A design method of impeller

A design method and impeller technology, which are applied in mechanical equipment, components of pumping devices for elastic fluids, non-variable-capacity pumps, etc. problem, to achieve the effect of improved design efficiency, high flow efficiency, compact geometry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0106] Example: The design process of a centrifugal impeller with a compact pre-swirl air intake in an industrial transonic structure is as follows:

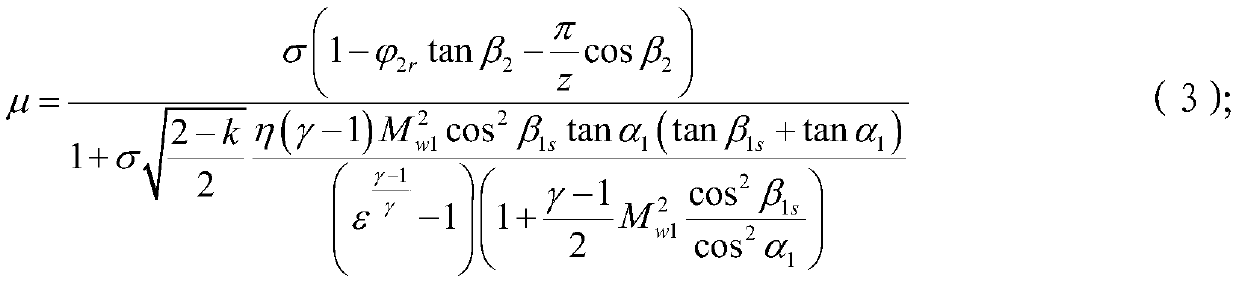

[0107]1) Given the design objectives of the centrifugal impeller: including isentropic efficiency η = 0.87, total pressure ratio ε = 6, flow coefficient φ = 0.12; given geometric constraints of the centrifugal impeller: including shape factor k = 0.85, radial airflow at the outlet of the centrifugal impeller Angle β 2 =38deg, centrifugal impeller outlet radial speed ratio The number of blades z=13, the specific enthalpy ratio σ=1.07, the centrifugal impeller inlet pre-rotation angle α 1 =30deg; given medium characteristic parameters: including gas constant R=287J / (kg k), adiabatic index γ=1.4;

[0108] 2) Set the initial enthalpy rise coefficient μ 0 =0.7;

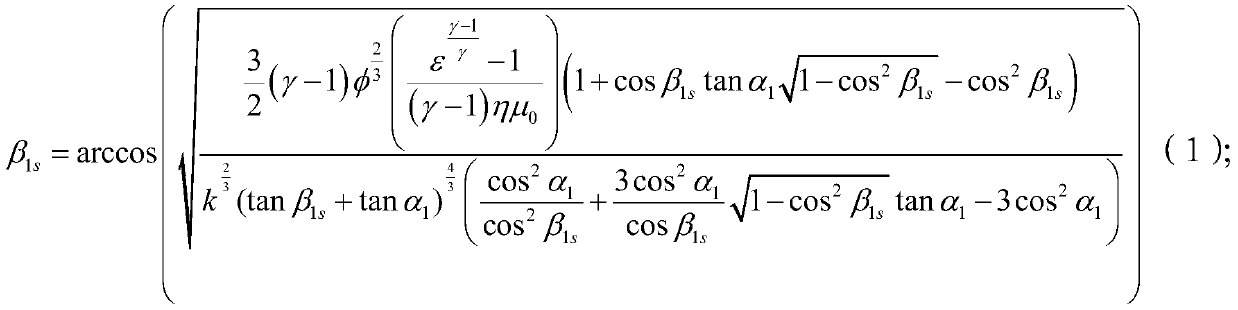

[0109] 3) Calculate the relative axial flow angle of the centrifugal impeller inlet cover, and the iterative result is β 1s =43deg;

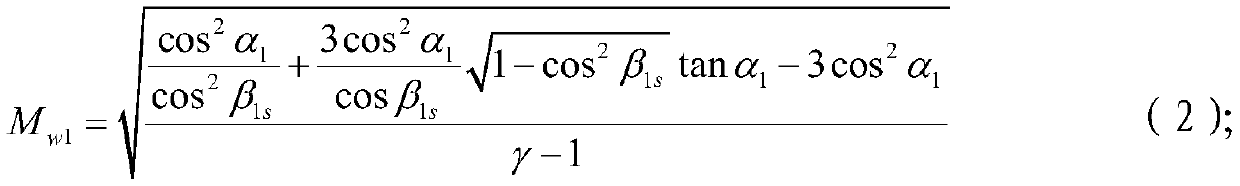

[0110] 4) Calculate the relative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com