Patents

Literature

533results about "Chloropene polymer coatings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

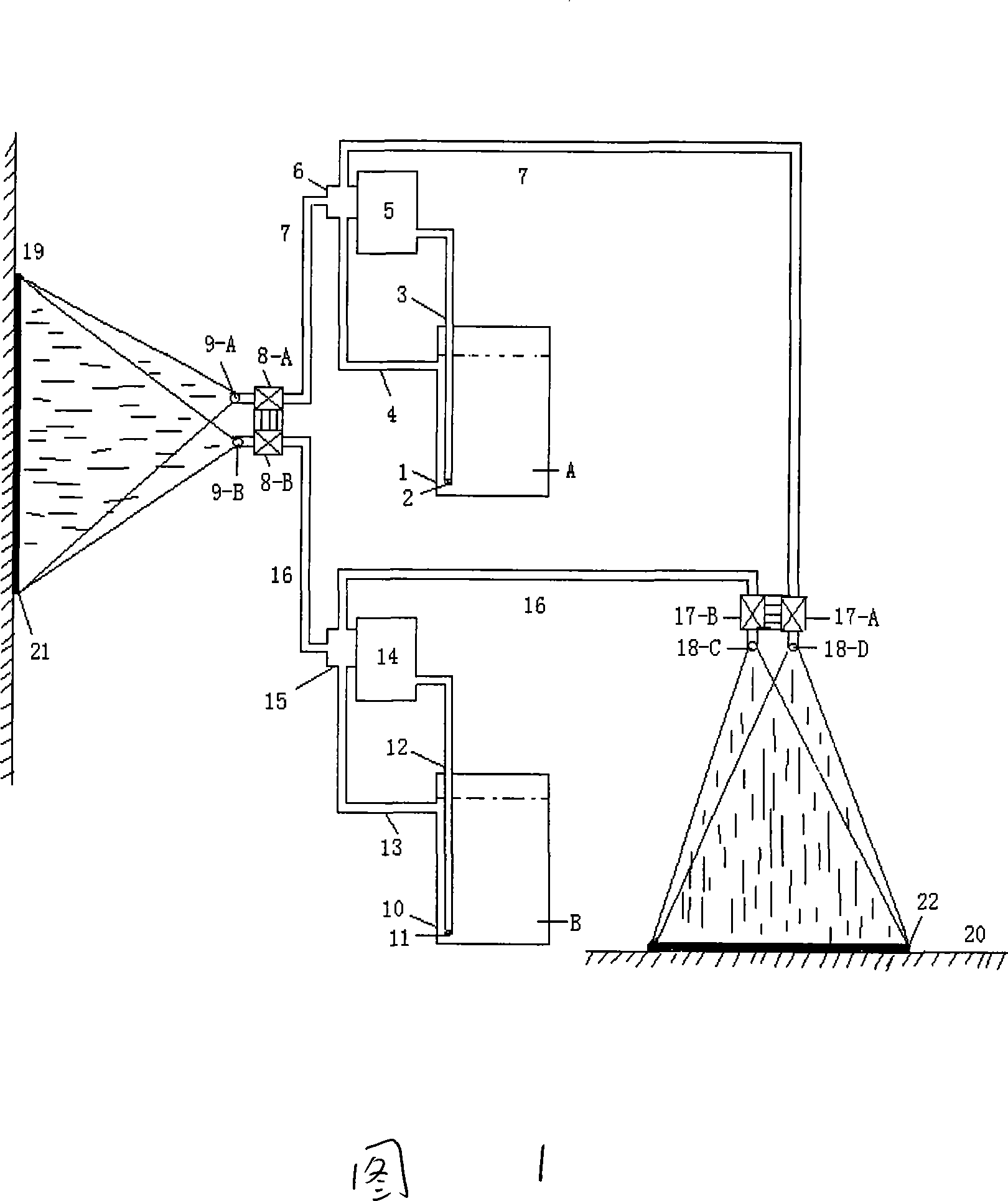

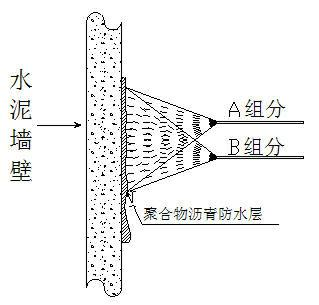

Multifunctional liquid rubber spray-coating material, preparation method, using method and special-purpose device

InactiveCN101235252AGood extensibilityImprove performanceSpraying apparatusConjugated diene hydrocarbon coatingsPolymer scienceSpray coating

Multifunctional liquid rubber spray coating comprises components of A, B, wherein A component comprises liquid rubber asphalt emulsion whose solid content is 50-75%, wherein 2-65% rubber elusion content, 30-97% asphalt elusion content, 0.0-5.0% carbon black, 0.0-6.0% ultra-fine powder, 0.025-2.50% anion dispersing agent and 0.025-3.00% anion surface activator, which is waterborne spray coating, and B component is water solution which comprises 3.0-18.0% concentration calcii chloridum (89.0-99.2%), sodium chloride (0.50-4.0%) and composite aluminum iron polymer (0.3-7.0%). The two components are sprayed on the same basal plane through adopting a double-component airless spraying device to form a gelatin film with 0.5-4mm after 3-5 seconds solidification, which has the characteristics of strong bonding, temperature resistance, weather resistance, and excellent chemical stability, heat insulation and puncture resistance. The A component can be individually sprayed, or can be combined with the double components.

Owner:大连美宸特环保节能产品有限公司

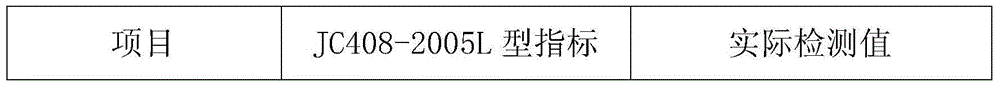

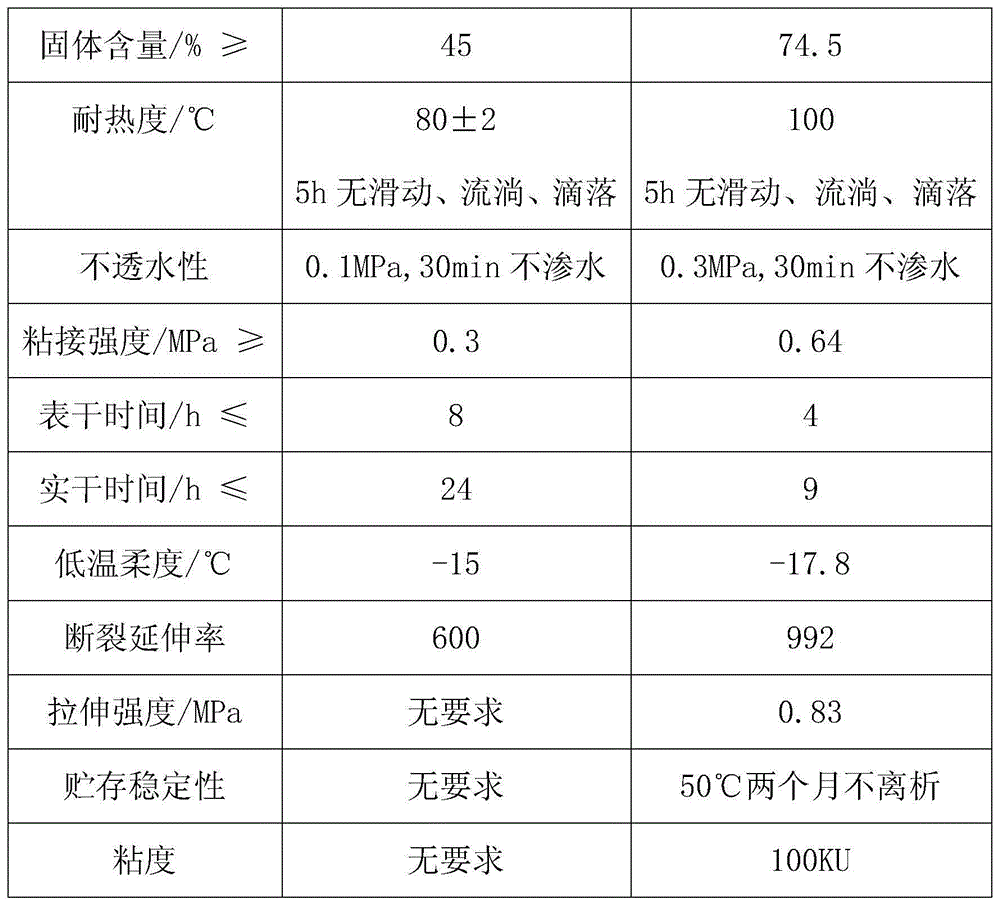

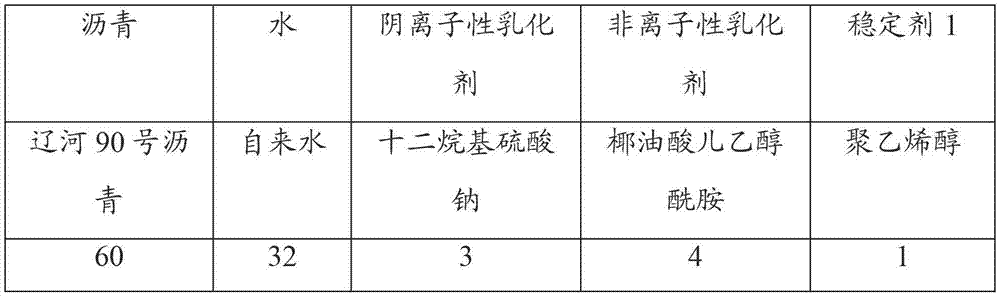

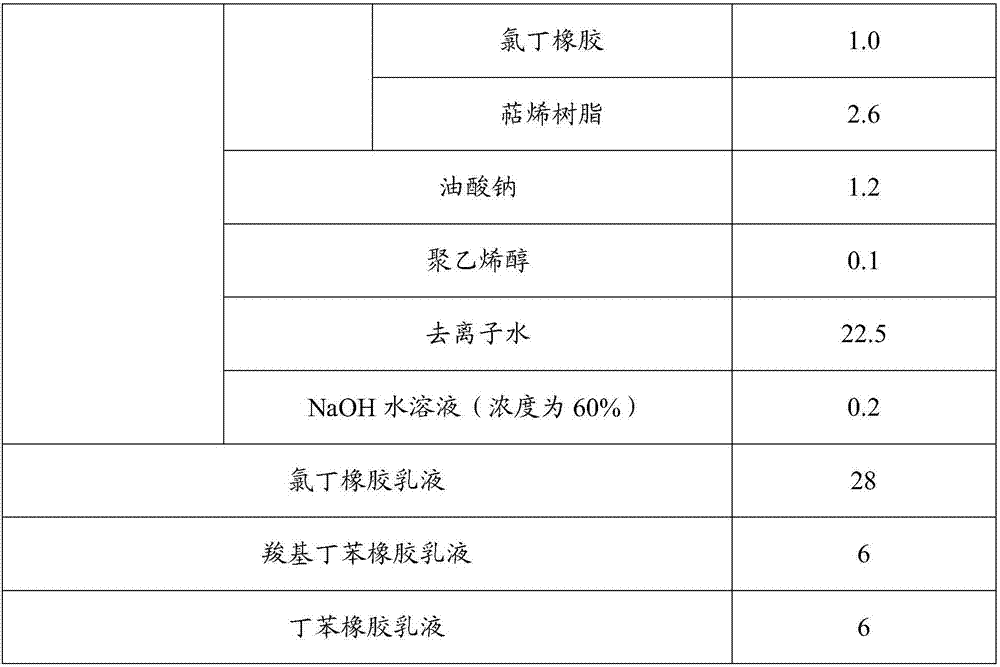

Composite emulsified asphalt waterproof coating and preparation method thereof

InactiveCN104449381AGood dispersionHigh viscosityConjugated diene hydrocarbon coatingsNatural rubber coatingsBituminous waterproofingEmulsion

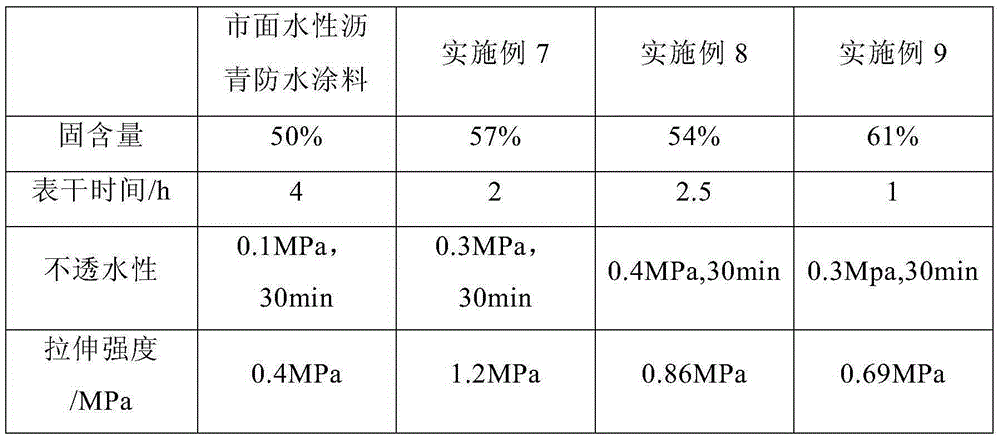

The invention relates to a composite emulsified asphalt waterproof coating and a preparation method thereof. The composite emulsified asphalt waterproof coating is prepared from the following raw materials in parts by weight: 150-220 parts of emulsified asphalt, 50-105 parts of a polymeric emulsion, 70-130 parts of inorganic powder, 0.5-2 parts of a stabilizer, 6-10 parts of a dispersant, 2-5 parts of a wetting agent, 1-3 parts of a thickener I, 1-3 parts of a thickener II, 2-7 parts of a defoaming agent and 15-40 parts of water. The invention further relates to a preparation method of the composite emulsified asphalt waterproof coating. The viscosity, strength, application property, solid content and storage stability of the emulsified asphalt waterproof coating are remarkably improved, and the cost is lowered to a great extent.

Owner:JINZHOU DONGFANG YUHONG BUILDING MATERIALS

Reaction bonding modified emulsified asphalt waterproof paint and preparation method thereof

ActiveCN102898947AImprove stabilityImprove bindingConjugated diene hydrocarbon coatingsChloropene polymer coatingsCross-linkBituminous waterproofing

The invention aims to provide a reaction bonding modified emulsified asphalt waterproof paint and a preparation method thereof. The reaction bonding modified emulsified asphalt waterproof paint comprises asphalt, a modifying agent, an emulsifying agent, a cross-linking agent and water. In the formula system of the reaction bonding modified emulsified asphalt waterproof paint, more modifying agents in an appropriate amount are adopted compared with the prior art, so that a rubber-asphalt mixture can achieve a good emulsifying effect, the elasticity and strength of a dried sealing layer are greatly improved, and the sealing effect can be better and lasting; and by using the cross-linking agent, a chemical coupling effect is achieved between the paint and concrete, so that the cohesive force of the concrete is promoted. The reaction bonding modified emulsified asphalt waterproof paint can be applied to waterproof construction of wall surfaces, roofs, roads, bridges and the like, and has a very high practical value.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

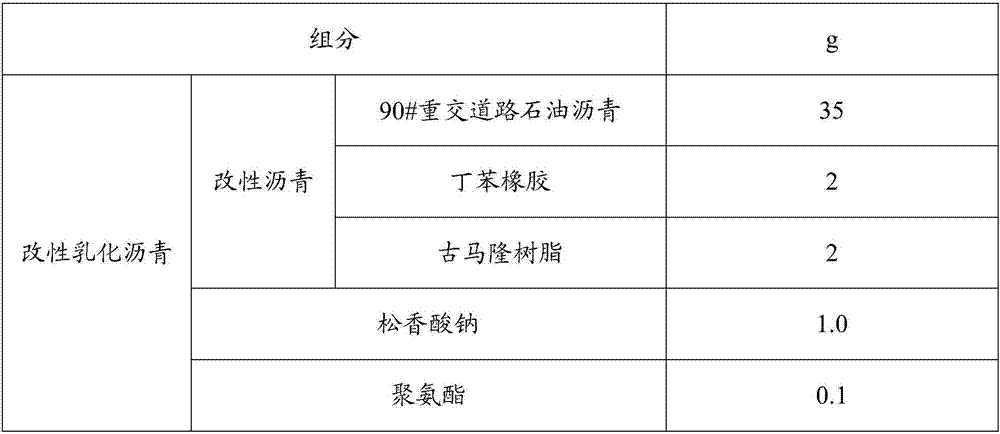

Waterproof coating capable of chemical crosslinking and physical mortise and tenon with cement

ActiveCN103333555AImprove adhesionGood extensibilityRosin coatingsConjugated diene hydrocarbon coatingsMortise and tenonSynthetic rubber

The invention provides a waterproof coating capable of chemical crosslinking and physical mortise and tenon with cement. The waterproof coating is characterized by comprising the following raw materials by weight: 20-50 parts of a synthetic rubber latex, 20-50 parts of emulsified asphalt, 0.5-2 parts of a functional additive and 0.5-2 parts of a dispersant, 20-40 parts of a filler and 10-25 parts of water. The principle is that through coupling effect of the functional additive, part of the molecules in the synthetic rubber and most molecules in the asphalt couple into large molecules with reaction activity; when the large molecules contact with a base plane, the non-reactive molecule segments of the rubber and asphalt and the base plane form physical adsorption, and the molecular segments with reaction activity conduct react with the base plane to form chemical bond effect, so as to generate strong adhesive force; and after bonding, the coating is hardly influenced by environmental factors. Therefore, the waterproof coating provided by the invention has excellent waterproof performance.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

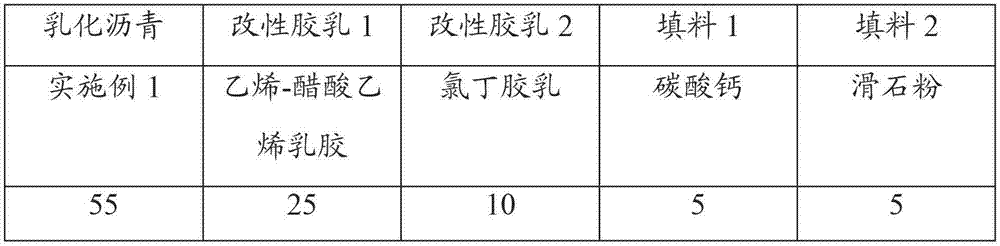

High-strength rubber asphalt waterproof paint and preparation method thereof

ActiveCN103205204AHigh strengthIncrease elasticityConjugated diene hydrocarbon coatingsChloropene polymer coatingsEmulsionPolymer science

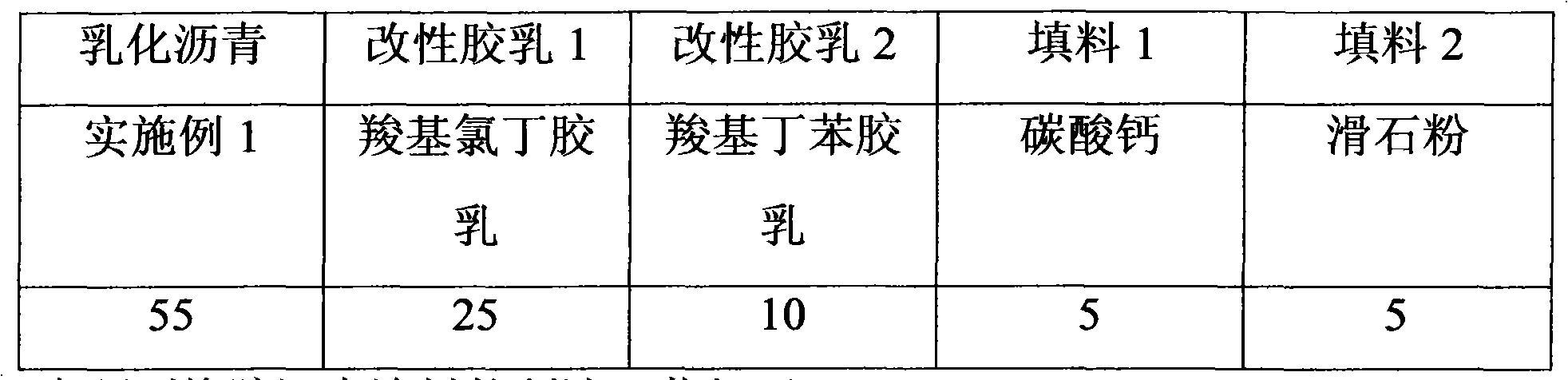

The invention discloses a high-strength rubber asphalt waterproof paint. The high-strength rubber asphalt waterproof paint is prepared from 55-65wt% of emulsified asphalt, 25-35wt% of modified latex, 5-10wt% filler and the like. The high-strength rubber asphalt waterproof paint is prepared from the following steps of adding the emulsified asphalt, the modified latex and the filler into a stirring cylinder, stirring for 20min at a high speed, standing for 1 hour and then filtering to obtain the rubber asphalt waterproof paint. According to the high-strength rubber asphalt waterproof paint disclosed by the invention, high-strength composite modified emulsion is used for modification. The high-strength rubber asphalt waterproof paint has the remarkable characteristics of high strength, perfect fit, high elasticity, seamlessness and the like and can be manually scrapped and coated; therefore, the defect that the strength of the traditional asphalt coating is insufficient is solved.

Owner:KUNMING FENGXING WATERPROOF MATERIAL +3

High-permeability liquid rubber spray coating

InactiveCN102329566AHigh bonding strengthImprove waterproof and anti-seepage performanceUnspecified rubber coatingsConjugated diene hydrocarbon coatingsPolymer scienceSpray coating

The invention discloses a high-permeability liquid rubber spray coating, and relates to the technical field of spray coatings. The high-permeability liquid rubber spray coating comprises a component A and a component B, wherein the component A is anionic liquid rubber asphalt emulsion; the component B is a coagulant solution; the component A has the solid content of liquid rubber asphalt emulsion of 50-75 weight percent, and comprises the following components in percentage by mass: 1 to 35 percent of rubber emulsion, 10 to 50 percent of asphalt emulsion, 0.01 to 2 percent of anionic dispersing agent, 0.01 to 2 percent of anionic surfactant, 0.1 to 10 percent of fatty alcohol-polyoxyethylene ether, 0.1 to 10 percent of alkali resistant wetting agent OEP-70 and 0.1 to 10 percent of alkali resistant wetting agent AEP; and the component B is an aqueous solution at the concentration of 3-18 percent, which is prepared by mixing calcium chloride and composite aluminum-iron polymer in percentage by mass. The wetting agents are added into the spray coating, and the coating has high permeability and wider application range.

Owner:DALIAN MEICHENTE TECH

Spraying quick-setting rubber asphalt waterproof coating material

ActiveCN103627258AWith anti-adhesive effectImprove adhesionConjugated diene hydrocarbon coatingsNatural rubber coatingsComposite constructionWater based

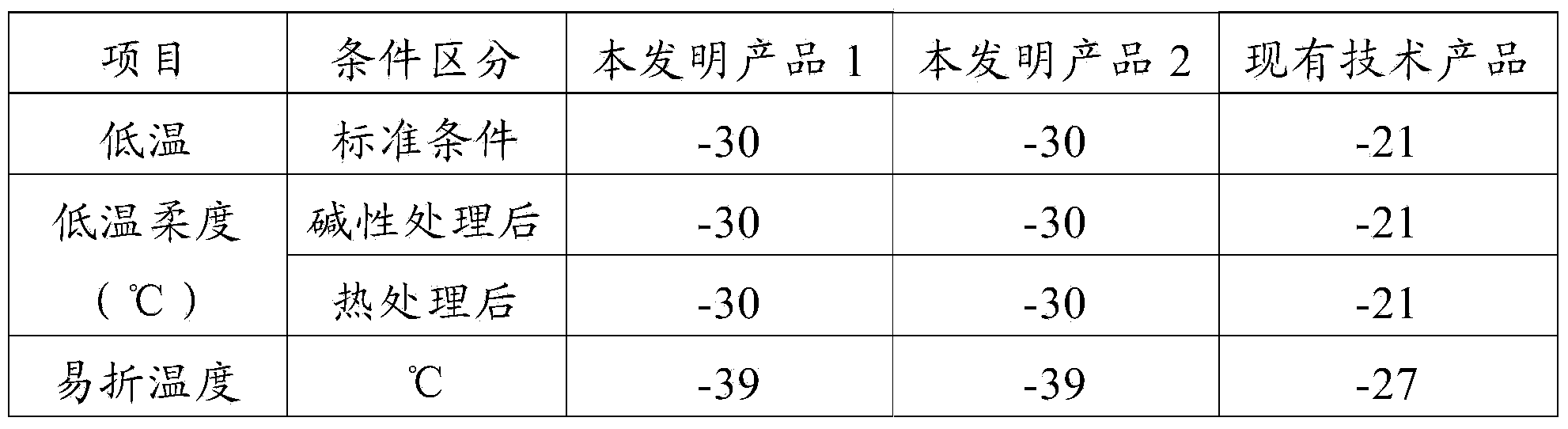

The invention relates to a spraying quick-setting rubber asphalt waterproof coating material. A special technology is adopted for preparation of the spraying quick-setting rubber asphalt waterproof coating material. The spraying quick-setting rubber asphalt waterproof coating material is a water-based spraying paint prepared according to a ratio, and a preparation method of the spraying quick-setting rubber asphalt waterproof coating material comprises following steps: a liquid rubber asphalt latex emulsion is prepared by mixing superfine, suspended and micro-emulsion modified emulsified asphalt with high-molecular polymer rubber latex; and the liquid rubber asphalt latex emulsion is mixed with a coagulant. Cold spraying construction is adopted for preparation of the spraying quick-setting rubber asphalt waterproof coating material; elastic coating film elongation is more than 1000%; restoration ratio is more than 95%. The spraying quick-setting rubber asphalt waterproof coating material possesses ultraviolet resistance, high construction efficiency, high bonding strength, excellent high-temperature resistance, excellent low temperature flexibility, and better quick setting effect; and is capable of forming films in 3 seconds. The spraying quick-setting rubber asphalt waterproof coating material is water based; is friendly to the environment; possesses no toxicity, and excellent endurance; is quick and convenient for construction; and is a novel environmental friendly waterproof paint with a wide application range. The spraying quick-setting rubber asphalt waterproof coating material is mainly used for various waterproof and anticorrosion projects. The spraying quick-setting rubber asphalt waterproof coating material is used for individual construction of waterproof projects, for composite construction of waterproof projects together with waterproof roll, and for individual construction of anticorrosion projects.

Owner:SHANDONG NORTH CHUANGXIN WATERPROOF SCI & TECH GRP CO LTD

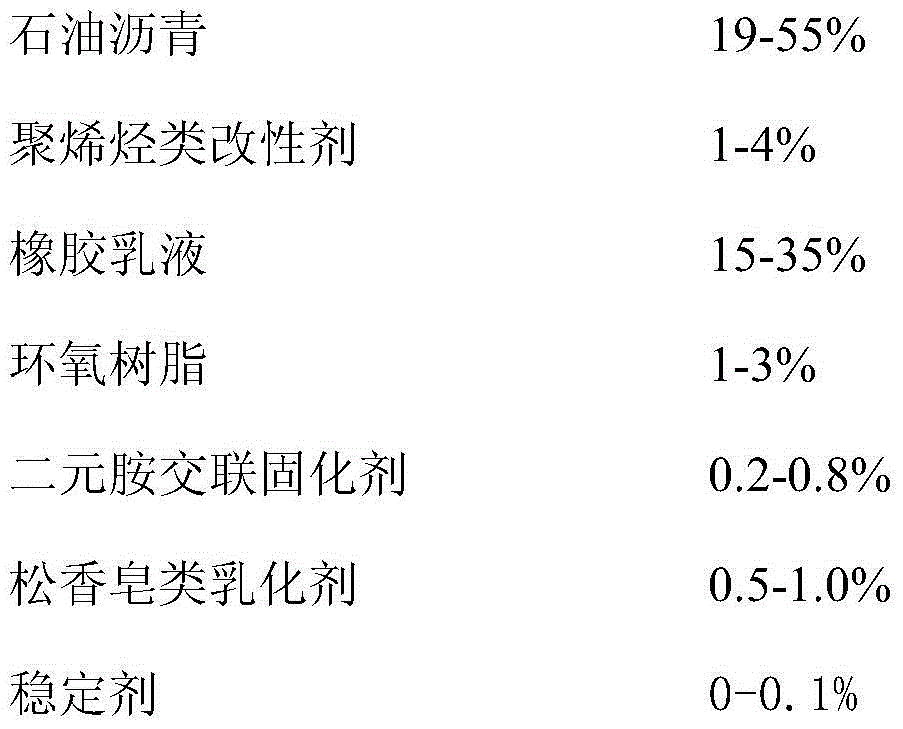

High-polymer modified water-emulsion asphalt-based thick waterproof paint and preparation method thereof

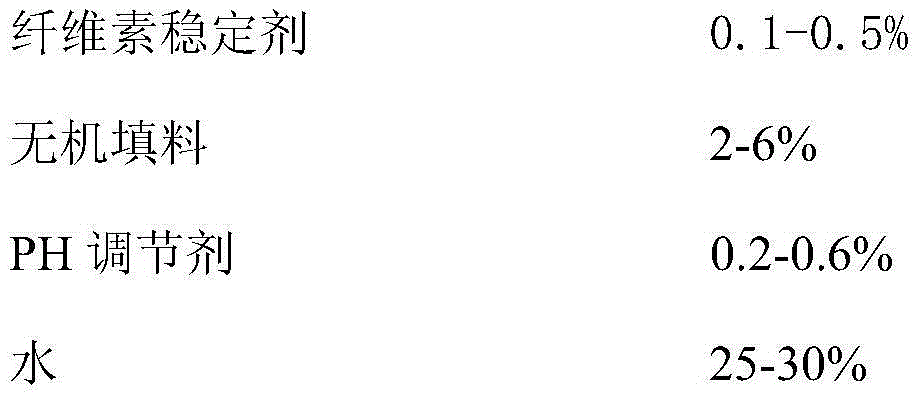

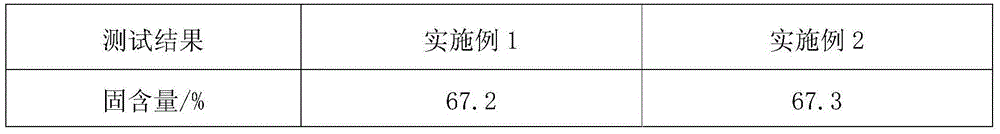

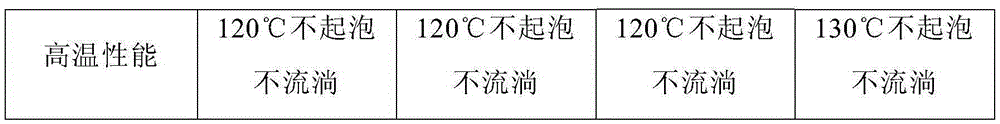

ActiveCN103555204AImprove low temperature performanceIncrease elasticityCellulose coatingsConjugated diene hydrocarbon coatingsHigh concentrationEpoxy

The invention discloses a high-polymer modified water-emulsion asphalt-based thick waterproof paint and a preparation method thereof. The paint is prepared by taking high-concentration ultrafine suspension microemulsion anion modified emulsified asphalt, a polyolefins modifier, rubber emulsions such as chloroprene rubber or butadiene styrene rubber or the like, multiple synthetic high-molecular polymers such as epoxy resin and the like, inorganic powders such as SiO2 and bentonite and the like as raw materials and mixing by employing a special production technology. Tests show that after a film is formed from the paint, no embrittlement happens at a low temperature of -20 DEG C, no flow happens at a high temperature of 120 DEG C, the elasticity recovery rate reaches up to 90%, and the paint can be stored stably for one year or more.

Owner:ZHEJIANG YUXI CORROSION CONTROL CORP

Environmental protection composite antifouling paint

InactiveCN1557896AInhibit growthNon-toxic withAntifouling/underwater paintsPaints with biocidesDisinfectantMildew

The environment protecting composite antifouling paint is prepared with organic resin, hot natural plant material, non-toxic mildew-preventing disinfectant, inorganic pigment, stuffing, assistant, exudation aid and solvent, and through physical mixing. The environment protecting composite antifouling paint has no toxicity, no pollution to marine environment and wide application range. It has the functions of resisting bacteria and preventing marine organism from attaching.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

Vulcanization composition having reduced allergenic potential, and elastomeric articles formed therewith

ActiveUS20120021155A1Reduced and eliminated allergic potentialAvoid problemsTeeth fillingPretreated surfacesPolymer scienceVulcanization

The present invention generally relates to vulcanization compositions used to vulcanize elastomeric articles, where the vulcanization compositions have reduced allergenic potential as compared to elastomeric articles formed using vulcanization compositions having non-fugitive accelerators. The present invention also relates to elastomeric articles formed using the vulcanization compositions. The invention further relates to methods for making a reduced-allergenicity vulcanization composition, and to methods for using the vulcanization compositions to vulcanize elastomeric articles.

Owner:ALLEGIANCE CORP

Seawater corrosion-resistant paint

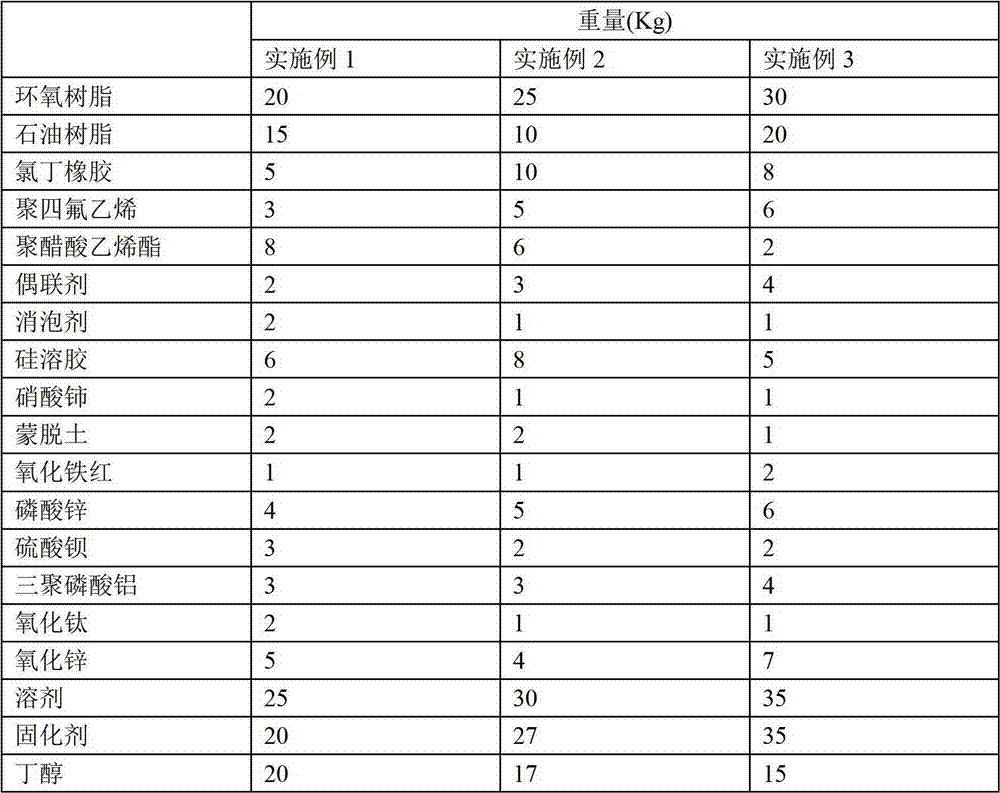

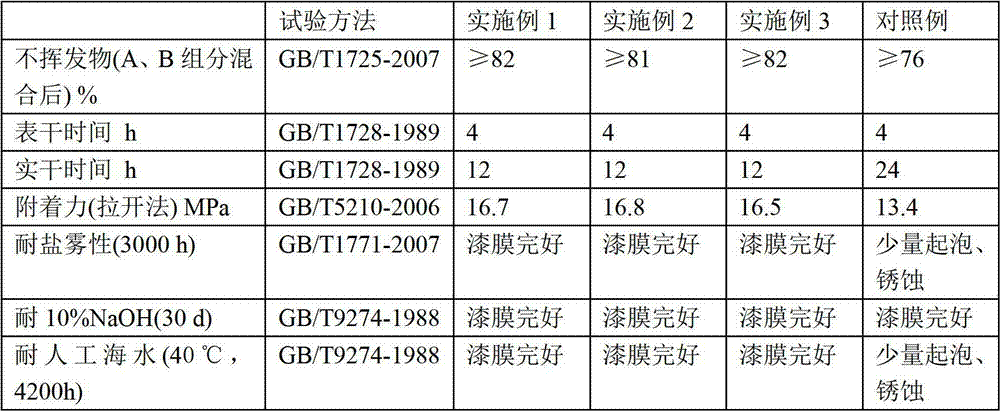

InactiveCN102876192AStrong resistance to seawater corrosionChloropene polymer coatingsAnti-corrosive paintsEpoxyCerium nitrate

The invention provides seawater corrosion-resistant paint which comprises component A and component B. The component A comprises the following materials by weight: 20-30 parts of epoxy resin, 10-20 parts of petroleum resin, 5-10 parts of chloroprene rubber, 3-6 parts of polytetrafluoroethylene, 2-8 parts of polyvinyl acetate, 2-4 parts of a coupling agent, 1-2 parts of a defoaming agent, 5-8 parts of silica sol, 1-2 parts of cerium nitrate, 1-2 parts of montmorillonite, 1-2 parts of iron red, 4-6 parts of zinc phosphate, 2-3 parts of barium sulfate, 3-4 parts of aluminum tripolyphosphate, 1-2 parts of titanium oxide, 4-7 parts of zinc oxide, 25-35 parts of and solvent. The component B comprises the following materials by weight: 20-35 parts of a curing agent, and 15-20 parts of butanol. The inventive paint has excellent seawater corrosion resistance, salt fog resistance above 2,000 hr, 10% NaOH solution resistance above 30 days, and artificial seawater resistance above 4,200 hr.

Owner:WUJIANG HUACHENG COMPOSITE MATERIAL SCI & TECH

Water-based liquid rubber waterproof paint and preparation method thereof

InactiveCN103965783AStrong surface adhesionImprove stabilityConjugated diene hydrocarbon coatingsChloropene polymer coatingsWater basedMagnesium salt

The invention discloses a water-based liquid rubber waterproof paint, comprising a component A and a component B, wherein the component A comprises the following raw materials in parts by weight: 35-65 parts of emulsified asphalt, 5-40 parts of chloroprene rubber emulsion, 5-40 parts of styrene-butadiene latex, 0.1-10 parts of polyvinyl alcohol (PVA) stabilizer, 0.1-5 parts of anionic dispersant, 0.1-5 parts of defoamer and 0.1-10 parts of pH modifier; the component B comprises the following raw materials in parts by weight: 75-95 parts of water and 5-25 parts of soluble calcium salt and magnesium salt. The water-based liquid rubber waterproof paint belongs to a water-based dual-component waterproof paint, and the component A and the component B are sprayed and mixed by special spray equipment in use according to a certain ratio, so as to instantaneously solidify and form a film. The water-based liquid rubber waterproof paint can be sprayed on any substrate surface, and is especially good in surface adhesion on metal, concrete, plastic and the like.

Owner:ZHUZHOU FEILU ADVANCED MATERIAL TECH CO LTD

High-temperature resistant spray fast-setting rubber asphalt waterproof coating

ActiveCN102965016ANo pollutionExtended service lifeConjugated diene hydrocarbon coatingsNatural rubber coatingsPolymer scienceSpray coating

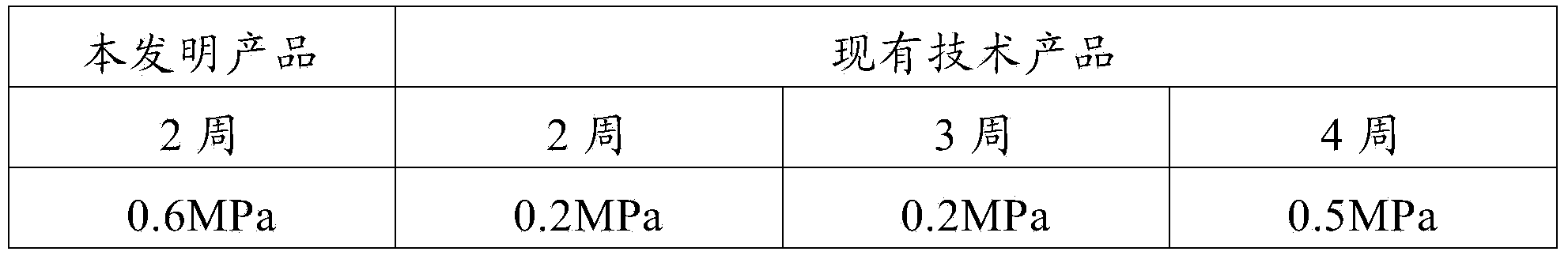

The invention relates to a high-temperature resistant spray fast-setting rubber asphalt waterproof coating which is a high-temperature resistant water-based spray coating prepared proportionally by adding a vulcanizing agent and a composite reinforcing agent into liquid rubber asphalt mastic emulsion prepared from modified emulsified asphalt and high-molecular polymer rubber latex and then mixing with a coagulating agent. The high-temperature resistant spray fast-setting rubber asphalt waterproof coating provided by the invention is a novel spray fast-setting rubber asphalt environment-friendly waterproof material which is nontoxic, tasteless and pollution-free and can be subjected to cold construction at normal temperature; and meanwhile, the high-temperature resistant spray fast-setting rubber asphalt waterproof coating has good heat resistance (160 DEG C), high elongation at break (greater than 1,000%), high elasticity recovery rate (greater than 90%), high bonding strength (greater than 0.5MPa), excellent low temperature resistance (without breakage at -30 DEG C) and excellent ageing resistance, acid / alkali resistance, cohesiveness and shear resistance, and can prevent structural damage caused by water penetration so as to prolong the service life of highway bridges.

Owner:SHANDONG NORTH CHUANGXIN WATERPROOF SCI & TECH GRP CO LTD

Creep type non-cured rubber asphalt based waterproof coating and preparation method thereof

InactiveCN103589340AConjugated diene hydrocarbon coatingsChloropene polymer coatingsPolymer modifiedWater leakage

The invention relates to a creep type non-cured rubber asphalt based waterproof coating and a preparation method thereof. According to a formula, the waterproof coating comprises, by weight: 10%-50% of asphalt, 20%-55% of solvent oil, 1%-20% of a polymer modifier, 5%-20% of tackifying resin, and 8%-30% of ordinary gelatine powder. The product involved in the invention can be used individually, and also can be used together with other waterproof coiled materials, and especially can effectively solve the water leakage problem caused by waterproof layer cracking resulted from base layer deformation.

Owner:JIANGSU CANLON BUILDING MATERIALS

Anionic emulsified modified asphalt and preparation method thereof and anionic high-adhesiveness waterborne asphalt waterproof coating

ActiveCN109575310AGood dispersionHigh strengthConjugated diene hydrocarbon coatingsChloropene polymer coatingsFiberCarbon fibers

The invention discloses anionic emulsified modified asphalt and a preparation method thereof and anionic high-adhesiveness waterborne asphalt waterproof coating. The anionic emulsified modified asphalt is prepared from, by mass, 50-70 parts of matrix asphalt, 1-20 parts of a polymer modifier, 0.5-2 parts of nano carbon fibers, 2-5 parts of a surface modifier, 1-2 parts of an anionic surfactant, 0.1-0.8 part of a pH regulator and 20-40 parts of water. A film formed by the waterproof coating has excellent creep performance and extending performance and is capable of well sealing cracks of a baselayer to effectively resist cracking caused by base layer settlement, deformation and the like, water channeling is prevented, and reliability of an upper waterproof roll is improved.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

Heat insulating coating surface glue and heat insulating coating

ActiveCN102206445AImprove insulation performanceNot easy to stainRubber derivative coatingsConjugated diene hydrocarbon coatingsChemical tankEnergy consumption

The invention discloses heat insulating coating surface glue for insulating heat through reflection and heat conversion. Based on reflection and heat insulation, a heat converting material is added into the heat insulating coating surface glue, after being absorbed by a coating layer, part of unreflected heat energy can be converted by the heat converting material into radiant energy to be released into the atmosphere, thus, 98% of heat from the sun can be insulated. The invention also provides a heat insulating coating which comprises the surface glue, intermediate glue and bottom glue, has excellent heat insulating performance, and can be used for remarkably reducing the temperature of buildings, industrial chemicals tanks and various equipments requiring heat insulation and reducing the energy consumption for temperature reduction.

Owner:开平市日固力涂料有限公司

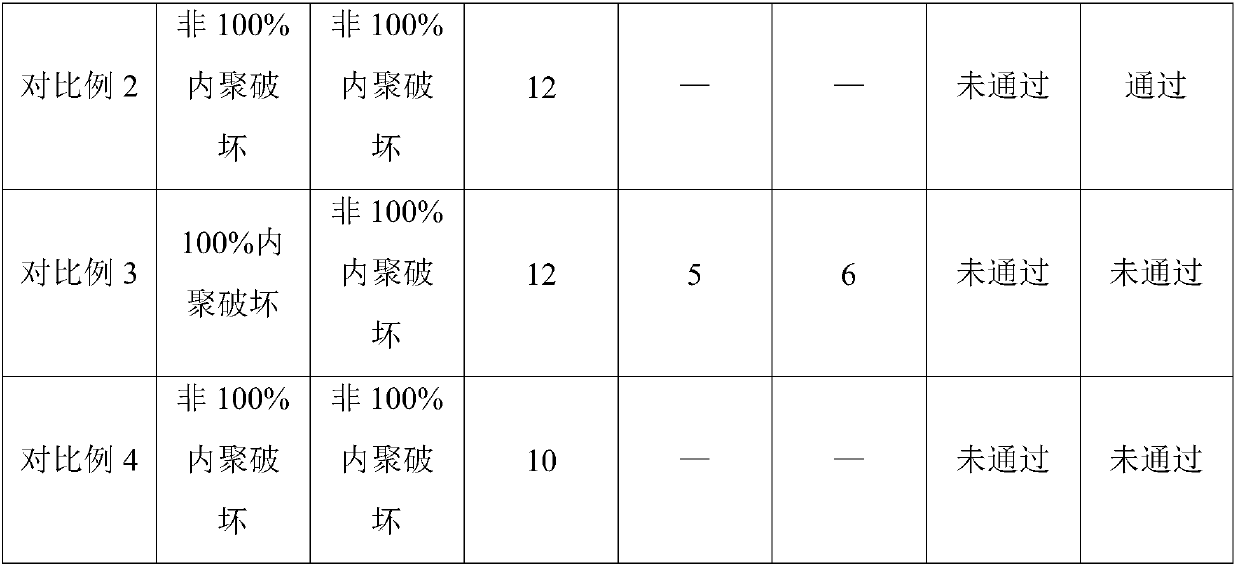

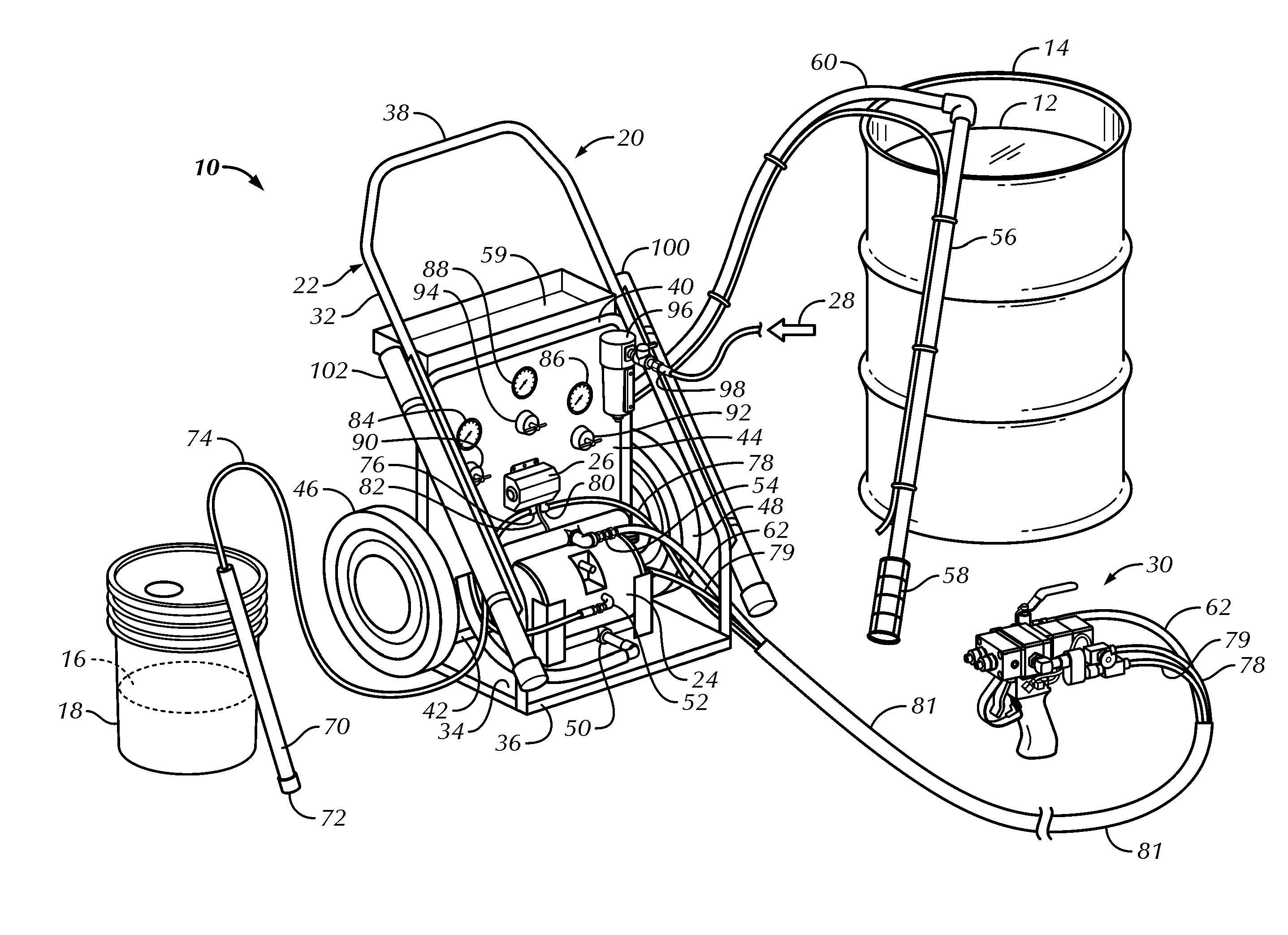

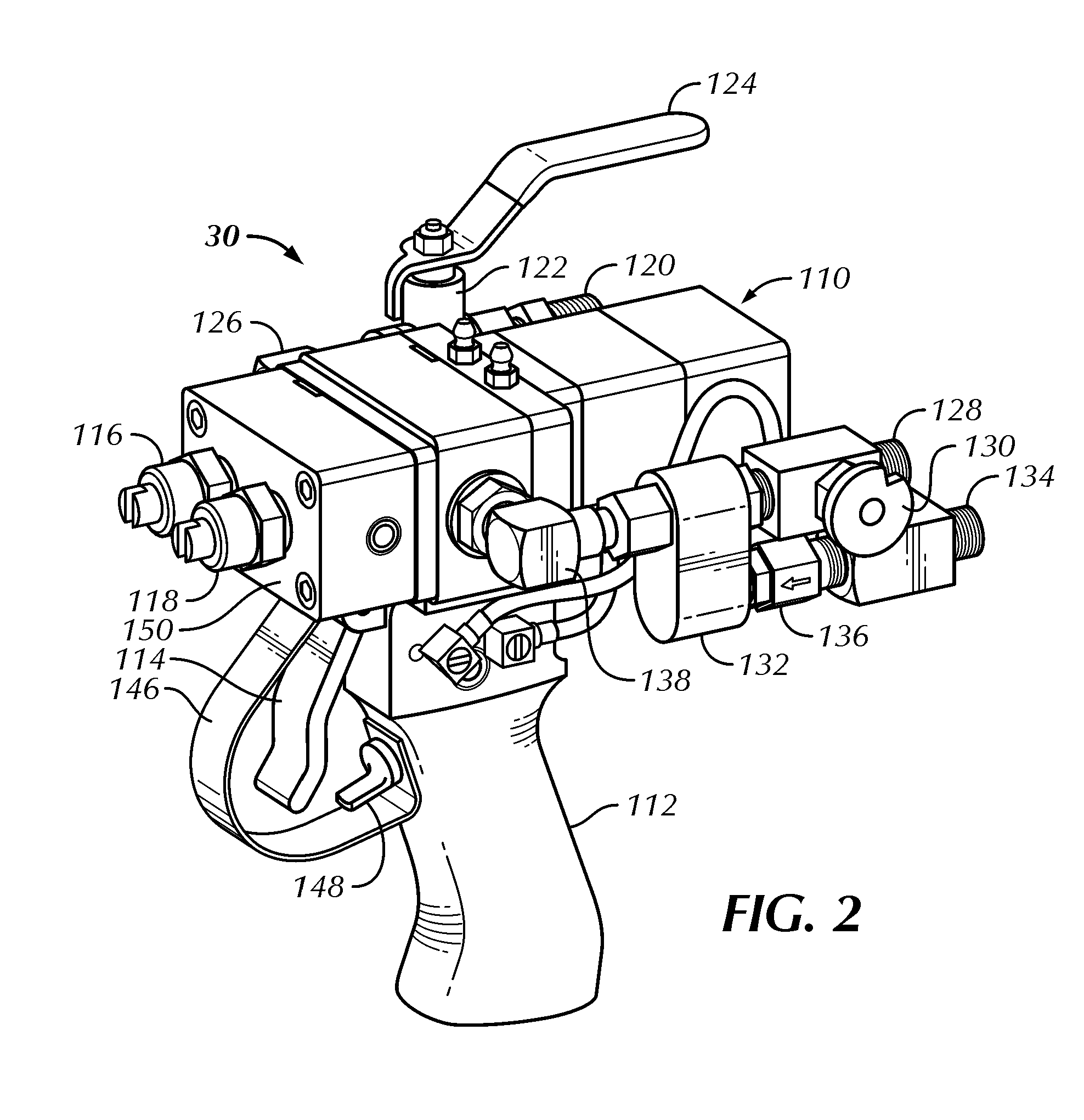

Waterproof Coating System and Method of Application

A coating comprises a resin solution including a solution of neoprene latex and liquid asphalt emulsion and an accelerator solution including an aqueous solution of zinc sulfate powder and water. A spray system for applying the coating includes a spray gun having first and second nozzles, a first pump fluidly connected between the first nozzle and a resin solution reservoir for delivering the resin solution to the first nozzle at a first fluid pressure, and a second pump fluidly connected between the second nozzle and an accelerator solution reservoir for delivering the accelerator solution to the second nozzle at a second fluid pressure different from the first pressure. The accelerator solution may be aerated by a source of compressed air prior to discharge from the second nozzle.

Owner:HARCO AMERICAS

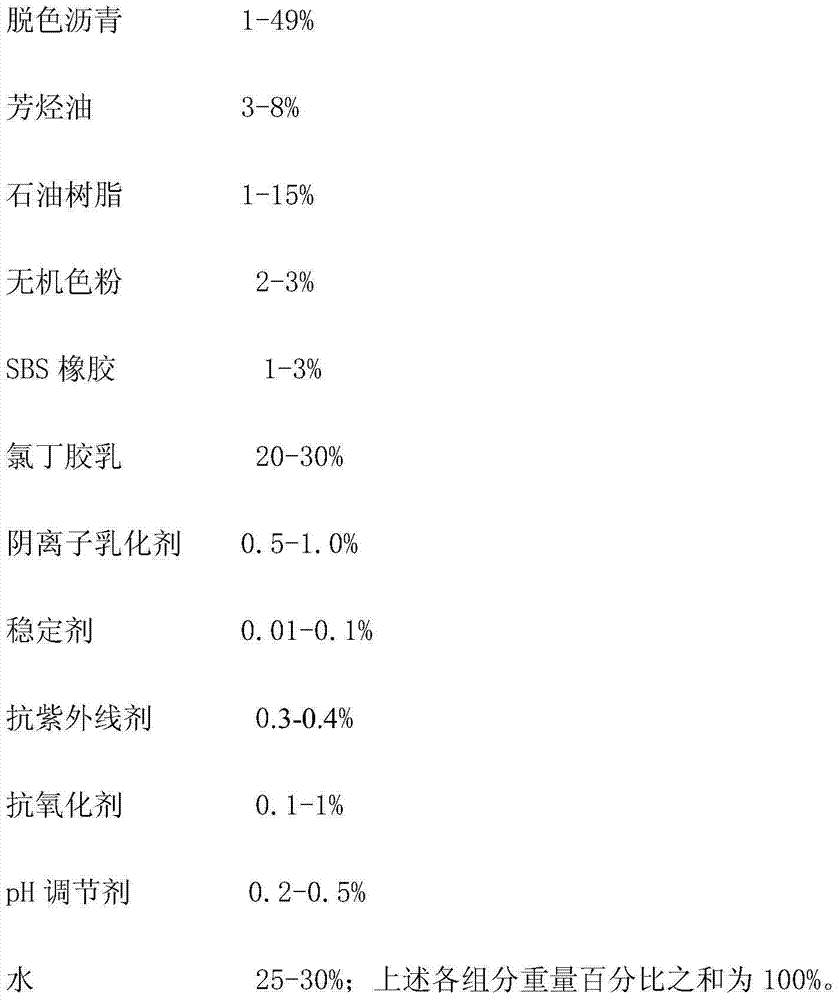

Emulsified asphalt, a preparation method thereof, applications thereof, a water-proof coating material and a water-proof coating

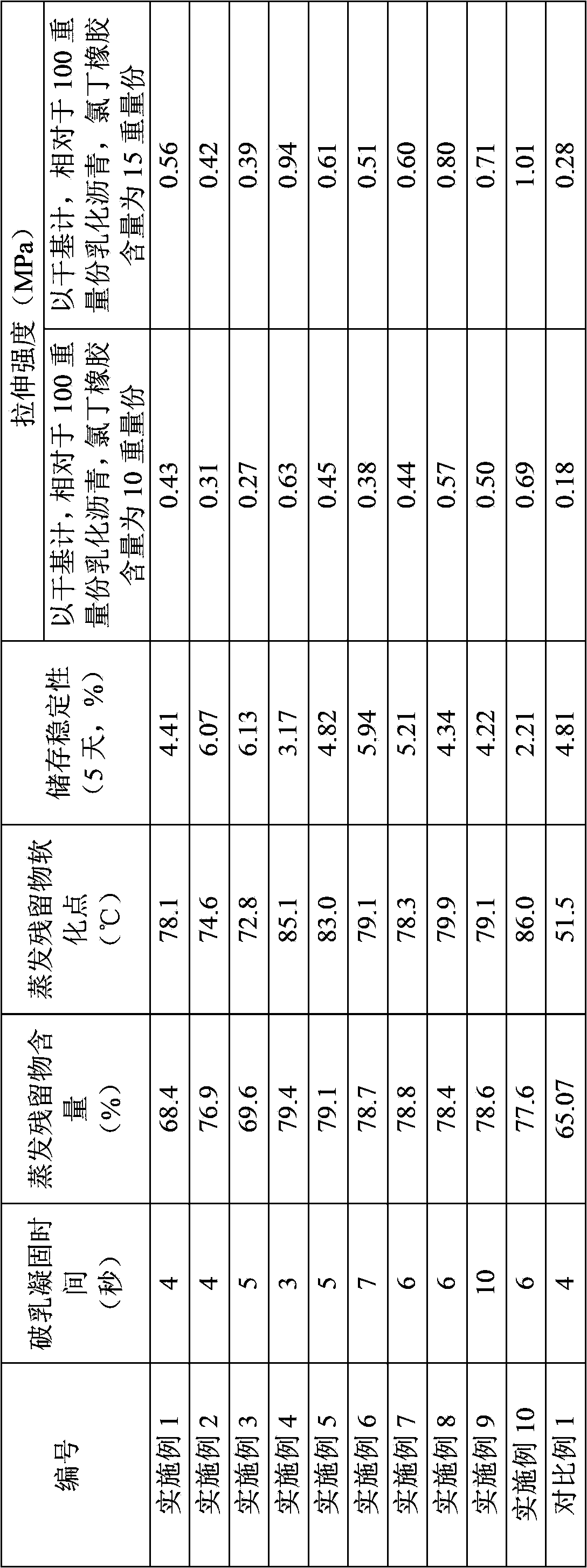

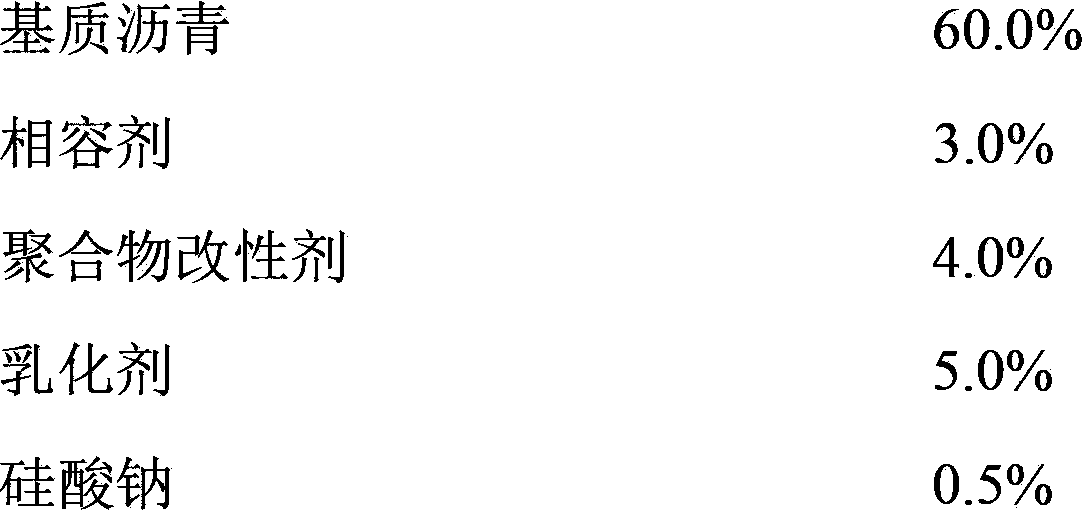

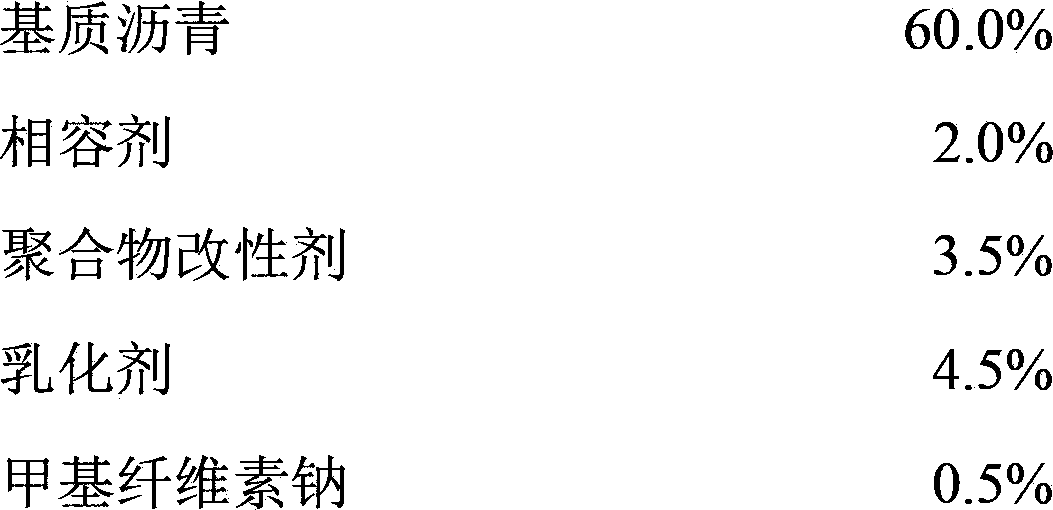

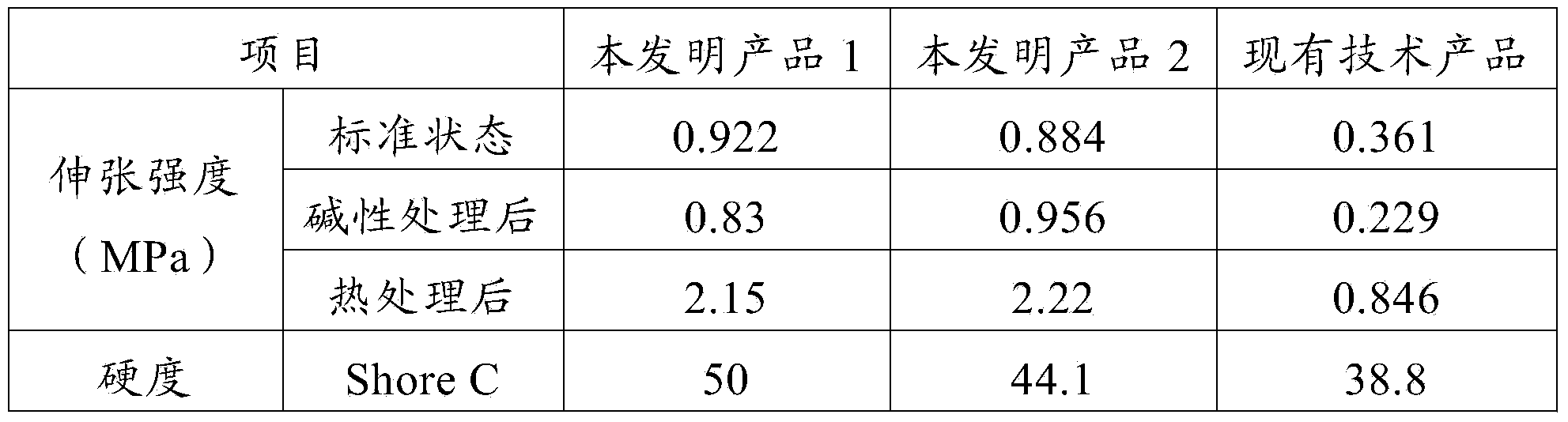

ActiveCN103788662AGood storage stabilityHigh curing and setting speedChloropene polymer coatingsBuilding insulationsPolymer modifiedUltimate tensile strength

The invention provides emulsified asphalt, a preparation method thereof and applications thereof. Based on the total weight of the emulsified asphalt, the emulsified asphalt comprises 50-70% by weight of polymer modified asphalt, 1.5-18% by weight of at least one anionic emulsifier and 22-48.5% by weight of water. The invention also provides a water-proof coating material and a water-proof coating formed by the coating material. The emulsified asphalt has good storage stability and the water-proof coating prepared from the emulsified asphalt has high curing and coagulating rate. In addition, the water-proof coating formed by the water-proof coating material prepared from the emulsified asphalt is high in strength.

Owner:CHINA PETROLEUM & CHEM CORP +1

Color polymer modified emulsion asphalt-base waterproof paint and preparation method thereof

ActiveCN103666260ACongeal fastEasy constructionChloropene polymer coatingsBituminous coatingsEpoxyHigh concentration

The invention belongs to the color polymer modified emulsion asphalt-base waterproof paint and a preparation method thereof. The color polymer modified emulsion asphalt-base waterproof paint is prepared by adopting multiple synthesis macromolecular polymers such as high-concentration ultrafine suspension micro-emulsion anion modified color emulsified asphalt, SBS (Styrene Butadiene Styrene) rubber, neoprene, macromolecular resin, epoxy resin and the like and multiple functional assistants such as the plasticizer as raw materials and by utilizing a special production process. After the color polymer modified emulsion asphalt-base waterproof paint forms a film, the color is bright, no brittle rupture exists at the low temperature of minus 30DEG C, no flowing exists at the high temperature of 120DEG C, the resilient return rate reaches 90 percent, the color polymer modified emulsion asphalt-base waterproof paint can be stably stored for more than 2 years, and the service life can reach 50 years.

Owner:ZHEJIANG YUXI CORROSION CONTROL CORP

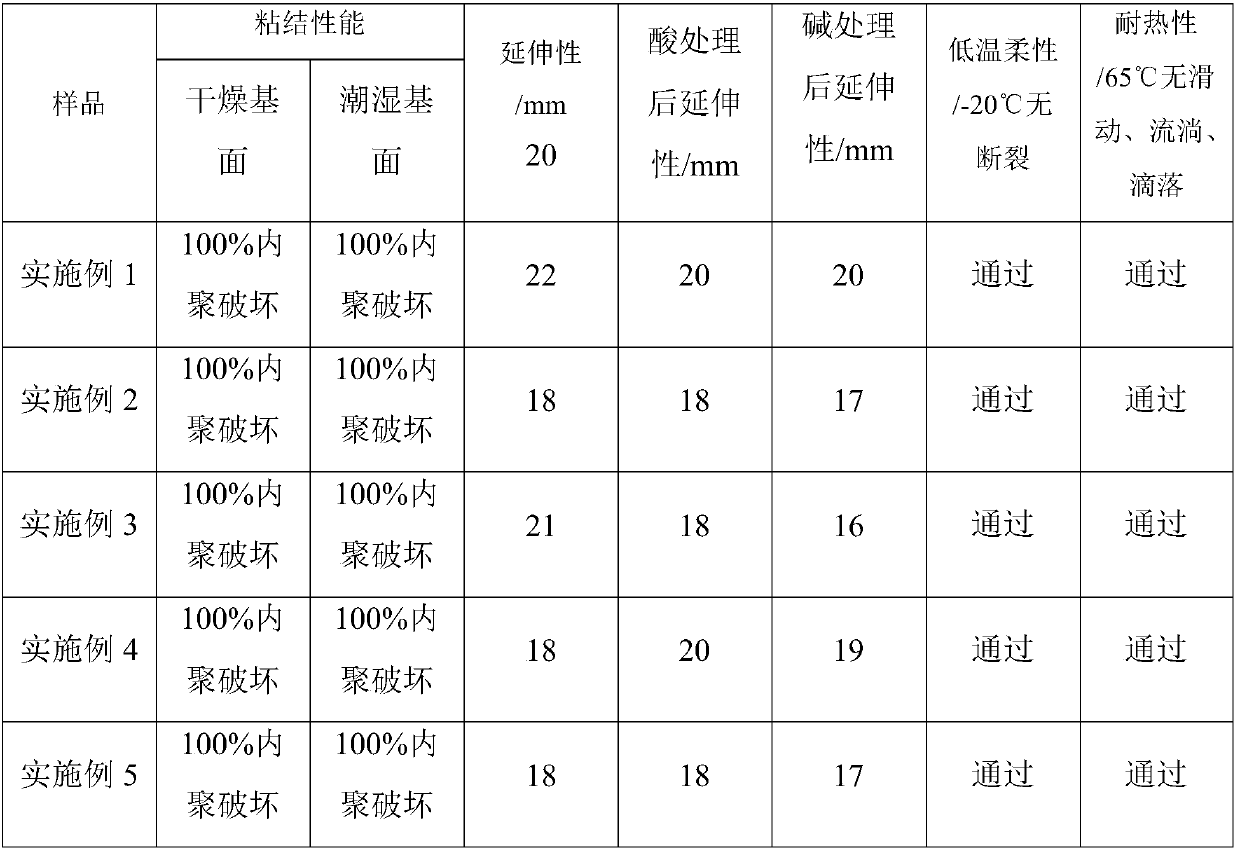

Rubber modified asphalt waterproof coating as well as preparation method and use method thereof

ActiveCN107118695ARapid demulsificationSimple construction processLiquid surface applicatorsConjugated diene hydrocarbon coatingsInorganic saltsEmulsion

The invention provides a rubber modified asphalt waterproof coating which comprises a component A and a component B, wherein the component A comprises modified emulsified asphalt and a rubber emulsion; the component B comprises inorganic salt and deionized water; the component A comprises the following components in parts by mass: 60-90 parts of the modified emulsified asphalt, and 10-40 parts of the rubber emulsion; and the component B comprises the following components in parts by mass: 9-14 parts of the inorganic salt and 86-91 parts of the deionized water. Through the development of the component A and the component B and application of a double-component spraying machine, the problem that cation emulsified asphalt is long in demulsification time is solved, full-pavement without seams and normal temperature cold construction of waterproof coatings are achieved, and in addition, the waterproof effect is greatly improved.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +2

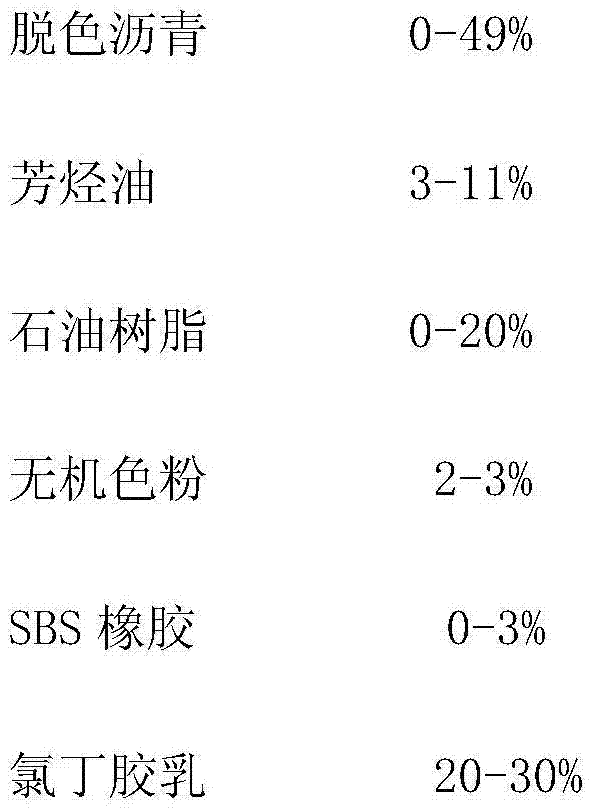

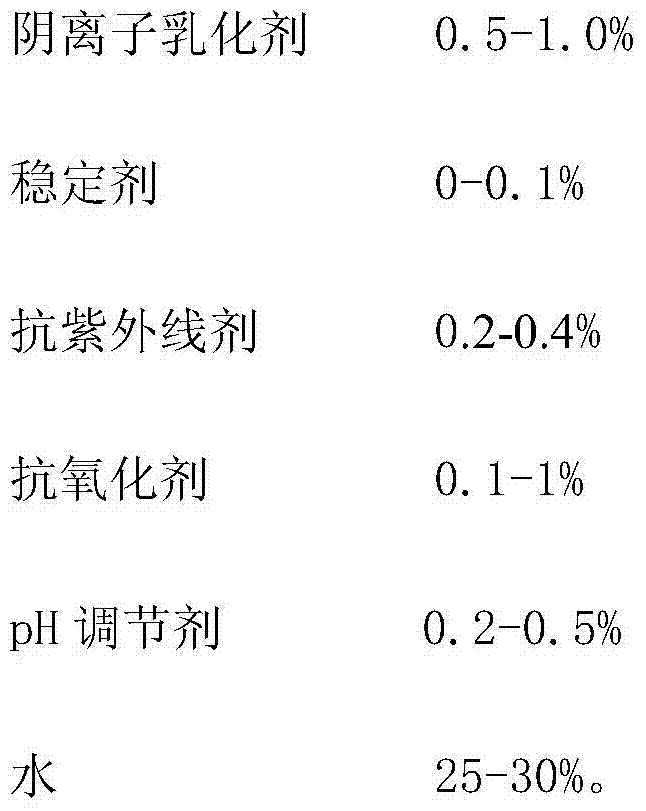

Polymer modified emulsified asphalt composition and preparation method thereof

ActiveCN102675889ARaw materials are cheap and easy to getImprove adhesionConjugated diene hydrocarbon coatingsChloropene polymer coatingsPolymer sciencePolymer modified

Owner:SHANXI MINGKESI TECH

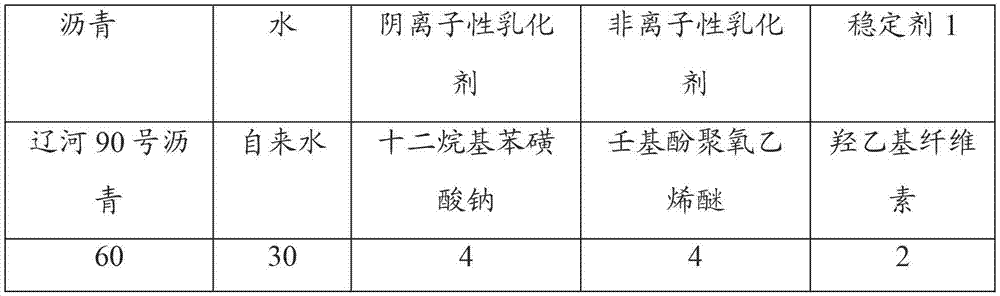

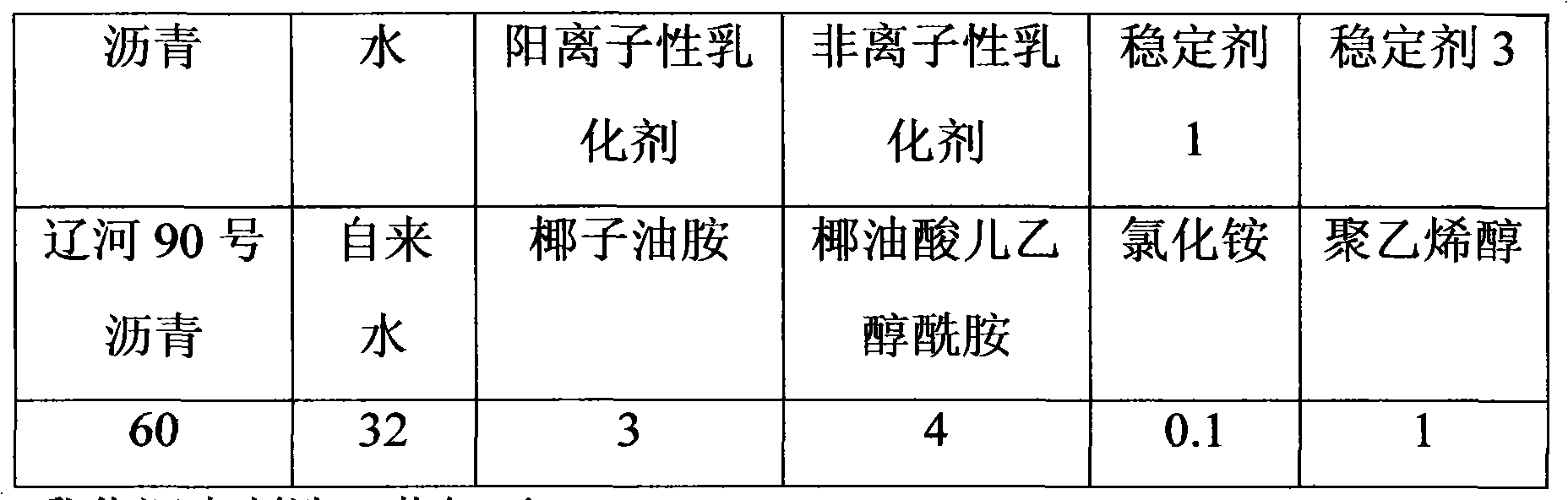

Self-hardening rubber asphalt paint

InactiveCN102108257AEliminates prone to low cloud point problemsLow densityConjugated diene hydrocarbon coatingsNatural rubber coatingsEmulsionSpray coating

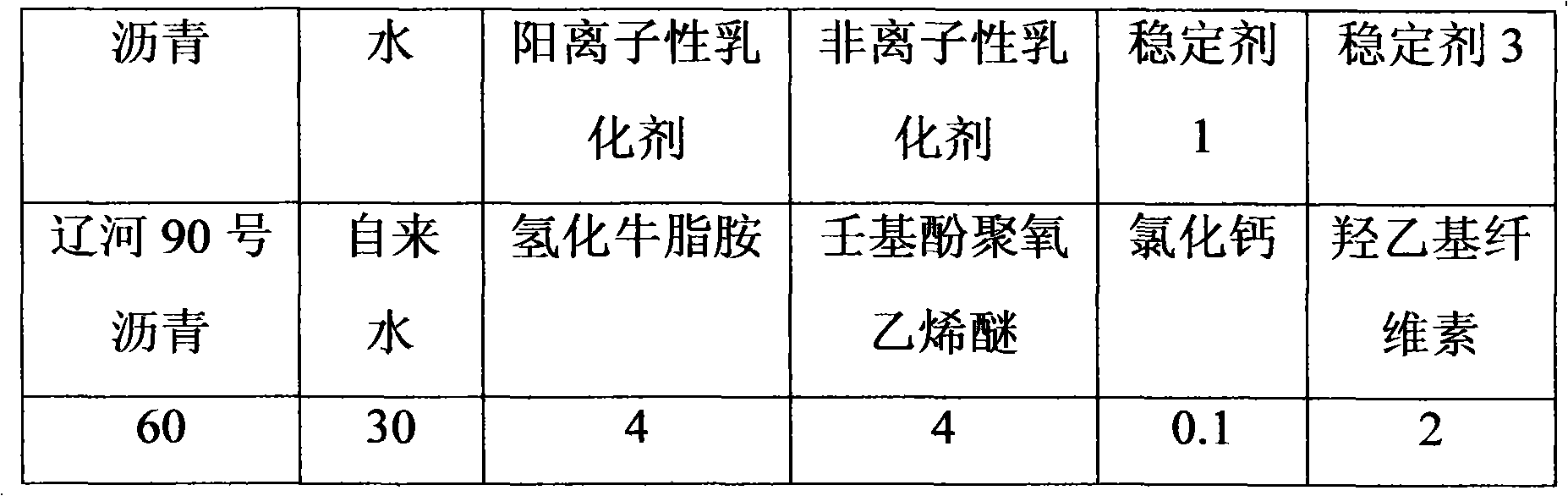

The invention provides self-hardening rubber asphalt paint which comprises the following components by weight percent: 50%-65% of asphalt, 3%-6% of cationic emulsifier, 3%-6% of nonionic emulsifier, 25%-35% of modified latex, 1%-3% of stabilizer and 5%-10% of filler. The invention further provides a preparation method of the self-hardening rubber asphalt paint, the rubber asphalt paint is modified through normal-temperature self-crosslinking emulsion, has the prominent characteristics of normal temperature spray coating, manual scrape-coating, instant shaping, perfect joint, high elastic force, zero joints and the like, and can fundamentally solve the technical difficulty of leakages at side angles, gaps and junction of irregular structures and the like, thereby thoroughly updating the traditional construction process and the method of waterproof material.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +1

Method for preparing and applying coating waterproof material, and coating waterproof material

ActiveCN104342029AImprove stabilityStrong heat and cold resistanceLiquid surface applicatorsConjugated diene hydrocarbon coatingsWater basedLatex rubber

The invention provides a method for preparing and applying a coating waterproof material, and the coating waterproof material. The method comprises the following steps: with a standard that the coating waterproof material accounts for 100 parts by weight, 20-90 parts by weight of vulcanized-rubber-modified anionic emulsified asphalt, 10-70 parts by weight of latex rubber and 0.1-10 parts by weight of an additive are mixed to form the coating waterproof material with a pH value of 7-13.5; the mixed coating waterproof material is coated onto a part to be coated with an injection method, and a mixed agent of a hardening agent and pure water is coated onto the part to be coated with an injection method at the same time; and the coating waterproof material is instantly subjected to a binding reaction with the mixed agent, such that a waterproof coating is formed through coagulation at the coated part. With the method provided by the embodiment of the invention, one or more functions of an existing water-based rubber asphalt coating waterproof material can be improved.

Owner:YUGREAT (BEIJING) INTERNATIONAL TECHNOLOGY CO LTD

Non-asphaltic waterborne spraying rapid hardening rubber waterproof paint and its manufacturing method

ActiveCN103360933AEasy constructionConjugated diene hydrocarbon coatingsChloropene polymer coatingsWhole bodyMaterials science

The invention discloses a non-asphaltic waterborne spraying rapid hardening rubber waterproof paint which comprises a component A and a component B. The component A comprises the following substances: by weight, 14-25% of an anion butylbenzene emulsion, 18-25% of an anion polyurethane-silicone-acrylate emulsion, 10-15% of an anion polychloroprene emulsion, 0.1-0.3% of a dispersant, 0.1-0.3% of an antifoaming agent, 0.2-0.4% of a nonionic emulsifier, 0.1-0.3% of an anion emulsifier, 3-6% of a low-temperature modifier, and 38-43% of ultrafine powdered steatile. The component B comprises the following substances: by weight, 80-90% of industrial calcium chloride, 3-6% of industrial sodium chloride, and 7-14% of a composite ferro-aluminium polymer. According to the invention, an advanced refrigeration and cold-spray technology is adopted; construction is simple; the whole body has advantages of seamlessness, no stripping and no water breakthrough; and the paint can obstruct various harmful gases, and is a waterproof, antiseep, anticorrosion, chemicals-resistant, anti-cracking, anti-puncturing, damping and noise-reducing protective coating.

Owner:KESHUN WATERPROOF TECH CO LTD

Spraying quenching rubber asphalt waterproof coating and preparation method thereof

InactiveCN107043598AHigh tensile strengthGood chemical resistanceConjugated diene hydrocarbon coatingsNatural rubber coatingsPolymer scienceEmulsion

Owner:北京日州科技有限公司

Flame-retardant spraying quick-settling rubber asphalt waterproof paint

ActiveCN102965019AFlame retardantImprove performanceFireproof paintsConjugated diene hydrocarbon coatingsPolymer scienceBituminous waterproofing

The invention relates to flame-retardant spraying quick-settling rubber asphalt waterproof paint, which achieves a flame retardant effect by adding certain flame retardant components on the basis of the conventional quick-settling rubber asphalt waterproof paint, and has excellent performance. The waterproof paint is water-based spraying paint and is prepared in proportion by the steps of: compounding superfine, suspended and micro-emulsion modified emulsified asphalt and macromolecule polymer rubber latex to obtain components of liquid rubber asphalt mastic emulsion and mixing the emulsion with coagulating agent components. Compared with the conventional waterproof paint, the flame-retardant spraying rubber waterproof paint provided by the invention is higher in elongation at break and bonding strength and has the outstanding characteristic of flame retardance. The flame-retardant spraying quick-settling rubber asphalt waterproof paint effectively makes up the shortage of flame retardance of the conventional waterproof paint, has the advantages of convenience in construction, aging resistance, long service life, flame retardance and the like, and can be widely applied to water prevention of roofs of various buildings.

Owner:SHANDONG NORTH CHUANGXIN WATERPROOF SCI & TECH GRP CO LTD

Spraying rapid-hardening rubber asphalt water proofing material for drinking water pond

InactiveCN102964929AEnsure safetyGuaranteed reliabilityConjugated diene hydrocarbon coatingsNatural rubber coatingsBitumen emulsionLiquid rubber

The invention provides a spraying rapid-hardening rubber asphalt water proofing material for a drinking water pond. According to the spraying rapid-hardening rubber asphalt water proofing material, emulsified asphalt and high-molecular polymer rubber latex are prepared into liquid rubber asphalt emulsion component in the ratio by the latest technology, and then the liquid rubber asphalt emulsion component is mixed with a coagulating agent in the ratio so as to obtain a water-based spraying material; the emulsified asphalt, the latex and the chemical stabilizer and the like in the prescription are all the non-volatile organic compounds and organic solvents; the construction is mainly carried in a chemical spraying way, wherein a film can be generated after spraying for 30 seconds; and the formed elastic film has the characteristics of high elongation (more than 1000%) and high elastic recovery rate (more than 90%), so that the spraying rapid-hardening rubber asphalt water proofing material has the water proofing effect greater than that of conventional material. The spraying rapid-hardening rubber asphalt water proofing material for the drinking water pond is produced, constructed and used without organic solvents, so that the spraying rapid-hardening rubber asphalt water proofing material is nonpoisonous and tasteless, zero-waste, and free from exhaust emission and pollution; and the spraying rapid-hardening rubber asphalt water proofing material for the drinking water pond is constructed at normal temperature without being heated and adopting open fire, so that the safety and the reliability can be ensured.

Owner:SHANDONG NORTH CHUANGXIN WATERPROOF SCI & TECH GRP CO LTD

Emulsified SBS modified asphalt and reparation method thereof, waterproof coating and reparation method thereof

InactiveCN105315471AImprove mechanical propertiesGood storage stabilityChloropene polymer coatingsBuilding insulationsBituminous waterproofingUltimate tensile strength

The invention discloses emulsified SBS modified asphalt and a reparation method thereof, a waterproof coating and a reparation method thereof. The emulsified SBS modified asphalt is prepared from, by mass, 80-110 parts of matrix asphalt, 2-12 parts of SBS, 0-6 parts of stabilizer, 0-4 parts of sodium hydroxide, 1-5 parts of anionic emulsifier, 0-5 parts of non-ionic emulsifier and 45-95 parts of water. According to the emulsified SBS modified asphalt and the reparation method thereof, the waterproof coating and the reparation method thereof, the SBS serves as a modifying agent, a continuous island structure is formed in matrix asphalt particles, the mechanical property is improved, meanwhile styrene and butadiene chain segments are introduced into the SBS, the compatibility between the emulsified SBS modified asphalt and polymer emulsion in the waterproof coating is improved, and the storage stability of the obtained waterproof asphalt coating can be improved; when JC / T408-2005 'Emulsified Asphalt Waterproof Coating is met while the tensile strength reaches over 0.6MPa, the content of polymer emulsion in the waterproof coating is lowered, and the cost is lowered.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

Impact-resistant high-adhesive-force inflaming-retarding modified bisphenol A epoxy resin paint

InactiveCN104293107AImprove impact resistanceImprove adhesionFireproof paintsChloropene polymer coatingsTitanium nitrideKetone

The invention discloses an impact-resistant high-adhesive-force inflaming-retarding modified bisphenol A epoxy resin paint which comprises the following raw materials in parts by weight: 66-69 parts of modified bisphenol A epoxy resin, 12-15 parts of glycerin alkyd resin, 13-16 parts of aldehyde ketone resin KR-130, 22-26 parts of graphene, 4-6 parts of titanium nitride, 5-8 parts of nano-magnesium hydroxide, 0.8-1.2 parts of a silane coupling agent KH-550, 2.4-2.8 parts of diphenyl phosphate ester, 1.6-1.9 parts of zinc borate, 1-2 parts of antimony trioxide, 0.6-0.9 part of a defoaming agent, 0.5-0.8 part of a smoothing agent, 0.4-0.7 part a mildew preventive, 1.2-1.5 parts of pigment and 50-53 parts of a solvent. The impact-resistant high-adhesive-force inflaming-retarding modified bisphenol A epoxy resin paint is strong in impact resistance, good in adhesive force and excellent in inflaming retarding performance.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

Processing technique of noctilucent glazing floors

ActiveCN103061487AImprove adhesionControl curing speedLaminationLamination apparatusWeather resistanceFloor slab

The invention belongs to the field of floor processing, in particular to a processing technique of noctilucent glazing floors. The processing technique is good in decoration and comprises the following steps of (1) processing a floor slab; (2) coating noctilucent primer on the floor slab processed in the step (1) to obtain a first floor slab; (3) coating elastic primer, wear-resisting primer and hardening primer on the first floor slab processed in the step (2) to obtain a second floor slab; and (4) coating glazing paint on the second floor slab processed in the step (3) to obtain the noctilucent glazing floors. The glazing paint is coated outside the noctilucent primer of the processed floors to enable the floors to give out full and soft light at night, simultaneously friction losses or oxidation of the noctilucent primer can be well avoided, weather resistance of the noctilucent primer is strengthened, and lighting service life of the noctilucent primer is prolonged. The glazing paint is applied to the surface of the floors, glossiness, abrasive resistance and fire resistance of the floors are strengthened, flame retardant efficiency of the floors is good, strength is high, and deformation caused by external temperature and humidity is not easy to cause.

Owner:如东文园投资开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com