Patents

Literature

33results about How to "Improve Outcoupling Efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

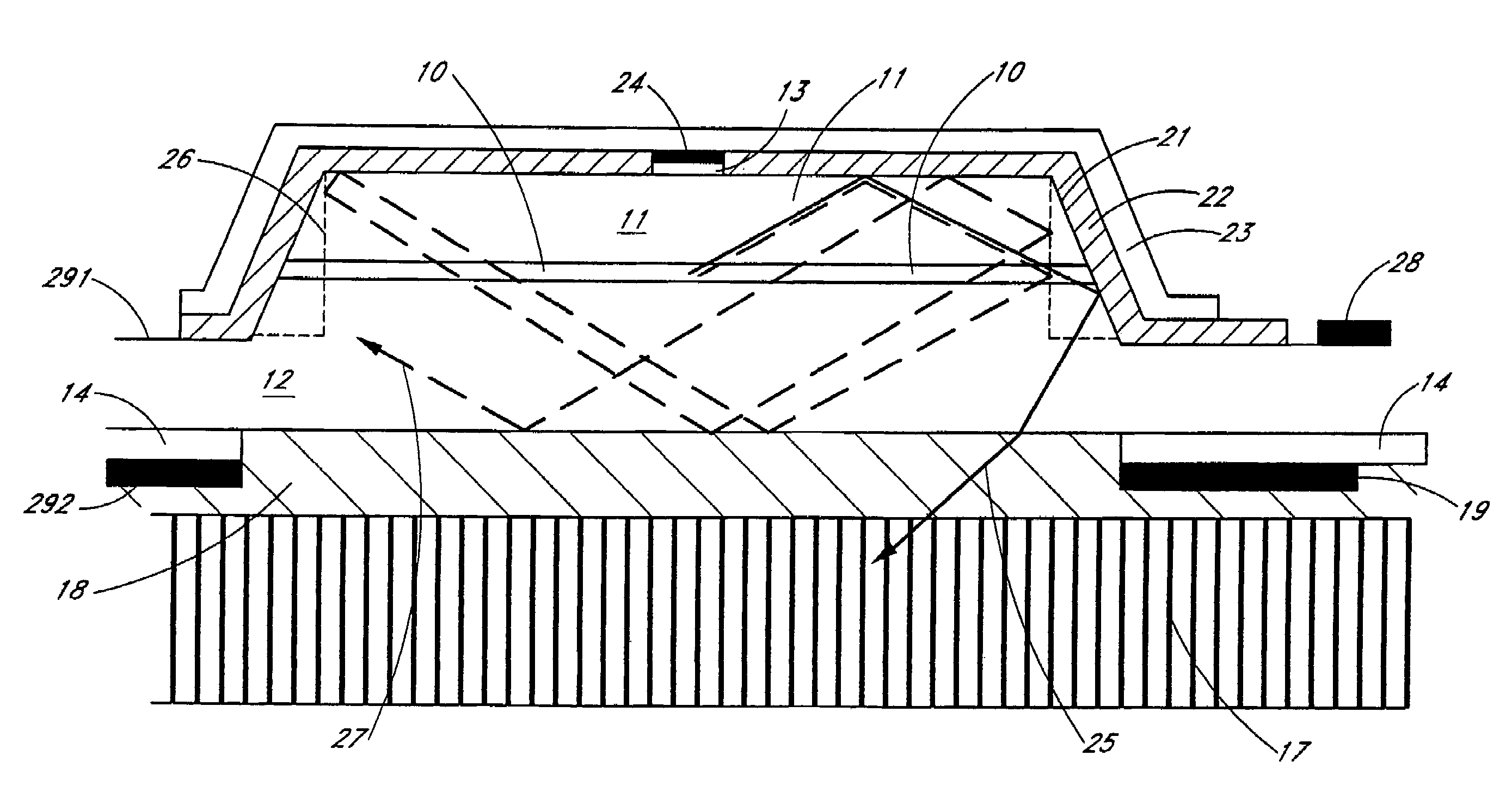

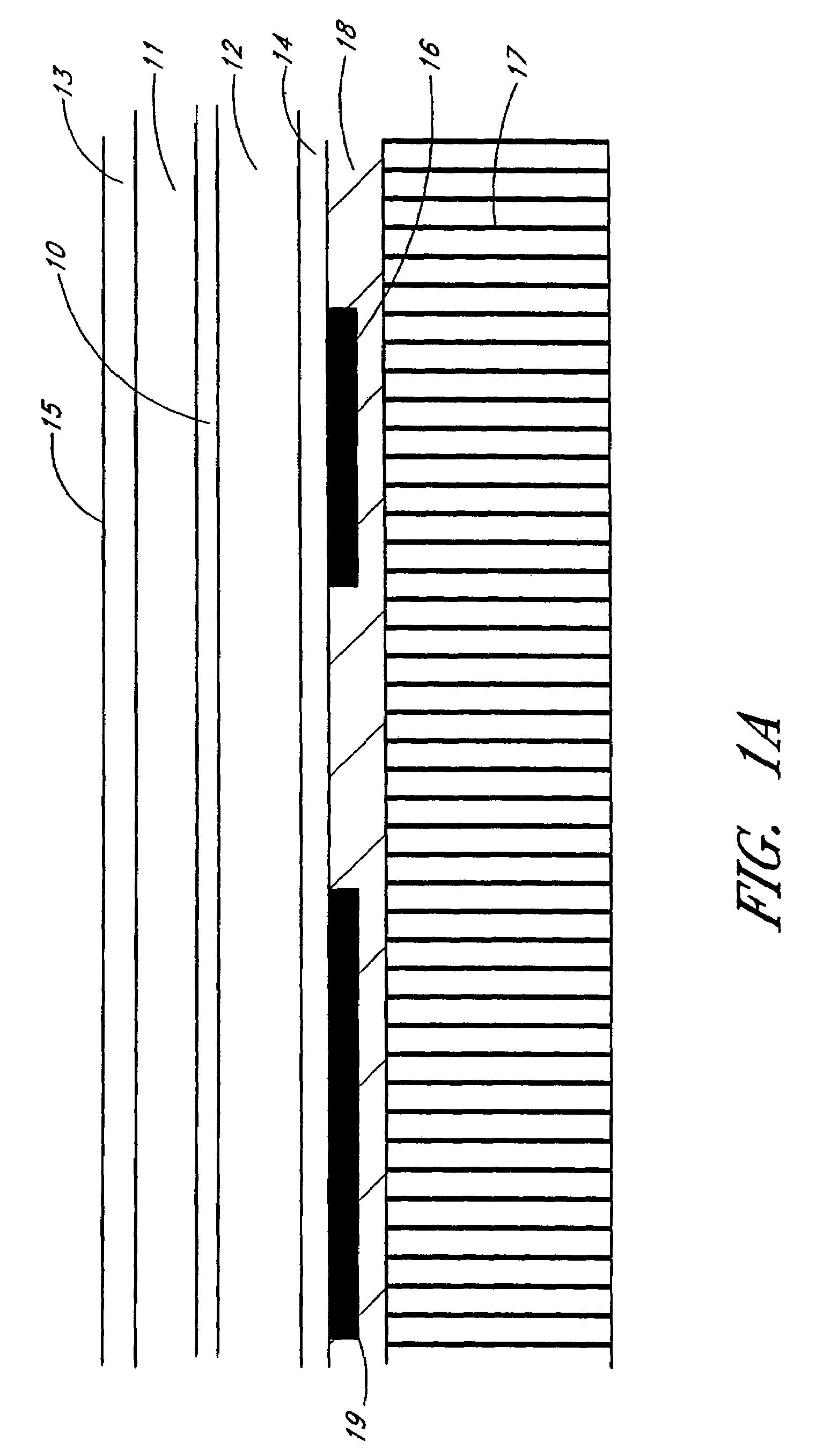

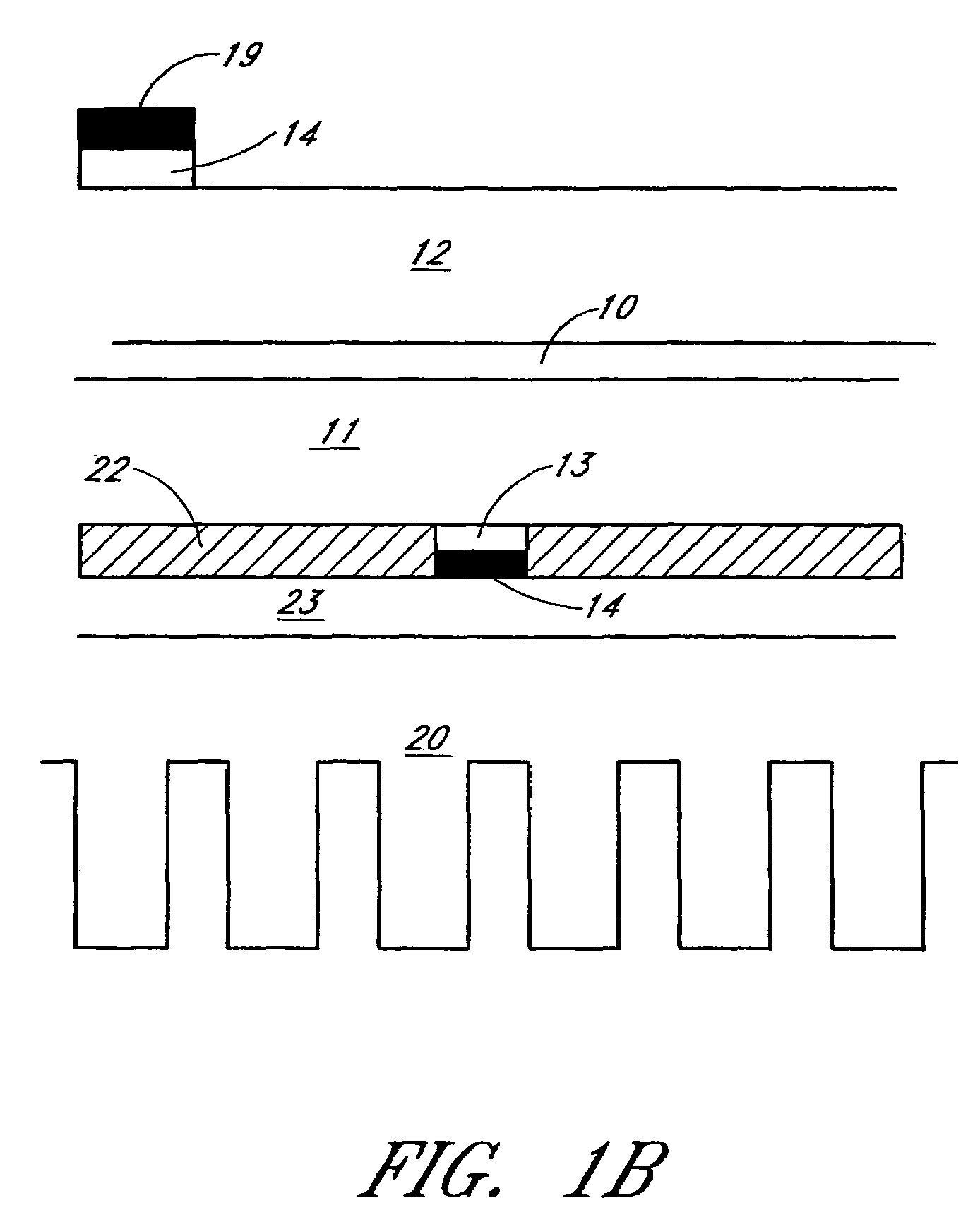

Method of manufacturing surface textured high-efficiency radiating devices and devices obtained therefrom

InactiveUS6504180B1Reduce charge effectReduce surface recombinationSolid-state devicesCoupling light guidesGratingCharge carrier

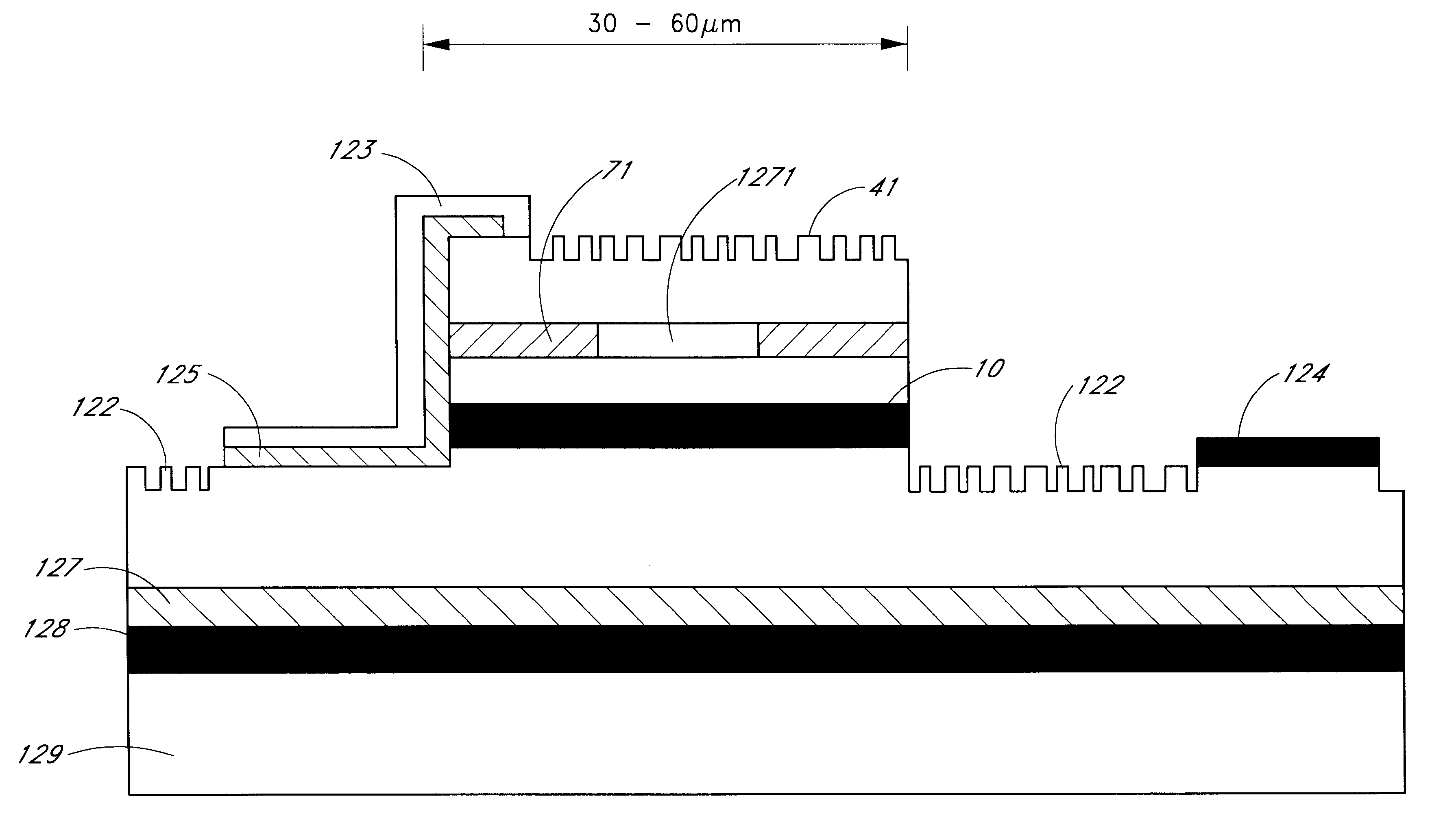

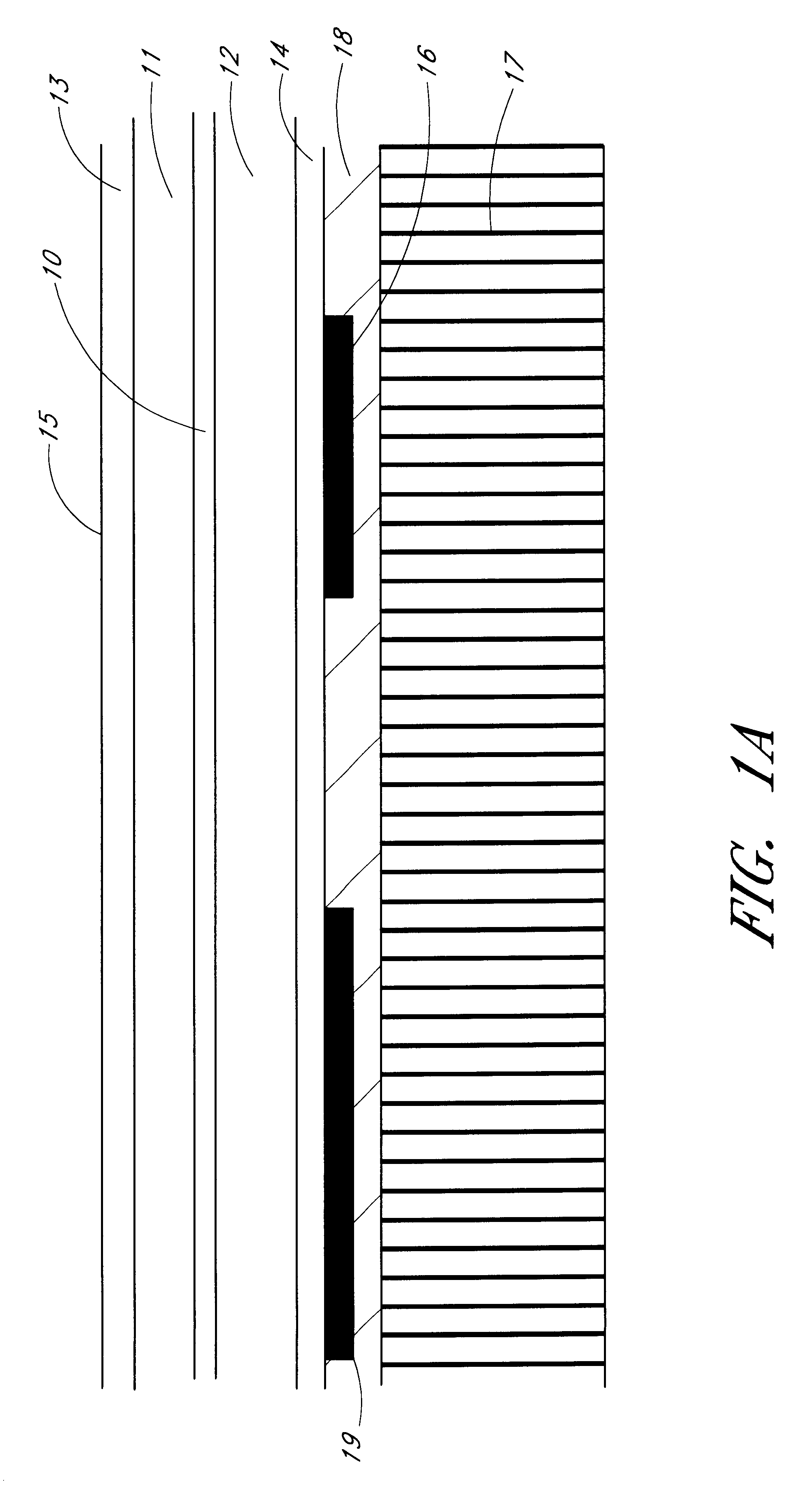

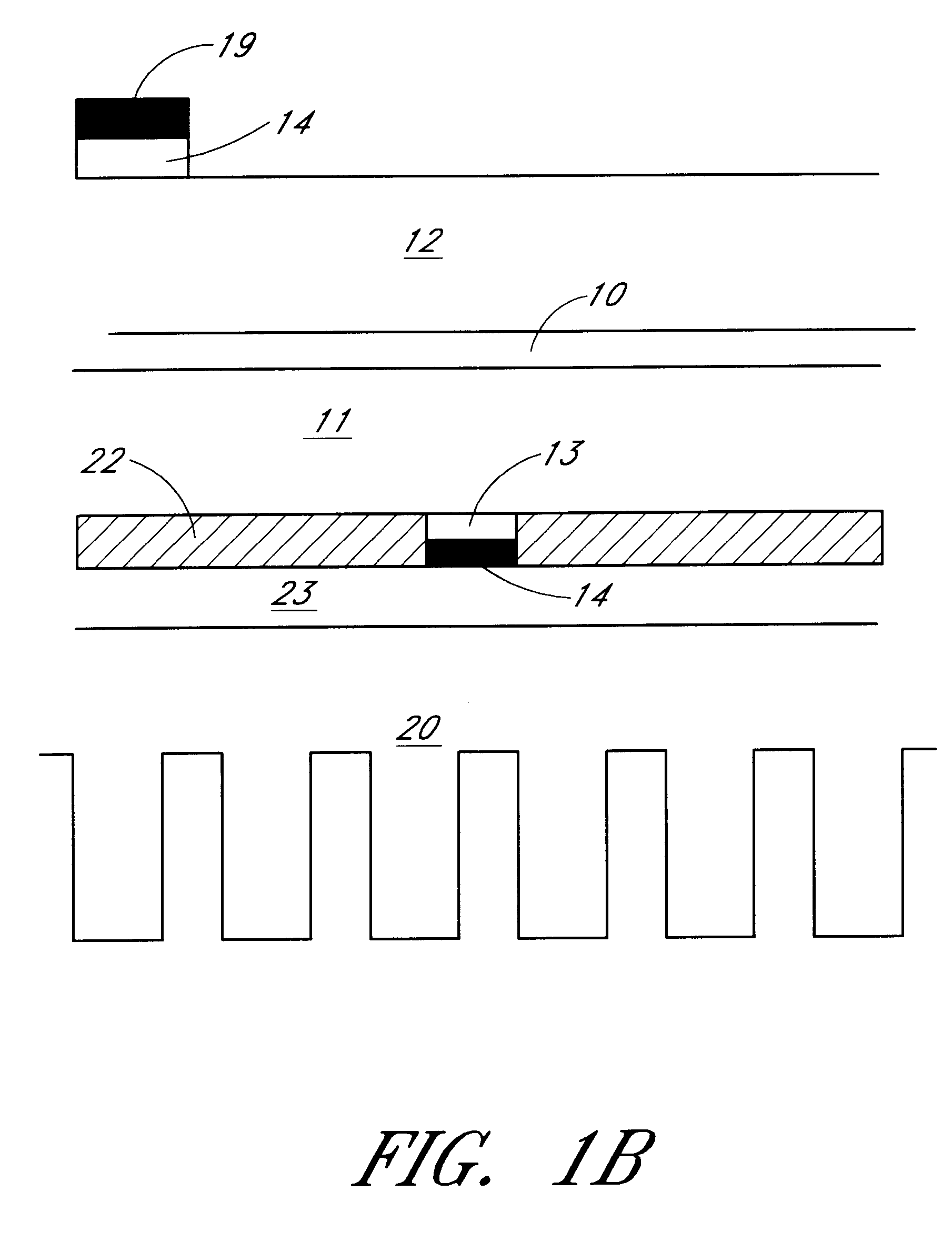

A device for emitting radiation at a predetermined wavelength is presented. This device has a cavity with an active layer in which said radiation is generated by charge carrier recombination. The edges of the device define the region or space for radiation and / or charge carrier confinement. At least one of the edges of this cavity has a substantially random grating structure. The edge of the device has substantially random grating structure and can extend as at least one edge of a waveguide forming part of this radiation emitting device. The radiation emitting device of the present invention can have a cavity comprising a radiation confinement space that includes confinement features for the charge carriers confining the charge carriers to a subspace being smaller than the radiation confinement space within the cavity. The emitting device can comprise at least two edges forming, in cross-section, a substantially triangular shape. The angle between these two edges is smaller than 45°. At least one of the two edges has a transparent portion. the devices according to the present invention can be arranged in arrays.

Owner:SIGNIFY HLDG BV

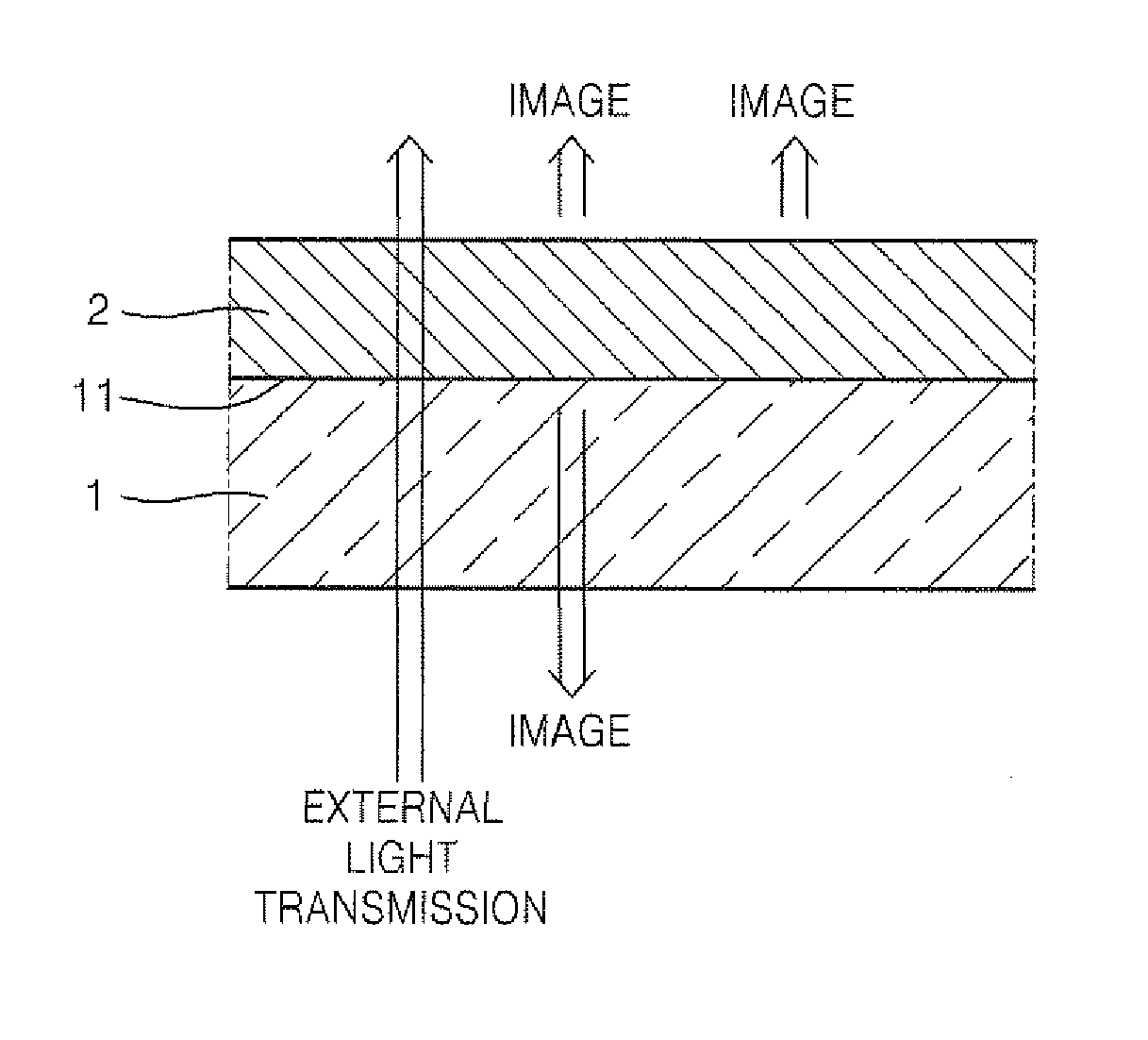

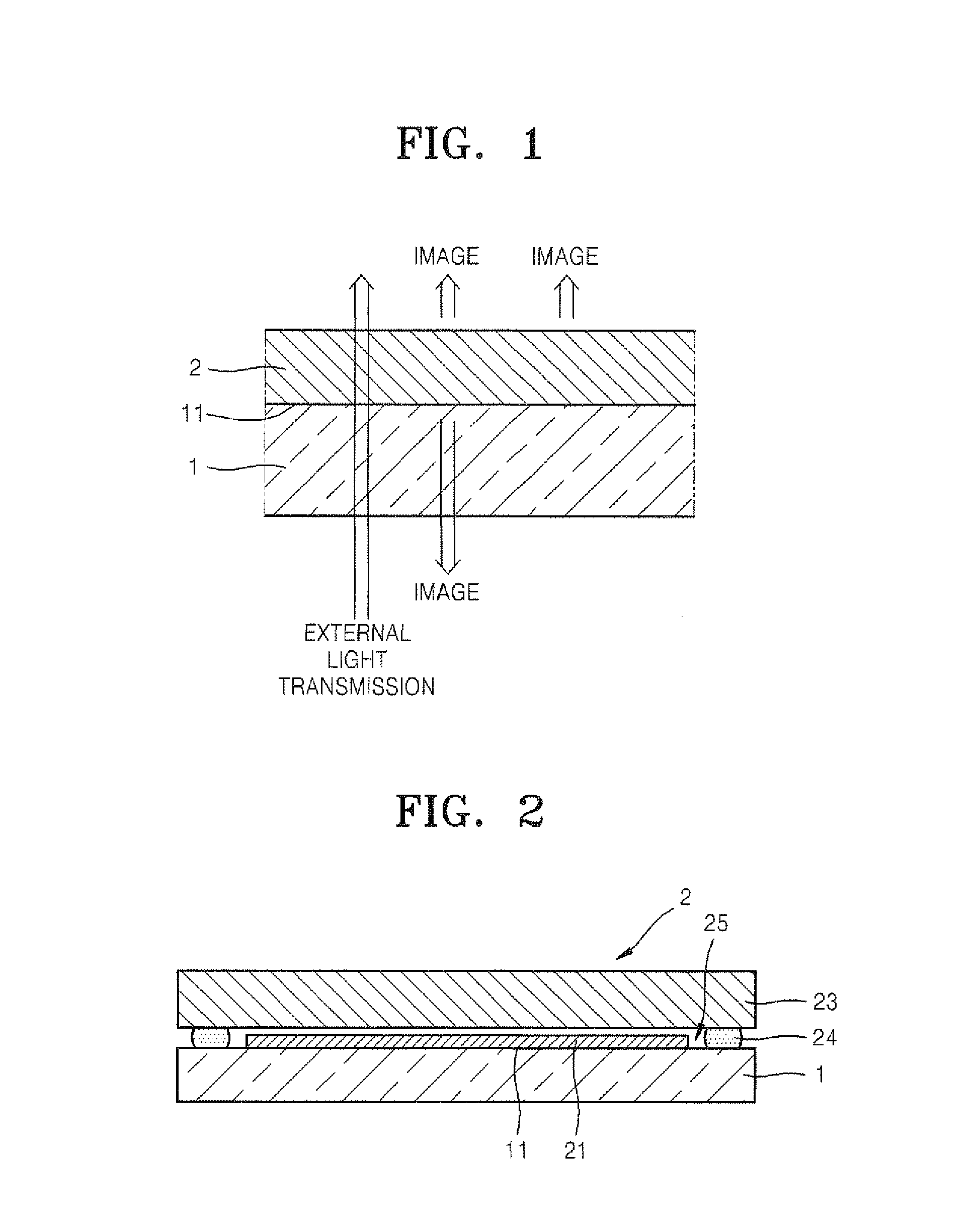

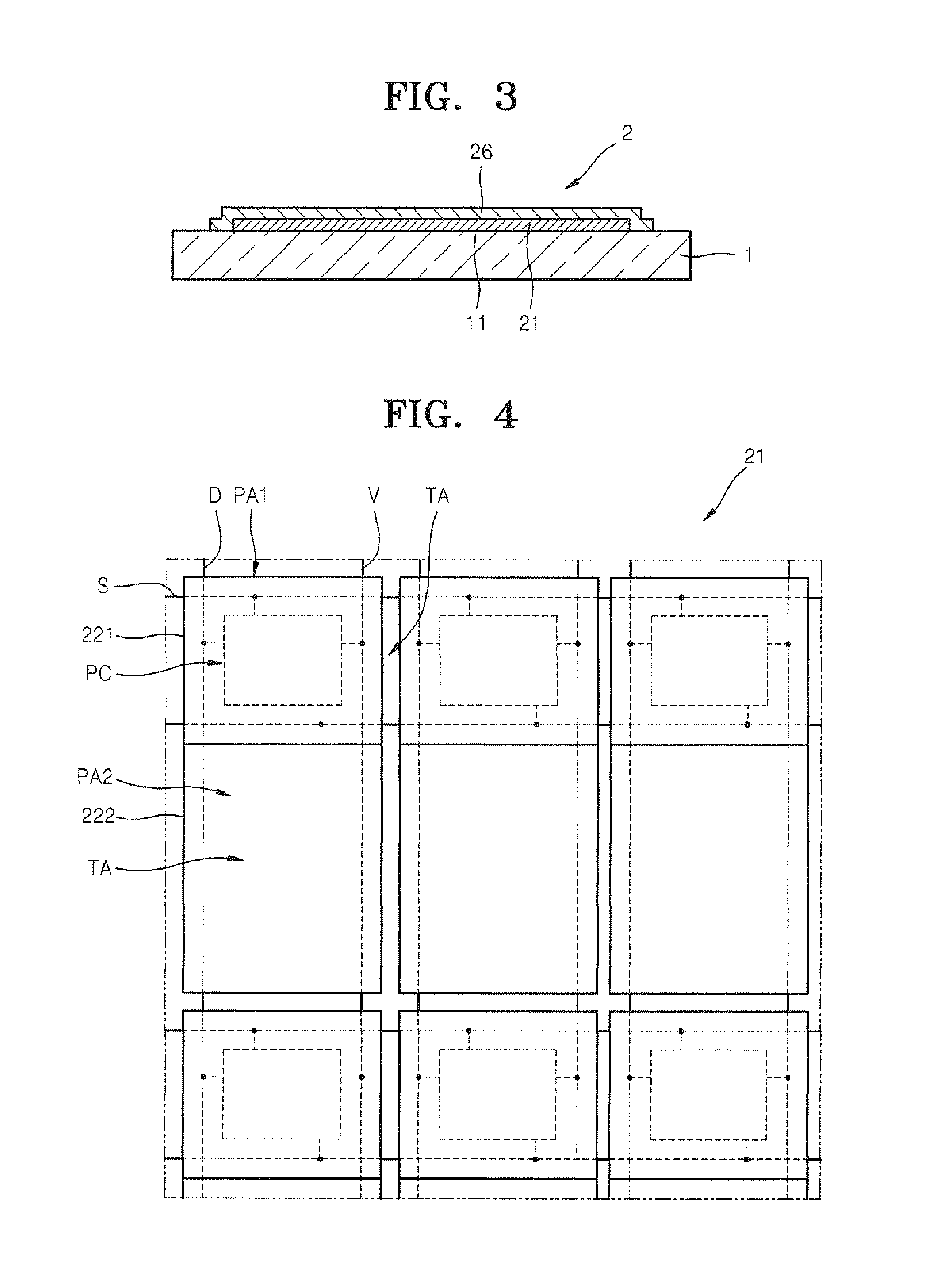

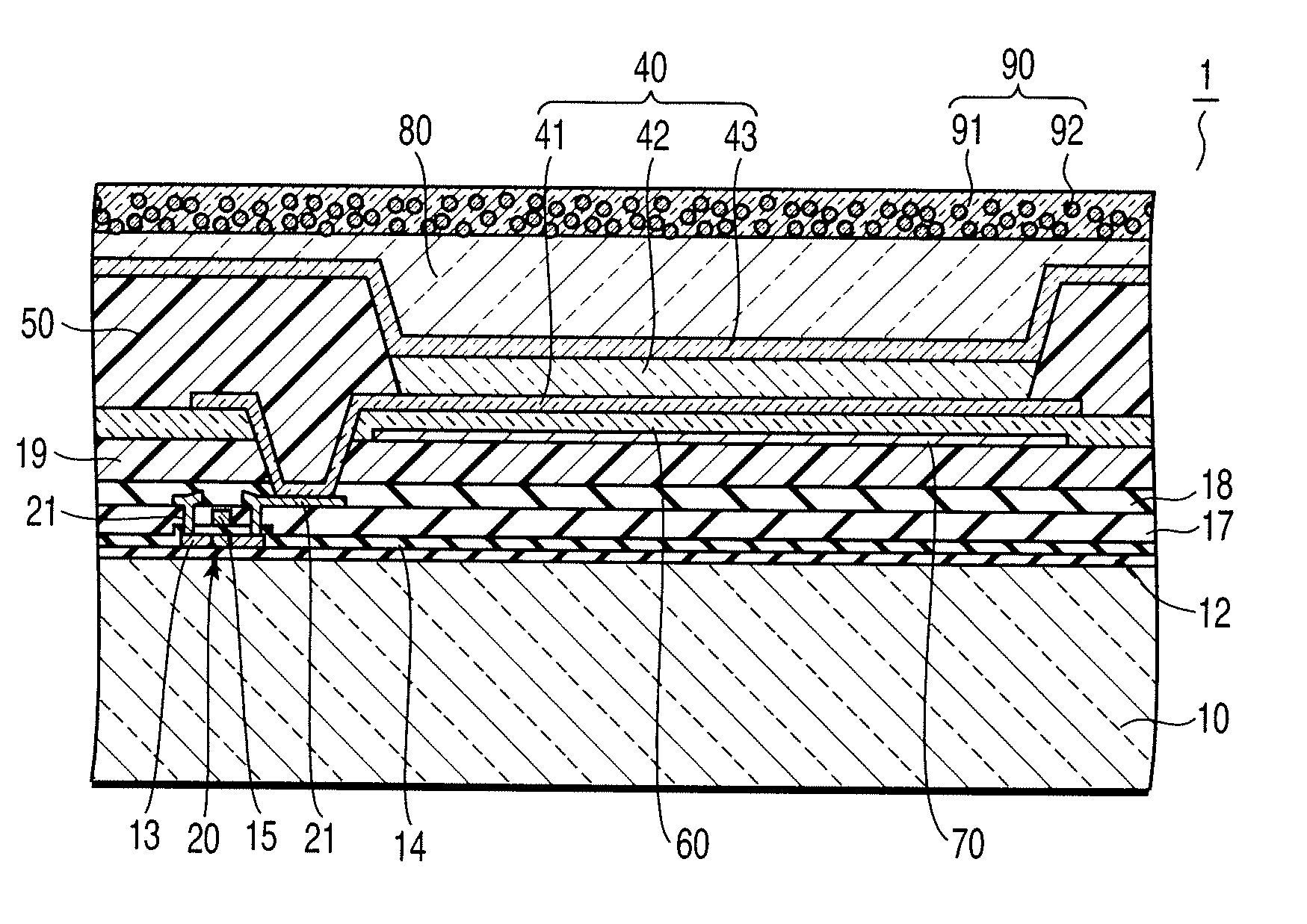

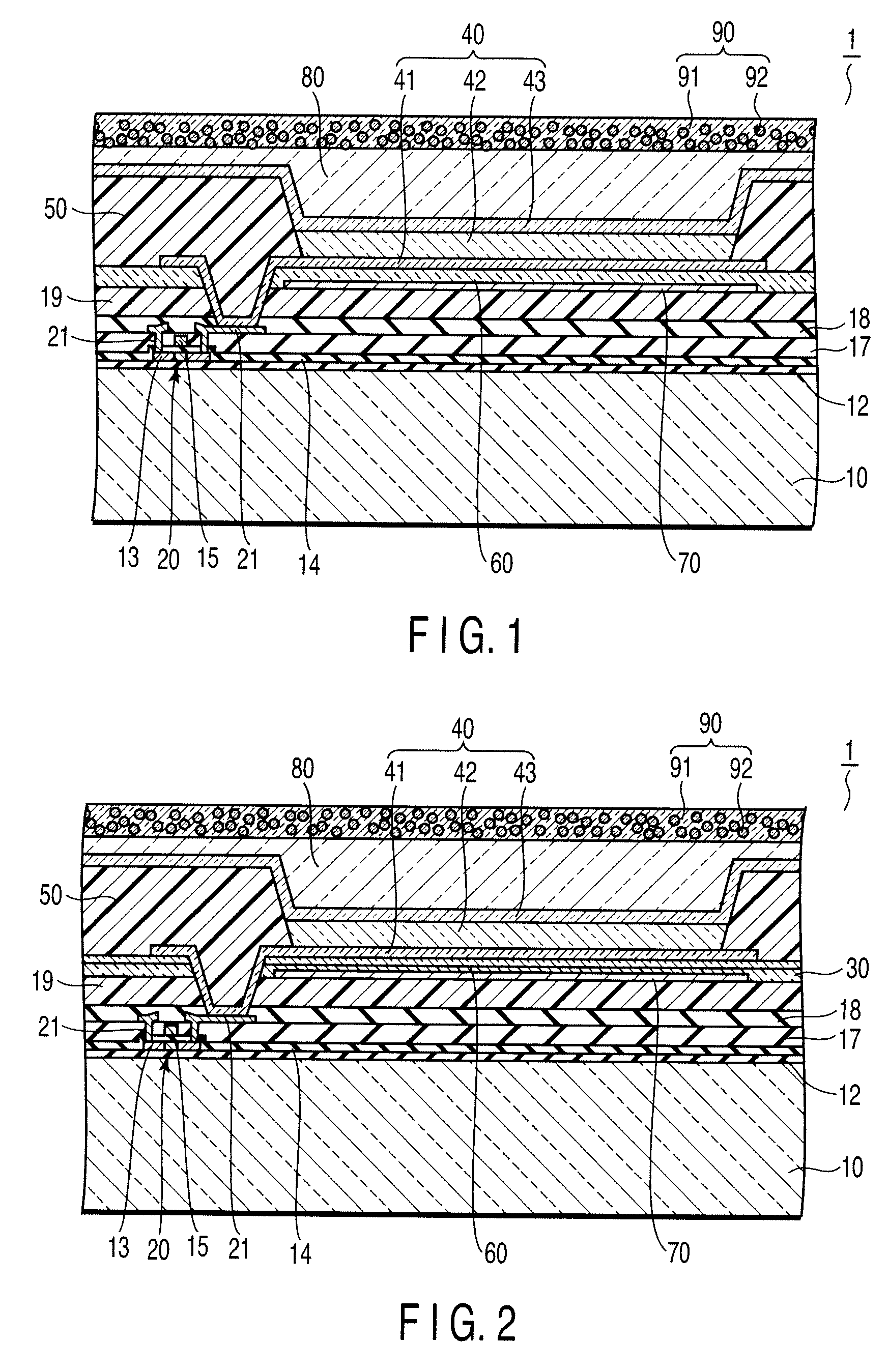

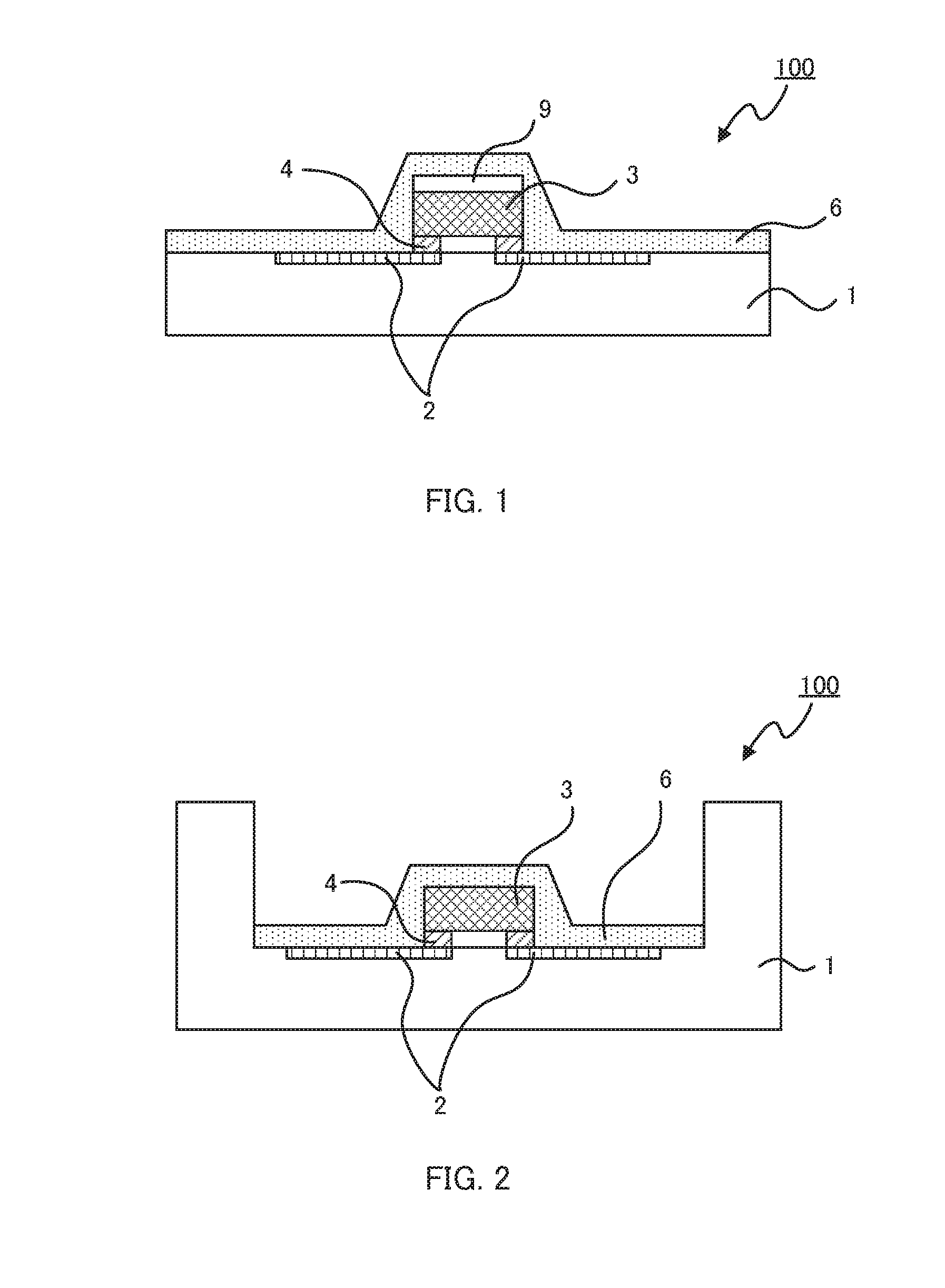

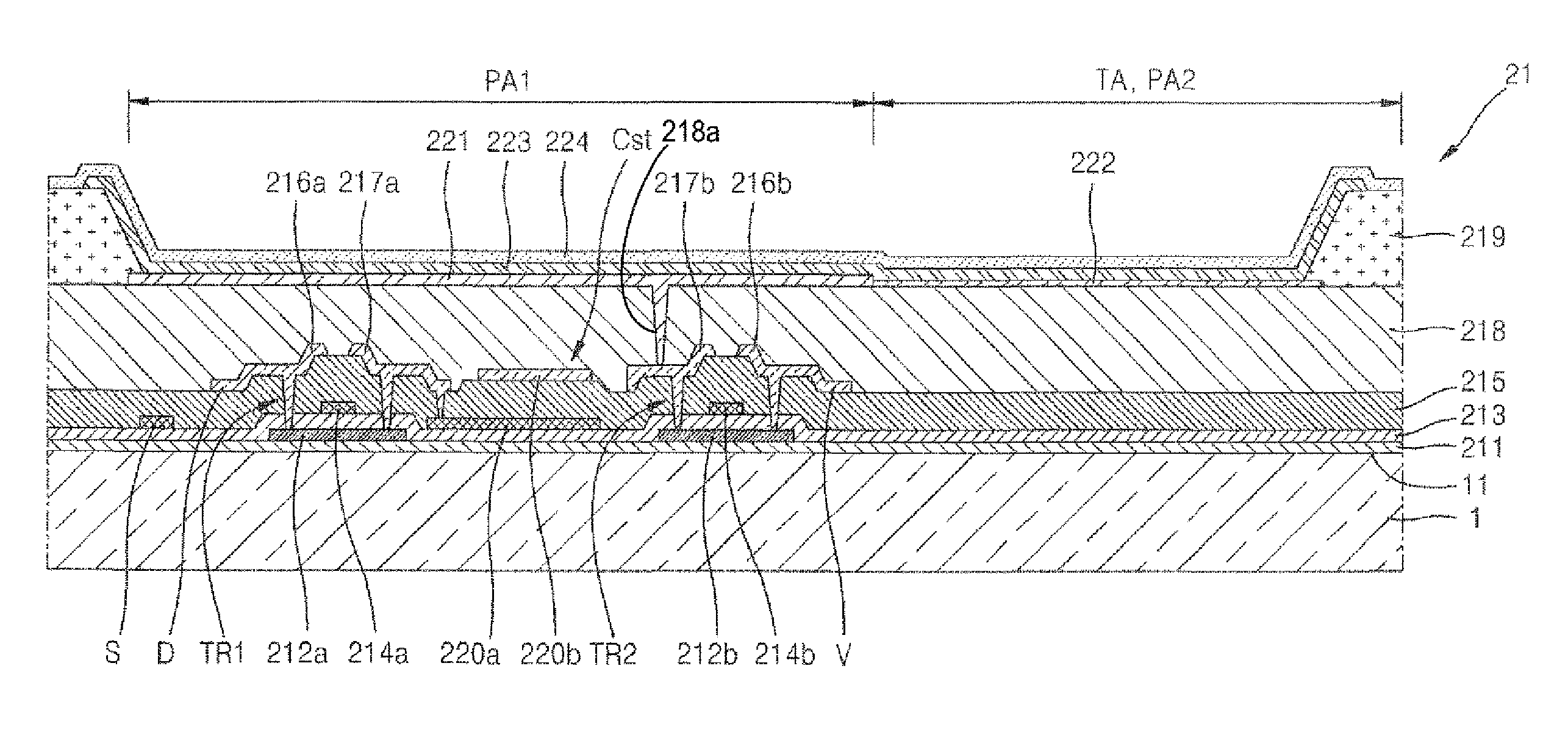

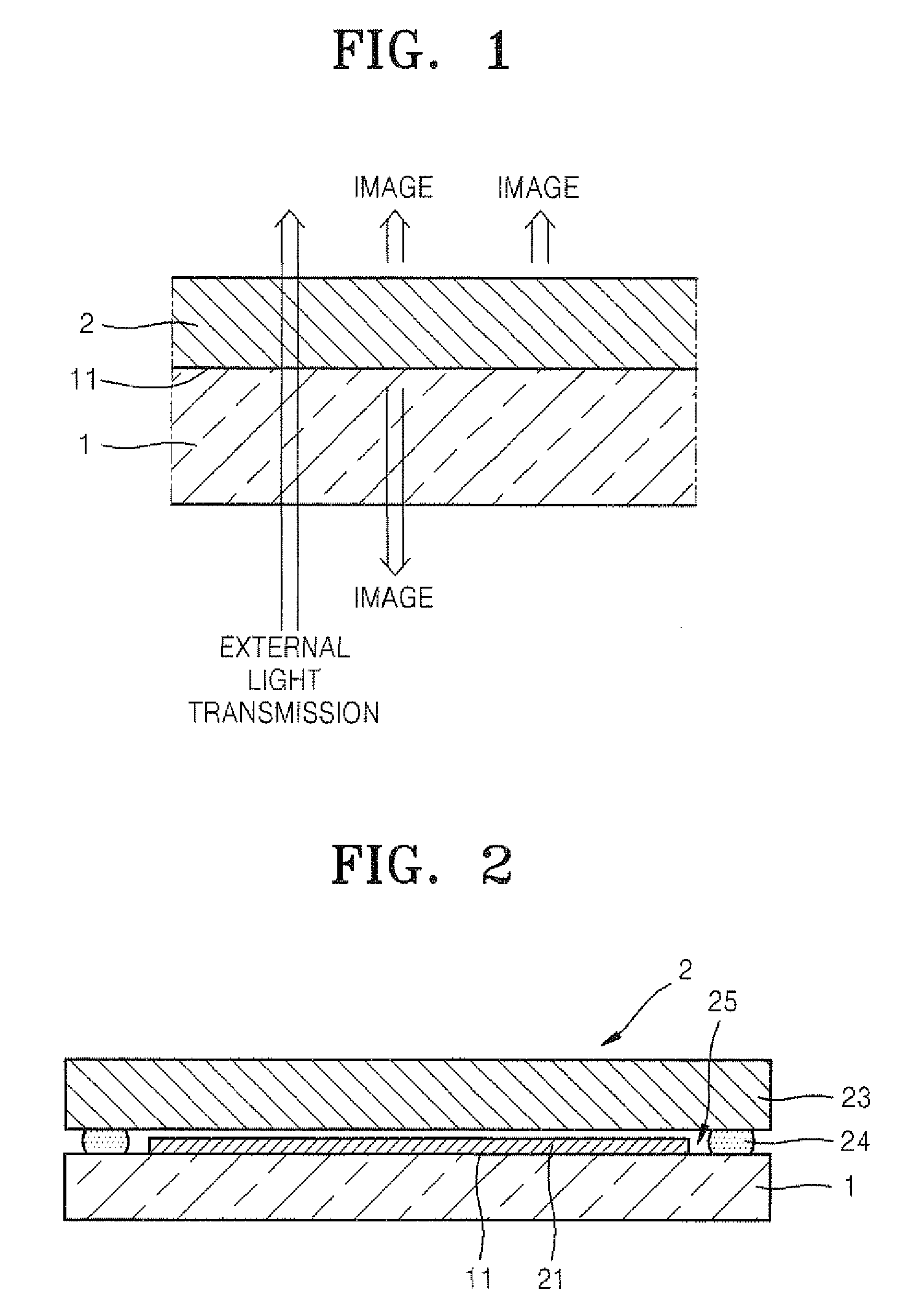

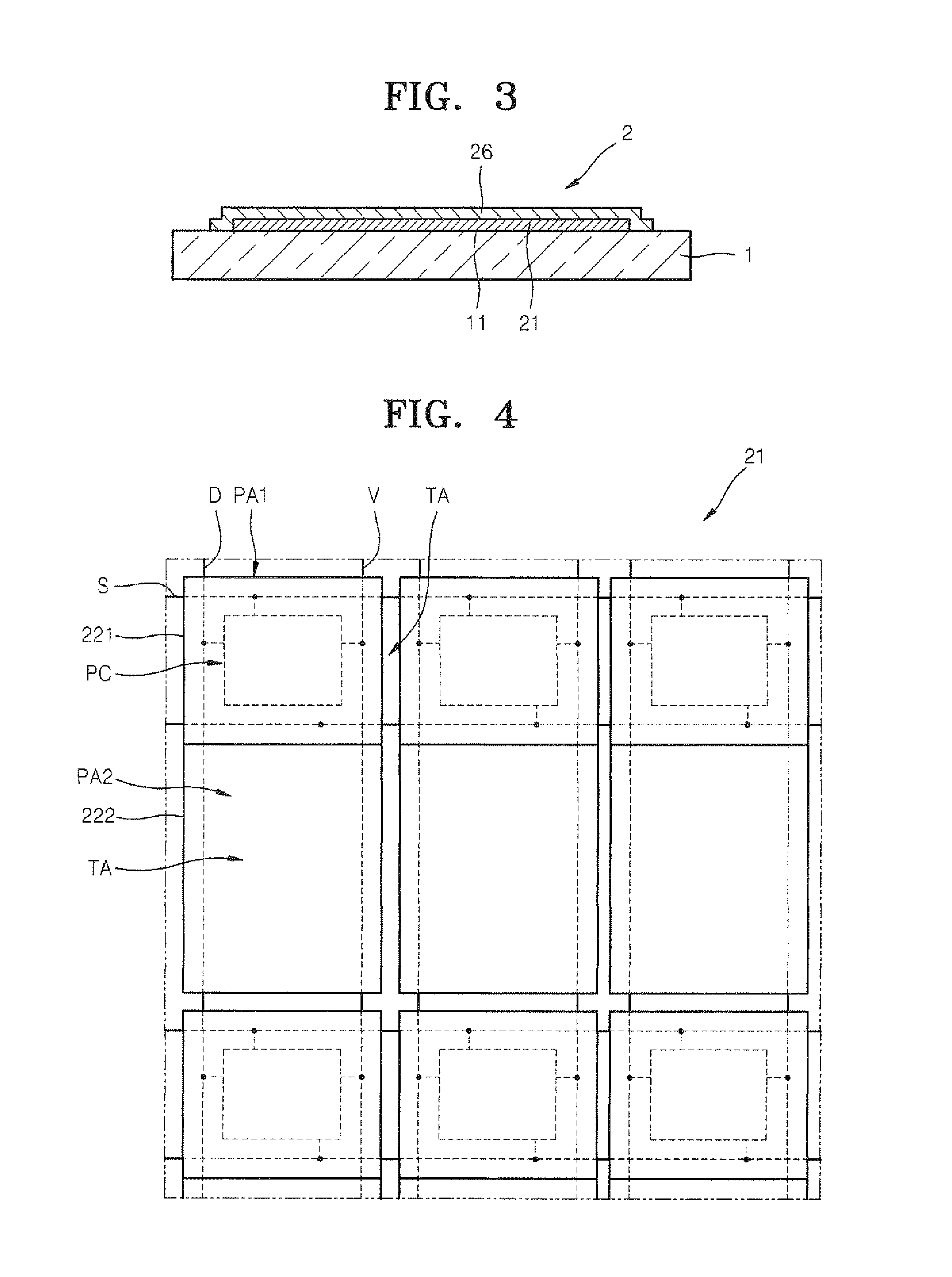

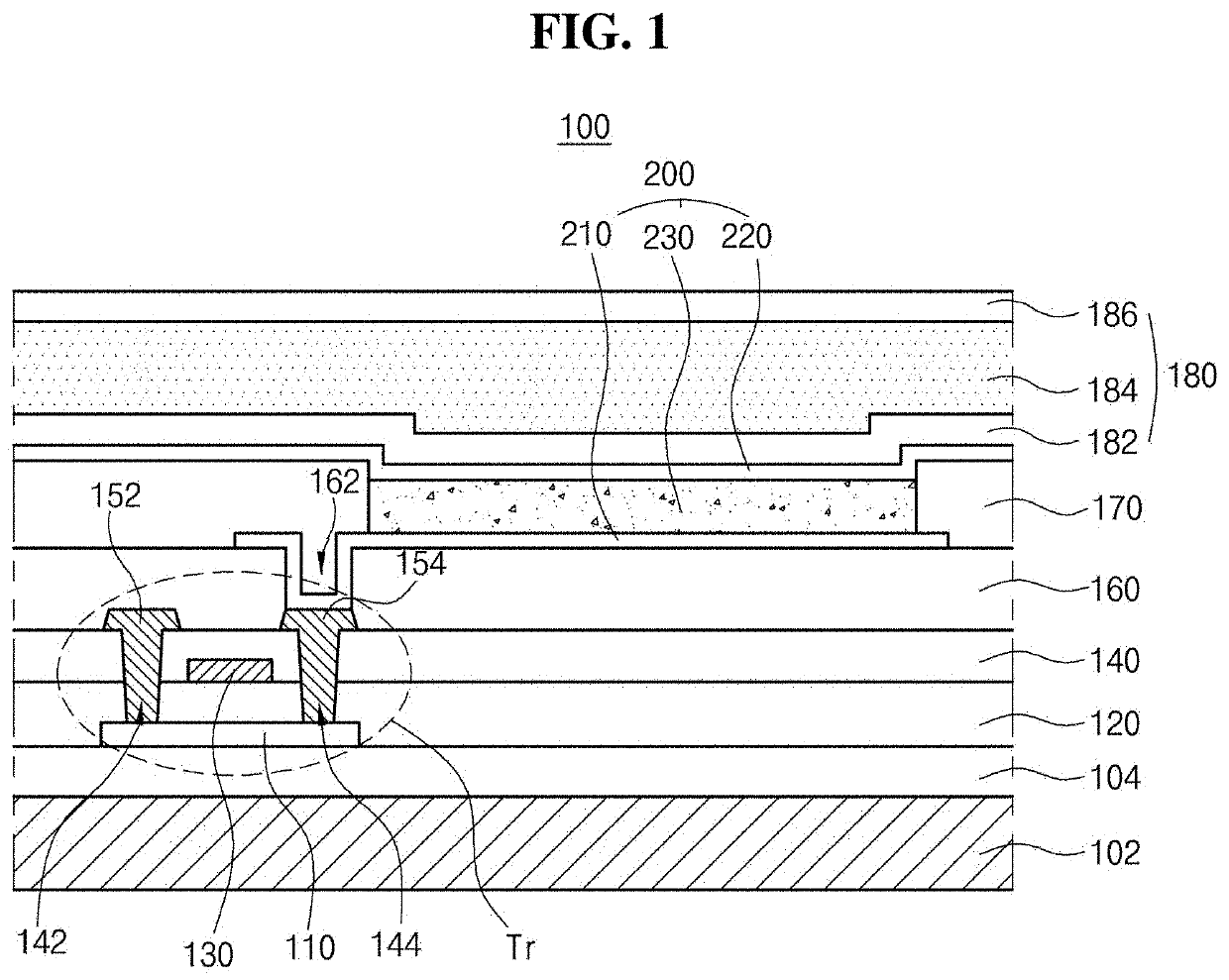

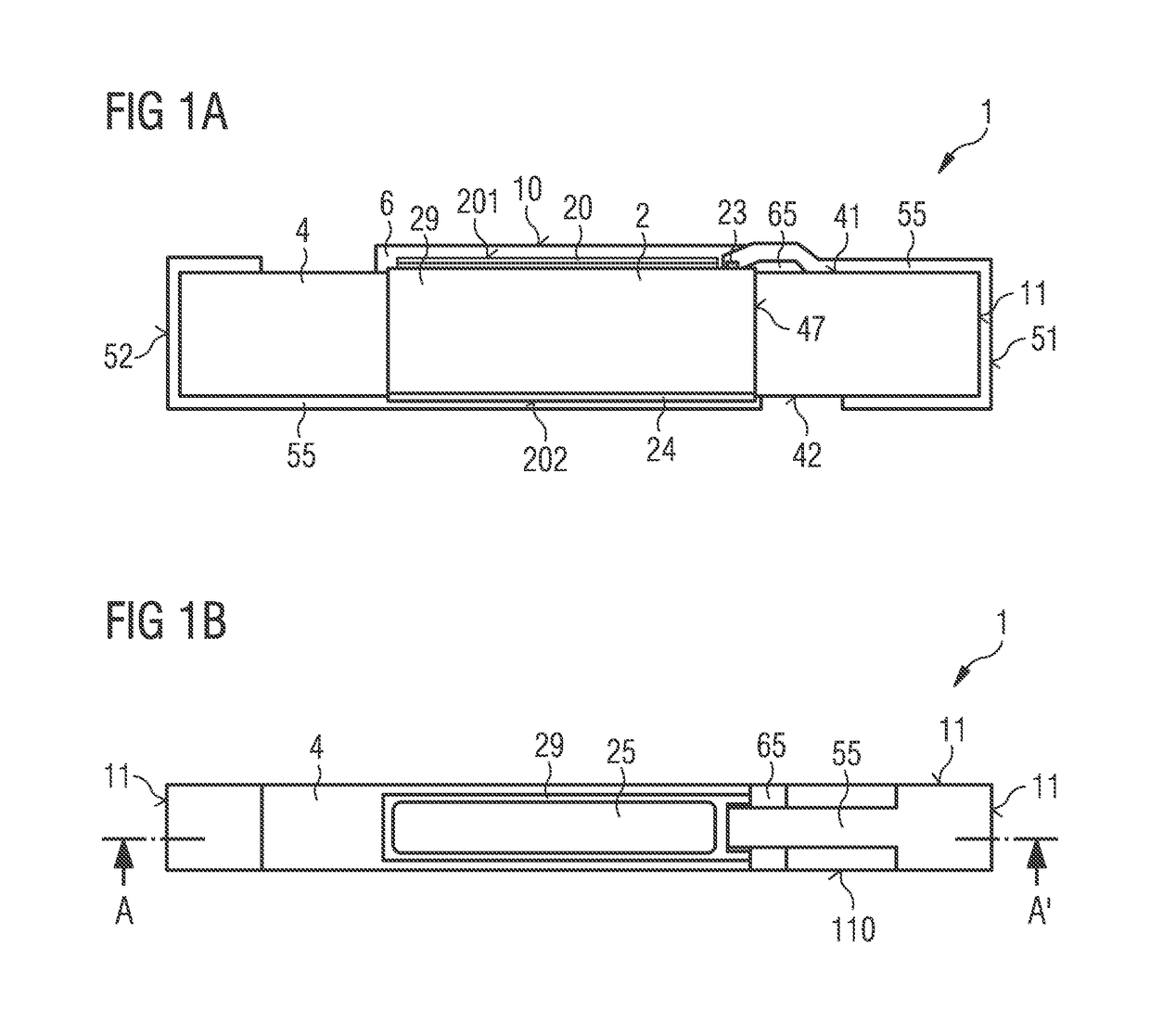

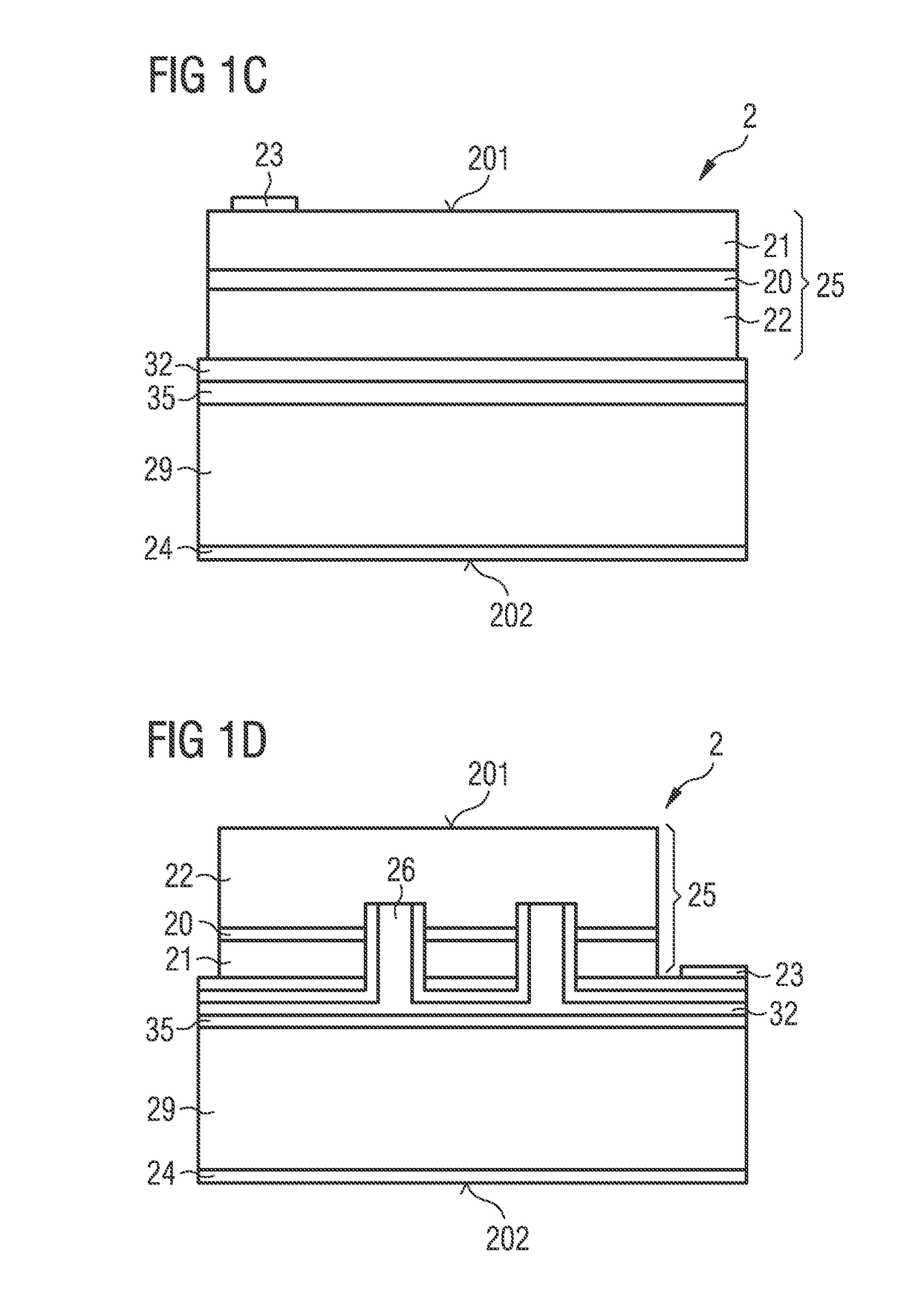

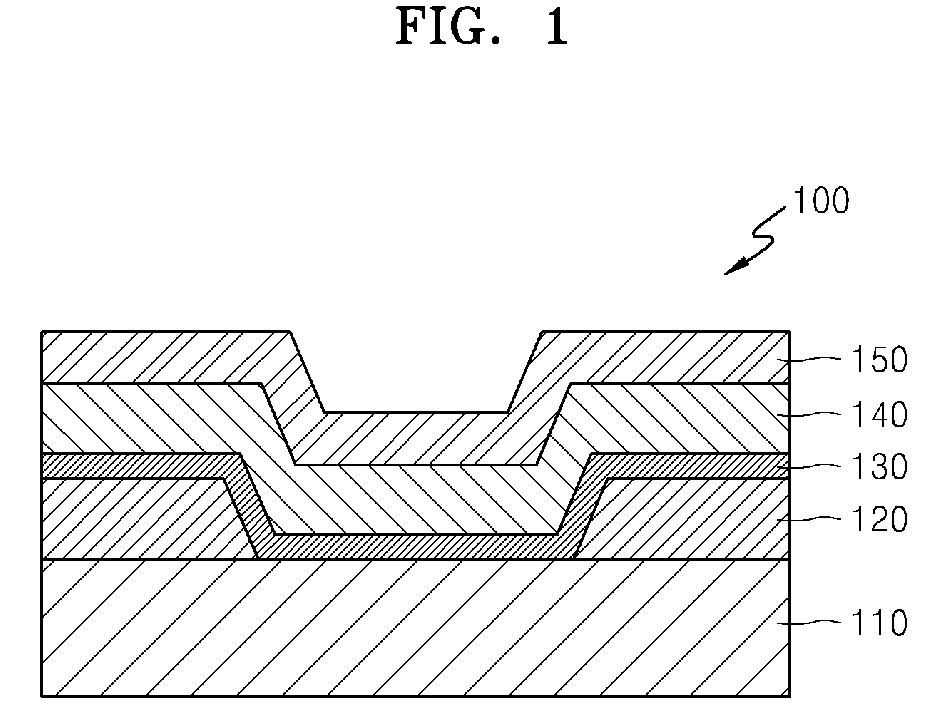

Organic Light Emitting Display Device

ActiveUS20110205198A1Improve transmittanceImprove Outcoupling EfficiencyElectroluminescent light sourcesSolid-state devicesTransmittanceOrganic layer

An organic light emitting display device comprises: a substrate; a plurality of thin film transistors (TFTs) formed on a first surface of the substrate; a passivation layer covering the plurality of TFTs; a plurality of first pixel electrodes formed on the passivation layer and respectively electrically connected to the plurality of TFTs, and overlapping with the plurality of TFTs so as to cover the plurality of TFTs, and including a reflection layer formed of a light-reflecting conductive material; a second pixel electrode formed of a light-transmitting conductive material and disposed on the passivation layer so as to be electrically connected to the plurality of first pixel electrodes; an opposite electrode formed such that light is transmitted or reflected therethrough, and disposed opposite the plurality of first pixel electrodes and the second pixel electrode; and an organic layer interposed between the plurality of first pixel electrodes and the second pixel electrode, and including an emission layer. Accordingly, transmittivity of the organic light emitting display device is increased, and optical outcoupling efficiency of the organic light emitting display device is also increased during double-sided emission.

Owner:SAMSUNG DISPLAY CO LTD

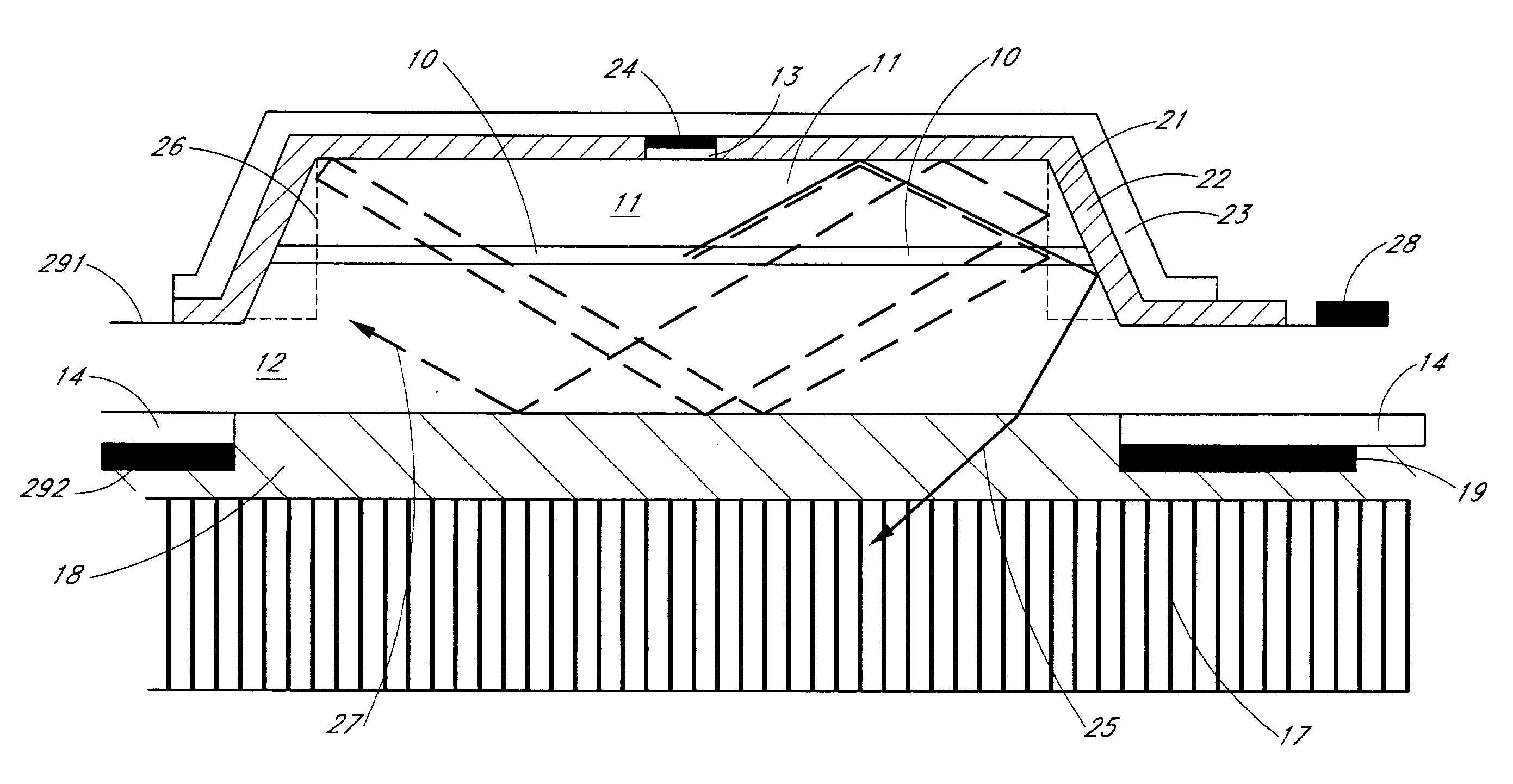

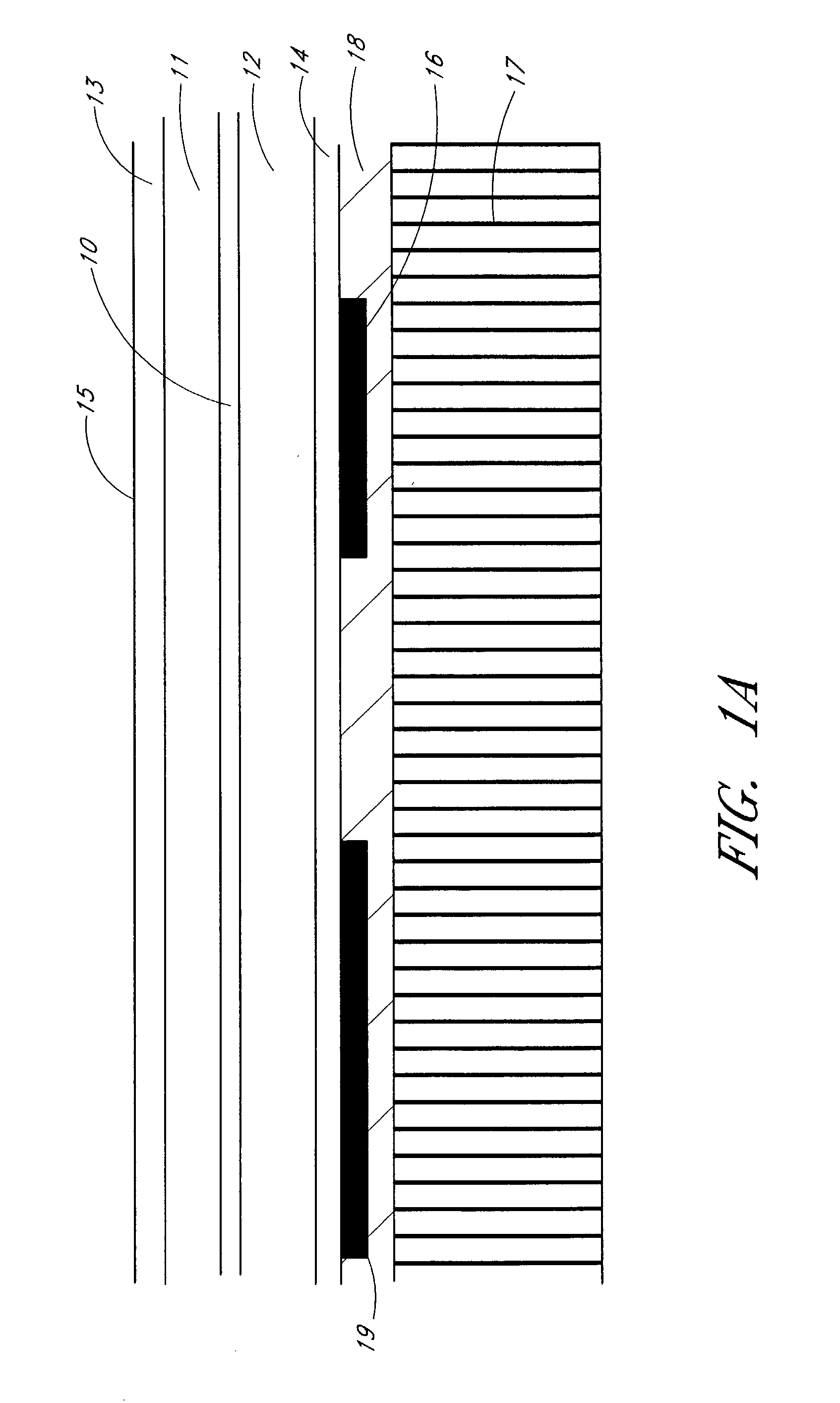

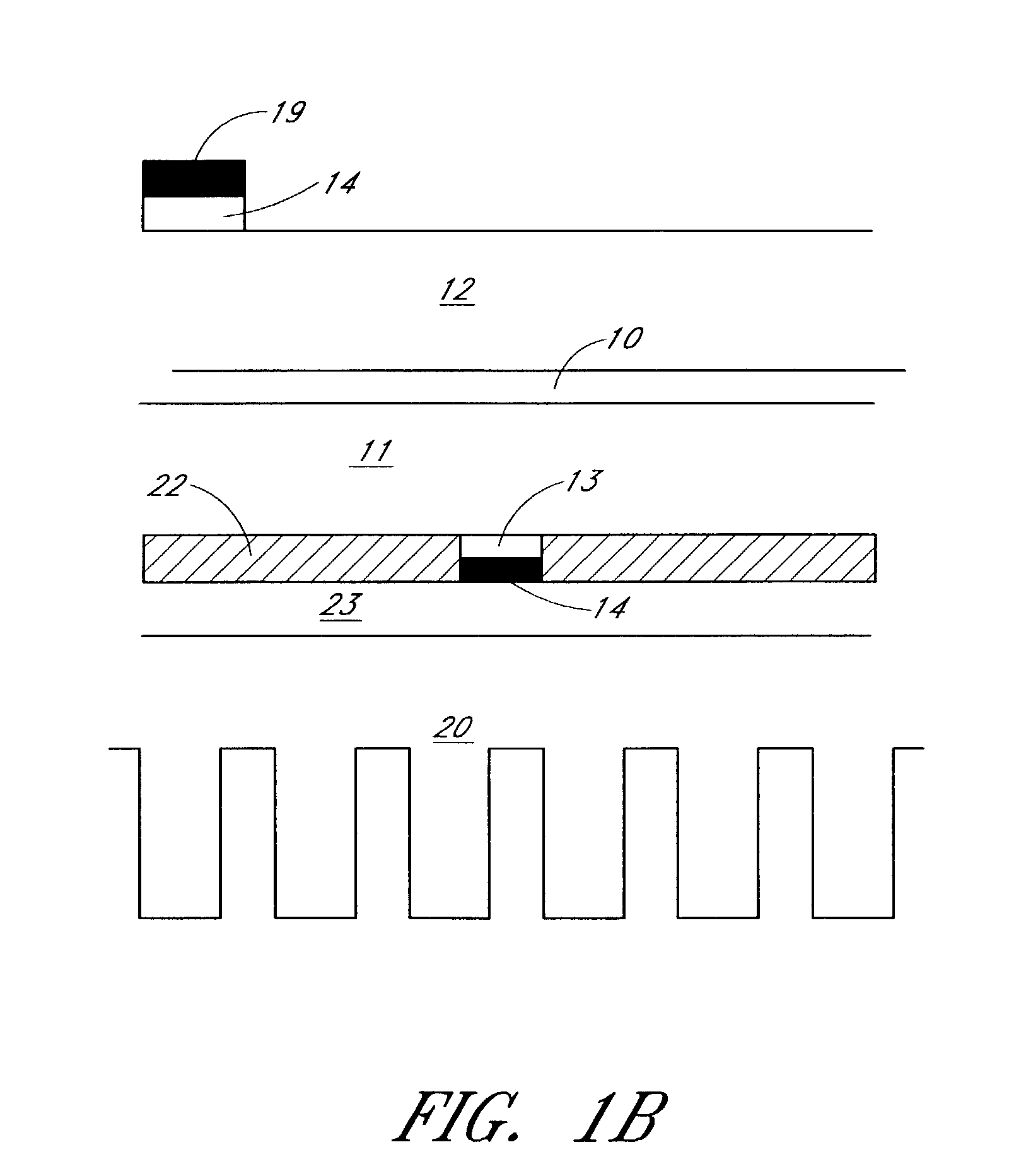

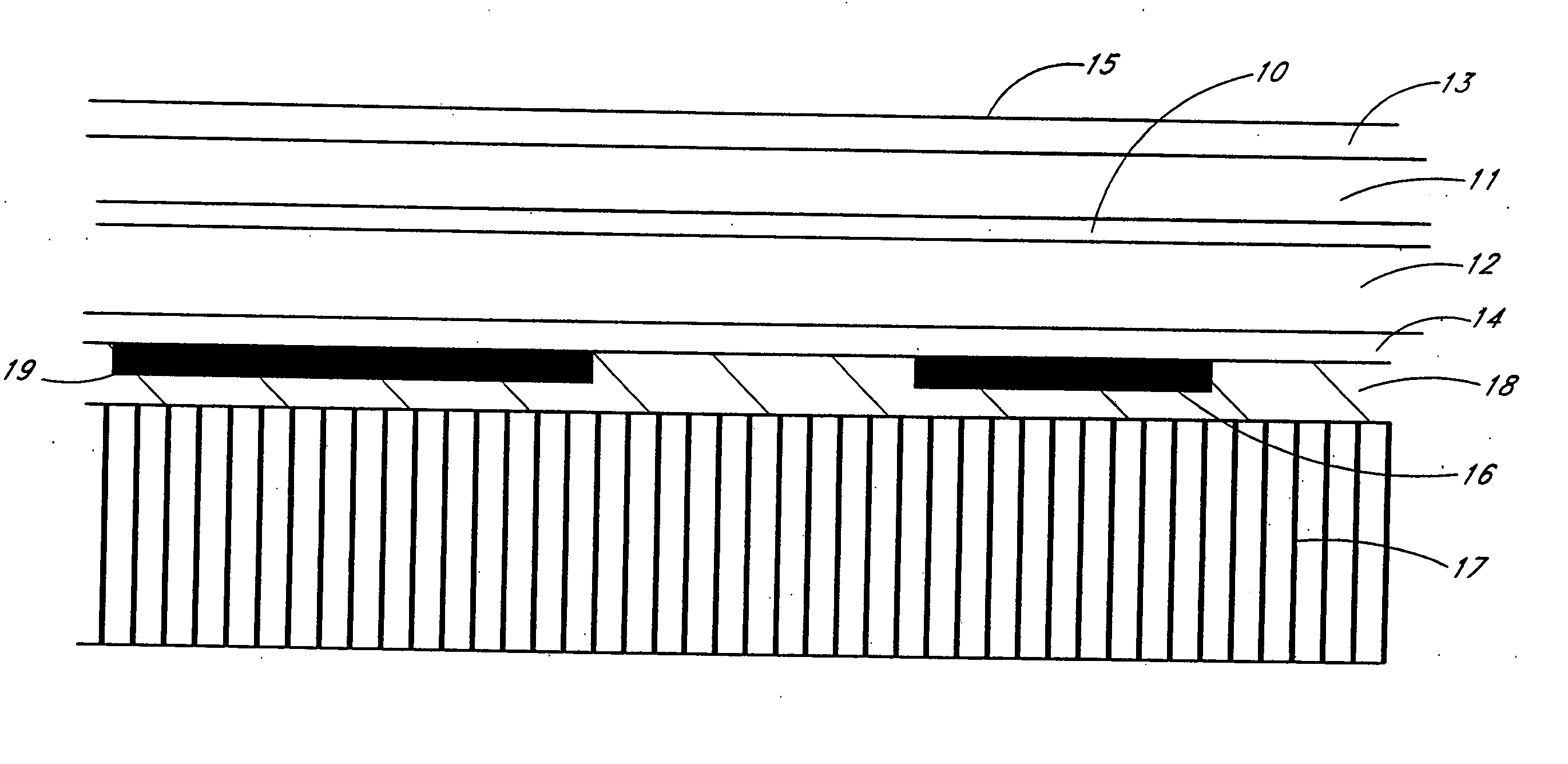

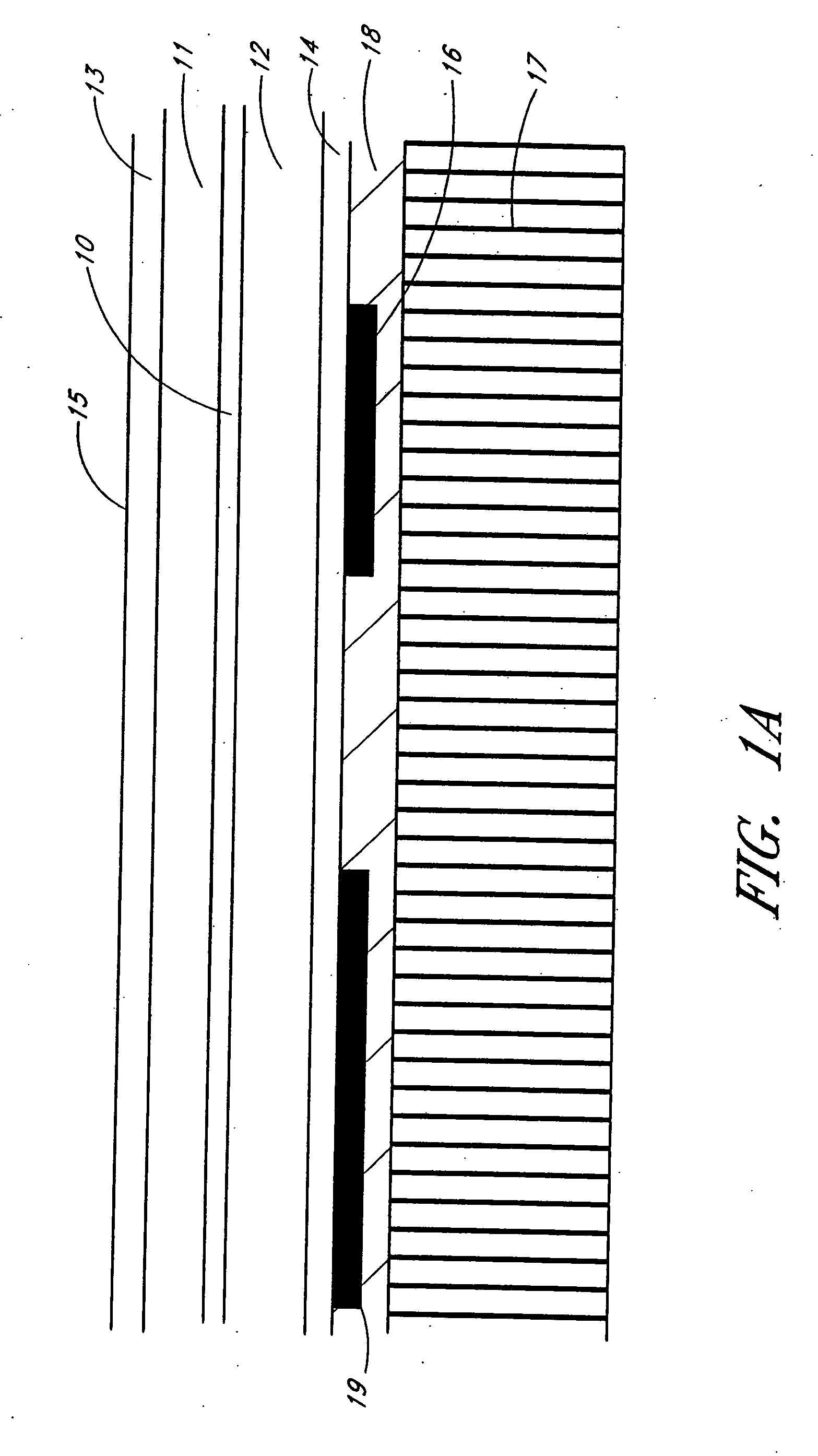

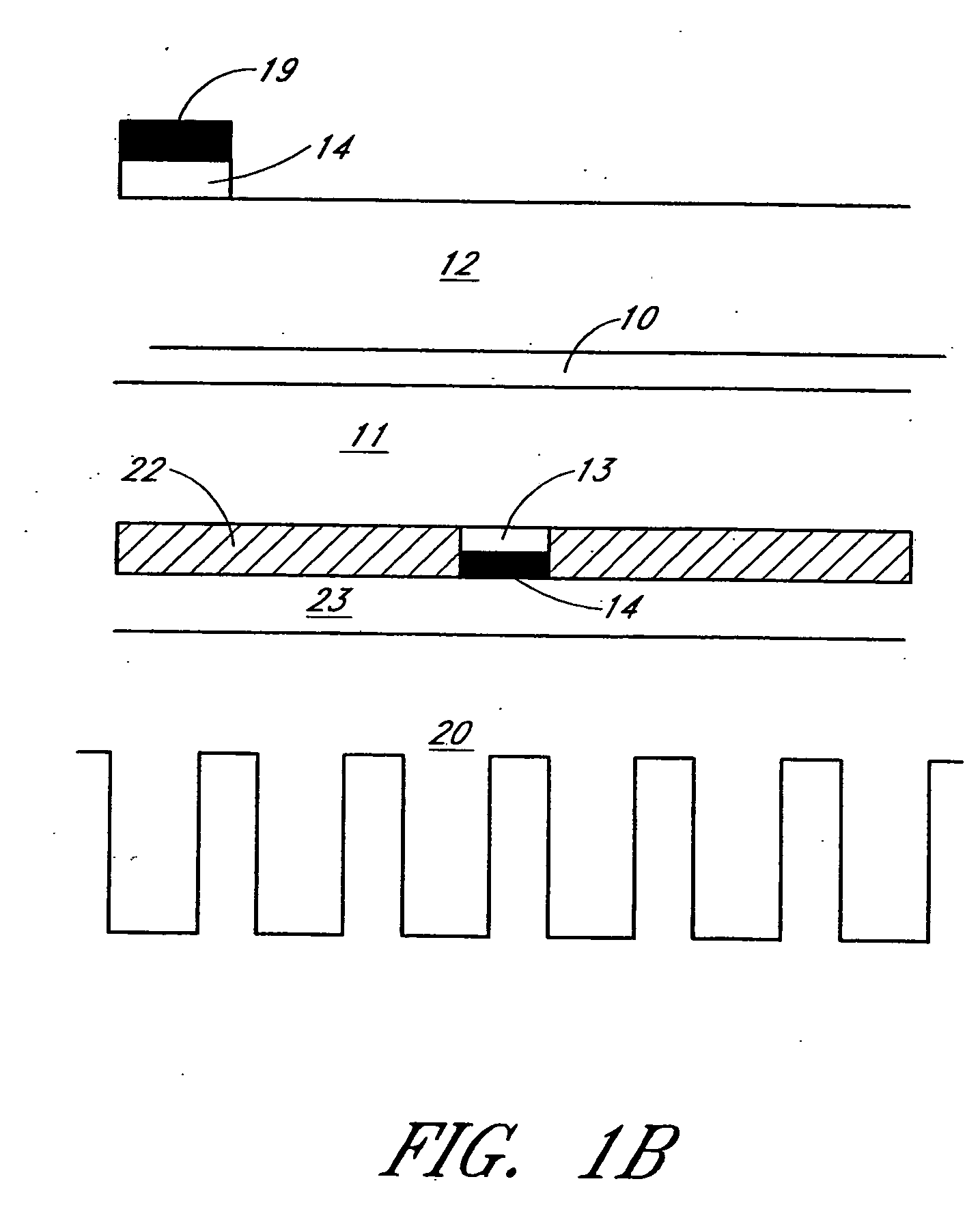

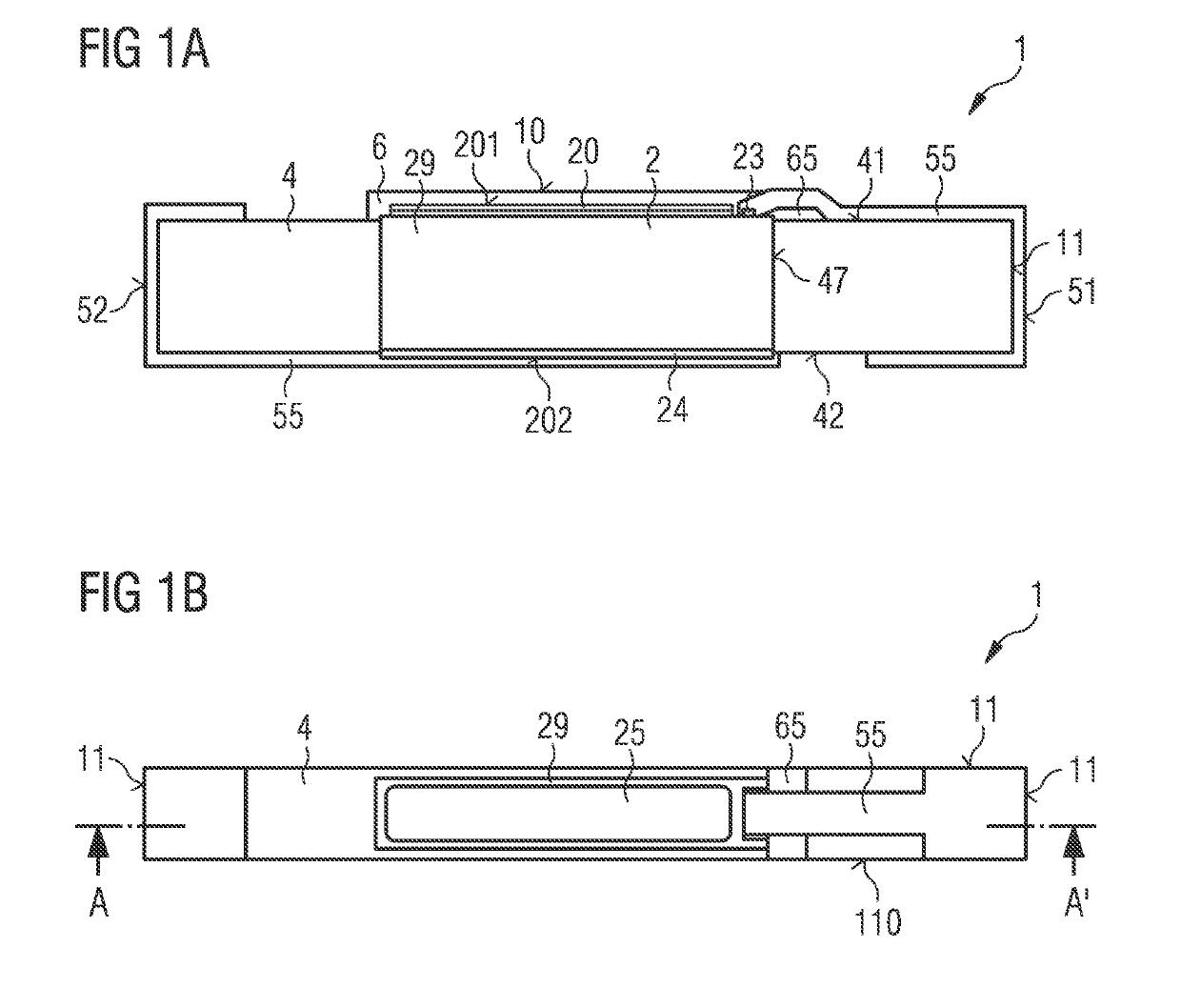

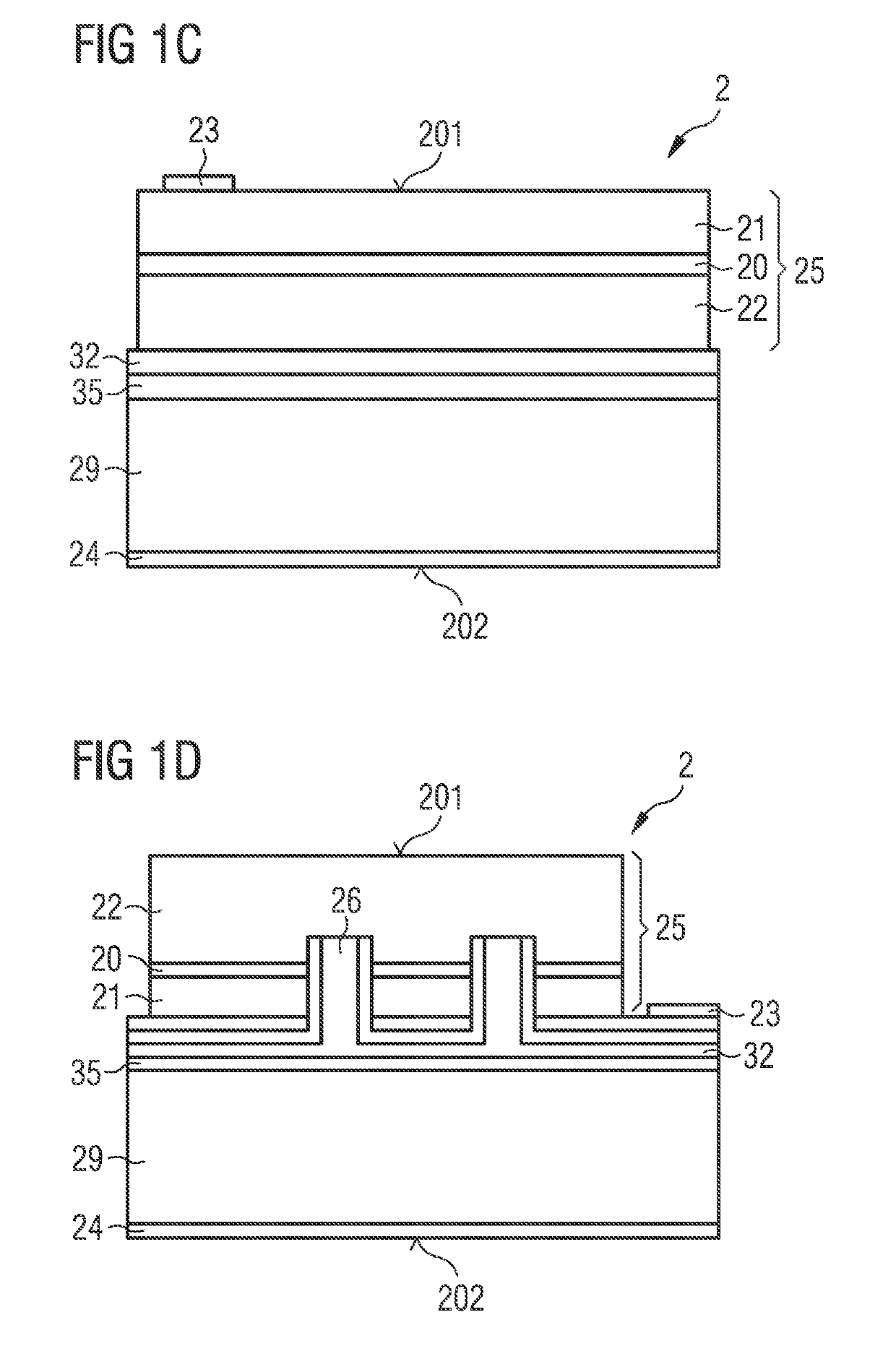

Method of manufacturing surface textured high-efficiency radiating devices and devices obtained therefrom

InactiveUS20030075723A1Reduce power consumptionImprove Outcoupling EfficiencySolid-state devicesSemiconductor/solid-state device manufacturingActive matrixEmission efficiency

The present invention relates to radiation, preferably light emitting, devices with a high radiation emission efficiency and to fabricating these as small devices in an array of such devices. In one embodiment, the emitting devices can be placed in dense arrays. In another embodiment, outcoupling efficiency of the devices is improved, which leads to a reduced power consumption for a given radiation output power. In another embodiment, the speed of the radiation is increased, hence the serial bandwidth per optical channel is increased. The invention further relates to light emitting devices that exhibit uniform radiation emission characteristics. The light emitting devices (diodes, LEDs) of the present invention can be used for applications wherein two-dimensional LED arrays, particularly low-power arrays, are useful, such as in display technology. Active matrix displays relying on liquid crystals (e.g. integrated on CMOS circuitry) could be replaced by LED arrays. Dense and bright one-dimensional LED arrays are useful for example for printing and copying. Also for single LED applications it is important to have a maximum of photons escaping from the light emitting surface. The intensity of light per unit area (the brightness) is larger, and this is useful in many applications. Furthermore, the packaging cost can be reduced. In order to achieve a large global efficiency, many conventional LEDs need an elaborate package that includes a cavity with mirrors, because the light is emitted from more than one surface of the LED.

Owner:SIGNIFY HLDG BV

High-efficiency radiating device

InactiveUS20050110033A1High radiation emission efficiencyReduce power consumptionSemiconductor devicesLength waveLight-emitting diode

A device emits radiation at a predetermined wavelength. The device includes a light-emitting diode (LED) which generates the radiation. The device further includes at least one edge having a substantially random diffraction grating structure in radiative communication with the LED.

Owner:SIGNIFY HLDG BV

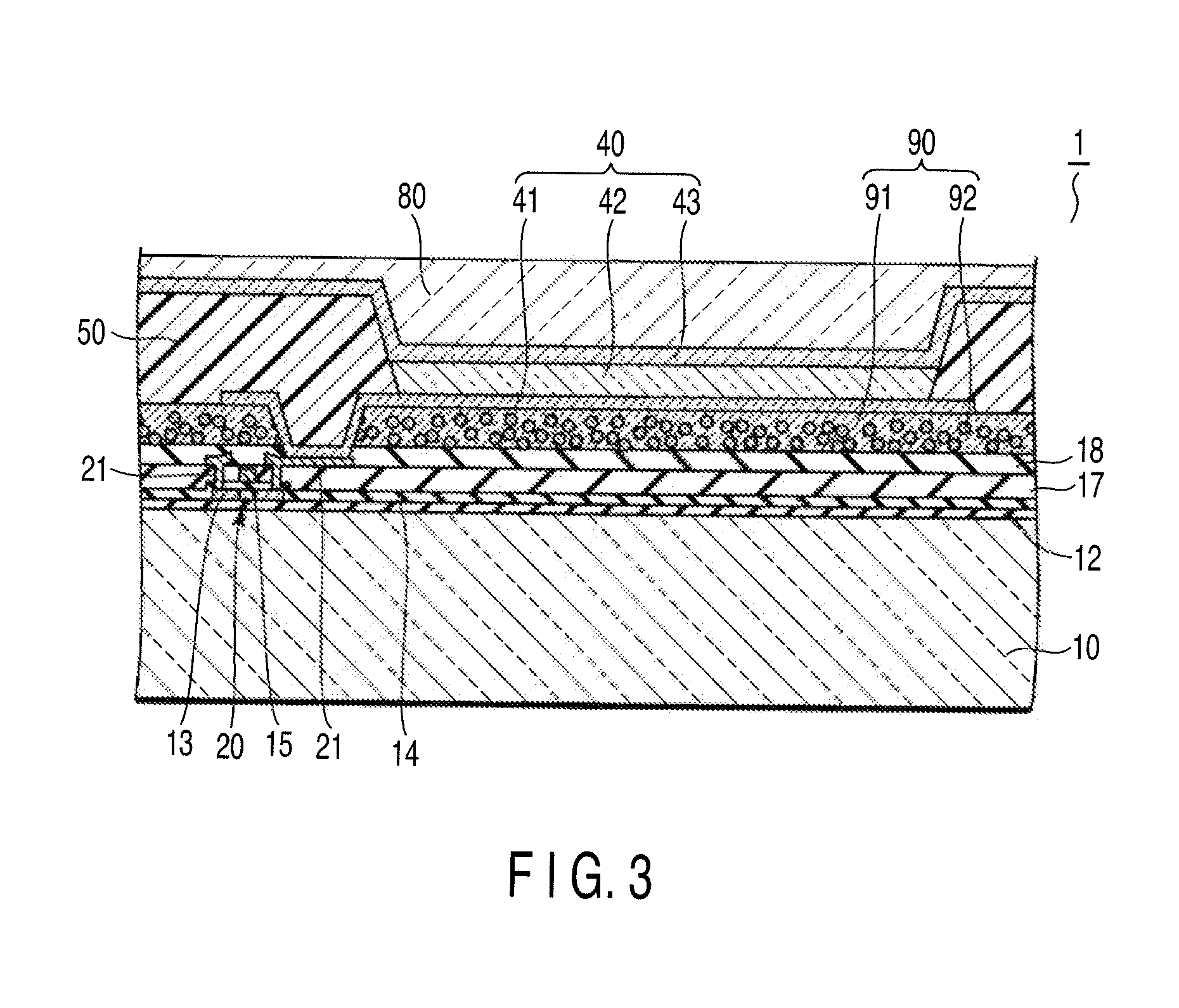

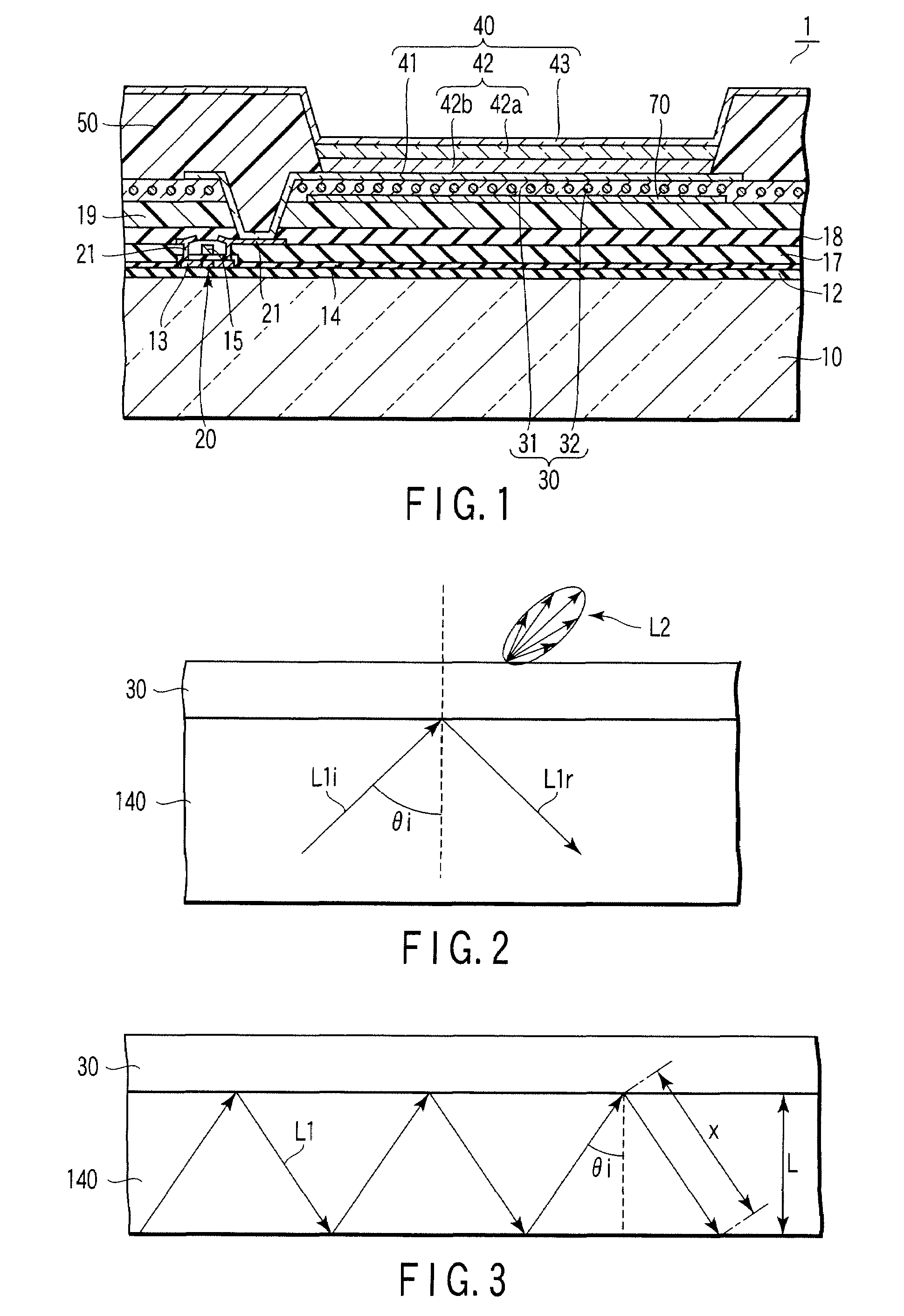

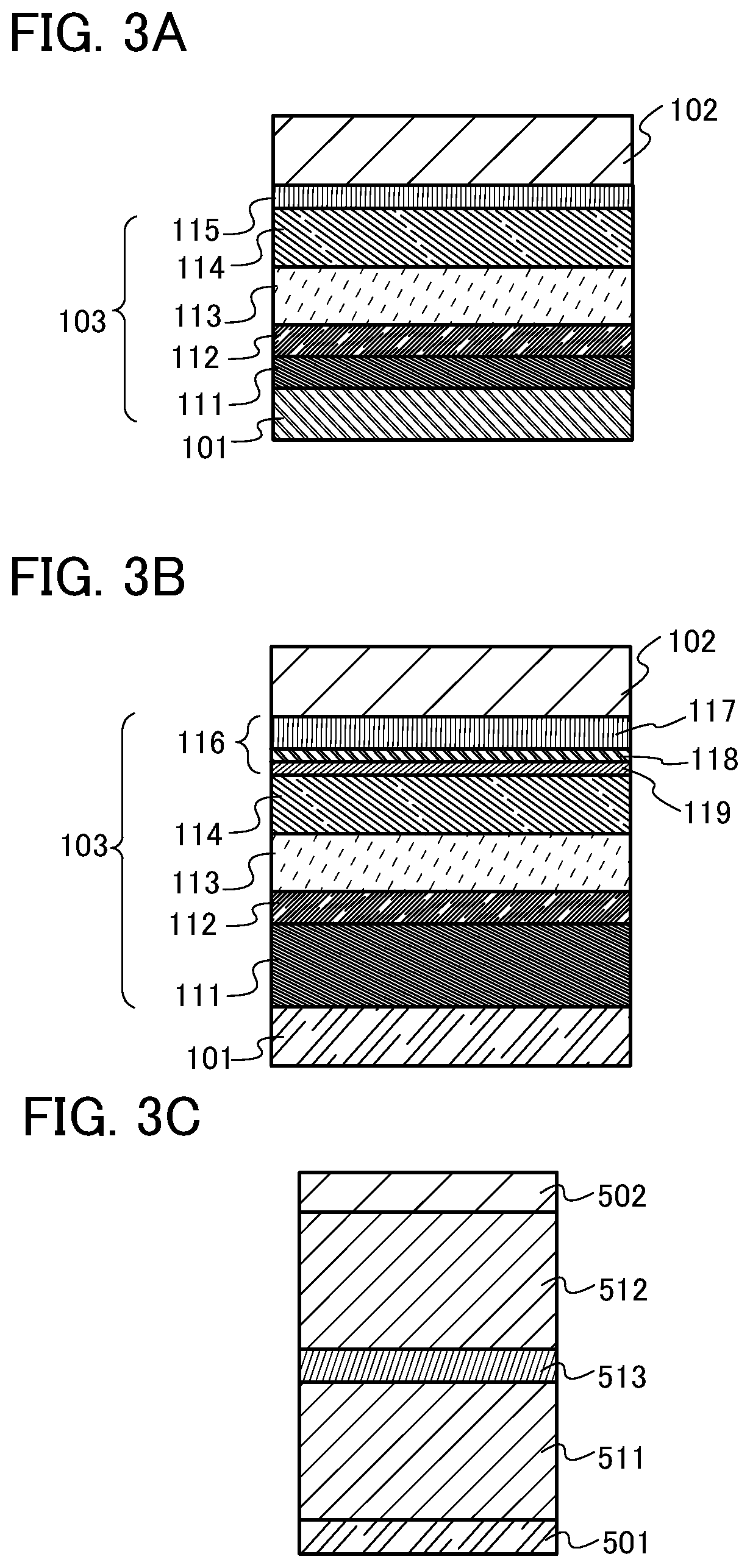

Display

InactiveUS20070126353A1Improve Outcoupling EfficiencyDischarge tube luminescnet screensElectroluminescent light sourcesForward scatterScattered light

A display includes a light-emitting element which includes a back electrode, a front electrode facing the back electrode, and an active layer interposed therebetween and including an emitting layer, and a light-scattering layer which is placed on a front side of the front electrode. The light-emitting element forms at least a portion of a microcavity structure. A forward-scattered light is greater in luminous energy than a back-scattered light when the light-scattering layer is irradiated with light from the microcavity structure.

Owner:KUBOTA HIROFUMI +2

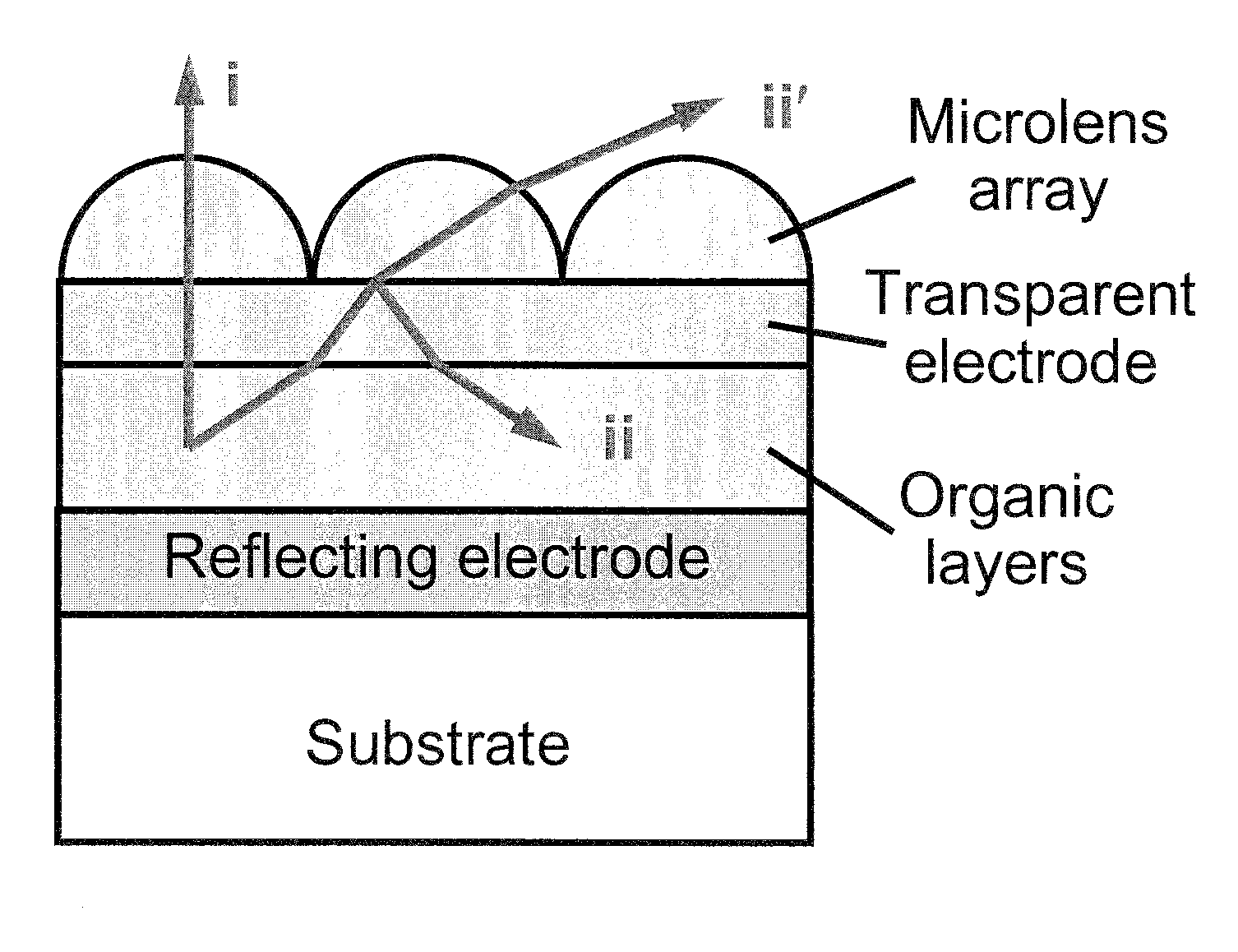

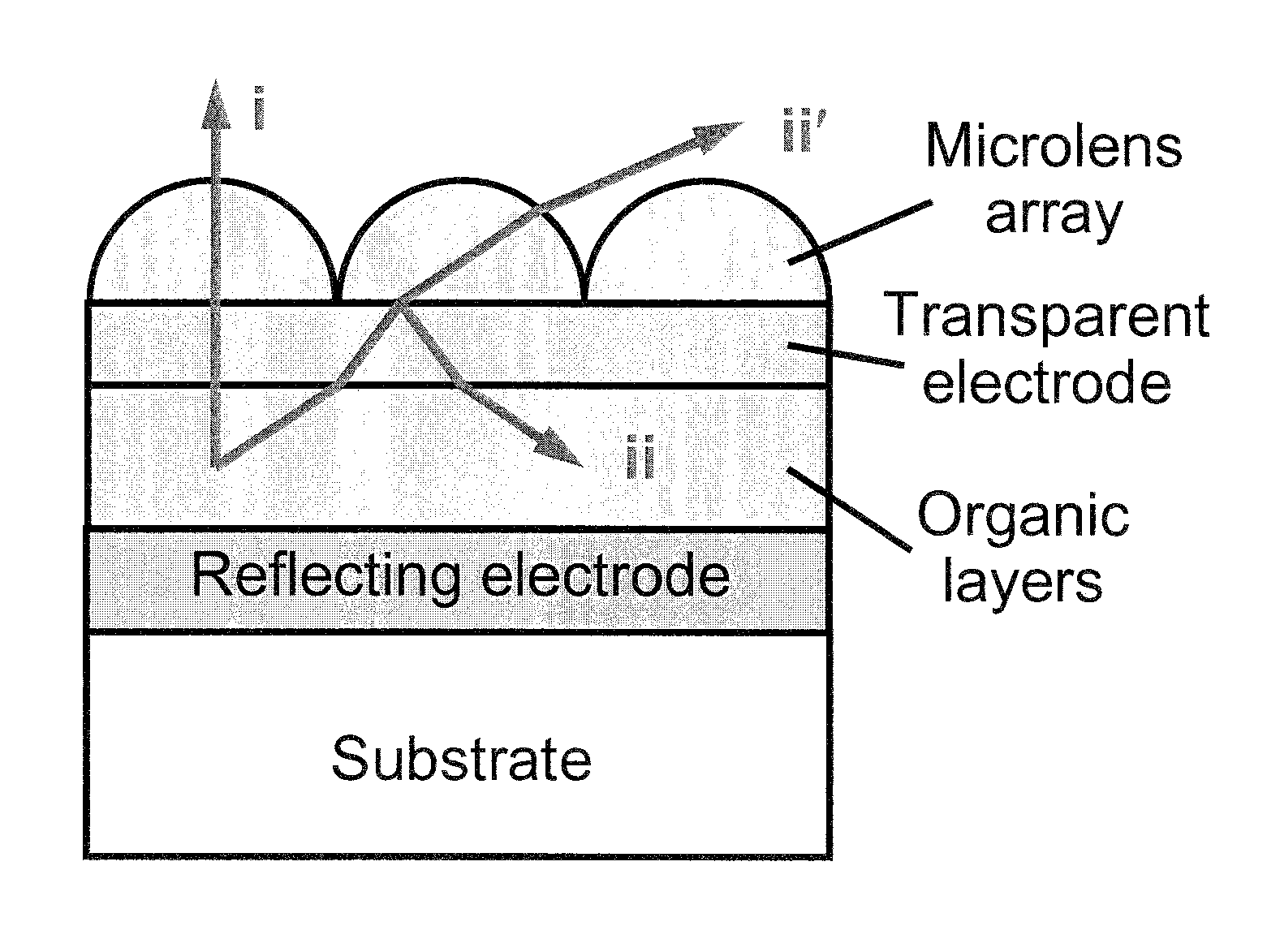

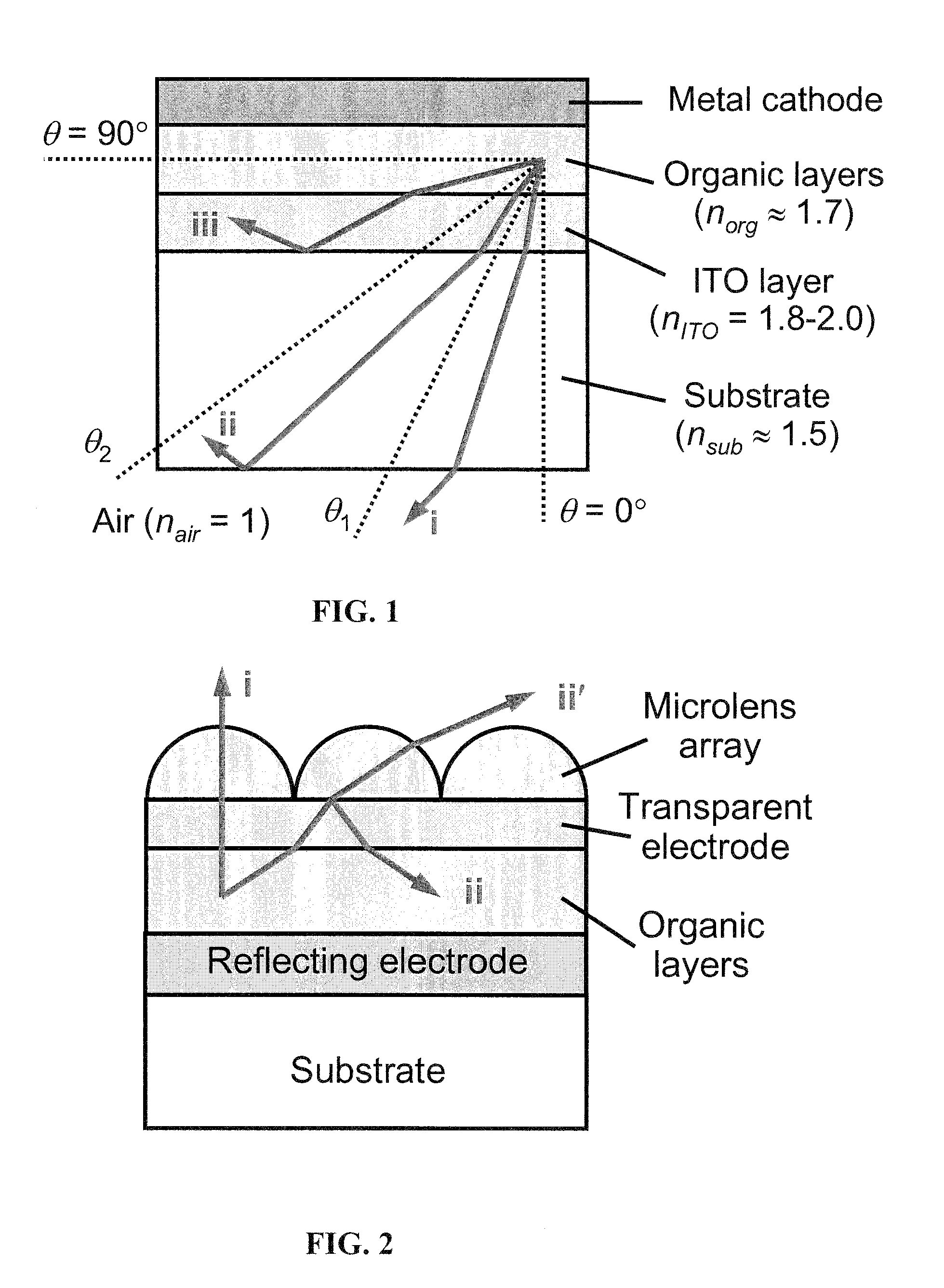

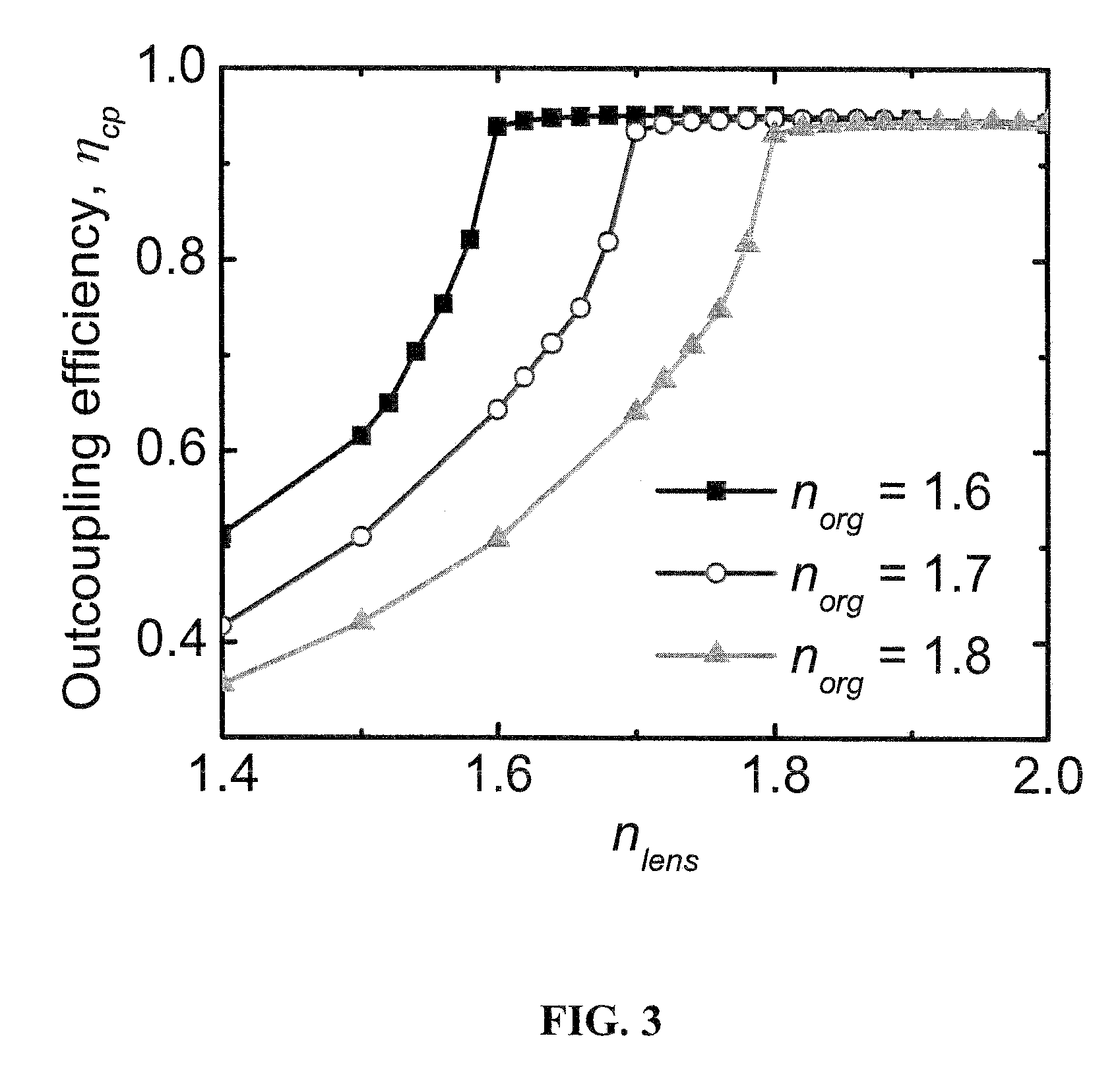

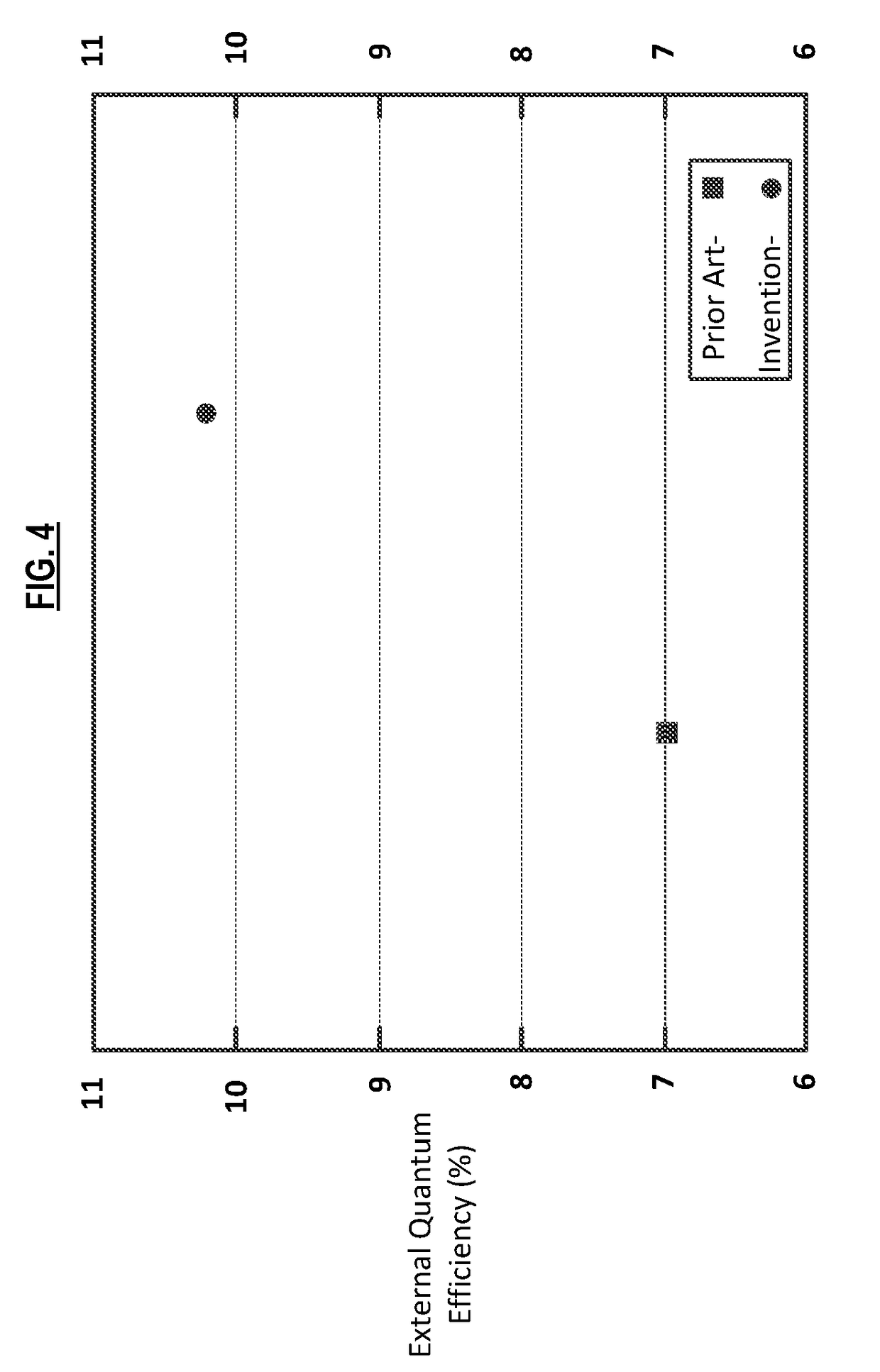

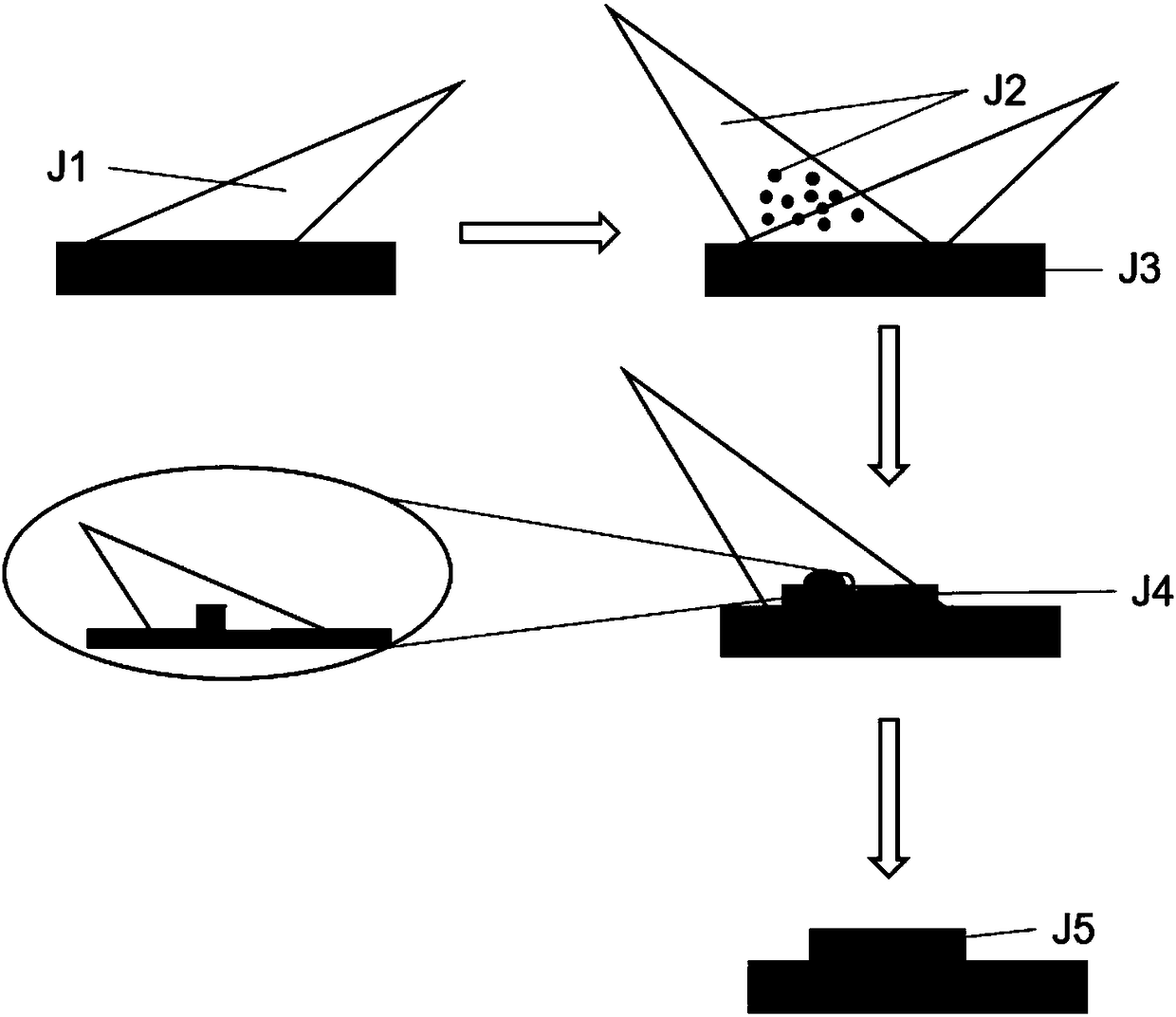

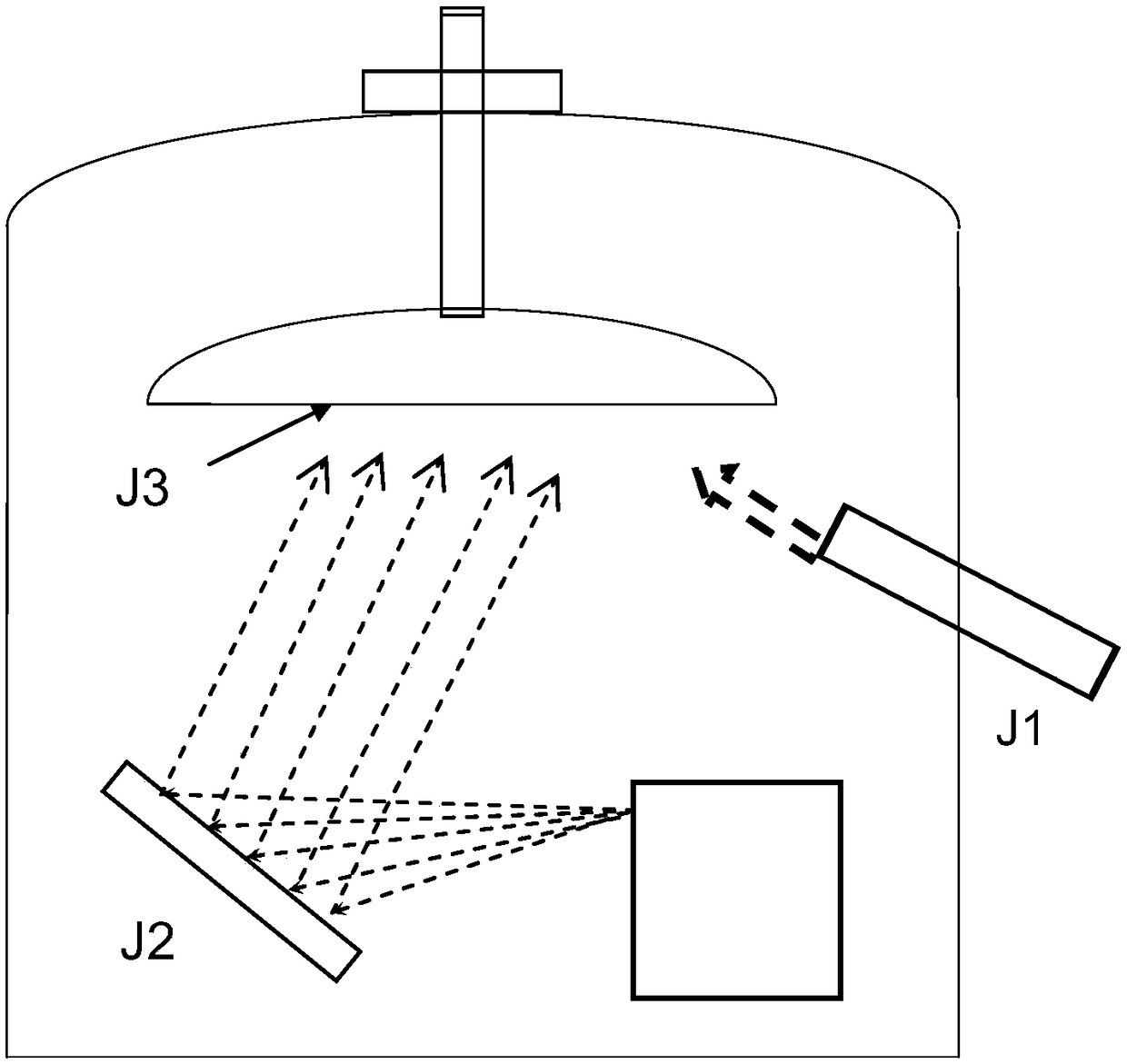

Top-Emission Organic Light-Emitting Devices with Microlens Arrays

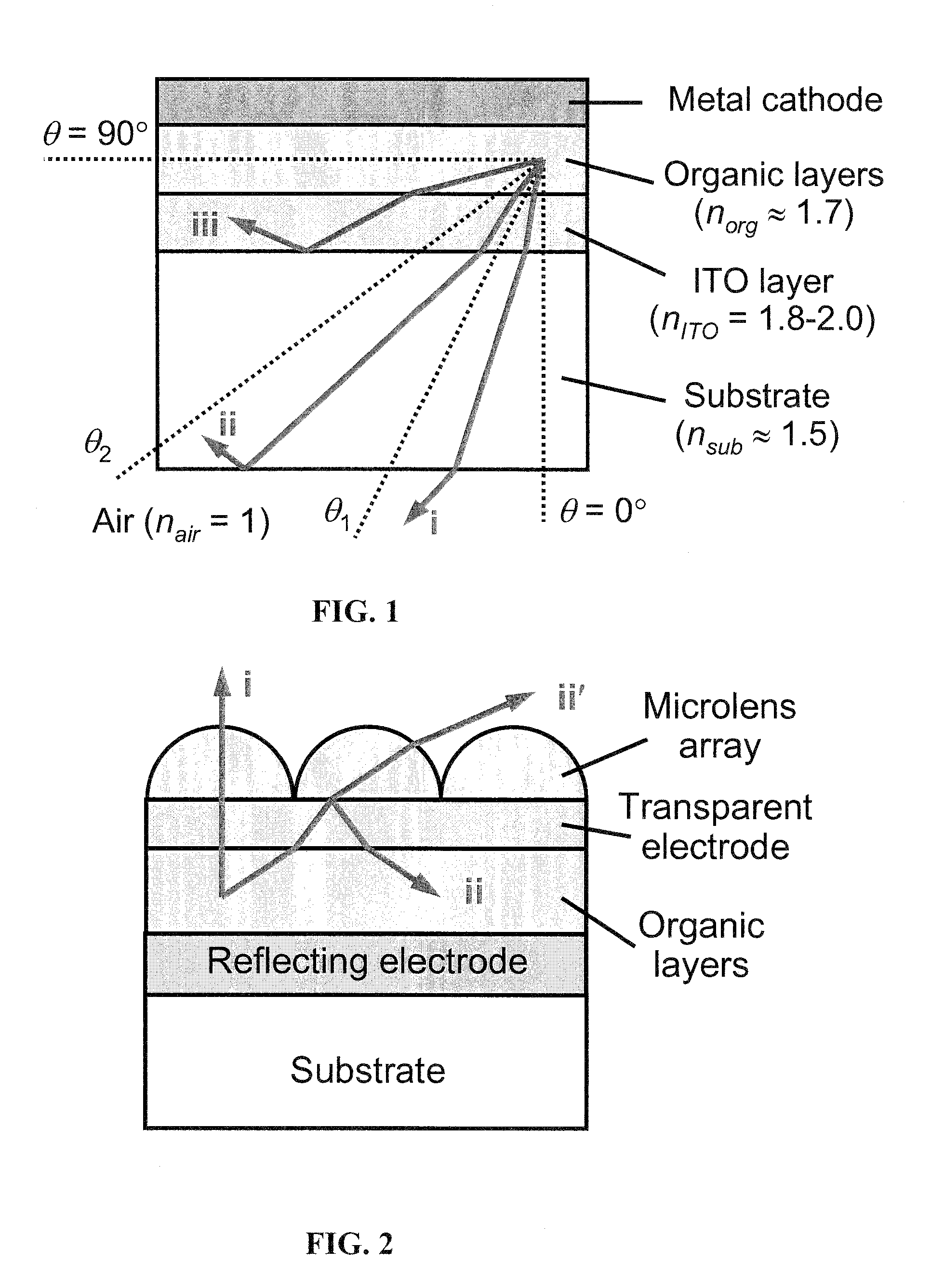

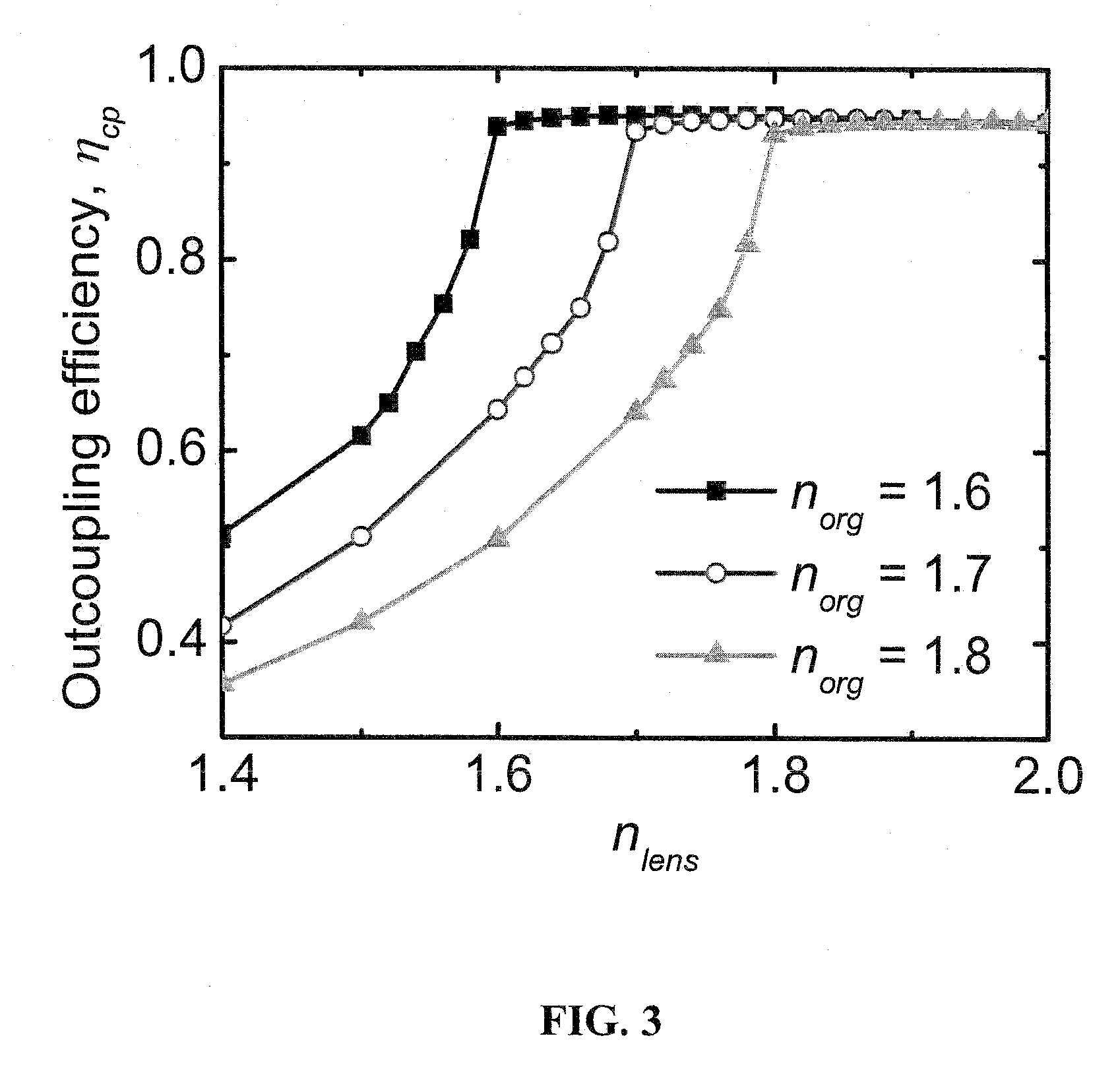

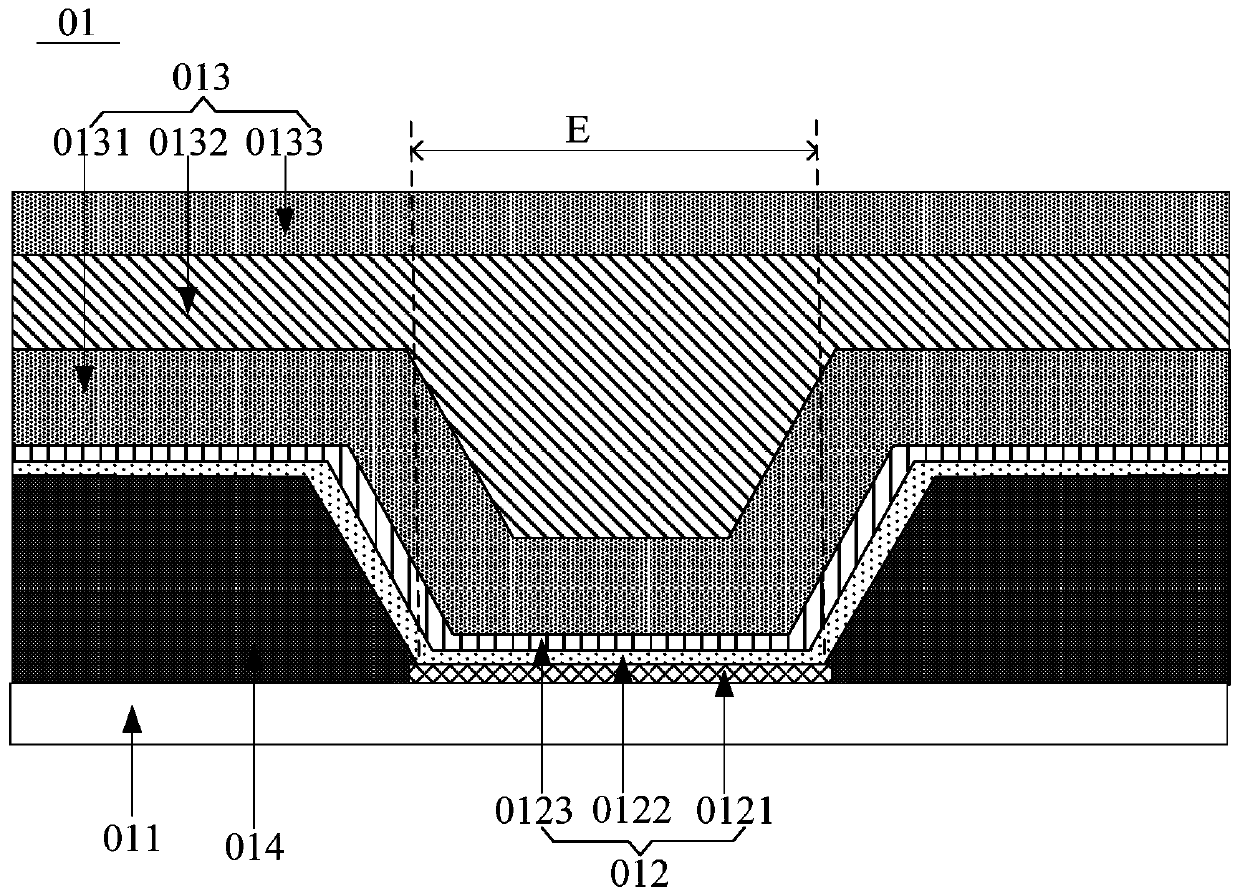

InactiveUS20100201256A1Improve Outcoupling EfficiencyDischarge tube luminescnet screensElectroluminescent light sourcesOrganic light emitting deviceMicro lens array

Embodiments of the invention can provide organic light-emitting devices (OLEDs) with enhanced outcoupling efficiency. Specific embodiments can enhance the outcoupling efficiency by more than four times. Embodiments of the invention incorporate microlens 5 arrays on the emitting surface of a top-emission OLED. Incorporation of microlens arrays on the emitting surface of a top-emission OLED can greatly enhance the outcoupling efficiency in OLEDs. With a microlens array attached to the emitting surface, much of, if not all, of the waveguiding modes can be extracted. The microlens array can be fabricated using the inkjet printing method or using other methods, including molding.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

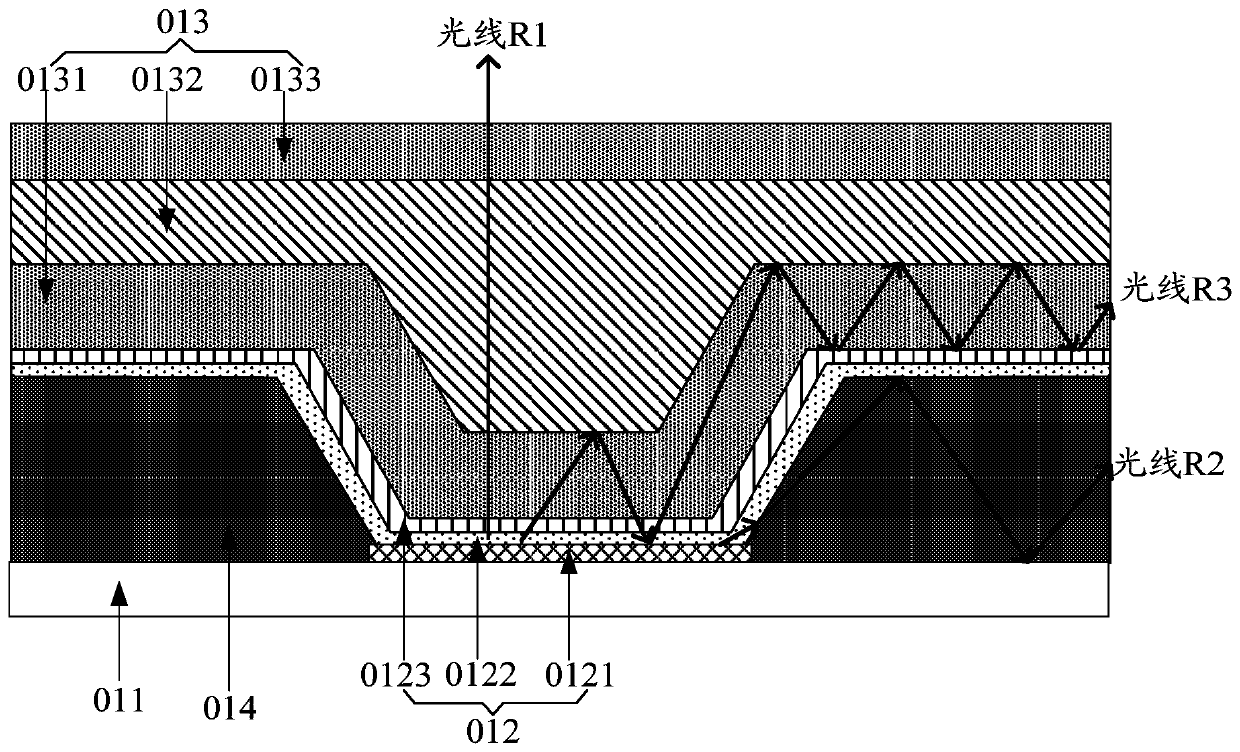

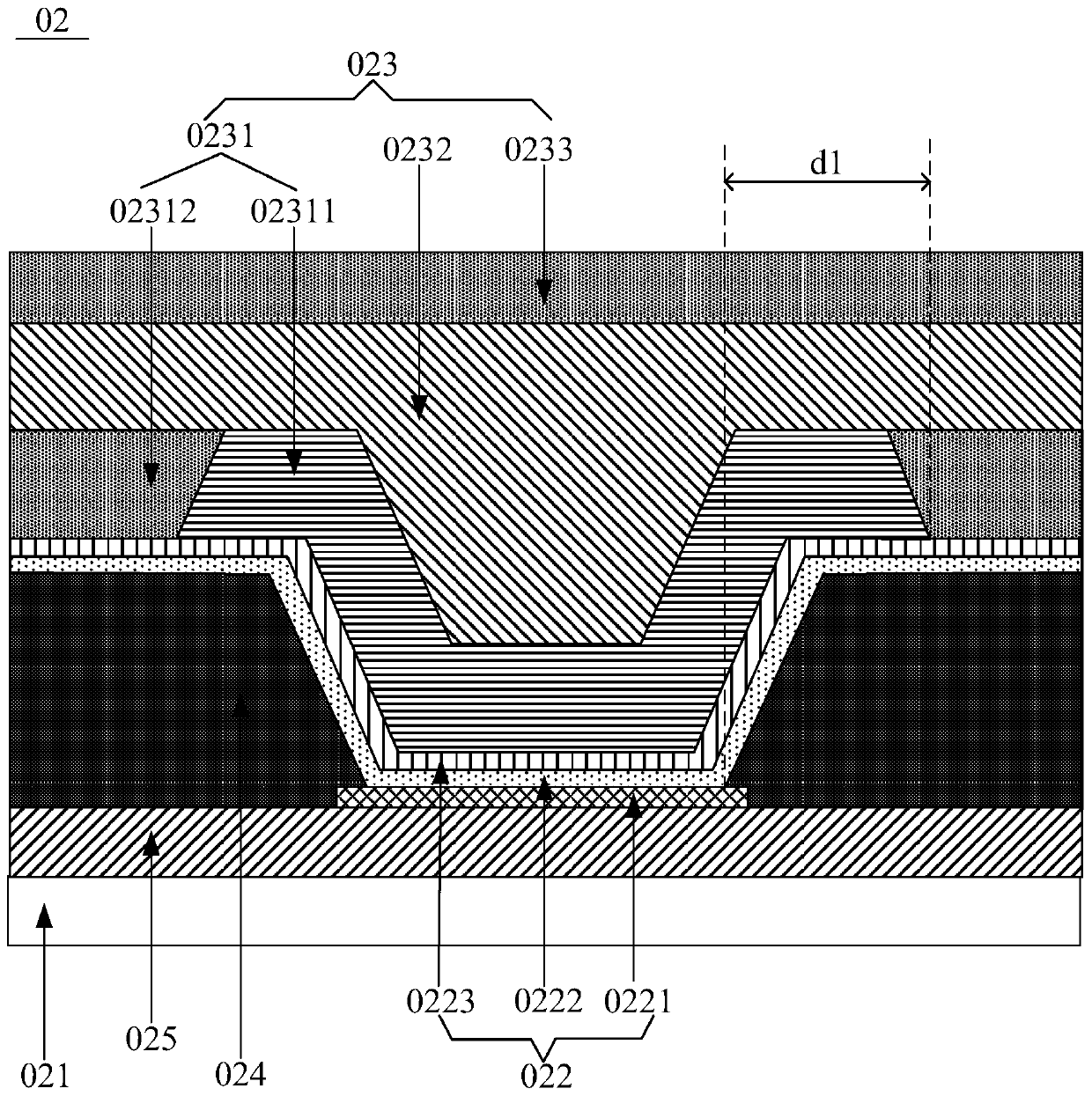

Luminescent device, manufacturing method thereof and display device

ActiveCN109904347AImprove Outcoupling EfficiencyAvoid the waveguide effectSolid-state devicesSemiconductor/solid-state device manufacturingRefractive indexDisplay device

The invention discloses a luminescent device, a manufacturing method thereof and a display device, and belongs to the field of luminescent devices. The luminescent device comprises a substrate, a luminescent unit and a thin film packaging structure, wherein the luminescent unit is arranged on the substrate; the thin film packaging structure is arranged on the side, far away from the substrate, ofthe luminescent unit; the thin film packaging structure comprises at least one packaging film; a target packaging film in the at least one packaging film is provided with a first packaging part and asecond packaging part which is located at the same layer with the first packaging part and in contact with the first packaging part; the positive projection of the first packaging part on the substrate covers the positive projection of the luminescent unit on the substrate; and the refractive index of the first packaging part is smaller than the refractive index of the second packaging part. The luminescent device is beneficial for avoiding the light emitted by the luminescent unit from generating a waveguide effect on the thin film packaging structure, and is beneficial for improving the external coupling efficiency of the luminescent device. The invention is used for luminescent devices.

Owner:BOE TECH GRP CO LTD

Top-emission organic light-emitting devices with microlens arrays

InactiveUS8373341B2Improve Outcoupling EfficiencyDischarge tube luminescnet screensElectroluminescent light sourcesOrganic light emitting deviceMicro lens array

Embodiments of the invention can provide organic light-emitting devices (OLEDs) with enhanced outcoupling efficiency. Specific embodiments can enhance the outcoupling efficiency by more than four times. Embodiments of the invention incorporate microlens 5 arrays on the emitting surface of a top-emission OLED. Incorporation of microlens arrays on the emitting surface of a top-emission OLED can greatly enhance the outcoupling efficiency in OLEDs. With a microlens array attached to the emitting surface, much of, if not all, of the waveguiding modes can be extracted. The microlens array can be fabricated using the inkjet printing method or using other methods, including molding.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

Sealant for LED device, LED device, and method for producing LED device

InactiveUS20150221837A1Improve adhesionHigh sulfide gas resistanceOther chemical processesSolid-state devicesSilane compoundsSilanes

The objective of the present invention is to provide a sealant for an LED device capable of forming a sealing layer having a high level of light extraction, outstanding resistance to sulfidizing gas, and not giving rise to cracking or peeling even when used for extended periods, as well as an LED device employing the same. In order to attain at least one of the abovementioned objective, a sealant for an LED device reflecting one aspect of the present invention contains 100 mass parts of a 1000-3000 mass average molecular weight polysiloxane polymerized from a trifunctional monomethyl silane compound and a tetrafunctional silane compound, 5 mass parts to 100 mass parts of an organometallic compound comprising a metal alkoxide or metal chelate containing a Group 4 or Group 13 metal, and a solvent.

Owner:KONICA MINOLTA INC

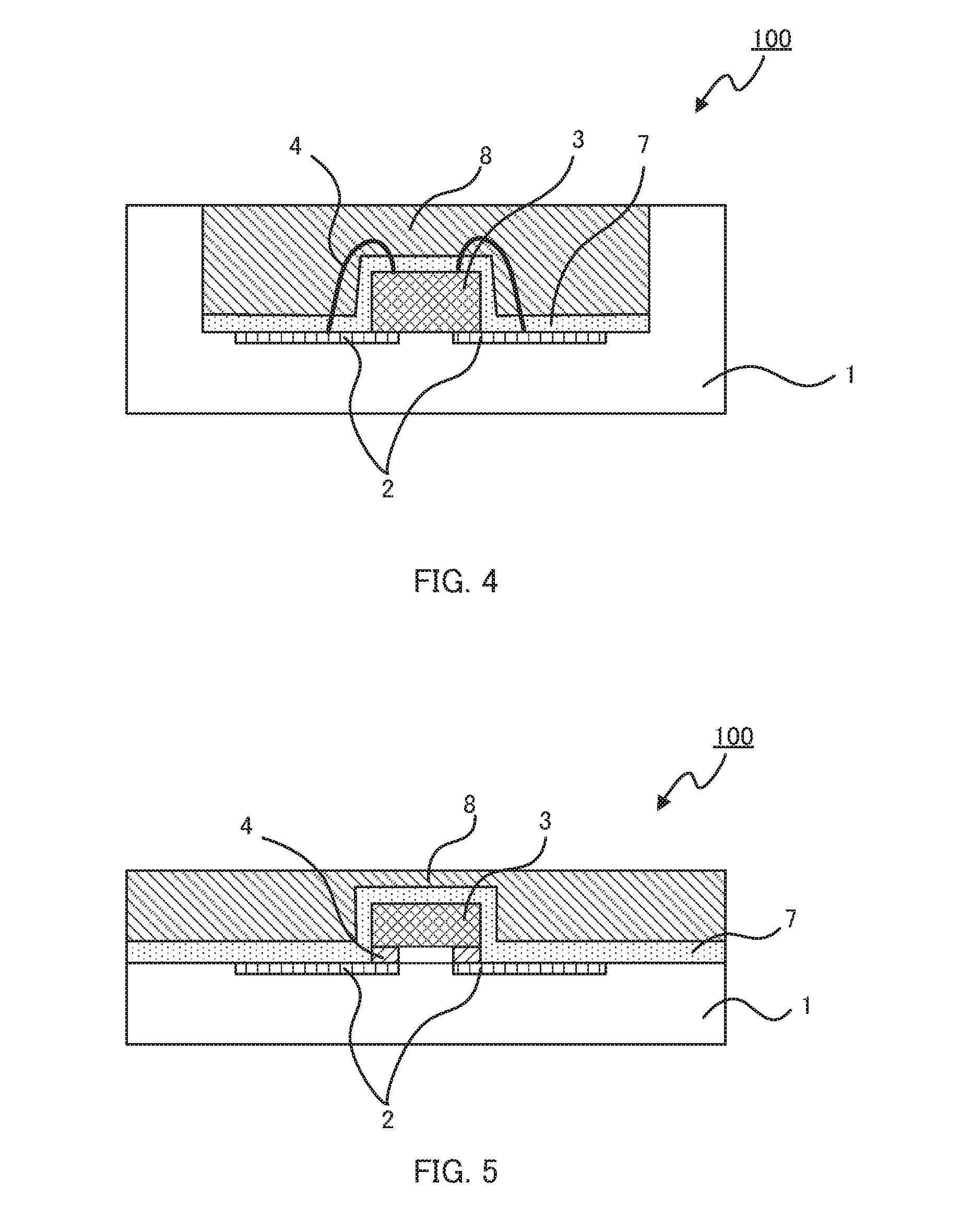

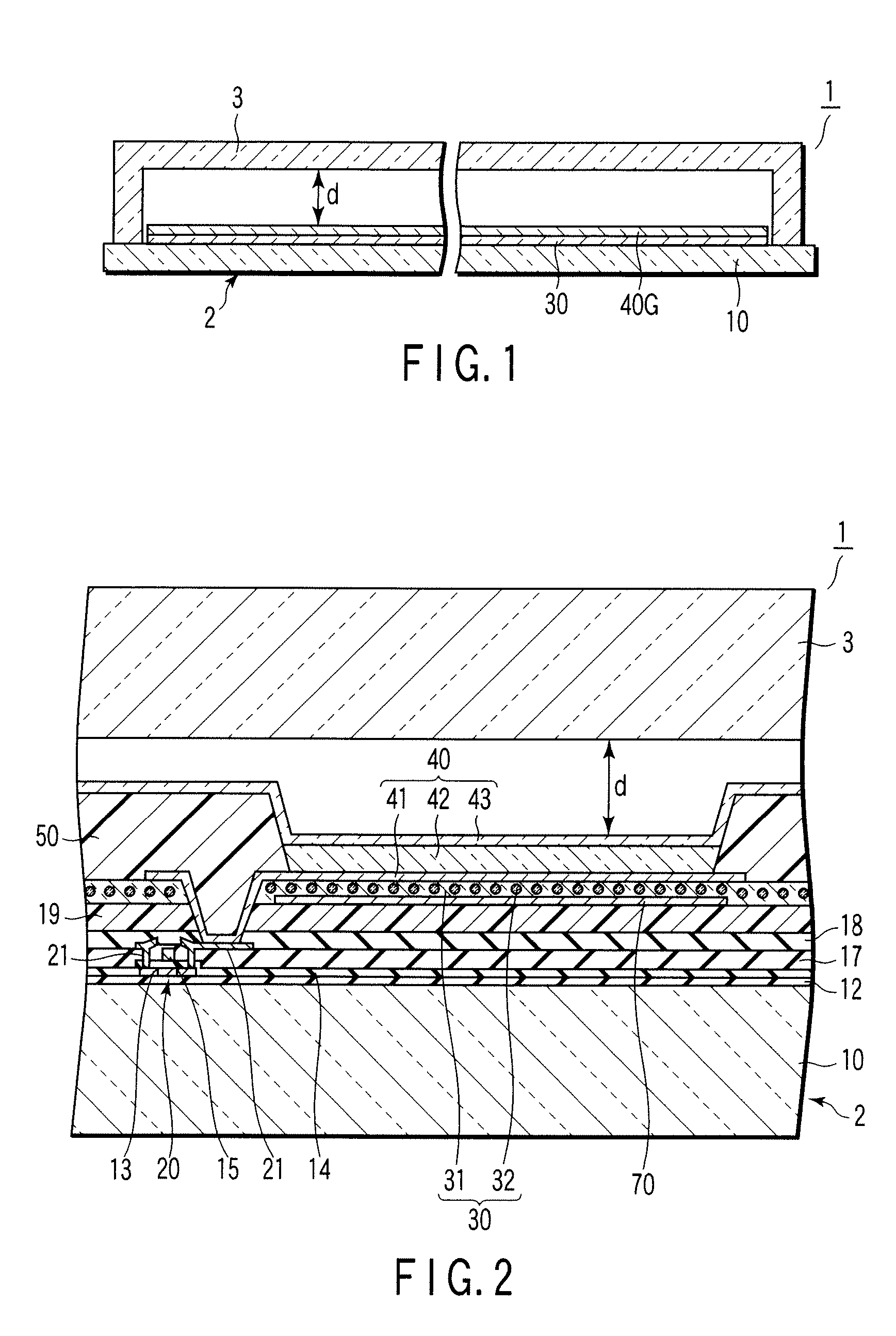

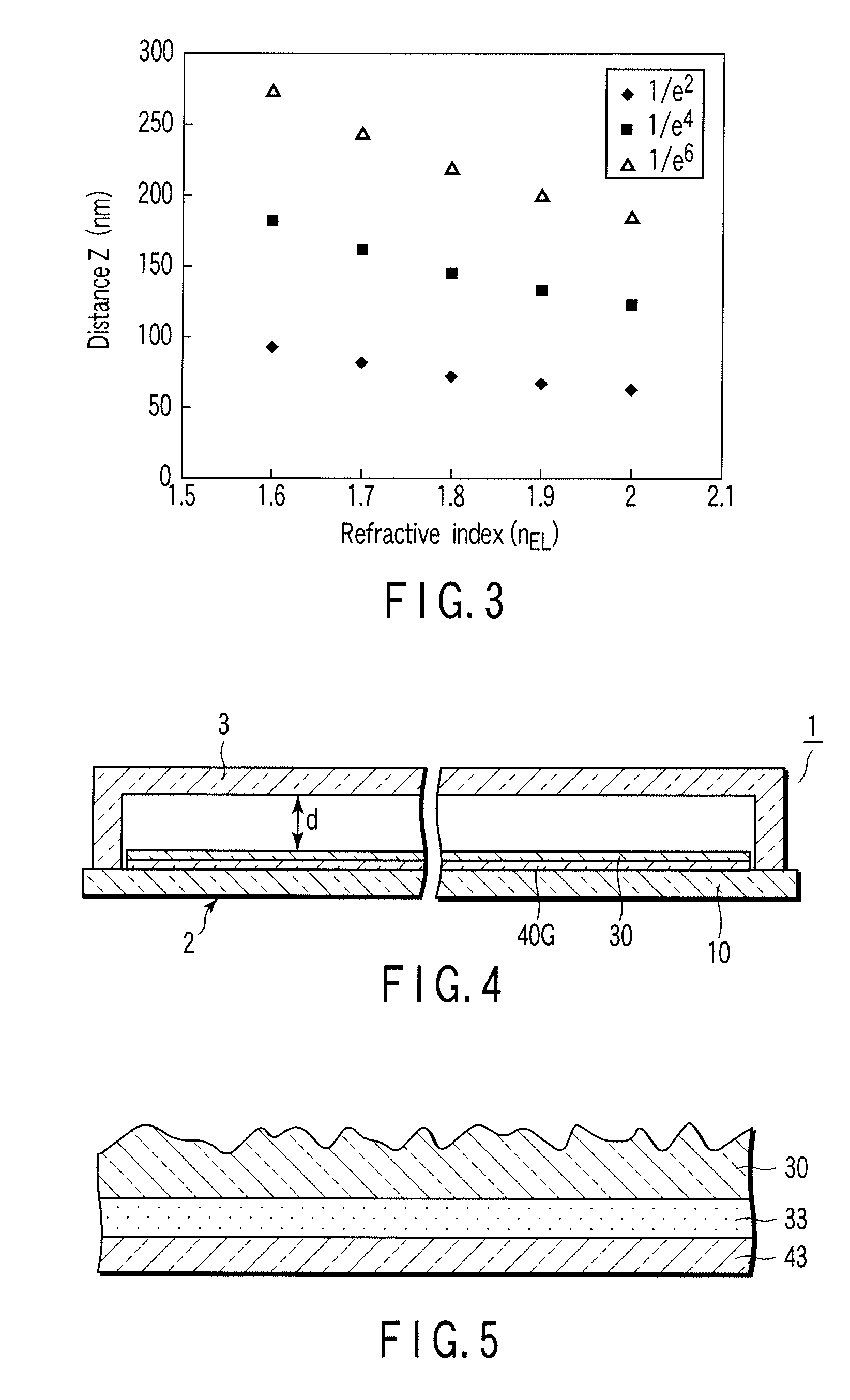

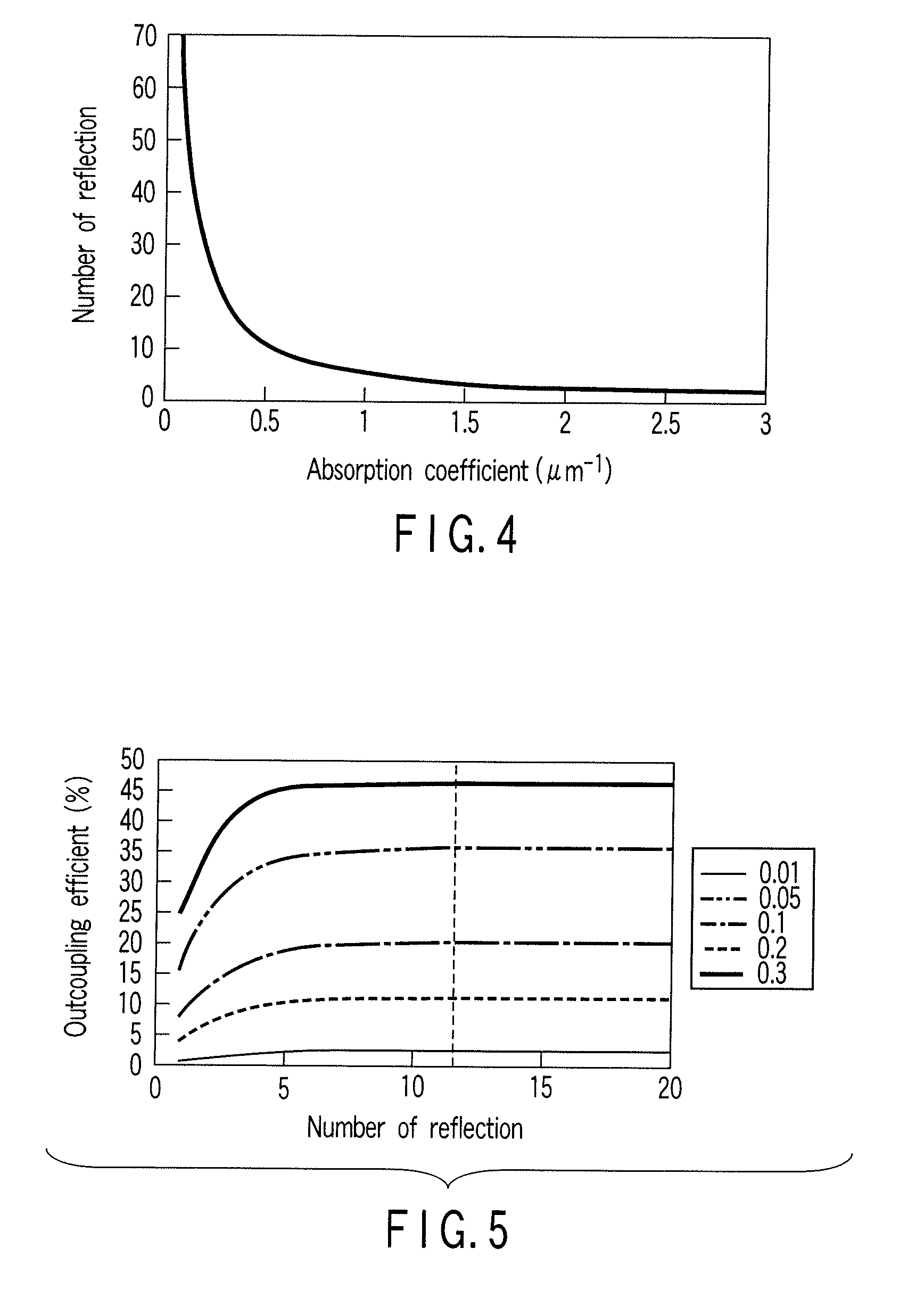

Organic el display

InactiveUS20070126358A1Improve Outcoupling EfficiencyMaterial nanotechnologyDischarge tube luminescnet screensIn planeDisplay device

A top emission organic EL display includes an array substrate including an insulating substrate, organic EL elements which are arranged on a main surface of the insulating substrate, and an outcoupling layer which extracts light components propagating in in-plane direction while causing multiple-beam interference from the organic EL element to make the light components travel in front of the organic EL element, and a sealing substrate facing and spaced apart from the organic EL elements. The display forms an enclosed space filled with an inert gas or evacuated between the sealing substrate and an element portion of the array substrate corresponding to the organic EL element. A distance between the element portion and the sealing substrate is 100 nm or longer.

Owner:TOSHIBA MATSUSHITA DISPLAY TECH

High-efficiency radiating device

InactiveUS7253445B2High radiation emission efficiencyReduce power consumptionSemiconductor devicesEngineeringLength wave

Owner:SIGNIFY HLDG BV

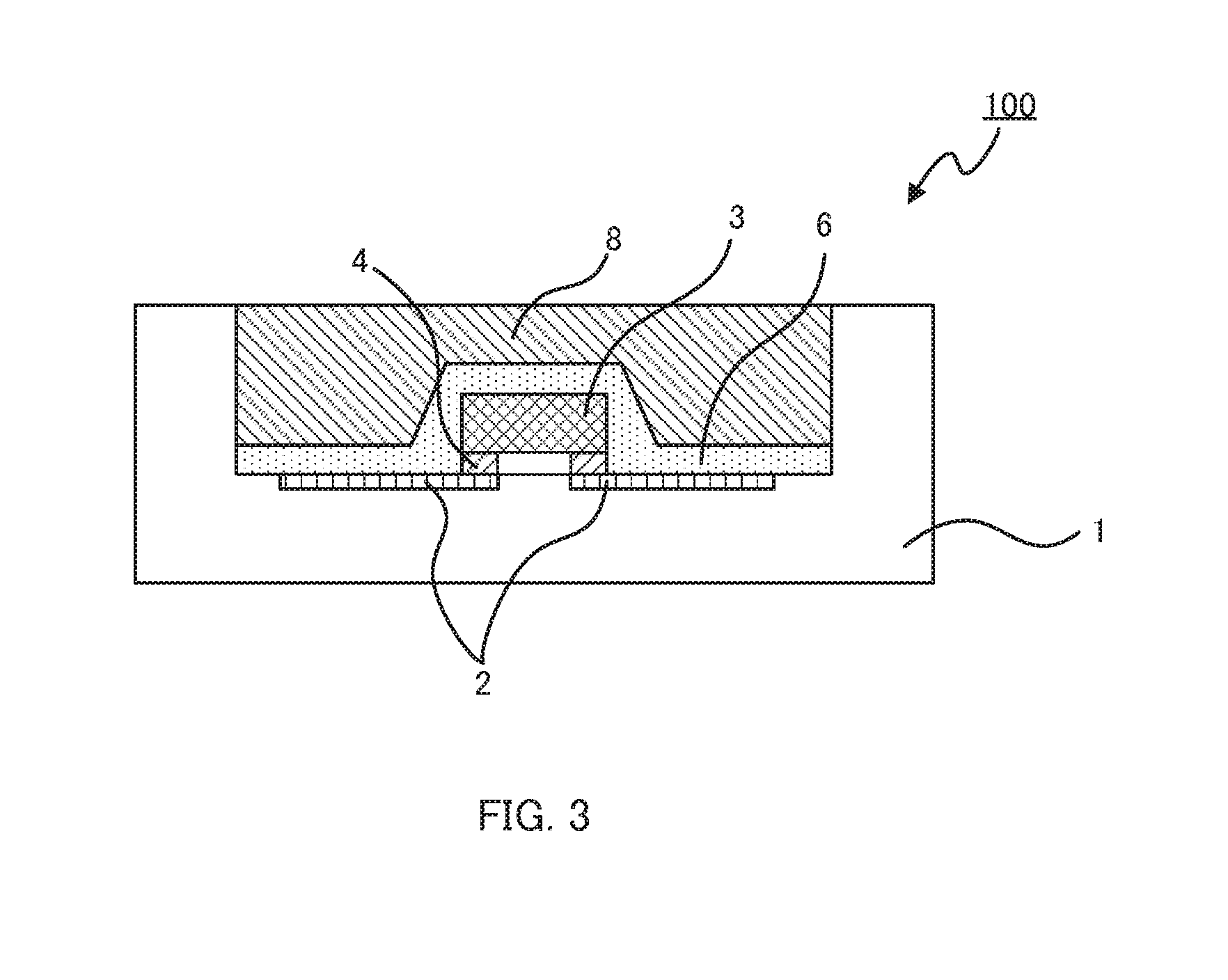

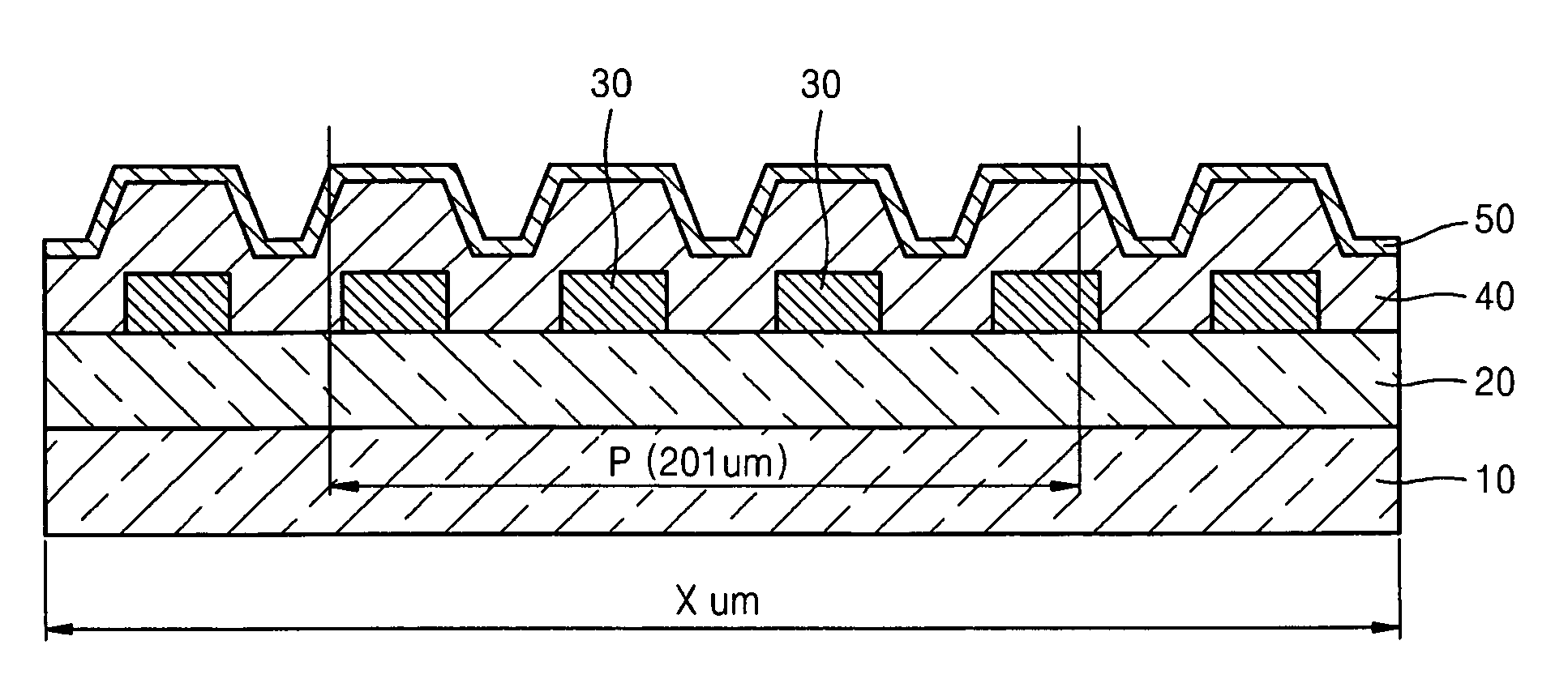

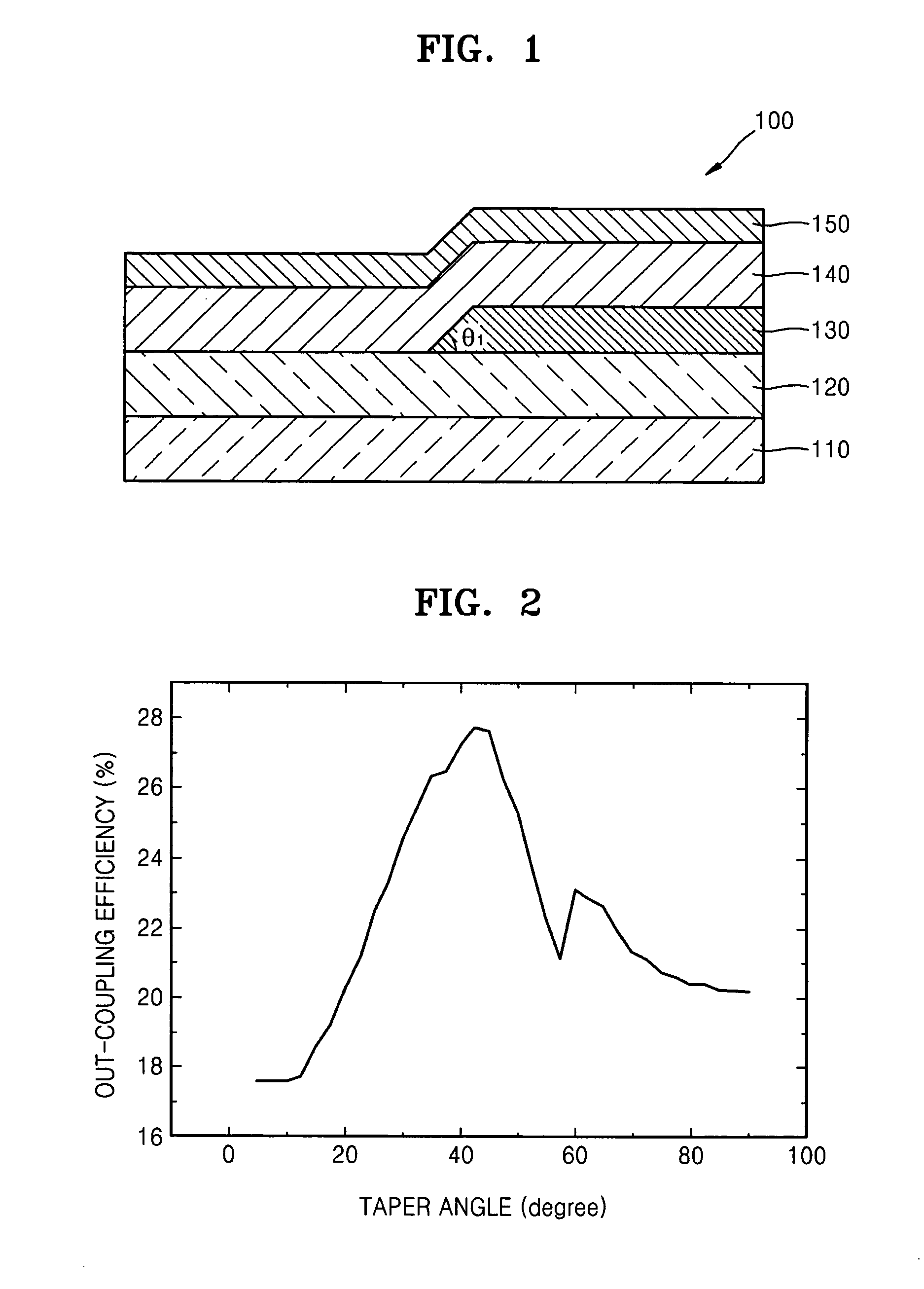

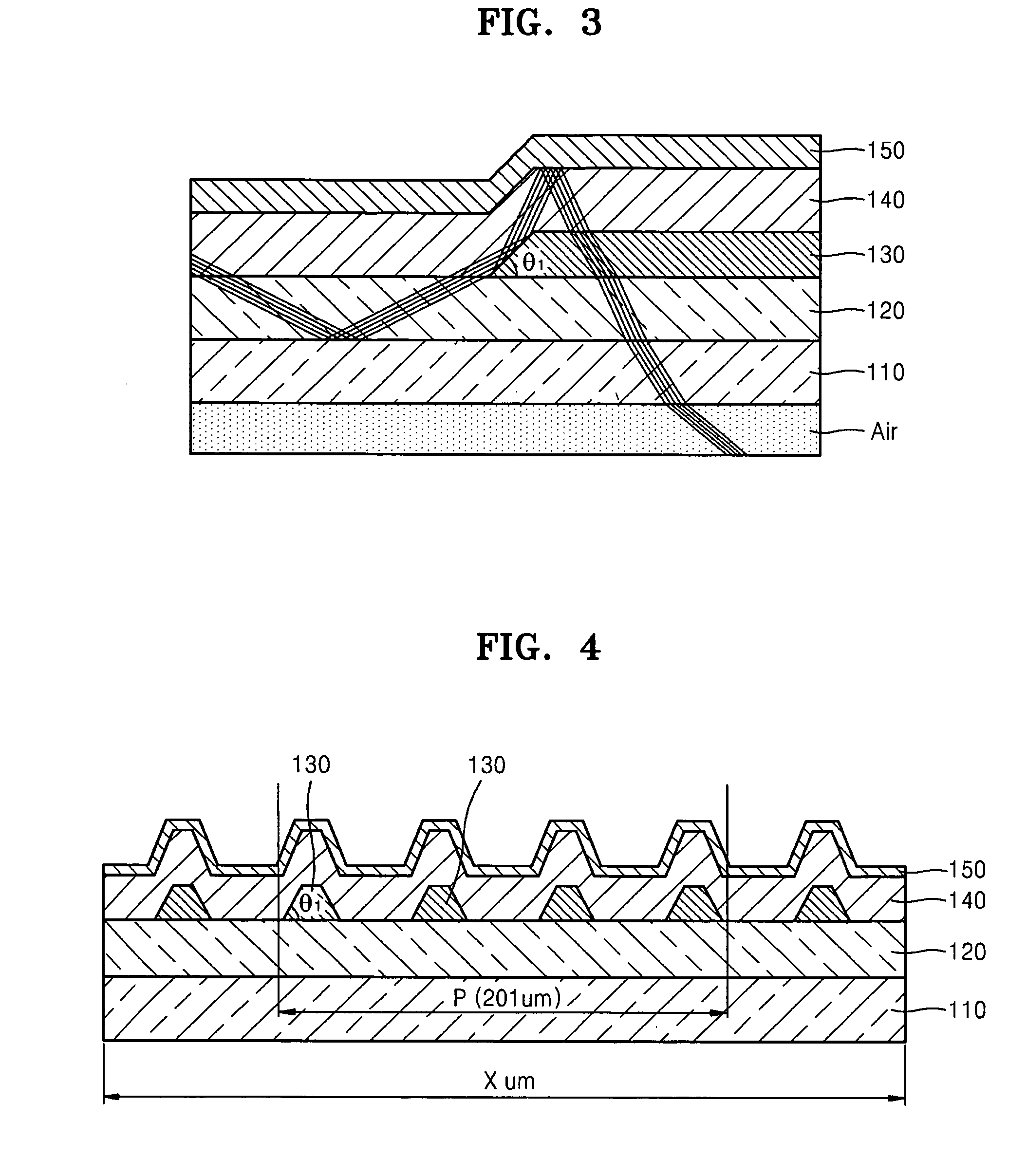

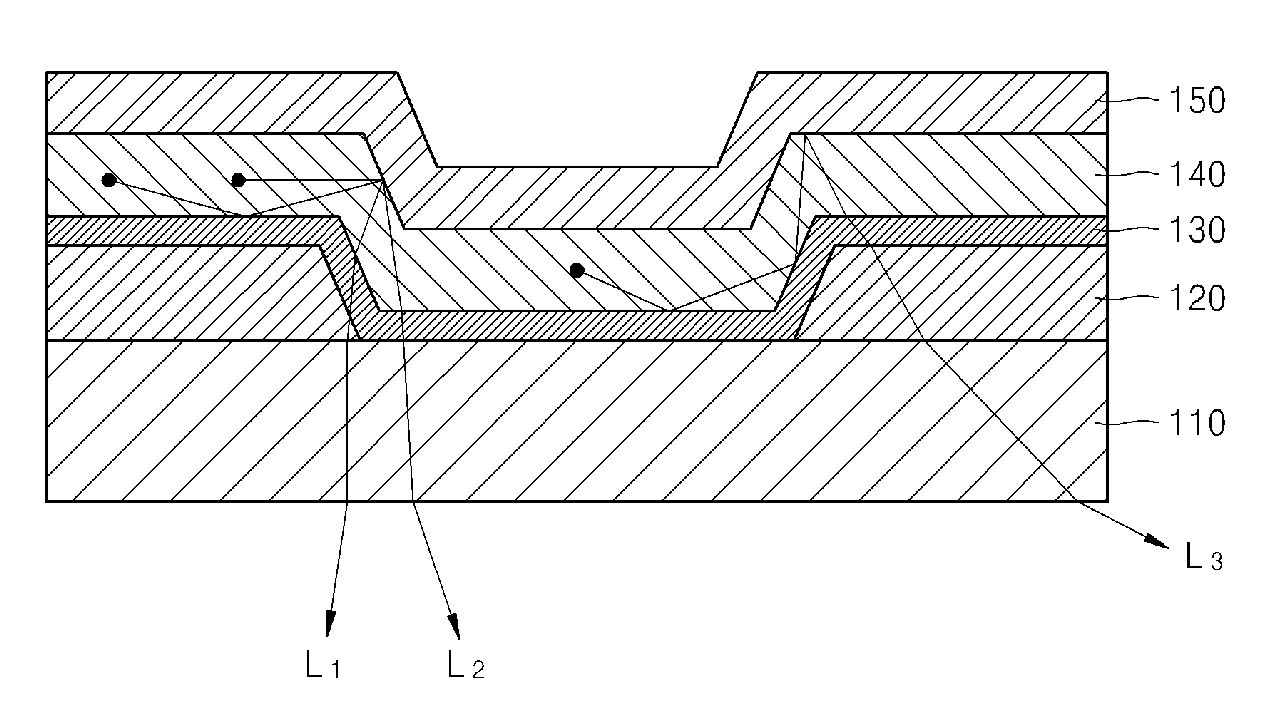

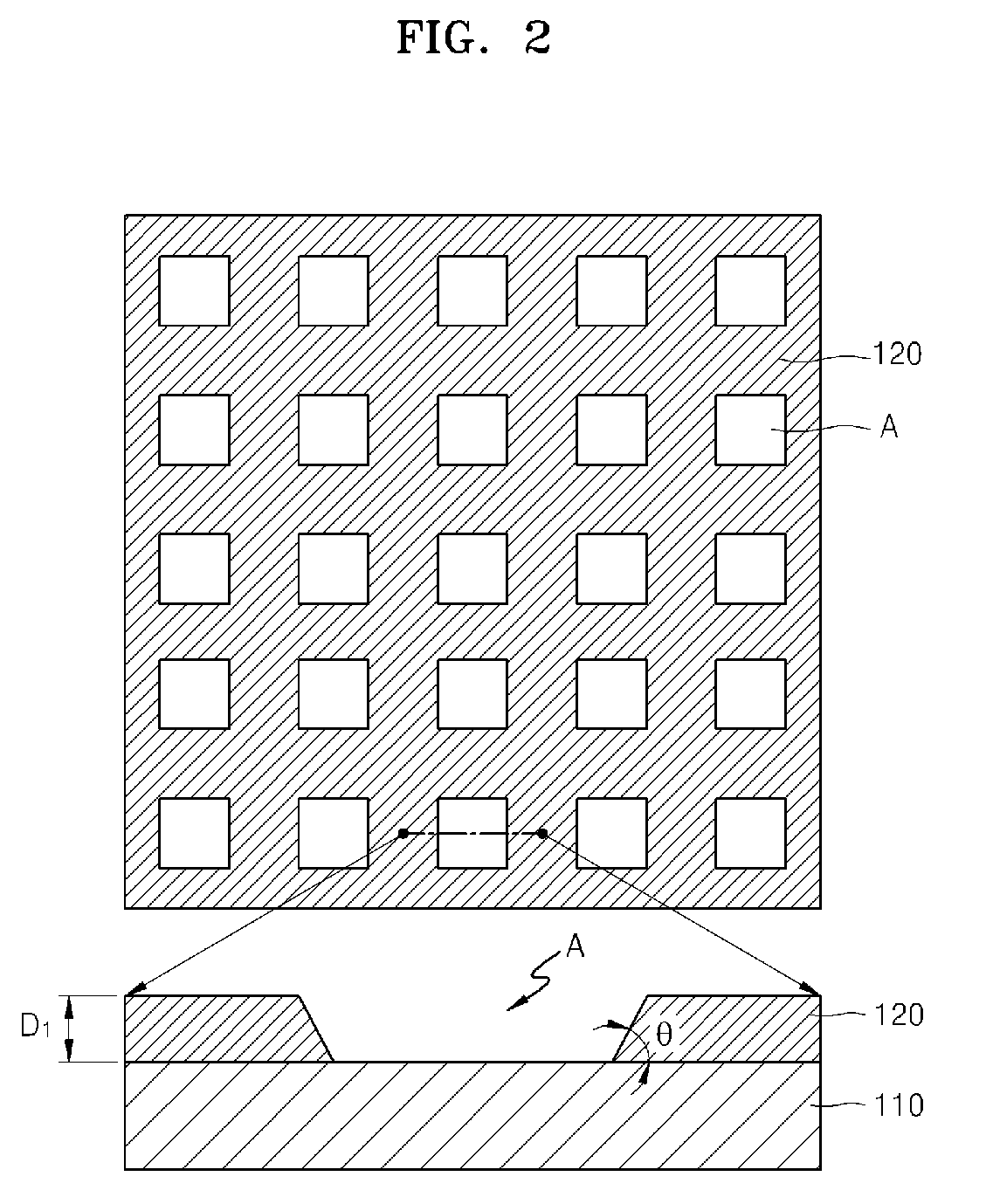

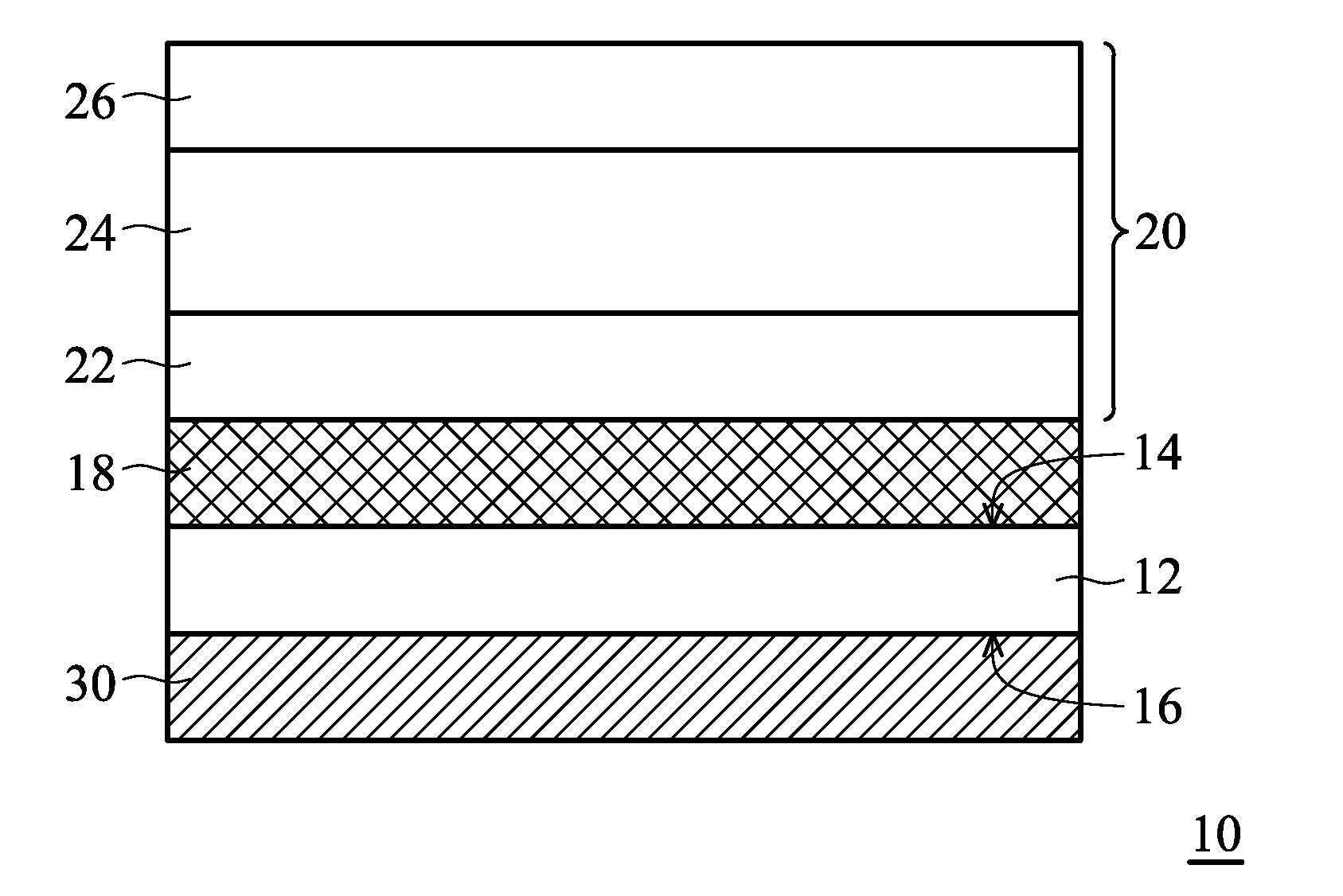

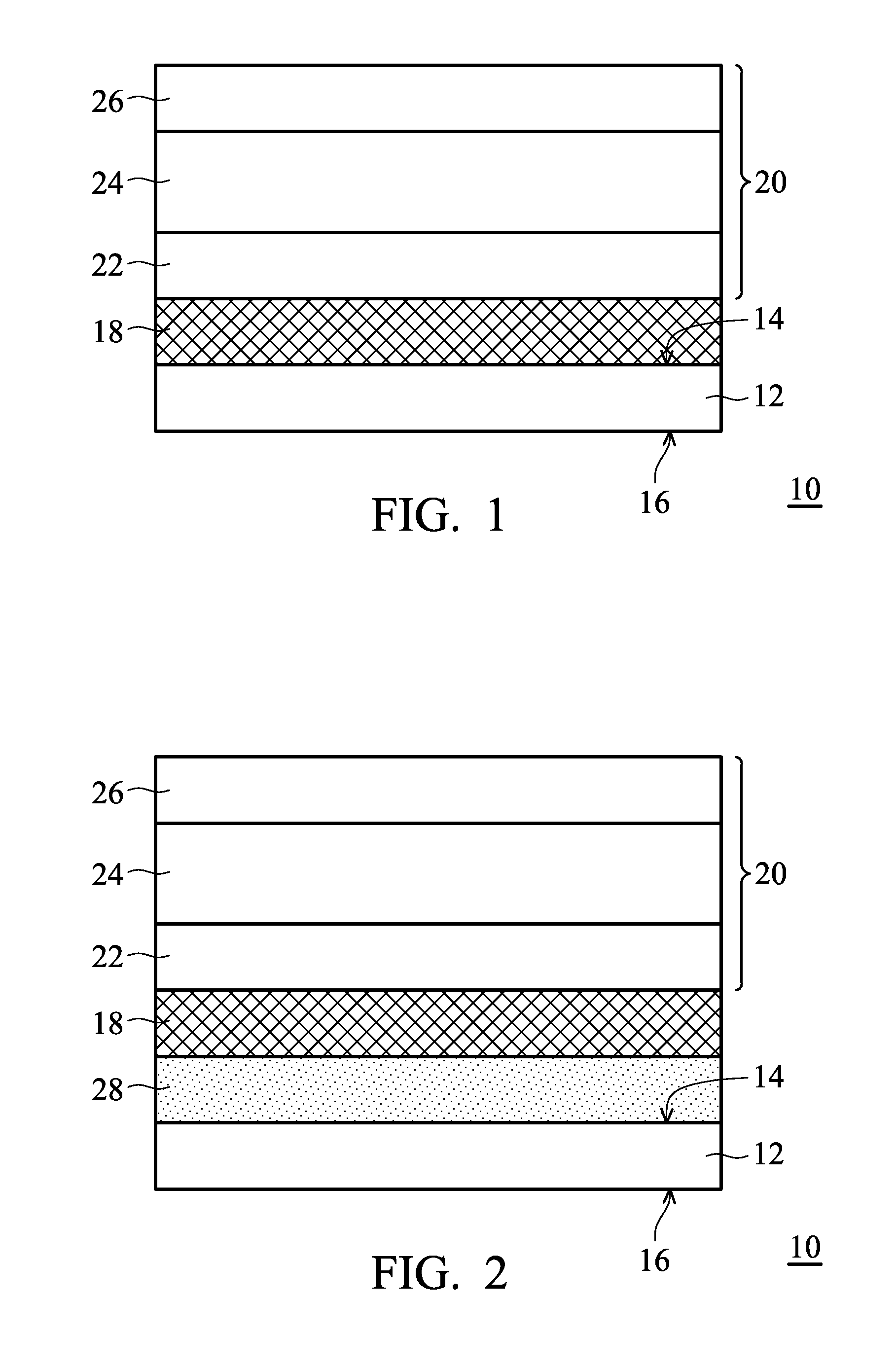

Organic-light emitting device, light equipment including the same, and organic light-emitting display apparatus including the same

InactiveUS20110140151A1Improve Outcoupling EfficiencyImprove efficiencySolid-state devicesSemiconductor/solid-state device manufacturingLight equipmentOrganic light emitting device

An organic light-emitting device includes a substrate, a first electrode layer on the substrate, a patterned refractive layer on the first electrode layer, a taper angle between a patterned end of the refractive layer and a surface of the first electrode being about 20 to about 60 degrees, the refractive layer including a material having a different refractive index than at least one of the first electrode layer and an organic light-emitting layer, the organic light-emitting layer that covers the refractive layer and is on the first electrode, the organic light-emitting layer contacting the patterned end of the refractive layer, and a second electrode layer on the organic light-emitting layer.

Owner:SAMSUNG DISPLAY CO LTD +1

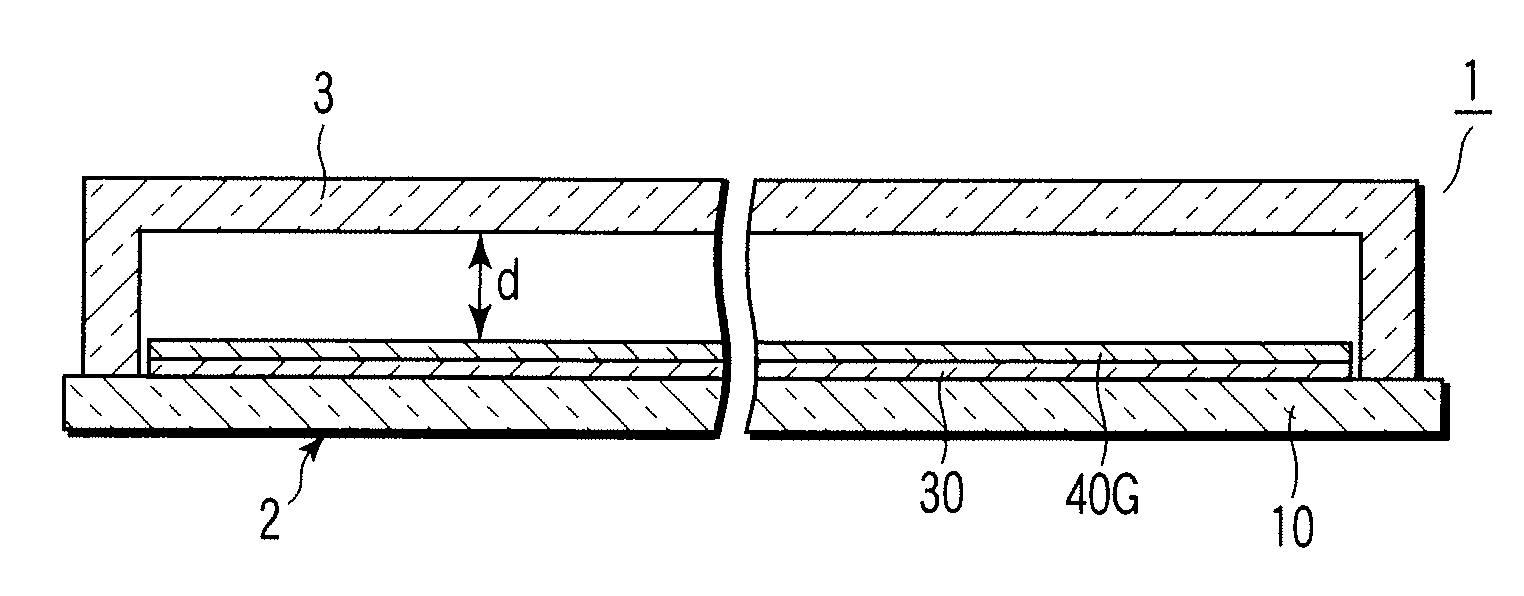

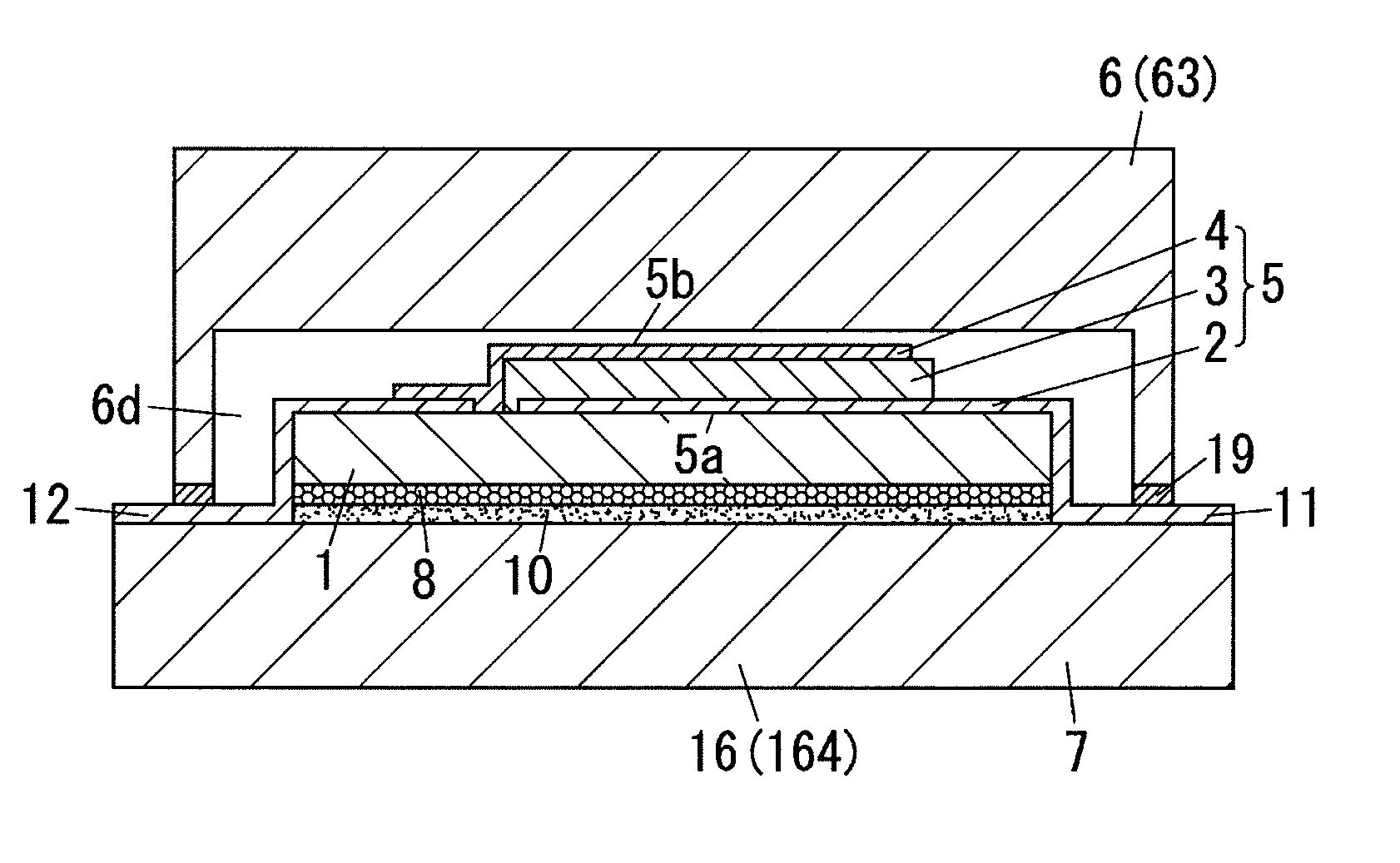

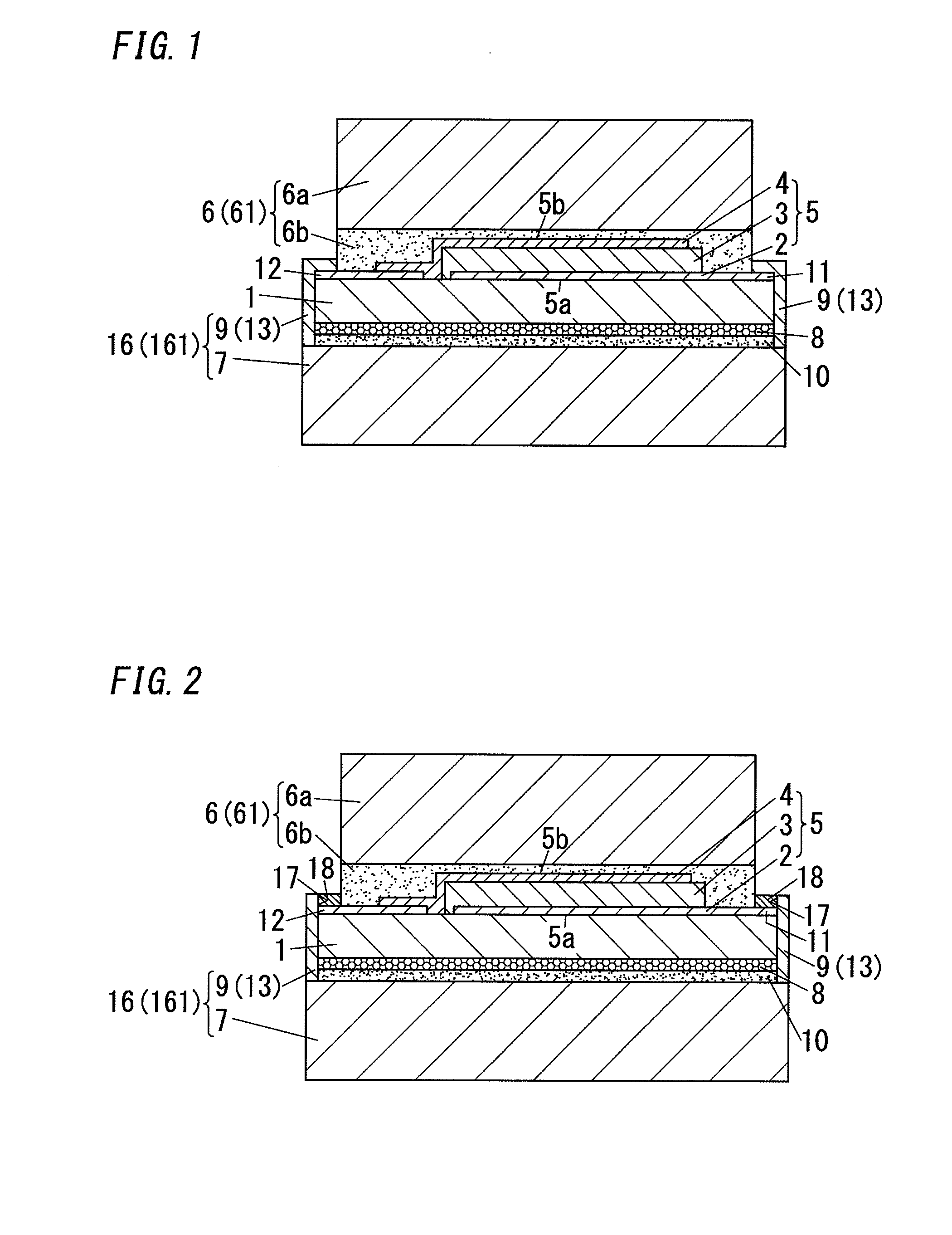

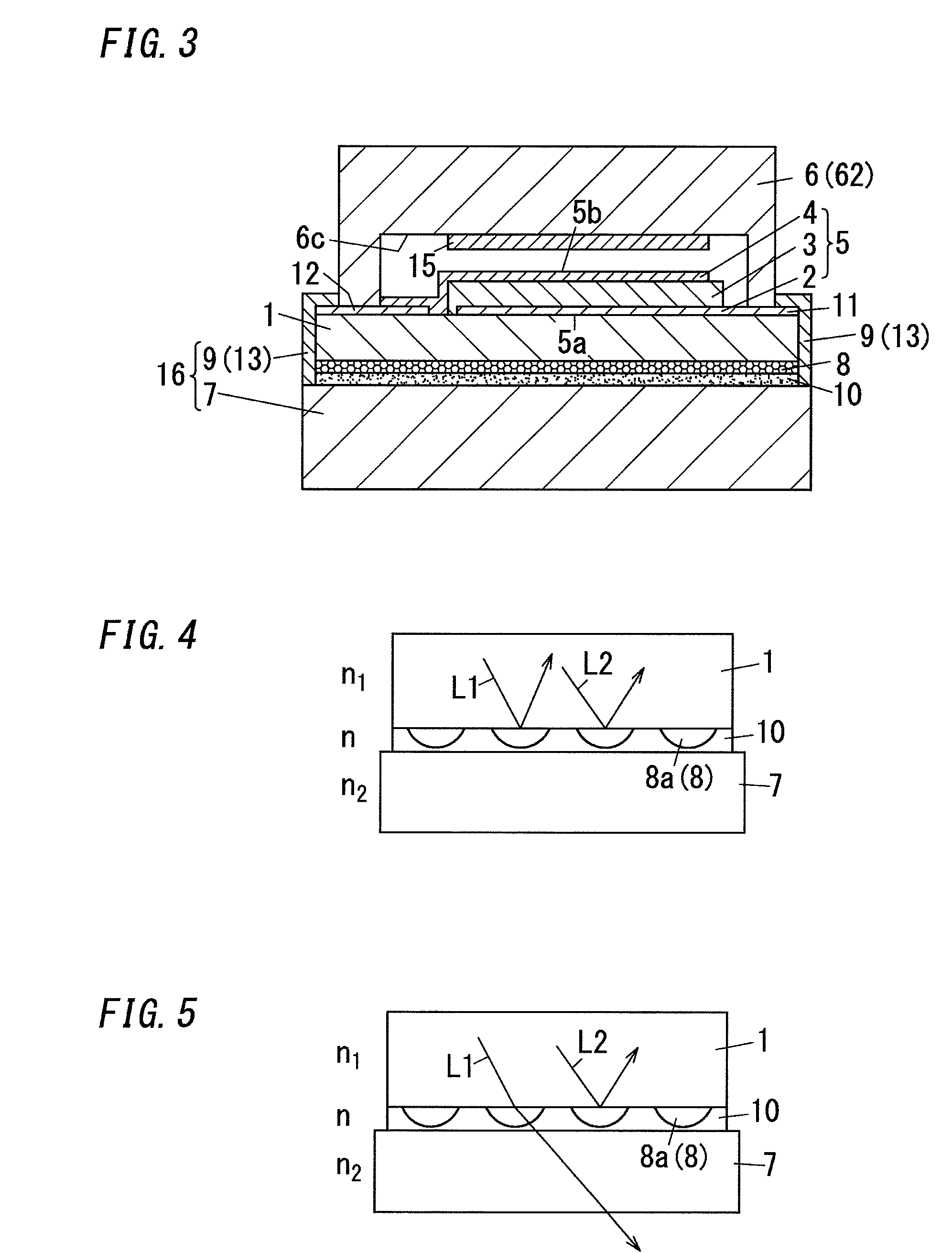

Planar light emitting device

InactiveUS20140225099A1Good weather resistanceReduce reflection lossSolid-state devicesSemiconductor/solid-state device manufacturingOrganic electroluminescenceLight emitting device

The planar light emitting device according to the present invention includes: an organic electroluminescence element; a formation substrate of a light transmissive resin material being adjacent to a first surface of the organic electroluminescence element; a light outcoupling structure provided to the formation substrate and suppressing reflection of light emitted from the organic electroluminescence element at a surface of the formation substrate; a first moisture preventer with a moisture proof property being over a second surface of the organic electroluminescence element to cover the organic electroluminescence element; and a second moisture preventer with a moisture proof property covering the formation substrate to prevent moisture from passing through the formation substrate and reaching the first surface of the organic electroluminescence element. The second moisture preventer includes an overlap overlapping the first surface in the thickness direction of the organic electroluminescence element. The overlap is of a light transmissive material.

Owner:PANASONIC CORP

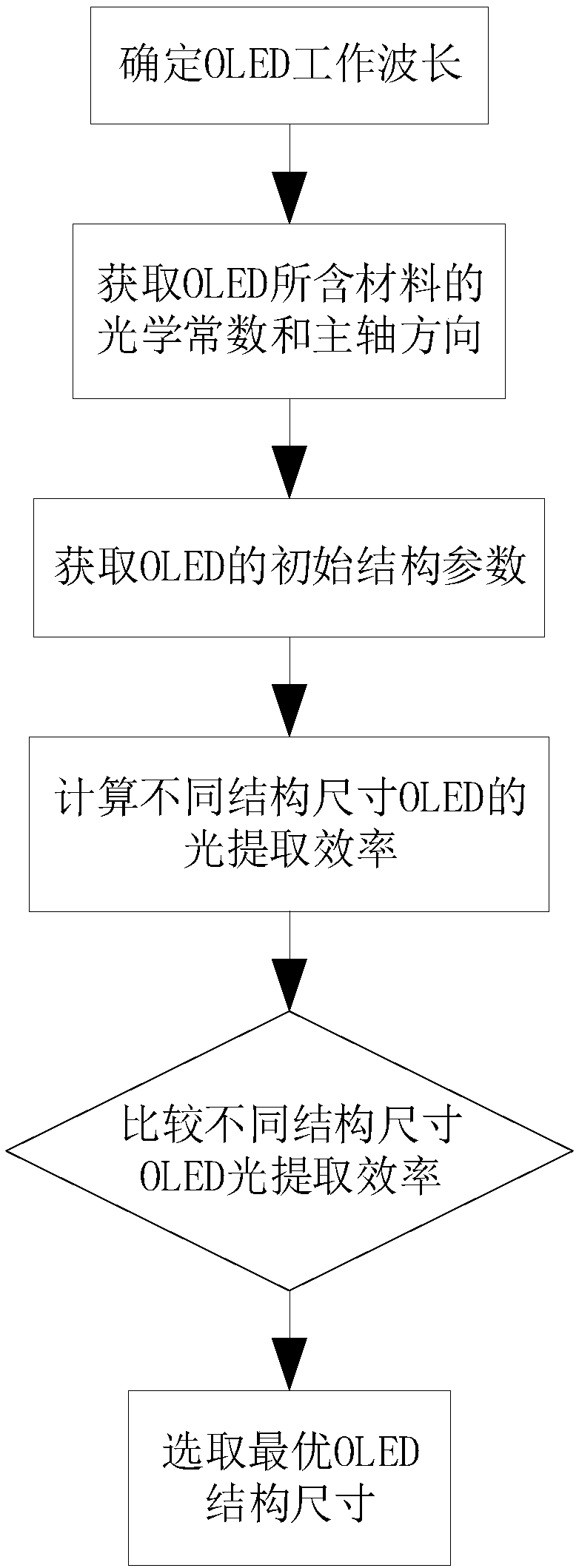

OLED structure dimension optimization design method and device

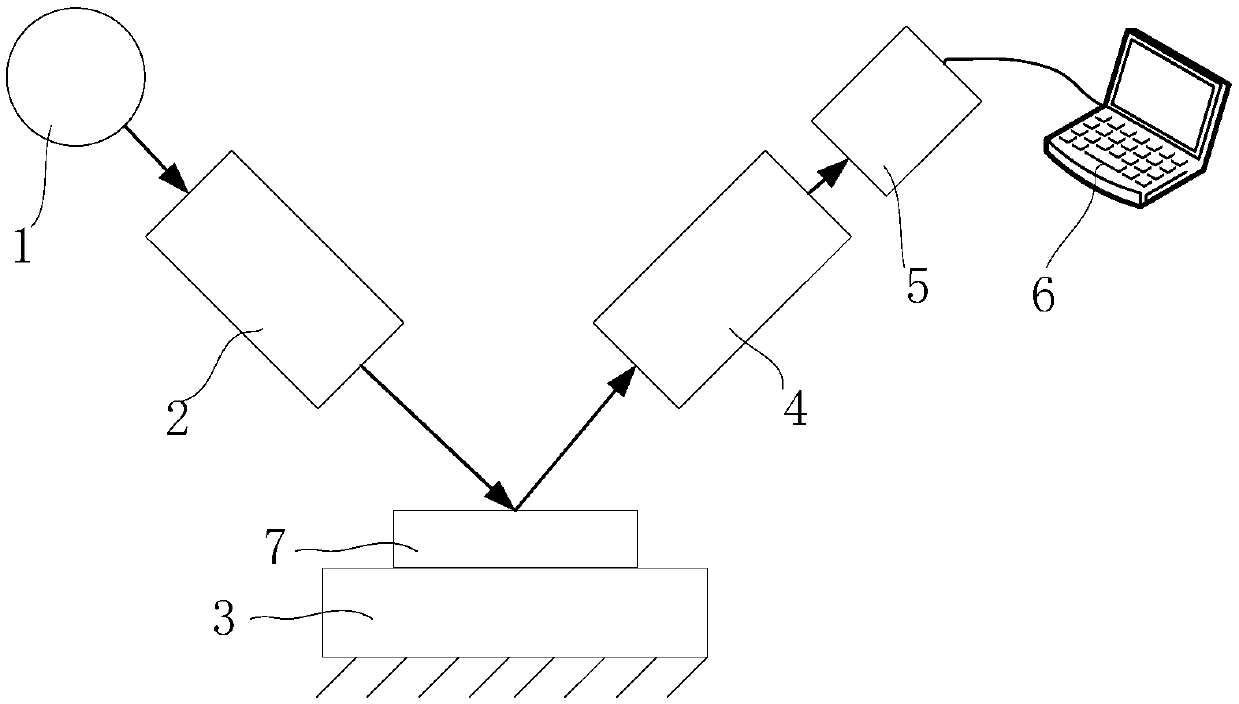

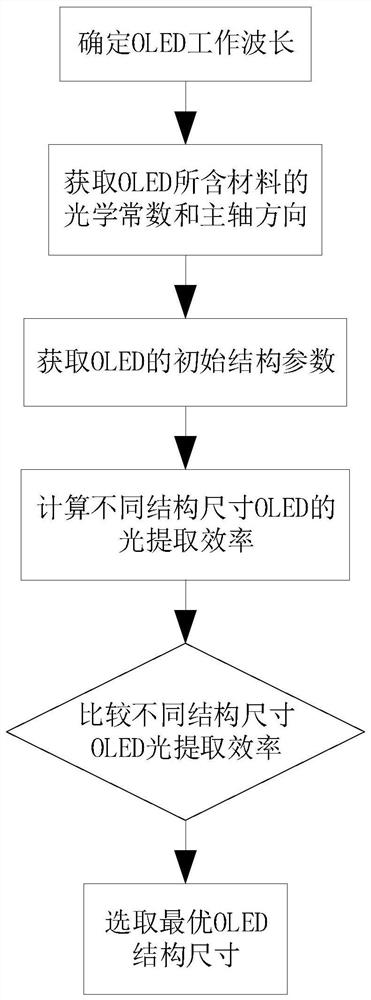

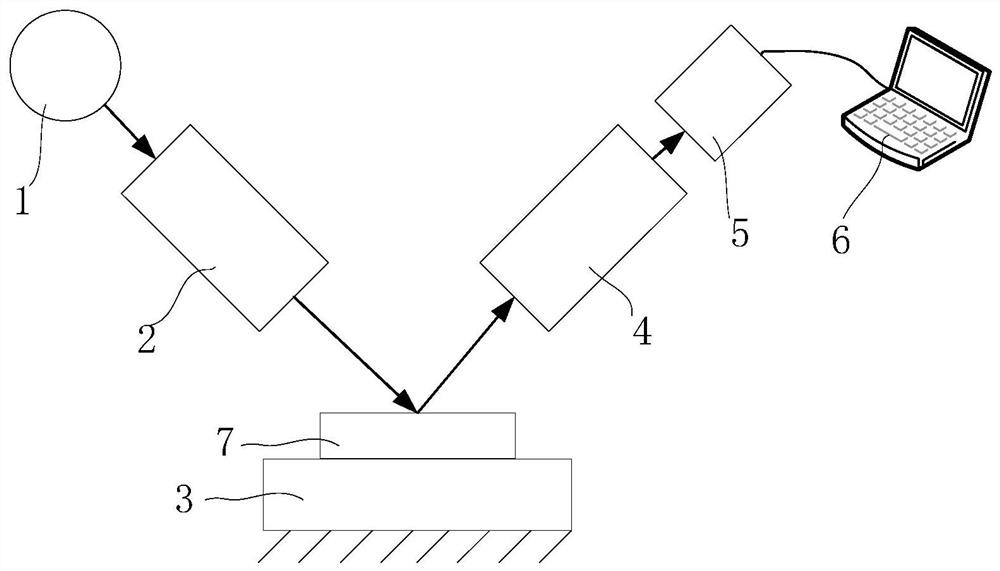

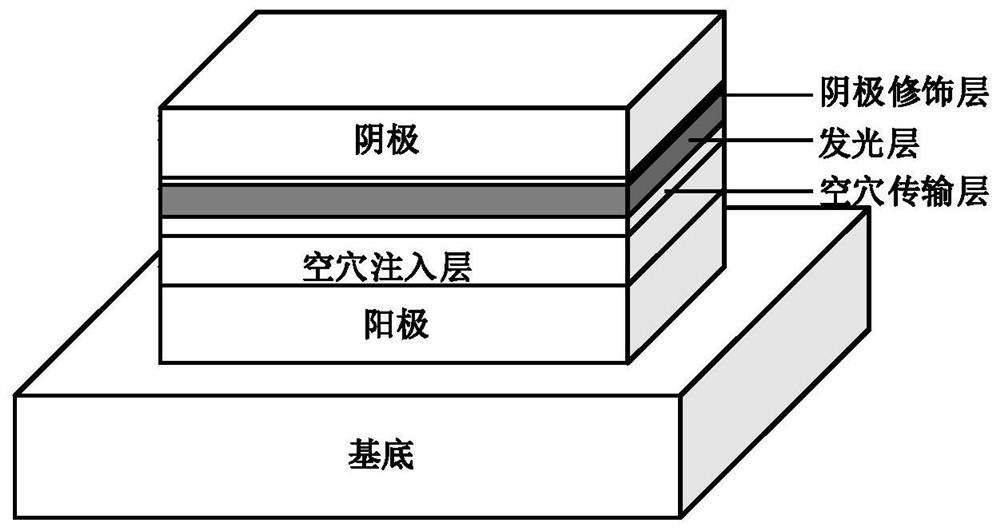

ActiveCN108287944AThe principle is simpleEasy to operateSolid-state devicesCAD circuit designCoupling efficiencyAzimuth

The invention discloses an OLED structure optimization design method and device and belongs to OLED field. The method includes the following steps: step 1, determining the working wavelength lambda ofOLED, the optical constant of each layer material of OLED, the initial design thickness value of each layer material of OLED and the azimuth of the main axis of anisotropic material in OLED, theta and psi; step 2, establishing the multi-layer stack optical model of OLED based on the parameters identified in step 1 and adjusting the thickness of cathode, cathode finish layer, luminous layer, holetransport layer, hole injection layer, anode and the layer to be optimized in the substrate. The simulation test is conducted to obtain the external coupling efficiency of OLED at different structurethicknesses and determine the maximum structural thickness of external coupling efficiency. The device is used to executive the above method. The method has the advantages of simple principle and easy-to-operate and can realize the simulation optimization calculation of OLED structure dimension.

Owner:武汉宇微光学软件有限公司

Organic light emitting display device

ActiveUS8664848B2Improve transmittanceImprove Outcoupling EfficiencyDischarge tube luminescnet screensElectroluminescent light sourcesTransmittanceOrganic layer

An organic light emitting display device comprises: a substrate; a plurality of thin film transistors (TFTs) formed on a first surface of the substrate; a passivation layer covering the plurality of TFTs; a plurality of first pixel electrodes formed on the passivation layer and respectively electrically connected to the plurality of TFTs, and overlapping with the plurality of TFTs so as to cover the plurality of TFTs, and including a reflection layer formed of a light-reflecting conductive material; a second pixel electrode formed of a light-transmitting conductive material and disposed on the passivation layer so as to be electrically connected to the plurality of first pixel electrodes; an opposite electrode formed such that light is transmitted or reflected therethrough, and disposed opposite the plurality of first pixel electrodes and the second pixel electrode; and an organic layer interposed between the plurality of first pixel electrodes and the second pixel electrode, and including an emission layer. Accordingly, transmittivity of the organic light emitting display device is increased, and optical outcoupling efficiency of the organic light emitting display device is also increased during double-sided emission.

Owner:SAMSUNG DISPLAY CO LTD

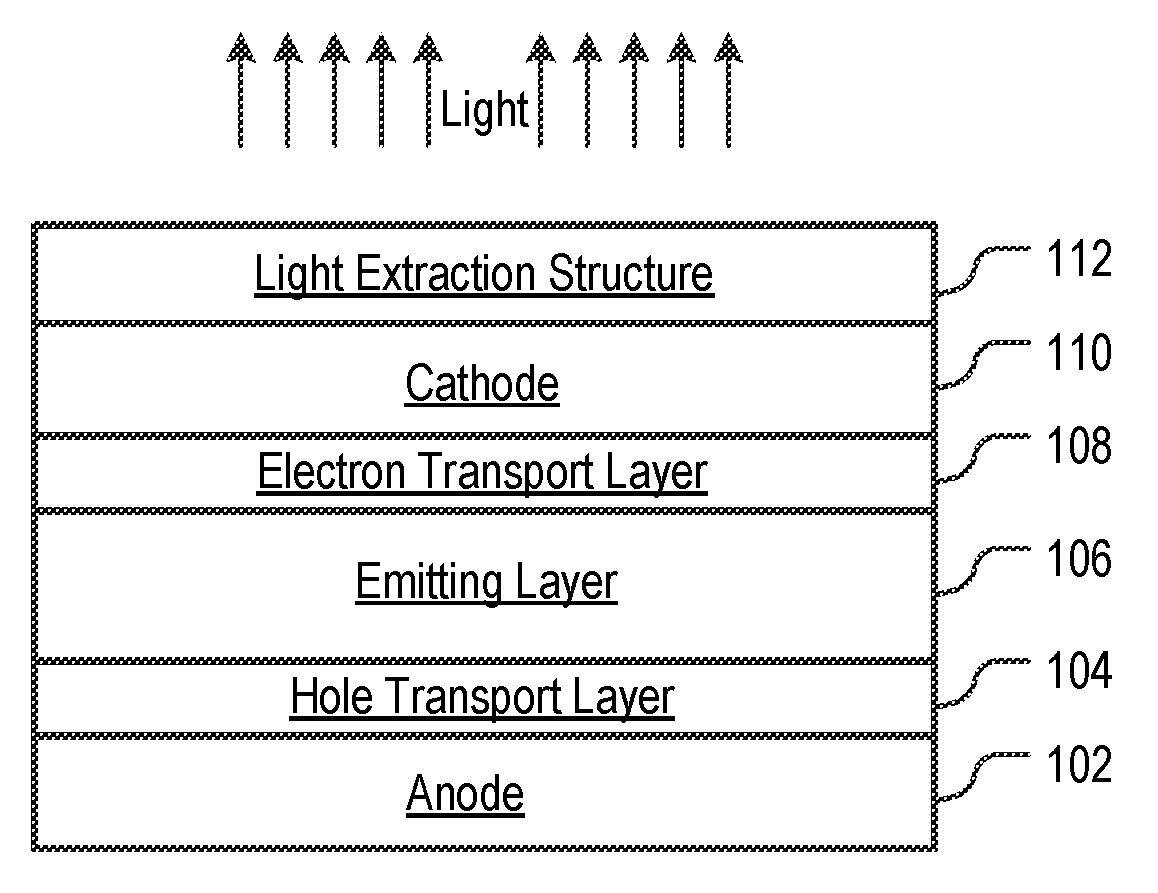

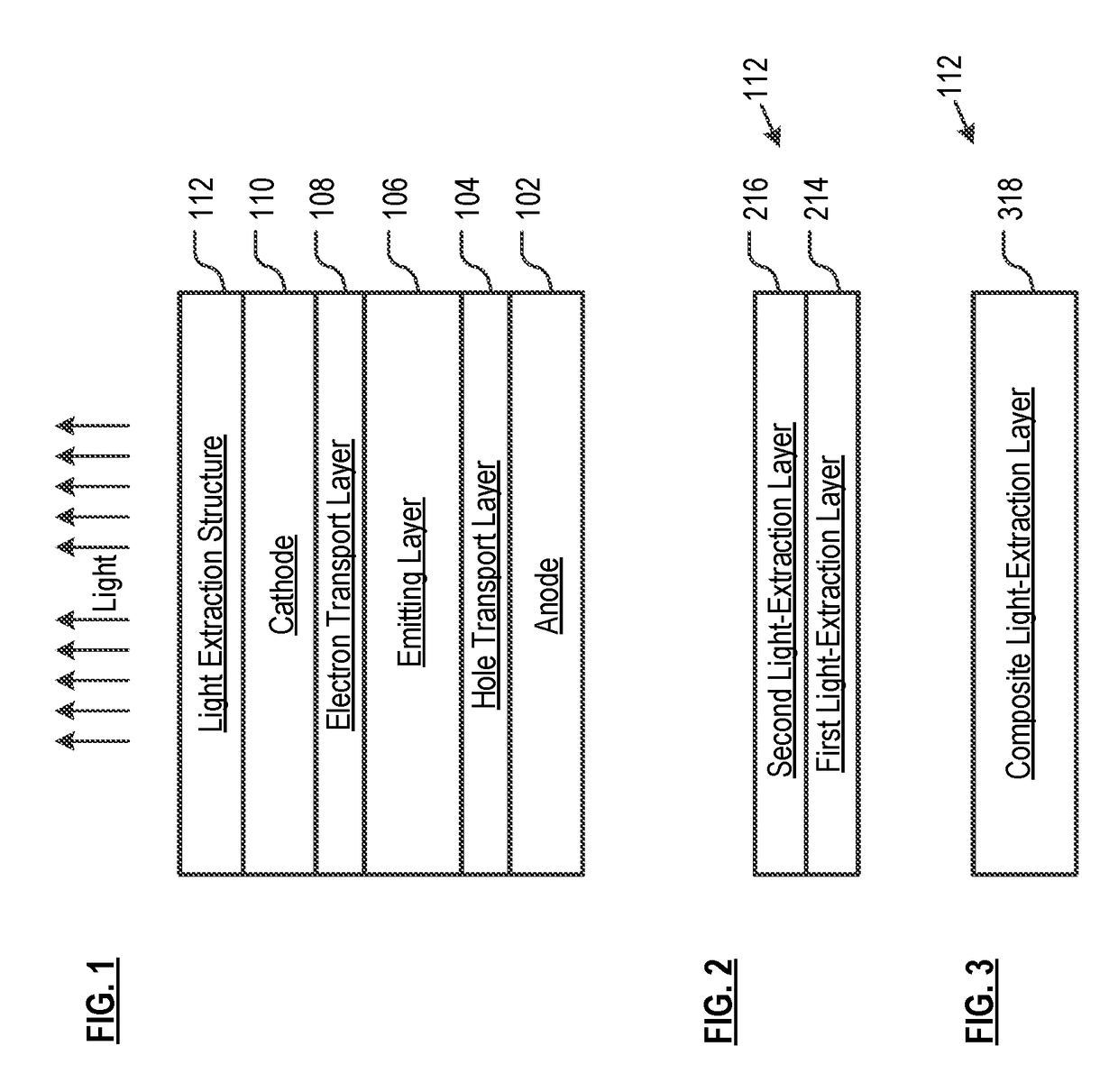

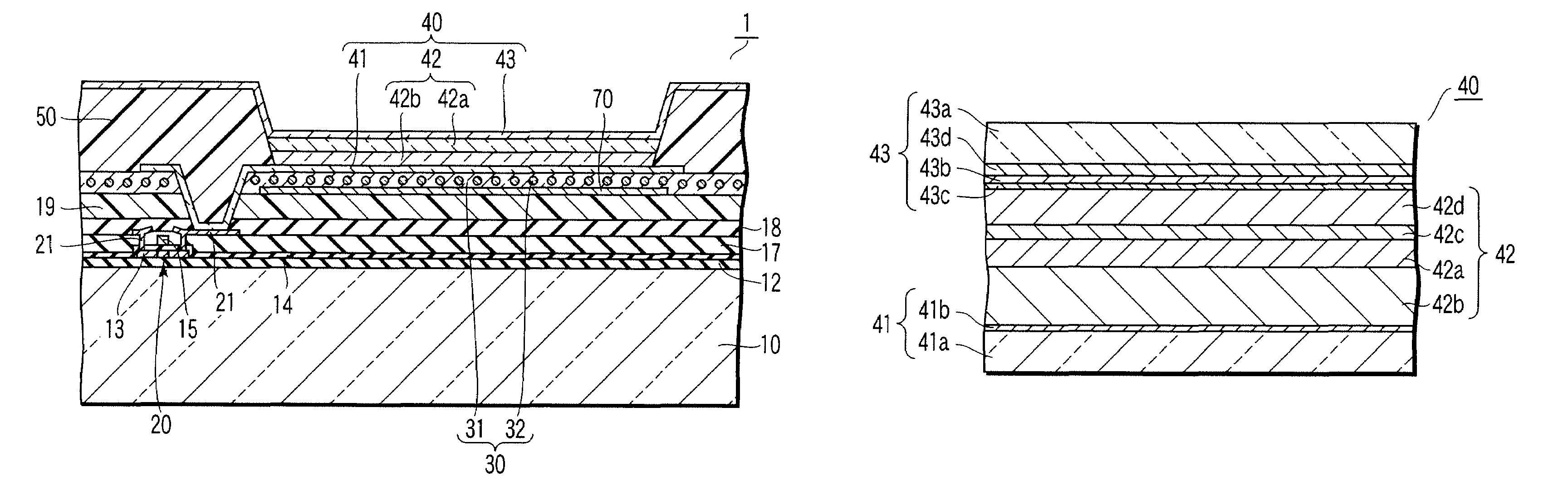

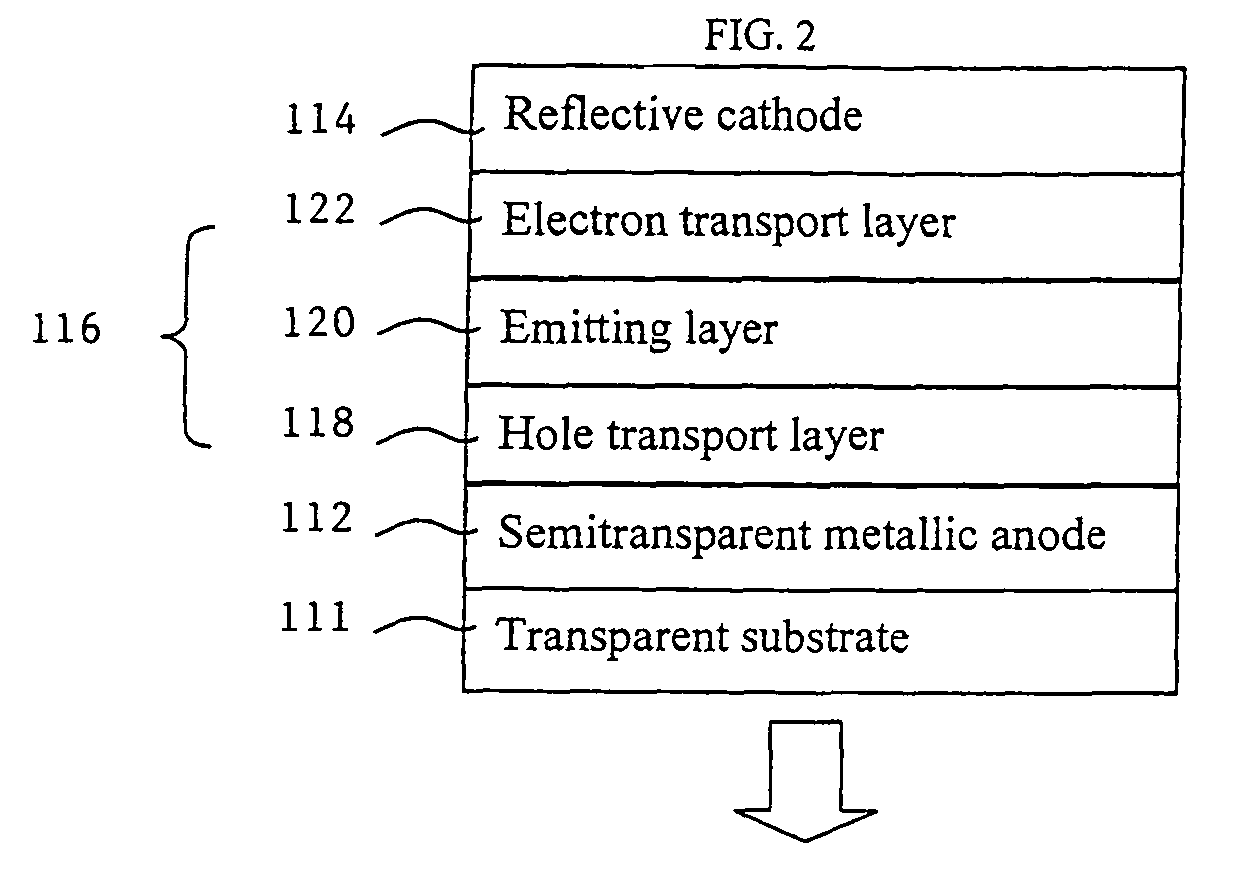

Top Emitting OLEDs with Increased Brightness

InactiveUS20180254438A1Improve Outcoupling EfficiencyIncrease brightnessSolid-state devicesSemiconductor/solid-state device manufacturingOLEDElectron

A top emitting OLED includes two organic light-extraction layers on top of an at least partially transparent cathode. At least one of the light-extraction layers comprises an electron transport material and at least one of the light-extraction layers comprises a hole transport material. In some embodiments, the electron transport material is Alq3 and the hole transport material is a triaryl amine derivative.

Owner:EMAGIN CORP

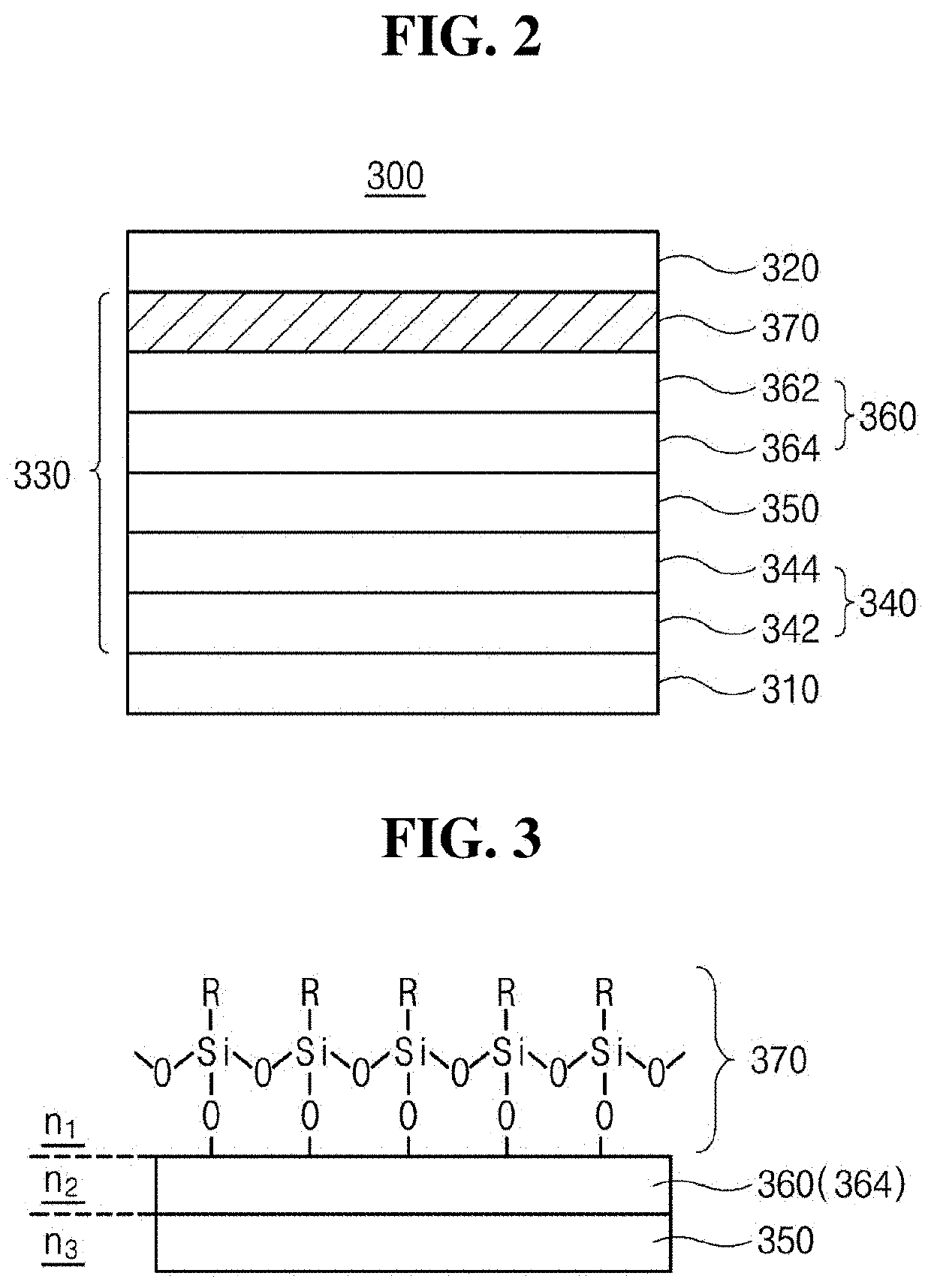

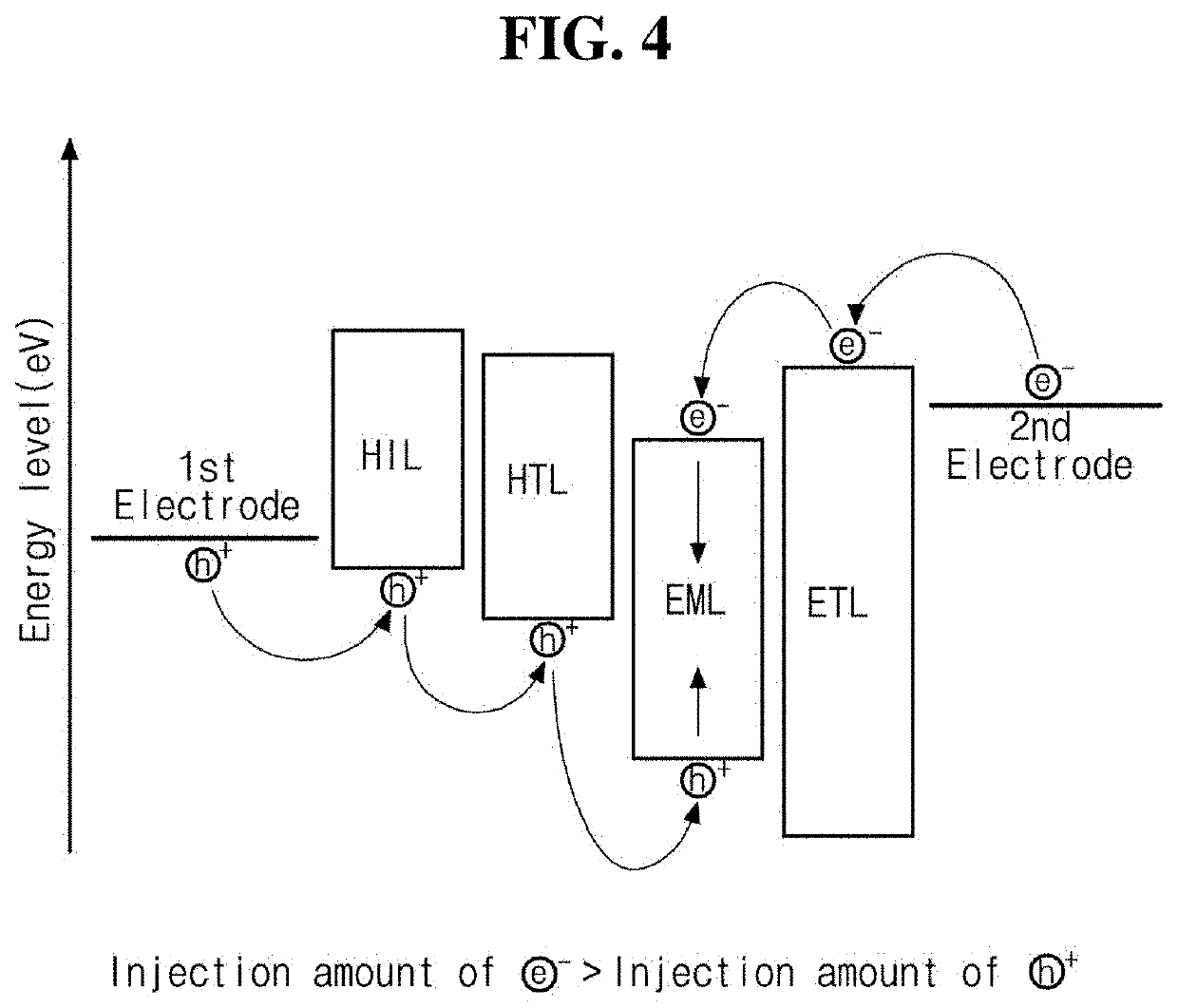

Light emitting diode and light emitting device having the same

ActiveUS20200168763A1Increase charge mobilityImprove Outcoupling EfficiencySemiconductor devicesCharge controlLight emitting device

The present disclosure relates to a light emitting diode that includes a charge control layer disposed between a charge transfer layer and one electrode and including polysiloxane-based material chemically bonded to a surface of the charge transfer layer and a light emitting device having the same. The charge control layer is configured to remove a surface defect of the charge transfer layer, to transport charges stably, and to reflect a part of light passing through the charge transfer layer, and thereby enhancing out-coupling efficiency. In addition, the charge control layer regulates a charge flow from the electrode to the charge transfer layer, so that charges may be injected into an emitting material layer in a balanced manner.

Owner:LG DISPLAY CO LTD

Organic EL display

InactiveUS7535166B2Improve Outcoupling EfficiencyDischarge tube luminescnet screensElectroluminescent light sourcesDisplay deviceLight beam

Owner:TOSHIBA MATSUSHITA DISPLAY TECH

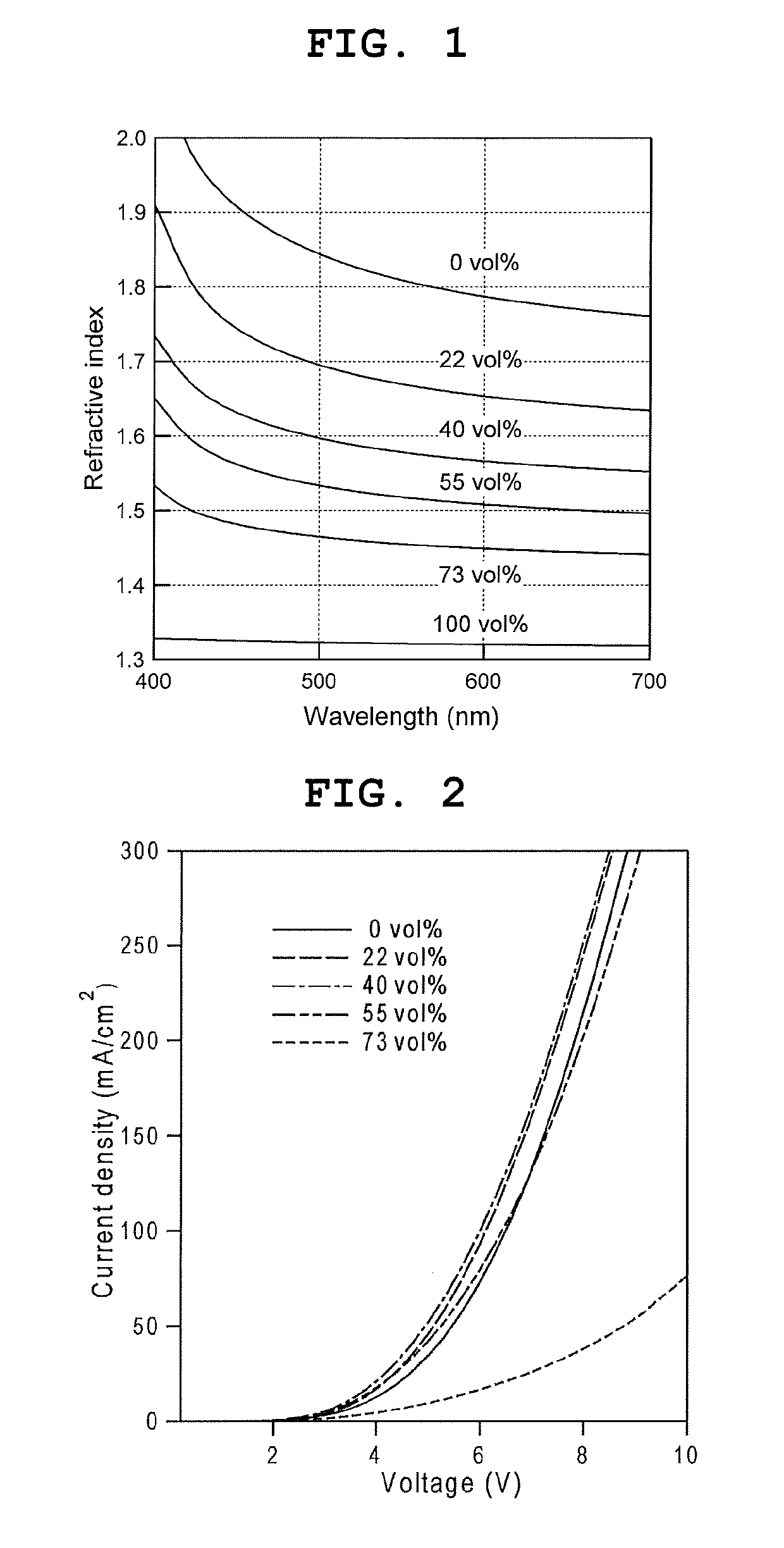

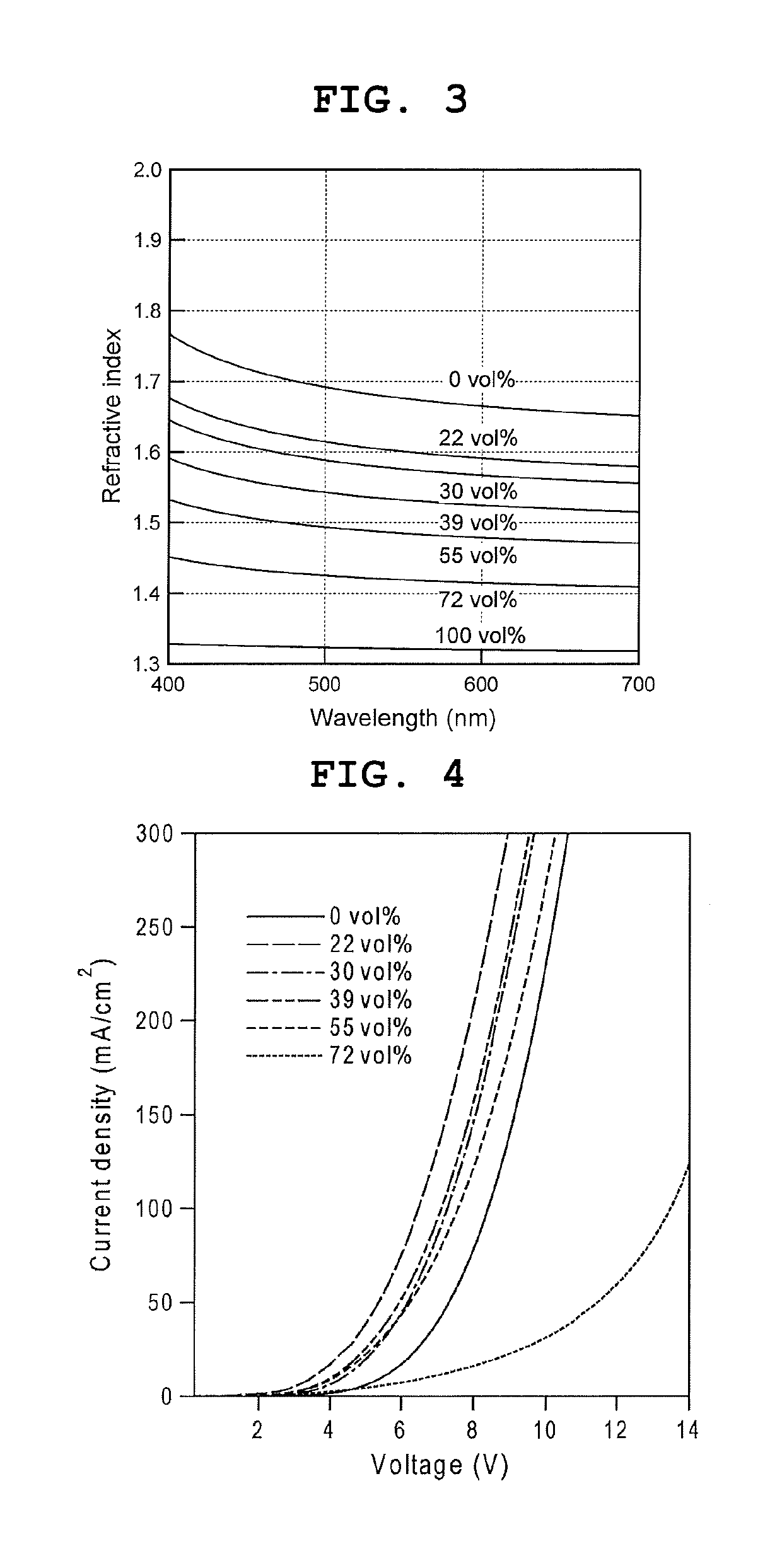

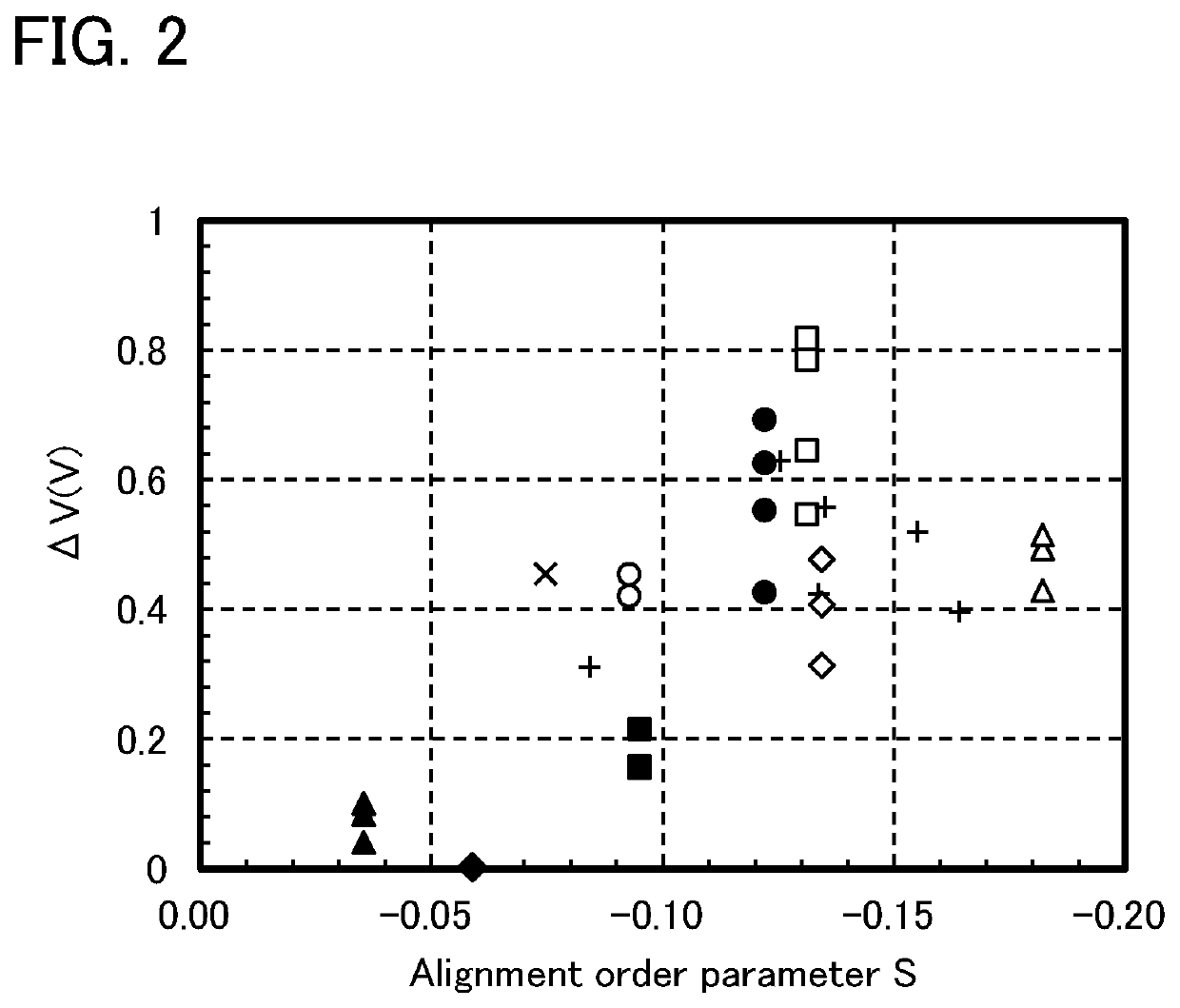

Organic charge transport layer, organic EL device, organic semiconductor device, and organic photoelectric device

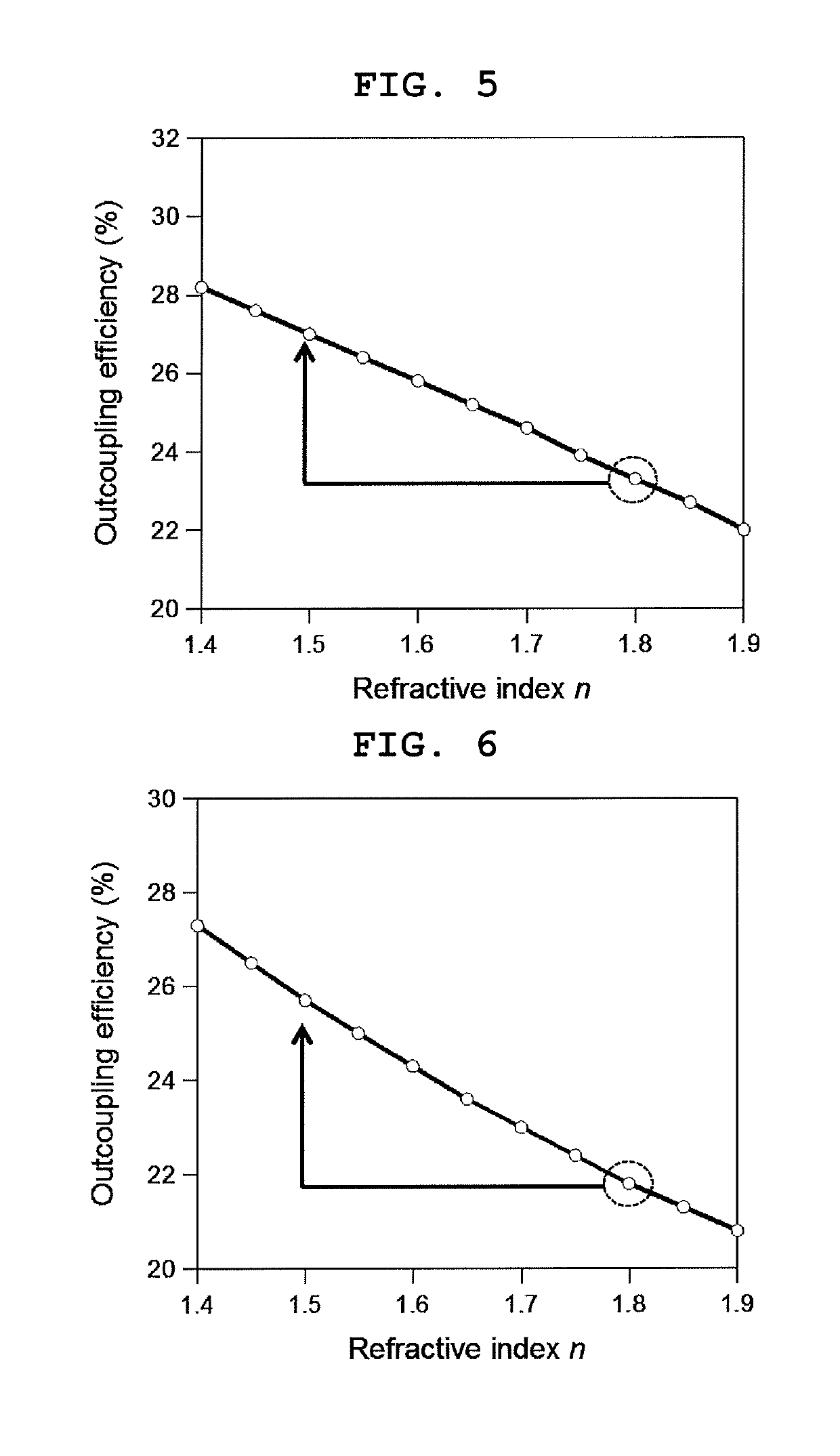

InactiveUS10381566B2Improve Outcoupling EfficiencyLower refractive indexSolid-state devicesSemiconductor/solid-state device manufacturingTransport layerRefractive index

The present invention relates to an organic charge transport layer having a low refractive index, and to an organic EL device, an organic semiconductor device, and an organic photoelectric device which are provided with the organic charge transport layer. An object of the present invention is to provide an organic semiconductor thin film having a dramatically reduced refractive index without impairing conductivity, by mixing a predetermined amount of an electret material into an organic semiconductor material. The organic charge transport layer according to the present invention is characterized by containing an organic semiconductor material and an electret material. It is preferable that the organic semiconductor material is a hole transport material and the electret material has a refractive index of 1.5 or lower.

Owner:YAMAGATA UNIVERSITY

Reflective electrode, method of manufacturing reflective electrode, and organic light emitting diode display including reflective electrode

ActiveUS10741785B2Improve Outcoupling EfficiencySolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceConductive materials

A reflective electrode, a method of manufacturing the reflective electrode, and an organic light emitting diode display including the reflective electrode are disclosed. The reflective electrode includes a first transparent conductive layer formed of a transparent conductive material, a reflective layer disposed on the first transparent conductive layer and including a plurality of grains formed of a reflective material, and a second transparent conductive layer disposed on the reflective layer and formed of a transparent conductive material. The adjacent grains are spaced from each other.

Owner:LG DISPLAY CO LTD

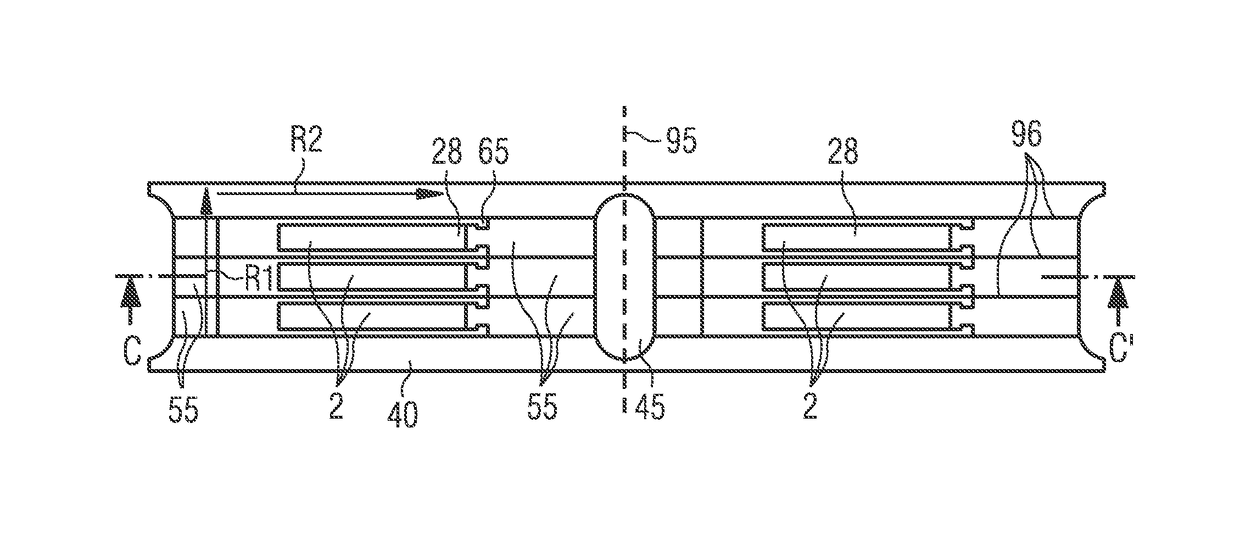

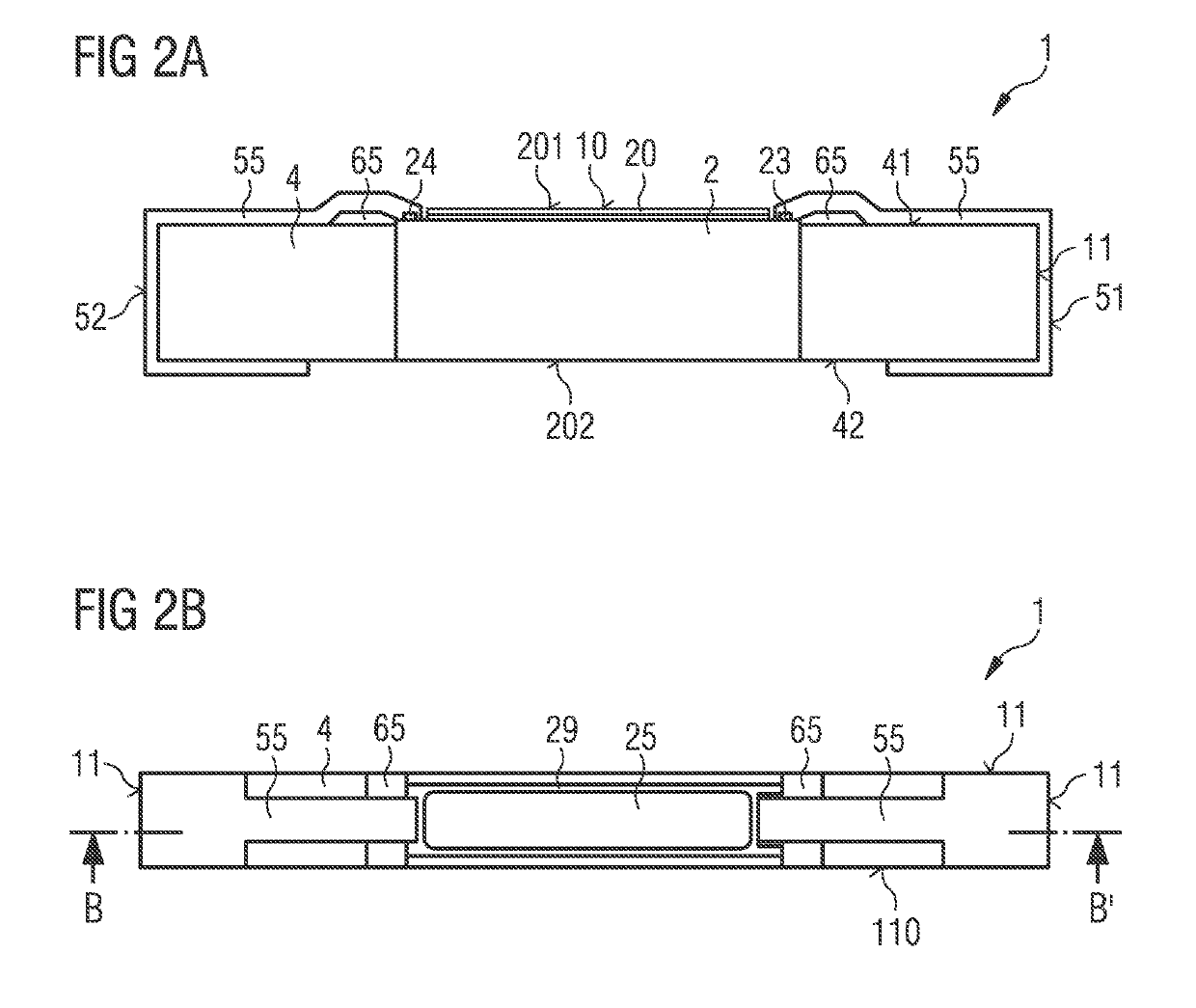

Semiconductor Device and Method for Producing a Plurality of Semiconductor Devices

ActiveUS20170338384A1Free accessLower overall heightSemiconductor/solid-state device detailsSolid-state devicesExit surfaceEngineering

A semiconductor device and a method for producing a plurality of semiconductor devices are disclosed. In an embodiment an optoelectronic semiconductor device includes a semiconductor chip having a semiconductor layer sequence with an active region, a radiation exit surface arranged parallel to the active region and a plurality of side faces arranged obliquely or perpendicular to the radiation exit surface. The device further includes a contact track electrically connecting the semiconductor chip to a contact surface configured to externally contact the semiconductor device, a molding and a rear side of the semiconductor chip remote from the radiation exit surface, the rear side being free of a material of the molding, wherein one of the side faces is configured as a mounting side face for fastening of the semiconductor device, and wherein the contact track runs on one of the side faces in places.

Owner:OSRAM OLED

Organic light emitting device, lighting apparatus and organic light emitting display apparatus

ActiveUS8410477B2Improve Outcoupling EfficiencyImprove work functionSolid-state devicesSemiconductor/solid-state device manufacturingOrganic light emitting deviceRefractive index

Owner:SAMSUNG DISPLAY CO LTD +1

Optoelectronic semiconductor device having a side face as mounting side

ActiveUS11276803B2Lower overall heightSufficient productionSemiconductor/solid-state device detailsSolid-state devicesDevice materialSemiconductor chip

In an embodiment an optoelectronic semiconductor device includes a semiconductor chip having a semiconductor layer sequence with an active region, a radiation exit surface arranged parallel to the active region and a plurality of side faces arranged obliquely or perpendicular to the radiation exit surface. The device further includes a contact track electrically connecting the semiconductor chip to a contact surface configured to externally contact the semiconductor device, a molding and a rear side of the semiconductor chip remote from the radiation exit surface, the rear side being free of a material of the molding, wherein one of the side faces is configured as a mounting side face for fastening of the semiconductor device, and wherein the contact track partially runs on one of the side faces.

Owner:OSRAM OLED

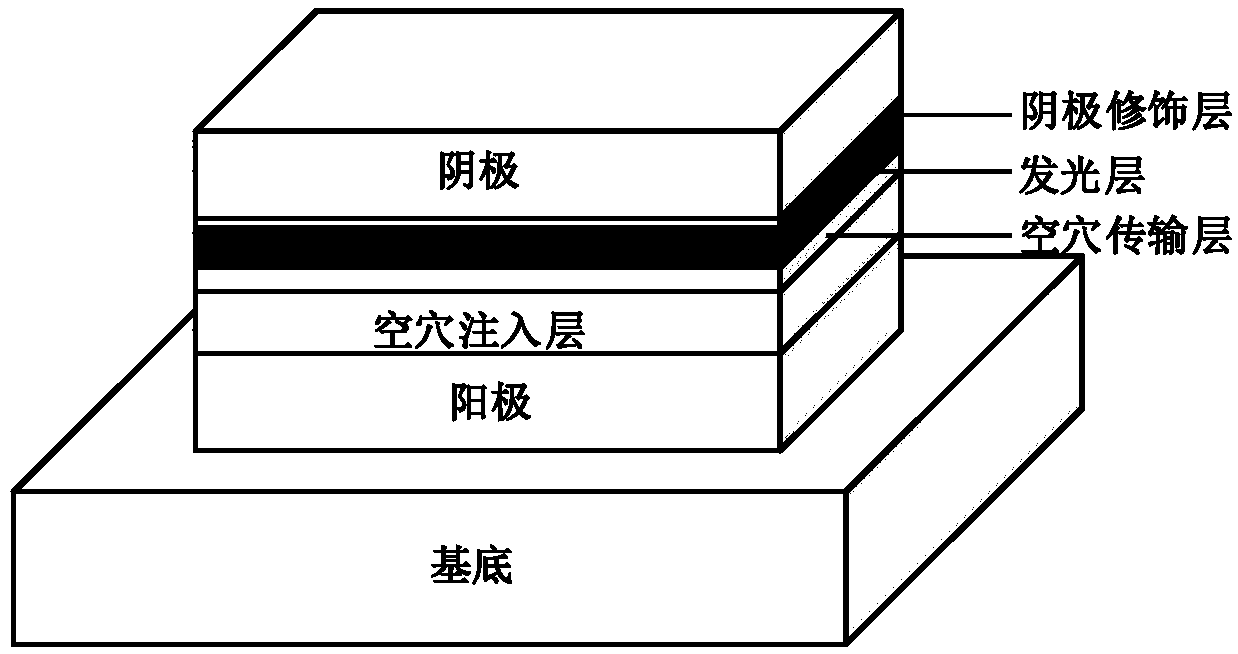

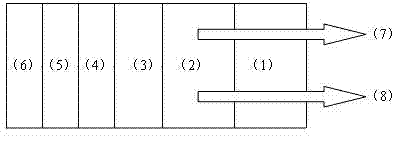

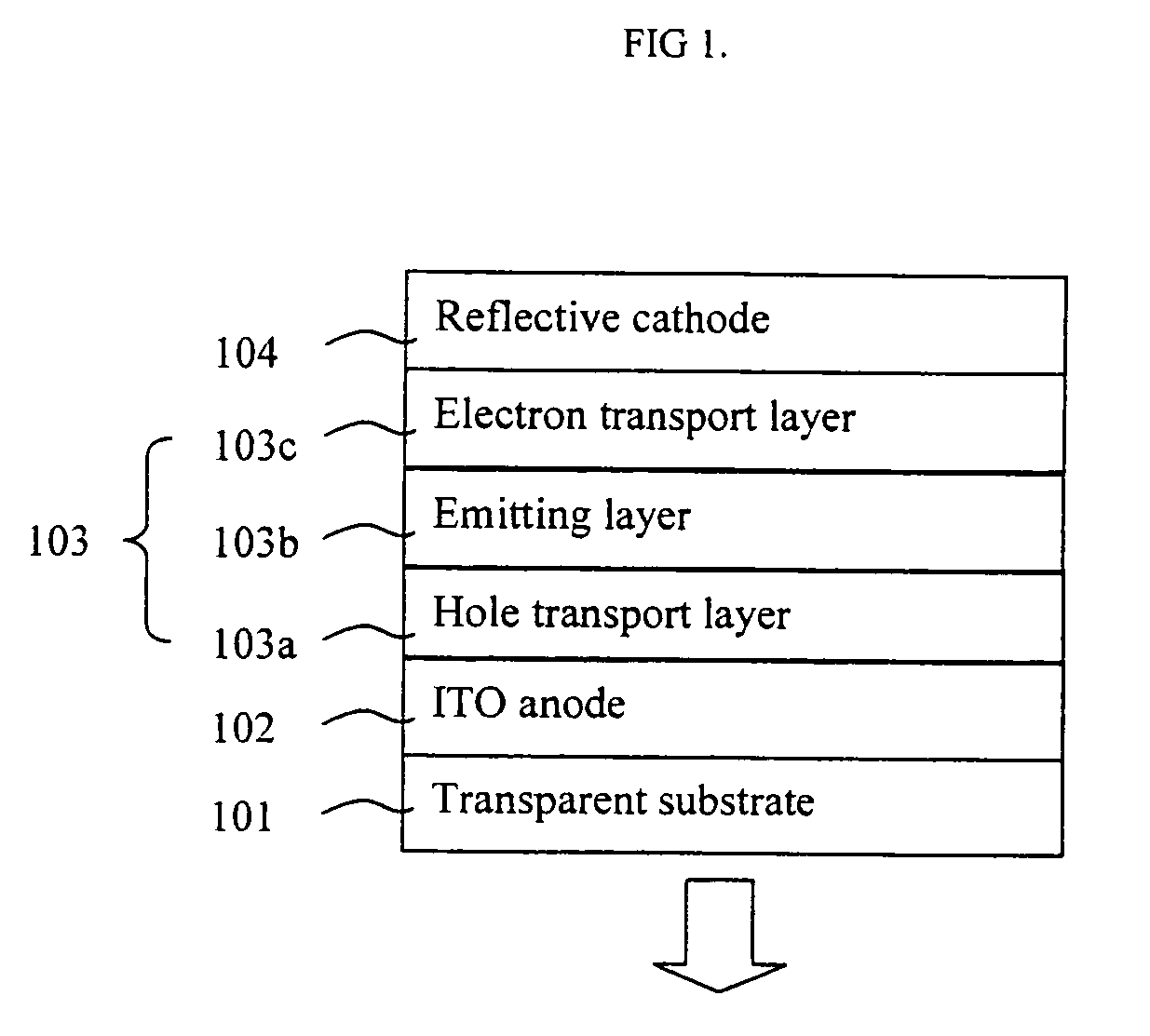

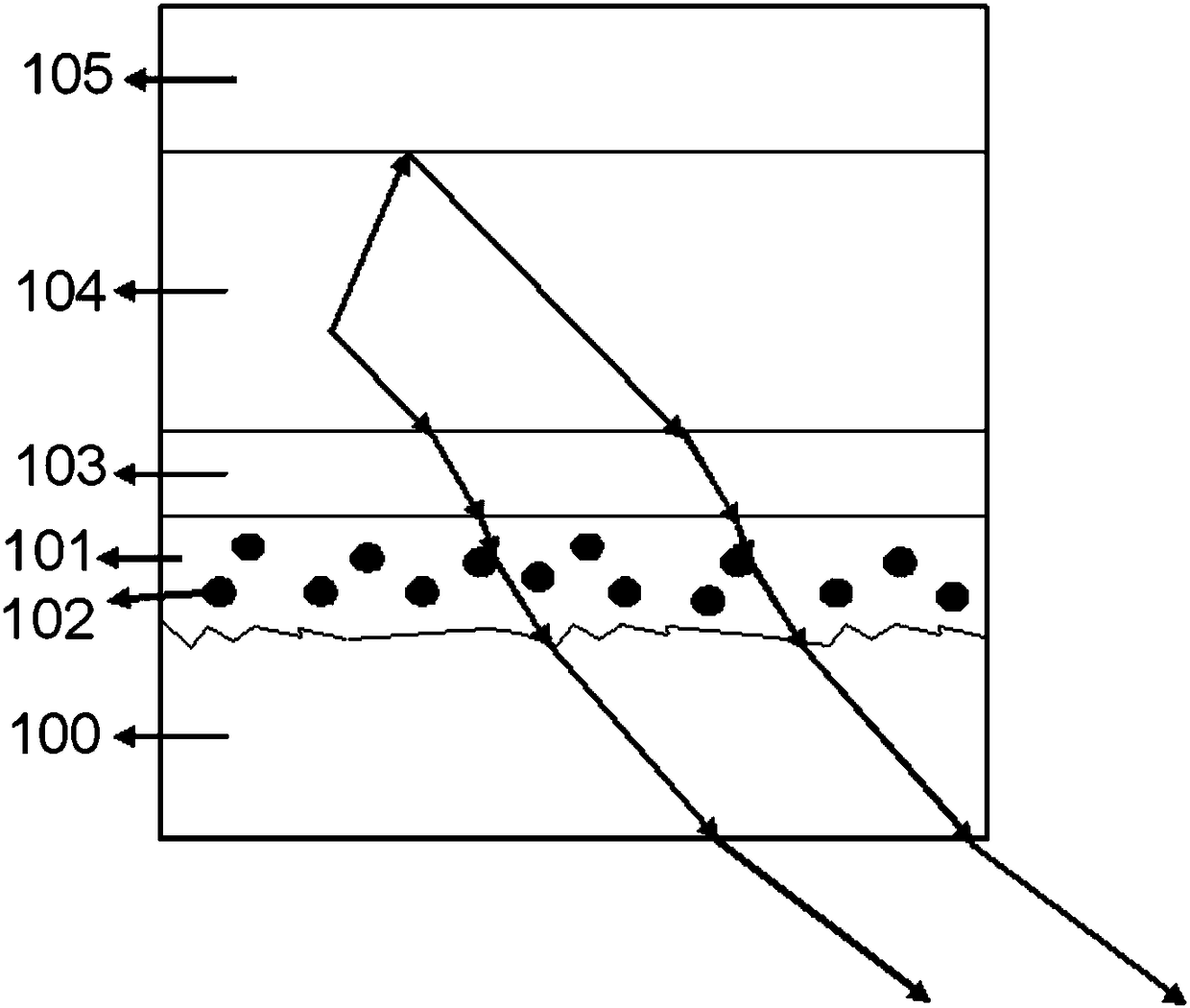

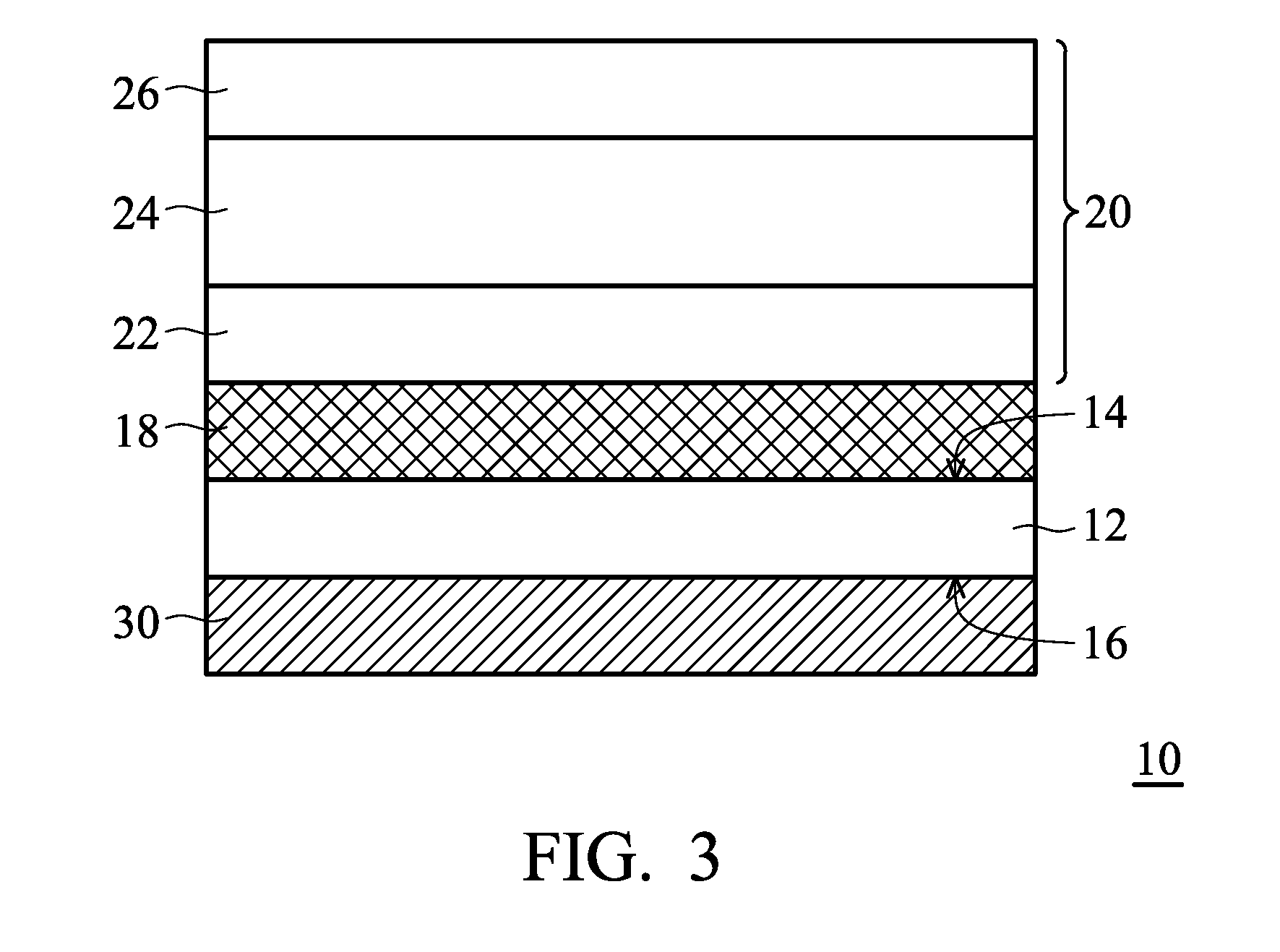

White organic electroluminescence device based on color conversion and manufacturing method thereof

InactiveCN102130301BPossesses hole transport propertiesImprove color conversion efficiencySolid-state devicesSemiconductor/solid-state device manufacturingElectronic transmissionComposite cathode

The invention relates to a white organic electroluminescence device realized by adopting a color conversion injection layer and a manufacturing method thereof. The white organic electroluminescence device consists of an indium tin oxide glass substrate (1), the color conversion injection layer (2), a hole transmission layer (3), a luminescent layer (4), an electronic transmission layer (5) and a composite cathode layer (6). The manufacturing method of the device comprises the steps of: preparing the color conversion injection layer (2) on the indium tin oxide glass substrate in a rotary coating manner, and then evaporating the hole transmission layer (3), the luminescent layer (4), the electronic transmission layer (5) and the composite cathode layer (6) in sequence. In the device, the structure is simple, only a single blue-light luminescent material is needed, and the color conversion layer is excited to emit red light, so that white light is realized. The white organic electroluminescence device has the advantages that the chromaticity is stable, the efficiency is high and the cost is low.

Owner:SHANGHAI UNIV

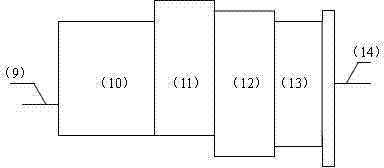

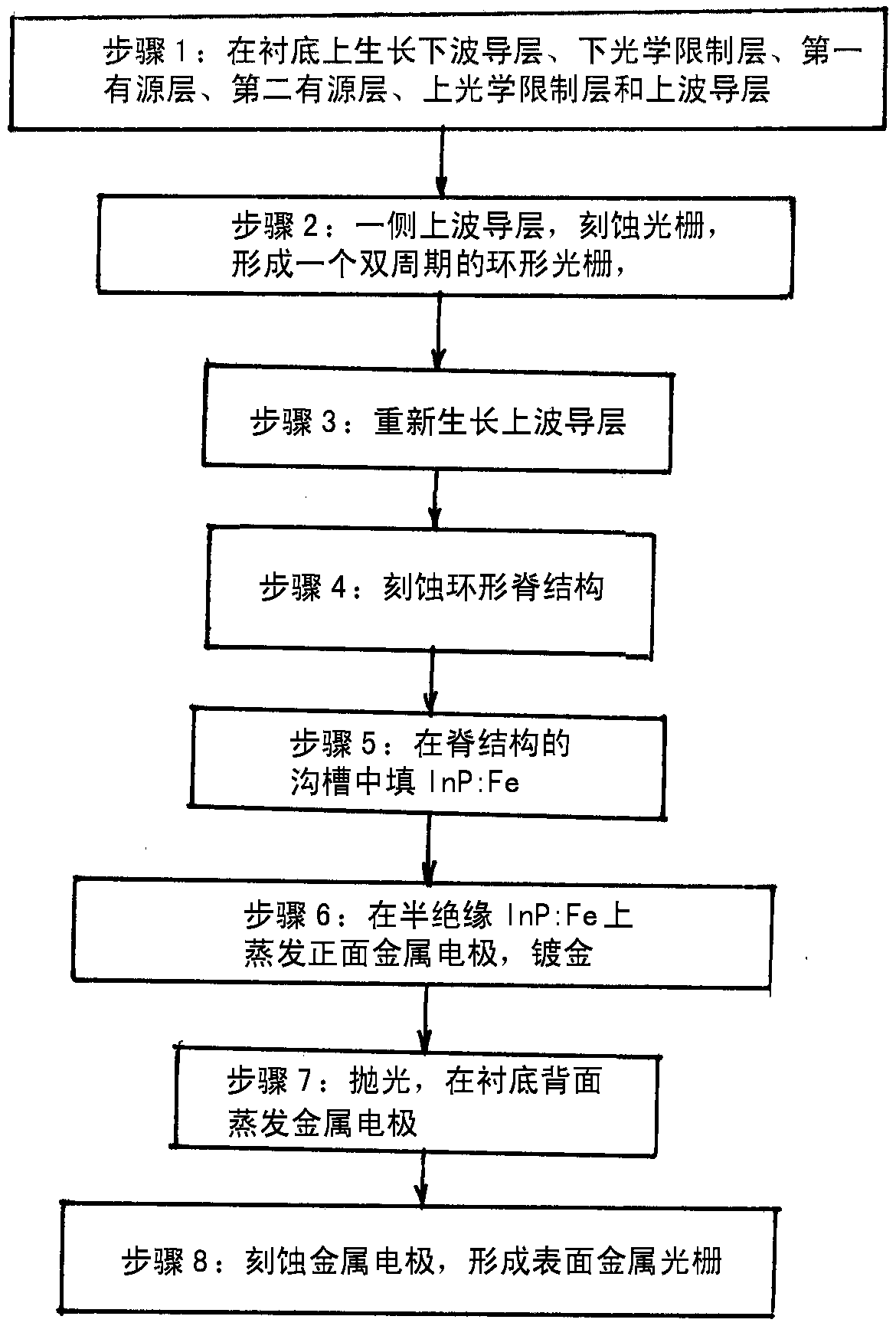

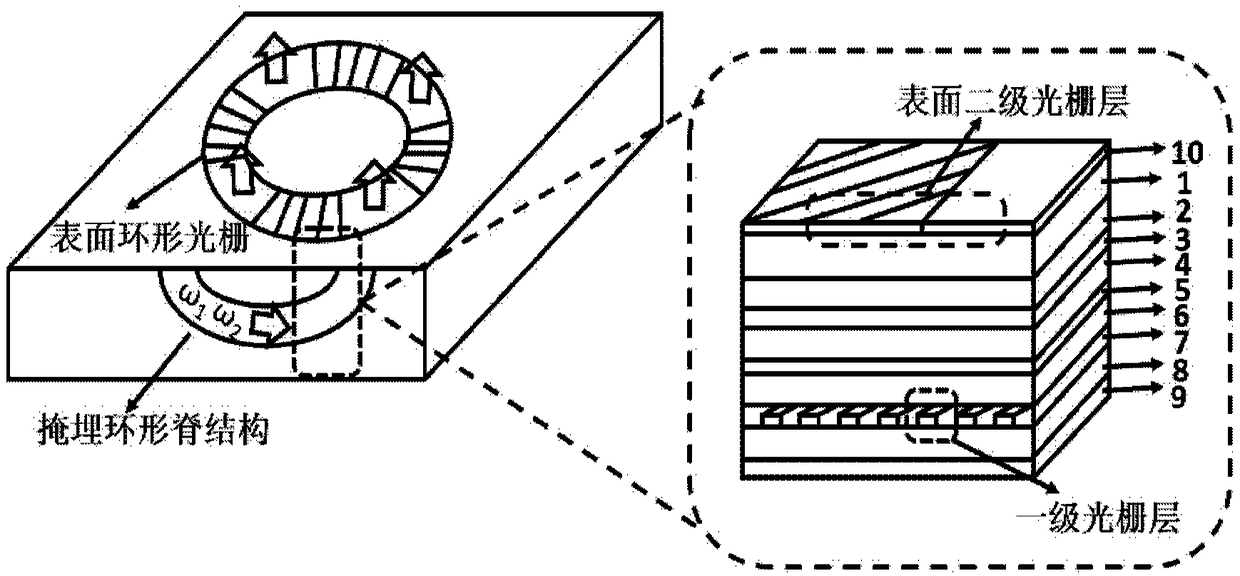

Fabrication method of ring cavity surface emission difference frequency terahertz quantum cascade laser

ActiveCN107069432BImprove Outcoupling EfficiencySolve the cooling problemLaser detailsLaser active region structureEvaporationOptical limiting

The invention discloses a preparation method of an annular cavity surface-equipped and difference frequency terahertz-emitting quantum cascading laser structure. The preparation method comprises the following steps of 1, enabling a lower waveguide layer, a lower optical limiting layer, a first active layer, an interval layer, a second active layer, an upper optical limiting layer and an upper waveguide layer to be grown on a substrate in sequence; 2, removing the upper waveguide layer, etching multiple gratings in the upper optical limiting layer in a radial pattern to form a dual-cycle annular grating; 3, performing re-growth of the upper waveguide layer on the etched upper optical limiting layer; 4, etching an annular ridge structure in the upper waveguide layer downwards, wherein the etching depth reaches the lower optical limiting layer; 5, filling the trenches of the etched annular ridge structure with semi-insulated InP: Fe; 6, performing evaporation of a front surface metal electrode on the annular ridge structure, the trenches of which are filled with the semi-insulated InP: Fe, and then performing gold plating; 7, performing thinning and polishing on the substrate, and performing evaporation of a back surface metal electrode on the back surface of the substrate; and 8, etching the metal electrodes to prepare two-stage annular surface metal gratings to complete preparation.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

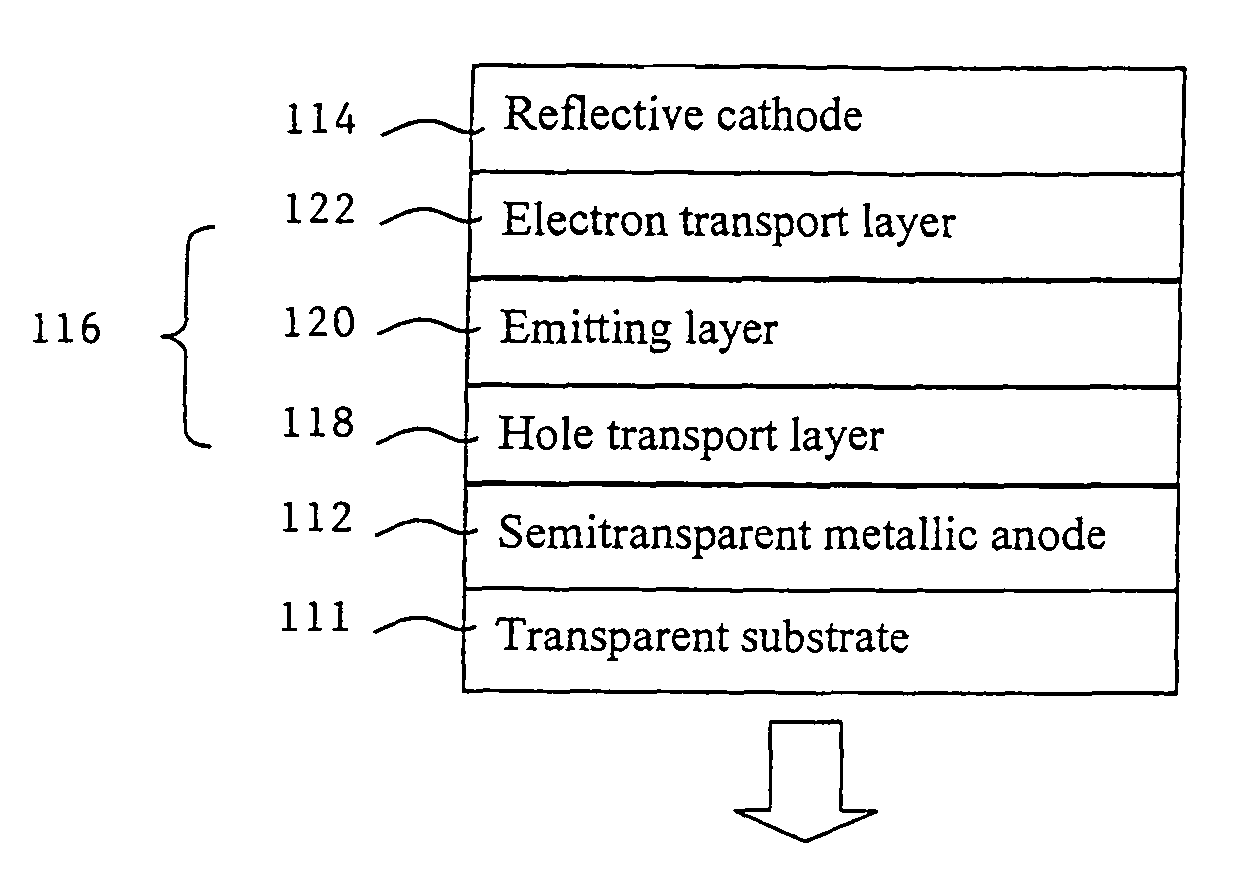

Metallic anode treated by carbon tetrafluoride plasma for organic light emitting device

InactiveUS9166197B2Improve abilitiesEasy to makeSolid-state devicesSemiconductor/solid-state device manufacturingHole injection layerOrganic light emitting device

Owner:THE HONG KONG UNIV OF SCI & TECH

A light extraction film having hollow bubbles and an organic light-emitting diode and a processing method thereof

ActiveCN108389980AImprove coupling light efficiencyImprove Outcoupling EfficiencySolid-state devicesSemiconductor/solid-state device manufacturingRefractive indexIon beam

The invention discloses a light extraction film having hollow bubbles and an organic light-emitting diode and a processing method thereof. The light extraction film having hollow bubbles is prepared based on high-refractive-index materials TiO2, ZnO, SiO2, ZnGe and ZrO2 and combined with dual ion beam sputtering technology to modify a thin film; and such structure can both serve as an external extraction film of the device and an internal extraction film of the device to increase output of the light. The processing method of the light extraction film is a preparation method for preparing a multiple-bubble structure film by introducing an assistant ion source in the sputtering process and through power adjustment of the assistant ion beam and rotation adjustment of a sample bench based on ion beam sputtering IBSD technology. The provided OLED illuminating device comprises the light extraction film having the hollow bubbles, so that under the premise of not damaging device structure, waveguide / substrate mode during light emission process is reduced, and coupling light extraction efficiency of the device is improved.

Owner:武汉华美晨曦光电有限责任公司

A kind of oled structure size optimization design method and equipment

ActiveCN108287944BImprove Outcoupling EfficiencyThe principle is simpleSolid-state devicesCAD circuit designHole injection layerHole transport layer

The invention discloses an OLED structure optimization design method and device and belongs to OLED field. The method includes the following steps: step 1, determining the working wavelength lambda ofOLED, the optical constant of each layer material of OLED, the initial design thickness value of each layer material of OLED and the azimuth of the main axis of anisotropic material in OLED, theta and psi; step 2, establishing the multi-layer stack optical model of OLED based on the parameters identified in step 1 and adjusting the thickness of cathode, cathode finish layer, luminous layer, holetransport layer, hole injection layer, anode and the layer to be optimized in the substrate. The simulation test is conducted to obtain the external coupling efficiency of OLED at different structurethicknesses and determine the maximum structural thickness of external coupling efficiency. The device is used to executive the above method. The method has the advantages of simple principle and easy-to-operate and can realize the simulation optimization calculation of OLED structure dimension.

Owner:武汉宇微光学软件有限公司

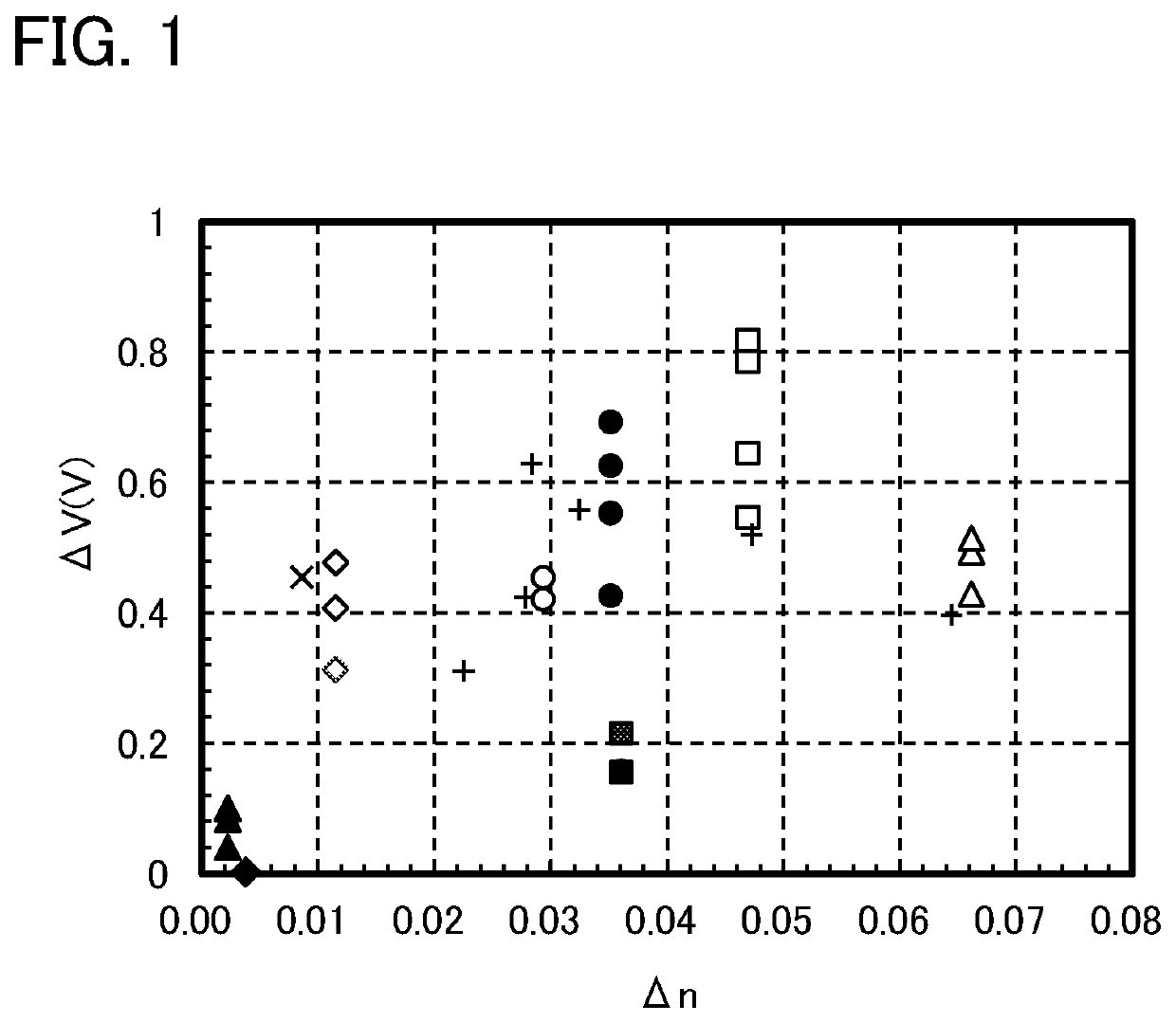

Light-emitting device, light-emitting apparatus, electronic apparatus, and lighting device

PendingUS20220077391A1Improve Outcoupling EfficiencyImprove carrier transport performanceOrganic chemistrySolid-state devicesLight equipmentRefractive index

A light-emitting device with high emission efficiency and low driving voltage is provided. A light-emitting apparatus, an electronic device, and a lighting device with low power consumption are provided. The following organic compound is provided: the organic compound has an arylamine structure; and when the organic compound is deposited to be a film, the ordinary refractive index of the deposited film with respect to light with a wavelength of 458 nm is greater than or equal to 1.50 and less than or equal to 1.75, the birefringence Δn of the deposited film with respect to light with a wavelength of 458 nm is greater than or equal to 0 and less than or equal to 0.008, or the alignment order parameter of the deposited film with respect to light with a wavelength corresponding to the longest wavelength where an absorption peak appears in the absorption spectrum is greater than or equal to −0.07 and less than or equal to 0.00.

Owner:SEMICON ENERGY LAB CO LTD

Optical device structures with the light outcoupling layers

ActiveUS8979324B2Improve luminous efficiencyImprove light outcoupling efficiencySynthetic resin layered productsSolid-state devicesOptoelectronicsCopolymer

An optical device structure with a light outcoupling layer is provided. The optical device structure includes a substrate having a first surface and a second surface, and a layer of polyimide (PI) or its copolymer formed on the first surface of the substrate, wherein the layer of polyimide or its copolymer is prepared from at least one aromatic diamine and at least one cycloaliphatic dianhydride, and an optical component formed on the layer of polyimide or its copolymer.

Owner:IND TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com