Patents

Literature

134results about How to "Realize continuous cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

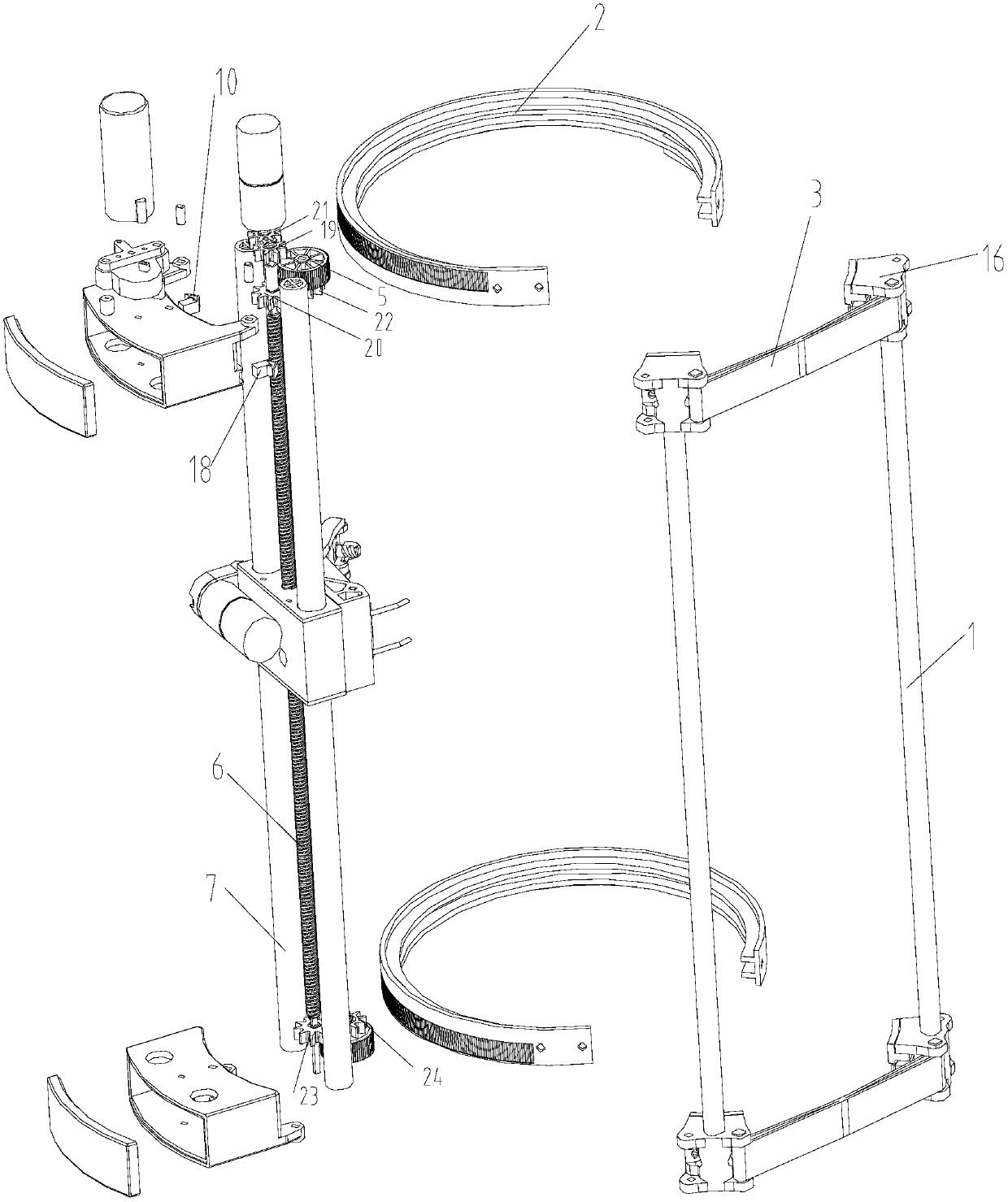

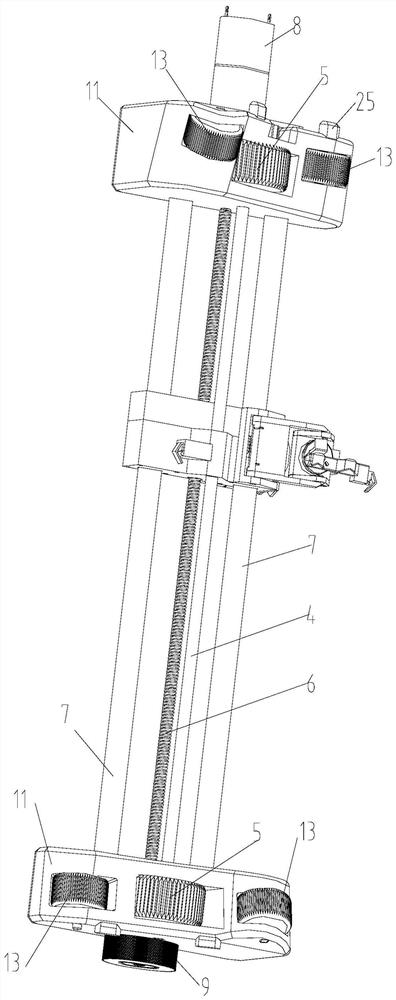

Rubber tapping machine and rubber tapping method

PendingCN107711410ARealize unmanned automatic tappingSolve labor intensityForestryEngineeringUltimate tensile strength

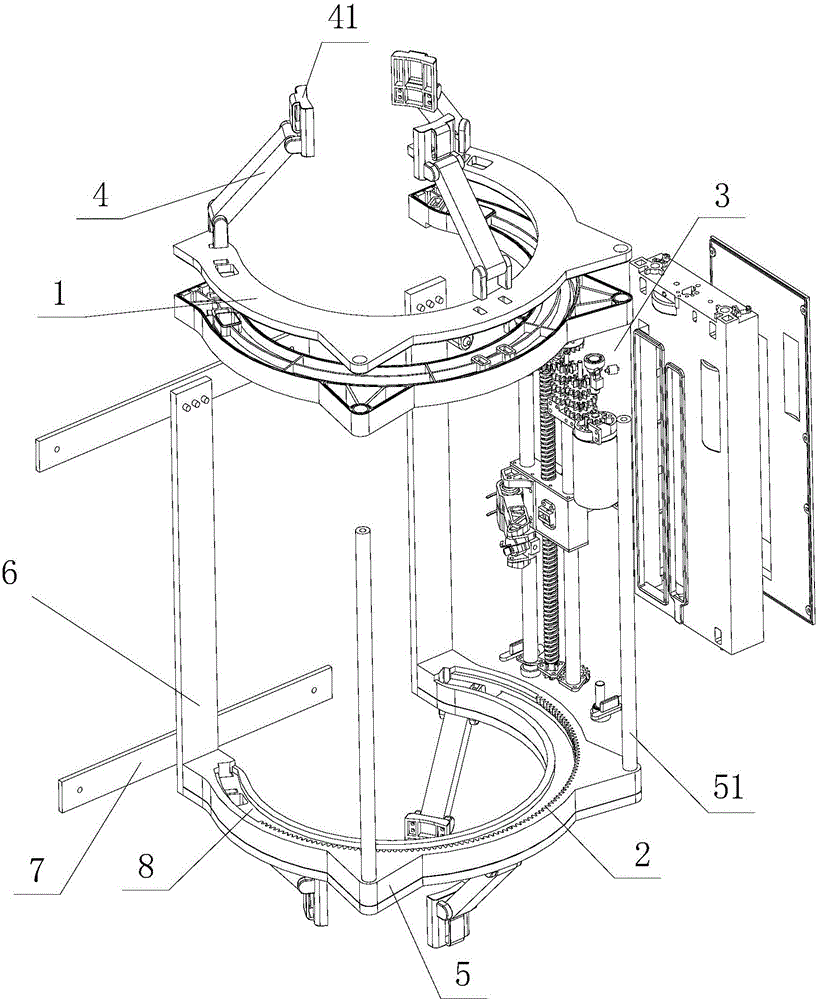

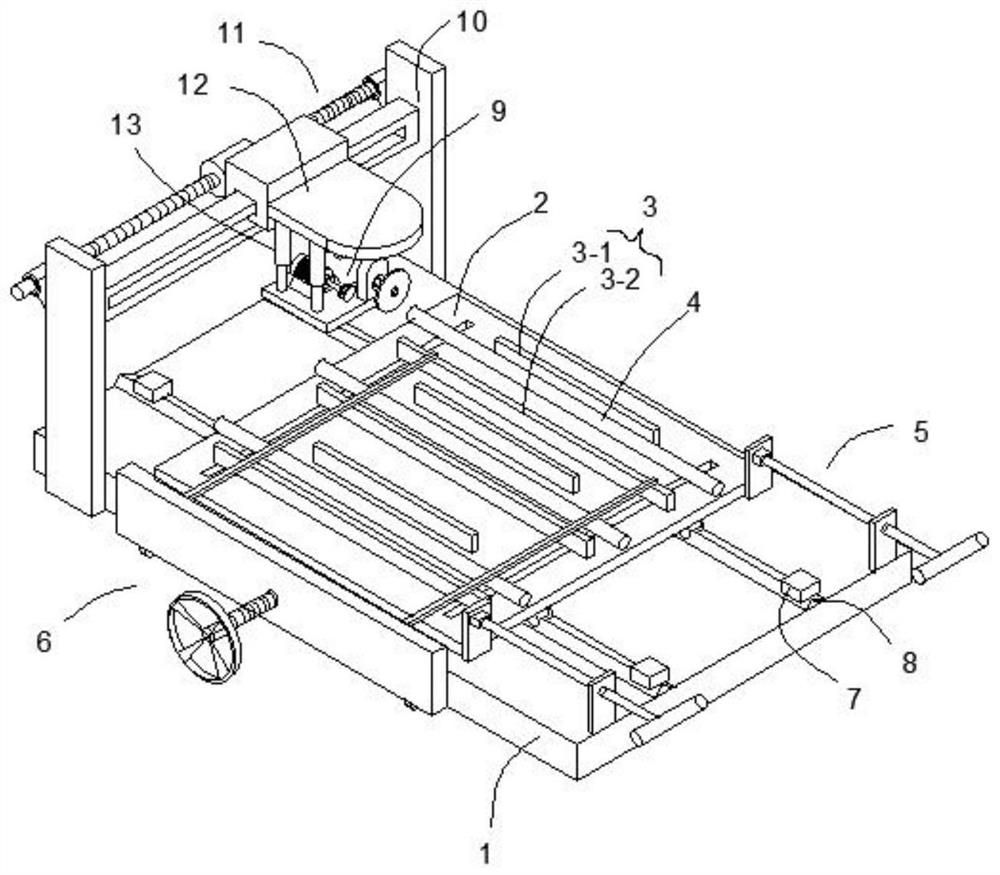

The invention discloses a rubber tapping machine and a rubber tapping method. The rubber tapping machine comprises support rods, a knife rest assembly and a rubber tapping knife assembly. A side of one of the support rods is connected with a side of the other support rod by flexible guide rails, the other side of each support rod is connected with the other side of the other support rod by tightening belts, and the flexible guide rails are opposite to the tightening belts on the sides opposite to the flexible guide rails; the knife rest assembly is provided with a motor, two track wheels capable of rolling along the outer sides of the flexible guide rails are mounted at the upper end and the lower end of the knife rest assembly, a lead screw and more than one fixing rod are further mountedin the knife rest assembly along the vertical directions, and the track wheels and the lead screw can be driven by the motor in the knife rest assembly to rotate. The rubber tapping machine and the rubber tapping method have the advantages that labor can be replaced by automatic machinery, accordingly, rubber can be automatically tapped from rubber trees in an unmanned manner, and the problems ofhigh labor intensity of manual rubber tapping and insufficient fineness of manual rubber tapping can be solved to the greatest extent.

Owner:NINGBO CIHEVEA TECH CO LTD

Great diameter SiC monocrystal cutting method

ActiveCN1739927ARealize continuous cuttingReduce lossesMetal working apparatusWire cuttingSingle crystal

The great diameter SiC monocrystal cutting method belongs to crystal material processing technology. SiC monocrystal is cut by means of diamond wire cutting machine with cutting wire of 150-450 micron diameter and coated with diamond grains. The diamond wire cutting wire in high speed reciprocation cuts great diameter SiC monocrystal. The present invention has the following advantages: capacity of cutting SiC monocrystal of size ove 2 in, less cutting loss, shallow cutting trace, less damage to cut chip, capacity of cutting chip with thickness as small as 200 micron, saving in cost, homogeneous thickness and less deformation of the cut chip, and simple cutting process.

Owner:SICC CO LTD

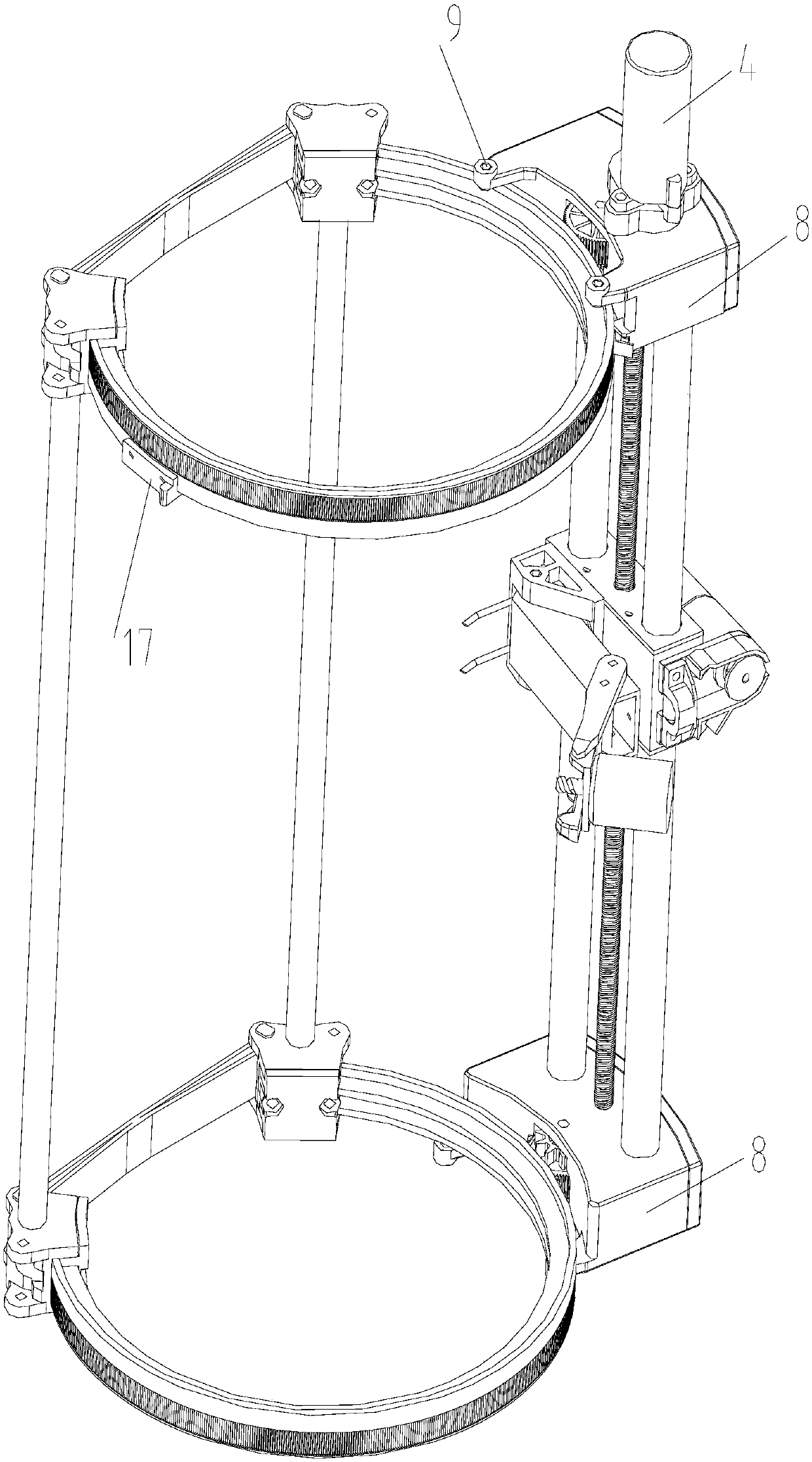

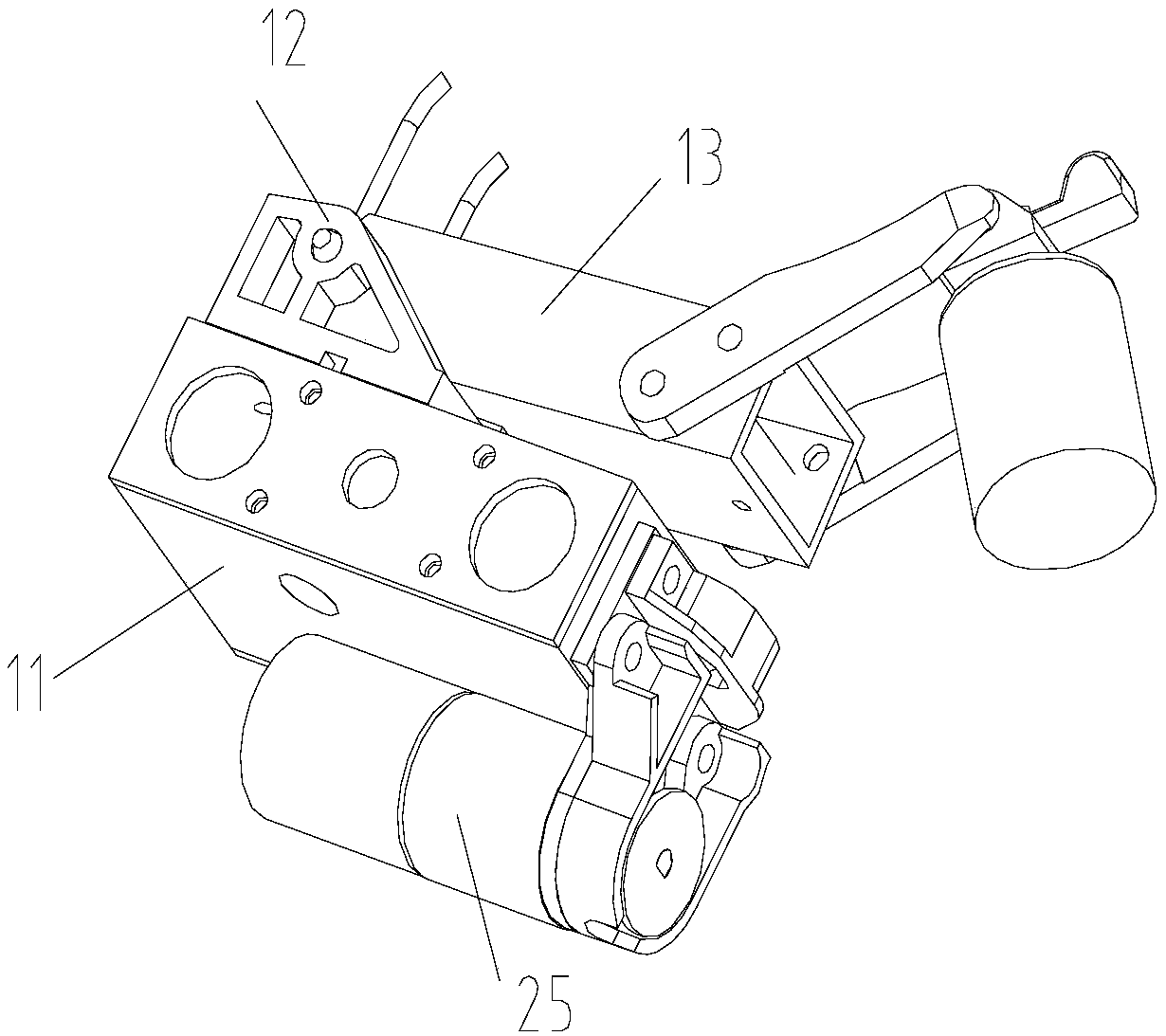

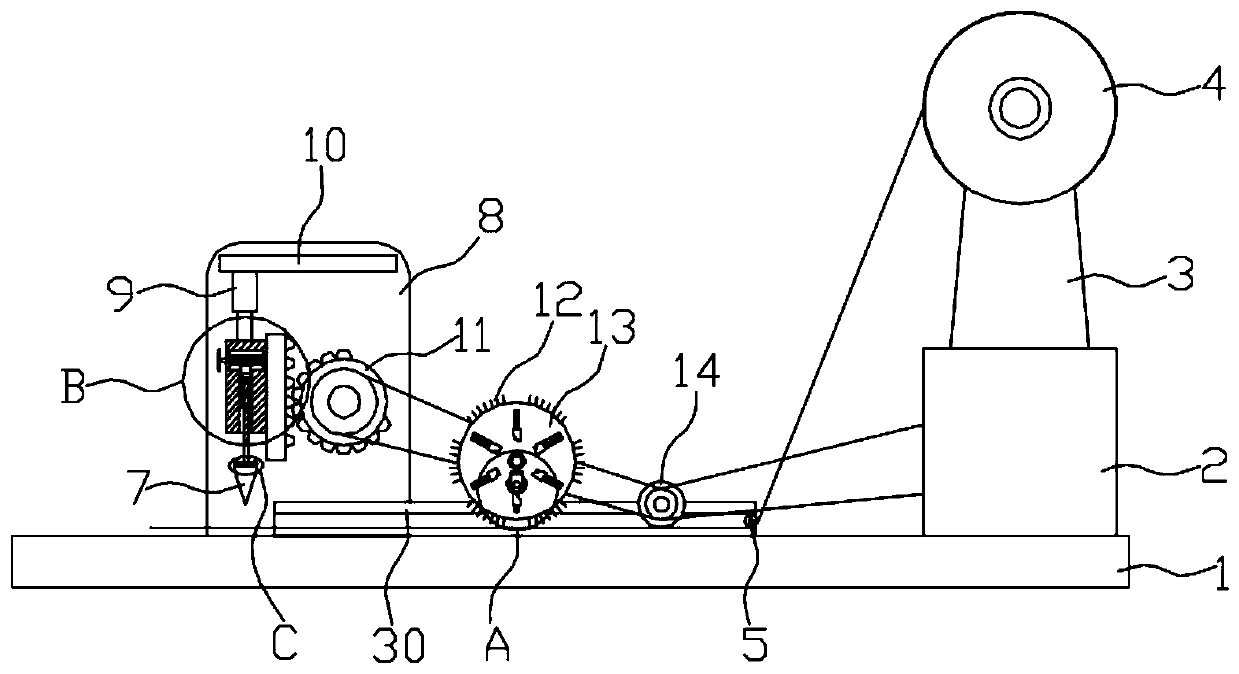

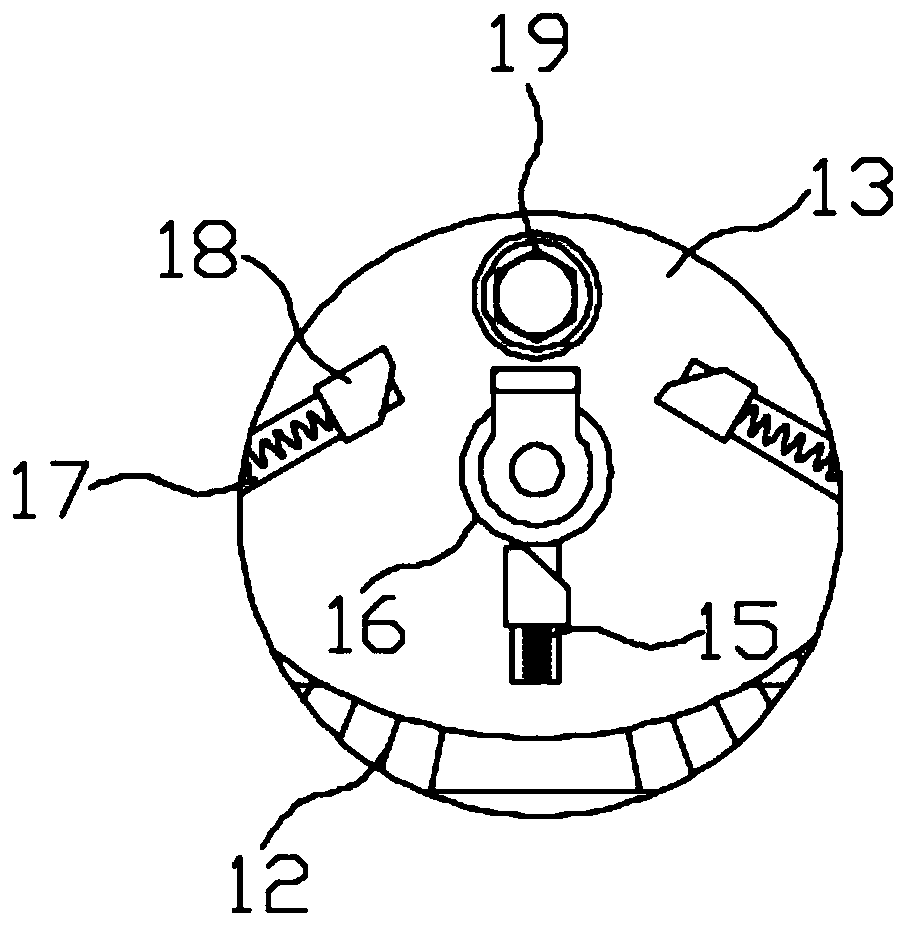

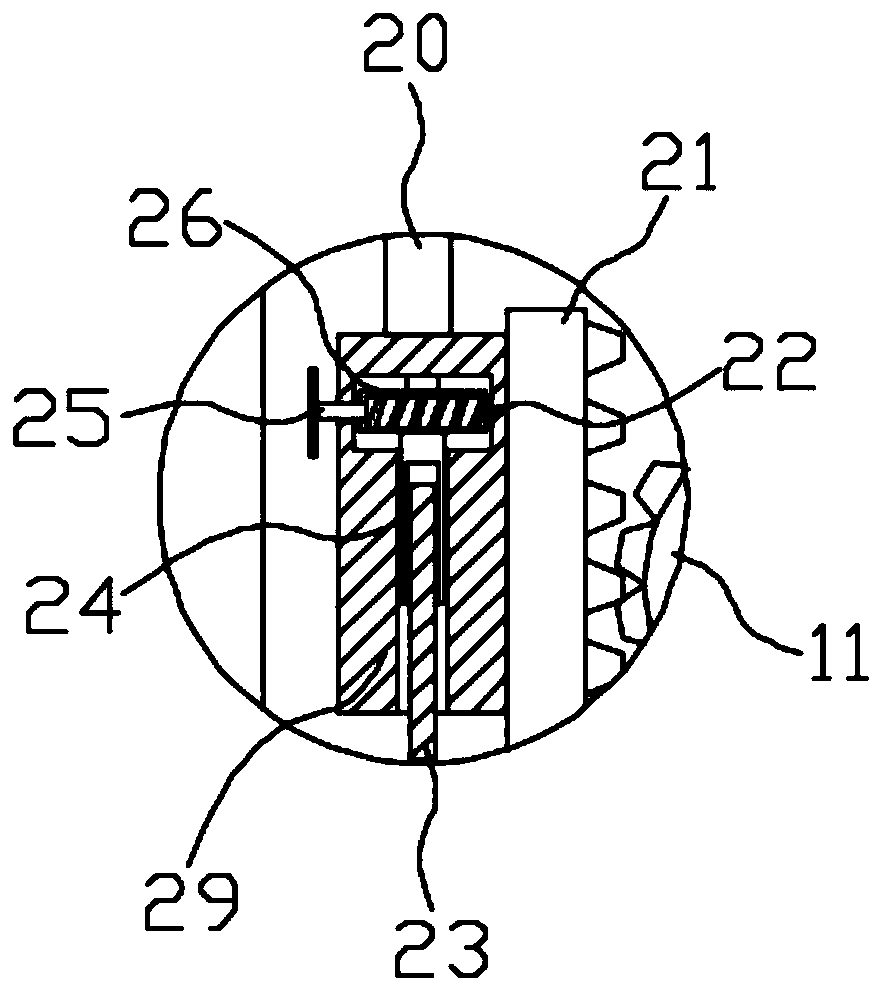

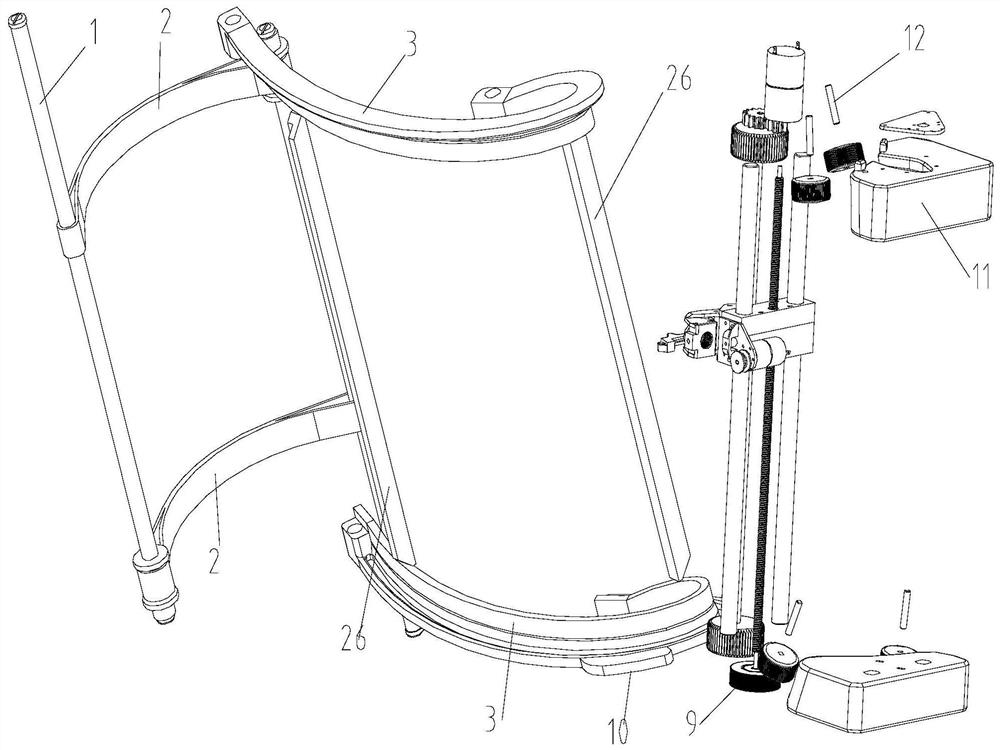

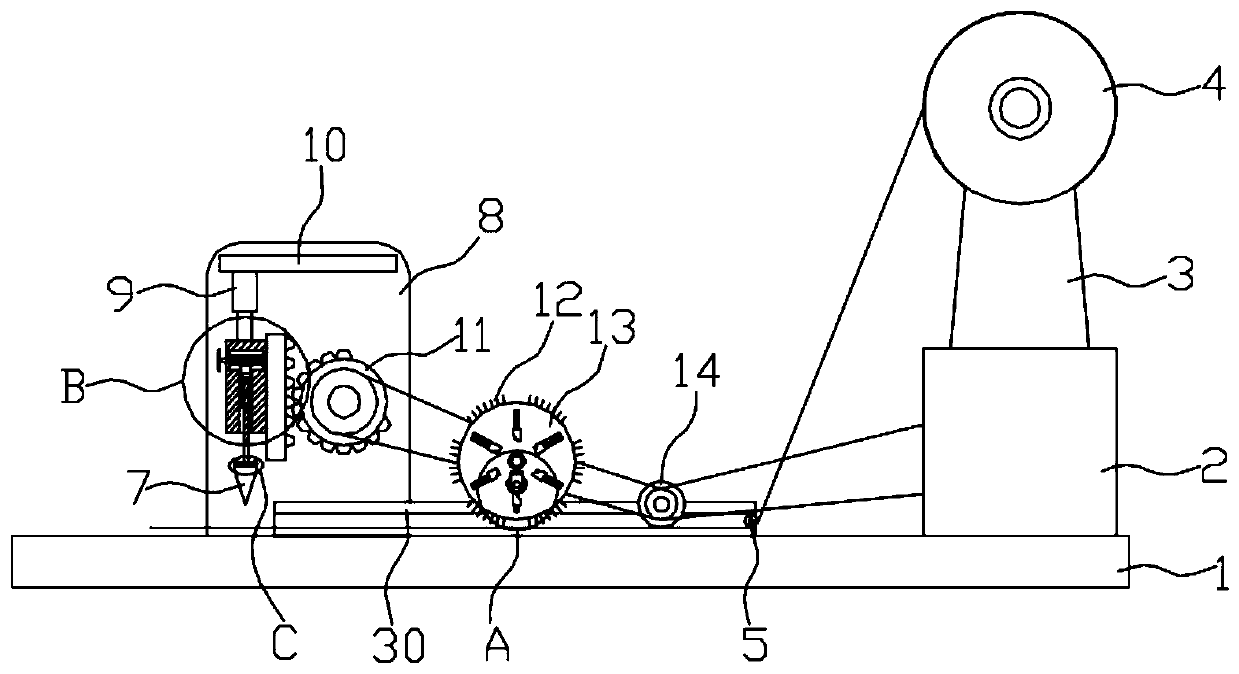

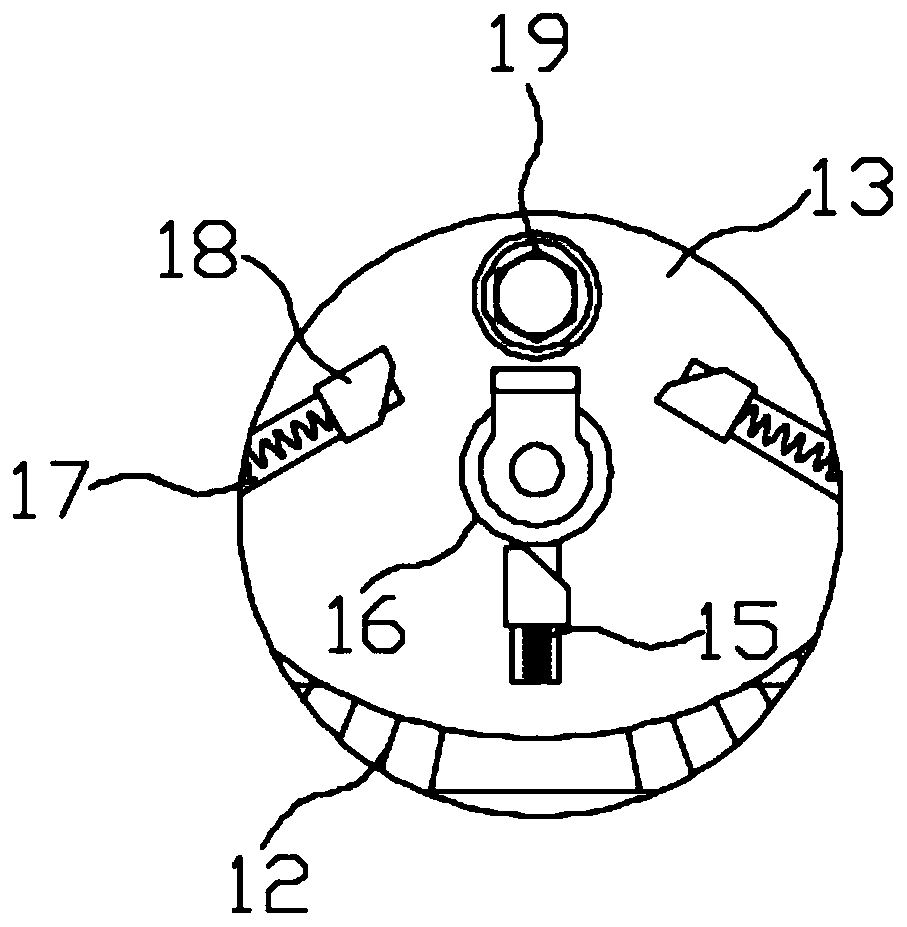

Rubber tapping machine and rubber tapping method

ActiveCN106034978ASolve labor intensitySolve the problem of insufficient fineness of manual tappingForestryEngineeringUltimate tensile strength

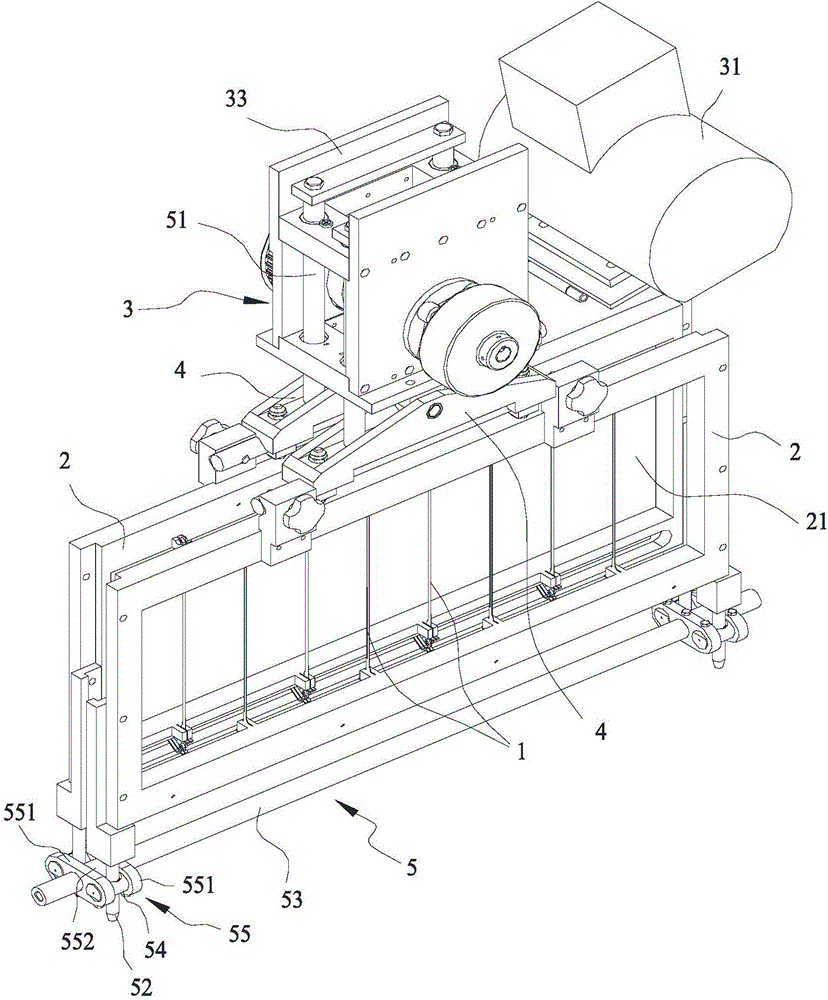

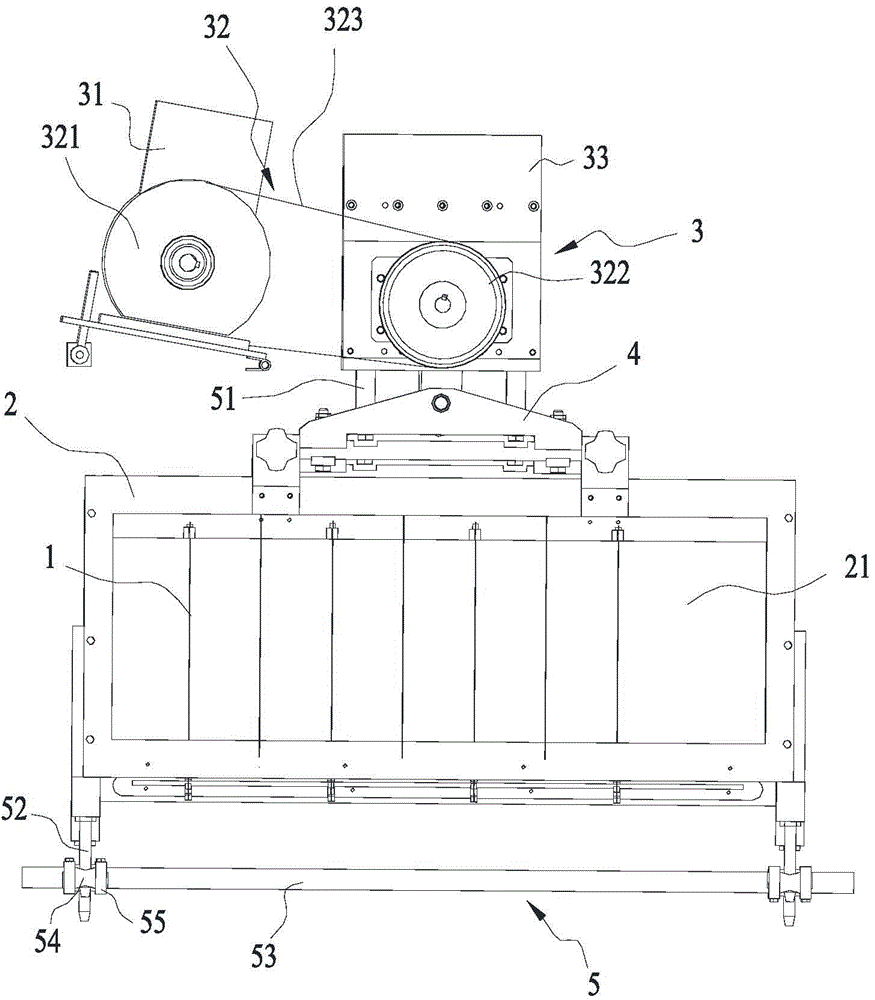

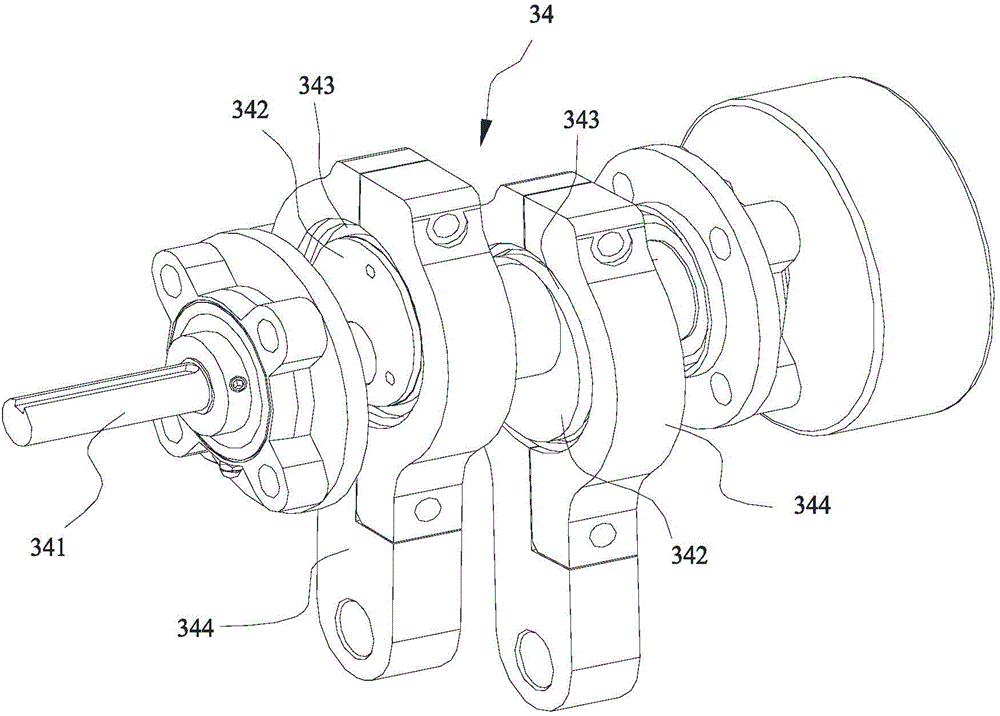

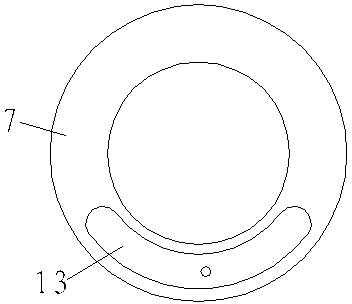

The invention discloses a rubber tapping machine and a rubber tapping method. The rubber tapping machine comprises a fixation frame, the top surface and the bottom surface of the fixation frame are respectively provided with annular planet gears in opposite arrangement, a knife rest assembly is installed between the top surface and the bottom surface of the fixation frame, the knife rest assembly is internally provided with a leading screw along a vertical direction, a rubber tapping assembly is installed on the leading screw and can be driven by the leading screw to vertically move along the leading screw, the rubber tapping assembly comprises a knife rest which is installed on the leading screw and can move vertically along the leading screw, one side of a cutter head swing arm is hinged to the knife rest through a torsion spring, the other side is hinged to a swing seat, the swing seat is provided with a cutter head angle adjustment seat, the top end of the cutter head angle adjustment seat is provided with a cutter head and a knife depth limiting member, and the knife rest is also provided with a knife collecting assembly which can overcome an elastic force of the torsion spring to draw the cutter head swing arm to the knife rest. The rubber tapping machine disclosed by the invention replaces labor with automatic machinery, realizes unmanned automatic rubber tapping for rubber trees, and solves the problems of large manual rubber tapping labor intensity and low manual rubber tapping precision to the maximum degree.

Owner:NINGBO CIHEVEA TECH CO LTD

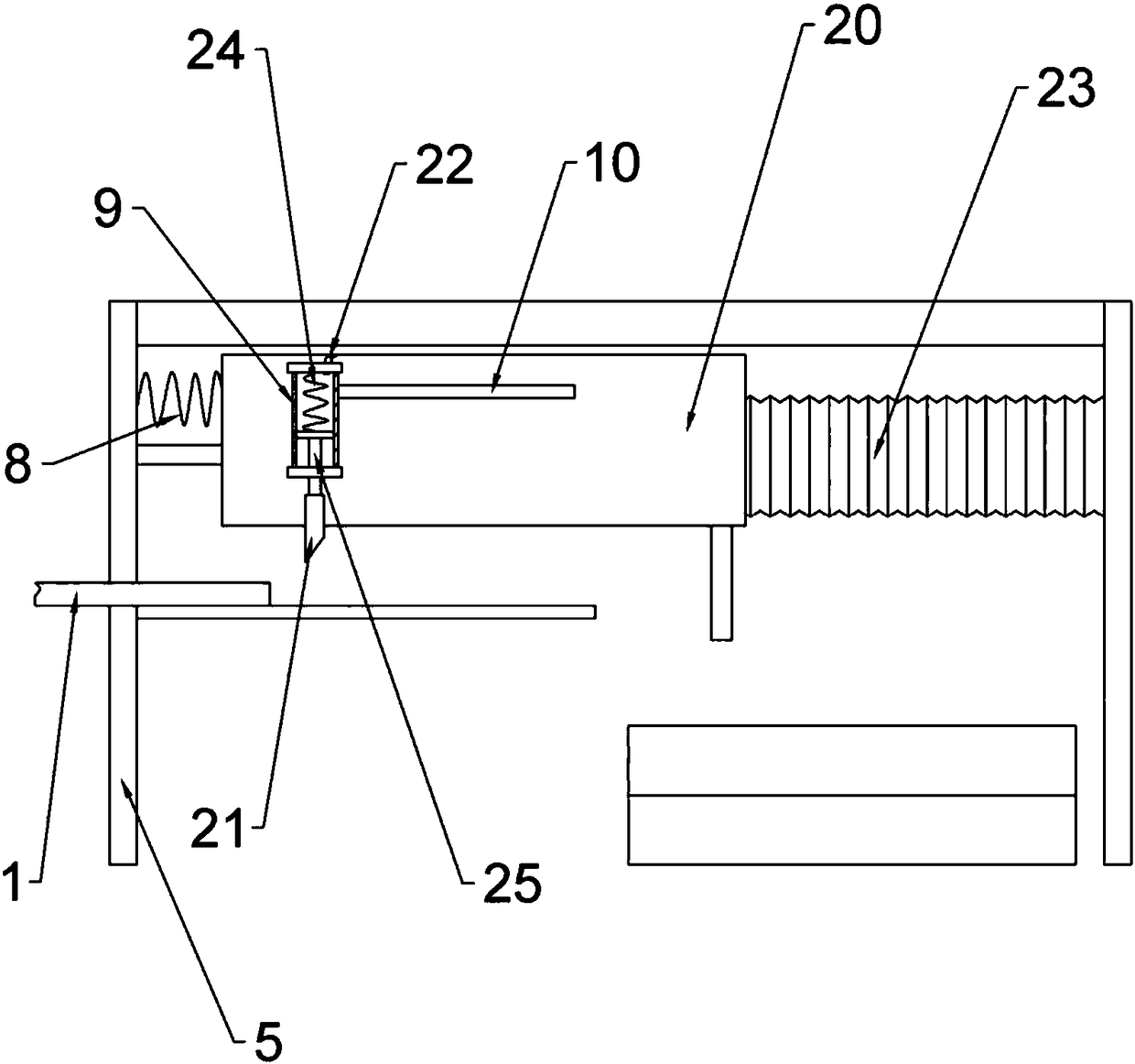

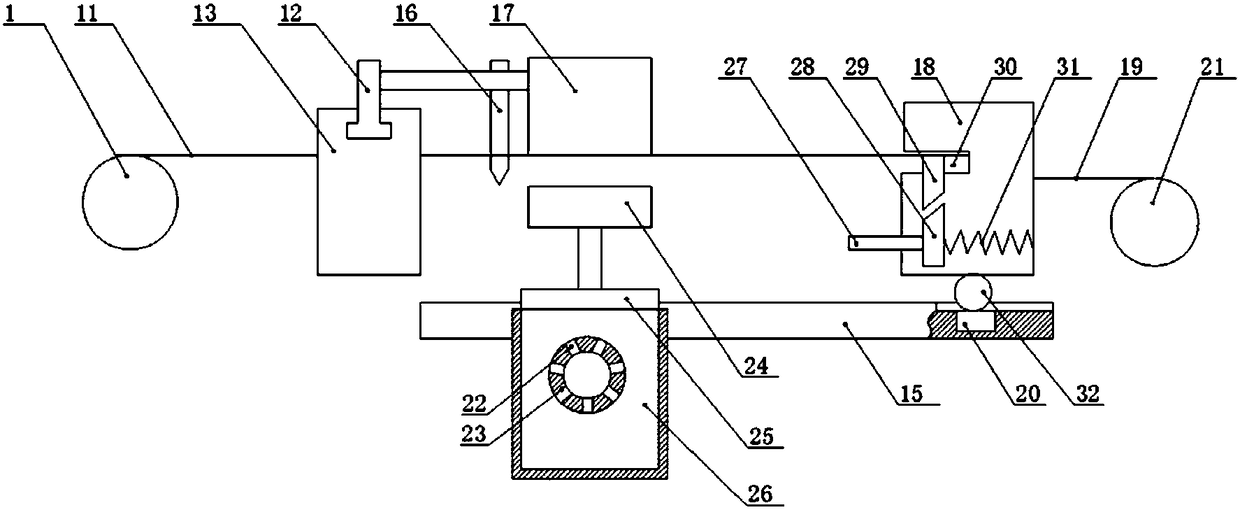

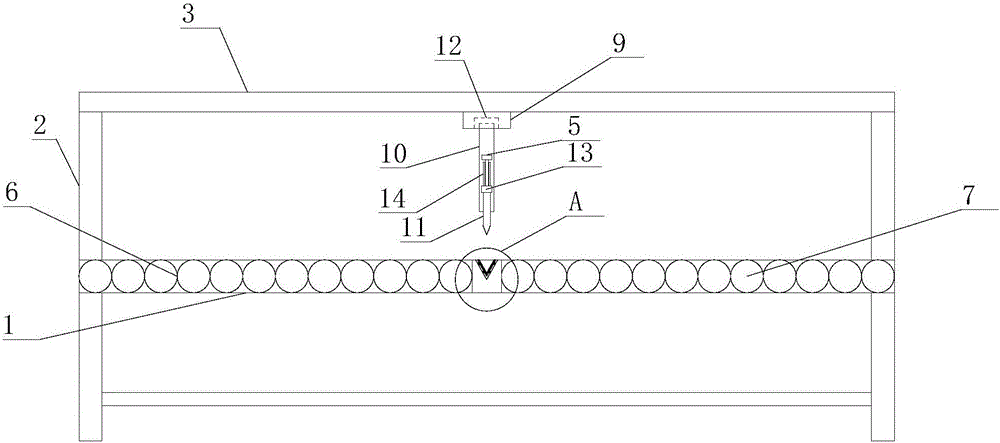

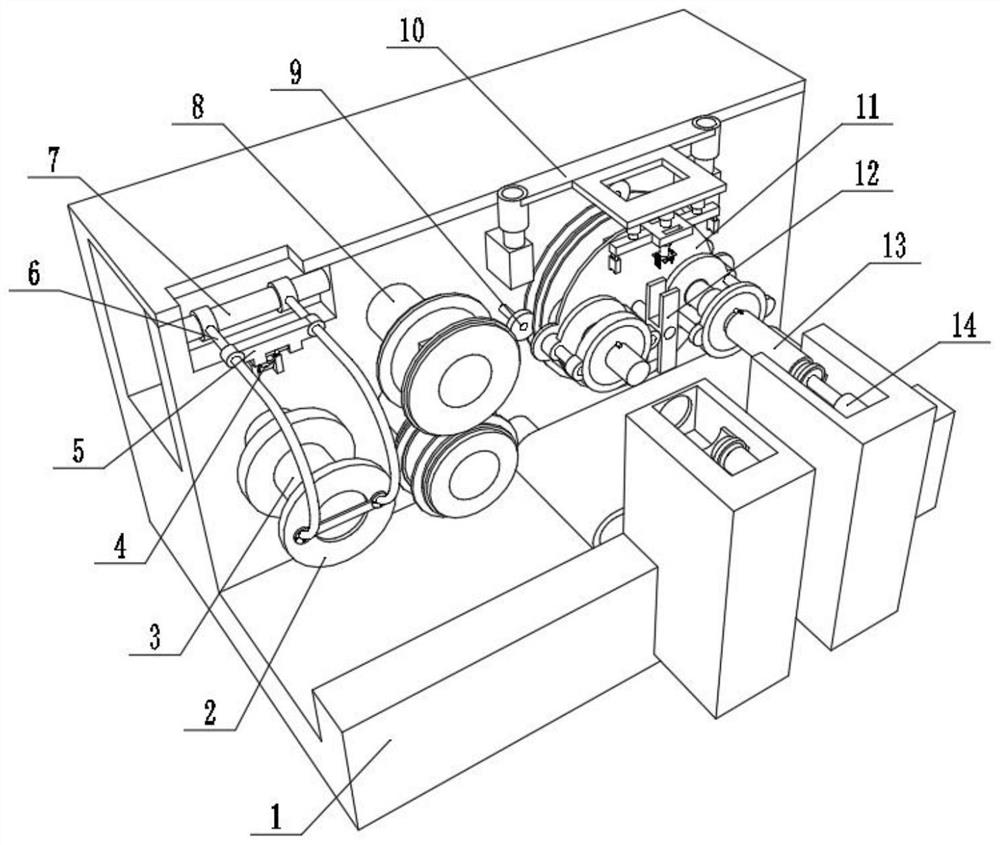

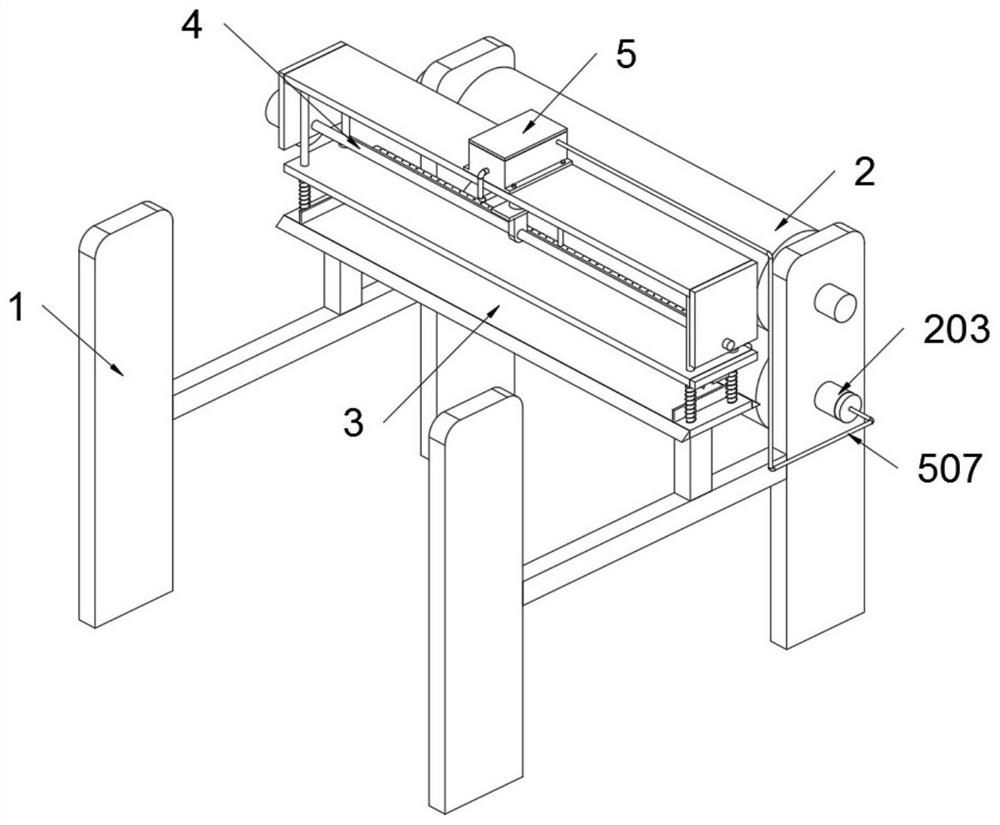

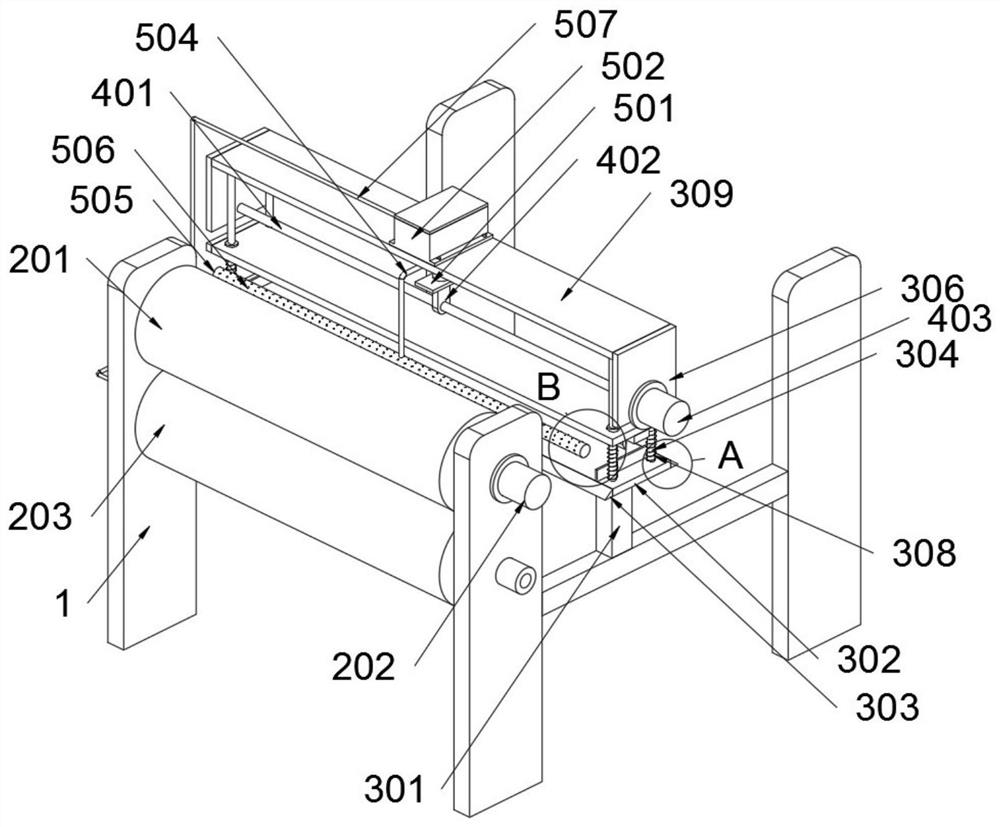

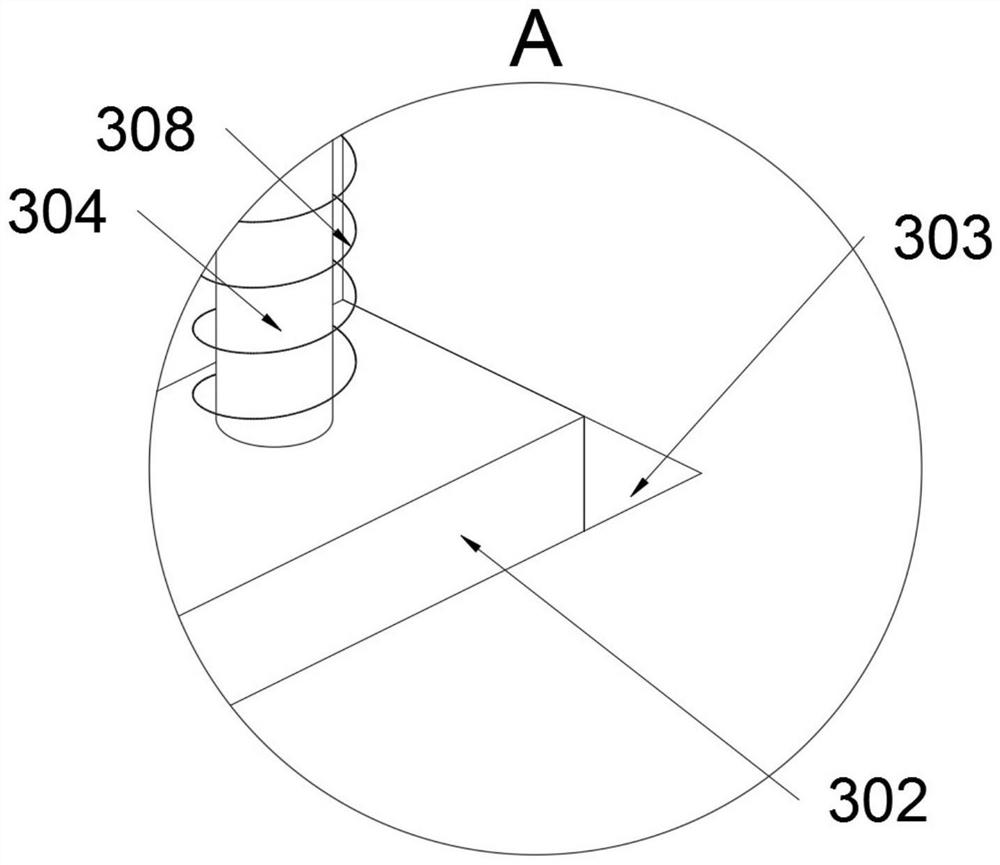

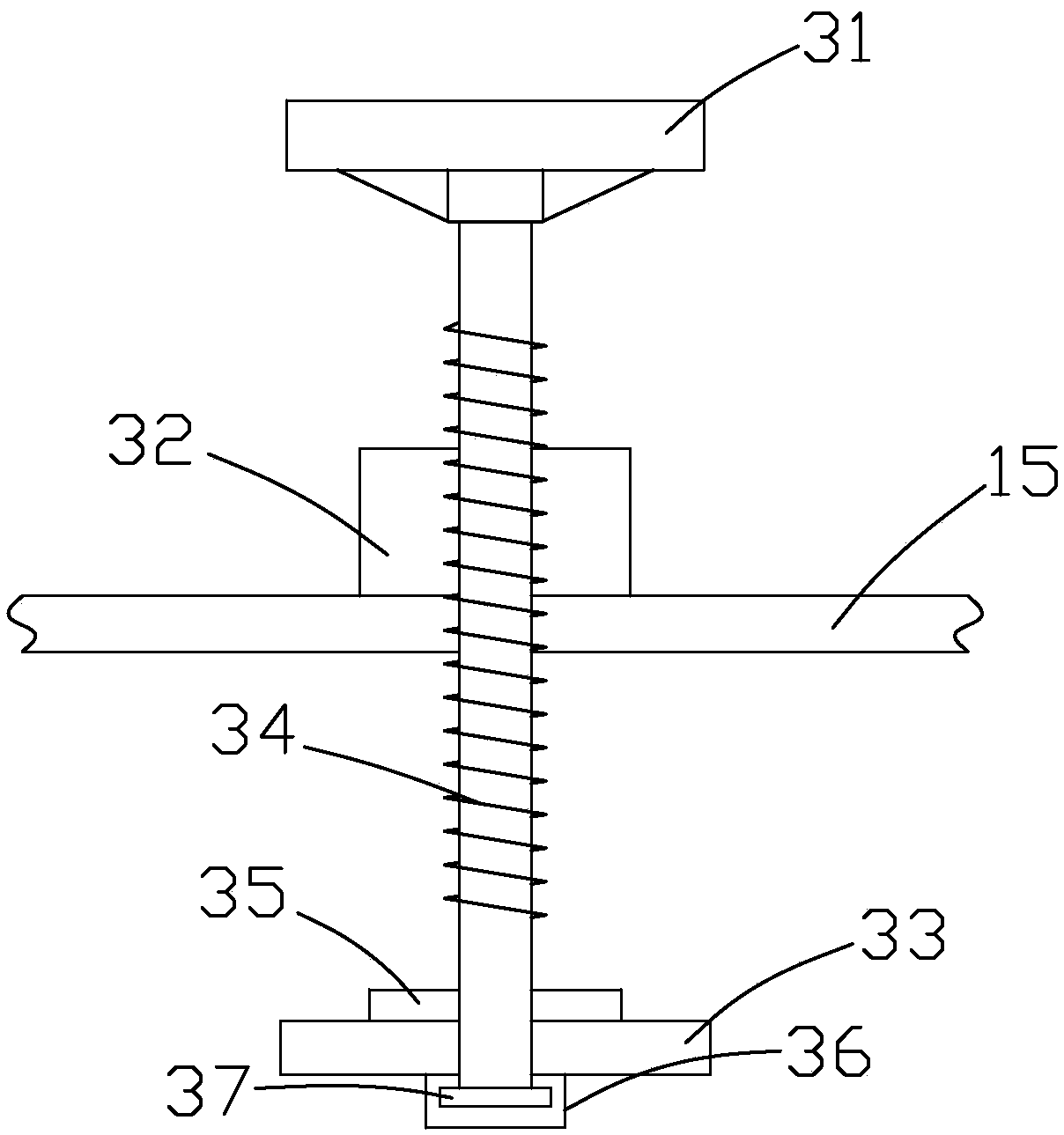

Fixed-length cutting device for tubular part

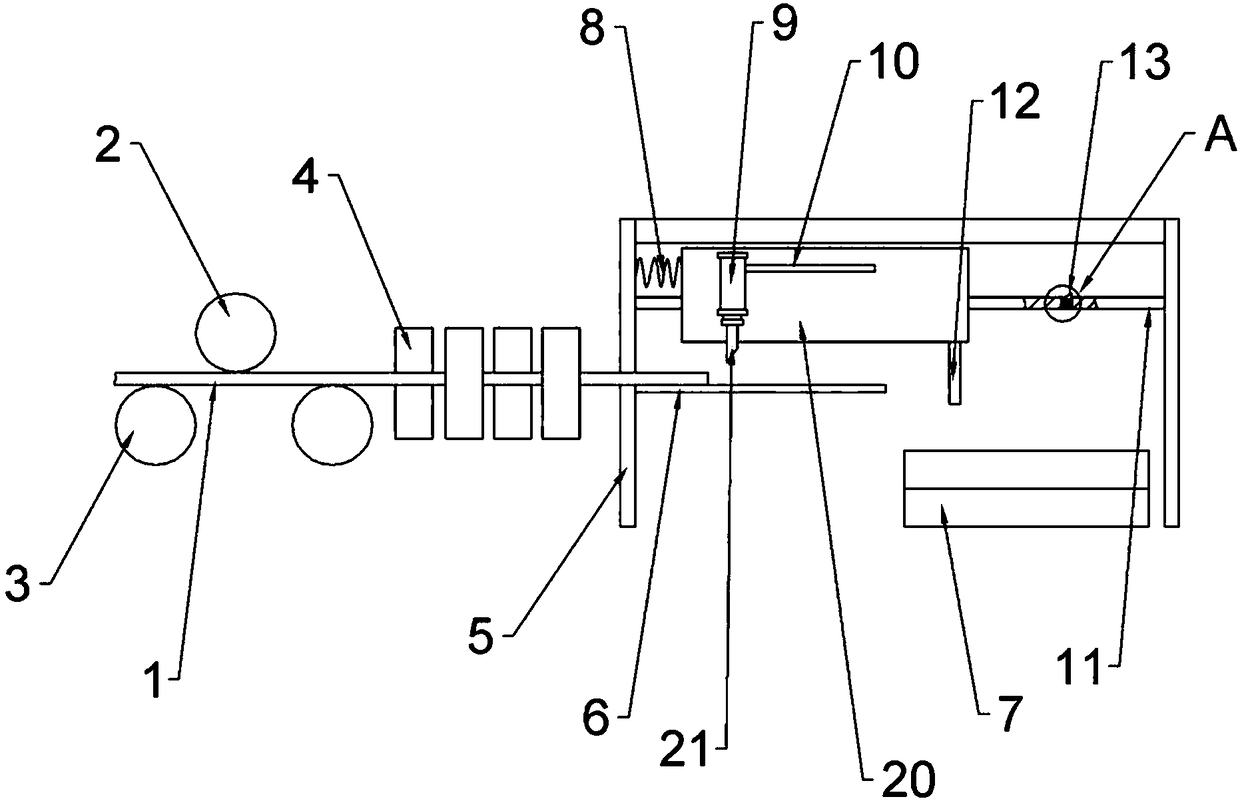

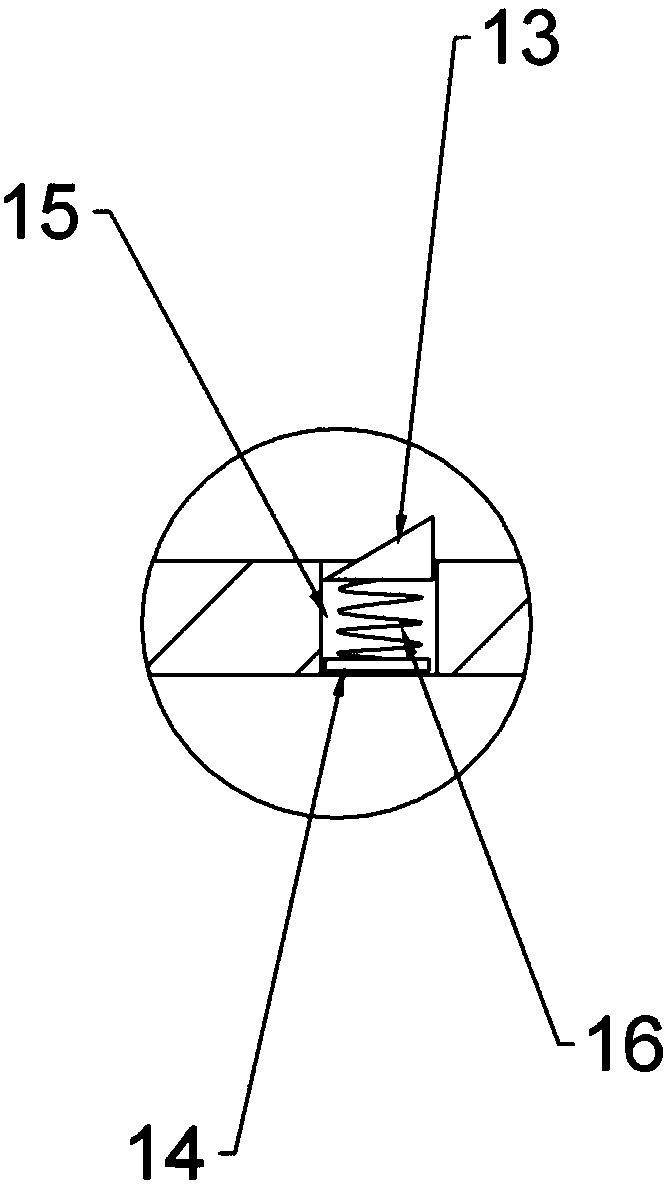

ActiveCN108480751AEasy to cutRealize continuous cuttingTube shearing machinesMetal working apparatusMotor vehicle partEngineering

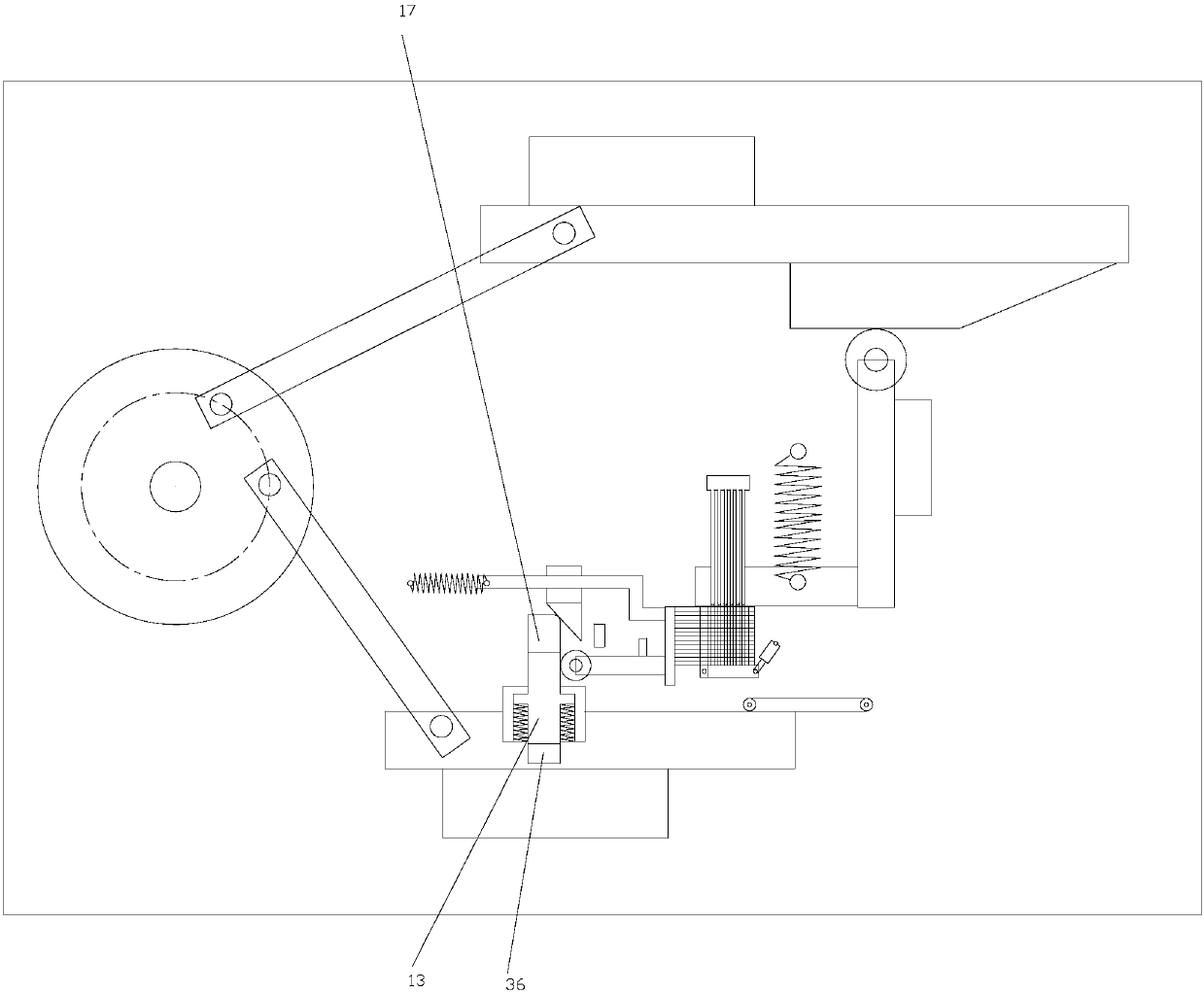

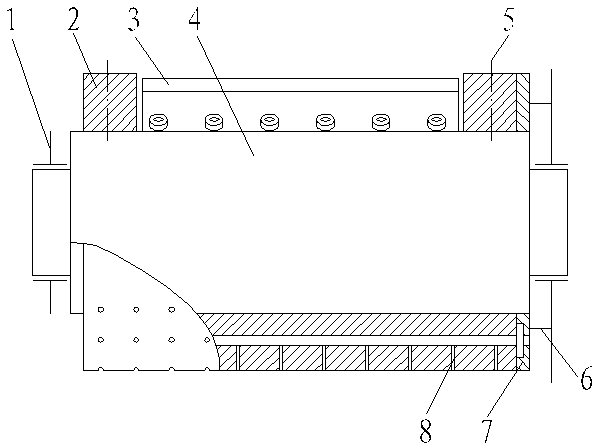

The invention belongs to the field of machining devices of automobile parts and particularly discloses a fixed-length cutting device for a tubular part. The fixed-length cutting device for the tubularpart comprises a rack, a cutter and a long pipe conveying mechanism for conveying a long pipe. The long pipe conveying mechanism is located on one side of the rack, the cutter is arranged on the rack, and the fixed-length cutting device for the tubular part further comprises an elastic part. The rack is provided with a sliding rail, the sliding rail is in sliding connection with a sliding seat, abaffle capable of abutting against the long pipe is arranged on the sliding seat, the baffle is perpendicular to the sliding rail, an air cylinder is arranged on the sliding seat and connected with apiston rod, and the piston rod is fixedly connected with the cutter which is parallel to the baffle. One end of the elastic part is connected with the sliding seat, and the other end of the elastic part is fixedly connected with the rack. The rack is provided with a control part capable of controlling the piston rod of the air cylinder to stretch out, and the sliding seat can trigger the controlpart. The device can achieve fixed-length cutting of the tubular part and ensures that all parts have the same length.

Owner:宁波鑫神泽汽车零部件有限公司

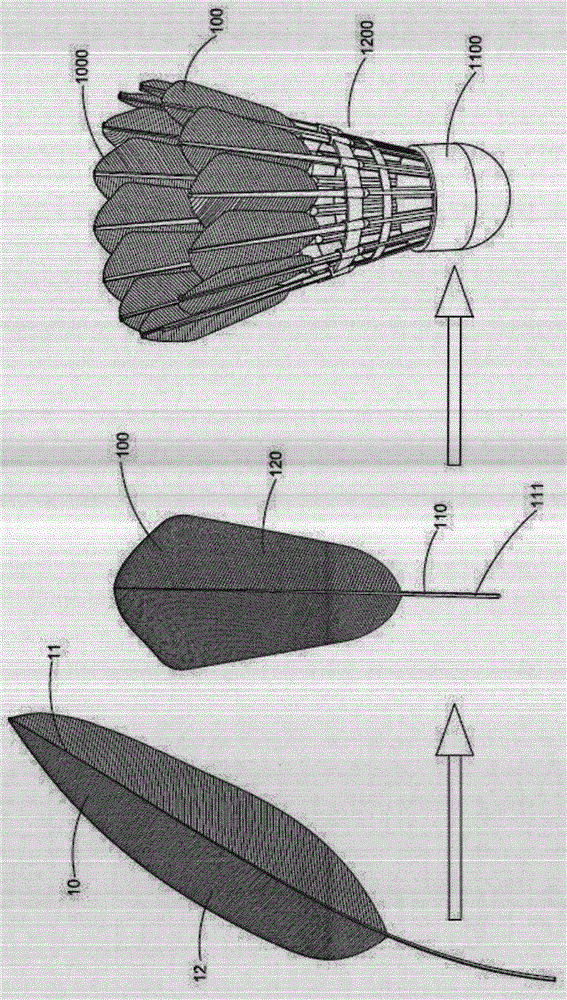

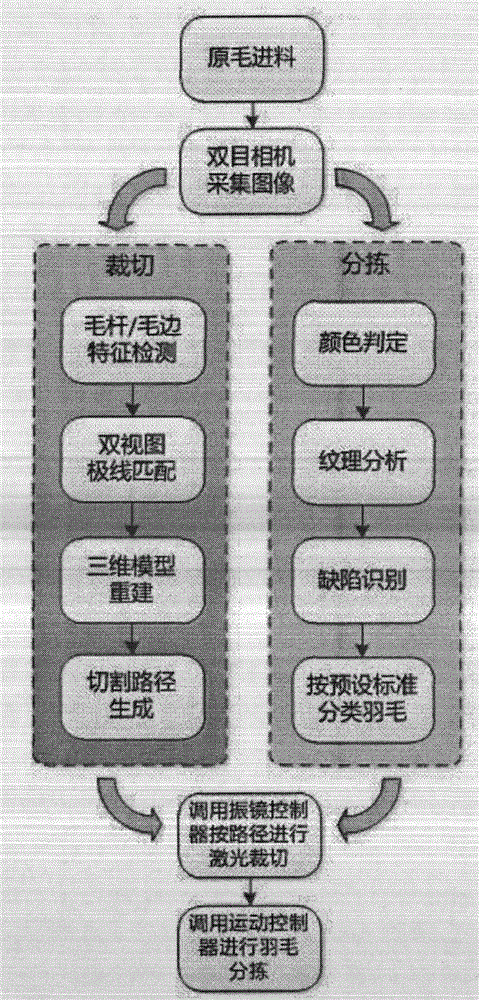

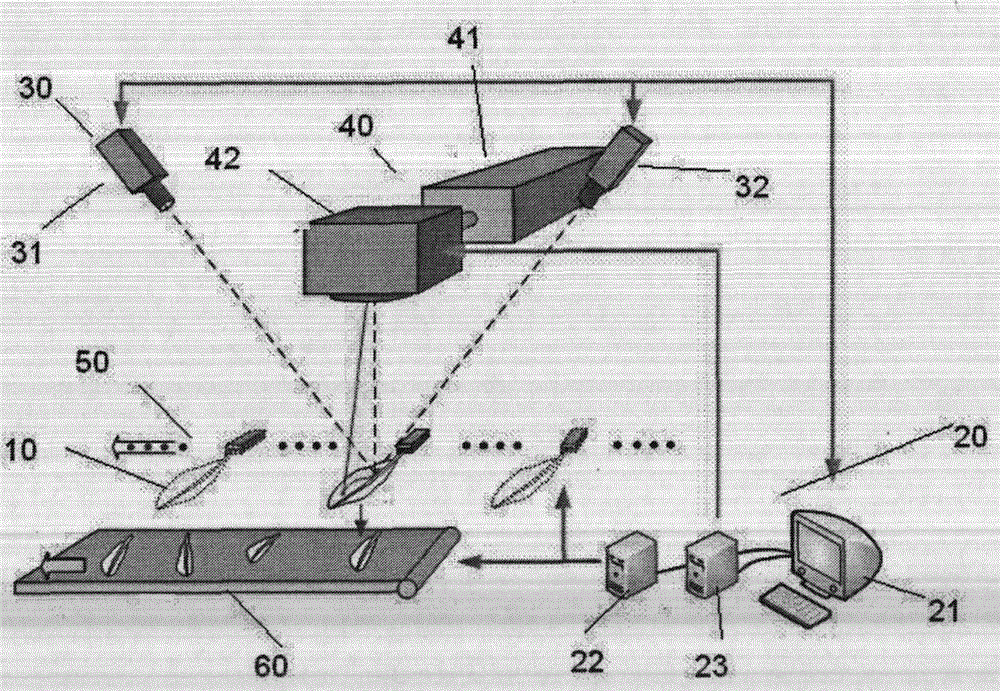

Intelligent processing system and method for feather pieces of shuttlecock

The invention discloses an intelligent processing system and method for feather pieces of a shuttlecock. The intelligent processing system comprises an image collecting system, an energy flow cutting system and a main control center, wherein the image collecting system obtains a preset number of parameter data of natural feather, the master control center provides one or more cutting models, after the parameter data are matched with a preset cutting model of the master control center, the master control center sends an instruction to the energy flow cutting system to cut the natural feather, and therefore the feather pieces used for making the shuttlecock are obtained.

Owner:戴见霖

Automatic garlic cutting equipment

ActiveCN107756497AAvoid the Hidden Dangers of Removing GarlicRemove constraintsMetal working apparatusInterference problemEngineering

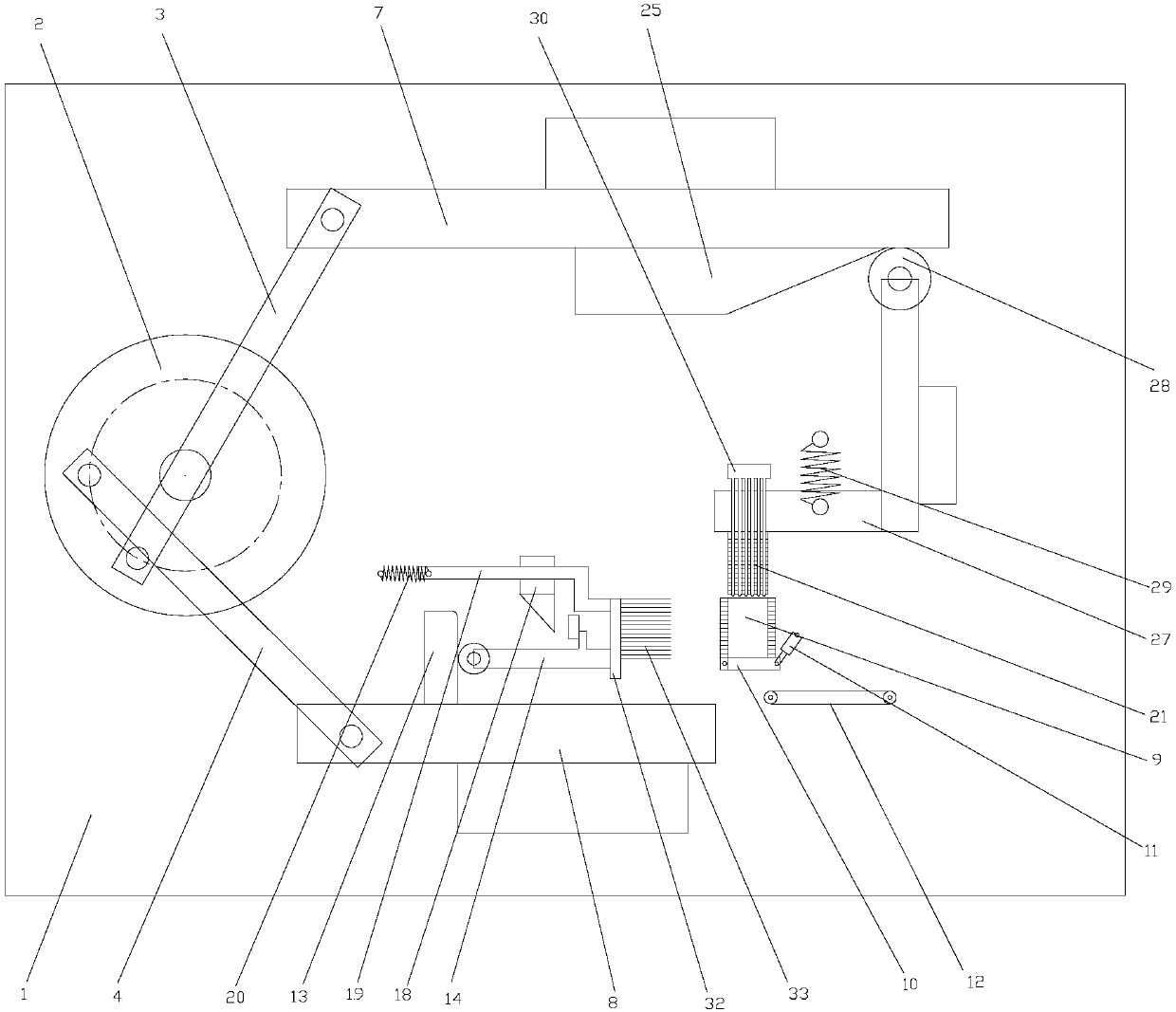

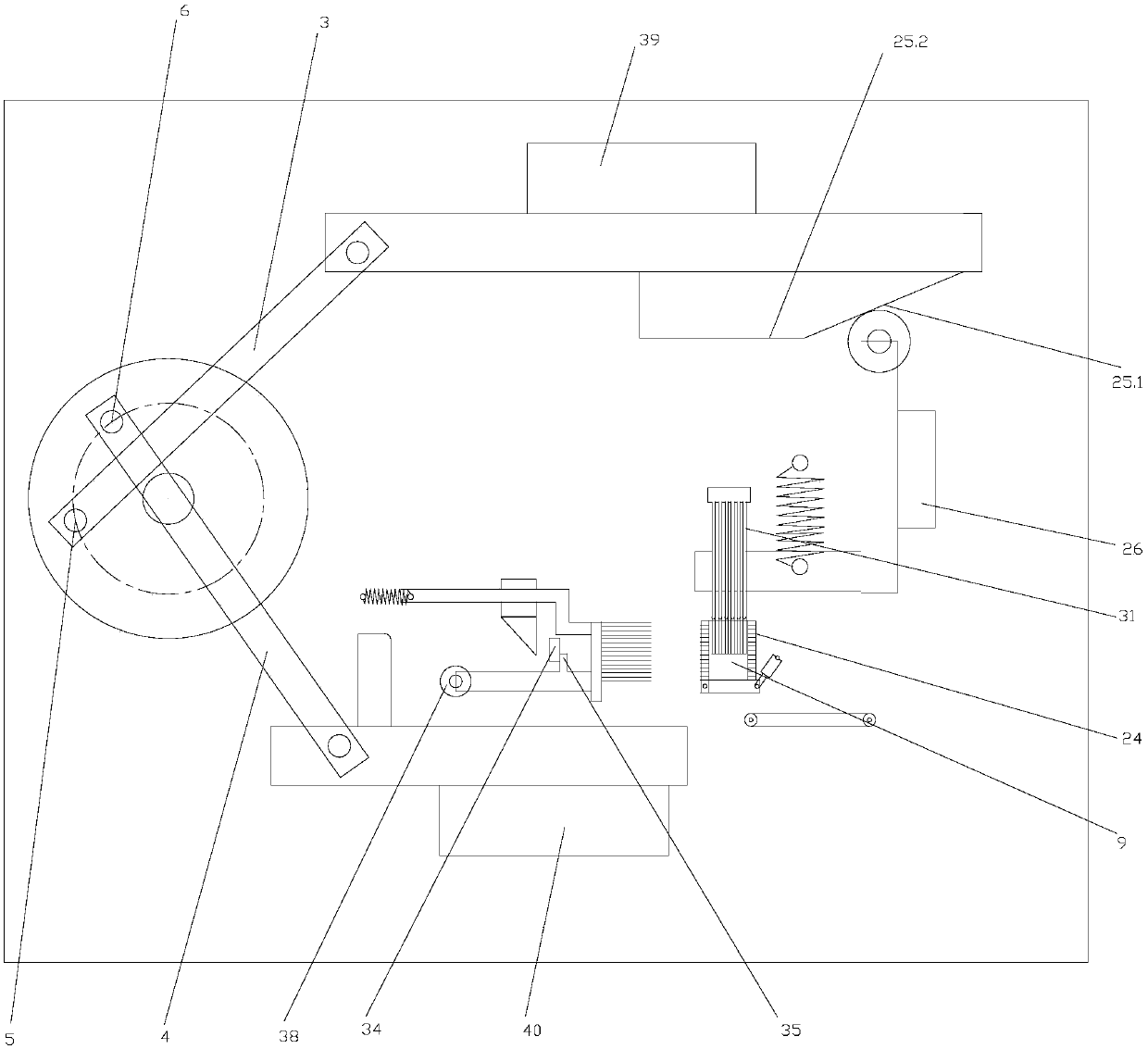

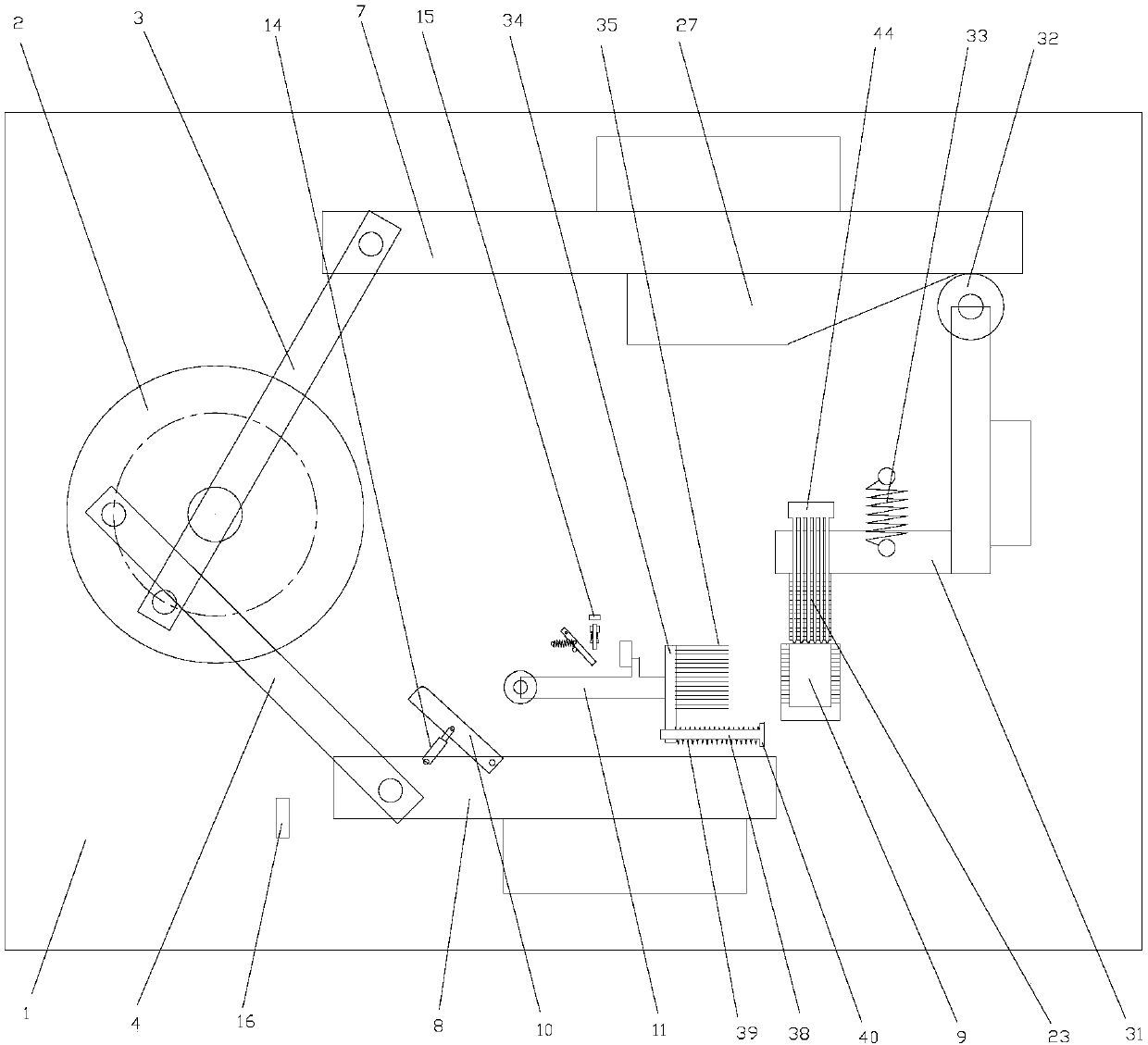

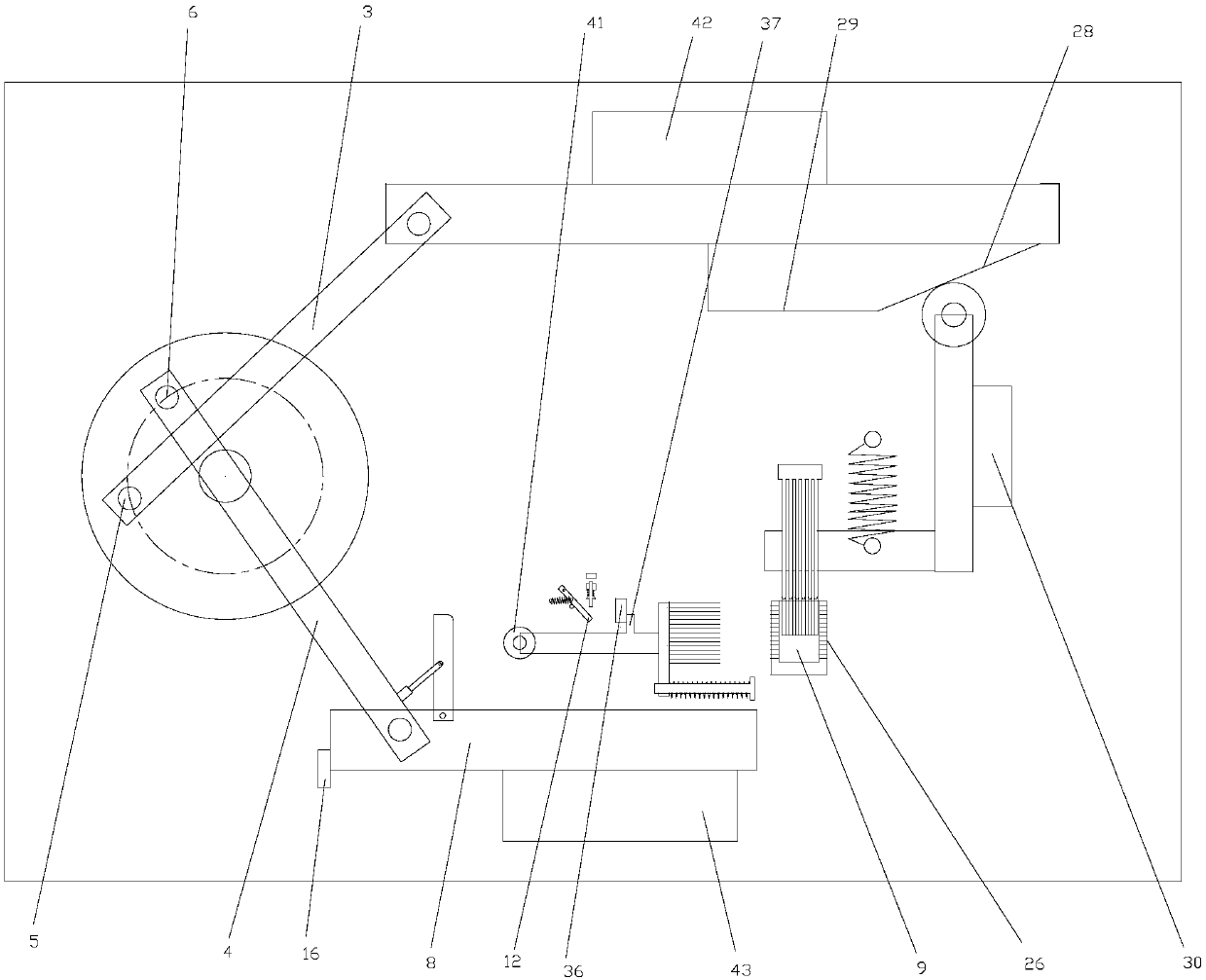

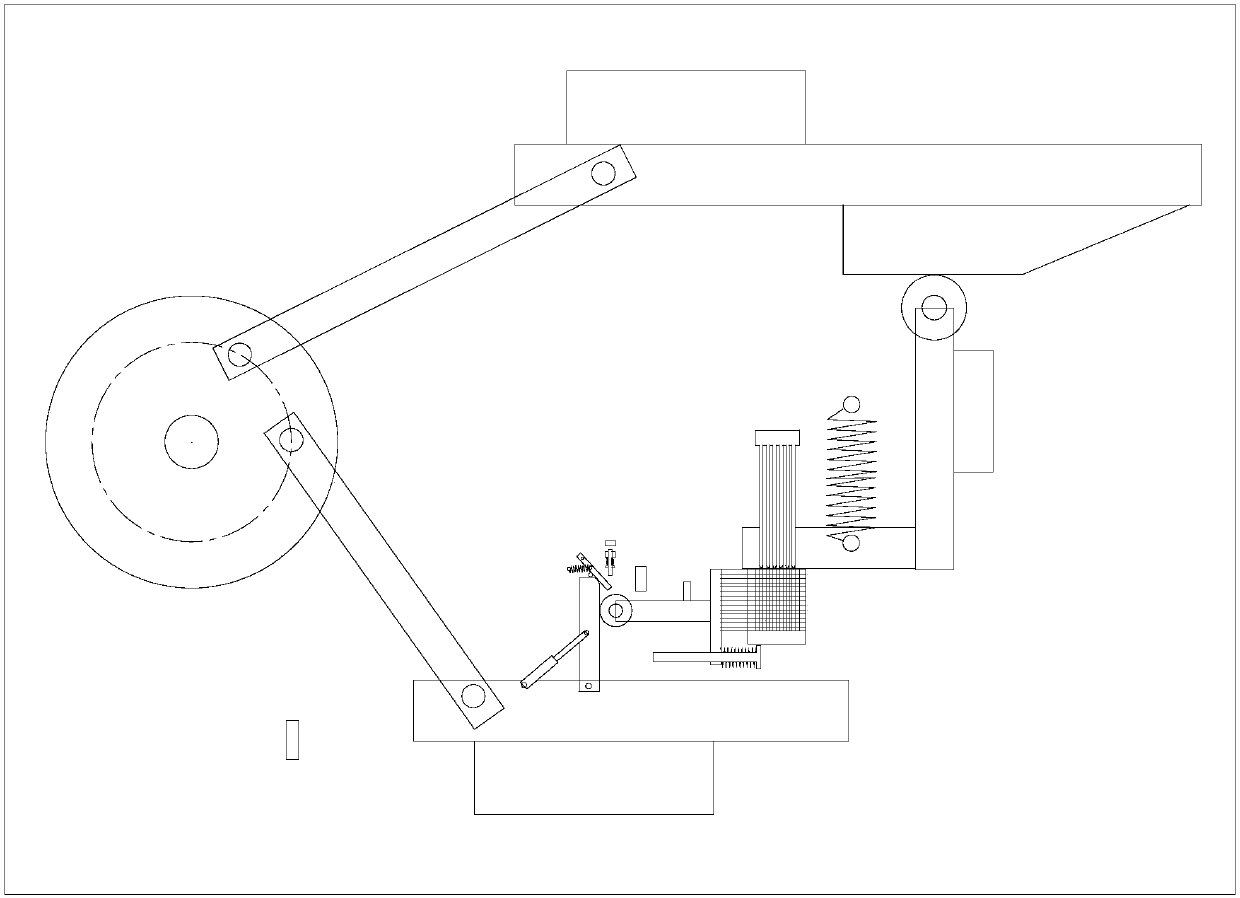

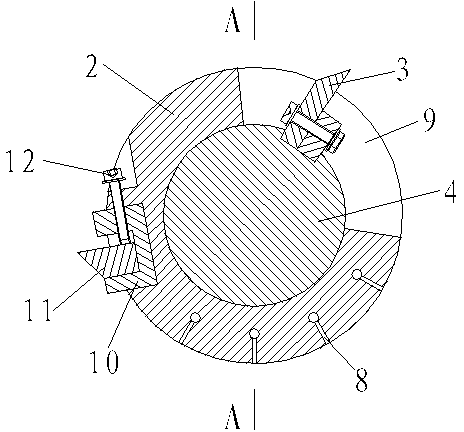

The invention discloses automatic garlic cutting equipment. The automatic garlic cutting equipment comprises a base. A disc is rotationally connected to the base; a motor used for driving the disc torotate is arranged on the base; the disc is rotationally connected with a first connecting rod through a first hinging point and rotationally connected with a second connecting rod through a second hinging point; the distance between the first hinging point and the axis of the disc is equal to the distance between the second hinging point and the axis of the disc; and the first hinging point and the second hinging point are distributed in a spaced mode in the circumferential direction of the disc. By arranging an upper crank sliding block mechanism and a lower crank sliding block mechanism onthe same disc simultaneously, longitudinal sliding of a cutter cylinder and transverse sliding of blades are achieved, the cutter cylinder and the blades work in a cross cutting mode, and accordinglygarlic is cut into minced garlic; and the motion interference problem does not exist during longitudinal sliding of the cutter cylinder and transverse sliding of the blades, so that the transmission stability of the whole device is improved, and the automatic garlic cutting equipment is higher in cutting efficiency and automation level.

Owner:金乡县天佳食品有限公司

Fabric cutting device for textiles

ActiveCN108411611AImprove the forceImprove flatnessSevering textilesMagnetic polesMechanical engineering

The invention relates to the technical field of textile product processing, in particular to a fabric cutting device for textiles. The device comprises a feeding roller, a clamping mechanism is slidably arranged on one side of the feeding roller, a fixing plate is arranged between the clamping mechanism and the feeding roller, a sliding rail is connected between the fixing plate and the clamping mechanism, the clamping mechanism can slides on the sliding rail, a fixing mechanism is arranged at the end, away from the fixing plate, of the sliding rail, a through hole for fabrics to penetrate through is formed in the fixing plate, a sliding groove is formed in the top of the fixing plate, a sliding rod is slidably arranged in the sliding groove, a driving mechanism is connected with the sliding rod, a pressing block made of electromagnet is arranged on the side, close to the fixing mechanism, of the sliding rod, a cutter is connected between the pressing block and the sliding rail, a first magnet is arranged below the pressing block, the magnetic poles of the opposite faces of the first magnet and the electromagnet are opposite, and a collecting mechanism is arranged below the first magnet. By means of the device, the technical problem of uneven cutting position of the fabric in the prior art can be solved.

Owner:NINGBO WENZE TEXTILE CO LTD

Cutting device for clothing processing

InactiveCN109881465ARealize continuous cuttingEase of mass productionMechanical cleaningPressure cleaningBristleDrive motor

The invention discloses a cutting device for clothing processing. The cutting device comprises a base, wherein the upper end of the base is fixedly connected with a first vertical plate, a second vertical plate, a third vertical plate and a fourth vertical plate in the horizontal direction in sequence, the upper end side wall of the fourth vertical plate is rotationally connected with a cloth winding roller, the upper end of the base is fixedly connected with a driving motor, an output shaft of the driving motor is in transmission connection with the cloth winding roller through a synchronousbelt, the upper end of the base is welded with two tracks used for cloth guiding, the side wall of the third vertical plate is rotationally connected with a conveying roller, the conveying roller is in transmission connection with the output shaft of the driving motor through a synchronous belt, and the side wall of the second vertical plate is rotationally connected with an ironing mechanism usedfor ironing cloth. The cutting device for clothing processing has the advantages that the to-be-cut cloth can be sterilized and ironed, bristles on the surface of a cylinder clean fluff on the surface of the cloth, chippings generated during cloth cutting are reduced, and the device can achieve continuous cutting and facilitate scale production.

Owner:JILIN TEACHERS INST OF ENG & TECH

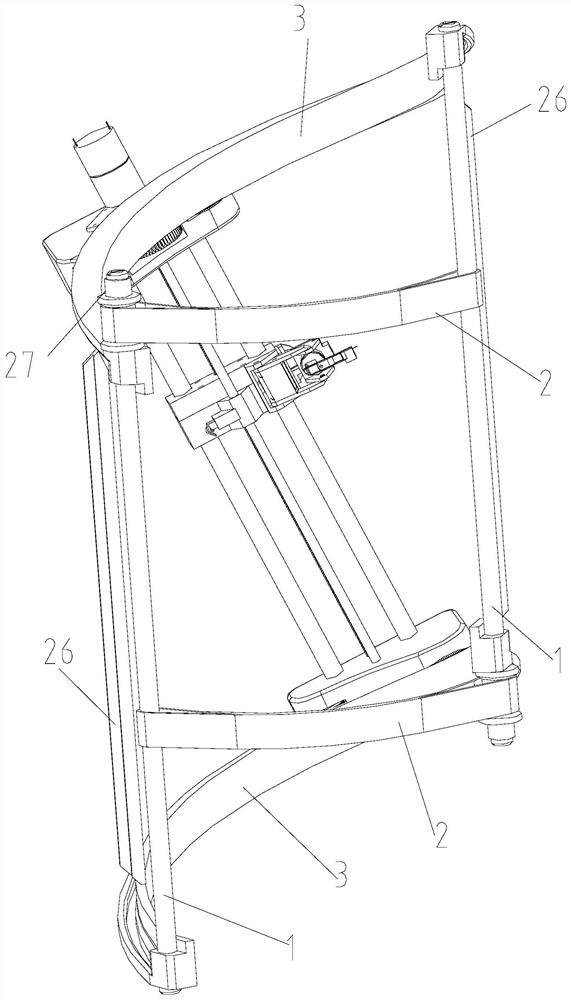

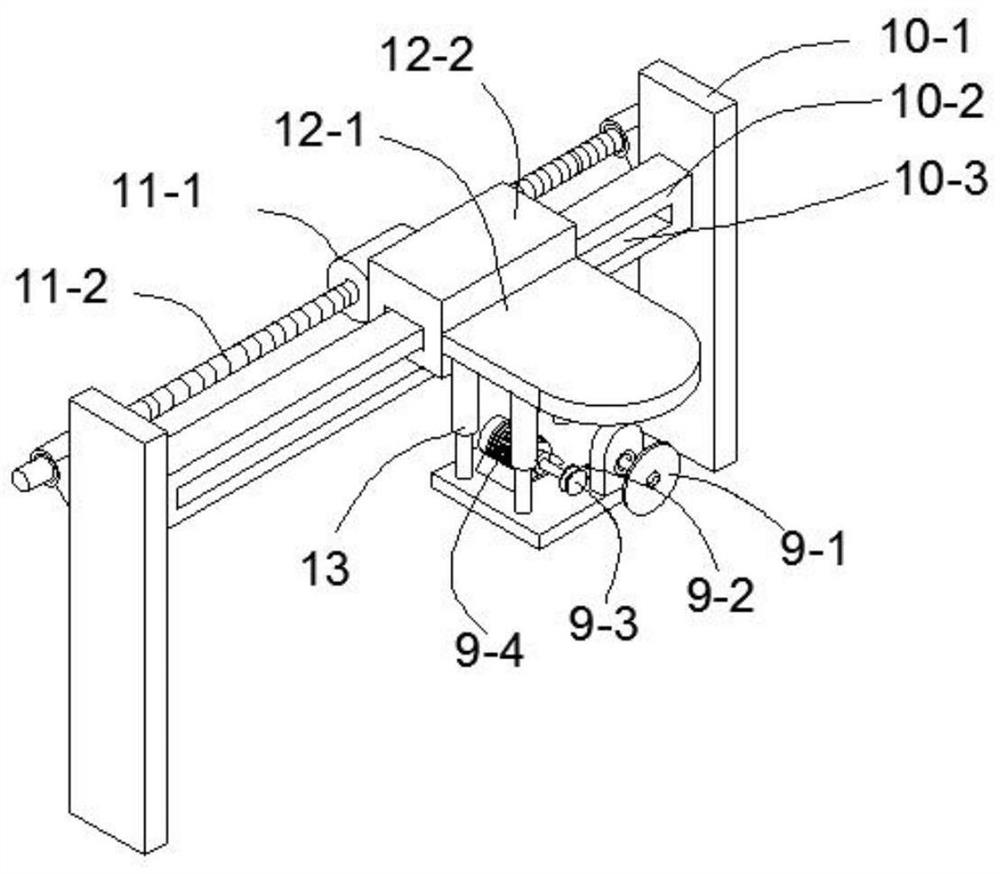

Rubber tapping machine and rubber tapping method

PendingCN111972250ARealize unmanned automatic tappingSolve labor intensityForestryElectric machineryEngineering

The invention discloses a rubber tapping machine and a rubber tapping method. The rubber tapping machine comprises two supporting steel pipes, wherein one sides of the two supporting steel pipes are connected through binding belts, the other sides of the two supporting steel pipes are connected through an upper spiral guide rail and a lower spiral guide rail, and the positions of the spiral guiderails are opposite to the positions of the binding belts on the opposite sides of the spiral guide rails; the rubber tapping machine further comprises a knife rest assembly with a motor and a limit switch; the upper end and the lower end of a power steel shaft of the knife rest assembly are provided with power wheels capable of rolling along the spiral guide rails respectively; in addition, the knife rest assembly is further provided with a lead screw and more than one fixing rod in the vertical direction; the upper end and the lower end of the knife rest assembly penetrate through the lead screw and the fixing rod to be provided with main machine shells respectively; the main machine shells are clamped in grooves of the spiral guide rails; guide roller shafts are arranged in the main machine shells; guide rollers are arranged on the corresponding guide roller shafts; and the rubber tapping machine further comprises a rubber tapping knife assembly. According to the rubber tapping machine, manual work is replaced with automatic machinery, unmanned automatic rubber tapping of a rubber tree is achieved, and the problems that the labor intensity of manual rubber tapping is large and manual rubber tapping is not refined enough are solved to the maximum extent.

Owner:NINGBO CIHEVEA TECH CO LTD

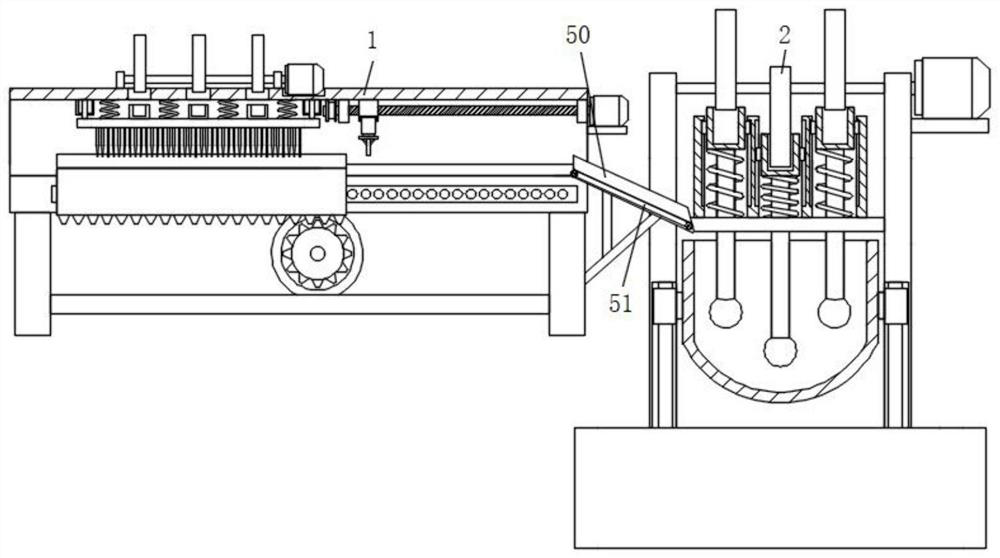

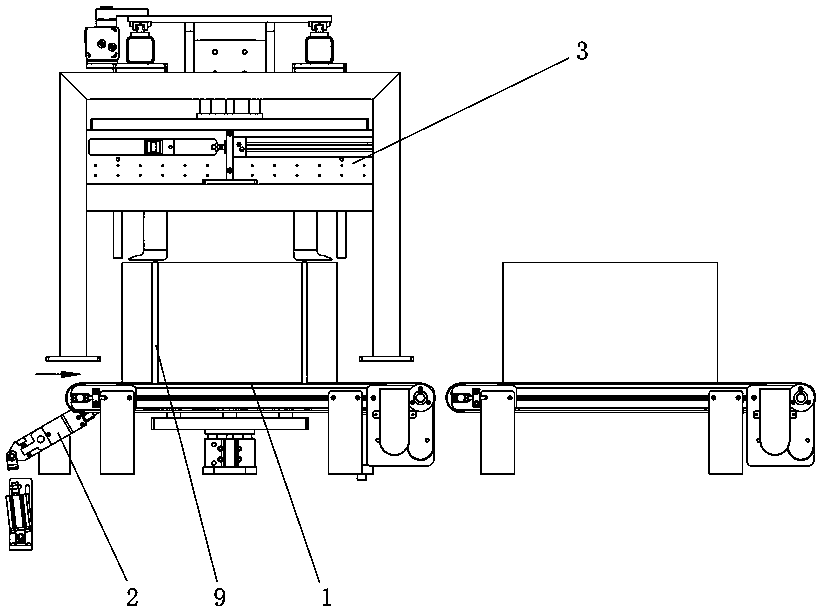

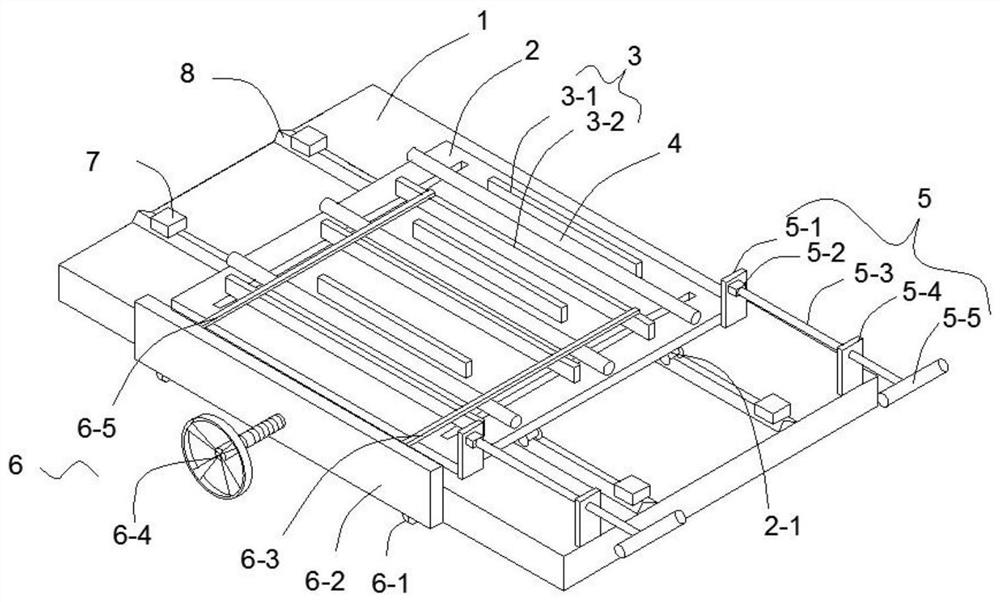

Paperboard cutting device for corrugated carton

ActiveCN105904496AAvoid damageRealize continuous cuttingMetal working apparatusArticle feedersCartonPaperboard

The invention provides a paperboard cutting device for a corrugated carton. The paperboard cutting device comprises a workbench, two side frames, a mounting plate, a cutting plate, a cutting mechanism, a first driving mechanism, a second driving mechanism, a third driving mechanism and a fourth driving mechanism. A first conveying roller set is arranged between the cutting plate and the feed end of the workbench. A second conveying roller set is arranged between the cutting plate and the discharge end of the workbench. A cutting groove is formed in the cutting plate in the direction perpendicular to the conveying direction of the first conveying roller set. The cutting mechanism comprises a mounting base, a mounting column and a cutting knife used for cutting paperboards. The first driving mechanism is used for driving the first conveying roller set to rotate. The second driving mechanism is used for driving the second conveying roller set to rotate. The third driving mechanism is used for driving the mounting column to move in the extending direction of the cutting groove. The fourth driving mechanism is used for driving the cutting knife to move in the vertical direction. The paperboards are continuously cut through mutual cooperation of the first conveying roller set, the second conveying roller set, the cutting plate and the cutting mechanism.

Owner:肇庆协隆机械制造有限公司

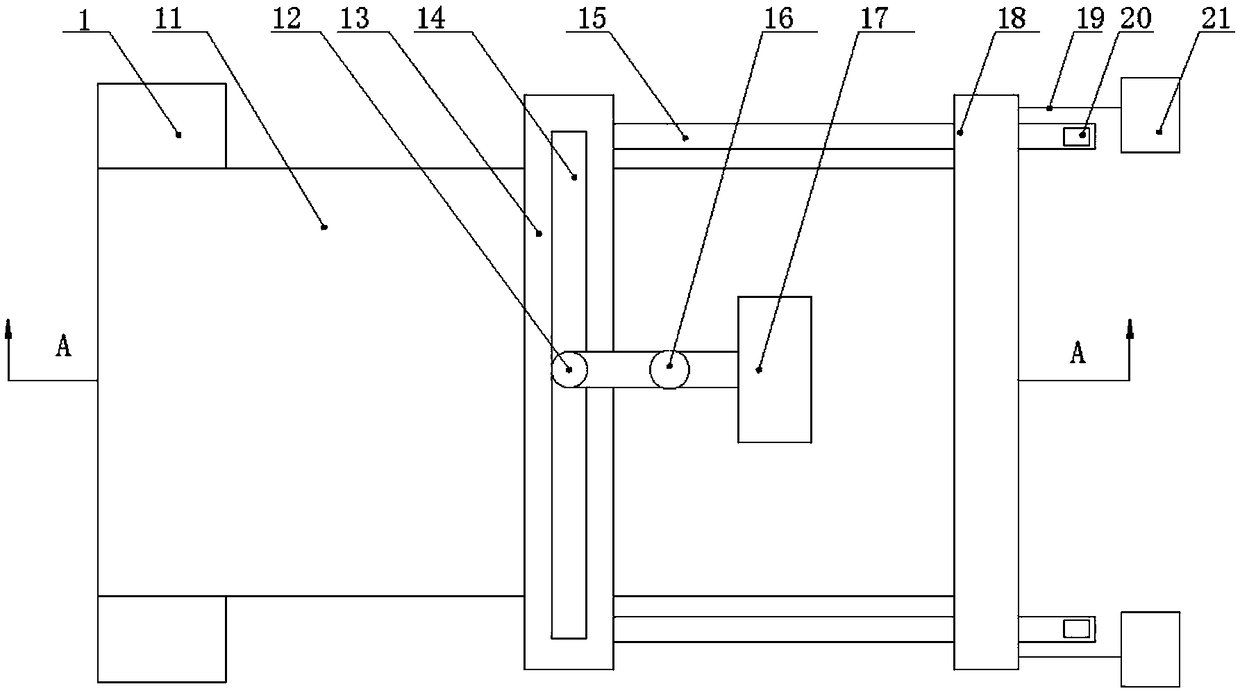

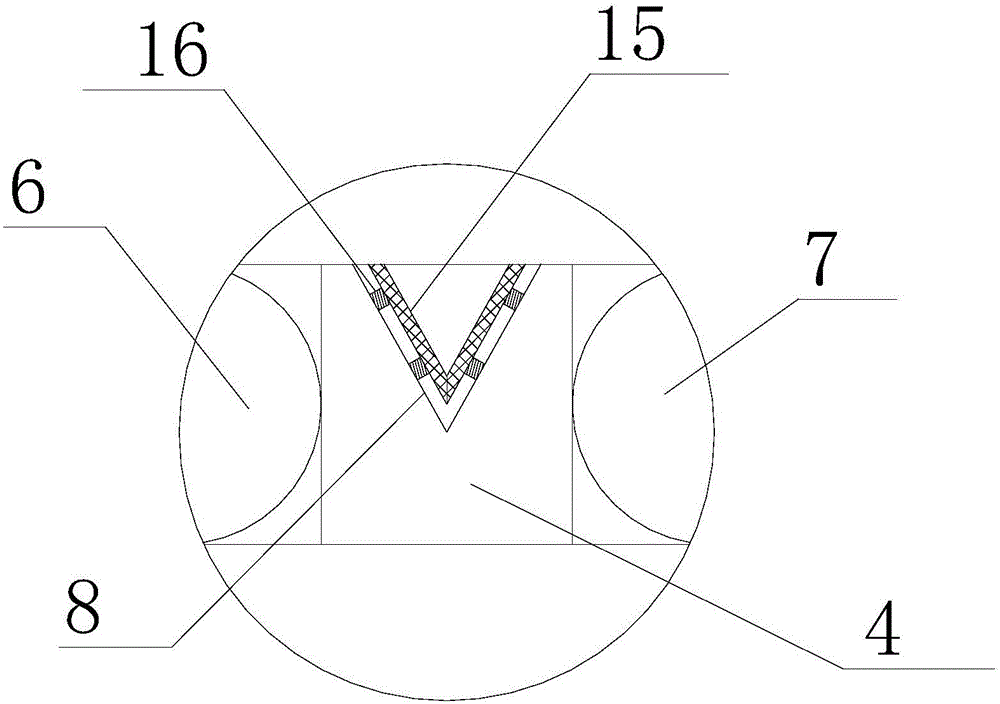

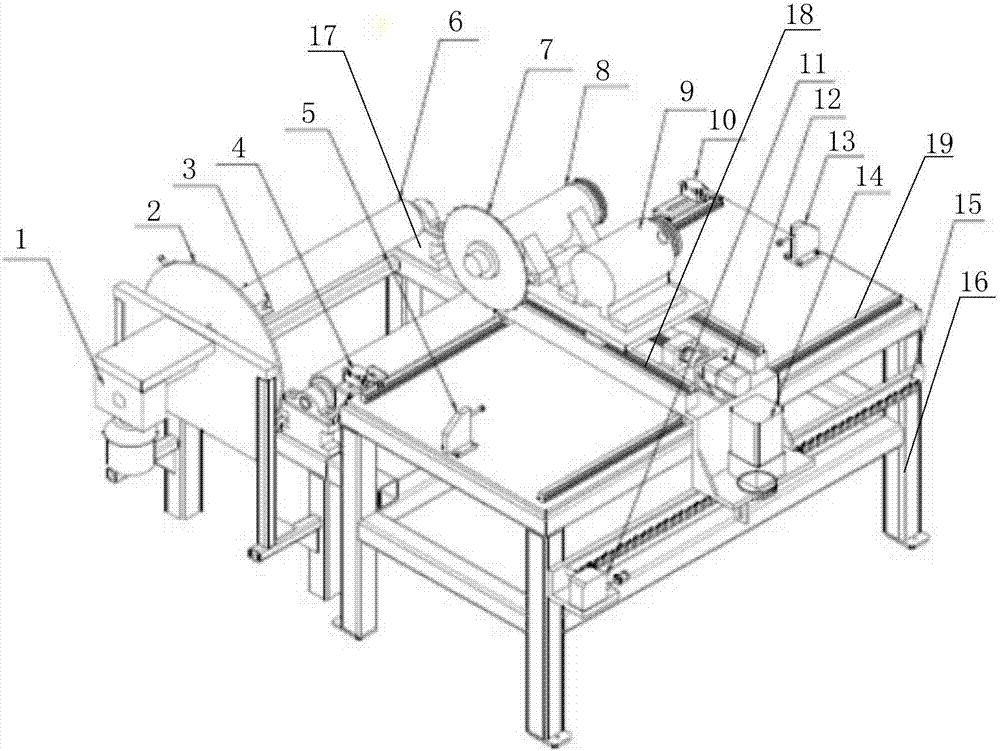

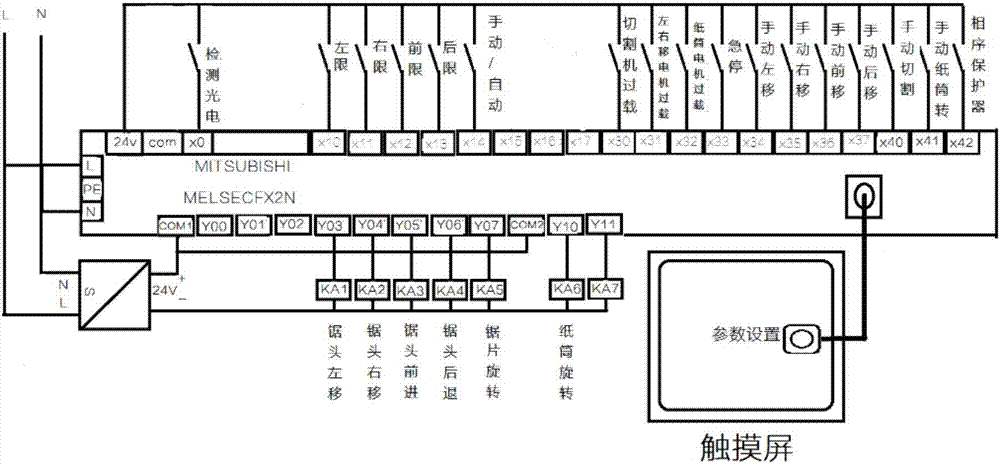

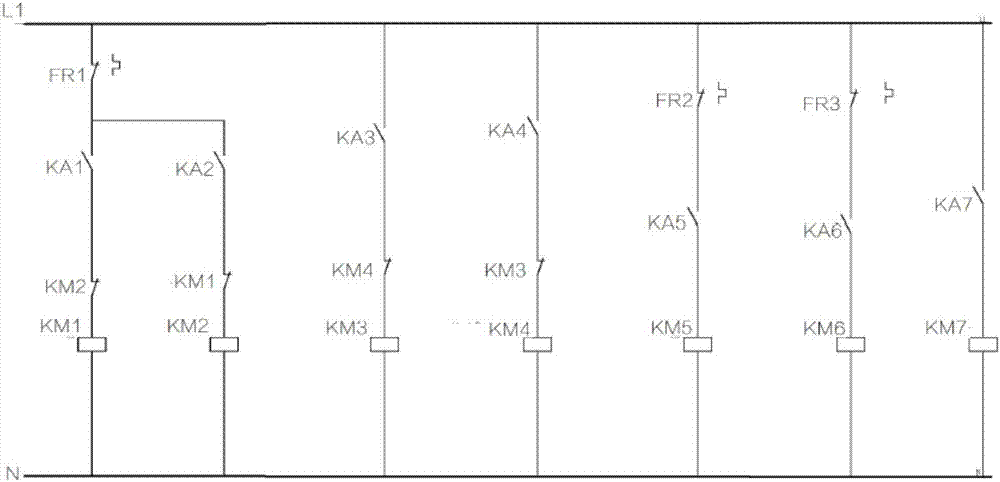

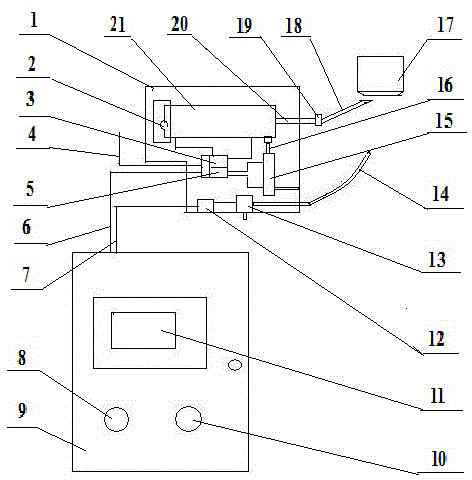

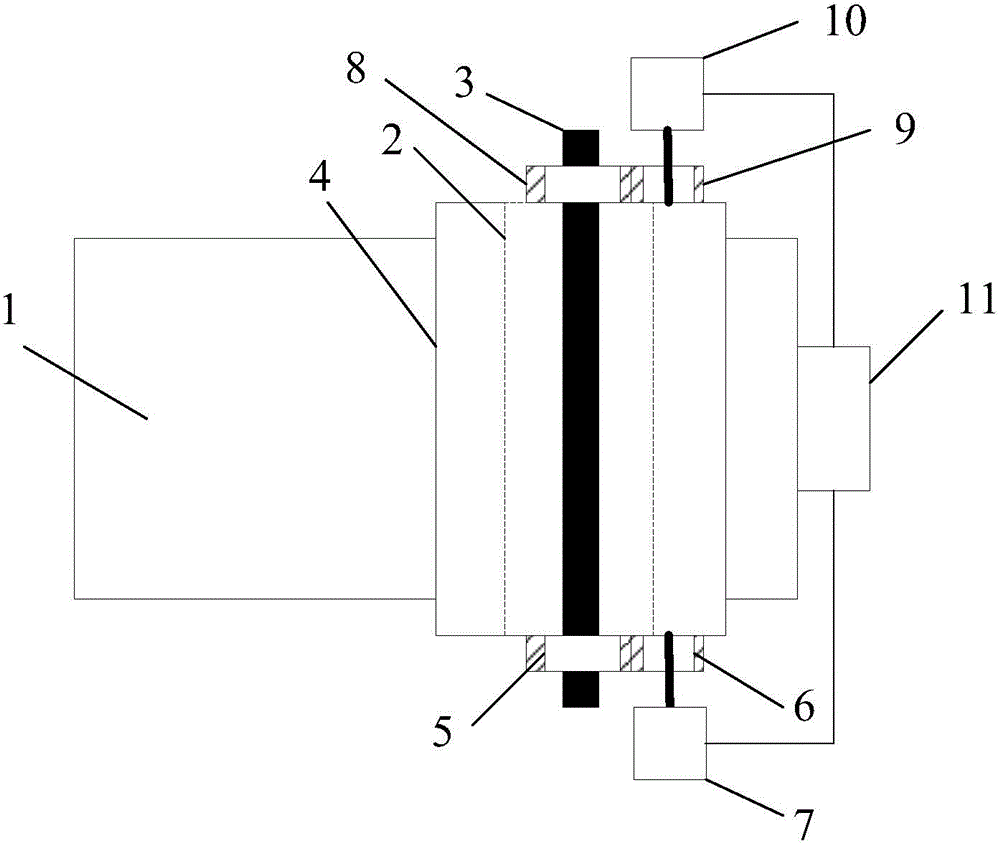

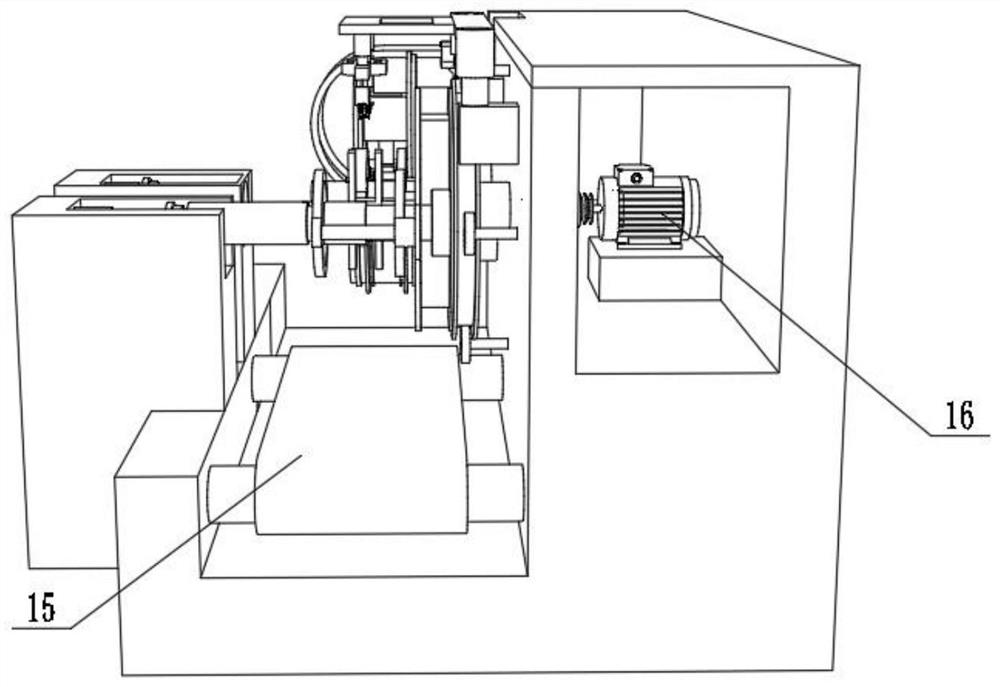

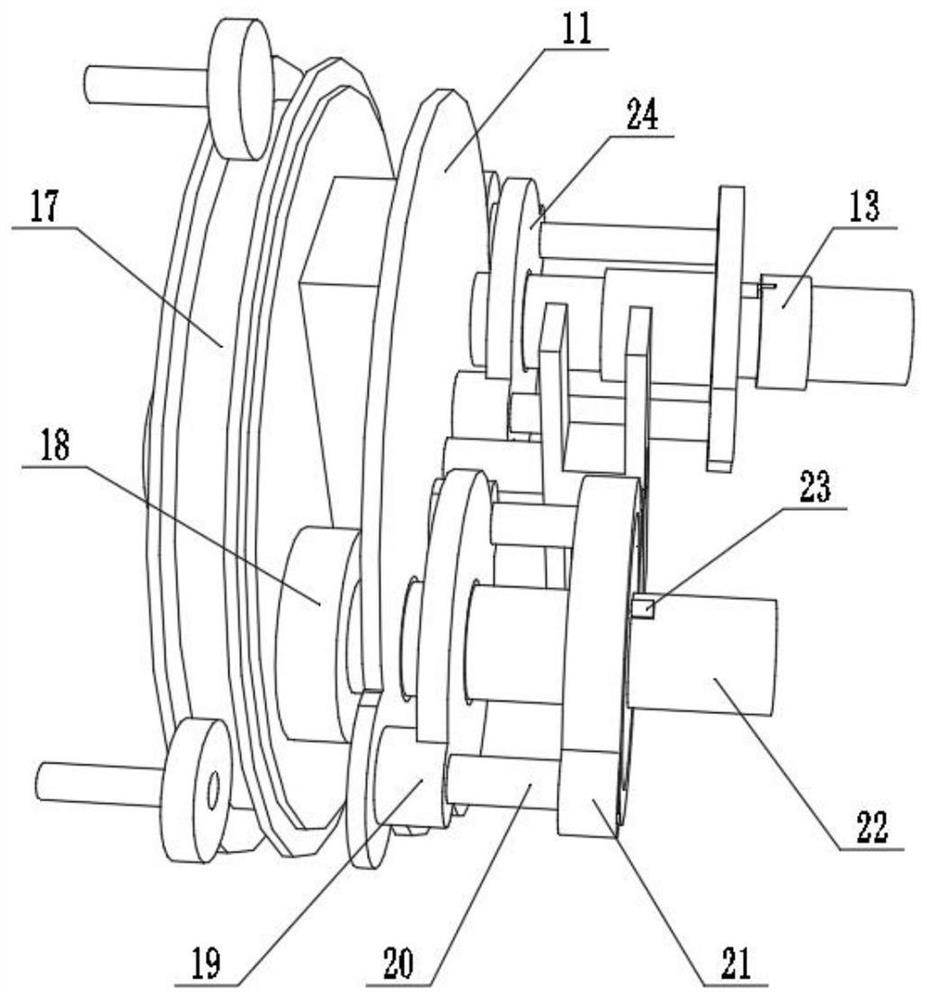

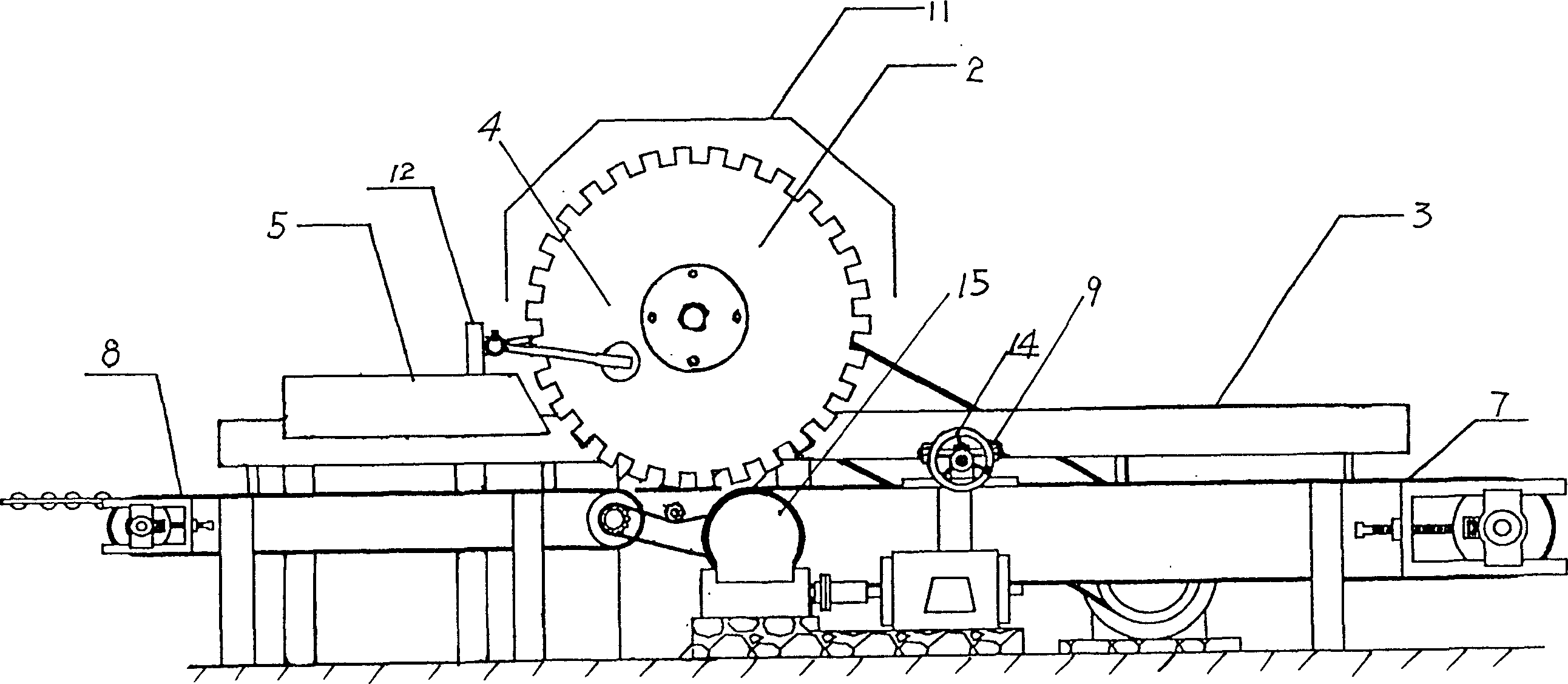

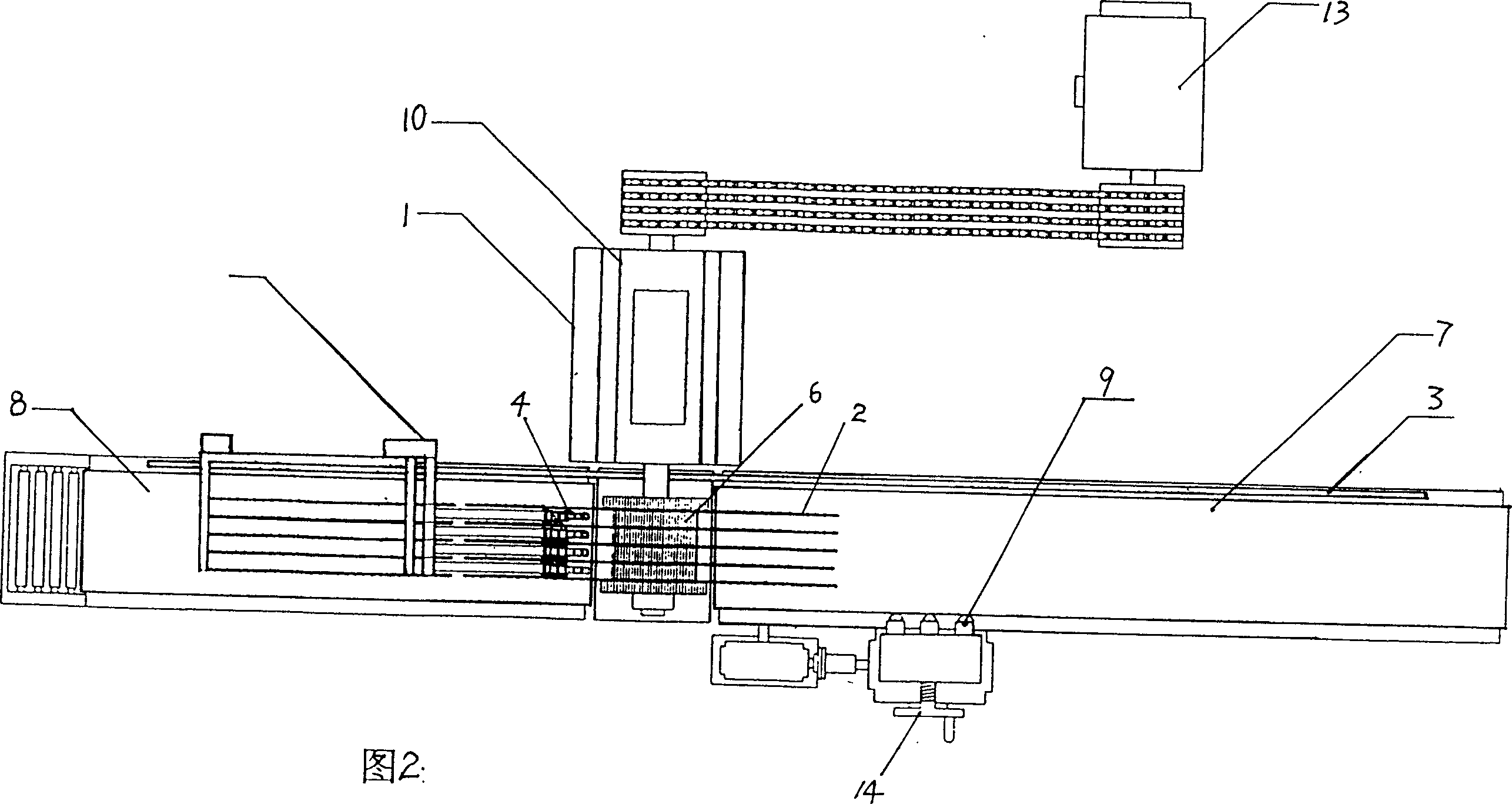

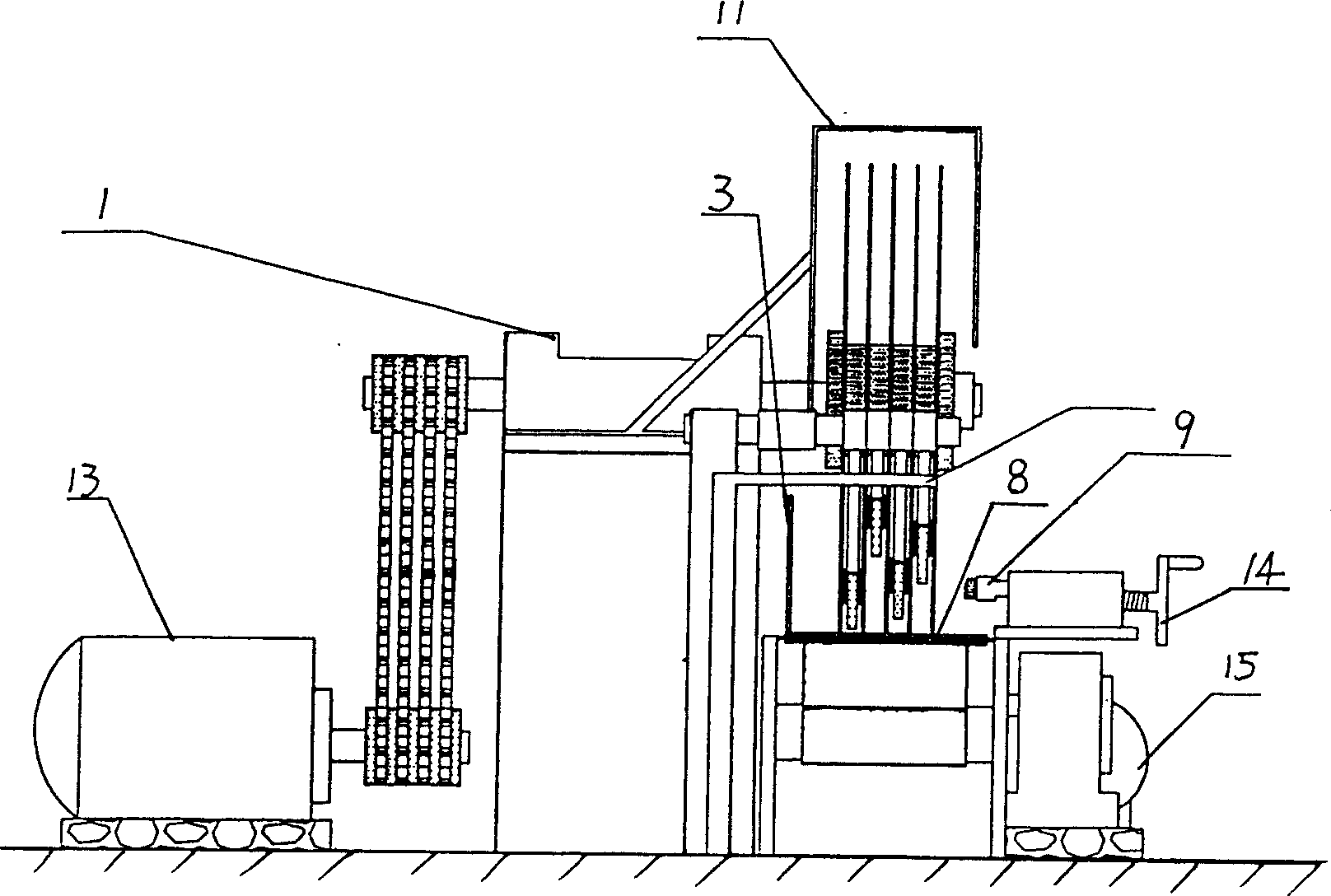

Integrated manual and automatic paper tube cutting device and cutting control method

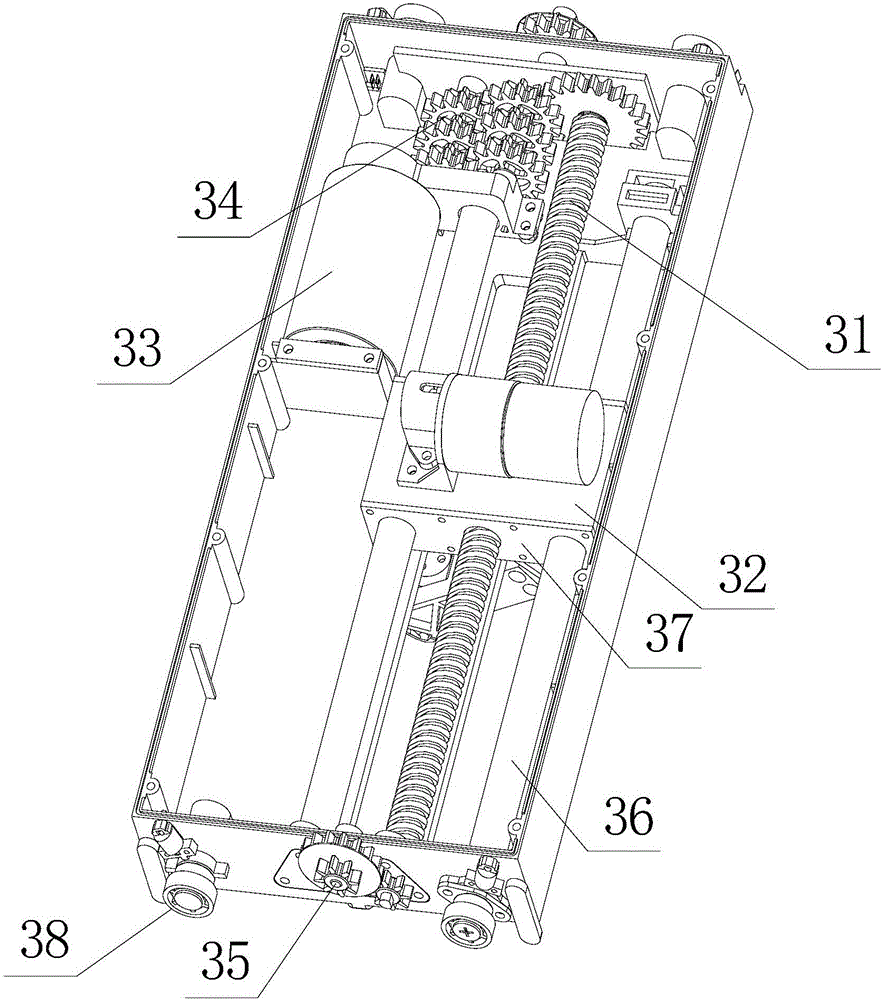

InactiveCN107139244AImprove cutting accuracyRealize continuous cuttingMetal working apparatusElectric machineryPulp and paper industry

The invention provides an integrated manual and automatic paper tube cutting device which comprises a rotation power unit, a flange plate, a locking claw, a right limiting switch, a supporting roller, a saw web, a saw head, a cutting motor, a left limiting switch, an electro-optical distance measurement device, a saw head power unit, a sizing driving device, a transmission toothed rack, a rear rack, a front rack, a front-back moving rail and a left-right moving rail. According to the integrated manual and automatic paper tube cutting device and a cutting control method, a bracket roller and a paper tube center positioning flange are adopted to position and clamp a paper tube; the manual and automatic cutting manners can be switched over to realize continuous paper tube cutting, so that the paper tube cutting efficiency and cutting precision are effectively improved.

Owner:ANHUI BAOSTEEL STEEL DISTRIBUTION

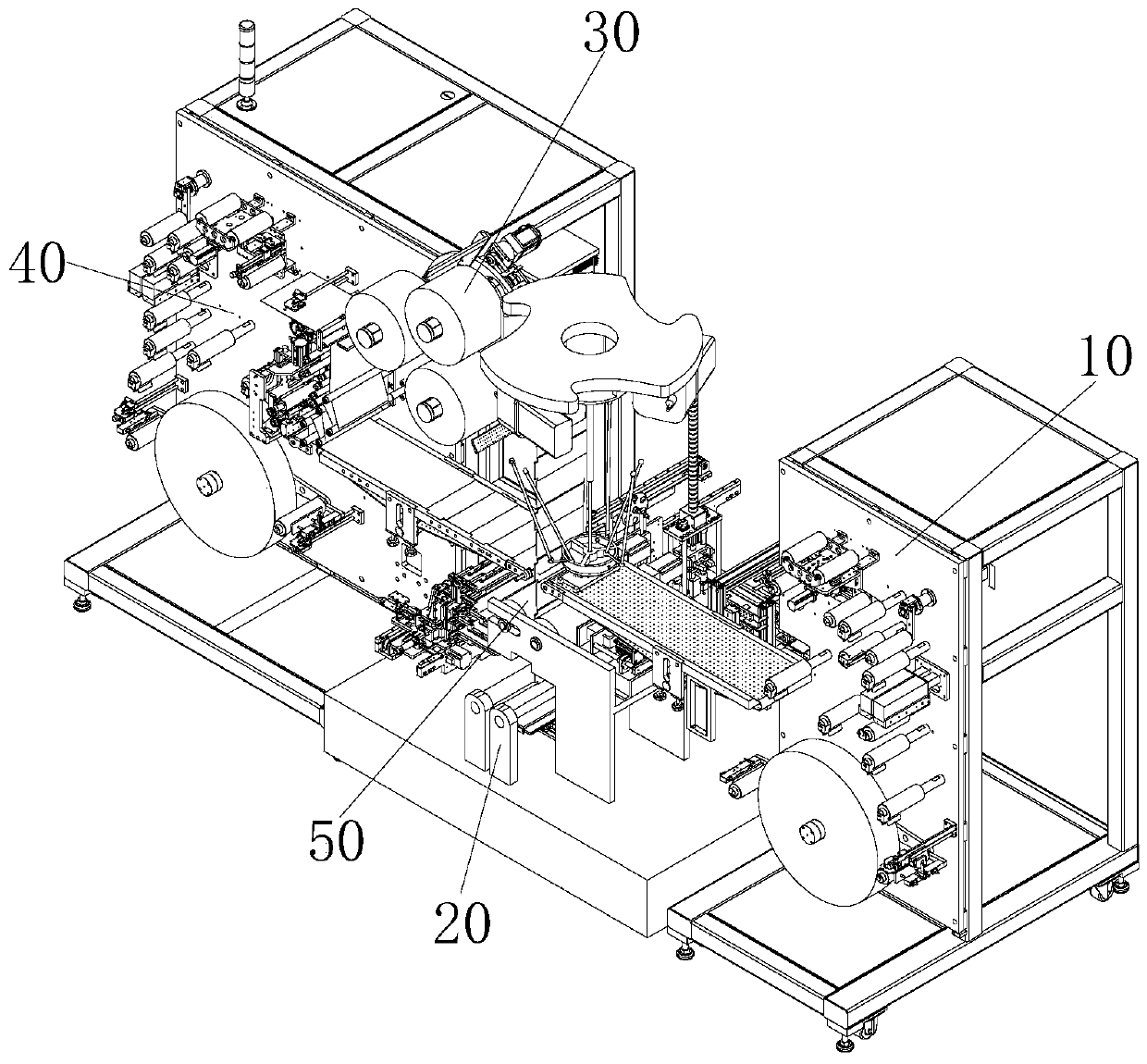

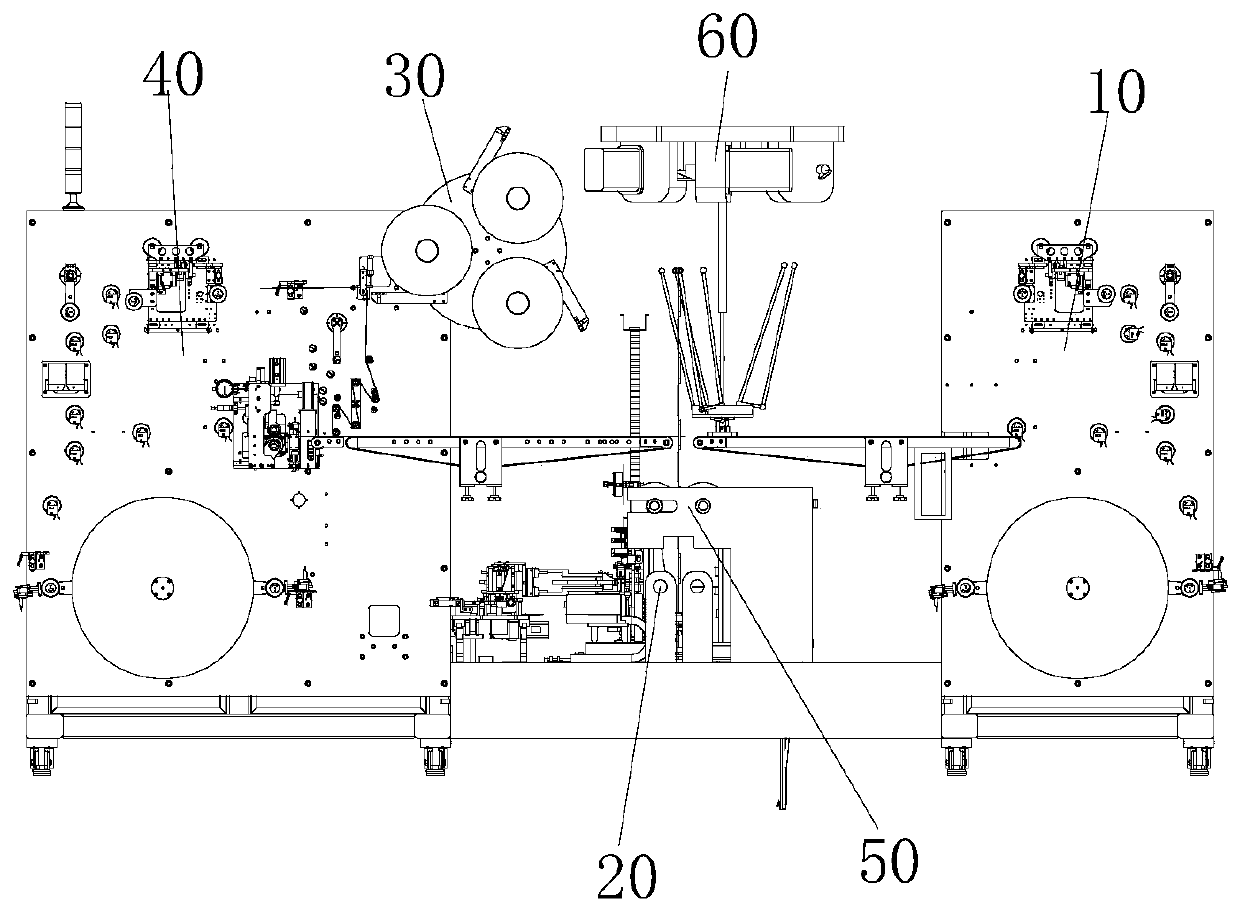

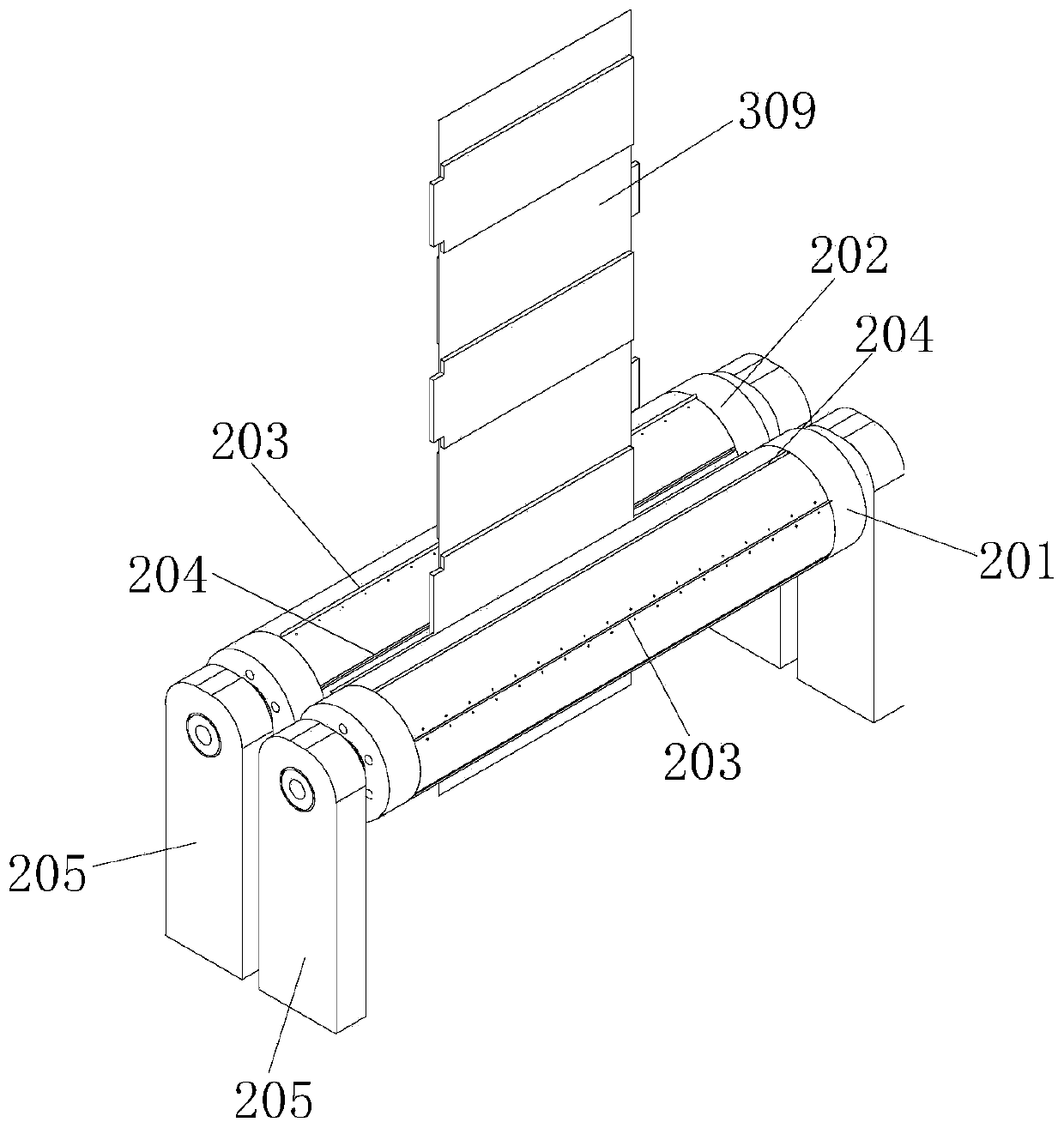

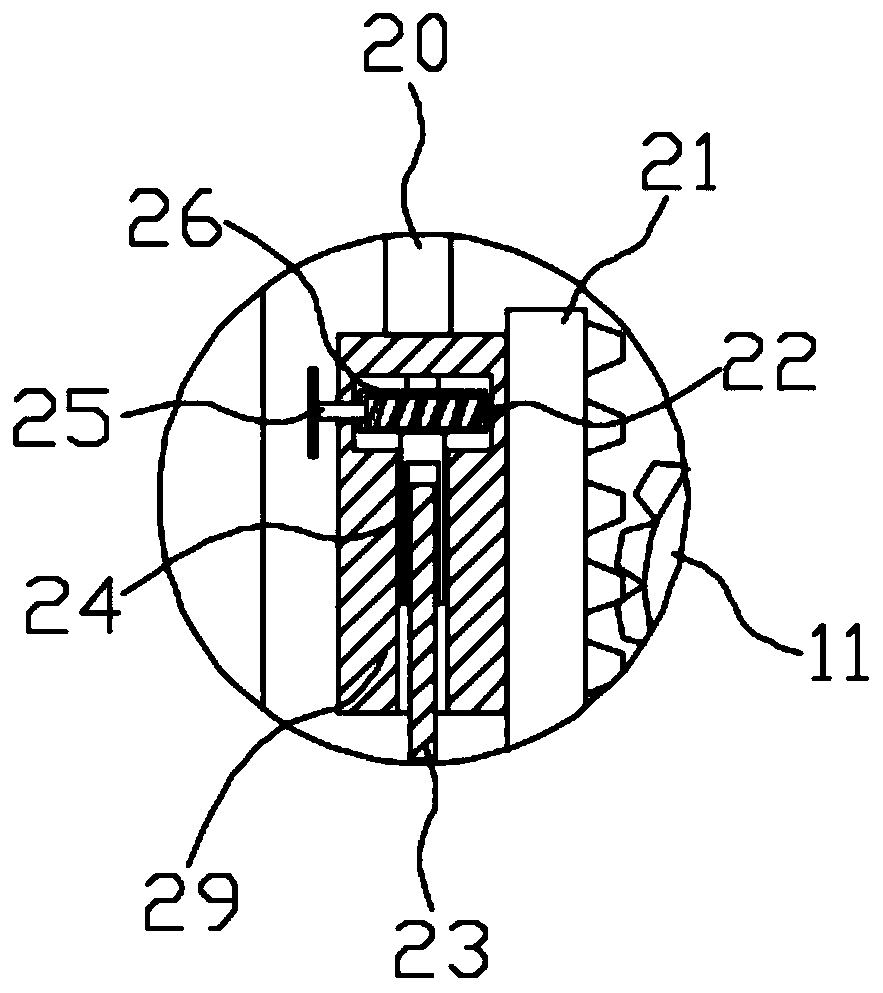

Die cutting and folding integrated machine

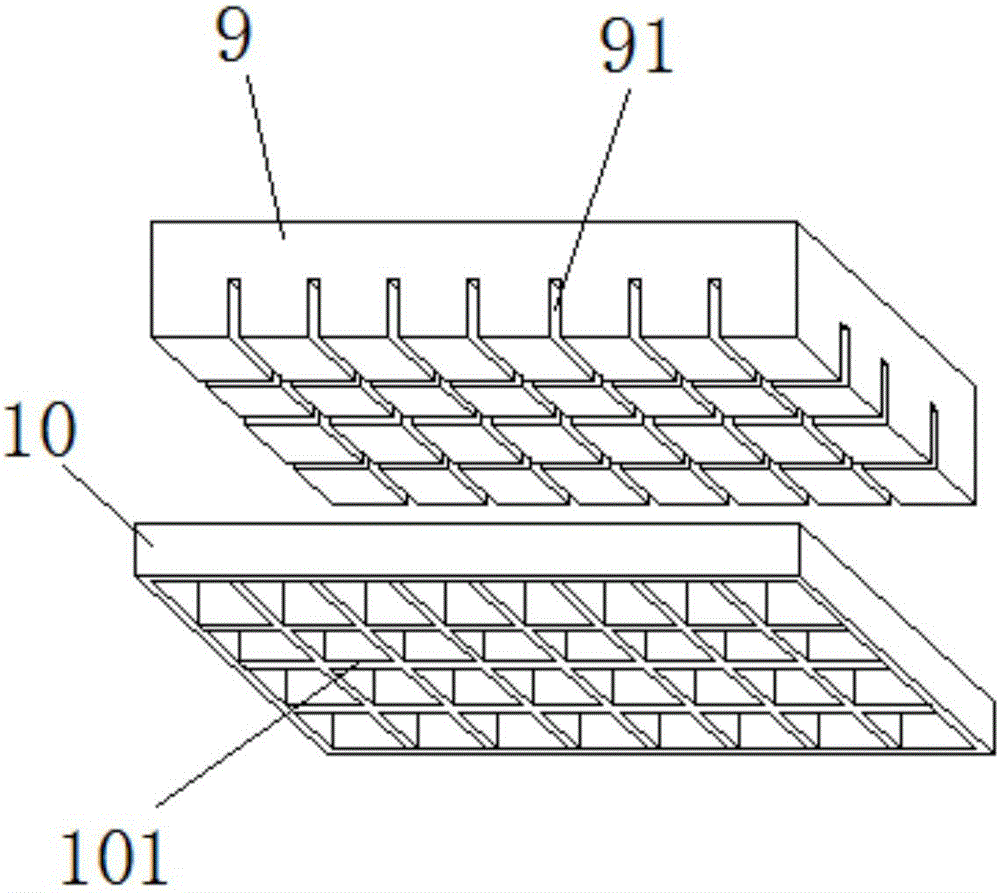

PendingCN111564654AExquisite structureSolve complex structuresAssembling battery machinesFinal product manufactureEngineeringMechanical engineering

The invention discloses a die cutting and folding integrated machine, and relates to the technical field of lithium battery lamination. The integrated machine comprises a positive plate die cutting assembly, a negative plate die cutting assembly, an automatic roll changing and tape splicing assembly, a composite rolling assembly and a battery cell folding assembly; the positive plate die cutting assembly and the negative plate die cutting assembly are oppositely arranged at the two sides of the automatic roll changing and tape splicing assembly; the positive plate die cutting assembly is usedfor providing a positive plate formed through die cutting; the negative plate die cutting assembly is used for providing a negative plate formed through die cutting; the automatic roll changing and tape splicing assembly is used for providing a diaphragm; the composite rolling assembly is positioned between the positive plate die cutting assembly and the negative plate die cutting assembly, and isused for rolling the positive plate, the negative plate and the diaphragm; and the battery cell folding assembly is positioned under the composite rolling assembly. The die cutting and folding integrated machine has the beneficial effects of being ingenious in structure and high in lamination speed, and the production efficiency of lithium batteries is improved.

Owner:SHENZHEN GREENSUN TECH CO LTD

Bean curd continuous slicing machine

InactiveCN106272581ARealize continuous cuttingShort processMetal working apparatusDry beanEngineering

The invention discloses a bean curd continuous slicing machine. The bean curd continuous slicing machine comprises a frame, wherein a delivery conveying belt and a compressing conveying belt are fixedly mounted on the upper side of the right part of the frame; a motor is fixedly mounted at the upper part of the compressing conveying belt; a speed changer is fixedly connected with the left side of the motor; a cam is fixedly mounted on the upper side of the left part of the frame; a squeezing block is movably connected with the front part of the cam through a connecting rod; a groove is formed in the inner cavity of the lower part of the squeezing block; a guide cylinder is movably connected with the outer side of the squeezing block; a cutting knife is arranged at the lower part of the guide cylinder; a blade is fixedly connected with the inner side of the cutting knife; a collecting hopper is arranged on the lower side of the cutting knife; a collecting conveying belt is arranged on the lower side of the collecting hopper; a collecting tank is arranged on the lower side of the right end of the collecting conveying belt. The bean curd continuous slicing machine is convenient and practical, improves the operating efficiency for dried bean curd slicing, reduces manual operation, guarantees the quality, improves the product quality, and greatly enhances the market competitiveness.

Owner:CHONGQING XINRUN AGRI DEV

Cutting method of super-hard crystal

InactiveCN101386192ARealize continuous cuttingReduce usageFine working devicesCopper wireReciprocating motion

The invention relates to a method for cutting superhard crystal, which belongs to the field of crystal processing. The invention adopts a wire-cutting method, prepares cutting slurry by mixing diamond micro-powder, boron carbide and olive oil according to proportion, and realizes the cutting of the superhard crystal by high-speed reciprocating motion of cutting copper wires and cutting slurry. The method can realize continuous cutting of the superhard crystal; comparing the preparation of the cutting slurry with a diamond cutting wire which directly uses the diamond micro-powder or plates diamond particles, the cutting cost is greatly reduced, the wafer angularity received by cutting is small with even thickness, thereby providing convenience for subsequent processing.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

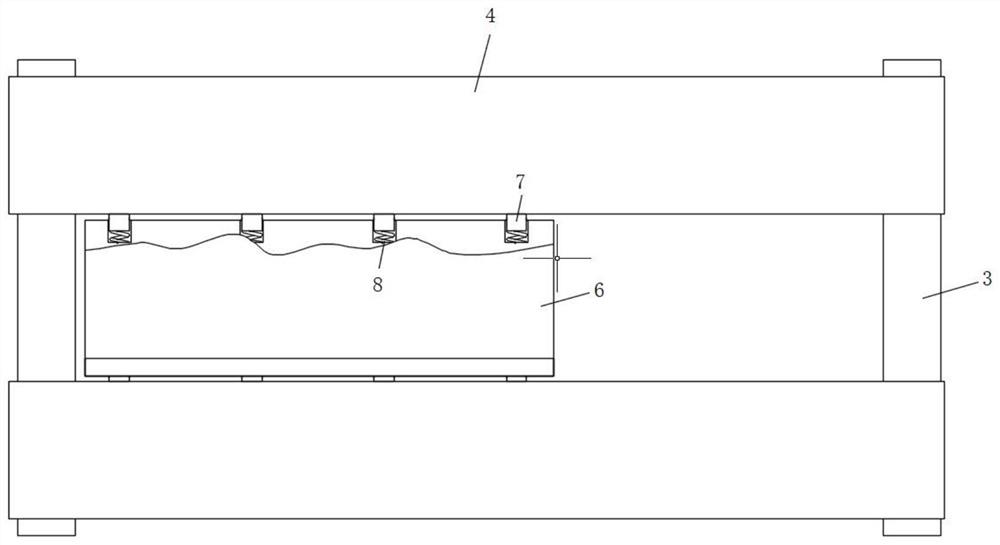

Mincing, kneading and pressing device for meat product processing

ActiveCN112006074AReasonable designRun smoothlyMeat processing devicesStructural engineeringManufacturing engineering

The invention discloses a mincing, kneading and pressing device for meat product processing. The device comprises a mincing mechanism and a kneading and pressing mechanism, the mincing mechanism comprises supporting seats, mounting beams are fixed on the front and rear sides of the top surface of each supporting seat, mounting grooves are formed in the ends, close to each other, of the two mounting beams, a cutting table is also connected between the two mounting grooves in a sliding manner, grooves are further formed in the front end and the rear end of the cutting table, a clamping block isconnected to the inner wall of each groove in a sliding manner, extrusion springs are fixed between the clamping blocks and the bottom faces of the grooves, clamping grooves are further formed in thebottom sides of the mounting grooves, the clamping block is arranged in each clamping groove, racks are further fixed to the bottom face of the cutting table, a first horizontal plate is further fixedly connected to the inner sides of the two supporting seats through screws, and a first servo motor is fixedly connected to the middle of the top face of the first horizontal plate through screws. Thedevice is reasonable in design and stable in operation, meat is cut in a chopping mode when the device is used so as to well guarantee that original protein in the meat is intact, discharging and cleaning of the device are convenient, and the meat cutting and kneading efficiency is greatly improved.

Owner:SUSONG XIANGYUAN POULTRY TRADE

Food slicing mechanism

ActiveCN104816323AReduce mistakesAffect the tasteMetal working apparatusBaked article cutting/slicingEngineering

The invention discloses a food slicing mechanism. The food slicing mechanism comprises blades, a knife rest and a driving mechanism, wherein the driving mechanism is used driving the knife rest to move back and forth, and the knife rest is provided with a window for foods to pass through; the blades are arranged on a window at intervals, one ends of the blades are fixedly connected to the upper edge of the window, and the other ends of the blades are fixedly connected to the lower edge of the window; the driving mechanism is connected with the knife rest in a driving way. According to the food slicing mechanism provided by the invention, foods can be cut with smaller kerfs, the excessive residues of a food detergent can be prevented, and the balanced taste of the sliced foods can be ensured.

Owner:GUANGZHOU FUYA MACHINERY

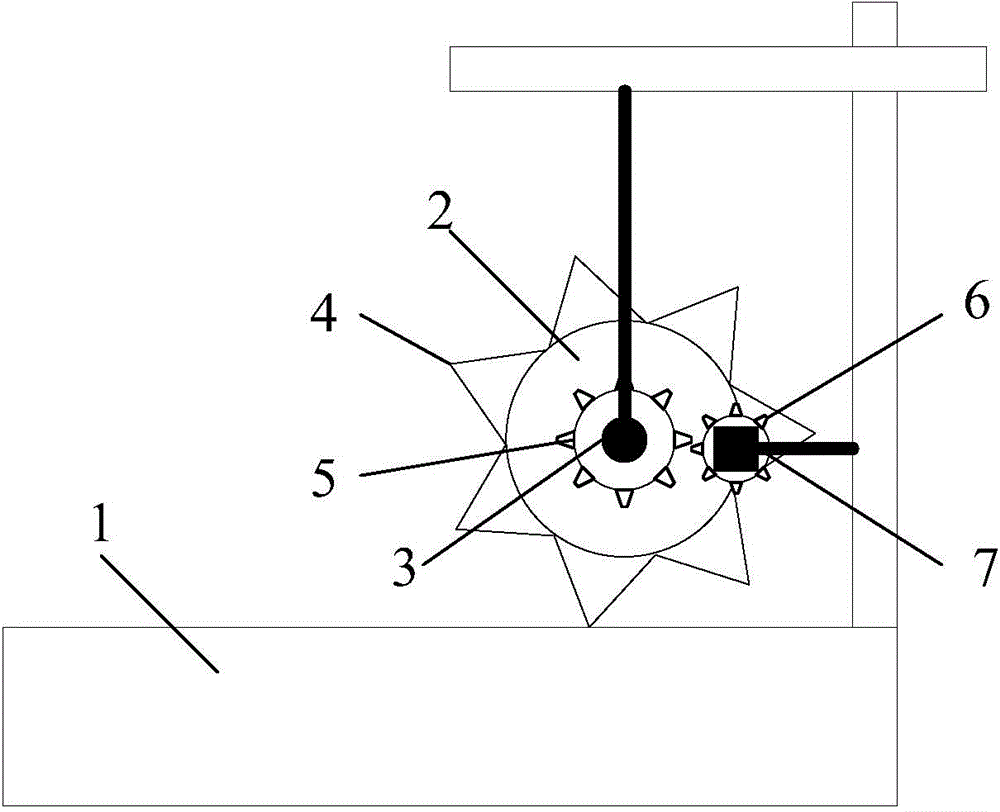

Automatic garlic dicing device

ActiveCN107616729AEliminate lateral constraintsReliable transmissionKitchen equipmentCircular discInterference problem

The invention discloses an automatic garlic dicing device. The automatic garlic dicing device comprises a base, a disc is rotationally connected to the base, and a motor used for driving the disc to rotate is arranged on the base; a first connecting rod and a second connecting rod are rotationally connected to the disc through a first hinge point and a second hinge point respectively, an upper sliding block and a lower sliding block in parallel are connected to the upper side and the lower side of the base respectively, the upper sliding block is rotationally connected with the first connecting rod, and the lower sliding block is rotationally connected with the second connecting rod. An upper slider-crank mechanism and a lower slider-crank mechanism are simultaneously arranged at the samedisc to achieve longitudinal sliding of a cutter cylinder and transverse sliding of a blade, and then garlic is cut into garlic dices; moreover, no motion interference problem exists between longitudinal sliding of the cutter cylinder and the transverse sliding of the blade, the transmission stability of the whole device is improved, and the automatic garlic dicing device is higher in cutting efficiency and higher in automation degree.

Owner:刘民佳

Packaging film cutting device

InactiveCN103057765AEasy to adjust the position relationshipRealize continuous cuttingPackagingEngineeringManufacturing line

The invention relates to a packaging film cutting device in a packaging machine. A film cutting roll of the packaging film cutting device comprises a roll, a cut-off knife and a dotted-line knife, and the cut-off knife and the dotted-line knife are fixedly mounted on the roll. The packaging film cutting device is characterized in that the roll comprises a tubular outer roll and an inner roll fittingly nested inside the outer roll, the inner roll and the outer roll are fixed relatively by a positioning device, a slotted hole is arranged on the outer roll, the dotted-line knife or the cut-off knife can extend out of the slotted hole, and the dotted-line knife and the cut-off knife are respectively fixedly mounted on the inner roll and the outer roll via knife holders. The packaging film cutting device has the advantages that the roll is multipurpose, a packaging film can be continuously cut off and conveyed, and the like. Besides, distances can be adjusted conveniently, so that the requirement on variation of the length of the packaging film within a certain range can be met, and an existing intermittent packaging production line can be changed into a continuous packaging production line.

Owner:NINGXIA SONGJIU AUTOMATION EQUIP

Gypsum line production line and gypsum line die joint-cutting mechanism

PendingCN110394888ARealize continuous cuttingReduce manual labor intensityCeramic shaping apparatusProduction lineDevice Monitor

Owner:宁波万立杰普顺装饰材料有限公司

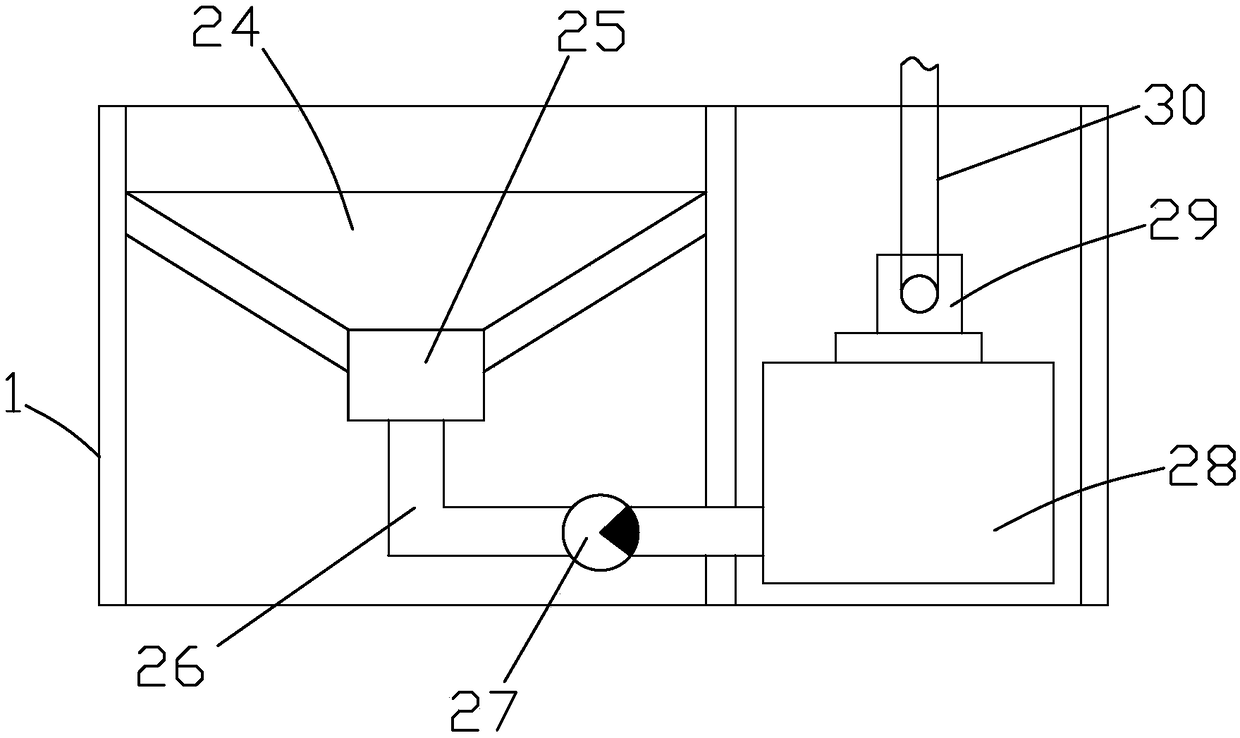

Automatic vermicelli cutting machine

InactiveCN104552400AAvoid sticking knifeWork process safetyMetal working apparatusSmall footprintFood processing

The invention discloses an automatic vermicelli cutting machine, relates to the field of food processing, and particularly relates to vermicelli and bean vermicelli cutting machines. The automatic vermicelli cutting machine is mounted at an outlet of a vermicelli squeezing machine, and vermicelli and bean vermicelli can be cut by the aid of relative movement of a cutter and the outlet. The automatic vermicelli cutting machine comprises a control box, a case, a cutter pushing cylinder, a cutter saddle, the cutter, a positioning cylinder, a cutter pushing air supply switch and a positioning cylinder air supply switch, and is characterized in that the cutter pushing cylinder, the cutter saddle, the cutter, the positioning cylinder, the cutter pushing air supply switch and the positioning cylinder air supply switch are mounted in the case, one end of the positioning cylinder is mounted on the case via a bolt, and the positioning cylinder can rotate around the bolt; a movable end is arranged at the other end of the positioning cylinder, a push rod which extends out of the movable end of the positioning cylinder extends out of the case, the cutter saddle is arranged on the top of the push rod, and the cutter is mounted on the cutter saddle. The automatic vermicelli cutting machine has the advantages that the automatic vermicelli cutting machine is small in occupied area and high in production efficiency and is safe and convenient, and cutter sticking can be prevented when the automatic vermicelli cutting machine is used; the cutter can be driven by the cutter pushing cylinder to move, so that vermicelli cutting procedures can be implemented, and the automatic vermicelli cutting machine is applicable to mass rice vermicelli production.

Owner:江西省五星食品有限公司

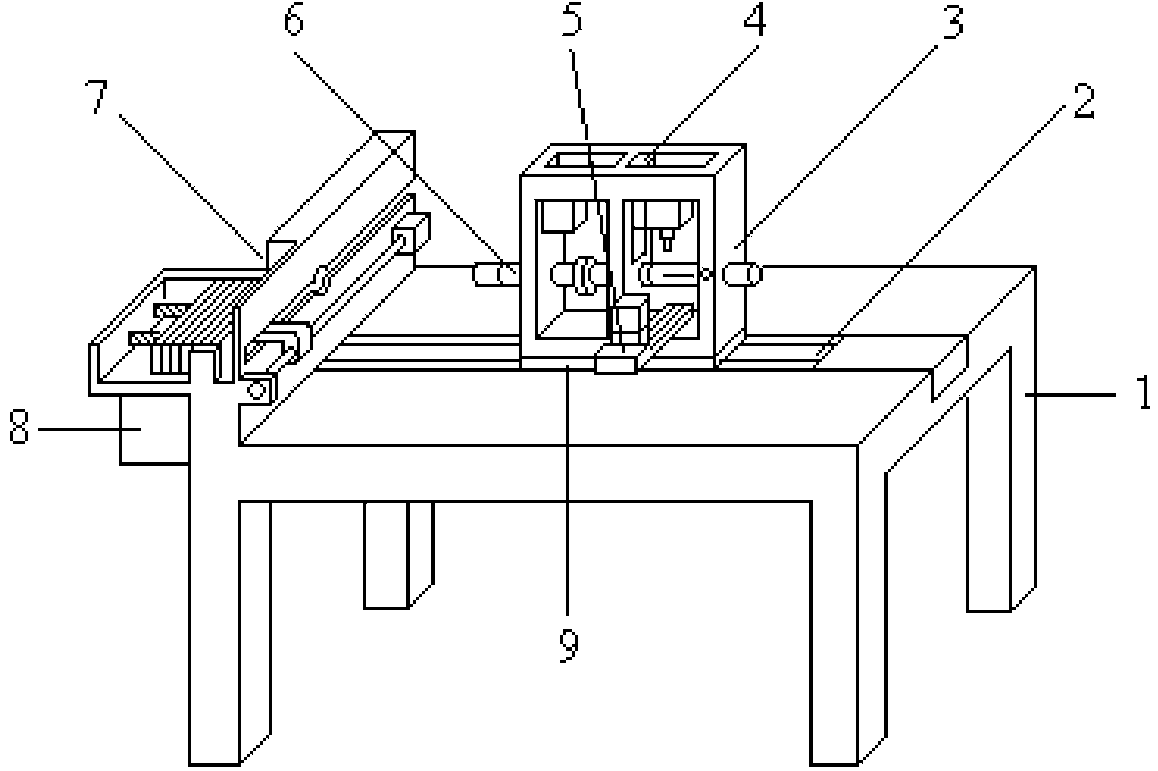

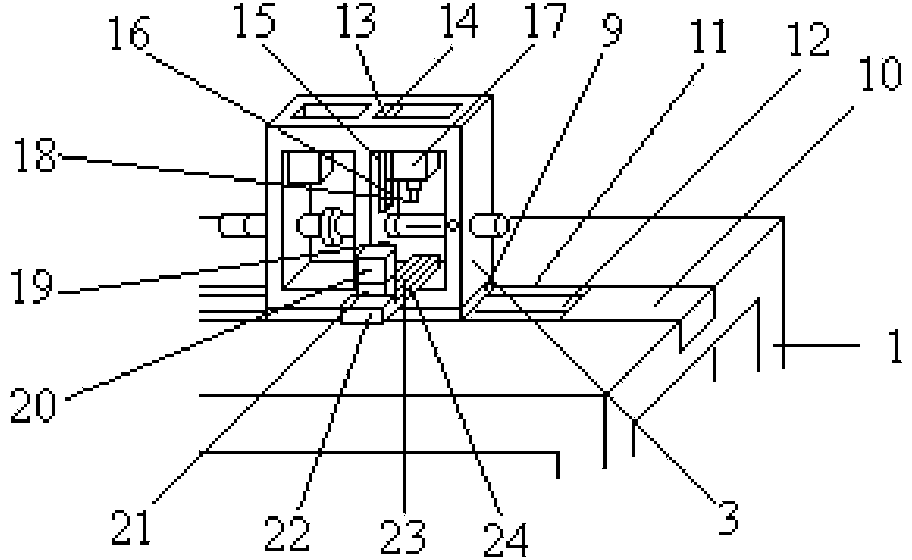

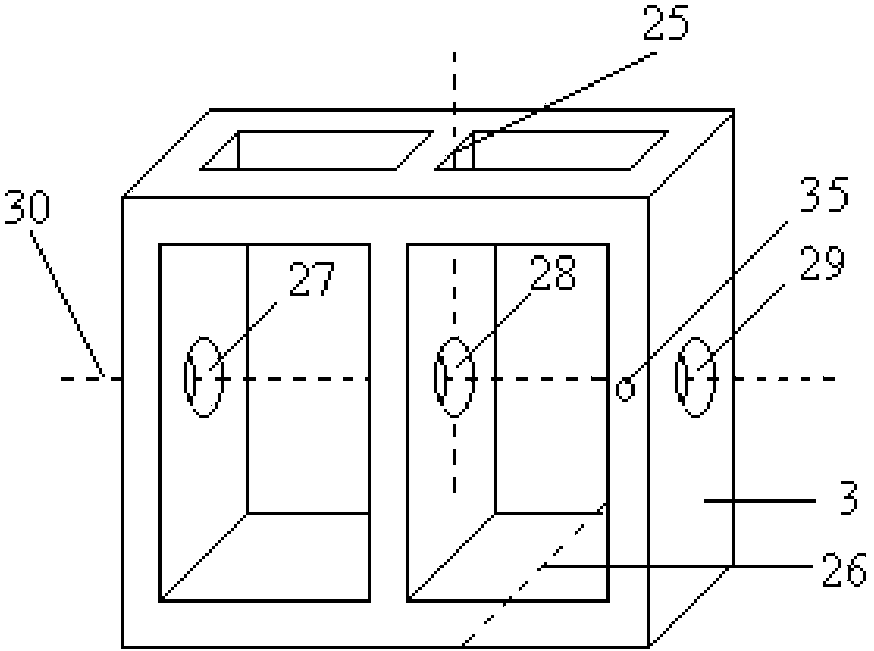

Full-automatic cutting perforating machine

The invention discloses a full-automatic cutting perforating machine which comprises a machine tool, a first linear motion mechanism, a machine frame, a second linear motion mechanism, a third linear motion mechanism, a cutting device, a feeding device and a controller, wherein the first linear motion mechanism is arranged on the machine tool; the machine frame is arranged on the first linear motion mechanism; two Z-direction rectangular through holes are formed in the front surface of the machine frame in parallel in a left-right manner; Y-direction rectangular through holes are formed in the upper parts of the two Z-direction rectangular through holes; the second linear motion mechanism is arranged in the right Y-direction rectangular through hole; the third linear motion mechanism is arranged in the right Z-direction rectangular through hole; the cutting device is inserted into the machine frame in a penetrating manner; the feeding device is arranged on the machine tool wall at the left end of the machine tool; the controller is arranged at the lower part of the feeding device. According to the full-automatic cutting perforating machine, a large amount of round bamboo blocks can be produced, and the small and thin round bamboo blocks can be quickly, automatically, vertically and crossly perforated; moreover, the full-automatic cutting perforating machine is simple in structure and high in production efficiency.

Owner:吴进明

Roller type tobacco cutting device

The invention discloses a roller type tobacco cutting device. The device comprises an operation platform, a roller, a plurality of uniformly distributed blades, a first gear, a second gear and a first motor. The roller is mounted on a rack through a rotation shaft and disposed at one end of the operation platform and rotates around the rotation shaft. The plurality of blades are arranged on the outer surface of the roller and parallel to the axis. The first gear is sleeved on the rotation shaft and fixedly connected with one end of the roller. The second gear is meshed with the first gear. The first motor is arranged on the rack, and a second gear is mounted on the output shaft. The second gear is driven by the first gear to rotate, and the roller is driven to rotate through the decelerating effect of the first gear, so that the blades on the roller cut tobacco leaves. According to the roller type tobacco cutting device, the tobacco leaves are cut into tobacco shreds by the roller type cutter, and due to the rotation of the roller, the cut tobacco shreds are pushed into an accommodation unit, the tobacco leaves are driven to move frontwards, and continuous cutting is achieved.

Owner:蓝德能源科技股份有限公司

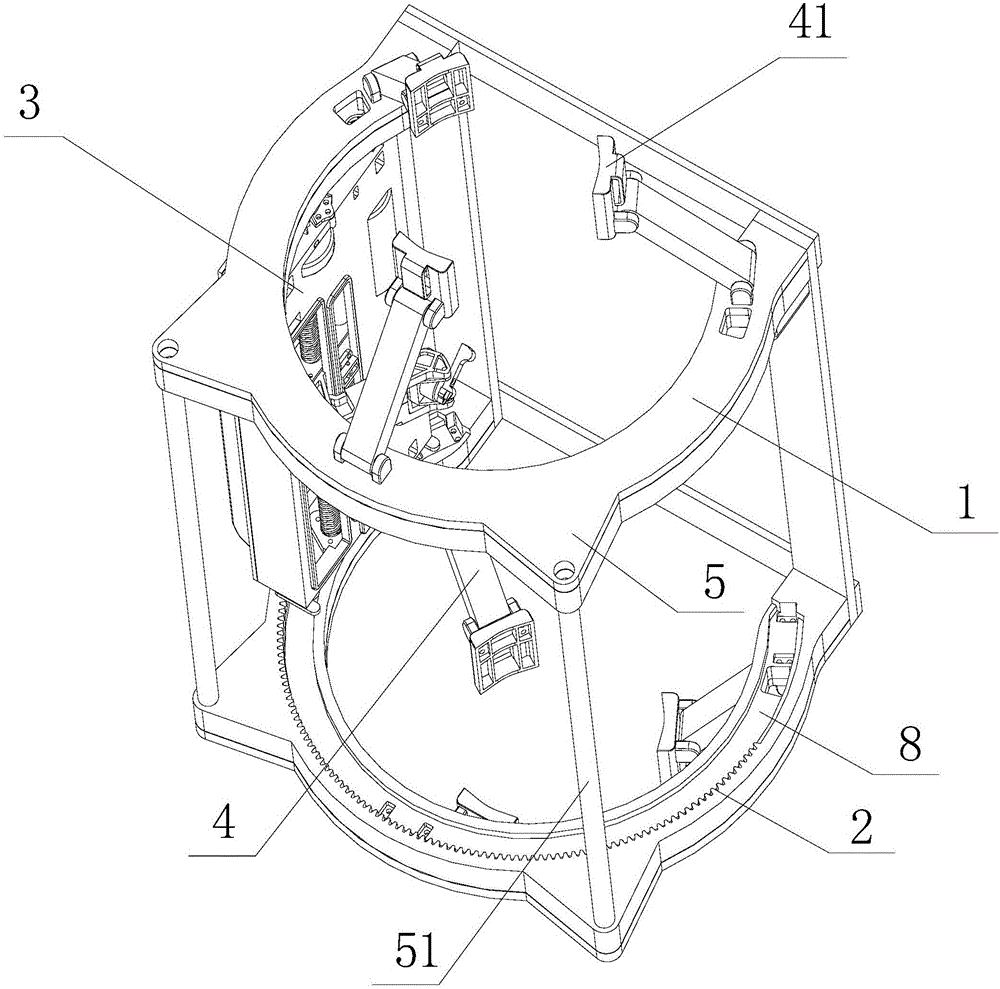

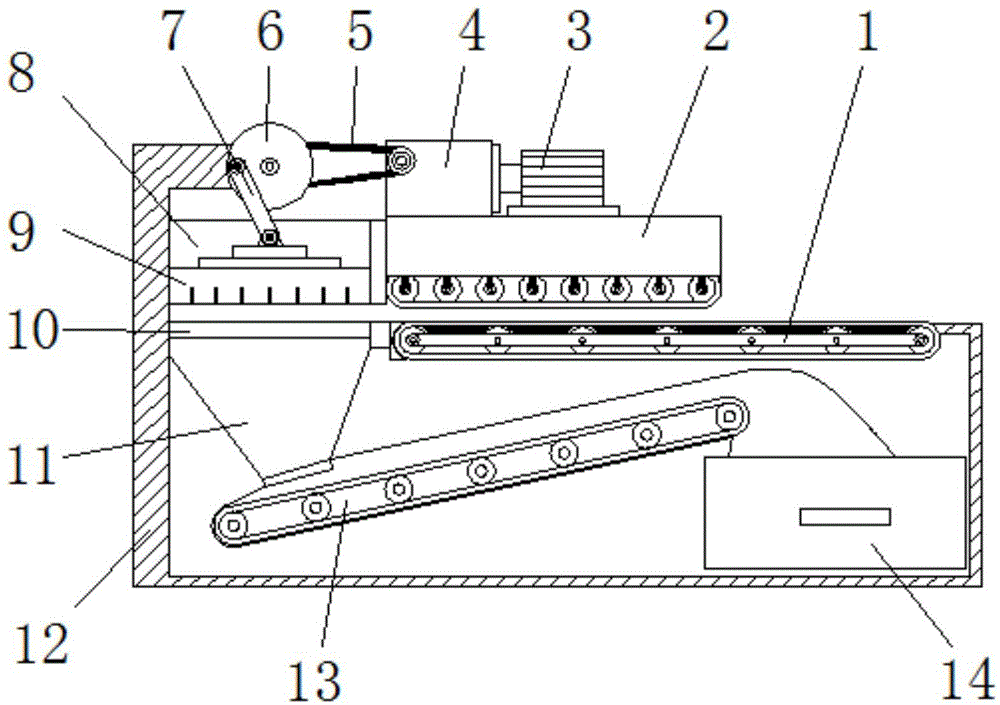

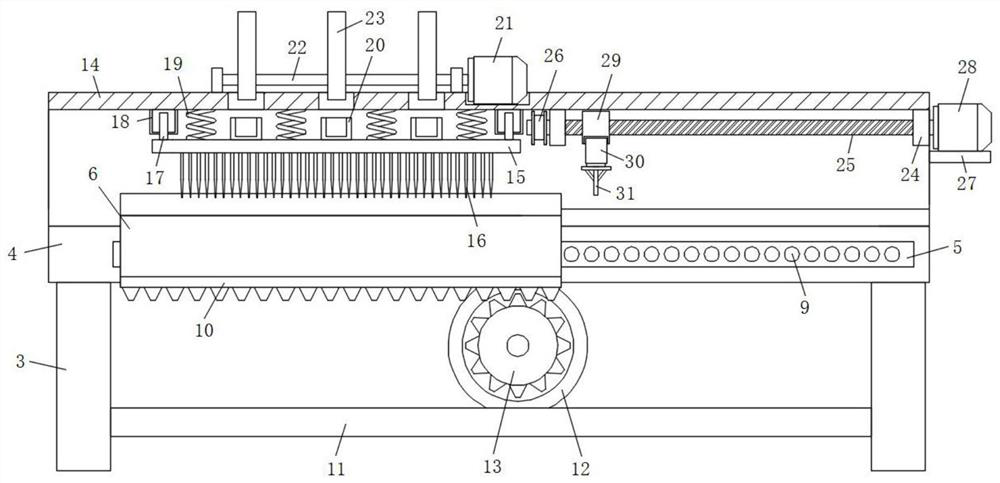

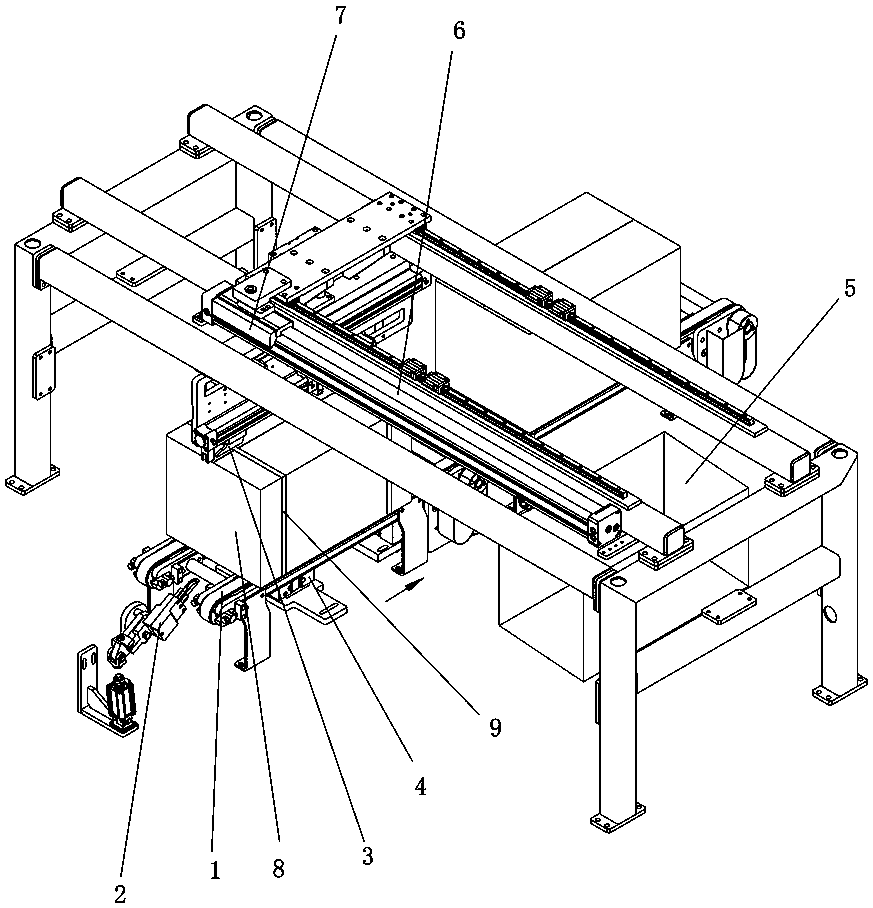

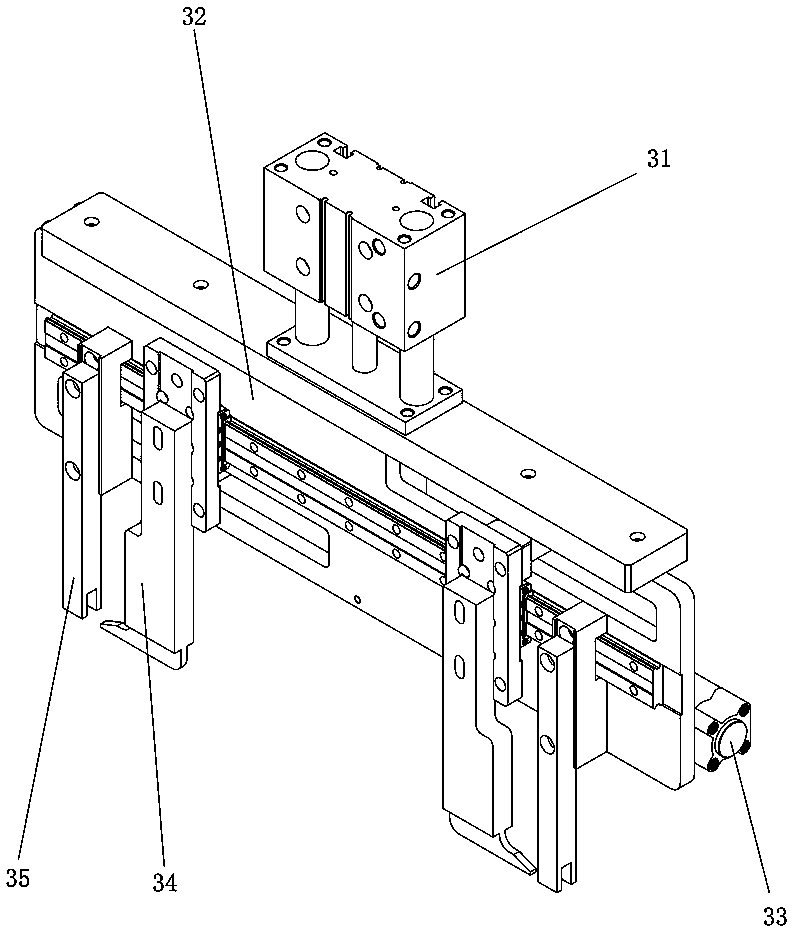

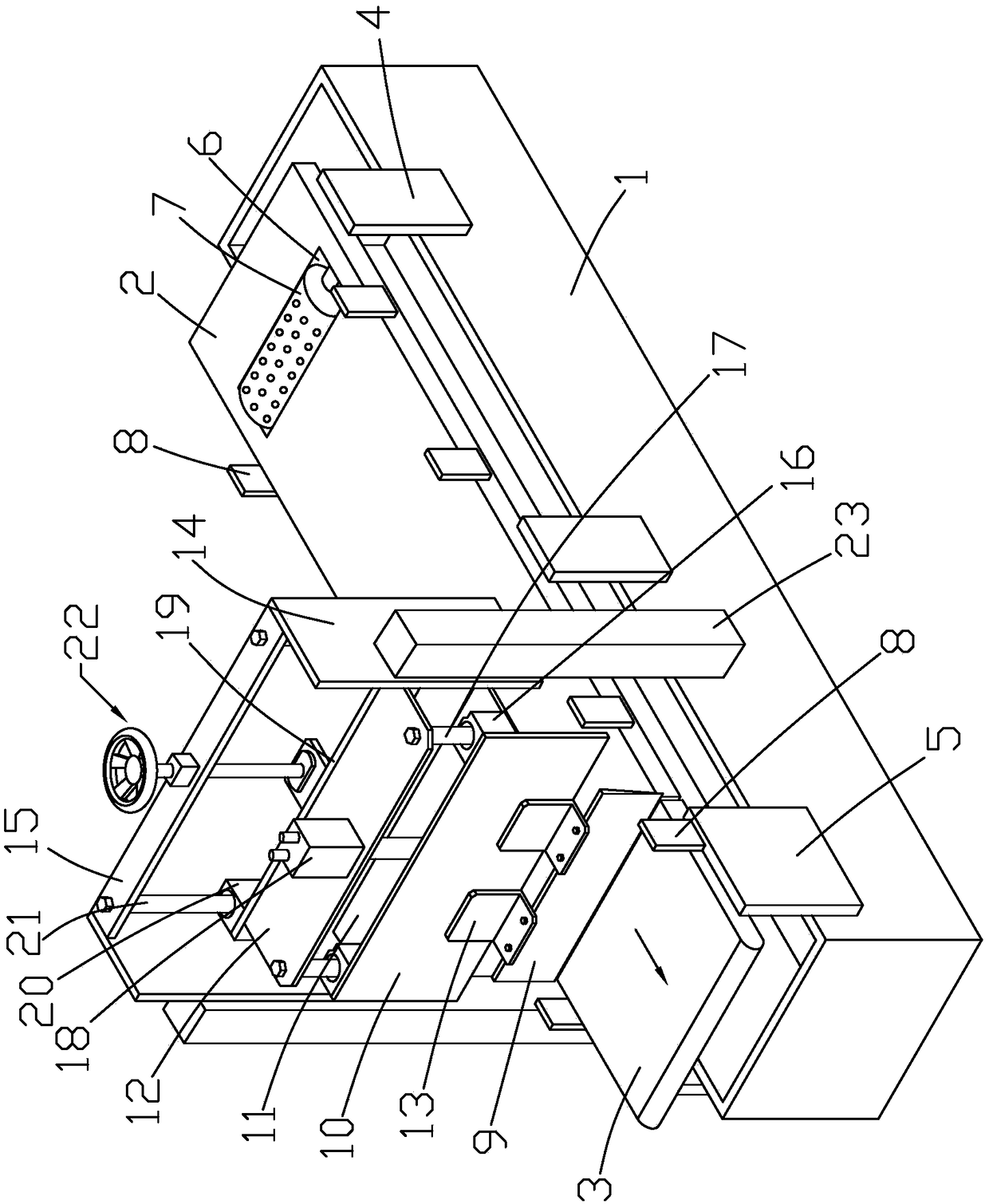

Packaging box strapping tape automatic removal device and method

PendingCN109677721AReduce manual labor intensityIncrease productivityBinding material removalStrappingEngineering

The invention discloses a packaging box strapping tape automatic removal device and method. The packaging box strapping tape automatic removal device comprises a box body conveying part, a cutter assembly and a strapping tape removal assembly. A cutoff station and a removal station are arranged in the conveying direction of the box body conveying part in sequence. The cutter assembly is arranged on the cutoff station and can cut off pieces of strapping tape at the bottom of a packaging box when the box body conveying part conveys the packaging box to the removal station. The strapping tape removal assembly is arranged on the removal station and can remove the strapping tape which is cut off. The packaging box strapping tape automatic removal method comprises the steps that S1, the box bodyconveying part (1) is started and conveys the packaging box (8); S2, the cutter assembly (2) cuts off the strapping tape (9) at the bottom of the packaging box (8) in the process that the packaging box (8) is conveyed to the removal station from the cutoff station; and S3, the packaging box (8) arrives at the removal station, and the strapping tape removal assembly (3) is started and removes thestrapping tape (9) which is cut off. The packaging box strapping tape automatic removal device and method have the advantages of being automatic, efficient, reliable in operation and the like.

Owner:TRUKING TECH LTD

Apparel processing and cutting device

InactiveCN109881465BRealize continuous cuttingEase of mass productionMechanical cleaningPressure cleaningBristleElectric machinery

Owner:JILIN TEACHERS INST OF ENG & TECH

Cable production cutting equipment with automatic feeding and discharging function

InactiveCN112139400ARealize continuous cuttingEasy to unloadElectric machineryStructural engineering

The invention discloses cable production cutting equipment with an automatic feeding and discharging function, and relates to the field of cable production. The problem that a cable cannot be continuously cut is solved. The cable production cutting equipment specifically comprises an outer shell and a winding drum. A conversion disc is rotationally connected to the inner wall of one side of the outer shell. Two connecting columns are welded to the two ends of the outer wall of the conversion disc respectively. The outer walls of the two connecting columns are fixedly connected with the same connecting disc through screws, and rotating rods are rotationally connected to the inner wall of the connecting disc. A second motor is fixed to the inner wall of one side of the connecting disc through screws. According to the cable production cutting equipment, the conversion disc and the rotating rods which are fixedly provided with a cable in a rotating mode are arranged, and the winding drum is rotated under the action of a first clamping block and a mounting opening; and then the cable is cut, the cut cable can be pushed out by a circular plate, one end of the remaining cable can be clamped onto the other rotating rod and the winding drum, and then the first motor is started. The conversion disc is rotated to exchange the positions of the two rotating rods, and the step of fixing thecable is repeated, so that continuous cutting of the cable is realized.

Owner:湖南新耒传导材料科技有限公司

Textile machine for cutting gauze

ActiveCN112575569ARealize continuous cuttingAchieve absorptionSevering textilesDirt cleaningAssembly lineManufacturing engineering

Owner:淮北悯农生物科技有限公司

Vertical multi-saw blade combined continuous cutting machine for stone

InactiveCN1569429ARealize continuous cuttingDelayed resetStone-like material working toolsSTONE CUTTEREngineering

The invention is a vertical multi-blade compound continuous stone cutter, belonging to stone cutter structure technology field. The cutter includes convey belt for transmitting stone, there arranges with vertical saw blades groups on the bracket above the convey belt. The invention can cut each kind of small stone, the whole stone can be cut into stone board in one time, and it can work continuously, the efficiency is high, and it is safe and reliable.

Owner:熊敏

Paper cutting device used for color printing and packaging

ActiveCN109352700AGuaranteed to move normallyImprove stabilityMetal working apparatusConveyor partsColor printingPulp and paper industry

The invention discloses a paper cutting device used for color printing and packaging. The paper cutting device comprises a box, a first conveying plate, a second conveying plate and a paper cutting mechanism. The first conveying plate and the second conveying plate are fixedly connected above the box through a first supporting plate and a second supporting plate correspondingly. The paper cuttingmechanism comprises a paper cutter, side plates, a manual lifting mechanism, a first lifting mechanism and a second lifting mechanism. The two side plates are symmetrically arranged on the two sides of the first conveying plate correspondingly and fixedly connected to the box through stand columns correspondingly. A cross beam is fixedly connected between the two side plates. The second lifting mechanism is arranged below the cross beam, and the first lifting mechanism is connected to the second lifting mechanism. The manual lifting mechanism is connected with the second lifting mechanism through the cross beam. A dedusting mechanism is arranged in the box. The paper cutting device is simple in structure and high in practicability, fast paper cutting can be achieved, production requirements of an assembly line are met, the working scope of the paper cutter is expanded, application and operation are flexible and convenient, and automatic operation is achieved.

Owner:佛山市顺德区皇奇纸类制品有限公司

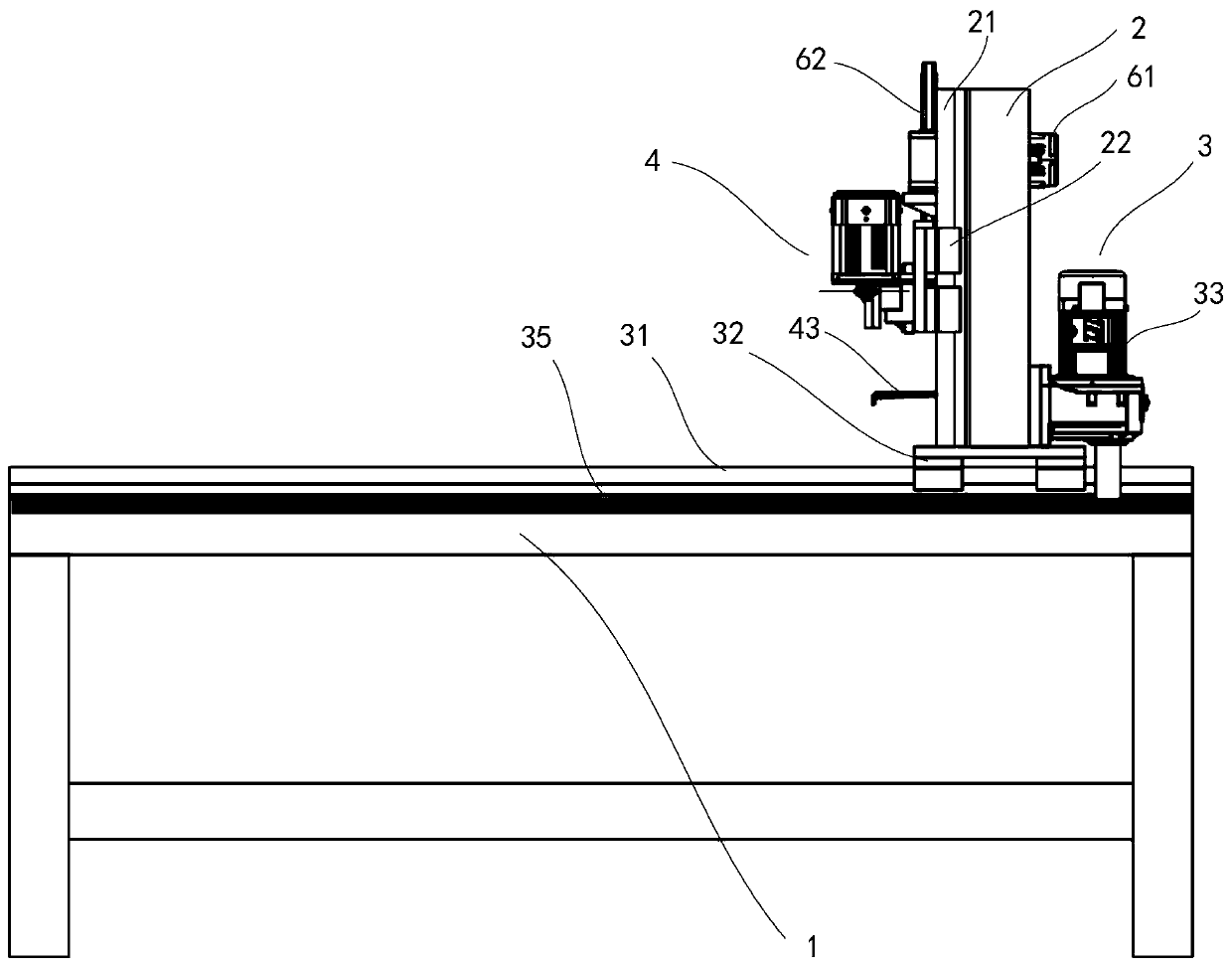

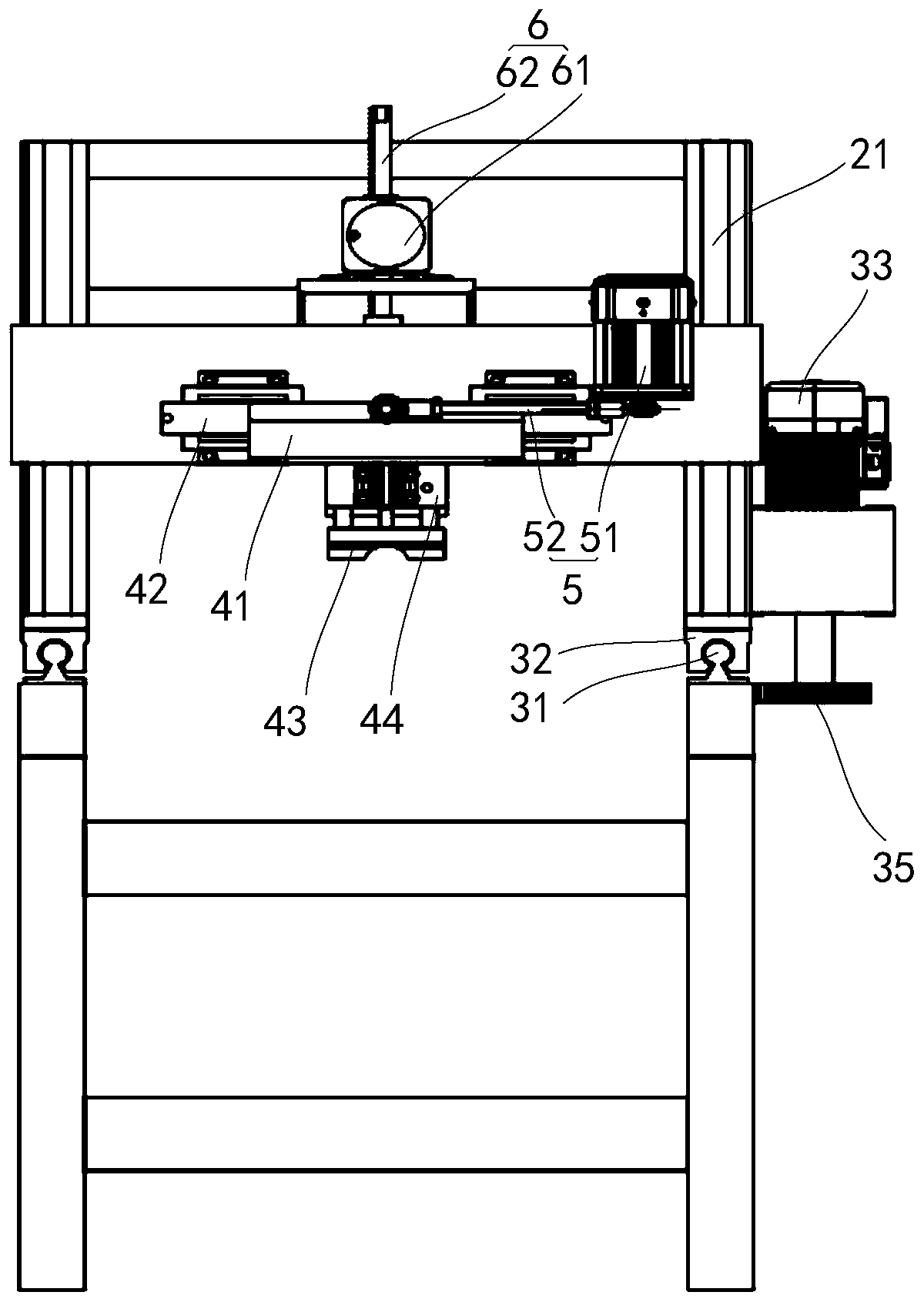

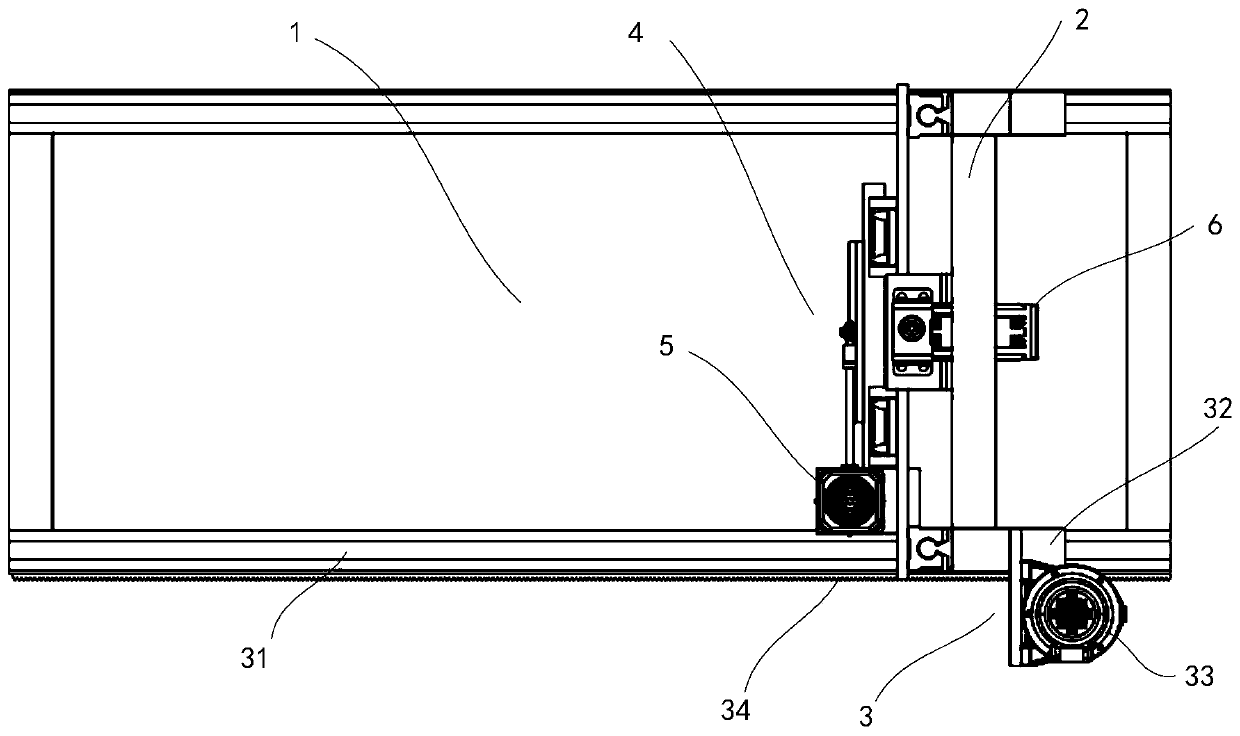

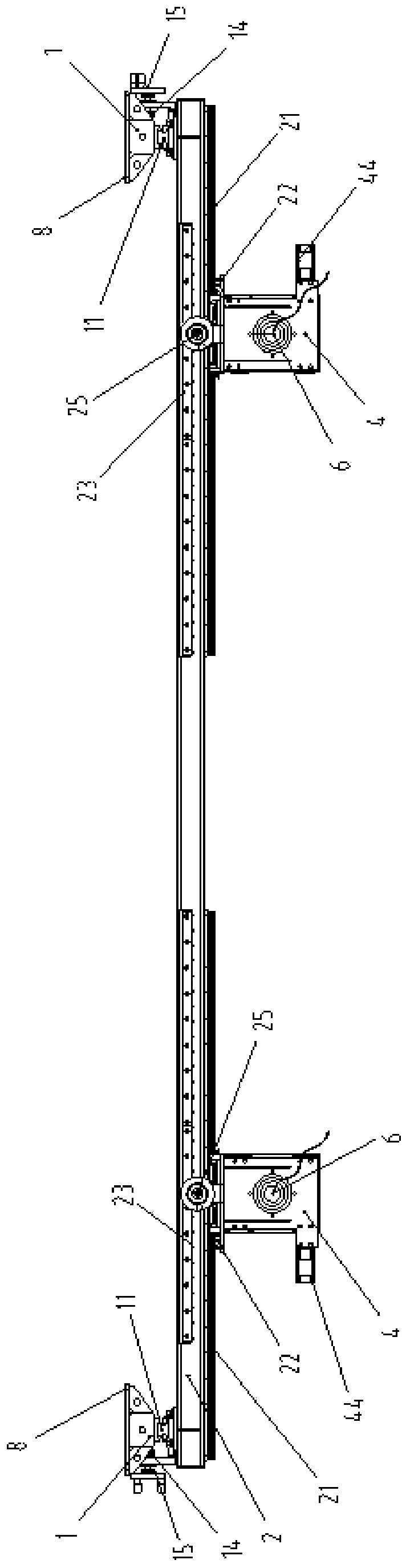

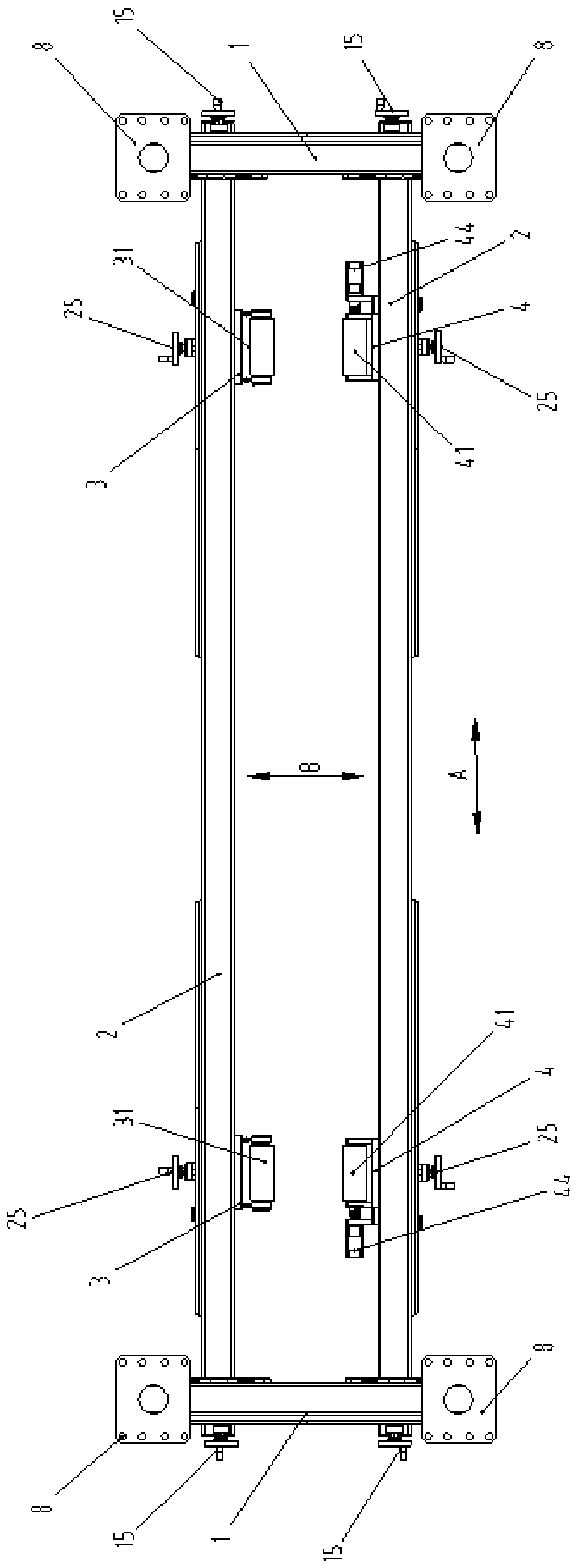

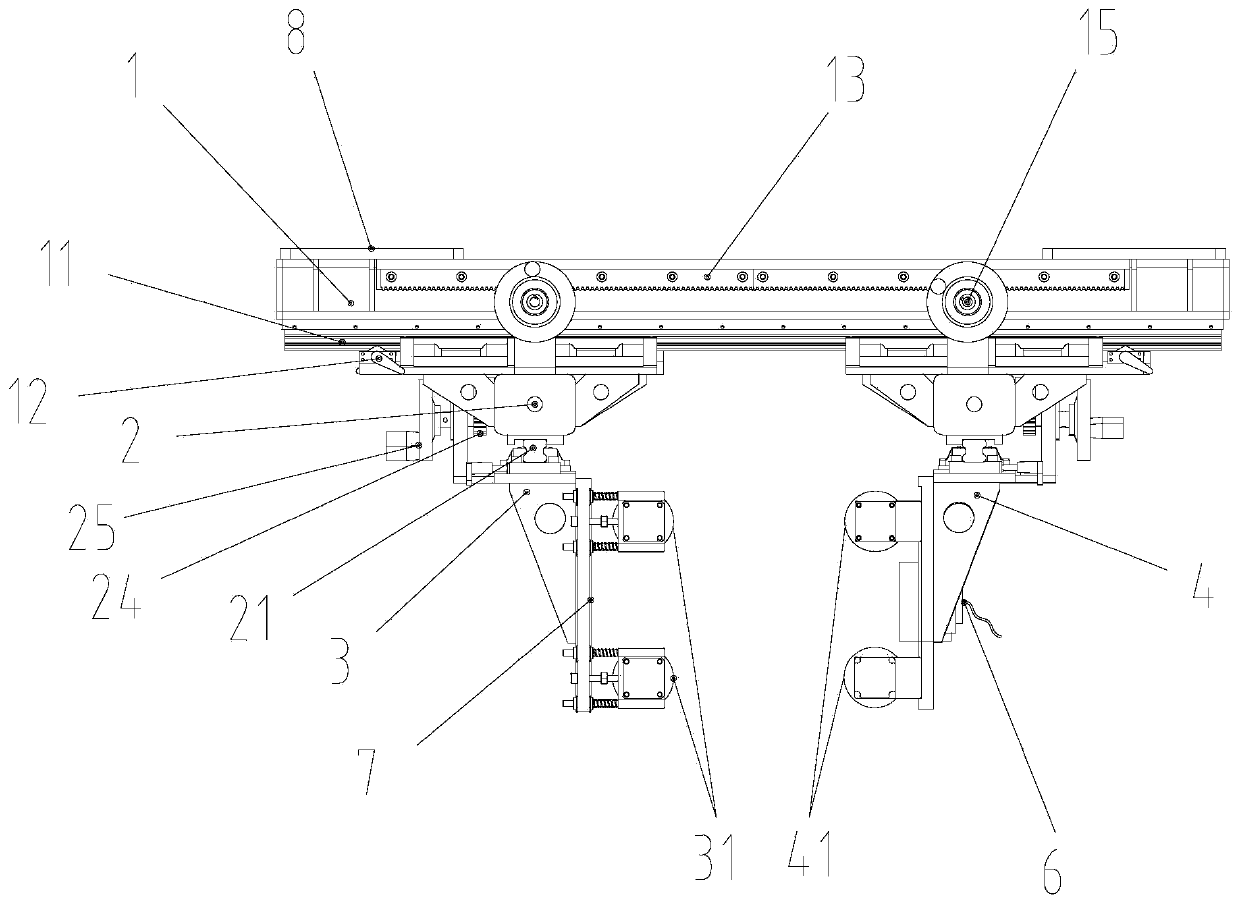

Substrate glass bait cutting equipment

ActiveCN111333313AImprove cut qualityReduce product lossGlass severing apparatusGlass productionStructural engineeringMechanical engineering

The invention relates to substrate glass bait cutting equipment, which comprises: two oppositely arranged first mounting beams (1) for fixing the cutting equipment; two second mounting beams (2) arranged between the two first mounting beams in a front-back moving mode and used for loosening or clamping base plate glass (5); two first driving device (3) arranged on one second mounting beam in a left-right moving manner; two second guide devices (4) are arranged on the other second mounting beam in a left-right moving mode, wherein the positions of the first guide devices on the two second mounting beams correspond to the positions of the second guide devices on the two second mounting beams; and a laser generator (6) installed on the second guide device and used for cutting the base plate glass when the base plate glass penetrates through the plane where the first mounting beam and the second mounting beam are located from top to bottom in the vertical state. According to the cutting equipment, base plate glass has excellent cutting quality during bait cutting, and the yield and the production efficiency are improved.

Owner:TUNGHSU TECH GRP CO LTD +1

Efficient plastic pipe cutting equipment

InactiveCN112606072ASimple structureRealize continuous cuttingMetal working apparatusStructural engineeringIndustrial engineering

The invention discloses efficient plastic pipe cutting equipment, and relates to the technical field of cutting. The efficient plastic pipe cutting equipment comprises a square base and a door-shaped cutter mounting frame arranged above one end of the square base, wherein a cutter mounting seat capable of moving along the top of the door-shaped cutter mounting frame is arranged on the door-shaped cutter mounting frame; a linear driving mechanism used for driving the cutter mounting base to move is arranged on the door-shaped cutter mounting frame; a horizontal plate is connected with the lower part of the cutter mounting base through a telescopic mechanism; a composite cutter mechanism is arranged on the horizontal plate; a moving platform is arranged on the square base; a plurality of groups of adjustable clamping assemblies used for clamping to-be-cut plastic pipes are parallelly arranged on the moving platform; and a distance adjusting mechanism capable of synchronously adjusting the clamping distances of all the groups of adjustable clamping assemblies is arranged on the square base. The efficient plastic pipe cutting equipment has the advantages that the structure is simple, as well as the clamping distances and the cutting heights are convenient to adjust.

Owner:贵州永丰科技管业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com