Colored 3D printing mortar and preparation method thereof

A 3D printing and mortar technology, used in the field of building materials, can solve the problems of dull color and surface efflorescence, and achieve the effects of good thixotropy, improved early strength and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

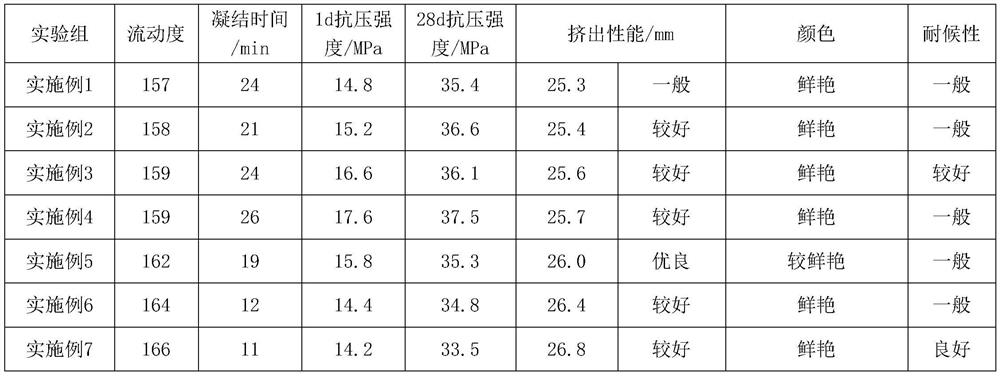

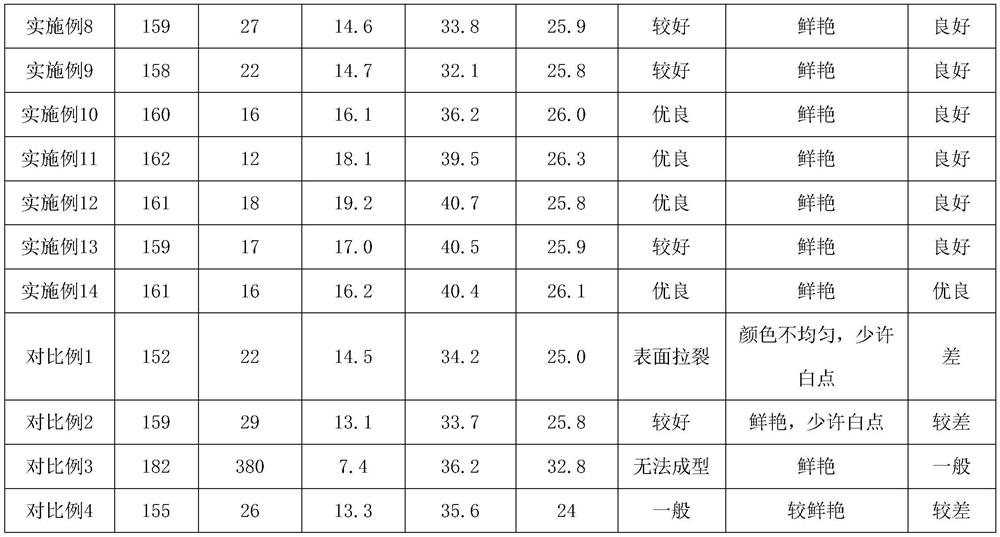

Examples

Embodiment 1

[0046] A colored 3D printing mortar, comprising the following components in parts by weight: 60 parts of white Portland cement, 29 parts of limestone powder, 3 parts of metakaolin, 6 parts of azo pigment permanent red, 2 parts of fly ash floating beads Parts, 90 parts of quartz sand, 0.8 parts of polypropylene fiber, 1.1 parts of shrinkage-reducing polycarboxylate superplasticizer, 3.2 parts of alkali-free accelerator, 1.9 parts of nano calcium silicate hydrate gel, 0.006 parts of alkyne diol defoamer 0.5 parts of water-soluble acrylic emulsion, 25 parts of water; the whiteness of white Portland cement is higher than 90, and the strength grade is 52.5Mpa; the whiteness of limestone powder is higher than 78, and the particle size is 800 mesh; continuously graded quartz sand Particle size 20-140 mesh, metakaolin particle size 800 mesh;

[0047] The preparation method of color 3D printing mortar comprises the following steps:

[0048] S1, mix and stir the quartz sand and fiber a...

Embodiment 2

[0054] A colored 3D printing mortar, comprising the following components in parts by weight: 60 parts of white Portland cement, 28 parts of limestone powder, 4 parts of metakaolin, 5 parts of azo pigment permanent red, 3 parts of fly ash floating beads Parts, 95 parts of quartz sand, 0.9 parts of polypropylene fiber, 1.0 parts of shrinkage-reducing polycarboxylate superplasticizer, 3.5 parts of alkali-free accelerator, 2.2 parts of nano calcium silicate hydrate gel, 0.007 parts of alkyne diol defoamer parts, 0.7 parts of water-soluble acrylic emulsion, and 25.5 parts of water.

Embodiment 3

[0056] A colored 3D printing mortar, comprising the following components in parts by weight: 60 parts of white Portland cement, 27 parts of limestone powder, 5 parts of metakaolin, 4 parts of azo pigment permanent red, and 4 parts of fly ash floating beads 100 parts of quartz sand, 1.0 parts of polypropylene fiber, 0.9 parts of shrinkage-reducing polycarboxylate superplasticizer, 3.9 parts of alkali-free accelerator, 2.6 parts of nano calcium silicate hydrate gel, 0.008 parts of alkyne diol defoamer parts, 0.9 parts of water-soluble acrylic emulsion, and 26 parts of water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| power level | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com