Patents

Literature

1394results about How to "Improve thickness uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

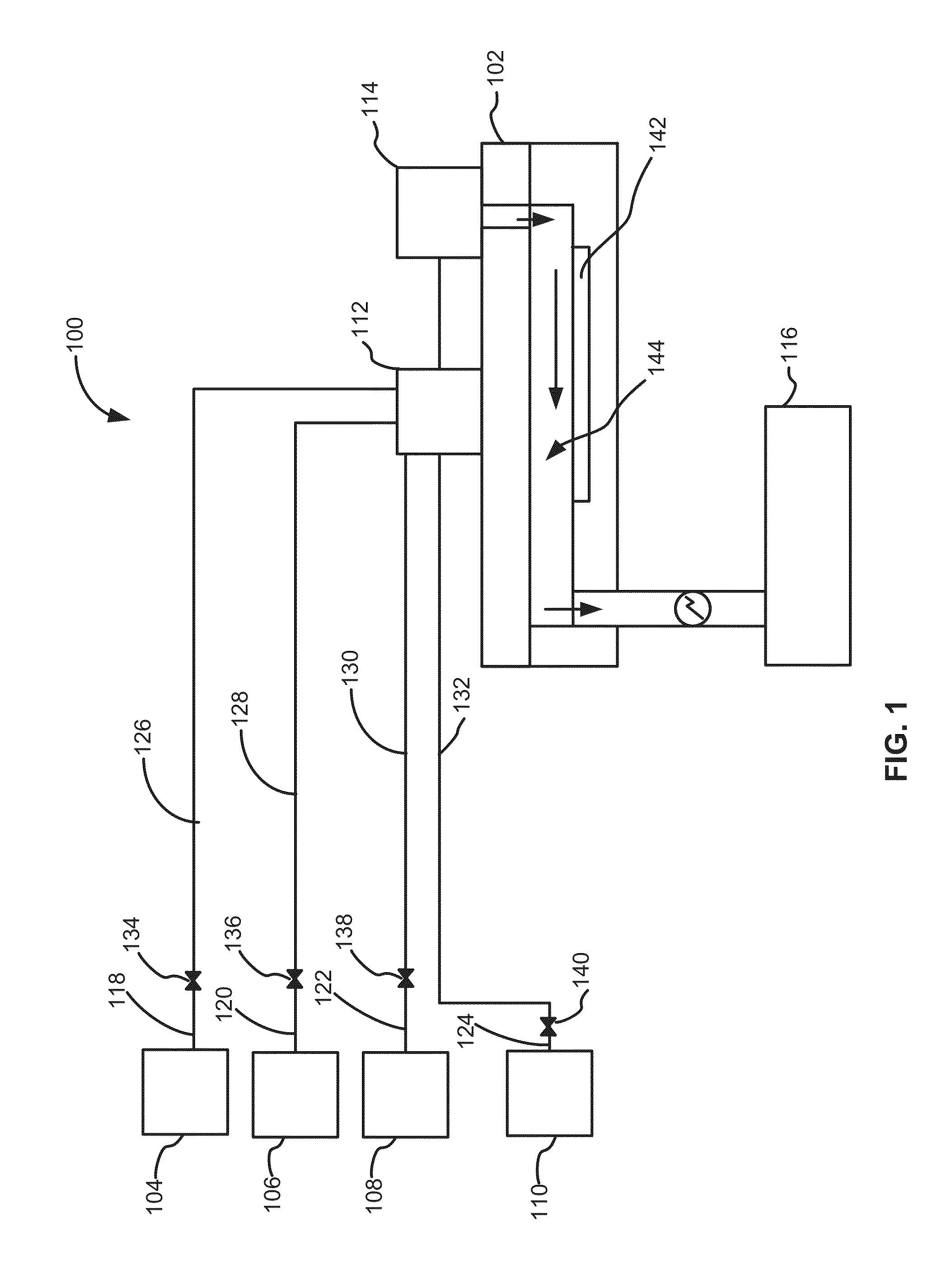

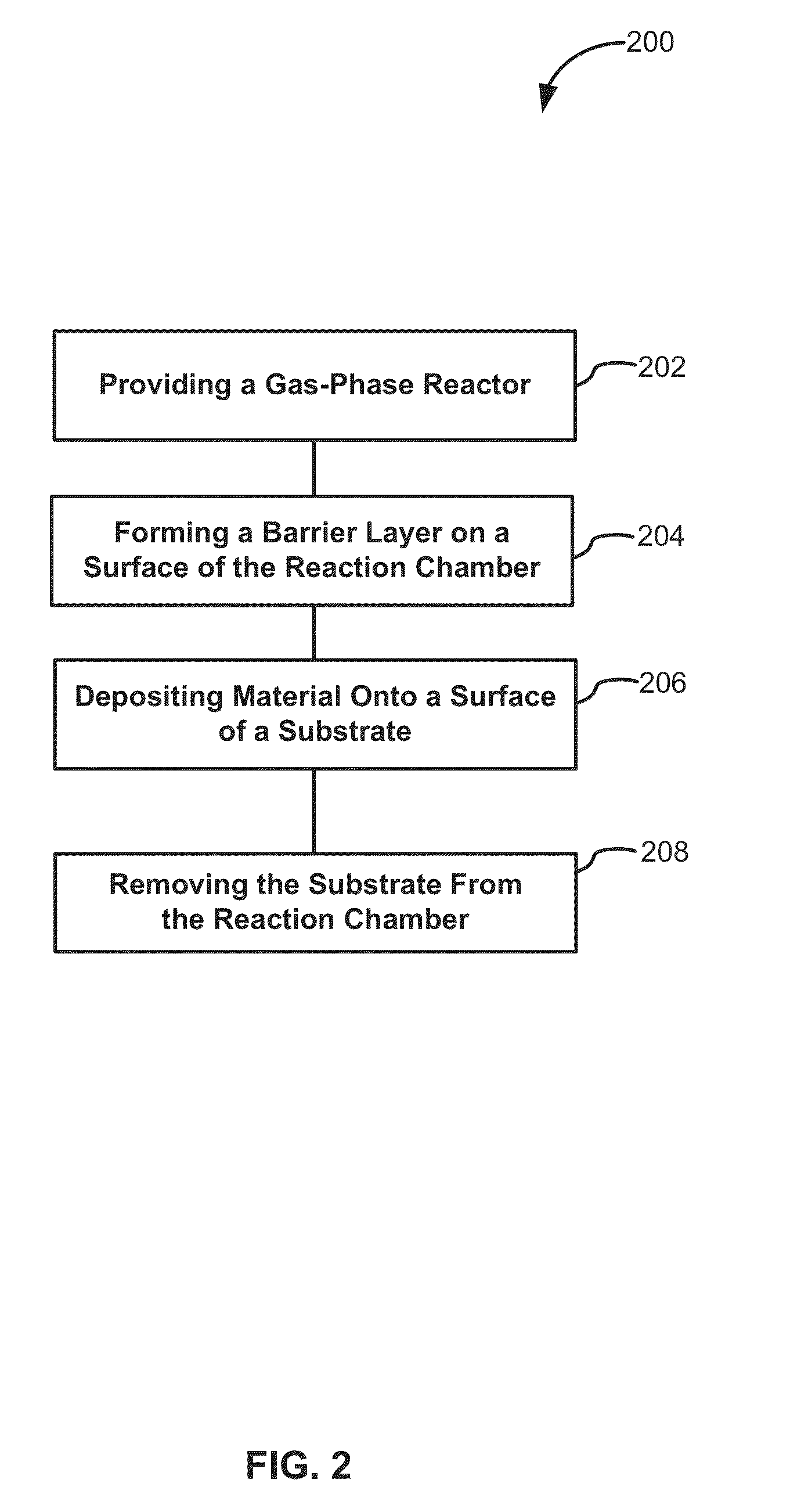

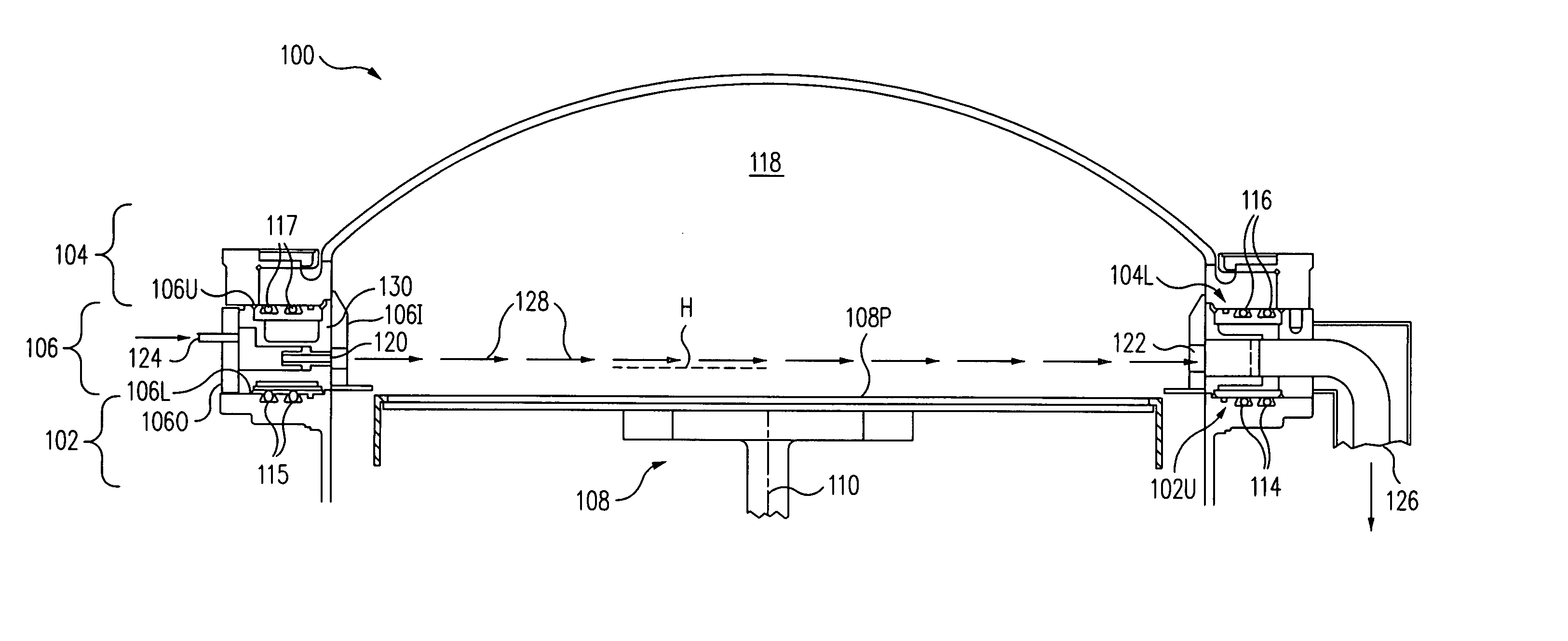

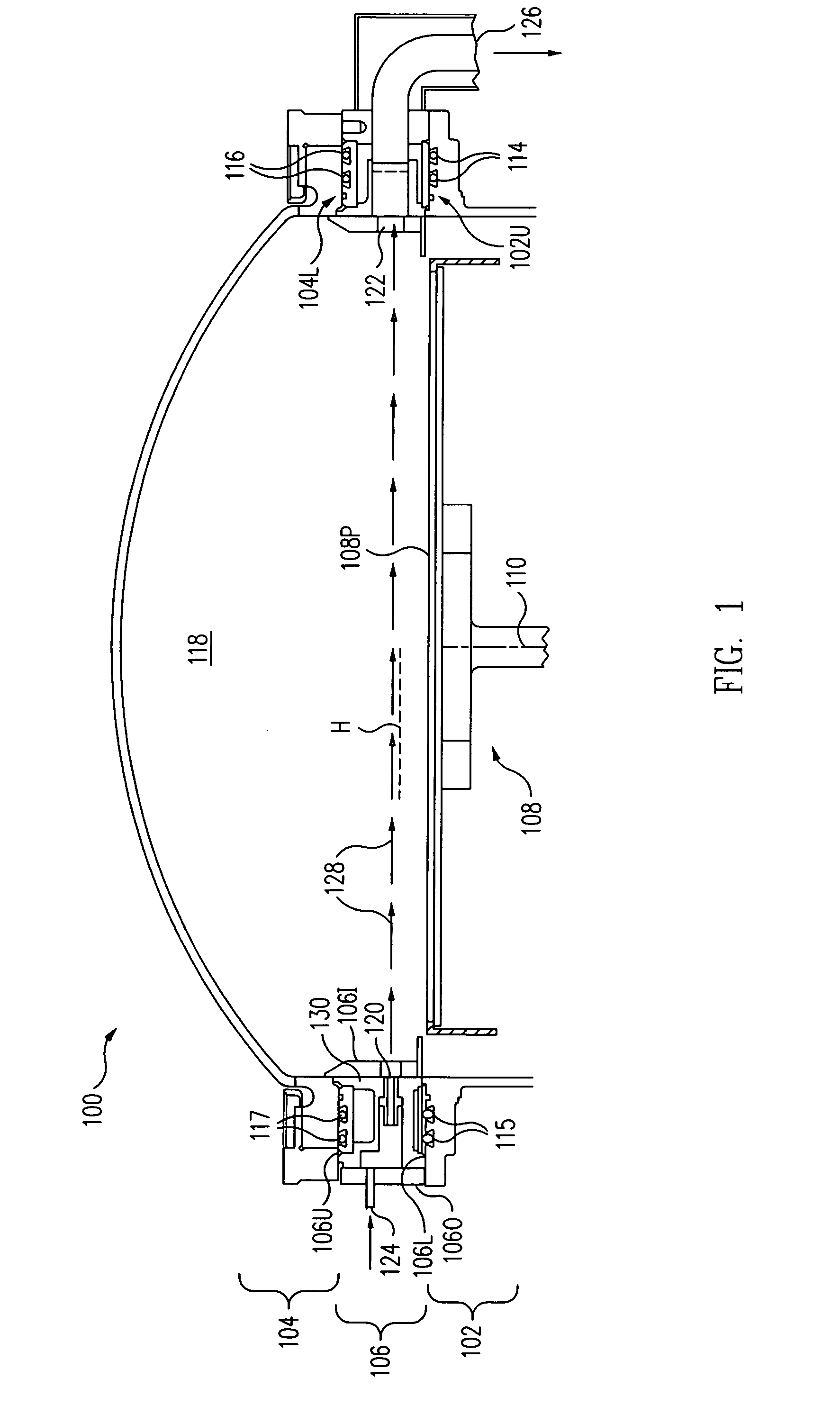

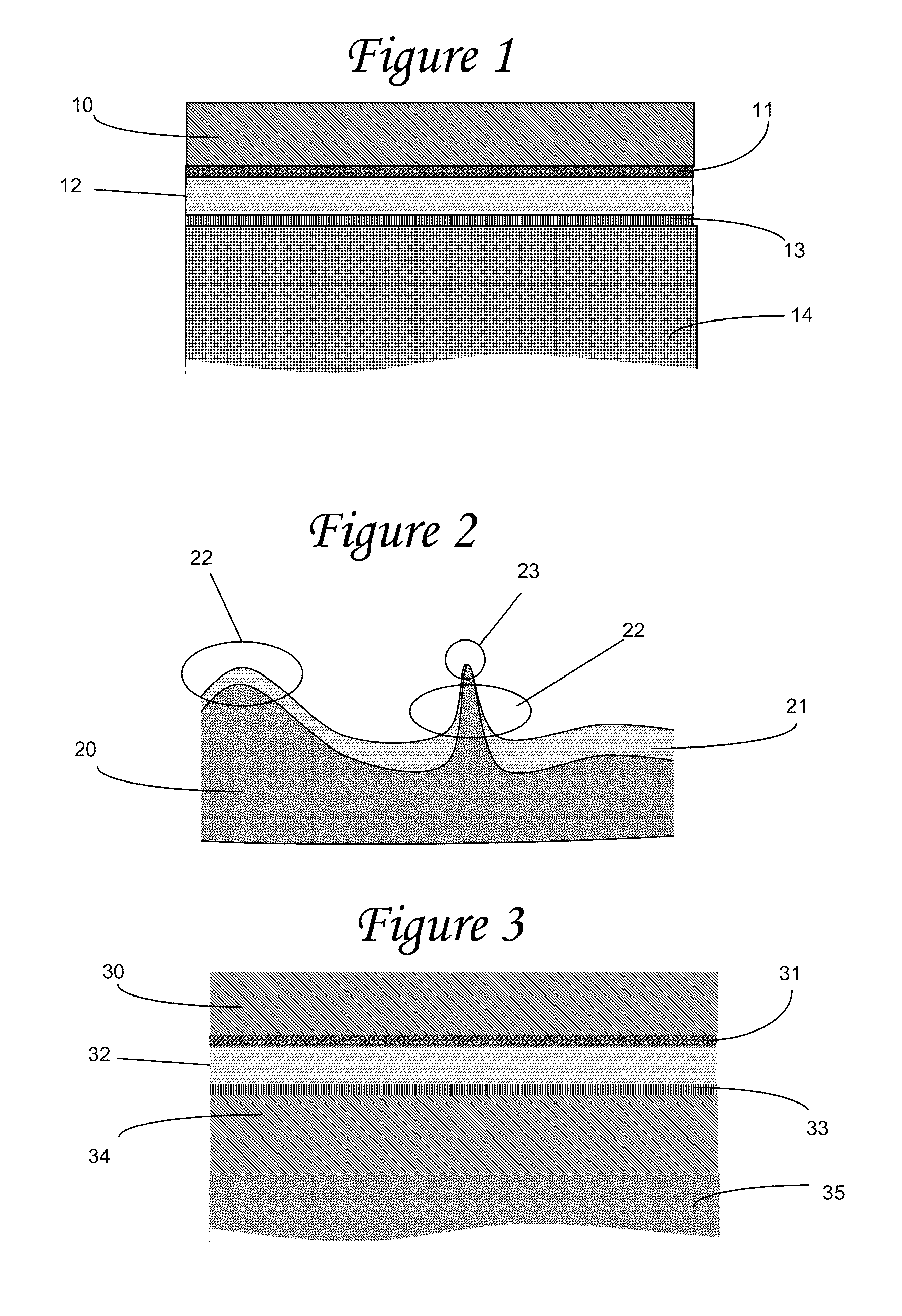

Method and system to reduce outgassing in a reaction chamber

ActiveUS20150140210A1Reduce outgassingImprove thickness uniformitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingOutgassingGas phase

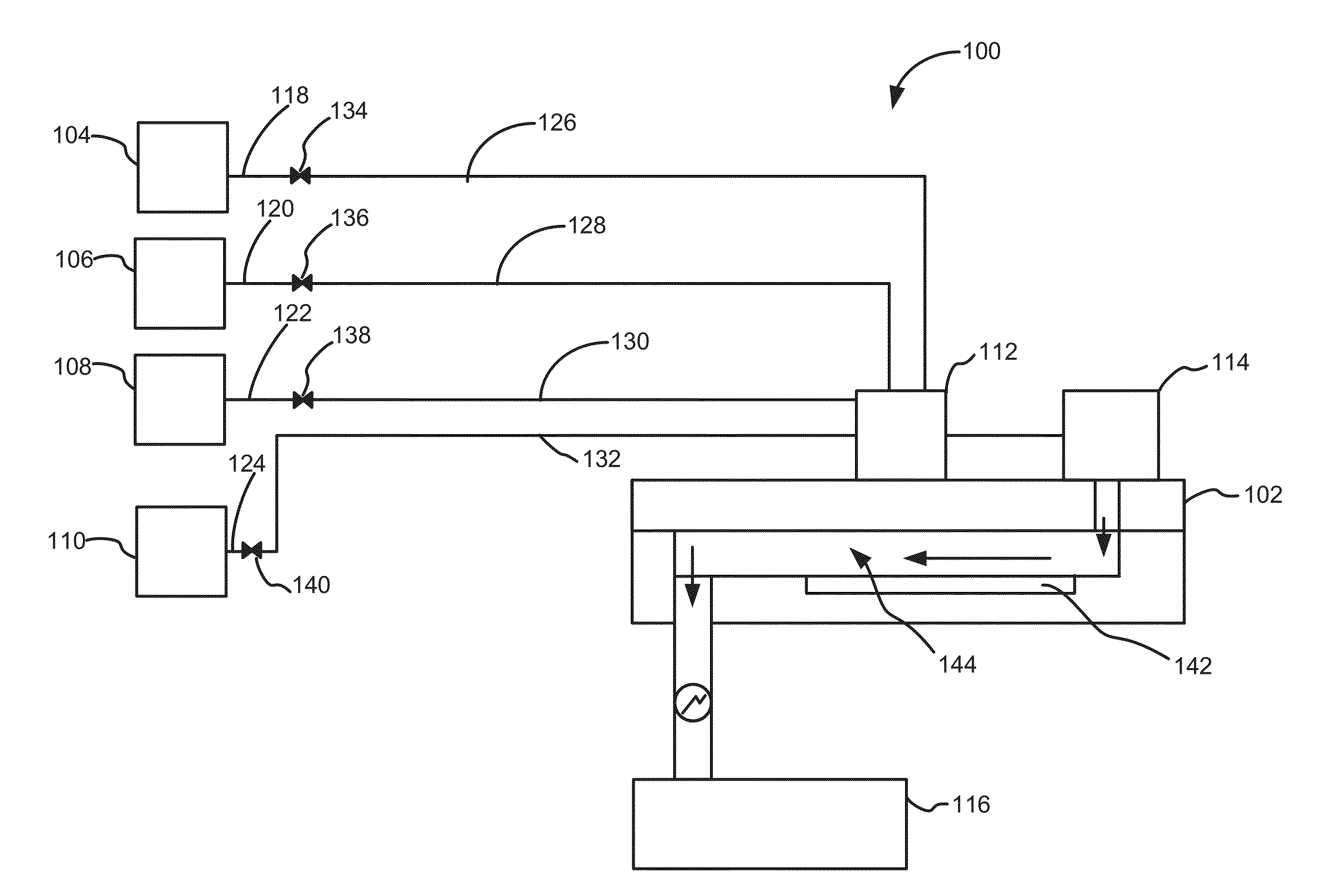

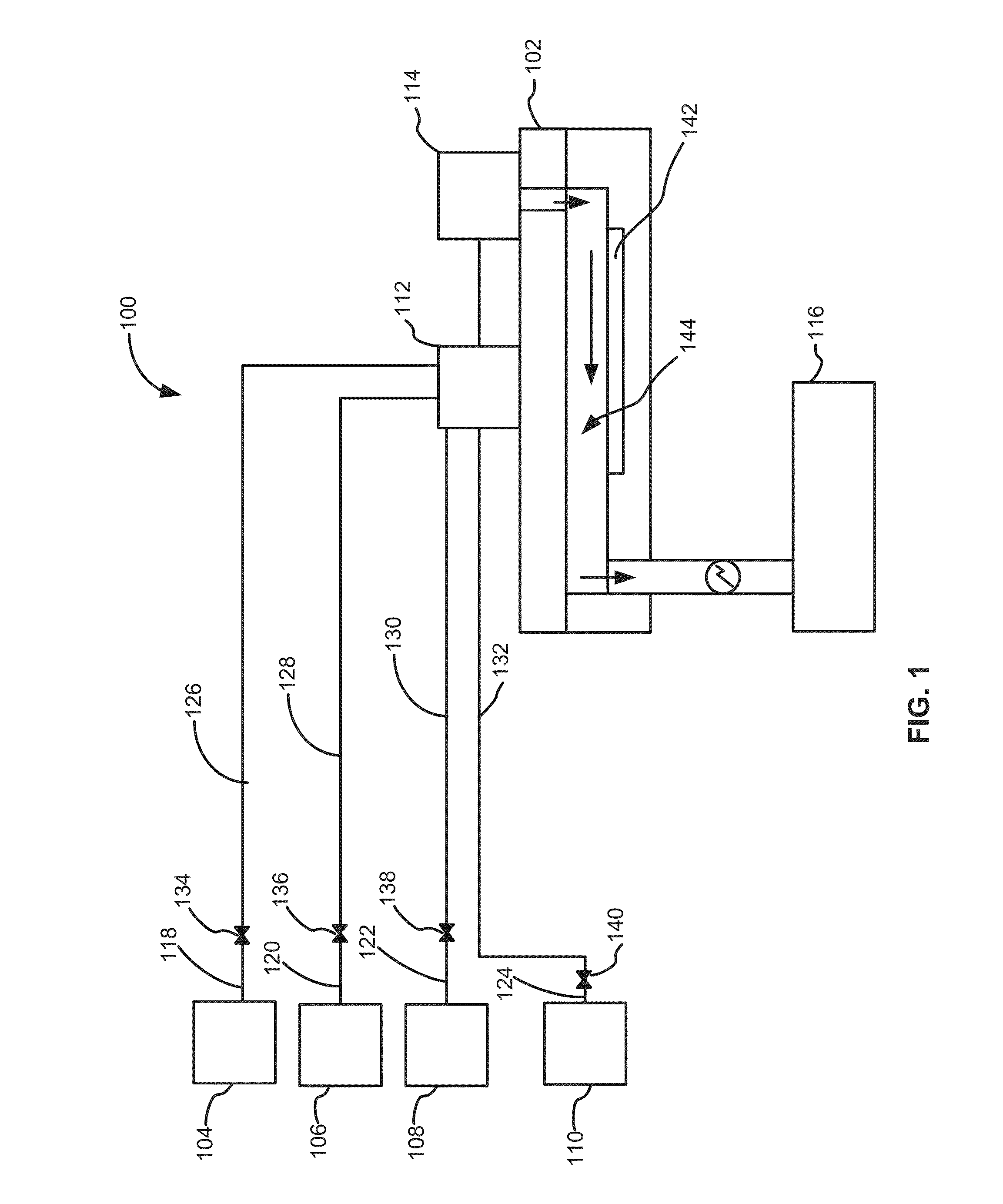

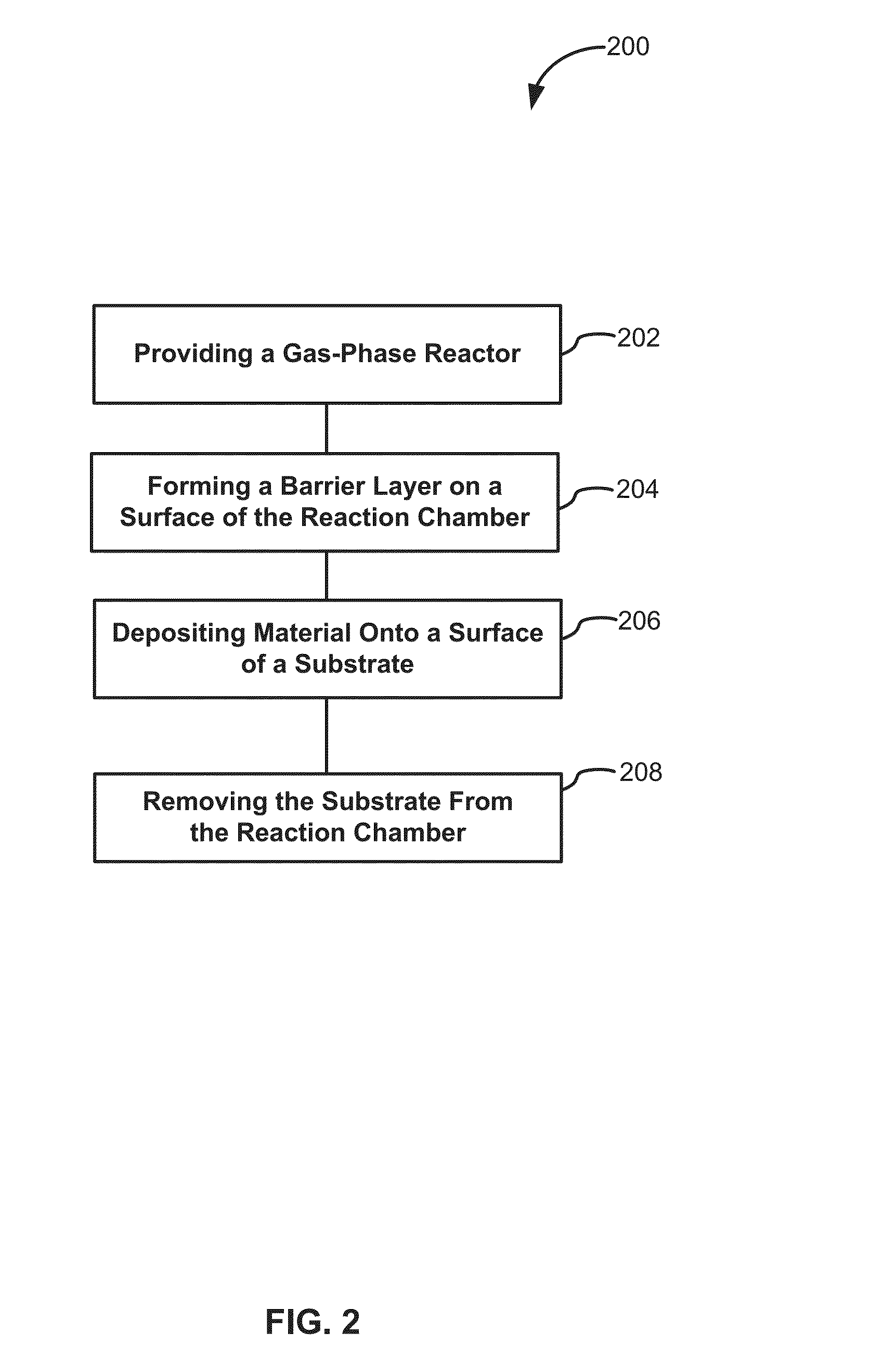

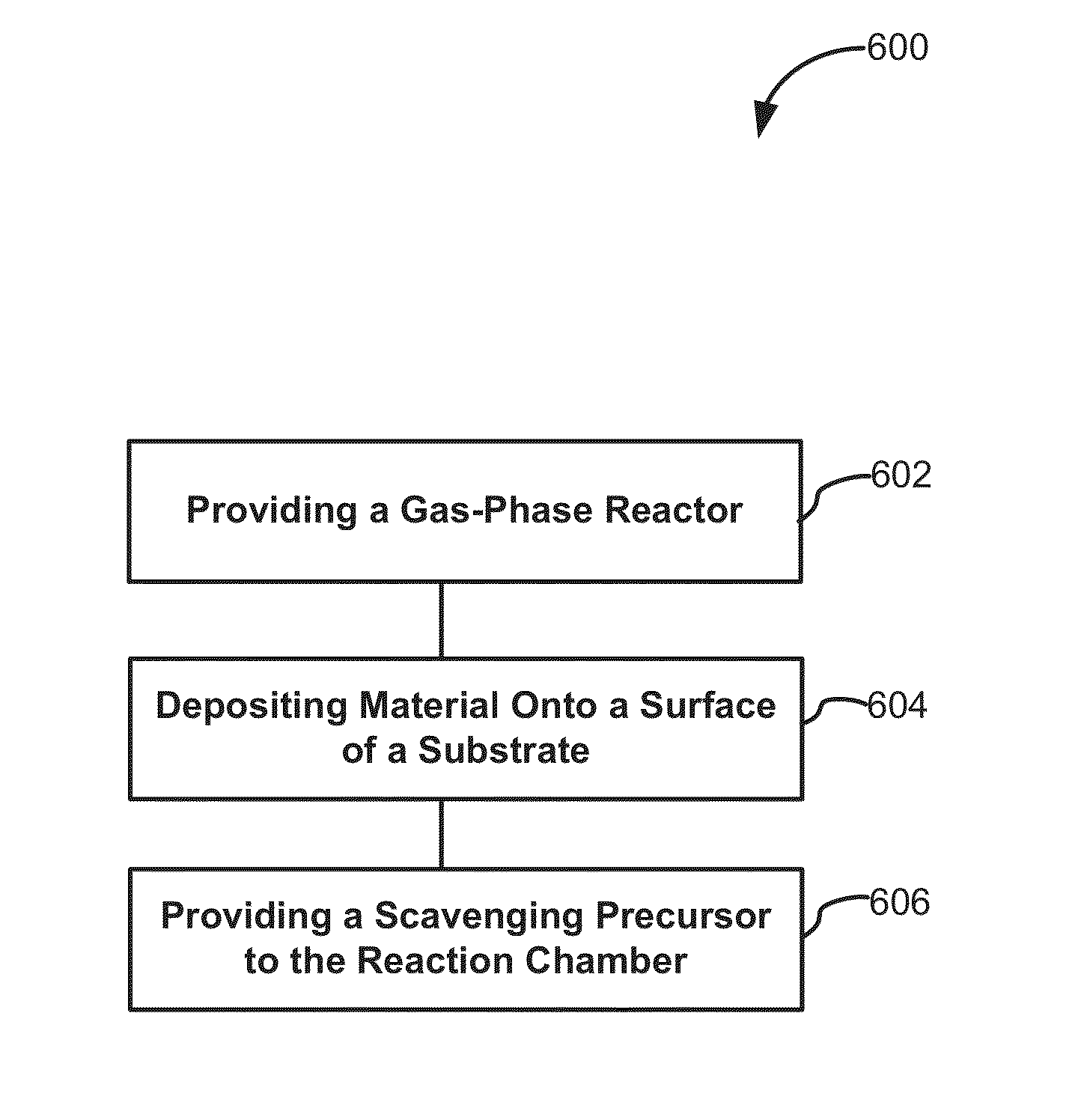

Systems and methods of reducing outgassing of a substance within a reaction chamber of a reactor are disclosed. Exemplary methods include depositing a barrier layer within the reaction chamber and using a scavenging precursor to react with species on a surface of the reaction chamber. Exemplary systems include gas-phase deposition systems, such as atomic layer deposition systems, which include a barrier layer source and / or a scavenging precursor source fluidly coupled to a reaction chamber of the system.

Owner:ASM IP HLDG BV

Method and system to reduce outgassing in a reaction chamber

ActiveUS8993054B2Reduce outgassingImprove thickness uniformityChemical vapor deposition coatingSemiconductor/solid-state device manufacturingGas phaseOutgassing

Systems and methods of reducing outgassing of a substance within a reaction chamber of a reactor are disclosed. Exemplary methods include depositing a barrier layer within the reaction chamber and using a scavenging precursor to react with species on a surface of the reaction chamber. Exemplary systems include gas-phase deposition systems, such as atomic layer deposition systems, which include a barrier layer source and / or a scavenging precursor source fluidly coupled to a reaction chamber of the system.

Owner:ASM IP HLDG BV

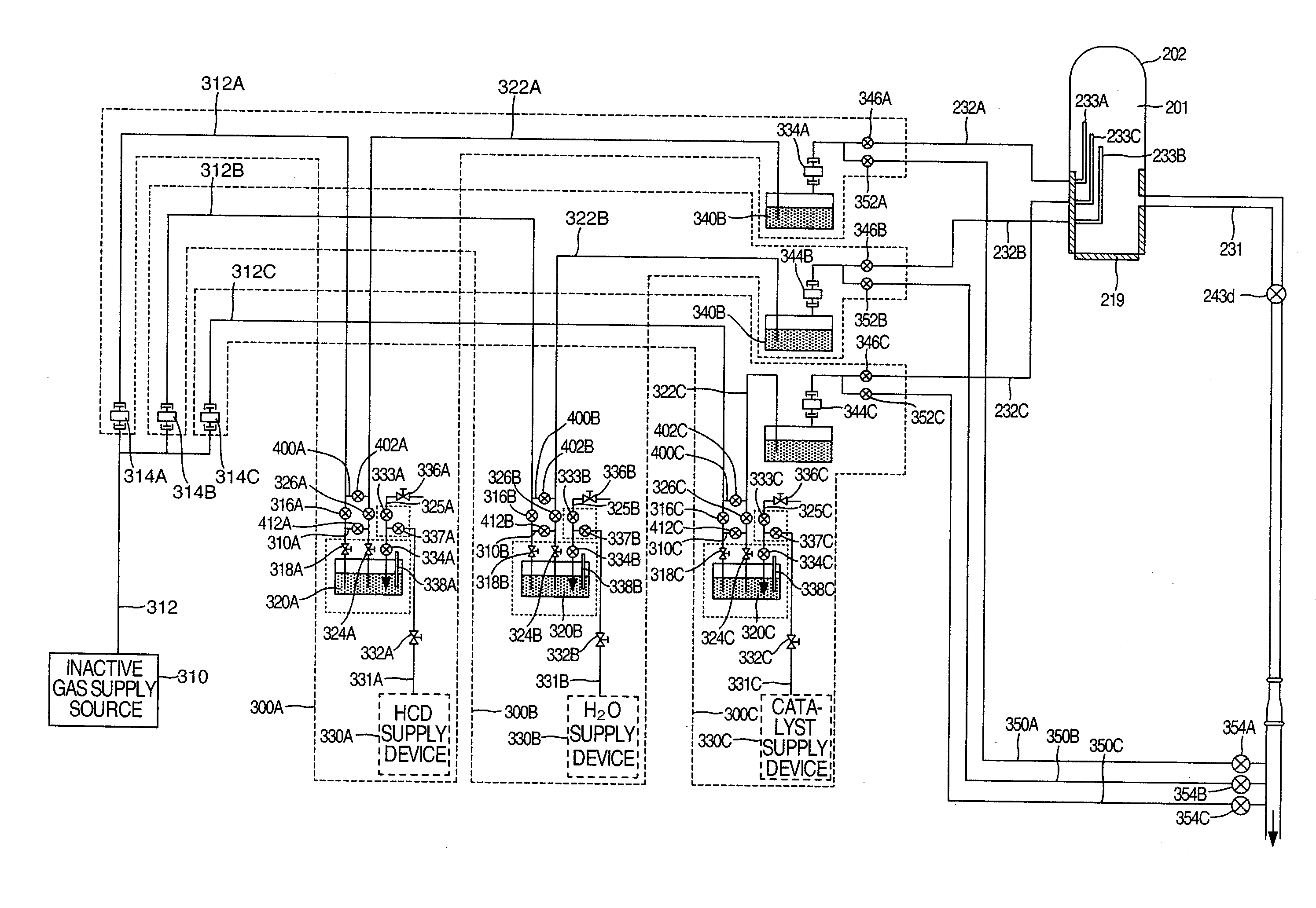

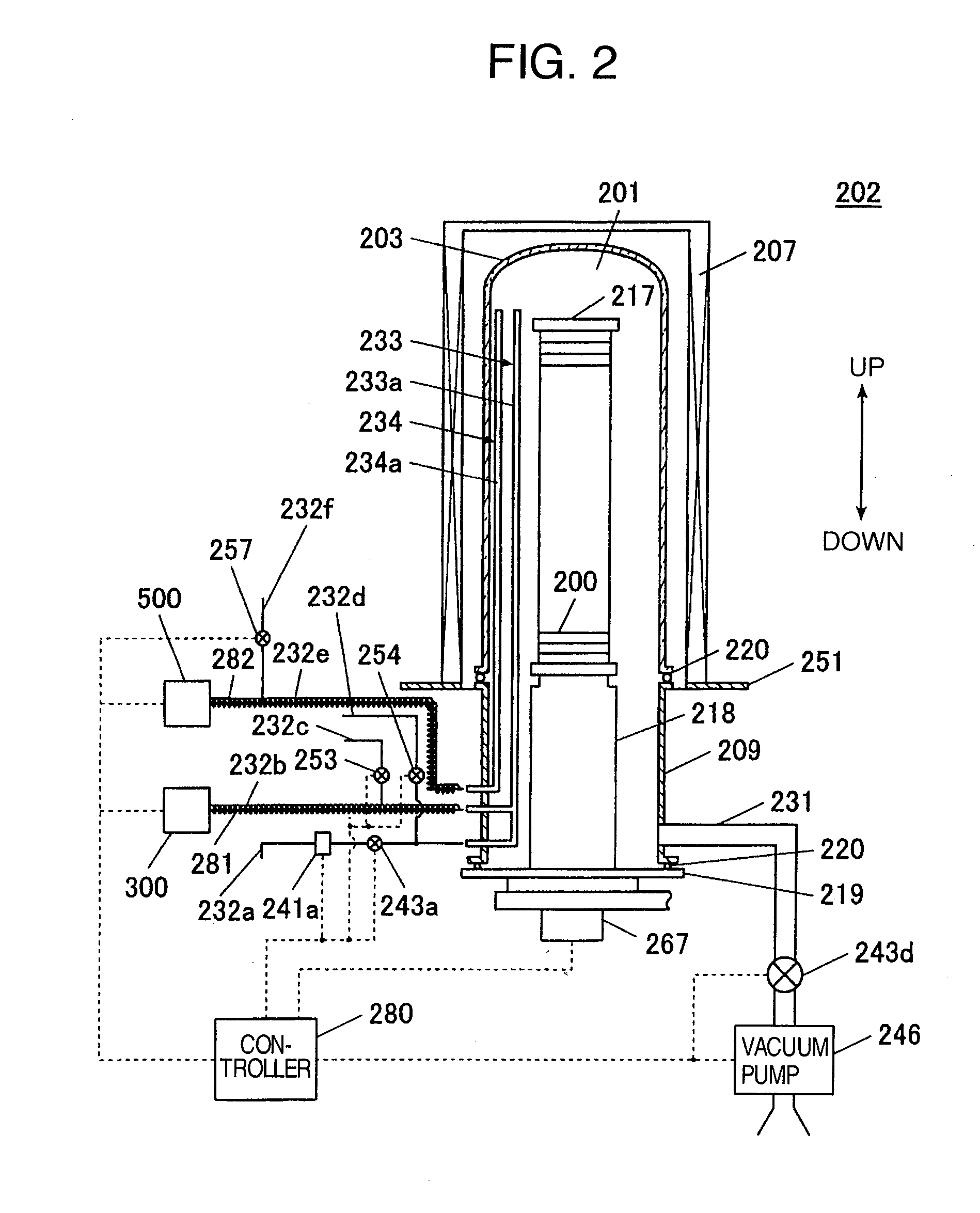

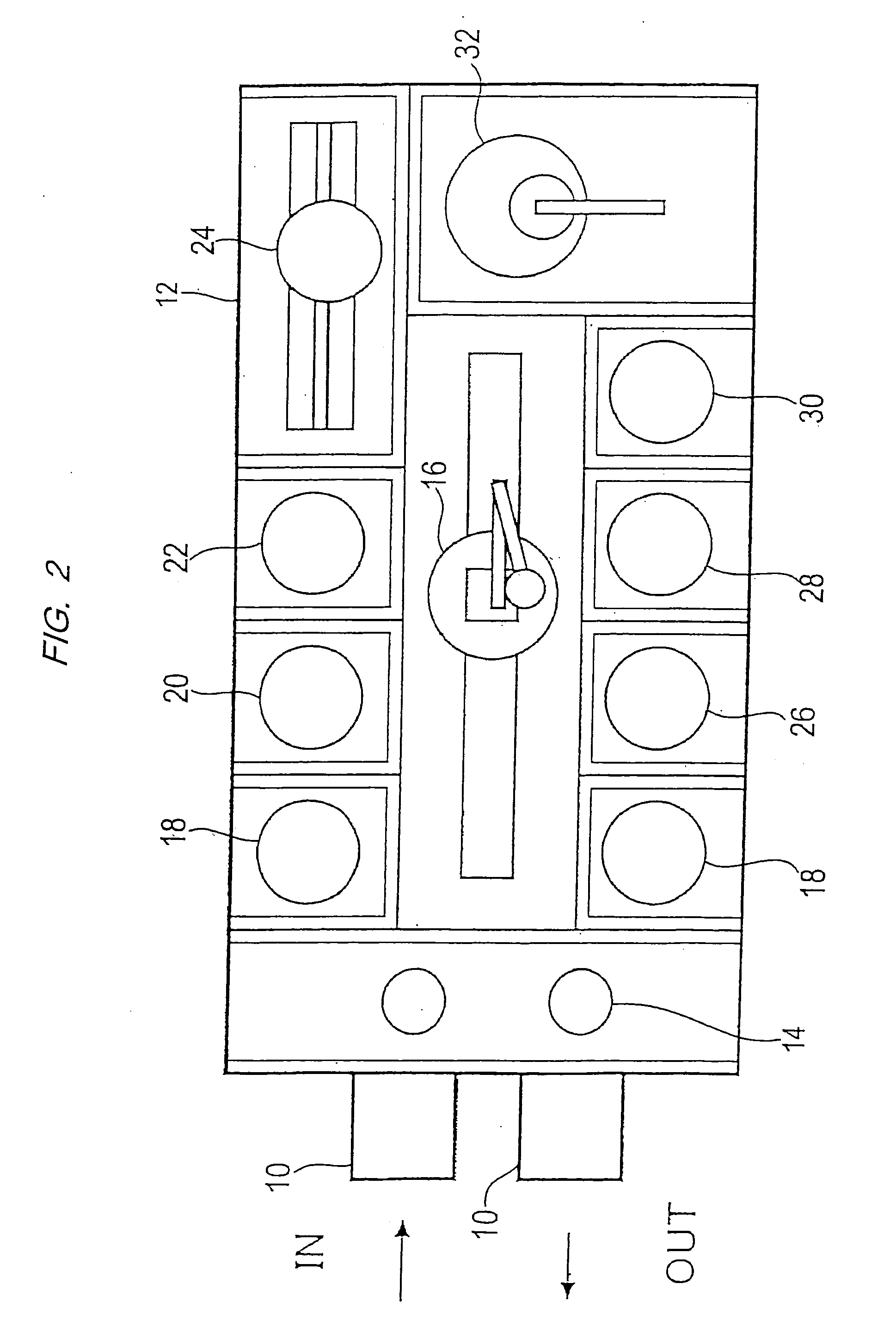

Substrate processing apparatus

InactiveUS20080305014A1Improve thickness uniformitySuppress productionFlow controlProcess engineeringProduct gas

A substrate processing apparatus which stably supplies a vaporized gas of liquid raw material to a processing chamber includes liquid raw material tanks storing a liquid raw material, a carrier gas supply line supplying a carrier gas to one of the tanks, a raw material supply line pressure-feeding to this tank the liquid raw material of the other tank, a carrier gas supply line feeding a carrier gas to the tank, a raw material supply line feeding to the processing chamber a vaporized gas of the liquid raw material of the tank, a mass flow controller which controls the flow rate of the carrier gas, a mass flow controller detecting the flow rate of the vaporized gas of the liquid raw material, and a feedback device feeding back a detection result of the mass flow controller to the former mass flow controller.

Owner:NTT MOBILE COMM NETWORK INC

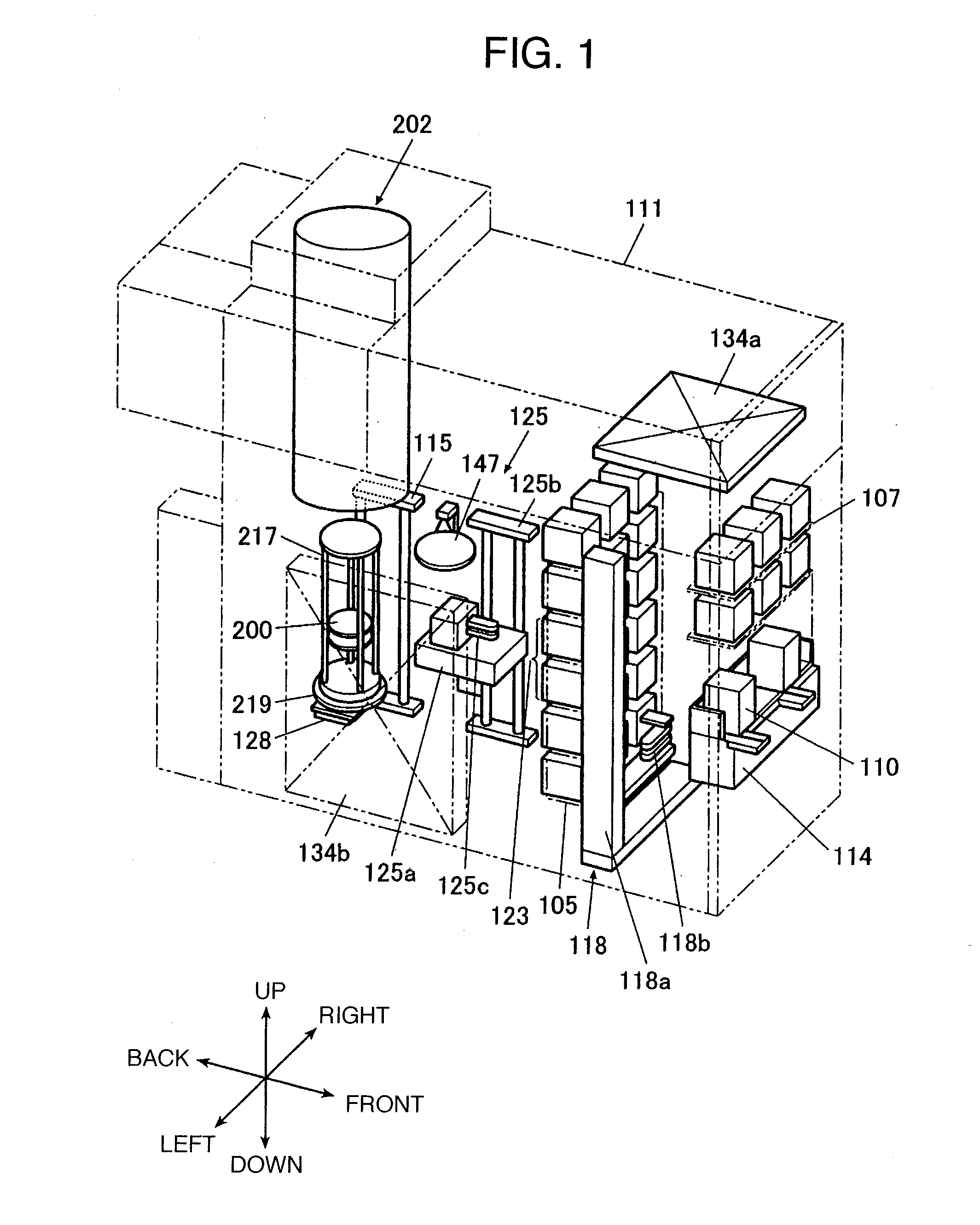

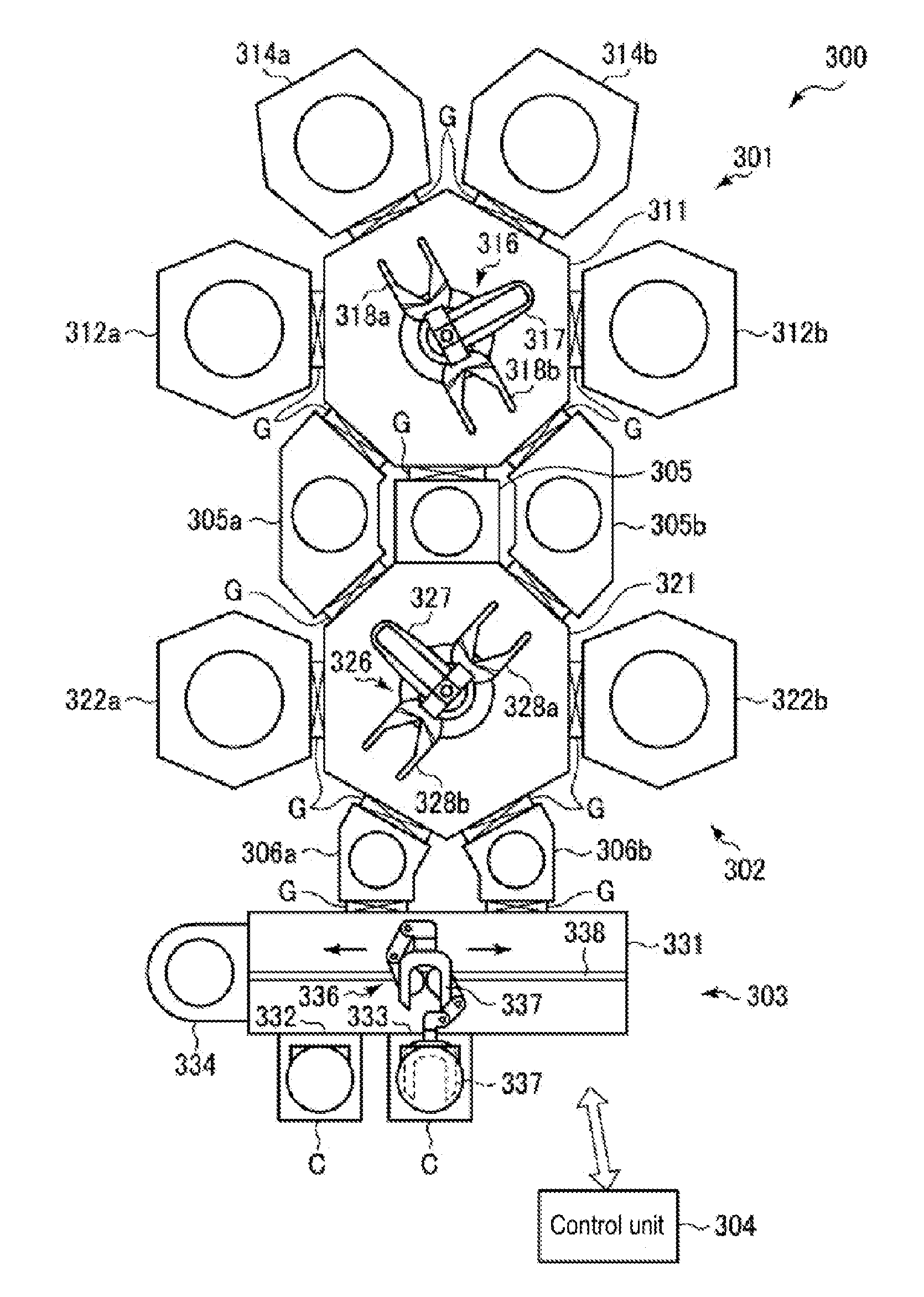

Film forming method, film forming apparatus and recording medium

ActiveUS20150325432A1Improve thickness uniformitySemiconductor/solid-state device detailsSolid-state devicesEngineeringMechanical engineering

A film forming method in which in a state in which a target substrate is loaded on a loading table body of a loading table installed in a processing container and an interior of the processing container is evacuated, a film forming material gas is supplied into the processing container while heating the target substrate with a heater installed in the loading table body, to be thermally decomposed or reacted on a surface of the target substrate to form a predetermined film on the target substrate, includes introducing a heat transfer gas containing an H2 gas or an He gas into the processing container to transfer heat of the loading table body to a radially outer side of the loading table body, before the film forming material gas is supplied.

Owner:TOKYO ELECTRON LTD

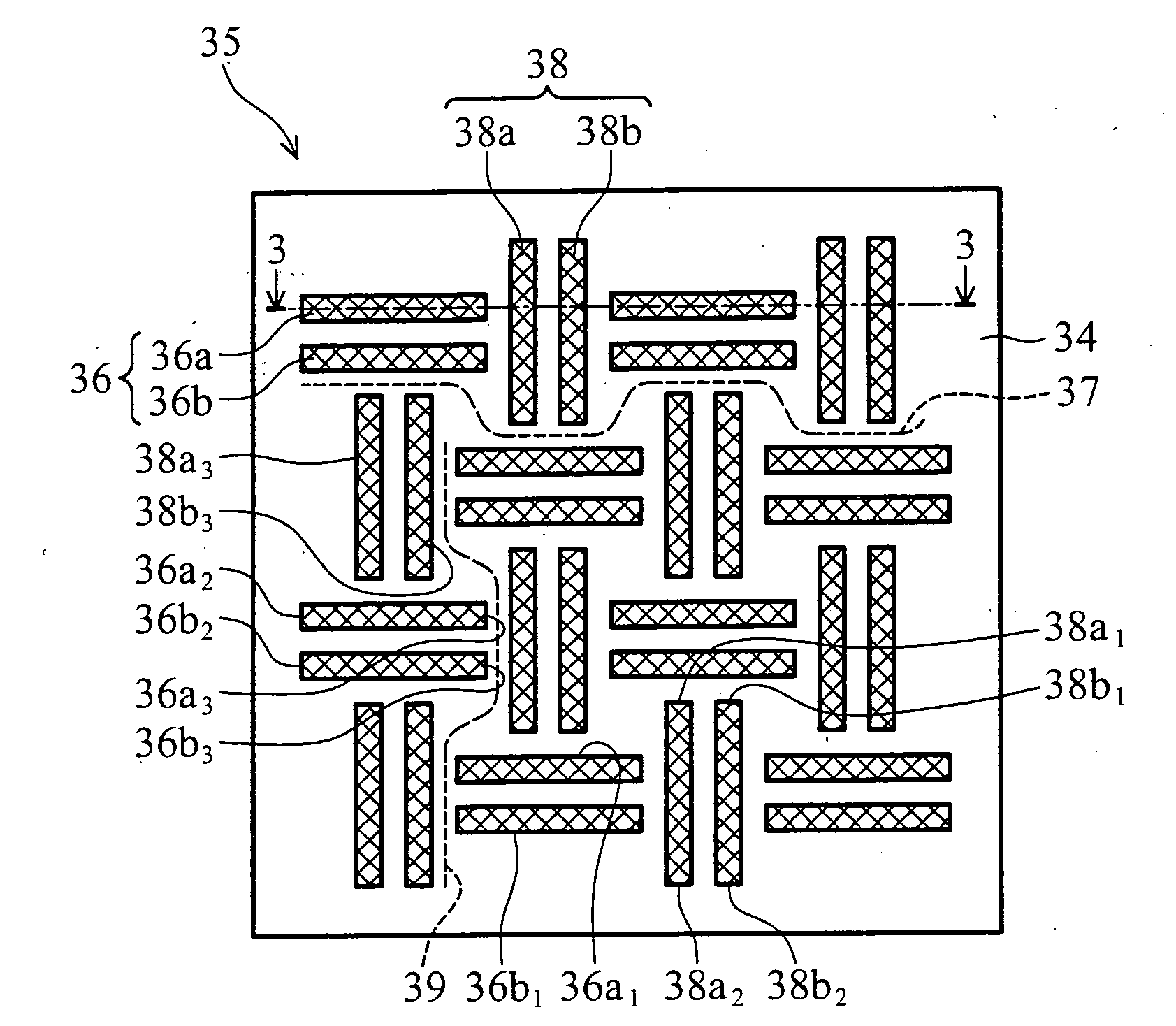

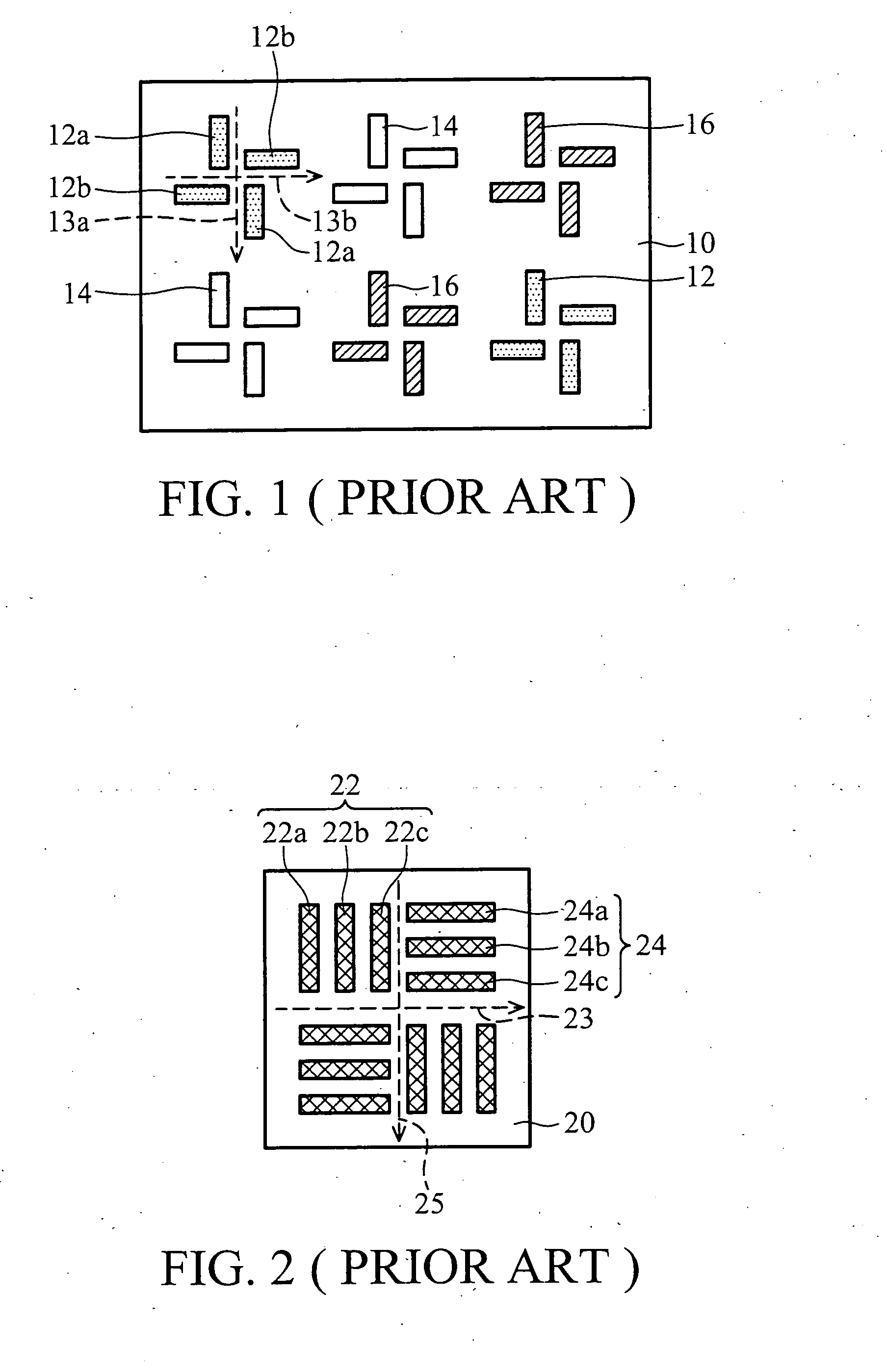

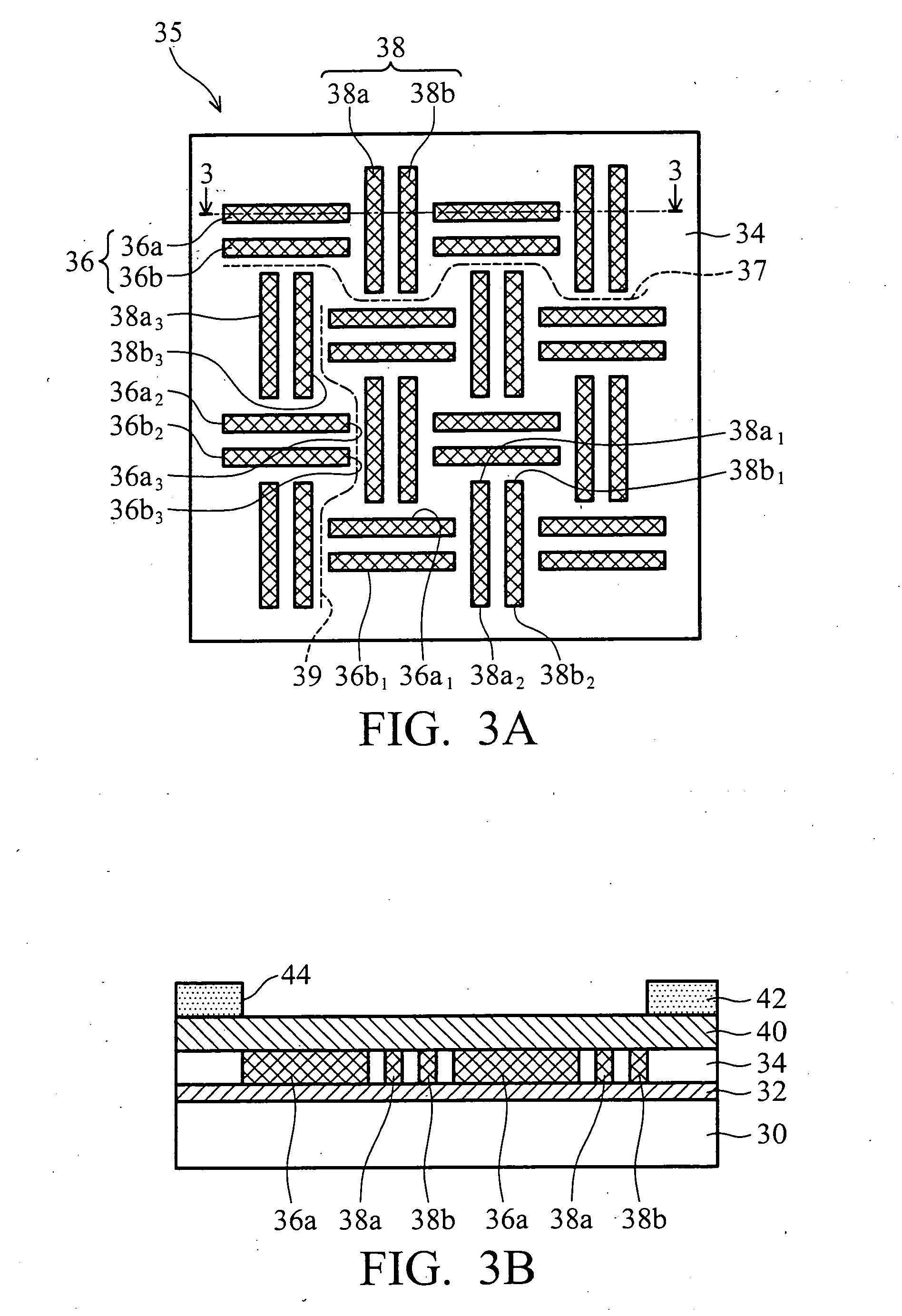

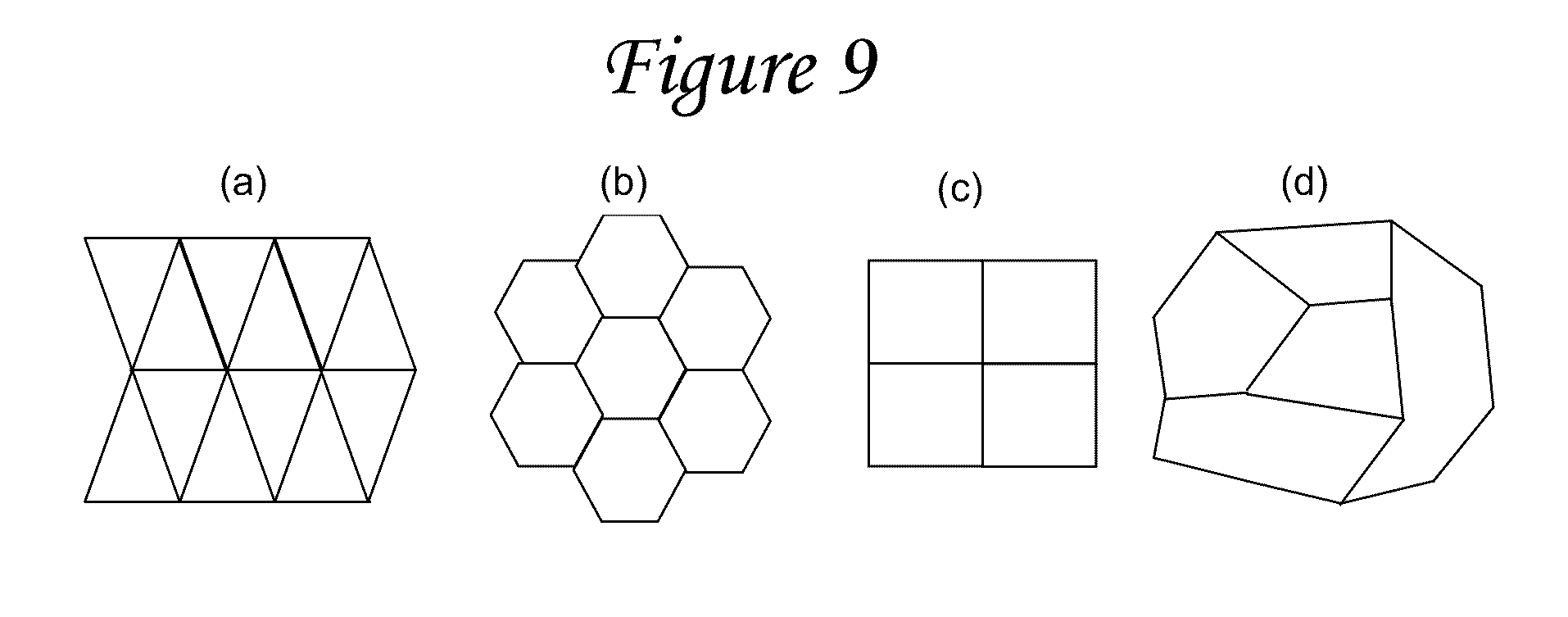

Via layout with via groups placed in interlocked arrangement

ActiveUS20070290361A1Improve critical dimension uniformityImprove thickness uniformitySemiconductor/solid-state device detailsSolid-state devicesEngineeringA domain

Via layout with via groups placed in an interlocked arrangement for suppressing the crack propagation along the domain boundary between the via groups. A structure has a metal via pattern located in a dielectric layer and having a first via group and a second via group adjacent to each other. The first via group has at least two first line vias extending in a first direction, and the second via group has at least two second line vias extending in a second direction. The first via group and the second via group are placed in an interlocked arrangement, and a domain boundary along the first direction or the second direction between the first via group and said second via group is not straight.

Owner:TAIWAN SEMICON MFG CO LTD

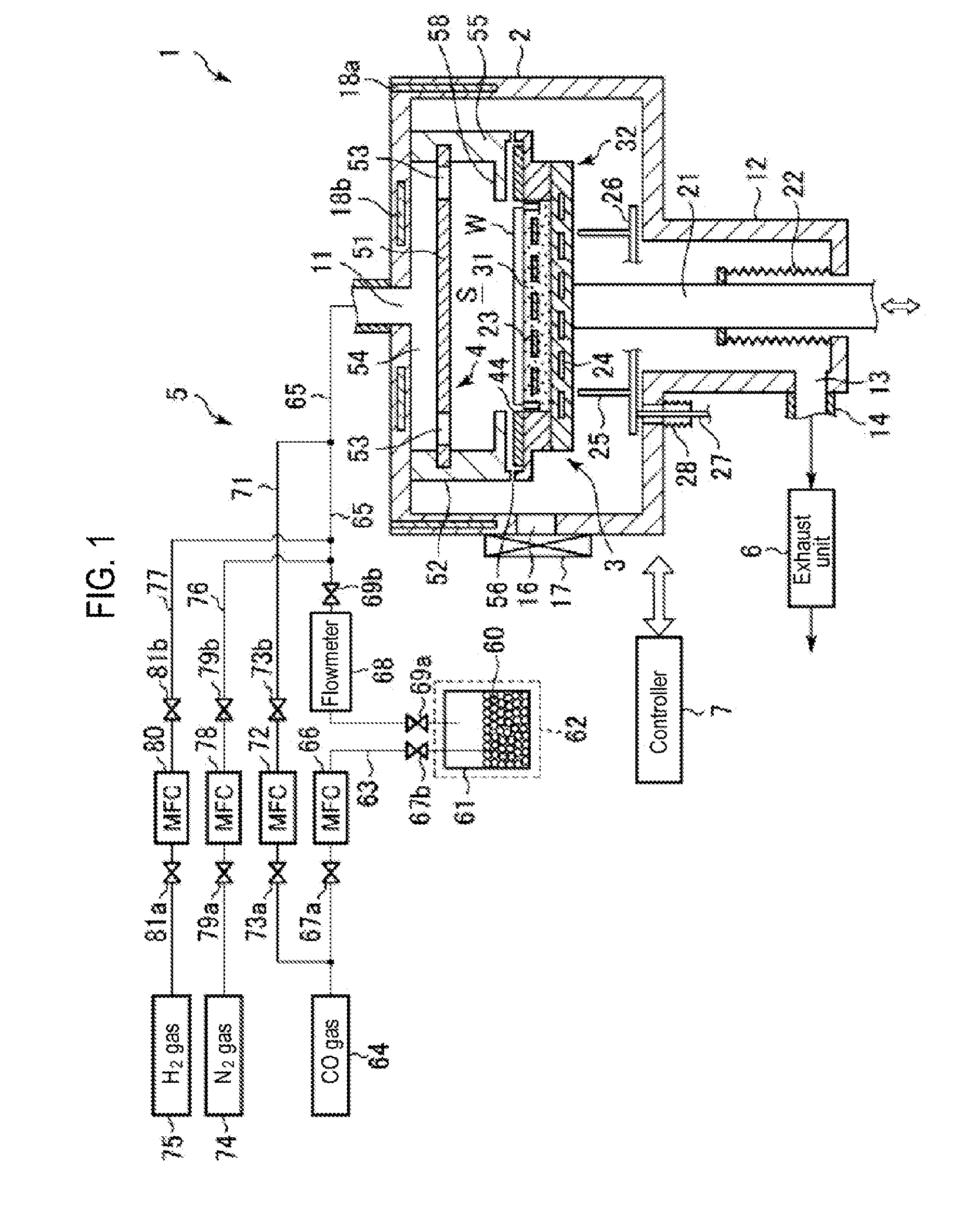

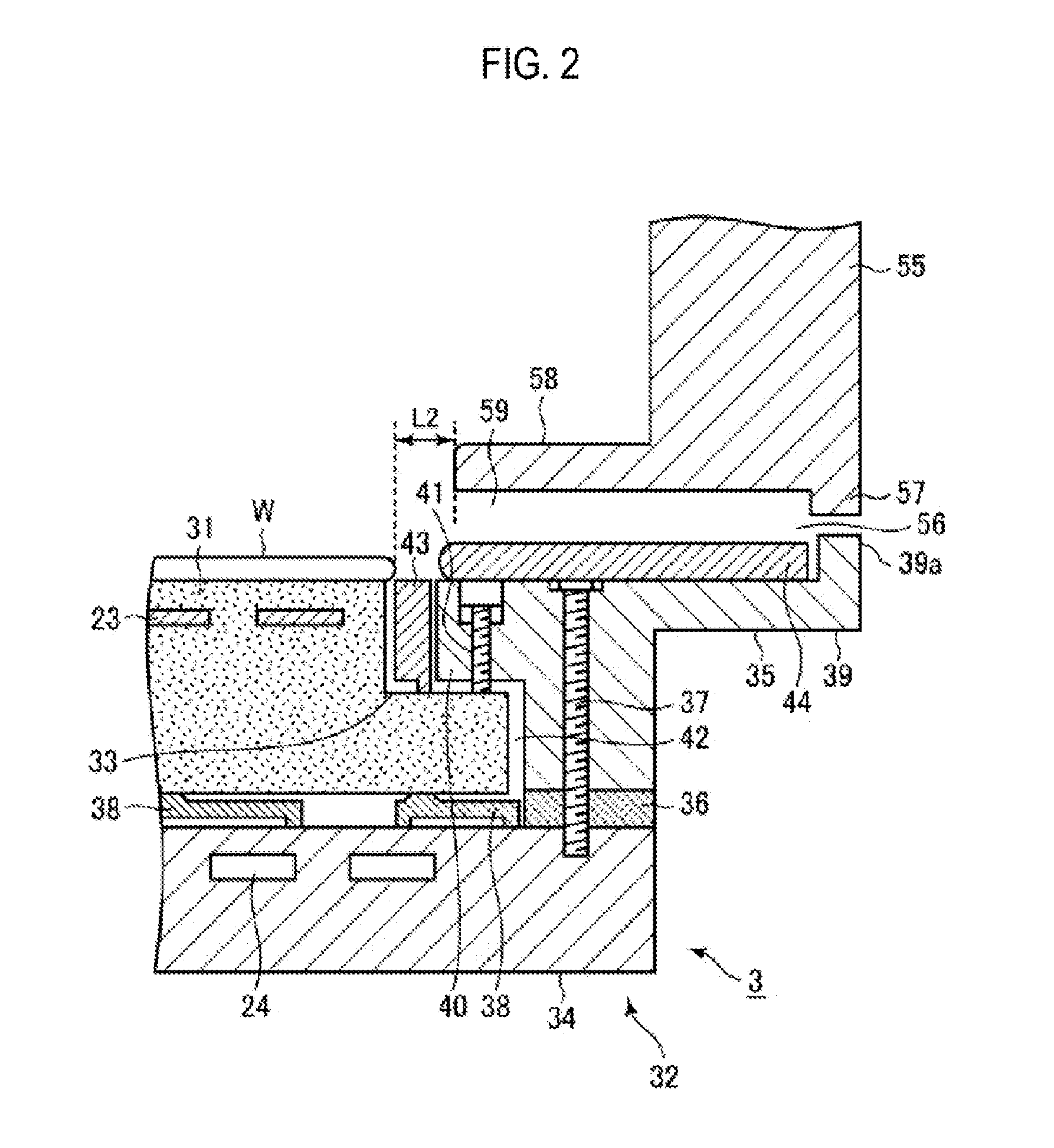

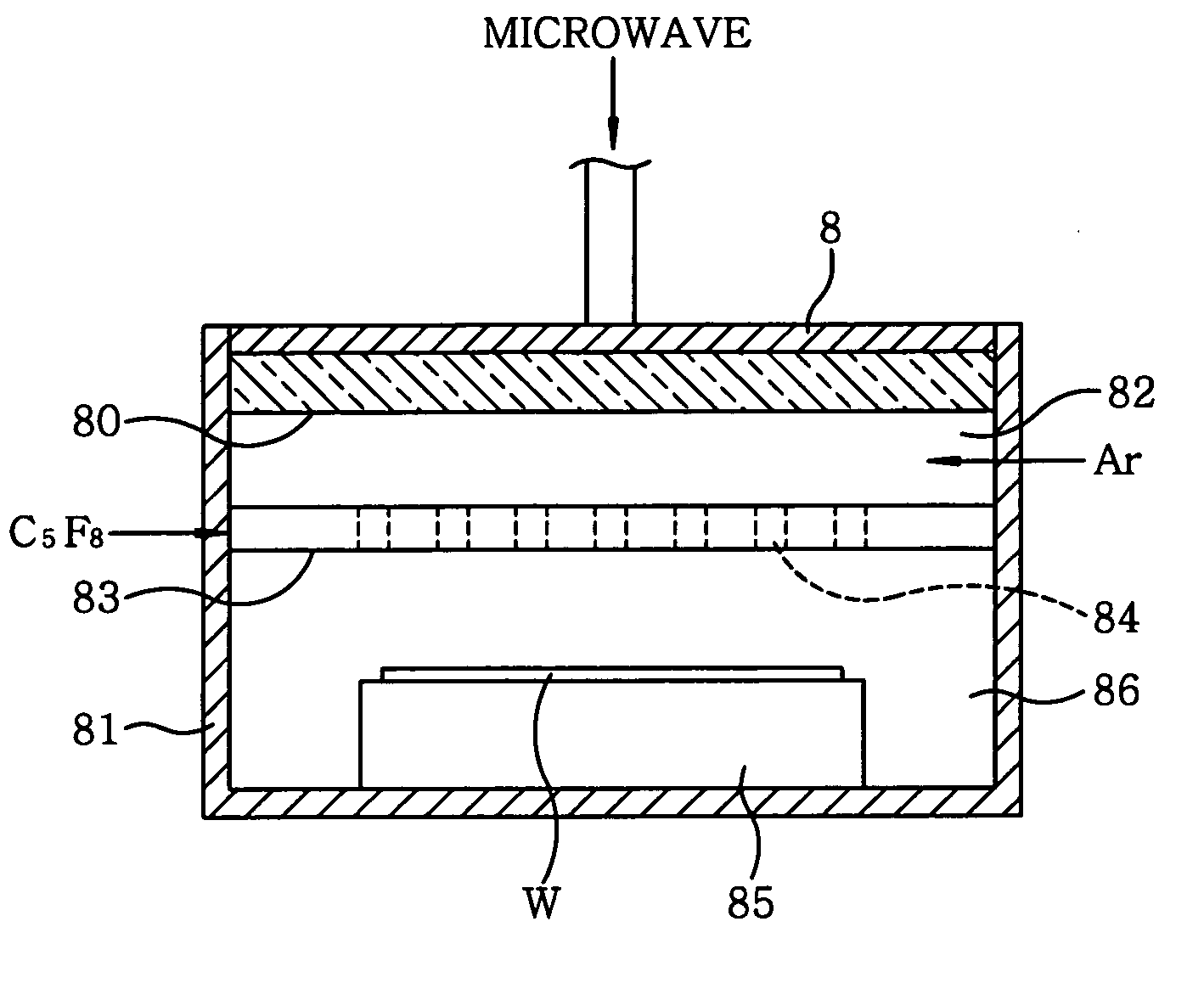

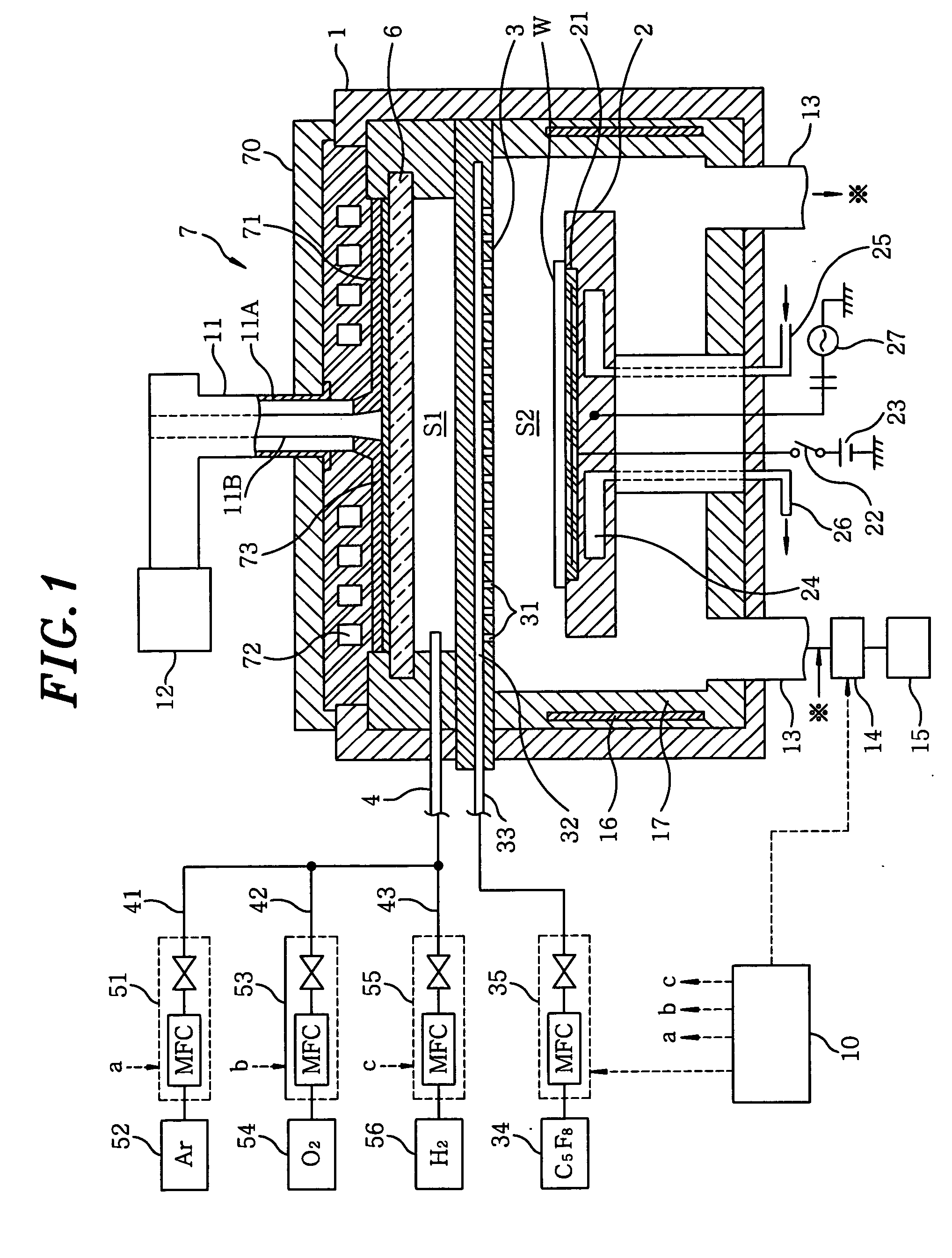

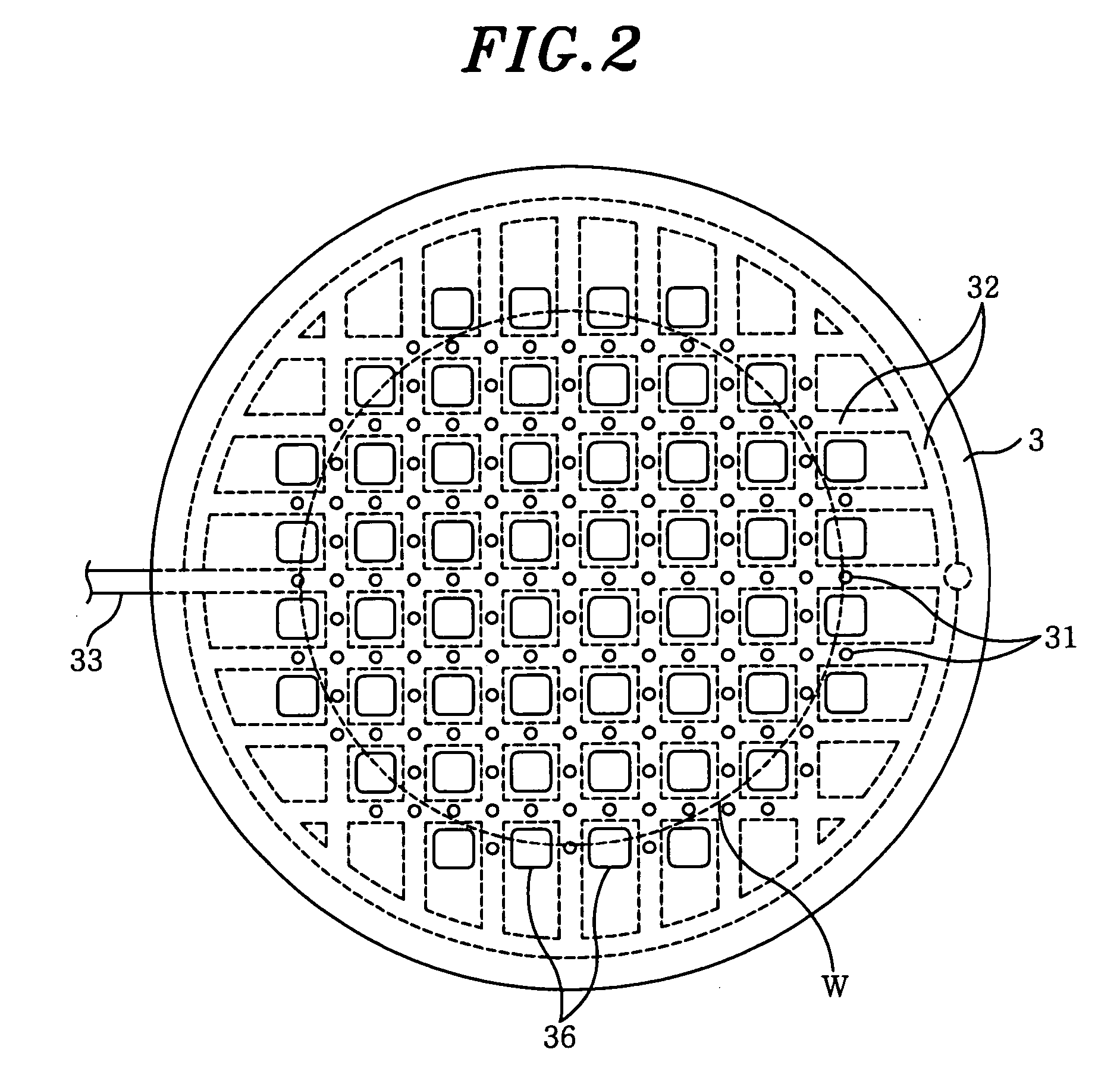

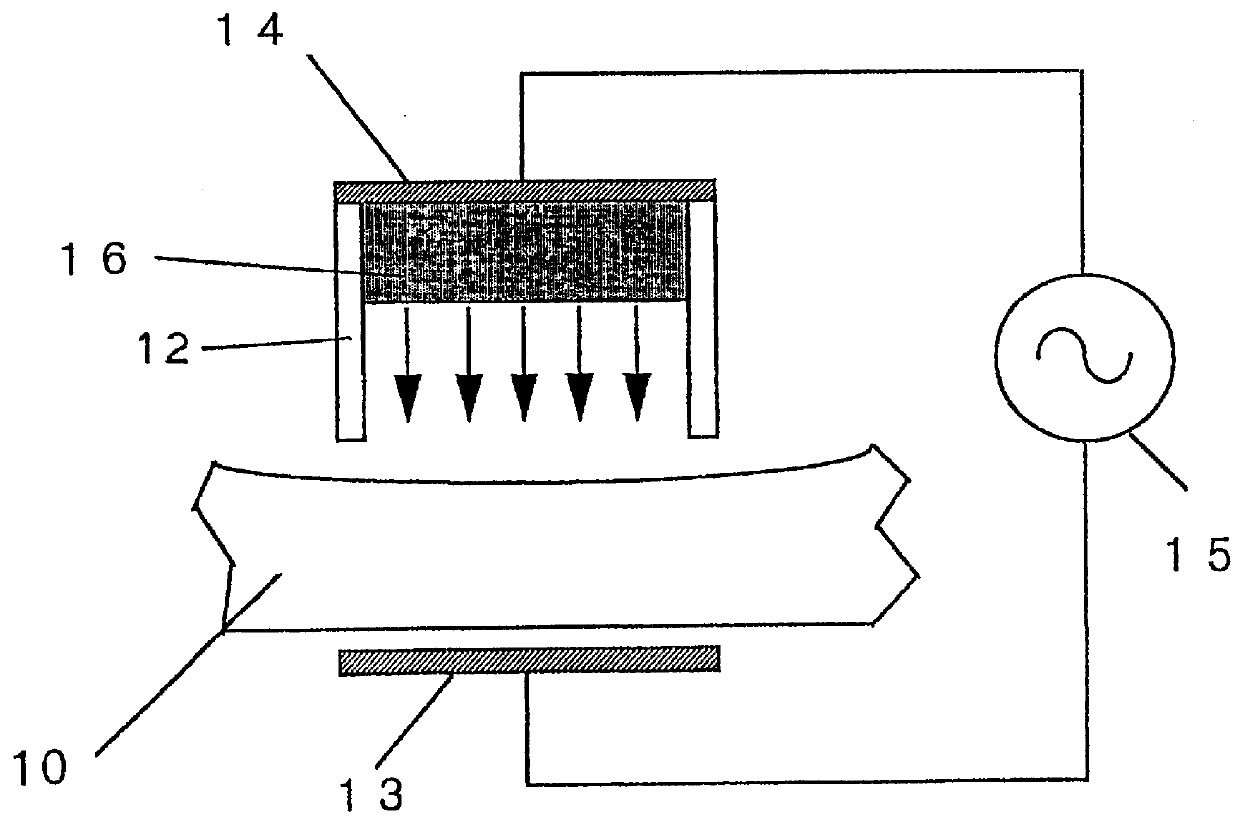

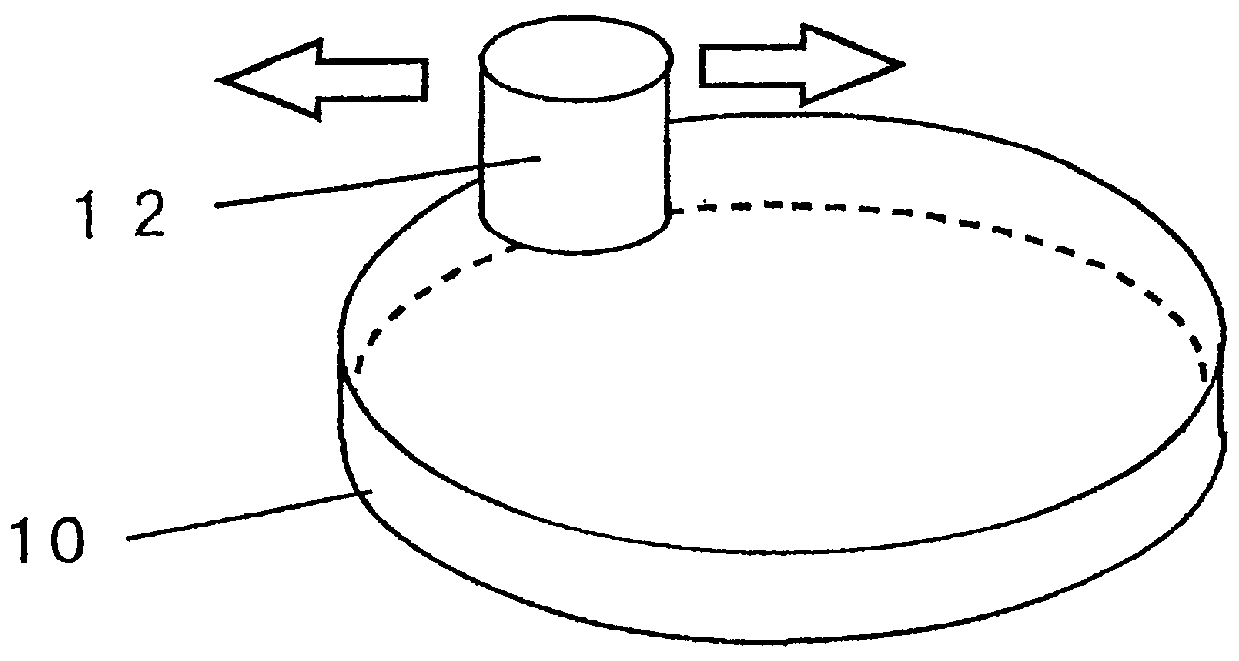

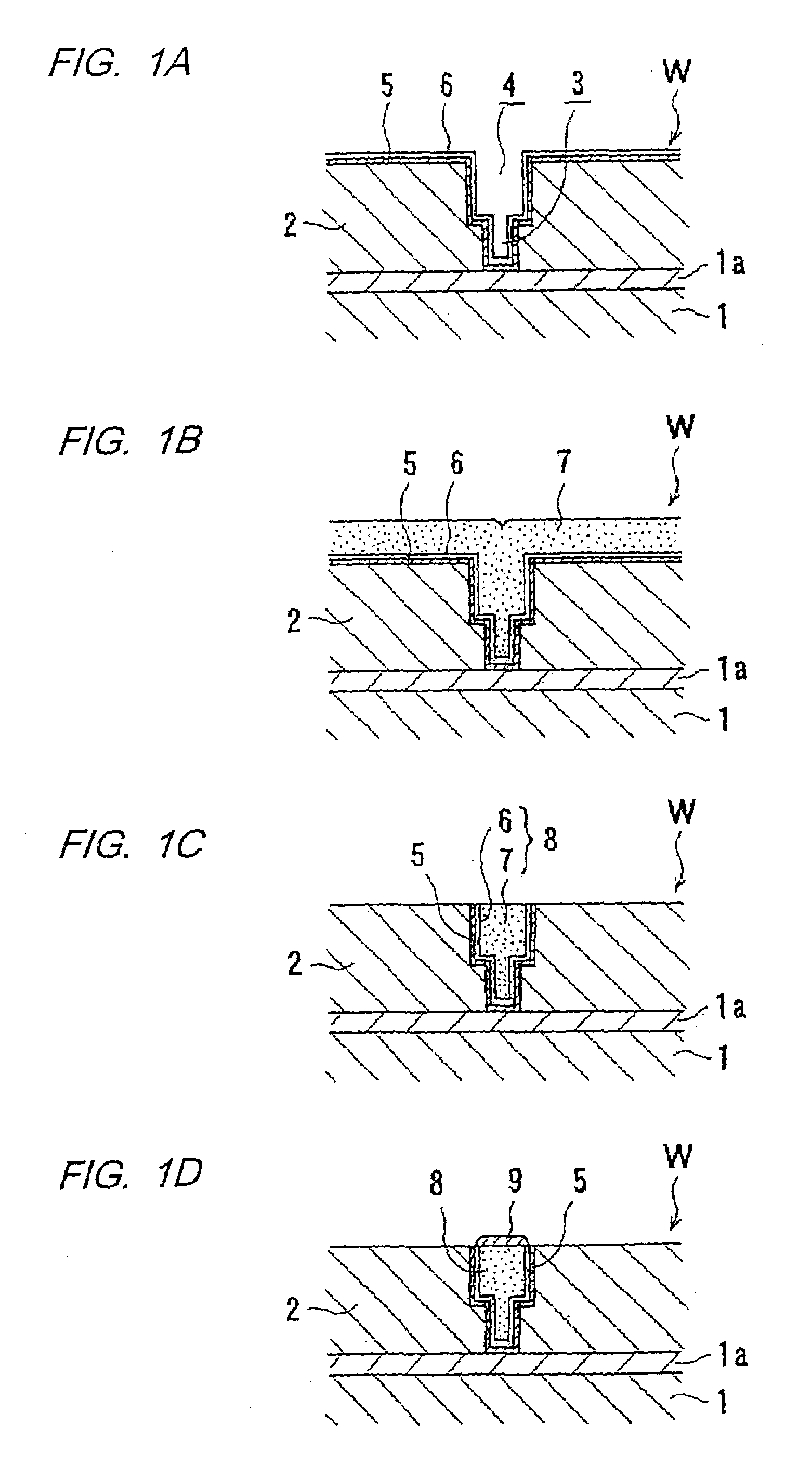

Plasma processing method and plasma processing apparatus

InactiveUS20070077737A1High densityLow electron temperatureElectric discharge tubesSemiconductor/solid-state device manufacturingCarbon filmEngineering

A microwave is radiated into a processing chamber (1) from a planar antenna member of an antenna (7) through a dielectric plate (6). With this, a C5F8 gas supplied into the processing chamber (1) from a gas supply member (3) is changed (activated) into a plasma so as to form a fluorine-containing carbon film of a certain thickness on a semiconductor wafer (W). Each time a film forming process of forming a film on one wafer is carried out, a cleaning process and a pre-coating process are carried out. In the cleaning process, the inside of the processing chamber is cleaned with a plasma of an oxygen gas and a hydrogen gas. In the pre-coating process, the C5F8 gas is changed into a plasma, and a pre-coat film of fluorine-containing carbon thinner than the fluorine-containing carbon film formed in the film forming process is formed.

Owner:TOKYO ELECTRON LTD

Adhesive layer for polyester film

InactiveUS6461802B1Improve dimensional stabilityImprove stabilityFilm/foil adhesivesSynthetic resin layered productsChemistryPolyester

Owner:AGFA GEVAERT AG

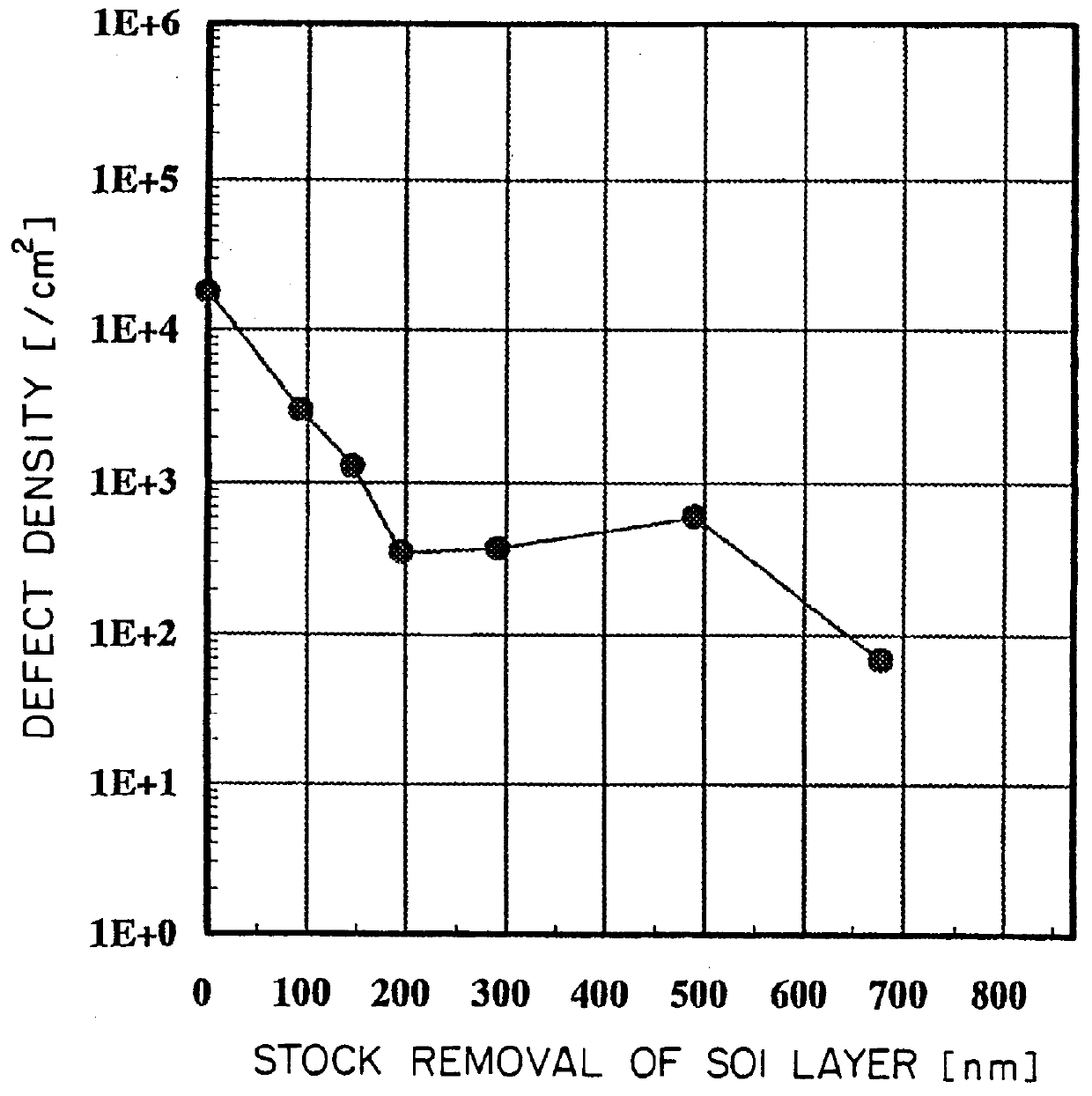

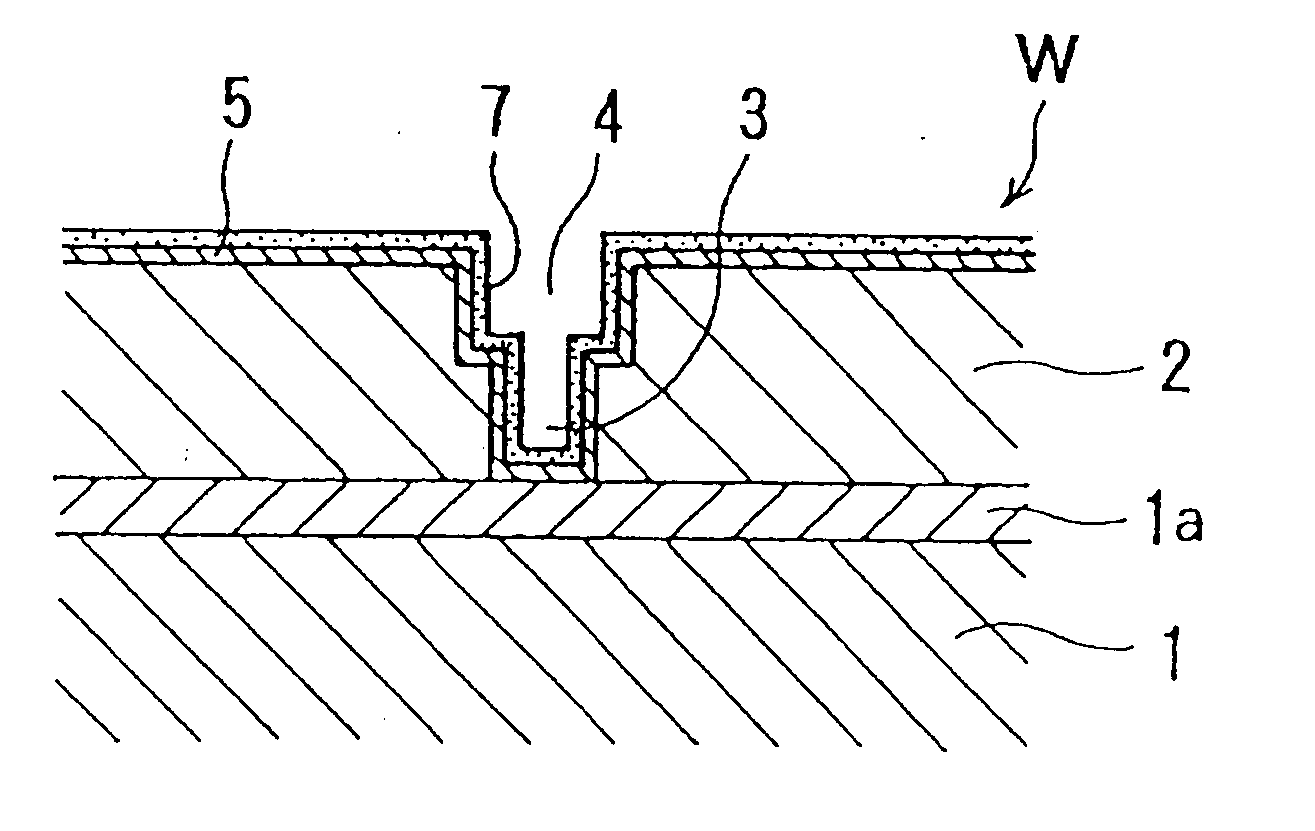

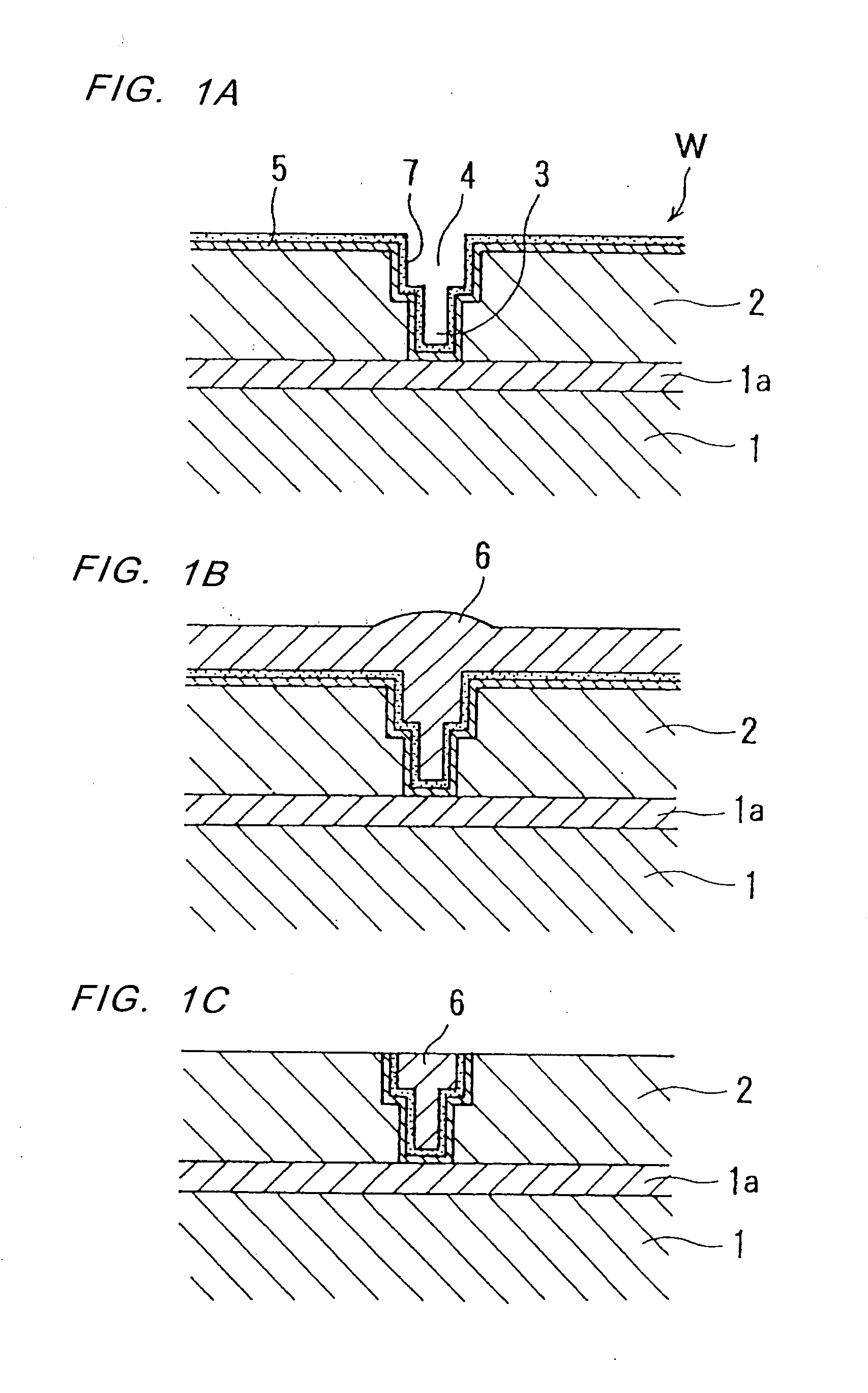

Method of fabricating an SOI wafer and SOI wafer fabricated thereby

InactiveUS6140210AReliably removedUniform thicknessSolid-state devicesSemiconductor/solid-state device manufacturingNoble gasEtching

In a method of fabricating an SOI wafer, an oxide film is formed on the surface of at least one of two silicon wafers; hydrogen ions or rare gas ions are implanted into the upper surface of one of the two silicon wafers in order to form a fine bubble layer (enclosed layer) within the wafer; the ion-implanted silicon wafer is superposed on the other silicon wafer such that the ion-implanted surface comes into close contact with the surface of the other silicon wafer via the oxide film; heat treatment is performed in order to delaminate a portion of the ion-implanted wafer while the fine bubble layer is used as a delaminating plane, in order to form a thin film to thereby obtain an SOI wafer. In the method, a defect layer at the delaminated surface of the thus-obtained SOI wafer is removed to a depth of 200 nm or more through vapor-phase etching, and then mirror polishing is performed. Therefore, the obtained SOI wafer has an extremely low level of defects and a high thickness uniformity.

Owner:SHIN-ETSU HANDOTAI CO LTD

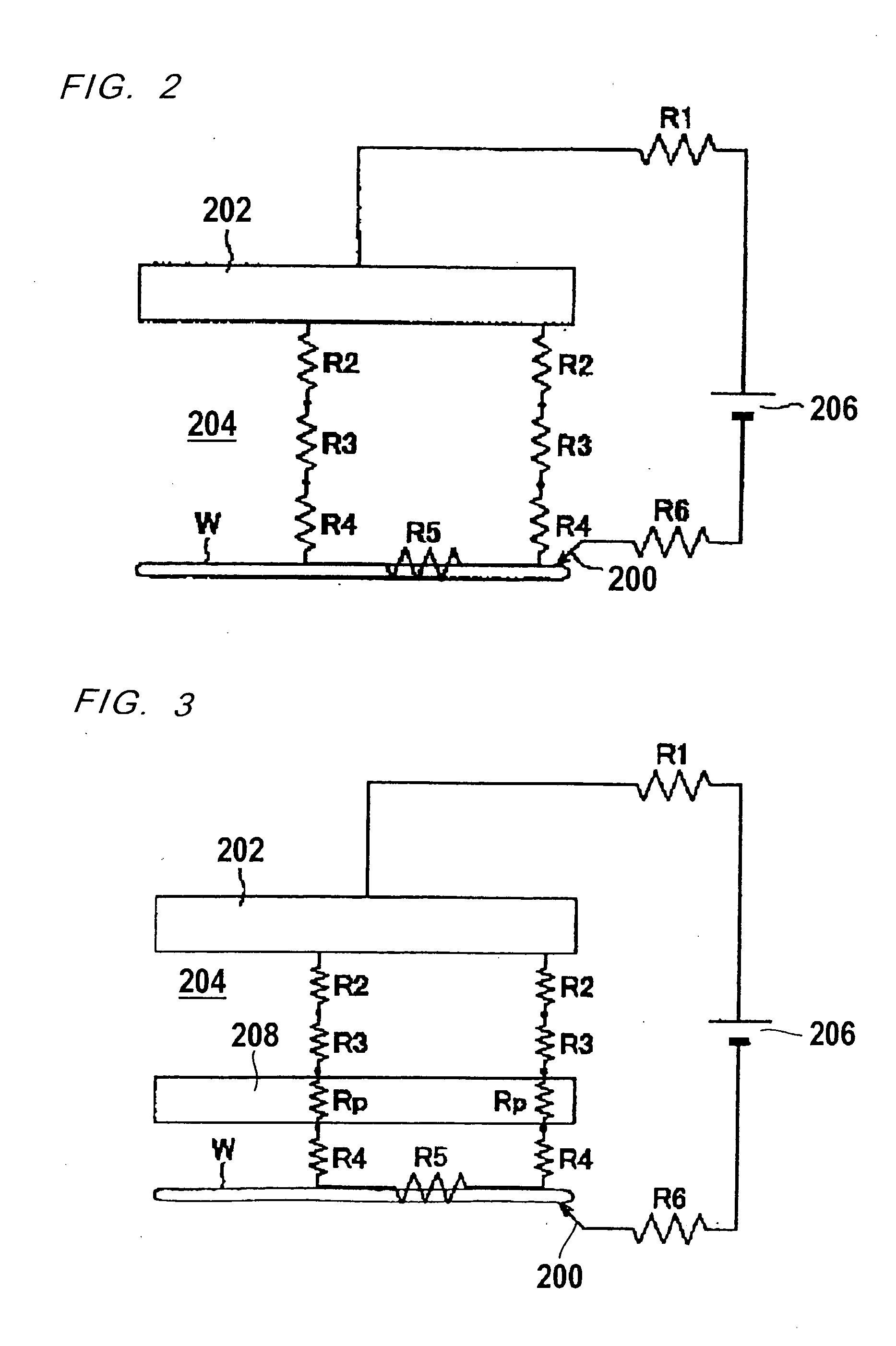

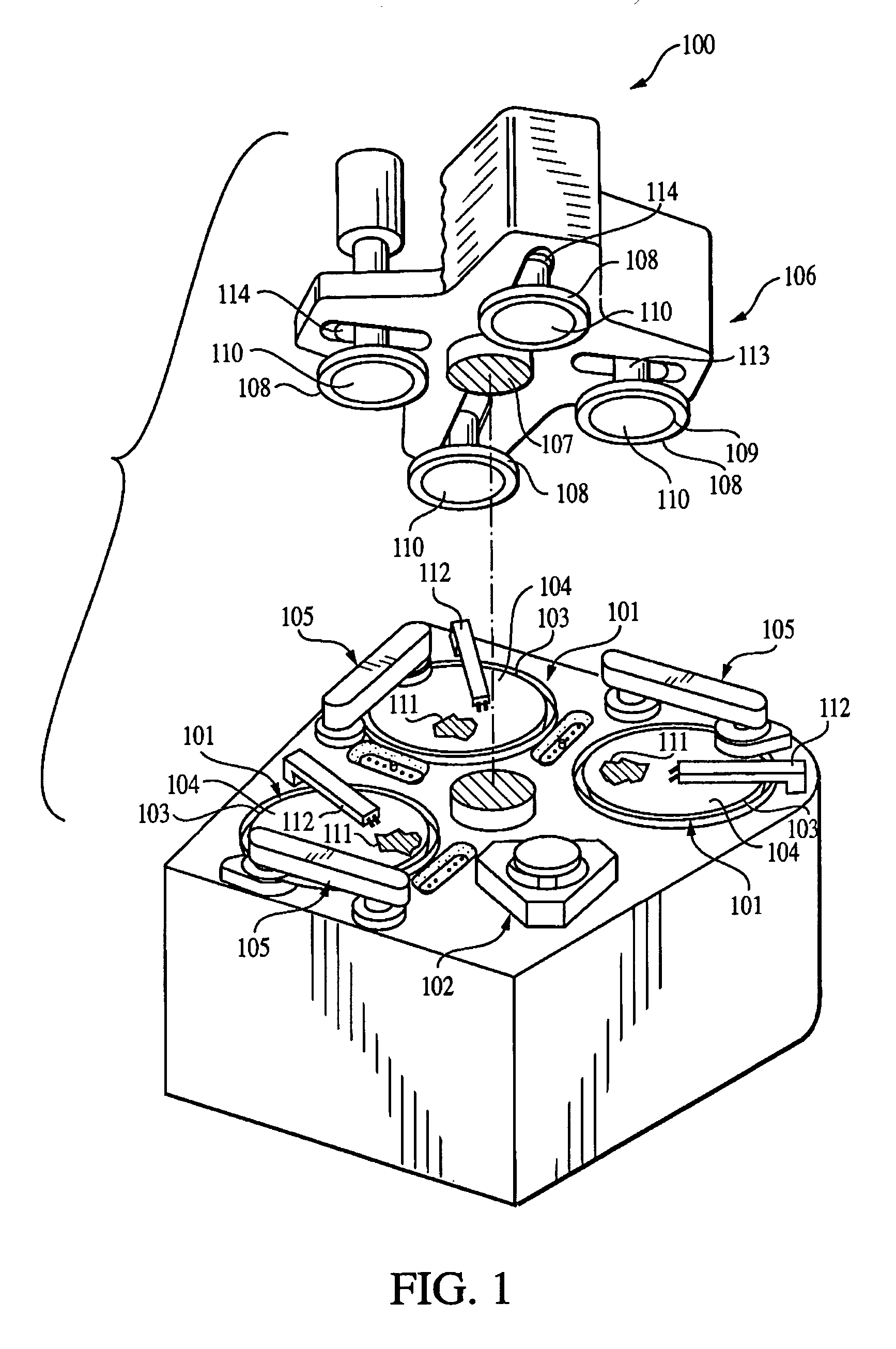

Plating apparatus and plating method

InactiveUS20070238265A1Improve thickness uniformityImprove in-plane uniformityLiquid surface applicatorsElectrolysis componentsHigh resistanceEngineering

A plating apparatus can form a plated film having a more uniform thickness over an entire surface of a substrate and can securely fill interconnect recesses with the metal without forming voids in the embedded metal even when the substrate has a high sheet resistance in the surface. The plating apparatus includes a substrate holder for holding a substrate, a cathode portion including a cathode for contact with the substrate held by the substrate holder to feed electricity to the substrate, and an anode, partly or wholly having a high resistance, disposed opposite a surface of the substrate held by the substrate holder, wherein plating of the surface of the substrate is carried out while filling between the anode and the substrate held by the substrate holder with a plating solution.

Owner:EBARA CORP

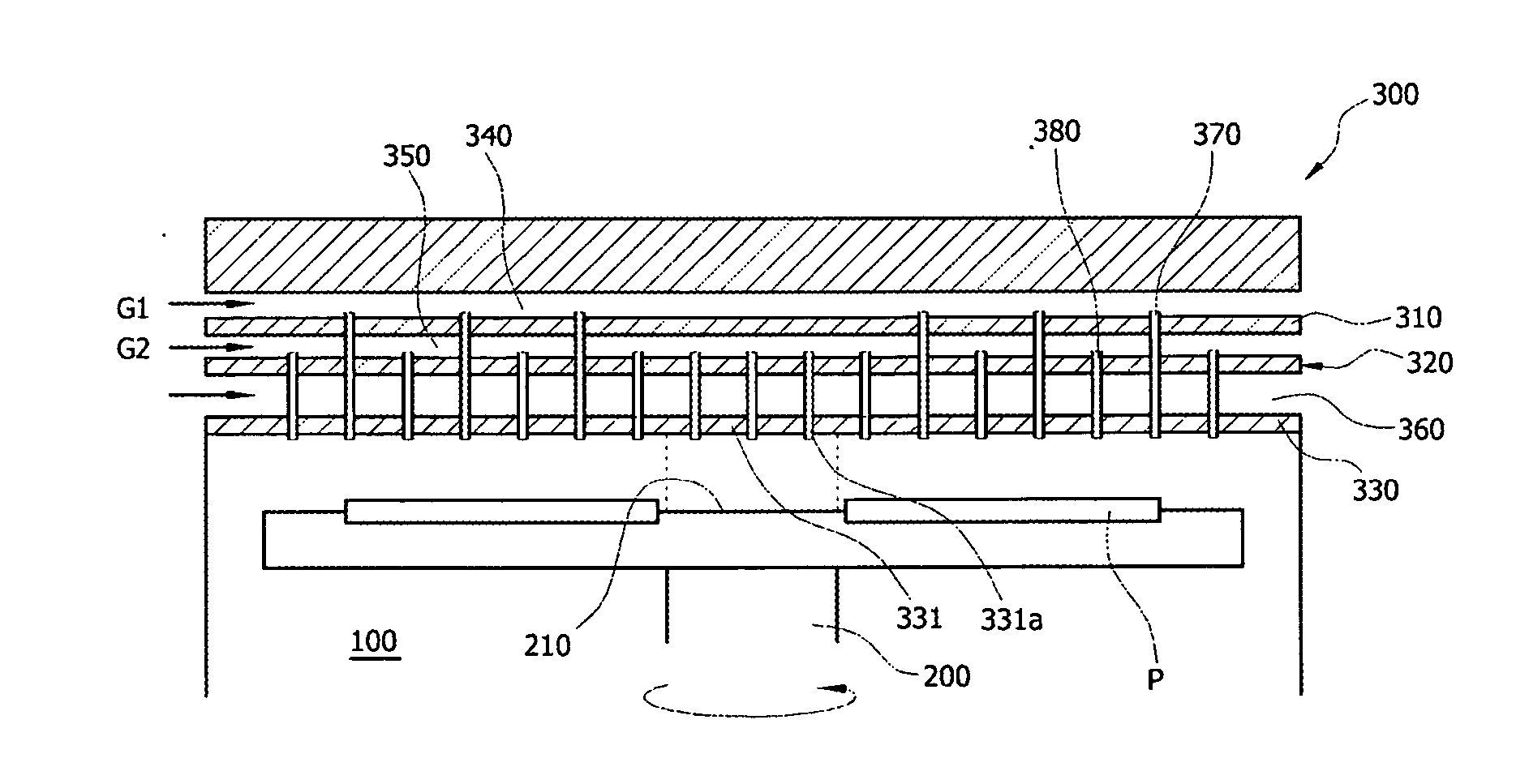

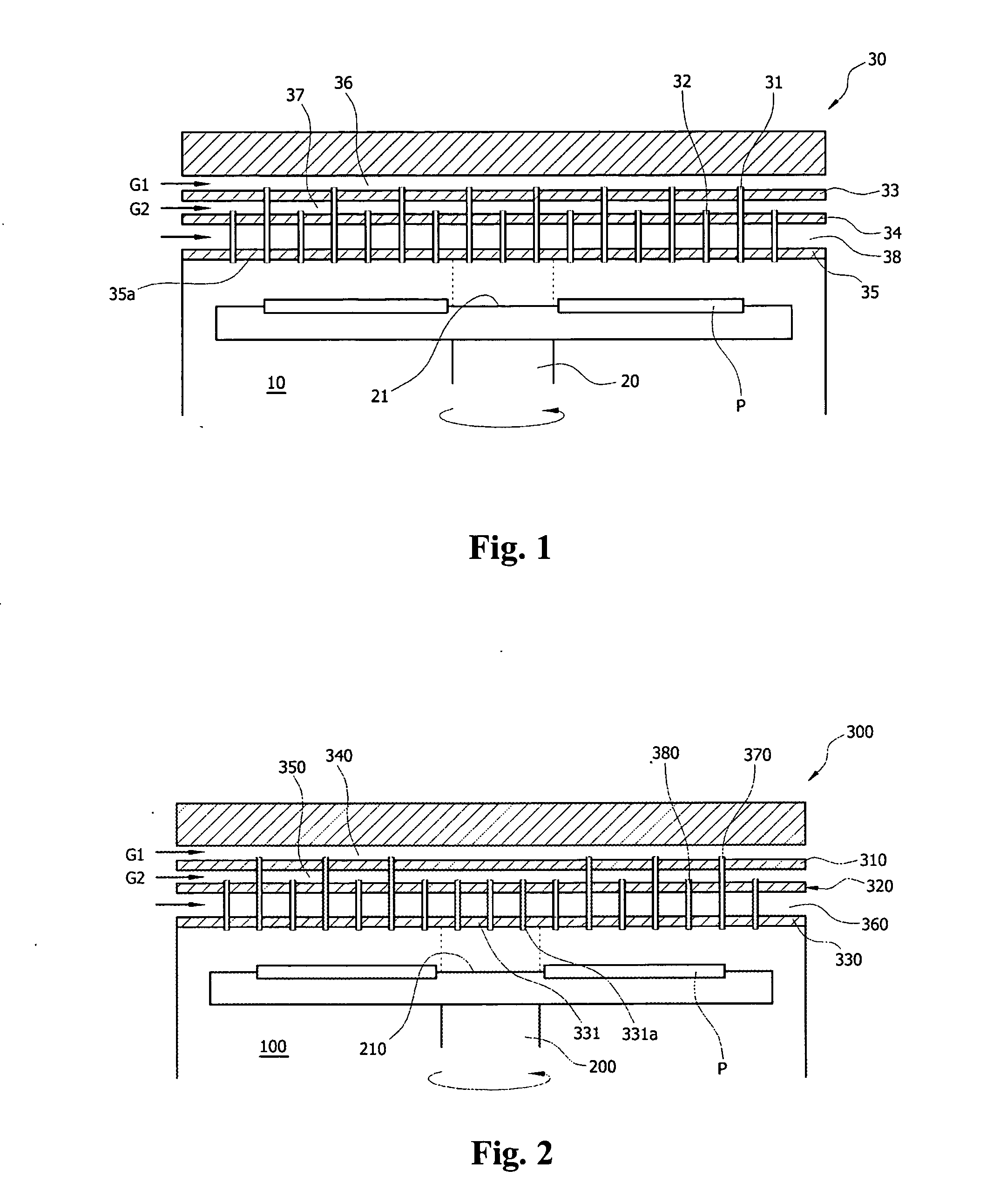

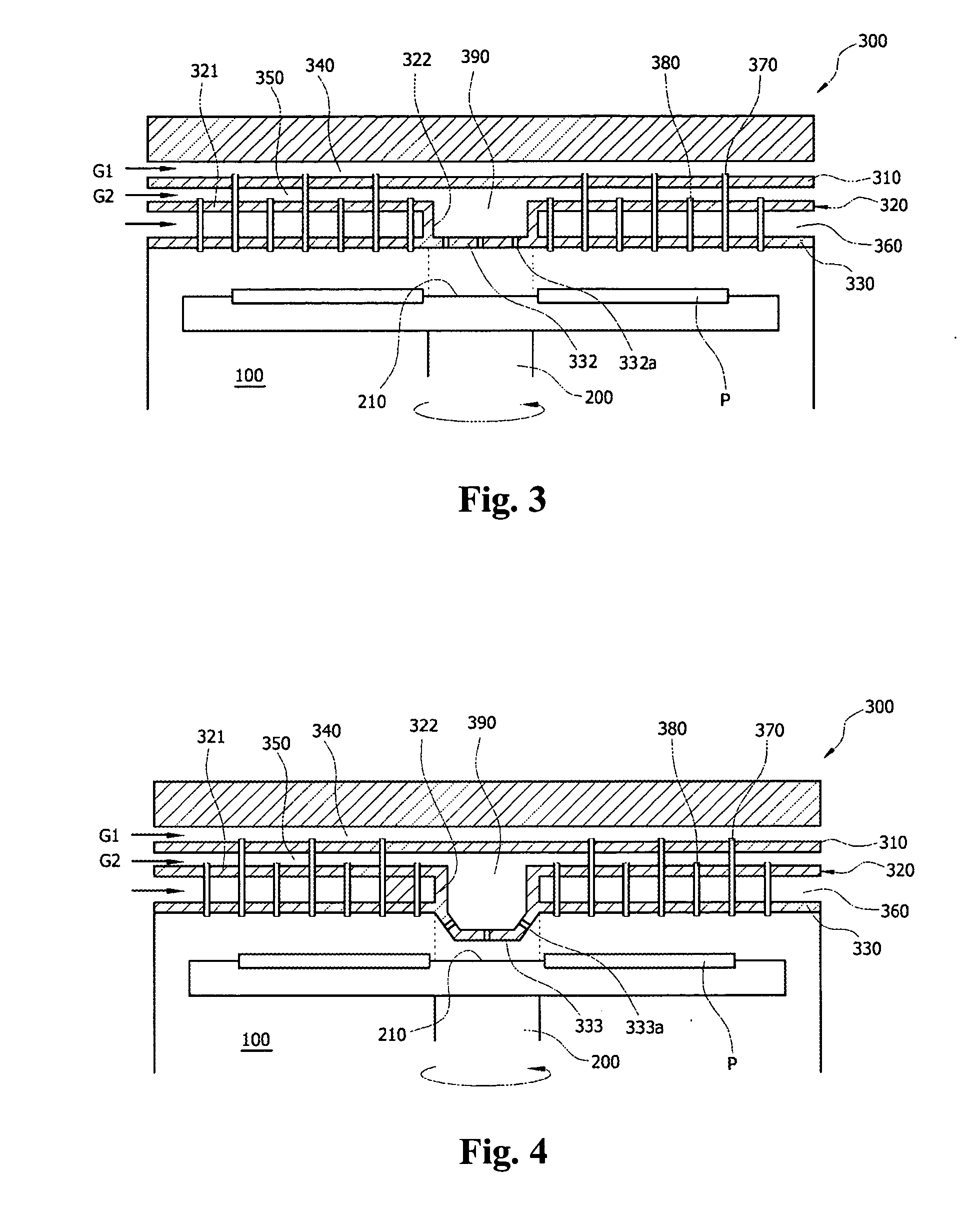

Chemical vapor deposition unit

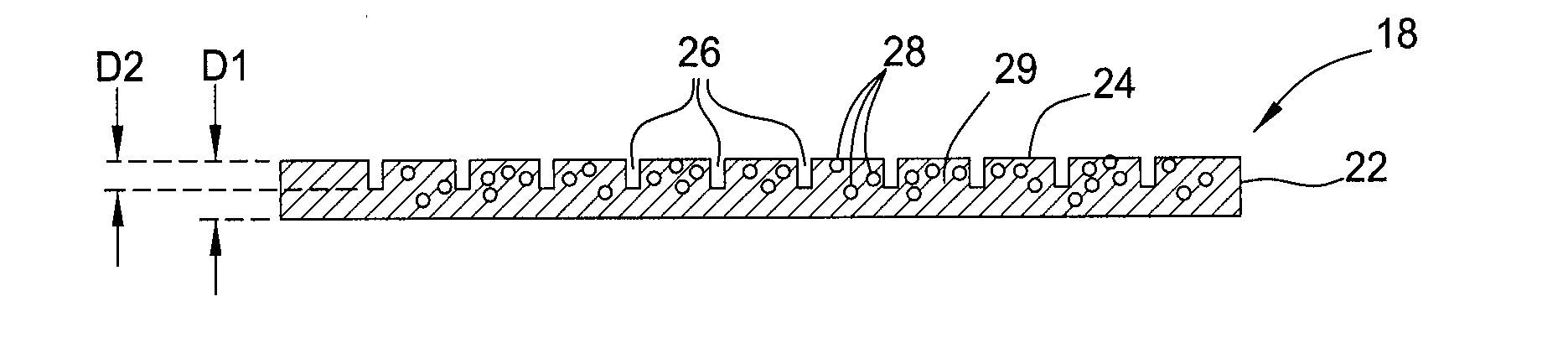

InactiveUS20050092248A1Improve uniformityImprove thickness uniformitySemiconductor/solid-state device manufacturingFrom chemically reactive gasesSusceptorGas phase

A chemical vapor deposition unit is invented for forming a uniform thin film over the entire surface of a substrat by the vapor-deposition. The chemical vapor deposition unit comprises a reaction chamber isolated from the outside and kept under vacuum, a susceptor, on which at least one substrate is placed, installed in the reaction chamber such that it can rotate, and an injector, including independently formed first and second gas passages, and first and second gas injecting pipes that communicate with the respective gas passages and respective outlets, for injecting respective first and second gases onto the susceptor, the injector injecting the different gases independently. The injector further comprises a gas injecting part for communicating with the second gas passage so that only the second gas, which is a non-reactive carrier gas, is injected in a central region of the susceptor.

Owner:SYSNEX

Electrostatographic imaging member

InactiveUS6303254B1Improve thickness uniformityReduces undesirable dirtElectrographic process apparatusMicrometerPolymer chemistry

An electrostatographic imaging member including: a flexible supporting substrate; an imaging layer having an optional adjacent ground strip layer coated on one side of the substrate; and an anti-curl backing layer coated on the other side of the substrate which layer is comprised of a film forming polymer binder, an optional adhesion promoting polymer, and a dispersion of polytetrafluoroethylene particles which dispersion has particles with a narrow diameter particle size distribution of from about 0.19 micrometer to about 0.21 micrometer, and an average diameter particle size of about 0.20 micrometer. The optional ground strip layer can include the same dispersion of polytetrafluoroethylene particles as the anti-curl backing layer.

Owner:XEROX CORP

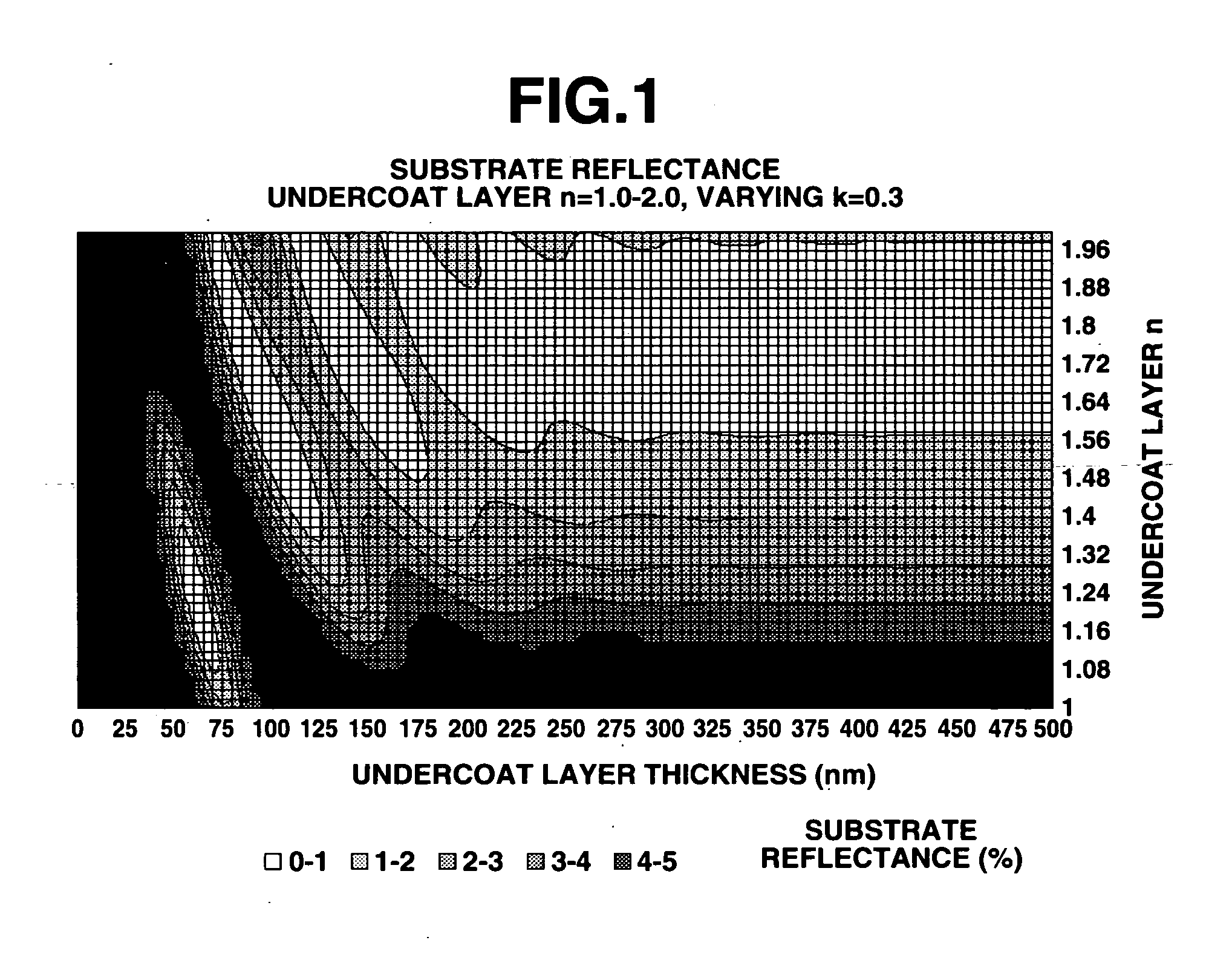

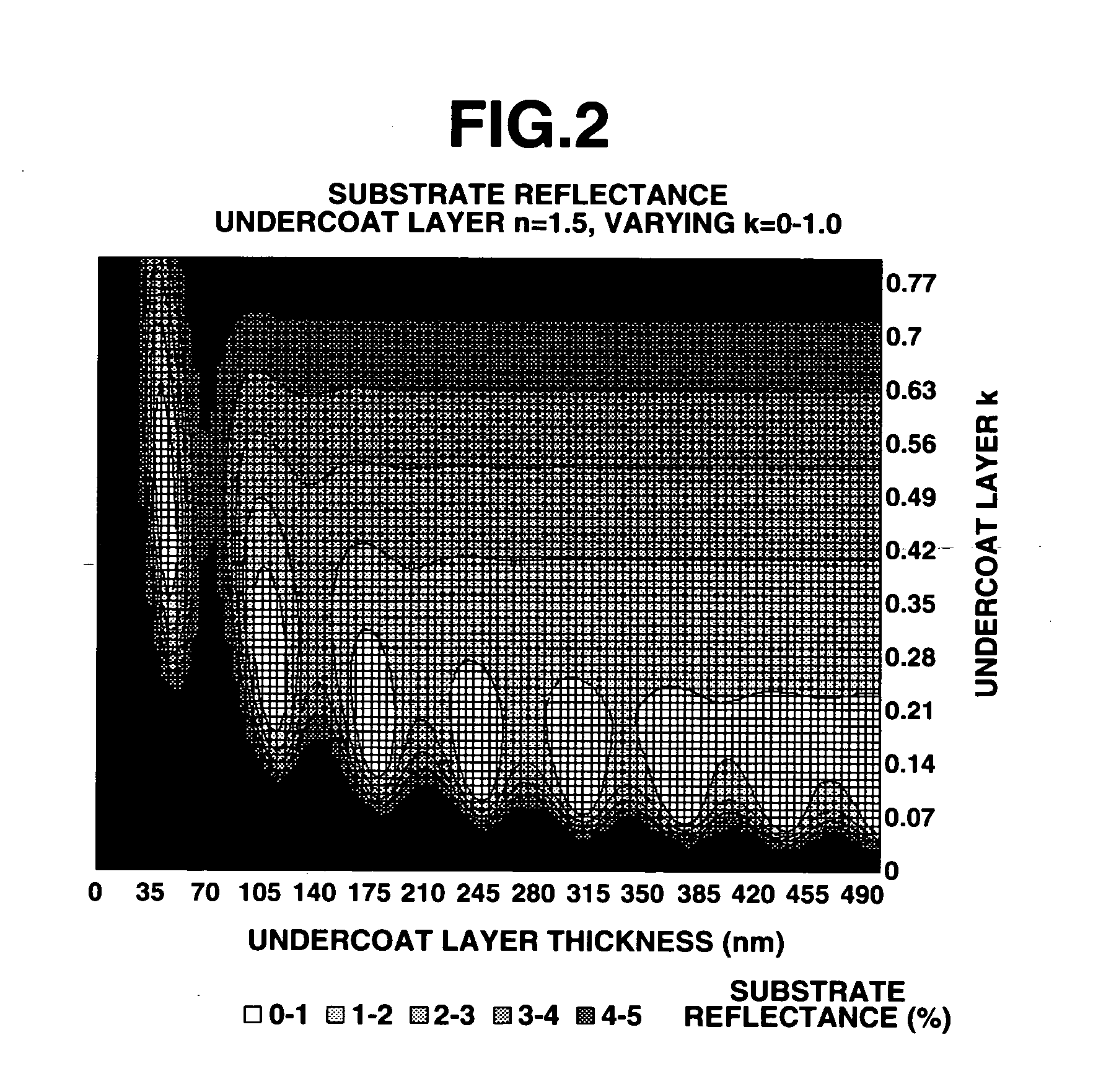

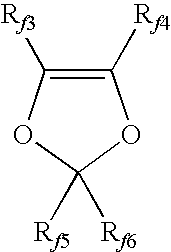

Resist undercoat-forming material and patterning process

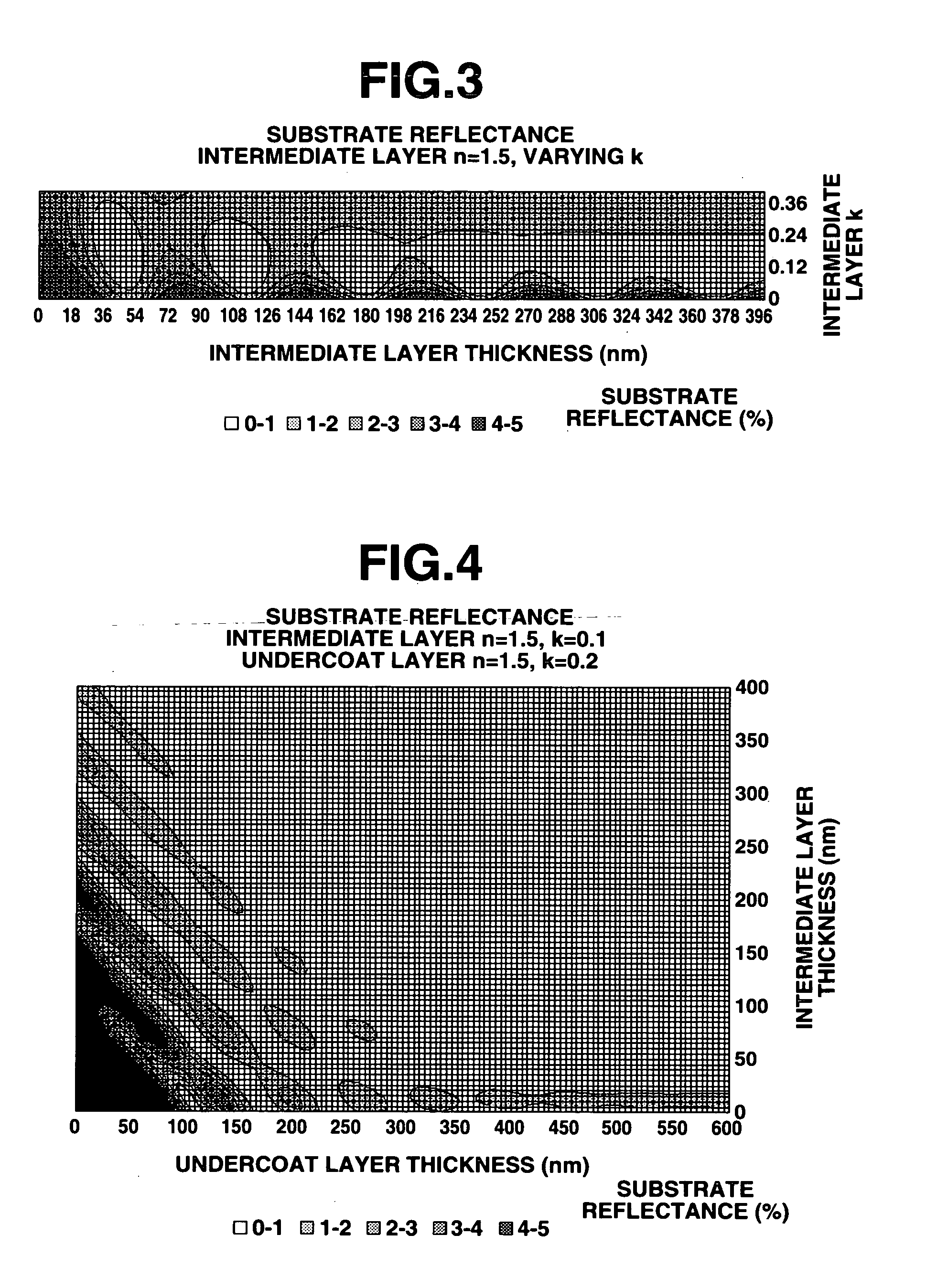

ActiveUS20070122740A1High transparencyExcellent etch resistancePhotosensitive materialsSemiconductor/solid-state device manufacturingResistAnti-reflective coating

In the lithographic multilayer resist process, a material comprising a copolymer of a hydroxy-containing vinylnaphthalene with hydroxy-free olefins is useful in forming a resist undercoat. The undercoat-forming material has a high transparency and optimum values of n and k so that it functions as an antireflective coating during short-wavelength exposure, and has etching resistance during substrate processing by etching.

Owner:SHIN ETSU CHEM IND CO LTD

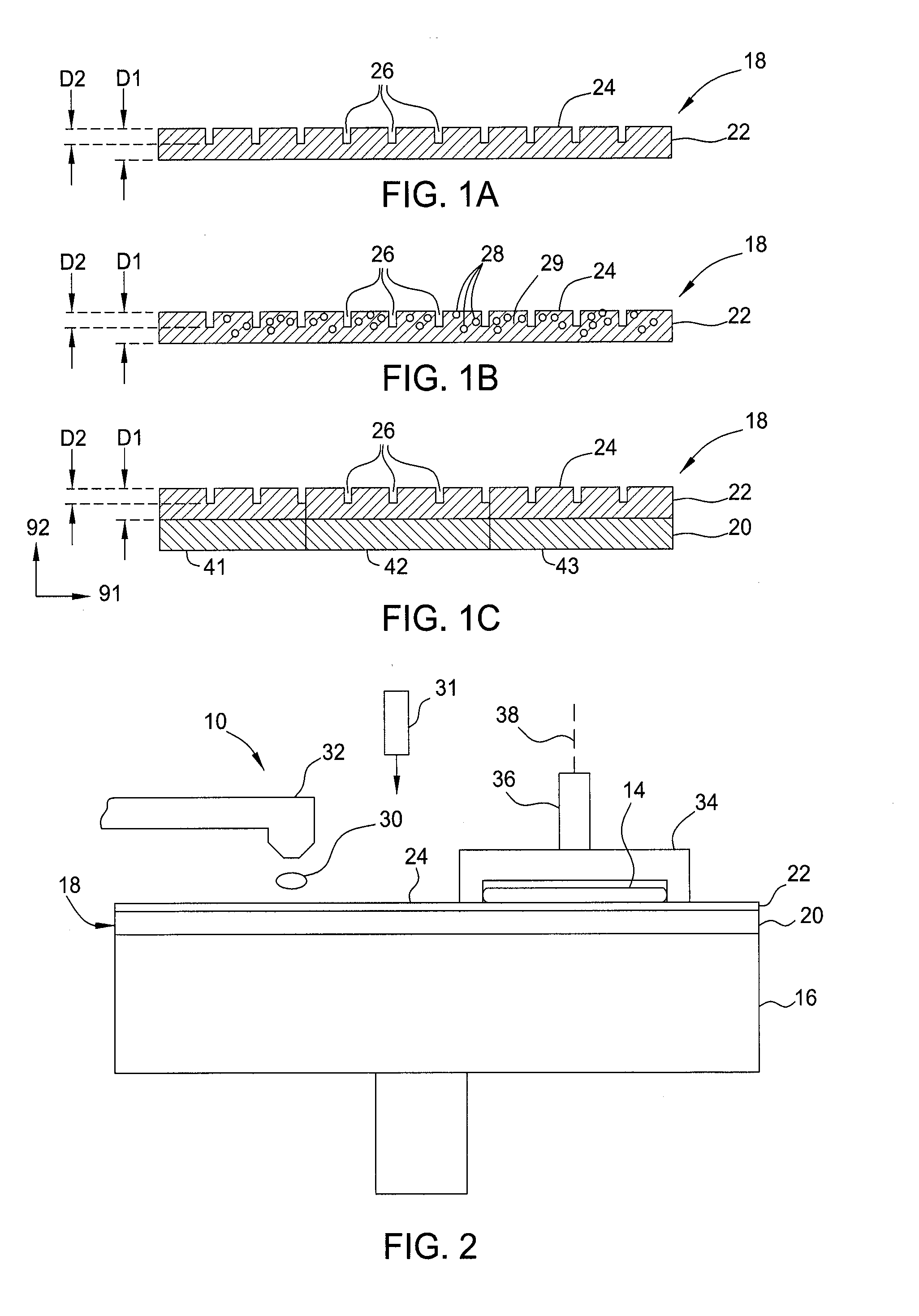

Gas ring and method of processing substrates

InactiveUS20070087533A1Improve thickness uniformityReduce turbulenceGaseous chemical processesLiquid-gas reaction of thin-film typeSusceptorProcess engineering

A process gas to a reactor volume of a semiconductor processing reactor is provided through gas injector ports of a gas ring. The process gas flows horizontally from the gas injector ports across a principal surface of a rotating susceptor to exhaust ports of the gas ring. The spent process gas is removed from the reactor volume through the exhaust ports.

Owner:MOORE EPITAXIAL

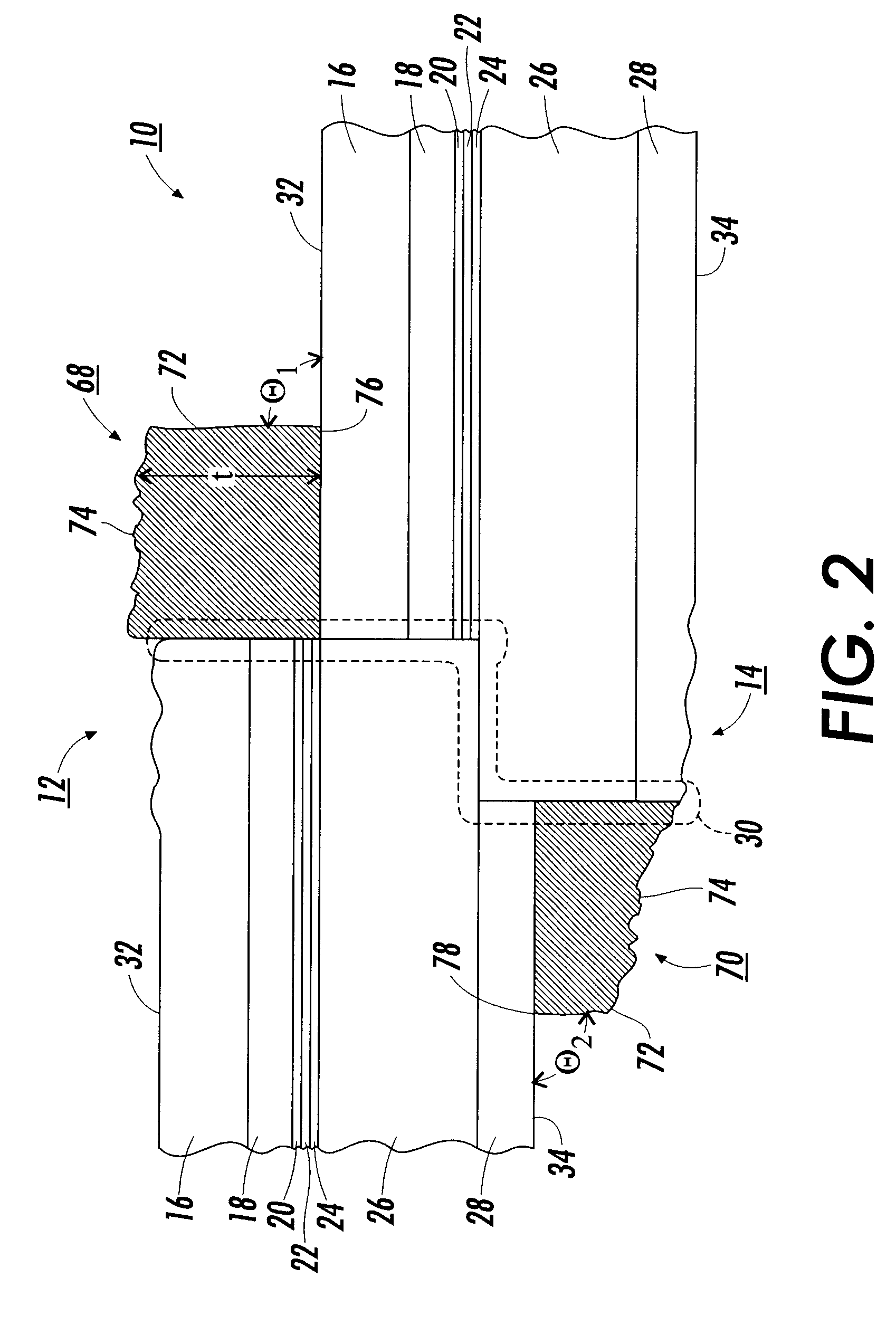

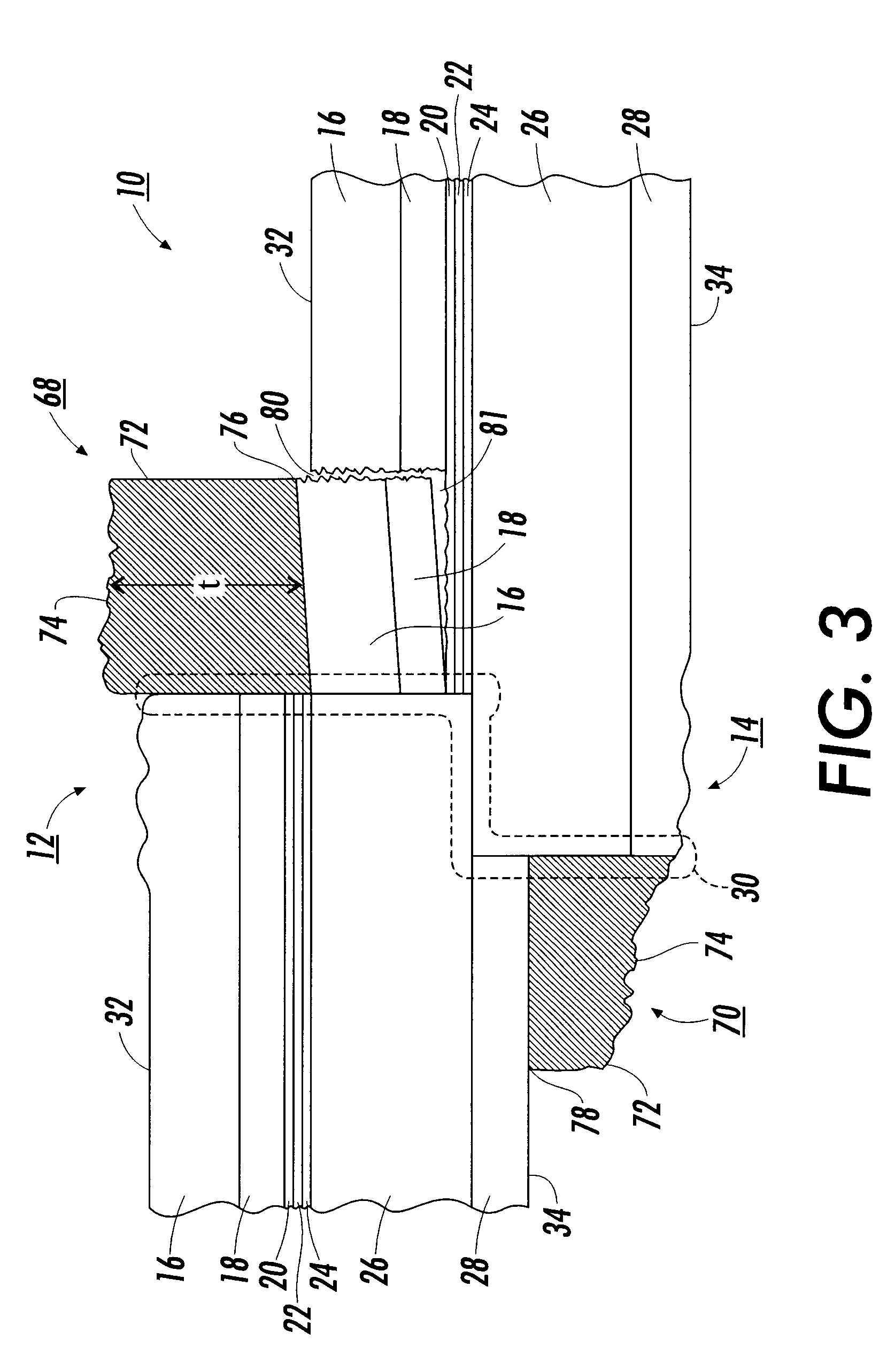

Extrusion die with supply groove transfer

InactiveUS20040022886A1High viscosityCooler) materialConfectioneryCeramic shaping apparatusEngineeringMechanical engineering

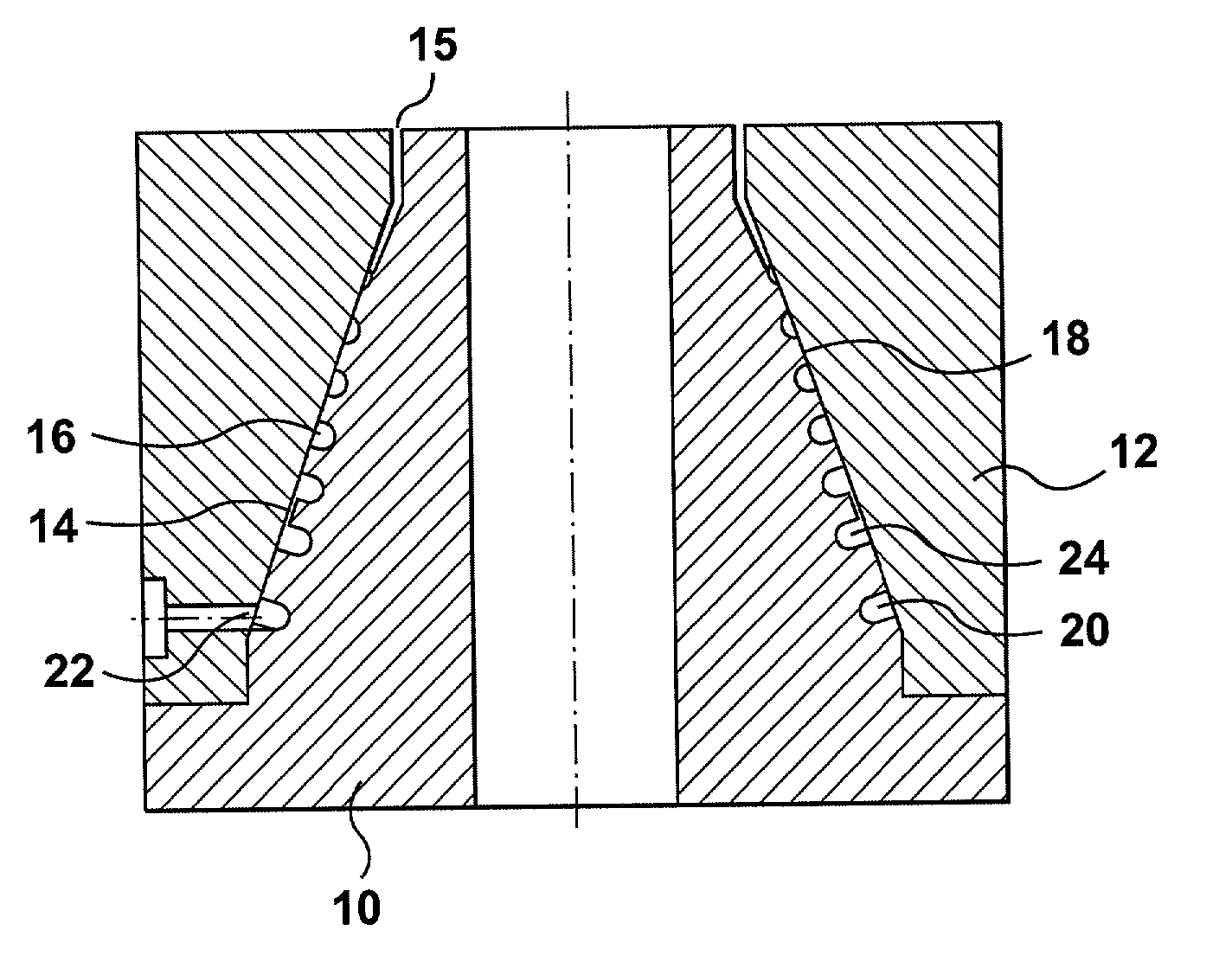

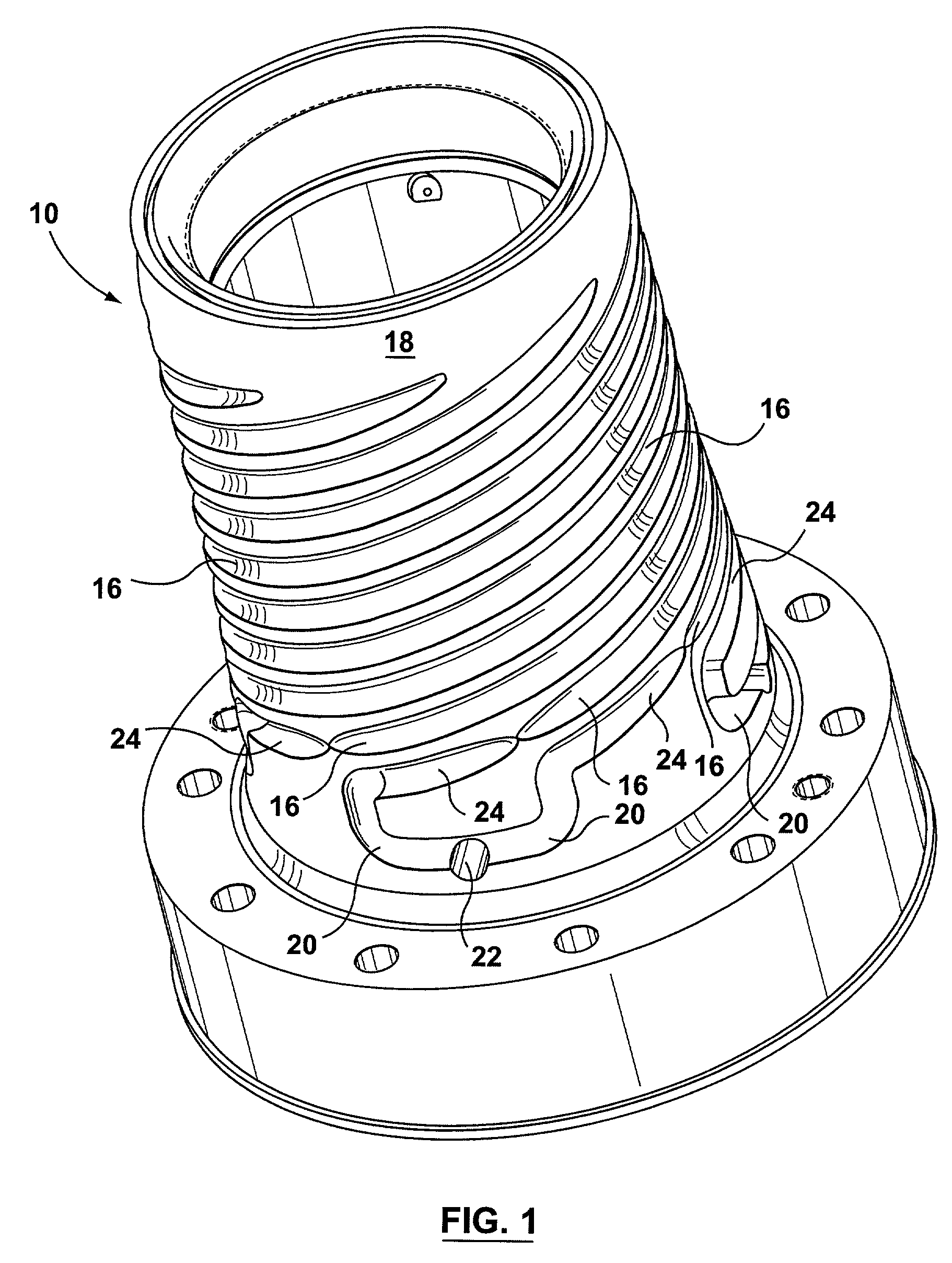

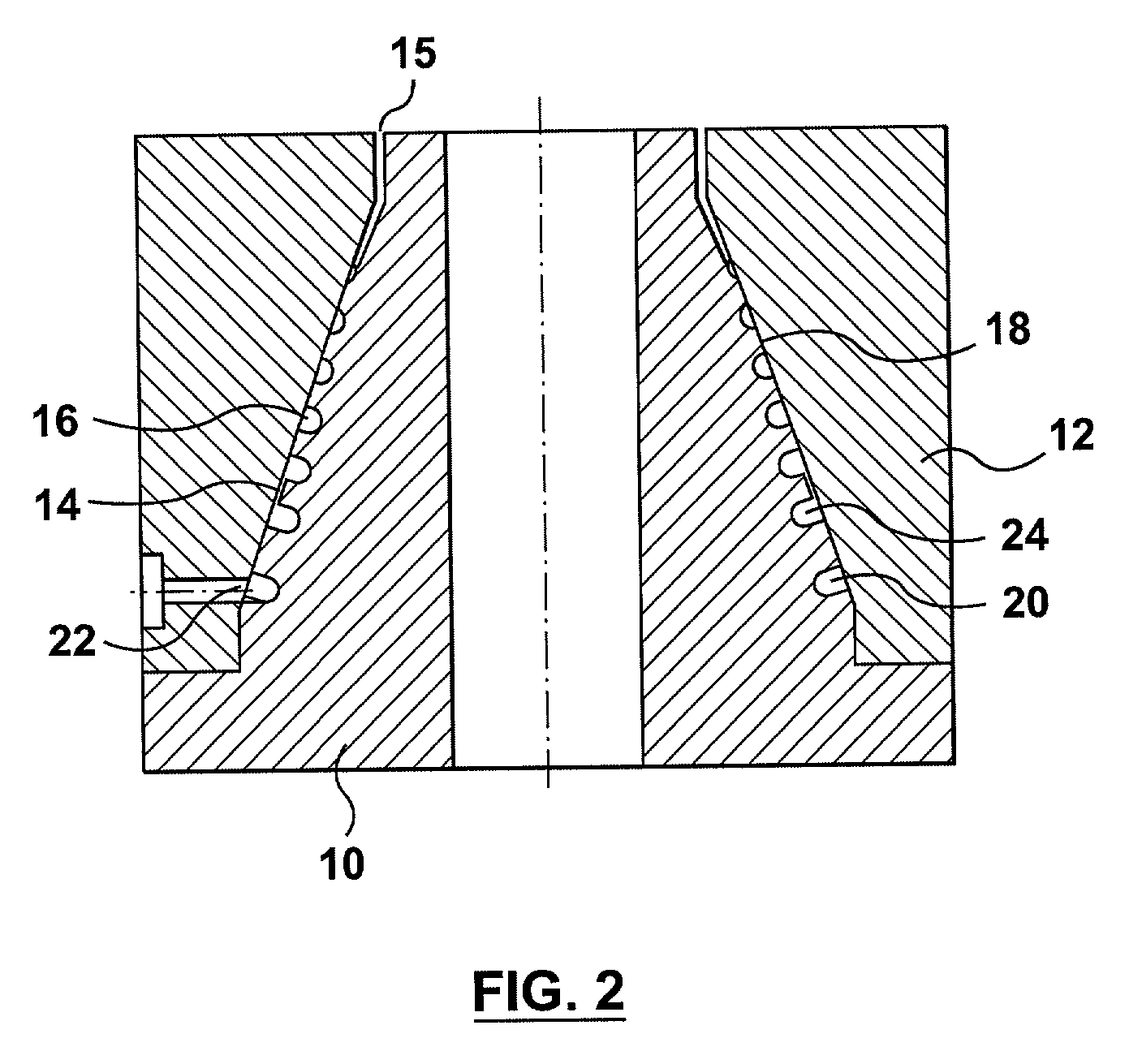

An extrusion die for extruding plastic material as a tubular film has mututally engaging first and second body members which form an annular extrusion orifice therebetween. One of the body members has main feed grooves in a surface thereof adjacent the other body member and extending in a spiral manner relative to the annular extrusion orifice, and one of the body members has supply grooves in a surface thereof adjacent the other body member for receiving plastic material from one or more extruders. Each supply groove has an end portion adjacent but spaced from an initial portion of a main feed groove, whereby plastic material from the extruder or extruders is received by the supply grooves and forced from the end portions thereof along a passage between the body members and into the initial portions of the spiral feed grooves.

Owner:MACRO ENG & TECH

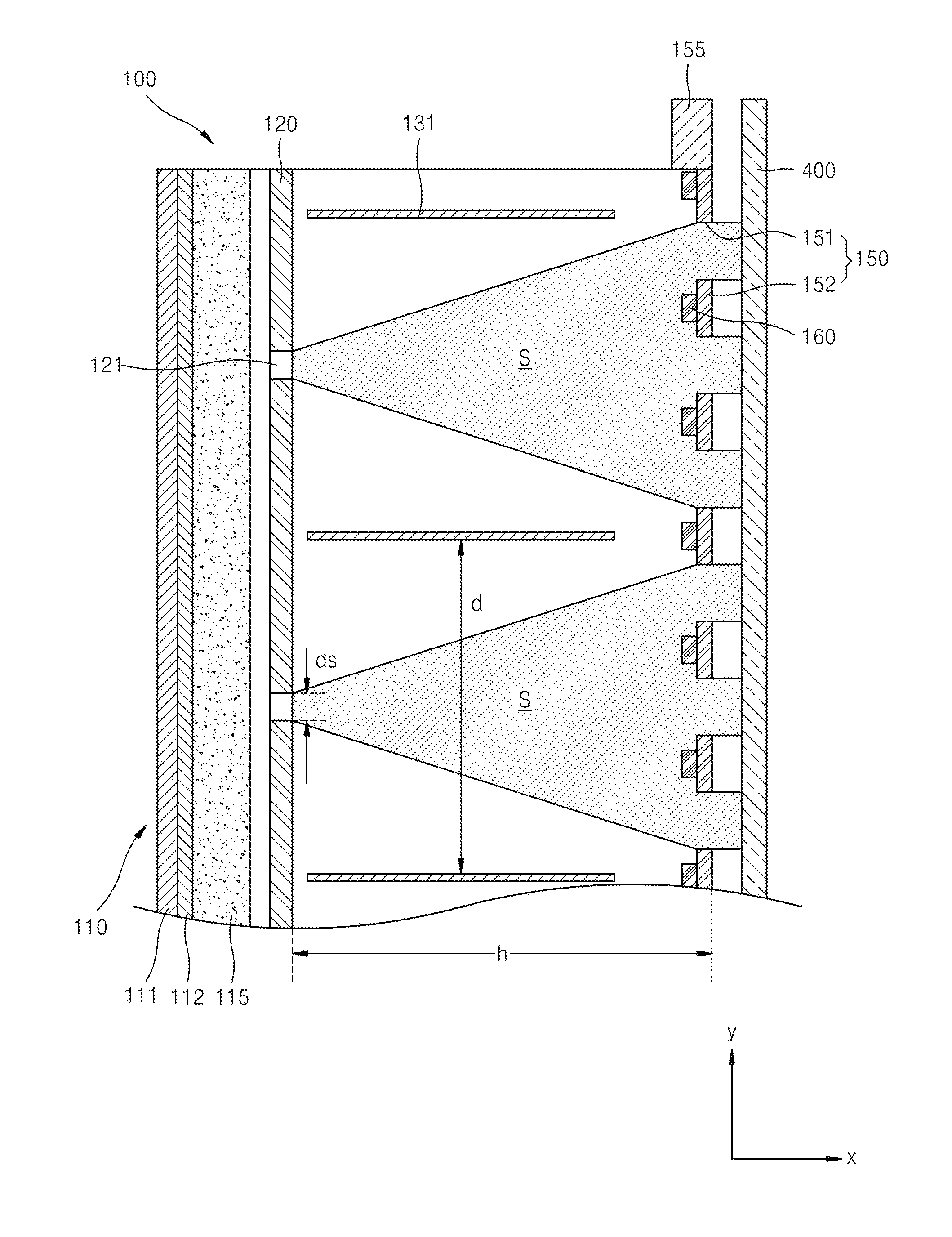

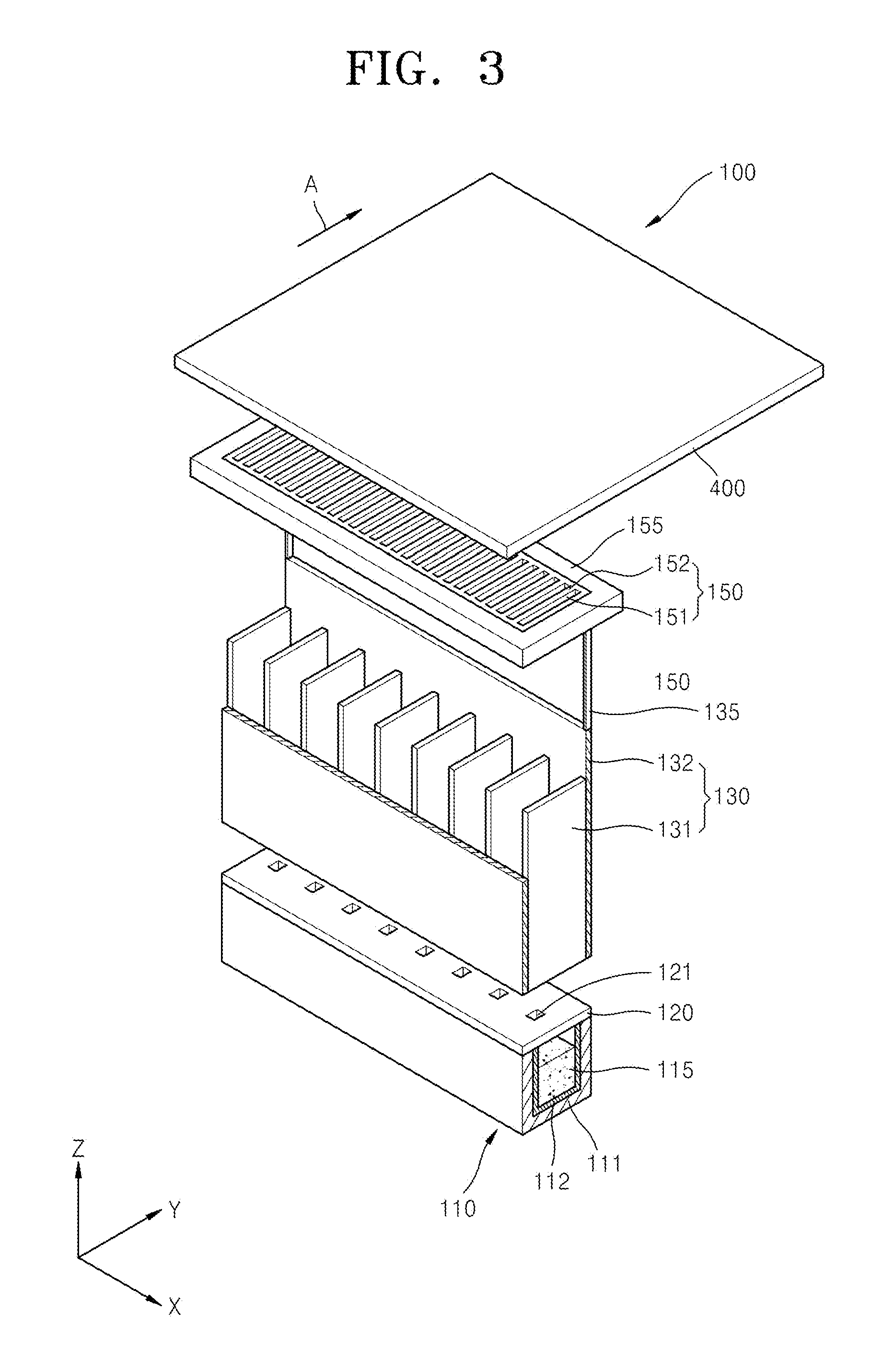

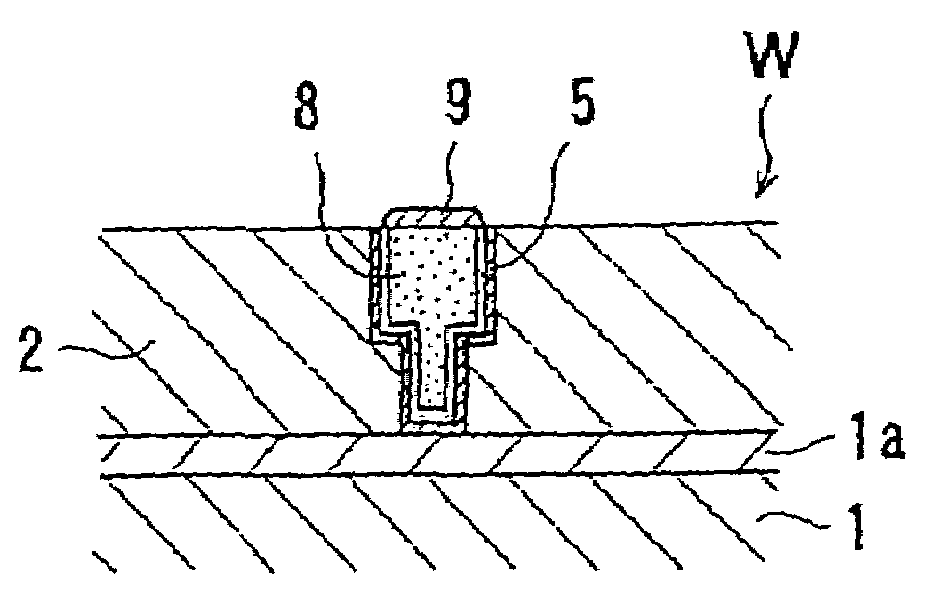

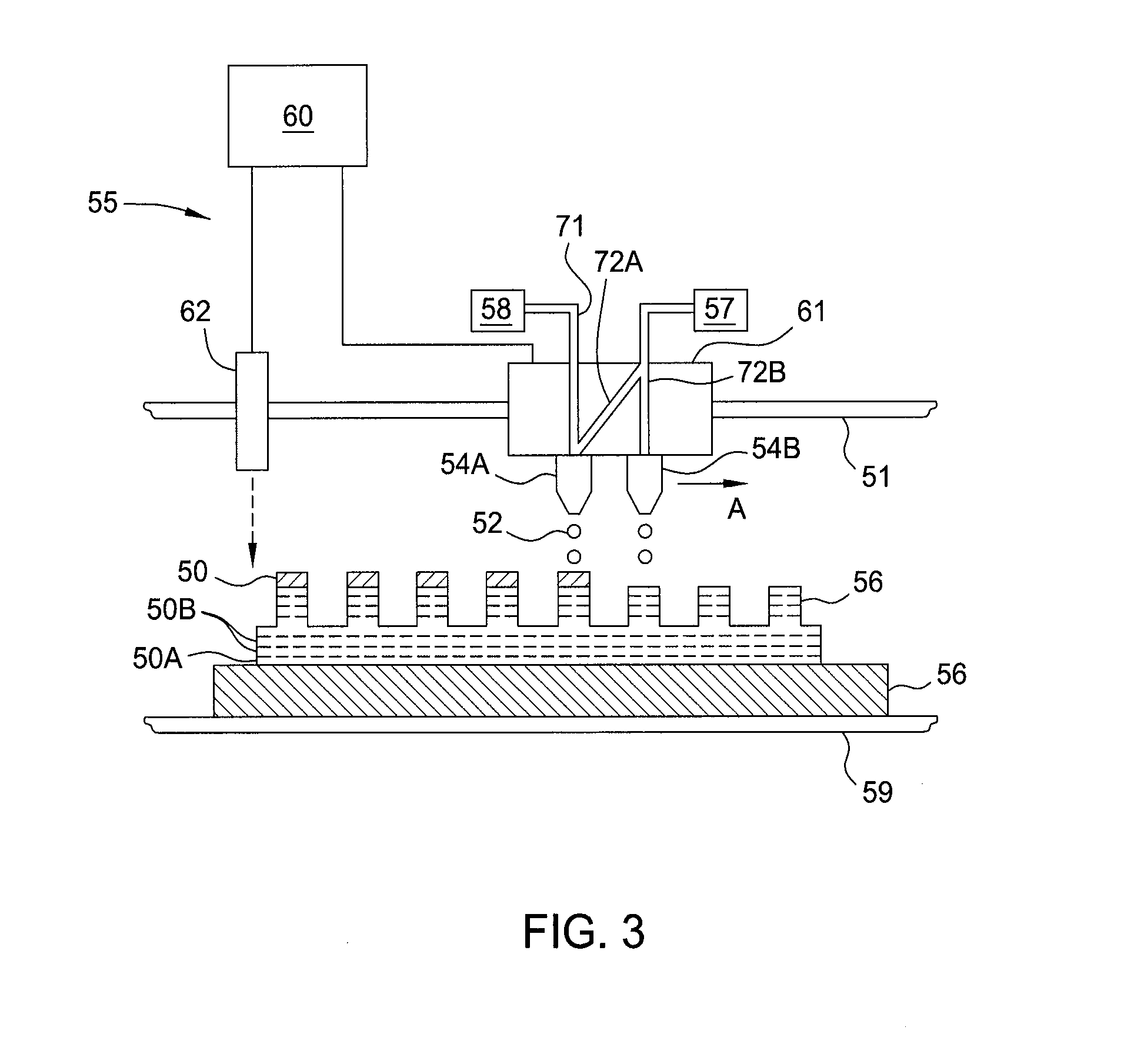

Thin film deposition apparatus and method of manufacturing organic light-emitting display device by using the same

ActiveUS20110053296A1Improve manufacturing yieldEasy to useVacuum evaporation coatingSolid-state devicesDisplay deviceThin membrane

A thin film deposition apparatus and a method of manufacturing an organic light-emitting display device by using the same, and more particularly, to a thin film deposition apparatus that can remove a deposition material deposited on a patterning slit sheet without performing an additional cleaning process, and a method of manufacturing an organic light-emitting display device by using the thin film deposition apparatus.

Owner:SAMSUNG DISPLAY CO LTD

Plating method and plating apparatus

ActiveUS7169705B2Improve in-plane uniformityGood embedding effectElectrolysis componentsSemiconductor/solid-state device manufacturingOrganic acidIn plane

A plating method is capable of depositing a plated film having excellent in-plane uniformity with respect to a thin seed layer and excellent embeddability with respect to fine damascene structures. The plating method includes: positioning an electric resistor between a conductive layer formed on at least a portion of a surface of a substrate and an anode; introducing respectively a plating solution into a space between the conductive layer and the anode on a conductive layer side, and an anode solution into a space between the conductive layer and the anode on an anode side, thereby filling the space with a plating bath composed of the plating solution and the anode solution, with the plating solution containing 25 to 75 g / L of copper ions and at least 0.4 mole / L of an organic acid or an inorganic acid, and the anode solution being of the same composition as the plating solution, or containing 0 to 75 g / L of copper ions and at most 0.6 mole / L of an organic acid or an inorganic acid; and applying a voltage between the conductive layer and the anode to plate a surface of the conductive layer.

Owner:EBARA CORP

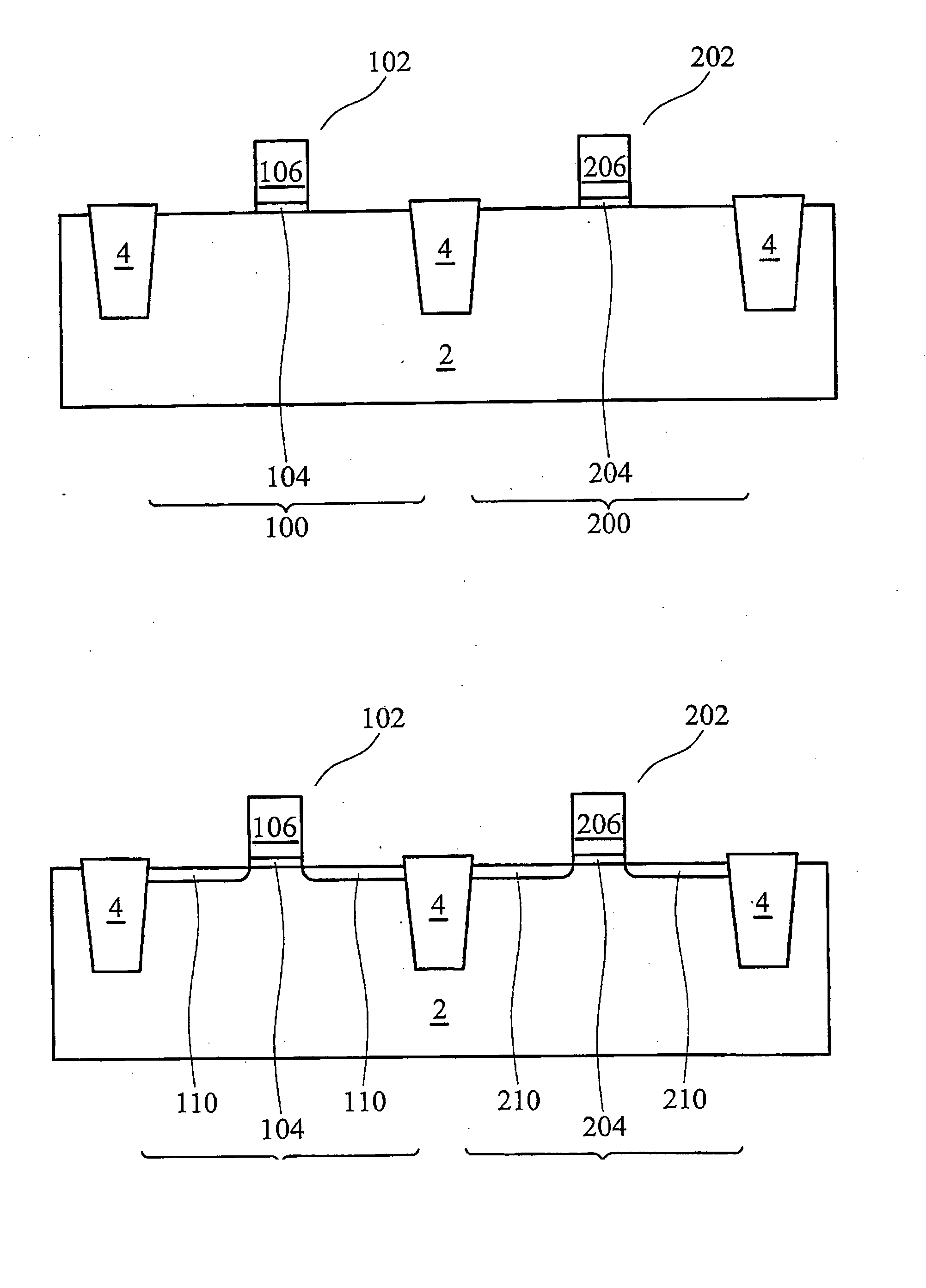

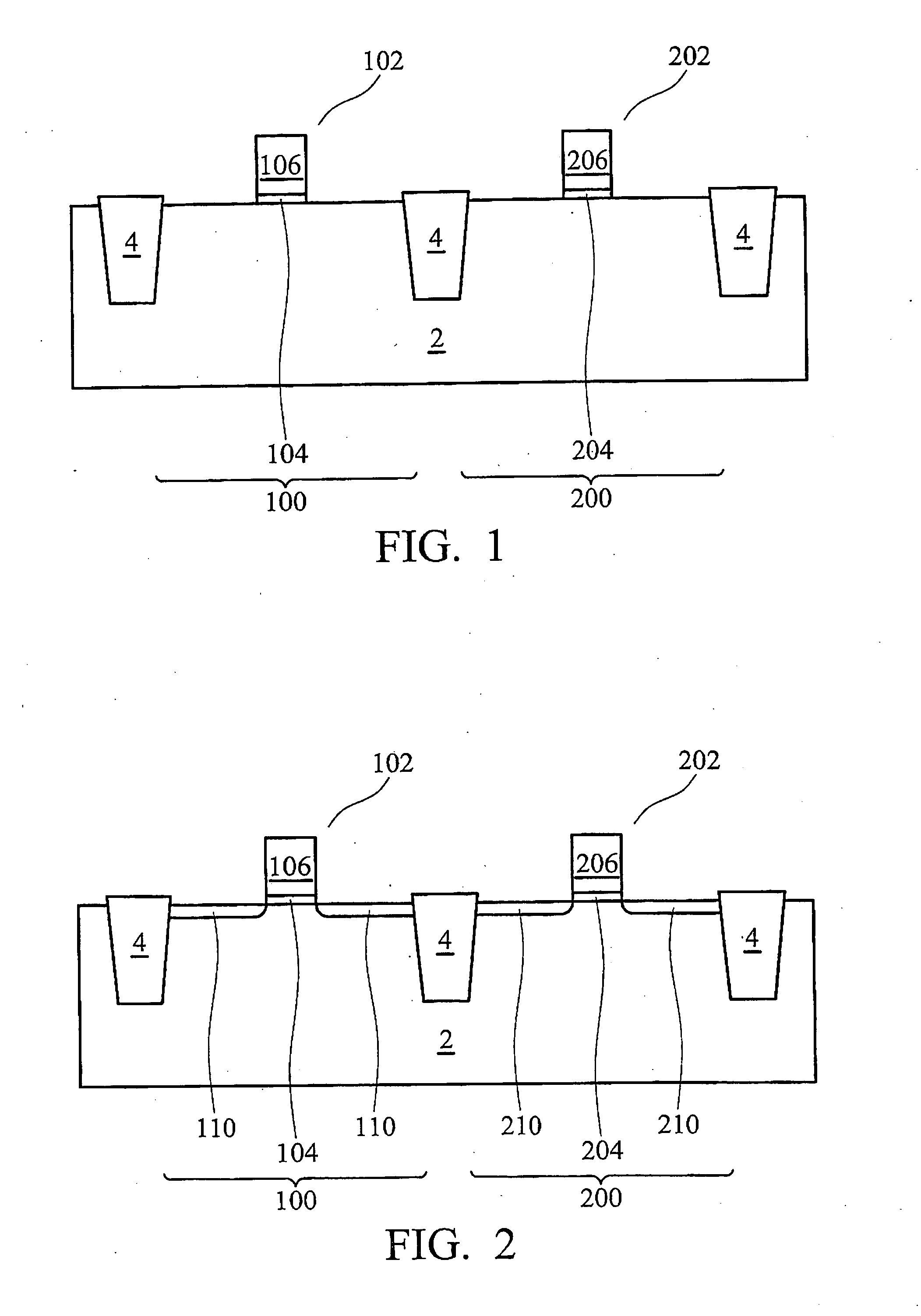

Resolving pattern-loading issues of SiGe stressor

ActiveUS20070190730A1Improve uniformityImprove thickness uniformitySemiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricEngineering

A method for improving uniformity of stressors of MOS devices is provided. The method includes forming a gate dielectric over a semiconductor substrate, forming a gate electrode on the gate dielectric, forming a spacer on respective sidewalls of the gate electrode and the gate dielectric, forming a recess in the semiconductor adjacent the spacer, and depositing SiGe in the recess to form a SiGe stressor. The method further includes etching the SiGe stressor to improve the uniformity of SiGe stressors.

Owner:TAIWAN SEMICON MFG CO LTD

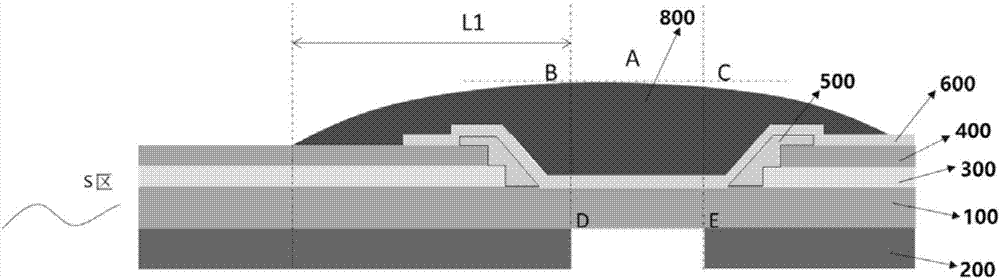

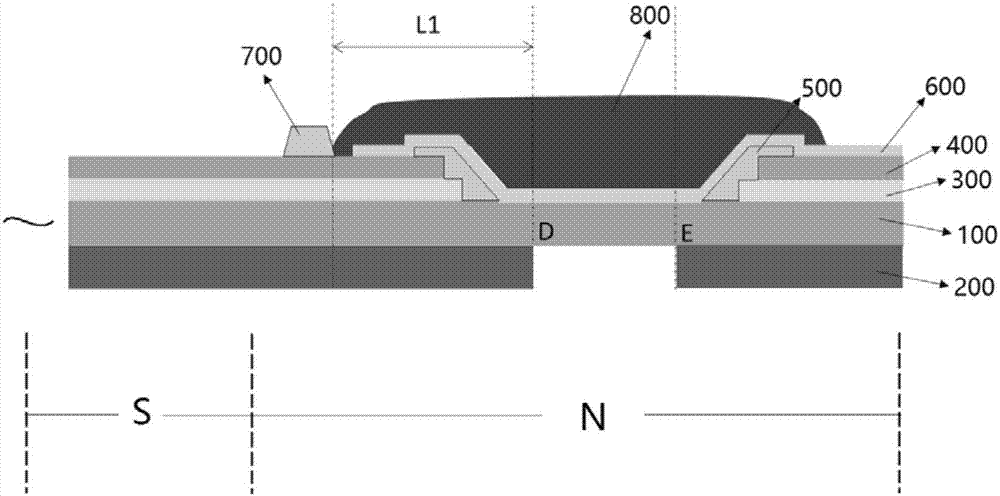

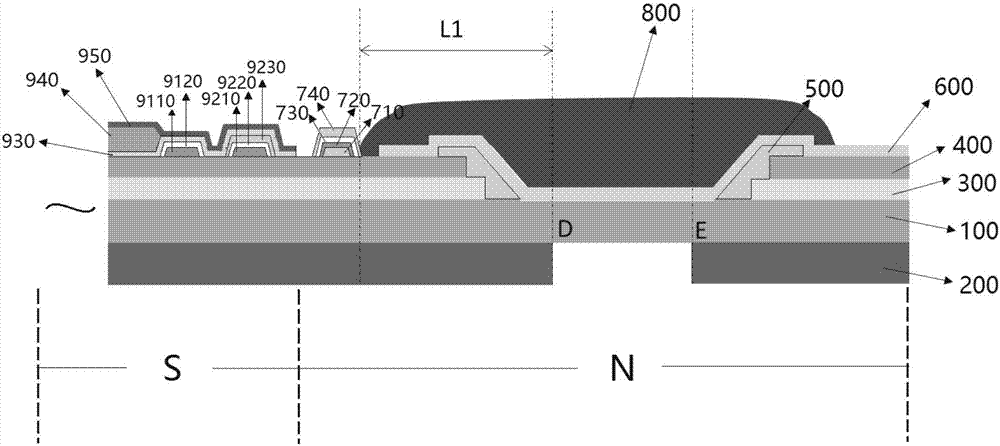

Flexible array substrate as well as manufacturing method and flexible display thereof

ActiveCN107123667ANarrow widthImprove thickness uniformitySolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention discloses a flexible array substrate as well as a manufacturing method and a flexible display thereof. The flexible array substrate comprises a flexible substrate, a display region arranged on one side of the flexible substrate, a non-display region arranged at the periphery of the display region, a protective layer used for covering a source and drain electrode layer of the non-display region and a protective layer block wall arranged on one side, close to the display region, of the non-display region and used for limiting a width of the protective layer. According to the flexible array substrate provided by the invention, the protective layer block wall is arranged on one side, close to the display region, of the non-display region and can limit a glue material from flowing toward a light emitting region when the protective layer of a bending region is manufactured, so that the width of the protective layer can also be limited while the uniformity of the coating thickness of the protective layer is guaranteed, a climbing region can be effectively shortened, and realization of the narrow frame effect is facilitated.

Owner:BOE TECH GRP CO LTD

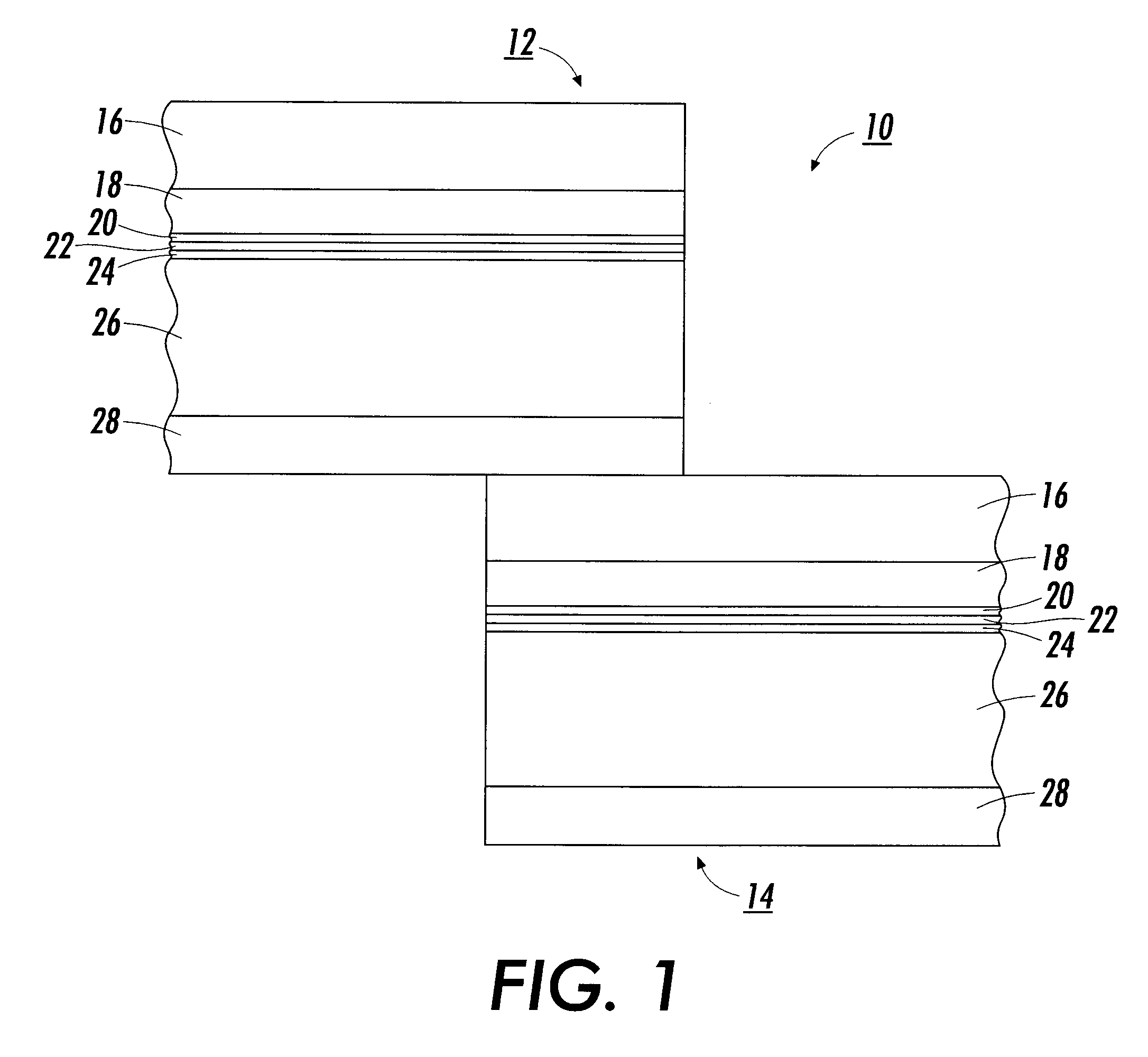

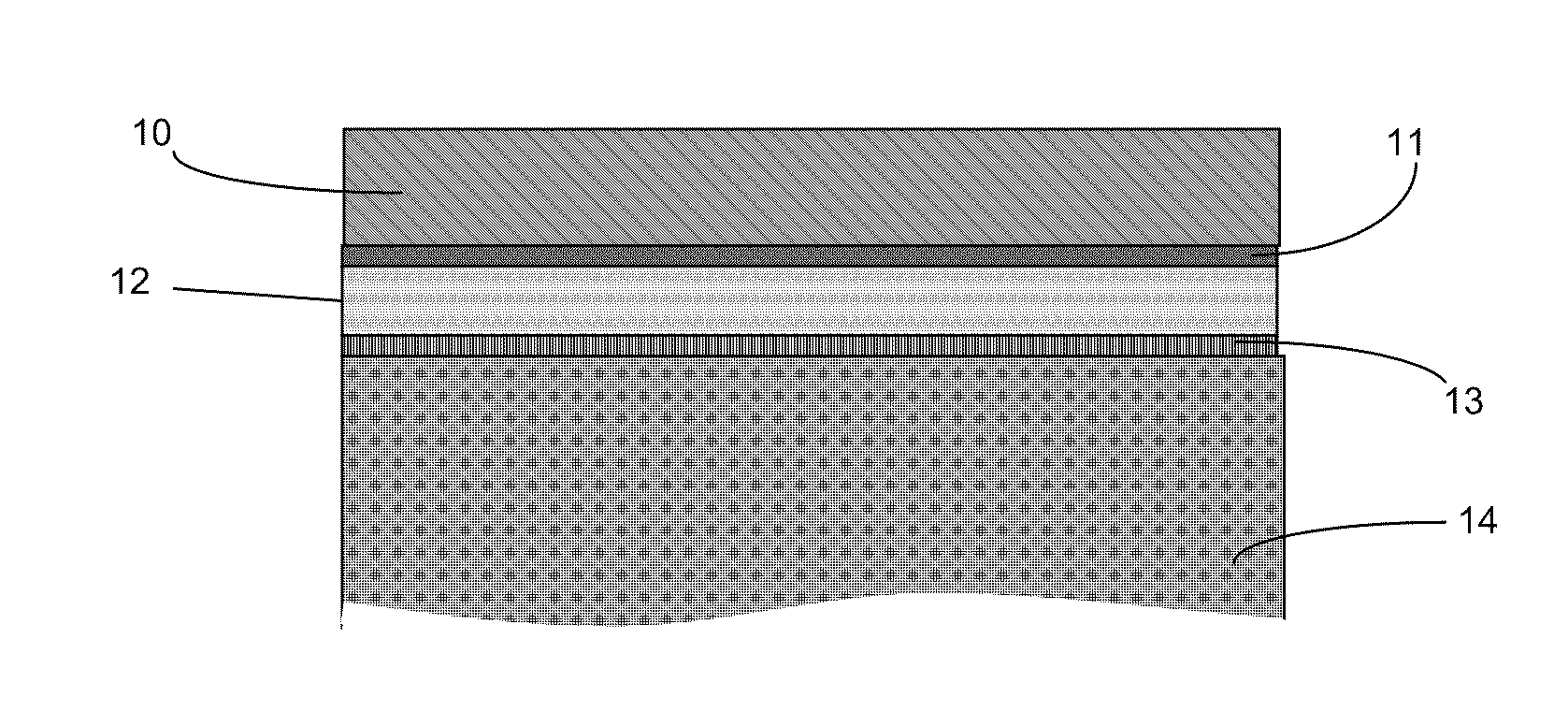

Low-emissivity structures

InactiveUS20110262699A1Reduce performanceMinimize wettingNanoinformaticsVacuum evaporation coatingLow emissivityEngineering

A multilayer radiant-barrier structure is formed on one or both sides of a substrate that can be attached to an insulating layer to produce a reflective insulating material. The metallized layer is protected from environmental degradation without interfering with flammability properties that are critical for radiant and reflective insulation materials used in housing applications. The metal layer is modified to insulate enclosures without blocking cellular communications and the protective functional layer in modified to minimize emissivity, create a hydrophobic and / or oleophobic surface, and / or prevent mold, fungi and bacteria growth. Solutions are provided to solve occupational-hazard problems associated with the use of these materials in enclosures that include power wires.

Owner:SIGMA LAB OF ARIZONA

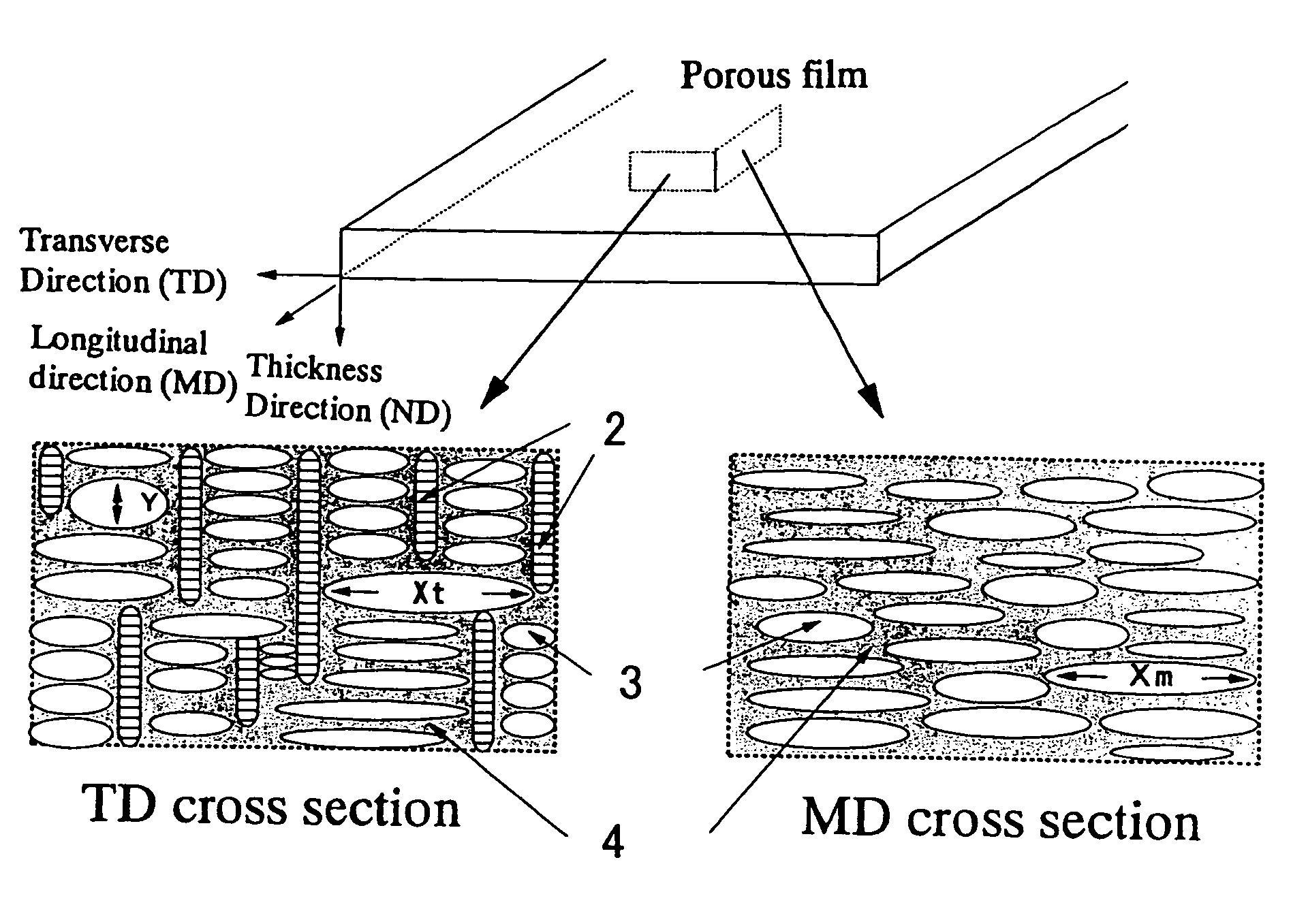

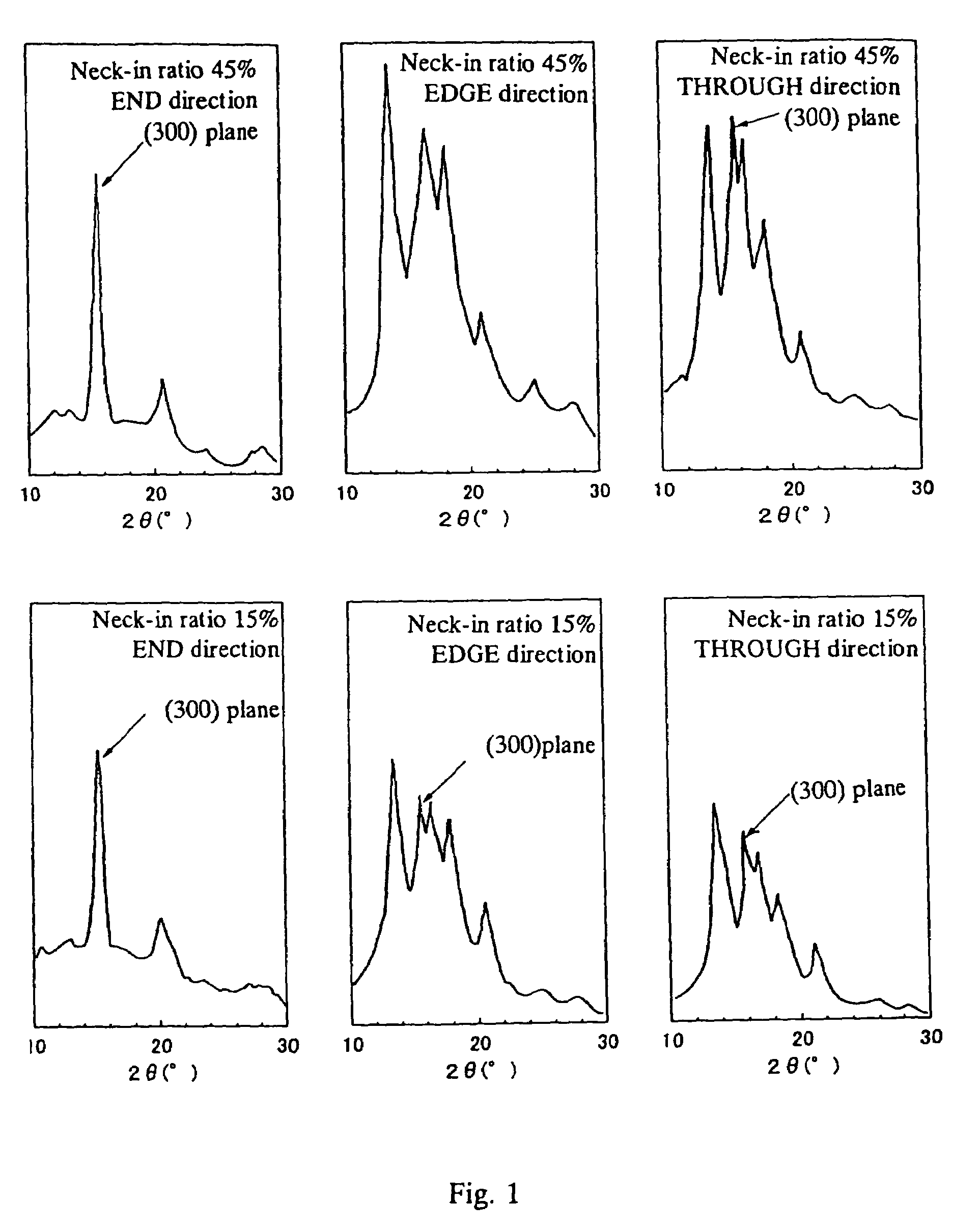

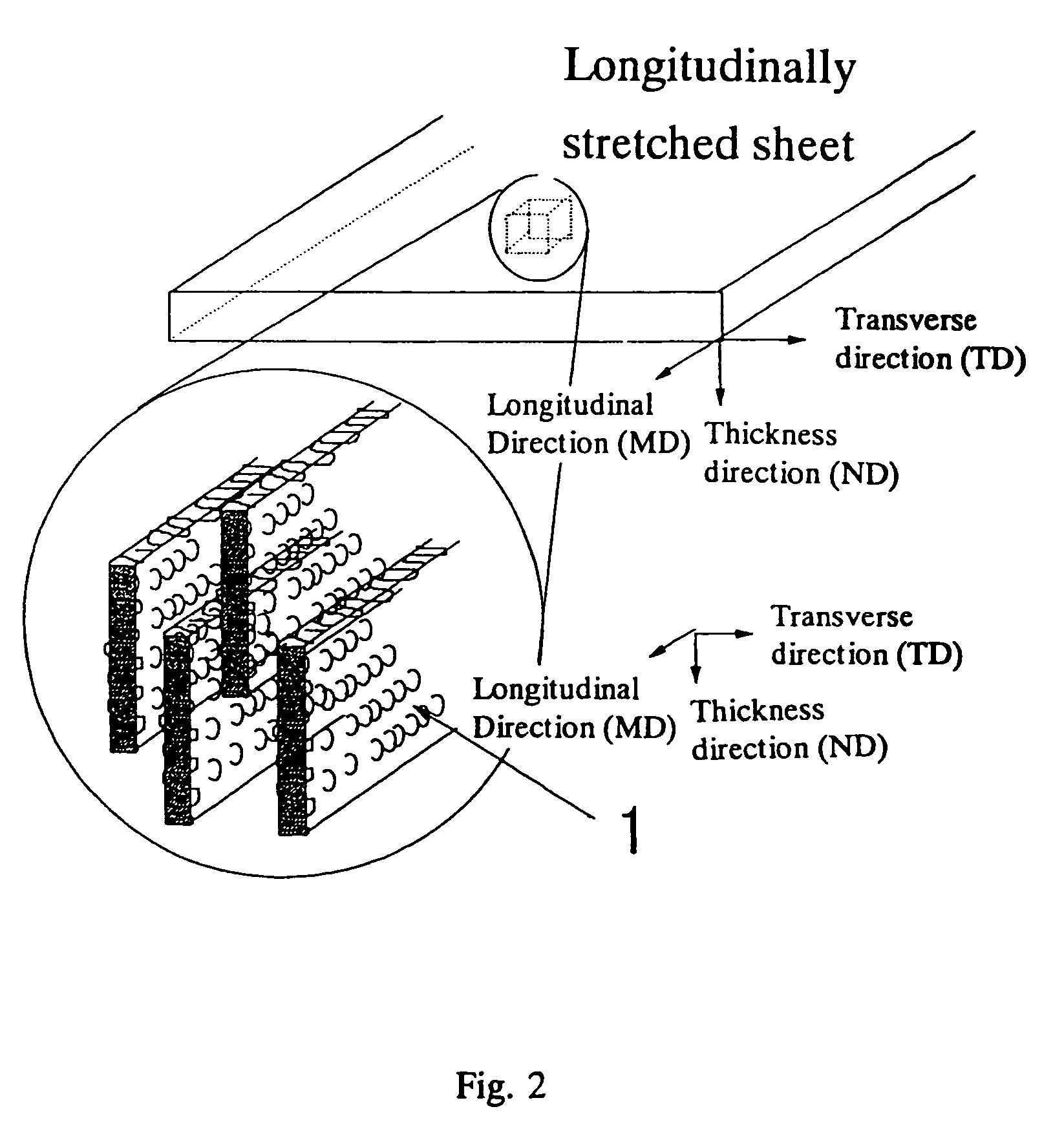

Successively biaxial-oriented porous polypropylene film and process for production thereof

InactiveUS7235203B2Feel goodGood electrical resistanceCell component detailsThin material handlingPorosityCrystal orientation

Disclosed is a successively biaxially stretched film obtained by successive biaxial stretching method comprising extruding a melt of a β-crystal nucleating agent-containing polypropylene-based resin composition from a T-die, cooling the extruded resin on a chill roll, and stretching the resulting web sheet longitudinally and then transversely, wherein the longitudinally stretched sheet is made to have a degree of β-crystal orientation of less than 0.3 by the following method (I) and / or (II), optionally subjected to annealing treatment, and transversely stretched:method (I): melting the polypropylene-based resin composition containing needle crystals of a specific β-crystal nucleating agent at a temperature not lower than m.p. of the polypropylene-based resin and lower than dissolution temperature of the β-crystal nucleating agent in the polypropylene-based resin melt, and extruding the melt from the T-die at the same temperature,method (II): adjusting neck-in ratio during longitudinal stretching to 25 to 55%.The porous polypropylene film has good breakage resistance during manufacture, excellent thickness uniformity, high porosity and air-permeability, and is useful for battery separators.

Owner:NEW JAPAN CHEM CO

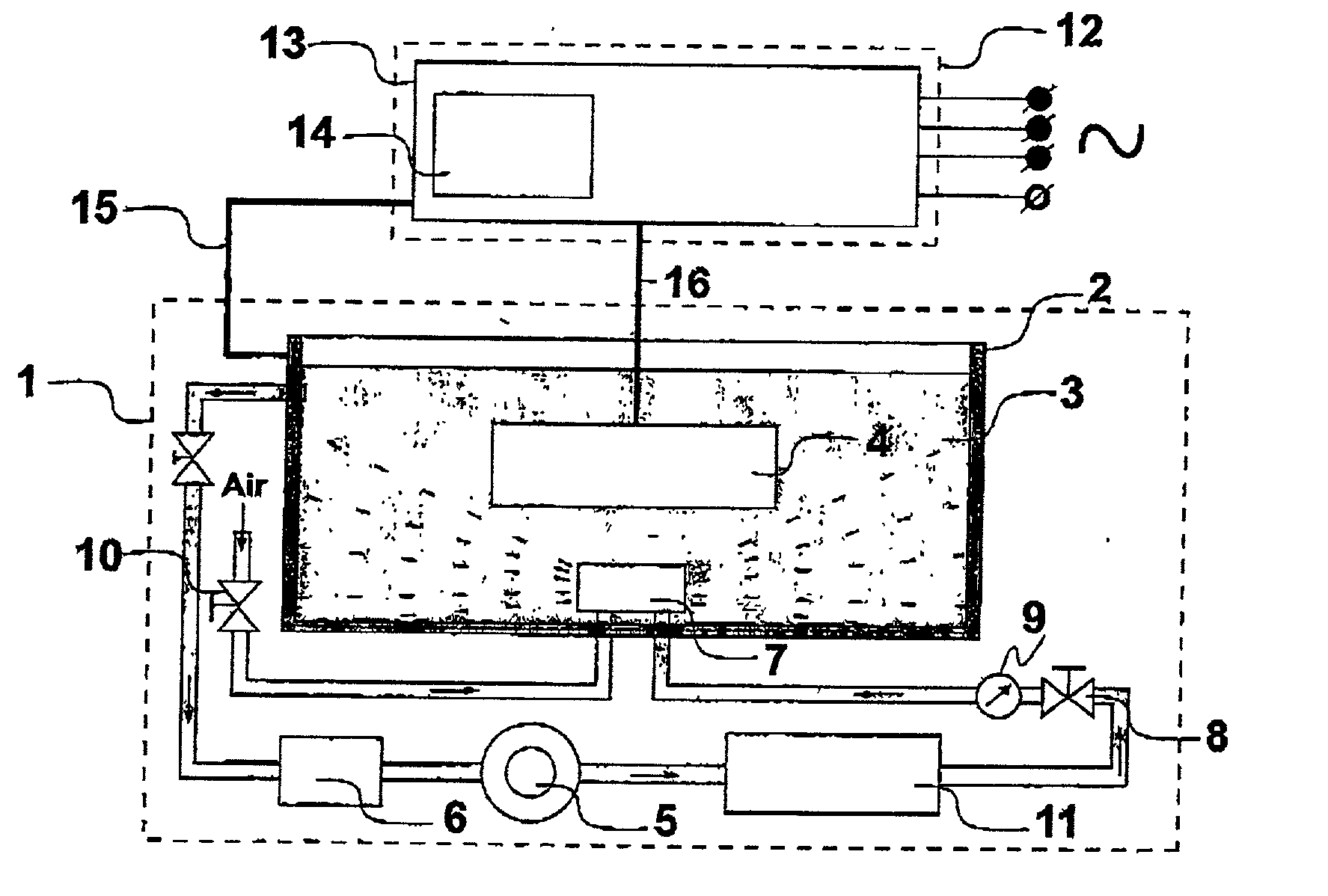

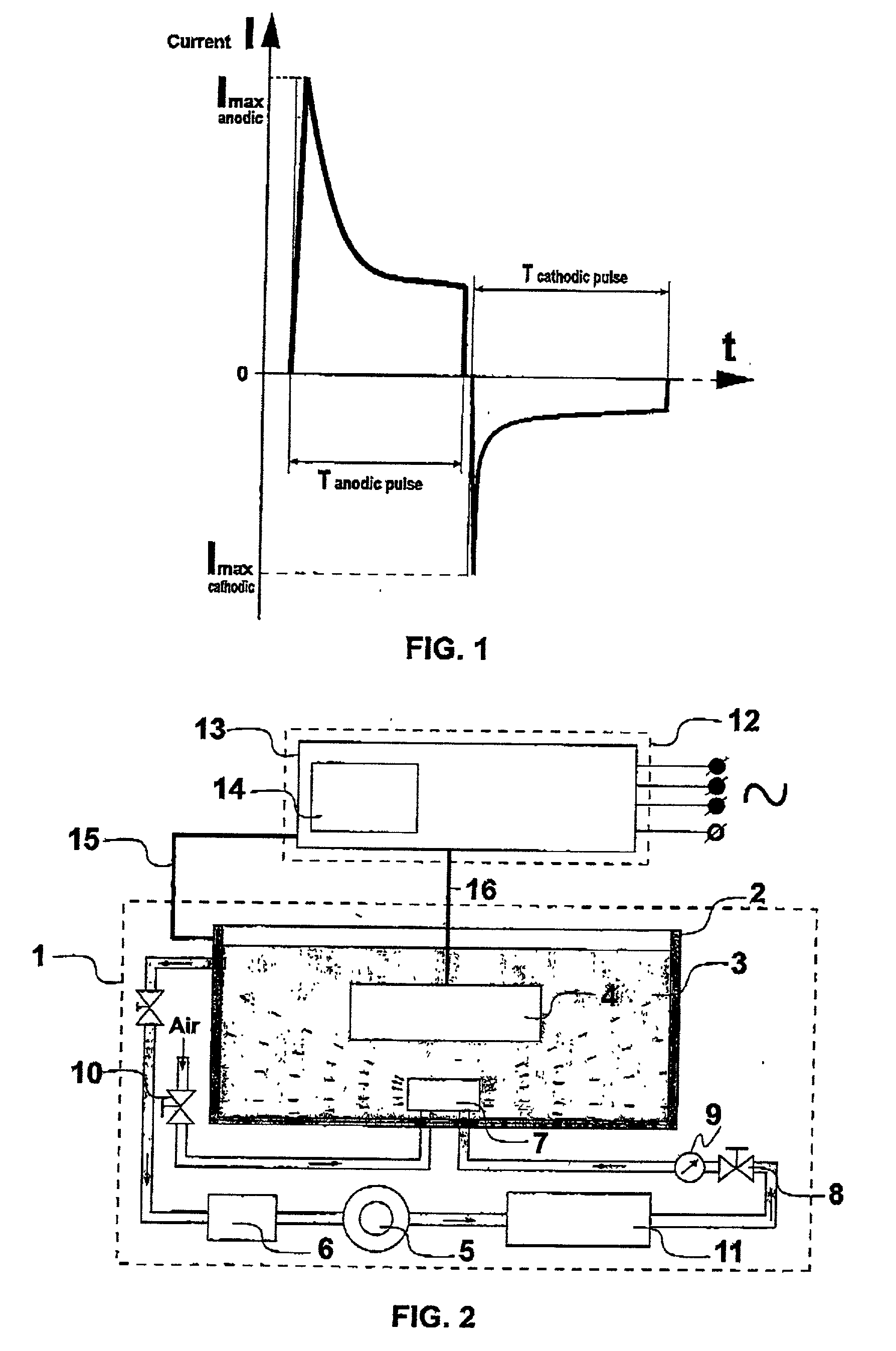

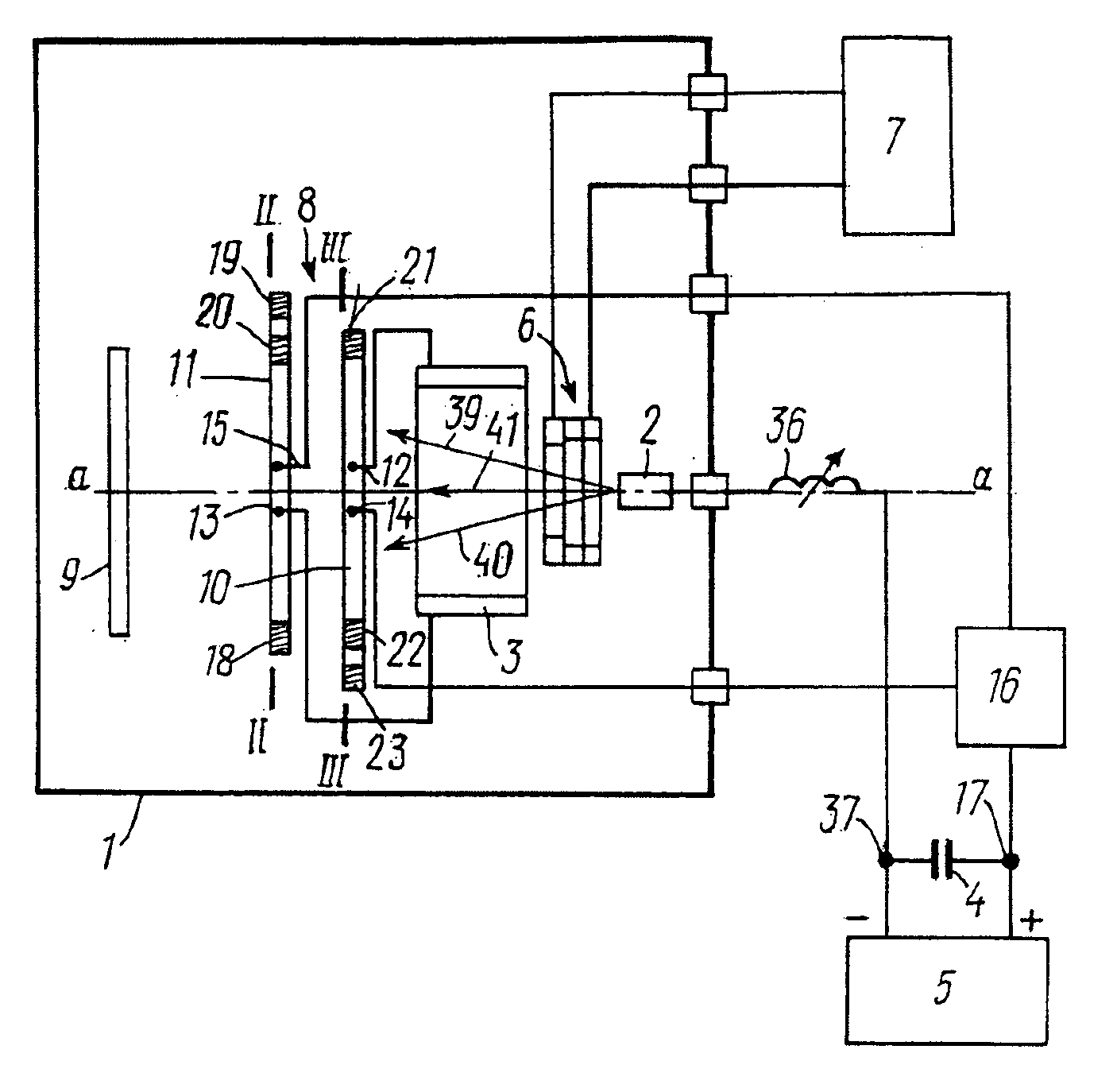

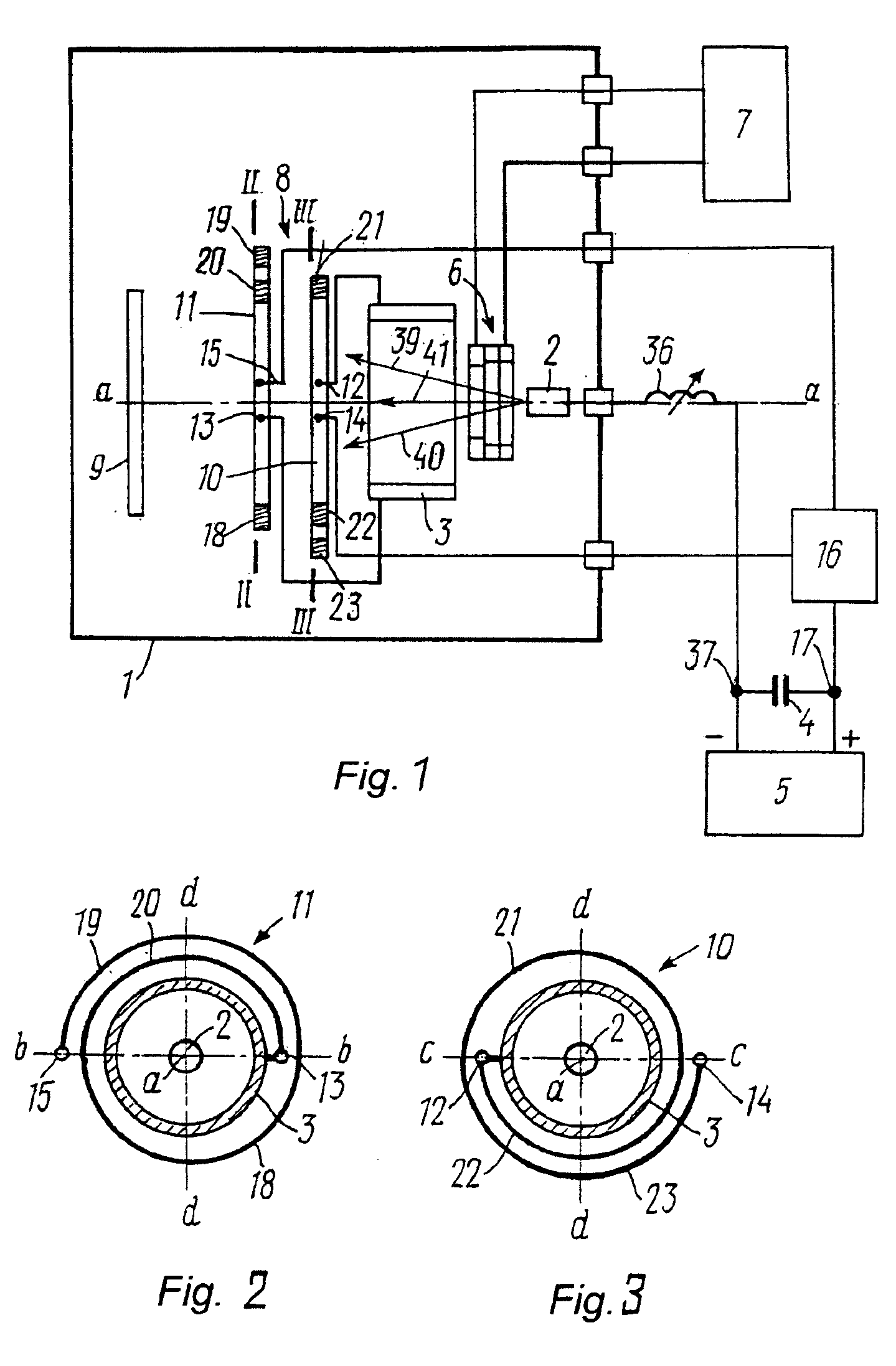

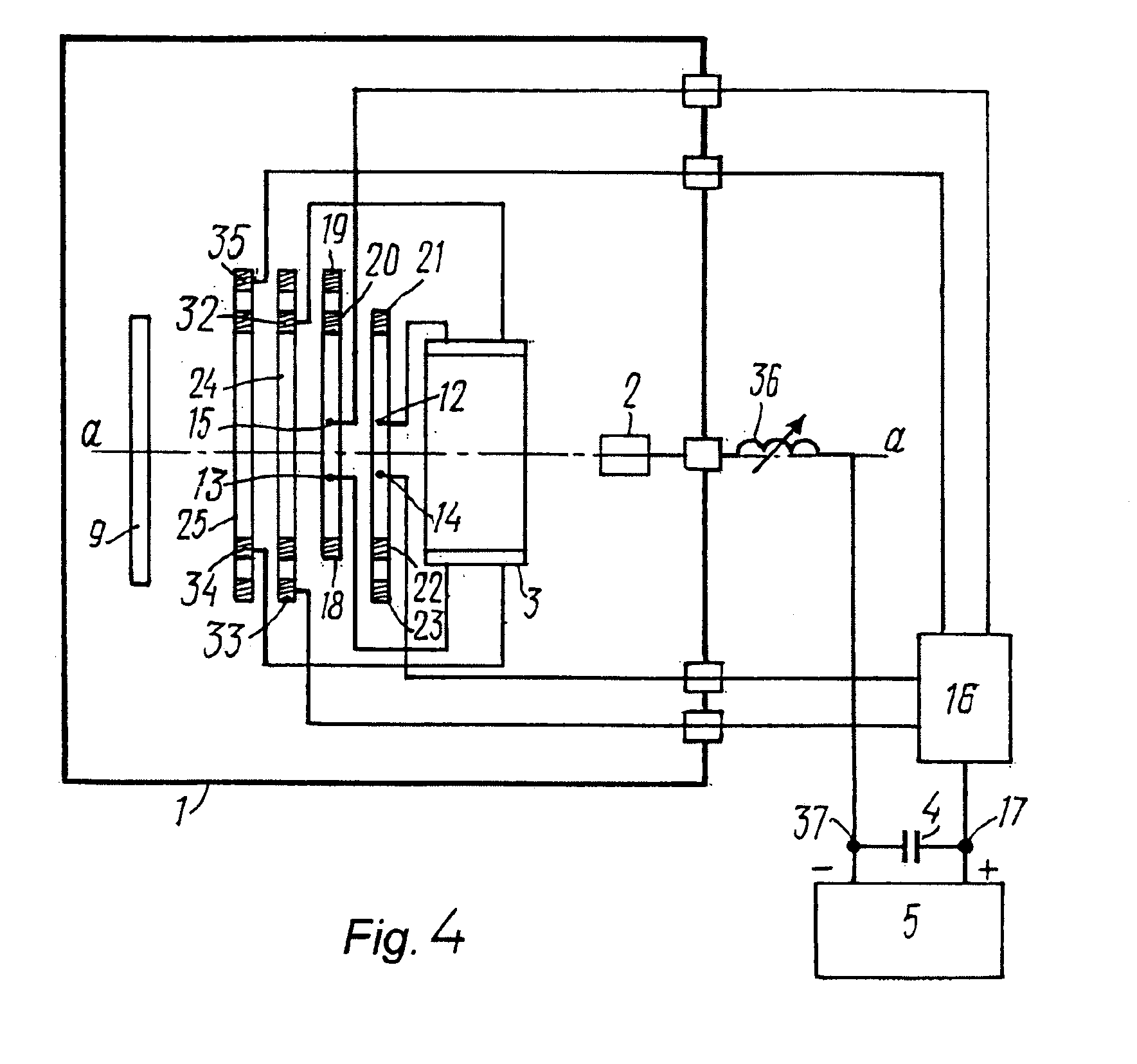

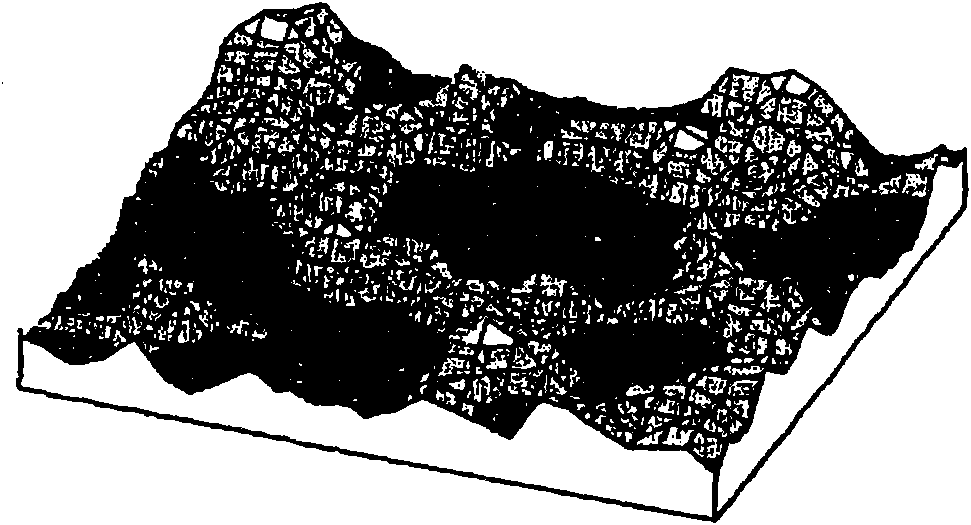

Process and device for forming ceramic coatings on metals and alloys, and coatings produced by this process

InactiveUS20030188972A1Reduce roughnessImprove thickness uniformityAnodisationCellsElectrolytic agentPlasma electrolytic oxidation

There is disclosed a process and apparatus for carrying out plasma electrolytic oxidation of metals and alloys, forming ceramic coatings on surfaces thereof at a rate of 2-10 microns per minute. The process comprises the use of high-frequency current pulses of a certain form and having a given frequency range, combined with the generation of acoustic vibrations in a sonic frequency range in the electrolyte, the frequency ranges of the current pulses and the acoustic vibrations being overlapping. The process makes it possible to introduce ultra-disperse powders into the electrolyte, with the acoustic vibrations helping to form a stable hydrosol, and to create coatings with set properties. The process makes it possible to produce dense hard microcrystalline ceramic coatings of thickness up to 150 microns. The coatings are characterised by reduced specific thickness of an external porous layer (less than 14% of the total coating thickness) and low roughness of the oxidised surface, Ra 0.6-2.1 microns.

Owner:KERONITE INT LTD

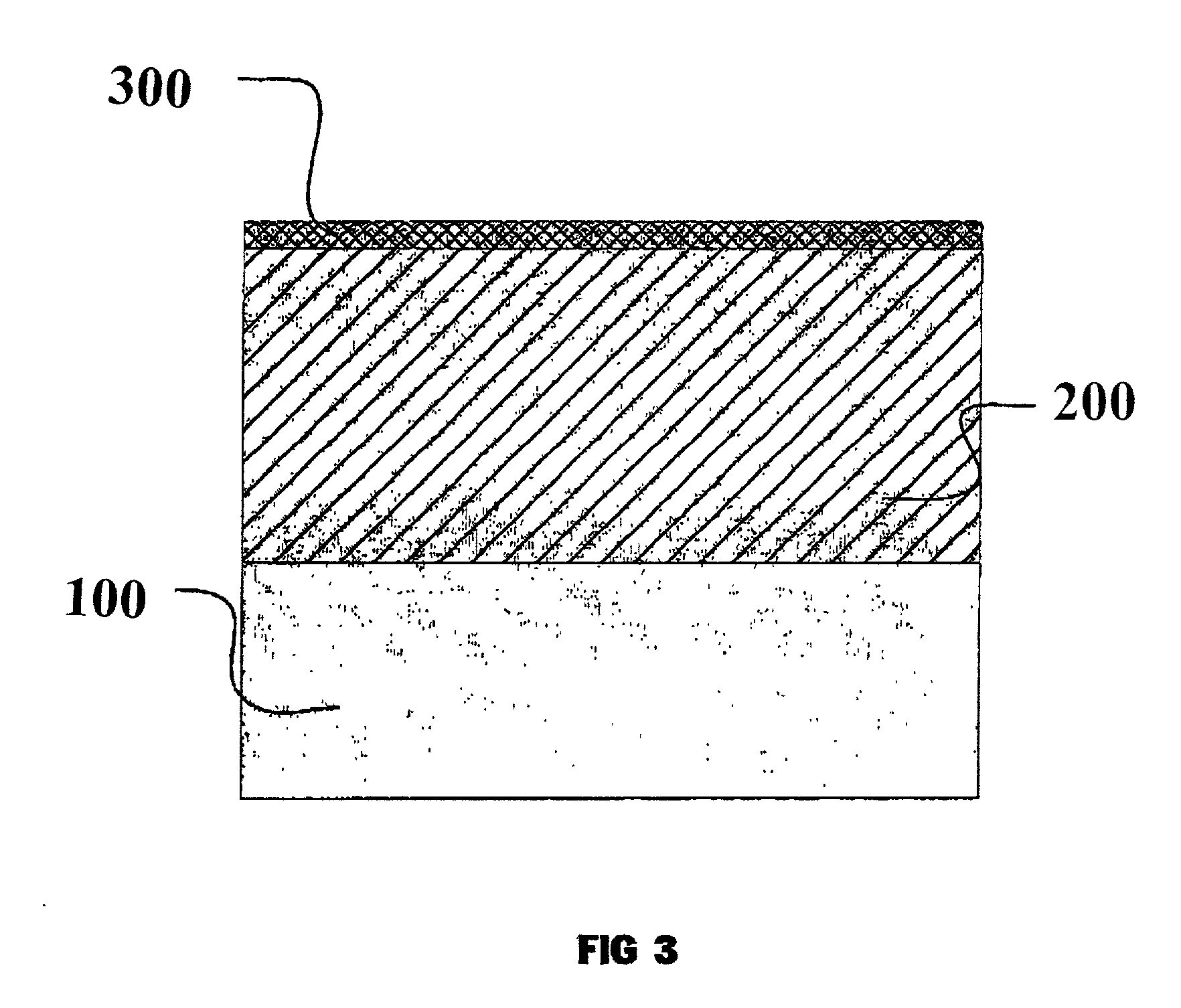

Printed chemical mechanical polishing pad

ActiveUS20160107288A1Tight toleranceWithout distorting thickness uniformityAdditive manufacturing apparatusAbrasion apparatusMetallurgyNozzle

A method of fabricating a polishing layer of a polishing pad includes successively depositing a plurality of layers with a 3D printer, each layer of the plurality of polishing layers deposited by ejecting a base material from a first nozzle and an additive material from a second nozzle and solidifying the base and additive material to form a solidified pad material.

Owner:APPLIED MATERIALS INC

Pulsed carbon plasma apparatus

InactiveUS6855237B2High degreeImprove life performanceCellsElectric discharge tubesDiamond-like carbonMachine parts

The present invention provides a pulsed carbon plasma apparatus to produce a diamond-like carbon coating over an extended object, the coating having a high degree of thickness uniformity achieved by scanning the plasma flow over the surface of the object. The pulsed carbon plasma apparatus of the invention comprises a carbon plasma flow scanning device having at least one pair of deflecting coils, where the deflecting coils have, in the scanning plane, a different number of turns on opposite sides. The object may be made of metal, ceramic, glass or plastic. The coatings may be used to improve life and operating performance of tools and machine parts, and as decorative coatings.

Owner:INT TECH EXCHANGE

Separator for electrochemical device and method for producing the same

InactiveUS6905798B2Improves texture uniformityImprove thickness uniformityHybrid capacitor separatorsHybrid capacitor electrolytesPolymer scienceHeat resistance

The present invention provide a separator for an electrochemical device which comprises a wet nonwoven fabric comprising one or more kinds of fibrillated organic fibers which are at least partially fibrillated into a fiber diameter of 1 μm or less, and one or more kinds of unfibrillated organic fibers having a fineness of 0.5 dtex or less, which exhibits excellent heat resistance, electrolyte holding properties, internal short-circuit preventing property, and winding property, which results in a lowered internal resistance and prolonged life of an electrochemical device, and a method for producing the same and an electrochemical device.

Owner:MITSUBISHI PAPER MILLS LTD

Antiglare film, antireflection film, polarizing plate and image display device

InactiveCN101685168AHigh yieldLow interference reflectionDiffusing elementsLayered productsDisplay deviceSolid content

An antiglare film is provided and includes: a transparent support; and an antiglare layer containing a binder and a light-transmitting fine particle. The light-transmitting fine particle has an average particle diameter of 3 to 15 [mu]m, the antiglare layer has an average thickness smaller than the average particle diameter of the light-transmitting fine particle by 0.1 to 2.0 [mu]m, the antiglarelayer contains the light-transmitting fine particle in an amount of 1.0 to 3.0 weight % based on all solid contents of the antiglare layer. The antiglare layer has a surface having a [theta](1) of 60to 98.5%, wherein the [theta](1) is a ratio of a surface region of 0 DEG <=[theta]<=1 DEG in the surface when [theta] represents a tilt angle of an irregularity on the surface.

Owner:FUJIFILM CORP

Compositions for compounding, extrusion and melt processing of foamable and cellular fluoropolymers

ActiveUS20090048359A1Improve insulation performanceImprove flammabilityFibre treatmentInsulated cablesThermoplasticElectrical conductor

The disclosure provides a composition or set of compositions and methods for producing cellular foamable, foamed, or blown perfluoropolymers or fluoropolymers and other thermoplastics to create products including a lower cost communications cable, conductor separator, conductor support-separator, jacketing, tape, wire insulation and in some cases a conduit tube as individual components or combined configurations that exhibit improved electrical, flammability and optical properties. The composition of the invention can be is chemically foamable yielding homogeneous foamed insulating structures which excel simultaneously in providing excellent insulating properties on metal wires or optical fibers, outstanding processing parameters for high speed cable manufacture and high performance ratings on flammability, smoke generation and fuel load. Specifically, the foamable perfluoropolymer cellular insulation composition comprises blending or individually utilizing; a selected perfluoropolymer in combination with magnesium carbonate, calcium carbonate and Aclyn® wax; a second composition comprising the first composition and an additional selected one or more perfluoropolymers; a third composition comprising; talc and the selected one or more perfluoropolymers; a fourth composition comprising; the second composition, the third composition and the selected one or more perfluoropolymers. A single compounded pellet or product resulting in cellular foams obtained from melt processing the pellets has also been realized by providing the melt combination of only talc and a perfluoropolymer. The present invention includes a foamable perfluoropolymer composition comprising at least one melt-processible per(halo)fluoropolymer; and a blowing agent comprising an effective amount of magnesium carbonate; andan active nucleating agent chosen among:at least one metal carbonate different from magnesium carbonate having decomposition temperature exceeding 350° C., generally chosen among CaCO3, BaCO3, ZnCO3 and PbCO3; and talc and mixtures thereof.

Owner:CABLE COMPONENTS GROUP

Great diameter SiC monocrystal cutting method

ActiveCN1739927ARealize continuous cuttingReduce lossesMetal working apparatusWire cuttingSingle crystal

The great diameter SiC monocrystal cutting method belongs to crystal material processing technology. SiC monocrystal is cut by means of diamond wire cutting machine with cutting wire of 150-450 micron diameter and coated with diamond grains. The diamond wire cutting wire in high speed reciprocation cuts great diameter SiC monocrystal. The present invention has the following advantages: capacity of cutting SiC monocrystal of size ove 2 in, less cutting loss, shallow cutting trace, less damage to cut chip, capacity of cutting chip with thickness as small as 200 micron, saving in cost, homogeneous thickness and less deformation of the cut chip, and simple cutting process.

Owner:SICC CO LTD

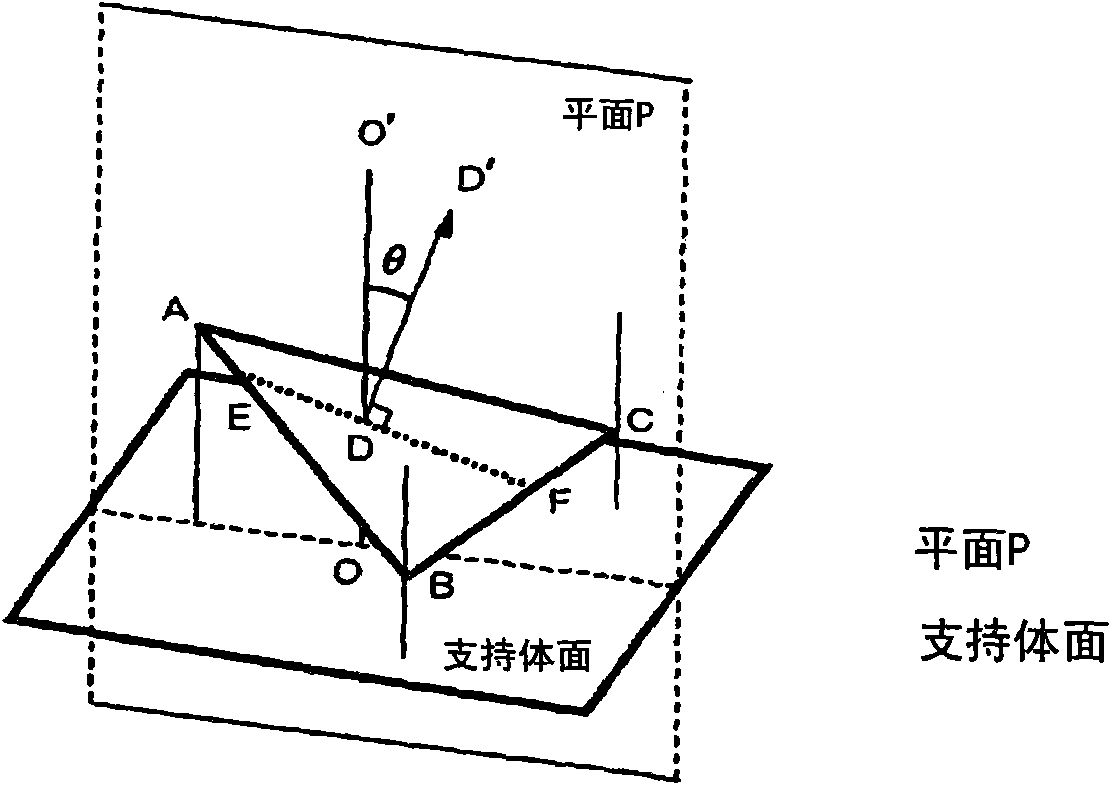

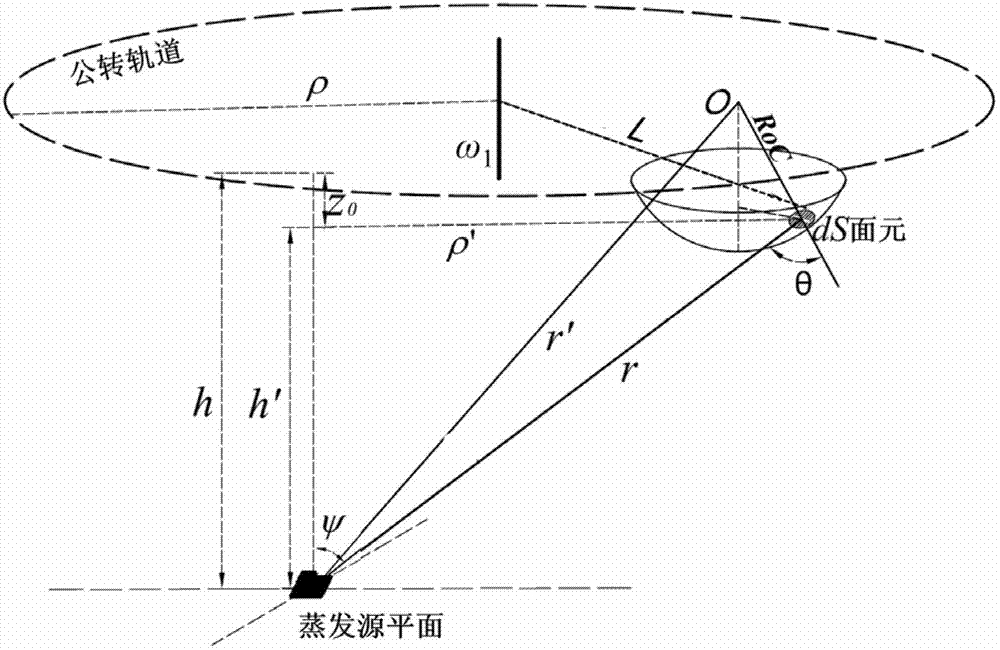

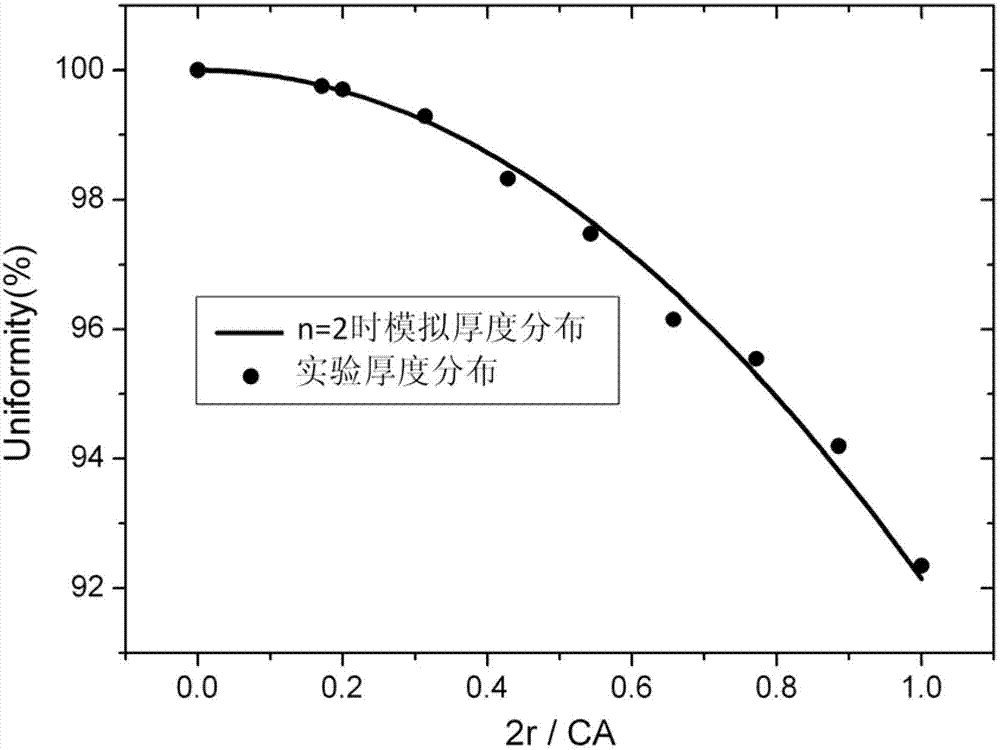

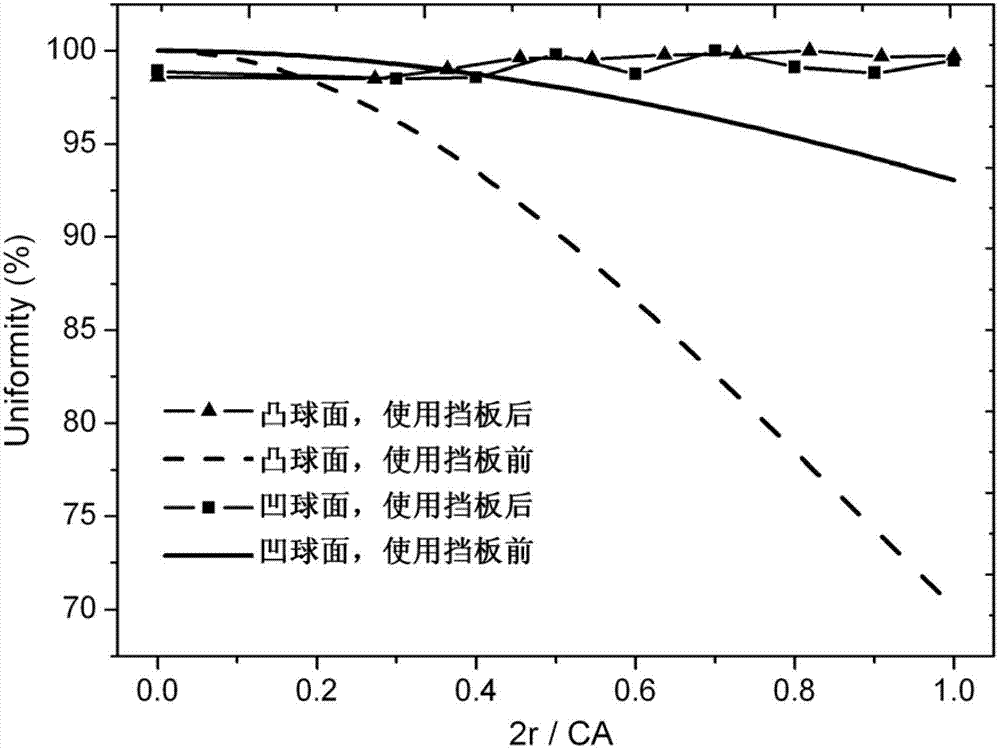

Method for designing coating uniformity correction mask for spherical optical elements on planetary rotating jigs of vacuum coating machines

ActiveCN102732844AImprove design efficiencyImprove thickness uniformityVacuum evaporation coatingSputtering coatingComputer optimizationMagnification

The invention discloses a method for designing a coating uniformity correction mask for spherical optical elements on planetary rotating jigs of vacuum coating machines, which is used for studying the film thickness distribution of a plane or spherical optical element (subjected to coating) on a planetary rotating jig through establishing a coating model in a vacuum environment. Through enabling an optical element coating process in a planetary rotating jig to be equivalent to a coating process in a simple rotating jig, the initial shape of the coating uniformity correction mask in the planetary rotating jig is designed. Through optimizing the arc length magnification factor of the correction mask by using a computer until the film thickness uniformity reaches the optimal result, the actual shape of the coating uniformity correction mask for the spherical optical elements is obtained. According to the invention, the control on the film thickness uniformity of the spherical optical element with a large caliber and a large caliber / curvature radius ratio can be realized, thereby obtaining the uniformity of multilayer-film spectral characteristics of the spherical optical element with a large caliber and a large caliber / curvature radius ratio.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

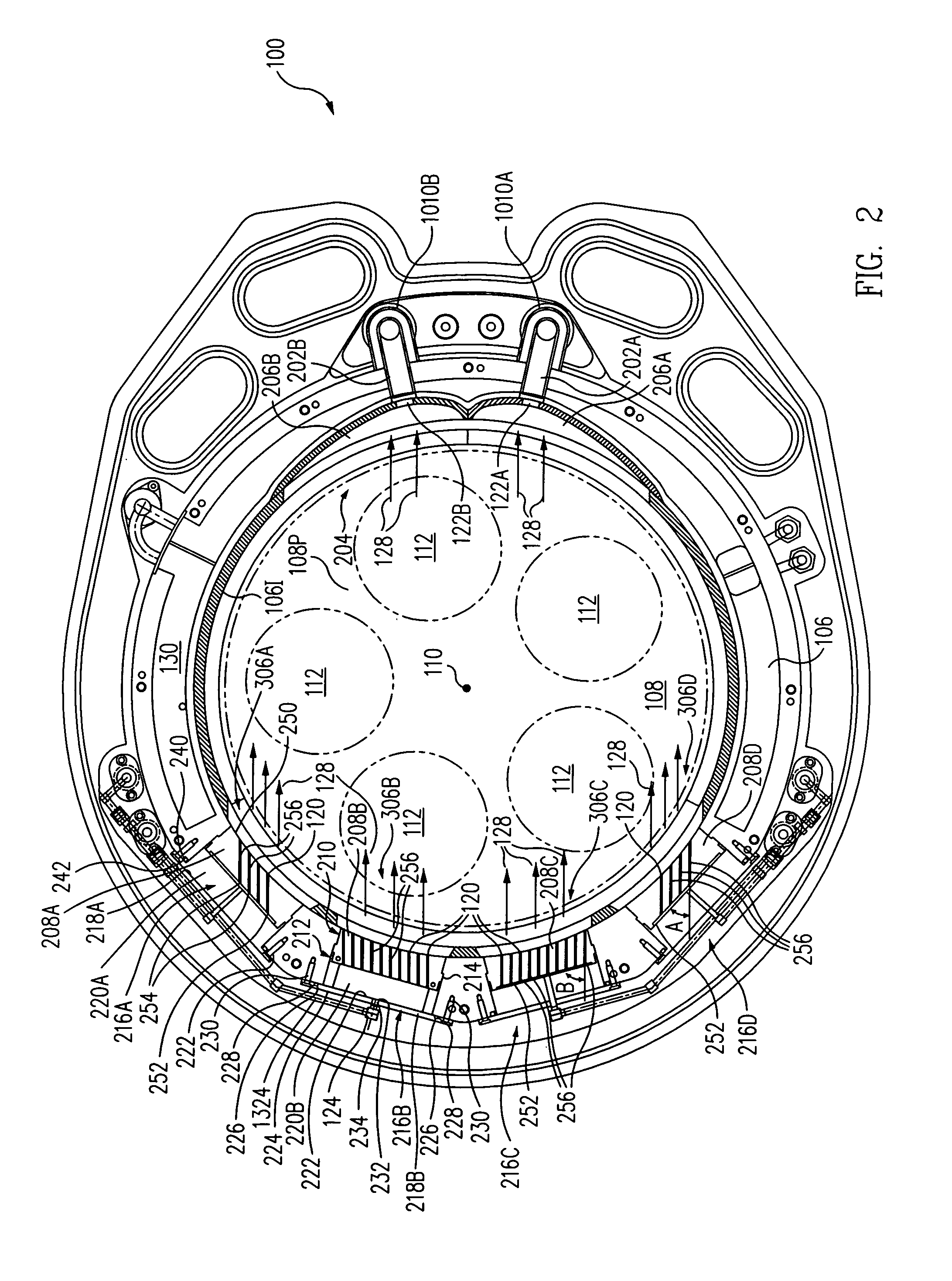

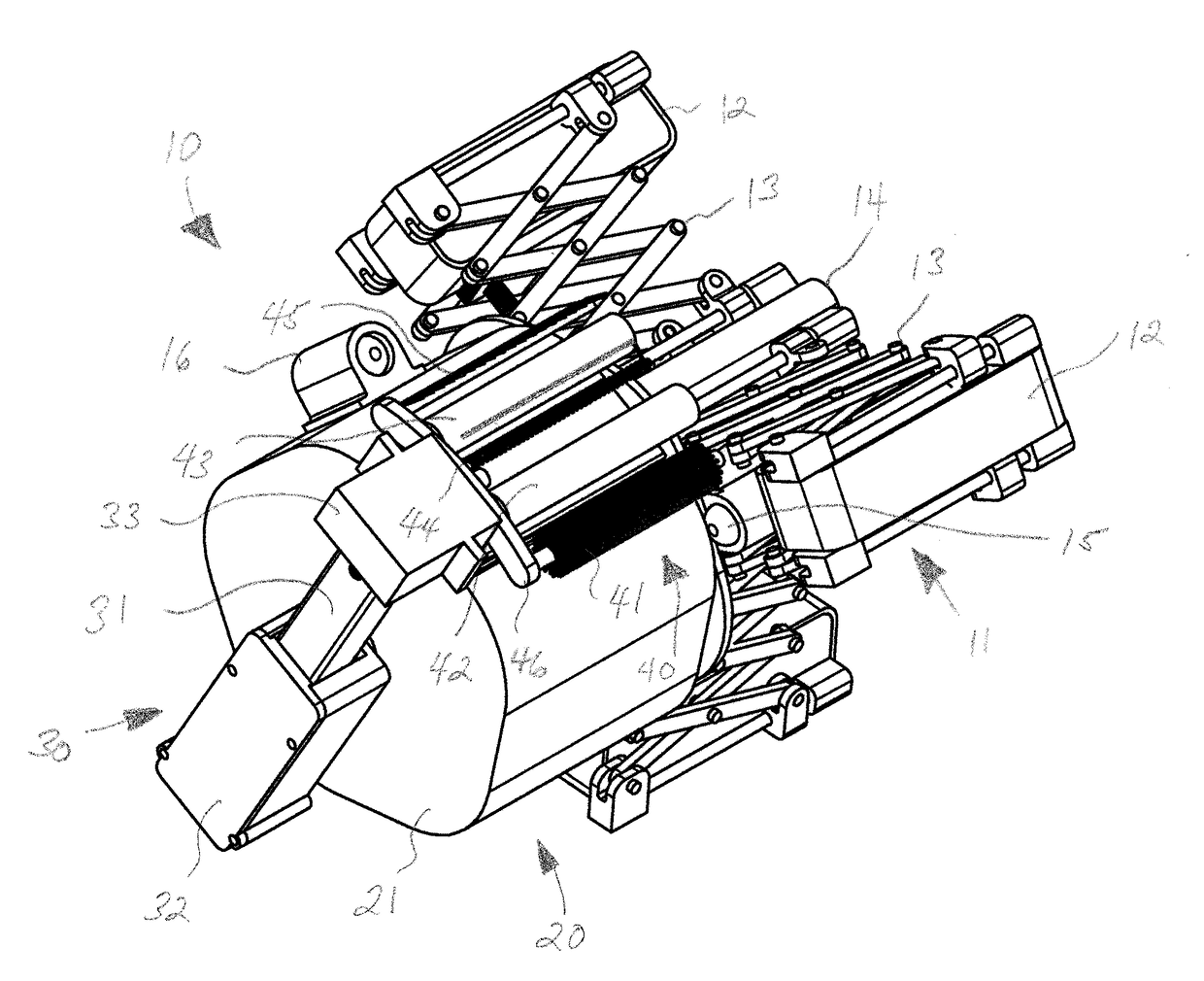

Taping Apparatus, System and Method for Pipe Lining Applications

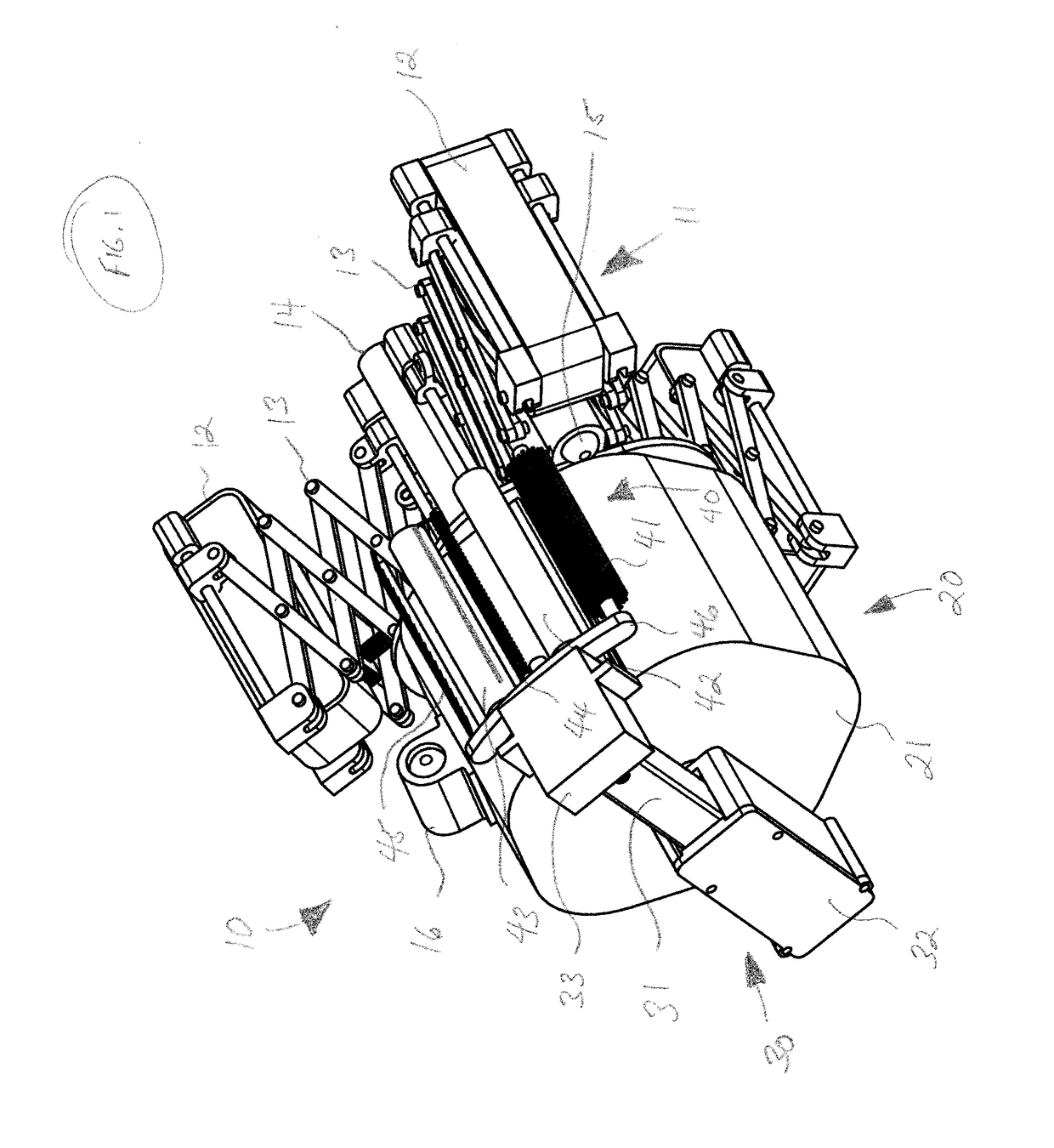

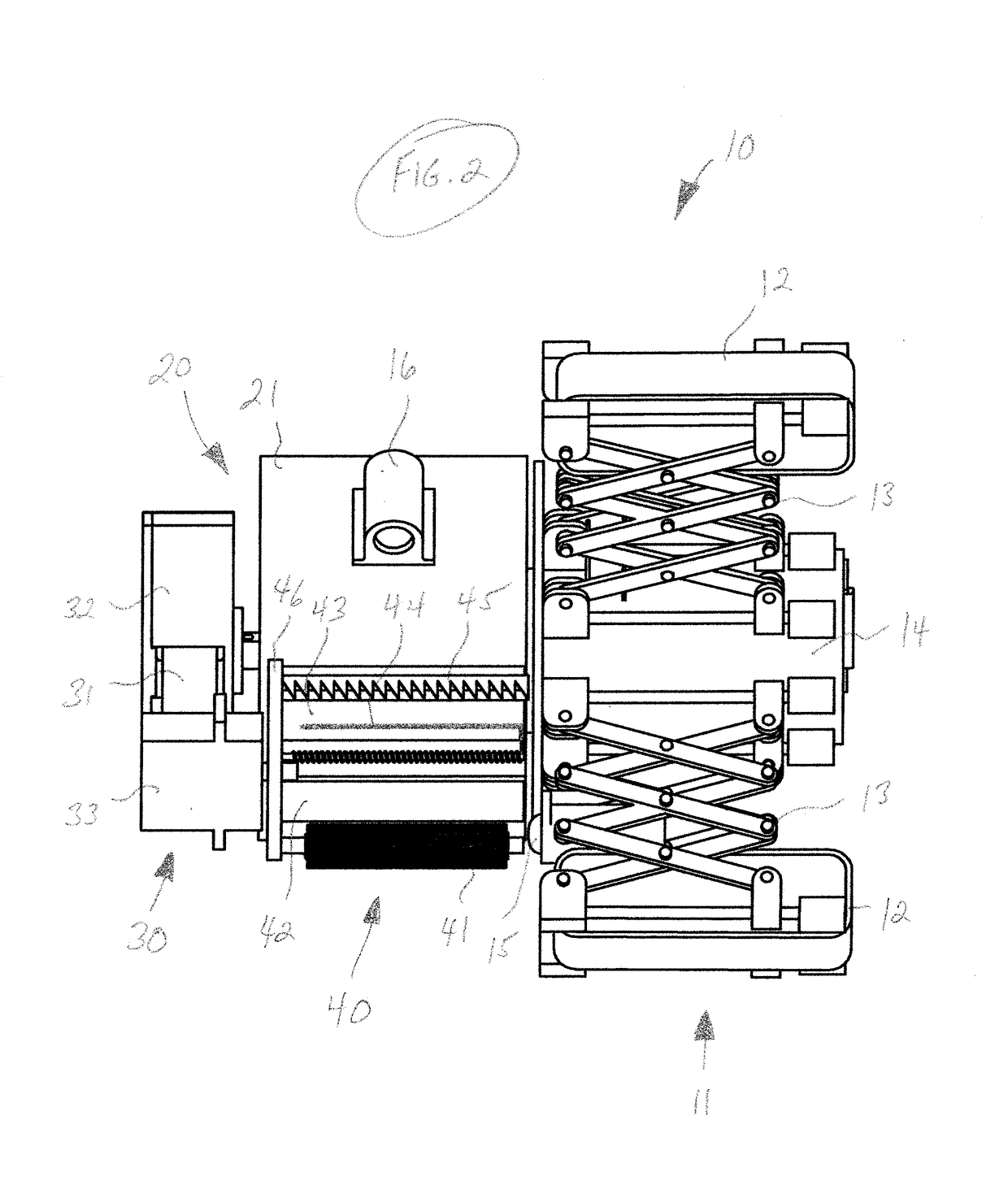

ActiveUS20180326679A1Improve thickness uniformityPrevent damage to valve operational efficacySpraying apparatusPigs/molesEngineeringMechanical engineering

A taping apparatus adapted to apply tape over voids on an interior pipe wall, the taping apparatus having a transport assembly adapted to move the apparatus through a pipe; and a rotatable taping assembly adapted to retain a roll of tape and apply said tape over a void on the interior wall of the pipe, said taping assembly comprising an extendable and tractable arm assembly and a tape applicator assembly.

Owner:SIPP TECH LLC

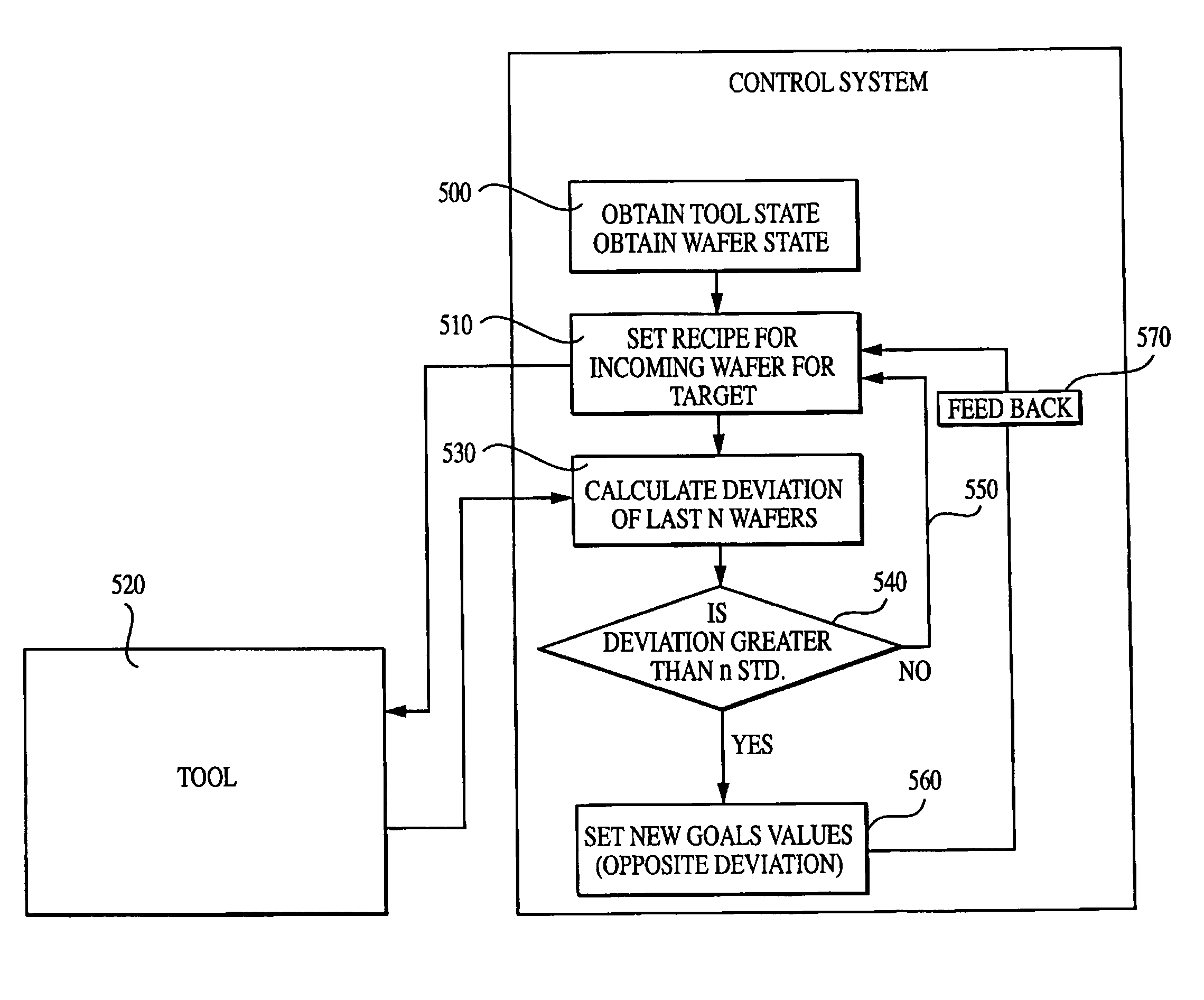

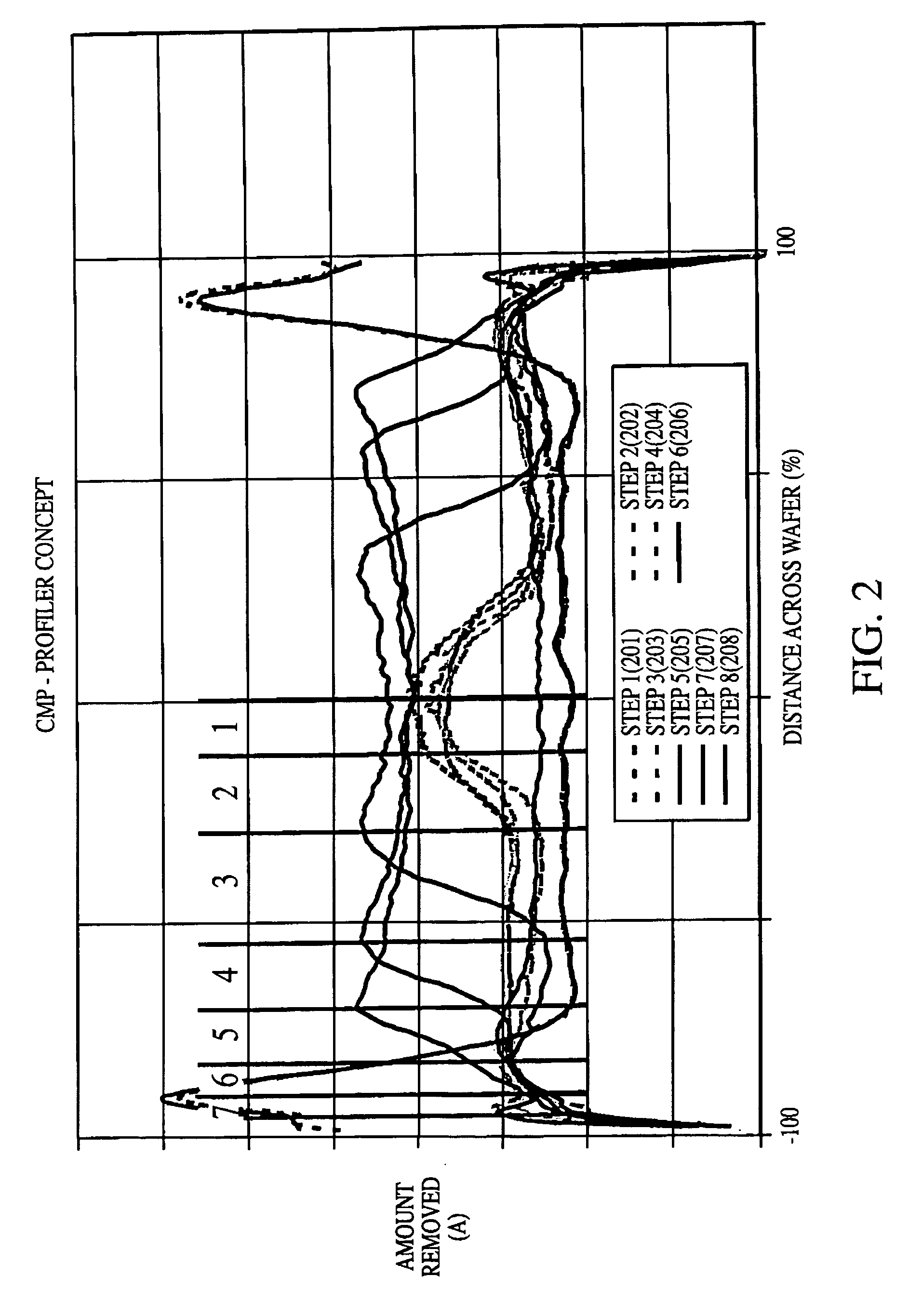

Feedback control of chemical mechanical polishing device providing manipulation of removal rate profiles

InactiveUS20070102116A1Optimal Operational ControlImprove thickness uniformitySemiconductor/solid-state device testing/measurementComputer controlMaterial removalModel quality

A method of controlling surface non-uniformity of a wafer in a polishing operation includes (a) providing a model for a wafer polishing that defines a plurality of regions on a wafer and identifies a wafer material removal rate in a polishing step of a polishing process for each of the regions, wherein the polishing process comprises a plurality of polishing steps, (b) polishing a wafer using a first polishing recipe based upon an incoming wafer thickness profile, (c) determining a wafer thickness profile for the post-polished wafer of step (b), and (d) calculating an updated polishing recipe based upon the wafer thickness profile of step (c) and the model of step (a) to maintain a target wafer thickness profile. The model can information about the tool state to improve the model quality. The method can be used to provide feedback to a plurality of platen stations.

Owner:APPLIED MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com