Patents

Literature

349results about How to "Liquid level stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

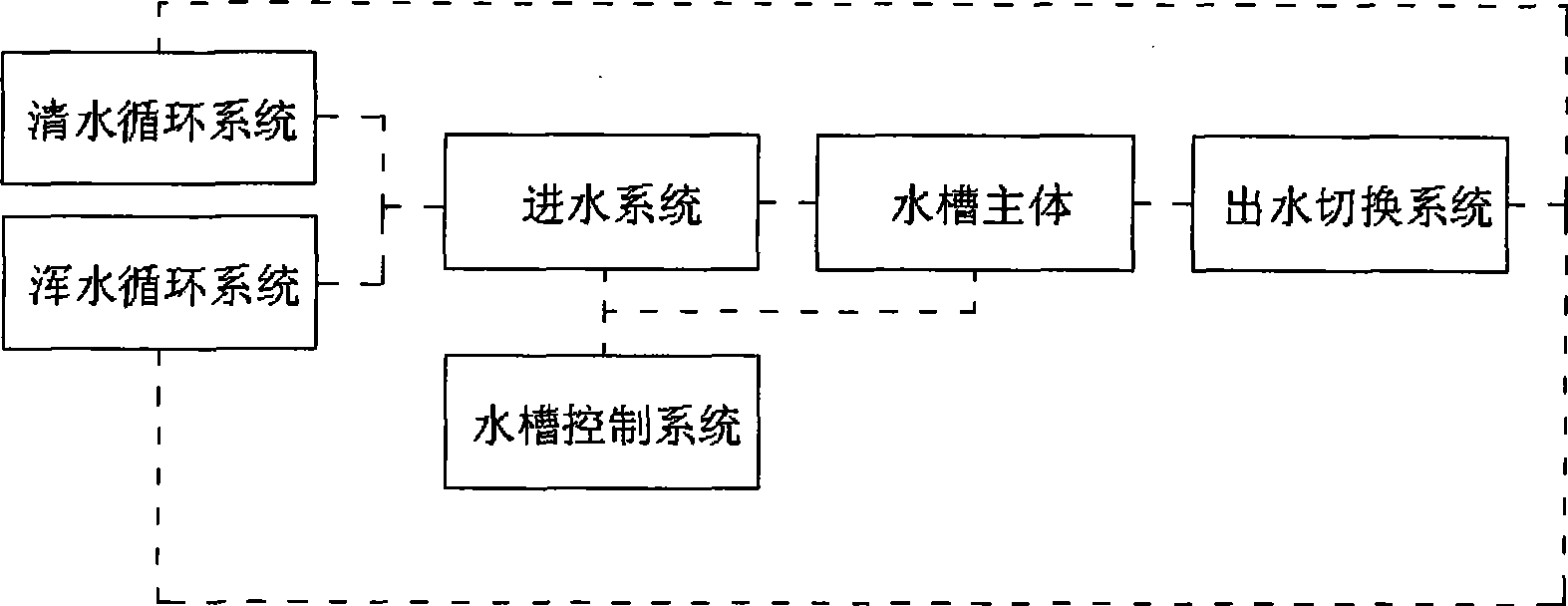

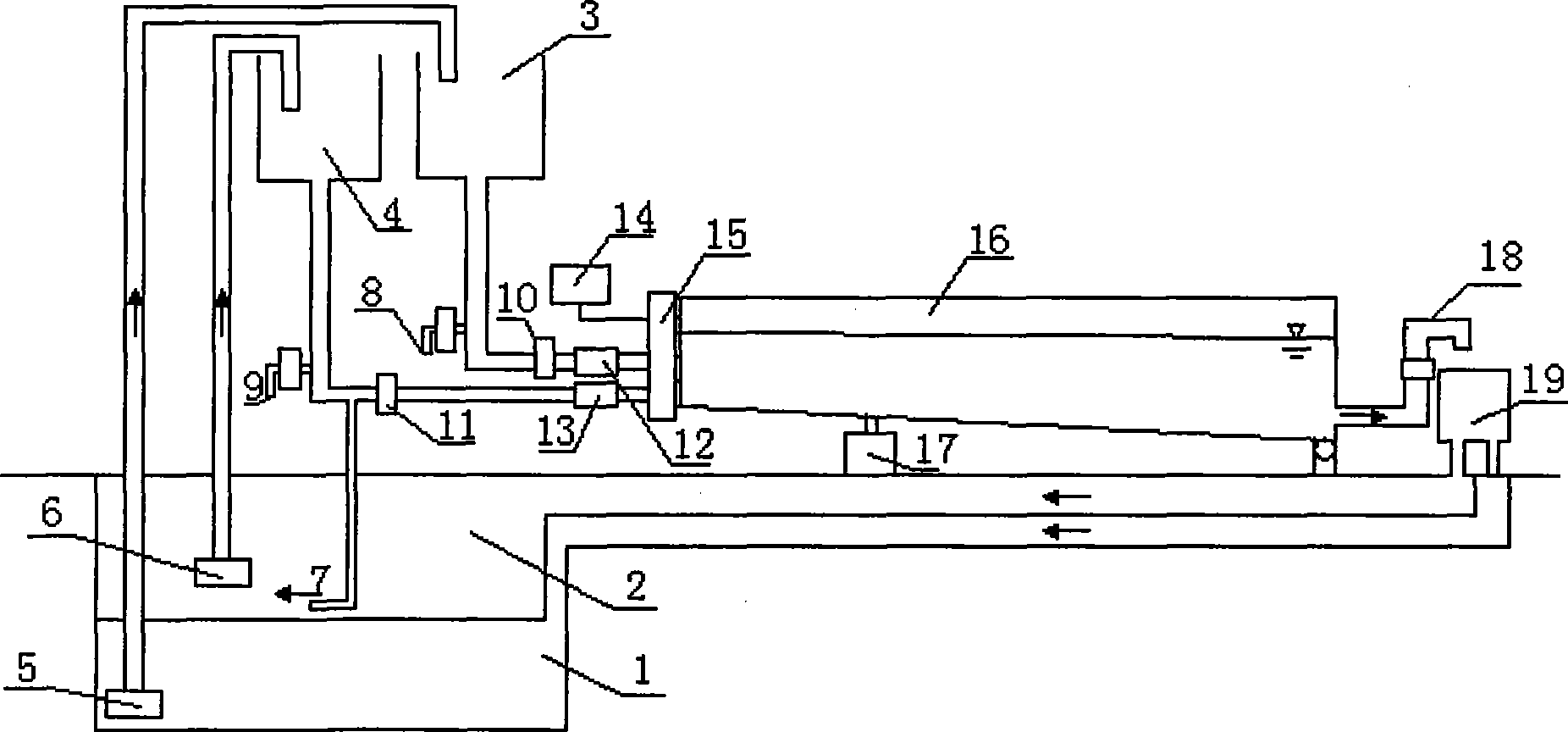

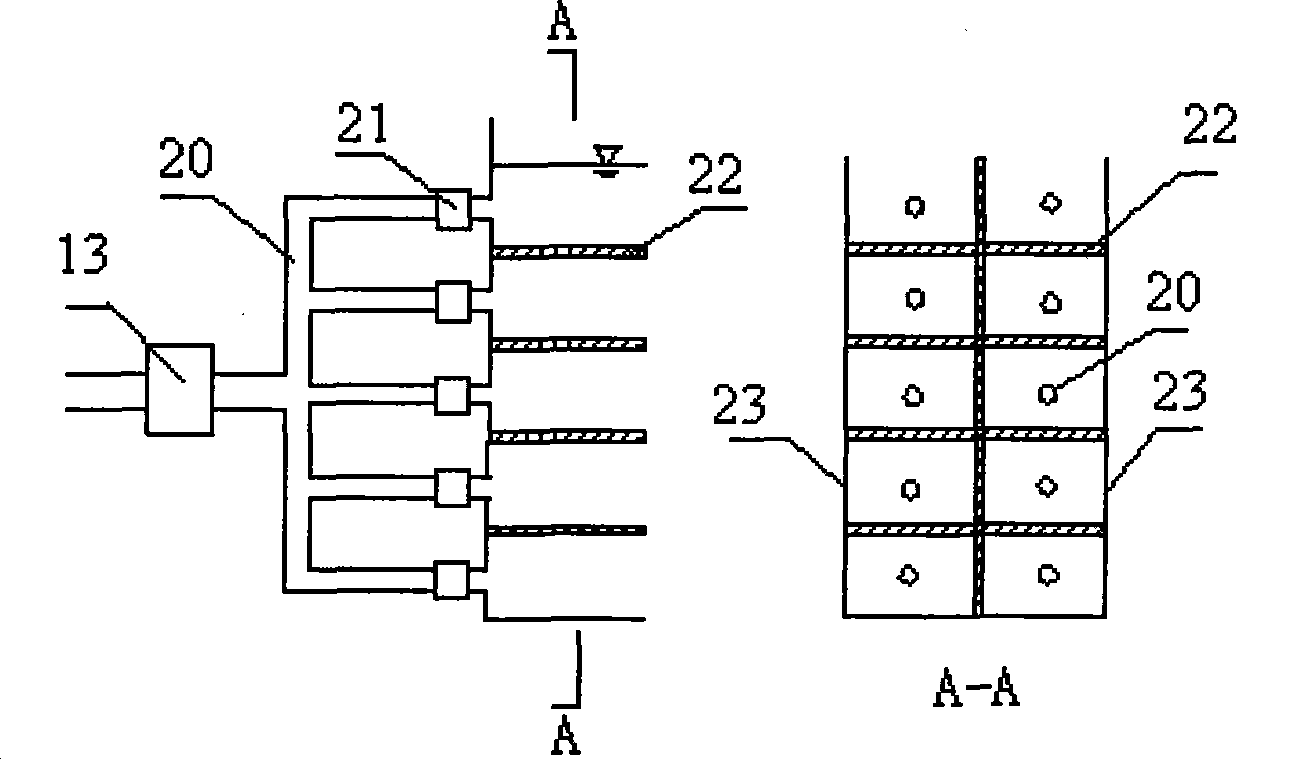

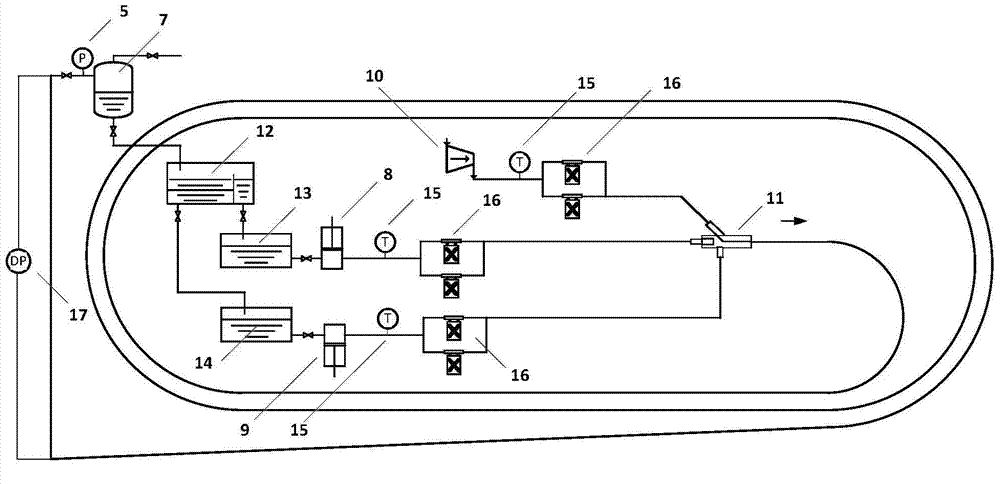

Polyphase fluid experimental tank system

InactiveCN101424587AFlow field stabilityEasy to observeHydrodynamic testingControl systemEngineering

The invention relates to a multiphase flow test flume system which comprises a main body, a clear water circulating system, a muddy water circulating system, a water inlet system, a control system and a water outlet switching system, wherein a support and a jack are arranged at the bottom of the main body and are fixed on the ground by supporting hinges for adjusting the width and the gradient of a flume, and the water inlet system comprises a sampling discharge outlet, a manual valve, a flowmeter and an electromagnetic valve and is connected with the top end of the main body; the control system is arranged at one side of the top end of the main body for controlling all switches, and the water outlet switching system is arranged at one outer side end of a water outlet of the main body and is connected with a clear underground water pool in the clear water circulating system and a muddy underground water pool in the muddy water circulating system. Due to the clear water circulating system and the muddy water circulating system which are independent, the invention reduces test water consumption and test cost and conveniently recycles and treats polluted water samples, and a clear water / muddy water switching device of a water outlet system is easily designed and conveniently operated so as to effectively solve the switching problem among different circulating systems.

Owner:SICHUAN UNIV

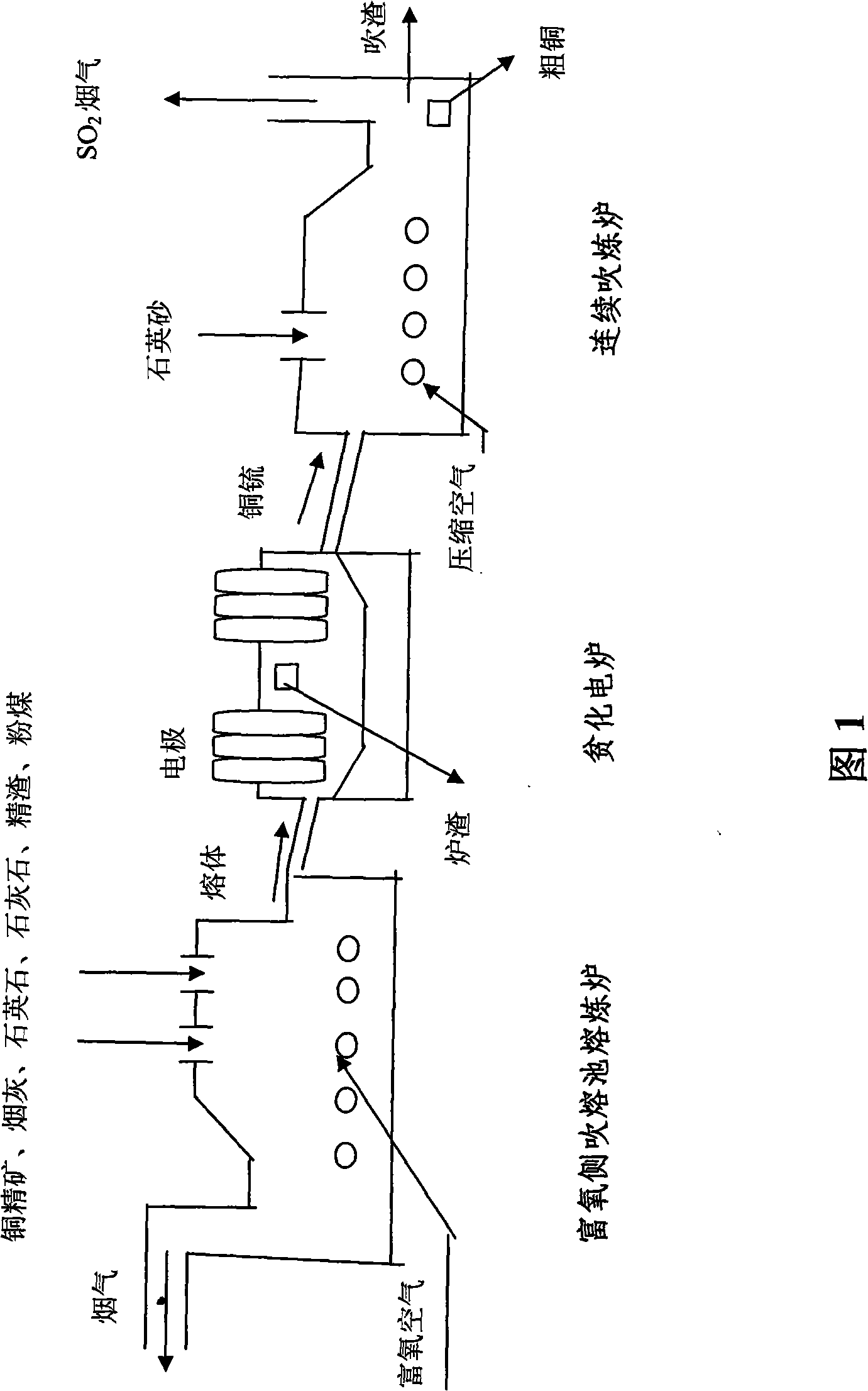

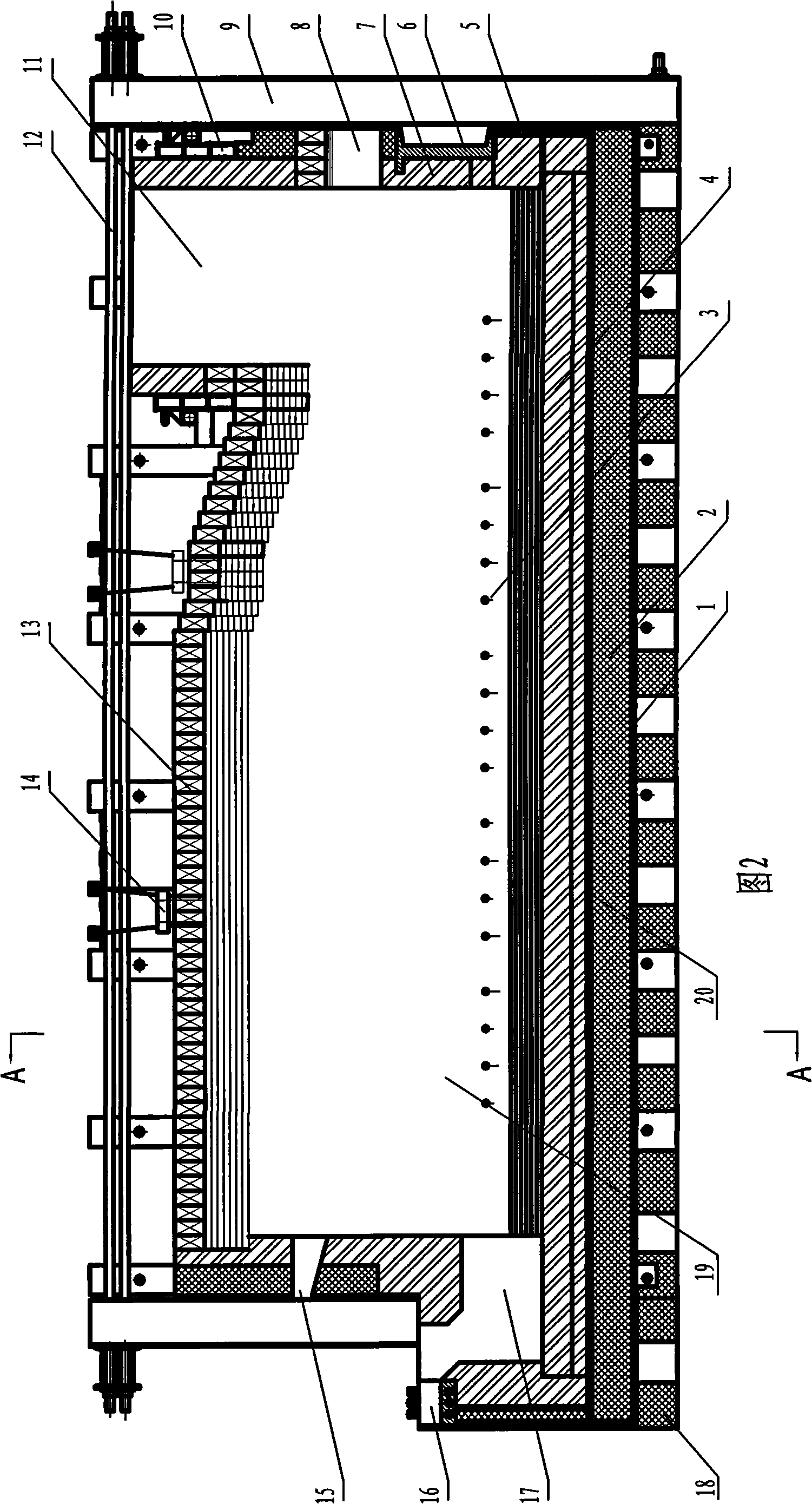

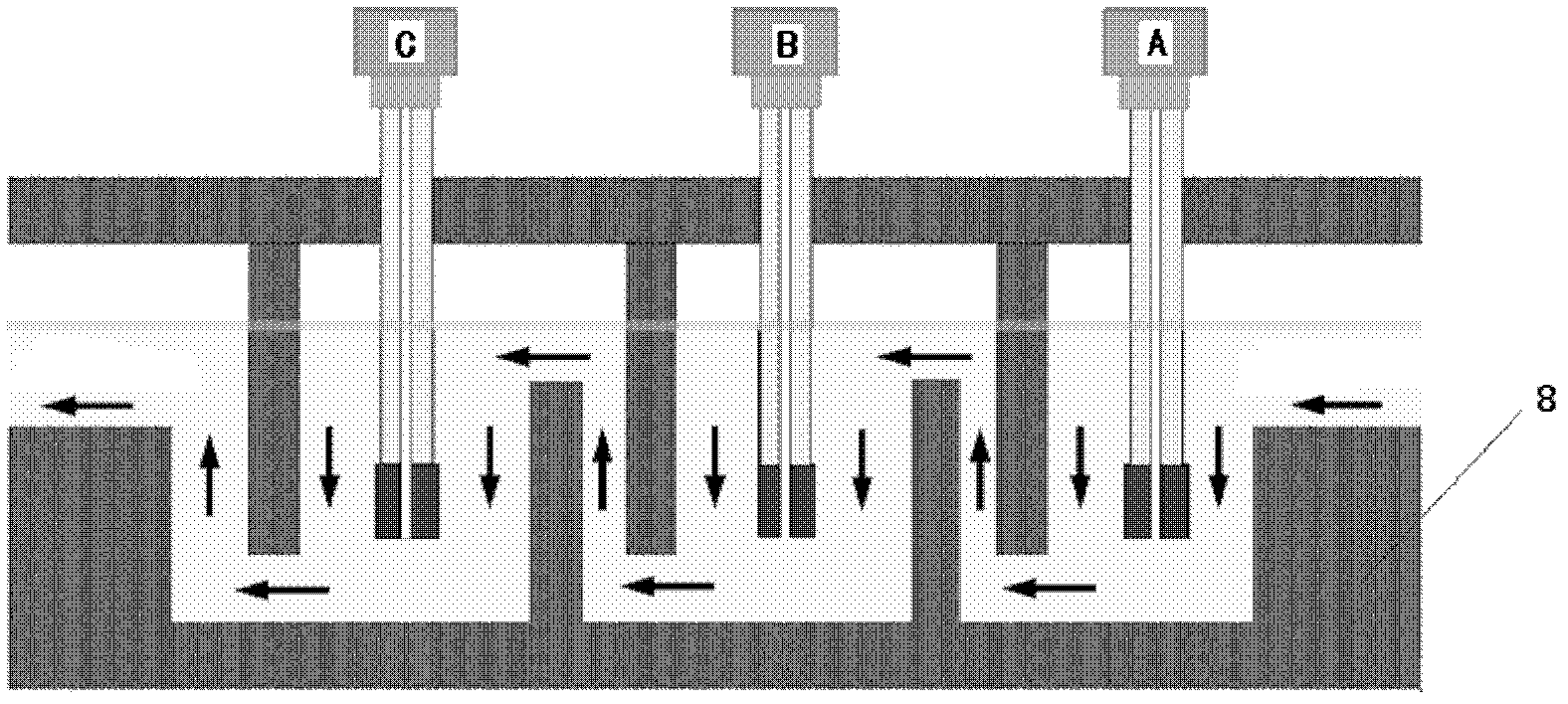

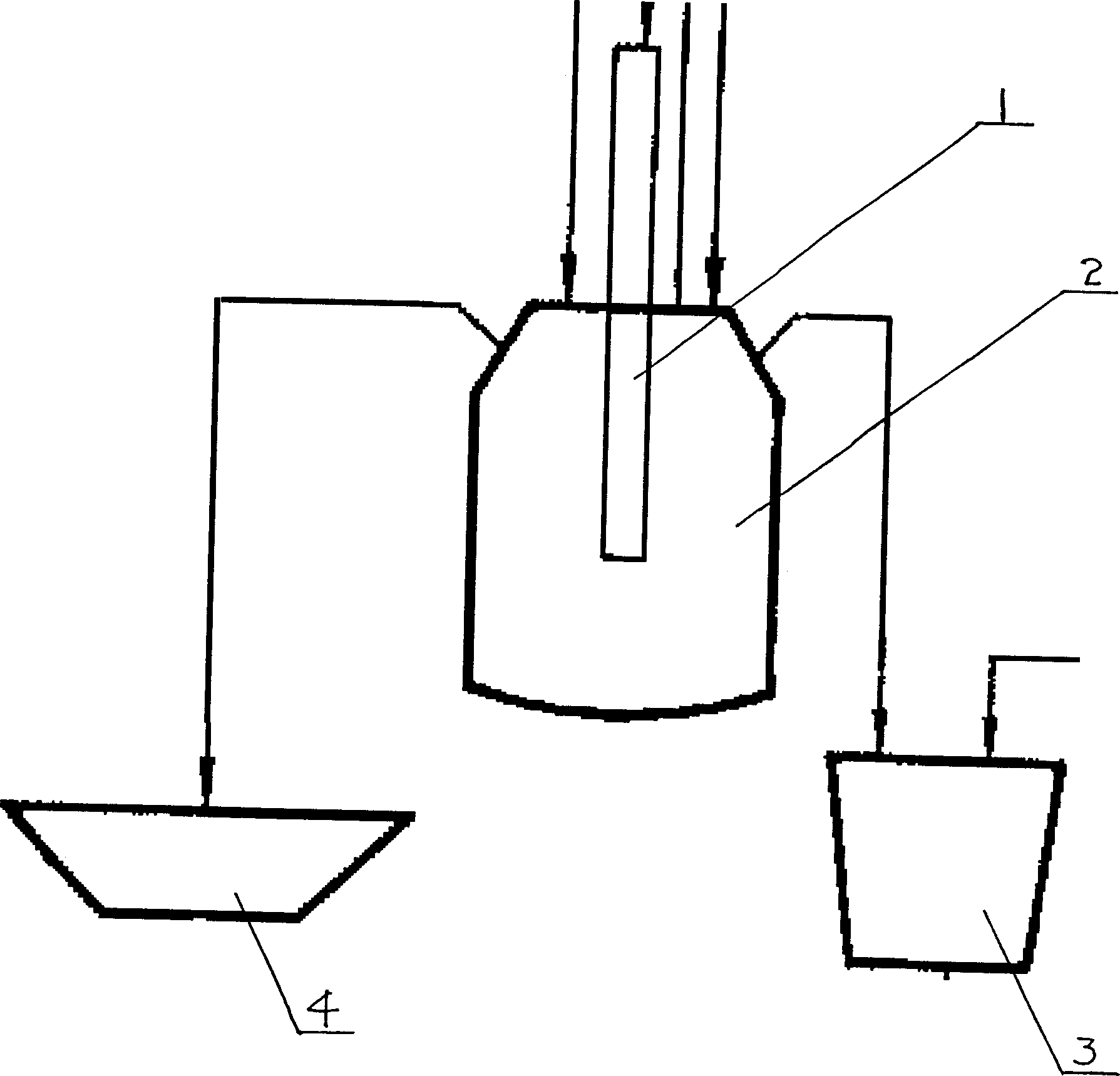

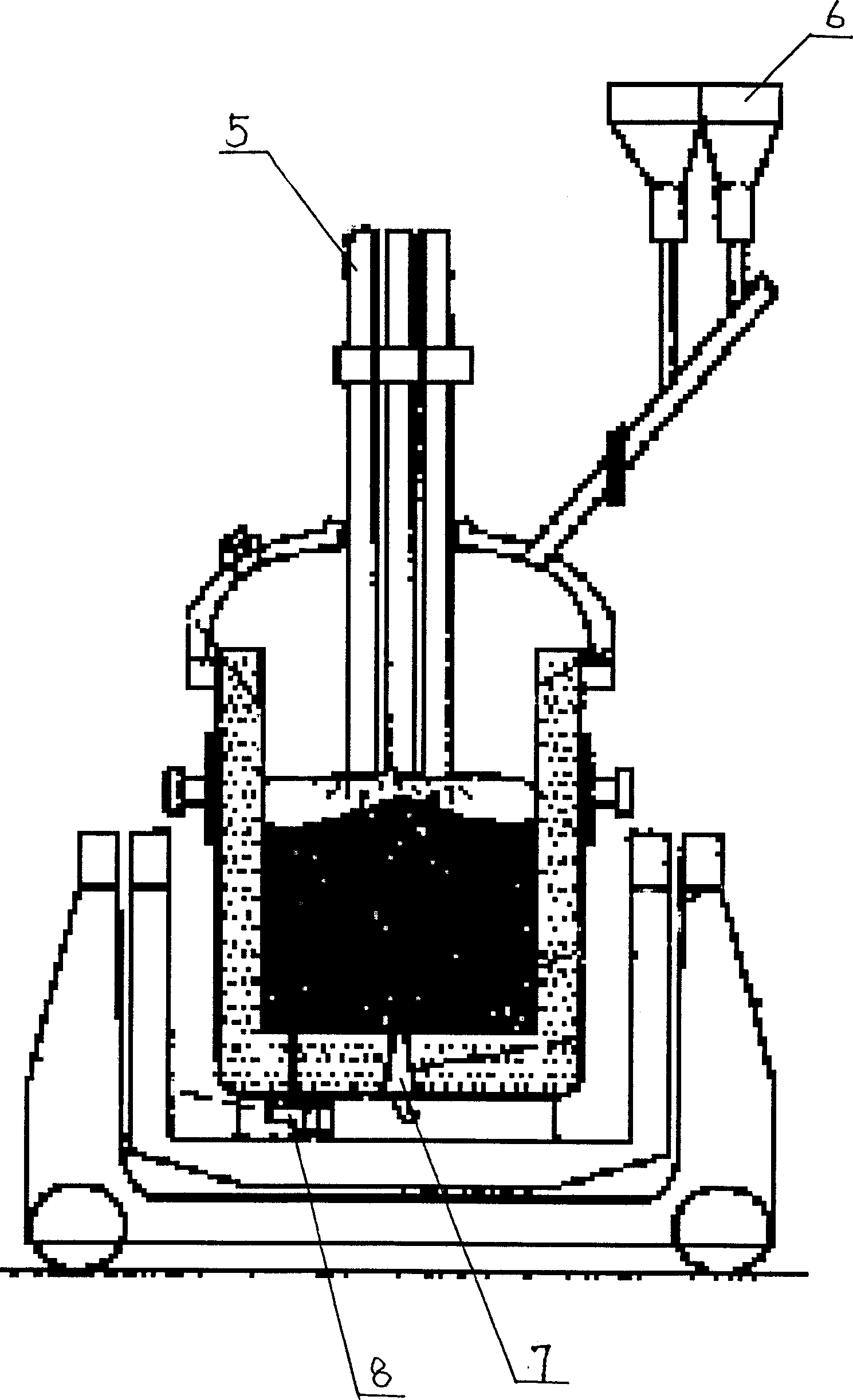

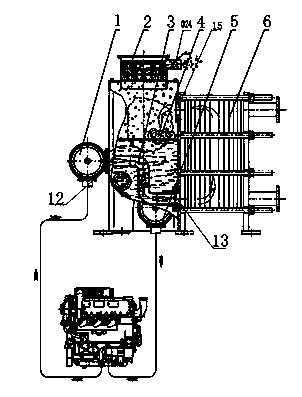

Manufacturing technique for oxygen-enriched side blowing molten pool raw copper smelting and special equipment thereof

InactiveCN101275185ALess investmentReduce energy consumptionRotary drum furnacesCrucible furnacesMelting tankHigh pressure oxygen

The invention disclose a production process for melting blister copper in a bath by side-blowing of oxygen enrichment and special apparatuses thereof, the process comprises the steps of melting concentrate of copper, diluting the slug and air refining copper matte, which is to say, adding the material comprising copper, quartz, limestone and fine coal into the furnace of bath and blowing the high pressure oxygen enrichment air into the furnace, the formed copper matte, slug are ceaselessly flowed into a diluting electric furnace, manufacturing acid after recycling waste heat by smoke gas at high temperature; overheating the slug through an electrode and separating the slug from copper matte to obtain the diluted slug and copper matte which is fed into the continuously-air-refining furnace through a chute slipway; reacting the copper matte with arenaceous quartz under the effect of compressed air to obtain the blister copper, performing mineral dressing to the air-refined slug, manufacturing the acid with SO<2>; the invention has less process investment, high heat utilization rate, low energy consumption, good effect of environmental protection, compact apparatus structure, small occupied area, great processing ability, light sticking in air flue, simple operations, diverse measures in adjusting the condition of furnace which is easy to control, high level of mechanization and low labor intensity.

Owner:YANTAI PENGHUI COPPER IND

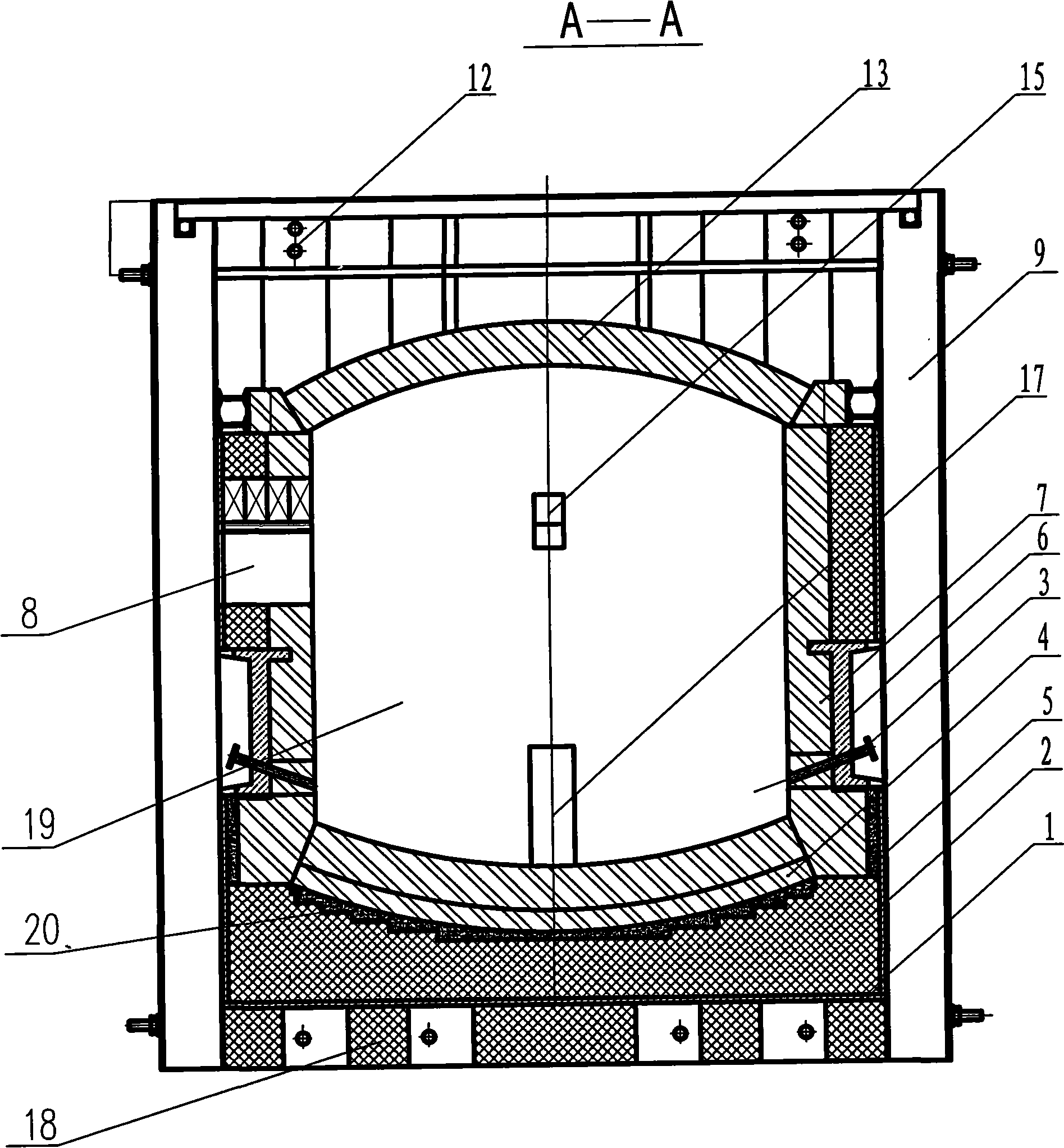

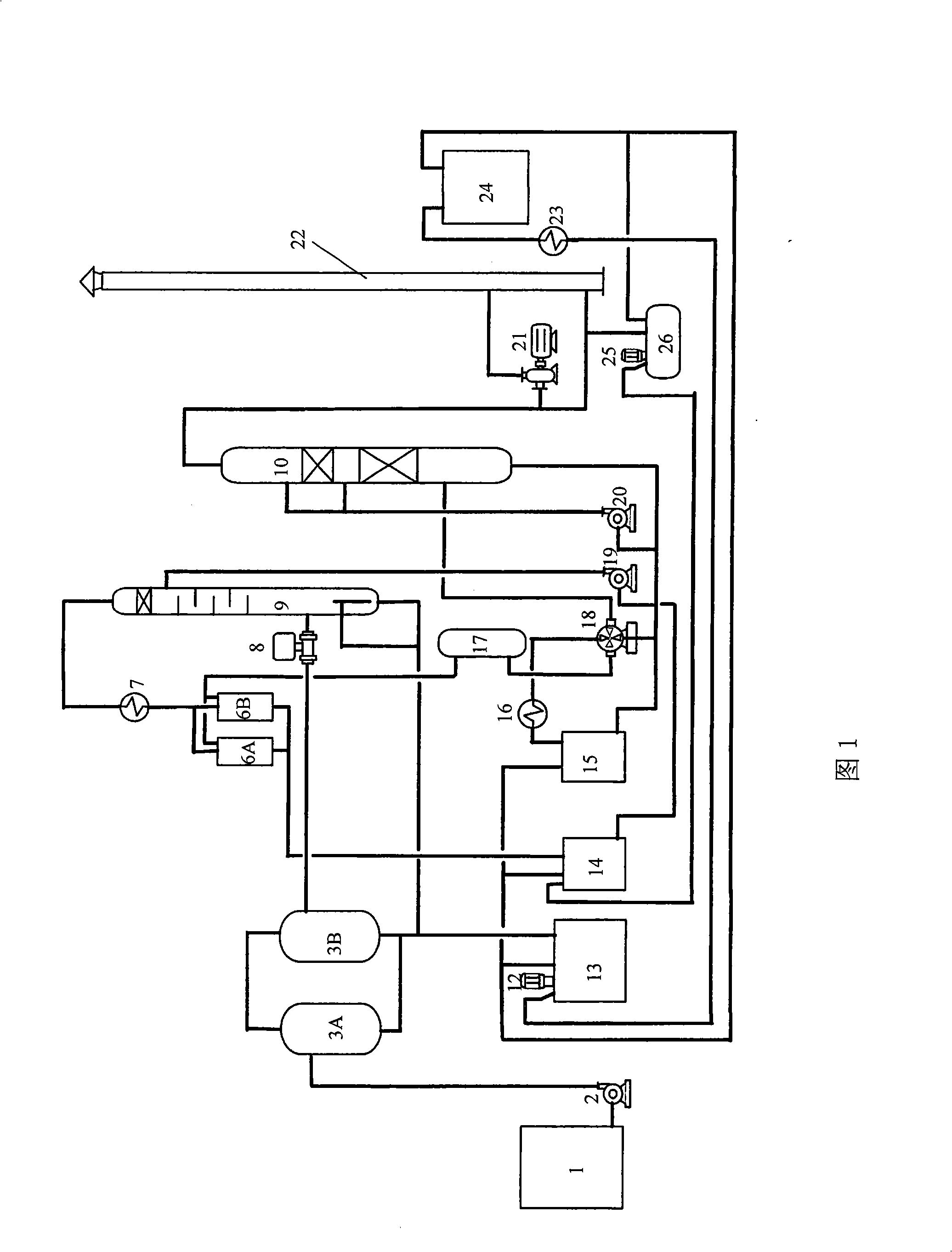

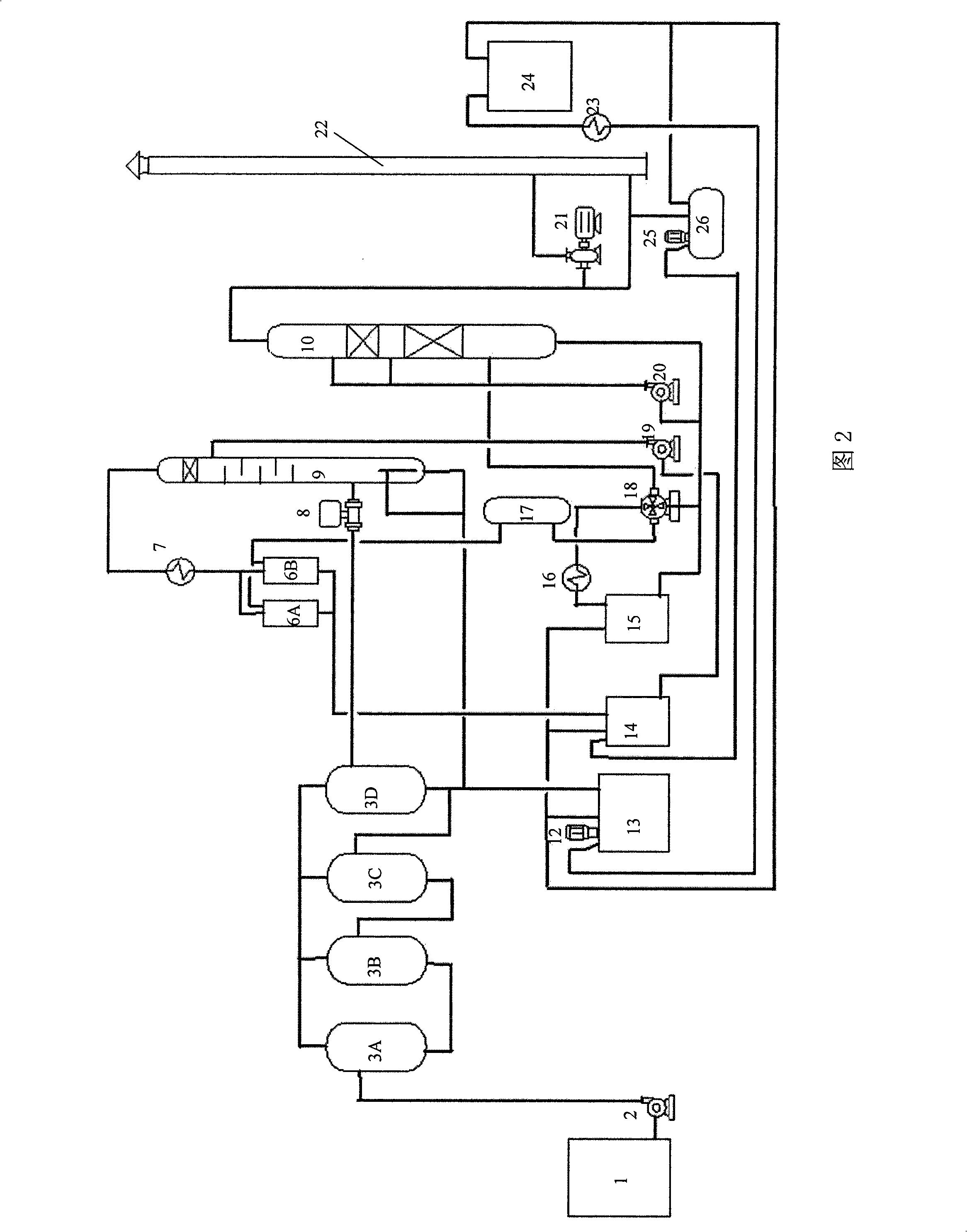

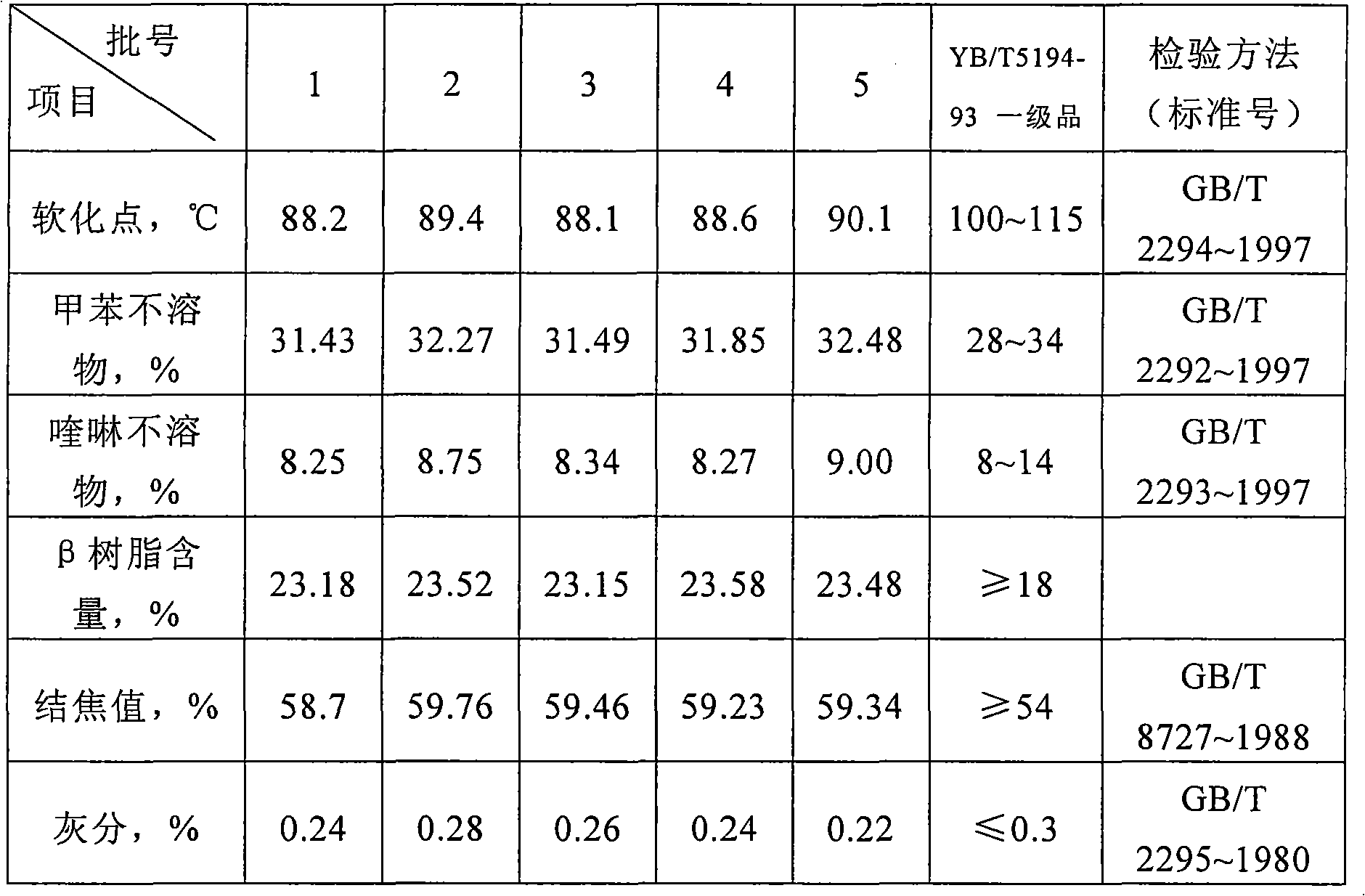

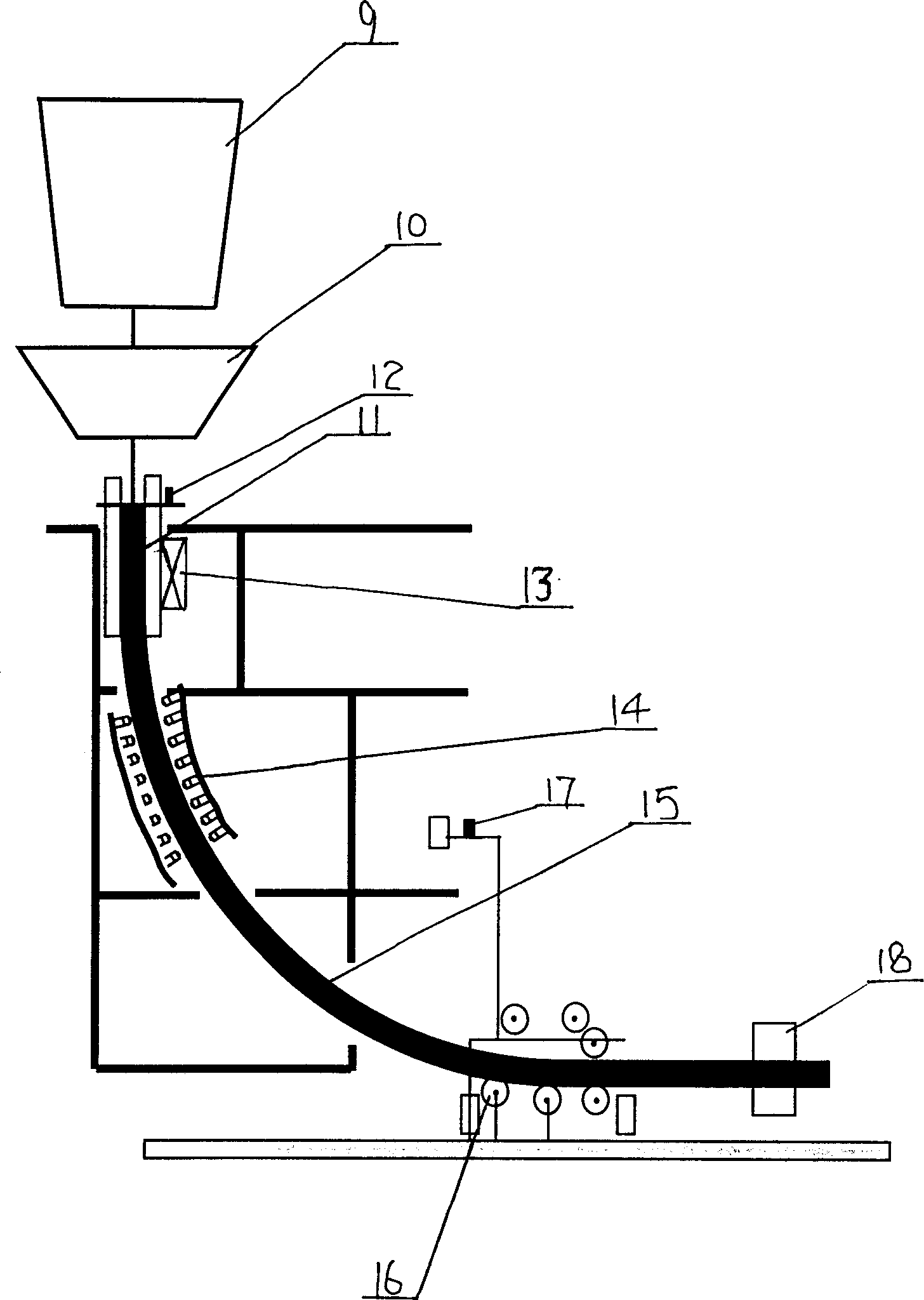

Process for producing moderate temperature modified bitumen by continuously pressurizing and hot-polymerizing at two stages connected in series

ActiveCN101289624AIncrease flexibilityLow equipment requirementsWorking-up pitch/asphalt/bitumen by chemical meansQuinolineEngineering

The invention relates to a method for manufacturing high-quality intermediate temperature modified pitch through two-section serial continuous pressurizing hot polymerization. The method comprises the following steps that: mid-temperature pitch is made into modified pitch by a two-section serial reaction kettle through low-pressure heating polycondensation; heating precracking reaction is carried out during a first section, while heating polycondensation reaction is carried out quickly during a second section so as to increase the content of toluene insoluble and reduce the content of quinoline insoluble, thereby increasing a beta value; the reacted material is fed in a flash tower, and the softening point of the modified pitch is adjusted inside the flash tower; and the tail gas of a flash system is fed in a flue gas absorption system to be absorbed by circular wash oil, and then is discharged through a chimney. The method can manufacture intermediate temperature modified pitch which meets special requirements and has a lower softening point (80 to 90 DEG C), a controllable softening point amplitude of between 1 DEG C below zero and 1 DEG C and higher beta resin content (more than 18 percent), thereby providing a high-quality raw material for making an ultra-high power graphite electrode.

Owner:山西宏特煤化工有限公司

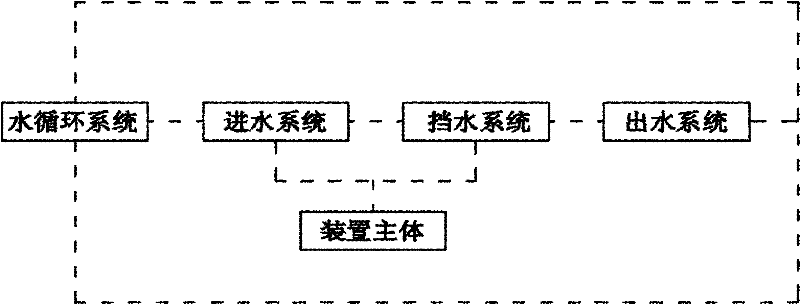

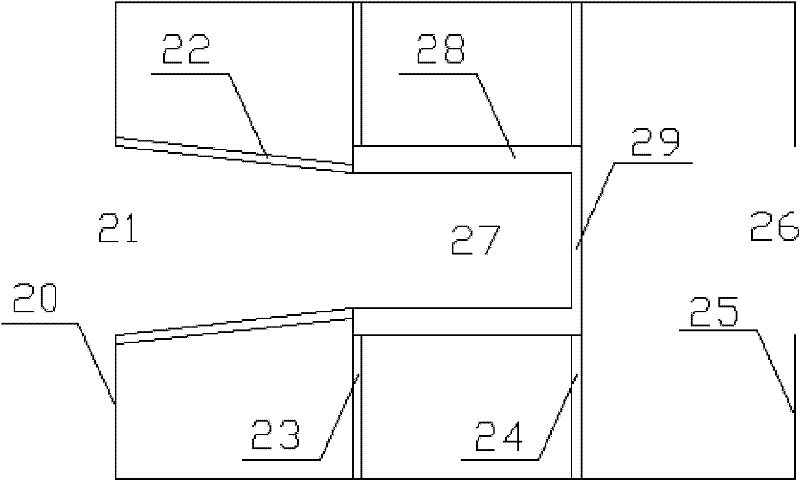

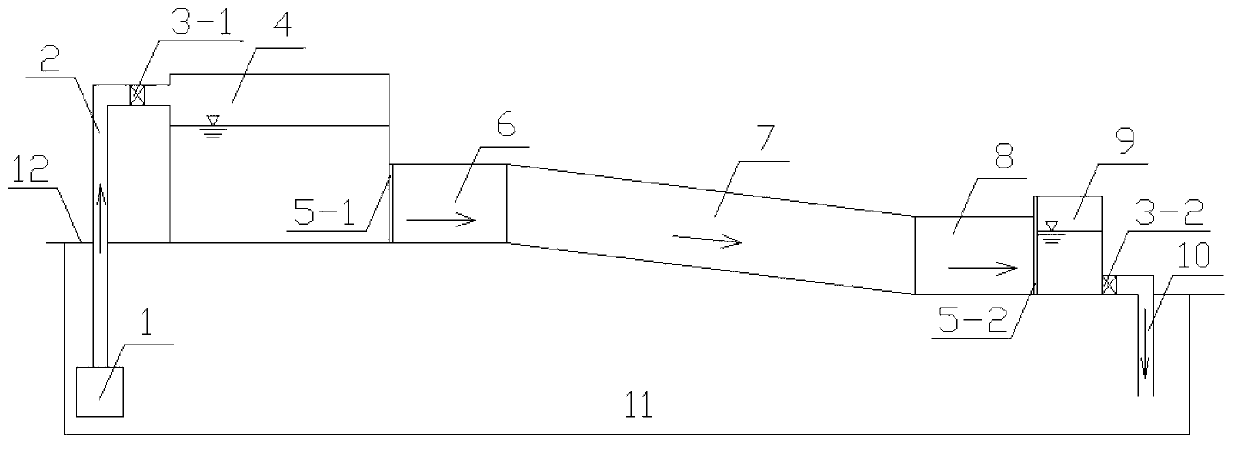

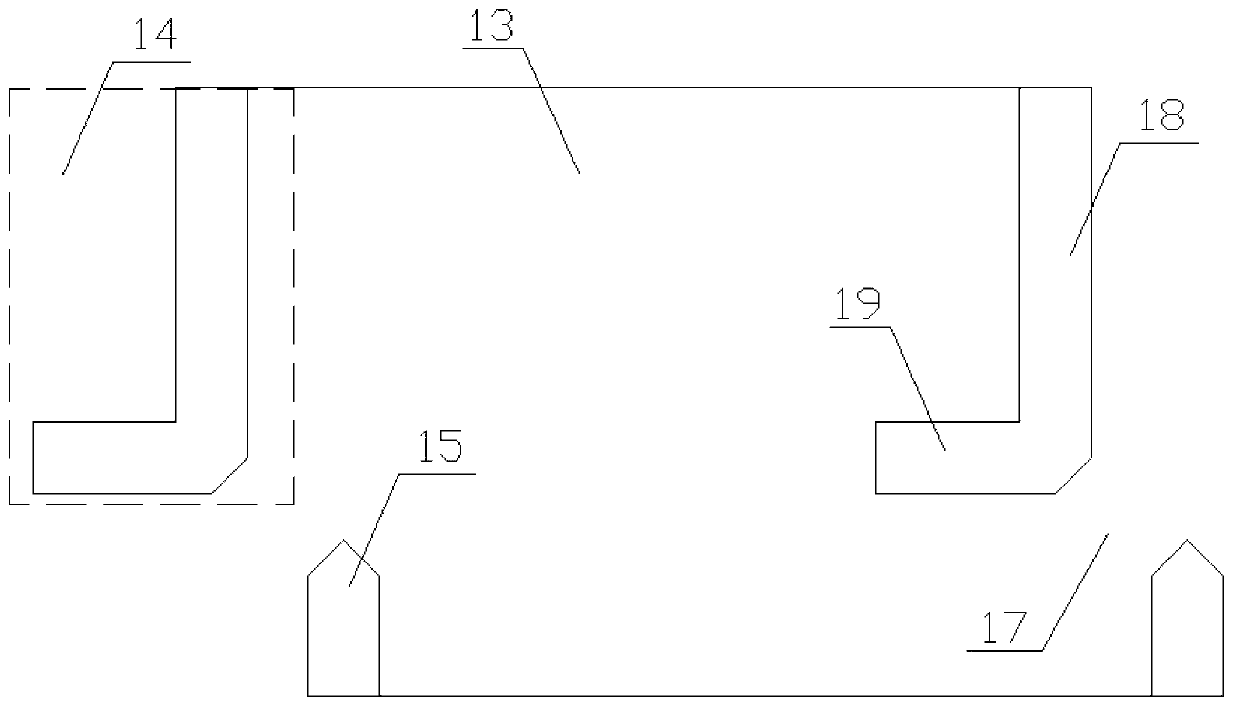

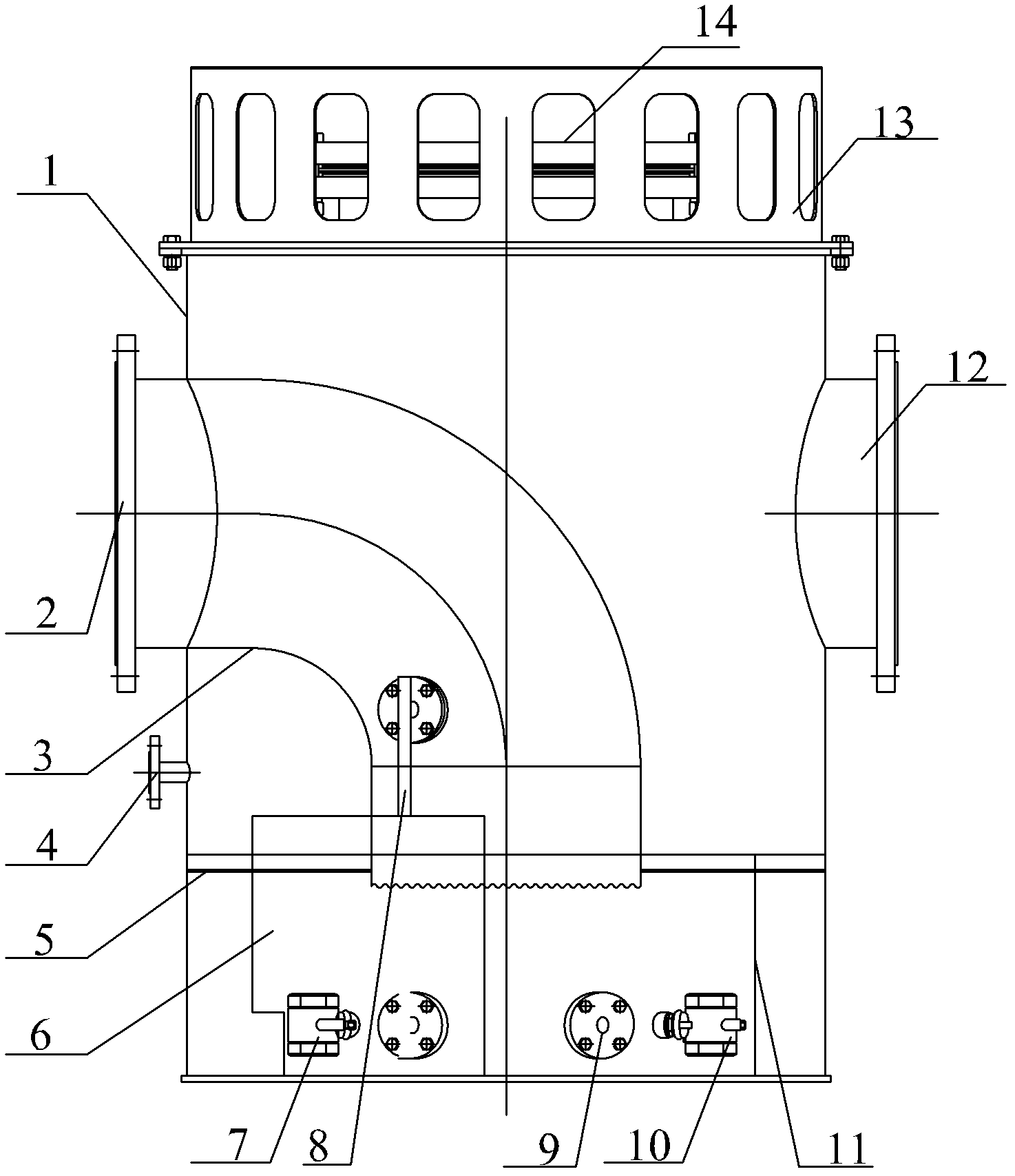

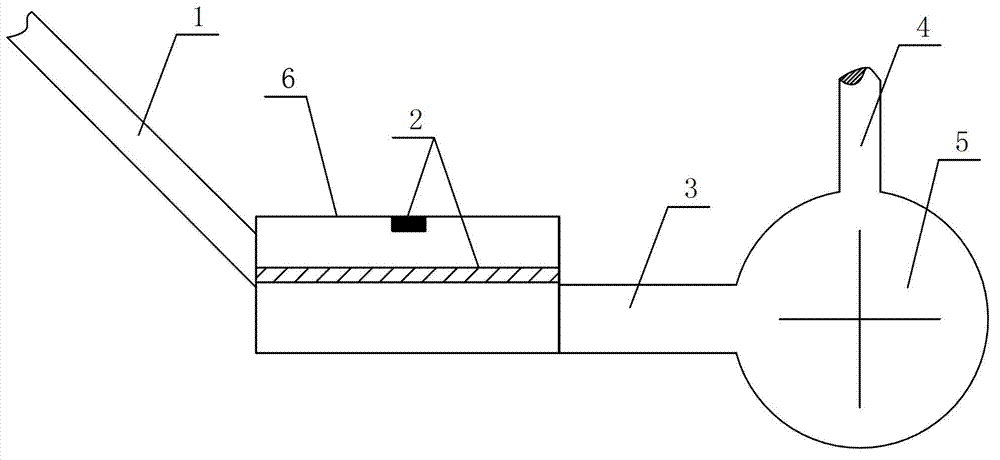

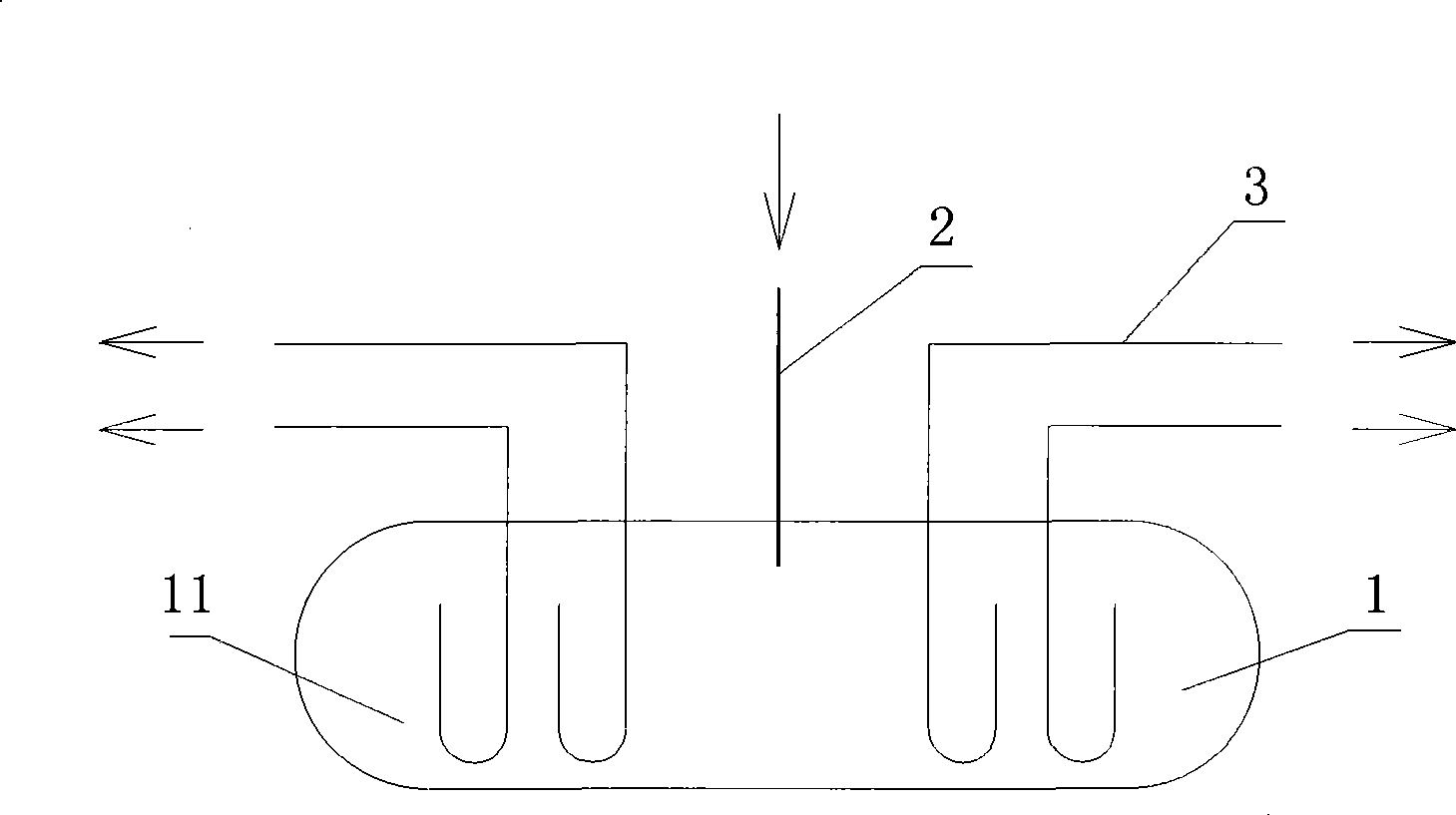

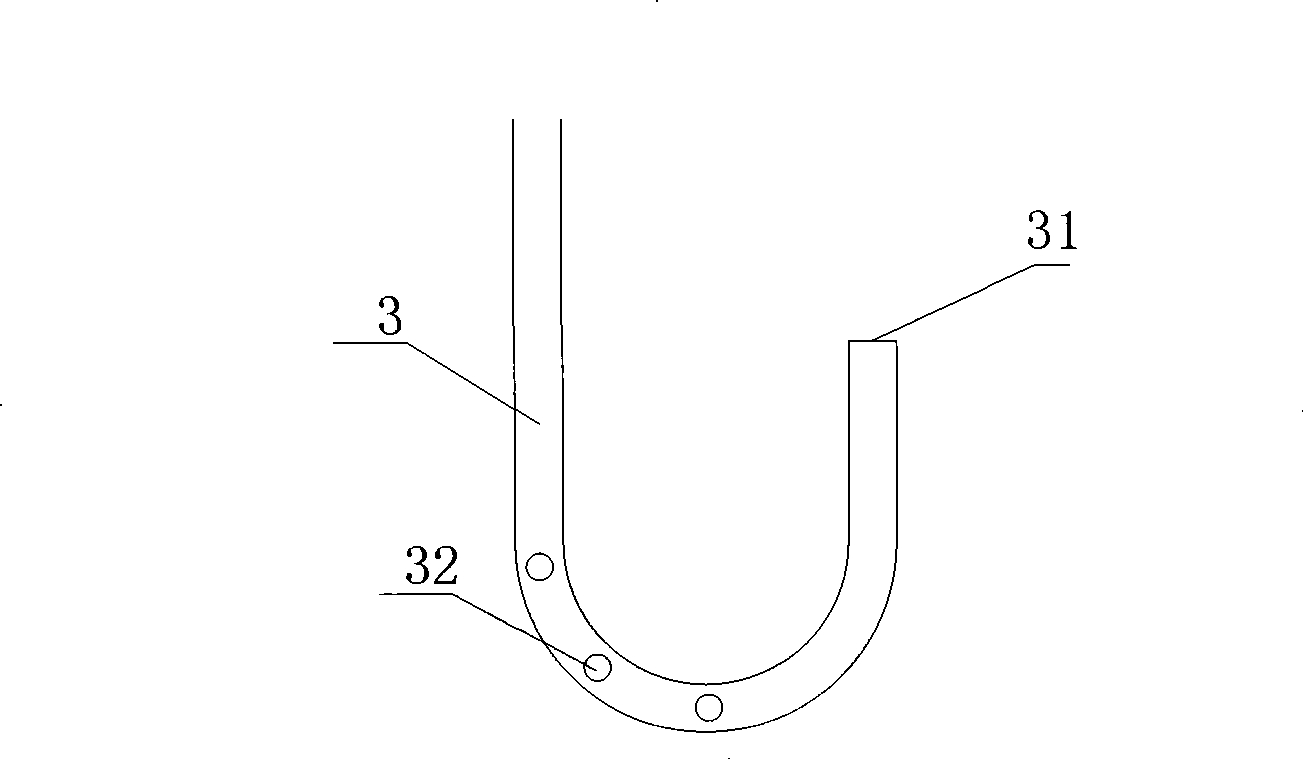

Slit type fishway experimental device with stages of falling sills and grooves

InactiveCN102176295AImprove applicabilityHigh degree of regulation automationHydrodynamic testingEducational modelsWater volumeThree stage

The invention relates to a slit type fishway experimental device with a plurality of stages of falling sills and grooves. The device mainly comprises a water inlet system connected with a water circulation system, a water retaining system connected with the water inlet system, and a water outlet system connected with the water retaining system. A water flow flows into the water inlet system through a ground water tank of the water circulation system, flows into a water tank of the water retaining system through a water flow buffer tank in the water inlet system, flows from a tail pond in the water inlet system into an underground pond through the water tank, and flows back into the ground water tank of the water circulation system through a draft tube.The water flow of the ground water tank is controlled by an upstream manual control valve, and the water flow of the tail pond is controlled by a downstream manual control valve. The device provided by the invention adopts the water circulation system, can recycle experimental water and reduces an experimental water volume and cost; three stages of falling sills are in fit with grooves so as to relatively more equally distribute energy dissipation to each energy dissipation part, improve the energy dissipation efficiency and reduce the degree of disorder of the water flow; and in a controllable range of the water flow, the flow rate and flow regime of the water flow are relatively closer to natural conditions, so a fish putting experiment meets actual conditions.

Owner:SICHUAN UNIV

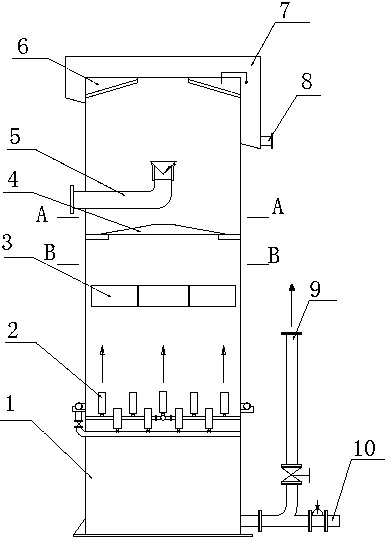

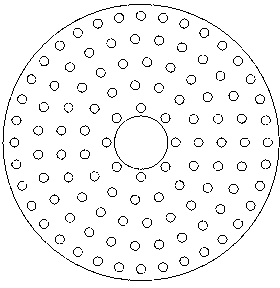

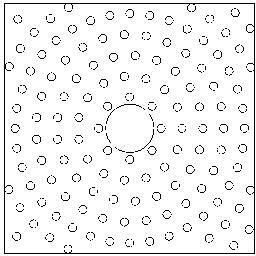

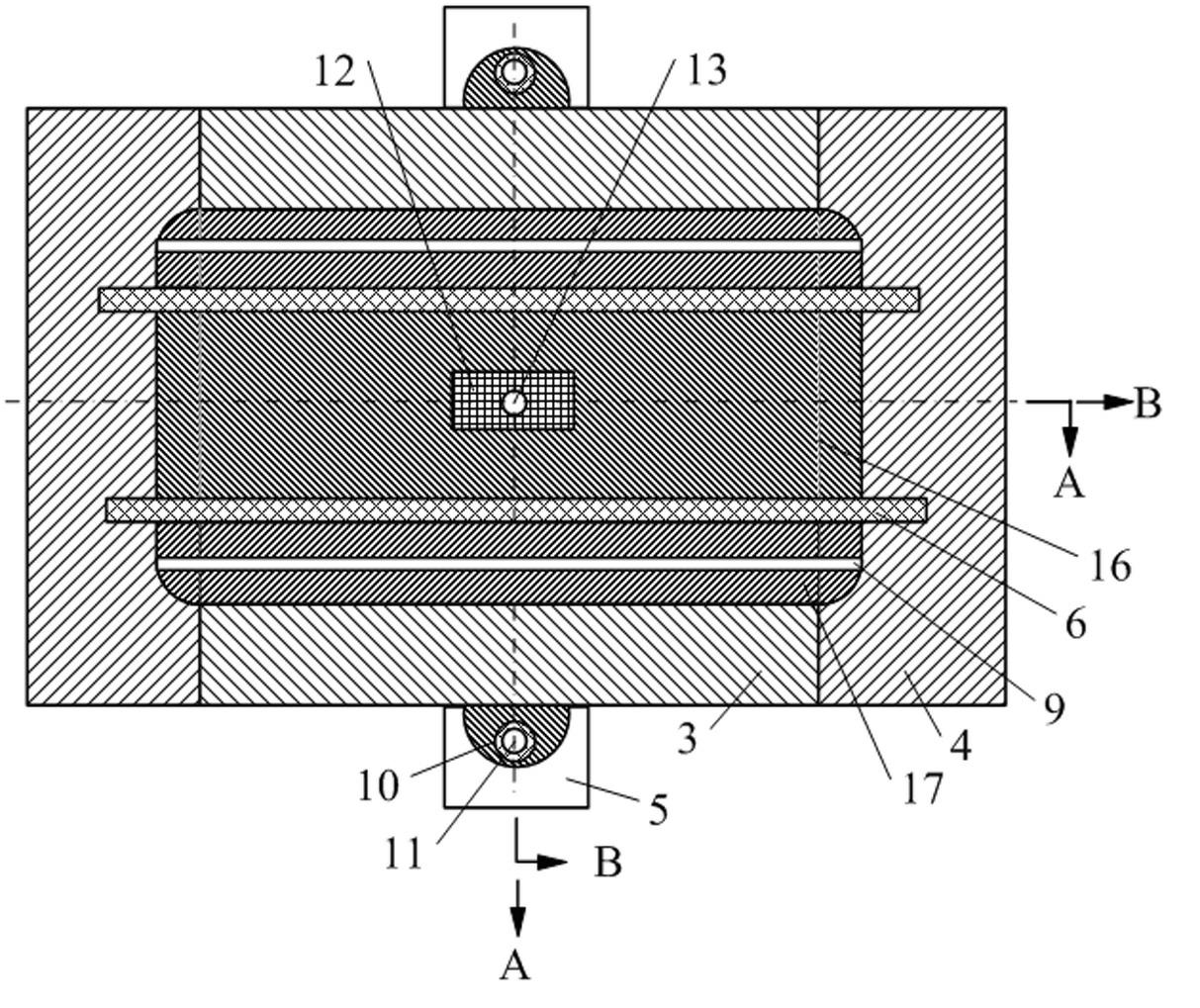

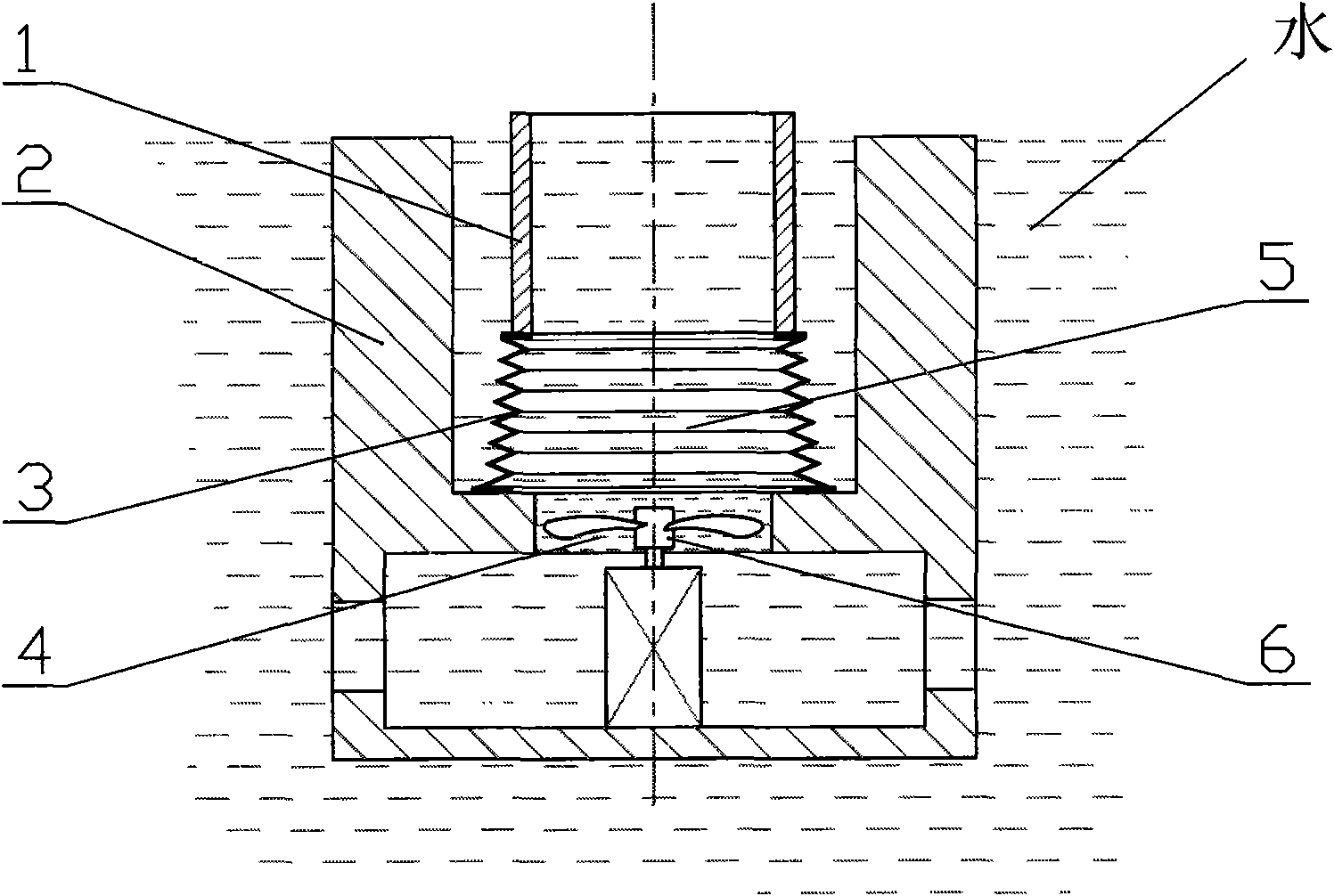

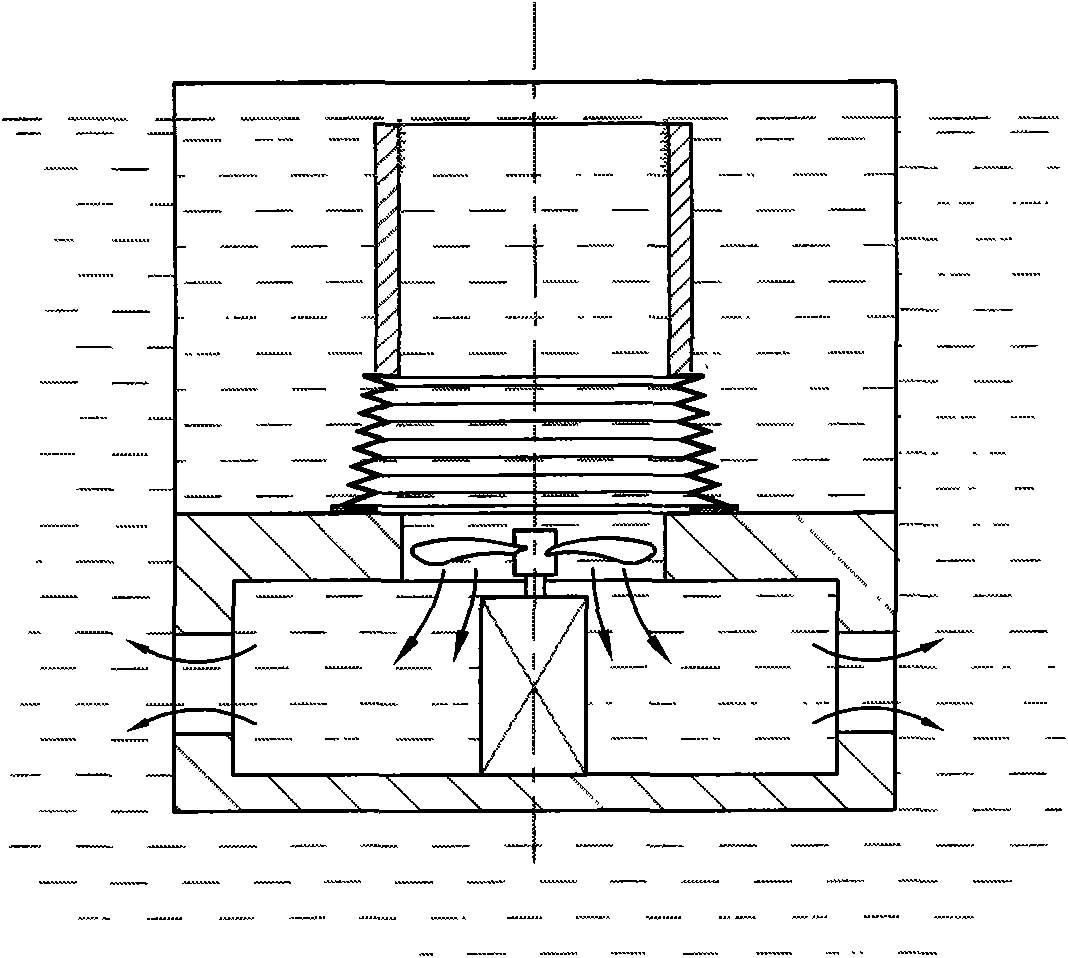

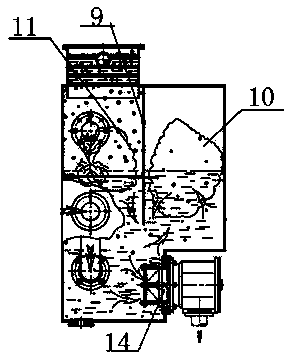

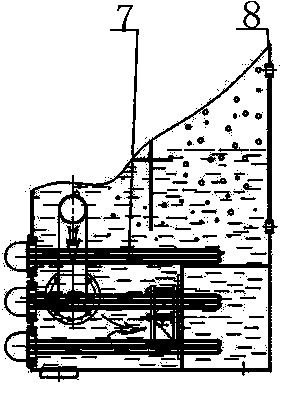

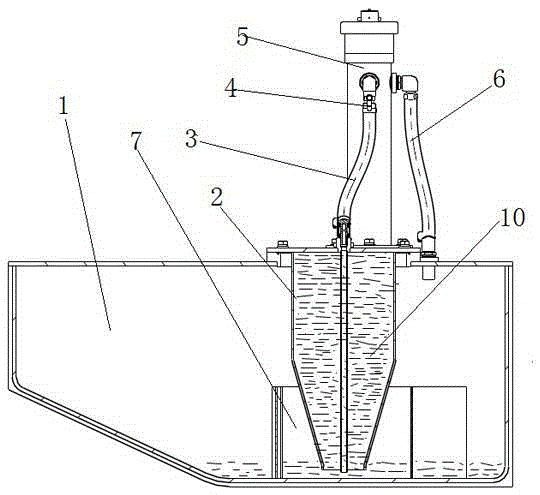

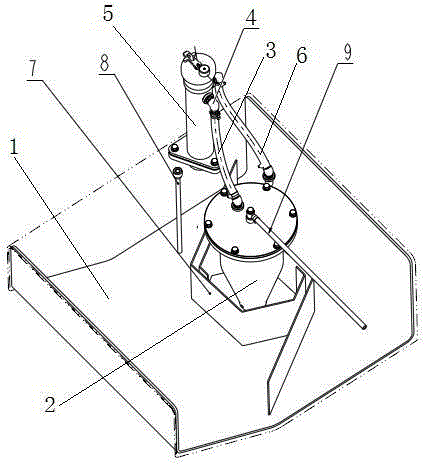

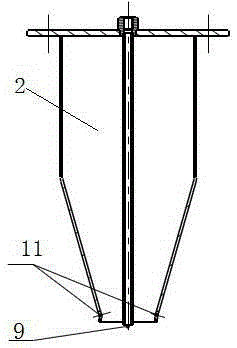

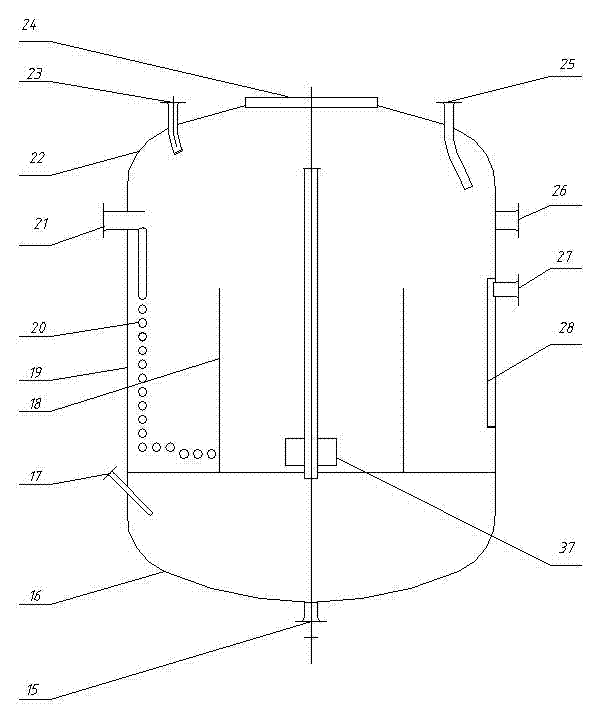

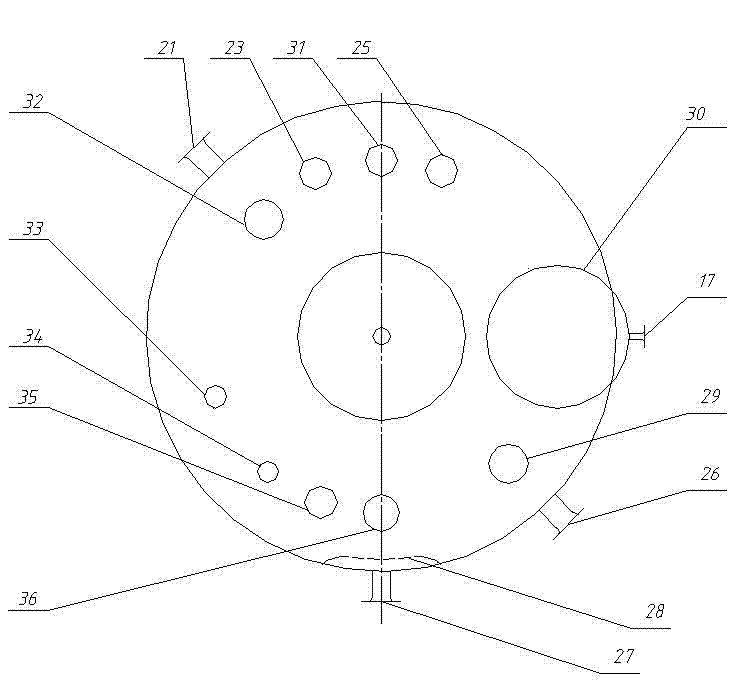

Short flotation column for selecting gold

The invention discloses a short flotation column for selecting gold. The short flotation column comprises a flotation column body (1) with a hollow structure; a foam tank (6), a foam overflow groove (7), an overflow pipe (8) and a feeding device (5) are arranged on the upper part of the flotation column body (1); the lower part of an inner cavity of the flotation column body is provided with a foaming device (2); the bottom of the flotation column body is provided with a blow-down pipe (10) and a tailing discharge device (9); and a steady flow plate (3) and an ore pulp dispersion cover (4) are respectively arranged on the upper part of the inner cavity of the flotation column body. The flotation column is shortened, and the steady flow plate of a well and the ore pulp dispersion cover are added, thereby guaranteeing the stability of a liquid level, and being beneficial to improving the treatment capacity and beneficiation indexes of the flotation column.

Owner:洛阳昶威机械制造安装有限公司

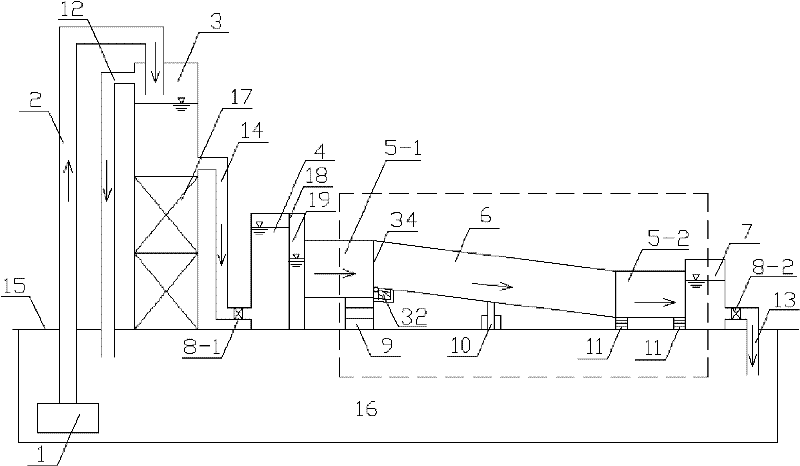

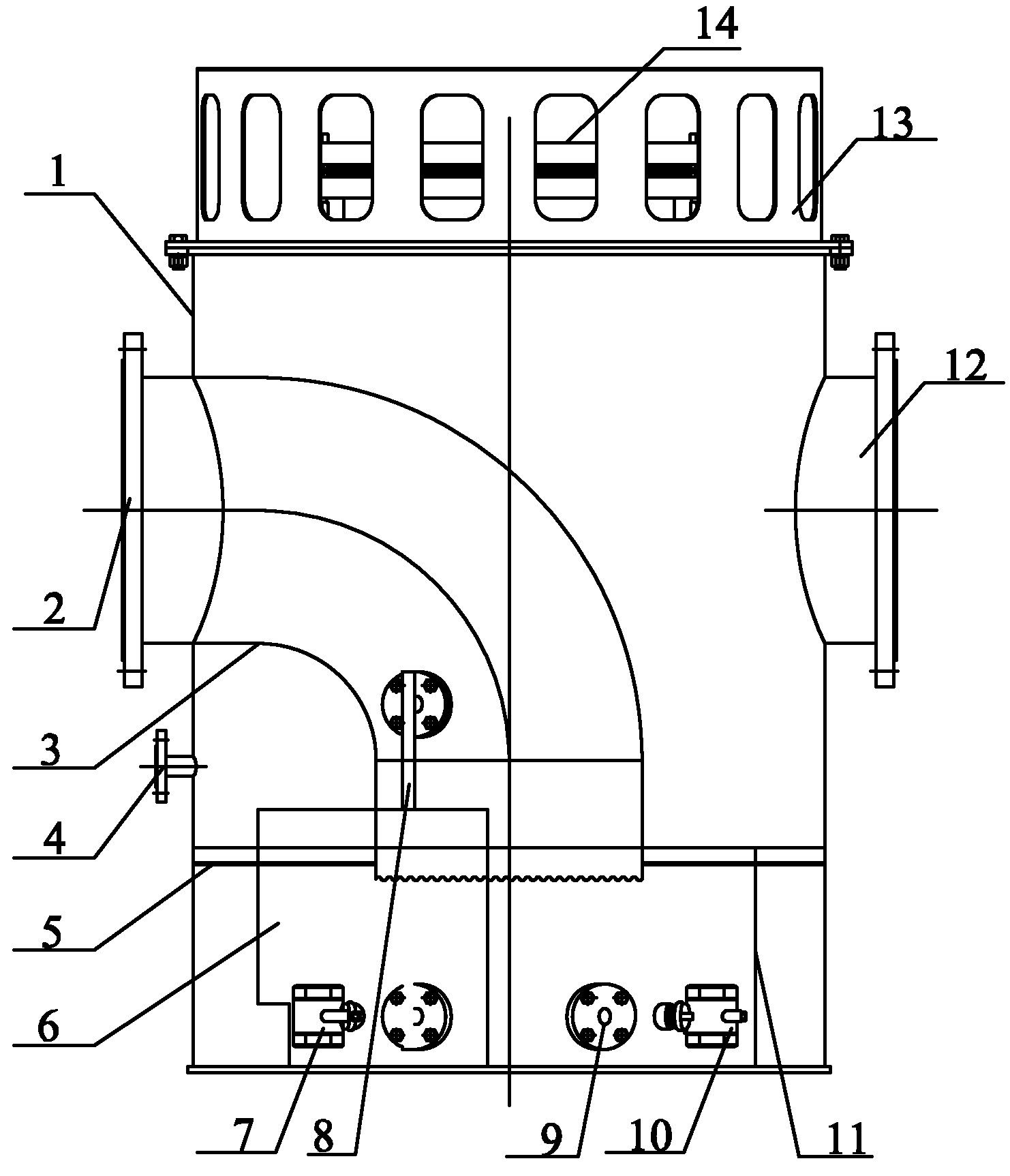

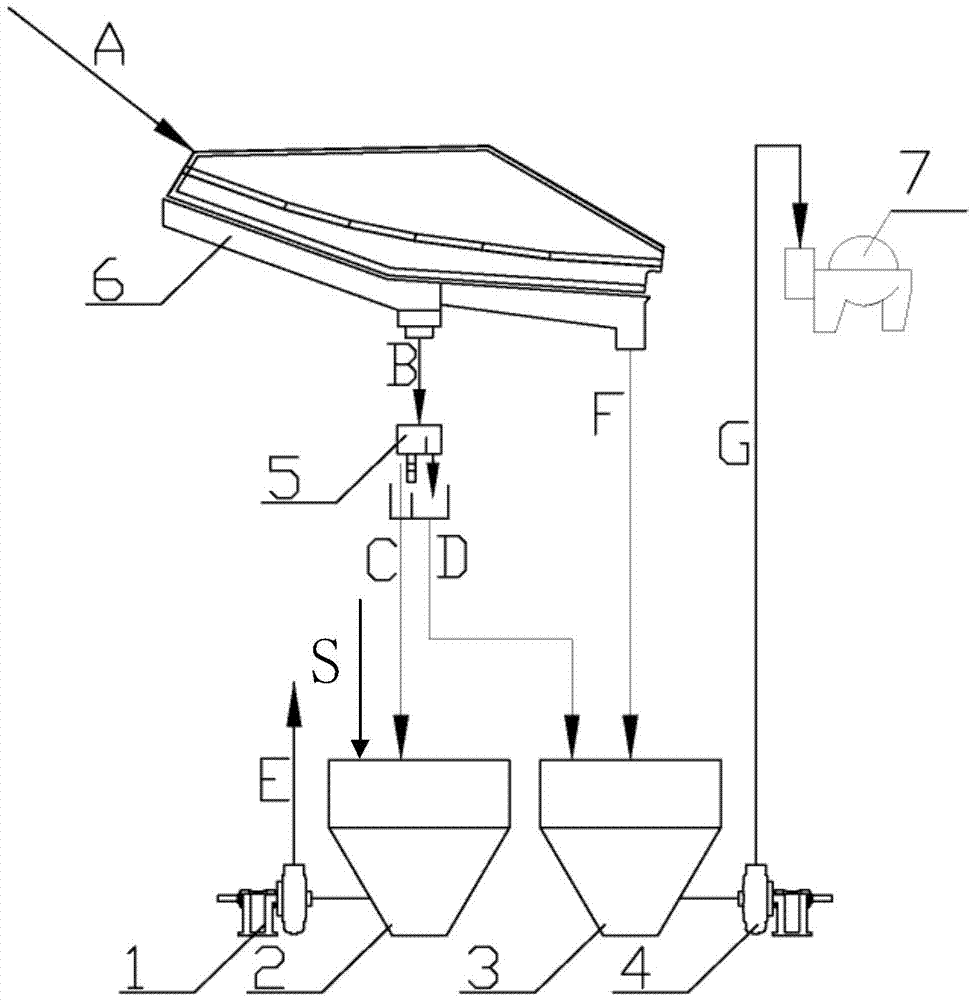

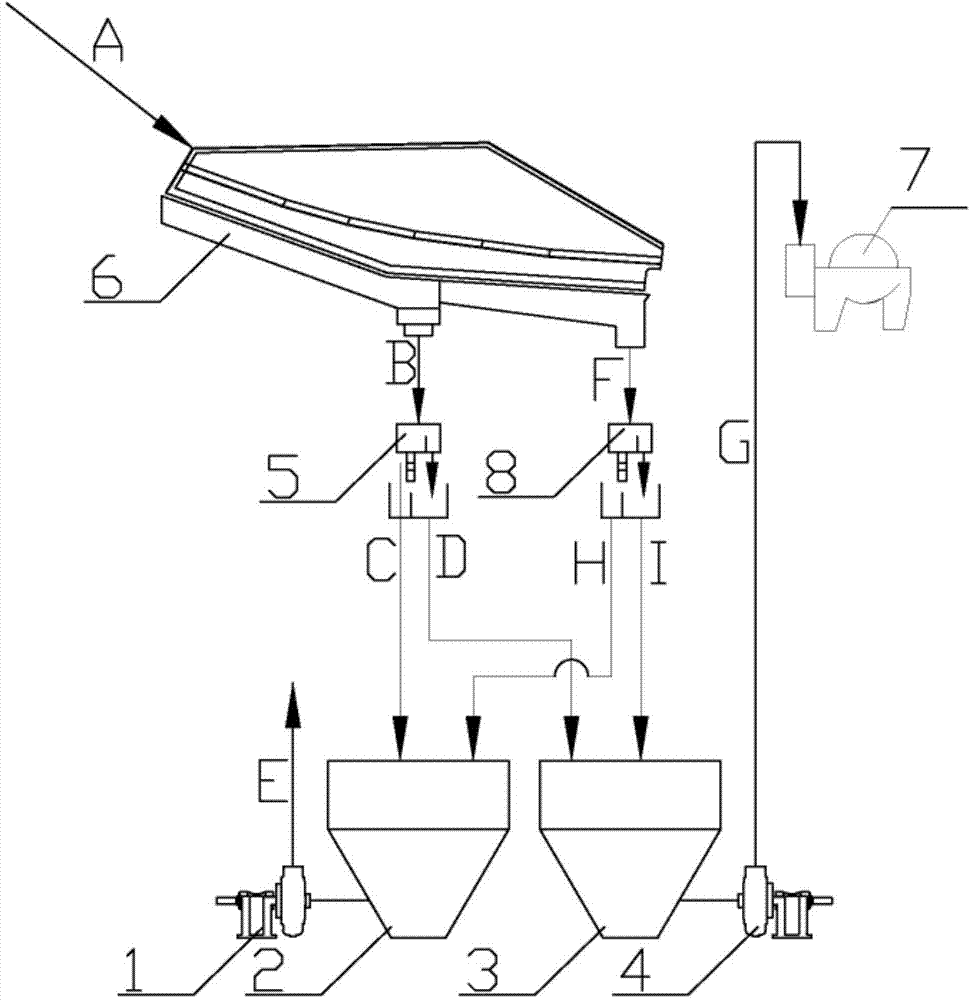

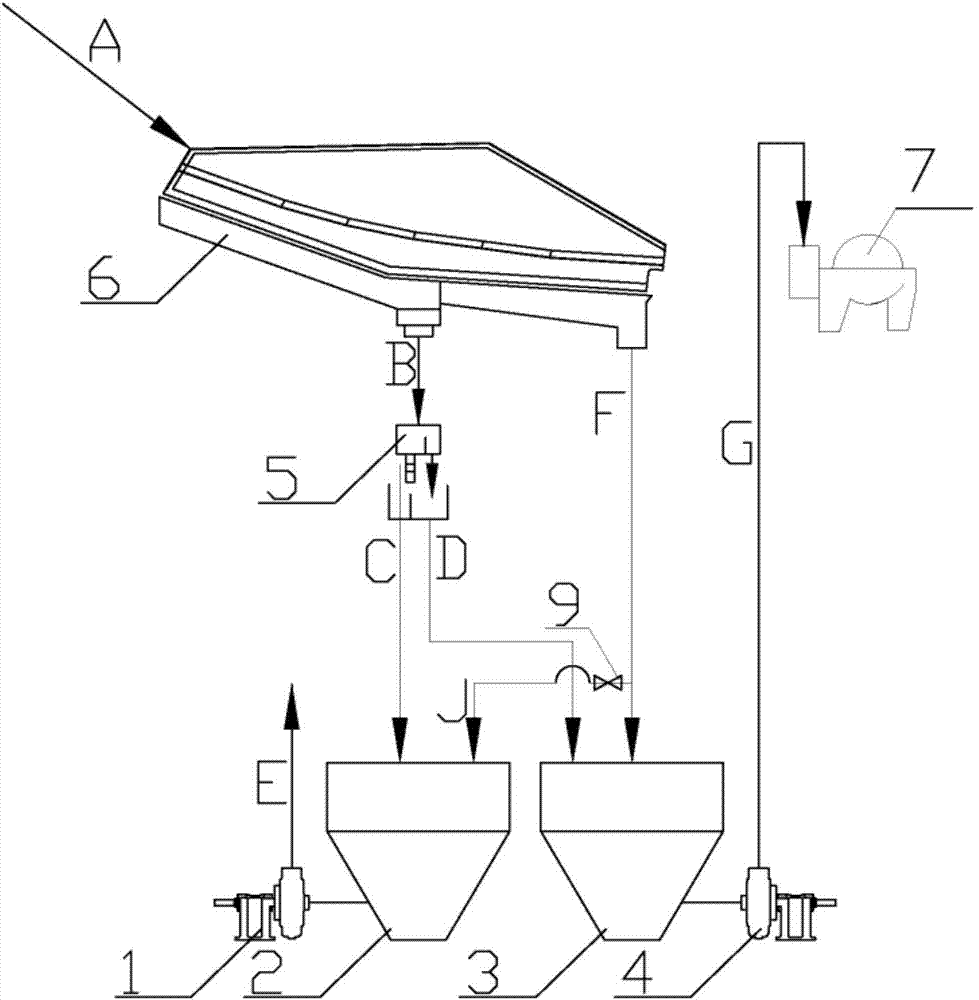

Vertical clearance type fish passing effect experimental system

InactiveCN103343524AReduce experimental water consumptionReduce experiment costHydraulic modelsWater flowEngineering

The invention relates to a vertical clearance type fish passing effect experimental system which comprises a water inlet system connected with a water circulation system, a water blocking system connected with the water inlet system and a water outlet system connected with the water blocking system. The water circulation system comprises a water suction pump, an overground water pool, an underground water pool, an upstream control valve and a downstream control valve. The water inlet system comprises an upstream flashboard and an upstream fish resting pool. The water blocking system is composed of a plurality of stages of fishponds. The water outlet system is composed of a downstream fish resting pool, a downstream water flow buffering box and an underground water pool. The vertical clearance type fish passing effect experimental system can be used for studying and analyzing hydraulics turbulent energy dissipation problem, a fish migration problem and hydraulics experimental model demonstration, due to the fact that the experimental system and an actual fishway partial project are built with a proportion of 1:1, the flow regime of the water flow in a fish passing facility is truly reflected, and the reliability and the accuracy of a water flow field in a fishway and the analysis of the fish passing effect are further guaranteed.

Owner:SICHUAN UNIV

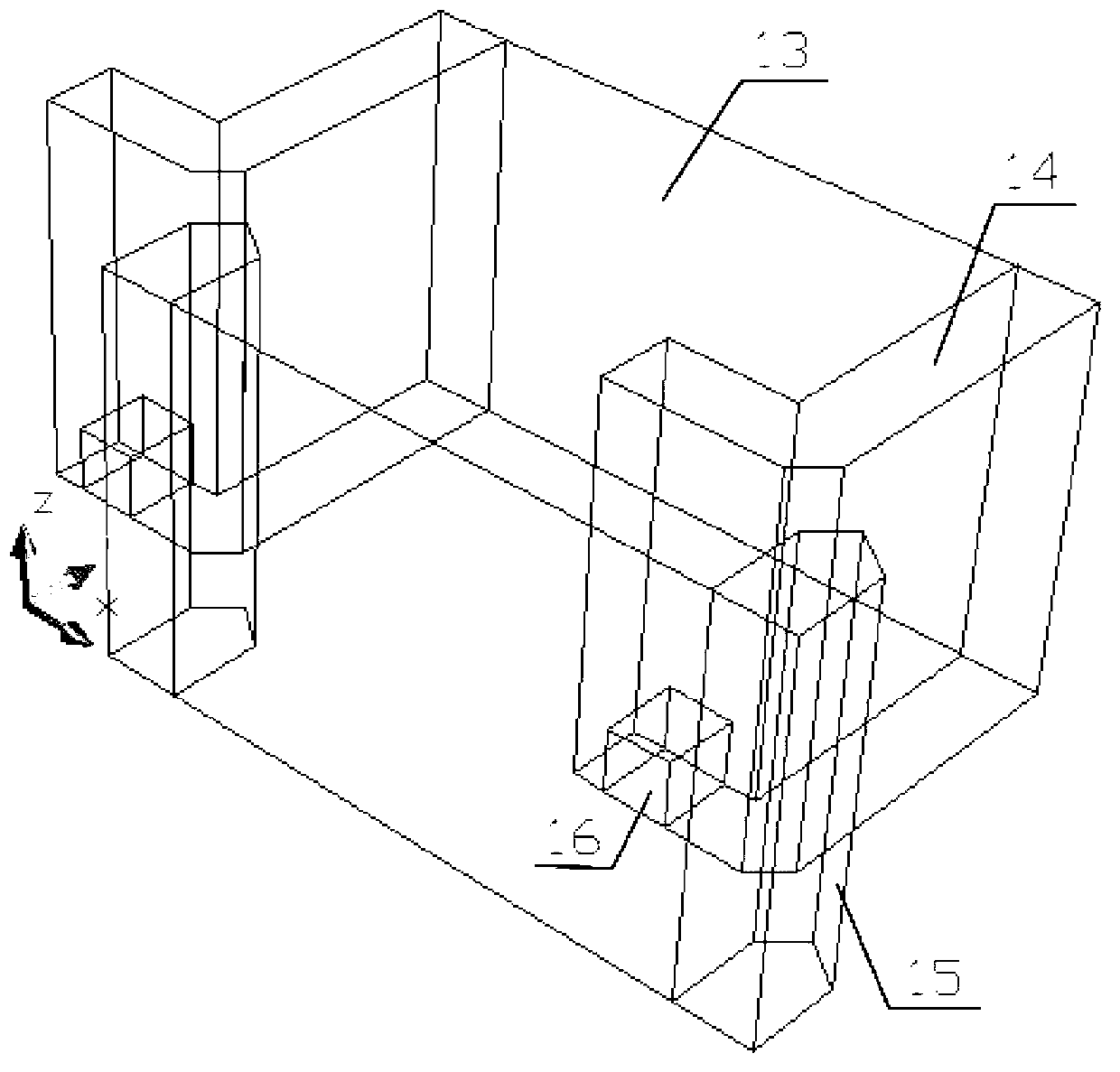

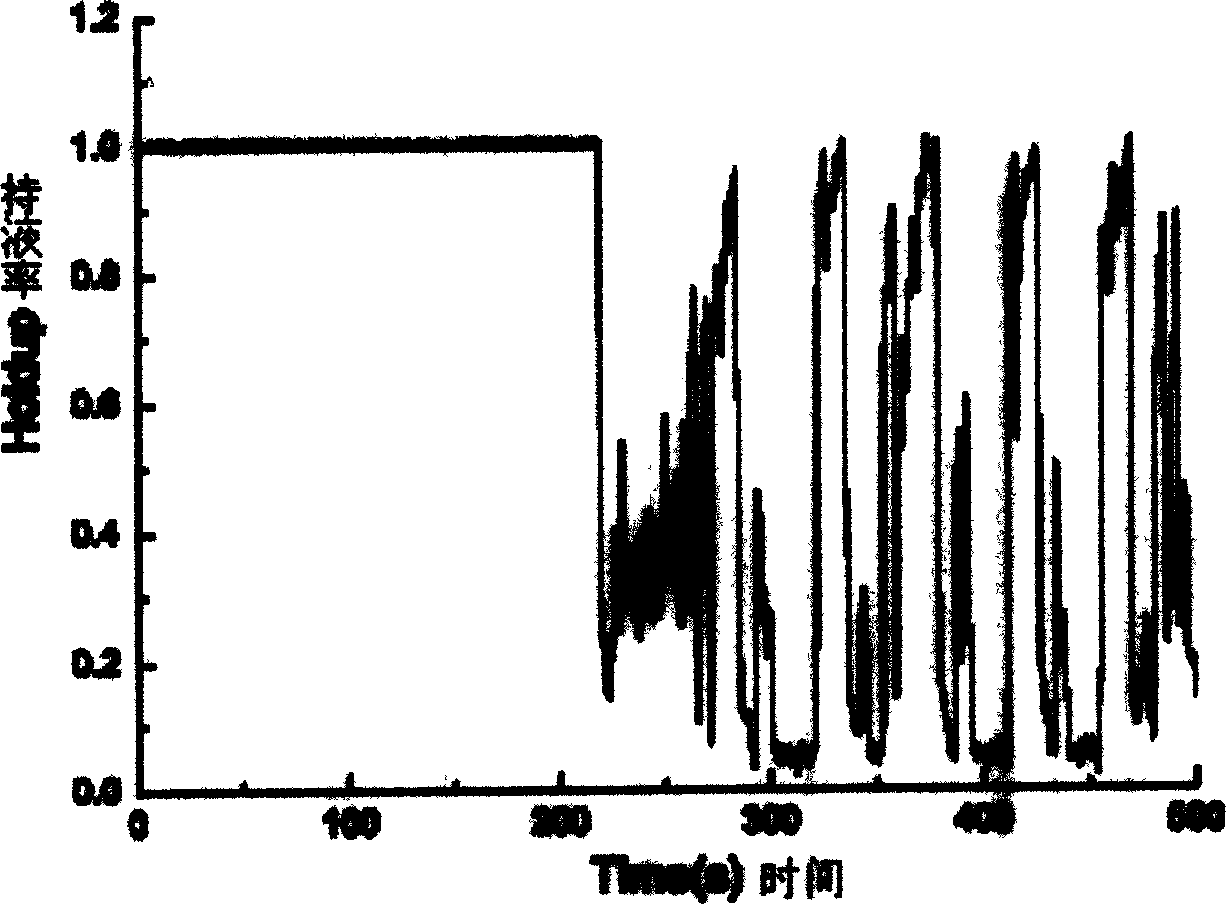

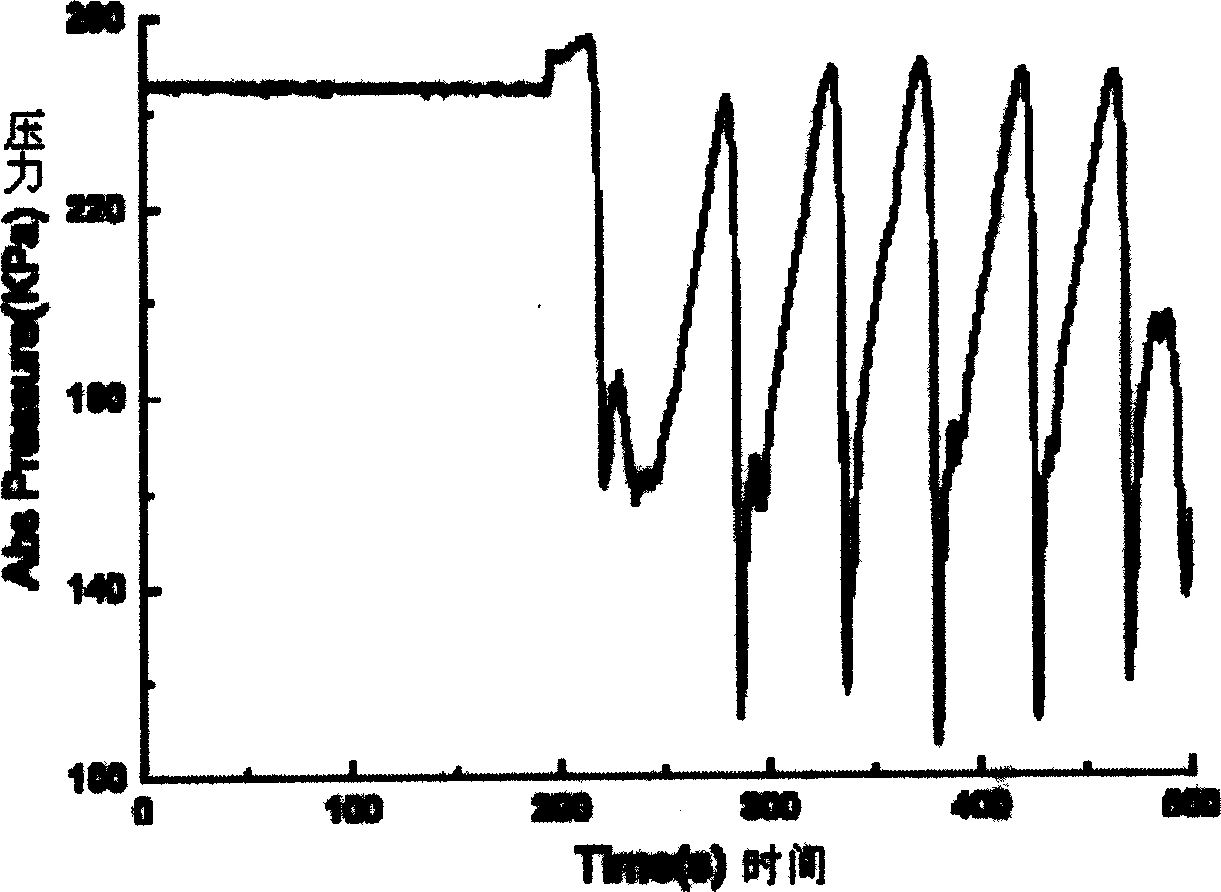

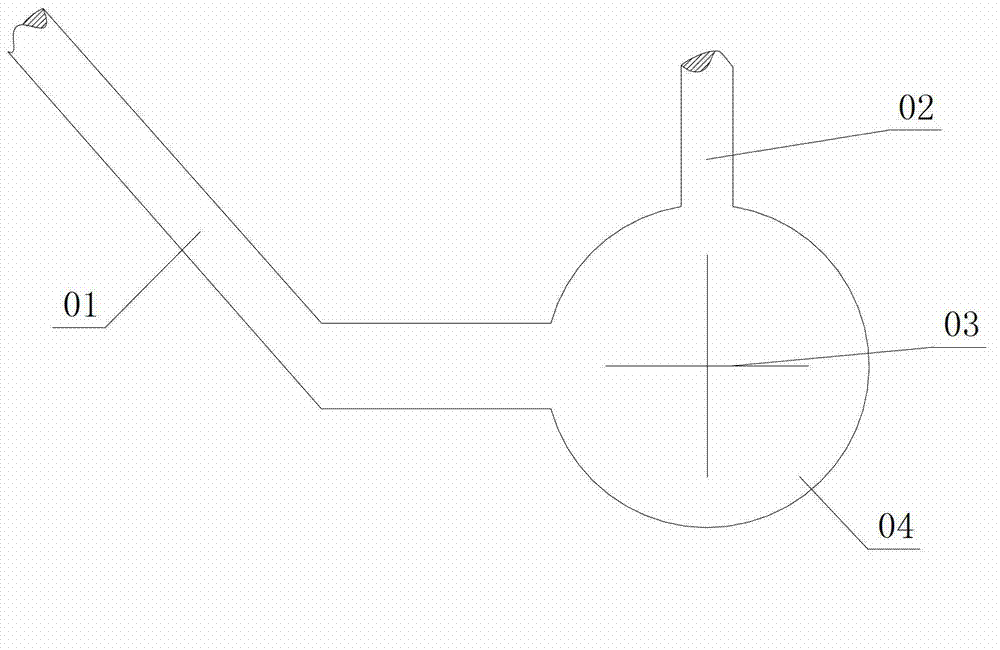

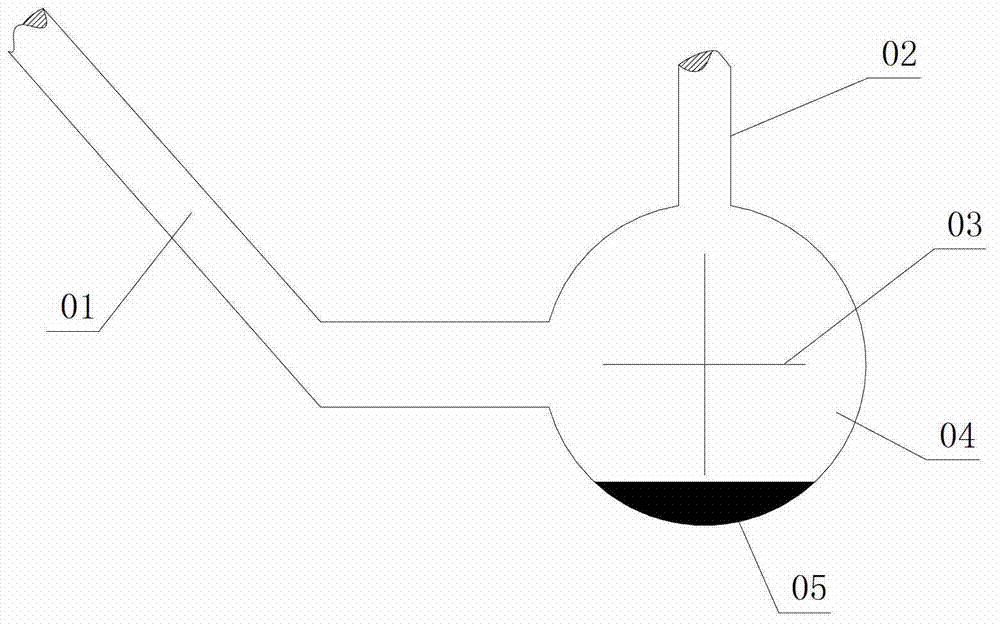

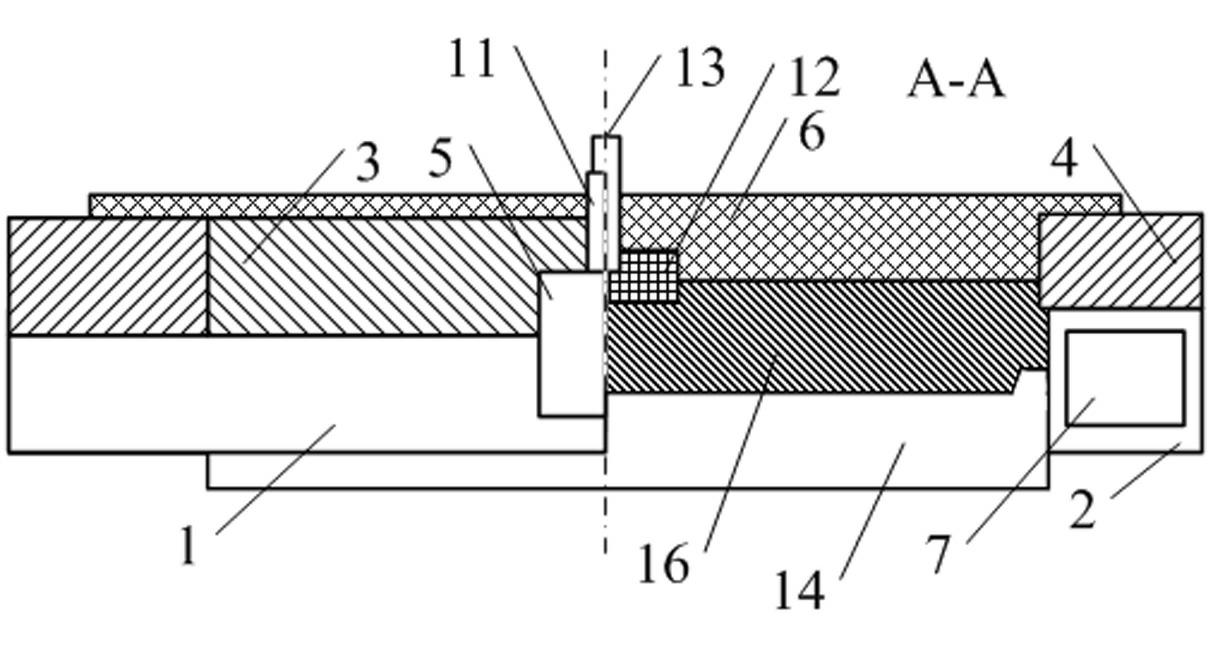

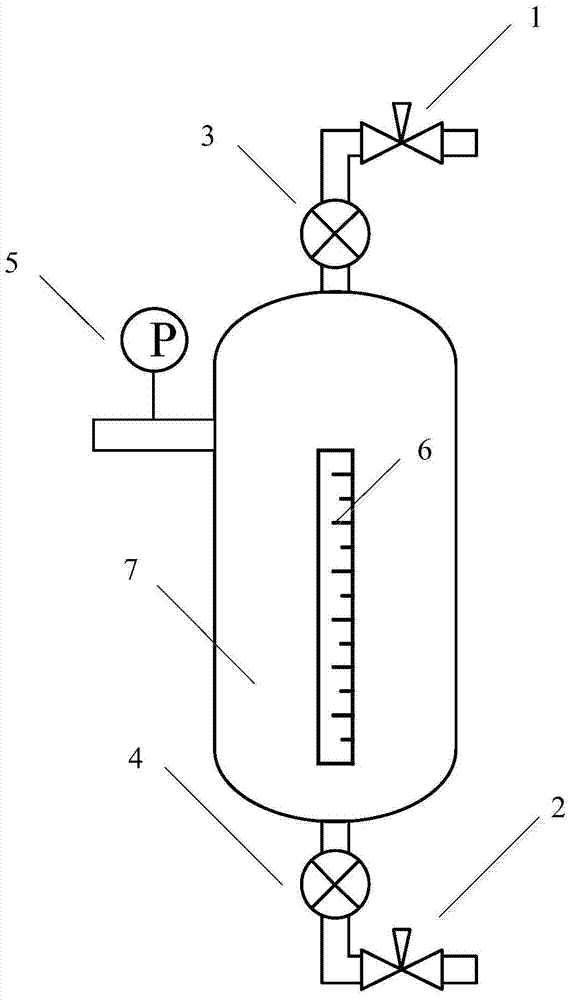

Separator and phase-split conveying method for eliminating plug flow on serious segments by utilizing same

InactiveCN1632369ASimple structureSpeed up the flowLiquid degasificationFluid removalPressure stabilizationLevel sensor

A separator and a phase-splitting conveying method for eliminating severe slug flow by using the separator. The separator includes a shell, which is connected with an incoming flow pipe and a gas riser pipe, and is provided with a liquid level sensor and a pressure sensor on the shell. A riser pipe is inserted and extended to the bottom of the shell, the part of the riser pipe protruding from the shell is provided with a liquid phase pump connected to the riser pipe through a valve, and a control valve is set on the gas riser pipe close to the outlet of the shell. The separator of the present invention is installed at the junction of the mixed pipeline and the rising pipe, the gas-liquid fluid in the mixed pipeline enters the shell of the separator through the incoming flow pipe, and the liquid level signal and pressure signal are used to adjust the control valve. The opening makes the liquid level and pressure stable. After the gas and liquid are separated in the separator, the liquid enters the riser and is pressurized by the liquid phase pump to be transported to the onshore platform device. The gas enters the onshore platform device through the gas riser through the control valve. The invention has a simple structure, can conveniently and accurately control the flow of gas and liquid, and achieves the purpose of eliminating severe slug flow.

Owner:XI AN JIAOTONG UNIV

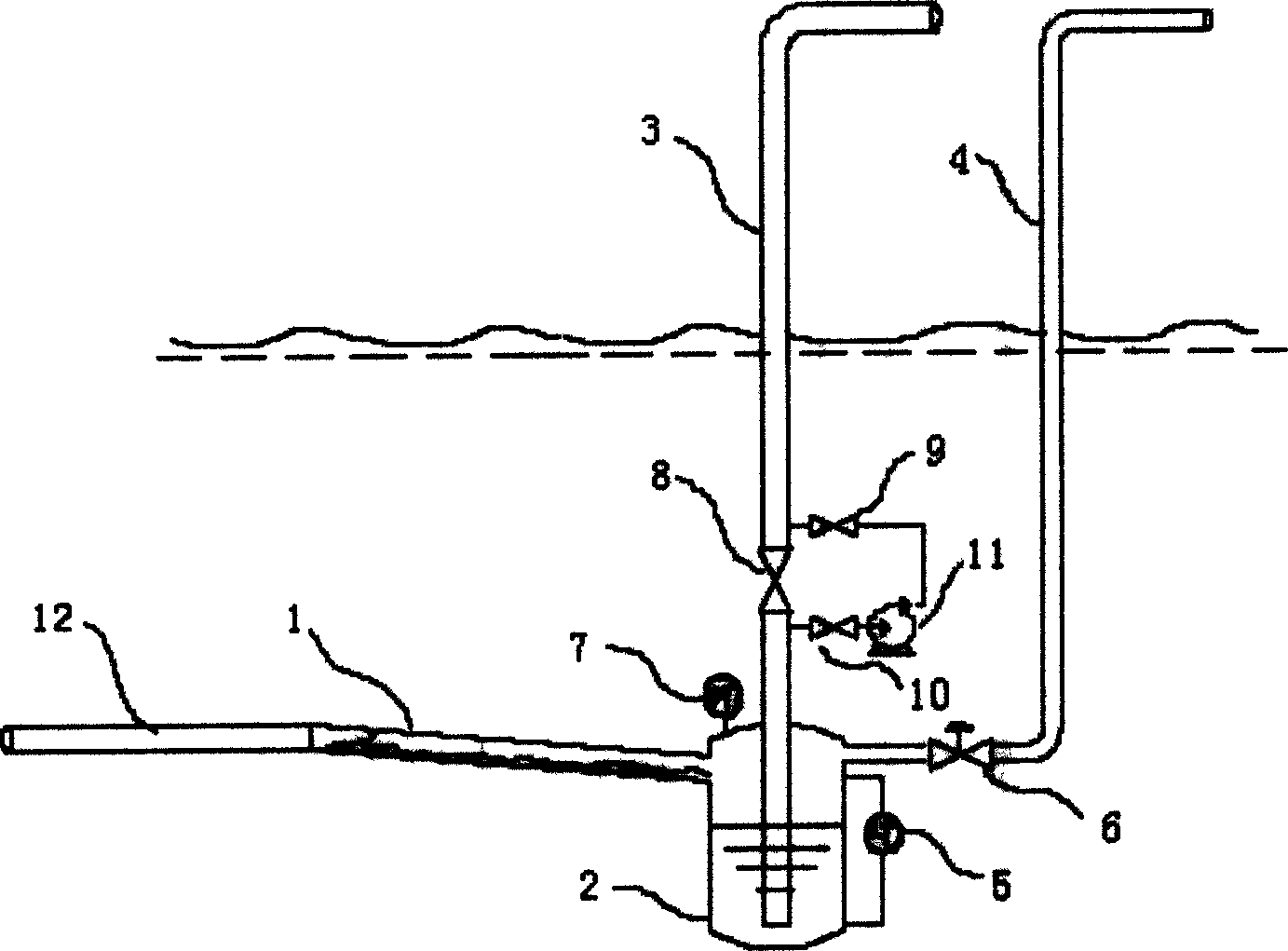

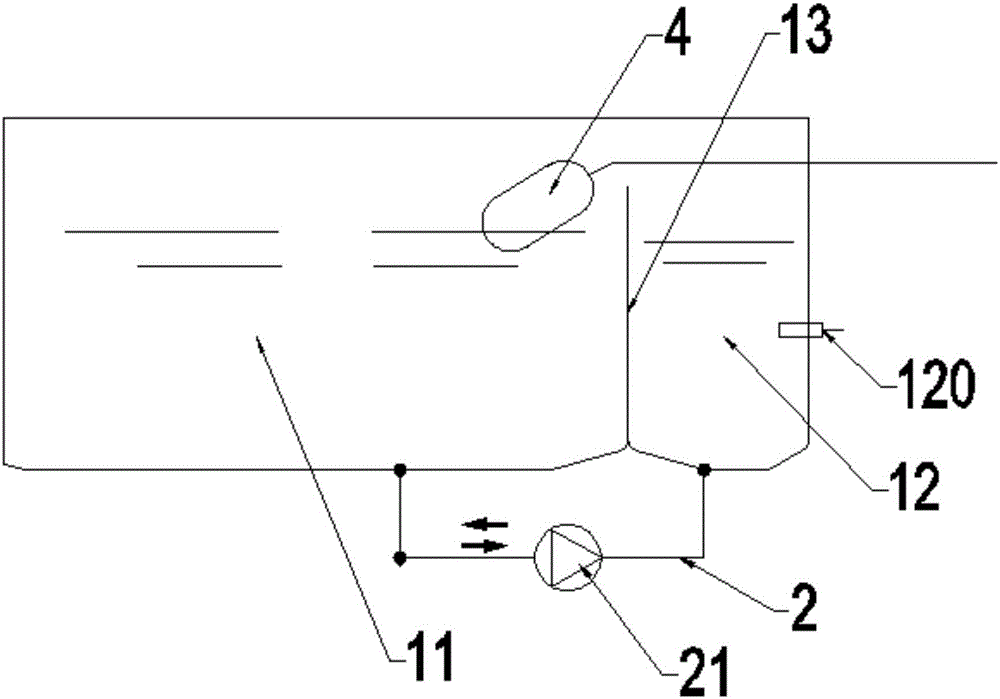

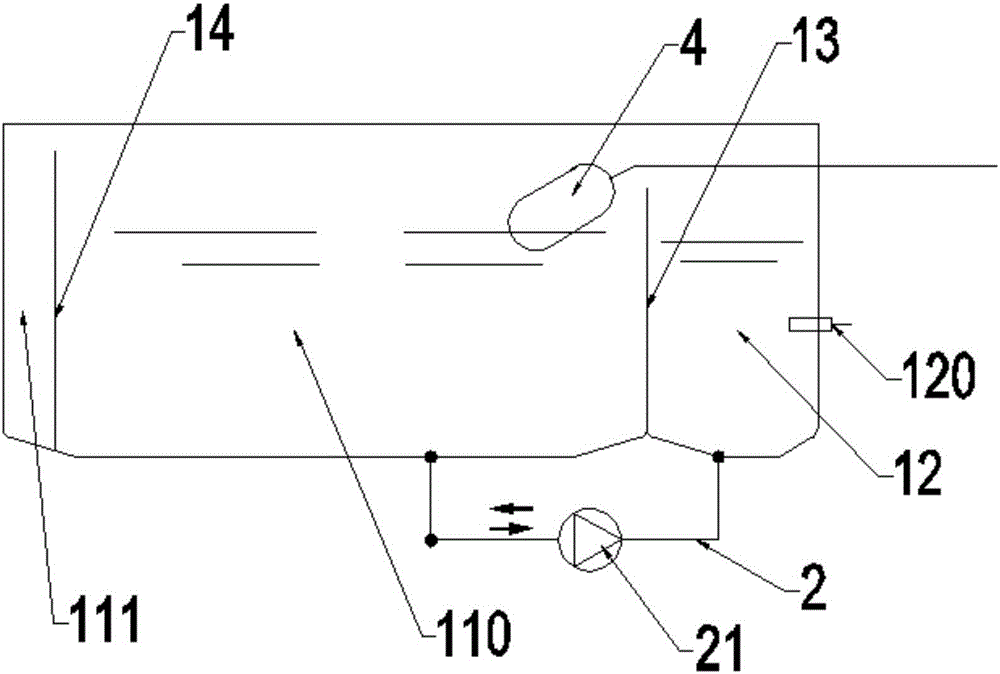

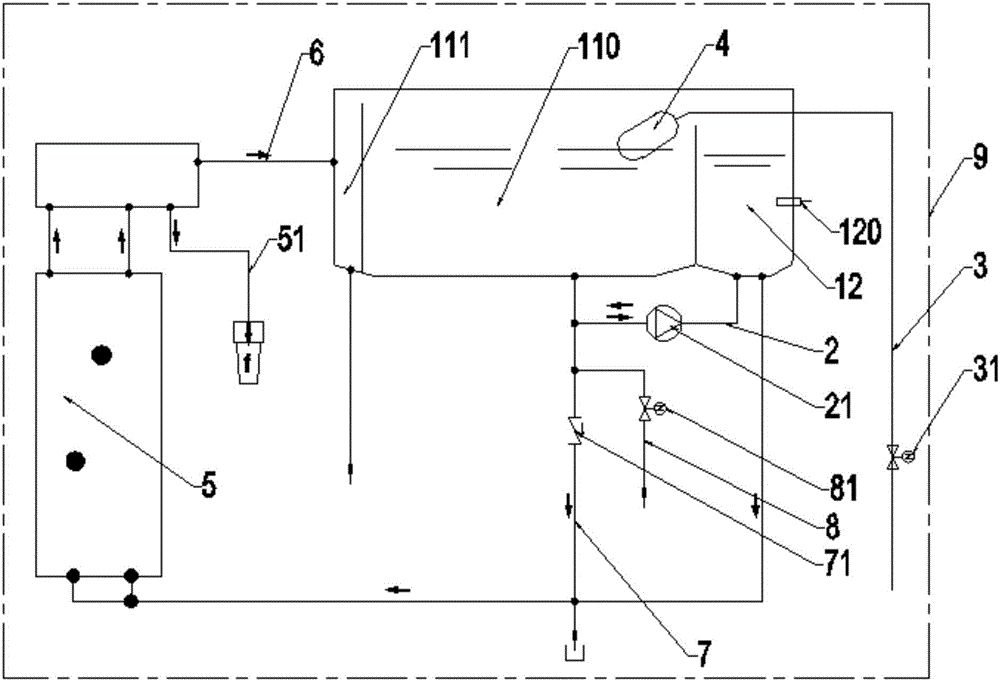

Integrated water tank and pipeline-type water dispenser provided with integrated water tank

The invention relates to the field of water dispensers, and discloses an integrated water tank and a pipeline-type water dispenser provided with the integrated water tank. The integrated water tank comprises a water tank main body, wherein a first partition board (13), by which the water tank main body is divided into a raw water tank (11) and a balanced water tank (12), is arranged in the water tank main body; the first partition board (13) is lower than the water tank main body; the capacity of the balanced water tank (12) is less than the capacity of the raw water tank (11); a reflux pipe (2) is arranged between the raw water tank (11) and the balanced water tank (12); a water pump (21) is arranged on the reflux pipe (2); and a water inlet, a water outlet and a water level switch (120) for detecting a water level in the balanced water tank (12) are arranged on the balanced water tank (12). According to the integrated water tank disclosed by the invention, a liquid level in a heating body (5) can be constantly kept stable when hot water is produced; and meanwhile, water stored in the raw water tank (11) in the machine (the water dispenser) can be utilized to the greatest extent when the machine still needs to produce the hot water after water supply is stopped.

Owner:ZHEJIANG QINYUAN WATER TREATMENT S T

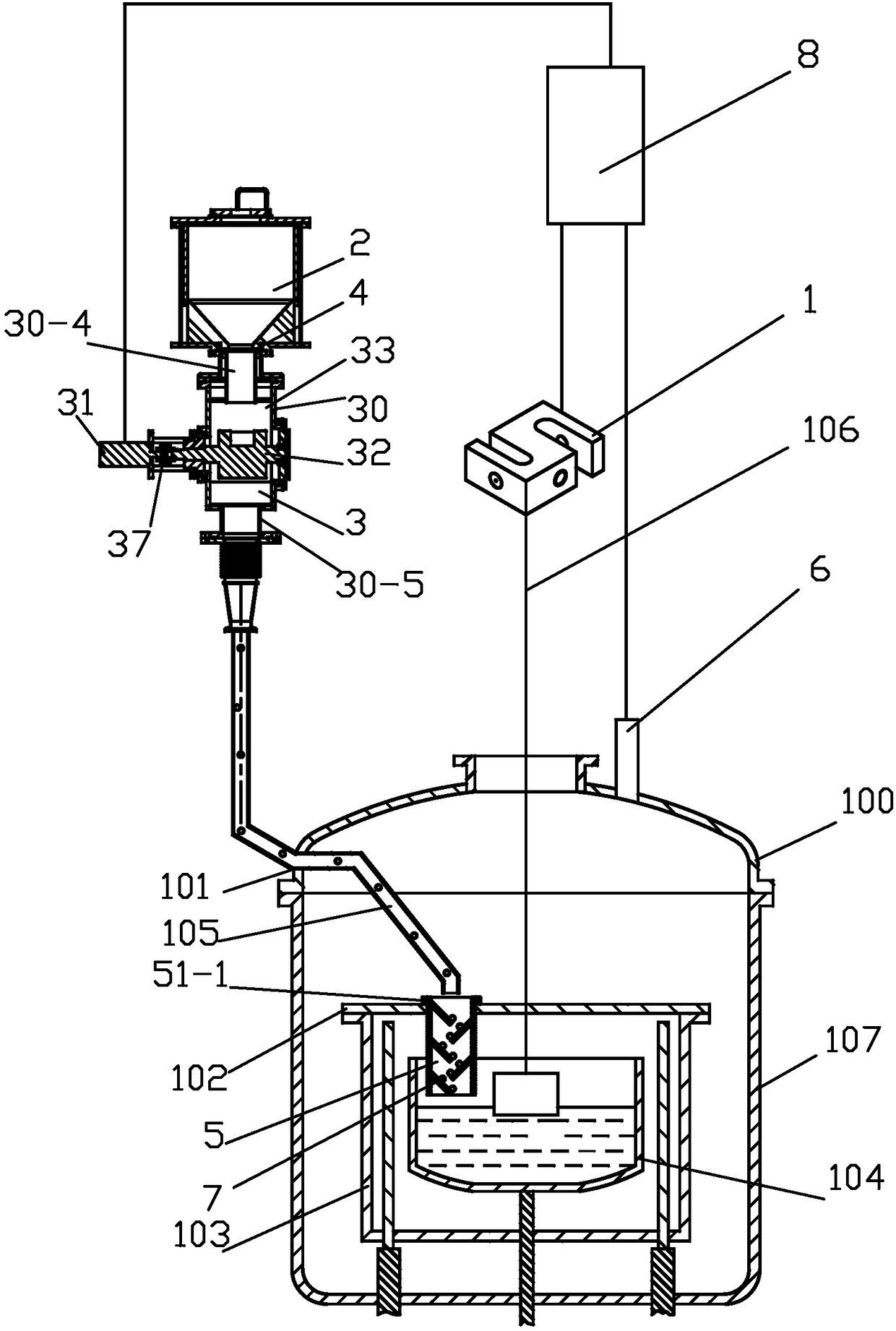

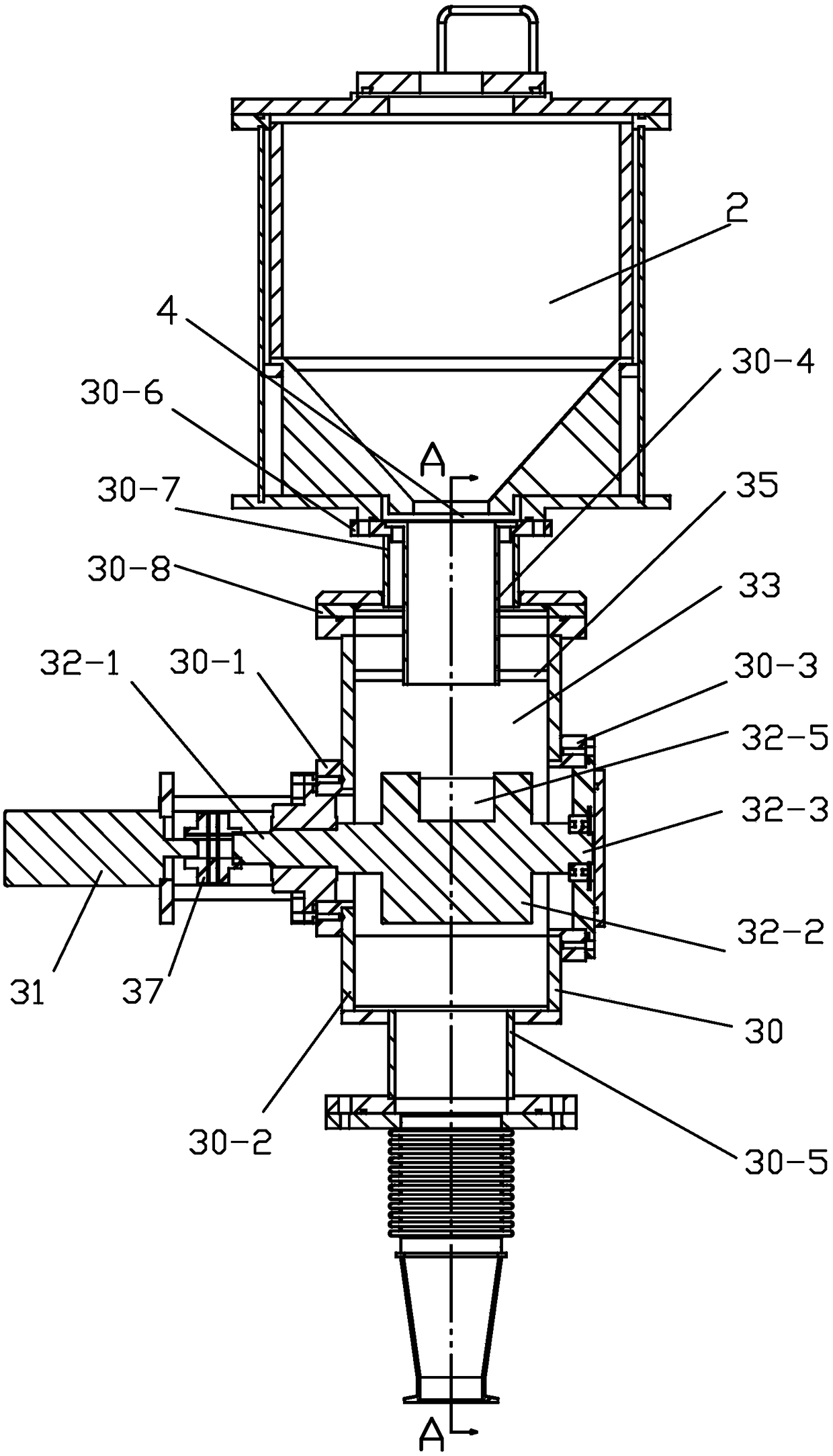

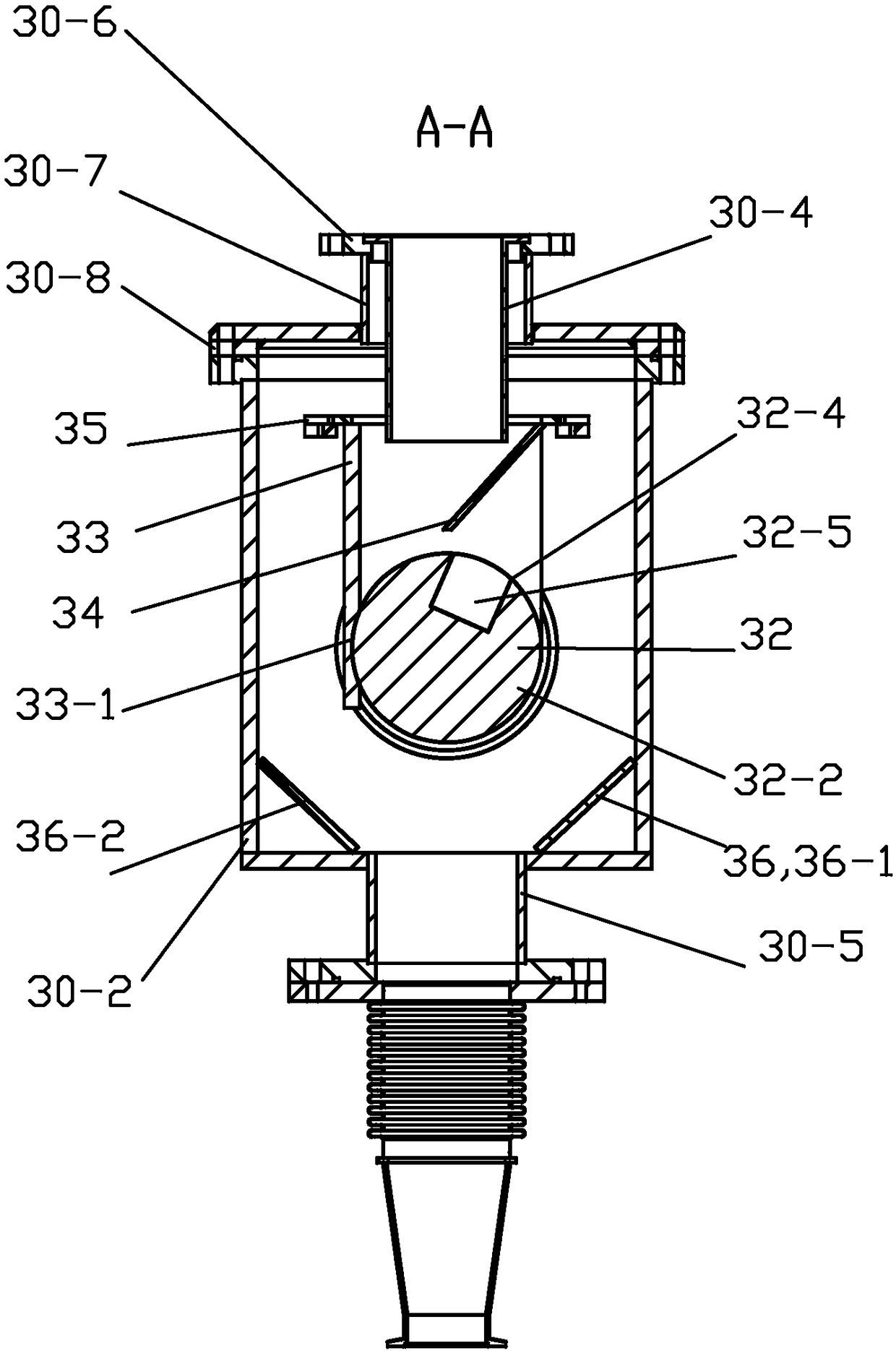

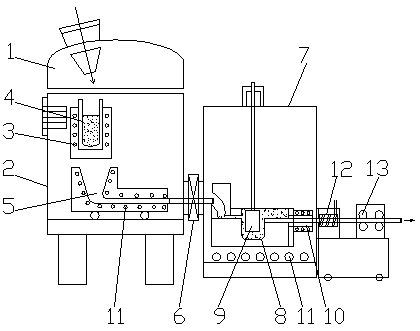

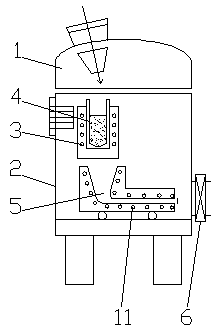

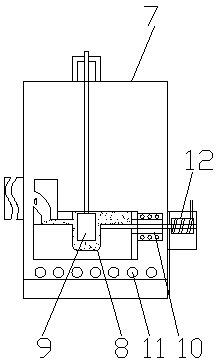

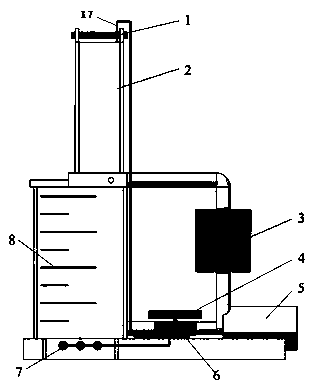

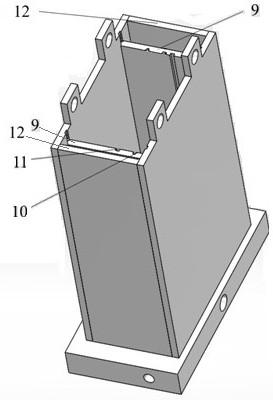

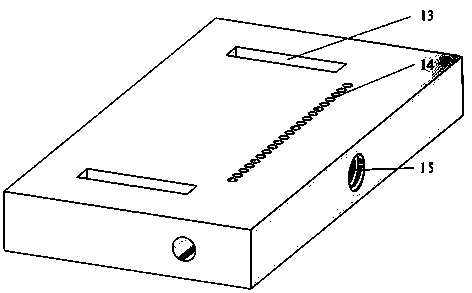

Automatic charging device for single crystal furnace and operation method of automatic charging device

PendingCN108103568APrevent splashLiquid level stabilityPolycrystalline material growthBy pulling from meltElectricityCrucible

The invention relates to an automatic charging device of a single crystal furnace and an operation method of the automatic charging device. The automatic charging device comprises a weighing mechanism, a main controller, a charging mechanism and a storage box, wherein the charging mechanism comprises a material box, a motor, a rotating shaft and a baffle; a feeding port and a discharging port areformed in the material box; the rotating shaft is rotationally connected onto the material box and fixedly connected with an output shaft of the motor, an opening is formed in the periphery of the axial middle of the rotating shaft, and the opening extends inwards in the radial direction to form a bin opening; the baffle is fixedly connected onto the material box and close to the periphery of theaxial middle of the rotating shaft; the storage box is fixedly connected at the feeding port of the material box and communicated with the feeding port. The motor and the weighing mechanism are both electrically connected with the main controller or connected with the main controller through wireless signals. By the aid of the single crystal furnace comprising the automatic charging device, in thecontinuous drawing process of single crystal rods, the liquid level of a liquid silicon material in a crucible can be kept stable during continuous charging, crystals can grow stably, and the phenomenon of polycrystalline growth can be avoided.

Owner:JIANGSU BAIR PHOTOELECTRIC EQUIP CO LTD

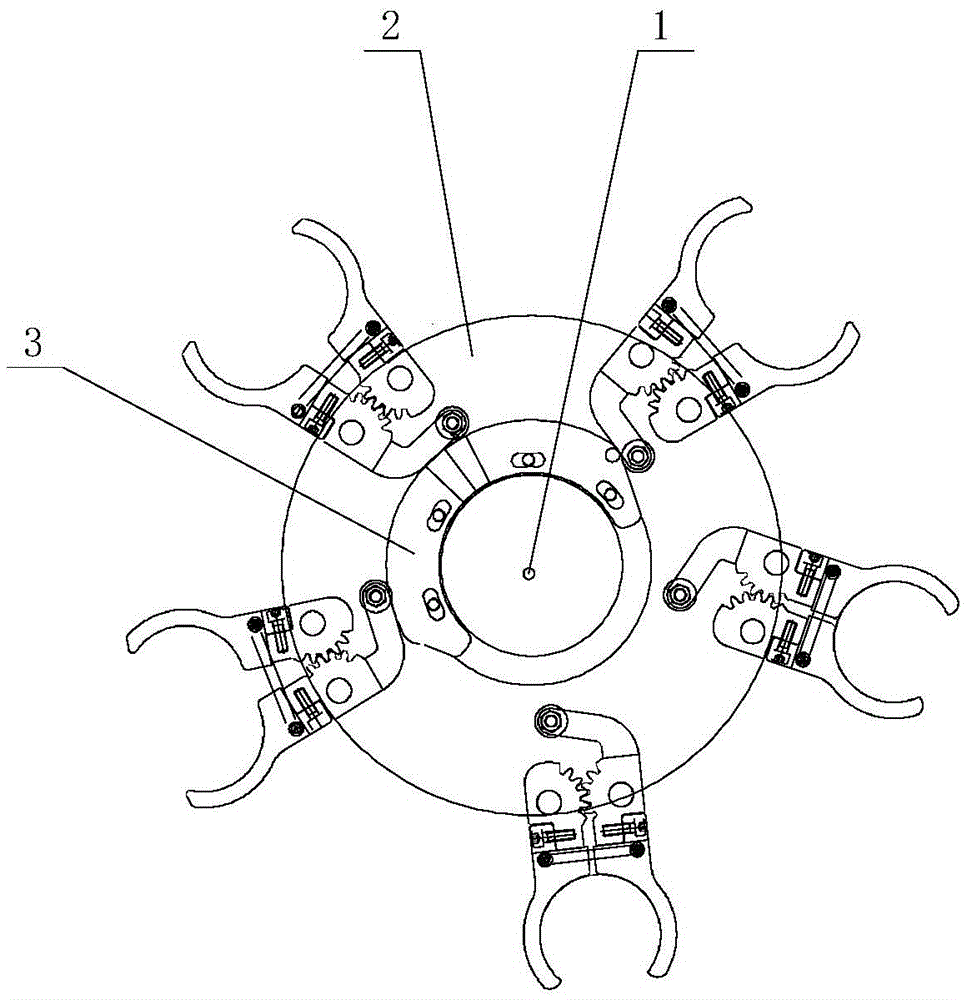

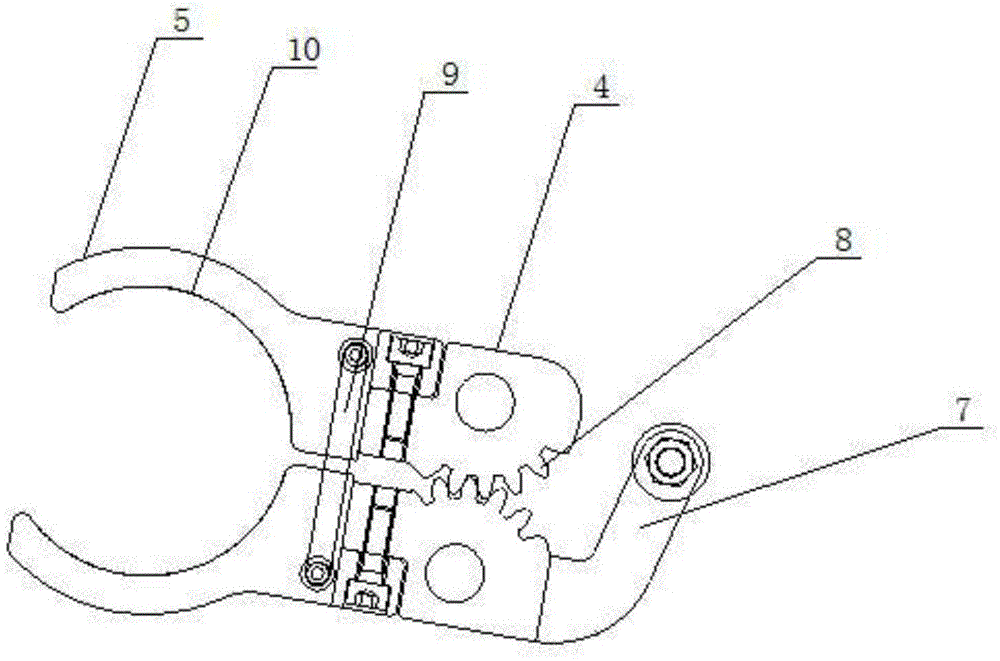

Bottle holding type transfer star wheel and achievement method thereof

InactiveCN105540170APrevent damageSimple structureConveyor partsRotary conveyorsTransfer procedureEngineering

The invention discloses a bottle holding type transfer star wheel and an achievement method thereof. The problems that an conveying belt or a clamping device adopted in the prior art transports bottles containing liquid products, a bottle overturning phenomenon and mutual extrusion easily occur during direct conveying of the conveying belt, the bottles are easily scratched in the conveying process, and the surfaces of the bottles are easily damaged in conveying of the clamping device are mainly solved. The bottle holding type transfer star wheel comprises a turntable, a motor driving the turntable, at least one cam and a supporting column for fixing the cam. The edge of the turntable is connected with multiple clamping claws. The cam is located in the turntable. The clamping claw located at the highest position of the cam is in an opened state, and the clamping claw located at the lowest position of the cam is in a closed state. By the adoption of the scheme, the bottle holding type transfer star wheel achieves the purpose that the bottles are not overturned, are not mutually extruded and are not damaged in appearance and has very high practical value and promotional value.

Owner:CHENGDU HONGRUI TECH

Three-phase hydrolytic polymerization process for nylon 6

The invention relates to a three-phase hydrolytic polymerization process for nylon 6. The process includes the steps of raw material preparing, pre-early polymerization reaction, early polymerization reaction, later polymerization reaction and cooling and slicing. The three-phase hydrolytic polymerization process for the nylon 6 has the advantages that a pre-early polymerization reaction kettle is added according to the hydrolytic polymerization reaction characteristics of fresh caprolactam, the highest pressure bearing ability of the pre-early polymerization reaction kettle is 15Bar, the early stage of the polymerization reaction of the fresh caprolactam is completed in the pre-early polymerization reaction kettle, and problems such as high product quality fluctuation caused by instable early polymerization liquid level can be solved; process controllability can be increased by adding the pre-early polymerization reaction kettle, product quality is increased, and the occurrence rate of polymerization accidents is reduced.

Owner:JIANGSU HONGSHENG NEW MATERIAL

Continuous casting device capable of achieving continuous feeding and production of high-purity single crystal copper rods

PendingCN111215591AReasonable methodIngenious designMelt-holding vesselsPolycrystalline material growthThermal insulationShielding gas

The invention relates to a continuous casting device capable of achieving continuous feeding and production of high-purity single crystal copper rods. The continuous casting device comprises a vacuumfurnace cover, a vacuum melting furnace, a smelting crucible, a vacuum gate valve, a thermal insulation continuous casting pot, a continuous casting crucible, a crystallizer, a cooling water jacket and a traction winding mechanism. The vacuum melting furnace is communicated with the inlet end of the thermal insulation continuous casting pot through the vacuum gate valve. The outlet end of the thermal insulation continuous casting pot is connected with the cooling water jacket and the traction winding mechanism through sealing pieces. After a raw material copper plate is melted in the smeltingcrucible, the shielding gas is introduced, the vacuum gate valve is opened, the smelting crucible tilts, the molten copper is poured into the continuous casting crucible, the liquid level of the molten copper in the continuous casting crucible is kept stable, and the traction winding mechanism carries out continuous and stable pulling to produce the high-purity single crystal copper rods. The continuous casting device has the beneficial effects that the method is reasonable and feasible, the design is ingenious, the stable and continuous uninterrupted production of the high-purity single crystal copper rods is realized, the performance is reliable, the production cost is reduced, and the production efficiency is improved.

Owner:河南国玺超纯新材料股份有限公司

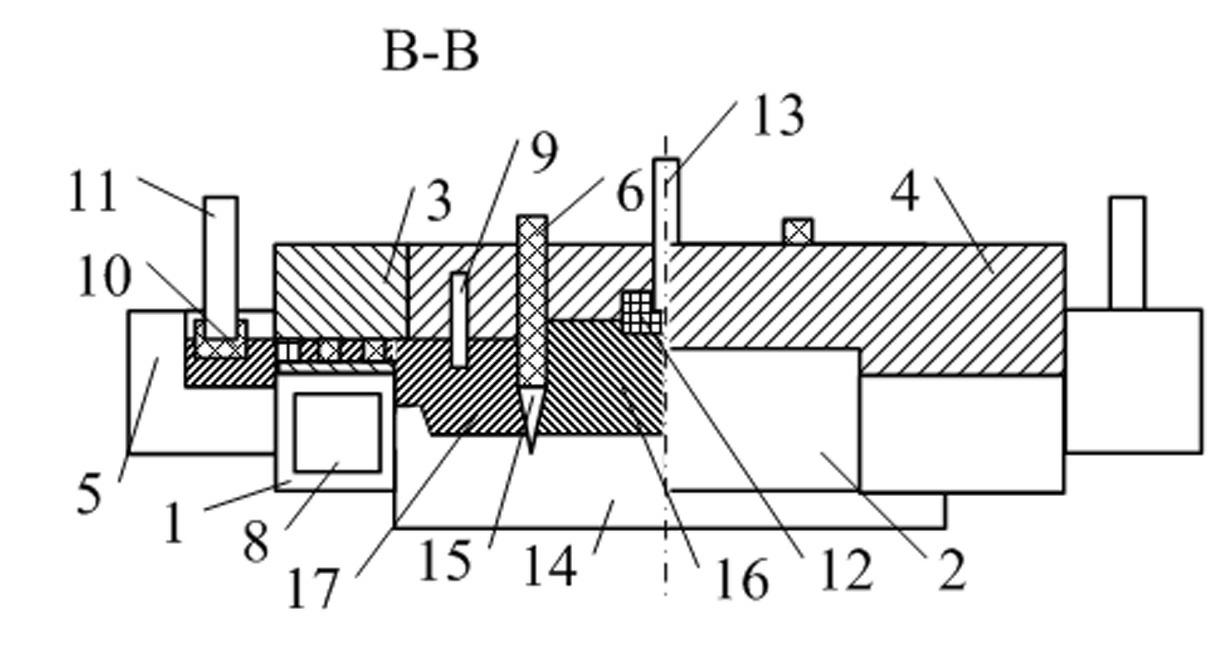

Individual overflow water seal fire relief and explosion release device

ActiveCN102278133ARealize the function of fire prevention and explosion reliefEasy to replaceDust removalFire preventionWater storageEngineering

The invention relates to an individual overflow water seal fire relief and explosion release device. The device provided by the invention is characterized by comprising a gas conveyer system, a wet gas safety bleeding valve and water seal fire arrestors, wherein the wet gas safety bleeding valve is arranged on a bypass pipeline of the gas conveyer system; the water seal fire arrestors are arranged at the starting end and tail end of the gas conveyer system; and each water seal fire arrestor comprises a shell, a gas inlet, a gas outlet, a gas conveyer pipe in the device, an explosion release port, an overflow drain tank and a liquid level control tank. The device provided by the invention can effectively achieve the effect of overflow water seal fire relief and explosion release. The device provided by the invention provides triple protection for stabilizing a liquid surface: (1) the gas inlet tail end is in a sawtooth shape, thereby segmenting large bubbles; (2) a pore plate under water enables the bubbles to be uniform; and (3) the overflow of the overflow drain tank is controlled. In the device provided by the invention, the drain frequency degree is low; the overflow drain tankhas the function of water storage and has the advantages of stable liquid surface and fewer times of water charging action; the pressure of the explosion release port can be set according to requirements; an explosion-proof rubber sheet is easy to exchange; and guardrails are arranged around the explosion release port, thus safety factors are high.

Owner:淄博淄柴新能源有限公司

Drainage system capable of lowering drainage noise of washing machine and control method thereof

ActiveCN102817214AReduce noiseAccurate startOther washing machinesControl devices for washing apparatusWater stateEngineering

The invention discloses a drainage system capable of lowering the drainage noise of a washing machine, which comprises a drainage pump, a drainage pump water inlet pipe and a drainage pump water outlet pipe, wherein the drainage pump water inlet pipe and the drainage pump water outlet pipe are arranged on the drainage pump; a water level detection device is arranged between the drainage pump water inlet pipe and the outer bucket of the washing machine; the water level detection device transmits a water level signal to an external controller; and the controller controls the drainage pump to be started and stopped in real time so as to ensure that the inside of the drainage pump is still kept at the full water state in the washing machine dewatering process. The drainage pump can be turned on and off according to the water level height by arranging the water level detection device on the drainage system of the washing machine, vibration noise generated by the washing machine is prevented from being overlaid with half dry adsorption noise of the drainage pump during high-speed dewatering, the noise is scattered, and the noise of the washing machine is lowered. Compared with the prior art, the drainage system has the advantages of simple structure, small noise, high drainage efficiency and low energy consumption.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

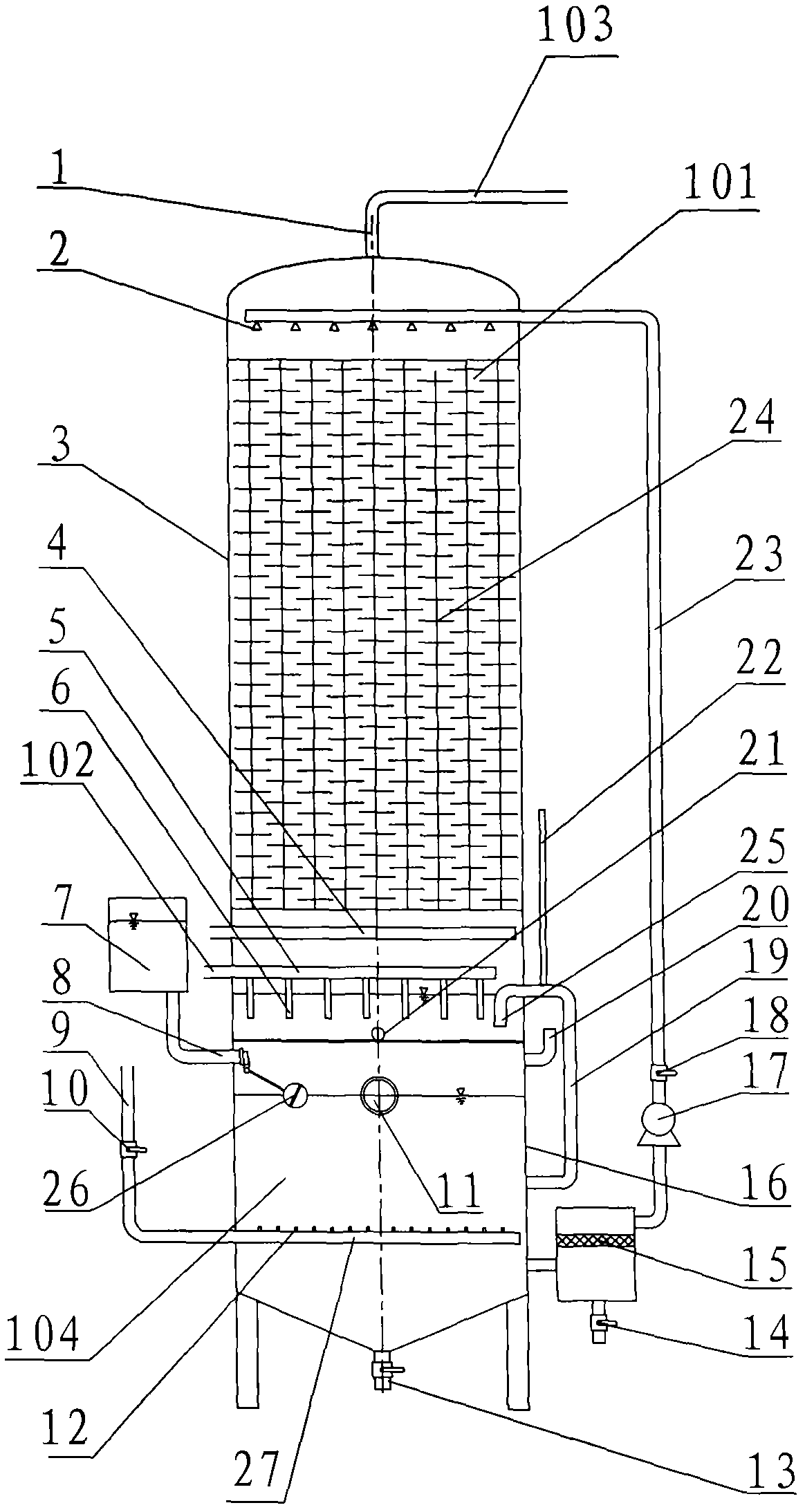

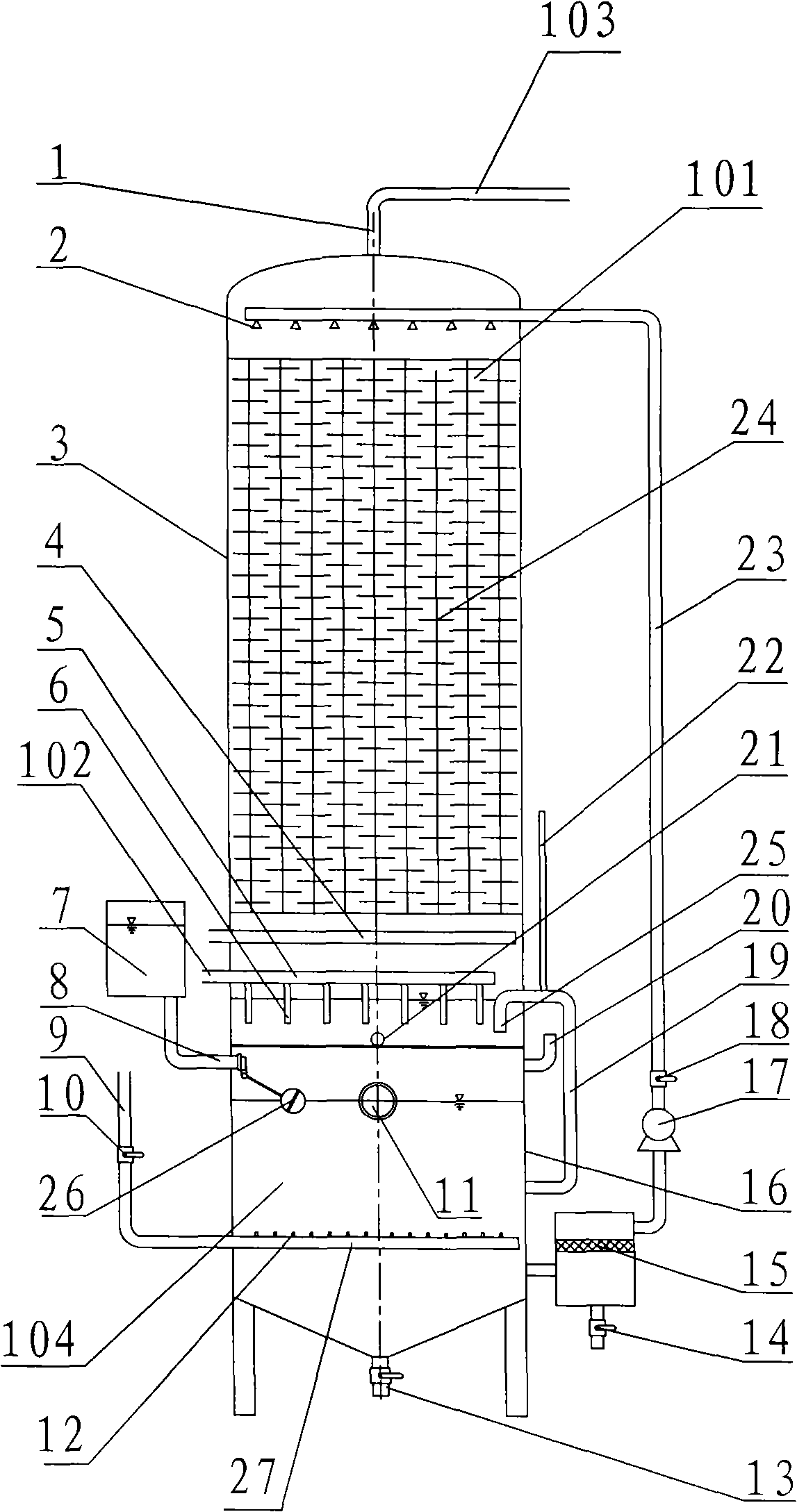

Integrated methane biological desulphurization device

The invention discloses an integrated methane biological desulphurization device which comprises a tower body composed of an upper desulphurization tower (3) and a lower desulphurization tower (16) which are isolated from each other, a spray system and a reflux system, wherein, the top of the upper desulphurization tower (3) is equipped with a methane outlet (1); the spray system comprises a spray header (2) arranged at the top half of an inner chamber of the upper desulphurization tower (3) and a delivery pipe (23) arranged outside the tower body; two ends of the delivery pipe (23) are respectively communicated with the spray header (2) in the upper desulphurization tower (3) and an inner chamber of the lower desulphurization tower (16); the delivery pipe (23) is equipped with a circulating pump (17); and the reflux system comprises a reflux pipe (19) arranged outside the tower body, and two ends of the reflux pipe (19) are respectively communicated with the bottom of the inner chamber of the upper desulphurization tower (3) and the inner chamber of the lower desulphurization tower (16). The integrated methane biological desulphurization device has the characteristics of being safe and efficient and being capable of monitoring technological parameters in real time and the like.

Owner:ZHEJIANG UNIV

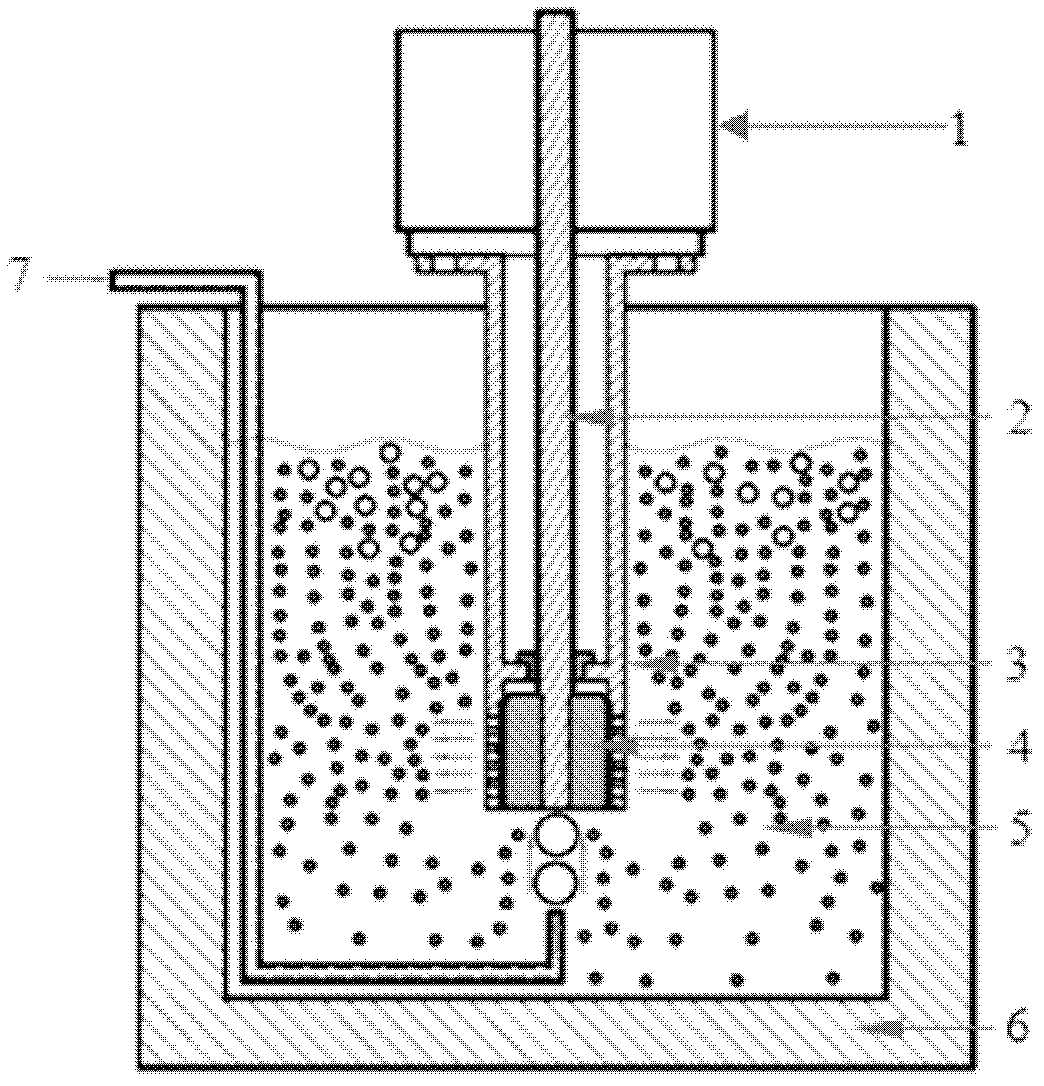

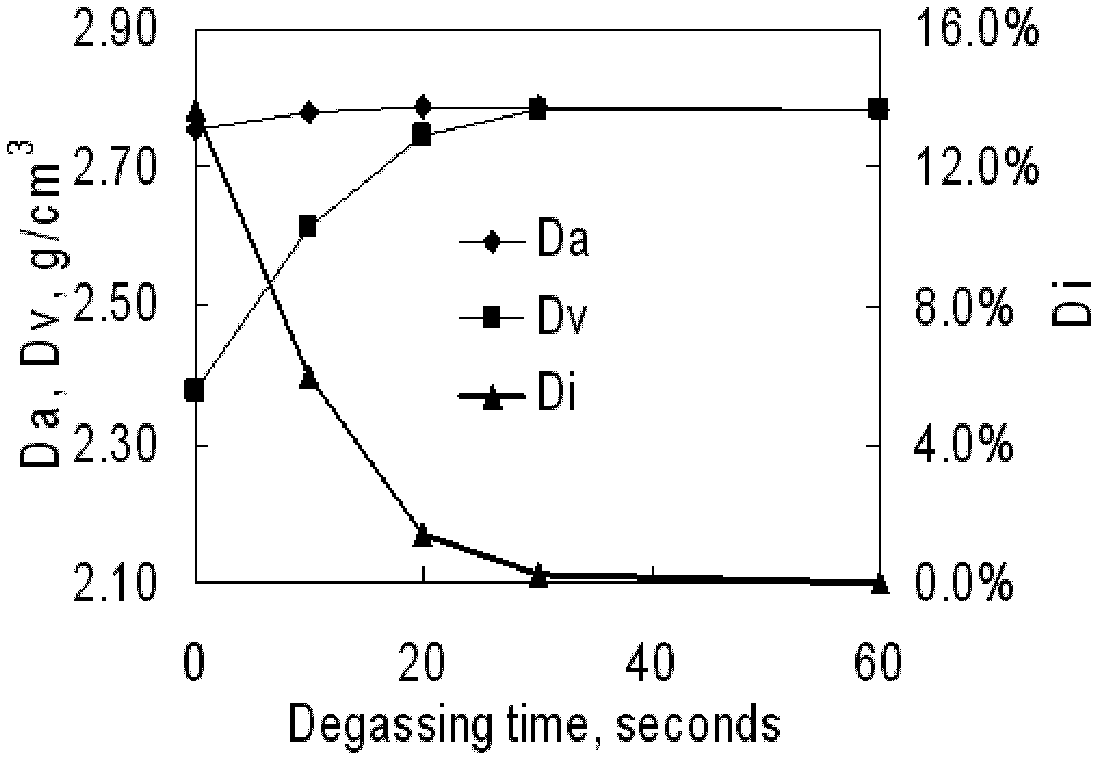

Alloy melt purifier and its method

The invention relates to an alloy melt purifier and its method, the purifier comprises a driving motor, a connection shaft, a stator and a rotor. The driving motor is directly connected with the connection shaft, the end portion of the connection shaft enables fixed connection with the rotor, the connection shaft and the rotor are arranged in the columnar stator, the stator is embedded and fixed in an insulation container, the alloy melt is filled in the insulation container, the stator is immersed in the alloy melt, an aperture is opened on the wall at the lower part of the stator, a vapor pipe is provided at one side of the insulation container, a gas outlet of the vapor pipe is in alignment with the lower part of the lower part of the rotor; The method for purifying the alloy melt by using the purifier comprises the following steps: the alloy melt and inert gas are sucked in the purifier through the high speed rotation of the rotor, high strength shearing effect formed by the stator and the rotor can be used, and the controllable forced convection can be generated under the liquid surface of the alloy melt, thereby the introduced inert gas bubbles can be smashed to fine bubbleswhich are uniformly distributed in the melt, the fine inert gas bubbles absorb impure gas in the melt and overflow the liquid surface, so that the purification of the melt with high efficiency can berealized.

Owner:NORTHEASTERN UNIV LIAONING

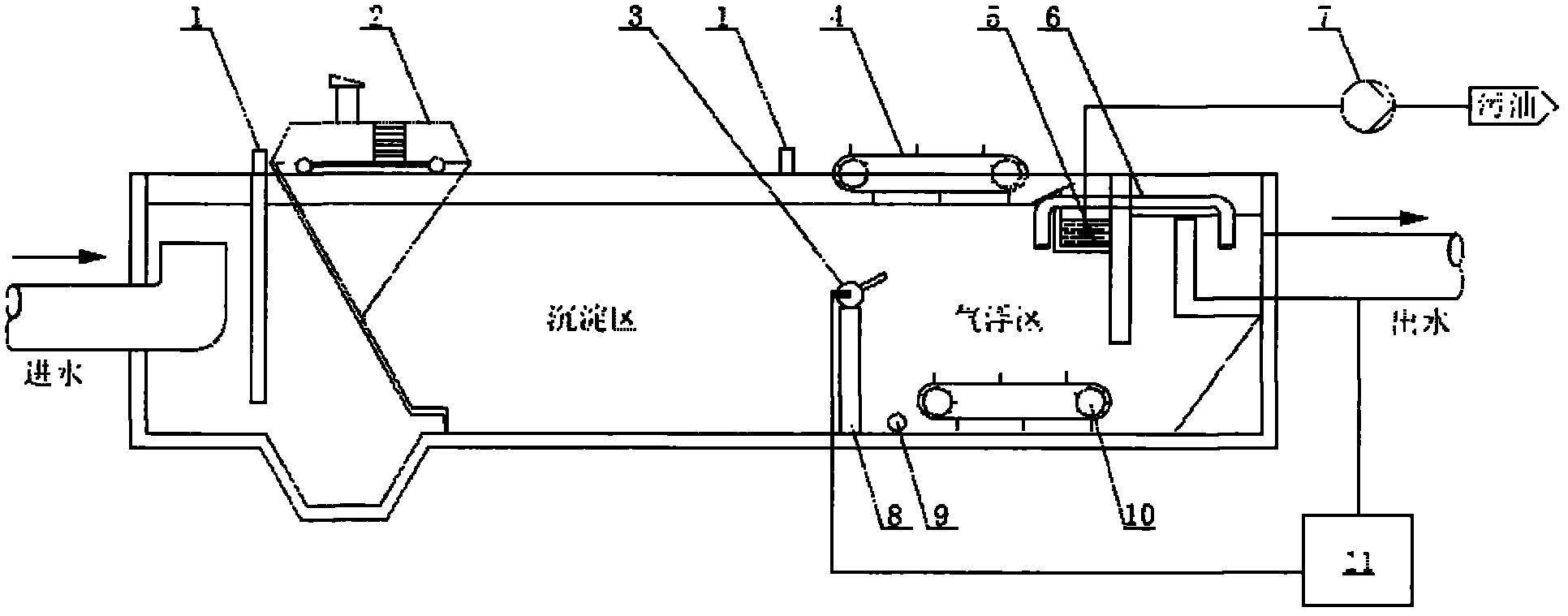

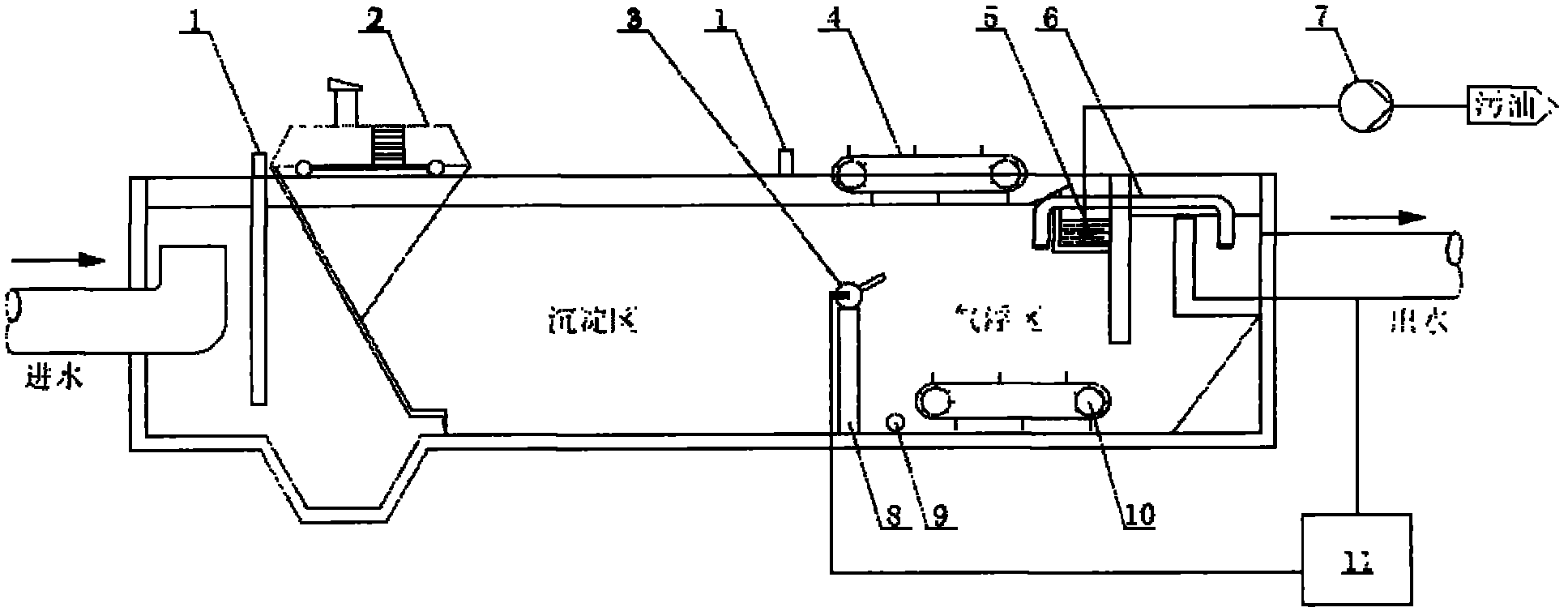

Method modifying horizontal flow sedimentation tank into sedimentation floatation tank and modified sedimentation floatation tank

InactiveCN102583615ALiquid level stabilityEasy to handleFatty/oily/floating substances removal devicesLiquid separationWater volumeControl system

The invention discloses a method modifying a horizontal flow sedimentation tank into a sedimentation floatation tank and the modified sedimentation floatation tank. The detailed method comprises: additionally arranging a separating device in the horizontal flow sedimentation tank to divide the horizontal flow sedimentation tank into a sedimentation area and a floatation area, additionally arranging a gas-dissolved water releaser and mud-discharging, oil-skimming and oil-collecting facilities in the floatation area simultaneously, and dividing the horizontal flow sedimentation tank into the sedimentation area and the floatation area which are independent to each other so that the corresponding functions are achieved well. A gas-dissolved device and a control system are additionally arranged outside the tank. Besides, an overflow pipe is additionally arranged, guarantees stability of the flat liquid level and adapts to the status of addition of treated water quantity, two functions including sedimentation and floatation are achieved, early sedimentation and later floatation are achieved, the treatment effect and the running stability of the horizontal flow sedimentation tank are greatly improved, and the method modifying the horizontal flow sedimentation tank into the sedimentation floatation tank and the modified sedimentation floatation tank are suitable for large-scale pre-treatment of sewage containing oil and suspended matter and can be used for a newly-built system and old equipment modification. Simultaneously, the modularized design achieves old equipment modification of the horizontal flow sedimentation tank in a short construction period, the investment is saved, and the production problem is solved.

Owner:LIAONING HUAFU ENVIRONMENTAL ENG

Qualified medium barrel dilute medium water complementing system and method used for dense-medium coal preparation

ActiveCN104289304AReduce distractionsLiquid level stabilityWet separationMagnetic separatorEngineering

The invention discloses a qualified medium barrel dilute medium water complementing system used for dense-medium coal preparation. The system comprises a dilute medium flow guide device, a dilute medium barrel, a dilute medium pump, a detection module and a control module. The dilute medium flow guide device is connected with a qualified medium barrel and leads dilute media into the qualified medium barrel; the dilute medium barrel is connected with a medium drainage screen and holds the dilute media removed from the medium drainage screen; one end of the dilute medium pump is connected with the dilute medium barrel, and the other end of the dilute medium pump is connected with a dilute medium magnetic separator; the detection module is installed on the qualified medium barrel and is used for detecting the density and the liquid level of dense-medium suspension liquid in the qualified medium barrel and sending density and liquid level parameters to the control module; the control module is installed on the dilute medium flow guide device and is used for controlling the dilute medium flow guide device to start and / or stop introducing the dilute media into the qualified medium barrel according to the density and liquid level parameters of the dense-medium suspension liquid in the qualified medium barrel. The invention further discloses a qualified medium barrel dilute medium water complementing method. By means of the qualified medium barrel dilute medium water complementing system and method, stability of the liquid level and the density of the dense-medium suspension liquid in the qualified medium barrel is guaranteed in dense-medium coal preparation.

Owner:CHINA SHENHUA ENERGY CO LTD +1

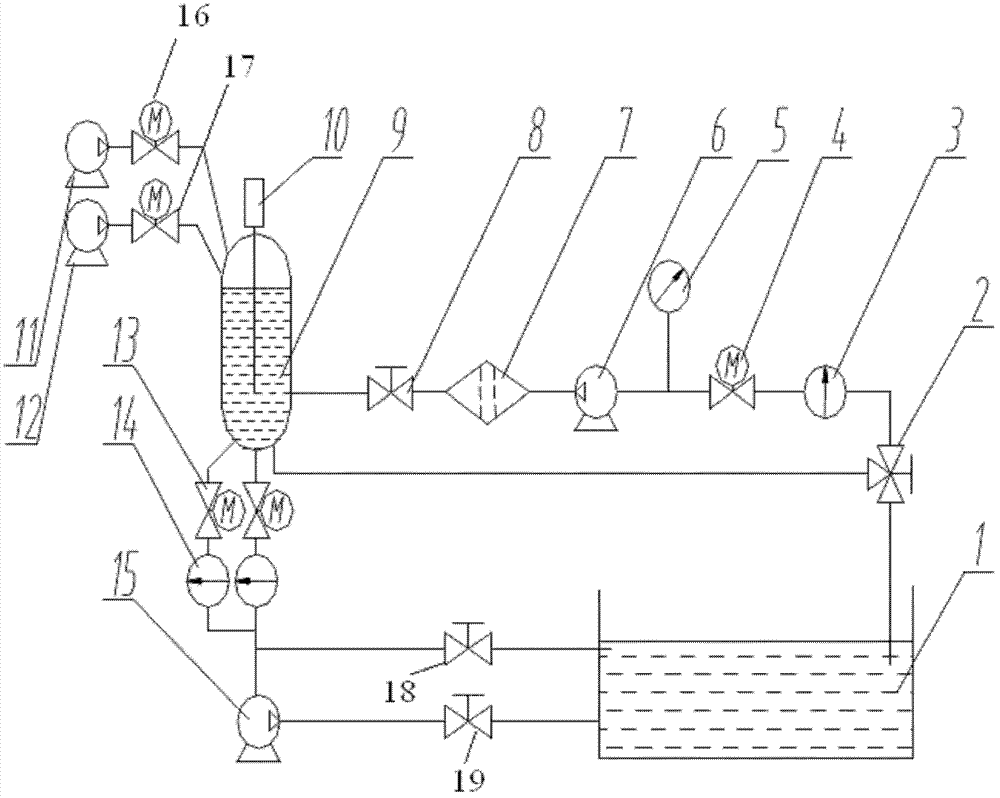

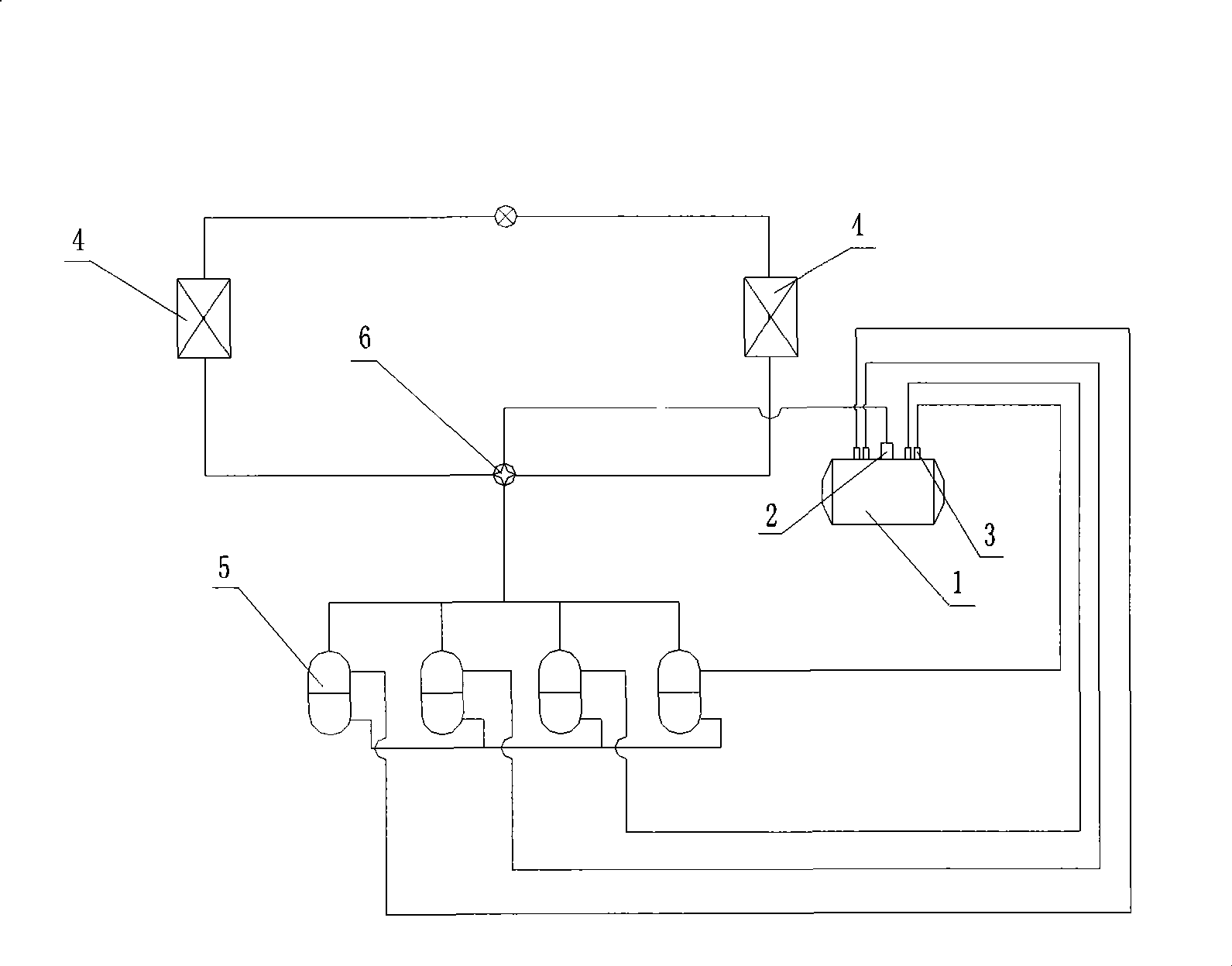

Control system and control method for opening and closing type pump test

ActiveCN103114984AHigh degree of automationHigh measurement accuracyPump testingPump controlElectromagnetic flowmeterWater storage tank

The invention belongs to the technical field of hydraulic transmission and control and particularly relates to a control system and a control method for an opening and closing type pump test. An input end of a booster pump of the system is connected with a pool. An output end is connected with an input end of an electromagnetic flowmeter B. An output end of the electromagnetic flowmeter B is connected with a water supplying opening of a water storage tank and the input end of the electromagnetic flowmeter B is further connected with the pool. A liquid level transmitter is arranged at the top of the water storage tank. A vacuum pump is connected with a vacuum opening of the water storage tank. An air compressor is connected with a booster opening of the water storage tank. An inlet of the water storage tank is connected with an outlet of an electric three-way valve. An outlet of the water storage tank is connected with an input end of a testing pump. An output end of the testing pump is connected with an input end of an electromagnetic flowmeter A. An output end of the electromagnetic A is connected with an operation end of the electric three-way valve. A water discharging end of the electric three-way valve is connected with the pool. According to the system, a cavitation test is performed to a tested pump on the condition of opening or closing and equal liquid level control is performed to liquid in the water storage tank on the condition of opening so that smooth completion of the cavitation test is guaranteed.

Owner:BEIJING AEROSPACE PROPULSION INST

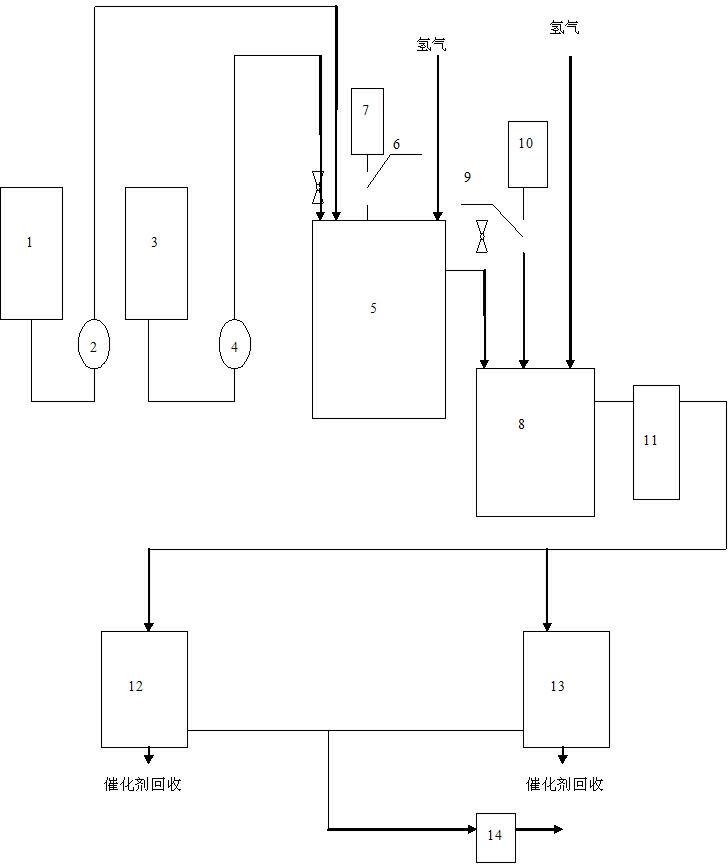

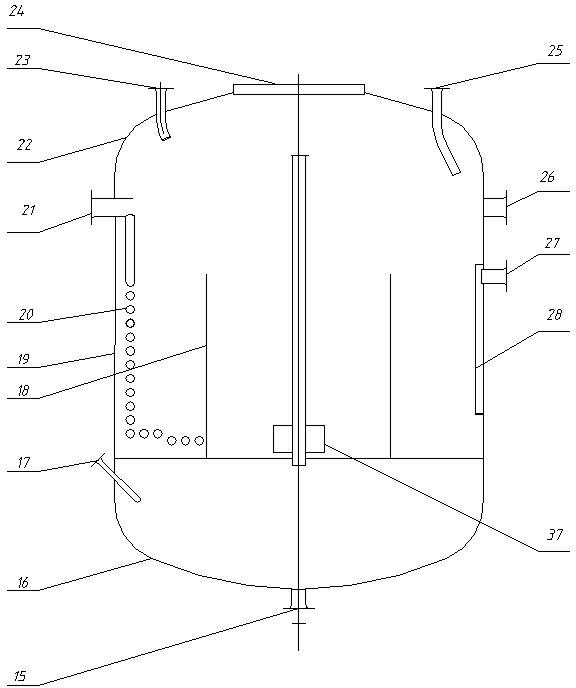

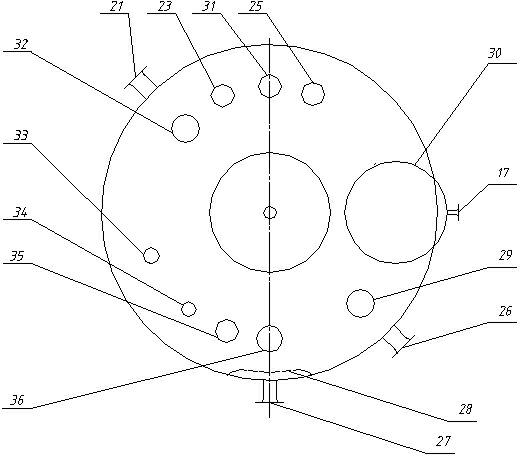

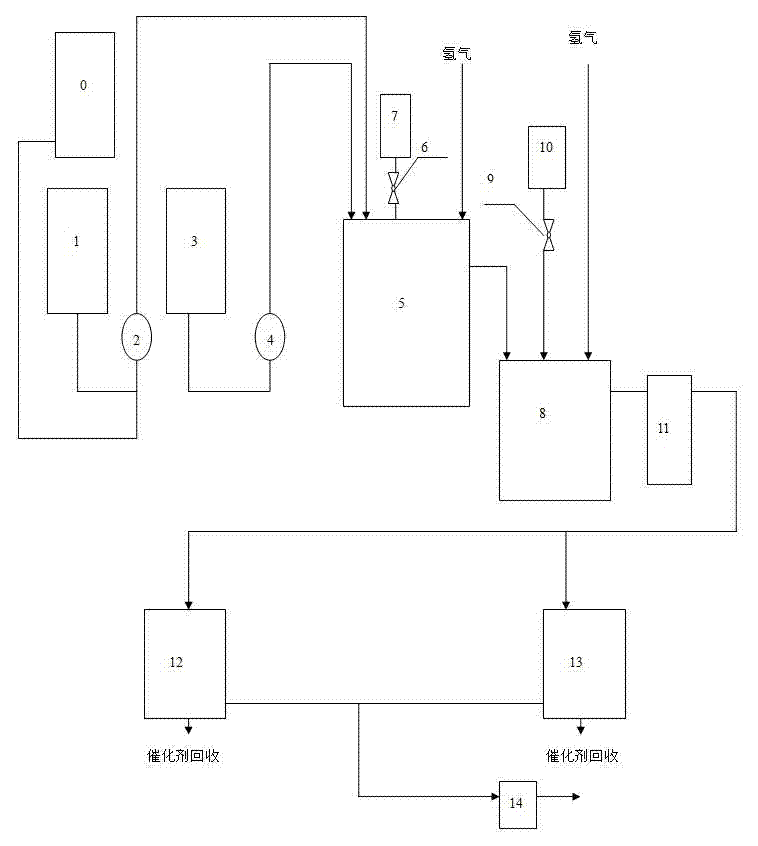

Method and device for producing p-phenylenediamine by using liquid phase continuous hydrogenation method

InactiveCN102276479AIncrease exposureReduce contentOrganic compound preparationChemical recyclingPtru catalystFluid phase

The invention discloses a method and device for producing p-phenylenediamine by using a liquid phase continuous hydrogenation method. The reaction is carried out in first-stage and second-stage hydrogenation reaction kettles which are connected in series. The method comprises the following steps of: adding methanol which is 50-70% of the volume of the reaction kettles into the first-stage and the second-stage hydrogenation reaction kettles, adding a catalyst which is 0.5-1.5% of the methanol, and continuously introducing hydrogen into the first-stage and the second-stage hydrogenation reaction kettles in a stirring state; after reaching a certain pressure in the first-stage and the second-stage hydrogenation reaction kettles, continuously adding methanol and paranitroaniline into the first-stage hydrogenation reaction kettle, continuously keeping the pressure in the first-stage and the second-stage hydrogenation reaction kettles, meanwhile, discharging from the first-stage hydrogenation reaction kettle to the second-stage hydrogenation reaction kettle, and continuously discharging from the second-stage hydrogenation reaction kettle; recycling the catalyst from the reaction liquid from the second-stage hydrogenation reaction kettle through a settling tank; and removing methanol and water by rectifying the reaction liquid after the catalyst is recycled so as to obtain the p-phenylenediamine. The method and the device disclosed by the invention have the advantages of low cost, high yield, good safety and environment friendliness.

Owner:JIANGSU KESHENG CHEM MACHINERY

Continuous casting method and device for aluminum alloy compounded ingot

The invention discloses a continuous casting method and a continuous casting method for an aluminum alloy compounded ingot and belongs to the technical field of aluminum alloy casting. The device comprises a split crystallizer, an alloy liquid distributor, a hot top plate and a dummy ingot; the upper part of the dummy ingot is fixedly connected with two baffle plates; the upper part of each baffle plate is connected with a cooling plate; and two cooling plates divide the interior of the split crystallizer into a core material melt cavity and a coating material melt cavity. The method comprises the following steps of: smelting, refining and standing two kinds of alloys to be compounded; introducing cooling water into a cooling plate water cavity and a water box and keeping the water flowing; leading the core material alloy liquid into the core material melt cavity; leading the coating material alloy liquid into the coating material melt cavity; and starting the aluminum alloy and casting. The device and the method can ensure that the coating material alloy liquid flow uniformly and has a stable liquid surface and uniform temperature, and can eliminate the triangular area with high cooling intensity, ensure that a supporting surface formed under the cooling plate has the uniform temperature along the horizontal direction of the cooling plate and ensure the comprehensive metallurgical combination of the compounded surface.

Owner:NORTHEASTERN UNIV

Method and device for dynamically balanced collection of oil slick and scum

ActiveCN101684645AAbility to seek balanceRealize dynamic balance working stateWater cleaningGeneral water supply conservationInlet channelEnergy consumption

The invention discloses a method for the dynamically balanced collection of oil slick and scum, which is a method for the overflow and flow-collecting collection of the oil slick and scum by vertically placing an oil slick and scum collecting barrel on a water surface, and is characterized in that: the upper part of the oil slick and scum collecting barrel is provided with a liquid inlet channel;the lower part of the oil slick and scum collecting barrel is provided with a liquid outlet channel and a sealed cavity with an adjustable spatial height; the sealed cavity is communicated with a liquid outlet channel at the lower part of the collecting barrel and a pumping system; a buoyancy balancing member is arranged outside the collecting barrel; and the sealed cavity is connected with the buoyancy balancing member. A device for the dynamically balanced collection of the oil slick and scum which is designed according to the method for the dynamically balanced collection comprises a flow collecting device and a water draining device, and also comprises an oil discharge device when collecting oil slick. The device has the advantages of simple structure, low energy consumption, high efficiency, no secondary pollution, wide application range and the like.

Owner:黄海峰

Coal separating process of crude coal slime hydroseparation

The invention relates to a coal separating process of crude coal slime hydroseparation, belonging to a coal separating technology. The following technological procedures are added to a traditional crude coal slime hydroseparation process: coal slime water enters a coal slime screen drainage pool and then is conveyed into an inclined plate depositing tank through a water pump to finish the concentration and grading operations of the coal slime water, wherein an inclined plate overflows and enters a flotation system, and the bottom of the inclined plate flows through a buffer tank and enters a crude coal slime hydroseparator; and circulating water in a circulating water pool is sent into the crude coal slime hydroseparator for carrying out separation operations through a water circulating pump, a valve, a check valve, a pressure reducing valve, a pressure gage and an electromagnetic flow meter through a U-shaped pipeline. The process improves the separation effect and the separation efficiency of the crude coal slime, reduces the coal loss and the coal separation processing cost and optimizes the coal separation and treatment process of the crude coal slime.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Flat plate electroplating experiment device for electrolytic copper foil

InactiveCN110205657ALiquid level stabilityStable temperatureCellsElectroforming processesLow voltageLiquid storage tank

The invention discloses a flat plate electroplating experiment device for electrolytic copper foil. The device comprises an electrolytic cell, a liquid storage tank, an electrolyte circulating system,a temperature control system and a power supply; a cathode titanium plate and an anode plate are arranged in the electrolytic cell; the power supply is a low-voltage high-current rectifier; the electrolyte circulating system is composed of a magnetic pump a valve, a flow meter and a pipeline connected between the liquid storage tank and the electrolytic cell, overflow plates on the two sides of the electrolytic cell, overflow holes positioned in a bottom plate of the electrolytic cell and the like; the temperature control system consists of a temperature controller and a heating rod which isconnected with the temperature controller and is arranged at the lower end of the liquid storage tank; and the anode plate and the cathode plate are parallel to each other and the distance between theanode plate and the cathode plate is adjustable. By means of the flat plate electroplating device, the condition of an electrolytic copper foil production line can be well simulated, the process parameters are convenient to adjust, and the influence of each parameter on the copper foil performance is easily analyzed.

Owner:ZHEJIANG UNIV +1

Technological process of making flat spring steel for automobile

The flat spring steel for automobile is produced via converter smelting process. Compared with available technology, the present invention has the following advantages and positive effects: utilizing molten iron with less harmful elements as material to result in high flat spring steel quality; higher finished product rate and lower power consumption to result in lower cost than production in electric furnace; casting molten steel into small square billet to omit the billet cutting step and lower cost; and high size precision of the continuously cast small square billet to ensure high size precision of flat spring steel.

Owner:青岛钢铁控股集团有限责任公司

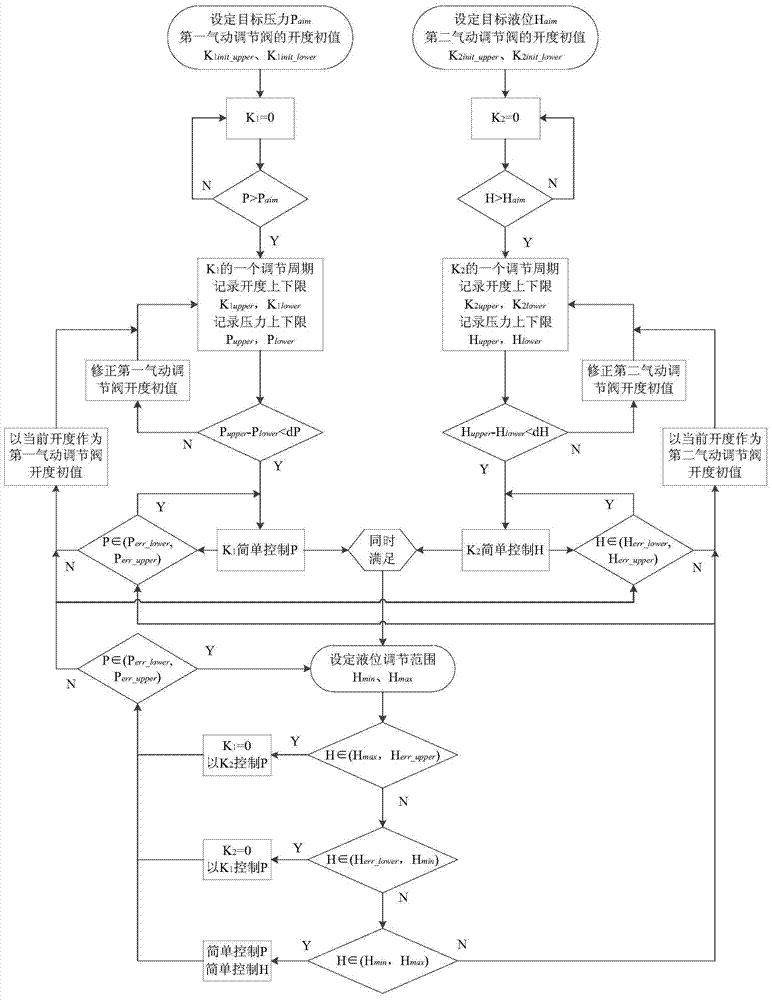

Liquid level-pressure coordinated control method used for gas-liquid separator

ActiveCN104850158AEasy to separateStable pressureSimultaneous control of multiple variablesVapor–liquid separatorGas phase

The invention relates to a liquid level-pressure coordinated control method used for a gas-liquid separator, used to set a liquid level-pressure coordinated control device. The method comprises: presetting each target value and opening initial values; determining whether gas-phase pressure is larger than a preset gas-phase pressure target value, calculating a valve opening value of a first pneumatic control valve and feeding back to a valve to operate; determining the relations between the difference value of the maximum value and the minimum value of pressure measuring values and pressure fluctuation errors; determining whether liquid level measuring values are larger than a preset liquid level height target value, calculating the valve opening value of a second pneumatic control valve and feeding back to a valve to operate; determining relations between the difference value of the maximum value and the minimum value of liquid level measuring values and liquid level fluctuation errors; performing simple control on gas-phase pressure and liquid level height in the gas-liquid separator; determining received liquid level height; and a liquid level-pressure operation control module determining whether the received gas-phase pressure exceeds an error range, and determining whether the received liquid level height exceeds an error range.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Diesel engine external-cycle oil tank structure

ActiveCN103437854ALiquid level is stableTimely exclusionMachines/enginesLubricant mounting/connectionProduct gasOil temperature

The invention relates to a diesel engine external-cycle oil tank structure which comprises an oil-gas separator assembly (2), an oil tank internal oil return bayonet tube (3), a defoaming partition (4), a lubricating oil heat exchanger (6) and an oil tank longitudinal partition (9), wherein the middle part of the oil tank is divided into a front oil storage unit (10) and a back oil storage unit (11) by the oil tank longitudinal partition (9); the oil tank longitudinal partition (9) is aligned and welded with the upper edge of the oil tank; the back oil storage unit (11) comprises the oil tank internal oil return bayonet tube (3), the defoaming partition (4) and a diesel engine oil inlet (14); the front oil storage unit (10) is provided with an oil filler hole (011); and the oil-gas separator assembly (2) is arranged on the upper part of the back oil storage unit (11), and communicated with the cavity part of the back oil storage unit (11). The invention can discharge gas in an oil solution in time, and prevents the oil gas from polluting the surrounding environment. The invention can also be used for filtering the oil solution and controlling the oil temperature; and a liquid level indicator is utilized to observe the liquid level, and measure and record the liquid level variation.

Owner:CHINA NORTH ENGINE INST TIANJIN

Fuel tank with oil collection device

ActiveCN105317601AImprove capacity utilizationLiquid level is stableMachines/enginesLiquid fuel feedersFuel tankOperation safety

The invention relates to fuel tanks in order to overcome the defect that an existing fuel tank oil collection device has a poor oil collection effect, and discloses a fuel tank with an oil collection device. The fuel tank comprises a tank body; an oil suction pipe is arranged at the bottom inside the tank body; the oil collection device comprises a vertically upward coaming on a bottom board inside the tank body; an oil collection cavity is defined by the coaming on the bottom board of the tank body; the coaming is provided with an oil collection channel in the horizontal direction; the oil collection channel is attached to the bottom board of the tank body and communicates the interior and the exterior of the oil collection cavity; the two ends of the oil collection channel are located in front and back of an oil suction opening of the oil suction pipe respectively. The oil collection device of the fuel tank further comprises an oil collection tank reversely fixed in the tank body; a tank opening of the oil collection tank is located in the bottom of the oil collection cavity; the oil suction opening of the oil suction pipe is located in the oil collection tank and in the position slightly lower than the tank opening of the oil collection tank; an exhaust device used for exhausting air towards the exterior of the tank body in a single direction is arranged on the top of the oil collection tank. The liquid face in the position of the oil suction opening of the oil suction pipe of the fuel tank is stable, operation safety of equipment is improved, and the volume utilization ratio of the fuel tank is high.

Owner:GUANGXI LIUGONG MASCH CO LTD

Gas-liquid separator suitable for air conditioning system with multi-compressor parallel connection

InactiveCN101430151AInhale evenlyInspiratory pressure is the sameRefrigeration componentsVapor–liquid separatorEngineering

A gas-liquid separator suitable for an air conditioning system with a plurality of parallel compressors relates to the gas-liquid separator in the air conditioning technical field. The gas-liquid separator comprises a shell, and a refrigerant feed tube and an air suction tube which are connected with the upper end of the shell. The structural feature of the gas-liquid separator is as follows: the refrigerant feed tube is a manifold communicated with the inner cavity of the shell, the air suction tube comprises a plurality of U-shaped tubes which are arranged at the bottom of the inner cavity of the shell, and the lower U-shaped section of each air suction tube is provided with a plurality of oil absorption holes. Compared with the prior art, the gas-liquid separator can smoothly take lubricating oil deposited in the pipeline of the system back into compressors to cause uniform oil return of each compressor and equalize suction pressure and suction amount of all compressors.

Owner:WUXI TONGFANG ARTIFICIAL ENVIRONMENT +2

Method and device for producing phenylenediamine by taking water as solvent through liquid phase continuous hydrogenation method

ActiveCN102827008AIncrease exposureReduce consumptionOrganic compound preparationAmino compound preparationNitro compoundPtru catalyst

The invention discloses a method and device for producing phenylenediamine by taking water as a solvent through a liquid phase continuous hydrogenation method. The method comprises the following steps of: adding a mixed solution of water and phenylenediamine into primary and secondary hydrogenation reaction kettles, adding a catalyst, and continuously introducing hydrogen into the primary and secondary hydrogenation kettles in a stirring state; after certain pressures are achieved in the primary and the secondary hydrogenation kettles, continuously adding water and a p-aromatic nitro compound into the primary hydrogenation reaction kettle, continually keeping the pressure in the primary and secondary hydrogenation kettles, discharging from the primary hydrogenation kettle to the secondary hydrogenation kettle, and continuously discharging from the secondary hydrogenation kettle; recovering the catalyst from a reaction liquid drained from the secondary hydrogenation kettle through a settling tank; and dehydrating the reaction liquid from which the catalyst is recovered by rectifying to obtain finished phenylenediamine. In the method and the device, water is taken as a solvent, so that solvent consumption and investment of equipment for recovering the solvent are saved, the production cost of the phenylenediamine is lowered, the operating safety is enhanced, and damages of a toxic solvent on operating personnel are avoided.

Owner:JIANGSU KESHENG CHEM MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com