Patents

Literature

39results about How to "Large aperture range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

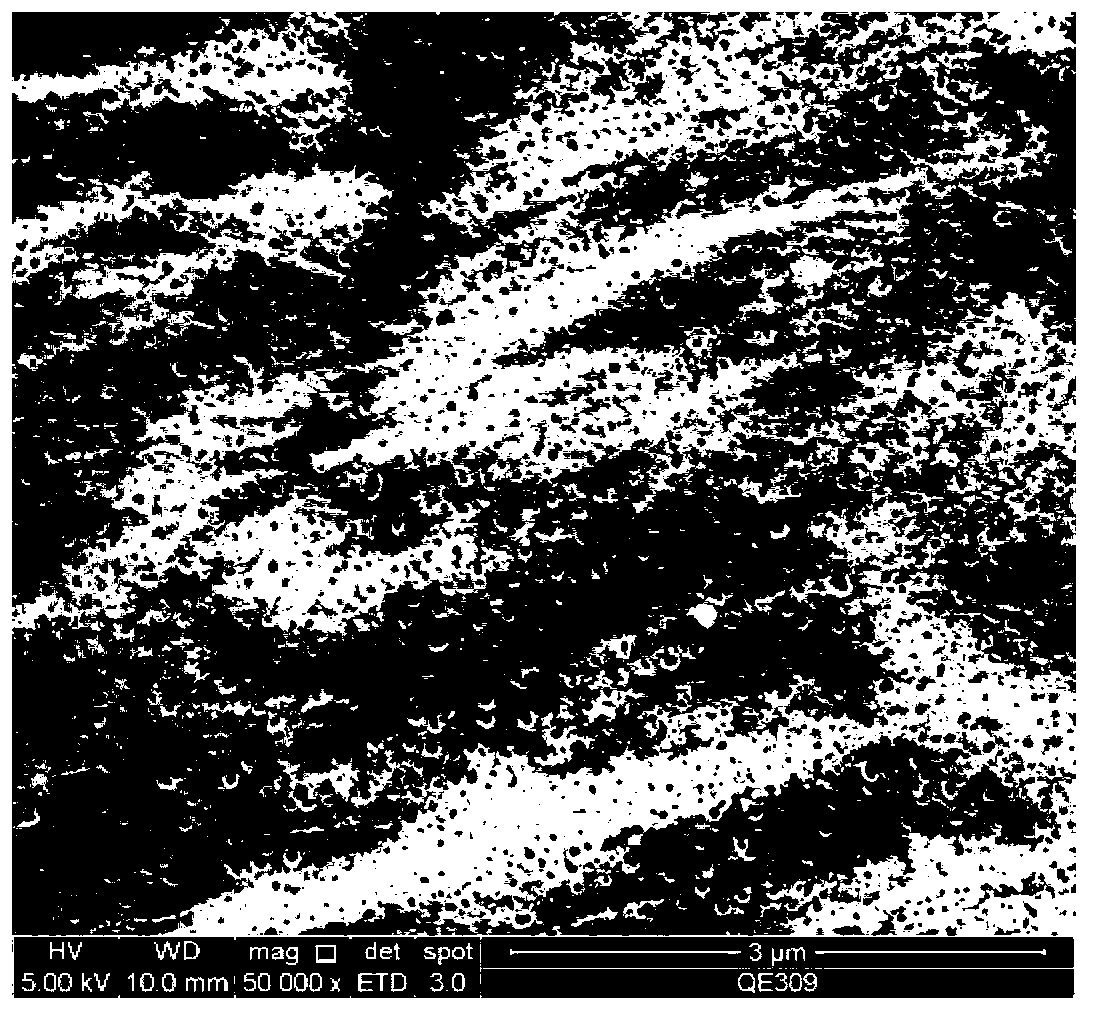

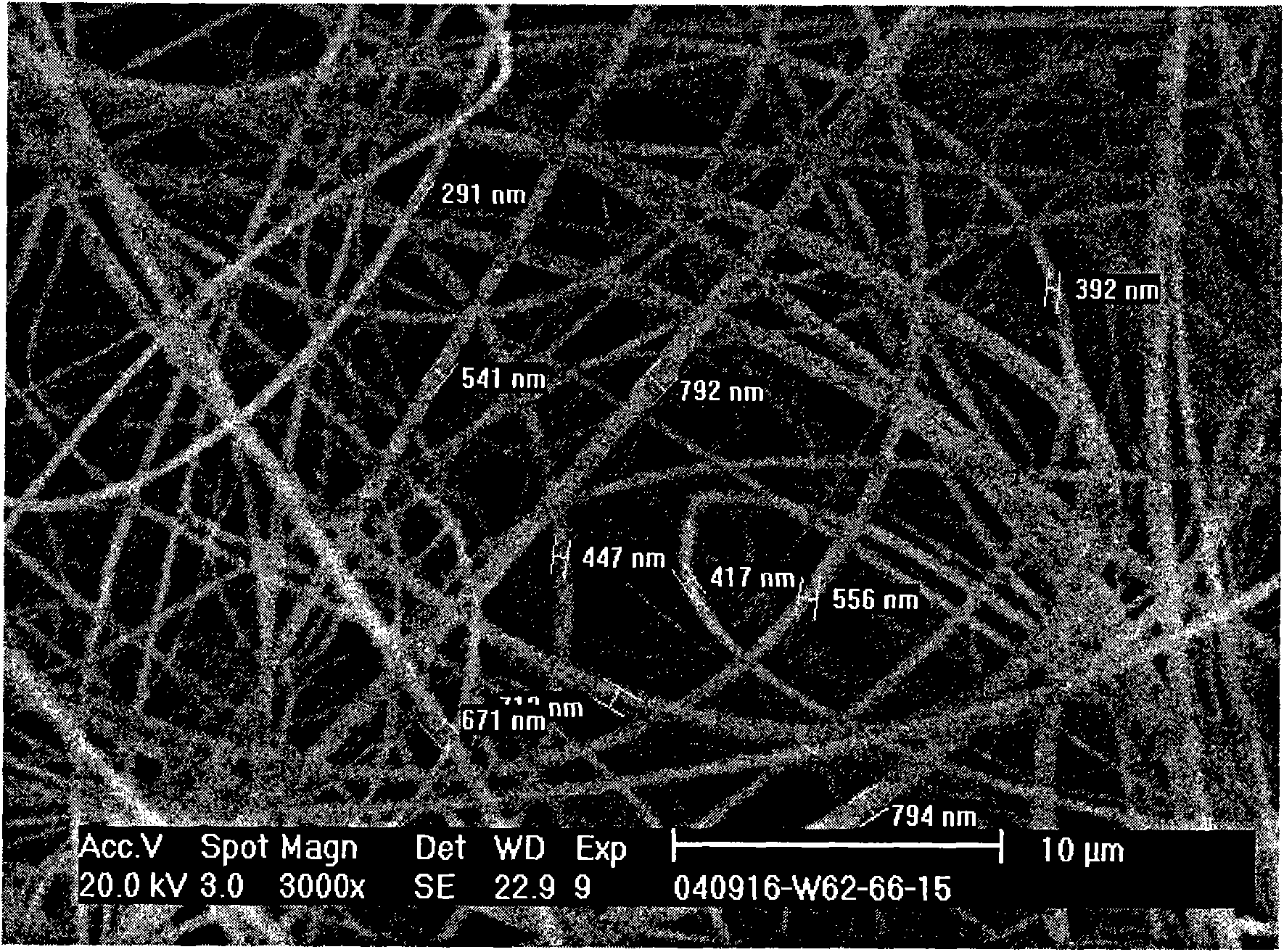

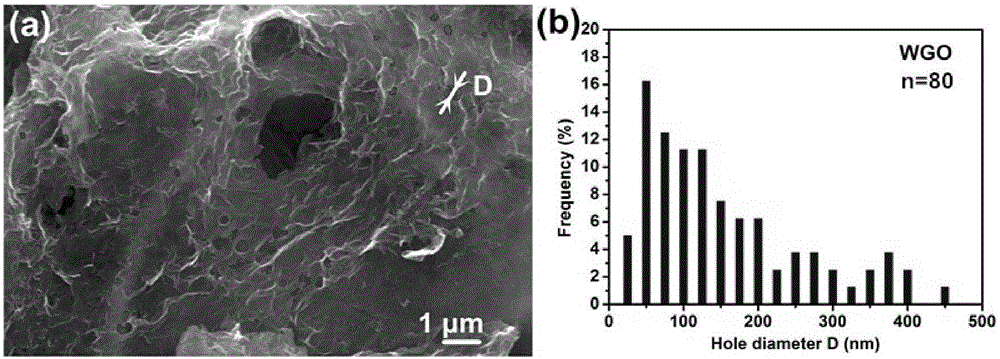

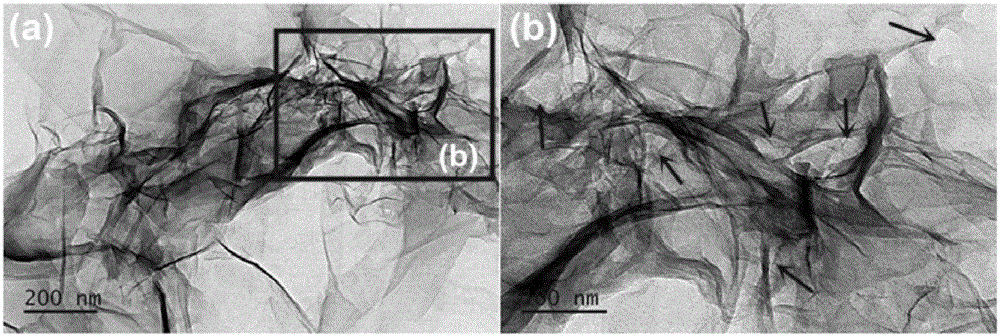

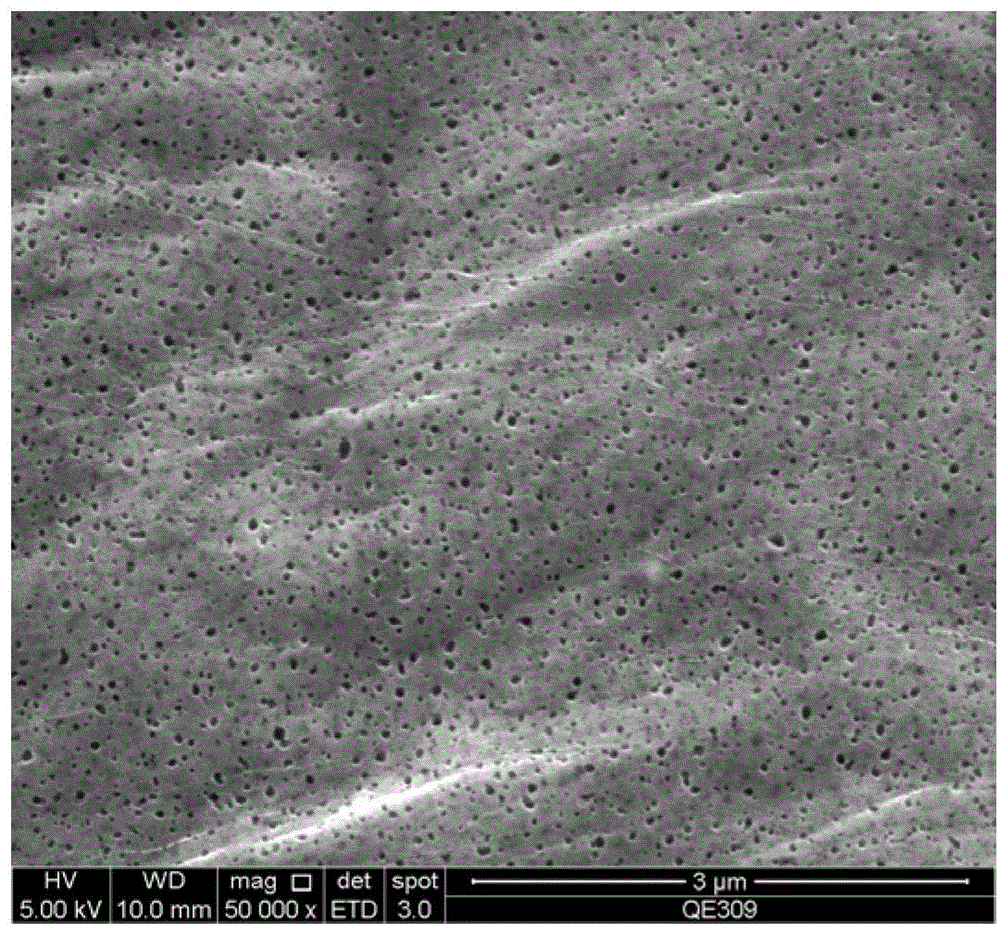

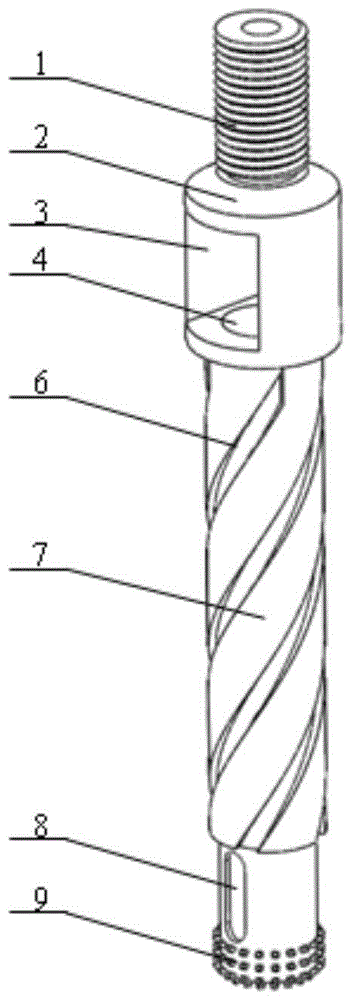

Preparation method of porous graphene

The invention provides a preparation method of porous graphene. The method comprises the steps of: heating a carbon material and an activator; obtaining the porous graphene after reaction, wherein the carbon material is modified graphene or graphene, and the activator is a transitional metal or a transitional metal compound; in the process of preparing the porous graphene, heating the graphene or the modified graphene and the activator: the transitional metal or the transitional metal compound to form a transitional metal carbide; further decomposing the transitional metal carbide into carbon and transitional metal to obtain the transitional metal for continuously reacting with the graphene; and circulating in this way to finally obtain the porous graphene. Compared with the prior art, as the transitional metal and the carbon material are reacted circularly, the porous graphene with larger aperture range can be obtained. Experimental result shows that the diameter of the porous graphene prepared by the invention is 1-100nm.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

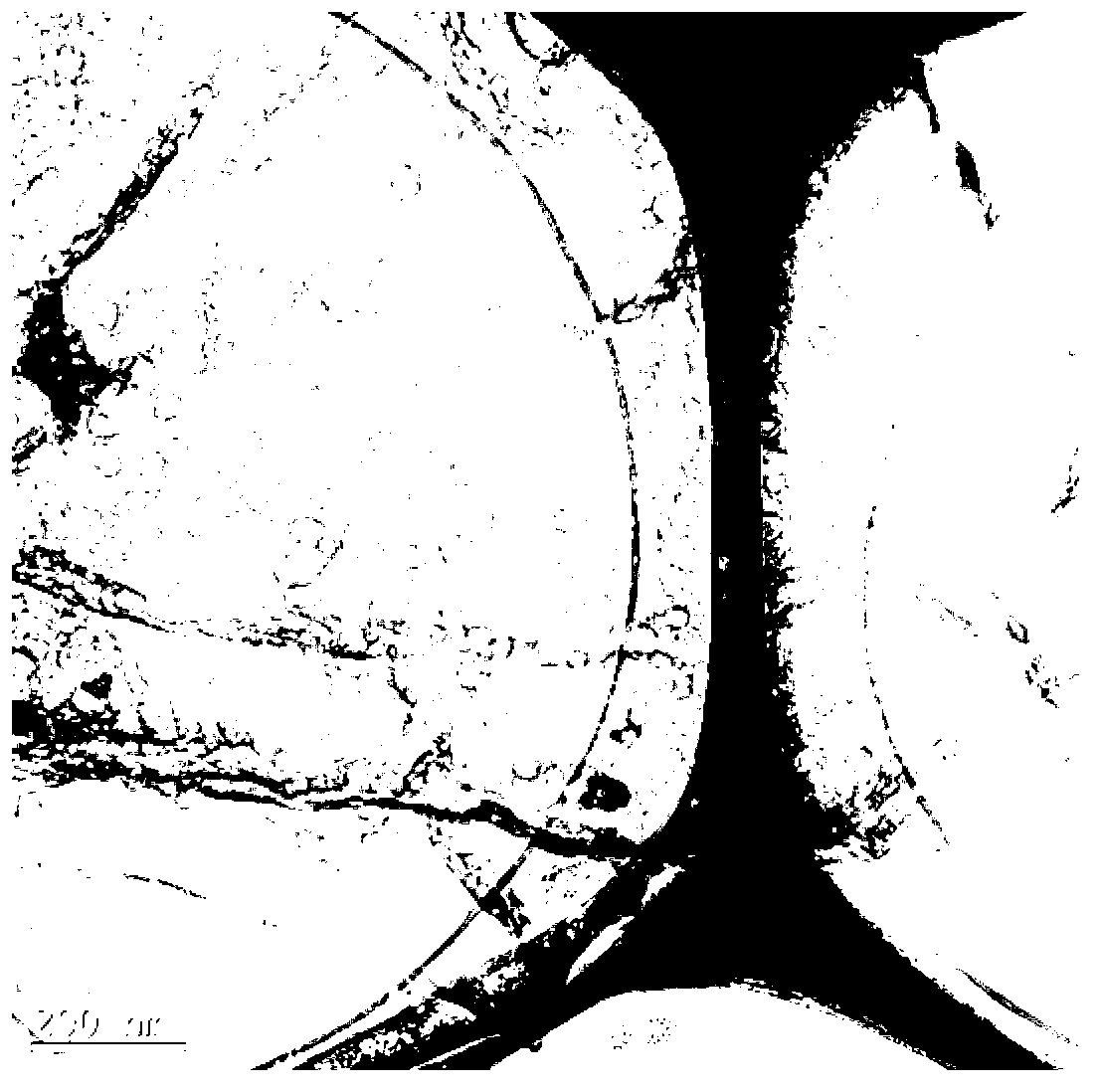

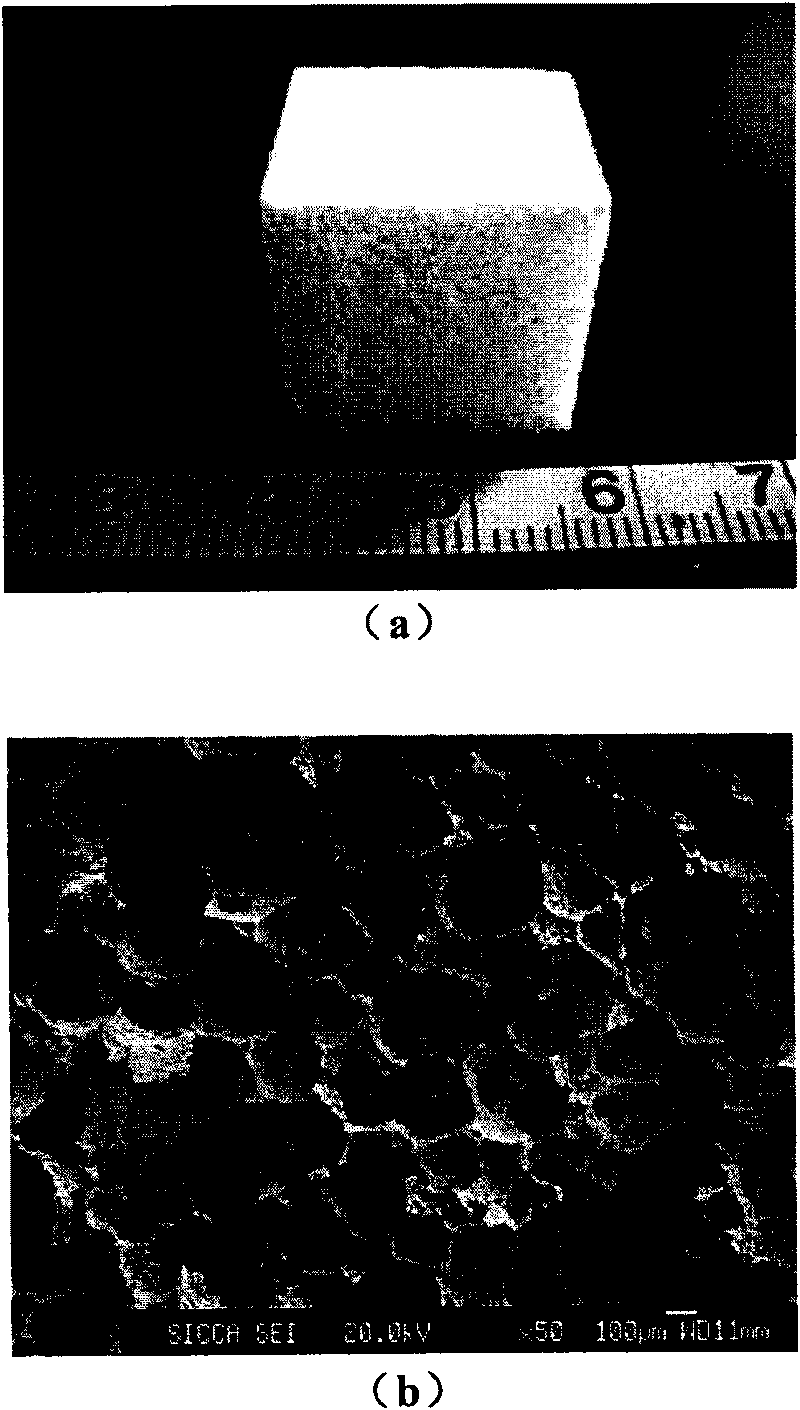

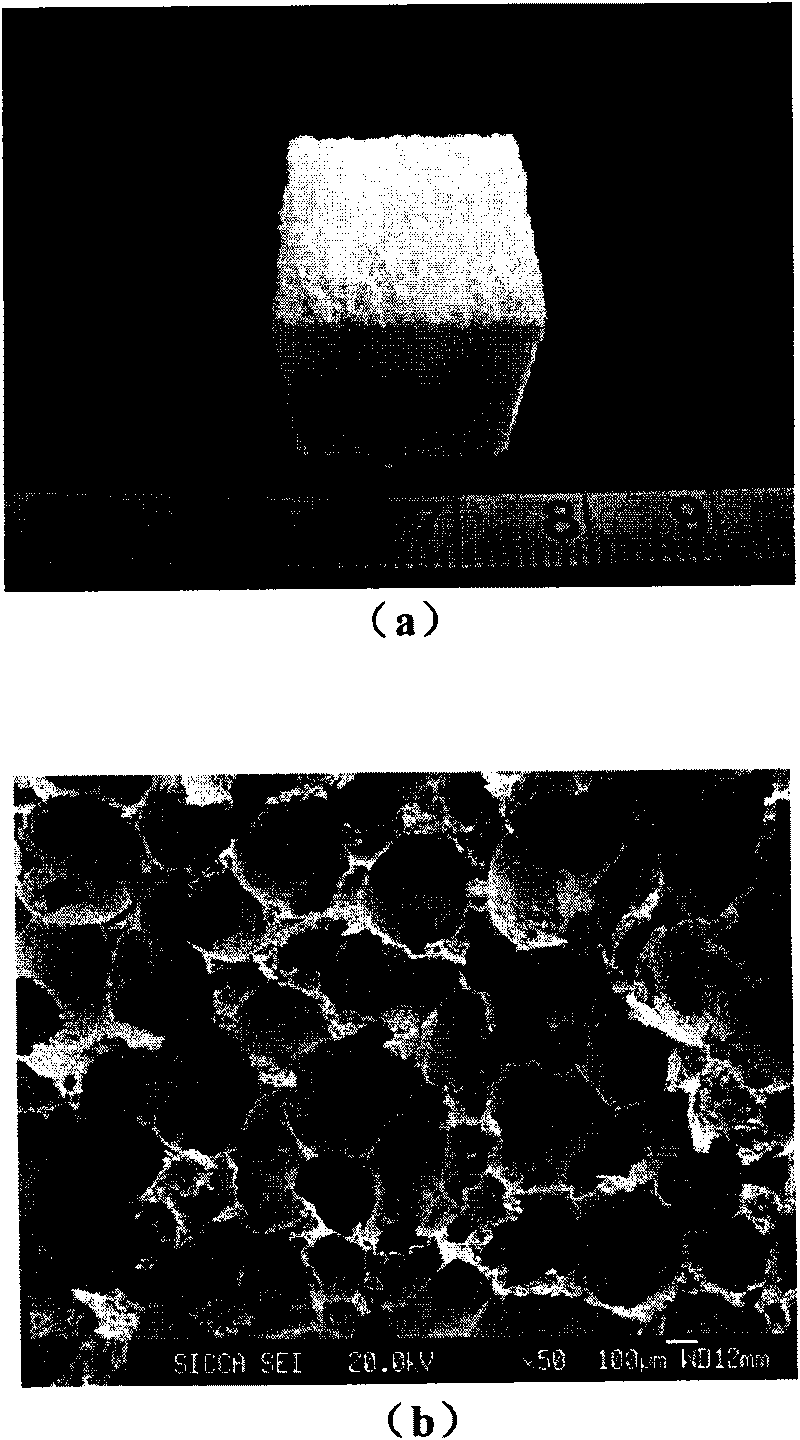

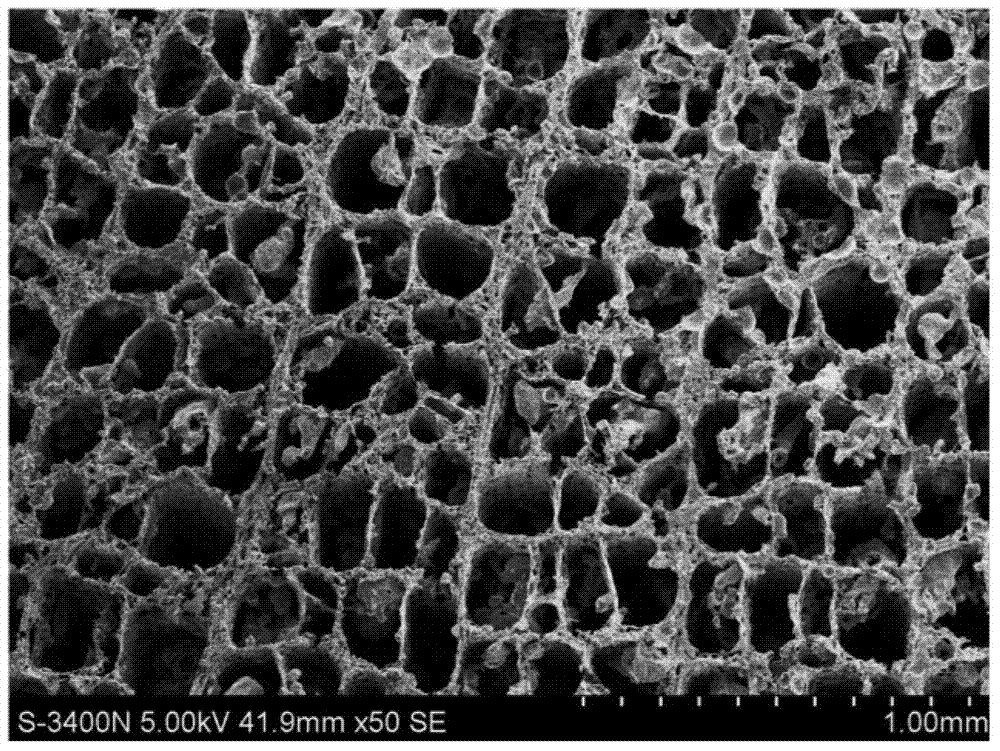

Bone tissue engineering bracket material and preparation method and application thereof

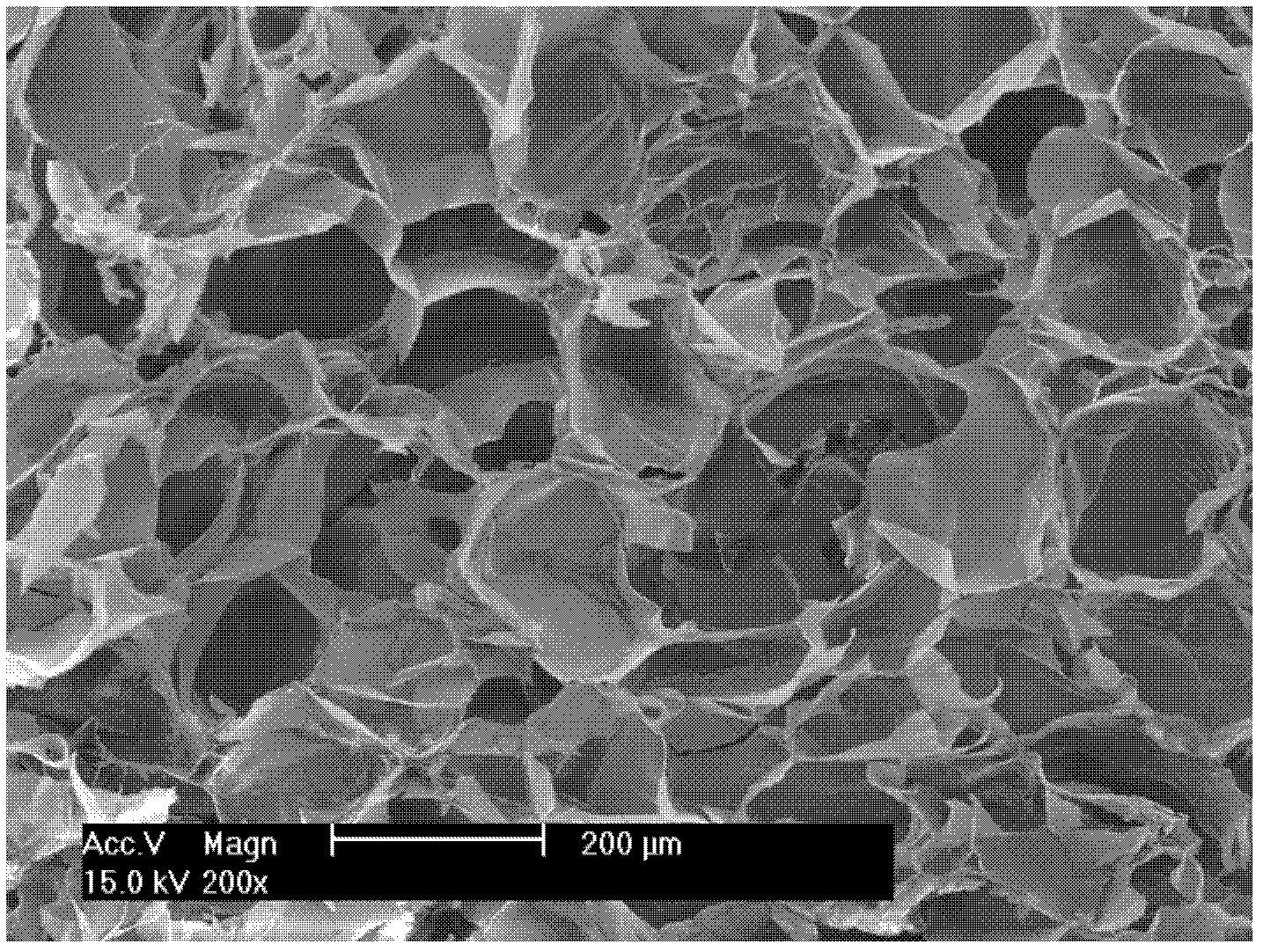

InactiveCN101721740AEasy to operateLarge aperture rangeStentsProsthesisBone tissue engineeringChemistry

The invention discloses a bone tissue engineering bracket material and a preparation method and application thereof. The bracket material is prepared from calcium phosphate diphase power and has a porous structure with the pore diameter of 100-600 micrometers, the through pore diameter of 45-130 micometers and the porosity of 45-93 percent. The calcium phosphate diphase power contains hydroxyapatite and tricalcium phosphate in the mol ratio of 0-1.

Owner:SHANGHAI TISSUE ENG LIFE SCI

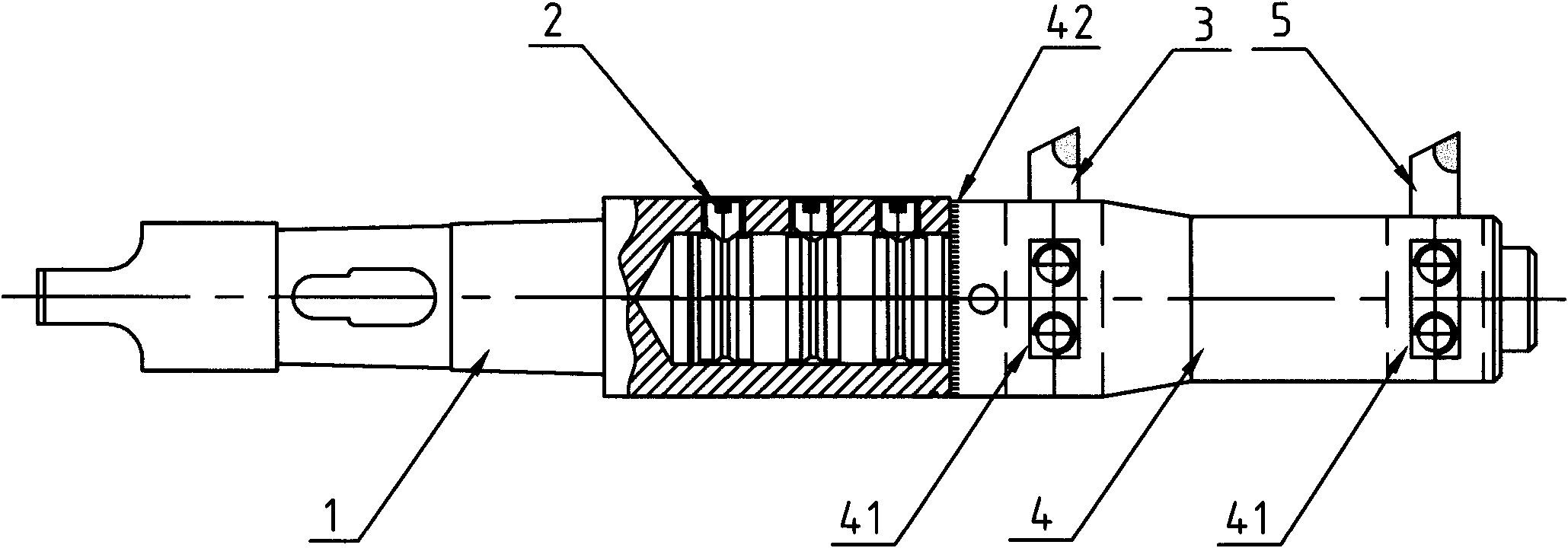

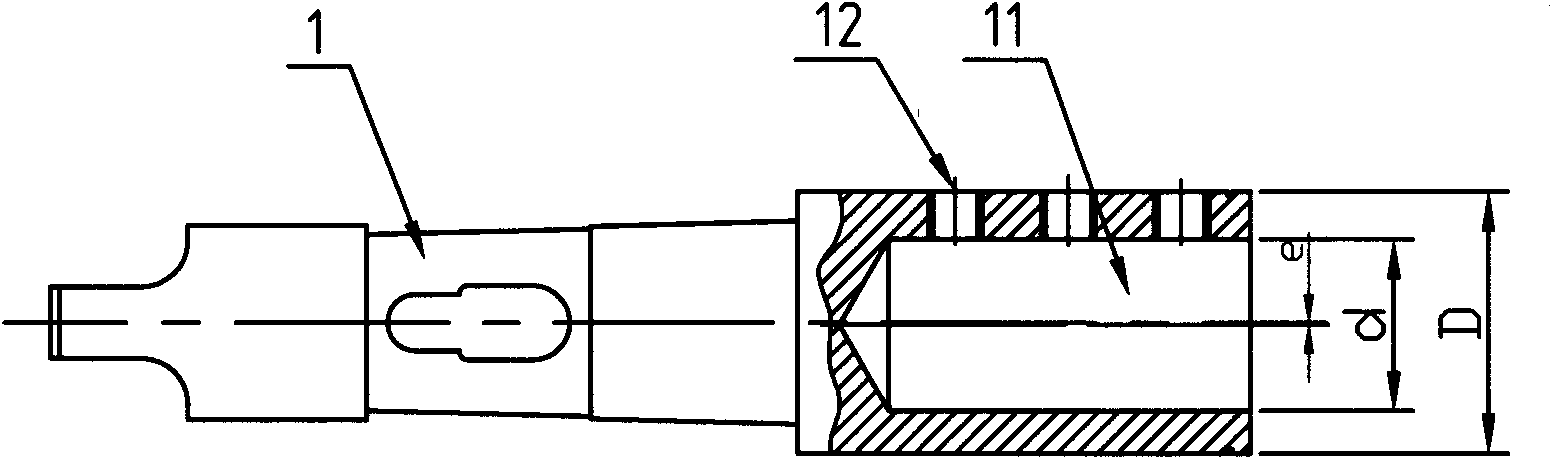

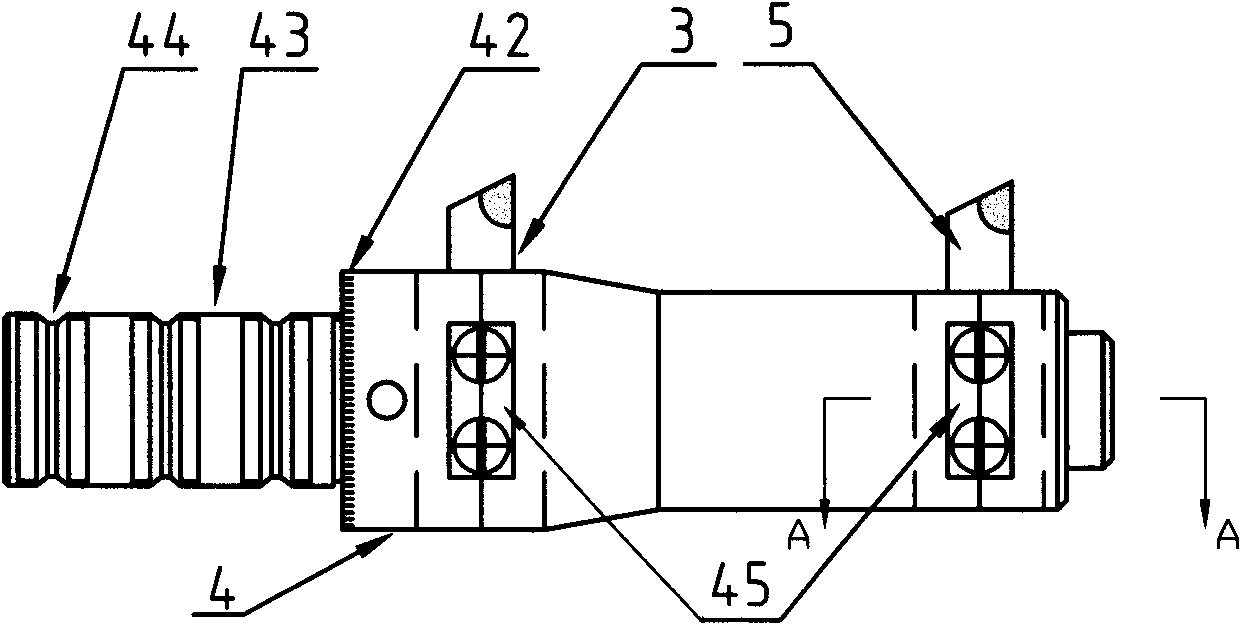

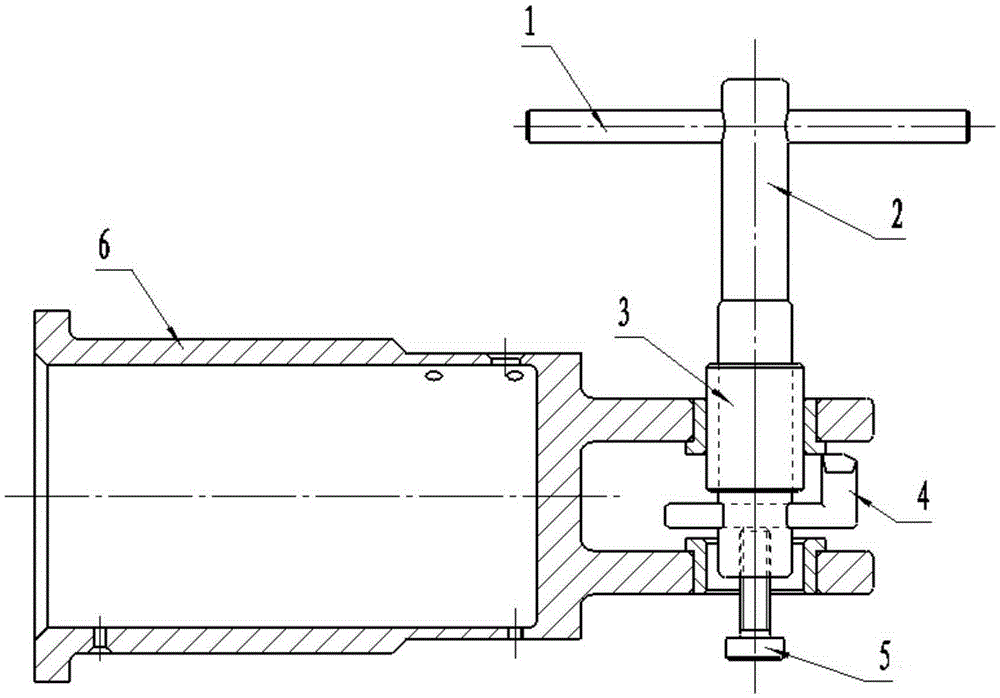

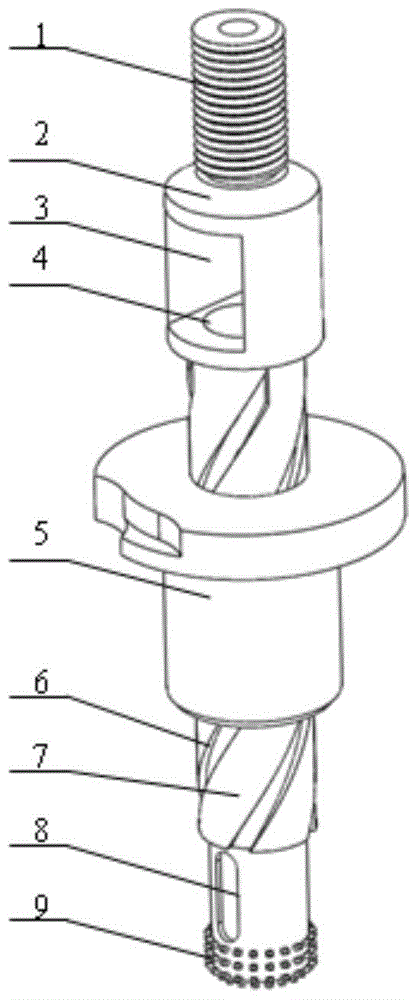

Cutter tool with fine adjustment for rough and fine hole boring

InactiveCN102335757ADecrease productivityReduce machining accuracyTurning toolsProcessing accuracyLarge aperture

The invention relates to a cutter tool with fine adjustment for rough and fine hole boring. The cutter tool comprises a cutter handle seat, a cutter bar seat and boring cutter heads, wherein the cutter handle seat is fixed on a main shaft of a boring machine; the cutter bar seat is connected to the cutter handle seat; the boring cutter heads are fixed on the cutter bar seat; the cutter tool is characterized in that: the cutter bar seat is eccentrically connected to the cutter handle seat and is provided with two mounting parts for fixing the boring cutter heads; and the cutter bar seat can be provided with two boring cutter heads at most. In the cutter tool, the cutter bar seat is eccentrically connected to the cutter handle seat, so that the cutter bar seat and the cutter handle seat produce an eccentric distance e; the processing radius of boring cutters can be changed by adjusting the relative angular relation of the center of a cutter bar and the center of a cutter handle, and the adjustment accuracy can be improved by performing the adjustment finely; meanwhile, the cutter bar seat is provided with a rough boring cutter head and a fine boring cutter head; the rough and fine boring can be finished by only clamping the cutter tool and a workpiece at one time, so that the working efficiency and the processing accuracy are improved; the cutter tool has a simple structure, and is easy to process and low in manufacturing cost; and a hole processed by the cutter tool has a large aperture range and high rigidity, so that the processing accuracy is improved.

Owner:KUNSHAN JINFA HYDRAULIC MACHINERY

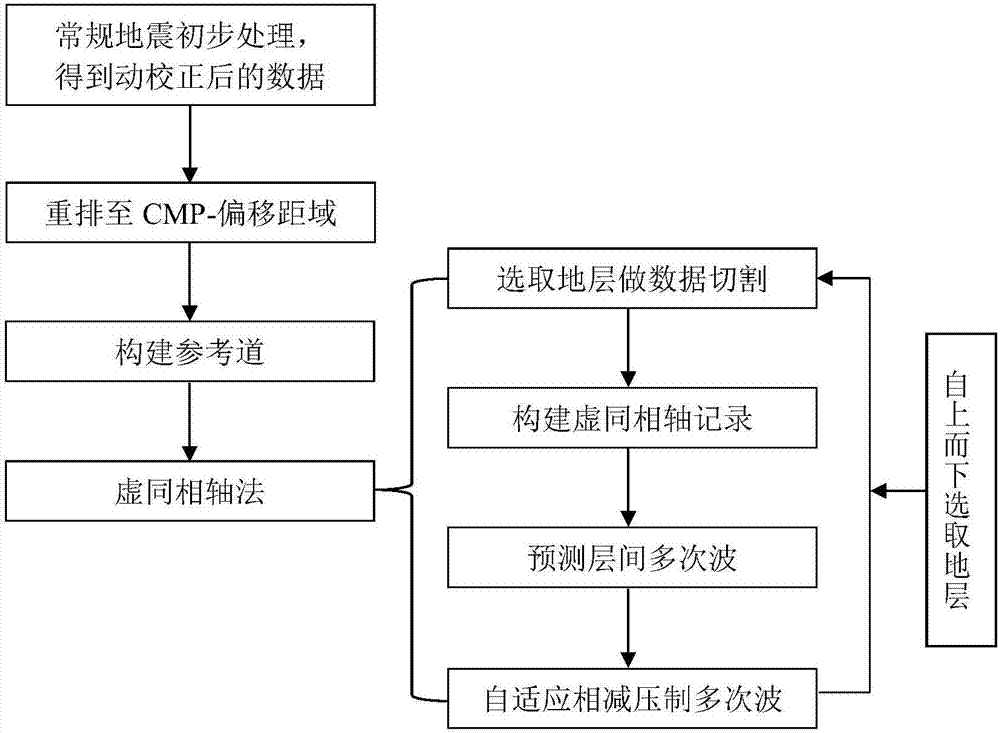

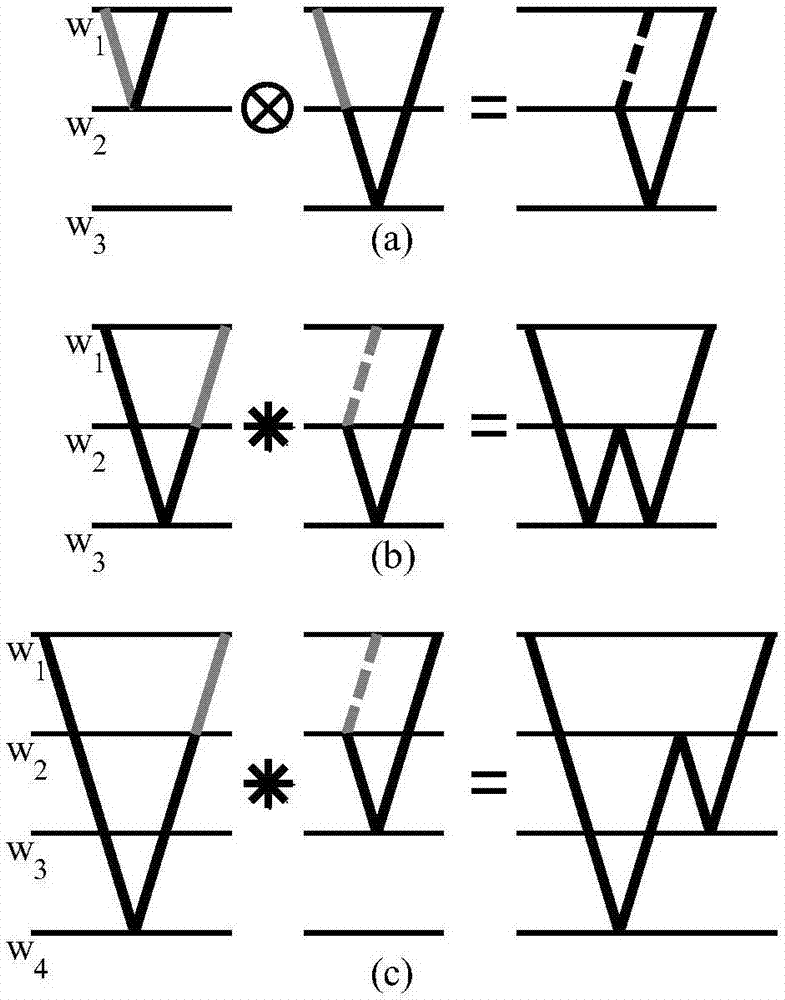

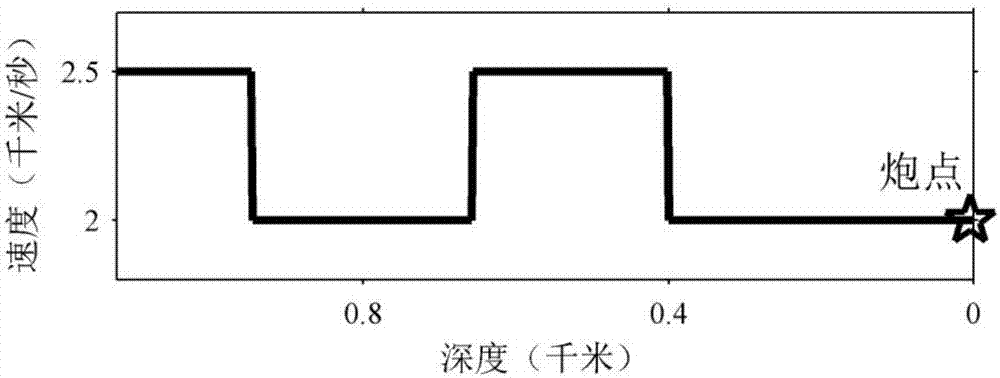

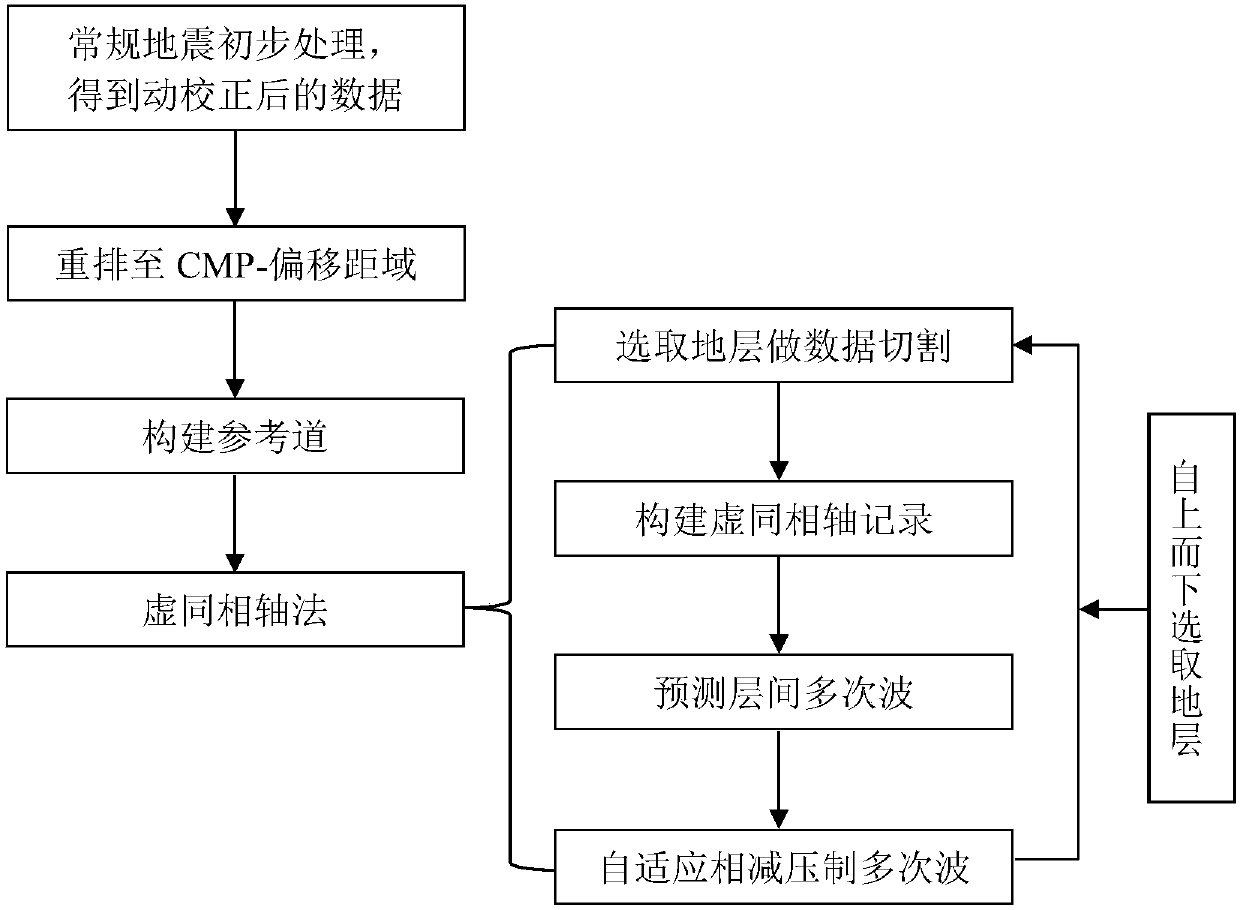

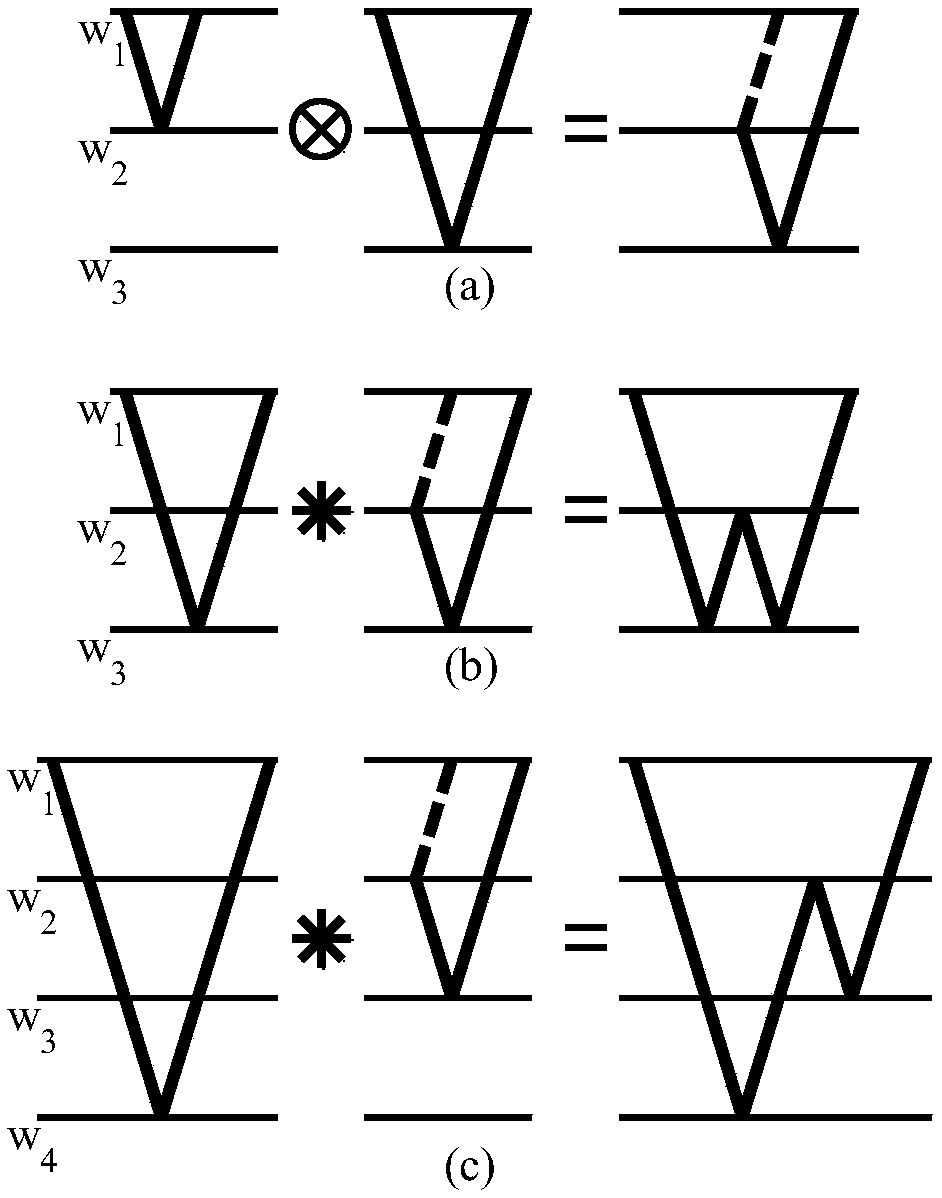

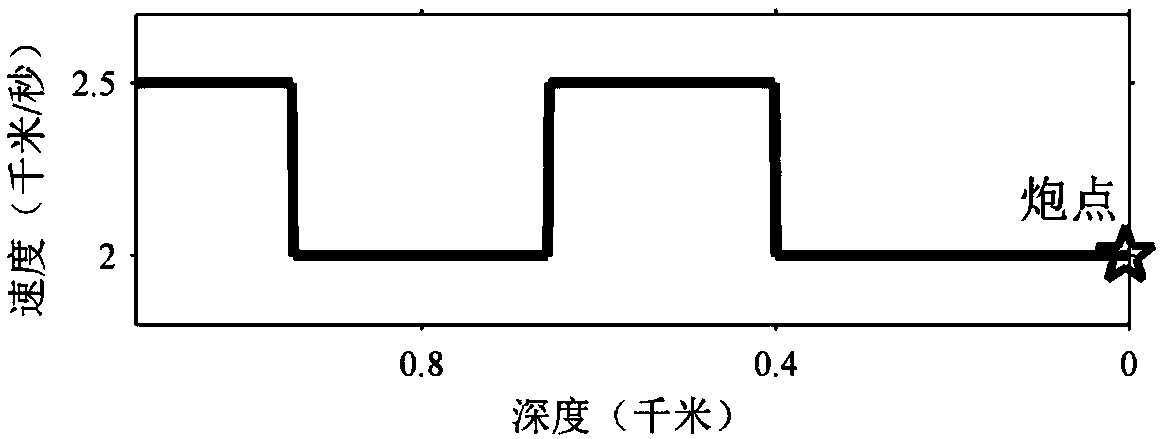

Dimensionality-reduction adaptive inter-layer multiple wave suppression method of land seismic exploration data

ActiveCN106932824AIntensive artillery check point distributionLarge aperture rangeSeismic signal processingCheck pointOffset distance

The invention belongs to the exploration seismic signal processing field and relates to an adaptive prediction and suppression method of land seismic exploration data inter-layer multiple waves, in particular, a dimensionality-reduction adaptive inter-layer multiple wave suppression method of land seismic exploration data. According to the method, inter-layer multiple wave prediction and suppression of the land seismic exploration data are realized in a pre-stack CMD (Common Middle Point) trace gather through using a virtual event method. The method includes the steps of input data preparation, reference trace construction and multiple wave suppression. According to the method, when dynamic correction is adopted to eliminate travel related to an offset distance caused by the distribution of shot check points, the method has no requirements for the distribution of the shot check points; two-dimensional or three-dimensional data are converted into one-dimensional data through dimensionality reduction, so that calculation efficiency is improved; and weighted stacking is performed, so that reference traces can be obtained, and therefore, the noise immunity of a system can be improved.

Owner:PEKING UNIV

Reductively biodegradable type honeycomb polyurethane support, and preparation method and application thereof

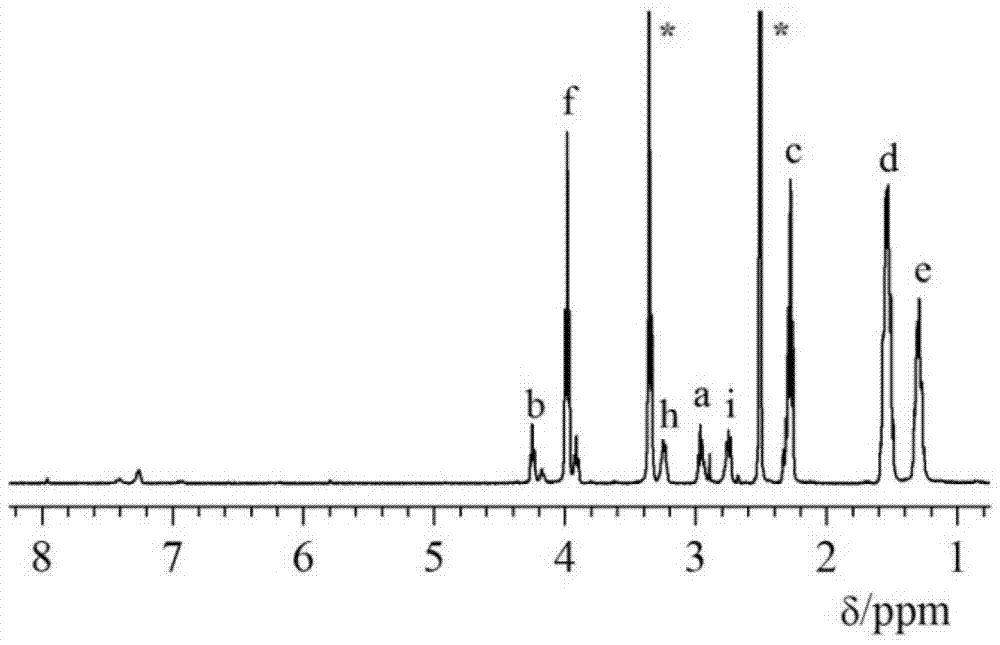

InactiveCN103495203AEffectively regulates degradabilityStrong controllability of biodegradationProsthesisPolyesterStructural formula

The invention discloses a reductively biodegradable type honeycomb polyurethane support, and a preparation method and application thereof. The preparation method comprises: taking 2,2'-dithiodiethanol as an initiator, employing a ring-opening polymerization method to synthesize double-hydroxy-terminated polycaprolactone containing disulfide bonds; reacting with diisocyanate containing a disulfide bond to form polyester type polyurethane containing disulfide bonds; then dipping a biological template wisteria sinensis with a sodium chloride solution and calcining to obtain a negative template porous sodium chloride of wisteria sinensis; and finally immersing the negative template porous sodium chloride of wisteria sinensis with a waterless organic solution of the polyester type polyurethane containing disulfide bonds, drying and removing the negative template to obtain the honeycomb polyurethane support, wherein the molecular structural formula of the polyurethane is shown in the description. The reductively biodegradable type honeycomb polyurethane support has the advantages of simple technology, easy batch preparation, and strong biodegradation controllability; and the honeycomb structure is beneficial to transportation of substances inside or outside the support, the support can be used as a porous support for tissue regeneration repair, and belongs to a tissue engineering support material with excellent comprehensive performances.

Owner:XI AN JIAOTONG UNIV

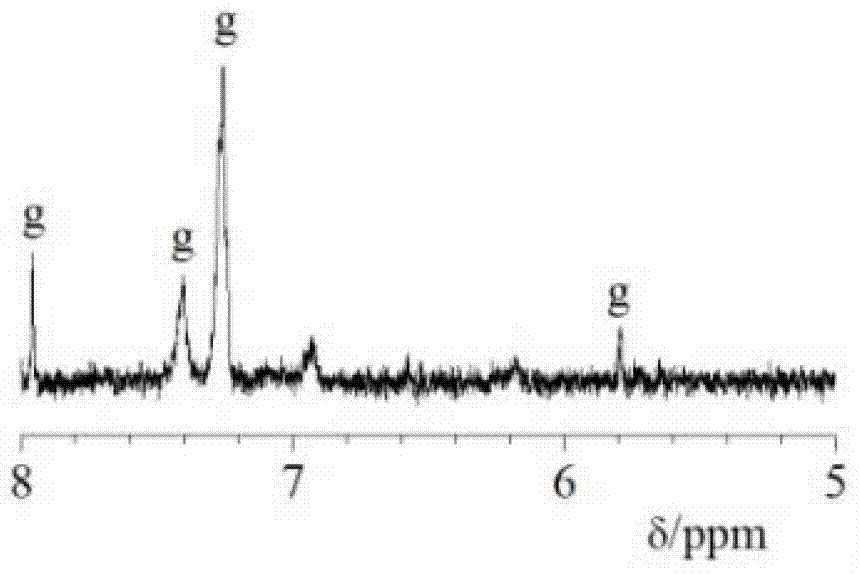

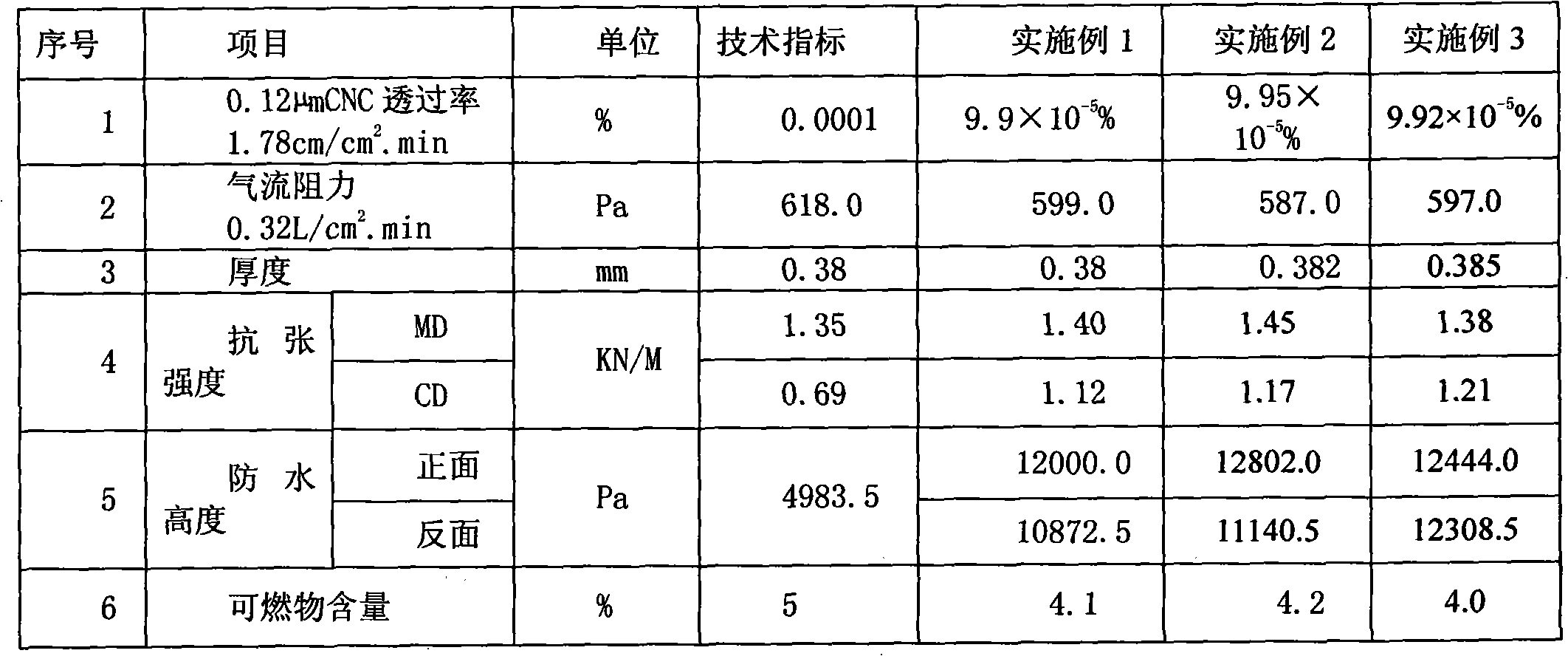

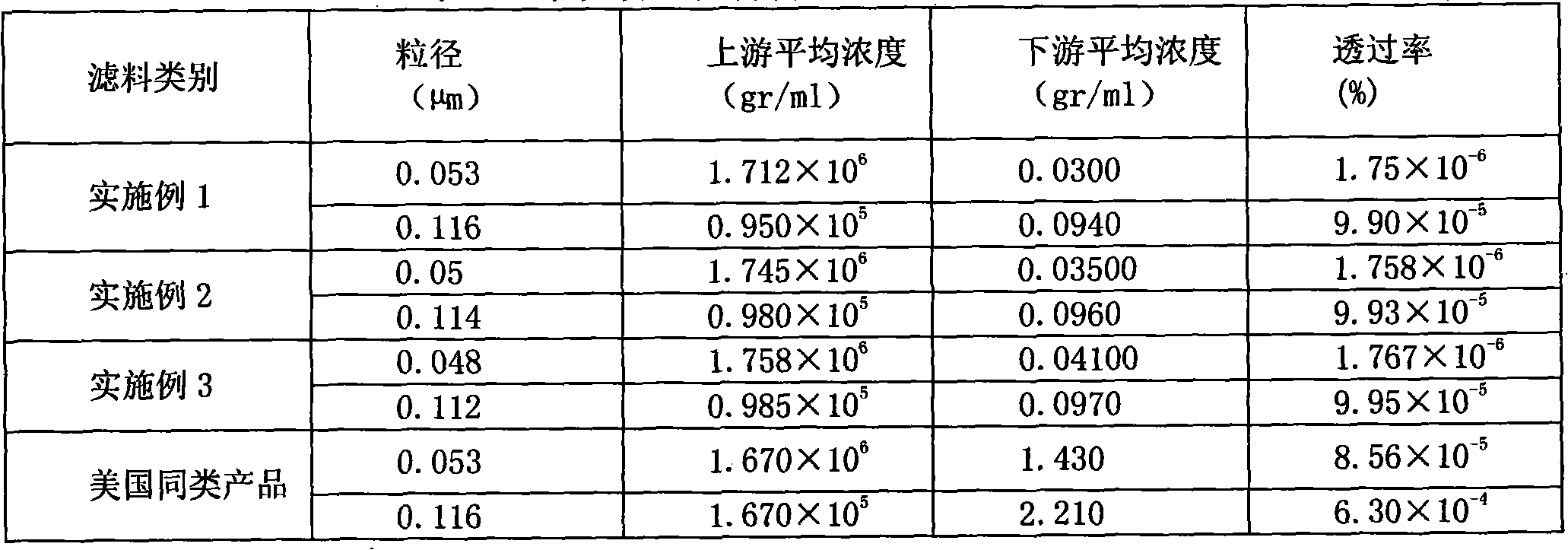

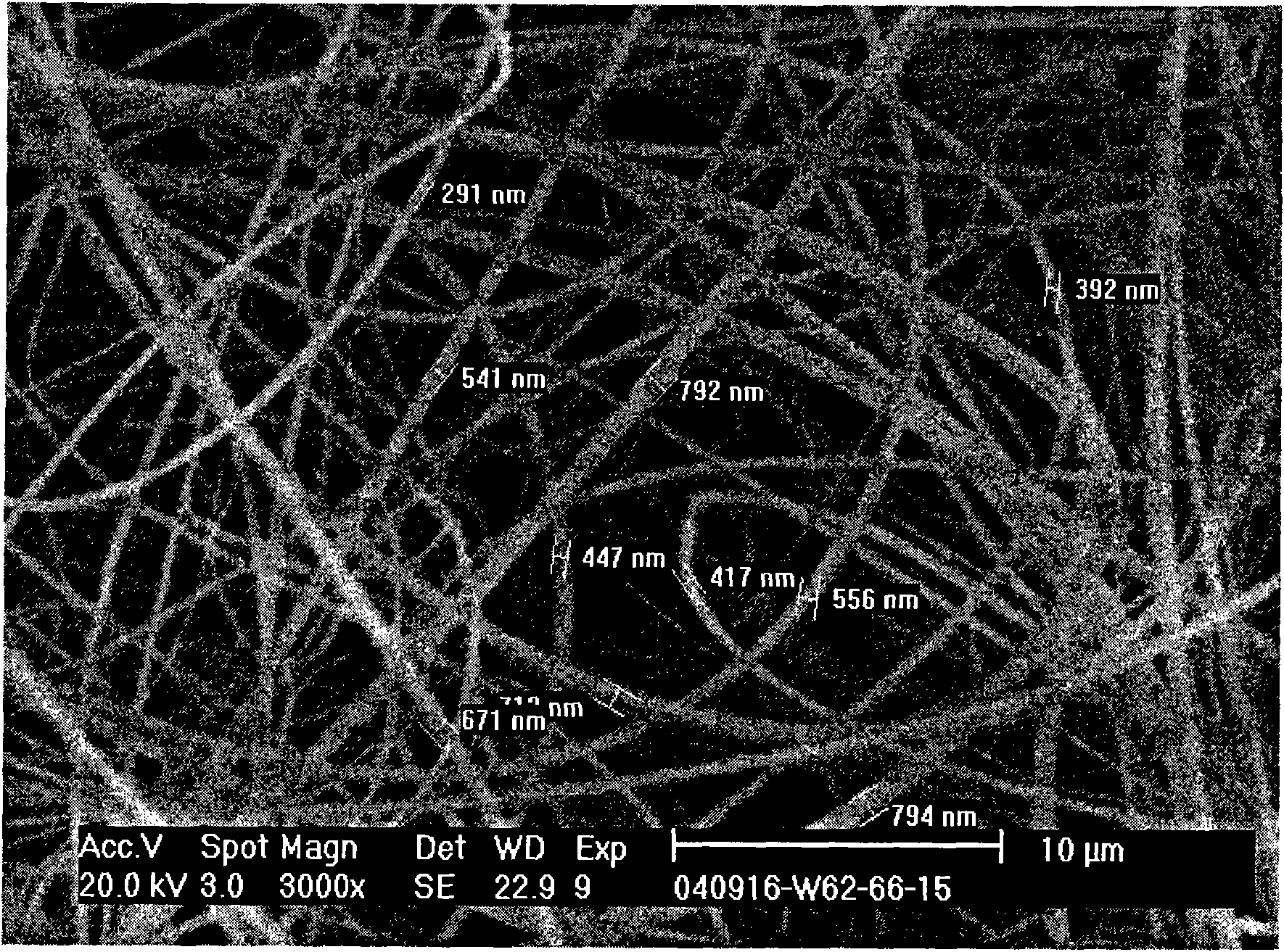

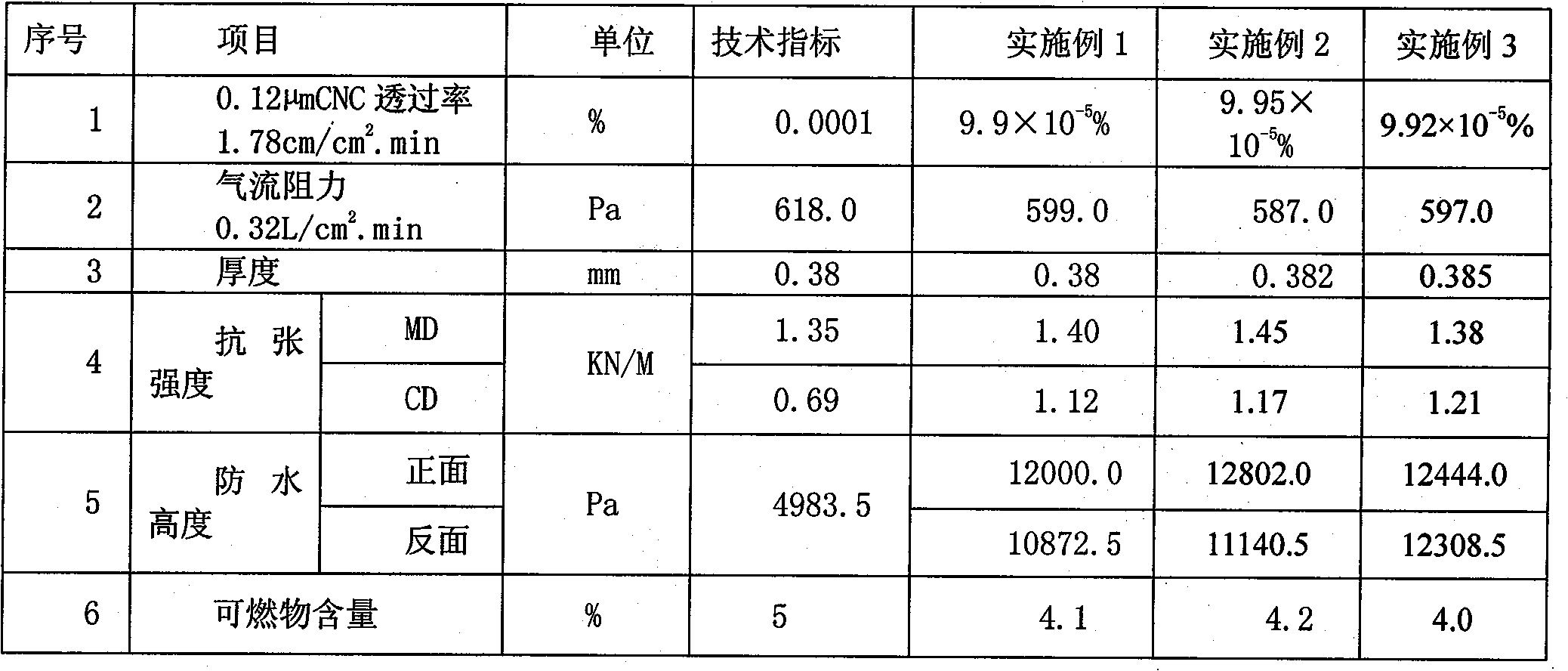

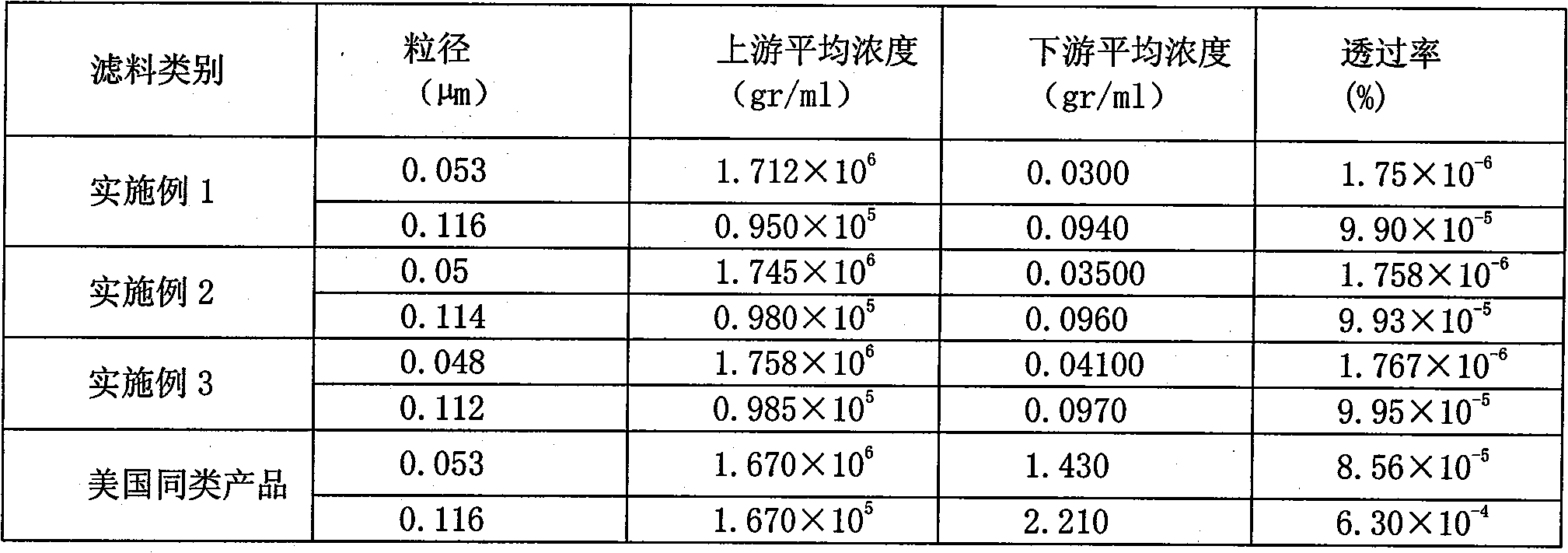

Preparation method of ULPA ultra performance air filter material

ActiveCN101644012AIncrease effective spaceLarge aperture rangeWater-repelling agents additionPulp beating methodsSizingAverage diameter

The invention discloses a preparation method of ULPA super performance air filter material, including the following steps: step (1), 20-30wt% of glass fiber with average diameter of 0.1-0.3 Mum, 28-35wt% of glass fiber with average diameter of 0.4-1 Mum, 15-20wt% of glass fiber with average diameter of 5-7 Mum and 20-30wt% of long glass fiber with average diameter of 15-20 Mum are dispersed in water by beating, mass concentration of size is controlled to be 4.5-5.5%, acidity is controlled to be pH 2.1-2.6, and time of beating is controlled to be 40-48min; step (2), size obtained by the step (1) is diluted and stored; step (3), paper is made; step (4), sizing is carried out; step (5), drying is carried out. The invention has the advantages of high poriness, high clogging capacity and high efficiency.

Owner:CHONGQING ZAISHENG TECH CORP

Method for preparing porous mullite fiber through coaxial electrostatic spinning

InactiveCN106868632AUniform diameter distributionSimple manufacturing processInorganic material artificial filamentsFiberN dimethylformamide

The invention relates to a method for preparing porous mullite fiber through coaxial electrostatic spinning and belongs to the science and technology technical field of materialsmaterial science. The fiber preparing method comprises the following steps: preparing anhydrous aluminum chloride, tetraethoxysilane, isopropyl ether and anhydrous dichloromethane into a reaction solution according to a certain molar ratio, then heating the reaction solution, triggering non-hydrolytic sol-gel reaction to synthesize mullite gel; mixing absolute ethyl alcohol and a certain amount of polyvinylpyrrolidone (PVP) according to a certain ratio to obtain a PVP ethanol solution, dissolving the synthesized mullite gel in the PVP ethanol solution, then adding N,N-dimethylformamide (DMF) to obtain a spinning precursor solution; taking liquid paraffin as an inner solution, taking the mullite precursor solution as an outer solution, preparing mullite gel / PVP composite fiber through a coaxial electrostatic spinning process, then calcining the mullite gel / PVP composite fiber under high temperature to obtain the porous mullite fiber. The preparation method of the porous mullite fiber is simple; the porous structure is easy to control; the porous mullite fiber has excellent heat insulation and heat preservation properties; a novel high-temperature heat insulation material is provided for the fields such as aviation and military industry and the like.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

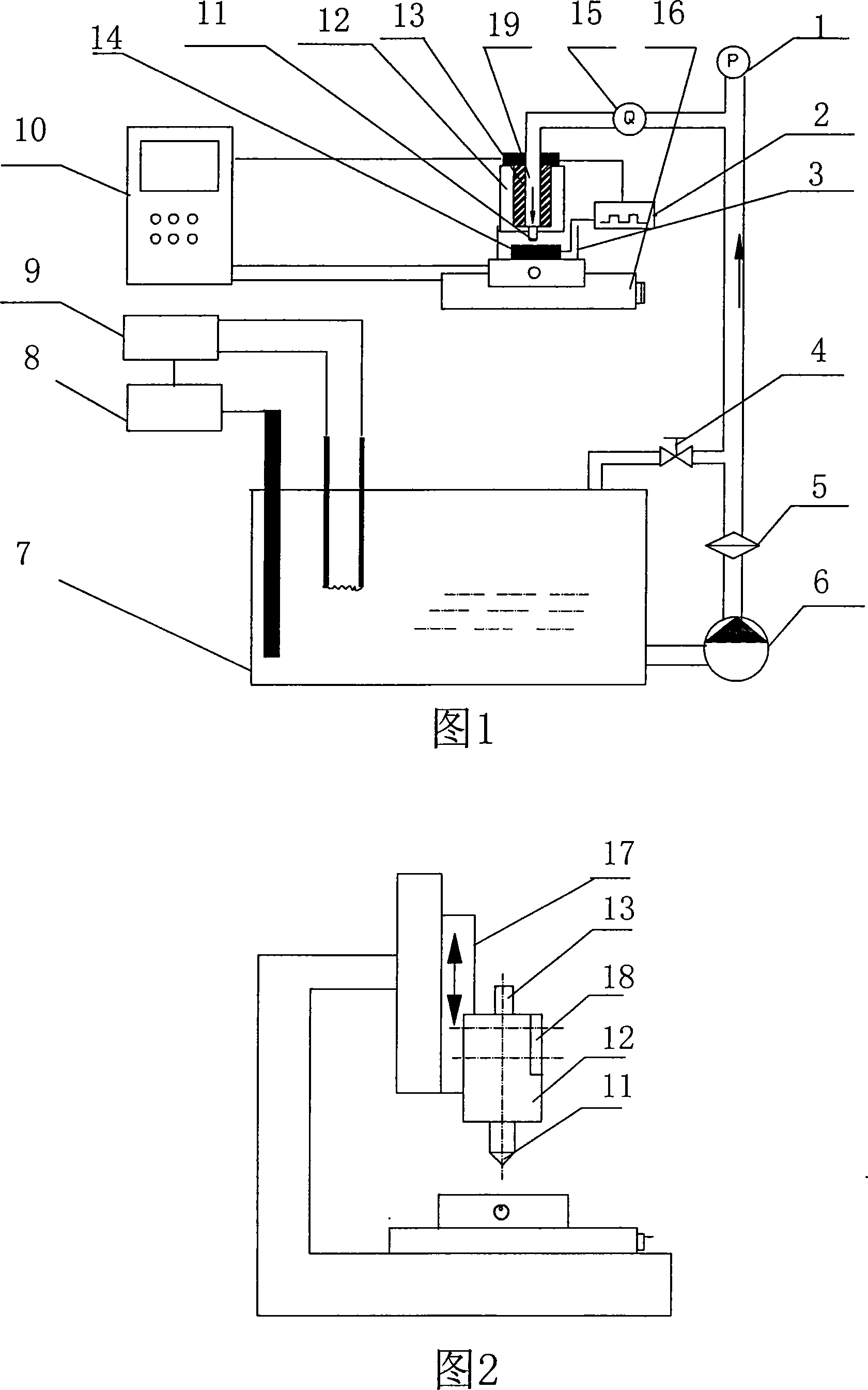

Jet electroform method and equipment for manufacturing foamed metal

InactiveCN101092719AChange the mass transfer processUniform thicknessElectroforming processesSpray nozzleMetallic materials

This invention discloses method and apparatus for producing electroplated foam metal by spraying. The method comprises: placing surface-treated cathode plate into an electroforming tank, controlling the temperature of the electroforming solution at 20-65 deg.C, spraying via the spray nozzle connected with the central chamber of the anode bar to the cathode plate at a rate of 1.5-7.5 m / s to obtain a branch-like or sponge-like metal deposition layer, controlling the current density at 200-750 A / dm2, controlling the movement of the spray nozzle along the vertical direction, the horizontal lateral direction and horizontal longitudinal direction to form a porous foam metal deposition layer with required thickness and shape, and drying the foam metal deposition layer. The method has such advantages as no need for auxiliary medium, simple process and convenient production.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

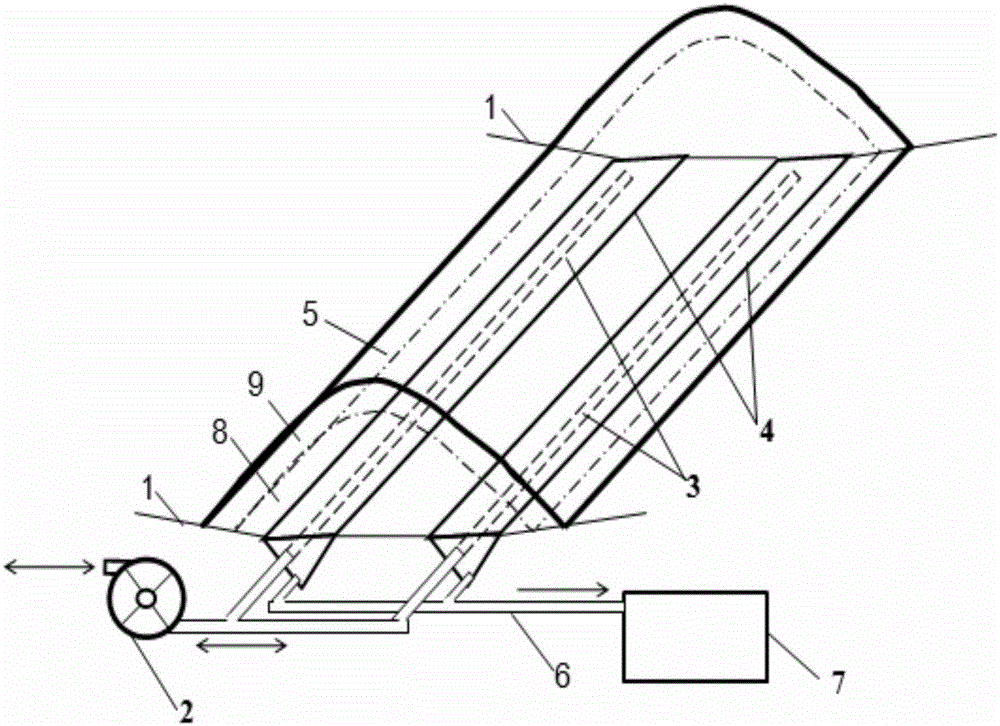

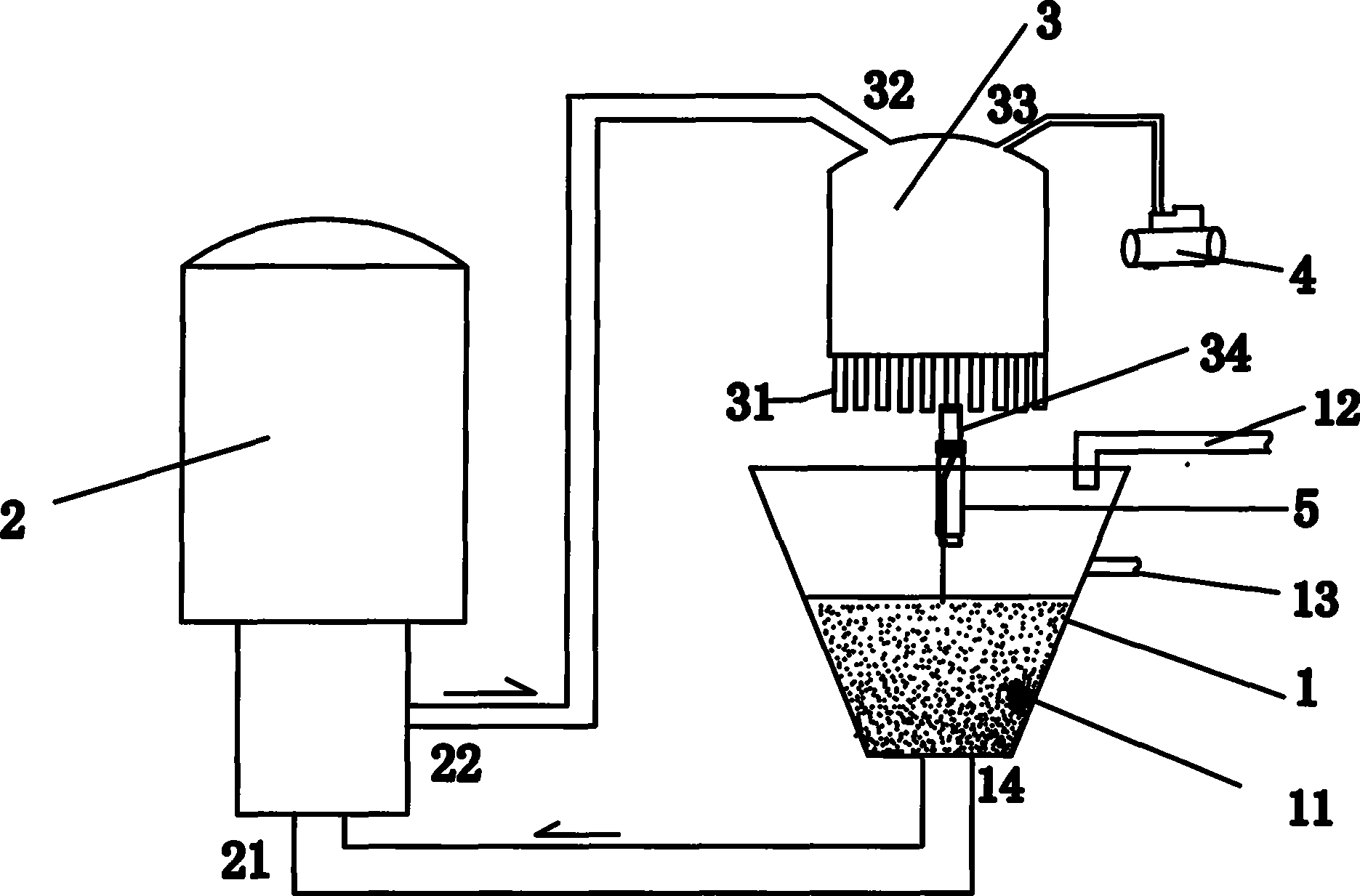

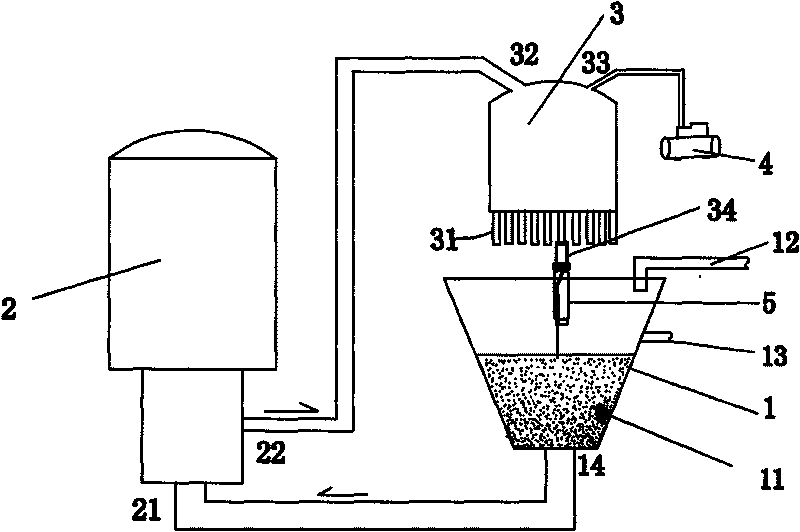

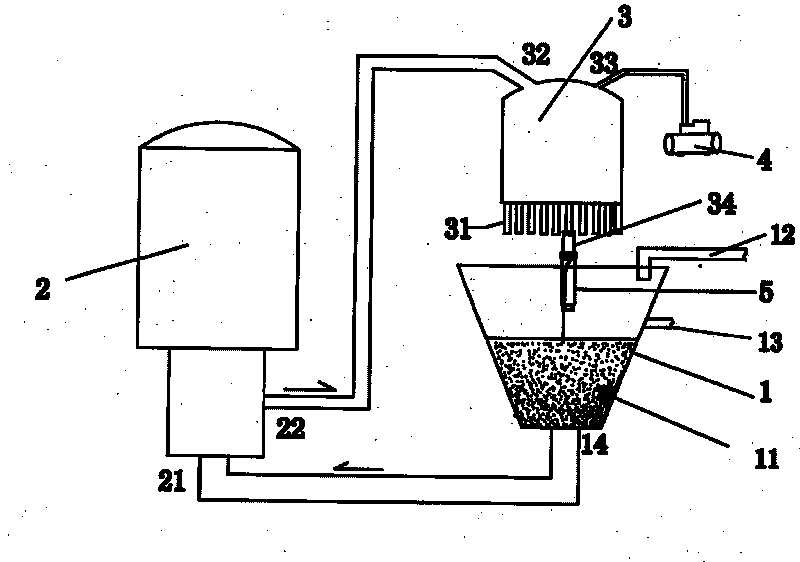

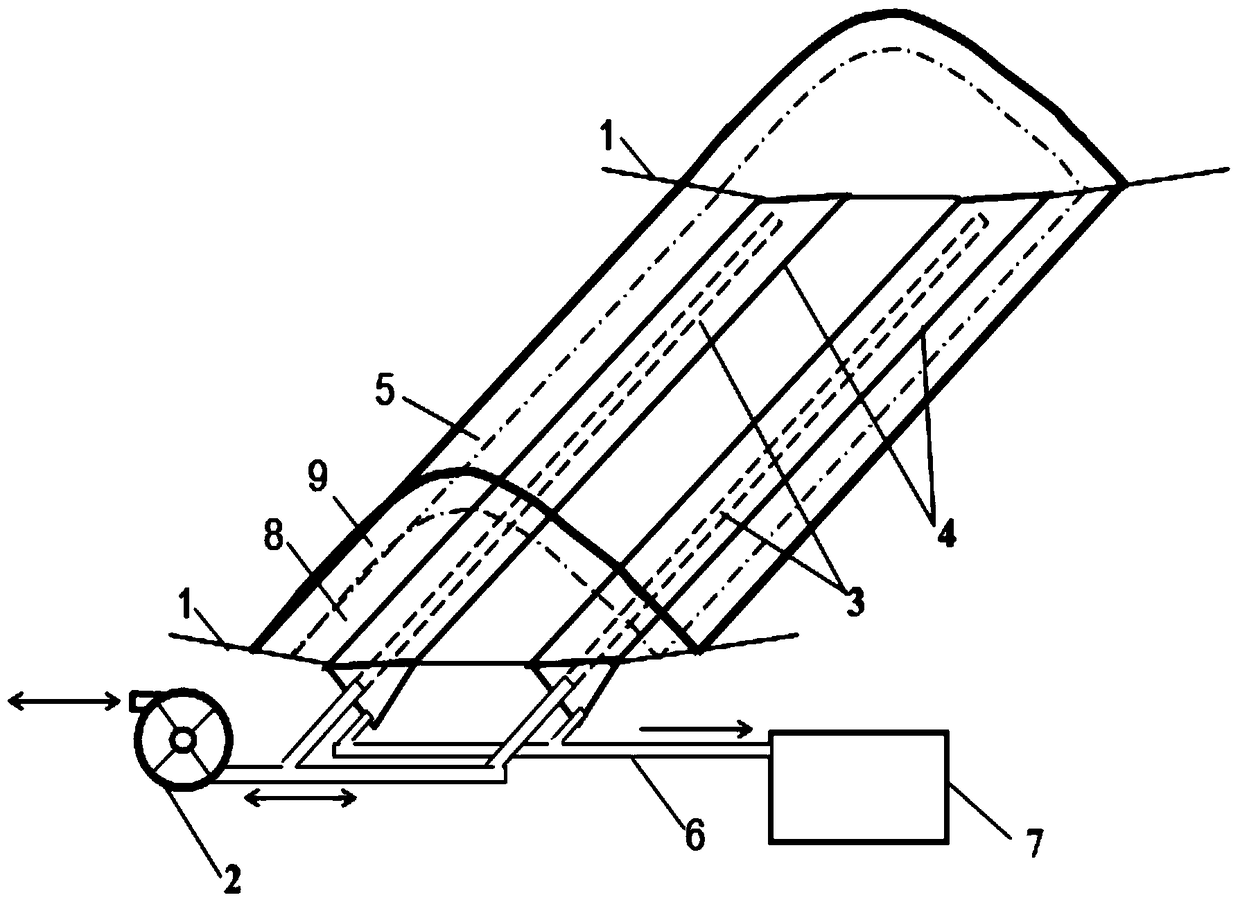

Three-layer rapid composting device and composting method by device

ActiveCN105198517ASave purchase costReduce biological oxygen consumptionBio-organic fraction processingOrganic fertiliser preparationEngineeringCompost

A three-layer rapid composting device and a composting method by the device relate to a composting device and a composting method by the device. The invention aims to solve problems of long composting period, odor pollution and low fermentation efficiency that exist in an existing membrane-covered composting method. The device of the invention comprises a trapezoid cement base, a draught fan, a perforated feed pipe, a V-shaped percolate guiding chute, a waterproof and breathable membrane, a percolate draft tube and a percolate collecting box. the method of the invention comprises the following steps: 1, burden distribution: a fermentation material and a compost clinker are mixed and the mixture is placed at the bottom of the three-layer rapid composting device, the compost clinker is covered, and a waterproof and breathable membrane is covered; 2, fermentation for 7-20 days. According to the invention, the compost clinker and the fermentation material are mixed without adding a conditioner. Thus, purchase expense of a conditioner is reduced, composting period is shortened, and energy consumption is decreased. By changing ventilation direction, no energy is additionally added. In addition, fermentation efficiency is enhanced, and composting period can be remarkably shortened.

Owner:HARBIN INST OF TECH

Three-dimensional chitosan hydrogel and preparation method thereof

ActiveCN102604149AGood biocompatibilityPromote degradationPharmaceutical non-active ingredientsProsthesisToxicantSoft tissue engineering

The invention discloses a method for preparing three-dimensional chitosan hydrogel by using a high temperature crosslinking method and the obtained chitosan hydrogel. The method comprises the following steps of: (a) dispersing chitosan powder into a deionized water; (b) adjusting the pH of chitosan dispersion obtained in the step (a) to be subacid; (c) carrying out high temperature crosslinking on the solution obtained in the step (b) at the high temperature of 80-125 DEG C; and (d) after the crosslinking reaction is completed, soaking and cleaning an obtained product by using a posttreatment liquid so as to remove a residual acid liquid. The high temperature crosslinking method is simple in the preparation process; the reaction time is short; raw materials are unnecessary for special treatment; highly-toxic chemical substances such as crosslinking agents are not introduced to a preparation course; no any chemical toxicant remains in a final product; and the three-dimensional chitosan hydrogel is even in pore structure, good in connectivity and easy to form, and is very suitably used as a support material of soft tissue engineering such as skin and cartilage.

Owner:SHANGHAI HUAYI BIO LAB CO LTD

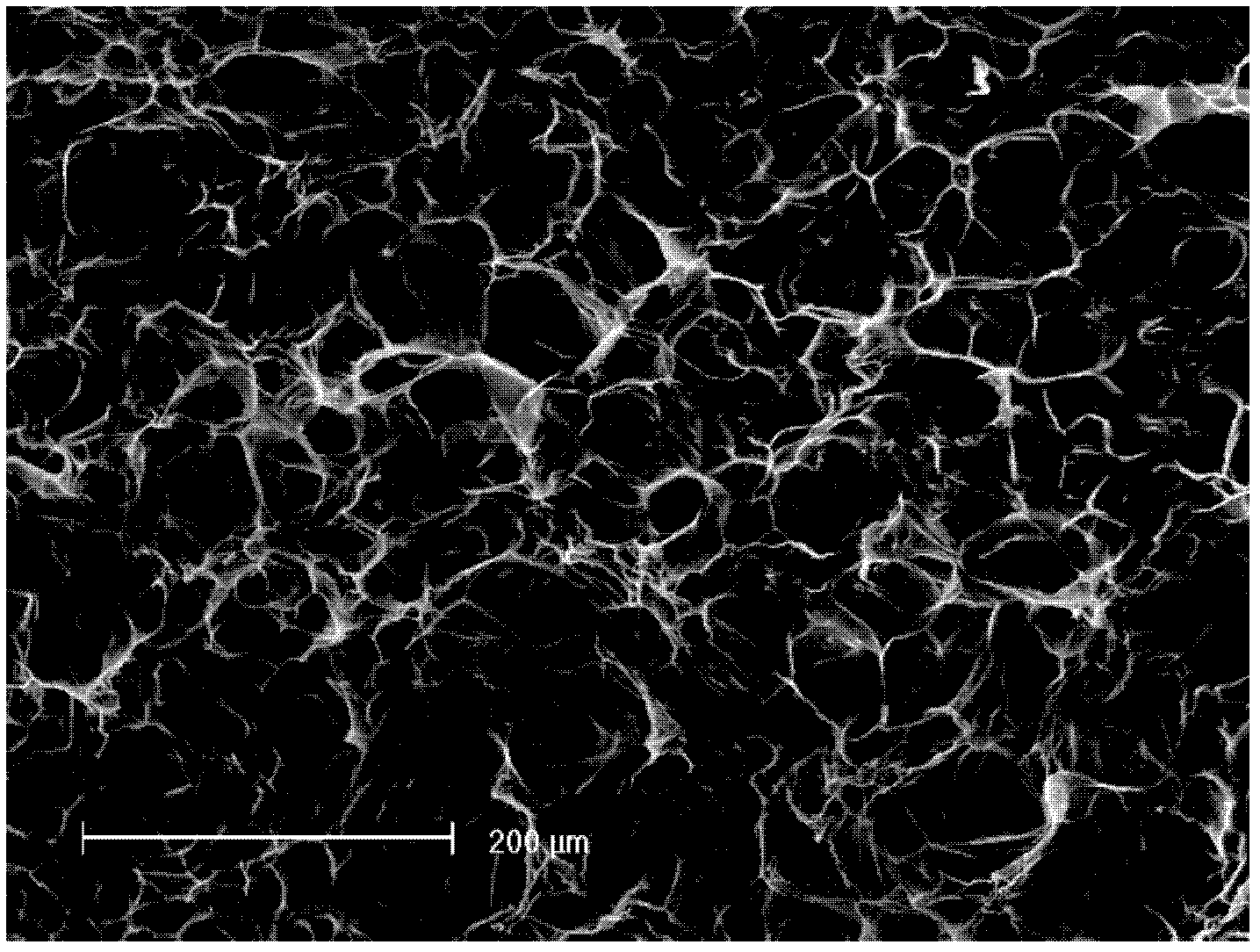

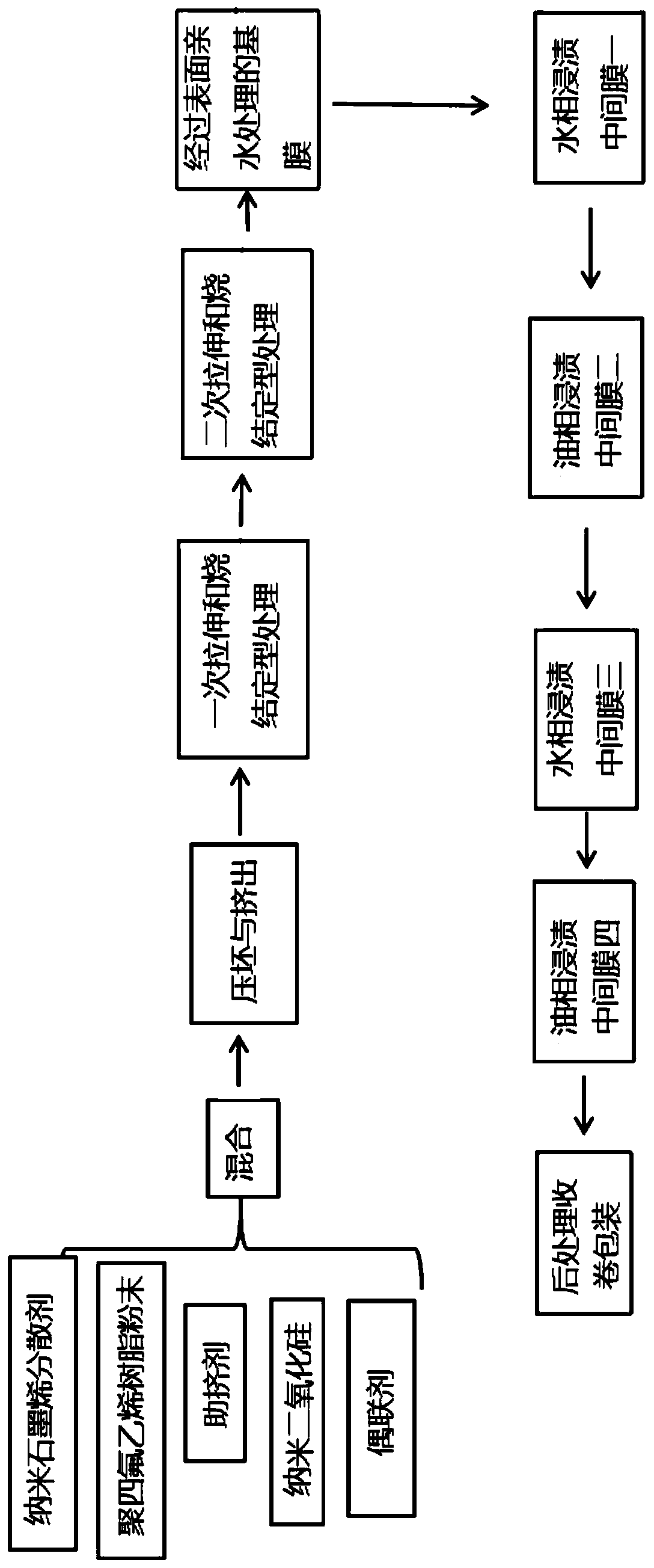

Battery diaphragm material and battery with corresponding diaphragm

InactiveCN103400952ALarge aperture rangeStrong mechanical propertiesCell component detailsNon-woven fabricsAbsorption rateElectrical battery

The invention relates to a battery diaphragm material and a battery with a corresponding diaphragm. The battery diaphragm material at least comprises two layers of materials, which are composited together, wherein a layer of material is obvious in fiber orientation arrangement, and the other layer of material is small in aperture size but large in porosity and is of a three-dimensional network structure; the two layers of materials are composited through a non-hot-rolling process; the surface density of the battery diaphragm material is 40g / m<2> to 100g / m<2>, the alkaline absorption speed of the material is 8cm / 30min to 15cm / 30min, and the alkaline absorption rate of the material is 300 to 500 percent; the statistical value of an average fiber orientation angle of the material obvious in fiber orientation arrangement is less than 30 degrees; the surface density of the material, which is small in aperture size but large in porosity and is of the three-dimensional network structure, is 20g / m<2> to 60g / m<2>, the aperture of the material is 0.5 to 30 microns, and the porosity of the material is 75 to 95 percent. The battery comprises a positive plate, a negative plate, an alkaline electrolyte, and the battery diaphragm between the positive plate and the negative plate. The specific discharge capacity of the battery is more than 280mAh / g, and the discharge capacity retention ratio of the battery is more than 70 percent.

Owner:DONGHUA UNIV

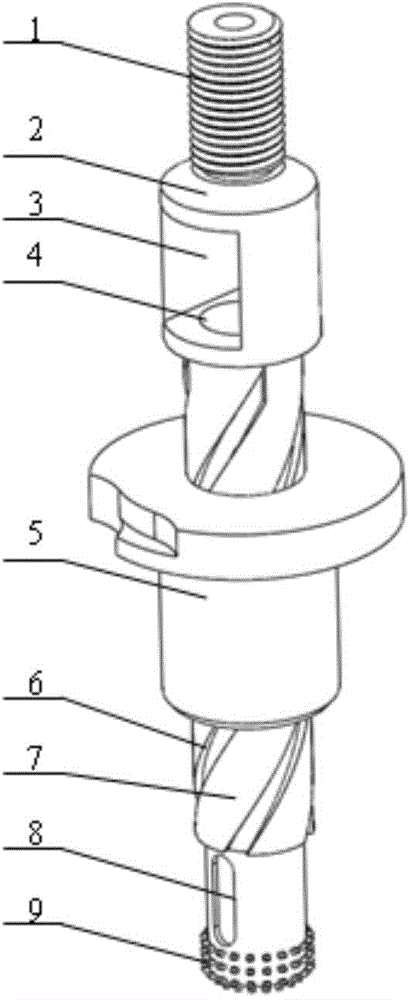

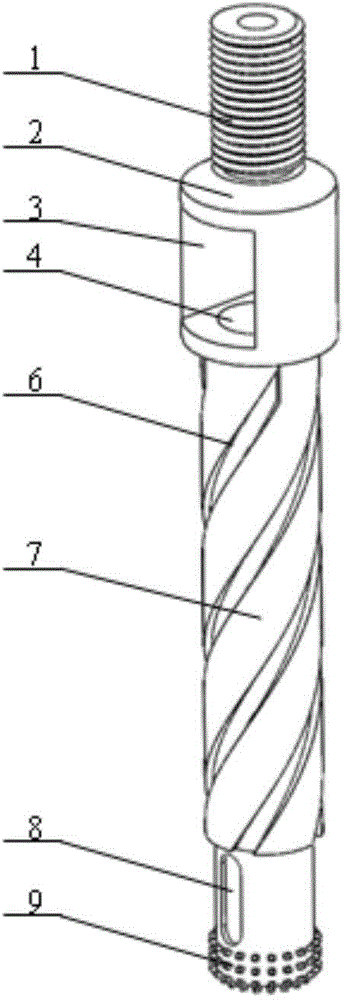

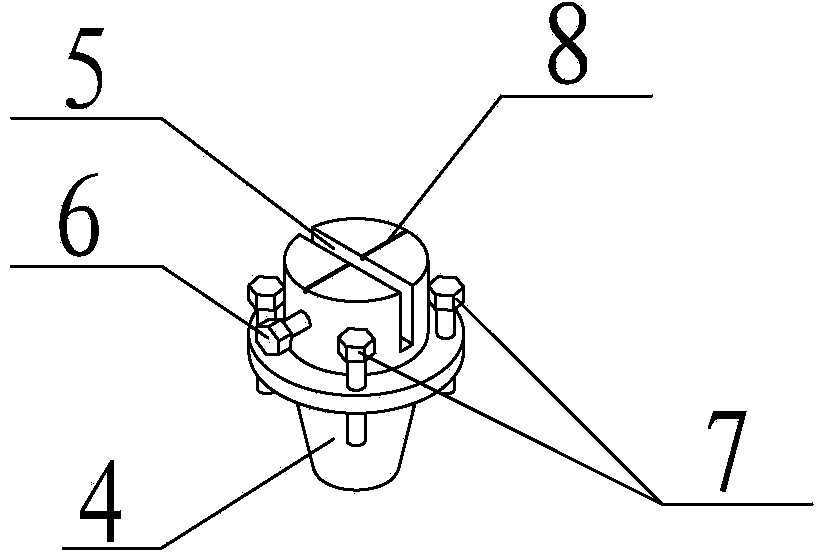

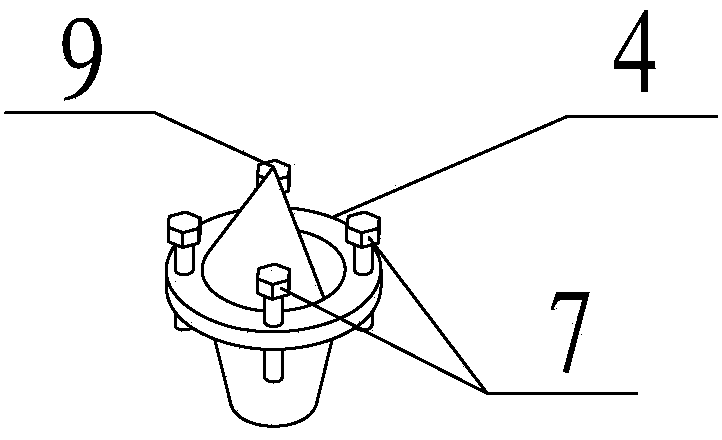

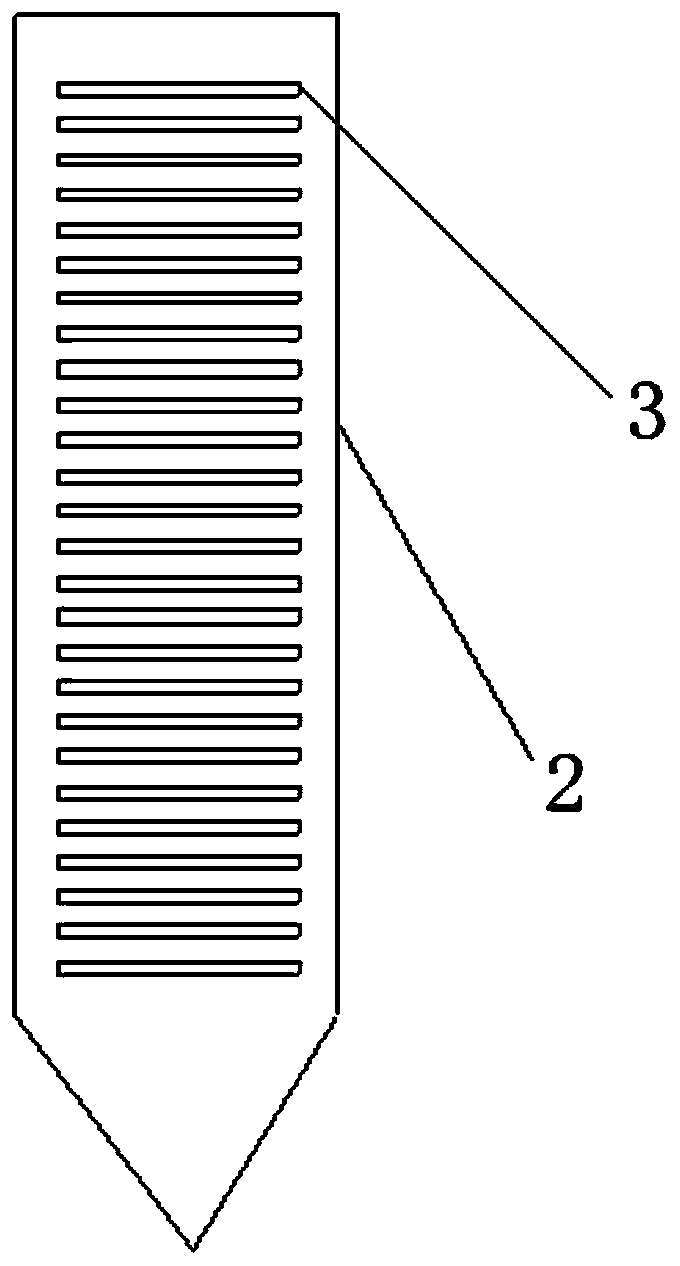

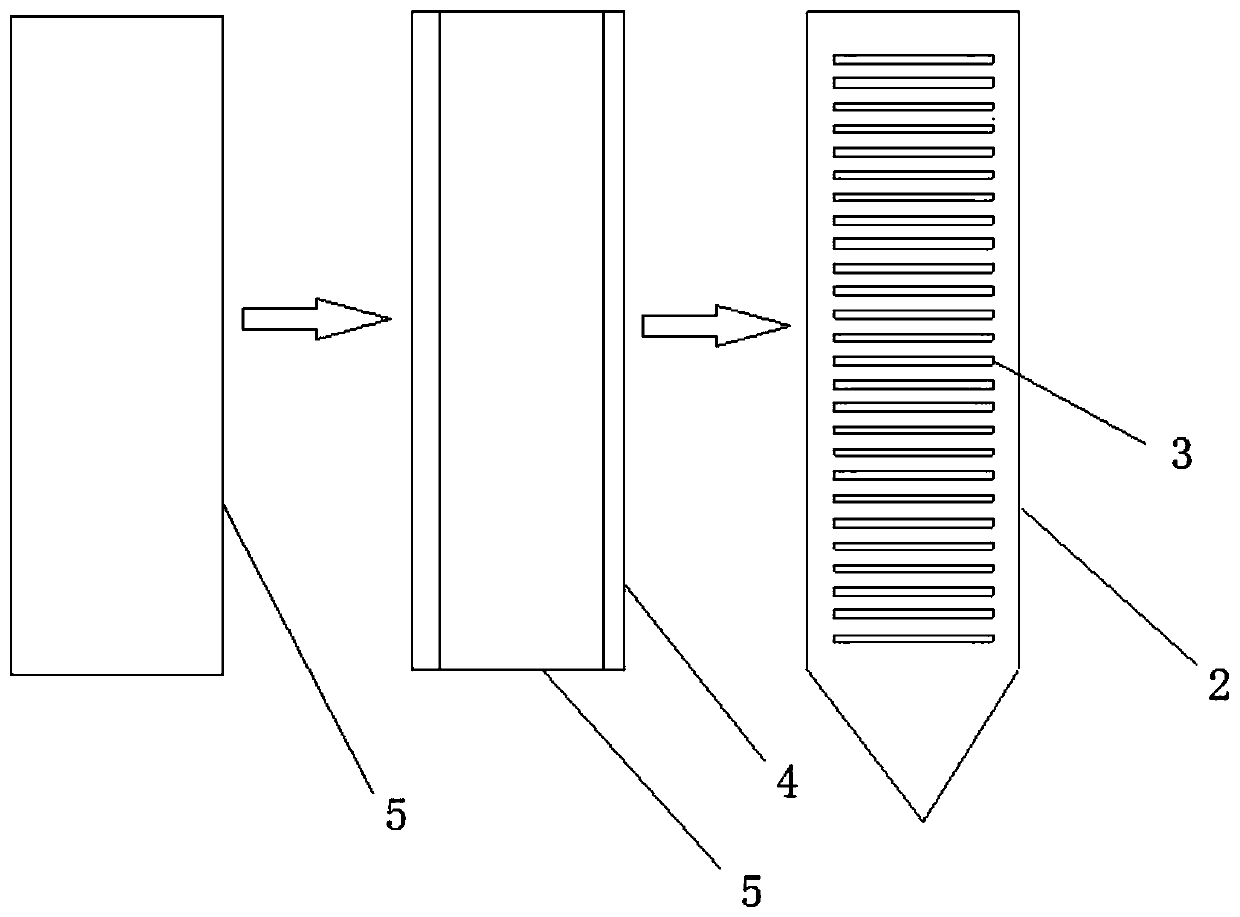

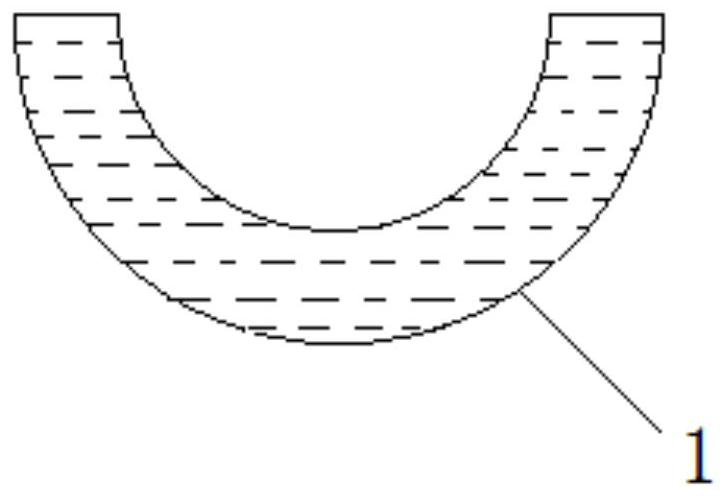

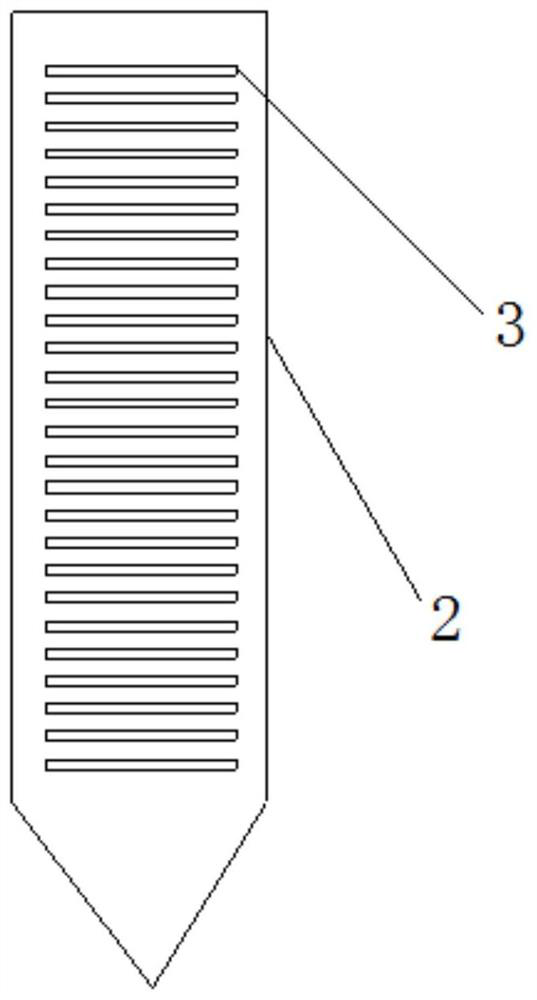

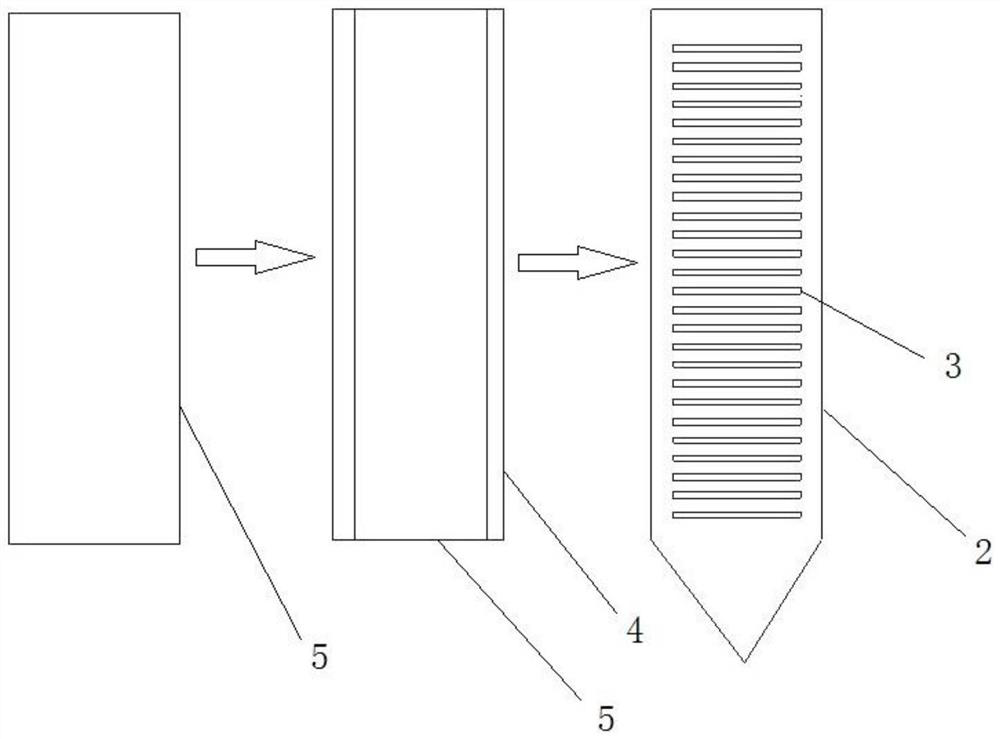

Diamond sleeve grinding cutter suitable for drill sleeve guide

ActiveCN104475826APrevent sticking sleeveReduce wearDrilling/boring measurement devicesTransportation and packagingEngineeringScrew thread

A diamond sleeve grinding cutter suitable for drill sleeve guide comprises a circular drill rod and a guide drill sleeve. The guide drill sleeve is positioned on the middle lower portion of the drill rod and connected with a drill template, the drill rod comprises a threaded handle (1), a 120-degree positioning conical surface (2), a core discharging port (3), a core discharging guide hole (4), a dust chip discharging spiral groove (6), a spiral guide surface (7), a dust chip discharging straight groove (8) and a cutter cutting edge (9) from top to bottom, double cylindrical surfaces are combined to from the guide drill sleeve, and a through hole is formed in a core, so that the drill rod conveniently penetrates the through hole. The diamond sleeve grinding cutter is an integrated cutter, the quality of a machined hole is fine, defects are fewer, hole forming efficiency is high, a composite hole with a large diameter can be machined once, dust cuttings are fewer and almost discharged in the form of material cores, environmental pollution is low, and materials can be repeatedly used.

Owner:BEIHANG UNIV +1

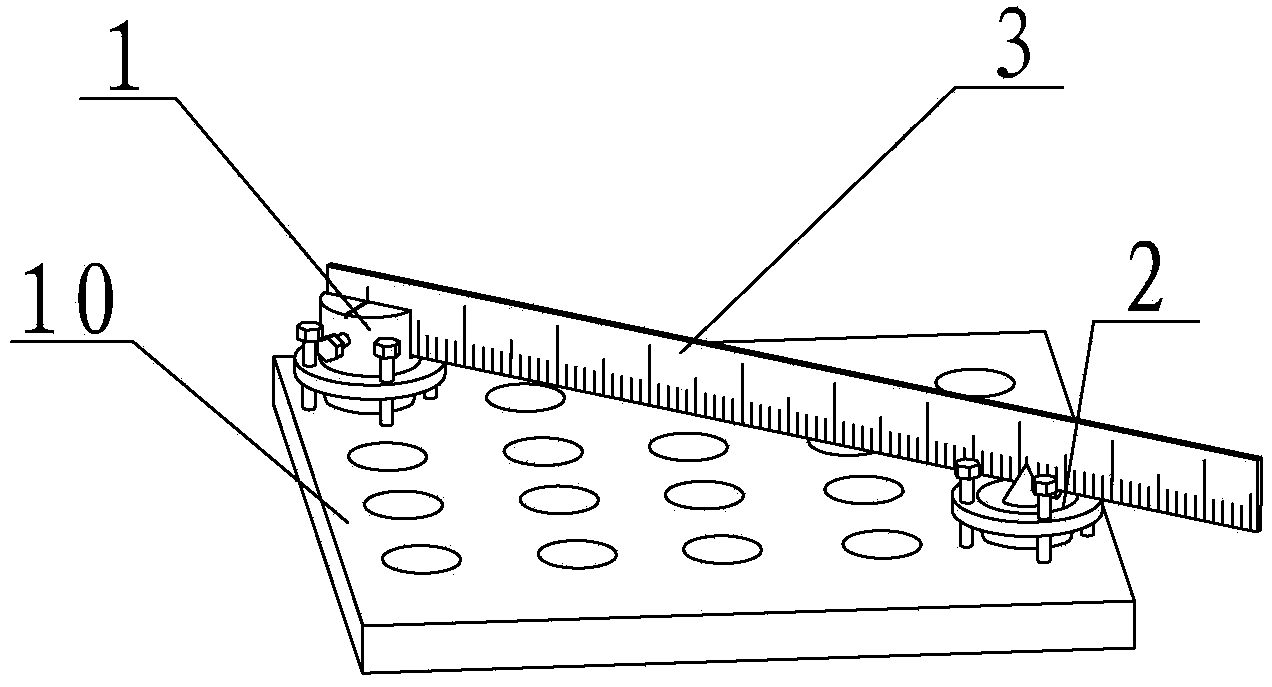

Bole pitch measurement apparatus

InactiveCN104111016AEasy to operateEliminate subjective judgment errorsMechanical clearance measurementsMeasurement deviceEngineering

The invention relates to a bole pitch measurement apparatus comprising a starting end hole plug (1), a reading end hole plug (2) and a ruler (3). The apparatus is characterized in that the upper portion of the starting end hole plug (1) has a cylindrical structure; and a clamp groove is formed in the top at the radial direction. The upper portion of the reading end hole plug (2) has a semi-cone-shaped structure; and a pointer (9) is formed at the tip point of the top of the cone. Annular circular truncated cones (4) are formed at the middle portions of the starting end hole plug (1) and the reading end hole plug (2); and the lower portions have the cone-shaped structures with the large upper portions and small lower portions. One end of the ruler (3) is arranged in the ruler clamp groove (5) of the starting end hole plug (1) and the other end is placed at the annular circular truncated cone (4) of the reading end hole plug (2). According to the invention, the structure is simple; the measurement precision is high; and the application range is wide. The measurement of the hole pitch is not influenced by the subjective judgment of the measurement screw, so that the pitch measurement becomes precise, visual and objective.

Owner:湖北精工钢结构有限公司

Environment-friendly preparation method of porous graphene

ActiveCN106350544AMild reaction conditionsNo pollution in the processMicroorganism based processesFermentationPorous grapheneBiological oxidation

The invention discloses an environment-friendly preparation method of porous graphene. The environment-friendly preparation method comprises the following steps: inoculating spore suspension liquid of white-rot fungi into a seed culture solution containing bacterial cellulose membrane blocks, and carrying out culturing, so as to obtain fixed white-rot fungi membrane blocks; inoculating the fixed white-rot fungi membrane blocks into a liquid nutrition-limited culture medium, carrying out culturing for 1-3 days, and adding oxidized graphene suspension liquid to react for 5-24 hours until oxidized graphene adsorbs the surfaces of hyphae of the fixed white-rot fungi membrane blocks; carrying out biological oxidation and degradation, so as to obtain degraded oxidized graphene membrane blocks; peeling hyphae externally adsorbed with oxidized graphene by virtue of tweezers, adding the peeled hyphae into diluted hydrochloric acid, and heating to dissolve; carrying out centrifuging and washing, so as to obtain purified porous graphene suspension liquid; and finally, drying, so as to obtain porous graphene. According to the preparation method, the porous graphene is prepared from fixed white-rot fungi under mild conditions, so that the reaction process is environmentally friendly, the cost is low, and the hole distribution of porous graphene is relatively wide.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

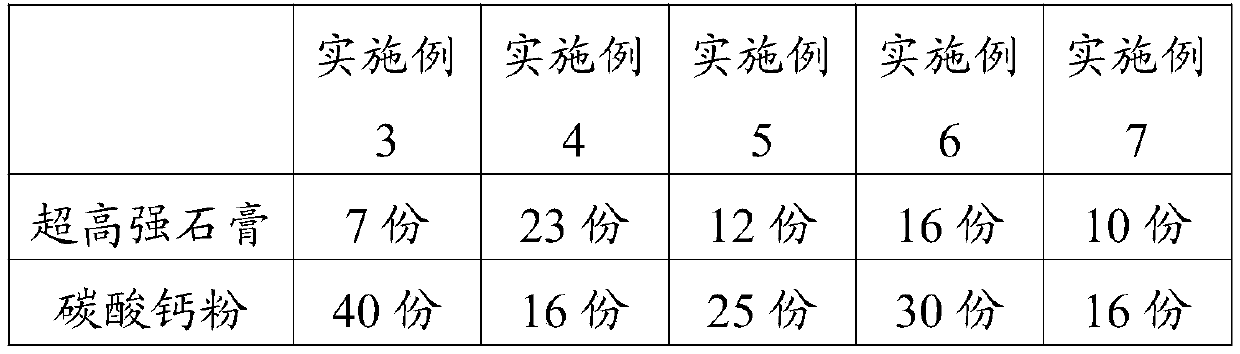

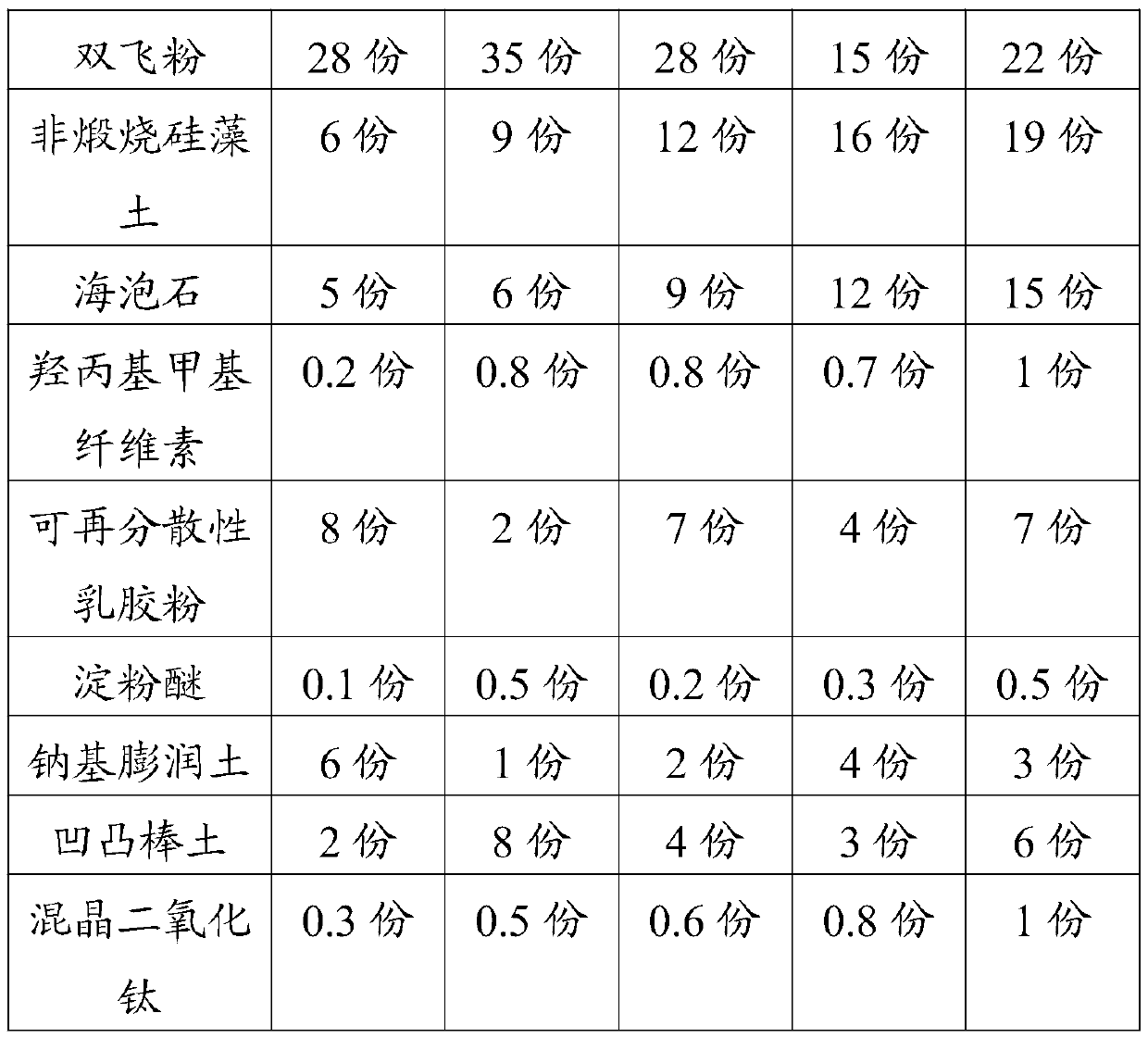

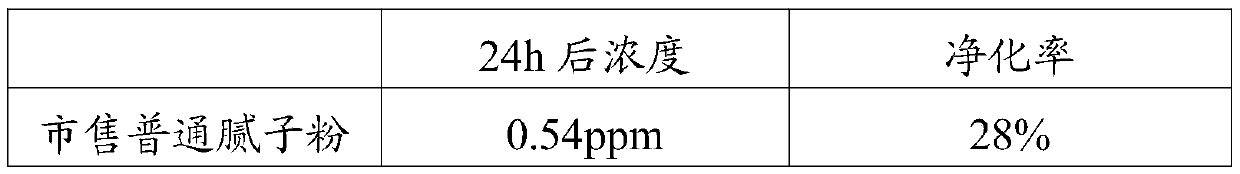

Neutral environment-friendly putty powder and preparation method thereof

InactiveCN110204944AImprove adsorption capacityLarge aperture rangeFilling pastesSodium BentoniteLiving environment

The invention discloses a neutral environment-friendly putty powder which has the air purification property and is free of coating brushing and smooth in appearance. The putty powder is prepared from,by weight, 7-23 parts of ultra-high-strength gypsum, 16-40 parts of calcium carbonate powder, 15-35 parts of calcium carbonate, 6-19 parts of non-calcined kieselguhr, 0.2-1 part of hydroxypropyl methyl cellulose, 2-8 parts of redispersible latex powder, 0.1-0.5 part of starch ether, 1-6 parts of sodium bentonite, 5-15 parts of sepiolite, 2-8 parts of attapulgite and 0.1-1 part of mixed crystal titanium dioxide. Accordingly, the putty powder has the properties of good safety, environmental protection, water resistance, respiratory hygroscopicity, formaldehyde and harmful gas elimination and the like, and has good capacity of improving the quality of the living environment; meanwhile, the surface of the putty powder is smooth, firm and white, other coating or wallpaper can be omitted, and the effects of protecting the environment and reducing the cost can be achieved.

Owner:长沙标朗住工科技有限公司

Deburring method and device of steps inner-holes

ActiveCN101396804ASimple structureEasy to operateEdge grinding machinesLapping machinesPulp and paper industryHigh pressure

The invention discloses a deburring method for internal holes of steps and a deburring device; the deburring method comprises the steps as follows: water is used as a medium; grinding material is mixed in water to form grinding liquid; the mixed weight ratio of the grinding material and the water is 1:25-1:35; after being mixed, the grinding liquid is injected into the step hole of the workpiece by a high pressure pump under the pressure of 0.4-0.6MPa; the deburring device comprises a grinding liquid mixer, a grinding pump, a clamp with an injection pipe and an air press; the clamp is provided with a clamp liquid inlet and a high pressure gas inlet; the injection pipe is arranged at the lower end of the clamp; the grinding liquid mixer is arranged at the lower end of the injection pipe; the grinding liquid mixer is provided with a grinding material inlet, a water inlet and a grinding liquid outlet; the grinding liquid outlet is connected with the liquid inlet of the grinding liquid pump; the liquid outlet of the grinding liquid pump is connected with the clamp liquid inlet of the clamp; the gas outlet is connected with the high pressure gas inlet of the clamp. Compared with the prior art, the deburring device has simple structure and easy operation and has wide applicable aperture range for the workpiece.

Owner:NANTONG WIEDSON FUEL INJECTION EQUIP

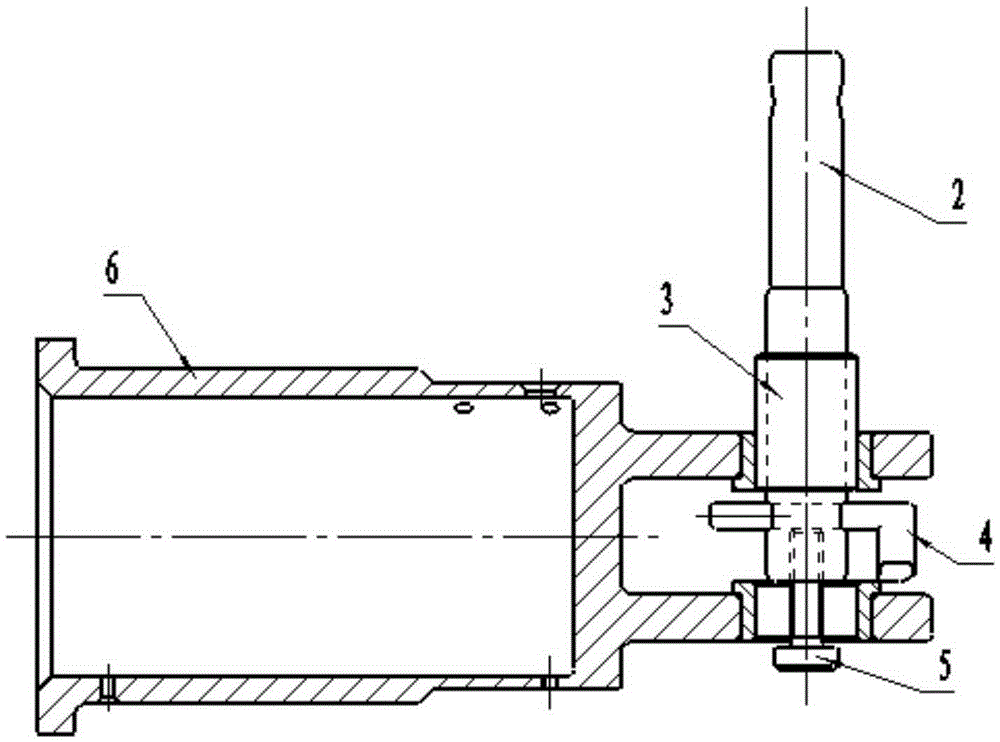

Rotary trimming and chamfering device capable of being used obversely and reversely

The invention discloses a rotary trimming and chamfering device capable of being used obversely and reversely and provides a burr trimming tool. According to the burr trimming tool, operation is easy and convenient, the other finish-machined surfaces are not prone to scratches, the machining efficiency is high, and the surfaces are smooth after burr treatment. According to the technical scheme, the front end of a tool bar guiding body (2) is provided with a hole access guiding body; an L-shaped cutting tool (4) passes through a radial through hole of the hole access guiding body in the radial direction in a length-adjustable mode, and chamfering blades are manufactured on the two sides of a tool bit of the L-shaped cutting tool; the cutting edge of the L-shaped cutting tool is locked and fixed in the axial direction through a locking bolt (5) after being turned downwards or upwards. The rotary trimming and chamfering device is mainly used for removing burrs, which cannot be turned easily, on a rotary surface, and the burrs can be removed manually and can also be removed on a vertical drilling machine. When the rotary trimming and chamfering device is in use, the corresponding tool bar guiding body is selected or a proper hole guiding bush is assembled according to the size of an inner hole of a part, and the burrs are removed through rotary cutting after the position of the cutting tool is adjusted and fixed according to the positions of the burrs.

Owner:SICHUAN LINGFENG AVIATION HYDRAULIC MACHINERY

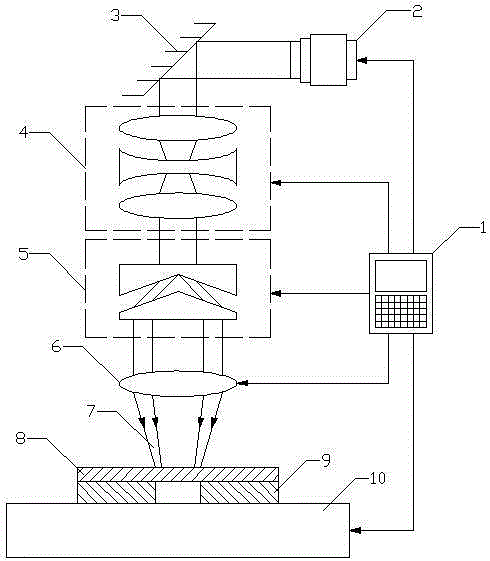

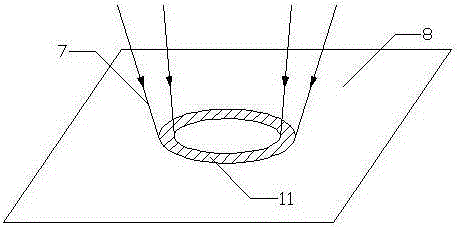

A method for processing small holes in carbon fiber composite materials by ring pulse laser

ActiveCN103071928BReduce thermal effectsLarge aperture rangeLaser beam welding apparatusShock waveLaser processing

The invention relates to a laser drilling technology, in particular to a method for machining a small hole in a carbon fiber composite material by annular pulse laser. A plate is irradiated by using the annular pulse laser; the annular laser cuts into a material layer by layer under mutual combination of heat effect of irradiation of the annular pulse laser and force effect of shock wave; and finally, the carbon fiber composite material at an entire irradiation region is cut through to finish machining of the small hole. According to the characteristics of the carbon fiber composite material, the pulse width, the energy, the frequency and the light spot size of the annular pulse laser are adjusted. The phenomenon that burrs, tearing and layering are produced during machining of the carbon fiber composite material is effectively avoided, the thermal effect is reduced, and the machining quality of the small hole of the carbon fiber composite material is guaranteed.

Owner:JIANGSU UNIV

Preparation method of antibacterial electromagnetic shielding type plywood

InactiveCN109366638AHigh electromagnetic shieldingEnhanced π-conjugated structureWood veneer joiningChlorhexidine AcetateAdhesive

The invention discloses a preparation method of an antibacterial electromagnetic shielding type plywood, and belongs to the technical field of plates. According to the method, the polyaniline monomersare used as raw materials, the arrangement and conformation of the polyaniline main chains are changed; the conductivity of the polyaniline reaches the maximum value; the electromagnetic shielding performance of the modified polyaniline solution is greatly improved; the wood core board is placed in the modified polyaniline solution for dipping, so that the modified polyaniline solution with the electromagnetic shielding effect is attached to the surface of the wood core plate; the honeysuckle contains rich achyranthes bidentata, inositol, tannic acid and other effective components and can beused for inhibiting various bacteria; silica gel is amorphous silicon dioxide, the chlorhexidine acetate solution can be adsorbed by silica gel, due to the use of the chlorhexidine acetate solution, the antibacterial performance of the plywood prepared by the method can be improved; 3-Glycidoxypropylthrimethoxysilane is used as a coupling agent, mixed and stirred with silica gel adsorbed with chlorhexidine acetate, so that the antibacterial silica gel adhesive is fully fused into an adhesive state. The antibacterial electromagnetic shielding type plywood has a wide application prospect.

Owner:赵顺全

Preparation method of ULPA ultra performance air filter material

ActiveCN101644012BIncrease effective spaceReduced void volumeWater-repelling agents additionPulp beating methodsGlass fiberFiber

The invention discloses a preparation method of ULPA super performance air filter material, including the following steps: step (1), 20-30wt% of glass fiber with average diameter of 0.1-0.3 Mum, 28-35wt% of glass fiber with average diameter of 0.4-1 Mum, 15-20wt% of glass fiber with average diameter of 5-7 Mum and 20-30wt% of long glass fiber with average diameter of 15-20 Mum are dispersed in water by beating, mass concentration of size is controlled to be 4.5-5.5%, acidity is controlled to be pH 2.1-2.6, and time of beating is controlled to be 40-48min; step (2), size obtained by the step (1) is diluted and stored; step (3), paper is made; step (4), sizing is carried out; step (5), drying is carried out. The invention has the advantages of high poriness, high clogging capacity and high efficiency.

Owner:CHONGQING ZAISHENG TECH CORP

Current collector etched foil and preparation method thereof, electrode and lithium battery

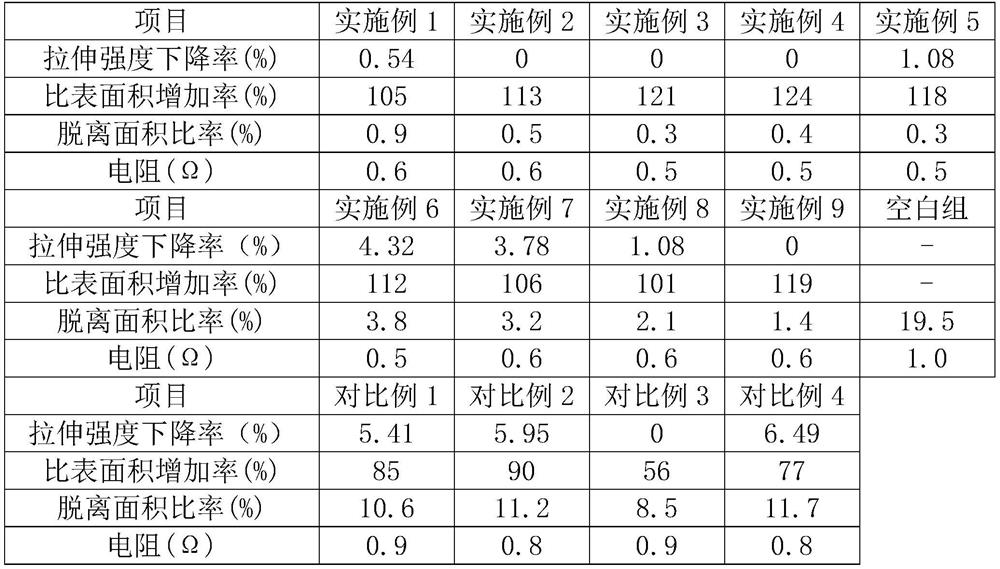

ActiveCN114744208AIncrease surface wetting tensionDoes not affect tensile strengthElectrode carriers/collectorsSecondary cellsMetallurgyMetal foil

The invention discloses a current collector etched foil and a preparation method thereof, an electrode and a lithium battery, and the preparation method of the etched metal foil comprises the following steps: providing a metal foil; the metal foil is subjected to etching treatment, and the metal foil sequentially enters a pickling tank, an alkaline washing tank, a pickling tank and a cleaning tank; and carrying out drying treatment on the etched metal foil. The preparation method is simple, and the etched metal foil is large in specific surface area, small in resistance and good in adhesive force with an electrode layer.

Owner:FOSHAN SINO SCI NANO TECH MATERIAL CO LTD

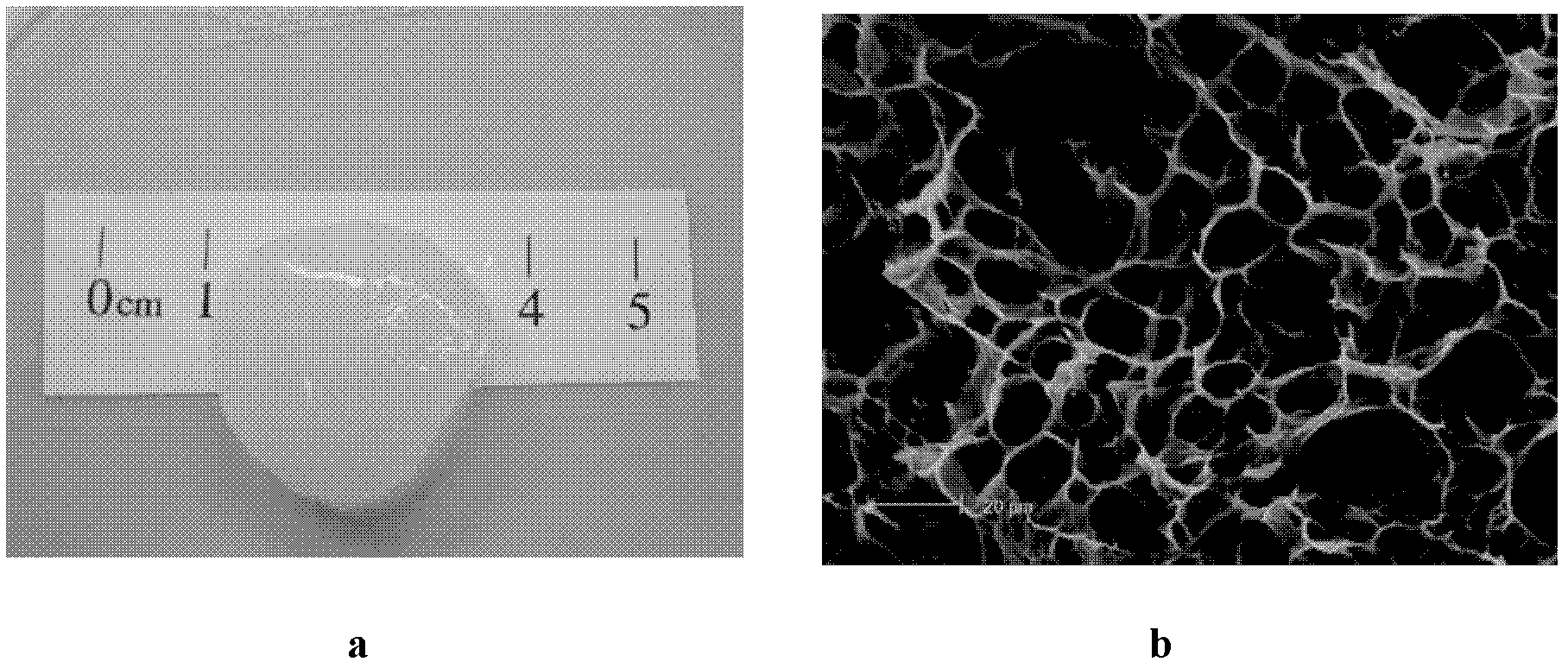

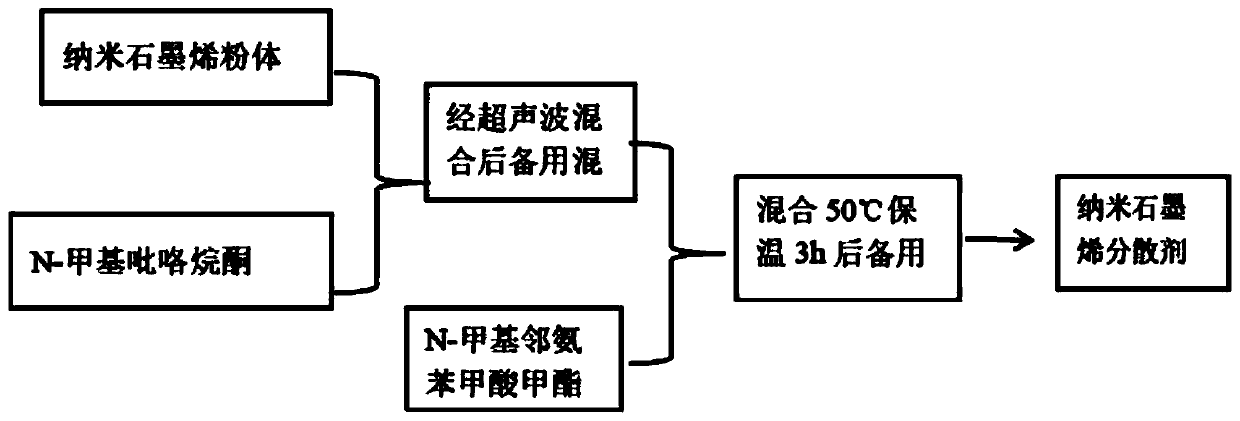

Preparation method of permanent hydrophilic nano graphene polytetrafluoroethylene hollow fiber nanofiltration membrane

InactiveCN111545080AHigh strengthThe method is simpleMembranesReverse osmosisPolymer scienceGraphene

The invention discloses a preparation method of a permanent hydrophilic nano graphene polytetrafluoroethylene hollow fiber nanofiltration membrane. The method comprises the following steps: mixing andpressing polytetrafluoroethylene dispersion resin, a nano graphene material, an extrusion aid, nano silicon dioxide and a coupling agent to obtain a green body; extruding the green body through a pushing and pressing machine to form a polytetrafluoroethylene hollow pipe, carrying out stretching and sintering heat setting in a drying oven, and carrying out surface hydrophilic stabilizer treatmentto obtain a permanent hydrophilic nano graphene polytetrafluoroethylene hollow fiber base membrane;; and carrying out water-phase impregnation, oil-phase impregnation and aftertreatment to prepare thepermanent hydrophilic nano graphene polytetrafluoroethylene hollow fiber nanofiltration membrane. The manufacturing method of the permanent hydrophilic nano graphene polytetrafluoroethylene hollow fiber nanofiltration membrane is based on the existing preparation process and equipment of the polytetrafluoroethylene hollow fiber membrane, additional slitting and wrapping equipment does not need tobe added, and the method is simple and easy to implement, low in cost and high in practical value.

Owner:颇尔(河北)环保设备有限公司

Method and sampling device for separating and purifying water body micro-organism strains

ActiveCN110029064AImprove bindingReduce resistanceMicroorganism separationBiological material testing proceduresGermplasmOil phase

The present invention relates to a method and a sampling device for separating and purifying water body micro-organism strains. The method comprises the following steps: step 1, a sample to be separated and purified and a calcium carbonate solution are added to a sodium alginate solution to obtain a precipitate and a suspension; step 2, the suspension is added to an oil phase A composed of sorbitan fatty acid ester and liquid paraffin to obtain a mixed system A; step 3, 6-10 ml of glacial acetic acid is added to the mixed system A, reaction is conducted at 22-25 DEG C for 8-12 min to obtain amixed system B, a calcium chloride solution is added to the mixed system B to obtain microcapsules, and the microcapsules are washed with sterilized water to obtain a microcapsule micro-organism strain bank; and step 4, the microcapsule micro-organism strain bank is inoculated one by one into porous plates to be cultured to obtain single colonies, and the porous plates are loaded with a BM liquidculture medium solution loaded with the micro-organism strains to be separated and purified. The method combines an emulsified micro-balloon method and a porous plate method, and can be used for database foundation and separation for environment functional micro-organism ecological germplasm resources.

Owner:SHAANXI UNIV OF SCI & TECH

Method and sampling device for separation and purification of microbial strains in water body

ActiveCN110029064BHigh mechanical strengthPlay a protective effectMicroorganism separationBiological material testing proceduresMicrosphereGermplasm

A method and a sampling device for the separation and purification of microbial strains in a water body of the present invention, comprising step 1, adding the sample to be separated and purified and calcium carbonate solution into a sodium alginate solution to obtain a precipitate and a suspension; step 2, adding the sample to the lost Add suspension to oil phase A composed of sorbitan fatty acid ester and liquid paraffin to obtain mixed system A; step 3, add 6-10ml of glacial acetic acid to mixed system A, react at 22-25°C for 8- 12min to obtain the mixed system B, add calcium chloride solution to the mixed system B to obtain microcapsules, wash the microcapsules with sterilized water to obtain the microcapsule strain bank; step 4, inoculate the microcapsule strain bank into the porous plate one by one Cultivate a single colony, in which the BM liquid culture medium solution of the bacteria to be separated and purified is installed in the porous plate; the present invention combines the emulsified microsphere method and the porous plate method, and can be used as a library and a library for environmental functional microbial ecological germplasm resources. separate.

Owner:SHAANXI UNIV OF SCI & TECH

Deburring method and device of steps inner-holes

ActiveCN101396804BSimple structureEasy to operateEdge grinding machinesLapping machinesPulp and paper industryHigh pressure

Owner:NANTONG WIEDSON FUEL INJECTION EQUIP

Preparation method of porous graphene

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

A Diamond Sleeve Grinding Tool Suitable for Drill Sleeve Guidance

ActiveCN104475826BPrevent sticking sleeveReduce wearDrilling/boring measurement devicesTransportation and packagingEngineeringConical surface

A diamond sleeve grinding cutter suitable for drill sleeve guide comprises a circular drill rod and a guide drill sleeve. The guide drill sleeve is positioned on the middle lower portion of the drill rod and connected with a drill template, the drill rod comprises a threaded handle (1), a 120-degree positioning conical surface (2), a core discharging port (3), a core discharging guide hole (4), a dust chip discharging spiral groove (6), a spiral guide surface (7), a dust chip discharging straight groove (8) and a cutter cutting edge (9) from top to bottom, double cylindrical surfaces are combined to from the guide drill sleeve, and a through hole is formed in a core, so that the drill rod conveniently penetrates the through hole. The diamond sleeve grinding cutter is an integrated cutter, the quality of a machined hole is fine, defects are fewer, hole forming efficiency is high, a composite hole with a large diameter can be machined once, dust cuttings are fewer and almost discharged in the form of material cores, environmental pollution is low, and materials can be repeatedly used.

Owner:BEIHANG UNIV +1

A kind of green preparation method of porous graphene

ActiveCN106350544BLarge aperture rangeMild reaction conditionsMicroorganism based processesFermentationPorous grapheneSporeling

The invention discloses an environment-friendly preparation method of porous graphene. The environment-friendly preparation method comprises the following steps: inoculating spore suspension liquid of white-rot fungi into a seed culture solution containing bacterial cellulose membrane blocks, and carrying out culturing, so as to obtain fixed white-rot fungi membrane blocks; inoculating the fixed white-rot fungi membrane blocks into a liquid nutrition-limited culture medium, carrying out culturing for 1-3 days, and adding oxidized graphene suspension liquid to react for 5-24 hours until oxidized graphene adsorbs the surfaces of hyphae of the fixed white-rot fungi membrane blocks; carrying out biological oxidation and degradation, so as to obtain degraded oxidized graphene membrane blocks; peeling hyphae externally adsorbed with oxidized graphene by virtue of tweezers, adding the peeled hyphae into diluted hydrochloric acid, and heating to dissolve; carrying out centrifuging and washing, so as to obtain purified porous graphene suspension liquid; and finally, drying, so as to obtain porous graphene. According to the preparation method, the porous graphene is prepared from fixed white-rot fungi under mild conditions, so that the reaction process is environmentally friendly, the cost is low, and the hole distribution of porous graphene is relatively wide.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Dimensionality reduction adaptive interlayer multiple suppression method for land seismic exploration data

ActiveCN106932824BIntensive artillery check point distributionLarge aperture rangeSeismic signal processingCheck pointOffset distance

The invention belongs to the exploration seismic signal processing field and relates to an adaptive prediction and suppression method of land seismic exploration data inter-layer multiple waves, in particular, a dimensionality-reduction adaptive inter-layer multiple wave suppression method of land seismic exploration data. According to the method, inter-layer multiple wave prediction and suppression of the land seismic exploration data are realized in a pre-stack CMD (Common Middle Point) trace gather through using a virtual event method. The method includes the steps of input data preparation, reference trace construction and multiple wave suppression. According to the method, when dynamic correction is adopted to eliminate travel related to an offset distance caused by the distribution of shot check points, the method has no requirements for the distribution of the shot check points; two-dimensional or three-dimensional data are converted into one-dimensional data through dimensionality reduction, so that calculation efficiency is improved; and weighted stacking is performed, so that reference traces can be obtained, and therefore, the noise immunity of a system can be improved.

Owner:PEKING UNIV

A fast composting device with a three-layer structure and a composting method using the device

ActiveCN105198517BSave purchase costReduce ventilationBio-organic fraction processingOrganic fertiliser preparationEngineeringFermentation

A three-layer rapid composting device and a composting method by the device relate to a composting device and a composting method by the device. The invention aims to solve problems of long composting period, odor pollution and low fermentation efficiency that exist in an existing membrane-covered composting method. The device of the invention comprises a trapezoid cement base, a draught fan, a perforated feed pipe, a V-shaped percolate guiding chute, a waterproof and breathable membrane, a percolate draft tube and a percolate collecting box. the method of the invention comprises the following steps: 1, burden distribution: a fermentation material and a compost clinker are mixed and the mixture is placed at the bottom of the three-layer rapid composting device, the compost clinker is covered, and a waterproof and breathable membrane is covered; 2, fermentation for 7-20 days. According to the invention, the compost clinker and the fermentation material are mixed without adding a conditioner. Thus, purchase expense of a conditioner is reduced, composting period is shortened, and energy consumption is decreased. By changing ventilation direction, no energy is additionally added. In addition, fermentation efficiency is enhanced, and composting period can be remarkably shortened.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com