Method of electrochemically fabricating multilayer structures having improved interlayer adhesion

a multi-layer structure and electrochemical technology, applied in the field of three-dimensional structure formation, can solve the problems of destructive separation of masking material from substrate, and achieve the effect of improving the properties of fabricated structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

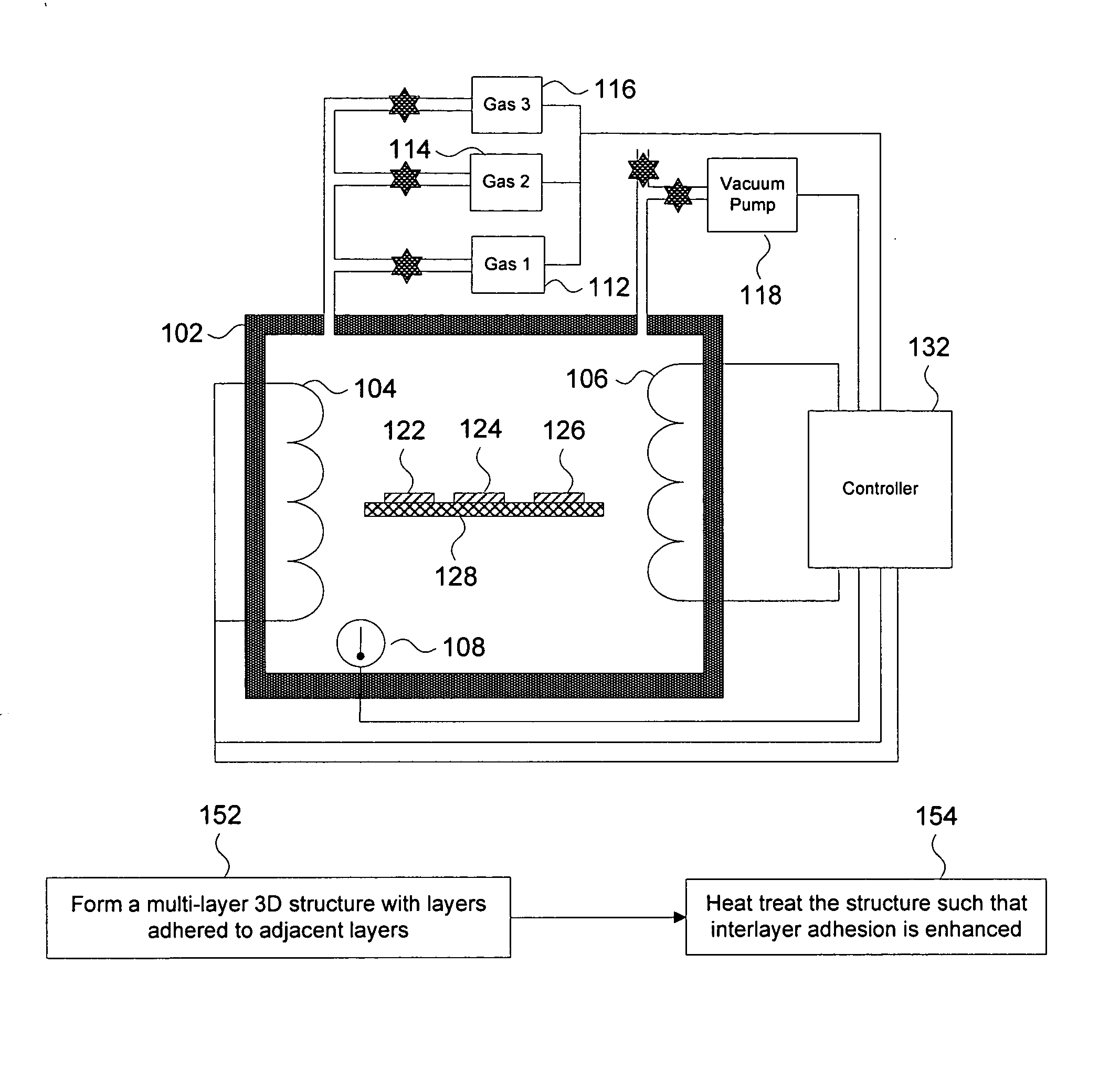

[0097]FIG. 6 depicts a block diagram of the invention where a multilayer three-dimensional structure is formed and then heat treated such that, for example, interlayer adhesion is improved. Element 152 of FIG. 6 calls for the formation of a multi-layer structure from a plurality of adhered layers. This formation process may involve one of the electrochemical fabrication processes discussed above, one of the fabrication processes incorporated herein by reference or some other fabrication process that results in layers being formed on previously formed layers and adhered thereto. After formation of the structure the process moves forward to element 154 which calls for the supplying of a heat treatment to the structure such that interlayer adhesion, for example, is enhanced. The heat treatment may be applied by a heating system such as that illustrated in FIG. 5, or it may be applied in a different manner. The heat treatment is applied at a temperature and for a time that results in a ...

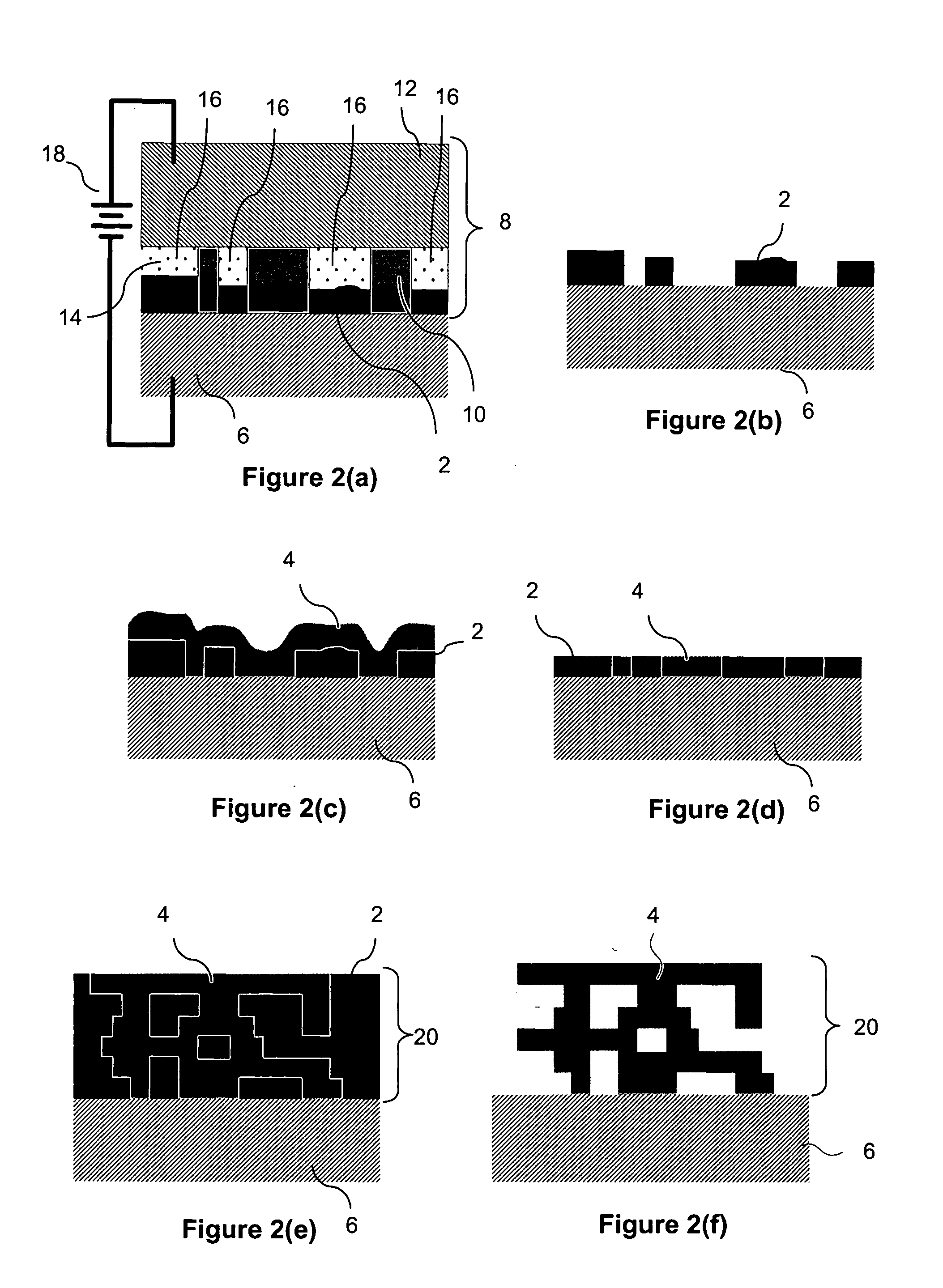

second embodiment

[0098]FIG. 7 depicts a block diagram of the invention where the formation of a multilayer three-dimensional structure includes an operation to planarize deposited layers of material and wherein the structure is subjected to heat treatment after formation. Element 162 of FIG. 7 calls for the formation of a three-dimensional structure which includes a plurality of adhered layers. The formation process will include the depositing of at least one material onto a substrate or previously formed layer such that at least a portion of the layer is formed. Then at least a portion of the deposited material is removed to obtain a planarized surface that may form an outward facing portion of the structure or alternatively it may form a surface onto which additional material may be adhered. Planarization may occur for example by lapping, polishing, chemical mechanical polishing, milling, diamond fly cutting, or the like. After the depositing and removing of material to form a first layer or porti...

third embodiment

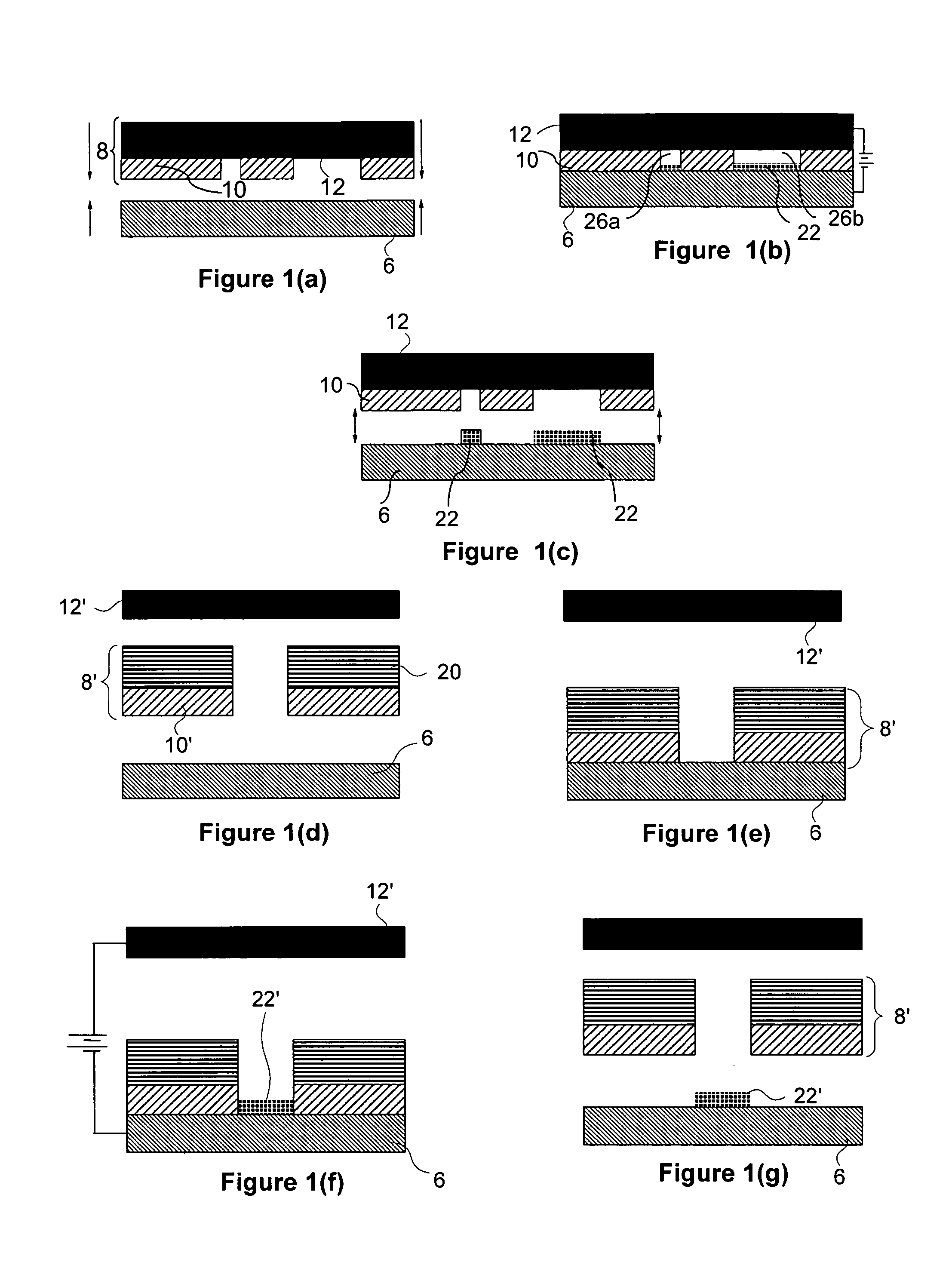

[0099]FIG. 8 depicts a block diagram of the invention wherein the formation of a multi-layer structure includes subsequently patterned layers of material that are adhered directly to immediately preceding patterned layers of material and wherein the structure is subjected to heat treatment after formation. Element 172 of FIG. 8 calls for the formation of a three-dimensional structure from a plurality of adhered layers. The first operation involves the forming of a first layer from a deposit of at least one material where the material has a patterned configuration. The material may be deposited in a patterned manner or it may be deposited in a blanket fashion where patterning occurs after deposition. The formation of the first layer may include the deposition of a second material or further materials, it may also include removal operations for the purpose of patterning or the purpose of planarization, and / or it may also include other operations such as cleaning operations, activation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com