On-site construction method for anti-seepage air bag for bottom of river channel

A technology of on-site construction and air-permeable bags, which is applied in the direction of river regulation, etc., can solve the problem of low air permeability of anti-seepage materials, and achieve the effect of ensuring strength and convenient on-site construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

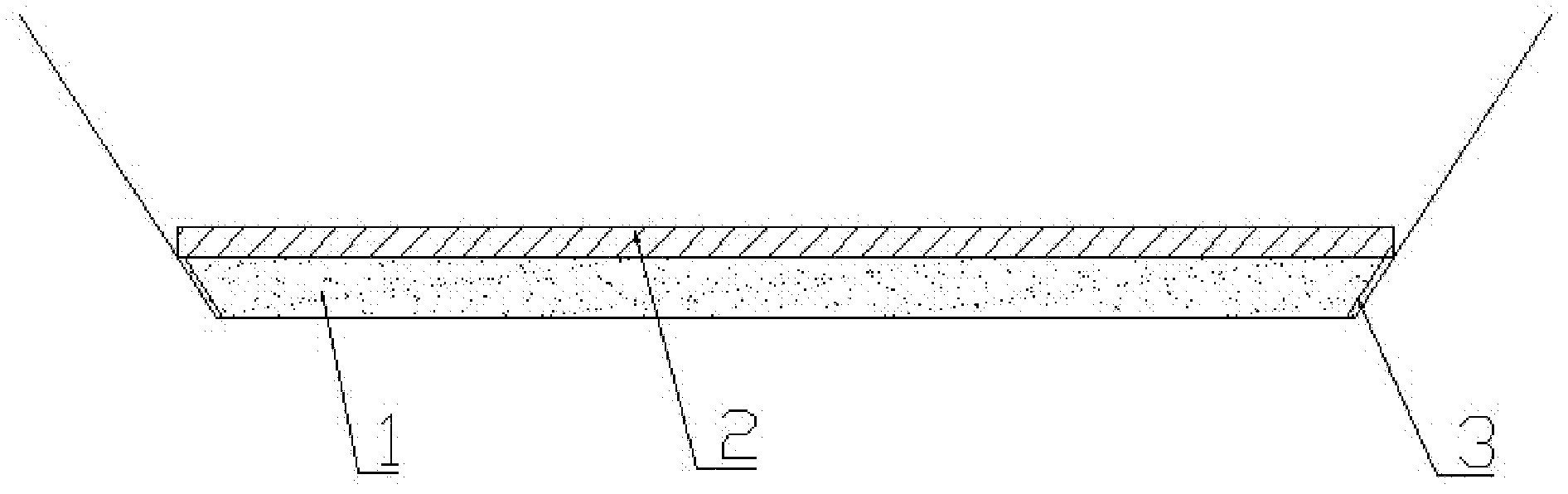

[0037] The anti-permeable air bag used for the bottom of the river channel of the present invention is to fill the anti-permeable gas particles 1 in the air-permeable wall bag 3 to form the required anti-permeable air bag, and lay it to the bottom of the river according to the needs of the river.

[0038] The on-site construction method of the anti-permeable air bag includes: selecting an appropriate size according to the size requirements of the river channel and laying the air-permeable wall bag 3 with one side open, and selecting a piece of rigidity that matches the size of the air-permeable wall bag 3 The sheet 2 fixes the air-permeable wall 3 bag along its length and width directions, so that the full space inside the air-permeable wall bag 3 can be propped up, and the height of the rigid sheet 2 from the river ground is equal to the air-permeable The thickness of the wall bag 3 is about 3-5 cm, and the air-permeable wall bag 3 is filled with the anti-permeation gas particles...

Embodiment 2

[0048] The anti-permeable air bag used for the bottom of the river channel of the present invention is to fill the anti-permeable gas particles 1 in the air-permeable wall bag 3 to form the required anti-permeable air bag, and lay it to the bottom of the river according to the needs of the river.

[0049] The on-site construction method of the anti-permeable air bag includes: selecting an appropriate size according to the size requirements of the river channel and laying the air-permeable wall bag 3 with one side open, and selecting a piece of rigidity that matches the size of the air-permeable wall bag 3 The plate 2 fixes the air-permeable wall bag 3 along its length and width directions, so that the entire space inside the air-permeable wall bag 3 can be propped up, and the height of the rigid plate 2 from the river ground is equal to the air-permeable The thickness of the wall bag 3 is about 2-10cm, and the air-permeable wall bag 3 is filled with the anti-permeation gas particl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com