Anionic emulsified modified asphalt and preparation method thereof and anionic high-adhesiveness waterborne asphalt waterproof coating

A technology of emulsified modified asphalt and asphalt waterproof coatings, which is applied in the direction of asphalt coatings, chloroprene homopolymer coatings, coatings, etc., and can solve the problems of self-adhesive waterproof membrane layer swelling, unfavorable membrane construction, and environmental smoke. Air pollution and other issues, to achieve excellent anti-aging performance and bonding performance, improve chemical aging resistance, the effect of large construction thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

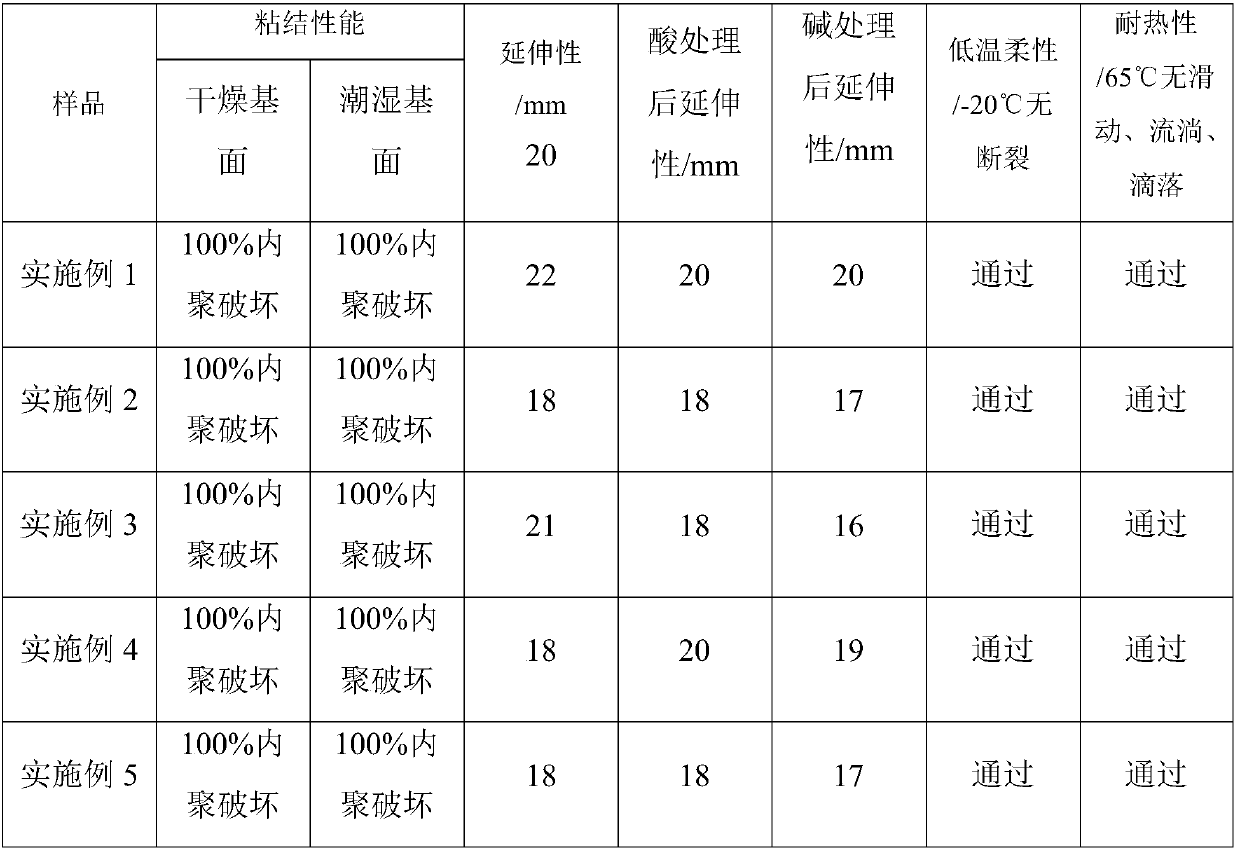

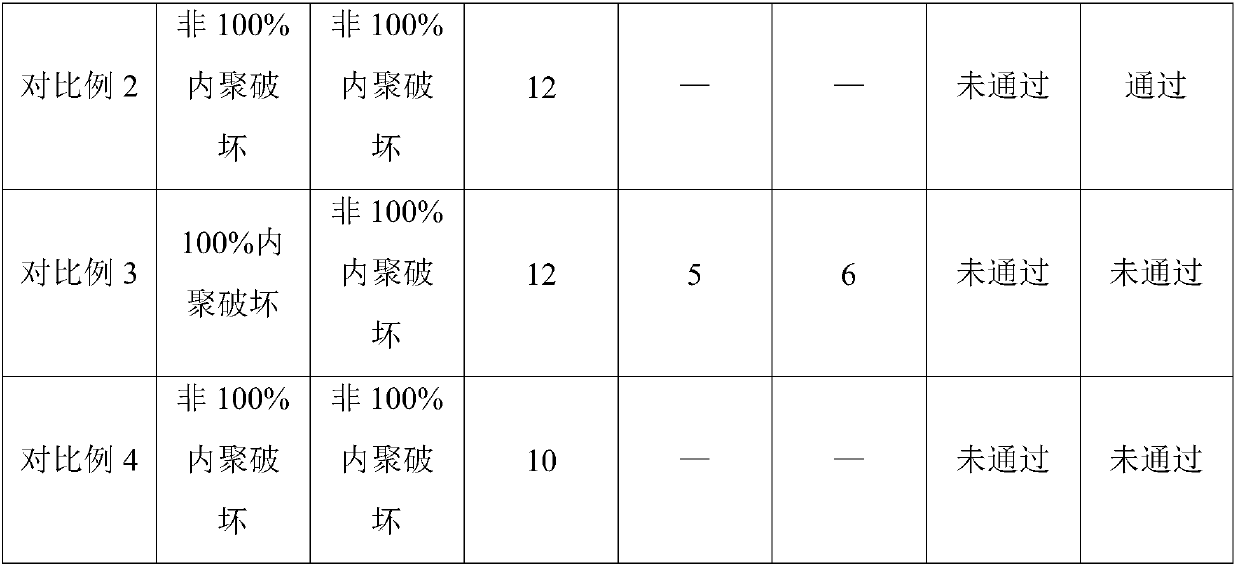

Examples

preparation example Construction

[0026] A second aspect of the present invention provides a method for preparing the above-mentioned anionic emulsified modified asphalt, the preparation method comprising the following steps:

[0027] (1) Mixing the carbon nanofiber, the surface modifier and the macromolecular modifier uniformly to obtain a modified solution;

[0028] (2) uniformly dispersing the modified liquid in the molten base asphalt to obtain modified asphalt;

[0029] (3) uniformly mixing the anionic surfactant, pH regulator and water to obtain a soap solution;

[0030] (4) Mixing the soap liquid and the molten modified asphalt evenly to obtain the anionic emulsified modified asphalt.

[0031] As a preferred solution, step (2) is to add the modified liquid in the form of spray into the molten matrix asphalt stirred by high-speed shearing, and disperse evenly to obtain the modified asphalt;

[0032] Step (4) is to pass the soap solution and the molten modified asphalt through a colloid mill to obtain t...

Embodiment 1

[0051] This embodiment provides an anionic high-bonding water-based asphalt waterproof coating, which consists of 75 parts of anionic emulsified modified asphalt, 15 parts of acrylic emulsion, 7 parts of water-based SBR viscosity-increasing emulsion, 60 parts of slurry, and 1.5 parts of alcohol ester dodeca and 2 parts of bentonite, and mix the above-mentioned raw materials uniformly in a mixer to obtain the anionic high-binding water-based asphalt waterproof coating.

[0052] Among them, the anionic emulsified modified asphalt consists of 70 parts of 90# heavy traffic asphalt, 5 parts of neoprene latex, 6 parts of liquid butyl rubber, 1 part of nano-carbon fiber, 0.5 parts of aminosilane coupling agent, 1.4 parts of tall oleic acid, Composed of 0.6 parts of sodium hydroxide and 35 parts of water; the specific preparation method is: disperse neoprene latex, liquid butyl rubber, nano-carbon fiber and aminosilane coupling agent through a homogenizer to obtain a modified liquid; a...

Embodiment 2

[0055] The present embodiment provides an anionic high-bonding water-based asphalt waterproof coating, consisting of 70 parts of anionic emulsified modified asphalt, 10 parts of acrylic acid emulsion, 10 parts of chloroprene latex, 40 parts of slurry, 5 parts of water-based SBR viscosity-increasing emulsion, It is composed of 1 part of alcohol ester dodecane and 1 part of alkali-swellable acrylic thickener. The above-mentioned raw materials are uniformly mixed in a mixer to obtain the anionic high-binding water-based asphalt waterproof coating.

[0056] Among them, the anionic emulsified modified asphalt consists of 60 parts of 110# asphalt, 8 parts of SBR emulsion, 5 parts of liquid butyl rubber, 0.8 parts of nano-carbon fiber, 2 parts of multi-branched alcohol modified surfactant, 1.2 parts of tetradecyl Alcohol ether sodium carboxylate, composed of 0.6 parts of sodium hydroxide and 35 parts of water; the specific preparation method is: uniformly dispersing SBR emulsion, liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com