Device for electrode slice production with lithium strap and electrode slice production method

A technology of lithium ribbon and tabs, which is applied in the field of lithium ribbon production equipment, can solve problems such as lithium ribbon battery quality, unfavorable processing, and wrinkles that restrict the lithium ribbon battery process, so as to improve the quality and automation level of lithium ribbon wafer production, overcome Defects in production methods and the effect of solving production problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, the present invention will be further described in detail through embodiments in combination with the drawings.

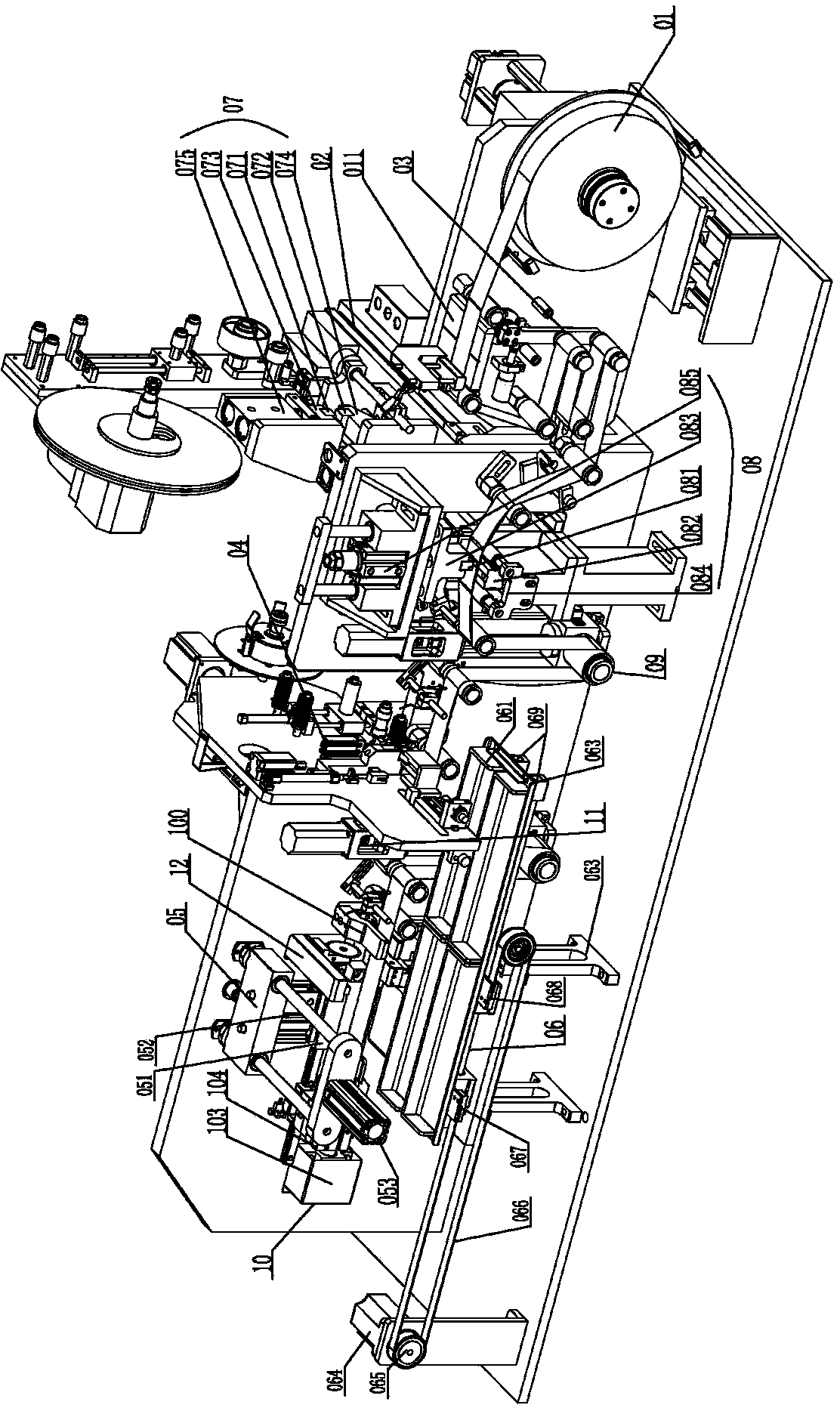

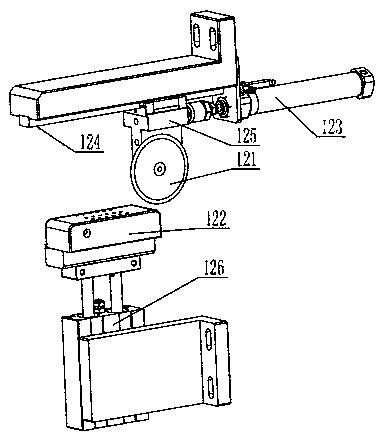

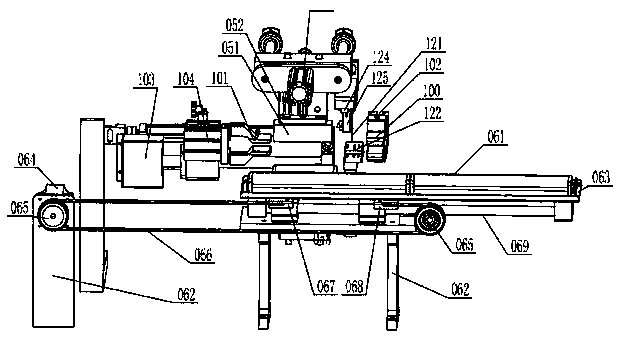

[0037] See Figure 1-Figure 4 , The lithium belt sheet making device of an embodiment includes a lithium belt conveying mechanism, a lithium belt adding lug mechanism, a glue applying mechanism 04, a lithium belt cutting mechanism 12, and a discharging structure 05. The lithium belt adding lug mechanism includes a pole The lug conveying mechanism 02, the lug knurling mechanism 07 and the lug pressing mechanism 08, the lug conveying mechanism 02 is used to send the lugs to the lithium belt conveying mechanism to transport the lithium belt and cut off, the The lug knurling mechanism 07 is located on the path of the lug conveying mechanism and is used to knurl the lugs into an uneven surface. The lug pressing mechanism 08 is used to knurl the knurled poles. The ears are pressed onto the lithium belt. All the above-mentioned mechanisms can be fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com