Patents

Literature

409results about "Special visual effect coatings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fibrous product with a rastered embossing and method for producing same

InactiveUS20110223381A1Improve visual effectsIncrease visual appearanceSpecial visual effect coatingsMechanical working/deformationFiberGrating

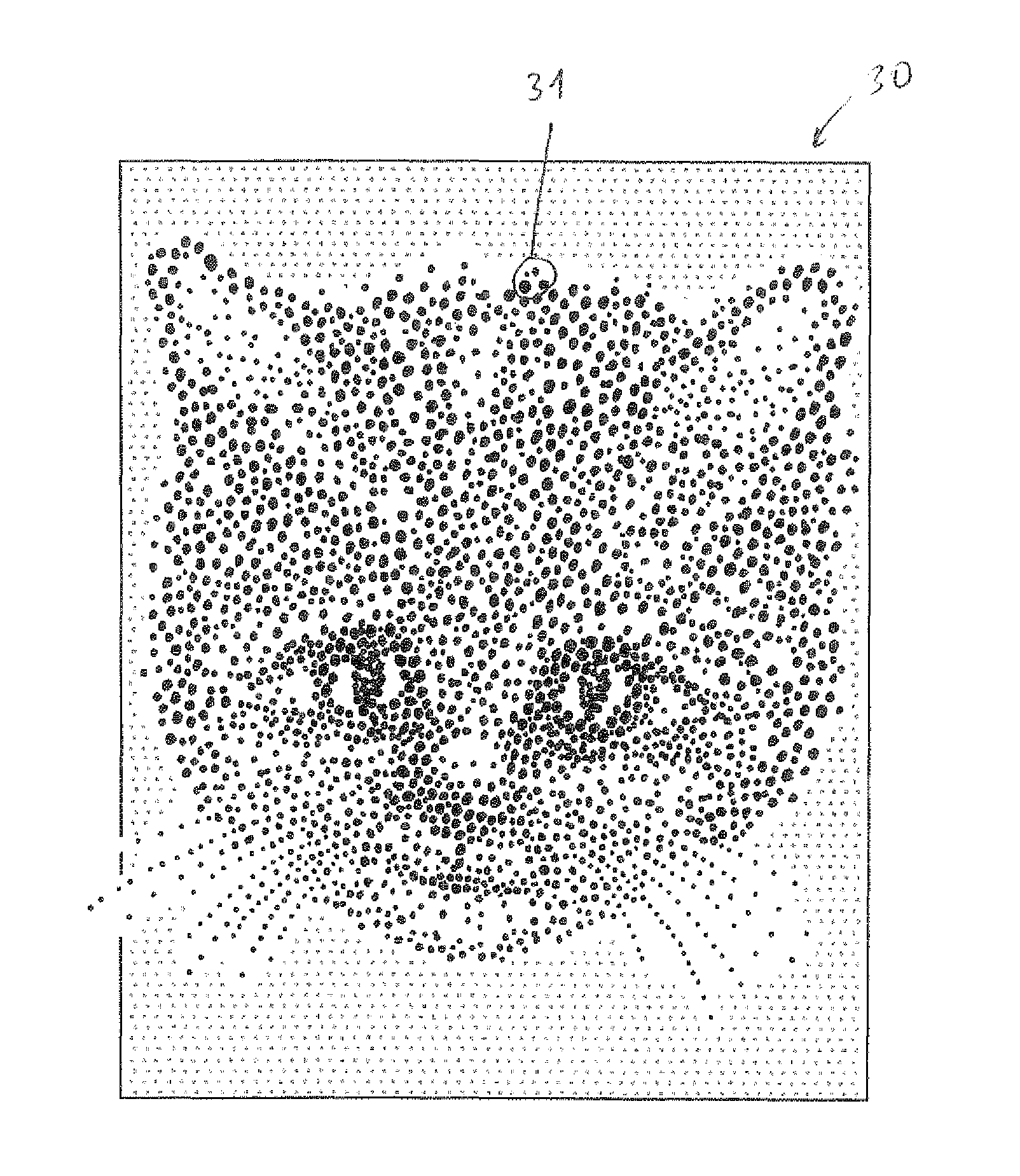

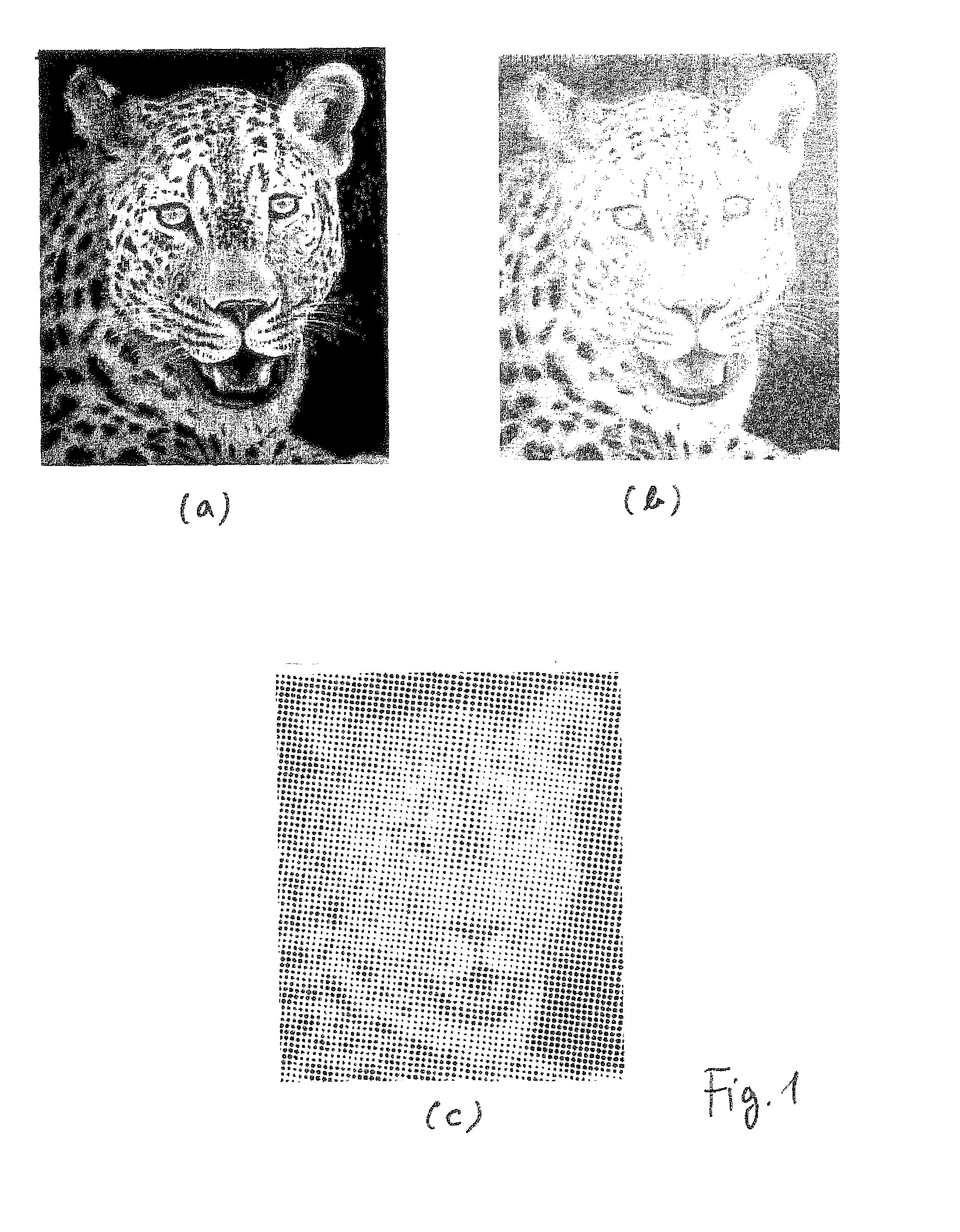

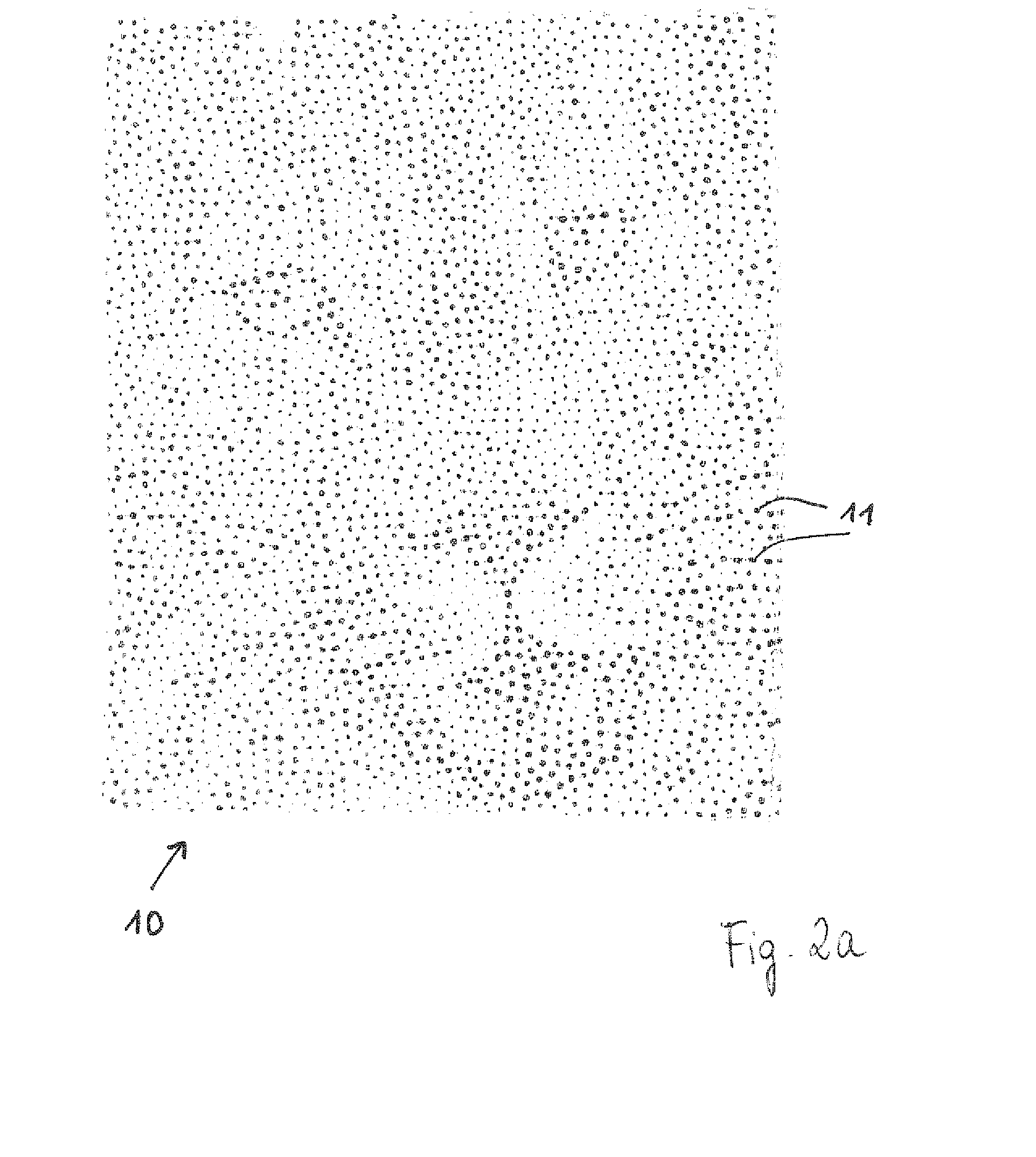

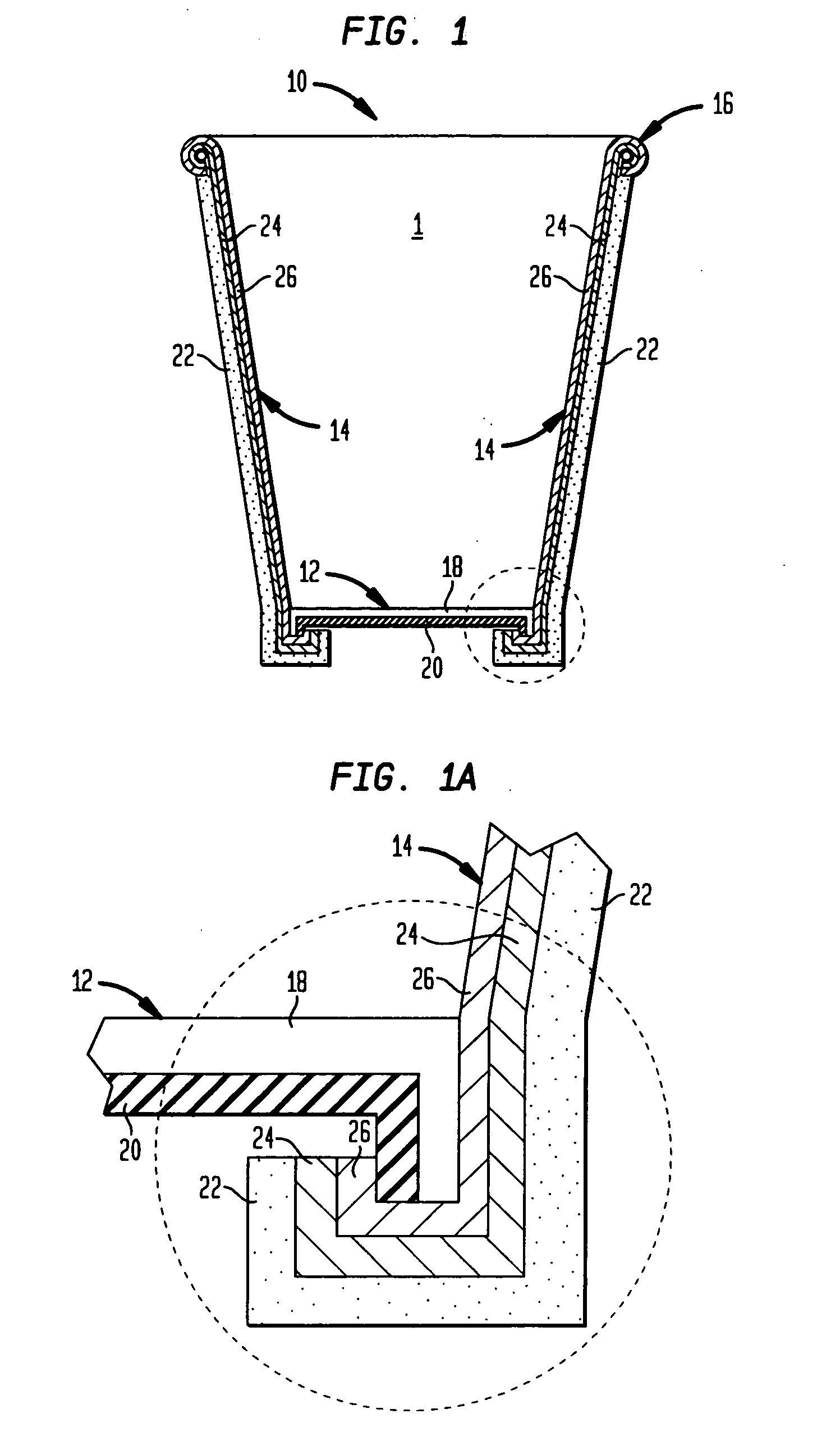

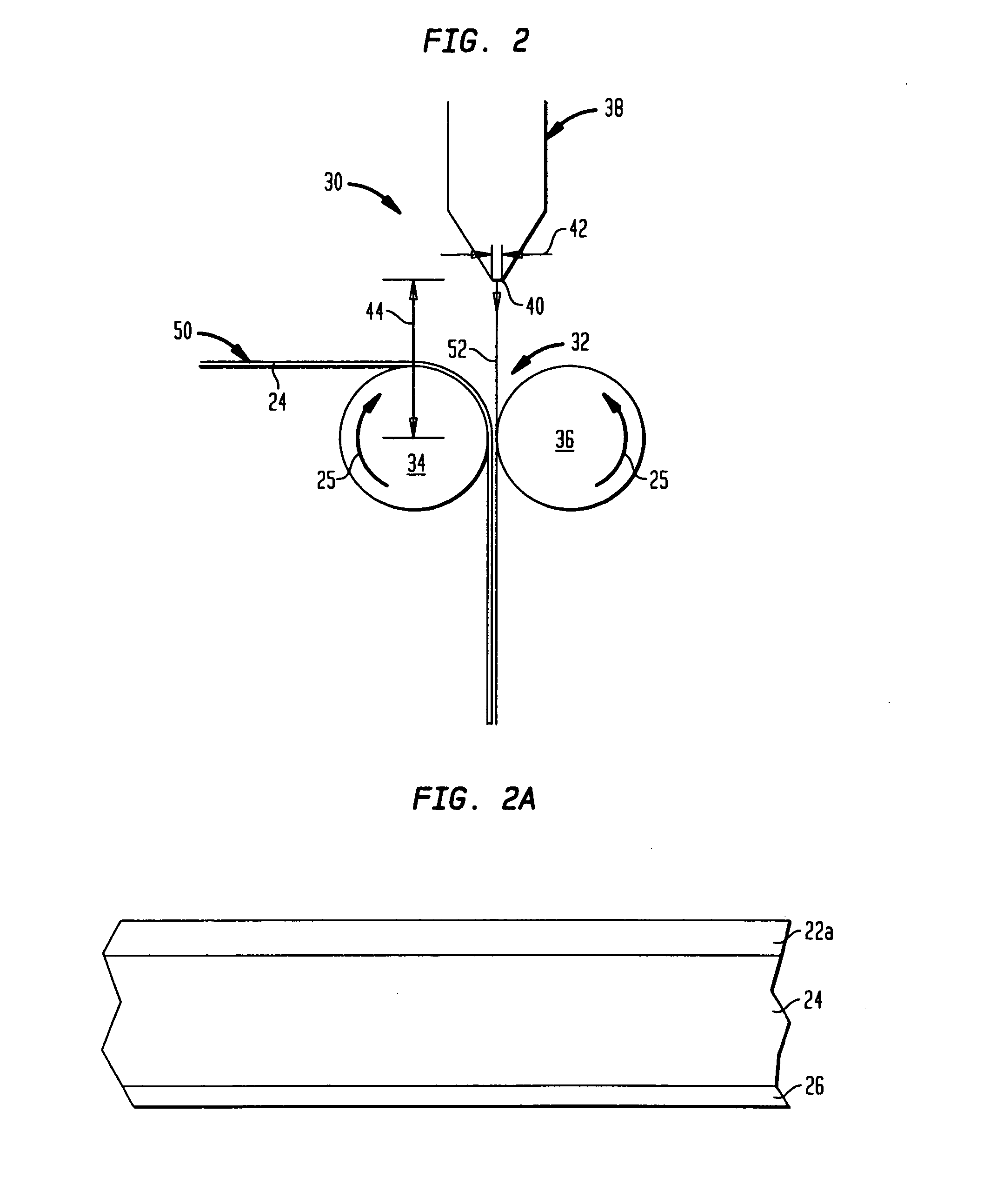

A fibrous product (10, 20, 20b, 30), especially tissue paper product, non-woven products or a hybrid thereof, and preferably hygiene and cleaning product has at least one first ply (42; 62; 84; 104) with at least one embossing pattern including embossed depressions starting from a base plane of the ply; the embossed pattern being characterized by the following features: the embossing pattern has a minimum motive surface area of at least 3 cm×3 cm; the pattern includes a high number of embossed depressions which are sized and / or positioned such as to form a motive element covering the motive surface area; wherein at least some of the embossed depressions are sized and / or positioned such that minimum distances between pairs of consecutively arranged embossed depression vary. A method for producing such a fibrous product is also described.

Owner:SCA HYGIENE PROD AB

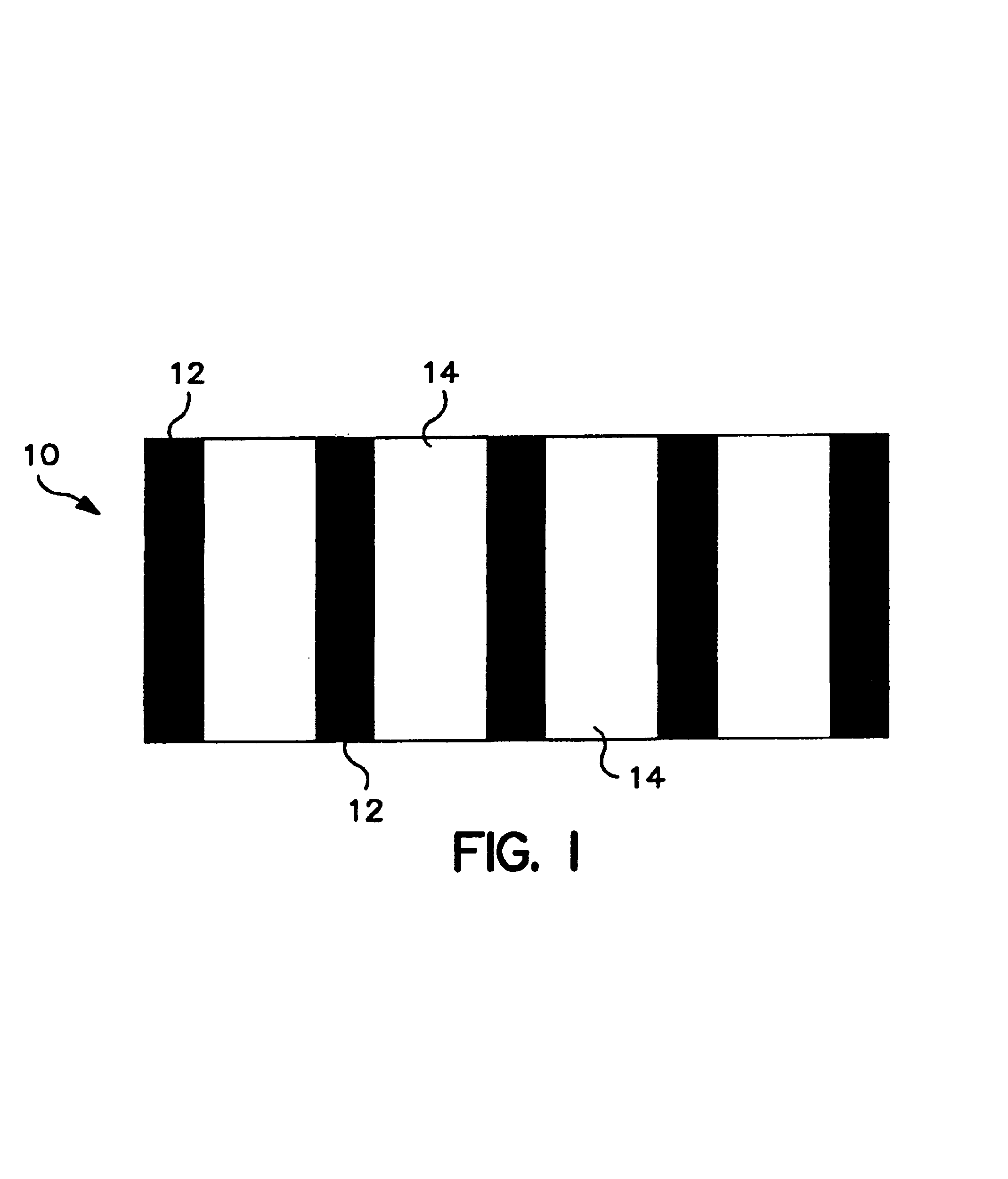

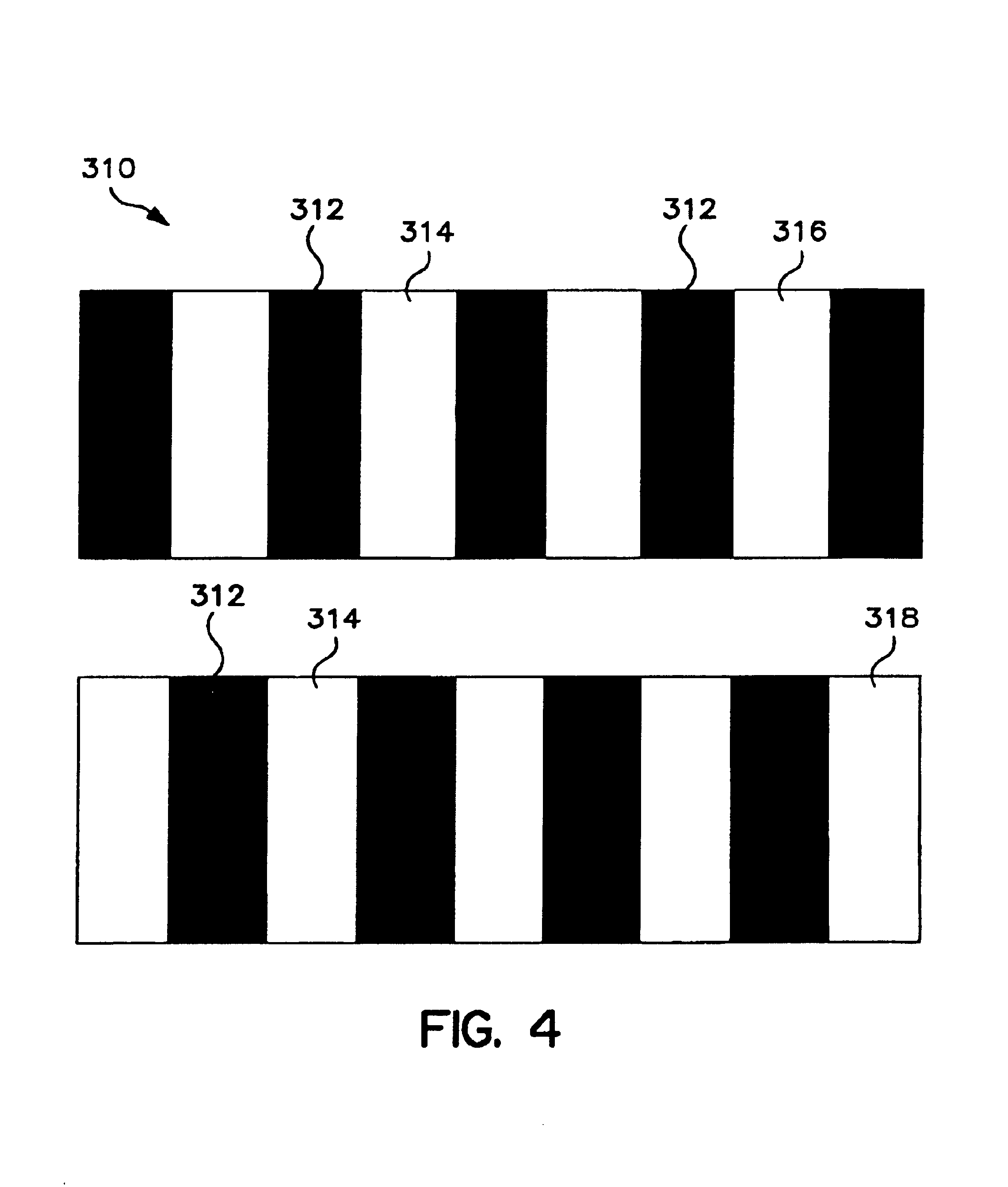

Paper wiping products treated with a hydrophobic additive

InactiveUS6896766B2Improve propertiesMaintaining acceptable wetability propertyCosmetic preparationsBiocideProcess regionPaper towel

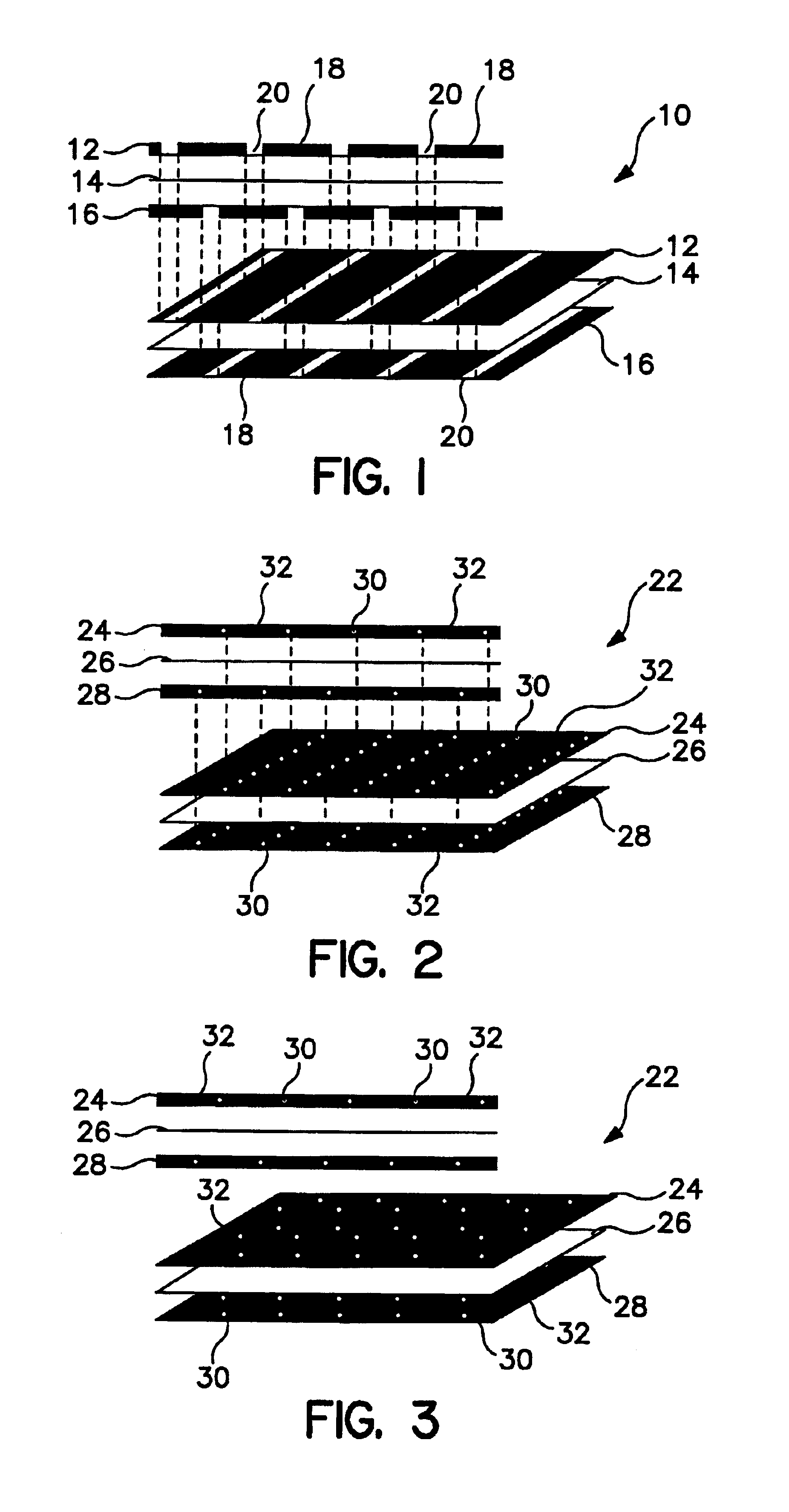

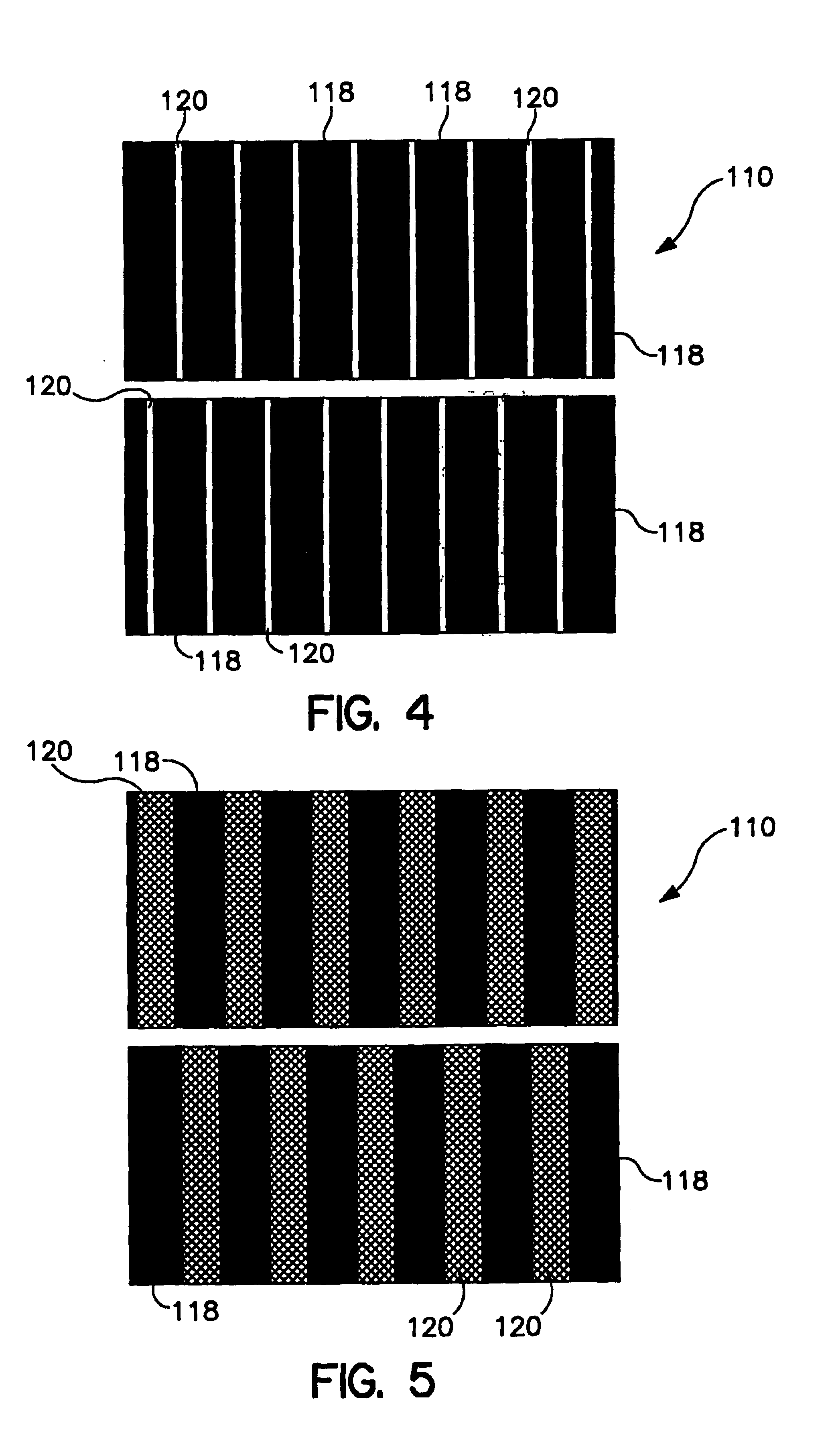

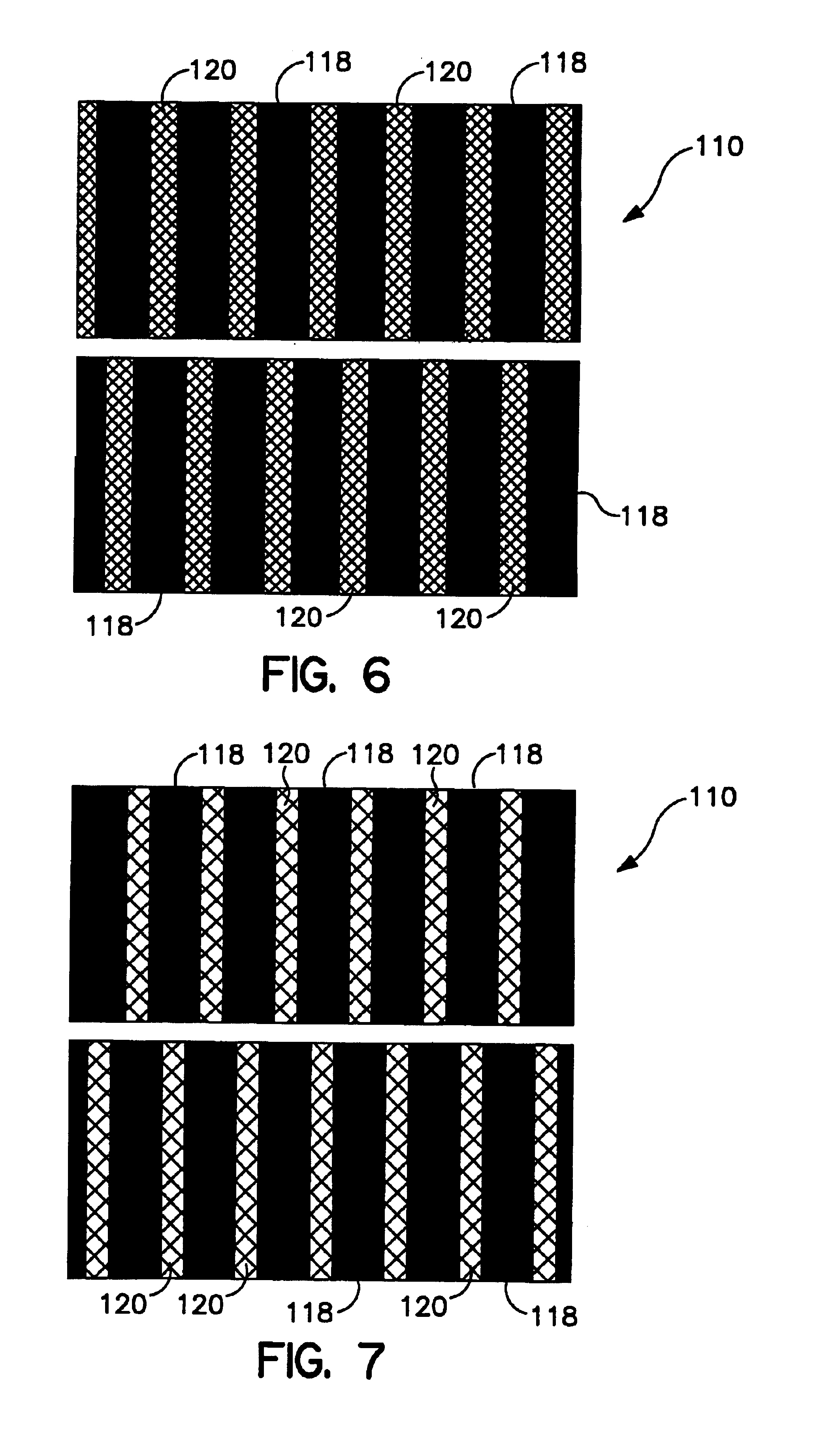

Paper products treated on two surfaces with a liquid resistant composition are disclosed. The paper products can be, for instance, bath tissues, facial tissues, paper towels, and industrial wipers. The liquid resistant compositions can include any additive that provides benefits to the product. For instance, the liquid resistant composition can be a softener containing a hydrophobic additive. In one embodiment, the hydrophobic additive is a polysiloxane. In accordance with the present invention, the water resistant composition is applied to each surface according to a pattern. Each of the patterns includes treated and untreated areas. The patterns are positioned on the paper product such that untreated areas on one surface are in correspondence with the treated areas on the other surface of the sheet.

Owner:KIMBERLY-CLARK WORLDWIDE INC

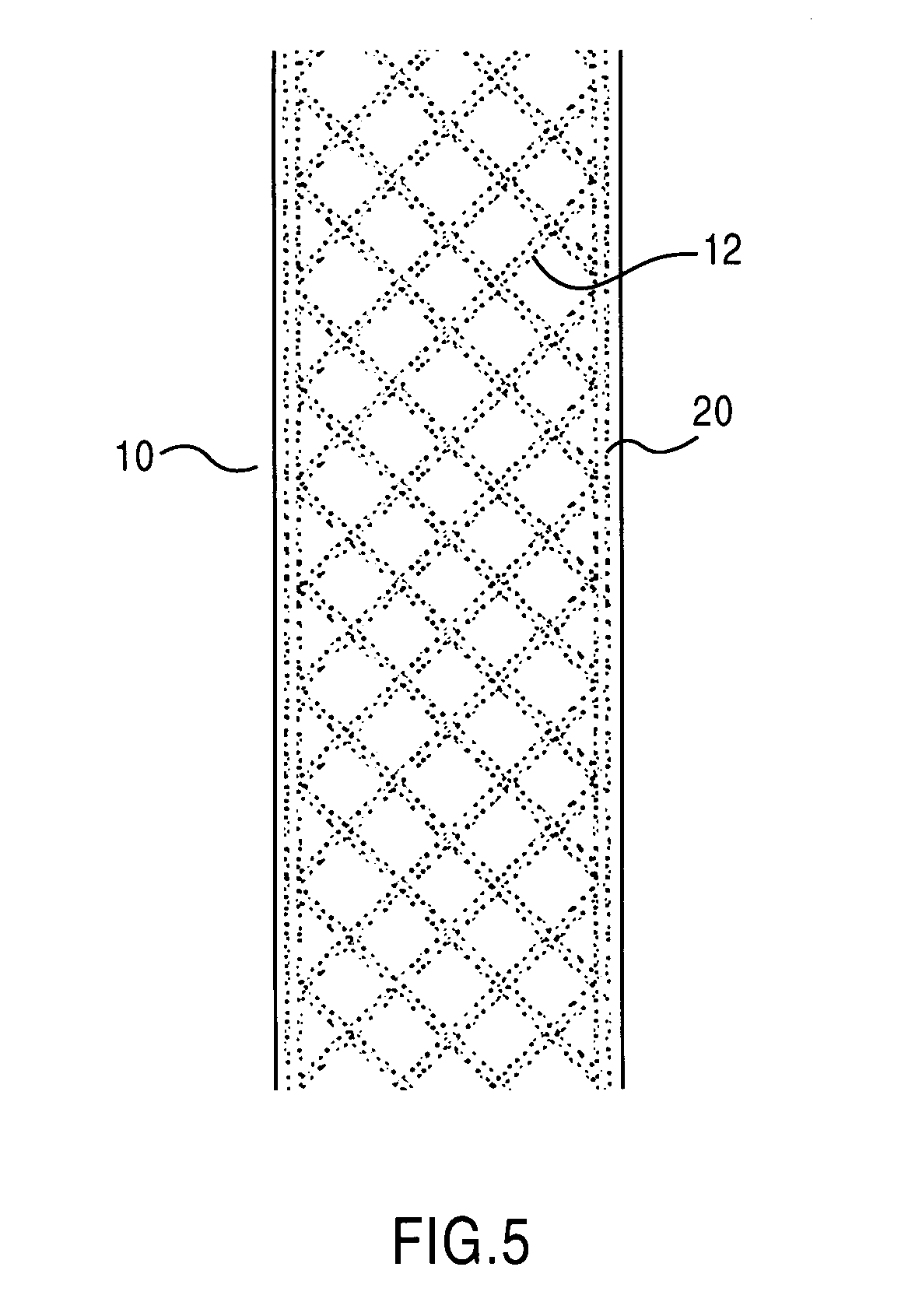

Patterning on surface with high thermal conductivity materials

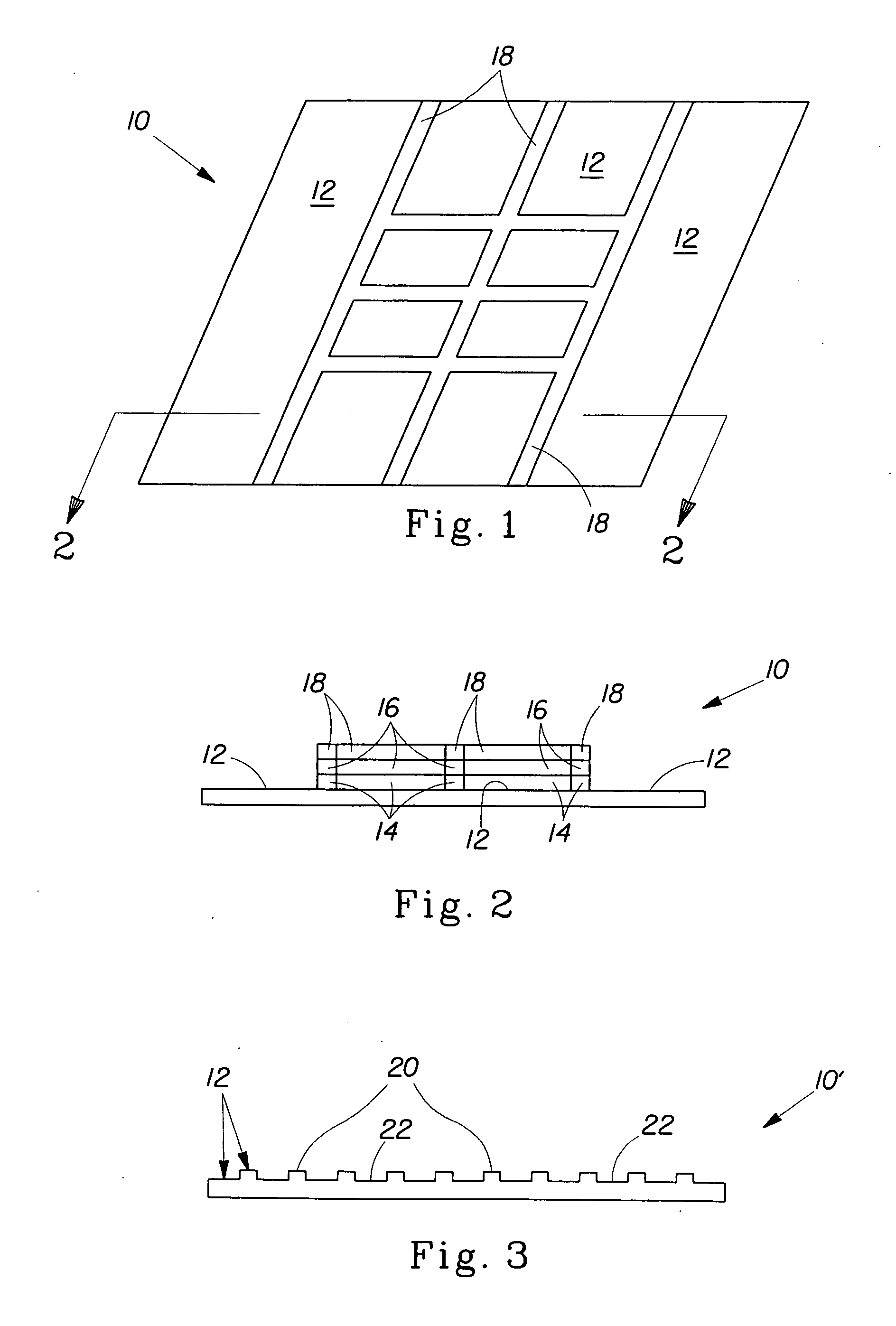

ActiveUS20060234576A1Improve thermal conductivityHigh resistivityAdhesive articlesPaper/cardboardNanometreThermal transmittance

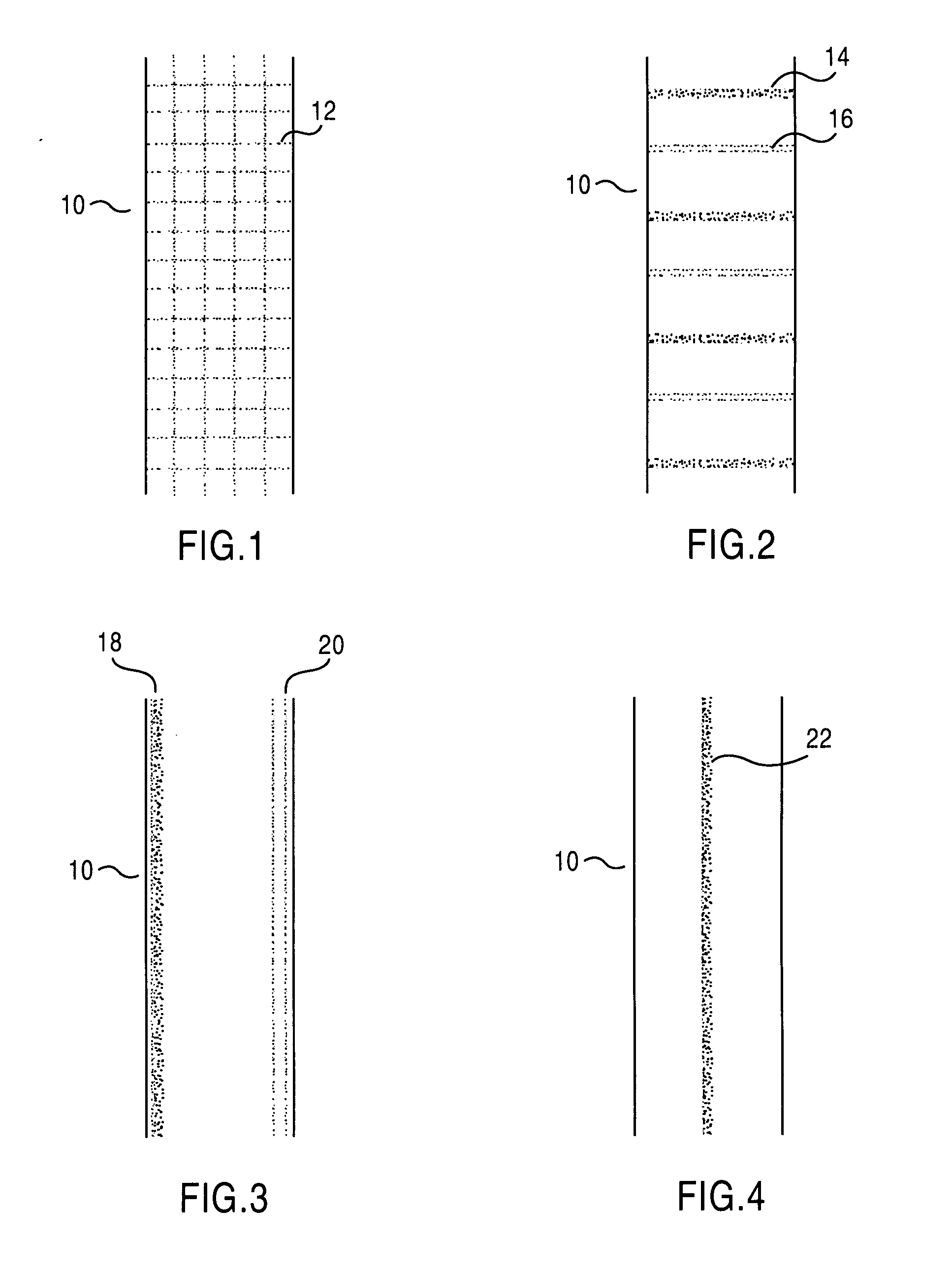

The present invention provides for high thermal conductivity paper that comprises a host matrix (10), and high thermal conductivity materials (12) added to a surface of the host matrix in a specific pattern (12). The high thermal conductivity materials are comprised of one or more of nanofillers, diamond like coatings directly on the host matrix, and diamond like coatings on the nanofillers. In particular embodiments the specific pattern comprises one or more of a grid, edging, banding centering and combinations thereof and the high thermal conductivity materials cover 15-55% of the surface of the host matrix. Multiple surfaces, including sub layers my have patterning.

Owner:SIEMENS ENERGY INC

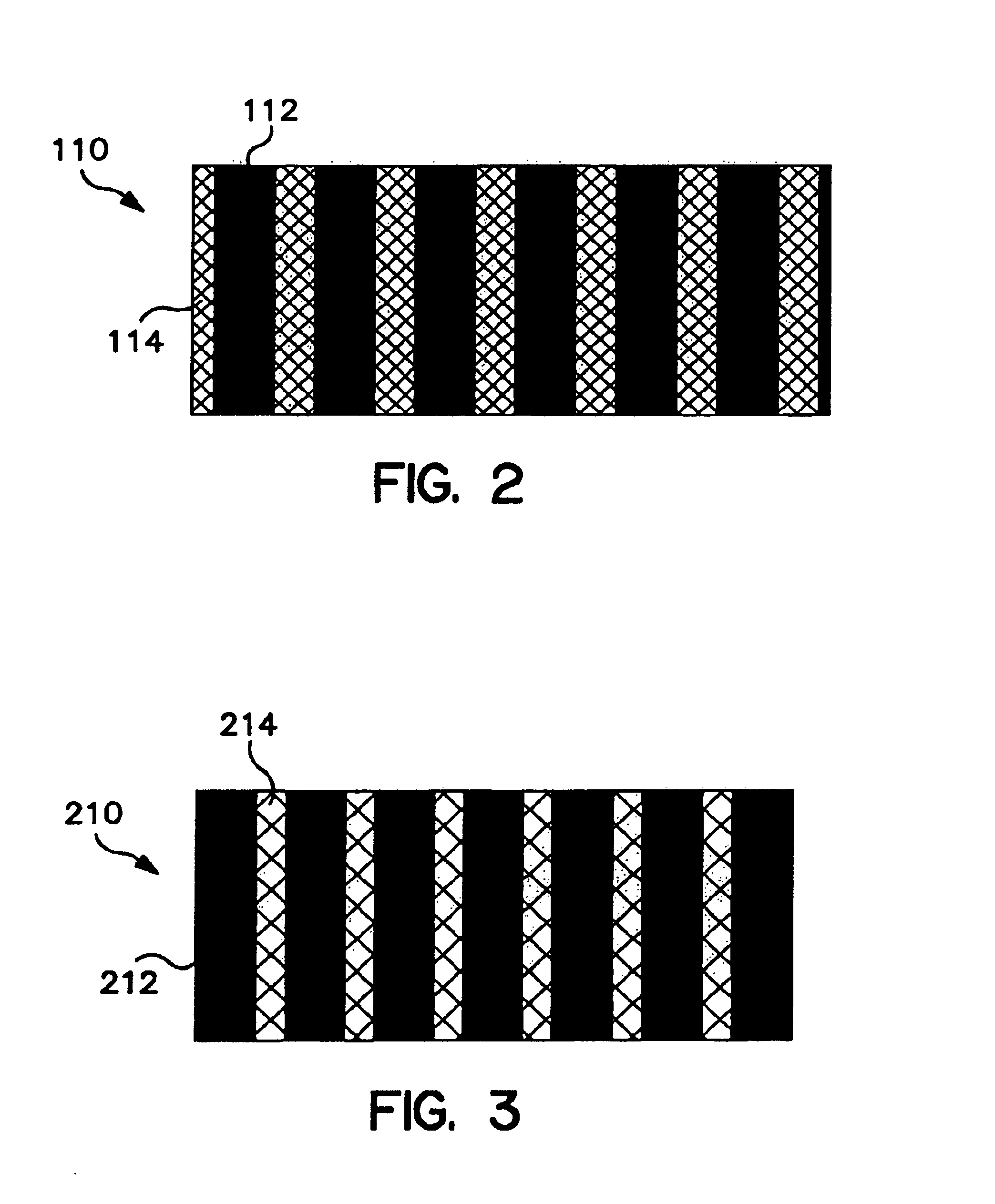

Tissue products having uniformly deposited hydrophobic additives and controlled wettability

InactiveUS6949167B2Improve propertiesAcceptable wettability characteristicBiocideNatural cellulose pulp/paperChemistryWetting

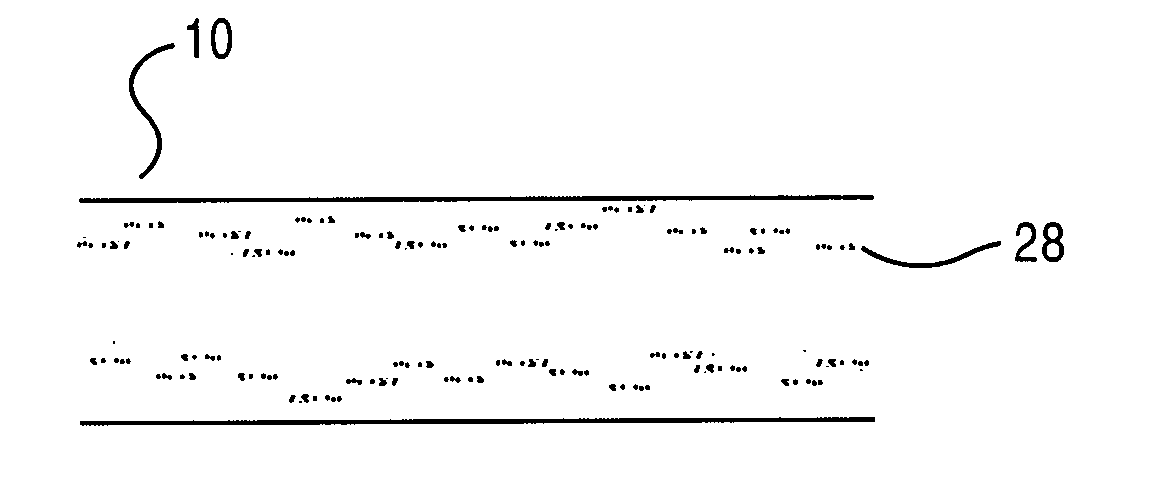

Tissue products are disclosed that contain a hydrophobic additive, such as a polysiloxane. In accordance with the present invention, the tissue products are further treated with a wetting agent. The wetting agent may be applied after application of the hydrophobic additive to one or more surfaces of the base sheet. The wetting agent improves the wettability properties of the base sheet.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Waterborne paper or paperboard coating composition

InactiveUS20010036990A1Trend downHigh molecular weightMaterial nanotechnologyNon-fibrous pulp additionEmulsionPolymer science

A waterborne pigmented paper or paperboard coating composition containing as pigment 50% to 100%, by weight based on pigment weight, calcium carbonate and from 1% to 25%, as dry weight based on pigment weight, of an aqueous polymeric dispersion including (a) 95-25% by weight, based on the weight of the solids of the aqueous polymeric dispersion, of a first emulsion polymer having an average particle diameter of 150 to 3000 nanometers and (b) 5-75% by weight, based on the weight of the solids of the aqueous polymeric dispersion, of a second emulsion polymer having an average particle diameter of 40 to 600 nanometers wherein the ratio of the average particle diameter of the first emulsion polymer to the average particle diameter of the second emulsion polymer is from 1.2 to 60, wherein at least the first emulsion polymer particles, when dry, contain at least one void, and wherein the first emulsion polymer is prepared in the presence of the second emulsion polymer or the second emulsion polymer is prepared in the presence of the first emulsion polymer is provided, as is a method for improving the sheet gloss of paper or paperboard coated with the coating composition.

Owner:BOBSEIN BARRETT RICHARD +2

Materials Having a Textured Surface and Methods for Producing Same

ActiveUS20080268203A1Rich varietyReduces and eliminates damageConfectioneryRoller and ring machinesMetallurgyRadiation

The present disclosure features processes and equipment for forming a variety of textured materials, including both release webs, and finished products such as flooring materials, wall coverings, textured laminates and the like. The processes described herein allow curing radiation to be passed through a texturing medium, rather than through the substrate to which the curable material is applied.

Owner:SAPPI NORTH AMERICA INC

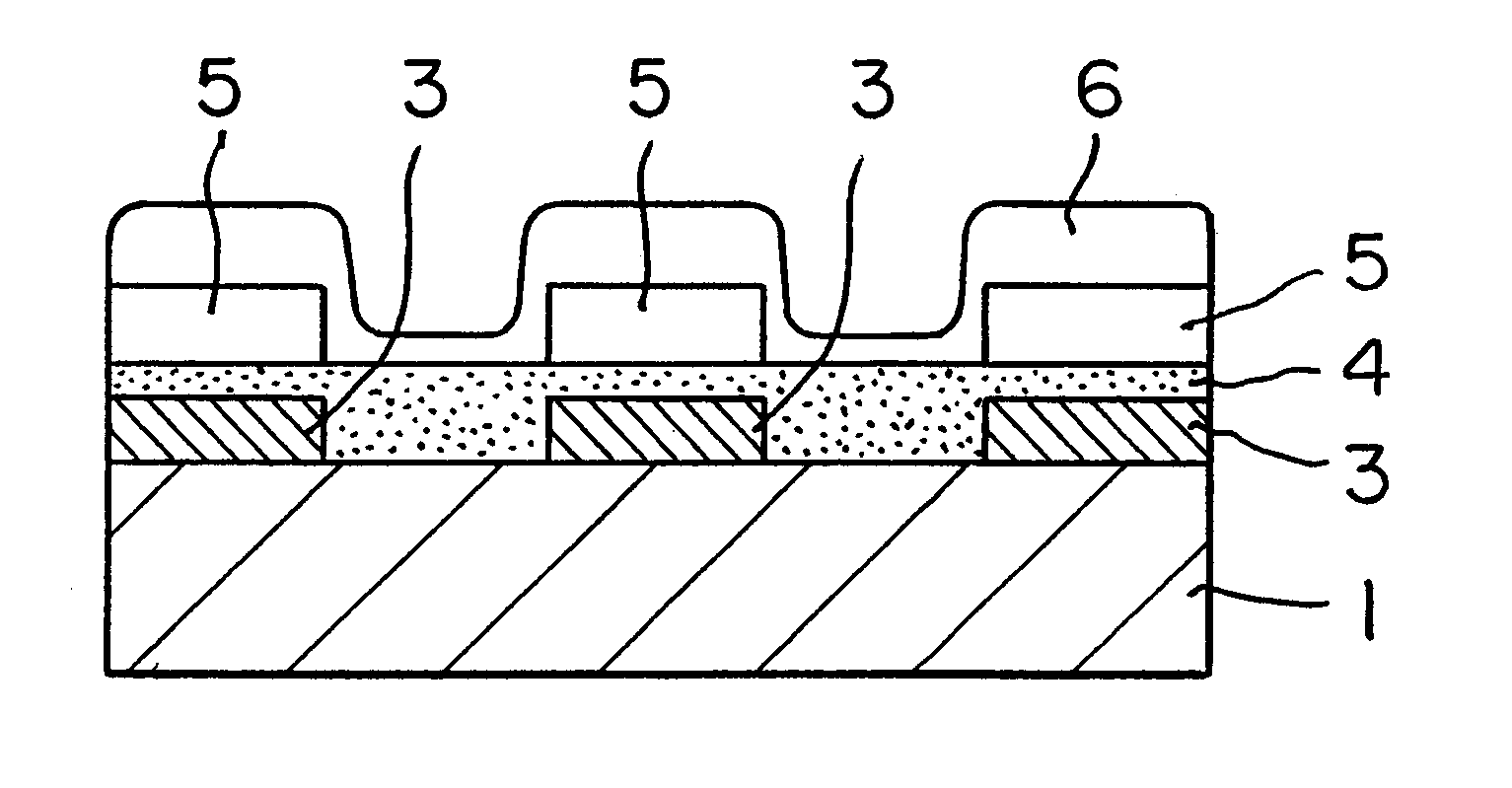

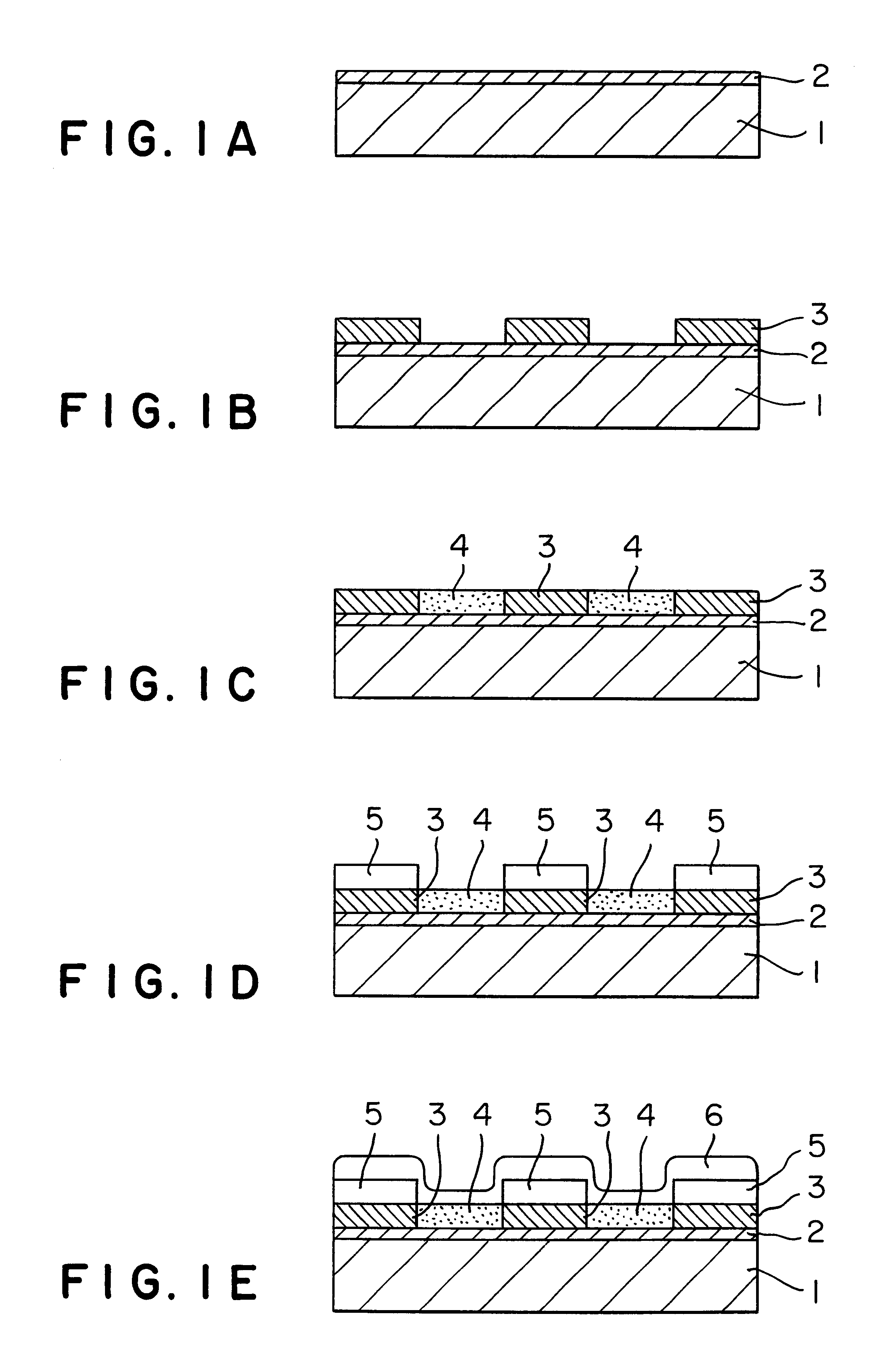

Synchronously embossed decorative sheet and method for producing the same

InactiveUS6326074B1Efficiently formedRealistic appearanceSpecial visual effect coatingsDecorative surface effectsEngineeringCoating

A synchronously embossed decorative sheet is provided which has excellent three-dimensional effect in sharp tune with a pattern layer and, at the same time, has good scratch resistance. The synchronously embossed decorative sheet comprises: a substrate; a pattern layer provided on the substrate; a penetrable layer provided on the substrate at least in its portions not having thereon the pattern layer, the penetrable layer comprising a coating composition penetrable by an ionizing radiation curing resin; a nonpenetrable layer provided, on or above the pattern layer, in tune with the pattern in the pattern layer, the nonpenetrable layer comprising a coating composition nonpenetrable by an ionizing radiation curing resin; and a top coat provided so as to cover the layers on the substrate and to conform to the shape of concaves and convexes in the pattern layer.

Owner:DAI NIPPON PRINTING CO LTD

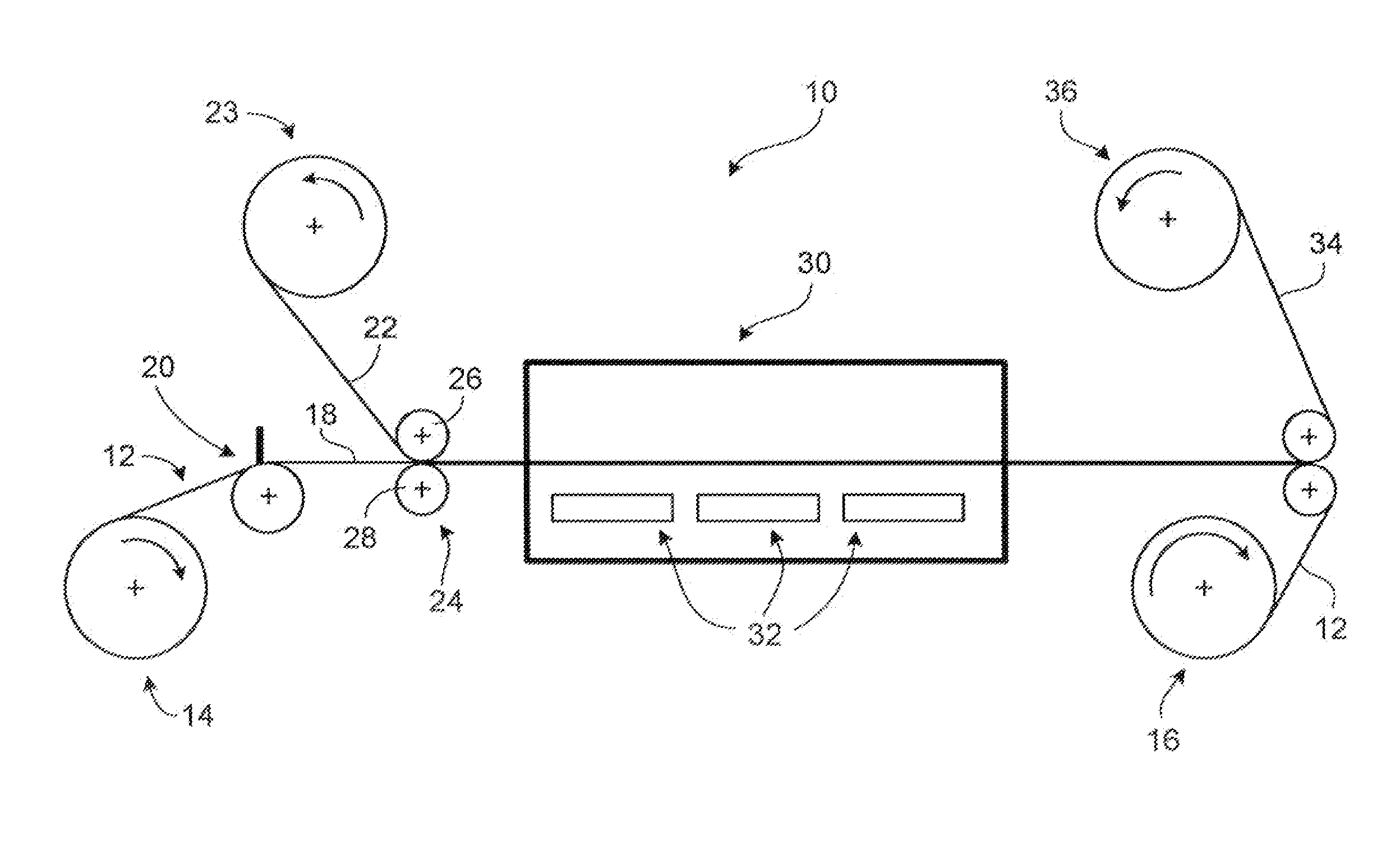

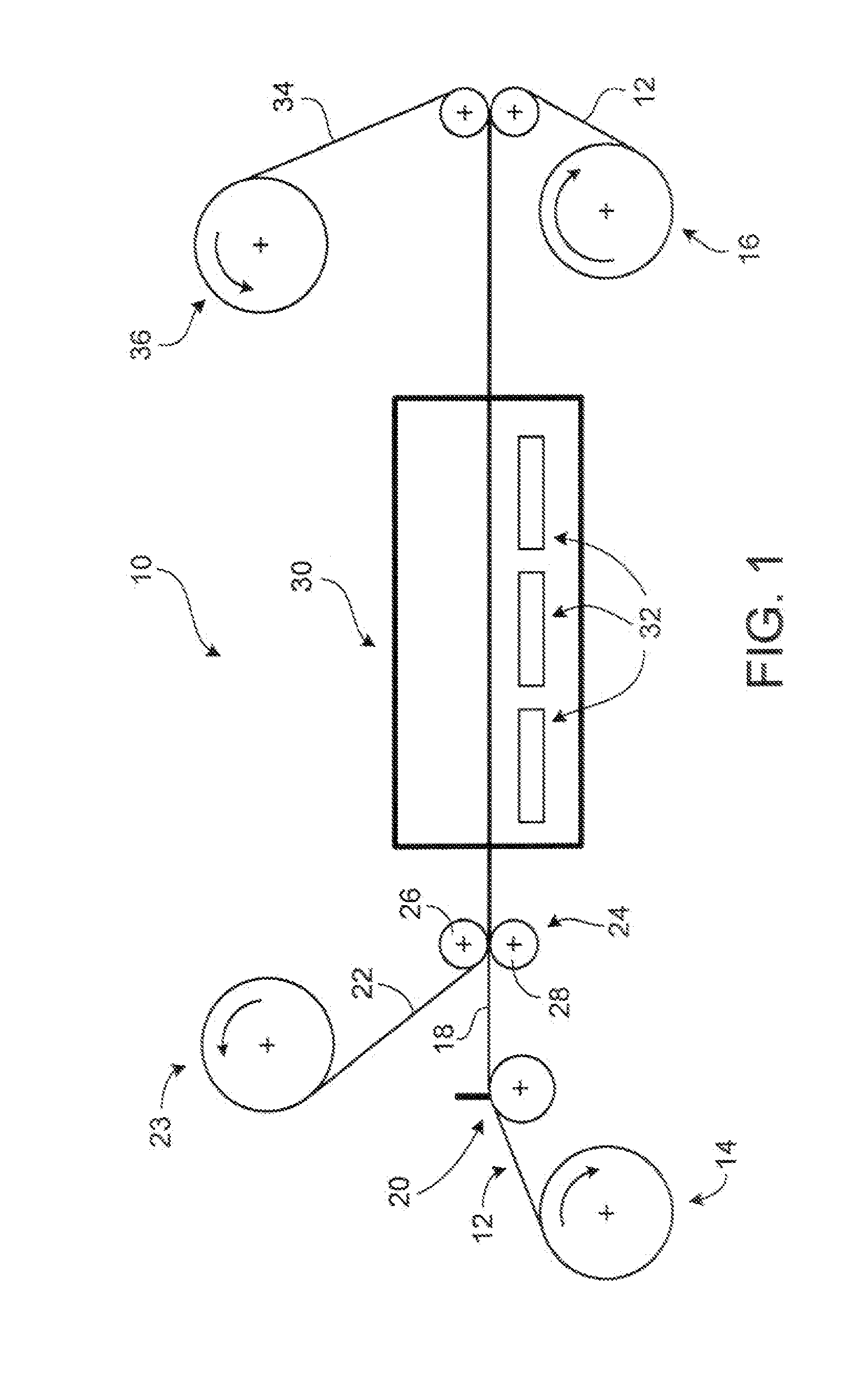

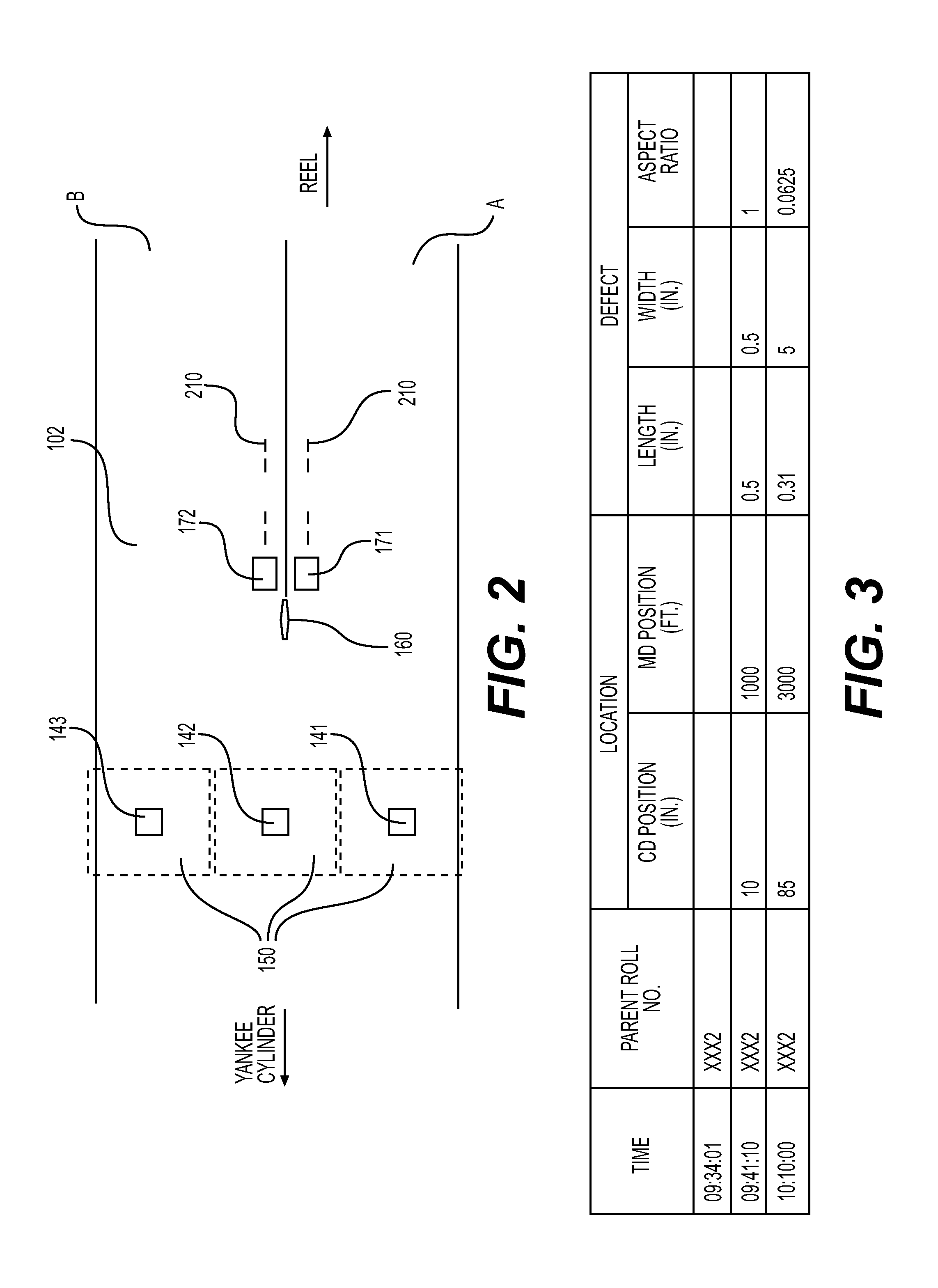

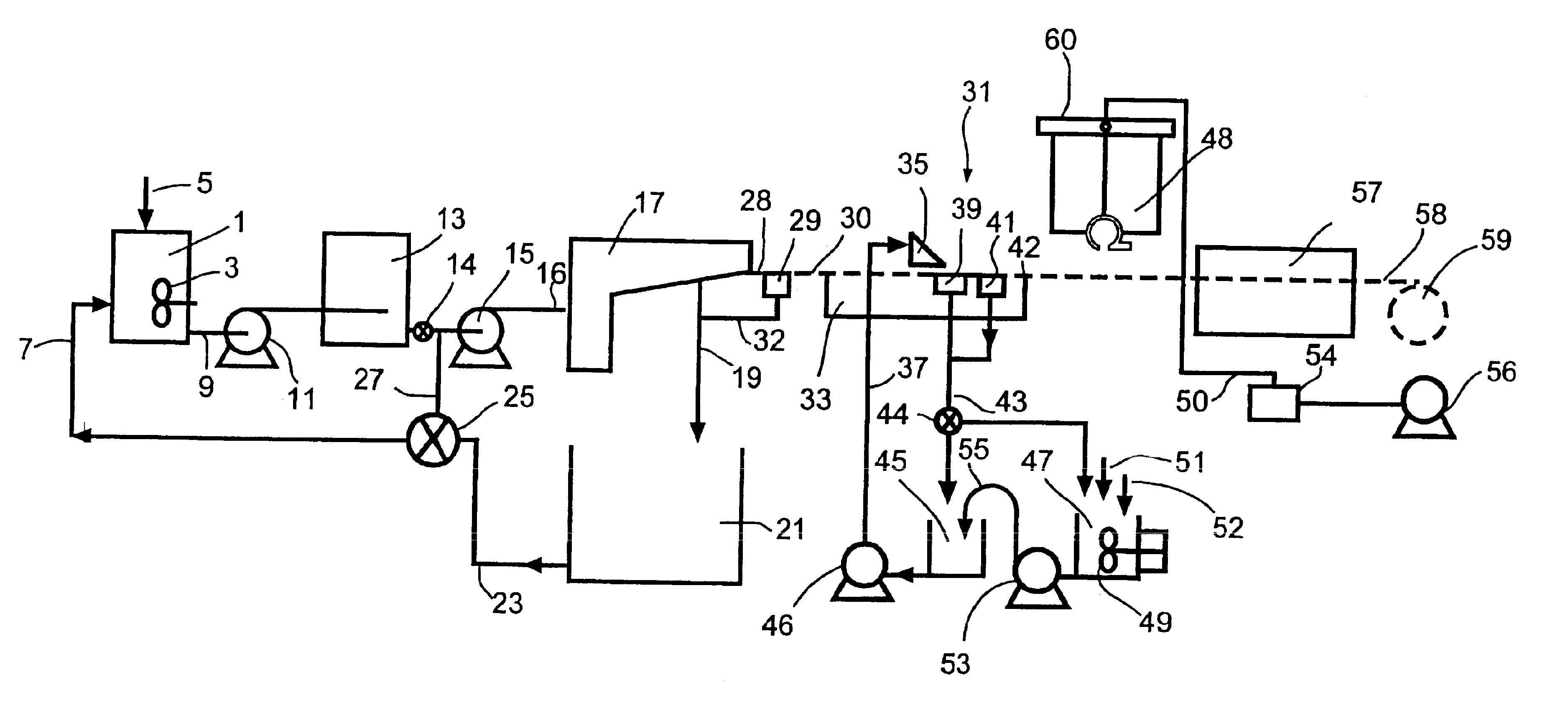

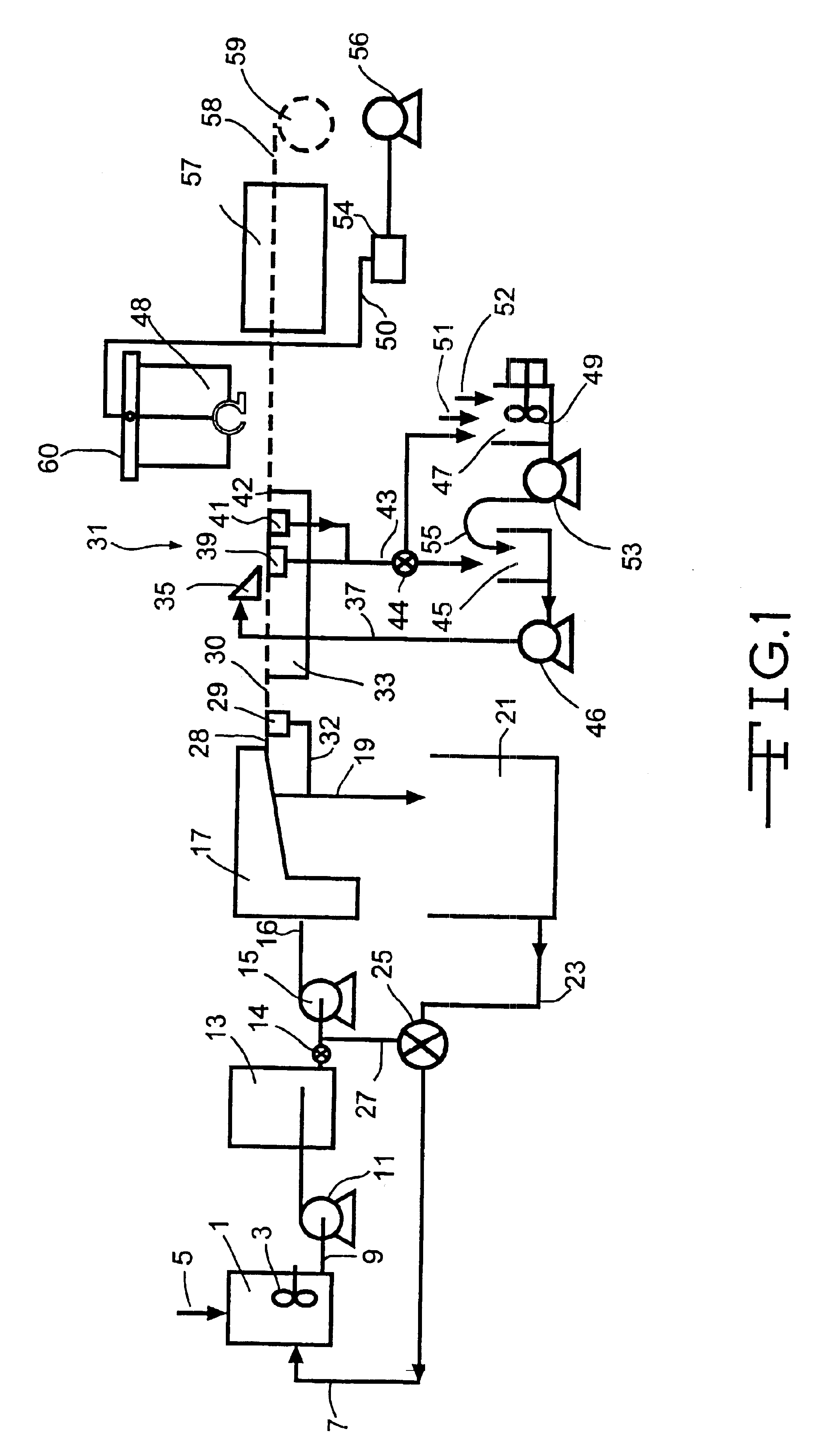

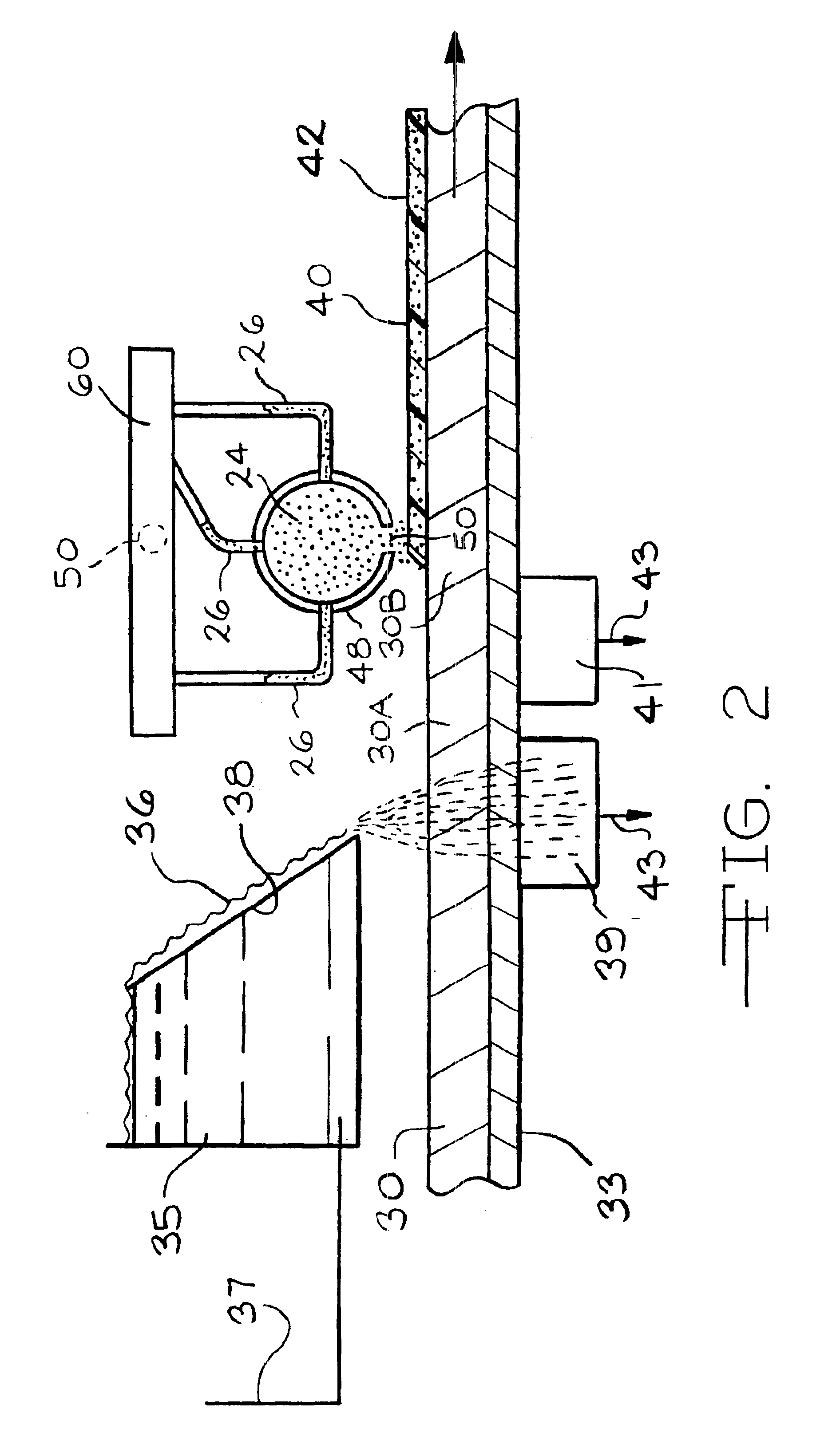

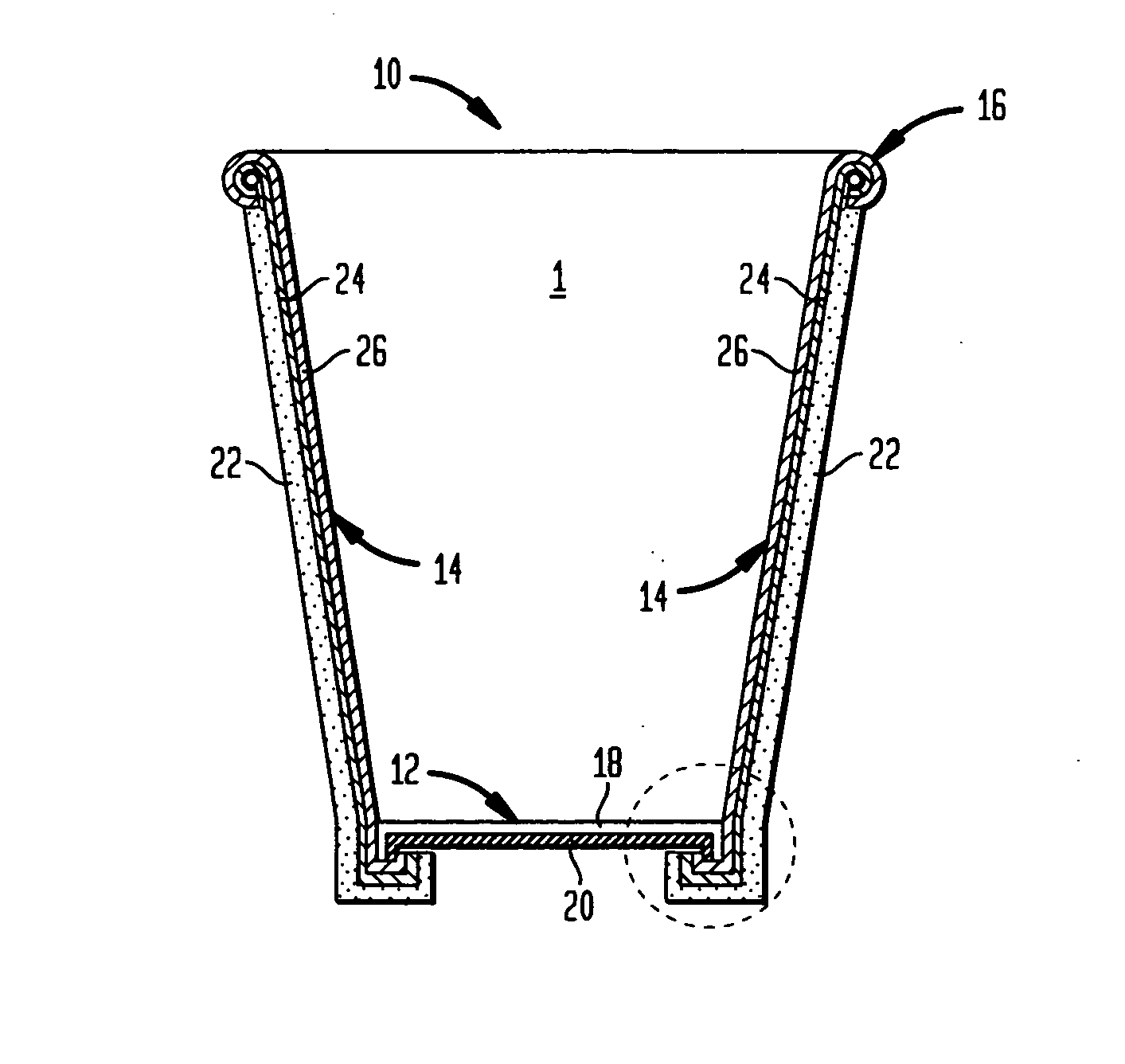

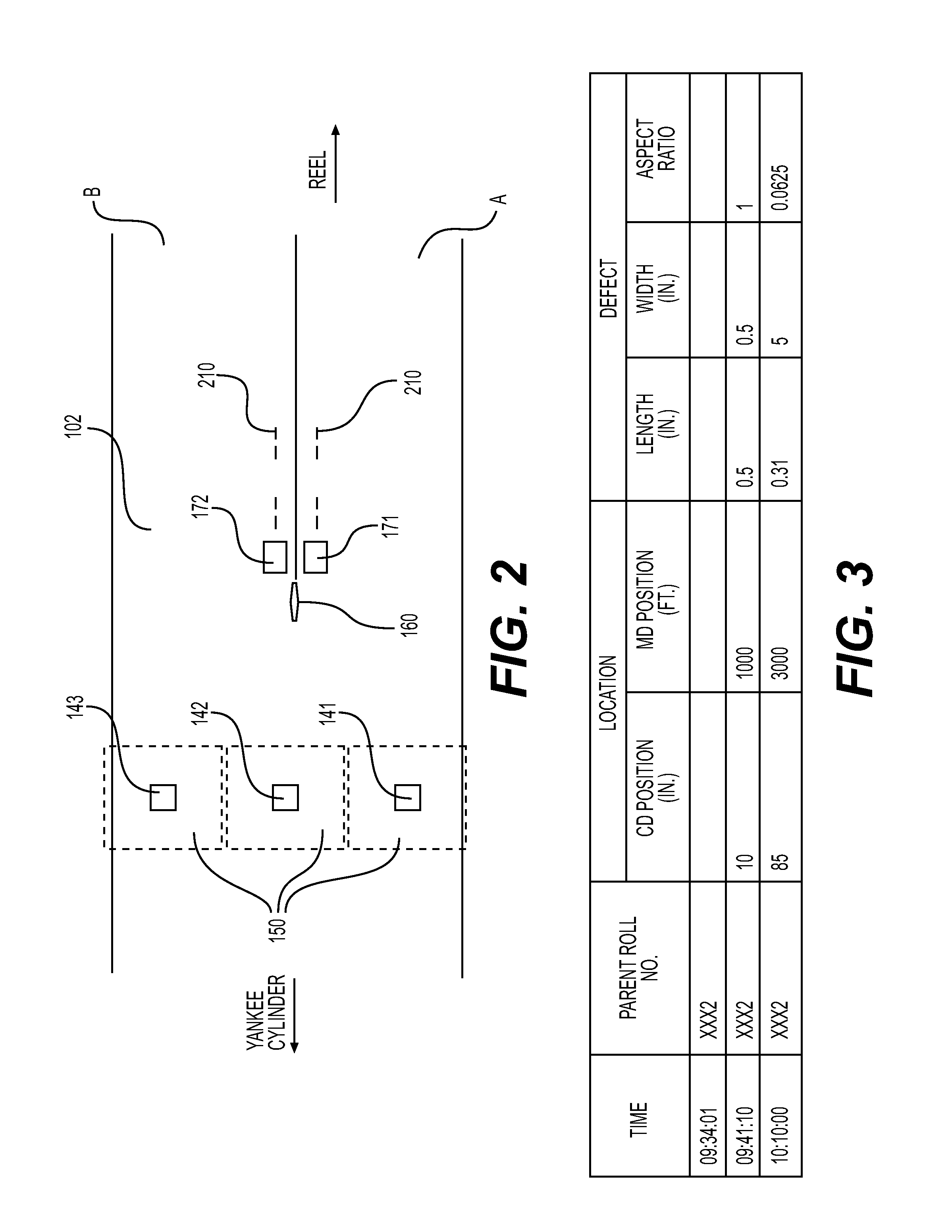

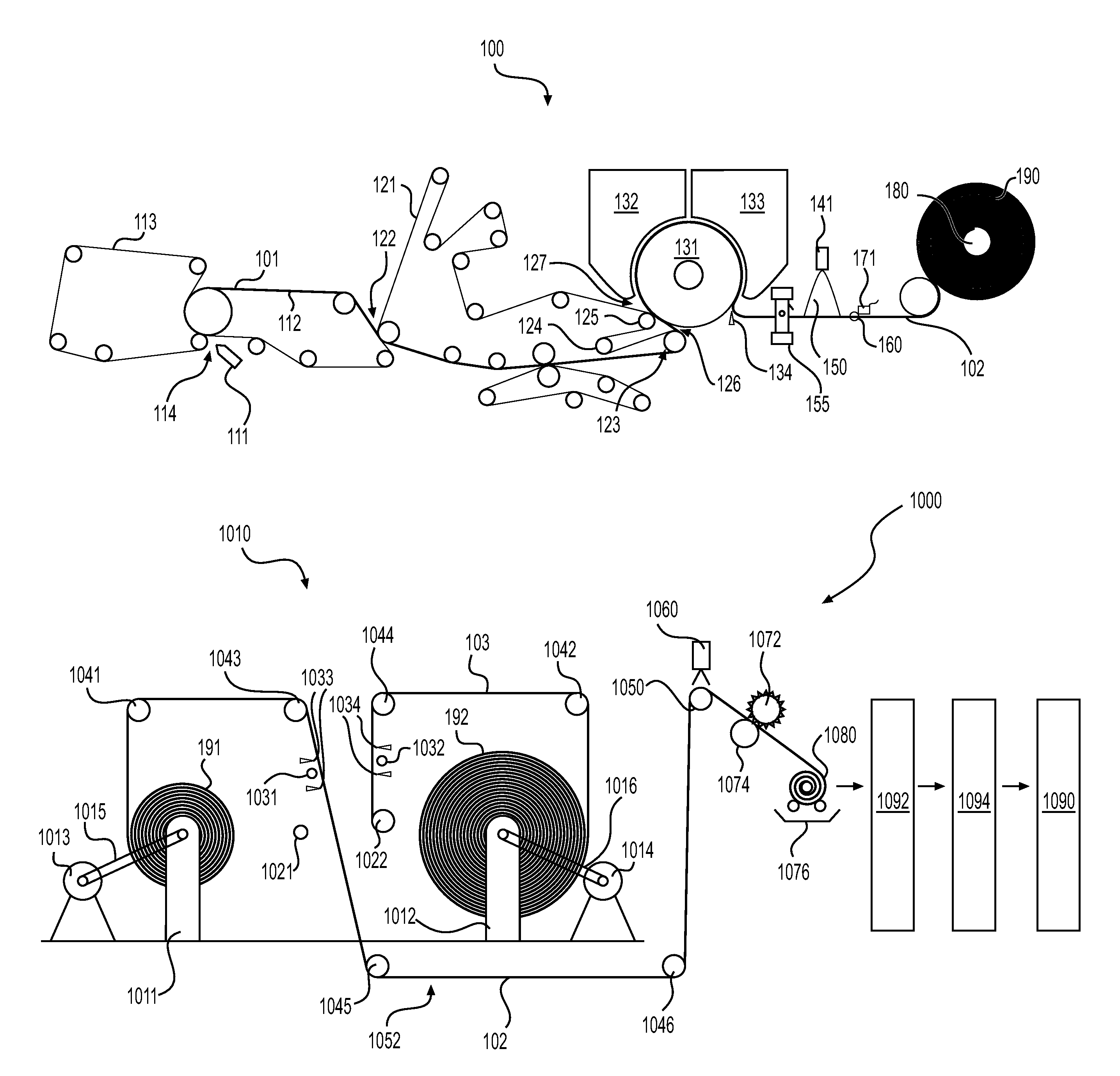

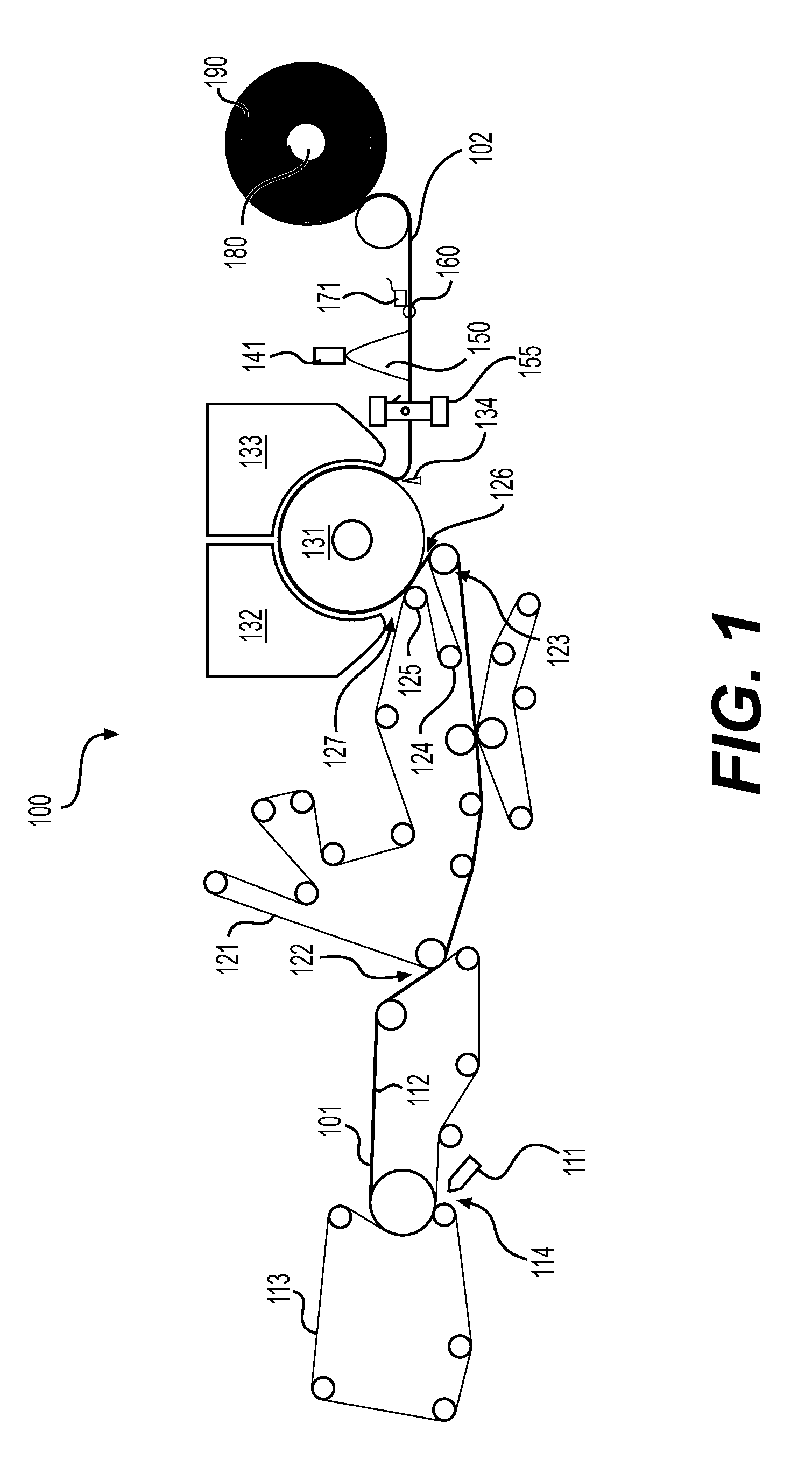

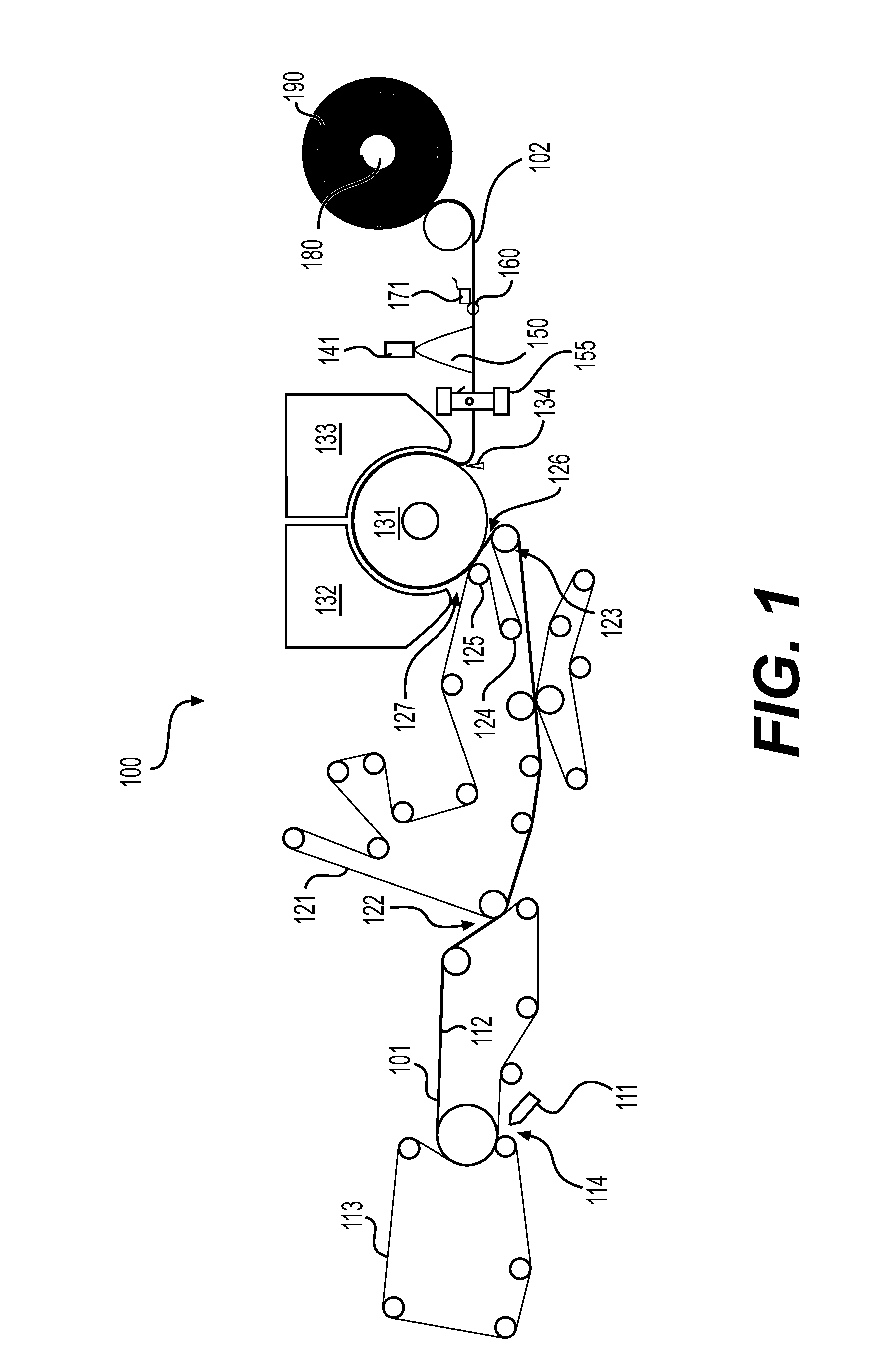

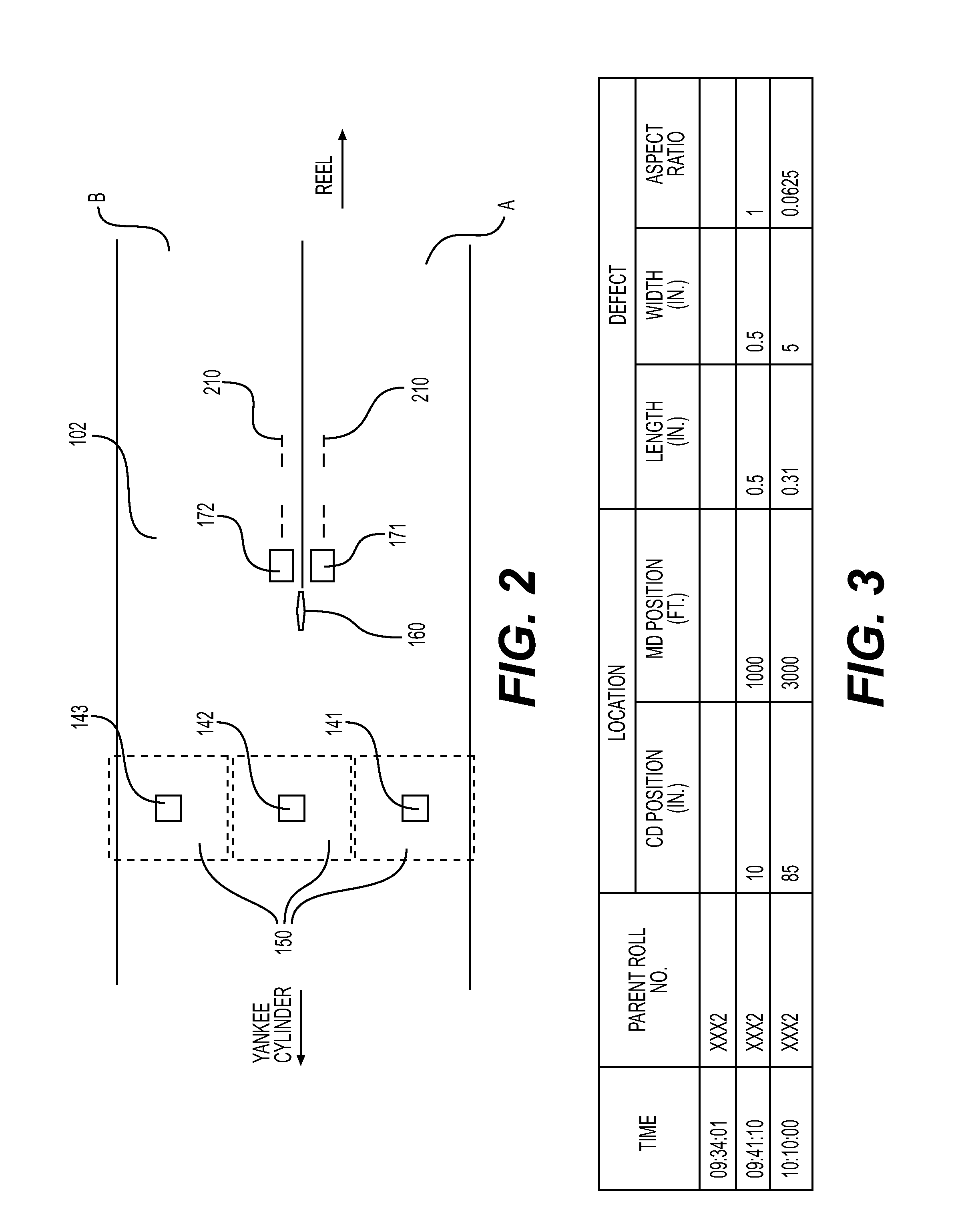

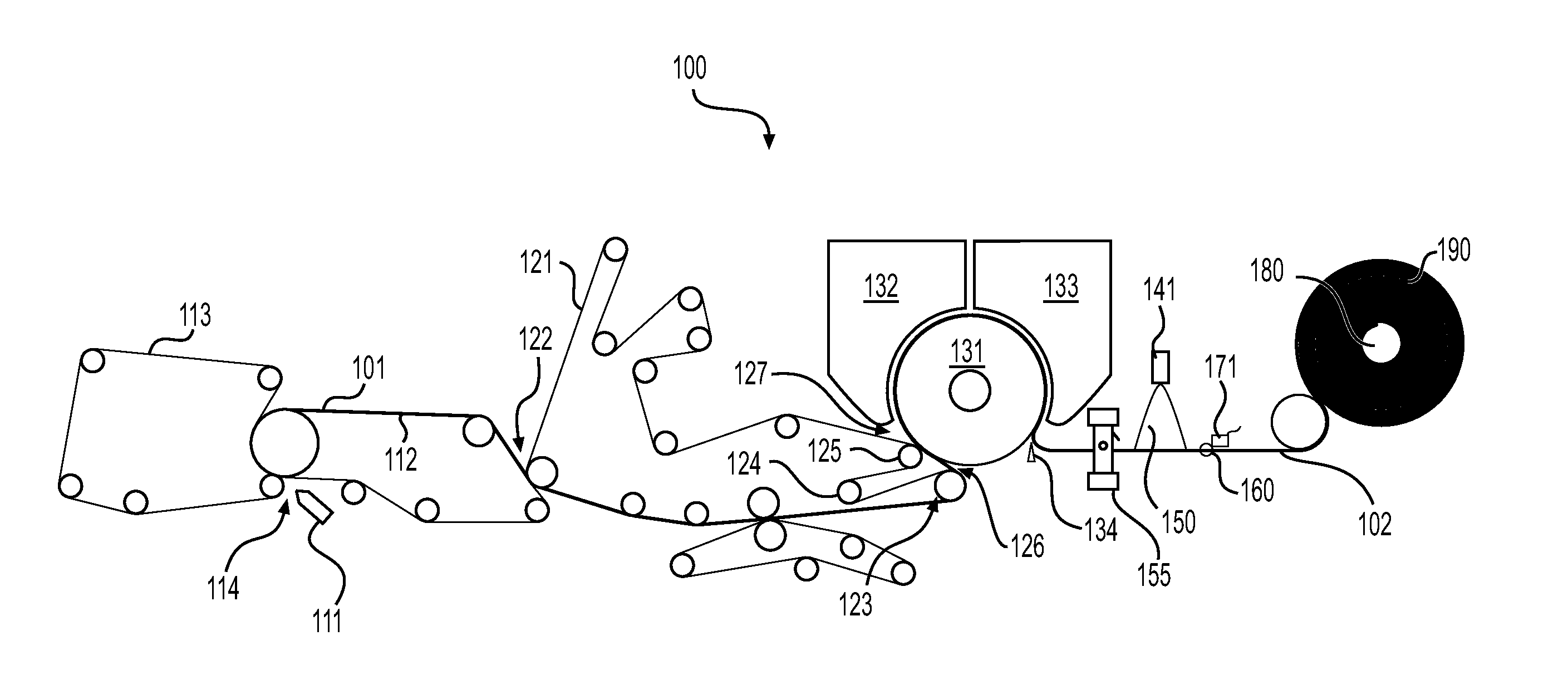

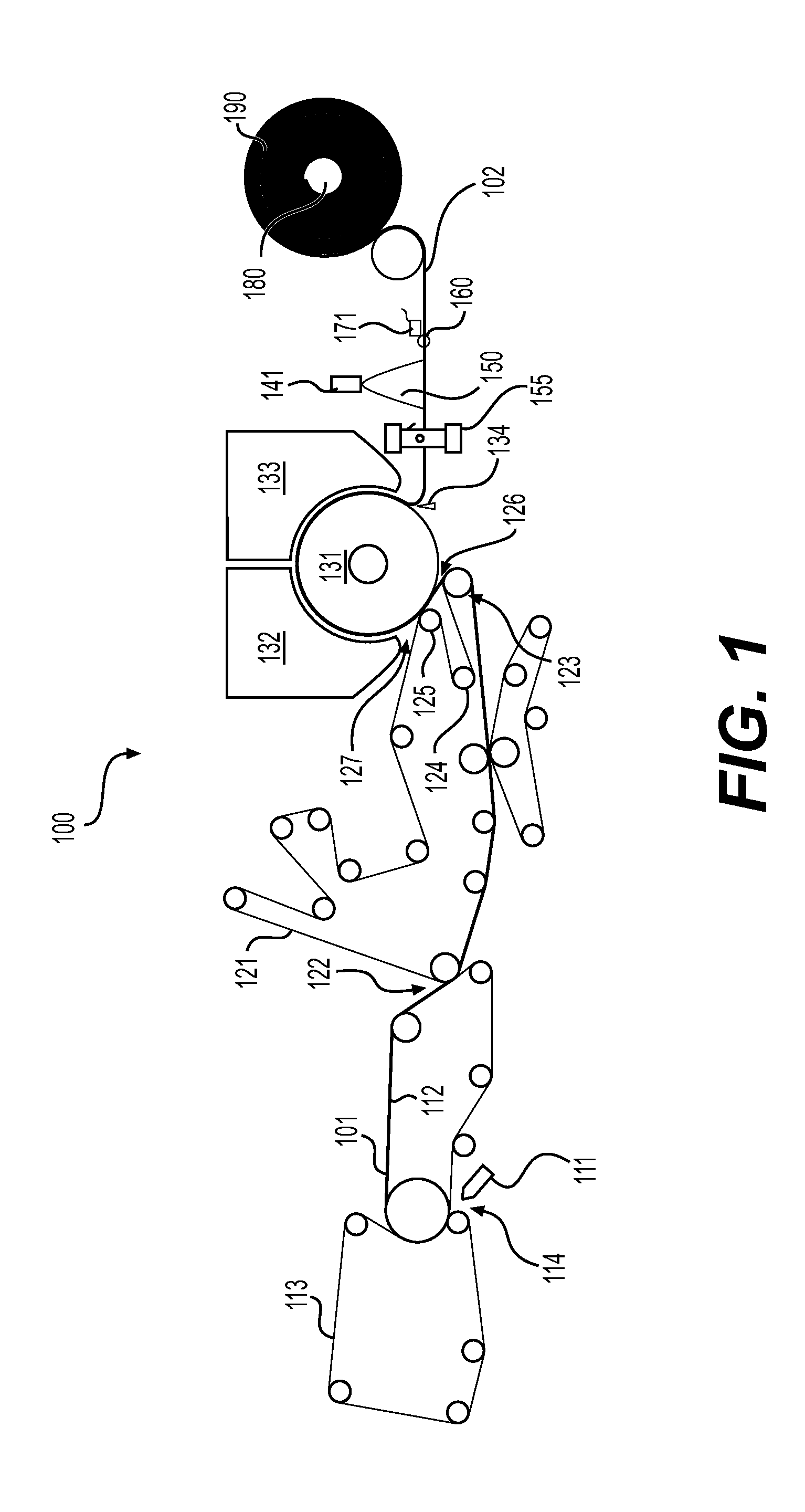

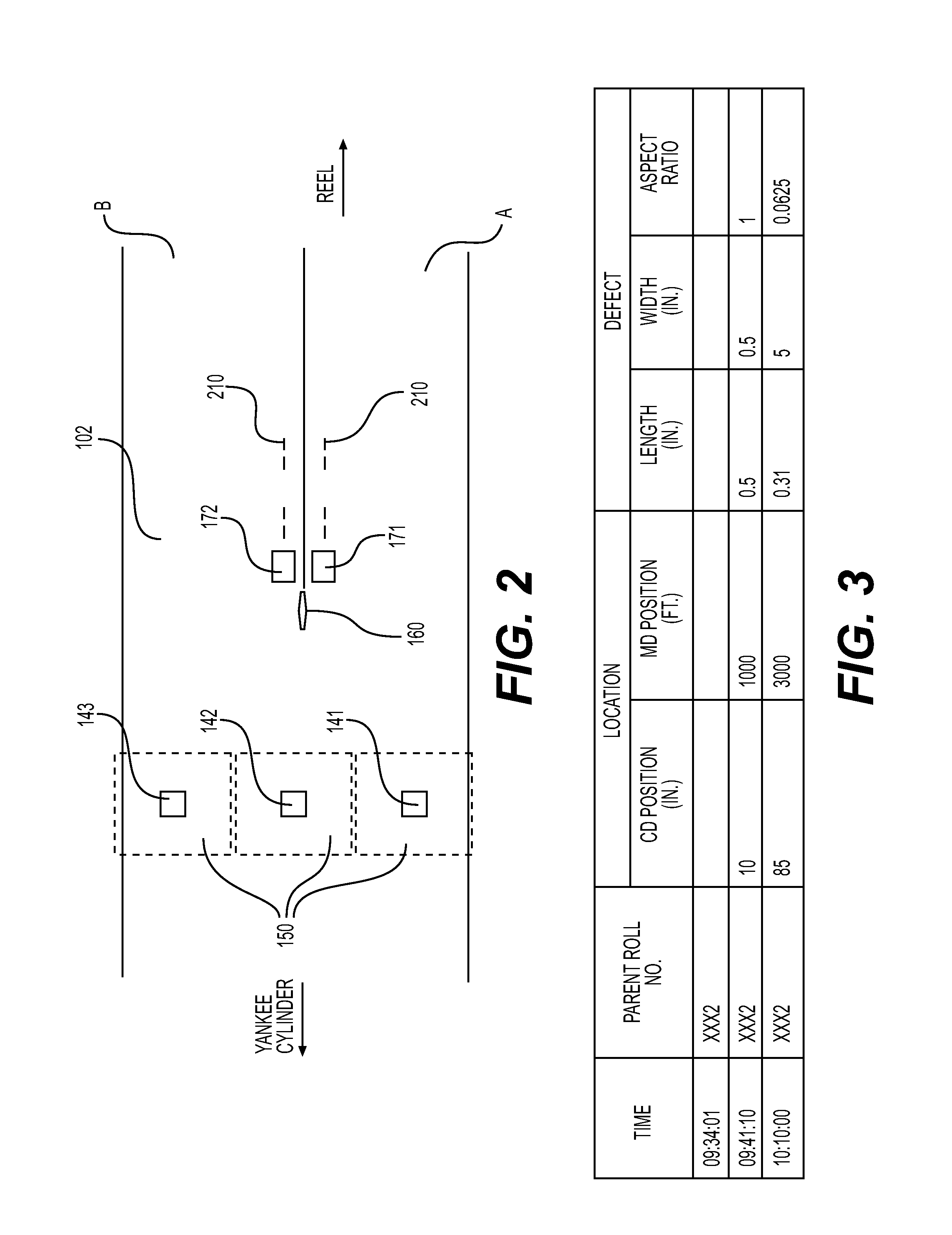

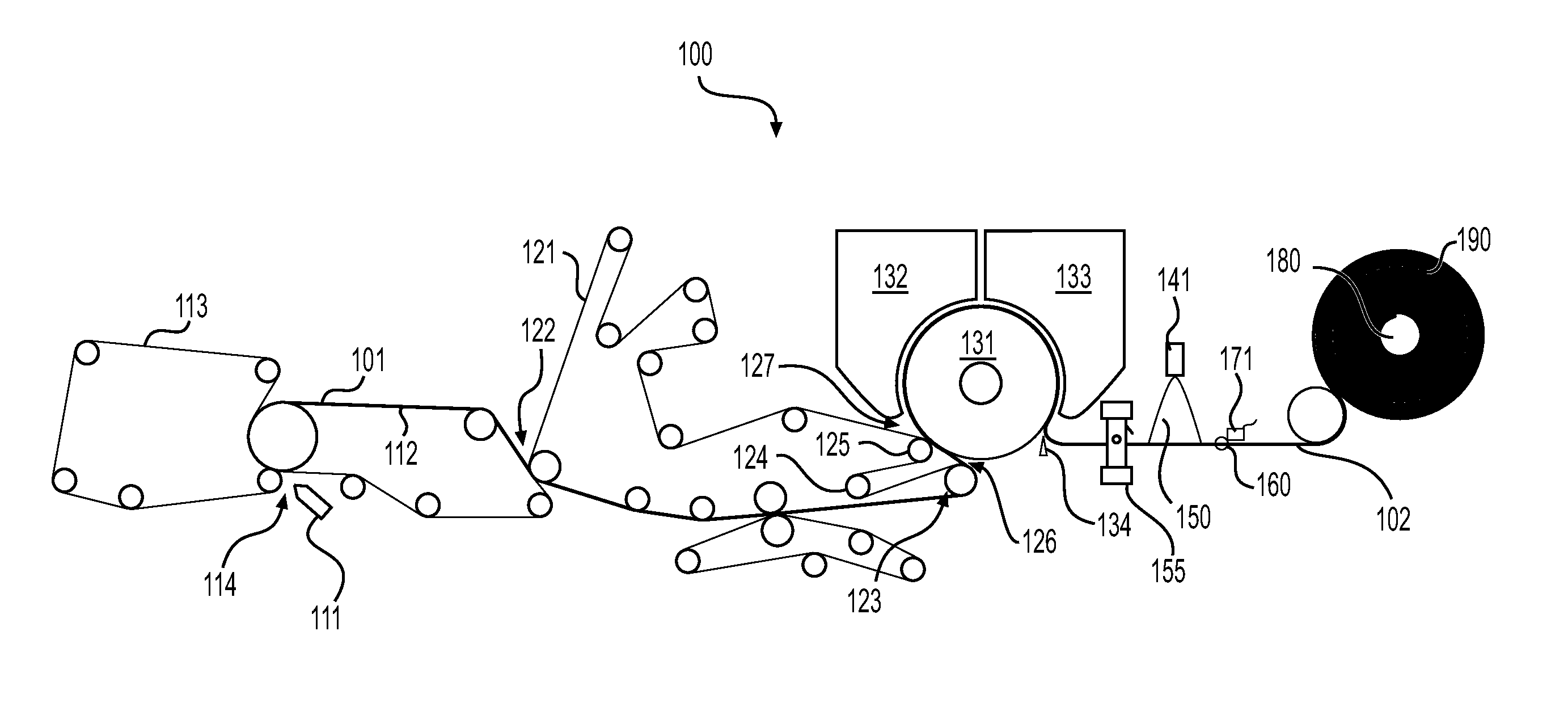

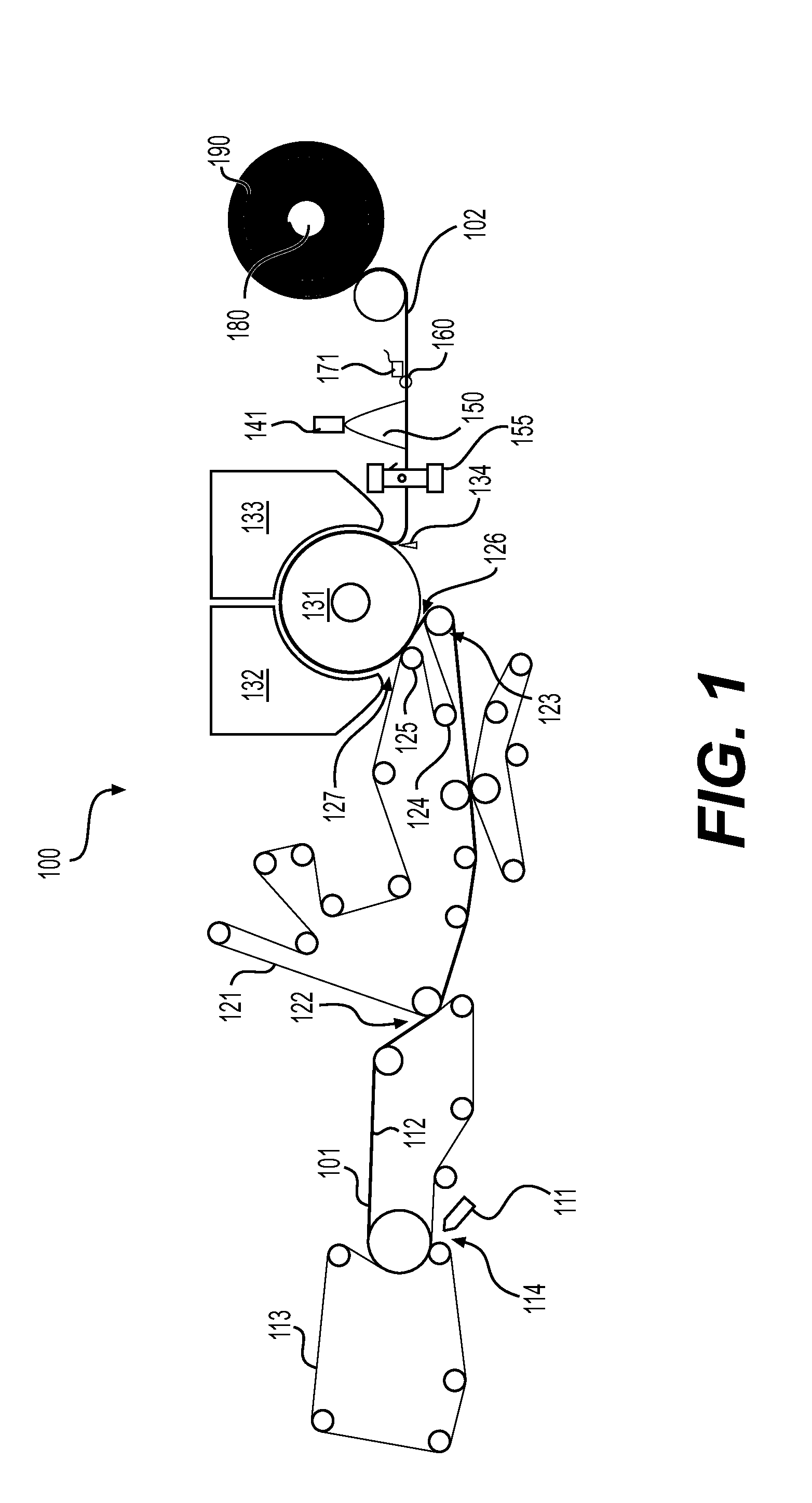

Methods and apparatuses for controlling a manufacturing line used to convert a paper web into paper products by reading marks on the paper web

ActiveUS20150292155A1Special visual effect coatingsLiquid surface applicatorsPulp and paper industryManufacturing line

Owner:GPCP IP HLDG LLC

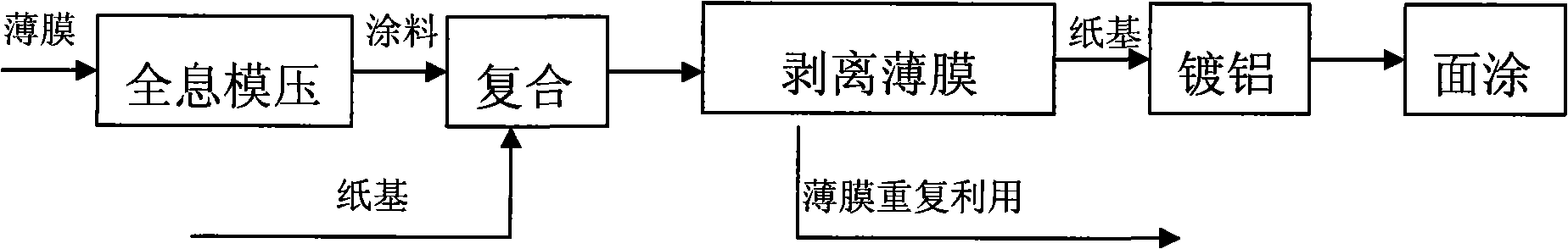

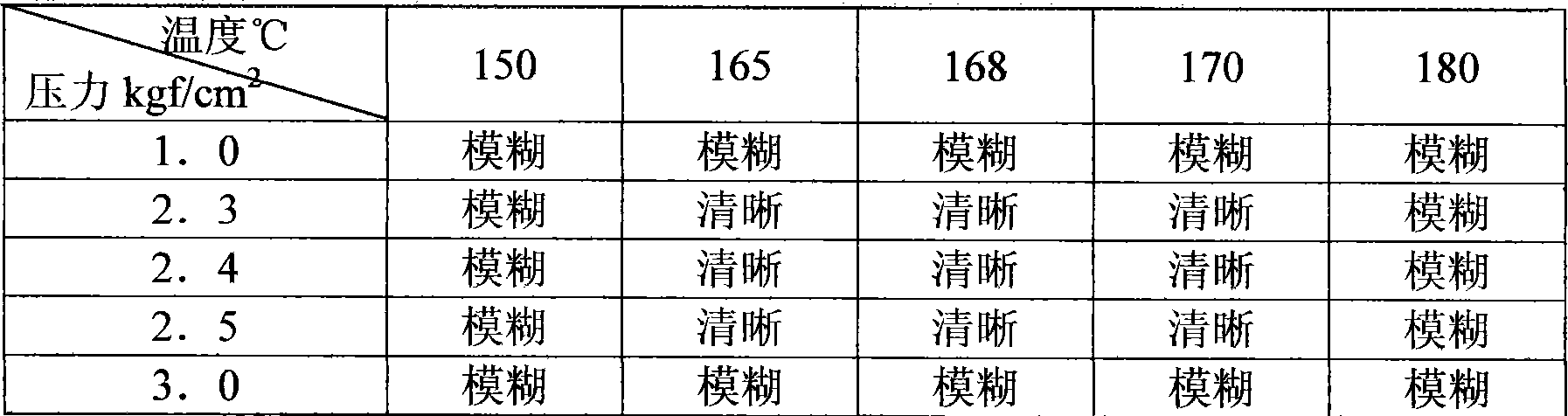

Method for preparing holography sputtering internal lining paper

InactiveCN101270557AImprove product qualityReduce defectsSpecial visual effect coatingsMechanical working/deformationPulp and paper industryWater requirement

The invention relates to a manufacture method for holographic direct plating lining paper which belongs to the technical field of an aluminum-plated paper manufacture method. The working procedures include: (1) providing a film; (2) carrying out laser holographic contour forging treatment on the film; (3) coating a layer of compound glue dope on the surface of the film with the holographic layer and then compounding with a lining paper base; (4) peeling off the film to obtain the paper base with holographic information and meeting the water requirements of aluminum plating; (5) plating aluminum on the coat of the paper base; (6) subsequent treatment of aluminum plating; core: compounding the coat printed with a holographic pattern on the paper base to replace the spreading pre-treatment on the paper base and directly carrying out vacuum aluminum plating on the surface of a dope layer. The invention has the effects that: 1, the quality of the holographic lining paper is high and completely removes various defects of the lining paper manufactured by a common direct plating method; 2 the technique step is simple; besides, as a BOPP film can be repeatedly used, the cost can be reduced, thus being suitable for batch manufacture; 3, compared with the common direct plating lining paper, the holographic pattern is added, thus being beneficial to anti-fake of the product and improving the grade of the product.

Owner:YANTAI BOYUAN TECH MATERIALS

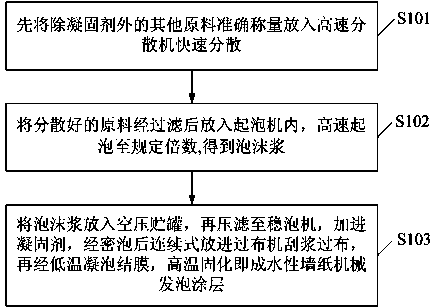

Foam coating glue of water-based wallpaper, preparation method thereof and wallpaper

InactiveCN104004473AImprove adhesionGood flexibilitySpecial visual effect coatingsSpecial paperWater basedPolymer science

The invention discloses a foam coating glue of water-based wallpaper. The foam coating glue includes 40-60% of a main body emulsion resin, 35-55% of a compounding agent and 1-10% of water. The main body emulsion resin is selected from one or more of neoprene latex, nitrile rubber latex, styrene-butadiene latex, water-based acrylate resin, water-based polyurethane resin and ethylene-vinyl acetate resin. The compounding agent includes a dispersing agent, an emulsifier, a thickening agent, a foam-starting agent, a foam-stabilizing agent, a foaming agent, a coagulating agent and a foam-densifying agent. Correspondingly, the invention discloses a preparation method of the foam coating glue of the water-based wallpaper and wallpaper prepared by using the foam coating glue of the water-based wallpaper. Through the preparation method, the foam coating glue of the water-based wallpaper is environmental-friendly and energy-saving, has an excellent foaming effect and can form an excellent-performance foam coating on the water-based wallpaper.

Owner:佛山市三水灏诚合成树脂有限公司

Method of making foam coated mat online

InactiveUS6875308B2Large fiber diameterNon abrasiveNatural cellulose pulp/paperSpecial paperFiberGlass fiber

A new foam coated nonwoven fibrous mat having properties particularly suited for a facer on gypsum wallboard, laminates made therefrom and the method of making the mat is disclosed. The mat preferably contains a major portion of glass fibers and a minor portion of a resinous binder. The foam coating is permeable and reduces fiber dust and abrasion experienced in the past with relatively coarse, relatively inexpensive glass fibers in the mat. Contrary to previous methods, the foam coated fibrous mat is made in-line on a wet mat forming production line by applying a wet foam binder onto a wet, fibrous web followed by drying and curing in-line.

Owner:JOHNS MANVILLE INT INC

Foam-paperboard laminates, articles incorporating same and methods of making the same

InactiveUS20060286325A1Increase speedReduce orientationDomestic containersThin material handlingPolymer sciencePaperboard

The present invention relates to foam-paperboard laminates (foam-paperboard laminates) prepared using an in situ foaming process. The foam-paperboard laminates of the present invention are formed by extruding LDPE polymer onto a moisture containing paperboard to provide a LDPE-coated paperboard material. Upon heating of the LDPE-coated paperboard, the moisture in the paperboard causes steam to act as a blowing agent for the LDPE and a LDPE foam is obtained. The foam is adhered to the paperboard by way of physical adhesion of the polymer to the paperboard. The foam-paperboard laminates of the present invention exhibit insulating and cushioning properties. The foam-paperboard laminates are suitable for use, for example, in insulating beverage cups, food service containers, packaging material, and in other products where laminates can be useful.

Owner:DIXIE CONSUMER PROD

Coated paper including a pseudo-watermark, and a method of manufacture

InactiveUS6630055B1Reduce thicknessNon-fibrous pulp additionNatural cellulose pulp/paperPulp and paper industryWetting

The present invention relates to a method of manufacturing a coated paper having at least one mark resembling a watermark, the method being characterized in that said mark is made after the drying step which follows the last coating operation, by performing steps in which: a) a re-wetting solution is applied to at least one face of the coated paper, in one or more determined zones; and b) pressure and heat are applied in said re-wetted zone(s) of the coated paper so as to evaporate said solution and densify the coated paper in said zone(s) relative to the remainder of the paper. The present invention also provides a coated paper including at least one mark resembling a watermark, characterized in that one or more determined zones of the coated paper present a reduction in thickness relative to the remainder of the coated paper, the density per unit area in said zone(s) of the coated paper being identical to that in the remainder of the paper.

Owner:ARJO WIGGINS PAPIERS COUCHES

Lotioned fibrous structures

InactiveUS20070071797A1Equal performanceThin applicationNon-fibrous pulp additionSpecial visual effect coatingsPolymer scienceFiber structure

Owner:THE PROCTER & GAMBLE COMPANY

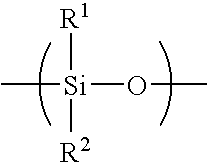

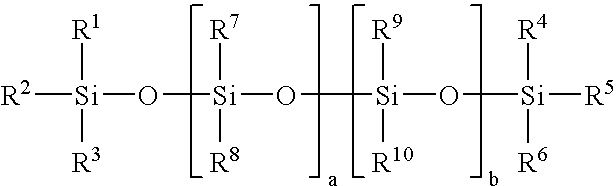

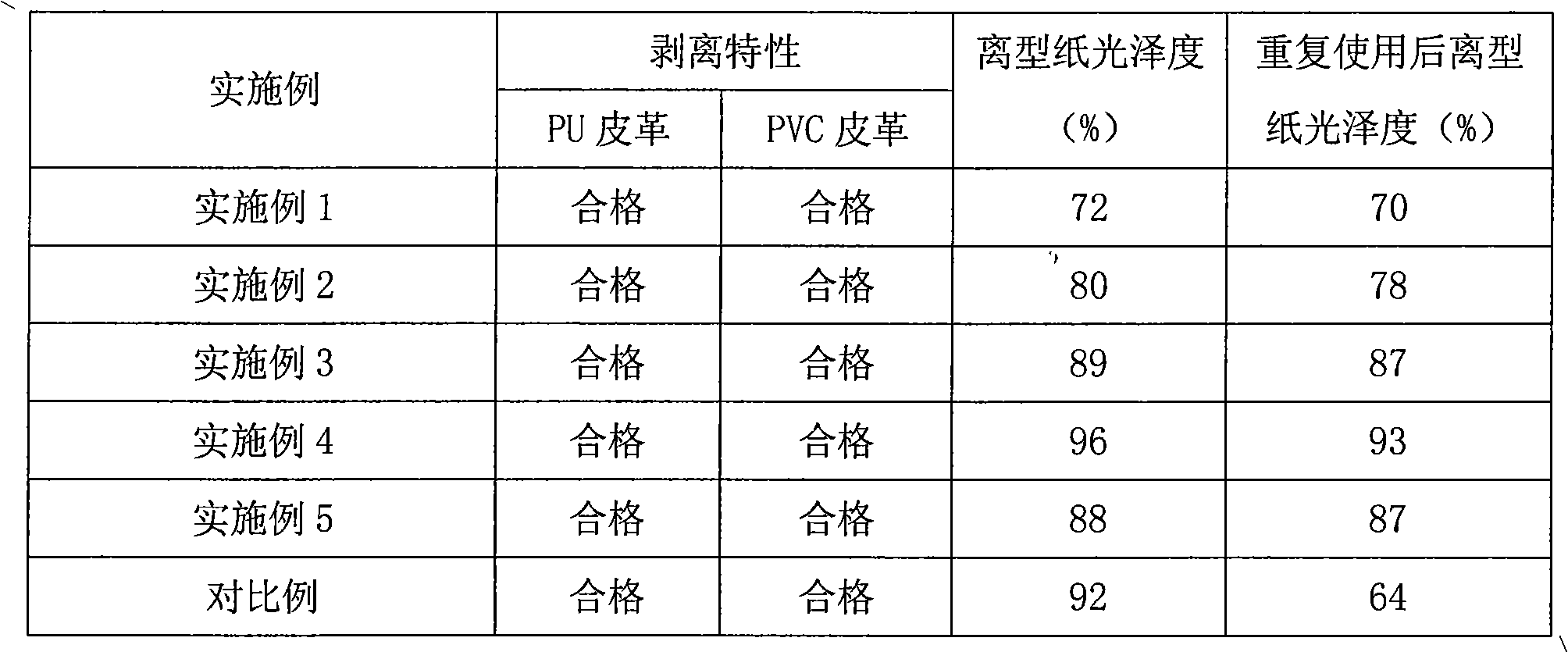

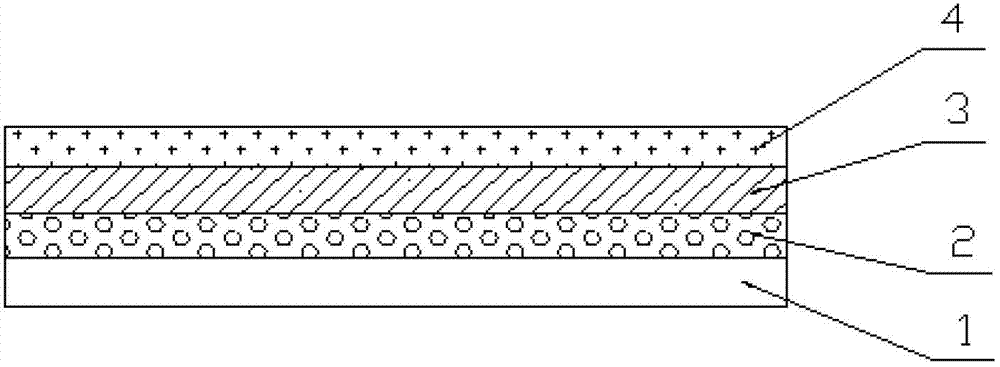

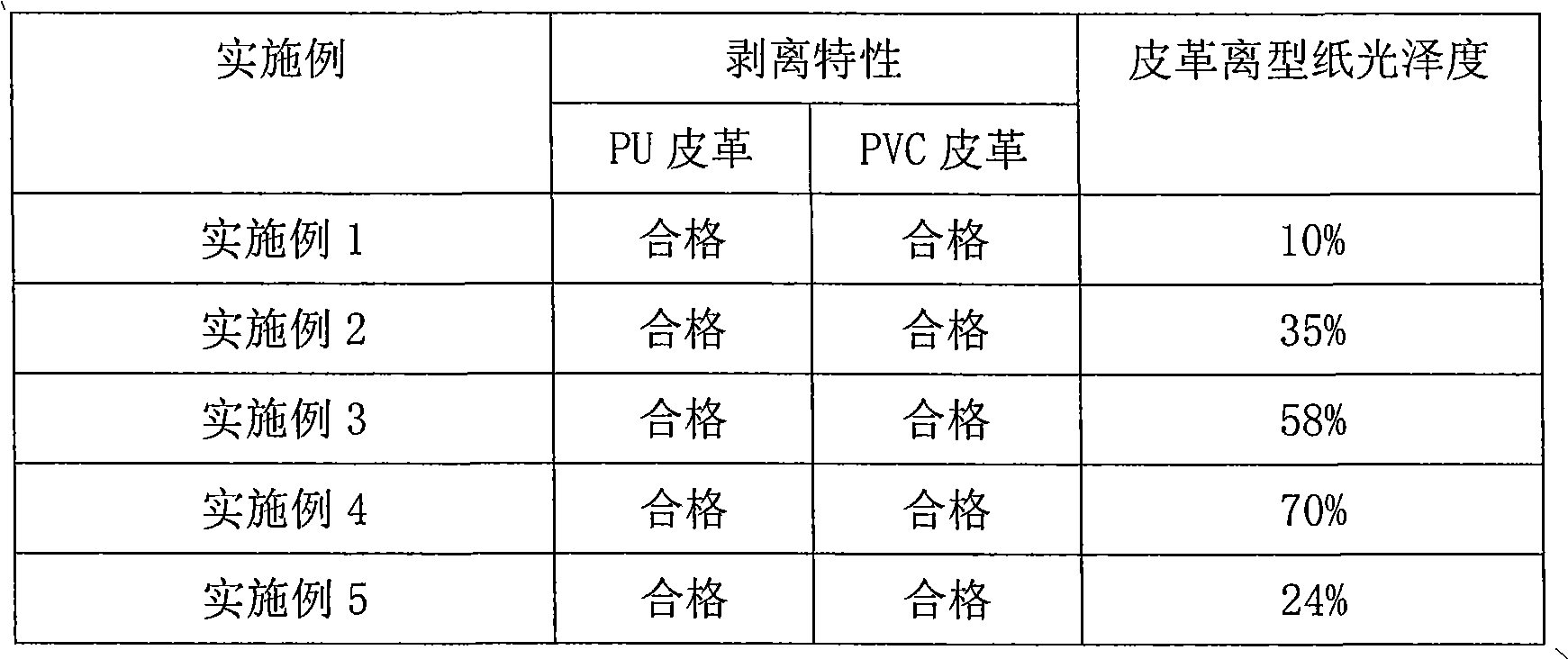

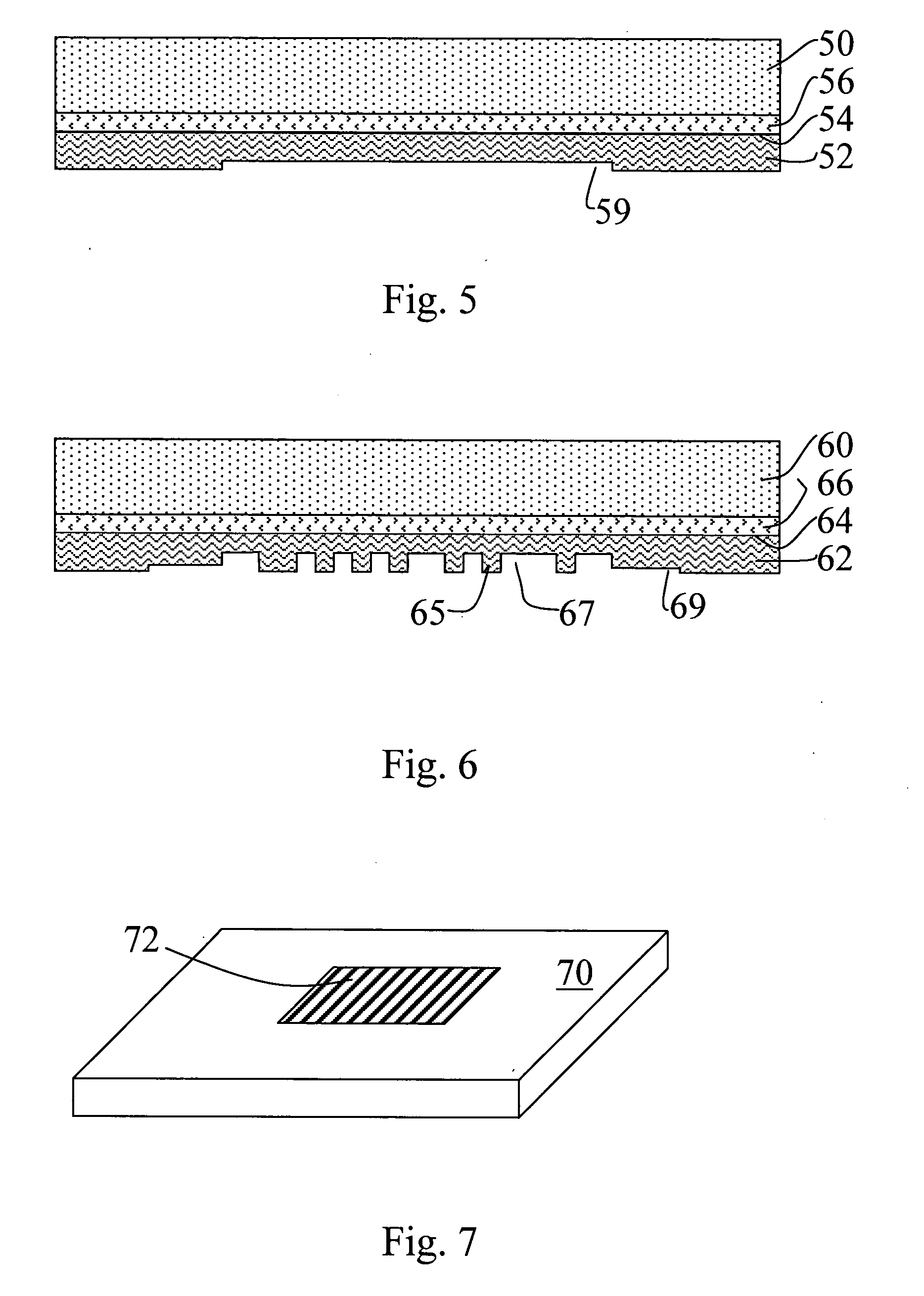

High-light release paper for synthetic leather

ActiveCN101565918ASimple structureGood lookingSpecial visual effect coatingsSurfactants additionInorganic particleAdhesive

A high-light release paper for synthetic leather is provided with a multi-functional layer between a substrate and a release layer; the multi-functional layer comprises 30 to 80 parts by weight of inorganic particles, 20 to 80 parts by weight of adhesives, 30 to 80 parts by weight of water, 1 to 8 parts by weight of dispersing agent, and 1 to 5 parts by weight of surfactant; and the forming materials of the release layer comprise alkyd modified silicone resin, melamine resin and acid catalyst. The invention has the advantages of low cost, good performance, excellent re-use performance, and over 70 percent of gloss for the angle of 60 degrees measured according to ISO-2813.

Owner:CHINA LUCKY FILM CORP +1

Preparing technological process of laser aluminum plating paper

ActiveCN101324040AHigh glossGood film formingSpecial visual effect coatingsDecorative surface effectsSurface tension gradientAdhesive

The invention relates to a process method for preparing laser aluminium-plated paper, comprising the steps as follows: OPP film or PET film is coated with a disjuncting layer which is coated with an imaging layer that is mould pressed with laser patterns; the mould pressing layer is coated with adhesive; the OPP film or the PET film is stripped and enwound by a stripping machine, thus obtaining a paper substrate containing the disjuncting layer, the imaging layer and the mould pressing layer; the paper substrate is directly plated with aluminium in vacuum and the aluminium is plated on the disjuncting coating layer; the aluminium-plated layer is coated with a waterborne environmental-protective profile coating protection layer; the laser aluminium-plated paper is obtained by moisture reobtaining and resolved shearing; the process of the invention reasonably chooses resin solvent and adhesive on the basis of a plurality of tests, simultaneously, the process of the invention utilizes suitable tenacity endowed by the molecular structure when the resin and the adhesive are in a coating state, and the performance of the adhesion to optimize the proportion according to the principle of combined surface tension gradient distribution between layers, thus forming the coating layer with high blare, good film-forming performance, environmental-protection and excellent printing performance and good alkali solution permeability simultaneously.

Owner:青州金青云新材料有限公司

Picture-grade high-light water-proof colour ink-jet printing paper

InactiveCN1814913AHigh transparencyHigh whitenessSpecial visual effect coatingsMetal coatingsPulp and paper industrySilicon

Photo-stage high brightness water-proof color ink-jet printing paper includes a basic material and a coat coated on it characterizing that said coat contains nm modified Al2O modified by a strong anode ion dispersing agent and a bonder, since the coat contains modified Al2O with the diameter of 30-80nm and inorganic silicon sol with the diameter smaller than 20nm, the invented paper can either absorb water ink or make the ink not to disperse.

Owner:SHANTOU XINXIE SPECIAL PAPER TECH

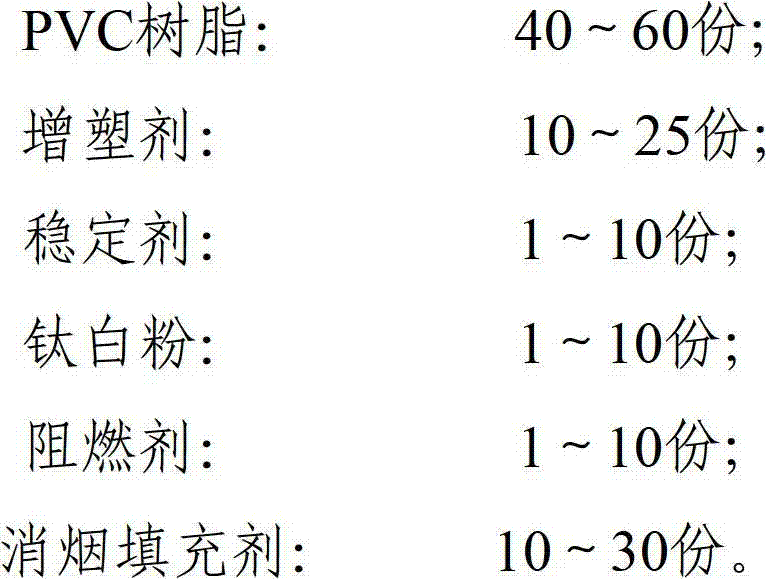

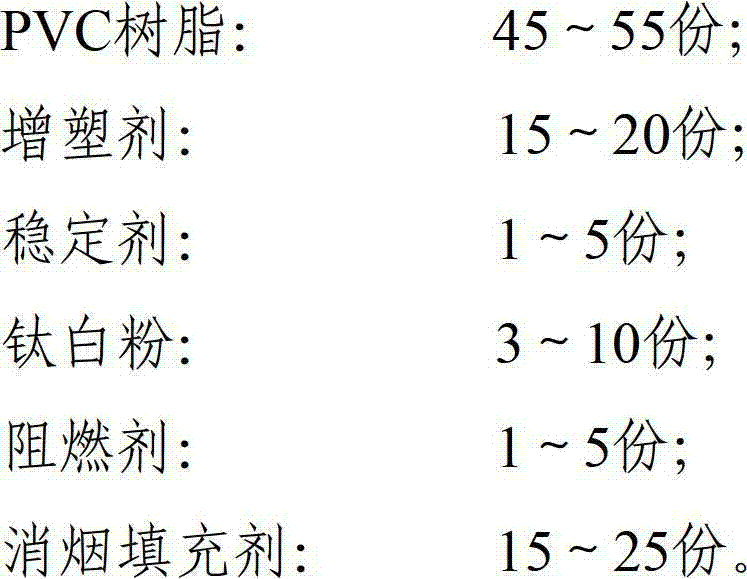

Flame retardant wallpaper and preparation method thereof

ActiveCN102926292AMeet the design requirementsLow toxicitySpecial visual effect coatingsCovering/liningsPolymer sciencePlasticizer

The invention relates to flame retardant wallpaper. The flame retardant wallpaper comprises a wallpaper substrate, a PVC (Poly Vinyl Chloride) layer, a printing layer and an embossing layer, wherein the PVC layer comprises PVC resin, a plasticizer, a stabilizer, titanium dioxide, a flame retardant and a smoke abatement filling agent. The invention also relates to preparation method of the flame retardant wallpaper. The flame retardant wallpaper provided by the invention adopts the novel flame retardant which is collaboratively compounded with the novel smoke abatement filling agent, thus being good in flame retardant effect and avoiding a highly toxic metal flame retardant. The preparation method provided by the invention is simple and convenient in process, can be used for obtaining the environmentally-friendly flame retardant wallpaper, is suitable for large-scale production, and has excellent economic value and social value.

Owner:BEIJING TOPLI DECORATIVE MATERIALS

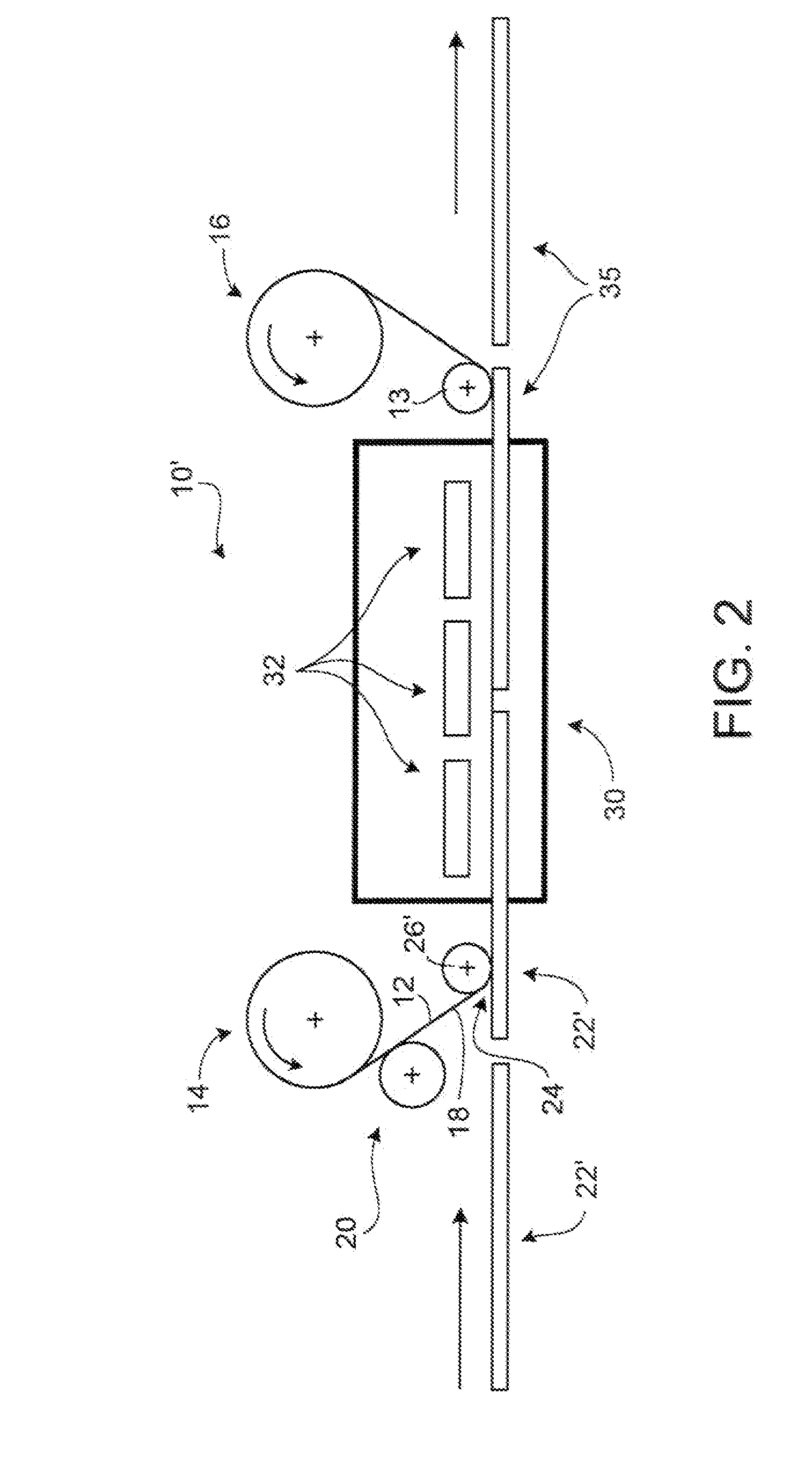

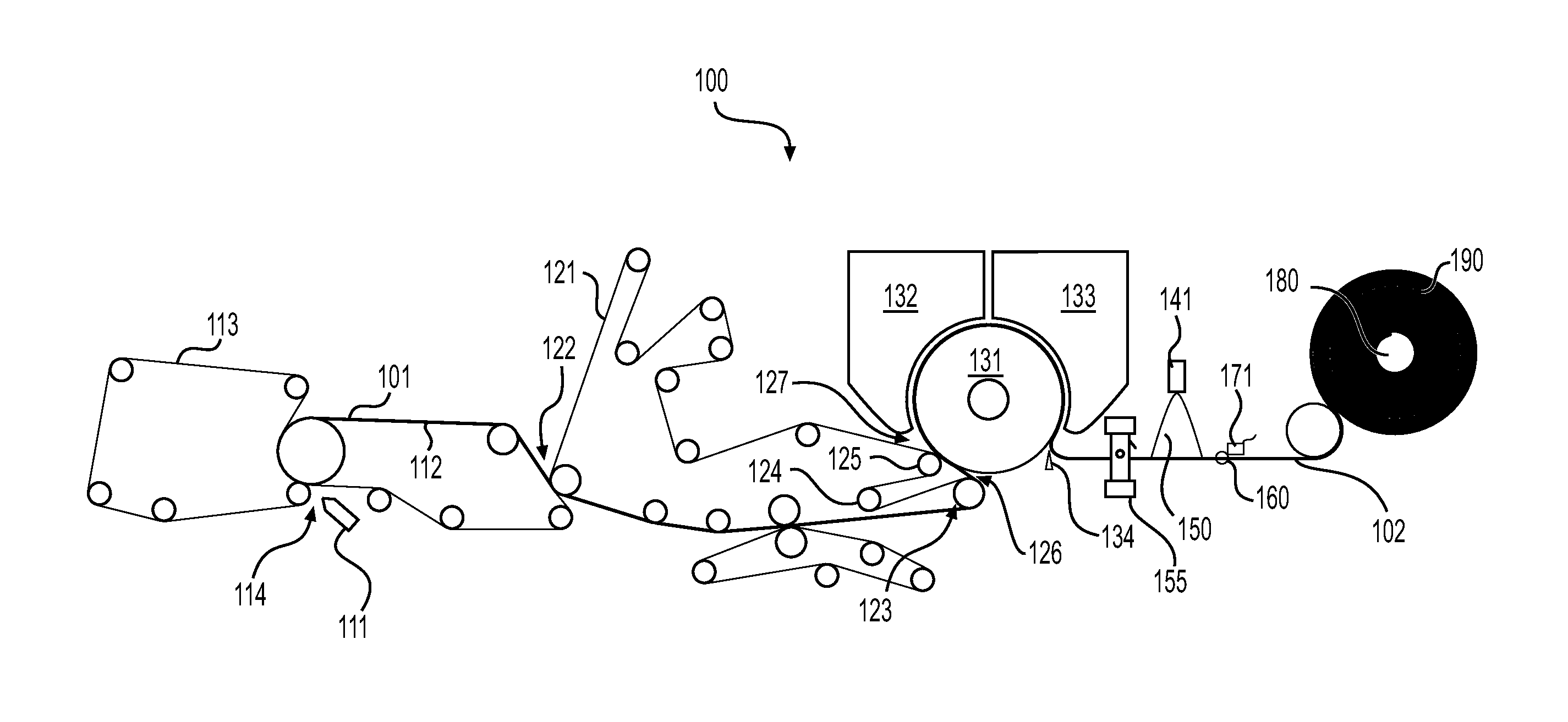

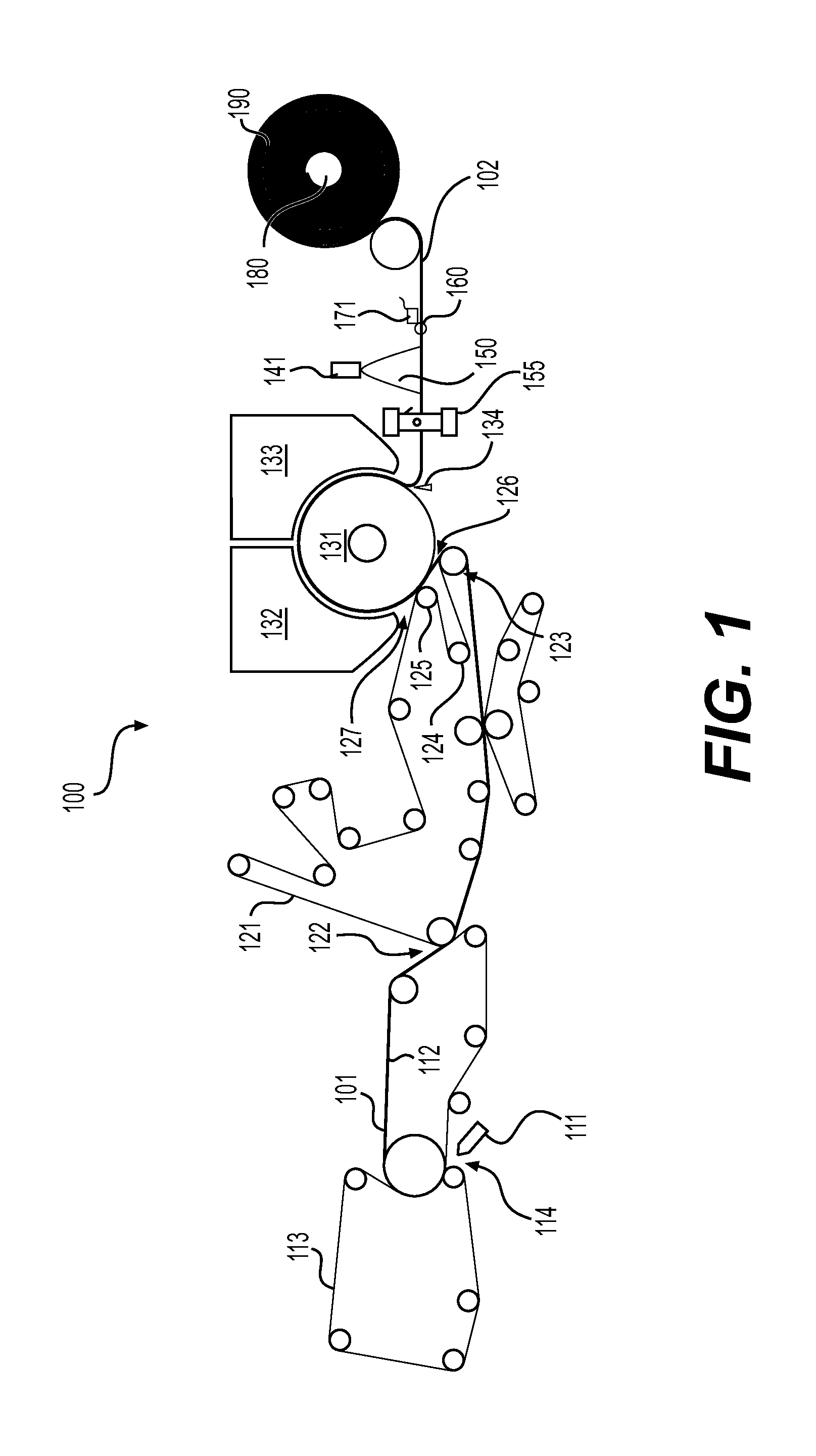

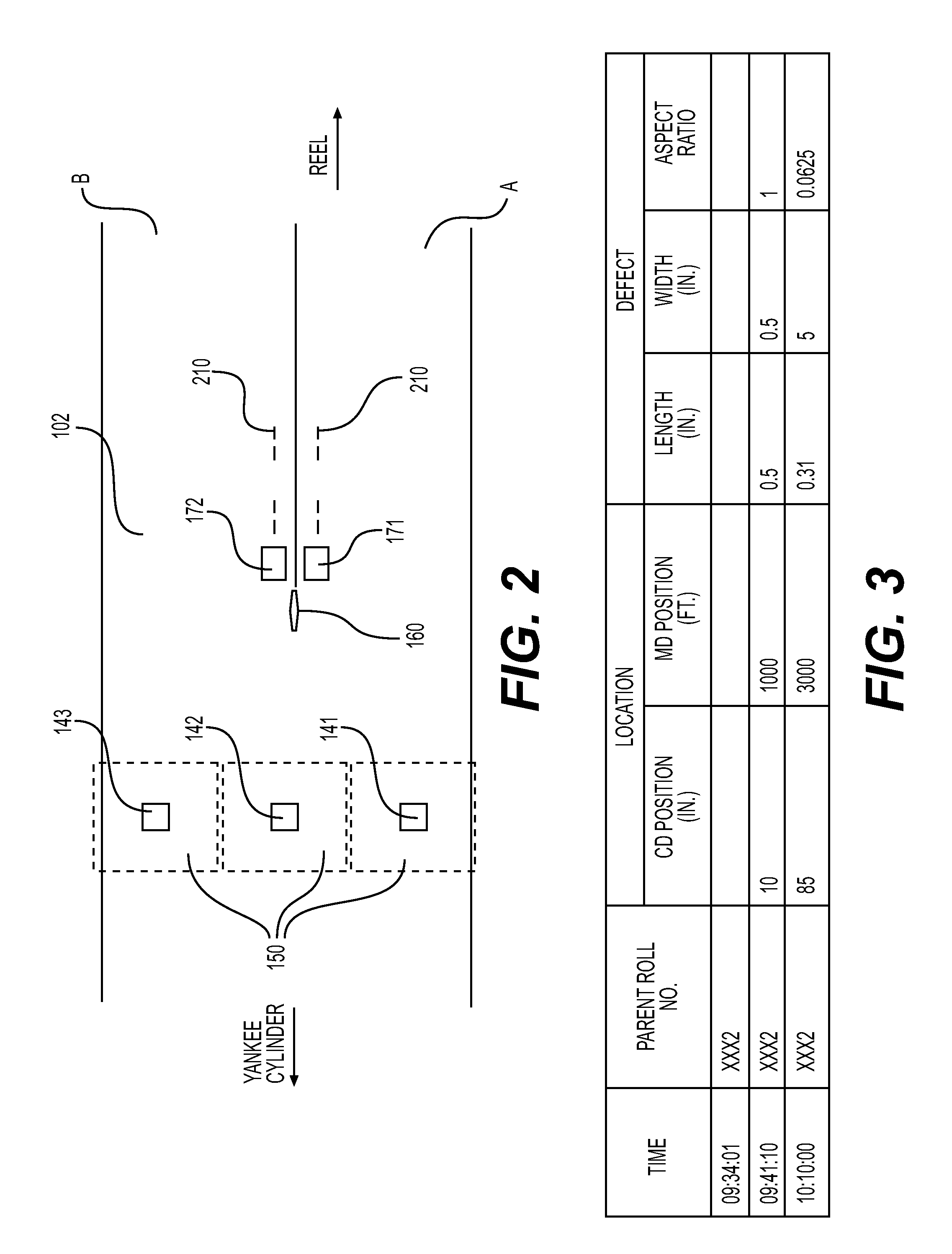

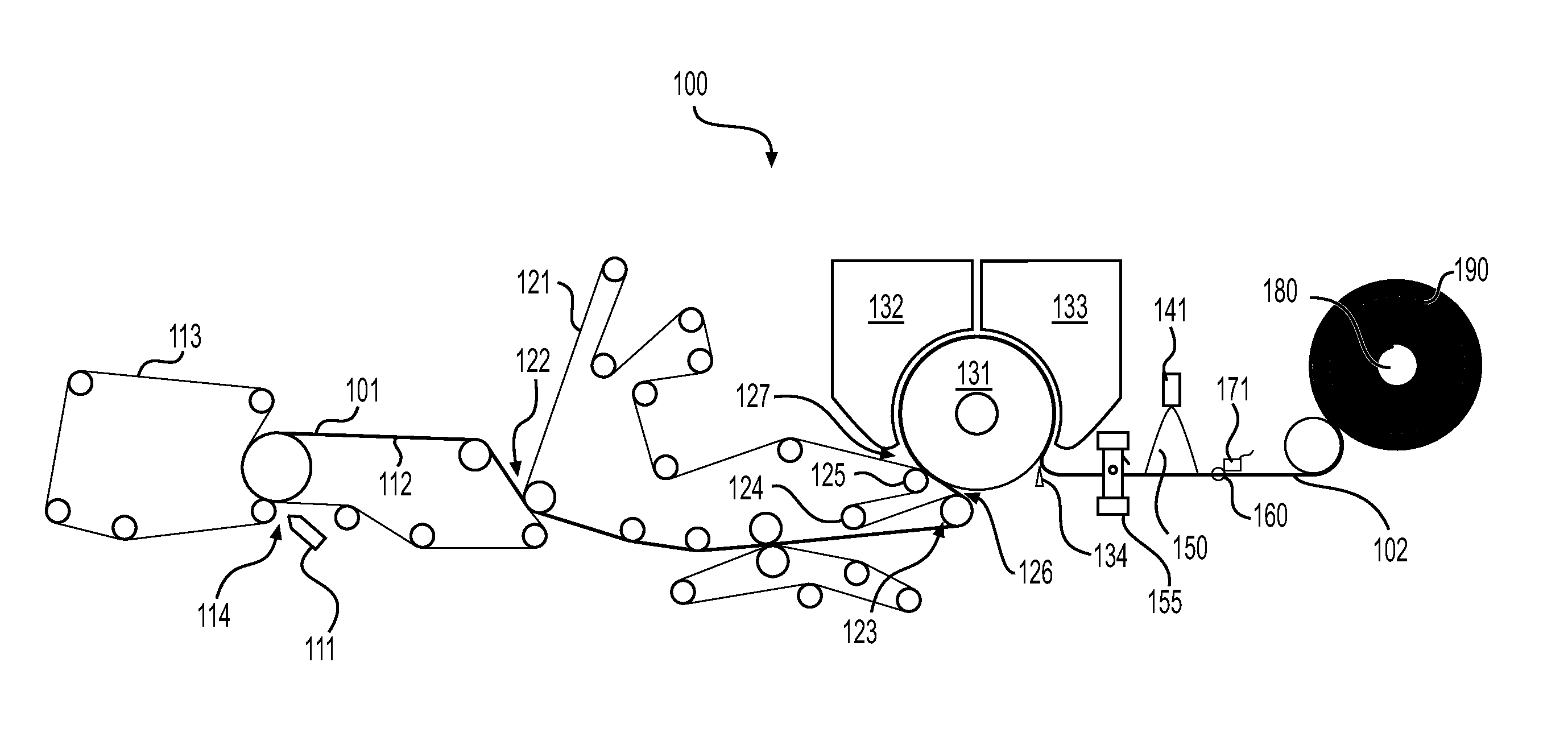

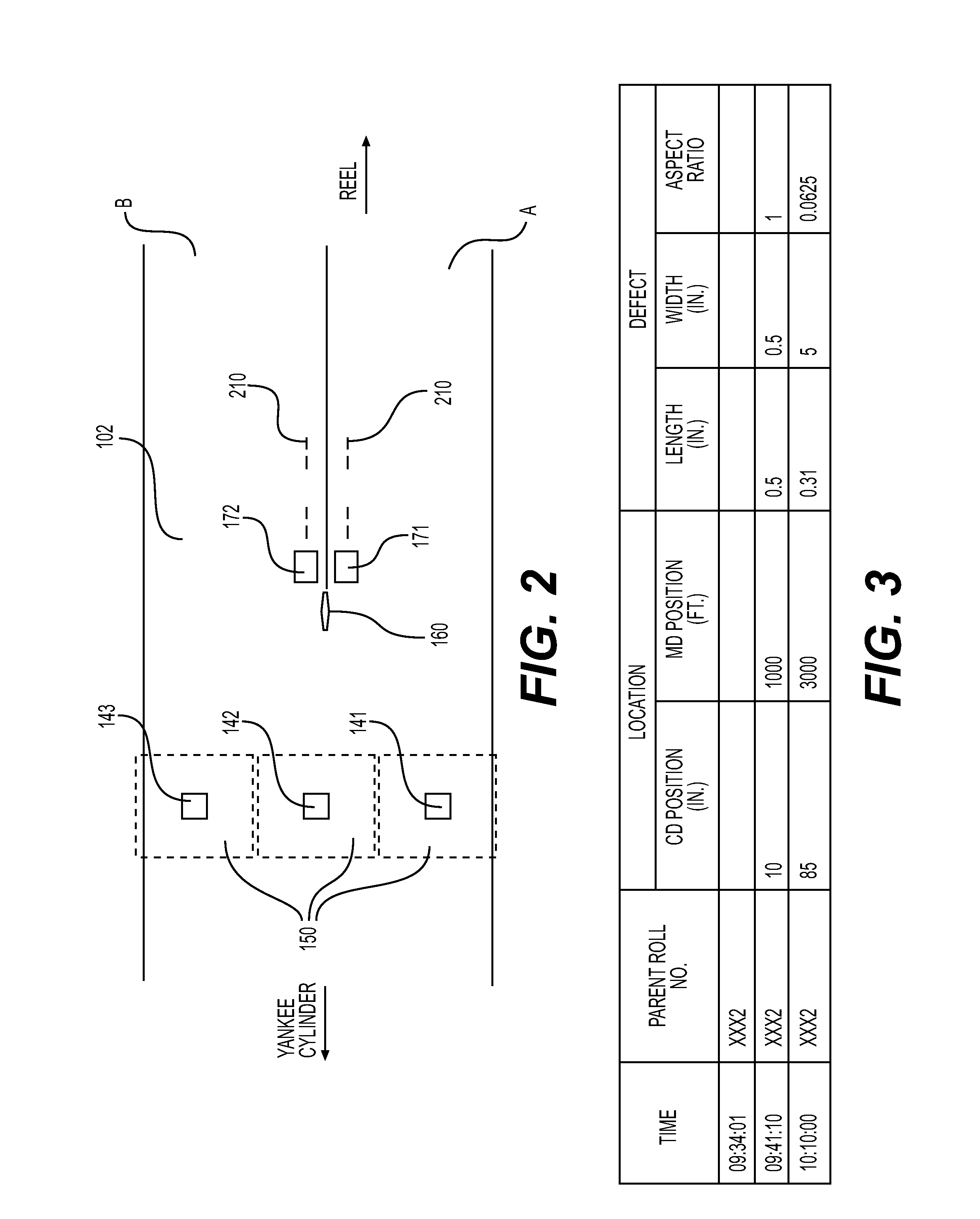

Methods and apparatuses for controlling a manufacturing line used to convert a paper web into paper products by reading marks on the paper web

ActiveUS20150292163A1Special visual effect coatingsLiquid surface applicatorsMarking outProcess engineering

A system for producing a paper product. The system includes a paper machine, an analysis tool, and a converting line. The paper machine forms a paper web having a plurality of sections, inspects the paper web to identify web properties, and marks the paper web with a plurality of marks. The analysis tool assigns action scores to each section of the paper web based upon the identified properties that section of the paper web. The converting line reads at least one of the plurality of marks on the paper web, obtains the action score associated with a second one of the plurality of marks, calculates a distance between the at least one mark read by the reading unit and the second one of the plurality of marks, and changes at least one operational parameter of the converting line when the calculated distance is less than a threshold.

Owner:GPCP IP HLDG LLC

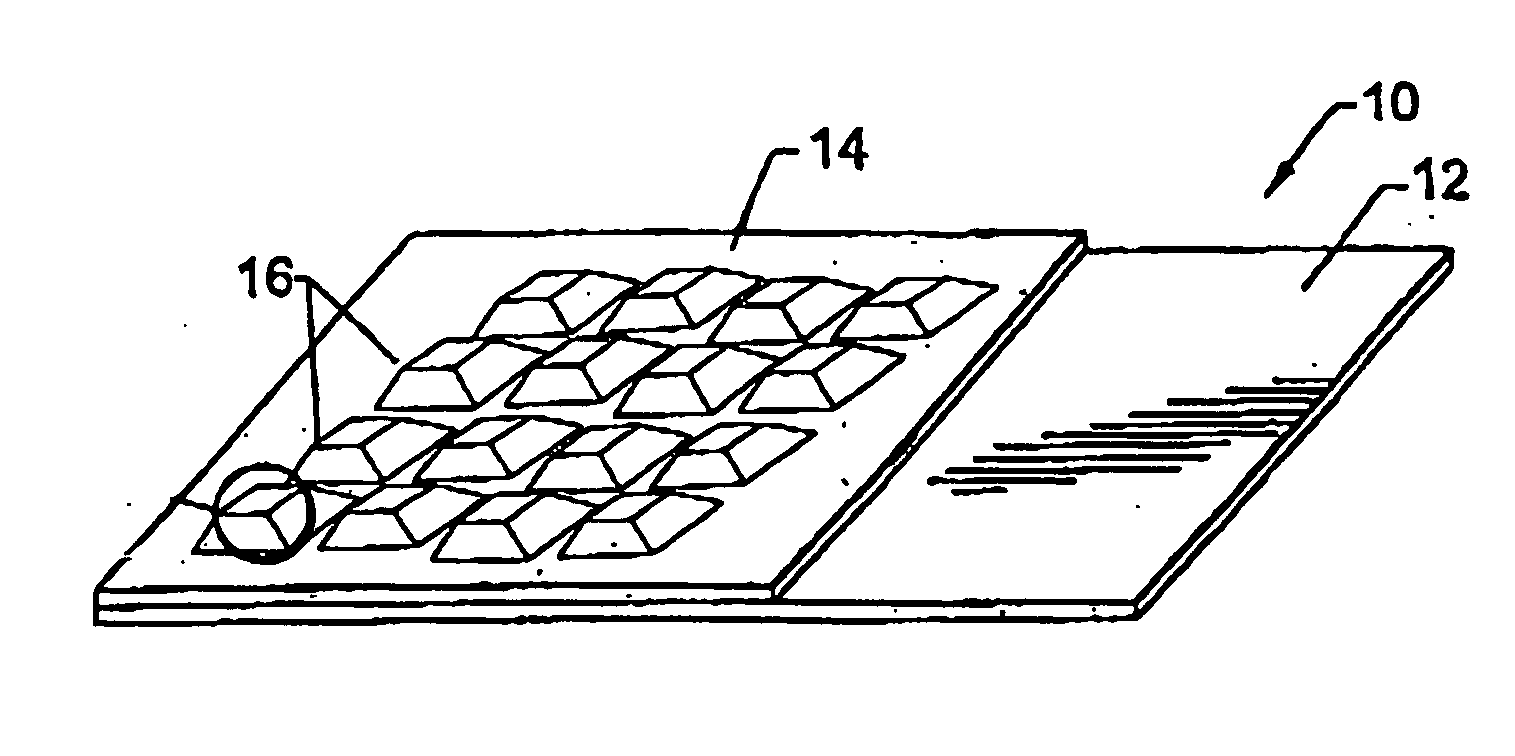

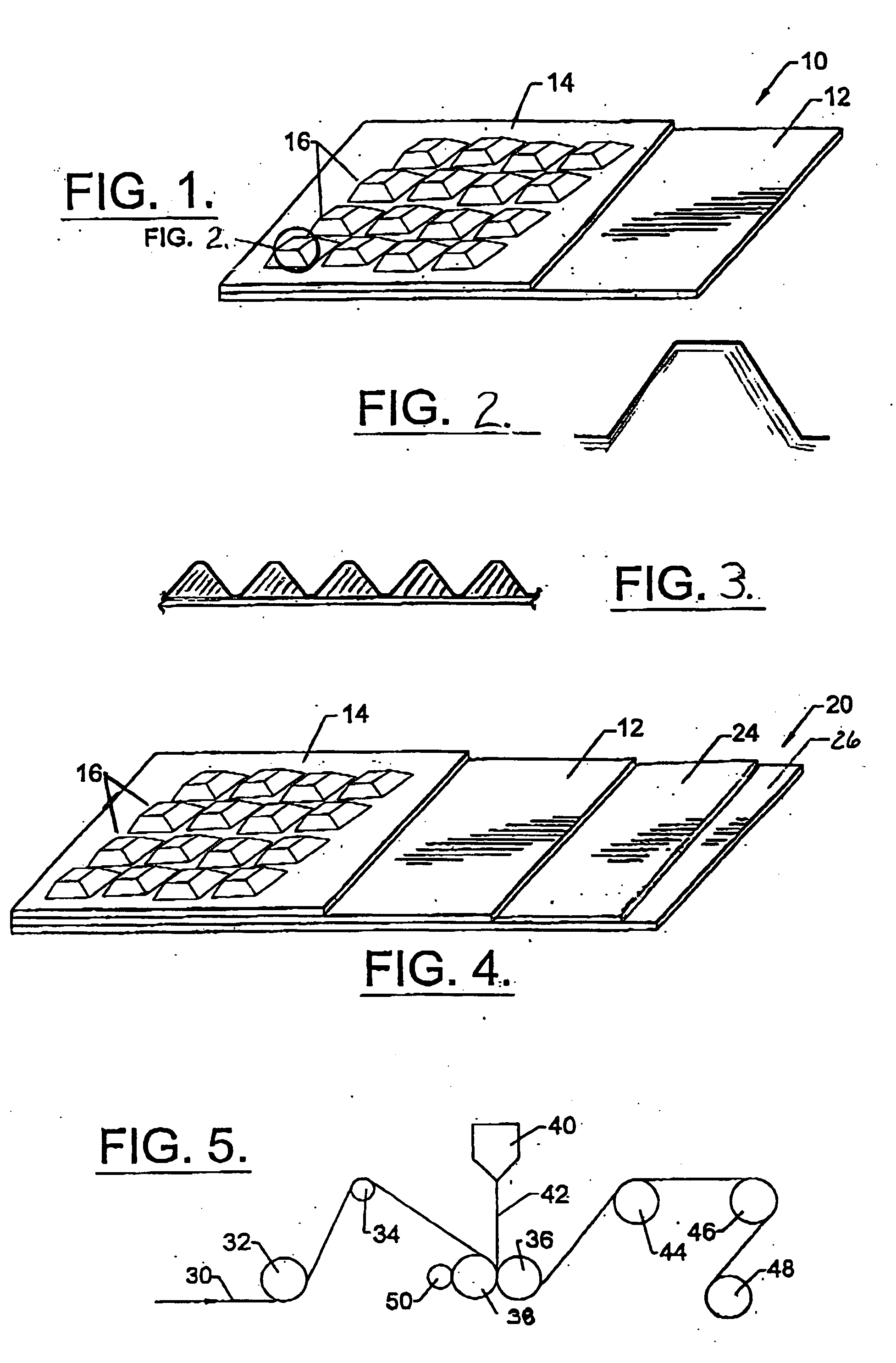

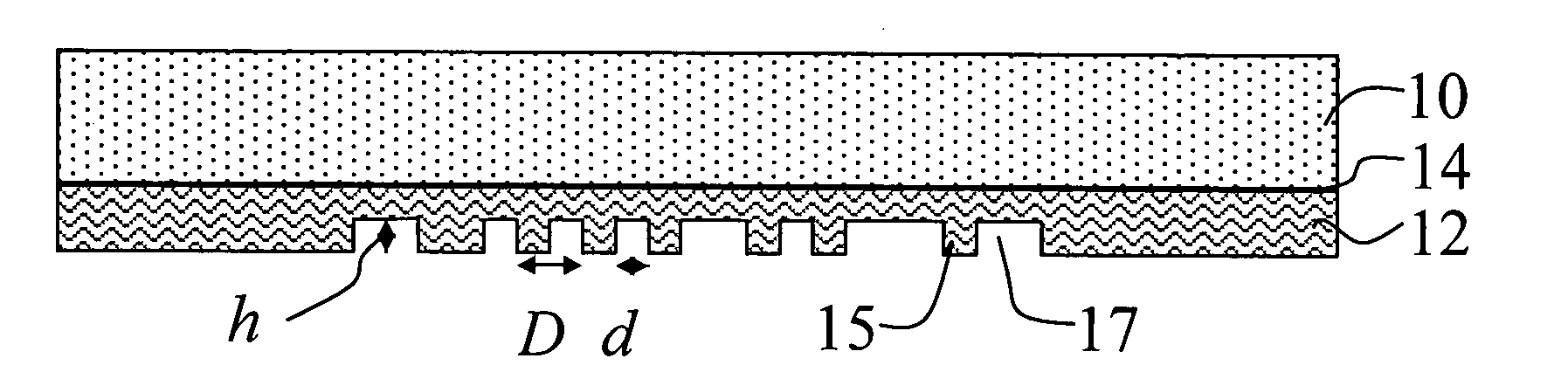

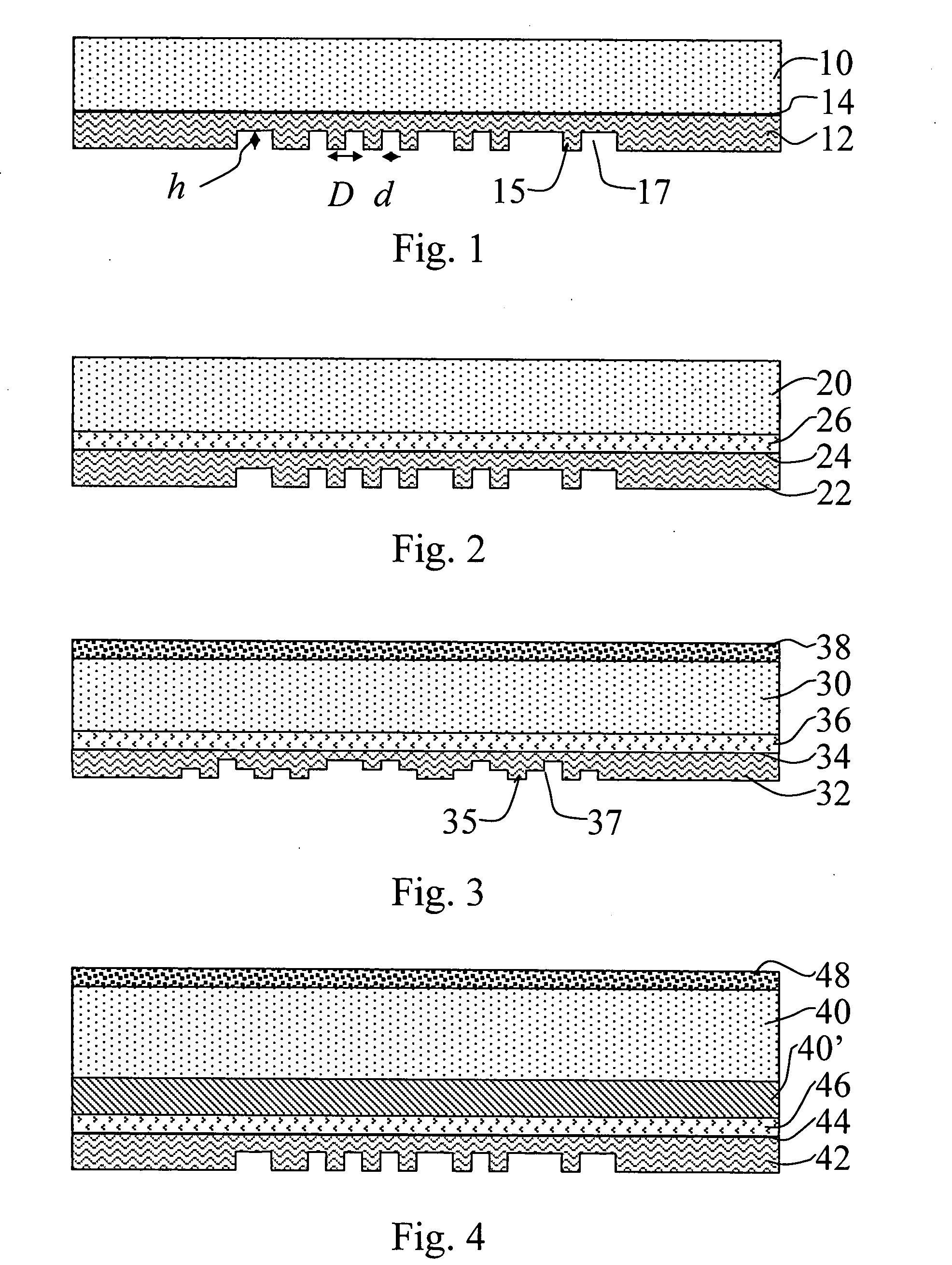

Engineered structured release liner and processes for making the same

InactiveUS20050074573A1Good at feeding propertySmooth and uniform appearanceDead plant preservationArtificial flowers and garlandsRegular patternPolyolefin

Highly roughened, precision engraved, patterned surface upon a substrate, preferably a polyolefin coated substrate, and processes for making the same. A chill roll is used to impart an engineered, highly structured surface upon the polyolefin coating of the substrate. The structured polyolefin coated substrates preferably have highly regular patterns, and those patterns may include either quadragravure, trihelical, or other regular, reproducible pattern.

Owner:LOPAREX

Matte release paper for synthetic leather

ActiveCN101565919AIncreasing the thicknessIncrease production costSpecial visual effect coatingsSurfactants additionInorganic particleAdhesive

A matte release paper for synthetic leather is characterized in that a multi-functional layer is arranged between a substrate and a release layer; the multi-functional layer comprises 30 to 80 parts by weight of inorganic particles, 20 to 80 parts by weight of adhesives, 30 to 80 parts by weight of water, 1 to 8 parts by weight of dispersing agent, and 1 to 5 parts by weight of surfactant; and the release layer comprises matting particles which account for 0.01 percent to 5 percent of the total weight of the release layer. The invention leads the product structure to be simpler and the cost to be lower, and obtains a release layer with controllable gloss by adding the matting particles.

Owner:CHINA LUCKY FILM CORP +1

Novel Markings and Method of Producing the Same

InactiveUS20080145620A1Simplified and cost-effective techniqueSpecial visual effect coatingsMechanical working/deformationCardboardEngineering

The invention relates to a method for producing a visually identifiable diffractive pattern on a substrate by subjecting the substrate to pressure by bringing it into contact with a surface of an embossing plate. An imprinted paper or paperboard sheet, which is varnished at the contacting area of the embossing plate and the substrate is used as a substrate for the embossing. The invention relates also to a product manufactured using the described method. The method is applicable, for example, for common packaging materials, which contain a paperboard, imprinting and a varnish layer for producing a visually attractive and unique marking.

Owner:M REAL OYJ

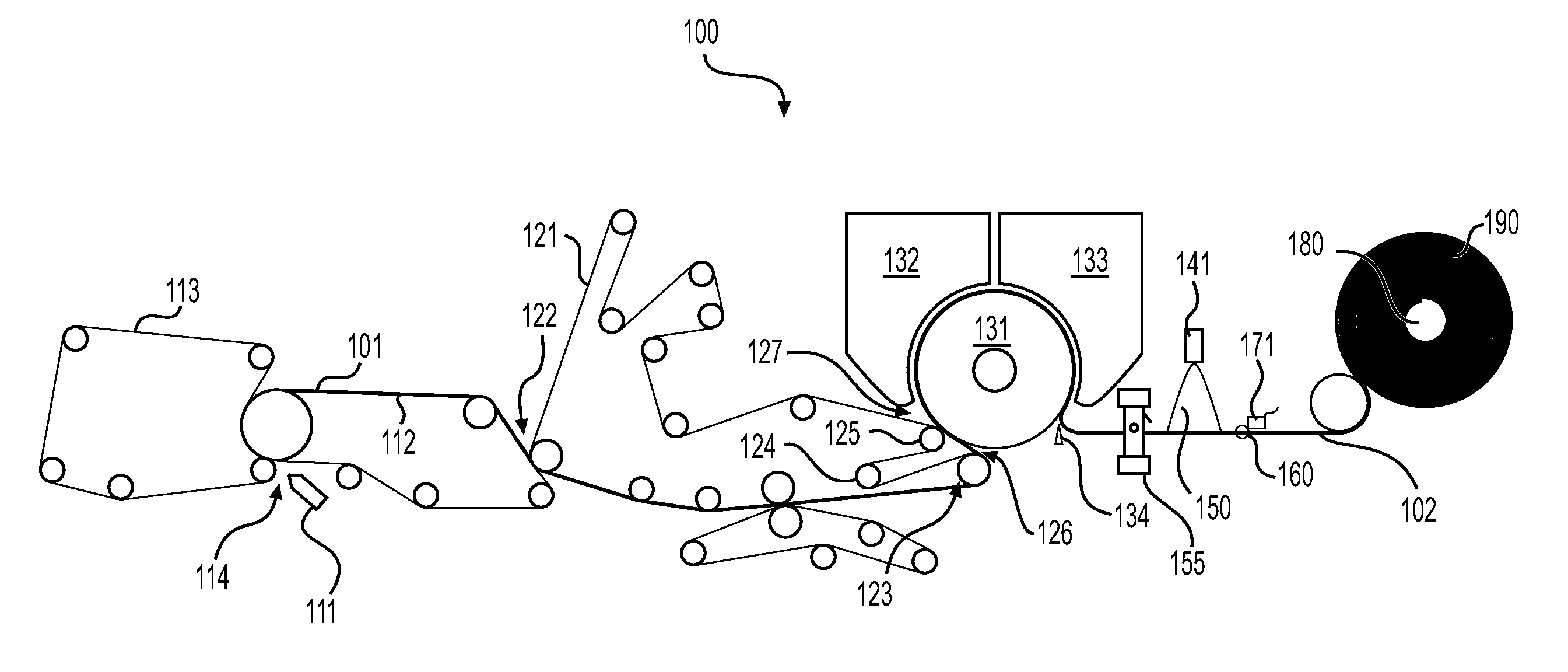

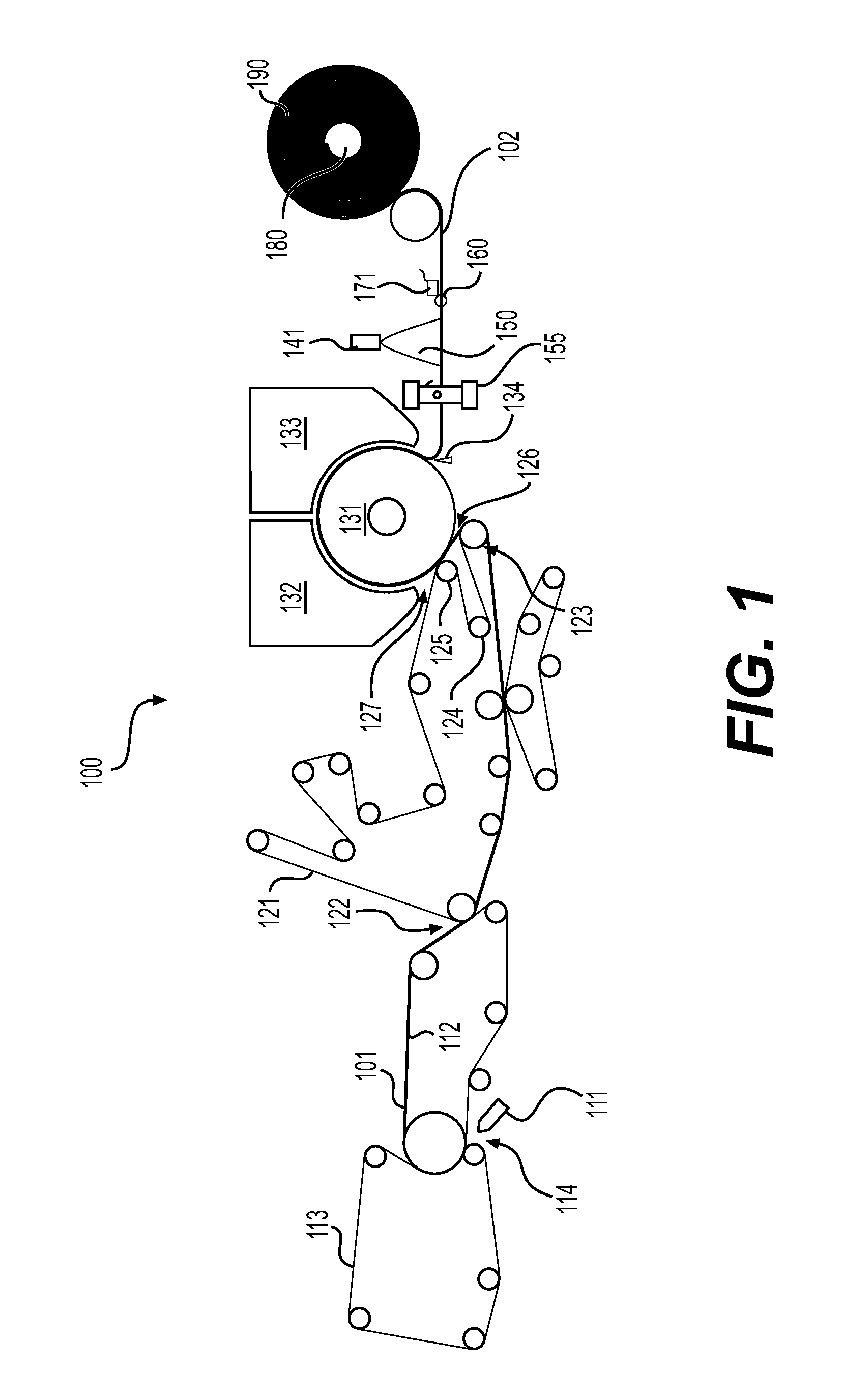

Methods and apparatuses for controlling a manufacturing line used to convert a paper web into paper products by reading marks on the paper web

ActiveUS9518362B2Special visual effect coatingsLiquid surface applicatorsMarking outProcess engineering

A system for producing a paper product. The system includes a paper machine, an analysis tool, and a converting line. The paper machine forms a paper web having a plurality of sections, inspects the paper web to identify properties, and marks the paper web with a plurality of marks, at least one mark being assigned to each of the plurality of sections. The analysis tool assigns a paper rating to each section of the paper web based upon the identified properties in that section of the paper web. The converting line has a plurality of operational parameters and converts the paper web into the paper product. The converting line reads at least one of the plurality of marks on the paper web, obtains the paper rating associated with the mark read, and changes at least one operational parameter of the converting line based upon the paper rating.

Owner:GPCP IP HLDG LLC

Coated paper

InactiveUS20040265542A1Inhibit the generation of cracksEasy to set upLayered productsTraffic signalsEngineeringGlass transition

A coated paper comprised of a paper substrate, at least one surface of which is provided with at least one coating layer, characterized in that the surface of said coating layer has cracks of a width of 0.2 to 3.0 mum and a length of 3 to 1000 mum in an amount of 1 to 1000 cracks per mm<2 >is provided. In another embodiment, a coated paper comprised of a paper substrate, at least one surface of which is provided with at least two coating layers, characterized in that an inner coating layer adjoining said paper substrate comprises a pigment having a crystal structure selected from the group consisting of acicular crystal, spindle-shape crystal, columnar crystal, and rice-shape granulated crystal, and starches, and an outermost coating layer formed on said inner coating layer comprises crack formation promoting particles and a styrene-butadiene copolymer having a glass transition temperature of 20 to 150° C. is provided.

Owner:OJI PAPER CO LTD

Non-woven embossed wallpaper

InactiveCN103215859ANot easy to fall offMeet the consumption levelSpecial visual effect coatingsSpecial paperFiberPolyvinyl chloride

The invention discloses non-woven embossed wallpaper which solves the problems that a foaming layer of the traditional wallpaper is thin easily falls off from a printing layer. The non-woven embossed wallpaper is characterized by being made by adopting a secondary foaming process, namely, a PVC (Polyvinyl Chloride) coating is coated on the surface of fiber non-woven paper to carry out primary foaming, an inhibitor is used for inhibiting, so that an area on which the inhibitor is coated cannot be foamed due to high temperature, and therefore a required wallpaper pattern is obtained; and a PVC sizing agent is used for carrying out secondary foaming, so that the product of which the foaming height can reach 0.5mm at most can be obtained. According to the non-woven embossed wallpaper, a foaming layer is thick and difficulty falls off, the stereoscopic impression is strong, the texture is soft, the sense of touch is good, the patterns are distinct, the cleaning is convenient, and non-woven embossed wallpaper can be directly scrubbed.

Owner:HUAIBEI NUOFEIYA NEW MATERIAL WALLPAPER

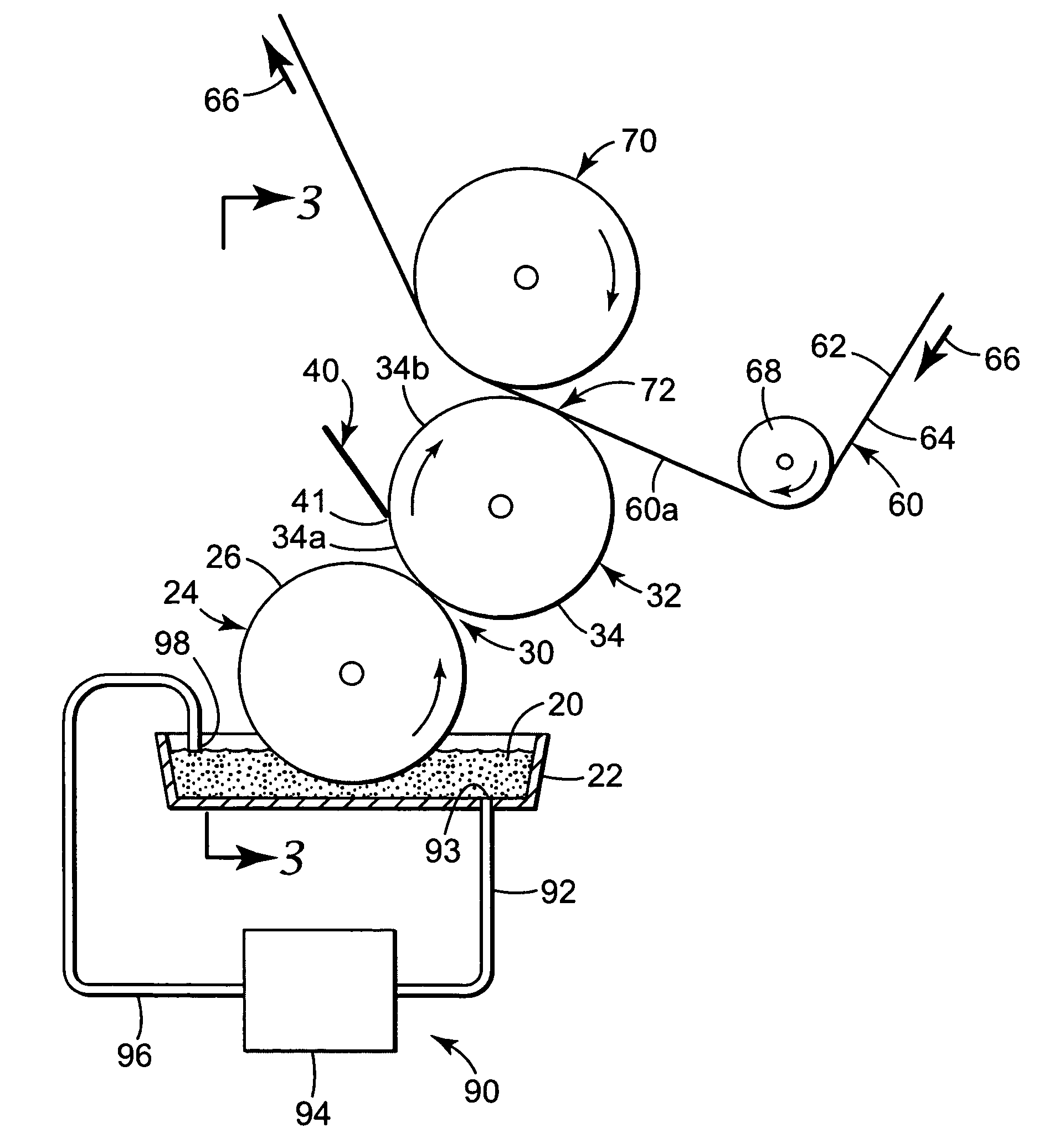

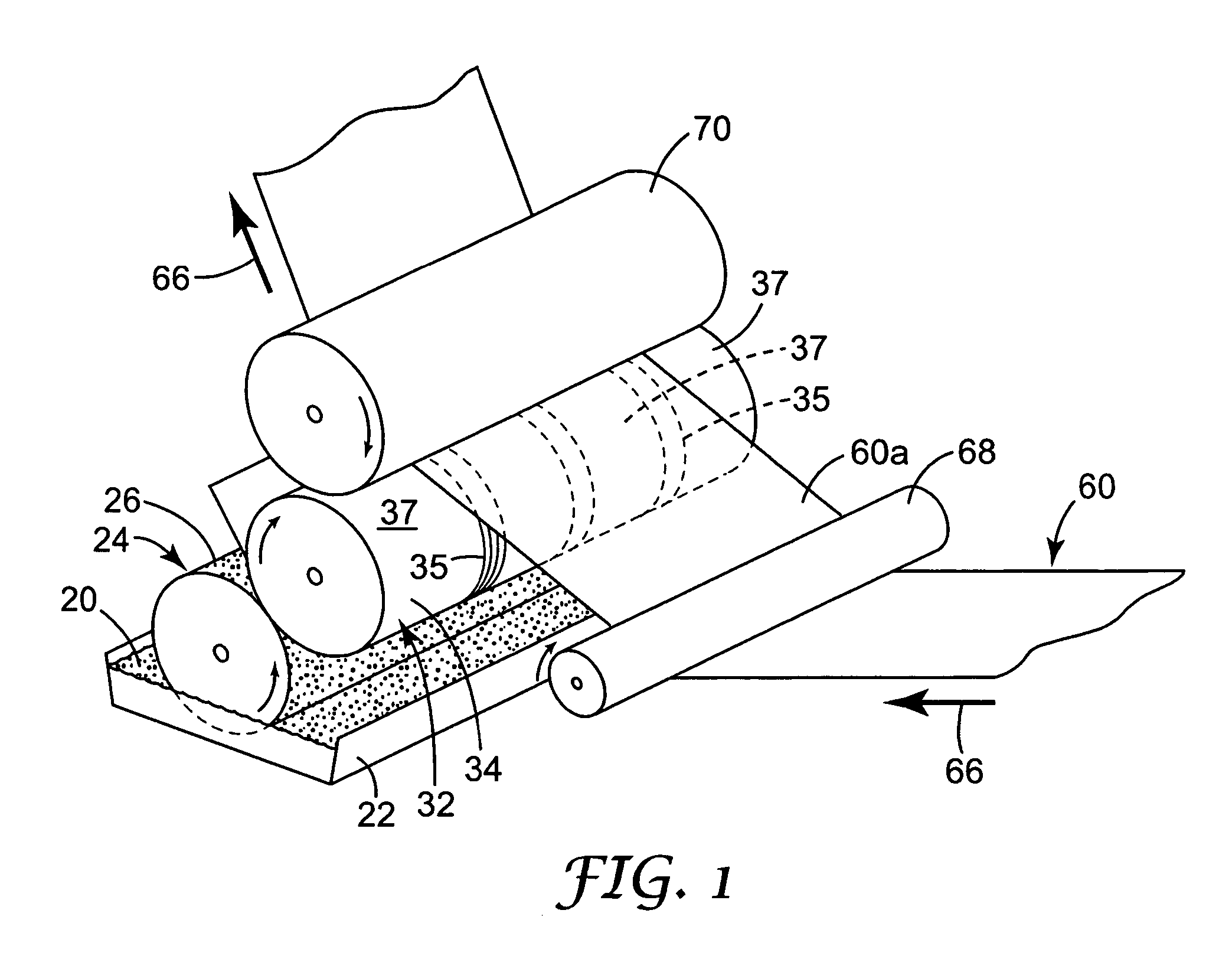

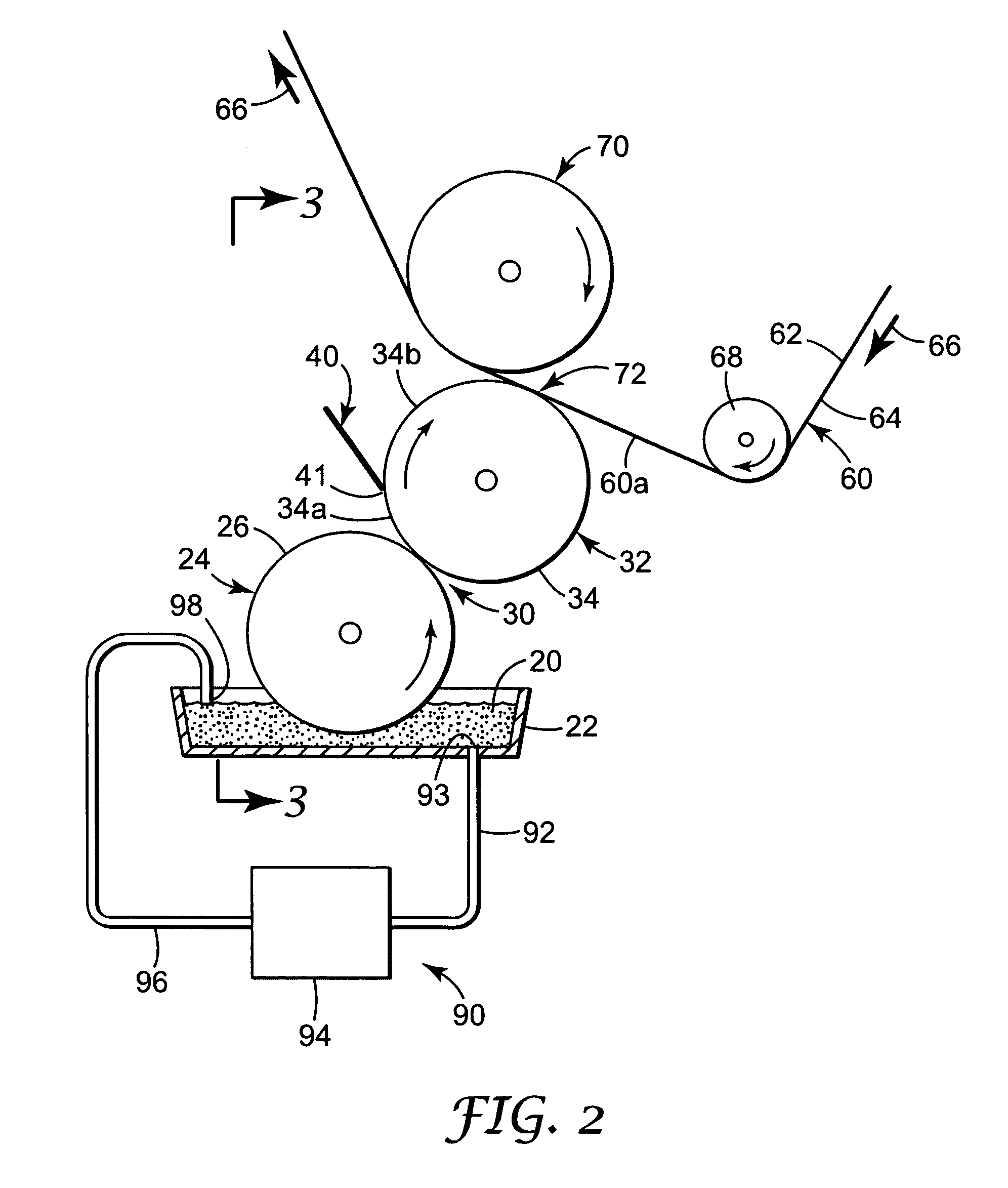

Method for defining a coating fluid pattern

InactiveUS20060147637A1Limited amountNon-fibrous pulp additionSpecial visual effect coatingsMicrosphereTopography

A method of defining a pattern of coating fluid on a surface includes introducing coating fluid containing microspheres onto a surface of an applicator roll, wherein the topography of the applicator roll surface comprises at least one longitudinally extending circumferential, helical groove portion which is sized to at least partially receive the microspheres of the coating fluid therein, and at least one circumferential, longitudinally extending smooth surface portion. The method further includes engaging the applicator roll surface with a doctor blade to remove coating fluid from the smooth surface portions thereof and to limit the amount of microspheres advanced past the doctor blade by the helical groove portion of the applicator roll surface. Thus, a pattern of coating fluid containing microspheres remains on the applicator roll surface which is defined by the helical groove portion thereon and is formed to define at least one stripe of coating fluid containing microspheres. The pattern of coating fluid is transferred from the applicator roll surface to a moving web by a reverse kiss coating.

Owner:3M INNOVATIVE PROPERTIES CO

Methods and apparatuses for controlling a manufacturing line used to convert a paper web into paper products by reading marks on the paper web

ActiveUS20150292162A1Special visual effect coatingsLiquid surface applicatorsProduction linePulp and paper industry

A converting line for producing a paper product. The converting line includes a paper web being unwound from a parent roll. The paper web has a plurality of sections with at least one mark, associated with an action score, assigned to each of the plurality of sections. The converting line also includes a mark reading unit, which reads one of the plurality of marks on the paper web. The converting line further includes a controller configured to obtain the action score associated with a second one of the plurality of marks; to calculate a distance between the one mark read by the reading unit and the second one of the plurality of marks; and to change at least one operational parameter of the converting line based upon the action score of the second one of the plurality of marks when the calculated distance is less than a threshold.

Owner:GPCP IP HLDG LLC

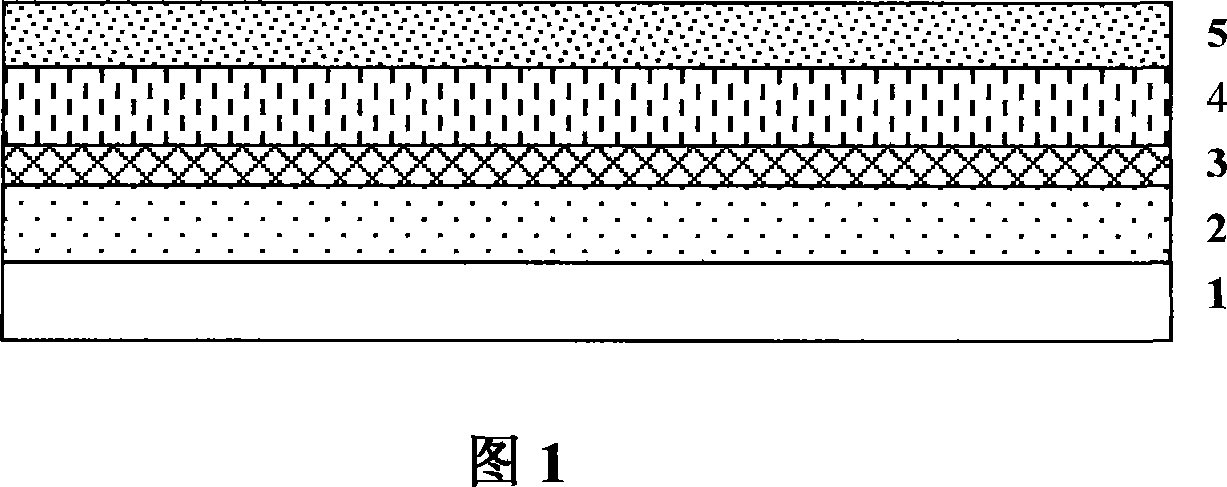

Packing paper with micro-sign for cigarette and producing method thereof

ActiveCN101168943AImprove identification rateBright metal textureSpecial visual effect coatingsFlexible coversCigarette usePulp and paper industry

The invention relates to cigarette packing tipping paper, in particular to a production method of a cigarette-purpose tippling paper with a laser microfilm anti-counterfeit sign. The tipping paper comprises a bottom layer, a binding layer, an aluminum coating, a surface coating and a printing layer which are mutually compounded in sequence, wherein, a microfilm anti-counterfeit sign composed of a microfilm character or a RMB paper money line is arranged on a surface coating, and the size of the microfilm anti-counterfeit sign can reach 0.2 mm. The invention has the production method of the cigarette-purpose tipping paper with the microfilm anti-counterfeit sign that a strippable surface coating is coated on a high molecule light film in advance, and then the laser microfilm anti-counterfeit sign which forms an aluminum transferring film after vacuum aluminum coat is molded and is compounded with the original paper, then various patterns are printed after uncovering the light film, and therefore the cigarette-used tippling paper with the laser microfilm anti-counterfeit sign can be obtained. The product of the invention has nicer anti counterfeit performance.

Owner:JIANGSU DAYA NEW PACKAGING MATERIALS

Methods and apparatuses for controlling a manufacturing line used to convert a paper web into paper products by reading marks on the paper web

ActiveUS20150292161A1Non-fibrous pulp additionLayered productsPulp and paper industryManufacturing line

Owner:GPCP IP HLDG LLC

Methods and apparatuses for controlling a manufacturing line used to convert a paper web into paper products by reading marks on the paper web

ActiveUS20150292156A1Non-fibrous pulp additionNatural cellulose pulp/paperMarking outProcess engineering

A system for producing a paper product. The system includes a paper machine, an analysis tool, and a converting line. The paper machine forms a paper web having a plurality of sections, inspects the paper web to identify properties, and marks the paper web with a plurality of marks, at least one mark being assigned to each of the plurality of sections. The analysis tool assigns a paper rating to each section of the paper web based upon the identified properties in that section of the paper web. The converting line has a plurality of operational parameters and converts the paper web into the paper product. The converting line reads at least one of the plurality of marks on the paper web, obtains the paper rating associated with the mark read, and changes at least one operational parameter of the converting line based upon the paper rating.

Owner:GPCP IP HLDG LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com