Diatomite chloroprene type sealant

A technology of sealant and diatomite, which is applied in the field of sealant, can solve the problem of single function and achieve the effects of stable chemical properties, good weather resistance, and strong heat and wear resistance

Inactive Publication Date: 2012-06-20

TIANCHANG CITY TONGTIAN CHEM

View PDF8 Cites 22 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

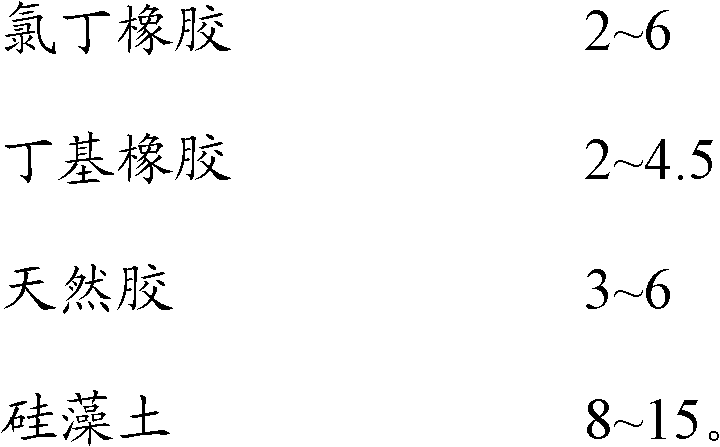

[0040] A kind of diatomite chloroprene type sealant comprises the following components by weight parts:

[0041]

[0042]

Embodiment 2

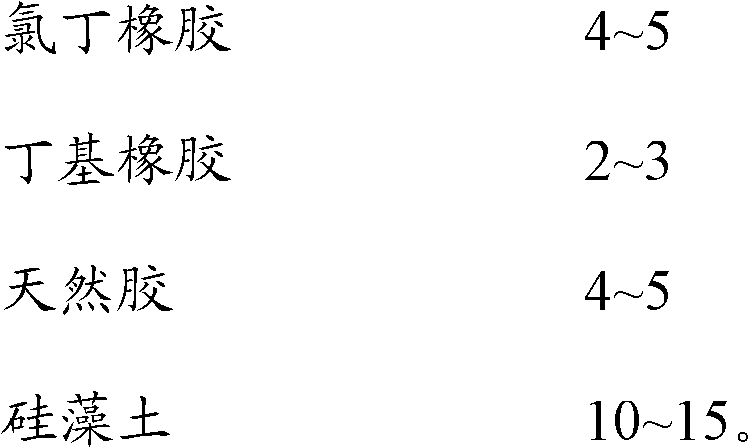

[0044] A kind of diatomite chloroprene type sealant comprises the following components by weight parts:

[0045]

Embodiment 3

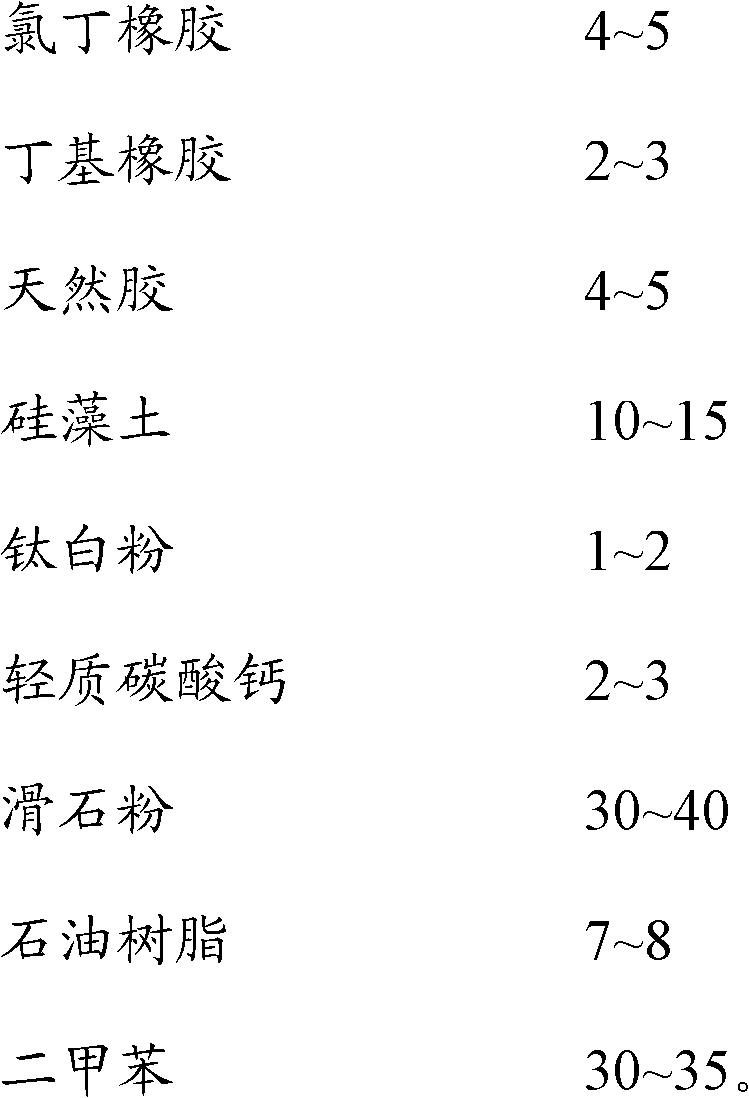

[0047] A kind of diatomite chloroprene type sealant comprises the following components by weight parts:

[0048]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Login to View More

Abstract

The invention belongs to the technical field of sealants, and specifically to a diatomite chloroprene type sealant. The diatomite polychloroprene type sealant is prepared by carrying out milling and kneading the following materials according to a formula, wherein the materials comprise chloroprene rubber, butyl rubber, natural rubber, diatomite, a reinforcing agent, a filler, a viscosity regulator, a vulcanizing agent, a stabilizer and other commonly used additives. According to the present invention, the diatomite has a special structure and physical properties, the other raw materials in the formula are reasonably selected, the ratio is appropriate, and the diatomite chloroprene type sealant has characteristics of good anti-aging performance, good weather resistance, strong heat resistance, strong wear resistance, rare sagging, good surface smoothness, environmental protection, and long service life, and can be used for family decoration and other fields.

Description

technical field [0001] The invention belongs to the technical field of sealants, and in particular relates to a diatomite neoprene sealant used in the fields of home decoration and the like. Background technique [0002] Sealant is a sealing material that deforms according to the shape of the sealing surface, is not easy to flow, and has a certain degree of adhesion. It is an adhesive used to fill the configuration gap and seal it. It has the functions of anti-leakage, waterproof, anti-vibration, sound insulation and heat insulation. Usually dry or non-dry viscous materials such as asphalt, natural resin or synthetic resin, natural rubber or synthetic rubber are used as the base material, and inert fillers such as talcum powder, clay, carbon black, titanium dioxide and asbestos are added. Plasticizers, solvents, curing agents, accelerators, etc. It can be divided into three categories: elastic sealant, liquid gasket and sealing putty. Widely used in construction, transpo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09J111/00C09J107/00C09J123/22C09J11/04C09K3/10

Inventor 卢齐元

Owner TIANCHANG CITY TONGTIAN CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com