Patents

Literature

269results about How to "Solve production problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

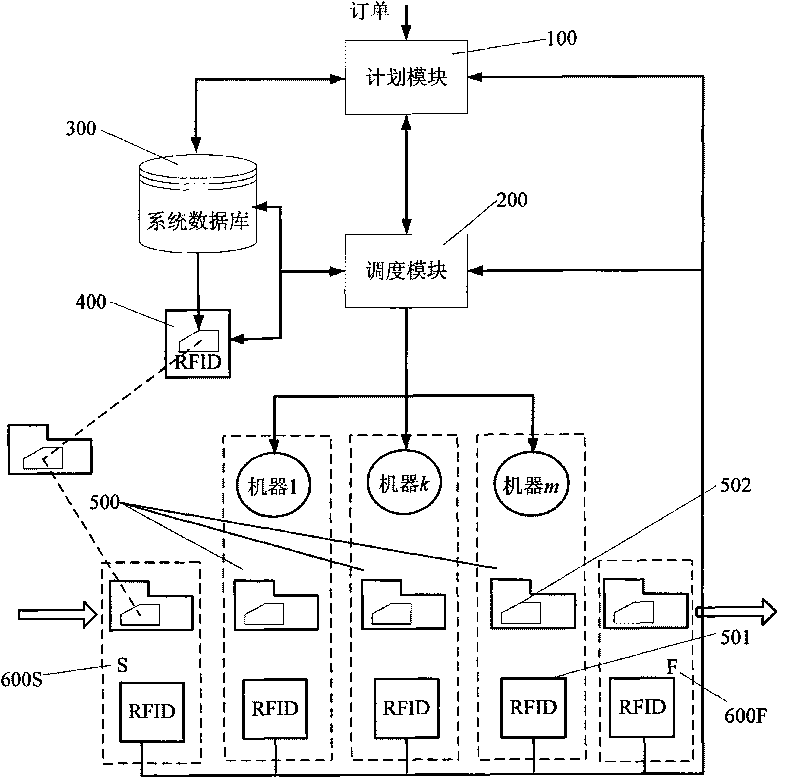

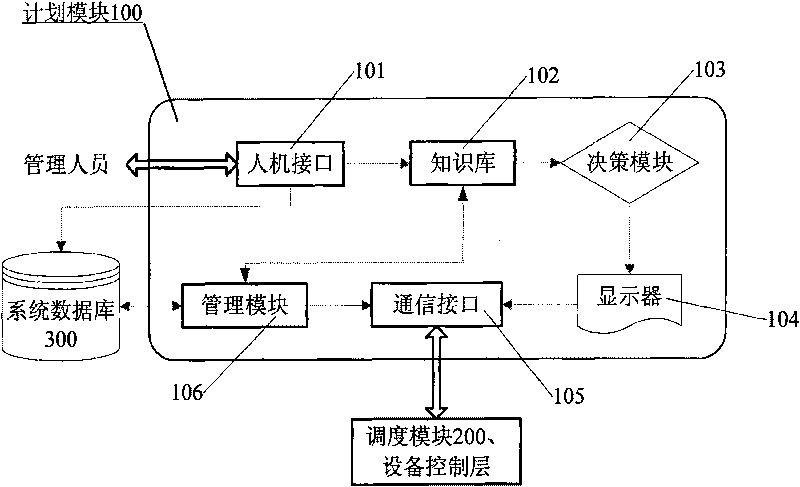

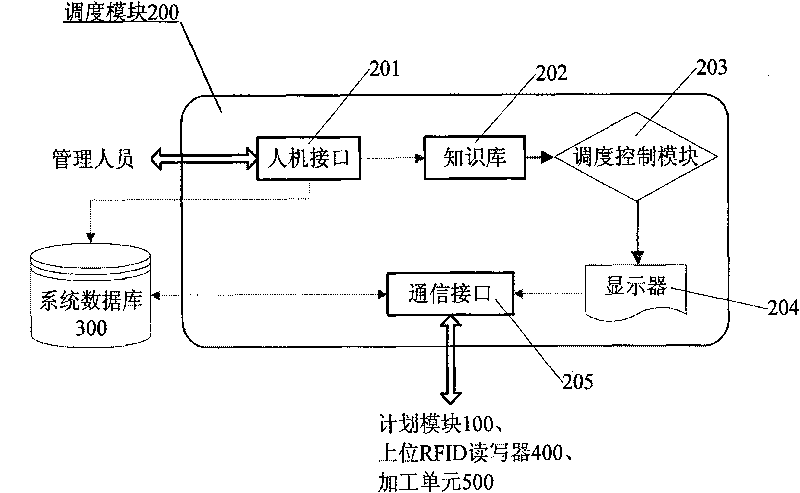

Order-driven Single-piece small-batch combined flow production method for processing workshop

InactiveCN101706886AIncrease productivityReduce manufacturing costCo-operative working arrangementsResourcesControl layerOrder form

The invention provides an order-driven single-piece small-batch combined flow production method for a processing workshop, which has high intellectualization degree and strong practicability. In the method, a manufacturing system of the processing workshop is divided into a planning module, a scheduling module, a system database, an upper RFID reader-writer and an equipment control layer, wherein the planning control module, the scheduling module and an equipment control unit are all realized by Agent (intelligent agent) technology. All the parts of the manufacturing system are connected into a multi-Agent (intelligent agent) manufacturing system through a network and a communication protocol. Under normal conditions, the system carries out machining according to a preset operation working procedure through static scheduling; and when the system is abnormal, the system completes a processing task through dynamic scheduling. Accordingly, staff members can dynamically master production process information in real time. The production method can effectively improve processing efficiency and reduce production cost.

Owner:SOUTH CHINA UNIV OF TECH

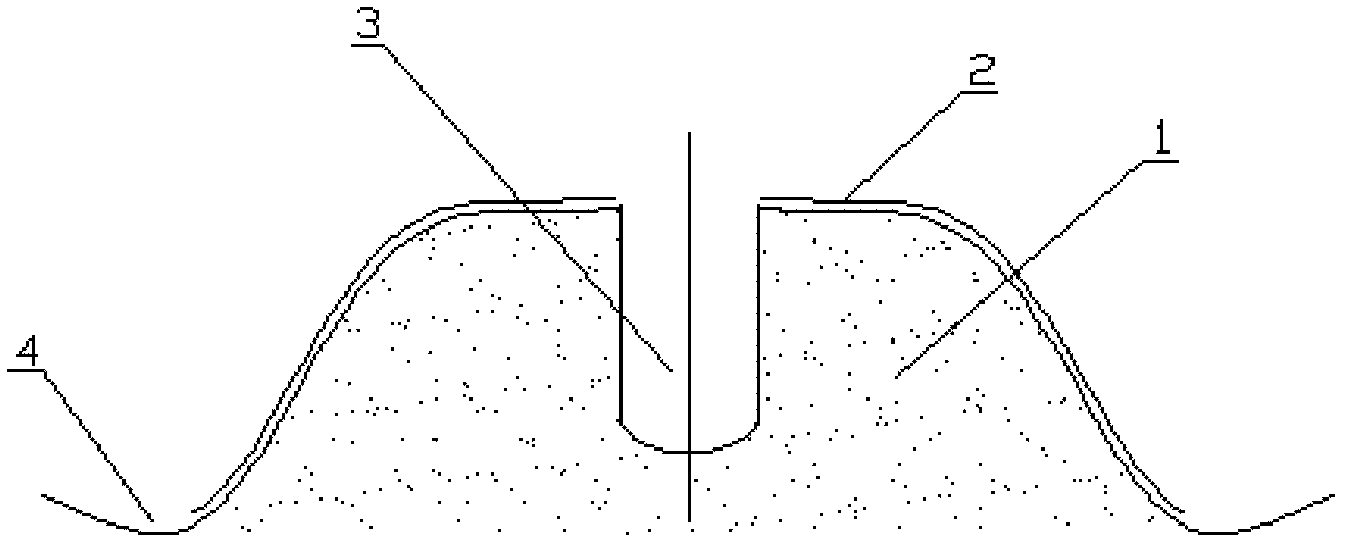

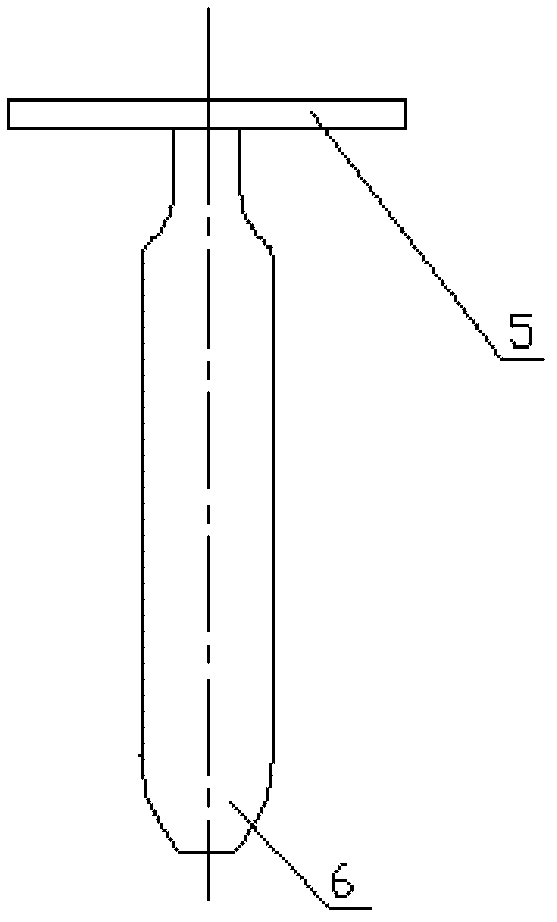

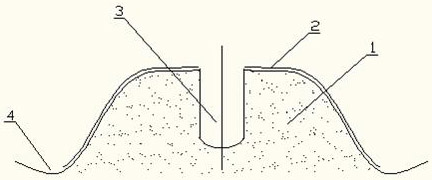

Flue-cured tobacco mulch film well cellar type seedling transplanting method

InactiveCN102365918ASeedling operation is simplifiedReduce the risk of infectionHorticultureFlueCuring of tobacco

The invention relates to a flue-cured tobacco mulch film well cellar type seedling transplanting method. The method comprises the following steps: (1) preparing soil, forming ridge and coating a film; (2) selecting a transplantation period; (3) digging a transplanting well cellar; (4) transplanting tobacco seedlings; (5) spraying root-fixing water and fertilizing; and (6) filling soil and sealingthe film. The method is a technical revolution of flue-cured tobacco mulch film cultivation and has the advantages of solving the problems caused by weak tobacco seedlings in the optimal transplanting period in a flue-cured tobacco cultivation district, the problem that weather is drought in the transplanting period so as not to be beneficial to transplantation, the problem caused by irregular transplantation, the problem that transplantation schedule is slow and the problems that seedling-returning period is long and the uniformity and consistency of field tobacco plants are poor, and also reducing the generation of aphid-transmitted virus diseases in the field period. The method is suitable for cultivation of crops such as flue-cured tobacco, burley tobacco, sun-cured tobacco and the like.

Owner:TONGREN CITY COMPANY OF GUIZHOU PROVINCE TOBACCO

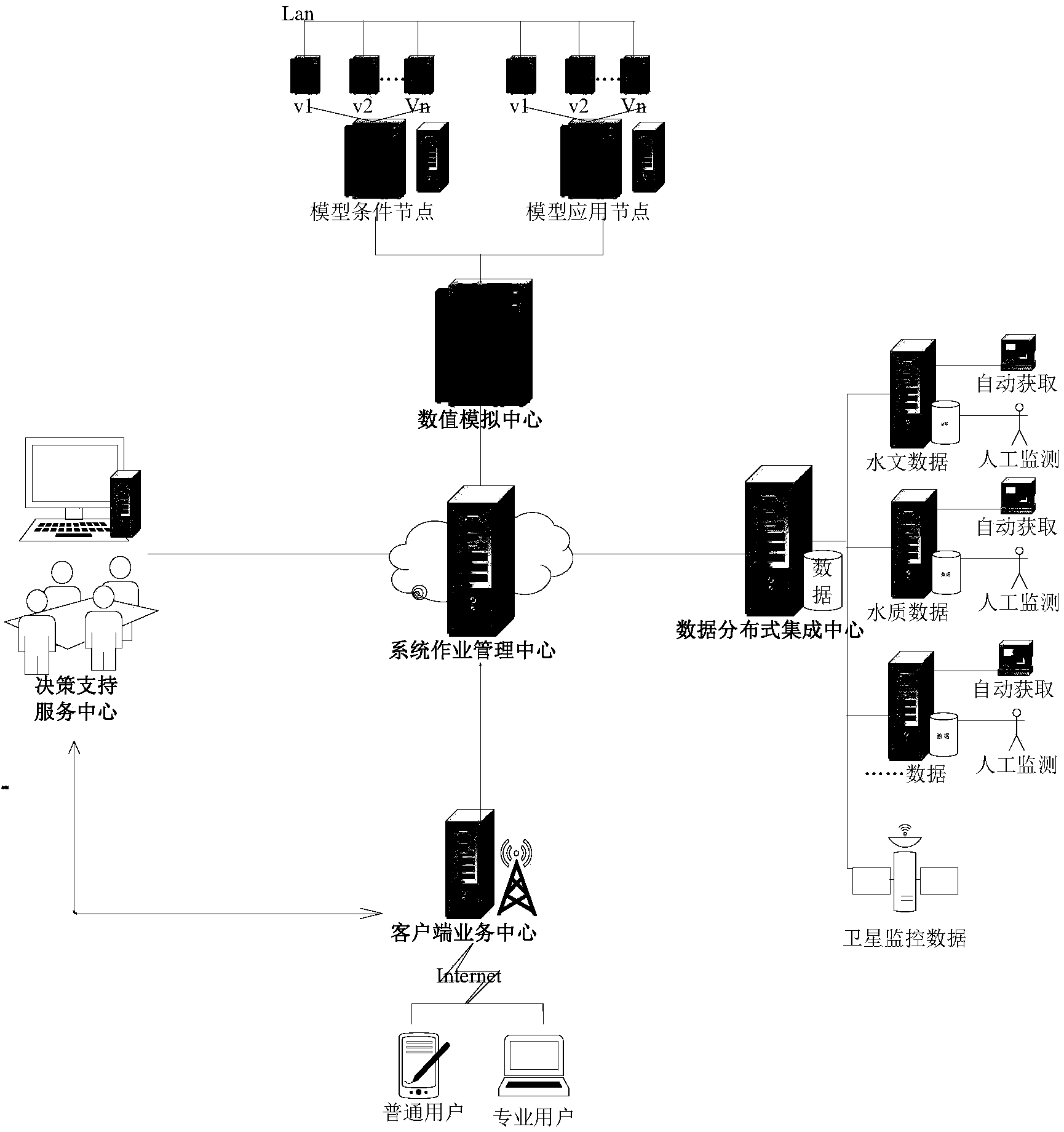

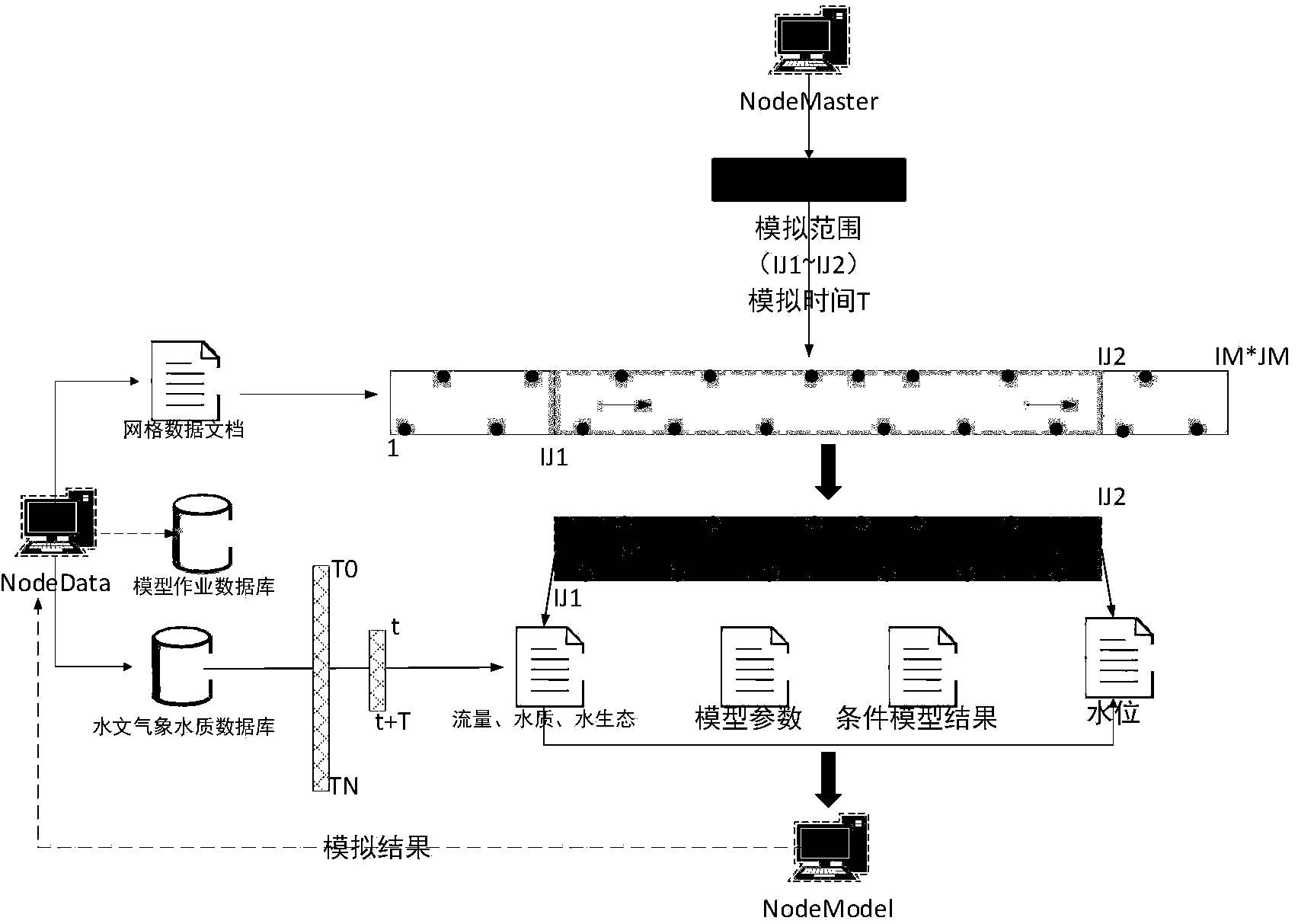

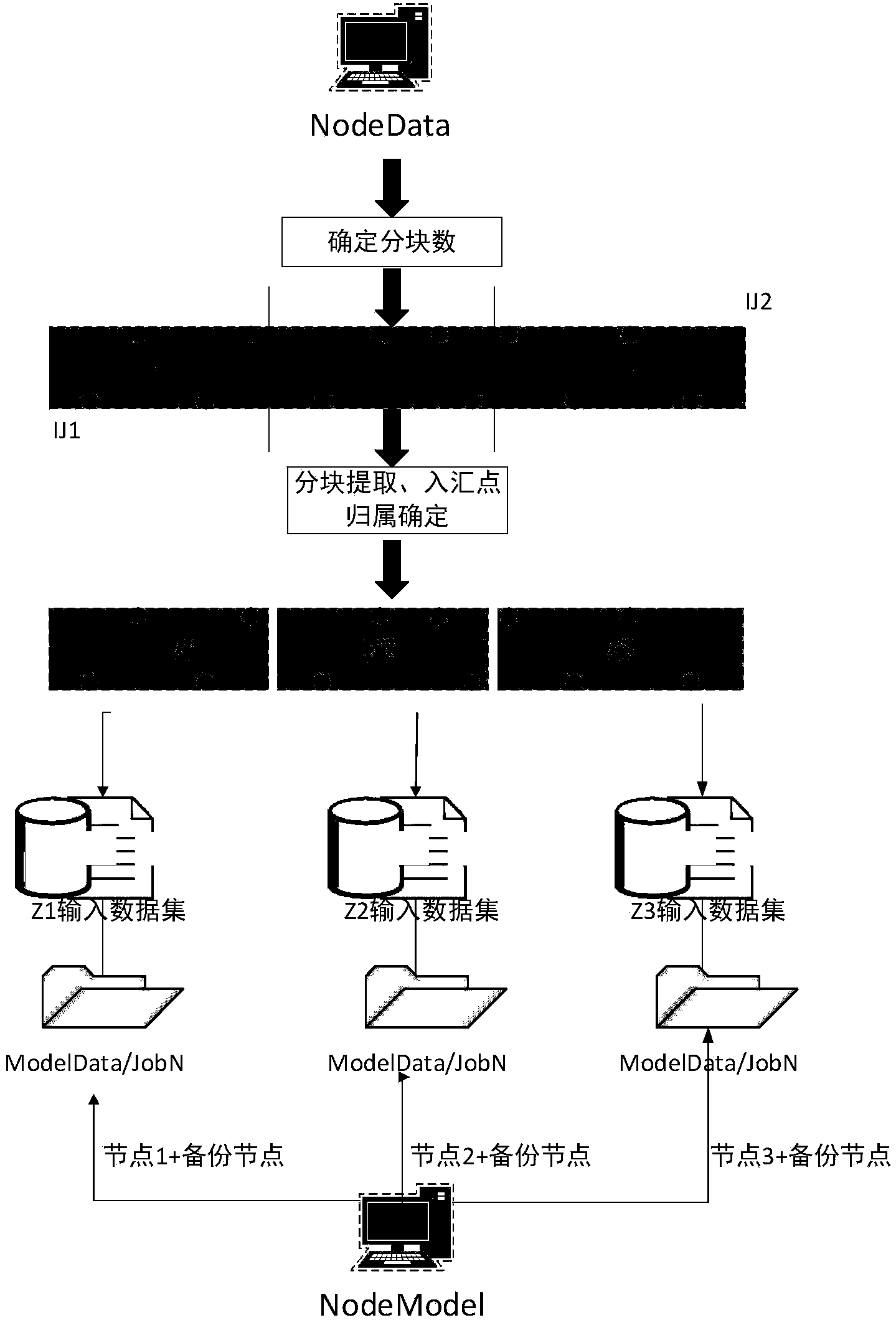

Multi-center watershed water environment distributed cluster management system and method

ActiveCN104268695AEfficient managementEnsure safetyResourcesSpecial data processing applicationsResource poolComputer resources

The invention discloses a multi-center watershed water environment distributed cluster management system and method. The system creates a system operation management center, a numerical simulation center, a data center, a decision command center and a client-side service center, all of which are of different management levels and function levels. By means of division and cooperation of the different centers, computer resources of centers of units of the watershed water environment can be integrated, a resource pool is formed, services are provided according to demands of functions of the centers of the units of the watershed, the problems, such as waiting time losses, the low watershed scale simulation computing speed, low efficiency and resource waste for repeated construction, of a traditional watershed model system due to serial computation can be solved, the watershed water environment simulation efficiency is greatly improved, hardware resources and data resources of the whole watershed are integrated, water environment management, current situation evaluation, future trend prediction and sudden event emergence simulation and decision support of the whole watershed are achieved, and safety of the watershed water environment is guaranteed.

Owner:珞珈浩景数字科技(湖北)有限公司

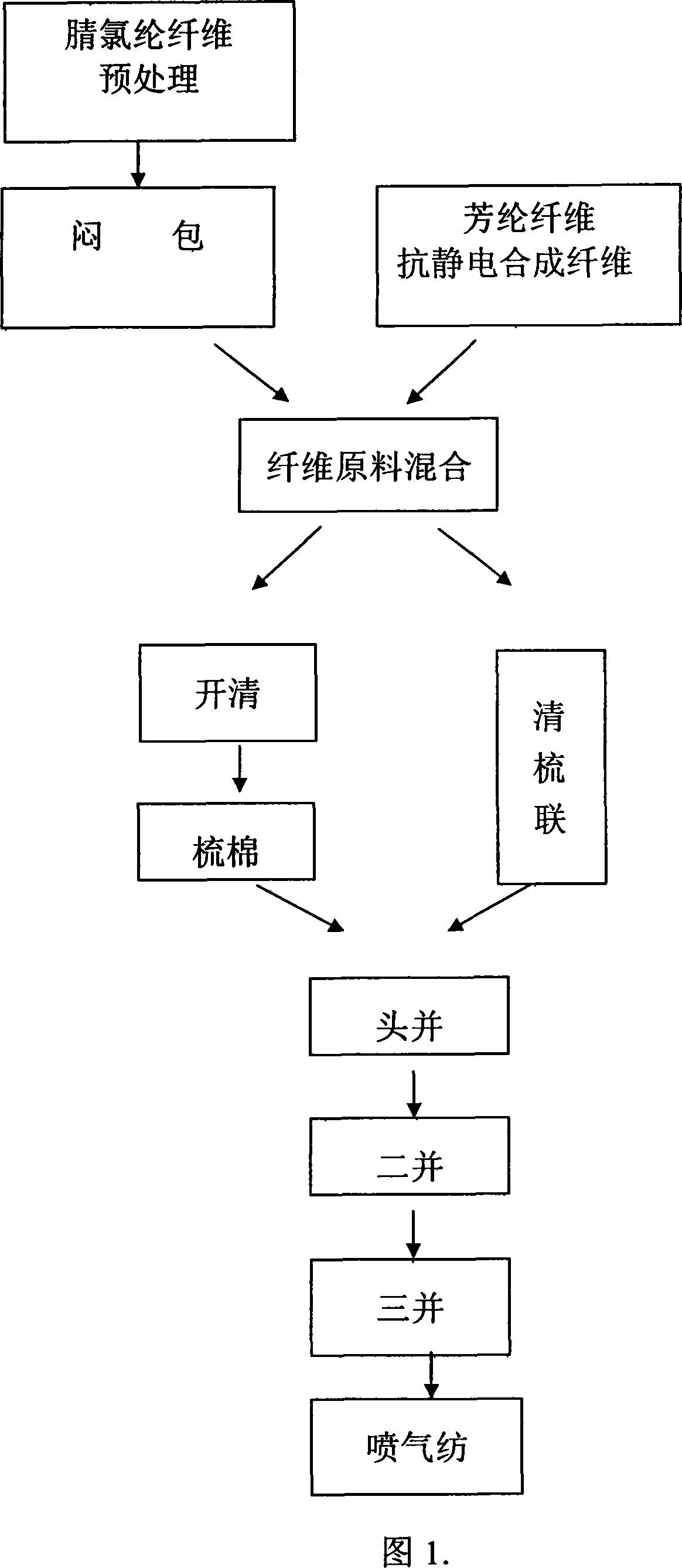

Aromid fiber blend yarn and processing method thereof

InactiveCN101067254AOvercome the defect of prone to static electricityReduce accidental elongationFibre treatmentContinuous wound-up machinesYarnAntistatic agent

The present invention is one kind of blended aramid yarn and its production process. The blended aramid yarn consists of aramid fiber 10-60 wt%, polyacrylic-polyvinyl chloride fiber 30-80 wt% and antistatic synthetic fiber 1-10 wt%, and has fiber length of 38 mm or 51 mm and spinning count of 10 s-50 s. It is produced through mixing material, producing card sliver, drawing and jet spinning. The production process includes spraying the polyacrylic-polyvinyl chloride fiber with antistatic agent, two card sliver producing modes, etc. The blended aramid yarn has excellent wear resisting property, excellent fireproof performance and high electrically insulating performance, and the fabric produced with the blended aramid yarn may be used in special suits for use in high temperature, electric welding and high voltage environment, and used in making fireproof decoration.

Owner:SHANGHAI YUFENG SCI & TECH +1

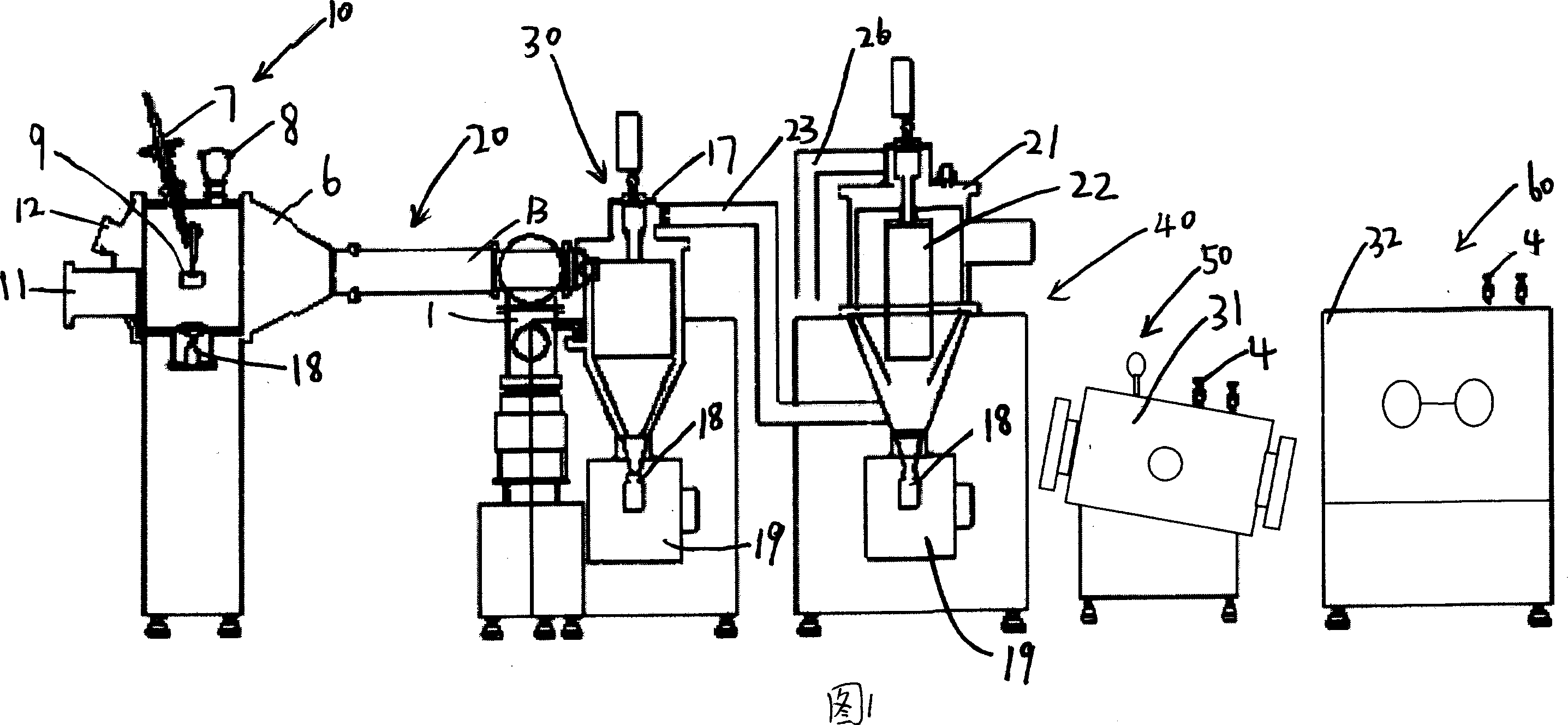

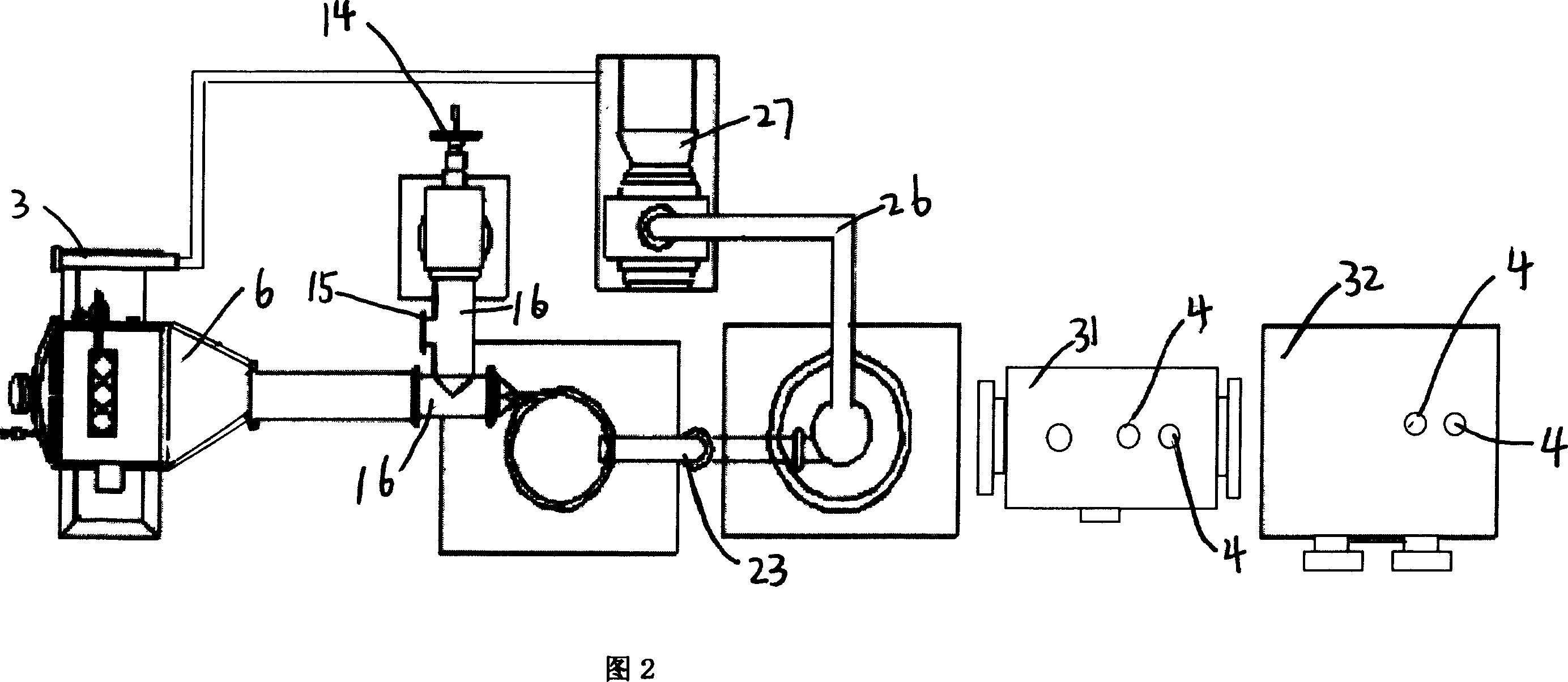

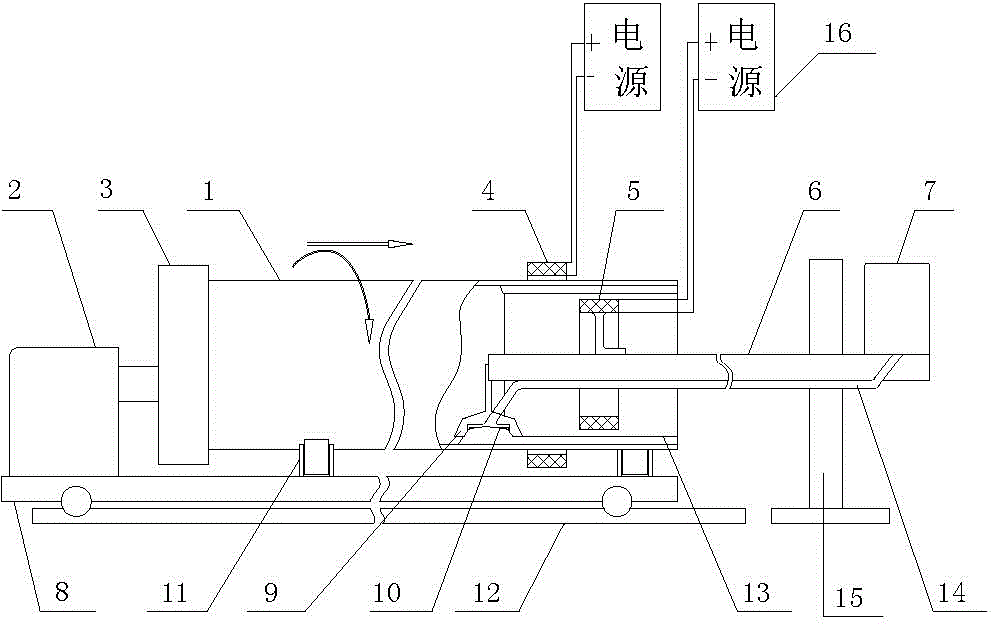

Continuous production apparatus for nano metal powder

The invention discloses a nanometer metal powder continuous producing device, comprising a vacuum measuring aerating system, a plasma / sensitive heating evaporating powder preparing system, a particle controlling system, a nanometer metal powder cyclone grading collecting system, a nanometer powder catching collecting system, a gas cooling circulating system, a water cooling circulating system, an electric controlling detecting system, a metal nanometer powder inactivating system and a powder vacuum packing storing system. The invention has high vacuum and three-gun structure, uses plasma constant-weight packing storing device, and plasma / electromagnetic sensitive evaporation or the like to realize continuous production of nanometer metal powder, change gas component and flux or the like.

Owner:MIYOU GROUP

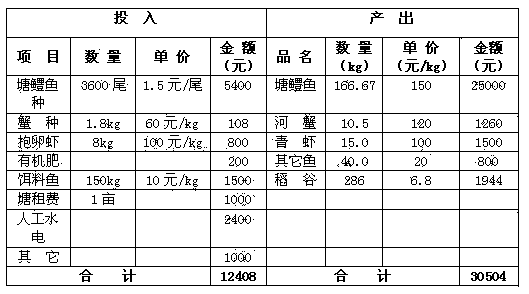

Method for breeding Odontobutis obscura through fish-rice symbiosis in pool

InactiveCN103891659AExtended growing seasonImprove farming outputClimate change adaptationPisciculture and aquariaNutrientFertilizer

The invention relates to a method for aquaculture, in particular to a method for breeding Odontobutis obscura through fish-rice symbiosis in a pool. According to the method, rice is planted in the pool for Odontobutis obscura aquaculture. The fish-rice symbiosis method is adopted for breeding food organisms in water to provide natural baits for fishes, and the rice is used for providing ingestion, shielding and inhabiting space for the fishes, shrimps, crabs and others; the fishes and the crabs prey on insect pests to control ineffective tillering of the rice; original ecology planting mode that no pesticide is sprayed, no fertilizer is applied, and residual baits and excrement are used as nutrients is adopted, , so that while the problem of nutrient enrichment of aquaculture water is effectively solved, shading and cooling are achieved in summer; heat preservation and temperature constancy are achieved in winter, an inhabiting place is provided for the bred variety, the growth period is prolonged, so that the breeding yield and quality and the specification on the market are improved, and the high yield and efficiency are achieved. According to the method, the production problem that wild and natural prey of the Odontobutis obscura is converted into artificial breeding is solved, the environment of breeding water quality, apparent availability and breeding production benefits are improved, and the method is of great importance in protecting natural resources.

Owner:嘉善县净水渔业种苗基地(普通合伙)

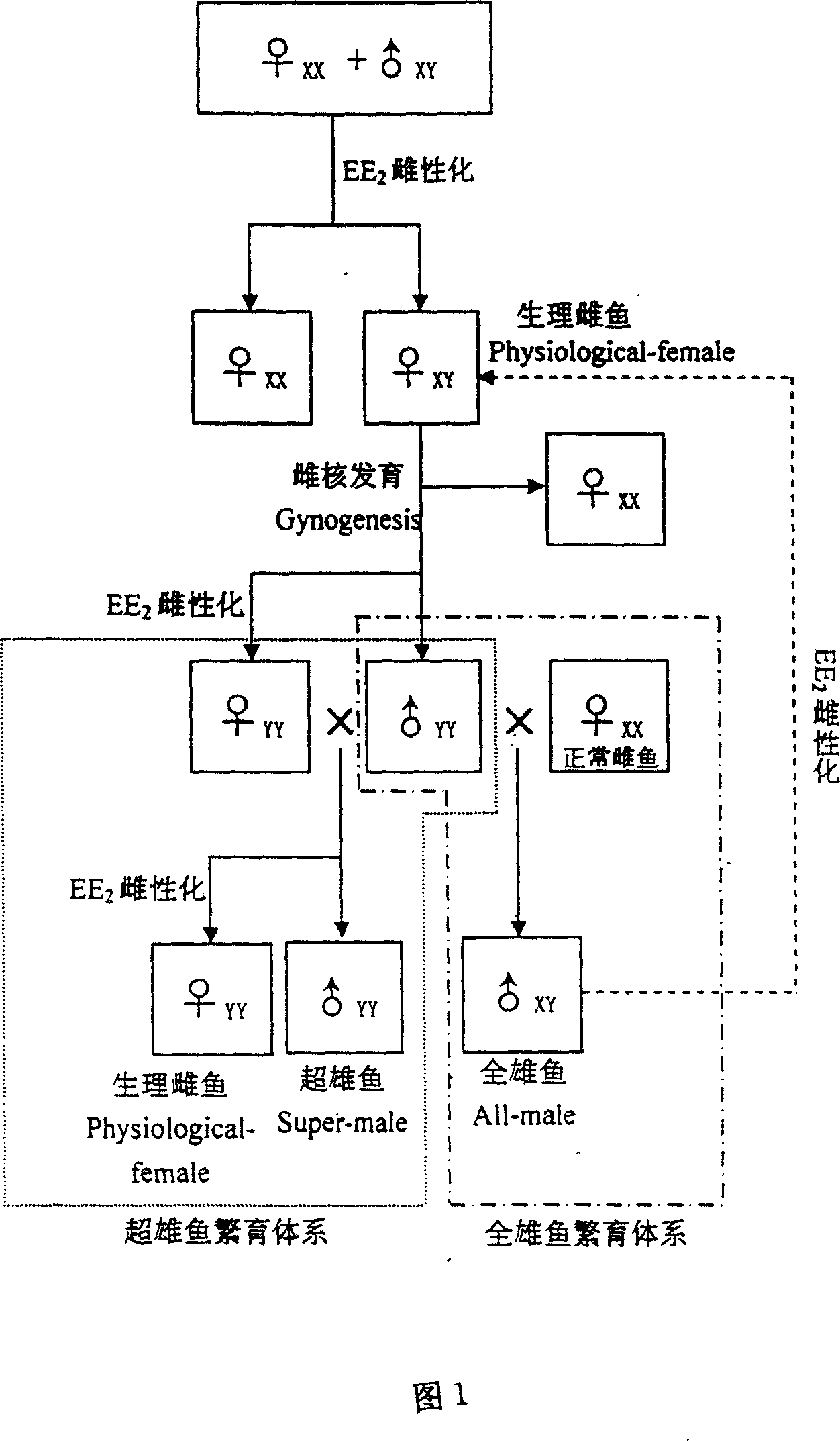

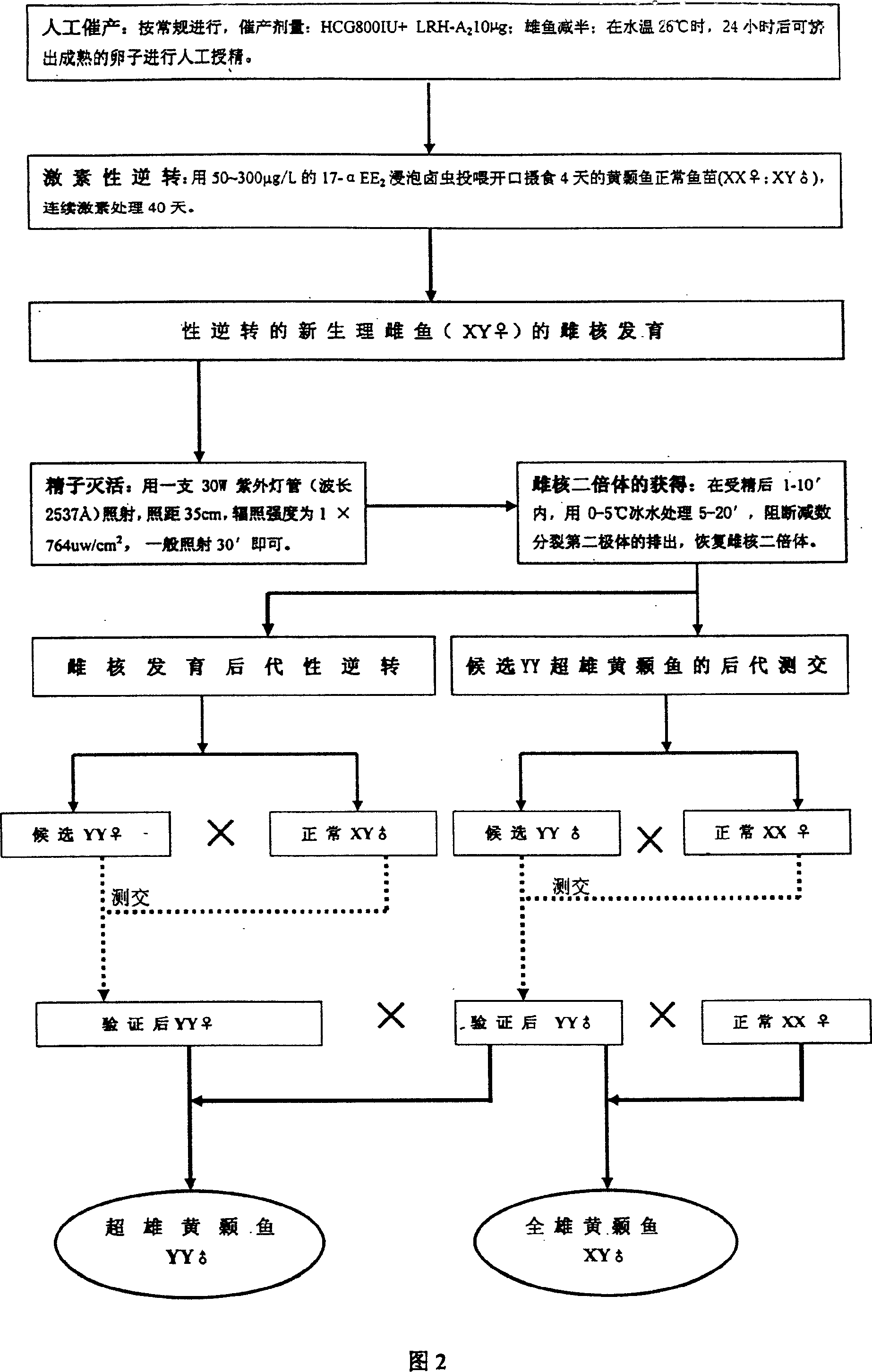

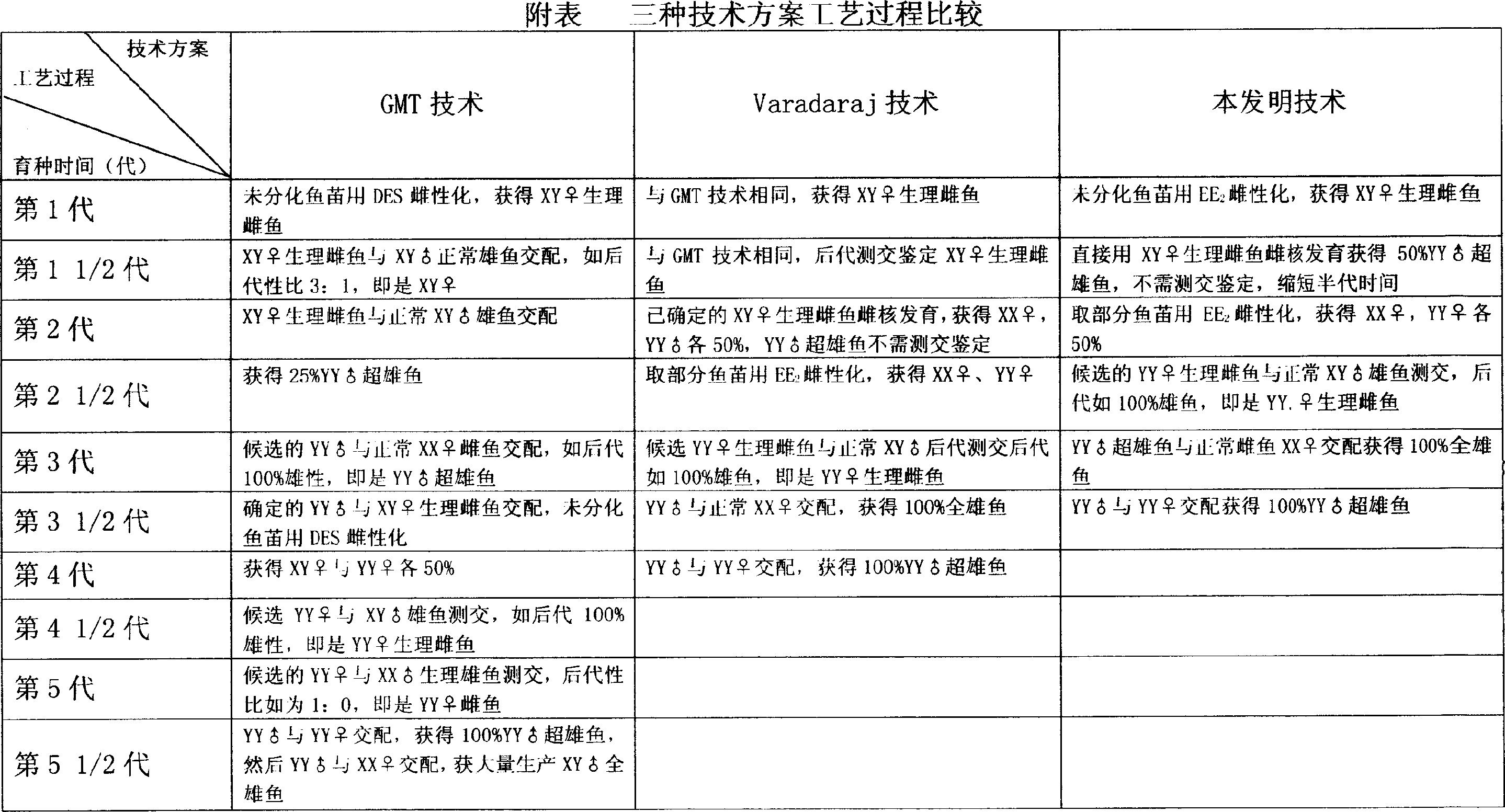

Method for continuously producing complete male pelteobagrus fulvidraco by sex reversion and embryonic development

InactiveCN1994072AShorten breeding timeImprove ergonomicsAnimal reproductionClimate change adaptationNormal femaleFishery

The invention relates to a method for producing male fish, wherein it comprises that: artificially inducing; artificially inducing the female and male fishes; artificial insemination; inverting hormone; feeding seed with Artemia which contains hormone; converting male into biological female; the female grows. The invention comprises sperm inactivation and female diploid generation, to generate ready male fish and normal female fish; crosses the male fish and female fish to obtain the full male fish; inverts the male fish into biological female fish to cross with male fish, to obtain the full super male fish.

Owner:INST OF AQUATIC LIFE ACAD SINICA

Riser heating and insulating agent

InactiveCN101798233AHas the double effect of heat preservationWith feverFoundry mouldsFoundry coresCarbon graphiteSteel casting

The invention discloses a riser heating and insulating agent, which comprises the following components in percentage by weight: 5 to 35 percent of Al, 10 to 25 percent of AlN, 3 to 20 percent of low-carbon graphite, 5 to 25 percent of magnesia-alumina spinel, 5 to 15 percent of quartz, 10 to 30 percent of ferric oxide powder, 5 to 20 percent of corundum, 5 to 10 percent of organosilicon phlogopite, and 1 to 10 percent of MgO; and the riser heating and insulating agent is prepared by the following processes: crushing, pulverizing, mixing, pelletizing, drying, and the like. The riser heating and insulating agent has double effects of heating and insulating, and has good insulating effect. Because the riser heating and insulating agent has a granular appearance, dust and smoke are not generated in the using process, and the environment is not polluted. Due to the adoption of the low-carbon graphite, castings do not have carburizing phenomenon, and the molten steel is not polluted. The riser heating and insulating agent is particularly applied to open risers of low carbon steel large-scale steel castings and stainless steel castings with the weight of over 80 tons.

Owner:HENAN UNIV OF SCI & TECH

PTT fiber and celluse fiber one-bath dyeing method

The invention discloses PTT and cellulose fibers one bath process dyeing method. It includes the following steps: adding dyeing assisted carrier into the bath; dying PTT fiber by disperse dyes; adding auxiliary agent to do reduction clearing; removing loose color; adding activated dye and auxiliary agent to dye cellulose fiber; soaping; washing; and fixing by fixing agent; mellowing; dehydrating; and drying. The invention solves the problem of blending PTT and protein fibers low temperature one bath process dyeing, and the production problem of no corresponding high temperature pressure dyeing device for enterprise, which is the key of deep processing for blending fiber product, the necessary condition for its market popularization and application.

Owner:QUANZHOU HAITIAN MATERIAL TECH CORP

Preparation method of biological feed

InactiveCN101164428AReduce total usageSolve production problemsFood processingAnimal feeding stuffCorn flourFermentation starter

The present invention relates to a preparation method of biological feed. It is made up by using crop straw and stalk, wheat bran, corn flour, soybean cake, fish powder and urea as raw material, and its preparation method includes the following steps: mixing above-mentioned raw materials according to a certain mixing ratio, adding fermentation agent into the above-mentioned mixture to make fermentation, then mixing the fermented mixture with mold fungus, bacillus and lactic acid bacteria, granulating by using glanulating machine so as to obtain the invented biological feed granules finished product.

Owner:于亦胜

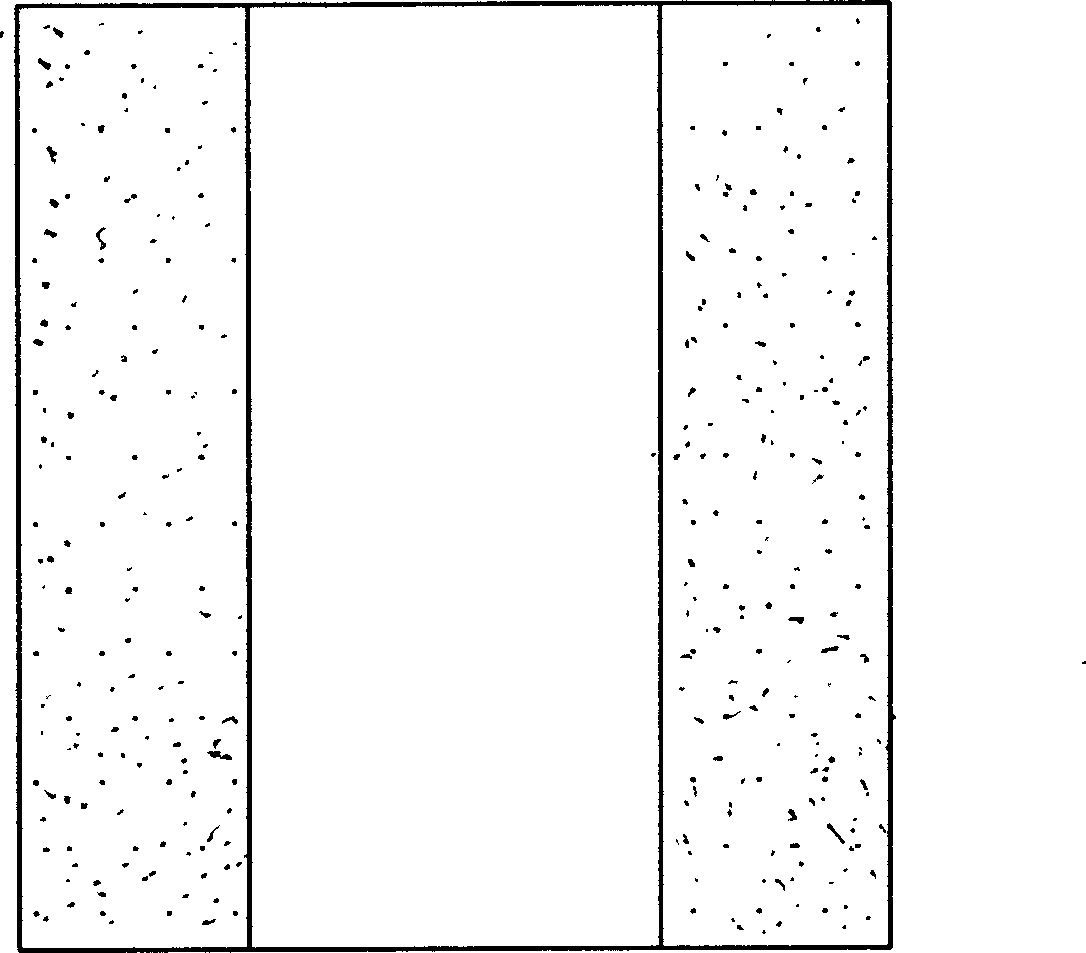

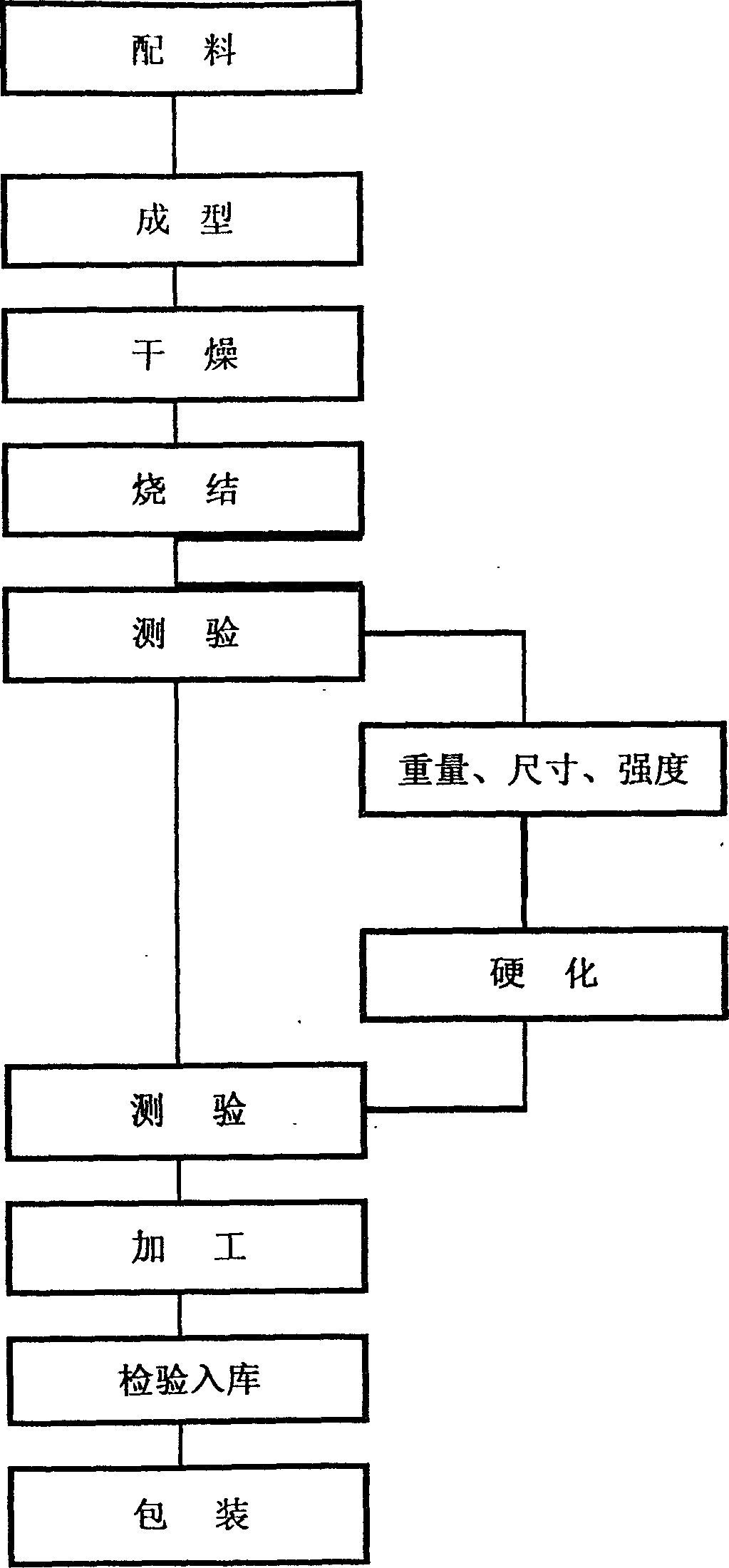

Cubic boron nitride ceramic binder parallel abrasion wheel and its production method

A flat adhesive disk for grinding the workpiece made of high-speed steel is prepared from cubic boron nitride, dextrin powder, white corundum, wetting agent and ceramic adhesive through proportional mixing, shaping, drying, sintering, examining and trimming. Its advantages are high hardness, toughness, high-temp strength and antiwear performace and long service.

Owner:HENAN FLINT SUPERHARD ABRASIVE

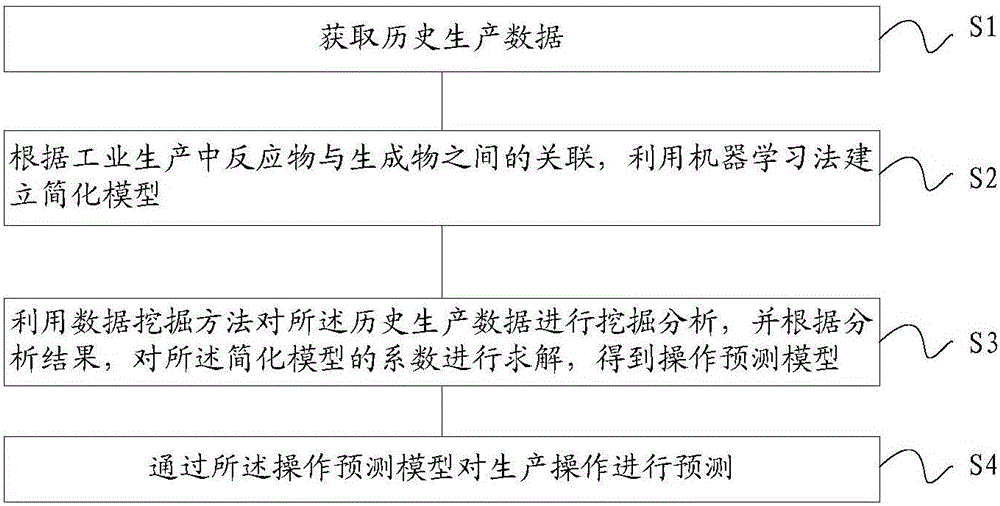

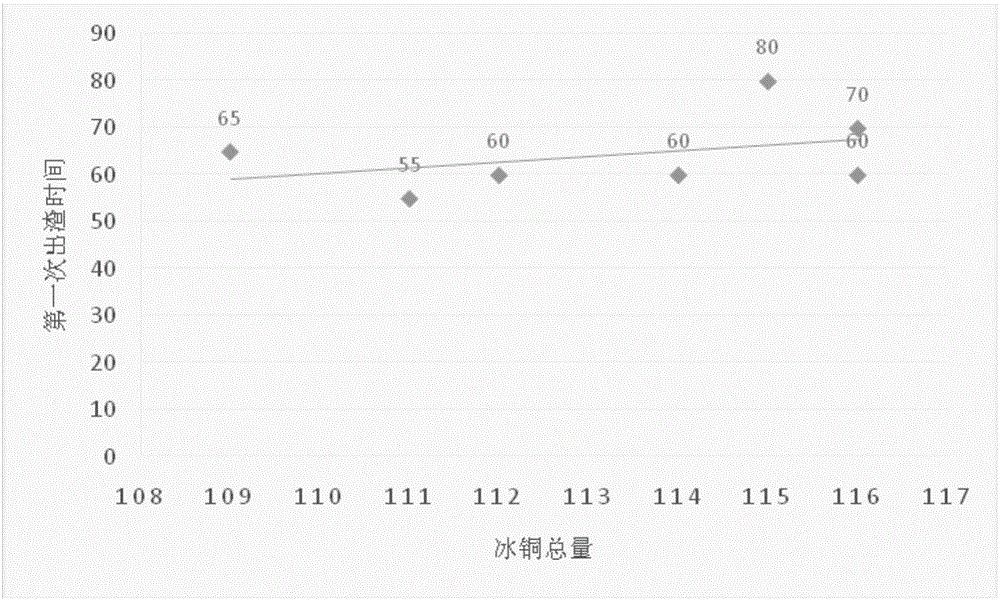

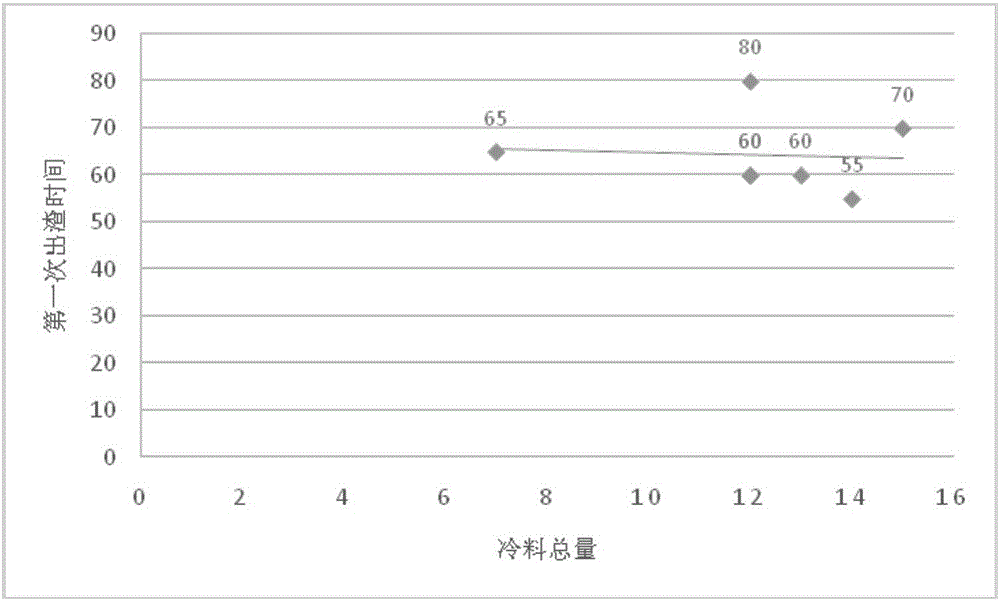

Industrial production flow prediction method

InactiveCN105807741AImprove the level of standardized workSolve production problemsTotal factory controlProgramme total factory controlReduced modelPredictive methods

The invention provides an industrial production flow prediction method. With the method adopted, production operation can be predicted, and the standard operation level of industrial production can be improved. The method includes the following steps that: historical production data are acquired; a machine learning method is utilized to establish a simplified model according to the associations between reactants and resultants in the industrial production; a data mining method is utilized to perform mining analysis on historical production data, and the coefficients of the simplified model are solved according to analysis results, so that an operation prediction model can be obtained; and production operation is predicted through the operation prediction model. The industrial production flow prediction method of the invention is suitable for the industrial production process control field.

Owner:UNIV OF SCI & TECH BEIJING

Three-in-one coupling insertion-pull type water surface photovoltaic power generation unit and power generation system thereof

ActiveCN107317544ASolve the problem of non-standard water installationSolve the problem of irregular installationPhotovoltaic supportsWaterborne vesselsMulti functionalityPhotovoltaic power generation

Disclosed are a three-in-one coupling insertion-pull type water surface photovoltaic power generation unit and a power generation system thereof. The photovoltaic power generation unit comprises a passage floating body and a connecting floating body arranged on a side wall of the passage floating body, wherein a power generation element is arranged on the connecting floating body. The system is formed by assembling three-in-one coupling insertion-pull type water surface photovoltaic power generation units vertically and horizontally. Horizontally, the passage floating body is assembled with a passage floating body of another three-in-one coupling insertion-pull type water surface photovoltaic power generation unit, and so on, mounting is completed. Vertically, the connecting floating body is assembled with the passage floating body of another three-in-one coupling insertion-pull type water surface photovoltaic power generation unit, and so on, mounting is completed. Finally, connecting floating bodies of a horizontal row of three-in-one coupling insertion-pull type water surface photovoltaic power generation units are independently fixed with passage floating bodies, so as to complete mounting of the whole power generation system. The unit has the characteristics of simple structure, convenient mounting and multi-functionality. The system assembly has the characteristics of simple structure and convenient mounting.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

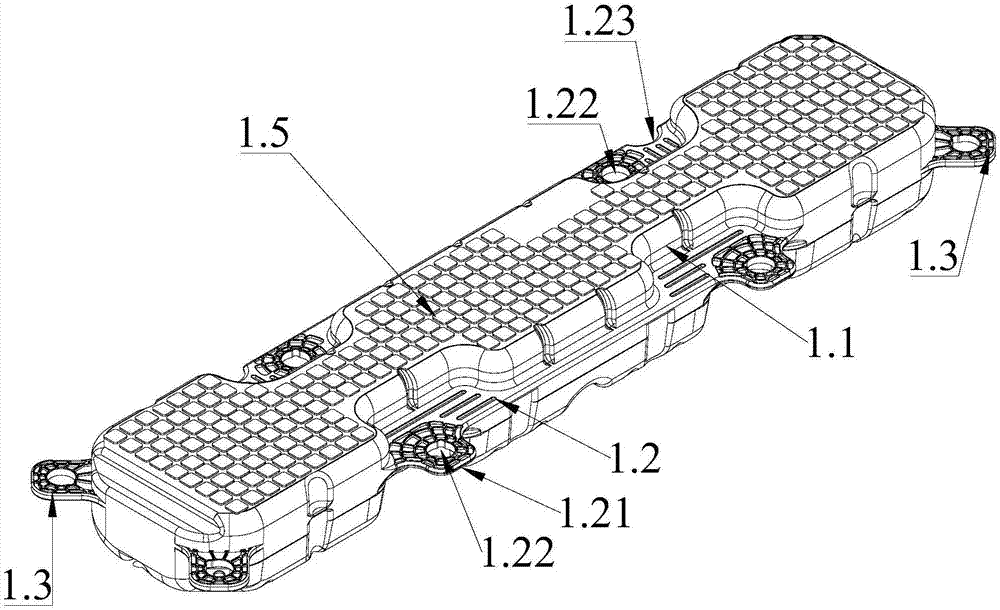

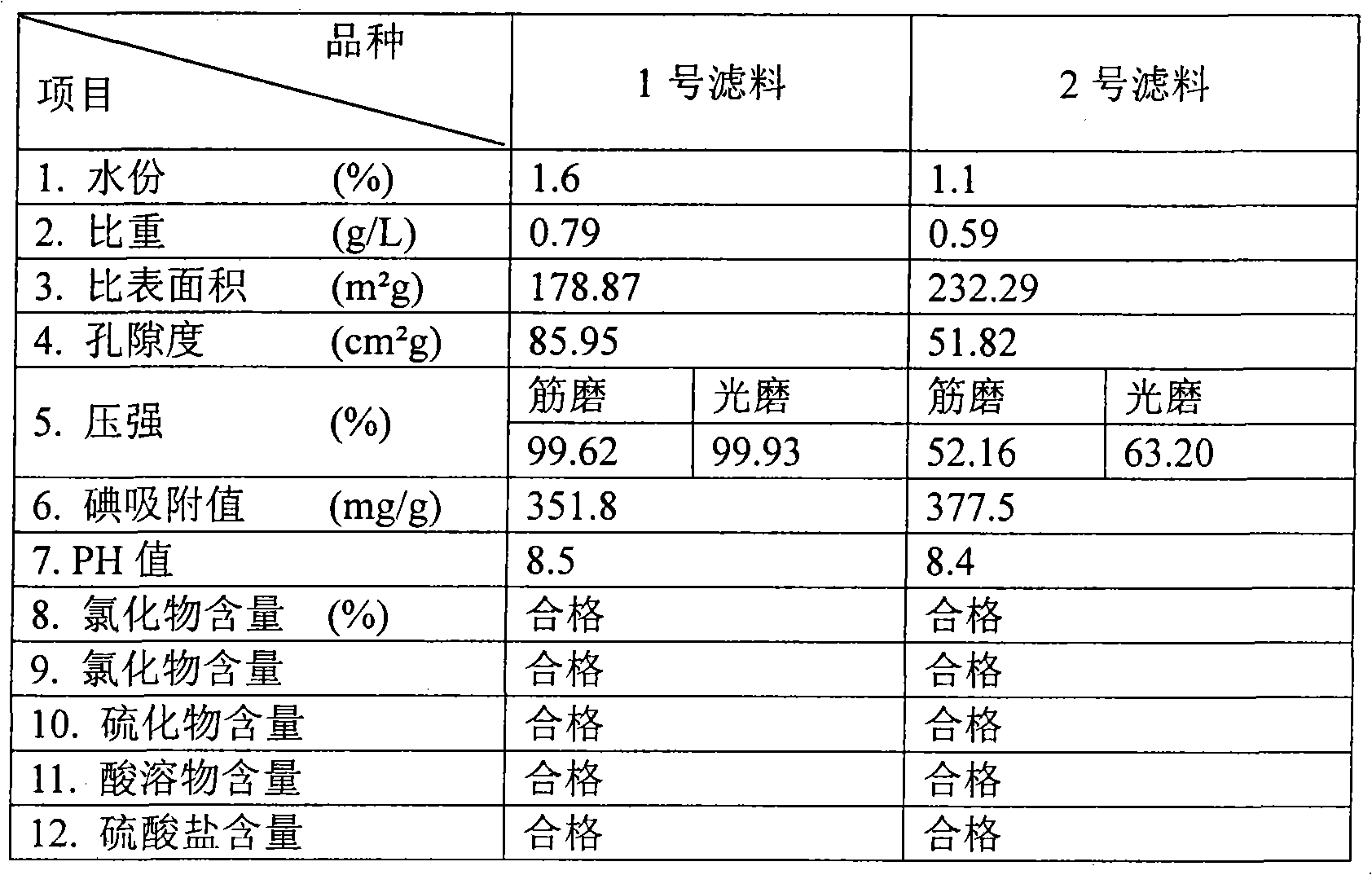

Composite filtering material for activating and regenerating coal ash and production method thereof

InactiveCN101274172ALow costReduce processingOther chemical processesFiltration separationFiltrationGranularity

The invention discloses a fly ash activation regeneration composite filtration material and a manufacture method of the filtration material, belonging to the field of water treatment technique. The fly ash activation regeneration composite filtration material consists of 80 to 90 portions of fly ashes or furnace ashes (by weight) with the grain diameter not less than 80 meshes and 10 to 20 portions of porous aluminosilicate mixed powders (by weight); the fly ash or the furnace ash are bonded as grain shape with the granularity less than 8mm; the porous aluminosilicate mixed powders are enwrapped on the surface of the fly ashes or the furnace ashes and burned so as to form a ceramic layer which is provided with an adsorption micro-hole which is communicated with an internal core. The fly ash activation regeneration composite filtration material is fabricated and formed by the steps of raw material mixing, primary granulation, secondary granulation, drying, roasting, etc., and has the advantages of low cost and good purification effect.

Owner:江苏正本净化节水科技实业有限公司

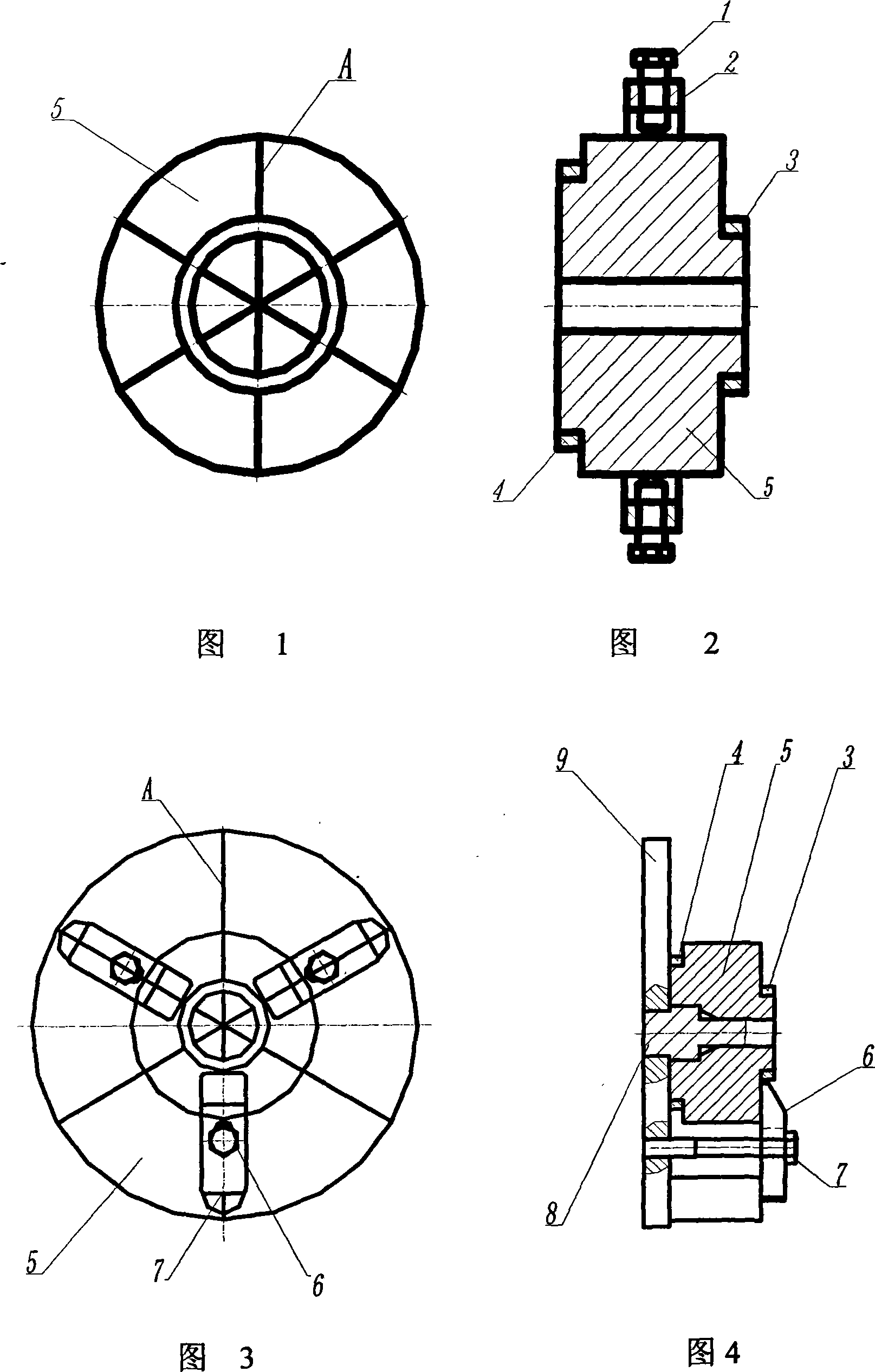

Precision shaping molds separating group processing method

InactiveCN101214530AGuaranteed process requirementsImprove processing pass rateFoundry mouldsFoundry coresEngineeringMechanical engineering

The invention relates to a splitting and assembling processing method for a fine forming die which leads about 30mm of a movable mould core blank and utilizes a linear cutting processing to divide into a plurality of equal parts, codes running numbers according to sequence and carries through plane furbishing and polishing processing on a cutting parting surface; then utilizes the radial actions of an anchor ear and trip bolt to fix the movable mould core; clamps and turns the locating devices at two ends and then utilizes a fine jig mill to process a datum hole; then utilizes a self-turning mode and adopts the modes that a floral disc and a mandrel are tightly cooperated and the mandrel is cooperated with the datum hole of the movable mould core in small clearance to carry through fine forming processing on the inner shape and outer taper of a product. The die forming product processed by the method has the advantages of large extent improving on the surface quality and dimension precision, completely qualified quality, no security hidden troubles, convenient processing. The processing equipment used has the advantages of simple structure and lower cost.

Owner:CHANGAN AUTOMOBILE (GRP) CO LTD

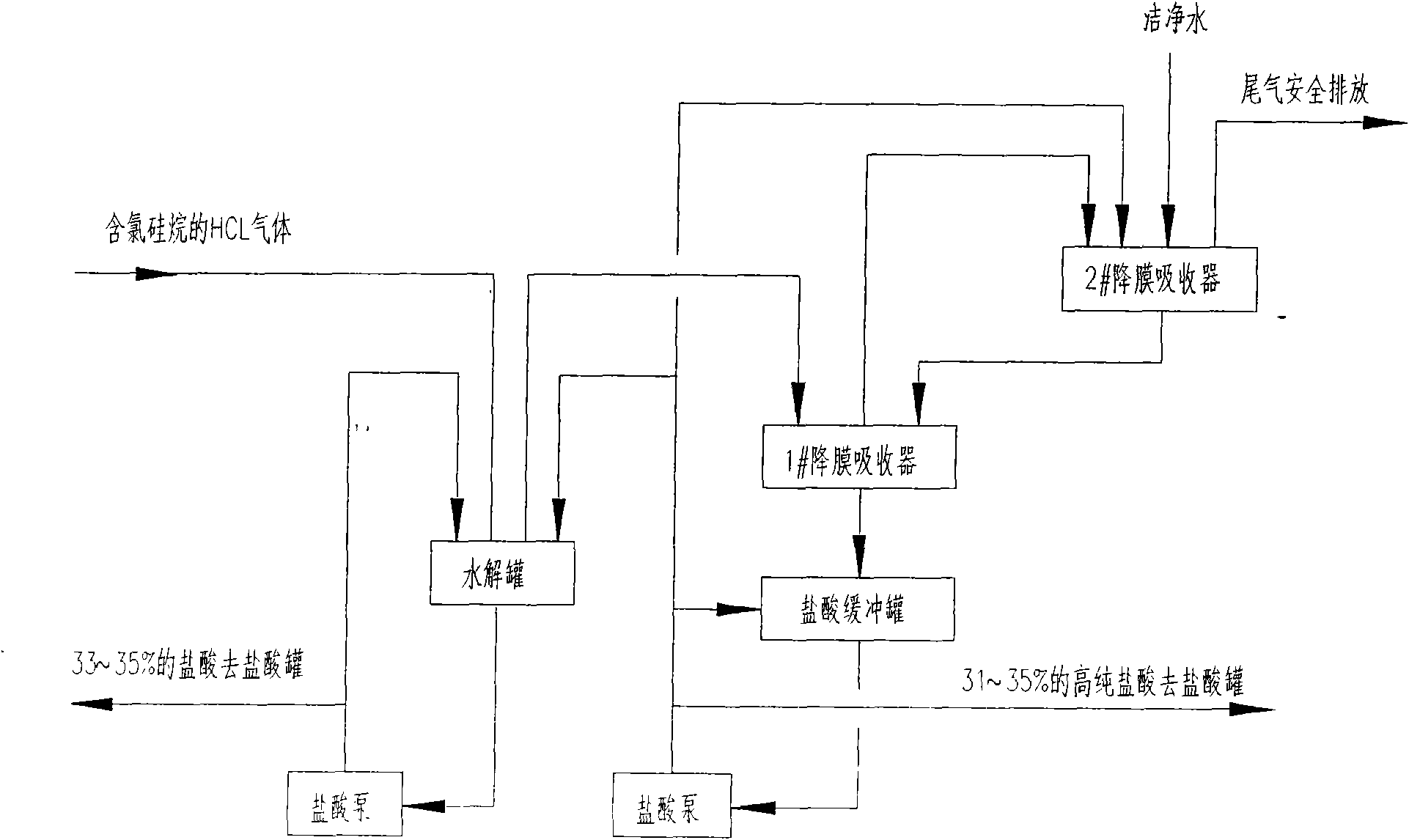

Method for producing high-purity concentrated hydrochloric acid by adopting hydrogen chloride gas containing chlorosilane

ActiveCN101628710AHigh purityImprove production stabilityChlorine/hydrogen-chloride purificationPhysical chemistryWater circulation

The invention discloses a method for producing high-purity concentrated hydrochloric acid by adopting hydrogen chloride gas containing chlorosilane, which comprises the following steps: injecting hydrogen chloride gas containing chlorosilane into a hydrolyzer, carrying out hydrolyzation reaction with water in concentrated hydrochloric acid in the hydrolyzer, removing chlorosilane in the gas, adopting water circulation to absorb hydrogen chloride in the gas in falling film absorbers after the gas passes through at least two serial falling film absorbers in sequence to obtain concentrate hydrochloric acid, and discharging tail gases after the hydrogen chloride is absorbed. By utilizing the method, the high-purity concentrated hydrochloric acid is produced by adopting hydrogen chloride gas containing chlorosilane, thus the problem that pure hydrochloric acid can not be obtained in the traditional method that water is directly used for absorbing hydrochloric acid is solved; the production stability, the mutual independence and the flexible operability of a polysilicon production device are increased; and meanwhile, the high-purity hydrochloric acid can be also obtained, recycled and sold as a by-product.

Owner:SINOPEC NANJING ENG & CONSTR

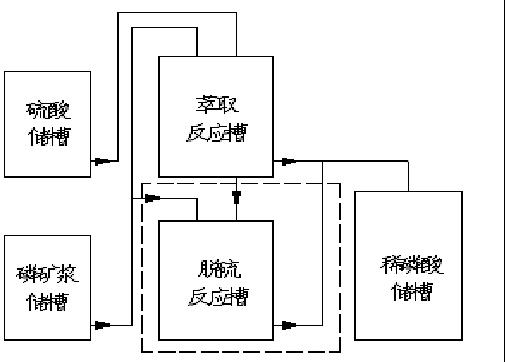

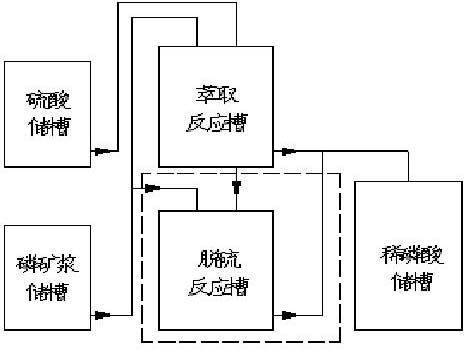

Method for reducing SO3 concentration in diluted phosphoric acid

InactiveCN102431981ASave the cost of extraction processReduce the cost of the concentration processPhosphorus compoundsDiammonium phosphateChemistry

The invention relates to a method for reducing SO3 concentration in diluted phosphoric acid, which is characterized in that a desulfurizer is additionally arranged between a wet process phosphoric acid extraction tank and a diluted phosphoric acid storage tank, an ore pulp storage groove is connected into the desulfurizer through a pipeline, the diluted phosphoric acid obtained through filtering and extraction through the phosphoric acid extraction tank is connected to the desulfurizer through a pipeline, the desulfurizer is also connected to the diluted phosphoric acid storage tank through a pipeline, the diluted phosphoric acid obtained through the filtering and the extraction through the phosphoric acid extraction tank is pumped into the desulfurizer through a pump, simultaneously, ore pulp is also pumped into the desulfurizer, the diluted phosphoric acid and the ore pulp take reaction in the desulfurizer for reducing the free sulfuric acid content in the diluted phosphoric acid, and the desulfurized diluted phosphoric acid is pumped into the diluted phosphoric acid storage tank through the pump. The method has solves the problem of ammonium phosphate production affected by mass fluctuation of the phosphate ore and has the advantages that: (1) the quality of the ammonium phosphate product is stable, 1 percent of SO3 in the phosphoric acid is reduced, the total nutrient content of the produced monoammonium phosphate product is improved by about 1.0 percent, and the total nutrient content of the produced diammonium phosphate product is improved by about 0.6 percent; and (2) the extraction work procedure cost is saved, and simultaneously, the contraction work procedure cost is reduced.

Owner:GUIZHOU KAILIN GRP CO LTD

Slow-release high-yield crop fertilizer

ActiveCN101519331ASolve the blind purchase of fertilizerSolve the problem of blind fertilizationAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersDiammonium phosphateNitrogen

The invention provides a slow-release high-yield crop fertilizer which comprises the ingredients of nitrogen, phosphate and kalium, wherein the nitrogen comprises large-particle slow-release urea and small-particle slow-release urea, the phosphate comprises diammonium phosphate and monoammonium phosphate, and the kalium comprises imported potassium chloride and imported potassium sulfate. The invention mainly solves the problems that the prior fertilizer has insufficient nutrients, low content and unreasonable nitrogen-phosphate-potassium proportion and can not be singly fertilized or de-fertilized, also solves the peasant fertilizer-selecting difficulty problem and the great before-sowing fertilizer-mixing labor expense problem generally existed in the prior production, omits additional fertilizer for planting corn and rice and has the advantages of fertilizer effect improvement, final crop yield improvement, and the like.

Owner:李财

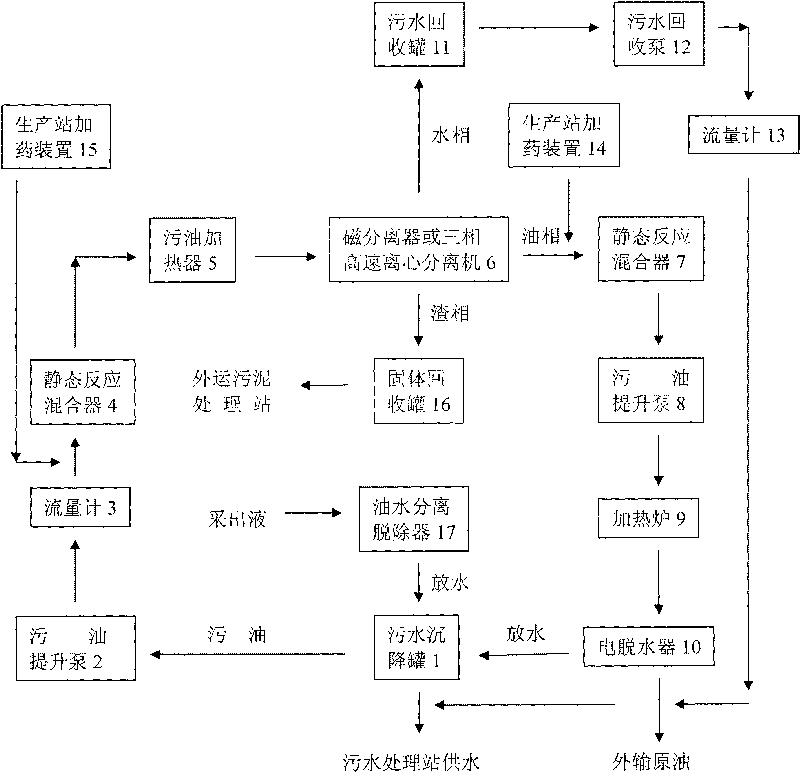

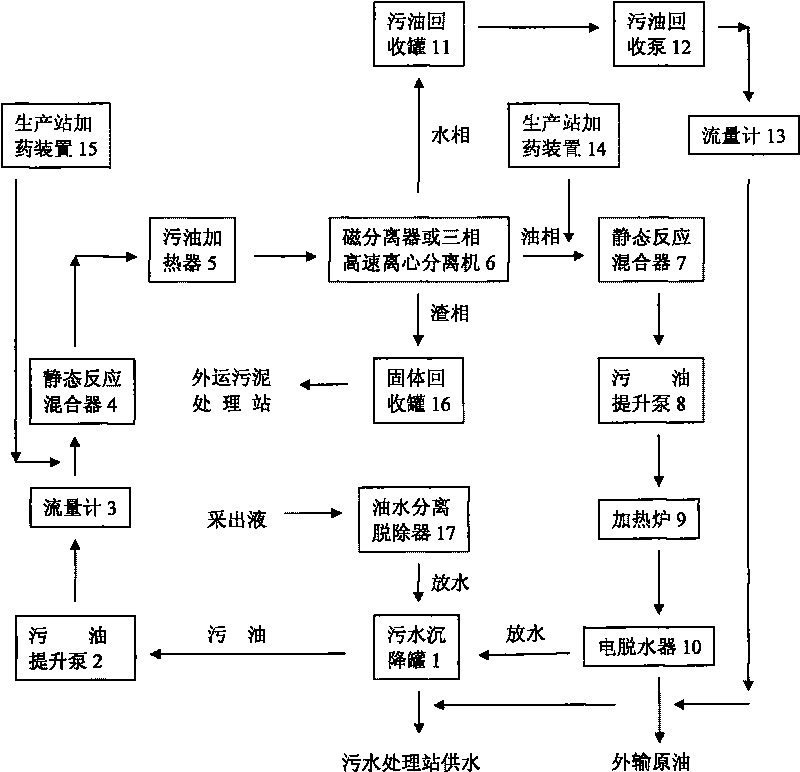

Recovery and treatment technology of dirty oil produced in sewage setting tank in produced liquid treatment

ActiveCN101735851AEasy to implementEasy to operateDewatering/demulsification with chemical meansDewatering/demulsification with electric/magnetic meansProcess equipmentOil field

The invention discloses a recovery and treatment technology of dirty oil produced in a sewage setting tank in produced liquid treatment. The technology adopts built facilities of the traditionally produced liquid treatment technology and uses other additional process equipment, such as a static reaction mixer, a three-phase high-speed centrifugal separator and the like, so that sulfide particle impurity which affects the normal running of an electrical dehydrator is separated out of dirty oil, the dirty oil in the electrical dehydrator can be recovered for sure, the collapse of the electric field of the electrical dehydrator can not occur during the dehydration process, and the normal production running can not be affected; and the recovery and treatment technology of dirty oil has the advantages of simple implementation, convenient operation, good processing effect and economic project investment, is a treatment technology which is advanced in the oil fields at home at present and can be implemented, and achieves the purpose for solving practical production problems, therefore, the recovery and treatment technology of dirty oil is suitable for wide matching application in the renovation project of oil fields.

Owner:DAQING OILFIELD CO LTD +2

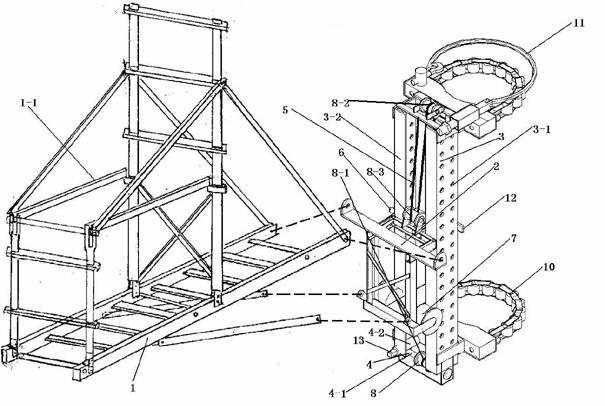

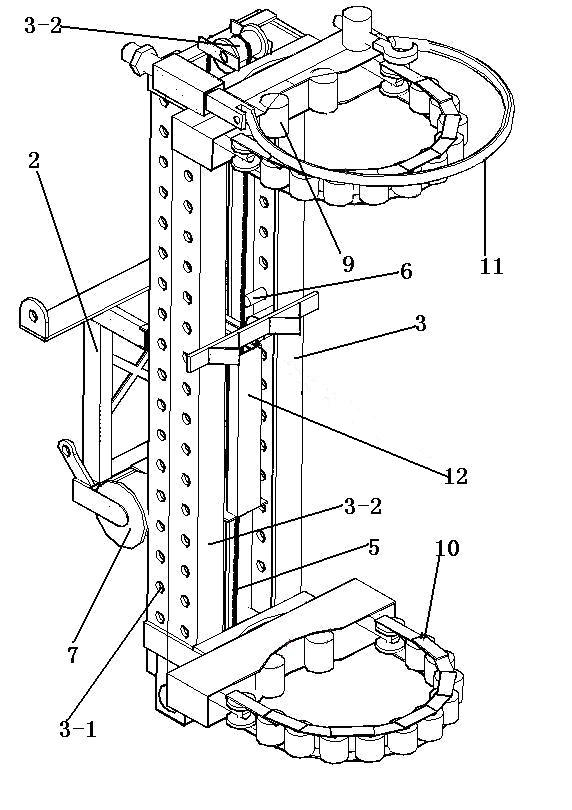

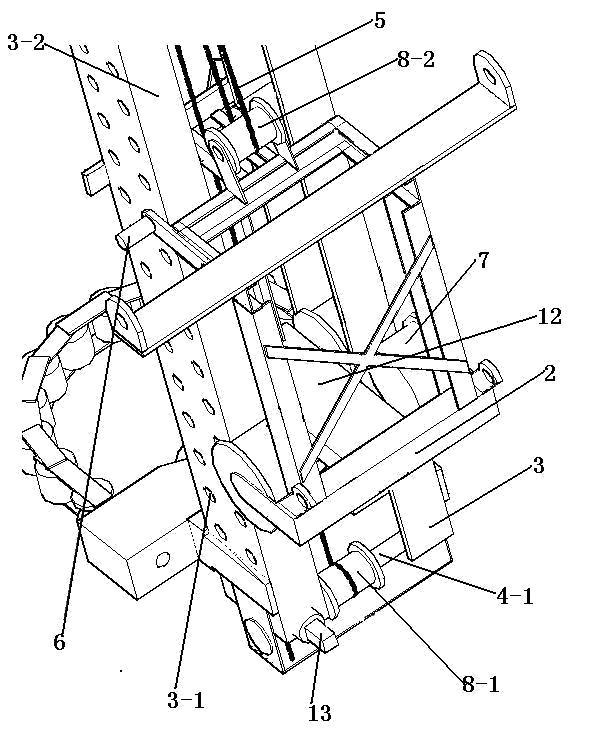

Lifting type rail insulation operation platform

ActiveCN102623923AAvoid misuseProtection securityLifting devicesApparatus for overhead lines/cablesMobile deviceIndustrial engineering

The invention discloses a lifting type rail insulation operation platform which comprises a mobile device and an insulation platform body that is provided with a rail, wherein the mobile device comprises an up-down lifting device, a left-right moving device and an insulation platform bracket; the up-down lifting device comprises a guide rail, a worm and gear device, a pulley block, a lifting rope and a lifting limiter; the worm and gear device is arranged at the bottom end of the guide rail; the pulley block comprises guide rail pulleys fixed on the insulation platform bracket and used for clamping the guide rail and a lifting pulley penetrating and guiding the lifting rope; one end of the lifting limiter is fixed on the insulation platform bracket, the other end of the lifting limiter is matched and fixed with the guide rail; the insulation platform bracket is arranged in front of the guide rail and is fixed with the insulation platform body, the insulation platform bracket moves up and down along the guide rail through the guide rail pulleys arranged at the upper end and the lower end of the bracket; and the left-right moving device comprises a support pulley, two pulley chains and a metal fixing chain. According to the invention, up-down and left-right regulations of an operation position can be carried out, thus the safety of a hot line work is improved.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +2

Oil-soluble viscosity reducer for extremely-viscous oil

InactiveCN101845298ASolve production problemsReduce manufacturing costDrilling compositionReducerSolvent

The invention relates to a viscosity reducer, in particular to an oil-soluble viscosity reducer for extremely-viscous oil. The technical scheme is that: the viscosity reducer comprises the following components in percentage by weight: (1) 50 to 65 percent of solvent, (2) 20 to 30 percent of polyoxyethylene ether, (3) 3 to 5 percent of emulsifier 1, and (4) 3 to 5 percent of emulsifier 2. The viscosity reducer has the advantages of completely overcoming difficulty in the exploitation of the viscous oil and providing good technical conditions for great increase in the yield of the viscous oil and the reduction of production cost.

Owner:宁夏大生生物科技有限公司

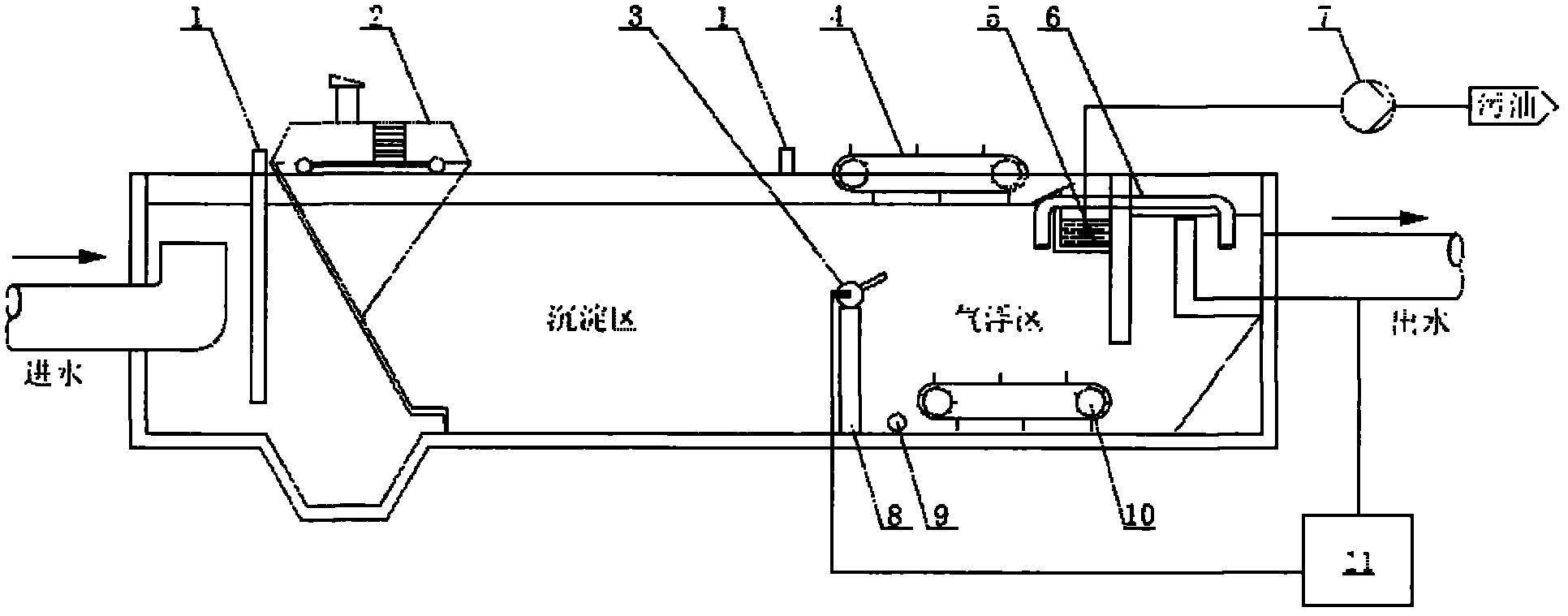

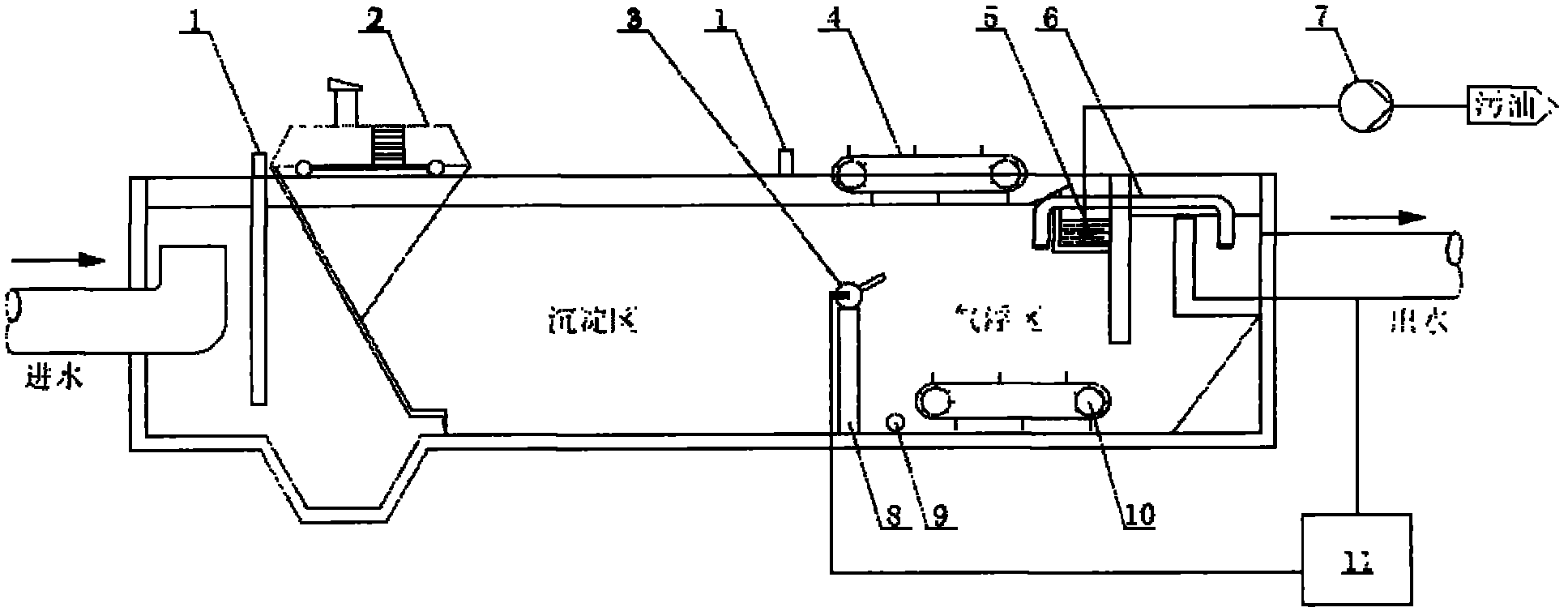

Method modifying horizontal flow sedimentation tank into sedimentation floatation tank and modified sedimentation floatation tank

InactiveCN102583615ALiquid level stabilityEasy to handleFatty/oily/floating substances removal devicesLiquid separationWater volumeControl system

The invention discloses a method modifying a horizontal flow sedimentation tank into a sedimentation floatation tank and the modified sedimentation floatation tank. The detailed method comprises: additionally arranging a separating device in the horizontal flow sedimentation tank to divide the horizontal flow sedimentation tank into a sedimentation area and a floatation area, additionally arranging a gas-dissolved water releaser and mud-discharging, oil-skimming and oil-collecting facilities in the floatation area simultaneously, and dividing the horizontal flow sedimentation tank into the sedimentation area and the floatation area which are independent to each other so that the corresponding functions are achieved well. A gas-dissolved device and a control system are additionally arranged outside the tank. Besides, an overflow pipe is additionally arranged, guarantees stability of the flat liquid level and adapts to the status of addition of treated water quantity, two functions including sedimentation and floatation are achieved, early sedimentation and later floatation are achieved, the treatment effect and the running stability of the horizontal flow sedimentation tank are greatly improved, and the method modifying the horizontal flow sedimentation tank into the sedimentation floatation tank and the modified sedimentation floatation tank are suitable for large-scale pre-treatment of sewage containing oil and suspended matter and can be used for a newly-built system and old equipment modification. Simultaneously, the modularized design achieves old equipment modification of the horizontal flow sedimentation tank in a short construction period, the investment is saved, and the production problem is solved.

Owner:LIAONING HUAFU ENVIRONMENTAL ENG

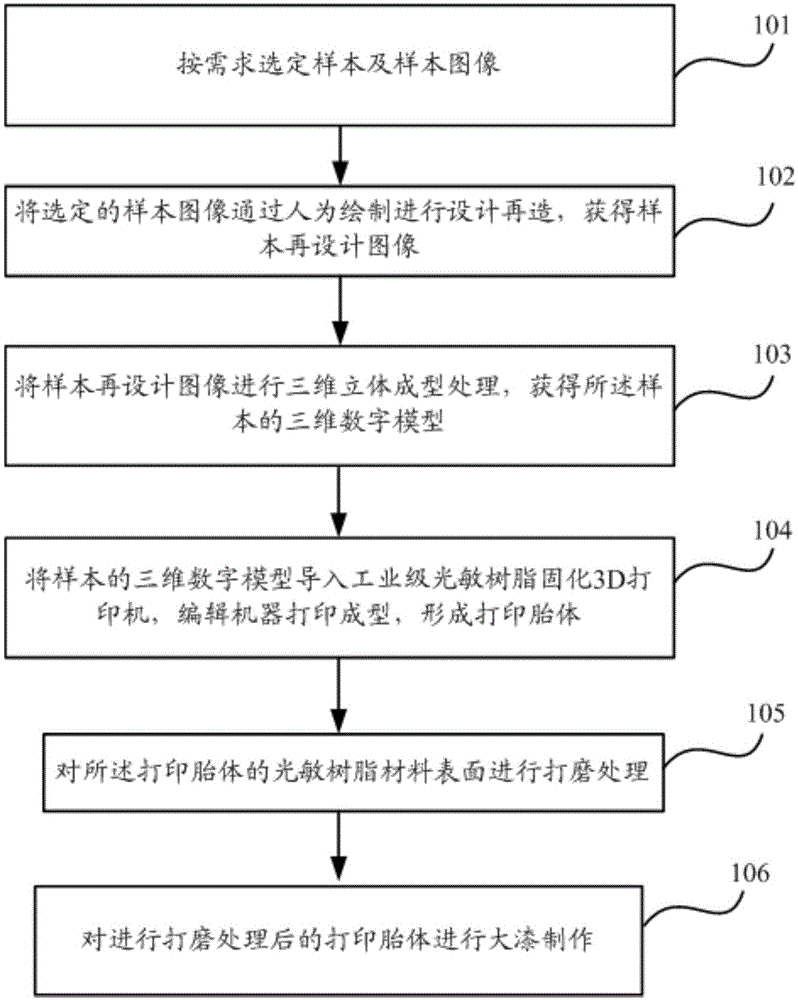

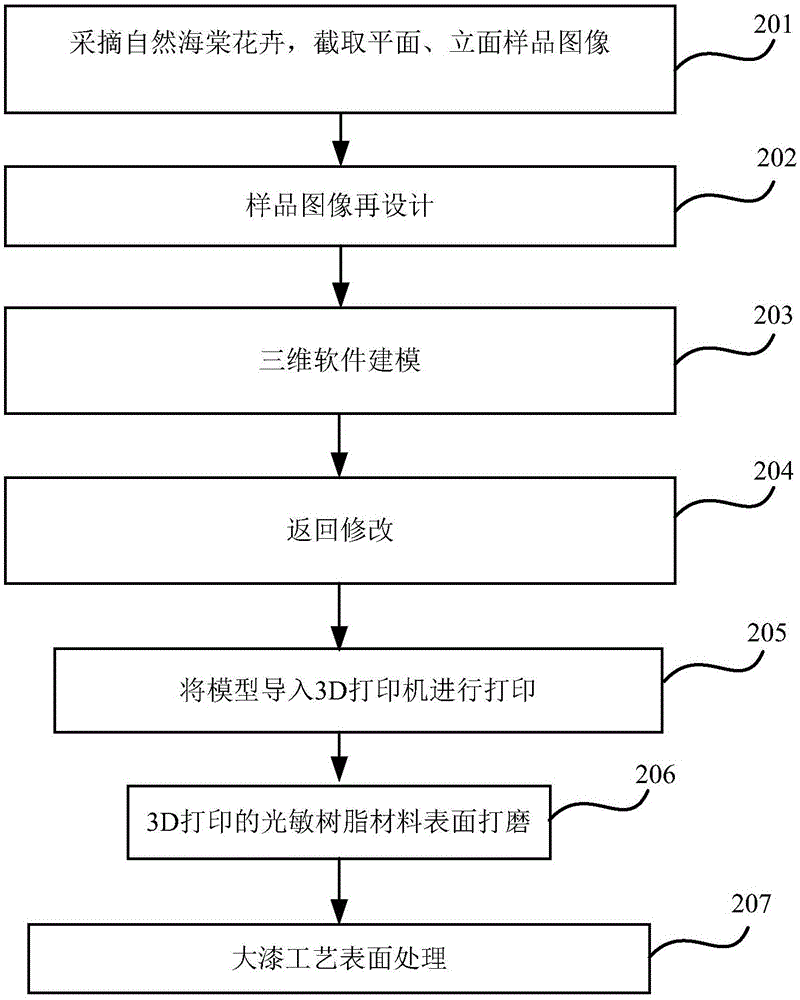

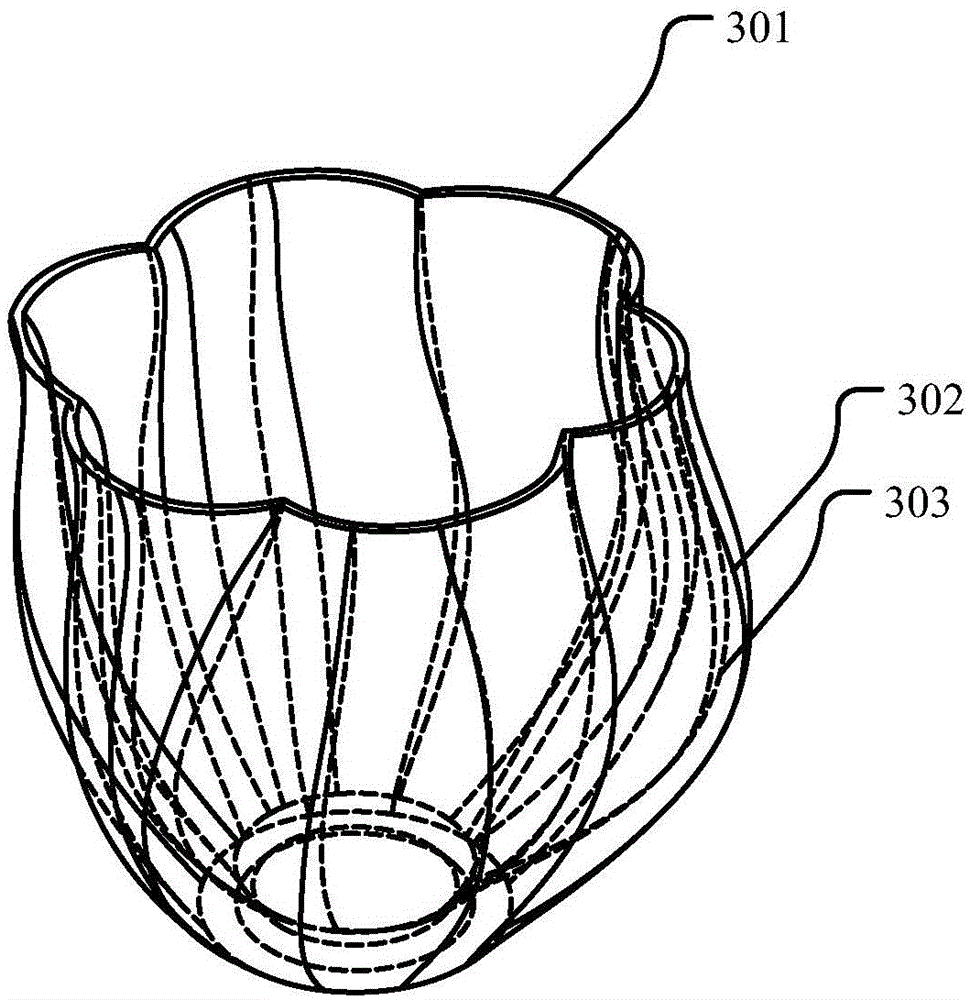

Method for manufacturing matrix by adoption of 3D printing technology

InactiveCN105058799AHigh degree of completionSmooth surfaceAdditive manufacturing apparatusSample imageLacquer

The invention provides a method for manufacturing a matrix by the adoption of a 3D printing technology. The method comprises the steps that a sample and a sample image are selected according to needs; the selected sample image is designed and remade through manual drawing, and a redesigned sample image is obtained; the redesigned sample image is subjected to three-dimensional forming treatment, and a three-dimensional digital model of the sample is obtained; and the three-dimensional digital model of the sample is guided into a 3D printer, the machine is edited for printing treatment, and a printed matrix is formed. The method provides a novel rapid lacquer matrix manufacturing mode, the defect occurring when a traditional matrix is manufactured is overcome, and as the photosensitive resin 3D printed matrix and paper matrix completeness is high and the surface is smooth, financial resource, material and labor consumption caused by matrix manufacturing in the earlier stage is greatly reduced and the technique processes are reduced. The matrix can be obtained only by slight polishing, priming and lacquer coating. Time and labor are saved, and more crafts and techniques can be tried.

Owner:BEIJING ZHONGHONG SHENGJING LANDSCAPE DESIGN CO LTD

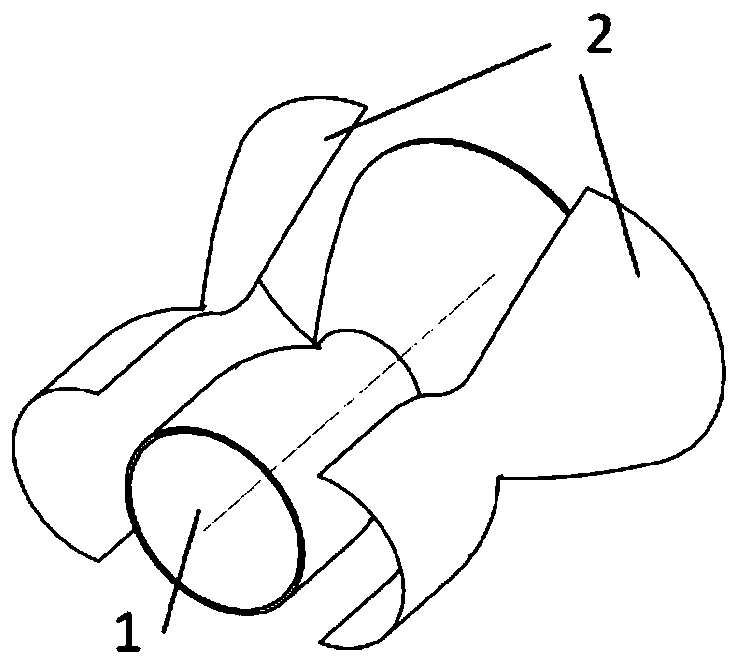

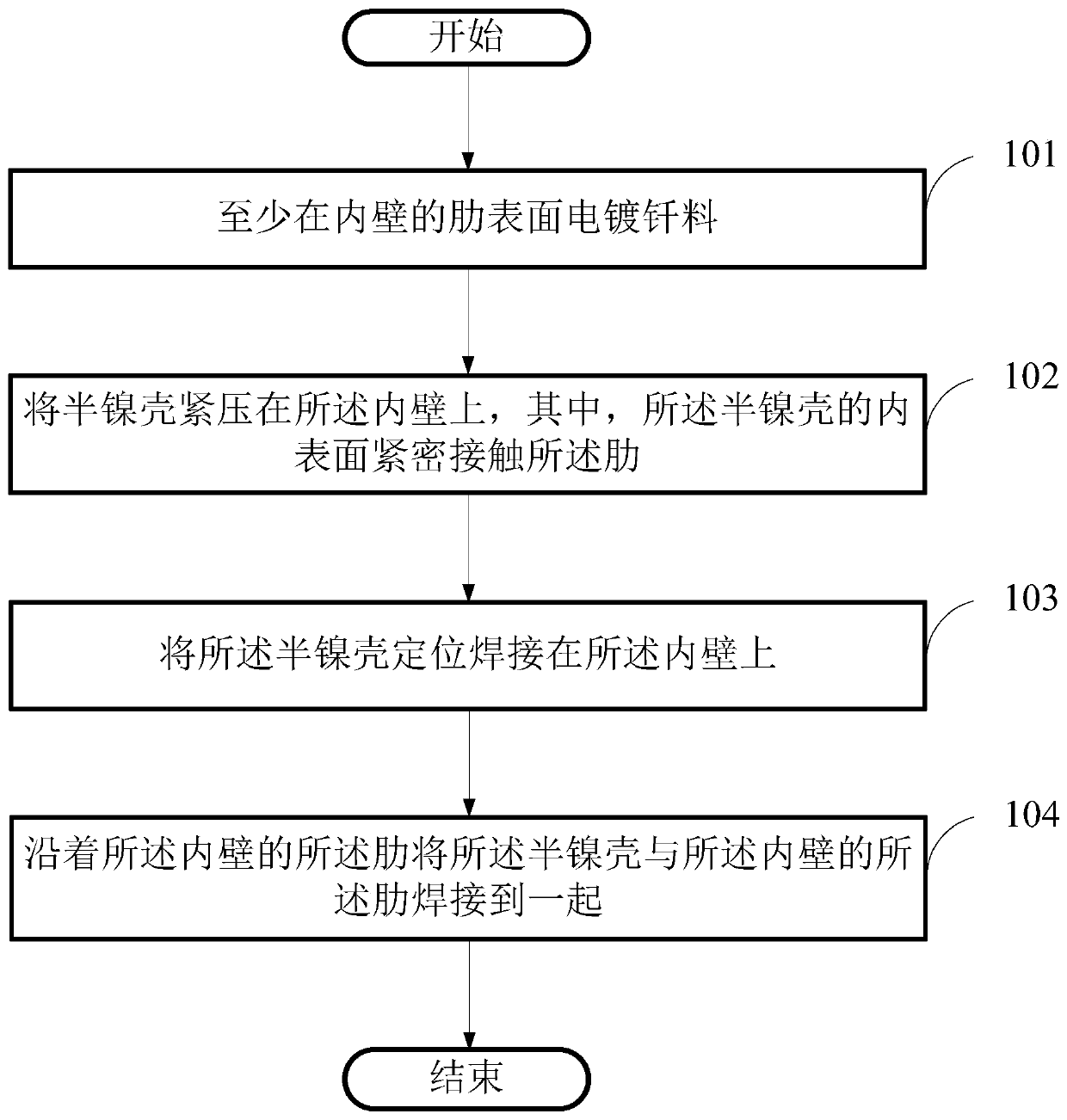

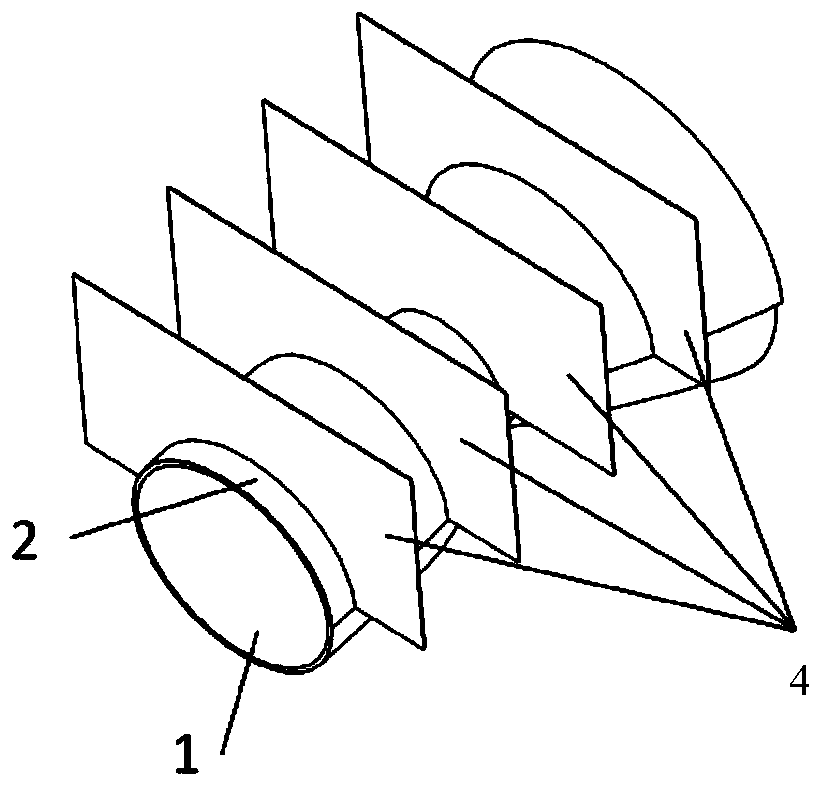

Manufacturing method of pressure-resistant interlayer of thrust chamber of liquid rocket motor

The invention provides a manufacturing method of a pressure-resistant interlayer of a thrust chamber of a liquid rocket motor. The manufacturing method comprises the following steps that brazing filler metal electroplating is conducted on the surface of a rib of an inner wall at least; a half nickel shell is tightly pressed on the inner wall, wherein the inner surface of the half nickel shell is in close contact with the rib; the half nickel shell is located to be welded to the inner wall; the half nickel shell and the rib of the inner wall are welded together along the rib of the inner wall;multiple times of repeating welding are conducted on the half nickel shell and the rib of the inner wall along the rib of the inner wall according to the technology requirements; the outer surface ofthe half nickel shell after being welded is polished smoothly; and nickel layer electroforming or steel bushing wrapping and clamping is conducted on the surface of the half nickel shell. According tothe manufacturing method of the pressure-resistant interlayer of the thrust chamber of the liquid rocket motor, the degree of automation of thrust chamber body part machining can be remarkably improved, the bearing strength of the thrust chamber is improved, the quality is stabilized, and the cost is lowered.

Owner:BEIJING LANDSPACETECH CO LTD

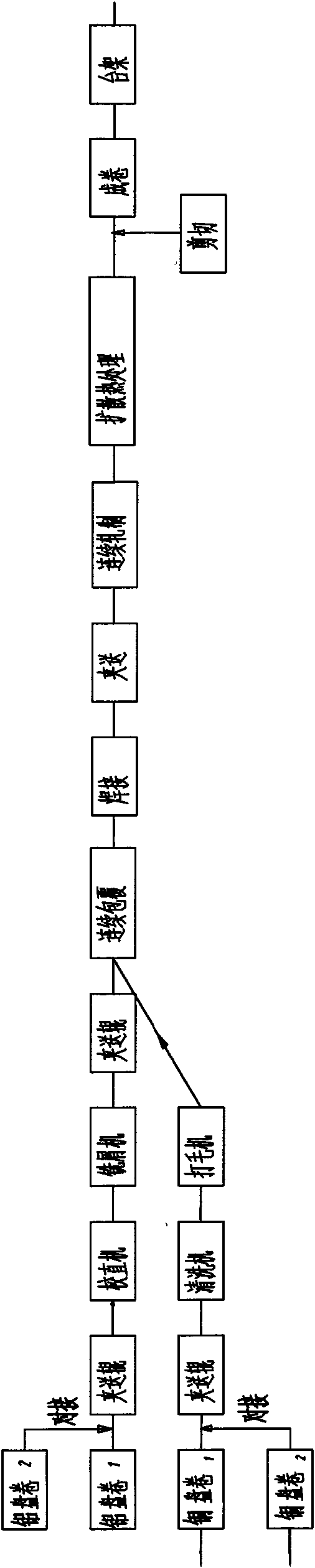

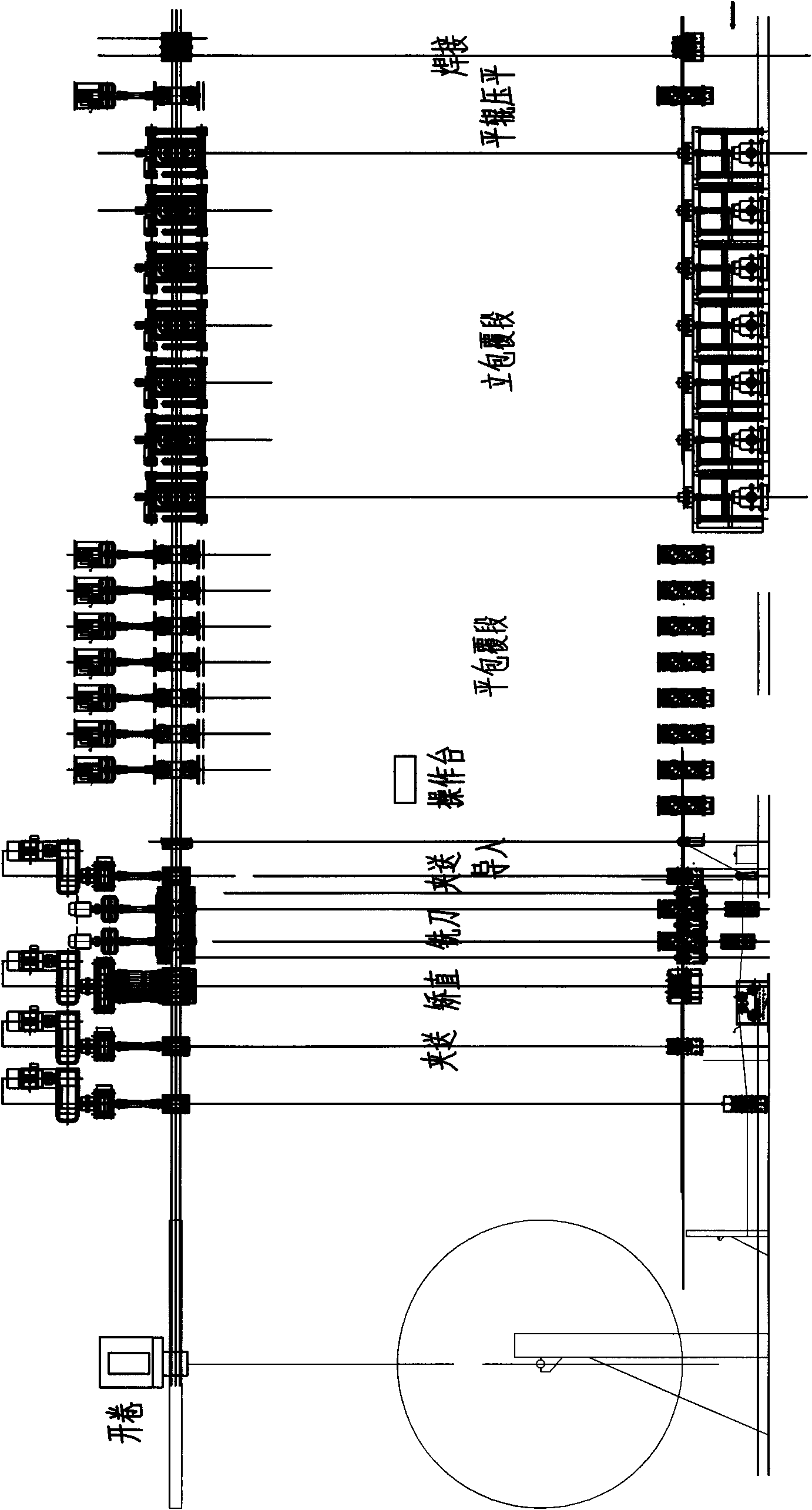

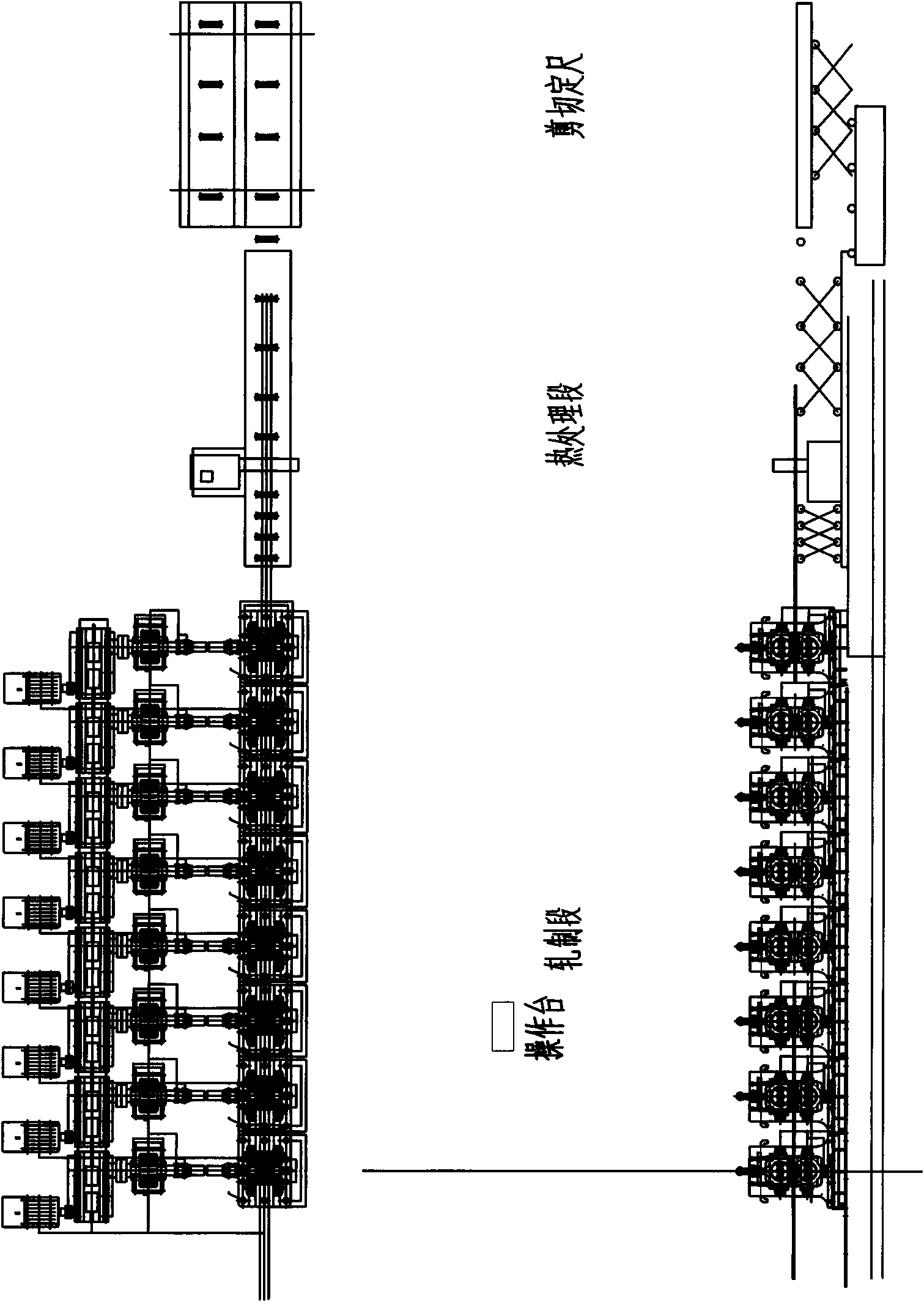

Continuous metallurgical composite production process for copper-clad aluminum rows

InactiveCN101685687AUniform thicknessFull and uniform metallurgical bondingSingle bars/rods/wires/strips conductorsMetal/alloy conductorsCopper coatingEconomic benefits

The invention relates to a continuous metallurgical composite production process for copper-clad aluminum rows. The process comprises a pretreatment step, a continuous coating step, a welding step, acontinuous rolling step, an on-line automatic monitoring step and a diffusion heat treatment step, thereby achieving the following technical effects of: (1) ensuring full uniform combination of coppersheets and aluminum rows, as well as uniform thickness of copper coating; and (2) greatly improving finished-product rate and ensuring yield and quality. Therefore, the production process solves theproblem of producing the copper-clad aluminum rows with various specifications, is particularly applicable to the manufacture of large-size copper-clad aluminum rows, and has huge economic benefit.

Owner:谢洪善 +1

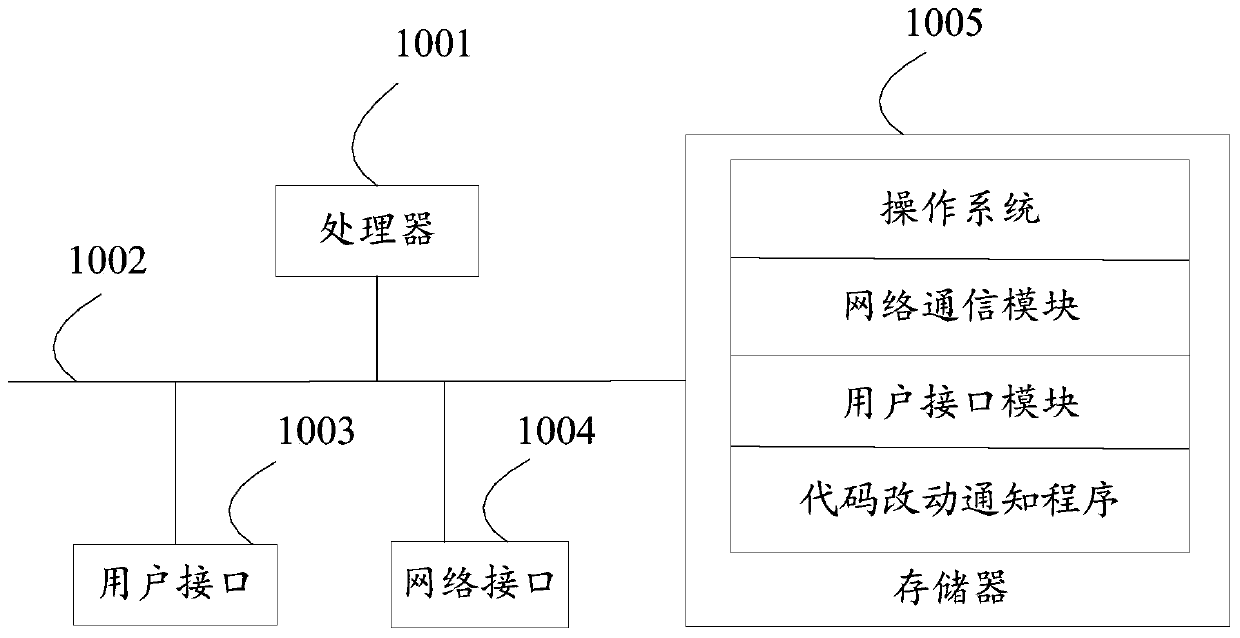

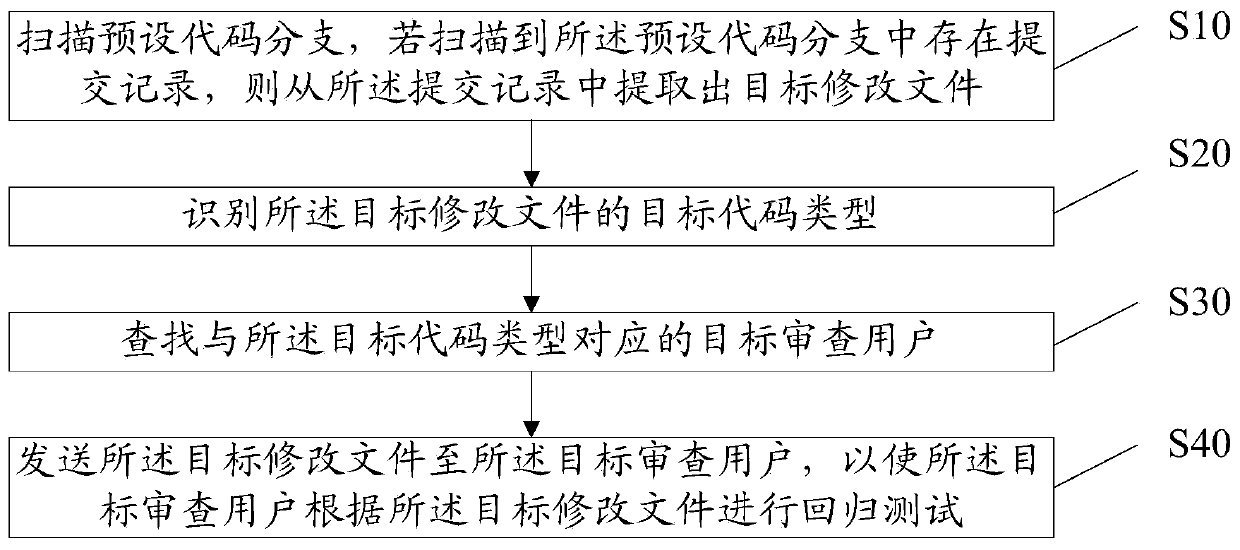

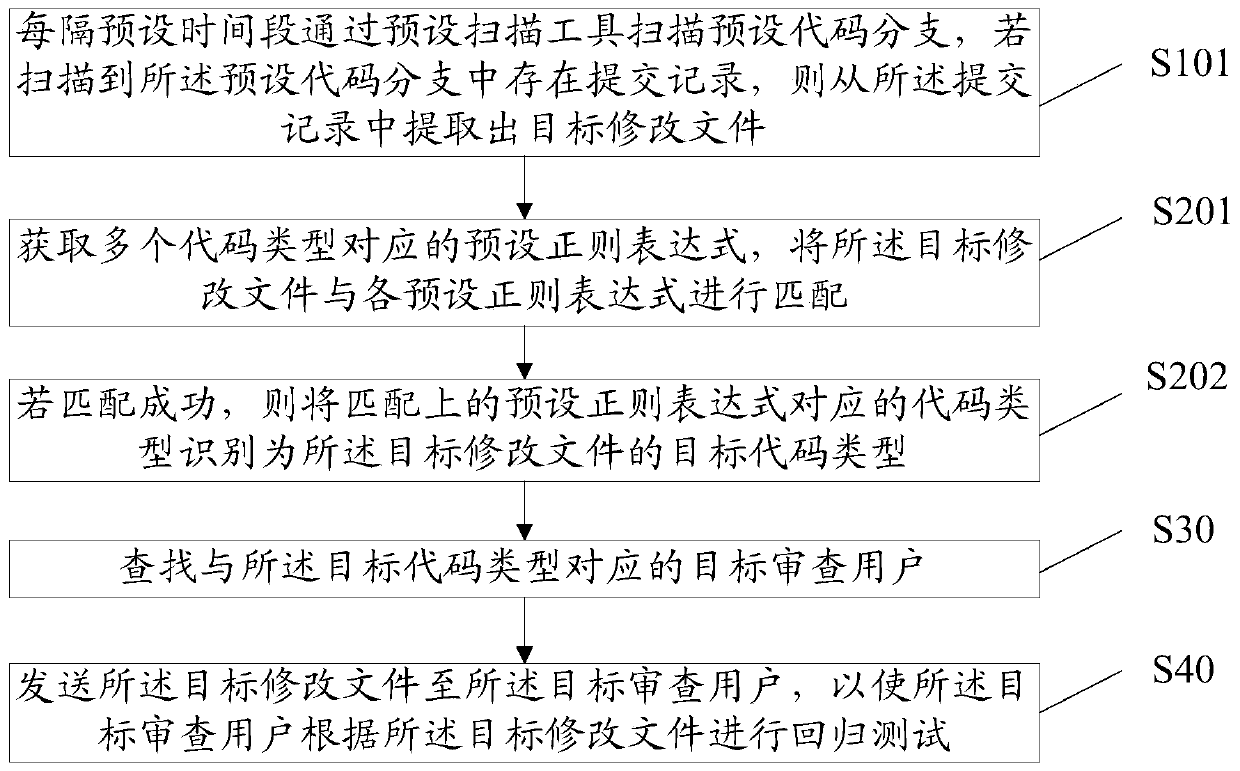

Code change notification method, equipment, storage medium and device

PendingCN109783128AAvoid missingSolve production problemsVersion controlSoftware testing/debuggingObject codeDatabase

The invention discloses a code change notification method, equipment, a storage medium and a device, and the method comprises the steps: scanning a preset code branch, and extracting a target modification file from a submission record if the submission record exists in the preset code branch through scanning; Identifying a target code type of the target modification file; Searching a target examination user corresponding to the target code type; And sending the target revision file to the target revision user, so that the target revision user performs a regression test according to the targetrevision file. by scanning the preset code branch, each code submission of a developer can be monitored, and the target revision file is sent to the target revision user, so that the target revision user performs test verification according to the target revision file, and the production problem caused by untested verification due to code change is avoided.

Owner:PINGAN PUHUI ENTERPRISE MANAGEMENT CO LTD

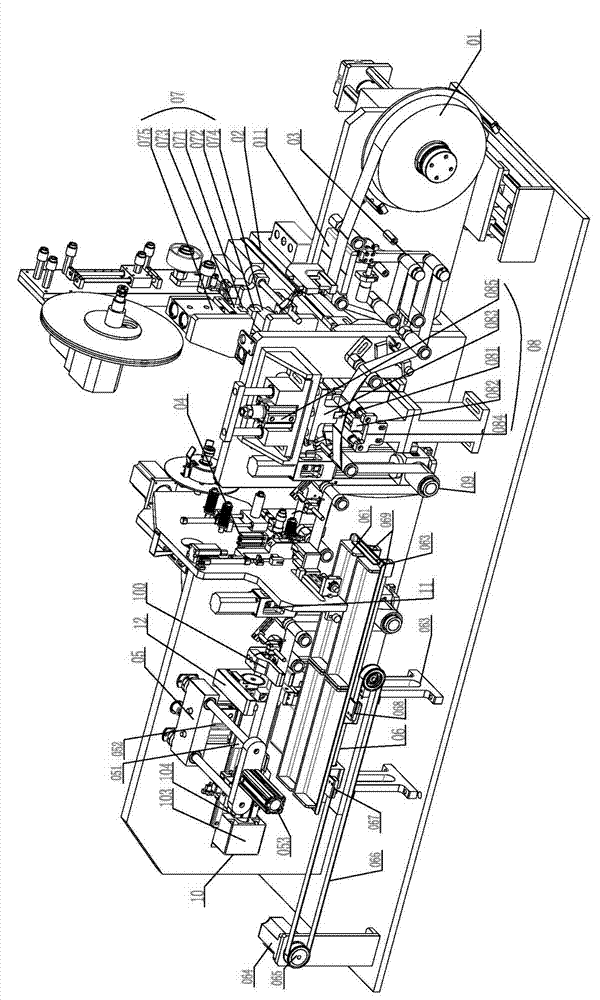

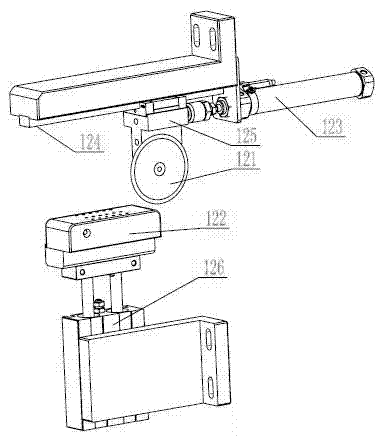

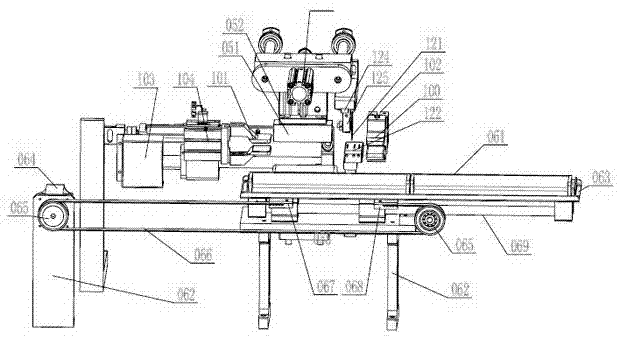

Device for electrode slice production with lithium strap and electrode slice production method

ActiveCN102738433AAvoid the problem that the lithium ribbon is easily damaged by weldingAvoid the problem of weld through damageCell electrodesCell component detailsLithiumEngineering

The invention discloses a device for electrode slice production with a lithium strap. The device includes a lithium strap conveying mechanism, a lithium strap tab adding structure, a rubberizing mechanism, a lithium strap cutting mechanism and a feeding mechanism. The lithium strap tab adding mechanism comprises a tab conveying mechanism, a tab knurling mechanism and a tab laminating mechanism. The tab conveying mechanism is used for conveying a tab to a lithium strap conveying path of the lithium strap conveying mechanism and cutting it off. The tab knurling mechanism is positioned on a tab conveying path of the tab conveying mechanism for knurling of the tab to make it have an uneven surface. The tab laminating mechanism is used for laminating the knurled tab to the lithium strap. The invention also discloses a method for electrode slice production with a lithium strap. The device and method of the invention can overcome the defects existing in traditional modes of electrode slice production with lithium straps, and improve the quality and automation level of electrode slice production with lithium straps.

Owner:SHENZHEN YINGHE TECH

Hollow near-forming forging method of large MW wind power main shaft

InactiveCN109290503AAdd depthAvoid foldingMetal-working apparatusEngine componentsElectricityPunching

The invention discloses a hollow near-forming forging method of a large MW wind power main shaft. The method is characterized by comprising the following specific steps that 1, a steel ingot is heatedto 1200-1250 DEG C, heat preservation is carried out, then chamfering is carried out, water removing and upsetting are carried out, and blanking is carried out after the steel ingot is pulled out; 2,the steel ingot subjected to the first step is heated to 1200-1250 DEG C, heat preservation is carried out, then upsetting is carried out by adopting a special anti-extrusion leakage disc, then the hole is punched downwards to a certain height through a special punching core rod, and then the special punching core rod is used for drawing to a certain size; 3, the steel ingot subjected to the second step is heated to 1200-1250 DEG C, heat preservation is carried out, then upsetting is carried out by adopting a special anti-extrusion leakage disc, then the hole is punched downwards to a certainheight through a special punching core rod, and then a flange is printed out; and 4, the steel ingot subjected to the third step is heated to 1150-1250 DEG C, heat preservation is carried out, then locally upsetting the flange through the leakage disc, and finally the flange is formed and finished to obtain a finished product. According to the method, the problem that the small-head-end inner hole is very small in wind power main shaft production is solved, the waste of raw materials in the production process is greatly reduced, and the production cost is low.

Owner:SHANDONG LAIWU JINLEI WIND POWER TECH

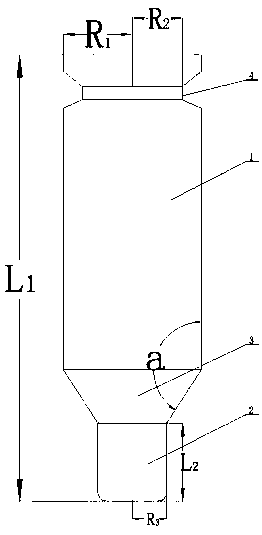

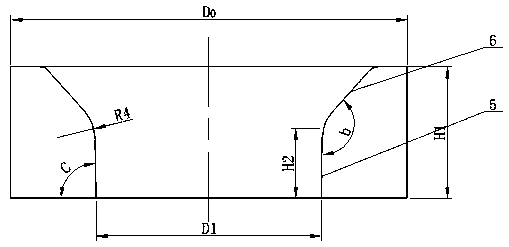

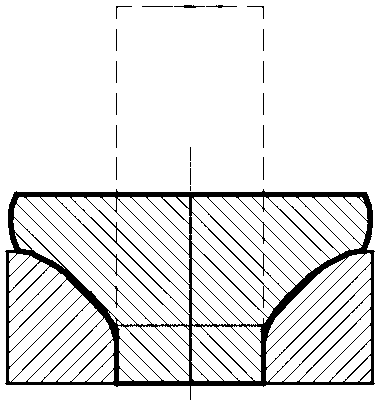

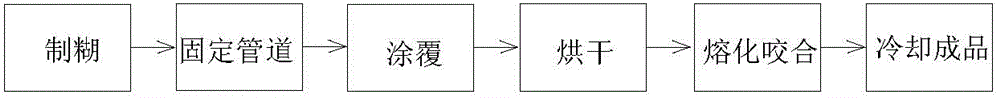

Quick manufacturing method of anti-corrosion compound pipeline

InactiveCN102978608ASolve production problemsSimple methodMetallic material coating processesHeating timeSurface layer

The invention relates to a quick manufacture method of an anti-corrosion compound pipeline. The quick manufacture method can be used for effectively solving the problem of manufacturing the anti-corrosion compound pipeline at high efficiency and low cost. The technical scheme adopted by the invention comprises the following steps of: presetting an alloyed powder body bonded with a binder at the inner wall of a metal pipeline which rotates at a high speed, adjusting the electromagnetic induction frequency by virtue of an electromagnetic induction heating method, and controlling the heating depth and the heating time, so that the alloyed powder body can not be completely fused to be slightly fused with the surface layer of the inner wall of the pipeline; enabling a heating device to move along the axis relative to the rotating pipeline, and solidifying the fused alloy and surface-layer base body metal, which depart from a heating region to produce metallurgical bonding and form an anti-corrosion alloy layer with flat and beautiful surface and high bonding strength, so that an anti-corrosion compound pipeline can be manufactured. The manufacturing method comprises the following steps of: preparing water glass and alloy powder paste; fixing the pipeline to be machined onto a power head; coating the alloy powder paste; drying; biting in a fusing way; and cooling to obtain the anti-corrosion compound pipeline. The quick manufacturing method is simple, easy to operate, high in production efficiency, good in product quality, and long in service life.

Owner:山西焦煤爱钢装备再制造股份有限公司 +1

Method for producing stalk biological granulated forage

InactiveCN1785033AReduce total usageSolve production problemsFood processingAnimal feeding stuffBiotechnologyYeast

A granular biologic feed for domestic animals and fowls features that the lignin and cellulose in straw and stalk are decomposed into saccharide, fat and lactic acid. Its preparing process includes such steps as pulverizing straw and stalk, mixing it with wheat bran, corn flour, bean dregs, fish powder and salt, proportionally adding yeast, bacteria and actinomycess, fermenting, and granulating.

Owner:曹明军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com