Patents

Literature

200 results about "Choked flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Choked flow is a compressible flow effect. The parameter that becomes "choked" or "limited" is the fluid velocity. Choked flow is a fluid dynamic condition associated with the Venturi effect. When a flowing fluid at a given pressure and temperature passes through a constriction (such as the throat of a convergent-divergent nozzle or a valve in a pipe) into a lower pressure environment the fluid velocity increases. At initially subsonic upstream conditions, the conservation of mass principle requires the fluid velocity to increase as it flows through the smaller cross-sectional area of the constriction. At the same time, the Venturi effect causes the static pressure, and therefore the density, to decrease at the constriction. Choked flow is a limiting condition where the mass flow will not increase with a further decrease in the downstream pressure environment for a fixed upstream pressure and temperature.

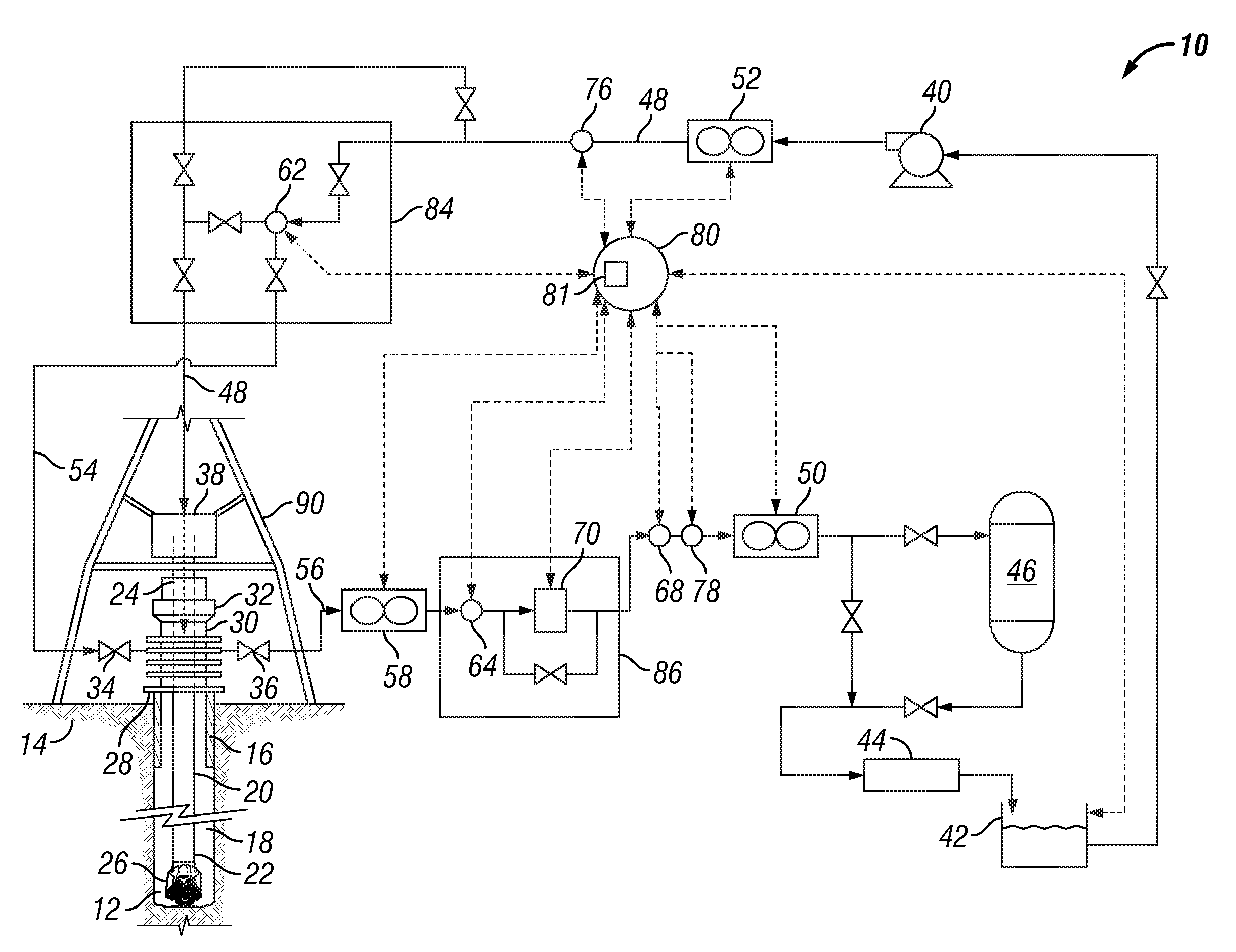

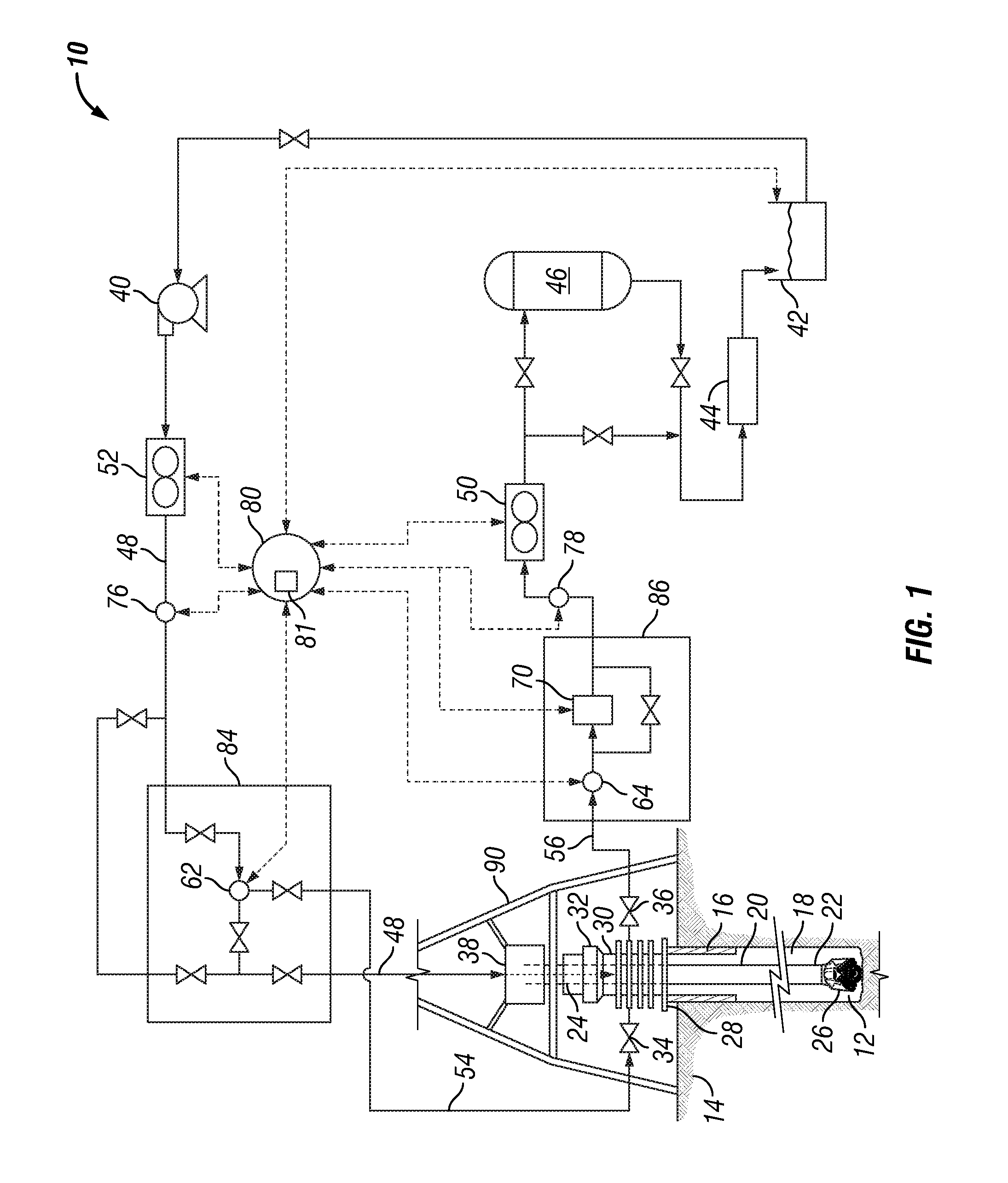

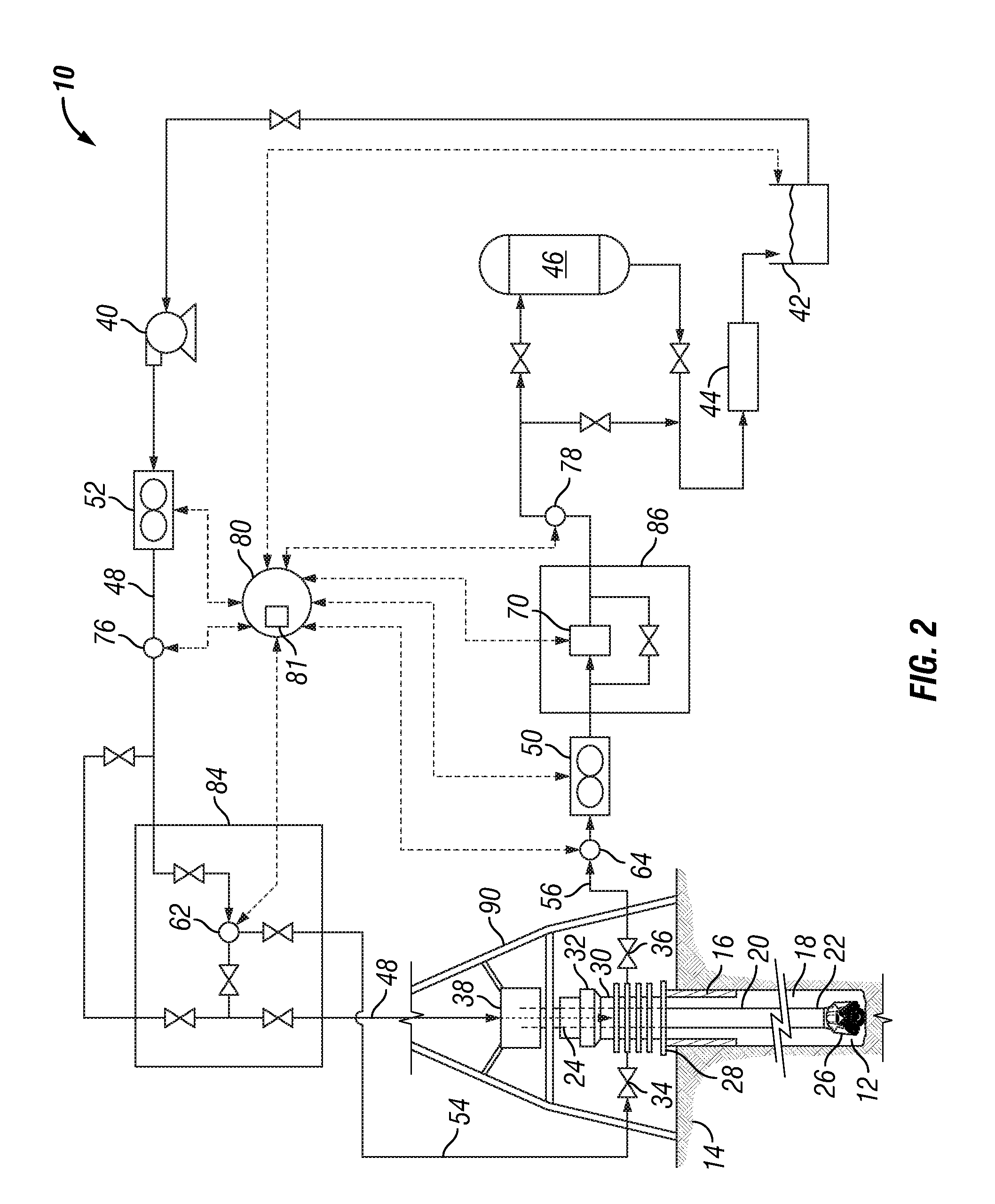

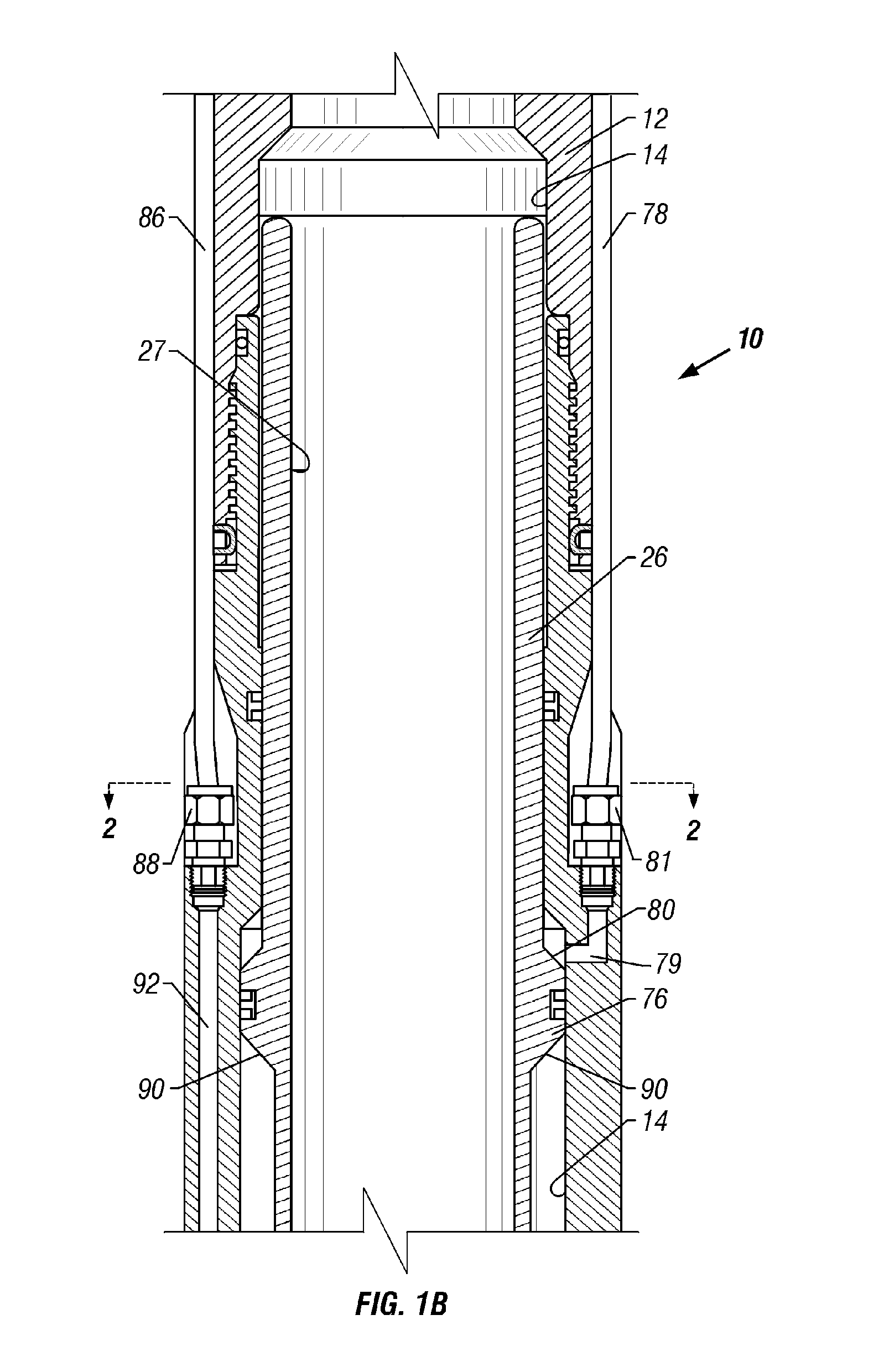

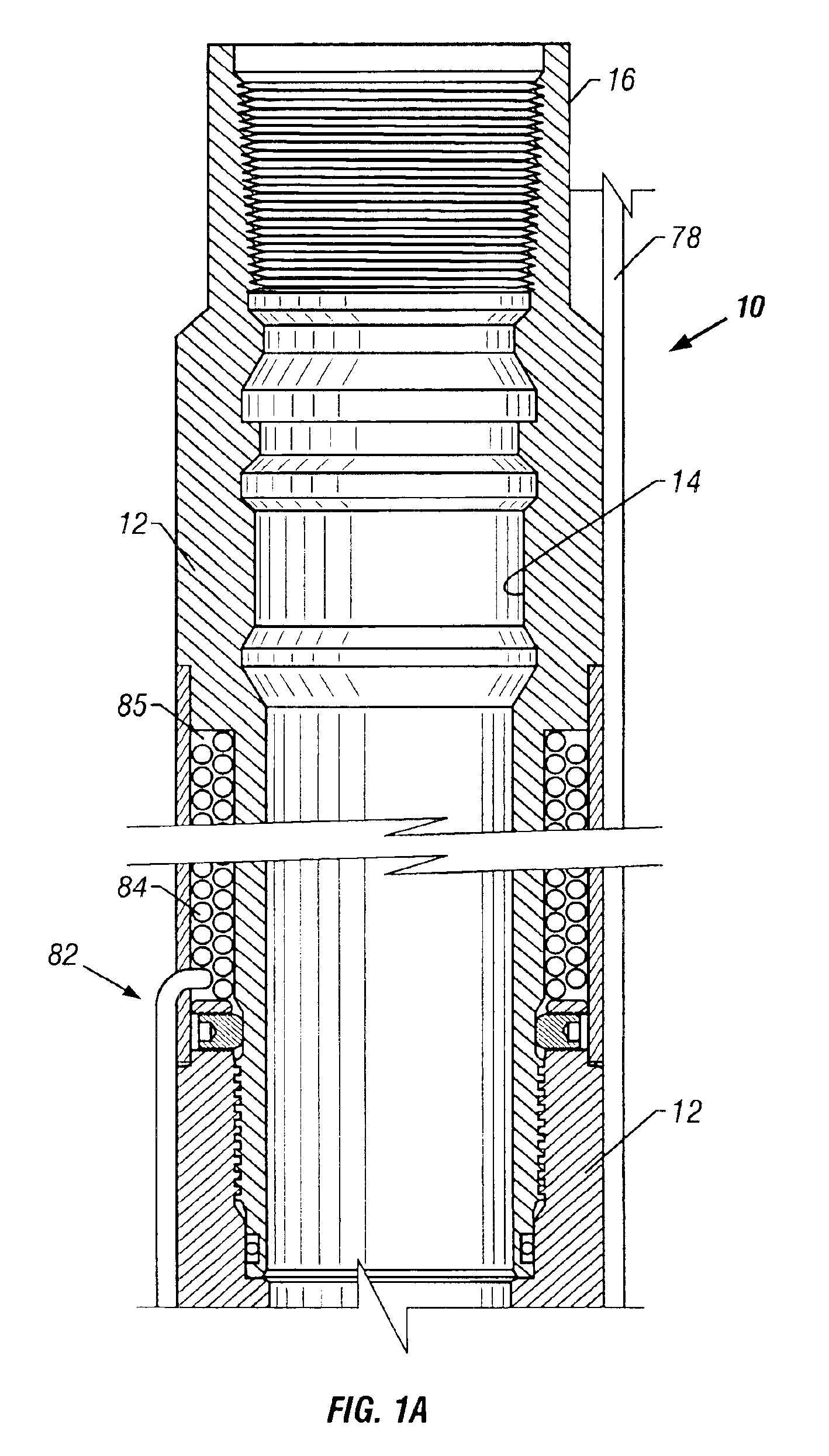

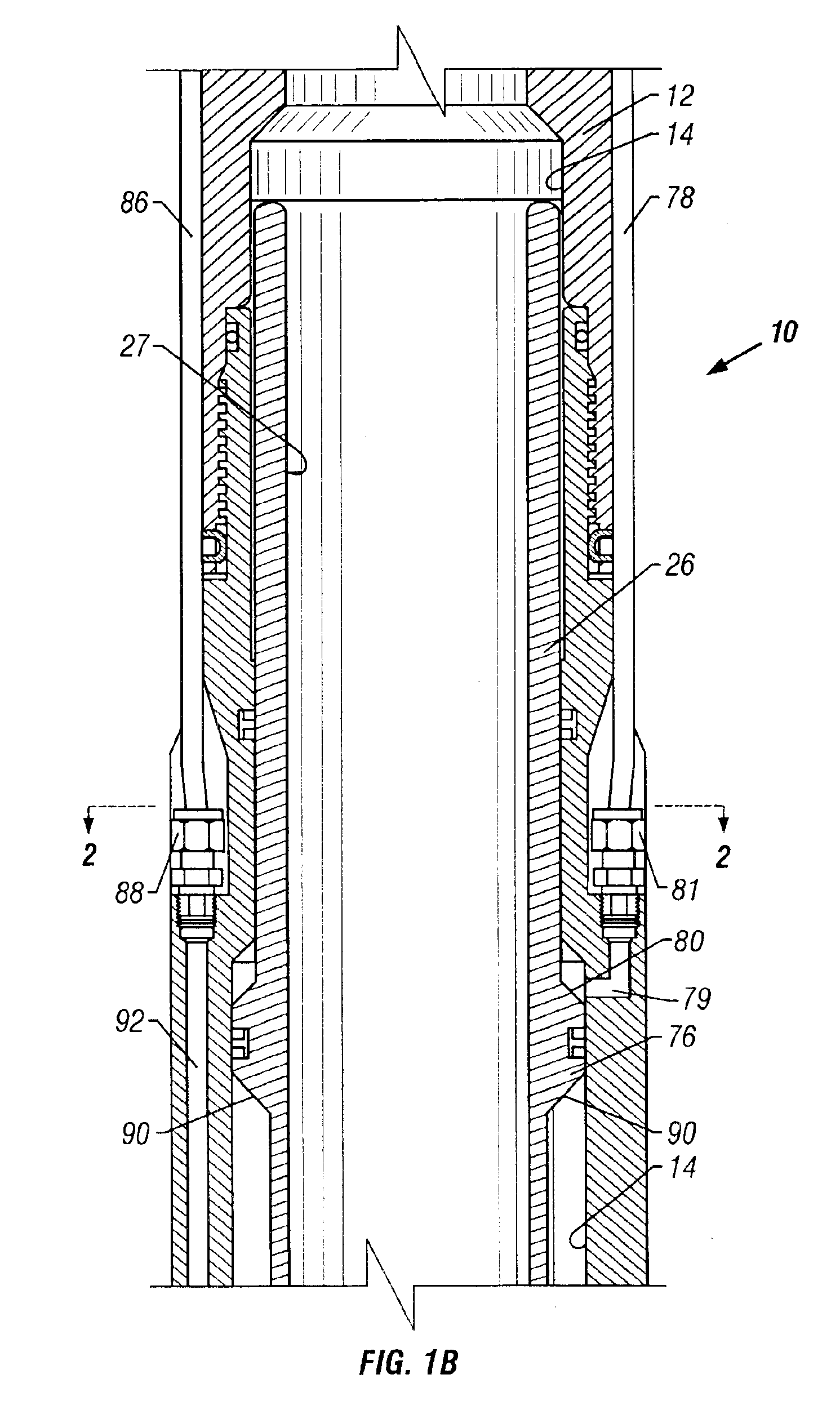

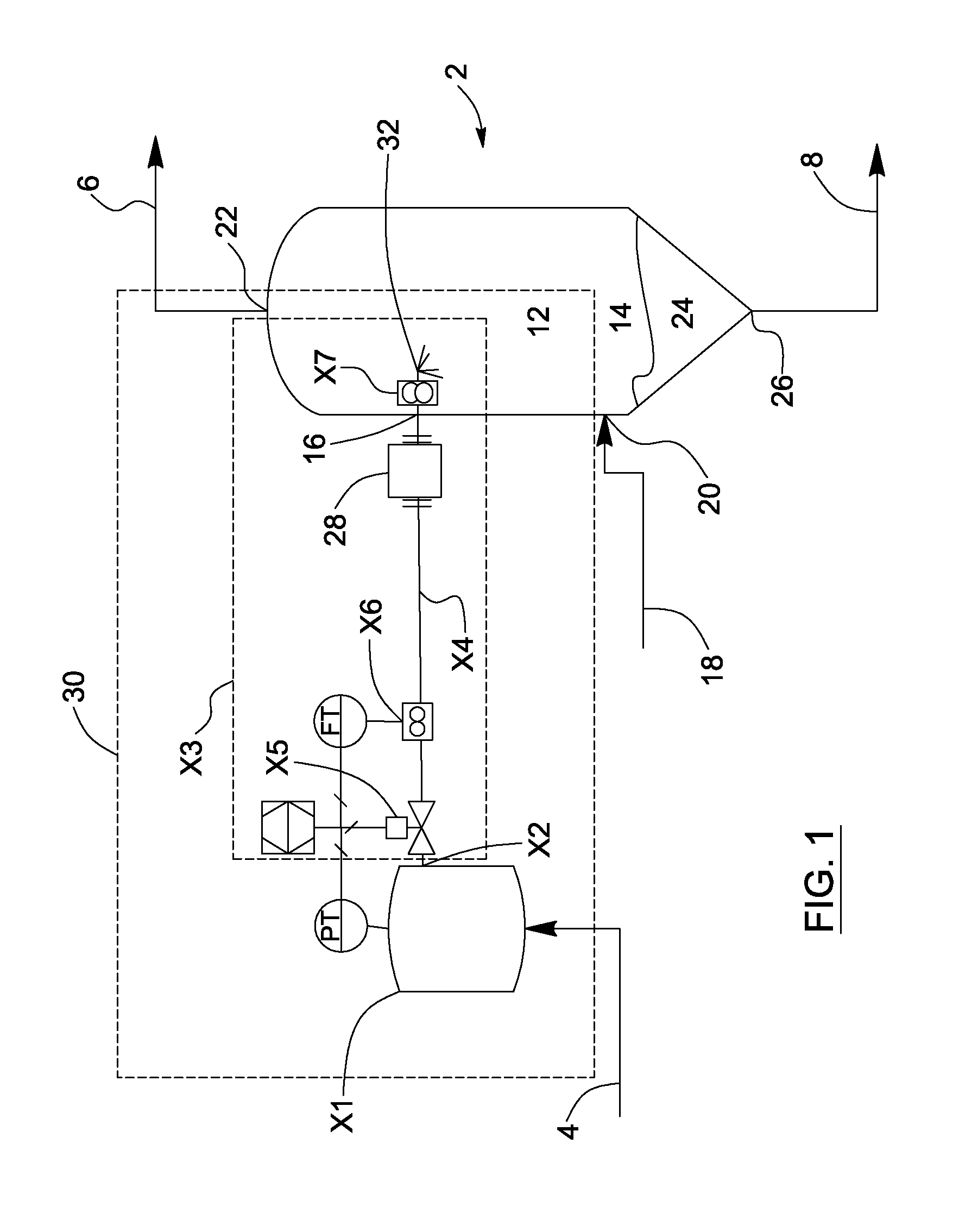

System and method for safe well control operations

ActiveUS20110214882A1Facilitate well control operationFacilitates hands-on trainingDrilling rodsFluid removalLine tubingWell drilling

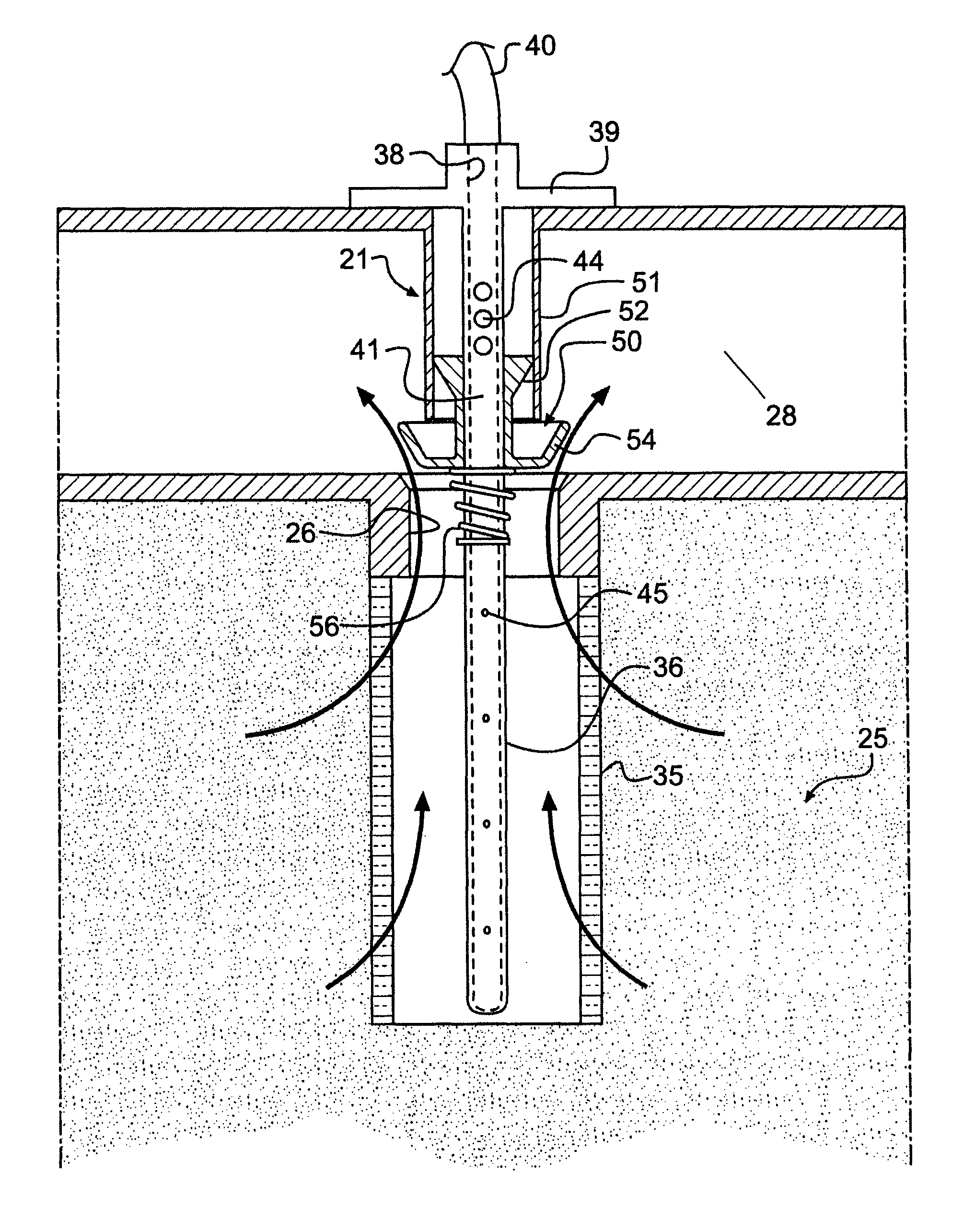

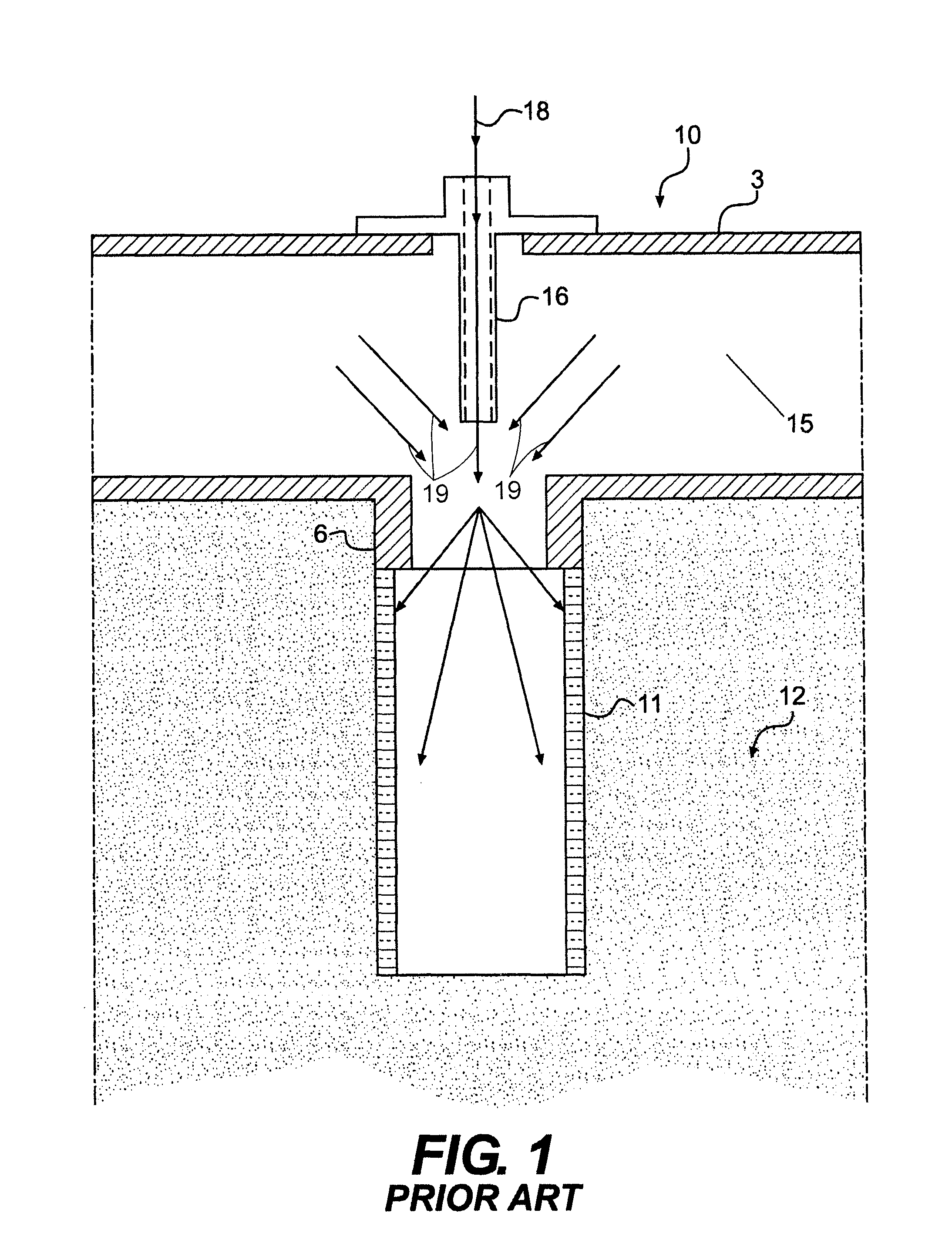

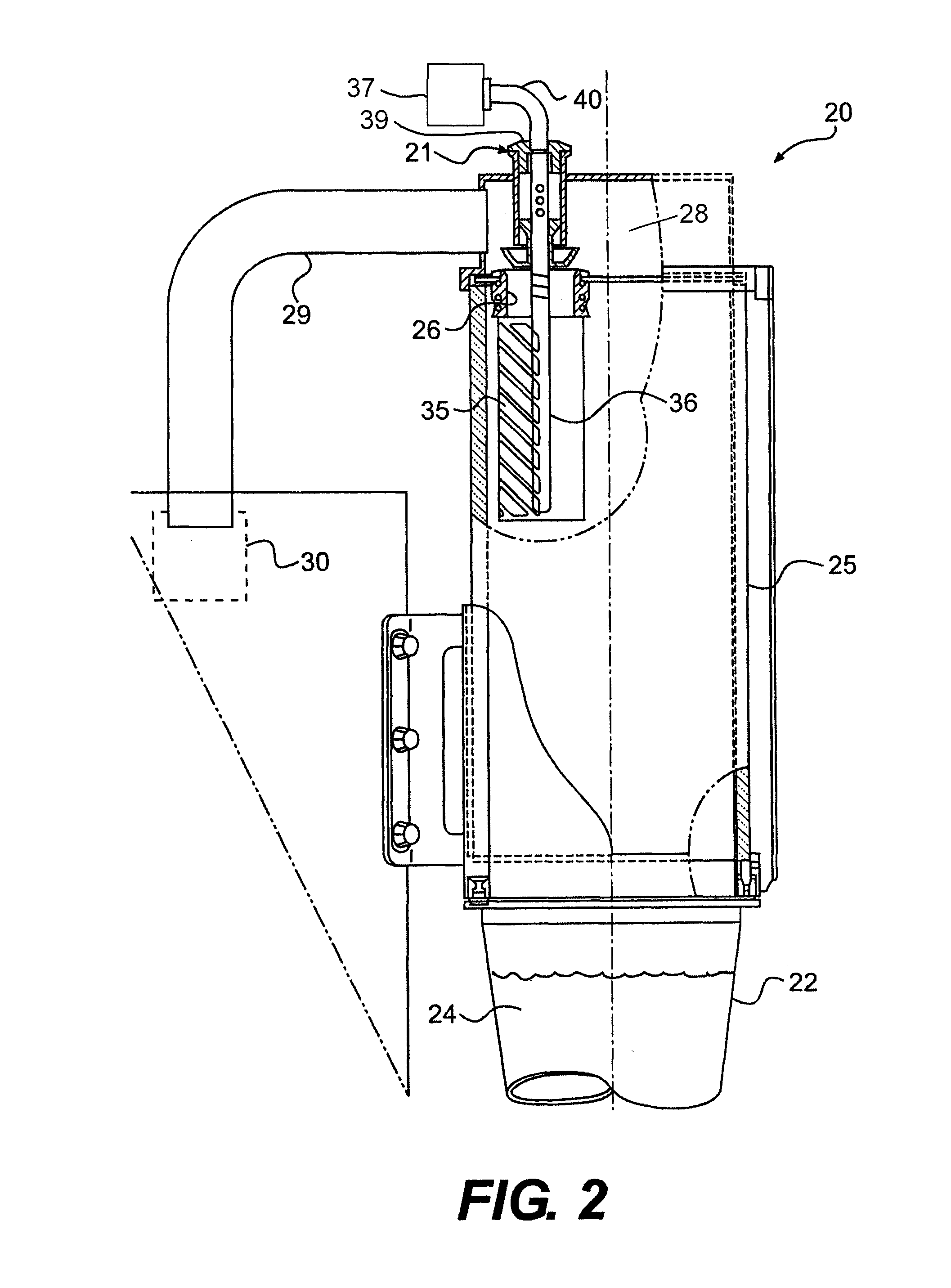

A system and method for safely controlling a well being drilled or that has been drilled into a subterranean formation in which a conventional blow-out preventer operates to close the well bore to atmosphere upon the detection of a fluid influx event. Fluid pressures as well as fluid flow rates into and out of the well bore are measured and monitored to more accurately and confidently determine the fracture pressure and pore pressure of the formation and perform well control operations in response to a fluid influx event. During a suspected fluid influx event, one or more of the fluid flow and pressure measurements are used to confirm the fluid influx event and to safely regain well control by circulating the fluid influx out of the well through a choke line while maintaining the pressure inside the well between specified, selected limits, such as between the fracture and pore pressures.

Owner:SAFEKICK AMERICAS LLC

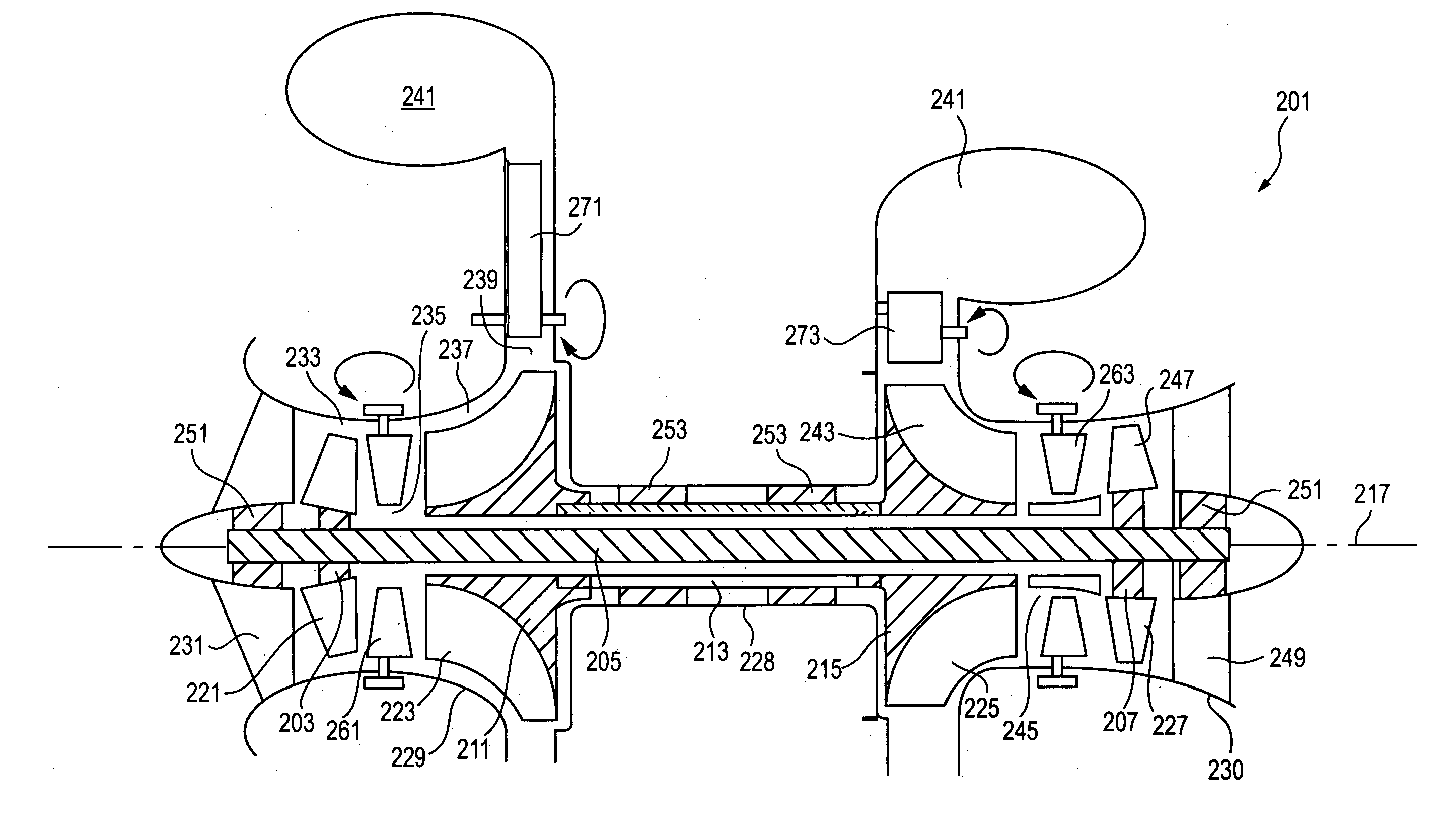

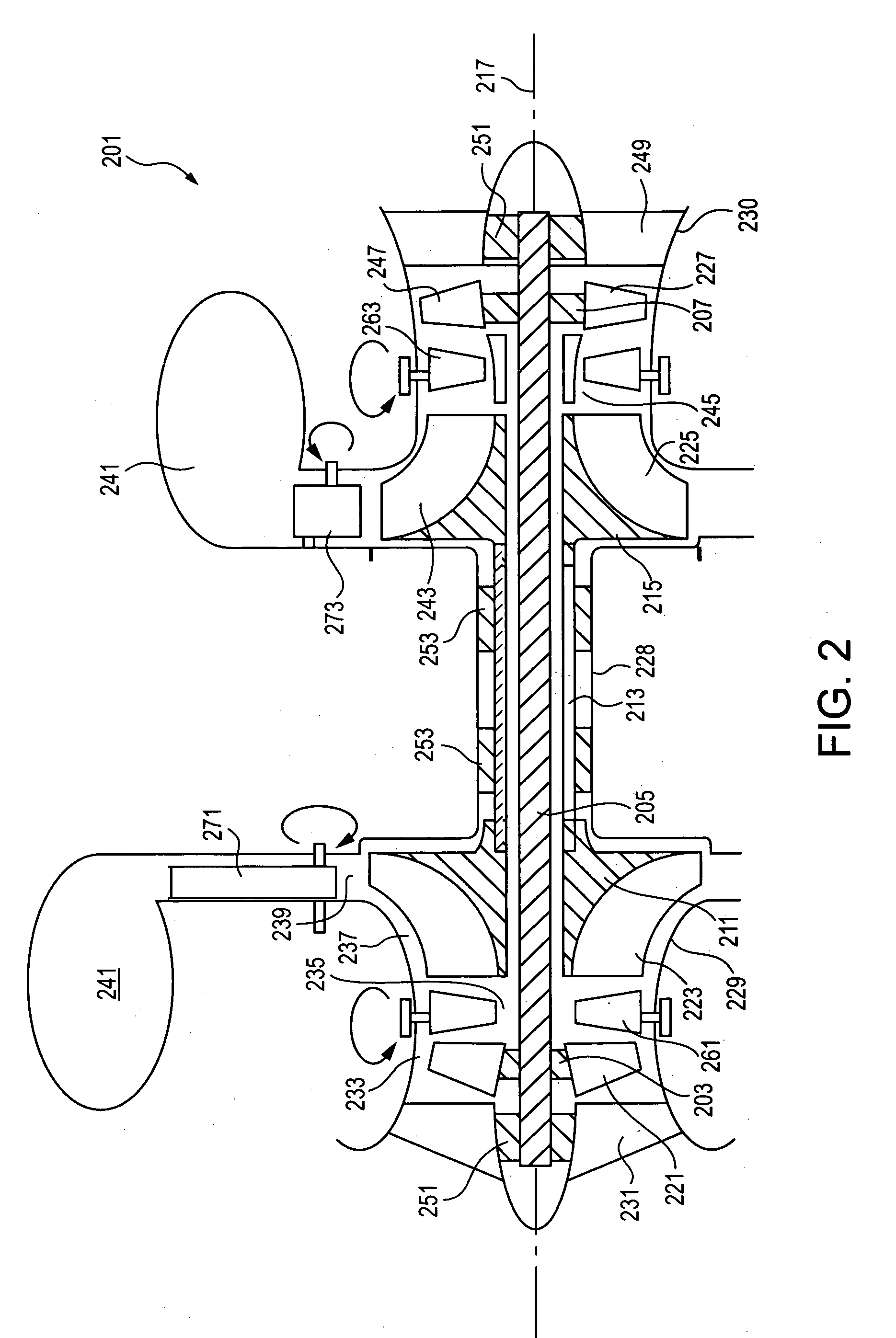

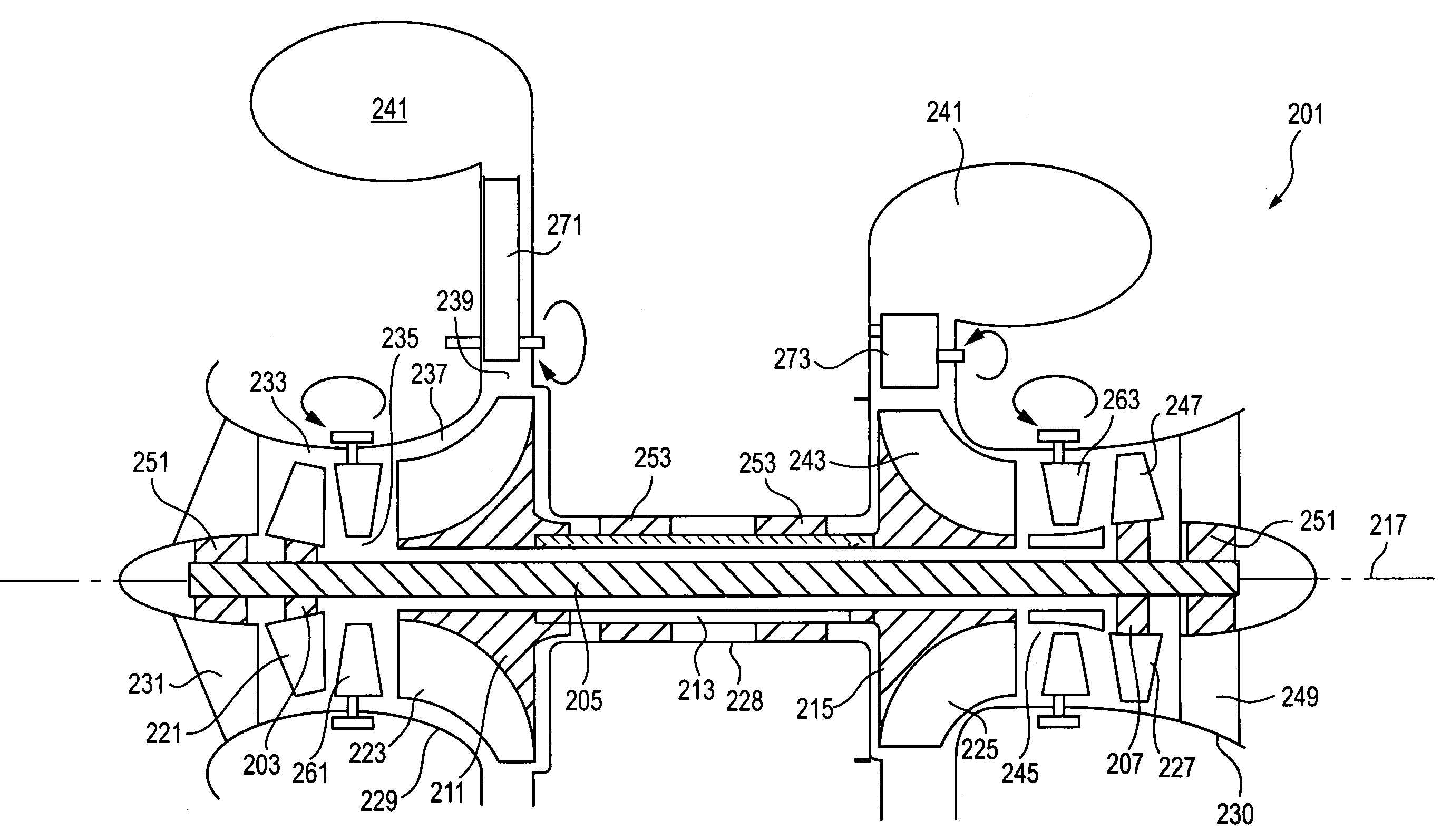

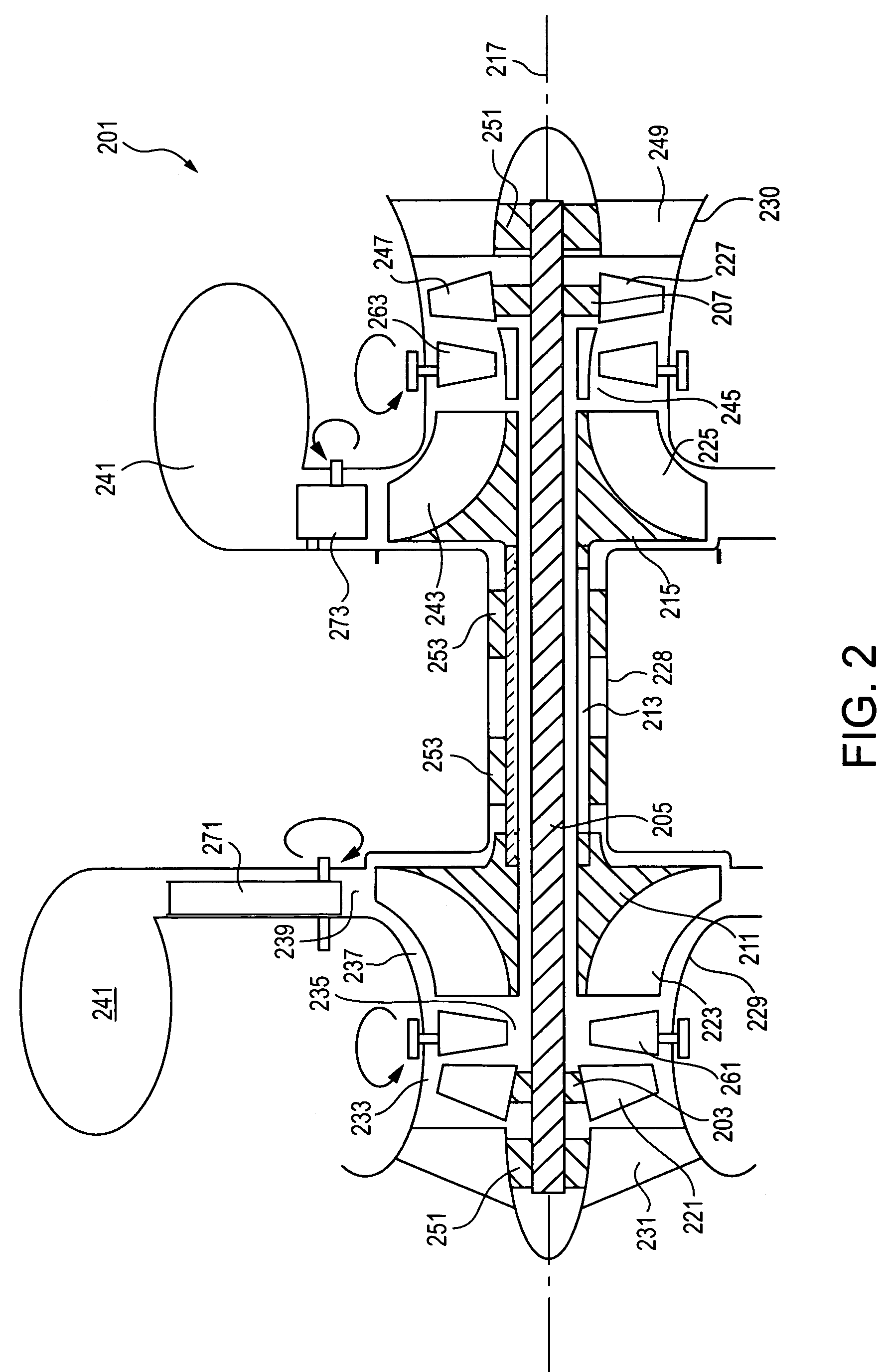

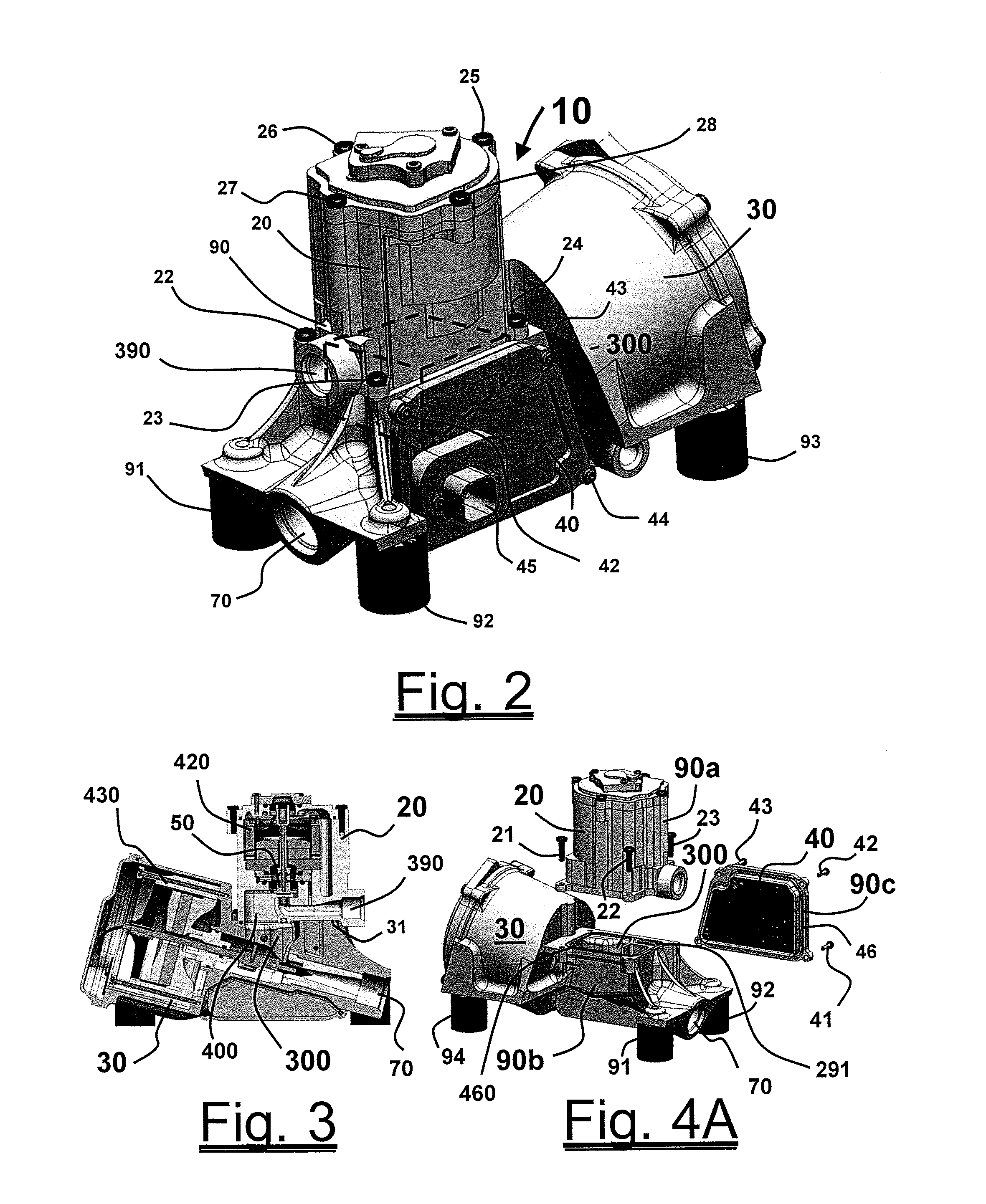

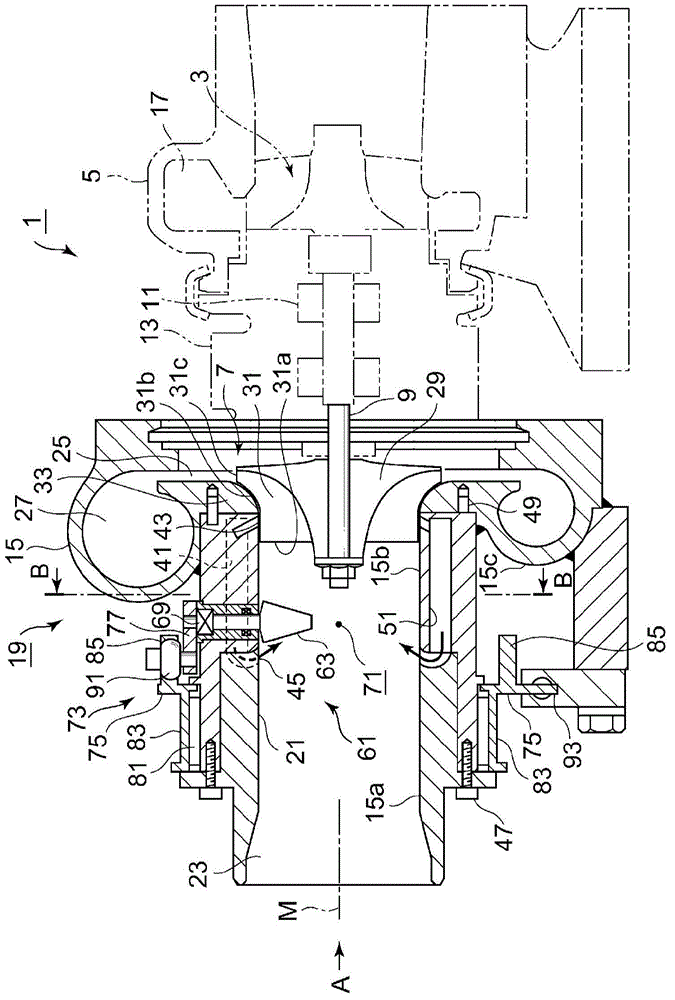

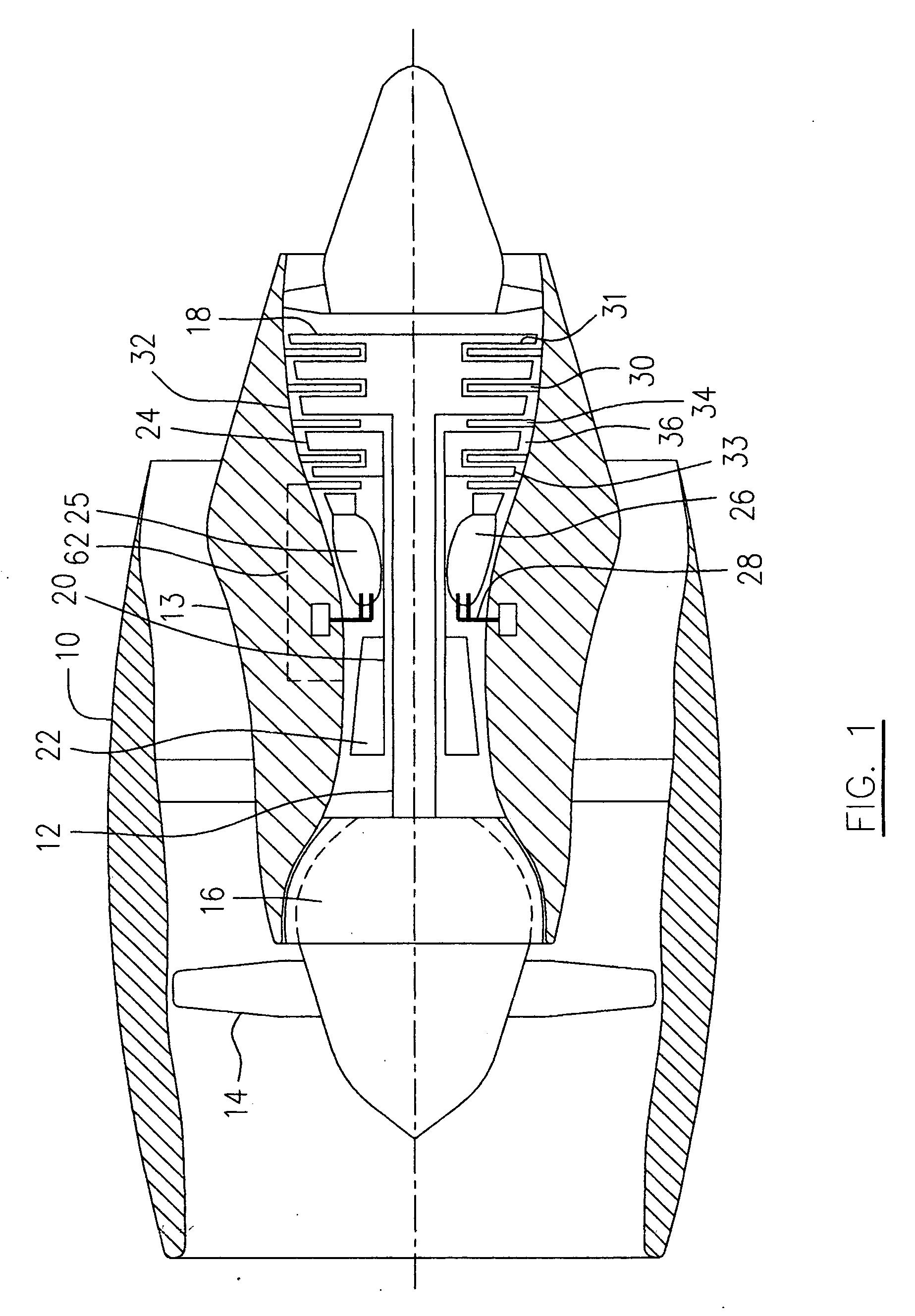

Two-shaft turbocharger

InactiveUS20070204615A1Improve transient response timeReduce morbidityInternal combustion piston enginesCombination enginesAxial compressorTurbine blade

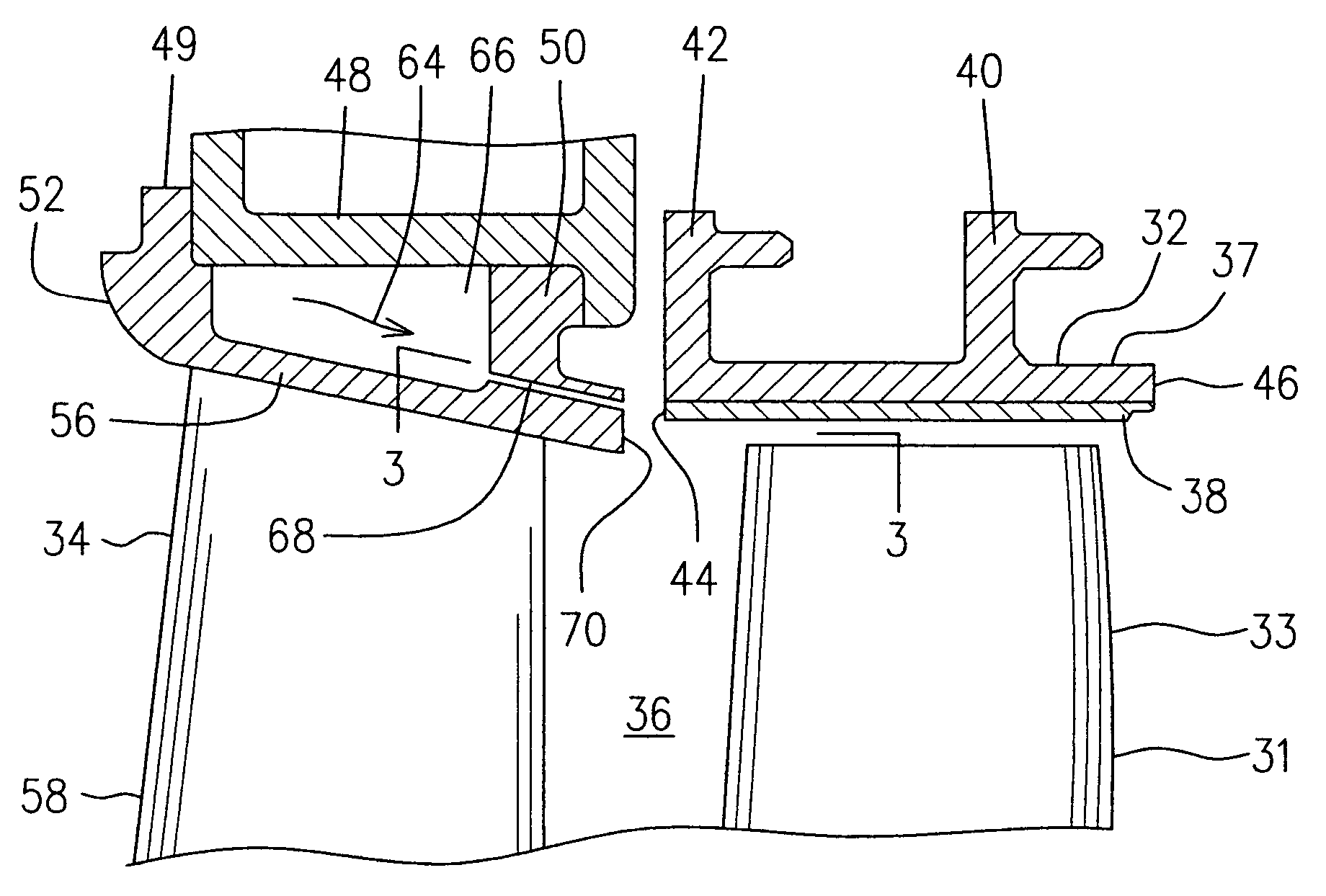

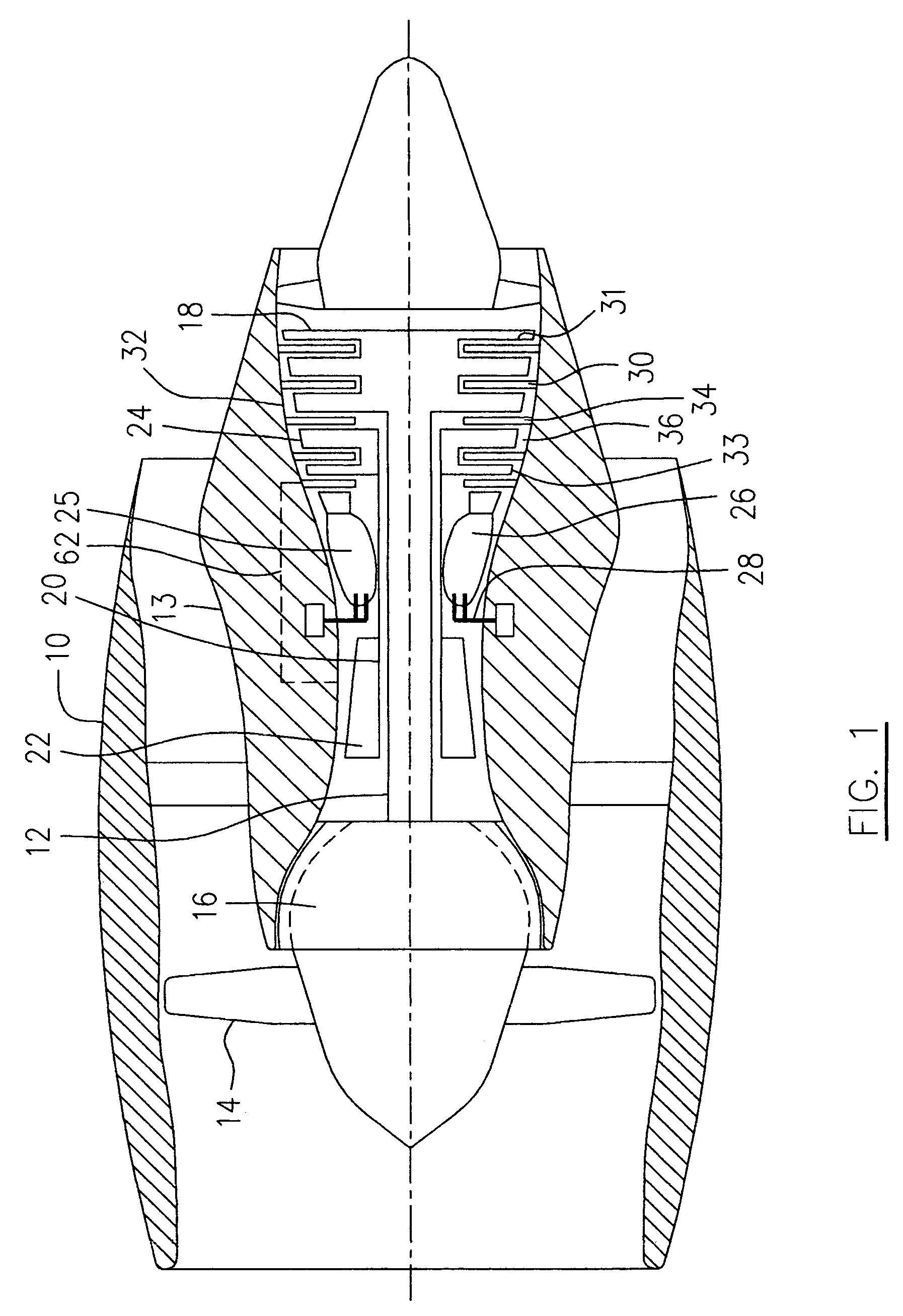

A turbocharger, having an axial compressor wheel and an axial turbine wheel mounted on a first shaft supported by a housing, and a radial compressor wheel and a radial turbine wheel mounted on a second shaft, the second shaft concentrically extending around the first shaft and being supported by the housing. The housing defines a first duct extending axially from the exducer of the axial compressor to the inducer of the radial compressor, and a second duct extending axially from the exducer of the radial turbine to the inducer of the axial turbine. A plurality of controllable compressor guide vanes extend through the first duct, and a plurality of controllable turbine stator vanes extend through the second duct. The housing is provided with variable diffuser vanes at the exducer of the radial compressor, and with variable turbine vanes at the inducer of the radial turbine. The variable turbine vanes and the turbine stator vanes are controlled to accurately control the rotation rate of the radial and axial turbines. The compressor guide vanes are controlled to minimize surge and maximize choke flow rate.

Owner:HONEYWELL INT INC

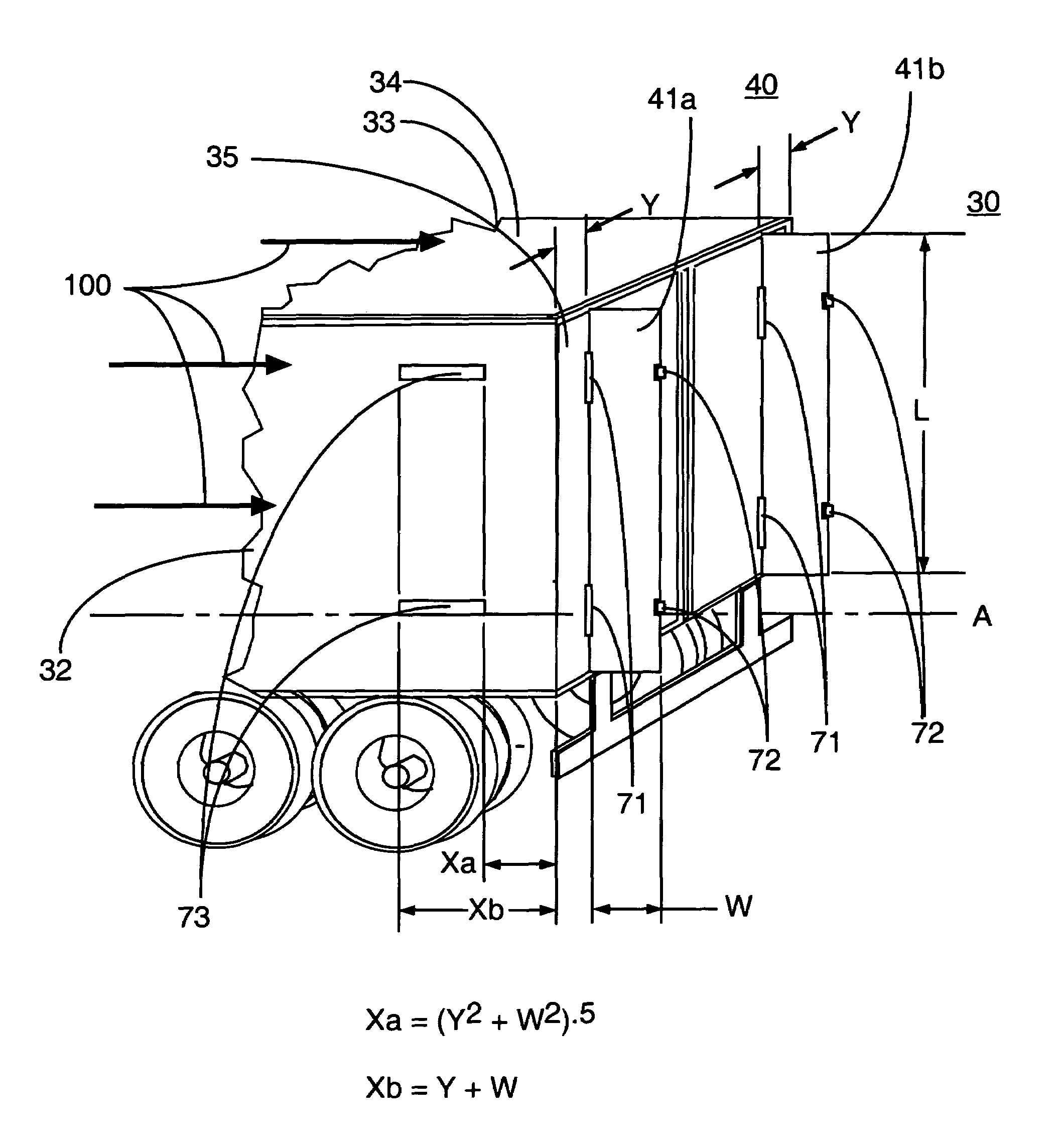

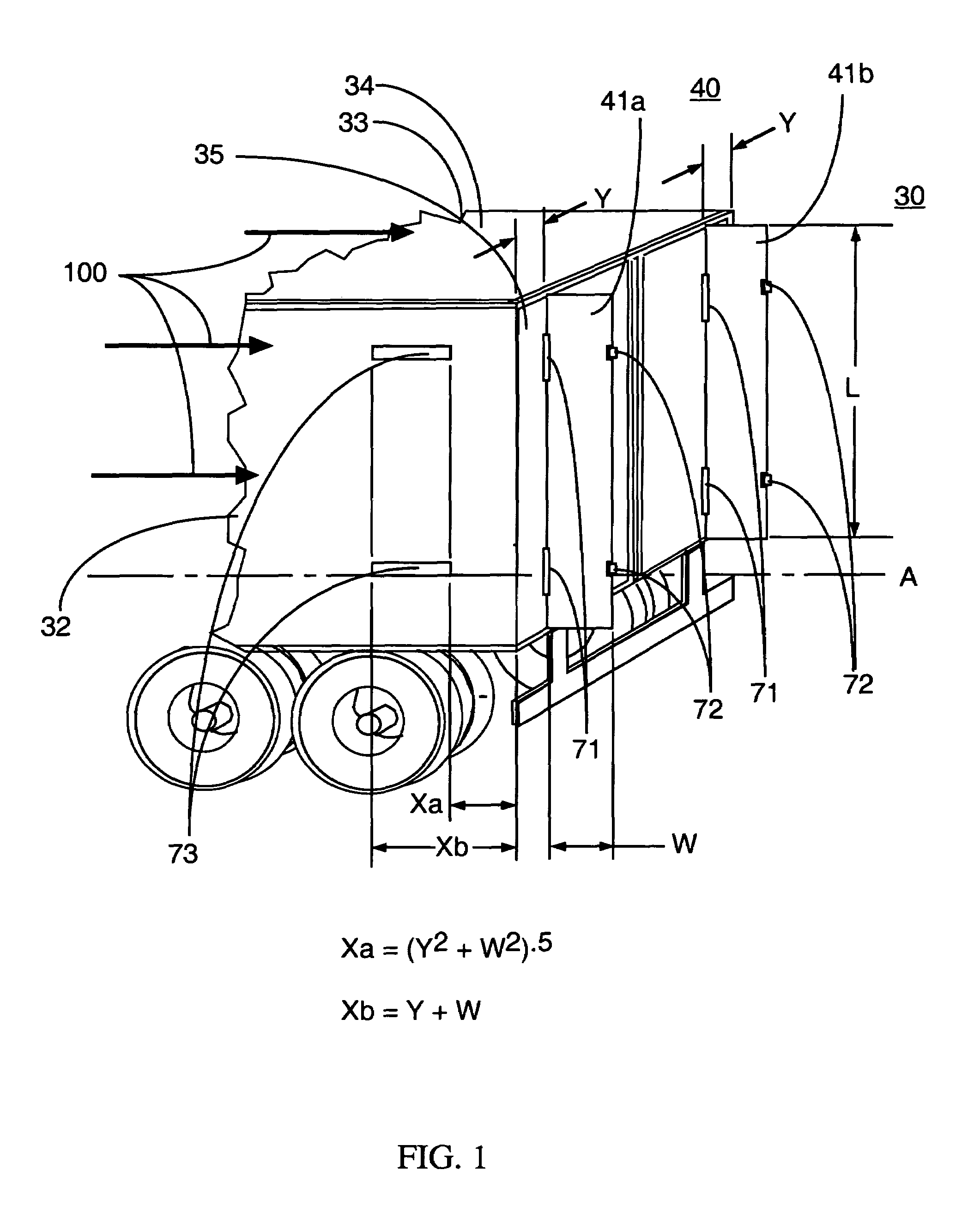

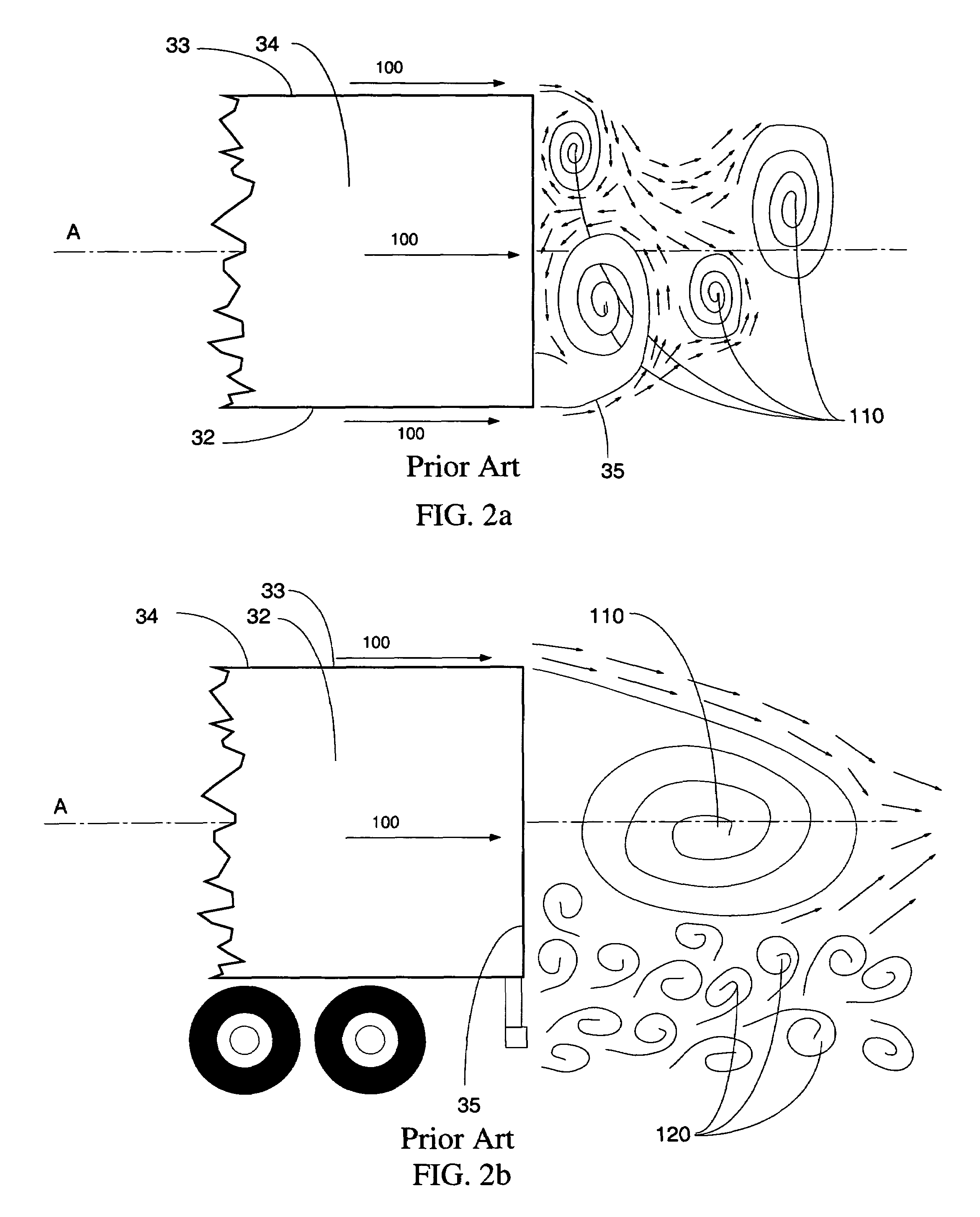

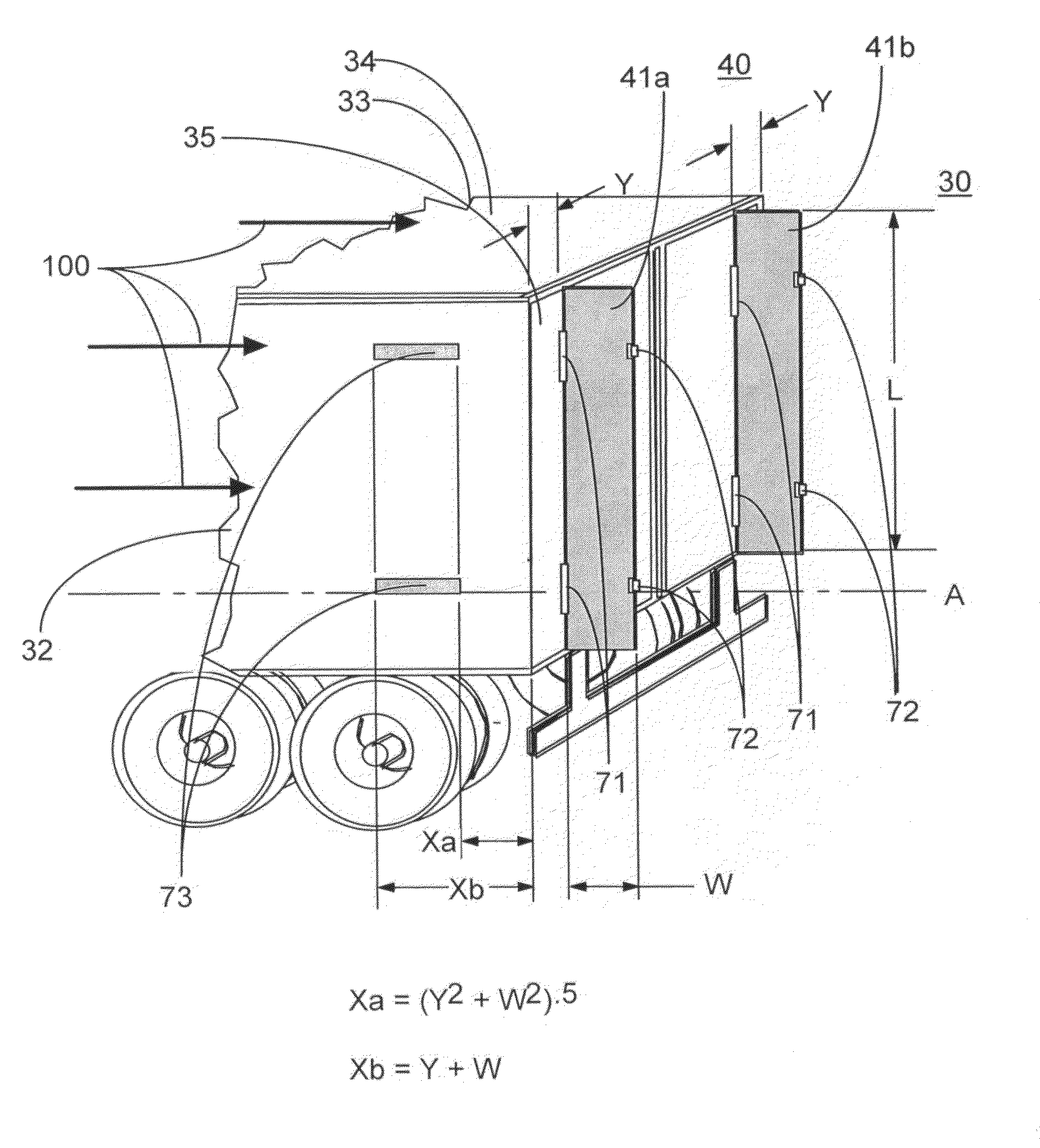

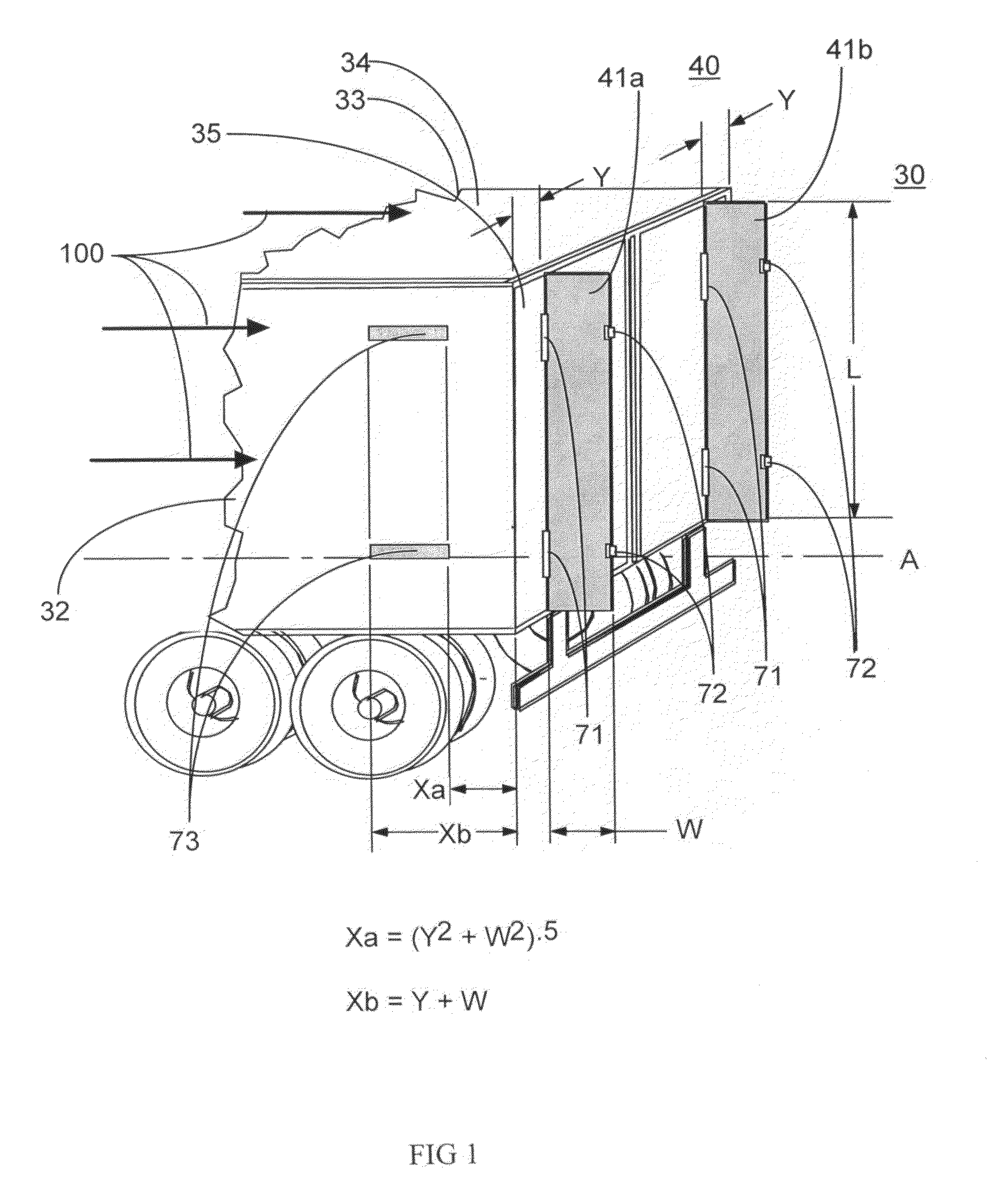

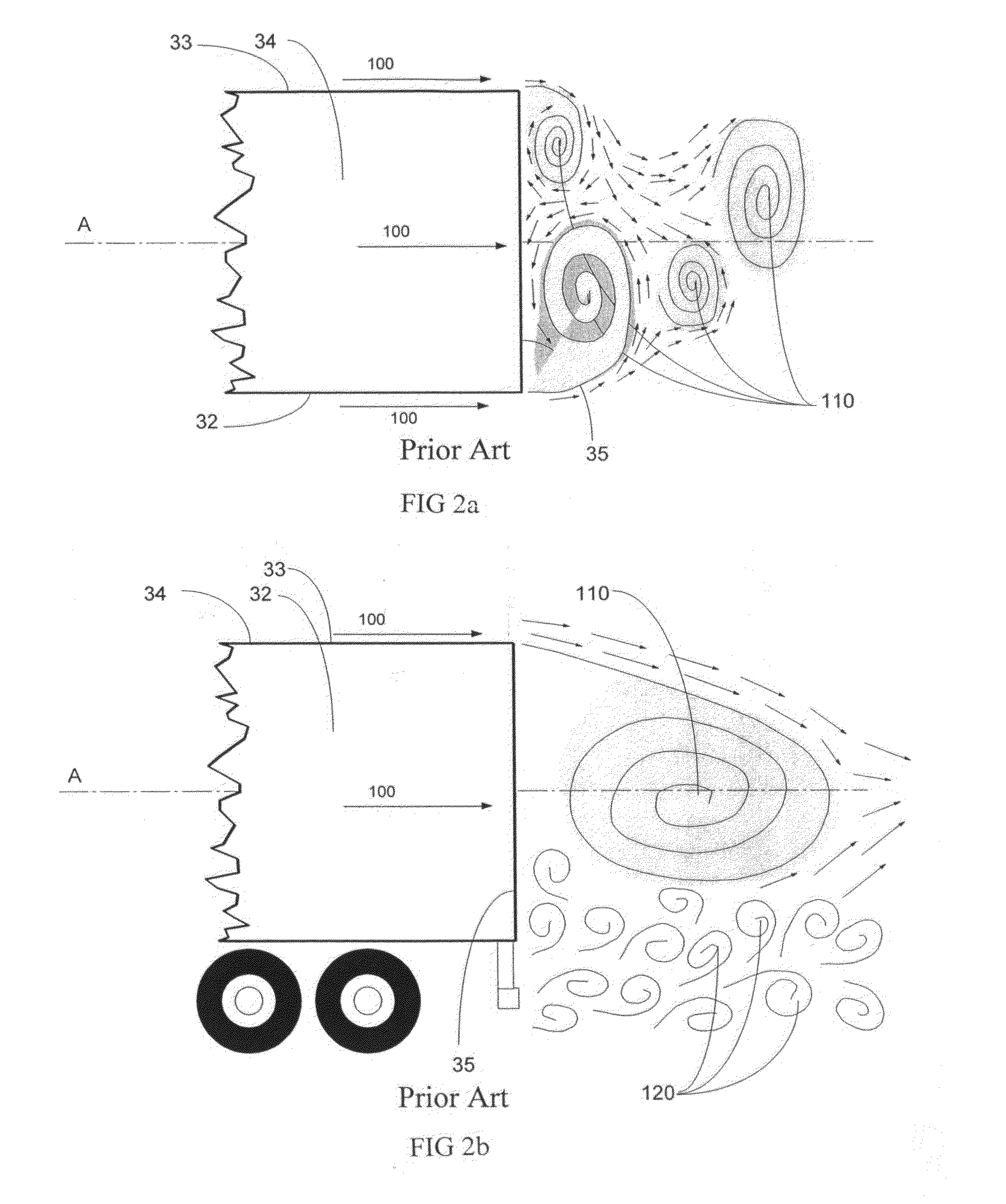

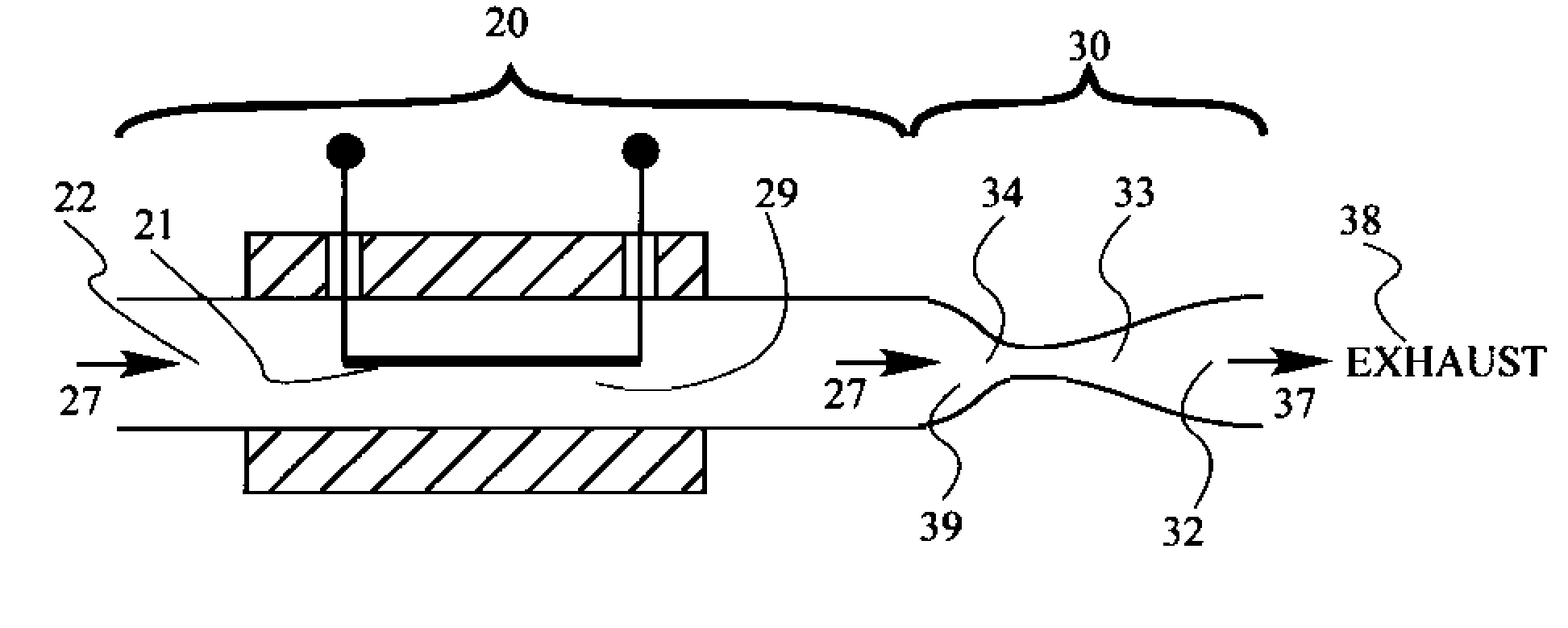

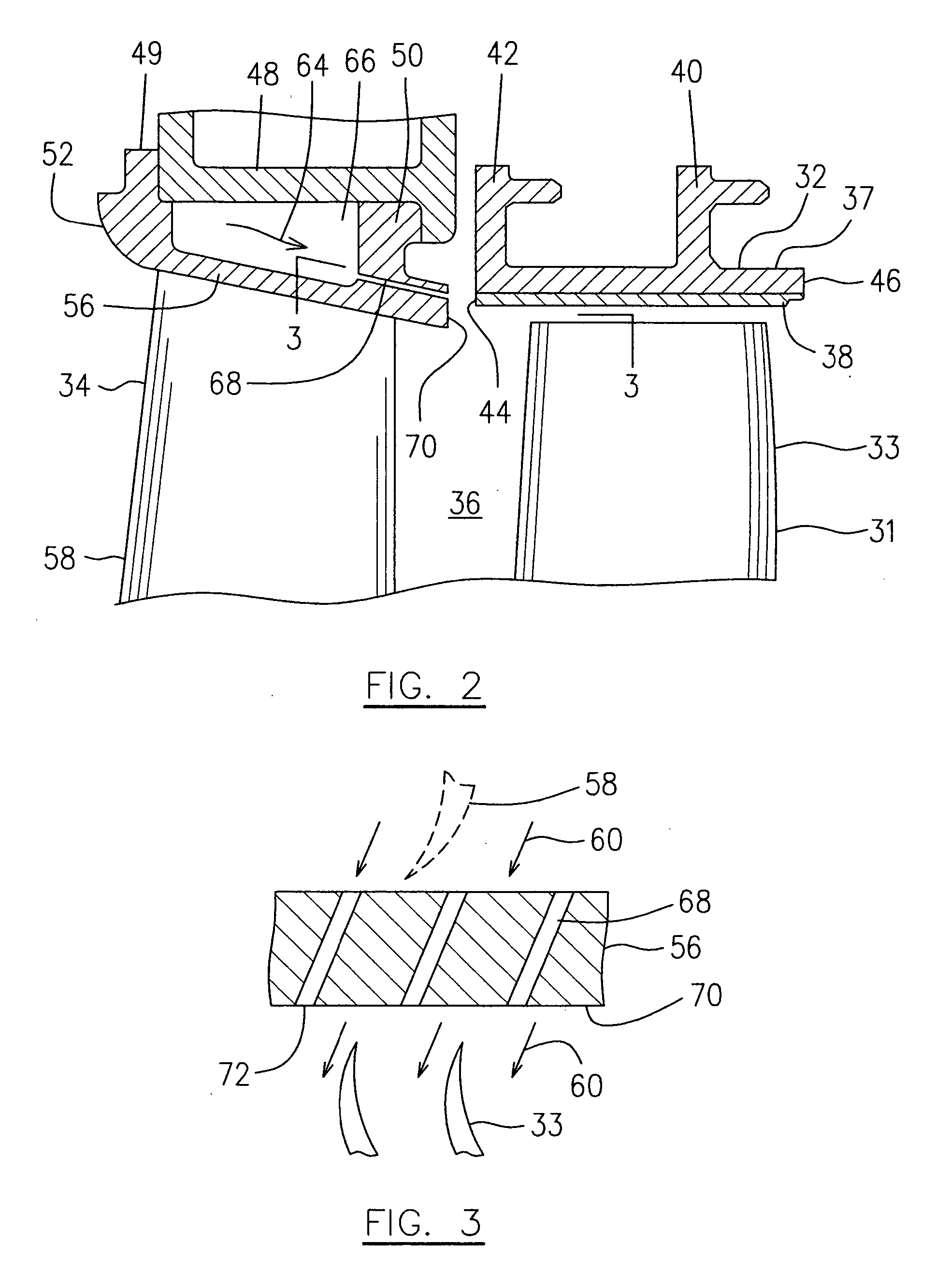

Wake stabilization device and method for reducing the aerodynamic drag of ground vehicles

An improved method and device for the reduction of aerodynamic drag and for improved performance of bluff base vehicles by increasing the pressure on the bluff base of the vehicle by controlling the wake flow and the interaction of the wake flow with the vehicle bluff base region. An improved method and device for generating a reduction in drag force on the bluff base of a body moving through a fluid. The apparatus consists of two opposing panels attached to the bluff base and aligned approximately parallel to the side edge of the bluff base and lying in a plane that is parallel to the vehicle centerline. The drag force reduction results from controlling the flow entering the bluff base trailing wake from the left side surface, right side surface, bottom surface, and top surfaces of the vehicle. The objects and advantages also extend to other applications in which an object, body, or vehicle is moving through either a gas or a fluid.

Owner:WOOD RICHARD MICHAEL

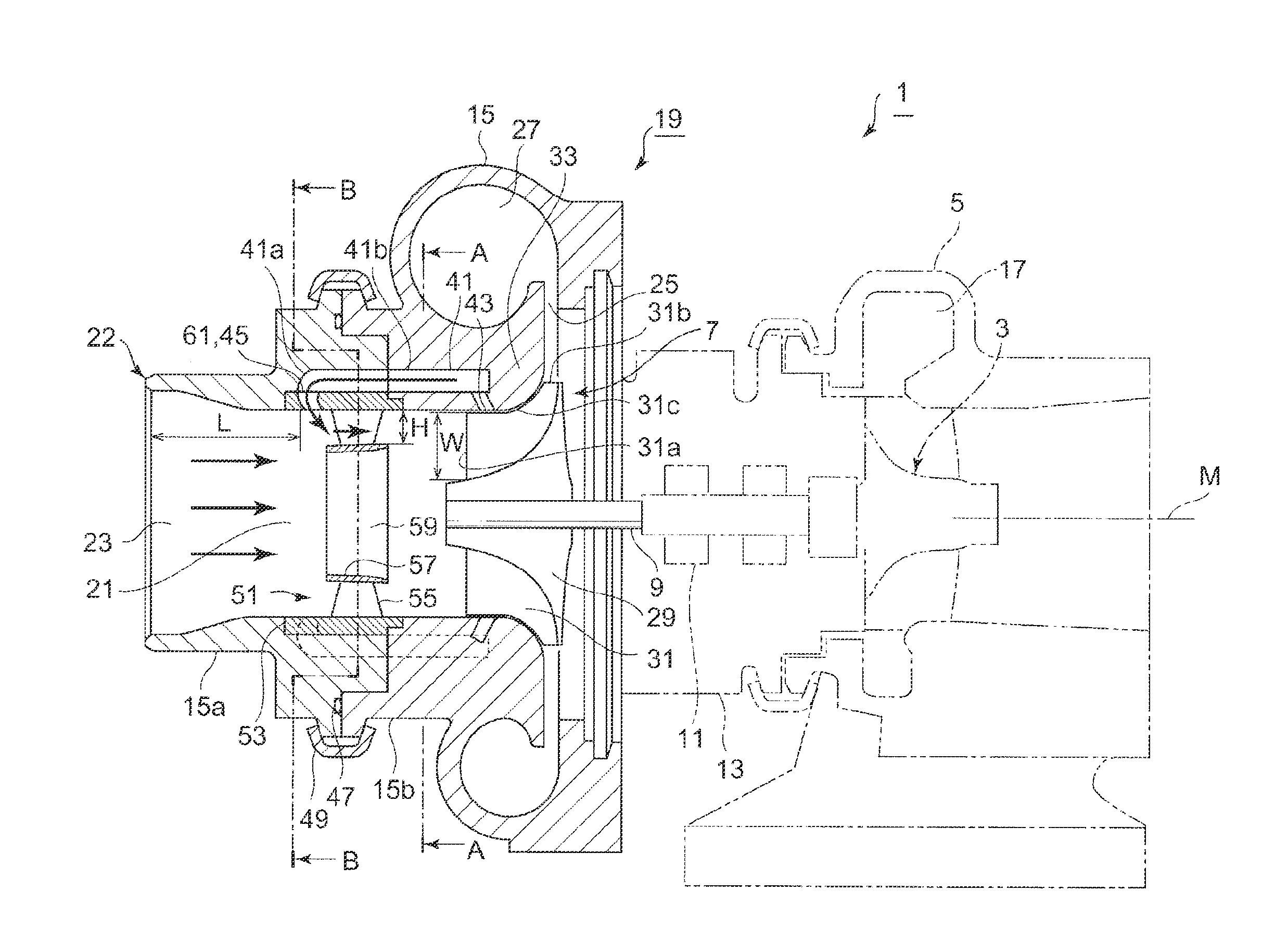

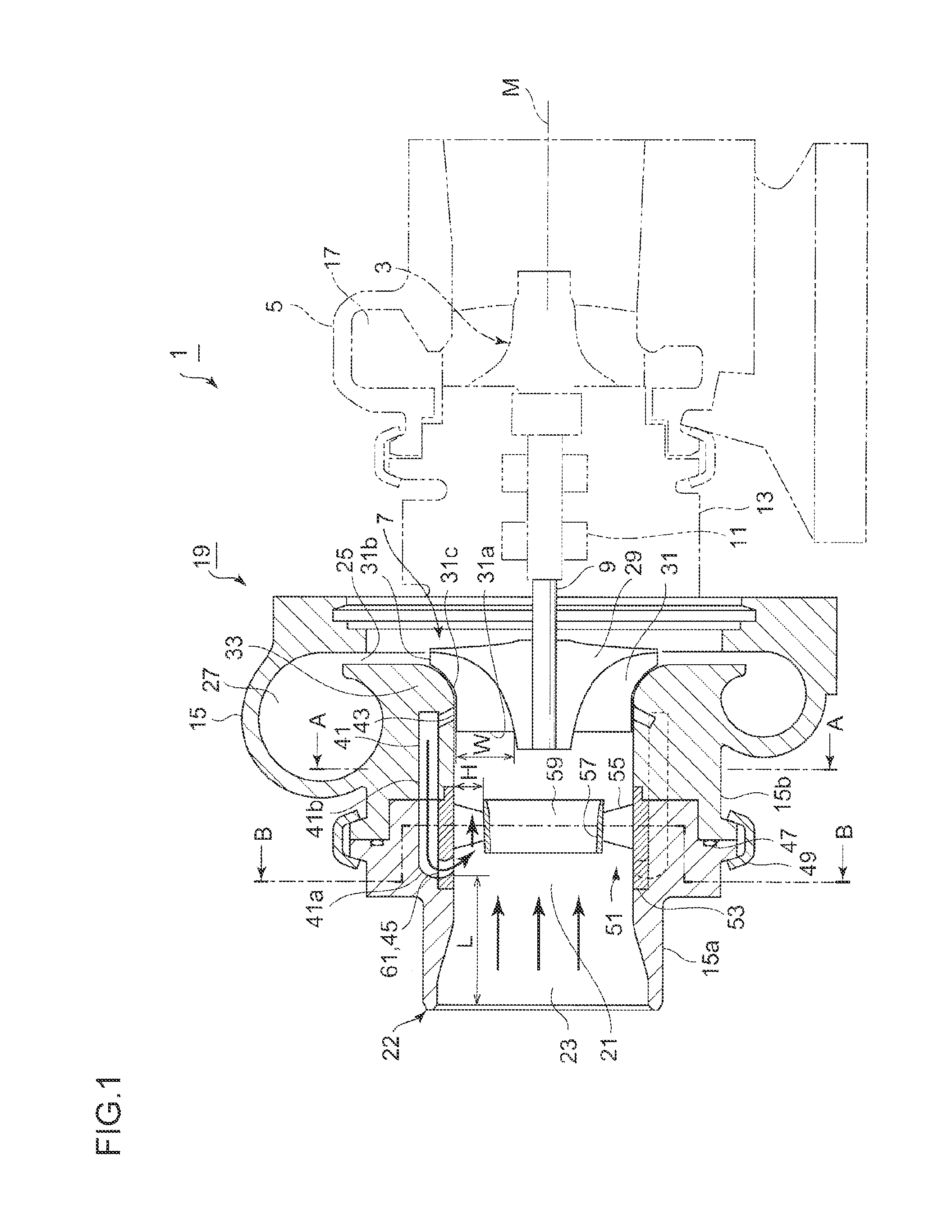

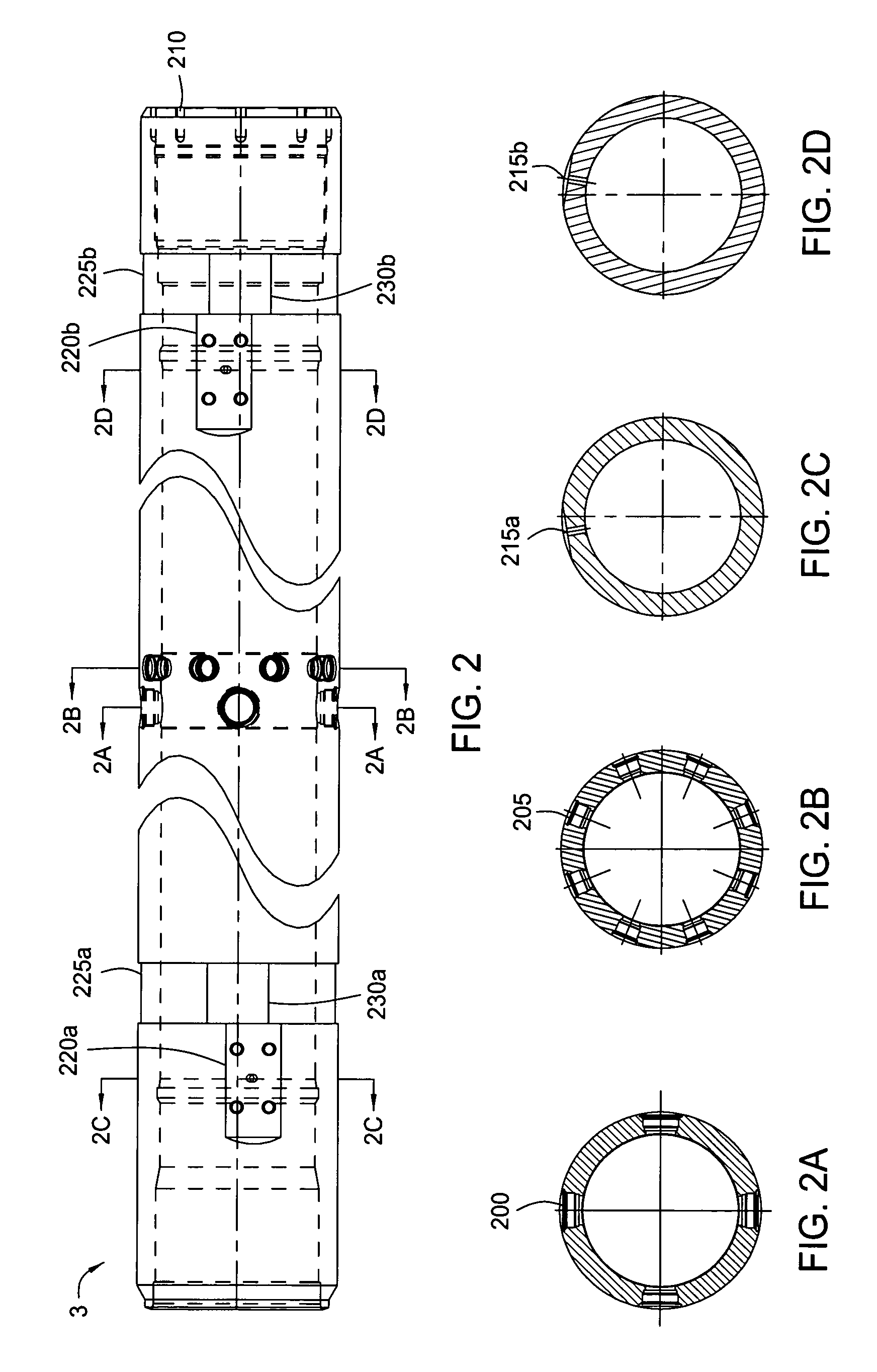

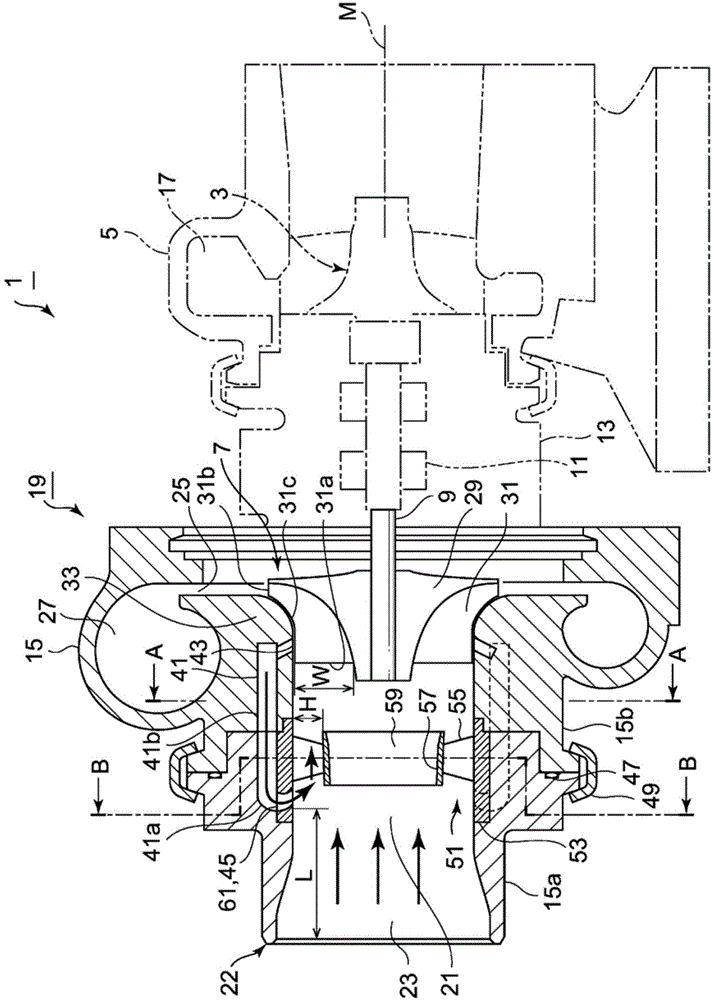

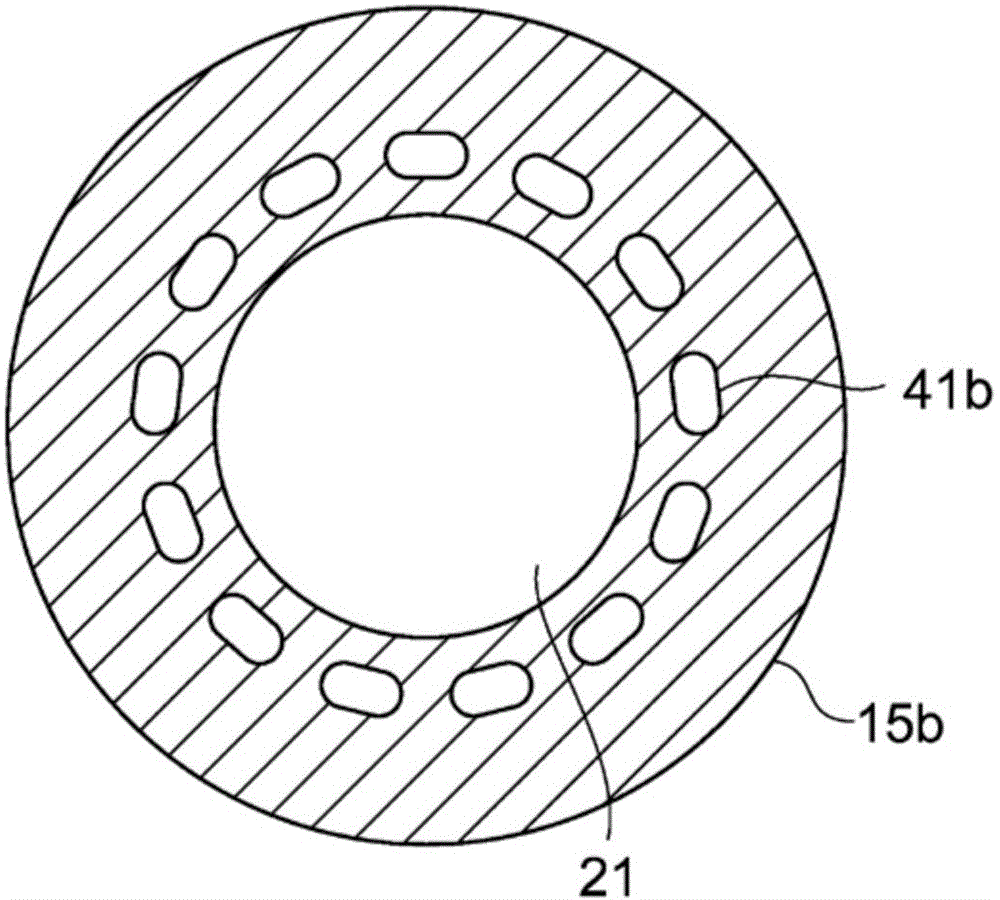

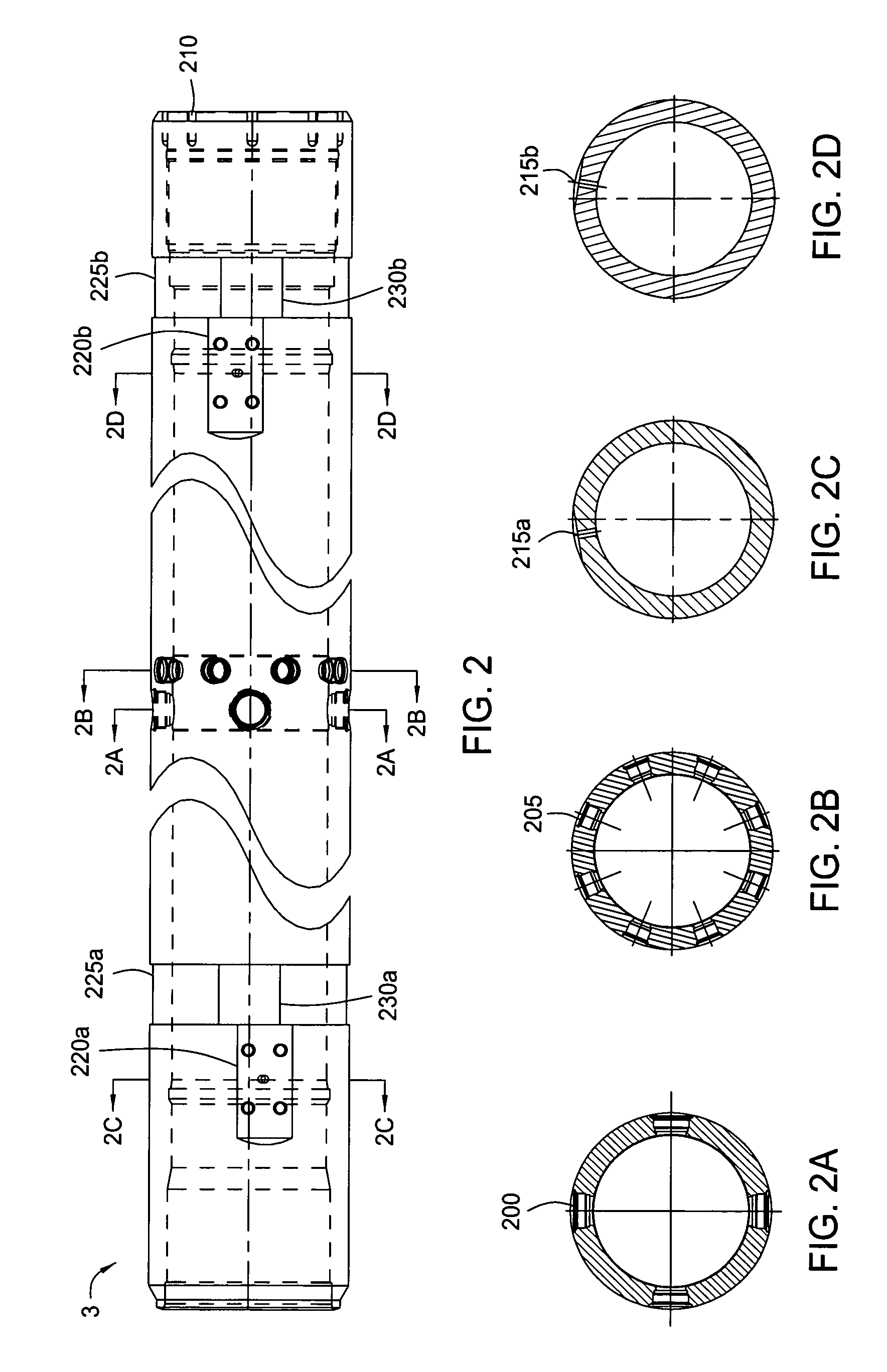

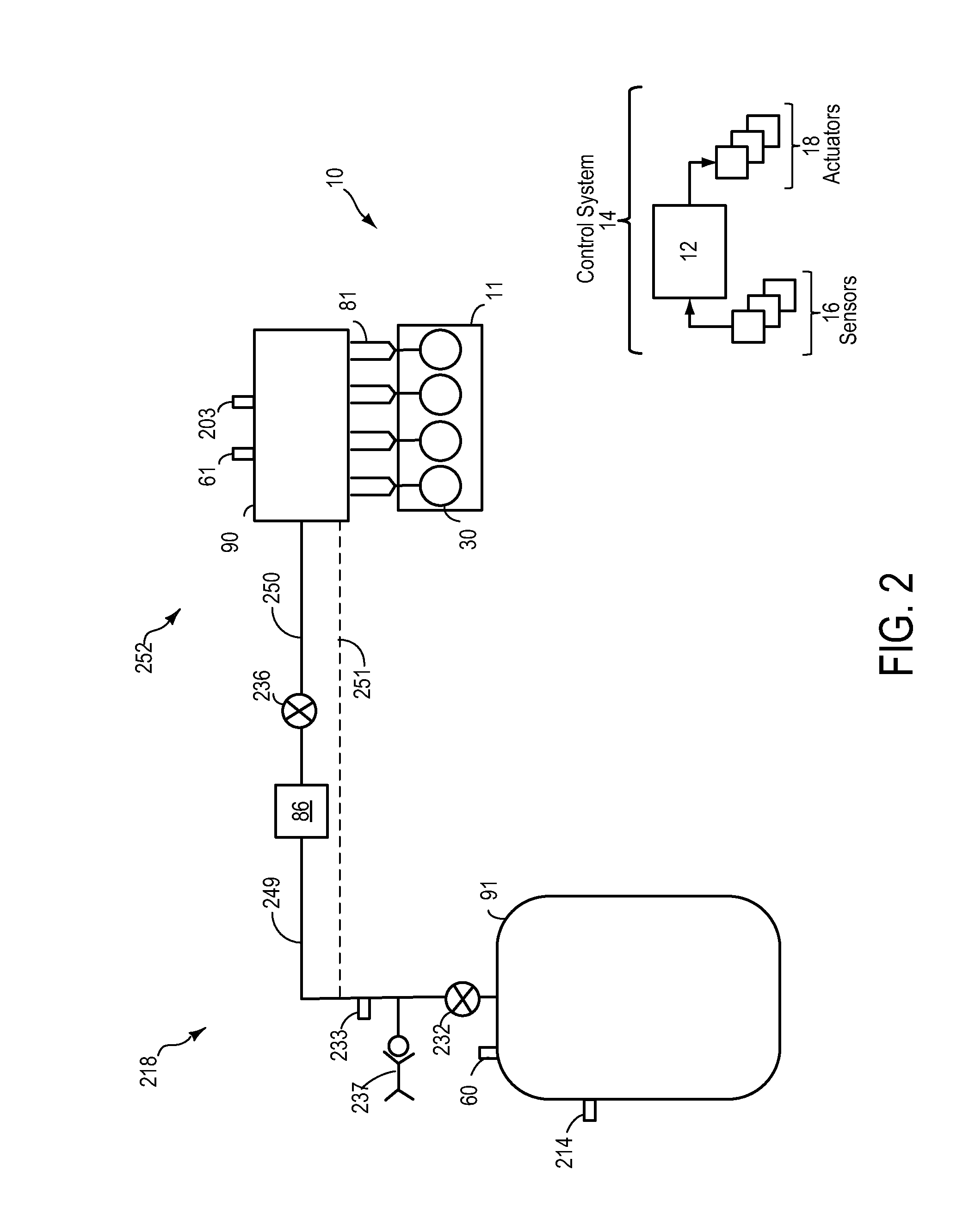

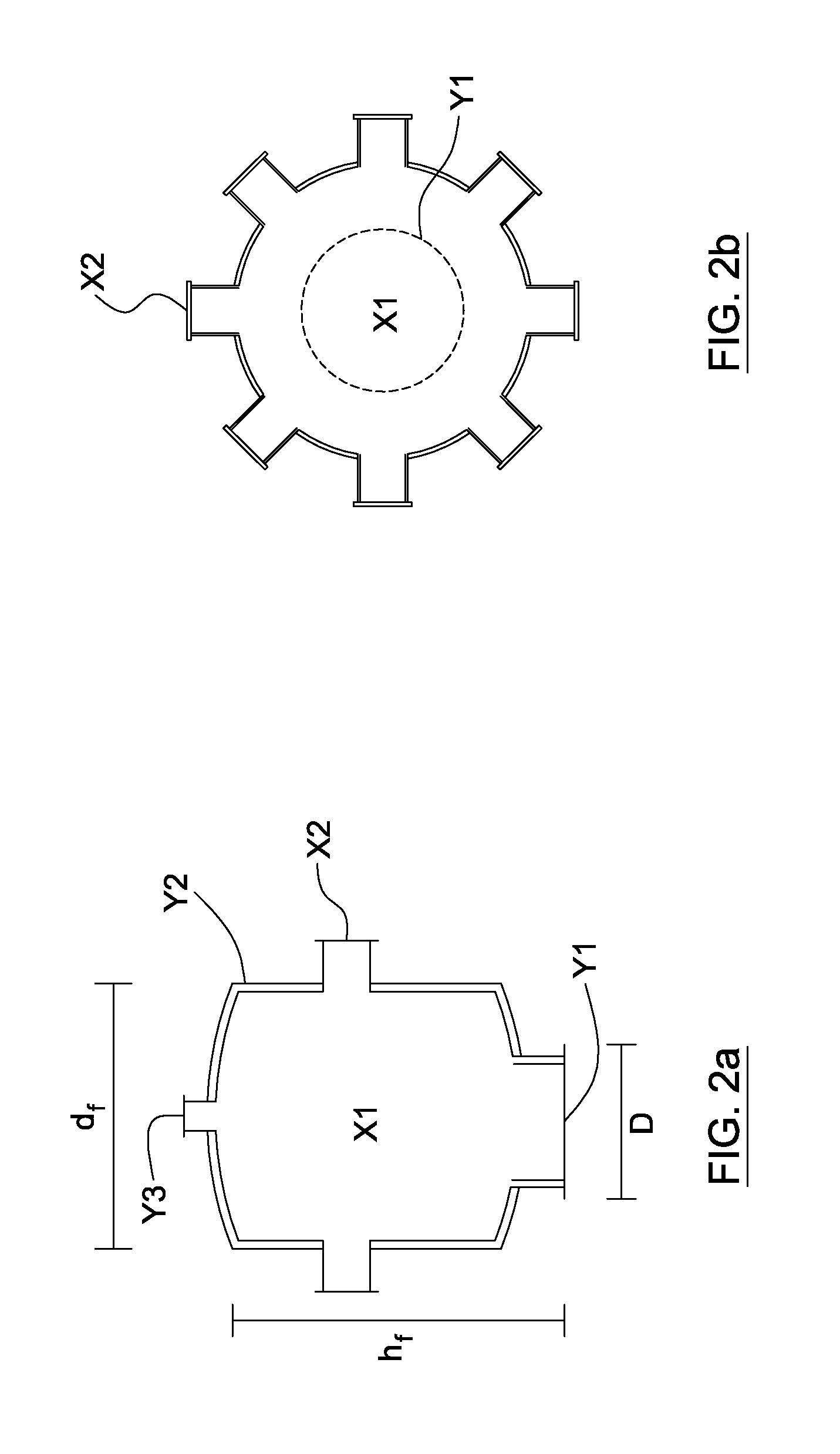

Centrifugal compressor

ActiveUS20150192147A1Improve surge marginReducing choke flowInternal combustion piston enginesEngine manufactureRotational axisChoked flow

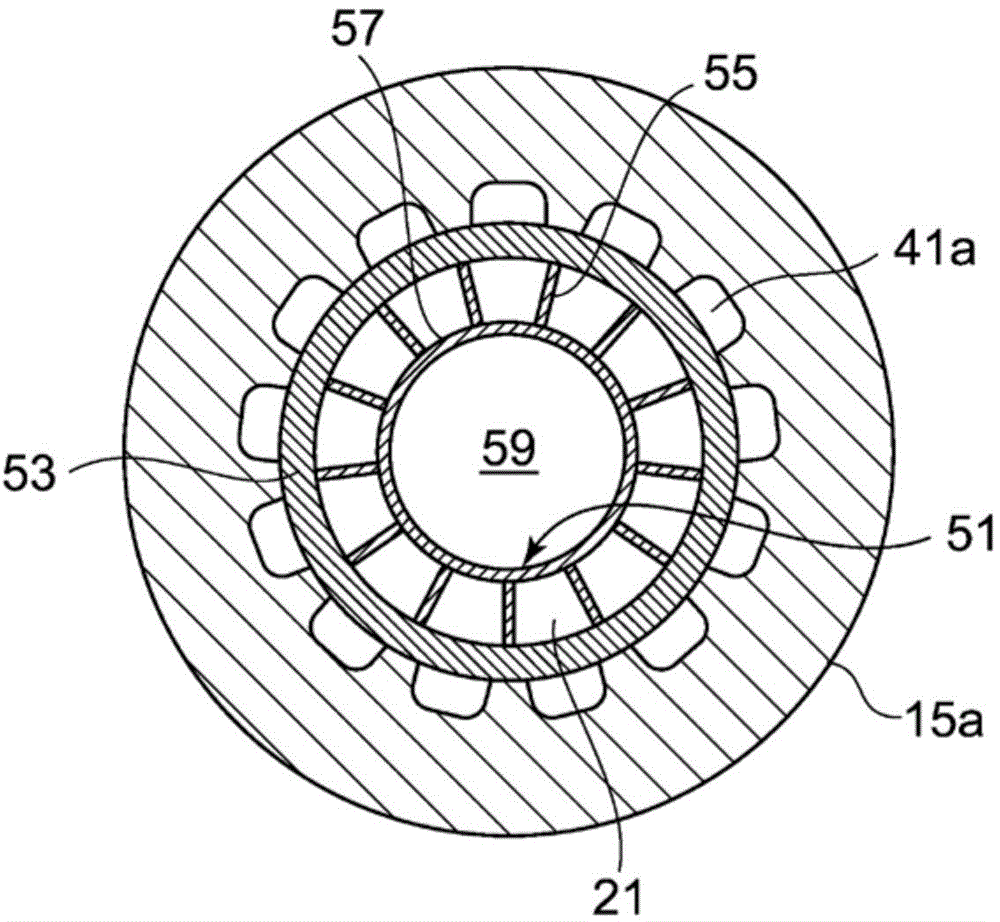

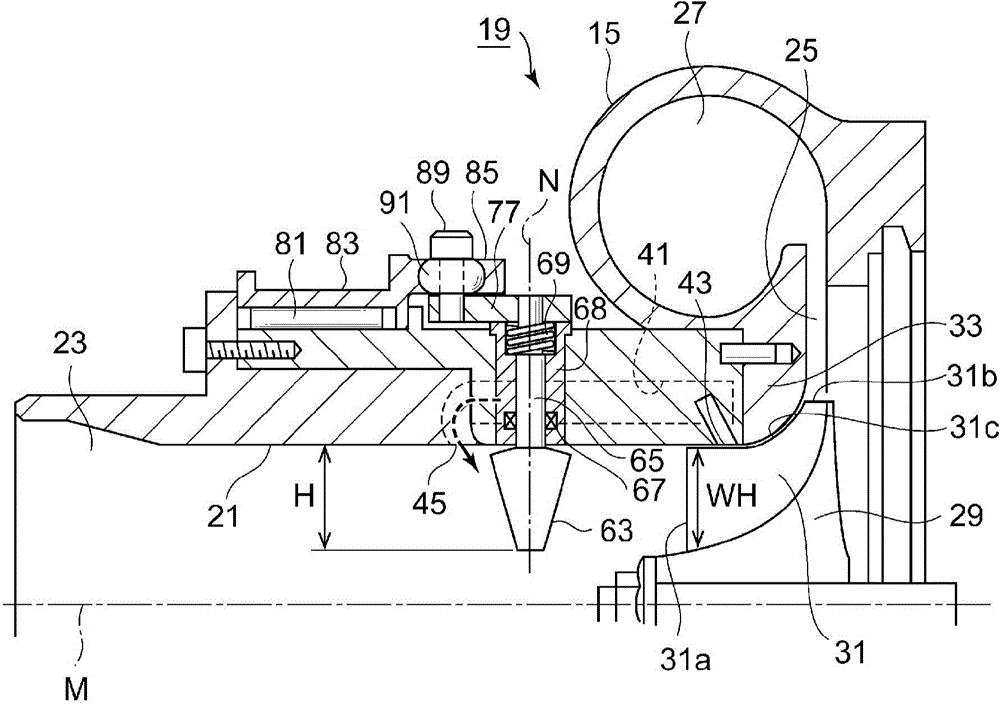

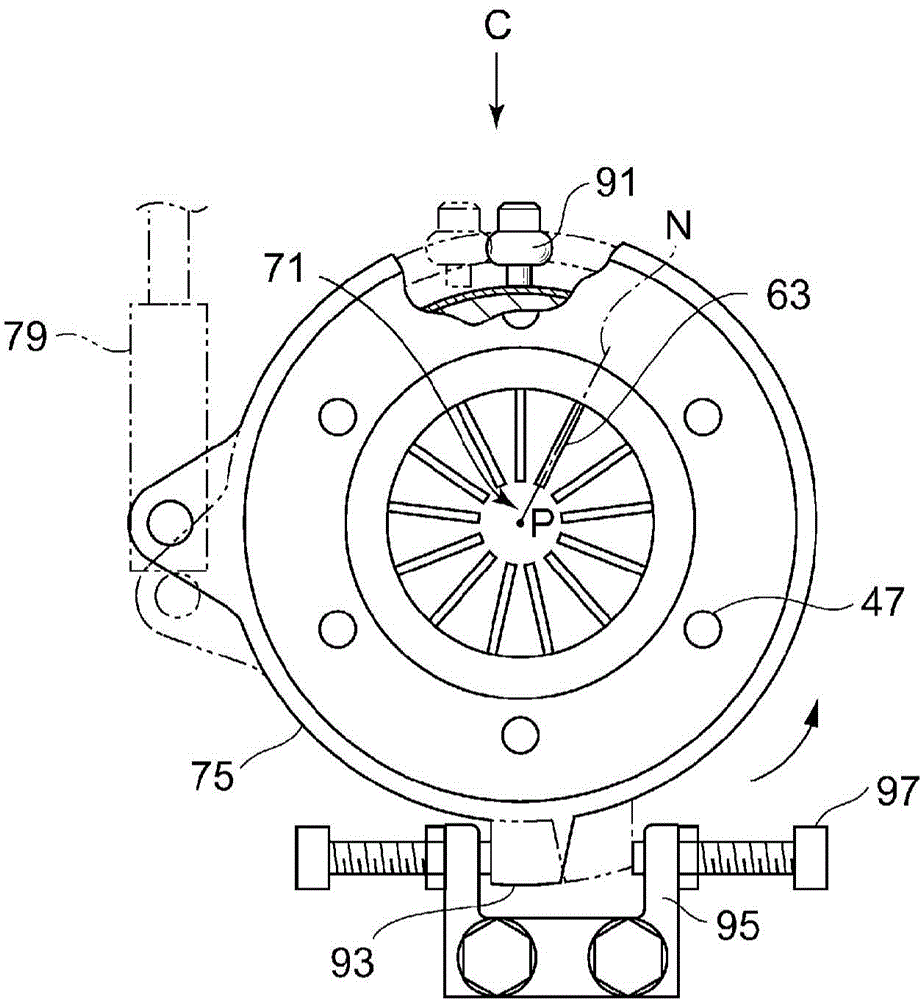

An object is to position a plurality of guide vanes for generating swirl flow at a housing inner circumferential side in front of an impeller wheel to improve a surge margin and to restrict the decrease in a choke flow rate, thereby increasing an operation range of a compressor. A compressor 19 includes a compressor housing 15, an impeller wheel 7 which compresses intake gas flowing in from an intake-air inlet 23, a swirl-flow generating part including a plurality of guide vanes 55 disposed circumferentially along an inner circumferential wall of the intake-air channel 21 between the intake-air inlet 23 and the impeller wheel 7 and which swirls the intake gas from the intake-air inlet 23 around the rotational axis, and a central intake-air flow path 59 formed inside the guide vanes 55 to allow intake gas to flow to the impeller wheel 7 without passing through the guide vanes 55.

Owner:MITSUBISHI HEAVY IND LTD

Wake stabilization device and method for reducing the aerodynamic drag of ground vehicles

A wake stabilization device for reducing the aerodynamic drag of ground vehicles. An improved device for the reduction of aerodynamic drag and for improved performance of bluff base vehicles by increasing the pressure on the bluff base of the vehicle by controlling the wake flow and the interaction of the wake flow with the vehicle bluff base region. The device generates a reduction in drag force on the bluff base of a body moving through a fluid. The apparatus consists of two opposing panels attached to the bluff base and aligned approximately parallel to the side edge of the bluff base and lying in a plane that is parallel to the vehicle centerline. The drag force reduction results from controlling the flow entering the bluff base trailing wake from the left side surface, right side surface, bottom surface, and top surfaces of the vehicle. The objects and advantages also extend to other applications in which an object, body, or vehicle is moving through either a gas or a fluid.

Owner:WOOD RICHARD

Two-shaft turbocharger

InactiveUS7571607B2Easy to controlIncrease pressure ratioInternal combustion piston enginesCombination enginesAxial compressorImpeller

Owner:HONEYWELL INT INC

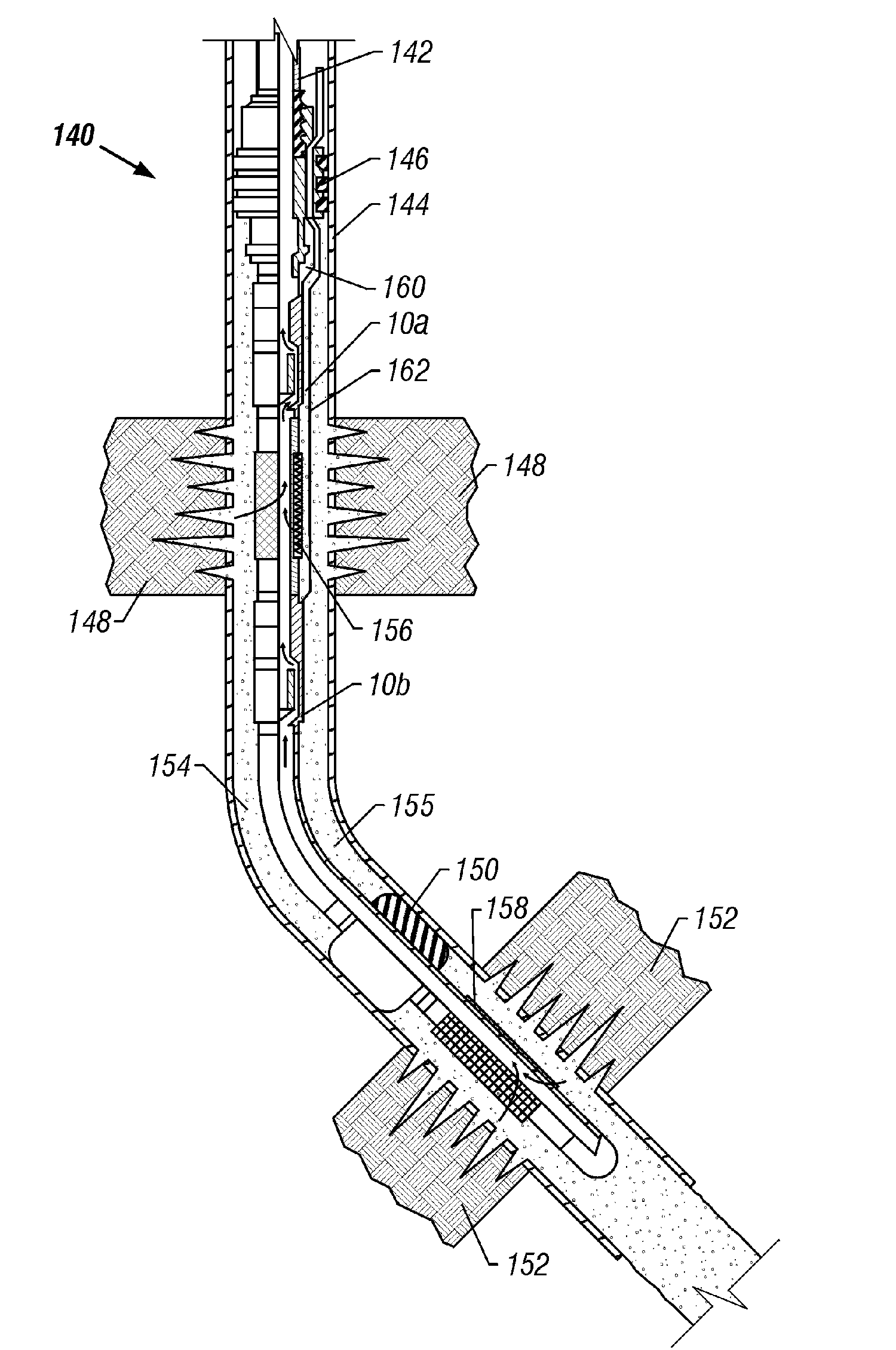

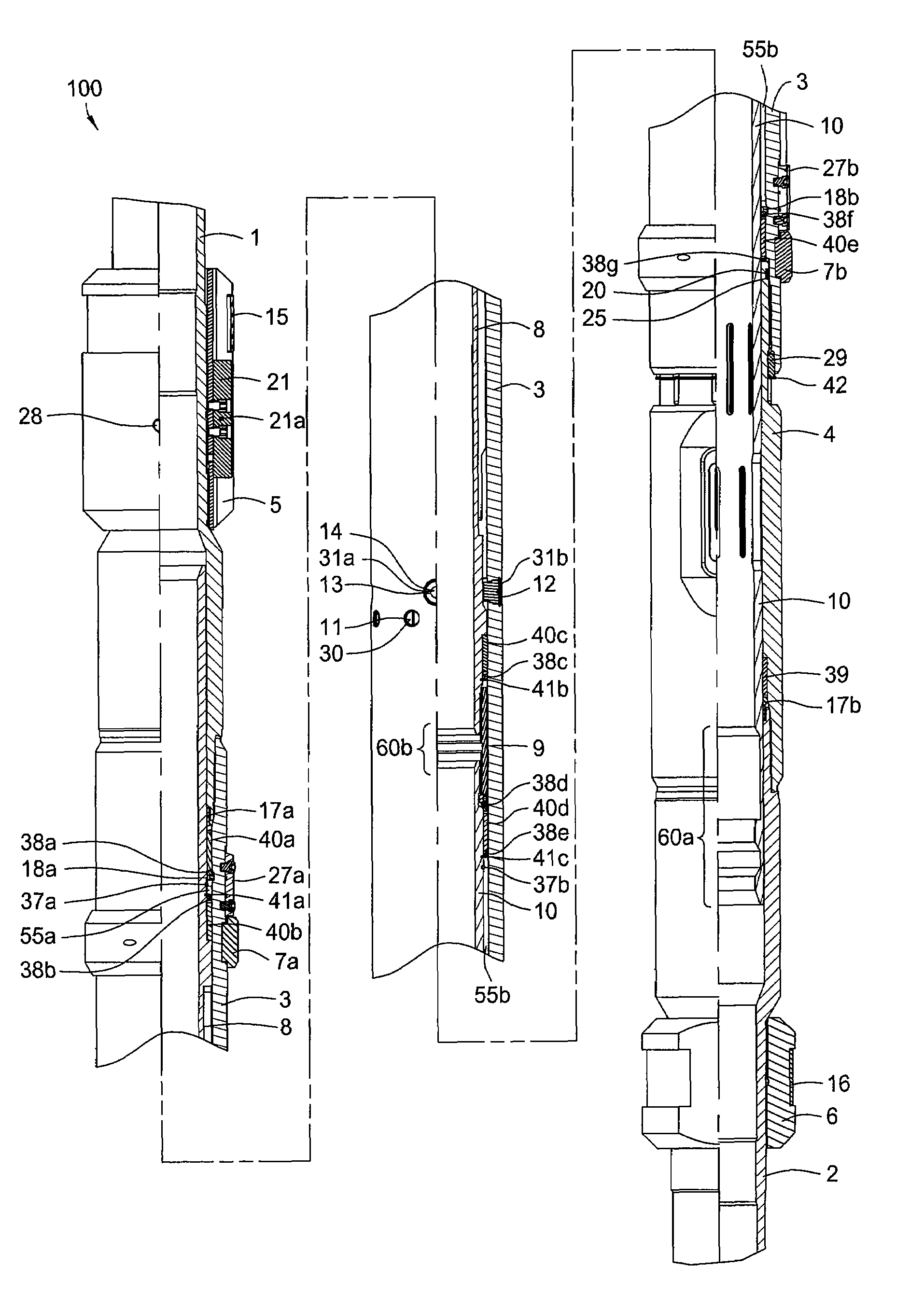

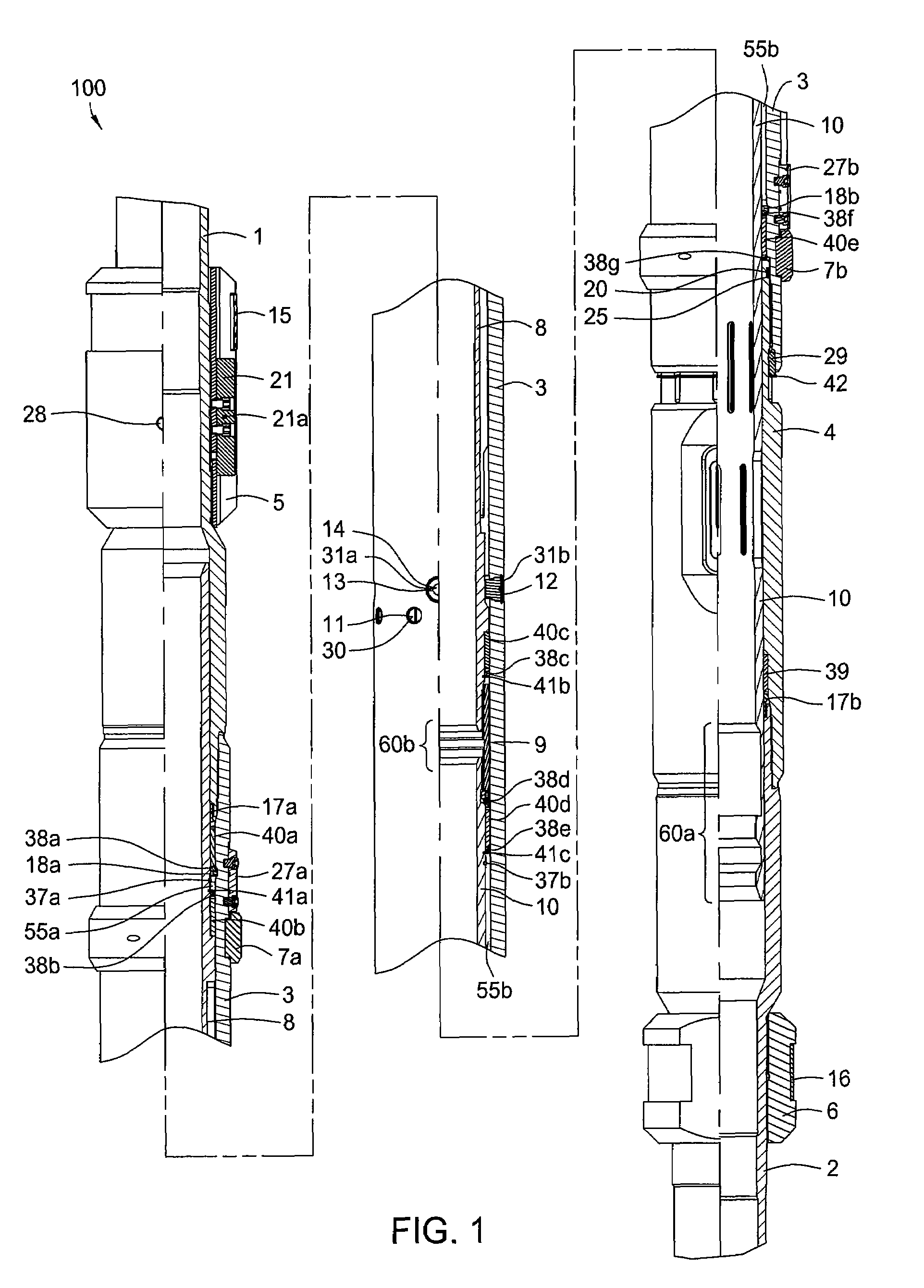

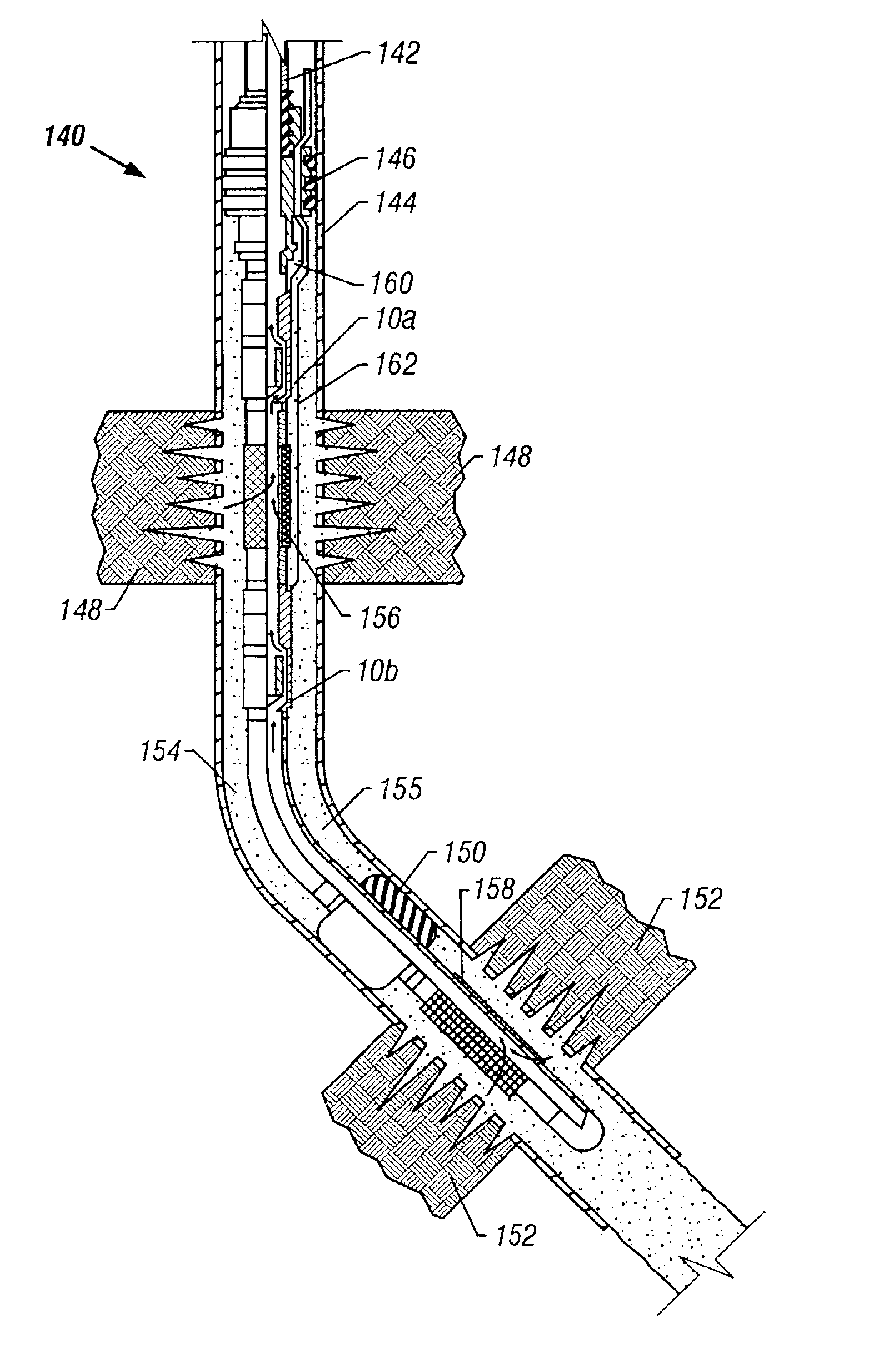

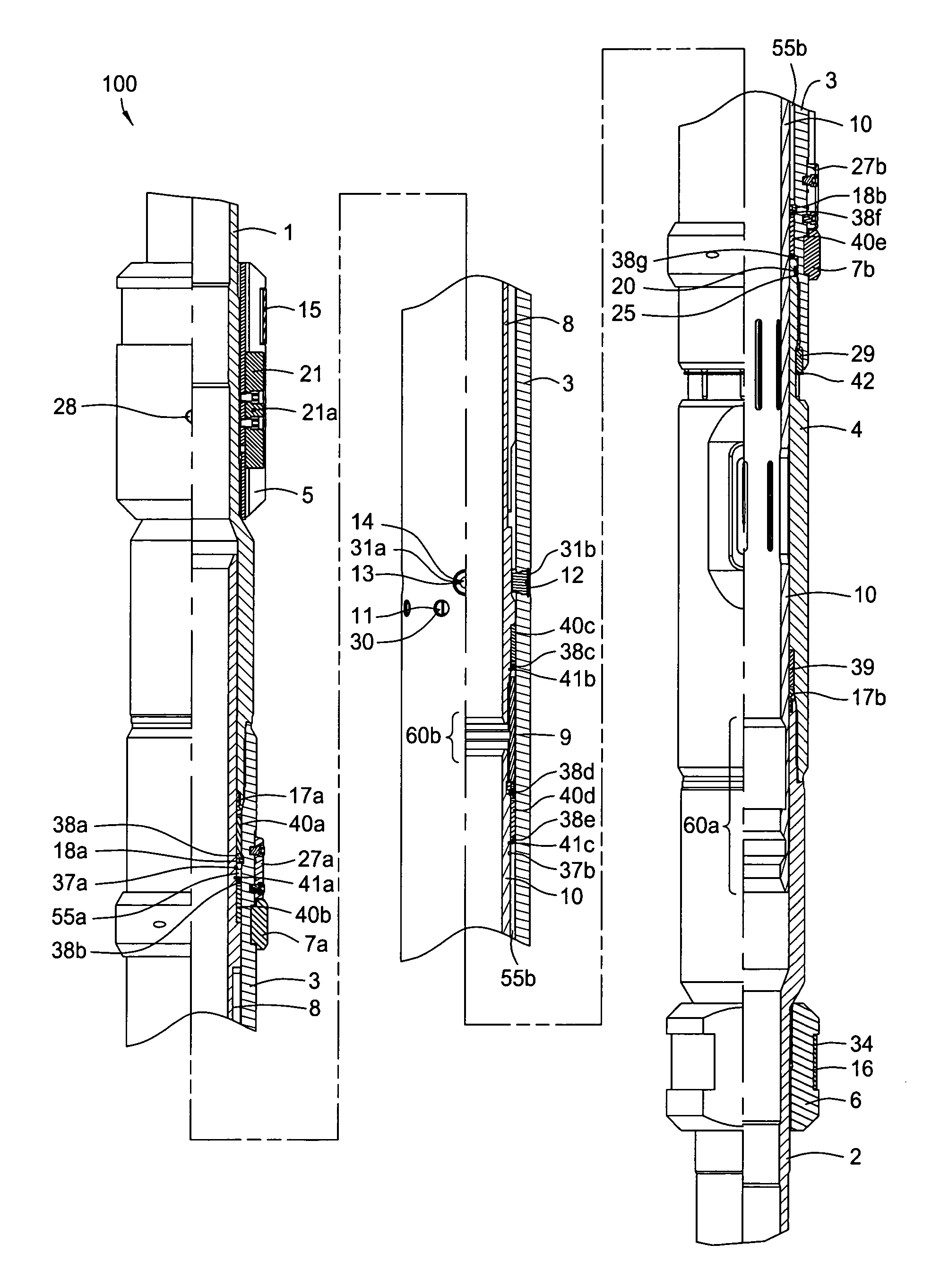

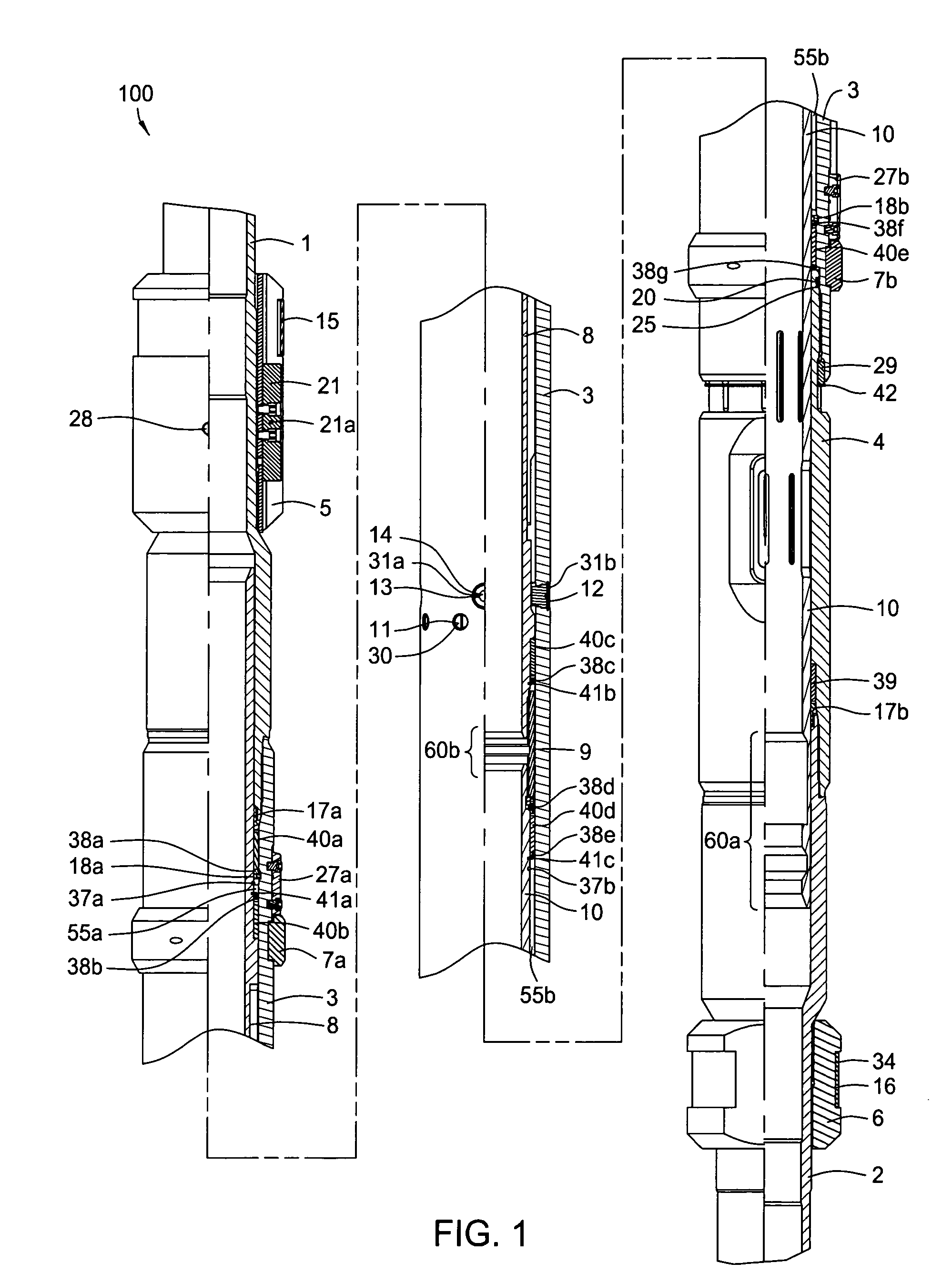

Method & Apparatus for Selective Injection or Flow Control with Through-Tubing Operation Capacity

Owner:SCHLUMBERGER TECH CORP

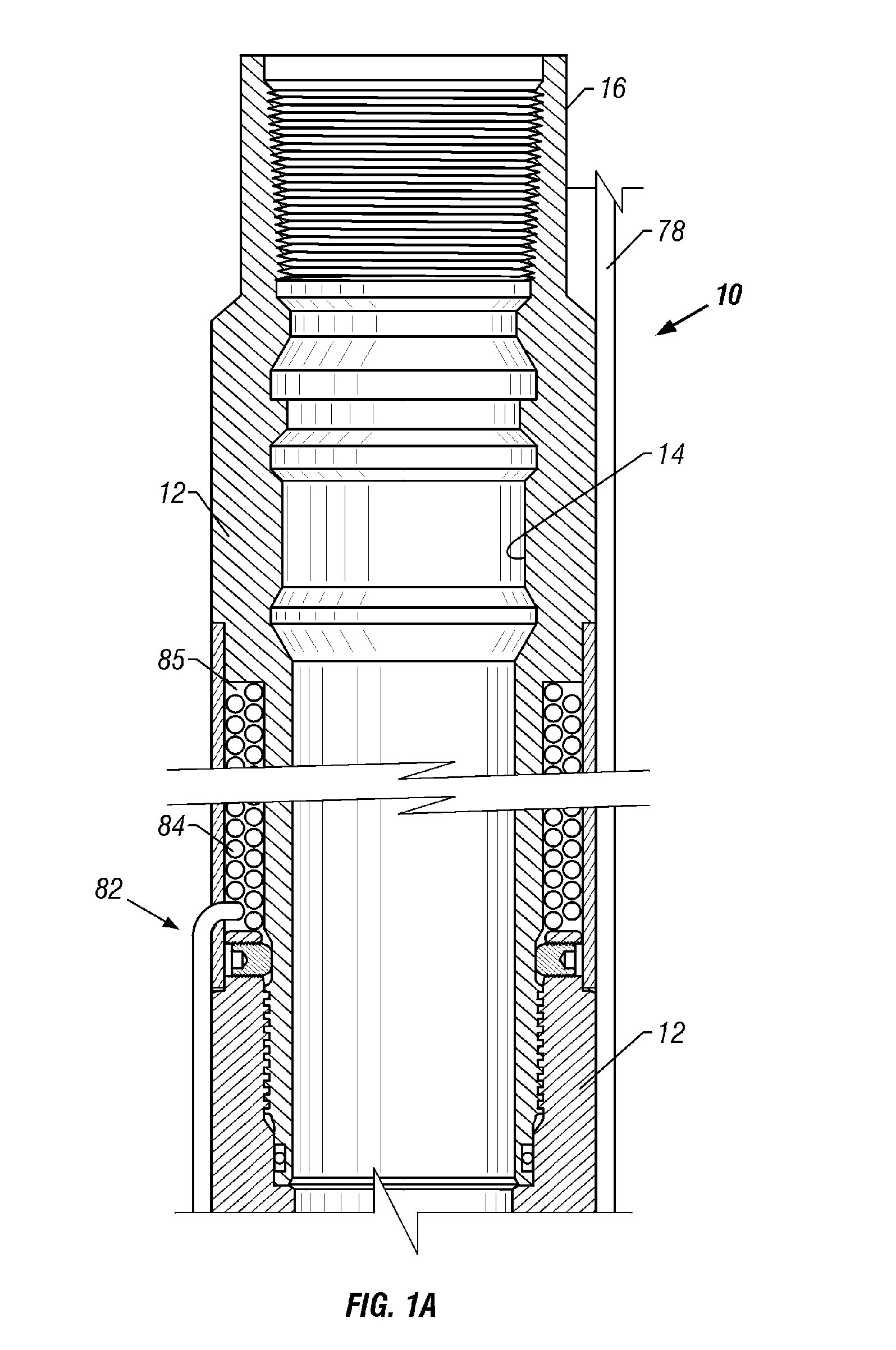

Variable choke valve

Embodiments of the present invention generally provide a more reliable variable choke flow control valve. In one embodiment, a variable choke valve for use in a wellbore is provided. The valve includes a tubular housing having an axial bore therethrough and a port through a wall thereof. The valve further includes a tubular sleeve having an axial bore therethrough and first and second holes through a wall thereof and disposed within the housing. The first hole is larger than the second hole, and the sleeve is actuatable among three positions: a first position where the first hole is aligned with the port, a second position where the second hole is aligned with the port, and a third position where the sleeve wall is aligned with the port.

Owner:WEATHERFORDLAMB

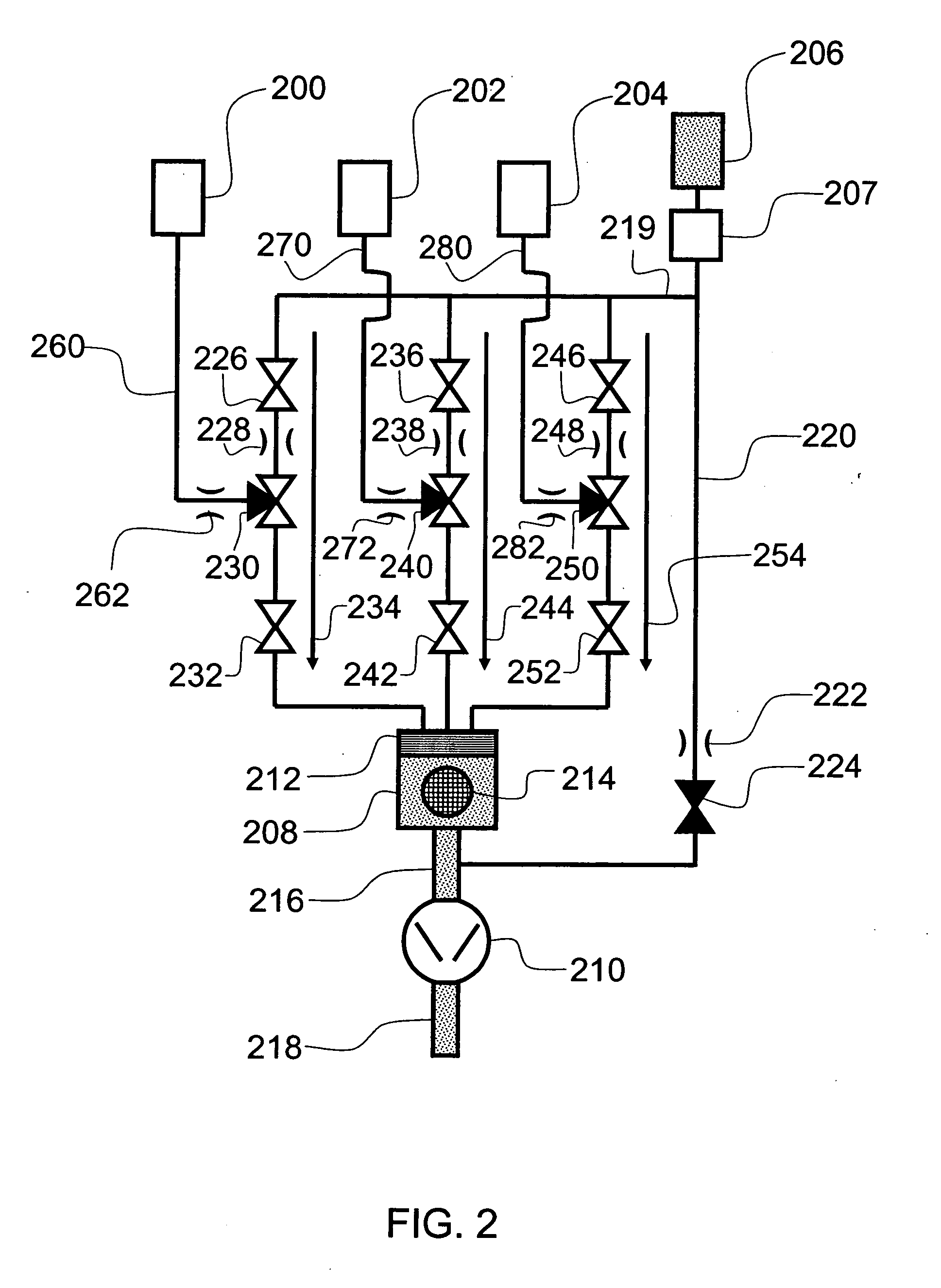

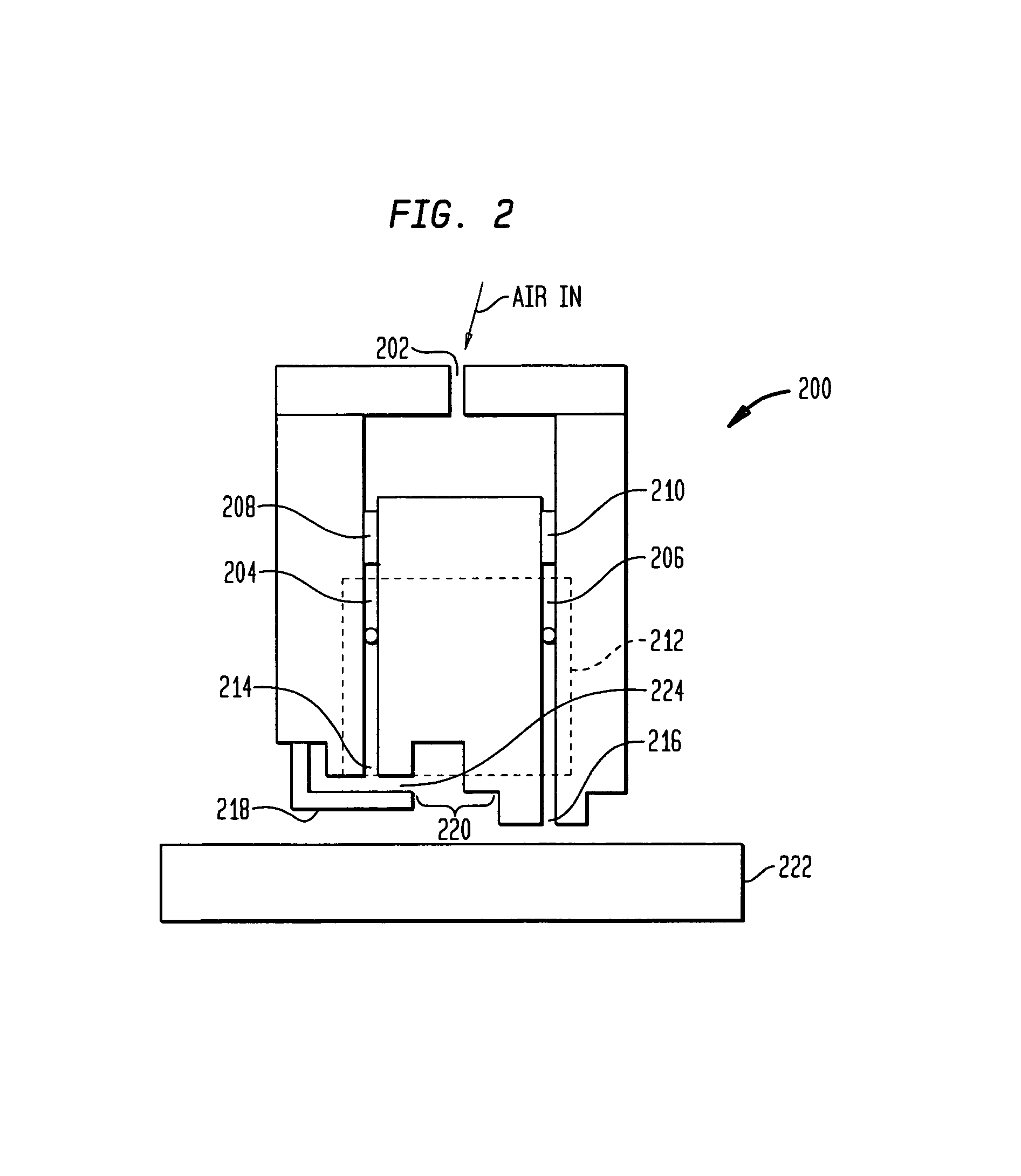

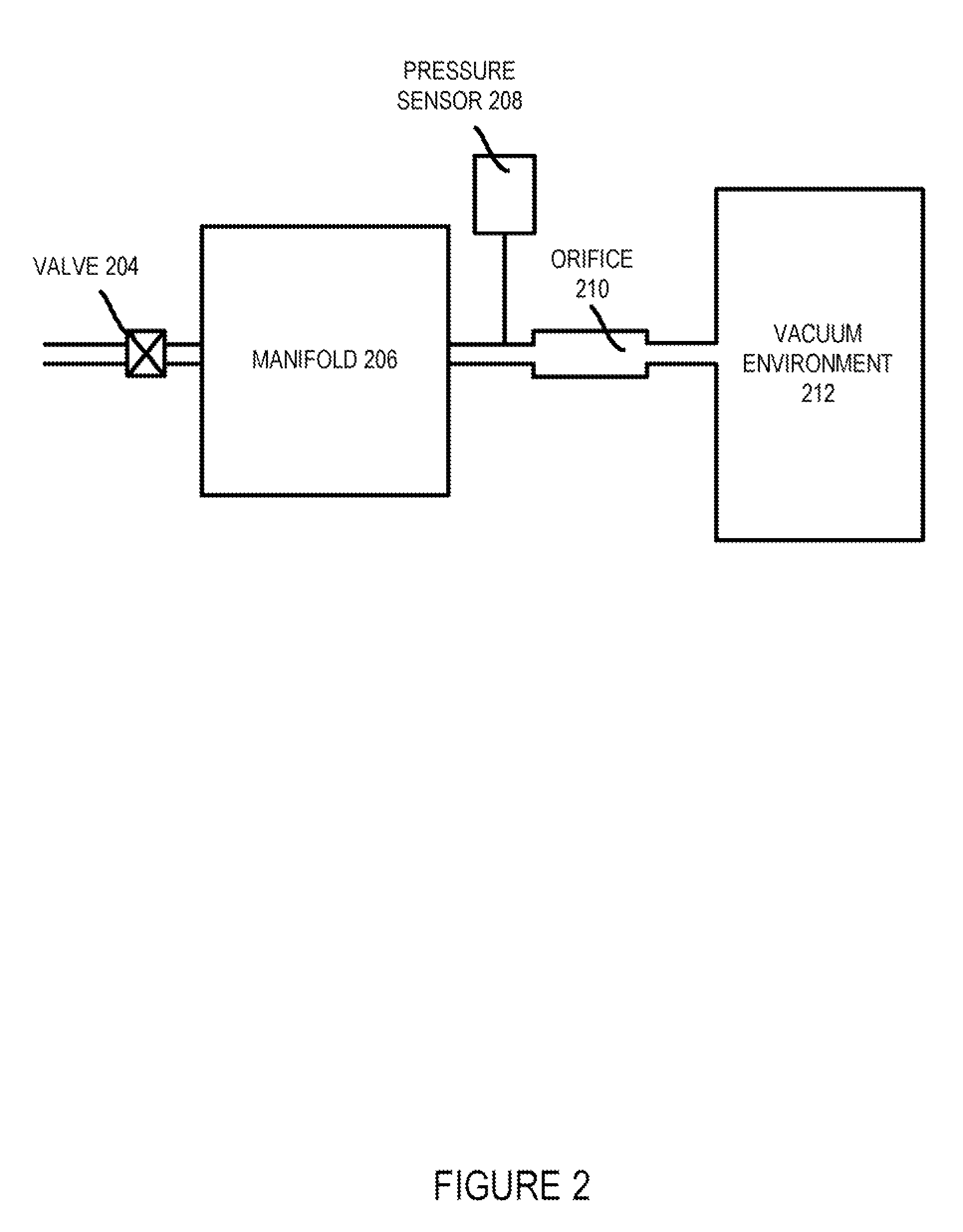

Vapor reactant source system with choked-flow elements

A source system for introducing gaseous source chemicals to a reaction space is provided. The source system comprises an inactive gas source, a pressure controller, a reactant supply source, a gas flow control valve and a choked-flow element.

Owner:ASM INTERNATIONAL

High resolution gas gauge proximity sensor

ActiveUS7021120B2Reduce decreasePhotomechanical treatmentFluid pressure measurement by mechanical elementsProximity sensorChoked flow

In a gas gauge, effects due to changes in the local environment are reduced by causing a measurement nozzle and a reference nozzle to react as if they were co-located, or located at approximately the same position. This is achieved by venting the reference nozzle in very close proximity to the measurement nozzle. A reference chamber surrounding the reference plate and reference nozzle is vented at approximately the same location as the measurement nozzle. In an embodiment for use in a vacuum environment, the measurement nozzle is surrounded with an annular ring. The measurement annular ring is connected to an annular ring around the reference nozzle, which acts to co-locate the reference nozzle and the measurement nozzle. To avoid choked flow, another annular ring or rings may be placed around the measurement annular ring.

Owner:ASML HLDG NV

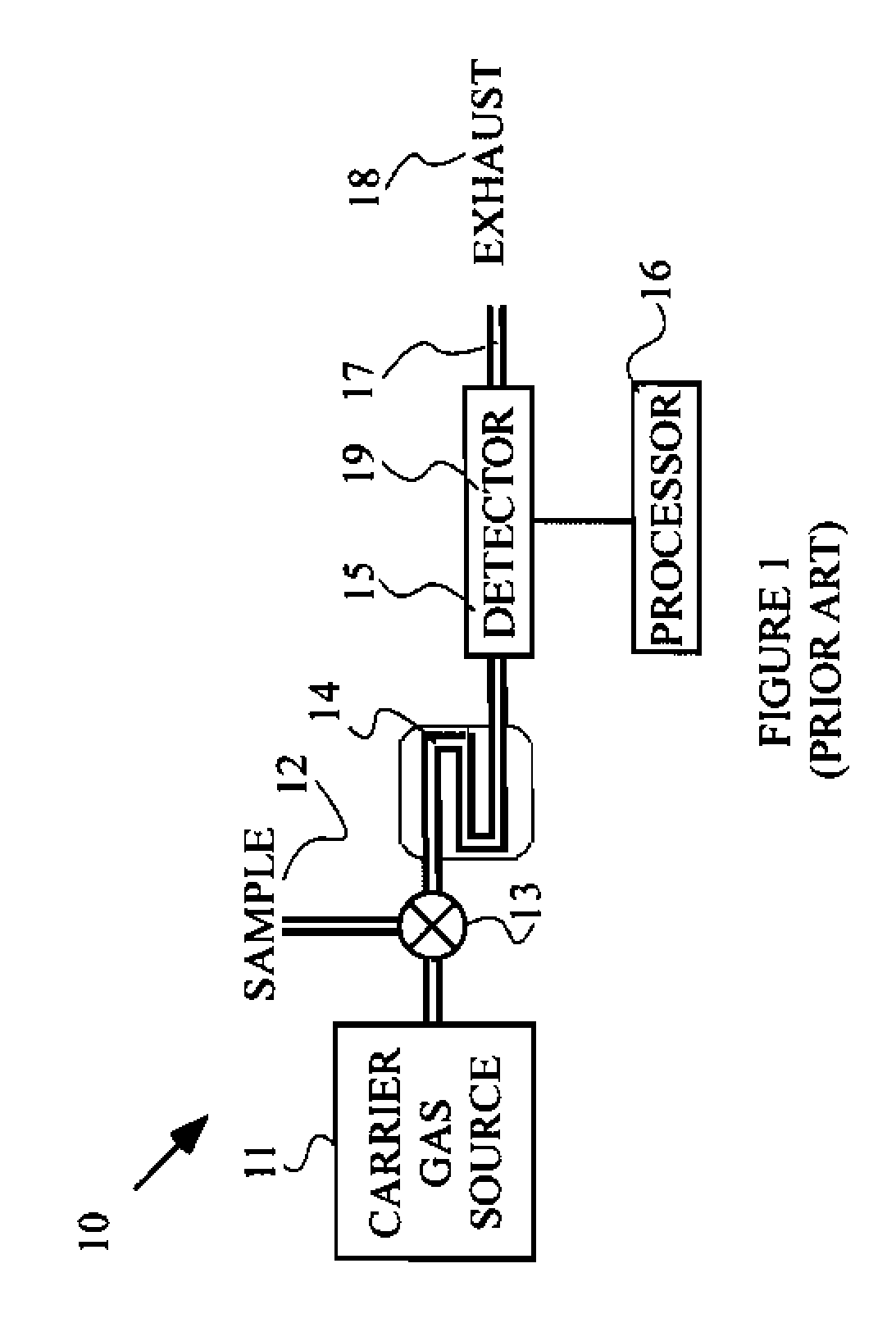

Choked Flow Isolator for Noise Reduction in Analytical Systems

An apparatus and a method of making a measurement using the same. The apparatus includes a channel through which a fluid flows, a detector, and a choked flow channel. The detector measures a property of the fluid by generating a signal that depends on that property. The signal generated also depends on a pressure of the fluid in the detector. The choked flow channel receives the fluid at a first pressure after the fluid has been measured by the detector, and then transmits the fluid to a downstream location at a second pressure. The fluid reaches a supersonic velocity at one point in the choked flow channel. The choked flow channel may include a convergent-divergent nozzle or an orifice in a structure located in the choked flow channel.

Owner:AGILENT TECH INC

Method and apparatus for selective injection or flow control with through-tubing operation capacity

An in-line flow control device for a well chokes flow through a conduit while allowing access therethrough.

Owner:SCHLUMBERGER TECH CORP

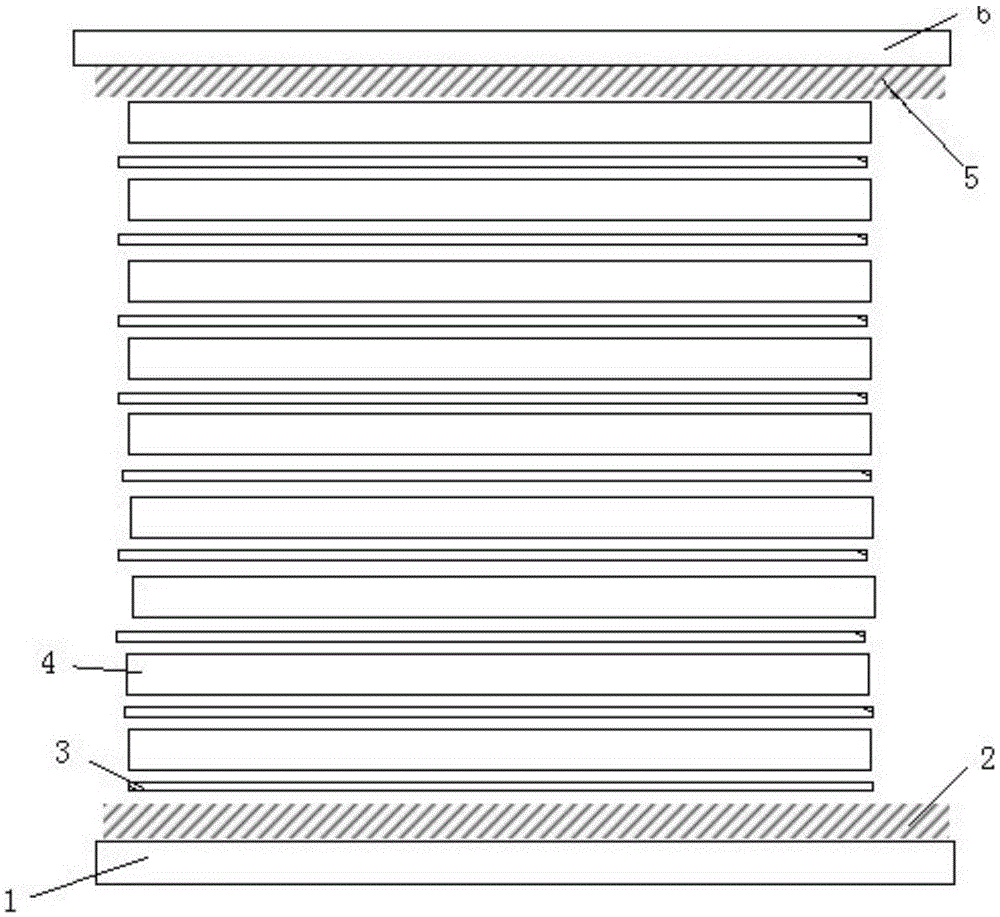

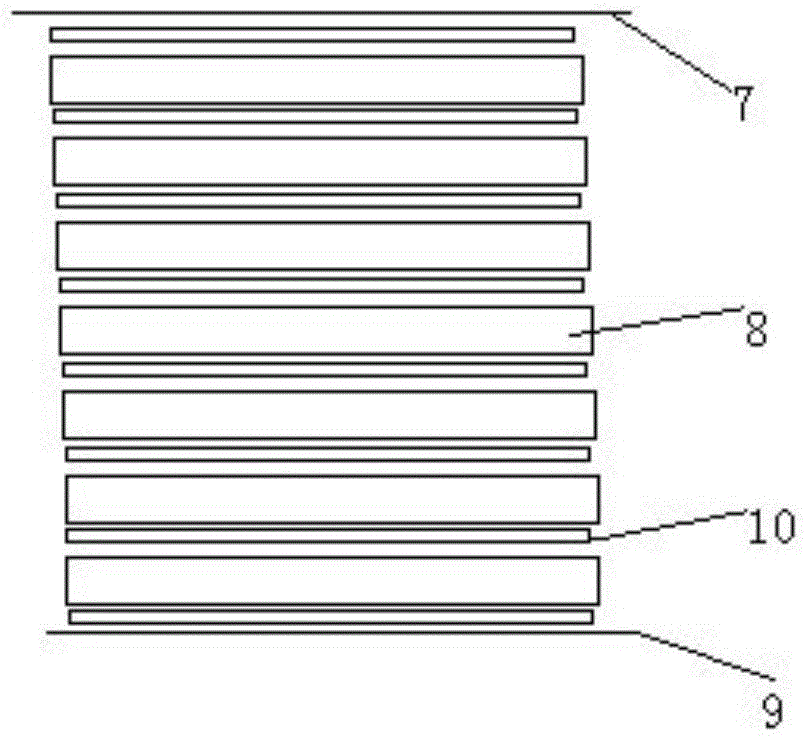

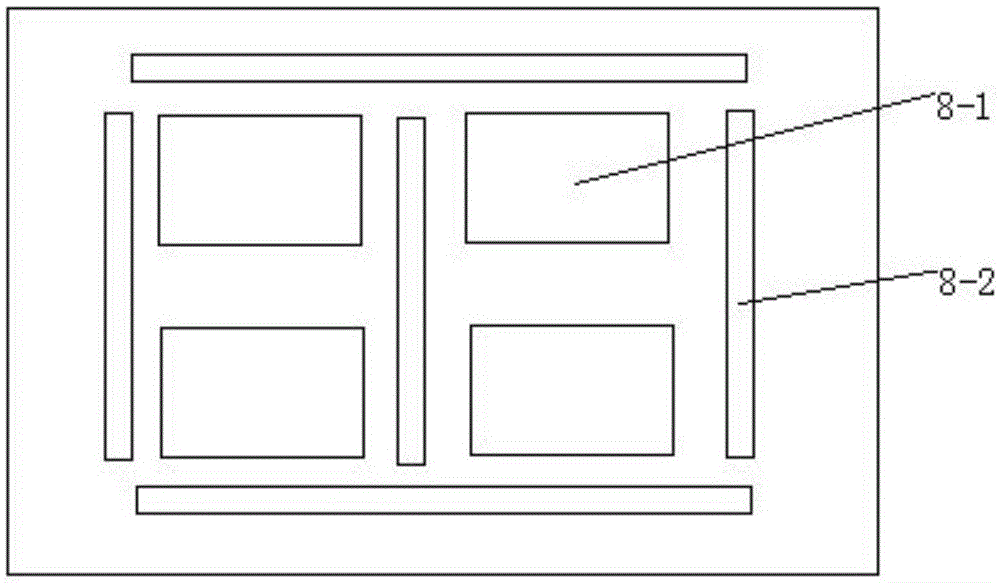

Control method for uniformly laminating multi-layered PCB

A control method for uniformly laminating a multi-layered PCB is disclosed. The control method comprises the steps of PCB laminating and pressing. The control method is simple, convenient, and easy to operate and master; the layers are aligned accurately and the PCB is pressed uniformly; board sliding and decompression can be avoided, and high product quality can be achieved; the lamination process is easy to control, and easy machining and low cost are realized as well; the relatively consistent uniformity of the thickness of each laminated board among different layers can be accurately ensured; sufficient and uniform flowing adhesive in all directions is supplied; the thickness and the impedance of a laminated dielectric layer are moderate; the board edge is designed in a choked-flow manner; the overall uniformity of the laminated PCB is high; the fused flowing time of resin in a prepreg is prolonged, so that sufficient stuffing among the multiple core plate layers is ensured, uniform fused resin flowing is realized, and the efficiency is greatly improved; and in addition, the service life of equipment is prolonged, the lamination quality is effectively ensured, and the production cost is lowered.

Owner:AOSHIKANG TECH CO LTD

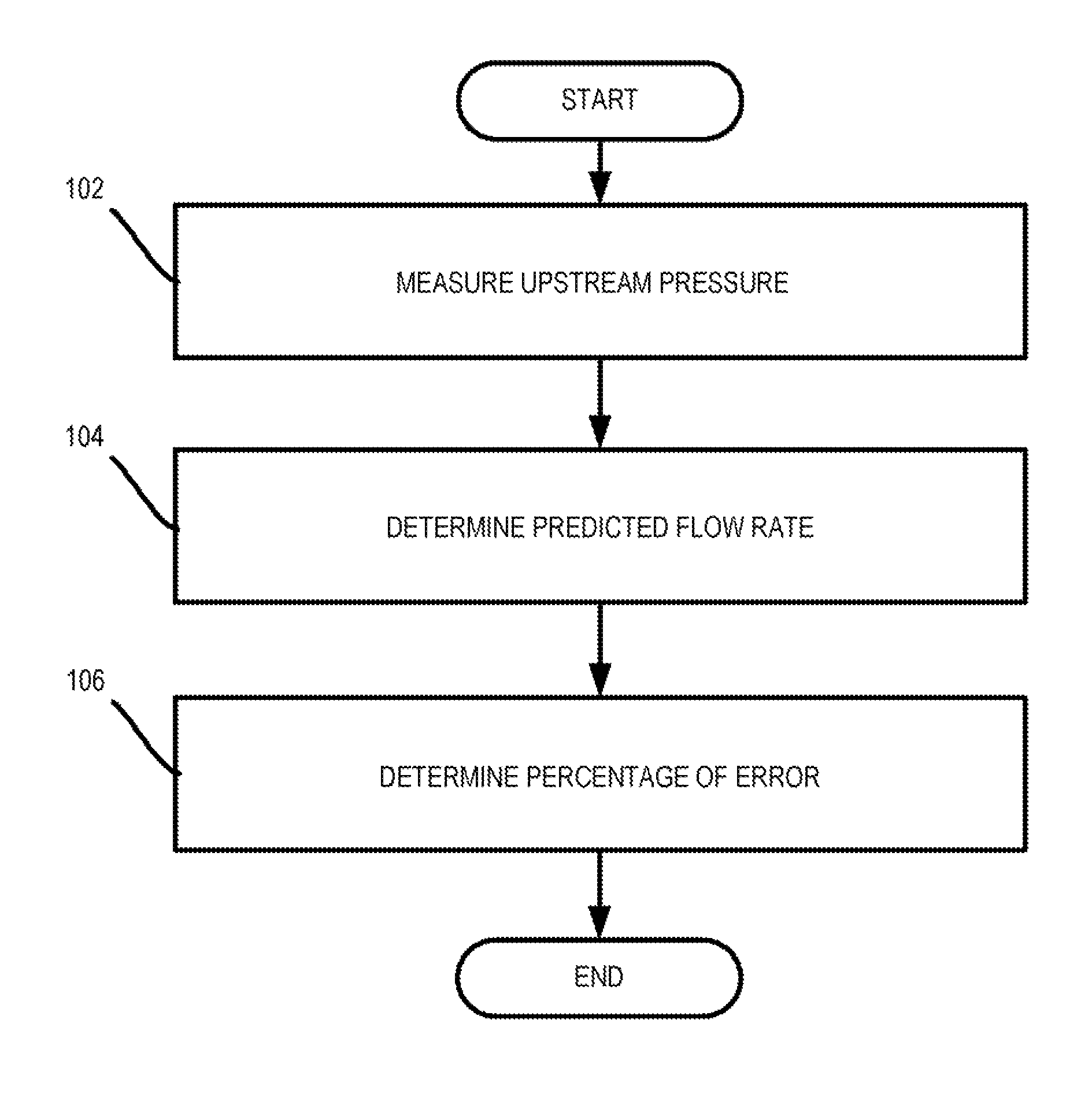

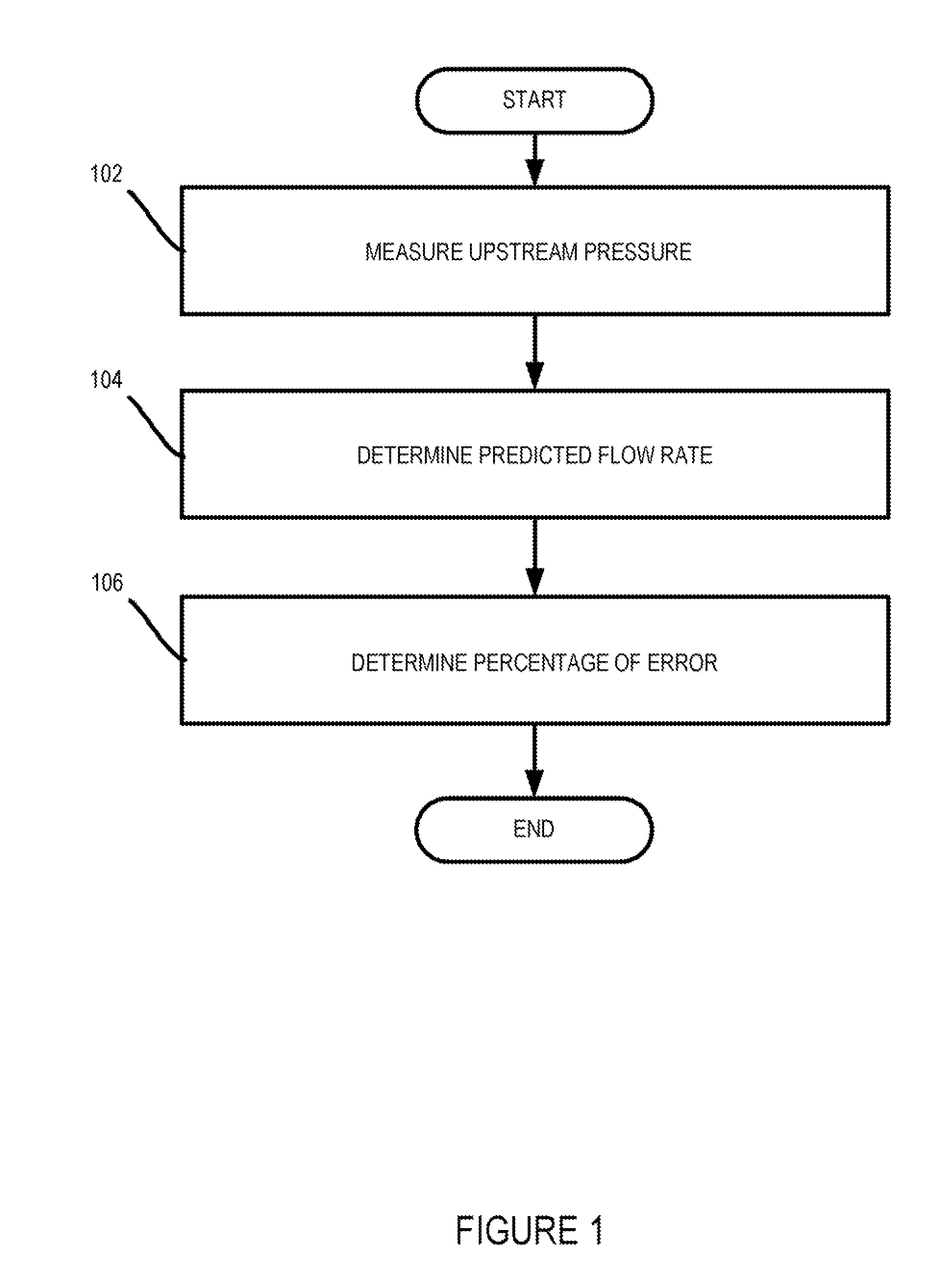

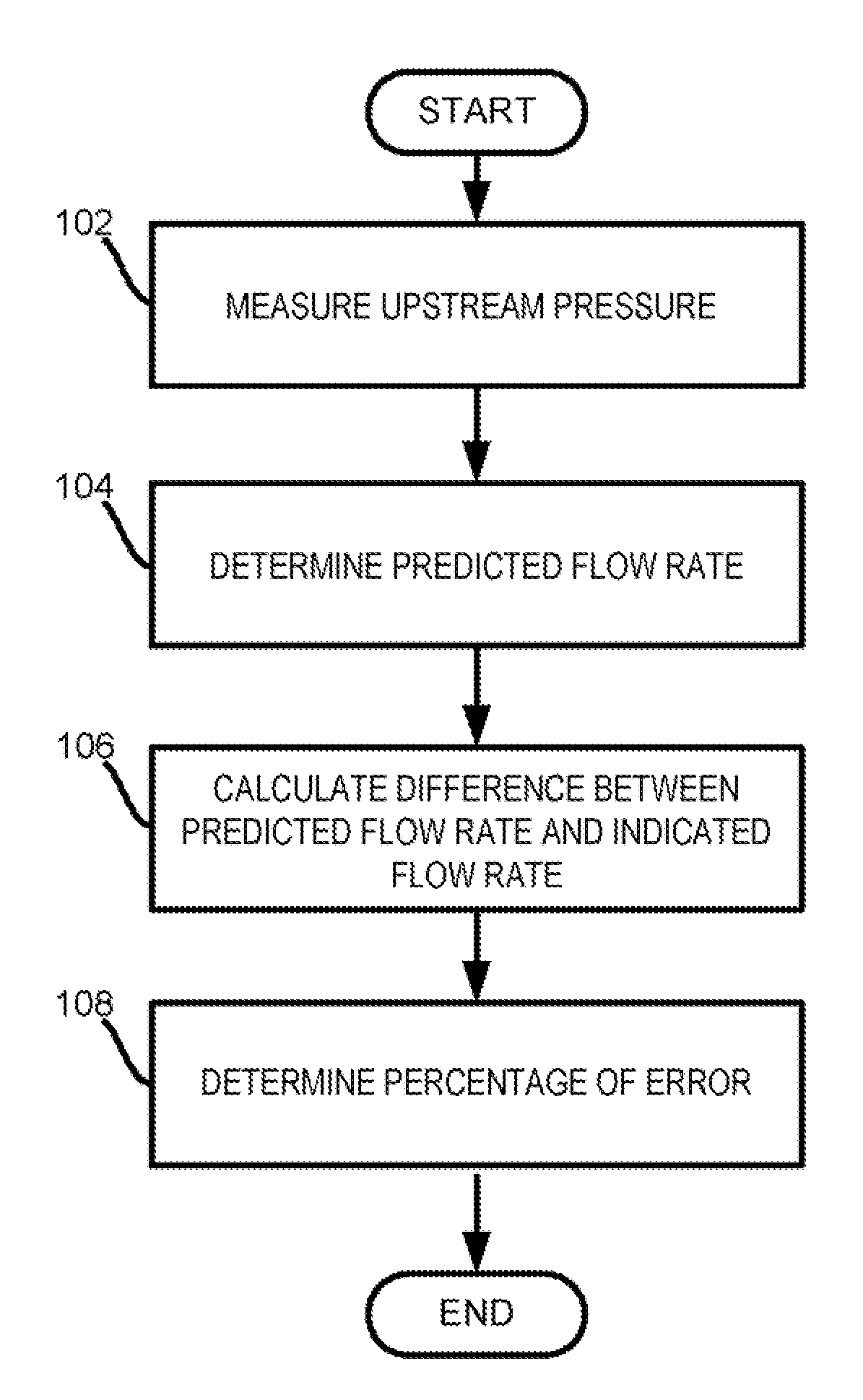

Methods for performing transient flow prediction and verification using discharge coefficients

ActiveUS7881886B1Testing/calibration apparatusFluid pressure measurementChoked flowProcess engineering

A method for determining an actual gas flow rate as gas flows through a gas flow delivery system is provided. The method includes sending the gas through the gas flow delivery system into a gas conduit, wherein a section of the gas conduit is widened to form an orifice. The method also includes pressurizing the gas to create a choked flow condition within the orifice of the gas conduit. The method further includes measuring upstream pressure of the gas via a set of pressure sensors. The method yet also includes calculating the actual flow rate based on the upstream pressure of the orifice of the gas conduit.

Owner:LAM RES CORP

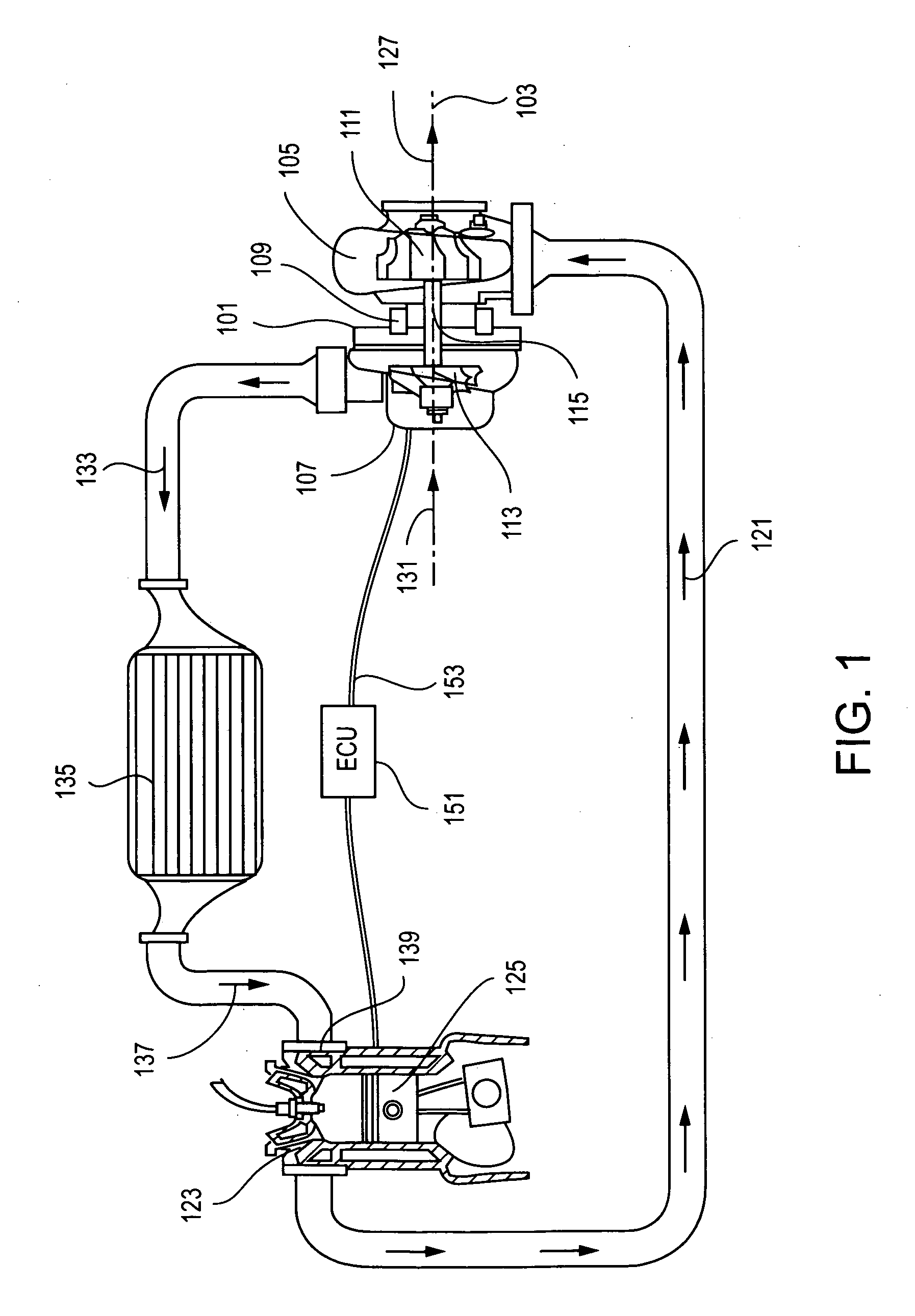

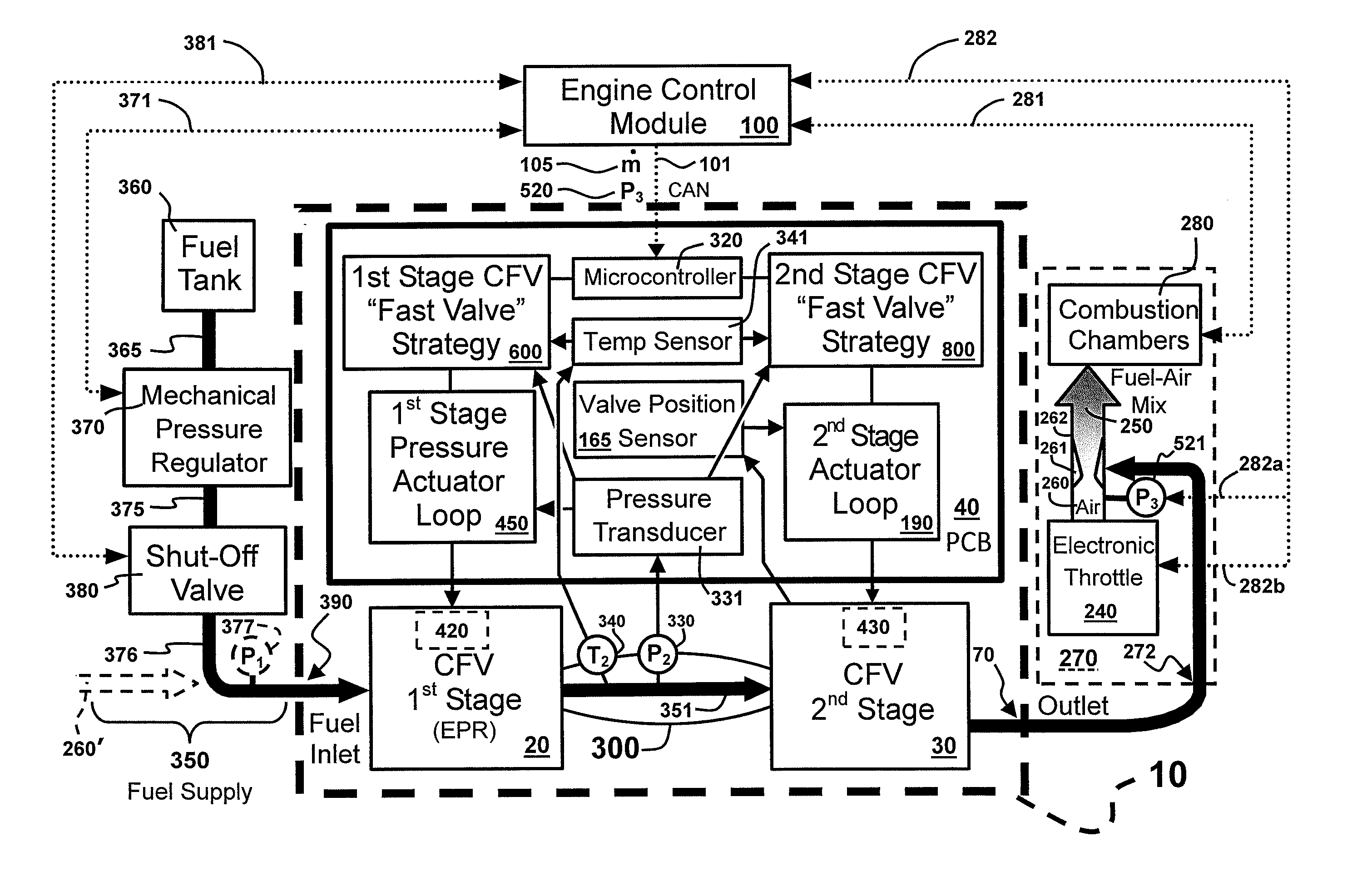

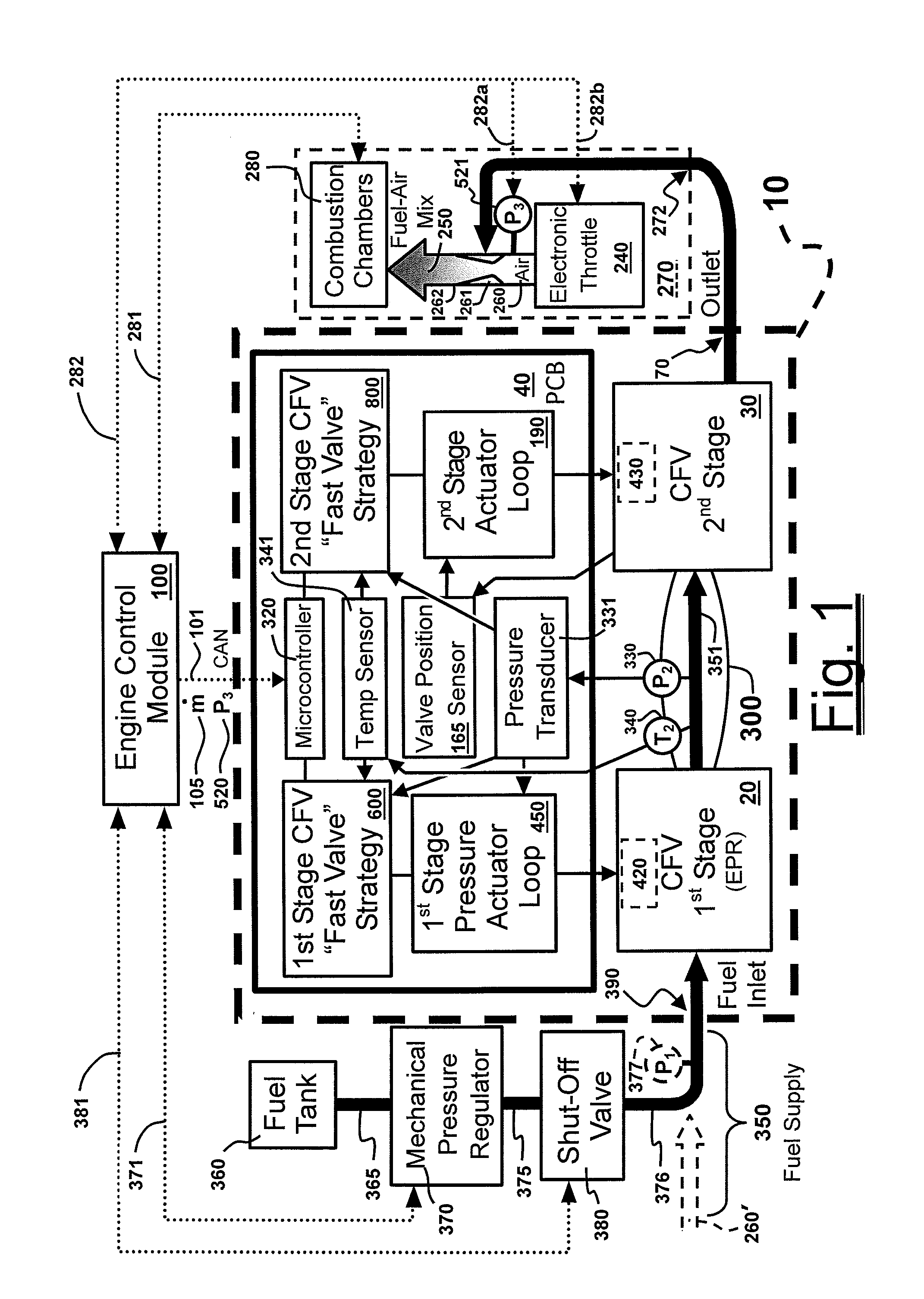

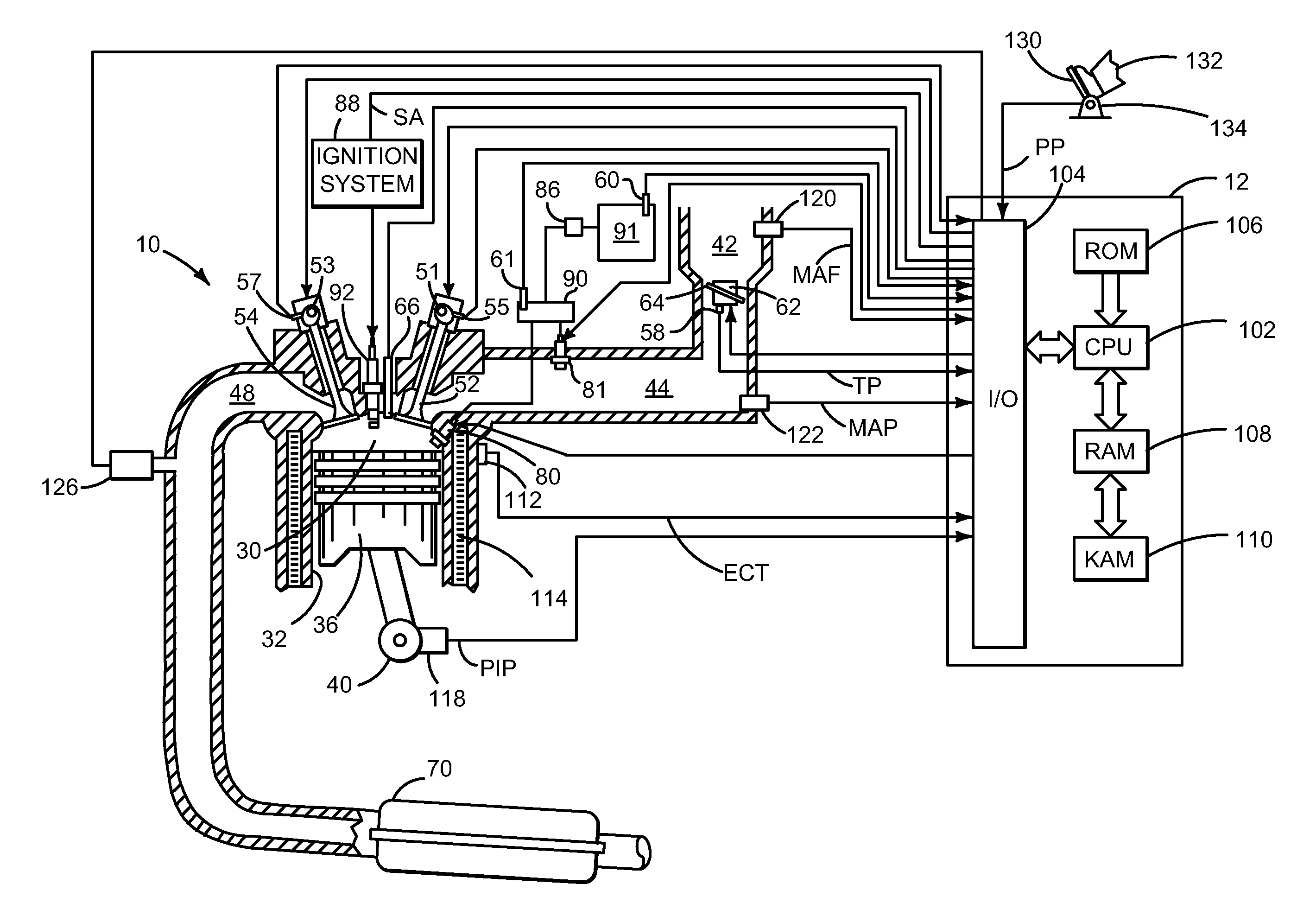

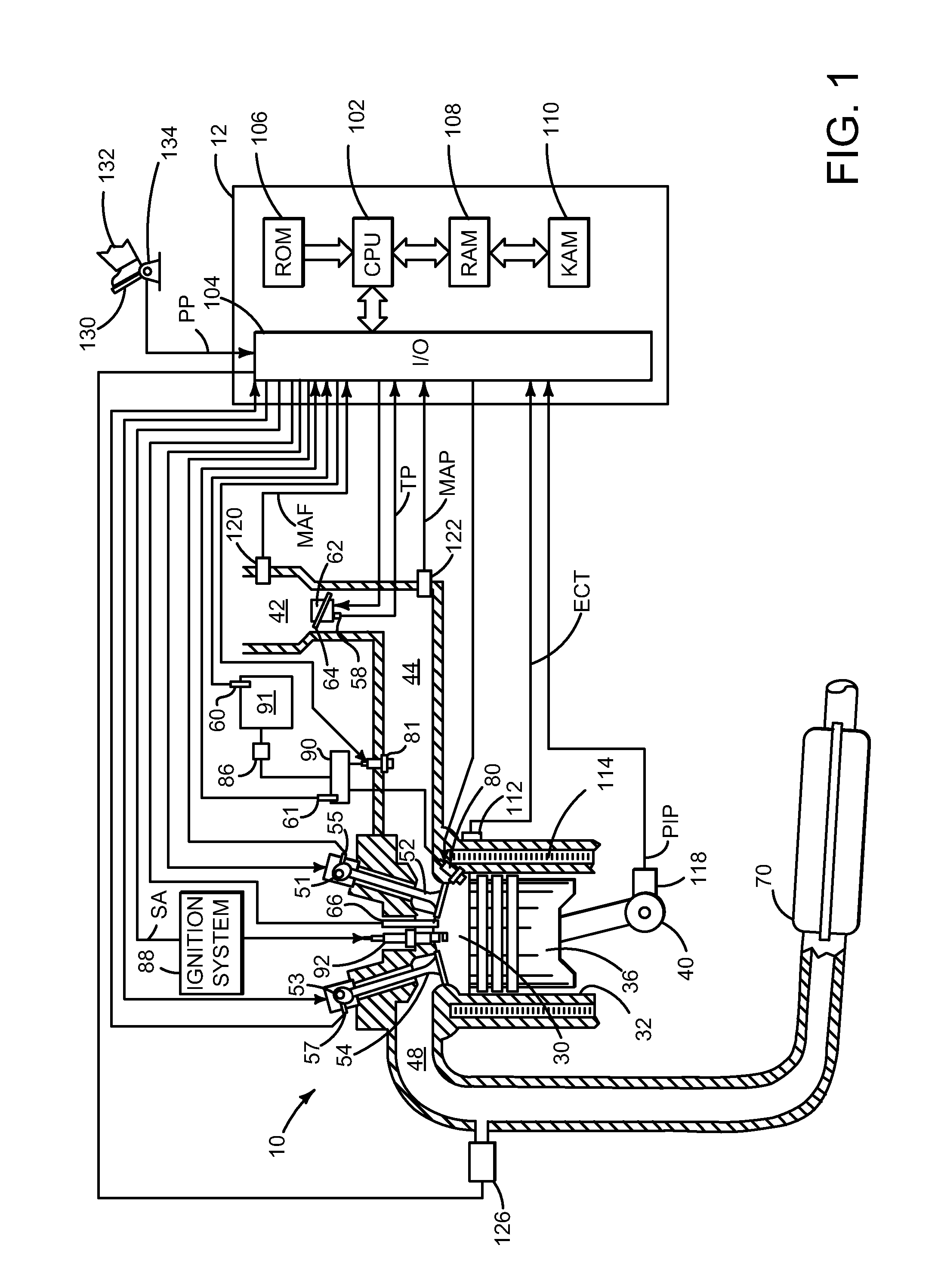

Highly Accurate Continuous-Flow Vaporized Fuel Supply for Large Dynamic Power Ranges

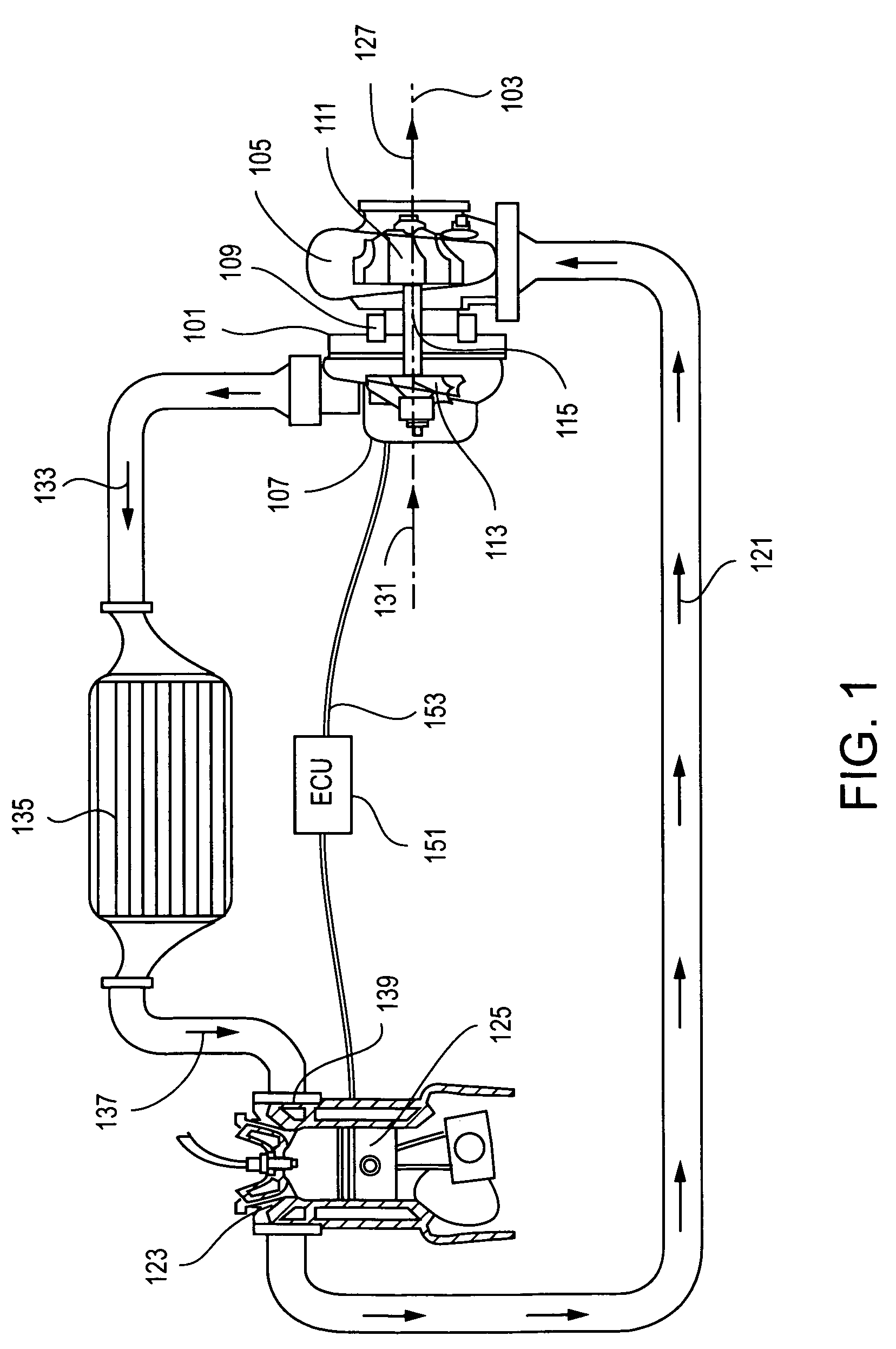

ActiveUS20130333671A1Extreme accuracyHighly-accurate gaseous fuel flowrate controlElectrical controlInternal combustion piston enginesDual stageValve actuator

Methods and systems for accurate and precise fuel supply control for continuous-flow of gaseous fuel to an internal combustion engine over a large dynamic power range, including a dual-stage valve that allows optimal control—a first stage in the form of a voice-coil driven electronic pressure regulator, and a second stage in the form of a voice-coil-driven choked-flow valve; monitoring the pressure of the fuel intermediate the two stages and making appropriate adjustments to the first stage via a pressure actuator loop; feeding the gaseous fuel mixture through a unitary block assembly into the second stage; monitoring the pressure of the air / fuel mixture and making appropriate adjustments to the second stage via a valve actuator control loop.

Owner:ECONTROLS LLC

High resolution gas gauge proximity sensor

ActiveUS20050241371A1Reduce decreasePhotomechanical treatmentFluid pressure measurement by mechanical elementsProximity sensorChoked flow

In a gas gauge, effects due to changes in the local environment are reduced by causing a measurement nozzle and a reference nozzle to react as if they were co-located, or located at approximately the same position. This is achieved by venting the reference nozzle in very close proximity to the measurement nozzle. A reference chamber surrounding the reference plate and reference nozzle is vented at approximately the same location as the measurement nozzle. In an embodiment for use in a vacuum environment, the measurement nozzle is surrounded with an annular ring. The measurement annular ring is connected to an annular ring around the reference nozzle, which acts to co-locate the reference nozzle and the measurement nozzle. To avoid choked flow, another annular ring or rings may be placed around the measurement annular ring.

Owner:ASML HLDG NV

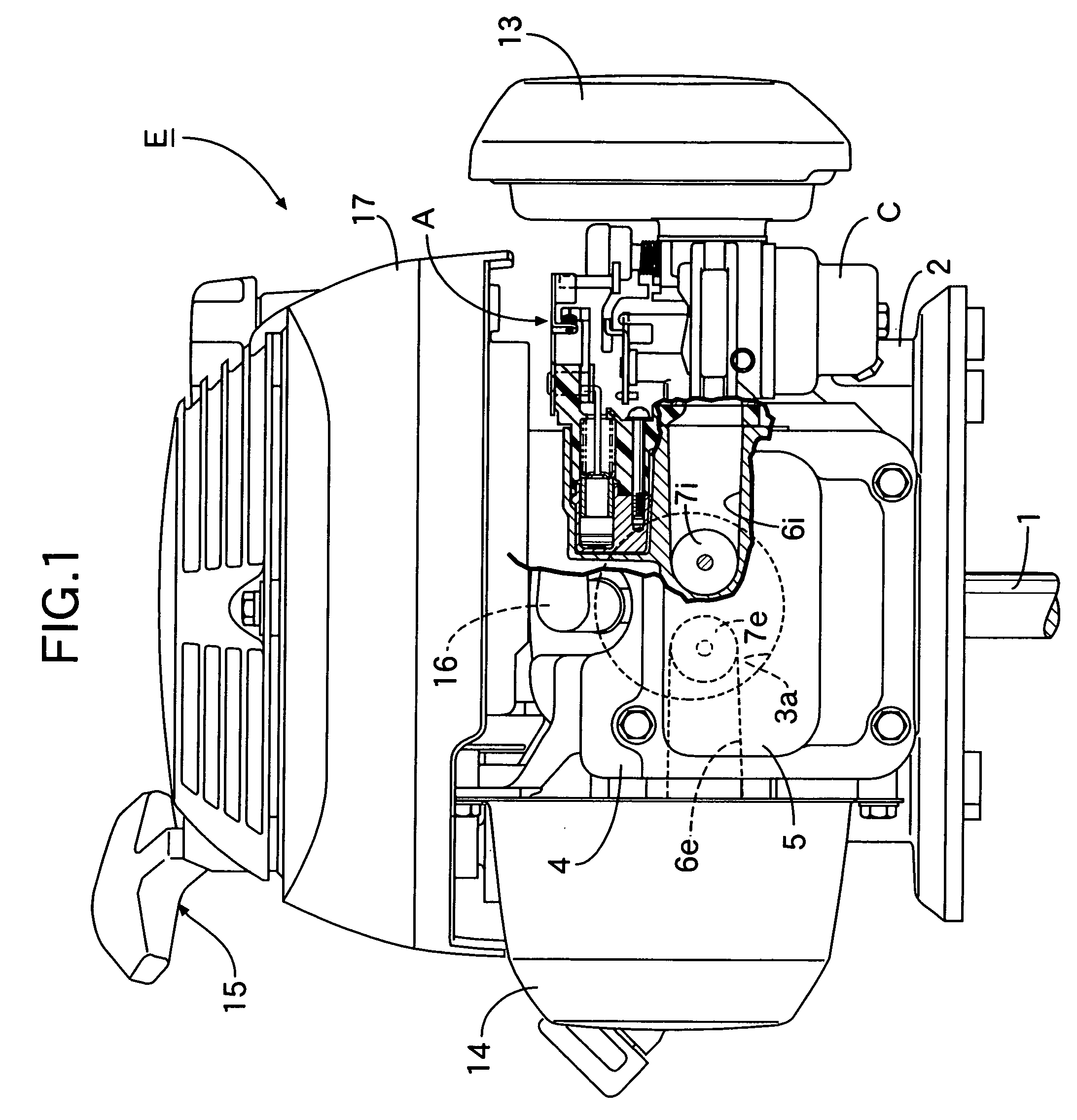

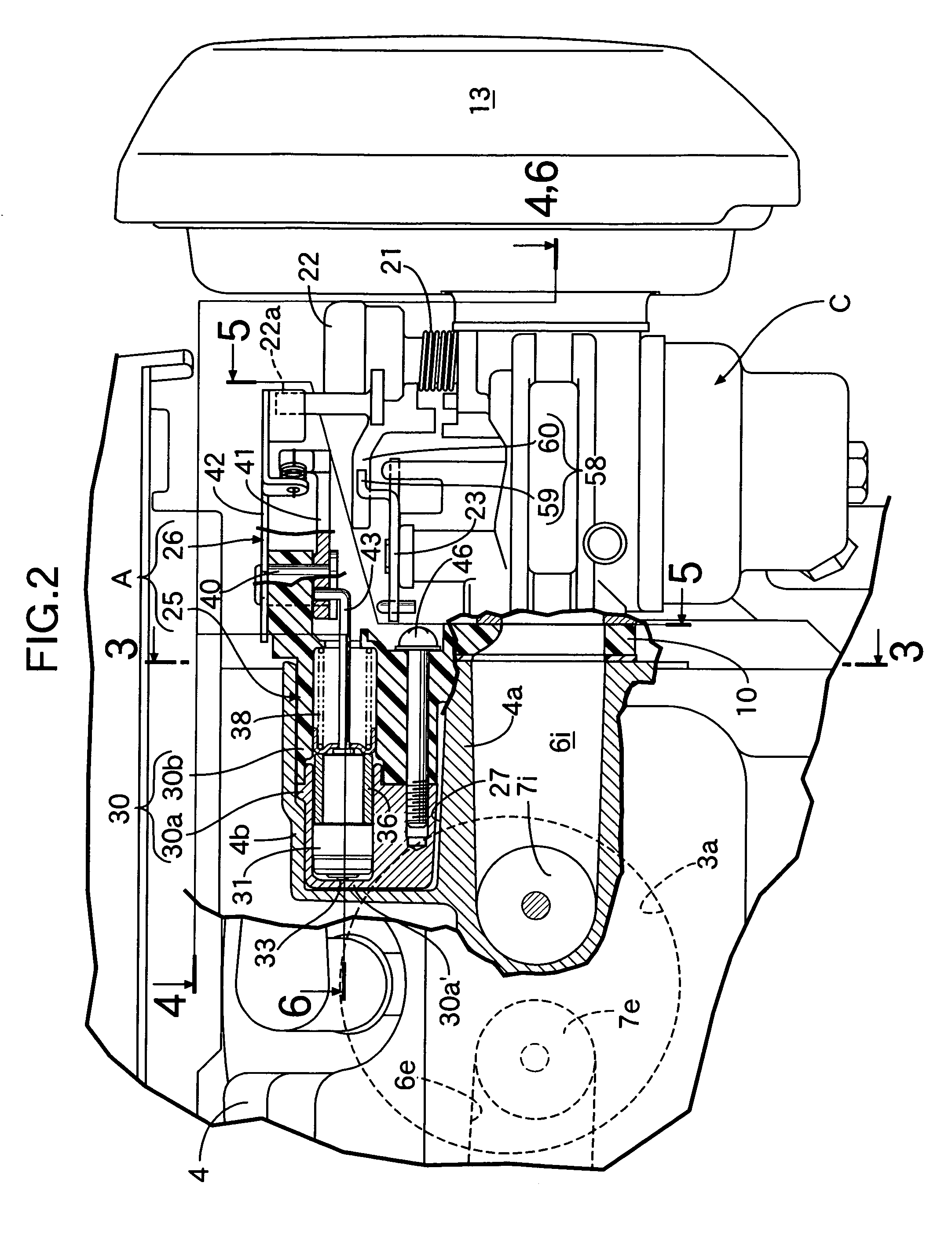

Carburetor throttle valve control system

InactiveUS7246794B2Stable conditionMake up bulkyLighting and heating apparatusUsing liquid separation agentAutomatic controlControl system

A carburetor valve control system for stabilizing engine warm-up operating conditions by automatically controlling the degree of opening of a throttle valve so as to be larger than a normal degree of opening for idling, without carrying out a special operation of appropriately strengthening the spring force of a governor spring. The carburetor throttle valve control system includes a throttle lever and a governor system coupled to the throttle lever. A choke return spring is connected to a choke lever, the choke return spring urging the choke lever to a choke valve closing side. An automatic choke system is disposed so as to face the choke lever. A throttle valve closure restricting member is provided between the throttle lever and the choke lever. During engine warming-up, when the spring force of a governor spring is adjusted to zero or a minimum, the choke lever restricts closing of the throttle valve via the throttle lever by means of the spring force of the choke return spring.

Owner:HONDA MOTOR CO LTD

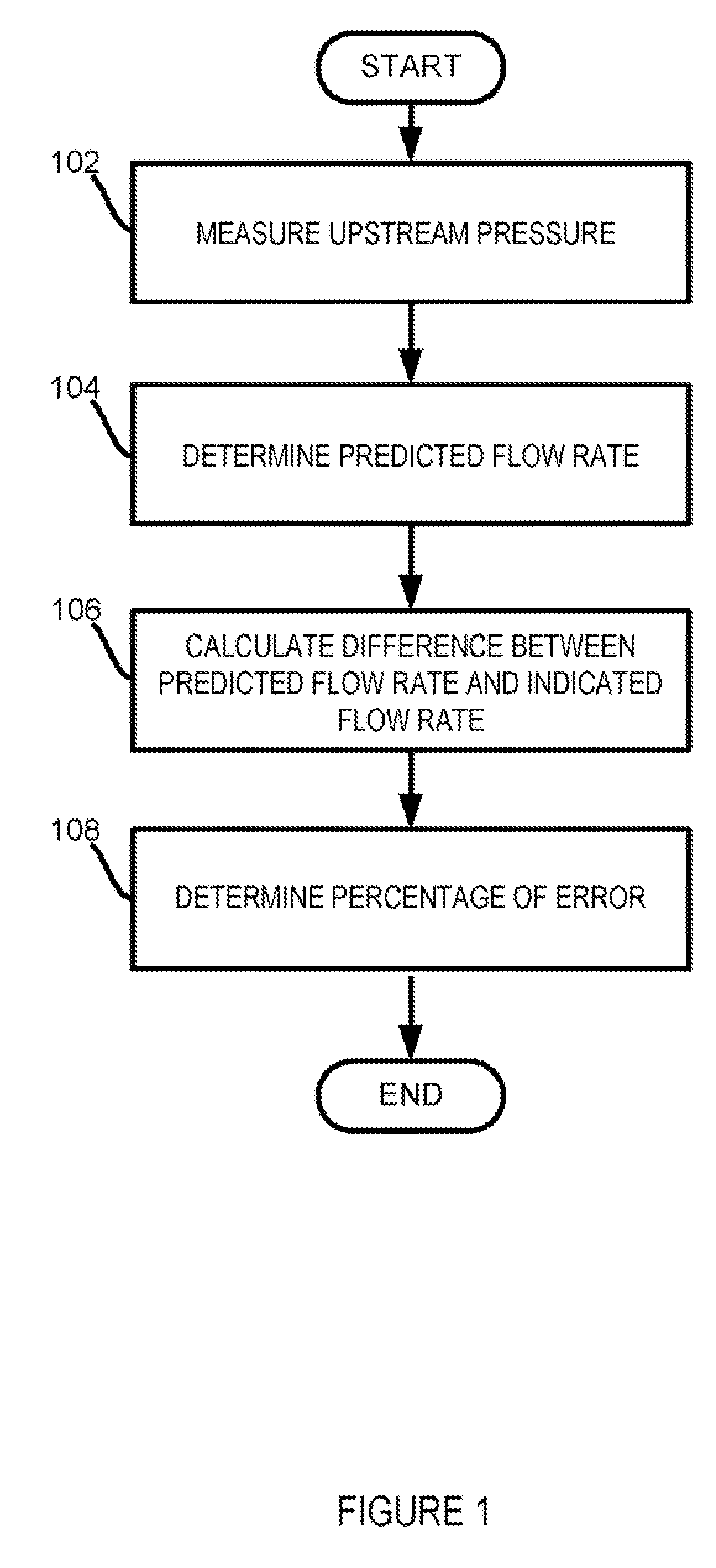

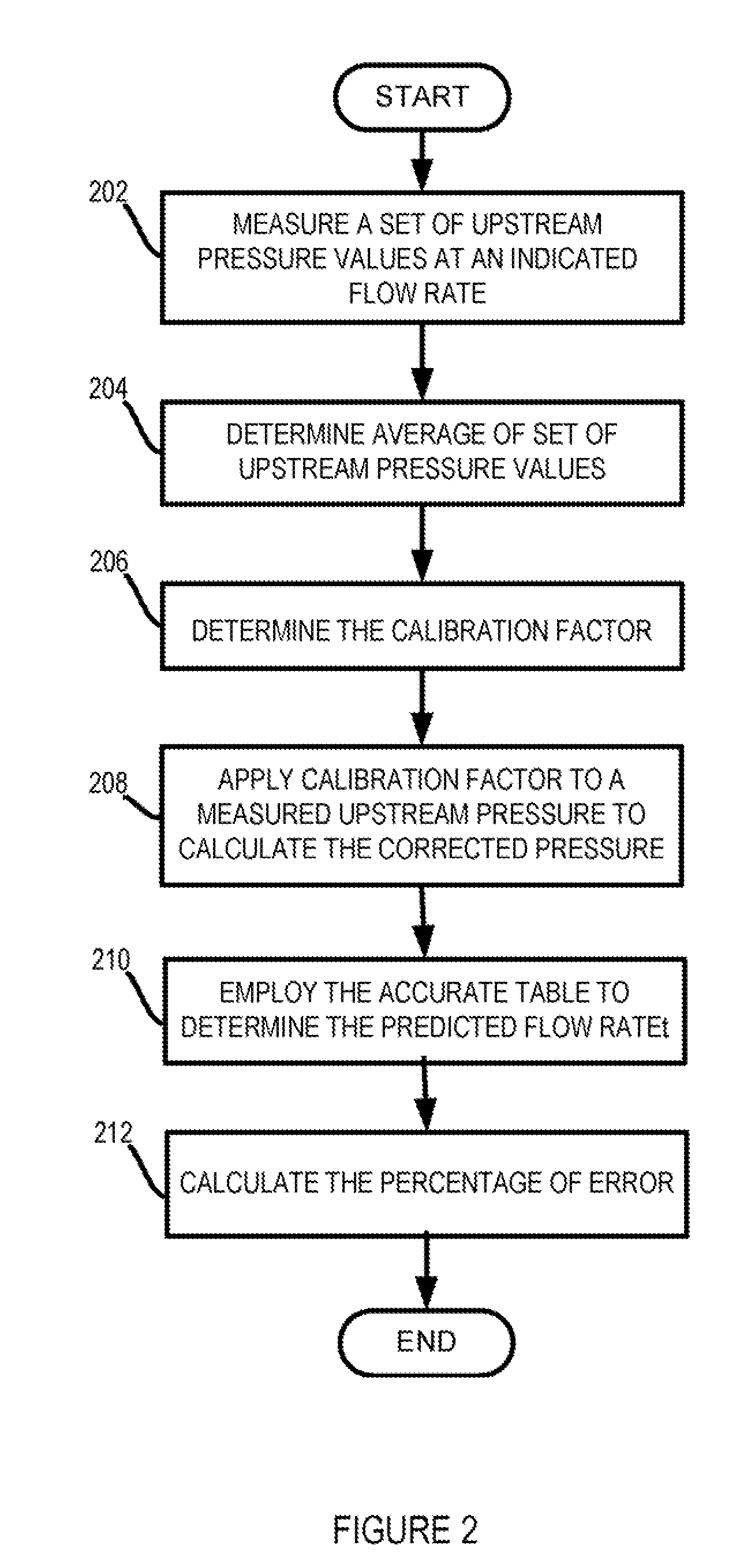

Methods for performing actual flow verification

ActiveUS20080115560A1Testing/calibration apparatusSemiconductor/solid-state device manufacturingChoked flowEngineering

A method for determining an actual gas flow rate in a reaction chamber of a plasma processing system is provided. The method includes delivering gas fay a gas flow delivery system controlled by a mass flow controller (MFC) to an orifice, which is located upstream from the reaction chamber. The method also includes pressurizing the gas to create a choked flow condition within the orifice. The method further includes measuring a set of upstream pressure values of the gas via a set of pressure sensors. The method yet also includes applying a calibration factor of a set of calibration factors to determine the actual flow rate. The calibration factor is a ratio of an average of the set of upstream pressure values to an average of a set of golden upstream pressure values, which is associated with an indicated flow rate for an MFC.

Owner:LAM RES CORP

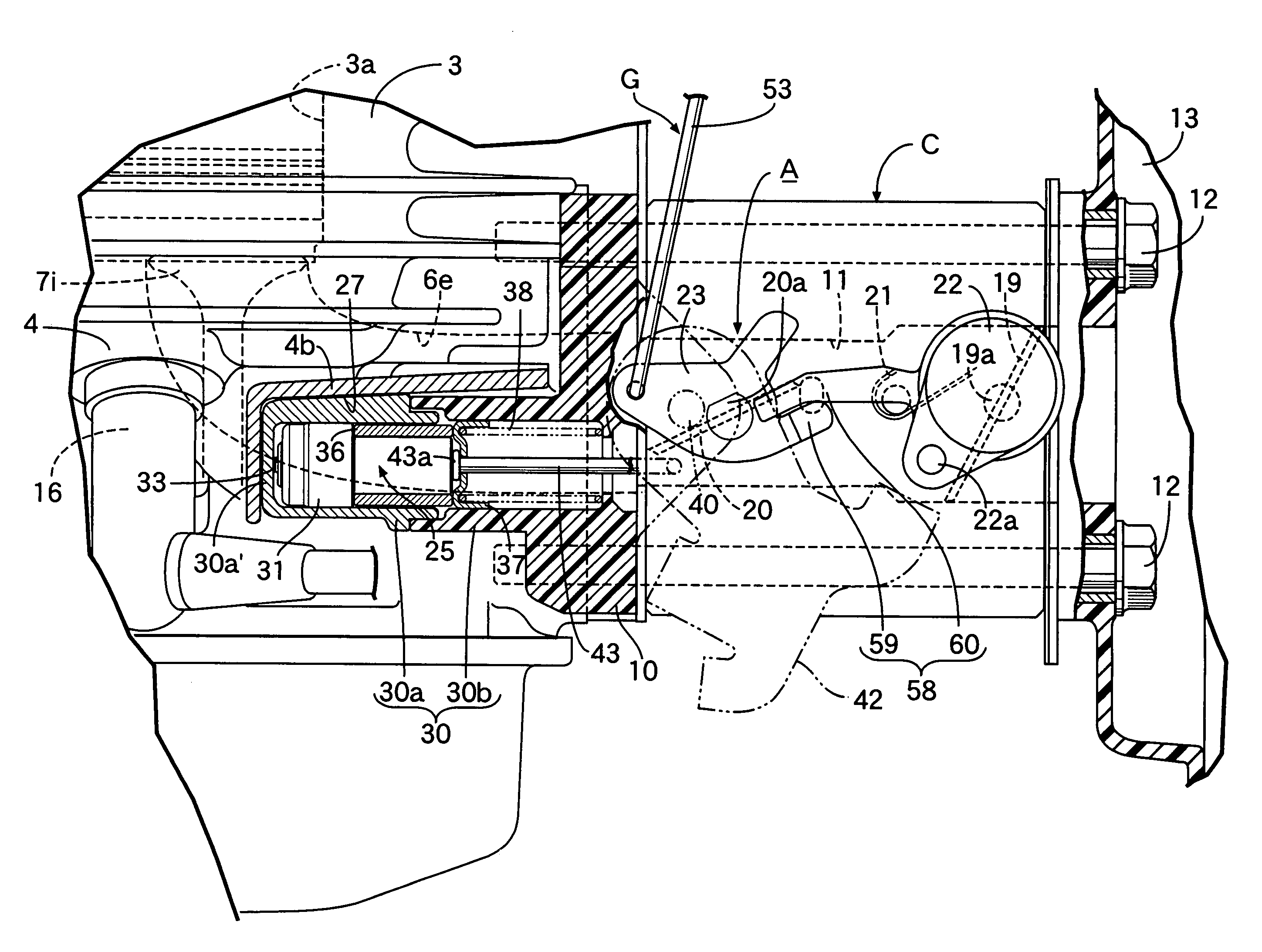

Centrifugal compressor

ActiveCN104428539ALarge range of motionReduce chokeInternal combustion piston enginesEngine manufactureRotational axisChoked flow

An object is to position a plurality of guide vanes for generating swirl flow at a housing inner circumferential side in front of an impeller wheel to improve a surge margin and to restrict the decrease in a choke flow rate, thereby increasing an operation range of a compressor. A compressor 19 includes a compressor housing 15, an impeller wheel 7 which compresses intake gas flowing in from an intake-air inlet 23, a swirl-flow generating part including a plurality of guide vanes 55 disposed circumferentially along an inner circumferential wall of the intake-air channel 21 between the intake-air inlet 23 and the impeller wheel 7 and which swirls the intake gas from the intake-air inlet 23 around the rotational axis, and a central intake-air flow path 59 formed inside the guide vanes 55 to allow intake gas to flow to the impeller wheel 7 without passing through the guide vanes 55.

Owner:MITSUBISHI HEAVY IND LTD

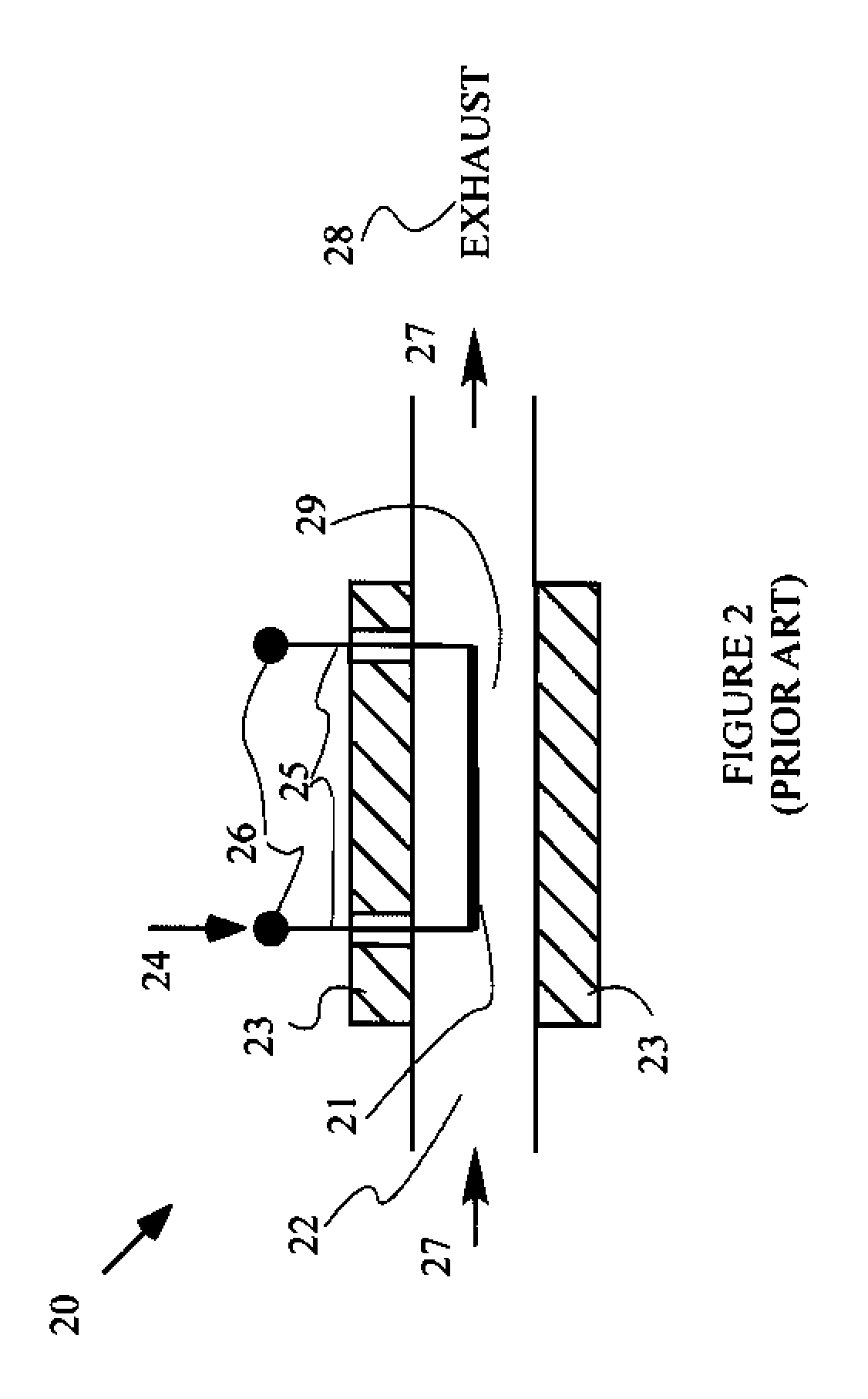

Automatic flow blocking system for reverse pulse filter cleaning

ActiveUS8876928B2Guaranteed uptimeEasy constructionCombination devicesAuxillary pretreatmentAir filterChoked flow

A powder processing system having a processing vessel into which powder is pneumatically supplied and an exhaust plenum that communicates with the processing vessel through an exhaust port. A filter is located at the exhaust port for filtering air borne powder from the air flow exiting the processing vessel, and a reverse pulse air filtering device is provided for selectively removing accumulated powder from the filter. The cleaning device includes a nozzle having a first portion within the air plenum and a second portion within the air filter, and a plunger is mounted on the first filter portion for movement to an exhaust port closing position as an incident to the direction of pressurized air through the first portion of the nozzle for enabling pressurized air from the second portion of the nozzle to thereupon be directed through the filter without hindrance of air exiting the processing vessel.

Owner:SPRAYING SYST

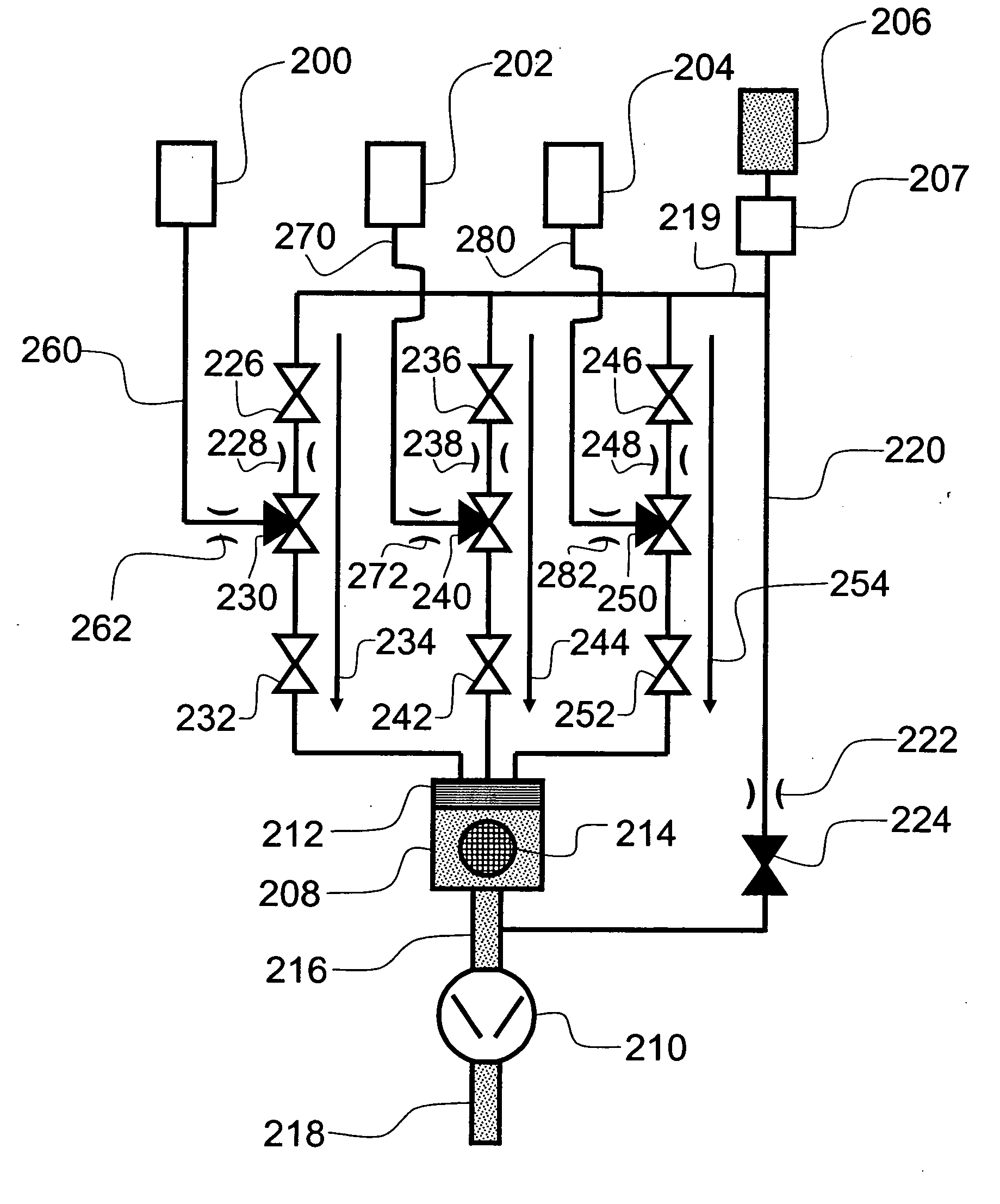

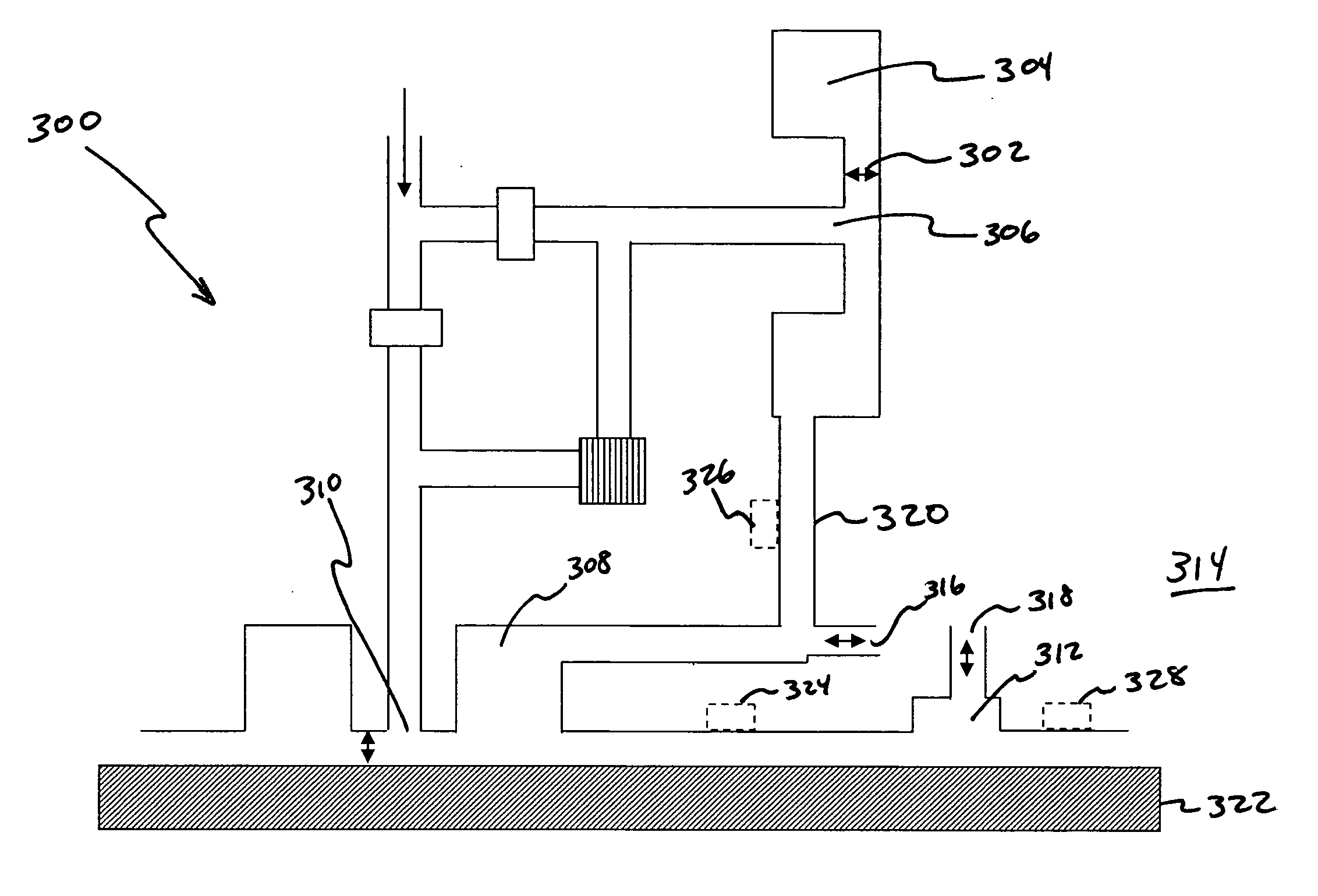

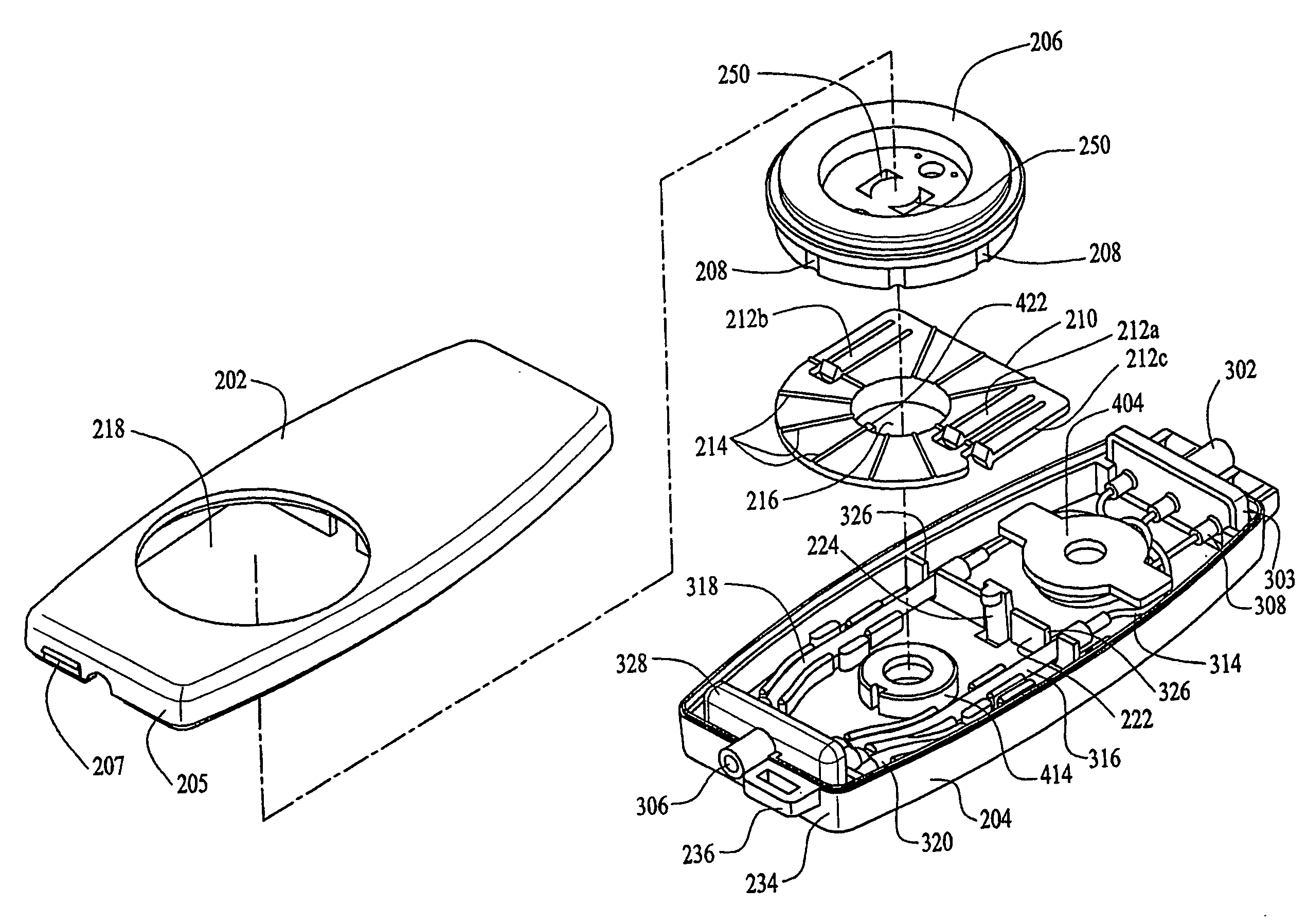

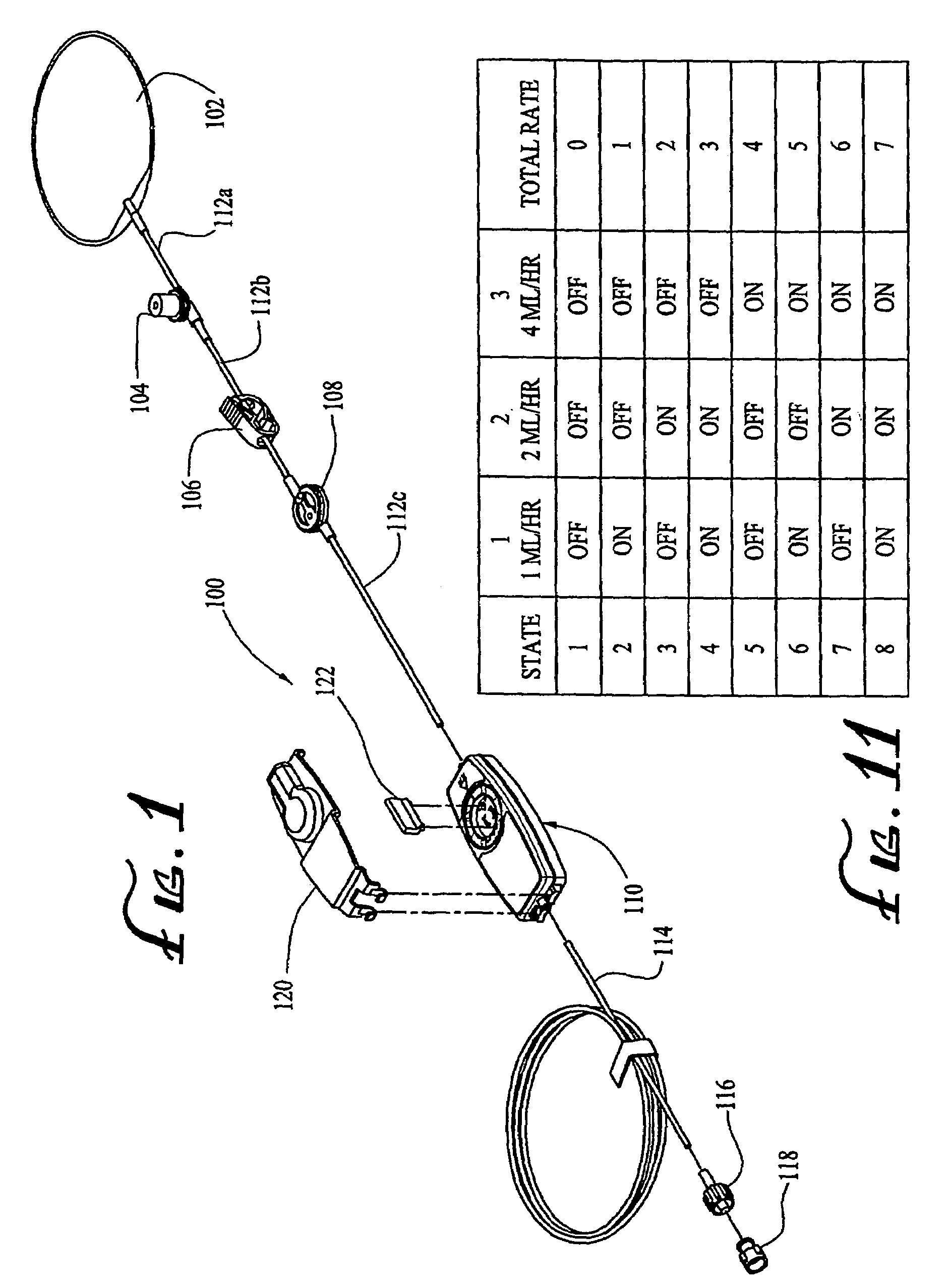

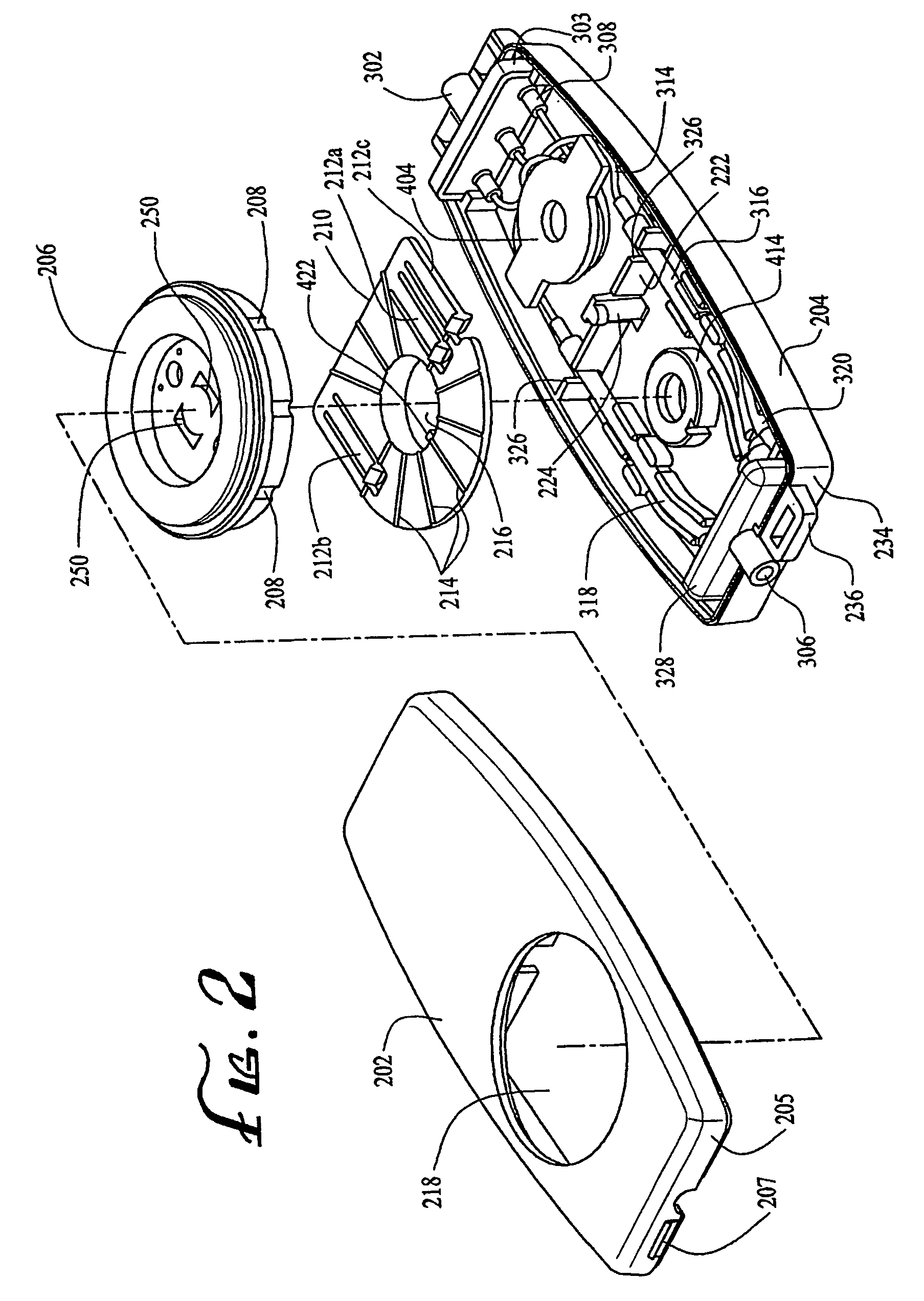

Device for selectively regulating the flow rate of a fluid

ActiveUS7455072B2Reduce manufacturing costSimple and reliable to useDiaphragm valvesOperating means/releasing devices for valvesChoked flowEngineering

A device for regulating the flow rate of a fluid includes a housing containing a plurality of flow conduits fluidly connecting an inlet and an outlet, each of the flow conduits comprising a flow control tube (310, 312, 314) and a resiliently compressive occlusion tube (316, 318, 320), wherein the flow control tubes are of substantially equal internal diameter. Each of the flow control tubes has a length associated with a different flow rate. A resilient flow-blocking element (212a, 212b, 212c) is operatively associated with each of the occlusion tubes and is movable into a flow-blocking compression against its associated occlusion tube. An actuation mechanism (206) in the housing is operable: (a) to selectively engage and move one or more of the flow-blocking elements into the flow-blocking compression against its associated occlusion tube, and (b) to selectively be disengaged from any of the flow-blocking elements.

Owner:AVENT INC

Centrifugal compressor

ActiveCN104428509ASmall inspiratory airflow resistanceReduce throttling flowInternal combustion piston enginesEngine manufactureRotational axisChoked flow

An object is to position guide vanes for generating swirl flow at a housing inner circumferential side in front of an impeller wheel to improve a surge margin and to restrict decrease in a choke flow rate, while making the inclination angle of the guide vanes variable. A centrifugal compressor 19 includes a compressor housing 15, an impeller wheel 7 which compresses intake gas from an intake-air inlet 23, a plurality of guide vanes 63 disposed circumferentially along an inner circumferential wall of the intake-air channel 21 between the intake-air inlet 23 and the impeller wheel 7 to swirl the intake gas around the rotational axis, a central intake-air flow path 71 formed at an inner side of the guide vanes 63 to allow the intake gas to flow to the impeller wheel without passing through the guide vanes 63, and a guide-vane moving mechanism 73 which simultaneously changes the inclination angle of the guide vanes 63.

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

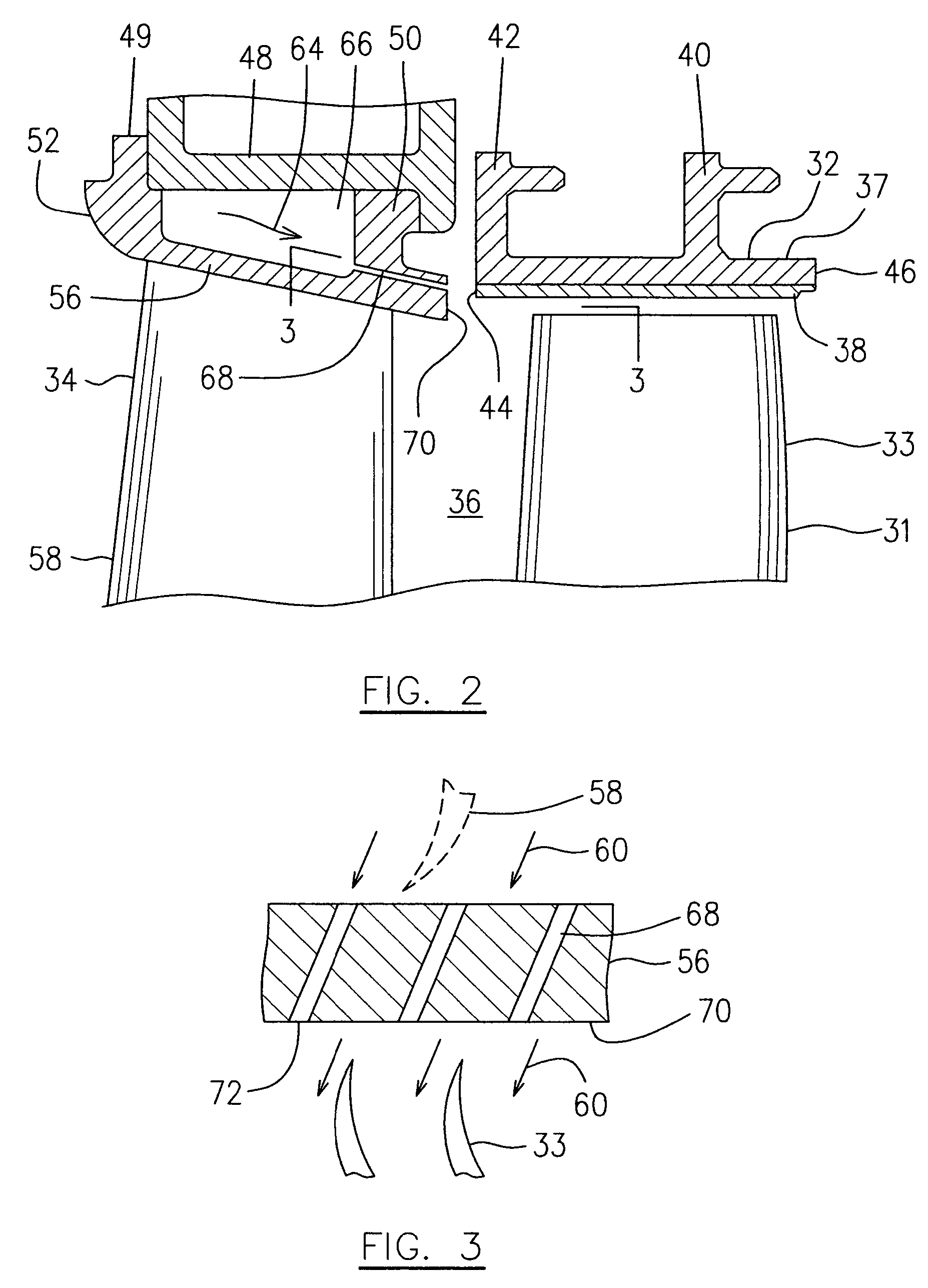

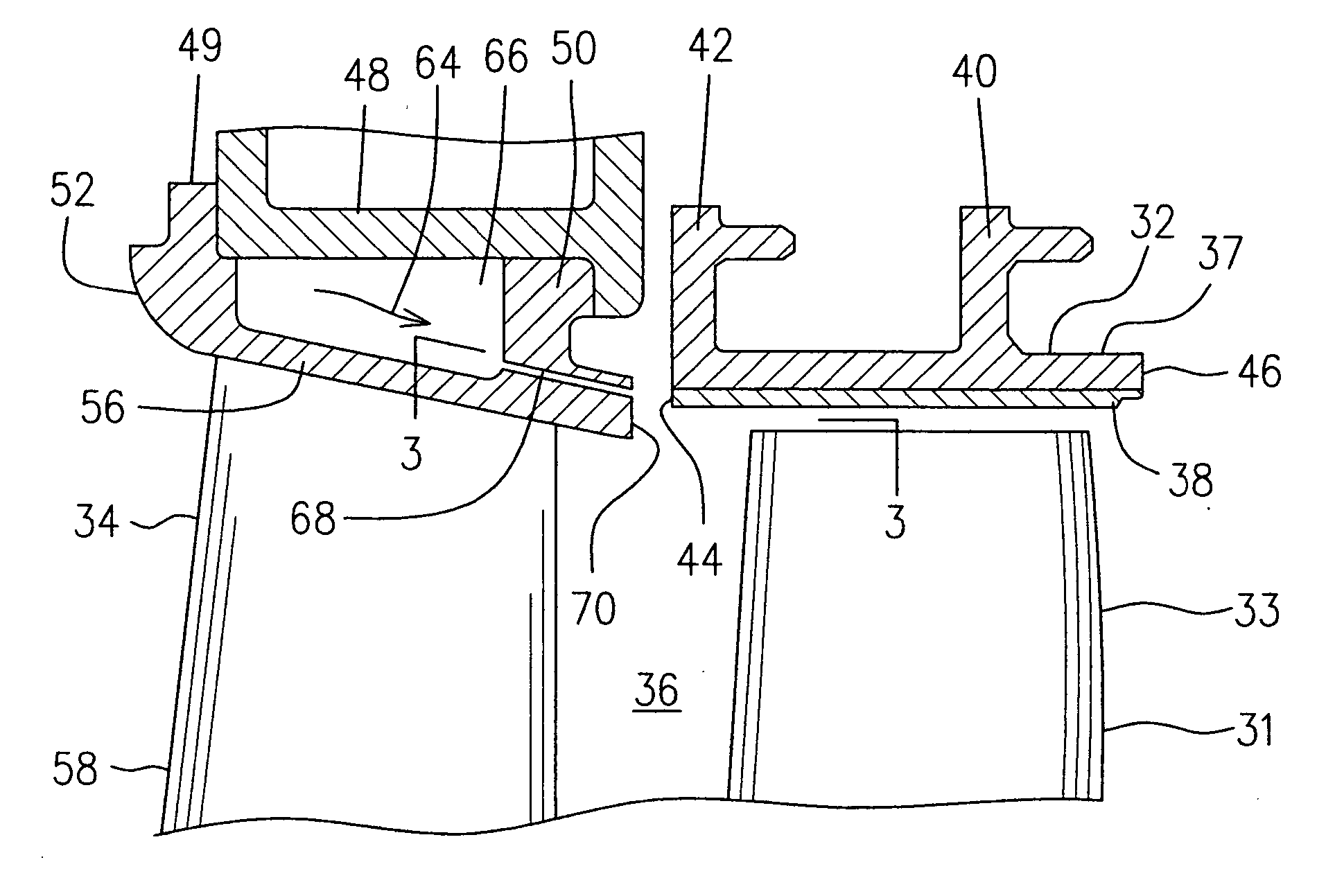

Shroud leading edge cooling

A cooling device includes a plurality of passages extending through outer platforms of turbine vane segments for directing cooling air in a choked flow condition towards a downstream turbine shroud.

Owner:PRATT & WHITNEY CANADA CORP

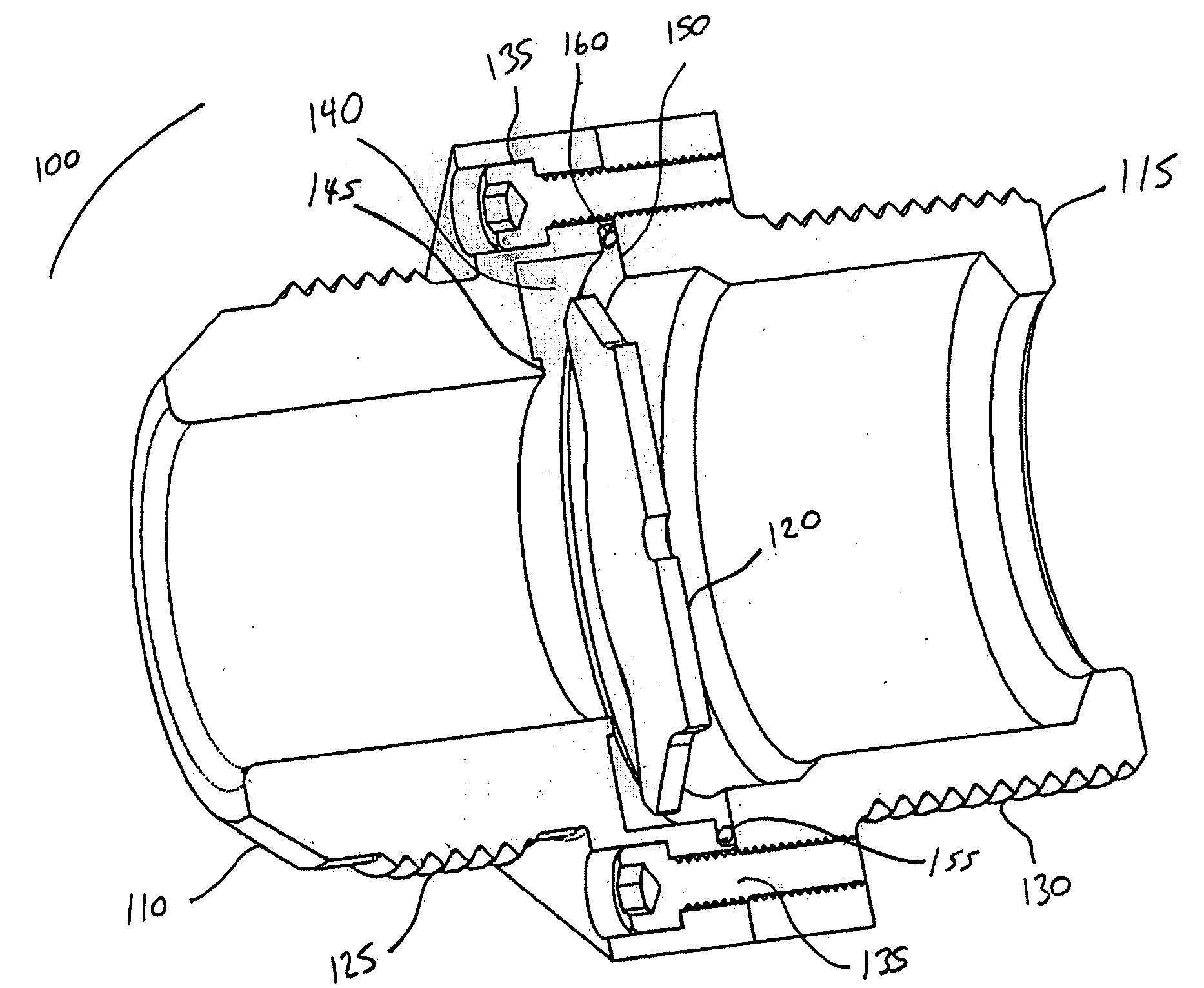

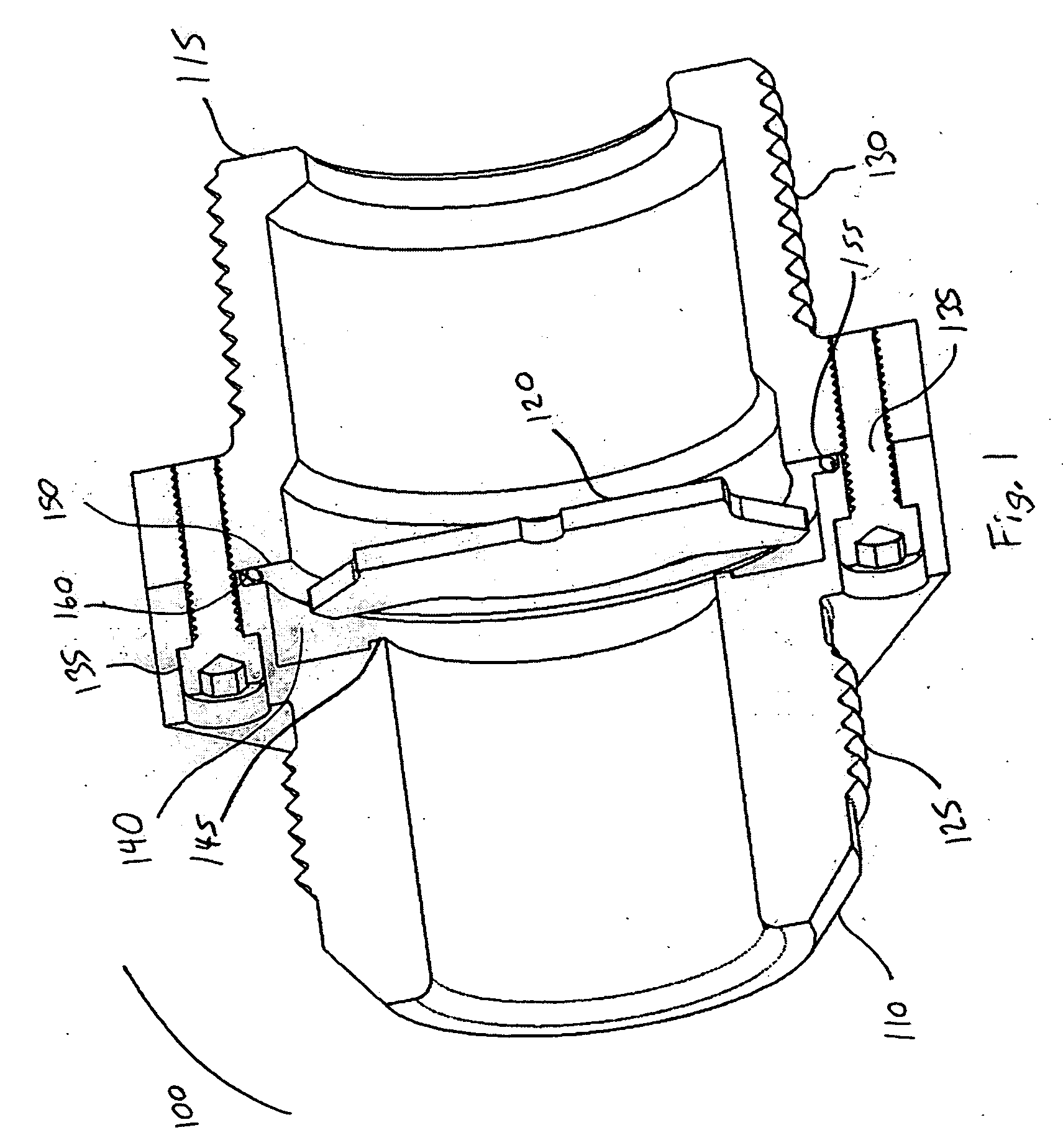

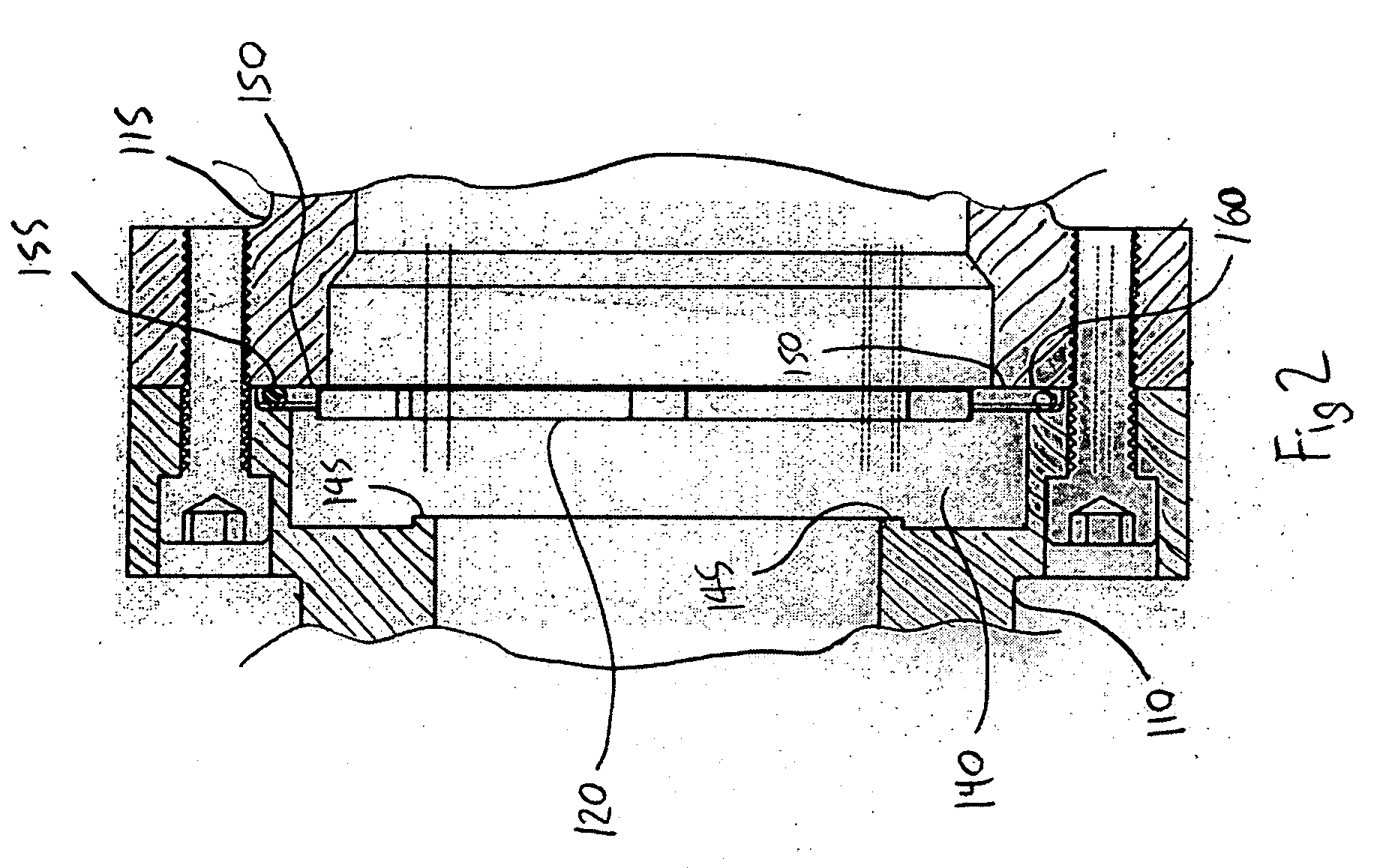

Variable choke valve

Embodiments of the present invention generally provide a more reliable variable choke flow control valve. In one embodiment, a variable choke valve for use in a wellbore is provided. The valve includes a tubular housing having an axial bore therethrough and a port through a wall thereof. The valve further includes a tubular sleeve having an axial bore therethrough and first and second holes through a wall thereof and disposed within the housing. The first hole is larger than the second hole, and the sleeve is actuatable among three positions: a first position where the first hole is aligned with the port, a second position where the second hole is aligned with the port, and a third position where the sleeve wall is aligned with the port.

Owner:WEATHERFORDLAMB

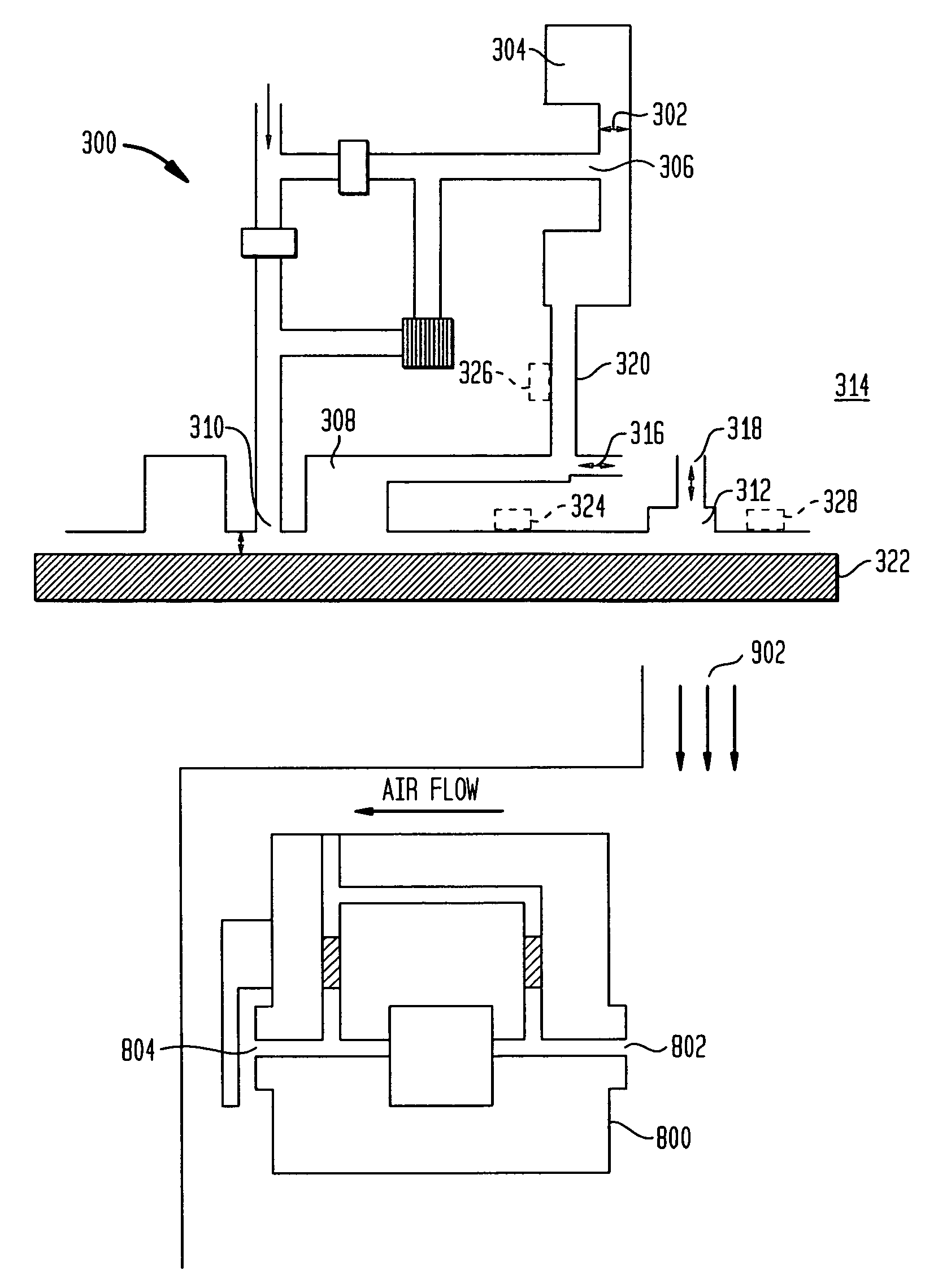

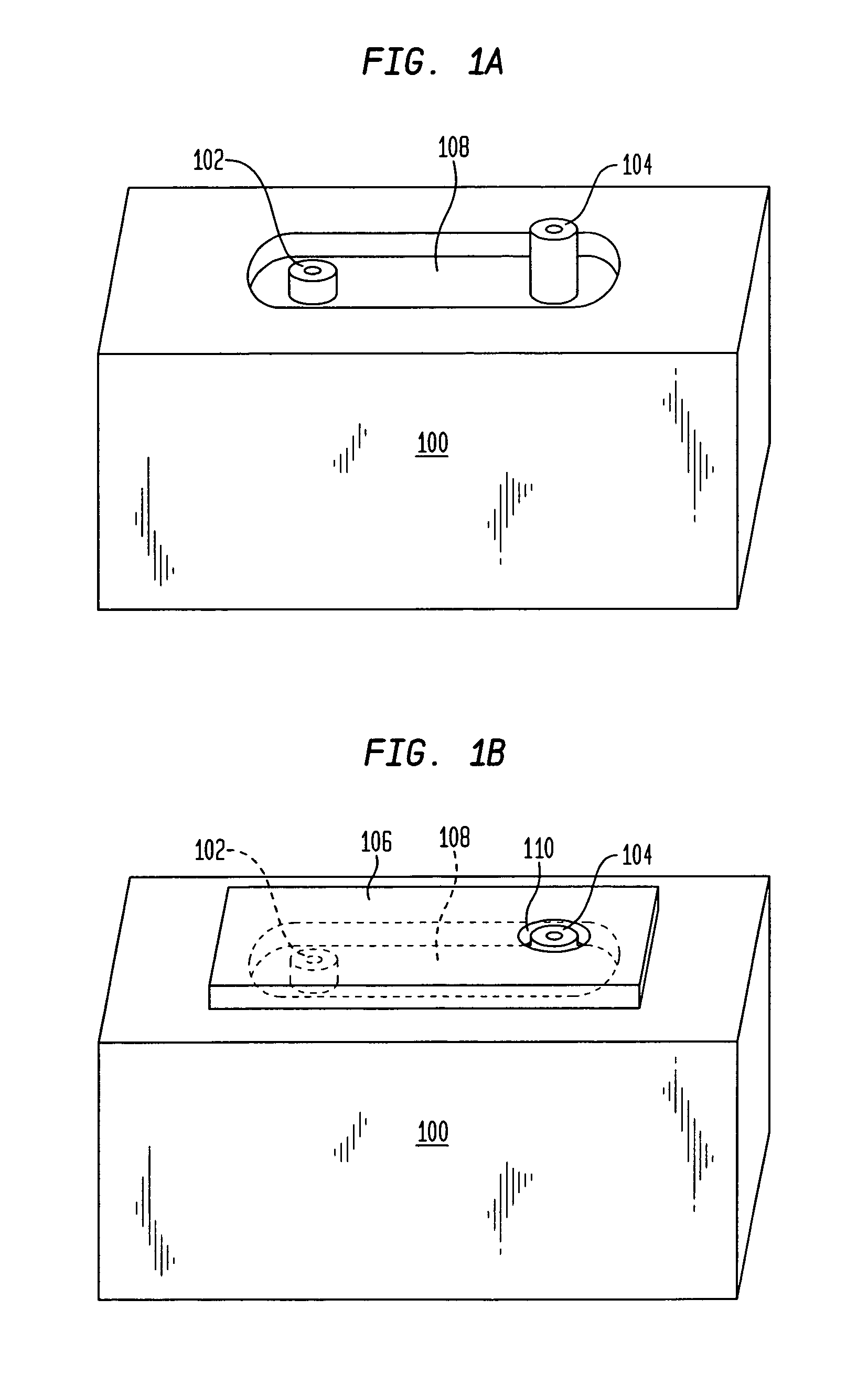

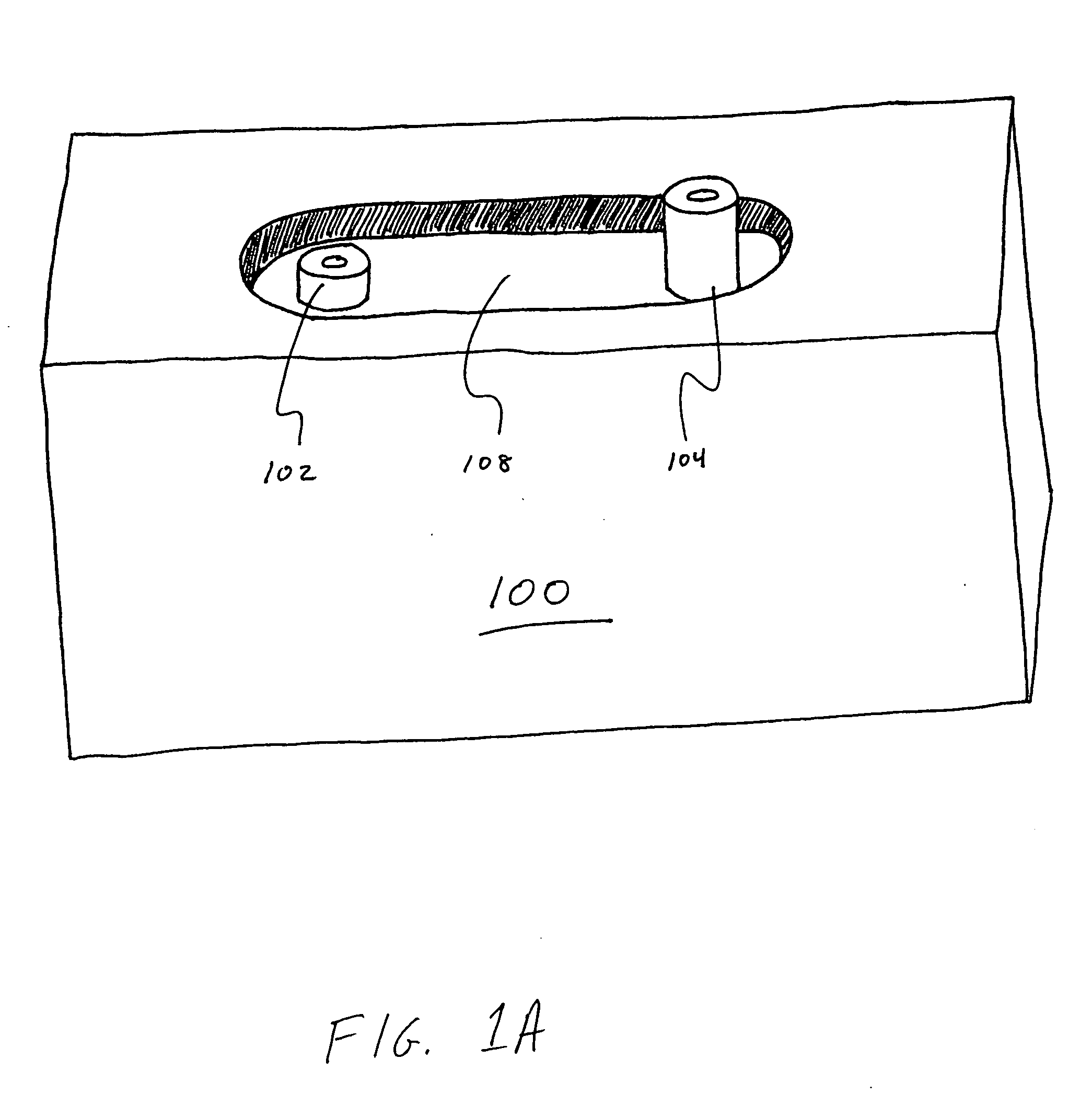

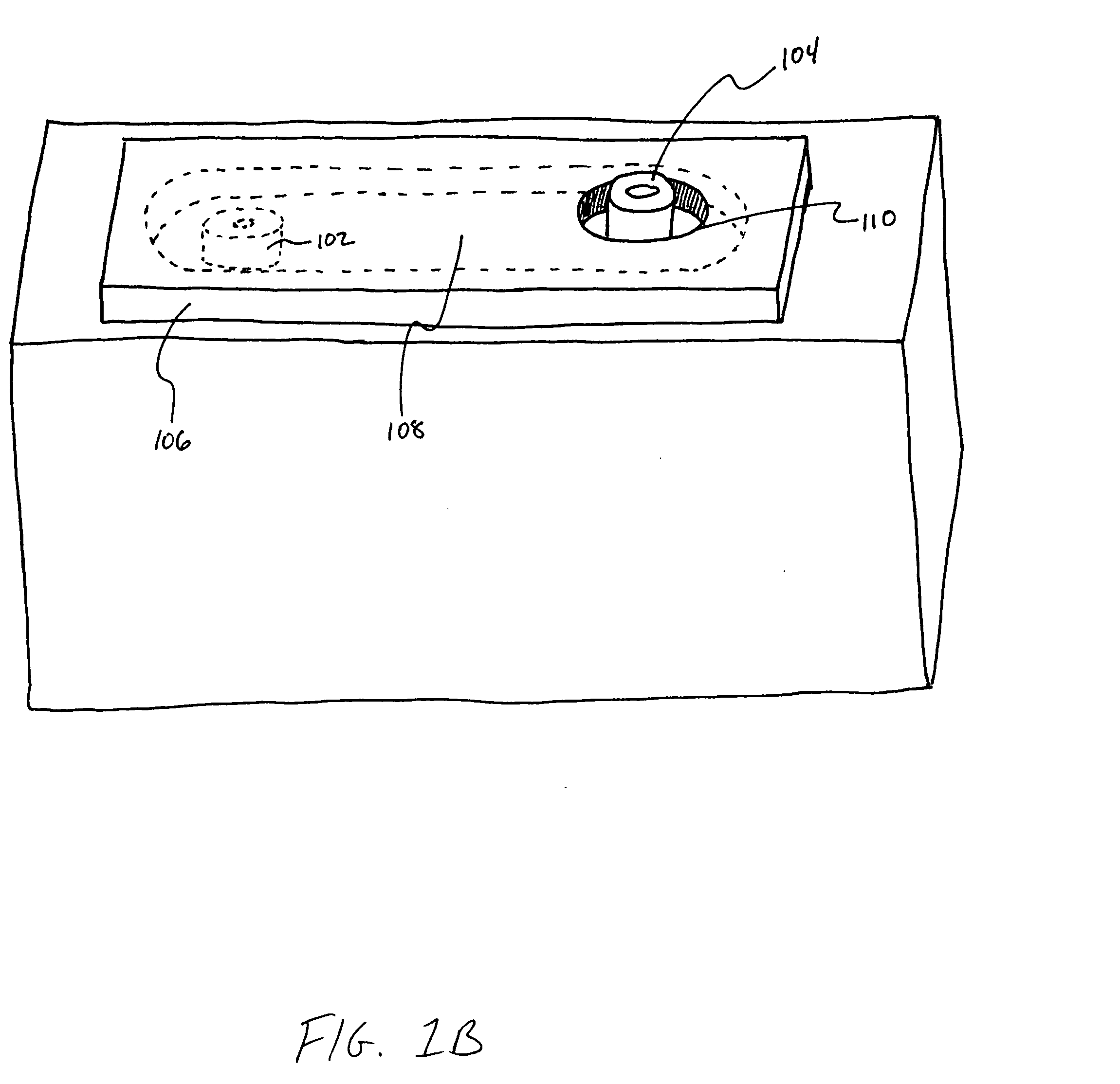

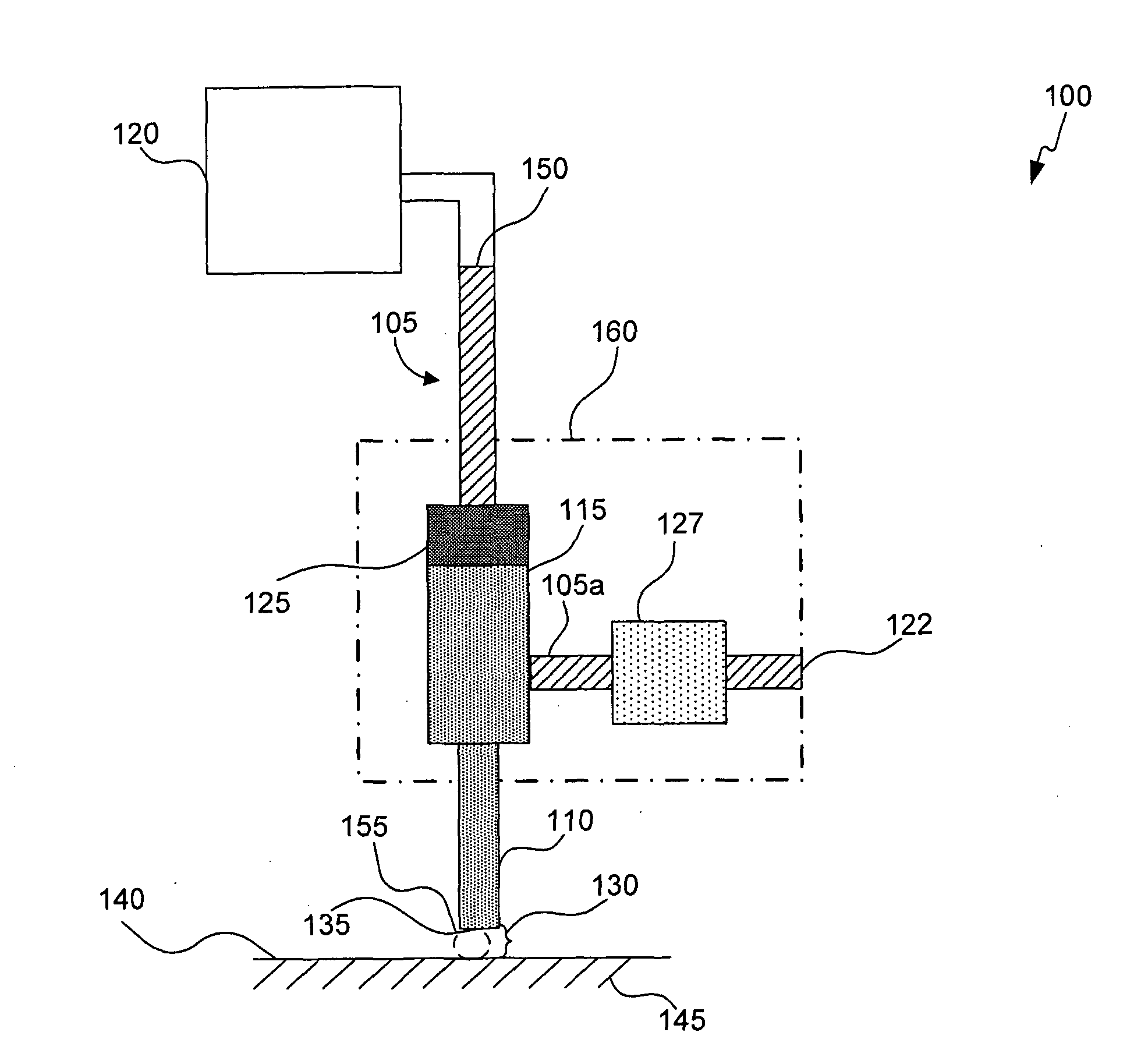

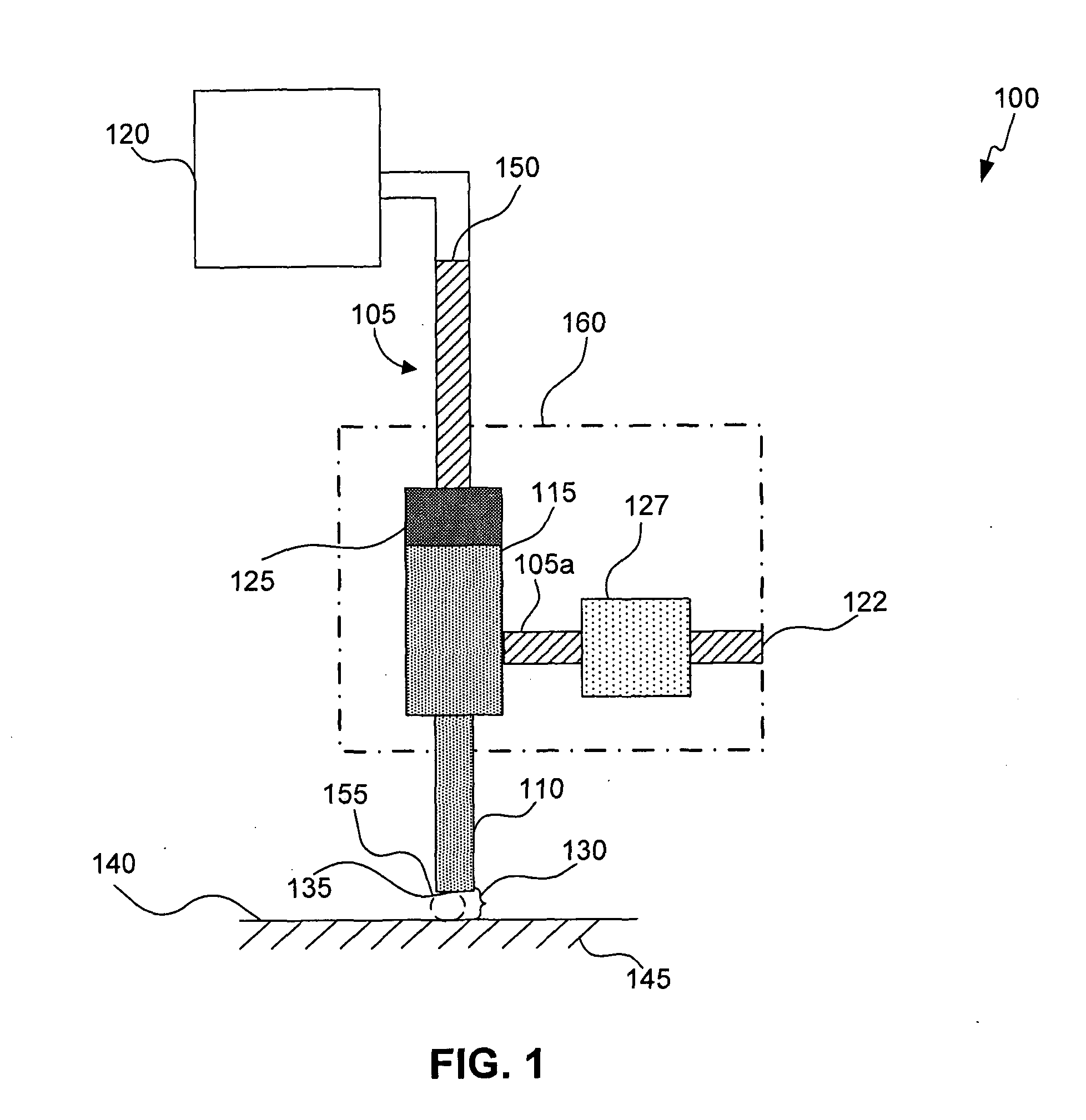

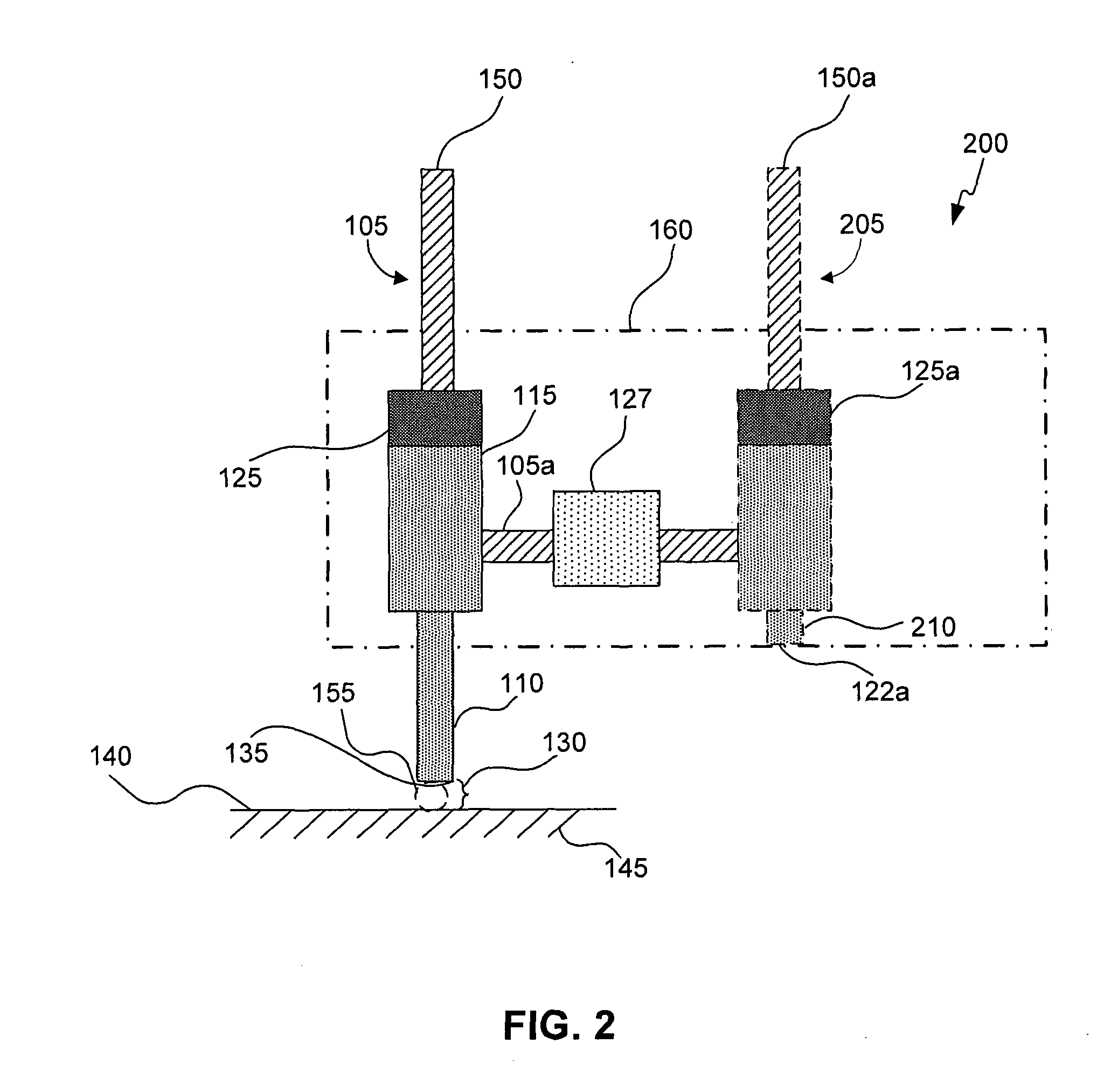

Gas Gauge Compatible With Vacuum Environments

InactiveUS20100309445A1Photomechanical treatmentPhotographic printingTarget surfaceDifferential pressure

A gas gauge (100) is provided for use in a vacuum environment having a measurement gas flow channel (105). The gas gauge comprises a measurement nozzle (110) in the measurement gas flow channel (105). The measurement nozzle (110) is configured to operate at a sonically choked flow condition of a volumetric flow being sourced from a gas supply (120) coupled to the measurement gas flow channel (105). The gas gauge (100) further comprises a pressure sensor (127) operatively coupled to the measurement gas flow channel (105) downstream from the sonically choked flow condition of the volumetric flow to measure a differential pressure of the volumetric flow for providing an indication of a gap (130) between a distal end of the measurement nozzle (135) and a target surface (140) proximal thereto.

Owner:ASML HLDG NV

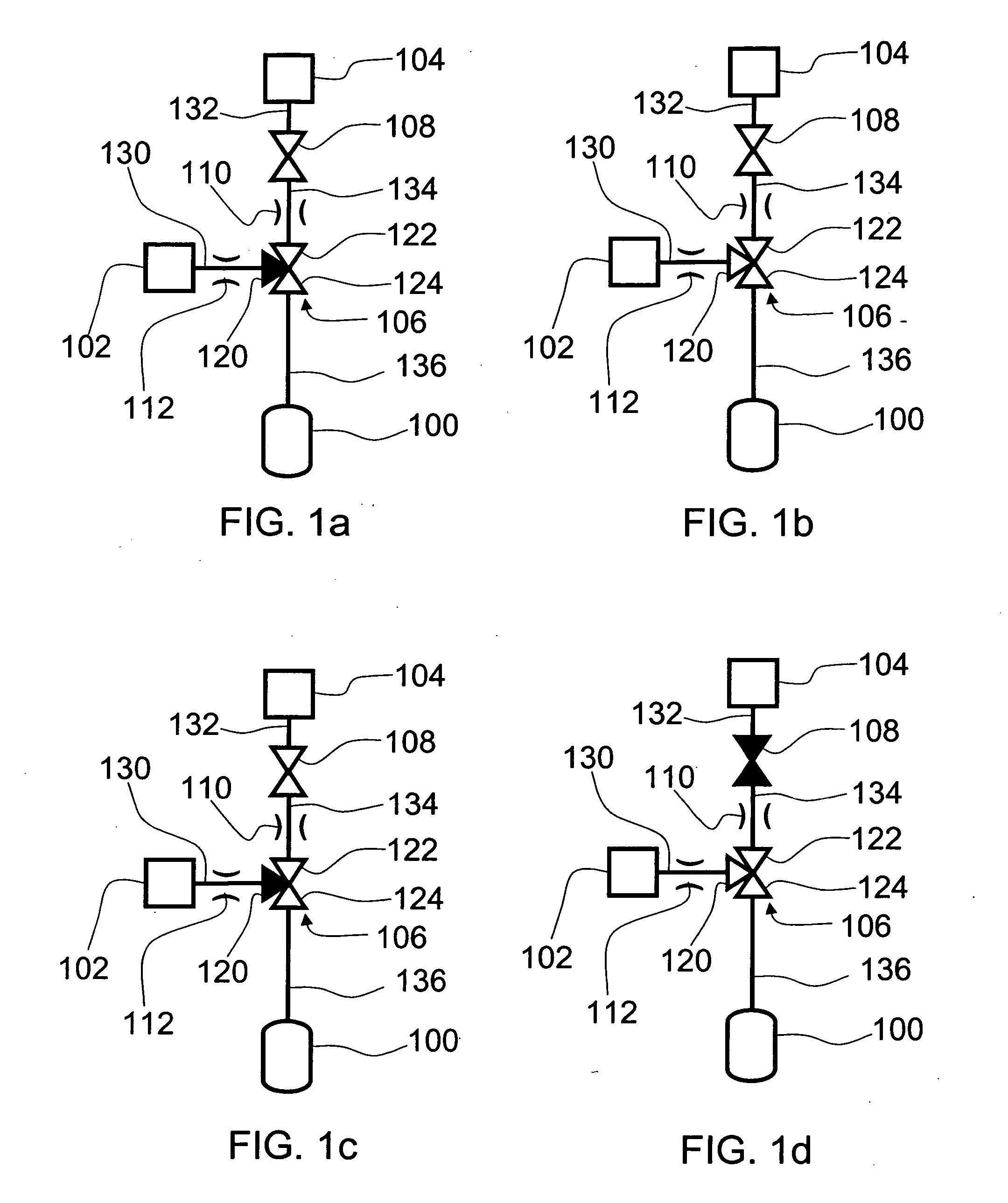

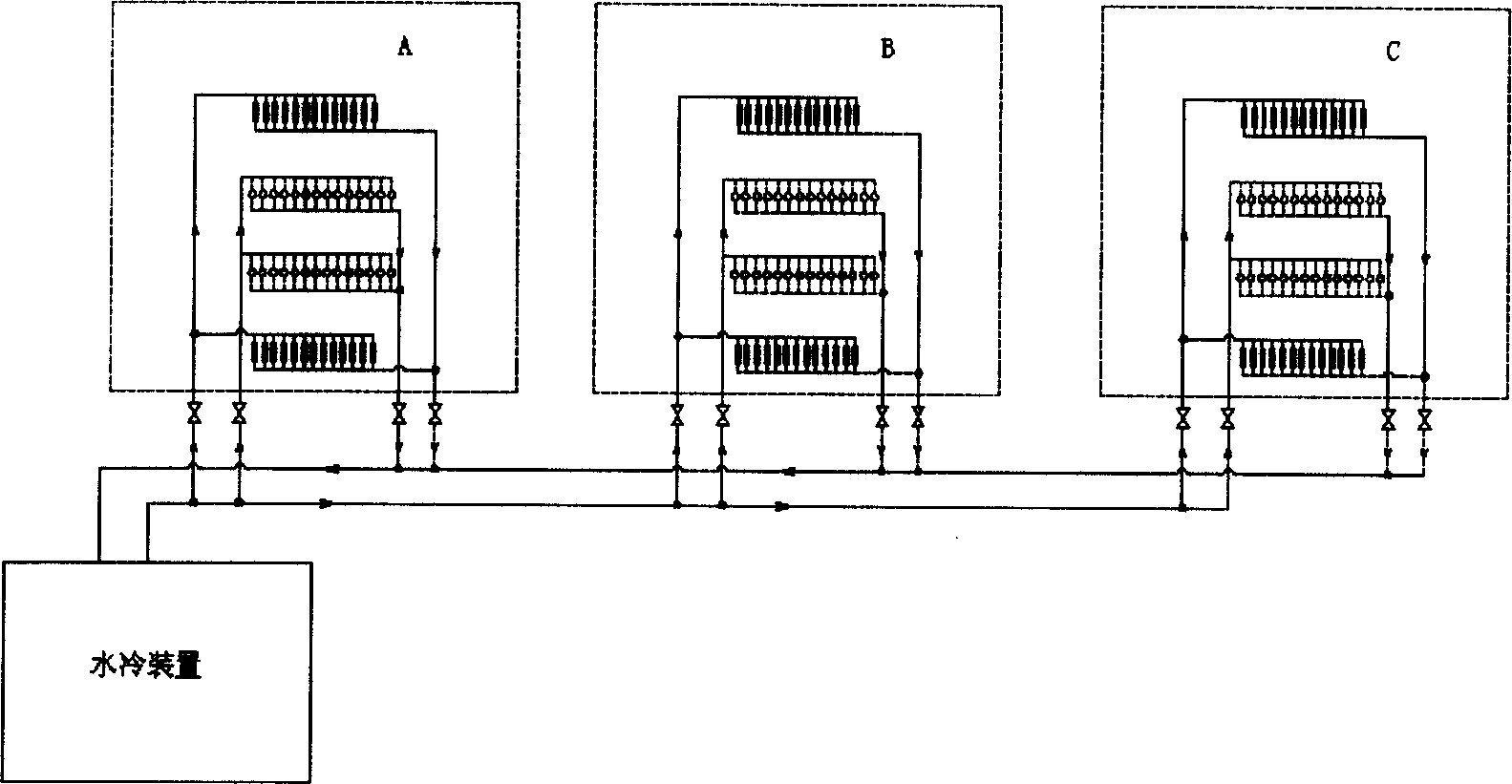

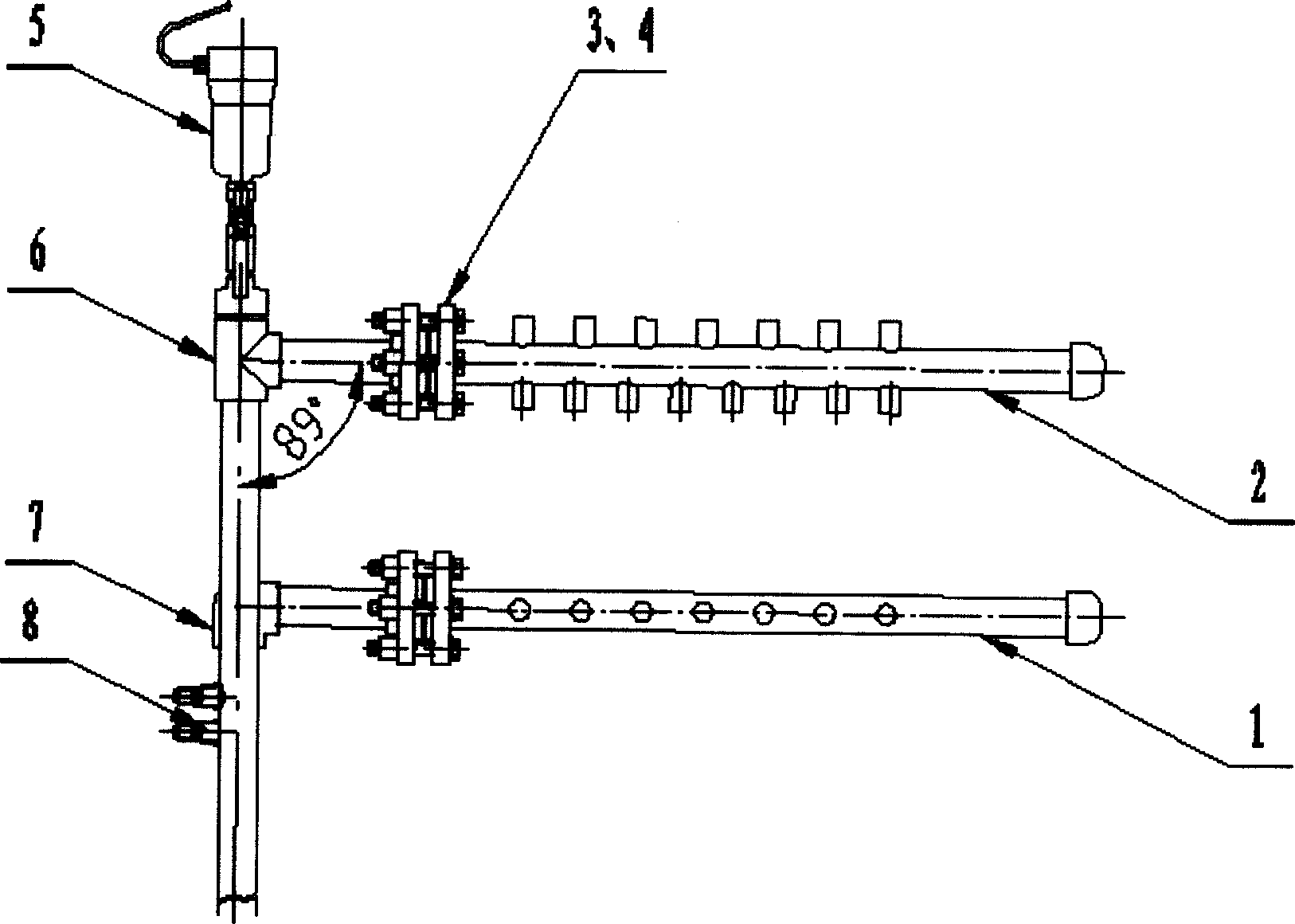

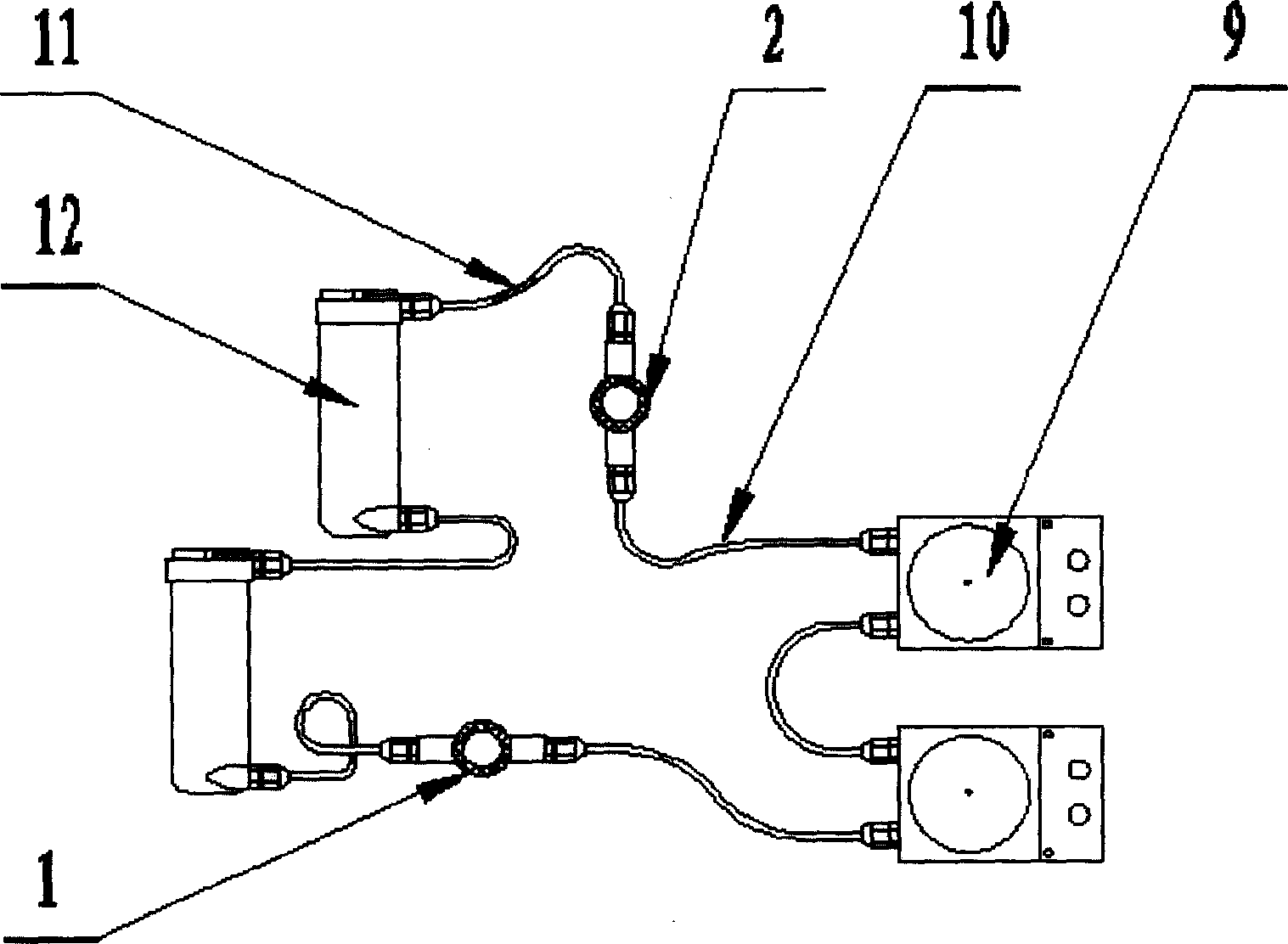

Water delivery and distribution pipeline system of standing reactive compensator thyristor velve set

ActiveCN1753173AAvoid accidentsSolve delivery problemsSemiconductor/solid-state device detailsSolid-state devicesExhaust valveChoked flow

The invention is a thyristor valve group water feeding and distributing pipeline system for static reactive power compensator, where the valve group is divided into three phases, and the pipeline adopts a parallel connecting mode, and the flow of the three phases are balanced; the devices in the valve group are arranged and combined in grouped crimping form, the valve-group water feeding and distributing hose adopts a mode of connecting in series or in parallel. The invention arranges a water-distributing mother pipe as a water distributor, arranges flow choking element in the water distributing hose, arranges proper slope and auto gas exhaust valve on the pipeline, and arranges equipotential column at special design point of the insulating pipeline. The sealing ring has multiple sealing water veins, the sealing water veins closely fits the sealing surface of the flange to achieve multiple sealing protection effects. The system has reasonable structure, uniform flow distribution, equipotential pipeline design, and multiple measures for assuring sealing of cooling medium and automatic gas exhaust.

Shroud leading edge cooling

A cooling device includes a plurality of passages extending through outer platforms of turbine vane segments for directing cooling air in a choked flow condition towards a downstream turbine shroud.

Owner:PRATT & WHITNEY CANADA CORP

Enhanced fuel injection based on choke flow rate

ActiveUS20140311454A1Maximized mass flow rateMinimize timeInternal combustion piston enginesFuel supply apparatusFuel tankChoked flow

A method is described for adjusting the amount of gaseous fuel injected based on the sonic choked flow rate through a restriction. Because the sonic choke flow rate continues to decrease as tank pressure decreases, the method includes computing the sonic choke flow rate through the restriction based on system variables and enforcing the rate of CNG injection to be less than the sonic choke flow rate through the restriction. Thereby, the mass flow rate to the fuel injector can be substantially maximized to substantially minimize the time for fuel tank emptying, particularly during the last amount of tank emptying when the contents of the gaseous storage tank is low.

Owner:FORD GLOBAL TECH LLC

Check valve

InactiveUS20070044846A1Reduce frictionReduce manufacturing costCheck valvesEqualizing valvesBlocked valvesChoked flow

Described is a check valve with a housing having an inlet side and an outlet side, a flow blocking valve element with centering protrusions, an inlet annular shoulder, an outlet annular shoulder, cylindrical valve element cavity with an aspect ratio such that the flow blocking valve element cannot be put in a position where it is jammed. The centering protrusions on the flow blocking valve element support it on the outlet annular shoulder and allow flow to pass between the central disc of the valve element and the larger diameter of the outlet orifice. When flow is attempted in the inhibited direction, the flow blocking valve element is pressed against the inlet annular shoulder, forming a seal and blocking the flow. The valve has the advantage of being inexpensive to manufacture and highly reliable.

Owner:TRANSPORTATION RES CORP

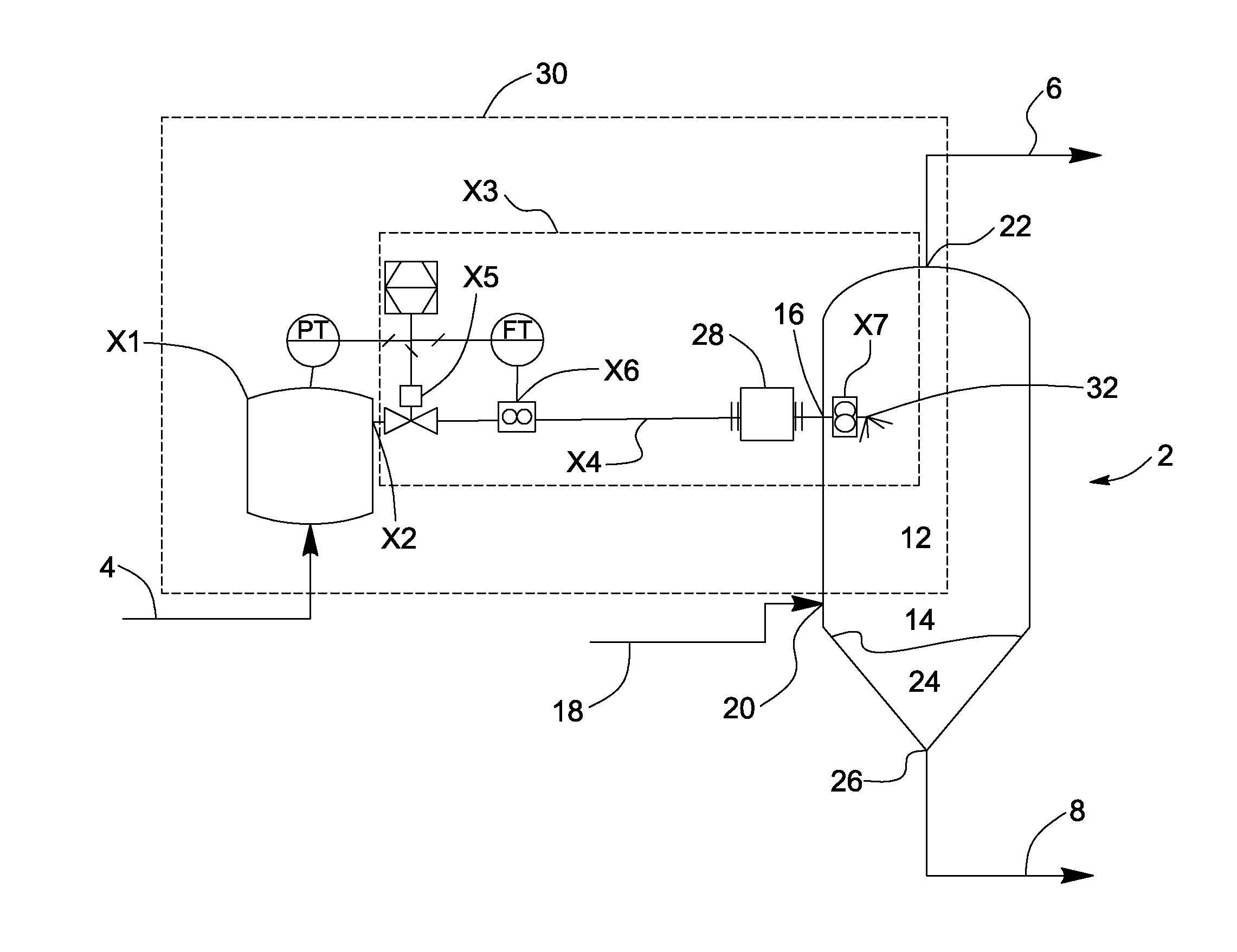

Tsru with inlet spray system configurations for distribution of solvent diluted tailings

InactiveUS20140048408A1Facilitating choked flowDewatering/demulsification with mechanical meansCharging-discharging device combinationsChoked flowSpray nozzle

Owner:TRUENORTH ENERGY CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com