Automatic charging device for single crystal furnace and operation method of automatic charging device

An automatic feeding device and single crystal furnace technology, applied in the direction of single crystal growth, single crystal growth, polycrystalline material growth, etc., can solve the phenomenon of broken ridge line or broken crystal line, polycrystalline growth, feeding quantity and crystal growth Match the quantity and other issues to achieve the effect of stable liquid level and avoid splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

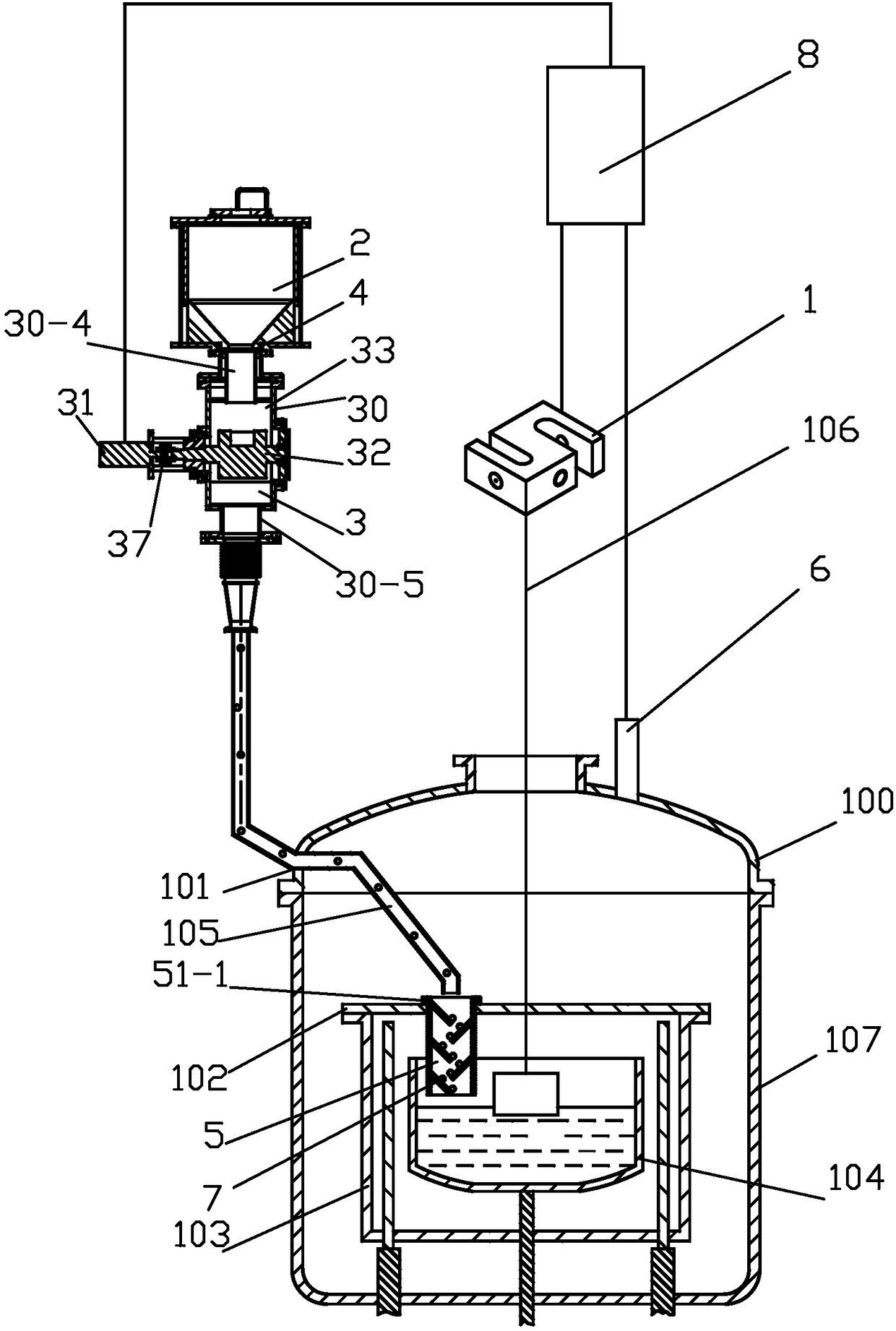

[0041] See figure 1 The automatic feeding device of the single crystal furnace in this embodiment includes a weighing mechanism 1 , a material storage box 2 , a feeding mechanism 3 , a valve, a material buffer device 5 , a liquid level tracking mechanism 6 and a main controller 8 . The valves include a first valve 4 and a second valve. The weighing signal output terminal of the weighing mechanism 1, the control terminal of the motor, the respective control terminals of the first valve 4 and the second valve, and the output terminal of the laser ranging signal of the liquid level tracking mechanism 6 are all electrically connected to the main controller or wireless signal connect.

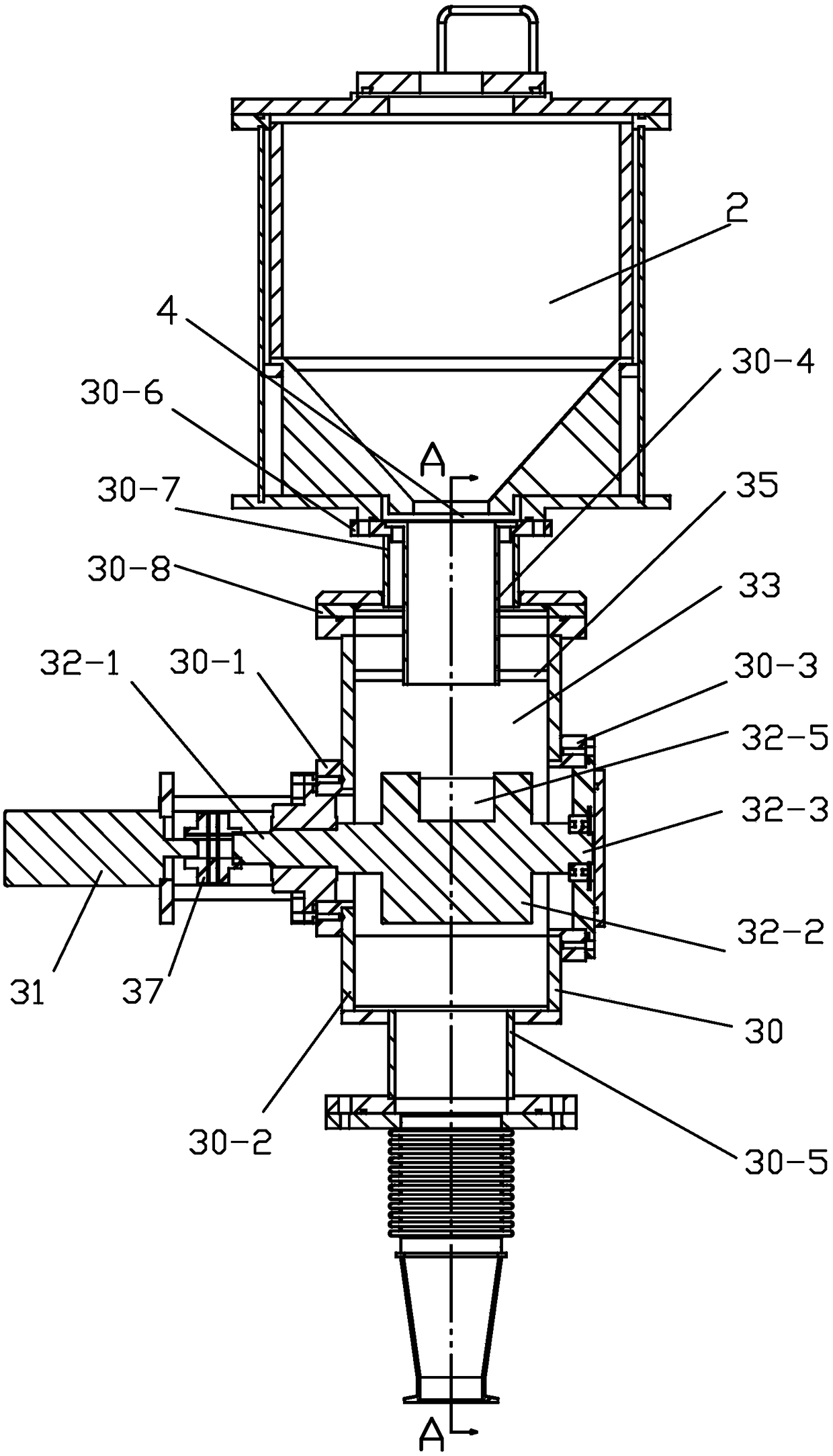

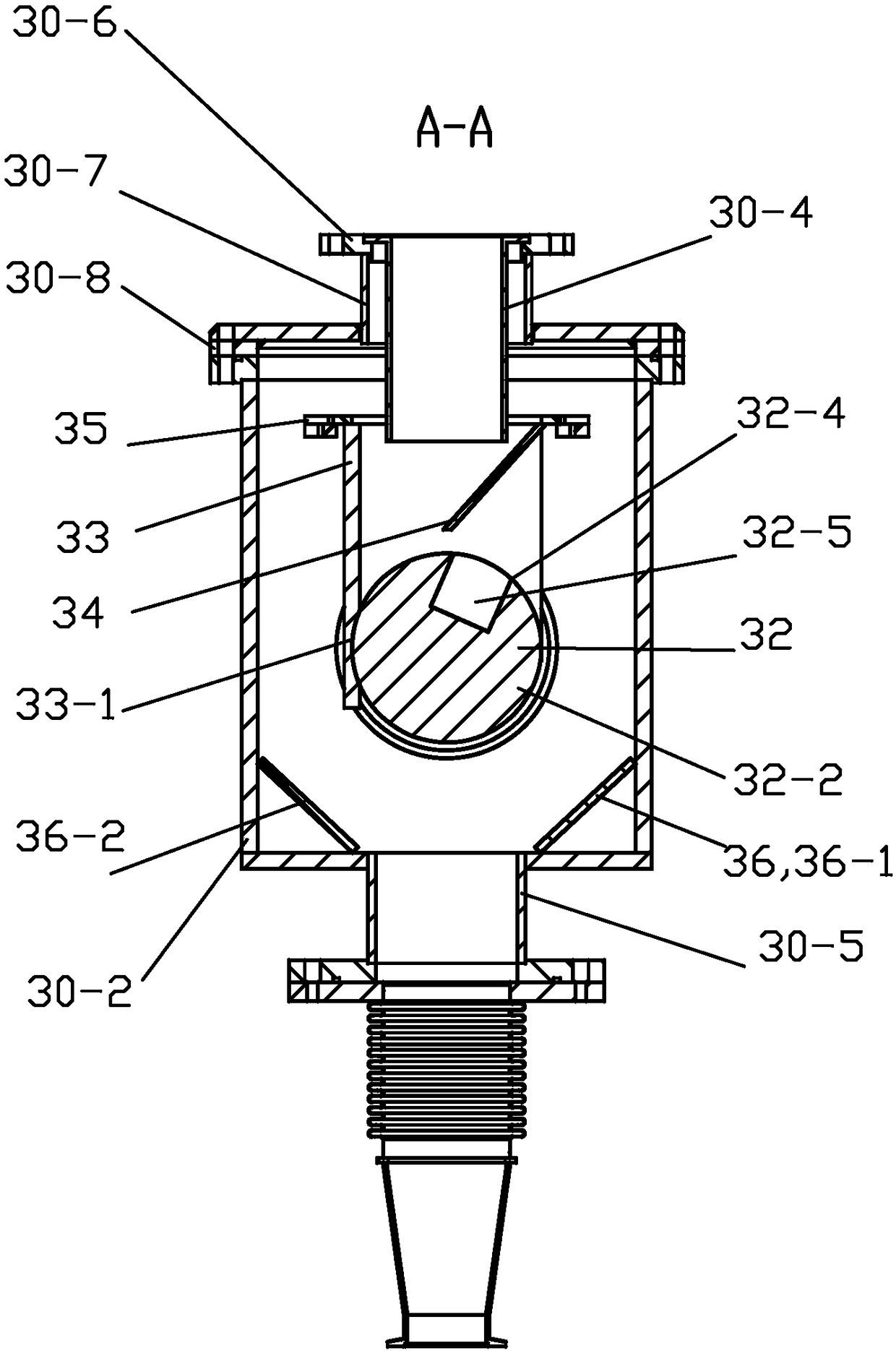

[0042] See Figure 1 to Figure 3 , the feeding mechanism 3 includes a material box 30 , a motor 31 , a rotating shaft 32 , a baffle plate 33 , a material guide plate 34 , a connecting plate 35 , a guide plate 36 and a coupling 37 . The materials of the material box 30, the rotating shaft 32, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com