A Diamond Sleeve Grinding Tool Suitable for Drill Sleeve Guidance

A diamond and cutting tool technology, applied in the field of mechanical processing tooling, can solve the problems of small hole diameter range, polluted environment, unstable processing, etc., and achieve the effect of reducing labor intensity of workers, reducing environmental pollution, and improving hole making efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

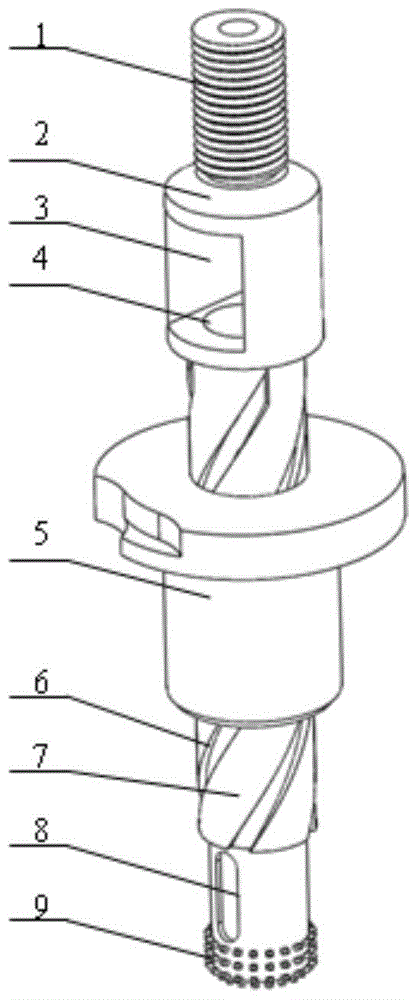

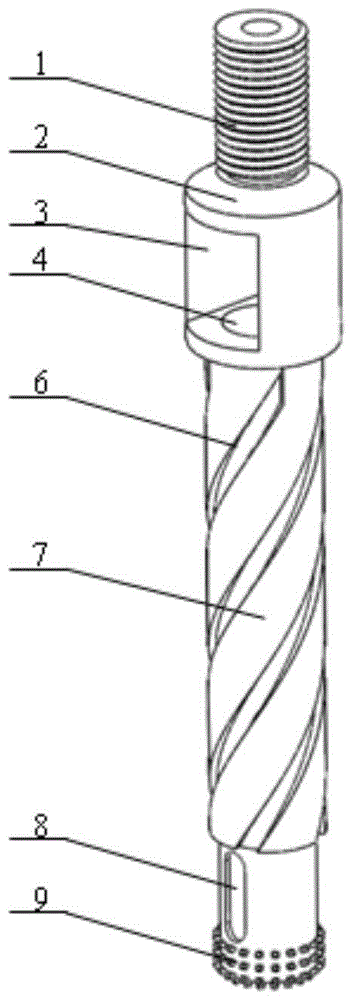

[0022] Such as figure 1 , figure 2 As shown, the present invention is suitable for a drill sleeve-guided diamond sleeve grinding tool, which is composed of a drill rod and a guide drill sleeve 5, and the guide drill sleeve 5 is located at the middle and lower part of the drill rod. The structural composition of the one-piece brazed or electroplated diamond sleeve grinding tool of the present invention includes a threaded shank 1, a 120° positioning cone surface 2, a core discharge port 3, a core discharge guide hole 4, a guide drill sleeve 5, and a spiral groove for dust removal 6. Spiral guide surface 7, dust removal straight groove 8, tool cutting edge 9. Steps of use: connect the tool to the machining spindle through a threaded shank, install the tool guide drill sleeve 5 on the drilling template, insert the tool into the guide drill sleeve 5, and then the workpiece can be ground and drilled.

[0023] Such as figure 1 , figure 2 As shown, the rear end of the set of kn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com