Production method of aqueous fluorocarbon-cement base building coating

A water-based fluorocarbon and cement technology, used in antifouling/underwater coatings, coatings, and biocide-containing paints. Cost, effect of improving weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

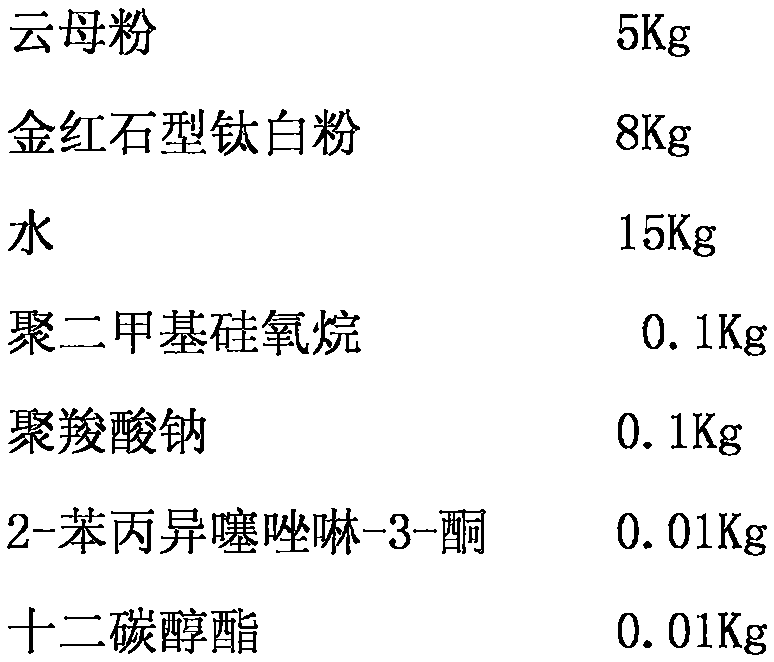

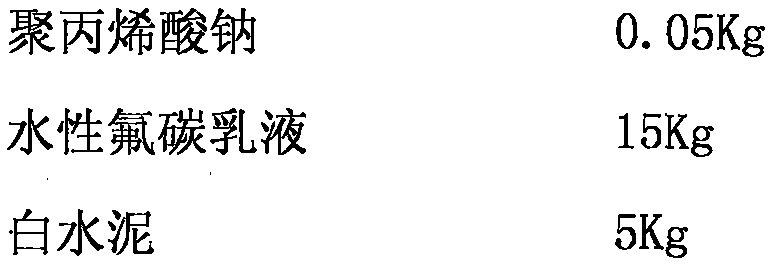

[0017] Production formula:

[0018]

[0019]

[0020] Weigh fillers, pigments, water, dispersants according to the above formula, add them into the batching tank, stir while adding materials, and control the stirring speed at 800-1400 rpm to make slurry A; in another batching tank After adding the water-based fluorocarbon emulsion according to the formula requirements, add white cement while stirring, and control the stirring speed at 300-500 rpm to obtain slurry B; add slurry B to the prepared slurry A while stirring, and finally According to the actual situation, add defoamer, anti-mold and fungicide, film-forming aid, etc., and stir evenly to prepare a water-based fluorocarbon-cement based architectural coating. After the prepared paint was left for 3 days, the prepared paint was applied to the cement sheet, and then the performance test was carried out after 7 days of natural air-drying.

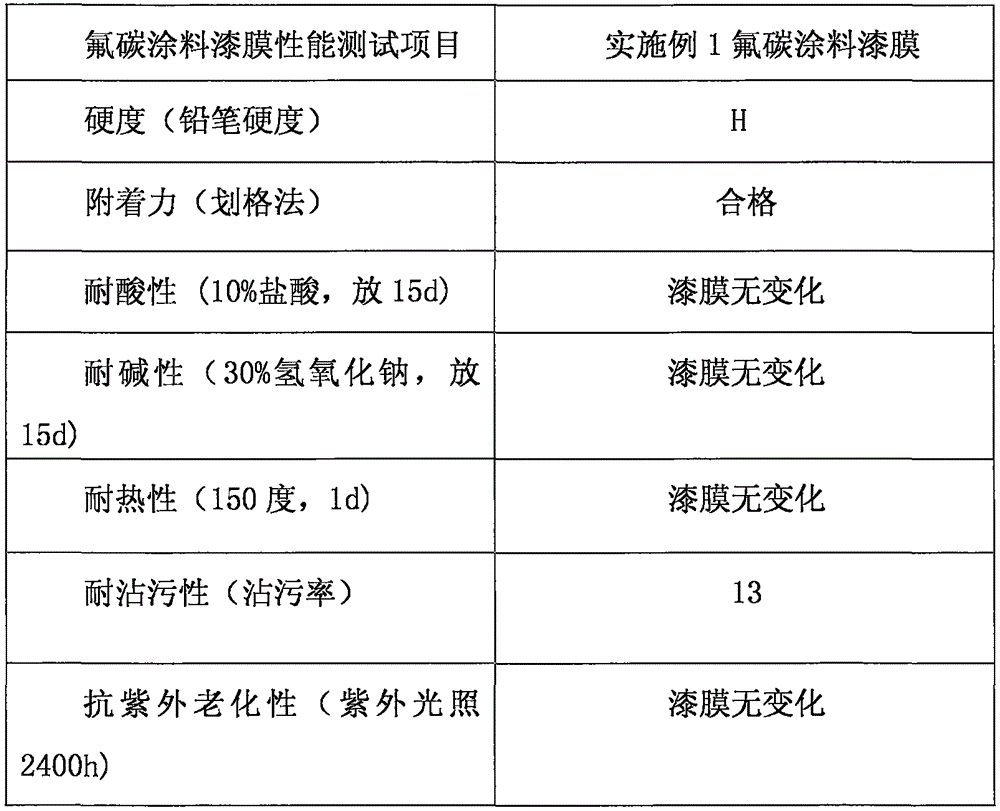

[0021] Table 1 Embodiment 1 performance test

[0022]

Embodiment 2

[0024] Production formula:

[0025]

[0026]

[0027] The materials were weighed according to the above formula, and water-based fluorocarbon-cement based architectural coatings were prepared and tested according to the method of Example 1. The coating performance test results are shown in Table 2.

[0028] Table 2 embodiment 2 performance test

[0029]

Embodiment 3

[0031] Production formula:

[0032]

[0033]

[0034] The materials were weighed according to the above formula, and water-based fluorocarbon-cement based architectural coatings were prepared and tested according to the method of Example 1. The coating performance test results are shown in Table 3.

[0035] Table 3 Embodiment 3 performance test

[0036] Fluorocarbon coating film performance test items

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com