Automatic vermicelli cutting machine

A powder-cutting and automatic technology, applied in metal processing and other directions, can solve the problems of easy sticking to the knife, low work efficiency and low safety, and achieve the effect of preventing rice noodles from sticking to the knife, high production efficiency and automatic operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

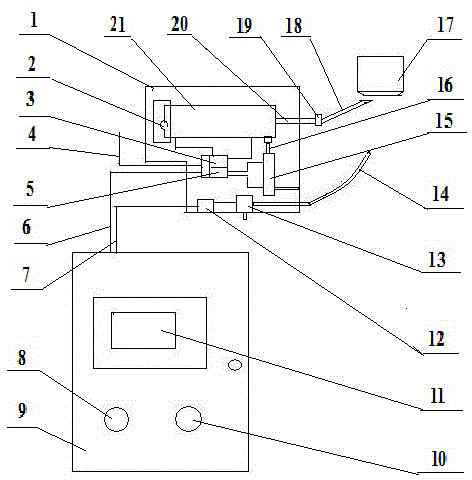

[0014] An automatic powder cutting machine, comprising a control box 9, a chassis 1, a push knife cylinder 21, a knife holder 19, a cutter 18, a positioning cylinder 15, a push knife air supply switch 3, and a positioning cylinder air supply switch 5, and is characterized in that: Push knife cylinder 21, knife rest 19, cutter 18, positioning cylinder 15, push knife air supply switch 3, positioning cylinder air supply switch 5 are installed in the cabinet 1, and one end of push knife cylinder 21 is installed on the cabinet 1 by bolt 2, Push knife cylinder 21 can rotate around bolt 2; On the frame 19; the movable end is connected with the piston of the positioning cylinder 15, and the positioning cylinder 15 is in the cabinet 1, and the installation position is perpendicular to or installed at an angle to the pusher gas, 21; the inlet and outlet air pipes of the pusher cylinder 21 are connected to the pusher gas supply switch 3 connection, the air inlet and outlet pipes of the p...

Embodiment 2

[0018] When the tap water supply pressure is sufficient, the water supply switch 12 and the electric water pump 13 in Embodiment 1 are replaced with solenoid valves, and the PLC circuit controls the solenoid valves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com