All-section rock tunneling machine cutter layout design optimization method

A design method and optimized design technology, applied to mining equipment, earthwork drilling, tunnels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

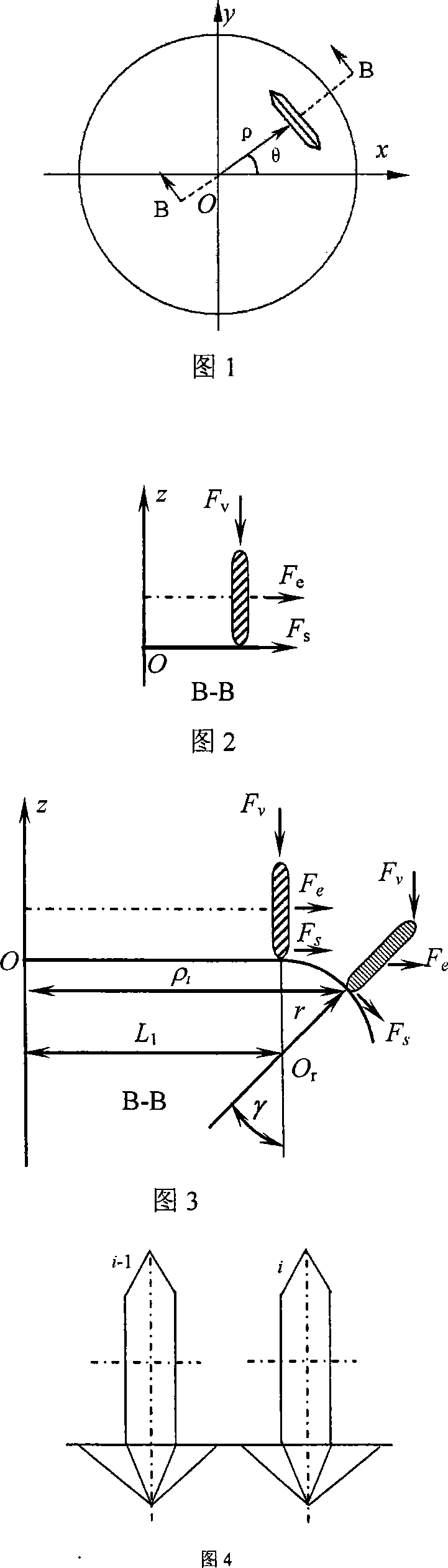

Embodiment Construction

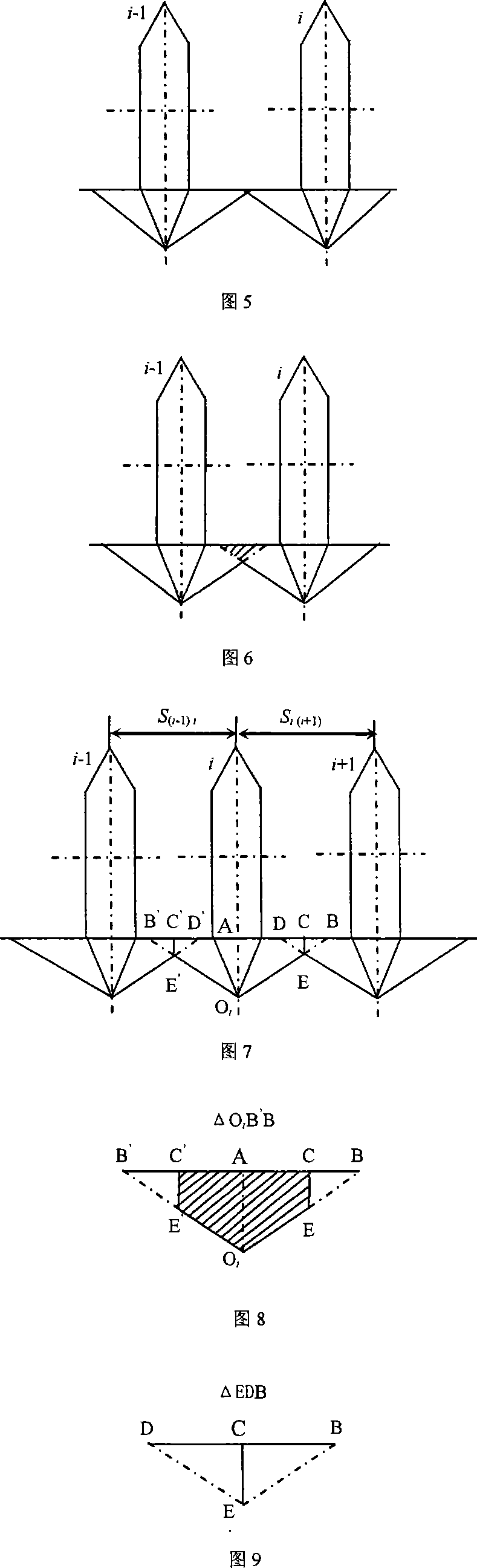

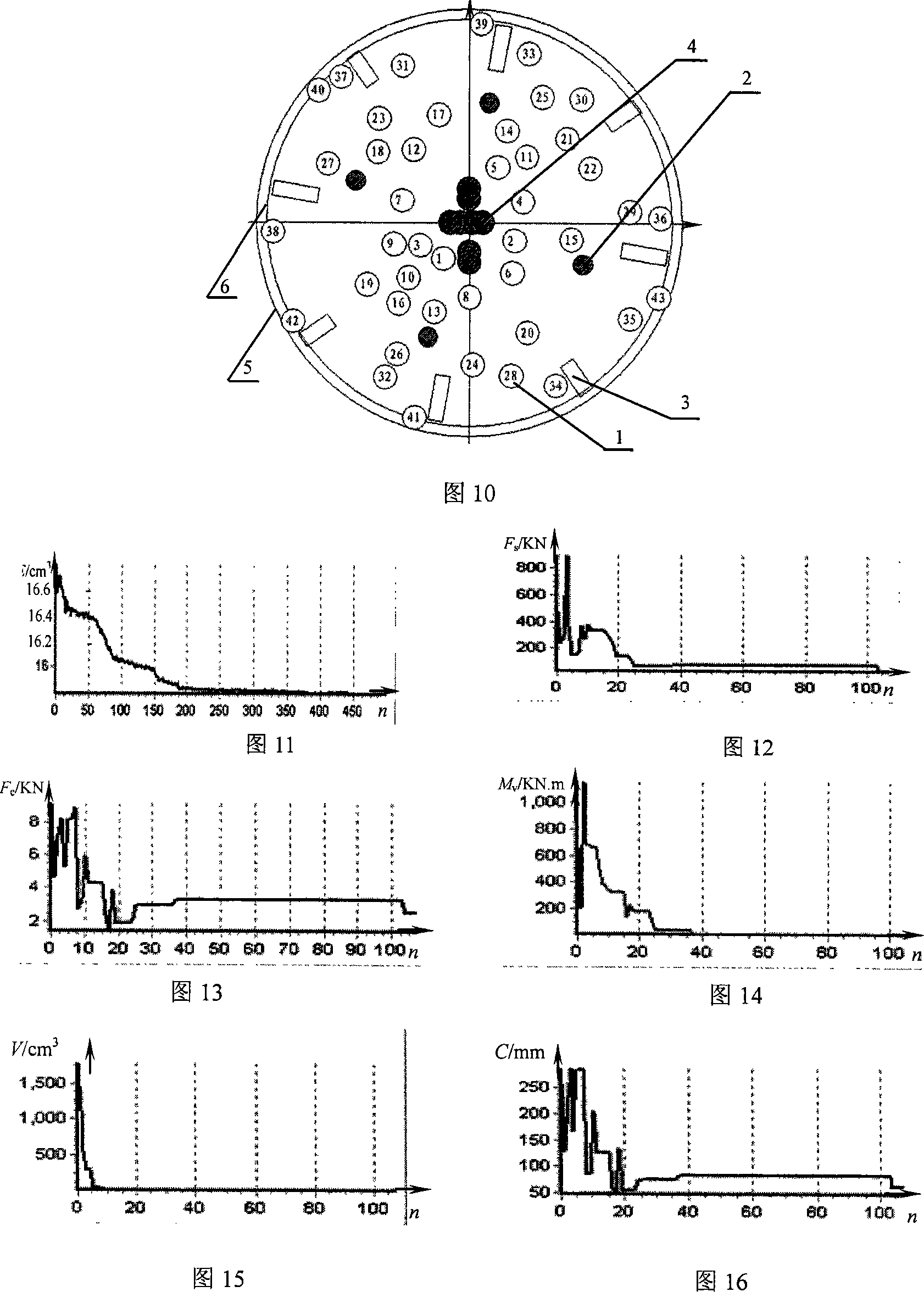

[0066] In conjunction with the accompanying drawings, the implementation of the present invention is described in detail. The present invention takes the geological conditions of a water diversion tunnel project as an example. 51 disc cutters are arranged on the panel cutter head, 8 center cutters, 11 side cutters, and 32 front cutters. The known conditions are as follows: ① Geological parameters: rock unconfined shear strength τ = 8 (MPa), rock uniaxial compressive strength σ = 80 (MPa), ② basic parameters of the cutterhead of the roadheader: the radius of the cutterhead R = 4.015m, the rotating speed ω=6(r / min)=0.6283rad / s of the cutterhead, the mass M of the disk cutter=200kg, the diameter collection D=19 inches of the disk cutter=483mm, the depth of cut of the disk cutter h=10mm, The rock breaking angle of the disk cutter β=1.3734rad, the indentation angle between the disk cutter and the rock surface =0.28878 rad, the cutter edge angle α=2.09434 rad, the radius of the manh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com