Patents

Literature

31results about How to "Avoid sticking knife" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

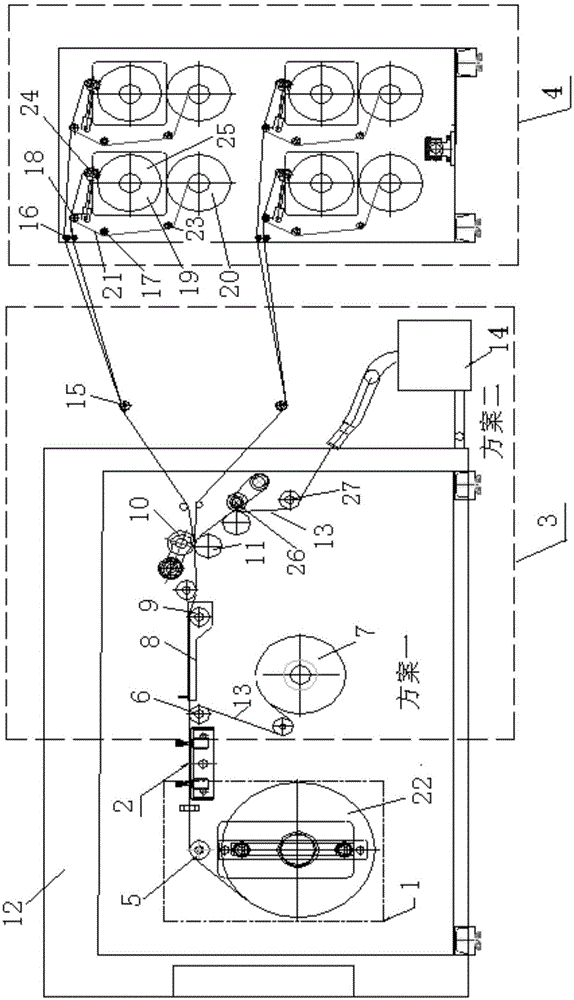

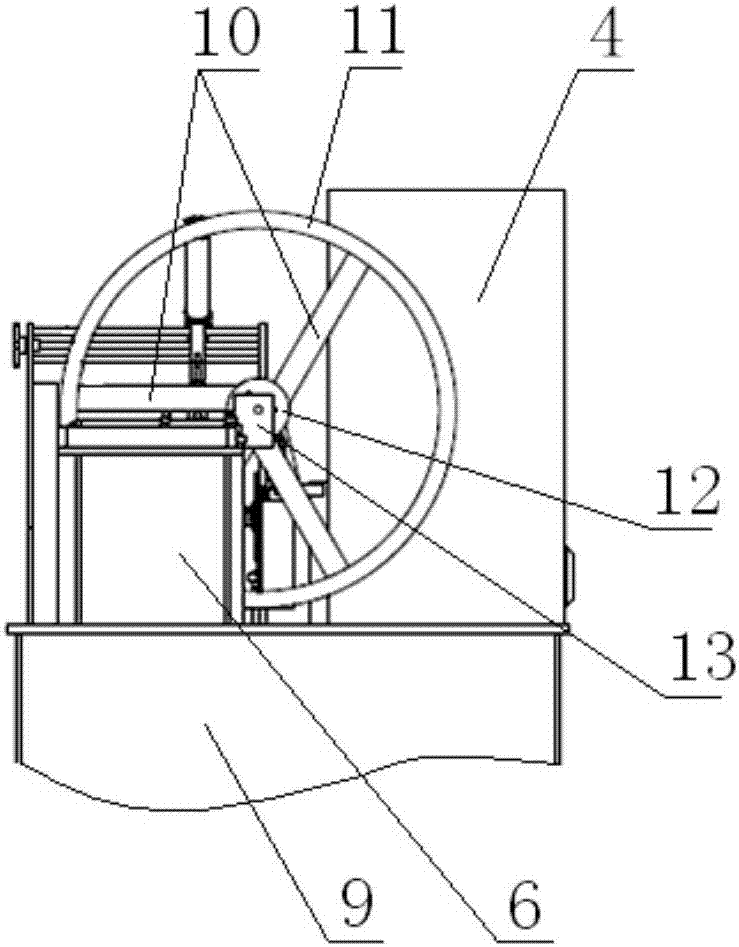

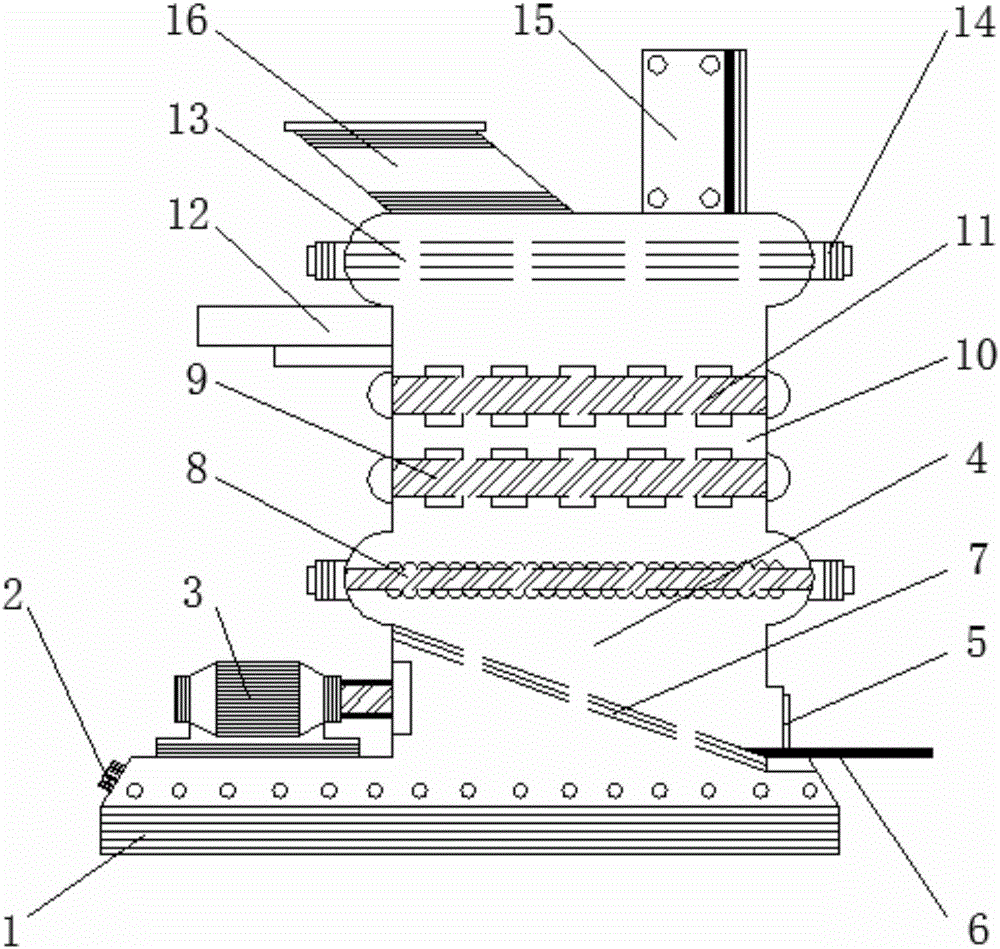

Device for electrode slice production with lithium strap and electrode slice production method

ActiveCN102738433AAvoid the problem that the lithium ribbon is easily damaged by weldingAvoid the problem of weld through damageCell electrodesCell component detailsLithiumEngineering

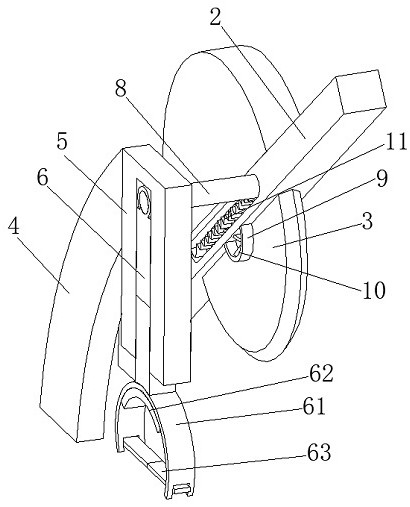

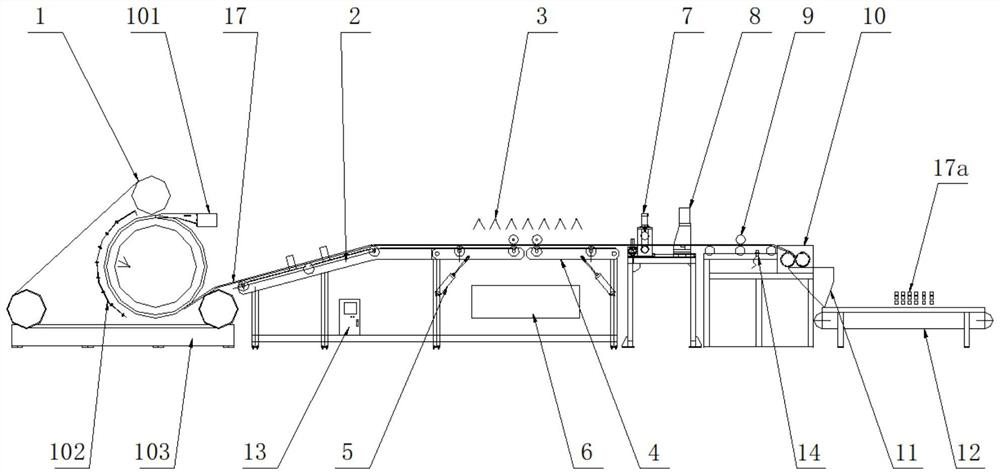

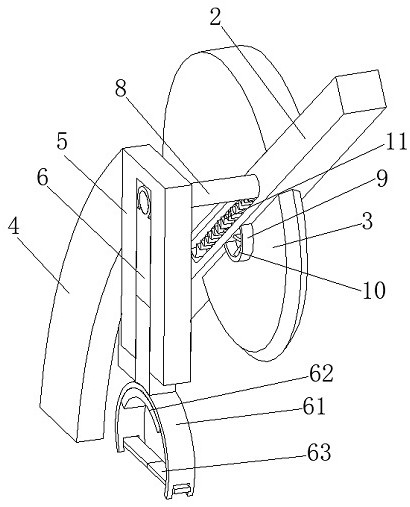

The invention discloses a device for electrode slice production with a lithium strap. The device includes a lithium strap conveying mechanism, a lithium strap tab adding structure, a rubberizing mechanism, a lithium strap cutting mechanism and a feeding mechanism. The lithium strap tab adding mechanism comprises a tab conveying mechanism, a tab knurling mechanism and a tab laminating mechanism. The tab conveying mechanism is used for conveying a tab to a lithium strap conveying path of the lithium strap conveying mechanism and cutting it off. The tab knurling mechanism is positioned on a tab conveying path of the tab conveying mechanism for knurling of the tab to make it have an uneven surface. The tab laminating mechanism is used for laminating the knurled tab to the lithium strap. The invention also discloses a method for electrode slice production with a lithium strap. The device and method of the invention can overcome the defects existing in traditional modes of electrode slice production with lithium straps, and improve the quality and automation level of electrode slice production with lithium straps.

Owner:SHENZHEN YINGHE TECH

Slitting preparation method suitable for hot-melt pre-impregnated filament

The invention provides a slitting preparation method suitable for a hot-melt pre-impregnated filament. The slitting preparation method comprises the following steps: in a low-temperature tank ranging from 5 DEG C to the room temperature, uncoiling a pre-impregnated belt with paper back lining and plastic coating by virtue of an uncoiling assembly; after being forcibly cooled, feeding the pre-impregnated belt to an upper cutter and a lower cutter to carry out slitting, wherein the slitting width of the pre-impregnated belt ranges from 4mm to 12 mm; transmitting slit pre-impregnated filaments with coating as wide as the pre-impregnated belt to a coiling assembly, and fitting plastic coating with width greater than those of the pre-impregnated filaments with the pre-impregnated filaments with coating as wide as the plastic coating; and finally, winding, according to a fixed line shape, the pre-impregnated filaments with upper and lower layers of plastic coating to a pre-impregnated filament coiling shaft of the coiling assembly. According to the slitting preparation method, in order to solve the problems that a great number of pre-impregnated filaments have roller-sticking, folding, filament-splitting, width-reducing, and the like because of great viscosity in a high-viscosity pre-impregnated filament coiling process, the invention discloses a method for carrying out slitting coiling on the pre-impregnated belt under a low-temperature condition, thereby preventing problems such as knife-sticking, roller-sticking, filament-winding, width-reducing and the like in a pre-impregnated filament slitting process.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

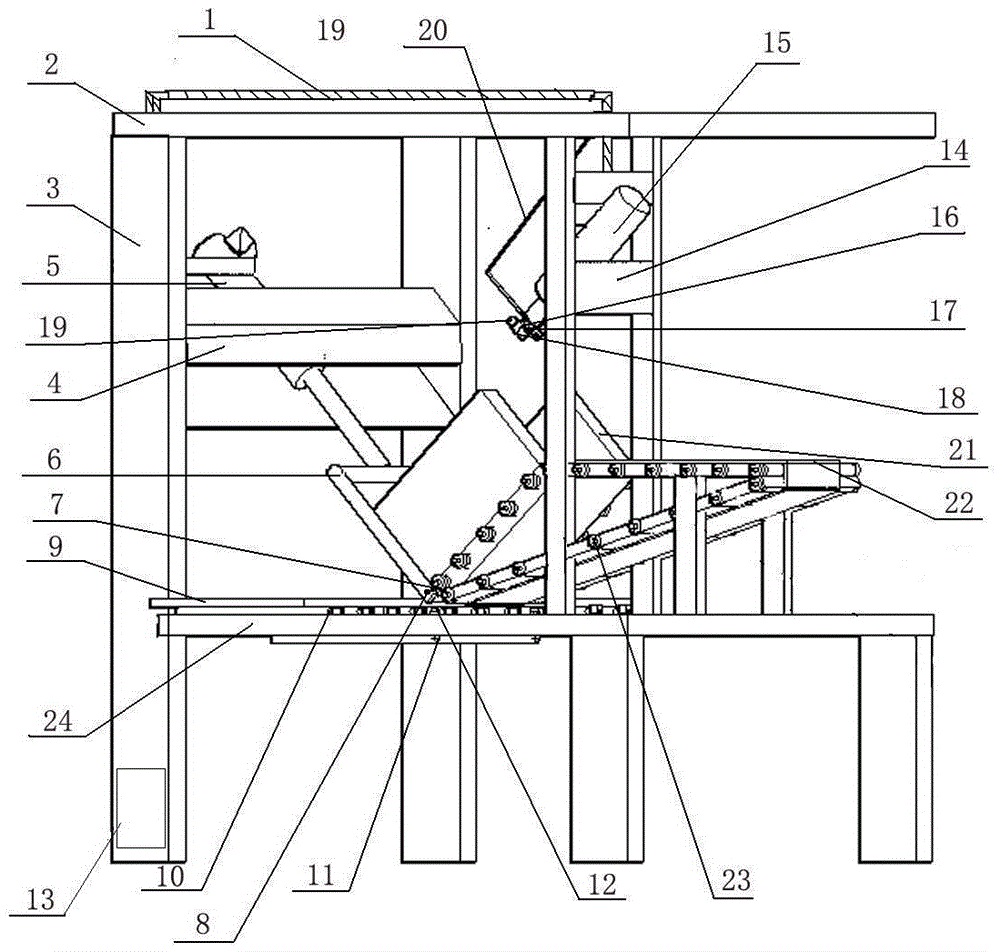

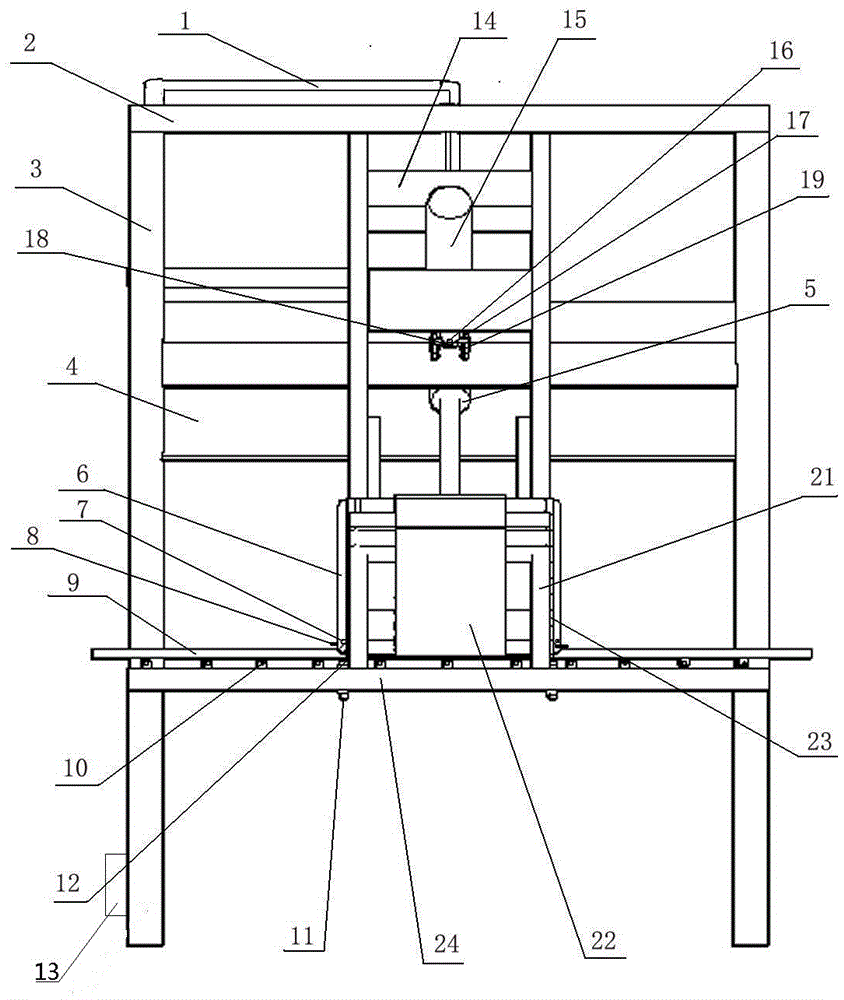

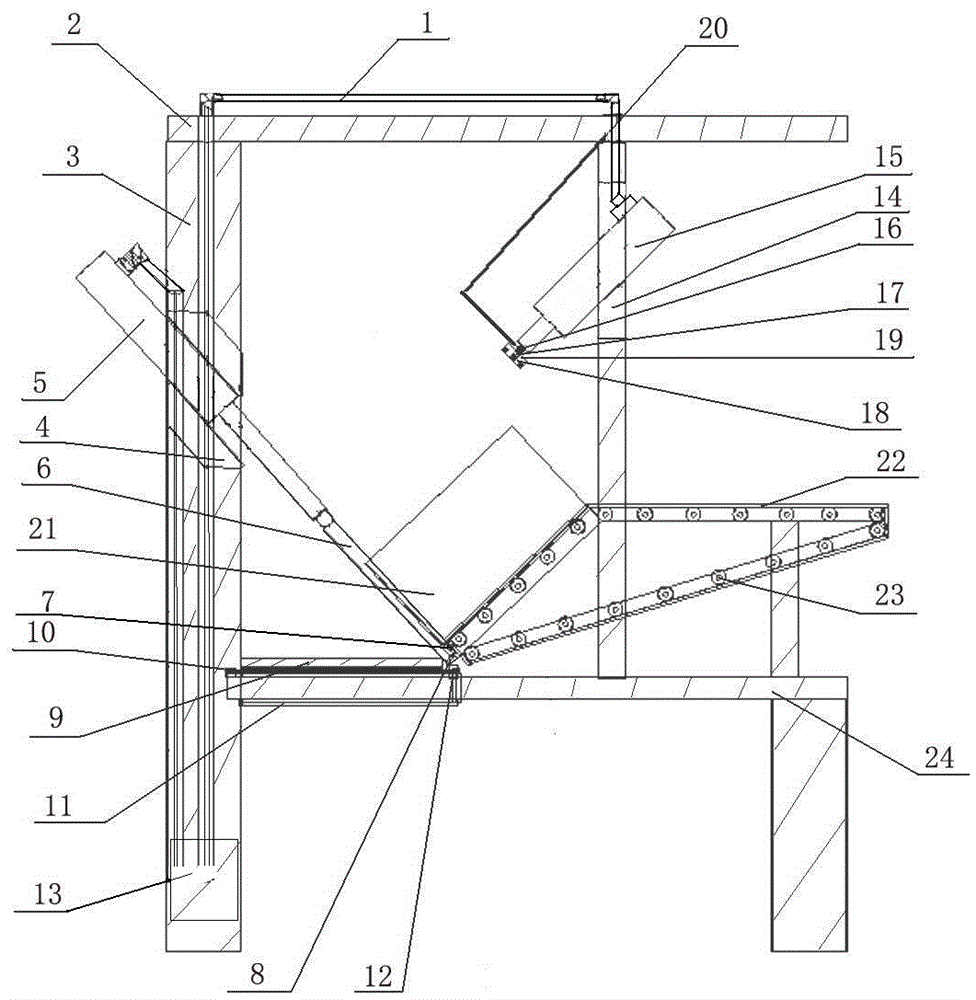

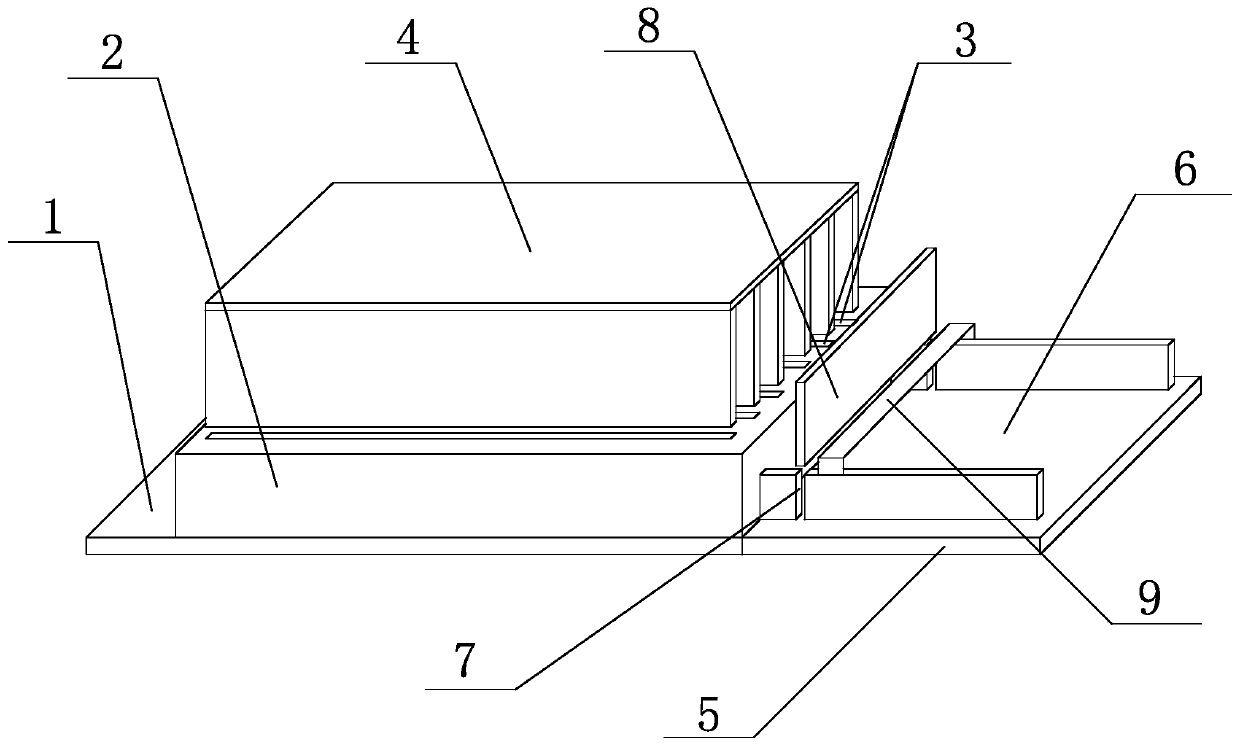

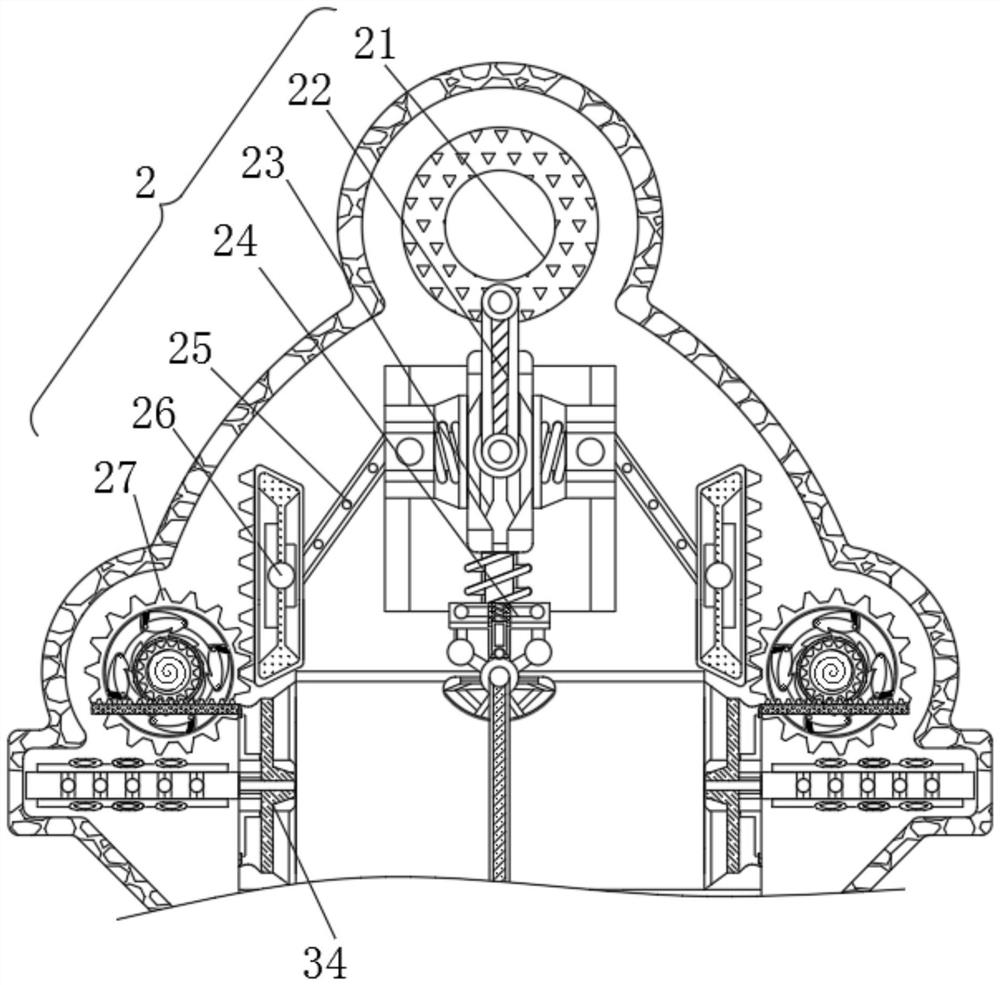

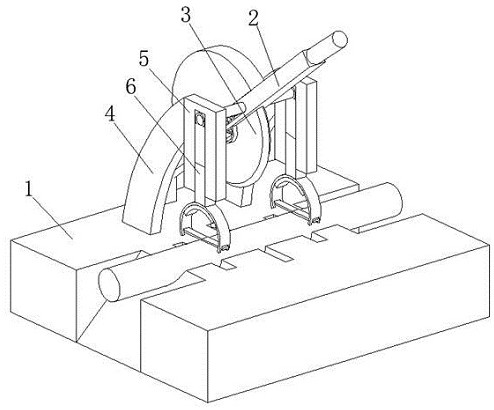

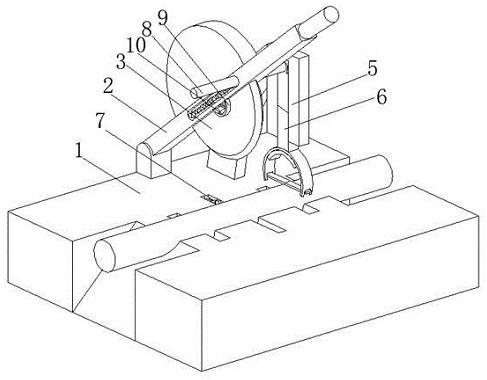

Viscous food slicing device

The invention discloses a viscous food slicing device, which comprises a frame (3), a beam A (4) in the middle of a column, an oil cylinder A (5) protruding from the top surface of the shaft and equipped with a knife rest (6), a knife rest (6 ) is equipped with a steel wire (8), a panel (24) is installed under the frame (3), a roller A (10) is installed above the panel (24), a transmission plate (9) is placed above the roller A (10), and the panel (24) A trigger switch (12) is installed at the top of the corresponding tool holder (6). The triangular shelf under the small column fixes the feeding trough (21), the conveyor belt (22), the roller B (23), and the oil cylinder B (15 ) is equipped with a manipulator trigger switch (16) and a retractable solenoid valve (18) in the middle of the top, and a retractable telescopic shaft (17) is installed on the left and right sides of the telescopic solenoid valve (18), and a manipulator (19) is installed on the top of the telescopic shaft (17). ), the present invention is simple in structure, convenient and practical.

Owner:唐能慧

Viscous food slicer

InactiveCN106142185AAvoid sticking knifeSimple structureMetal working apparatusEngineeringMechanical engineering

Owner:唐能慧

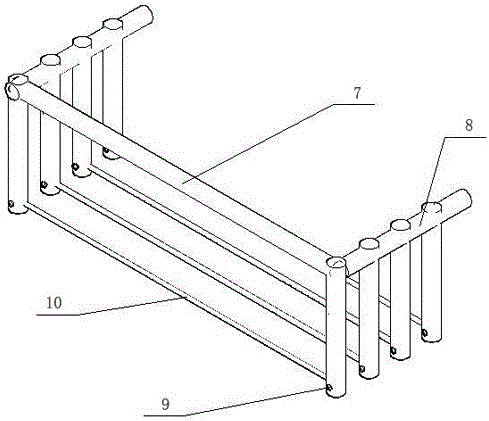

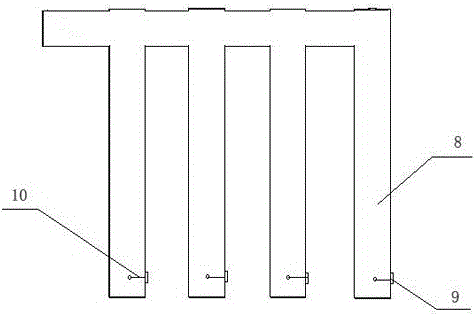

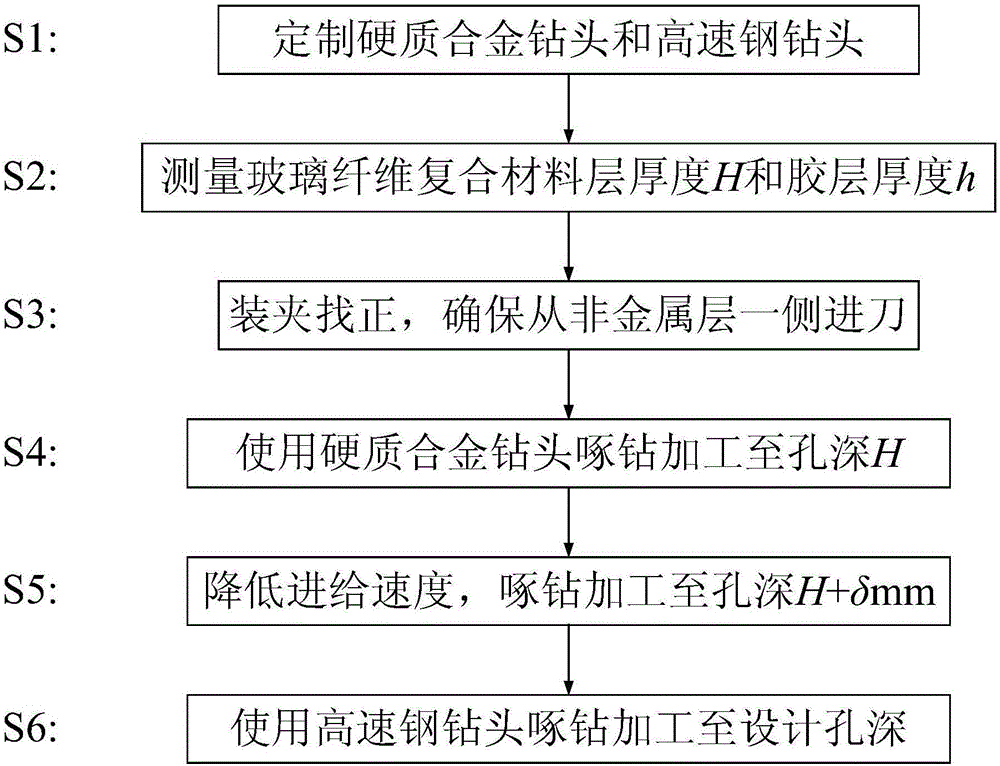

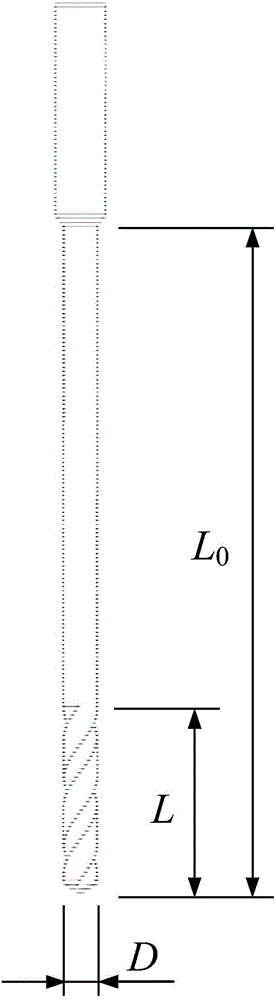

Method for machining large-depth-diameter-ratio small hole of glass fiber composite-aluminum alloy layered material

InactiveCN106825655AImprove rigidityReduced risk of breakageBoring/drilling machinesGlass fiberDiameter ratio

The invention relates to a machining technology, in particular to a method for machining a large-depth-diameter-ratio small hole of the glass fiber composite-aluminum alloy layered material. The technology comprises specific steps that firstly, two drill bots of specification sizes are prepared, wherein the drill bits comprise a hard alloy drill bit used for glass fiber composite machining and a high-speed steel drill bit used for aluminum alloy machining; secondly, the thickness of the glass fiber composite layer is measured and recorded, and the thickness of a rubber layer is measured and recorded; thirdly, a product is clamped, and it is ensured that during subsequent machining, tool feeding is achieved from one side of non metal; fourthly, the hard alloy drill bit is clamped, reasonable machining parameters are set, and after the glass fiber composite is subject to peck drilling and is drilled through, tool retreating is achieved; fifthly, the feeding speed is reduced, and peck drilling is carried out until a certain depth is achieved, and tool retreating is achieved; sixthly, the high-speed steel drill bit is replaced, the reasonable machining parameters are set, and peck drilling is carried out until the design depth is achieved, and tool retreating is carried out. Through the method, the problem of the high drill bit breakage rate in the small hole machining can be effectively solved, and the yield is greatly improved.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Dried tofu slicing machine

The invention discloses a dried tofu slicing machine comprises a underframe and a tool rest, wherein the underframe comprises at least two first supporting tubes, at least one second support tube, a supporting disk, multiple connecting tubes, a vertical plate and multiple base plate; a guide cylinder is arranged on the supporting disk; the tool rest comprises a tool disk and blades; the upper end surfaces of the blades are provided with guide columns; the tops of the guide columns are provided with handles; the bottom surface of the tool disk is provided with multiple blade grooves which are arranged in parallel at equal intervals; the blades are positioned in the blade grooves and are in detachable connection with the tool disk; springs are arranged on the blades; one ends of the springs are provided with pushing blocks; the height of each blade is 5 centimeter less than the height of each first supporting tube; multiple knife grooves are formed in the base plate, and the distance between two adjacent knife grooves are the same as the distance between two adjacent blades; and the width of each knife groove is greater than the width of each blade, and the length of each knife groove is greater than the length of each blade. The dried tofu slicing machine overcomes defects that the existing manual slicing of dried tofu is low in efficiency, and the size of sliced dried tofu is non-uniform.

Owner:CHONGQING SHUNYUANTONG FOOD

Processing method of herba cistanche

PendingCN109381522APreservation contentRapid saccharificationPlant ingredientsCold airSteam pressure

The invention relates to the technical field of traditional Chinese medicinal material processing, in particular to a processing method of herba cistanche. The processing method comprises following steps: a fresh herba cistanche material is cleaned and screened; the herba cistanche is steamed for 20-40 min under the steaming pressure of 0.80-0.95 MPa and dried in cold air; the herba cistanche dried in the cold air is placed at the normal temperature for 3-10 h and sliced; herba cistanche slices are aired in the ventilated position. According to the method, the fresh herba cistanche material issubjected to direct steaming by rapid high-flow steam at high temperature and enabled to be rapidly saccharified, meanwhile, enzyme can be killed rapidly, and content of echinacoside is saved to thegreatest extent. A cold air quick-drying technology is adopted after steaming, so that the overall herba cistanche is compact and has increased density, mildew rate is reduced, content loss is reduced, and long-term echinacoside storage is ensured. The herba cistanche is sliced after being placed at the normal temperature for an appropriate period of time, thereby being prevented from adhering toa knife, the herba cistanche slices are neat and stable, and storage and transportation are facilitated.

Owner:JIANCHANGBANG CHINESE HERBAL MEDICINE CO LTD

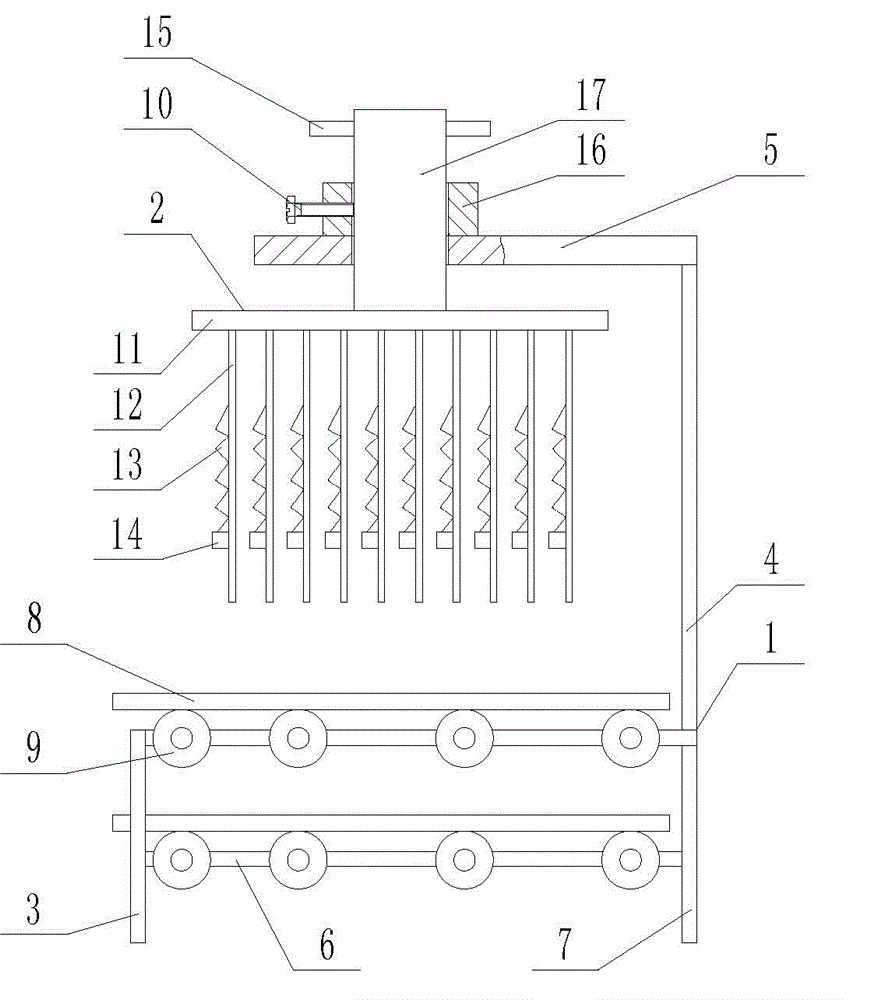

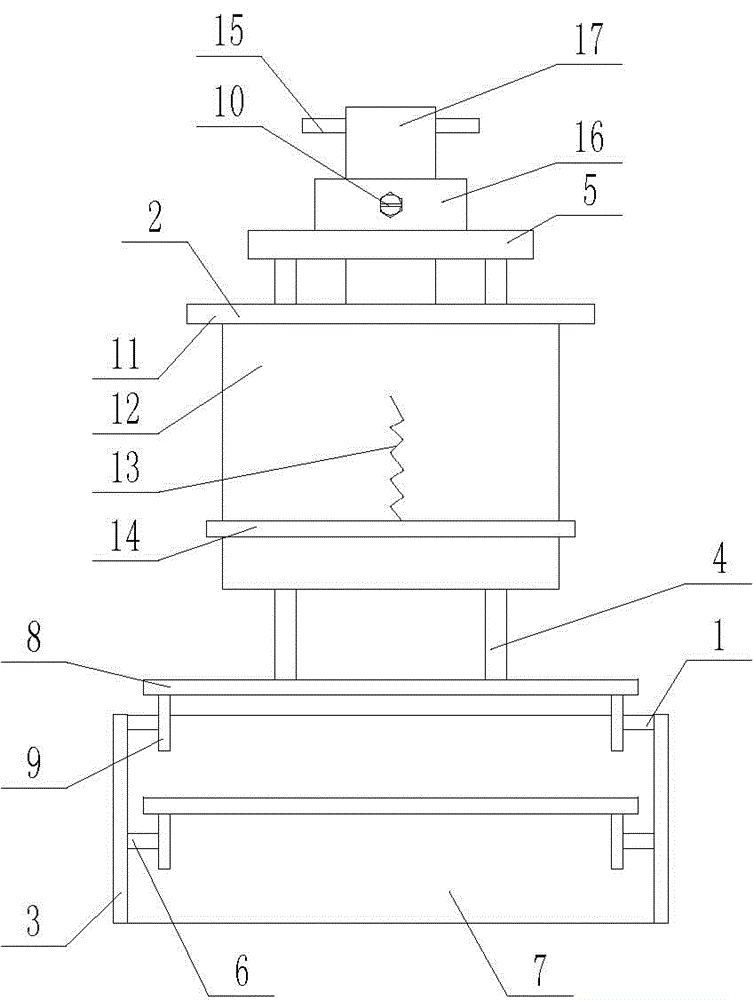

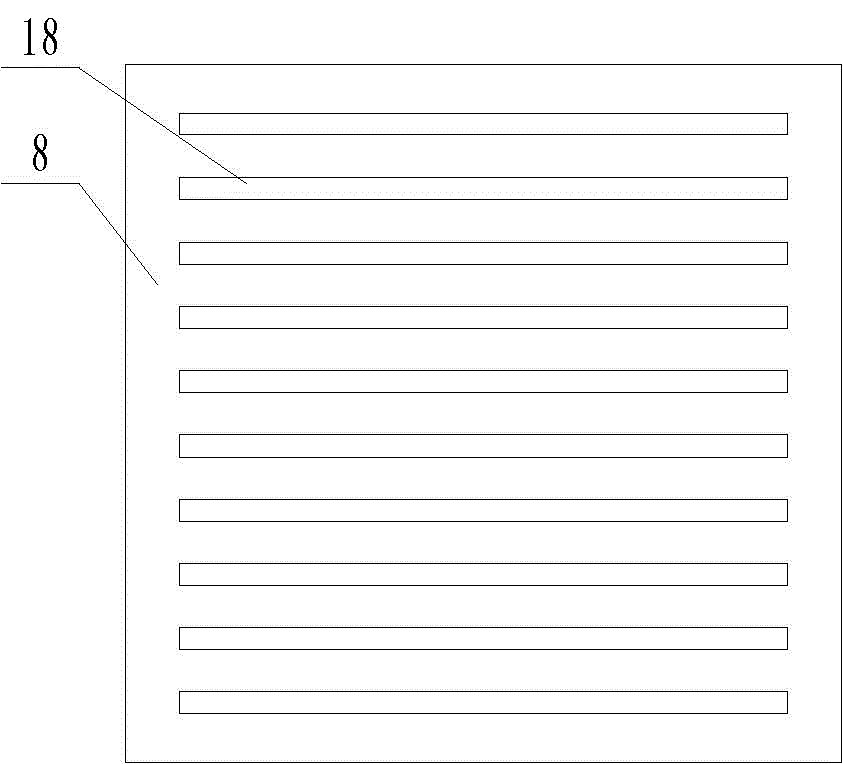

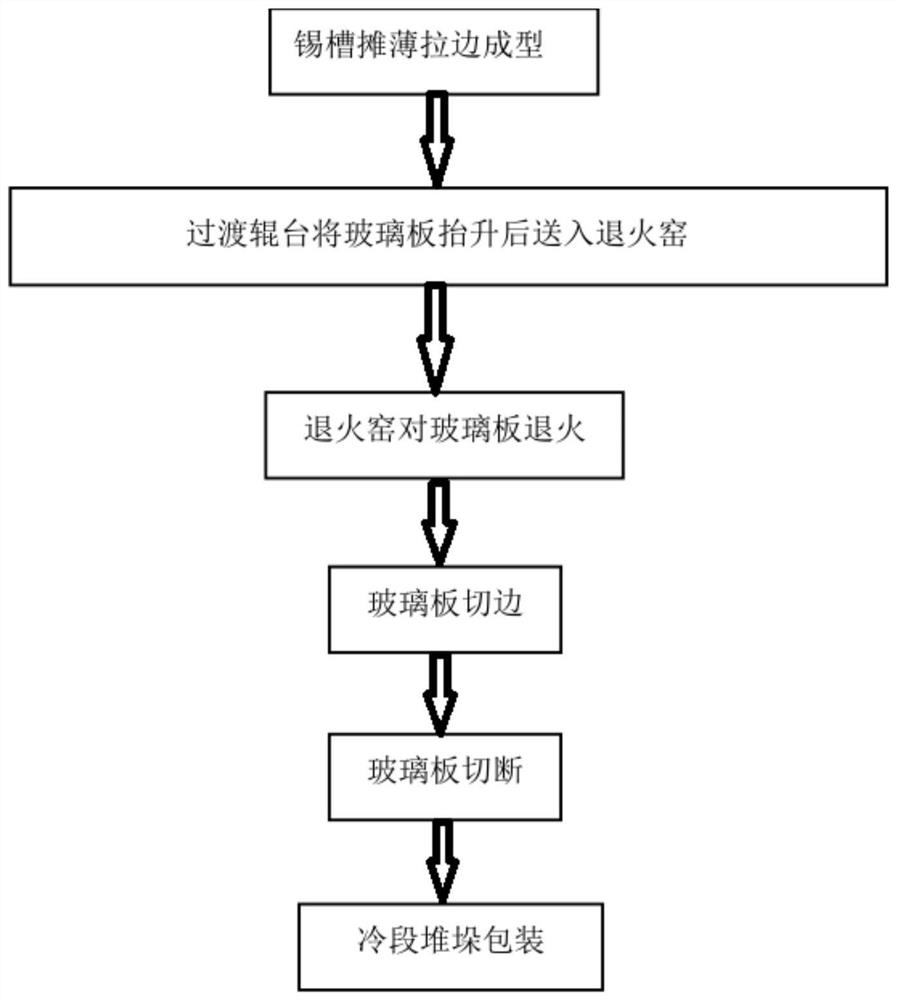

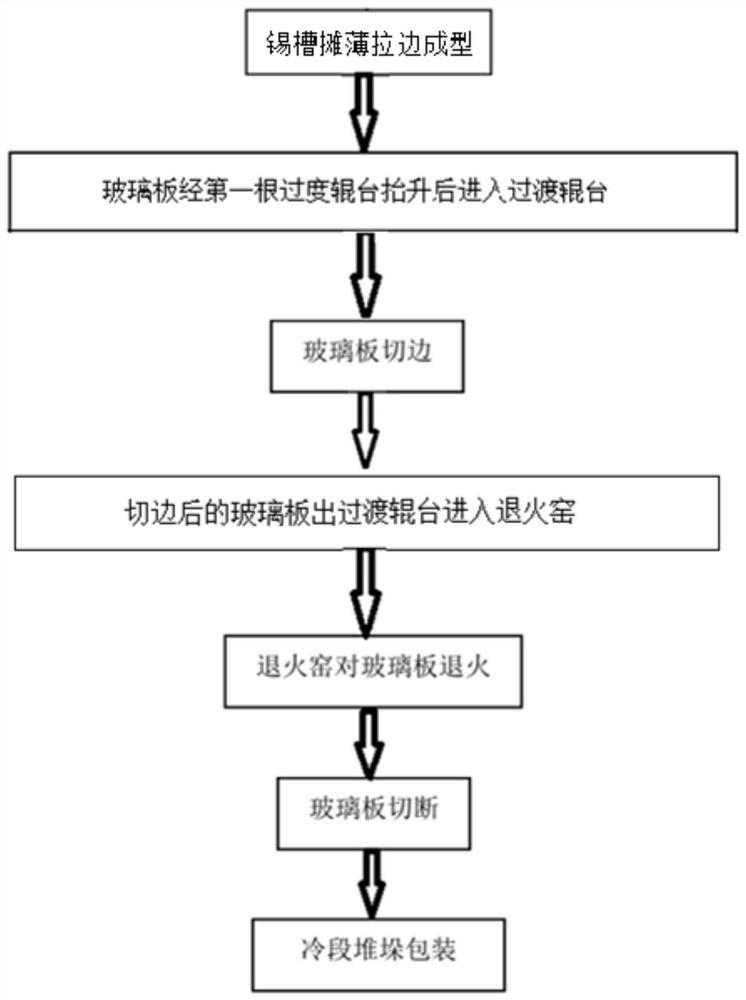

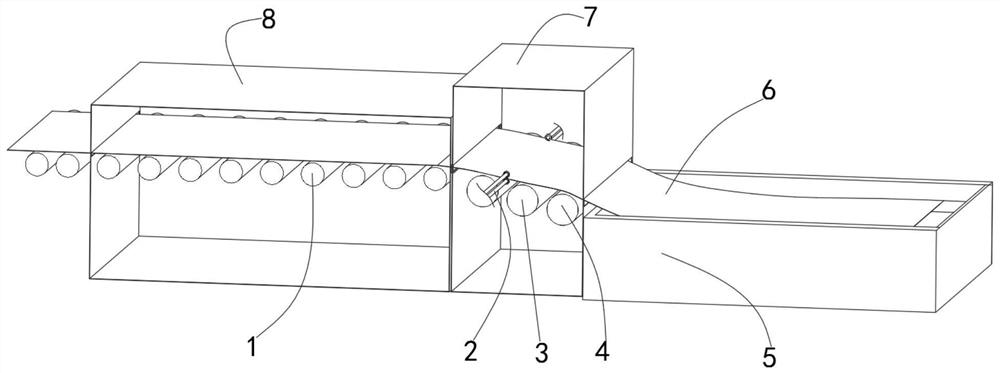

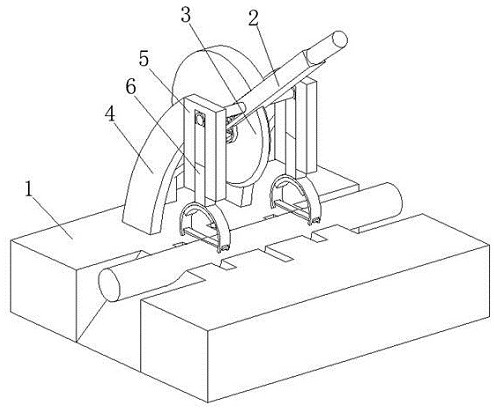

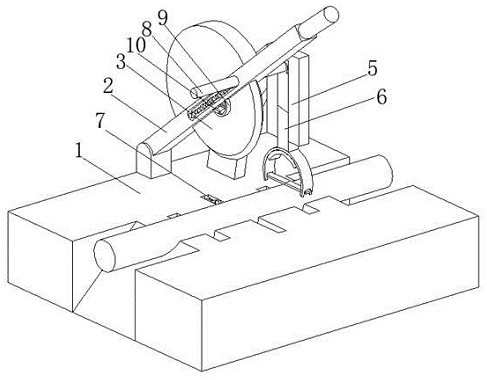

Plate edge thermal cutting process and device in production of ultra-thin float glass

PendingCN113185098AReduce the difficulty of manufacturing processSolve production drawbacksEngineeringThin glass

The invention discloses a plate edge thermal cutting process and device in production of ultra-thin float glass, relates to the technical field of ultra-thin float glass, and solves the technical problem of low qualified rate of finished products in annealing and rear-end cutting of ultra-thin glass caused by production defects of float glass. The method comprises the steps: step 1, enabling a glass plate formed in a tin bath to be pulled into transition roller table equipment through a first transition roller of a transition roller table; step 2, enabling the first transition roller to pull the glass plate entering the transition roller table equipment, and performing edge trimming through a cutting device before softening; step 3, separating the edge part and the middle part of the trimmed glass plate; and step 4, annealing the separated glass plate through an annealing section, and performing cutting and packaging the glass plate at a cold end. The method is used for manufacturing ultra-thin glass with the thickness being smaller than 1 mm and has the advantages that the ultra-thin glass is high in qualified rate and good in quality, and the surface of the glass is free of micro scratches.

Owner:MIANYANG AIJIA TECH

Aluminum material machining and producing cutting equipment

ActiveCN113997092APrevent rollingAvoid damagePositioning apparatusMetal working apparatusEngineeringBar pressing

The invention relates to the technical field of cutting equipment, and discloses aluminum material machining and producing cutting equipment which comprises a workbench, the top of the workbench is rotationally connected with a pressing rod through a torsional spring, a cutting machine is arranged on the surface of the pressing rod, the top of the workbench is fixedly connected with a supporting plate, and the front portion of the supporting plate is fixedly connected with a limiting plate. A telescopic rod is slidably connected to the inner wall of the limiting plate, an arc-shaped plate is fixedly connected to the bottom of the telescopic rod, a rubber block is fixedly connected to the lower surface of the arc-shaped plate, a rotating plate is rotatably connected to the inner wall of the arc-shaped plate through a torsional spring, and a transmission rod is rotatably connected to the inner wall of the telescopic rod; through cooperative use of the pressing rod, the cutting machine, the transmission rod, the limiting plate, the telescopic rod, the arc-shaped plate, the rubber block and the rotating plate, bars can be fixed during cutting, then the fixed bars are cut by the cutting machine, rolling of the bars can be prevented, and the production quality of products is improved.

Owner:河南万众金属材料有限公司

Paper box die-cutting process

InactiveCN104802448APrevent cardboard from sticking to knivesSimple processBox making operationsPaper-makingGraph drawingPulp and paper industry

The invention discloses a paper box die-cutting process and relates to the field of packaging. A die-cutting plate is manufactured by virtue of 7 process steps, namely die-cutting graph drawing, template cutting, cutter line and indentation line loading, checking, die-cutting rubber strip gluing, trial base plate cutting and putting into operation; the paper box die-cutting process is simple in process and high in preparation rate; the die-cutting plate manufactured is good in quality; the production efficiency is improved and the production cost is reduced.

Owner:ANHUI JIAXIN PACKAGING & PRINTING

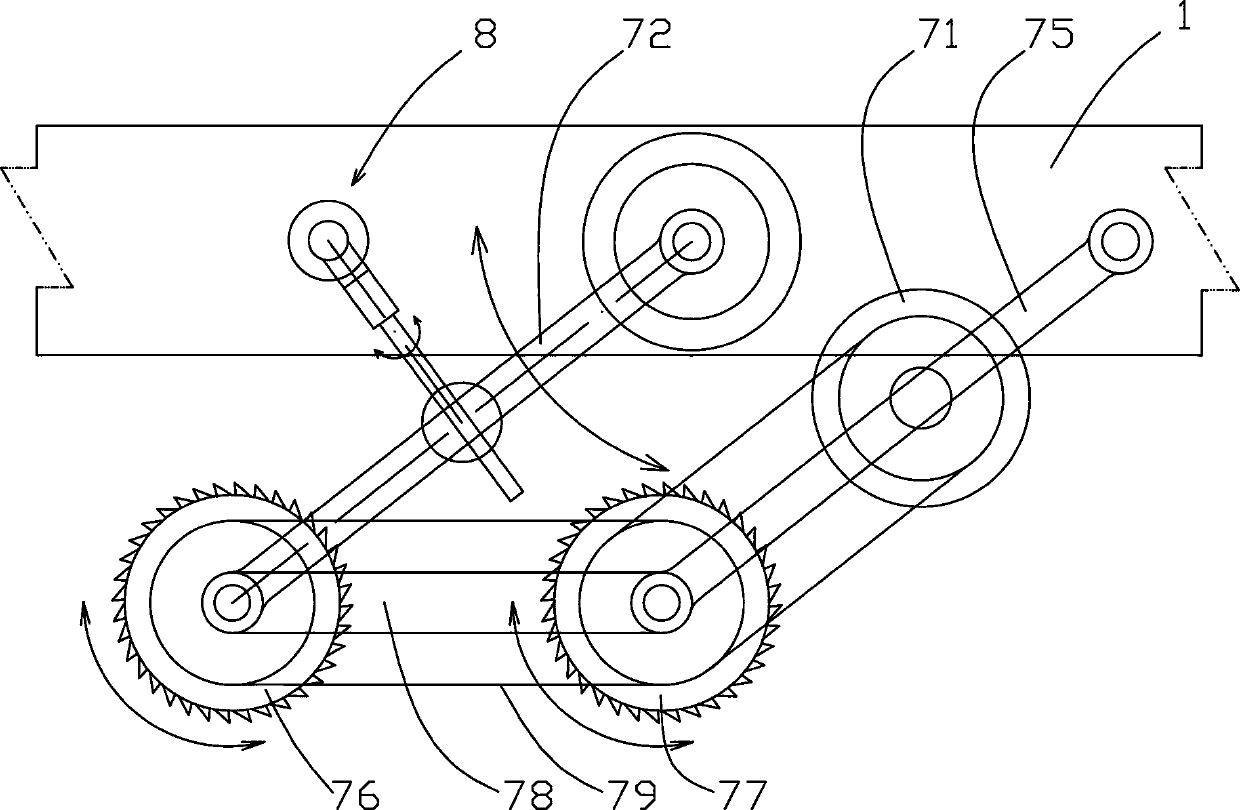

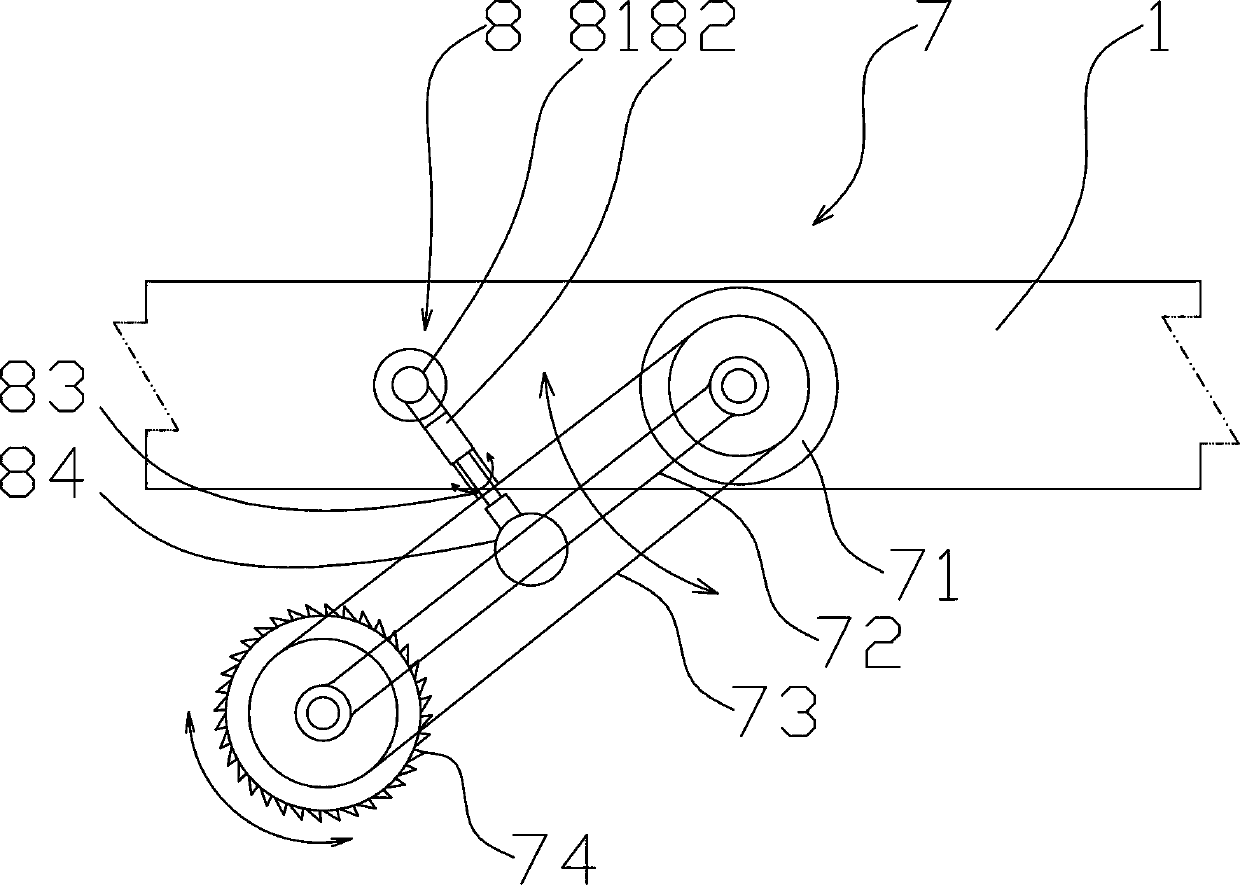

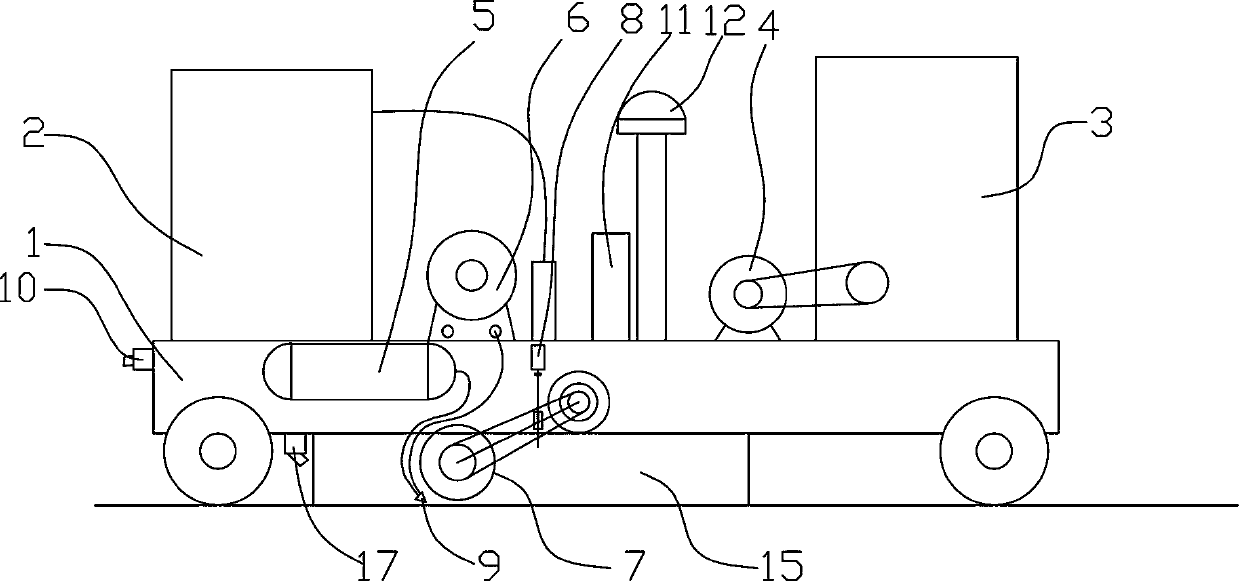

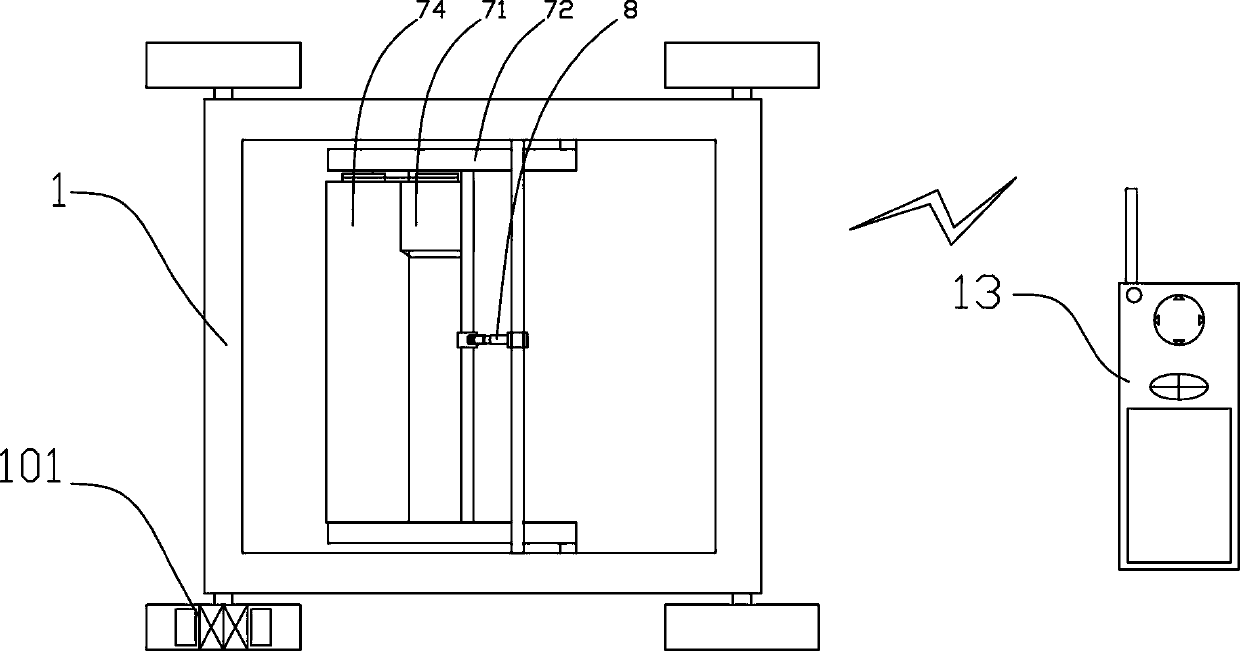

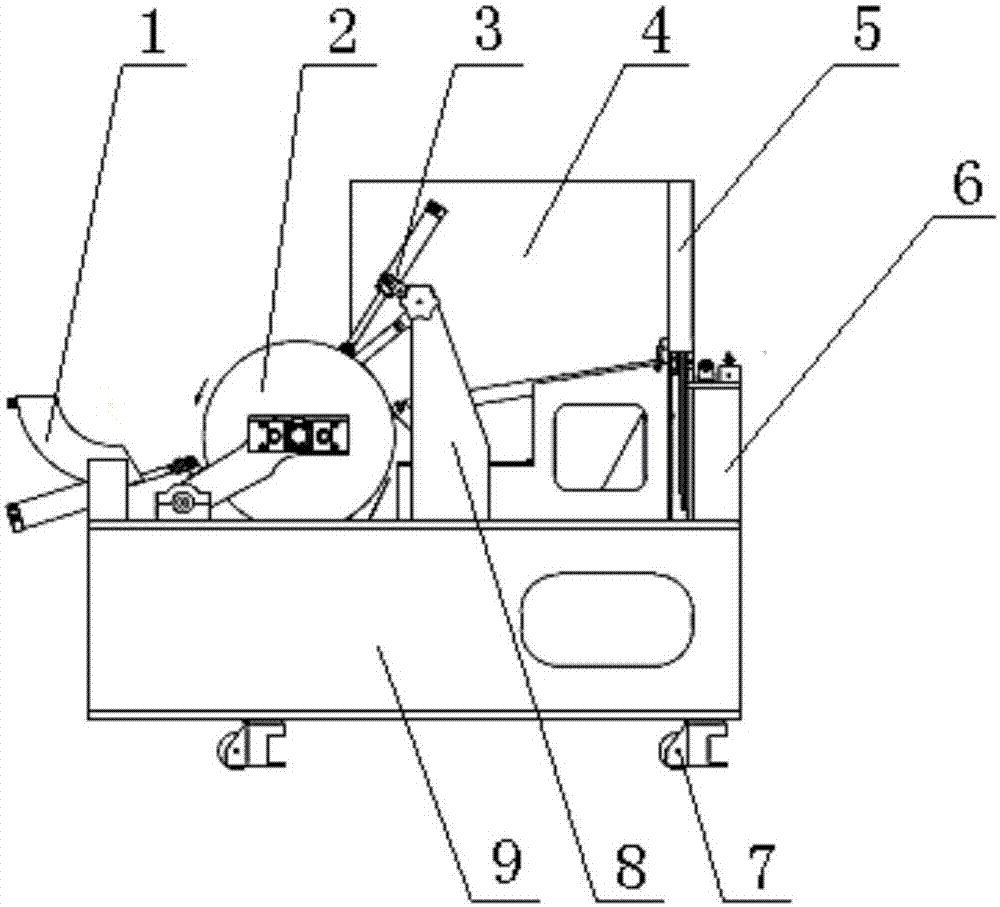

Pavement marker line removing device

InactiveCN110983930AAvoid sticking knifeImprove removal efficiencyRoads maintainenceElectric machineryStructural engineering

The invention provides a pavement marker line removing device. The pavement marker line removing device comprises a swing frame, a planing and milling roller installed on the swing frame, a driving device used for driving the planing and milling roller to rotate and a swing frame lifting device used for adjusting feeding of the planing and milling roller. One end of the swing frame is pivoted to awalking vehicle body, the other end of the swing frame is provided with the rotatable planing and milling roller, and the axis of the planing and milling roller is parallel to the ground. A planing and milling driving motor is arranged on the walking vehicle body or the swing frame and is connected with the planing and milling roller through a transmission mechanism. The swing frame lifting device is arranged between the walking vehicle body and the swing frame. By means of the scheme in which a refrigerant nozzle sprays low-temperature airflow to embrittle a pavement marker, planing, millingand removing are facilitated, knife sticking in the construction process is avoided, and the removing efficiency can be further greatly improved through a multi-saw-blade roller structure. The devicecan be used for removing pavement marker lines, and can also be used for removing defects of asphalt concrete pavements, such as bulges, indentations and cracks.

Owner:松塔技术咨询武汉有限公司

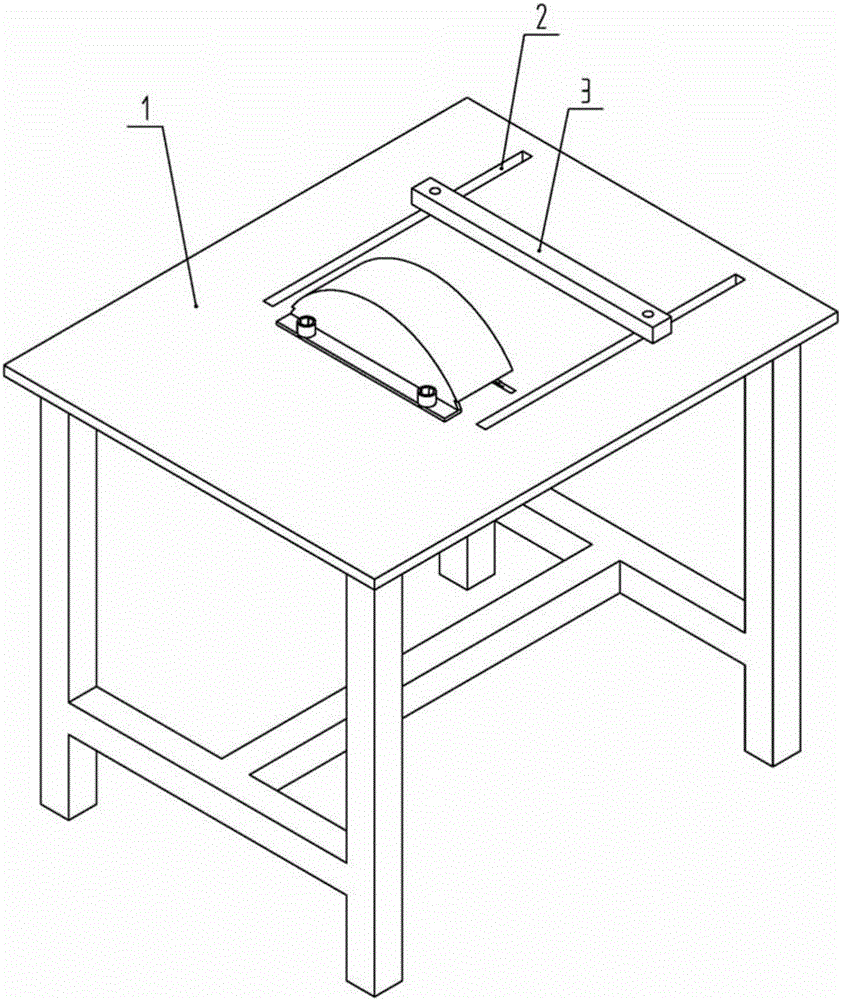

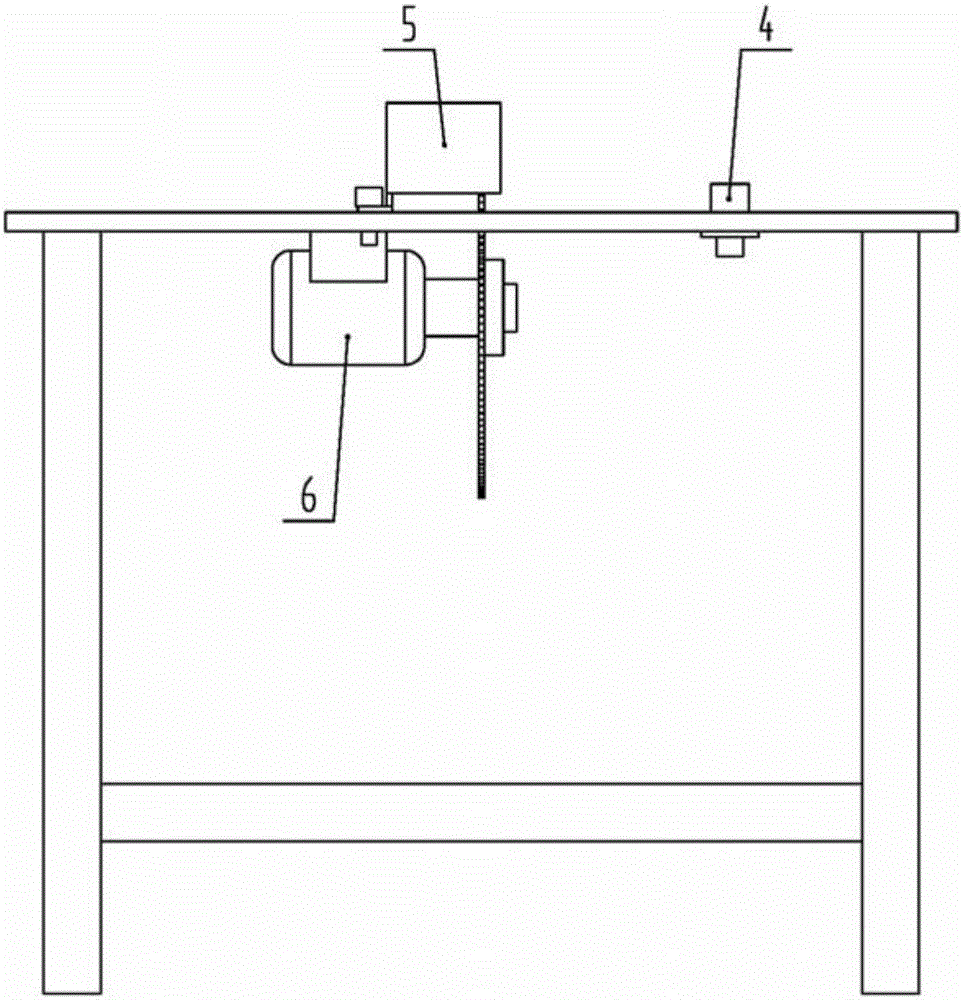

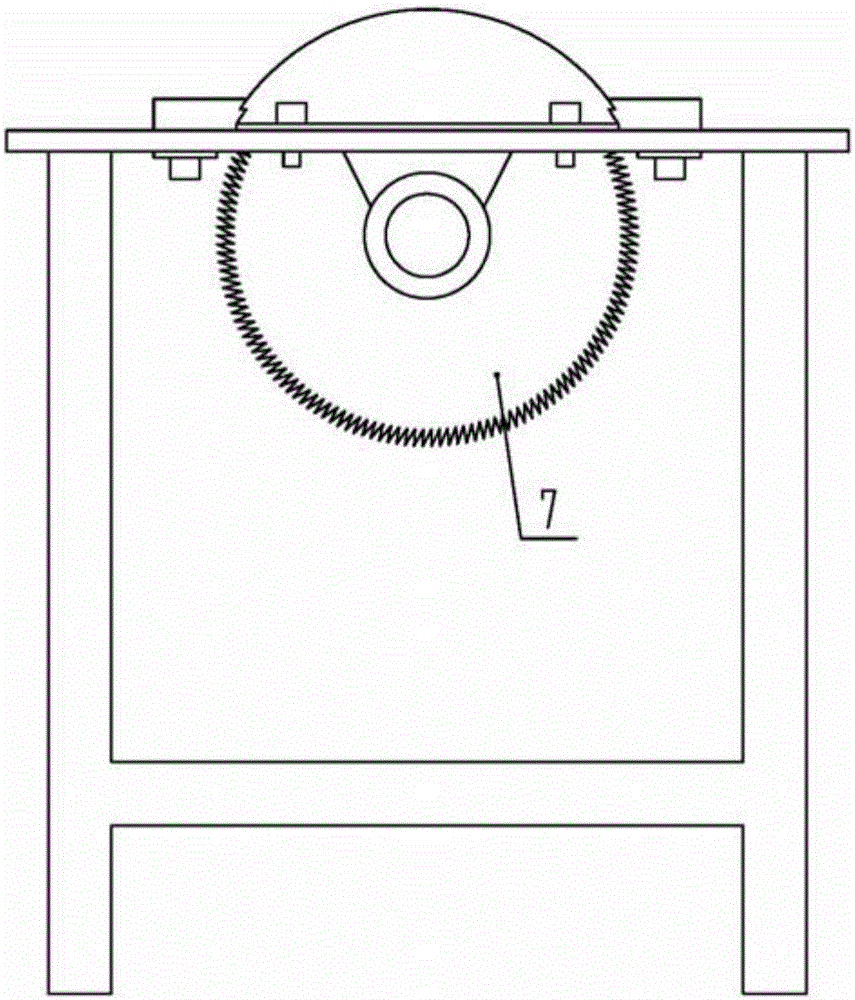

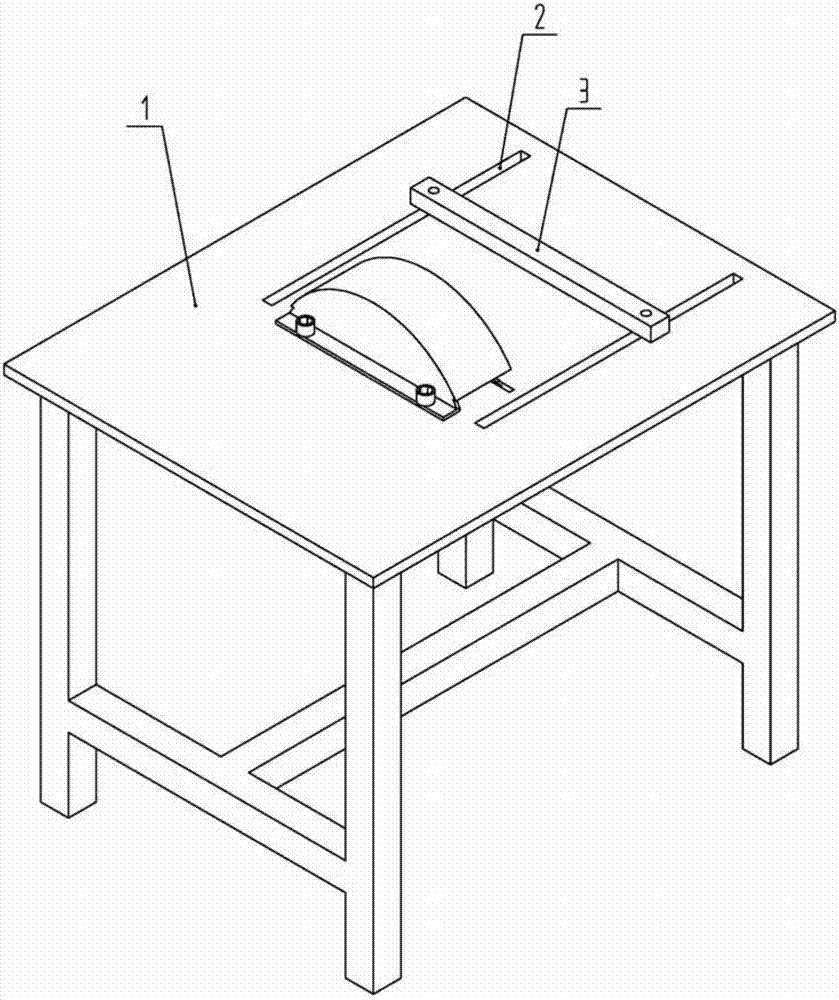

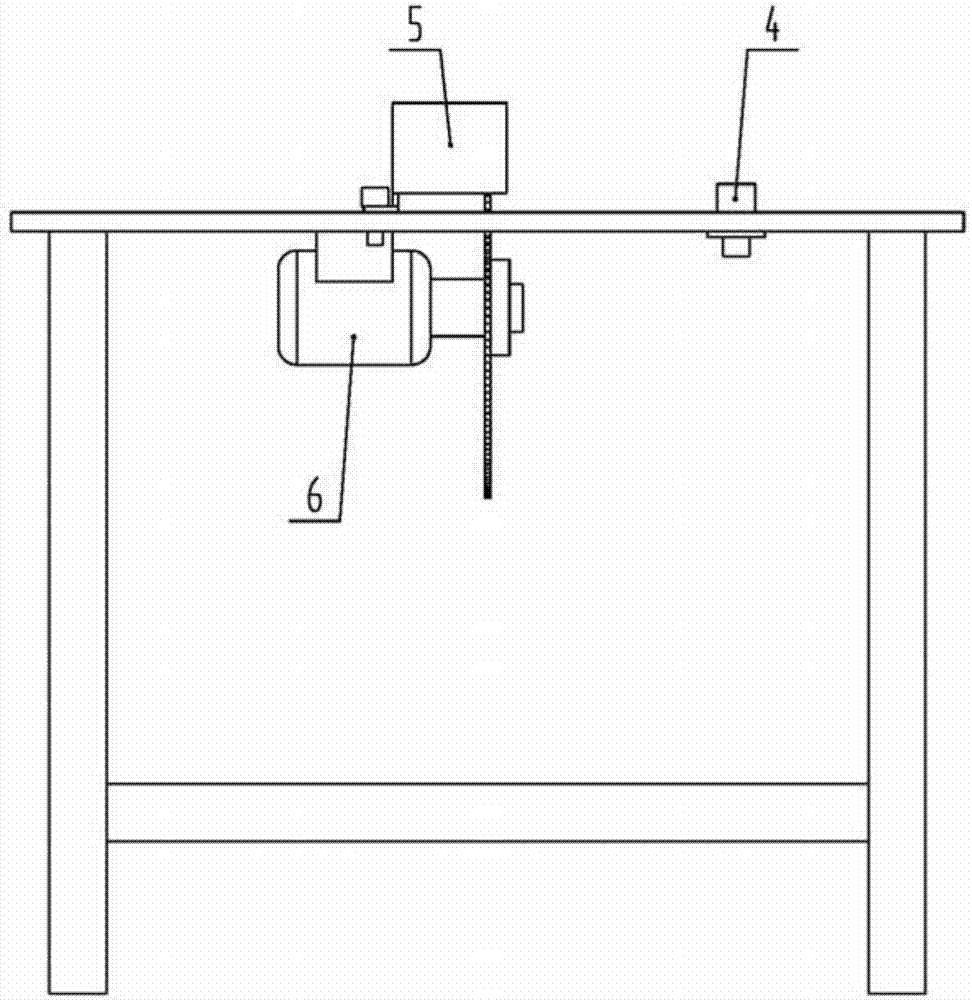

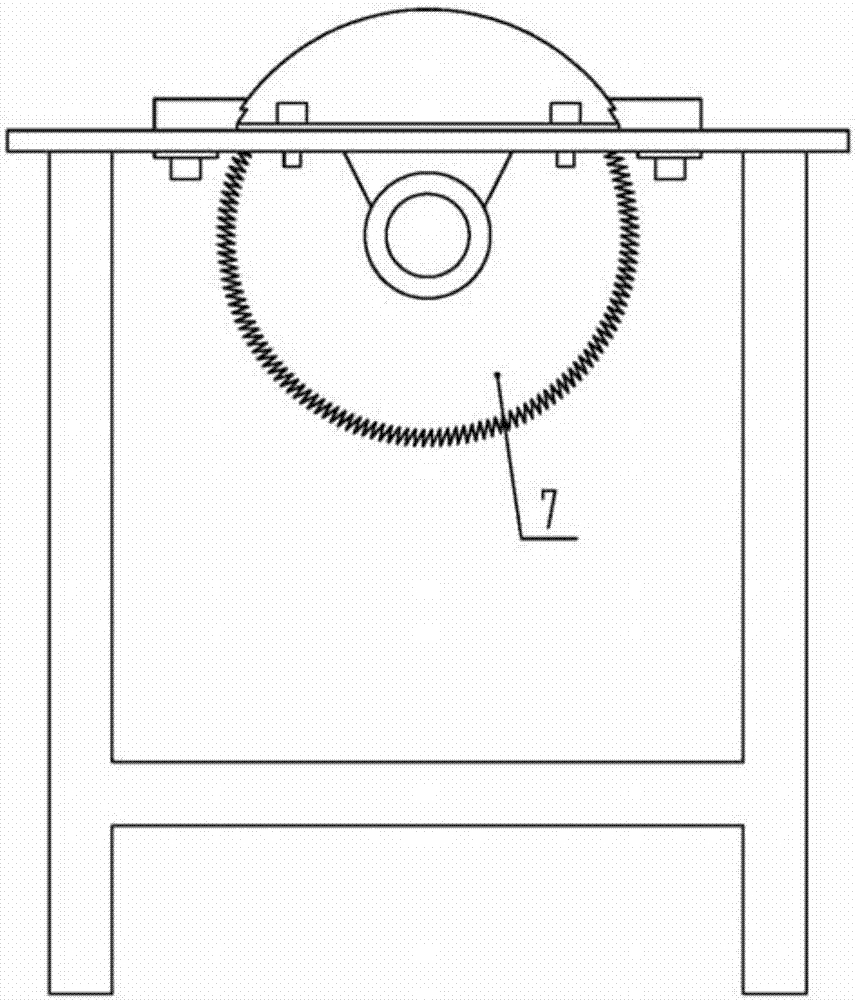

Cutting jig for PU panel

InactiveCN105965572AImprove machining accuracyAvoid shakingMetal working apparatusEngineeringMechanical engineering

The invention discloses a cutting jig for a PU panel. The cutting jig comprises a machine table, a driving device mounted on the bottom of the machine table, and a saw blade mounted on an output end of the driving device, and further comprises a backer, wherein a saw groove for allowing the saw blade to stretch out is formed in the table surface of the machine table; a pair of long grooves perpendicular to the saw blade is formed in the table surface of the machine table; guide bolts are mounted at the two ends of the backer; the backer and the long grooves are slidably assembled through the guide bolts at the two ends; lock nuts are further mounted on the guide bolts in a matching manner to lock the backer on the machine table; locating scale lines are further printed in the positions, close to notches of the long grooves, on the table surface of the machine table; a pressing cover covering the upper part of the saw blade is mounted on the table surface of the machine table; and a clearance for allowing a workpiece to pass through exists between the bottom of the pressing cover and the table surface of the machine table. According to the cutting jig, the pressing cover is mounted on the table surface of the machine table, so that on one hand, the pressing cover produces the function of a dust shield to prevent chips from splashing to injure a user, and on the other hand, the pressing cover acts as a guide part to firmly press the PU panel on the table surface of the machine table to prevent a tilting phenomenon.

Owner:SUZHOU ZHUOCHENG TITANIUM EQUIP

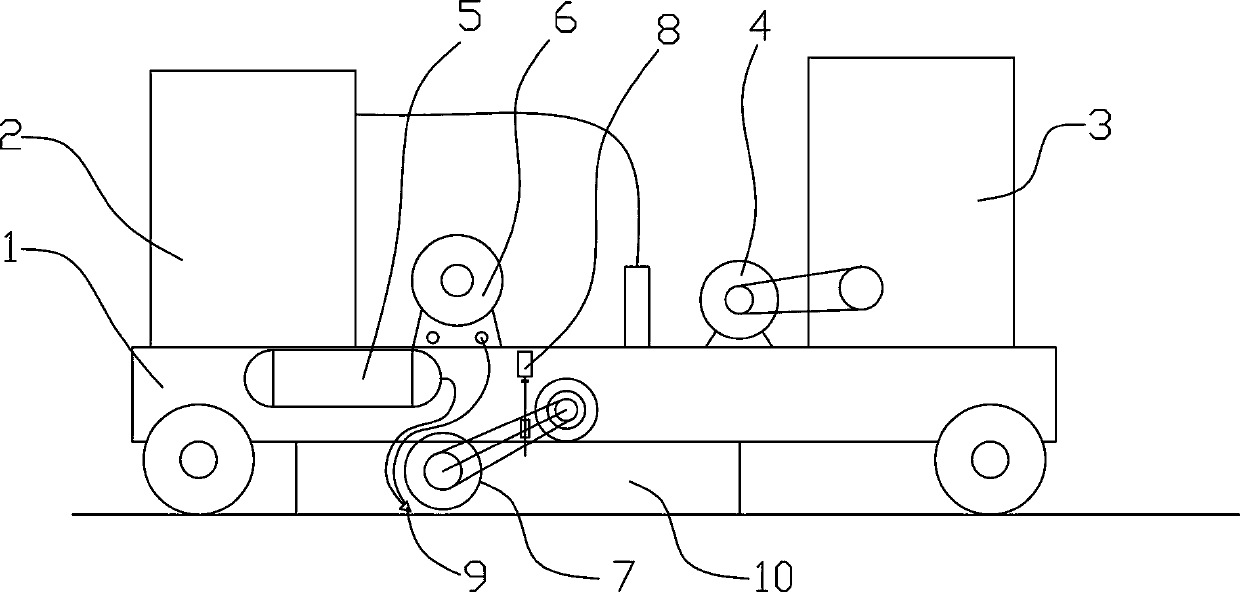

Intelligent asphalt pavement repairing vehicle and construction method

InactiveCN111045049AEasy to removeAvoid sticking knifeCharacter and pattern recognitionSatellite radio beaconingGyroscopeStructural engineering

The invention provides an intelligent asphalt pavement repairing vehicle and a construction method. The intelligent asphalt pavement repairing vehicle comprises a walking vehicle body, wherein a planing and milling device capable of ascending and descending is arranged on the walking vehicle body; a refrigerant nozzle is arranged in front of the planing and milling device, is connected with a refrigerant storage tank, and is used for spraying a refrigerant to cool the pavement of a pavement sign to be treated; a GPS positioning device and a gyroscope are arranged on the walking vehicle body; and a camera device is at least arranged at the bottom of the walking vehicle body and faces the direction of the pavement. According to the scheme that low-temperature airflow is sprayed out through the refrigerant nozzle to embrittle the pavement sign, planing, milling and removing are facilitated, knife sticking in the construction process is avoided, and the removing efficiency can also be greatly improved through the adopted multi-saw-blade roller structure. By adopting an intelligent control positioning scheme, the equipment control difficulty of an operator can be greatly reduced, and the construction efficiency and safety are improved. The intelligent asphalt pavement repairing vehicle can be used for repairing defects of the asphalt concrete pavement, and can also be used for removing pavement marker lines.

Owner:HUBEI YITONG CONSTR ENG CO LTD

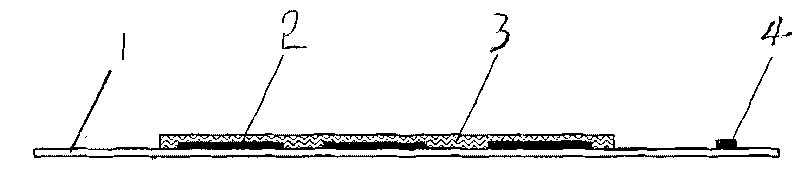

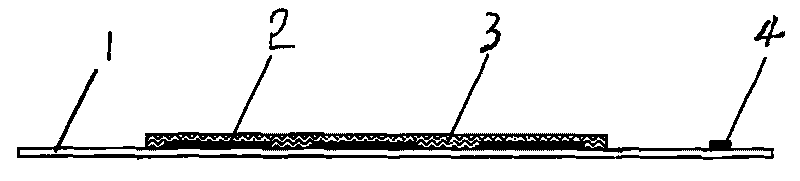

Food packaging heat shrinking film printed with pictures and texts

InactiveCN101717011AAvoid sticking knifeGraphic effect is goodFlexible coversWrappersEngineeringFood packaging

The invention discloses a food packaging heat shrinking film printed with pictures and texts, which comprises a heat shrinking film basic layer, wherein picture and text layers and sealing and cutting color batches are sequentially printed on the upper surface of the heat shrinking film basic layer at intervals, and a gloss oil layer is respectively printed on the upper surface of each printed picture and text layer within a range of not smaller than 2-3 centimeters away from both sides of each color batch. A gloss oil layer is respectively covered on the surfaces of the printed pictures and texts by keeping away from the color batches, so the phenomenon that the gloss oil adheres to a knife when in cutting can be effectively avoided; and the food packaging heat shrinking film has the advantages of good picture and text protection effect, high production efficiency and low cost.

Owner:HENAN MIDUOQI FOOD

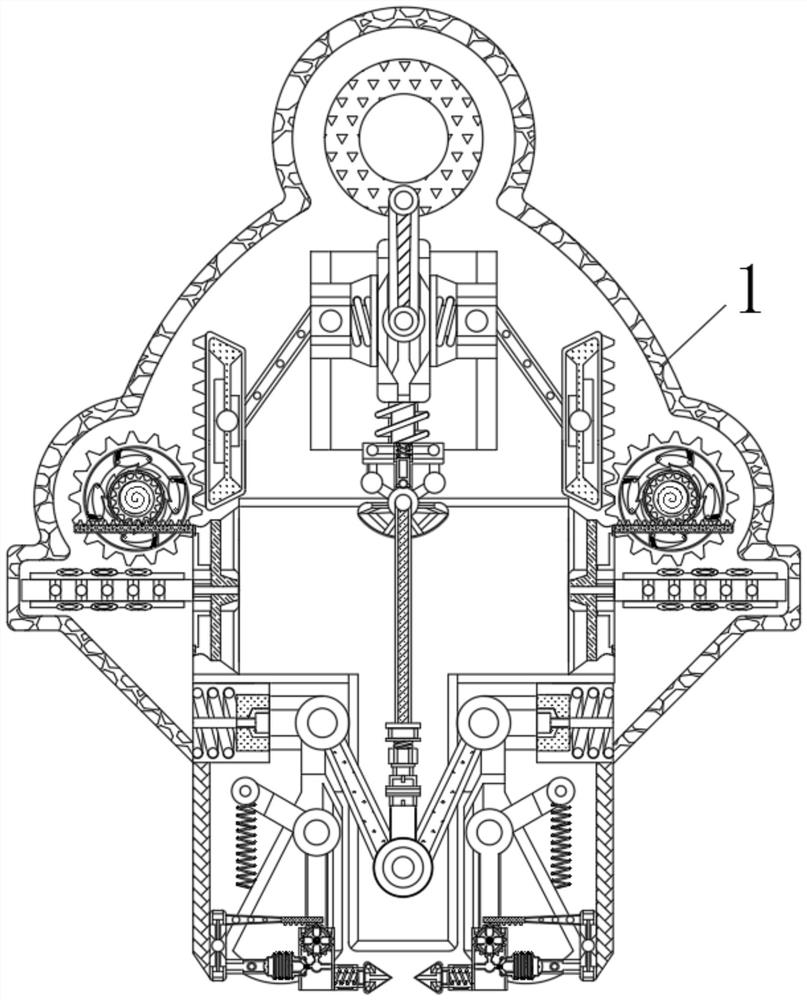

Meat cutting equipment that can prevent meat from sticking to the knife

The invention discloses meat cutting equipment capable of preventing meat loaf from adhering to a knife. The meat cutting equipment comprises a workbench, the workbench is provided with a meat cutting box, openings are formed in the two end faces of the meat cutting box, the meat cutting box and the workbench form a channel which is opened at the two ends, and multiple parallelly formed knife entering openings are formed in the top face of the meat cutting box; a cutter set is arranged above the knife entering openings; a loaf cutting table is arranged at one opened end of the channel, and is provided with a cutting groove communicated with the channel, the two side walls of the cutting groove are parallel to the channel, a cutting opening is formed in each of the two sides walls of the cutting groove, a meat loaf cutter is arranged above the cutting opening, and a scratch board perpendicular to the side wall of the cutting groove is connected to the upper portion of the cutting groove, the scratch board is located at the side, away from the meat cutting box beside the cutting opening. The meat cutting equipment capable of preventing the meat loaf from adhering to the knife can fast cut the meat loaf, reduce manual operation, prevent the meat loaf from adhering to the knife and cause secondary cutting smashing of the meat loaf, therefore cannot damage the shape of the meat loaf, and enables the prepared pork shashlik to better conform to the requirement.

Owner:德阳市东泽食品有限公司

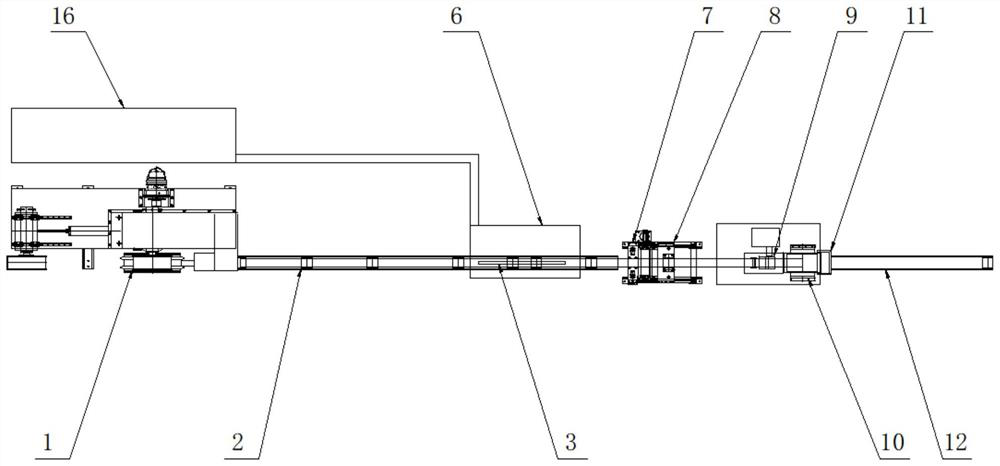

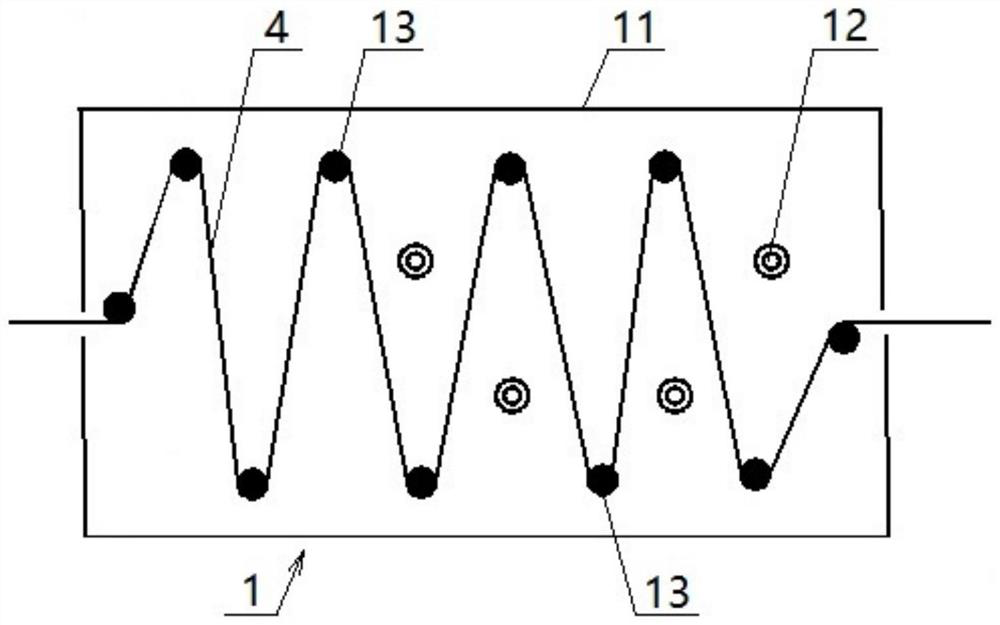

Lead shot continuous production line and process thereof

PendingCN114131030AEasy to pelletizeReduce production linksCasting parameters measurement/indication devicesIngot castingContinuous caster

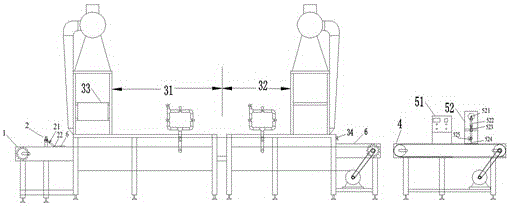

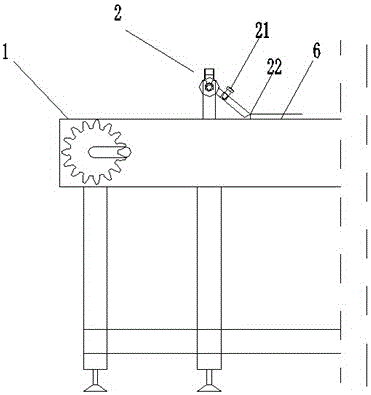

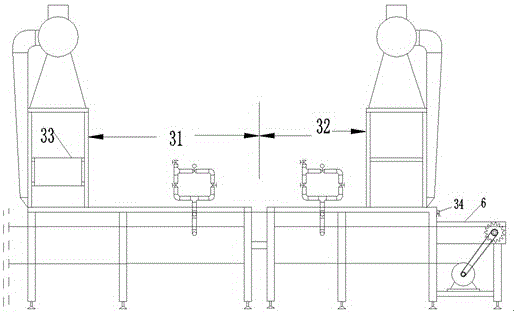

The invention discloses a lead granule continuous production line which comprises a continuous casting machine, an online cooling device, a traction machine, a granulator and a lead granule collecting mechanism, the continuous casting machine is used for casting lead liquid into a continuous lead belt blank, and the lead belt blank is conveyed backwards on a conveying roller frame under traction of the traction machine; the on-line cooling device is arranged in front of the traction machine and is used for cooling the lead belt blank; the traction machine is used for conveying the lead belt blank into the granulator for granulating, and the lead granule collecting mechanism is used for collecting lead granules output by the granulator. According to the lead shot continuous production line and the process thereof, the production links of ingot casting, lead ingot slicing or thinning and the like in the prior art are reduced, and the production efficiency is greatly improved through the continuous production mode.

Owner:河北通燊智能科技有限公司

A kind of sintering process of thermistor

ActiveCN107689277BAvoid undesired phenomena that are not easy to disperseAvoid sticking knifeResistor chip manufactureAluminium oxideThermal resistor

The embodiment of the invention discloses a sintering process of a thermal resistor. The process comprises the following steps of primary sintering: flatly placing blocks subjected to glue distribution; performing sintering for forming porcelain; secondary sintering: covering and pressing the blocks subjected to primary sintering by a flat aluminum oxide base sheet; putting the blocks into a sintering furnace for sintering; tertiary sintering: flatly placing the blocks subjected to secondary sintering onto a carrying plate for sintering. The sintering process has the beneficial effects that the sintering process of the thermal resistor provided by the invention has the advantages that the occurrence of adverse phenomena such as cutter sticking, product deformation and sticky sheet scattering difficulty during the cutting can be effectively avoided; meanwhile, the operation difficulty of the block manufacturing process after the glue distribution can be reduced through whole block sintering; the problems of block crushing, edge breaking, corner breaking and sticking sheet occurrence during the sintering can be effectively solved.

Owner:DONGGUAN SENSICOM ELECTRONICS TECH

Novel anti-sticking knife unit

InactiveCN104552348AAvoid sticking knifeMetal working apparatusMetal-working hand toolsStructural engineeringMechanical engineering

The invention discloses a novel anti-sticking knife unit provided with arc grooves 1 and a common knife 2. The novel anti-sticking knife device is characterized in that the arc grooves 1 are directly spaced in the two sides of the common knife 2 and function in preventing food from sticking on the knife during cutting.

Owner:李勇

Automatic food production and processing equipment and production and processing method

ActiveCN104041858BGood tasteAvoid the danger of manual burns by hot water vaporFood shapingEngineeringHeating system

The invention belongs to the field of food processing and production and discloses equipment for automatically producing and processing foods. The equipment comprises a first conveying belt, a feeding hole, a shaping groove, a segmental heating system, a second conveying belt and an automatic cutting system, wherein the shaping groove is fixed on the first conveying belt, the head and the tail of the shaping groove are connected with each other to surround the first conveying belt for a circle; the feeding hole is connected to the shaping groove; the segmental heating system comprises a first heating region and a second heating region; the first conveying belt penetrates through the first heating region and the second heating region in sequence and is butted with the second conveying belt; the automatic cutting system is erected above the second conveying belt and is used for segmentally cutting the foods on the second conveying belt. Meanwhile, the invention further discloses a method for automatically producing and processing the foods. According to the equipment and the method, segmental heating is directly carried out after feeding and shaping, and finally the foods are automatically cut into required foods; the mouth feel and the quality of the foods are improved, wastes cannot be generated, the operation is safe, simple and convenient, the labor cost is reduced, and the production efficiency is improved.

Owner:XIAMEN DELI FOOD MACHINERY LIMITED

Uniform dough cutting mechanism based on cooked wheaten food processing

InactiveCN114868778ASmall processing spaceAvoid sticking knifePre-baking dough treatmentDough shaping and cutting apparatusEngineeringPasta processing

The invention relates to the field of food processing, and discloses a dough uniform cutting mechanism based on wheaten food processing, the dough uniform cutting mechanism comprises a cutting mechanism and a yeast mechanism, when the device is used, a driving rotating wheel starts to rotate at the moment, the driving rotating wheel rotates to drive a material pressing head to move downwards, and when the material pressing head moves downwards, dough is extruded at the moment; when a reciprocating sliding block moves upwards, a contraction block is driven to move rightwards to extrude the dough, so that the processing space of the dough is reduced, meanwhile, when a material pressing head moves downwards, a linkage rod is driven to move downwards, and the linkage rod moves downwards to drive a swing cutting rod to swing; the swinging cutting rod swings to drive the linkage sliding block to move leftwards, the linkage sliding block moves leftwards, the linkage sliding block moves leftwards to drive the dough cutter to move leftwards, the dough cutter and the symmetrical end are used for cutting the dough, and therefore the function of automatically and evenly cutting the dough is achieved.

Owner:李兴江

High-performance blade processing technology

The invention discloses a high-performance blade processing technology. The high-performance blade processing technology includes the following steps that a, the high-speed steel is used as a raw material, the blade model is drawn by using three-dimensional software, and 1 mm margin is set; b, the blade model drawn by using three-dimensional software in the step a is used as a processing model, and the high-speed steel is punched by using a punching die to obtain a blade billet; c, annealing treatment is conducted on the billet obtained in the step b; d, milling processing is conducted on theblade by using a grinder, the shape processing is completed, and the cutter edge is not processed; e, the cutter edge processing is conducted by using the high-speed grinder; f, detecting is conductedon the billet after the step e; g, the detecting-qualified billet is placed into a vacuum heating furnace, the heat insulation is conducted for 1-1.5 hours at the temperature of 1000-1100 DEG C, thenthe heat insulation is conducted for 30-60 minutes at the temperature of 700-800 DEG C, and finally, natural cooling is conducted; h, the cutter edge of the billet is re-polished; and i, a blade finished product is obtained. The high-performance blade processing technology greatly improves the efficiency of blade processing, the quality of the blade finished product is ensured, and the overall performance of the blade is improved.

Owner:江苏扬碟钻石工具有限公司

A pu cutting tool

InactiveCN105965572BAvoid threatsAvoid warpingMetal working apparatusEngineeringMechanical engineering

The invention discloses a cutting jig for a PU panel. The cutting jig comprises a machine table, a driving device mounted on the bottom of the machine table, and a saw blade mounted on an output end of the driving device, and further comprises a backer, wherein a saw groove for allowing the saw blade to stretch out is formed in the table surface of the machine table; a pair of long grooves perpendicular to the saw blade is formed in the table surface of the machine table; guide bolts are mounted at the two ends of the backer; the backer and the long grooves are slidably assembled through the guide bolts at the two ends; lock nuts are further mounted on the guide bolts in a matching manner to lock the backer on the machine table; locating scale lines are further printed in the positions, close to notches of the long grooves, on the table surface of the machine table; a pressing cover covering the upper part of the saw blade is mounted on the table surface of the machine table; and a clearance for allowing a workpiece to pass through exists between the bottom of the pressing cover and the table surface of the machine table. According to the cutting jig, the pressing cover is mounted on the table surface of the machine table, so that on one hand, the pressing cover produces the function of a dust shield to prevent chips from splashing to injure a user, and on the other hand, the pressing cover acts as a guide part to firmly press the PU panel on the table surface of the machine table to prevent a tilting phenomenon.

Owner:SUZHOU ZHUOCHENG TITANIUM EQUIP

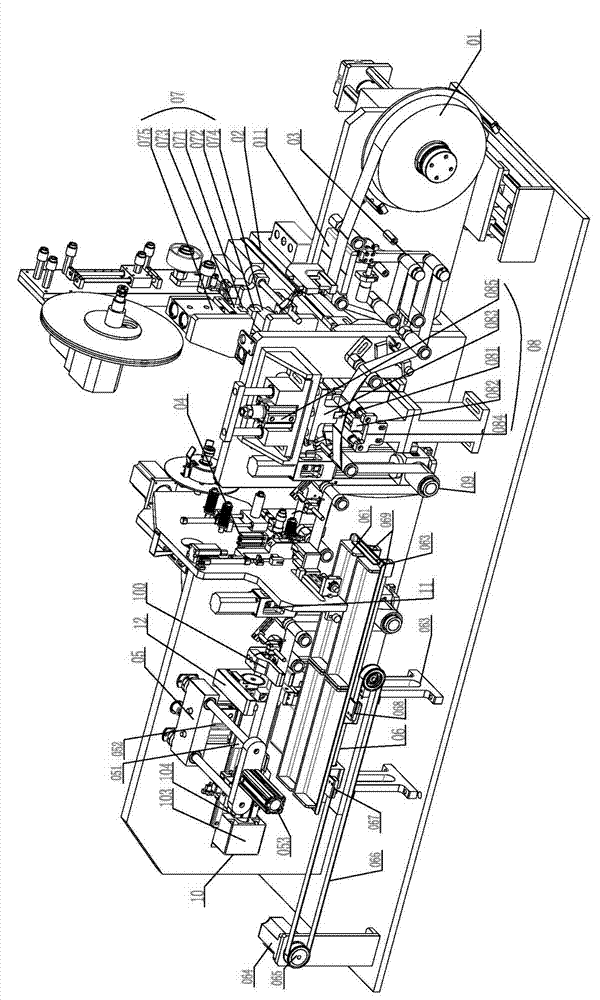

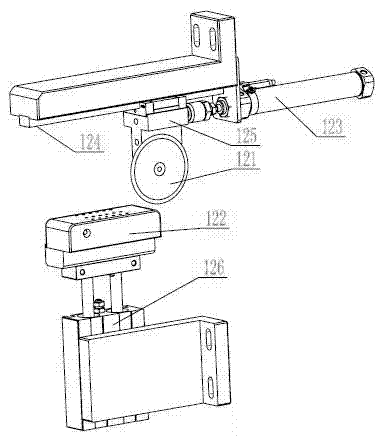

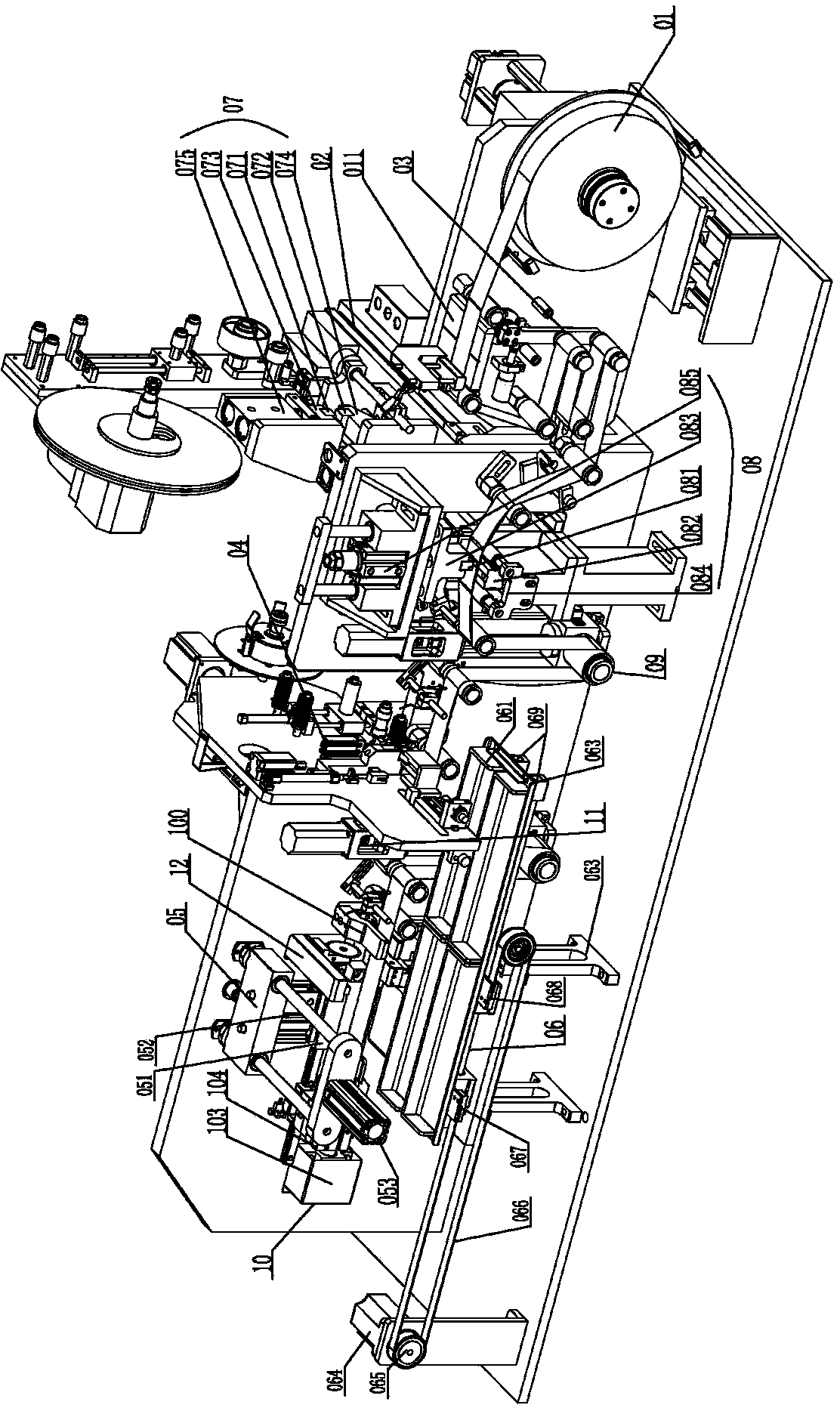

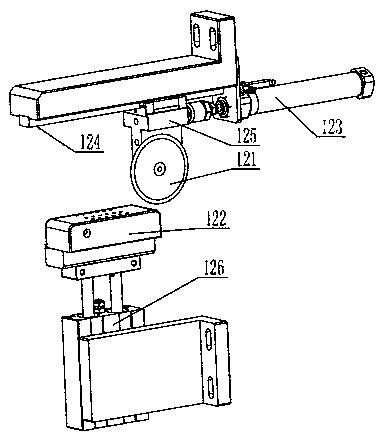

Device for electrode slice production with lithium strap and electrode slice production method

ActiveCN102738433BAvoid the problem that the lithium ribbon is easily damaged by weldingAvoid the problem of weld through damageCell electrodesCell component detailsLithiumKnurling

The invention discloses a device for electrode slice production with a lithium strap. The device includes a lithium strap conveying mechanism, a lithium strap tab adding structure, a rubberizing mechanism, a lithium strap cutting mechanism and a feeding mechanism. The lithium strap tab adding mechanism comprises a tab conveying mechanism, a tab knurling mechanism and a tab laminating mechanism. The tab conveying mechanism is used for conveying a tab to a lithium strap conveying path of the lithium strap conveying mechanism and cutting it off. The tab knurling mechanism is positioned on a tab conveying path of the tab conveying mechanism for knurling of the tab to make it have an uneven surface. The tab laminating mechanism is used for laminating the knurled tab to the lithium strap. The invention also discloses a method for electrode slice production with a lithium strap. The device and method of the invention can overcome the defects existing in traditional modes of electrode slice production with lithium straps, and improve the quality and automation level of electrode slice production with lithium straps.

Owner:SHENZHEN YINGHE TECH

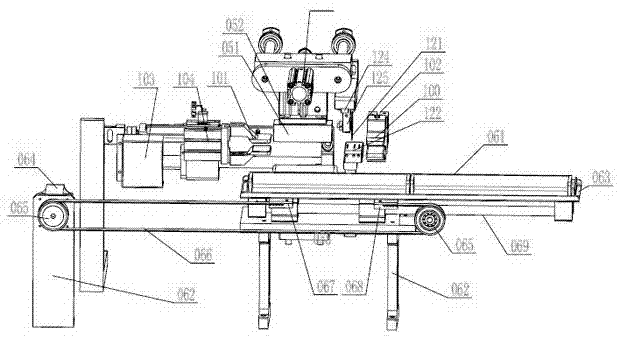

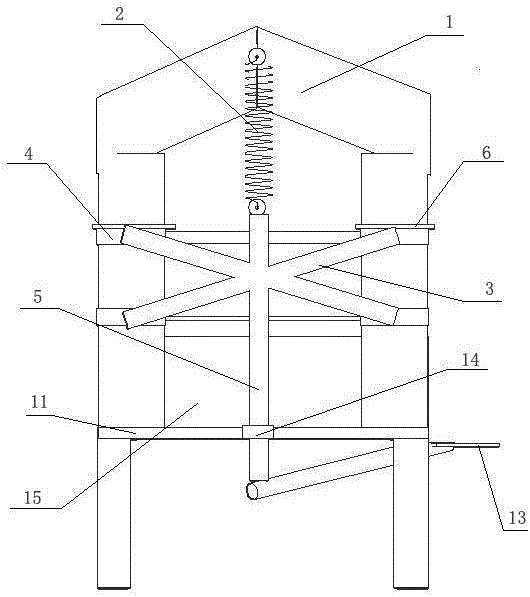

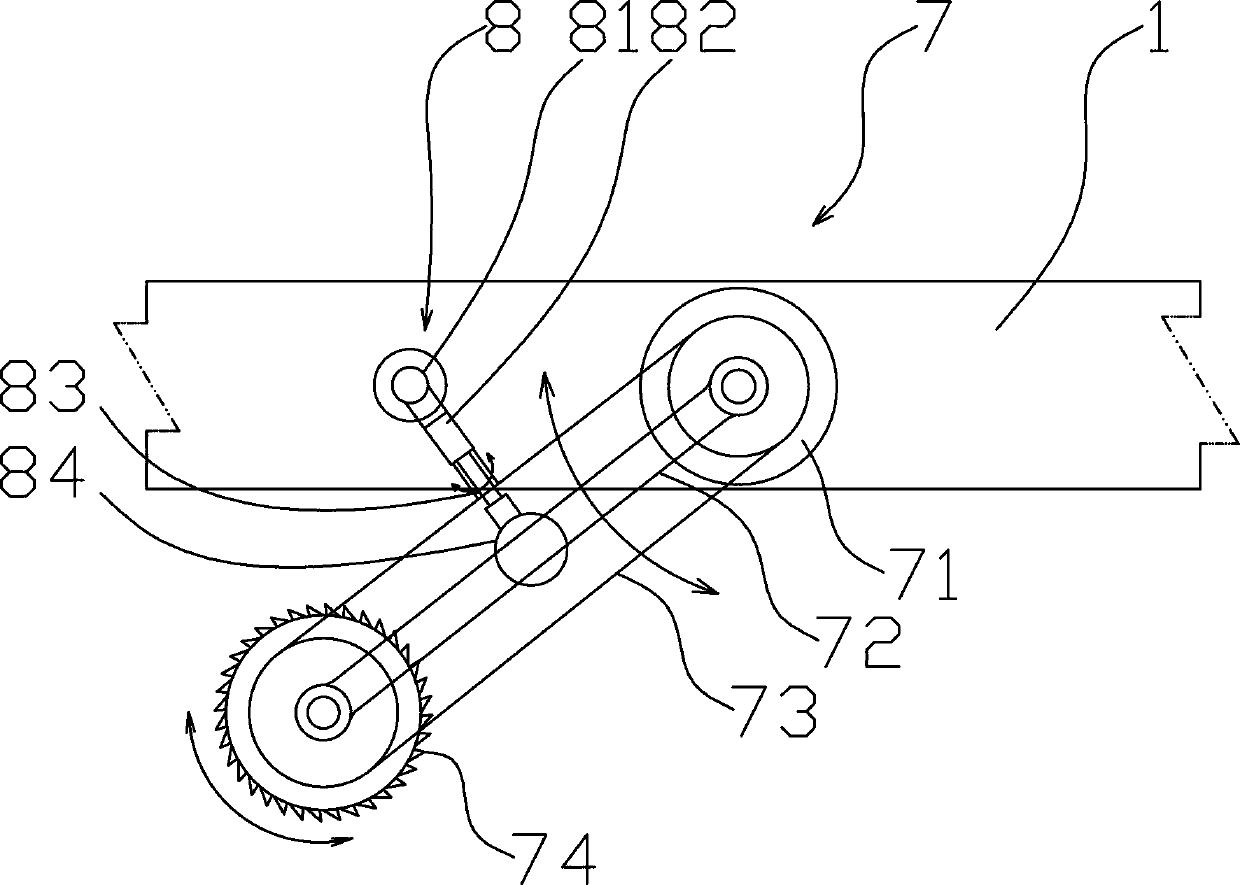

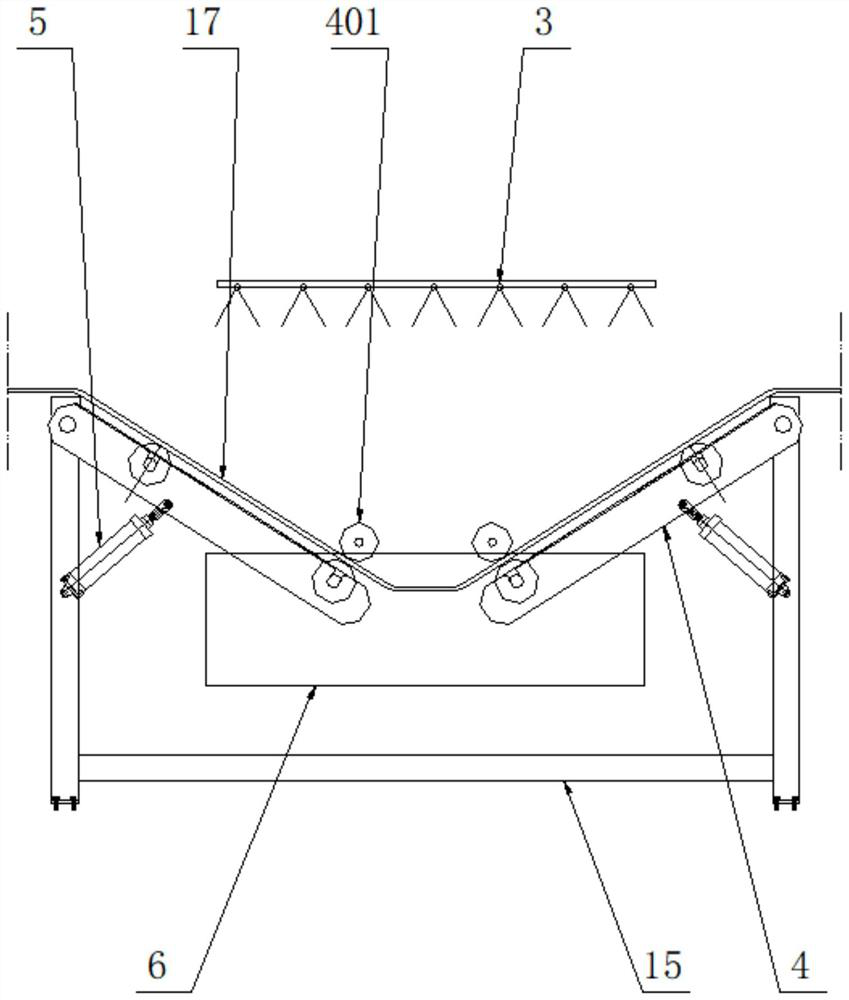

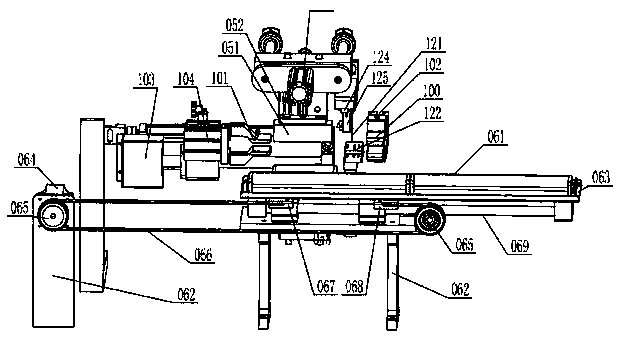

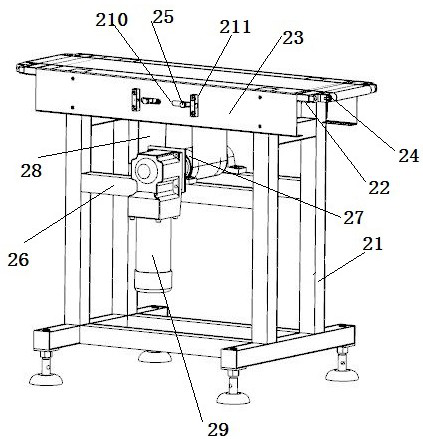

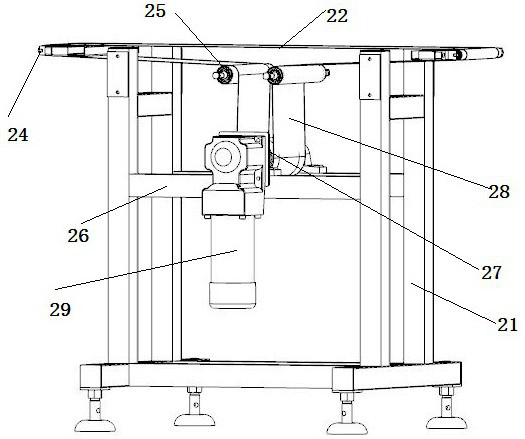

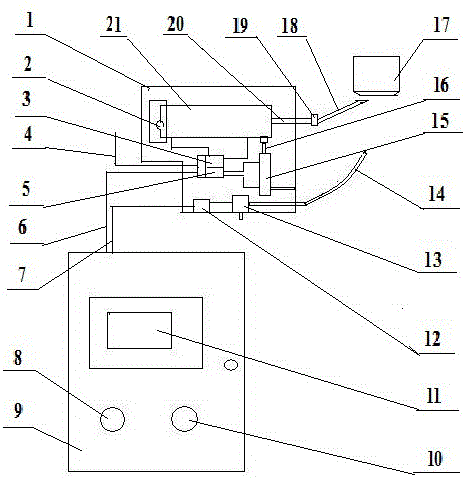

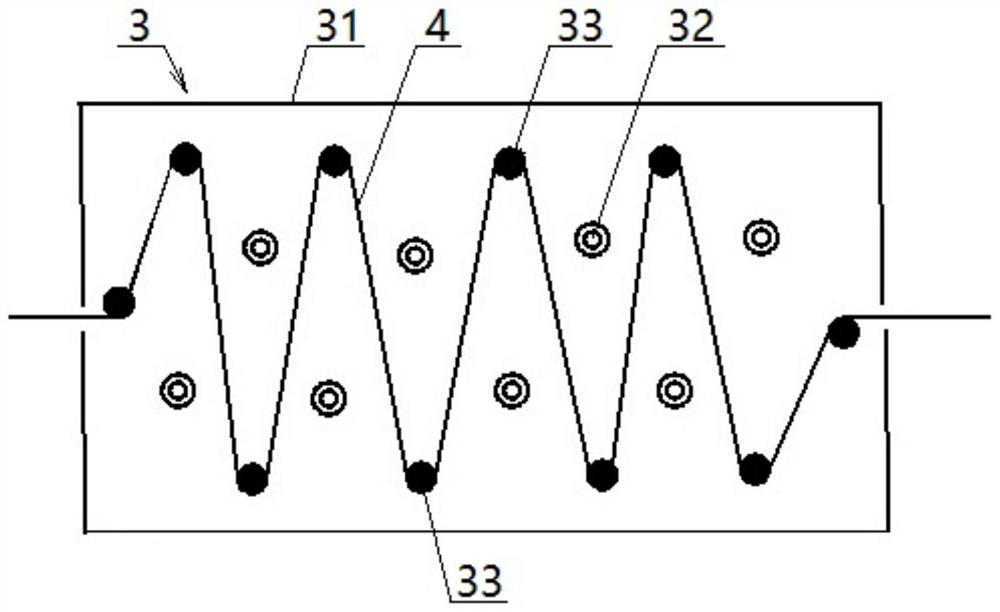

Rubber belt winding machine

InactiveCN107499993AAvoid sticking knifeImprove winding qualityWebs handlingWinding machineEngineering

The invention discloses a rubber belt winding machine, which comprises a base, a feeding mechanism, a power mechanism, a roll changing bracket, a winding mechanism, a pressing mechanism and a cutting mechanism. The feeding mechanism is located on one side above the base , the roll-changing bracket is located on the other side above the base, there are a cutting mechanism, a winding mechanism and a pressing mechanism between the feeding mechanism and the rolling bracket, and the cutting mechanism is located on the feeding mechanism On the side, the cutting mechanism includes a circular knife holder, a ratchet wheel that drives the circular knife holder to rotate, and three cutting blades that are evenly distributed along the radius of the circular knife holder, and each of the cutting blades is connected to the circle The ring knife holder is detachably connected. A rubber belt winding machine of the present invention adopts such a structure. Compared with the prior art, the method of cutting up and down is improved to the method of rotating and cutting, so that the moving direction of the cutting blade is always in one direction, which can avoid rubber band cutting during the cutting process. With sticky knife, it improves the winding quality.

Owner:芜湖拓达电子科技有限公司

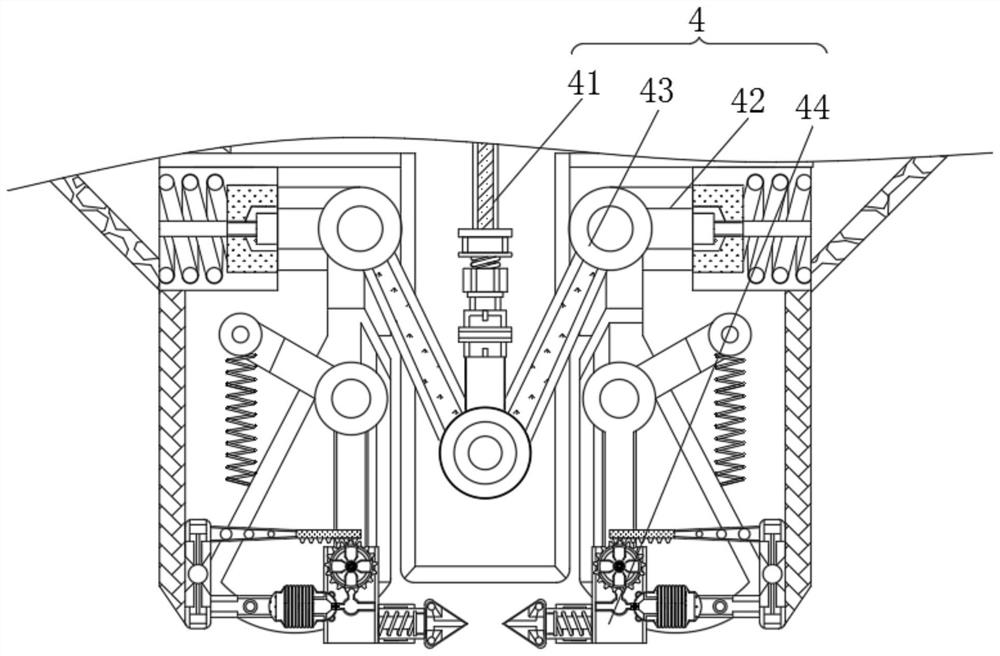

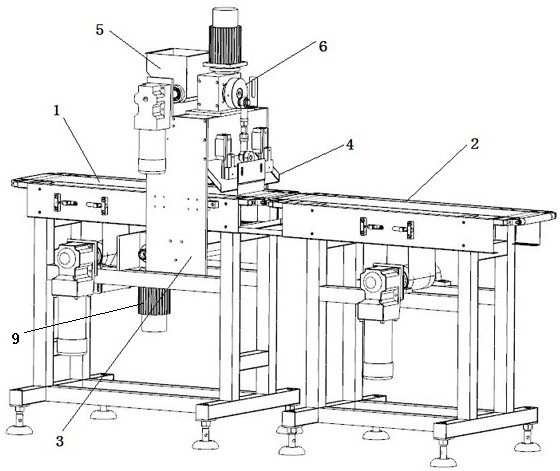

Slicing device for food processing

PendingCN112476582AAvoid sticking knifeImprove cutting efficiencyMetal working apparatusEngineeringSlide plate

The invention discloses a slicing device for food processing. The device comprises a feeding conveying device and a discharging conveying device, wherein vertical plates are symmetrically arranged ontwo sides, close to the right end of the feeding conveying device, of the dicing device, the vertical plates and the feeding conveying device are arranged in a left-right sliding mode, and a driving mechanism for driving the vertical plates to slide is arranged below the top of the feeding conveying device; a sliding plate with the bottom extending to the position above the right end of the feeding conveying device is obliquely arranged between the two vertical plates, a powder scattering device is arranged between the two vertical plates located above the top of the sliding plate, a slicing mechanism is arranged between the vertical plates on the lower right part of the powder scattering device, and an execution part of the slicing mechanism extends to the position above the feeding conveying device on the right side of the tail end of the sliding plate. An execution part of the slicing device is arranged close to the tail end of the sliding plate. The slicing efficiency can be effectively improved, and materials can be effectively prevented from adhering to a knife.

Owner:东台市汉源食品机械制造有限公司

A kind of aluminum processing and production cutting equipment

ActiveCN113997092BPrevent rollingAvoid damagePositioning apparatusMetal working apparatusEngineeringBar pressing

The present invention relates to the technical field of cutting equipment, and discloses a cutting equipment for processing and producing aluminum materials, including a workbench, the top of the workbench is rotatably connected to a pressing bar through a torsion spring, and a cutting machine is arranged on the surface of the pressing bar. The top of the workbench is fixedly connected with a support plate, the front of the support plate is fixedly connected with a limit plate, the inner wall of the limit plate is slidably connected with a telescopic rod, and the bottom of the telescopic rod is fixedly connected with an arc-shaped plate , the lower surface of the arc-shaped plate is fixedly connected with a rubber block, the inner wall of the arc-shaped plate is rotatably connected with a rotating plate through a torsion spring, and the inner wall of the telescopic rod is rotatably connected with a transmission rod. The combination of machine, transmission rod, limit plate, telescopic rod, arc plate, rubber block and rotating plate can fix the bar during cutting, and then let the cutting machine cut the fixed bar, which can prevent The bar stock is rolled, increasing the production quality of the product.

Owner:河南万众金属材料有限公司

An automatic powder cutting machine

InactiveCN104552400BAvoid sticking knifeWork process safetyMetal working apparatusSmall footprintFood processing

The invention discloses an automatic vermicelli cutting machine, relates to the field of food processing, and particularly relates to vermicelli and bean vermicelli cutting machines. The automatic vermicelli cutting machine is mounted at an outlet of a vermicelli squeezing machine, and vermicelli and bean vermicelli can be cut by the aid of relative movement of a cutter and the outlet. The automatic vermicelli cutting machine comprises a control box, a case, a cutter pushing cylinder, a cutter saddle, the cutter, a positioning cylinder, a cutter pushing air supply switch and a positioning cylinder air supply switch, and is characterized in that the cutter pushing cylinder, the cutter saddle, the cutter, the positioning cylinder, the cutter pushing air supply switch and the positioning cylinder air supply switch are mounted in the case, one end of the positioning cylinder is mounted on the case via a bolt, and the positioning cylinder can rotate around the bolt; a movable end is arranged at the other end of the positioning cylinder, a push rod which extends out of the movable end of the positioning cylinder extends out of the case, the cutter saddle is arranged on the top of the push rod, and the cutter is mounted on the cutter saddle. The automatic vermicelli cutting machine has the advantages that the automatic vermicelli cutting machine is small in occupied area and high in production efficiency and is safe and convenient, and cutter sticking can be prevented when the automatic vermicelli cutting machine is used; the cutter can be driven by the cutter pushing cylinder to move, so that vermicelli cutting procedures can be implemented, and the automatic vermicelli cutting machine is applicable to mass rice vermicelli production.

Owner:江西省五星食品有限公司

Manufacturing method for low magnetic anchor chain accessory

PendingCN112570988ASmall temperature differenceImprove surface qualityWaterborne vesselsSolution treatmentMachining

The invention discloses a manufacturing method for a low magnetic anchor chain accessory. The method comprises the following steps of I, feeding by way of sawing; II, a cogging and swaging direction shall be along a material rolling direction, wherein the forging ratio per fire does not exceed 2.5 during casting; III, ultrasonic flaw detection; IV, initially forged blank heating: forging and heating, wherein the initial forging temperature is 1100-1250 DEG C, the final forging temperature is not lower than 900 DEG C, and the total forging ratio is not less than 3; V, furnace cooling or sand burying cooling for the finally forged blank; VI, solution treatment for the finally forged blank; VII, flaw detection; VIII, machining of the finally forged blank, wherein the amount of feed per time does not exceed 0.5 mm; VIII, inspection and warehousing; and X, ageing treatment. By reducing the heating speed and shortening the temperature difference of a workpiece, cracking is prevented. By reducing the single time deformation and reducing the deformation resistance, the forming quality is improved. During machining, by reducing the amount of feed, tool adhesion is avoided, so that the surface quality of the low magnetic anchor chain accessory is improved.

Owner:JIANGSU ASIAN STAR ANCHOR CHAIN

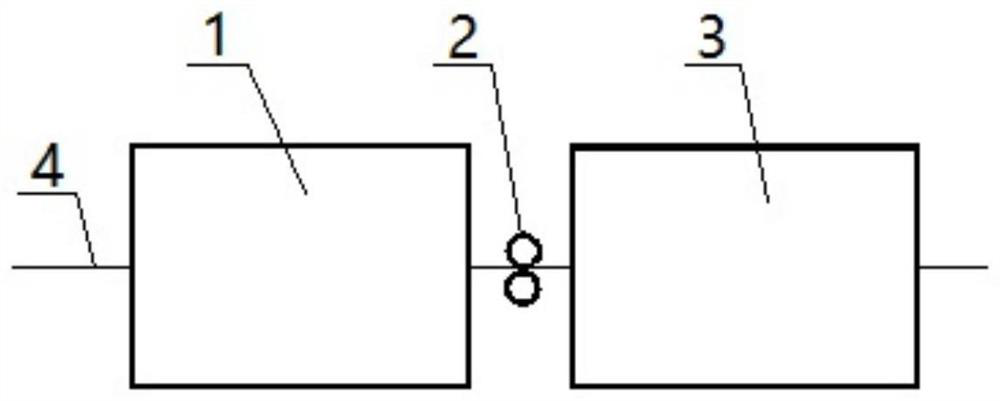

Cutting equipment for OCA flexible adhesive tape

PendingCN114851272AHigh hardnessHardness hasMetal working apparatusGlass productionAdhesiveSilicone tape

The invention provides cutting equipment for an OCA (Optical Clear Adhesive) soft adhesive tape, which is used for cutting the OCA soft adhesive tape and comprises a cooling device, a cutting device, a cutting device, a cutting device and a cutting device, and is characterized in that the cooling device is provided with a cooling inlet and a cooling outlet and is used for cooling the OCA soft adhesive tape entering the cooling device through the cooling inlet; the cutting device is used for cutting the OCA soft adhesive tape sent out from the cooling outlet; and the heating device is provided with a heating inlet and a heating outlet and is used for heating the cut OCA flexible adhesive tape entering the heating device through the heating inlet, and the heated OCA flexible adhesive tape is sent out from the heating outlet. According to the cutting equipment for the OCA flexible adhesive tape, the OCA flexible adhesive tape is cooled through the cooling device, so that the hardness of the OCA flexible adhesive tape is enhanced, the cutting device can conveniently and flexibly select a cutting tool, the defect that in the cutting process, a nicking plate is produced is overcome, the problem that the cutting cost of the OCA flexible adhesive tape is high due to the fact that dependence on the cutting tool is too large is solved, and the cutting efficiency of the OCA flexible adhesive tape is improved. And the cut OCA flexible adhesive tape is heated, so that the situation that water drops are condensed on the surface of the OCA flexible adhesive tape due to temperature difference, and subsequent winding of the OCA flexible adhesive tape is affected is avoided.

Owner:WUJIANG TENGDA PACKING PROD +1

Small intelligent pelletizing machine convenient to operate

InactiveCN106491367AImprove efficiencyQuality improvementPharmaceutical product form changeEngineeringAccess port

The invention discloses a small intelligent pelletizing machine convenient to operate. The small intelligent pelletizing machine comprises a fixed support, a first storage barrel, a discharging conveying belt, a second storage barrel, a supporting platform and a fixing nut, wherein a power supply access port is formed in the upper left side of the fixed support; a motor is arranged on the right side of the power supply access port; a material outlet is formed in the right side of the first storage barrel; a measurement conveying plate is mounted on the lower side of the material outlet; a buff spindle is arranged on the upper side of the discharging conveying belt; a second stage of pressure roller pelletizing shaft is mounted on the upper side of the buff spindle; the right side of the supporting platform is fixedly connected with the second storage barrel; a stirring dust extraction device is mounted in the second storage barrel; the left side of the fixing nut is fixedly connected with the stirring dust extraction device through the second storage barrel; an intelligent controller and a feeding funnel are arranged on the upper side of the stirring dust extraction device. The small intelligent pelletizing machine can be regulated and controlled according to operation requirements when in use, and is more efficient to operate, more stable in integral structure and more stable in operation.

Owner:陈锹

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com