Patents

Literature

763results about "Chloroprene adhesives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sprayable water-based adhesive

InactiveUS20070224395A1Efficient use ofProlong lifeAdhesive processesRoof covering using sealantsWet bondingWater based

Water-based adhesive compositions are improved by the incorporation of hollow polymeric microspheres having outer surfaces coated with one or more barrier materials such as calcium carbonate particles. The adhesive compositions exhibit enhanced rheology, sprayability, drying time, tack and storage stability as compared to analogous adhesives that are not modified with coated hollow polymeric microspheres. Such compositions are useful as both contact adhesives as well as wet bonding one-way adhesives.

Owner:HENKEL IP & HOLDING GMBH

Pressure-sensitive adhesive composition and tapes

InactiveUS6022914AImprove flame retardant performanceReduce viscosityAluminium compoundsNon-macromolecular adhesive additivesHalogenFire retardant

The present invention relates to a pressure-sensitive adhesive composition containing a non-halogen, non-intumescent flame-retardant system comprising at least one flame-retardant agent with the provisos that the flame-retardant system does not comprise Sb2O3 or does not consist only of alumina trihydrate.

Owner:3M INNOVATIVE PROPERTIES CO

Reaction bonding type node sealant and preparation method thereof

ActiveCN102911638AImprove stabilityImprove bindingNon-macromolecular adhesive additivesOther chemical processesChemical LinkagePolyvinyl chloride

The invention provides a reaction bonding type node sealant and a preparation method thereof. The sealant comprises asphalt, modifiers, an emulsifier, a crosslinking agent, thickeners, a reinforcing agent and water. In the formula system, more appropriate modifiers are adopted compared with the prior art, so that a rubber asphalt mixture can achieve good emulsification effect, elasticity and strength of a sealing layer after drying are greatly improved, and the sealing effect can be good and lasting; the chemical linkage effect with concrete is formed by using the crosslinking agent, and bonding force with the concrete is improved; and a lot of thickeners are used for adjusting the stickness of the sealant system, so that the reaction bonding type node sealant can better adhere to the surface of a pentatricopeptide repeats (PPR) or polyvinyl chloride (PVC) pipe, and good sealing at positions where PPR or PVC water supply and drainage pipes are connected with base surfaces of concrete.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

Resin composition for vibration-damping material, vibration-damping material, and sound-insulating member

InactiveUS7041377B2Reduce nipping temperatureGood release effectOther chemical processesFibre treatmentPolymer scienceChlorinated paraffins

The object of the invention is to provide sound insulating members exhibiting both high vibration damping performance and high sound insulation performance, a vibration damping material for affording such members and a resin composition for forming the vibration damping material. The invention provides a first resin composition for vibration damping materials which contains 100 parts by weight of a chlorine-containing thermoplastic resin, and 20 to 200 parts by weight of a chlorinated paraffin having 12 to 16 carbon atoms on average. The thermoplastic resin contains preferably 20 to 70 wt. %, more preferably 30 to 70 wt. %, of chlorine. The chlorinated paraffin is preferably 30 to 70 wt. %, more preferably 35 to 65 wt. %, in chlorination degree.

Owner:SEKISUI CHEM CO LTD

Environmental protection chloroprene rubber adhesive agent and production method thereof

InactiveCN101418197AHigh viscosityGood storage stabilityHalogen rubber derivative adheisvesChloroprene adhesivesGas phaseEnvironmental labeling

The invention discloses an environment-friendly chloroprene rubber adhesive agent which comprises the following compositions: neoprene, alloprene, thixotropic agent, 2402 phenolic resin, extra light calcined magnesia, catalyst, cyclohexane, acetic ether, environment-friendly solvent oil and antioxidant BHT. The invention simultaneously discloses a method for producing the environment-friendly chloroprene rubber adhesive agent. The environment-friendly chloroprene rubber adhesive agent has the following advantages: 1. the agent is environment-friendly, does not contain toxic solvents of triphen and halogenated hydrocarbon, and meets the standard requirement of Technical Requirement for Environmental Labeling Products-Adhesives HJ / T 220-2005 2. the anhydrous catalyst is adopted for the preparation of a pre-reaction solution which has high viscosity and good storage stability; 3. gas phase method silica aerogel is added as the thixotropic agent; and the thixotropic index can reach 1.5 and is convenient for construction; and 4. the neoprene and the alloprene are combined for use to greatly improve the adhesive force and peeling strength to metal and other polar materials.

Owner:GUANGDONG SANVO CHEM IND TECH

Light and high-strength rubber conveyor belt and preparation method thereof

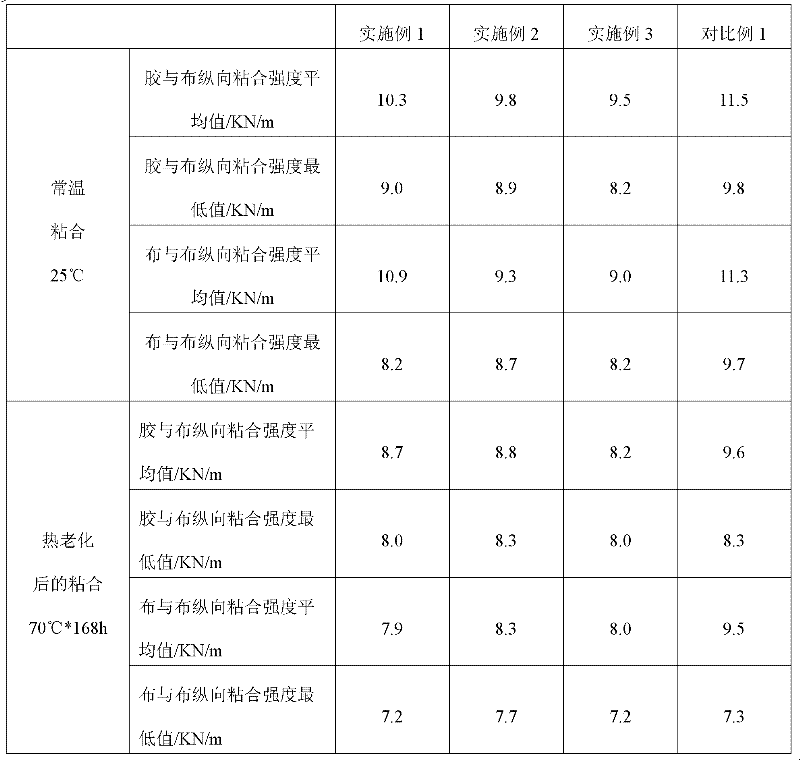

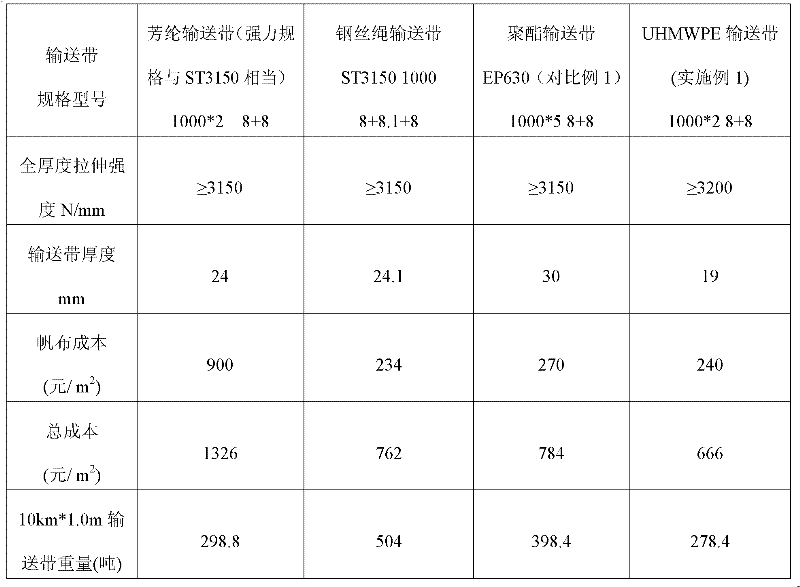

The invention relates to a light and high-strength rubber conveyor belt and a preparation method tof the conveyor belt. The conveyor belt comprises a framework layer, an adhesive glue, and upper and lower cover rubber laminated structures; the framework layer adopts mixed woven canvas of ultra-high molecular weight polyethylene fibers and polyester fibers which are treated by plasma, simultaneously adopts low-temperature vulcanization technology to be subjected to covulcanization with the adhesive glue and a cover rubber at a low temperature, and solves the problem of the bonding of ultra-high molecular weight polyethylene fiber cloth and rubber. Compared with the conventional high-strength conveyor belt of wire rope core, the light and high-strength rubber conveyor belt in the invention not only has high strength, and good corrosion resistance, wear resistance, shock resistance and fatigue resistance, but also greatly reduces the weight and thickness, thereby reducing the conveying power energy consumption, which is expected to have long service life and good energy saving and environment friendly performances. Therefore the light and high-strength rubber conveyor belt disclosed in the invention is particularly suitable for the long-distance material conveying in the industries of coal mine, metallurgy, mine and the like.

Owner:BEIJING UNIV OF CHEM TECH +1

Acrylic copolymer for use in highly filled composites

ActiveUS20090111915A1Film/foil adhesivesConductive materialChlorinated polyvinyl chloridePolymer chemistry

The invention relates to an acrylic copolymer additive useful as a process aid in highly filled polyvinyl chloride (PVC) and chlorinated polyvinyl chloride (CPVC) composites. The acrylic additive is especially useful in highly filled PVC flooring tiles, rolled flooring, pipe and siding. The acrylic copolymer additive contains from 50 to 79 weight percent of methyl methacrylate monomer units, and has a Tg of less than 90° C.

Owner:ARKEMA INC

Two-component high-temperature-resisting adhesive for assembling loudspeaker and preparation method thereof

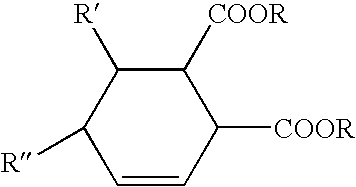

ActiveCN103725206AImprove high temperature resistanceSolve high temperature resistanceNatural rubber adhesivesNon-macromolecular adhesive additivesAdhesivePlasticizer

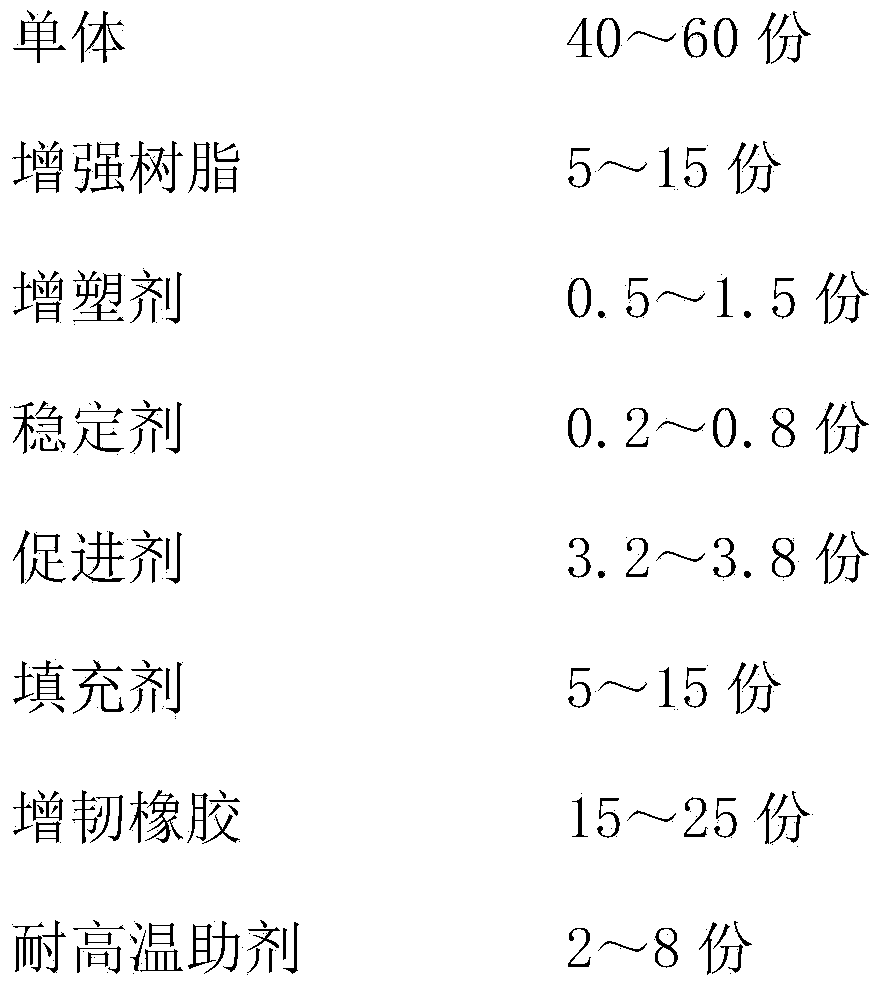

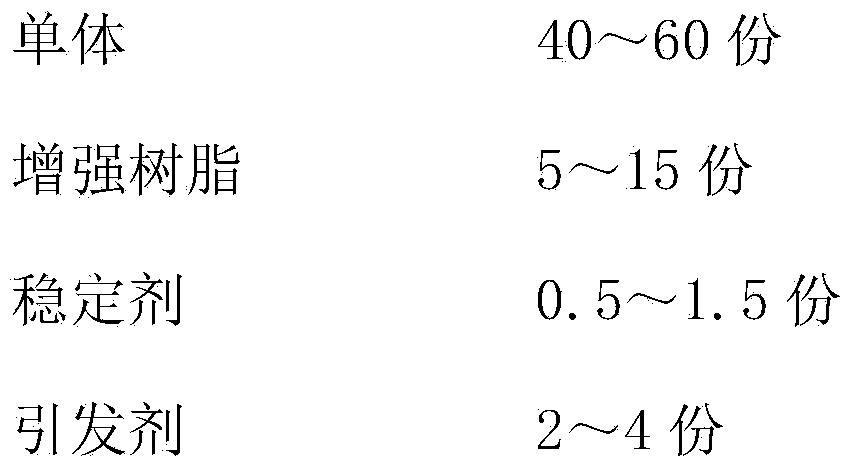

The invention discloses a two-component high-temperature-resisting adhesive for assembling a loudspeaker. The two-component high-temperature-resisting adhesive comprises a main agent and a curing agent, wherein the main agent comprises the following ingredients in parts by weight: 40 to 60 parts of monomer, 5 to 15 parts of reinforcing resin, 0.5 to 1.5 parts of plasticizer, 0.2 to 0.8 part of stabilizer, 3.2 to 3.8 parts of promoter, 5 to 15 parts of filler, 15 to 25 parts of toughening rubber and 2 to 8 parts of high-temperature-resisting additive; the curing agent comprises the following ingredients in parts by weight: 40 to 60 parts of monomer, 5 to 15 parts of reinforcing resin, 0.5 to 1.5 parts of stabilizer, 2 to 4 parts of initiator, 5 to 15 parts of filler, 5 to 15 parts of toughening rubber and 4 to 8 parts of high-temperature-resisting additive. The adhesive can be cured at normal temperature, and the high-temperature-resisting effect is good.

Owner:江苏东禾电声配件有限公司

Water-base joint grouting glue for normal temperature road

InactiveCN101643636AAct as a seam sealStrong viscosity and permeabilityMonocarboxylic acid ester polymer adhesivesOther chemical processesWater basedAdhesive

The invention relates to water-base joint grouting glue for a normal temperature road, namely an environment-friendly joint grouting and joint sealing material having high viscosity, high cementing power and high adhesive property, which is formed by special processes of copolymerizing water, a water-base adhesive, bitumen and a dispersing agent, then modifying a macromolecular water-soluble resinand a rubber latex, and adding the auxiliary agents of a stabilizing agent, a thickening material and the like, and can be used for treating and sealing various types of cracks of bitumen and cementroad surfaces and joint seams of cement road surfaces and bridge surfaces. The joint grouting glue is in a gel state at normal temperature, can be stirred but cannot flow, thus the joint grouting gluecan enter joints directly without slotting and cannot infiltrate downwards so as to play a role in sealing the joints; and simultaneously the joint grouting glue is soluble in water; therefore, the joint grouting glue can be mixed with water to prepare strong-permeability joint grouting materials with any viscosities, and can be effectively poured into deep parts of the cracks of road surfaces without slotting. The joint grouting glue combines the advantages of slotting and non-slotting repairing methods, and simultaneously avoids the disadvantages of the two methods.

Owner:李志刚 +2

Multifunctional glue spray formula and process

ActiveCN102295912AMonocarboxylic acid ester polymer adhesivesMineral oil hydrocarbon copolymer adhesivesPolymer scienceButadiene-styrene rubber

The invention relates to the technical field of chemical detergents, in particular to a multifunctional spray glue formula and process. The spray glue formula comprises the following components in percentage by weight: 1-12 percent of rubber, 1.0-15 percent of synthetic resin, 10-40 percent of tackifying resin, 10-60 percent of hydrocarbon solvent, 30-75 percent of propellent, 10-40 percent of chlorine solvent, 3-30 percent of cosolvent, 2-8 percent of plasticizer and 0.05-1 percent of essence. The spray glue is prepared by the following steps of: adding the hydrocarbon solvent, the chlorine solvent and a part of cosolvent such as acetone and the like into a stirring kettle according to formula metering, opening and stirring; adding rubber such as SBS (Styrene-Butadiene-Styrene) thermoplastic elastomer and the like and synthetic resin such as acrylate resin and the like in a stirring state and stirring until the rubber and the synthetic resin are fully dissolved; adding the tackifyingresin such as rosin and the like and stirring until the rosin is fully dissolved; adding remaining cosolvent such as the acetone and the like and the plasticizer and stirring until glue liquid is fully dispersed; and filtering and canning, sealing, and inflating a can. The spray glue formula has the advantages of no toxin, no pollution, super-strong viscosity and adaptation to gluing of various materials, and is white and non-yellowing.

Owner:DONGGUAN DAYANG CHEM

Esterified Fatty Acids for Pvc Plasticization

InactiveUS20080200595A1Improve compatibilityAvoid problemsChloroprene adhesivesPlasticizerOleic Acid Triglyceride

At least one esterified fatty acid, particularly a fatty acid from tall oil that undergoes a Diels-Alder reaction or a fatty acid from oleic sunflower oil that undergoes an epoxydation reaction, is used as a PVC plasticizer, particularly for floor coverings.

Owner:GERFLOR

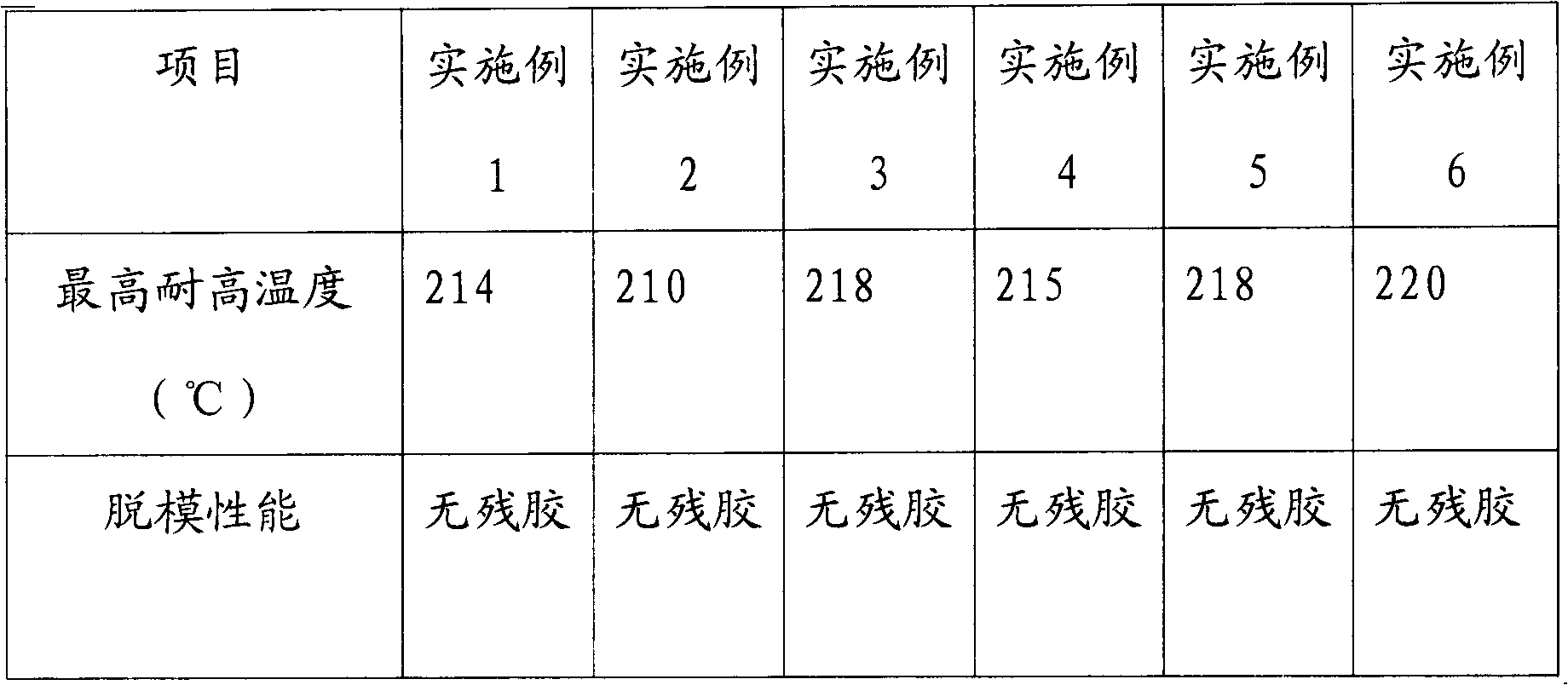

High temperature resistant vacuum bag sealing adhesive tape

The invention discloses a high temperature resistant vacuum bag sealing adhesive tape, which is characterized by adopting butyl rubber, chloroprene rubber, polyisobutene and nano calcium carbonate as main matrixes, then adding an auxiliary recessive high temperature vulcanizing agent, stirring and mixing, and extruding and molding, thus forming the high temperature resistant vacuum bag sealing adhesive tape. The high temperature resistant vacuum bag sealing adhesive tape is air-proof when vacuumizing is carried out, has no residual adhesive after demoulding and has good high temperature resistance, the highest resistant temperature of the sealing adhesive tape can reach 220DEG C.

Owner:科建高分子材料(上海)股份有限公司

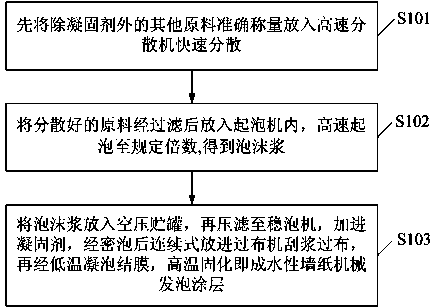

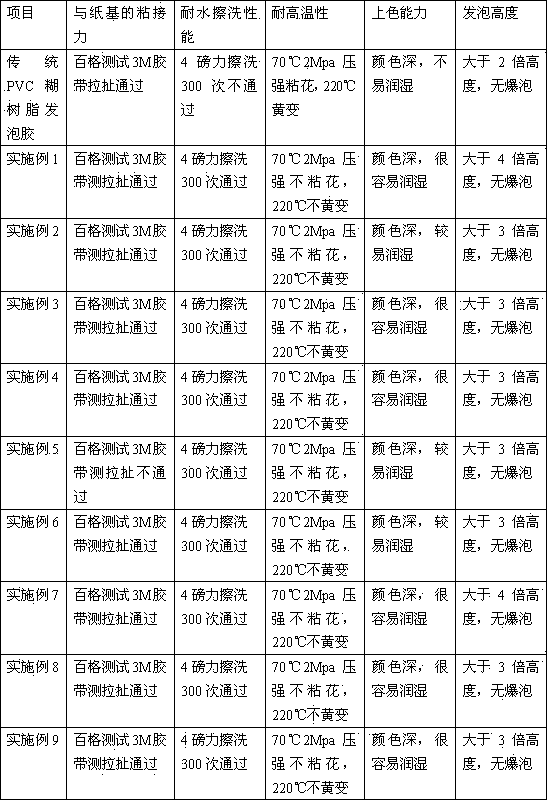

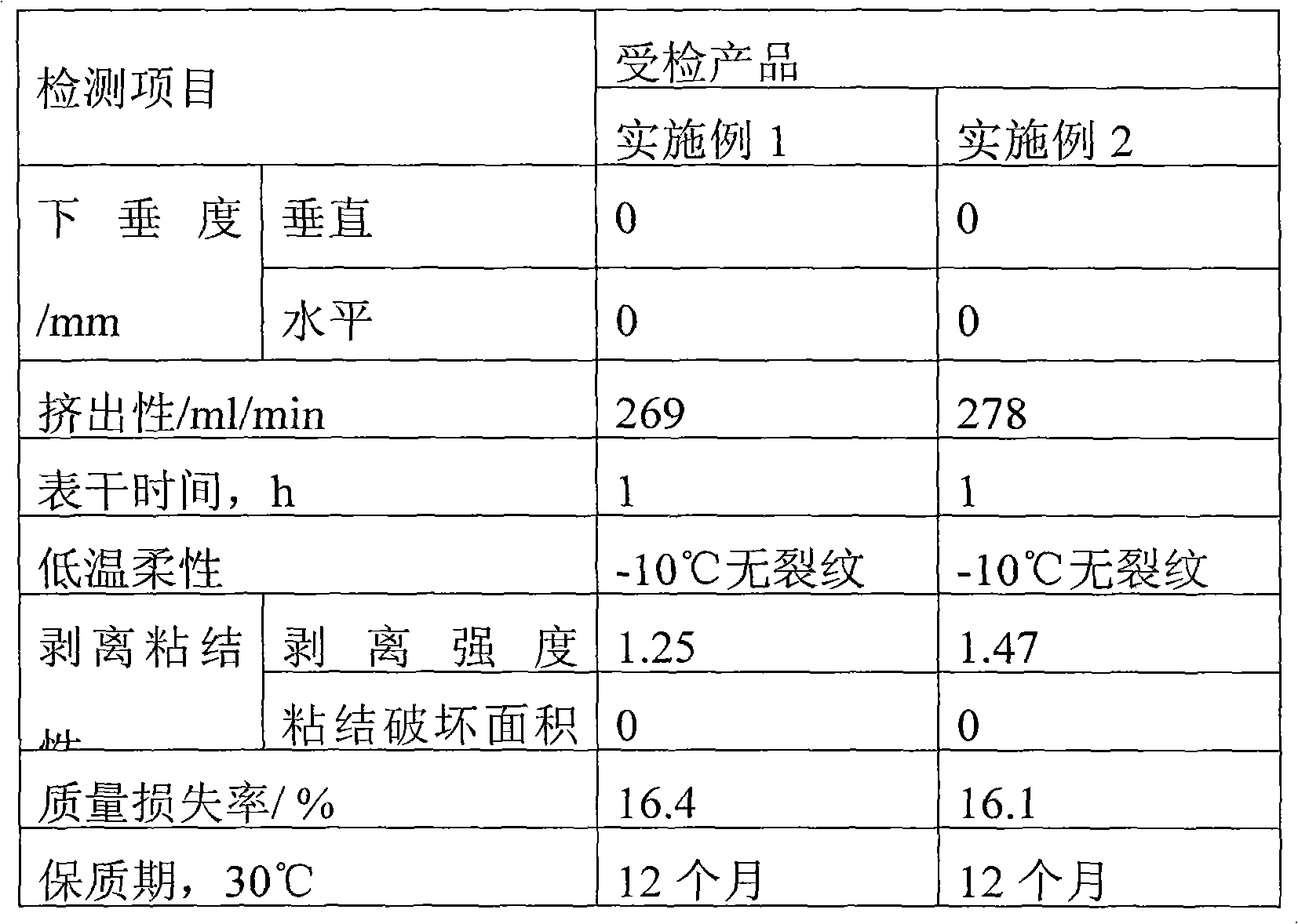

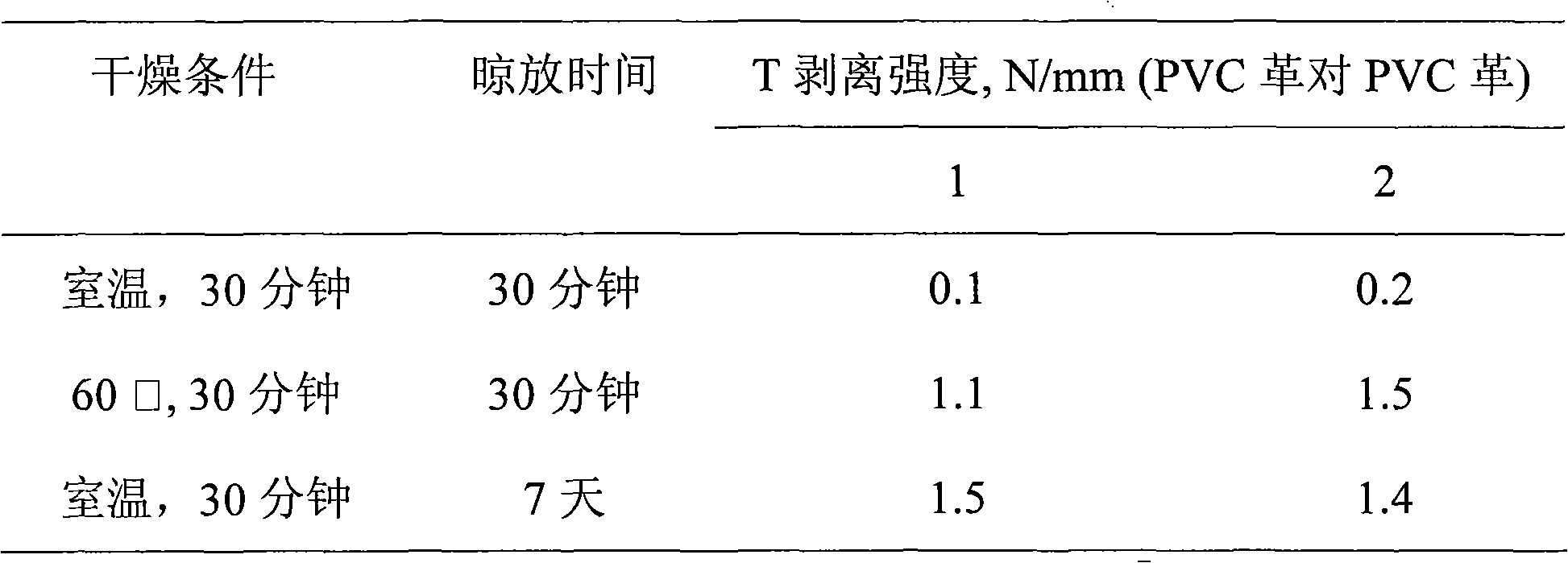

Foam coating glue of water-based wallpaper, preparation method thereof and wallpaper

InactiveCN104004473AImprove adhesionGood flexibilitySpecial visual effect coatingsSpecial paperWater basedPolymer science

The invention discloses a foam coating glue of water-based wallpaper. The foam coating glue includes 40-60% of a main body emulsion resin, 35-55% of a compounding agent and 1-10% of water. The main body emulsion resin is selected from one or more of neoprene latex, nitrile rubber latex, styrene-butadiene latex, water-based acrylate resin, water-based polyurethane resin and ethylene-vinyl acetate resin. The compounding agent includes a dispersing agent, an emulsifier, a thickening agent, a foam-starting agent, a foam-stabilizing agent, a foaming agent, a coagulating agent and a foam-densifying agent. Correspondingly, the invention discloses a preparation method of the foam coating glue of the water-based wallpaper and wallpaper prepared by using the foam coating glue of the water-based wallpaper. Through the preparation method, the foam coating glue of the water-based wallpaper is environmental-friendly and energy-saving, has an excellent foaming effect and can form an excellent-performance foam coating on the water-based wallpaper.

Owner:佛山市三水灏诚合成树脂有限公司

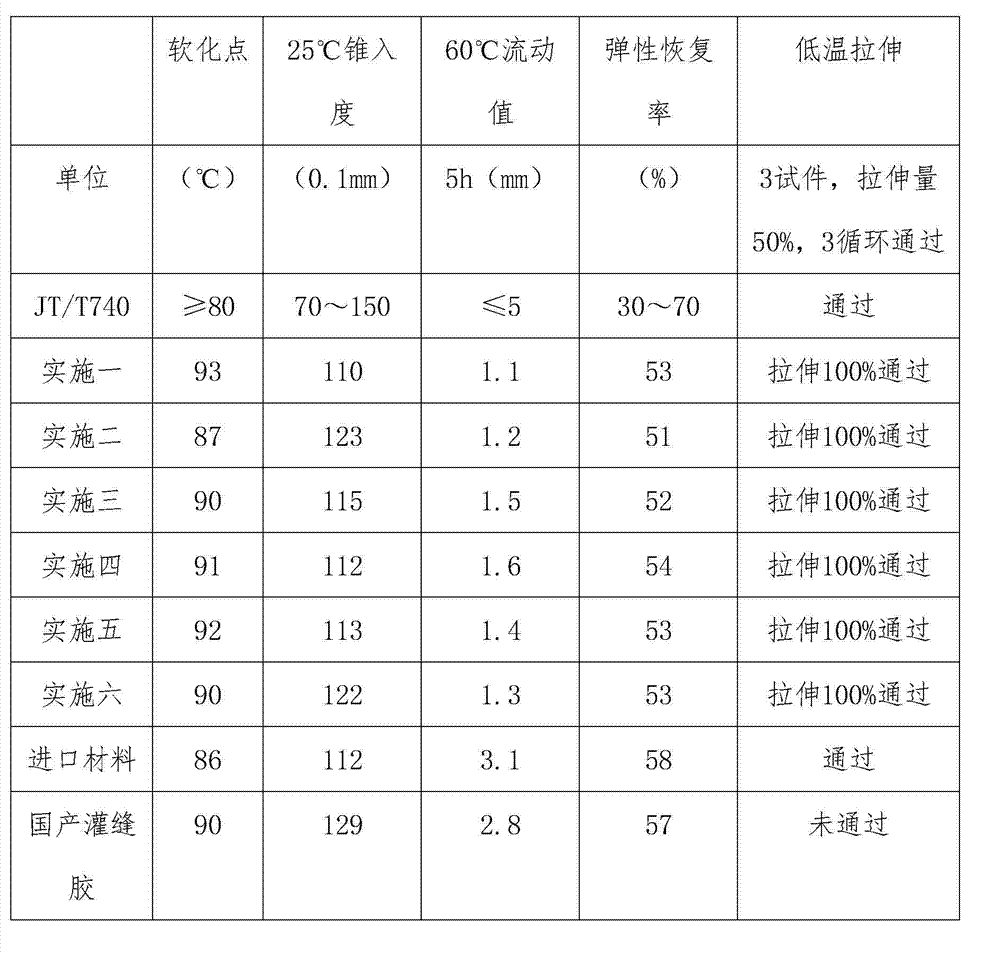

High elasto-plasticity waterproof caulking sealant used in outdoor and preparation method thereof

ActiveCN101935505AImprove water resistanceGood weather resistanceOther chemical processesConjugated diene hydrocarbon adhesivesAdhesive cementOrganic solvent

The invention discloses a high elasto-plasticity waterproof caulking sealant used in outdoor and a preparation method thereof. The high elasto-plasticity waterproof caulking sealant comprises the following raw materials in parts by mass: 120-140 parts of organic solvent, 60-80 parts of base rubber, 20-40 parts of tackifier, 90-120 parts of softener, 3-5 parts of anti-aging agent, 400-500 parts of filler and 5-10 parts of thickener. The preparation method comprises the following steps: refining the base rubber into lamellas by utilizing a two-roll rubber refining machine; cutting into pieces; placing the organic solvent, the tackifier, the softener, the anti-aging agent and the rubber blocks obtained in the above step into a reactor; stirring and dissolving into adhesive cement; and placing the filler and the thickener into the reactor; stirring, vacuumizing, and discharging to obtain the finished product. The product obtained by the invention has better water resistance, weather resistance, low temperature resistance, strong adhesion, better flexibility and excellent sealing performance.

Owner:GUANGZHOU JOINTAS CHEM

Method for manufacturing environment-friendly pressure sensitive adhesive material

InactiveCN102153962AImprove propertiesAvoid pollutionNatural rubber adhesivesNon-macromolecular adhesive additivesEvaporationSolvent

The invention discloses a method for manufacturing an environment-friendly pressure sensitive adhesive material. The method mainly comprises the following steps of: 1, in a closed environment, heating solvent type pressure sensitive adhesive to the temperature of between 60 and 200 DEG C so that the solvent contained in the solvent type pressure sensitive adhesive is evaporated and 50 to 99.9 mass percent of pressure sensitive adhesive is obtained; 2, adding a curing agent into the pressure sensitive adhesive obtained in the step 1, and mixing the curing agent and the pressure sensitive adhesive uniformly by using a vibrating bar or a screw extruder; 3, coating; and 4, rolling. The evaporation time of the solvent during coating the pressure sensitive adhesive can be reduced, so that the coating production efficiency is greatly improved.

Owner:SUZHOU SIDIKE NEW MATERIALS SCI & TECH

Chloroprene rubber latex adhesive, preparation and uses thereof

InactiveCN101492594AGood value for moneyImprove initial tackEster polymer adhesivesChloroprene adhesivesPolymer scienceEmulsion

The invention discloses a neoprene latex type adhesive, a preparation method and the application thereof. The neoprene latex type adhesive adopts acrylic esters monomers such as butyl acrylate, gadoleic acid isooctyl ester and the like as well as styrene having sufficient source and low price; styrene-acrylic emulsion is prepared by simple technique; neoprene latex is modified by the emulsion and matched with coagulator solution and other accessory ingredients, so that rubber latex type chloroprene rubber adhesive agent can be prepared; the performance of the rubber latex type chloroprene rubber adhesive agent is similar to that of the commercially available solvent-borne type chloroprene rubber adhesive agent, and the rubber latex type chloroprene rubber adhesive agent even has some indexes being superior to the indexes of the commercially available solvent-borne type chloroprene rubber adhesive agent; furthermore, the neoprene latex type adhesive has high cost performance, wide application scope as well as remarkable social and economic benefits. The neoprene latex type adhesive can meet the needs of different base materials such as a mattress, a chair, a couch, a sofa, a screen, a handbag, industrial polyfoam and the like, is low in cost and simple in preparing method, and has the excellent properties of good storage stability, large temperciance, rapid intensity foundation, high bonding strength, etc.

Owner:SOUTH CHINA UNIV OF TECH

A kind of glue spray formula and process

ActiveCN102277130AToxin-freeNo pollution in the processMineral oil hydrocarbon copolymer adhesivesFibre treatmentThermoplastic elastomerAdhesive

The invention, relating to the technical field of chemical spray adhesive, especially relates to a spray adhesive formula and a technology thereof. The spray adhesive comprises the following ingredients: 1-12 wt% of rubber, 1-5 wt% of dispersant, 10-40 wt% of tackifying resin, 10-60 wt% of varsol, 10-55 wt% of chlorinated solvent and 35-70 wt% of propellent. The technology of preparing the spray adhesive comprises the following steps: (1) adding varsol and chlorinated solvent in a stirring tank according to the amount in the formula, starting the stirring tank for stirring; (2) adding SBS thermoplastic elastomer and other rubbers with stirring until the rubbers completely dissolve; (3) then adding rosin and other tackifying resin with stirring until rosin completely dissolves, then addingorganic bentonite dispersant, continuously stirring until organic bentonite completely disappears; and (4) filtering and then canning, and carrying out sealing and then inflating the tank. The spray adhesive has no toxins and no pollution, and can be used on white fabrics without yellowing or blackening with ideal bonding effect.

Owner:吕大洋

Aqueousneoprene type environment-friendly glue and preparation method thereof

ActiveCN101560367ATransportation safetyHigh bonding strengthAcid polymer adhesivesAldehyde/ketone condensation polymer adhesivesAcrylic resinFireproofing

The invention discloses an aqueous neoprene type environment-friendly glue which comprises aqueous rosin emulsion with low grain diameter and high stability, aqueous acrylic resin emulsion, ethane-vinyl acetate emulsion, anion type neoprene latex, aqueous foam suppressor, wetting dispersant, preservative, tackifier, nanometer calcium carbonate concentrated slurry, aerosol, and the like. The invention also discloses a preparation method of the aqueous neoprene type environment-friendly glue; the aqueous neoprene type environment-friendly glue takes water as a dispersed media, is uniform milky liquid, has the comprehensive advantages of no organic solvent, no heavy metal, insipidity, good initial adhesive force, excellent bond strength, excellent hold tack, excellent heat resistance and aging resistance, short drying time, long opening time, large spray area of unit weight, glue saving, excellent oily leather resistance, fireproofing, safe transportation, and the like, has the advantages of reducing environment pollution, improving operation and construction environment, saving large amounts of organic fuel, insipidity, and the like, is widely applied to industries of soft furniture of cases and bags, sofas, swivel chairs, mattresses, pillows, folding screens, and the like, and is especially suitable for application of green high-grade export products of occident.

Owner:黄楚填

Silencing film for automobile

InactiveCN101497768AEasy to break awayGood workmanshipMineral oil hydrocarbon copolymer adhesivesFilm/foil adhesivesElectrophoresisCar manufacturing

The invention relates to a binding material, in particular to an automobile sound deadening film which is used on metal plates for locally reinforcing the metal plates and particularly on automobile doors to reduce noises generated by the vibration of a running automobile. The automobile sound deadening film is prepared by mixing and extruding 10-25 percent of synthetic rubber, 5-15 percent of thermoplastic resin, 5-20 percent of thickening resin, 10-25 percent of plasticizing agent, 25-50 percent of vibration damping and sound deadening agent, 10-20 percent of oil absorbing and filling agent and 5-10 percent of reinforcing filling material. The automobile sound deadening film can be used for the large-area sound deadening and vibration damping of the metal plates during the automobile manufacturing process. When being used, the automobile sound deadening film can be operated by hands, is innoxious and odorless, is easy to separate from release paper, has good manufacturability, can not shift after being pasted, is less susceptible to oil washing, phosphating process, electrophoresis, paint spraying and drying, and other subsequent automobile body manufacturing processes and is convenient to use.

Owner:广州市东明扬汽车部件有限公司

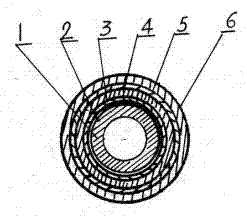

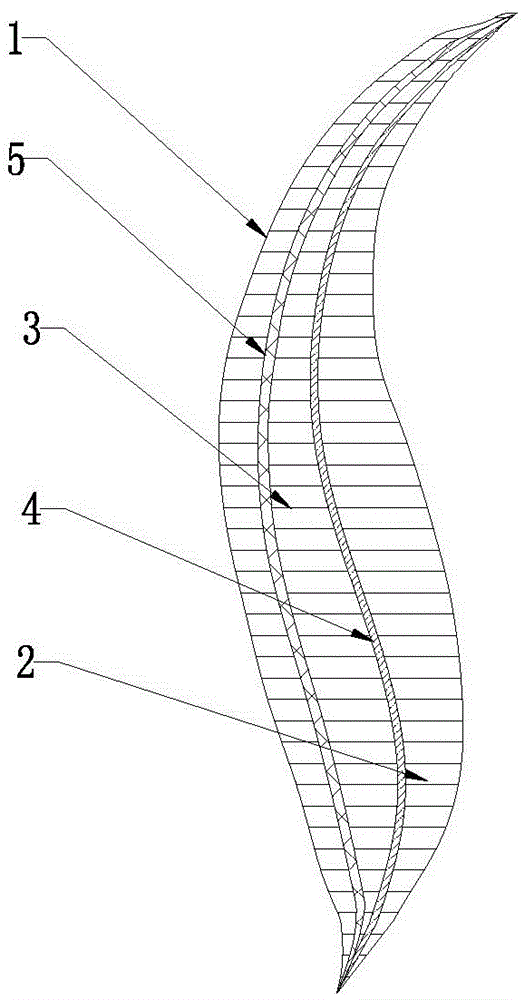

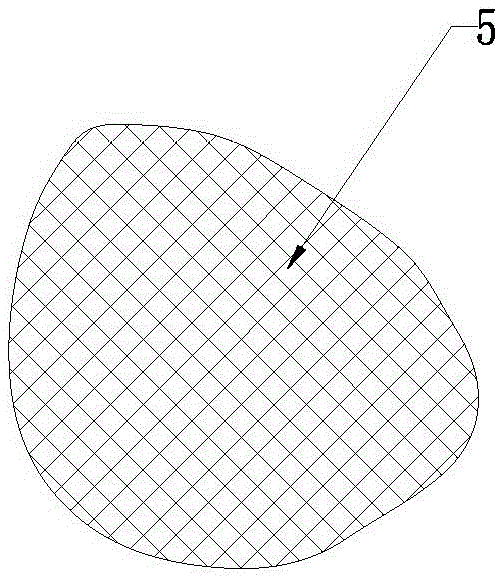

Corrosion-resistant high-pressure hose and production method thereof

ActiveCN102865420ATightly bondedImprove impact resistanceNatural rubber adhesivesFlexible pipesHigh pressureButyl rubber

The invention discloses a corrosion-resistant high-pressure hose and a production method thereof. The corrosion-resistant high-pressure hose comprises an inner pipe layer (1), a steel wire enhancing layer (3), a middle glue layer (4) and an outer glue layer (6). The hose is characterized in that the inner pipe layer is made from hydrogenated butyl rubber and is coated with an aramid fabric layer (2), the steel wire enhancing layer is wound or woven outside the aramid fabric layer, the middle glue layer, namely a middle glue bonding layer, is arranged outside the steel wire enhancing layer, a second steel wire enhancing layer (5) is wound or woven outside the middle glue bonding layer, the middle glue bonding layer and the wound or woven steel wire enhancing layer are fused together, and the outermost layer of the hose is the outer glue layer which is a protective layer. The production method is implemented through carrying out processes such as banburying and extrusion on materials of the inner pipe layer made from the hydrogenated butyl rubber, the middle glue bonding layer and the outer glue protective layer, and winding the steel wire enhancing layer and coating the aramid fabric layer respectively. The corrosion-resistant high-pressure hose disclosed by the invention is good in stability, strong in corrosion resistance and H2S prevention, and wear-resisting especially; and the impact resistance of the hose is improved, the strength and flexibility of the hose are enhanced, and the service life of the hose is effectively prolonged by more than 50%.

Owner:HEBEI JINGBO PETROLEUM MACHINERY

Environment-friendly and decorative nail-free glue and preparation method thereof

ActiveCN103484043AReduce contentNo pollution in the processMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesElastomerPolymer science

The invention belongs to environment-friendly and decorative glue, particularly relates to environment-friendly and decorative nail-free glue and a preparation method thereof. The environment-friendly and decorative nail-free glue comprises the following components: 5.0 to 20.0 percent of rubber elastomers, 10.0 to 30.0 percent of tackifying resin, 15.0 to 35.0 percent of reinforcing fillers, 2.0 to 8.0 percent of a thixotropic agent, 10.0 to 40.0 percent of a solvent and 0.1 to 1.0 percent of anti-oxidant; the preparation method of the environment-friendly and decorative nail-free glue comprises the following steps: putting the solvent into a high-speed stirrer, sequentially adding the rubber elastomers and the tackifying resin after a stirrer is started, stirring for 2 to 8 hours until all materials are dissolved to be a uniform liquid, then slowly adding the enhancing fillers and stirring uniformly so as to prepare a flowable slurry mixture, then adding the thixotropic agent and the anti-oxidant, and stirring uniformly so as to prepare the environment-friendly and decorative nail-free glue. The environment-friendly and decorative glue provided by the invention is environmental-friendly, is convenient to use, has high product bonding intensity and is excellent in durability.

Owner:GLEIHOW NEW MATERIALS CO LTD

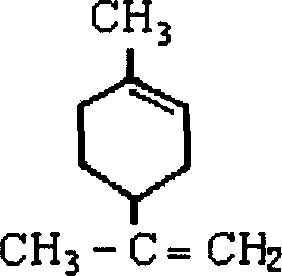

Binder in use for jointing covering rubber on table tennis bat

InactiveCN101003711AImprove solubilityShort manufacturing timeNatural rubber adhesivesConjugated diene hydrocarbon adhesivesPolymer scienceTennis racket

This invention discloses a pressure-sensitive adhesive for rubber layer on table tennis racket. The adhesive is composed of: solvent 60-90 wt. %, rubber 8-20 wt. %, and thickening resin 2-20 wt. %. The solvent is 1, 8-terpadiene, or a mixture of 1, 8-terpadiene and one or two of ethyl acetate, methanol and ethanol. The rubber is one or two of nonpolar rubbers such as natural rubber, and polar rubbers such as polychlorobutadiene, or rubber compound. 1, 8-terpadiene used as the solvent has high solvency for rubber layer on table tennis racket, and is harmless and environmentally friendly. The adhesive, when used on rubber layer on table tennis racket, has such advantages as rapid swelling, long elasticity-enhancing effect, and simple process.

Owner:徐昊为

Expanding damping adhesive with good damp heat resistance ageing performance

ActiveCN102516899AGood moisture and heat aging resistancePlay the role of cushioning and dampingNatural rubber adhesivesNon-macromolecular adhesive additivesFoaming agentAdhesive

The invention relates to an expanding damping adhesive with good damp heat resistance ageing performance, which belongs to the technical field of the expanding damping adhesive and mainly solves the problems that the damp heat resistance aging performance of the existing expanding damping adhesive is not good enough so as to affect service life of the expanding ageing performance. The expanding damping adhesive is mainly characterized by comprising the following components, by weight, 10-40 parts of liquid polybutadiene, 0-10 parts of solid rubber, 0-20 parts of softener, 0-10 parts of tackifier, 0-10 parts of sulphur, 0-10 parts of accelerating agent, 0.1-3 parts of antioxygen, 0.1-10 parts of active agent, 0-3 parts of foaming agent and 10-50 parts of filler. The expanding damping adhesive has good strength keeping rate after damp heat ageing and long service life, is widely used for adhesion and filling between an outer plate and a strengthening beam of an auto-body panel of a welding line, and has buffering and damping effects.

Owner:HUBEI HUITIAN NEW MATERIALS STOCK CO LTD

Low-water-absorptivity acrylate structural adhesive and preparation method thereof

InactiveCN102850973ALow water absorptionEasy to usePolyureas/polyurethane adhesivesEster polymer adhesivesAdhesive cementPolymer science

The invention relates to a double-component acrylate structural adhesive which is prepared by mixing a component A and a component B in a mass ratio of 1:1, wherein the component A is composed of 30-70 parts of acrylate monomer, 10-40 parts of toughening resin, 0.1-10 parts of initiator, 0.01-1 part of stabilizer, 0-6 parts of thixotropic agent and 0.1-2 parts of paraffin; and the component B is composed of 30-70 parts of acrylate monomer, 10-40 parts of toughening resin, 0.1-5 parts of accelerator, 0.01-1 part of stabilizer, 0-6 parts of thixotropic agent and 0.1-2 parts of paraffin. The adhesive provided by the invention has the advantages of low water absorptivity (lower than 2%), high curing speed, high initial adhesive force and high storage stability, and is convenient to use. The bonding strength of the bonded structural sample piece can still have the retentivity of 70% or so after the structural sample piece is boiled in water for 24 hours.

Owner:BEIJING HYSTIC NEW MATERIALS

Vertical cotton breathable bra cup pad with silica gel net and preparation method thereof

The invention relates to the technical field of bra cup pad, and specifically relates to a vertical cotton breathable bra cup pad with a silica gel net and a preparation method thereof. The vertical cotton breathable bra cup pad comprises a vertical cotton outer layer and a vertical cotton inner layer; a vertical cotton interlayer is arranged between the vertical cotton outer layer and the vertical cotton inner layer; an adhesive layer is arranged between the vertical cotton interlayer and the vertical cotton inner layer; and a silica gel net layer is arranged between the vertical cotton outer layer and the vertical cotton interlayer. The vertical cotton breathable bra cup pad is prepared by a combined technology of hot pressing and cold pressing. The pad is made of vertical cotton, and is light, comfortable, and breathable. A silica gel layer is arranged between vertical cotton layers, the performance of the pad on resisting water washing is enhanced, the anti-collapse effect is good, three-dimensional effect of the cup pad is long-lasting and stable, and the deformation is difficult to happen.

Owner:HONGJI UNDERWEAR CO LTD

Pavement crack repairing material and preparation method

InactiveCN103589390AImprove adhesionSuitable for patchingIn situ pavingsNon-macromolecular adhesive additivesCrack resistancePolymer science

Provided is a pavement crack repairing material. The pavement crack repairing material comprises the following ingredients, by weight, 35-65% of asphalt, 6-12% of modifiers, 6-10% of special leftover material powder, 2-5% of plasticizers, 8-15% of softening oil, 10-25% of waste rubber power, and 3-10% of tackifiers or nano-oxides. The special leftover material powder is obtained after leftover materials of beef tendon sole rubber and chloroprene rubber at a weight ratio of 3:2.5 are ground by a grinding mill. The repairing material has good low-temperature crack resistance, high-temperature stability, interface binding property, ageing resistance and fatigue resistance. The repairing material is suitable for repairing of cracks and seams of asphalt or cement concrete pavements under extremely cold weather conditions.

Owner:GUANGDONG ESUN HEAVY IND CO LTD

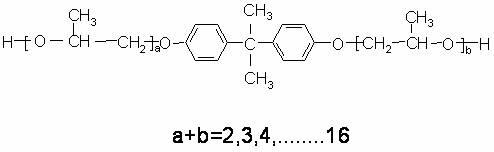

Hot-melt adhesive for bonding layer of artificial leather and preparation method as well as application thereof

InactiveCN102618204AImprove high temperature resistanceGood chemical resistanceNatural rubber adhesivesNon-macromolecular adhesive additivesPolymer scienceAdhesive

The invention relates to a hot-melt adhesive for the bonding layer of artificial leather and a preparation method as well as application thereof. The preparation method comprises the following steps of: firstly reacting low polymer polyalcohol, an expoxy resin and aromatic polyhydroxy special polyether with diisocyanate, then adding a hydrophilic chain extender and a micromolecule polyalcohol chain extender for carrying out chain extension reaction to obtain an intermediate product, neutralizing by using organic amine, emulsifying by using water to generate a polyurethane emulsion, finally removing an organic solvent at a reduced pressure to obtain a waterborne polyurethane emulsion, adding a special organic silicon surface active agent, a FeCl3 aqueous solution, a waterborne curing agent, natural rubber, chloroprene rubber, nitrile butadiene rubber and a thickening agent, and preparing the hot-melt adhesive for the bonding layer of artificial leather. The bonding layer of artificial leather is used for compositing spinning fabrics and PVC (Polyvinyl Chloride) / cloth in the fields of bags, suitcases and clothing. The prepared adhesive has the excellent performances of firm bonding strength, water resistance, acid resistance, alkali resistance and the like and is applied to the artificial leather fields of clothing, bags, suitcases and the like.

Owner:江阴市诺科生物新材料科技有限公司

Aqueous dispersion, and laminate, adhesive for footwear, and footwear made using same

ActiveUS20140137435A1Improve adhesionInhibit aggregationSolesThin material handlingPolymer sciencePolyolefin

An aqueous dispersion including an acid-modified polyolefin resin (A) having a content of an unsaturated carboxylic acid component of 0.1 to 10% by mass, a rubber component (B), a tackifier component (C) and an aqueous medium, wherein in relation to 100 parts by mass of the acid-modified polyolefin resin (A), the content of the rubber component (B) is 5 to 1900 parts by mass, and in relation to 100 parts by mass of the total amount of the acid-modified polyolefin resin (A) and the rubber component (B), the content of the tackifier component (C) is 5 to 300 parts by mass.

Owner:UNITIKA LTD

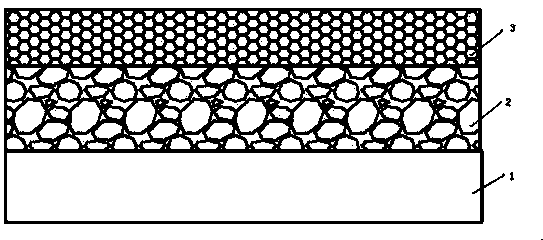

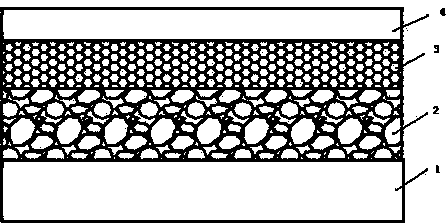

Soundproof floor mat

ActiveCN103774833AAvoid noiseReduce noiseNon-macromolecular adhesive additivesFlooring insulationsQuality of lifeEngineering

The invention relates to an article for daily life such as a floor mat, in particular to a soundproof floor mat, which comprises a first moisture-proof film, an all-open cell foam material or softwood layer and a closed cell foam material layer, wherein the first moisture-proof film layer is arranged in a bottom layer; the all-open cell foam material or softwood layer is arranged in a middle layer, and is positioned on the first moisture-proof film layer; the closed cell foam material layer is arranged in an upper layer, and is positioned on the all-open cell foam material or softwood layer. According to the soundproof floor mat, the advantages of a closed cell foam material, softwood and an all-open cell foam material in sound insulation and noise reduction are integrated, and the soundproof floor mat is laid under a floorboard by a multilayer composite technology, so that the shortcomings of each material are effectively overcome, high-frequency and low-frequency noise can be eliminated to effectively realize sound insulation and noise reduction, noise between floors is effectively lowered, 80 percent of impact sounds (knocking noise produced by high heels or other hard objects) from upper floors can be reduced and remarkably improved, and the quality of life is improved; due to the adoption of a three-layer structure, the foot-feel can be improved, and the floorboard can be protected.

Owner:ZHEJIANG RUNYANG NEW MATERIAL TECH

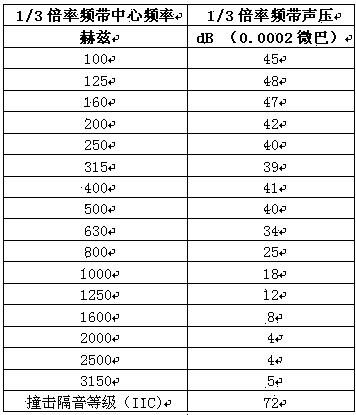

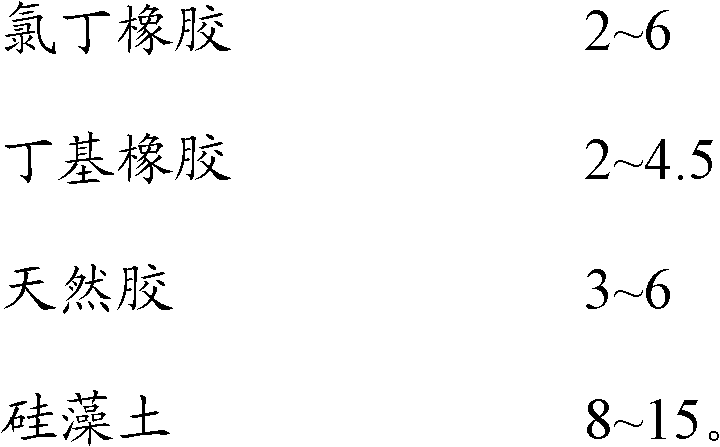

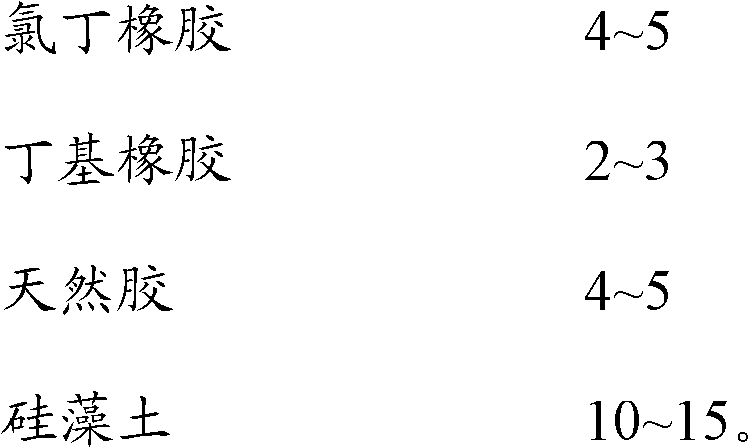

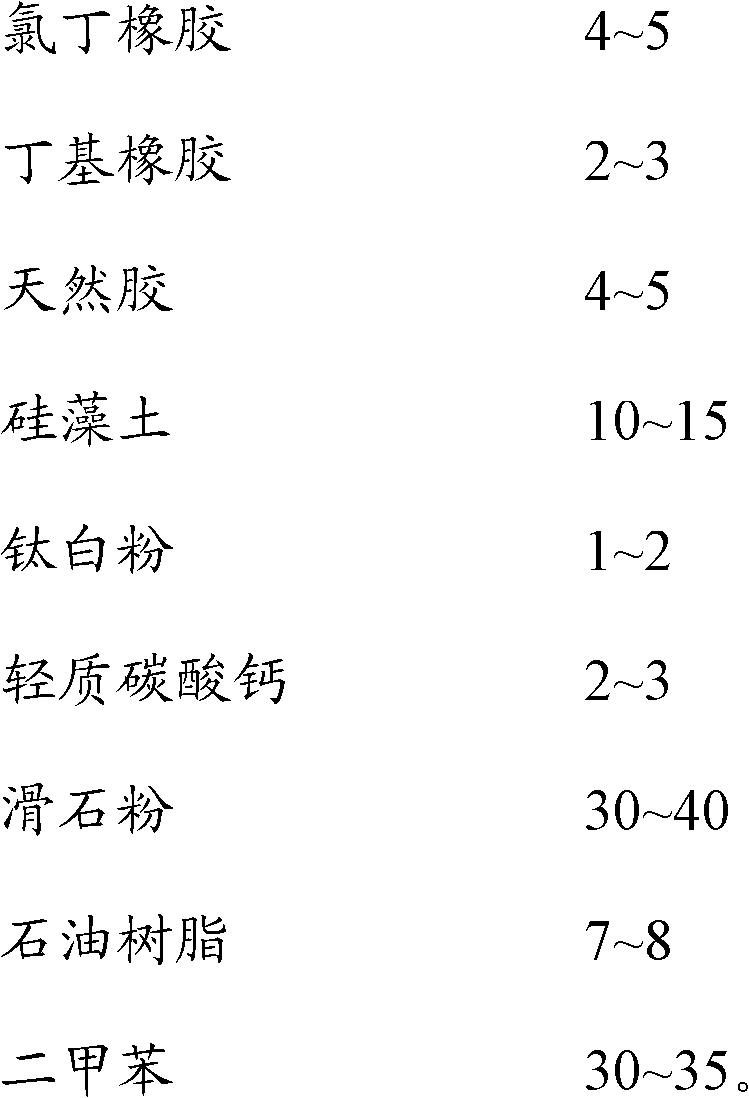

Diatomite chloroprene type sealant

InactiveCN102504722AHigh porosityStrong absorptionNatural rubber adhesivesNon-macromolecular adhesive additivesWeather resistanceHeat resistance

The invention belongs to the technical field of sealants, and specifically to a diatomite chloroprene type sealant. The diatomite polychloroprene type sealant is prepared by carrying out milling and kneading the following materials according to a formula, wherein the materials comprise chloroprene rubber, butyl rubber, natural rubber, diatomite, a reinforcing agent, a filler, a viscosity regulator, a vulcanizing agent, a stabilizer and other commonly used additives. According to the present invention, the diatomite has a special structure and physical properties, the other raw materials in the formula are reasonably selected, the ratio is appropriate, and the diatomite chloroprene type sealant has characteristics of good anti-aging performance, good weather resistance, strong heat resistance, strong wear resistance, rare sagging, good surface smoothness, environmental protection, and long service life, and can be used for family decoration and other fields.

Owner:TIANCHANG CITY TONGTIAN CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com