Electrolytic apparatus, methods purification of aqueous solutions and synthesis of chemicals

An electrolysis device and purification method technology, applied in chemical instruments and methods, electrolysis components, electrolysis process, etc., can solve the problems of inability to reduce the concentration of pollutants, decolorization, lack of sufficient industrial wastewater, etc., and achieve low update and maintenance costs, The effect of complete destruction and complete mineralization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment I

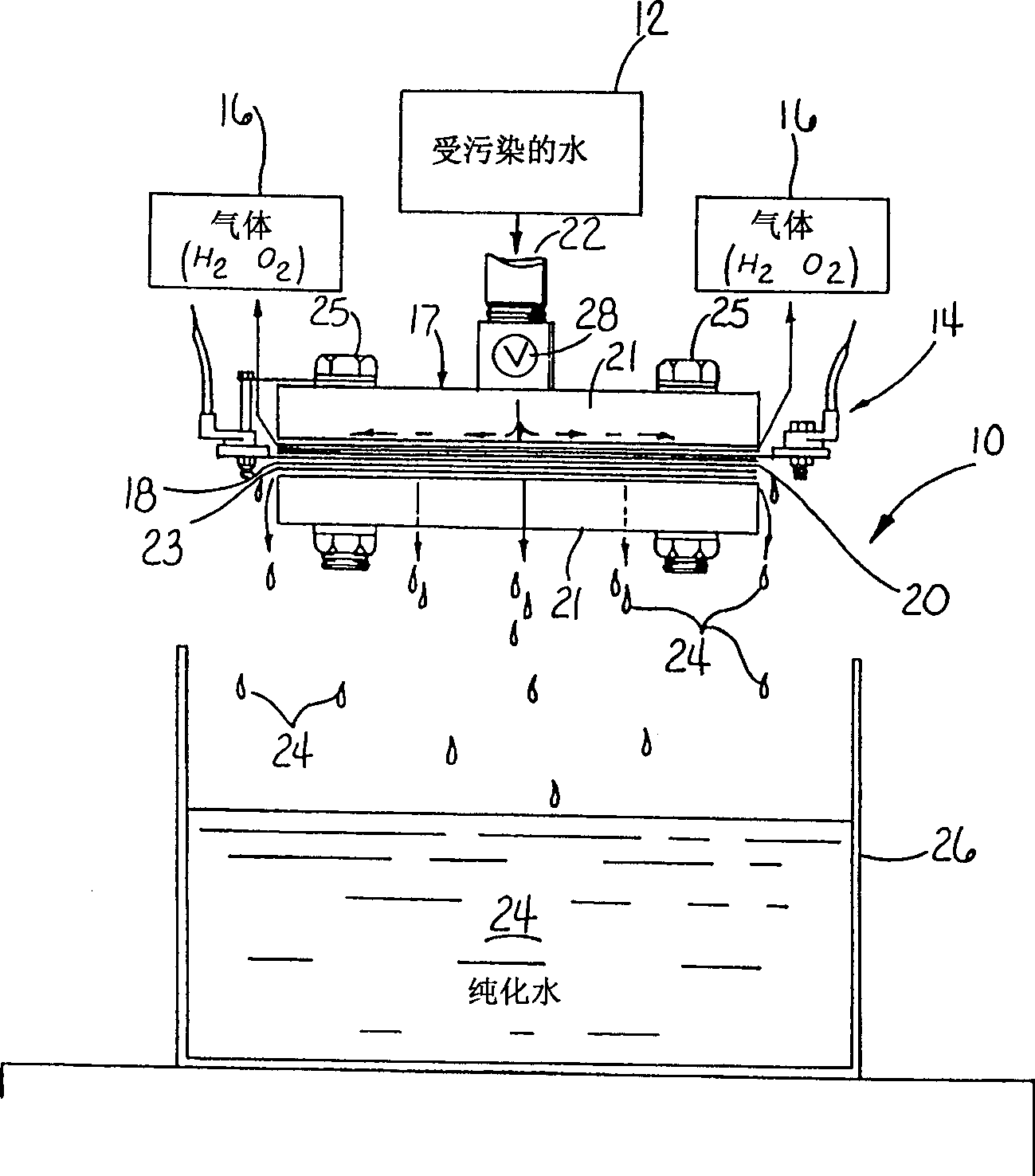

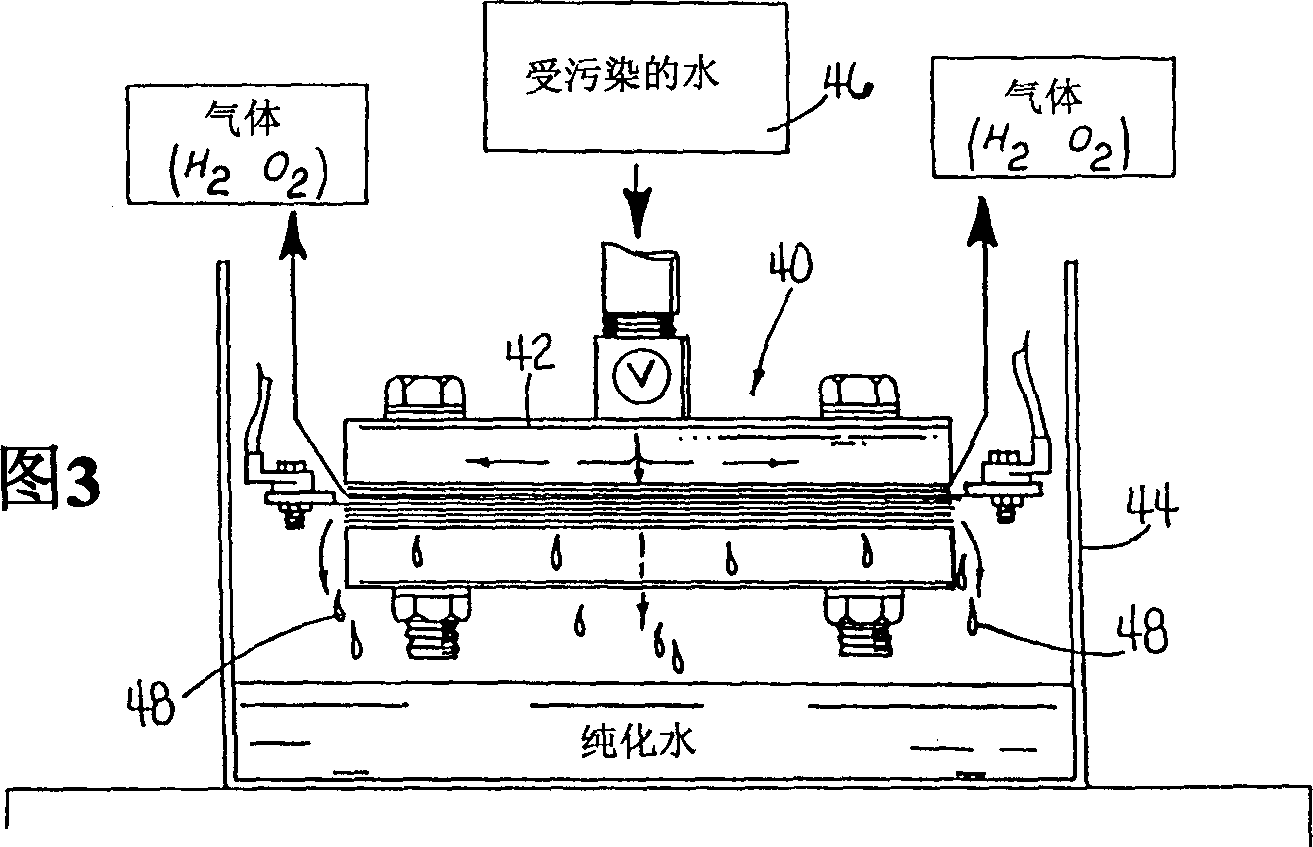

[0104] A monopolar electrochemical cell with an open structure was set up with an electrode assembly comprising 316 stainless steel end plates with a diameter of 12.065 cm and a thickness of 0.95 cm. A central cathode consisting of 316 stainless steel mesh with 7.8 x 7.8 openings / linear centimeter, 0.046 cm wire diameter, 0.081 cm opening width, and 41% open area was also incorporated into the electrode set. The anode consisted of two platinized niobium electrodes manufactured by Blake Vincent Metals, Rhode Island, USA. An anode electrodeposited on both sides of the niobium substrate, having a thickness of 635 microns, was drawn into a mesh having a thickness of about 0.51 cm and a diamond-shaped gap of 0.159 cm. Separators between adjacent electrodes were fabricated from polyethylene mesh with 8.27 x 8.27 openings / linear centimeter, 0.0398 cm wire diameter, 0.084 cm opening width, and 46% open area at Cree, Ohio, USA Supplied by McMaster-Carr of Forlan. The gap between the ...

Embodiment II

[0106] To demonstrate decolorization in textile industry effluent, a 1 liter solution containing 0.1 g of the textile dye Remazol was prepared in tap water TM Black B (Hoechst Celanese company), 0.1 gram surfactant Tergitol TM 15-S-5 (Union Carbide) and 1 g of sodium chloride.

[0107] The composition of the test solution was similar to typical effluents from textile dyeing and finishing processes, where even a very low concentration of Remazol Black imparted a very dark color to the solution. Remazol Black is a particularly difficult textile dye to process. So far, other methods used to treat Remazol Black, such as by the action of ozone or the use of hypochlorite bleach, have failed to produce the desired depigmentation effect.

[0108] In the monopolar electrolyzer installed in the embodiment 1, with 25 ampere constant currents, electrolyze the above-mentioned solution containing Remazol Black. The cell voltage was about 25 volts, and the temperature of the solution re...

Embodiment III

[0110] Further tests were carried out to show the decontamination effect of groundwater. Humic acids are typical pollutants in groundwater produced by the decomposition of plant matter. Water containing humic acid, even in low concentrations, is dark in color, and the color is difficult to remove.

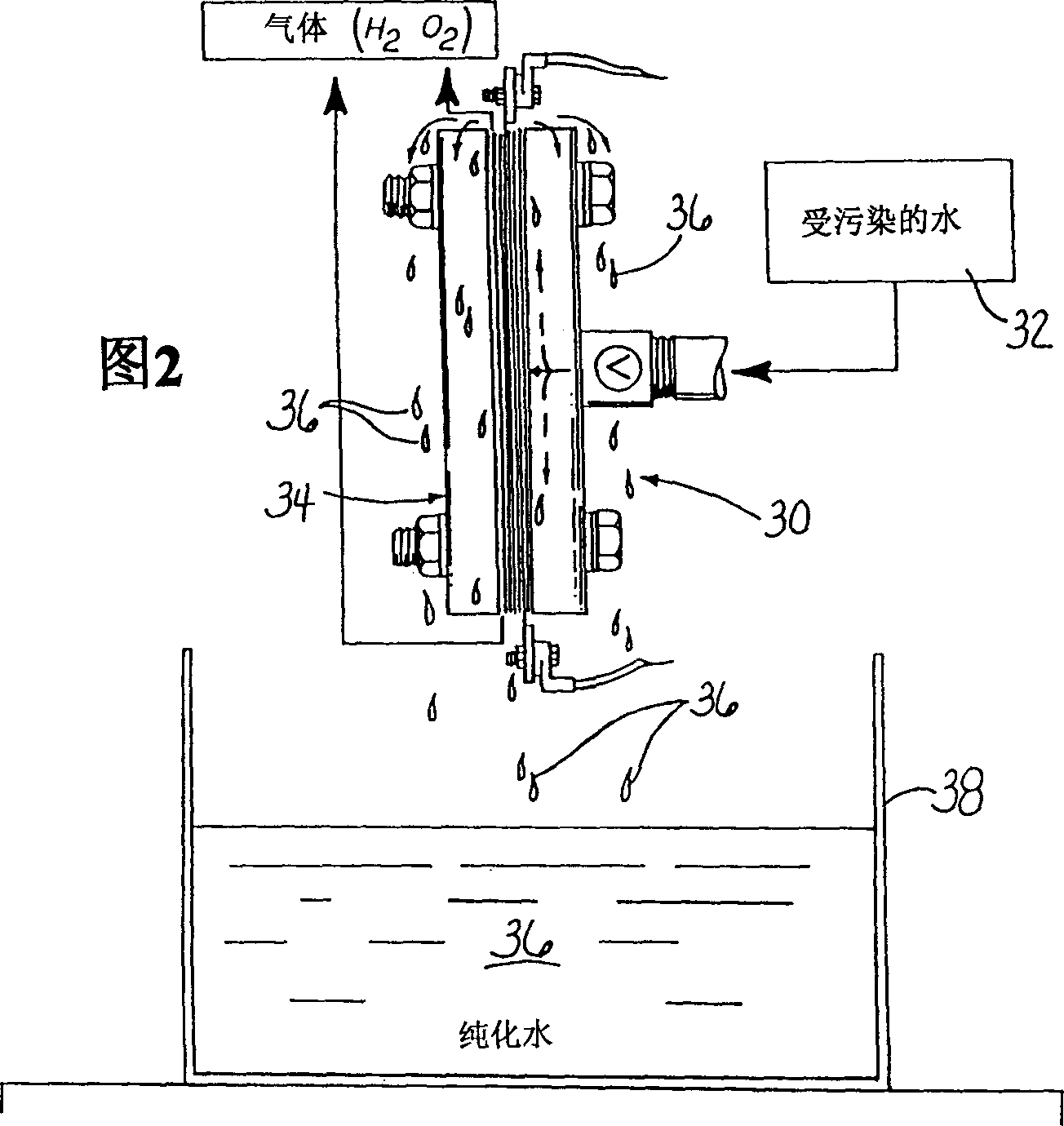

[0111] A dark brown solution in tap water was prepared containing 30 ppm of the sodium salt of humic acid (Aldrich) without additives to increase the conductivity of the solution. The solution was circulated through a monopolar electrochemical cell similar to that used in Example 1, but equipped with only one anode and two cathodes. A constant current of 10 amps was applied for 2.5 hours. The cell voltage was 24-25 volts, and the temperature reached 58°C. At the end of the test, the solution was completely clear, indicating effective destruction of humic acids.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com