A half-cycle acceleration inspection method for aero-engine

An aero-engine and inspection method technology, which is applied in engine testing, machine/structural component testing, instruments, etc., can solve problems such as low engine margin, insufficient engine margin, and reduced engine stability margin, so as to increase the surge Vibration margin, improve stable working margin, and ensure the effect of stable working

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A half-range acceleration inspection method for an aero-engine, specifically comprising the following steps:

[0025] 1) Inspection process; first, set the aero-engine as the "reference state" when the acceleration fuel supply is adjusted during the normal test run. In the "reference state", increase the acceleration fuel supply of the main fuel pump regulator and adjust the acceleration Add x circles to the oil screw, and perform a half-speed acceleration inspection according to the prescribed test procedure;

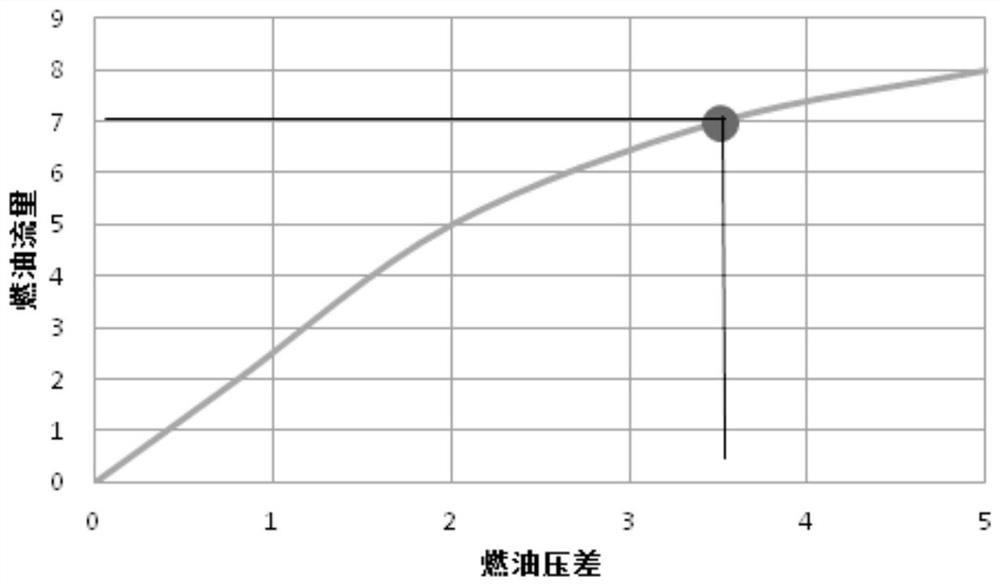

[0026] 2) Test data processing; determination of the transient fuel oil-gas ratio at 80% high-pressure speed: According to the measured fuel pressure difference and fuel flow at different steady-state speeds of the aero-engine, draw a fuel pressure difference-fuel flow curve, such as figure 1 As shown, the dots are the linear interpolation of the transient fuel pressure difference on the curve when the high pressure speed is 80%, and the transient fuel flow when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com