Patents

Literature

36results about How to "Improve surge margin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

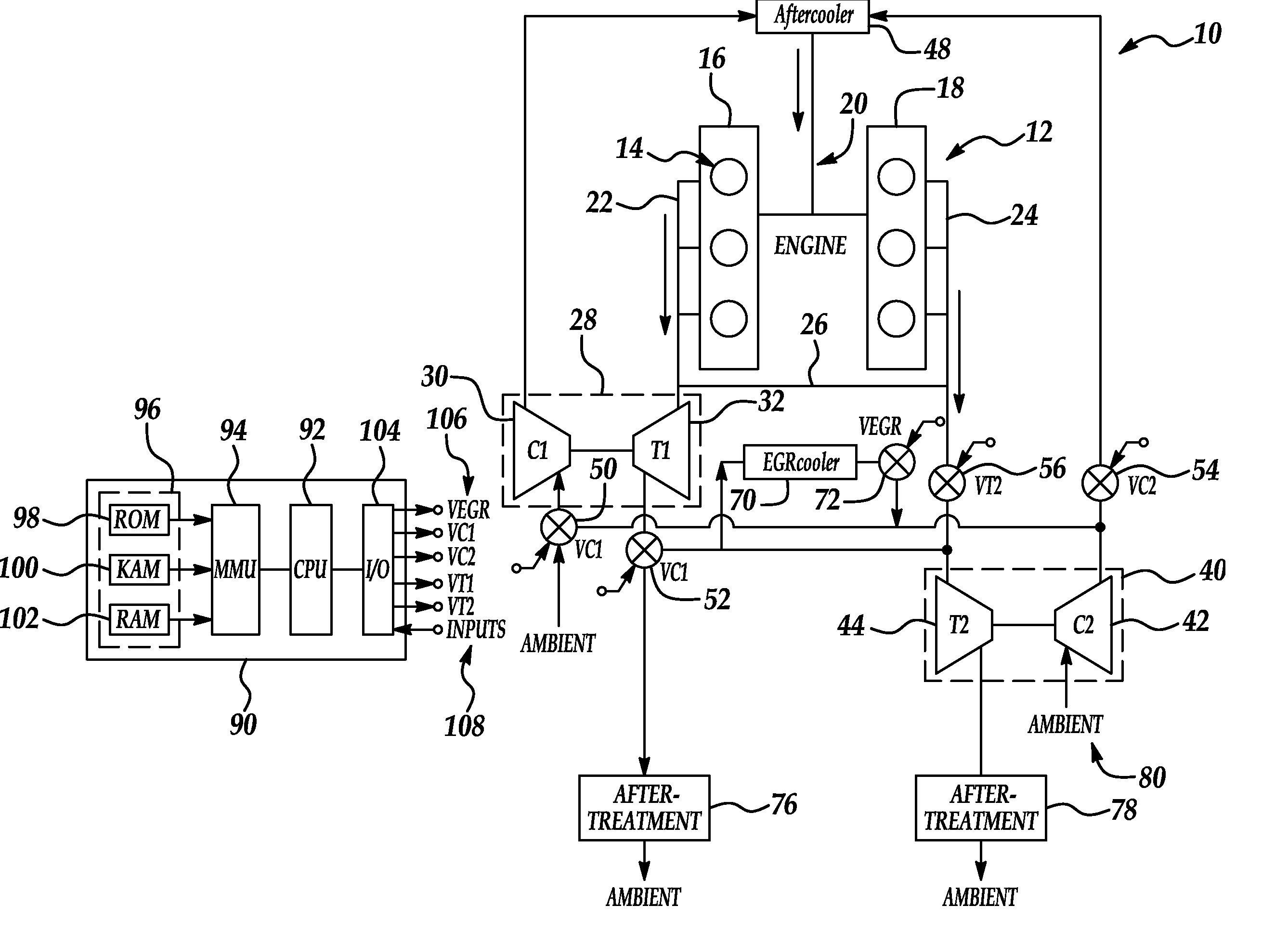

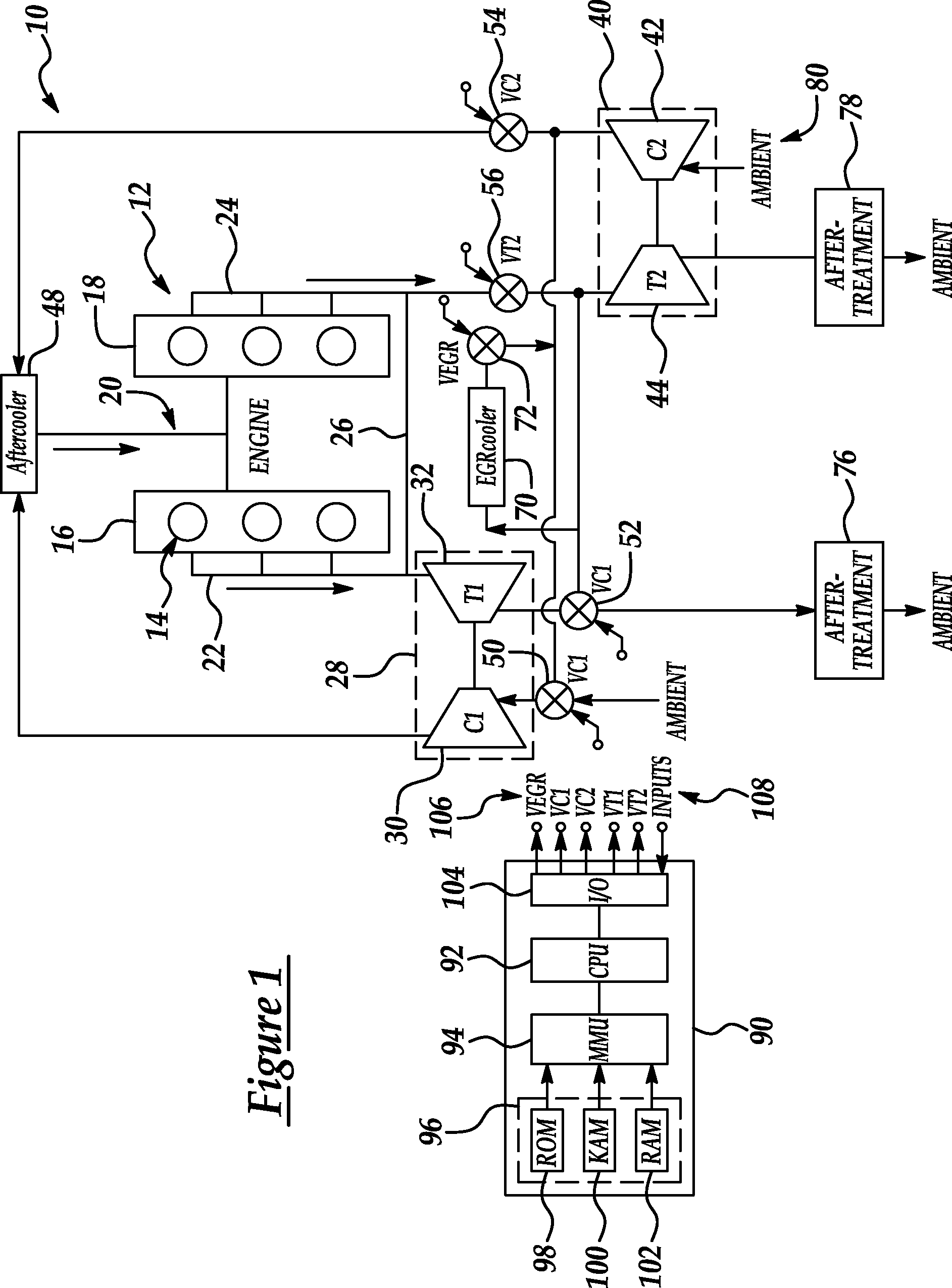

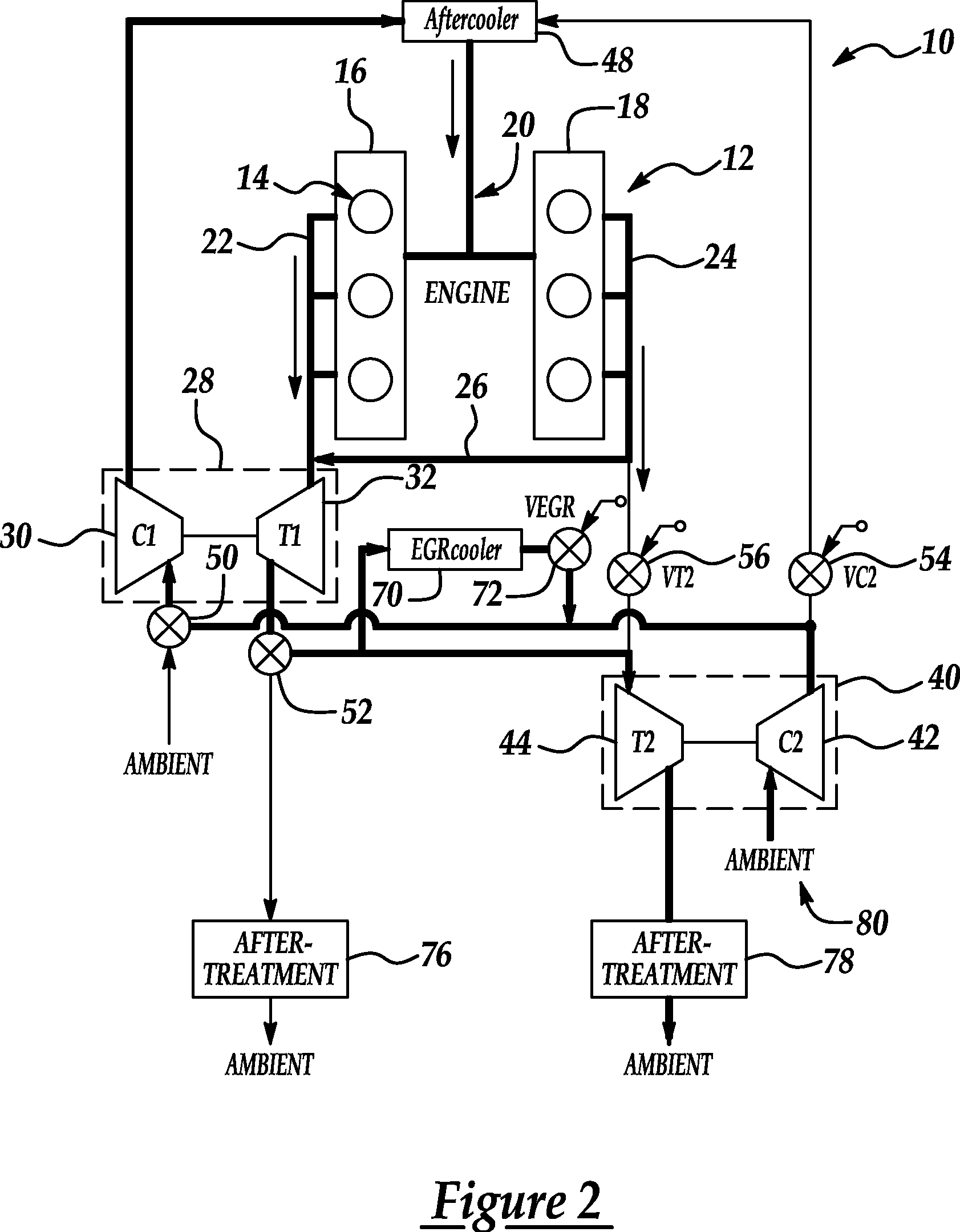

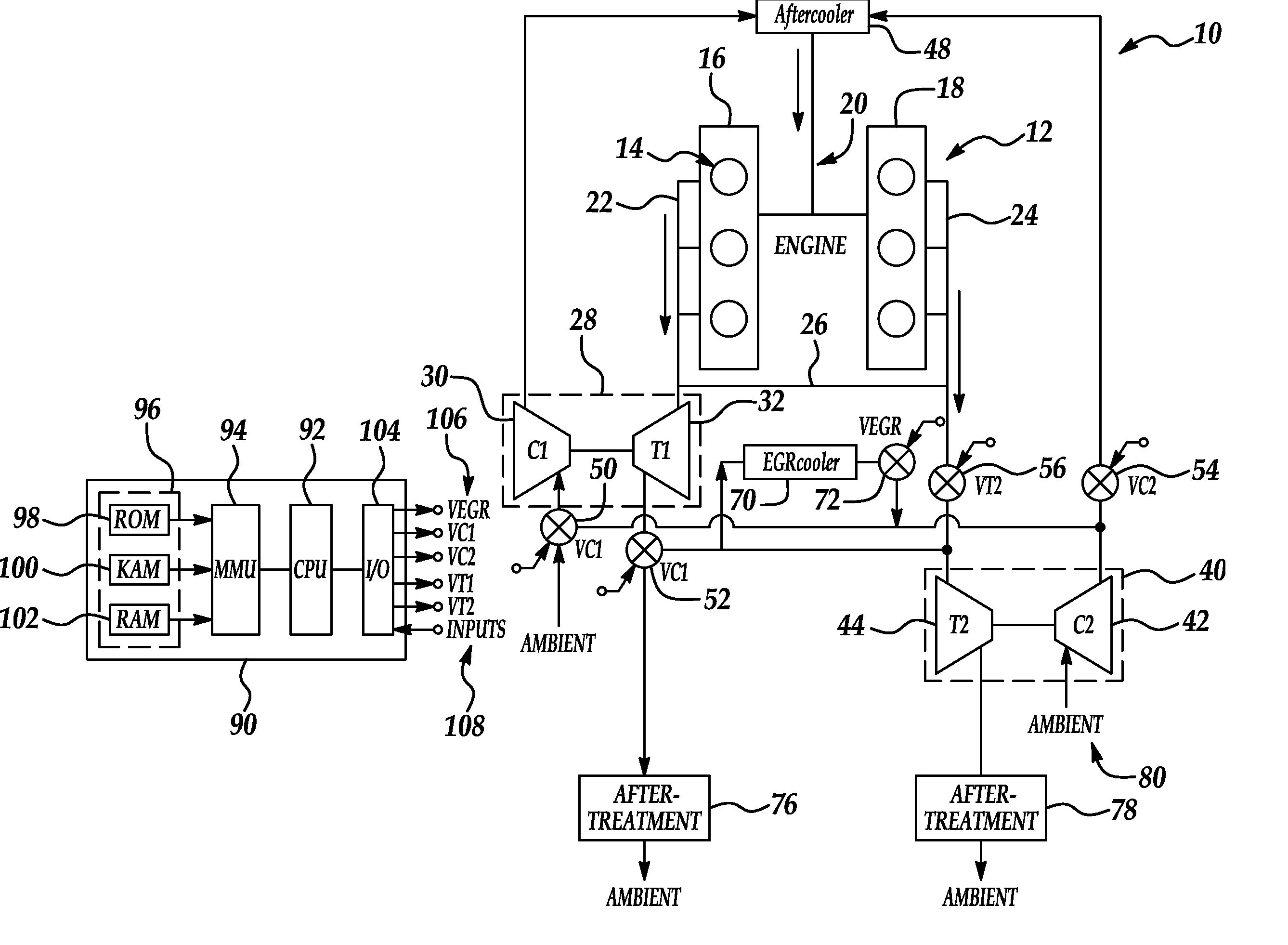

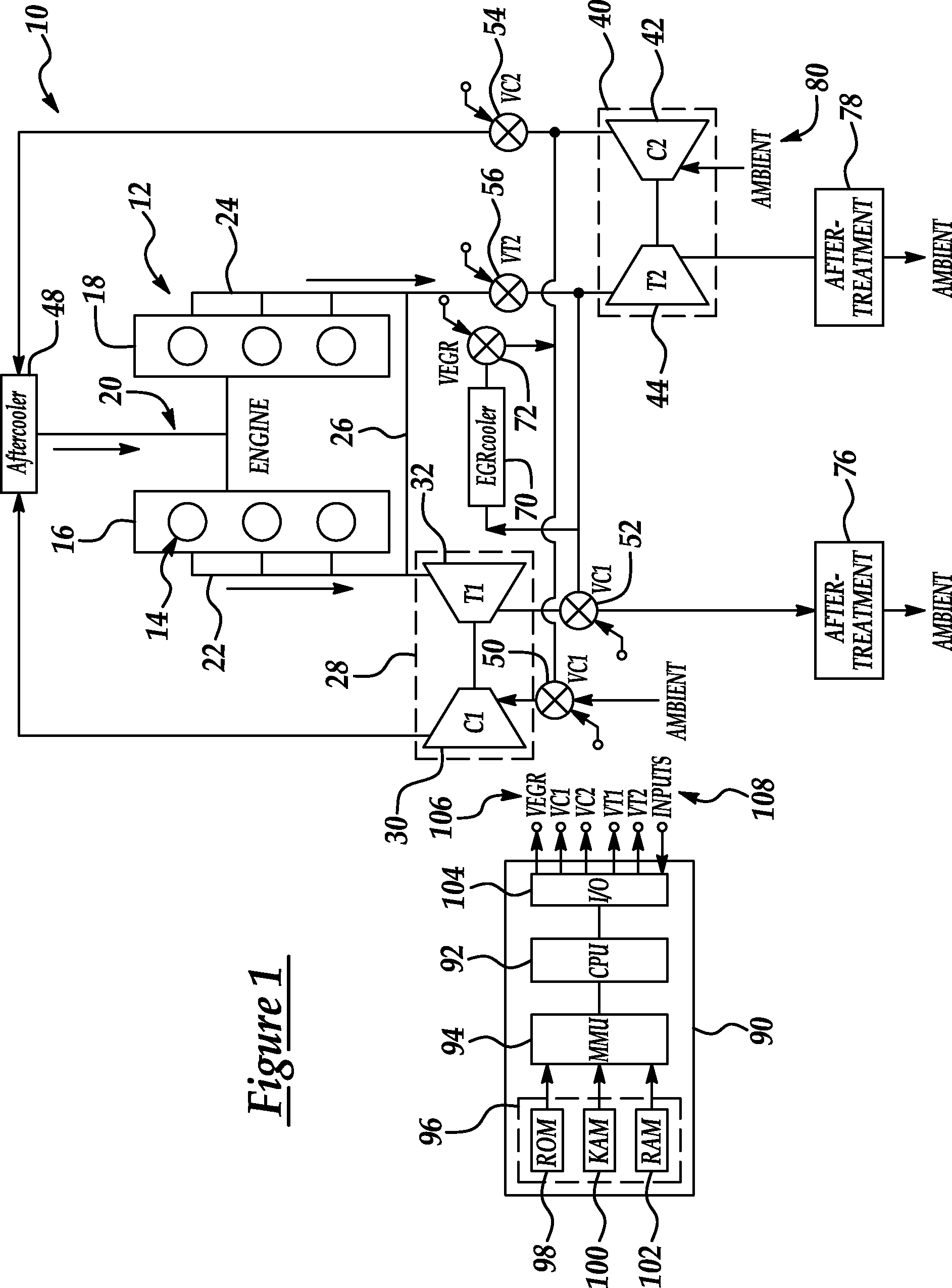

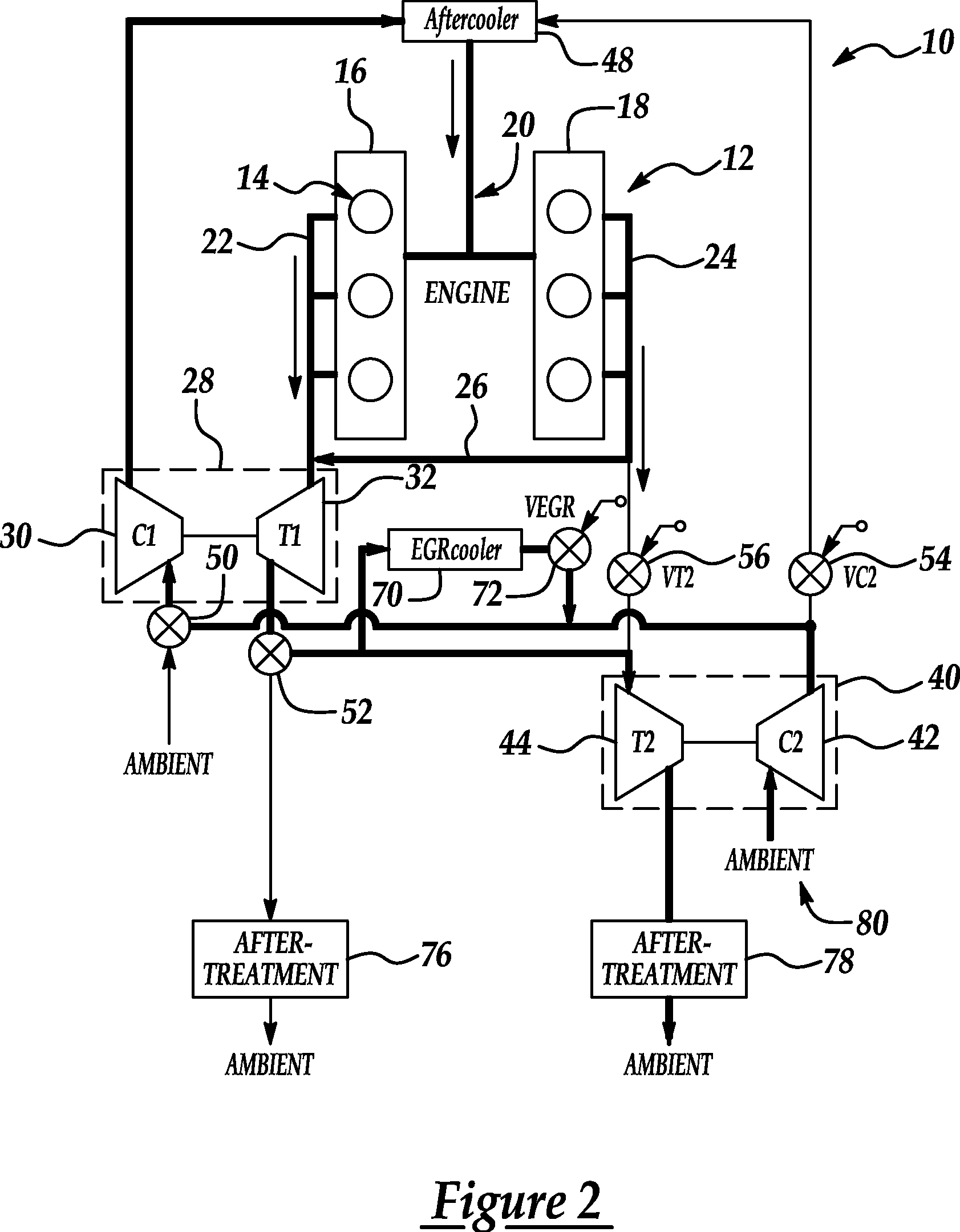

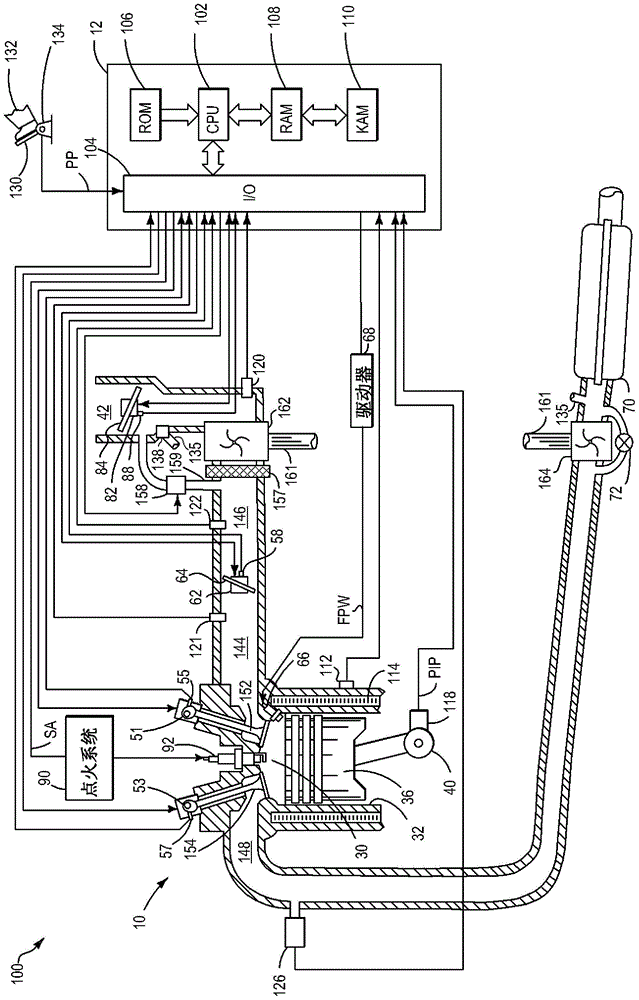

Series/parallel turbochargers and switchable high/low pressure EGR for internal combustion engines

InactiveUS20060021347A1Promote generationSufficient handling capacityElectrical controlInternal combustion piston enginesTurbochargerHigh pressure

Systems and methods for turbocharging an internal combustion engine include operating two turbochargers in a series configuration for a first operating region and a parallel configuration for a second operating region. Systems and methods for controlling exhaust gas recirculation (EGR) in a turbocharged internal combustion engine provide low pressure EGR upstream of a compressor inlet for a first operating region and high pressure EGR downstream of a compressor outlet for a second operating range to further improve turbocharger operating margin and overall efficiency.

Owner:FORD GLOBAL TECH LLC

Series/parallel turbochargers and switchable high/low pressure EGR for internal combustion engines

InactiveUS7165403B2Promote generationImproved vehicle launchElectrical controlNon-fuel substance addition to fuelTurbochargerExternal combustion engine

Systems and methods for turbocharging an internal combustion engine include operating two turbochargers in a series configuration for a first operating region and a parallel configuration for a second operating region. Systems and methods for controlling exhaust gas recirculation (EGR) in a turbocharged internal combustion engine provide low pressure EGR upstream of a compressor inlet for a first operating region and high pressure EGR downstream of a compressor outlet for a second operating range to further improve turbocharger operating margin and overall efficiency.

Owner:FORD GLOBAL TECH LLC

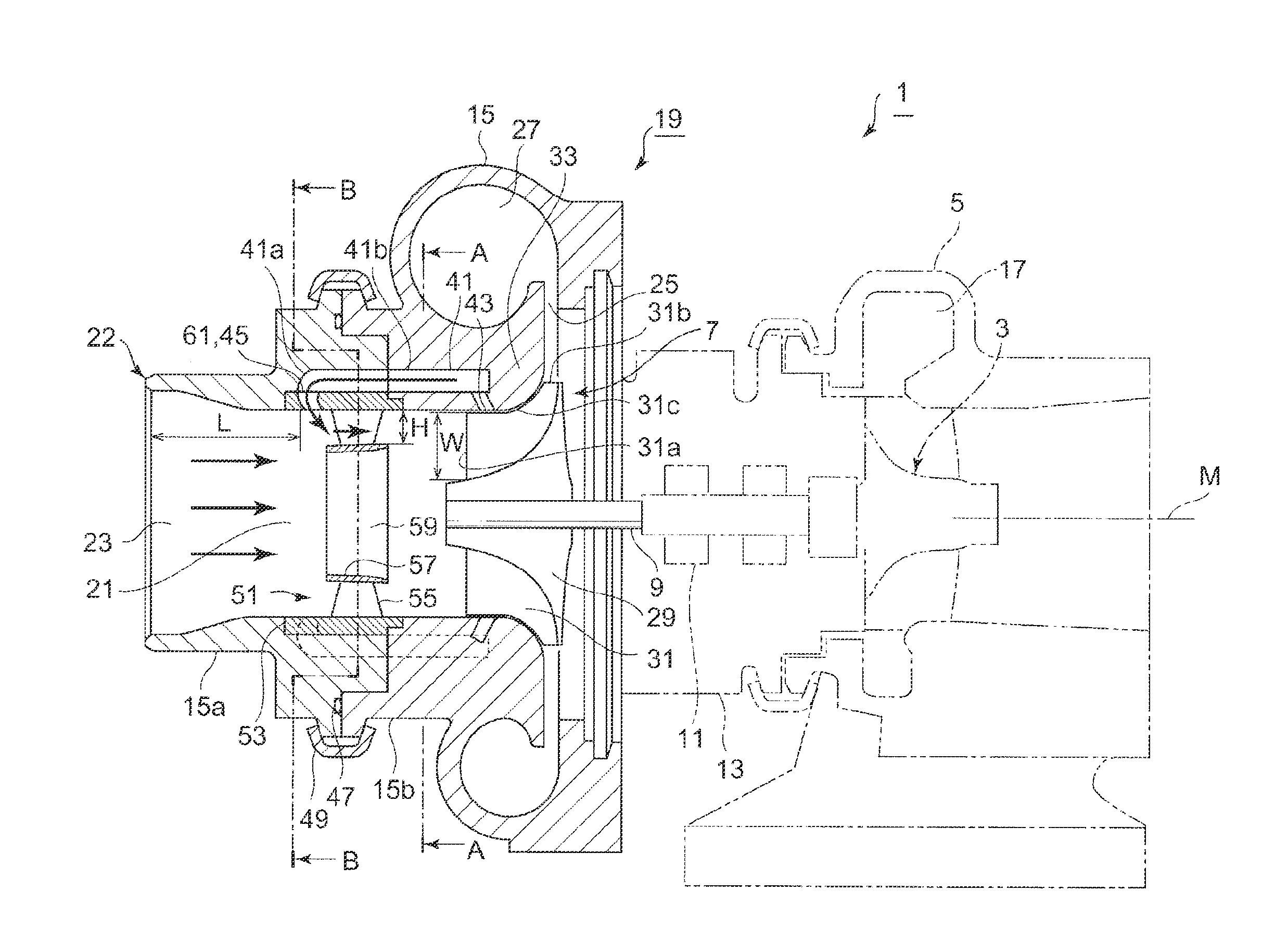

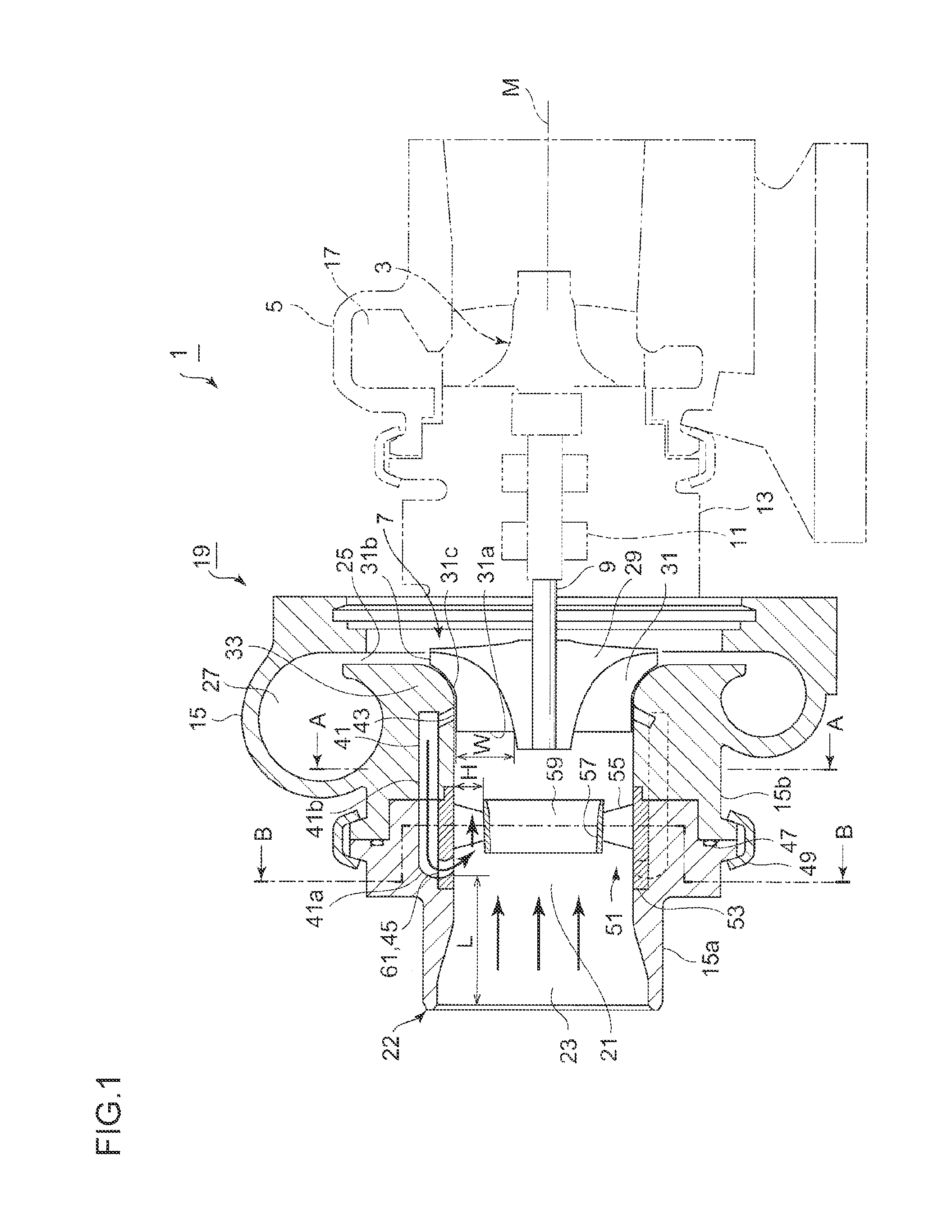

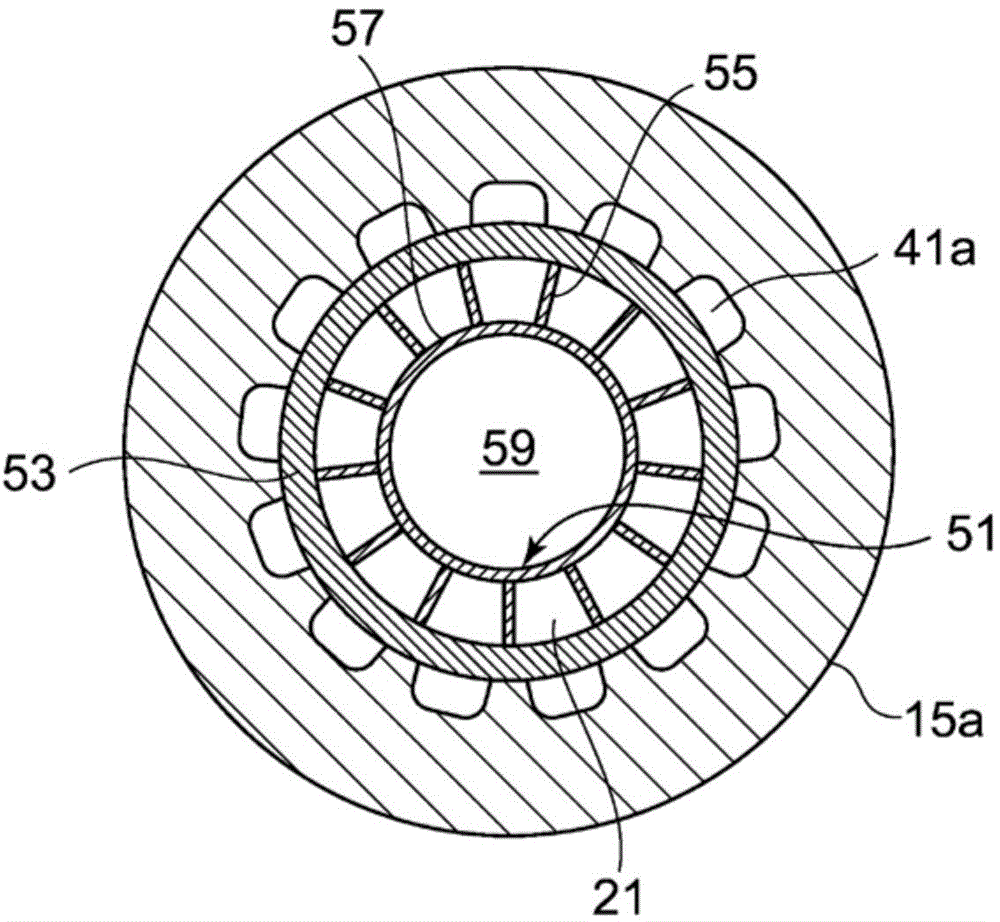

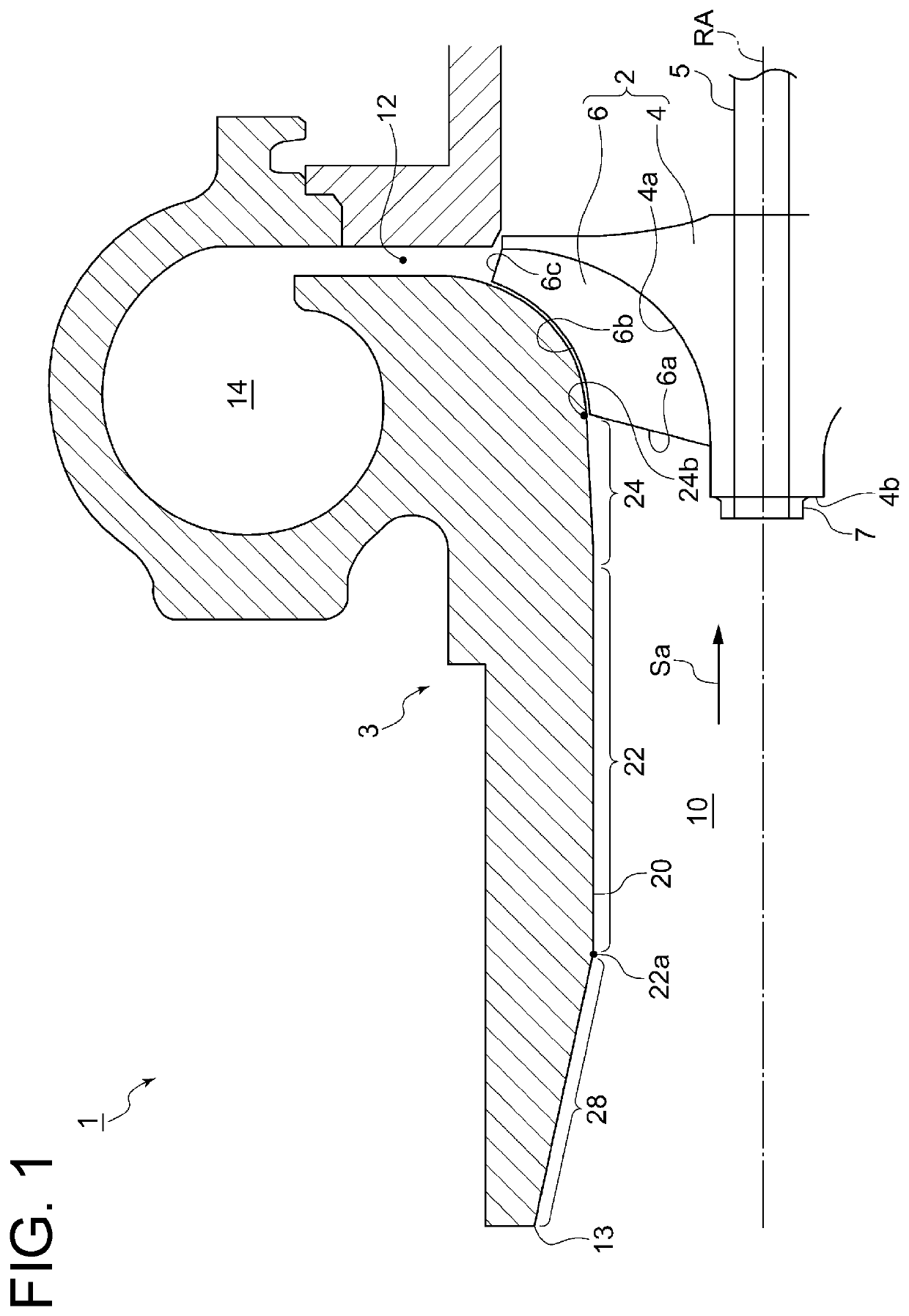

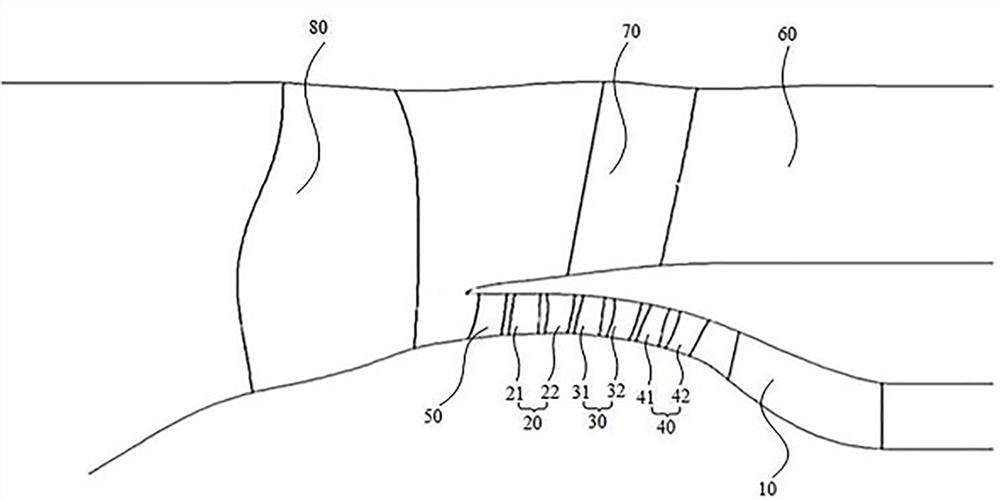

Centrifugal compressor

ActiveUS20150192147A1Improve surge marginReducing choke flowInternal combustion piston enginesEngine manufactureRotational axisChoked flow

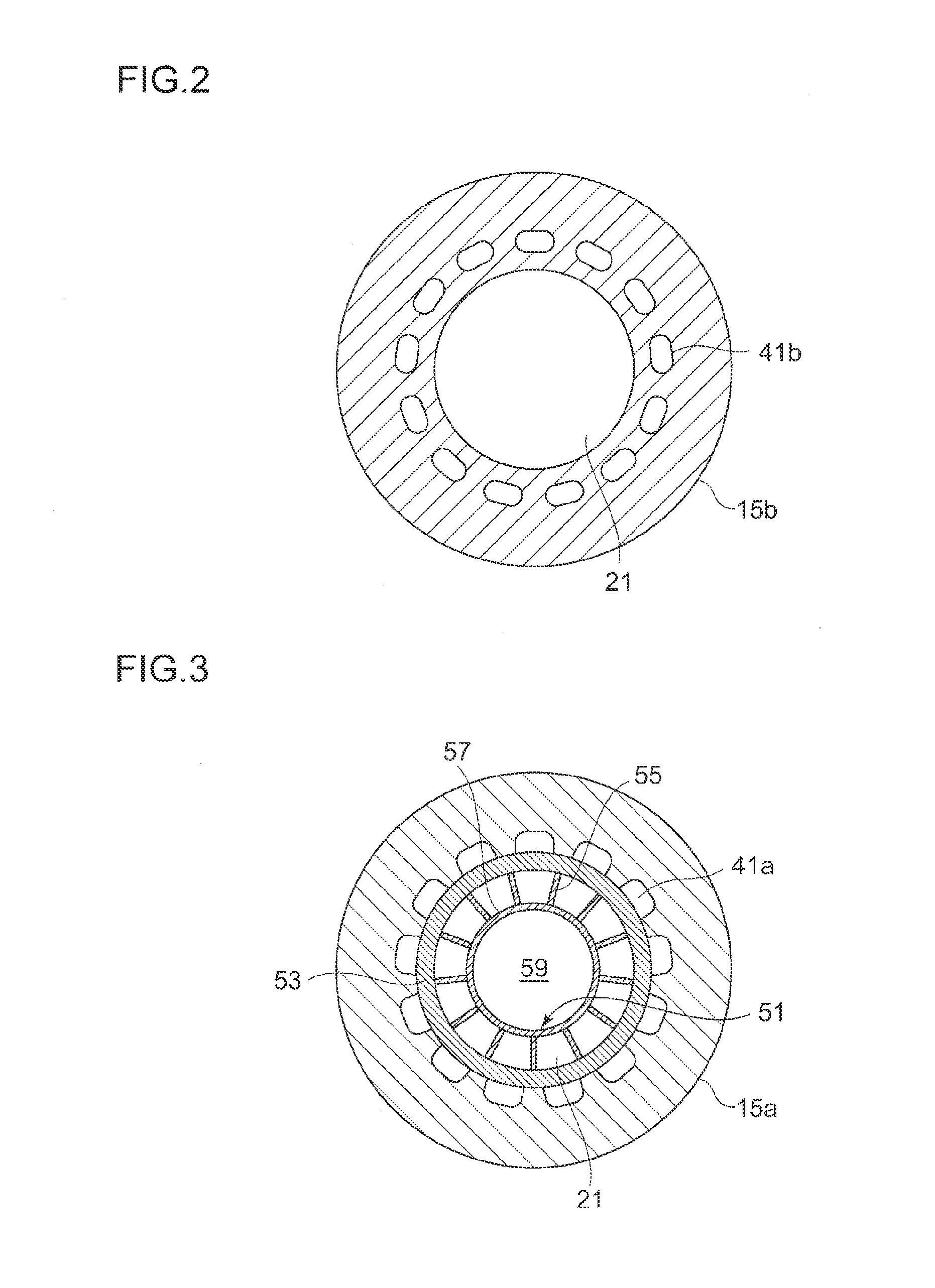

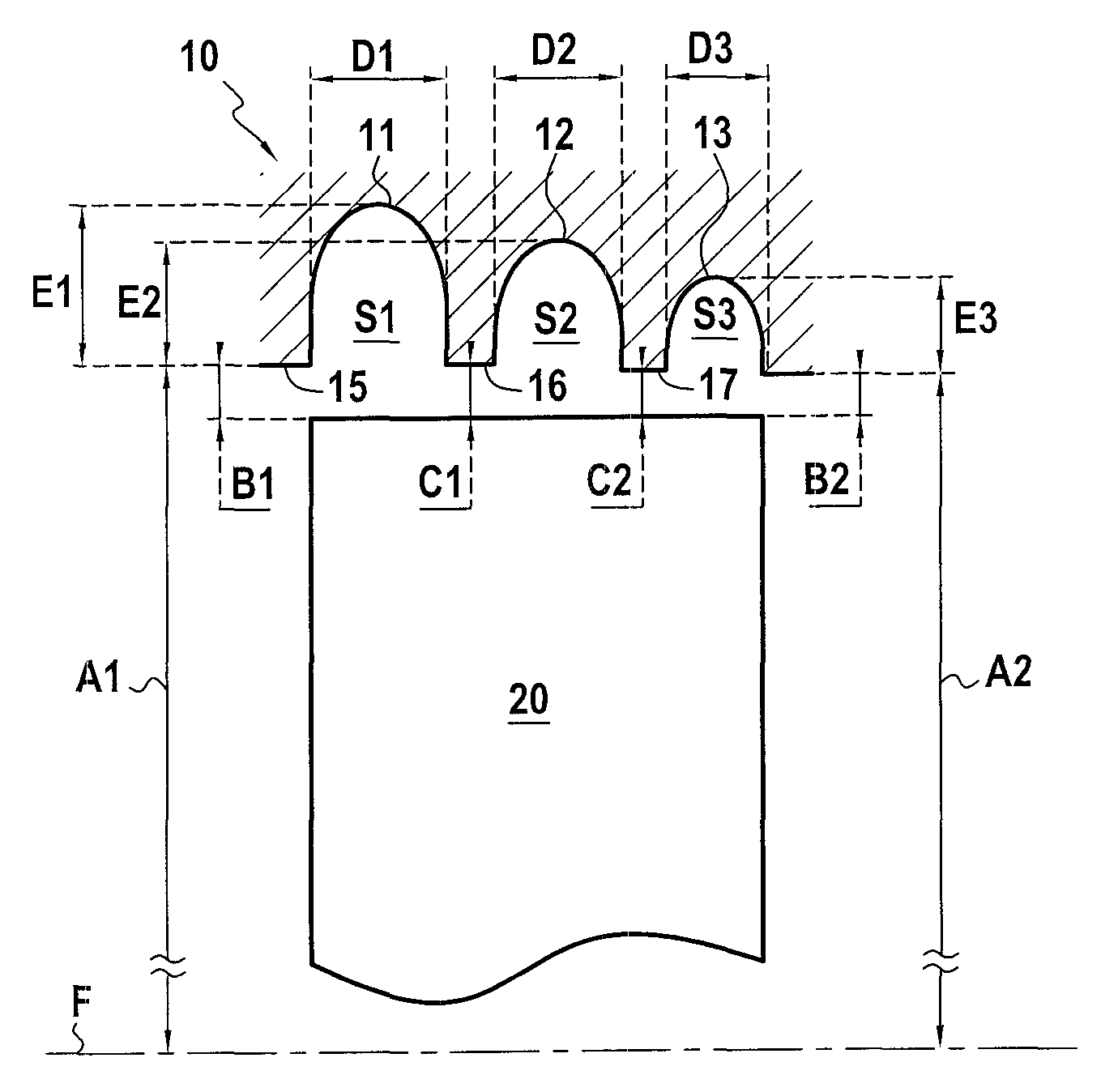

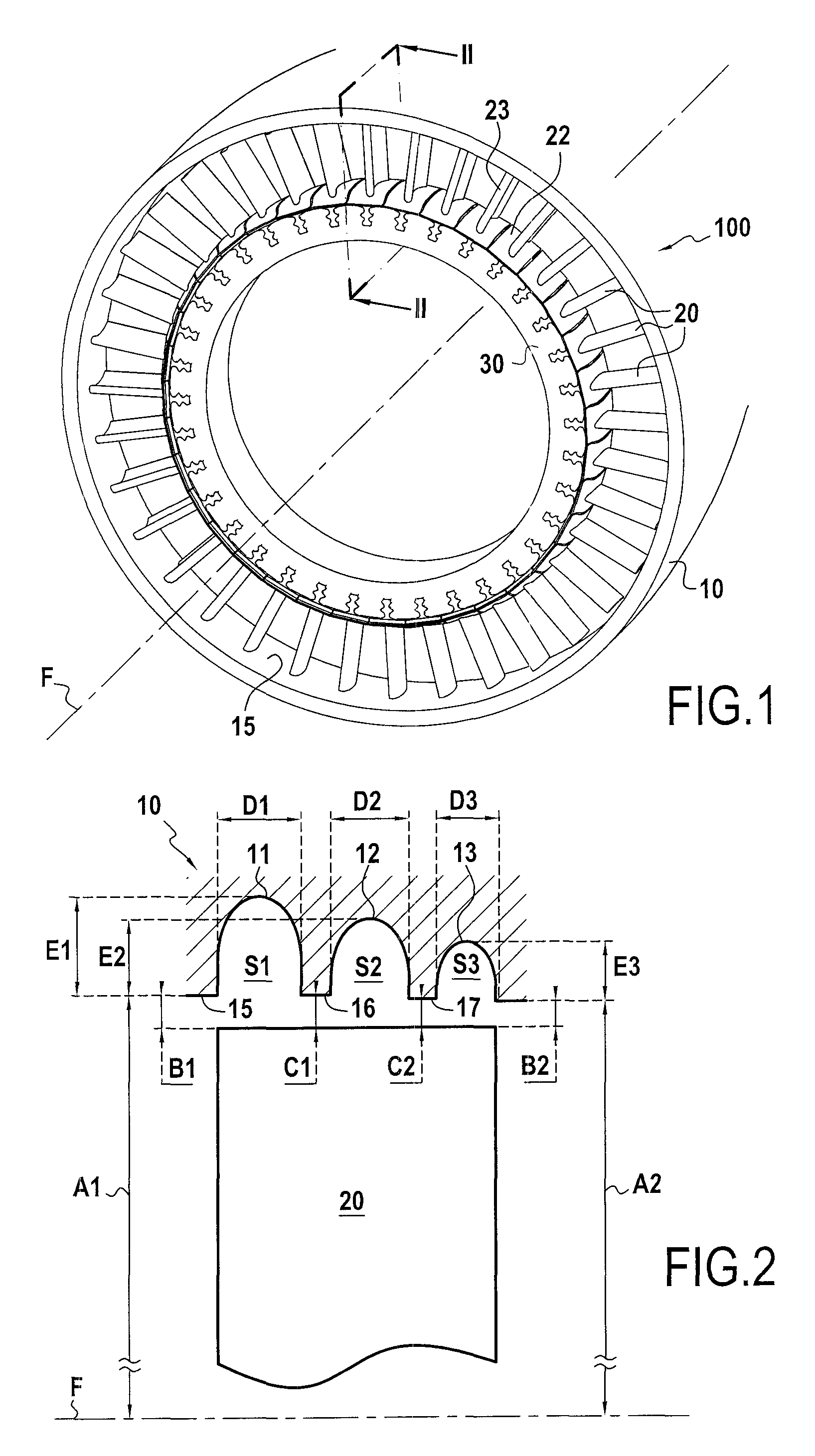

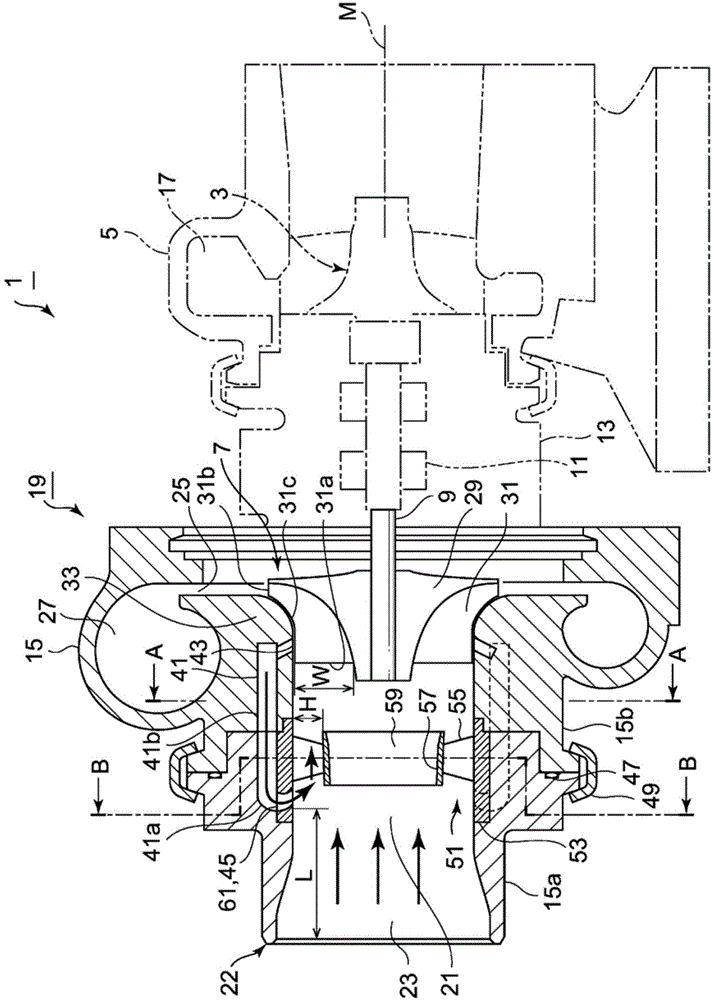

An object is to position a plurality of guide vanes for generating swirl flow at a housing inner circumferential side in front of an impeller wheel to improve a surge margin and to restrict the decrease in a choke flow rate, thereby increasing an operation range of a compressor. A compressor 19 includes a compressor housing 15, an impeller wheel 7 which compresses intake gas flowing in from an intake-air inlet 23, a swirl-flow generating part including a plurality of guide vanes 55 disposed circumferentially along an inner circumferential wall of the intake-air channel 21 between the intake-air inlet 23 and the impeller wheel 7 and which swirls the intake gas from the intake-air inlet 23 around the rotational axis, and a central intake-air flow path 59 formed inside the guide vanes 55 to allow intake gas to flow to the impeller wheel 7 without passing through the guide vanes 55.

Owner:MITSUBISHI HEAVY IND LTD

Casing for a moving-blade wheel of turbomachine

ActiveUS8777558B2Reduce contributionImprove efficiencyPump componentsRotary non-positive displacement pumpsImpellerEngineering

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

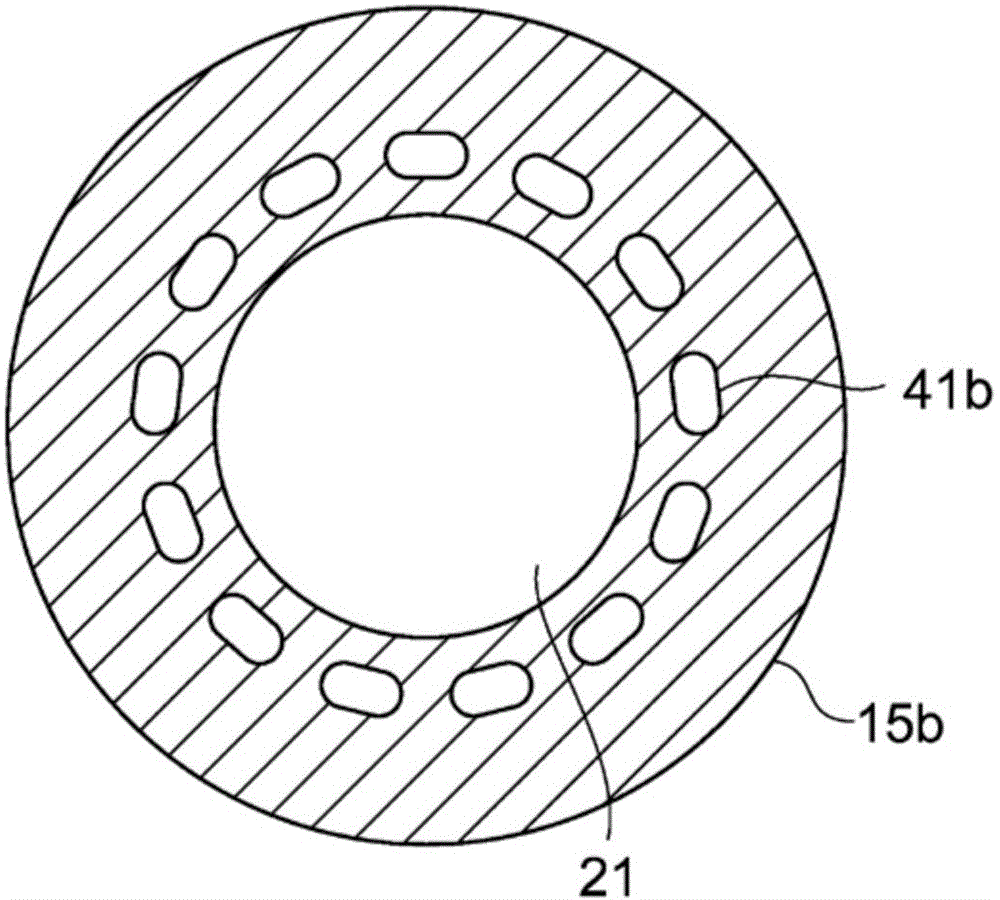

Centrifugal compressor

ActiveCN104428539ALarge range of motionReduce chokeInternal combustion piston enginesEngine manufactureRotational axisChoked flow

An object is to position a plurality of guide vanes for generating swirl flow at a housing inner circumferential side in front of an impeller wheel to improve a surge margin and to restrict the decrease in a choke flow rate, thereby increasing an operation range of a compressor. A compressor 19 includes a compressor housing 15, an impeller wheel 7 which compresses intake gas flowing in from an intake-air inlet 23, a swirl-flow generating part including a plurality of guide vanes 55 disposed circumferentially along an inner circumferential wall of the intake-air channel 21 between the intake-air inlet 23 and the impeller wheel 7 and which swirls the intake gas from the intake-air inlet 23 around the rotational axis, and a central intake-air flow path 59 formed inside the guide vanes 55 to allow intake gas to flow to the impeller wheel 7 without passing through the guide vanes 55.

Owner:MITSUBISHI HEAVY IND LTD

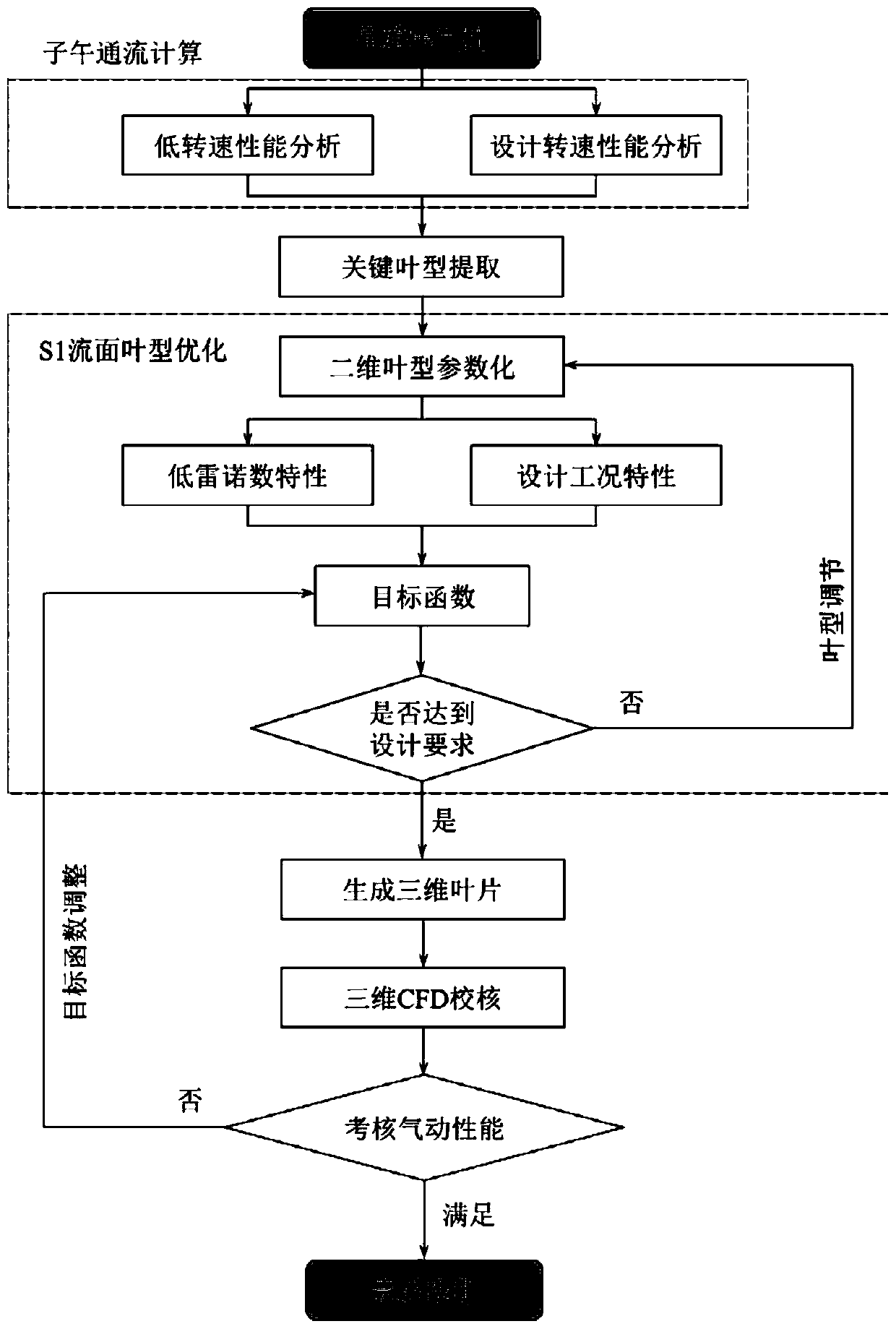

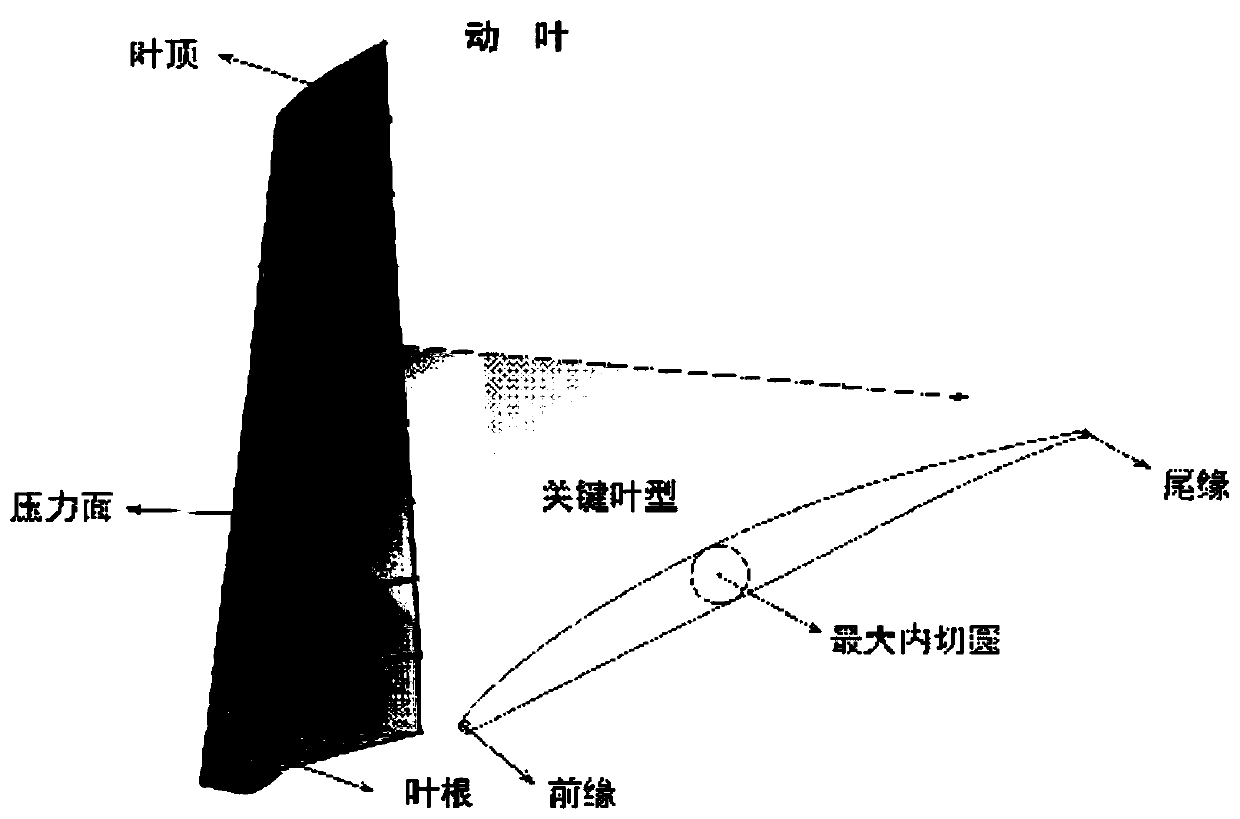

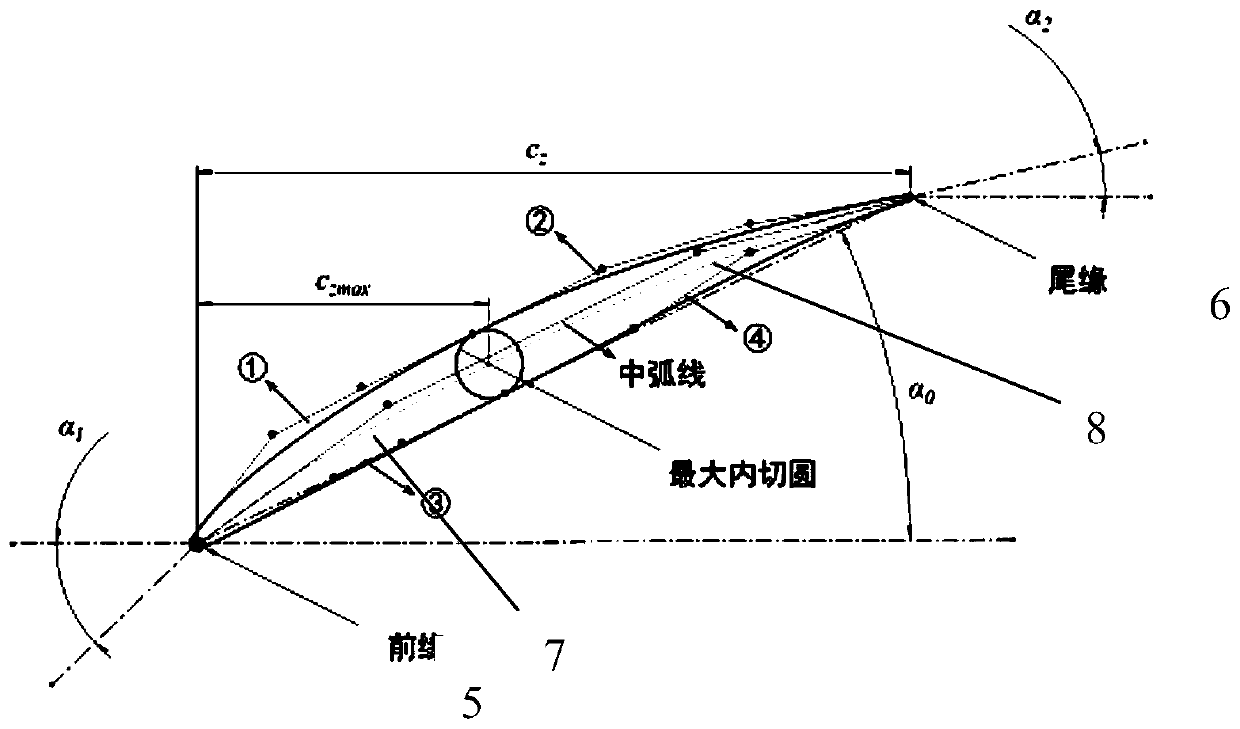

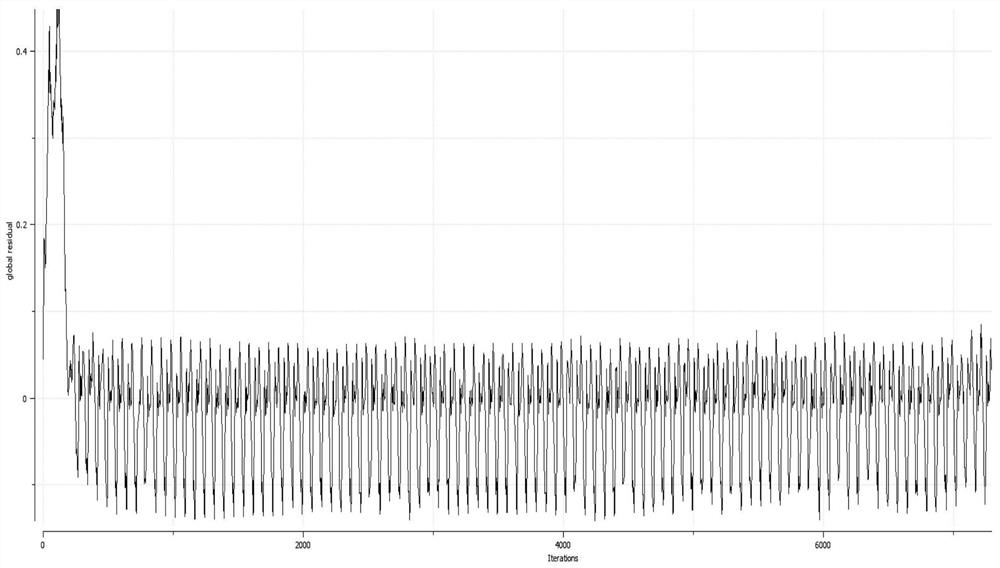

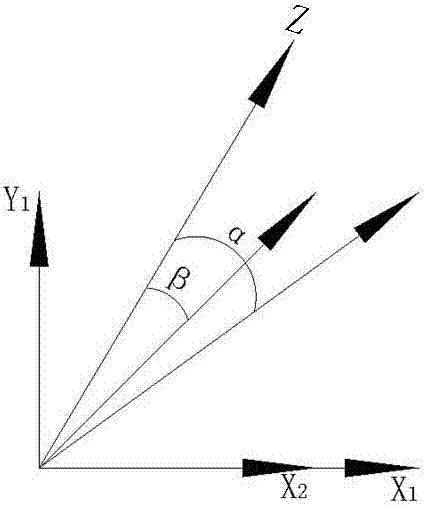

Two-dimensional blade profile optimization method for compressor considering low Reynolds number working performance

ActiveCN109779972AImprove aerodynamic performanceIncrease stall marginPump componentsPumpsGenetic algorithmEngineering

The invention relates to a two-dimensional blade profile optimization method for a compressor considering a low Reynolds number working performance; the optimization method is characterized by comprising the following steps of: step 1: analyzing the meridional flow performance of a prototype multistage axial flow compressor at different rotating speeds; step 2: determining a key two-dimensional blade profile section to be optimized; step 3: performing parametric fitting to the key two-dimensional blade profile in step 2; step 4: analyzing the aerodynamic performance of the two-dimensional blade profile, and analyzing the aerodynamic performance of the parameterized two-dimensional blade profile to obtain the variable attack angle performance of the blade profile under a low Reynolds numberworking condition and the variable attack angle performance under a high Reynolds number working condition; and step 5: optimizing the modeling parameters of the two-dimensional blade profile, adjusting the two-dimensional modeling parameters according to the variable attack angle performance parameters of the two-dimensional blade profile obtained in step 4 at different Reynolds numbers, using agenetic algorithm to circularly iterate steps 3 and 4 until a two-dimensional blade profile design reducing loss and increasing stall margin is obtained, and then obtaining a new two-dimensional blade profile. According to the invention, the performance optimization of the two-dimensional blade profile of the axial flow compressor at different Reynolds numbers and different attack angles is realized; the designed working performance of the compressor is improved while the aerodynamic performance of the compressor at the low rotation speed working condition is improved; and the flow efficiencyis improved while the normal starting and stable working of the compressor are ensured.

Owner:HANGZHOU TURBINE POWER GRP

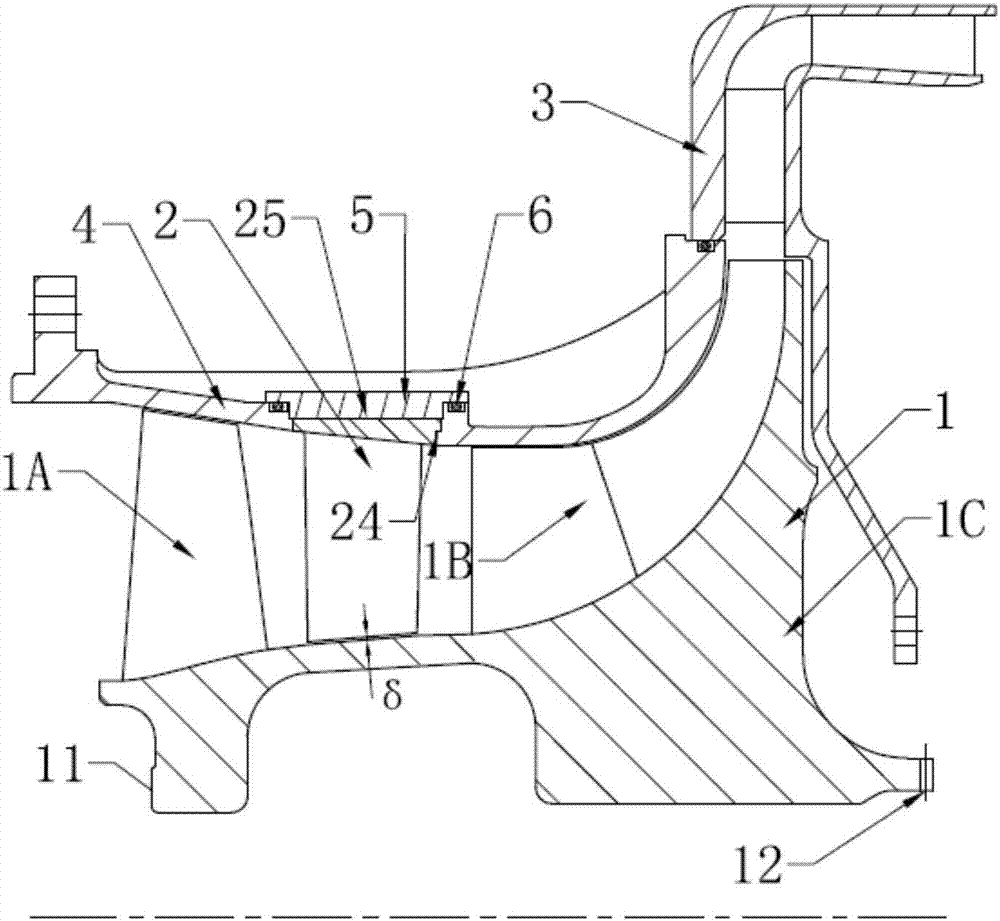

Axial flow-centrifugation integral bladed disc type combined compression system

The invention discloses an axial flow-centrifugation integral bladed disc type combined compression system. An axial flow impeller and a centrifugal impeller are integrally connected to form an integral bladed disc; an axial flow stator is arranged between an axial flow rotor and the centrifugal impeller; an impeller outer ring of an axial flow gas compressor and an impeller outer ring of a centrifugal gas compressor are integrally connected to form an integral impeller outer ring; one assembling reserving cavity for assembling stator outer rings is formed in the integral impeller outer ring; the axial flow stator is divided into a plurality of equal parts in the circumferential direction; the stator outer rings equally divided are mounted in the assembling reserving cavity; the stator outer rings are limited in the radial direction through a cylindrical surface at the top of the assembling reserving cavity; and the stator outer rings are compressed through compression rings. The axial flow-centrifugation integral bladed disc type combined compression system simplifies the structure to improve the reliability of an engine and reduce the production cost; a cantilever stator is adopted to increase the surge margin of an axial flow gas compressor stage so as to further increase the surge margin of the combined compression system and expand the operational covered wire of the engine.

Owner:中科航星科技股份有限公司

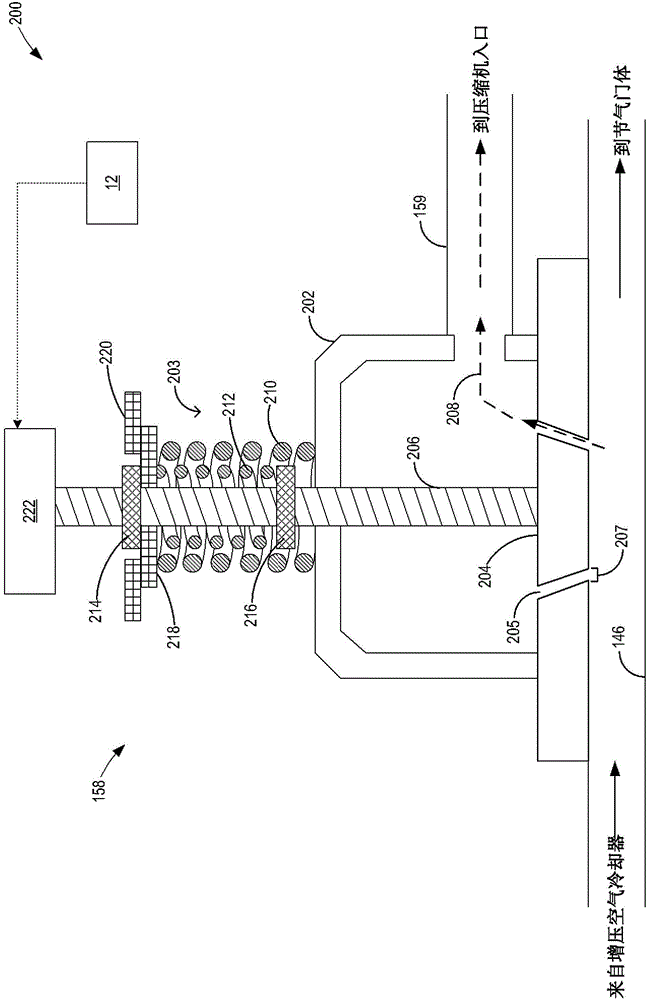

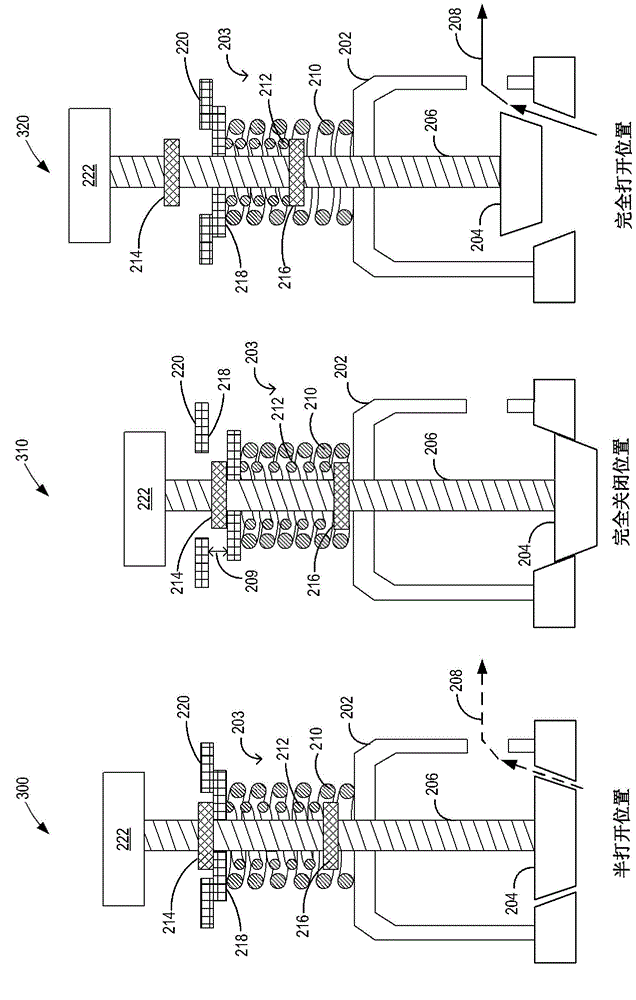

Methods and systems for surge control

InactiveCN104373202AReduced need for actuationIncrease marginInternal combustion piston enginesEngine operationsSemi openMechanical engineering

Owner:FORD GLOBAL TECH LLC

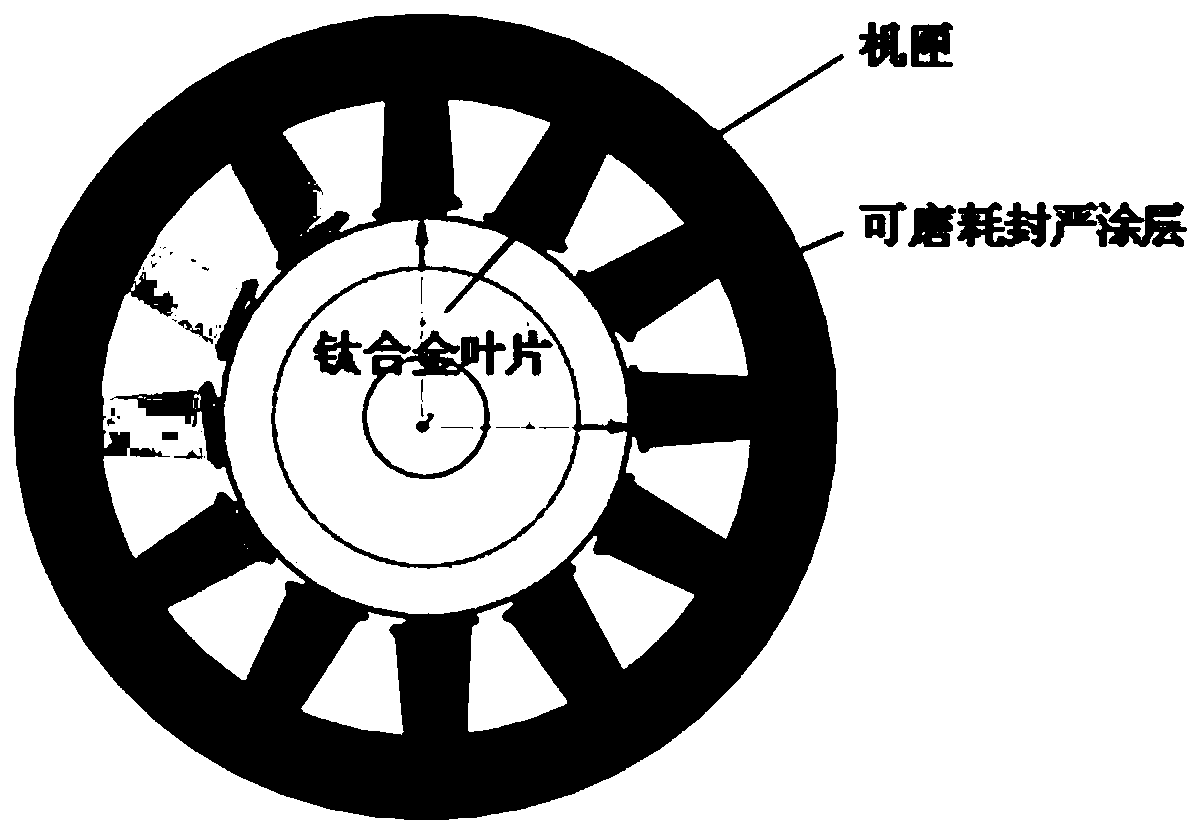

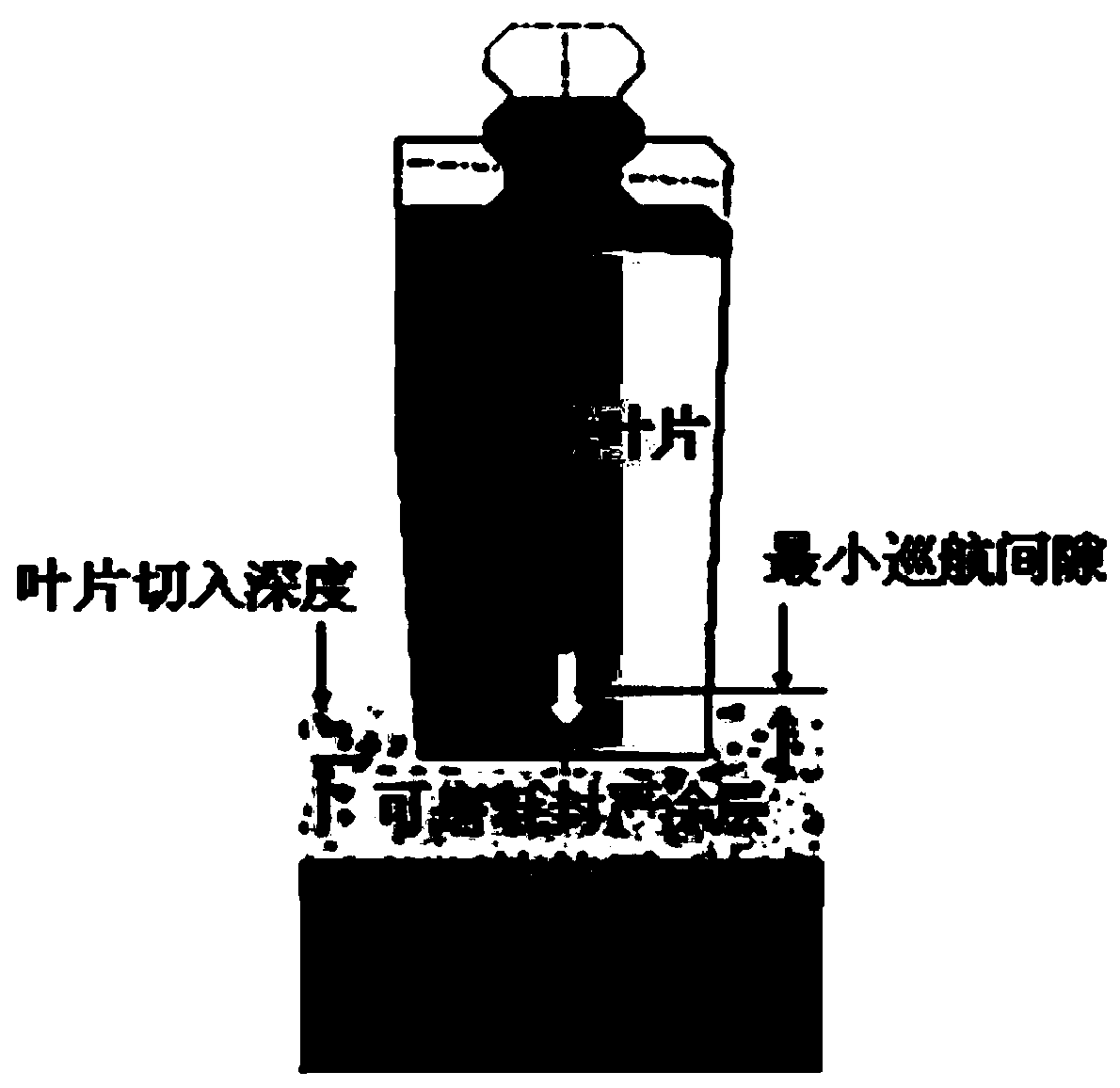

Control method of titanium alloy compressor tip clearance

InactiveCN110905607AReduce gas leakage rateImprove surge marginLeakage preventionMachines/enginesAviationTitanium alloy

The invention aims to provide a control method of a titanium alloy compressor tip clearance. The control method is characterized in that an abradable sealing coating is sprayed on the inner wall of acasing; tips of rotor blades are compositely electroplated with a Ni / c-BN coating; and the abradable sealing coating and the Ni / c-BN coating are used as a pair of abradable sealing friction pair, thereby forming a novel gas circuit sealing coating structure. In the operation process of an engine, the tips of the rotor blades can cut into the abradable sealing coating on the inner wall of the casing, thus grooves capable of improving the sealing effect are reserved, ideal radial airflow gaps are formed, and the maximum pressure difference is obtained, so that the power of the engine is remarkably improved, the consumption of aviation kerosene is reduced, and the one-time test run percent of pass of the whole engine is improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

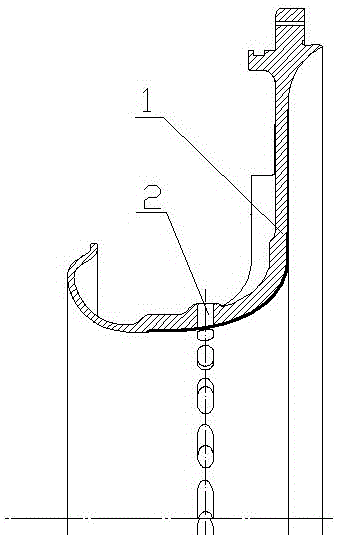

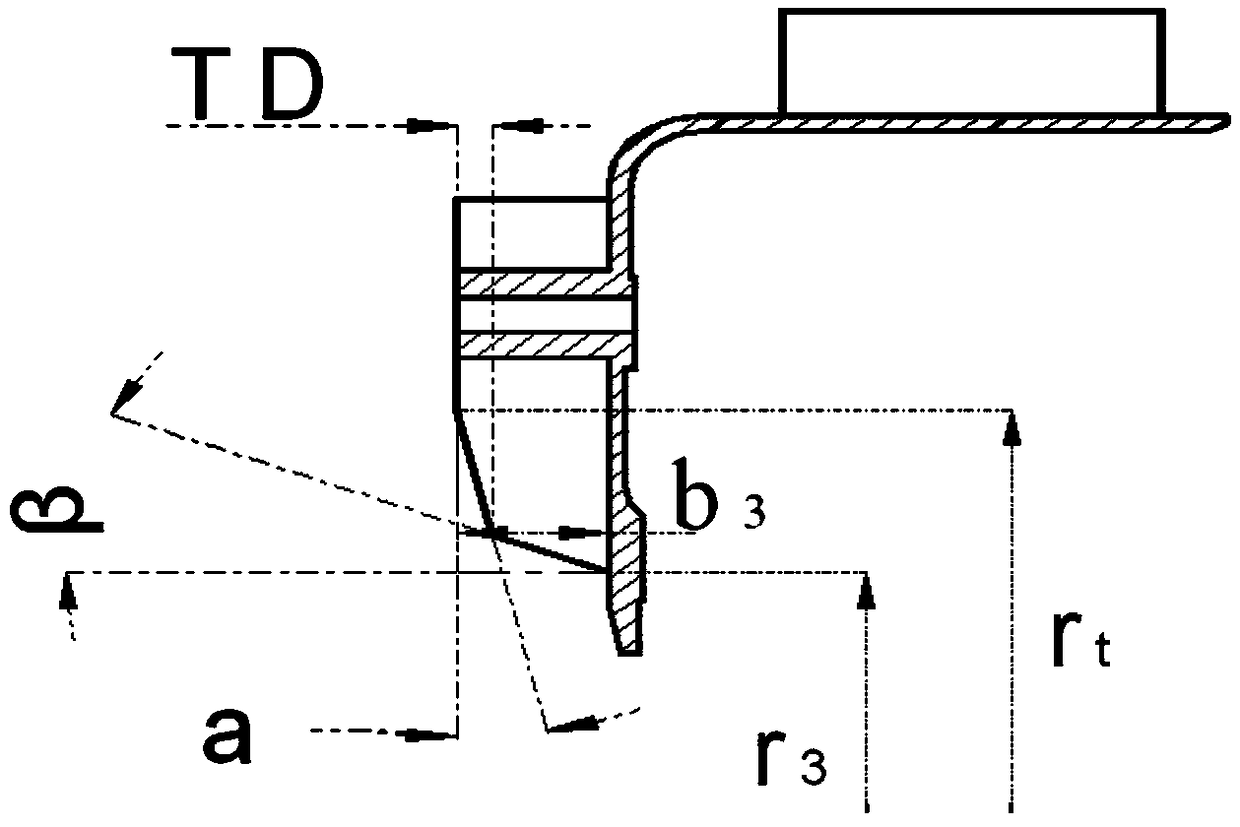

Casing treatment structure for improving surge margin of single-stage centrifugal compressor and compressor

The invention provides a casing treatment structure for improving the surge margin of a single-stage centrifugal compressor, and relates to the technical field of compressors. A surge expanding through hole is arranged on a casing ingeniously, when the air inlet amount needed by the compressor is increased, part of air enters the casing from the surge expanding through hole, so that the amount of air entering the casing from an air inlet way is reduced, and the surge margin is accordingly increased. Furthermore, the direction of the surge expanding hole is set to form a certain angle with a tangent line of the inner diameter of the air guide casing, so that airflow entering the casing from the surge expanding hole is basically the same in circumferential speed direction of airflow. The casing treatment structure is simple in process, low in product cost, safe, reliable, easy to maintain and simple in structure, and the compressor surge margin can be obviously improved.

Owner:CHINA AVIATION POWER MACHINE INST

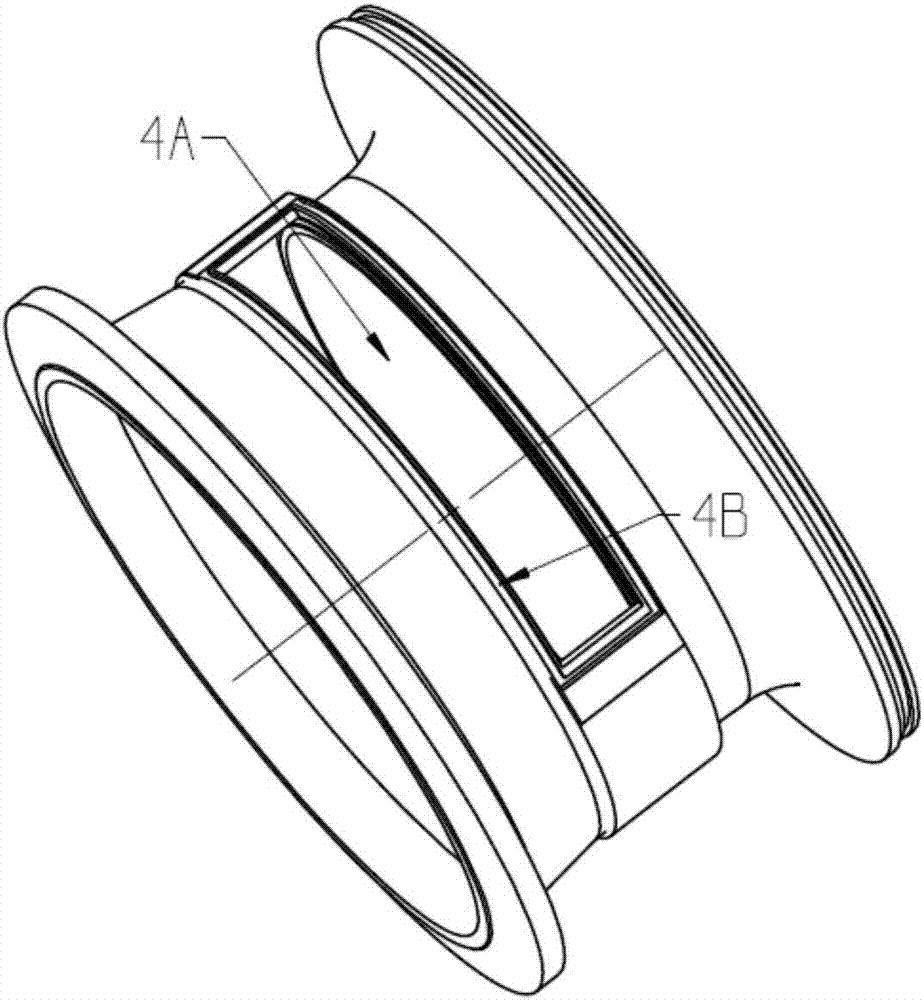

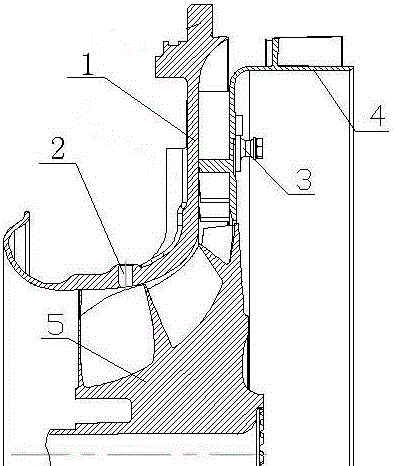

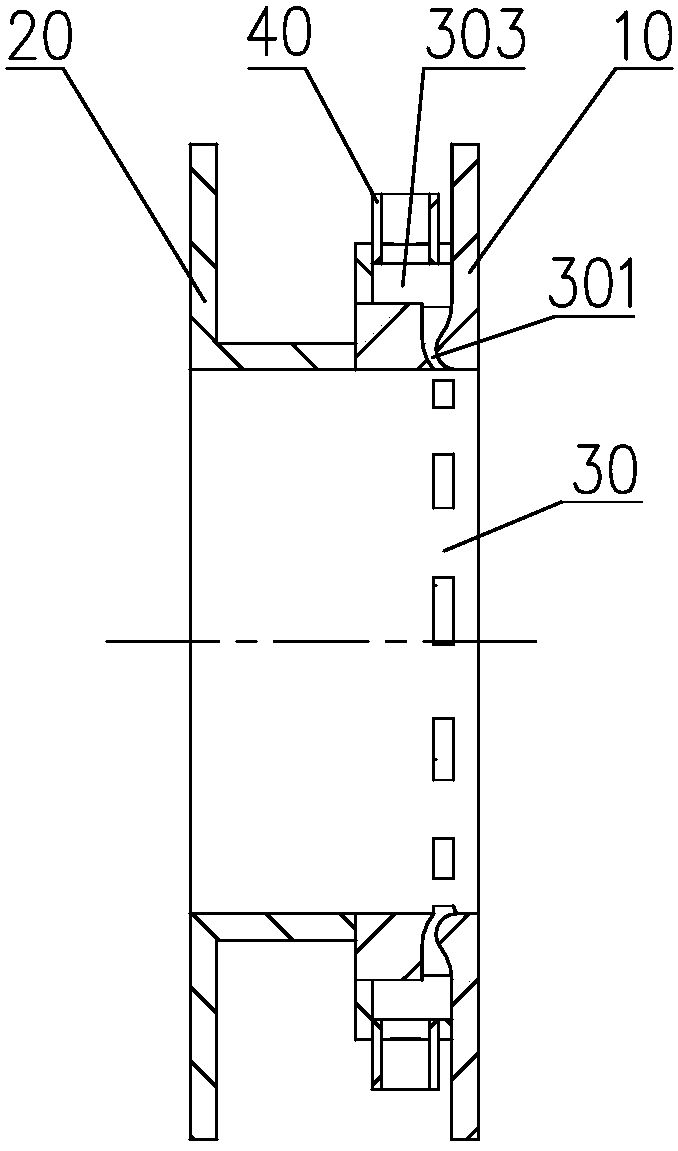

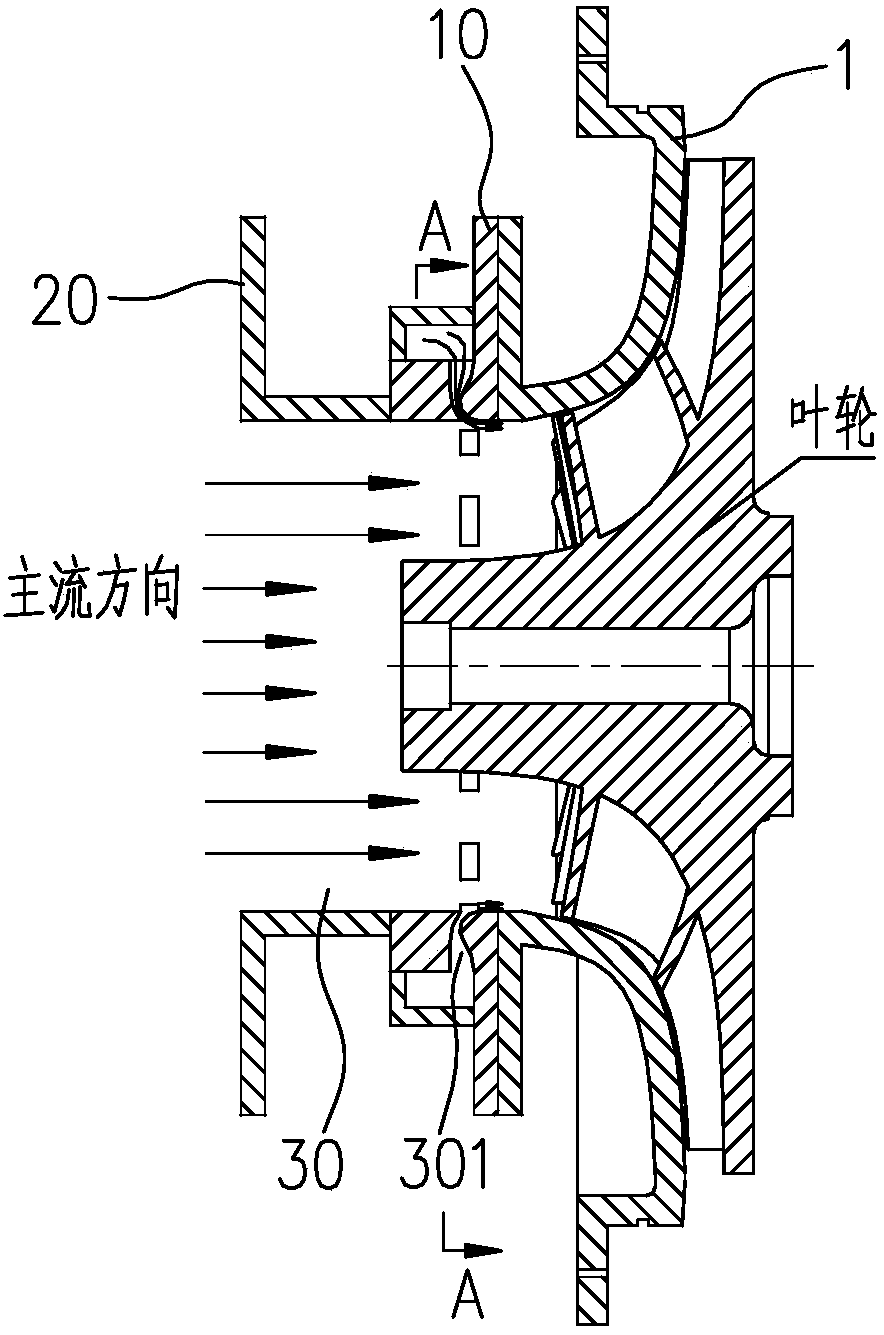

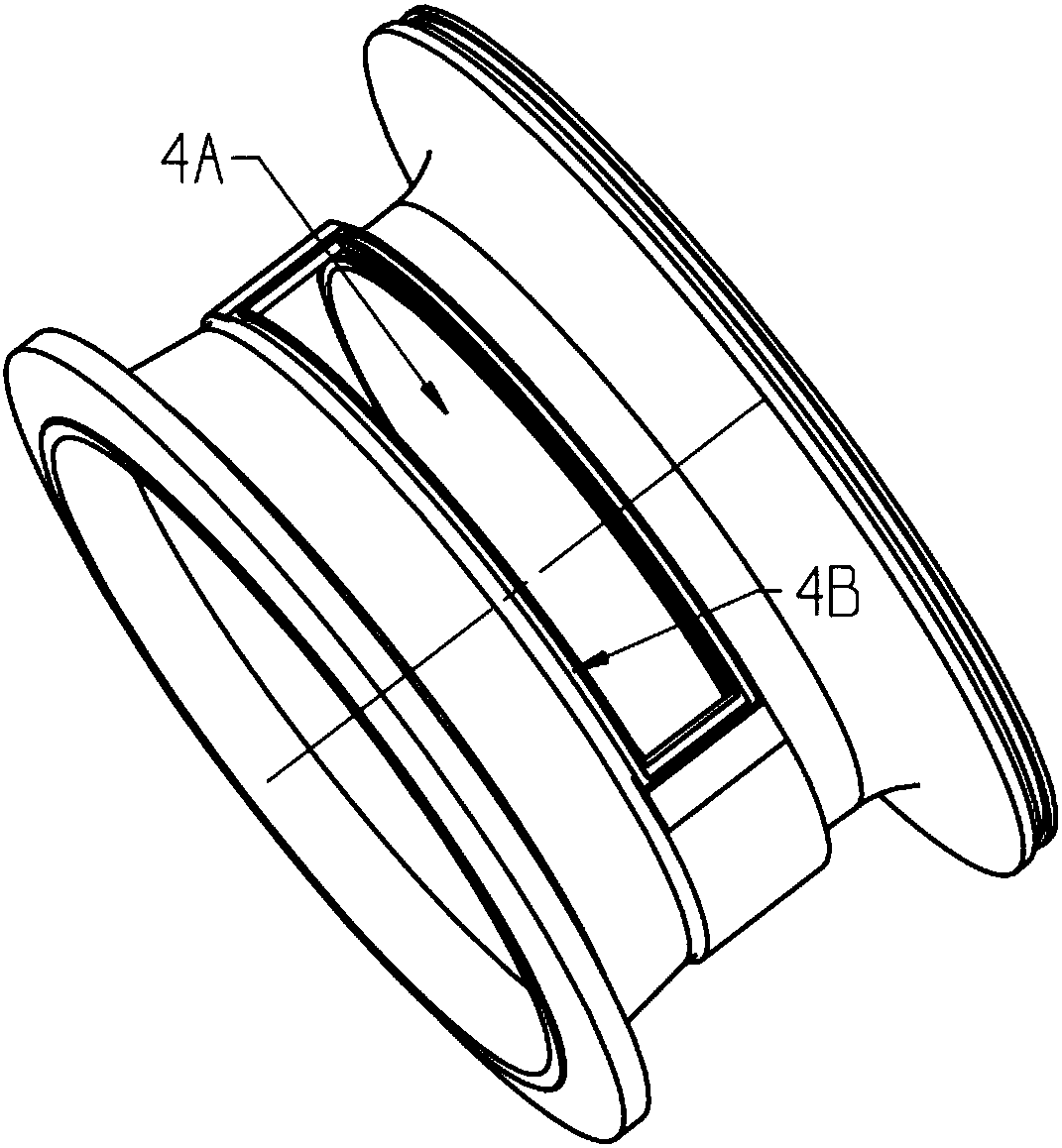

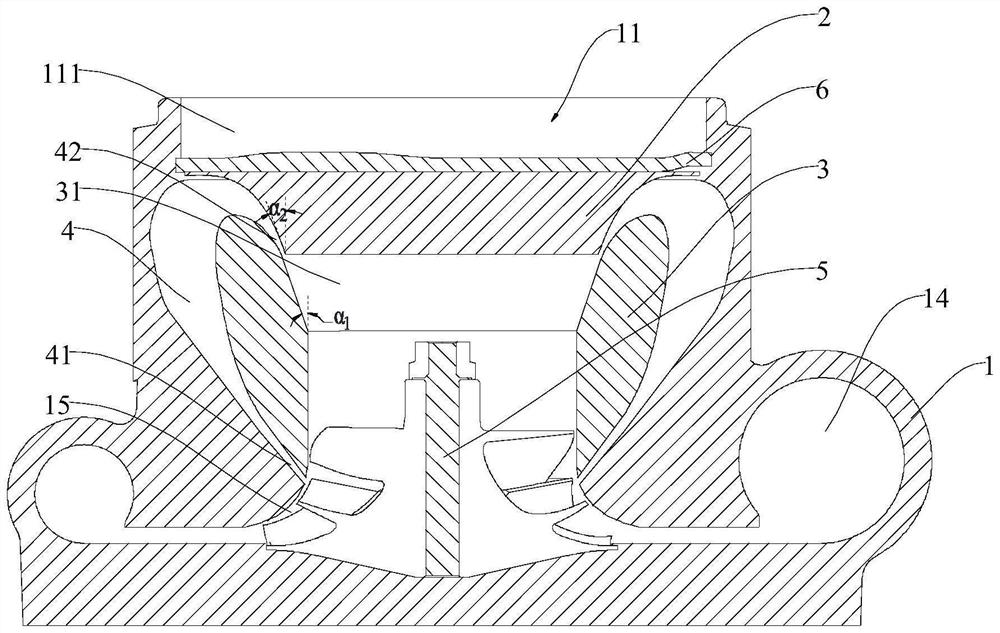

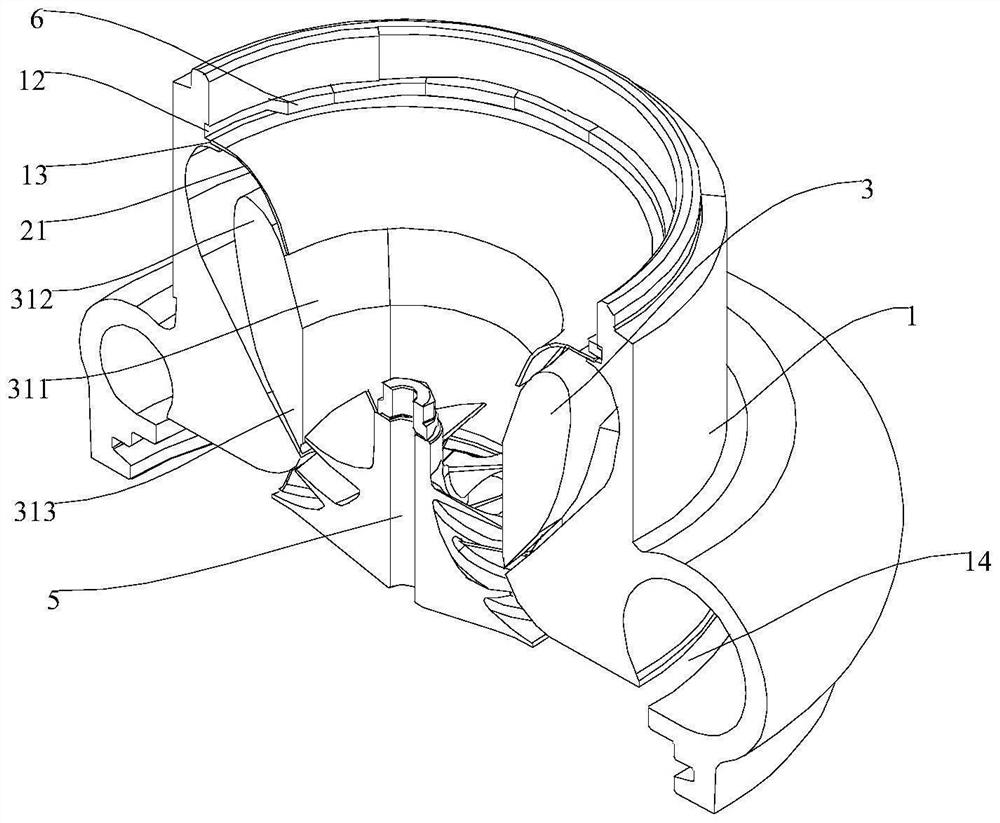

Stability extending device of centrifugal compressor

The invention discloses a stability extending device of a centrifugal compressor. The device is external. A first flange plate and a second flange plate which are seamlessly connected to a front cover plate and a suction pipeline of the centrifugal compressor are separately arranged on two sides of the device. The first flange plate and the second flange plate are arranged in parallel, and a main flow pipeline perpendicular to the flange plates is arranged between the two flange plates; and the main flow pipeline communicates with a gas inlet pipeline for external gas supply. A plurality of injection holes are formed in the peripheral direction of an inner wall face of the main flow pipeline, gas collection cavities are formed in the outer wall faces of the injection holes, and connectors which communicate with the gas inlet pipeline are arranged on the gas collection cavities; an external compressed gas flow enters the gas collection cavities from the gas inlet pipeline and then enters the main flow pipeline of the compressor through the injection holes which are formed in the peripheral direction; through the injection holes, gas enters radially and is sprayed out in the tangential direction of the inner surface of a flow path. The stability extending device of the centrifugal compressor is simple in structure and convenient to mount and disassemble, and can effectively expand the operating margin of the centrifugal compressor.

Owner:HEFEI GENERAL MACHINERY RES INST

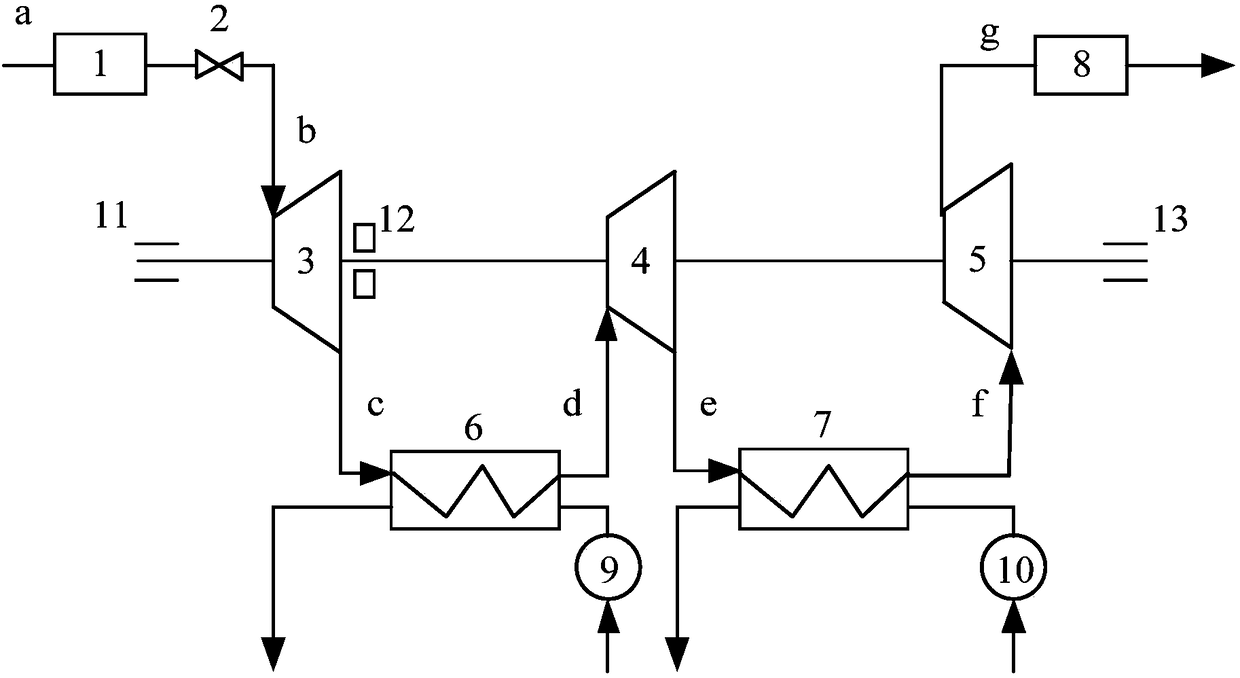

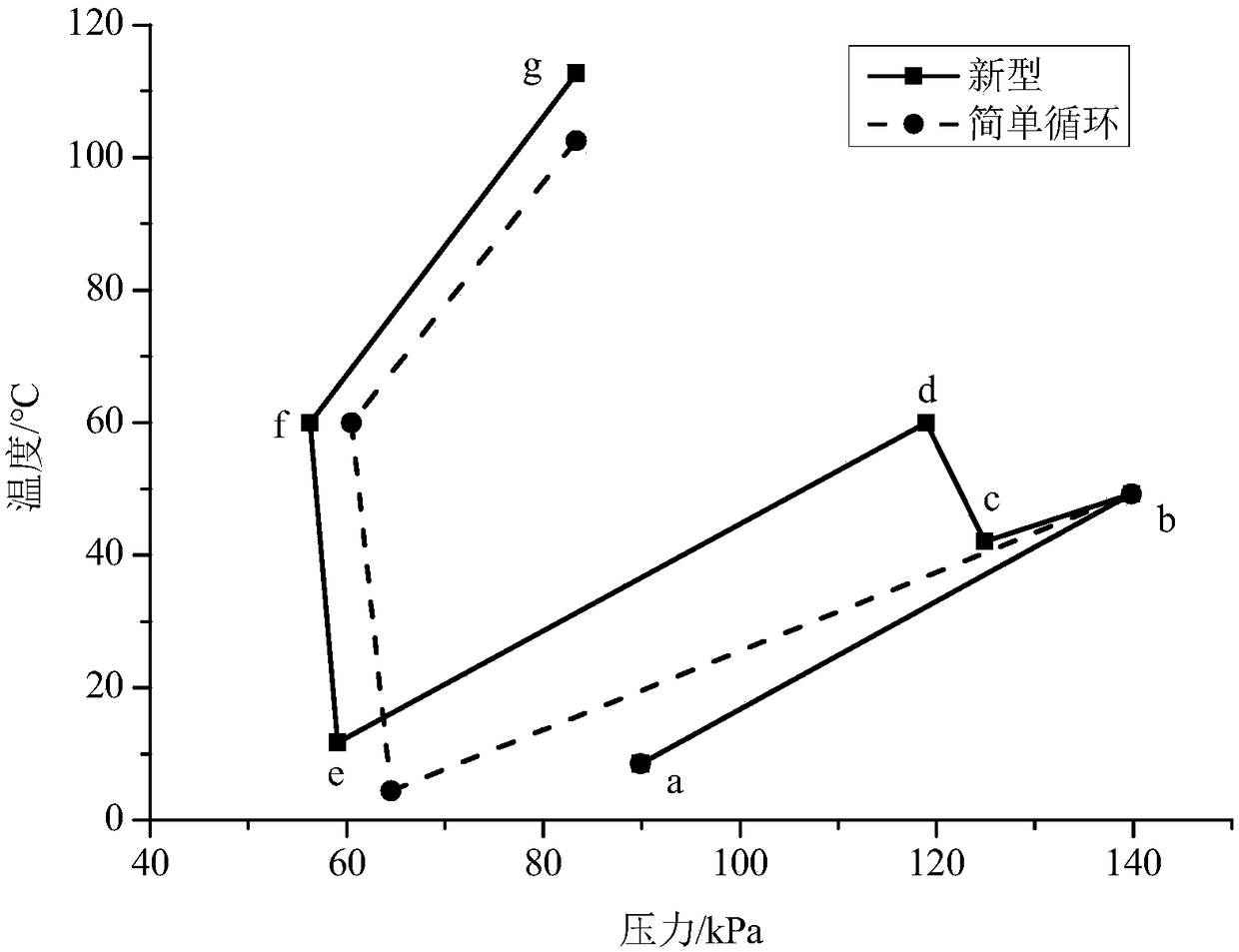

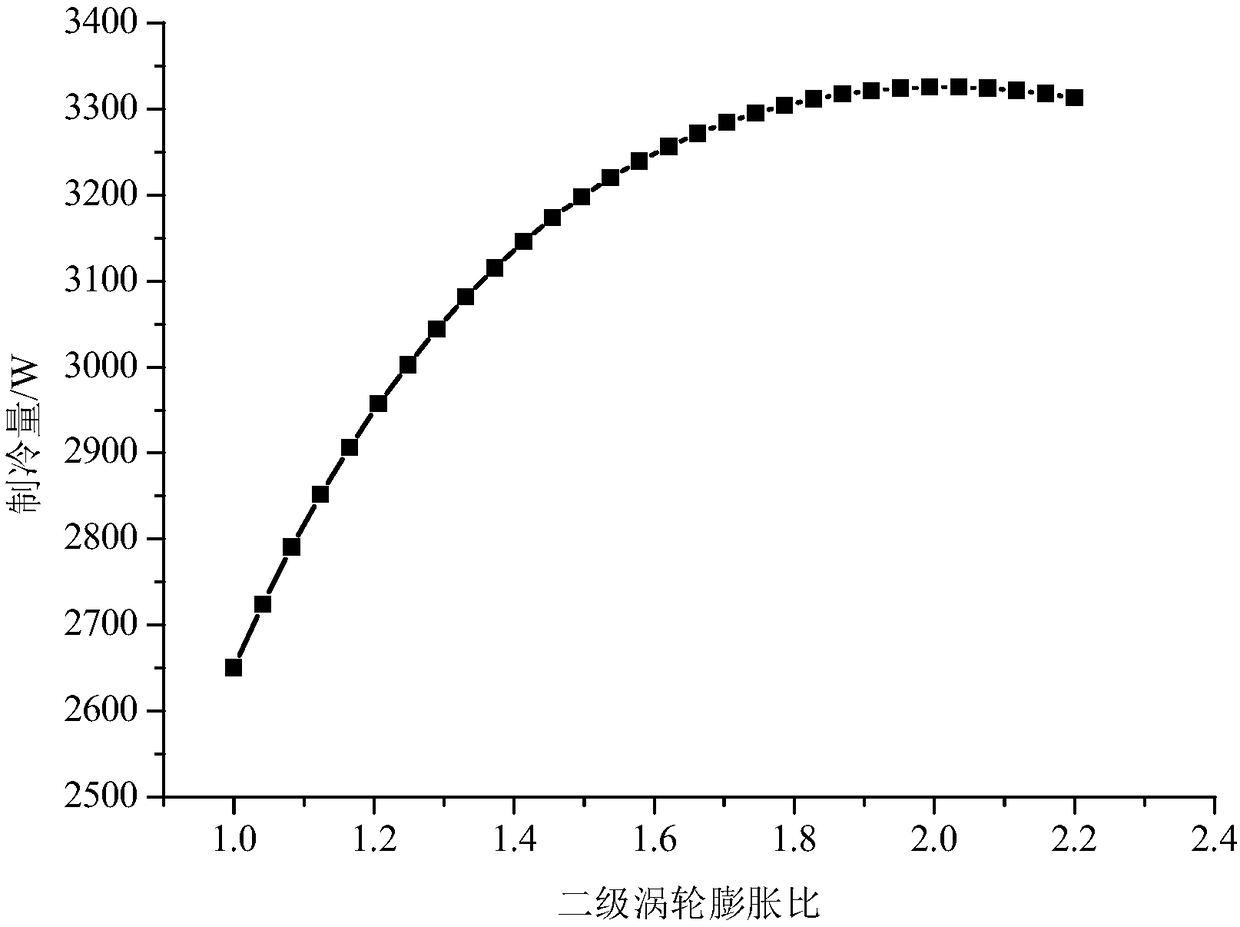

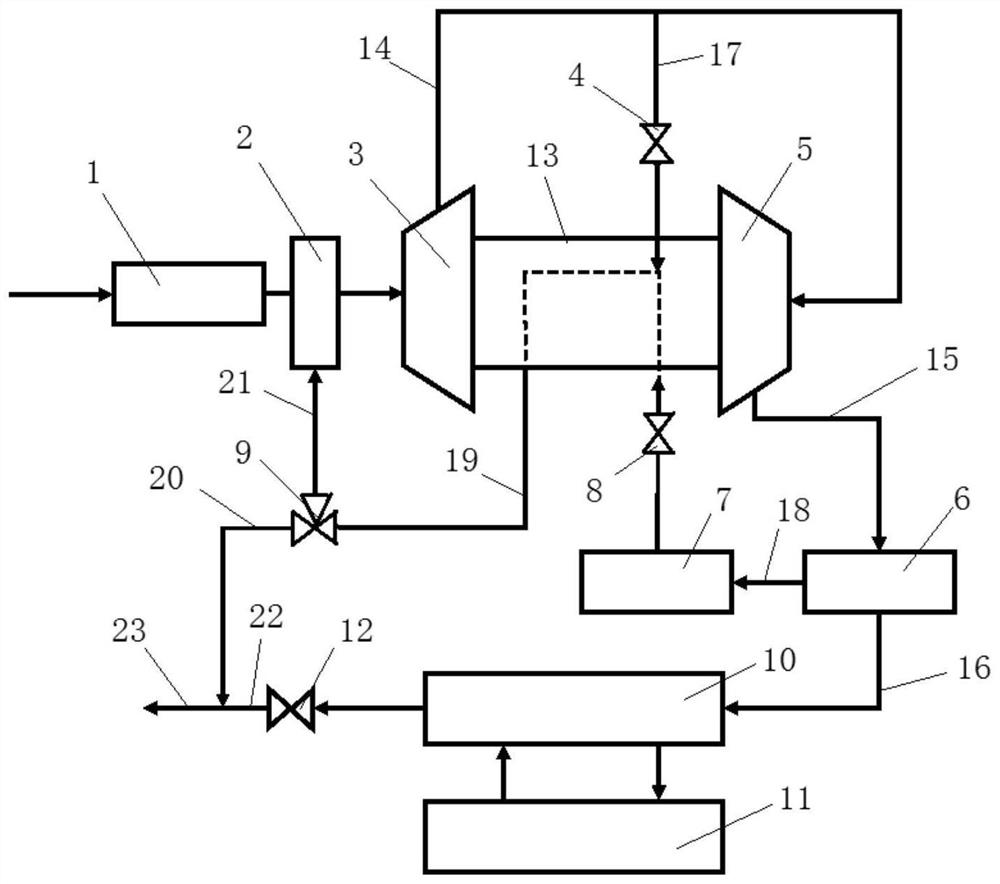

Middle reheating type turbine cooler system applied to airplane pod

InactiveCN108216642AAlleviate power tensionReduce power consumptionAir-treatment apparatus arrangementsEnergy efficient board measuresSelf weightAir compressor

The invention discloses a middle reheating type turbine cooler system applied to an airplane pod. By adopting middle reheating circulation, the system efficiency is obviously improved. The system comprises an air inlet system, a first-stage turbine, a second-stage turbine, a first-stage heat exchanger, a second-stage heat exchanger, an air compressor and an exhaust system. By means of the system,ram-air in the flying process of an airplane is used as a power source, and after two-stage turbine expansion cooling, a primary surface heat exchanger cools air in an electronic cabin. By means of the system, middle heat re-exchange circulation is adopted, and the unit flow energy heat exchange capability of a turbine cooler is obviously improved; a liquid circulation heat exchange system is notneeded, the primary surface heat exchanger is adopted to lower the weight of the heat exchangers, and the system weight is obviously lowered; the system has a very low additional power consumption amount, and energy consumption of the cooling system is obviously lowered; an air bearing system is adopted by the system, an oil lubricating system is not needed, the system self-weight is lowered, andmeanwhile, the system maintenance is improved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

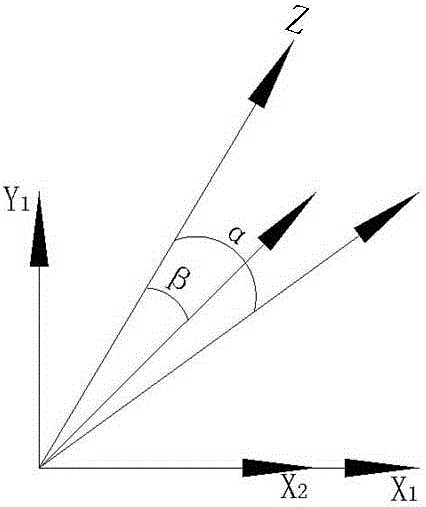

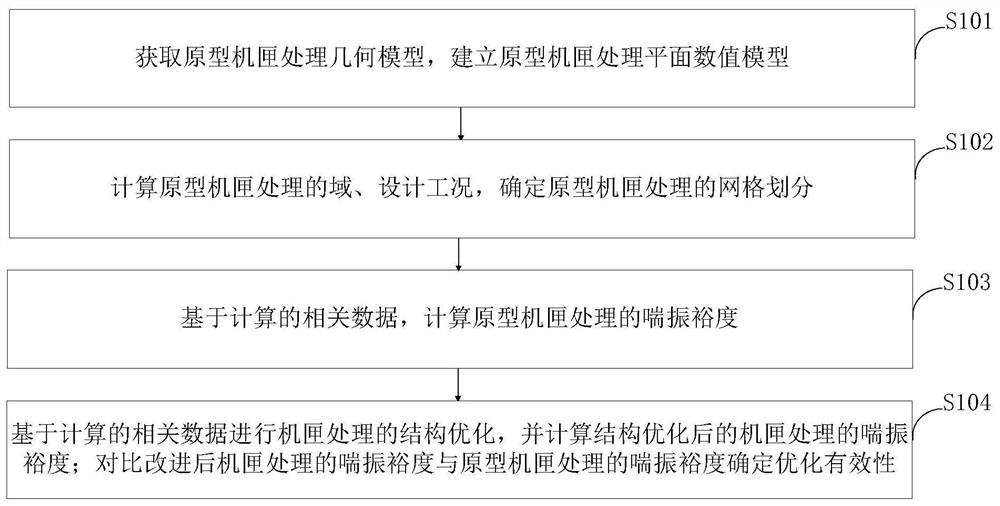

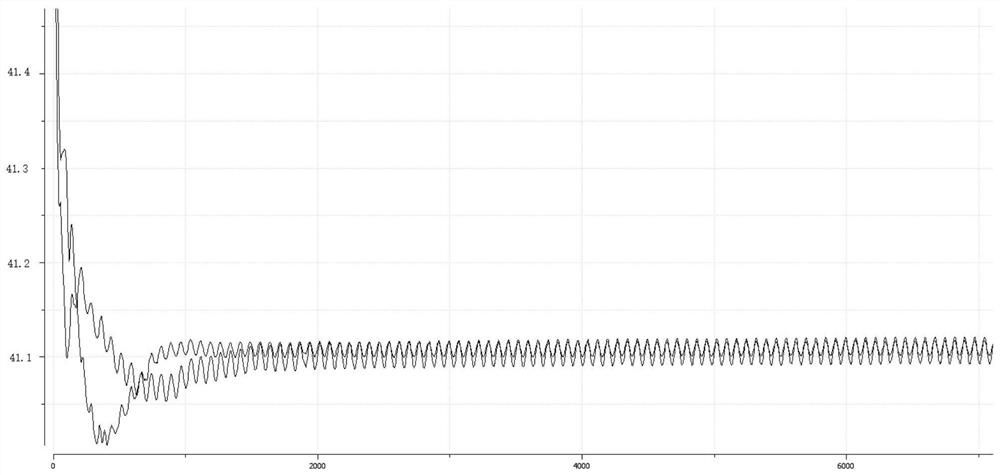

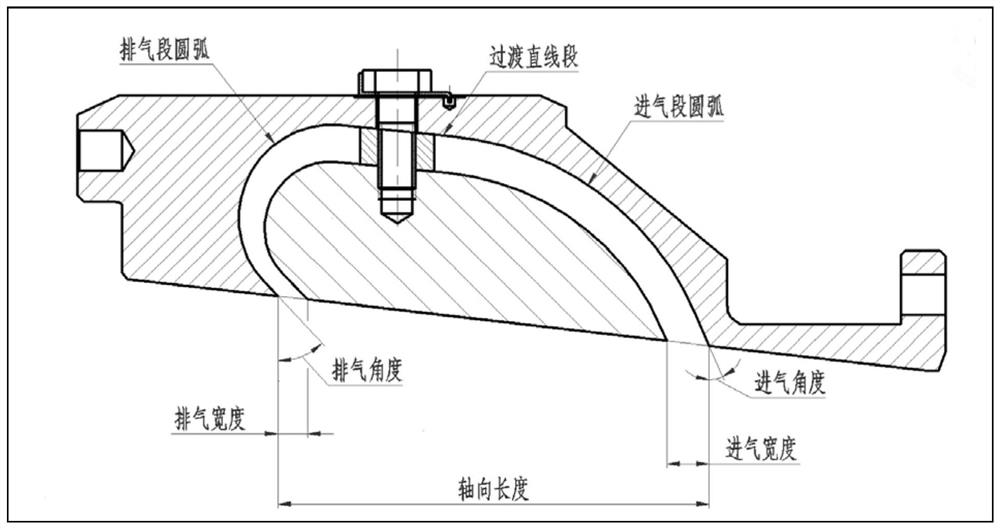

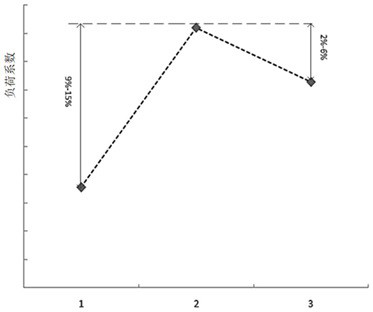

Method, system and terminal for optimizing gas compressor casing treatment to improve stability margin

PendingCN113283198AEasy to handleStability margin improvement effect is goodGeometric CADPump componentsGas compressorMarine propulsion

The invention belongs to the technical field of gas compressors of gas turbines for ship propulsion, and discloses a method, a system and a terminal for optimizing gas compressor casing treatment to improve the stability margin. The method for optimizing gas compressor casing treatment to improve the stability margin comprises the following steps: carrying out numerical simulation on an original casing with an axial chute and a backflow cavity and a parameter improved casing; determining the structural form of casing treatment, increasing the axial speed, adopting the whole annular air inlet and increasing the air inlet amount by adjusting an inlet of an air inlet section and enlarging the air inlet angle; and in the air outlet section, adopting an inclined shrinkage nozzle as an air outlet, increasing the outlet speed, optimizing the exhaust section, adopting the IGG / AutoGrid5 for calculation of a grid to carry out single-channel grid division, and optimizing the treatment effect of the compressor casing. According to the method, the exhaust section treatment casing can be effectively optimized, the improvement effect on the working stability margin of the gas compressor under the low working condition is the best, and the stability margin is improved by 6.04%.

Owner:NAVAL UNIV OF ENG PLA

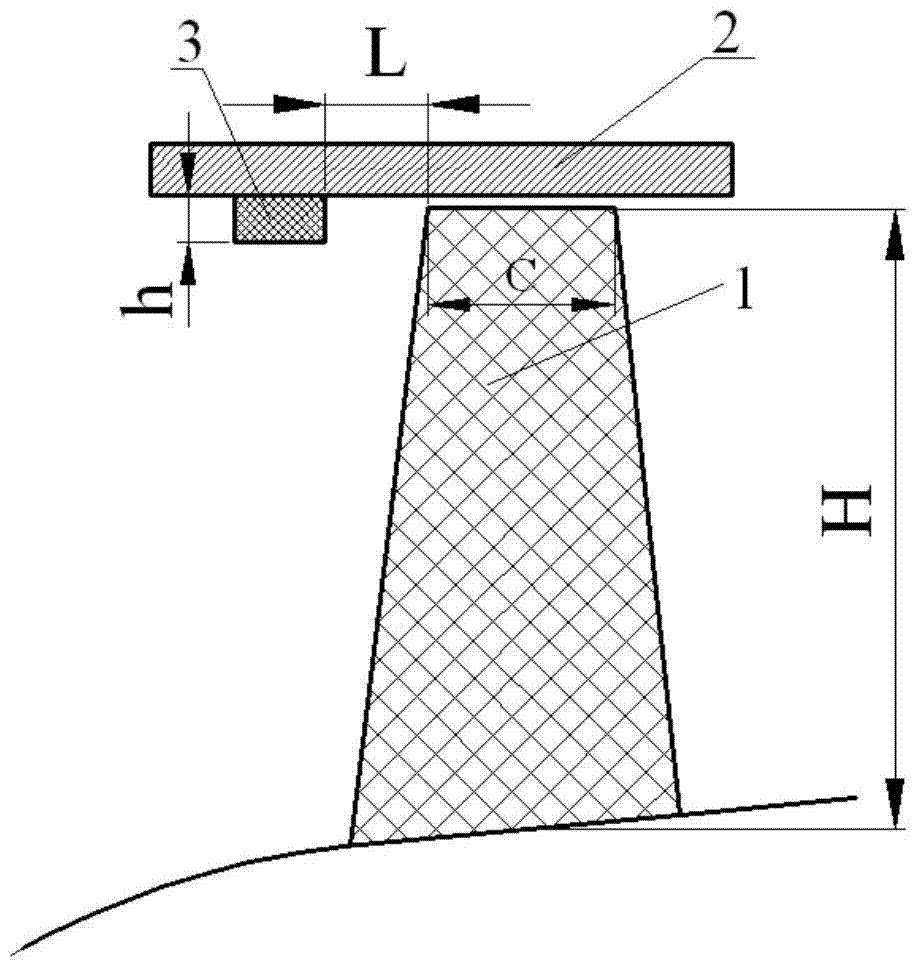

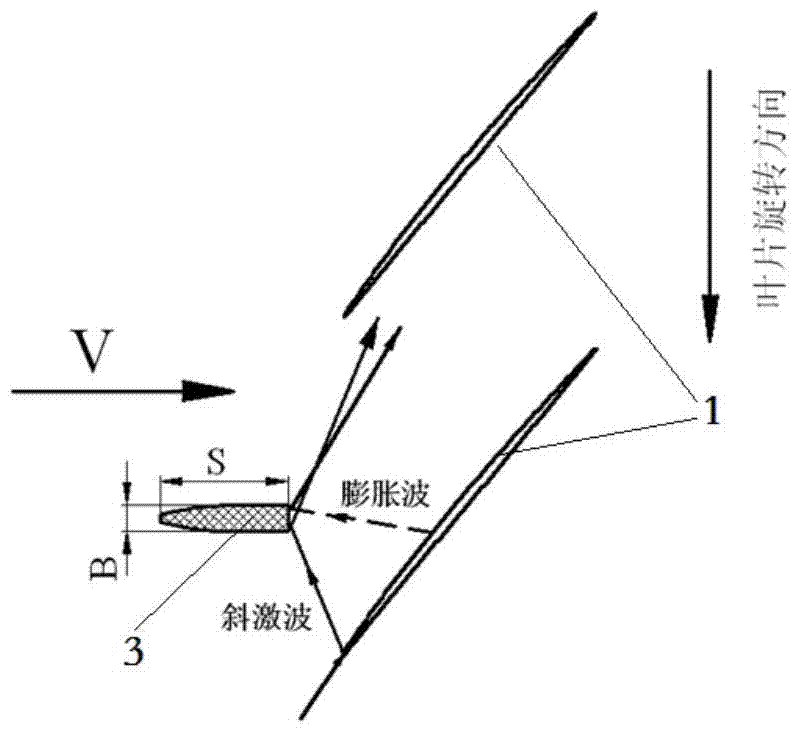

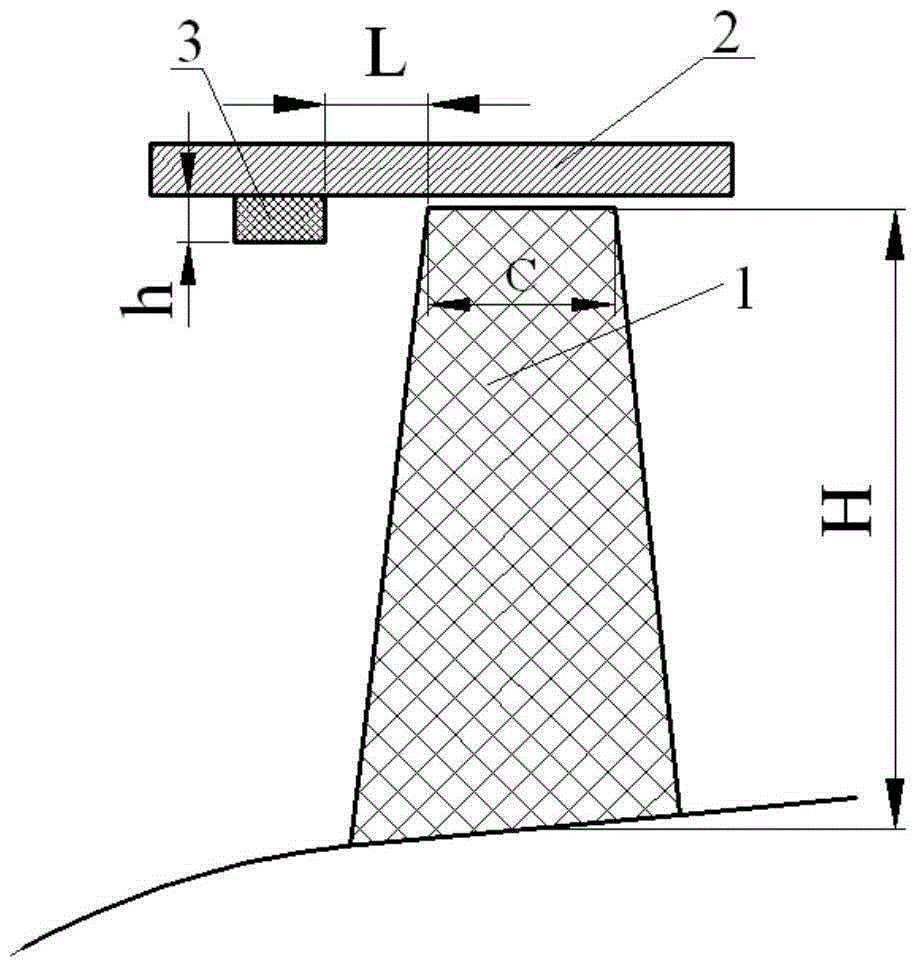

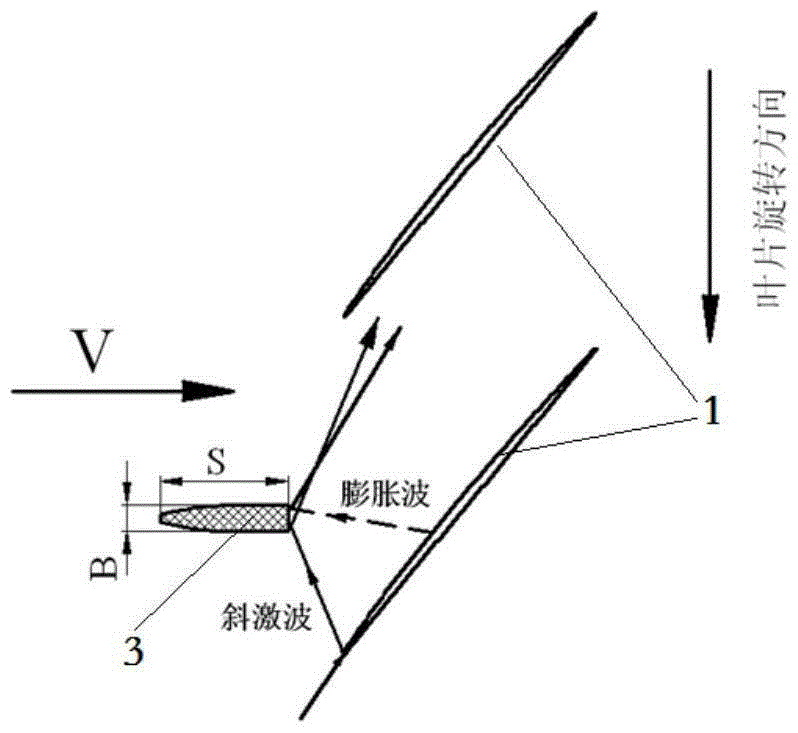

Super/transonic compressor with front sharp and blunt trailing edge bodies and design method thereof

The invention discloses a super / transonic compressor with front sharp and blunt trailing edge bodies and a design method of the super / transonic compressor, and belongs to the technical field of aero-engine compressors. The super / transonic compressor is characterized in that the multiple sharp and blunt trailing edge bodies with certain height, length and width are evenly distributed on an outer machine case of an inlet of the compressor in the circumferential direction. The super / transonic compressor can be directly used as a high-performance aviation gas turbine engine compressor. On the premise that the layout and the pneumatic performance of an existing compressor are not changed, the stable working margin of the compressor is substantially improved. According to the super / transonic compressor, due to the fact that the front sharp and blunt trailing edge bodies are reasonably designed, the super / transonic compressor not only can work normally under the condition that only one gas inlet angle exists, but also can work normally under the condition that a certain positive attack angle or a certain negative attack angle is formed between the gas inlet direction and the front edge of an attracting force face, and the stable working margin of the compressor is improved on the premise that the efficiency of a fan or the compressor is not changed basically.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

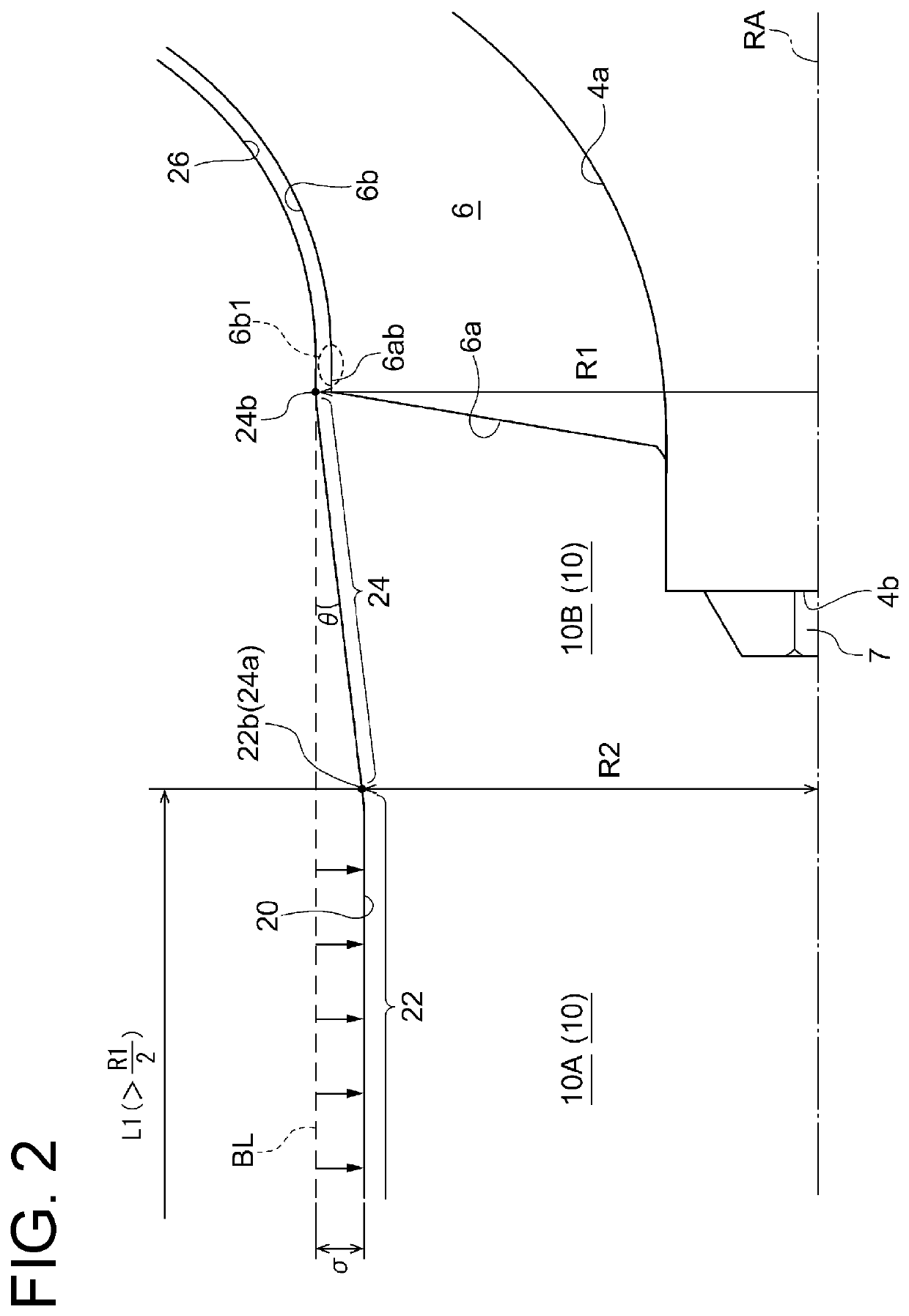

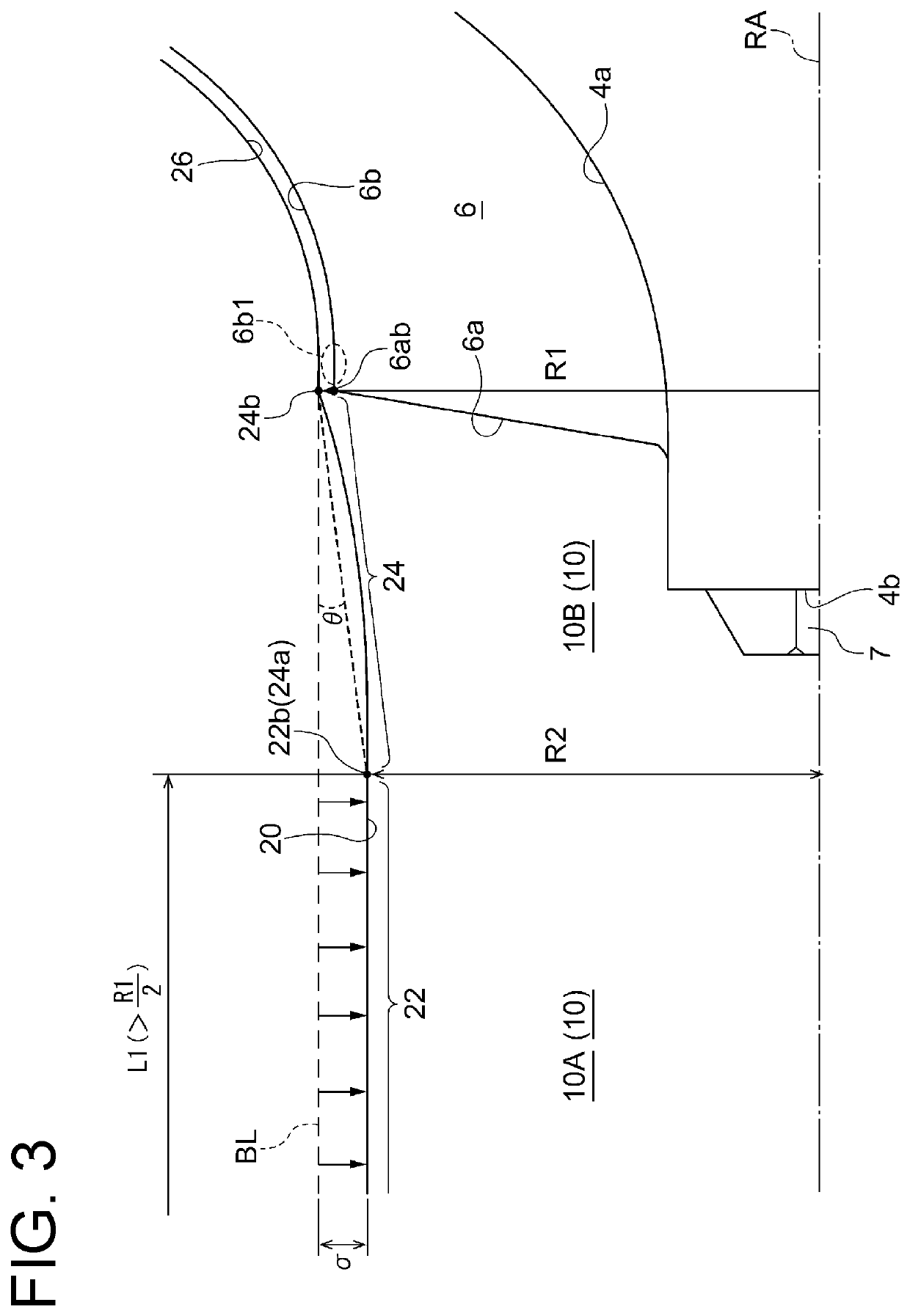

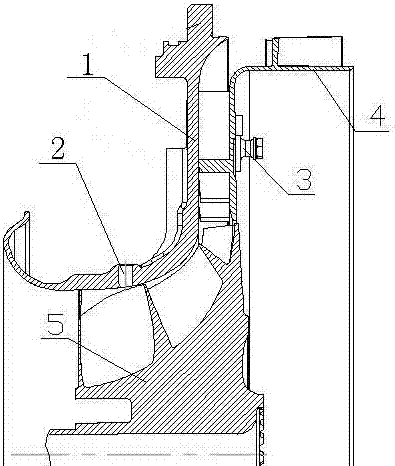

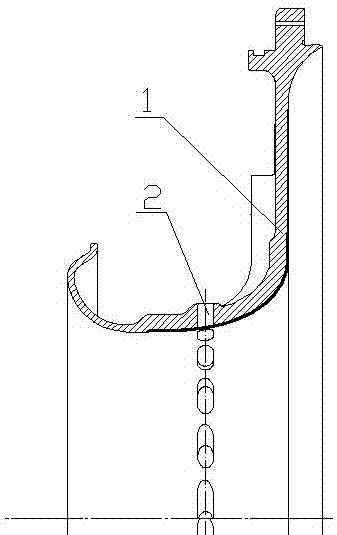

Centrifugal compressor and turbocharger

ActiveUS20200063751A1Improve surge marginSimple structureInternal combustion piston enginesEngine manufactureRotational axisTurbocharger

A centrifugal compressor includes an impeller including a hub and a plurality of blades disposed on an outer peripheral surface of the hub at intervals in a circumferential direction, and a casing accommodating the impeller and defining an inlet passage for introducing air along an axial direction of the impeller. An inner peripheral surface of the inlet passage includes a narrowed portion, and an inclined portion connected to a downstream side of the narrowed portion and having a radial distance from a rotational axis of the impeller gradually increasing toward the vicinity of tips of leading edges of the blades. Further, 0.01R1≤σ≤0.1R1 is satisfied, where R1 is radial distance between a downstream end of the inclined portion and the rotational axis, R2 is radial distance between a downstream end of the narrowed portion and the rotational axis, and σ is constriction amount which is a difference between R1 and R2.

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

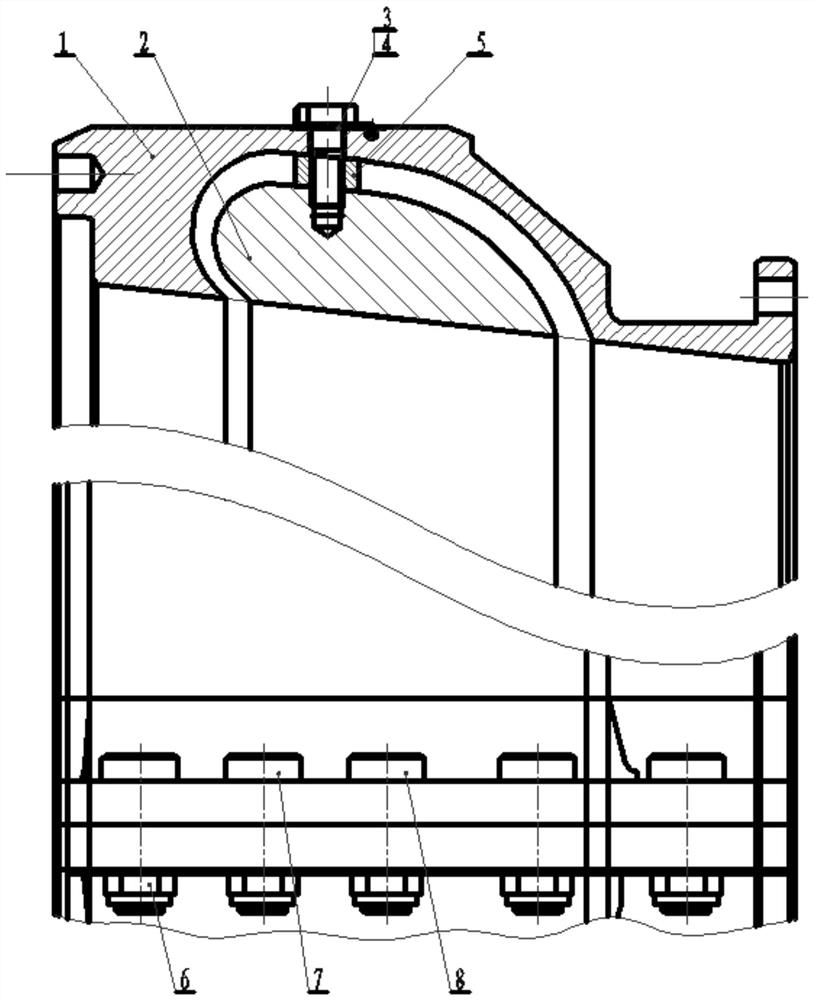

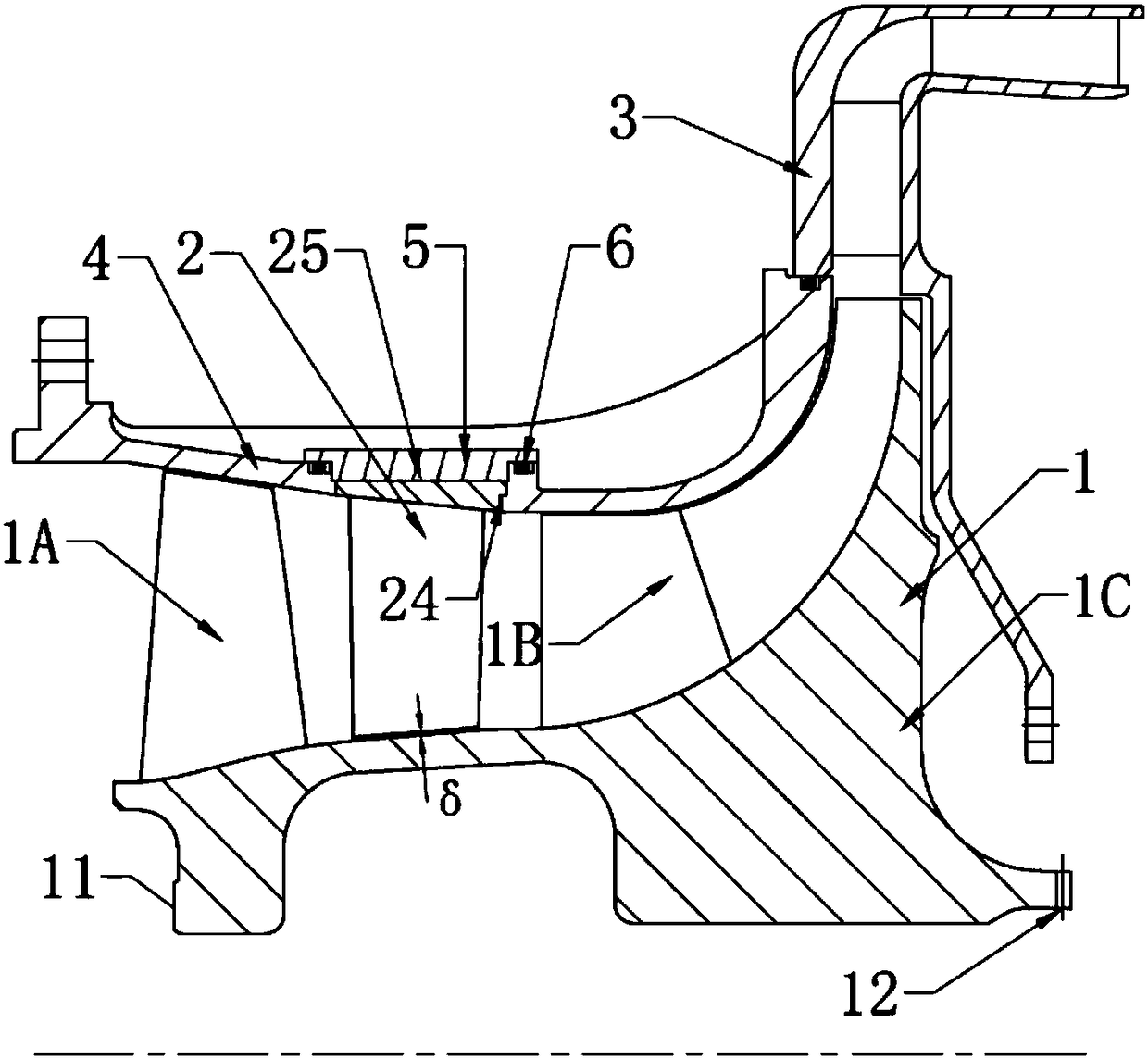

Self-circulation type treatment casing structure of gas compressor of ship gas turbine

PendingCN113606192AImprove surge marginDelayed stallPump componentsPumpsIndustrial gasMarine engineering

The invention provides a self-circulation type treatment casing structure of a gas compressor of a ship gas turbine. According to the self-circulation type treatment casing structure of the gas compressor of the ship gas turbine, firstly, a self-circulation type treatment casing is composed of an outer ring and an inner ring, the outer ring and the inner ring are connected through a bolt, and a gap between the outer ring and the inner ring forms an air guide flow channel of the treatment casing; secondly, in order to increase the connection strength between the inner ring and the outer ring, a boss is welded on the outer side of the inner ring; thirdly, three important structural parameters (the axial length of the air guide flow channel, the width of an air inlet flow channel and the width of an exhaust flow channel) of the self-circulation type treatment casing are determined through the design method of the self-circulation type treatment casing of the gas compressor of the ship gas turbine; and finally, the self-circulation type treatment casing adopts an up-down halving structure, so that treatment casings with different structural forms can be quickly replaced and mounted on a gas compressor test bed. Meanwhile, the self-circulation type treatment casing structure is not limited to a ship gas turbine axial flow compressor and is also suitable for various industrial gas turbine axial flow compressors and aero-engine axial flow gas compressors with treatment casings.

Owner:中国船舶重工集团公司第七0三研究所

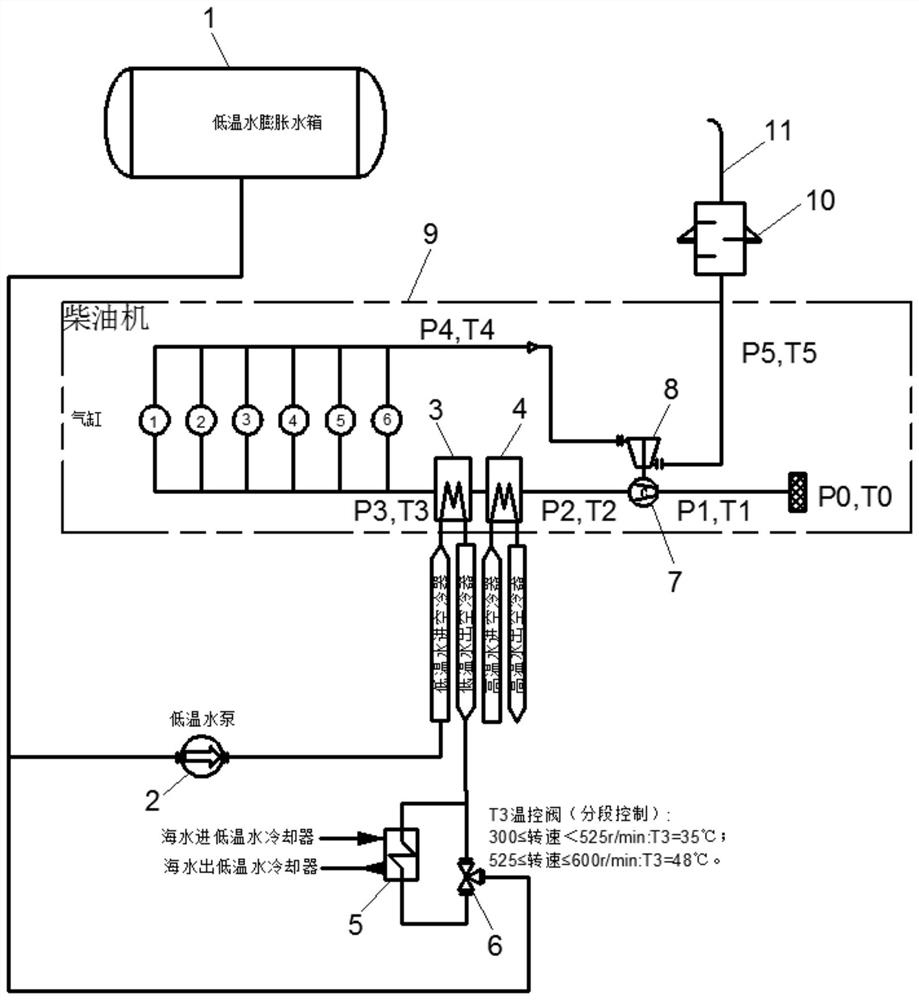

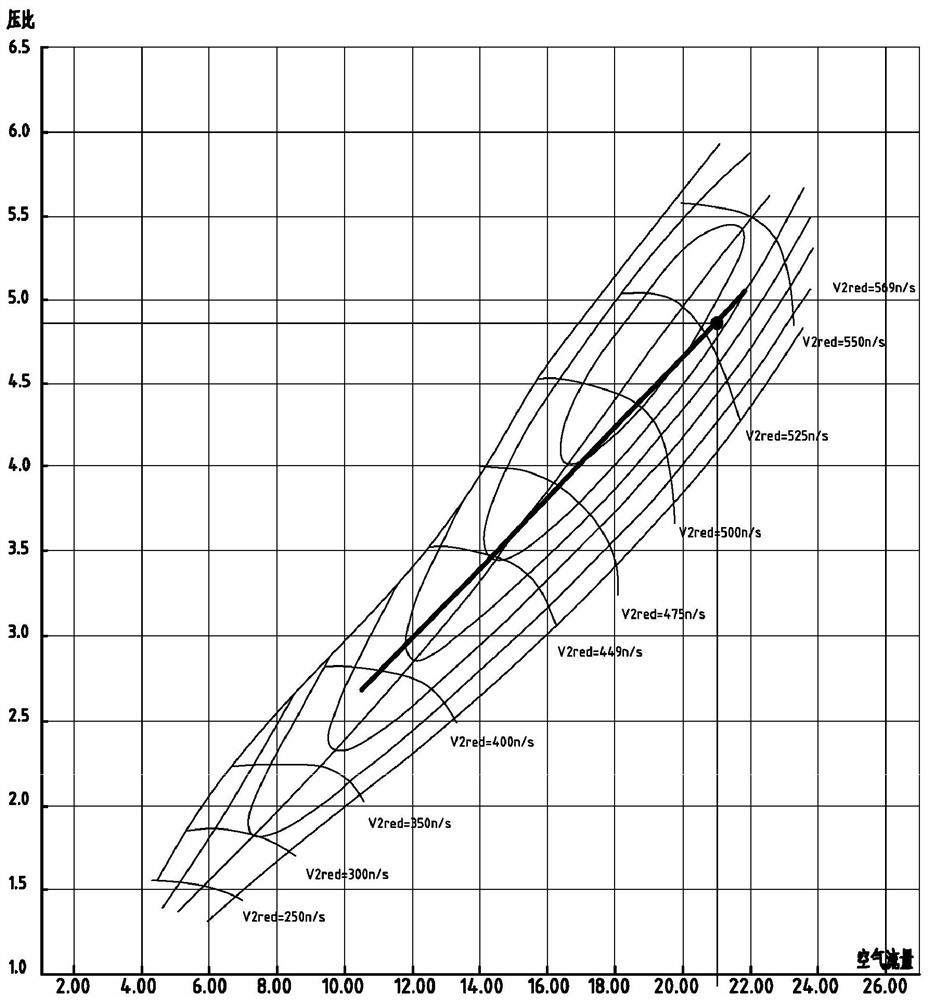

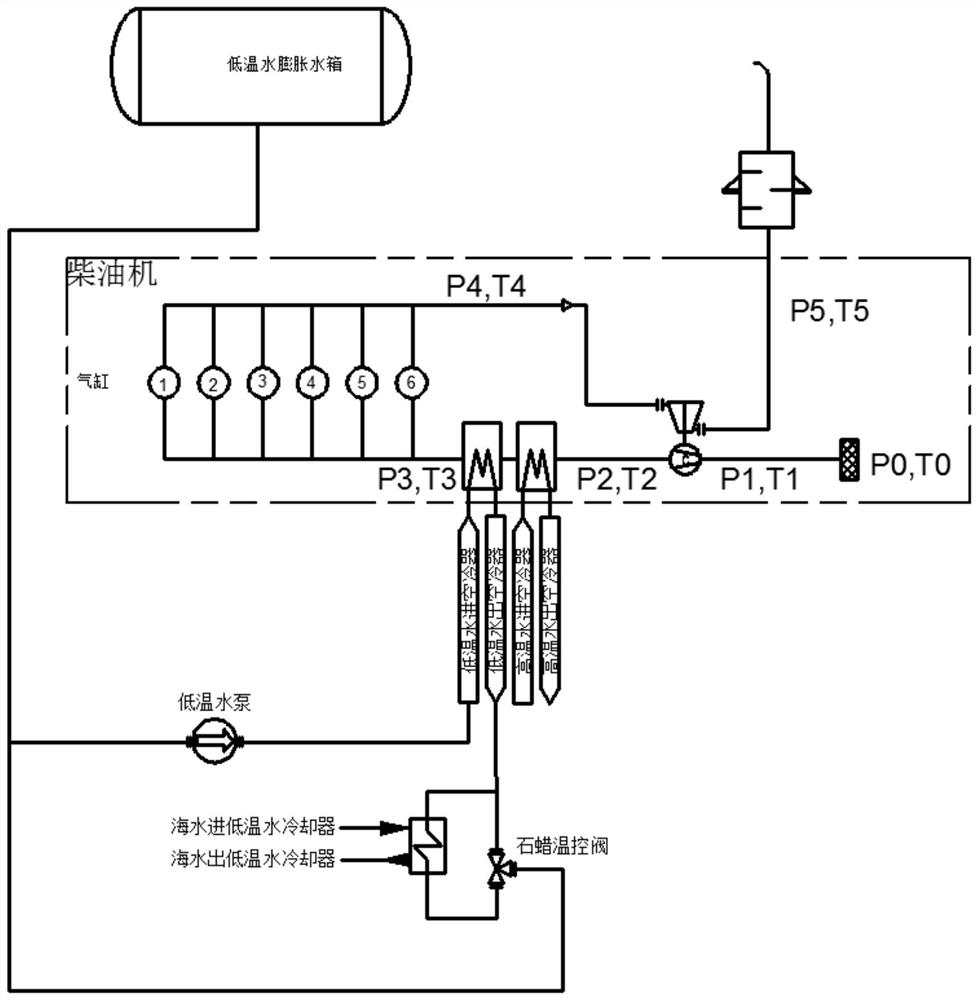

Marine propulsion diesel engine supercharged air temperature sectional type control system

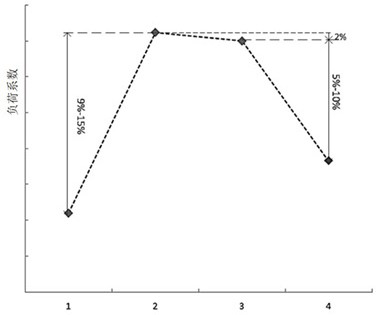

InactiveCN112412616AImprove surge marginImprove performanceInternal combustion piston enginesMarine propulsionControl manner

The invention provides a marine propulsion diesel engine supercharged air temperature sectional type control system, belongs to the technical field of diesel engines, and aims to overcome the defectsin the prior art, break through the matching concept of a traditional supercharger and a diesel engine and provide a new control thought for the defects of two existing control modes in the operationof a fixed-pitch propeller propulsion diesel engine. Through a sectional control method of the supercharger supercharged air temperature under different rotating speed sections, the surge margin of the supercharger under partial load of the diesel engine is increased under the condition that low-load combustion is not affected, good performance matching performance of the supercharger and the diesel engine is achieved, the comprehensive performance of the diesel engine is improved, precious experience and practice bases are provided for subsequent matching of the supercharger and the diesel engine, and the method is effective, convenient to implement and low in application cost.

Owner:SHANNXI DIESEL ENGINE HEAVY IND

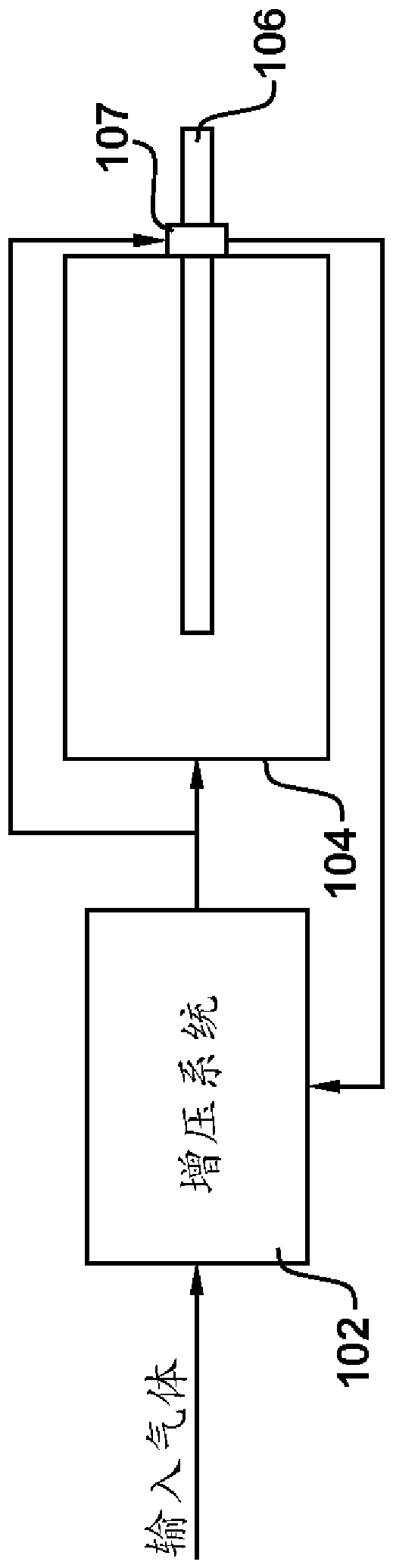

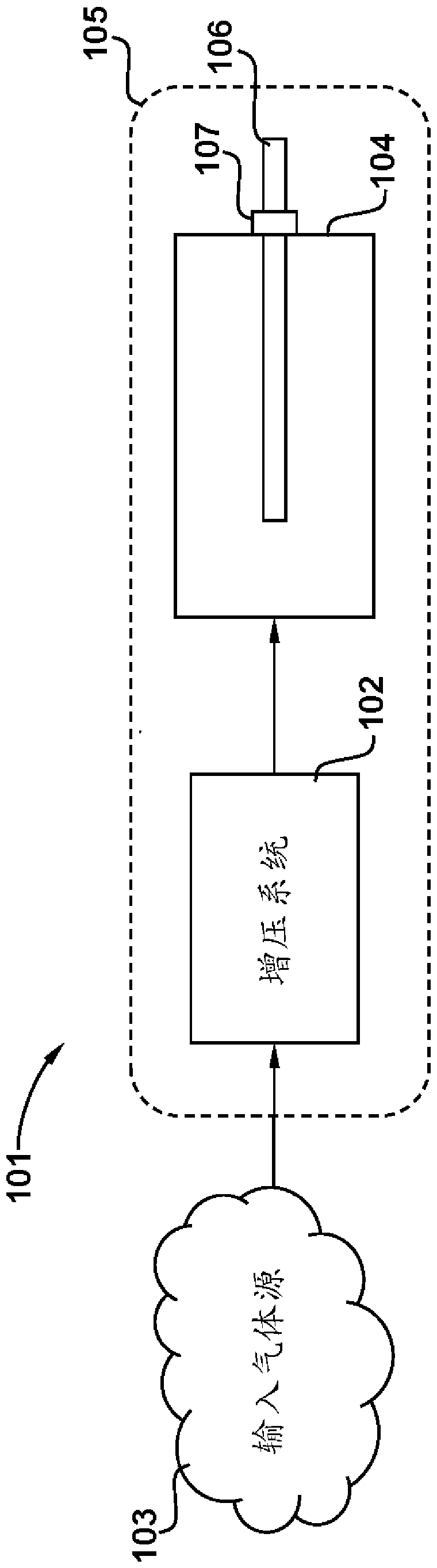

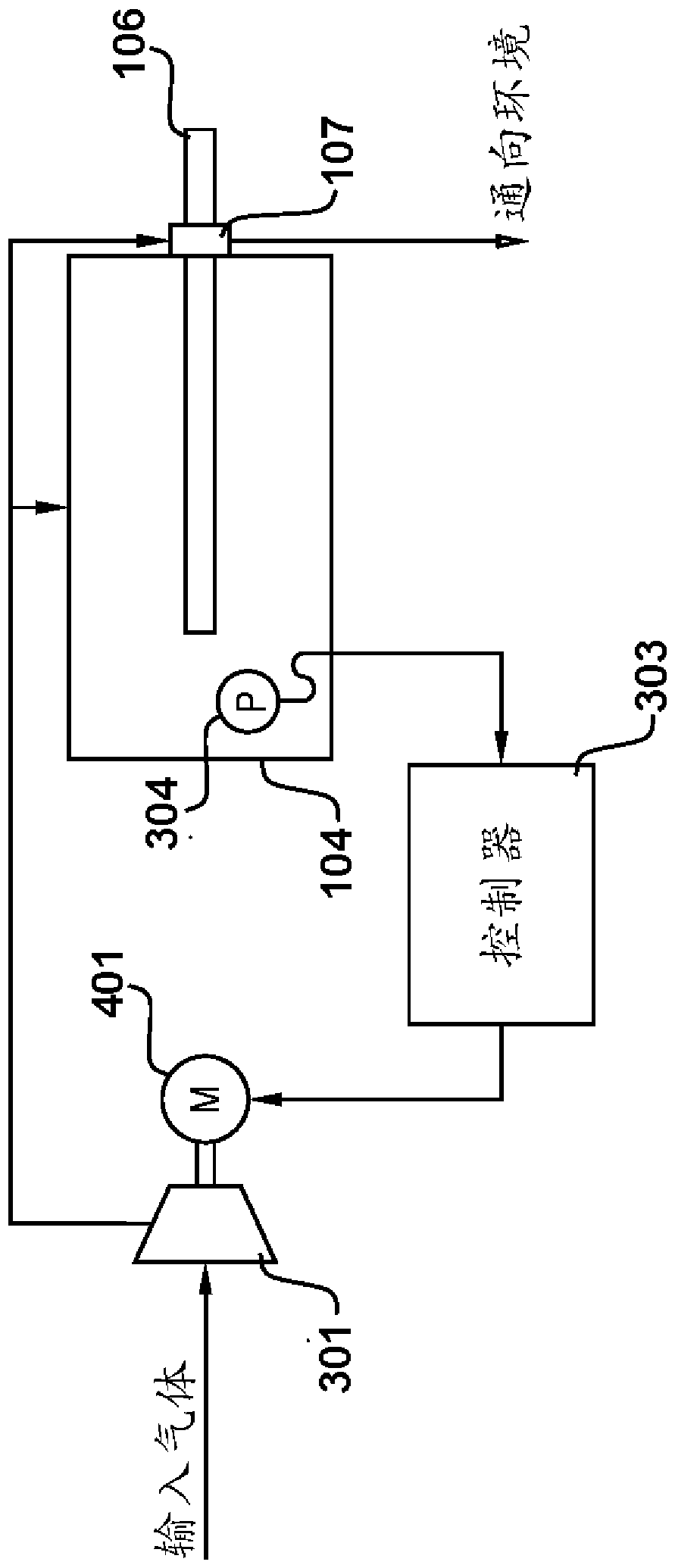

Preventing electrical breakdown

PendingCN108964325AImprove surge marginReduce parasitic lossGas turbine type power plantsAir-treatment apparatus arrangementsExternal pressureElectrical and Electronics engineering

An electric machine (101) for an aircraft is shown. The electric machine has a casing (104) containing electrical and electromechanical components, a shaft (106) which extends outside of the casing and which is connected to the propulsive fan, a seal (107) to seal the casing around the shaft, and a pressurization system (102) which pressurises the casing above an external pressure to prevent electrical breakdown within gas in the casing of the electric machine.

Owner:ROLLS ROYCE PLC

Supercharging stage device and turbofan engine

ActiveCN113090412BIncrease boost effectImprove performancePump controlJet propulsion plantsControl theoryTurbofan

Owner:AECC SHANGHAI COMML AIRCRAFT ENGINE MFG CO LTD +1

An air cooling system for an electric centrifugal air compressor

The invention discloses an air cooling system for an electric centrifugal air compressor, which includes a flow mixer, a first-stage compressor, a valve A, a second-stage compressor, an intercooler, a second air filter, a valve B, a three-way valve, and a motor , Compressed air pipe 1, compressed air pipe 2, compressed air pipe 3, cooling air pipe 1, cooling air pipe 2, cooling exhaust pipe, exhaust pipe 1, return air pipe and exhaust main pipe; compressed air from the primary compressor Enter compressed air pipe 1, part of the compressed air enters cooling air pipe 1 at the branch point, and the compressed air in cooling air pipe 1 enters the motor through valve A for cooling; the compressed air from the secondary compressor enters compressed air pipe 2 and enters the middle The cooler comes out of an outlet of the intercooler and enters the cooling air pipe 2, is filtered by the second air filter, and enters the motor to cool the motor. The invention is applied to the electric centrifugal air compressor, and can realize better cooling effect and better comprehensive efficiency.

Owner:HYDROWELL (TAICANG) ENERGY TECH CO LTD

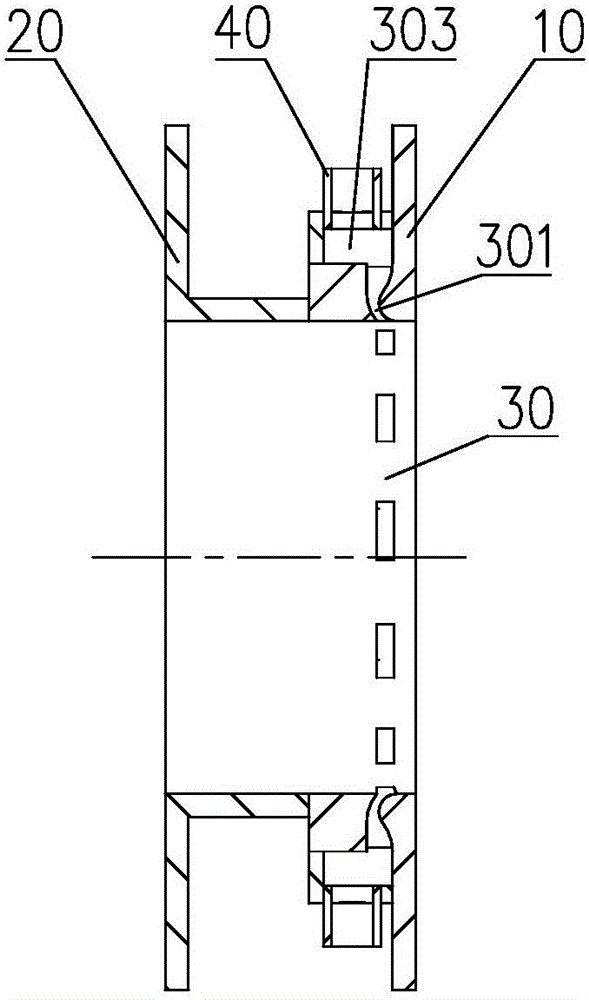

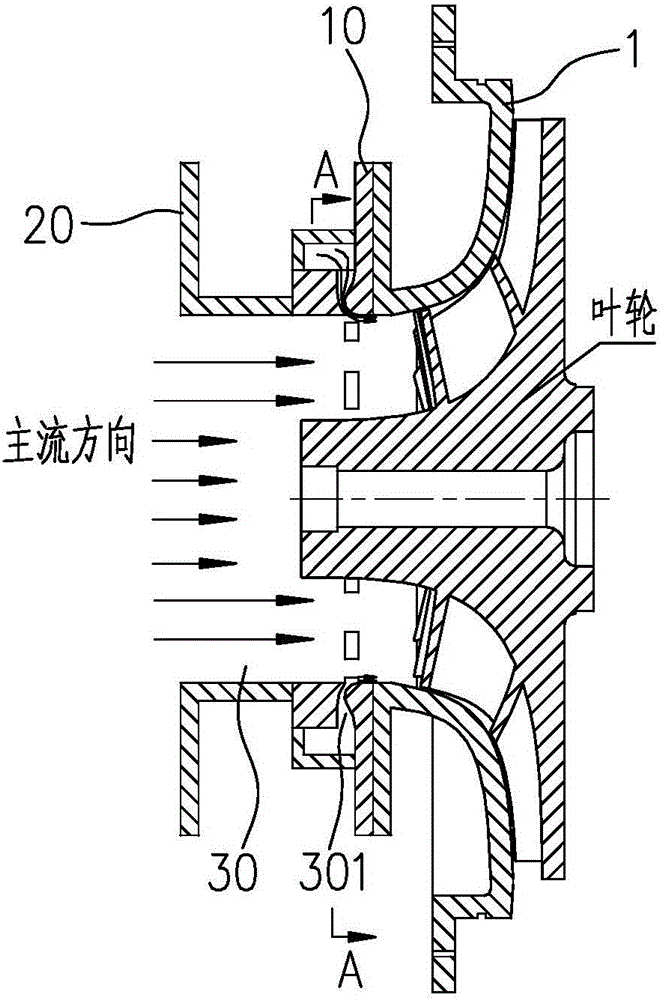

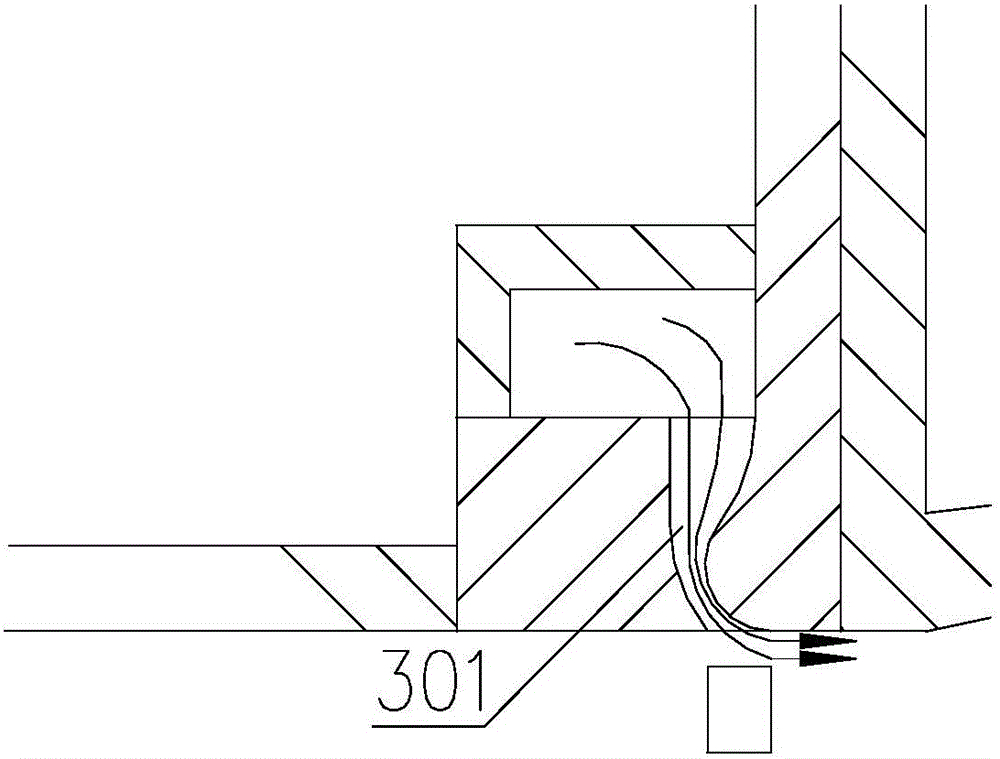

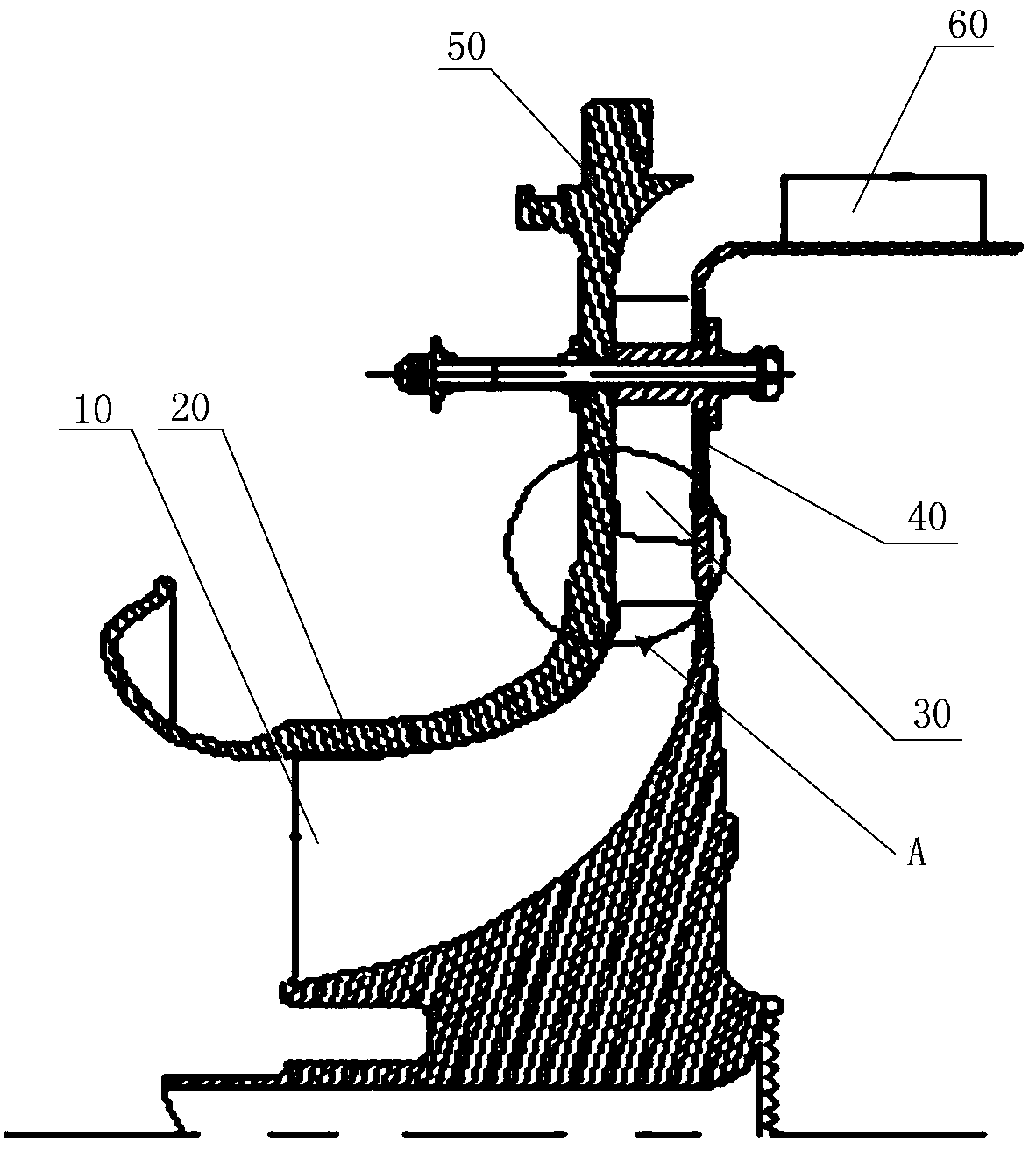

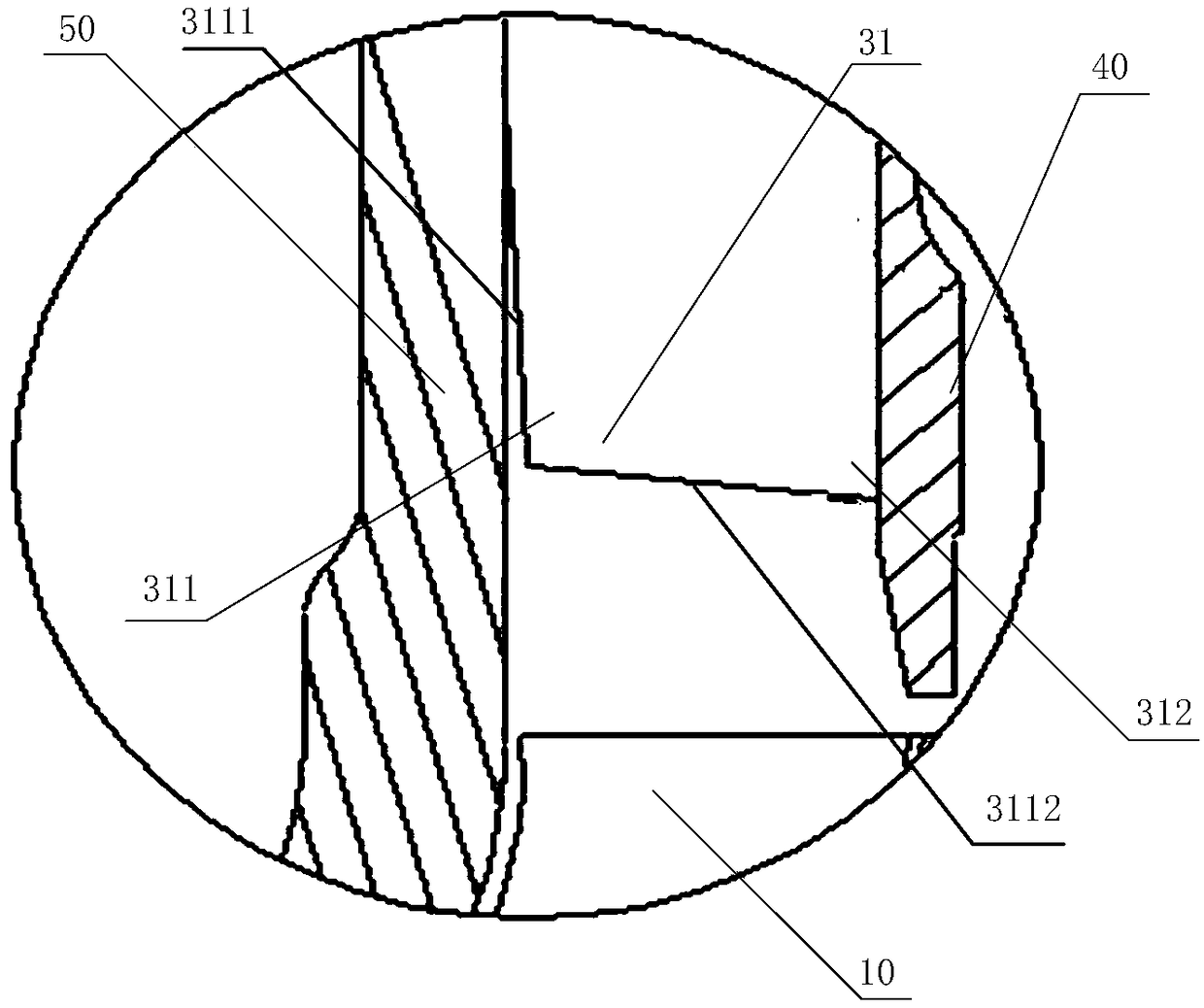

A stabilizing device for a centrifugal compressor

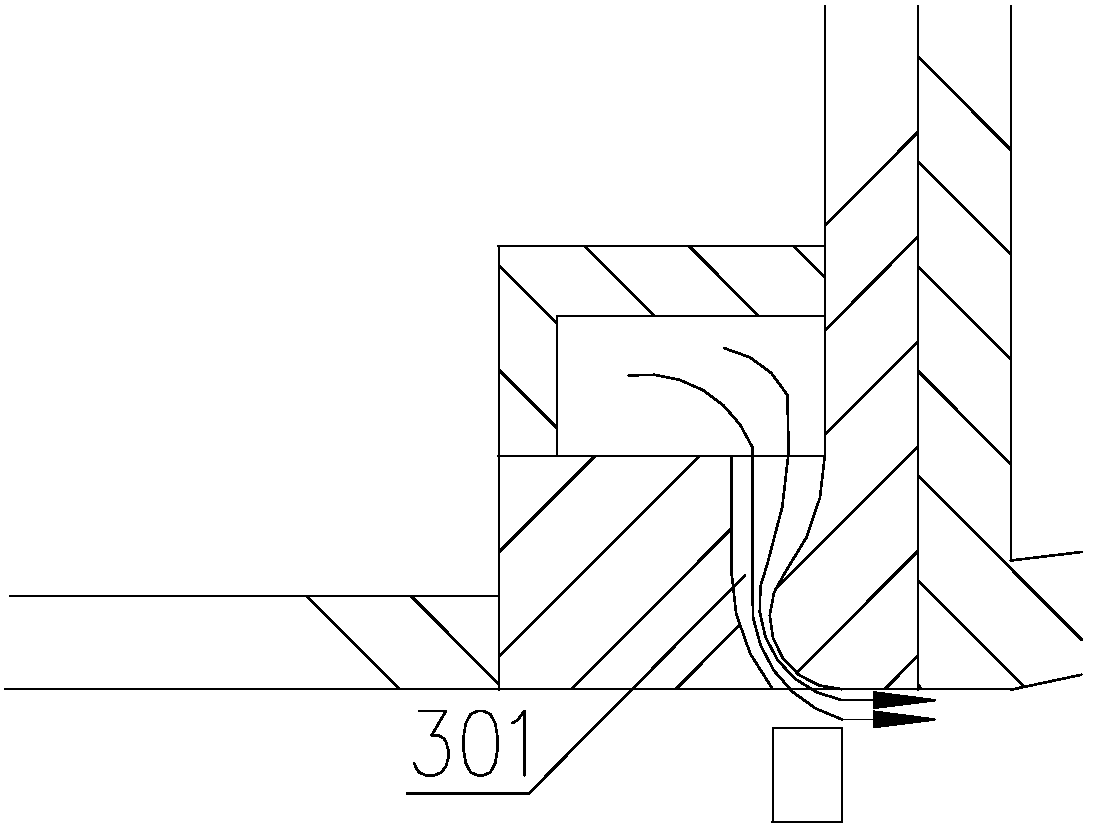

ActiveCN105782117BImprove mobilityImprove surge marginPump componentsPumpsCentrifugal compressorFlange

Disclosed is a centrifugal compressor stability enhancement device. The device is an external device, two sides of the device are provided with a first flange (10) and a second flange (20) which are respectively used to be seamlessly connected to a front cover plate (1) of a centrifugal compressor and a suction pipeline, the first flange and the second flange are arranged in parallel, and a main flow pipeline (30) which is perpendicular to the flanges is arranged between the two flanges; and the main flow pipeline communicates with an air intake pipeline (40) through which external air is supplied. The main flow pipeline is provided with a plurality of jet holes (301) along the circumferential direction of the inner wall surface thereof, an air gathering cavity (303) is arranged on the outer wall surfaces of the jet holes, and the air gathering cavity is provided with an interface which communicates with the air intake pipeline; external compressed airflow enters the air gathering cavity from the air intake pipeline, and enters the main flow pipeline of the compressor via the jet holes arranged circumferentially, such that the air is radially introduced, and is jetted out in the tangential direction of the inner surface of the flow passage. The centrifugal compressor stability enhancement device is simple in structure, is convenient to mount and dismount, and can effectively broaden the operating margin of the centrifugal compressor.

Owner:HEFEI GENERAL MACHINERY RES INST

A super/transonic compressor with a front sharp blunt trailing edge body and its design method

ActiveCN103498814BImprove surge marginHigh speedPump componentsPumpsSuction forceTransonic compressor

The invention discloses a super / transonic compressor with front sharp and blunt trailing edge bodies and a design method of the super / transonic compressor, and belongs to the technical field of aero-engine compressors. The super / transonic compressor is characterized in that the multiple sharp and blunt trailing edge bodies with certain height, length and width are evenly distributed on an outer machine case of an inlet of the compressor in the circumferential direction. The super / transonic compressor can be directly used as a high-performance aviation gas turbine engine compressor. On the premise that the layout and the pneumatic performance of an existing compressor are not changed, the stable working margin of the compressor is substantially improved. According to the super / transonic compressor, due to the fact that the front sharp and blunt trailing edge bodies are reasonably designed, the super / transonic compressor not only can work normally under the condition that only one gas inlet angle exists, but also can work normally under the condition that a certain positive attack angle or a certain negative attack angle is formed between the gas inlet direction and the front edge of an attracting force face, and the stable working margin of the compressor is improved on the premise that the efficiency of a fan or the compressor is not changed basically.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

A casing processing structure and a compressor for improving the surge margin of a single-stage centrifugal compressor

Owner:CHINA AVIATION POWER MACHINE INST

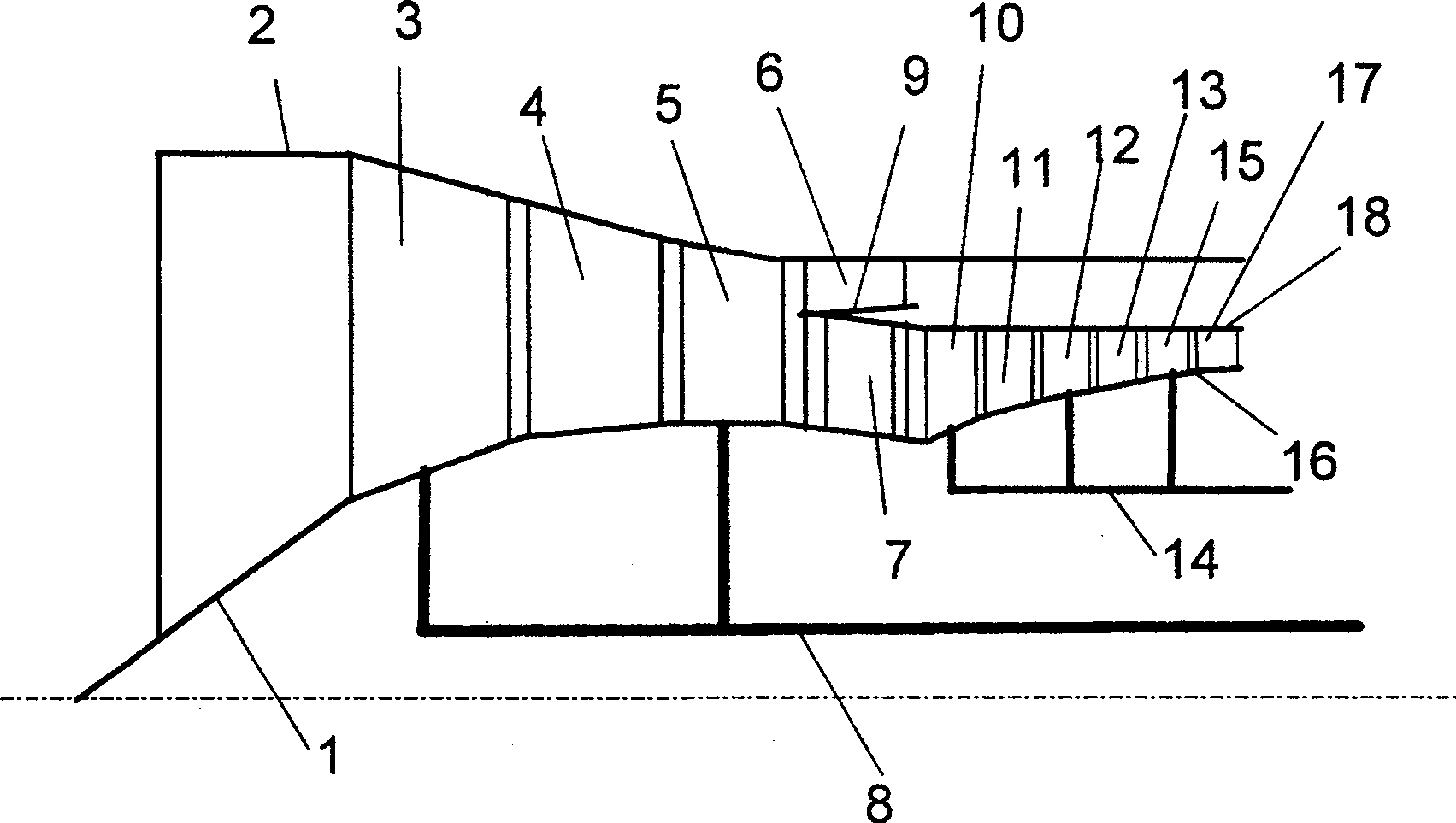

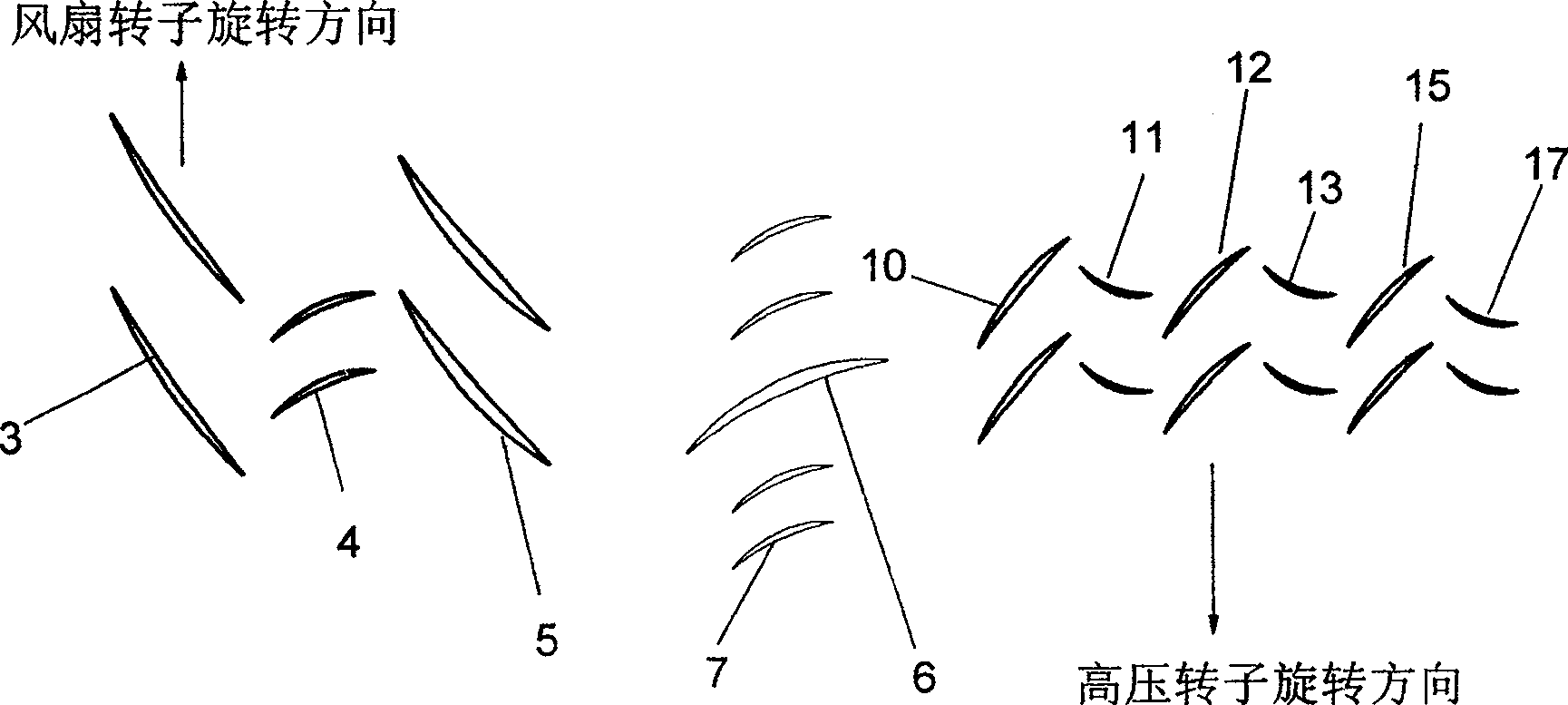

Compact pneumatic overall arrangement of compression system in aerial turbo fan engine

InactiveCN100494692CIncrease pressure ratioImprove efficiencyPump componentsPump installationsAviationEngineering

This invention relates to a design of compact pneumatic layout of the compression system of an aviation turbofan engine, which eliminates the transition section and fan output stator between the fan of an existing turbofan engine and a high pressure compressor and applies a diffusion cascade or a large corner expansion cascade to the inlet guide vane of the compressor to the outlet stator, the compressor inlet guide vane and bearing plate to a row of cascades and realizes compression of them, at the same time, it applies a high load design to the fan and the high pressure compressor to realize the same boost ratio with less stages.

Owner:BEIHANG UNIV

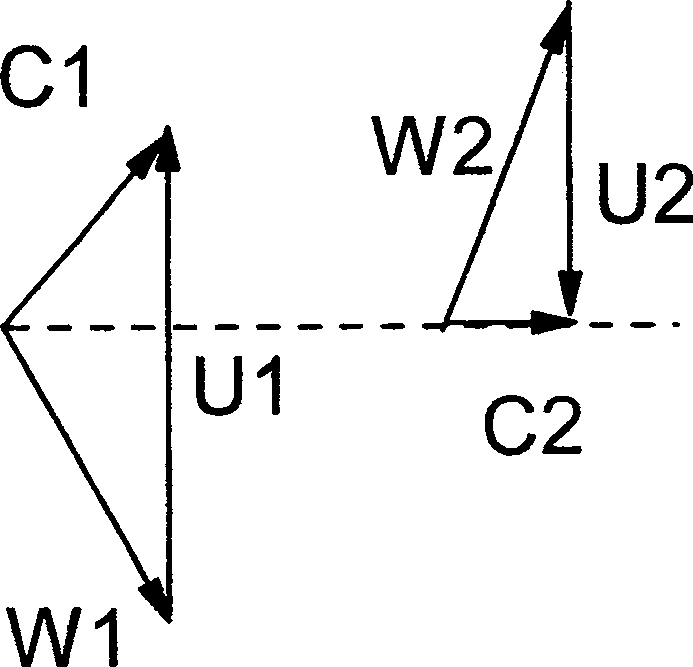

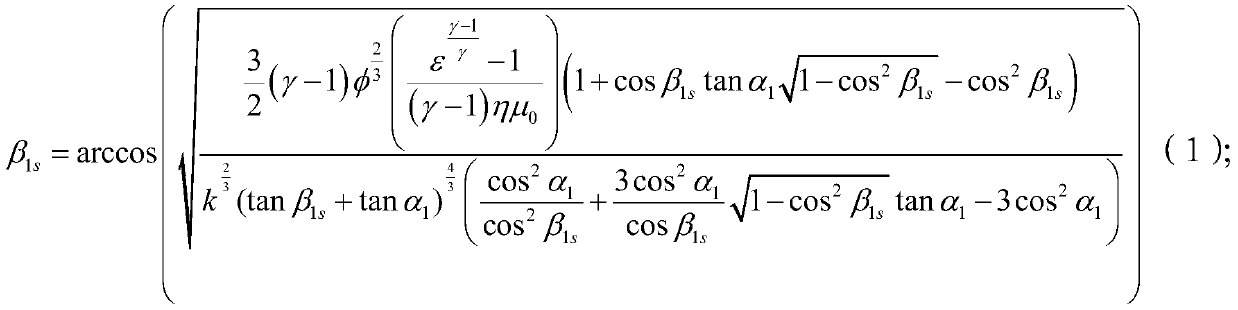

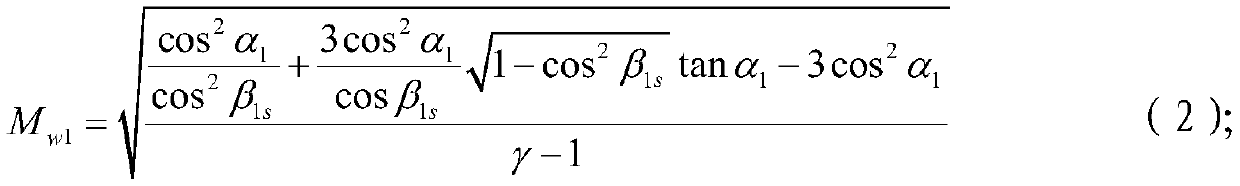

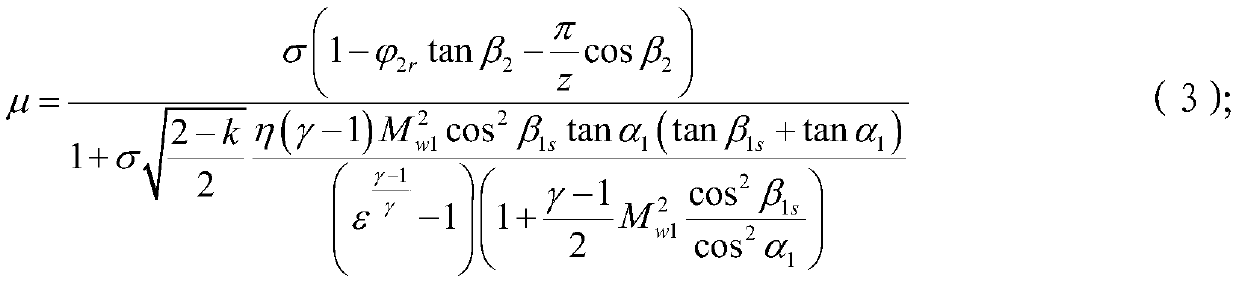

A design method of impeller

ActiveCN110005635BImprove design efficiencyLarge circulation capacityPump componentsPumpsImpellerDesign methods

The invention discloses a design method of an impeller. The rapid and accurate impeller design method is provided, the aerodynamic performance and the design efficiency of the impeller are improved, and the method comprises the steps of giving the impeller dimensionless parameters; setting an initial enthalpy rise coefficient; calculating the optimal centrifugal impeller inlet impeller cover relative axial airflow angle; calculating the centrifugal impeller inlet impeller cover relative mach number; calculating the enthalpy rise coefficient; judging whether the relative error between the enthalpy rise coefficient and the initial enthalpy rise coefficient is smaller than 1% or not, if the relative error is larger than or equal to 1%, resetting the initial enthalpy rise coefficient; if the relative error is smaller than 1%, judging as iterative convergence and performing the next step; calculating the ratio of the centrifugal impeller inlet impeller cover diameter to the centrifugal impeller outlet diameter and the ratio of the centrifugal impeller outlet width to the centrifugal impeller outlet diameter; giving the centrifugal impeller dimensional parameters; and according to the calculation result and the given parameters, obtaining impeller design parameters. Through the method, the aerodynamic performance of the impeller can be improved, and the design period can be shortened.

Owner:TIANJIN UNIV

centrifugal compressor

ActiveCN105736457BReduce lossesExpand the scope of workPump componentsPumpsLeading edgeMechanical energy

The invention discloses a centrifugal compressor. The centrifugal compressor comprises a centrifugal impeller, an air bleeding receiver, a radial diffuser, a diffuser inner receiver and a diffuser outer receiver, wherein the centrifugal impeller is used for converting mechanical energy into gas kinetic energy; the air bleeding receiver is arranged around the centrifugal impeller and forms a first airflow passage together with the centrifugal impeller; the radial diffuser is positioned at an outlet of the first airflow passage and is used for converting the gas kinetic energy converted by the centrifugal impeller into pressure energy; the diffuser inner receiver is connected with the radial diffuser and is used for positioning the radial diffuser; the diffuser outer receiver is connected with the air bleeding receiver and is used for covering the radial diffuser; the radial diffuser is in a wedge shape and comprises a leading edge, the leading edge is positioned on one end which is close to the centrifugal impeller, the leading edge comprises a tip and a root which integrally extends together with the tip, and the tip is provided with a sweepback surface which sweeps back relatively to the root. According to the centrifugal compressor provided by the invention, the shape of the leading edge of the diffuser is changed, so as to adapt to the outlet airflow of the centrifugal impeller, thereby effectively reducing the diffuser loss, extending the working range and increasing the surge margin.

Owner:CHINA AVIATION POWER MACHINE INST

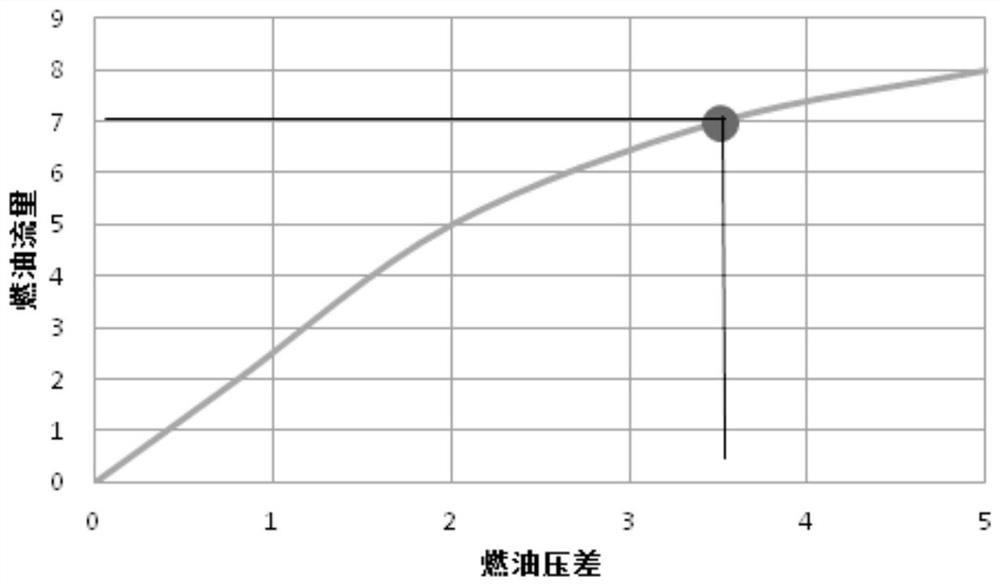

A half-cycle acceleration inspection method for aero-engine

ActiveCN112485005BImprove surge marginStable jobSustainable transportationEngine testingEngine testingTest equipment

The invention belongs to the field of aero-engine testing, and in particular relates to an aero-engine half-cycle acceleration inspection method. The technical scheme of the present invention is as follows: a method for half-cycle acceleration inspection of an aero-engine, which uses fuel flow testing equipment to detect the aero-engine, calculates and interpolates the test data to obtain the transient fuel-gas ratio, and adjusts the transient fuel-gas ratio Increment, to measure the surge margin of the aero-engine, and to judge that the aero-engine is an accessory quality problem or the accessory and the main engine are not well matched. By adjusting or replacing the accessory, the stability margin during the acceleration process of the aero-engine can be improved. The inspection method for the half-cycle acceleration of the aeroengine provided by the invention can effectively evaluate and adjust the oil-gas matching situation in the engine acceleration process, and adjust in real time to ensure a stable working margin in the engine acceleration process.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Turbocharger pressure shell assembly and gas compressor

PendingCN114576204AImprove nearby efficiencyReduce velocity componentInternal combustion piston enginesPump componentsTurbochargerEngineering

The invention relates to a turbocharger pressure shell assembly and a gas compressor. The device comprises a pressing shell, the pressing shell comprises an air inlet channel, and the air inlet channel comprises an air inlet; the silencing cover is mounted at the air inlet of the pressing shell; the connecting part is arranged in the air inlet channel; the casing groove flow channel is formed between the connecting part and the inner wall of the pressing shell and between the connecting part and the silencing cover, the casing groove flow channel comprises a casing groove inlet and a casing groove outlet, the casing groove inlet is located between one end of the connecting part and the inner wall of the pressing shell, and the casing groove outlet is located between the other end of the connecting part and the inner wall of the pressing shell. And the outlet of the casing groove is positioned between the other end of the connecting part and the silencing cover. The noise reduction cover is arranged in the pressure shell, the noise reduction cover is matched with the casing groove flow channel to play a flow guide role, the velocity component of backflow gas in the circumferential direction when the backflow gas is converged into main gas flow is reduced, the velocity component in the axial direction is increased, and the efficiency of a supercharger compressor close to a surge area can be improved.

Owner:WUXI WEIFU HIGH TECH CO LTD

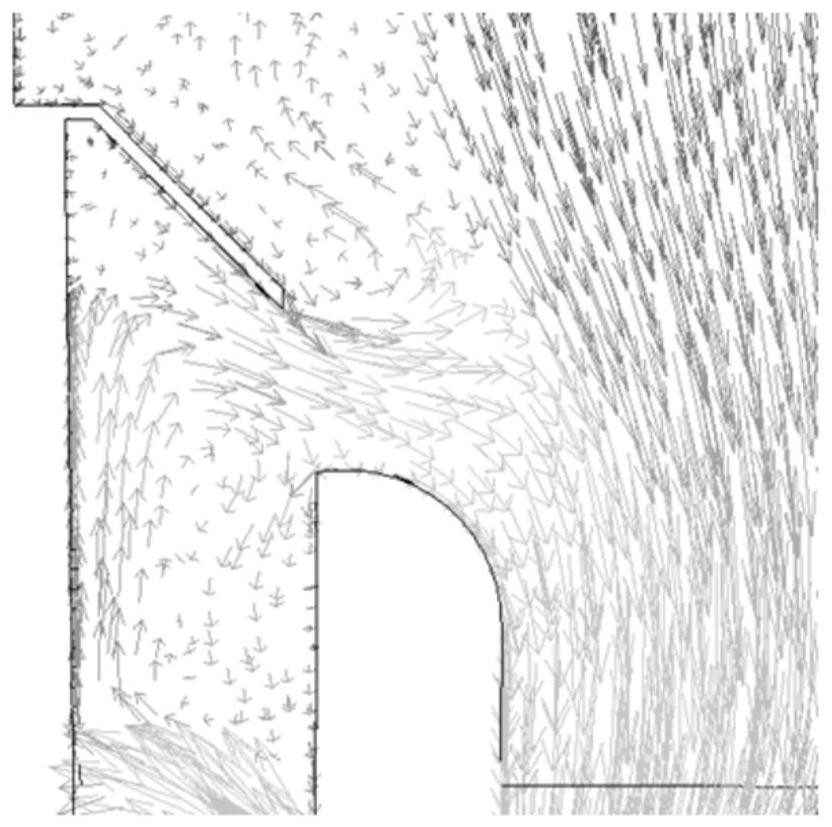

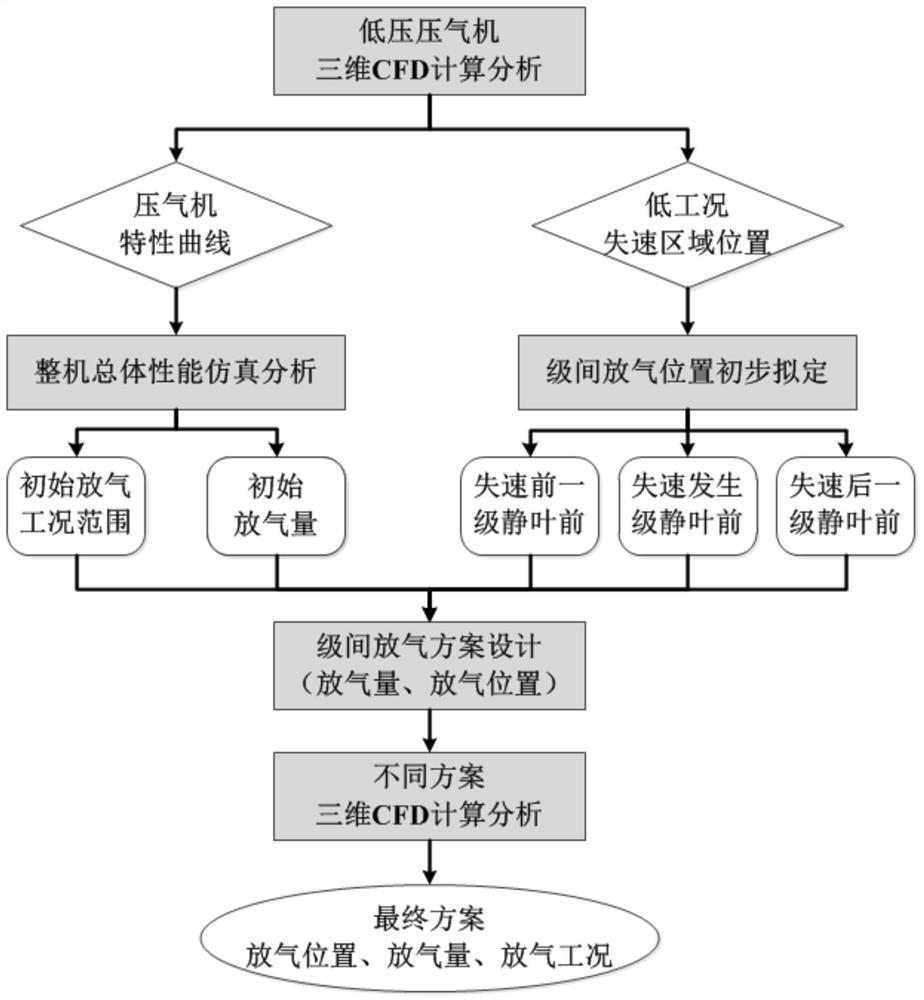

Low-working-condition interstage deflation anti-surge method for low-pressure compressor of marine gas turbine

PendingCN113792503AImprove surge marginEfficient and stable operating rangeDesign optimisation/simulationPump controlControl theoryMechanics

The invention aims to provide a low-working-condition interstage deflation anti-surge method for a low-pressure compressor of a marine gas turbine, which comprises the following steps: obtaining a characteristic curve of a low-pressure compressor and a stall area position at a low-working-condition surge boundary point through three-dimensional CFD calculation, carrying out simulation analysis on the overall performance of the whole machine, according to the stall area position, obtained through three-dimensional CFD calculation, of the low-pressure compressor under the low working condition when the low-pressure compressor is close to a surge point, preliminarily determining a low-pressure compressor interstage deflation position scheme, performing permutation and combination according to the preliminarily determined deflation amount and deflation position, screening a sample scheme out, and determining a final low-pressure compressor interstage deflation scheme. While the surge margin is improved, the influence of interstage deflation on internal flow of the compressor is reduced to the minimum, and the efficient and stable operation working range of the low-pressure compressor is effectively expanded.

Owner:中国船舶重工集团公司第七0三研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com