Patents

Literature

514results about How to "Improve interlayer adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

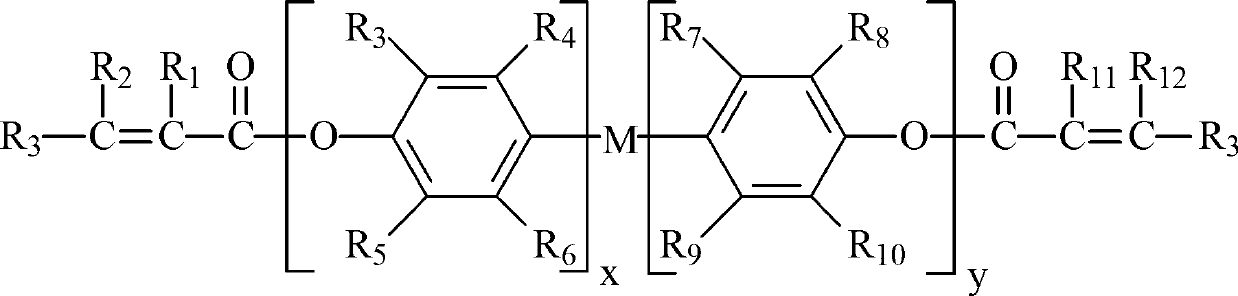

Radiation-curable coating compounds

InactiveUS6605669B2Inhibition of polymerizationNo surface defectsPolyurea/polyurethane coatingsPrinting after-treatmentMeth-Functional monomer

Coating compounds curable by means of high-energy radiation, comprising as binderA) at least one (meth)acrylic copolymer containing olefinic double bonds capable of free-radical polymerization and hydroxyl groups with a C=C equivalent weight from 100 to 10,000 and an OH-value from 20 to 250 mg KOH / g, which is prepared from monomers comprising:A1) at least one olefinically unsaturated, epoxy-functional monomer capable of free-radical polymerization,A2) at least one olefinically unsaturated, carboxy-functional monomer capable of free-radical polymerization andA3) at least one further olefinically unsaturated monomer capable of free-radical polymerization which is different from A1) and A2), andB) at least one component with free isocyanate groups and process for multilayer coating using the coating compounds.

Owner:AXALTA COATING SYST IP CO LLC

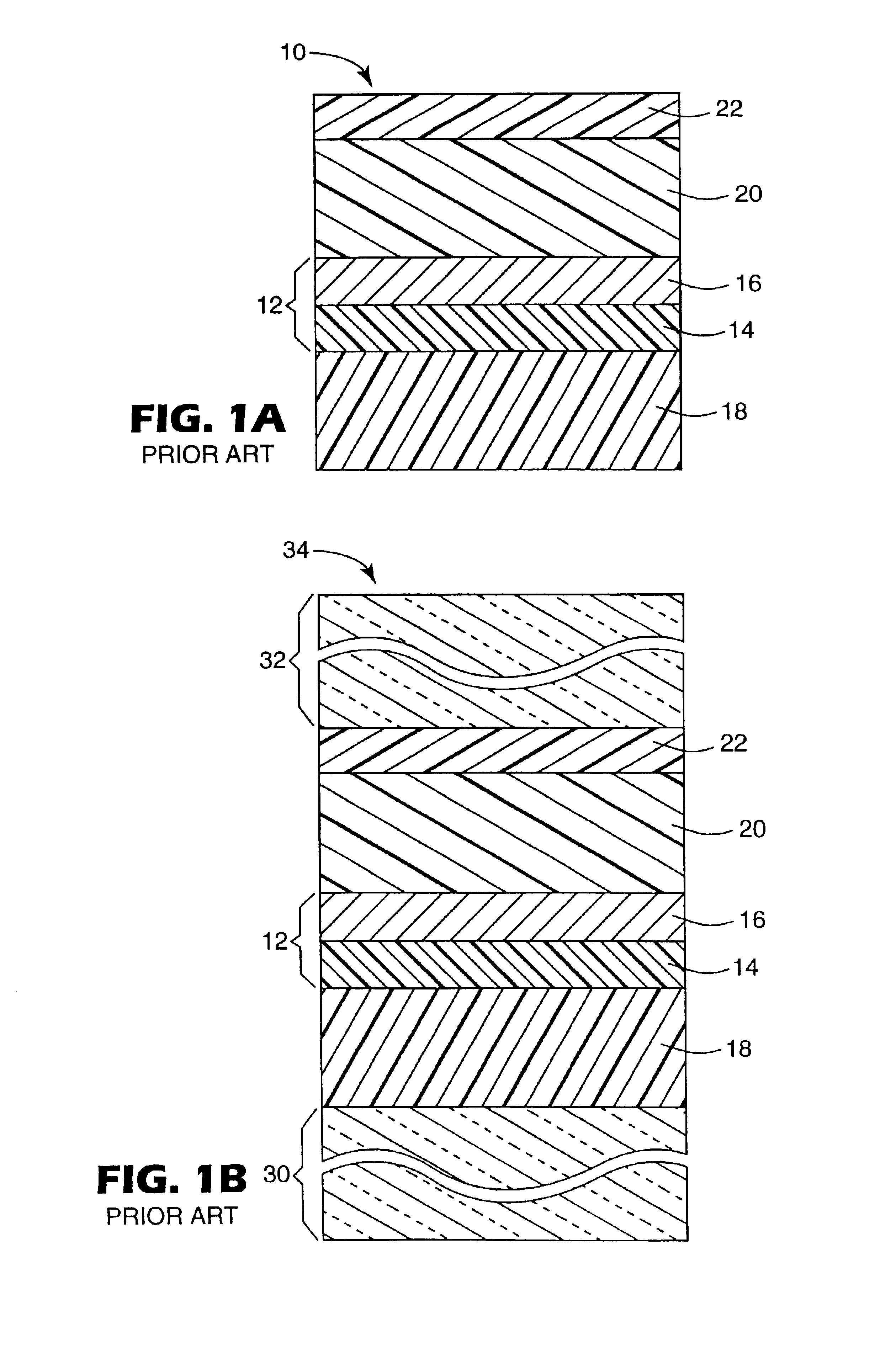

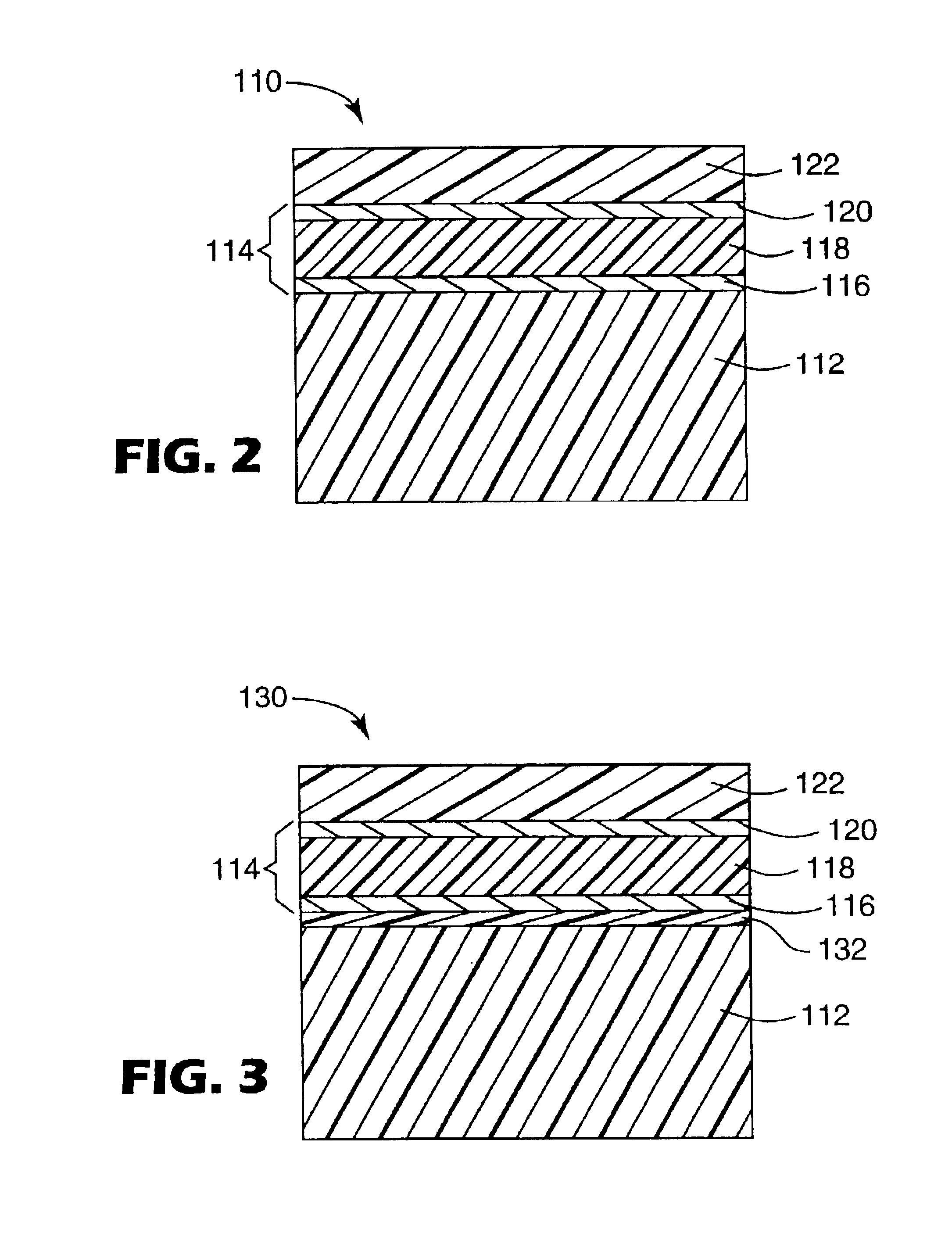

Enhanced heat mirror films

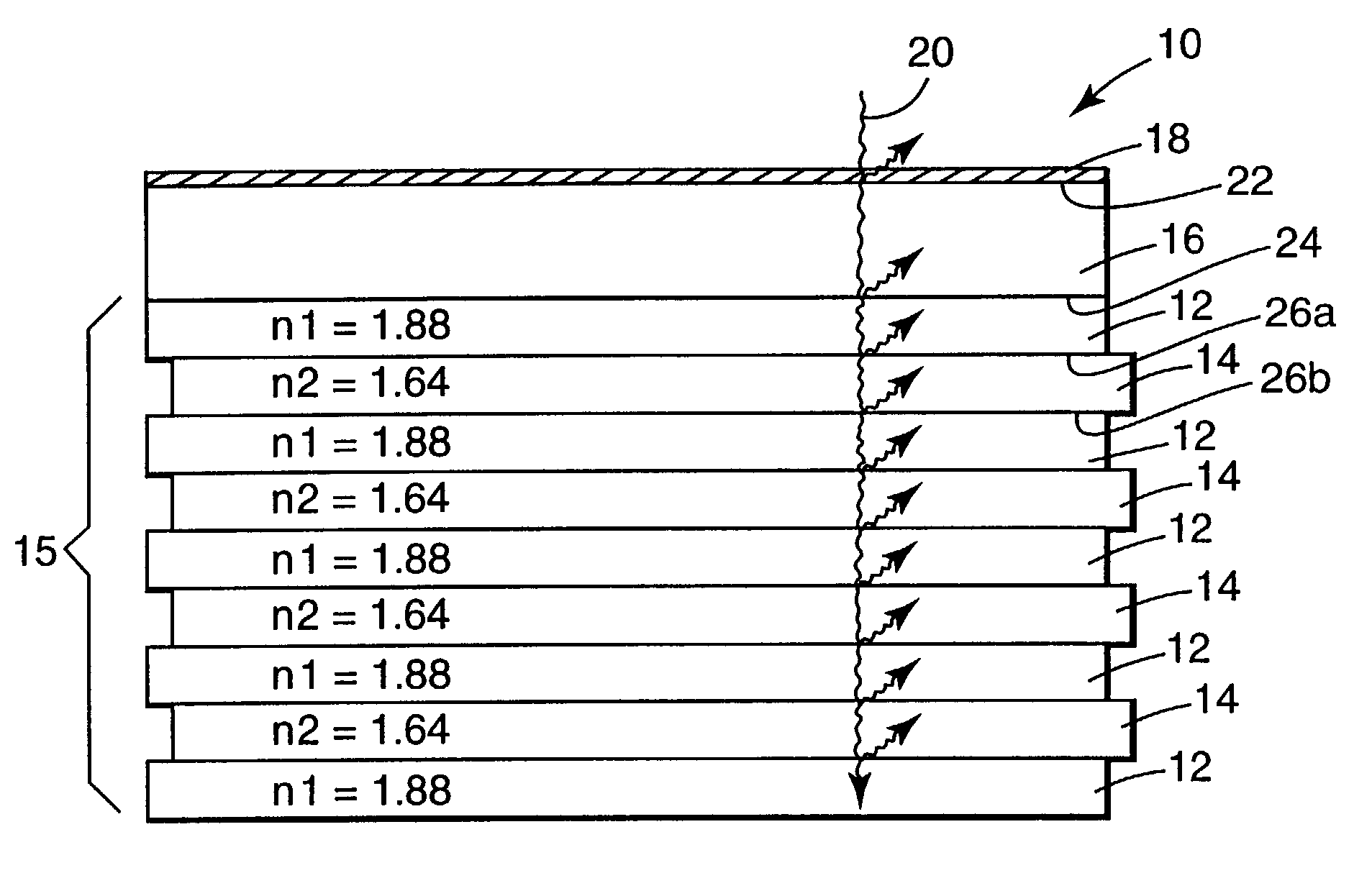

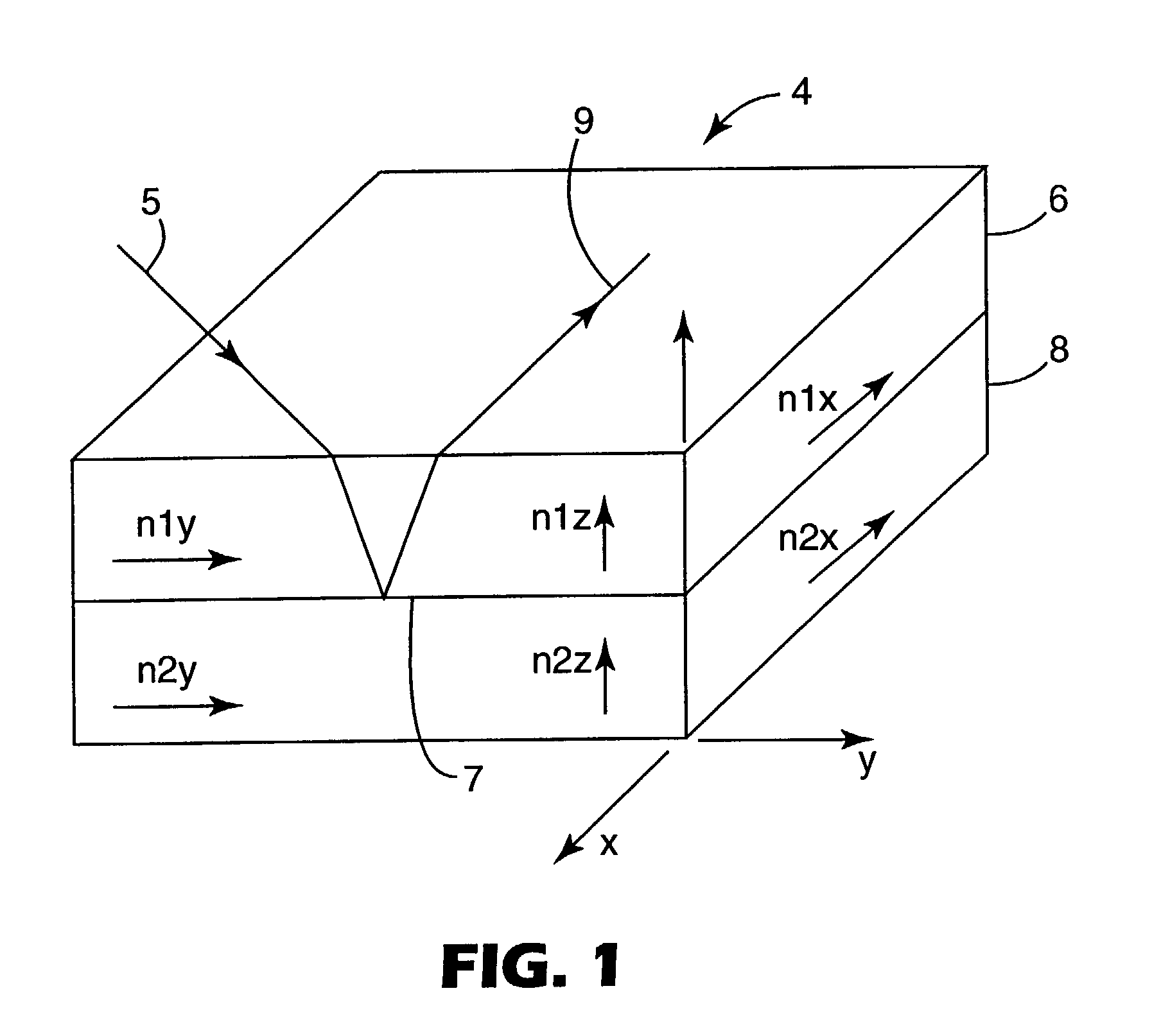

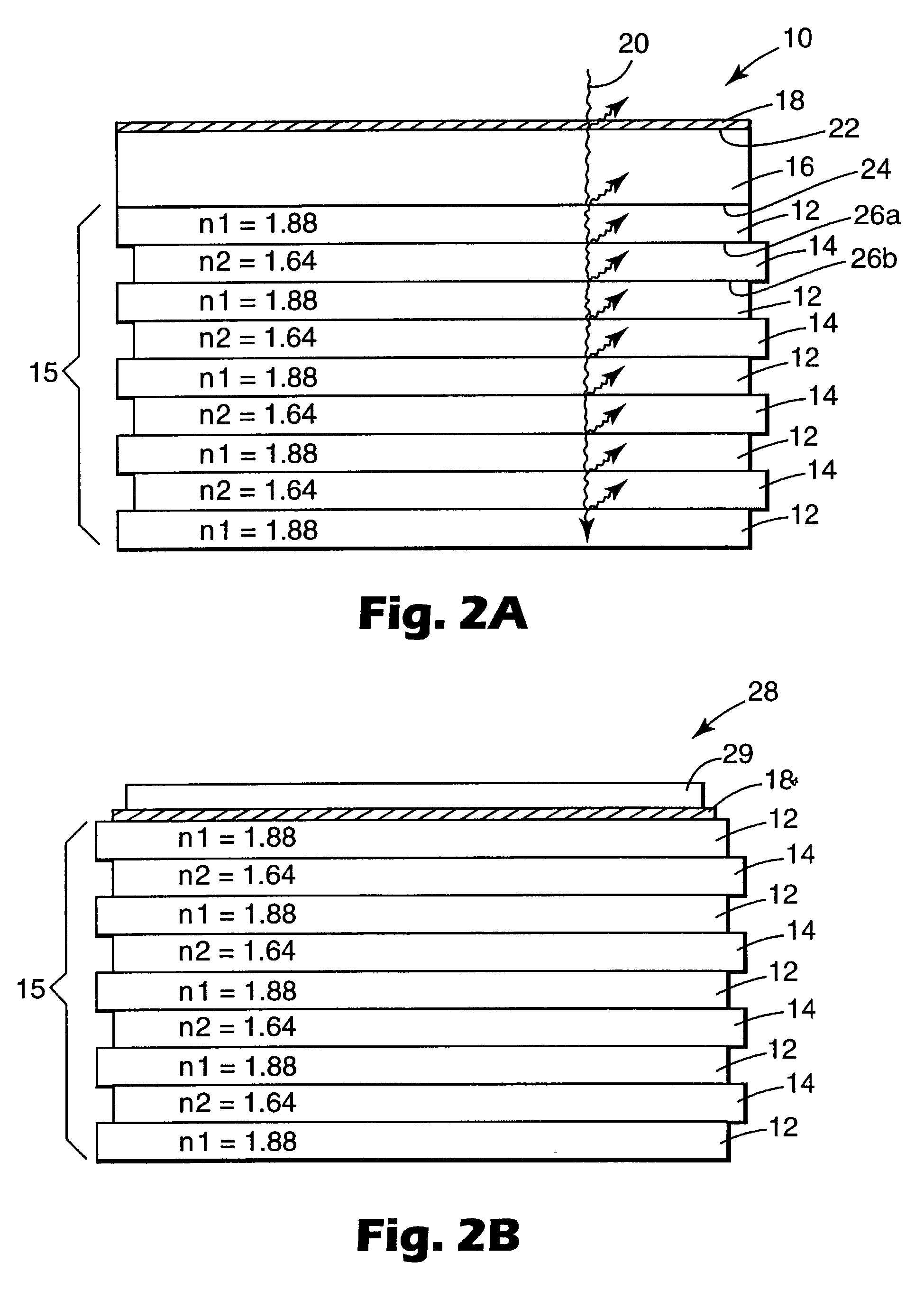

ActiveUS7215473B2Function increaseImprove interlayer adhesionMirrorsSynthetic resin layered productsMetal alloyHot mirror

A heat mirror film containing visible light-transmissive and infrared reflective film comprising a birefringent dielectric multilayer support that reflects at least 50% of light in a band at least 100 nm wide in a wavelength region of interest, a metal or metal alloy layer whose thickness is such that the film is visible light-transmissive and its reflection band is broadened, and a crosslinked polymeric layer has improved infrared reflecting properties. The film can be joined or laminated into glazing (especially non-planar vehicular safety glazing) with reduced likelihood that the metal or metal alloy layer will be damaged or distorted.

Owner:3M INNOVATIVE PROPERTIES CO

Extensible, visible light-transmissive and infrared-reflective film and methods of making and using the film

InactiveUS6929864B2Enhance vehicle aerodynamicsImprove outward visibilityOptical filtersSynthetic resin layered productsMetal alloyPolymer

A film contains first and second metal or metal alloy layers separated by a crosslinked polymeric spacing layer whose thicknesses are such that the film is extensible visible light-transmissive and infrared reflective. The film can be joined or laminated into glazing (especially non-planar vehicular safety glazing) with reduced likelihood that the metal or metal alloy layers will be damaged or distorted.

Owner:3M INNOVATIVE PROPERTIES CO

Resin composition and use thereof

ActiveCN102993683AImprove heat resistanceIncrease crosslink densitySynthetic resin layered productsPrinted circuit aspectsVitrificationDouble bond

The invention discloses a resin composition and a use thereof. The resin composition comprises modified polyphenyl ether and organic silicon compound containing an unsaturated double bond. The invention further discloses a manufacturing method for a high frequency circuit base plate by the resin composition and a high frequency circuit base plate manufactured by the manufacturing method. The high frequency circuit base plate has a high glass transition temperature, a high thermal decomposition temperature, high interlayer bonding force, a low dielectric constant and tangent low-medium loss, and is very suitable for being used as a circuit base plate of a high frequency electronic device.

Owner:GUANGDONG SHENGYI SCI TECH

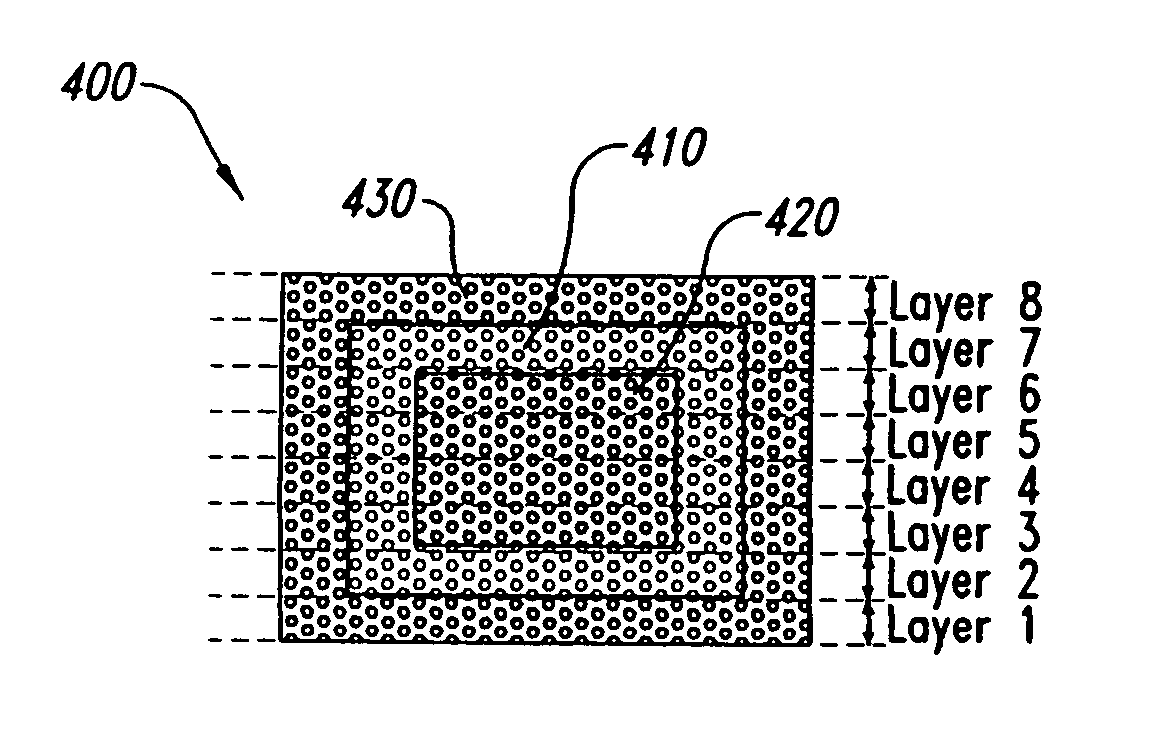

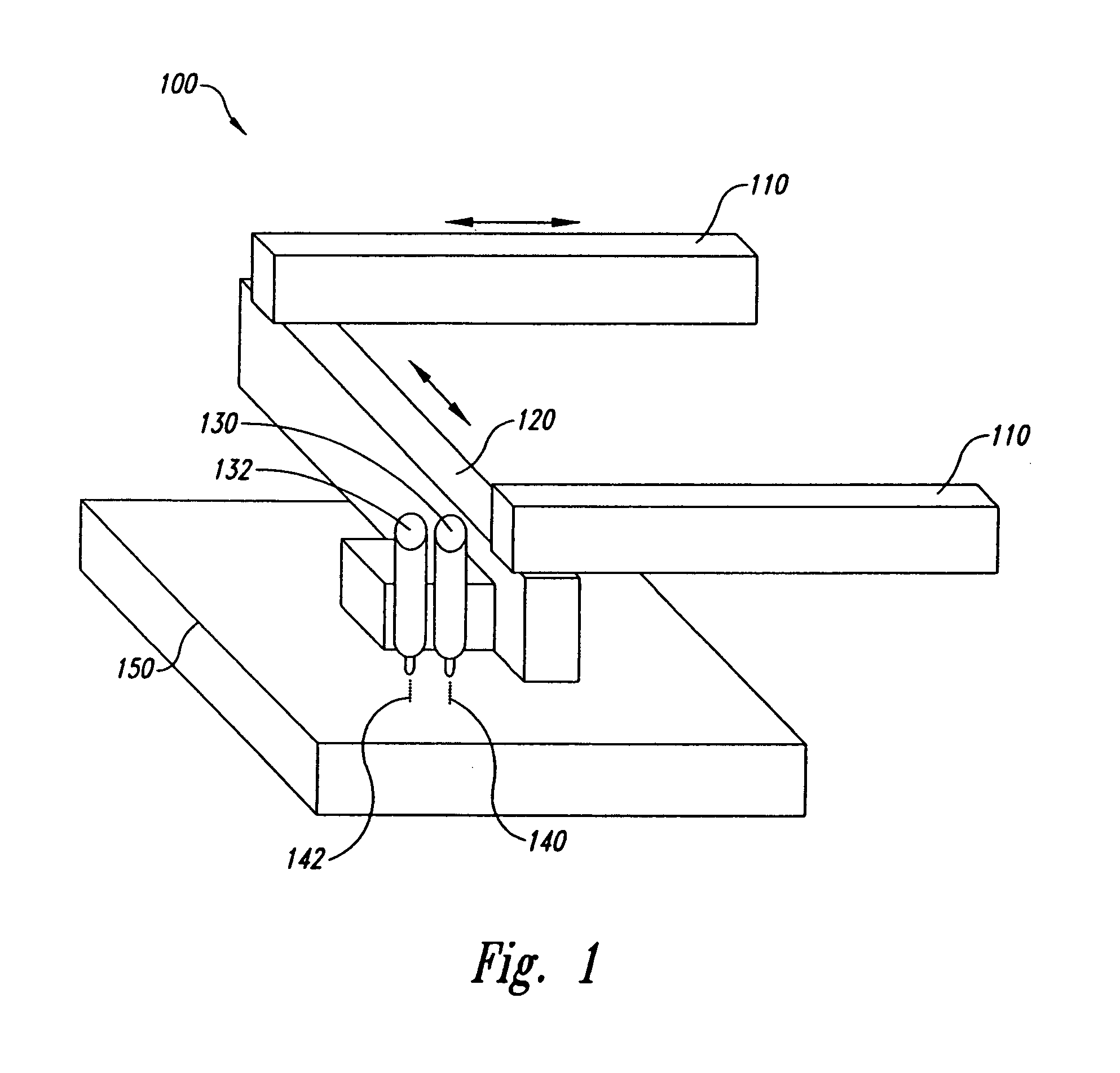

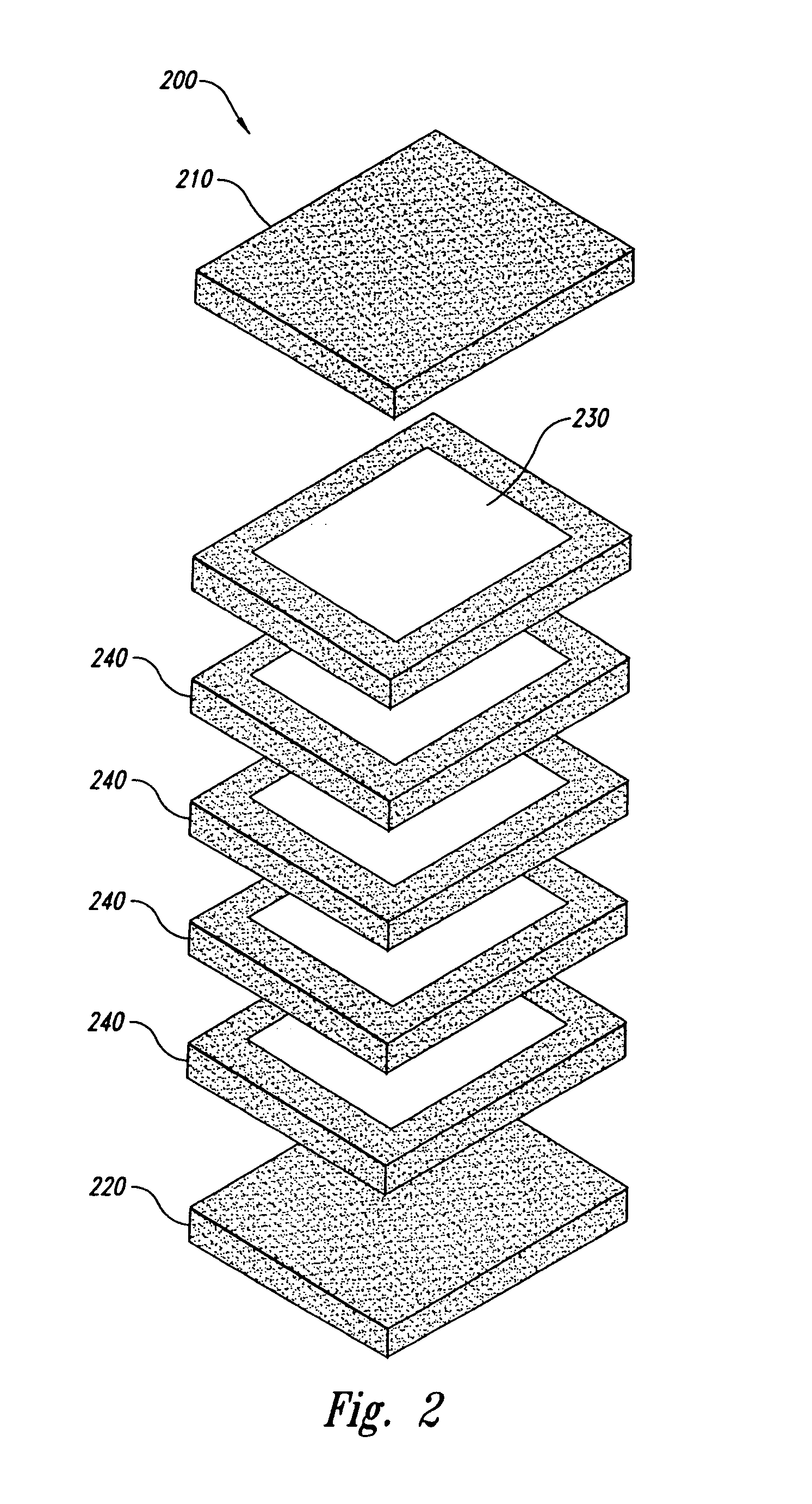

Method and form of a drug delivery device, such as encapsulating a toxic core within a non-toxic region in an oral dosage form

InactiveUS7276252B2Promote absorptionSmall crystal sizeBiocideAdditive manufacturing apparatusHazardous substanceBioavailability

A drug delivery device such as an oral dosage form (ODF) with a toxic or potent core encapsulated by a non-toxic region. The non-toxic region may be a region including multiple layers, coatings, shells, and combinations thereof, which provides protection to and isolation from the toxic or potent core. The drug in the toxic or potent core is incorporated into the dosage form via, for example, three-dimensional printing, as a solution, solubilization or suspension of solid particles in liquid, rather than by the more conventional handling and compressing of dry powder. This minimizes the likelihood of creating airborne particles of the toxic drug during manufacturing, hence controlling and minimizing the exposure of manufacturing personnel to the hazardous substance. Wet dispensing of the toxic or potent drug further provides greater bioavailability of the drug to the patient.

Owner:APRECIA PHARMA LLC +1

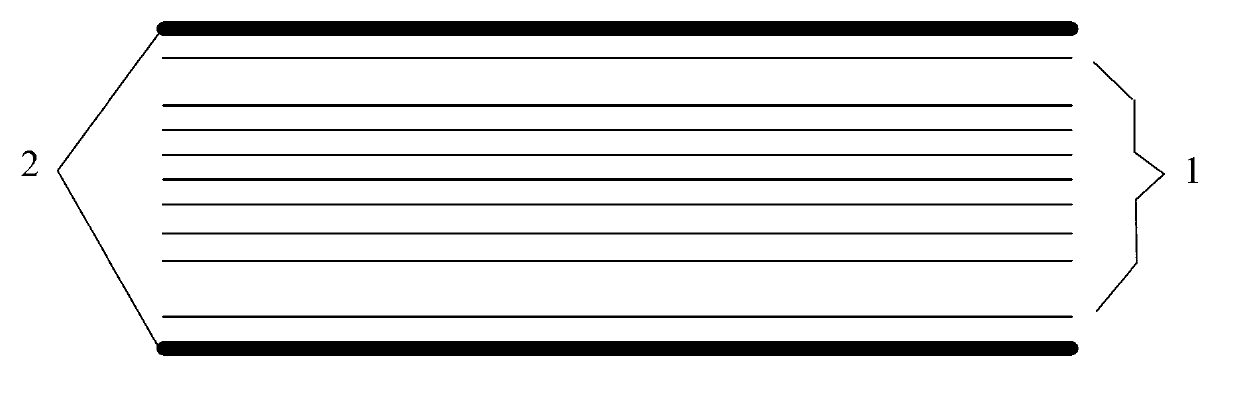

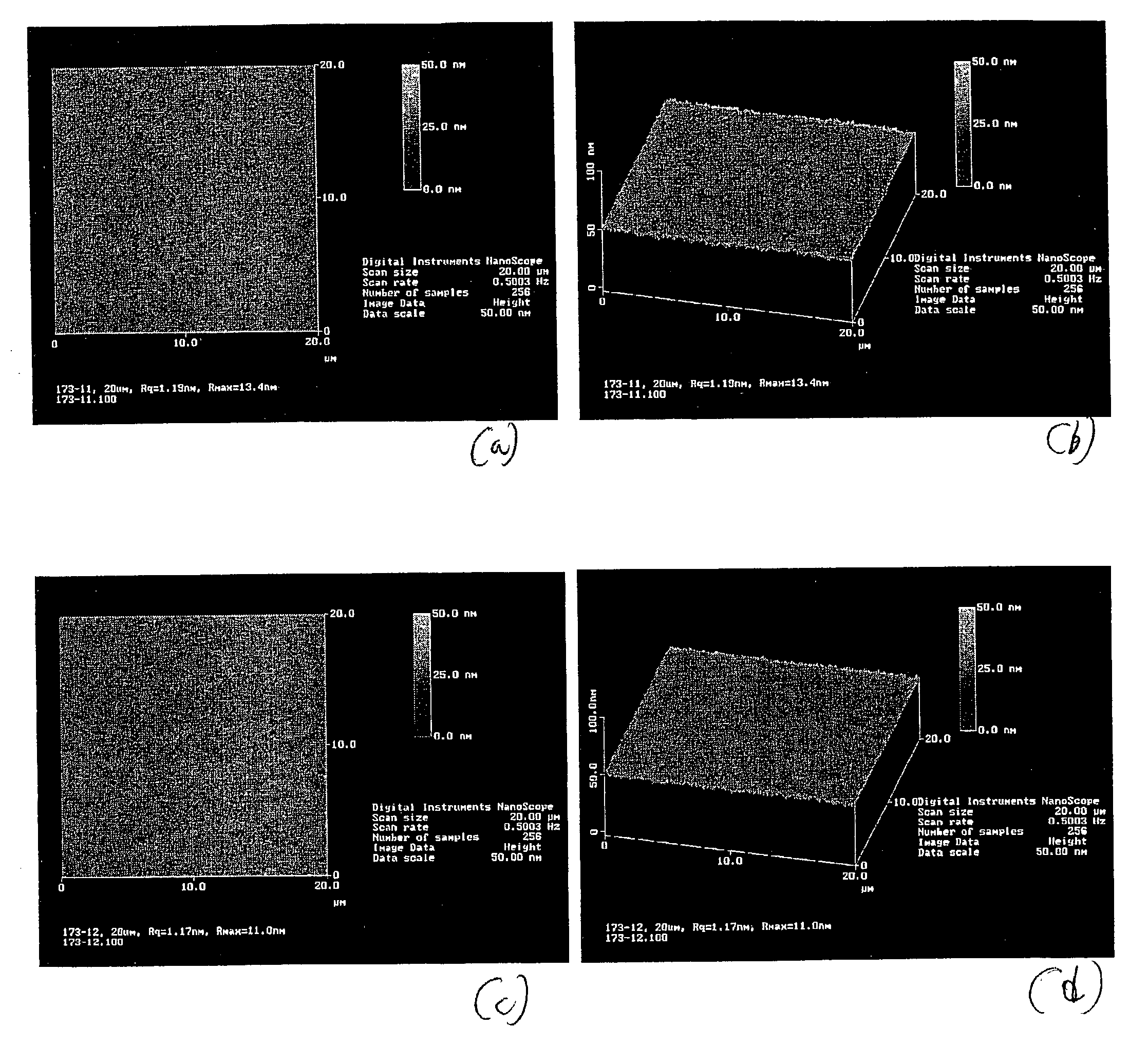

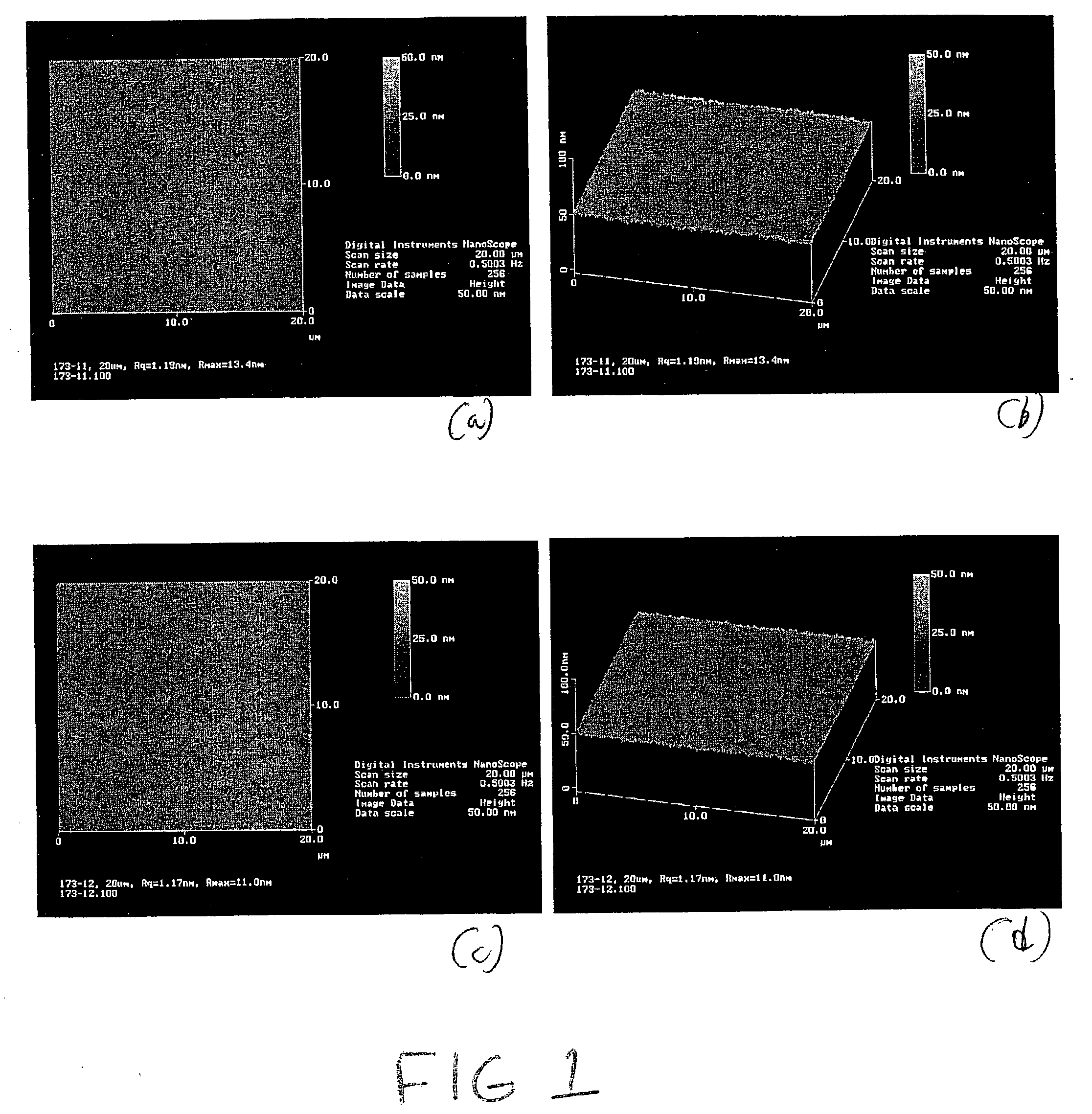

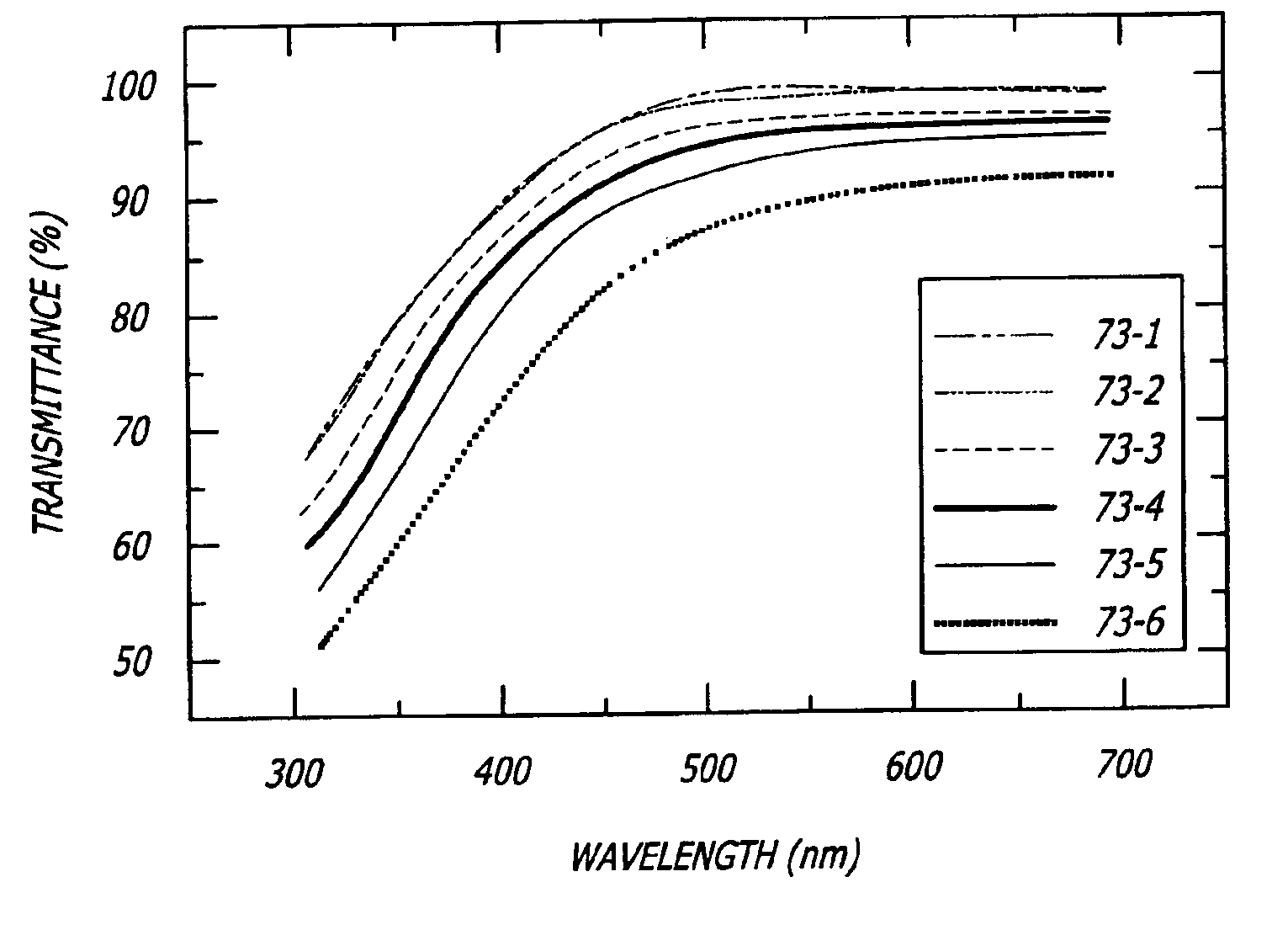

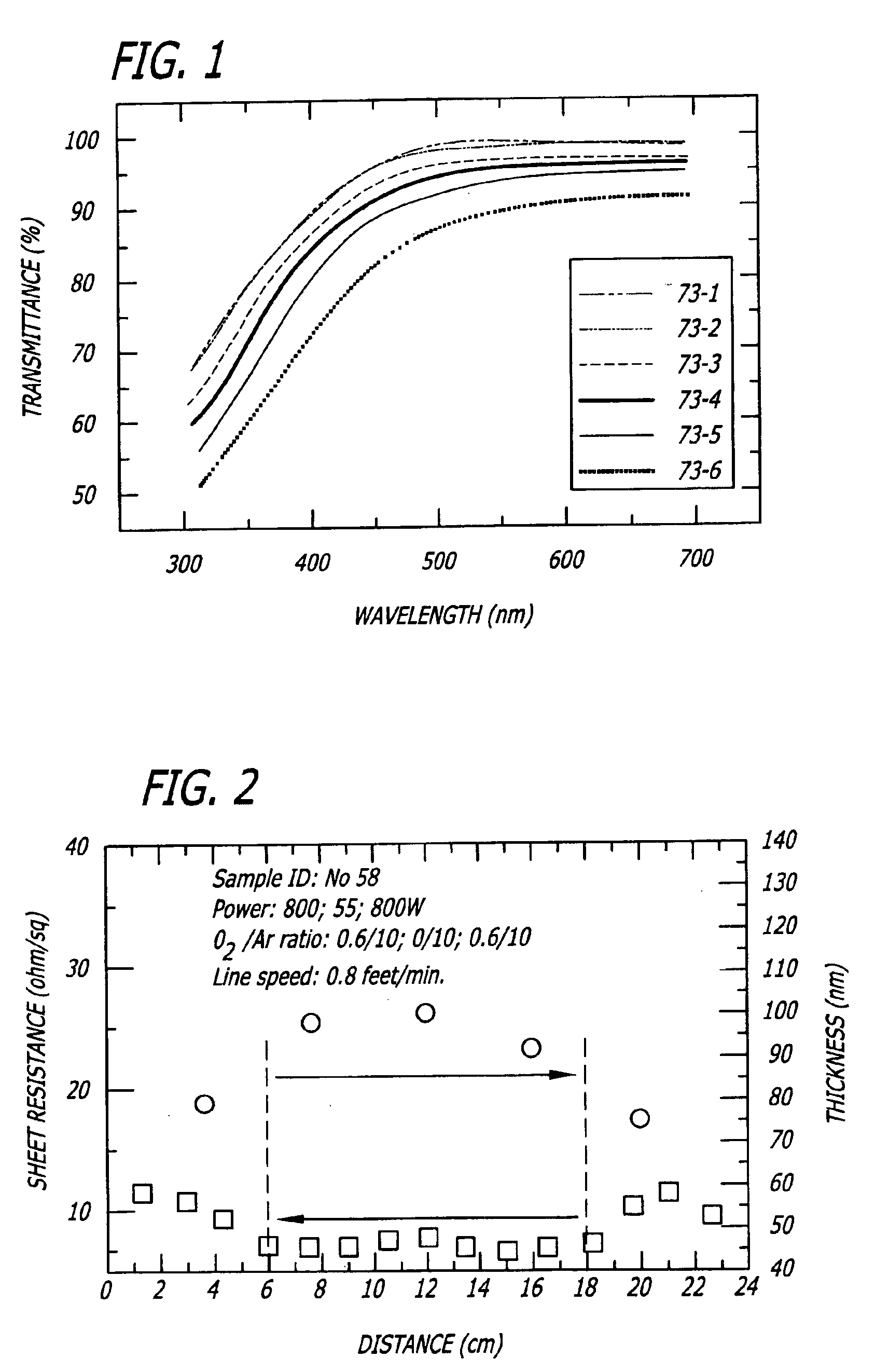

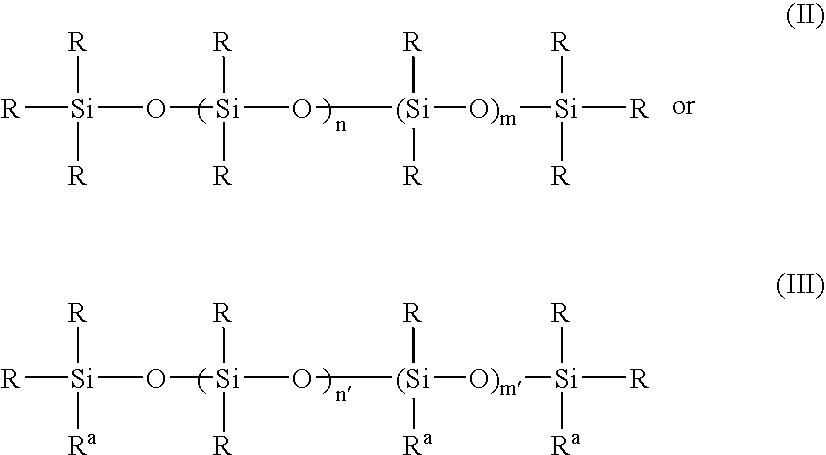

Transparent conductive film for flat panel displays

ActiveUS20040086717A1High transmittanceLow electric resistanceSolid-state devicesVacuum evaporation coatingTransmittanceIndium

Transparent conductive films for flat panel displays and methods for producing them are disclosed. In general, a method according to the present invention comprises: (1) providing a flexible plastic substrate; (2) depositing a multi-layered conductive metallic film on the flexible plastic substrate by a thin-film deposition technique to form a composite film, the multi-layered conductive metallic film comprising two layers of an alloy selected from the group consisting of indium cerium oxide (InCeO) and indium tin oxide (ITO) surrounding a layer of an alloy of silver, palladium, and copper (Ag / Pd / Cu); and (3) collecting the composite film in continuous rolls. Typically, the thin-film deposition technique is DC magnetron sputtering. Another aspect of the invention is a composite film produced by a method according to the present invention. Still another aspect of the invention is a composite film comprising a multilayered film as described above formed on a flexible plastic substrate, wherein the composite film has a combination of properties including: transmittance of at least 80% throughout the visible region; an electrical resistance of no greater than about 10 Omega / square; a root-mean-square roughness of no greater than about 2.5 nm; and an interlayer adhesion between the multi-layered metallic film and the remainder of the composite film that is sufficiently great to survive a 180° peel adhesion test.

Owner:XYLON LLC

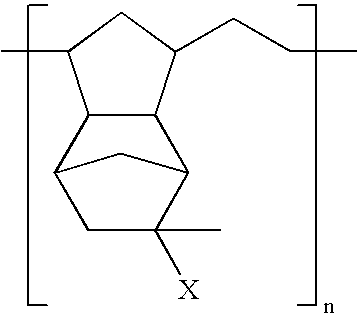

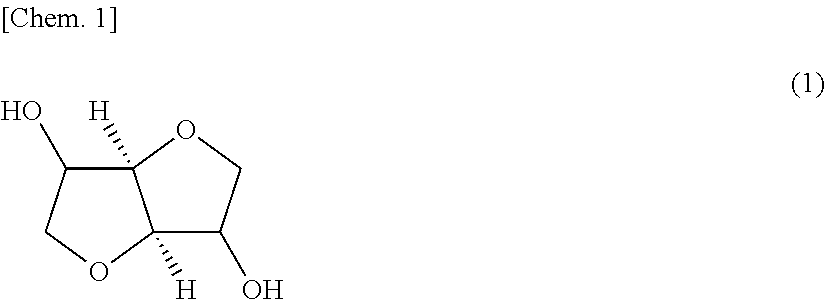

Sheet for card, and card

InactiveUS20130075480A1Excellent in of of embossabilityImprove heat resistanceSynthetic resin layered productsBooksCard stockPolymer science

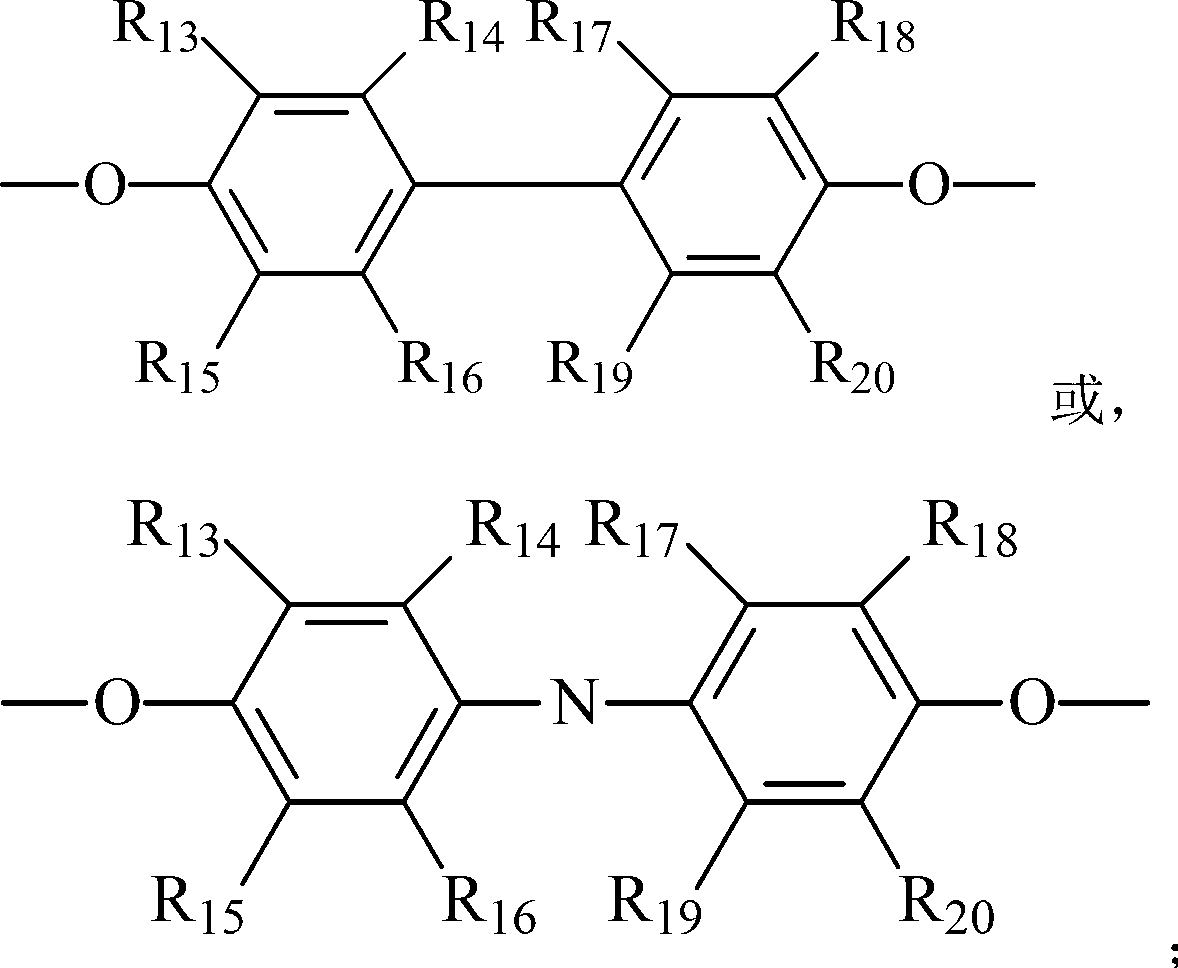

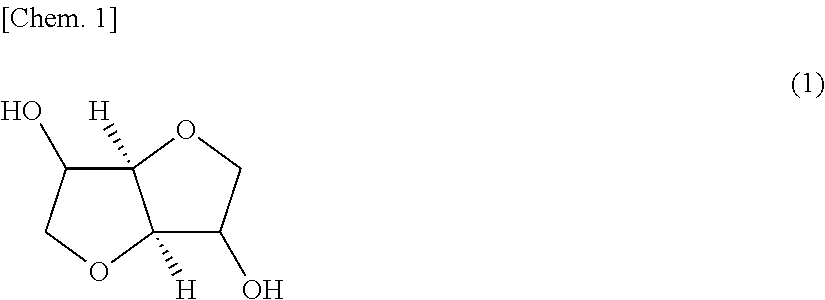

The invention is to provide a sheet for cards which is excellent in terms of all of heat resistance, weatherability, rigidity, punchability, and embossability and which employs a plant-derived resin, and to provide a card. The invention relates to a sheet for cards which has a layer constituted of a resin composition (X) containing, as a main component, a polycarbonate resin (A) that contains structural units (a) derived from a dihydroxy compound represented by the following formula (1) and that has a glass transition temperature lower than 130° C.

Owner:MITSUBISHI CHEM CORP +1

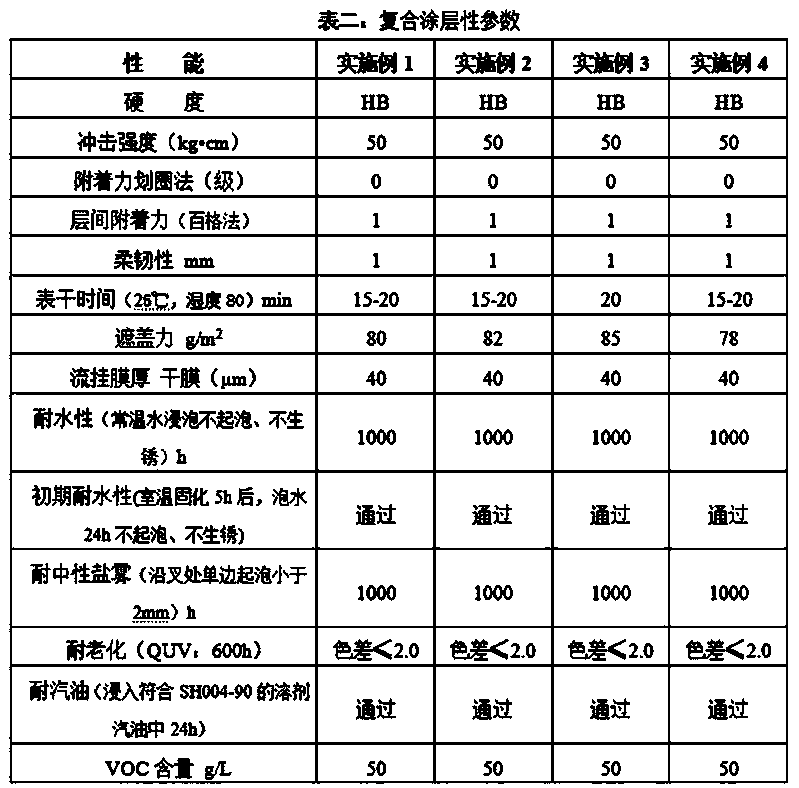

Thermo-setting acrylic-acid emulsion, its preparing method and paint containing same

This invention discloses a thermoset crylic acid latex and its preparation method and a corrosion resistant bottom coat containing such latex and used in the Al fins of the heat converter of air conditioners, in which, said latex includes a crylic acid kind monomers, an ionic vinyl monomers, an ethene monomers, a vinyl silane coupler, a crosslink monomers, a surface active agent and an initiator to be got by seed latex and semi-continuous drop technology. Said bottom coat includes said thermoset crylic acid latex, water-base coating resin, water-base cross-linker, booster solvent, neutralization agent, a water-base adhesive force accelerant, a catalyst and water.

Owner:GUANGZHOU HUMAN CHEM

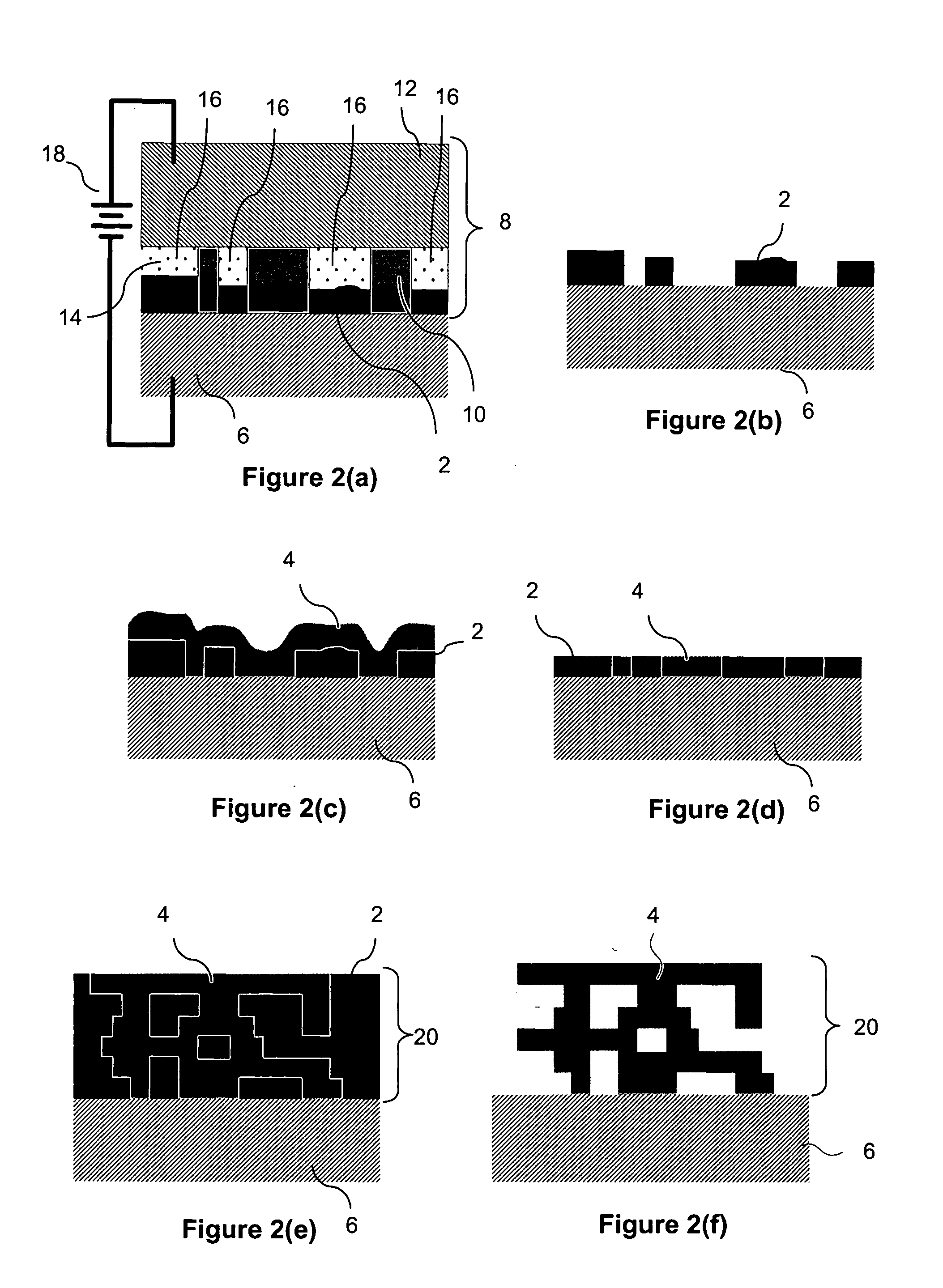

Method of electrochemically fabricating multilayer structures having improved interlayer adhesion

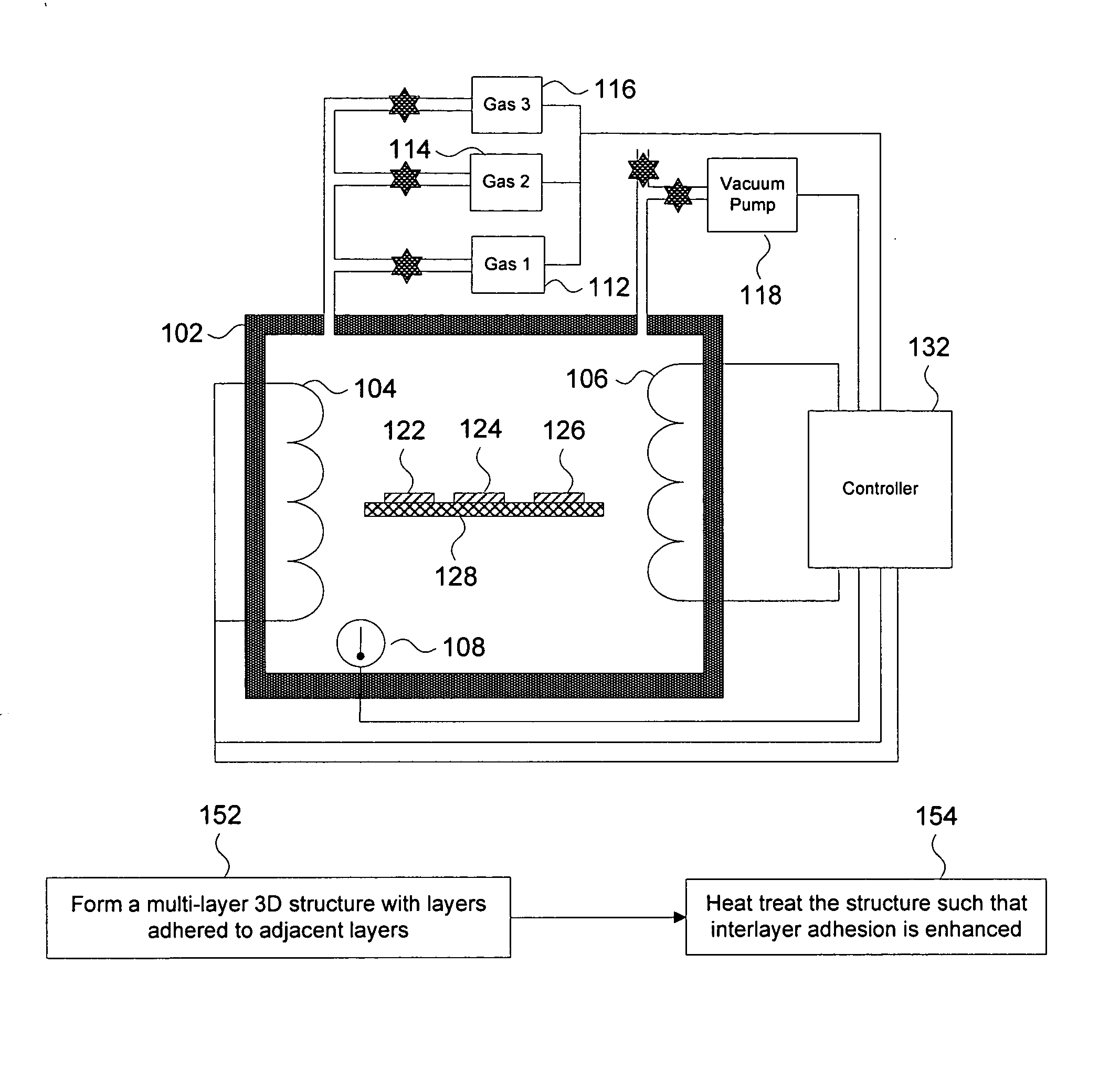

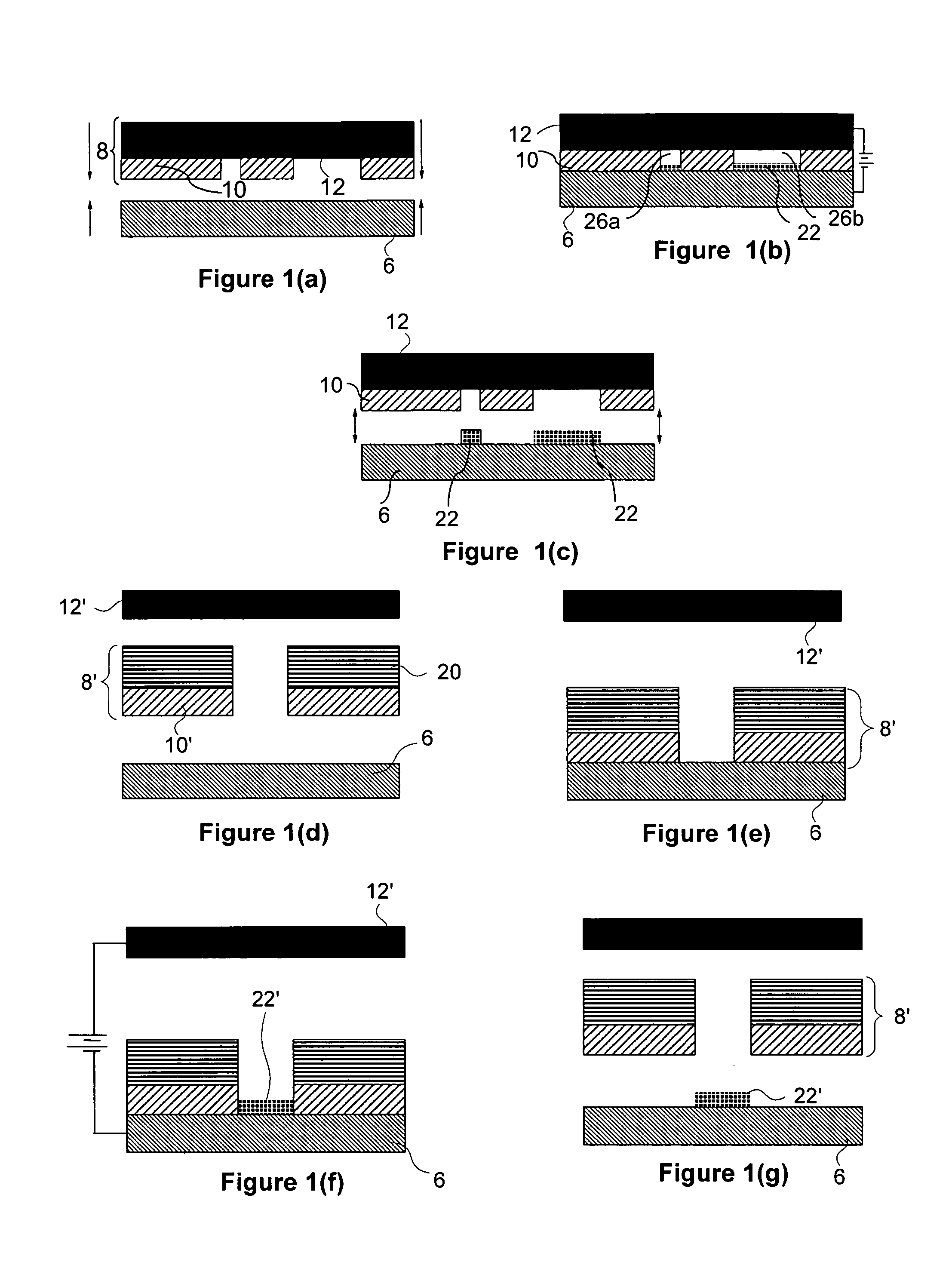

InactiveUS20050045585A1Improve propertiesImprove interlayer adhesionDecorative surface effectsSemiconductor/solid-state device manufacturingReducing atmosphereHeat treating

Multi-layer microscale or mesoscale structures are fabricated with adhered layers (e.g. layers that are bonded together upon deposition of successive layers to previous layers) and are then subjected to a heat treatment operation that enhances the interlayer adhesion significantly. The heat treatment operation is believed to result in diffusion of material across the layer boundaries and associated enhancement in adhesion (i.e. diffusion bonding). Interlayer adhesion and maybe intra-layer cohesion may be enhanced by heat treating in the presence of a reducing atmosphere that may help remove weaker oxides from surfaces or even from internal portions of layers.

Owner:UNIV OF SOUTHERN CALIFORNIA

Automotive fuel hose and method for producing the same

InactiveUS20050208248A1Low layerSimple molding processSynthetic resin layered productsLaminationEngineeringAutomotive fuel

An automotive fuel hose excellent in interlaminar adhesion between a low permeability resin layer and a rubber layer, wherein the low permeability resin layer and the rubber layer are directly adhered to each other without forming an adhesive layer at the interface between both layers. The automotive fuel hose has a laminated structure of a low permeability resin layer and a rubber layer, the low permeability resin layer is formed by the following (A) and the rubber layer is formed by the following (B). (A) a polyphenylene sulfide resin containing a softening component, or a modified fluororesin. (B) a rubber composition composed of at least one of an amine additive and an amine vulcanizing agent as an essential component.

Owner:SUMITOMO RIKO CO LTD

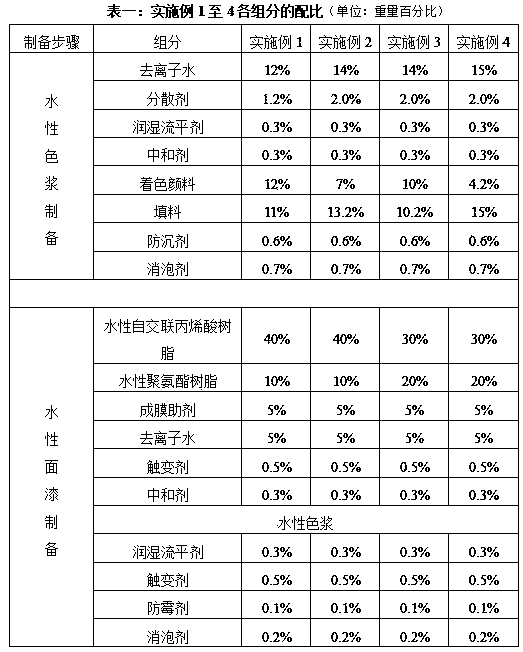

Single-component water-based natural drying finishing coat for construction crane and preparation method thereof

InactiveCN103788787AImprove water resistanceImprove aging resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxySolvent based

The invention discloses a single-component water-based natural drying finishing coat for a construction crane and a preparation method thereof. The raw material formula of the single-component water-based natural drying finishing coat comprises the following components by weight percent: 40-50% of water-based resin, 1-3% of dispersant, 4-20% of coloring pigment, 8-15% of filler, 0.5-1.5% of anti-settling agent, 0.5-1% of leveling wetting agent, 1-2% of thixotropic agent, 0.5-1% of defoamer, 0.1-0.8% of mildew preventive, 1-5% of coalescing agent, 0.5-1% of neutralizer and 10-20% of deionized water. The invention also discloses the preparation method of the single-component water-based finishing coat. The film of the water-based natural drying finishing coat is curable at the room temperature, energy-saving and environmental friendly, and capable of meeting the requirements of safe production of enterprises; in the meantime, the film is good in closure to a primer, and has excellent early-stage waterproofness and ageing resistance; the single-component water-based finishing coat is matched with a room temperature curable water-based double-component epoxy primer in use, so that the film formed is excellent in corrosion resistance, and the comprehensive properties of the single-component water-based natural drying finishing coat are up to the property indexes of similar solvent type finishing coats.

Owner:GUANGZHOU KINTE IND +1

Holography positioning alumite high speed thermoprint back glue and preparation method

ActiveCN101343522AGood chemical propertiesGood weather resistancePolyureas/polyurethane adhesivesAldehyde/ketone condensation polymer adhesivesHot stampingPrinting ink

The invention discloses a high-speed hot stamping gum used for holographic positioning electrochemical aluminium and the preparation method. The gum prepared through the formulation and the method of the invention can achieve good adhesive effect under the appropriate temperature and pressure, and the appropriate release coating is added, thus the holographic image information of the holographic electrochemical aluminium can be stripped and cemented on the surface of the scalded object at the high speed. The fragileness of the gum is moderate, therefore, the trimming performance of the holographic image is good in the hot stamping process, the gum is particularly applied to high-speed hot stamping on the surface of the sheet paper and the printing ink with which the density and the hardness are big, the surface energy is low, the surface wettability is poor, and the general coating liquor is difficult to be transferred and cemented on.

Owner:湖北省葛店开发区晨光实业有限公司 +1

Circuit substrate and preparation method thereof

ActiveCN103755989ALow dielectric constantSolve the signal delay problemPrinted circuit liquid treatmentFilm/foil adhesivesGlass fiberSignal delay

The invention provides a preparation method of a bonding sheet forming a circuit substrate. The method comprises a step of pretreating a glass fabric by use of a pretreatment glue solution of which the dielectric constant (Dk) is the same with or close to the Dk value of the adopted glass fabric. The invention also provides a bonding sheet and a circuit substrate prepared by the method. The preparation method of the circuit substrate provided by the invention does not need equipment transformation and adjustment, the cost is relatively low, the difference of the dielectric constant of the prepared circuit substrate in the longitudinal direction and latitudinal direction is less, and the problem of signal delay can be effectively solved.

Owner:GUANGDONG SHENGYI SCI TECH

Coating composition and film system therefrom

ActiveUS20080076868A1Improve the immunityGood lookingOrganic dyesEmulsion paintsCarbamatePolymer chemistry

A coating composition is used to form a clearcoat layer of a film system including a basecoat layer and the clearcoat layer. The coating composition includes a carbamate functional polymer, a cross-linking agent reactive with the carbamate functional polymer, and an acid functional polymer substantially non-reactive with the carbamate functional polymer and the cross-linking agent. The acid functional polymer has an acid value of at least 50 mg KOH / g and contributes to an increased resistance to acid etch of the clearcoat layer. The acid functional polymer also contributes to an increased intercoat adhesion of the basecoat layer and the clearcoat layer thereby decreasing a possibility of separation / delamination of the basecoat layer and the clearcoat layer.

Owner:BASF CORP

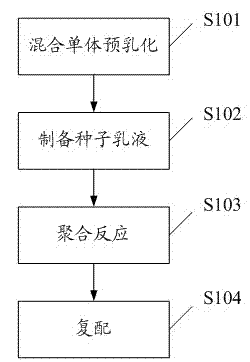

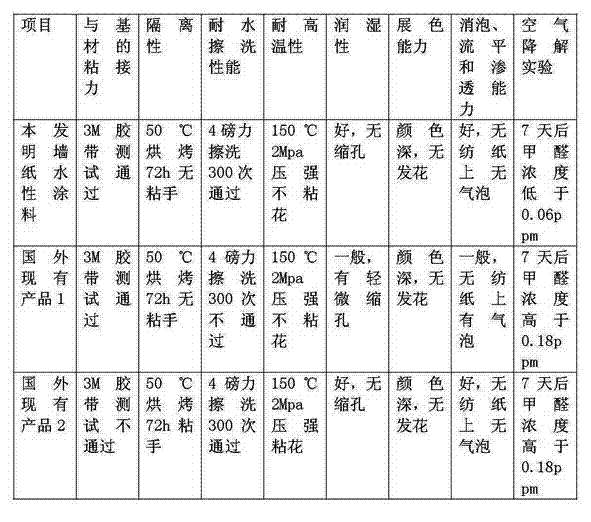

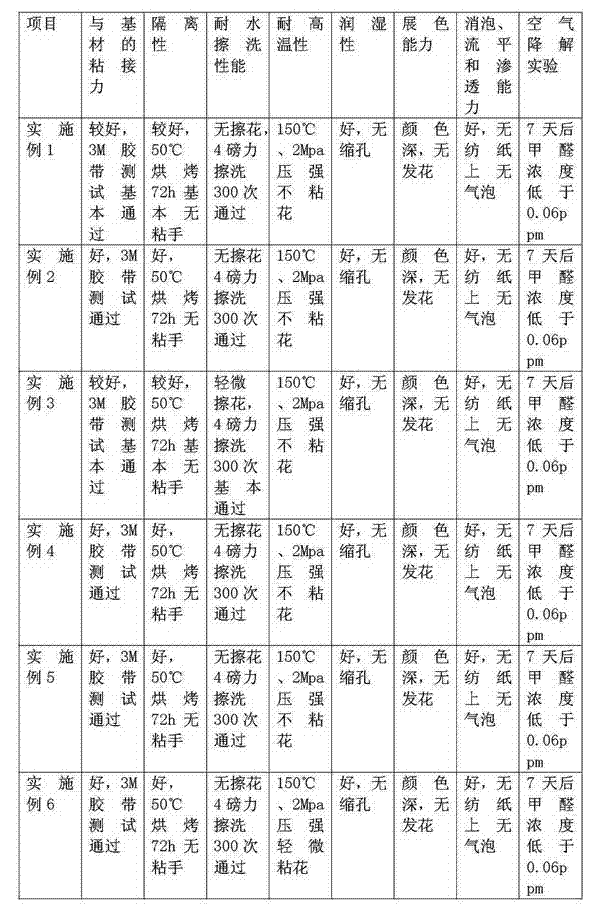

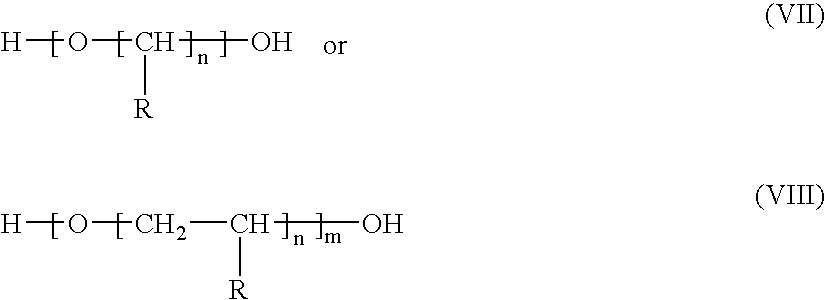

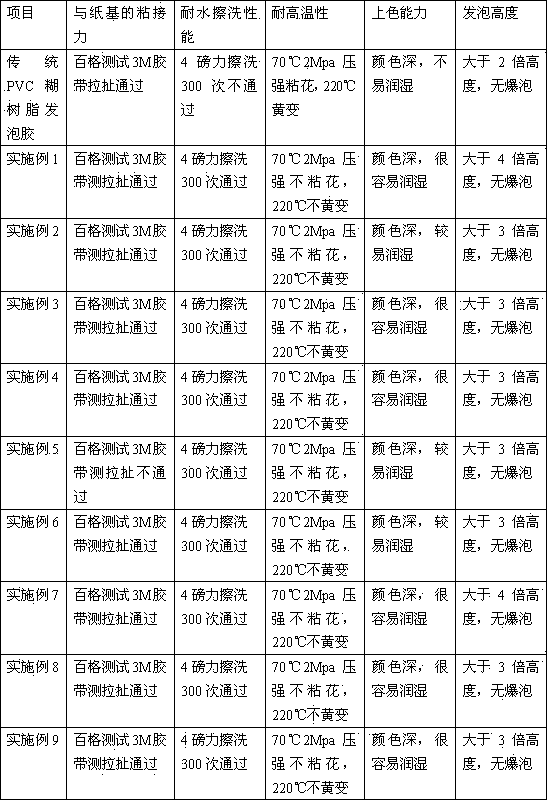

Wallpaper water-based paint, preparation method thereof and wallpaper

The invention discloses wallpaper water-based paint. The wallpaper water-based pain is water-based acrylate emulsion with solid content being 20-40% and the water-based acrylate emulsion is mainly made from a (methyl) acrylate monomer, a functional polymerizable monomer, an emulsifier, a photocatalyst, an initiator and deionized water through an emulsion polymerization method and a sol-gel method. Accordingly, the invention also discloses a method for preparing the wallpaper water-based paint and wallpaper made by adopting the wallpaper water-based paint. The wallpaper water-based paint is obviously improved in wallpaper substrate adaptability, the wallpaper water-based paint has good adhesive force, isolation, wettability and colour developing capability and is resistant to scrubbing and high temperature, defoaming is realized and the hole shrinkage phenomenon of a substrate is avoided; meanwhile, the wallpaper water-based paint also has light degradation property and can purify indoor air.

Owner:佛山市三水灏诚合成树脂有限公司

Electroplating effect imitated plastic paint and preparation method, diluent and process of using same

The invention discloses a plastic paint with simulated electroplating effect. The composition and the weight ratio of the invention are as follows: 30 to 45 of acrylic resin with 50 percent of solid content and 70 to 90 DEG C of Tg, 20 to 30 of cellulose acetate butyrate with 20 percent of solid content, 8 to 12 of triad copolymer vinyl chloride-acetate resin with 30 percent of solid content, 6 to 10 of non-floating aluminum and silver pulp with an average diameter less than or equal to 20 Mum, 0.3 to 0.5 of dispersant, 0.2 to 0.4 of flatting agent, 0.4 to 0.6 anti-settling agent, 6.0 to 10.0 of toluene, 3.5 to 6.0 of ethyl acetate, 3.5 to 6.0 methy isobutyl ketone, 3.0 to 5.0 of isobutanol and 4.0 to 7.0 of glycol butyl ether. The special diluent of the invention, according to the weight ratio, is made from the following components evenly mixed: 20 of white gas, 10 of toluene, 22 of ethyl acetate, 15 of acetone, 25 of isobutanol and 8 of glycol butyl ether. The main paint which comprises the composition and the diluent are evenly mixed according to the ratio of 1: 2-3, then the mixture is used for spray coating; the metallic appearance of the paint film obtained is very close to the effect of the electroplating, and the paint film has good alcohol resistance with high hardness and strong wear resistance, and also has simple process. The aluminum and silver pulp used is a common type, the cost of which is only 5 percent to 10 percent of the simulated electroplating aluminum and silver pulp and about 2 percent of electrosilvering.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

Preparation method of scratch-resistant polyurethane matt black finish for woodware

ActiveCN103013325AEliminate Bubble ProblemsNo surface foggingPolyurea/polyurethane coatingsLacquerSolvent

The invention relates to a preparation method of a scratch-resistant polyurethane matt black finish for woodware. The scratch-resistant polyurethane matt black finish comprises a resin paint component A and a curing agent component B in the weight ratio of 1: 0.5, wherein the resin paint component A comprises alkyd resin, extinction powder, a dispersing agent, carbon black paste, a modifying flatting agent, an antifoaming agent, an anti-settling agent and a solvent; and the curing agent component B comprises a TDI-HDI (Toluene Diisocynate-Hexamethylene Diisocyanate) mixed tripolymer or a TDI / TMP (Trimethylolpropane) affixture, an HDI tripolymer and a solvent. The scratch-resistant double-component polyurethane matt black finish for woodware, prepared by the preparation method provided by the invention, brings no precipitate during being stored, is high in solidity, low in viscosity and excellent in leveling property; and the filming can be realized at one time, and the film is thick, free from sagging, and soft, full, fine, smooth, slippery in hand feel, shows alternate kindness with severity, is given the effect of full decoration like a mirror plane, brings a graceful and comfortable feel, and is adapted to modern aesthetic view and widely popular with the market and customers. The scratch-resistant polyurethane matt black finish is widely applied to protective decoration of surfaces of products such as the woodware, metals and plastics.

Owner:UNION FOSHAN CHEM +1

Method for roll-to-roll deposition of optically transparent and high conductivity metallic thin films

InactiveUS6811815B2Excellent propertyHigh light transmittanceLayered productsPrinted circuit aspectsComposite filmRms roughness

Methods for roll-to-roll deposition of optically transparent and high conductivity metallic thin films are disclosed. In general, a method according to the present invention comprises: (1) providing a flexible plastic substrate; (2) depositing a multi-layered conductive metallic film on the flexible plastic substrate by a thin-film deposition technique to form a composite film; and (3) collecting the composite film in continuous rolls. Typically, the thin conductive metallic film is an InCeO-Ag-InCeO film. Typically, the thin-film deposition technique is DC magnetron sputtering. Another aspect of the invention is a composite film produced by a method according to the present invention. Still another aspect of the invention is a composite film comprising InCeO-Ag-InCeO film formed on a flexible plastic substrate, wherein the composite film has a combination of properties including: transmittance of at least 90% throughout the visible region; an electrical resistance of no greater than about 10 Omega / square; a root-mean-square roughness of no greater than about 2.5 nm; and an interlayer adhesion between the InCeO / Ag / InCeO metallic film and the remainder of the composite film that is sufficiently great to survive a 180° peel adhesion test.

Owner:STREAMING SALES

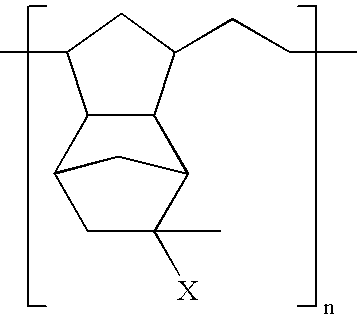

Flexible packaging laminate films including a block copolymer layer

InactiveUS20070026251A1Improve clarityImprove interlayer adhesionSynthetic resin layered productsDomestic containersPolyolefinPolymer science

A flexible packaging laminate film having improved interlayer adhesion and toughness without compromising other physical properties which is a laminate of at least one film layer of a polyolefin and at least one film layer of a block copolymer. The block copolymer employed in the present invention includes an unhydrogenated block copolymer having a monoalkenyl arene content equal to or greater than 60 weight percent and a modulus less than about 100,000 psi.

Owner:KRATON POLYMERS US LLC

Multi-layer composites formed from compositions having improved adhesion, coating compositions, and methods related thereto

InactiveUS20050042463A1Poor interlayer adhesionImprove interlayer adhesionLiquid surface applicatorsSynthetic resin layered productsMaterials scienceComposite coating

The present invention provides an improved multi-layer composite of two or more polymeric layers at least one of which is formed from a thermosetting composition. The composite includes at least a first polymeric layer formed on a substrate and a second polymeric layer over the first polymeric layer, wherein in the absence of a boron-containing compound, the first and second polymeric layers have poor interlayer adhesion. The improvement resides in the inclusion of at least one boron-containing compound in one or both of the first and second polymeric layers in an amount sufficient to improve the interlayer adhesion between the first and second polymeric layers. Also provided is an improved curable coating composition used to form a multi-layer composite coating of two or more cured coating layers, at least one of which is formed from the thermosetting composition. Related methods and coated substrates are also provided.

Owner:PPG IND OHIO INC

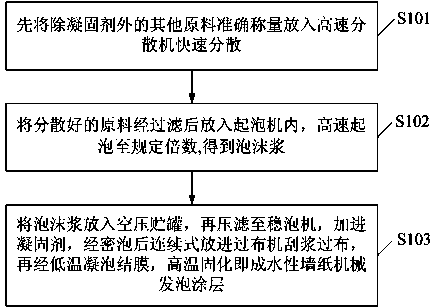

Foam coating glue of water-based wallpaper, preparation method thereof and wallpaper

InactiveCN104004473AImprove adhesionGood flexibilitySpecial visual effect coatingsSpecial paperWater basedPolymer science

The invention discloses a foam coating glue of water-based wallpaper. The foam coating glue includes 40-60% of a main body emulsion resin, 35-55% of a compounding agent and 1-10% of water. The main body emulsion resin is selected from one or more of neoprene latex, nitrile rubber latex, styrene-butadiene latex, water-based acrylate resin, water-based polyurethane resin and ethylene-vinyl acetate resin. The compounding agent includes a dispersing agent, an emulsifier, a thickening agent, a foam-starting agent, a foam-stabilizing agent, a foaming agent, a coagulating agent and a foam-densifying agent. Correspondingly, the invention discloses a preparation method of the foam coating glue of the water-based wallpaper and wallpaper prepared by using the foam coating glue of the water-based wallpaper. Through the preparation method, the foam coating glue of the water-based wallpaper is environmental-friendly and energy-saving, has an excellent foaming effect and can form an excellent-performance foam coating on the water-based wallpaper.

Owner:佛山市三水灏诚合成树脂有限公司

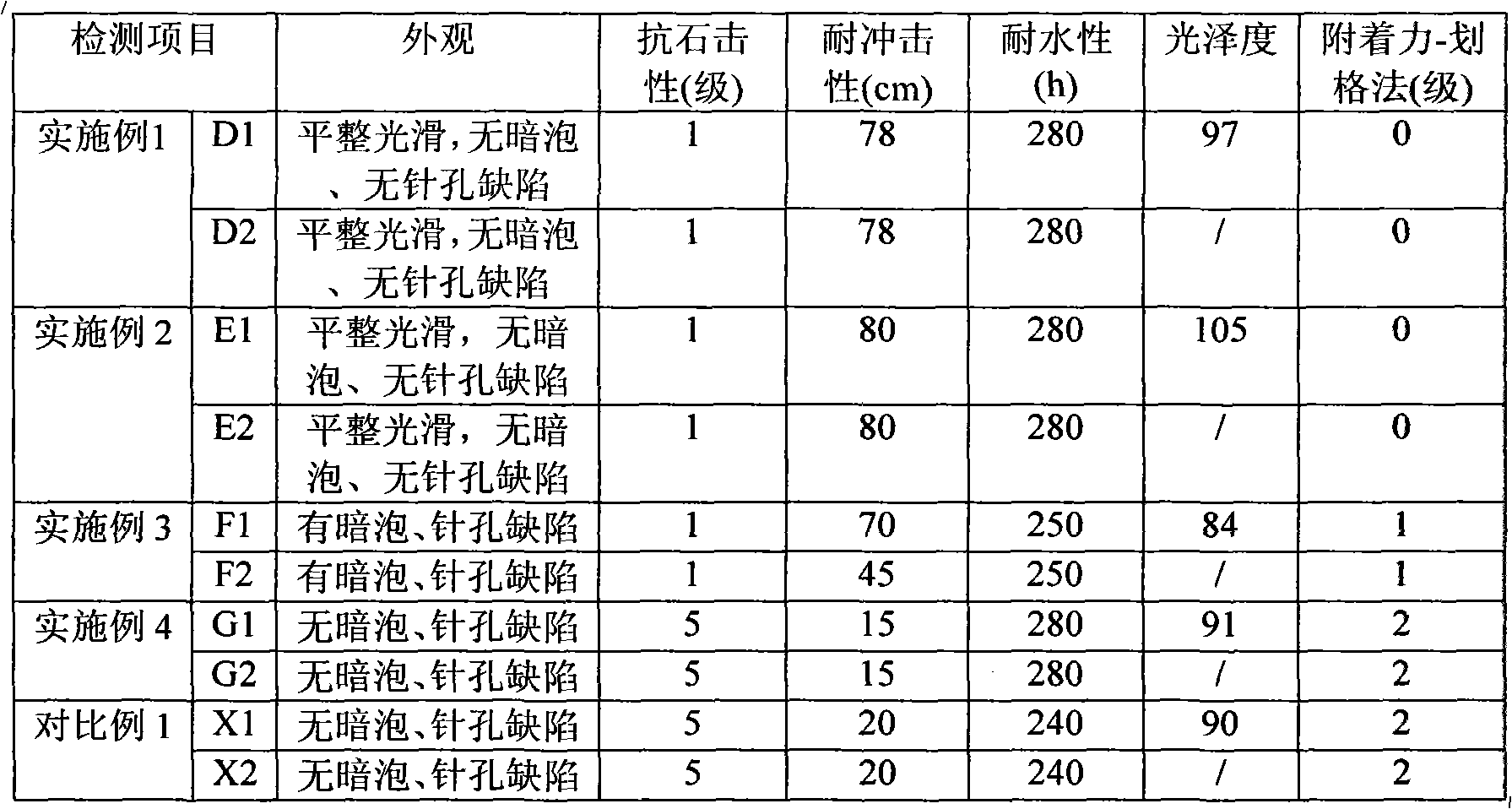

Two-component polyurethane coating used for automobile and preparation method thereof

InactiveCN102010652AHigh glossImprove interlayer adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsPolyesterAcrylic resin

The invention discloses a two-component polyurethane coating used for an automobile and a preparation method thereof. The coating comprises two components, namely a component A and a component B, and hydroxy acrylic resin in the component A and aliphatic series polyisocyanates in the component B are taken as the basic components, The preparation method comprises the following steps: adding linear saturated polyester, solvent, auxiliaries and color padding into the basic components, wherein the weight ratio of the component A to the component B is (2.5-5.5):1, the component A comprises hydroxide radical, the linear saturated polyester, wetting dispersing agent, catalyst, coloringpigment, padding, rust resisting pigment and solvent, and the component B comprises the aliphatic series polyisocyanates and solvent. The coating provided by the invention can be used for improving the glossiness of an under-coat coating, the adhesion between the layers of the under-coat coating and antirust primer, the weather fastness and stone-impact resistance of a solidified coating film, and the shock resistance and water resistance of the solidified coating film at the same time.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of wear-resistant super-hydrophobic nanometer titania coating

InactiveCN105602412AExtended service lifeImprove protectionEpoxy resin coatingsPigment treatment with organosilicon compoundsEpoxyWear resistant

The invention discloses a preparation method of a wear-resistant super-hydrophobic nanometer titania coating. The preparation method includes firstly, dissolving silane coupling agent in ethyl alcohol and then heating and stirring to react to obtain a solution; secondly, adding nanometer titania into the solution and then stirring and drying to obtain hydrophobic nanometer titania powder; thirdly, mixing a certain quantity of epoxy resin with hardener while adding in diluting agent to dilute the resin completely to obtain a diluted liquid, adding the hydrophobic nanometer titania powder into the diluted liquid, then subjecting the mixture to ultrasonic dispersion with complete stirring to allow the nanometer titania to contact with the resin completely so as to obtain a suspension liquid; and finally, coating the suspension liquid on a base material and drying completely so as to obtain the wear-resistant super-hydrophobic nanometer titania coating. Compared with the pure hydrophobic nanometer coating, the wear-resistant super-hydrophobic nanometer titania coating prepared by the method has the advantages that coating hardness is improved greatly, and super-hydrophobic property of the coating is guaranteed while interlayer adhesion and inner binding force of the nanometer coating are improved greatly.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Flexible packaging laminate films including a block copolymer layer

ActiveUS20070020473A1Improve interlayer adhesionImprove toughnessSynthetic resin layered productsDomestic containersPolymer sciencePolyolefin

What is claimed is a flexible packaging film having improved toughness without compromise of other physical properties. The flexible packaging film is a laminate of at least two film layers of a polyolefin and at least one film layer of a block copolymer. The block copolymer employed in the present invention is a selectively hydrogenated high vinyl block copolymer.

Owner:KRATON POLYMERS US LLC

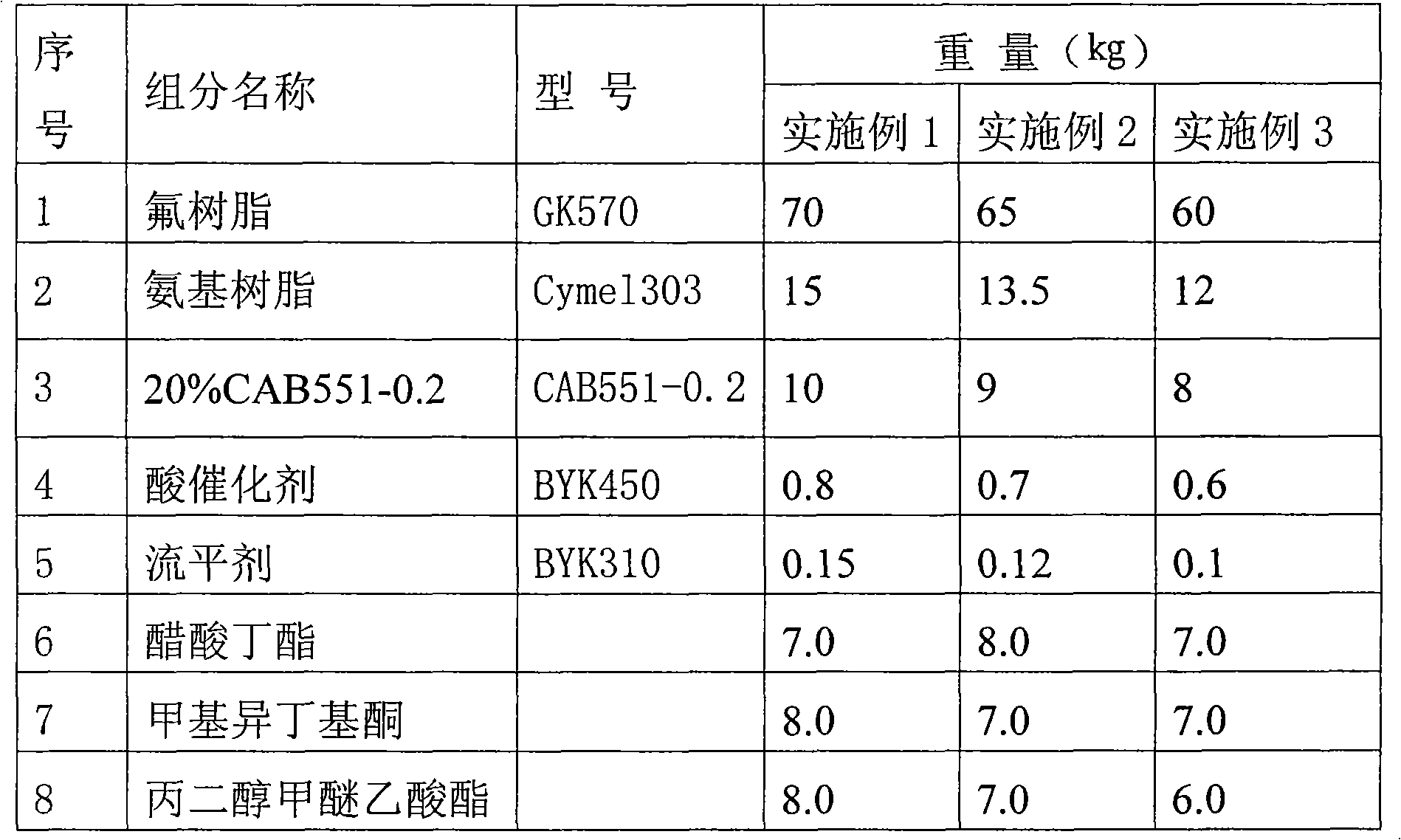

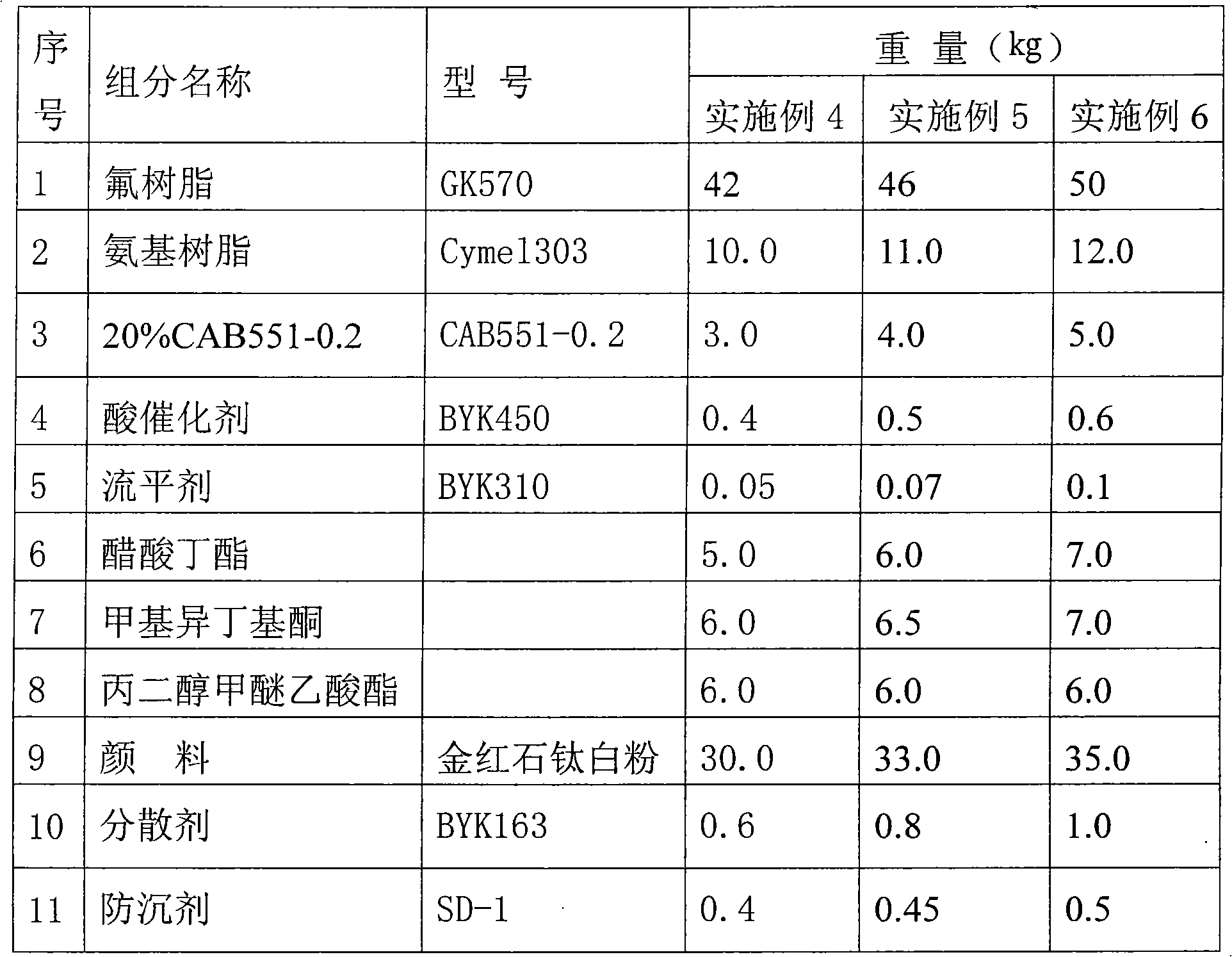

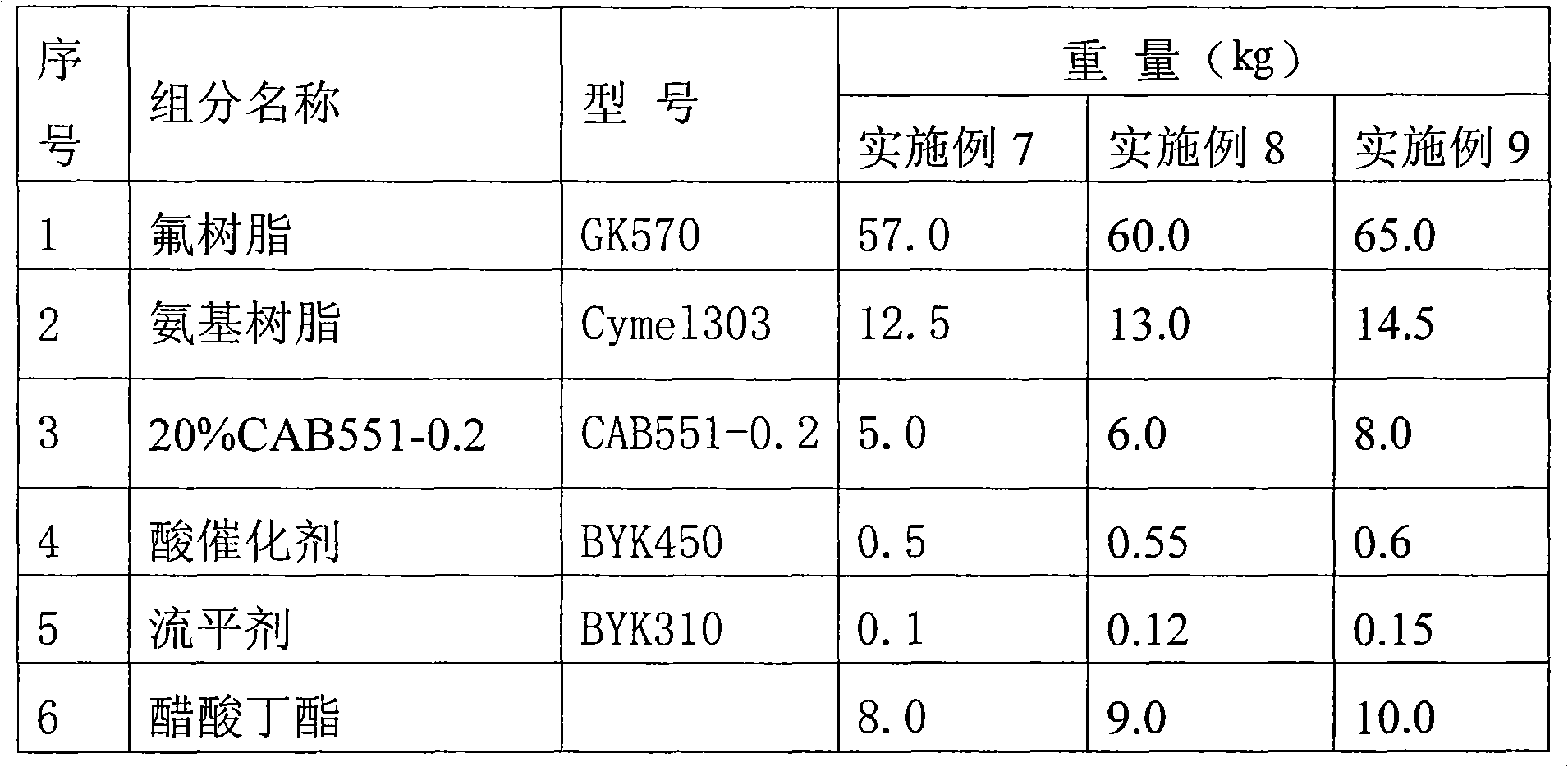

Medium-temperature baking type fluorine-carbon paint and its use method

ActiveCN101319113AIncrease productivityReduce energy consumptionPretreated surfacesCoatingsWeather resistanceLacquer

The invention provides moderate temperature baking type fluorocarbon lacquer. The compositions in portion by weight of the fluorocarbon lacquer are: 40 to 70 portions of fluororesin, 10 to 15 portions of aminoresin, 2 to 10 portions of 20 percent CAB551-0.2, 0.4 to 0.8 portions of acid catalysis, 0.05 to 0.15 portions of flatting agent, 15 to 25 portions of mixed solvent, 0 to 35 portions of pigment, 0 to 2 portions of dispersing agent, 0 to 0.6 portions of anti-settling agent, 0 to 3 portions of UV light stabilizer and 0 to 8 portions of dulling agent, wherein the fluororesin is a polymer of tetrafluoroethylene / vinyl ether monomer with the content of fluorine of between 35 and 40 percent; the aminoresin is hexamethoxymethyl melamine resin with the content of solid more than or equal to 98 percent; and the pigment reaches to eight grade in lightfastness and five grade in weathering resistance, and can resist a high temperature of more than 180 DEG C. When used, the fluorocarbon lacquer is mixed evenly with a diluent agent formed by mixed xylene, methyl isobutyl ketone, propylene glycol methyl ether acetate and DBE according to a weight ratio of between 1:0.4 and 1:0.6 so as to carry out spray coating. The moderate temperature baking type fluorocarbon lacquer has better weathering resistance than PVDF fluorocarbon lacquer as well as high hardness, abrasion resistance, impact resistance, excellent bending resistance and wide color selection range; moreover, the baking type fluorocarbon lacquer has excellent workability and ply adhesion, and does not need special treatment during recoating.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

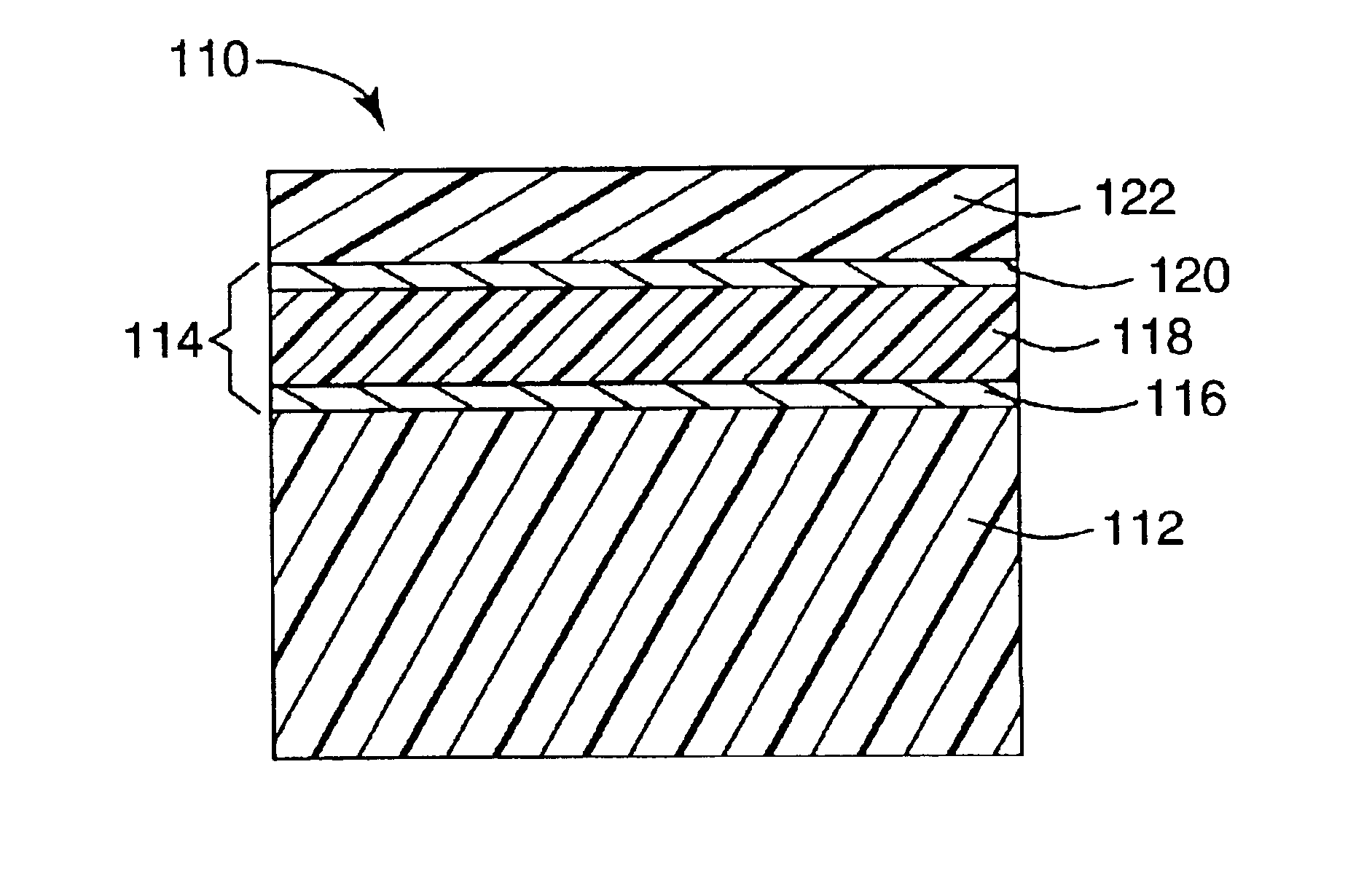

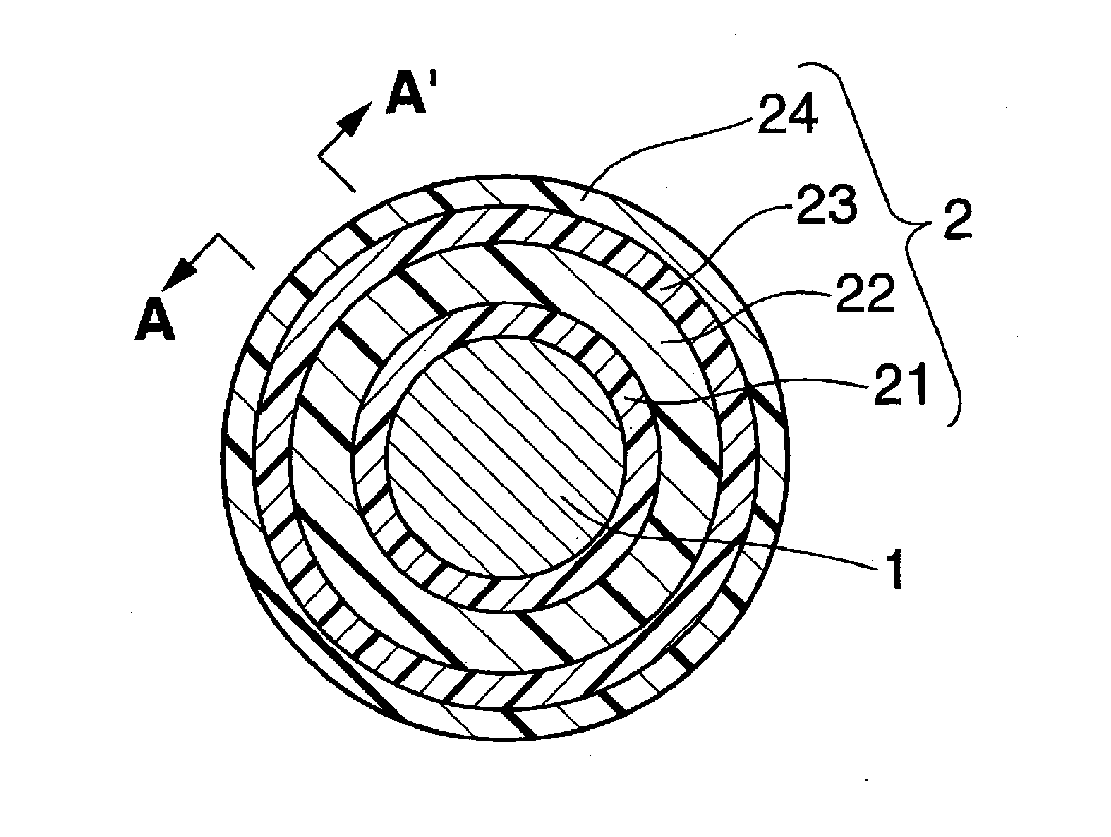

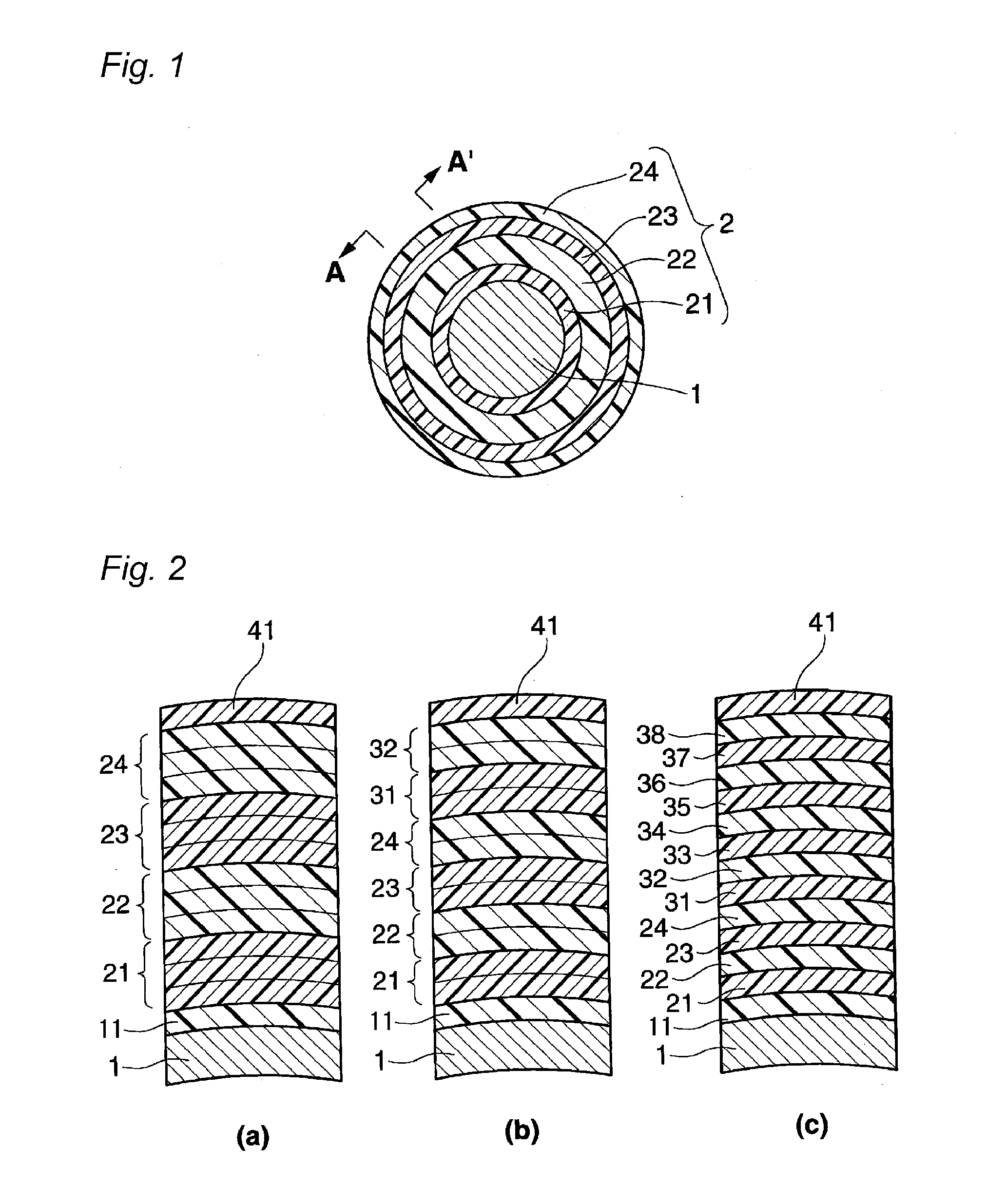

Insulated wire

InactiveUS20120285724A1Increase resistanceImprove interlayer adhesionInsulated cablesInsulatorsElectrical resistance and conductanceElectrical conductor

{Problems} To provide an insulated wire, which is high in a dielectric breakdown resistance even if insulating resin coatings are laminated, because the interlayer adhesiveness is excellent, and which is excellent in a partial discharge resistance, because the dielectric constant is low.{Means to solve} An insulated wire, having directly or indirectly on a conductor (1), at least two laminate units each formed by laminating an insulating layer (21,23) and an insulating layer (22, 24) higher in a dielectric constant than the insulating layer (21, 23), in this order from the conductor side.

Owner:FURUKAWA ELECTRIC CO LTD +1

Rubber powder modified asphalt macadam bridge surface waterproof layer and construction method

InactiveCN101220579AImprove adhesionImprove waterproof performanceIn situ pavingsBridge structural detailsChipsealCrack resistance

The invention relates to a rubber powder modified asphalt gravel bridge deck waterproof layer and a construction method thereof. The bridge deck waterproof layer of the invention is arranged between a bridge cement concrete paving layer and a bridge deck asphalt paving layer, and the bridge deck waterproof layer consists of a signal particle diameter gravel layer, a rubber powder modified asphalt layer, and an interlayer interface connection layer from top to bottom. The cement concrete paving layer is gigged and cleaned clearly during the period of construction, and then the interlayer interface connection material, the rubber powder modified asphalt and the signal particle diameter gravel are sprayed sequentially. After the rubber-tyre rolling and health preservation, the traffic can be open to the construction vehicles or the construction of the bridge deck asphalt paving layer starts. The bridge deck waterproof layer of the invention has the advantages of good waterproof effect, high interlayer cohesive performance, good high-temperature stability, good low-temperature crack resistance and excellent fatigue resistance, and efficient property of absorbing and reducing the interlayer stress.

Owner:徐培华

Waterborne epoxy floor level coating and preparation method thereof

ActiveCN104087120AIn line with the concept of environmental protectionWill not polluteEpoxy resin coatingsPolymer scienceTap water

The invention discloses a waterborne epoxy floor level coating and a preparation method thereof. The coating comprises a waterborne epoxy seal primer, a waterborne epoxy floor level intermediate coat and waterborne epoxy floor level coating finish, wherein the primer, the intermediate coat and the finish are same in component A which comprises 85-95 parts of liquid epoxy resin and 5-15 parts of an epoxy active diluent; the components B are different according to different characteristics of the primer, the intermediate coat and the finish but the main components consist of a waterborne epoxy curing agent and tap water. The waterborne epoxy floor level coating disclosed by the invention is environment-friendly, low in VOC content, good in wear-resisting property, high in hardness and excellent in chemical corrosion-resisting property.

Owner:西北永新涂料有限公司

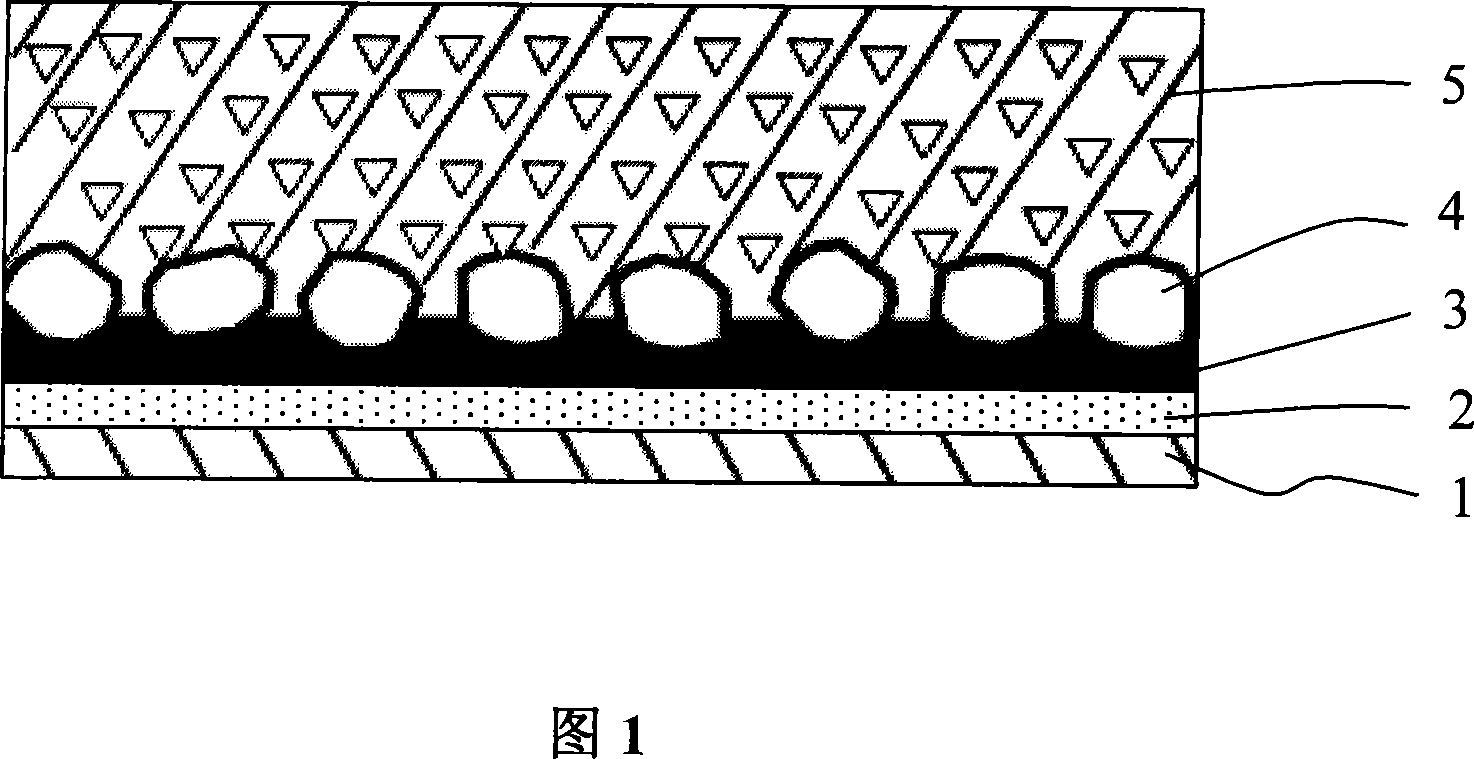

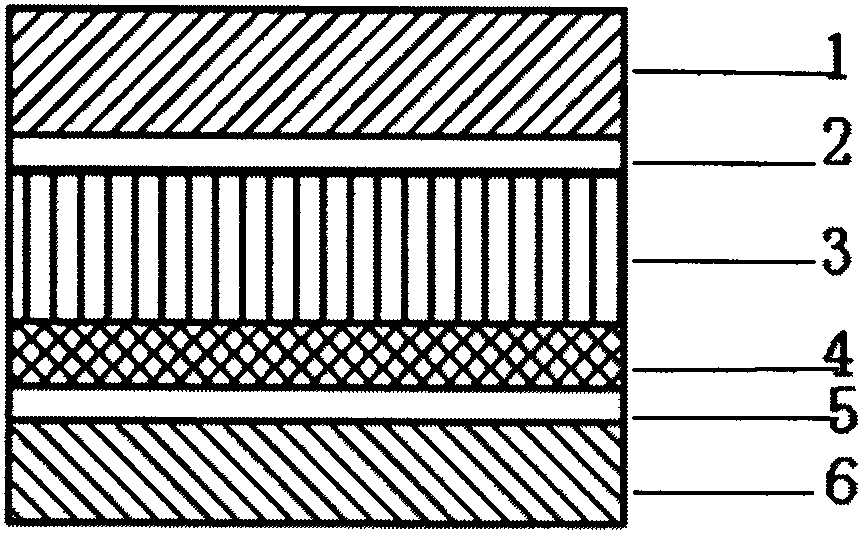

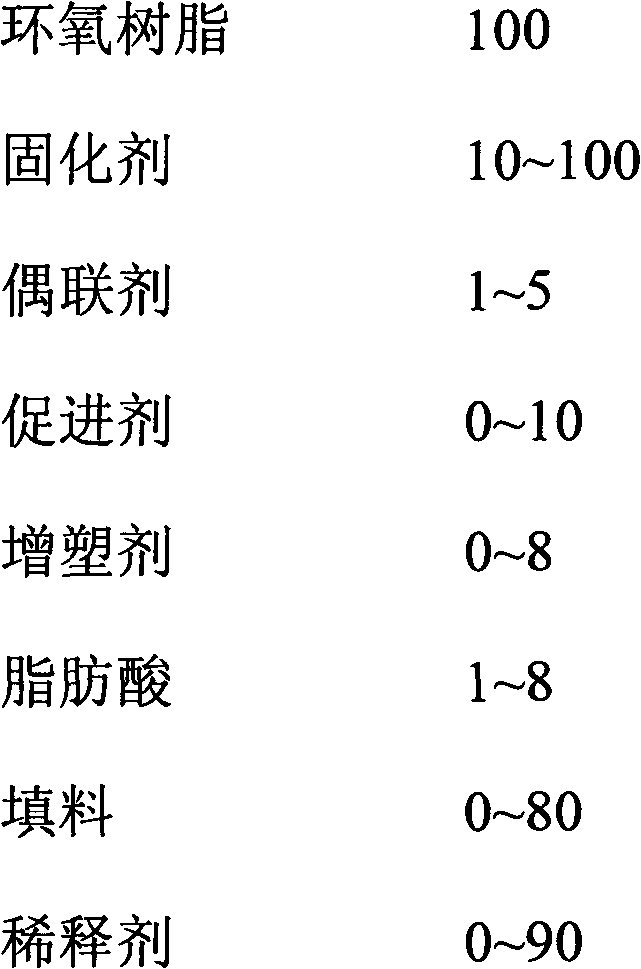

Epoxy adhesion for lithium battery flexible package and lithium battery flexible package material

InactiveCN102703010AHigh peel strengthImprove interlayer adhesionFlexible coversWrappersAluminum compositesFilm structure

The invention provides an epoxy adhesion for a lithium battery flexible package. The epoxy adhesion is mixed by bisphenol type epoxy resin, an amine or anhydride curing agent and an assistant at normal temperature according to certain proportion, and the epoxy adhesion, by weight, is composed of 100 parts of the epoxy resin, 10-100 parts of the curing agent, 1-5 parts of coupling agent, 0-10 parts of accelerating agent, 1-8 parts of plasticizer, 1-8 parts of fatty acid, 0-80 parts of padding and 0-90 parts of diluent. The epoxy adhesion further provides a lithium battery flexible package material which adopts a six-layer polyethylene-aluminum composite film structure, and the lithium battery flexible package material comprises an outer base layer, a middle aluminum foil layer an inner heat sealing layer. A polyurethane adhesion agent enables the base layer and the outer surface of the aluminum foil layer to be compounded, chromium phosphating is carried out on the inner surface of the aluminum foil layer, by means of high-strength composition of the epoxy resin adhesion agent and the heat sealing layer, peel strength between the aluminum foil layer and the heat sealing layer is high, separation performance and electrolyte resisting performance of the lithium battery flexible package material are improved, and a lithium battery has stability for long-time use.

Owner:EAST CHINA UNIV OF SCI & TECH

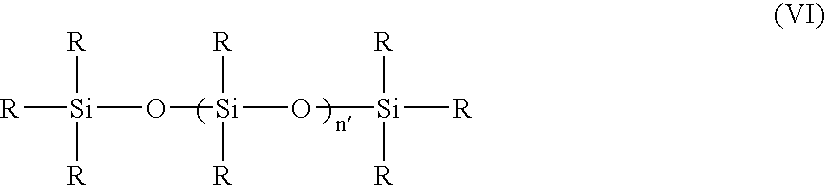

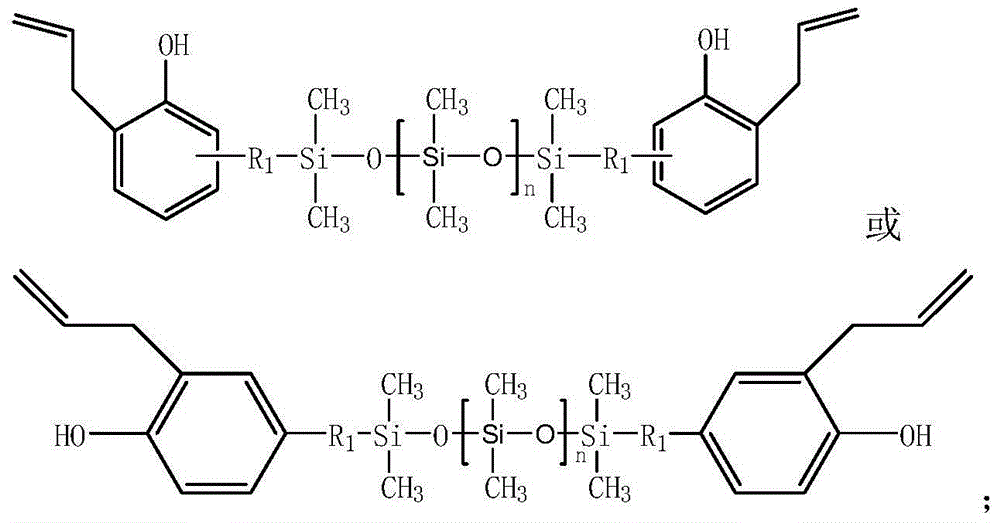

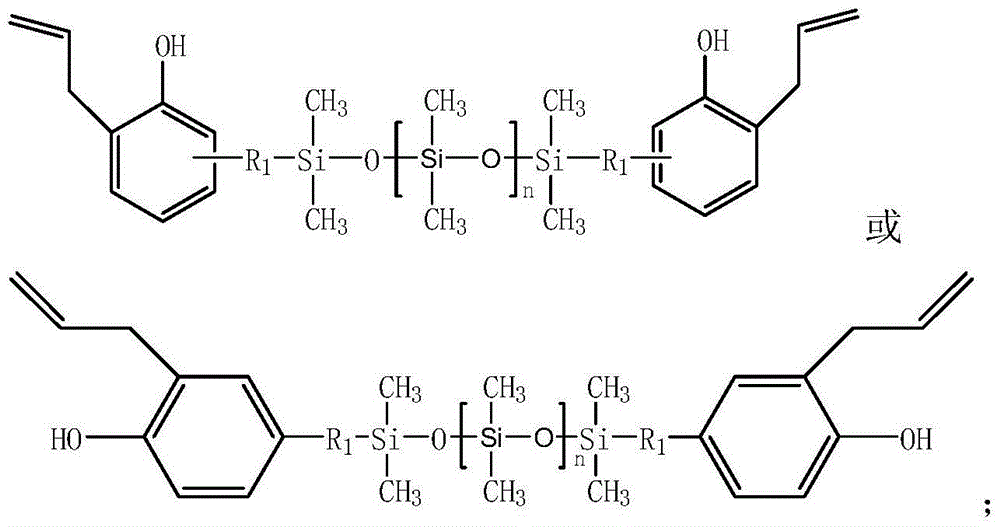

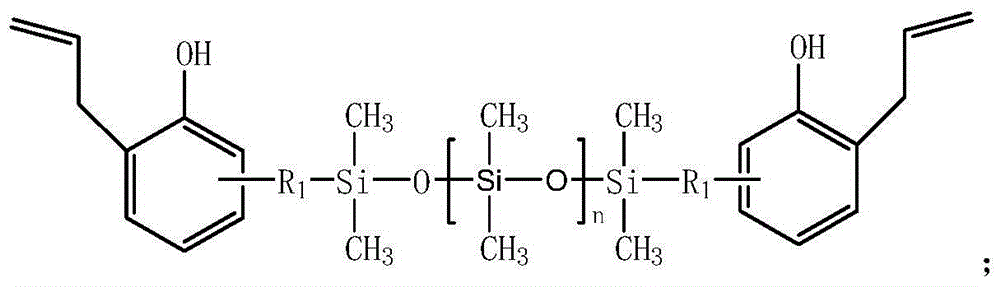

Resin composition and prepreg laminated board manufactured by employing same

InactiveCN104830059AImprove performanceGood thermal expansion performanceSynthetic resin layered productsMetal layered productsThermal expansionSilorane Resins

The invention discloses a resin composition which comprises the following solids by weight: (a) 100 parts of a bismaleimide resin prepolymer, (b) 5-80 parts of cyanate ester, (c) 0-50 parts of a flame retardant and (d) 0-65 parts of inorganic filler, wherein the bismaleimide resin prepolymer is obtained by carrying out reaction on an allyl compound and bismaleimide resin and the ratio of bismaleimide resin and allyl compound by weight is 100: (10-120). According to the resin composition disclosed by the invention, by adopting siloxane containing allyl at the tail end as a modifier of bismaleimide resin and limiting the content of siloxane in the modifier, unreacted siloxane resin is not generated in reaction, so that the advantages and characteristics of siloxane resin can be fully exerted and the interlaminar adhesive force at the high temperature is greatly improved. Moreover, the thermal expansion properties of the solids are optimized, so that the resin composition satisfies the requirements on high precision electronic substrate materials.

Owner:SHENGYI TECH SUZHOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com