Patents

Literature

500results about How to "Good air-permeability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Super absorber polymer felt and method for the production thereof

InactiveUS20120036733A1High mechanical strengthGood air permeabilityStampsWrappersSpecial designTextile

The invention relates to a felt material comprising at least one felt layer and an absorbing layer, to a method for producing the felt material, and to the use of the felt material in textiles, shoes, technical application or medical applications. The felt material according to the invention has the advantages of conventional felt materials regarding the warming and damping properties and is permeable to air in the dry state. Due to the special design, however, it is waterproof in the wet state and thus it is suitable for sealing many materials. The felt material according to the invention binds more humidity or binds water in a different way than common felt materials.

Owner:IQTEX PATENTVERWALTUNG UG HAFTUNGSBESCHRANKT

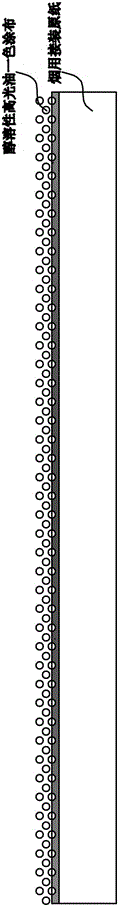

Lithium ion battery composite diaphragm and preparation method and application thereof

InactiveCN104157811AGood air permeabilityImprove securitySecondary cellsCell component detailsLithium electrodePolymer

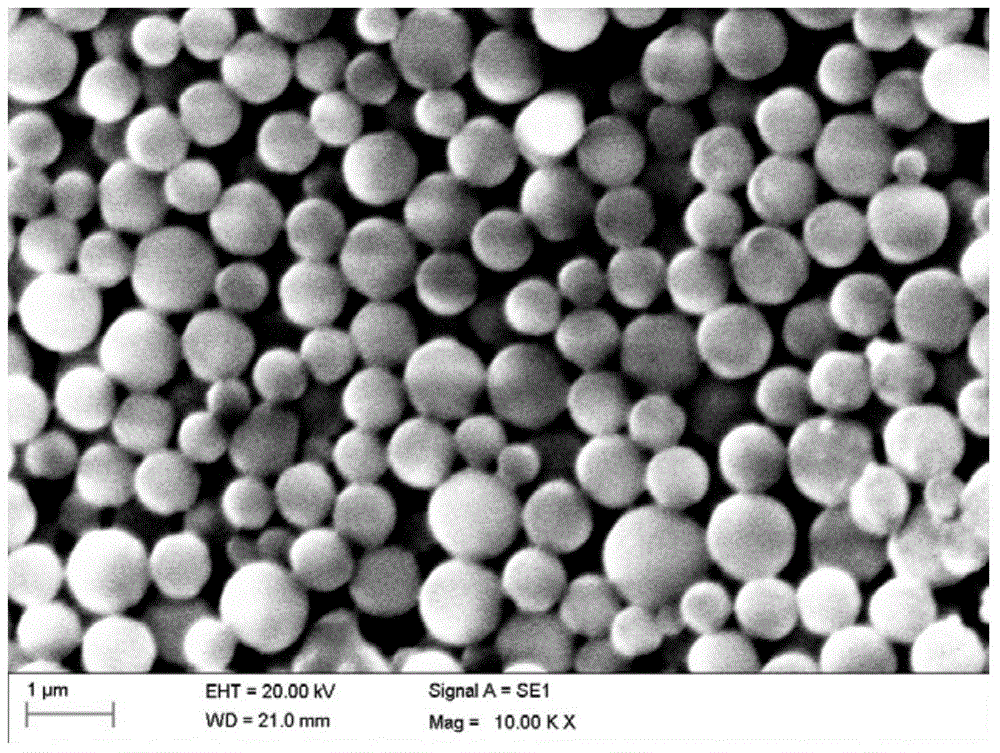

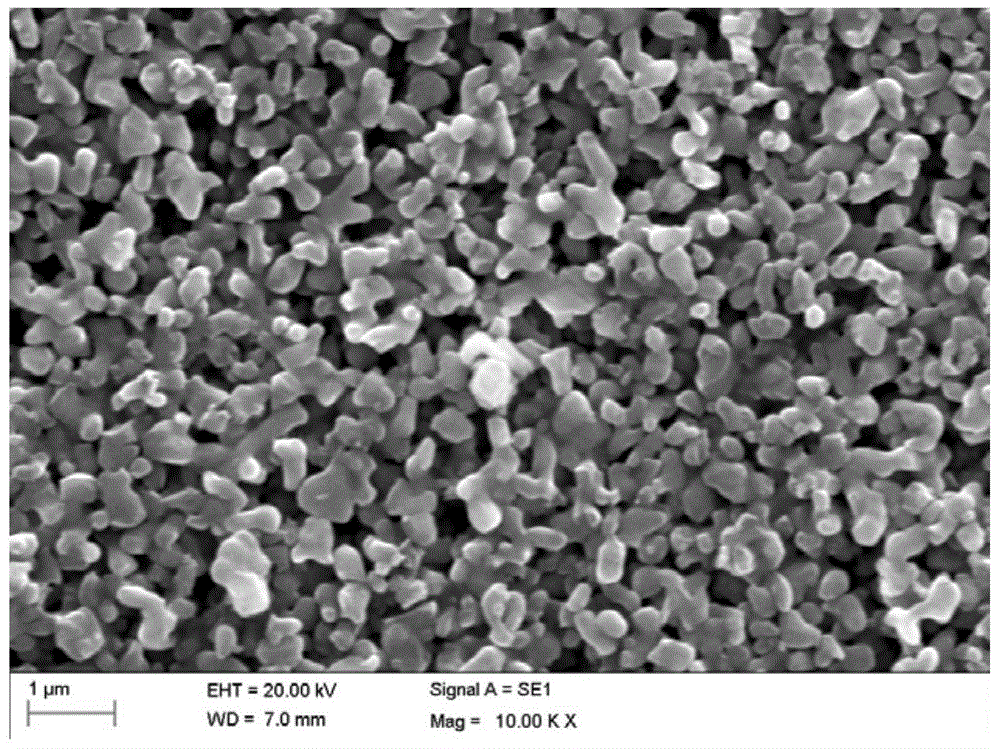

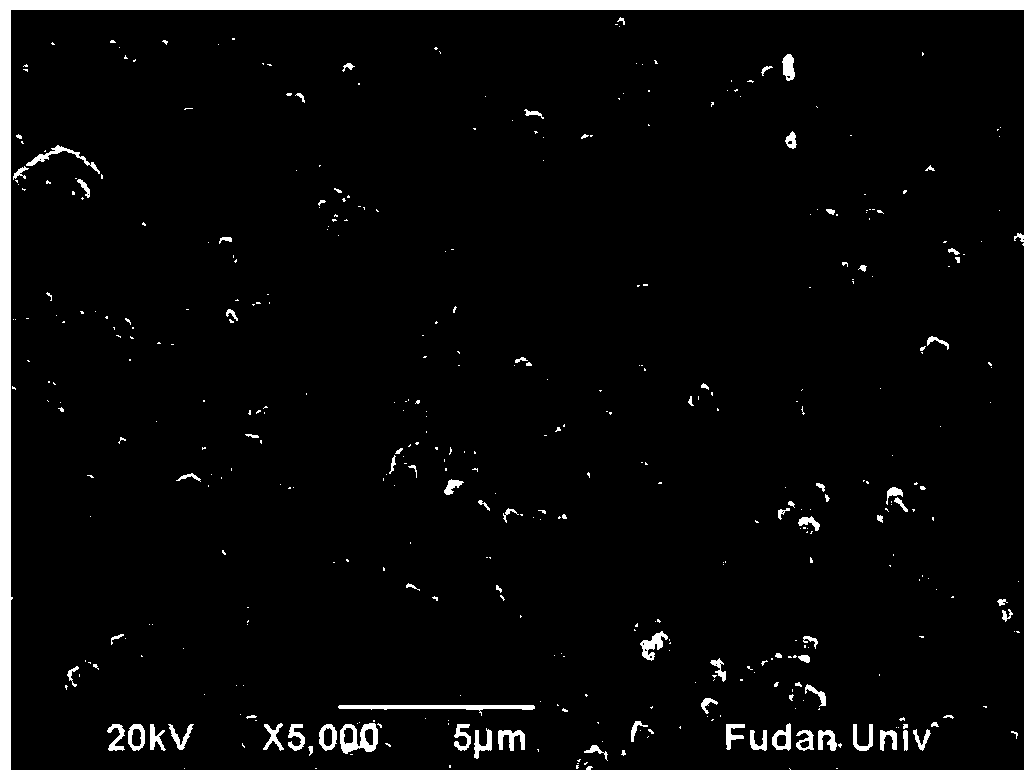

The invention discloses a lithium ion battery composite diaphragm and a preparation method and an application thereof, belonging to the technical field of lithium ion batteries. The composite diaphragm comprises a polyolefin microporous membrane, a polymer microsphere based coating on one side surface of the polyolefin microporous membrane, and an inorganic ceramic-based coating on the other side surface of the polyolefin microporous membrane. The lithium ion battery composite diaphragm has good air permeability, liquid retaining capability and high-temperature resistance and can remarkably improve the security and the circulation property of the battery. The melting point or softening point of the polymer microsphere-based coating in the composite diaphragm is 90-140 DEG C, and when the temperature of the battery is increased, the polymer microsphere based coating is molten or swelled within a short time, then the apertures of the polyolefin microporous membrane are blocked rapidly, the thermal turn-off effect of the diaphragm is achieved, a lithium ion conveying channel is cut off, and short circuit inside the battery is prevented; meanwhile as ceramic grains inside the inorganic ceramic-based coating have the high-temperature resistance property, the polyolefin microporous membrane is effectively prevented from shrinkage, and the situation that positive and negative films directly come into contact to cause short circuit of the battery.

Owner:SHANGHAI FANNENG NEW MATERIAL TECH CO LTD

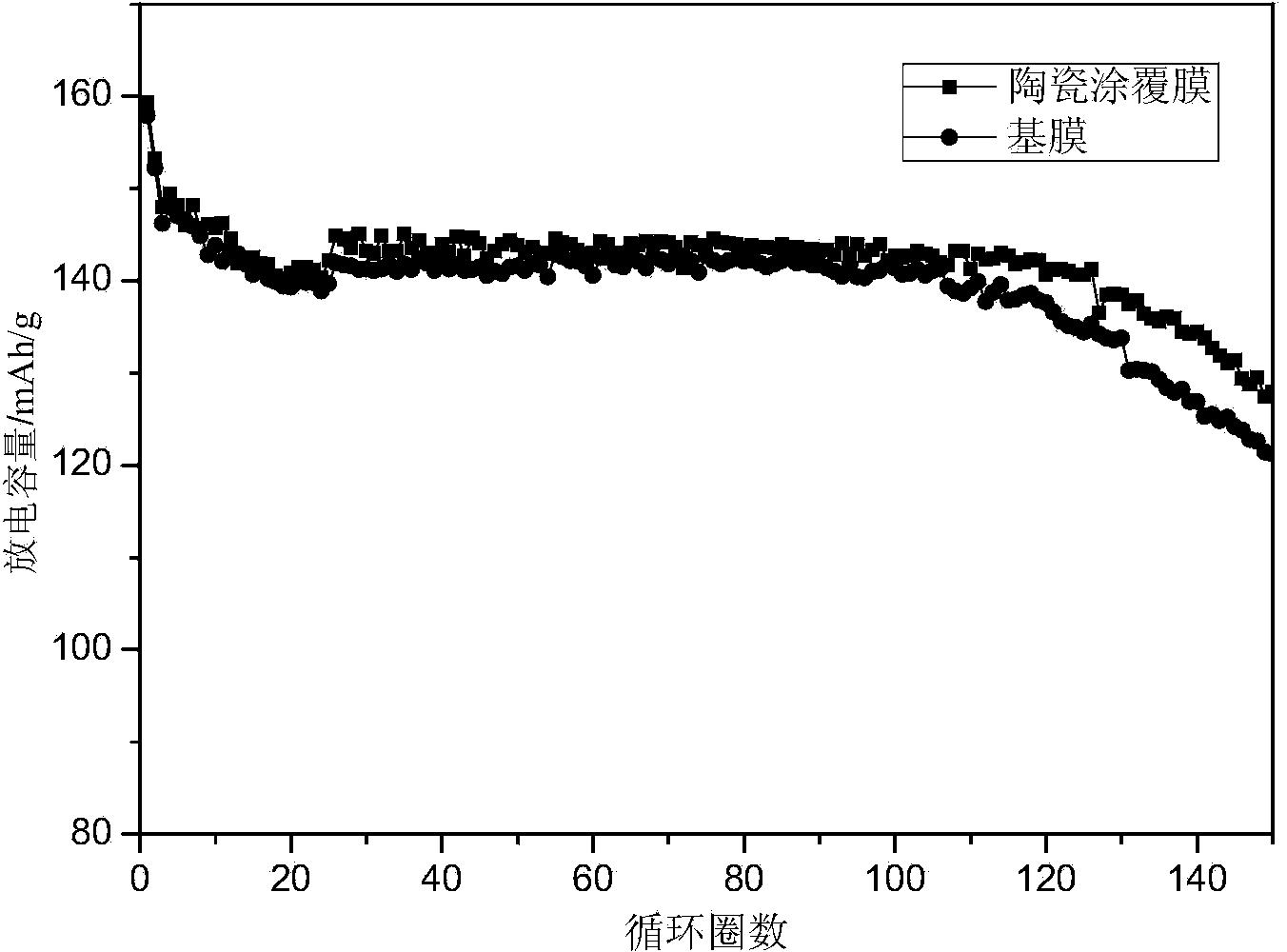

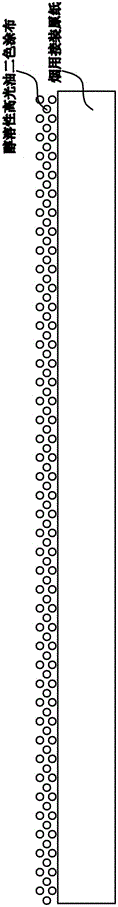

Ceramic coating diaphragm for lithium battery and preparation method of ceramic coating diaphragm

InactiveCN104269509AGood air permeabilityImprove peel forceCell component detailsCeramic coatingDiameter ratio

The invention discloses a ceramic coating diaphragm for a lithium battery and a preparation method of the ceramic coating diaphragm, and belongs to the technical field of batteries. The ceramic coating diaphragm comprises a ceramic coating and a substrate diaphragm, wherein the ceramic coating is prepared by uniformly coating the substrate diaphragm with water-based ceramic coating slurry; the ceramic coating slurry comprises components in percentage by weight as follows: 10%-30% of aluminum oxide, 0.5%-3% of a bonding agent, 0.2%-1.0% of an additive and 0.01%-0.1% of an auxiliary; and the aluminum oxide is nanometer aluminum oxide powder with the grain diameter ratio D1 / D2 of 0.10-0.20. According to the technical scheme, the safety of the ceramic coating diaphragm is improved, the wetting ability of electrolyte is improved, and the cycle life of the battery can be prolonged when the ceramic coating diaphragm is applied to the lithium battery.

Owner:SHANGHAI ELECTRICGROUP CORP

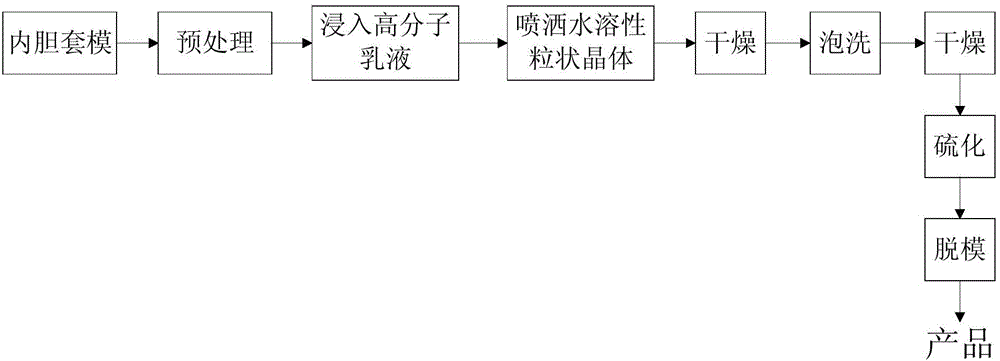

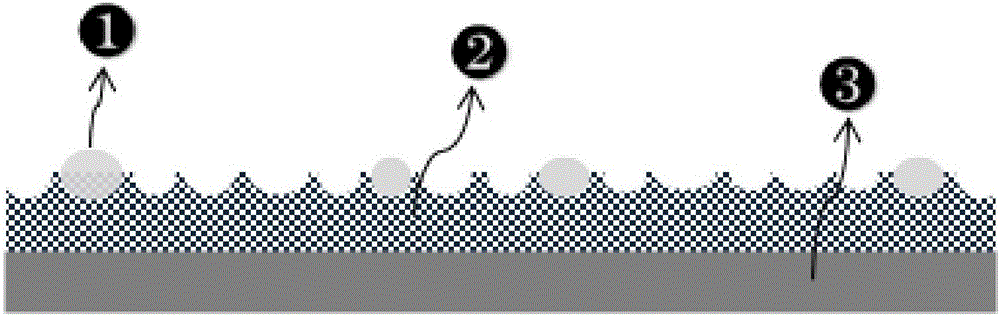

Anti-slip breathable operating gloves and preparation method thereof

ActiveCN106072923AGood anti-skid effectGood air permeabilityGlovesProtective garmentPre treatmentEmulsion

The invention provides a pair of anti-slip breathable operating gloves and a preparation method thereof. The preparation method comprises the steps that 1, macromolecular emulsion is prepared; 2, a mold is sleeved with an inner container of each glove, the inner container of each glove is immersed into the prepared macromolecular emulsion to form a macromolecular coating after pretreatment; 3, water-soluble granular crystals are sprayed on the surface of the unsolidified macromolecular coating, then drying treatment is performed, and the water-soluble granular crystals on the surface of the unsolidified macromolecular coating are dissolved with water; 4, the inner containers of the gloves treated in the step 3 are subjected to coating drying, vulcanization and demoulding treatment to obtain glove products. The macromolecular coating is formed on the inner container of each glove, the water-soluble granular crystals are sprayed on the surface of the unsolidified macromolecular coating, the water-soluble granular crystals are dissolved with water after the macromolecular coating solidifies, accordingly a large amount of micropores are formed on the macromolecular coating so as to form a concave-convex structure, and the gloves have an excellent anti-slip effect, good breathability, softness and abrasion resistance.

Owner:WONDERGRIP CHINA CO LTD

Rapid heat dissipation foundry molding sand and preparation method thereof

InactiveCN104475654AHigh strengthGood air permeabilityFoundry mouldsFoundry coresMolding sandAluminium oxide

The invention relates to rapid heat dissipation foundry molding sand, which is prepared from the following raw materials by weight: 200-220 parts of clay, 20-30 parts of zirconite powder, 20-30 parts of boiler slag, 15-20 parts of graphite powder, 2-3 parts of epoxy soybean oil, 1-1.5 parts of Tween 80, 4-6 parts of water glass, 5-8 parts of fused millite powder, 3-5 parts of nanometer alpha-alumina, 2-3 parts of yttria, a proper amount of water, and 20-30 parts of an auxiliary agent. According to the rapid heat dissipation foundry molding sand, the molding sand has characteristics of high strength, good gas permeability, art cast product quality improving and recycling; the graphite powder and the nanometer alpha-alumina are used, such that the dispersity and the thermal conductivity of the molding sand are increased, the production efficiency is increased, the high temperature collapsibility is good, the cast surface quality is good, and the labor intensity is reduced; the auxiliary agent of the present invention adopts alumina and other high temperature resistance materials, such that the auxiliary agent can not melt during casting, the adhesion of the clay particles can be prevented, the recycling is easily performed; and the auxiliary agent has good fluidity.

Owner:繁昌县琦祥铸造厂(普通合伙)

Hydrogel of composite semipermeable membrane and preparation method thereof

InactiveCN103611184AHigh transparencyGood air permeabilityLayered productsAbsorbent padsChemistryBiocompatibility Testing

The invention relates to a hydrogel of a composite semipermeable membrane and a preparation method thereof. The hydrogel comprises a semipermeable membrane and a hydrogel functional layer, wherein one side of the hydrogel functional layer is attached to the semipermeable membrane; the hydrogel functional layer is prepared from 10-90wt% of hydrophilic polymer material and 90-10wt% of water by adopting any one or combination of more than two of physical crosslinking, chemical crosslinking and radiation crosslinking. The hydrogel material prepared by the method has excellent performances such as high moisture content of the hydrogel and good biocompatibility, also has the characteristics of controlled moisture release rate of the semipermeable membrane; the service time of the hydrogel is prolonged; meanwhile, one side of the semipermeable membrane can be further combined with other accessories such as an adhesive tape, so as to meet more complicated functional requirements.

Owner:长春吉原生物科技有限公司 +1

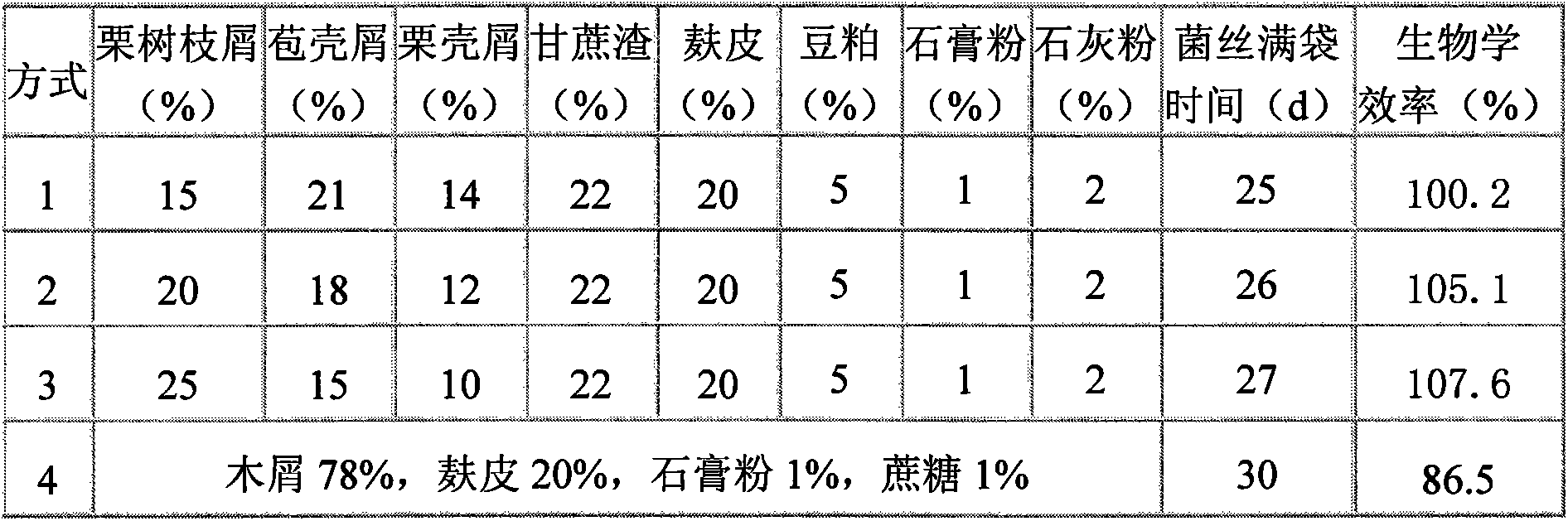

Compatibility and manufacturing method of Pleurotus eryngii cultivation material

InactiveCN103408369AReasonable ratioGood air permeabilityBio-organic fraction processingOrganic fertiliser preparationWater contentMacromolecular Substances

The invention provides a Pleurotus eryngii cultivation material, which is characterized by comprising main raw materials of chestnut branch sawdust, bud shell shreds and chestnut shell shreds, and accessory materials of bagasse, wheat bran, soybean meal and gesso; and the water content of the cultivation material is 63-65% The invention also comprises a manufacturing method of the cultivation material. Compared with sawdust cultivation material, the cultivation material provided by the invention has the following advantages: 1, the cultivation material has reasonable ratio, good permeability and strong water retention, so as to realize vigorous growth of Pleurotus eryngii mycelia and short sackful time; 2, the chestnut branch sawdust, bud shell shreds and chestnut shell shreds are subjected to daylight insolation, accumulation aging and biological fermentation to remove poisonous bacteriostatics and degrade macromolecular substances, so as to benefit absorption of the Pleurotus eryngii mycelia and increase the output by 15-25%; and 3, the method widens channels of the cultivation raw materials and substantially reduces production cost.

Owner:邬金飞

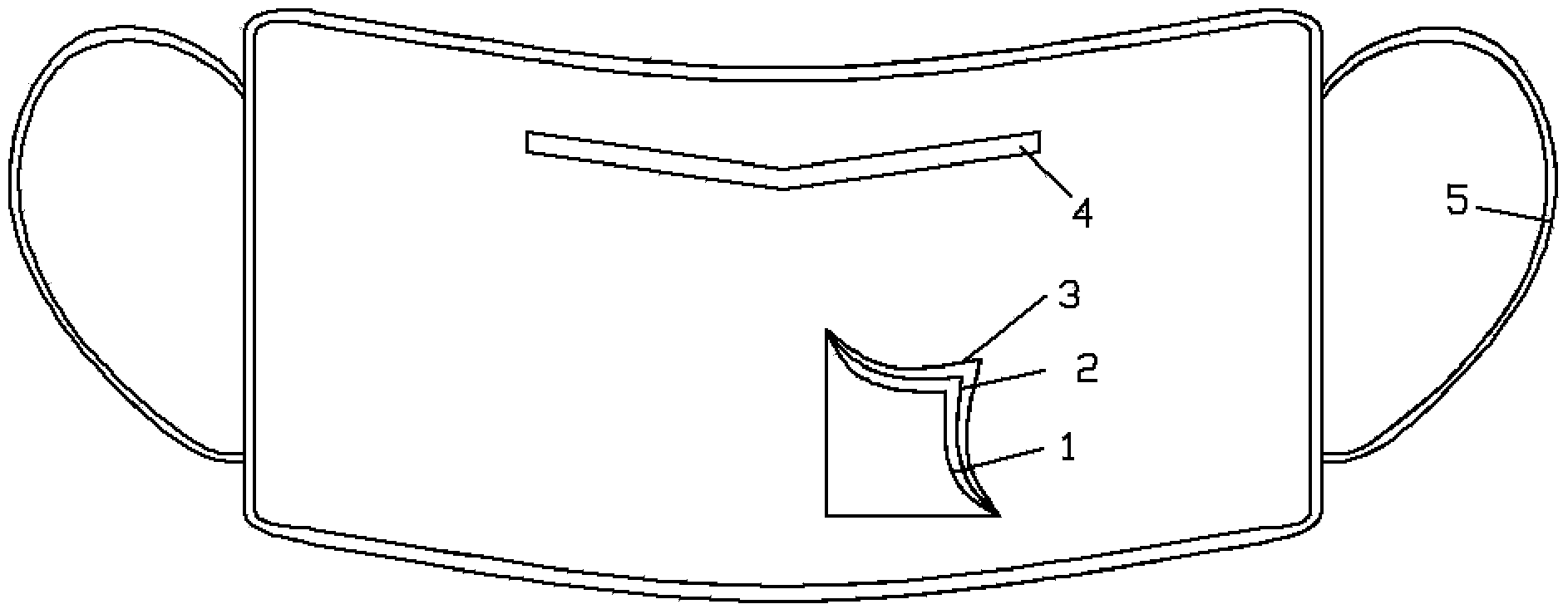

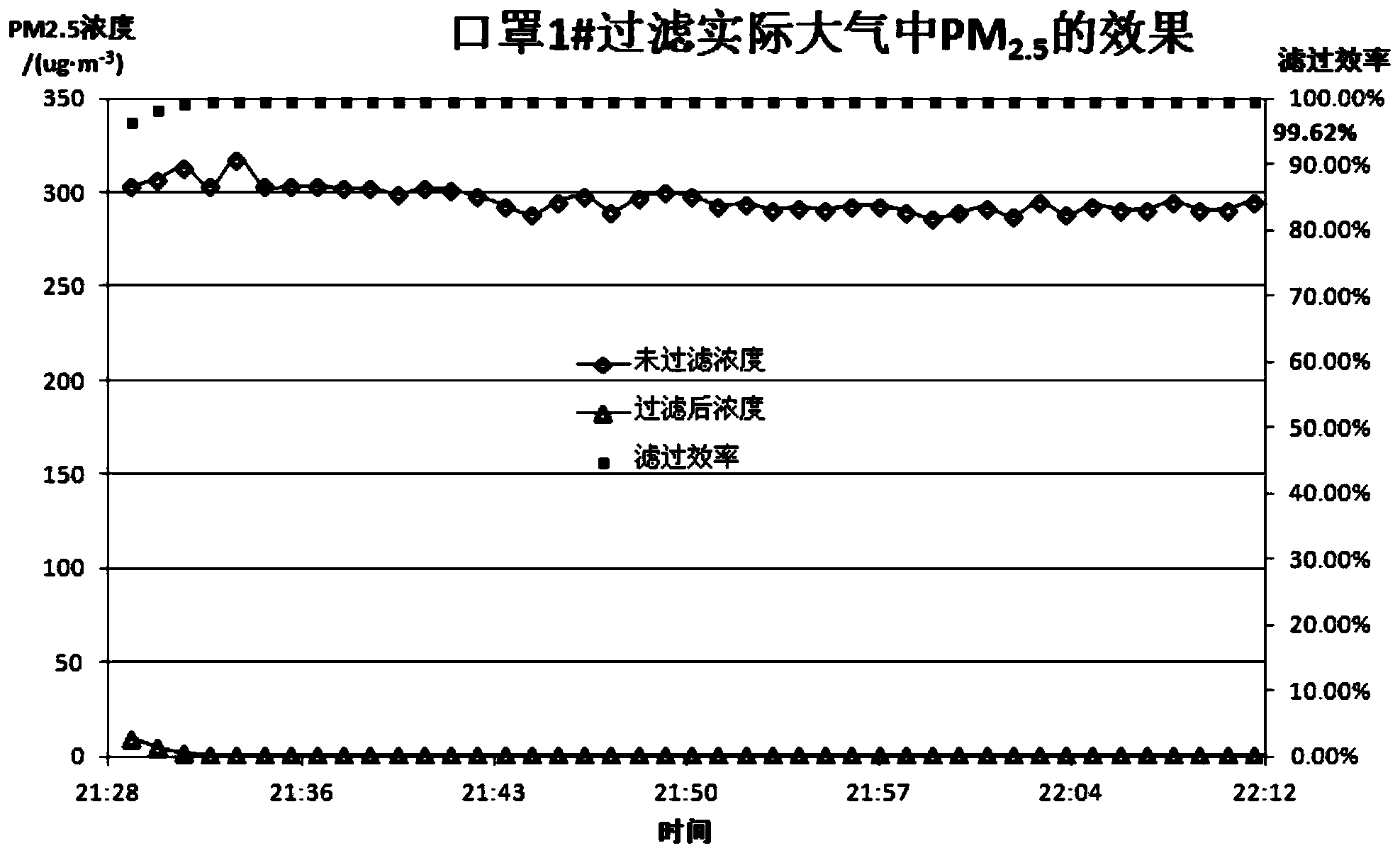

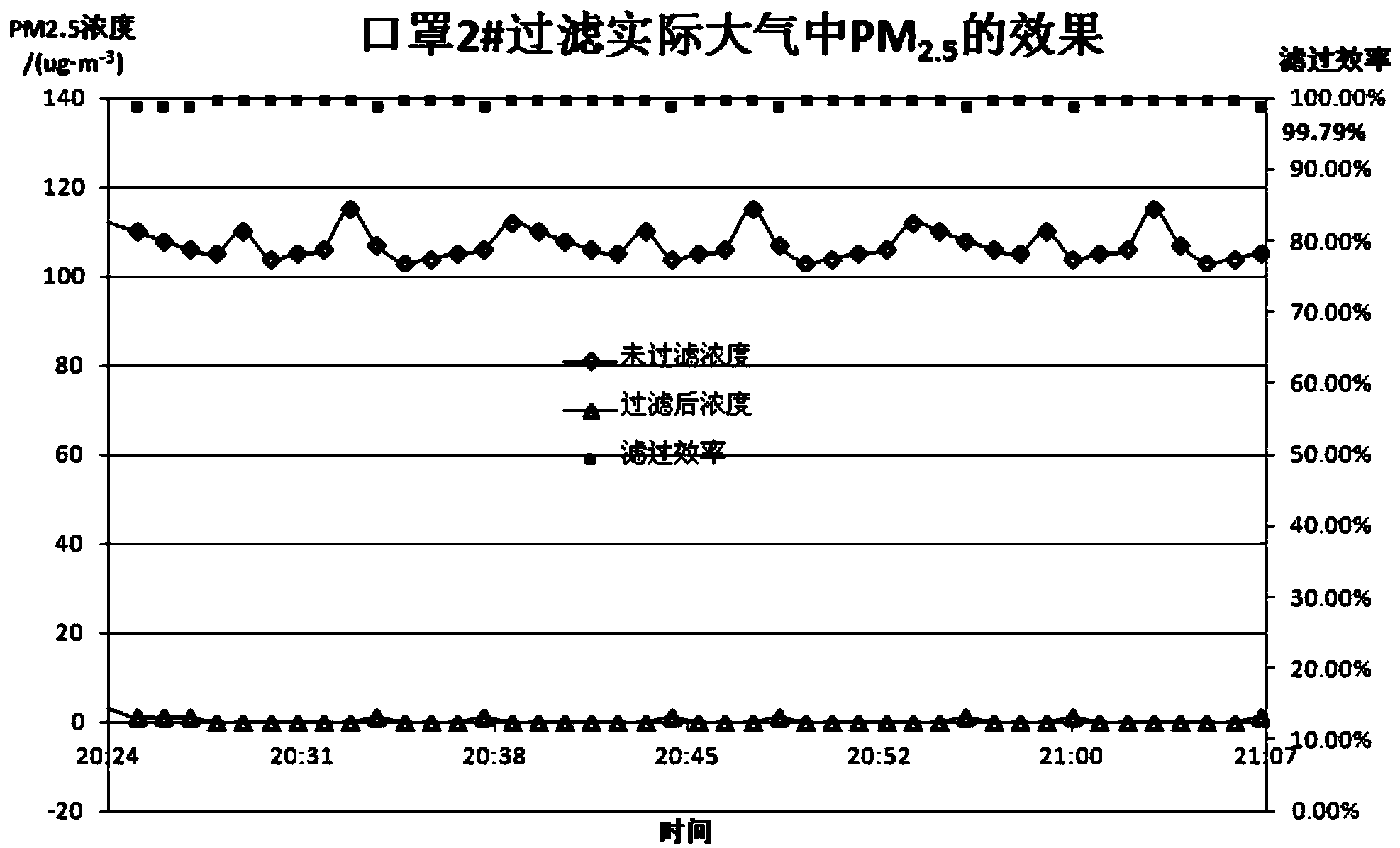

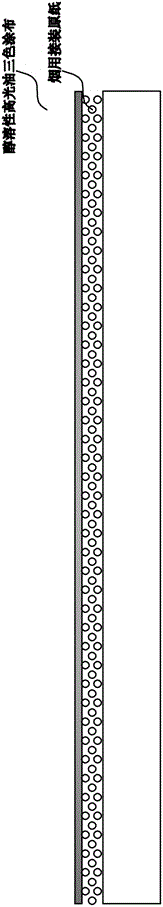

Planar mask for efficiently filtering PM 2.5

InactiveCN103637431AGood wearing feelingGood air permeabilityProtective garmentWoven fabricEngineering

The invention relates to a planar mask for efficiently filtering PM 2.5. The planar mask comprises a mask body used for covering the mouth and the nose of a wearer. A pair of ear hooking portions are formed on the two sides of the mask body in an extending mode and used for being hooked on the ears of the wearer. The mask body is of a three-layer structure in a stacked mode, and the three-layer structure comprises a polypropylene fiber spunbonded non-woven fabric outer layer, a superfine fiber electret melt-blown non-woven fabric middle layer and a polypropylene fiber spunbonded non-woven fabric inner layer in sequence from outside to inside. The weight per unit area of the superfine fiber electret melt-blown non-woven fabric middle layer is 20-60g / m<2>. The planar mask for efficiently filtering the PM 2.5 has the advantages of being high in filtration rate and low in choked flow, has prominent obstruction and capturing capability for the PM 2.5 and is good in breathability, low in weight, comfortable to wear and high in PM 2.5 filtering efficiency in high level. The filtering efficiency can reach up to more than 99%, the weight is low, and breathability and comfortable sensation of the mask are ensured at the same time.

Owner:SHANDONG UNIV

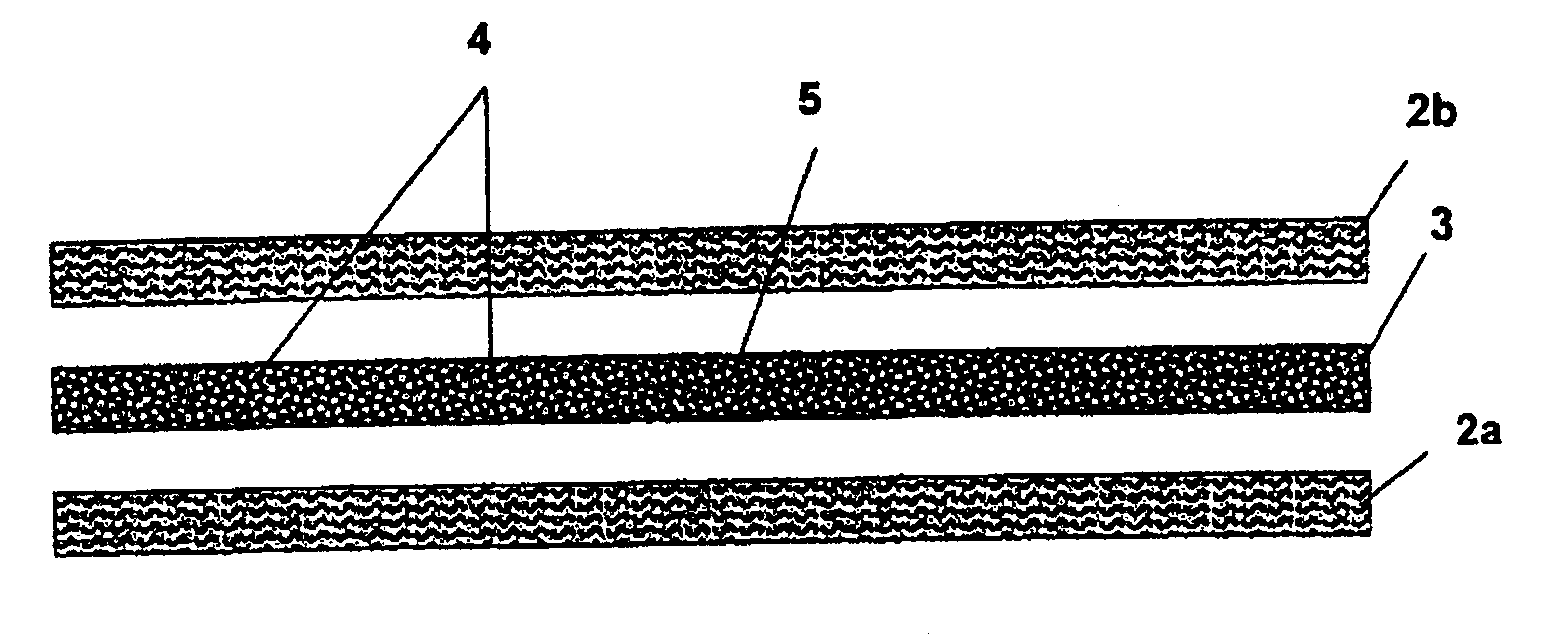

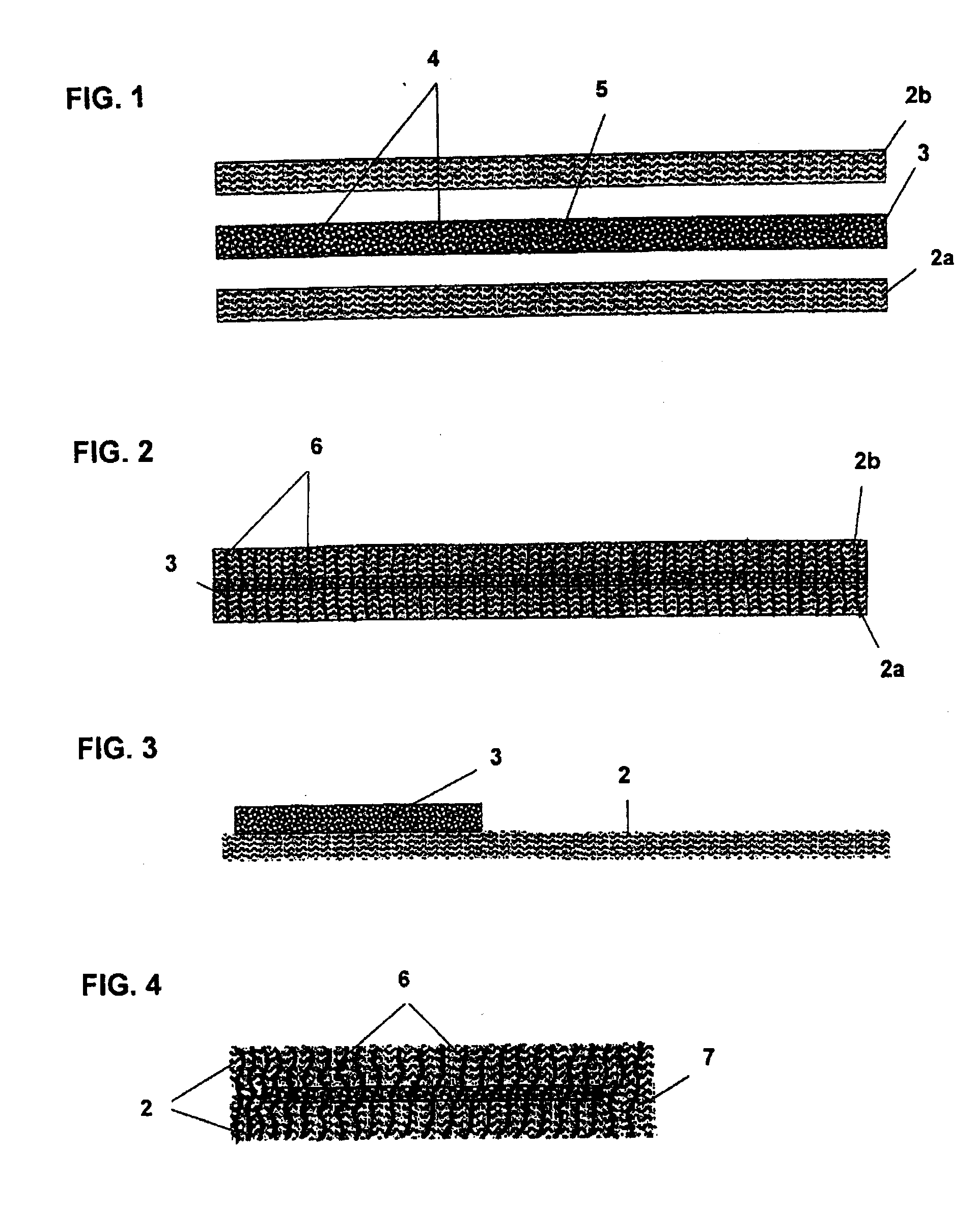

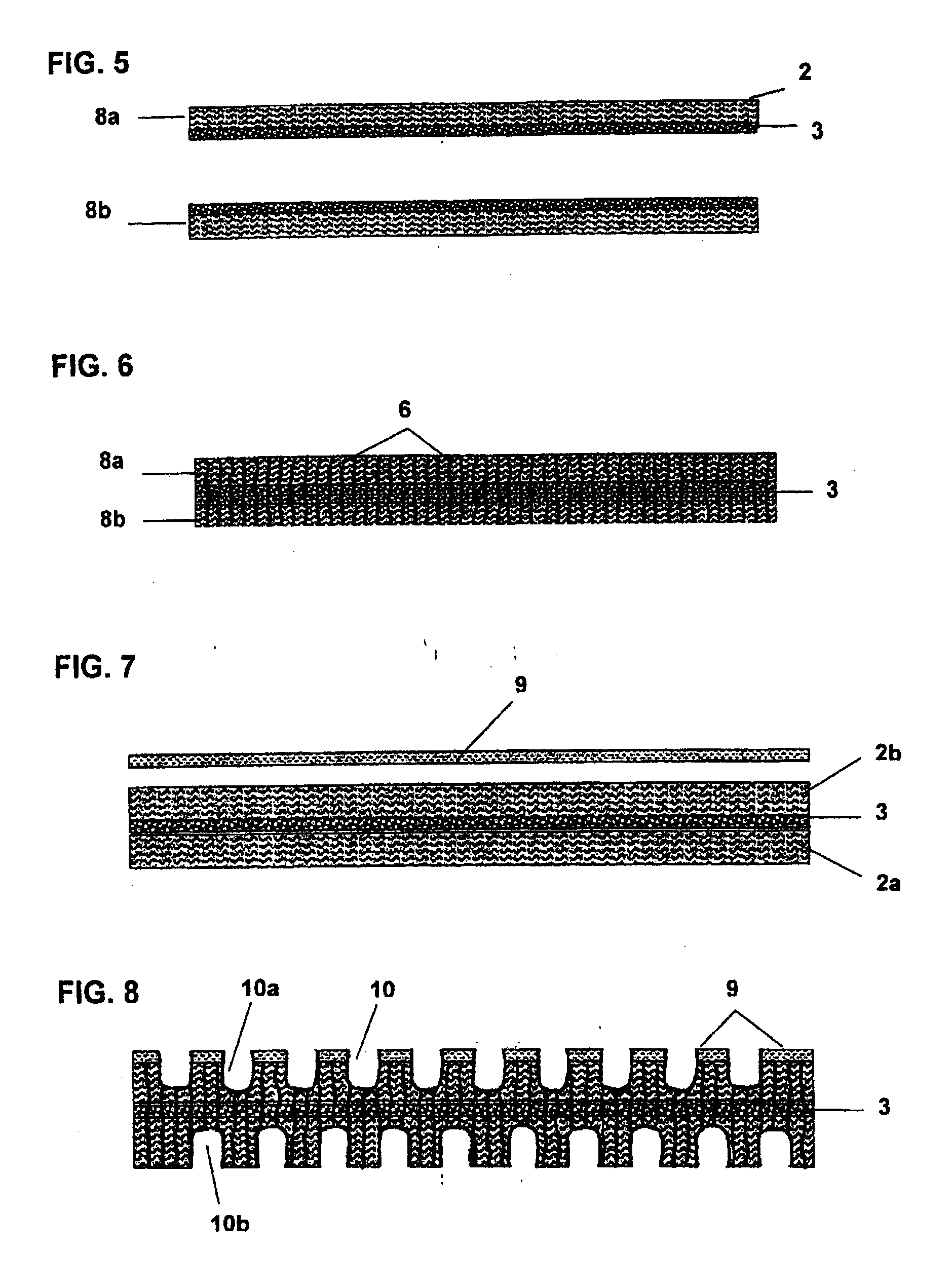

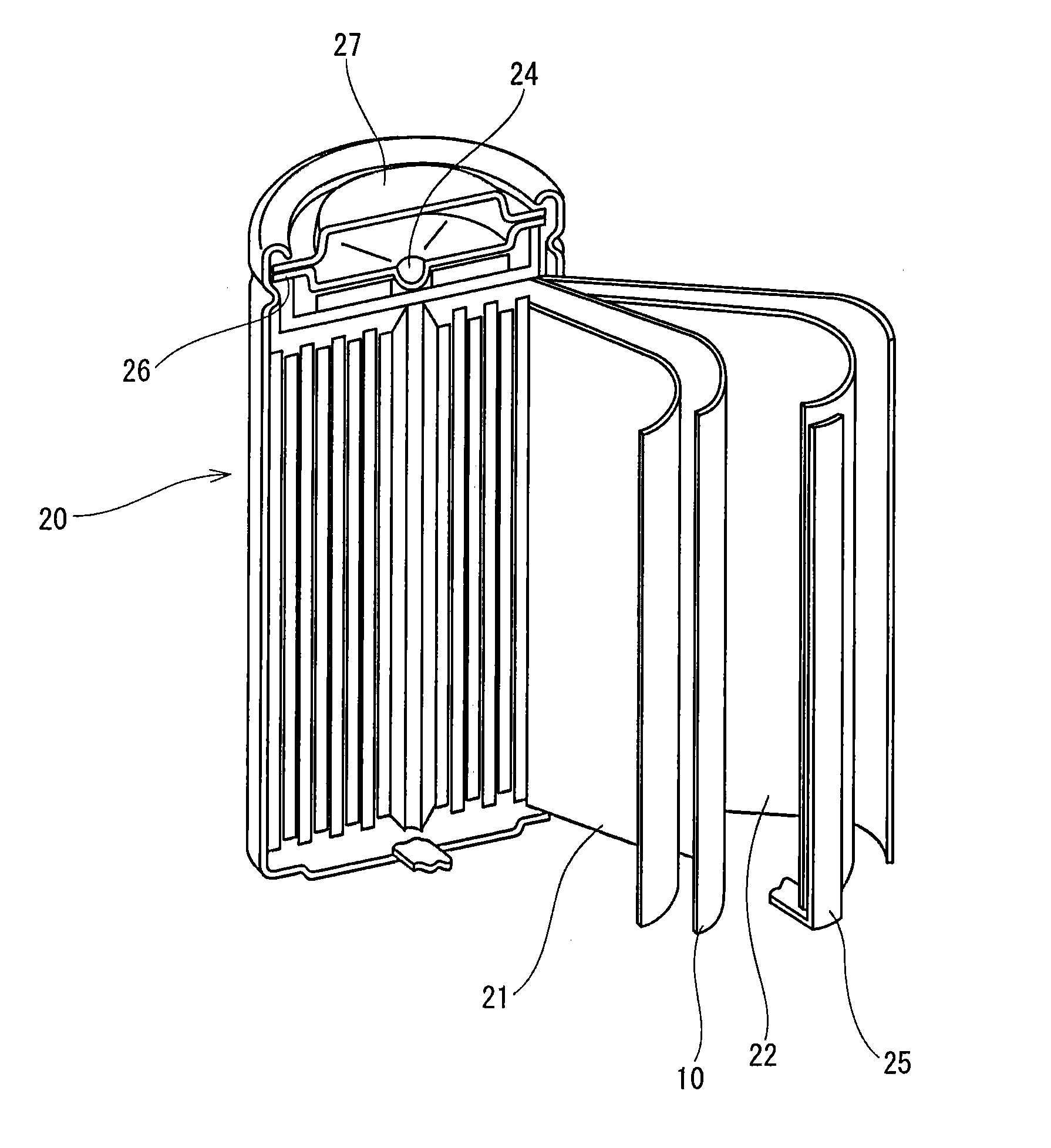

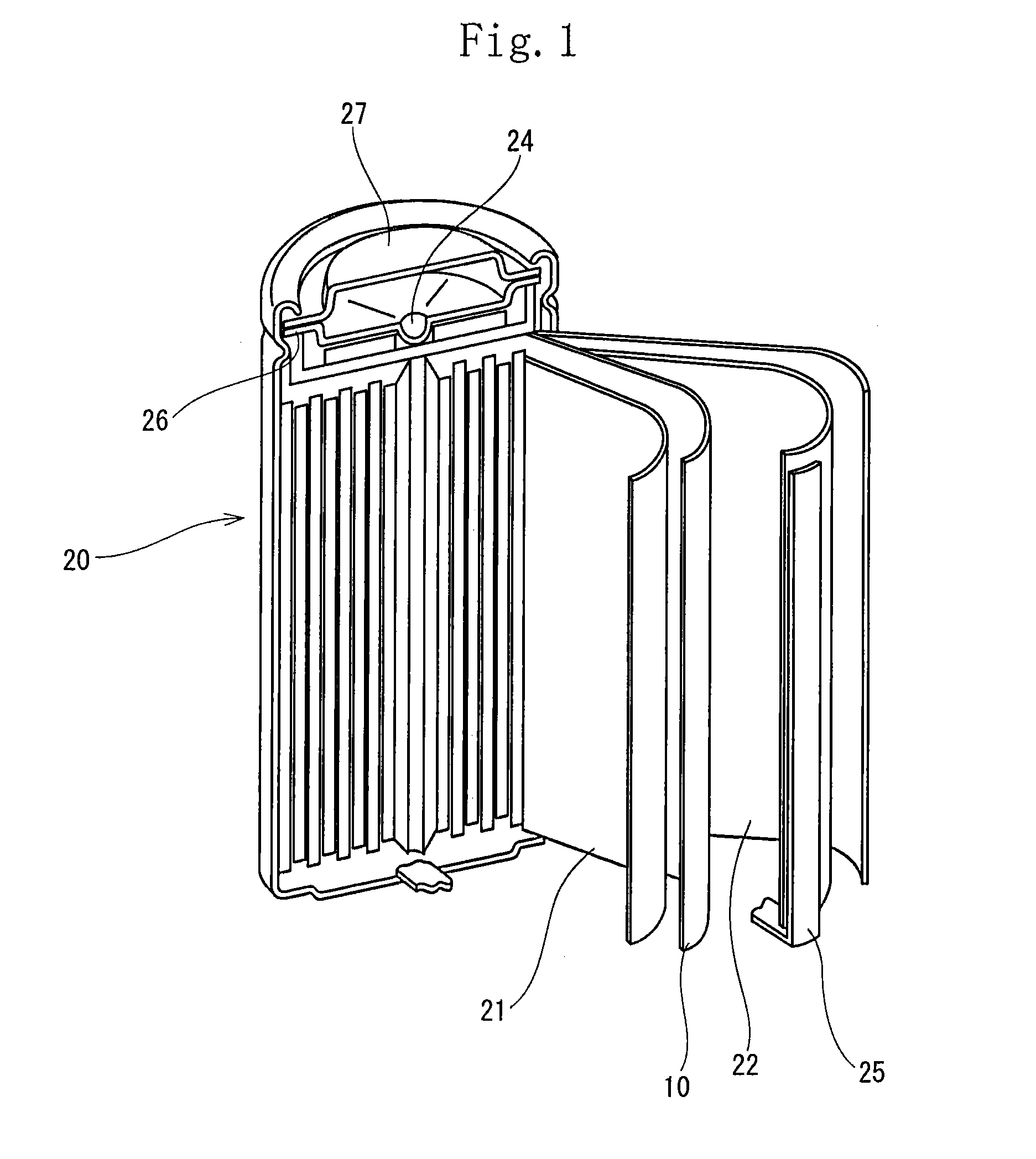

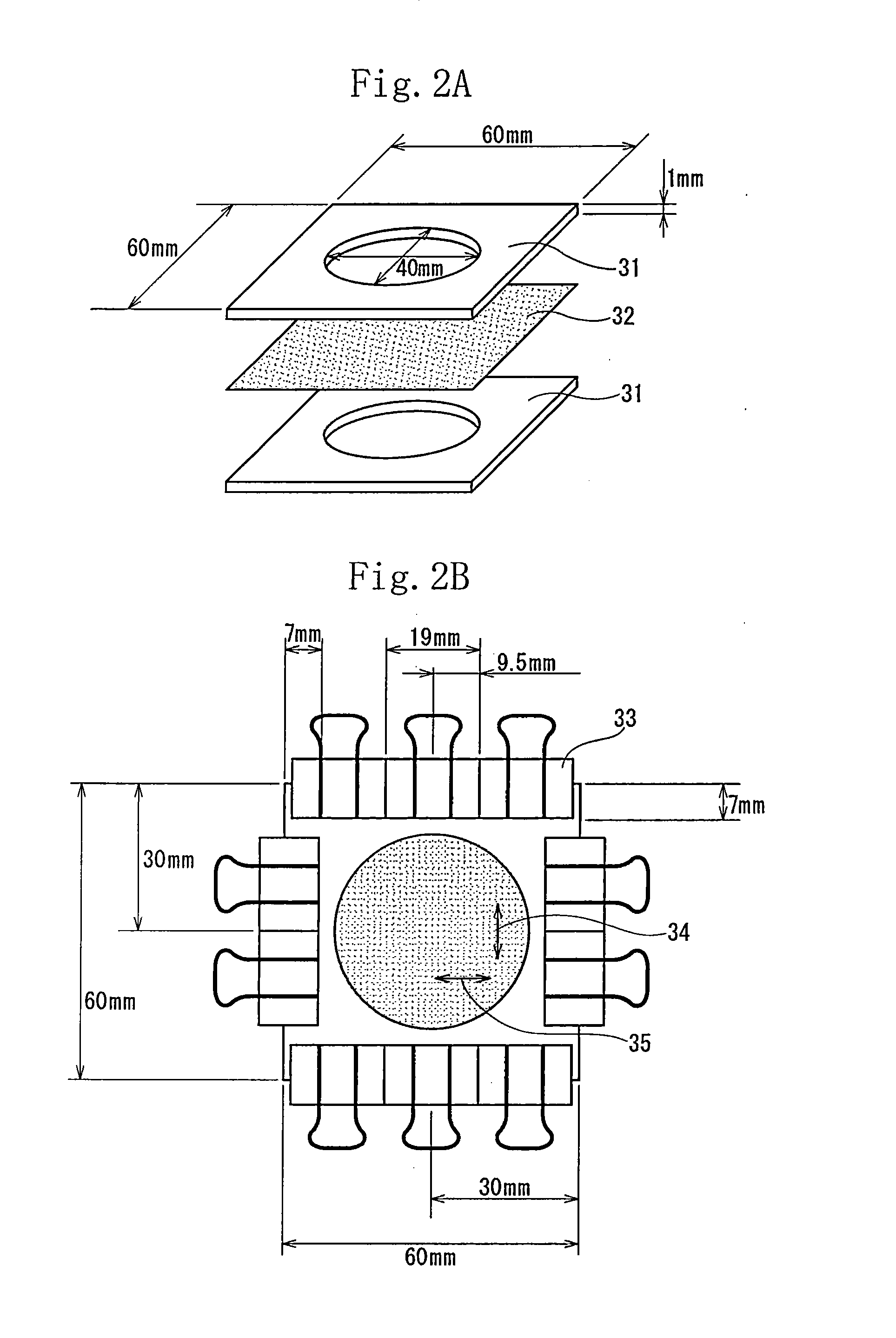

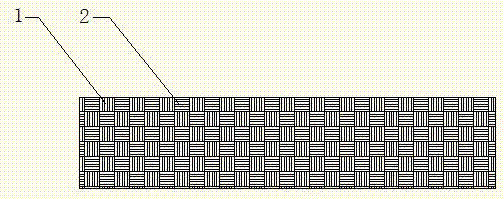

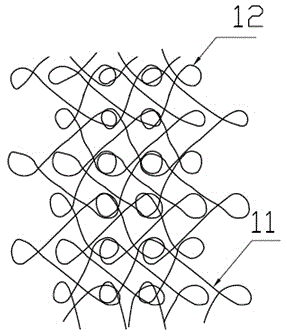

Laminated porous film, separator for battery, and battery

InactiveUS20130196208A1Good air permeabilitySynthetic resin layered productsCell component detailsElectricityThermoplastic

The purpose is to provide a laminated porous film having shutdown characteristics, which are important in terms of ensuring safety, while also having excellent air permeation performance, which contributes to electrical performance, when used a separator for a battery. The present invention is a laminated porous film characterized by comprising: a porous film layer having a thickness of 10 um or more, the main component thereof being a thermoplastics resin composition having a crystal-melting peak temperature of 150-250° C.; and a nonwoven fiber layer having a fiber diameter of 1 um or less, the main component thereof being a thermoplastic resin composition having a crystal-melting peak temperature of 100° C. to less than 150° C.; the air permeability of the laminated porous film being 10-10,000 s / 100 mL.

Owner:MITSUBISHI PLASTICS INC

Anhydrous stemming for blast-furnace tapping hole

The invention discloses an anhydrous stemming for a blast-furnace tapping hole. Tar oil with specific weight of 1.15-1.16 or mixed oil of tar oil and anthracene oil is used as a binding agent, more than 50% of coarse and middle particles are added into a particle composition of the formulation, the content of fine powder with the particle size not more than 0.088 mm is controlled below 50%, a great amount of sericite is added into the formulation, and 40-70 mesh refined quartz sand is added. The stemming has good air permeability and rapid sintering performance and can be rapidly hardened within 20-30 min, the gas can be exhausted through ventilation holes, the strength of the stemming can be rapidly increased within short time and can satisfy about 30 min continuous opening tapping of single tapping holes of large and medium blast furnaces.

Owner:HUNAN XIANGGANG RUITAI TECH +1

Needle mushroom cultivation matrix formula and its preparation method

InactiveCN103497018AGood air permeabilityWide variety of sourcesFertilizer mixturesNutritionAmino acid

The invention relates to a needle mushroom cultivation matrix formula which is prepared from the following components and raw materials: by weight, 30-40 parts of modified rice chaff, 25-35 parts of camellia oleifera seed husk, 10-15 parts of vinegar residue, 5-10 parts of soybean cake, 5-10 parts of pine scale, 20-30 parts of cotton seed hull, 2-4 parts of potassium dihydrogen phosphate, 1-2 parts of zeolite powder, 10-15 parts of modified plant ash and 4-5 parts of nutritive soil. The cultivation base has good air permeability and wide raw material sources, reduces the windage loss of the plant ash, and realizes the economic benefit of waste matter utilization. The needle mushroom cultivated by the cultivation base has the characteristics of high contents of trace elements, vitamins and amino acids, and is quick in growth speed, high in yield and low in raw material cost.

Owner:HEFEI QIANXI MOUNTAIN VILLA AGRI ECOLOGICAL PARK

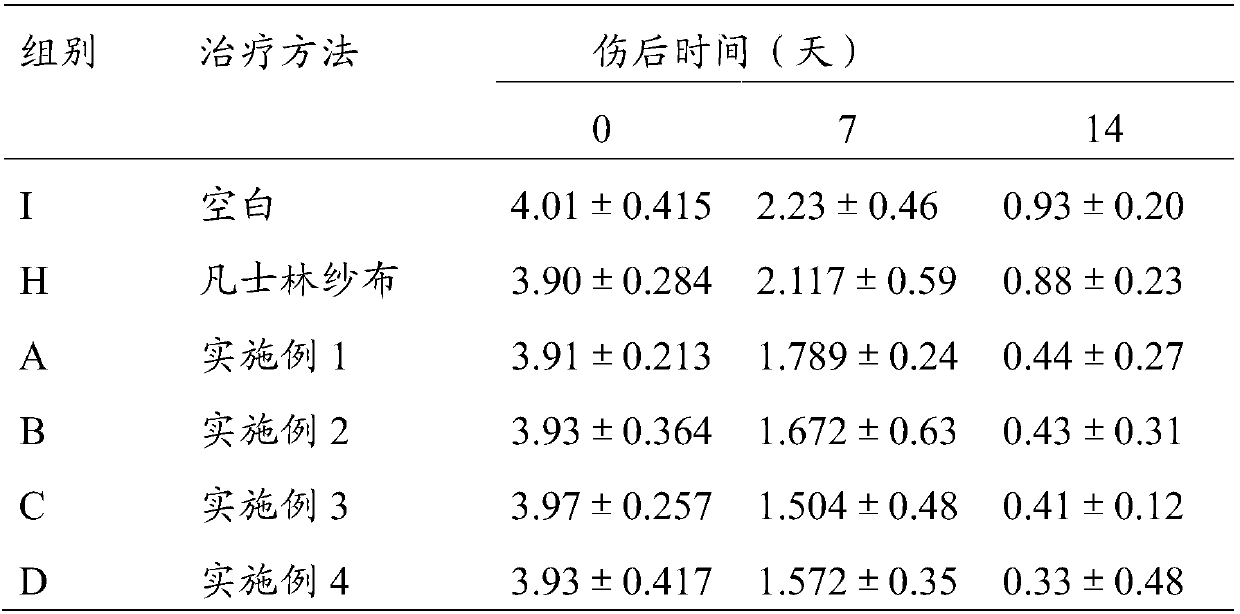

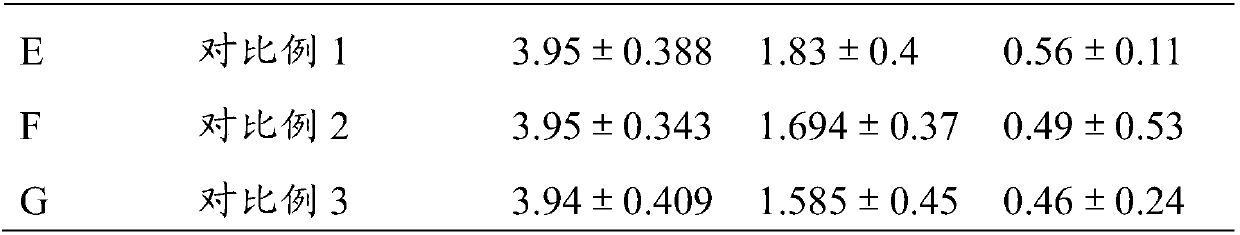

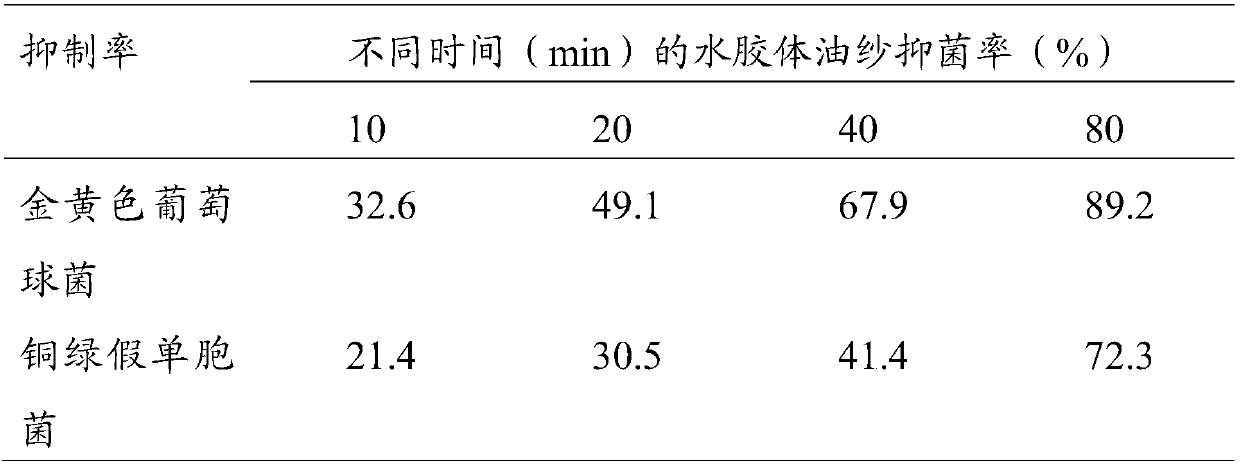

Hydrocolloid oil yarn and preparation method thereof

ActiveCN108126232AGood air permeabilityGood compatibilityAbsorbent padsBandagesParaffin waxSodium carboxymethylcellulose

The invention relates to a hydrocolloid oil yarn. The hydrocolloid oil yarn comprises a base material and a hydrocolloid ingredient, wherein the base material is netty polyester fiber; the hydrocolloid ingredient comprises the following raw materials in parts by weight: 8 to 10 parts of thermoplastic elastomers, 16 to 30 parts of sodium carboxymethylcellulose, 1 to 5 parts of growth factor microspheres, 1 to 5 parts of chitosan, 100 to 200 parts of liquid paraffin, 30 to 40 parts of Vaseline and 5 to 10 parts of wool fat. The content of grown factors inside the grown factor microspheres is 0.01wt% to 0.03wt%.

Owner:GUANGZHOU RAINHOME PHARM&TECH CO LTD

Plant culture medium for hill afforestating vegetation

InactiveCN1781882AGood adhesionGood air permeabilityHorticulture methodsFertilizer mixturesAdhesiveCulture mediums

The present invention belongs to the field of afforesting technology, and is especially plant culture medium for hill afforesting vegetation. The plant culture medium is prepared with tree bark, stalk, soil, plant ash, carbon powder, paper pulp, organic fertilizer, grass seed, flower seed, tree seed, water retaining agent, curing agent, adhesive, etc. and through mixing. It is sprayed for being adhered to hill rock surface. It is ventilating, integral, and suitable for plant growth, and can form afforesting vegetation well on hill.

Owner:于树林

Tundish diffuse type air brick and preparation method thereof

The invention discloses a tundish diffuse type air brick and a preparation method thereof. The brick is mainly prepared by adopting the following raw materials in percentage by weight: 60-80% of forsterite particle, 10-30% of magnesia fine powder, 1-7% of silicon micro powder, 2-7% of silicon nitride fine powder and 1-5% of forsterite micro powder. The air brick adopts forsterite as the main raw material and has the characteristics of low cost, good air permeability, strong anti-erosion ability, uniform and stabile bubble, no pollution on liquid steel and high cost performance; the air brick can be prepared through low temperature baking only and the fuel consumption in the high temperature baking process is avoided, so that the production cost is reduced and the air brick has the characteristics of environmental protection and energy saving in the production process. The method comprises the steps of mixing according to requirement, adding water and stirring, casting and moulding, maintaining and drying. The air brick is obtained through the low temperature baking only with on need for high temperature baking, so that the method has the characteristics of environmental protection, energy saving and no pollution.

Owner:TANGSHAN GUOLIANG SPEICAL REFRACTORY MATERIAL

Chilled mud-core molding sand manufactured from chromite sand and method for manufacturing chilled mud-core molding sand

InactiveCN103495695AGood air permeabilityHigh strengthFoundry mouldsFoundry coresMolding sandSulfonic acid

The invention discloses chilled mud-core molding sand manufactured from chromite sand. The chilled mud-core molding sand is characterized by comprising, by weight, 70-90 parts of recycled sand, 240-260 parts of the chromite sand, 10-15 parts of coal dust, 30-35 parts of sepiolite, 35-40 parts of bentonite, 4-5 parts of rapeseed oil, 35-40 parts of alkali-free glass fibers, 2-3 parts of copper naphthenate, 1-2 parts of boric acid, 5-8 parts of furan resin, 40-45 parts of nanometer-sized kaolin, 2-3 parts of sodium tripolyphosphate, 2-3 parts of benzene sulfonic acid and an appropriate amount of water. A method for manufacturing the chilled mud-core molding sand includes calcining the chromite sand, the sepiolite and the bentonite; then calcining the chromite sand, the sepiolite and the bentonite at a high temperature; dispersing the boric acid, the copper naphthenate and the like into the chromite sand, the sepiolite and the bentonite and grinding raw materials to obtain the molding sand. The chilled mud-core molding sand and the method have the advantages that the chilled mud-core molding sand is excellent in gas permeability, adhesion, toughness, plasticity and collapsibility; the strength of the molding sand is improved owing to the glass fibers and the boric acid; the organic resin and the rapeseed oil are used as adhesion agents, so that the chilled mud-core molding sand is high in plasticity and high-temperature collapsibility; the chilled mud-core molding sand has a chilled characteristic, and the production efficiency is high.

Owner:HEFEI CITY TENVER PRECISION CASTING

Hydrophilic processing method for zinc nickle alkaline accumulator diaphragm

InactiveCN101471431AGood air permeabilityGood hydrophilic and liquid absorption performanceCell component detailsChemistryPolypropylene

The invention provides a hydrophilic treatment method of Zn-Ni alkaline storage battery diaphragm, which comprises the following steps: preparing a hydrophilic treatment solution and a coating layer solution; soaking a hydrophobic polypropylene diaphragm, a polyethylene diaphragm, a polysulfone diaphragm and a polyvinyl chloride diaphragm in the hydrophilic treatment solution and the coating layer solution; washing the diaphragm with water; and drying in an oven or in air; or directly applying the coating layer solution on a hydrophilic polypropylene diaphragm, a polyethylene diaphragm, a polysulfone diaphragm, a polyvinyl chloride diaphragm and cellulose acetate diaphragm. The diaphragm treatment method has the advantages that the diaphragm subjected to hydrophilic treatment has good air permeability and hydrophilic solution adsorption performance; and the diaphragm treated by the coating layer is applied with an additive capable of stopping or suppressing the growth of zinc dendrites, so that the Zn electrode has more stable performance in circle use and prolonged circle life, thereby improving the circle life of the Zn-Ni battery and widening the use range of the Zn-Ni battery.

Owner:HENAN HUANYU GROUP

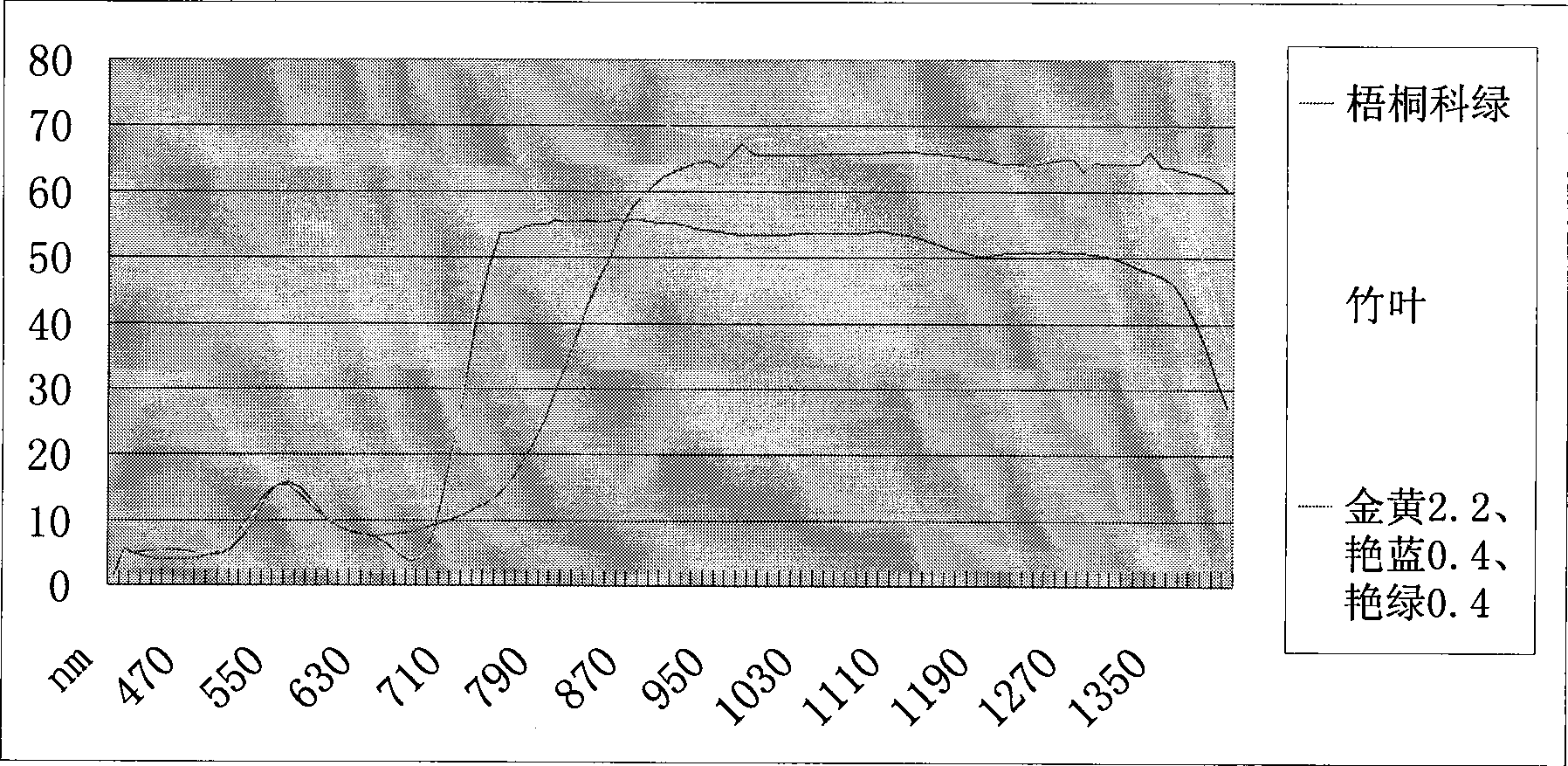

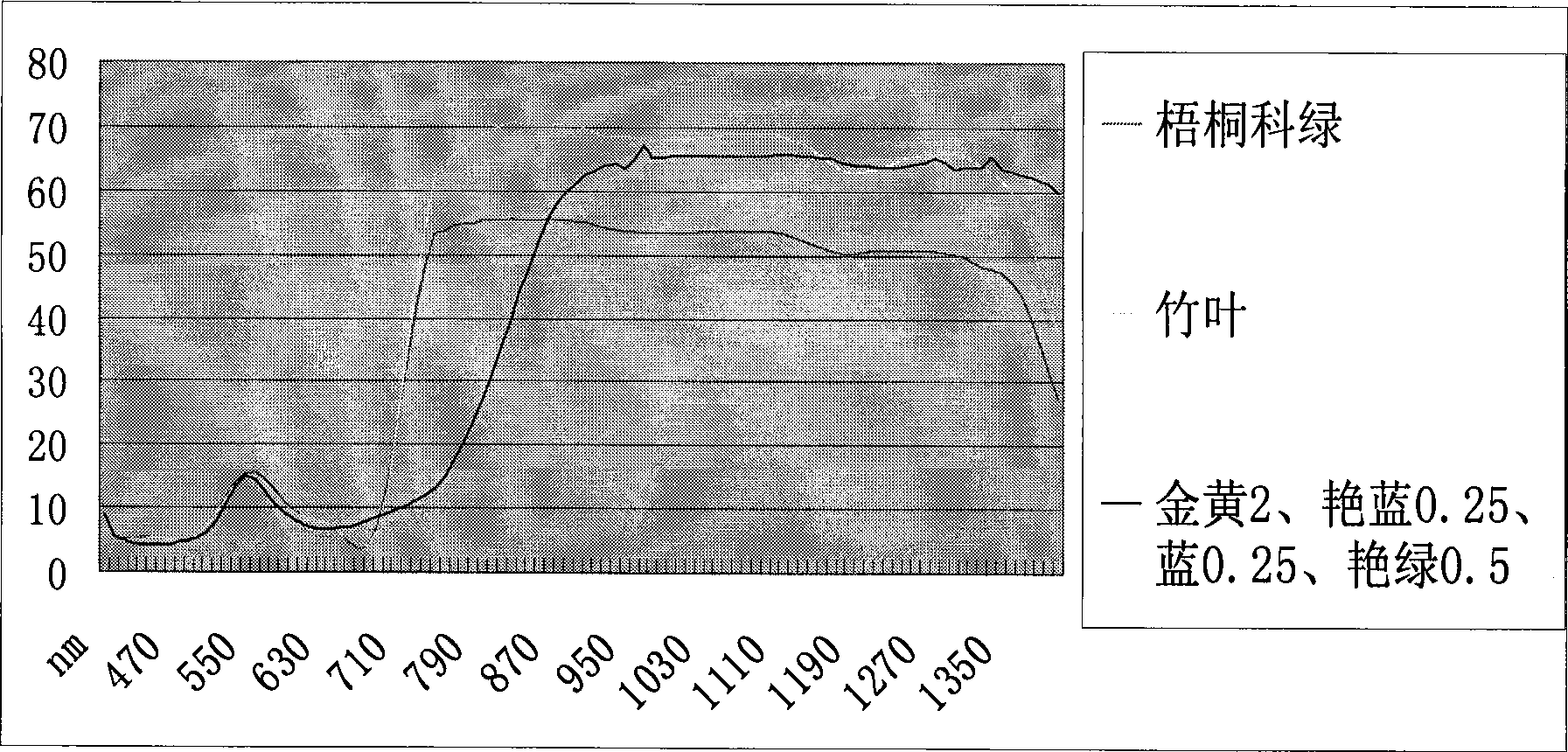

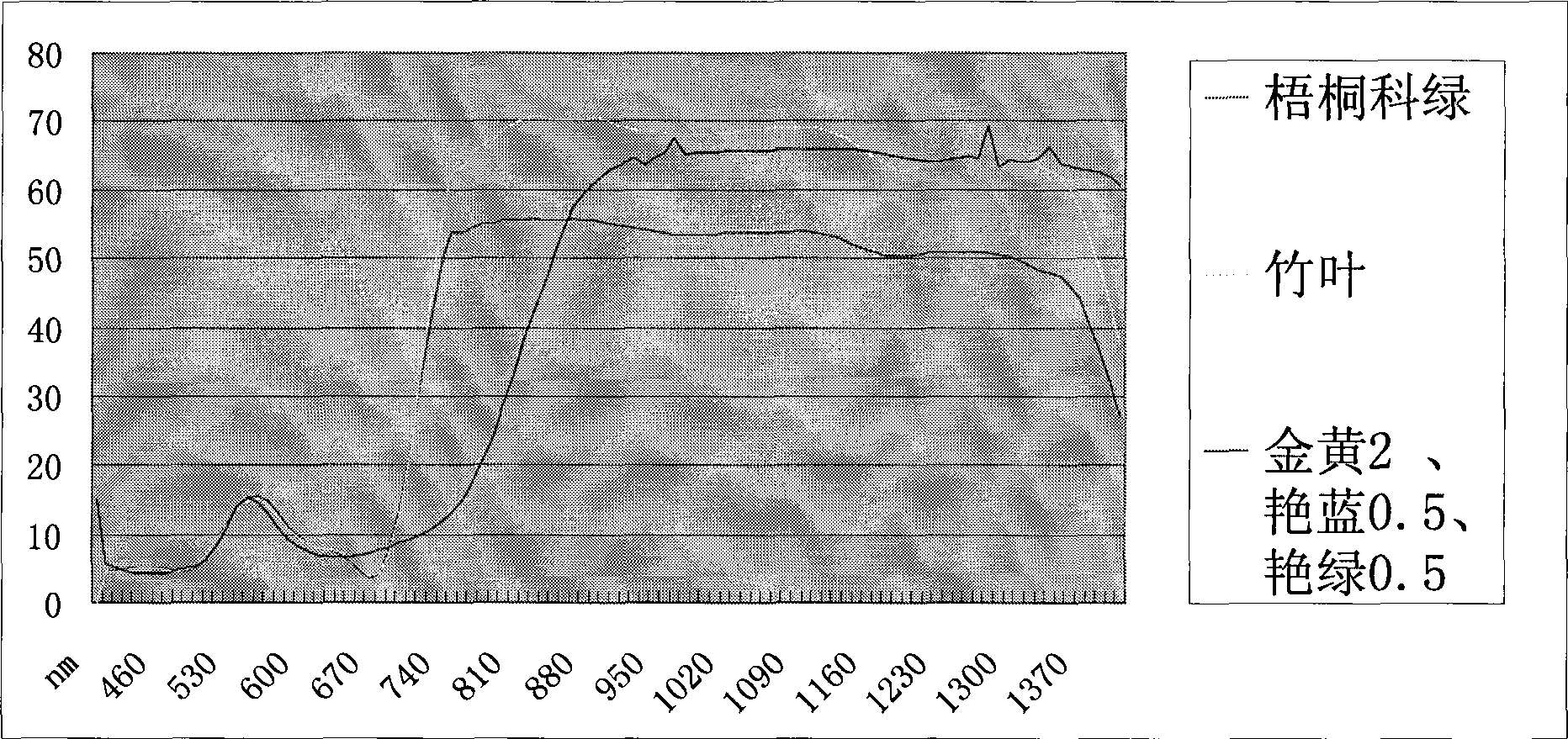

Method for preparing near-infrared concealed cotton textiles

The invention relates to a method for preparing a near infrared stealthy cotton textile, which comprises the following steps: a reducing dye is weighed and put into a clean conical beaker A; distilled water, NaOH and vat powder Na2S2O4 are added; then distilled water which accounts for one fourth of the total amount of a needed dyeing liquor is added for stirring evenly; another conical beaker B is taken out, and the distilled water which accounts for three fourths of the total amount of the needed dyeing liquor and NaOH are added; the two conical beakers are placed into a constant-temperature water bath, and the temperature is increased to 60 DEG C to ensure that the dye is reduced into a leuco dyeing liquor; then the vat powder Na2S2O4 is added into the conical beaker B to be dissolved; the mixture is added into the conical beaker A to stir evenly; after the configuration of a leuco dye bath is finished, mercerized bleached cotton cloth which is moistened in water is extruded to be dried and then is added into the dye bath with a temperature of 60 DEG C to be dyed for 30 minutes; after the dyeing is finished, the test sample is taken out, oxidized by air, washed by cold water, soap boiled and dried; and a waveband of between 400 and 1400nm is taken as a test waveband to perform the test of a reflectance curve to the sample. The near infrared stealthy cotton textile has the advantages of comfortable wearing, good air permeability, and good various color fastnesses.

Owner:DONGHUA UNIV

On-site construction method for anti-seepage air bag for bottom of river channel

The invention relates to an anti-seepage air bag for the bottom of a river channel, in particular to an on-site construction method for the anti-seepage air bag. According to the on-site construction method for the anti-seepage air bag, a breathable wall bag of an appropriate size and with an opening arranged at one end is selected according to the requirement of a river channel, rigid plates matched with the size of the breathable wall bag are selected and are fixed along the length direction and the width direction of the breathable wall bag to support the inside space of the breathable wall bag, the height of the rigid plates from the ground of the river channel is equal to the thickness of the breathable wall bag, anti-seepage particles are filled in the breathable wall bag to form the anti-seepage air bag, and the opening end is sealed. According to the on-site construction method for the anti-seepage air bag for the bottom of the river channel, the appropriate breathable wall bag can be selected according to the size and scale requirements of the reformed river channel, the anti-seepage breathable particles are filled on site through inflation to form the anti-seepage air bag, and the problem of long-distance transportation of sand bags in existing river bank transforming construction can be solved. In addition, the sand bags processed on site don't have high requirements on sealing of the breathable wall bag, and on-site construction is extremely convenient.

Owner:RENCHSAND ECO ENVIRONMENT PROTECTION SCI & TECH CO LTD

Alcohol-soluble highlight oil and production process of tipping paper for highlight cigarettes

ActiveCN106351072AGood air permeabilityGood color saturationSpecial paperPaper coatingColor saturationAluminium

The invention discloses alcohol-soluble highlight oil. The alcohol-soluble highlight oil comprises the following components in percentage by mass: 5%-10% of silicon dioxide, 5%-10% of microcrystalline wax, 30%-40% of acrylic resin and 40%-60% of alcohol. The invention further discloses a production process of tipping paper for highlight cigarettes. According to the production process, the home-made alcohol-soluble highlight oil is printed to raw tipping paper for cigarettes so as to obtain semi-finished tipping paper for the highlight cigarettes, and home-made colored ink is printed to the semi-finished tipping paper for the highlight cigarettes in a gravure manner, so that the produced finished tipping paper for the highlight cigarettes has the advantages that the crimping and the curling are avoided, the air permeability is good, the color saturation is high, and the appearance is exquisite and attractive; furthermore, the production cost and the warehouse cost are low, the production efficiency is high, and the turnover rate of products is high. Compared with tipping paper for aluminum-free coating-aiding highlight transfer cigarettes and production process of the tipping paper, the production process disclosed by the invention has the advantages that a PET film is not used, so that the production process is relatively simple, the energy conservation and environment protection effects are relatively good, and the production cost is lowered.

Owner:浙江荣丰纸业有限公司

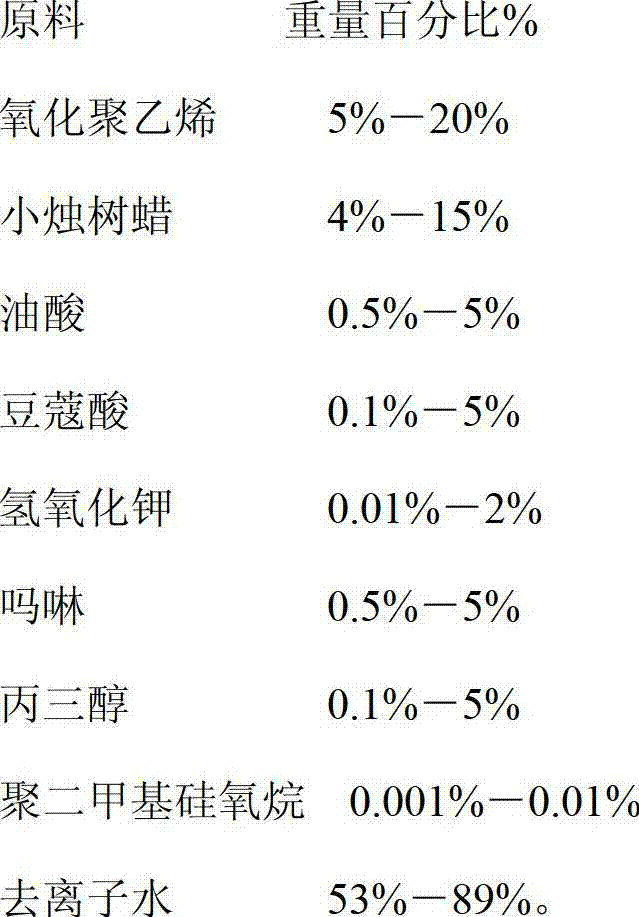

Formula, preparation method and application thereof of fruit freshness-retaining wax

ActiveCN103039600AGood air permeabilityLow leesFruits/vegetable preservation by coatingEmulsionChemistry

The invention discloses a formula, a preparation method and application thereof of fruit freshness-retaining wax. According to the invention, the fruit freshness-retaining wax compounding oxidized polyethylene, candelilla wax and the like is prepared by adopting a phase inversion emulsion method, aiming at the characteristics of high air permeability of the oxidized polyethylene and high water-retaining property of the candelilla wax, and selecting high-quality oleic acid, myristic acid, morpholine, glycerol, potassium hydroxide, polydimethylsiloxane and deionized water and selecting the proper emulsion temperature and time of emulsifying wax and the adding speed and speed of the deionized water to form O / W type emulsion. The fruit wax synthesized by the method has extremely excellent film-forming property, has luster, does not whiten, has high air permeability, and retains water and freshness. The excellent performance of the fruit wax completely exceeds that of the conventional imported fruit wax and is more excellent than that of other domestic fruit wax, and the requirements of food on environmental friendliness and safety and mechanized waxing are met.

Owner:HUAZHONG AGRI UNIV

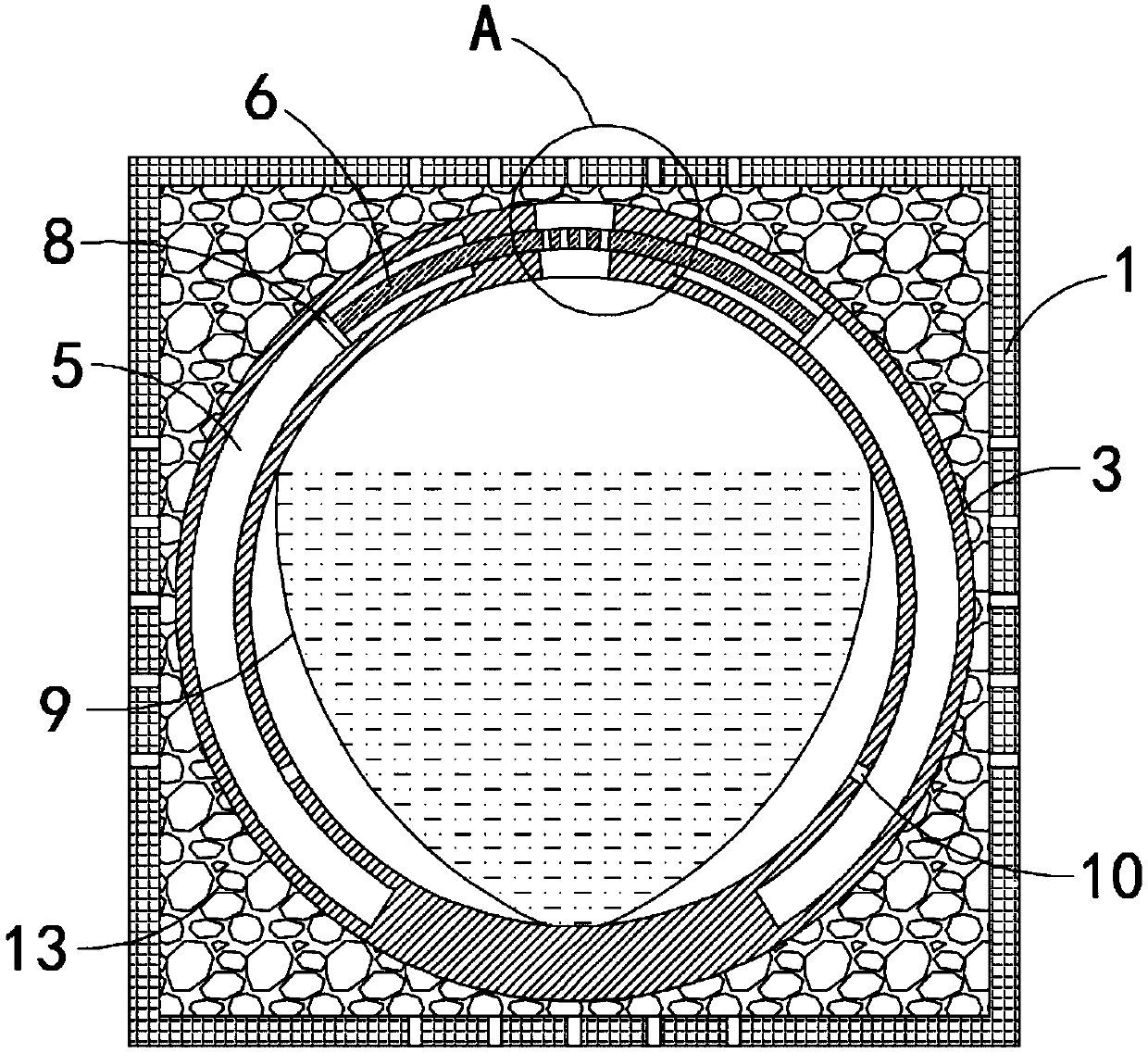

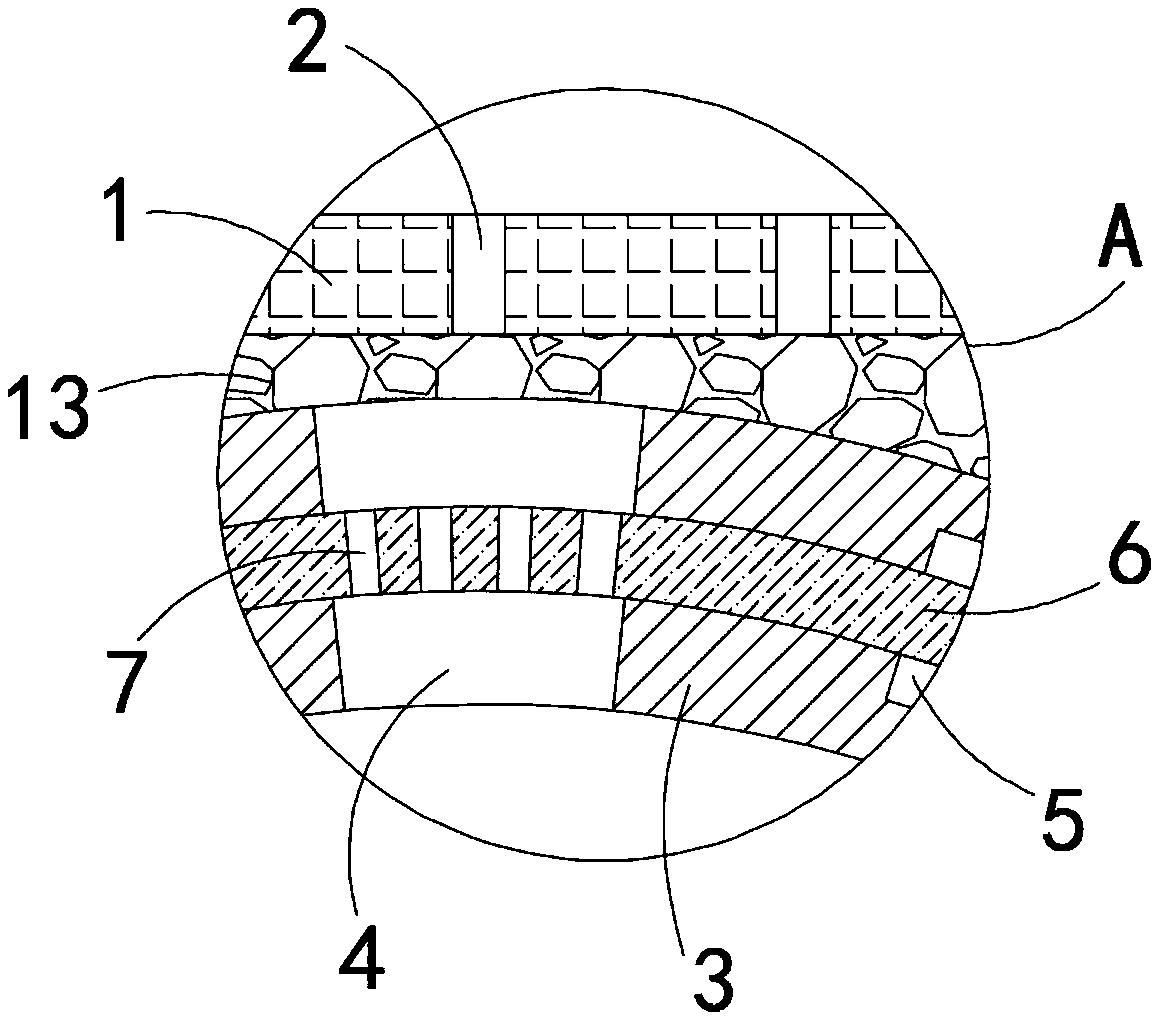

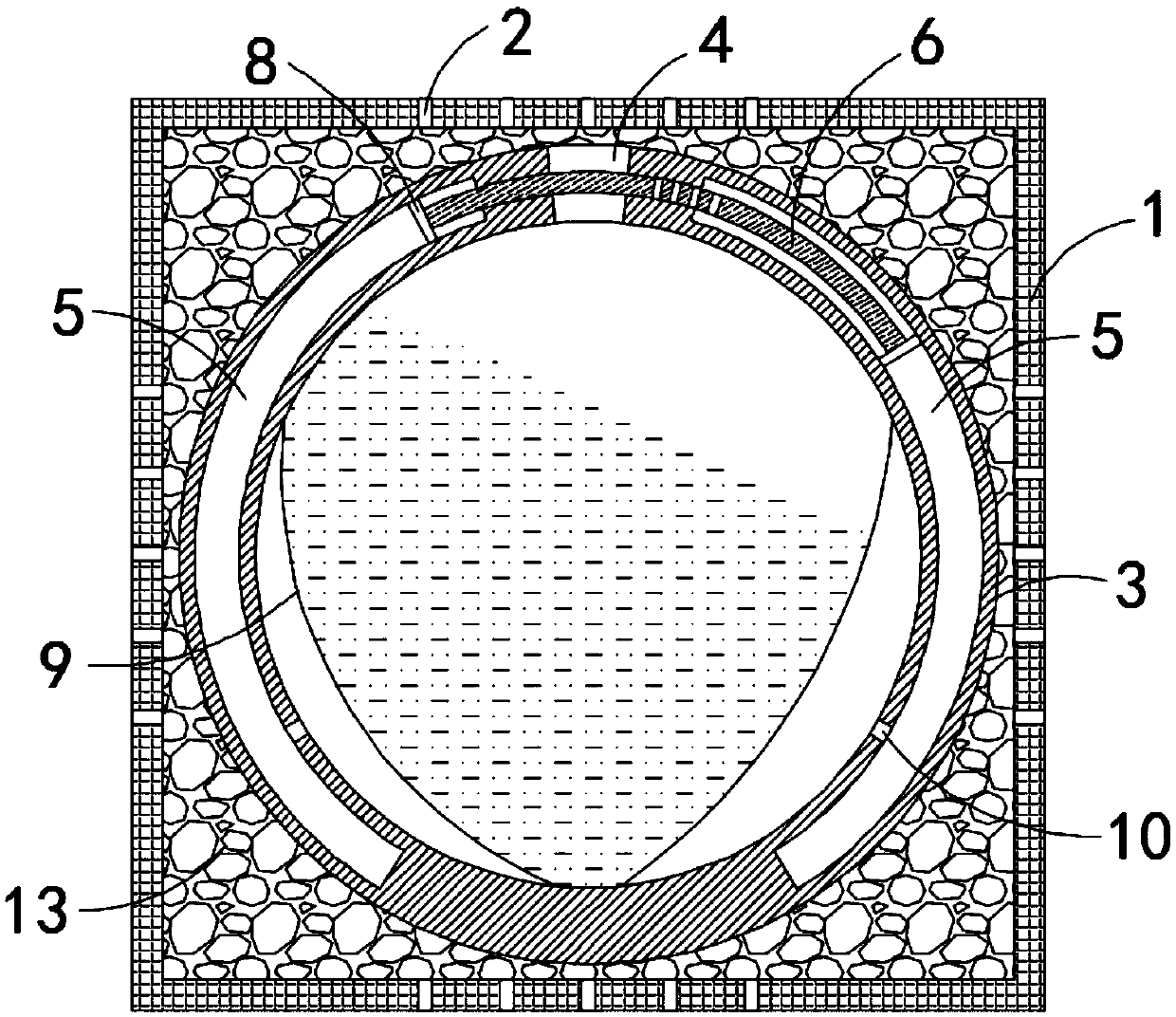

Fresh logistics transportation box

InactiveCN109533588AGood air permeabilityPrevent water leakagePisciculture and aquariaSealingEngineeringAir exchange

The invention belongs to the field of logistics transportation, and particularly relates to a fresh logistics transportation box. The fresh logistics transportation box comprises a box body, a plurality of air-permeable holes are formed in the side wall of the box body, a cylindrical shell is fixedly connected in the box body, and the gap between the cylindrical shell and the box body is filled with a buffer material; an air-permeable groove is formed in the upper side wall of the cylindrical shell, arc-shaped cavities are both formed in the portions, located on the two sides of the air-permeable groove, of the cylindrical shell, an arc-shaped plate is arranged in the air-permeable groove, and an air exchange hole corresponding to the air-permeable groove is formed in the middle of the arc-shaped plate; the two ends of the arc-shaped plate both extend into the two arc-shaped cavities, sealing blocks are fixedly connected to one ends, located in the arc-shaped cavities, of the arc-shaped plates, the sealing blocks are in sliding sealing connection with the arc-shaped cavities, elastic air bags are both fixedly connected to the left side wall and the right side wall of the cylindrical shell, and the elastic air bags communicate with the arc-shaped cavities through the air-permeable holes. According to the box, the air permeability is good, the leakage is not easy, and the survival rate of an aquatic product can be improved.

Owner:天地灵美(北京)农业科技有限公司

Composite cellulose viscose filament yarn with composite cellulose pulp as raw materials made of cotton, wood, hemp and bamboo mixture, and preparation method thereof

InactiveCN1865547AShinyGood air permeabilityConjugated cellulose/protein artificial filamentsSpinning solutions preparationManufacturing efficiencyNatural fiber

The invention discloses a composite fiber viscose filament and preparing method, which adopts the following random two or more combination as raw material: cotton velvet, hemp, wood, bamboo, straw and crust. The preparing method comprises the following steps: blending pulp; immersing; squeezing; grinding; etiolating; adhering glue to grind; dissolving; grinding; filtering; ripening; debubbling; spinning; refining; drying to make cylinder. The invention reduces cost to improve manufacturing efficiency with excellent paintability, elasticity, desiccating and air permeability, which is better than kinds of synthesizing fiber.

Owner:YIBIN GRACE

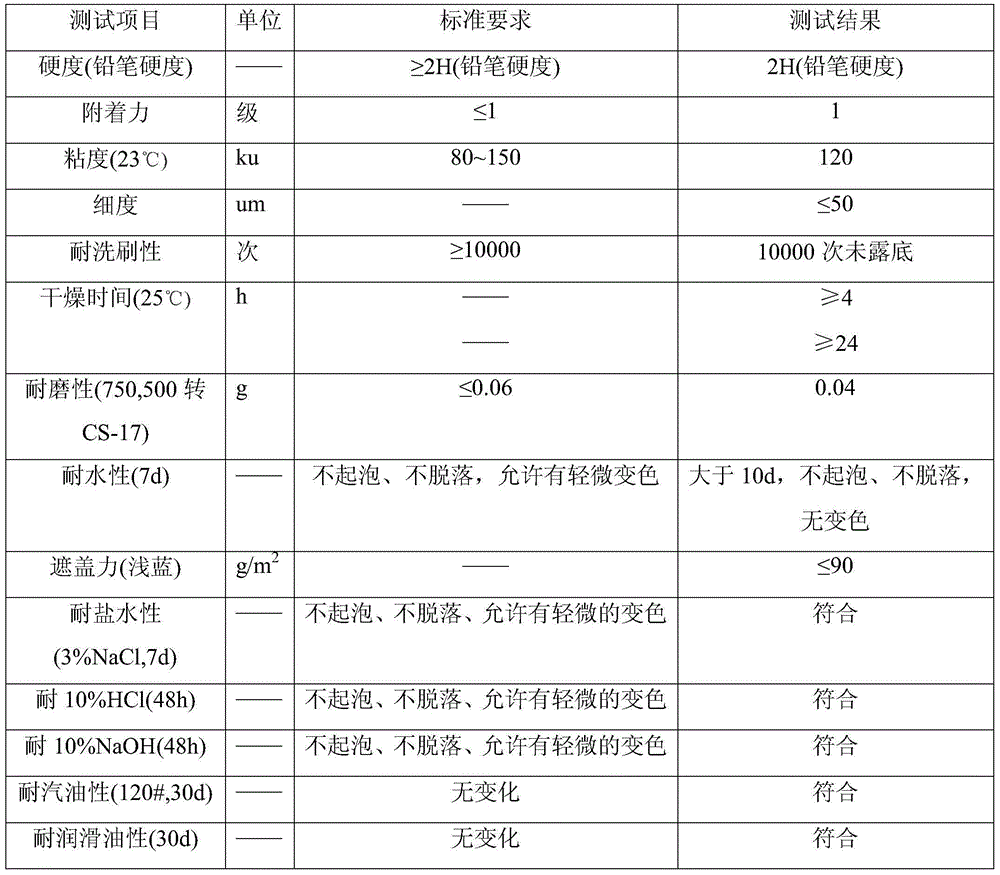

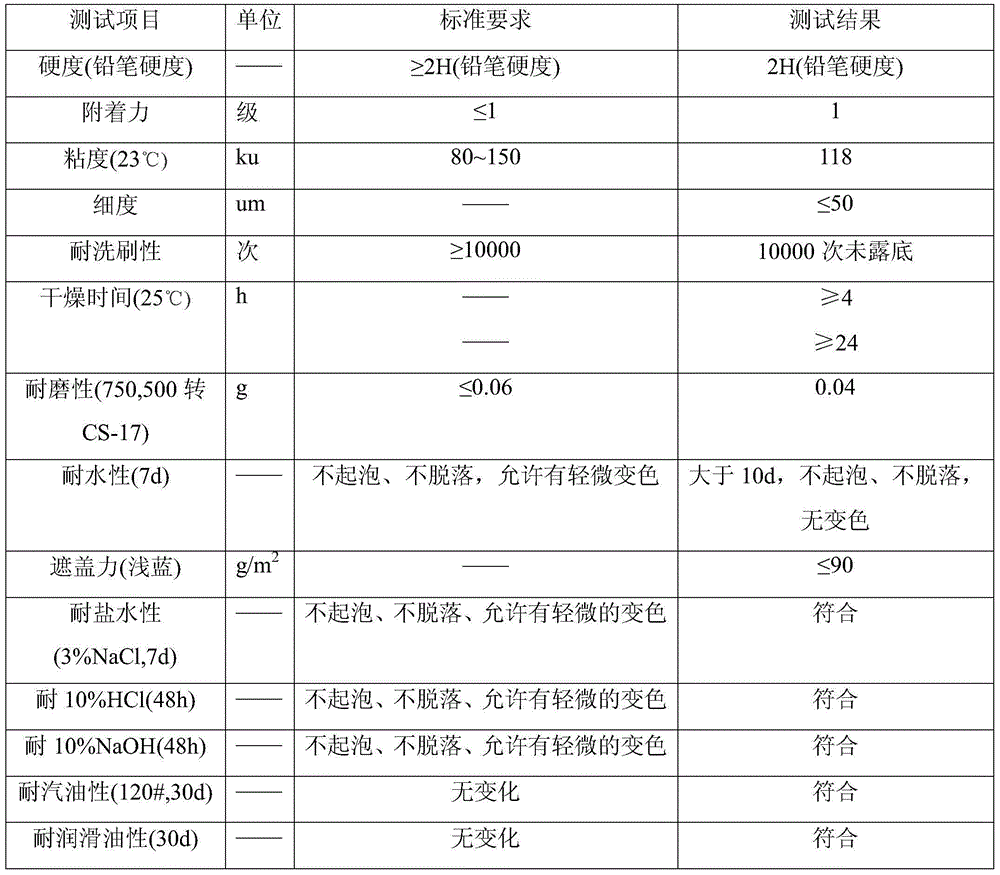

Pure waterborne epoxy floor paint as well as preparation method and use method thereof

InactiveCN104559665AGood air permeabilityNot easy to bubble and peel offAnti-corrosive paintsEpoxy resin coatingsWaxEmulsion

The invention discloses pure waterborne epoxy floor paint which comprises the following components in percentage by weight: 26.7-30.7 percent of purified water, 29.3-31.3 percent of a main agent and 38-42 percent of a curing agent, wherein the main agent comprises 1.95-2.00 percent of a dispersant, 0.60-0.70 percent of a wetting agent, 1.60-1.70 percent of a defoamer, 3.25-3.35 percent of wax powder, 49.00-50.00 percent of rutile titanium dioxide, 9.85-9.95 percent of glass powder, and 32.00-33.50 percent of quartz powder; the curing agent is a waterborne epoxy curing agent. A preparation method of the pure waterborne epoxy floor paint comprises the following steps: preparing slurry; mixing the slurry and the waterborne epoxy curing agent; adding 0.5-1.5 percent of color paste. The use method of the pure waterborne epoxy floor paint comprises the step: when the pure water-based epoxy floor paint is used, first, uniformly stirring 65% of the pure water-based epoxy floor paint not subjected to color mixing or subjected to color mixing and 35% of a waterborne epoxy resin emulsion. The pure waterborne epoxy floor paint is high in air permeability, not likely to bubble, soft in gloss, high in fullness and hardness, favorable in environment-friendly performance and chemical resistance, and long in service life.

Owner:SHENZHEN HAOXUE NEW MATERIAL TECH

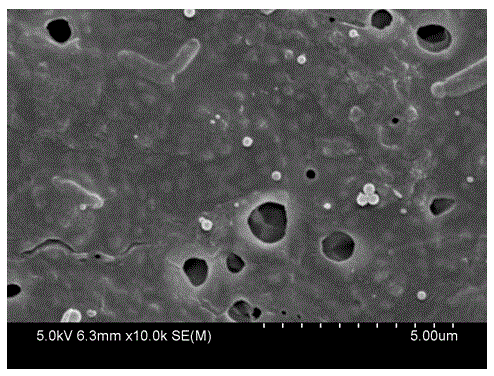

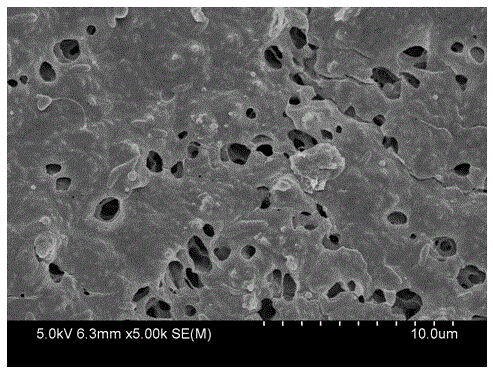

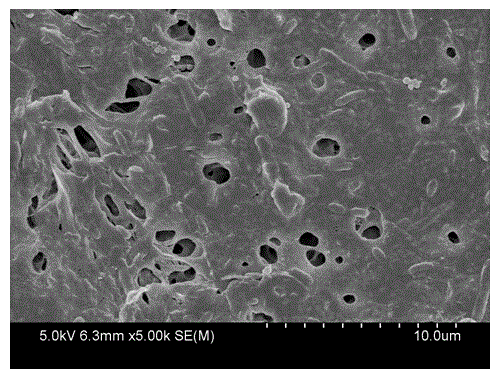

Preparing method of super-hydrophobic polyvinylidene fluoride membrane and its application in gas-liquid membrane contactors

InactiveCN104888624AGood air permeabilityImprove wetting resistanceSemi-permeable membranesDispersed particle separationPolyvinylidene fluorideComposite material

The invention relates to the technical field of membrane preparation, in particular to a preparing method of a super-hydrophobic polyvinylidene fluoride membrane and its application in gas-liquid membrane contactors. Based on self-cleaning bionics, the polyvinylidene fluoride membrane surface of a micro-nano double-rough structure is prepared by a weak solidifier cured phase-inversion method; a substance of low surface energy is introduced to the rough polyvinylidene fluoride membrane surface by a coating process so as to modify the low surface energy and obtain a super-hydrophobic polyvinylidene fluoride flat membrane good in breathability; the surface water contact angle of such membrane is up to 151.24 degrees. The preparing method has the advantages that moisture resistance of the membrane contactors can be evidently improved, mass transfer resistance of the membrane contactors is lowered, the service life of each membrane contactor is prolonged, and the service performance of each gas-liquid membrane contactor is improved; the preparing method is simple, low in cost and easy to operate and allows feasibility for the preparation of large-area super-hydrophobic membrane surfaces.

Owner:TANGSHAN COLLEGE +1

Antibacterial underwear fabric

InactiveCN102771903AGood air permeabilityGood skin affinityWoven fabricsYarnAnti bacterialPolymer chemistry

The invention discloses an antibacterial underwear fabric comprising warp yarn and weft yarn, wherein the warp yarn is formed by blending bamboo fiber, natural mulberry silk and polyester filament yarn in a certain proportion, the weft yarn is made of pearl fiber. Because the weft yarn is made of flexible and health-care natural mulberry silk and green and antibacterial bamboo fiber, the fabric has the new functions of natural antibacterial performance, bacterium inhibition, mite removal, deodorization, ultraviolet ray resistance and the like when having the properties of flexibility, comfortableness, good air permeability and the like; meanwhile, because the weft yarn is made of the pearl fiber, the fabric has the characteristics of beautifying and protecting skin, clearing fever and vanquishing toxin, whitening the skin and the like; and as a high-grade underwear fabric, the underwear fabric has good skin affinity and obvious antibacterial and health-care performances.

Owner:CHANGSHU JIANHUA WEAVING

Organic fertilizer for flowers and production process of organic fertilizer

InactiveCN103641629AGood air permeabilityStrong water storage capacityFertilizer mixturesEnvironmental chemistryPeanut hull

The invention relates to an organic fertilizer for flowers and a production process of the organic fertilizer. The production process comprises the following steps: selecting corn straws, wheat straws, soybean straws and sesame straws according to a mass ratio of 2:2:1:1 and crushing straw grains; adding water, urea and ammonia water, and pre-treating to obtain a mixture A; treating respectively chicken manure and chicken feathers taken according to the mass ratio of 10:1 by ultraviolet lights and then treating by ozone; mixing to obtain a mixture B; adding aspergillus niger and saccharomycetes into a mixture of crushed peanut shells, crushed fallen leaves of broad-leaved trees and the water to obtain a mixture C; mixing the mixture A, the mixture B, the mixture C, shell powder and sodium humate; adding an EM bacterium agent and fermenting to obtain a mixture D; adding bone meal, plant ash and charcoal dust into the mixture D; then carrying out ozone sterilization, drying, split charging; and ultraviolet light sterilizing to obtain the organic fertilizer for the flowers. The produced organic fertilizer for the flowers contains various nutritional ingredients needed by the growth of the flowers and can be used for conditioning soil, activating the active rate of microorganisms in the soil, overcoming soil hardening and improving the air permeability of the soil.

Owner:RUZHOU JIULONG ANIMAL HUSBANDRY

Ganoderma lucidum powder production method

ActiveCN101449803AImprove survival rateGood air permeabilityFungiFood preparationWater contentGanoderma pseudoferreum

The invention provides a production method for Ganoderma Lucidum powder, which includes steps of: selecting corn and wheat with high quality according to weight ratio of 1 to 1-1.5, respectively rinsing, extruding to granule with diameter of 2-3 mm, mixing, adding water until water content reach 40%, filling in polypropylene plastic bag, sterilizing for 60-90 minutes at 0.15MPa, grafting liquid Ganoderma Lucidum strain after sterilization, culturing in shade for 15-20 days at 25-28 DEG C, digging out cultured fermentation product, drying at 70-80 DEG C, crushing, and sieving with screen of 80-200 meshes to obtain the Ganoderma Lucidum powder. The invention uses crushed raw grain as culture medium to graft liquid strain, which has fast strain growth speed, high fungus bag survival rate and good permeability, and is benificial to mycelium growth. The invention totally uses solid fermentation Ganoderma Lucidum mycelium and whole metabolite, the obtained product has rich nutrition and good taste, the Ganoderma Lucidum powder has wide raw material source and low price, and can be popular nutrition foodstuff.

Owner:山西瑞芝生物科技有限公司

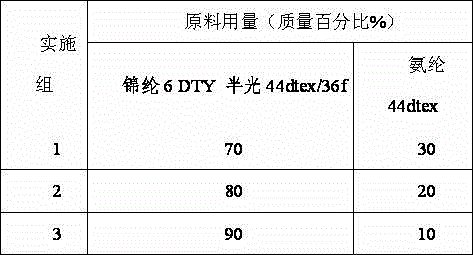

Artificial cotton texture athletic undergarment fabric and preparation method thereof

InactiveCN104404710AImprove poor wear resistanceGood air permeabilityWarp knittingWarping machinesAfter treatmentEngineering

The invention discloses an artificial cotton texture athletic undergarment fabric and a preparation method thereof. The fabric is woven by the following fiber raw materials, by mass percent, 70 to 90% of chinlon 6DTY semi-gloss 44dtex / 36f and 10 to 30% of spandex 44dtex. The preparation method of the fabric comprises steps of warping, weaving and after treatment, wherein the after treatment comprises steps of washing, presetting, dying and finished product forming. The artificial cotton texture athletic undergarment fabric improves the defects that cotton fabric is poor in wear resistance, large in shrinkage rate, poor in dying bright colors and the like by velvet flat weave matching of the chinlon 6DTY semi-gloss 44dtex / 36f and the spandex 44dtex, achieves best cotton hand feeling. has comfort and flexible characteristics of the cotton fabric, is good in breathability, excellent in recovery performance and noble and elegant.

Owner:广东汇星新材料科技股份有限公司

Hexagonal boron nitride type mold shell investment precoat for precision casting of magnesium alloy investment

ActiveCN104399874AGood suspension and thixotropyGood air permeabilityFoundry mouldsFoundry coresIonEmulsion

The invention discloses a hexagonal boron nitride mold shell investment precoat for precision casting of a magnesium alloy investment. The mold shell investment precoat takes silica sol as a binder and a hexagonal boron nitride powder body as a refractory raw material and comprises the following components in parts by weight: 100 parts of silica sol, 5-10 parts of deionized water, 0.100-0.15 part of bactericide, 400-600 parts of hexagonal boron nitride micropowder, 20-30 parts of polyvinyl acetate emulsion, 0.100-0.150 part of wetting dispersant and 0.050-0.100 part of defoamer. The mold shell investment prepared from the hexagonal boron nitride mold shell investment precoat disclosed by the invention has the characteristics that the reaction activity between the mold shell investment and a magnesium alloy is low; besides, hexagonal boron nitride is not infiltrated by a magnesium alloy melt, so a magnesium alloy casting is benefited; particularly, the mold filling of the magnesium alloy casting with the large-area thin-wall structural characteristics is benefited; in addition, other various performance indexes respectively meet the requirement of the magnesium alloy investment on precision casting.

Owner:SHANGHAI JIAO TONG UNIV

Biological fermentation primary liquid mask and preparation method and storing method thereof

InactiveCN104922050AGood air permeabilityGood flexibilityCosmetic preparationsToilet preparationsAir atmosphereDry skin

The invention provides a biological fermentation primary liquid mask and a preparation method and a storing method thereof and belongs to the field of cosmetics. The biological fermentation primary liquid mask is free of a carrier, is attached to the face and free of washing. The biological fermentation primary liquid mask is formed in the mode that blueberries, ginseng, roses, chamomile, soybean and tremella are decocted and fermented. The preparation method comprises the following steps that raw materials are screened, weighed and cleaned in sequence and then mixed, water is added, decocting is conducted, cooling and filtering are conducted, a product is poured into a mould containing original fungi, and then fermentation is conducted for 5-7 days at the temperature of 30-32 DEG C with the humidity being 40%-45% in an air atmosphere; in this way, the biological fermentation primary liquid mask is obtained, wherein the pH value is about 6.8. The storing method of the biological fermentation primary liquid mask comprises the steps that the mask is stored in storage liquid, sealed in vacuum and then stored in a shady, cool and dry place, wherein the storing liquid comprises lemon hydrosol, tea tree hydrosol, lavender hydrosol and mycose. The biological fermentation primary liquid mask achieves the purposes of whitening skin, removing beverage, redness, acne and wrinkles, shrinking pores, eliminating fat granules, improving dark and dry skin, removing dead skin and the like at a time.

Owner:哈尔滨瑞康源生物科技有限公司 +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com