Foam coating glue of water-based wallpaper, preparation method thereof and wallpaper

A foam coating, wallpaper technology, applied in specific visual effect coatings, paper, papermaking and other directions, can solve the problems of PVC surface wallpaper plasticizer migration, contrary to the concept of residents' healthy life, not meeting the requirements of environmental protection policies, etc. Achieve the effect of low cost of raw materials and equipment, improve product competitiveness, and reduce the concentration of harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

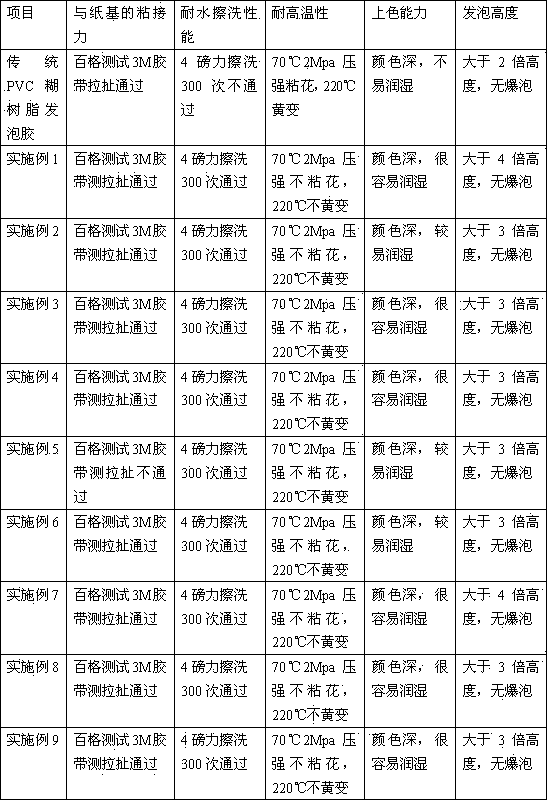

Examples

Embodiment 1

[0105] (1) Raw material formula

[0106] Body Emulsion Resin 50%

[0107] water 8%

[0108] Dispersant 10%

[0109] Emulsifier 3%

[0110] Thickener 3%

[0111] Foaming agent 4%

[0112] Foam stabilizer 6%

[0113] Blowing agent 7%

[0114] Coagulant 7%

[0115] Foaming agent 2%

[0116] Wherein, the main emulsion resin is selected from water-based acrylate resin; the dispersant is selected from acrylic acid copolymer sodium salt; the emulsifier is selected from sodium lauryl sulfate; the thickener is selected from a synthetic acrylic thickener; Potassium oleate is selected as the agent; ammonium oleate soap is selected as the foam stabilizer; ammonium bicarbonate is selected as the foaming agent; polyvinylpyrrolidone is selected as the coagulating agent; sodium polyacrylate is selected as the foam denser.

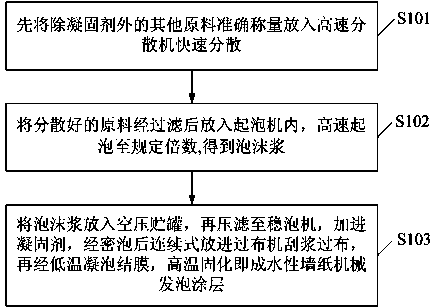

[0117] (2) Preparation method

[0118] A. Accurately weigh other raw materials except the coagulant according to (1) raw material formula, and put them into the hi...

Embodiment 2

[0122] (1) Raw material formula

[0123] Body Emulsion Resin 45%

[0124] water 10%

[0125] Dispersant 15%

[0126] Emulsifier 1%

[0127] Thickener 1%

[0128] Foaming agent 1%

[0129] Foam stabilizer 2%

[0130] Foaming agent 10%

[0131] Coagulant 10%

[0132] Foaming agent 5%

[0133] Wherein, the main emulsion resin is selected from water-based acrylate resin; the dispersant is selected from acrylic acid copolymer sodium salt; the emulsifier is selected from sodium lauryl sulfate; the thickener is selected from a synthetic acrylic thickener; Potassium oleate is selected as the agent; ammonium oleate soap is selected as the foam stabilizer; ammonium bicarbonate is selected as the foaming agent; polyvinylpyrrolidone is selected as the coagulating agent; sodium polyacrylate is selected as the foam denser.

[0134] (2) Preparation method

[0135] A. Accurately weigh other raw materials except the coagulant according to (1) raw material formula, and put them into t...

Embodiment 3

[0139] (1) Raw material formula

[0140] Body Emulsion Resin 48%

[0141] water 5%

[0142] Dispersant 12%

[0143] Emulsifier 6%

[0144] Thickener 5%

[0145] Foaming agent 6%

[0146] Foam stabilizer 5%

[0147] Foaming agent 5%

[0148] Coagulant 5%

[0149] Foaming agent 3%

[0150] Among them, the main emulsion resin is selected from water-based acrylate resin and styrene-butadiene latex (water-based acrylate resin: styrene-butadiene latex = 1:1); the dispersant is selected from polyalkoxy copolymer; the emulsifier is selected from glycerol oleate The thickener is selected from bentonite; the foaming agent is selected from ammonium oleate; the foam stabilizer is selected from potassium hydroxide; the foaming agent is selected from ammonium bicarbonate; the coagulant is selected from fluorosilicate; Described close foam agent selects polyvinylpyrrolidone for use.

[0151] (2) Preparation method

[0152] A. Accurately weigh other raw materials except the coagula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com