Patents

Literature

214 results about "Polychloroprenes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Elastomer compositions for use in a hydrocarbon resistant hose

InactiveUS20050059764A1Improve impermeabilityGood oil resistanceSynthetic resin layered productsSpecial tyresElastomerPolymer science

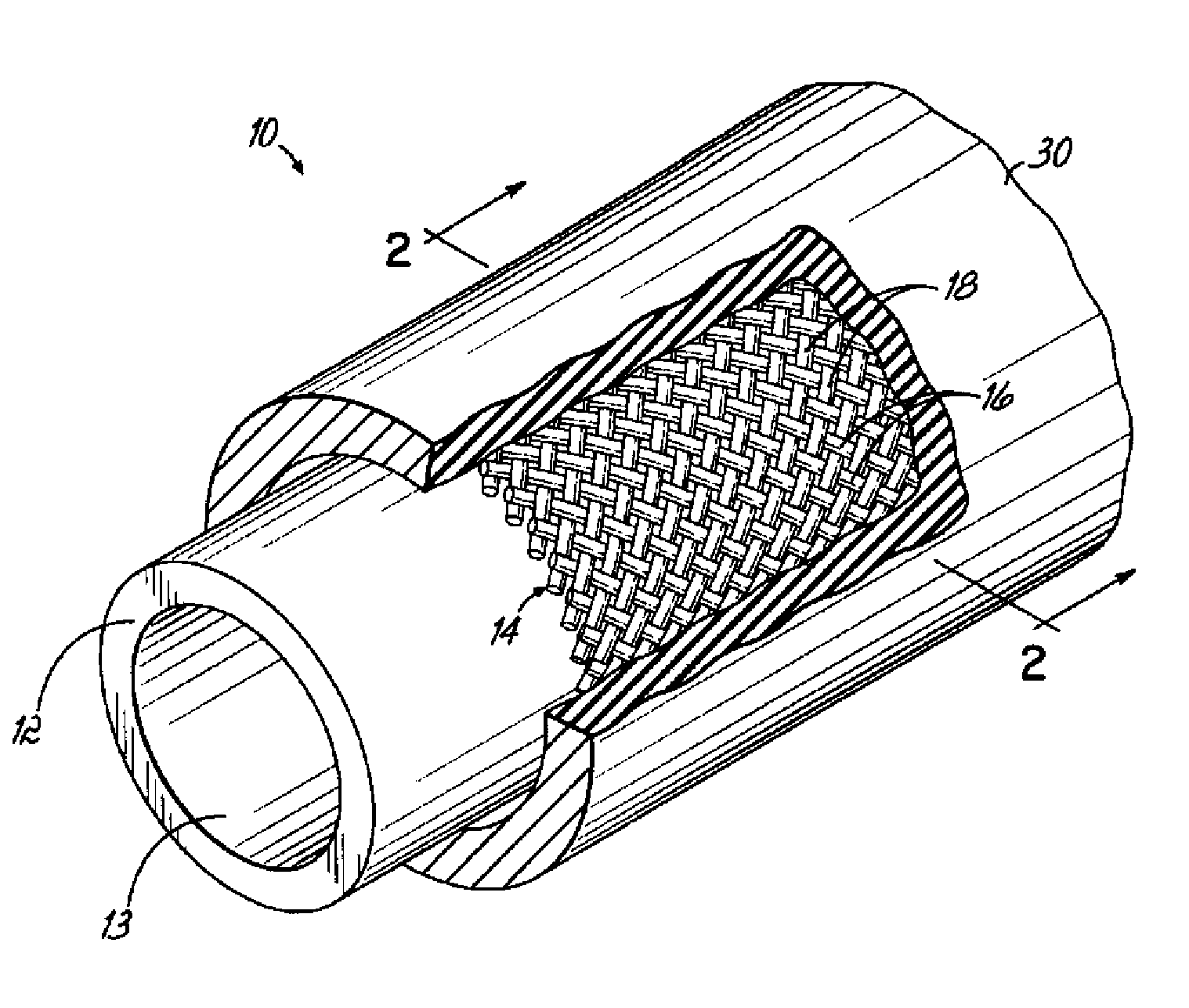

A heat tolerant, pressure resistant elastomeric composition comprising a blend of a first ethylene-vinyl ester copolymer and a second copolymer selected from the group consisting of chlorosulfonated polyethylene (CSM), chlorinated polyethylene (CPE), polychloroprene (CR), ethylene-acrylic elastomer (AEM), alkyl-acrylate copolymer (ACM), polyvinyl acetate (PVA), nitrile-butadiene rubber (NBR), hydrogenated nitrile-butadiene rubber (HNBR), and mixtures thereof, a hose manufactured therefrom; and a method for preparing the hose are described.

Owner:FLUID ROUTING SOLUTIONS

Dehydrochlorination stabilization of polychlorinated alkanes

InactiveUS6534688B2Suppression problemReduces and preventsHalogenated hydrocarbon separation/purificationAlkaneMonomethyl ether

Owner:OCCIDENTAL CHEM CORP

Polymer blends of nitrile rubber and polychloroprene

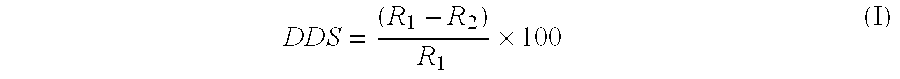

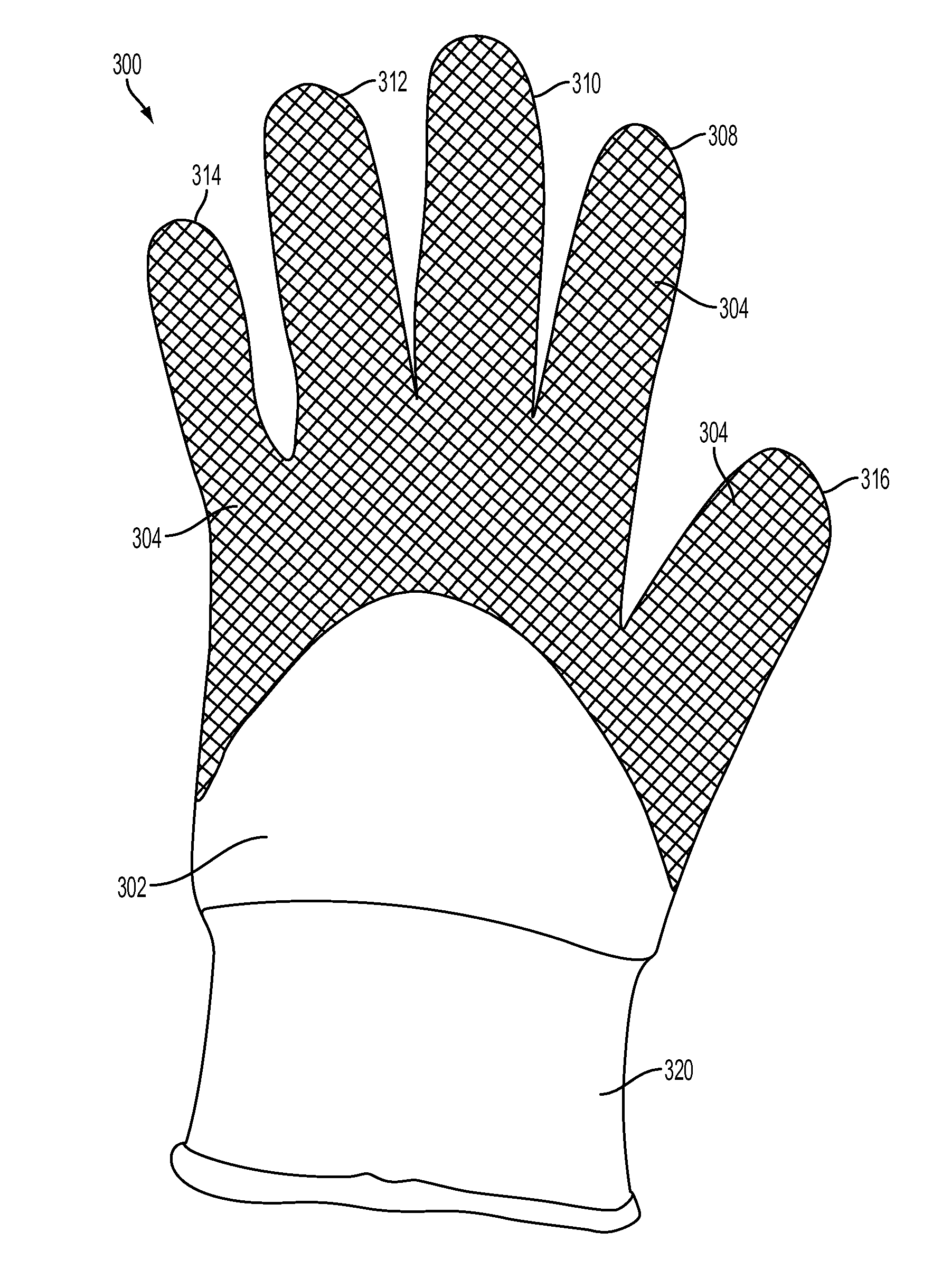

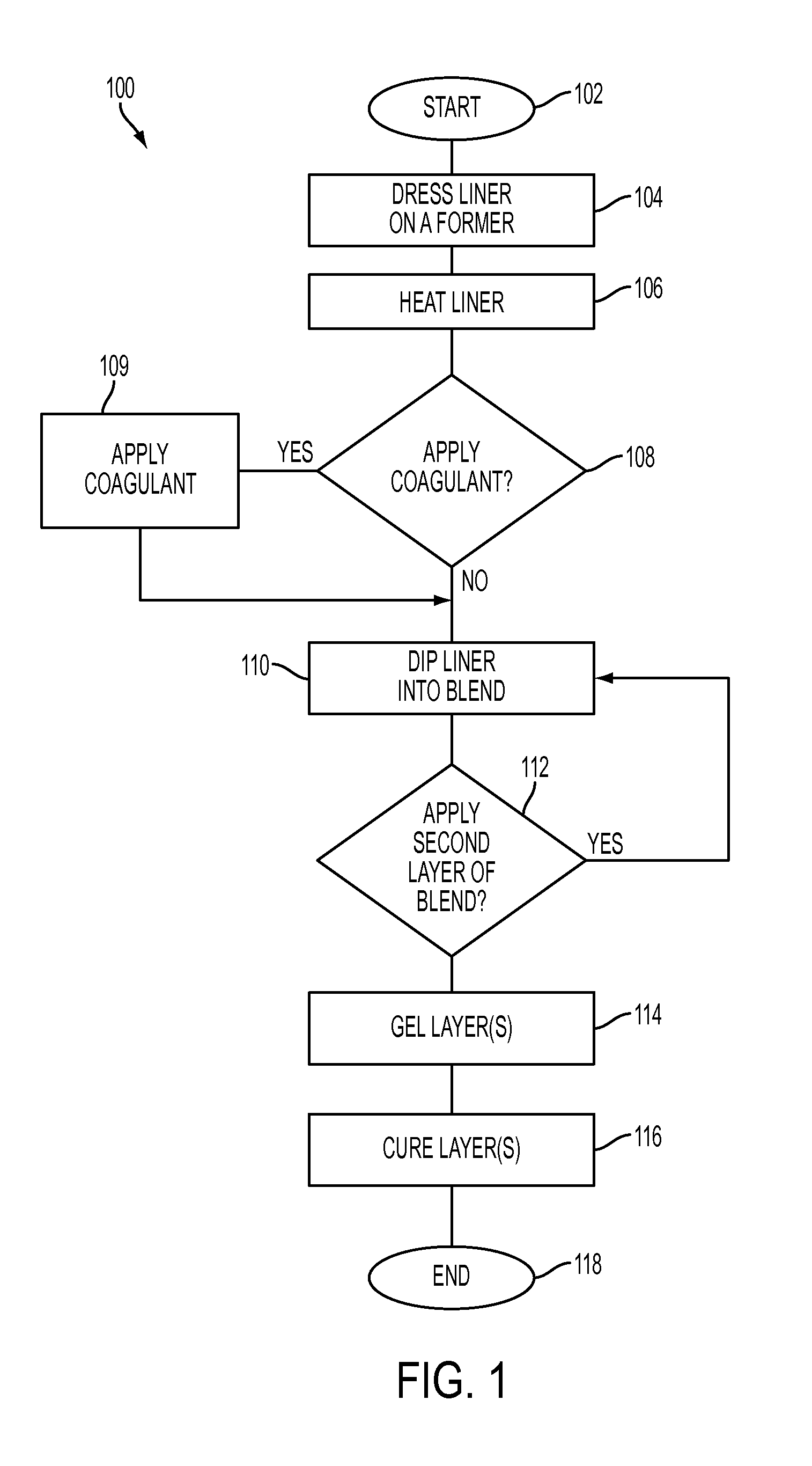

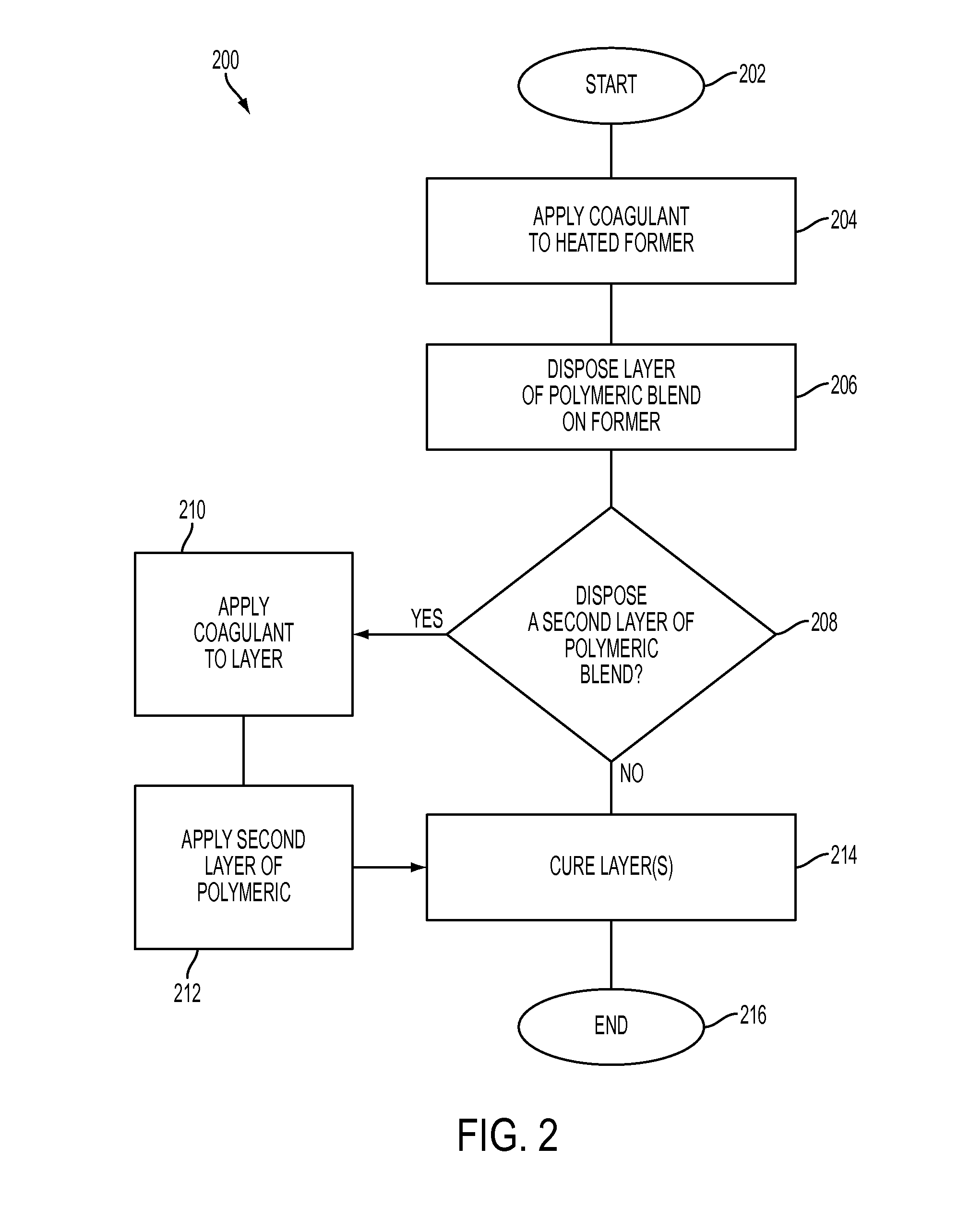

Polymer compositions including blends of approximately 90 to approximately 60 percent by weight acrylonitrile butadiene copolymer and approximately 10 to approximately 40 percent by weight polychloroprene copolymer are disclosed. Methods for manufacturing unsupported gloves and for supported gloves including a knitted liner with the polymer compositions, producing gloves having an ANSI abrasion resistance level 4, are also disclosed.

Owner:ANSELL

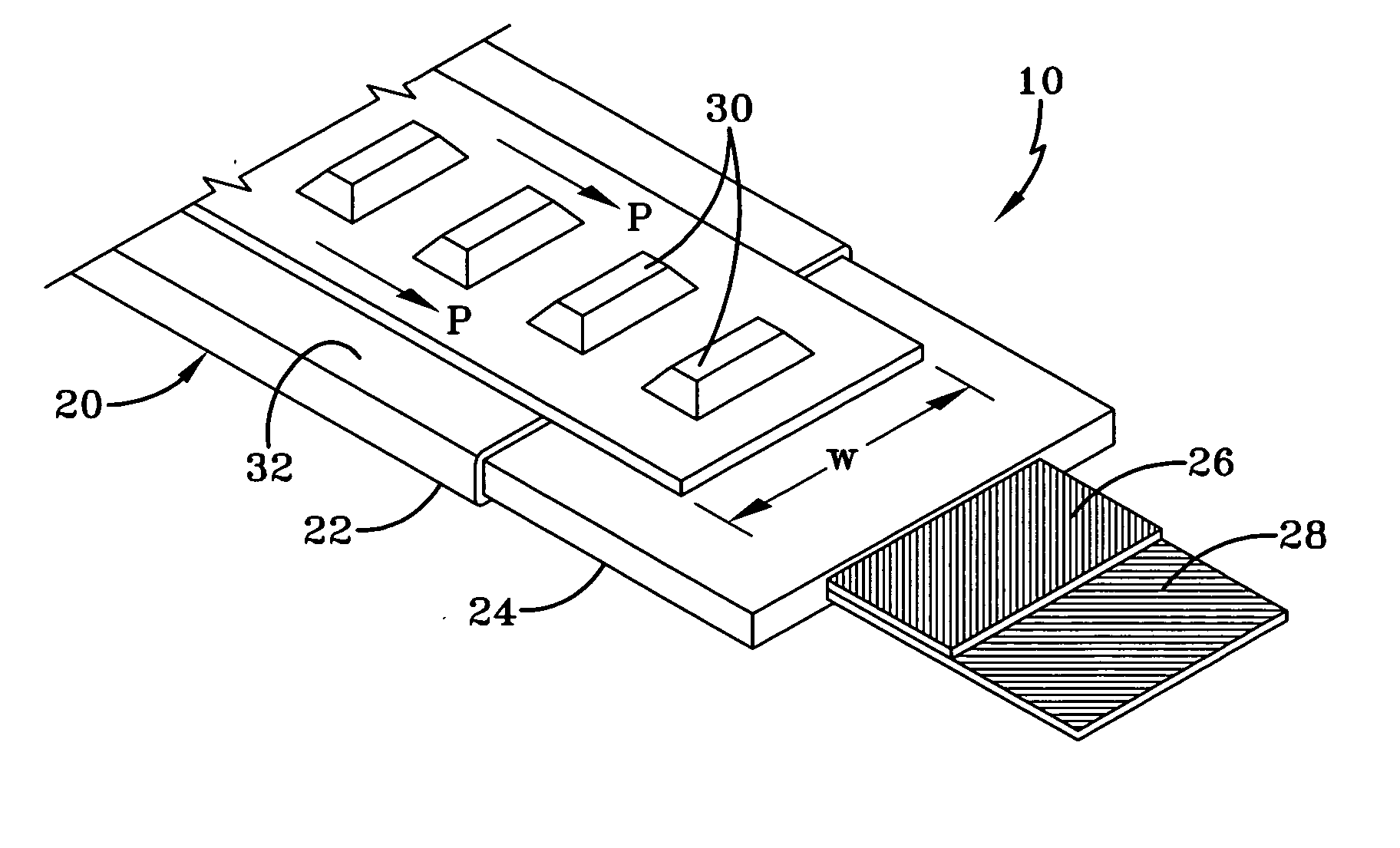

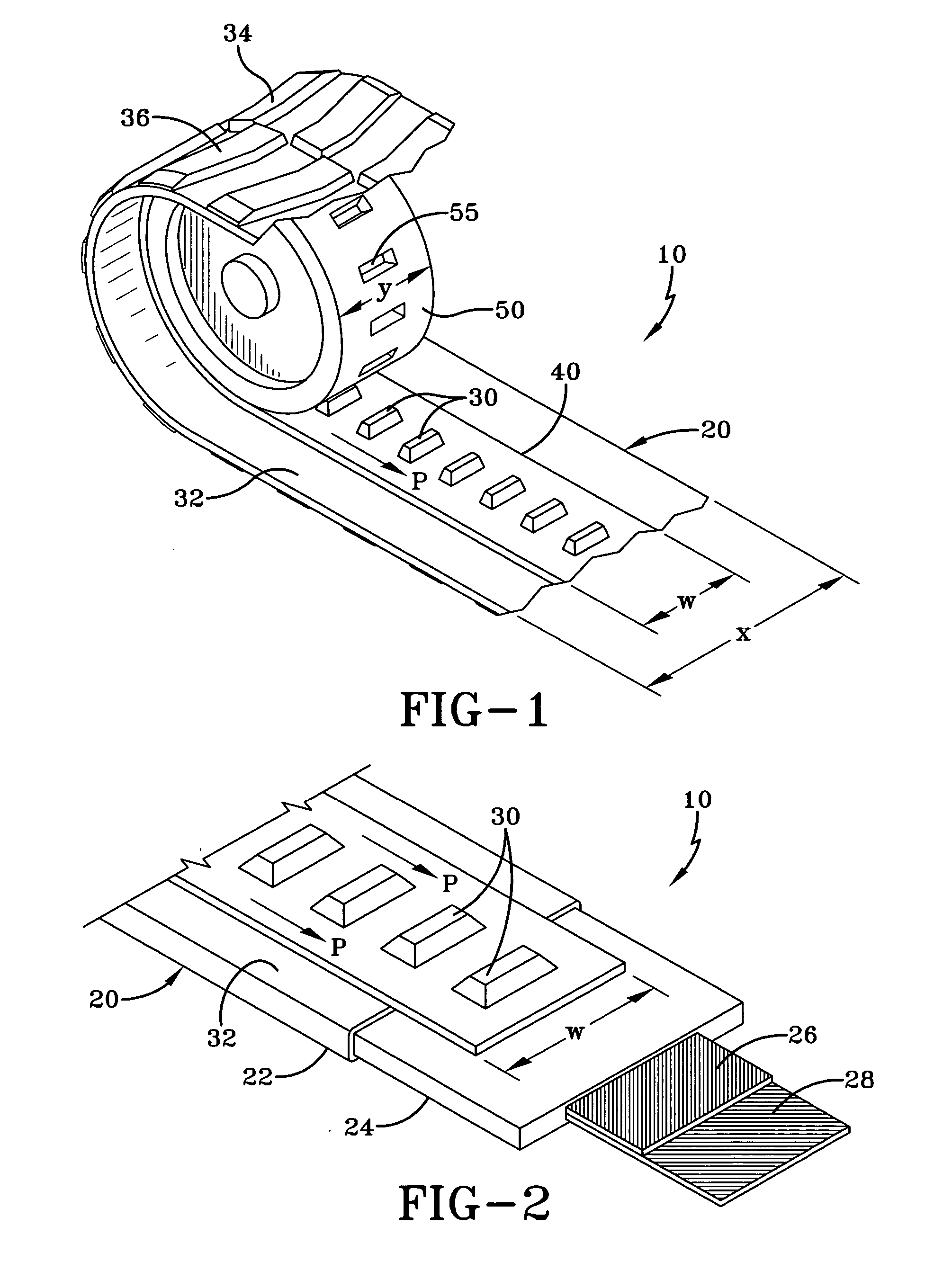

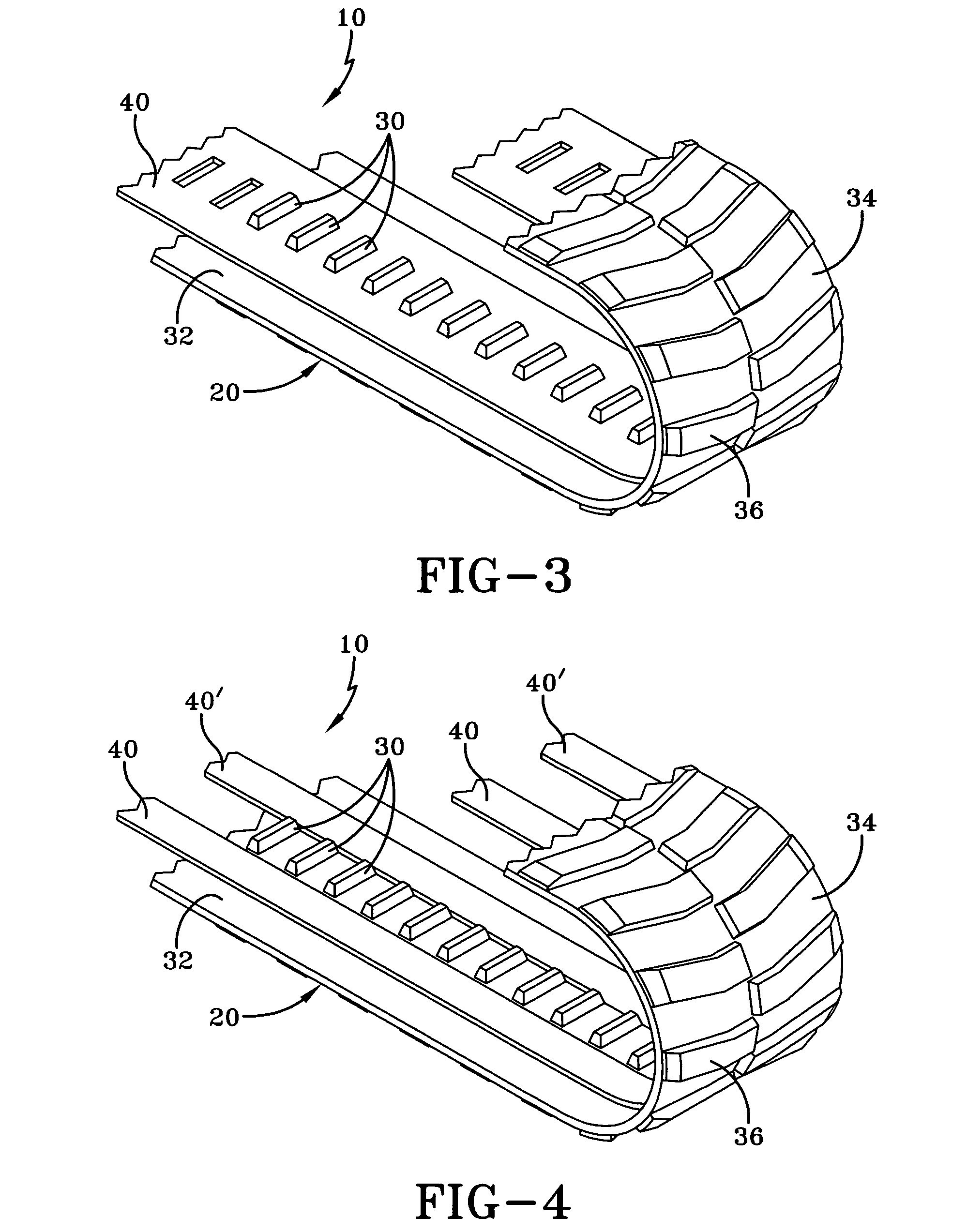

Rubber track

A rubber track having improved corrosion resistance along the wheel path provided by a polychloroprene layer operatively affixed to the inner surface of the track. The polychlorprene rubber layer may include a polychloroprene rubber selected from WRT type neoprene, W type neoprene, GRT type neoprene, and blends of WRT type neoprene, W type neoprene, and GRT type neoprene.

Owner:VEYANCE TECH

Elastomer compositions for use in a hydrocarbon resistant hose

InactiveUS20060270783A1Improve impermeabilityGood oil resistanceFibre treatmentFlexible pipesElastomerPolymer science

A heat tolerant, pressure resistant elastomeric composition comprising a blend of a first ethylene-vinyl ester copolymer and a second copolymer selected from the group consisting of chlorosulfonated polyethylene (CSM), chlorinated polyethylene (CPE), polychloroprene (CR), ethylene-acrylic elastomer (AEM), alkyl-acrylate copolymer (ACM), polyvinyl acetate (PVA), nitrile-butadiene rubber (NBR), hydrogenated nitrile-butadiene rubber (HNBR), and mixtures thereof; a hose manufactured therefrom; and a method for preparing the hose are described.

Owner:YH AMERICA

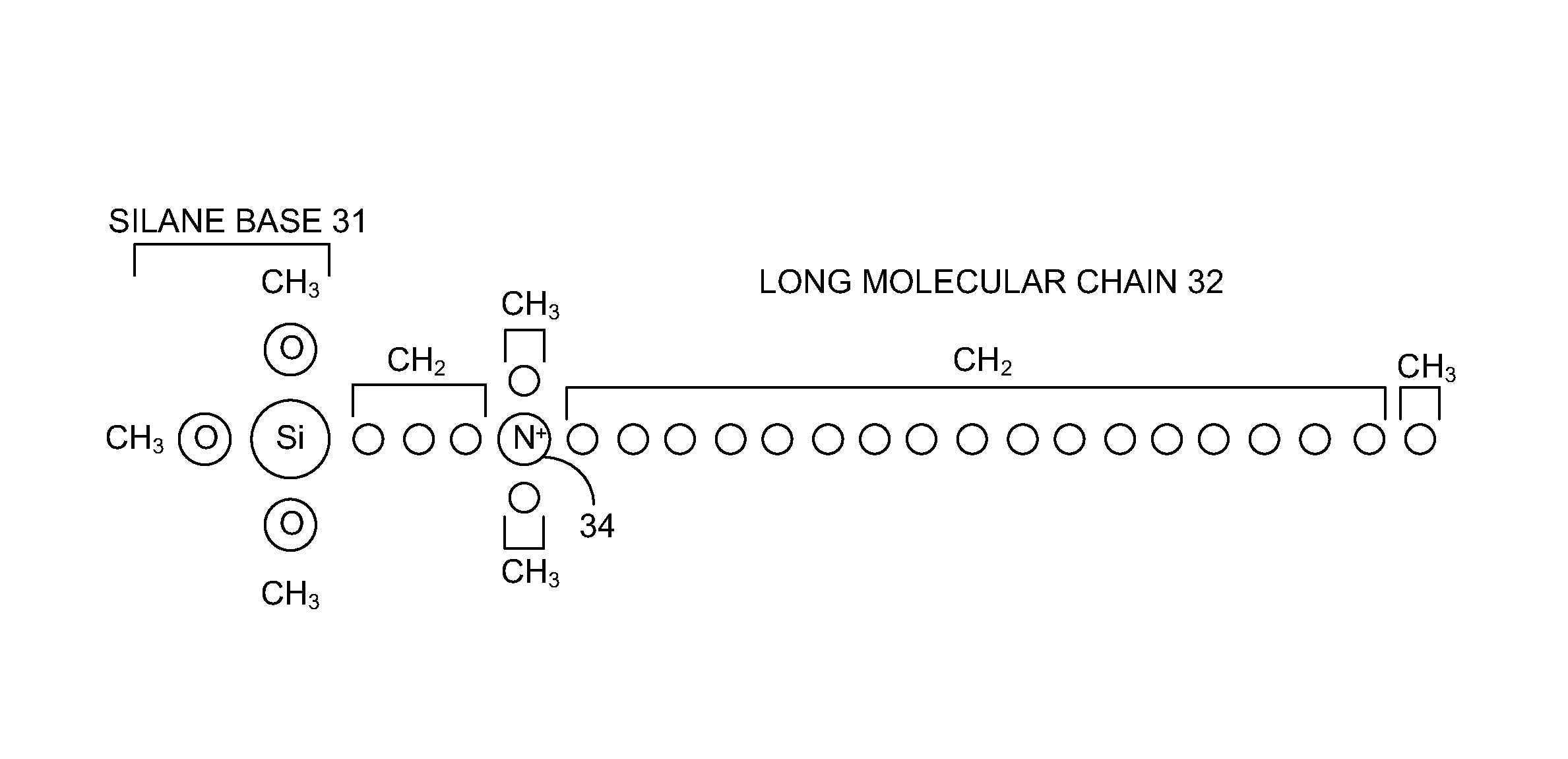

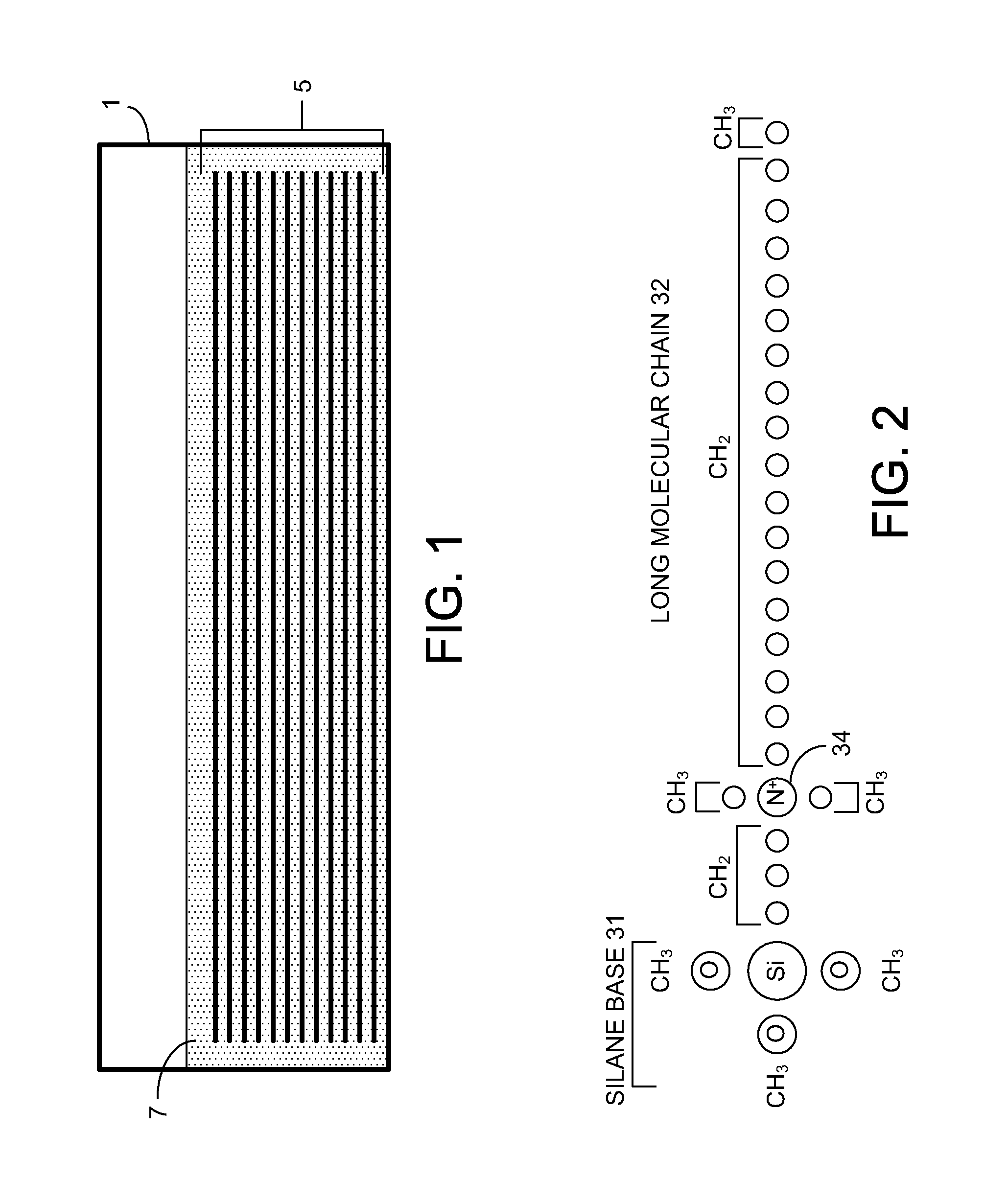

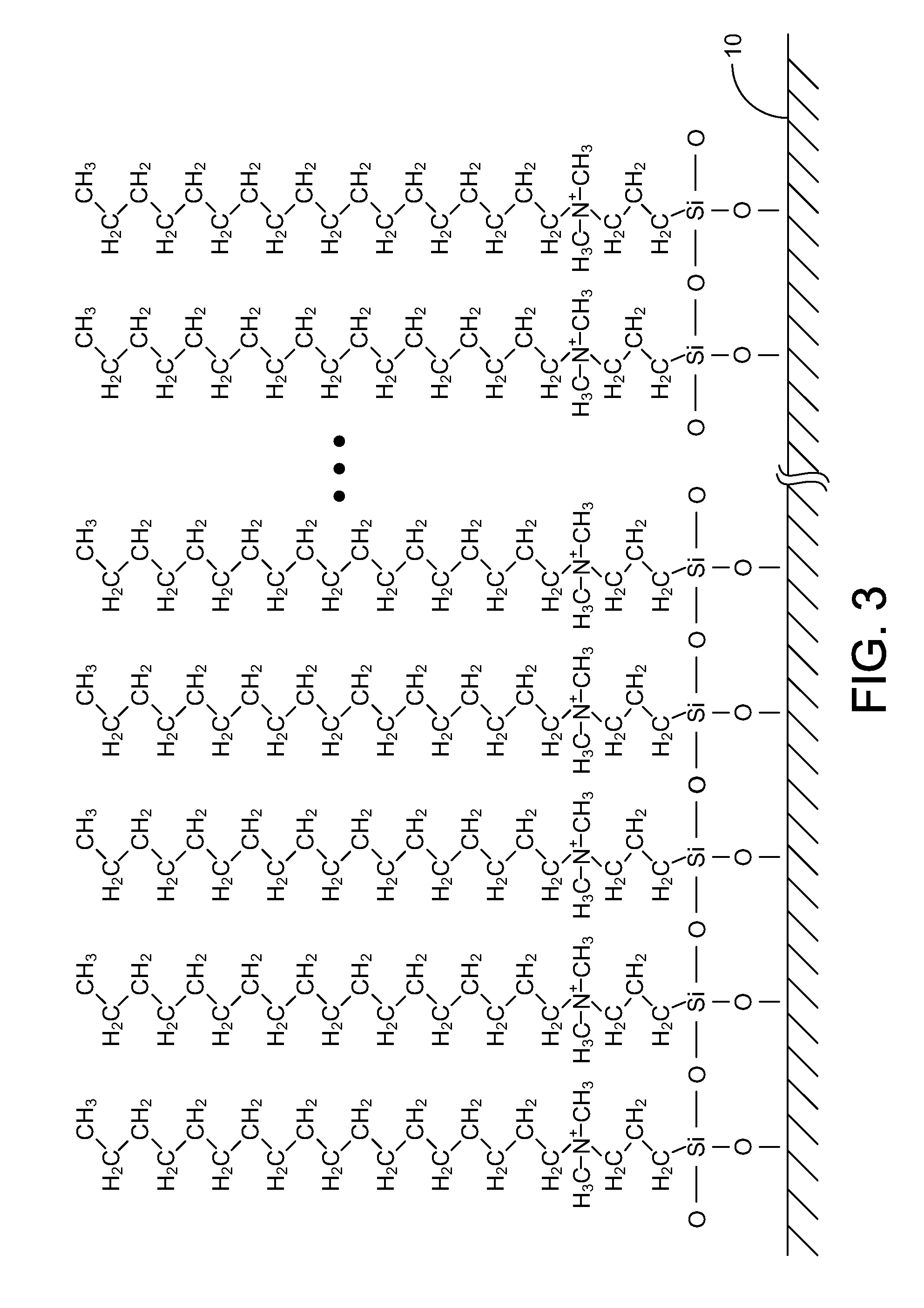

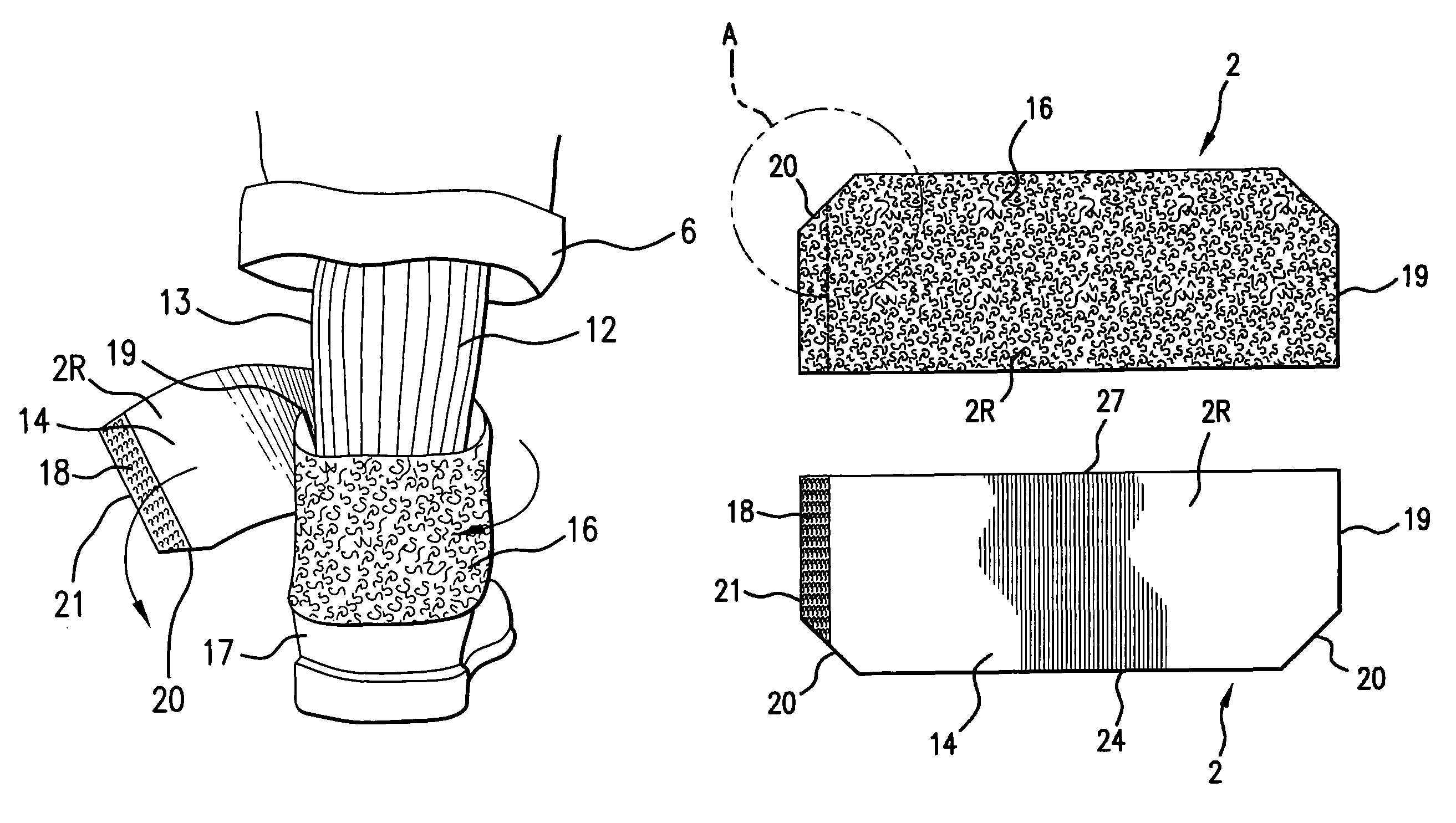

Antimicrobial isopropyl alcohol and organofunctional silane solution

A surface of an object may be treated using an antimicrobial wipe presoaked in an antimicrobial treatment solution. Alternatively, the antimicrobial treatment solution may be sprayed directly on the surface. The antimicrobial treatment solution may be made of isopropyl alcohol and an unreacted organofunctional silane antimicrobial substance that is substantially free from arsenic, silver, tin, heavy metals and polychlorinated phenols. The antimicrobial substance may include any one of: 3 trimethoxysilylpropyloctadecyldimethyl ammonium chloride; hyaluronan and its derivatives; triclosan; and a copolymer of chloropropyltrihydroxysilane and octadecylaminodimethyltrihydroxysilylpropyl ammonium chloride.

Owner:PARASOL MEDICAL

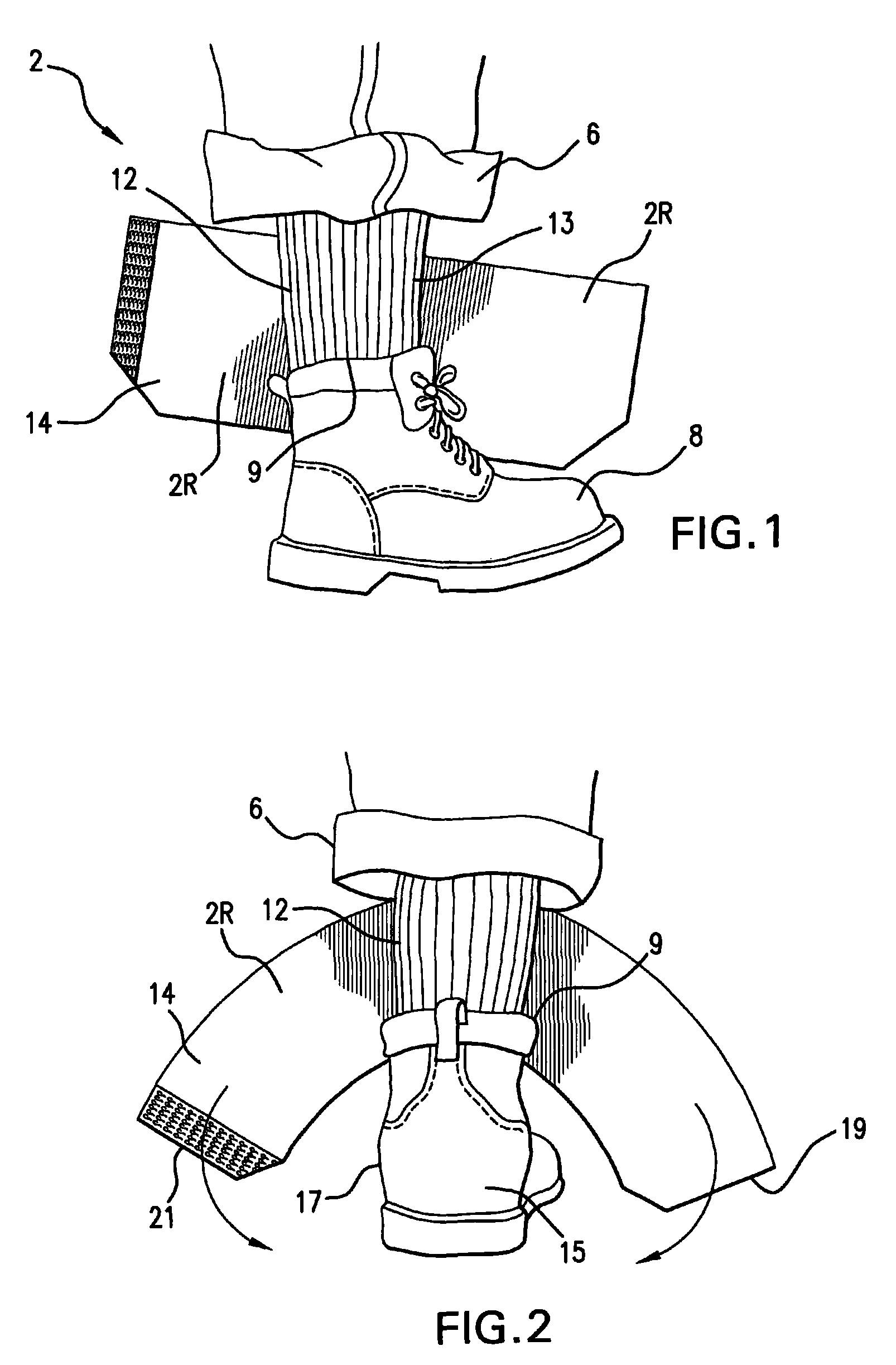

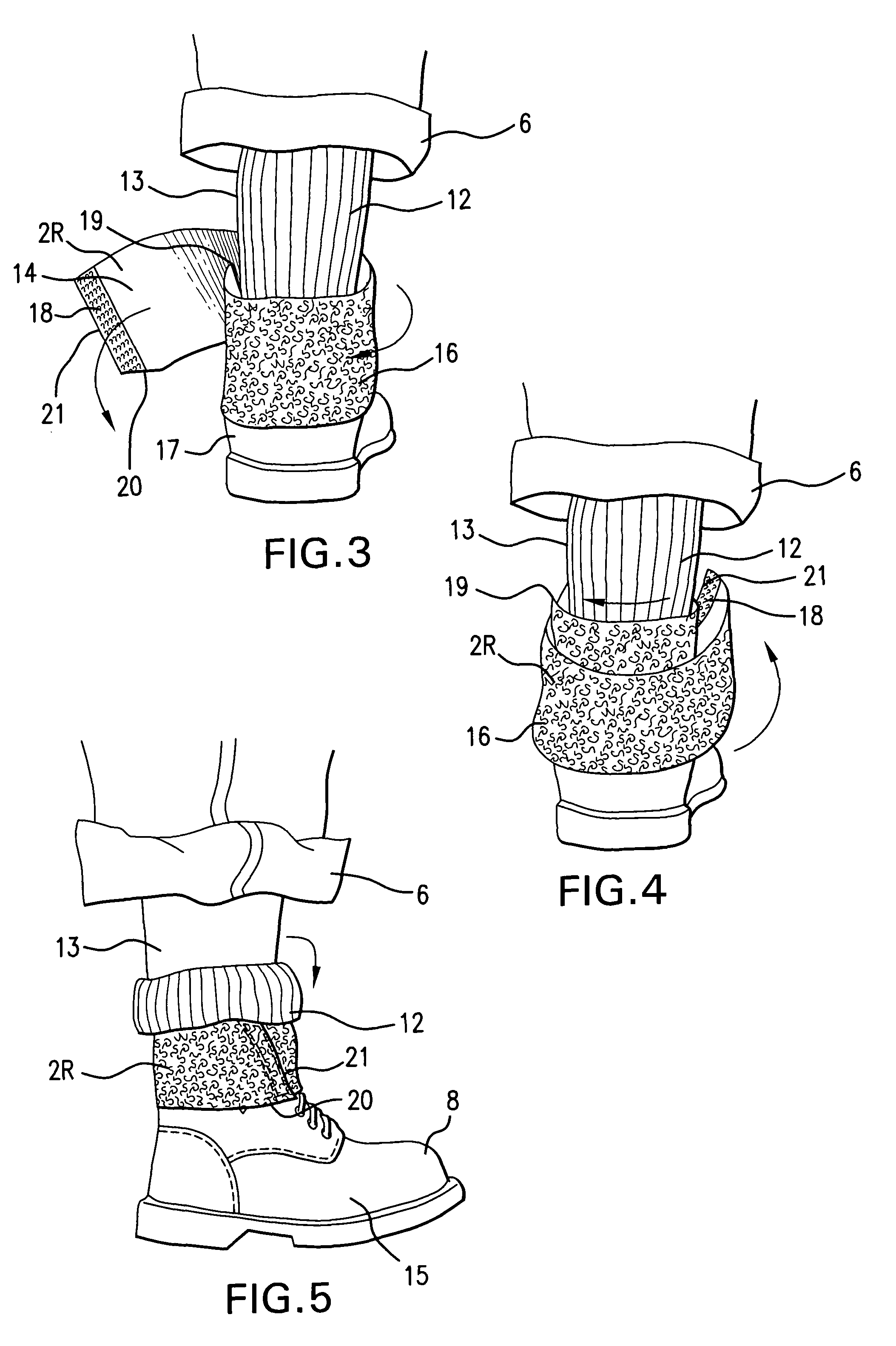

Flexible footwear cover

A flexible, elastic gaiter device designed to doubly encircle an upper rim of a wearer's footwear as well as the wearer's ankle to block ingress of debris into the footwear upper rim while bracing wearer's ankle protecting it against external and internal injury. The device is an elongated generally rectangular article. It comprises a closed loop nylon plush fabric outer layer to which is foamed an inner layer of synthetic rubber based on polychloroprene. At one end of the article's rubbery layer a fastener strip of hook elements is attached. The gaiter device is applied with its rubbery layer bridging the footwear upper rim, and firmly stretched to a double wrap, then secured by fastening the strip of hook elements with the plush outer layer. Lower edge corners of the article are diagonally cropped so that, when stretched, the lower edge will not have unsightly exposed portions.

Owner:KREHBIEL JAMES K

Elastomer compositions for use in a hydrocarbon resistant hose

InactiveUS20060263556A1High-temperature and pressure resistanceImproved hydrocarbon fluid resistanceLayered productsFibre treatmentElastomerAcrylic rubber

A vinyl ester composition; a tubular structure such as a hose for conveying fluids in an automotive engine cooler, transmission oil cooler, power transmission cooler, radiator or heater; and a method for preparing the tubular structure are described. The tubular structure includes a single layer of a heat tolerant, pressure resistant, hydrocarbon fluid impermeable composition comprising a copolymer of a first vinyl ester and a second vinyl ester, and one or more additives. The composition may, optionally contain a second polymeric component such as an ethylene-vinyl ester of a C2 to C6 carboxylic acid, chlorinated polyolefins, chlorosulfonated polyolefins, polychloroprene, ethylene-acrylic rubber, alkyl acrylate copolymer, polyvinyl acetate, acrylonitrile-butadiene rubber, hydrogenated acrylonitrile-butadiene rubber, ethylene-propylene-diene terpolymer, styrene-butadiene rubber, ethylene-propylene rubber, butyl rubber, cis-polybutadiene, cis-polyisoprene, polyurethane, polyamide and combinations thereof.

Owner:YH AMERICA

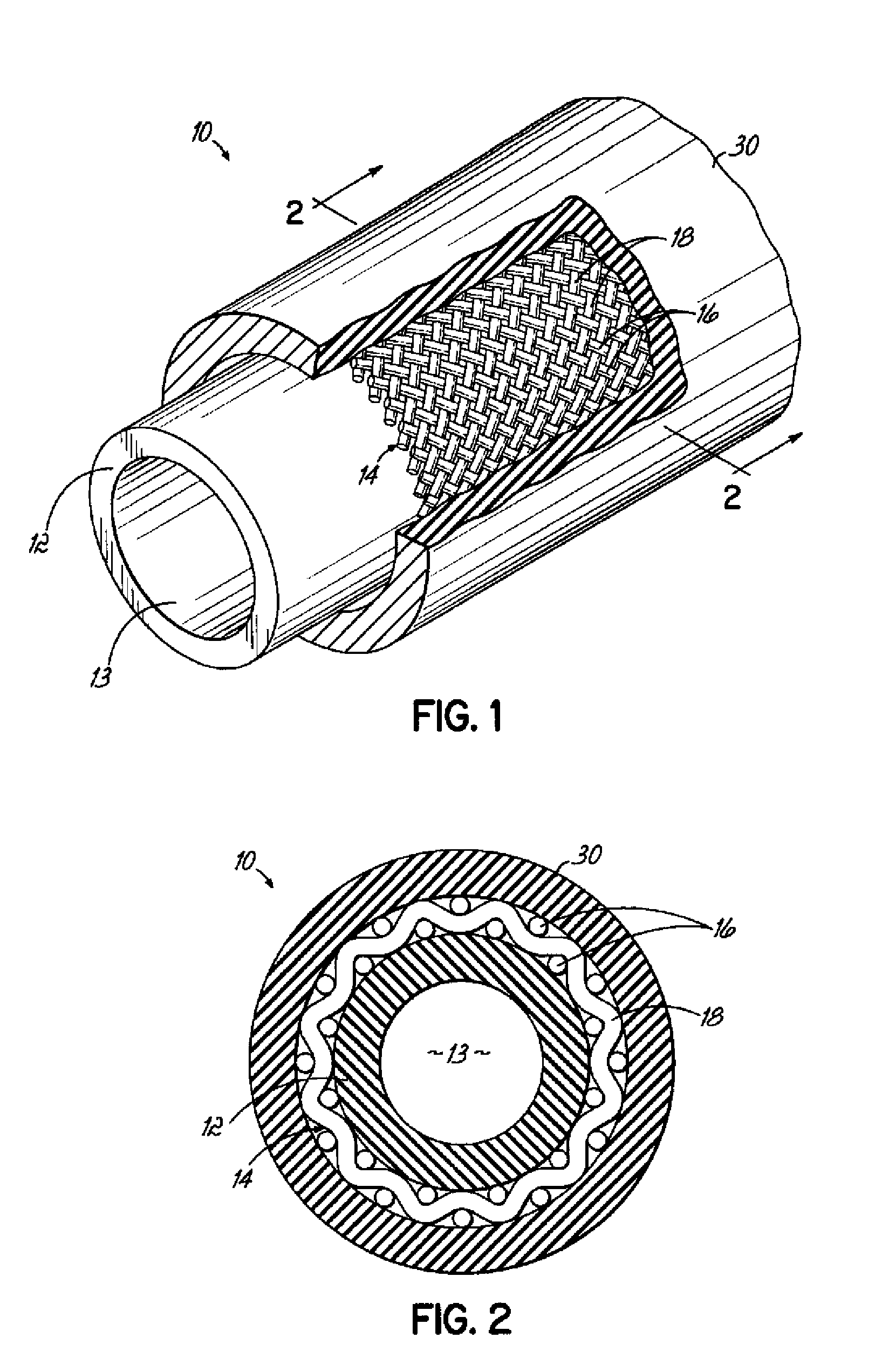

Fluid resistant high temperature hose

InactiveUS20120090720A1Improve the immunityWithout compromising flexural characteristic and burst strengthSynthetic resin layered productsFlexible pipesElastomerBursting strength

The present invention is based on the unexpected discovery that the fluid resistance of hoses can be greatly enhanced by adding a chlorinated paraffin to a chlorinated polyethylene elastomer or a chlorosulfonated polyethylene elastomer which is used as the tubular inner core layer of the hose. Hoses made using this approach offer the advantage of having improved resistance to modern automotive fluids, including power steering fluid, transmission fluid, and the like, without compromising flexural characteristics or burst strength. Accordingly, the hoses of this invention provide a longer service life and better reliability then hoses made utilizing conventional technology. The present invention more specifically discloses a hose which is comprised of (1) an elastomeric tubular inner core layer defining a lumen, (2) a friction layer, and (3) an elastomeric cover, wherein the elastomeric tubular inner core layer is comprised of (i) a chlorinated elastomer selected from the group consisting of epichlorohydrin, polychloroprene, chlorinated polyethylene and chlorosulfonated polyethylene, (ii) 1 phr to 50 phr of a chlorinated paraffin, and (iii) 30 phr to 120 phr of carbon black. It is typically preferred for the chlorinated elastomer to be chlorinated polyethylene or chlorosulfonated polyethylene.

Owner:CONTITECH USA INC

Elastomer compositions for use in a hydrocarbon resistant hose

InactiveUS20050059763A1High-temperature and pressure resistanceIncrease fluid resistanceSpecial tyresFlexible pipesElastomerPolyolefin

A vinyl ester composition; a tubular structure such as a hose for conveying fluids in an automotive engine cooler, transmission oil cooler, power transmission cooler, radiator or heater; and a method for preparing the tubular structure are described. The tubular structure includes a single layer of a heat tolerant, pressure resistant, hydrocarbon fluid impermeable composition comprising a copolymer of a first vinyl ester and a second vinyl ester, and one or more additives. The composition may, optionally contain a second polymeric component such as an ethylene-vinyl ester of a C2 to C6 carboxylic acid, chlorinated polyolefins, chlorosulfonated polyolefins, polychloroprene, ethylene-acrylic rubber, alkyl acrylate copolymer, polyvinyl acetate, acrylonitrile-butadiene rubber, hydrogenated acrylonitrile-butadiene rubber, ethylene-propylene-diene terpolymer, styrene-butadiene rubber, ethylene-propylene rubber, butyl rubber, cis-polybutadiene, cis-polyisoprene, polyurethane, polyamide and combinations thereof.

Owner:DAYCO PROD INC

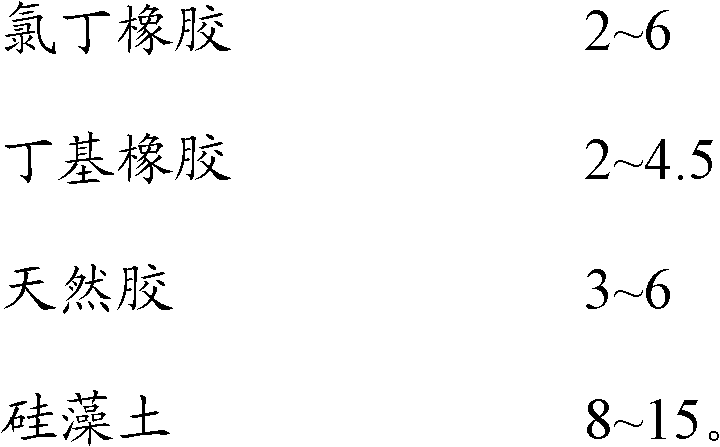

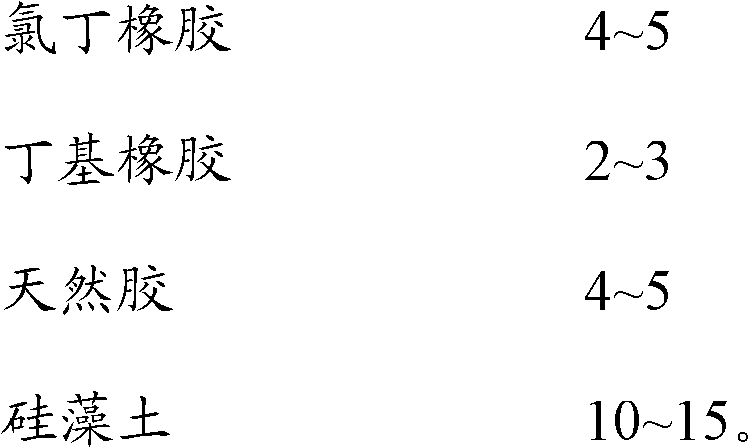

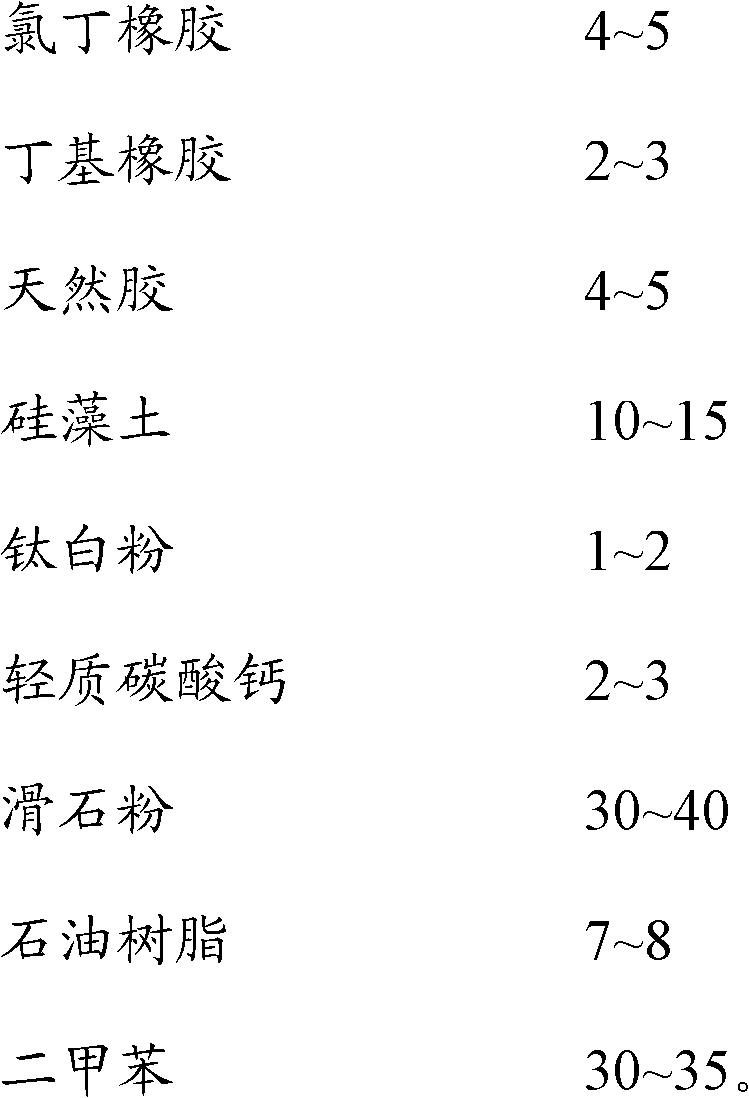

Diatomite chloroprene type sealant

InactiveCN102504722AHigh porosityStrong absorptionNatural rubber adhesivesNon-macromolecular adhesive additivesWeather resistanceHeat resistance

The invention belongs to the technical field of sealants, and specifically to a diatomite chloroprene type sealant. The diatomite polychloroprene type sealant is prepared by carrying out milling and kneading the following materials according to a formula, wherein the materials comprise chloroprene rubber, butyl rubber, natural rubber, diatomite, a reinforcing agent, a filler, a viscosity regulator, a vulcanizing agent, a stabilizer and other commonly used additives. According to the present invention, the diatomite has a special structure and physical properties, the other raw materials in the formula are reasonably selected, the ratio is appropriate, and the diatomite chloroprene type sealant has characteristics of good anti-aging performance, good weather resistance, strong heat resistance, strong wear resistance, rare sagging, good surface smoothness, environmental protection, and long service life, and can be used for family decoration and other fields.

Owner:TIANCHANG CITY TONGTIAN CHEM

Marine oils with reduced levels of contaminants

InactiveUS20040022923A1Lower Level RequirementsReduce pressureOrganic chemistryFatty-oils/fats refiningFuranPolycyclic aromatic hydrocarbon

A method is provided for the removal of polychlorinated contaminants including polychlorinated dioxins, furans, byphenyls, and polycyclic aromatic hydrocarbons from marine oils by a process that minimizes processing of the oil, and the degradation of polyunsaturated fatty acids. Also provided are marine oils such as cod liver oil obtained by the method of the invention than can be used otherwise unrefined as a source of economical, contaminant-reduced bulk marine oil.

Owner:LYSI HF

Non-asphaltic waterborne spraying rapid hardening rubber waterproof paint and its manufacturing method

ActiveCN103360933AEasy constructionConjugated diene hydrocarbon coatingsChloropene polymer coatingsWhole bodyMaterials science

The invention discloses a non-asphaltic waterborne spraying rapid hardening rubber waterproof paint which comprises a component A and a component B. The component A comprises the following substances: by weight, 14-25% of an anion butylbenzene emulsion, 18-25% of an anion polyurethane-silicone-acrylate emulsion, 10-15% of an anion polychloroprene emulsion, 0.1-0.3% of a dispersant, 0.1-0.3% of an antifoaming agent, 0.2-0.4% of a nonionic emulsifier, 0.1-0.3% of an anion emulsifier, 3-6% of a low-temperature modifier, and 38-43% of ultrafine powdered steatile. The component B comprises the following substances: by weight, 80-90% of industrial calcium chloride, 3-6% of industrial sodium chloride, and 7-14% of a composite ferro-aluminium polymer. According to the invention, an advanced refrigeration and cold-spray technology is adopted; construction is simple; the whole body has advantages of seamlessness, no stripping and no water breakthrough; and the paint can obstruct various harmful gases, and is a waterproof, antiseep, anticorrosion, chemicals-resistant, anti-cracking, anti-puncturing, damping and noise-reducing protective coating.

Owner:KESHUN WATERPROOF TECH CO LTD

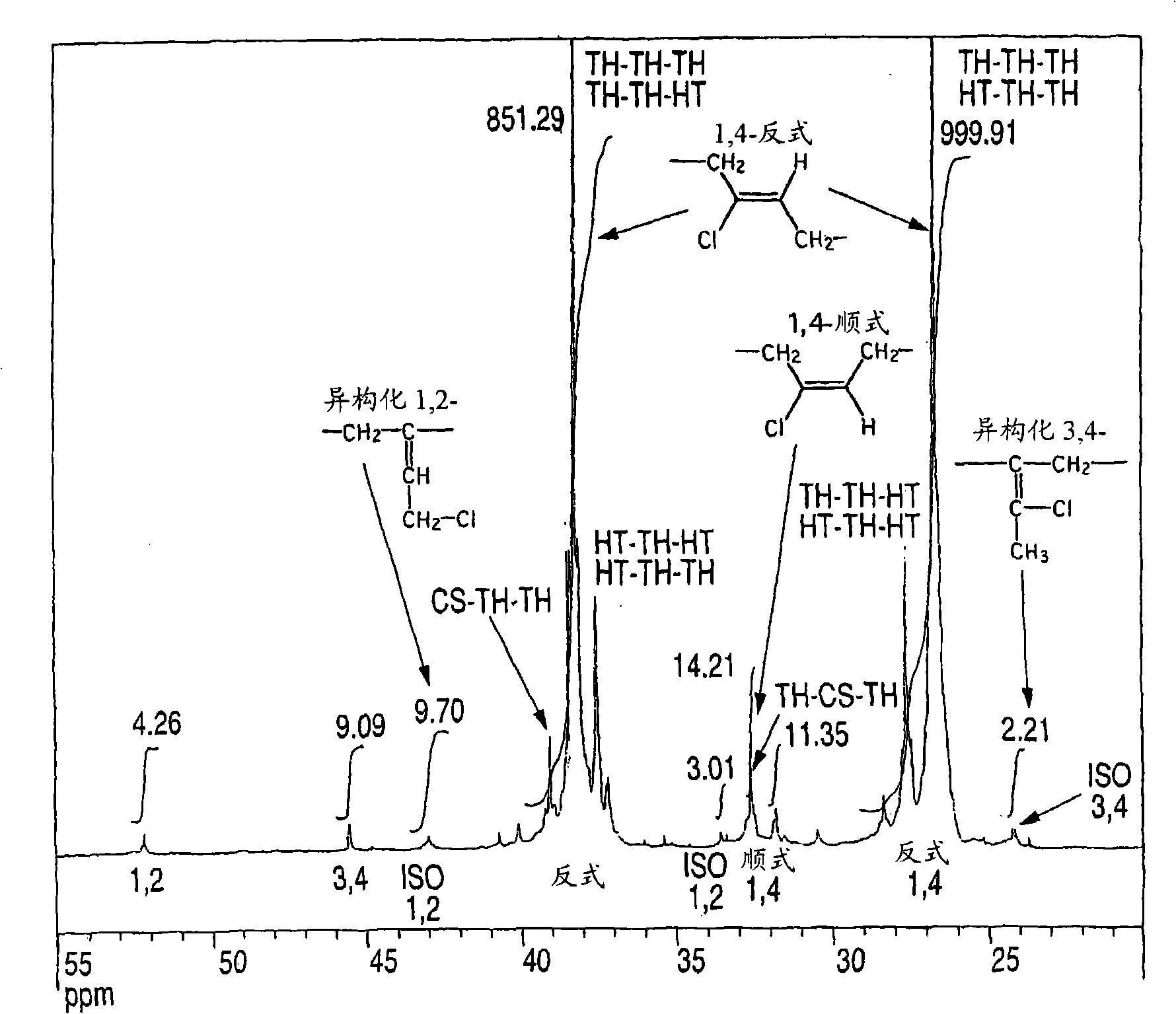

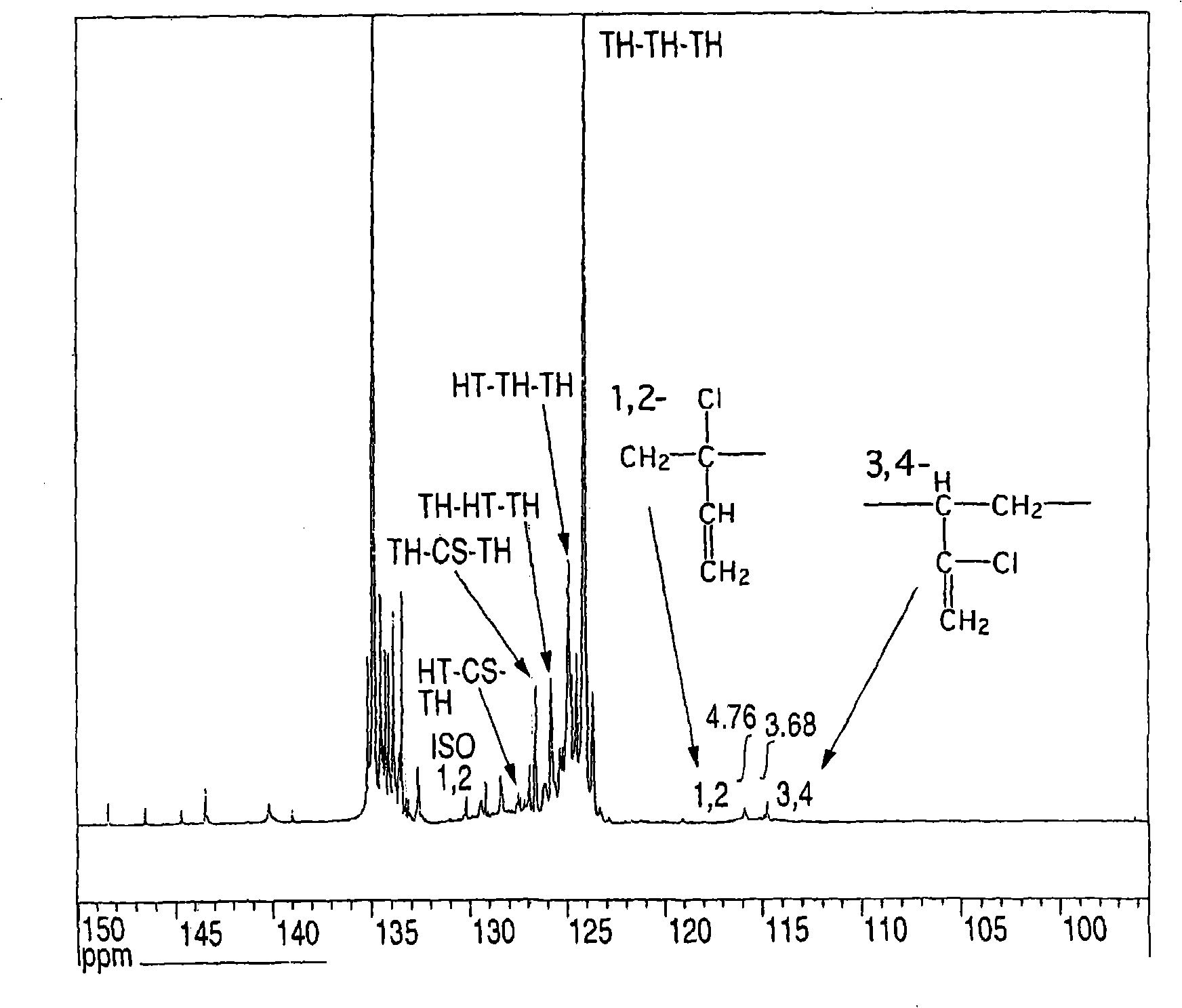

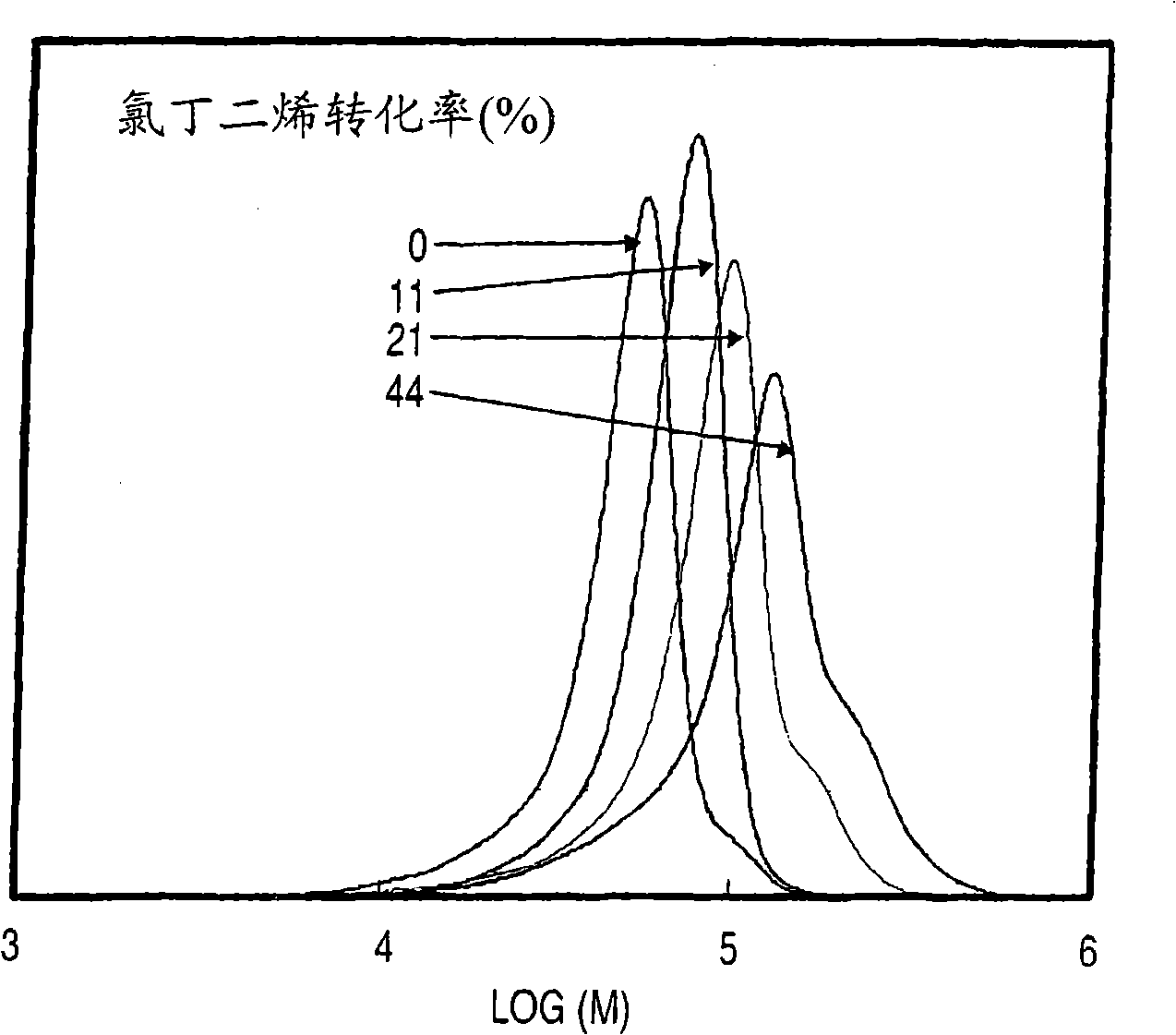

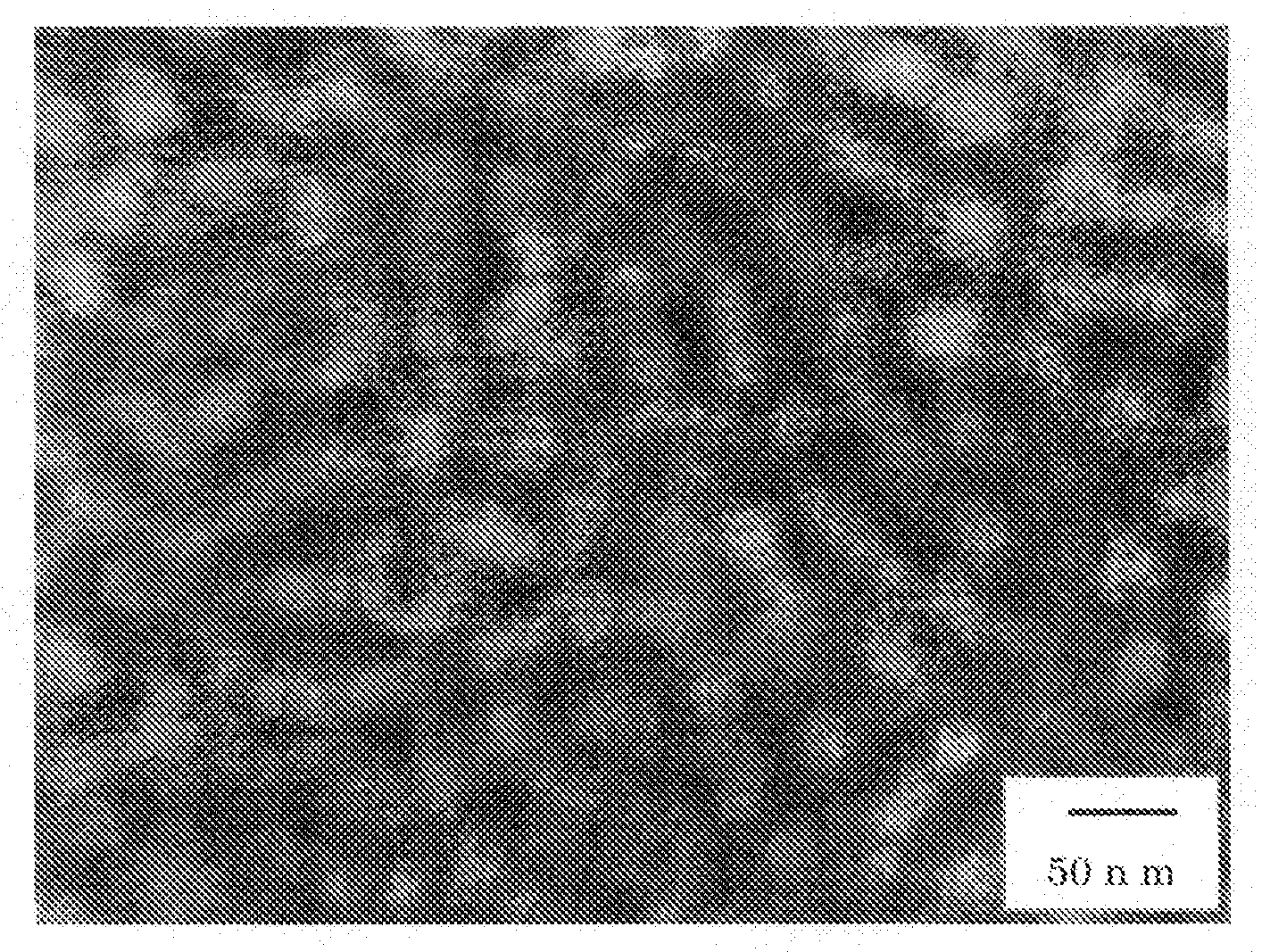

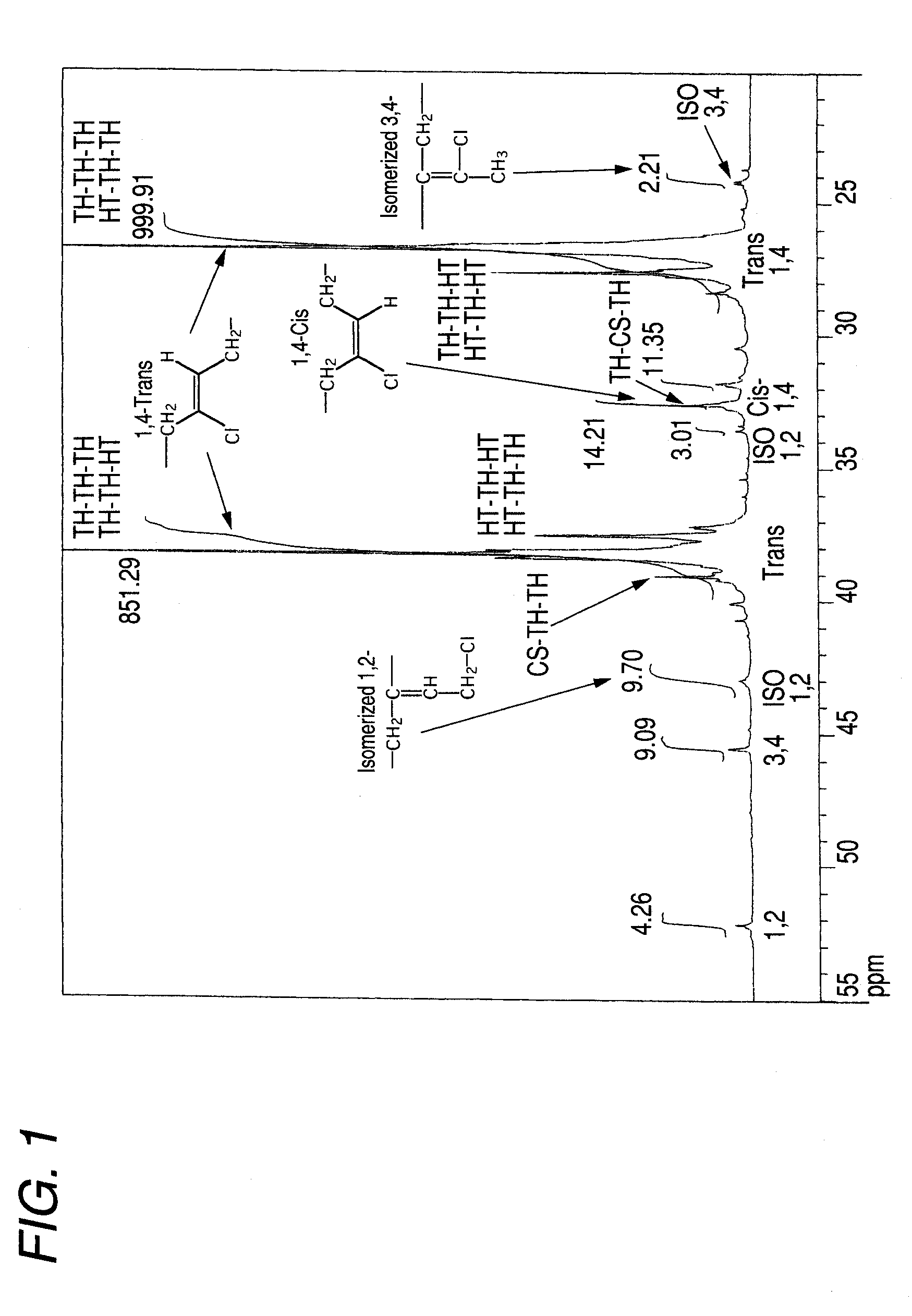

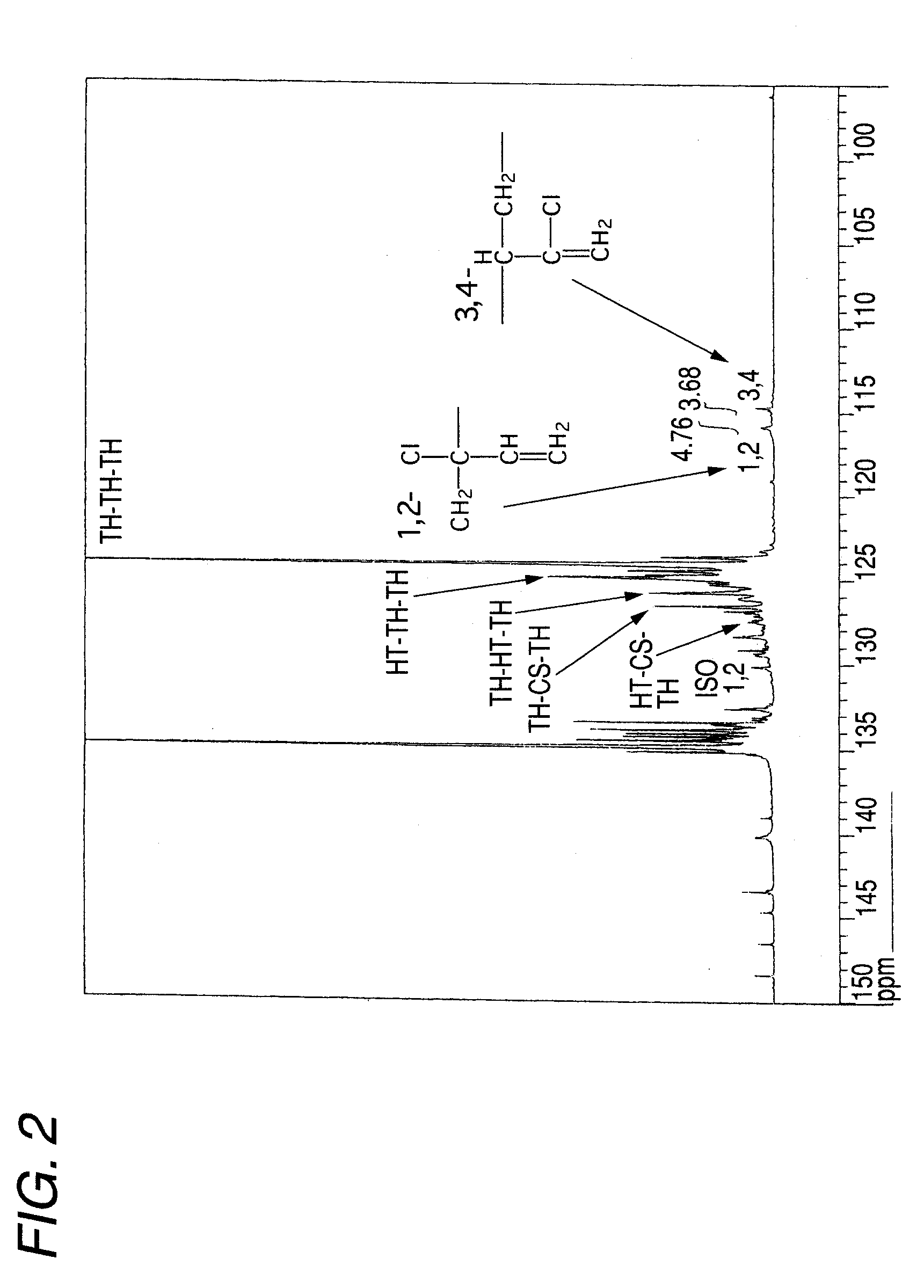

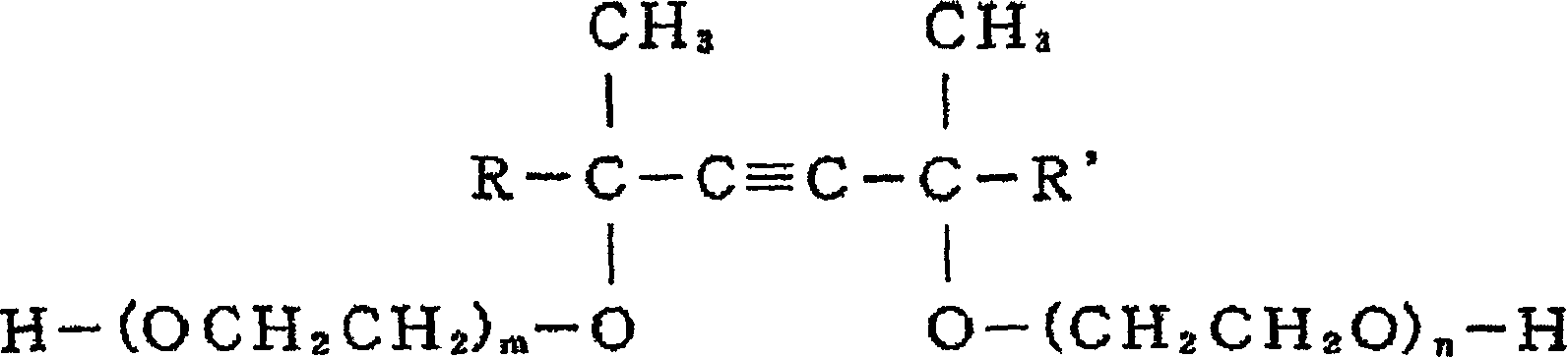

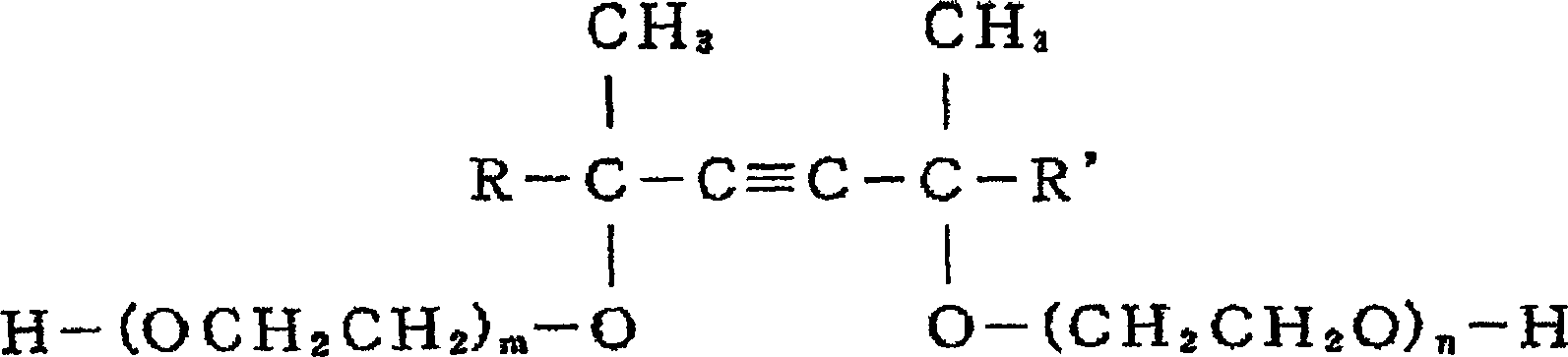

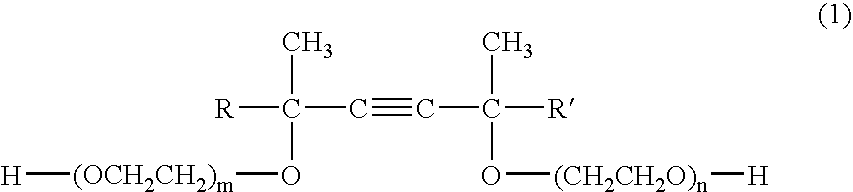

Chloroprene block copolymer and soapless polychloroprene latex, and processes for production of copolymer and latex

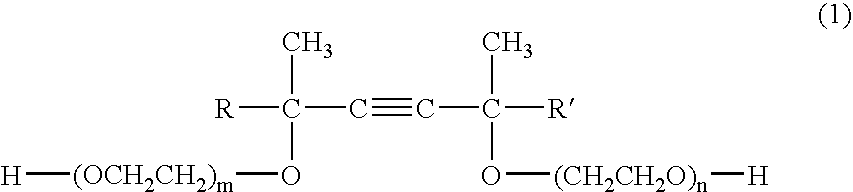

Disclosed are a novel polychloroprene copolymer, a soapless polychloroprene latex, and a process for producing the copolymer or latex in a simple manner, which are intended to be used for the improvement in adhesion property and water resistance of a conventional polychloroprene adhesive or the improvement in oil resistance and adhesion property of a conventional styrene-butadiene block copolymer. A chloroprene block copolymer comprising a polymer (A) having the composition represented by the general formula (1) in the description and a chloroprene polymer (B), the polymer (A) being linked to one terminal or both termini of the chloroprene polymer (B), and the total amount of the 1,2-bond and the isomerized 1,2-bond in the chloroprene polymer (B) as measured by carbon-13 nuclear magnetic resonance spectrometry being 2.0 mol% or less; a soapless polychloroprene latex comprising an amphiphilic chloroprene copolymer having a hydrophobic chloroprene polymer and a hydrophilic oligomer or polymer having an acidic functional group attached to the hydrophobic chloroprene polymer and 2 wt% or less of an emulsifying agent; and a process for producing the chloroprene block copolymer or soapless polychloroprene latex.

Owner:TOSOH CORP

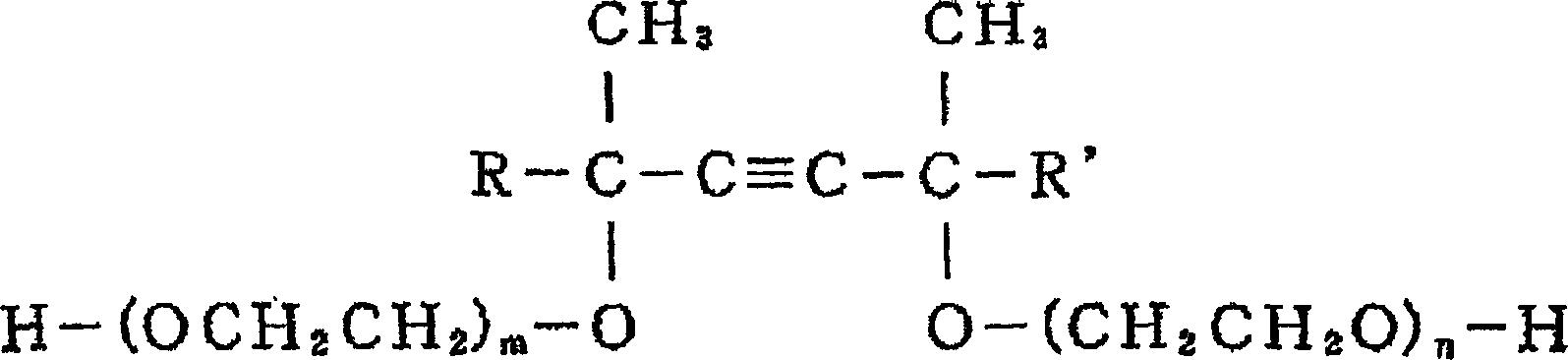

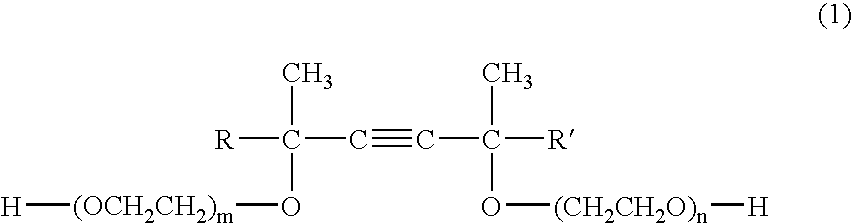

Chloroprene-based block copolymer, soapless polychloroprene-based latex, and processes for producing the same

InactiveUS20090036608A1Improve adhesionGood adhesivenessCarboxyl rubber adhesivesGraft polymer adhesivesPolymer scienceAdhesive

An object of the present invention is to provide a novel polychloroprene-based copolymer, a soapless polychloroprene-based latex, and a process for producing the same in a simple and convenient manner, which are intended to be used for the improvement in adhesiveness and water resistance of a conventional polychloroprene adhesive or the improvement in oil resistance and adhesiveness of a styrene-butadiene block copolymer.The invention relates to a chloroprene-based block copolymer comprising a polymer (A) having a composition represented by the following formula (1) and a chloroprene-based polymer (B), the polymer (A) being linked to one terminal or both terminals of the chloroprene-based polymer (B), and the total amount of the 1,2-bond and the isomerized 1,2-bond in the chloroprene-based polymer (B) as determined by carbon-13 nuclear magnetic resonance spectrometry being 2.0 mol % or less; a soapless polychloroprene-based latex comprising an amphipathic chloroprene copolymer having a hydrophobic chloroprene-based polymer and a hydrophilic oligomer or polymer having an acidic functional group linked to the hydrophobic chloroprene-based polymer and 2 wt % or less of an emulsifying agent; and a process for producing the same:wherein U represents hydrogen, a methyl group, a cyano group, or a substituted alkyl group; V represents a phenyl group, a substituted phenyl group, a carboxyl group, an alkoxycarbonyl group, a substituted alkoxycarbonyl group, an allyloxycarbonyl group, a substituted allyloxycarbonyl group, an acyloxy group, a substituted acyloxy group, an amido group, or a substituted amido group; X represents hydrogen, a methyl group, chlorine, or a cyano group; Y represents hydrogen, chlorine, or a methyl group; Q represents a polymerization residue of maleic anhydride, citraconic acid, maleic acid, fumalic acid, a maleate ester, or a fumalate ester; and k, n, and m each represents an integer of 0 or more.

Owner:TOSOH CORP

Aqueous adhesive dispersions

Aqueous polymer dispersions based on polyurethanes that include a) at least one polyurethane dispersion having a mean particle size of from 60 to 350 nm, and b) at least one polychloroprene dispersion having a mean particle size of from 60 to 300 nm, and c) at least one aqueous silicon dioxide dispersion having a particle diameter of the SiO2 particles of from 1 to 400 nm. The dispersion can be prepared by admixing a mixture of b) and c) with a). The dispersions can be used in adhesive compositions.

Owner:BAYER MATERIALSCIENCE AG

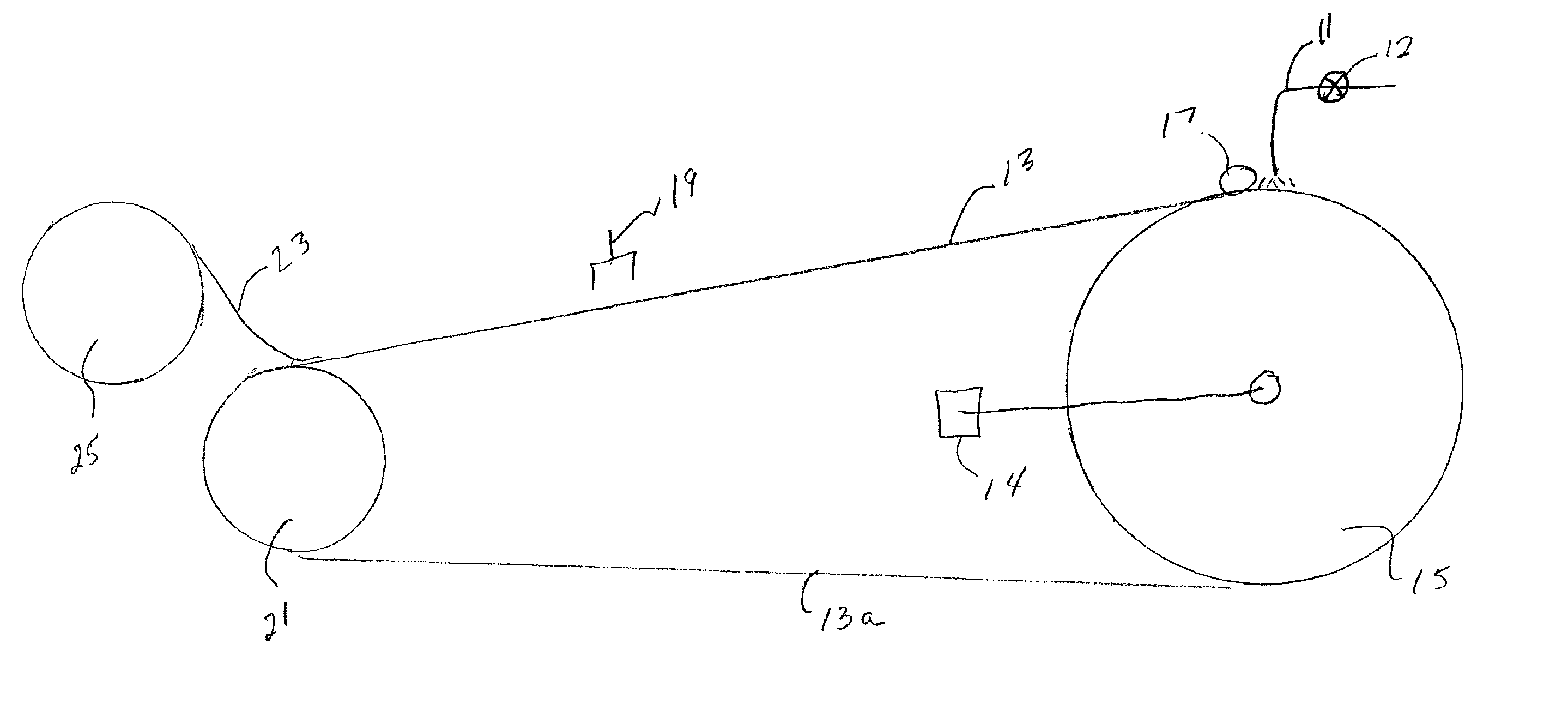

Method and apparatus for manufacturing latex free materials

InactiveUS6887061B2Improve abilitiesConfectioneryRoller and ring machinesPolychloroprenesEngineering

Owner:DUKAL LLC

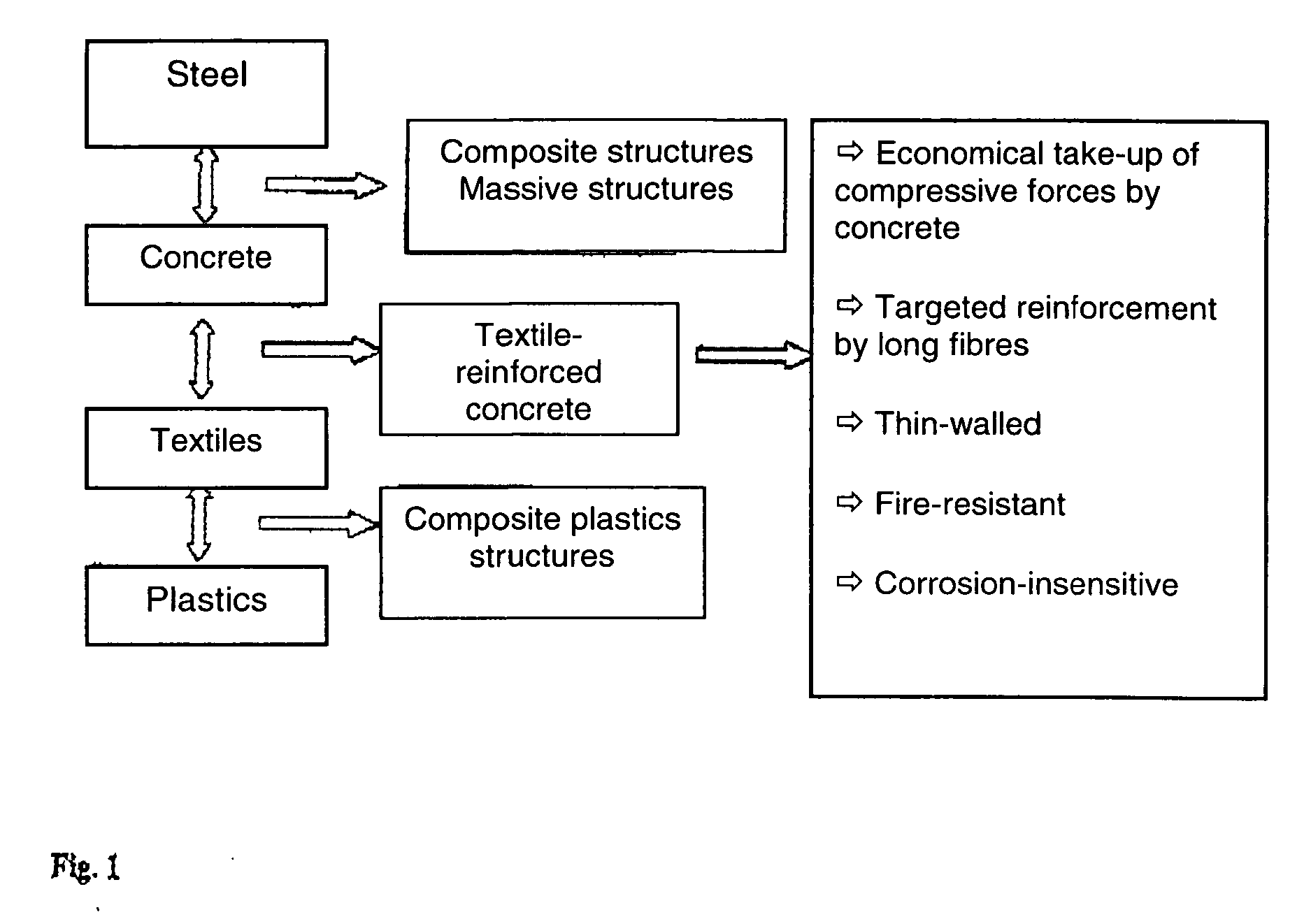

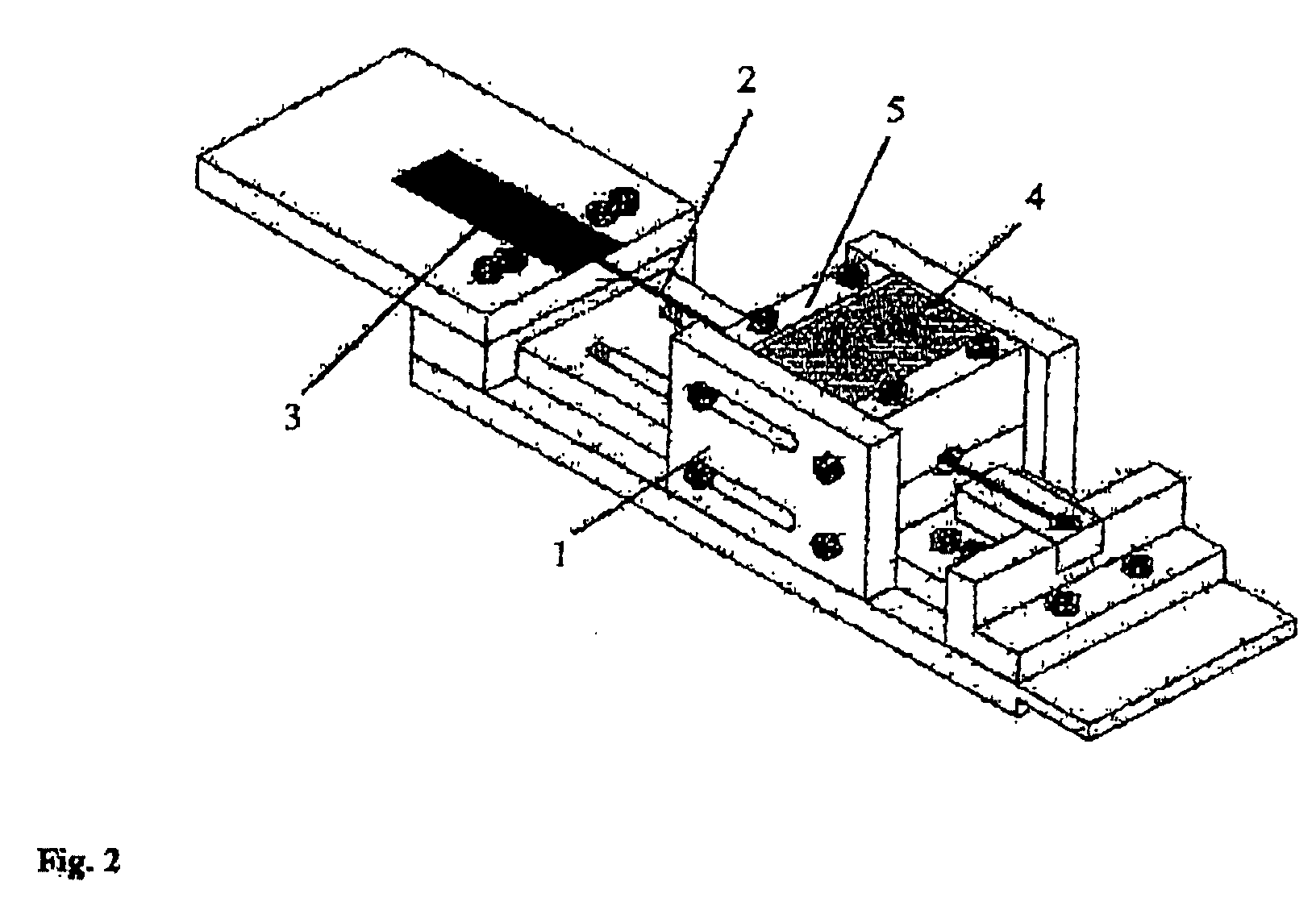

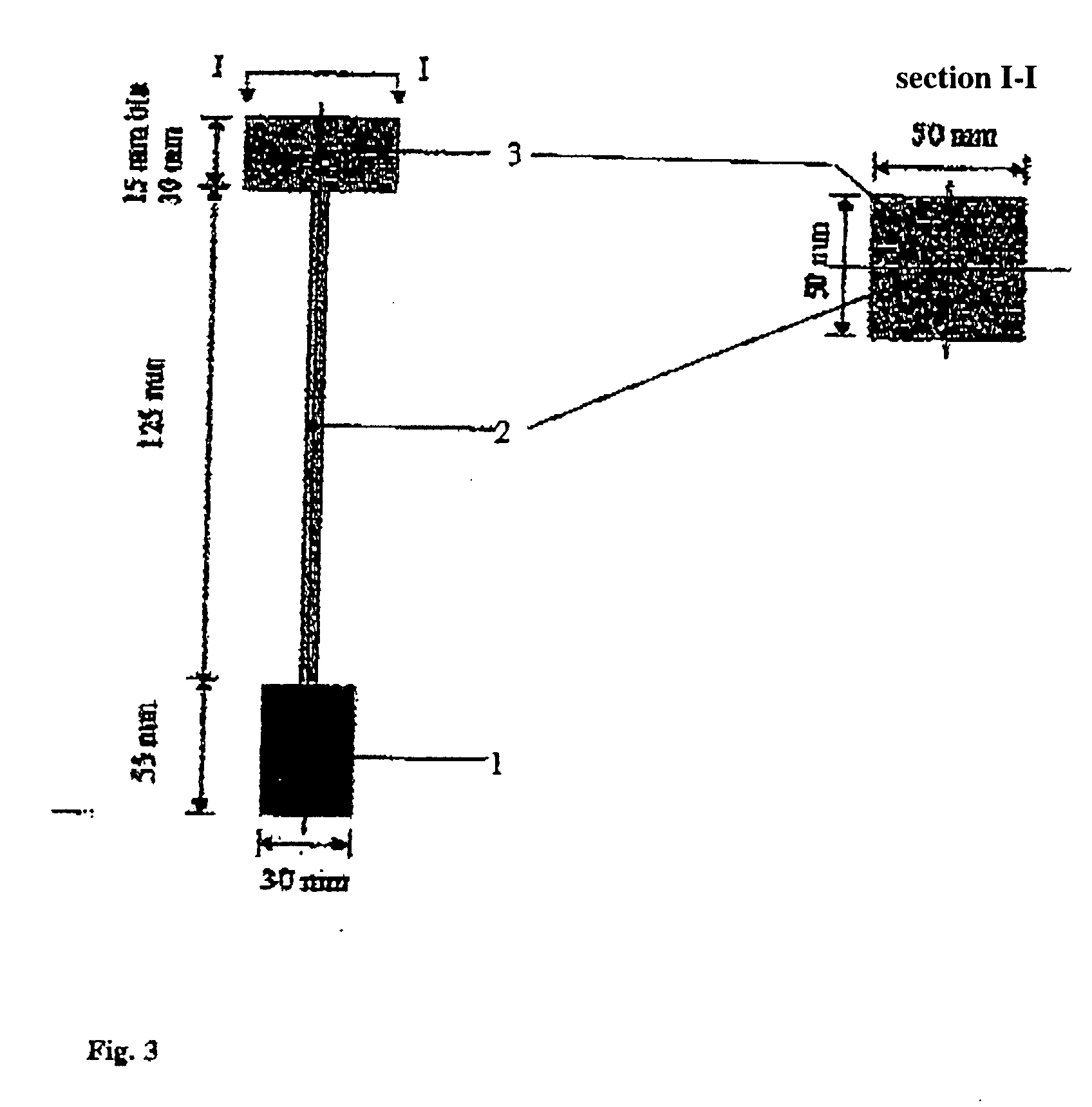

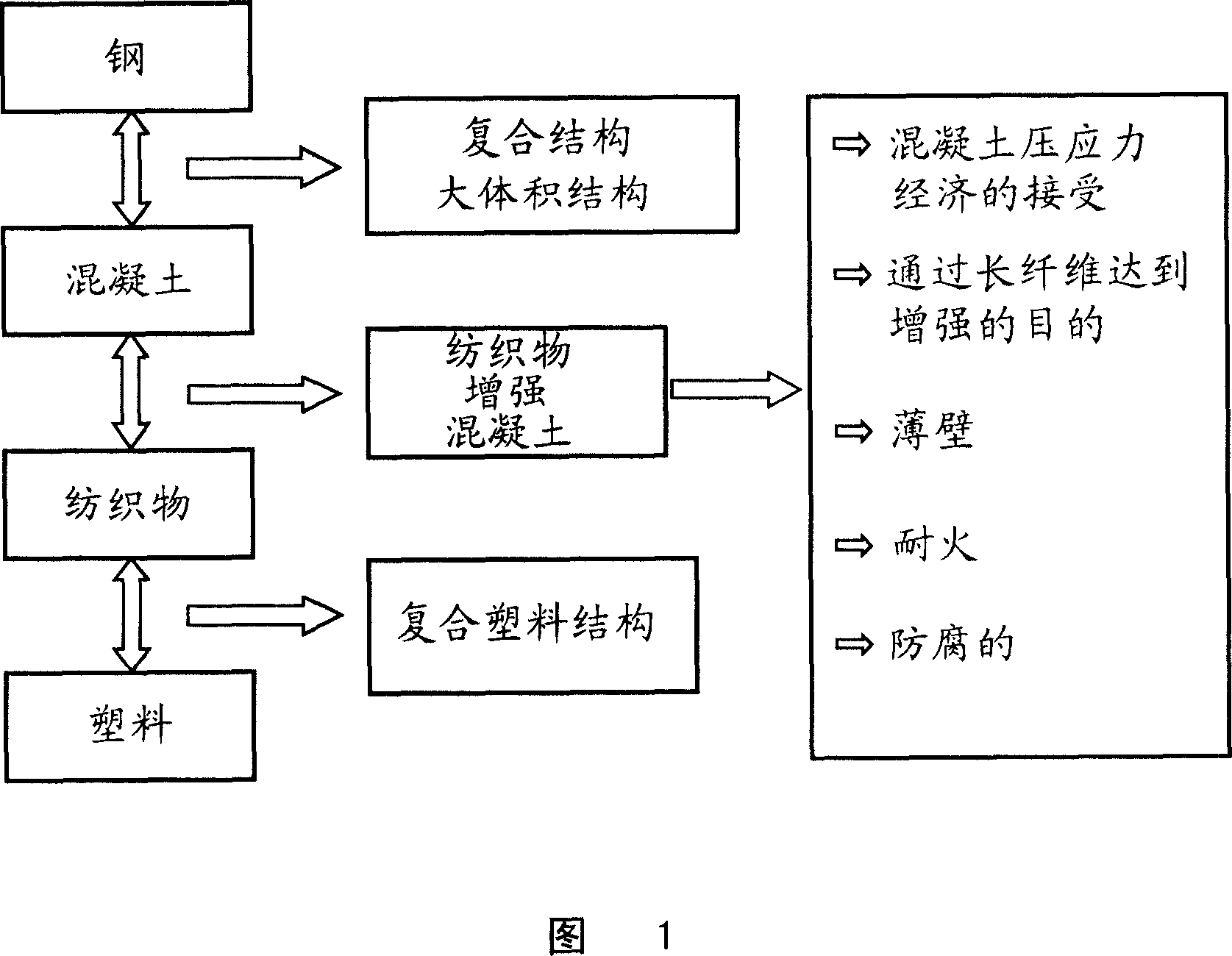

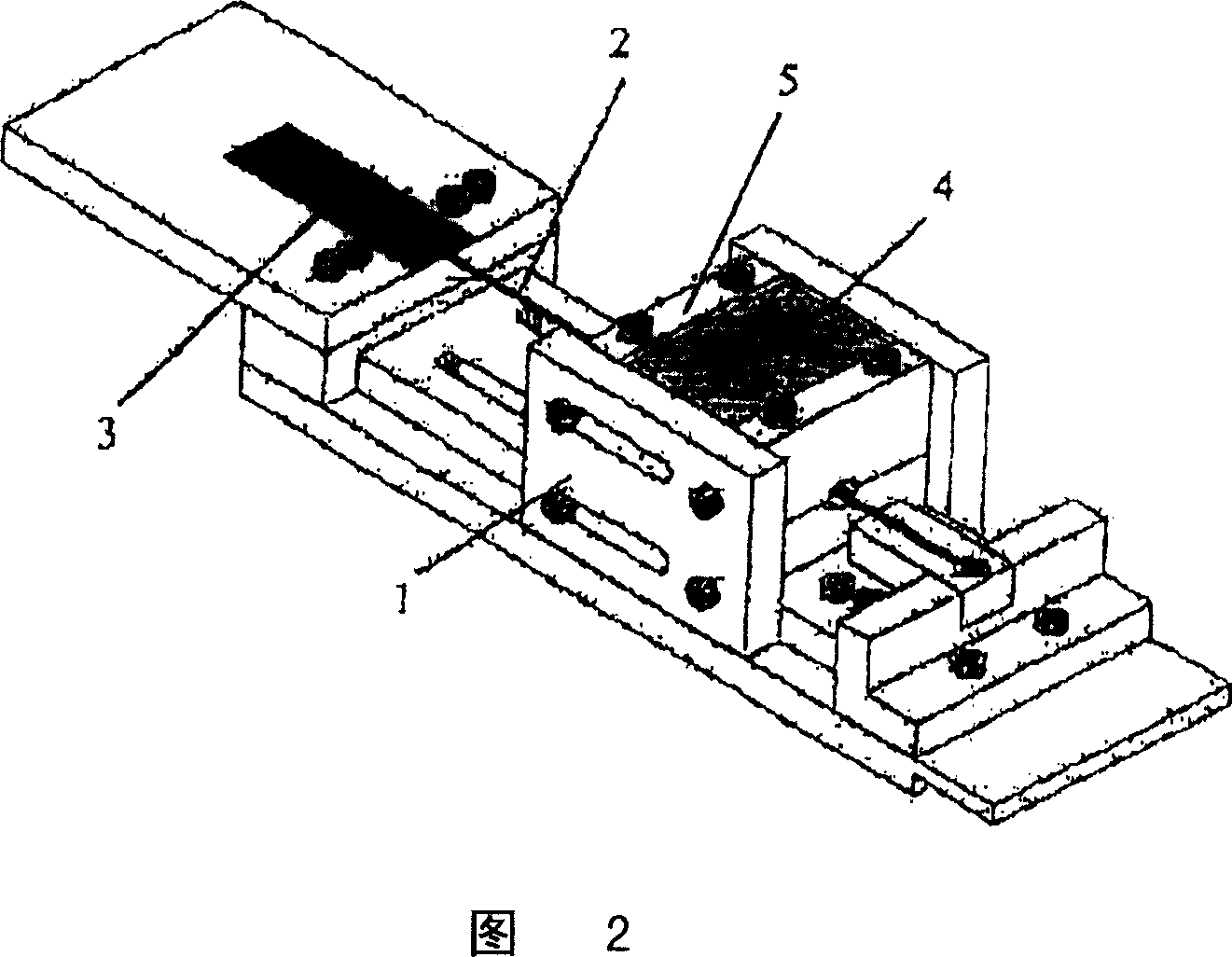

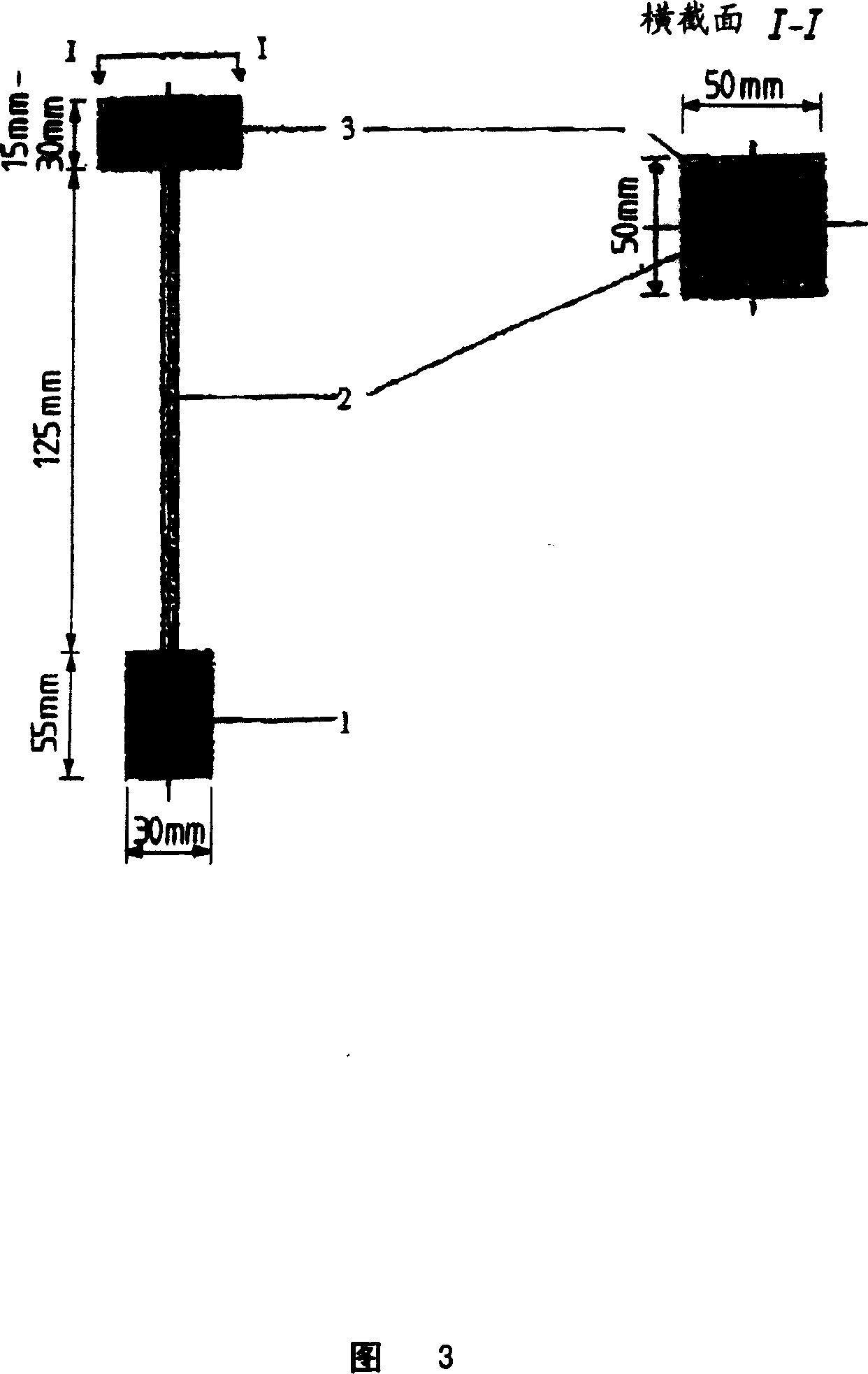

Preparations for use in concrete

InactiveUS20060115642A1Improve propertiesChloropene polymer coatingsThin material handlingPolymer sciencePolychloroprenes

The present invention provides a process for finishing fibrous products with a preparation based on aqueous dispersions of polychloroprene and a process for preparing textile-reinforced and fiber-reinforced concrete and other cement-based products including those finished products.

Owner:BAYER MATERIALSCIENCE AG

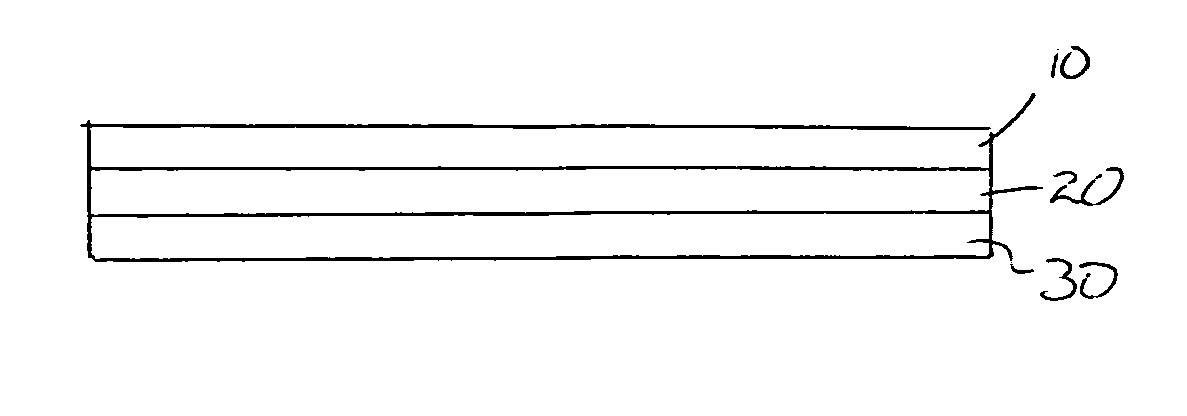

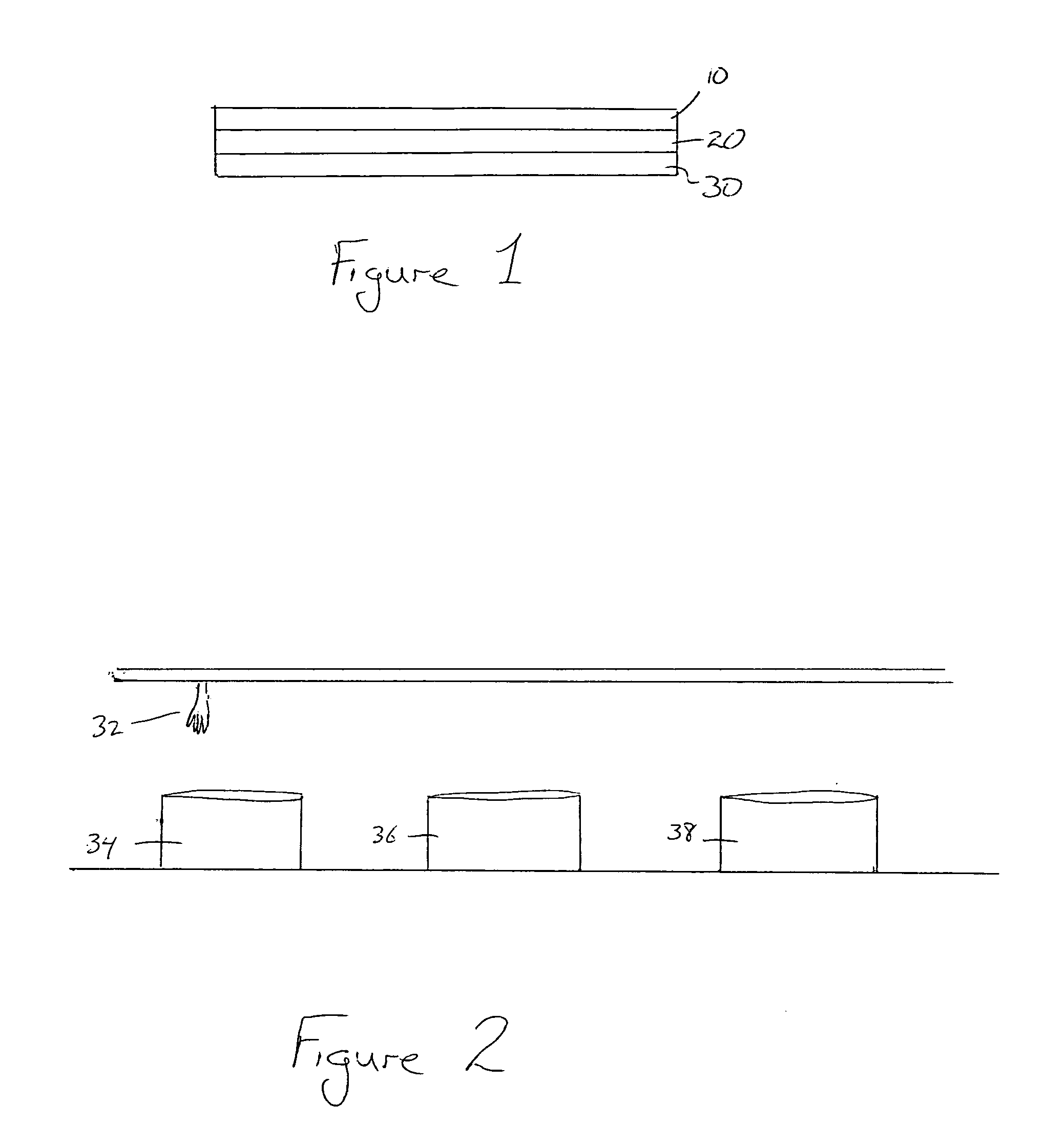

Glove having butyl rubber layer to provide resistance to ketone family chemicals

InactiveUS20070157363A1Improve the immunitySuperior and much improved resistanceGlovesCoatingsElastomerPolymer science

A laminate of three layers includes a middle butyl rubber layer, whereas the inner layer and outer layer materials could be chosen from natural rubber latex, carboxylated acrylonitrile butadiene rubber latex, polychloroprene, polyisoprene, carboxylated styrene butadiene, and other synthetic elastomers. Even with one material used for both inner layer and outer layer, different formulations could be used. The resultant multilayer structure provides good resistance to ketone family chemicals such as acetone and MEK. The glove also exhibits superior or much improved resistance to solvent such as DMSO, chloroform, methanol, et al as compared to currently commercially available thin wall gloves made from natural rubber latex and carboxylated acrylonitrile butadiene synthetic rubber latex. The time elapsed before the material experiences breakthrough after exposure to a ketone family solvent is directly related to the thickness of the butyl layer.

Owner:TAO JIAN

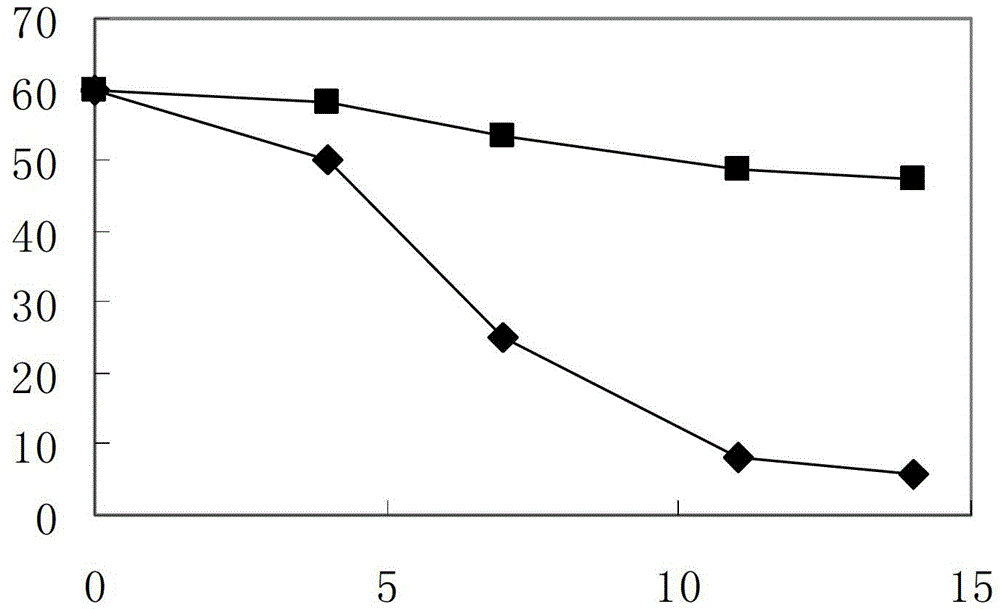

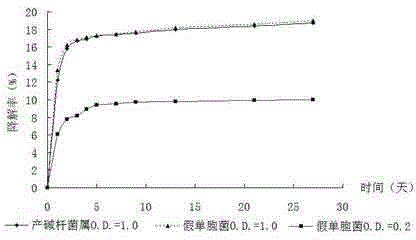

Preparation method and application of microbial inoculant for remediating poly-halohydrocarbon-polluted soil

InactiveCN103333823ASimple preparation processLow costBacteriaContaminated soil reclamationQuinoneHalohydrocarbon

The invention relates to a preparation method and application of a microbial inoculant for remediating poly-halohydrocarbon-polluted soil, belonging to the technical field of soil remediation in environmental engineering. The invention is characterized in that the microbial inoculant containing the quinone-reducing facultative anaerobe Shewanella sp. and poly-halohydrocarbon dehalogenated product facultative aerobic degrading bacterium is prepared by surplus sludge lysis solution preparation and culture medium optimization, and is used for remediating poly-halohydrocarbon-polluted soil. The microbial inoculant has the advantages of wide raw material sources, simple preparation technique and no secondary pollution during soil remediation, can effectively overcome the defect that the high operating cost of the biologically reinforced remediation of poly-halohydrocarbon-polluted soil limits the large-scale application, and has wide application prospects in remediation of soil polluted by poly-chlorine organic substances, poly-bromine aromatic hydrocarbons and poly-fluorine organic substances.

Owner:DALIAN UNIV OF TECH

Meeting with water, inflated rubber made from resin capable of inflating if absorbing water, and preparation method

In the present invention, resin expending on water absorption is prepared by polymerization of synthetic monomer of propenoic acid ester containing polyoxyvinyl ether, catalyst, initiator and cross-linking agent; rubber expending on water contact is prepared from resin expending on water absorption, polychloroprene, filler, softener, promoter and antiager through mixing and valcanizing.

Owner:JIANGSU CHEM RES INST

Polychloroprene latex composition and process for producing the same

InactiveCN1788046ALow viscosityHigh solid compositionChloropene polymer coatingsChloroprene adhesivesEmulsion polymerizationPolychloroprenes

The nonionic polychloroprene latex composition using polyvinyl alcohol as an emulsifying / dispersing agent has good chemical and mechanical stability, but due to high viscosity, there are problems such as restrictions on coating methods and difficulty in achieving high solid content . By emulsion polymerization of chloroprene alone or chloroprene and monomers that can be copolymerized with chloroprene in the presence of polyvinyl alcohol and non-ionic emulsifiers, low viscosity and high solid content can be obtained. Polychloroprene latex compositions.

Owner:DENKA CO LTD

Aqueous vacuum forming laminating adhesive composition, substrates and methods related thereto

InactiveUS6939432B2Synthetic resin layered productsOrganic non-macromolecular adhesivePolyolefinPolychloroprenes

The present invention provides an aqueous adhesive composition including a resinous phase dispersed in an aqueous medium, the resinous phase containing (a) a polychloroprene, (b) optionally, a halogenated polyolefin different from (a), and (c) optionally, an aminoplast resin. Further provided is an aqueous adhesive composition of a resinous phase dispersed in an aqueous medium wherein the resinous phase includes (a) a polychloroprene, (b) a halogenated polyolefin different from (a), and (c) a polyurethane polymer having ionic salt groups. A multi-layer composite and methods for adhering a thermoplastic material to a rigid substrate using the aqueous adhesive compositions also are provided.

Owner:PPG IND OHIO INC

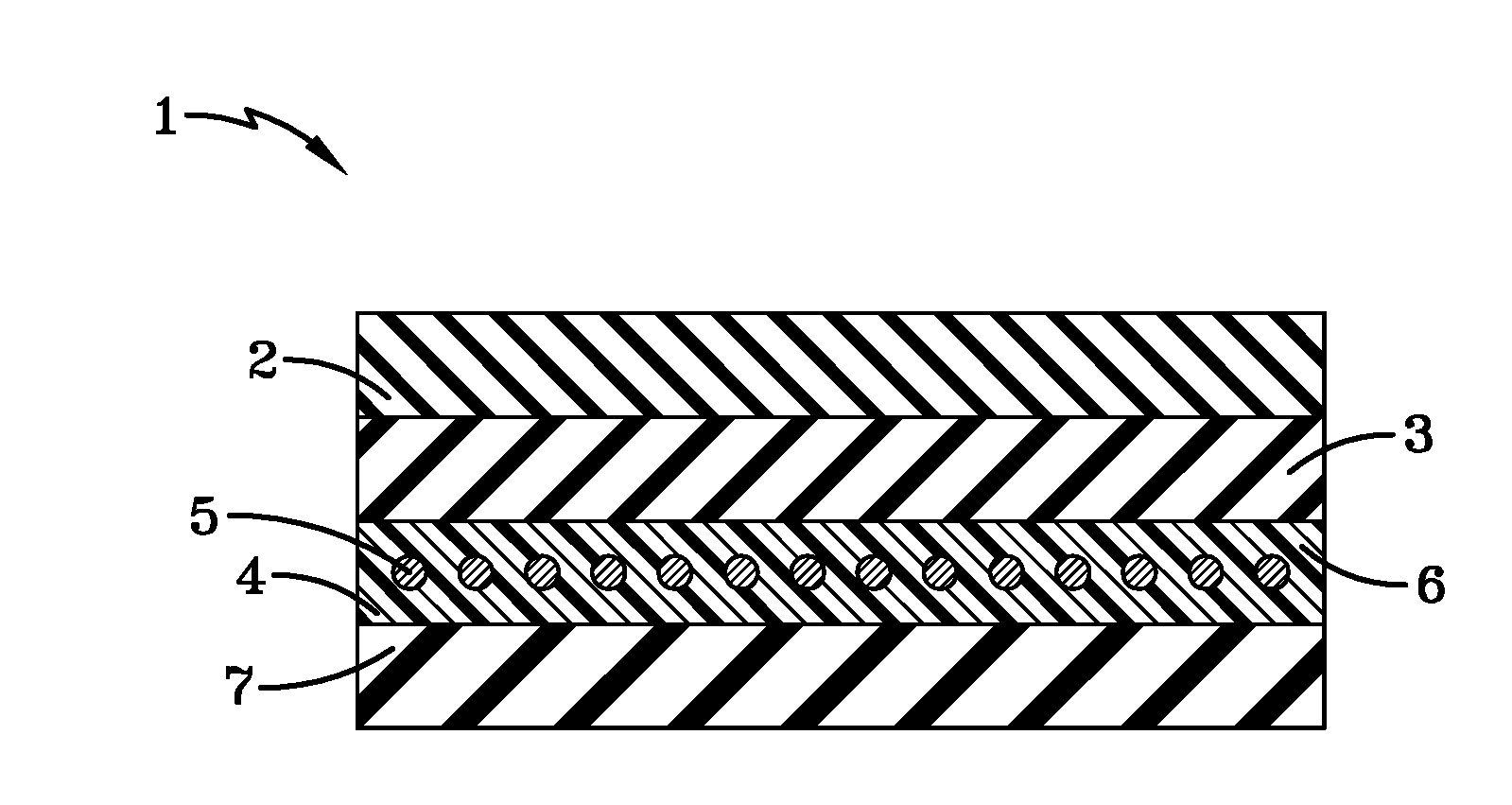

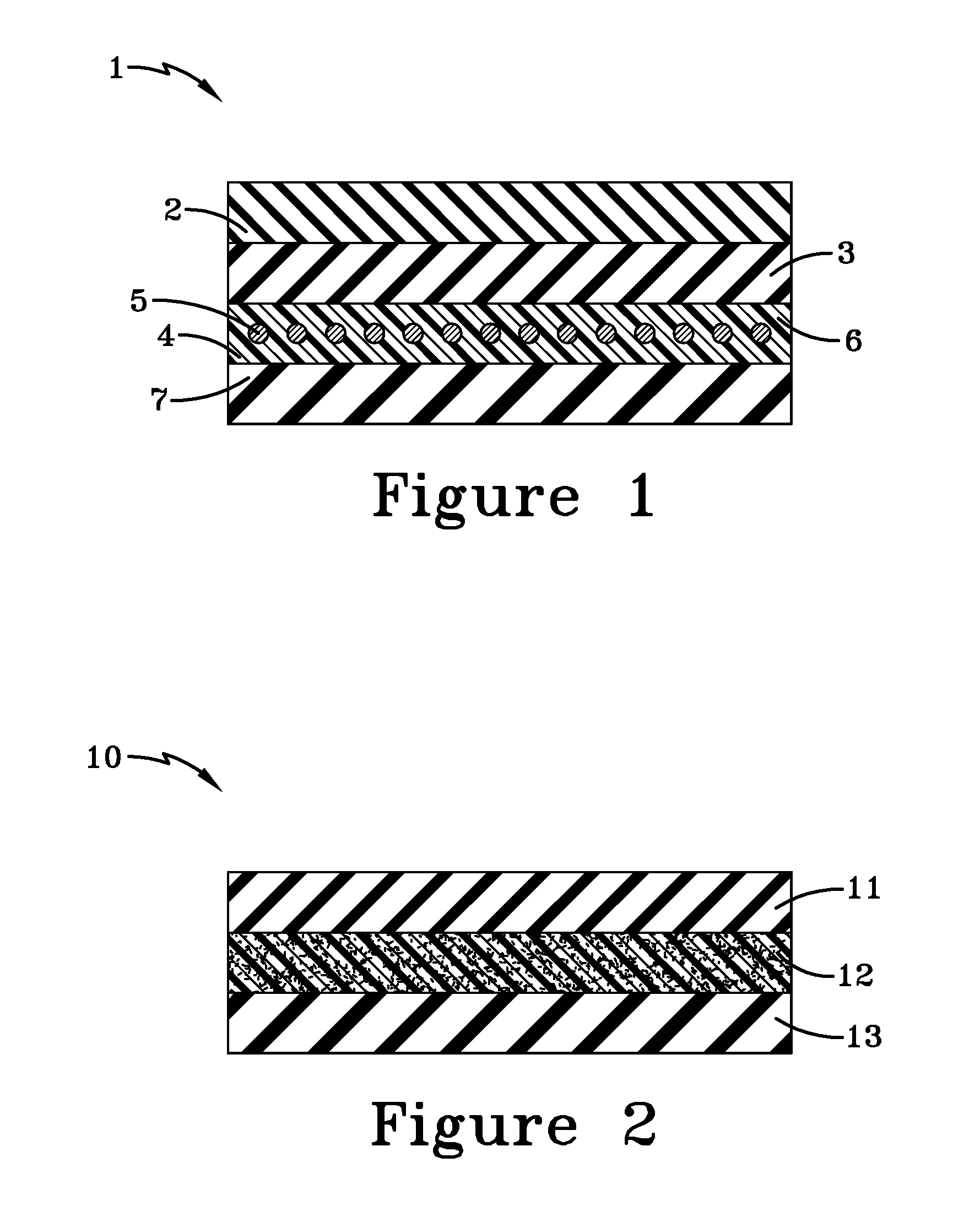

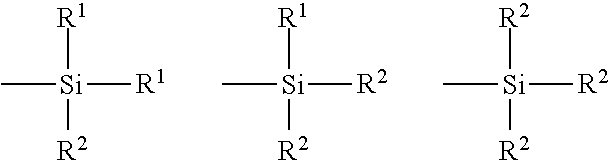

Conveyor belt

InactiveUS20150034458A1Improve wear resistanceSatisfactory adhesionConveyorsNitrile rubberPolyvinyl chloride

This invention reveals a conveyor belt which is comprised of a carry cover layer, a tie gum layer which is situated immediately below the carry cover layer, a reinforcement layer which includes steel cords which are embedded in polychloroprene and which is situated immediately below the tie gum layer, and a rubber layer which is situated immediately below the reinforcement layer, wherein the carry cover layer is comprised of a millable urethane rubber. The tie gum layer will typically be an alloy of polyvinylchloride and nitrile rubber to attain good adhesion between the carry cover layer and the reinforcement layer. The subject invention also reveals a conveyor belt which is comprised of a carry cover layer, a reinforcement layer which includes a resorcinol-formaldehyde-latex coated fabric reinforcement, and a rubber layer which is situated immediately below the reinforcement layer, wherein the carry cover layer is comprised of a millable urethane rubber.

Owner:CONTITECH USA INC

Polychloroprene latex composition and process for producing the same

InactiveUS20070072983A1Low viscosityHigh solid contentInksChloropene polymer coatingsPolyvinyl alcoholEmulsion polymerization

A nonionic polychloroprene latex composition employing a polyvinyl alcohol as an emulsifier / dispersant has favorable chemical and mechanical stability but has a high viscosity, and therefore it has such drawbacks that its coating method is limited, and it is hardly made to have a high solid content. A polychloroprene latex composition which has a low viscosity and which can be made to have a high solid content, can be obtained by emulsion polymerization of chloroprene alone or chloroprene and a monomer copolymerizable with chloroprene in the presence of a polyvinyl alcohol and a nonionic emulsifier.

Owner:DENKA CO LTD

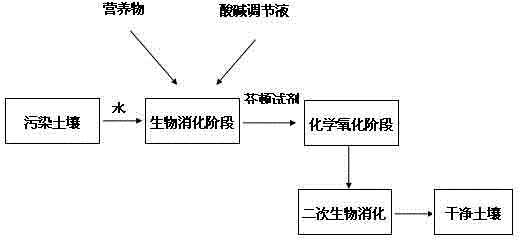

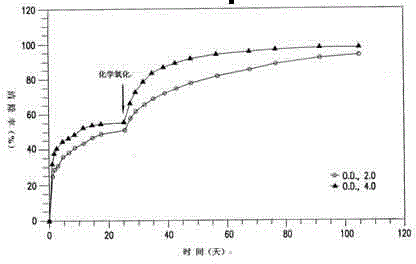

Method for degrading polycyclic aromatic hydrocarbon and polychlorocarbon pollutants in soil

The invention relates to a technology for polluted soil restoration. Pollutants in soil mainly comprise polycyclic aromatic hydrocarbons and polychlorocarbons. In a biological-chemical-biological treatment restoration order, the pollutants are degraded under suitable conditions.

Owner:KESHENG ENVIRONMENTAL PROTECTION TECH CO LTD

Compositions for use in concrete

The present invention provides a process for finishing fibrous products with a preparation based on aqueous dispersions of polychloroprene and a process for preparing textile-reinforced and fiber-reinforced concrete and other cement-based products including those finished products.

Owner:BAYER MATERIALSCIENCE AG

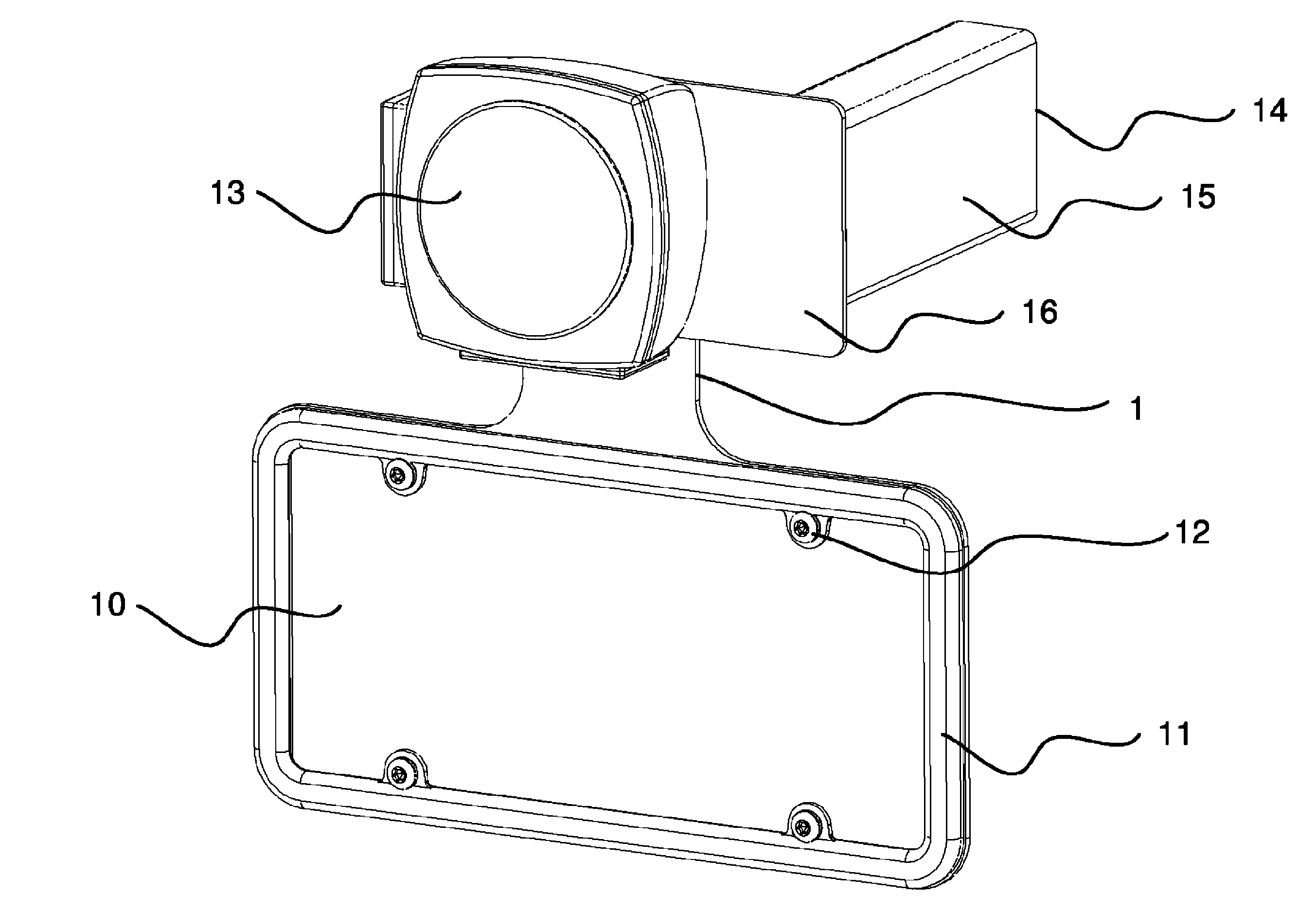

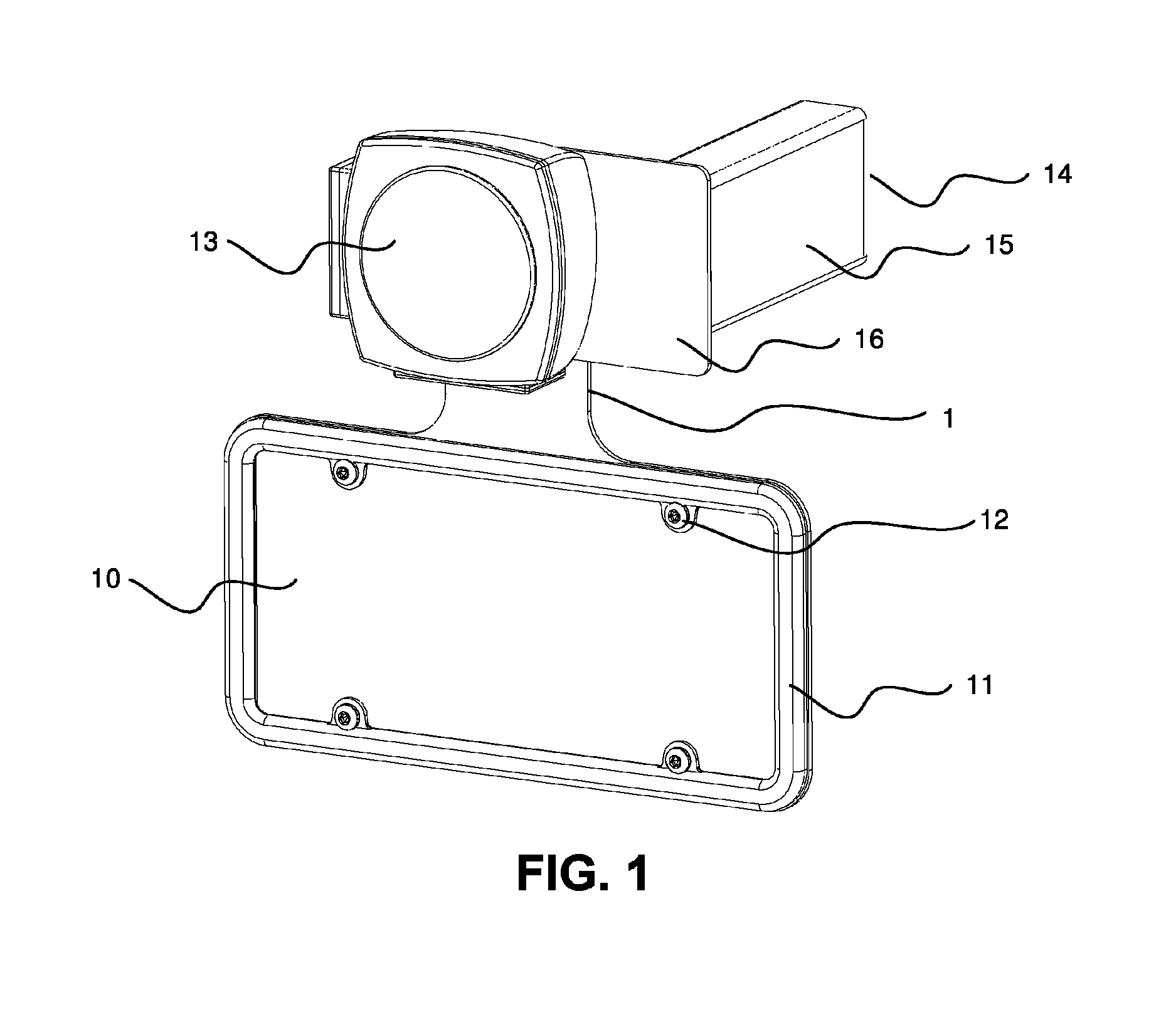

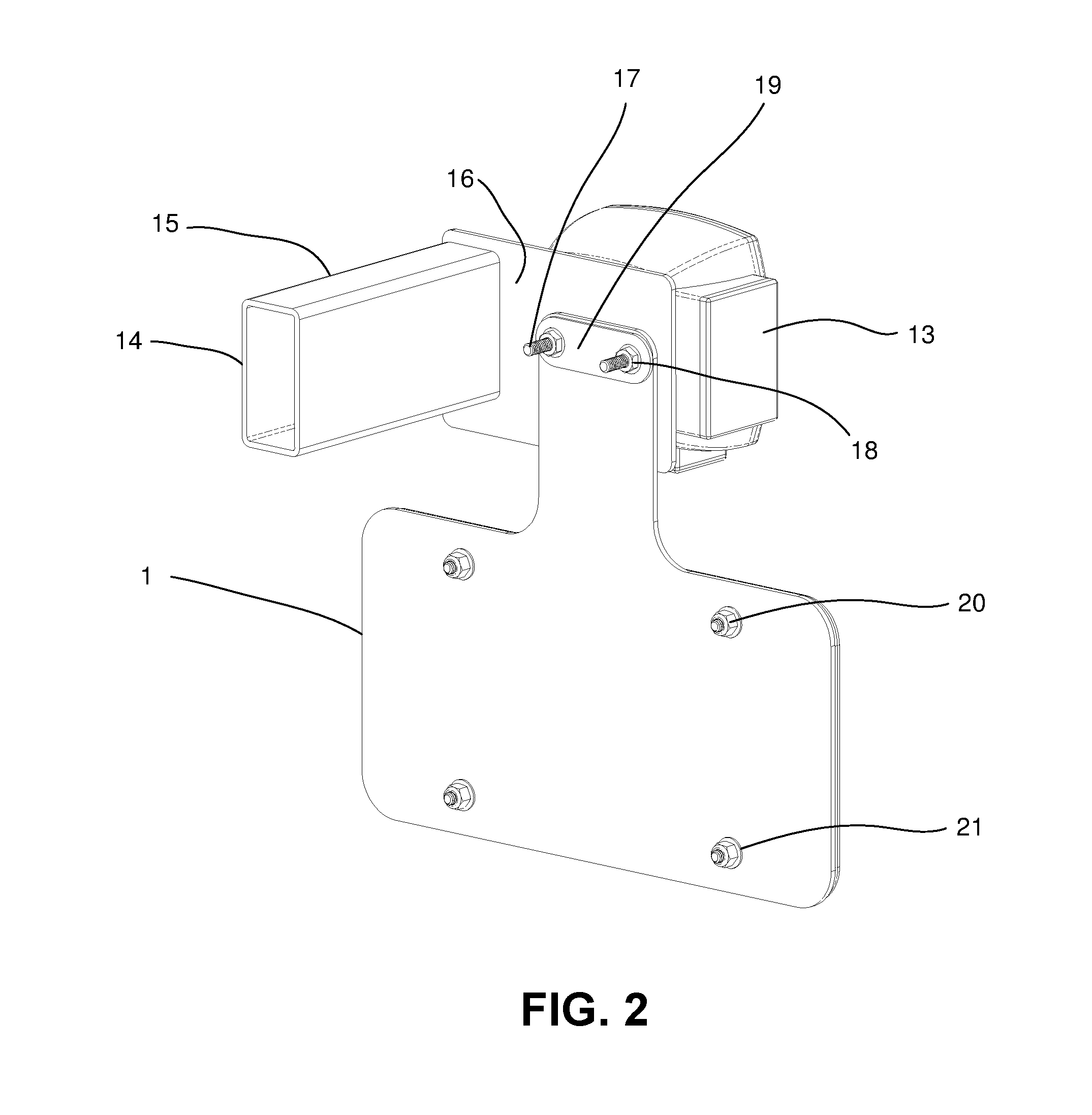

License plate holder

A license plate holder including a flexible body having a T-shape contour and a single layer of material or multilayer material including a material from the group of rubber, polychloroprene, nitrile, nitrile butadiene rubber, cyanocarbons, styrene butadiene rubber, ethylene propylene rubber and a combination thereof.

Owner:FONTAYNE DIEGO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com