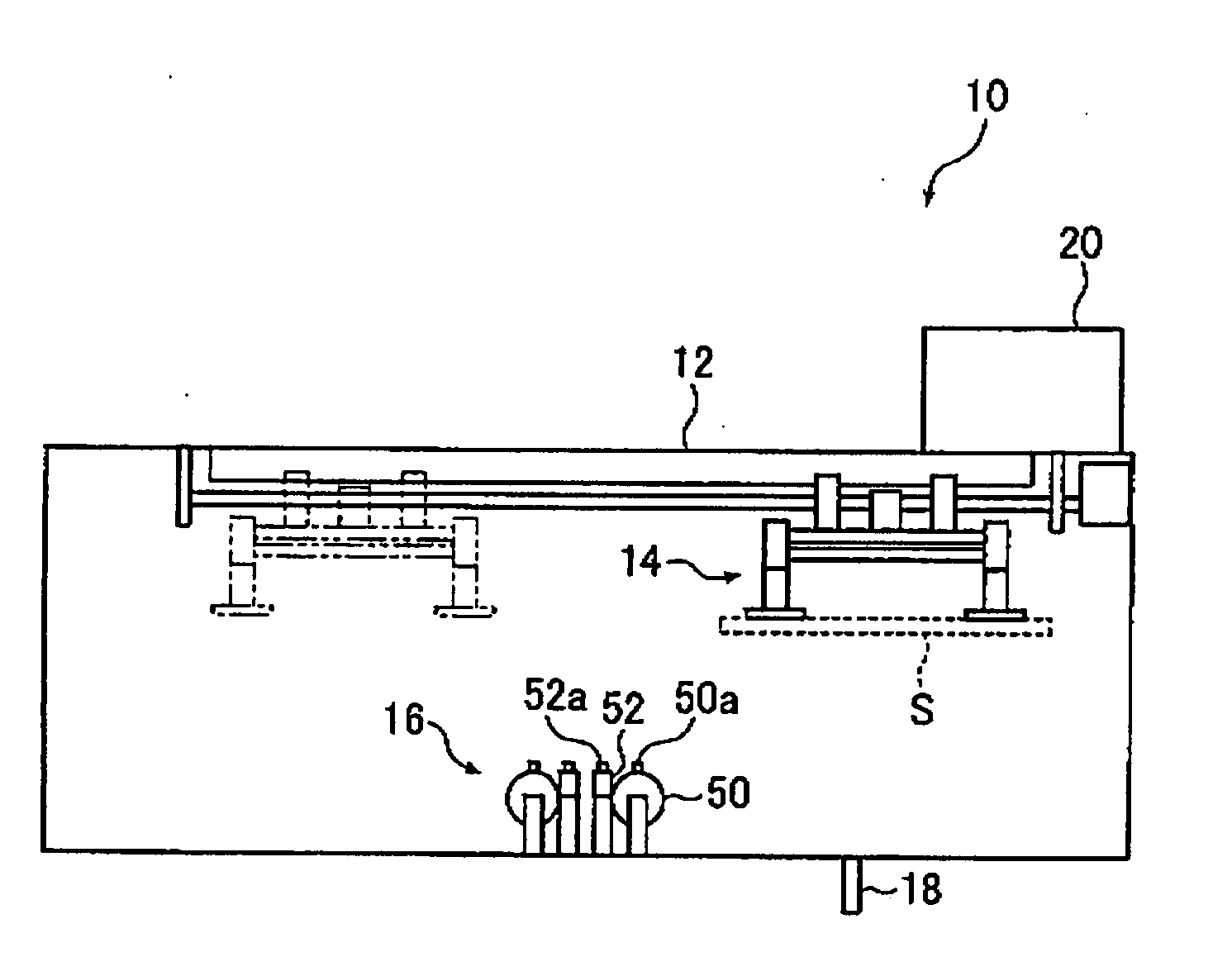

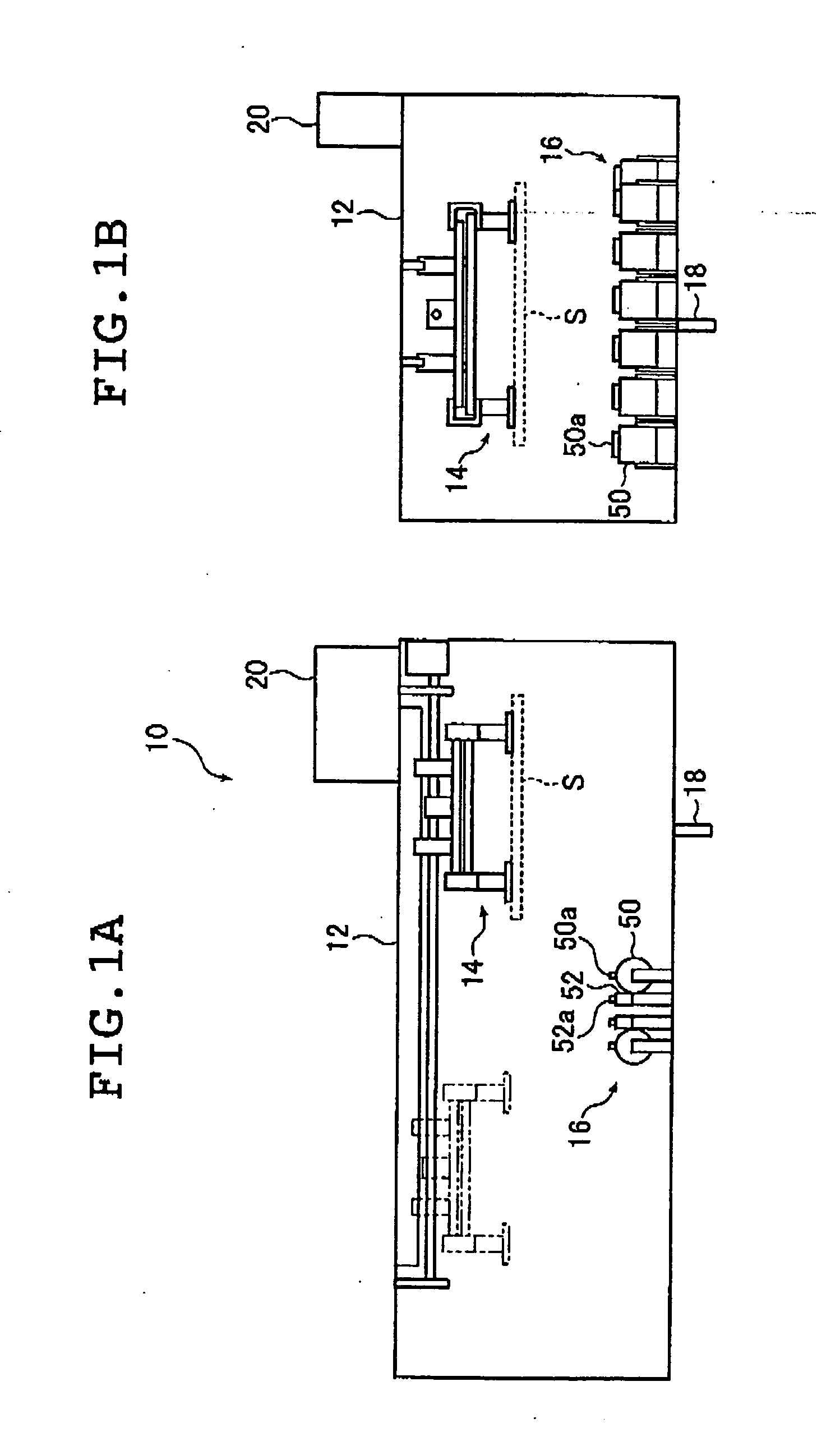

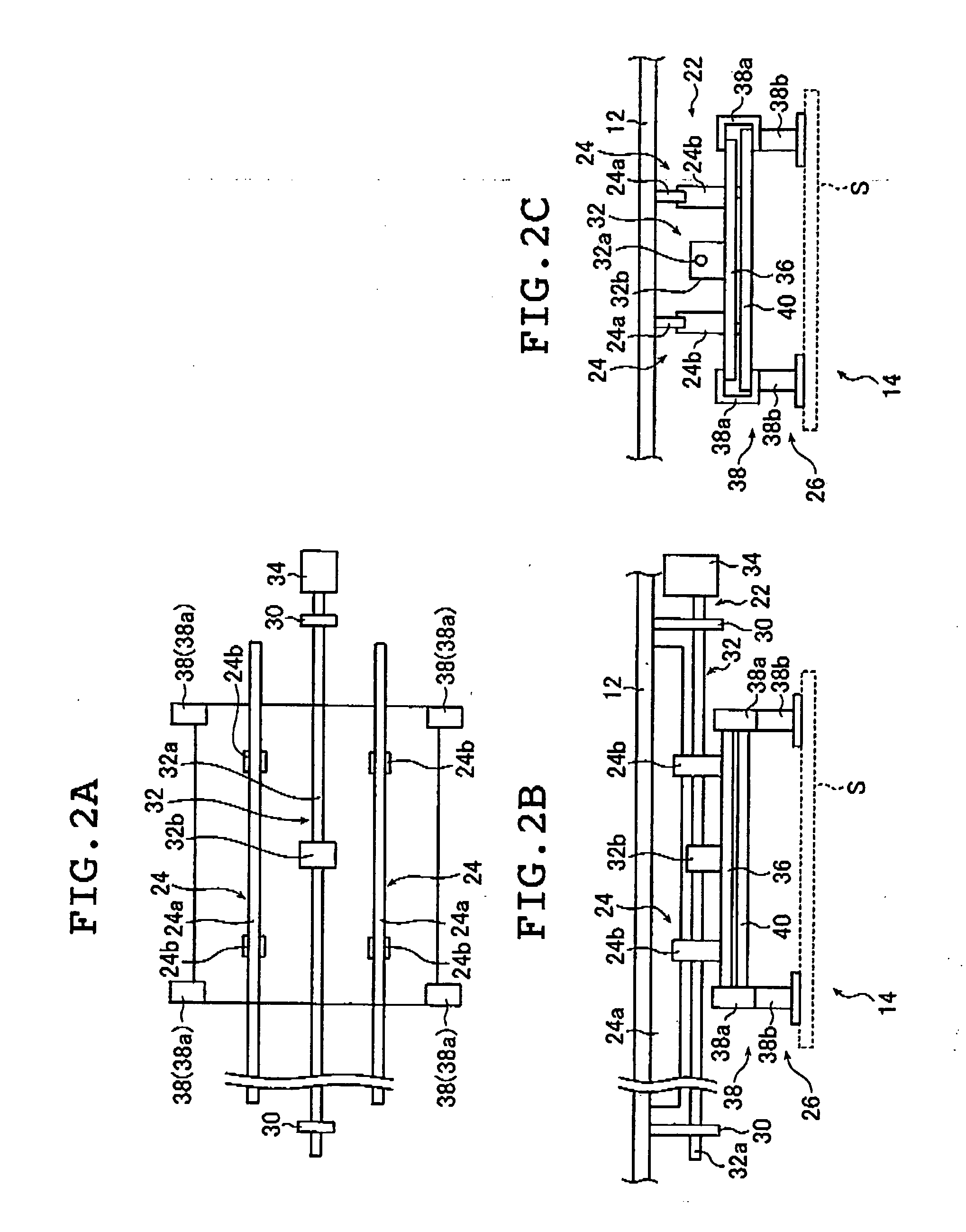

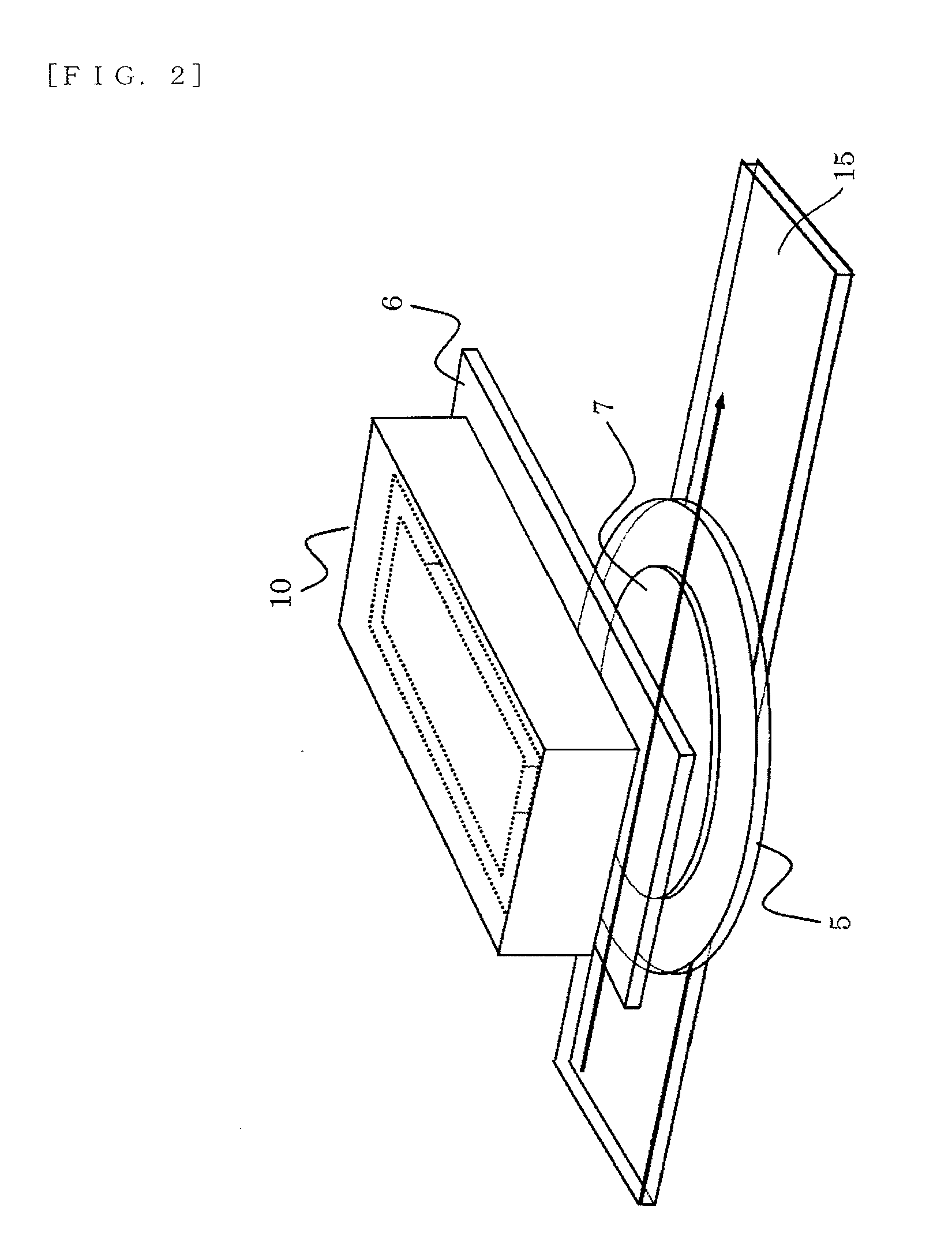

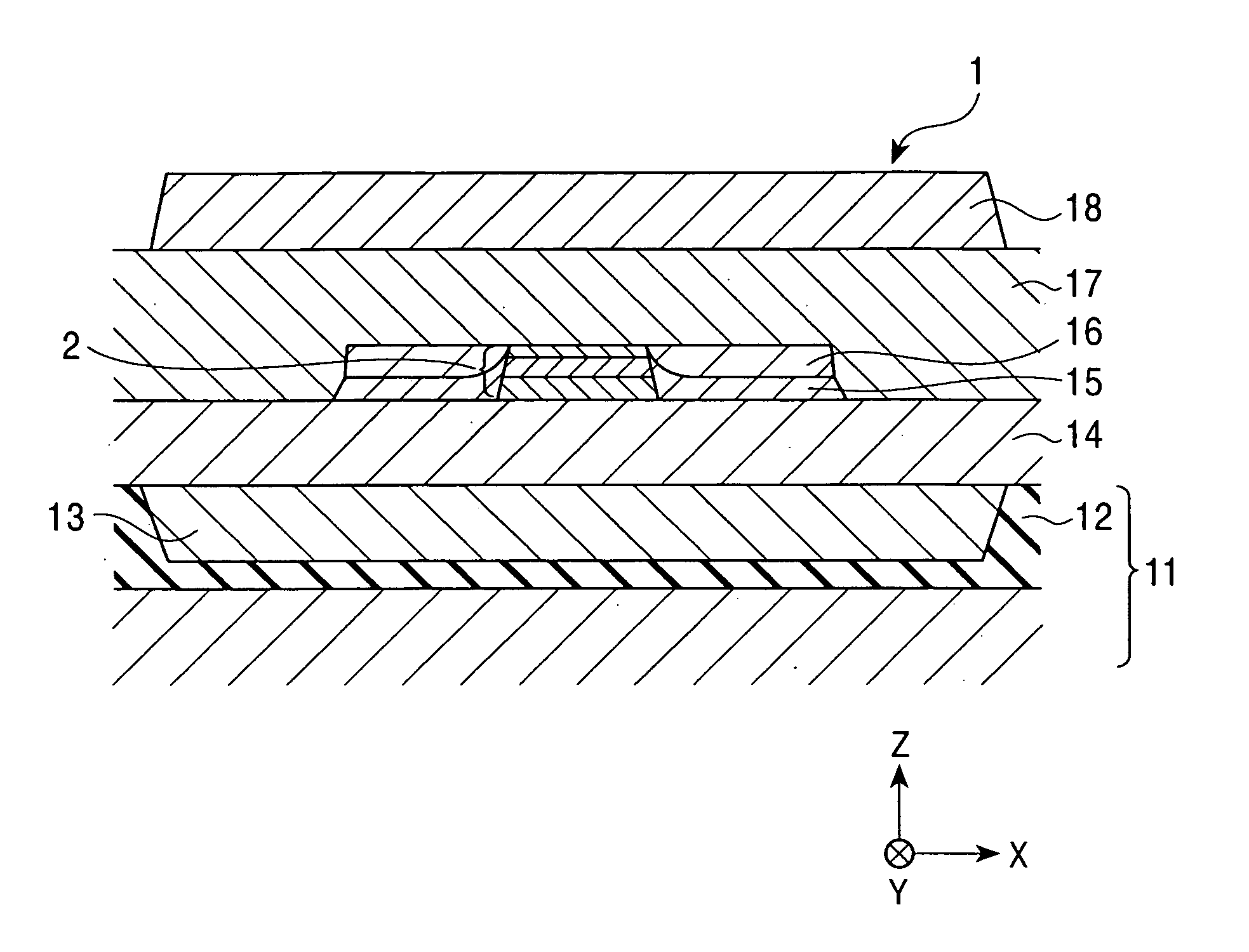

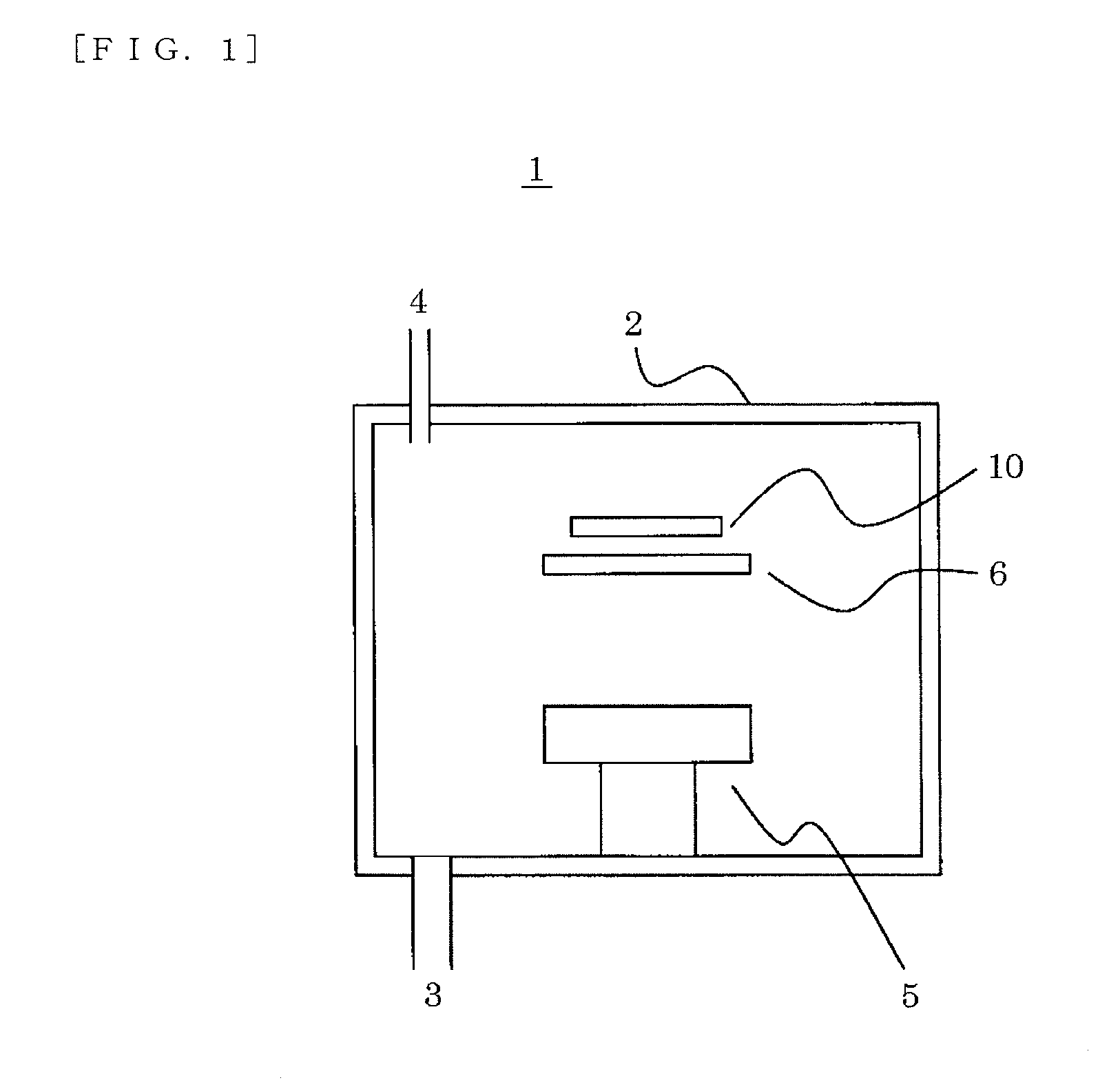

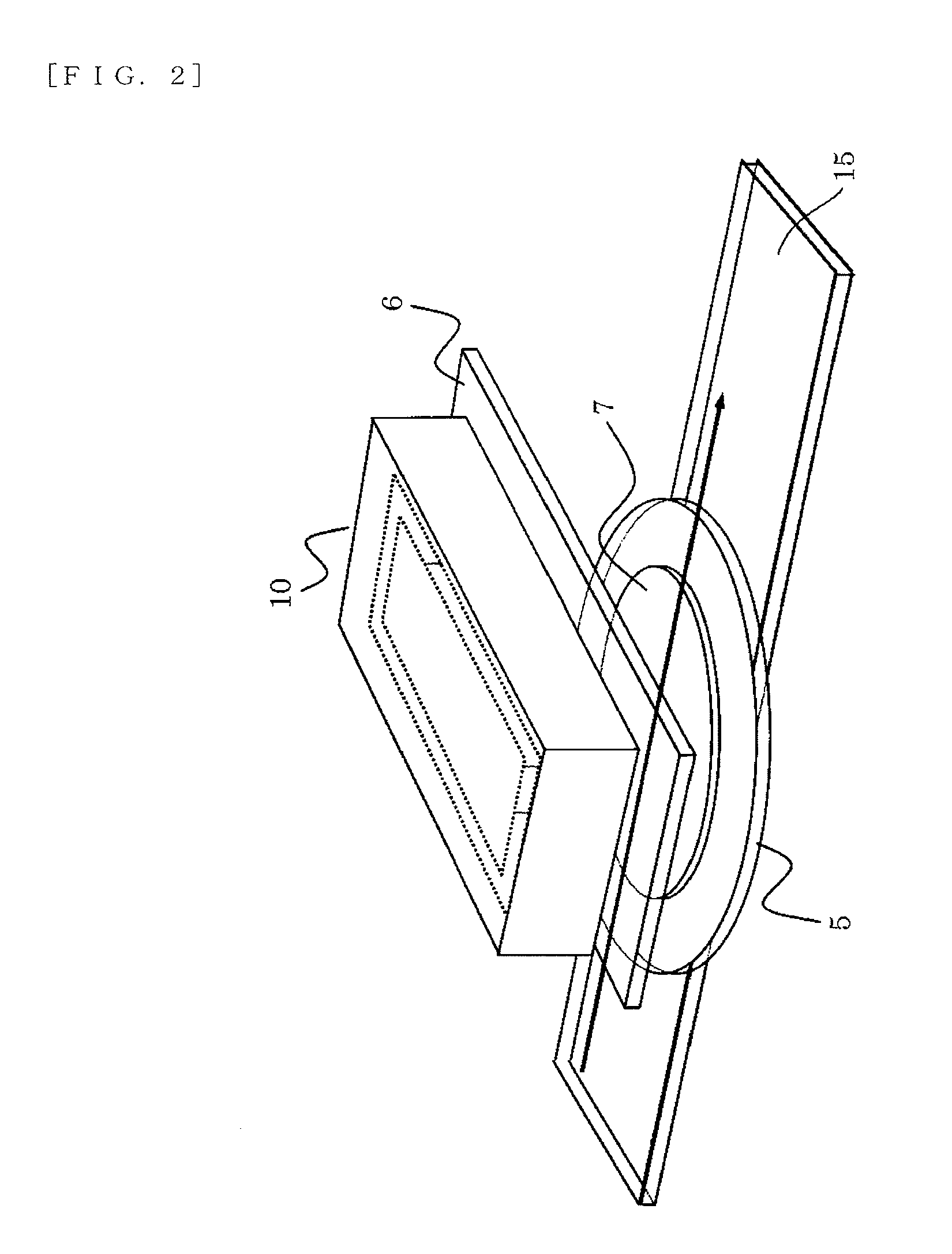

Vapor phase growth apparatus and method of fabricating epitaxial wafer

InactiveUS20070122323A1Uniform film thickness distributionDegree of reductionPolycrystalline material growthBacterial antigen ingredientsSusceptorGas phase

A vapor growth device which is constituted as a single-wafer type and has a gas introducing port through which a material gas is led into a reaction vessel. A dam member is disposed around a susceptor, and the material gas from the gas introducing port hits the outer peripheral surface of the dam ring and rides on an upper surface side, and then is allowed to flow along the main surface of a silicon single-crystal substrate placed on the susceptor. Guide plates for dividing the flow in the width direction of the material gas are disposed on the upper surface of the dam member. Accordingly, a vapor growth device capable of controlling the flow rate of material gas flowing on a silicon single-crystal substrate, and a production method for an epitaxial wafer using it are provided.

Owner:SHIN-ETSU HANDOTAI CO LTD

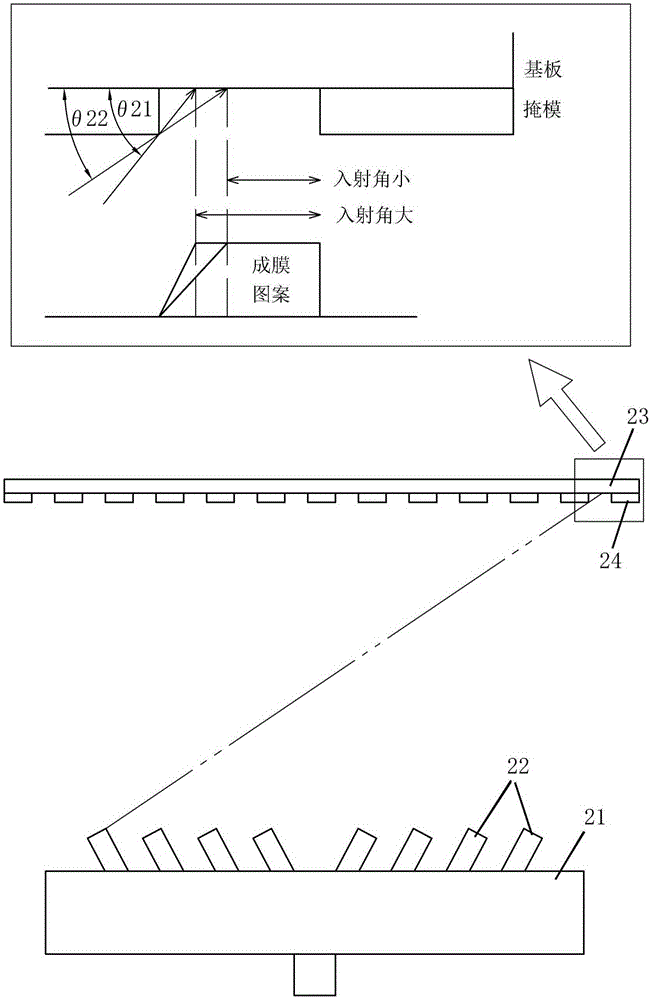

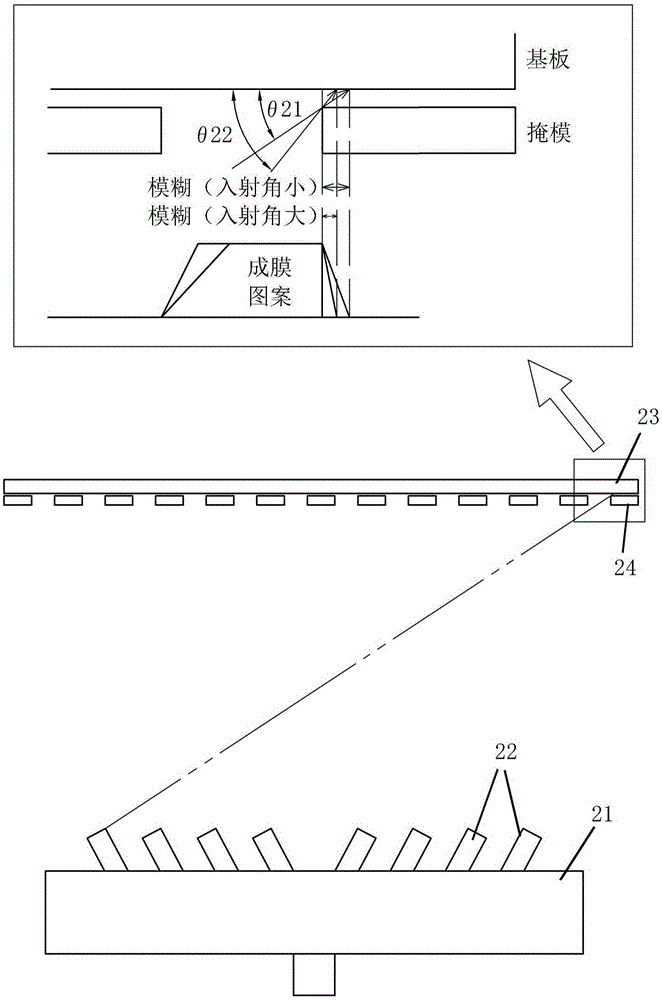

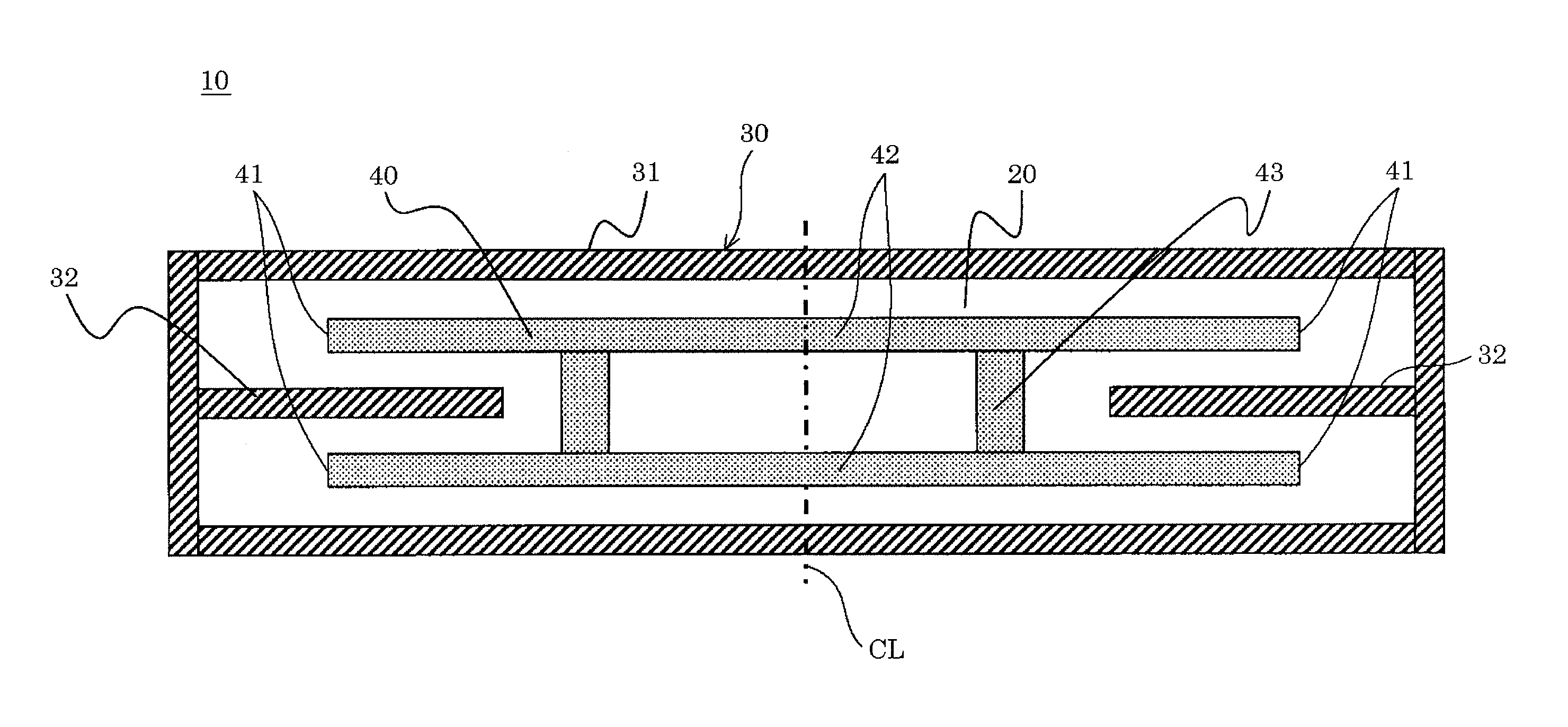

Vacuum evaporation apparatus

ActiveCN105734495ARaise the ratioSuppress blurVacuum evaporation coatingSputtering coatingOptoelectronicsVacuum evaporation

The present invention provides a vacuum evaporation apparatus. The blurring phenomenon of a pattern is avoided when the ratio of the flat portion of the film pattern is increased. Meanwhile, an evaporation film with the thickness thereof to be uniformly distributed is obtained. A plurality of evaporation openings (2) are formed on an evaporation source (1) along the length direction of the evaporation source. The evaporation source (1) is capable of moving relative to a substrate (3) arranged opposite to the evaporation source (1) in a direction vertical to the length direction of the evaporation source (1). The film formation material is ejected out of the evaporation openings (2). Therefore, an evaporation film is formed on the substrate (3). At least one pair of external evaporation openings (2), out of the plurality of evaporation openings (2), are respectively provided with an opening end surface inclined towards the outside along the length direction of the evaporation source (1). At least one internal evaporation opening (2), positioned on the inner side of the external evaporation openings (2) and selected out of the plurality of evaporation openings (2), is provided with an opening end surface inclined towards the centre along the length direction of the evaporation source (1).

Owner:CANON TOKKI CORP

Apparatus for forming deposited film

ActiveUS20120228129A1Uniform film thickness distributionGood film thickness distributionCellsElectric discharge tubesElectrical and Electronics engineeringElectrode

First and second electrodes are apart from each other in a chamber. Plates are disposed on a substrate in the second electrode. Each of the plates comprises first and second parts for supplying first and second gas to a space between the first and second electrodes, respectively, a first supply path for first gas connected to the first part, and a second supply path for second gas connected to the second part. The substrate comprises a heater for the first gas, a first introducing path for introducing the first gas to the first supply path, and a second introducing path for introducing the second gas to the second supply path. The second supply path comprises a mainstream part without the second part and branch parts with the second part. A connecting portion of the second introducing path and the mainstream part is positioned in an adjacent portion of the plates.

Owner:KYOCERA CORP

Tin plating solution

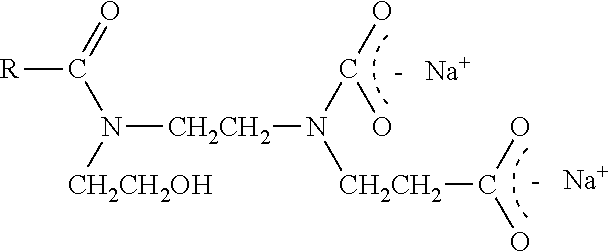

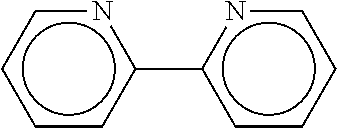

InactiveUS20120132530A1Uniform film thickness distributionPrinted circuit manufacturePhenanthrolineTin plating

To provide a tin plating solution having uniformity of through-hole plating, uniformity of film thickness distribution and no burn deposits even. The tin plating solution include a tin ion source, at least one non-ionic surfactant, imidazoline dicarboxylate and 1,10-phenanthroline.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

Preparation method of CdS thin-film

InactiveCN101820018AReduced sealing requirementsIncrease profitVacuum evaporation coatingSputtering coatingSource materialCarbon Dioxide / Helium

Owner:BYD CO LTD

Organic material evaporation source and organic vapor deposition device

InactiveCN1950536AUniform film thickness distributionControl heating temperatureElectroluminescent light sourcesSolid-state devicesVaporizationMembrane thickness

An organic material evaporation source capable of forming a membrane having a uniform membrane thickness distribution with respect to a large-sized substrate and capable of controlling heating temperature and evaporation rate during vapor deposition accurately and with good responsiveness; and an organic vapor deposition device using the source. A vaporization source comprises a vessel main body (31a) having a heating section consisting of a high frequency induction coil (50) and receiving a predetermined organic material, and a lid (31b) having a vaporization port (31c) for the vapor of the organic material to pass therethrough. The arrangement is such that the amount of vapor of the organic material discharged from the vaporization port (31c) in the lid (31b) steadily increases with respect to a two-dimensional position with a predetermined reference position used as a basis.

Owner:ULVAC INC

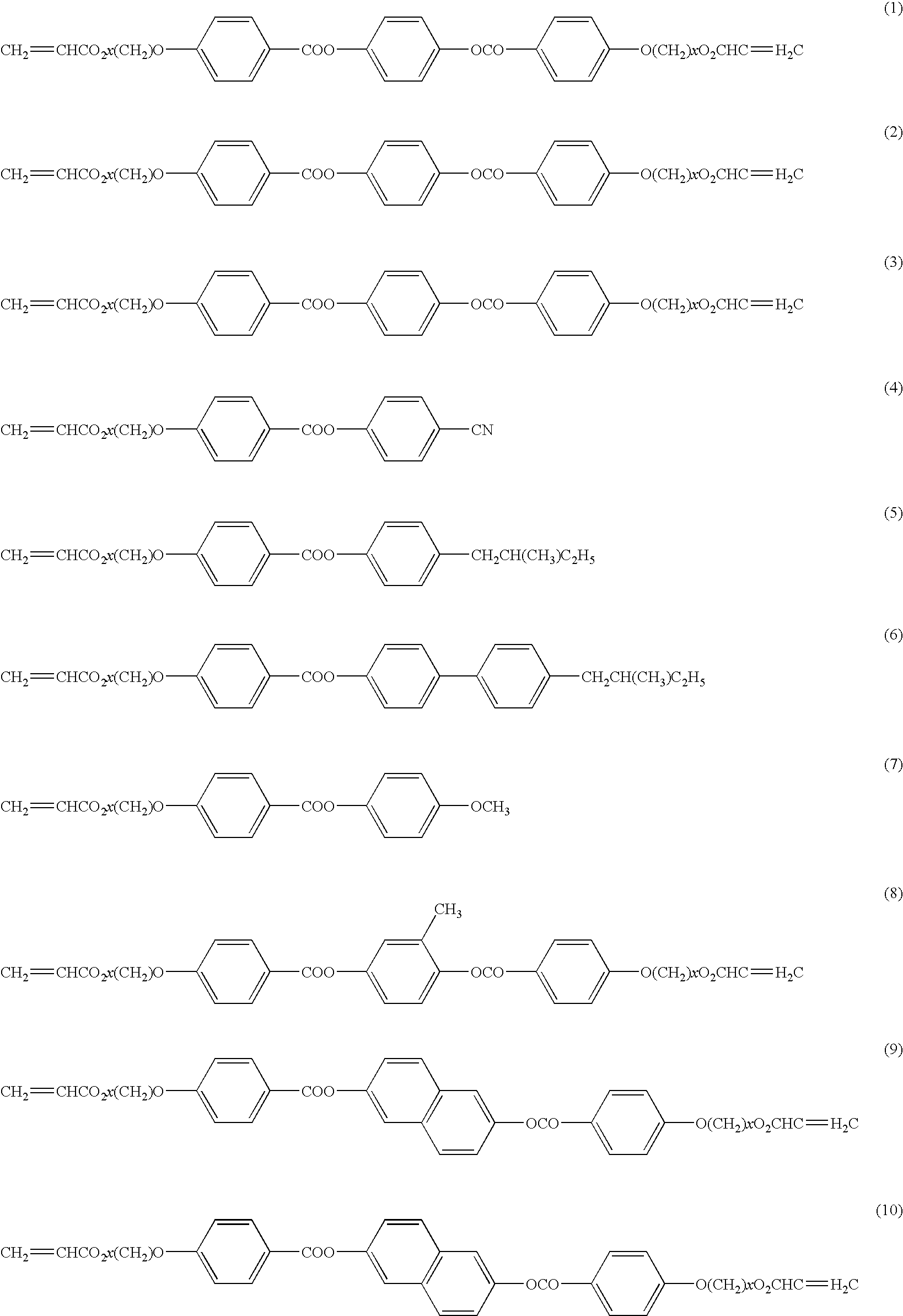

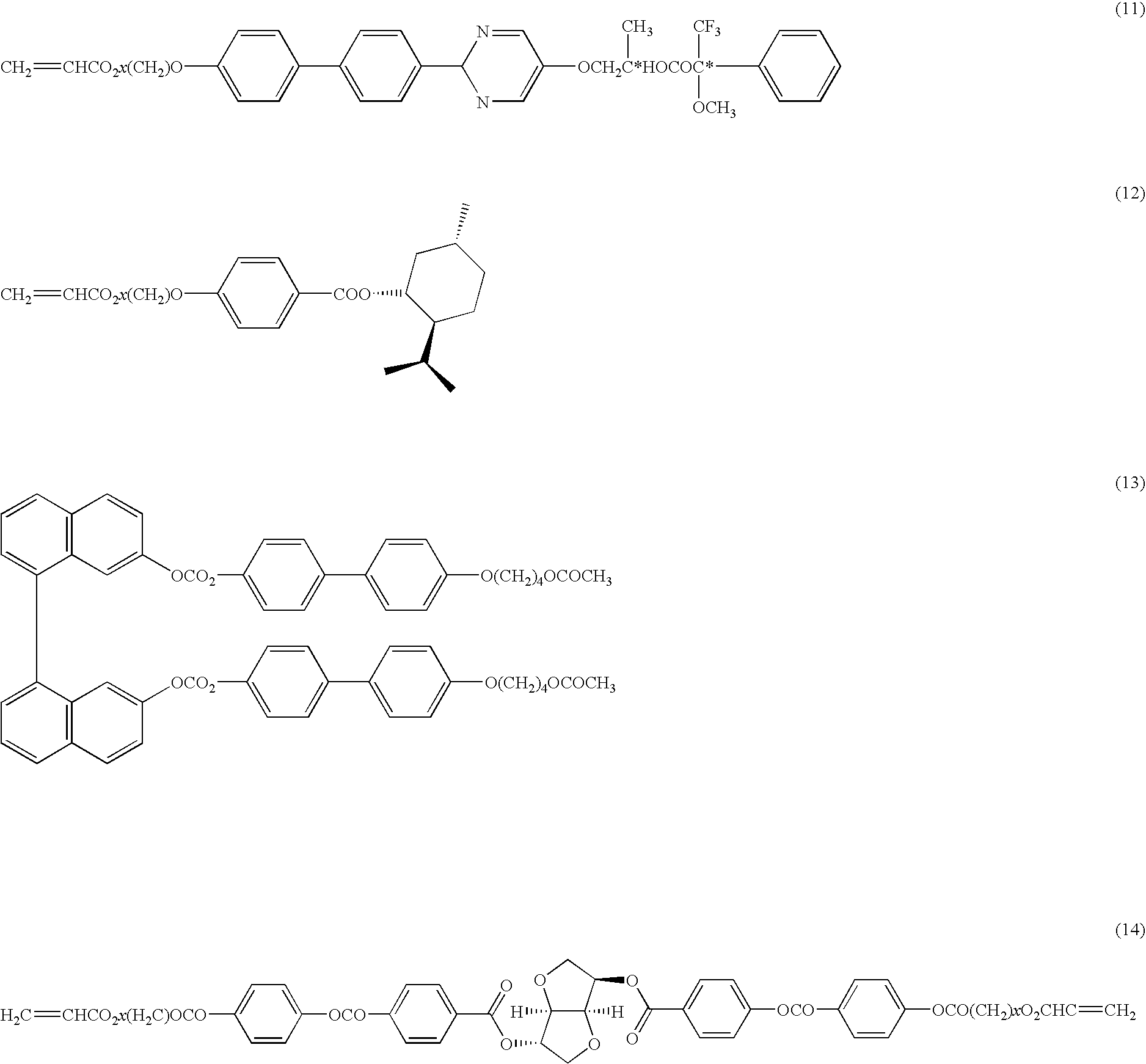

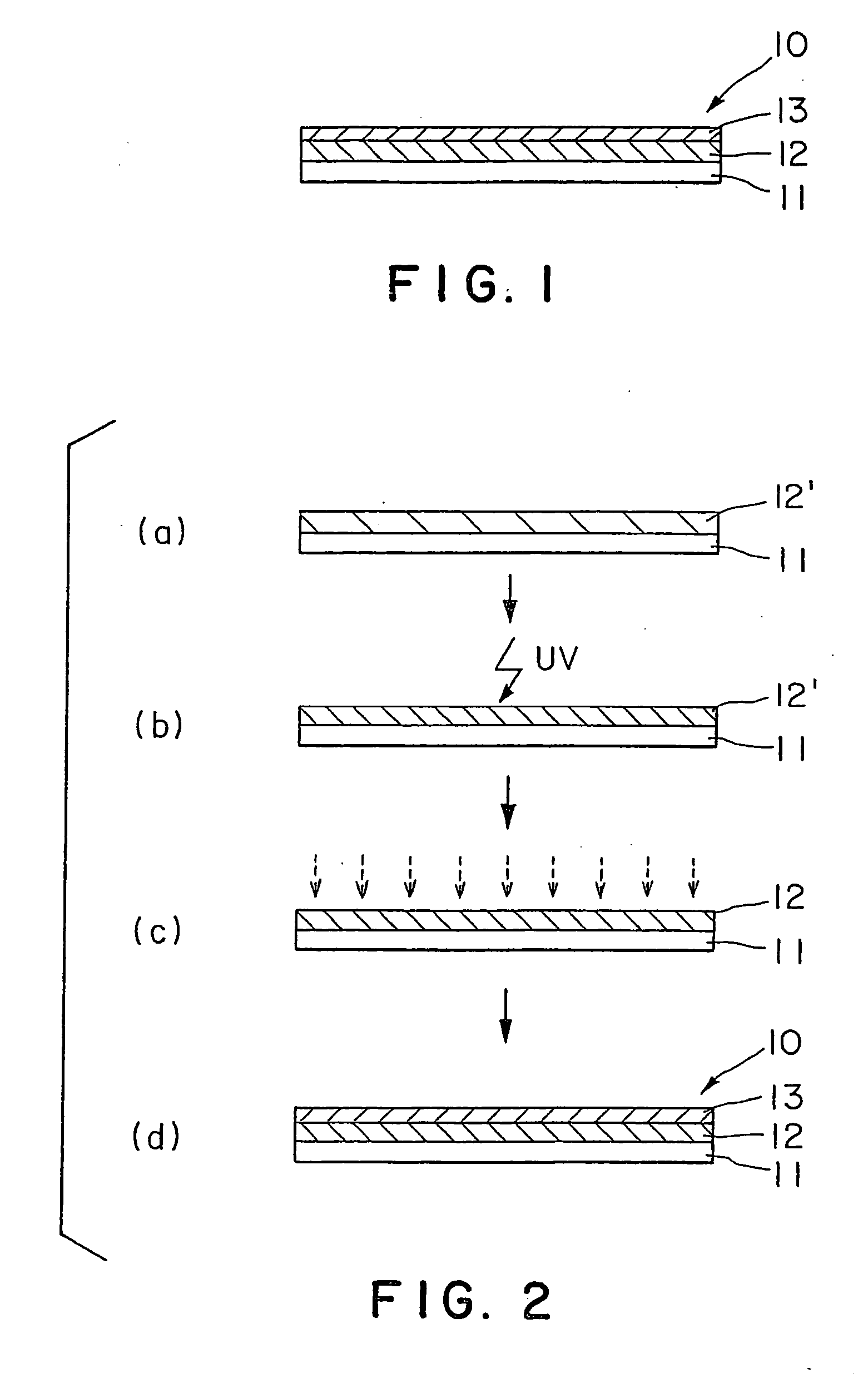

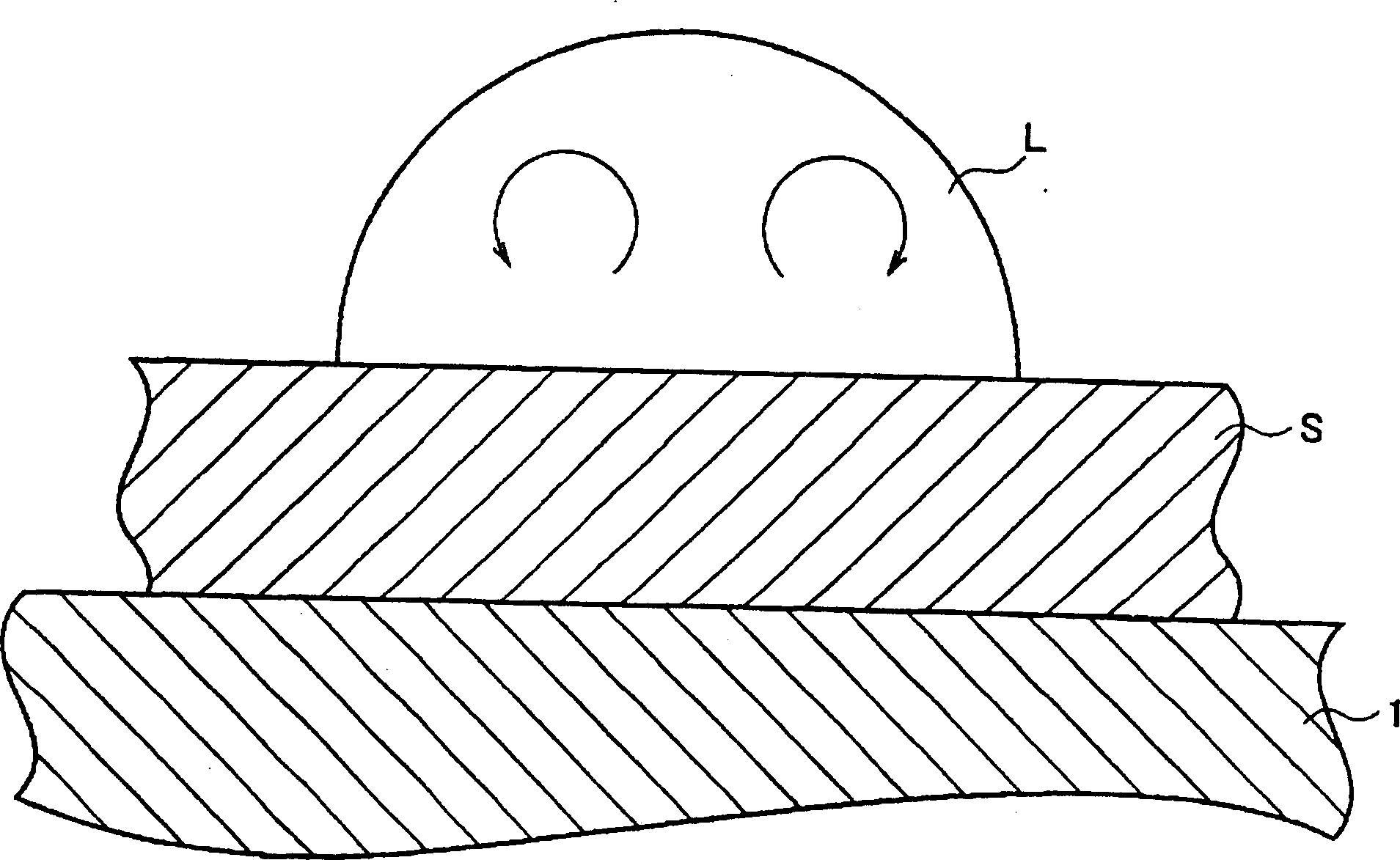

Optical element

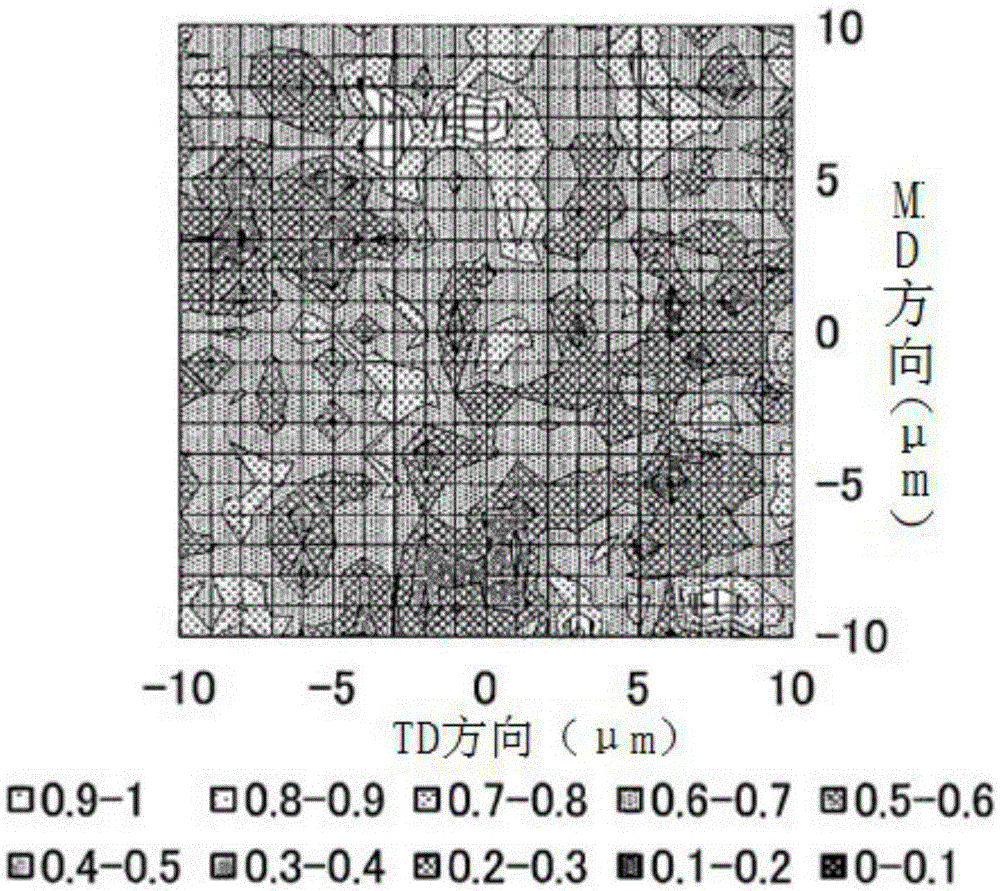

InactiveUS20040057007A1Improve display qualityUniform film thickness distributionPolarising elementsNon-linear opticsLiquid-crystal displayHardness

An optical element including: an alignment substrate; a liquid crystal layer formed on the alignment substrate, made by forming and curing a film of a liquid crystalline material; and a protective layer having high hardness, formed on the liquid crystal layer. The protective layer is for protecting the liquid crystal layer from being deformed by externally exerted forces. Preferably, the protective layer has a modulus of elasticity (=(elastic deformation) / (total deformation)) of 0.6 or more and a plastic deformation of 0.5 mum or less as determined by pushing an indenter into the protective layer with a test force of 2 mN in accordance with the universal hardness test method. The optical element has the advantages that the film thickness distribution of the liquid crystal layer remains uniform even when forces are externally exerted to the optical element in the process of production of the optical element or in the course of incorporation of the optical element in a liquid crystal display, and that the optical element can maintain its high displaying quality even when incorporated in a liquid crystal display.

Owner:DAI NIPPON PRINTING CO LTD

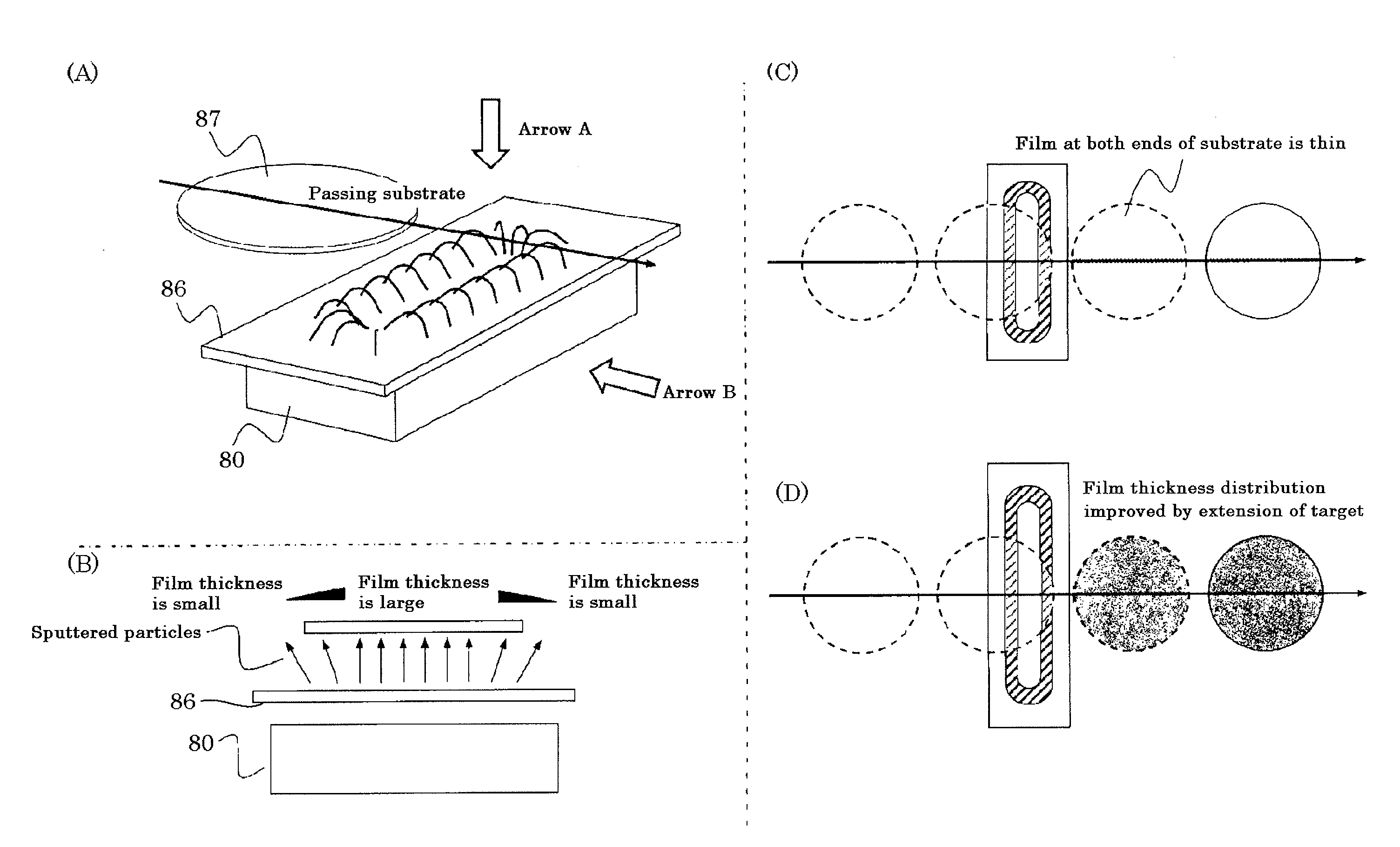

Magnet unit, and magnetron sputtering device

ActiveCN102037154AUniform film thickness distributionElectric discharge tubesVacuum evaporation coatingSputteringMagnetic poles

The invention provides a magnet unit and a magnetron sputtering device. Disclosed is a magnet unit which can homogenize the thickness distribution of a thin film to be formed on a substrate, without increasing the length and width of a target. The magnet unit (10) comprises an annular outer magnet (30) arranged over a yoke (20) on the back side of a cathode electrode and along the contour of a target (6), and an inner magnet (40) arranged in the annular outer magnet and made different in polarity from the outer magnet, whereby the tangents of magnetic lines of force (M) generated over the target form the magnetic tracks (MT) of a set of areas parallel to the target face. The magnet unit (10) also comprises extending magnetic poles (41) of an n-number (n indicates a positive integer of 2 or more) extending from the central portion of the inner magnet and approaching the two longitudinal ends of the outer magnet, and protruding magnetic poles (32) of a (n-1)-number protruding longitudinally inward from the inner sides of the two ends of the outer magnet and positioned between the extending magnetic poles of the n-number. The extending magnetic poles of the n-number and the protruding magnetic poles of the (n-1)-number form folded-back sections (U) of a (2n-1)-number at the two longitudinal ends of the magnetic track.

Owner:CANON ANELVA CORP

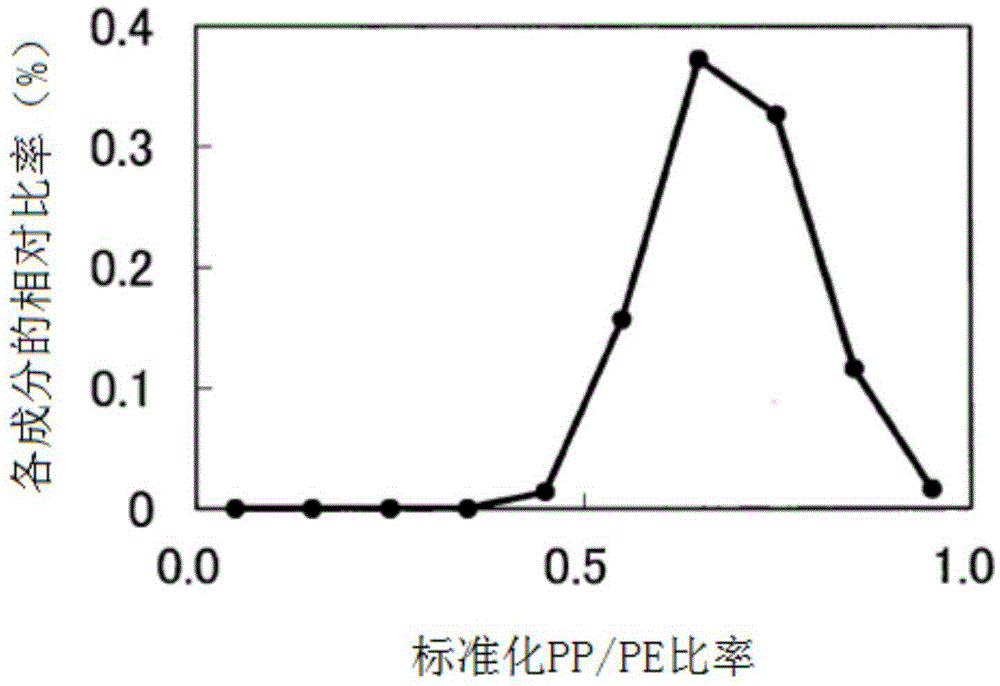

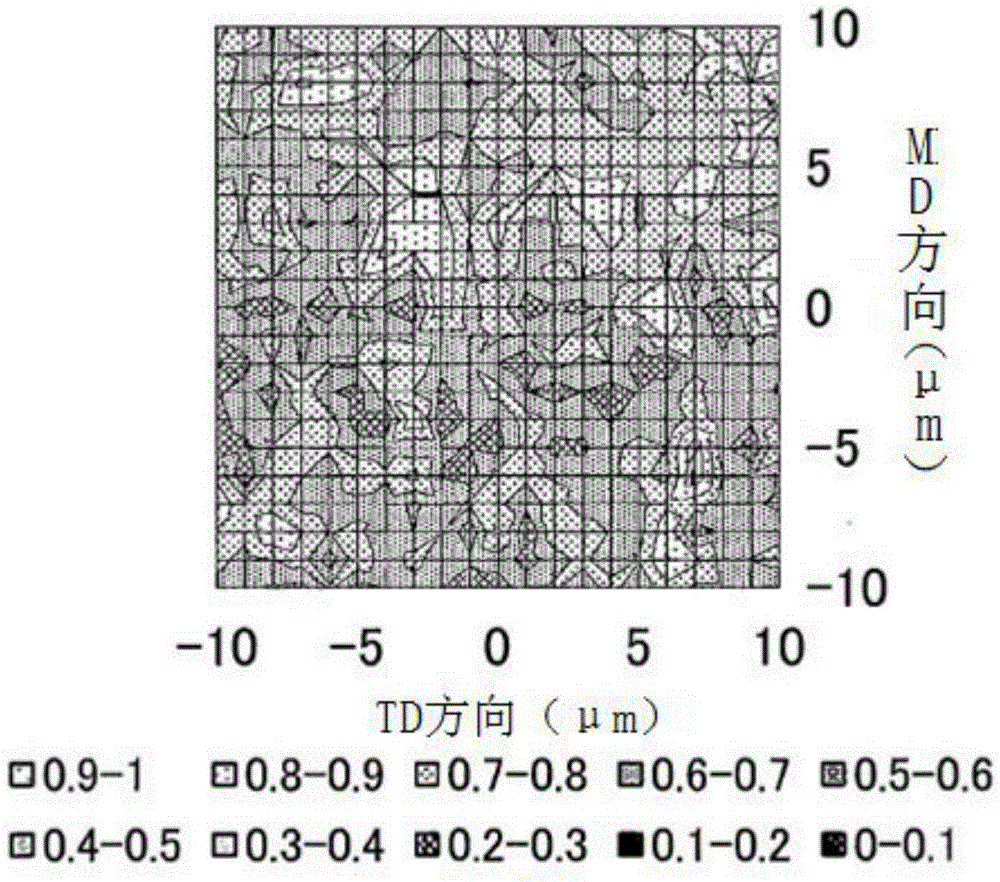

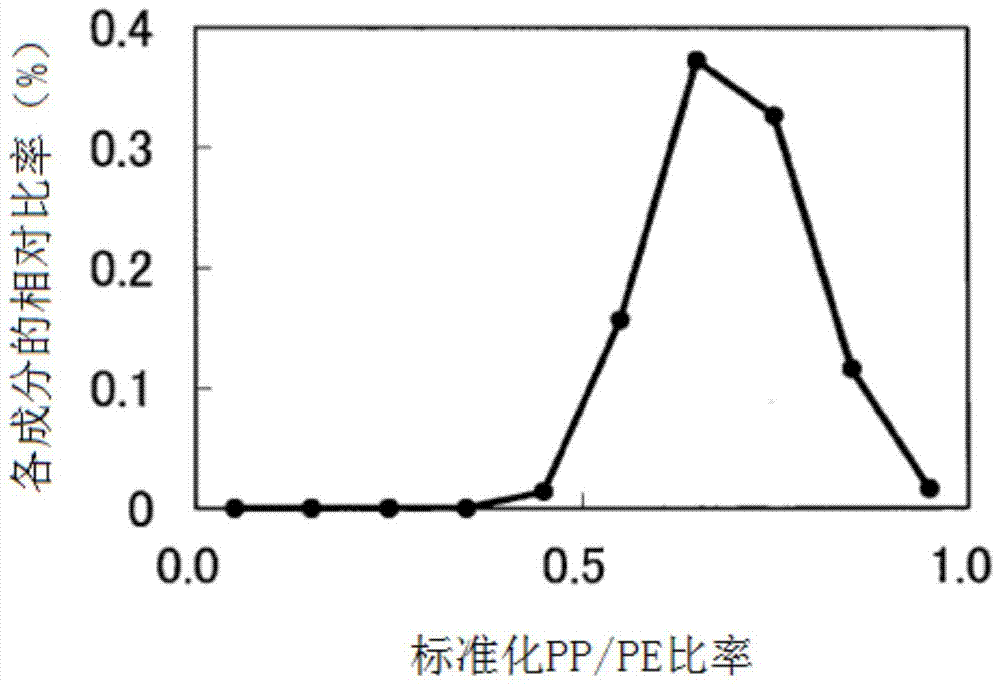

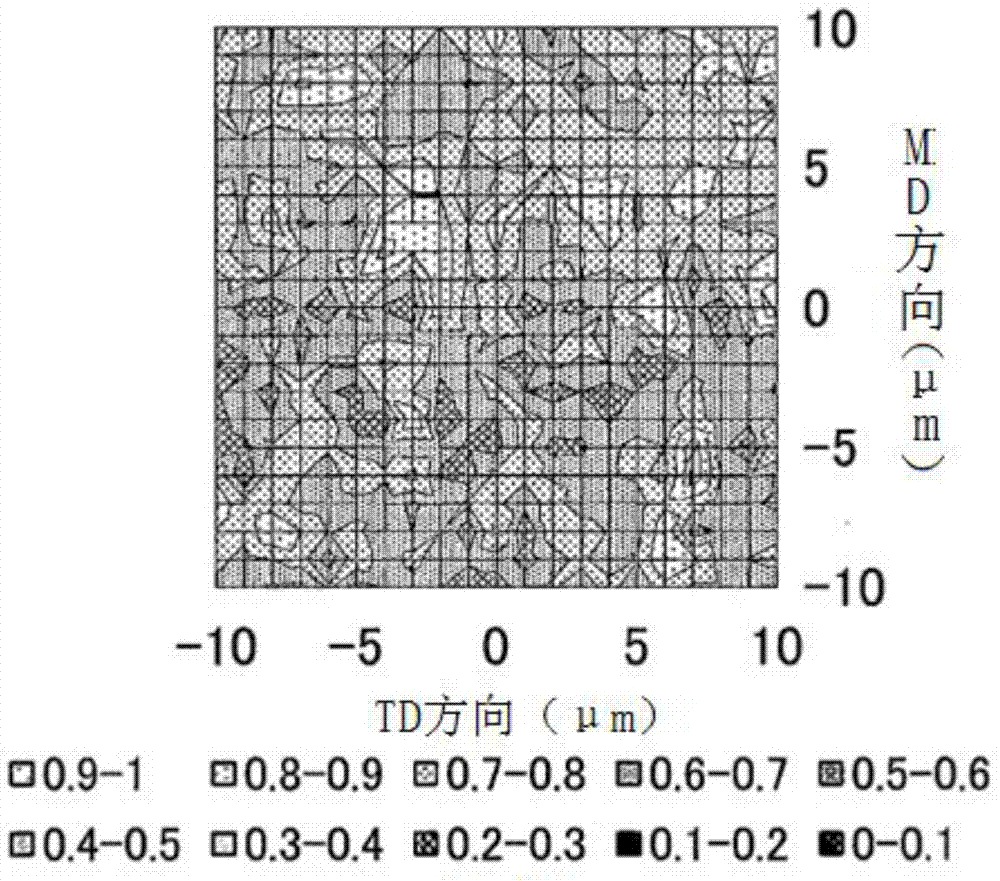

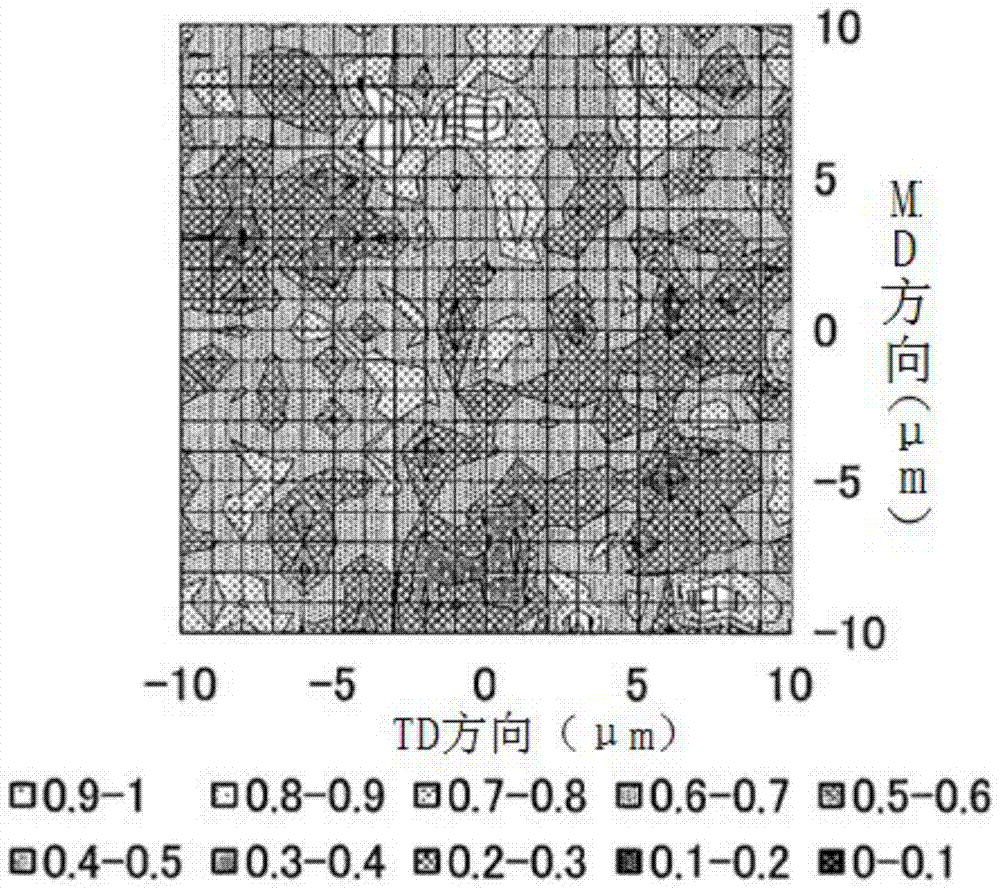

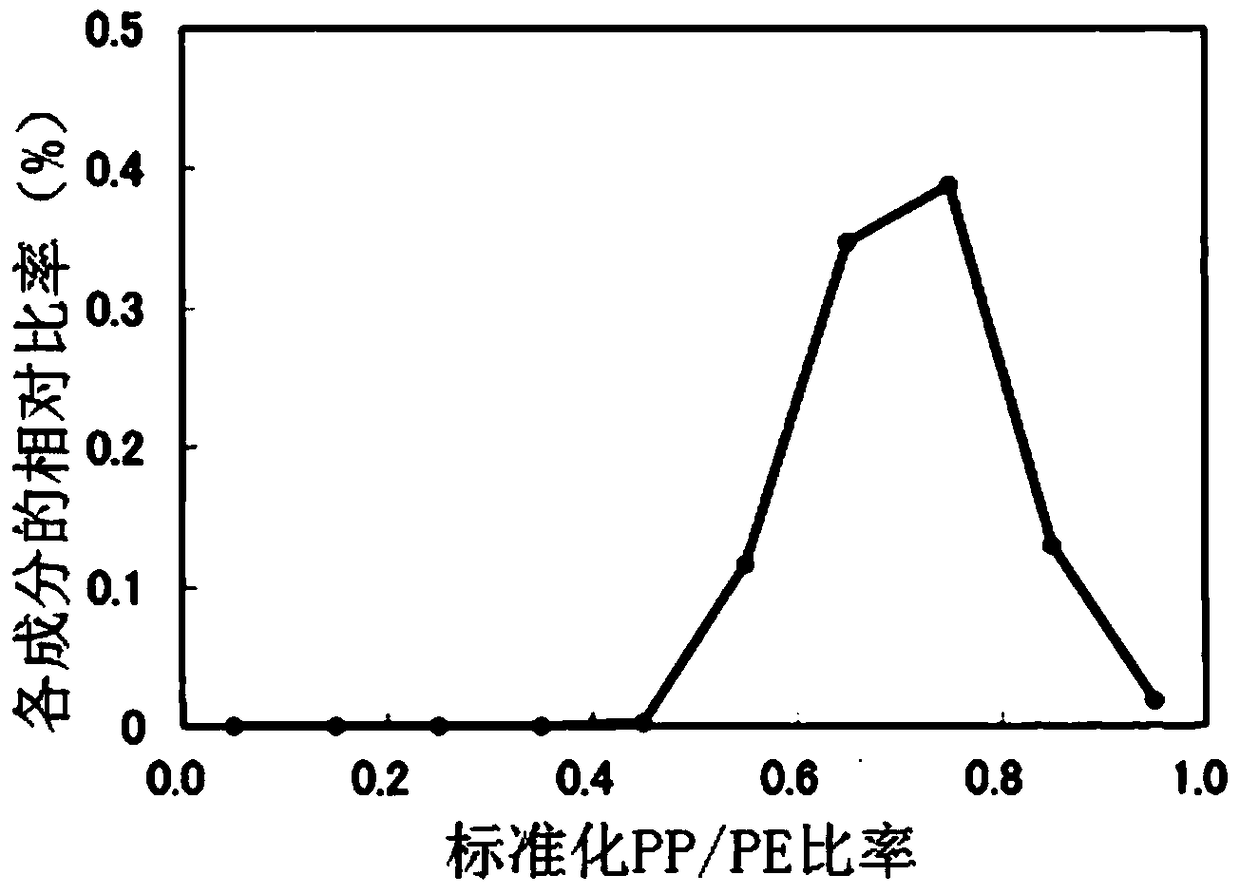

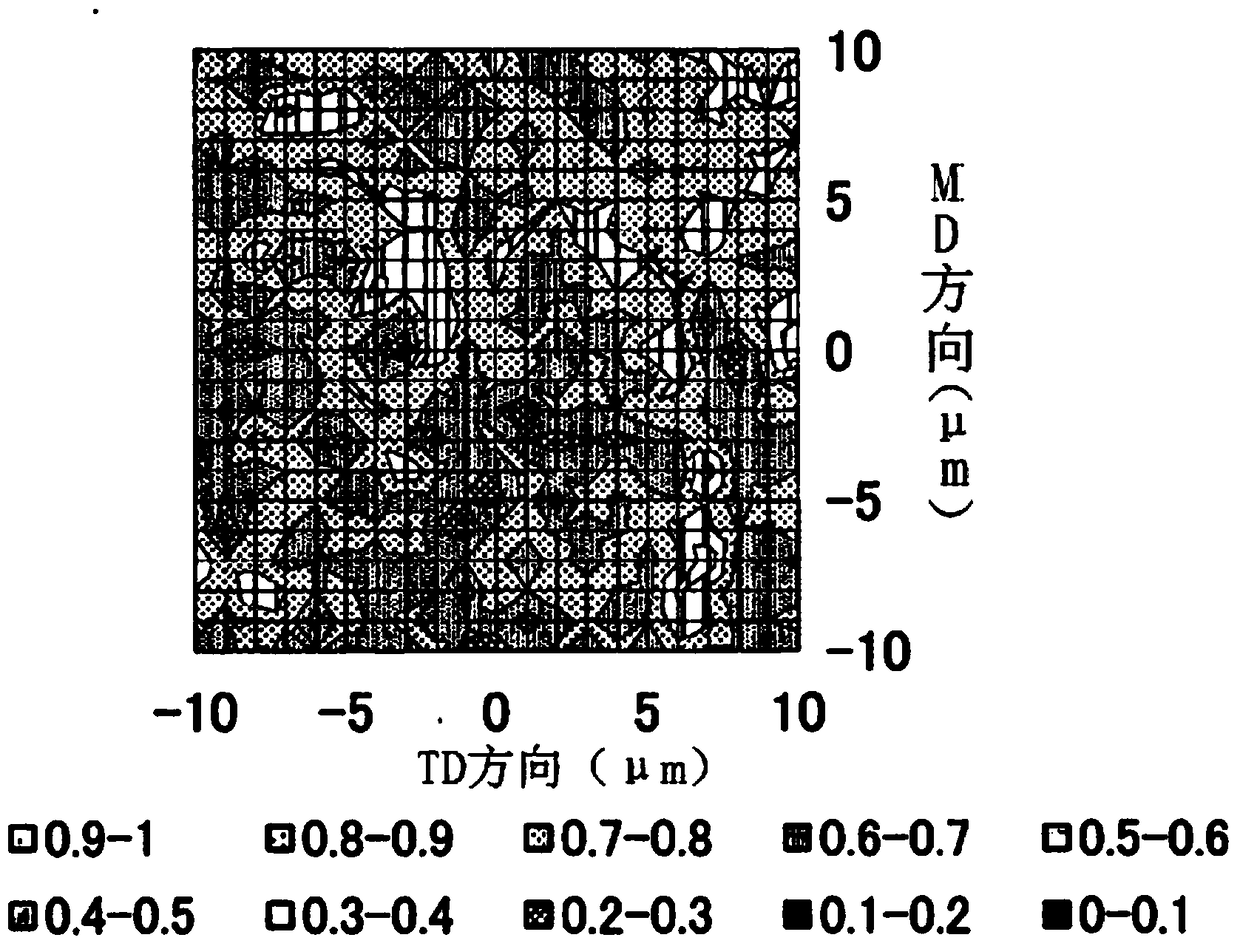

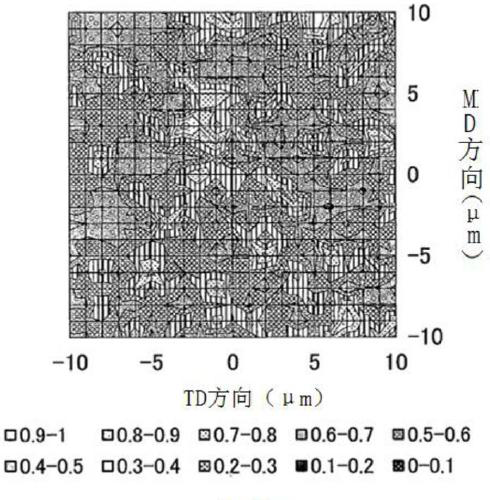

Multilayer, microporous polyolefin membrane, and production method thereof

ActiveCN105246692ASafety stopImprove oxidation resistanceSynthetic resin layered productsCell component detailsIn planeSurface layer

Provided is a microporous polyolefin membrane which has excellent oxidation resistance, electrolyte injection performance and shutdown characteristics, and which further has excellent permeability and strength balance. This multilayer, microporous polyolefin membrane is obtained by forming a gel-like sheet using a polyolefin resin that contains polypropylene, and by stretching said gel-like sheet in at least one direction and cleaning the same. The membrane has a first microporous layer containing polypropylene; at least one surface layer of the membrane is a first microporous layer, and the electrolyte injection performance is 20 seconds or less. The PP distribution in the first microporous layer is uniform in the in-plane direction, and the shutdown temperature is 132DEG C or less.

Owner:TORAY IND INC

Phosphor sheet manufacturing apparatus

InactiveUS20050279285A1Improve uniformitySatisfactory film thickness distributionVacuum evaporation coatingSputtering coatingElectrical resistance and conductanceFluorescence

There is provided a stimulable phosphor sheet manufacturing apparatus which forms a stimulable phosphor layer through vacuum evaporation in a vacuum chamber. A substrate is conveyed linearly, evaporation sources are arranged in a direction perpendicular to a direction in which the substrate is conveyed, and / or the apparatus includes the evaporation sources relying on resistance heating and a gas introducing nozzle for introducing an inert gas into a vacuum chamber during film formation. A phosphor layer of highly uniform film thickness distribution can be formed.

Owner:FUJIFILM HLDG CORP +1

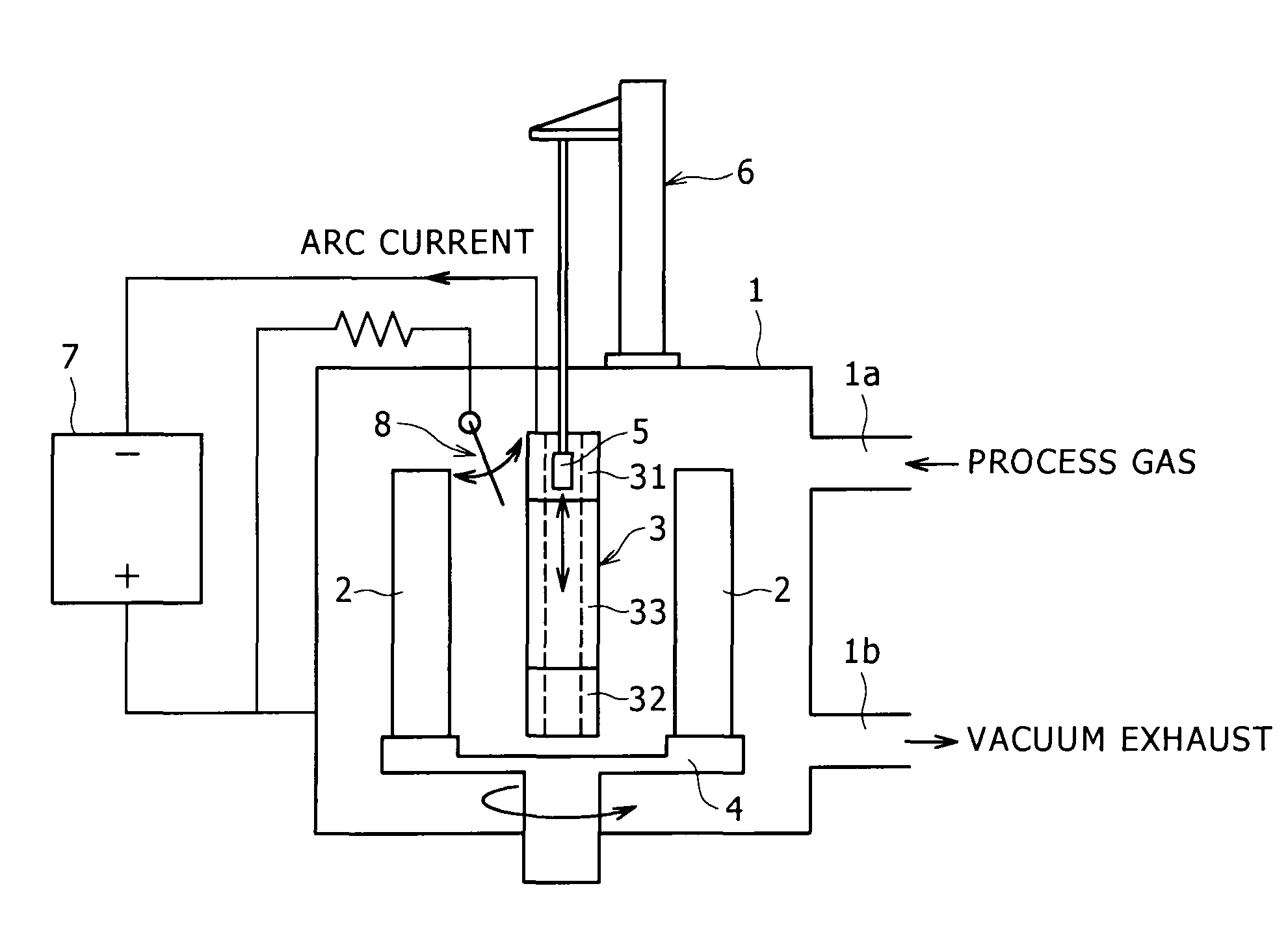

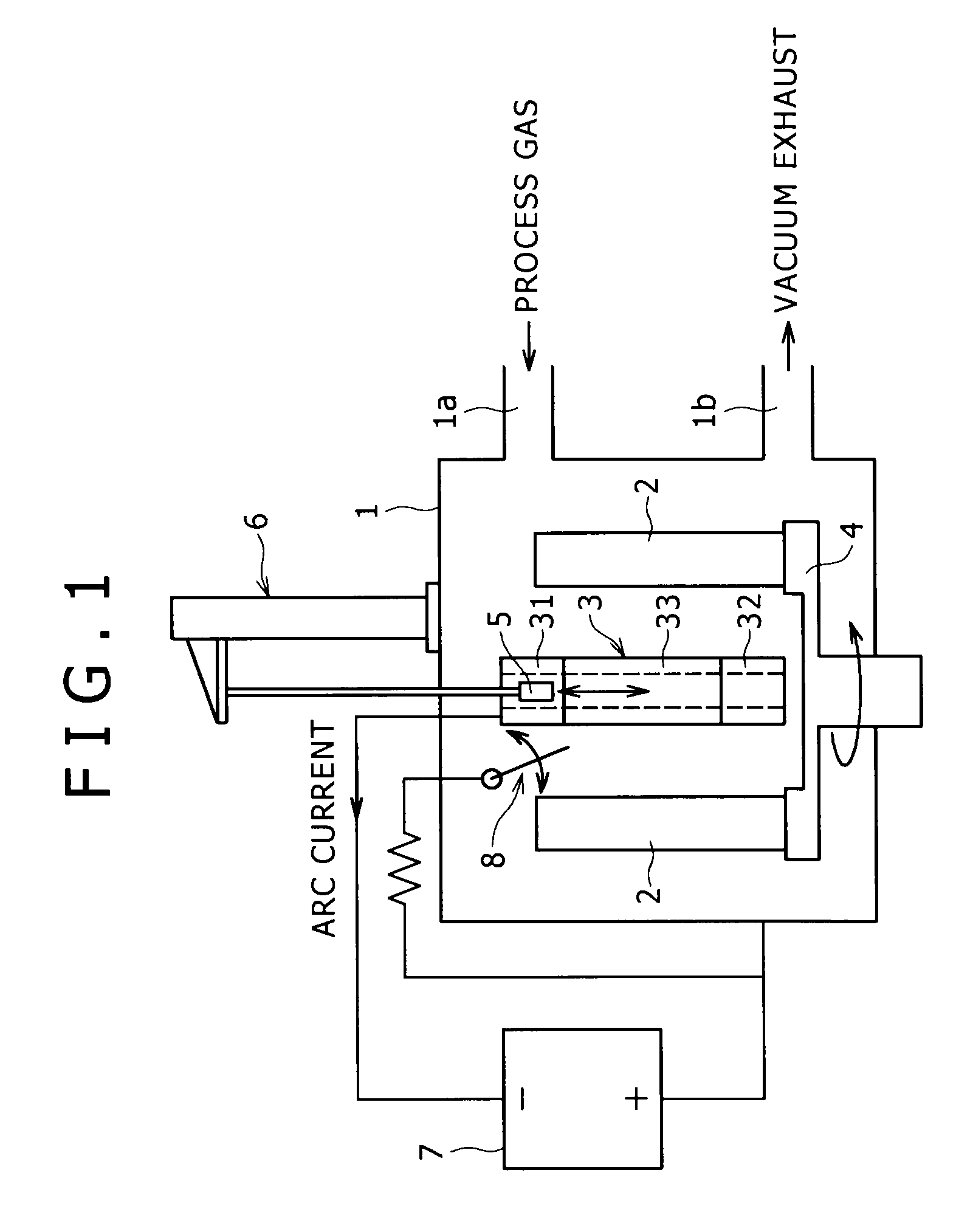

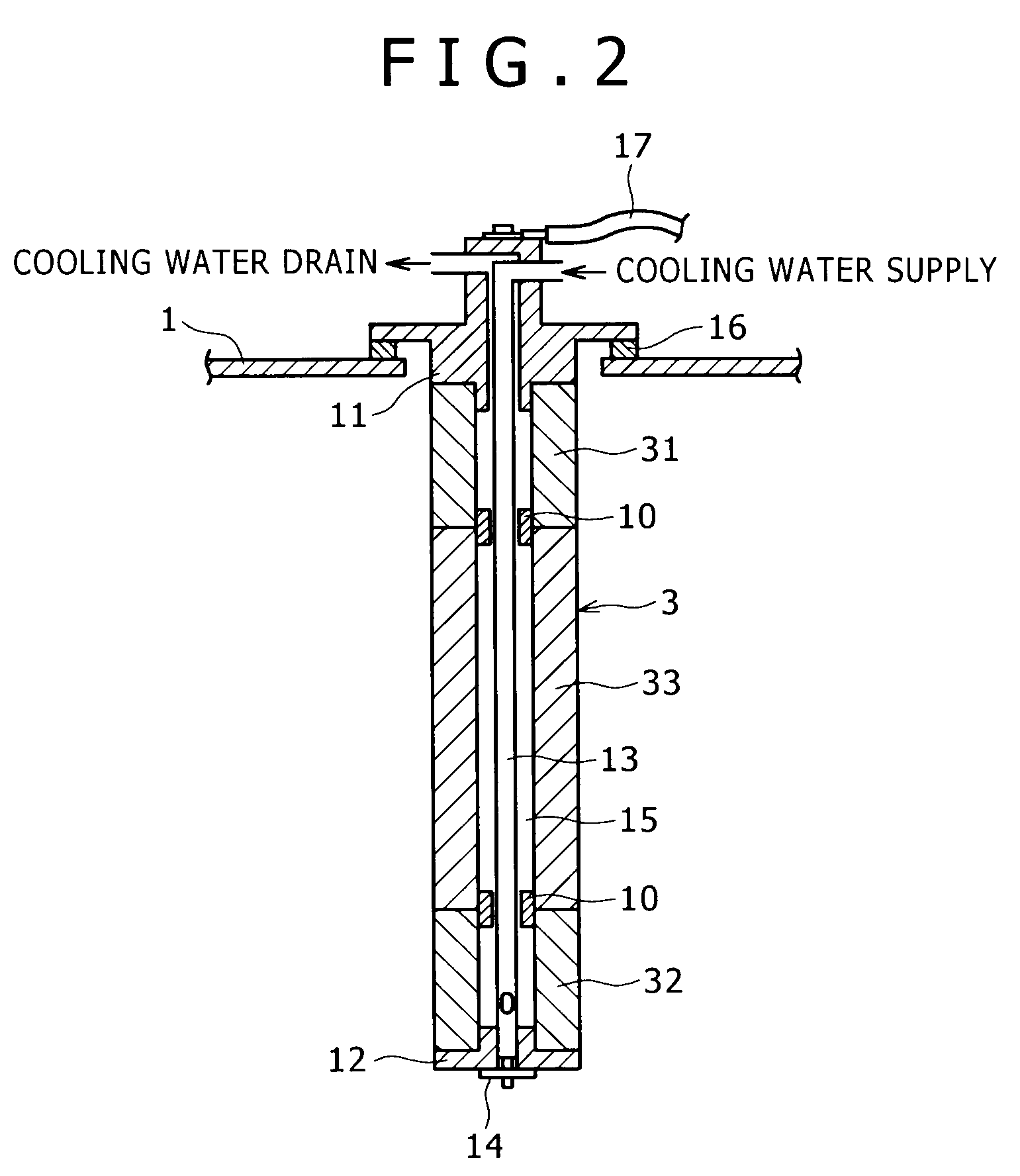

Method of arc ion plating and target for use therein

InactiveUS8133365B2Increase productionReduce manufacturing costCellsElectric discharge tubesEngineeringExtremity Part

In an arc ion plating method, the target is divided into a central portion and longitudinal end portions at both longitudinal ends of the central portion. A constituent material of the target is evaporated and ionized by vacuum arc discharge using the target as a cathode, wherein the position of an arc spot on a surface of the target is controlled such that the consuming speed of the longitudinal end portions becomes higher than that of the central portion, whereby at least one of the longitudinal end portions will reach its consumption limit before the target central portion reaches its consumption limit. Only the respective longitudinal end portion that has reached its consumption limit is thereafter replaced, and the film forming step is continued.

Owner:KOBE STEEL LTD

Magnet unit and magnetron sputtering apparatus

ActiveUS20110180401A1Uniform film thickness distributionCellsElectric discharge tubesTarget surfaceSputtering

The present invention provides a magnet unit, which can realize uniform film thickness distribution of a thin film formed on a substrate without increasing the length and width of a target.The magnet unit 10 includes an annular peripheral magnet 30, which is disposed on the yoke 20 on the back side of a cathode electrode so as to follow the outline of a target 6, and an inner magnet 40 disposed in the peripheral magnet and having a polarity different from the polarity of the peripheral magnet. The magnet unit provides a magnetic track MT that is a set of regions which tangents of magnetic field lines M generated on the target parallels to the target surface. The magnet unit further includes n (n is a positive integer of two or more) extending magnetic pole portions 41 and n−1 projecting magnetic pole portions 32. The n extending magnetic pole portions extend toward the both sides in its longitudinal direction from the central portion of the inner magnet and are adjacent to the both ends in the longitudinal direction of the peripheral magnet, and the n−1 projecting magnetic pole portions protrude inward in the longitudinal direction of the peripheral magnet from the inside of both ends of the peripheral magnet and are located between the n extending magnetic pole portions. The n extending magnetic pole portions and the n−1 projecting magnetic pole portions form 2n−1 folded shape portions U at the both ends in the longitudinal direction of the magnetic track.

Owner:CANON ANELVA CORP

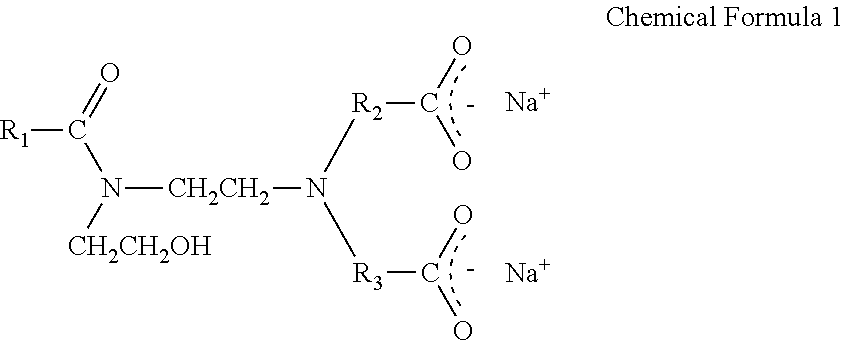

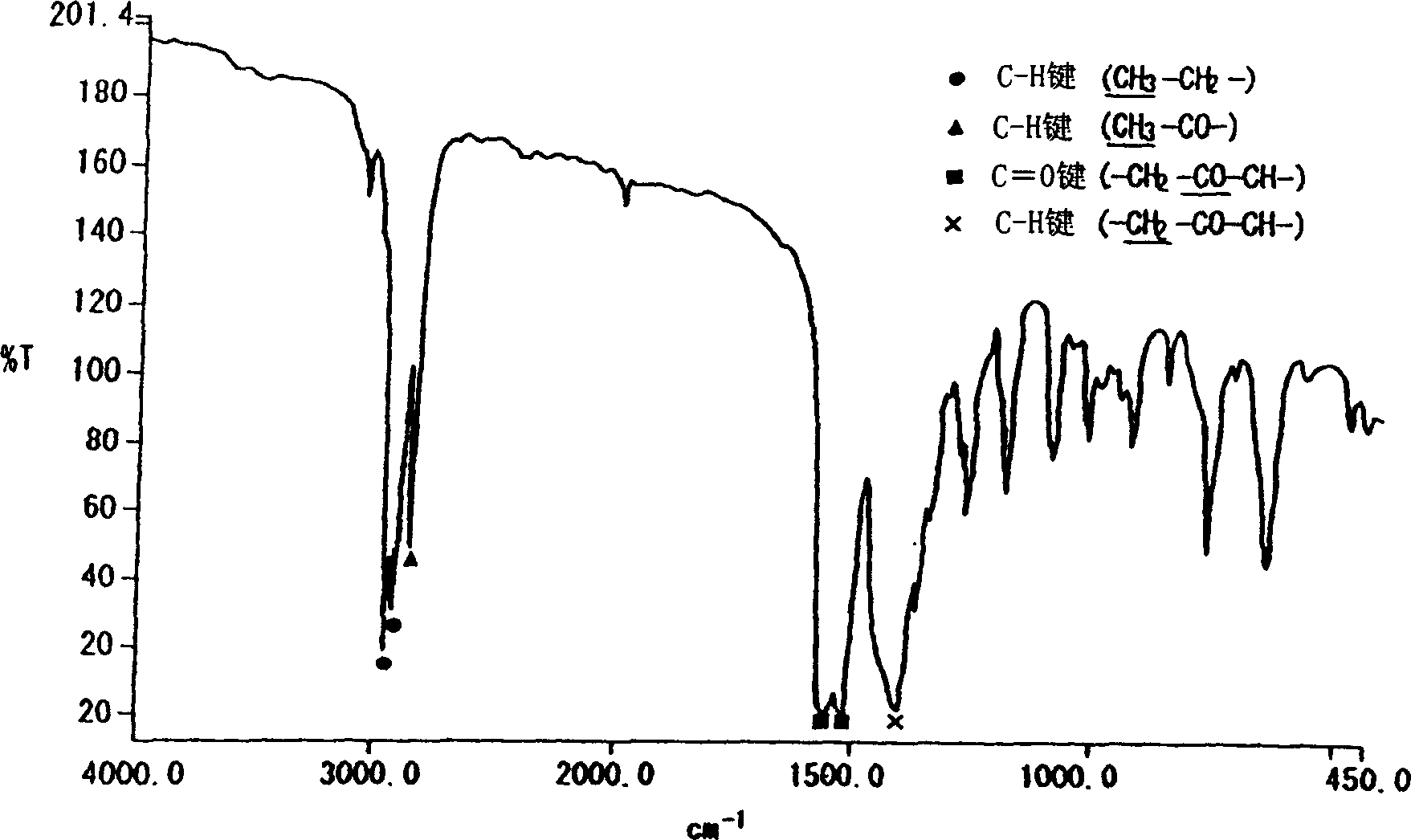

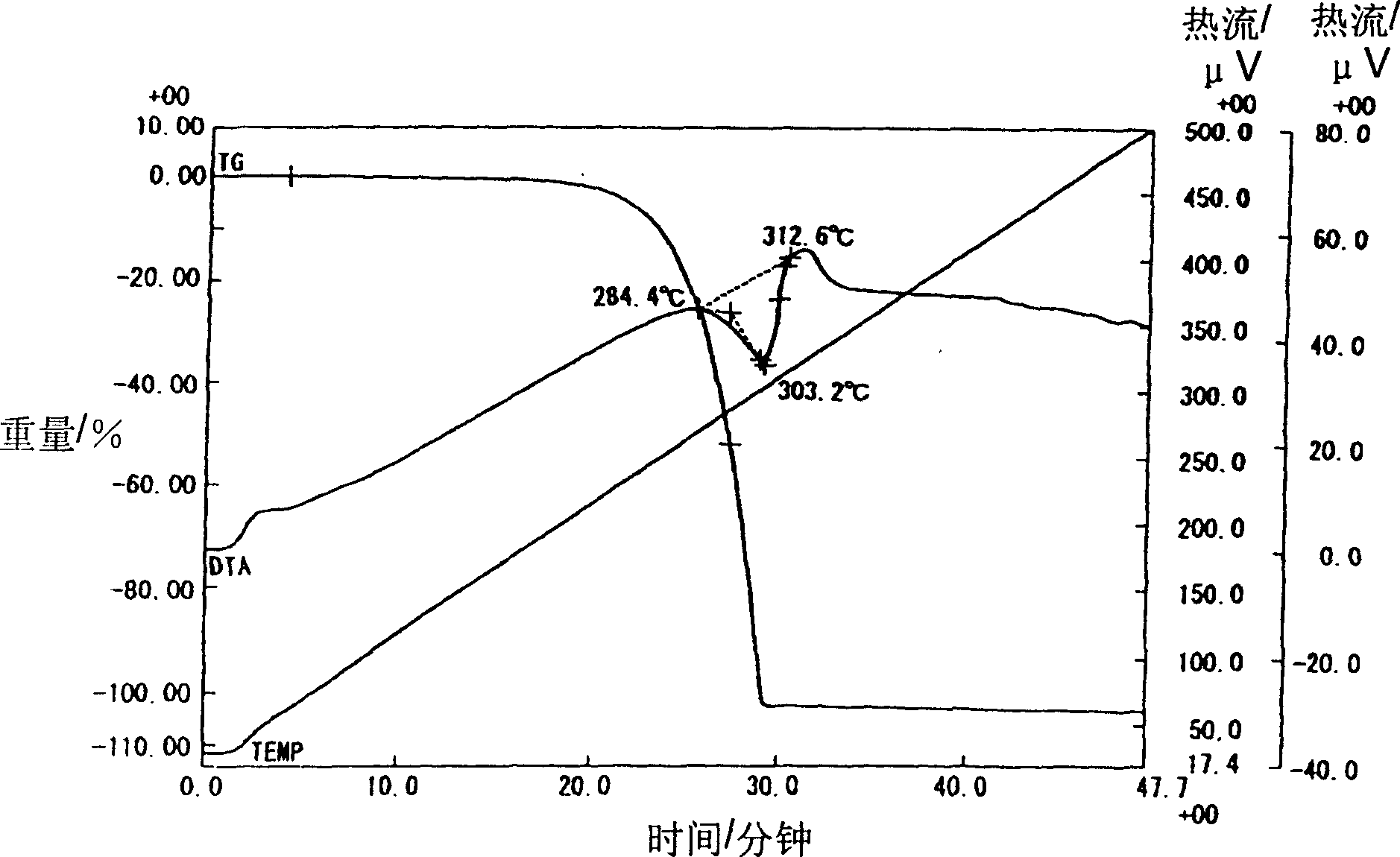

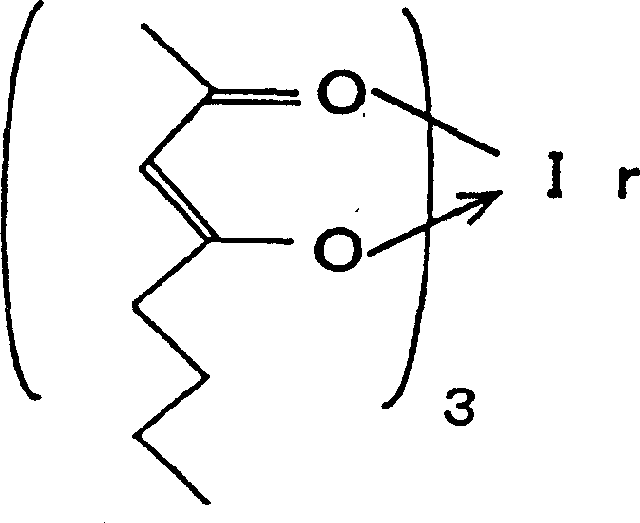

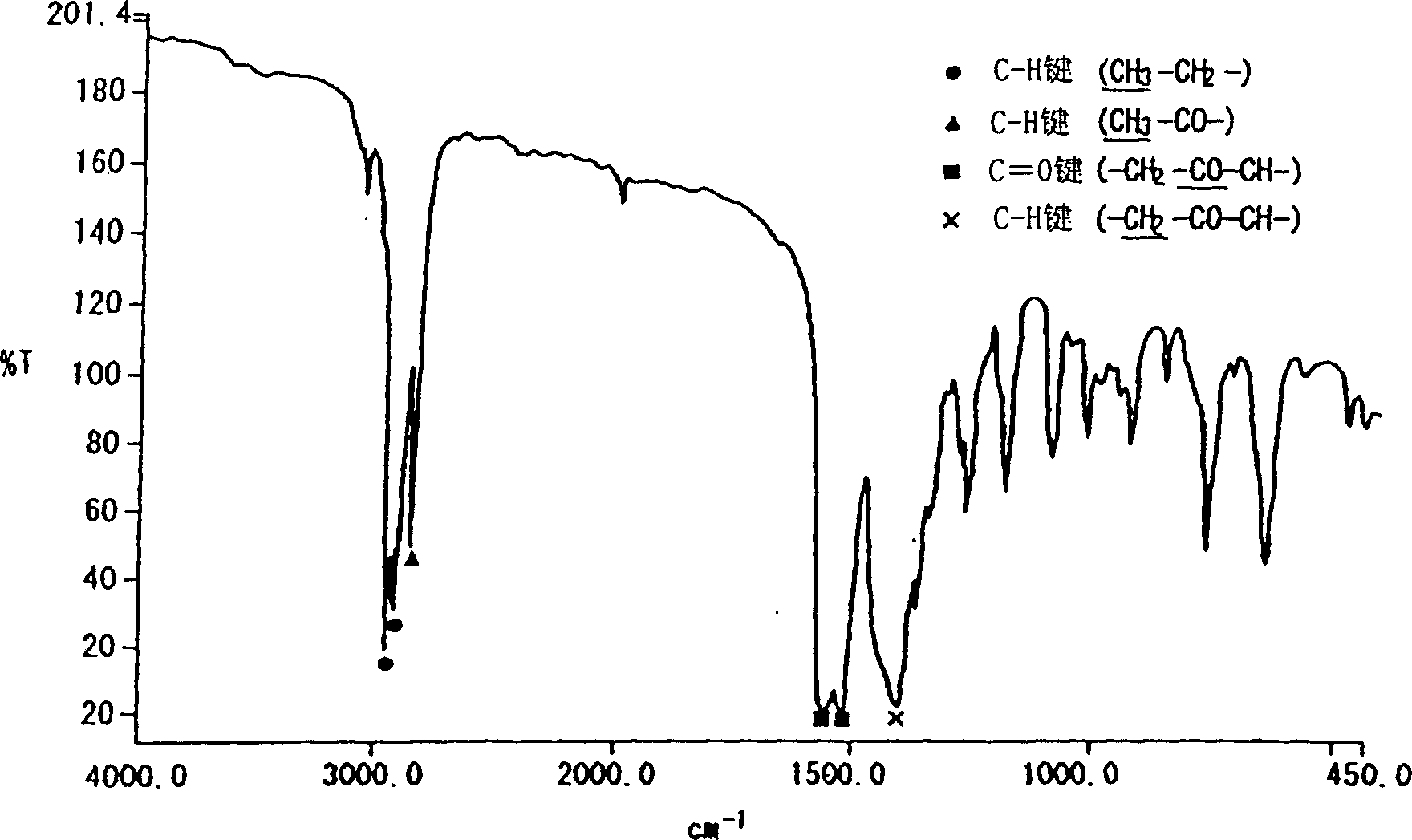

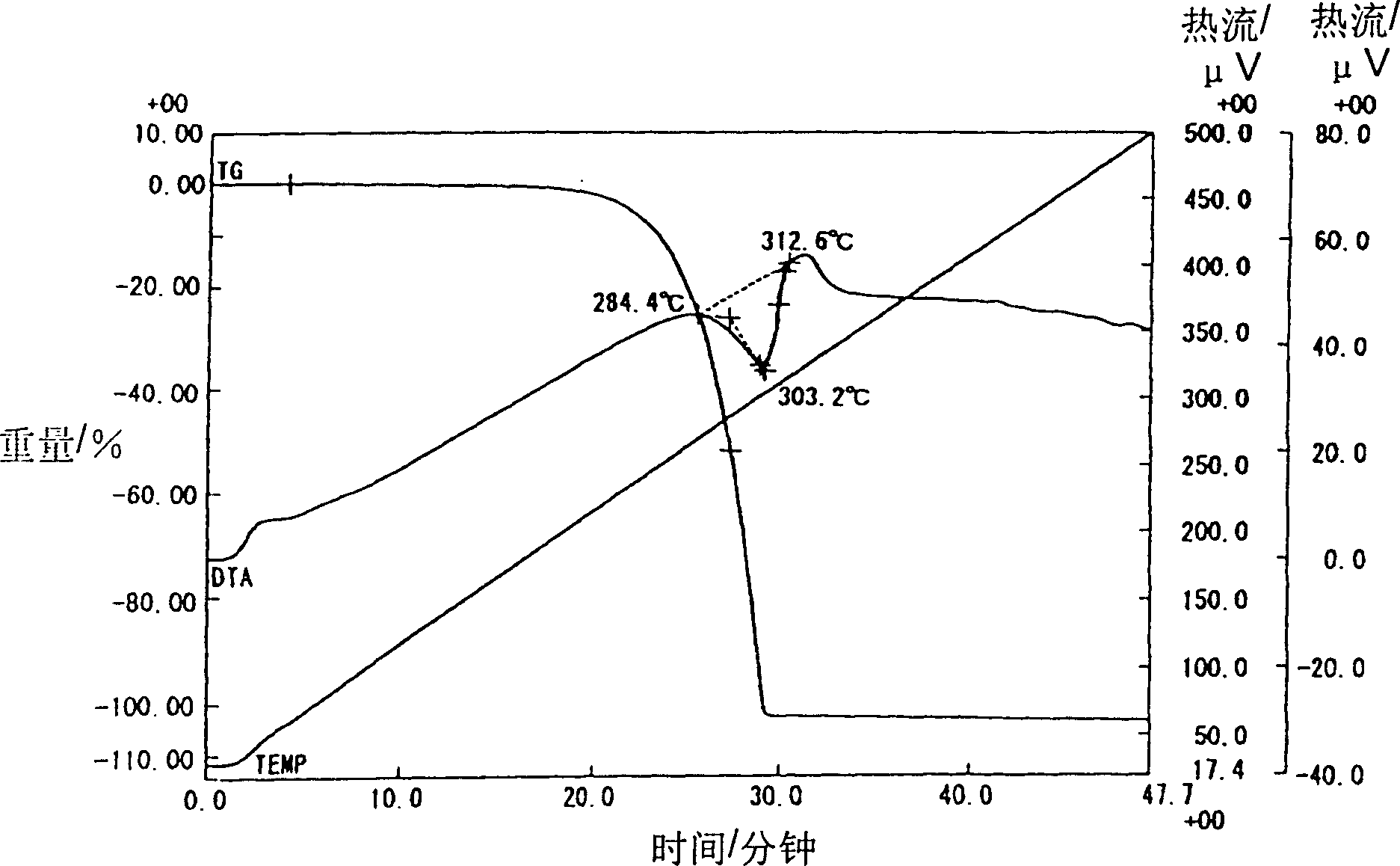

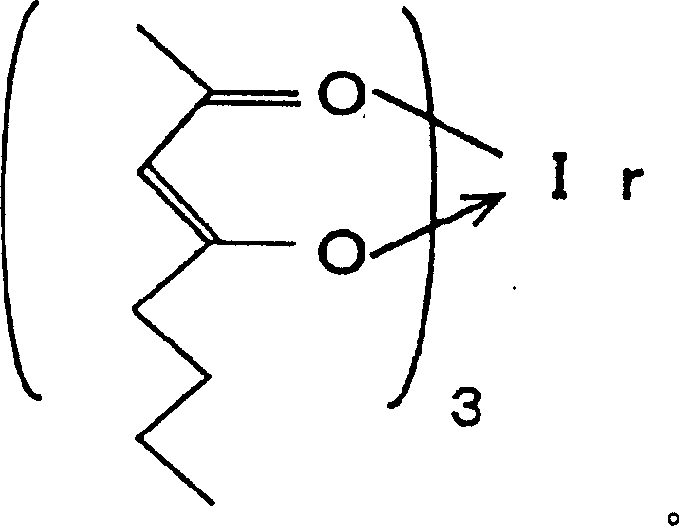

Raw material composition for CVD and its manufacturing method and chemical gas-phase evaporation plating method of iridium or iridium compound film

ActiveCN1517447AUniform film thickness distributionGood step coverageOrganic chemistryChemical vapor deposition coatingOrganoiridium compoundGas phase

The present invention relates to a raw material for CVD comprising an organic iridium compound as a main component, said organic iridium compound being tris(2,4-octanedionato)iridium represented by Formula 1. Particularly preferably, the raw material for CVD consists only of the trans isomer of tris(2,4-octanedionato)iridium.

Owner:TANAKA PRECIOUS METAL IND

Film forming method by sputtering apparatus and sputtering apparatus

InactiveUS20120247952A1Reduce generationUniform film thickness distributionCellsElectric discharge tubesEngineeringSupport surface

The present invention provides a film forming method which can reduce deterioration of film thickness distribution even if the thickness of a film to be formed is extremely small while improving use efficiency of a target and a sputtering apparatus. A film forming method by a sputtering apparatus according to one embodiment of the present invention has a first step of fixing a magnet to a first position and performing film formation on a substrate on a substrate support surface, a second step of moving the magnet to a second position different from the first position after finishing the film formation on the substrate and then fixing it thereto, and a third step of performing film formation on the substrate on the substrate support surface by using the magnet fixed to the second position.

Owner:CANON ANELVA CORP

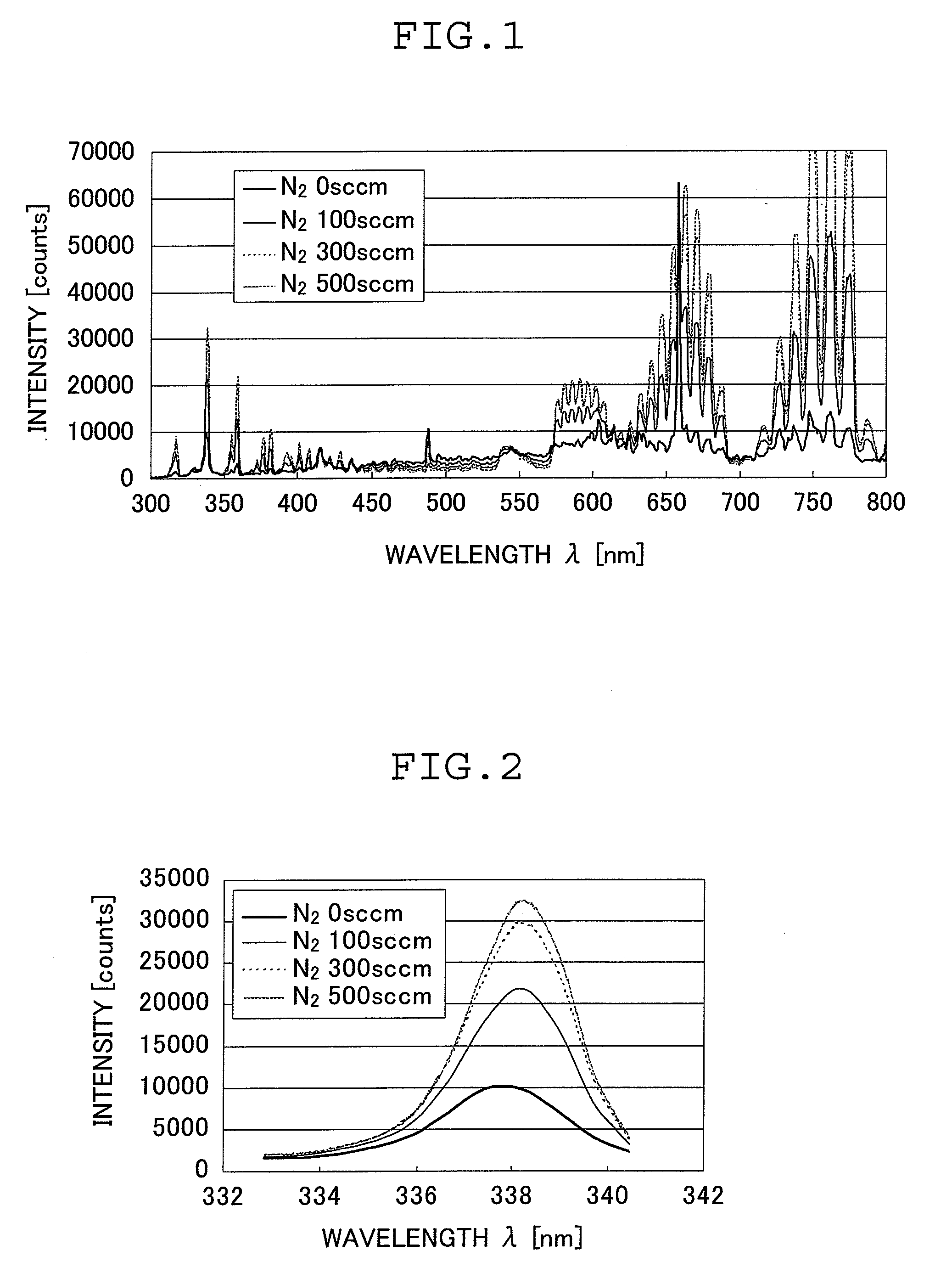

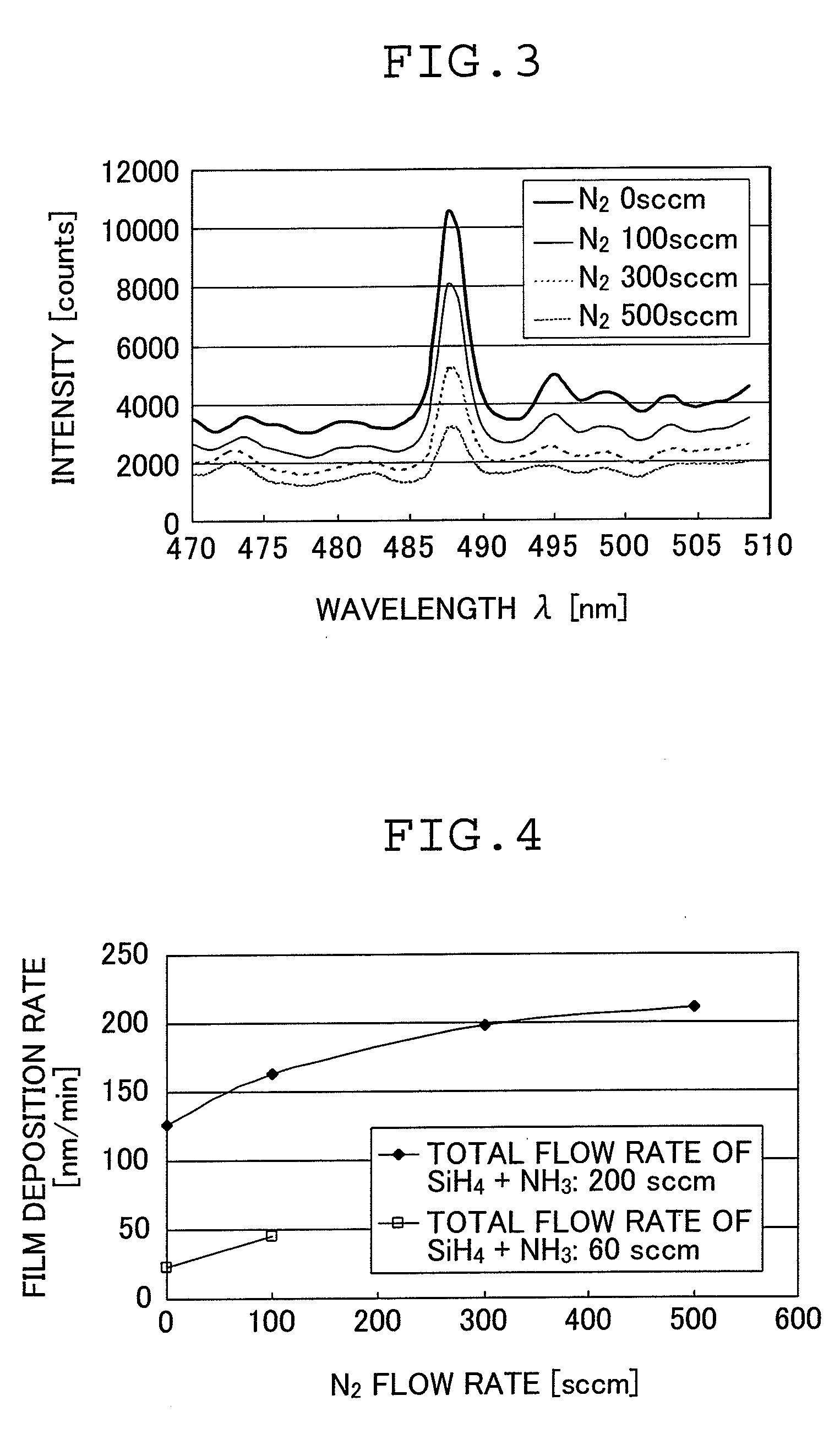

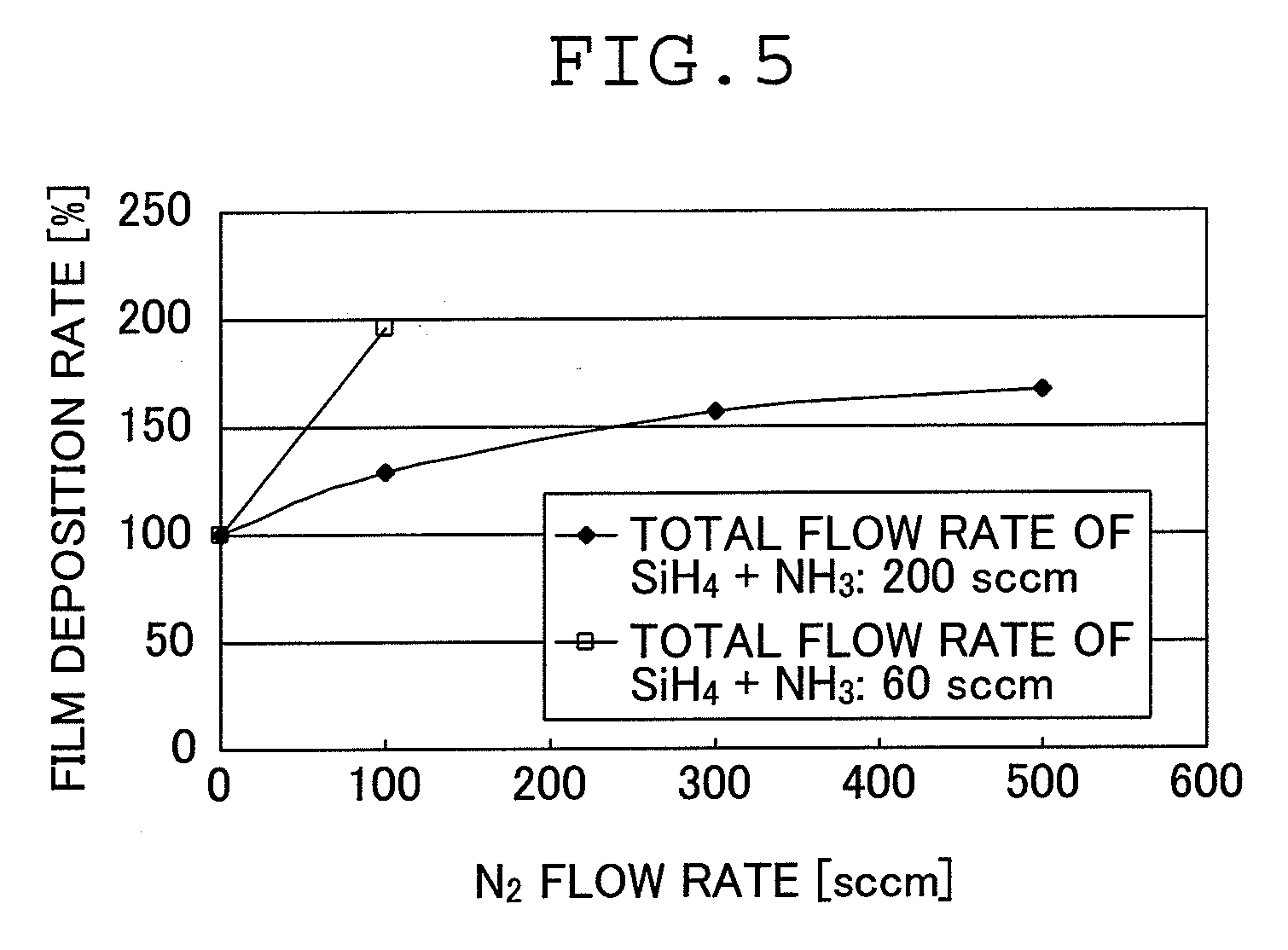

Method of forming silicon nitride films

InactiveUS20090087587A1Increased film deposition ratePreferable resultChemical vapor deposition coatingPlasma techniqueGas phaseSilanes

The silicon nitride film-forming method includes a step of supplying a gas material including silane gas, ammonia gas and nitrogen gas in such a manner that a flow rate of the nitrogen gas is 0.2 to 20 times a total flow rate of the silane gas and the ammonia gas, and a step of carrying out inductively coupled plasma-enhanced chemical vapor deposition to form a silicon nitride film. This method is capable of forming a silicon nitride film at a high film deposition rate.

Owner:FUJIFILM CORP

Optical element

ActiveUS20070052894A1Improve display qualityUniform film thickness distributionPolarising elementsNon-linear opticsLiquid-crystal displayHardness

An optical element including: an alignment substrate; a liquid crystal layer formed on the alignment substrate, made by forming and curing a film of a liquid crystalline material; and a protective layer having high hardness, formed on the liquid crystal layer. The protective layer is for protecting the liquid crystal layer from being deformed by externally exerted forces. Preferably, the protective layer has a modulus of elasticity (=(elastic deformation) / (total deformation)) of 0.6 or more and a plastic deformation of 0.5 μm or less as determined by pushing an indenter into the protective layer with a test force of 2 mN in accordance with the universal hardness test method. The optical element has the advantages that the film thickness distribution of the liquid crystal layer remains uniform even when forces are externally exerted to the optical element in the process of production of the optical element or in the course of incorporation of the optical element in a liquid crystal display, and that the optical element can maintain its high displaying quality even when incorporated in a liquid crystal display.

Owner:DAI NIPPON PRINTING CO LTD

Vacuum vapor desposition apparatus

InactiveUS20090169720A1Prevent unevenness in vaporizationEasy to handleBrushesVacuum evaporation coatingCrucibleEvaporation

A crucible is a monolithic structure extending over an entire area of a vaporizing chamber and has at least one slit groove provided in the upper surface thereof. The at least one slit groove has a length from one end of the upper surface of the crucible to other end thereof. The at least one slit groove is used as a portion for containing the evaporation material (dopant material or the like). Alternatively, a crucible is a monolithic structure extending over the entire area of the vaporizing chamber and has a plurality of holes provided in the upper surface thereof. The holes are used as portions for containing the evaporation material. Further, the crucible is divided into a plurality of regions, and individual electric heaters are provided under the lower surface of the crucible for the respective regions, whereby temperature can be individually controlled for the respective regions by the electric heaters.

Owner:SATO KEIICHI +4

Polyolefin multilayer microporous film and its manufacturing method

ActiveCN105246692BSafety stopImprove oxidation resistanceSynthetic resin layered productsCell component detailsSurface layerPolyolefin

The present invention provides a polyolefin multilayer microporous membrane which is excellent in oxidation resistance, electrolyte injection property, and shutdown characteristics, and further excellent in permeability and strength balance. The polyolefin multilayer microporous film is a polyolefin multilayer microporous film obtained by forming a gel-like sheet using a polyolefin resin containing polypropylene, stretching the gel-like sheet in at least one direction, and washing the polyolefin multilayer microporous film. The first microporous layer, at least one surface layer is the first microporous layer, the electrolyte injection property is below 20 seconds, and the polypropylene (PP) of the first microporous layer is distributed uniformly in the in-plane direction, The shutdown temperature is below 132°C.

Owner:TORAY IND INC

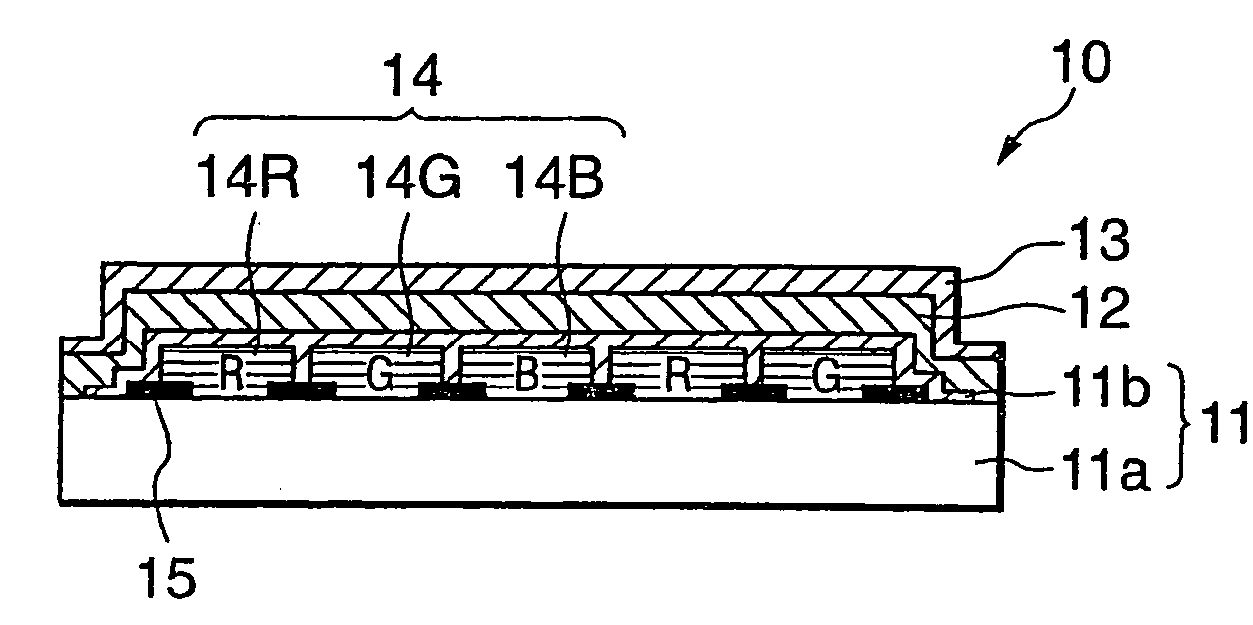

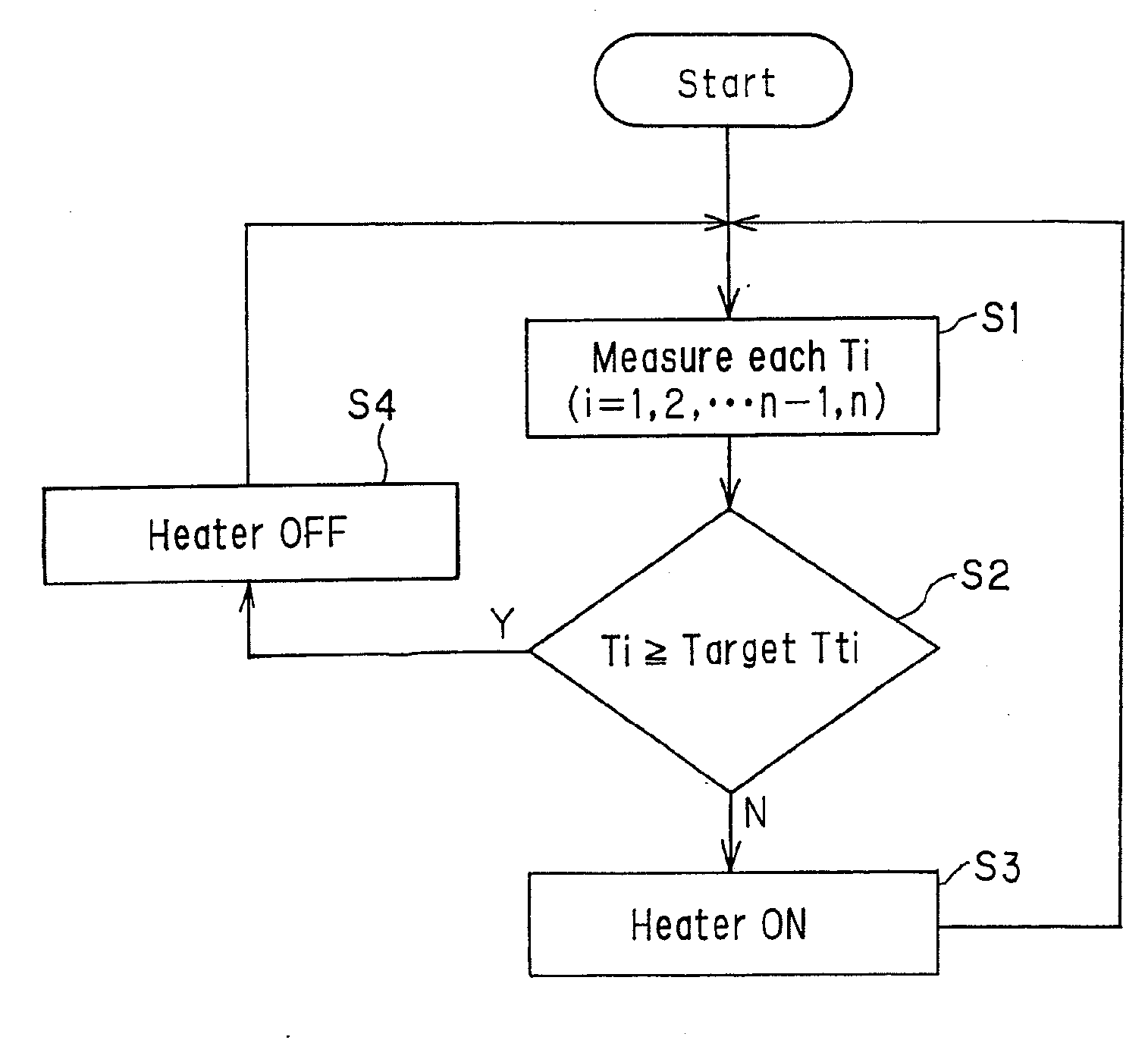

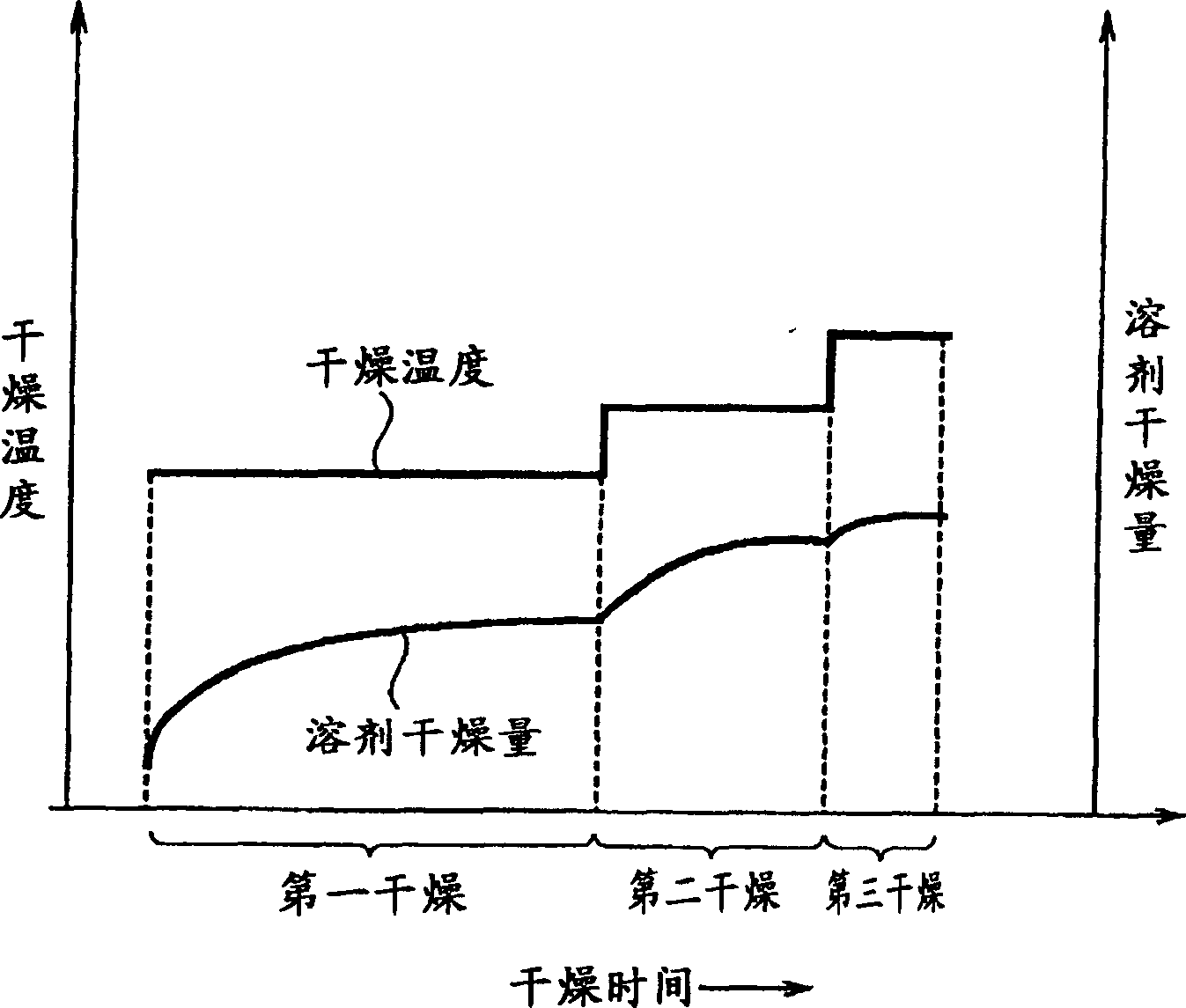

Method of liquid-drop jet coating and method of producing display devices

InactiveCN1806937AUniform film thickness distributionDrying solid materials with heatDrying solid materials without heatDisplay deviceSolvent

The present invention provides a liquid droplet spraying and applying method capable of obtaining a solidified object or film with a good thickness distribution when heating and drying a coating liquid, after spraying and applying liquid droplets of the coating liquid to a substrate by an inkjet application method, or the like. After spraying and applying the liquid droplets of the coating liquid containing a plurality of solvents to the surface of a material to be coated, the coating liquid applied on the surface of the material to be coated is dried by heating while sequentially elevating the heating temperature according to the respective boiling point temperatures of a plurality of the solvents.

Owner:KK TOSHIBA

Thin-film magnetic head and method of forming the same

InactiveUS20050036242A1Easy to controlImprove accuracyElectrical transducersNanomagnetismEngineeringElectrical and Electronics engineering

Owner:TDK CORPARATION

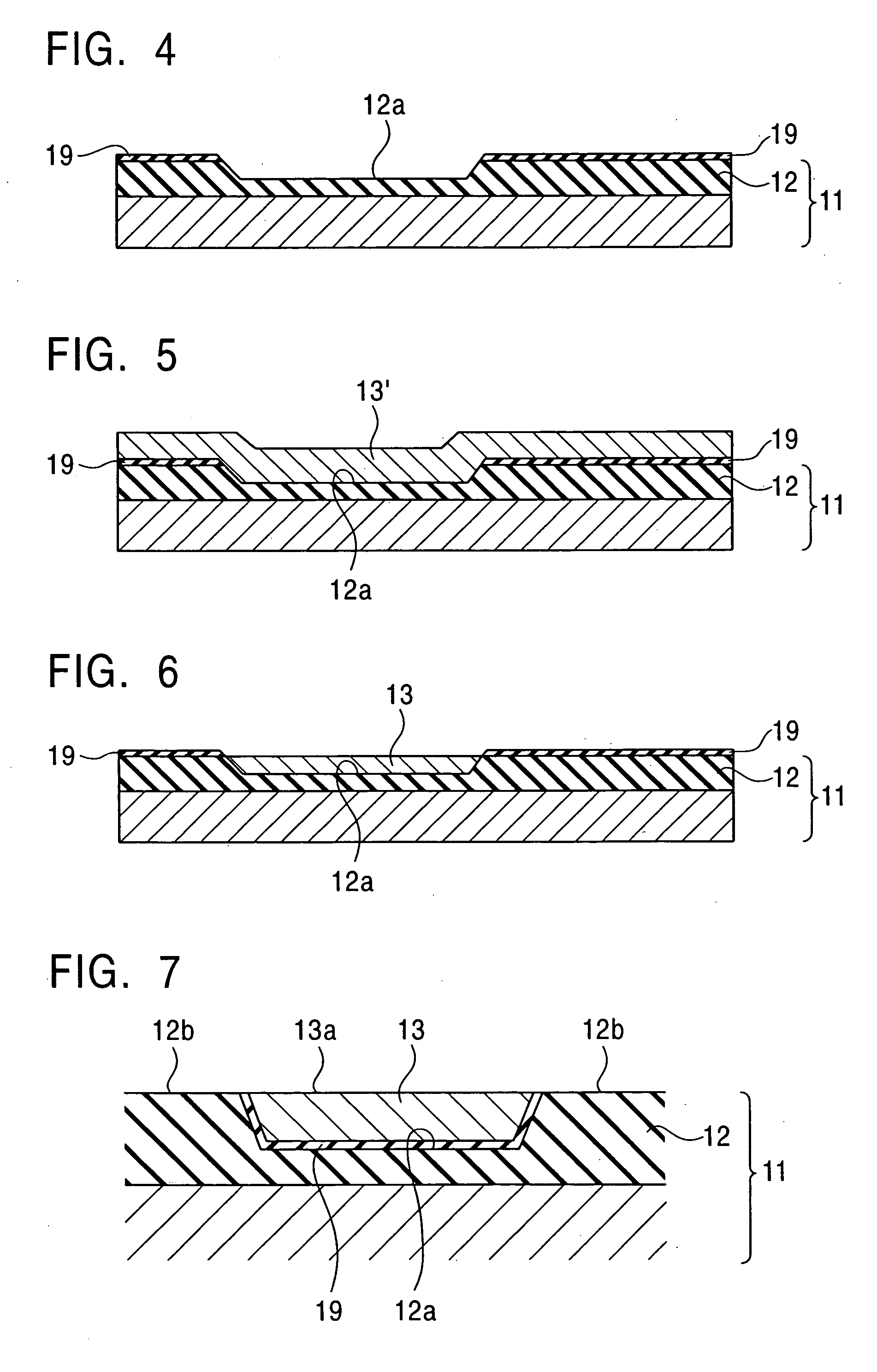

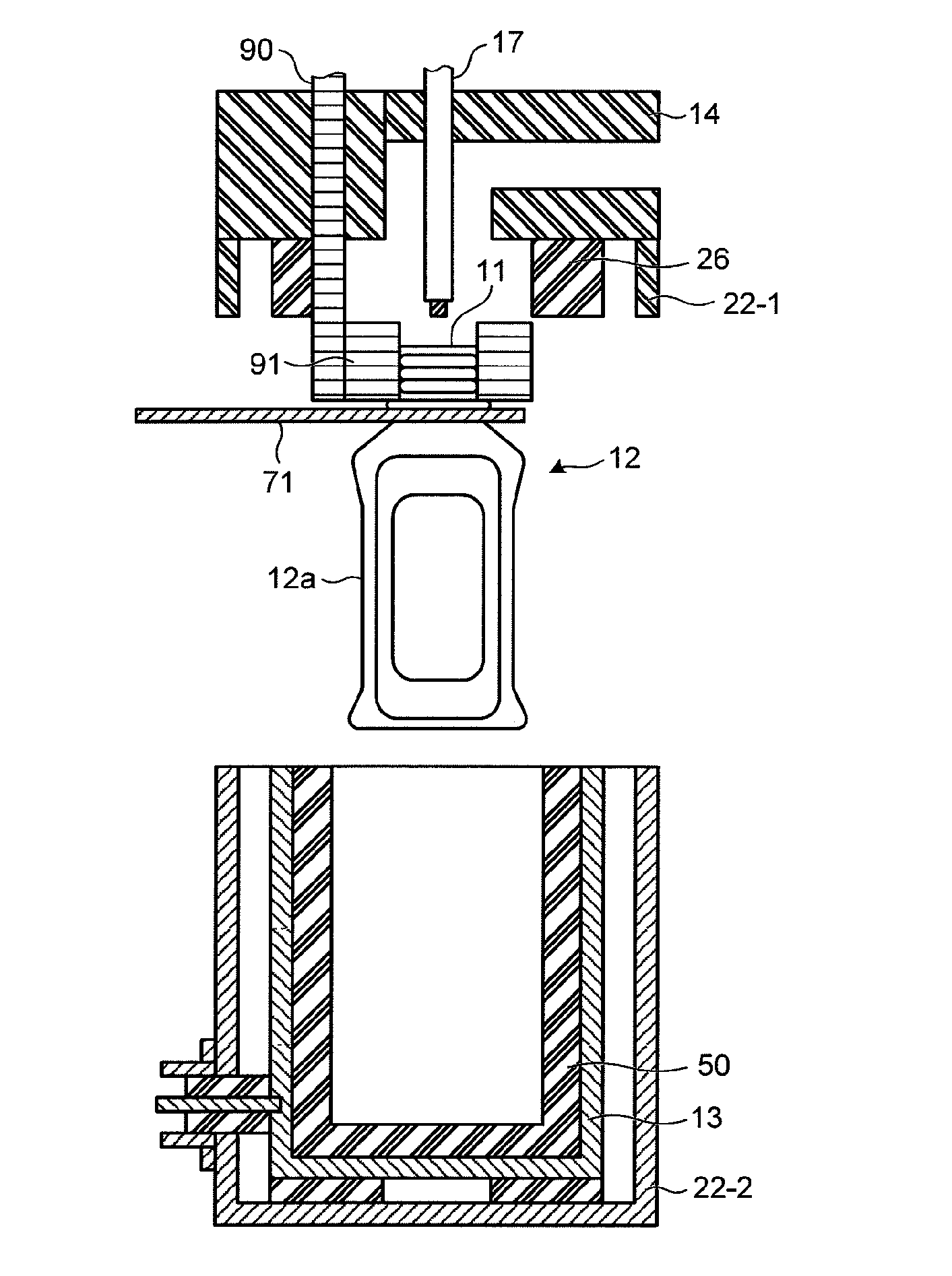

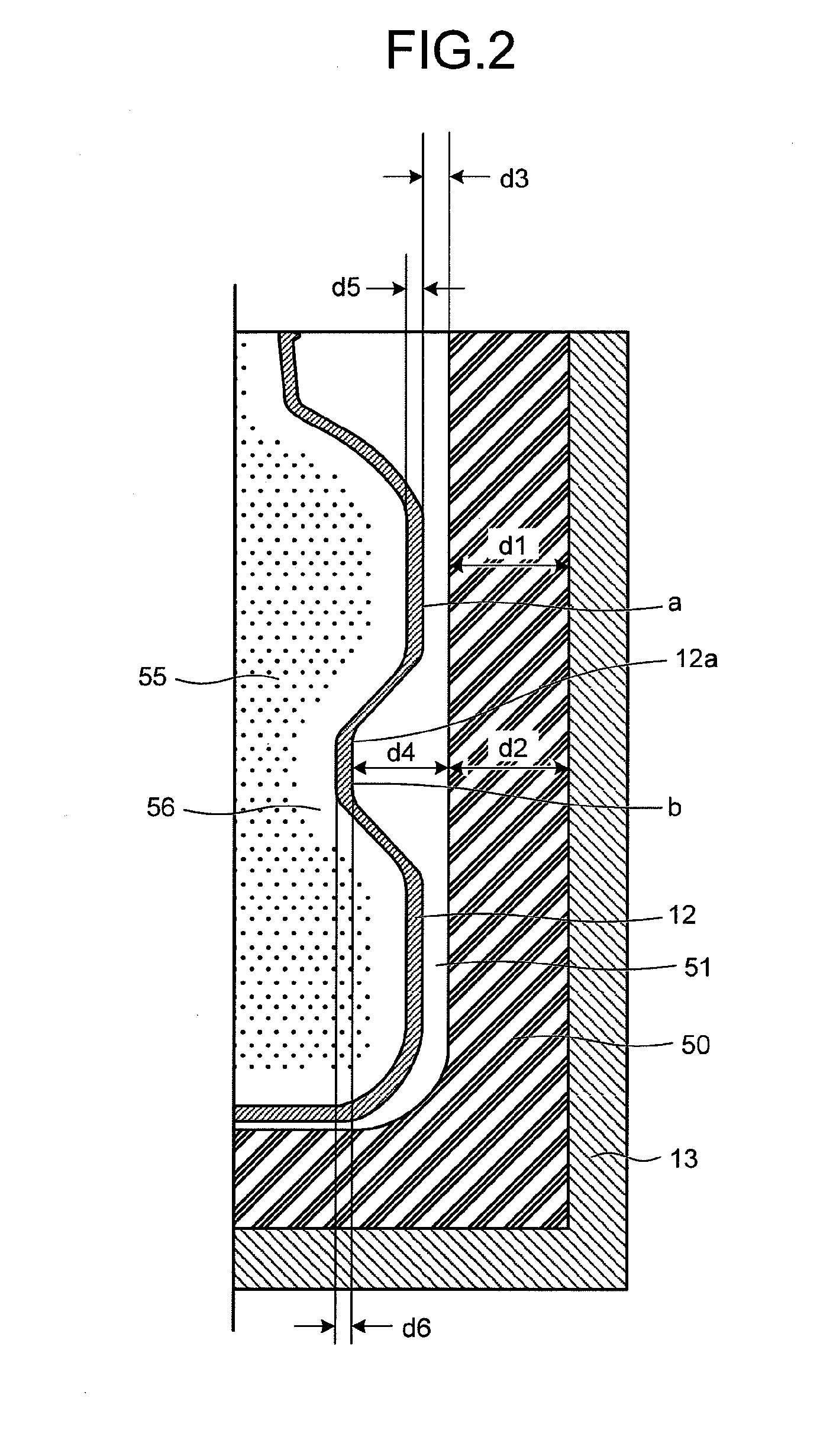

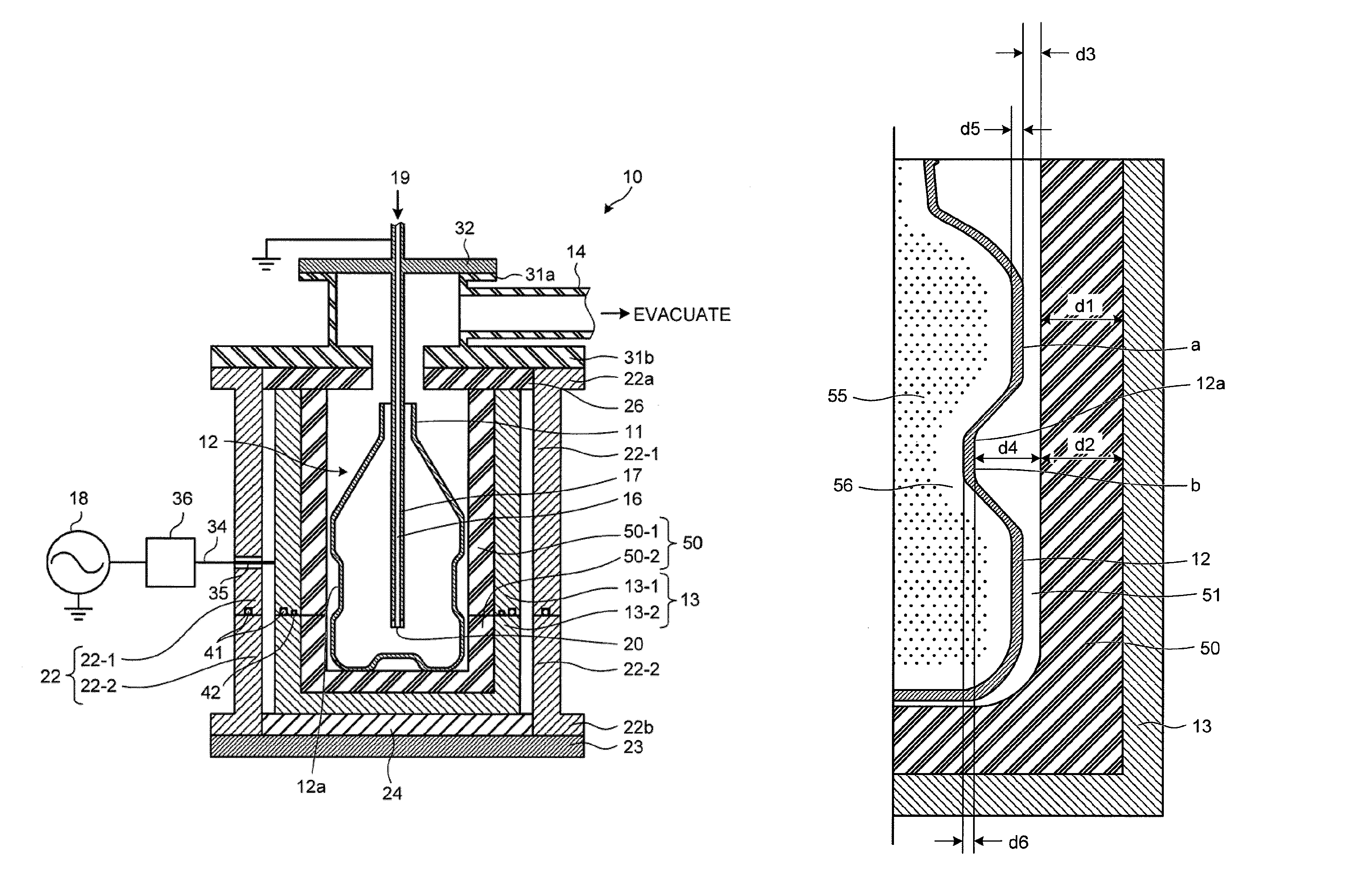

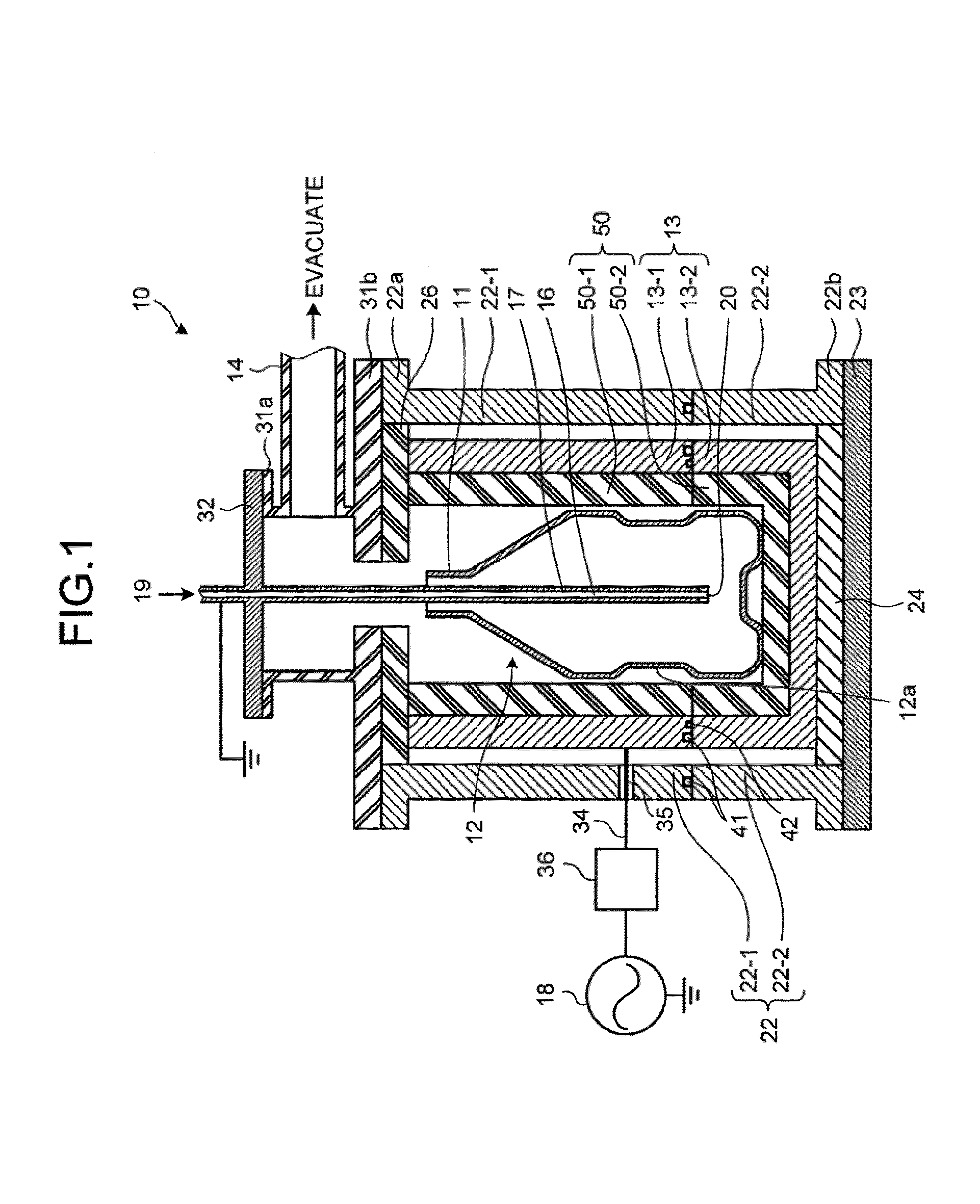

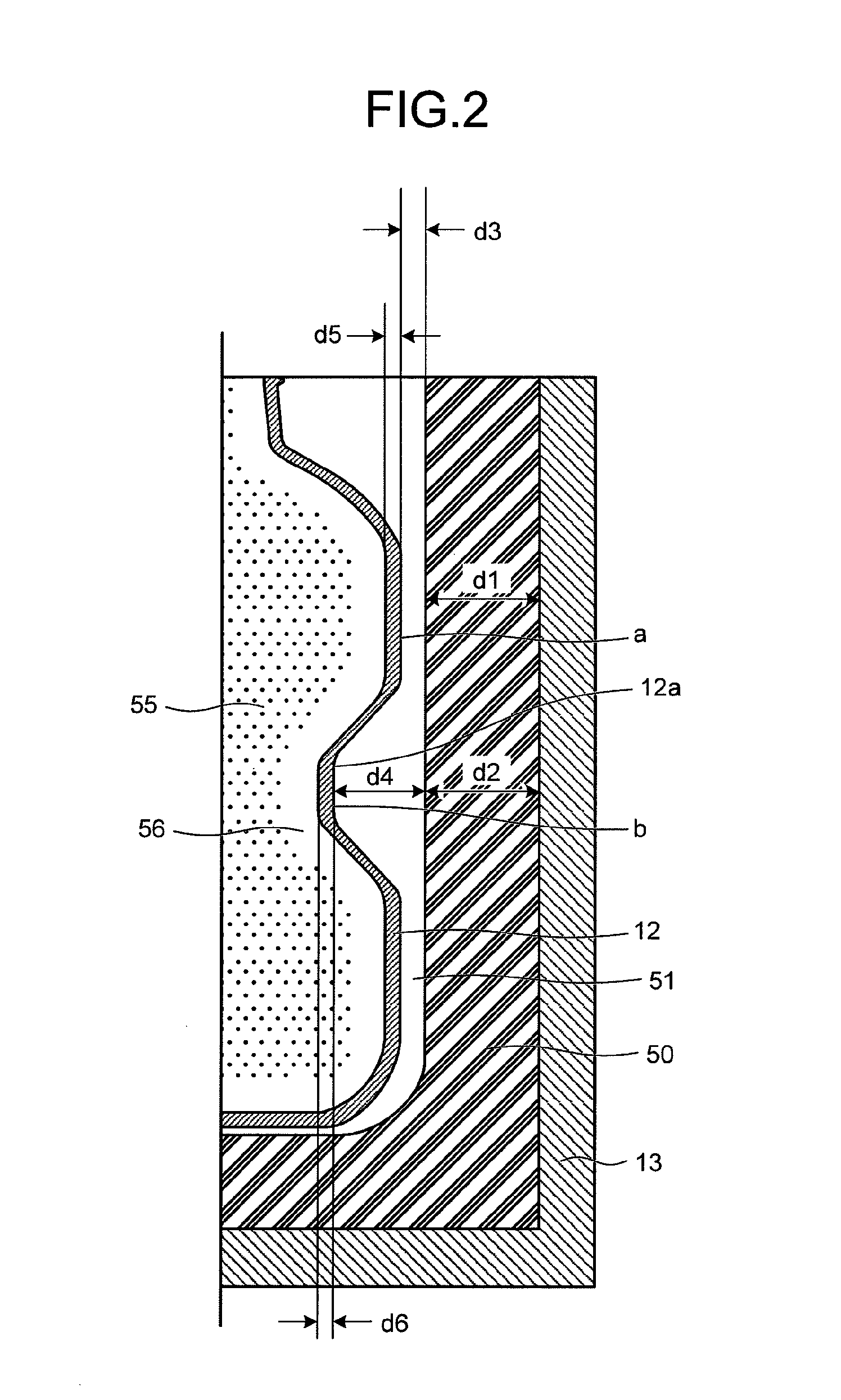

Barrier-film forming apparatus, barrier-film forming method, and barrier-film coated container

InactiveUS20150108031A1Improve barrier propertiesIncrease laborElectric discharge tubesPackaging corrosive chemicalsDielectricProduct gas

A barrier-film forming apparatus that forms a barrier film on an inner face of a container having a concave or convex portion as a processing target, including: a dielectric member having a cavity sized to enclose the container, an external electrode covering an outer circumference of the dielectric member, an exhaust unit installed on an end face of the external electrode on a side where a mouth of the container is located, with an insulating member interposed therebetween, and depressurizing inside of the container through an exhaust pipe, an internal electrode inserted from a side of the exhaust pipe and also serving as a gas blowout unit that blows out medium gas for generating a barrier film into the container, and an electric-field applying unit that applies an electric field for generating exhaust between the external electrode and a ground electrode.

Owner:MITSUBISHI HEAVY IND MACHINERY SYST LTD

Barrier-film forming apparatus, barrier-film forming method, and barrier-film coated container

ActiveUS8950356B2High barrier propertyImprove barrier propertiesLiquid surface applicatorsElectric discharge tubesElectric fieldEngineering

A barrier-film forming apparatus that forms a barrier film on an inner face of a container having a concave or convex portion as a processing target, including: a dielectric member having a cavity sized to enclose the container, an external electrode covering an outer circumference of the dielectric member, an exhaust unit installed on an end face of the external electrode on a side where a mouth of the container is located, with an insulating member interposed therebetween, and depressurizing inside of the container through an exhaust pipe, an internal electrode inserted from a side of the exhaust pipe and also serving as a gas blowout unit that blows out medium gas for generating a barrier film into the container, and an electric-field applying unit that applies an electric field for generating exhaust between the external electrode and a ground electrode.

Owner:KIRIN BREWERY CO LTD +1

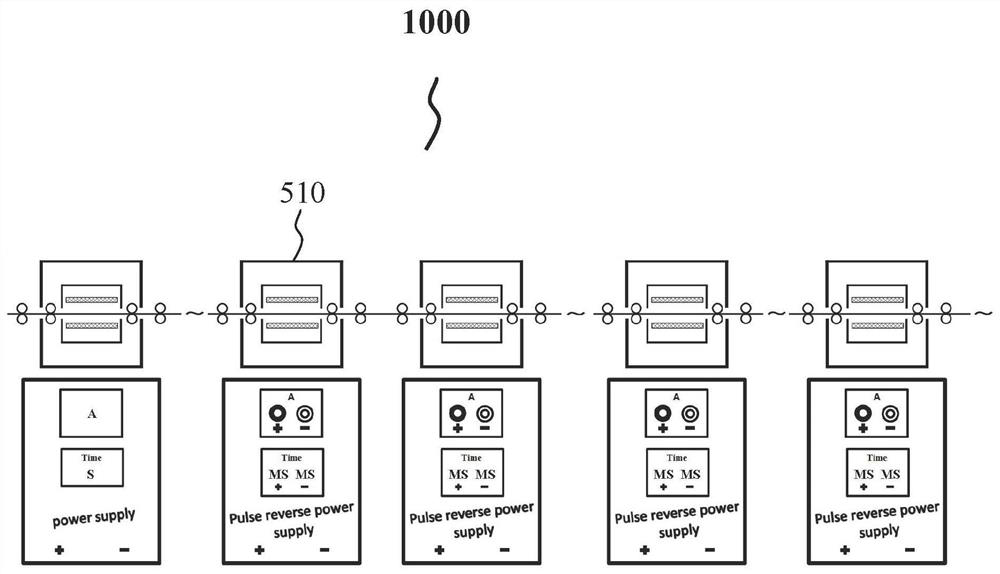

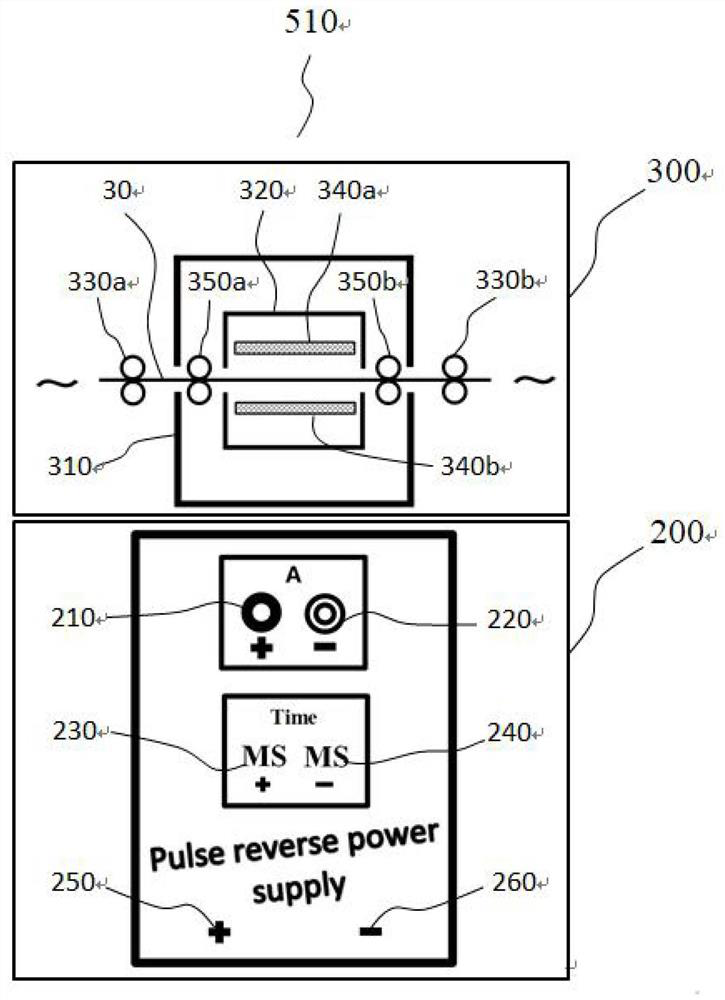

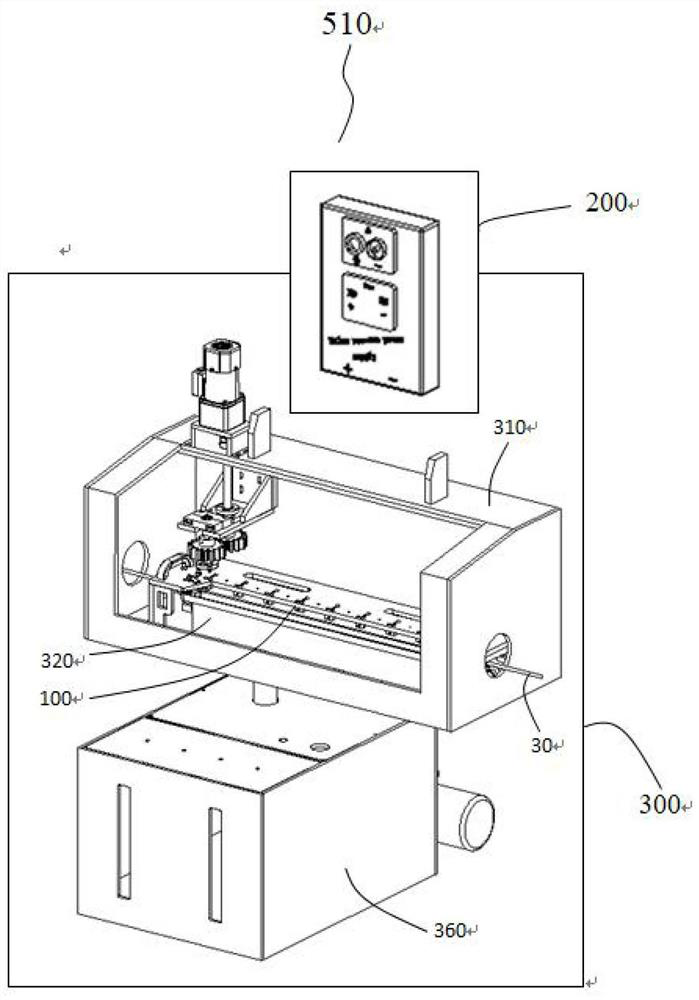

Electrolysis method of continuous terminal

ActiveCN112323111AImprove the pass rate of product qualitySolve the problem that the local part of one side of the strip cannot be processed effectivelyElectrolysisConveyor belt

The invention relates to the technical field of electrolytic surface treatment, in particular to an electrolysis method of a continuous terminal. Through fully shielding one surface of a material beltthrough a first conveyor belt, and partially shielding the other surface of the material belt through a second conveyor belt, the part, extending out of the outer periphery of the second conveyor belt, of the material belt can be processed, so that the purpose of local processing is realized, and the problem that the existing equipment cannot effectively process the local part of the single surface of the material belt is solved; and the pulse periodic reverse current is applied to the local surface of a continuous terminal material for electrolysis, so that electrolytic precious metal on thesurface of the continuous terminal material is adjusted and controlled to have required uniform precious metal film thickness distribution and excellent corrosion resistance.

Owner:KUNSHAN YIDING IND TECH CO LTD

Method for preparing OLED device

ActiveCN109686872AUniform film thickness distributionSolid-state devicesSemiconductor/solid-state device manufacturingEvaporationEngineering

The invention provides a method for preparing an OLED device. The method comprises the following steps of providing a substrate, defining a display area and a temporary coating area (dummy area) outside the edge of the display area on the substrate, wherein the temporary coating area is disposed adjacent to the edge of the display area; preparing a device structure in the display area through a solvent method on the substrate and coating a first solvent on the temporary coating area; removing the first solvent coated on the temporary coating area. According to the method for preparing the OLEDdevice, an additional evaporation area is arranged to offset the impact of the solvent on the edge s-pixel of the display area of the device during evaporation, so that uniform thickness distributionof the film thickness in s-pixel on rows and lines on the edge of the display area can be effectively ensured.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Polyolefin microporous membrane and its manufacturing method

ActiveCN105246957BEvenly distributedImprove oxidation resistanceSynthetic resin layered productsCell component detailsPolyolefinPolymer science

The present invention provides a polyolefin microporous membrane which is excellent in oxidation resistance, electrolyte injection property, and shutdown characteristics, and further excellent in permeability and strength balance. This polyolefin microporous membrane consists of polypropylene and polyethylene, has an electrolyte solution injection property of 20 seconds or less, a shutdown temperature of 132°C or less, and an air permeability of 700 seconds / 100cm when converted to a film thickness of 20 μm. 3 Hereinafter, the puncture strength when the film thickness is converted to 20 μm is 2,000 mN or more, and the distribution of polypropylene is uniform in the in-plane direction.

Owner:TORAY IND INC

Magnet unit and magnetron sputtering apparatus

ActiveUS8048277B2Uniform film thickness distributionCellsElectric discharge tubesSputteringTarget surface

A magnet unit, which can realize uniform film thickness distribution of a thin film formed on a substrate without increasing the length and width of a target. The magnet unit includes a peripheral magnet, which is disposed on the yoke on the back side of a cathode electrode so as to follow the outline of a target, and an inner magnet disposed in the peripheral magnet and having a polarity different from the polarity of the peripheral magnet. The magnet unit provides a magnetic track MT that is a set of regions which tangents of magnetic field lines M generated on the target parallels to the target surface. The magnet unit further includes n (n is a positive integer of two or more) extending magnetic pole portions and n−1 projecting magnetic pole portions, which form 2n−1 folded shape portions U at the both ends in the longitudinal direction of the magnetic track.

Owner:CANON ANELVA CORP

Heating apparatus

InactiveCN100430803CHeating evenlyAchieve homogenizationHot plates heating arrangementsNon-linear opticsRadiant heatRadiant heating

A heating apparatus (101), comprising a hot plate (2) heating a heated substrate (10) by radiation, lift pins (5) liftably disposed in through-holes (6) formed in the hot plate and lifting the heated substrate, and a proximity pin (11) fixed to the hot plate and holding the heated substrate so as to be separated from the hot plate while the heated substrate is heated. Heat reducing parts (13, 7) reducing radiant heat are installed in the hot plate around the proximity pin or around the through-holes.

Owner:NISSHA PRINTING COMPANY

Raw material composition for CVD and its manufacturing method and chemical gas-phase evaporation plating method of iridium or iridium compound film

ActiveCN1276992CUniform film thickness distributionGood step coverageOrganic chemistryChemical vapor deposition coatingOrganoiridium compoundPhysical chemistry

The present invention relates to a raw material for CVD comprising an organic iridium compound as a main component, said organic iridium compound being tris(2,4-octanedionato)iridium represented by Formula 1. Particularly preferably, the raw material for CVD consists only of the trans isomer of tris(2,4-octanedionato)iridium.

Owner:TANAKA PRECIOUS METAL IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com