Polychloroprene latex composition and process for producing the same

A technology of polychloroprene and chloroprene, which is applied in the direction of chloroprene adhesives, chloroprene homopolymer coatings, adhesives, etc., and can solve the problems of coating method limitations and concentration improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

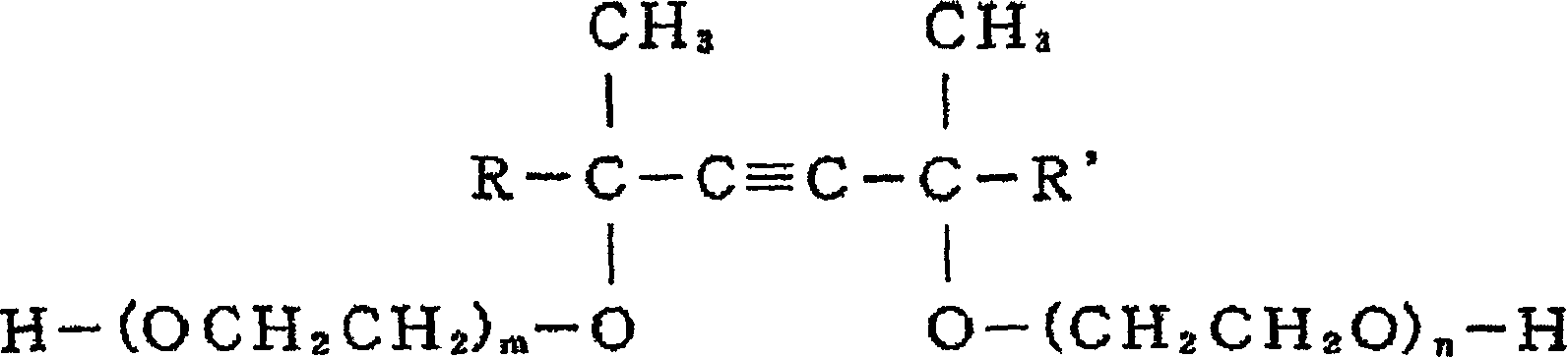

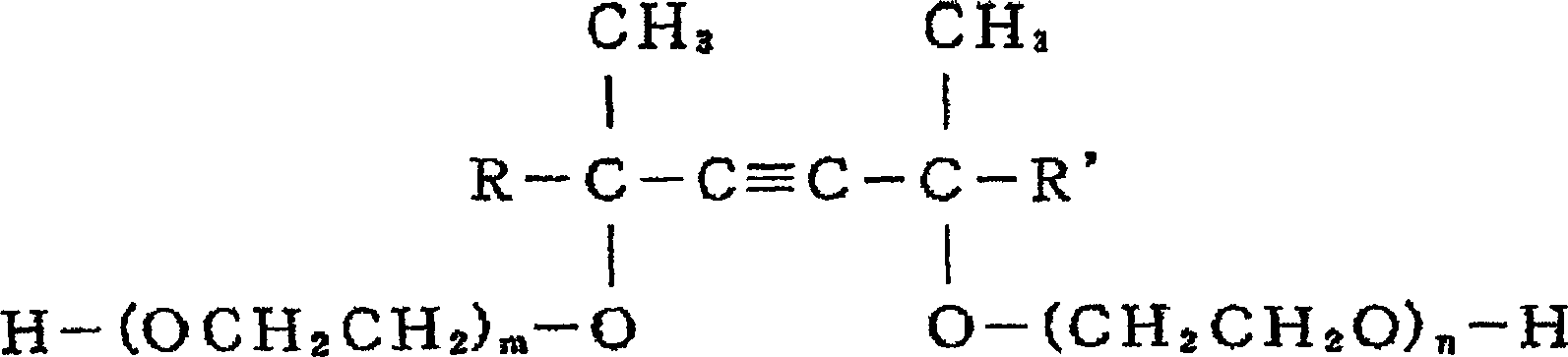

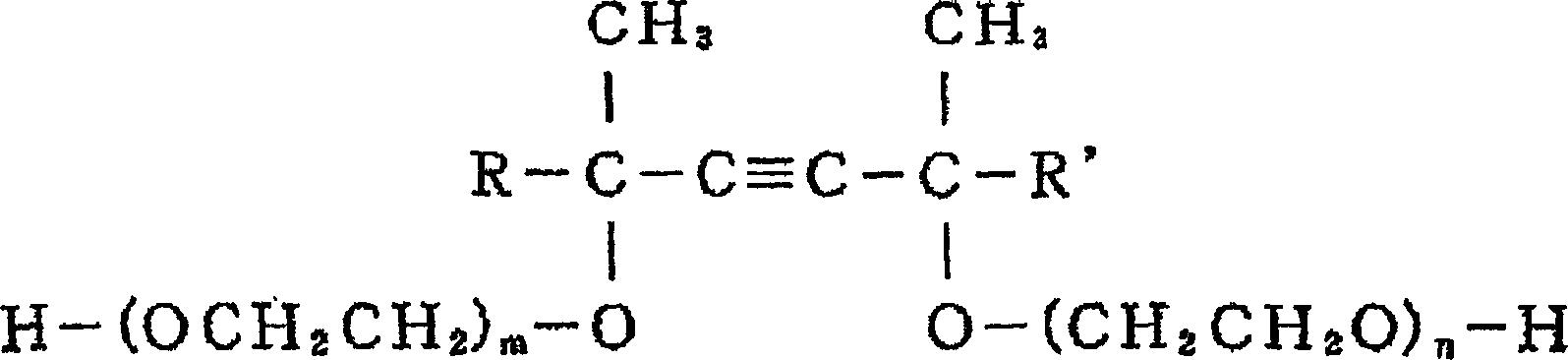

Image

Examples

Embodiment 1

[0072] In a reactor with an internal volume of 3 liters, 0.6 parts of polyvinyl alcohol (PVA203: made by Kuraray Co., Ltd.) and 3.0 parts of polyoxyethylene alkyl ether (EMALGEN 1118S -70: manufactured by Kao Corporation, HLB value 16.4) was dissolved in 95 parts of water. After cooling this polyvinyl alcohol / nonionic emulsifier aqueous solution to near room temperature, 97 parts of chloroprene monomers, 3 parts of methacrylic acid, and 0.3 parts of octyl mercaptan were added. Keep it warm at 45°C, and use sodium sulfite and potassium persulfate as initiators to carry out polymerization. After the polymerization heat was not generated during the polymerization, it was allowed to stand for 1 hour, and this was regarded as the end point of the polymerization. A 20% aqueous diethanolamine solution was added to the obtained polychloroprene latex composition to adjust the pH to 7, and concentrated by heating under reduced pressure to prepare samples with a solid content of 50% and...

Embodiment 2、3

[0097] Except that the ratio of polyvinyl alcohol / nonionic emulsifier in embodiment 1 becomes 1.2 / 2.4 (embodiment 2) and 1.8 / 1.8 (embodiment 3) respectively, same as embodiment 1, prepare latex sample, Test and evaluate.

Embodiment 4

[0099] In Example 1, except that the nonionic emulsifier was changed to polyoxyethylene alkyl ether (Emalgen 1135S-70: manufactured by Kao Corporation, HLB value 17.9), a latex sample was prepared and tested and evaluated in the same manner as in Example 1. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com