Patents

Literature

90results about How to "Low layer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

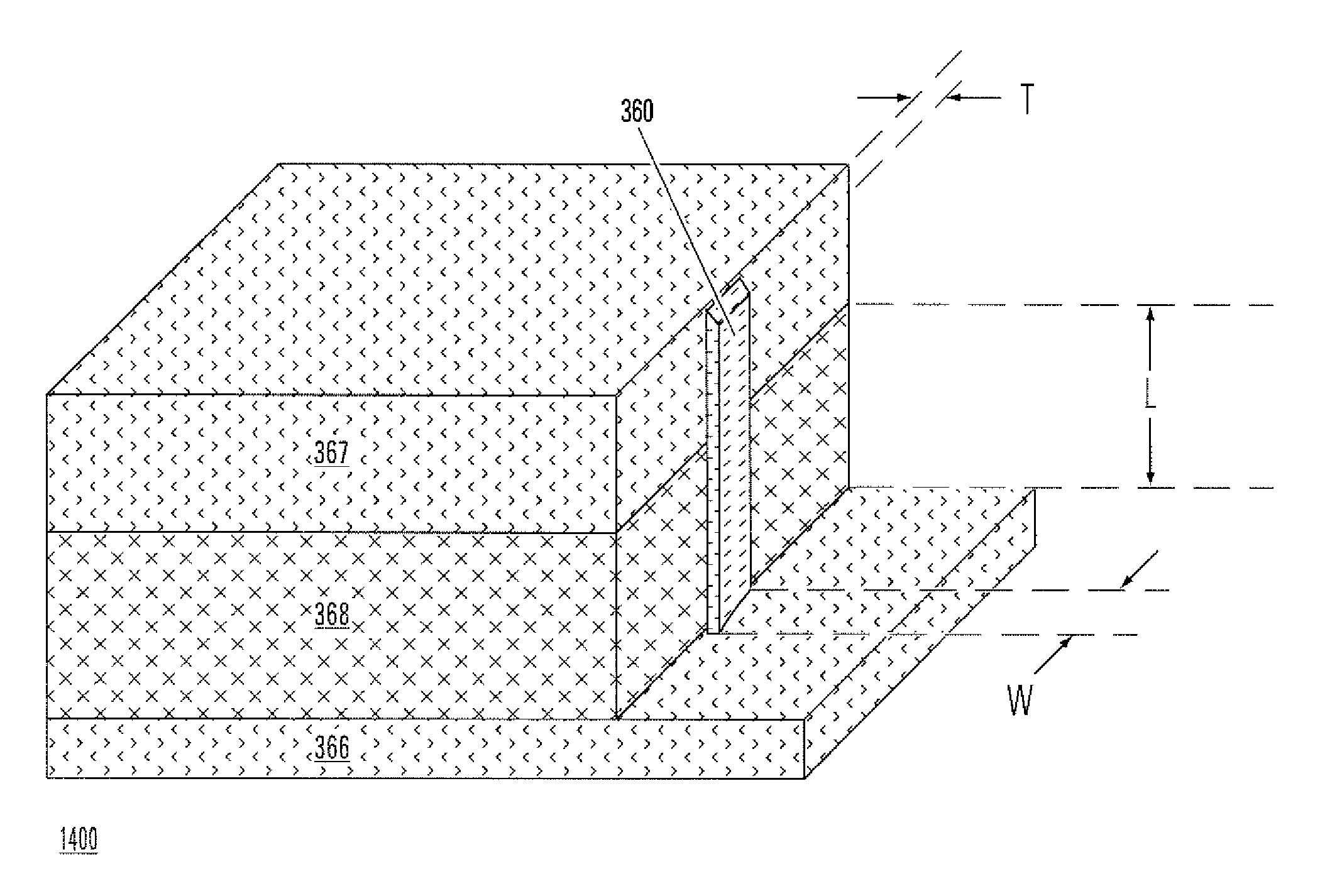

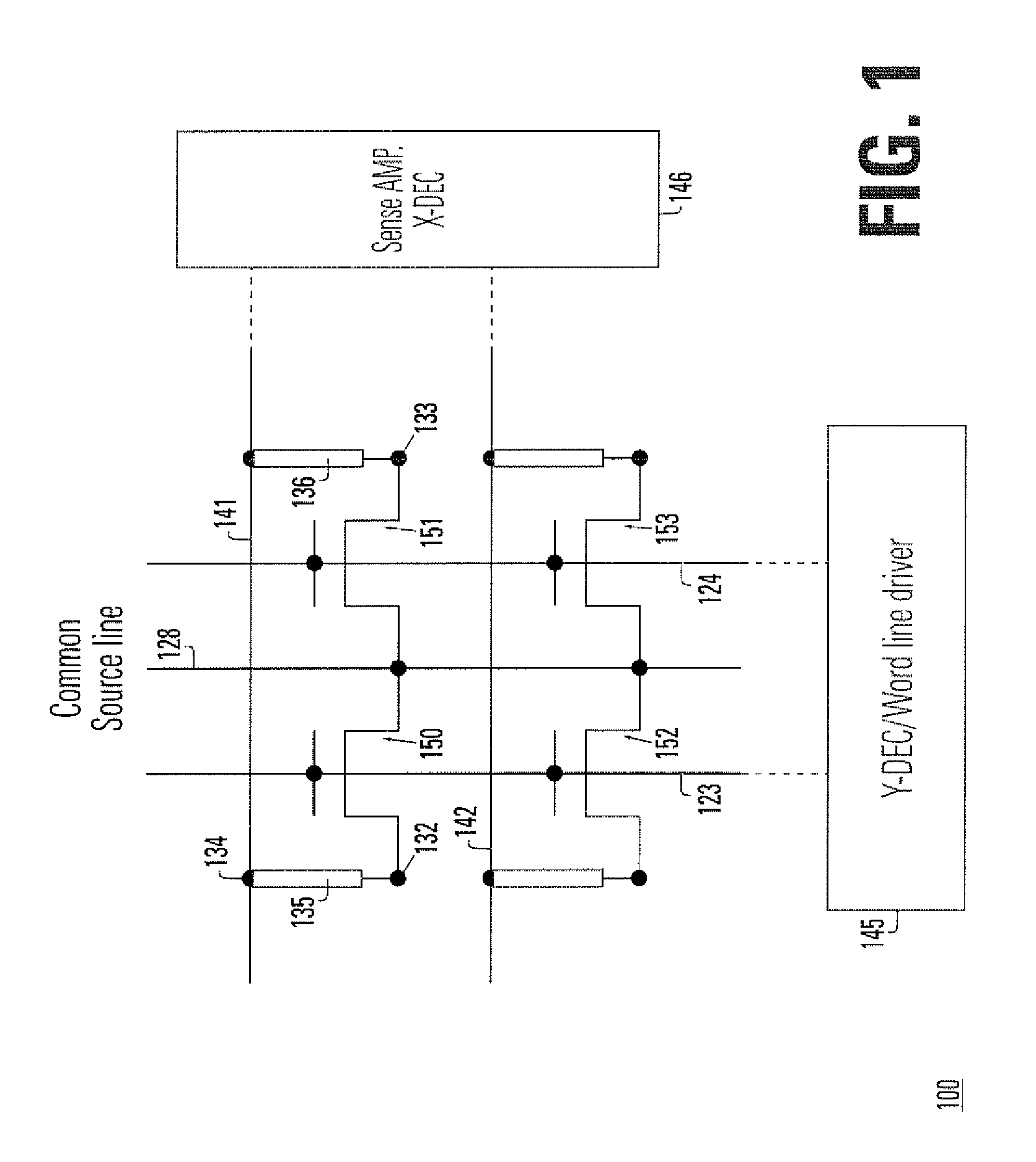

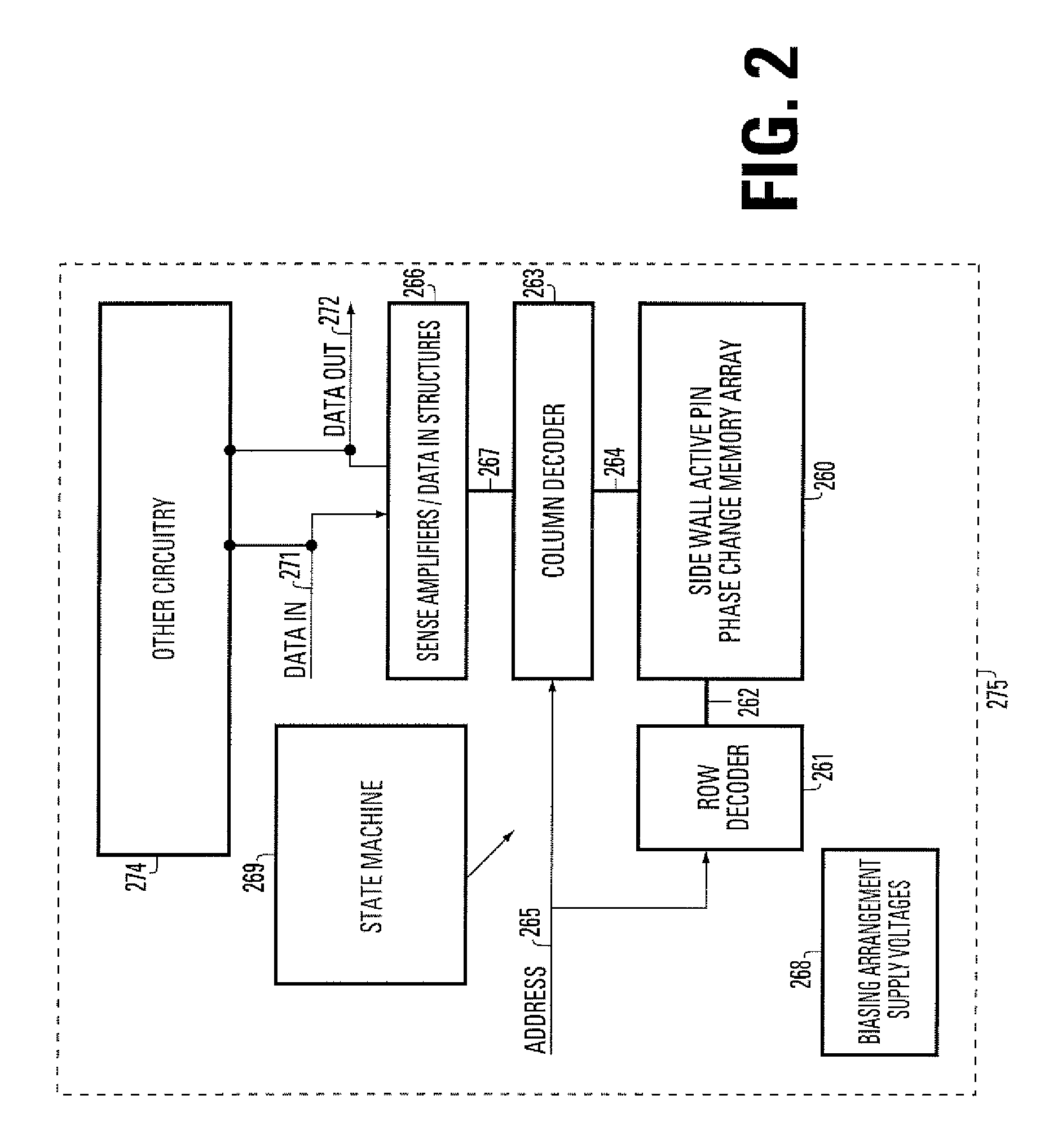

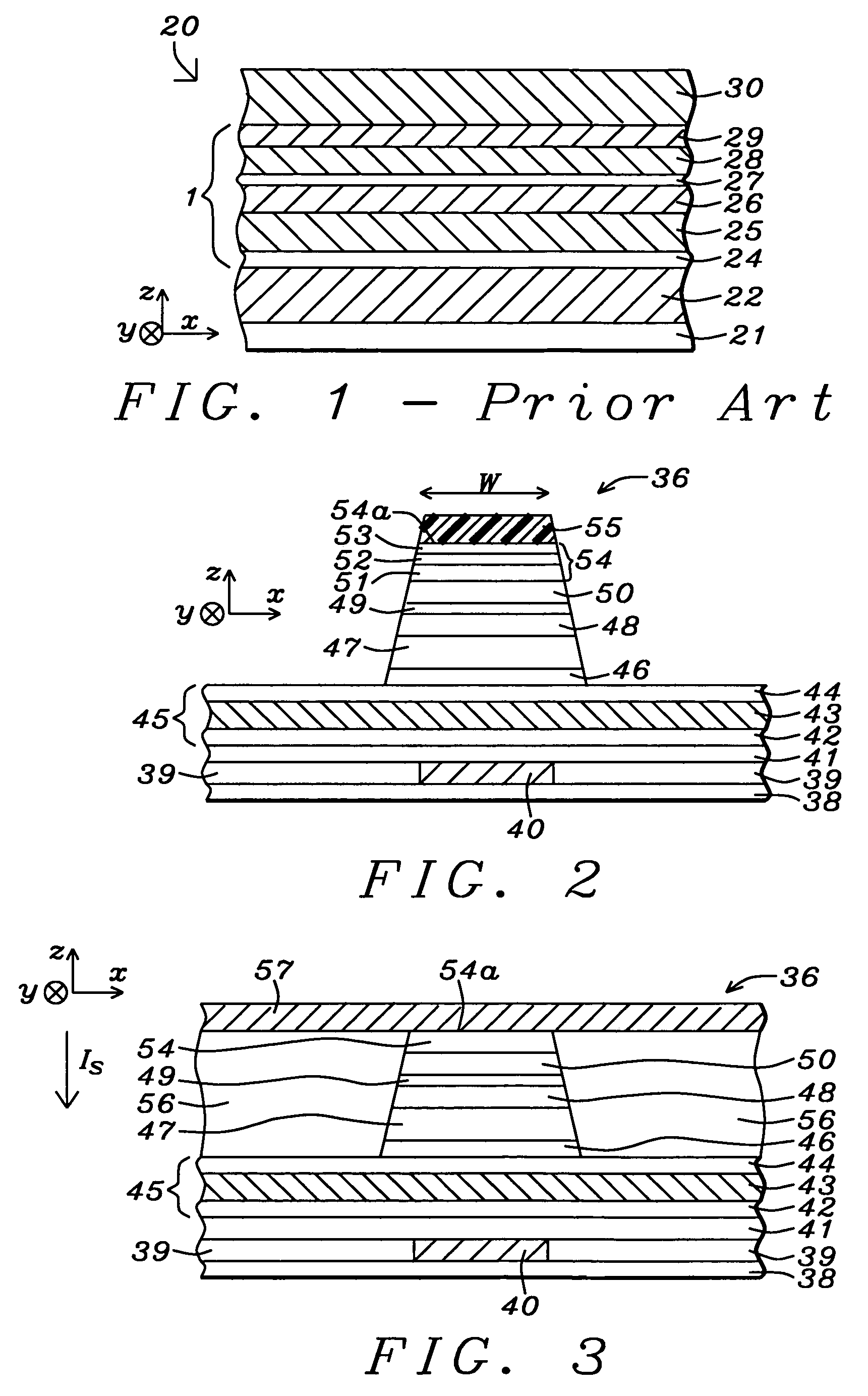

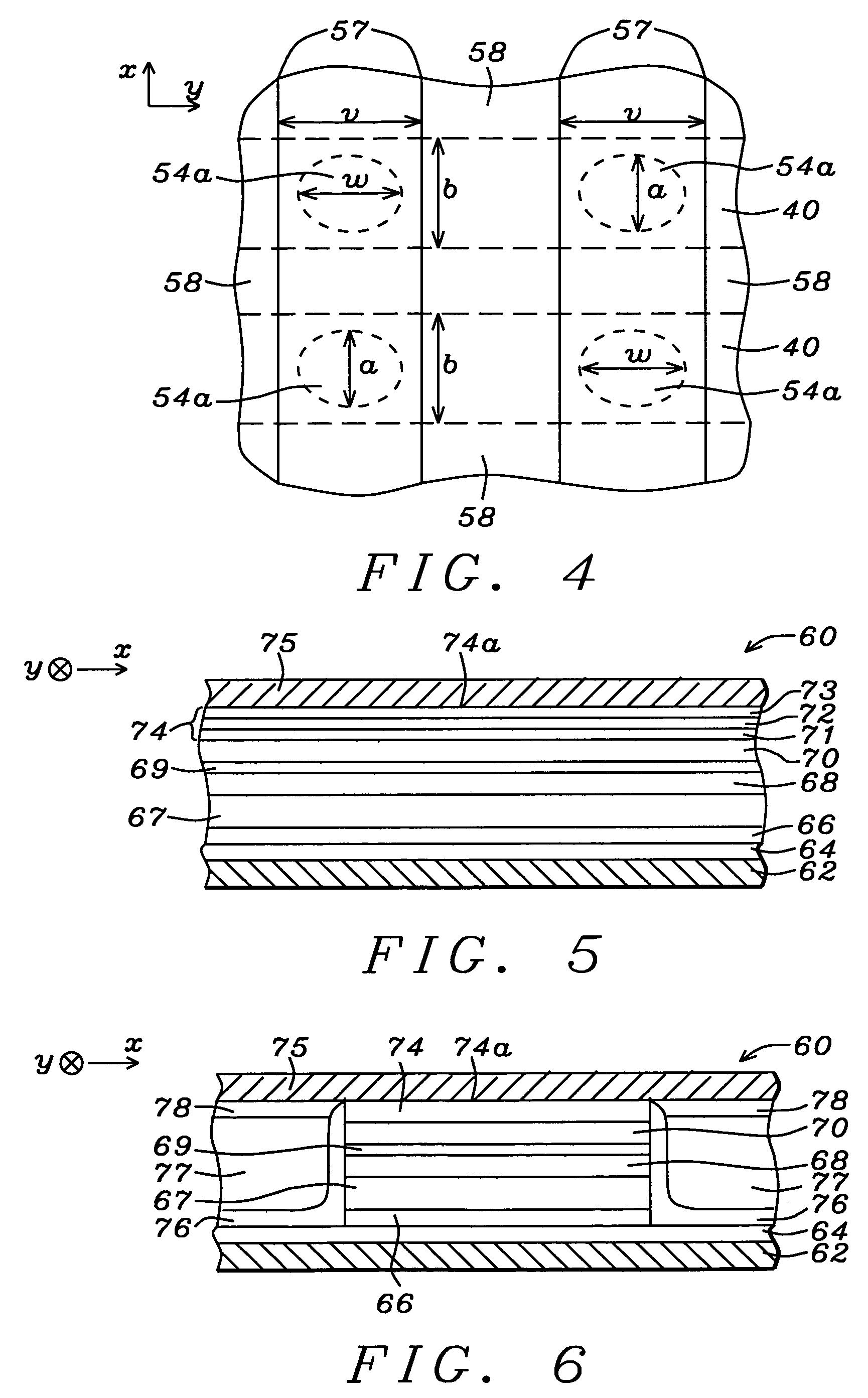

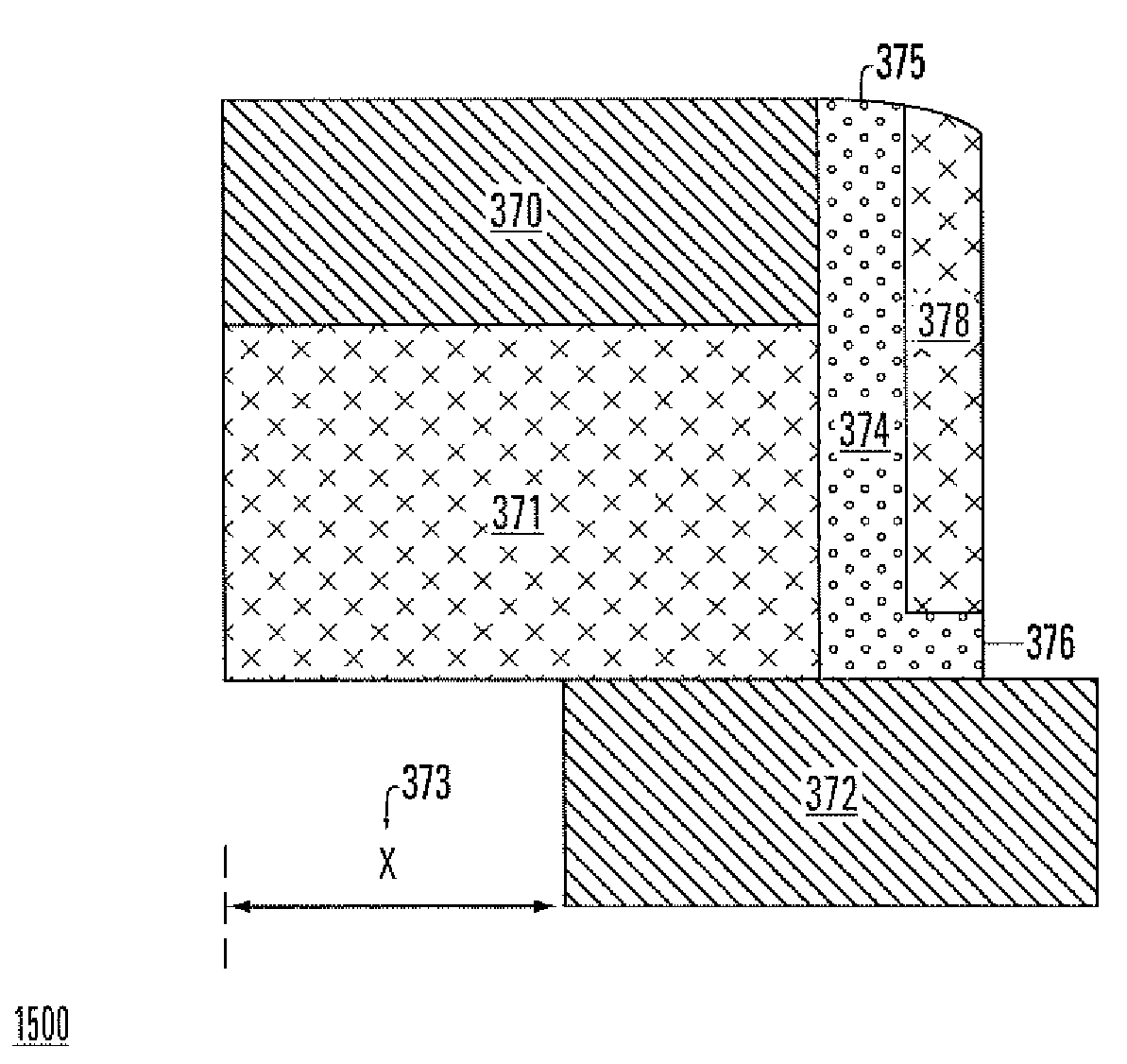

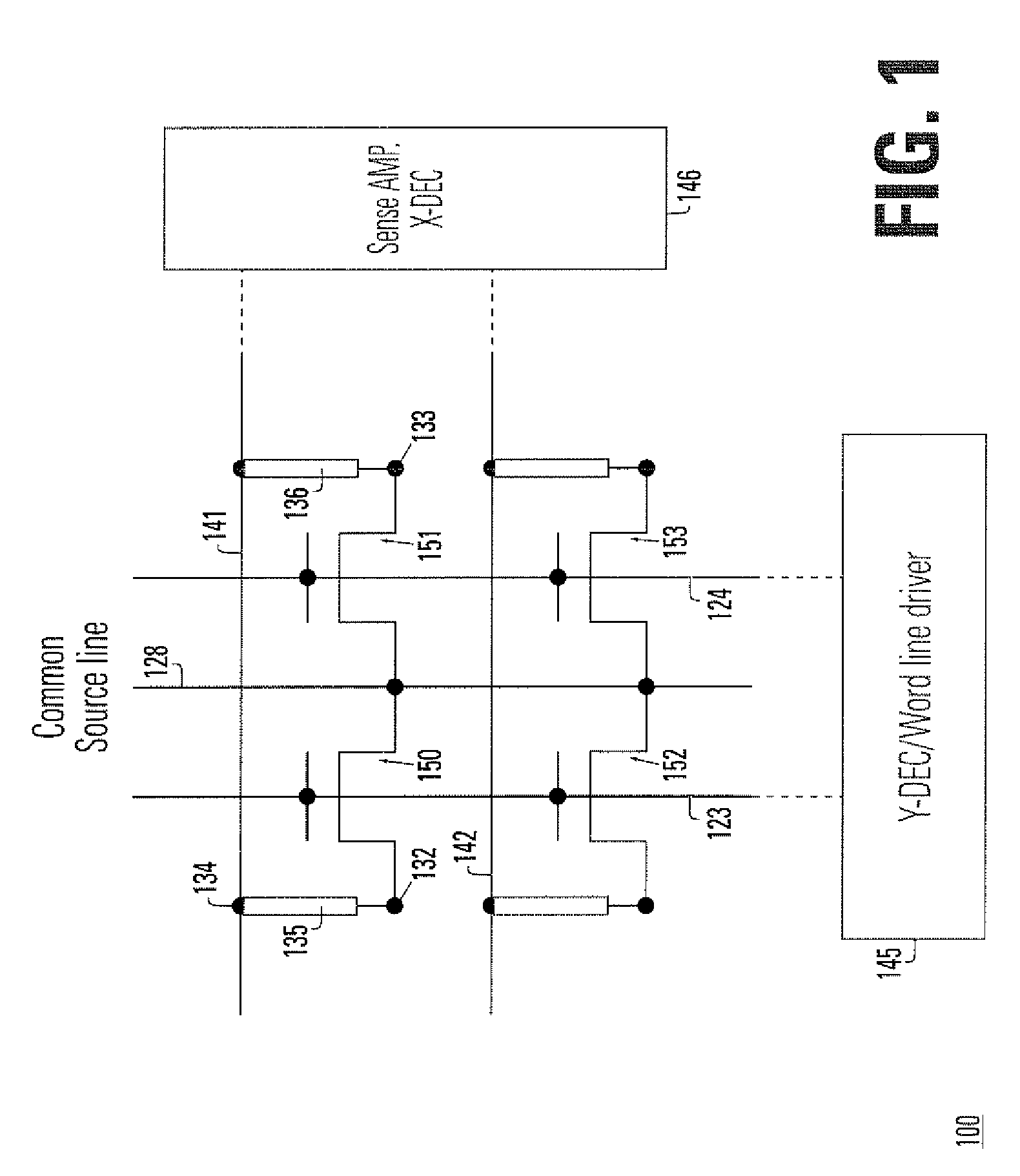

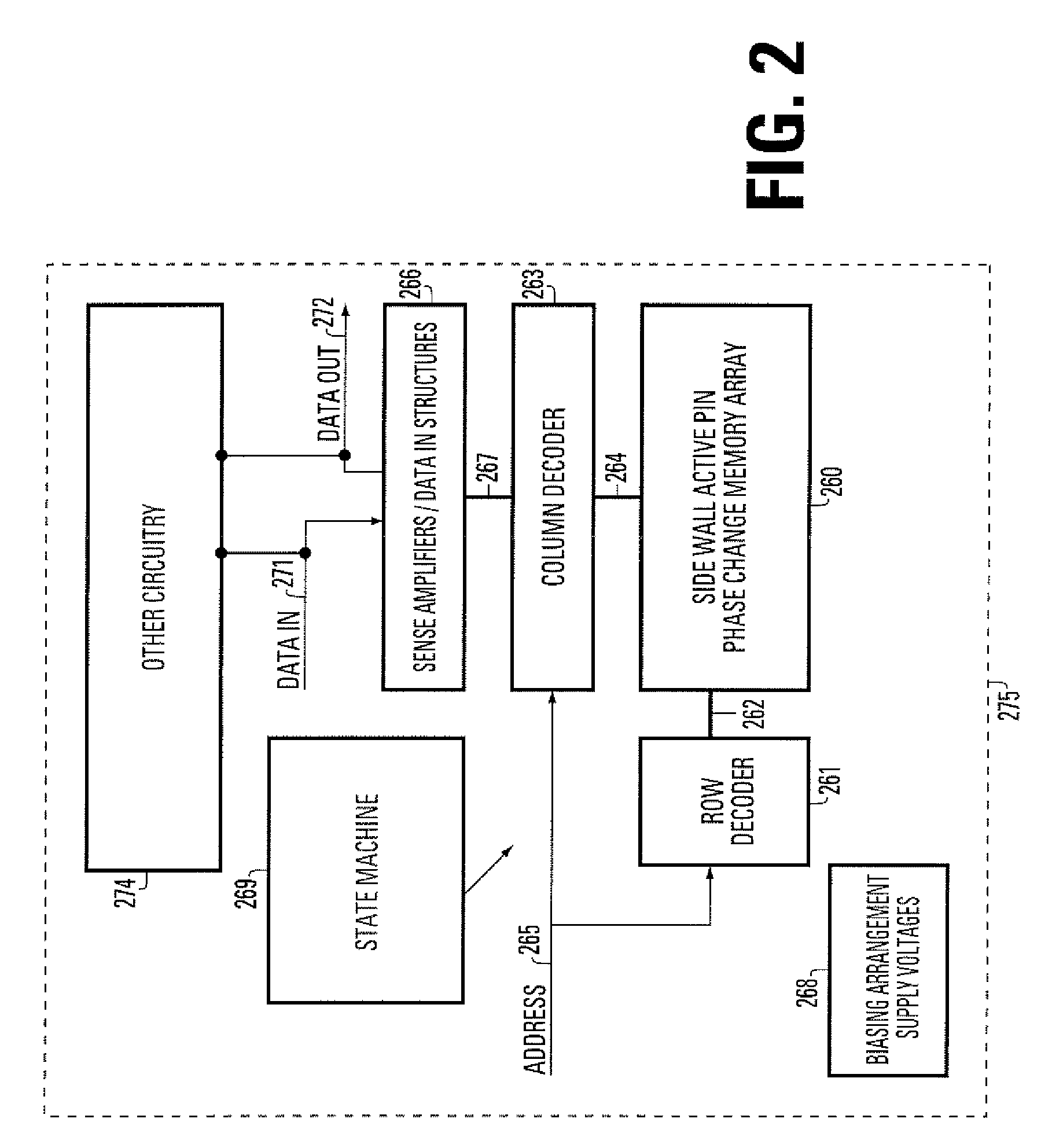

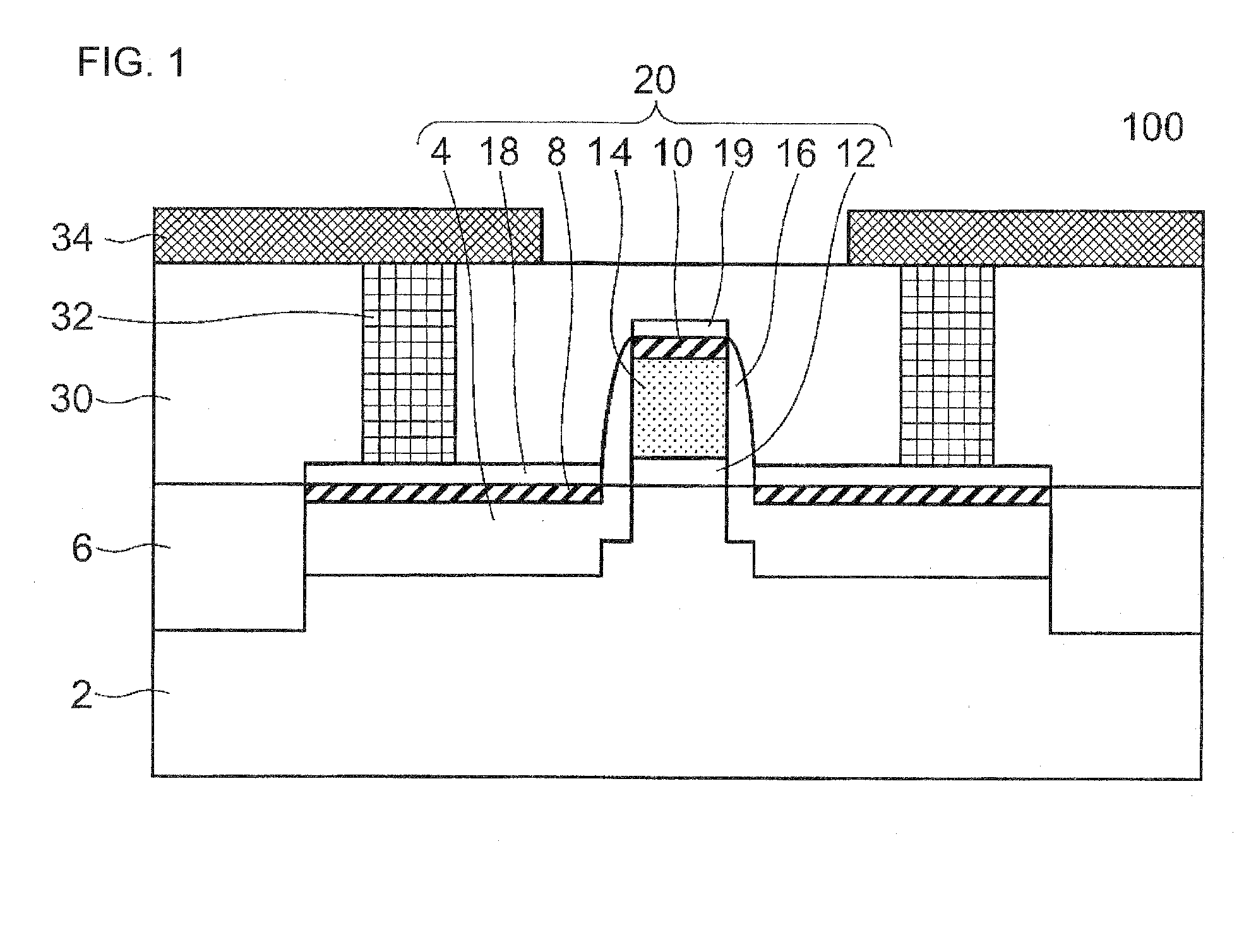

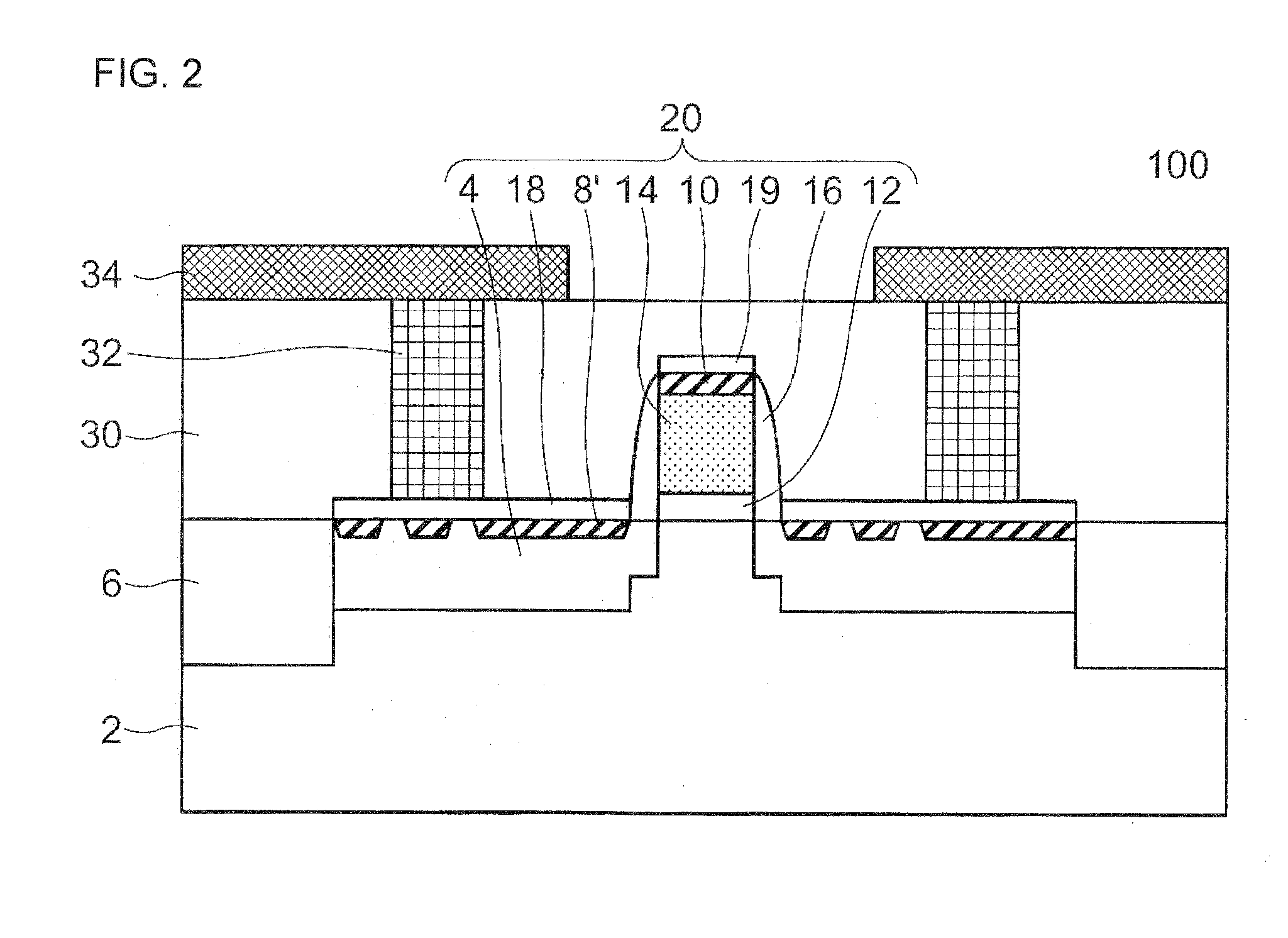

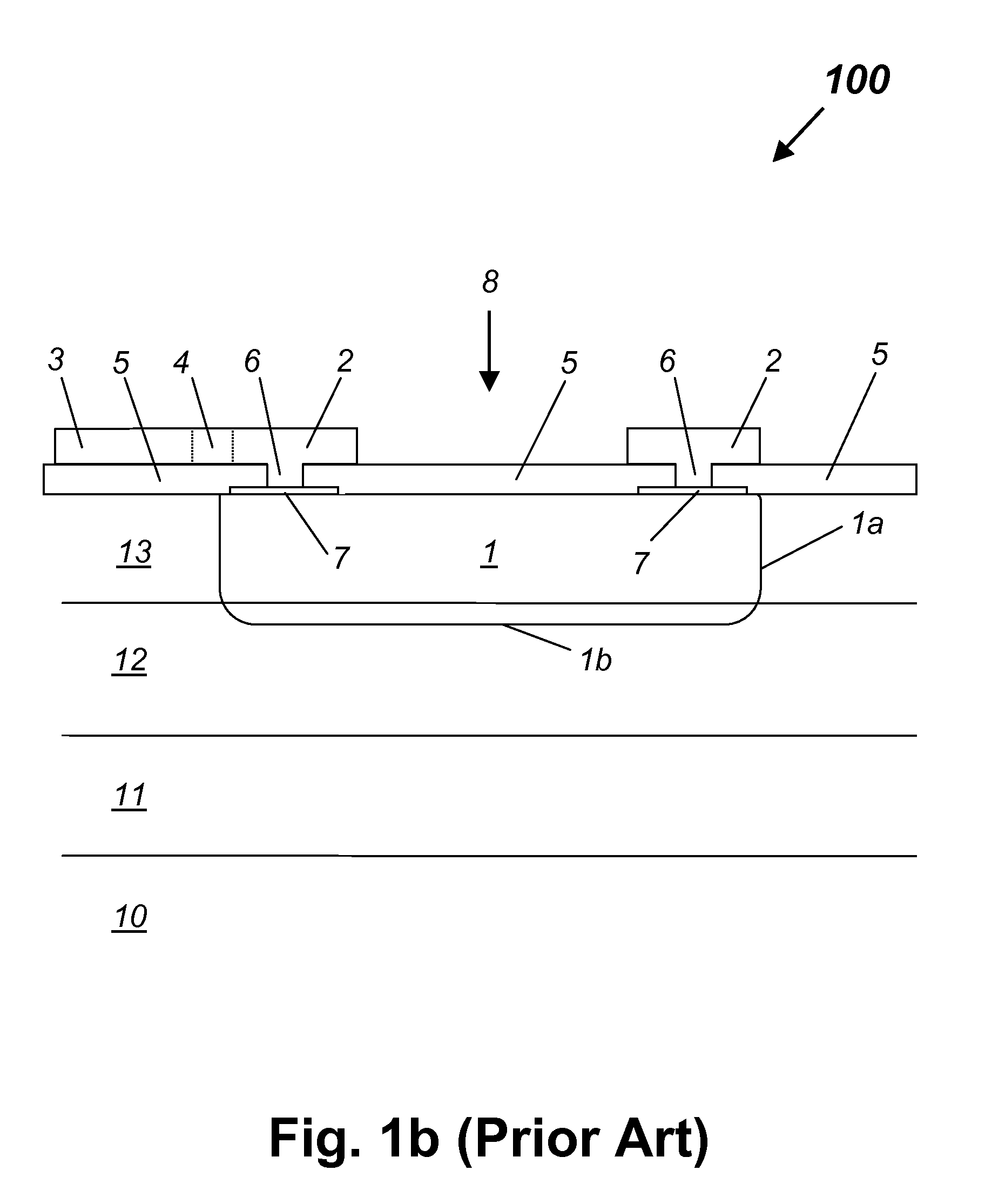

Vertical Side Wall Active Pin Structures in a Phase Change Memory and Manufacturing Methods

ActiveUS20070176261A1Reduce electrical currentLow resistivitySolid-state devicesSemiconductor devicesEngineeringPhase-change material

A programmable resistor memory, such as a phase change memory, with a memory element comprising narrow vertical side wall active pins is described. The side wall active pins comprise a programmable resistive material, such as a phase change material. In a first aspect of the invention, a method of forming a memory cell is described which comprises forming a stack comprising a first electrode having a principal surface with a perimeter, an insulating layer overlying a portion of the principal surface of the first electrode, and a second electrode vertically separated from the first electrode and overlying the insulating layer. Side walls on the insulating layer and on the second electrode are positioned over the principle surface of the first electrode with a lateral offset from the perimeter of the first electrode.

Owner:MACRONIX INT CO LTD

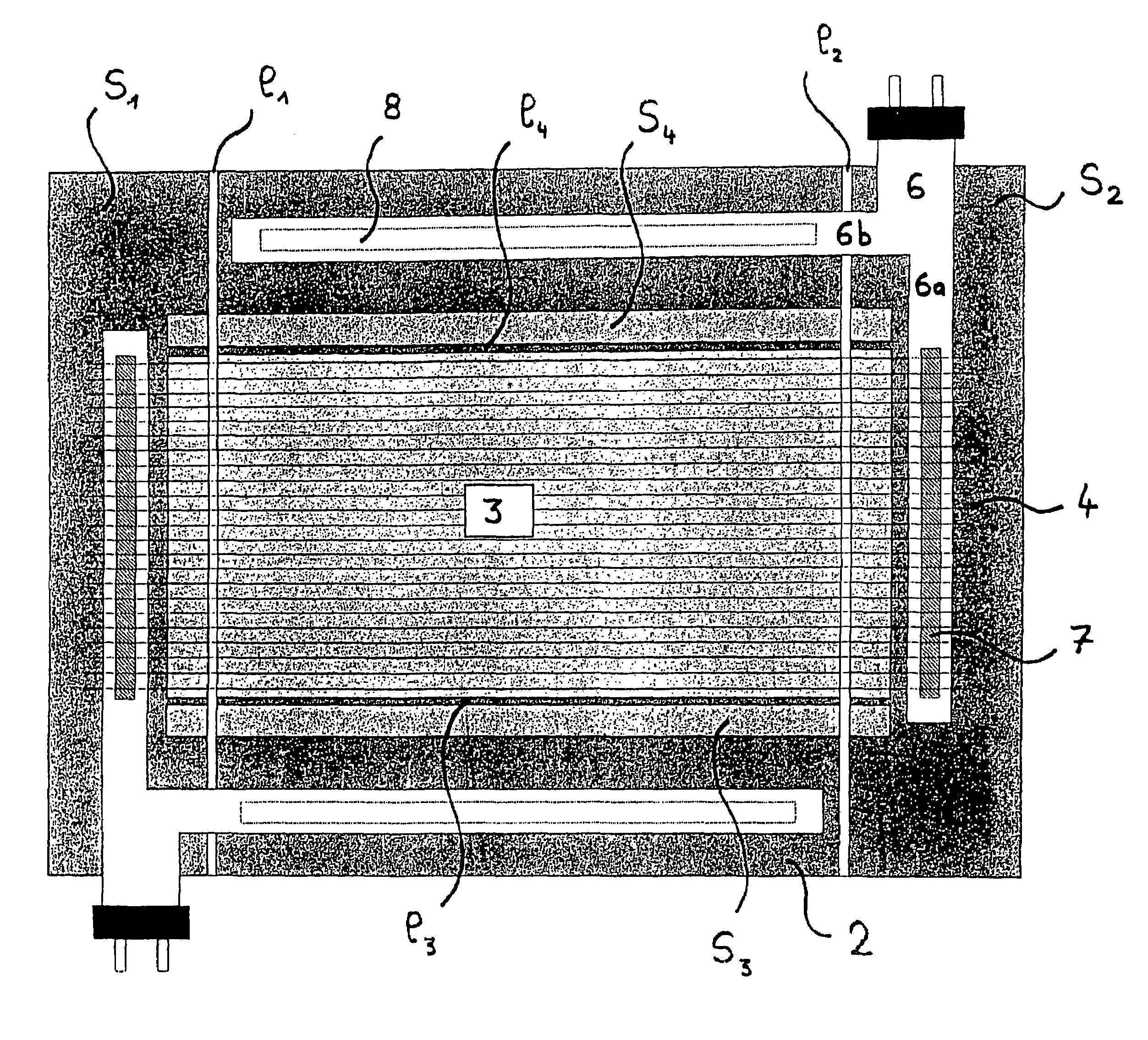

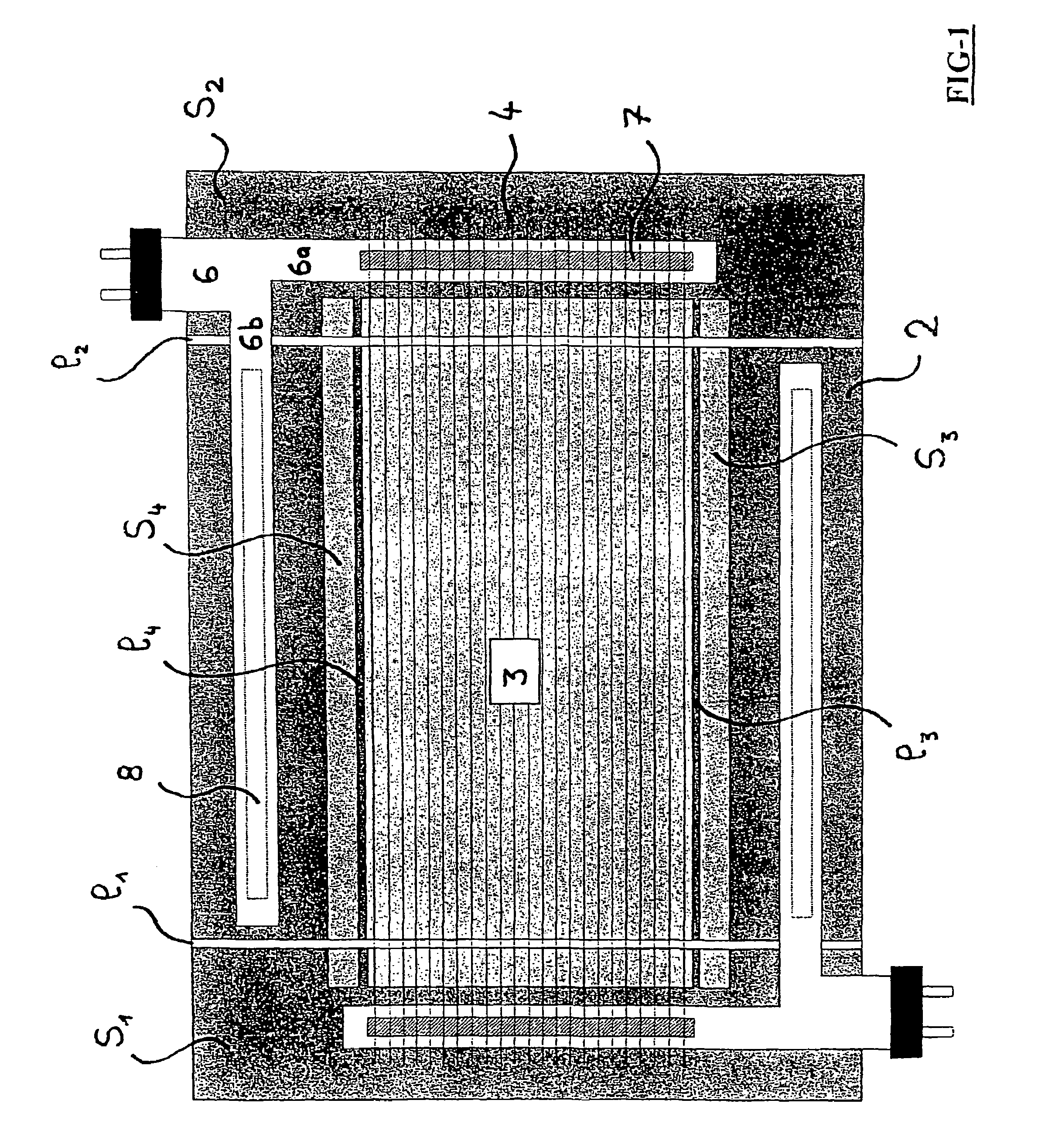

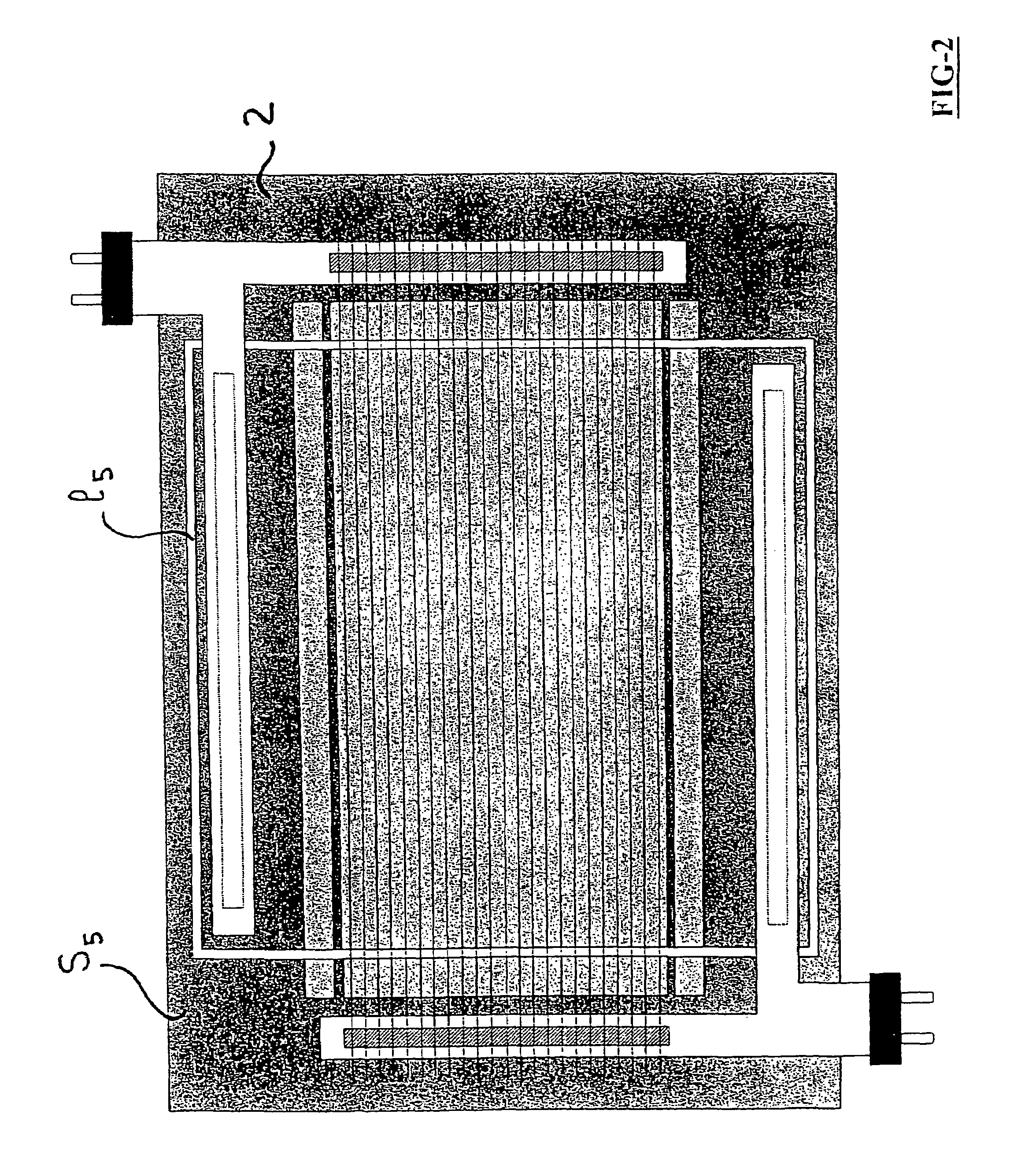

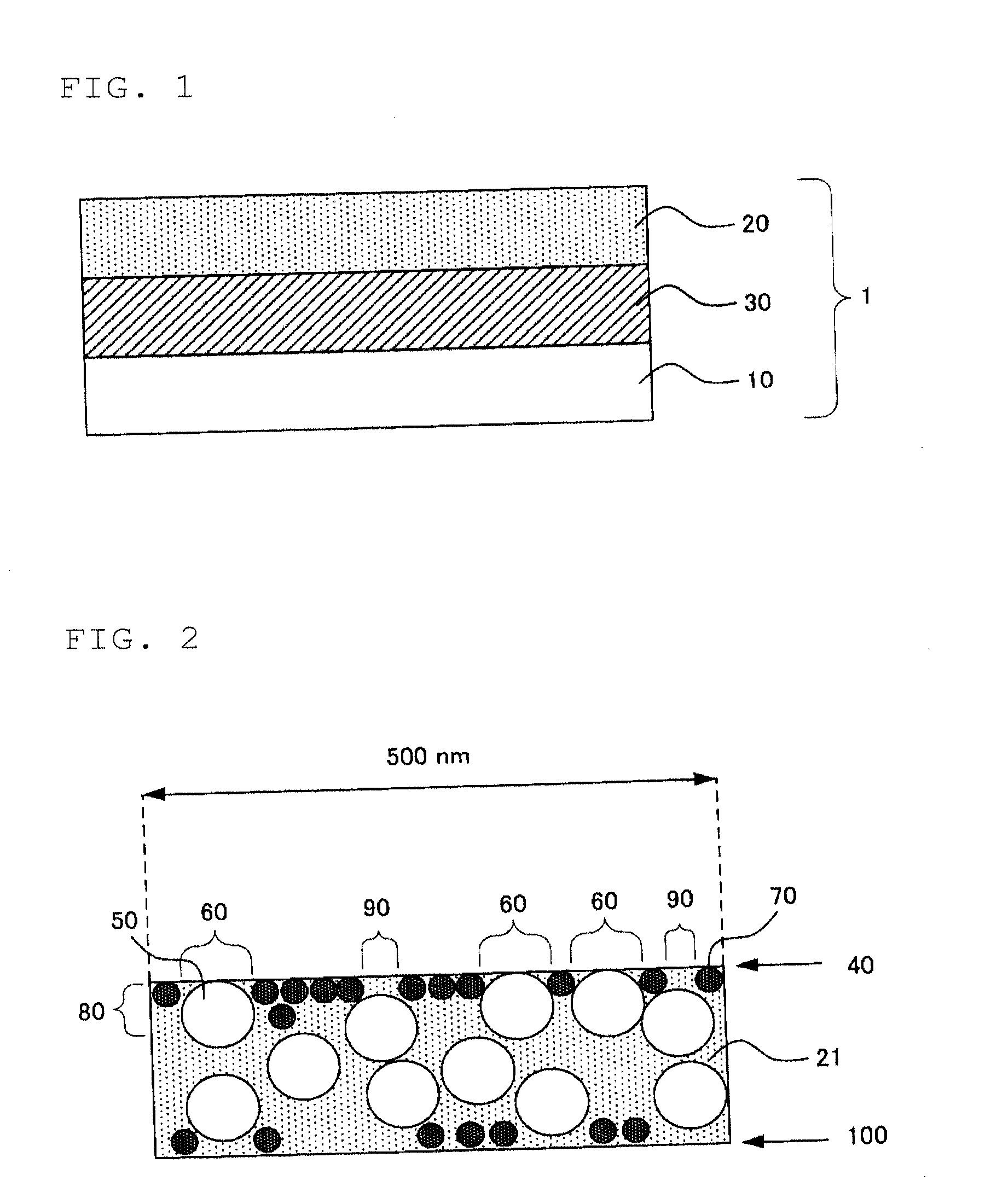

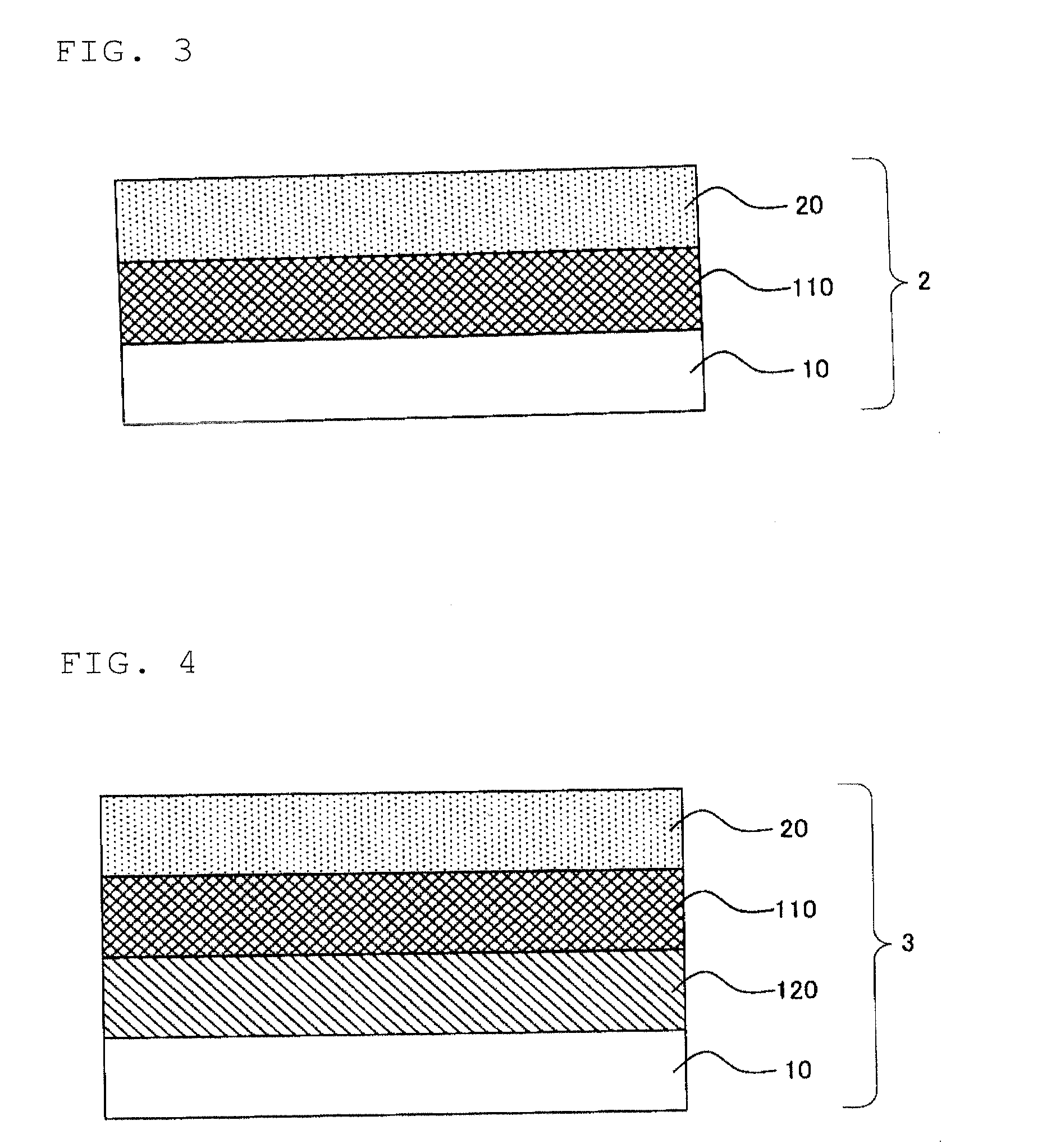

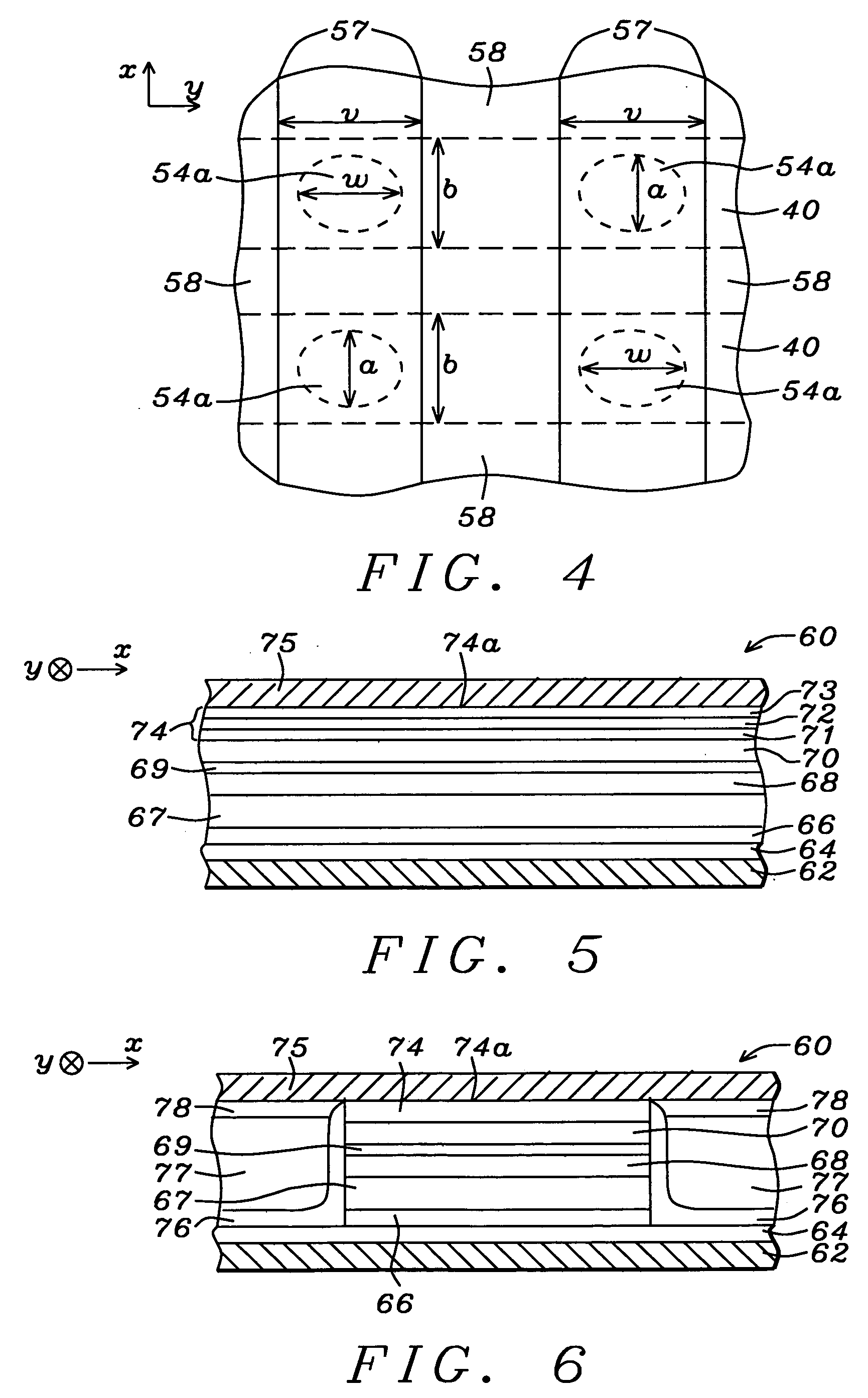

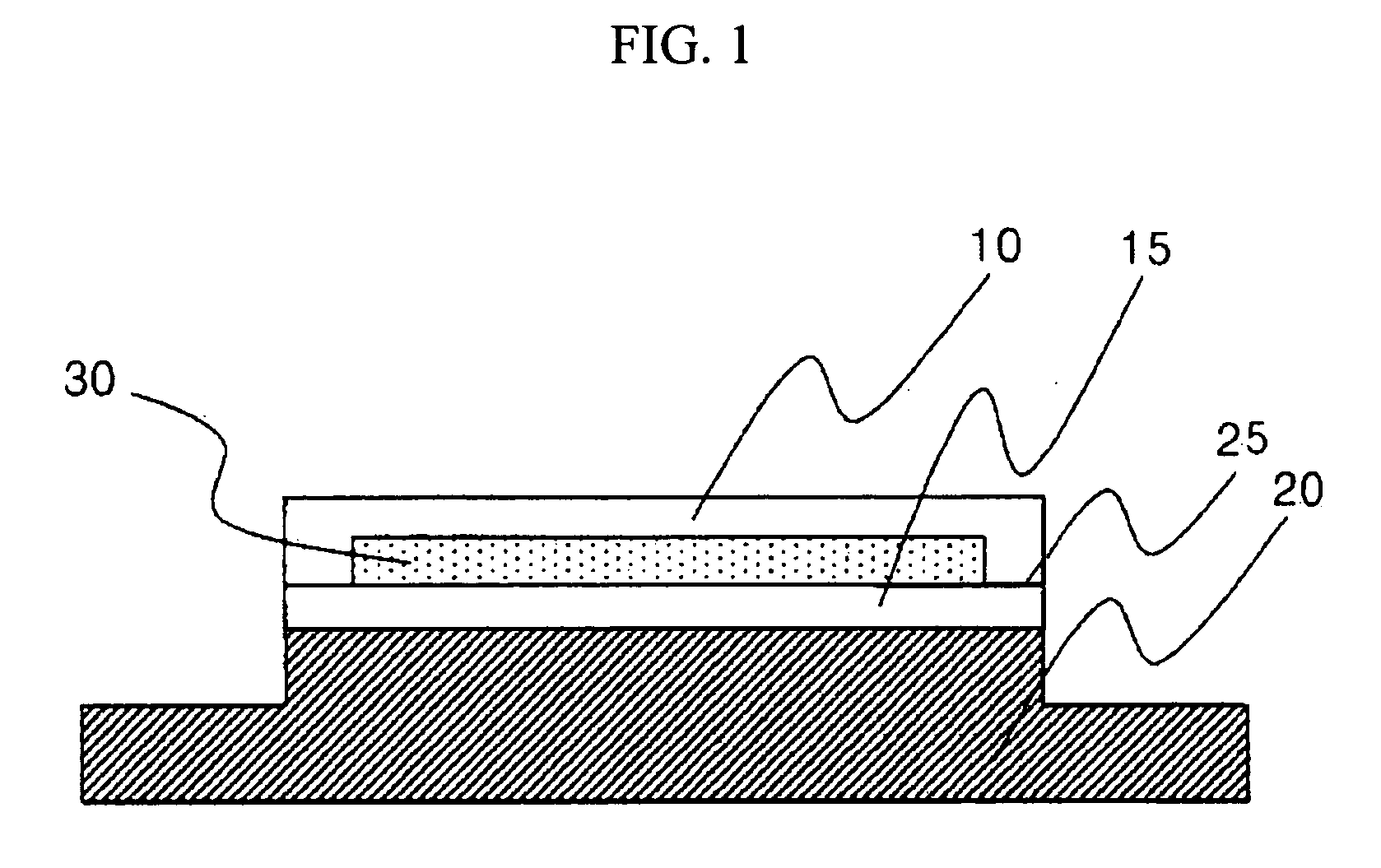

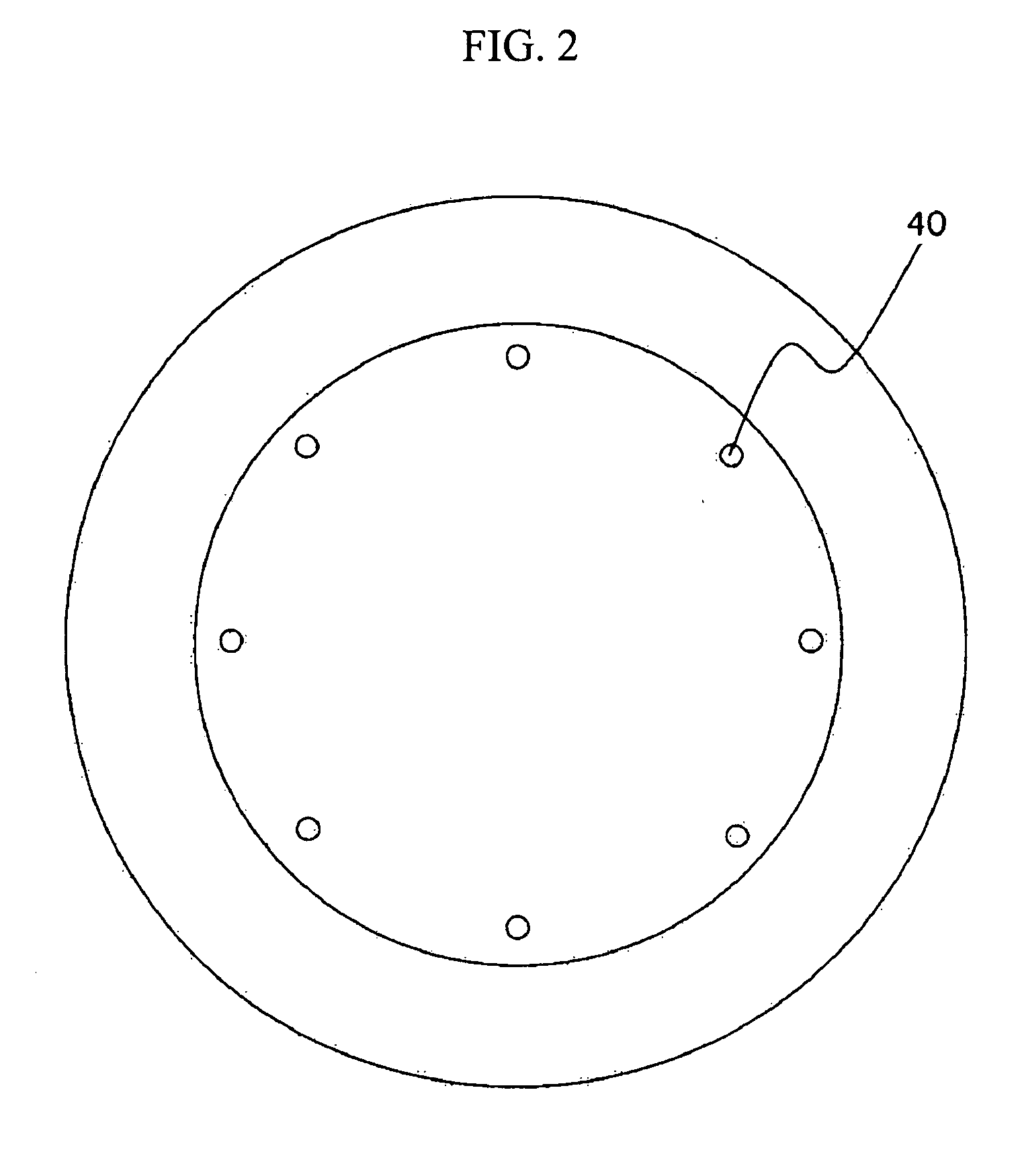

Electrochemical device such as electrochromic or photovoltaic device and electrical connection means thereof

InactiveUS7230748B2Smooth connectionSimple and flexible implementationElectrode carriers/collectorsSecondary cellsElectricityOptical property

An electrochemical device, especially an electrically controllable system with variable energy and / or optical properties or a photovoltaic device, including at least one substrate carrying an electroactive stack of layers arranged between a lower electrode and an upper electrode. Each electrode includes at least one electroconductive layer in electrical contact with at least one current lead. The current leads are arranged outside the region of the carrier substrate that is covered by the stack of electroactive layers.

Owner:SAINT-GOBAIN GLASS FRANCE

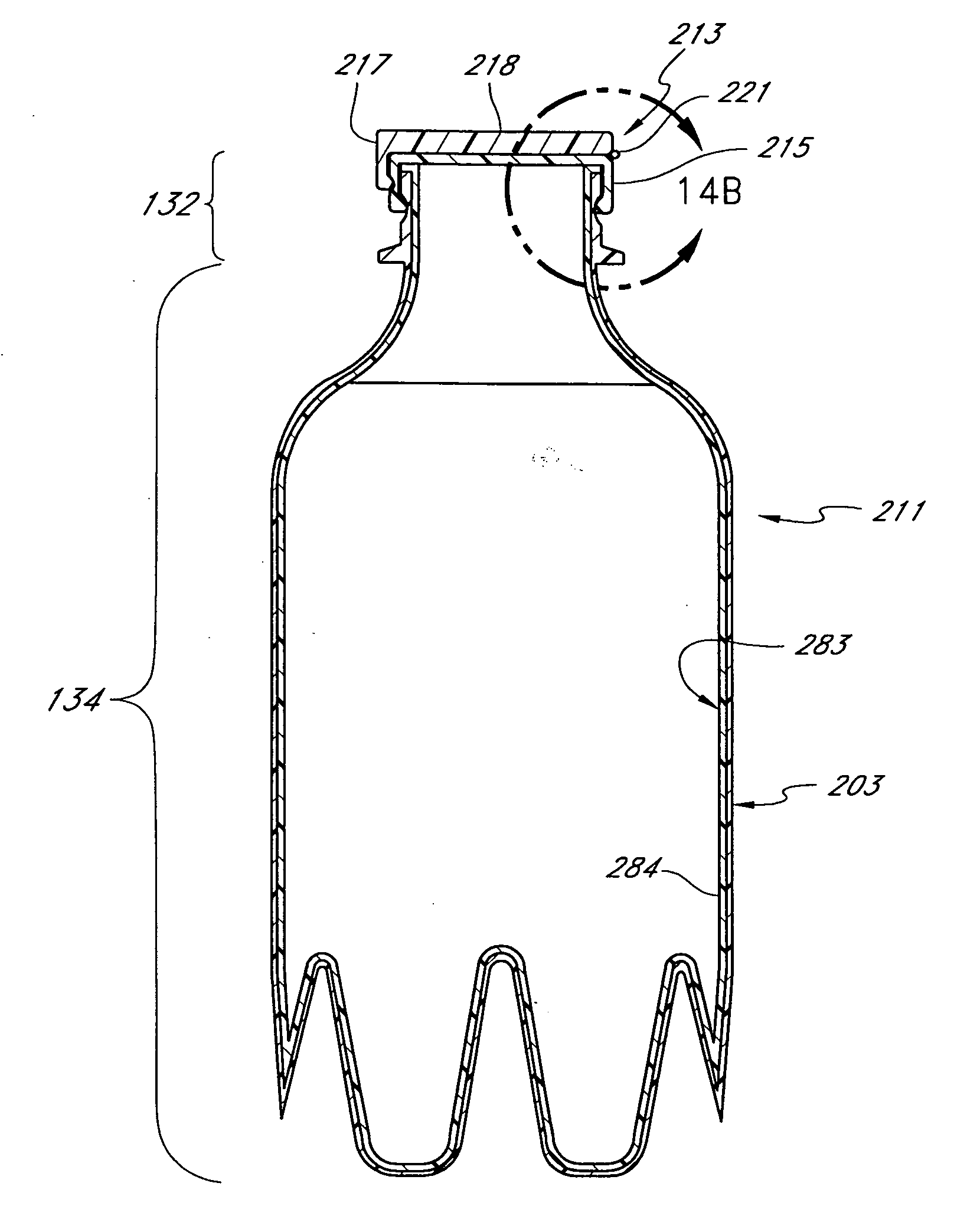

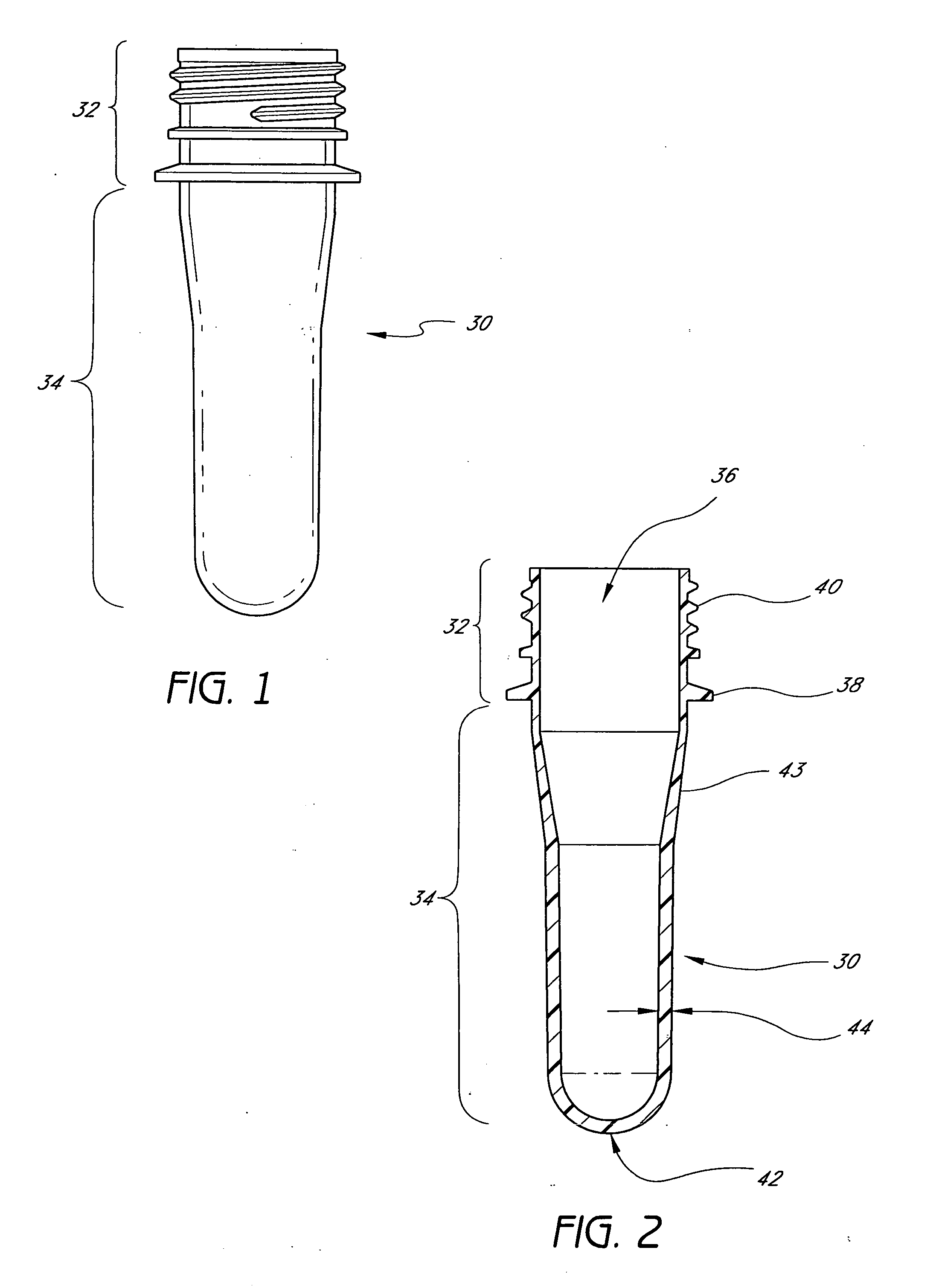

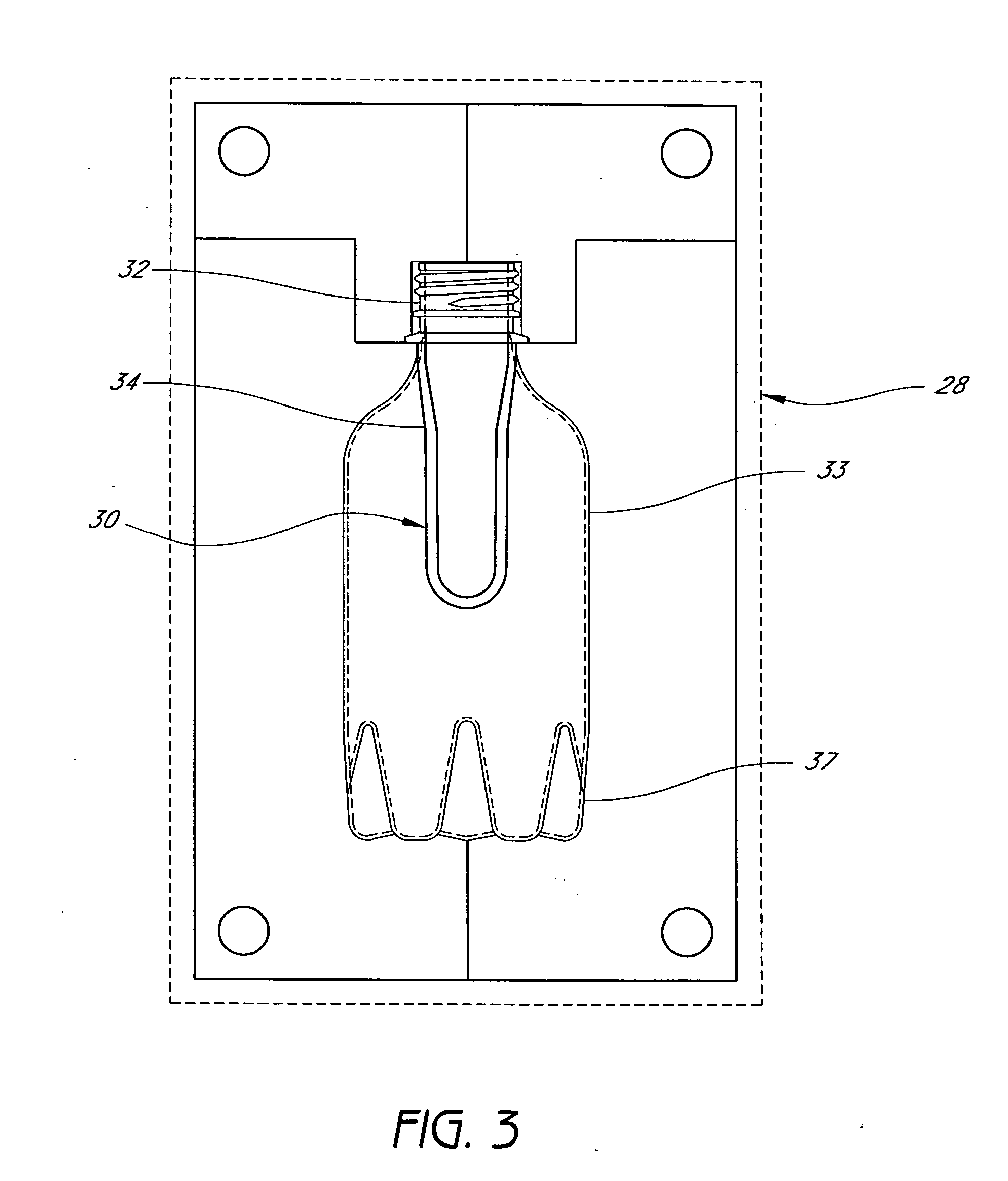

Mono and multi-layer articles and extrusion methods of making the same

InactiveUS20060073298A1Easy to processImprove melt strengthBottlesSynthetic resin layered productsThermoplasticPolyester

An extruded blow molded bottle comprises a neck portion and a body portion. The body portion comprises a first inner layer and a second layer. The first inner layer comprises a first material selected from a group consisting of polyester, phenoxy type thermoplastics, phenoxy-polyolefin thermoplastic blends, and combinations thereof. The second layer comprises a second material selected from a group consisting of virgin PET, recycled PET, PETG, foam, polypropylene, polyester, polyolefins, phenoxy type thermoplastic, phenoxy-polyolefin thermoplastic blends, regrind scrap materials, and combinations thereof. The second material is different from the first material.

Owner:PEPSICO INC +1

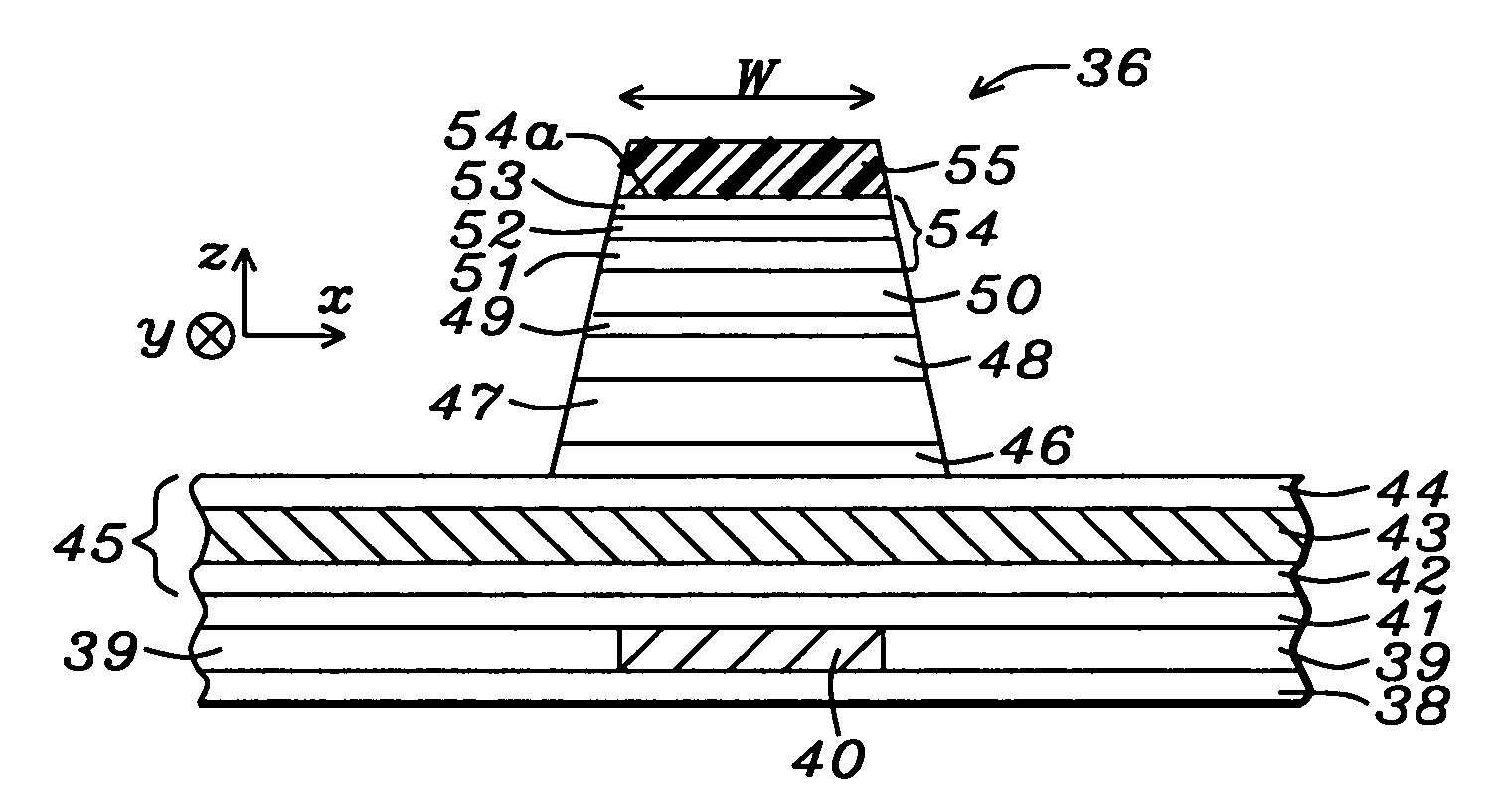

Capping layer for a magnetic tunnel junction device to enhance dR/R and a method of making the same

An MTJ in an MRAM array or TMR read head is disclosed in which a low magnetization capping layer is a composite having a NiFeHf inner layer formed on a NiFe or CoFeB / NiFe free layer, a Ta middle layer, and a Ru outer layer on the Ta layer. For example, a low magnetization NiFeHf layer is achieved by co-sputtering NiFe and Hf targets with a forward power of 400 W and 200 W, respectively. A higher Hf content increases the oxygen gettering power of the NiFeHf layer and the thickness is modified to change dR / R, RA, and magnetostriction values. A so-called dead layer between the free layer and capping layer is restored by incorporating a NiFeHf layer on the free layer to improve lattice matching. The Fe content in the NiFe target used to make the NiFeHf layer is preferably the same as in the NiFe free layer.

Owner:TAIWAN SEMICON MFG CO LTD

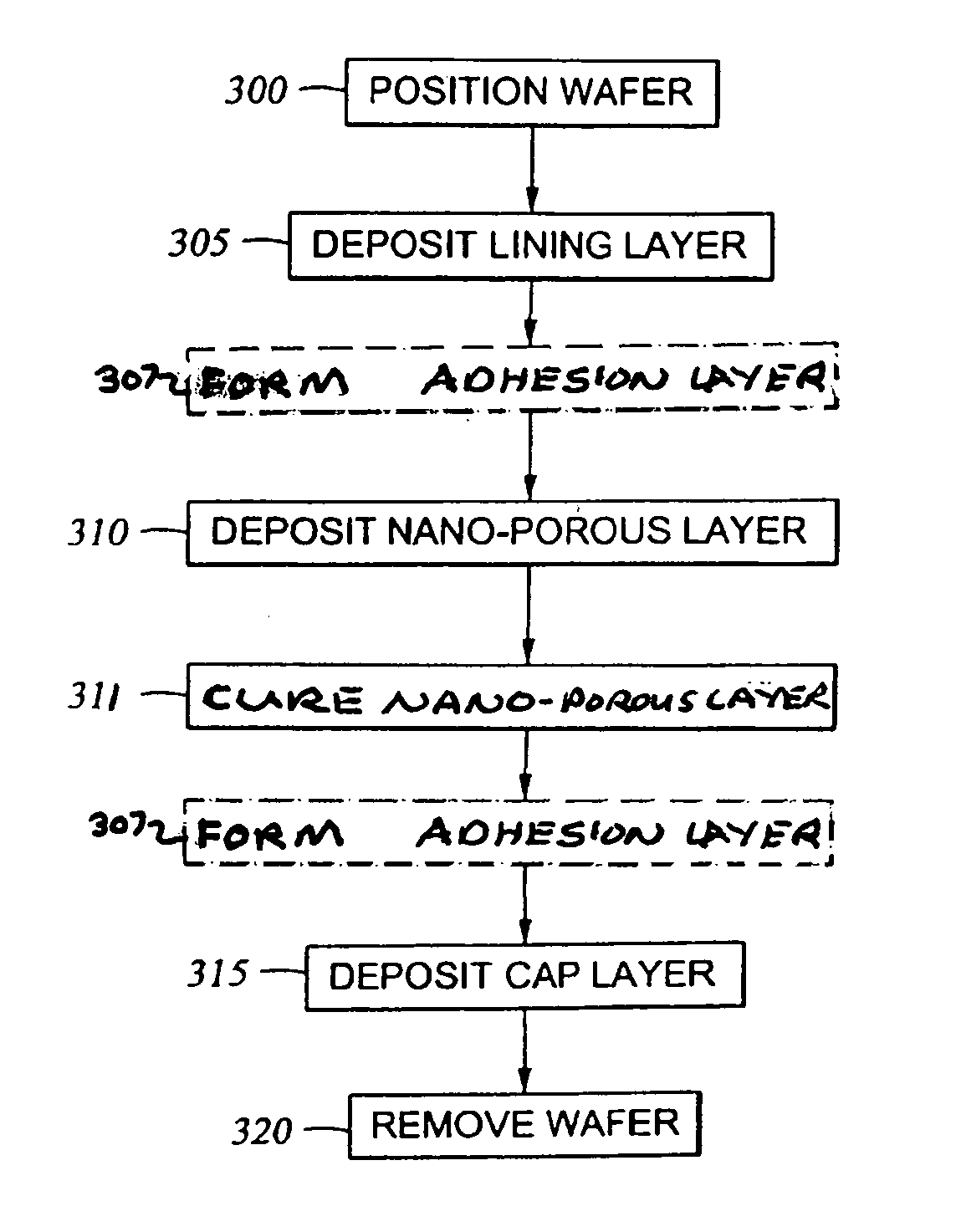

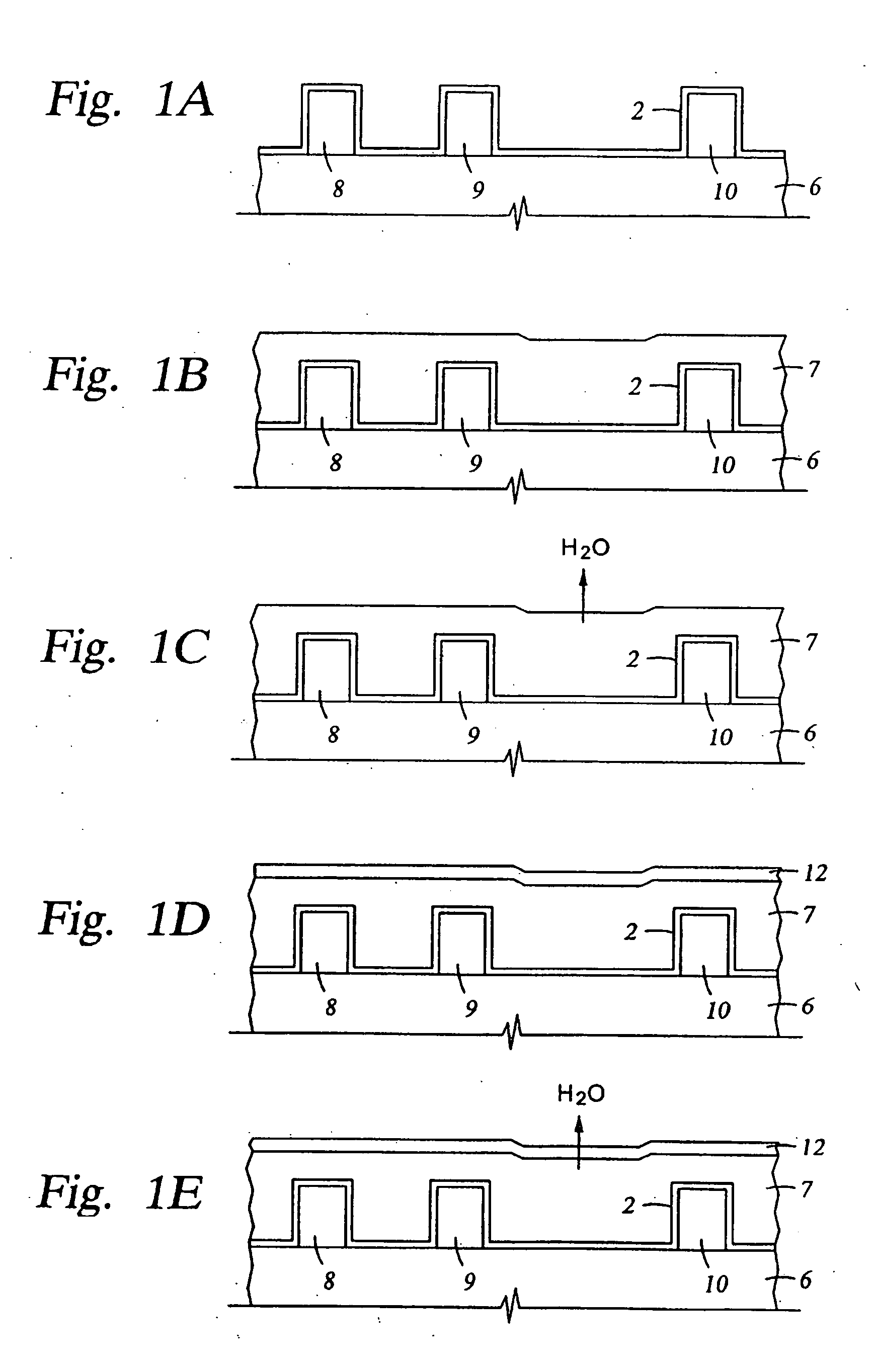

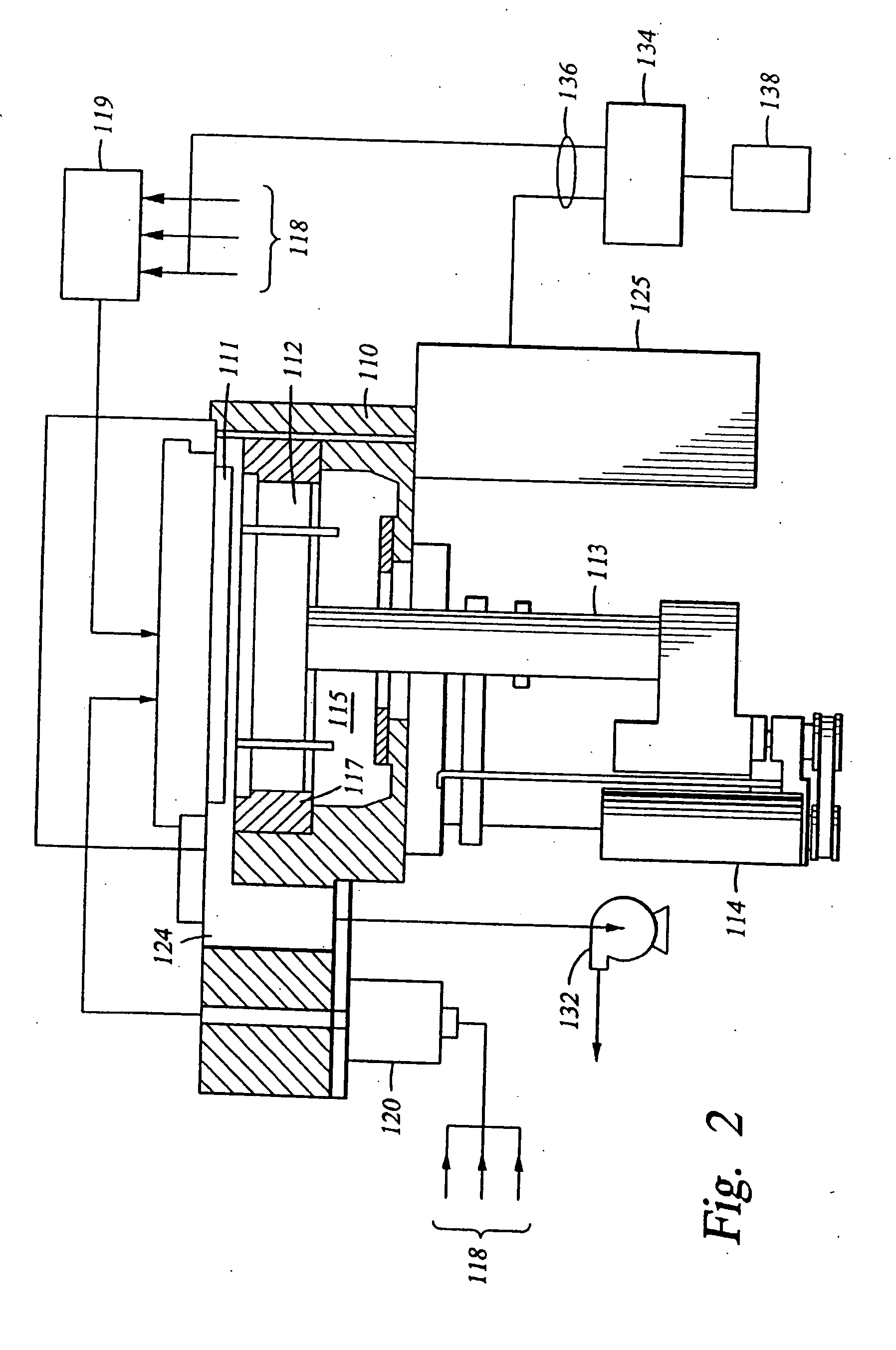

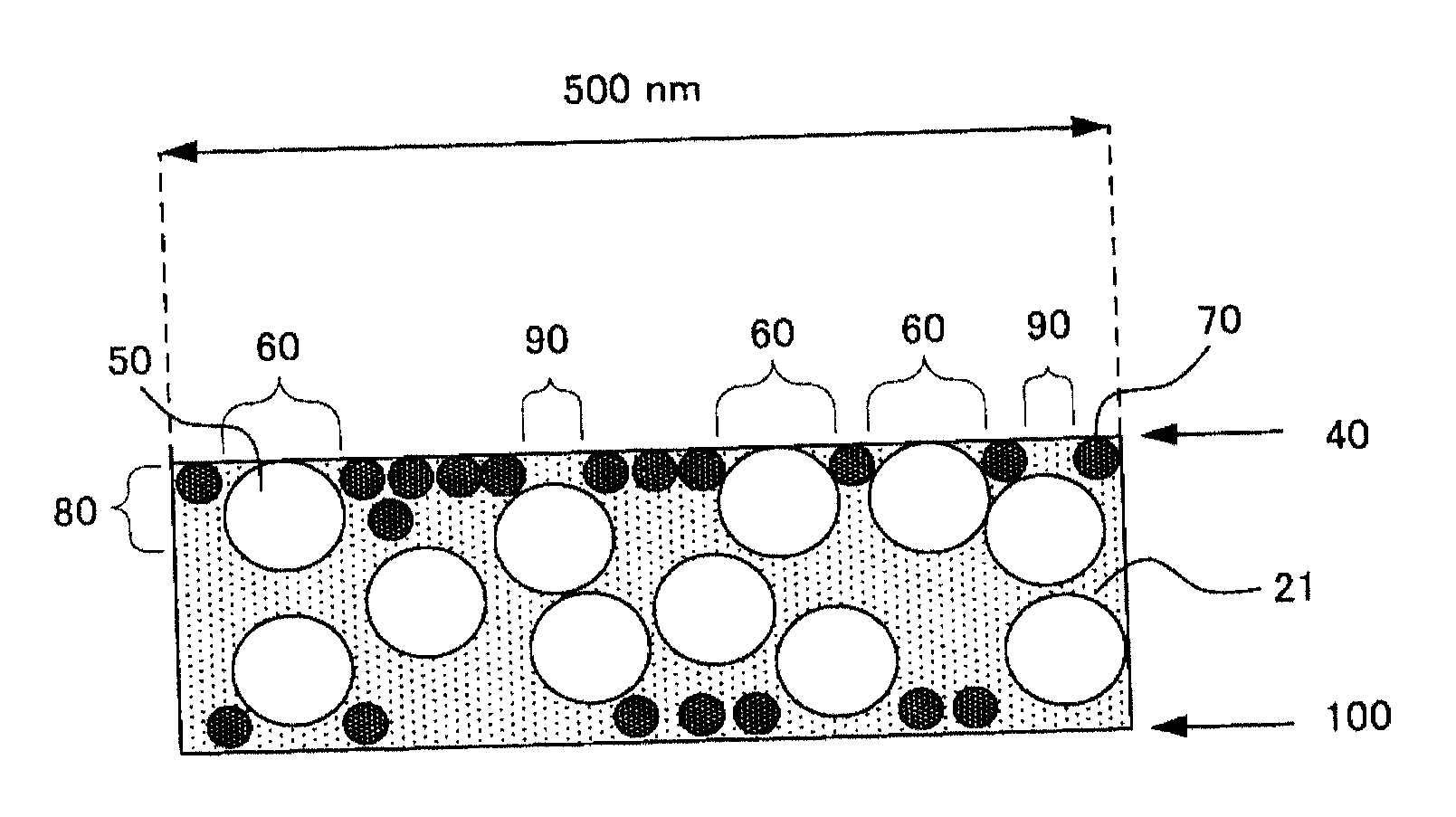

Techniques promoting adhesion of porous low K film to underlying barrier layer

ActiveUS20050233591A1Increase heatLow layerDecorative surface effectsSolid-state devicesPre treatmentThin oxide

Adhesion of a porous low K film to an underlying barrier layer is improved by forming an intermediate layer lower in carbon content, and richer in silicon oxide, than the overlying porous low K film. This adhesion layer can be formed utilizing one of a number of techniques, alone or in combination. In one approach, the adhesion layer can be formed by introduction of a rich oxidizing gas such as O2 / CO2 / etc. to oxidize Si precursors immediately prior to deposition of the low K material. In another approach, thermally labile chemicals such as alpha-terpinene, cymene, and any other non-oxygen containing organics are removed prior to low K film deposition. In yet another approach, the hardware or processing parameters, such as the manner of introduction of the non-silicon containing component, may be modified to enable formation of an oxide interface prior to low K film deposition. In still another approach, parameters of ebeam treatment such as dosage, energy, or the use of thermal annealing, may be controlled to remove carbon species at the interface between the barrier and the low K film. In a further approach, a pre-treatment plasma may be introduced prior to low k deposition to enhance heating of the barrier interface, such that a thin oxide interface is formed when low K deposition gases are introduced and the low K film is deposited.

Owner:APPLIED MATERIALS INC

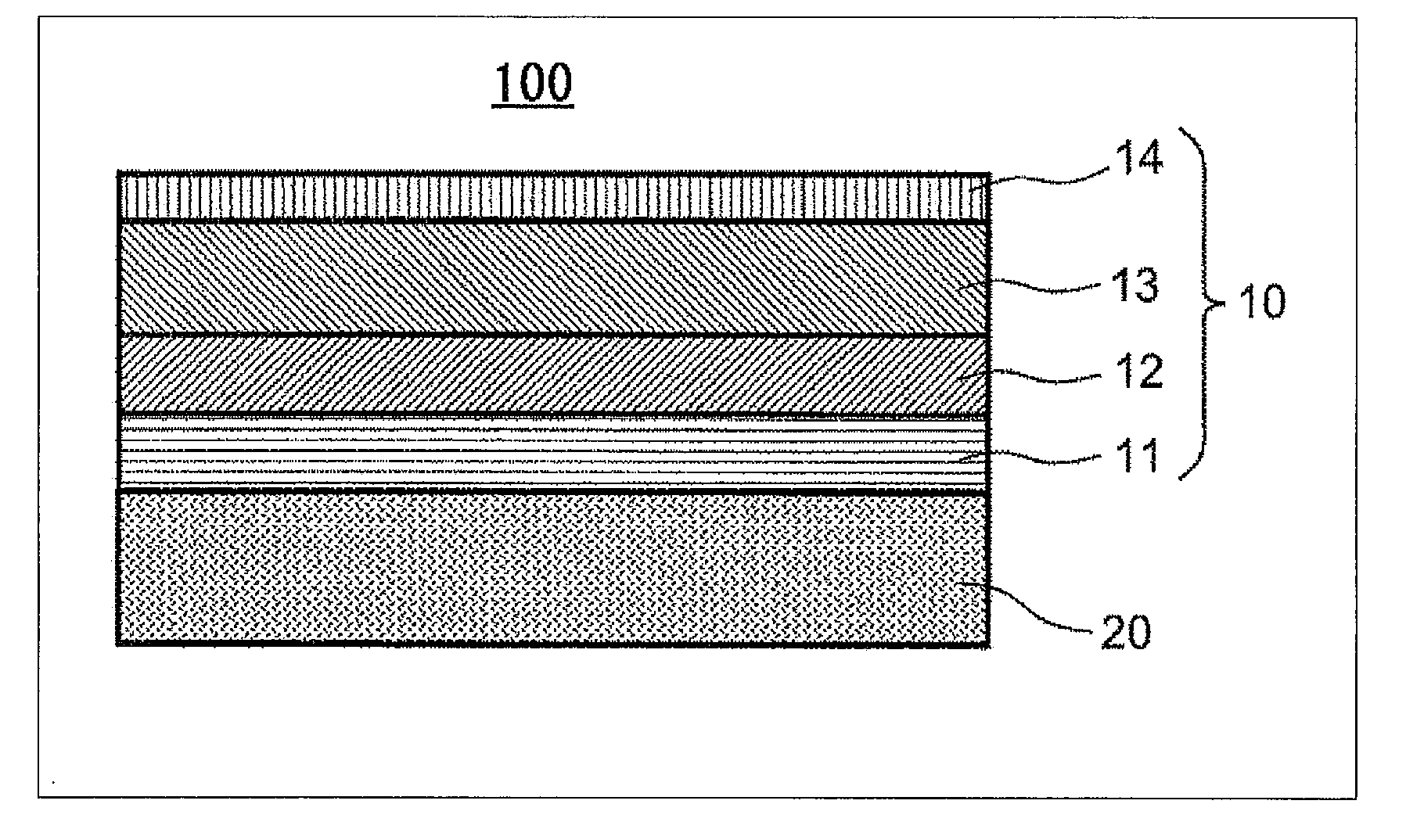

Optical film and display panel

ActiveUS20120200933A1Improve wear resistanceImprove anti-reflection abilityCoatingsNon-linear opticsRefractive indexDisplay device

An optical film having an optically-transparent substrate, and a low refractive index layer having a thickness d on one side of the optically-transparent substrate, a polarizing plate and a display panel provided with the same, and a display provided with the same.

Owner:DAI NIPPON PRINTING CO LTD

Reflective mask blank for EUV lithography and process for producing the same

ActiveUS20120322000A1Sufficient etching rateSimple processVacuum evaporation coatingSemiconductor/solid-state device manufacturingLithographic artistNitrogen

To provide an EUV mask blank provided with a low reflective layer, which has excellent properties as an EUV mask blank. A reflective mask blank for EUV lithography comprising a substrate, and a reflective layer for reflecting EUV light, an absorber layer for absorbing EUV light and a low reflective layer to an inspection light (wavelength: 190 to 260 nm) for a mask pattern, formed in this order on the substrate, wherein the low reflective layer has a stacked structure having a first layer containing at least 95 at % in total of silicon (Si) and nitrogen (N), and a second layer containing at least 95 at % in total of tantalum (Ta), oxygen (O) and nitrogen (N) or a second layer containing at least 95 at % in total of tantalum (Ta) and nitrogen (N), stacked in this order from the absorber layer side.

Owner:ASAHI GLASS CO LTD

Novel capping layer for a magnetic tunnel junction device to enhance dR/R and a method of making the same

ActiveUS20080023740A1Magnetization is so lowLow layerNanomagnetismSolid-state devicesSputteringMagnetization

An MTJ in an MRAM array or TMR read head is disclosed in which a low magnetization capping layer is a composite having a NiFeHf inner layer formed on a NiFe or CoFeB / NiFe free layer, a Ta middle layer, and a Ru outer layer on the Ta layer. For example, a low magnetization NiFeHf layer is achieved by co-sputtering NiFe and Hf targets with a forward power of 400 W and 200 W, respectively. A higher Hf content increases the oxygen gettering power of the NiFeHf layer and the thickness is modified to change dR / R, RA, and magnetostriction values. A so-called dead layer between the free layer and capping layer is restored by incorporating a NiFeHf layer on the free layer to improve lattice matching. The Fe content in the NiFe target used to make the NiFeHf layer is preferably the same as in the NiFe free layer.

Owner:TAIWAN SEMICON MFG CO LTD

Automotive fuel hose and method for producing the same

InactiveUS20050208248A1Low layerSimple molding processSynthetic resin layered productsLaminationEngineeringAutomotive fuel

An automotive fuel hose excellent in interlaminar adhesion between a low permeability resin layer and a rubber layer, wherein the low permeability resin layer and the rubber layer are directly adhered to each other without forming an adhesive layer at the interface between both layers. The automotive fuel hose has a laminated structure of a low permeability resin layer and a rubber layer, the low permeability resin layer is formed by the following (A) and the rubber layer is formed by the following (B). (A) a polyphenylene sulfide resin containing a softening component, or a modified fluororesin. (B) a rubber composition composed of at least one of an amine additive and an amine vulcanizing agent as an essential component.

Owner:SUMITOMO RIKO CO LTD

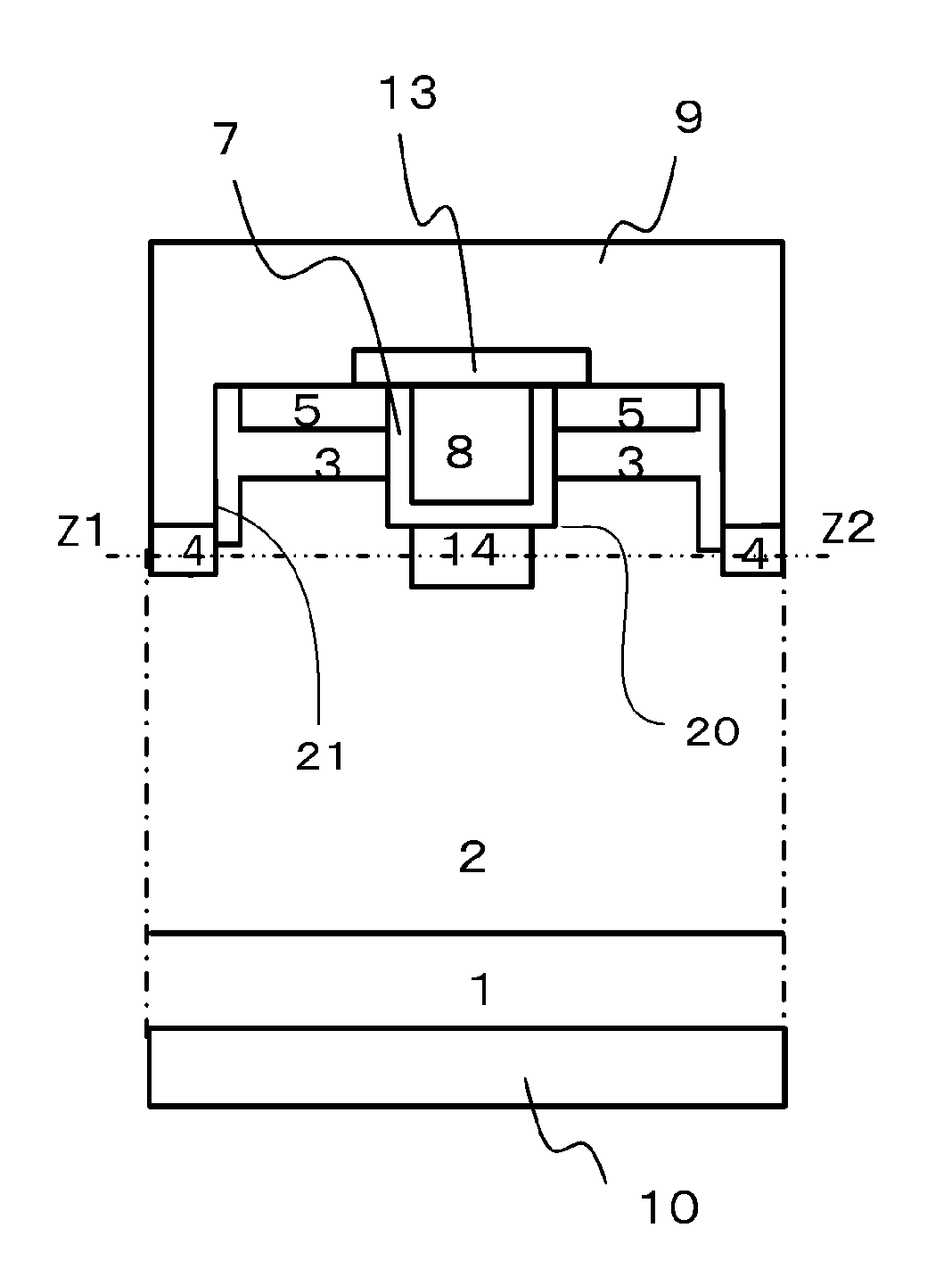

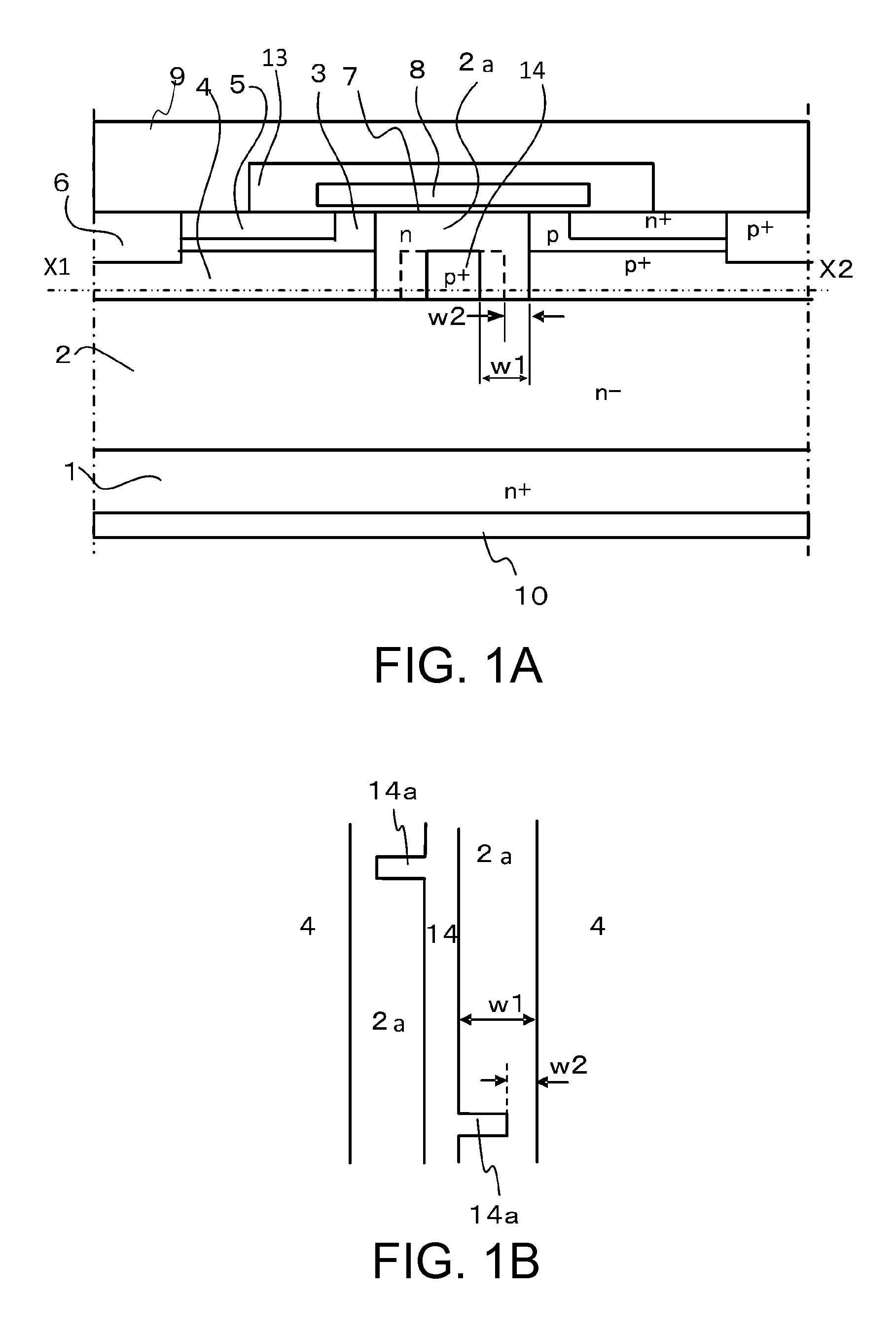

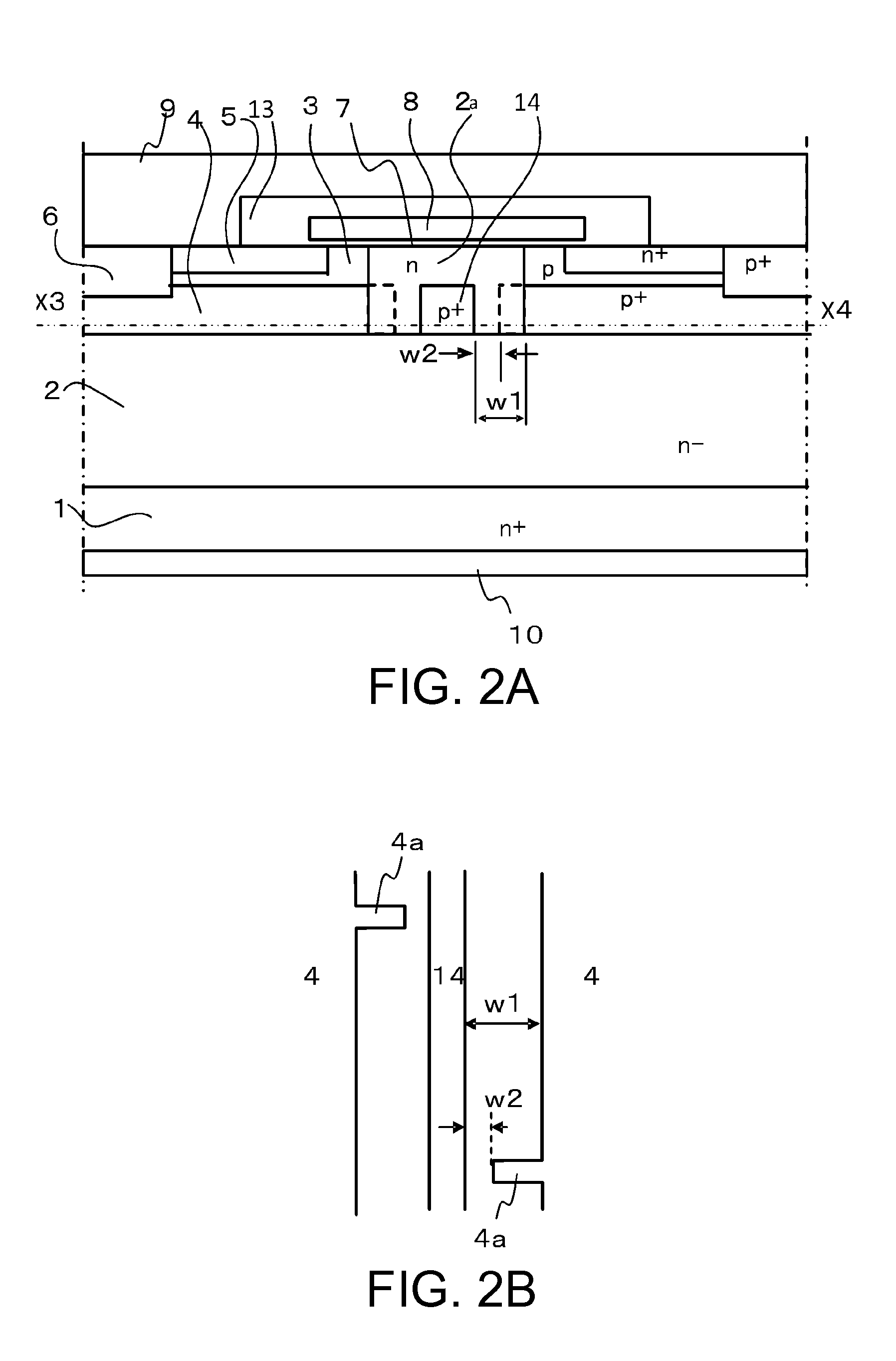

Wide bandgap insulated gate semiconductor device

ActiveUS20150053999A1Increase impurity concentrationReduce thicknessSemiconductor devicesDevice materialEngineering

A wide bandgap insulated gate semiconductor device includes a semiconductor substrate made of semiconductor having a bandgap wider than silicon; n− drift layer over the semiconductor substrate; p-channel regions selectively disposed over the drift layer; n+ semiconductor regions selectively disposed in respective surfaces in the channel regions; a plurality of p+ base regions in contact with bottoms of the respective channel regions; a protruding drift layer portion that is n-type region interposed between the p-channel regions and the p+ base regions thereunder; a gate electrode formed, through a gate insulating film, on the protruding drift layer portion and on respective surfaces of the p-channel regions; a source electrode in contact with the n+ semiconductor regions in the channel regions; and a p+ floating region inside the protruding drift layer portion, having side faces respectively facing side faces of the second conductivity type base regions, wherein respective gaps between the p+ base regions and the p+ floating region defined by the respective side faces have a wide portion and a narrow portion.

Owner:FUJI ELECTRIC CO LTD

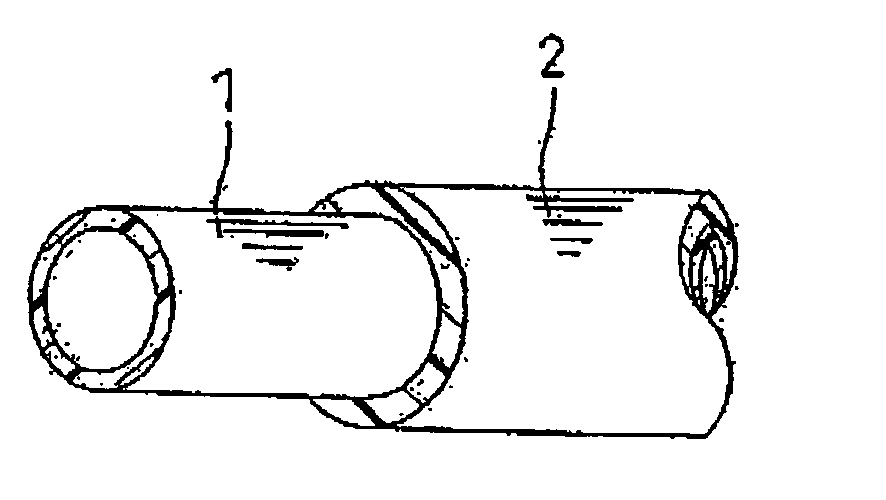

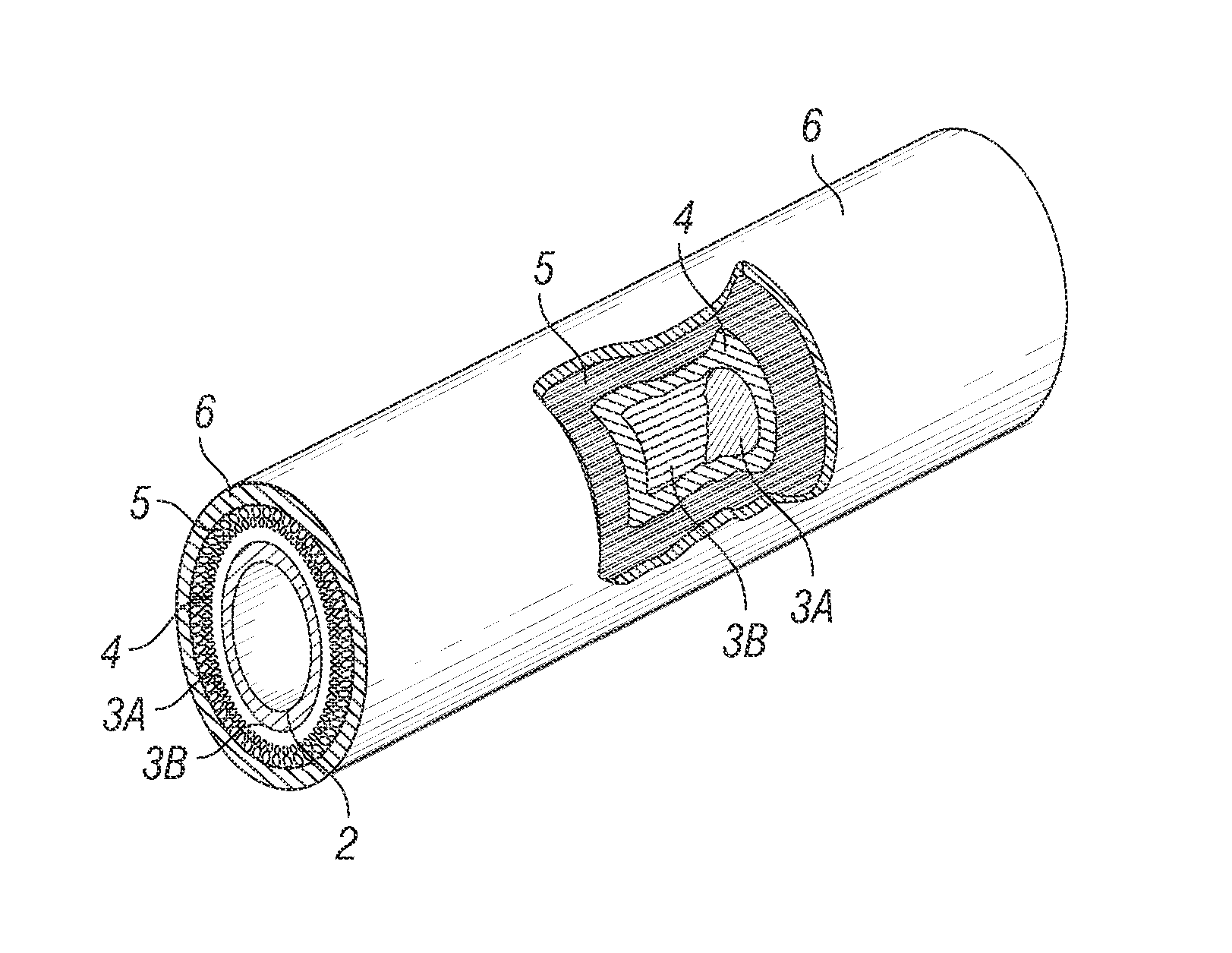

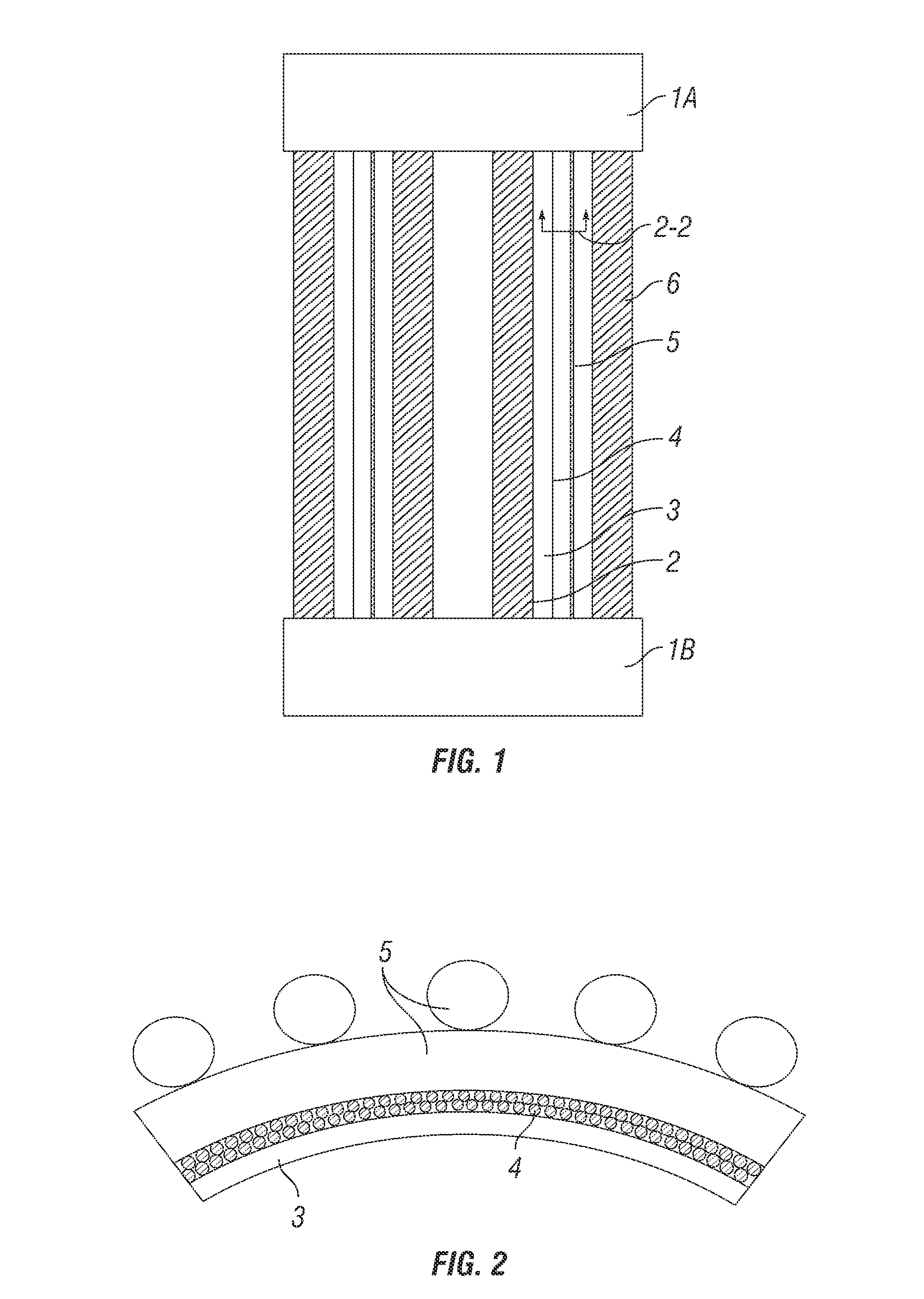

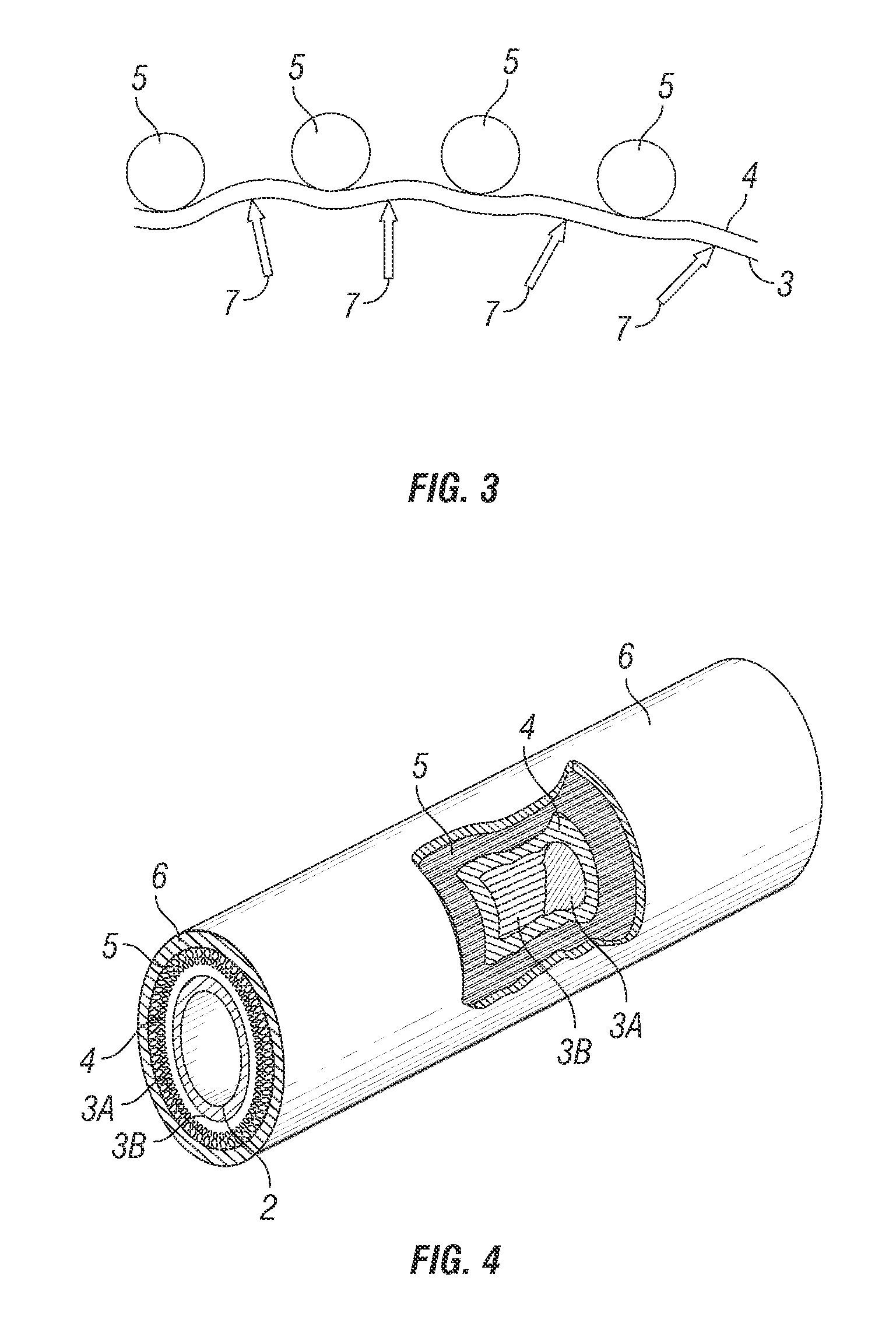

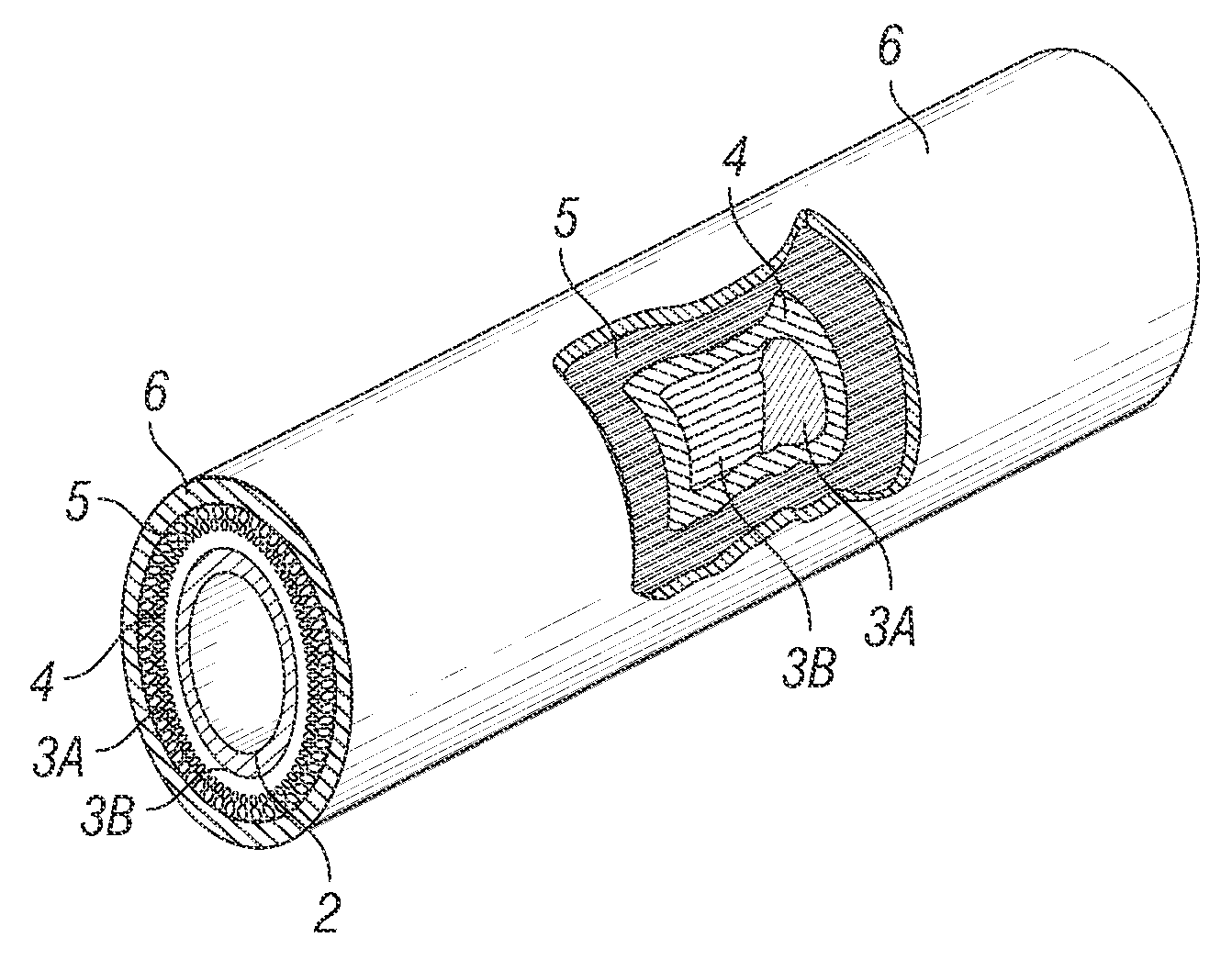

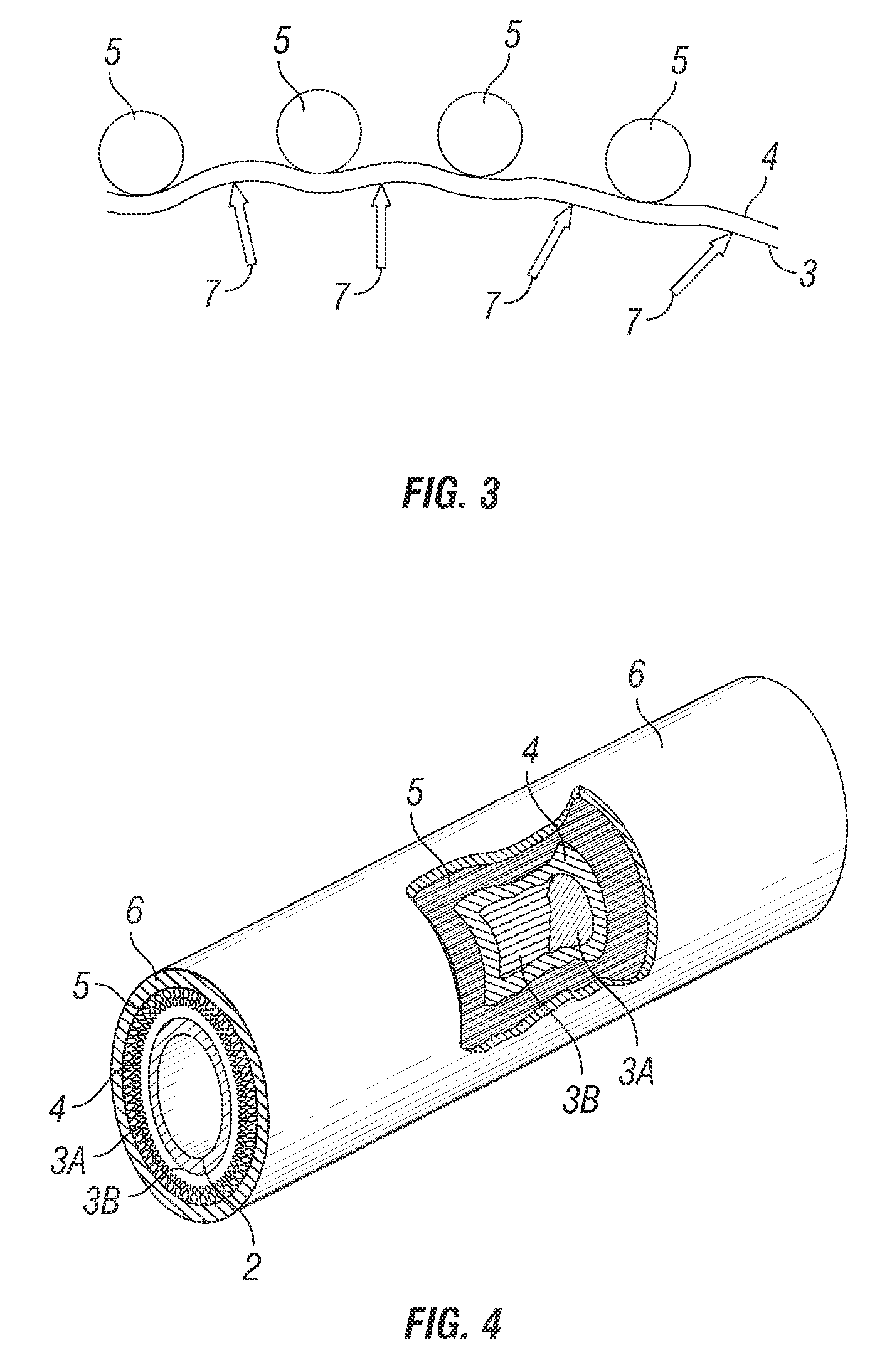

Packers and methods of use

Expandable packers and methods of using same are described. The expandable packers include an anti-extrusion layer comprising a fibrous layer having a first surface adjacent an outer surface of an inner expandable elastomeric member, and a cable layer adjacent the fibrous layer, the cable layer comprising a plurality of stacked unidirectional layers of cables. The cable layer is adapted to form a barrier substantially devoid of gaps through which the inner elastomer member would otherwise extrude into upon expansion of the inner elastomeric member. This abstract allows a searcher or other reader to quickly ascertain the subject matter of the disclosure. It will not be used to interpret or limit the scope or meaning of the claims. 37 CFR 1.72(b).

Owner:SCHLUMBERGER TECH CORP

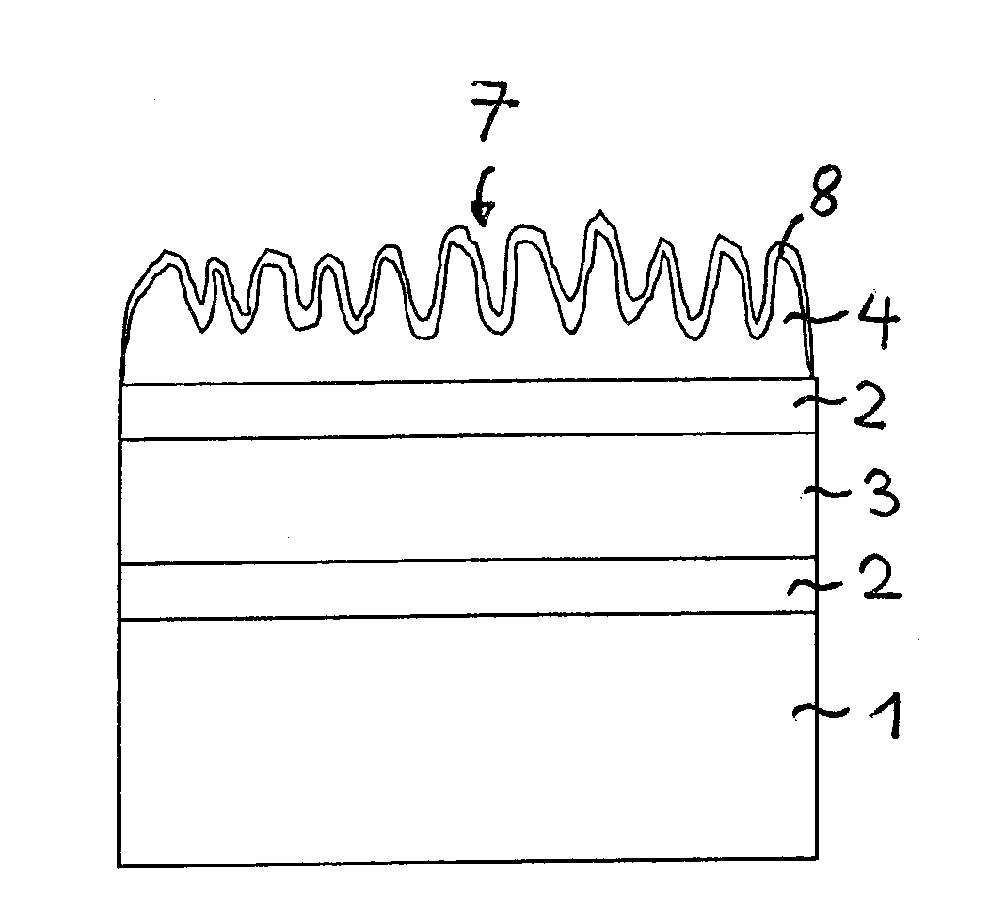

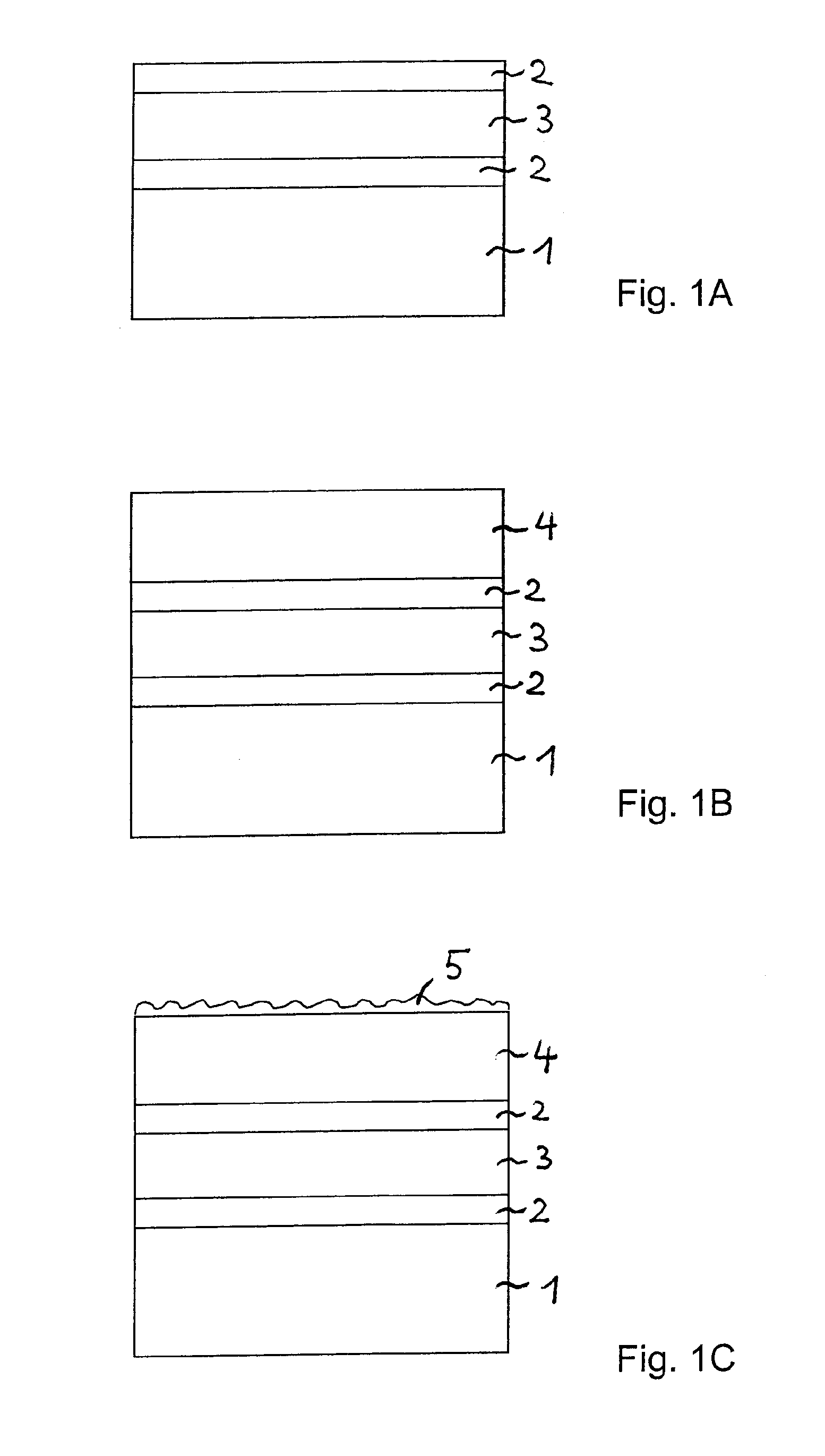

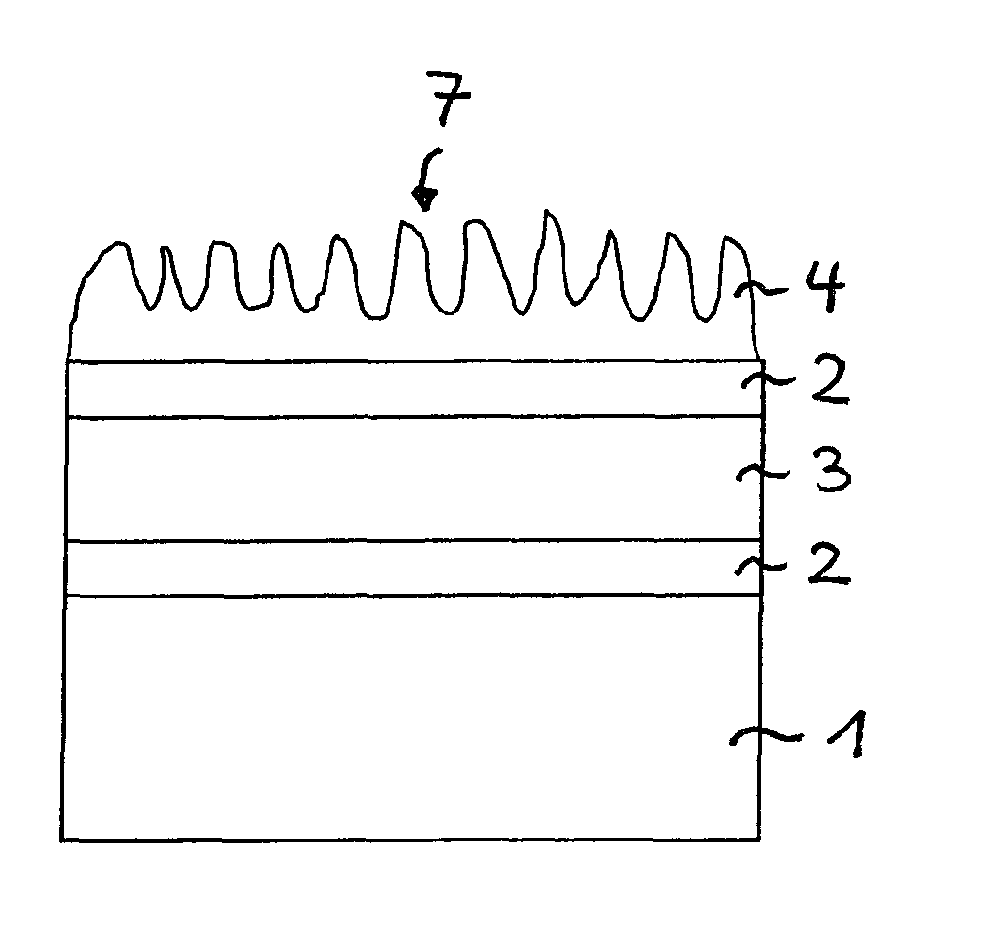

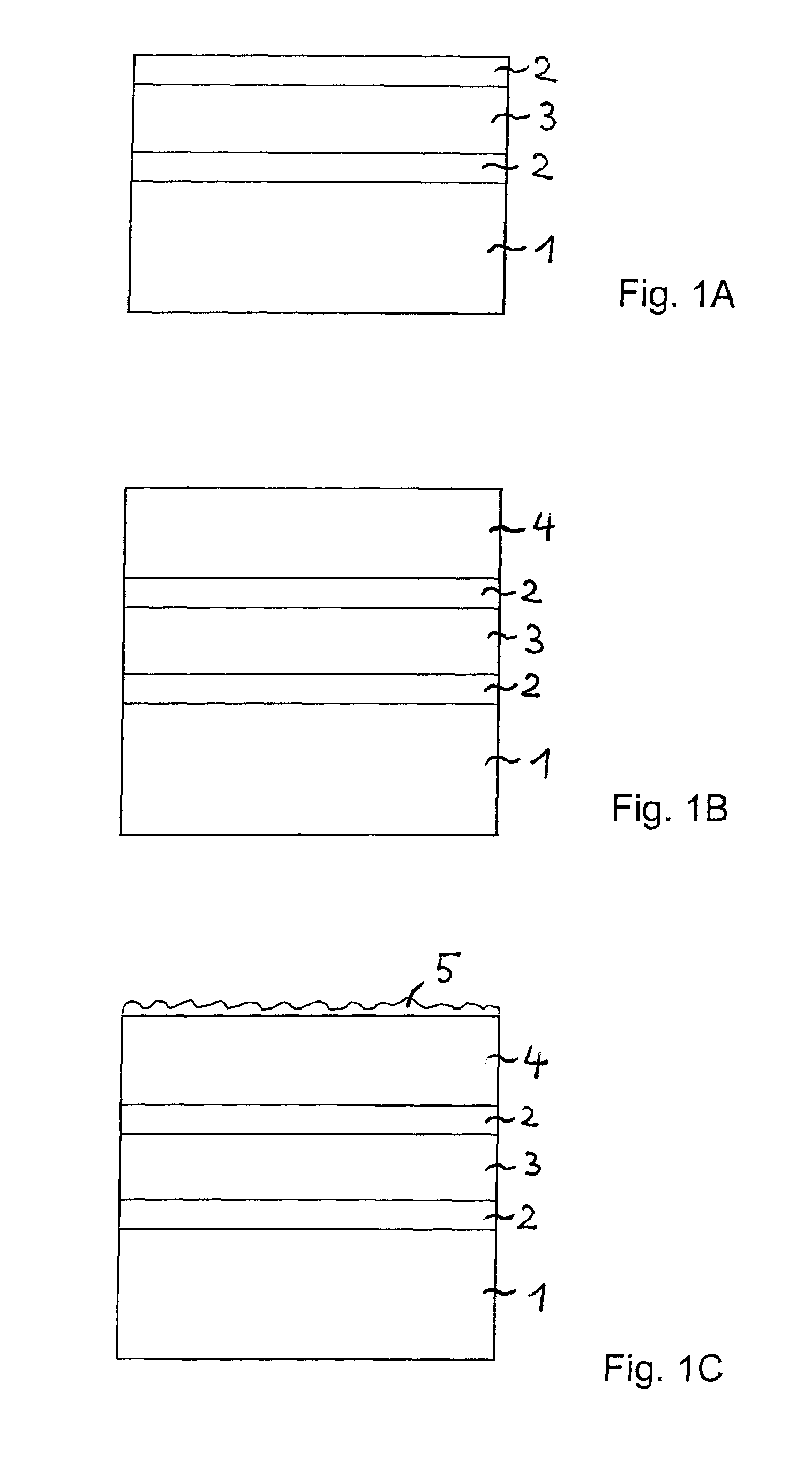

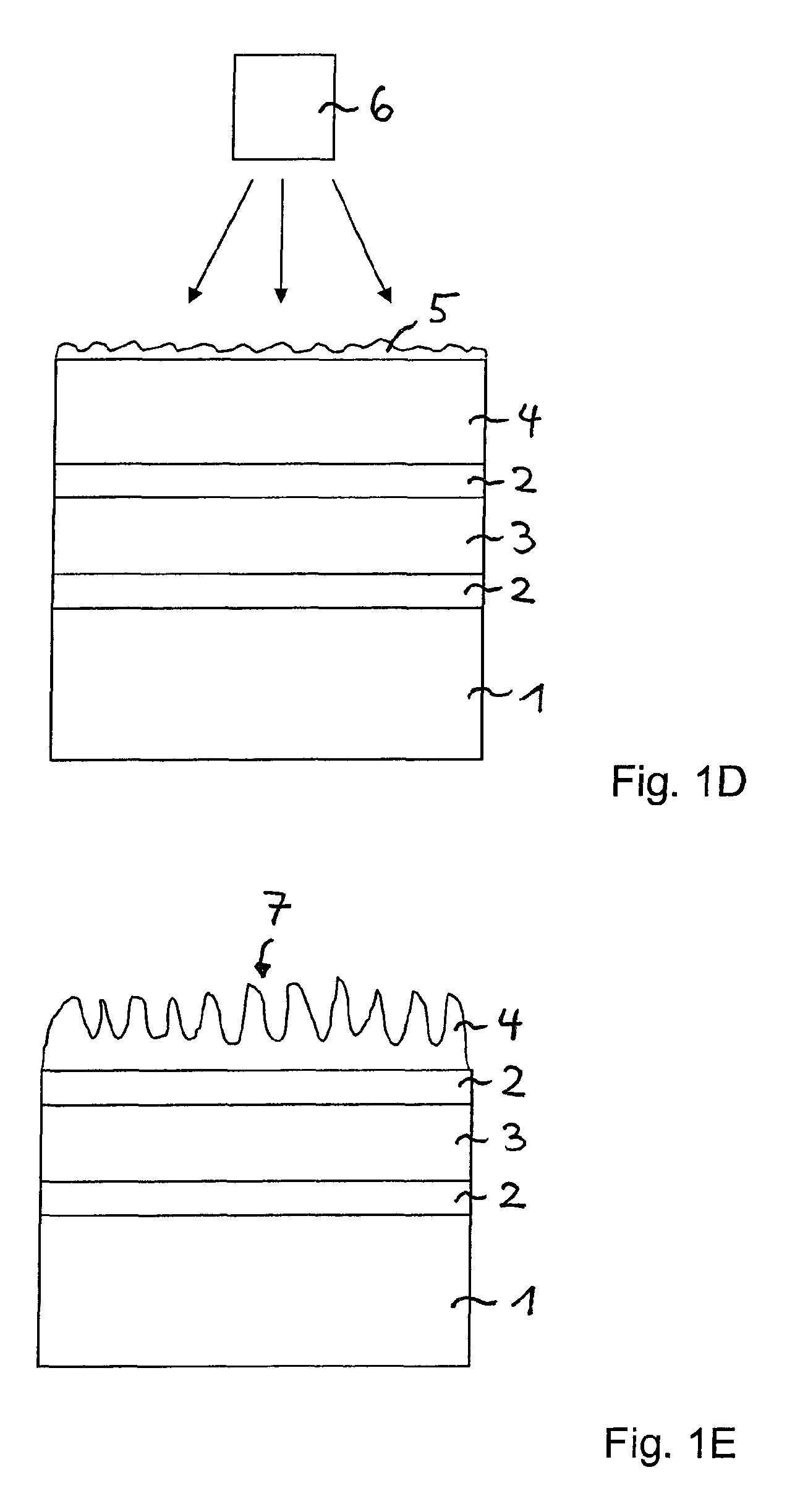

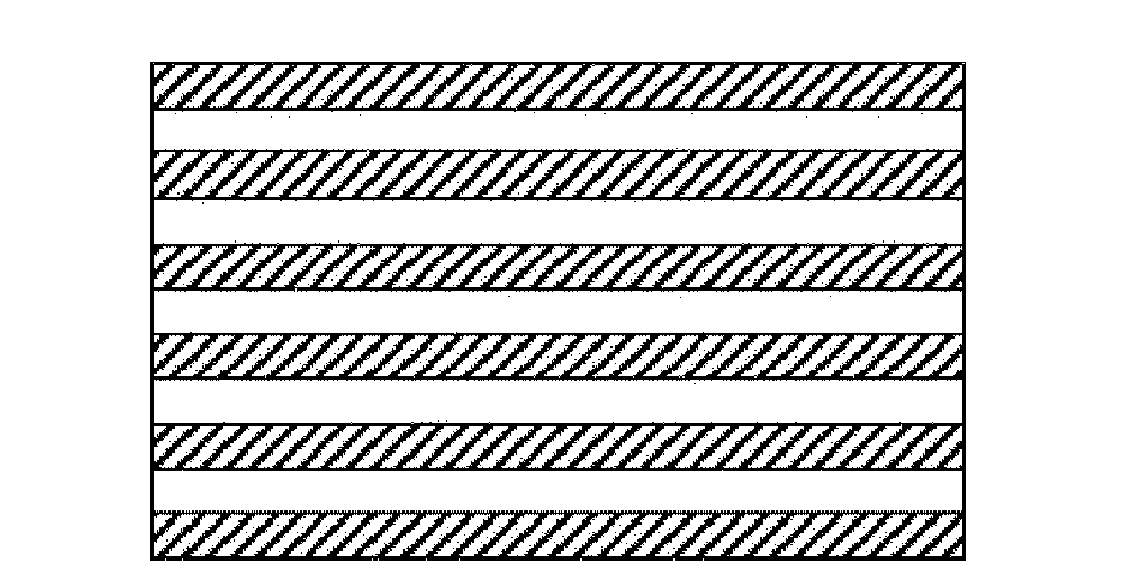

Reflection-Reducing Interference Layer System and Method for Producing It

ActiveUS20110051246A1Simple and cost-effective methodLow layerDecorative surface effectsPretreated surfacesHybrid materialRefractive index

A reflection-reducing interference layer system is disclosed, which has at least three alternating layers having different refractive indices. At least one nanostructured layer comprising an organic material or an organic-inorganic hybrid material is applied to the alternating layers. With the interference layer system, it is possible to obtain very low reflection over a wide wavelength and incident angle range.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

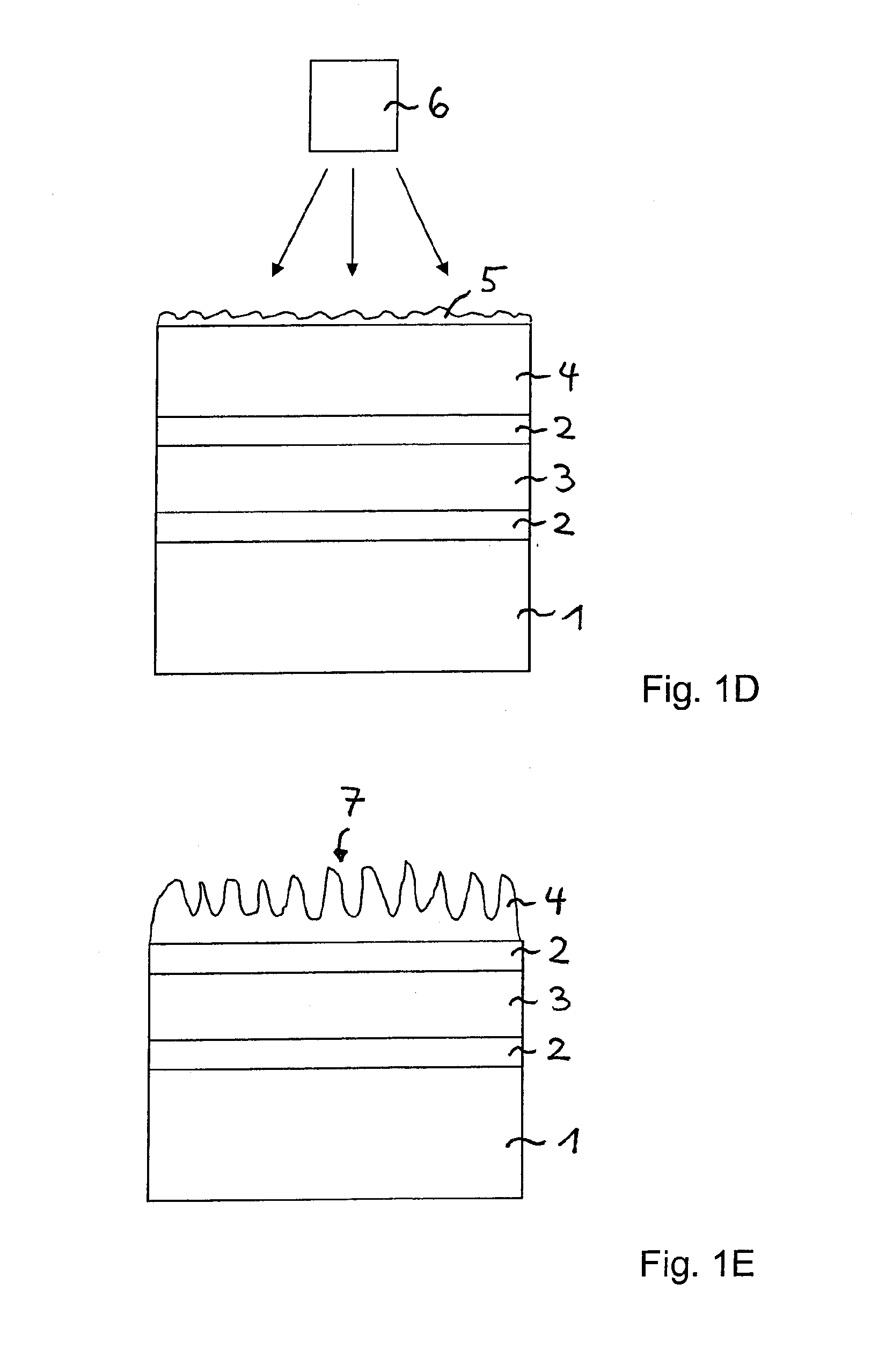

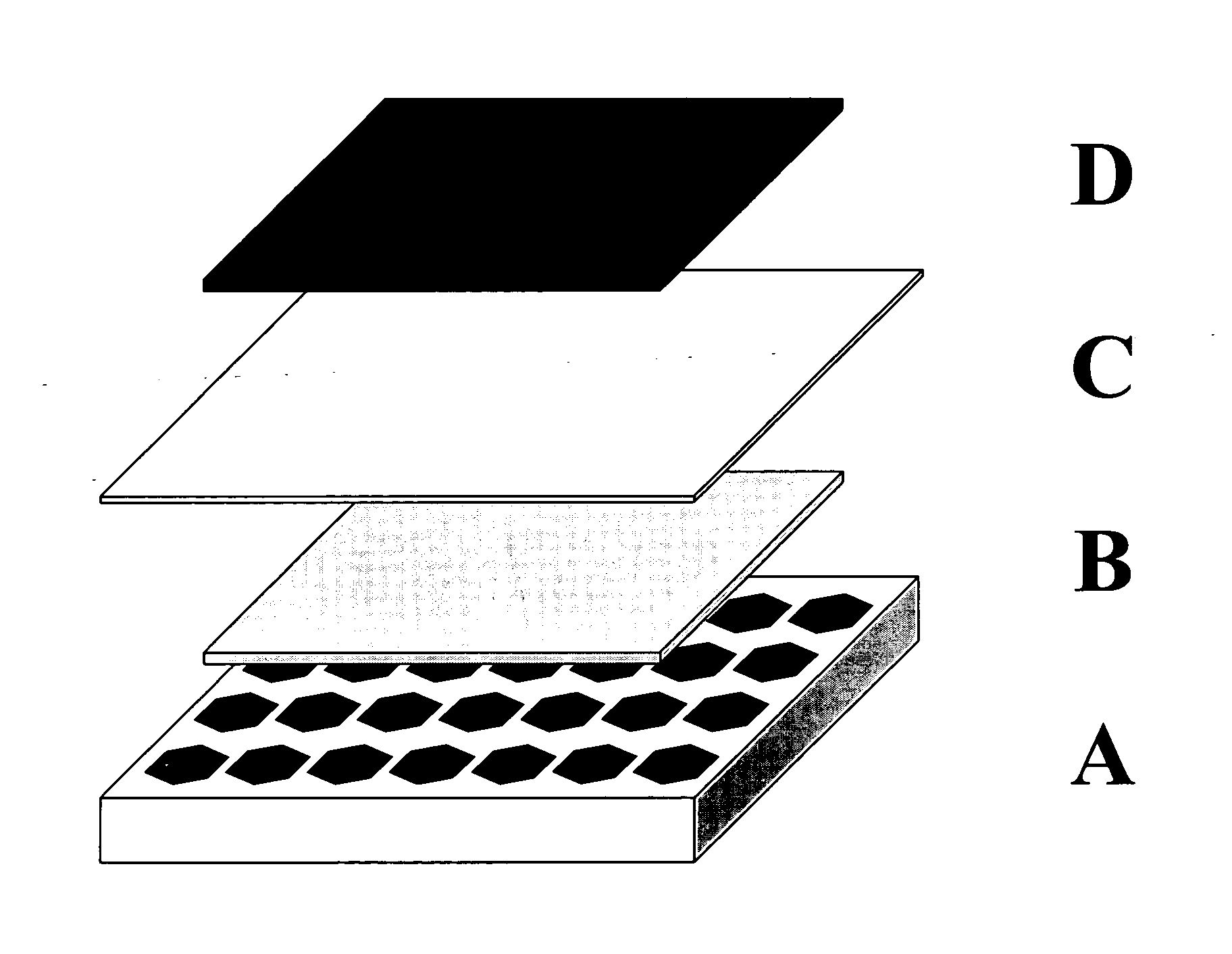

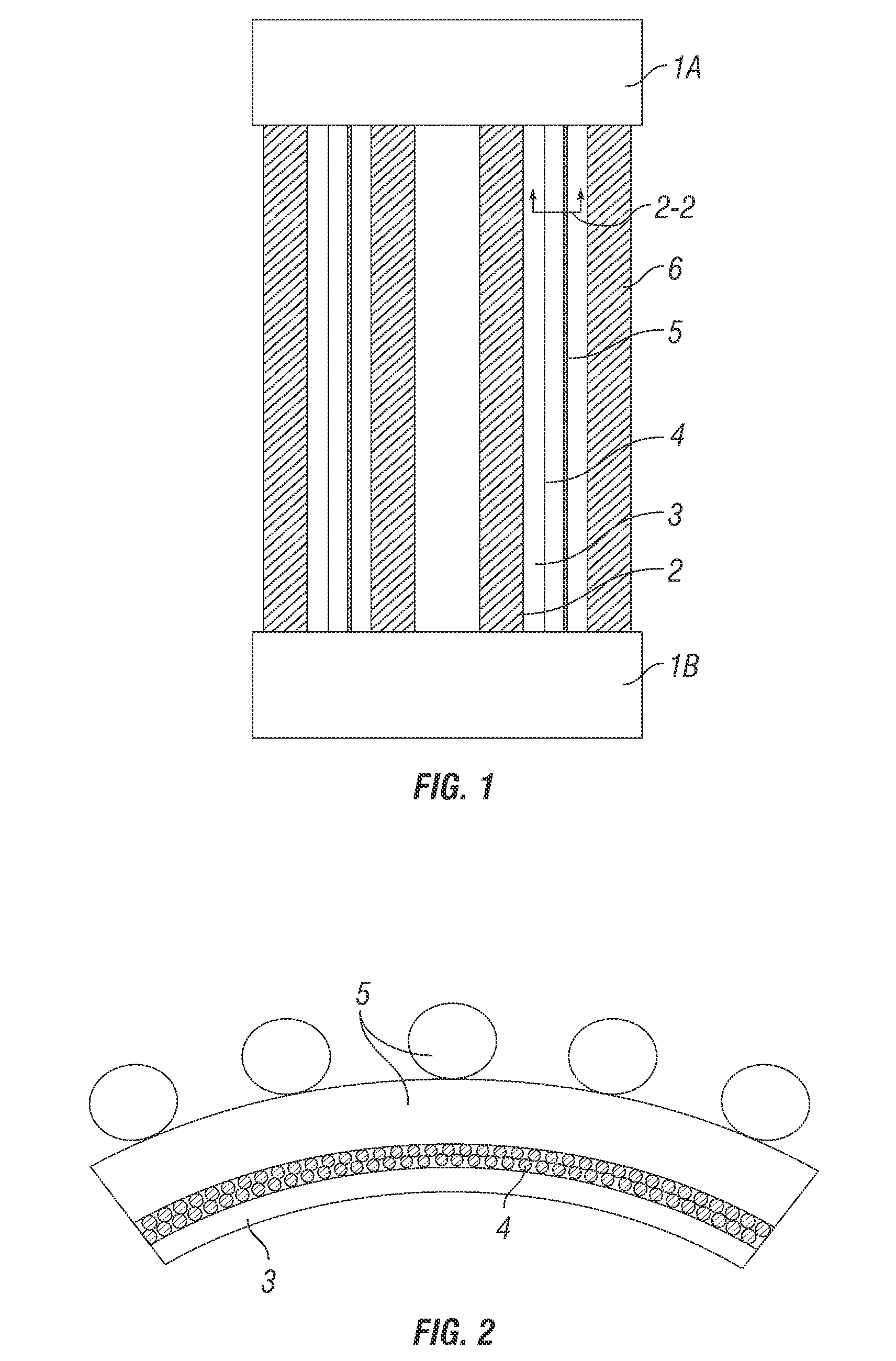

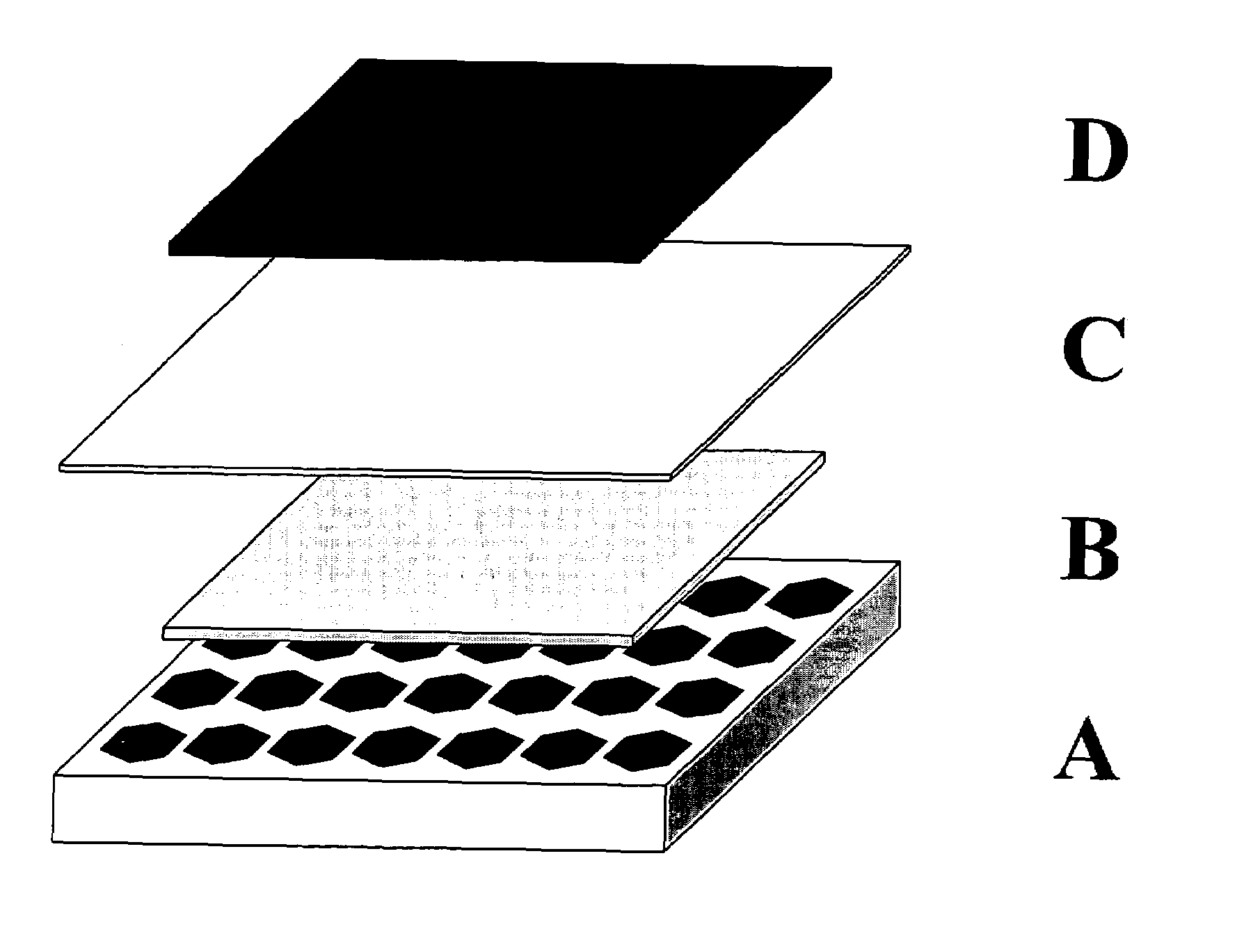

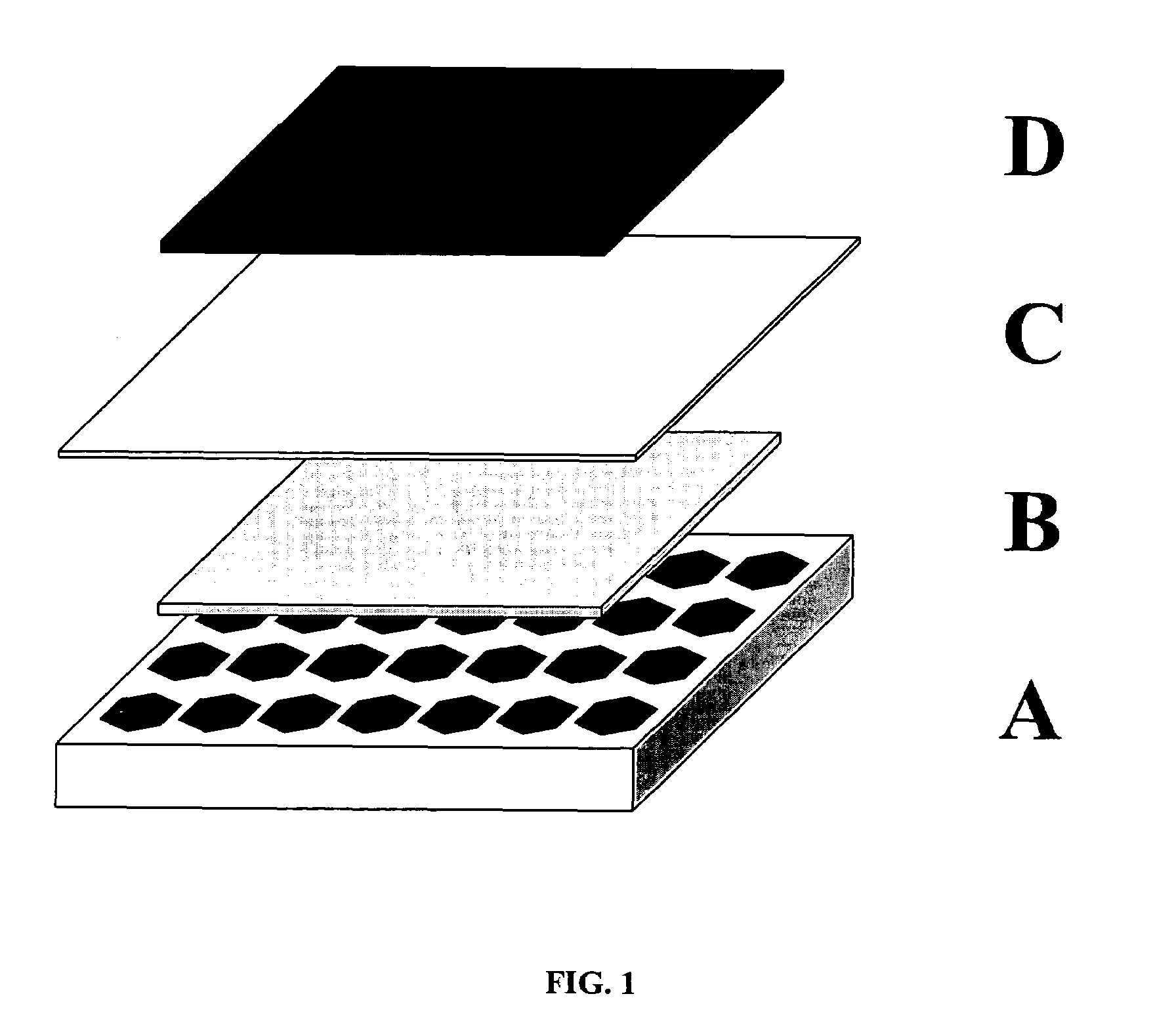

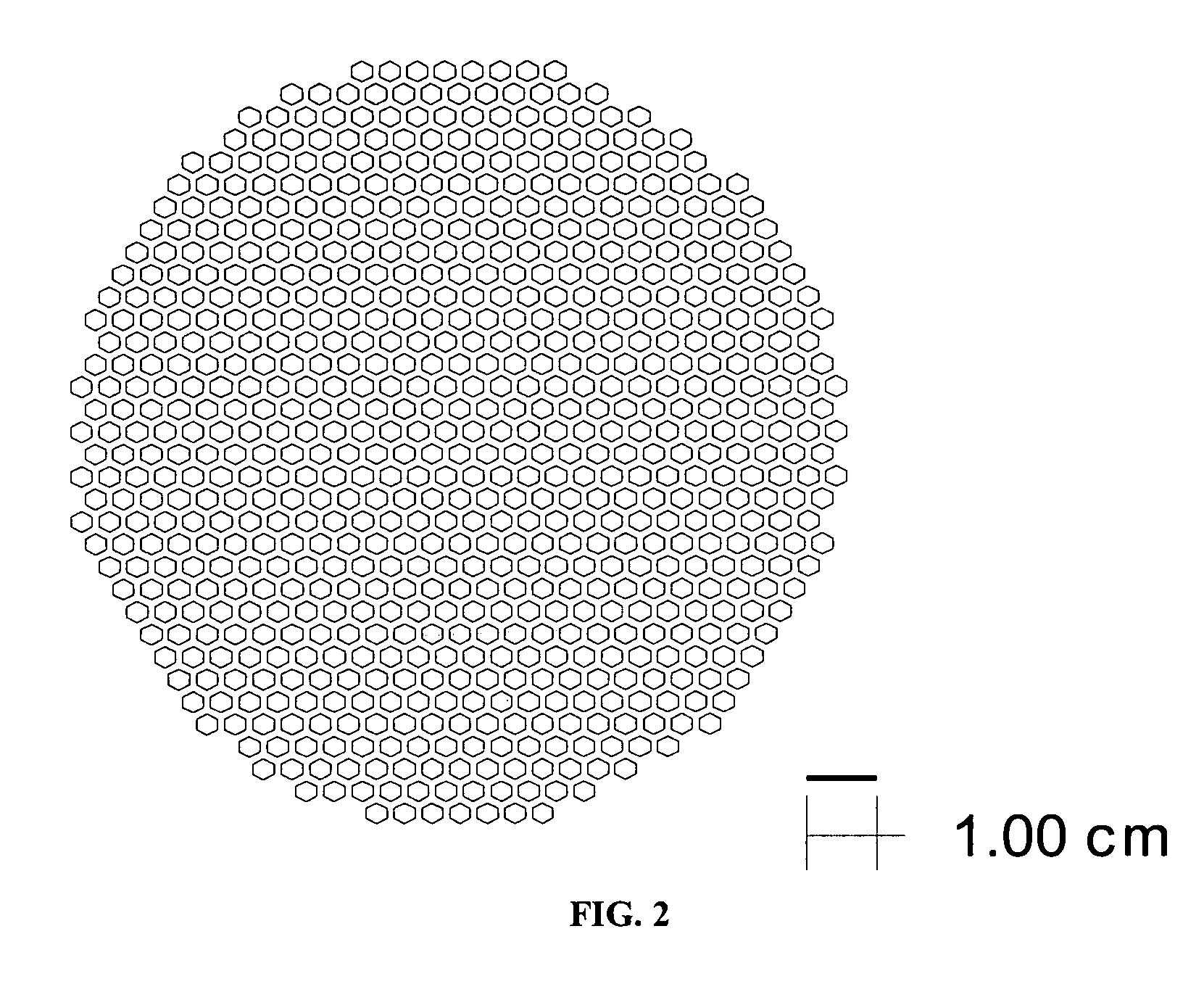

Ceramic membranes with integral seals and support, and electrochemical cells and electrochemical cell stacks including the same

InactiveUS20070054169A1High mechanical strengthAvoid Diffusion LimitationFuel cells groupingActive material electrodesCeramic membranePorous electrode

Ceramic membranes with integral seals and support, and related electrochemical cells and cell stacks. The membrane comprises a thin electrolyte layer supported on a porous electrode layer which in turn is supported on a thick ceramic support layer, preferably a ceramic electrolyte support. The support layer is divided into a plurality of self-supporting thin membrane regions by a network of thicker integrated support ribs. The thin electrolyte layer and thick ceramic support layer preferably define a sealing perimeter surrounding the porous electrode layer.

Owner:NEXCERIS INNOVATION HLDG LLC

System and method for detecting a structure failure

InactiveUS6972687B1Low friction slip layerMinimum bend radiusBridgesTransmission monitoringEngineeringSignal detector

A system for quickly and reliably detecting a failed structure includes a signal source, a cable attached to the structure, an anti-slip cable anchor, a signal detector, and user indicator. When the structure fails, the cable attached to the structure is also broken. The user indicator is operable to display the status of the cable. The cable breaks due to exceeding the elastic modulus of the cable, caused by elongation of the distance between two fixed points caused by the failing structure. Electric power must be provided to each signal source, signal detector and user indicator.

Owner:MARSHALL ROBERT A +1

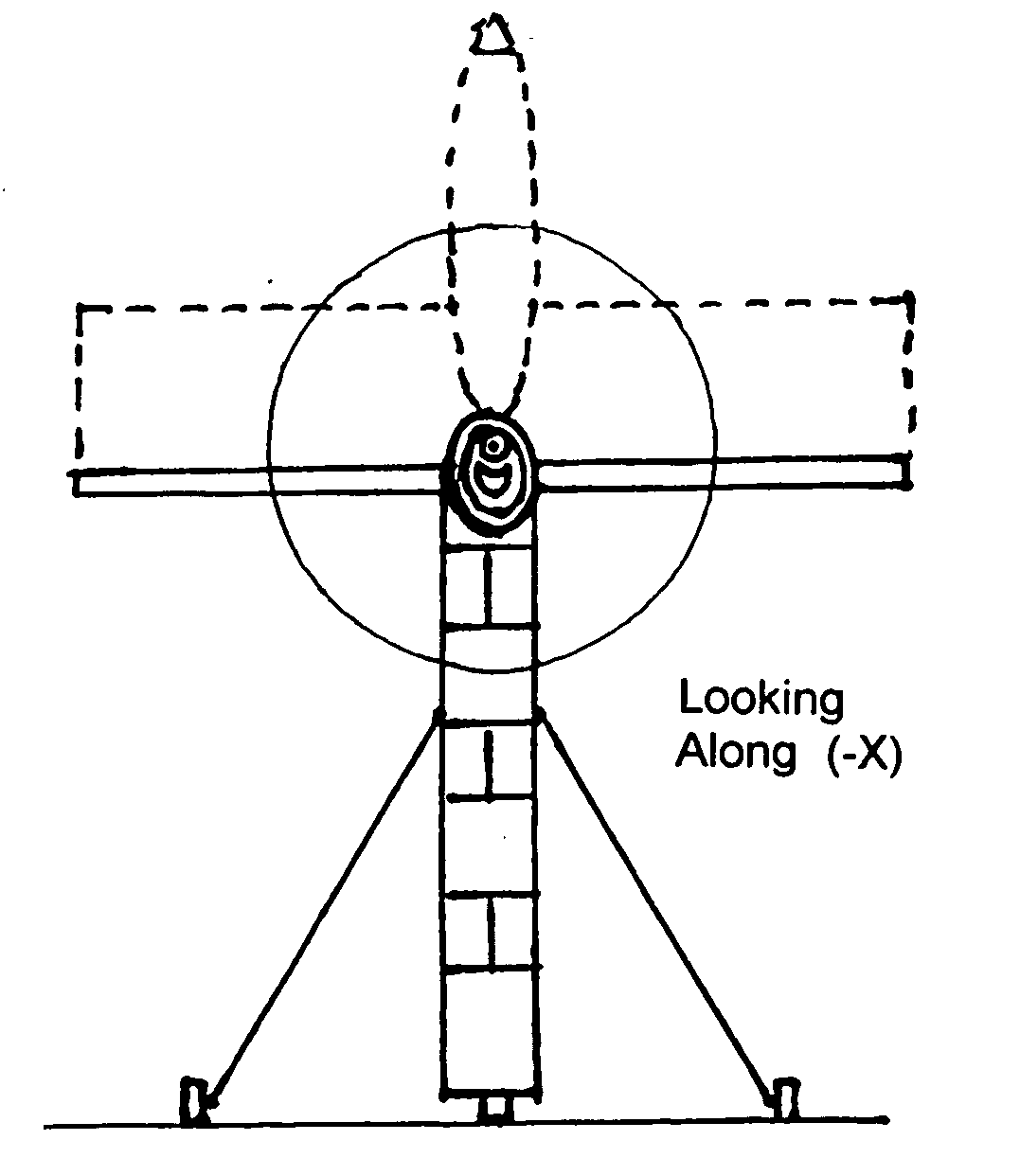

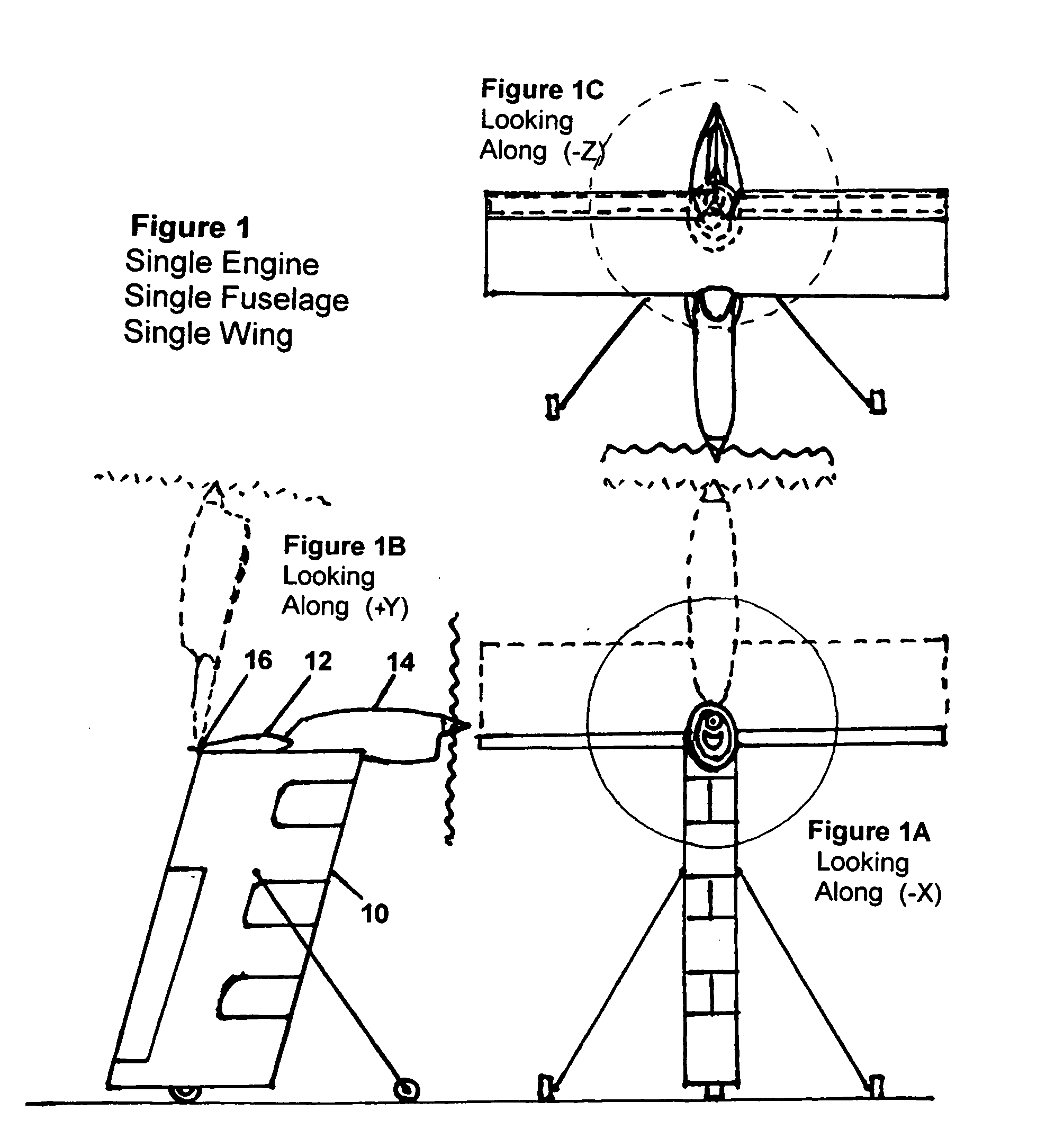

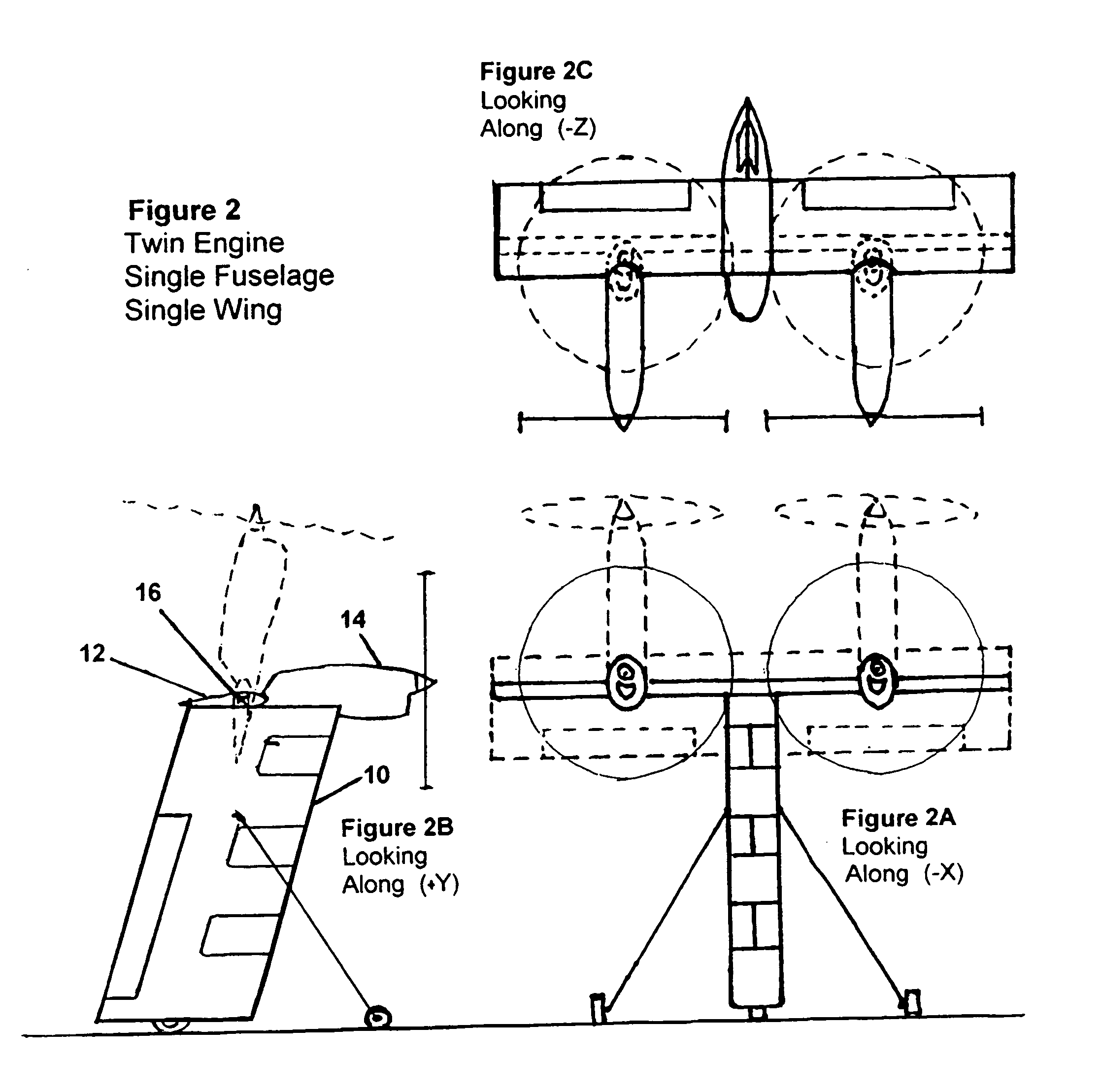

Tall V/STOL aircraft

InactiveUS20060032970A1Improve the stability of actionMinimizes ground effectAircraft stabilisationAll-wing aircraftLeading edgeHorizontal axis

A vertical or short takeoff and landing (V / STOL) airplane is described having a vertical form factor. Making the airplane tall has many advantages when operating in hover mode close to the ground. Several variations of the design are described. The preferred embodiment consists of two tall fuselage2 structures having an airfoil shape in plan view. As high above the ground as practical a “lift wing” spans the space between these fuselages. This wing may be equipped with lift augmentation systems to facilitate V / STOL flight. In the center of the span on the leading edge of the lift wing is placed a turboprop engine. Alternatively, the wing and attached engine can be made to tilt about a horizontal axis. For takeoff the wing will be tilted skyward. A second wing slightly below and behind the lift wing has a pusher engine located on the trailing edge. This lower wing and engine is also able to tilt about a horizontal axis parallel to the lift wing. During takeoff this lower engine is pointed downward toward the ground. This lower wing contains aerodynamic control surfaces to provide attitude and position control. Subsequent to liftoff the wings and engines tilt into a horizontal position to provide cruise lift and thrust. At the end of the flight the wings and attached engines are tilted back to provide vertical lift for hover, maneuvering, and soft landing. 2 “Fuselage” is used here even though it substantially differs from the conventional fuselage (and its French origins meaning, “spindle shaped”) since in plan view it is an airfoil shape of large thickness. It will be used here for lack of a better word. Think of fuselage as meaning “where the pilot, passengers and cargo are located”.

Owner:ALLEN NORMAN CARTER

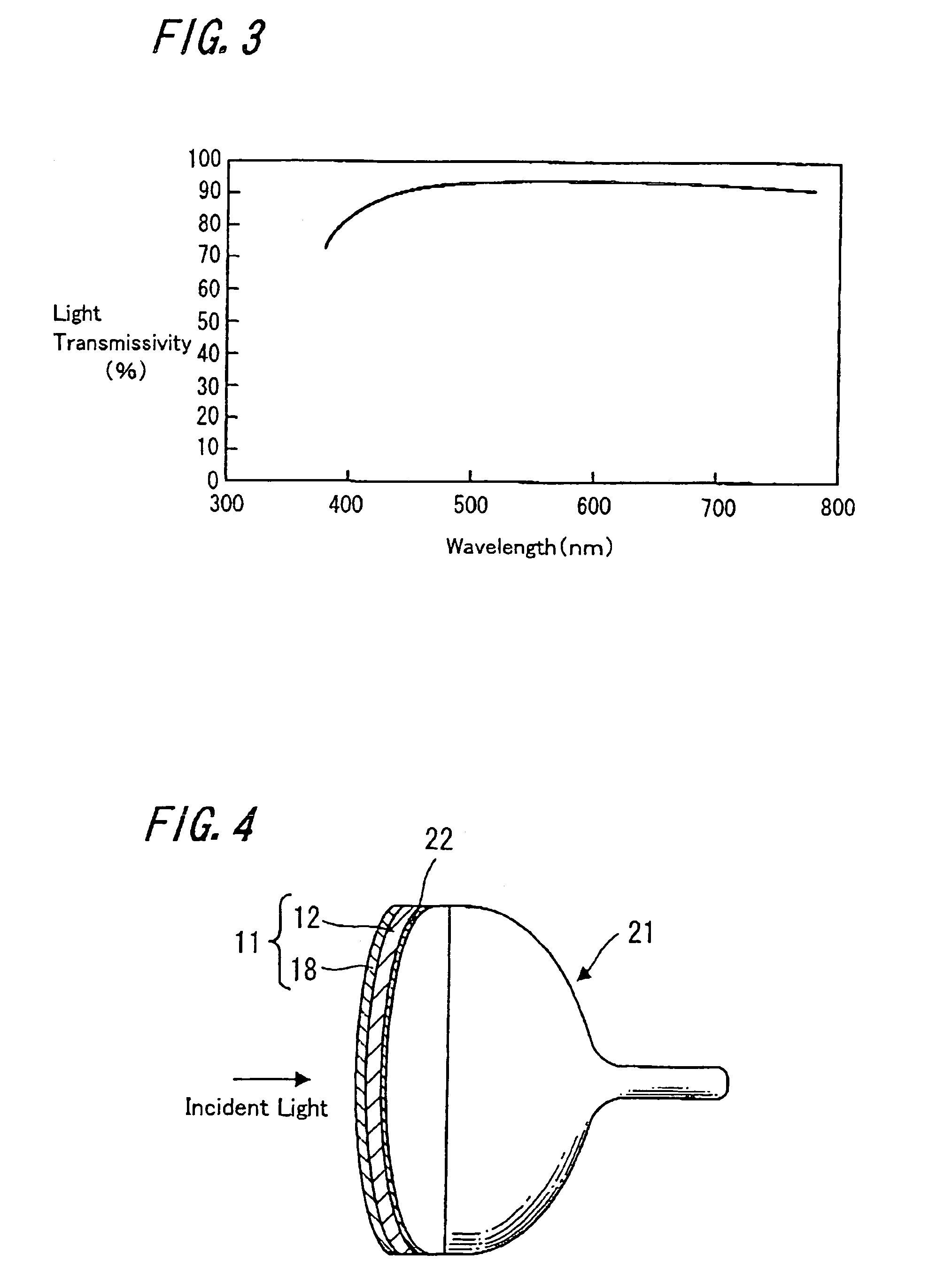

Anti-Reflection Coat and Optical Device

ActiveUS20140009835A1Improve adhesionIncreased durabilityLayered productsNanoopticsSilica particleRefractive index

An anti-reflection coat includes an intermediate layer and a low refractive index layer sequentially stacked on a substrate, and preventing the reflection of incident light by optical interference effect, wherein the low refractive index layer is a film formed on the surface of the intermediate layer by a wet film formation method using a coating liquid including layer-constituting raw materials which includes hollow silica particles adhering each other with a binder, and the intermediate layer is a layer mainly composed of an organometallic compound which adheres well to the binder and having wettability to the coating liquid; and provides an optical device including the anti-reflection coat.

Owner:TAMRON

Packers and methods of use

Expandable packers and methods of using same are described. The expandable packers include an anti-extrusion layer comprising a fibrous layer having a first surface adjacent an outer surface of an inner expandable elastomeric member, and a cable layer adjacent the fibrous layer, the cable layer comprising a plurality of stacked unidirectional layers of cables. The cable layer is adapted to form a barrier substantially devoid of gaps through which the inner elastomer member would otherwise extrude into upon expansion of the inner elastomeric member. This abstract allows a searcher or other reader to quickly ascertain the subject matter of the disclosure. It will not be used to interpret or limit the scope or meaning of the claims. 37 CFR 1.72(b).

Owner:SCHLUMBERGER TECH CORP

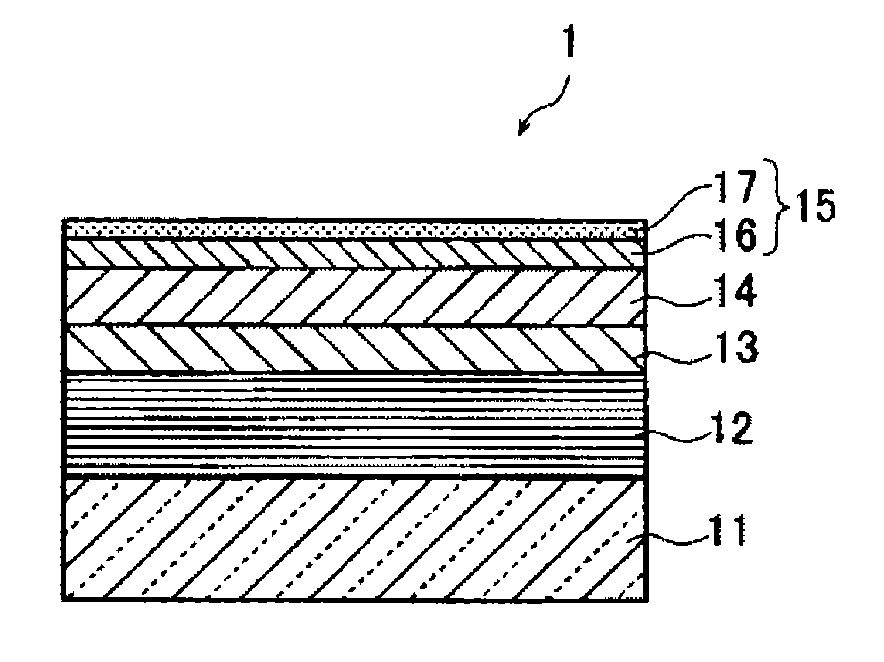

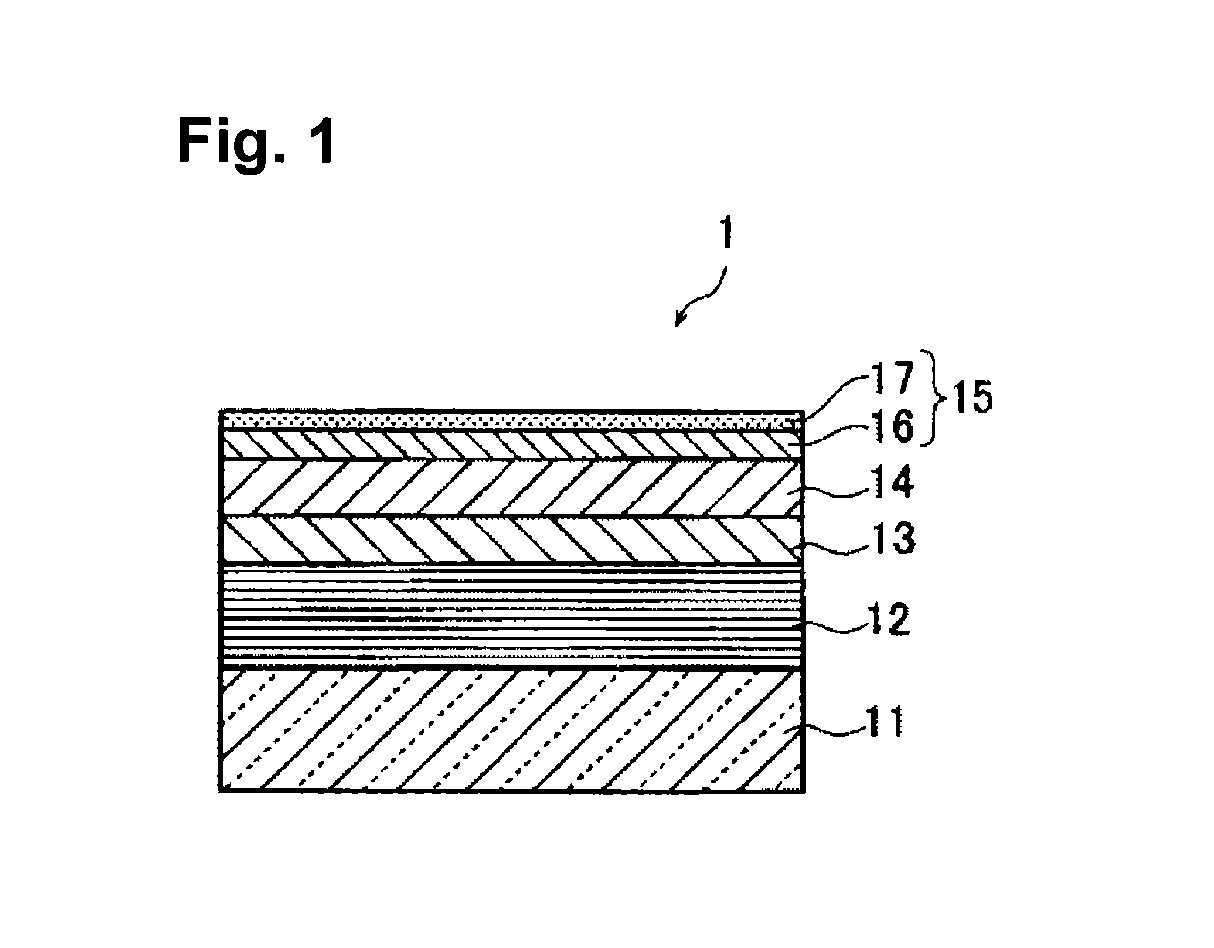

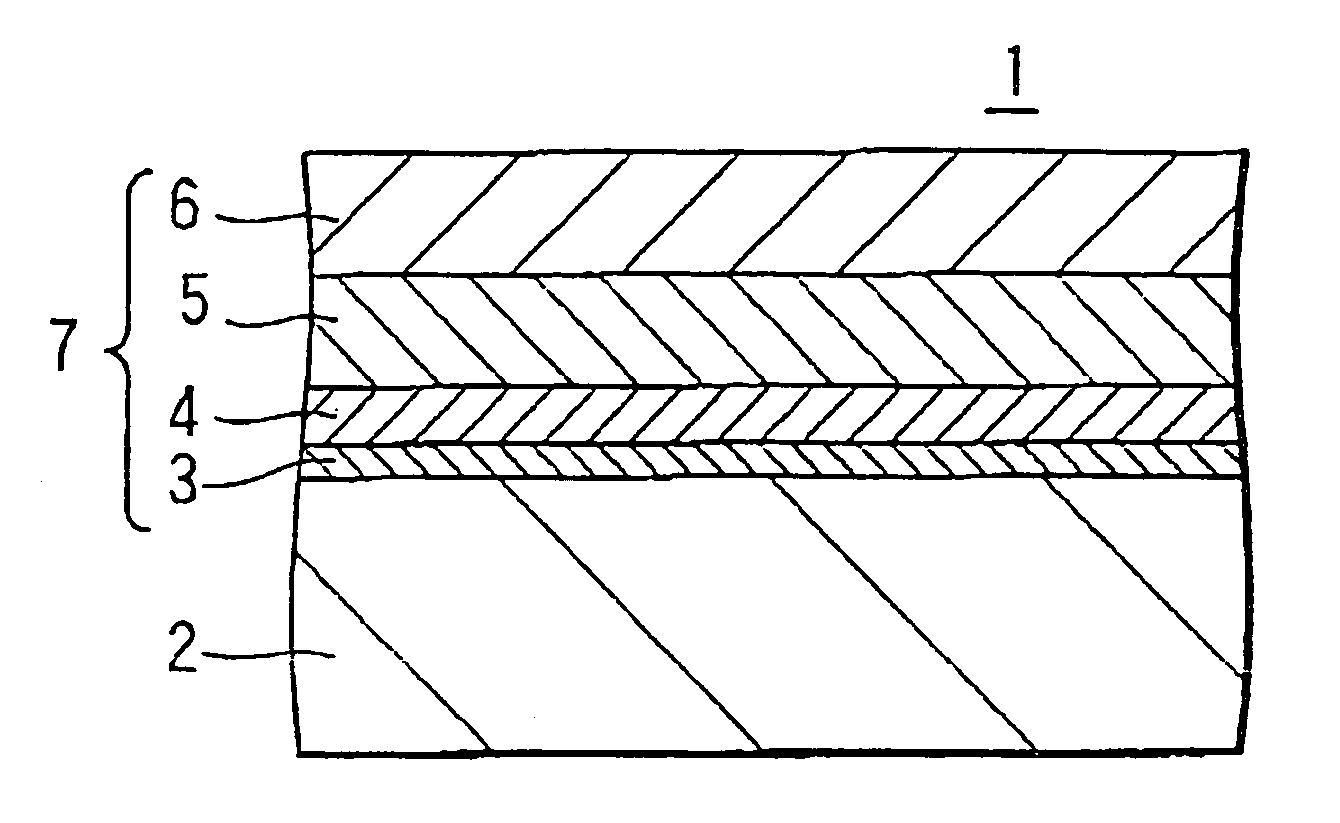

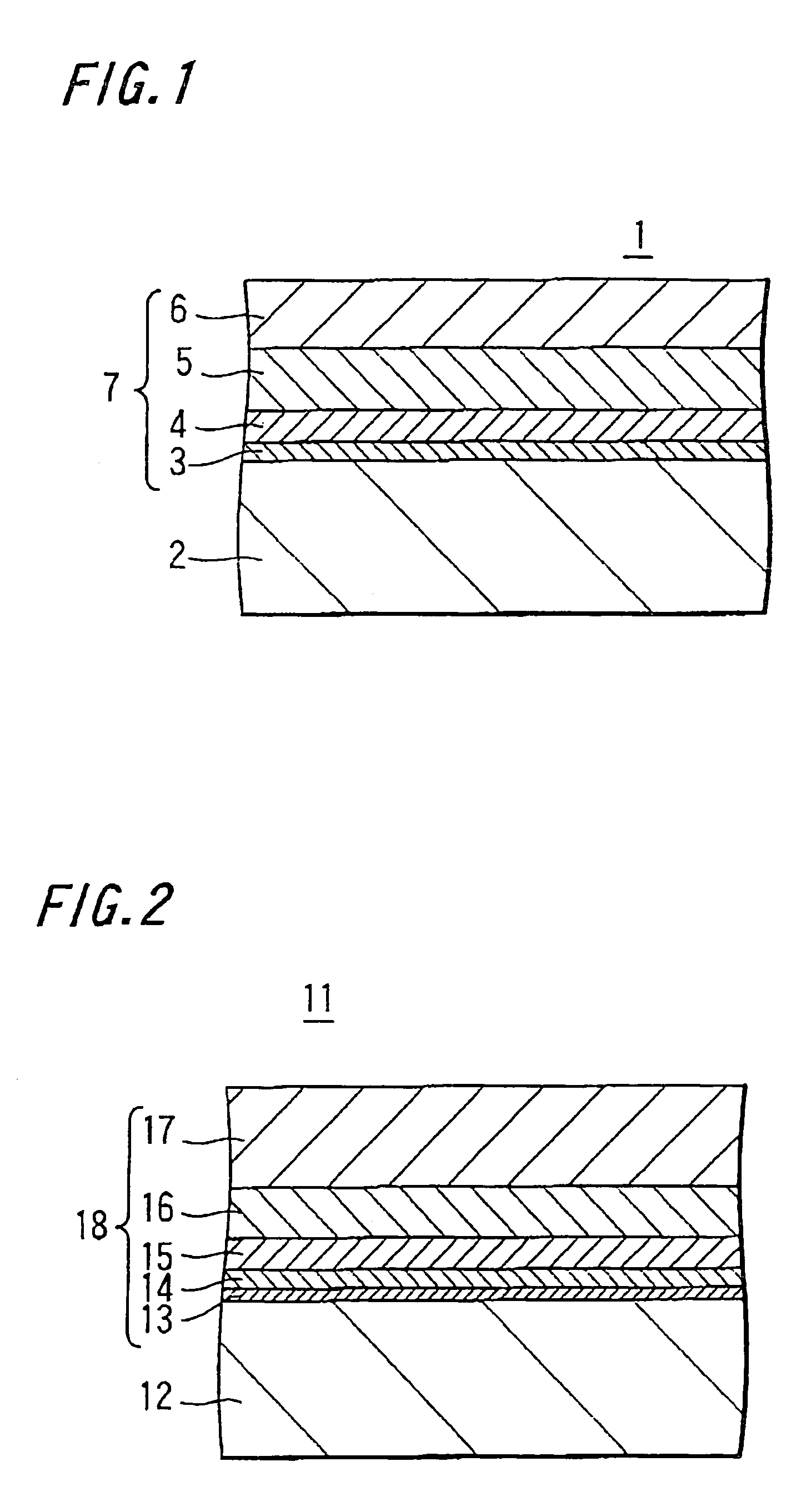

Display apparatus and antireflection substance

InactiveUS7405005B2Improve reliabilityIncrease production capacityVacuum evaporation coatingSputtering coatingRefractive indexMoisture

The present invention provides an antireflection substance such as an antireflection film having a low moisture-permeable characteristic, high quality and high reliability, and also provides a display apparatus comprising this antireflection substance. The antireflection substance according to the present invention includes an antireflection film formed on a transparent substrate, the antireflection film being composed of a multiple layer in which a first layer serving as an adhesion-improving layer, a second layer serving as a barrier layer against moisture, a third layer, a fourth layer and a fifth layer are laminated in this order, and in which the second layer and the fourth layer are each set to have a refractive index higher than that of the third layer and the fifth layer. The display apparatus according to the present invention comprises this antireflection substance on its display surface.

Owner:SONY CORP

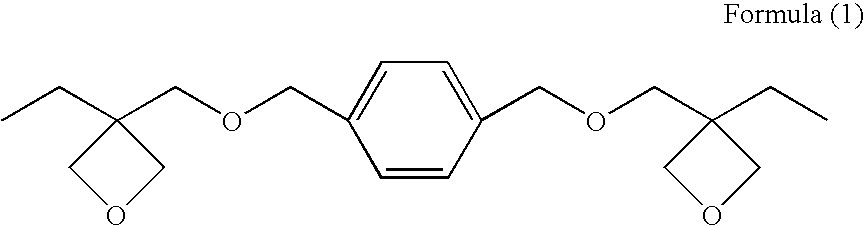

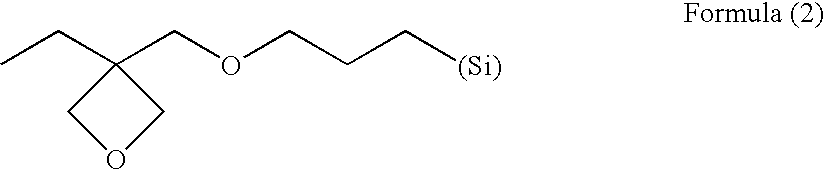

Antireflection film and making method

InactiveUS7229686B2Improve the level ofImprove anti-reflection functionSynthetic resin layered productsRecord information storageRefractive indexTitanium oxide

A high refractive index layer of a cured first coating composition comprising (A) metal oxide fine particles selected from among titanium oxide, aluminum oxide, zirconium oxide, cerium oxide, iron oxide, tin oxide, and compound oxides thereof and (B) a compound having an acrylic, methacrylic, vinyl or styryl group, and a low refractive index layer of a cured second coating composition comprising (D) voided silica-base inorganic oxide fine particles and (C) a compound having at least two epoxy and / or oxetane groups are successively stacked on a substrate to form an antireflection film.

Owner:SHIN ETSU CHEM IND CO LTD

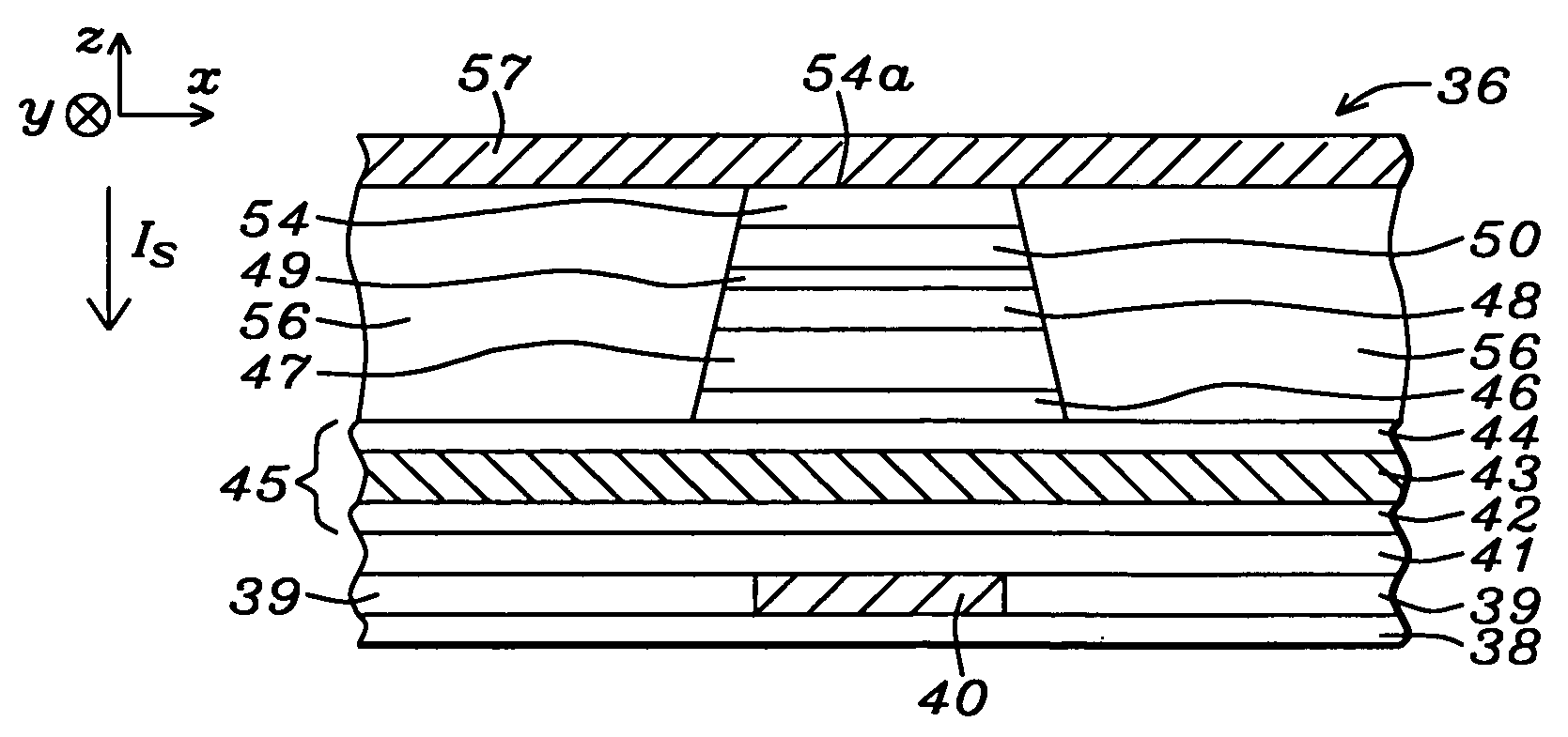

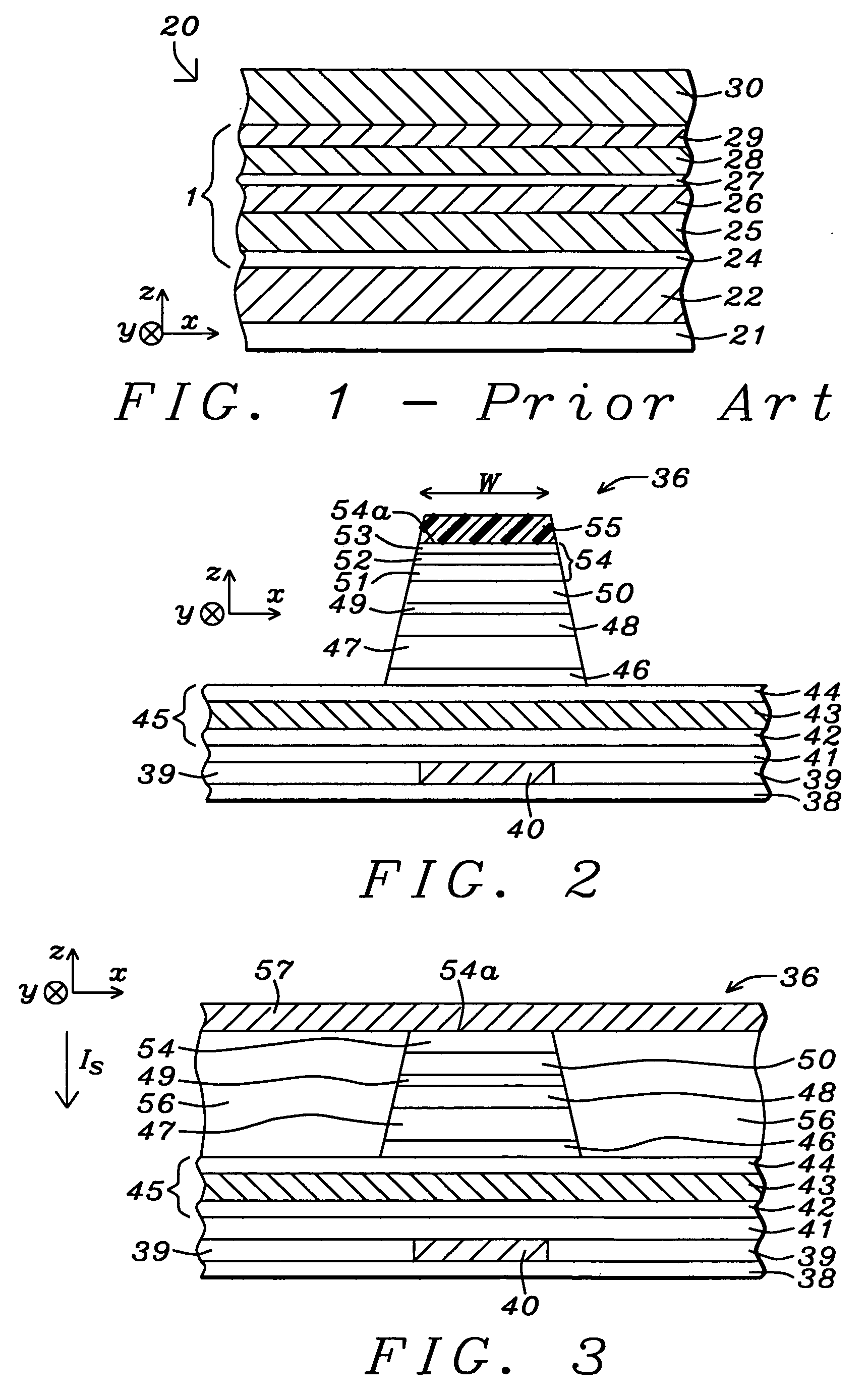

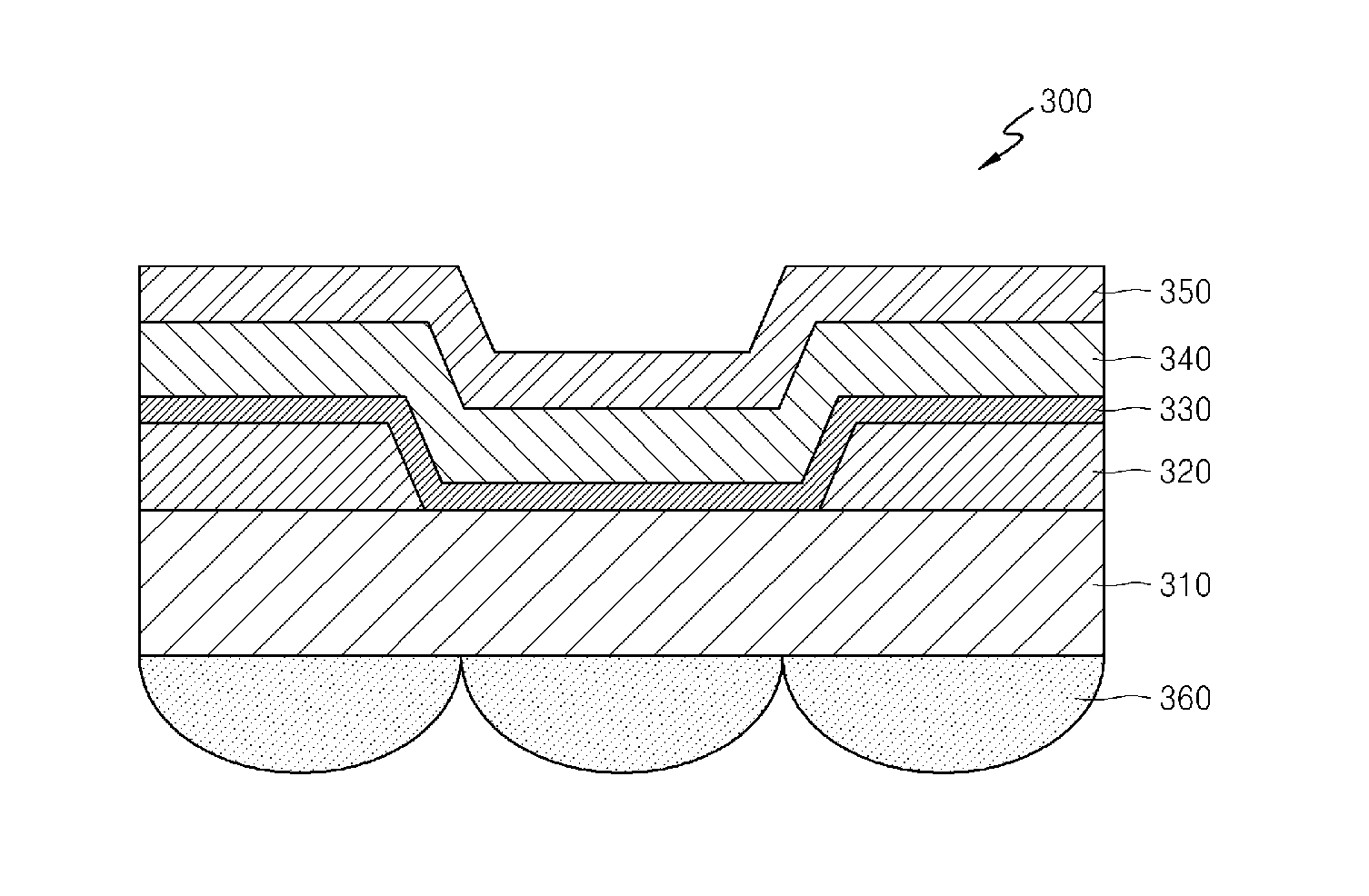

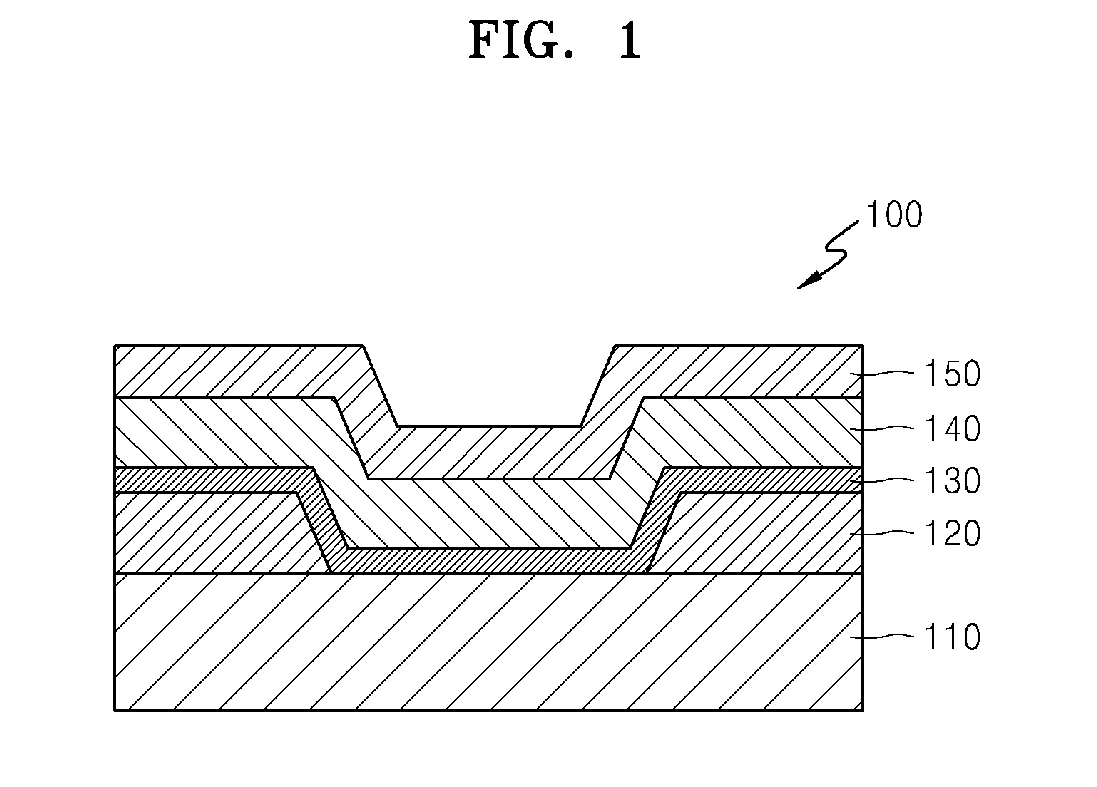

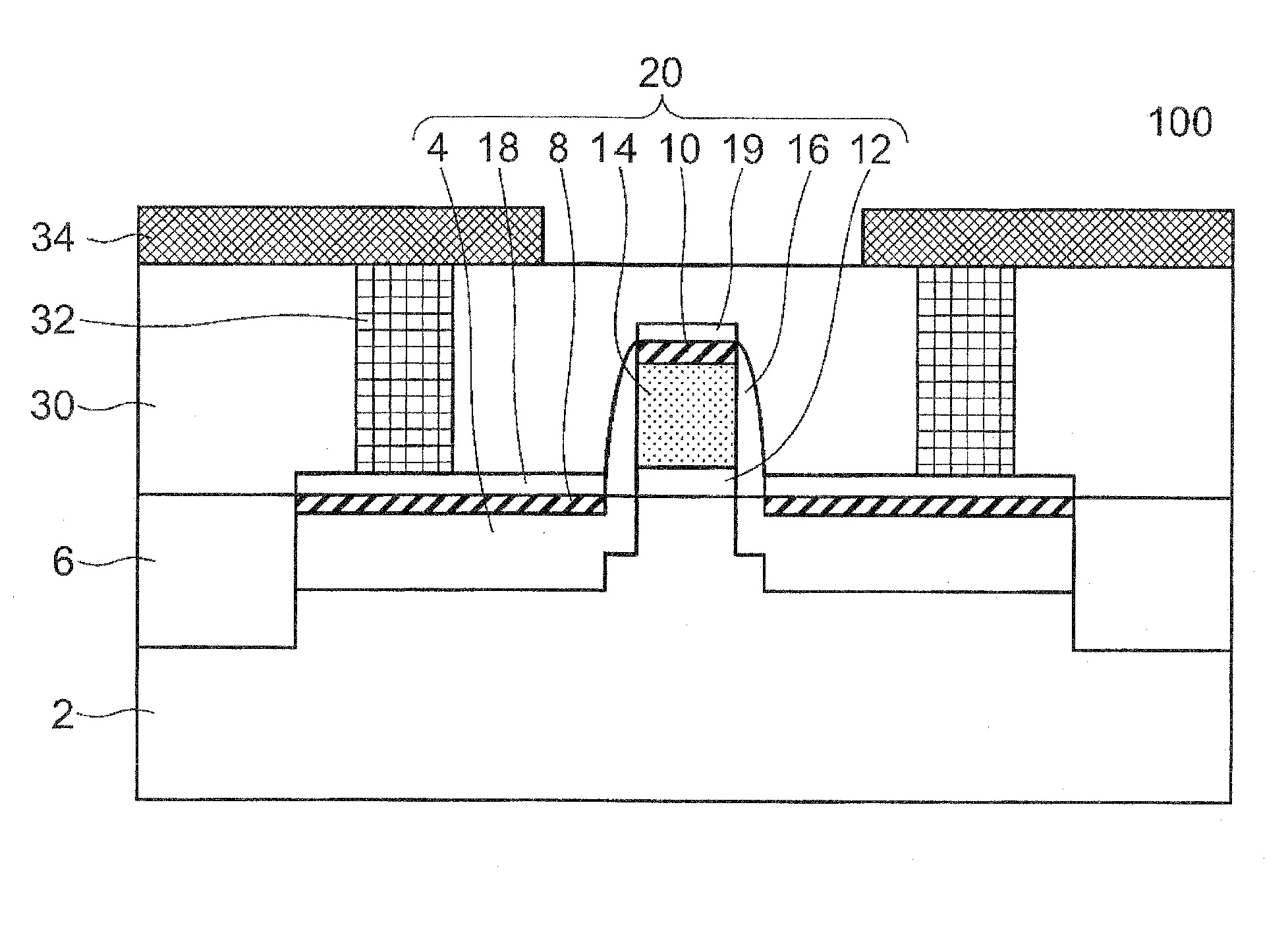

Vertical side wall active pin structures in a phase change memory and manufacturing methods

ActiveUS7456421B2Total current dropLow resistivitySolid-state devicesSemiconductor/solid-state device manufacturingPhase-change memoryEngineering

A programmable resistor memory, such as a phase change memory, with a memory element comprising narrow vertical side wall active pins is described. The side wall active pins comprise a programmable resistive material, such as a phase change material. In a first aspect of the invention, a method of forming a memory cell is described which comprises forming a stack comprising a first electrode having a principal surface with a perimeter, an insulating layer overlying a portion of the principal surface of the first electrode, and a second electrode vertically separated from the first electrode and overlying the insulating layer. Side walls on the insulating layer and on the second electrode are positioned over the principle surface of the first electrode with a lateral offset from the perimeter of the first electrode.

Owner:MACRONIX INT CO LTD

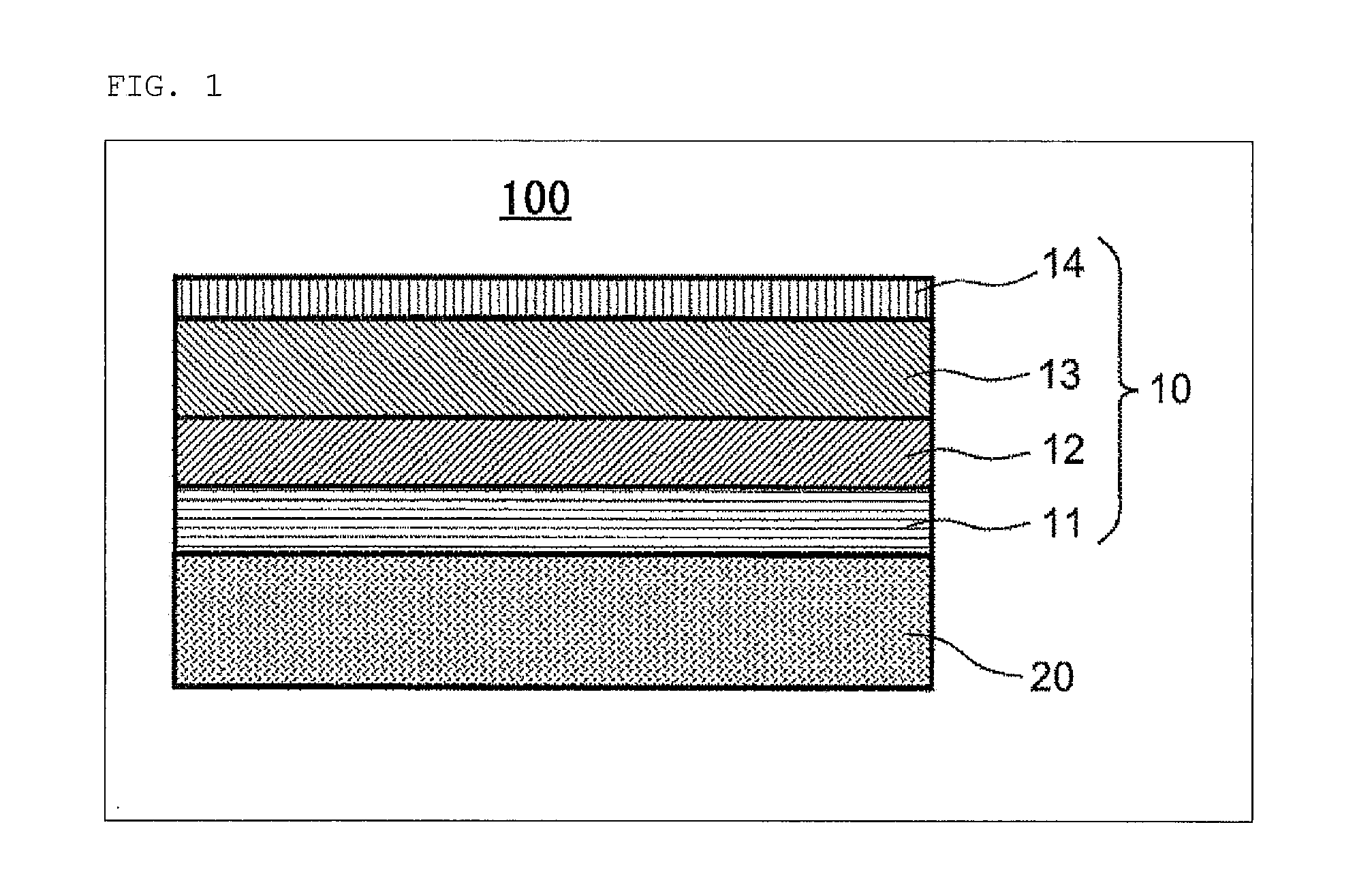

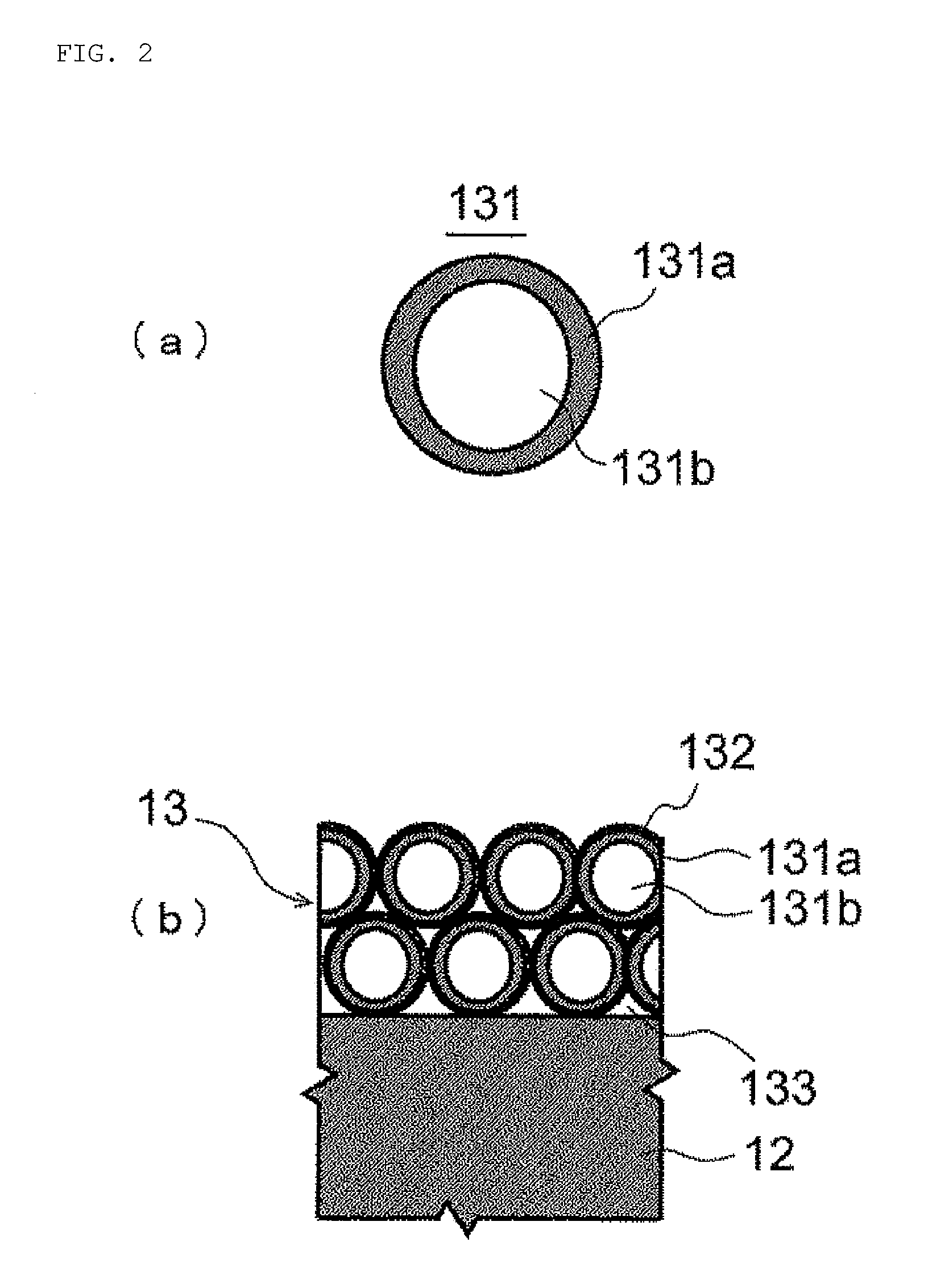

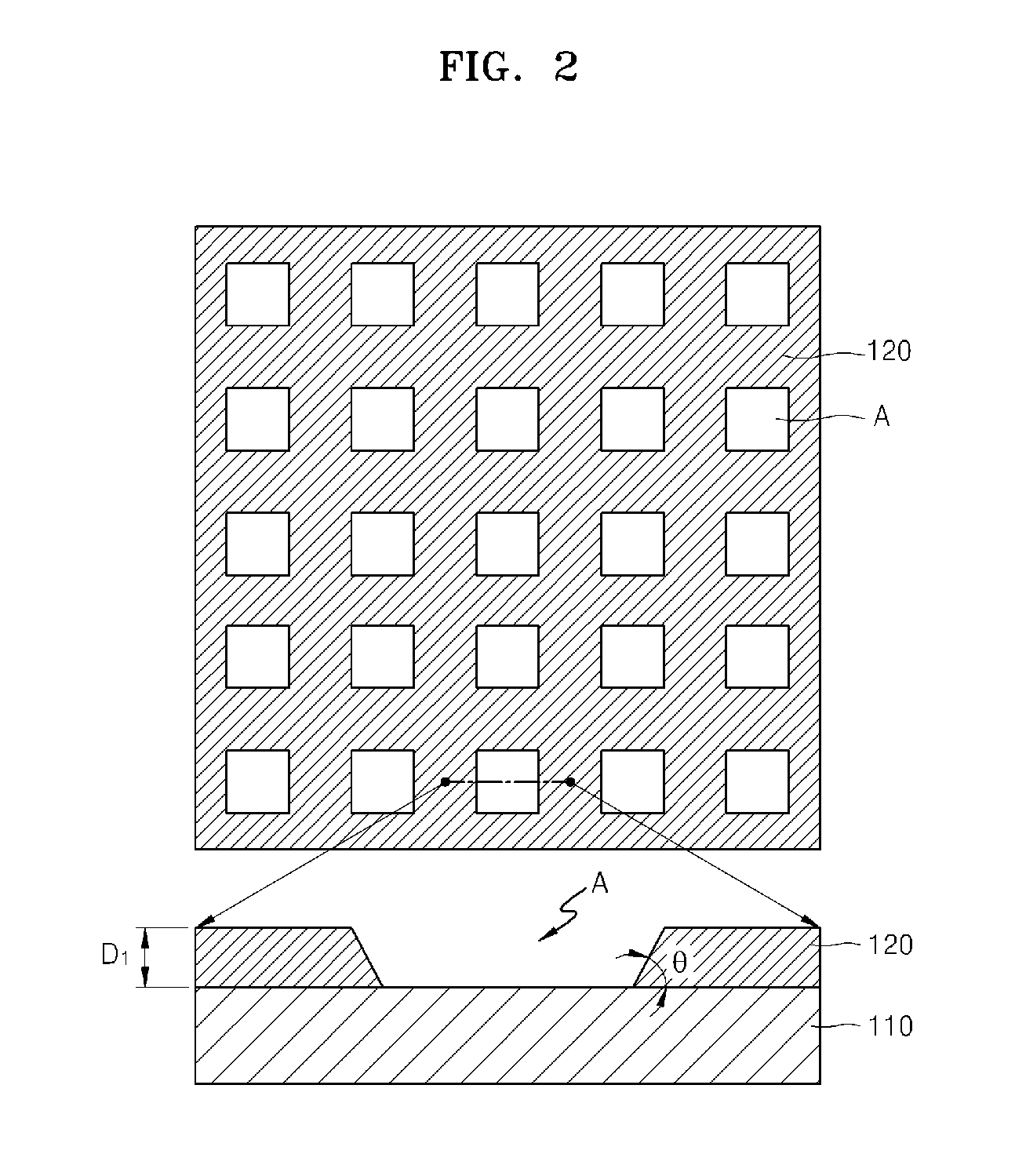

Organic light emitting device, lighting apparatus including organic light emitting device, and organic light emitting display apparatus including organic light emitting device

ActiveUS20110121272A1Improve Outcoupling EfficiencyImprove work functionSolid-state devicesSemiconductor/solid-state device manufacturingLight equipmentOrganic light emitting device

An organic light emitting device having increased outcoupling efficiency, a lighting apparatus including the organic light emitting device, and an organic light emitting display apparatus including the organic light emitting device. The organic light emitting device includes a substrate, a first electrode layer that is uniformly patterned on the substrate, a low refractive conductive layer disposed on the first electrode layer, and having a conductive material with a lower refractive index than a refractive index of an organic layer that is disposed on the low refractive conductive layer, and a second electrode layer formed on the organic layer.

Owner:SAMSUNG DISPLAY CO LTD +1

Electro-static chuck with non-sintered aln and a method of preparing the same

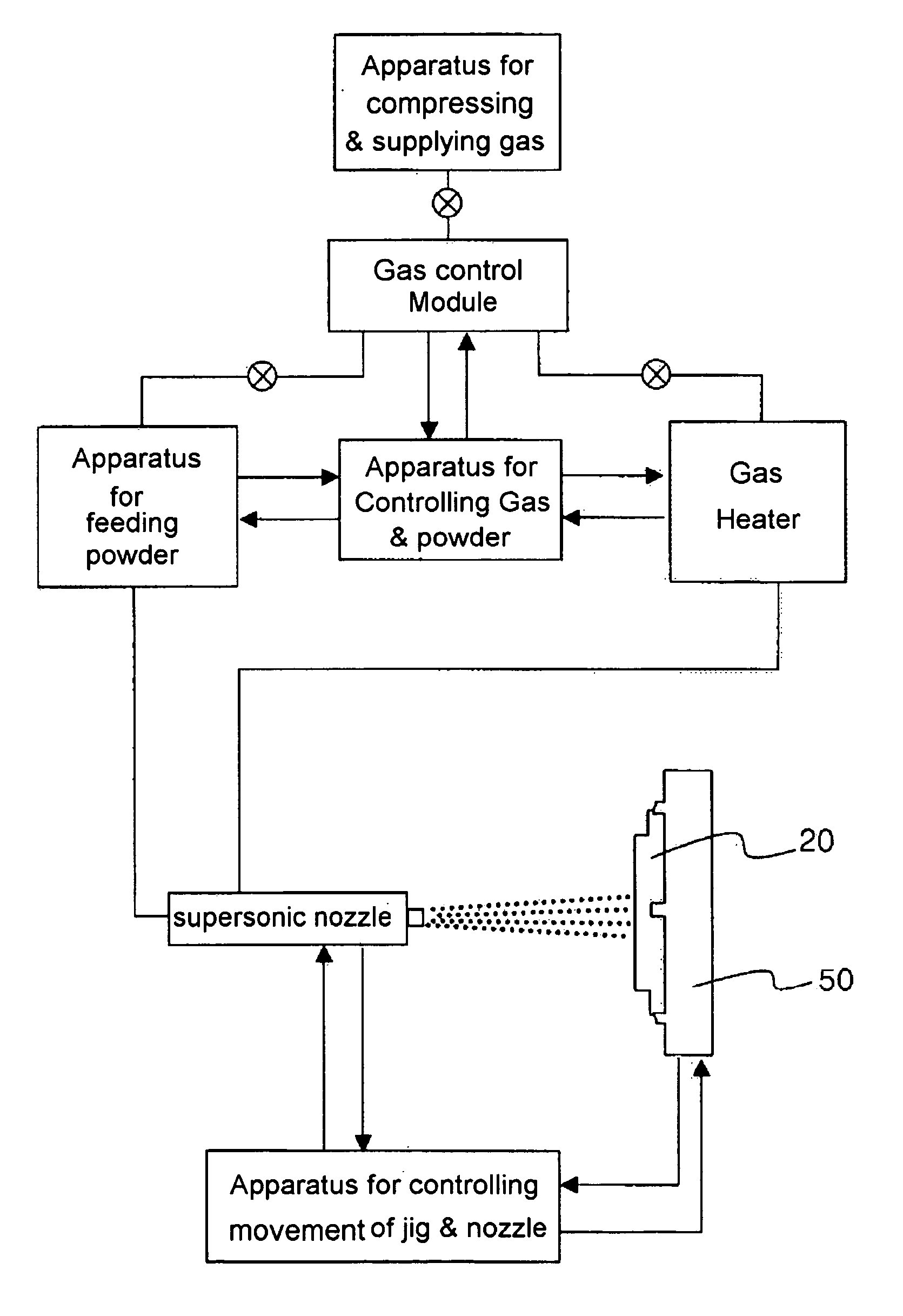

InactiveUS20070065678A1Excellent electrostatic propertyImprove thermal conductivityPretreated surfacesSemiconductor/solid-state device manufacturingBonding processNitride

The present invention relates to an electro-static chuck with non-sintered AlN and a method of preparing the same. Especially, the present invention relates to the electro-static chuck with non-sintered AlN which having coated aluminum nitride (AlN) layer as a dielectric one on the purpose of chucking the wafers in the process of wafers and a method of preparing the same. The electro-static chuck of the present invention has excellent dielectric characteristics, bonding strength and thermal conductivity by forming an AlN layer as a dielectric one without sintering process or bonding process with binders.

Owner:SNT CO LTD

Semiconductor device and manufacturing method thereof

InactiveUS20090085131A1Low layer resistanceLow layerTransistorSemiconductor/solid-state device manufacturingDevice materialDiffusion layer

The semiconductor device includes: a semiconductor substrate; a diffusion layer provided in the semiconductor substrate; a gate insulation film provided on the semiconductor substrate; a gate electrode provided on the gate insulation film; and a Ni silicide layer selectively provided on the diffusion layer, and a metal cap film having Co as a main component is selectively provided on the Ni silicide layer.

Owner:RENESAS ELECTRONICS CORP

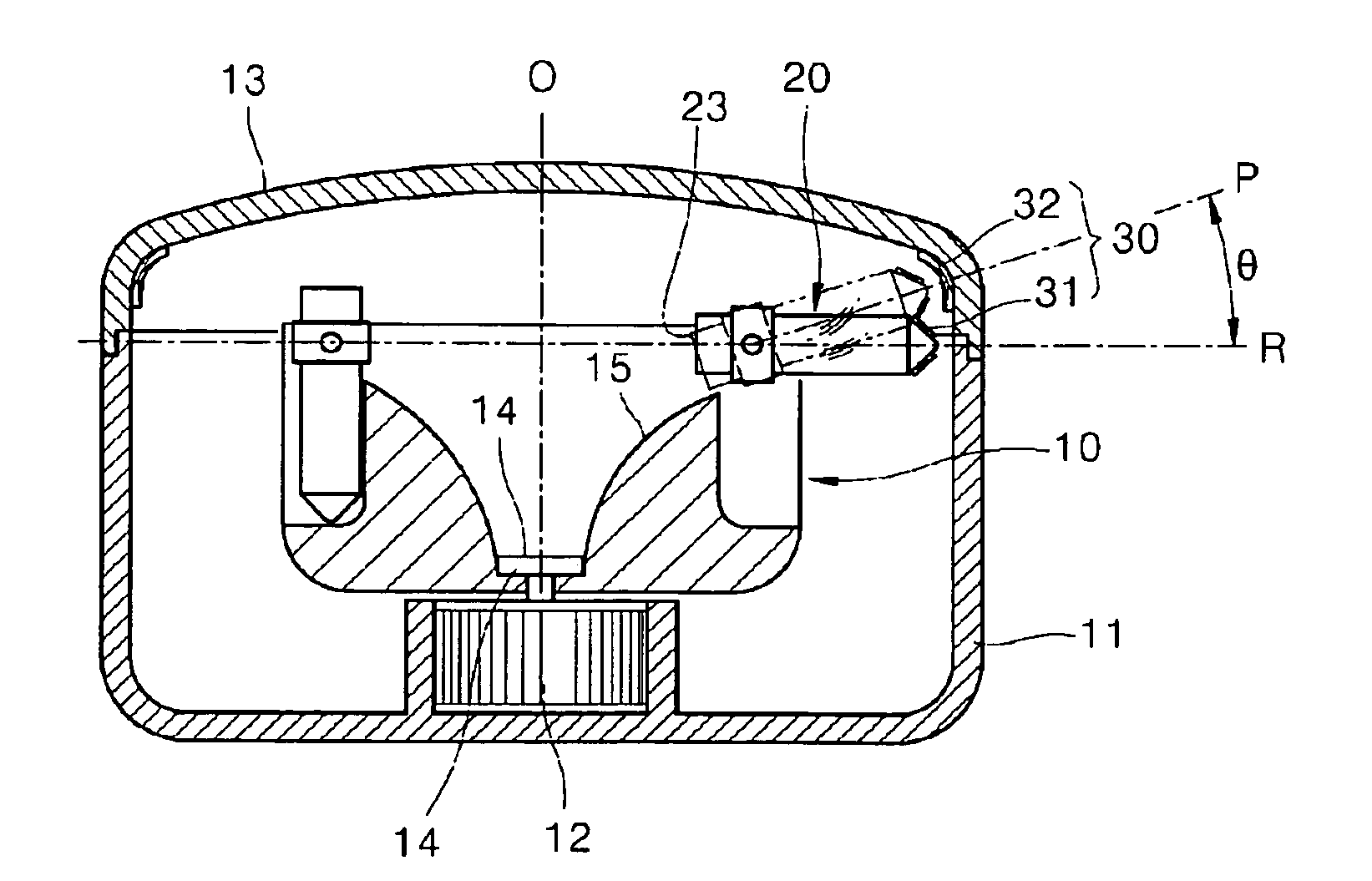

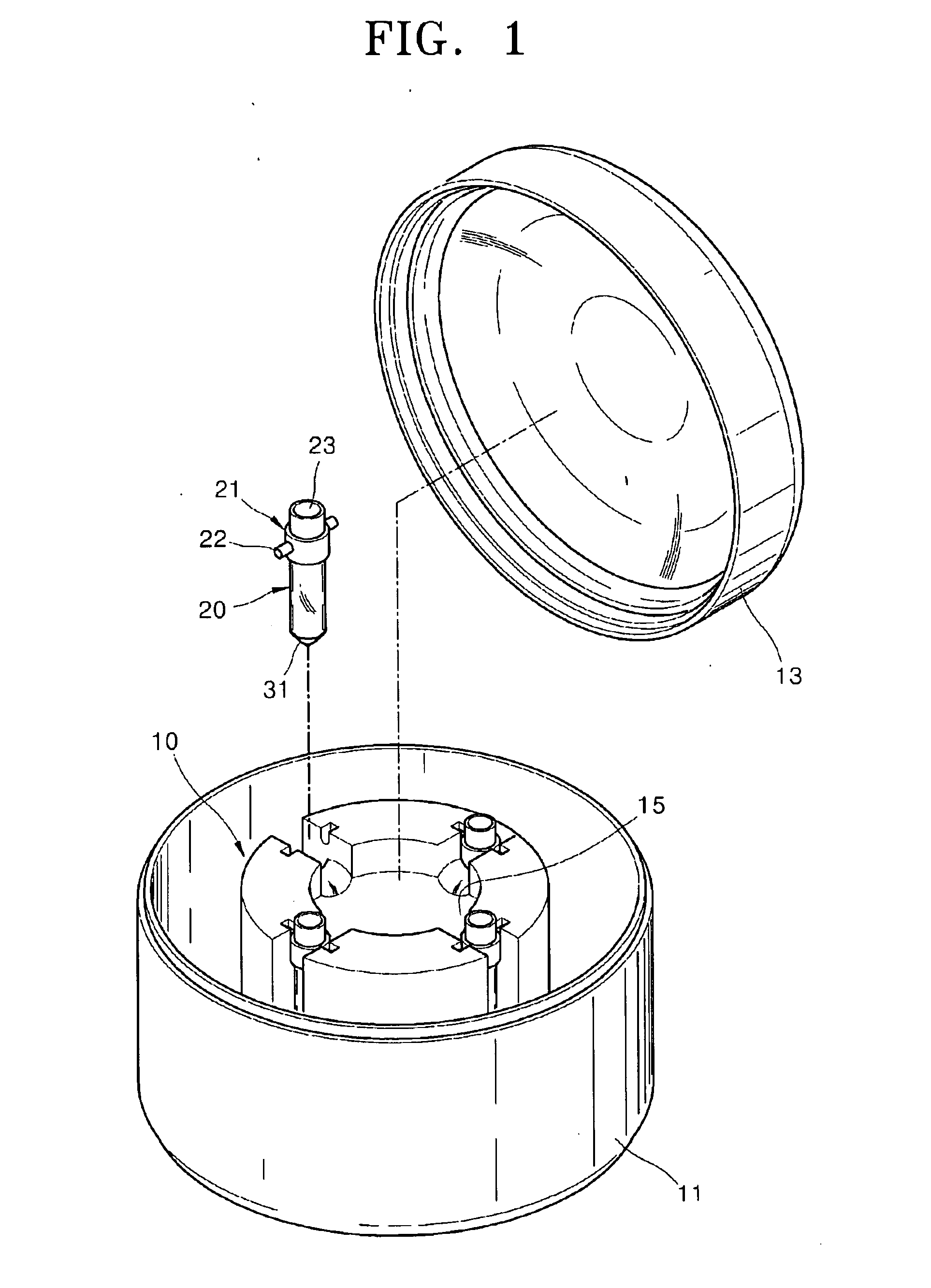

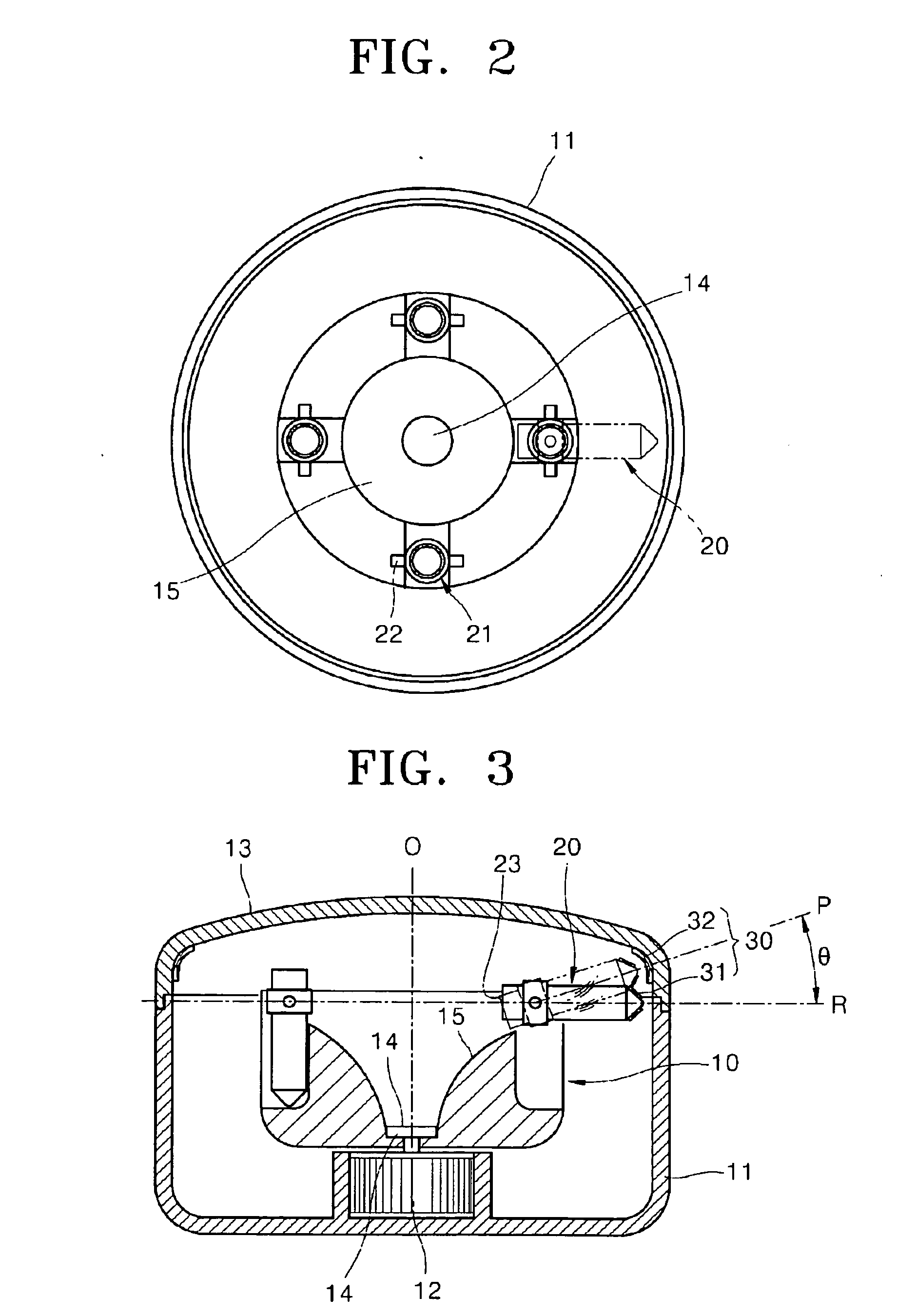

Centrifuge and centrifuging method

InactiveUS20090312169A1Promote stratificationLow layerDispersed particle separationCentrifugal force sediment separationRotational axisRotation flap

Provided are a centrifuge that rotates about a rotation axis to separate a material and a method of centrifugal separation. The container is coupled to the centrifuge to freely pivot upward and downward on a pivoting axis vertical to a rotation plane. The container has an opening at an upper end thereof and holds a material inside. An angle adjuster raises the central axis of the container beyond a perpendicular angle with the rotation axis while the centrifuge is rotating in order to arrange the opening of the container downward with respect to the rotation plane and point an end of the container opposite to the opening of the container upward with respect to the rotation plane, and allow a portion of layers formed during centrifugal separating to flow down through the opening.

Owner:YANG HYUN JIN

Optical film, polarizing plate and image display device

InactiveUS20070243370A1Lower refractive indexReduced durabilitySynthetic resin layered productsPolarising elementsRefractive indexOptical thin film

An optical film including a support and a layer provided by applying a coating composition as an outermost layer, wherein the coating composition contains a fluorine-containing compound having a fluorine content of 40% by weight or more, and a particle having a particle size of from 5 to 120 nm, and the outermost layer has a refractive index of from 1.20 to 1.38.

Owner:FUJIFILM CORP

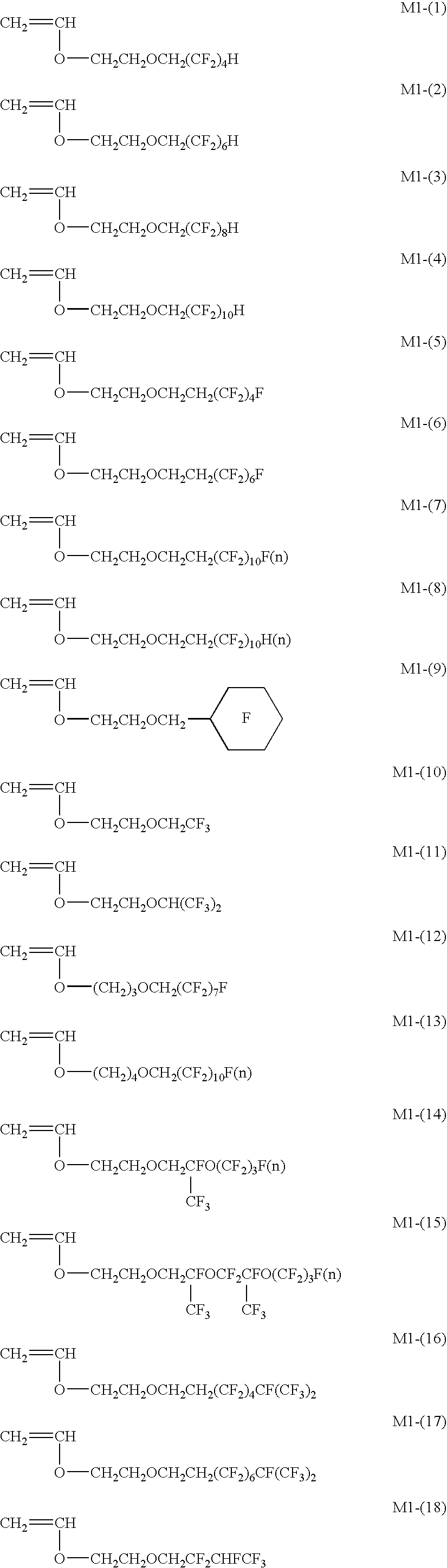

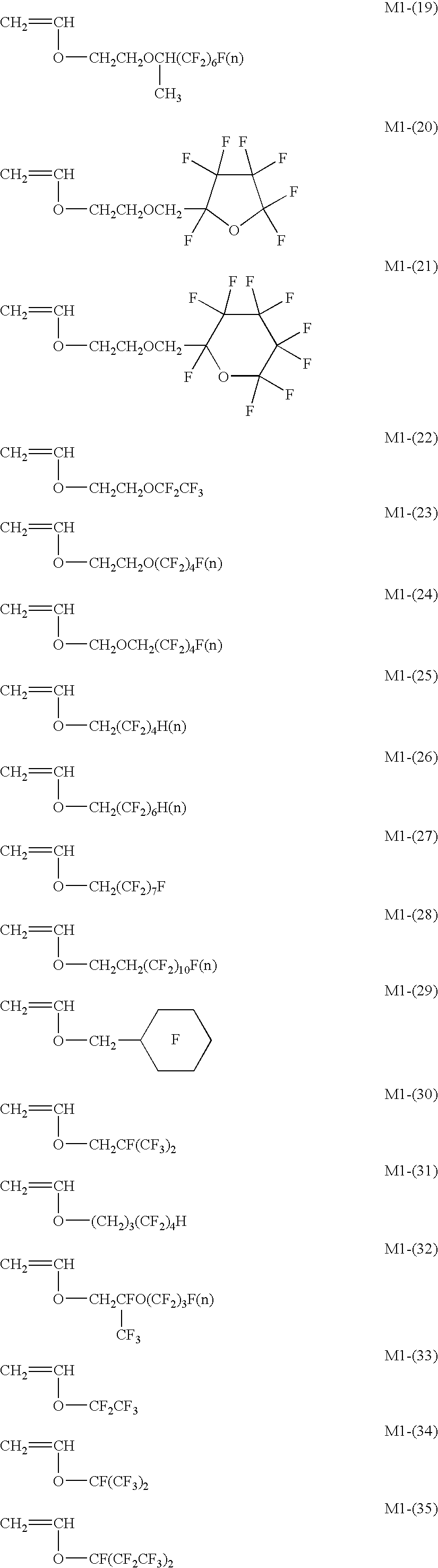

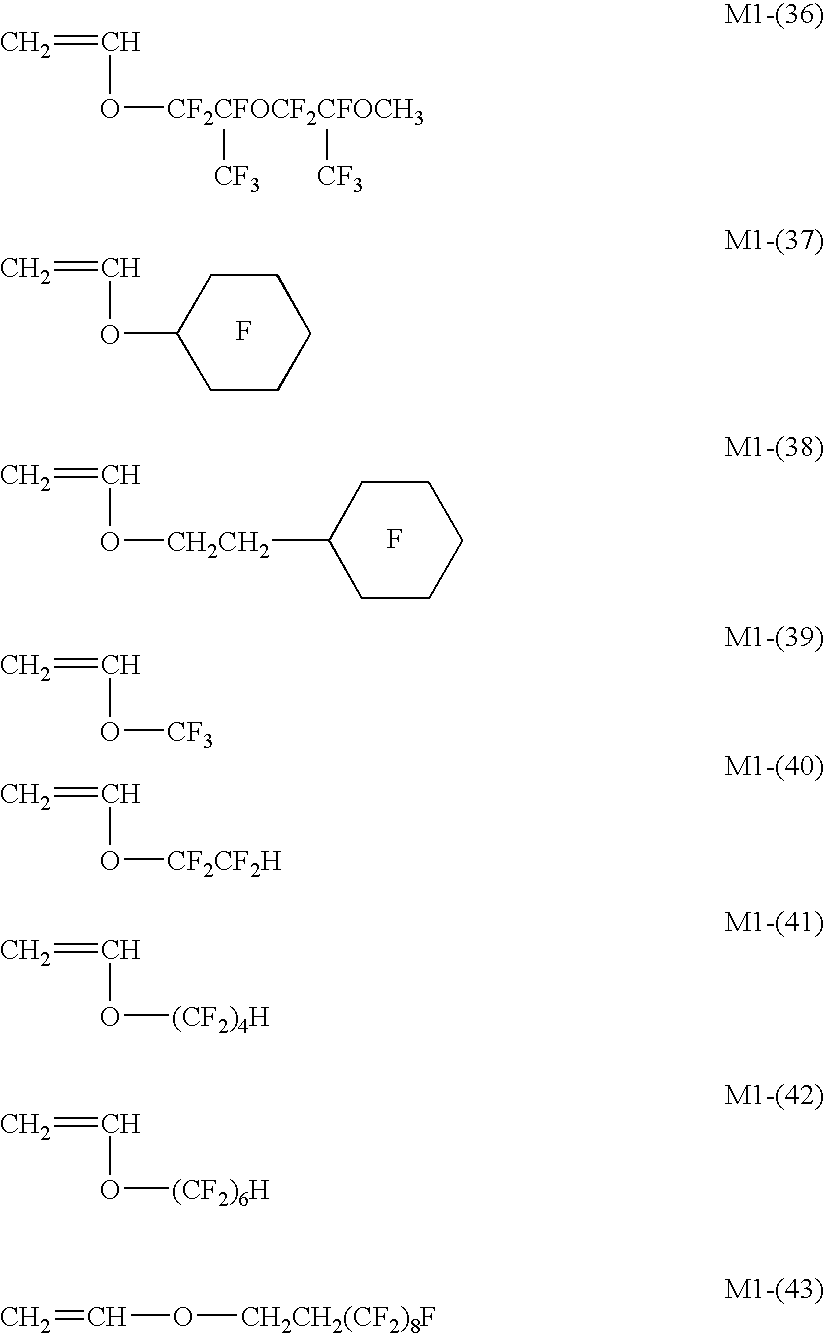

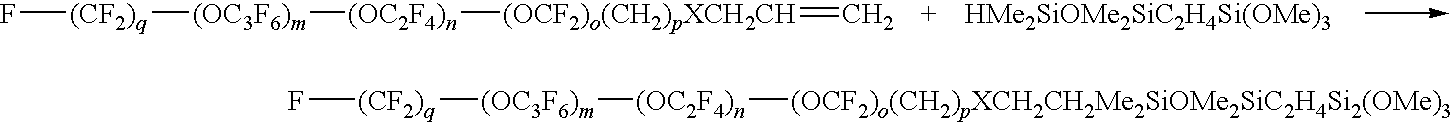

Surface modifier and its use

ActiveUS20090216035A1Well formedLow layerSilicon organic compoundsCoatingsMedicinal chemistrySurface modified

A surface modifier comprising an organosilicone compound represented by General Formula (A) and / or General Formula (B): F—(CF2)q—(OC3F4)m—(OC2F4)n—(OCF2)o(CH2)pXX″Si(X′)3-a(R1)a (A) and F—(CF2)q—(OC3F6)m—(OC2F4)n—(OCF2)o(CH2)pXX″(X′)2-a(R1)aSiO(F—(CF2)q—(OC3F6)m—(OC2F4)n—(OCF2)o—(CH2)pXX″(X′)1-a(R1)aSiO)zF—(CF2)q—(OC3F6)m—(OC2F4)n—(OCF2)o(CH2)pXX″(X′)2-a(R1)aSi(B) wherein q is an integer from 1 to 3; m, n, and o are independently integers from 0 to 200; p is 0, 1 or 2; X is oxygen or a bivalent organic spacer group: X″ is a bivalent organosilicone spacer group; X′ is hydrolysable group; and z is an integer from 0 to 10 when a is 0 or 1.

Owner:DAIKIN IND LTD +1

Reflection-reducing interference layer system and method for producing it

ActiveUS8192639B2Simple and cost-effective methodLow layerDecorative surface effectsOptical articlesRefractive indexHybrid material

A reflection-reducing interference layer system is disclosed, which has at least three alternating layers having different refractive indices. At least one nanostructured layer comprising an organic material or an organic-inorganic hybrid material is applied to the alternating layers. With the interference layer system, it is possible to obtain very low reflection over a wide wavelength and incident angle range.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Ceramic membranes with integral seals and support, and electrochemical cells and electrochemical cell stacks including the same

InactiveUS7736787B2Avoid Diffusion LimitationHigh mechanical strengthFuel cells groupingActive material electrodesCeramic membranePorous electrode

Ceramic membranes with integral seals and support, and related electrochemical cells and cell stacks. The membrane comprises a thin electrolyte layer supported on a porous electrode layer which in turn is supported on a thick ceramic support layer, preferably a ceramic electrolyte support. The support layer is divided into a plurality of self-supporting thin membrane regions by a network of thicker integrated support ribs. The thin electrolyte layer and thick ceramic support layer preferably define a sealing perimeter surrounding the porous electrode layer.

Owner:NEXCERIS INNOVATION HLDG LLC

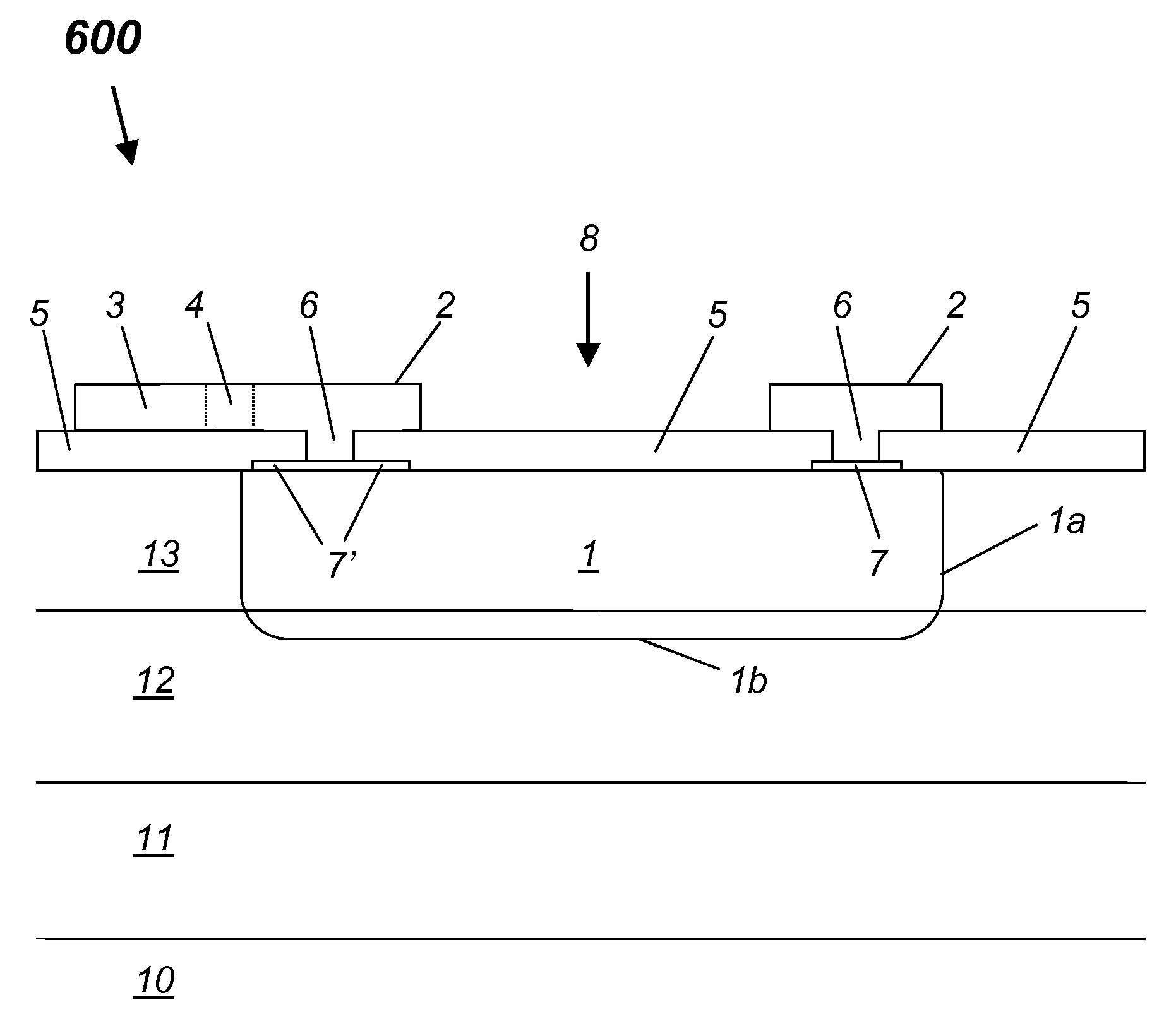

Laminate, infrared ray absorption filter, bandpass filter, method for manufacturing laminate, kit for forming bandpass filter, and image display device

InactiveUS20170090083A1Low costHigh refractive areaElectrical apparatusOptical filtersBandpass filteringAbsorption filter

Owner:FUJIFILM CORP

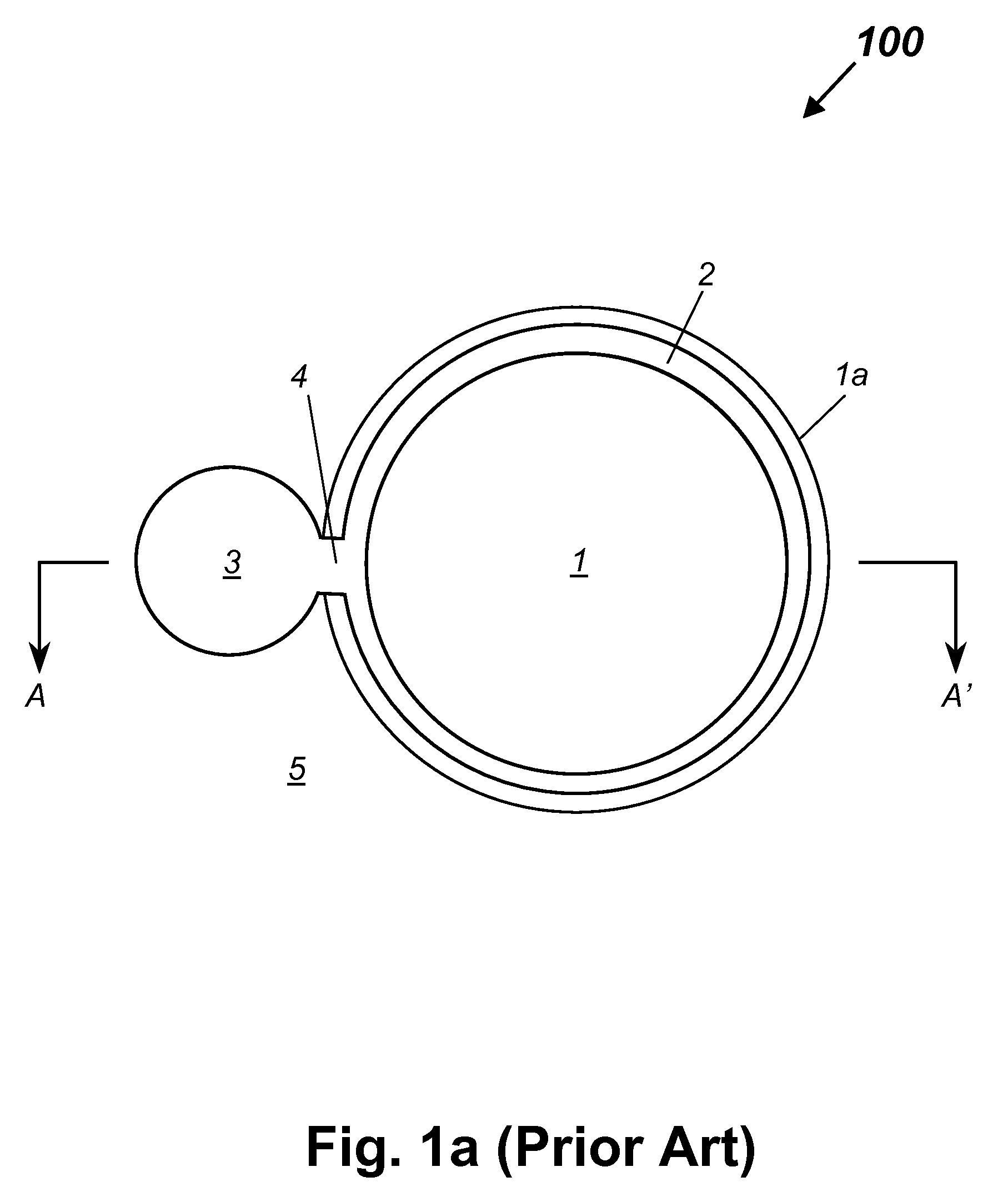

Photodiode with high ESD threshold

ActiveUS20100301441A1Current densityPromote lateral current spreadingSemiconductor/solid-state device manufacturingPhotovoltaic energy generationElectrical resistance and conductancePhotovoltaic detectors

A photodetector with an improved electrostatic discharge damage threshold is disclosed, suitable for applications in telecommunication systems operating at elevated data rates. The photodetector may be a PIN or an APD fabricated in the InP compound semiconductor system. The increased ESD damage threshold is achieved by reducing the ESD induced current density in the photodetector by a suitable widening of the contact at a critical location, increasing the series resistance and promoting lateral current spreading by means of a current spreading layer.

Owner:LUMENTUM OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com