Single-component water-based natural drying finishing coat for construction crane and preparation method thereof

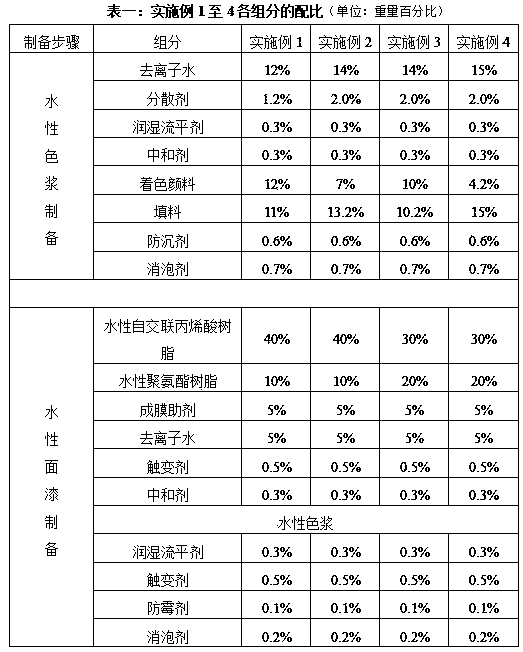

A crane, one-component technology, applied in the direction of anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., to achieve the effects of strong construction adaptability, excellent water resistance, and excellent aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

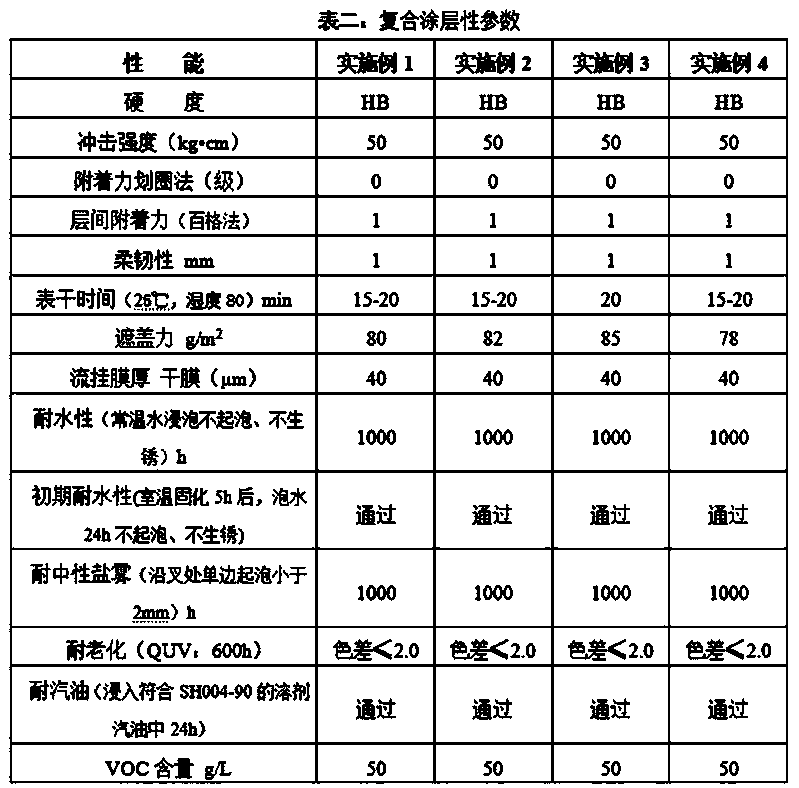

Examples

Embodiment 1

[0046] (1) Add part of deionized water, dispersant Dispersogen DIP, wetting agent and leveling agent surfynol 104DPM, 1 / 2 neutralizing agent ammonia water into the stirring tank, and then add colored pigment titanium dioxide and filler precipitated barium sulfate under stirring conditions , glass powder, anti-sedimentation agent fumed silica N20, after stirring evenly, add some defoamer GS-D101, disperse at high speed, then transfer to a sand mill to grind to a fineness of less than 15 microns, and obtain a pH value of 8.0-9.0 Water-based color paste.

[0047] (2) Add water-based self-crosslinking acrylic emulsion MAINCOTE into the stirring tank TM 1100A and auxiliary water-based polyurethane resin U4190, stir evenly, and dilute the film-forming aids dipropylene glycol butyl ether and propylene glycol butyl ether (ratio 7:3) with some deionized water, and then add it to the above water-based resin mixture under stirring conditions , then add 1 / 2 of the thixotropic agent SAMAS...

Embodiment 2

[0049] (1) Take part of deionized water, dispersant Solsperse 47000 and ZETASPERSE 3700 (mixing ratio 2:1), wetting agent leveling agent GS-850DPM, 1 / 2 neutralizing agent ammonia water into the stirring tank, and then stir Under the conditions, add coloring pigment organic scarlet F3RK and PR02, filler precipitated barium sulfate, glass powder, wollastonite, anti-sedimentation agent fumed silica T40, stir evenly, add part of defoamer GS-D101, disperse at high speed, and then transfer to Grinding with a sand mill to a fineness of less than 15 microns to obtain a water-based color paste with a pH value of 8.0-9.0.

[0050] (2) Add water-based self-crosslinking acrylic emulsion MAINCOTE into the stirring tank TM 1100A and auxiliary water-based polyurethane resin U4190, stir evenly, dilute the film-forming aids dipropylene glycol butyl ether and propylene glycol butyl ether (ratio 7:3) with the remaining deionized water, and then add it to the above water-based resin mixture under...

Embodiment 3

[0052] (1) Take part of deionized water, dispersant Dispersogen PTS and ZETASPERSE 3400 (mixing ratio 2:1), wetting agent leveling agent GS-850DPM, neutralizer AMP-95 into the stirring tank, and then under stirring conditions Next, add coloring pigment organic rhubarb PO-1304 and PY-1238, filler precipitated barium sulfate, glass powder, wollastonite, anti-sedimentation agent fumed silica AEROSIL 200, stir well, add defoamer GS-D101, and disperse at high speed , and then transferred to a sand mill to grind to a fineness of less than 15 microns to obtain a water-based color paste with a pH value of 8.0-9.0.

[0053] (2) Add water-based self-crosslinking acrylic emulsion YG A-51 and auxiliary water-based polyurethane resin CPT8240 into the stirring tank, stir evenly, and dilute the film-forming aids dipropylene glycol butyl ether and propylene glycol butyl ether with the remaining deionized water (ratio 7 : 3), and then added to the above water-based resin mixture under stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com