Three-layer rapid composting device and composting method by device

A three-layer structure and composting technology, which is applied in the direction of fertilization equipment, application, organic fertilizer, etc., can solve the problems of long composting cycle, odor pollution and fermentation efficiency, reduce purchase costs, improve fermentation efficiency, and reduce biological oxygen consumption and the effect of mechanical ventilation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

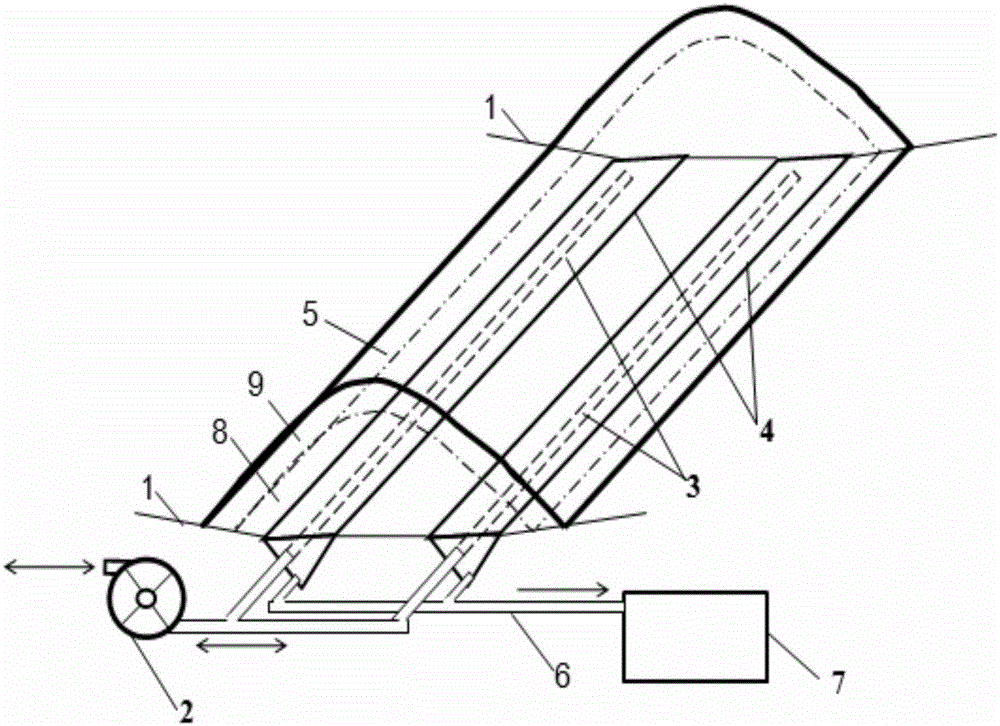

[0019] Specific implementation mode one: combine figure 1 As shown, the rapid composting device of the present embodiment has a three-layer structure, which includes a trapezoidal cement base 1, a fan 2, a perforated air distribution pipe 3, a V-shaped leachate guide trough 4, a waterproof breathable membrane 5, and a leachate flow pipe 6 , leachate collection box 7; the bottom end of the trapezoidal cement base 1 is provided with a plurality of V-shaped leachate guide troughs 4 in parallel intervals, and the top plate of the V-shaped leachate guide trough 4 is provided with a perforated plate, and a perforated air distribution pipe is arranged inside it 3. One end of the V-shaped leachate guide trough 4 is connected to the inlet of the leachate guide pipe 6 , and the leachate collection box 7 is installed at the outlet of the leachate guide pipe 6 .

specific Embodiment approach 2

[0020] Embodiment 2: This embodiment differs from Embodiment 1 in that the trapezoidal cement base 1 has a length, width, and height of 3-60m×1.5-10m×0.01-0.1m. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0021] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is that the length, width and height of the V-shaped leachate guiding trough 4 are 3-60m×0.1-1m×0.05-0.5m; The distance between the interval V-shaped leachate guiding channels is 0.2m-1m. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com