Preparation method of CdS thin-film

A technology of thin films and source materials, applied in the field of solar cells, can solve the problems of high operation requirements of annealing equipment and complicated procedures, and achieve the requirements of reducing sealing and corrosion resistance, as well as the difficulty of operation, uniform film thickness distribution, and labor saving. physical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

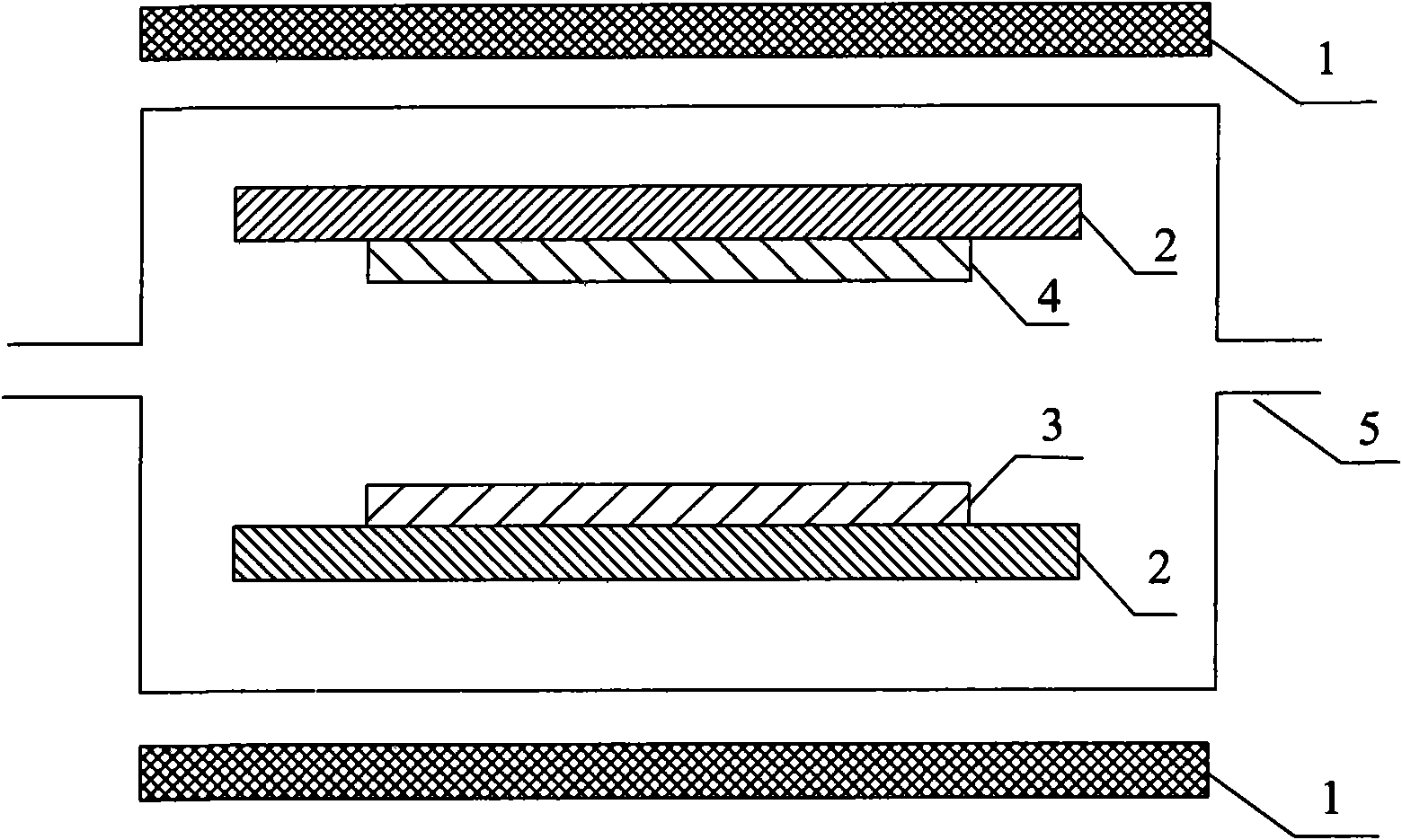

[0016] A preparation method for a CdS thin film, comprising:

[0017] a, preparation of evaporation source: the source material and CdCl 2 Adding it to a dispersant to make a slurry, coating the slurry on the surface of an evaporation container, and drying to form a source material coating;

[0018] b. Near-space sublimation: at 10 -3 -10 3 Under Pa, under the protection of protective gas, heat the evaporation container to evaporate the coating and deposit a film on the substrate;

[0019] c. Annealing: After the deposition is completed, keep it at a constant temperature for 10-40 minutes at the annealing temperature.

[0020] The source material may be CdS powder, or a mixture of Cd powder and S powder.

[0021] The source material of the present invention is preferably a mixture of Cd powder and S powder, and the mixing ratio of Cd powder:S powder is preferably 1:1-1:1.1.

[0022] The use of a mixture of Cd powder and S powder can reduce the cost of raw materials on the...

Embodiment 1

[0046] a. Preparation of evaporation source: mix Cd powder and S powder with a molar ratio of 1:1.1 to make a mixed powder; mix 95g of mixed powder, 5gCdCl 2 Add to 20 g of propylene glycol and make a slurry by grinding.

[0047] The slurry was coated on the evaporation source container (a high-purity graphite plate with an area of 210mm×210mm) by screen printing, and dried at 150°C for 5h to form a source material coating with a thickness of 100μm.

[0048] b. Near-space sublimation: Put the coated evaporation container into the near-space evaporation device, adjust the evaporation distance to 4mm, and feed argon and oxygen with a volume ratio of 1:1, and the air pressure is 100Pa.

[0049] Heat the evaporation vessel to 580°C at a ramp rate of 80°C / min.

[0050] The temperature of the substrate is 500°C, the temperature of the evaporation source is 580°C, and the film thickness of CdS is controlled to be 100nm by the deposition time.

[0051] c. Annealing: After the depo...

Embodiment 2

[0053] The difference from Example 1 is: the mixed powder of 99g, 1gCdCl 2 Add to 30 g of propylene glycol and make a slurry by grinding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com