Manufacturing and mounting method of artificial tablet stone

A slab and stone technology, applied in the field of architectural decoration, can solve the problems of natural stone, such as heavy weight, damage to the natural environment, and high cost, and achieve the effects of light weight, good economic and social benefits, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

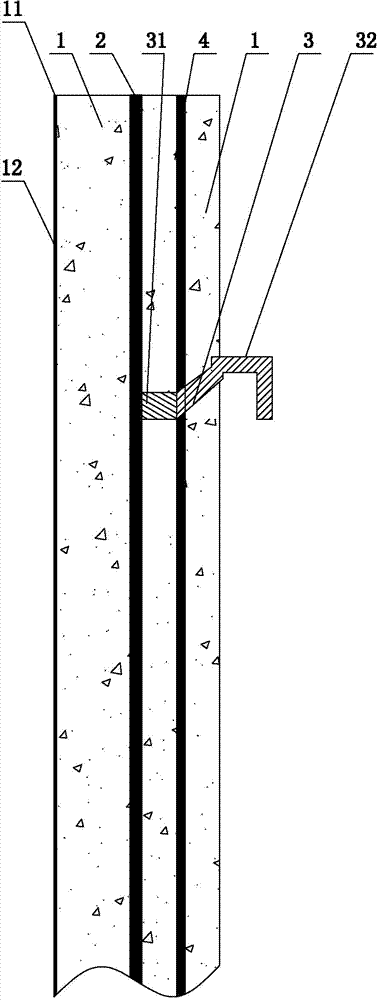

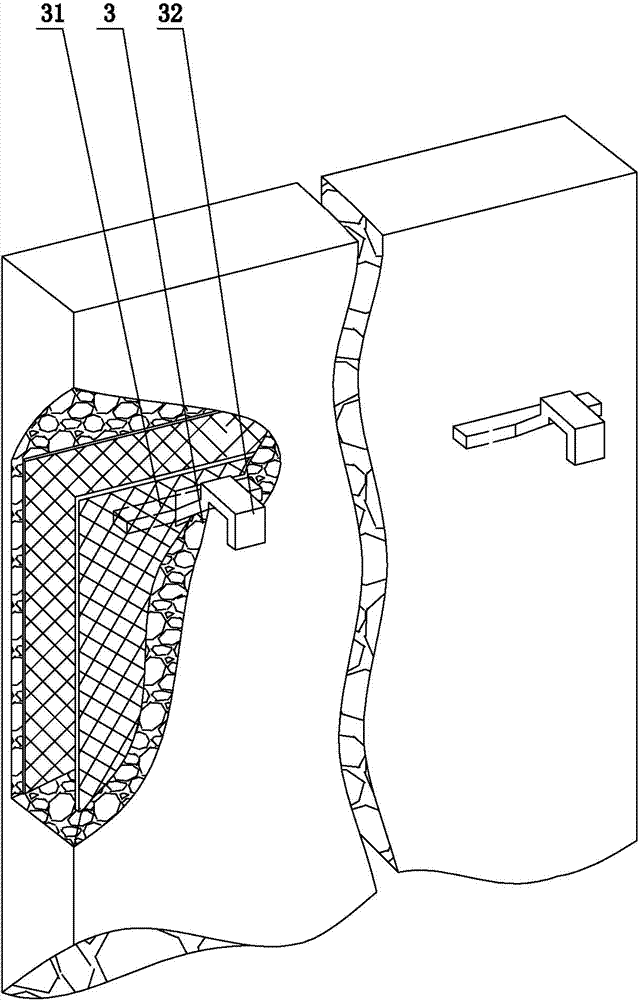

[0032] Example 1: figure 1 It is a schematic diagram of the structure of artificial flat stone, figure 2 It is a schematic diagram of a stainless steel pendant. As shown in the figure, the artificial slab stone includes a stone slab 1 made of concrete material 1. The stone slab 11 is provided with two layers of steel wire mesh 2, 4, and the back of the stone slab is provided with a stainless steel pendant 32. , the stainless steel pendant 32 is connected with the embedded board 31, and the embedded board 31 extends to two layers of steel wire mesh 2, 4 and is solidified with the concrete material 1 in the stone board, and a hydrophobic layer 12 is also provided on the surface of the stone board .

[0033] The manufacturing method of the artificial slab stone is as follows: 100 parts of white portland cement and 0.1 part of iron oxide pigment (or 0.2 part, 0.3 part, 0.5 part, etc. are all available, more pigments and deeper color) are mixed with a dry powder mixer. Pour the ...

Embodiment 2

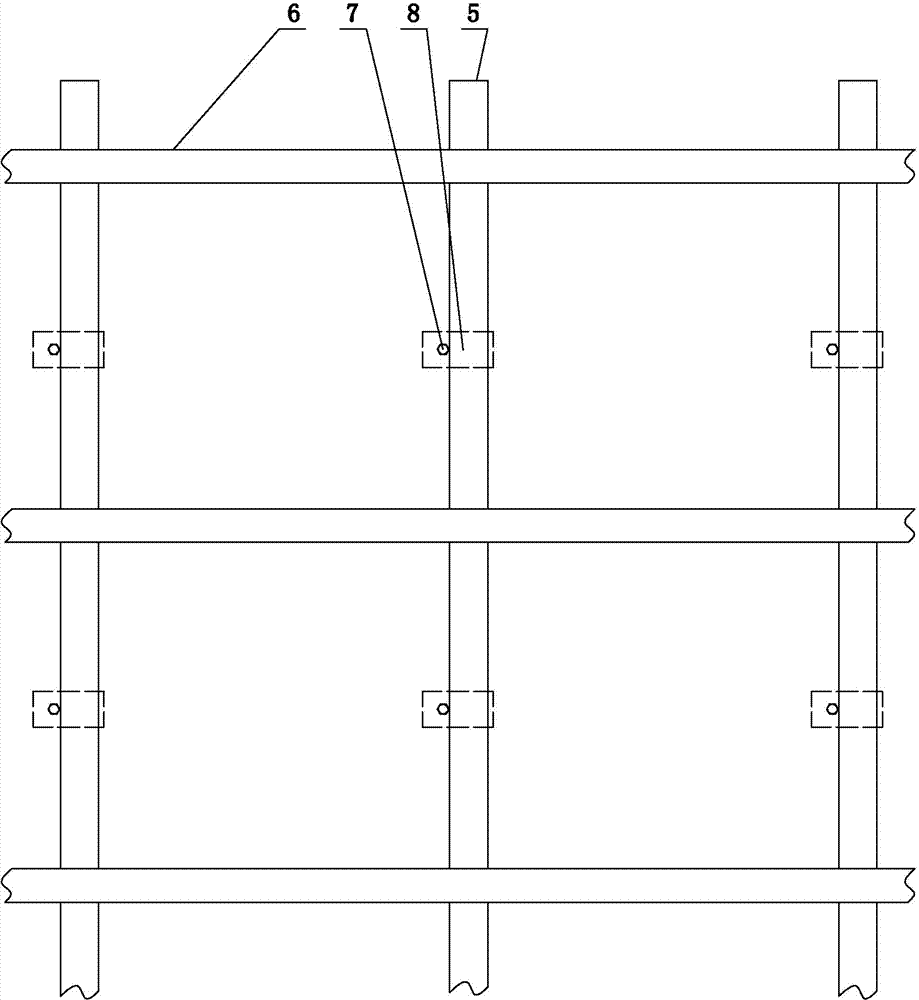

[0035]Embodiment 2: The preparation method of the artificial slab stone is: mix 100 parts of white Portland cement and 0.1 part of iron oxide pigment with a dry powder mixer. Pour the mixed dry powder into the concrete mixer, add 100 parts of colored sand, 50 parts of granite fine rice stone, 20 parts of superfine slag powder, 0.1 part of water reducing agent, 0.5 part of early strength agent, 20 parts of acrylic resin emulsion, add water and stir 10 minutes to make a paste concrete mix slurry 1. In the prepared flat mould, first drop the mixed slurry 1, the thickness of which is 1 / 2 of the height of the mould, and vibrate for 10 seconds. Then the first layer of steel wire mesh 2 is laid, and the stainless steel pendant 3 is placed. The stainless steel pendant 3 includes a pre-embedded plate 31, and the pre-embedded plate 31 is provided with a hook 32 extending to the outside of the artificial flat stone plate body 11. The length of the stainless steel pendant 3 is Not greate...

Embodiment 3

[0036] Embodiment 3: The manufacture method of the artificial slab stone is: mix 100 parts of white Portland cement and 2.5 parts of iron oxide pigment with a dry powder mixer. Pour the mixed dry powder into the concrete mixer, add 125 parts of colored sand, 75 parts of granite fine rice stone, 35 parts of superfine slag powder, 0.3 parts of water reducing agent, 1.25 parts of early strength agent, 32.5 parts of acrylic resin emulsion, add water and stir 10 minutes to make a paste concrete mix slurry 1. In the prepared flat mould, first drop the mixed slurry 1, the thickness of which is 2 / 3 of the height of the mould, and vibrate for 15 seconds. Then lay the first layer of steel wire mesh and place the stainless steel pendant. The stainless steel pendant 3 includes a pre-embedded plate 31. The pre-embedded plate 31 is provided with a hook 32 extending to the outside of the artificial flat stone plate body 11. The length of the stainless steel pendant 3 is not more than 100mm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com