Water delivery and distribution pipeline system of standing reactive compensator thyristor velve set

A pipeline system and thyristor valve technology, applied in the direction of electric solid devices, semiconductor devices, semiconductor/solid device components, etc., can solve problems such as insulation breakdown, high leakage current insulation breakdown, and unbalanced flow ratio. To achieve the effect of ensuring automatic removal, reasonable system structure and meeting the requirements of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

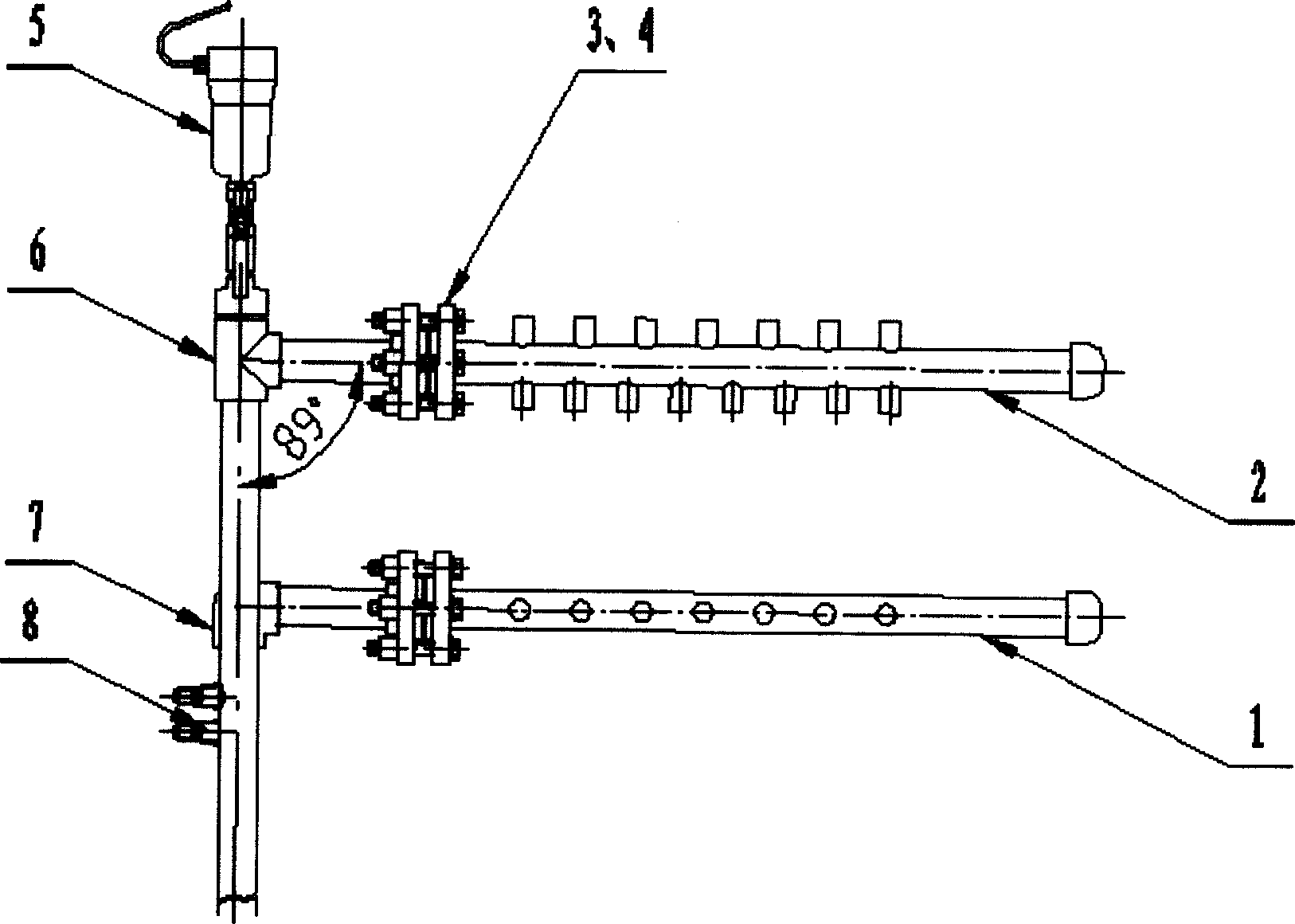

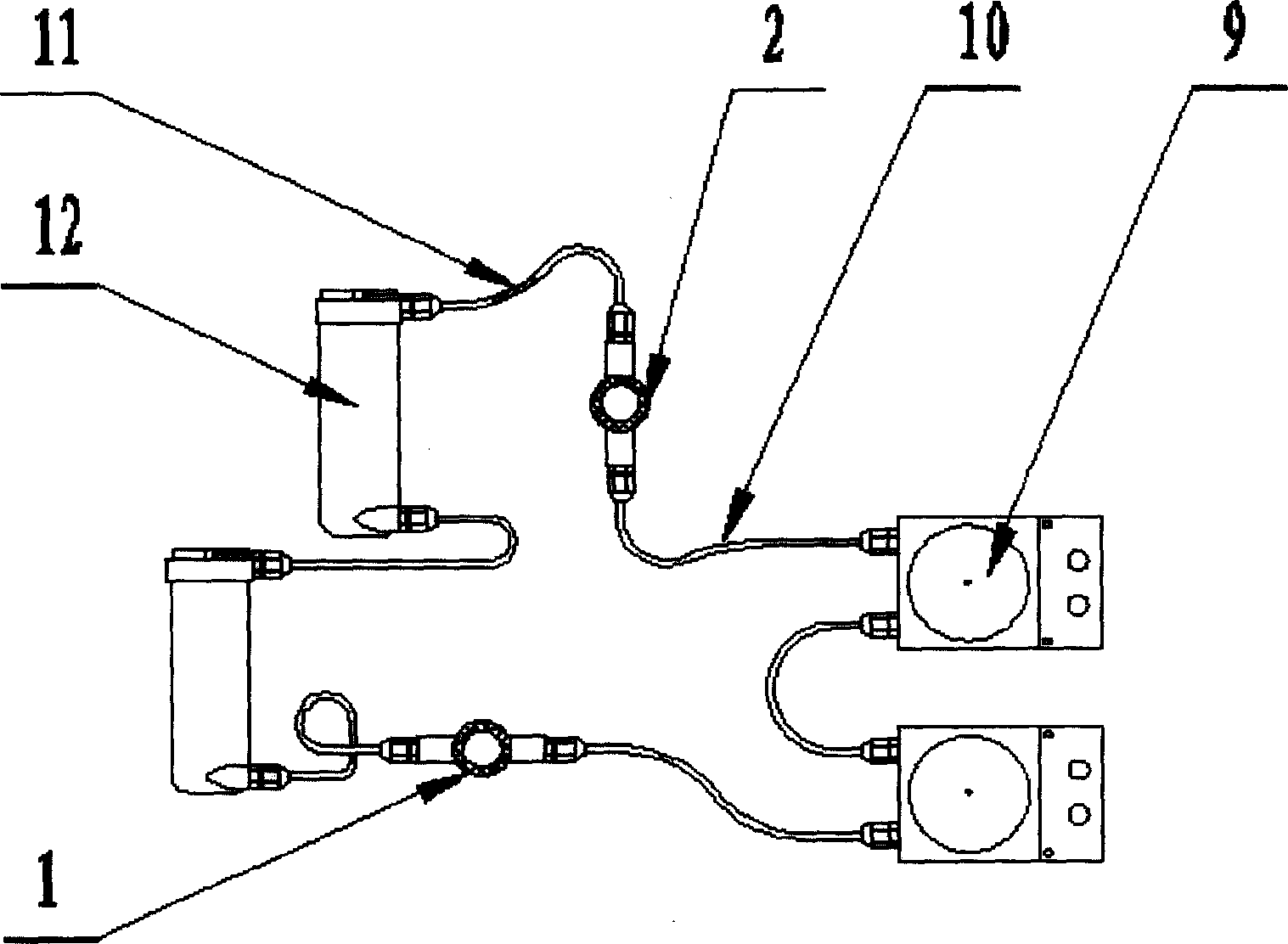

[0039] Referring to accompanying drawing, the technical scheme that the present invention solves its technical problem to take includes the following contents:

[0040] 1) Calculation of the leakage current of the waterway

[0041] The leakage current of the insulated water distribution channel includes the leakage current of the fluid medium and the leakage current of the pipeline. The calculation of the leakage current of the pipeline is one of the main basis for the selection of pipeline materials and specifications, and it is also one of the main parameters of the electrical design of the valve group.

[0042] I=UA / σL

[0043] I is the leakage current in mA,

[0044] σ is the volume resistivity, the unit is MΩ.cm,

[0045] U is the applied voltage in V,

[0046] A is the cross-sectional area, in cm 2

[0047] L is the length in cm.

[0048] Using the above formula for calculation, when the volume resistivity of the pipe material used is greater than 1×10 16 In the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com