Resin composition and prepreg laminated board manufactured by employing same

A resin composition and prepreg technology, applied in the direction of synthetic resin layered products, layered products, metal layered products, etc., can solve the problem of affecting the thermal expansion performance of the cured product, unable to meet the requirements of high-precision electronic substrates, and interlayer adhesion. It can reduce the thermal expansion coefficient and cohesion, improve the toughness, and improve the interlayer adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

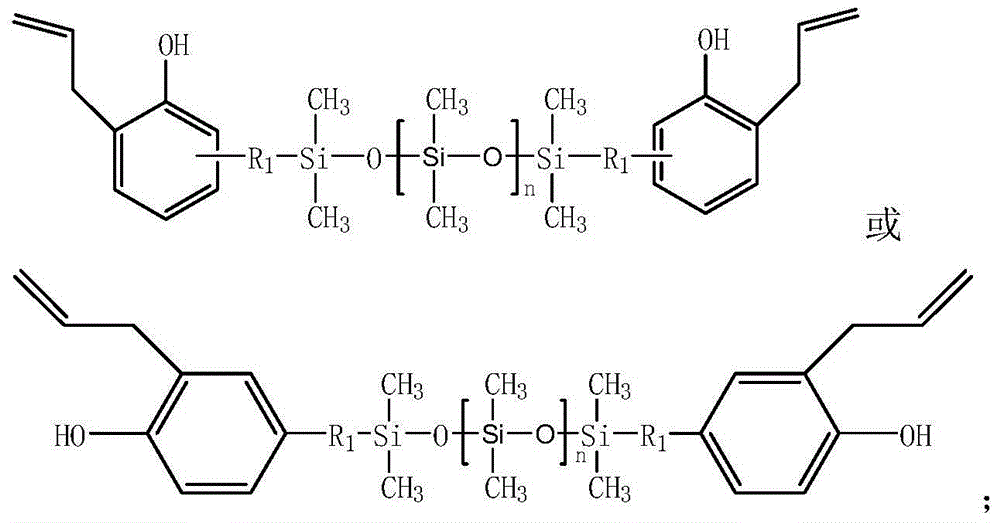

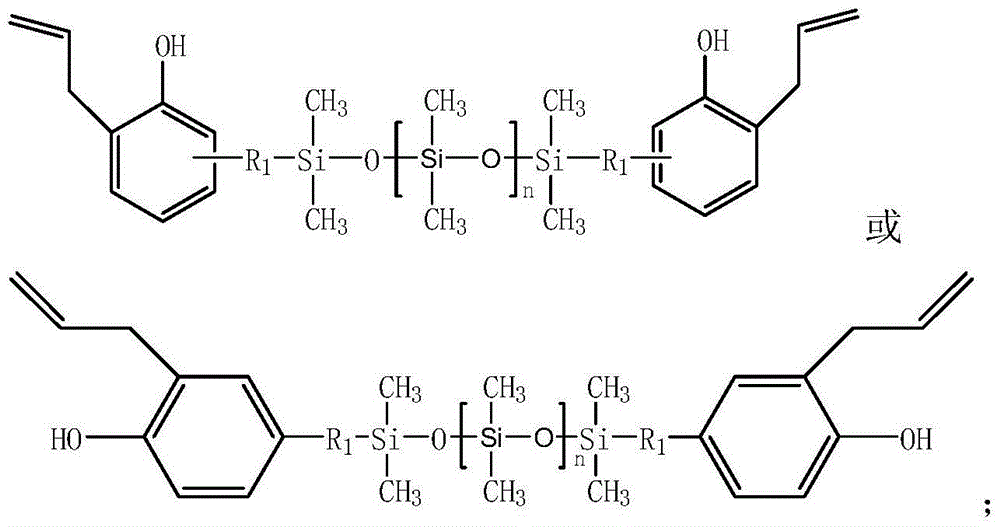

[0050] Using 100 parts of 4,4'-diphenylmethane bismaleimide resin and 20 parts of allyl compound (imported from Japan) shown in the following structural formula, reacted at 120°C for 30 minutes to prepare prepolymer (I), Add an appropriate amount of ketone organic solvent to dissolve; stir and mix evenly to obtain a prepolymer solution with a solid content of 62%.

[0051]

[0052] In the formula, n is an integer of 1-3.

Synthetic example 2

[0054] Use 100 parts of 4,4'-diphenyl ether bismaleimide resin and 50 parts of allyl compound (imported from Japan) shown in the following structural formula, and react at 150°C for 60 minutes to prepare the prepolymer (II). Add appropriate amount of ketone organic solvent to dissolve. Stir and mix evenly to obtain a prepolymer solution with a solid content of 45%.

[0055]

[0056] In the formula, n is an integer of 6-9.

Synthetic example 3

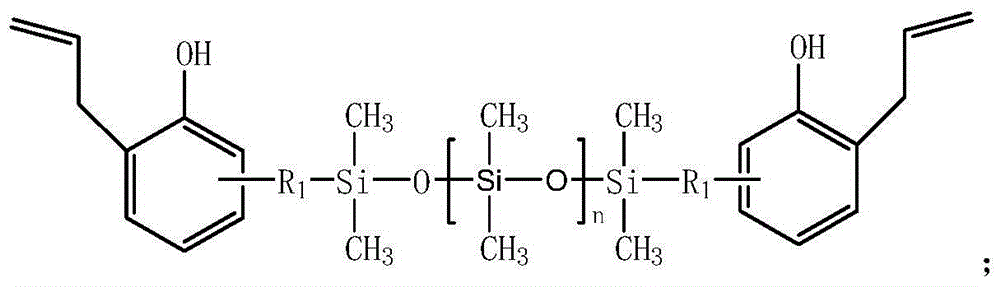

[0058] Use 100 parts of 4,4'-diphenylmethane bismaleimide resin and 45 parts of allyl compound shown in the following structural formula, react at 150°C for 60 minutes to prepare prepolymer (III), add appropriate amount of ketones Dissolved in organic solvents. Stir and mix evenly to obtain a prepolymer solution with a solid content of 62%.

[0059]

[0060] Then add cyanate resin, flame retardant, inorganic filler and appropriate ketone organic solvent to the above-mentioned prepolymer solution, and mix the resin glue solution for the prepreg.

[0061] Impregnate the above resin glue with E glass fiber cloth, and bake in an oven at 160°C for 7 minutes to make a prepreg.

[0062] Adopt above-mentioned prepreg to prepare copper-clad board, its manufacturing method comprises the following steps:

[0063] 1) superimposing 8 sheets of the prepregs,

[0064] 2) Copper foil is covered on both sides of the prepreg,

[0065] 3) Hot press forming, lamination must meet the follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com