Patents

Literature

182 results about "White Portland cement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

White Portland cement or white ordinary Portland cement (WOPC) is similar to ordinary, gray Portland cement in all aspects except for its high degree of whiteness. Obtaining this color requires substantial modification to the method of manufacture, and because of this, it is somewhat more expensive than the gray product.

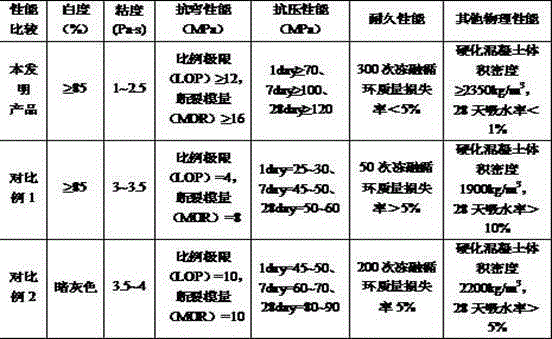

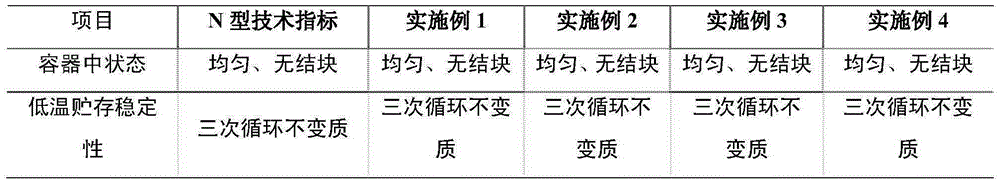

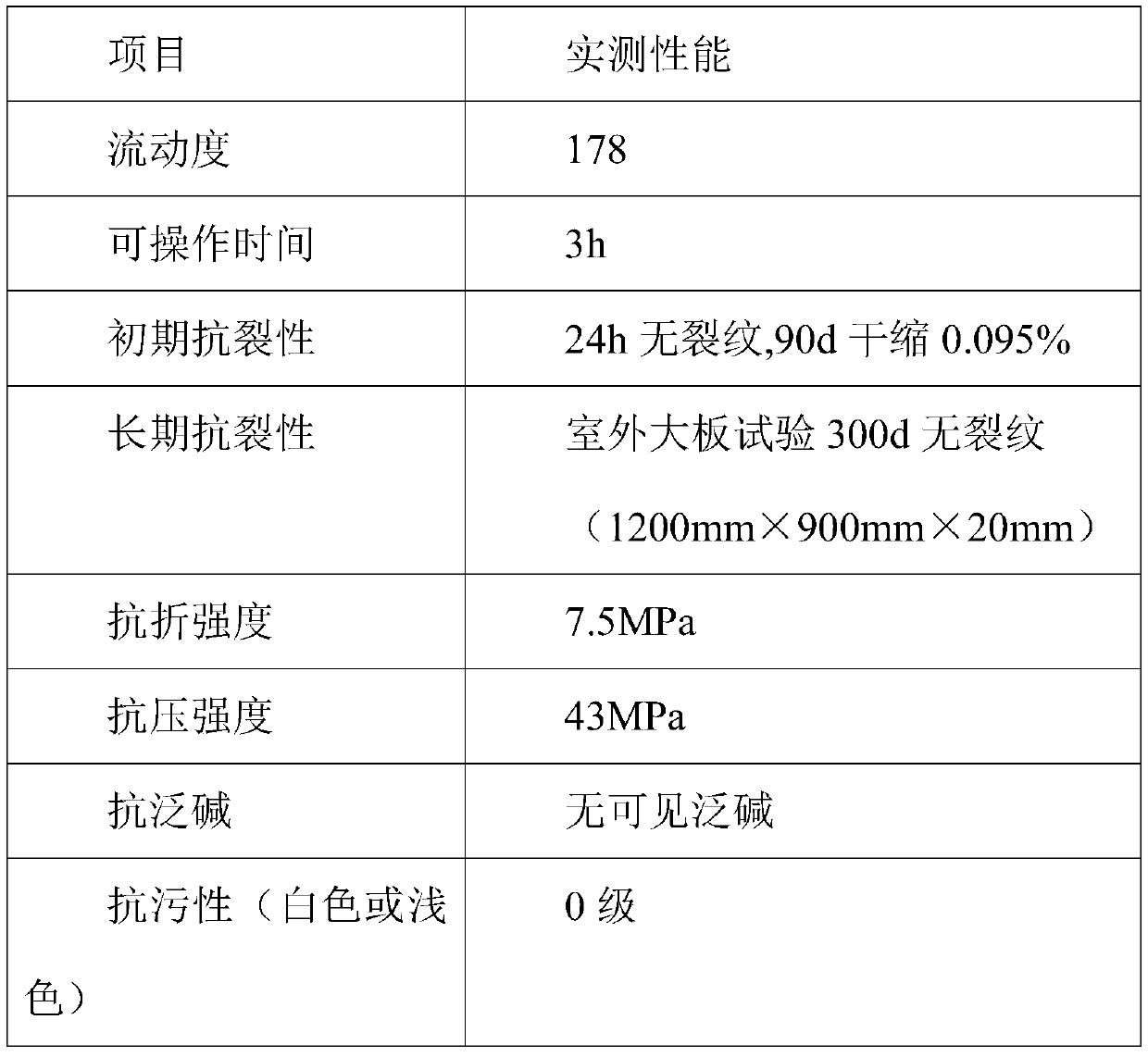

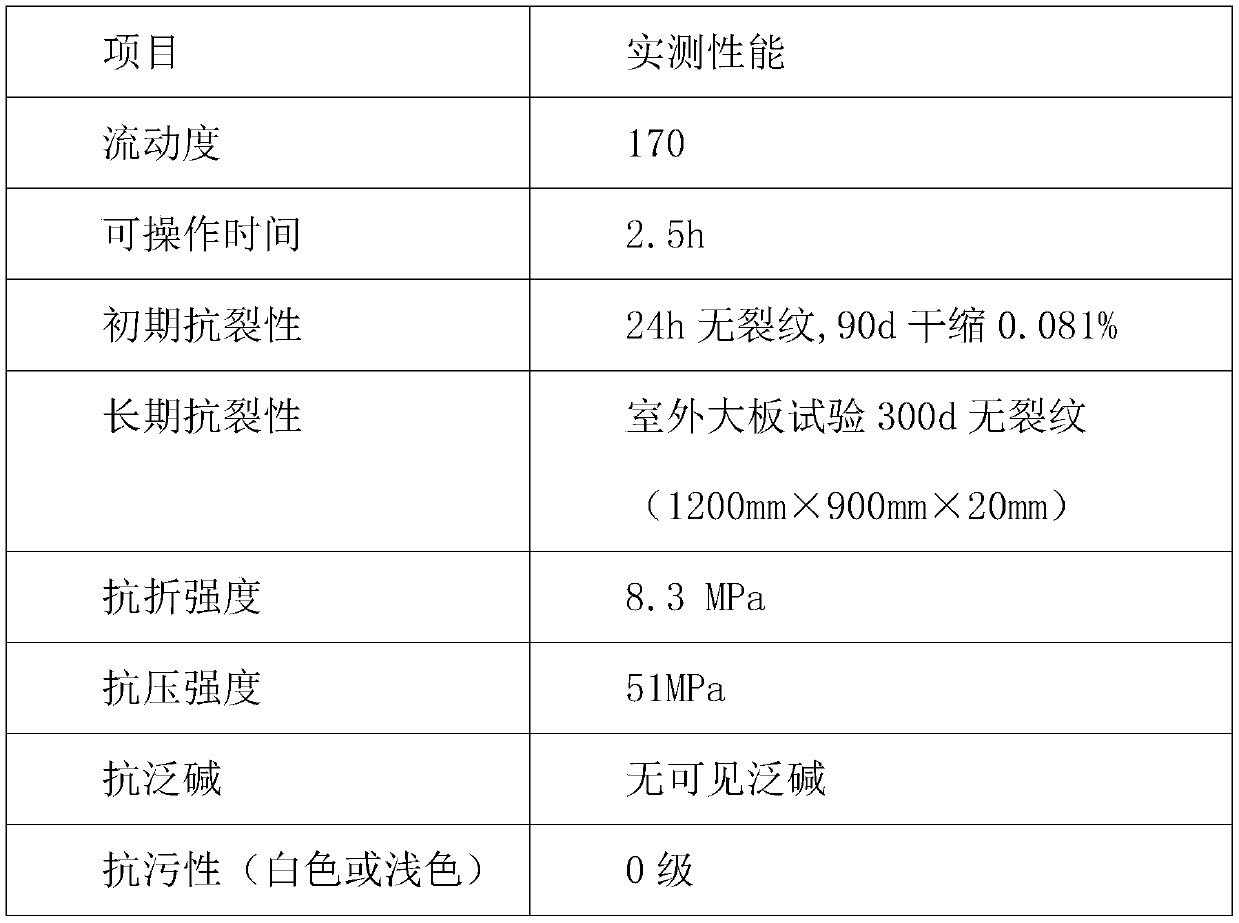

Ternary cementitious system stucco finish, and application method thereof

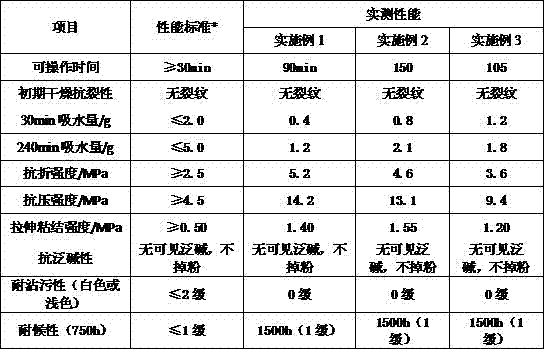

The invention belongs to the technical field of building material, and more specifically relates to a ternary cementitious system stucco finish, and an application method thereof. The ternary cementitious system stucco finish is composed of white Portland cement, sulphate aluminium cement, gypsum, superfine slag powder, zeolite powder, latex powder, cellulose ether, an air entraining agent, an antifoaming agent, a water repellent, a thixotropic agent, an inorganic pigment, an quartz sand. The ternary cementitious system stucco finish possesses excellent physical mechanical properties; setting time and operable time are controllable; development of early strength is rapid; strength is high; bonding strength with matrix is high; no shrinkage cracking is caused; durability is excellent; no crystalline bloom is caused; stain resistance is excellent; and decorative effect is excellent. The ternary cementitious system stucco finish is suitable for decoration engineering of building internal and external walls and building thermal-insulation decorative integrated systems; relatively mechanical strength is achieved in a relatively short term; construction efficiency is increased; performance of long-term application is excellent; and engineering quality is ensured.

Owner:TONGJI UNIV

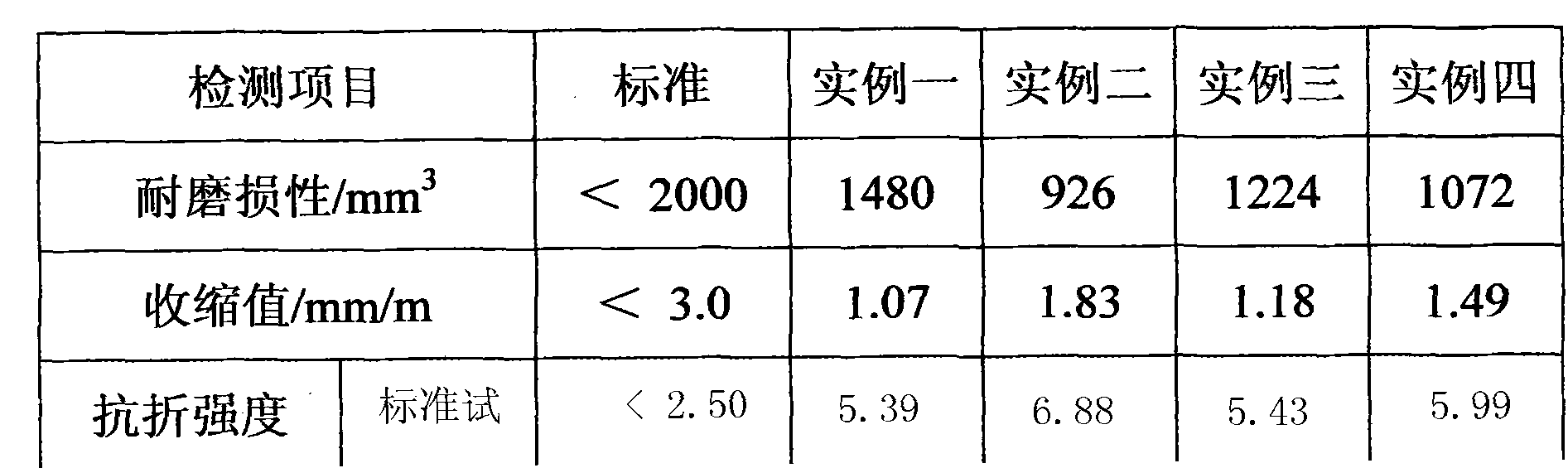

Colorful ceramic tile joint mixture and preparation technology thereof

InactiveCN102167554ALong-lasting colorImprove hydrophobicityCrack resistanceHydroxypropylmethyl cellulose

The invention relates to a colorful ceramic tile joint mixture which comprises the raw materials based on weight percentage as follows: 35%-50% of white portland cement, 45%-60% of quartz powder, 0.05%-0.3% of hydroxypropyl carboxymethyl hydroxypropyl cellulose, 0.055-0.25% of water repellent and 1%-3% of pigment. After the colorful ceramic tile joint mixture is used, the constructability is greatly improved, the deformability is improved, the water resistance is realized, the compactedness is increased, the cracking resistance is improved, and the color is more durable and gorgeous.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +2

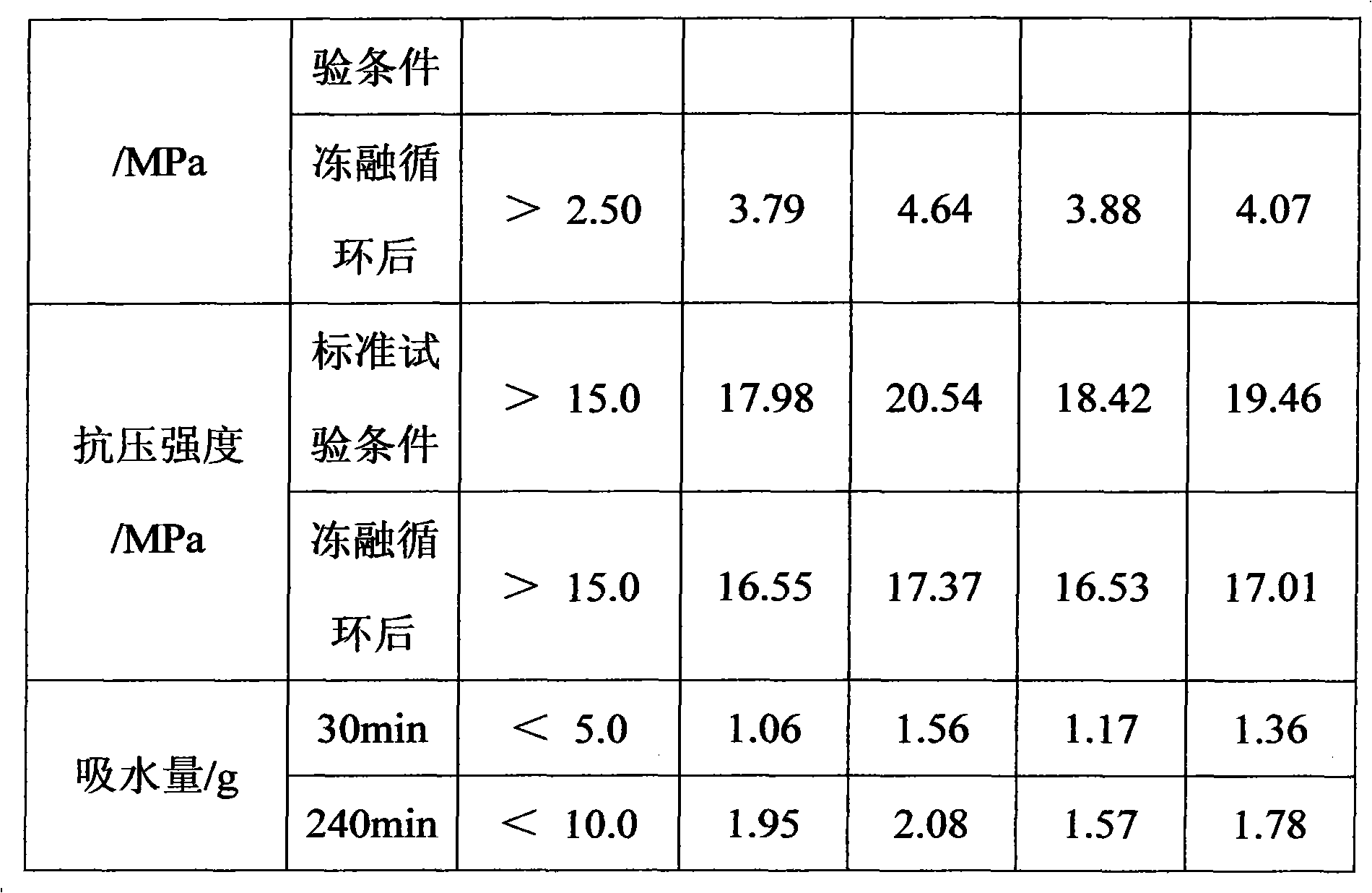

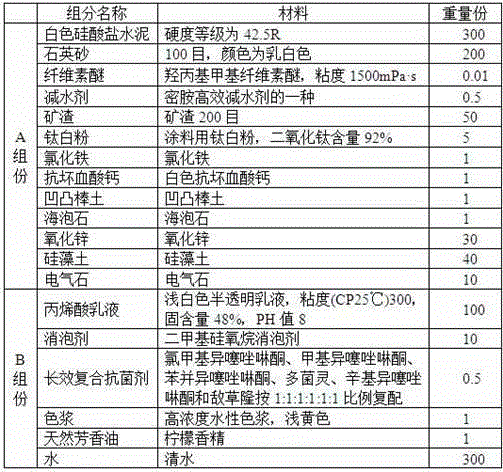

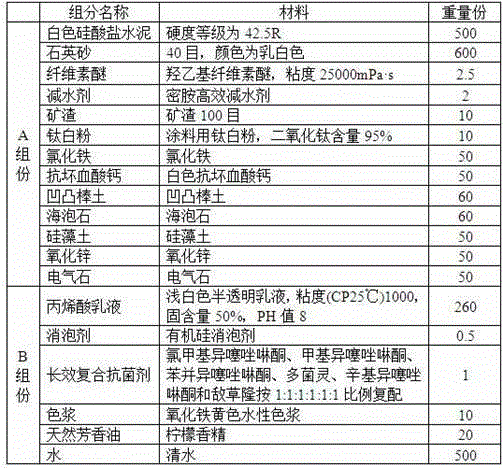

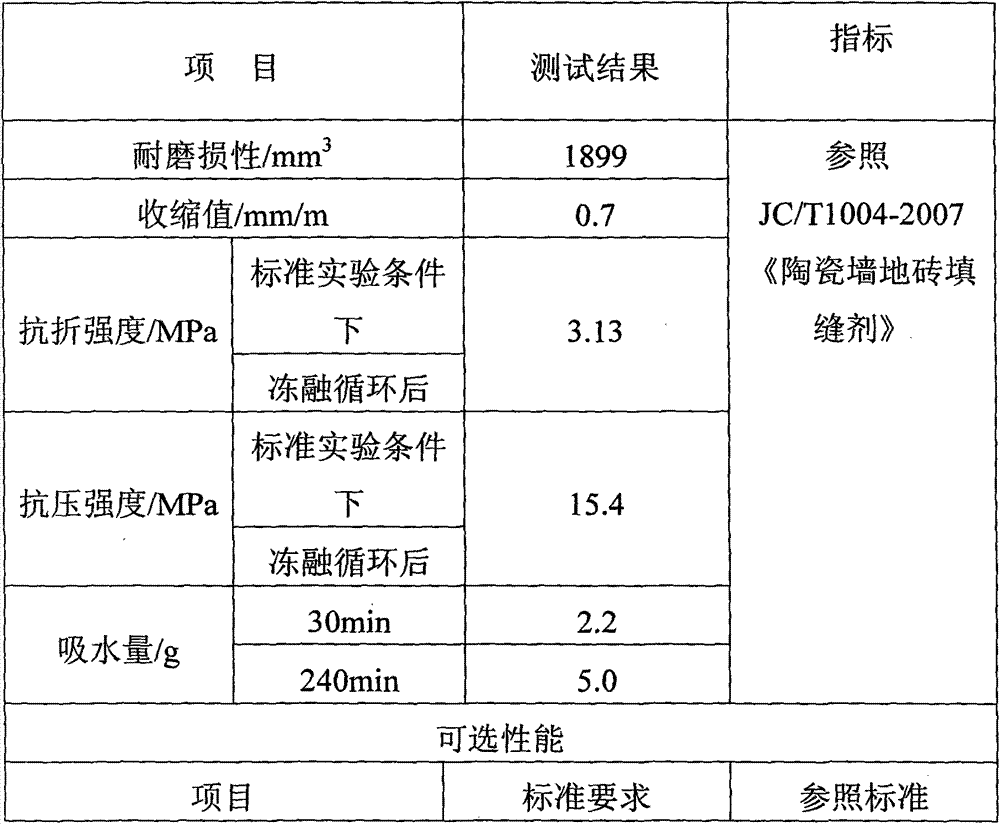

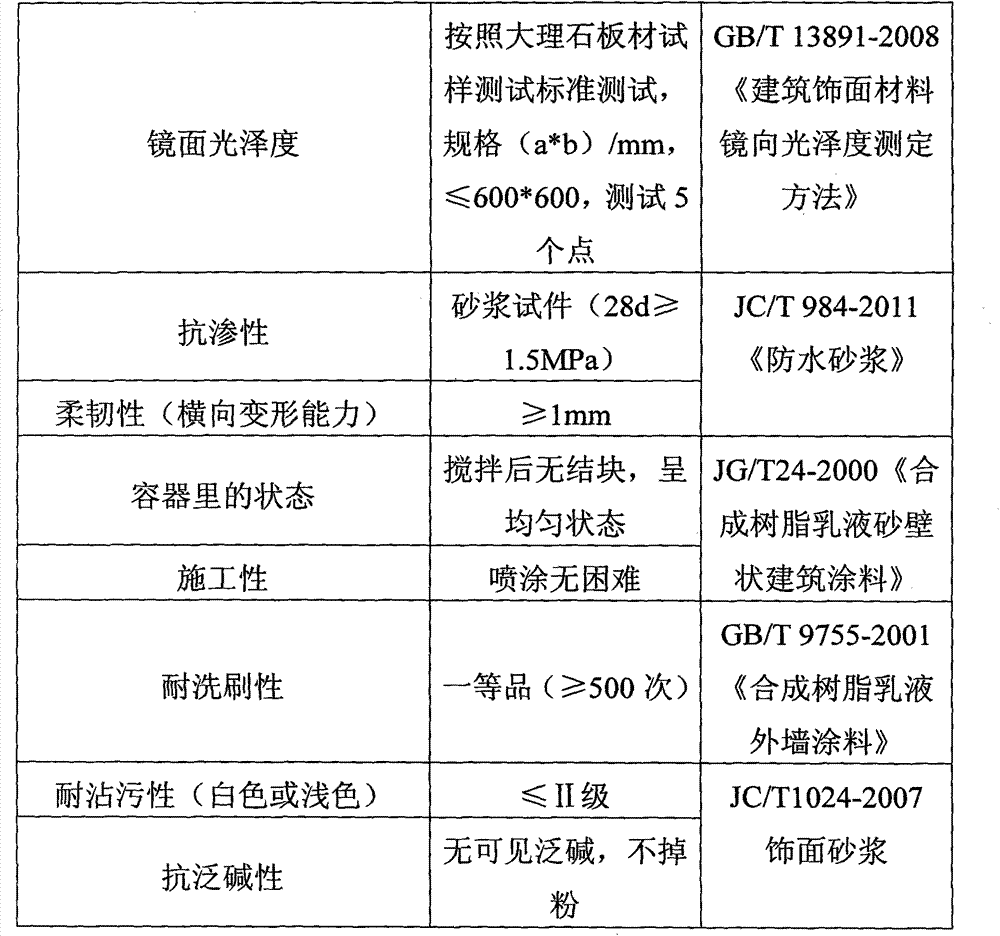

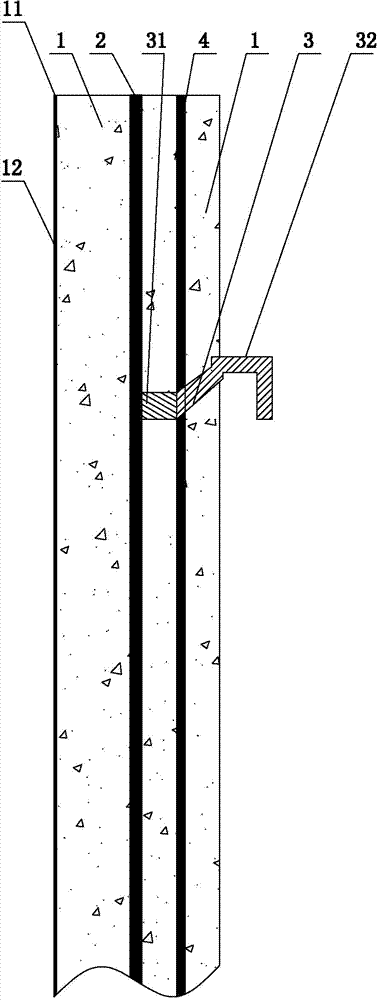

Waterproof slurry with sterilization function for toilet bath room decoration surfaces

ActiveCN103601442AImprove waterproof performanceImprove the decorative effectSolid waste managementPaints with biocidesCellulosePolymer science

The invention relates to waterproof slurry with a sterilization function for toilet bath room decoration surfaces. The waterproof slurry is composed of A and B double components, the A component comprises white portland cement, quartz sand, cellulose ether, a water reducing agent, slag, titanium dioxide, ferric chloride, calcium ascorbate, attapulgite, sepiolite, diatomite, tourmaline and zinc oxide, the B component comprises acrylic emulsion, a defoaming agent, color paste, a composite antibacterial agent, natural essential oil and water. The waterproof slurry uses cement-class inorganic components as main materials, also has decorative effects and a waterproof function, and can be used as decoration surface layers in a toilet, a bathroom, a rest room, and other long-term watery and moist environment, is good in decorative effect, and is scrub resistant; by adding of the composite antibacterial agent prepared according to the environment characteristics of the toilet, the bathroom and the rest room, growth of bacteria and mold can be effectively inhibited; through the use of a composite deodorizing technology of a combination of minerals and the natural essential oil, undesirable odor of the toilet, the bathroom and the rest room can be controlled.

Owner:西卡德高(上海)建材有限公司

Repair mortar specially used for low-density autoclaved aerated concrete slabs

ActiveCN103951340AImprove aestheticsTo achieve the purpose of comprehensive utilizationSolid waste managementFiberAdditive ingredient

The invention discloses a repair mortar specially used for low-density autoclaved aerated concrete slabs. According to a preparation method of the repair mortar, white Portland cement and sand are taken as base materials, and a filling material and a functional admixture are combined. The repair mortar comprises following ingredients, by weight, 20 to 30% of white Portland cement, 40 to 60% of sand, 0 to 15% of autoclaved aerated concrete milled powder, 0 to 15% of heavy calcium carbonate powder, 0.1 to 2% of dispersible adhesive powder, 0.01 to 0.5% of a water-retaining agent, and 0.01 to 0.5% of fiber. The repair mortar is convenient for construction and polishing; the texture of the repair mortar is similar to that of f autoclaved aerated concrete after hardening; and indexes, such as intensity, accords with existing standard requirements.

Owner:TIANJIN TIANZHU BUILDING MATERIALS

Clinker and white portland cement with a high sulfur content derived from a high sulfur content pet-coke used as fuel

The present invention relates to a family of white clinker compositions with a high capacity to fix sulfur derived from a high content pet-coke used as fuel in the manufacture thereof, which further exhibits low fuel consumption and fast setting, achieved by being comprised of the following amounts of clinker phases in percentage by weight: 3CaO.SiO2 (C3S): 40 to 75, 2CaO.SiO2 (C2S): 10 to 35, 3CaO.Al2O3 (C3A): 0 to 15, CaO.SO3 (CS): 0 to 10, 4CaO.3Al2O3.SO3 (C4A3{haeck over (S)}): 2 to 15, 11CaO.7Al2O3.CaF2 (C11A7.CaF2): 0 to 5, total % CaF2: 0.3 to 1.5 measured as CaF2, % Fe2O3: 0 to 0.5 and a SO3 content between 1.5 to 5% by weight obtained through the calcination of a raw meal containing CaO, SiO2, Al2O3, and CaF2, using as fuel, pet-coke with a sulfur content higher than 5% and at temperatures between 2192 and 2462° F., without the addiction of essentially any additive containing SO3 in the raw meal.

Owner:CEMEX RES GRP AG

Bright caulking compound and construction method thereof

InactiveCN104743990AImprove performanceOvercome disadvantagesAluminum magnesium silicateSuperplasticizer

The invention relates to a bright caulking compound. The bright caulking compound is prepared from the following raw materials by weight: 35 to 45 parts of common white Portland cement, 20 to 40 parts of quartz powder, 5 to 10 parts of light calcium, 1 to 3 parts of starch, 10 to 30 parts of heavy calcium carbonate powder, 0.15 to 0.25 part of hydroxypropyl methyl cellulose, 5 to 10 parts of pure acrylic glue powder, 0.08 to 0.1 part of a polycarboxylate superplasticizer, 0.1 to 0.3 part of an antifoaming agent, 0.2 to 0.3 part of an organosilicon water repellent, 0.1 to 0.4 part of aluminum-magnesium silicate, 0.4 to 0.6 part of a brightener, 1.5 to 3 parts of pigment, 0.3 to 0.5 part of a dispersant and 0.1 to 0.3 part of cellulosic fiber. According to the invention, since various properties of the caulking compound are improved through addition of proper additives, disadvantages of traditional cement-based caulking compounds are overcome, problems of a reactive resin type caulking compound are perfectly solved, the caulking compound disclosed in the invention has excellent resistance to corrosion, mildew, permeation, water, scrubbing, wear and contamination, excellent shrinkage deformation capability and other excellent properties, cost is saved, and production and construction steps are simplified.

Owner:FOSHAN JIAMITE WATERPROOF MATERIAL CO LTD

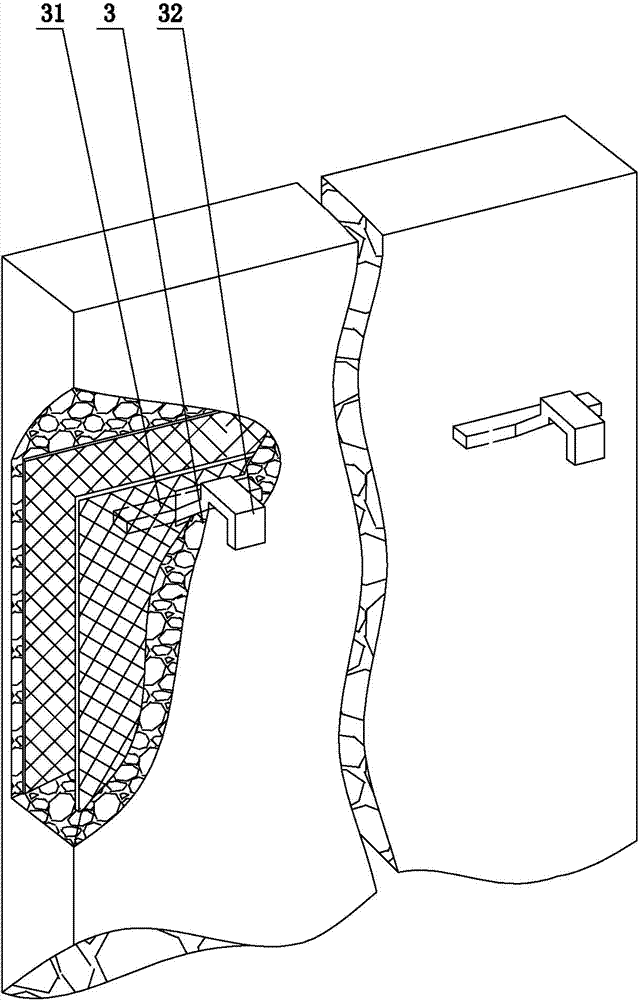

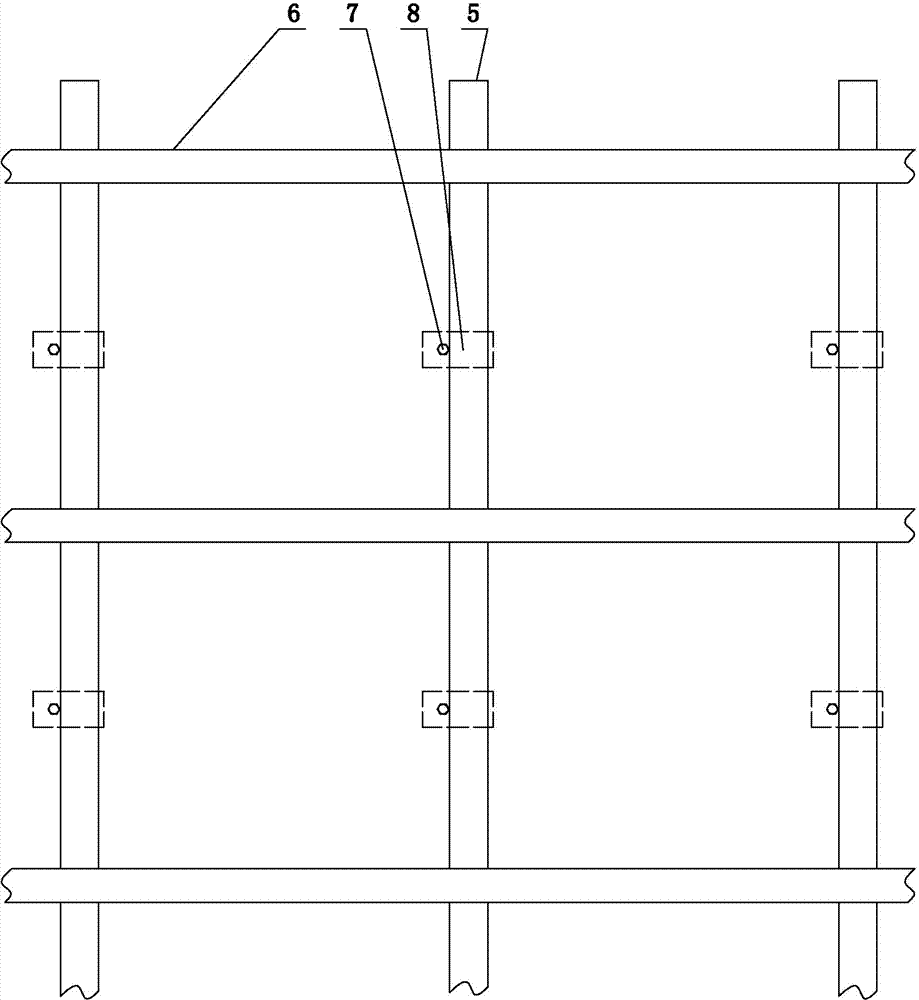

Manufacturing and mounting method of artificial tablet stone

ActiveCN103924762AAvoid destructionFast construction and installationCovering/liningsCeramic shaping apparatusAcrylic resinSlag

The invention discloses a manufacturing and mounting method of an artificial tablet stone. The artificial tablet stone comprises components including, by weight, 100 parts of white portland cement, 0.1-5 parts of iron oxide pigment, 100-150 parts of color sand, 50-100 parts of granite stone fine stones, 20-45 parts of superfine slag powders, 0.1-0.5 part of a water reducer, 0.5-2 parts of a hardening accelerator and 20-45 parts of an acrylic resin emulsion. The manufacturing and mounting method includes that the above materials are stirred to be made into a mixed mixture which is poured into a mould, a steel wire mesh and a stainless steel hanging piece are laid, and the tablet stone is manufactured through procedures of vibration, steam curing, surface treatment, waterproof layer spraying and the like. The manufacturing and mounting method has the advantages of light weight, low cost, convenience in mounting and the like; binding fixing and supporting functions of a simulated-stone material layer can be well achieved by a boundary layer and the steel wire mesh, crush resistance and tensile strength of the simulated-stone material layer can be improved by a hydrophobic layer, and a waterproof membrane is formed on the surface of the artificial tablet stone; the problem in manufacturing an existing simulated-stone material can be solved, and good social benefits can be achieved.

Owner:钟兵

Clinker and white portland cement with a high sulfur content derived from a high sulfur content pet-coke used as fuel

The present invention relates to a family of white clinker compositions with a high capacity to fix sulfur derived from a high sulfur content pet-coke used as fuel in the manufacture thereof, which further exhibits low fuel composition and fast setting, achieved by being comprised of the following amounts of clinker phases in percentage by weight: 3CaO.SiO2 (C3S): 40 to 75, 2CaO.SiO2 (C2S): 10 to 35, 3CaO.Al2O3 (C3A): 0 to 15, CaO.SO3 (CS): 0 to 10, 4CaO.3Al2O3.SO3 (C4A3{hacek over (S)}): 2 to 15, 11CaO.7Al2O3.CaF2 (C11A7.CaF2): 0 to 5, total % CaF2: 0.3 to 1.5 measured as CaF2, % Fe2O3: 0 to 0.5 and a SO3 content between 1.5 to 5% by weight obtained through the calcination of a raw meal containing CaO, SiO2, Al2O3, and CaF2, using as fuel, pet-coke with a sulfur content higher than 5% and at temperatures between 2192 and 2462° F., without the addition of essentially additive containing SO3 in the raw meal.

Owner:CEMEX RES GRP AG

Decorative concrete for building external envelope structure and preparation method thereof

The invention discloses a decorative concrete for building external envelope structures and a preparation method thereof. The decorative concrete is suitable for building external wall decoration, internal wall decoration and artistic sculptures and the like. The decorative concrete is composed of white Portland cement, low-viscosity decorative powder, ultrafine non-continuously-grading sand and a solution with addition of fibers in certain doping quantity. The decorative concrete can reach 50-100 years in service life, can achieve free regulation of colors, and satisfies the requirements in the aspects of strength, durability, decorative property, artistry, application property, self maintenance and the like.

Owner:江苏倍立达新材料科技有限公司

White cementitious compositions

A cementitious composition includes (i) white Portland cement having a fineness of about 350-550 m2 / kg, D90 between about 11-50 μm, and total combined iron oxide, manganese oxide, and chromium oxide <1.0% by weight (ii) light color pozzolan such as white silica fume, and (iii) at least one light color particulate material, such as ground granulated blast furnace slag (GGBFS) having a fineness greater than that of the white Portland cement, a D90 less than that of the white Portland cement, and total combined iron oxide, manganese oxide, and chromium oxide content <3.0% by weight and / or coarse limestone powder having a D90 greater than that of the white cement. The cementitious composition may include one or more of aggregates, fibers, or admixture. The cementitious composition can be a dry blend, fresh cementitious mixture, or hardened cementitious composition. The cementitious composition can be precast concrete, stucco, GFRC, UHPC or SCC.

Owner:ROMAN CEMENT

Anti-ultraviolet exterior wall coating and preparation method thereof

InactiveCN106883689AEffective absorptionImprove cooling effectAntifouling/underwater paintsPaints with biocidesAdhesiveUltraviolet lights

The invention discloses an anti-ultraviolet exterior wall coating and a preparation method thereof, and relates to the technical field of exterior wall coatings. The anti-ultraviolet exterior wall coating is prepared from 30 to 40 percent of a component A and 60 to 70 percent of a component B, wherein the component A is prepared from the following raw materials in parts by weight: 80 to 90 parts of EVA (ethylene-vinyl acetate) emulsion, 30 to 60 parts of nano TiO2, 20 to 30 parts of a filler, 10 to 15 parts of a compound adhesive, 2 to 10 parts of an ultraviolet light absorber, 2 to 8 parts of an assistant and 50 to 60 parts of deionized water; the component B is prepared from the following raw materials in parts by weight: 80 to 90 parts of styrene-acrylic emulsion, 30 to 60 parts of waste glass praseodymium and iron magnetic oxide composite powder, 20 to 30 parts of white Portland cement, 2 to 10 parts of coloring pigment and 30 to 60 parts of deionized water. According to the anti-ultraviolet exterior wall coating disclosed by the invention, an anti-ultraviolet material is added on the basis of waterproof property, so that ultraviolet rays can be effectively absorbed; the anti-ultraviolet exterior wall coating has the advantages of being relatively high in heat dissipating effect and weather fastness, safe and environment-friendly.

Owner:HEFEI OAKS NEW BUILDING MATERIAL CO LTD

Lightweight leveling putty and preparation method thereof

The invention relates to a lightweight leveling putty. The lightweight leveling putty comprises, by weight, 10-25 parts of white Portland cement, 15-25 parts of desulfurized gypsum powder, 10-15 parts of closed cell perlite, 35-45 parts of heavy calcium carbonate, 3-6 parts of talcum powder, 1-3 parts of renewable dispersible latex powder, 0.2-0.5 parts of cellulose, 0.1-0.2 parts of starch ether and 0.1-0.3 parts of an air entraining agent. The invention also provides a preparation method of the lightweight leveling putty. The lightweight leveling putt has the advantages of reduction of the heat conduction coefficient of mortar, and solving of masonry cold bridges, and the preparation method has the advantages of simplicity, easy operation, and convenience for industrial production and application.

Owner:广州市福恒嘉邦建材有限公司

Attapulgite water proof putty powder

The invention discloses attapulgite water proof putty powder. The key point of technical proposal of the invention is that the attapulgite water proof putty powder consists of purified attapulgite, white bentonite, white Portland cement, activated hydrated silica, polyvinyl alcohol fine powder, and rutile type titanium dioxide. The production method of the attapulgite water proof putty powder comprises the following steps: material charging, crushing, grinding powder, and packing to obtain the finished products of the attapulgite water proof putty powder. The attapulgite water proof putty powder has the characteristics of fine texture, quick drying, good adhesion property, strong adhesive force, water tightness, cracking resistance, powder fall-off prevention, paint conservation, and convenient construction. The attapulgite water proof putty powder has a long service life, does not need to be removed as a puffy layer before decorations in future and allows for carrying out following construction with only surface polishing and local repair, thereby improving the quality and decorative effect of finishing projects, and protecting buildings. The attapulgite water proof putty powder is suitable for the architectural finishing engineering.

Owner:南通亿科赛尔新型建材有限公司

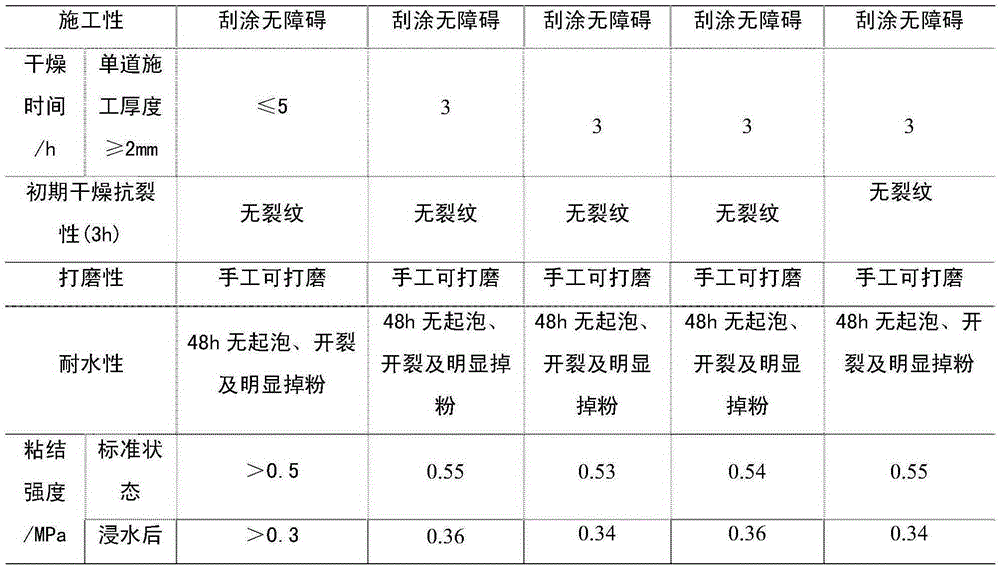

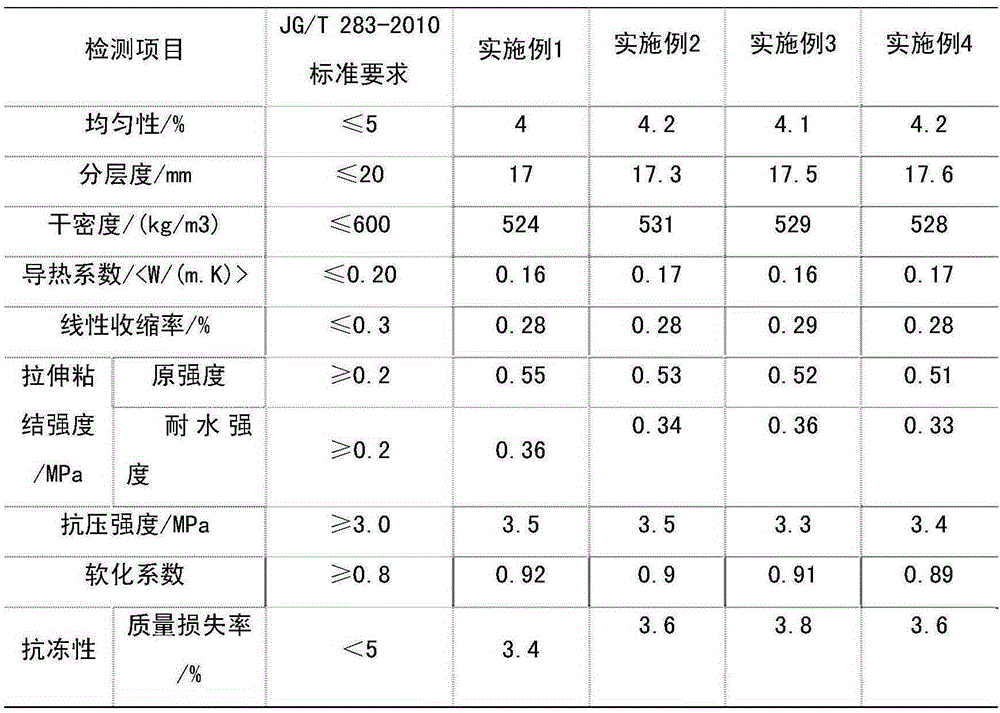

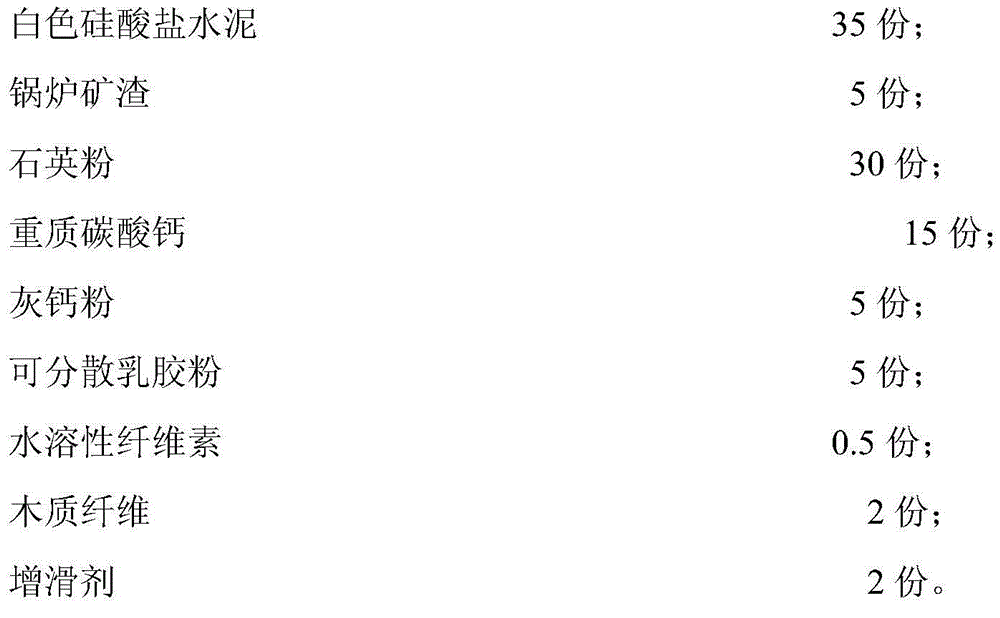

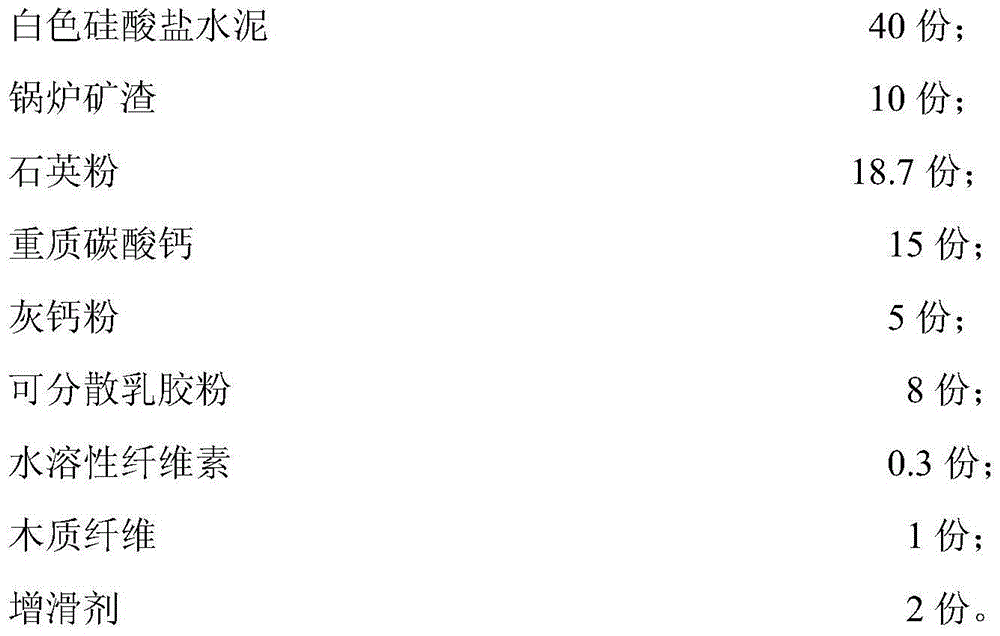

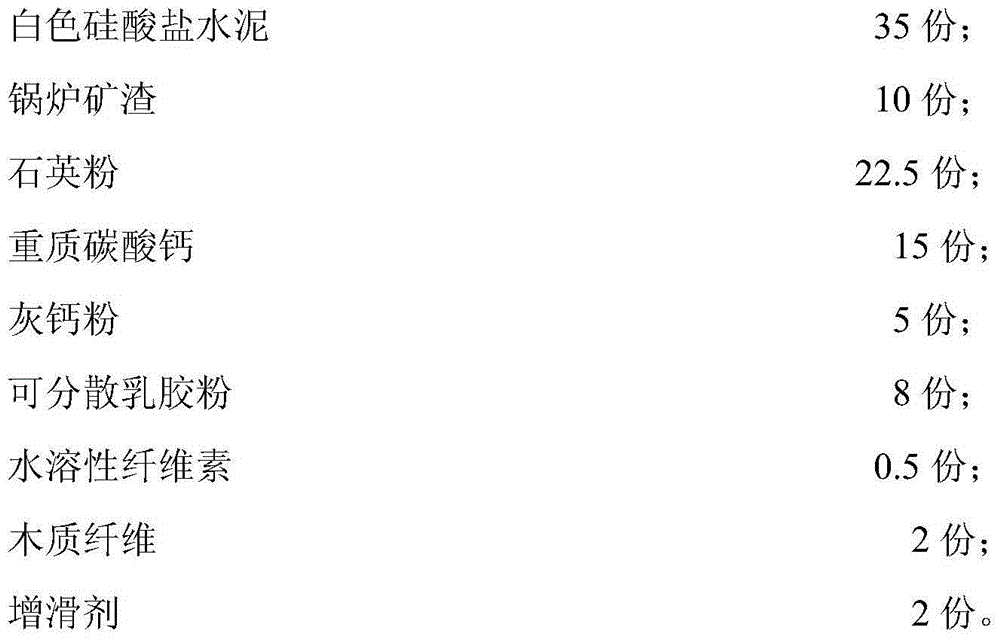

Environment-friendly high-adhesion-stress special putty for ceramic tile surfaces and preparation method thereof

InactiveCN104556898AHigh bonding strengthImprove water resistanceSolid waste managementCelluloseFiber

The invention discloses an environment-friendly high-adhesion-stress special putty for ceramic tile surfaces and a preparation method thereof. The special putty comprises the following raw materials in parts by weight: 35-40 parts of white portland cement, 5-10 parts of boiler residue, 15-30 parts of quartz powder, 15-30 parts of heavy calcium carbonate, 5-10 parts of ash calcium powder, 4-8 parts of dispersible emulsion powder, 0.3-1 part of water-soluble cellulose, 1-3 parts of wood fiber, and 2-4 parts of a slipping agent. According to the invention, by taking the boiler residue as an additive, the adhesion strength of the putty is improved, and industrial wastes can be effectively consumed so as to improve the ecological environment, therefore, the putty has a board industrial application prospect. The putty has excellent water resistance, alkali resistance, and low-temperature resistance, and also has the advantages that the putty after being subjected to blade coating is not easy to crack, does not fall off, and is not discolored; and the manufacturing cost of the putty is low, and the variety and application scope of the putty are expanded.

Owner:安徽朗凯奇科技股份有限公司

Attapulgite interior wall putty powder

The invention discloses attapulgite interior wall putty powder. The key point of technical proposal of the invention is that the attapulgite interior wall putty powder consists of purified attapulgite, activated attapulgite clay, white portland cement, polyacrylamide, anatase titanium dioxide. The production method of the attapulgite interior wall putty powder comprises the following steps: material mixing, crashing, grinding powder, and packing to obtain the finished products of the attapulagite interior wall putty powder. The blade coating can be performed by the following steps: putting the attapulgite interior wall putty powder into a container, adding water to wet the attapulgite interior wall putty powder for 5 to 30 minutes according to the ratio of the attapulgite interior wall putty powder to water of between 1:0.5 and 1:4, and mixing thoroughly and evenly for puttying construction. The attapulgite interior wall putty powder has the characteristics of whiteness, finesses, good hand feel, good adhesive property, strong adhesive force, water tightness, cracking resistance, powder fall-off prevention, paint conservation and the like. The attapulgite interior wall putty powder is applicable to the architectural finishing projects.

Owner:NANTONG CHENGYUE DECORATION GRP

Colorful decorative mortar

The invention discloses colorful decorative mortar. The colorful decorative mortar is prepared by mixing white Portland cement, padding, functional auxiliary materials, pigment and auxiliaries. According to the colorful decorative mortar, the best components and ratio are concluded from a large number of experiments, and due to the functional auxiliary materials mixed into the colorful decorative mortar, the performance of the mortar is improved, and meanwhile the production cost of the mortar can be saved. In addition, due to the added inorganic pigment iron oxide red, the mortar is uniform and bright in color, and has the good working and mechanical performance and color stability. In mortar, dispersible emulsion powder, cellulose ether, a water repellent, wood fiber and other auxiliaries can be added, so that the bonding strength of the mortar can be effectively improved, the mortar hydrophobicity is strong, the anti-cracking performance is good, and the colorful decorative mortar has the excellent durability and good comprehensive performance.

Owner:吴肖颜

Color steel waterproof heat-insulating coating and method for preparing same

The invention provides a color steel waterproof heat-insulating coating and a method for preparing the same. The color steel waterproof heat-insulating coating is prepared from the following raw materials in part by weight: 15 to 20 parts of vitrified small ball, 3 to 5 parts of sepiolite, 20 to 30 parts of building waterproof glue, 0.2 to 0.5 part of polypropylene fiber, 5 to 10 parts of aluminate cement, 15 to 20 parts of white Portland cement, 2 to 4 parts of sericite, 0.5 to 1 part of dispersible polymer powder, 0.2 to 0.4 part of Dibutyl phthalate, 0.2 to 0.4 part of polyscrylamide, 0.3 to 0.5 part of preservative, 0.2 to 0.4 part of defoaming agent and 10 to 15 parts of water. The color steel waterproof heat-insulating coating is prepared by blending liquid materials and powder materials, and is a combination of organic and inorganic materials, and after stirring, emulsion and polymerization, the waterproof heat-insulating property is improved to over 98 percent; and when the coating is used for steel structural surfaces in steel products, chemical grouting and the like, the bonding force is strong, the environmental protection energy saving capability is improved by over 65 percent if the coating is 10mm in thickness, and the waterproof property is high, and the service life is as long as 30 years. Thus, the coating of the invention is a preferable color steel surface waterproof heat-insulating coating.

Owner:张贵连

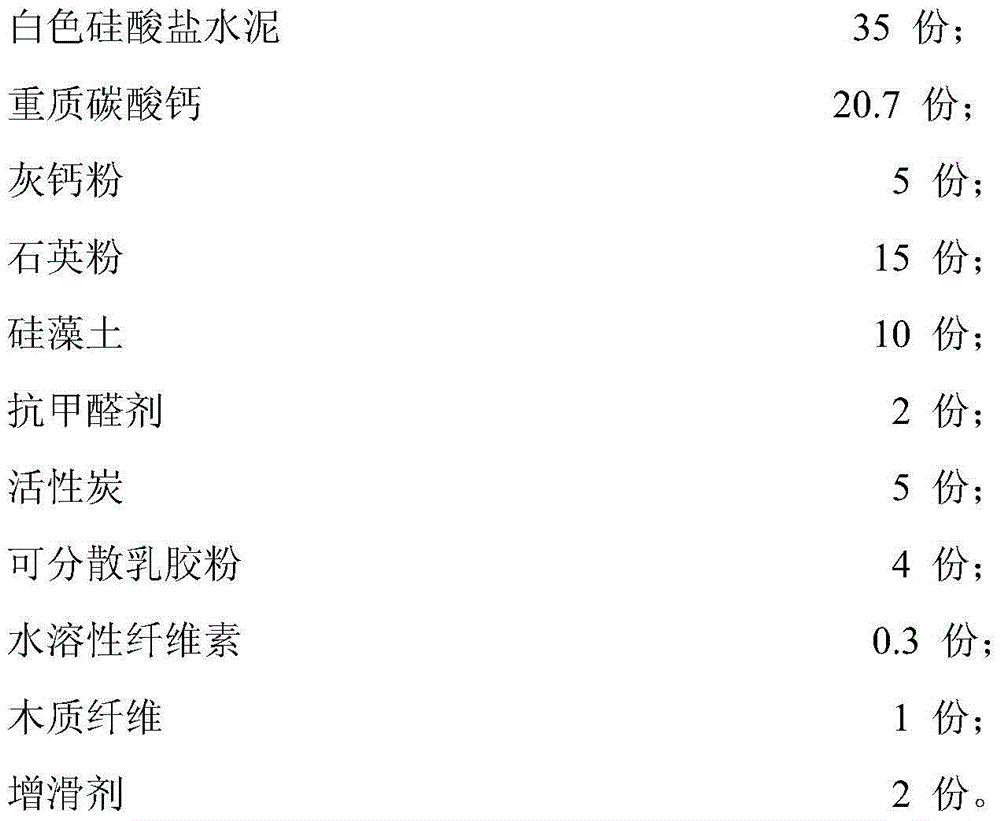

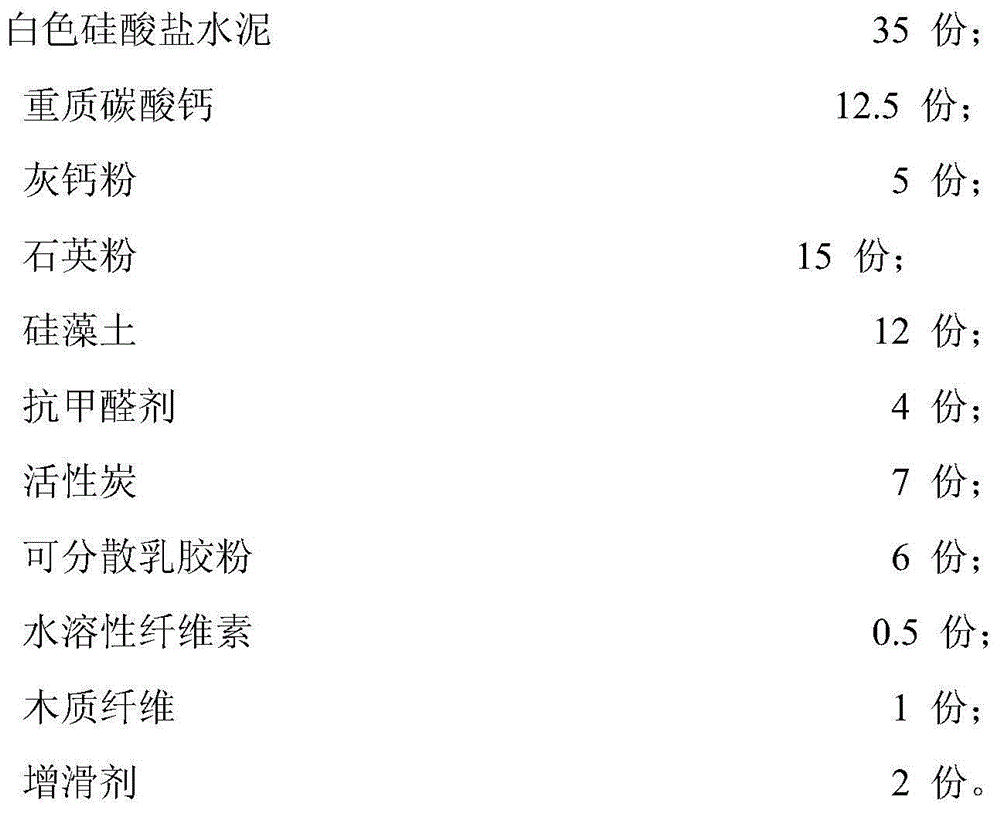

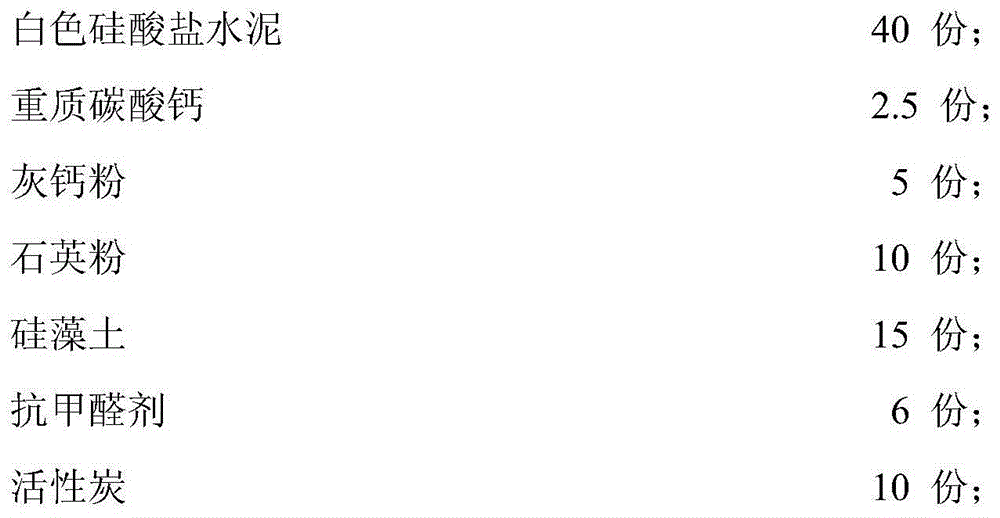

Special putty for ceramic tile surface with capability of adsorbing formaldehyde and high adhesion and preparation method of special putty

The invention discloses special putty for the ceramic tile surface with the capability of adsorbing formaldehyde and high adhesion and a preparation method of the special putty. The special putty is prepared from the following raw materials in parts by weight: 35-40 parts of white portland cement, 5-30 parts of heavy calcium carbonate, 5-10 parts of ash-calcium-powder, 5-30 parts of quartz powder, 10-15 parts of diatomite, 2-6 parts of a formaldehyde-resistant agent, 5-10 parts of activated carbon, 4-8 parts of disperable emulsion powder, 0.3-1 part of water soluble cellulose, 1-3 parts of lignocellulose and 2-4 parts of a slipping agent. The putty powder is capable of adsorbing the formaldehyde in air and removing the formaldehyde in a coating together by adsorbing, so that the indoor formaldehyde content is greatly lowered, and the human health is facilitated.

Owner:安徽朗凯奇科技股份有限公司

Heat insulation type tire mold casting gypsum powder and preparation process thereof

InactiveCN102701691AIncreased dry flexural strengthIncreased dry compressive strengthFiberAluminum silicate

The invention relates to heat insulation type tire mold casting gypsum powder and a preparation process thereof. The gypsum powder is prepared from the following raw materials in parts by weight: 100 parts of alpha-gypsum powder, 1.5-3.5 parts of sulfonated melamine formaldehyde resin, 0.1-0.5 part of peach gum, 5-10 parts of white portland cement and 0.5-1.5 parts of aluminum silicate fiber. The invention further relates to the preparation process of the heat insulation type tire mold casting gypsum powder. A mold prepared by utilizing the heat insulation type tire mold casting gypsum powder disclosed by the invention has the advantages of good heat insulation effect, high drying flexural strength, high drying compressive strength, wide range of application and long service life; and the preparation process has the advantages of simplicity and low manufacturing cost, and is beneficial to industrial production.

Owner:刘立文

Attapulgite putty powder for exterior wall

The invention discloses lacquer putty powder for the external wall of a concavo-convex rod. The technical proposal thereof comprises the key points that: the lacquer putty powder for the external wall of the concavo-convex rod consists of a purified concavo-convex rod, white bentonite, white Portland cement, high strength gypsum powder, hydroxypropyl methylcellulose and rutile type titanium dioxide. The method for producing the lacquer putty powder for the external wall of the concavo-convex rod is to prepare, crush, grind and pack the raw materials to a finished product of the lacquer putty powder for the external wall of the concavo-convex rod, wherein the lacquer putty powder for the external wall of the concavo-convex rod is placed in a vessel to be immersed by water for 5 to 30 minutes, and the proportion of the lacquer putty powder for the external wall of the concavo-convex rod to the water is 1:0.5-1:4; after being sufficiently and evenly stirred, the powder can be applied for scraping and coating. The lacquer putty powder for the external wall of the concavo-convex rod has the characteristics of good cohesive property, strong adhesive attraction, stable filming performance, high strength, long service life, water resistance, crack resistance, powder falling prevention, firm viscosity with coatings and paint conservation, and is applicable to coating project of construction.

Owner:NANTONG CHENGYUE DECORATION GRP

Water-resistant phosphogypsum block and preparation process thereof

InactiveCN107500698AImproved to alkalineAdjust clotting timeCement mixing apparatusPolyvinyl alcoholSuperplasticizer

The invention provides a water-resistant phosphogypsum block and a preparation process thereof. The water-resistant phosphogypsum block comprises the following raw materials by weight: 70%-100% of phosphogypsum, 50%-80% of water, 3-8% of polyvinyl alcohol, 3%-6% of styrene-acrylic ester emulsion, 0.05%-0.8% of paraffin emulsion, 0.01%-1.5% of hydrosilicone oil, 0.1%-2% of a naphthalene-series superplasticizer, 0.2%-2% of white portland cement, 0.1%-5% of sulphoaluminate cement, 0.1%-10% of calcium hydroxide, 0.01%-6% of aluminum potassium sulfate dodecahydrate and 0.01% to 1% of aluminum sulfate. The preparation process comprises four specific steps of pulp preparation, molding, stripping and drying. The phosphogypsum setting time and mechanical strength can be effectively adjusted by different components in the formula. Automated production is taken into account, and meanwhile the problems of low mechanical strength and poor water resistance of pure phosphogypsum under high alkalinity conditions can be effectively solved.

Owner:南通绿洲节能环保产品有限公司

Putty powder for exterior walls

The invention discloses putty powder for exterior walls, and relates to the field of coatings. The putty powder for the exterior walls comprises the following raw materials: white portland cement, light calcium carbonate powder, talcum powder, ash-calcium-powder, quartz powder, GN-1008 glue powder, an efficient general dispersant P-30A, polyacrylamide, organosilicone solid defoamer, a mould inhibitor BJ-75, easily dispersed fibers and nanometer zinc oxide. According to the invention, the light calcium carbonate powder, ash-calcium-powder and an anionic surfactant are added in the putty powder for the exterior walls, and can be mutually infiltrated and react to improve the stability and hardness of a putty powder layer; in addition, the quartz powder is added to enhance the hardness of the putty powder more effectively.

Owner:芜湖普乐士新型建筑材料配套有限公司

Inorganic high-strength filler for coating

InactiveCN102173679ARealize one-time coatingCrack resistantSolid waste managementFilling pastesCelluloseCoating system

The invention discloses an inorganic high-strength filler for a coating. The inorganic high-strength filler is prepared by fully mixing 220 to 300 weight parts of white portland cement used as a gelled material, 350 to 550 weight parts of white quartz sand and 150 to 250 weight parts of quartz powder which are used as aggregate, 50 to 100 weight parts of wollastonite powder, and 0.3 to 1.5 weightparts of polypropylene fiber anti-cracking material, and a dry powder material which is prepared by mixing 2 to 8 weight parts of cellulose ether and 10 to 30 weight parts of gelatine powder uniformly by a stirring machine, and packaging. The inorganic high-strength filler can be conveniently coated on a dry wall, is easy and convenient to construct, and is easy to level and polish; and when the inorganic high-strength filler is used as a penetration base layer of an inorganic penetration coating, first coat can be saved during coating construction of an inorganic coating, and the coating system can save materials and labor, is economic and reliable and save energy and is environment-friendly.

Owner:XIAMEN QIANRUI BUILDING MATERIALS TECH

High-performance microscopic microfiber building heat insulation and heat preservation slurry and using method thereof

ActiveCN102531465AReduce volumeLow thermal conductivityClimate change adaptationHeat proofingSlurrySilicon dioxide

The invention provides high-performance microscopic microfiber building heat insulation and heat preservation slurry with high tensile strength, compressive strength, heat insulation performance and tear resistance, and a using method thereof. The slurry comprises the following components of crylic synthetic resin, fluorinated silicone synthetic resin, a water retention thickening agent solution,a sepiolite fiber, a vermiculite fiber, a mullite fiber, powdered silicon dioxide, pearlife, a rock wool fiber, hollow ceramic microballs, a defoaming agent, a mildewproof bacteriacide and water; andfurthermore, white portland cement, a reinforcing agent and water which is 20 to 30 weight percent of a component A can be added.

Owner:FUJIAN OUNUOCHUANGNENG NEW MATERIAL TECH CO LTD

Quick-drying caulking agent with stain-resistant function

The invention discloses a quick-drying caulking agent with stain-resistant function,belongs to the field of caulking agent.The caulking agent is formulated by the following component by weight: 5-20 parts of white portland cement,15-30 parts of aluminate cement,4-10 parts of hemihydrategypsum, 0-2 parts of anhydrite, 0-5 parts of calcium powder, 40-50 parts of quartzsand, 0.5-1 parts of shrinkage reducing agent,0.5-2 parts of water repellent,0.5-3 parts of antifoam agent, 0.5-2 parts of cellulose ether. The invention acceleratesthe condensation of the caulking agent by using of aluminate cement semi-water gypsum ternary quick-drying system,and prevents the leakage of soluble salts to a certain extent, avoids the problem of saltpetering for materials from the source; and the construction period is greatly shorted, the labor costs is reduced;and at the same a dense material layer is formed,the compactness of the material is increased in combined with the role of hydrophobic agent and rubber powder, the invention improves the problems of loosen and porous and not stain-resistant of ordinary cement-based material, the stain-resistant performance of the caulking agent is greatly improved.

Owner:西卡(上海)管理有限公司

Putty powder for inside and outside walls

The invention discloses internal and external wall putty powder which consists of the following raw materials by weight portion: 3 to 7 portions of heavy calcium carbonate powder, 8 to 12 portions of light calcium carbonate powder, 50 to 60 portions of baryta powder or marble powder, 25 to 35 portions of white Portland cement, 1 to 4 portions of water-solubility synthetic resin flexible adhesive powder, and 0 to 2.5 portions of natural paint powder. A sampling check of the internal and external putty powder is performed by Chongqing Academy of Metrology and Quality Inspection; the tested sample meets the requirement of Exterior Building Walls JG / 157-2004 Industry Standard and is qualified. The internal and external putty powder has raw materials easily available, low user cost, varied and bright as well as unfading color for a long time, environmental protection, easy washing after the surface is dirty, convenient construction and no poison; and the constructed surface has high hardness, strong water proof property and long service life, does not craze or drop powder and does not have peeling.

Owner:文廷林

Baking-free antique black brick and preparation method thereof

The invention relates to a baking-free antique black brick and a preparation method thereof. The baking-free antique black brick comprises a basic layer and a surface layer, wherein the basic layer iscomprises clay residues, recycled aggregates and cement; the surface layer comprises white portland cement, slag powder, recycled fine aggregates, black iron oxide and green iron oxide. The clay residues are adopted to serve as one of the production raw materials of the baking-free antique black brick, the utilization rate and the additional value of the clay residues are improved, and the utilization of building waste resources is improved; moreover, the baking-free antique black brick prepared from the method can meet various performance indexes, and is suitable for masonry engineering anddecoration engineering; the production process is simple, the disposal efficiency is high, the treatment capacity is high, the field application effect is good, and the baking-free antique black brickhas good economic benefits and social benefits.

Owner:深圳市绿志新型建材研究院有限公司

Self-cleaning high-crack-resistance self-leveling veneer mortar and preparation method

The invention discloses a self-cleaning high-crack-resistance self-leveling veneer mortar. The mortar is prepared from, by weight, 25-35% of white cement, 0.5-1.0% of a water reducing agent, 1-2% of an expanding agent, 0.2-0.5% of nano titanium dioxide, 2-6% of alkali activation pulverized fuel ash and 10-13% of water. The sum of the weight percentage of all the raw materials is 100%. The invention further discloses a preparation method of the self-cleaning high-crack-resistance self-leveling veneer mortar. The method comprises the following steps that after the titanium dioxide and the alkaliactivation pulverized fuel ash are mixed and stirred, the mixture, white Portland cement, metakaolin, redispersible emulsion powder and the expanding agent are added into a stirrer according to a proportion, white sand is added for stirring for one minute, and finally fibers are added for stirring for 3-5 minutes. The self-cleaning high-crack-resistance self-leveling veneer mortar has better crack resistance, fluidity and self-cleaning performance and can be widely applied to large-size outer wall face layers of assembly-type buildings, and the social and economic benefits are obvious.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

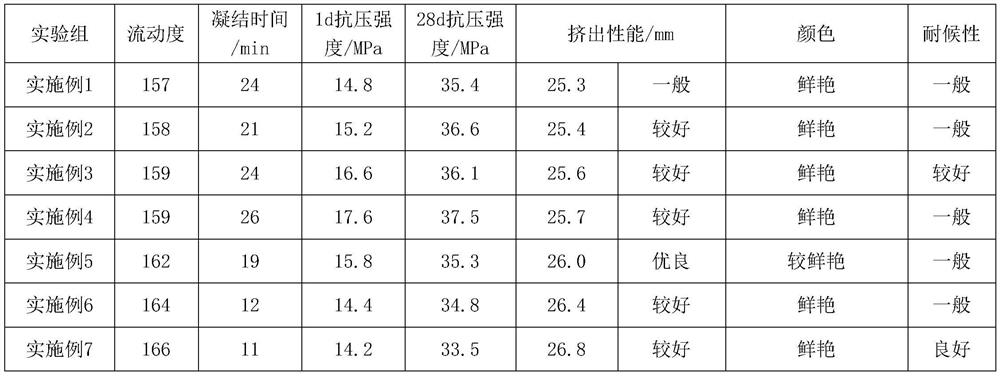

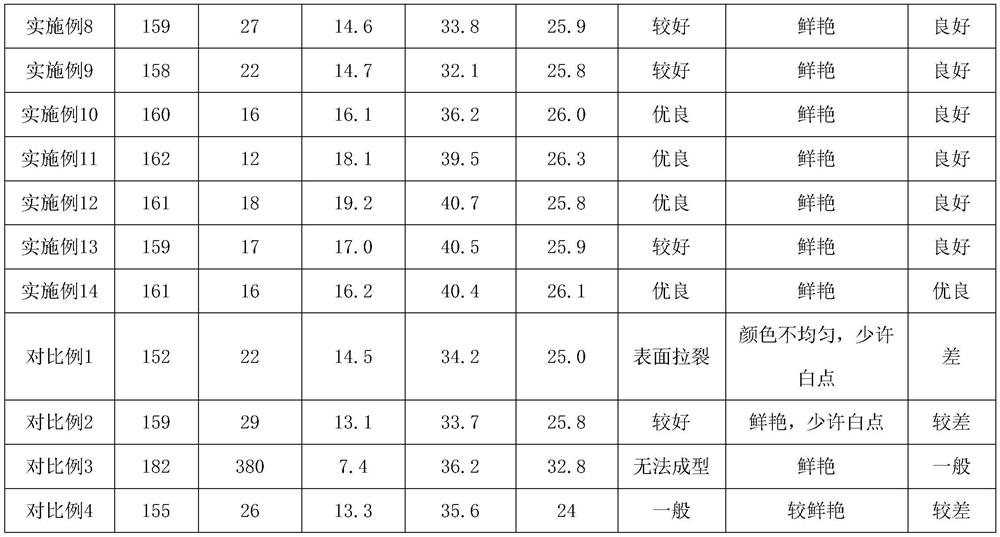

Colored 3D printing mortar and preparation method thereof

InactiveCN112723829AImprove thixotropyPrinting time is controllableAdditive manufacturing apparatusSolid waste managementFiberPolymer science

The invention relates to the field of 3D printing mortar, and particularly discloses colored 3D printing mortar and a preparation method thereof, the colored 3D printing mortar comprises the following components: white Portland cement, limestone powder, metakaolin, an organic pigment, an internal curing agent, quartz sand, fibers, a water reducing agent, an alkali-free accelerator, an early strength agent, a defoaming agent, a polymer emulsion and water; the preparation method comprises the following steps: S1, uniformly mixing quartz sand and fibers to obtain M1; S2, uniformly mixing cement, limestone powder, metakaolin, an internal curing agent and M1 to obtain M2; S3, uniformly mixing a water reducing agent, an early strength agent, a defoaming agent and water to obtain M3; S4, uniformly stirring the polymer emulsion and the organic pigment to obtain M4; and S5, uniformly mixing and stirring M3 and M2, adding M4 while stirring, finally adding an accelerator, and uniformly mixing. The prepared mortar is proper in flowability, good in thixotropy and excellent in extrusion performance; and after printing is completed, early strength and later strength are well developed, and the product is bright in color and good in weather resistance.

Owner:成都建工赛利混凝土有限公司

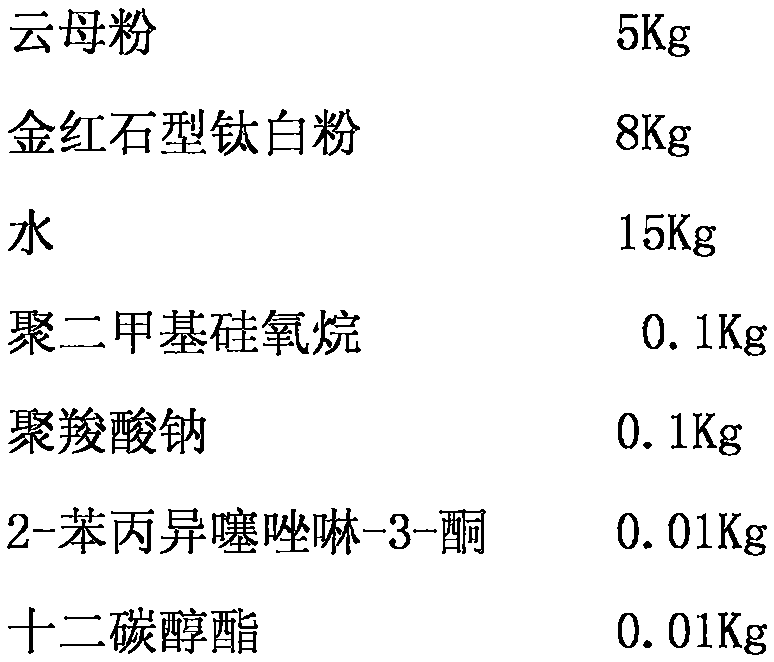

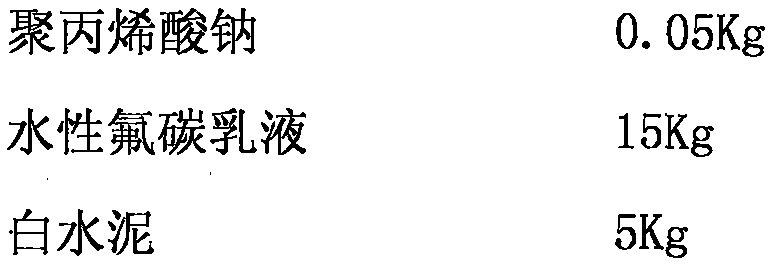

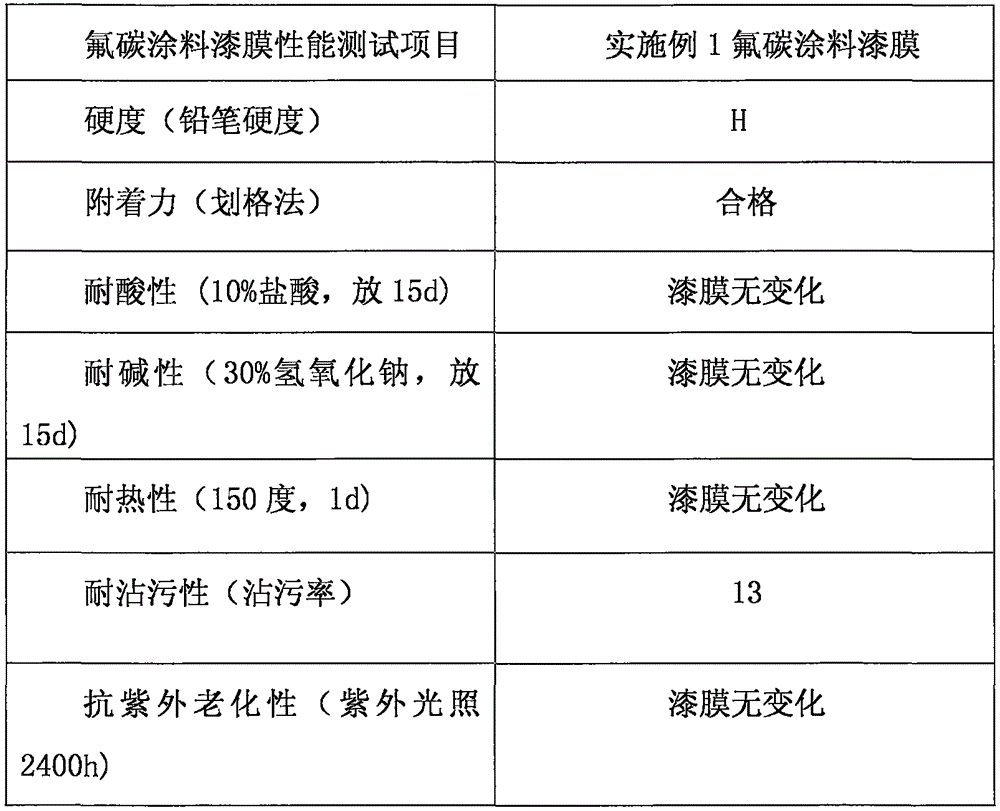

Production method of aqueous fluorocarbon-cement base building coating

InactiveCN105542583AGood weather resistanceGood chemical resistanceAntifouling/underwater paintsPaints with biocidesCalcium silicateNanoscopic scale

The invention discloses a production method for preparing a low-cost and high-performance fluorocarbon-cement base building coating through adopting an aqueous fluorocarbonpolymer emulsion and white Portland cement (white cement) as main film forming substances and adding a pigment, a filler, an assistant and water. The formula is reasonable, and nanometer calcium silicate hydrate (C-S-H) gel generated by hydrating the white cement is especially used to modify a coating, so the hardness, the weatherability, the chemical erosion resistance and the adhesiveness with a cement base building material of the coating are obviously improved; and the white cement is used as a film forming substance to substitute fluorocarbon resin, so the production cost of the above product is obviously reduced, and the market competitiveness of the coating is improved.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com