Bright caulking compound and construction method thereof

A technology of caulking agent and bright light, which is applied in the field of bright caulking agent and its construction, can solve the problems of high packaging cost, poor surface wear resistance, pollutant contamination, etc., achieve simplified production and construction steps, excellent performance, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] A bright joint filler, made of the following raw materials in parts by weight: ordinary white Portland cement 40, quartz powder 23, light calcium 5, starch 2, heavy calcium carbonate powder 20, hydroxypropyl methylcellulose 0.2, pure acrylic rubber powder 6, polycarboxylate superplasticizer 0.1, defoamer 0.2, silicone water repellent 0.2, magnesium aluminum silicate 0.3, brightener 0.5, pigment 2, dispersant 0.3, cellulose fiber 0.2.

Embodiment 2

[0015] A bright joint filler, made of the following raw materials in parts by weight: ordinary white Portland cement 42, quartz powder 23, light calcium 5, starch 2, heavy calcium carbonate powder 18, hydroxypropyl methylcellulose 0.2, pure acrylic rubber powder 6, polycarboxylate superplasticizer 0.1, defoamer 0.2, silicone water repellent 0.2, magnesium aluminum silicate 0.3, brightener 0.5, pigment 2, dispersant 0.3, cellulose fiber 0.2.

Embodiment 3

[0017] A bright joint filler, made of the following raw materials in parts by weight: ordinary white Portland cement 45, quartz powder 20, light calcium 5, starch 2, heavy calcium carbonate powder 20, hydroxypropyl methylcellulose 0.2, pure acrylic rubber powder 6, polycarboxylate superplasticizer 0.1, defoamer 0.2, silicone water repellent 0.2, magnesium aluminum silicate 0.3, brightener 0.5, pigment 2, dispersant 0.3, cellulose fiber 0.2.

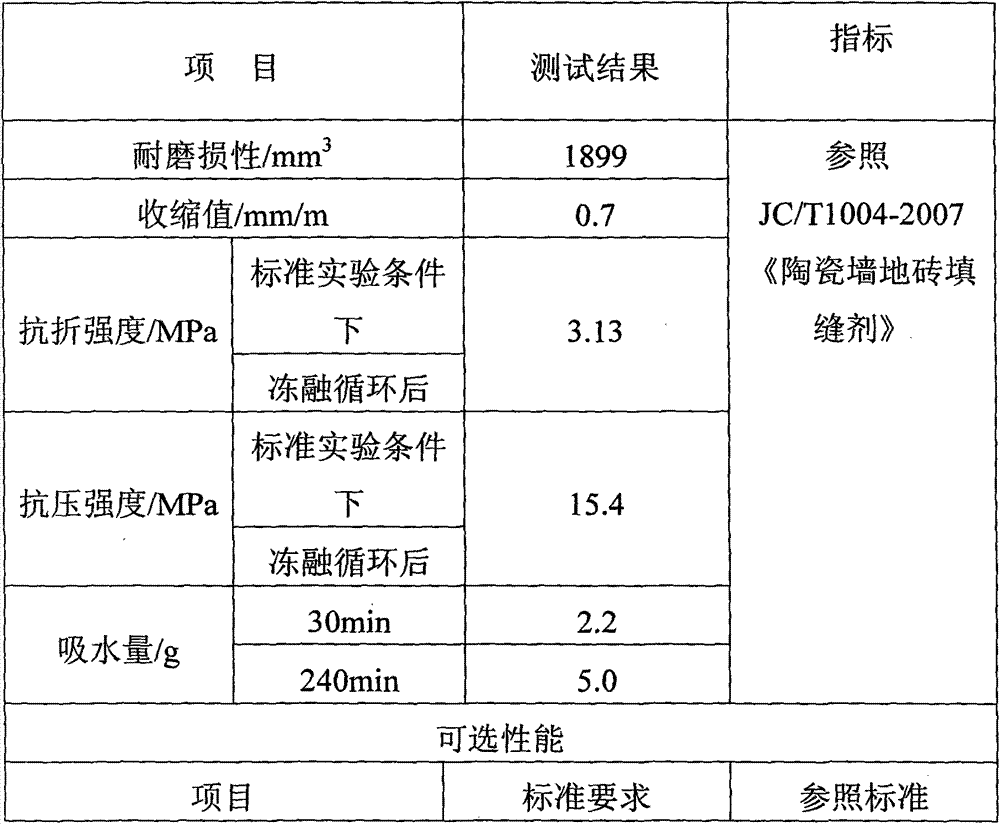

[0018] Important performance indicators of the glossy caulking agent of the present invention:

[0019]

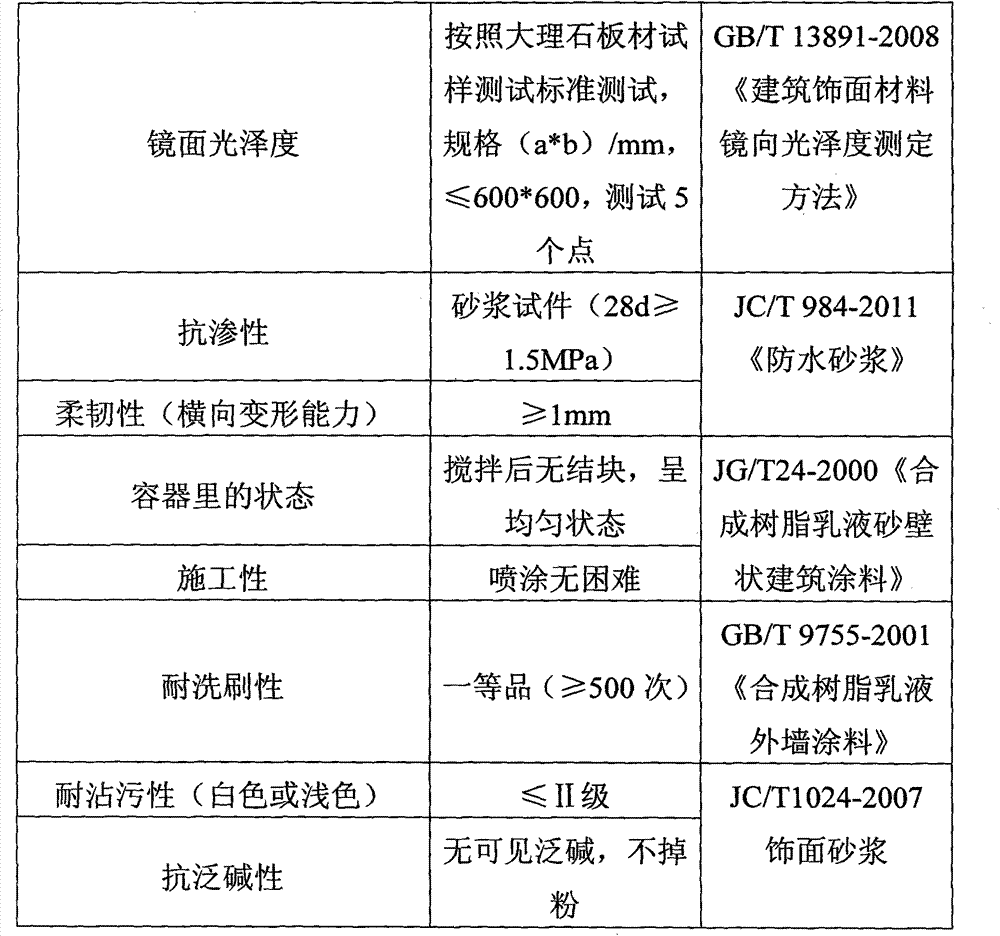

[0020]

[0021] The glossy caulking agent of the present invention also has the following outstanding properties:

[0022] 1) Excellent water resistance, durability, abrasion resistance, scrub resistance and stain resistance

[0023] The glossy caulking agent of the present invention contains acrylic acid copolymer and silicone water-repellent components, and its waterproof performance is comparable to that of the two-component...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| power level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com