Laser-electrolysis composite machining device and method of tiny holes in non-recast layer

A technology of compound machining and tiny holes, applied in the field of laser-electrochemical compound machining devices without tiny holes in the recast layer, can solve the problems such as insufficient removal of the recast layer, damage to important parts of the workpiece, and difficulty in removing dead corners, achieving electrolytic machining. The effect of good quality, high quality and efficient processing, and reduced workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

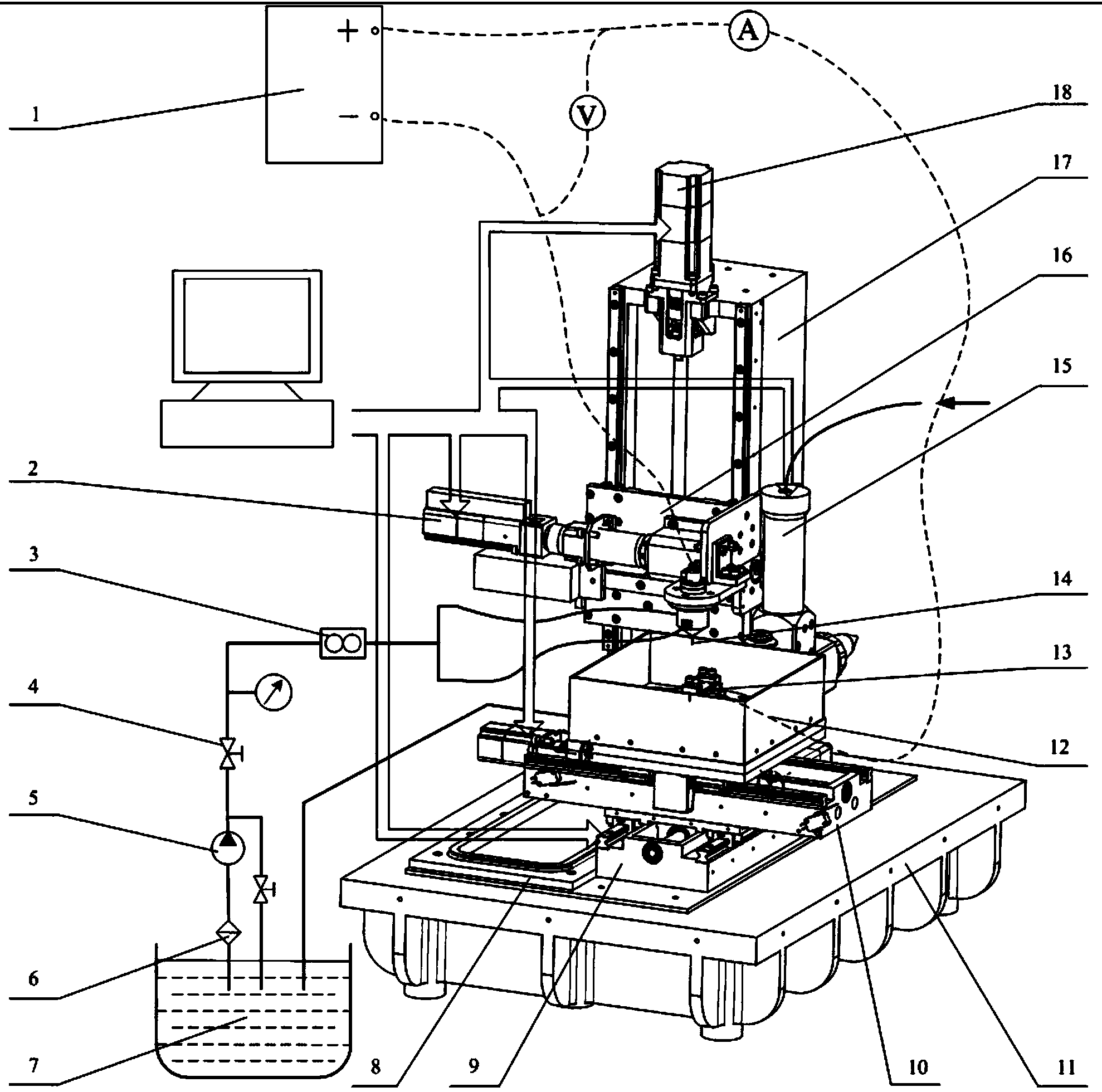

[0032] The present invention will be further described below in conjunction with the drawings.

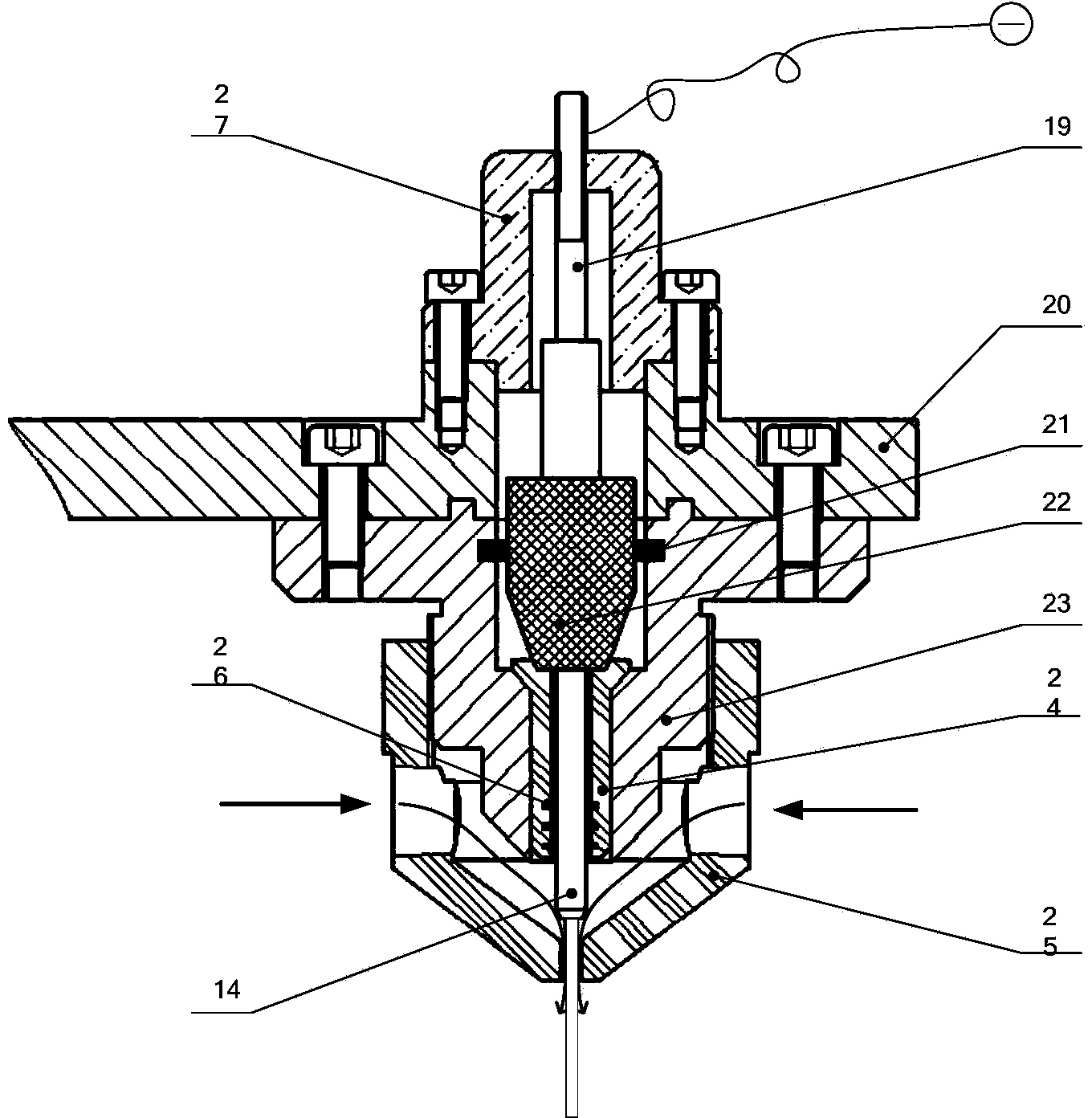

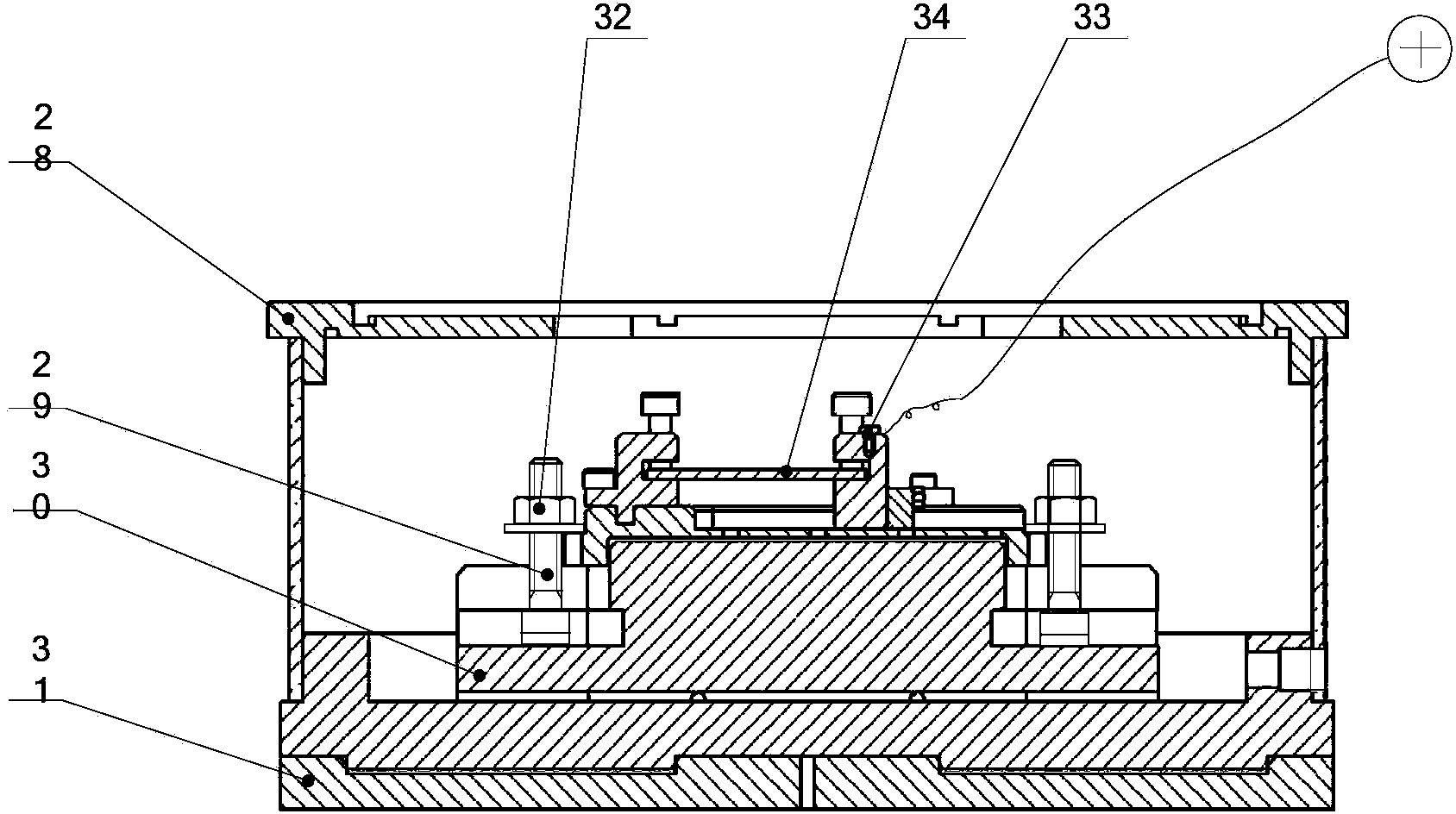

[0033] See figure 1 , A laser-electrolytic composite processing device without micro-holes in the recast layer includes a machine tool base 11 provided with a workpiece fixture 13, a machine tool column 17 is vertically provided on the machine tool base 11, and a y-axis worktable 10 is provided under the workpiece fixture 13. An x-axis worktable 9 is arranged under the y-axis worktable 10, and a positioning plate 8 is arranged on one side of the x-axis worktable 9. The conversion motor 2 is fixed on the machine tool column 17 through the z-axis worktable 16, and the z-axis worktable 16 is connected There is a z-axis servo motor 18, the x-axis worktable 9, the y-axis worktable 10 and the z-axis worktable 16 are all connected to the computer, and the electrochemical machining system fixed on the machine tool column 17 is fixed on the machine tool column 17 and converted by the conversion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com