Patents

Literature

221results about How to "Improved creep properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-conductivity aluminum alloy material for cable and preparation method thereof

InactiveCN101886198ALittle impact on electrical performanceEasy to stretchMetal/alloy conductorsRare-earth elementPliability

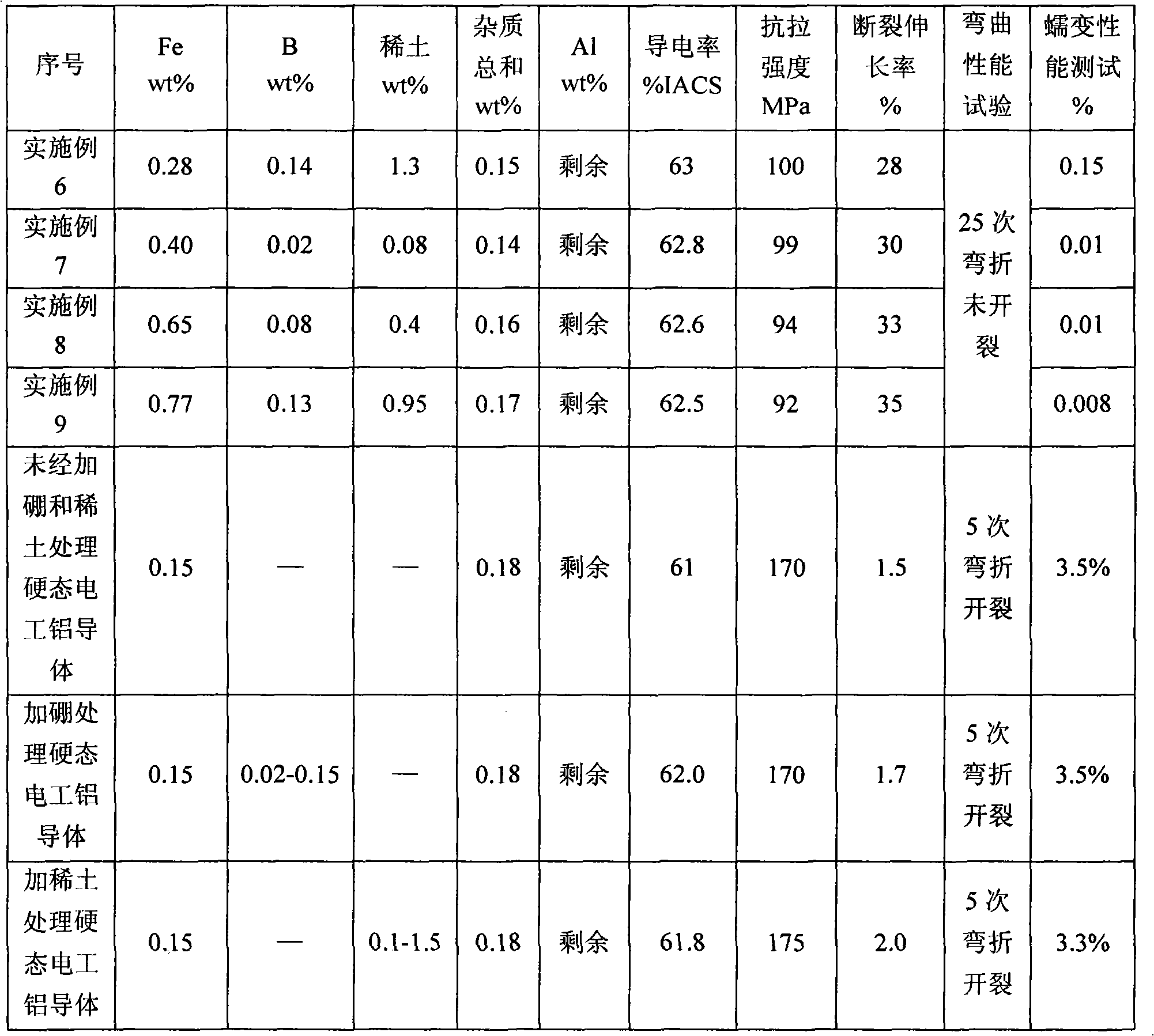

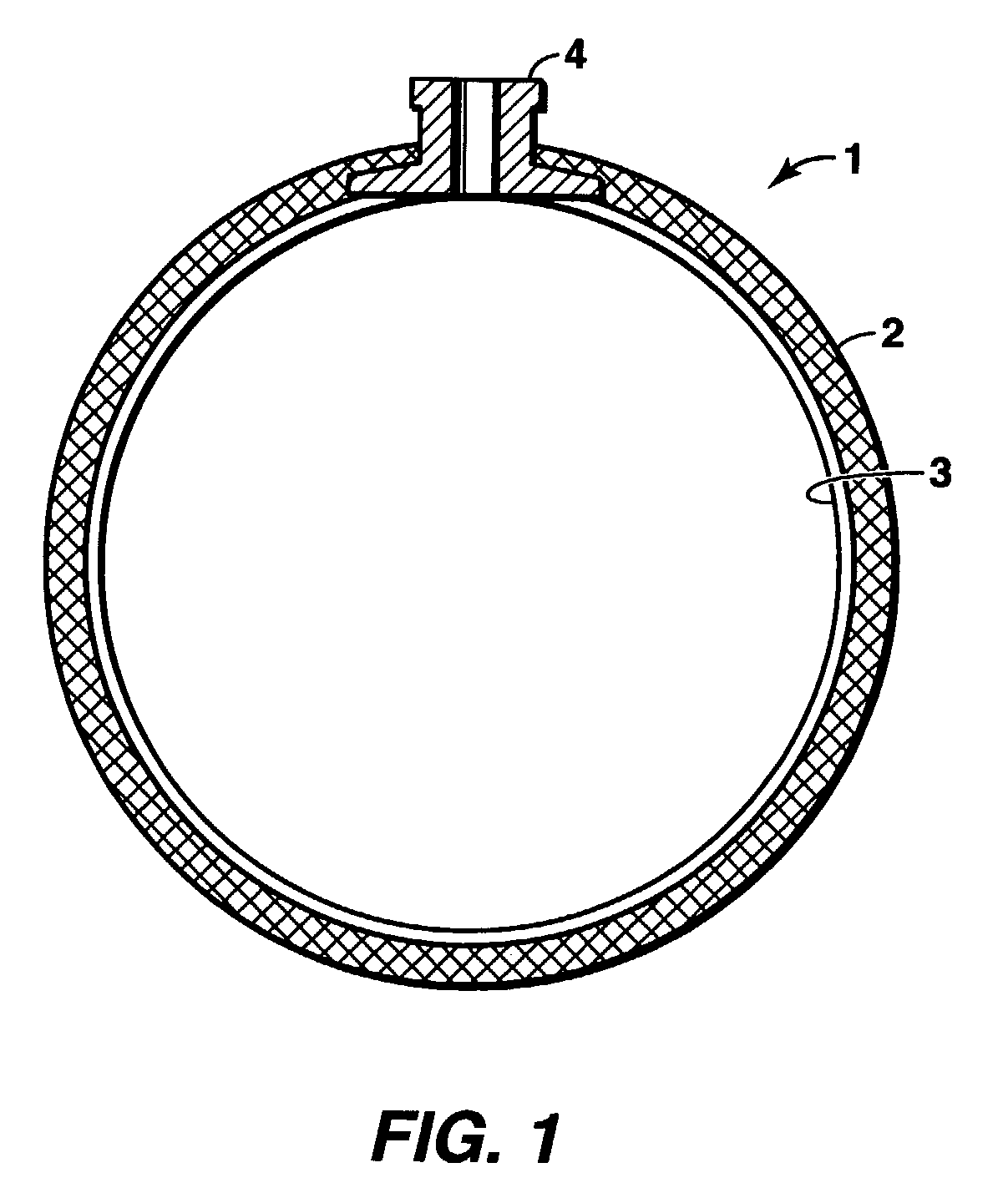

The invention relates to a high-conductivity aluminum alloy material for a cable and a preparation method thereof. The aluminum alloy material comprises the following components in percentage by weight: 0.25-0.80 percent of iron element, 0.02-0.15 percent of boron element, 0.1-1.5 percent of rare earth element and the balance of aluminum and inevitable impurities. The aluminum alloy is formed by adding an aluminum alloy intermediate alloy, an aluminum-boron alloy and an aluminum-rare earth intermediate alloy into an aluminum ingot of which the purity is more than 99.80 percent by weight and carrying out a casting process and annealing treatment on the mixture. Compared with a common electric aluminum conductor, the prepared aluminum alloy conductor has more excellent conductive performance and the conductivity reaching or exceeding 62.5 percent IACS (International Annealed Copper Standard); the aluminum alloy conductor treated by using a special process has excellent flexibility and creep resistance; and compared with a common electric aluminum conductor, the prepared aluminum alloy material used as a cable extrusion insulating lead core is more energy-saving and safer.

Owner:ANHUI JOY SENSE CABLE

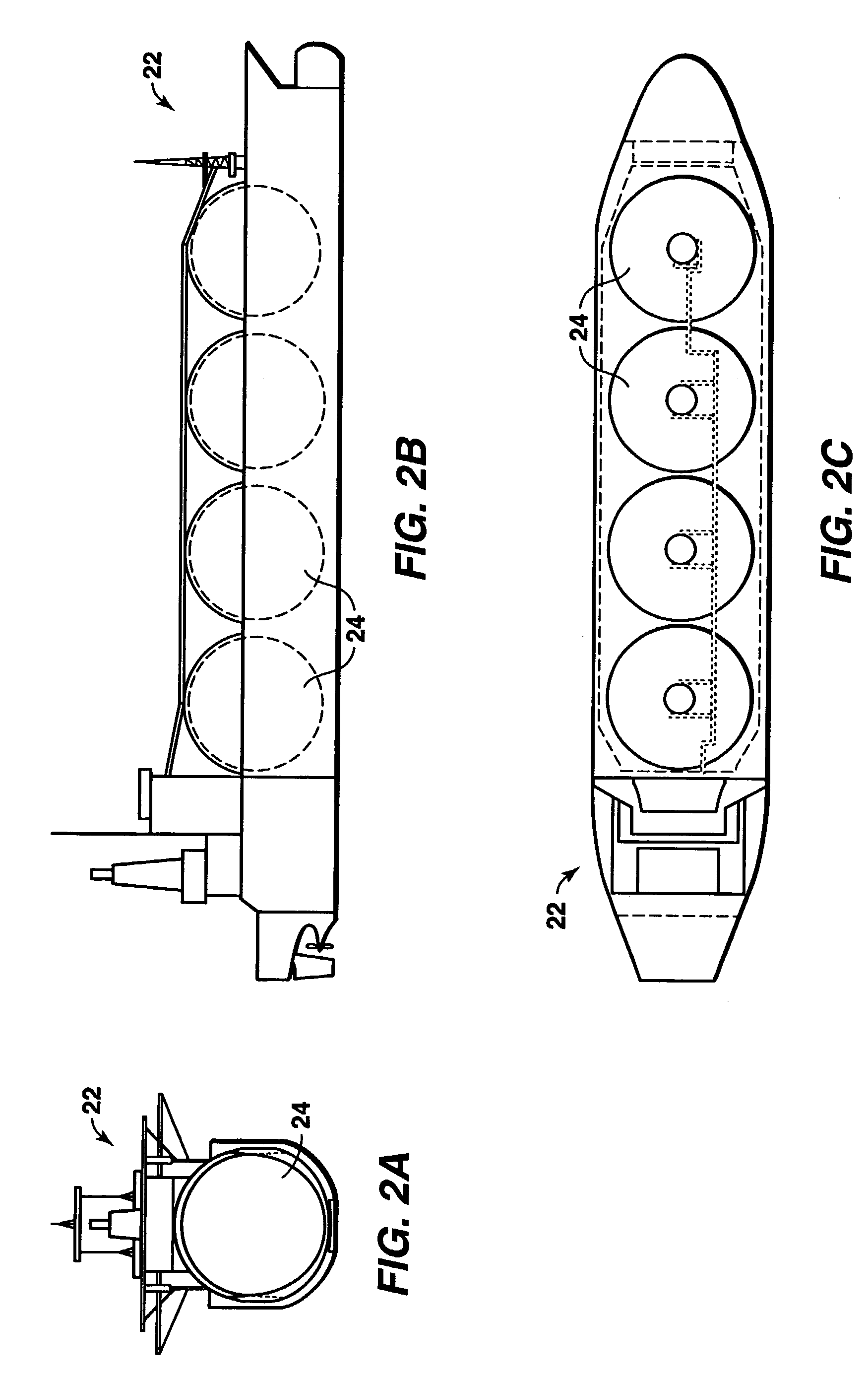

Containers and methods for containing pressurized fluids using reinforced fibers and methods for making such containers

InactiveUS7147124B2Improve creep performanceImprove compactionVessel mounting detailsVessel manufacturingFiberPolymer science

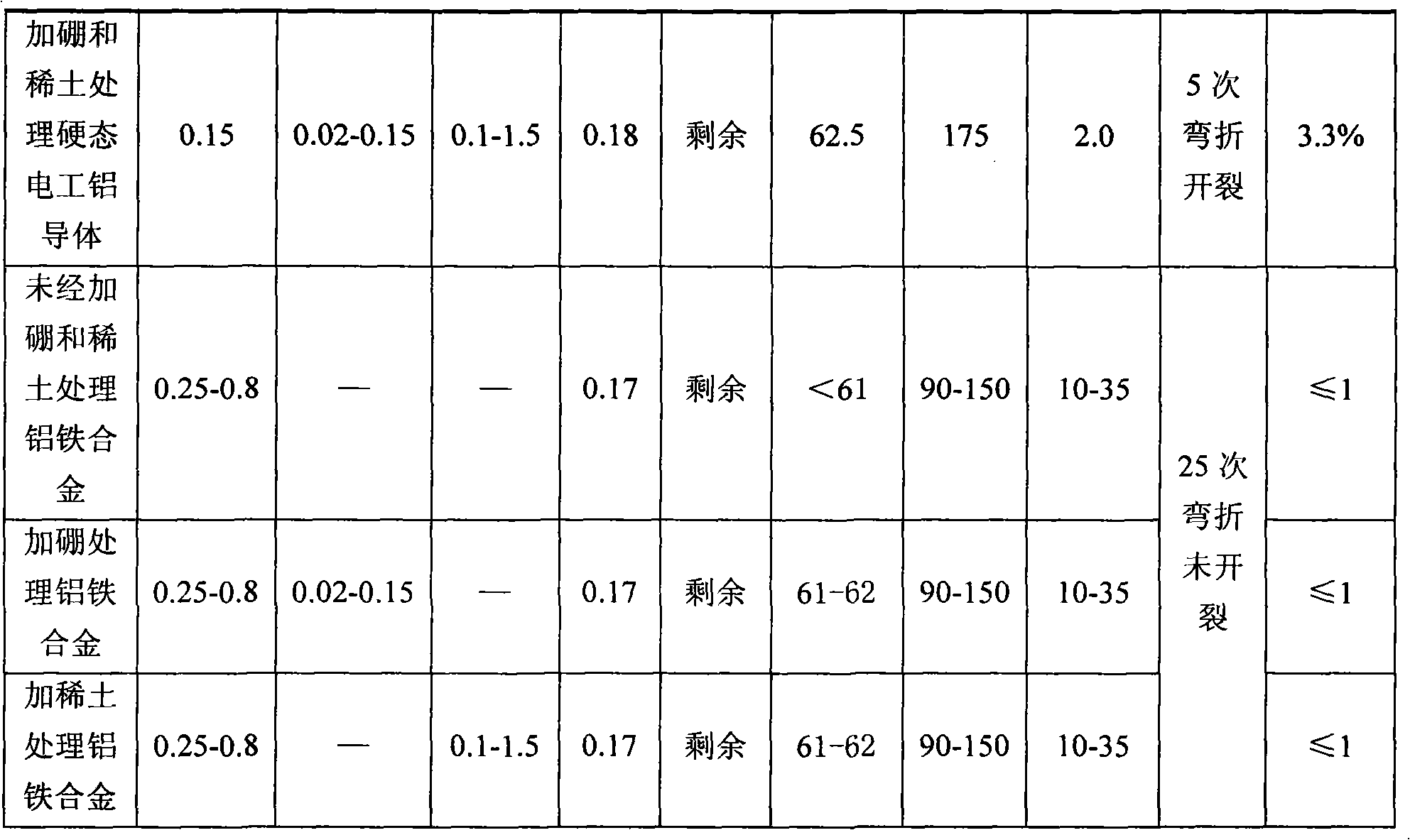

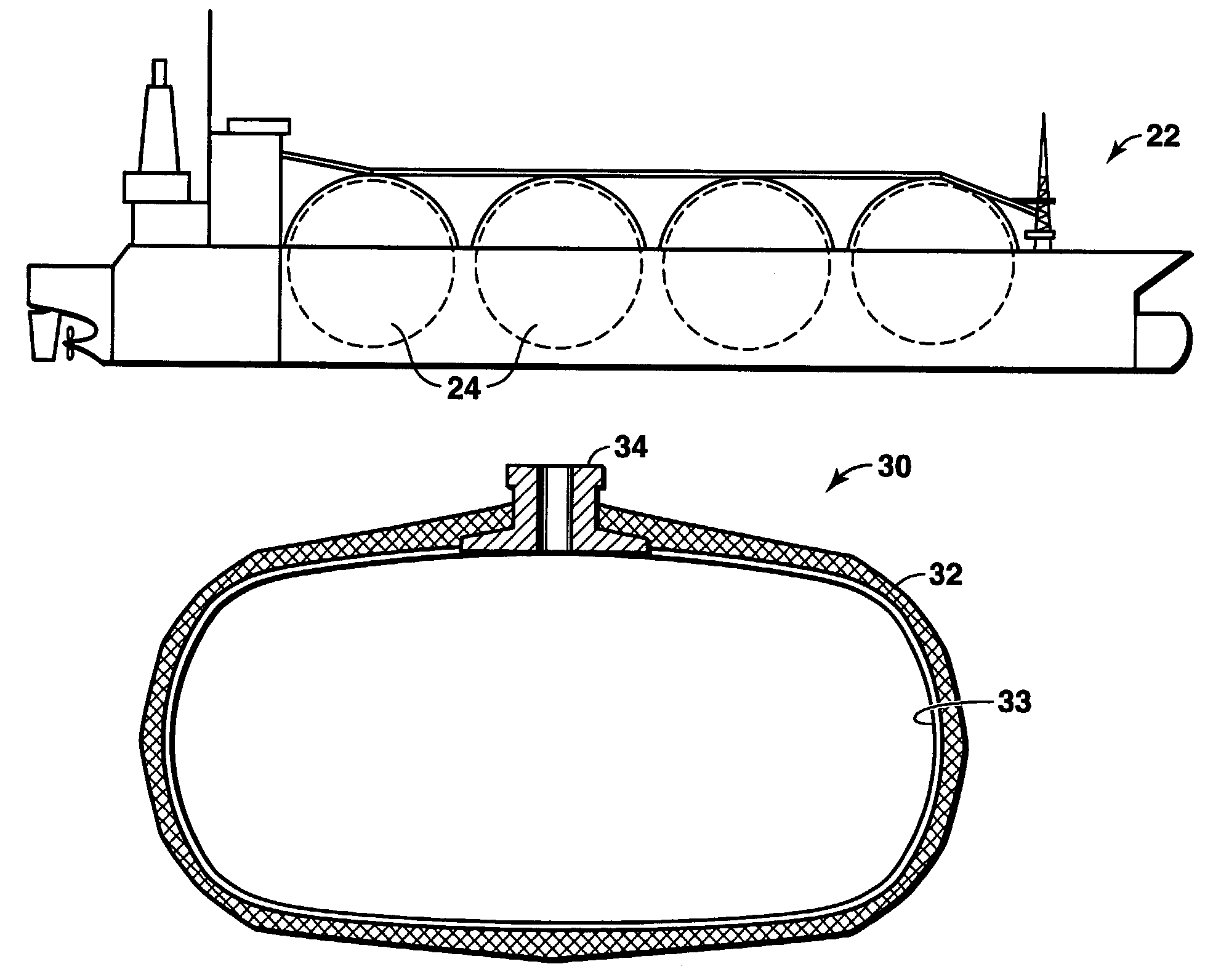

Containers suitable for storing pressurized fluids at cryogenic temperatures of −62° C. (−80° F.) and colder are provided and comprise a self-supporting liner and load-bearing composite overwrap, whereby means are provided for substantially preventing failure of the container during temperature changes.

Owner:EXXONMOBIL UPSTREAM RES CO

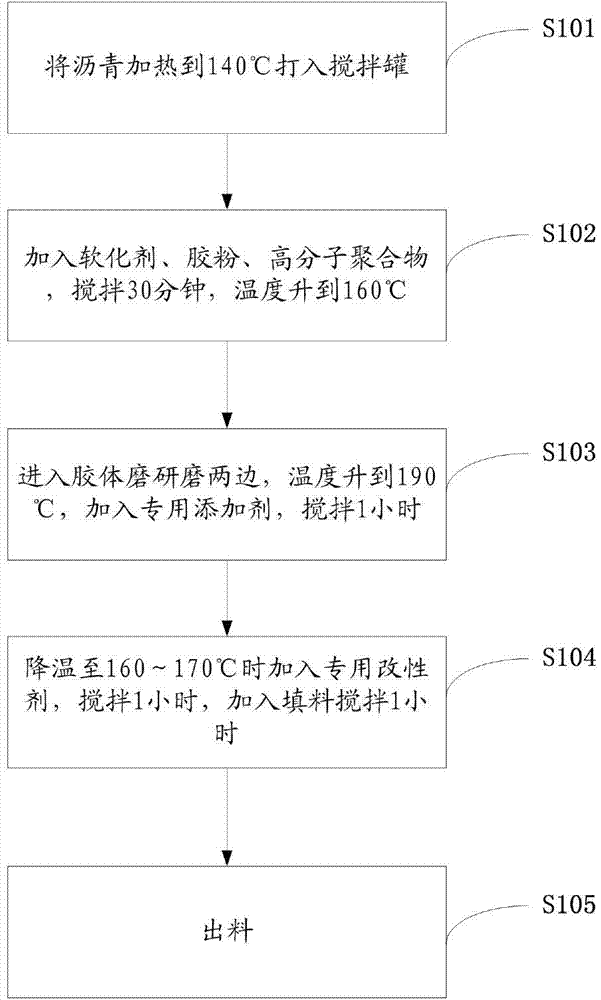

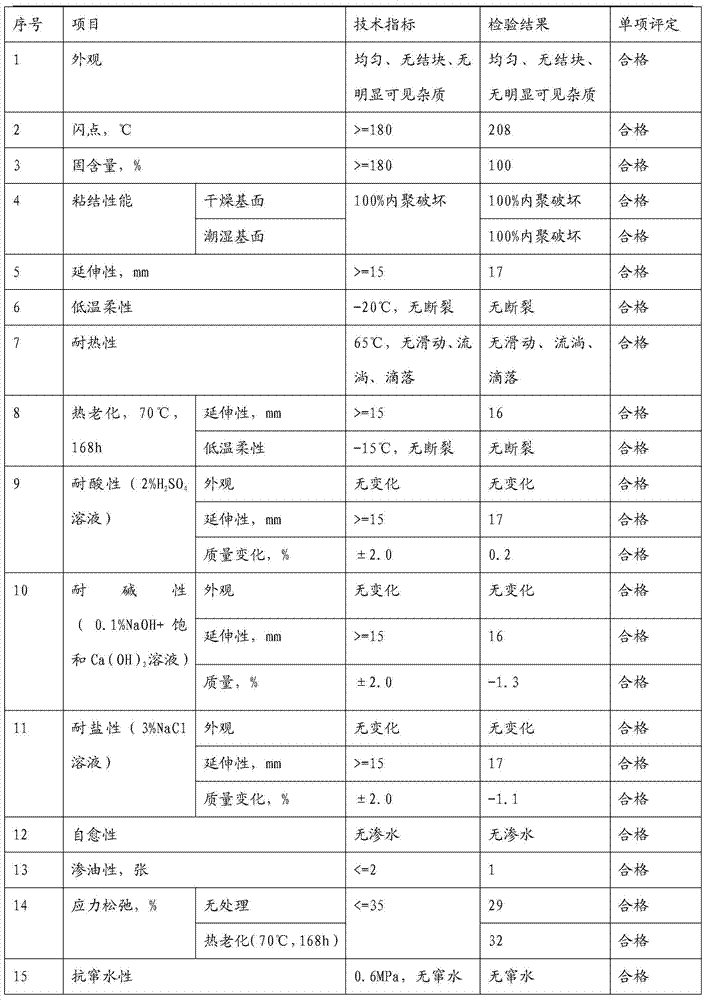

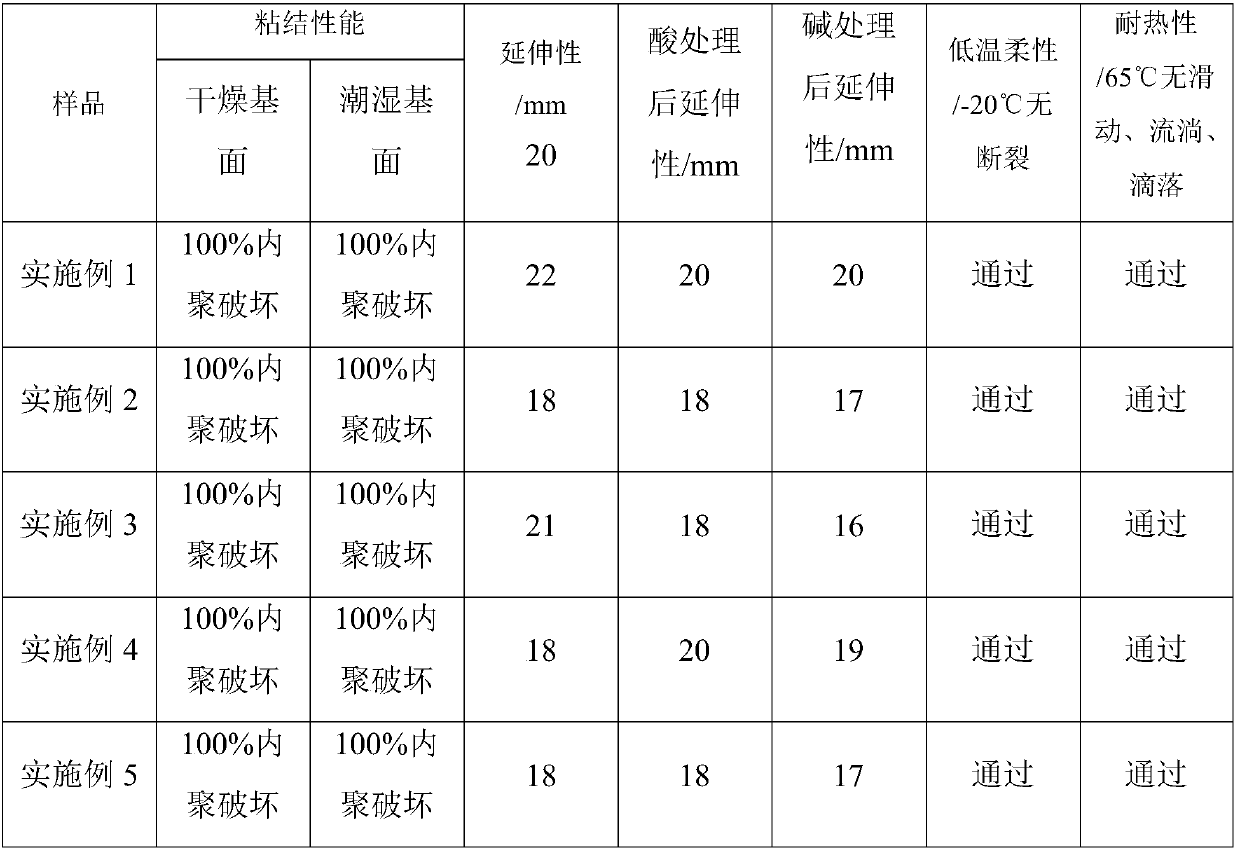

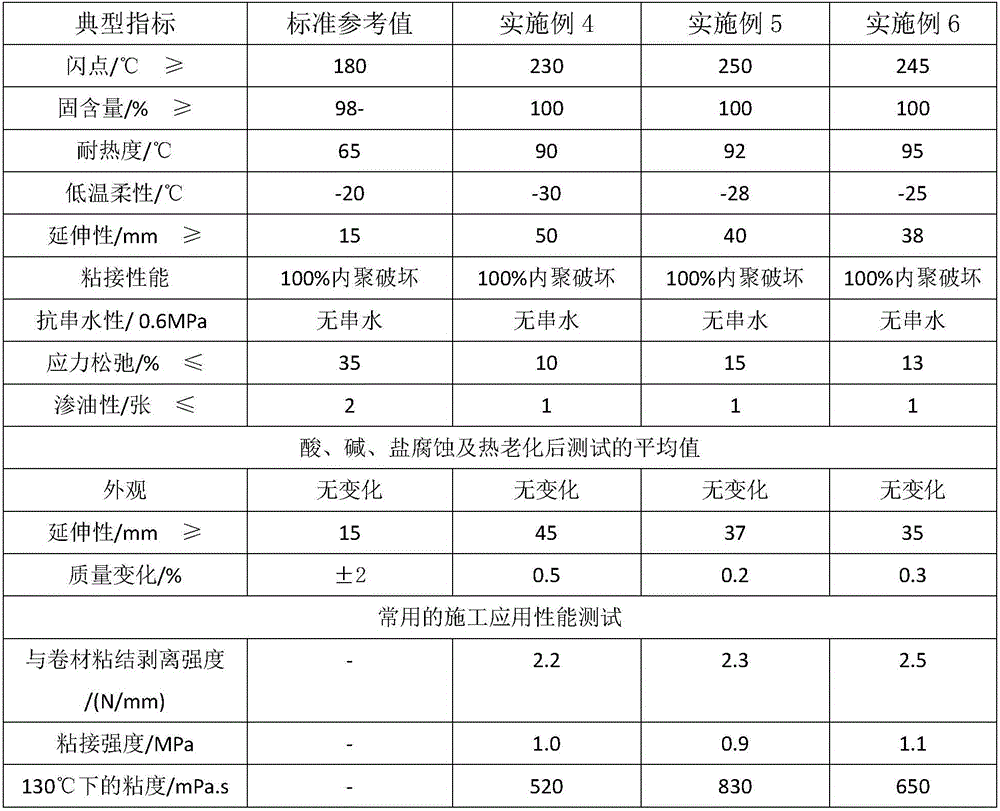

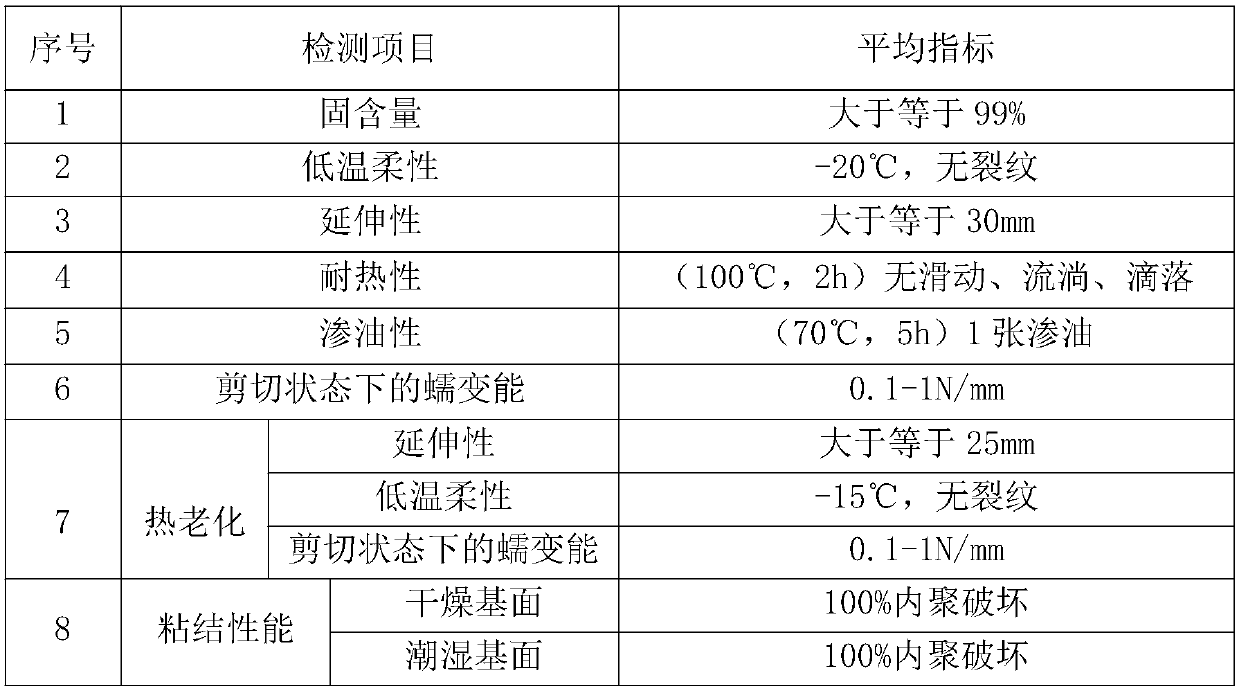

Non-cured rubber asphalt waterproof paint

InactiveCN104119799AWill not harmCompletely sealed and waterproofUnspecified rubber coatingsConjugated diene hydrocarbon coatingsBituminous waterproofingPolymer science

The invention discloses a non-cured rubber asphalt waterproof paint. The preparation technology of the paint comprises the following steps: heating the asphalt to 140 DEG C, loading the heated asphalt into a stirring tank, adding a softening agent, rubber powder, and polymer, stirring for 30 minutes, heating to 160 DEG C, delivering the mixture to a colloid mill to grind the two edges, heating to 190 DEG C, adding a special additive, stirring for one hour, cooling to 160 to 170 DEG C, adding an auxiliary agent, stirring for one hour, adding a filling material, stirring for one hour, and finally discharging. The paint solves the problems of waterproof layer fracture due to the cracking stress, which is transferred from the basic layer to the waterproof layer, and the accelerated aging due to the flexural fatigue and high stress state of the waterproof layer. Moreover, because of the cohesiveness of the paint, the capillary pores and cracks in the basic layer can be perfectly sealed by the paint, thus the problem of water leaking in the waterproof layer is solved, and the waterproof reliability is greatly improved.

Owner:徐立

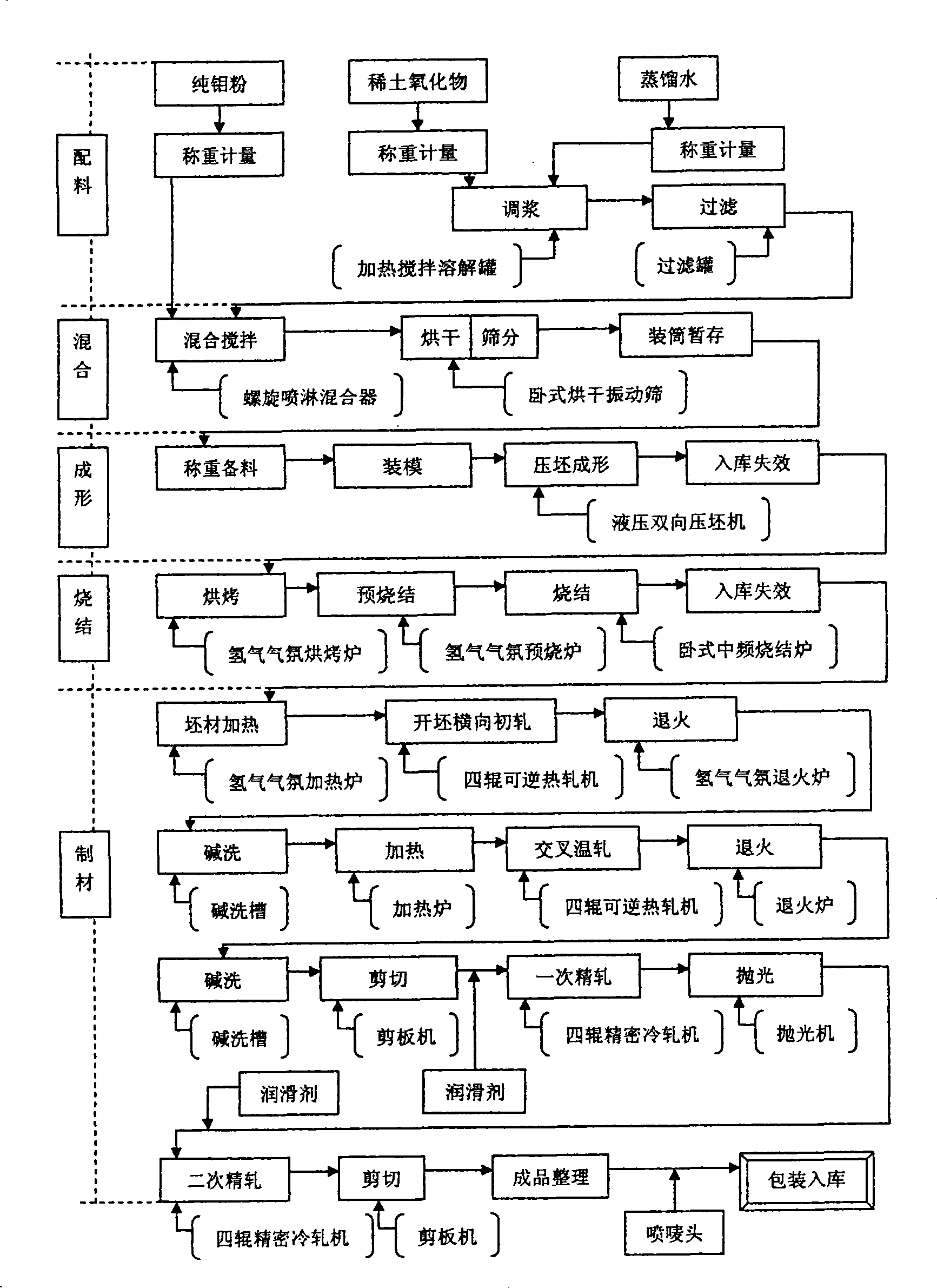

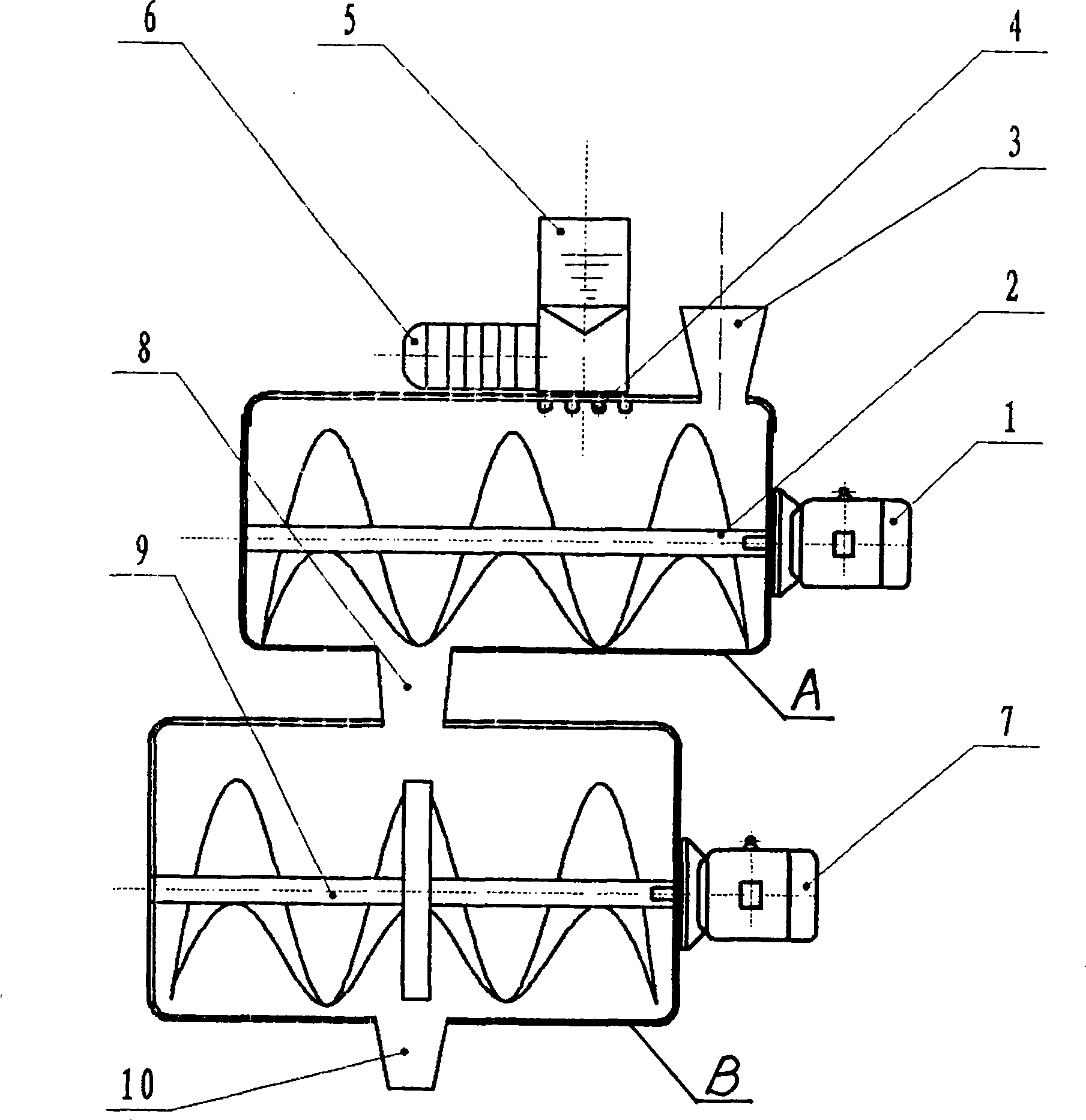

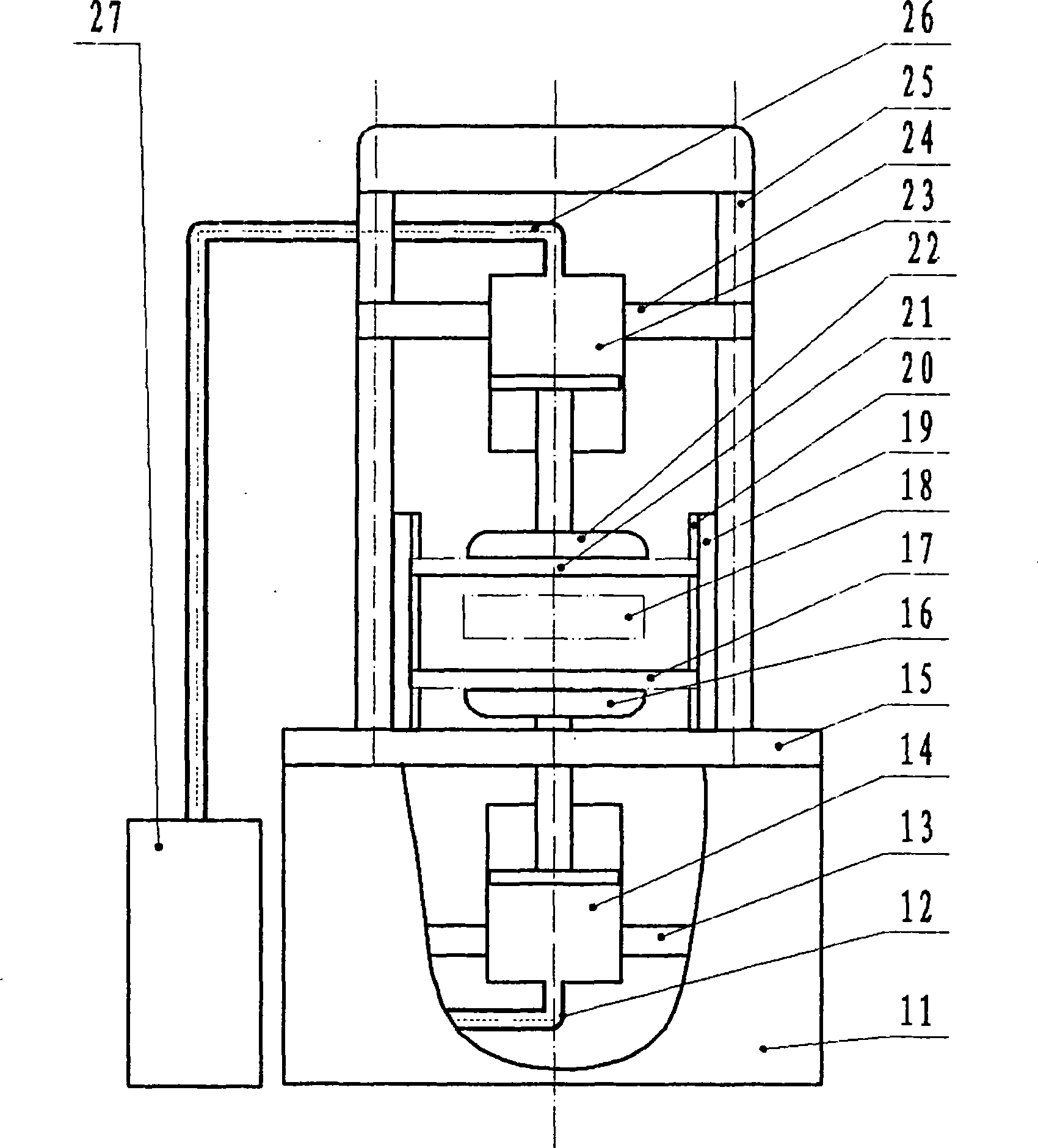

Manufacturing technology of molybdenum-based rare-earth alloy slab and equipment thereof

ActiveCN101423911AFull atomic diffusionFull liquidityRoll mill control devicesMetal rolling arrangementsExtensibilityManufacturing technology

The invention relates to a process for manufacturing the molybdenum based rare earth alloy plate and equipment for manufacturing the same, wherein pure molybdenum powder is simultaneously added with four rare earth oxides of ZrO2, Y2O3, La2O3 and Nd2O3 according to certain ratio, by utilizing the chrematistics of long and large crystal grain and strong sag resistance and anti-creep property of rare earth alloy elements and the dispersion strengthening function, the re-crystallization temperature of the metal molybdenum is increased, the mechanical performances of the molybdenum based material such as tensile property, yielding behavior and extensibility are improved, and the application range of the molybdenum based material is widened; and the manufacturing process comprises production procedures of material preparation treatment, mixing treatment, forming treatment, sintering treatment, material making treatment and the like and the setting of various technical parameters of special technical equipment and process. With the preparation process, the molybdenum based rare earth alloy plate which has the advantages of good electric conductivity and heat conductivity, excellent high-temperature resistance and corrosion resistance and better mechanical performances such as tensile property, yielding behavior and extensibility, and fills in domestic blank and can replace the imported material can be manufactured.

Owner:四平市北威钼业有限公司

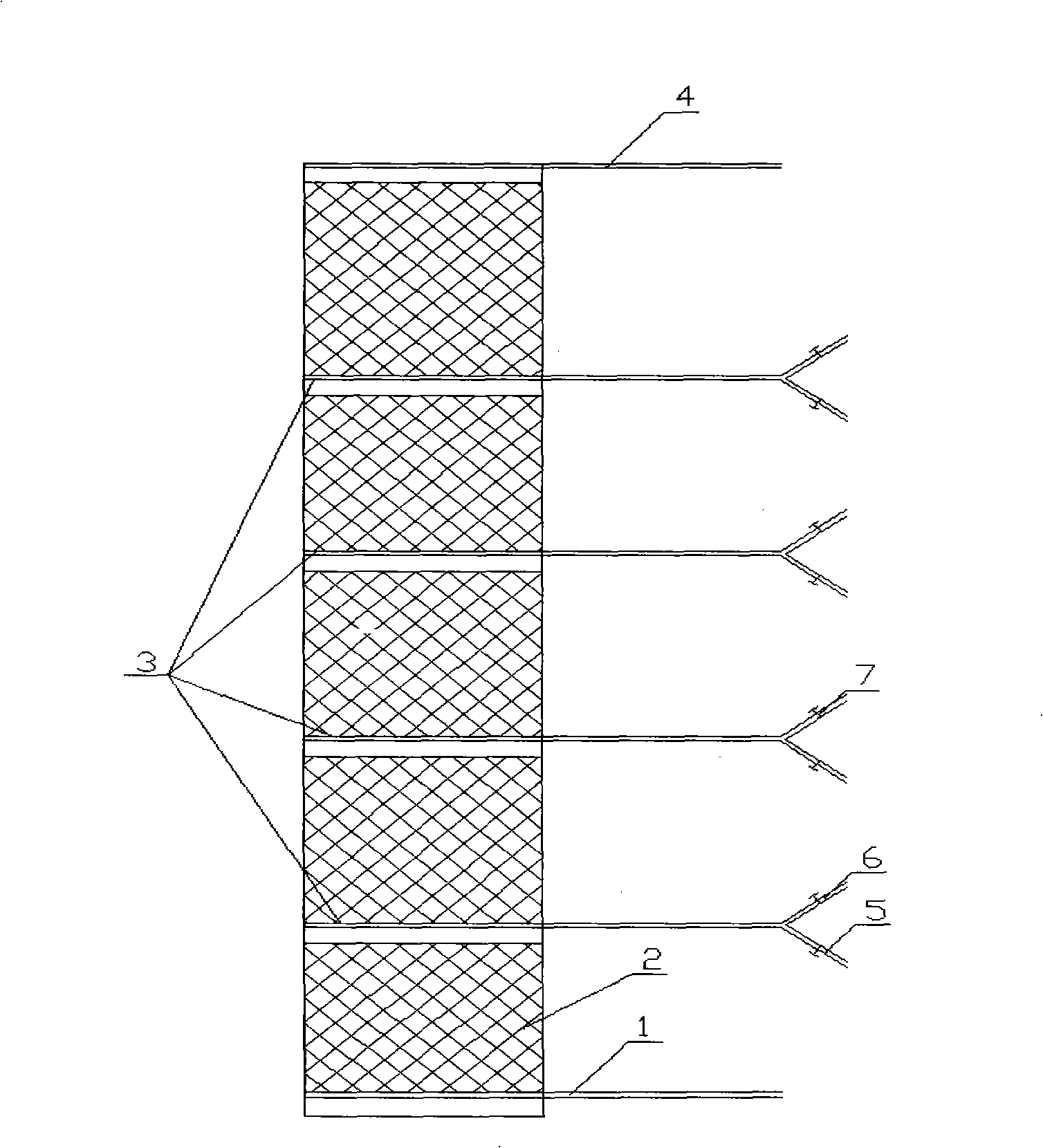

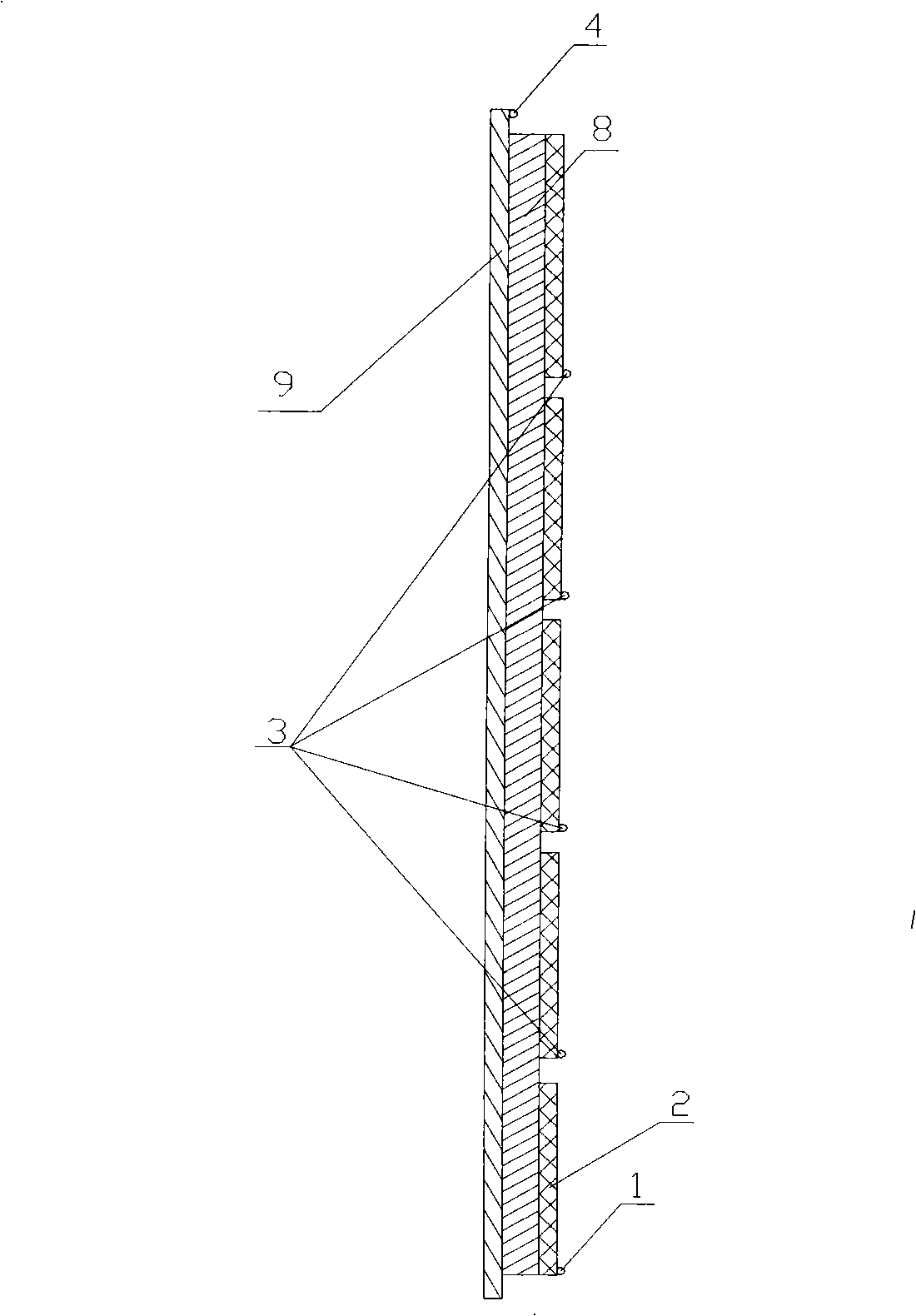

Vacuum auxiliary molding technique produced by high-facade composite material for ship

The invention discloses a vacuum assistant resin infused method for molding a high elevation part of composite materials used on ship and comprises the working procedures of raw material preparation, forming process, etc. The invention is characterized in that in the forming process, the direction of a resin channel is the same as the height direction of the product; a plurality of glue-injection pipes or exhaust pipes parallel to the width direction of the product are arranged in the height direction of the product; the product is divided into a plurality of forming units by the glue-injection pipes or exhaust pipes in the height direction; the distance between the edge of permeable medium and the glue-injection pipes or exhaust pipes is controlled and each unit comprises a flood protection material system of stream guidance, glue injection and gas exhaust, and the like; in the forming process, each unit is immersed successively from bottom to top in a relay style. The invention is used for molding the high elevation part of composite materials used on ship, increases the penetration degree and uniformity of the resin, raises the product quality, and gives good mechanical and sea-water proof property to the product with greatly reduced weight, thereby improving the loading capacity and ample stability of the operation platform on water surface and under water.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Anionic emulsified modified asphalt and preparation method thereof and anionic high-adhesiveness waterborne asphalt waterproof coating

ActiveCN109575310AGood dispersionHigh strengthConjugated diene hydrocarbon coatingsChloropene polymer coatingsFiberCarbon fibers

The invention discloses anionic emulsified modified asphalt and a preparation method thereof and anionic high-adhesiveness waterborne asphalt waterproof coating. The anionic emulsified modified asphalt is prepared from, by mass, 50-70 parts of matrix asphalt, 1-20 parts of a polymer modifier, 0.5-2 parts of nano carbon fibers, 2-5 parts of a surface modifier, 1-2 parts of an anionic surfactant, 0.1-0.8 part of a pH regulator and 20-40 parts of water. A film formed by the waterproof coating has excellent creep performance and extending performance and is capable of well sealing cracks of a baselayer to effectively resist cracking caused by base layer settlement, deformation and the like, water channeling is prevented, and reliability of an upper waterproof roll is improved.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

Asphalt waterproof paint for building and preparation method thereof

InactiveCN101921545AUnique performanceImprove performanceUnspecified rubber coatingsBituminous coatingsChemical industryBituminous waterproofing

The invention relates to an asphalt waterproof paint for a building and a preparation method thereof, belonging to the technical field of chemical industry. The asphalt waterproof paint for a building comprises the following raw materials according to parts by weight: 20-25 parts of plasticizer, 6-8 parts of modifier, 25-30 parts of asphalt, 20-30 parts of filler, 4-6 parts of tackifier, 0.2-0.3 parts of crosslink coupling agent, and 0.3-0.5 parts of dispersing agent. The invention has the advantages of reasonable compound design, good intensity, safety, environmental protection and stable product quality, and is capable of adapting the climatic conditions at high and low temperatures.

Owner:嘉兴市博豪家纺有限公司

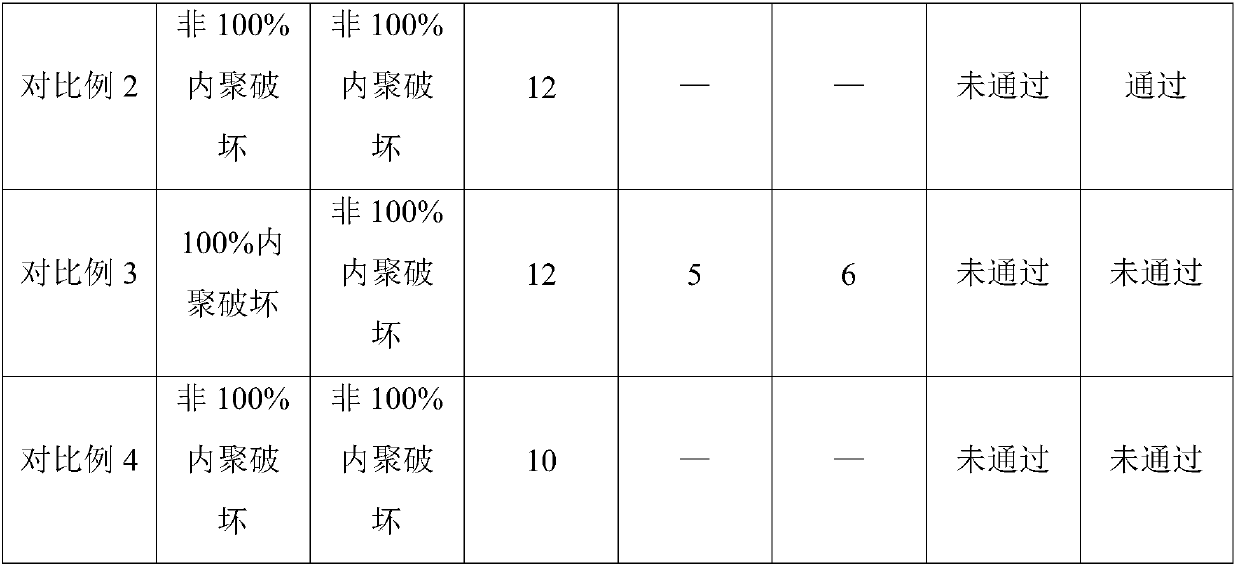

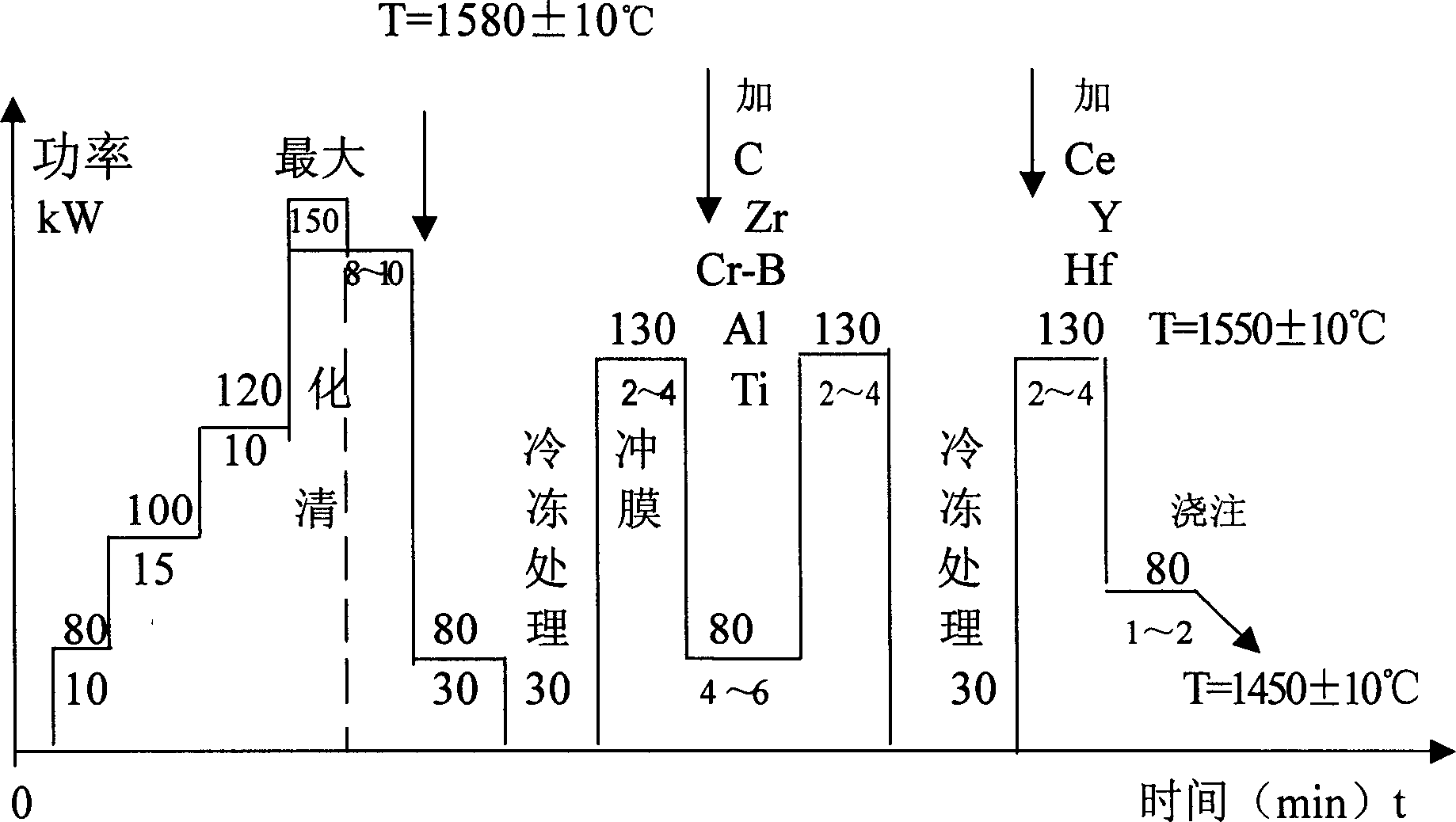

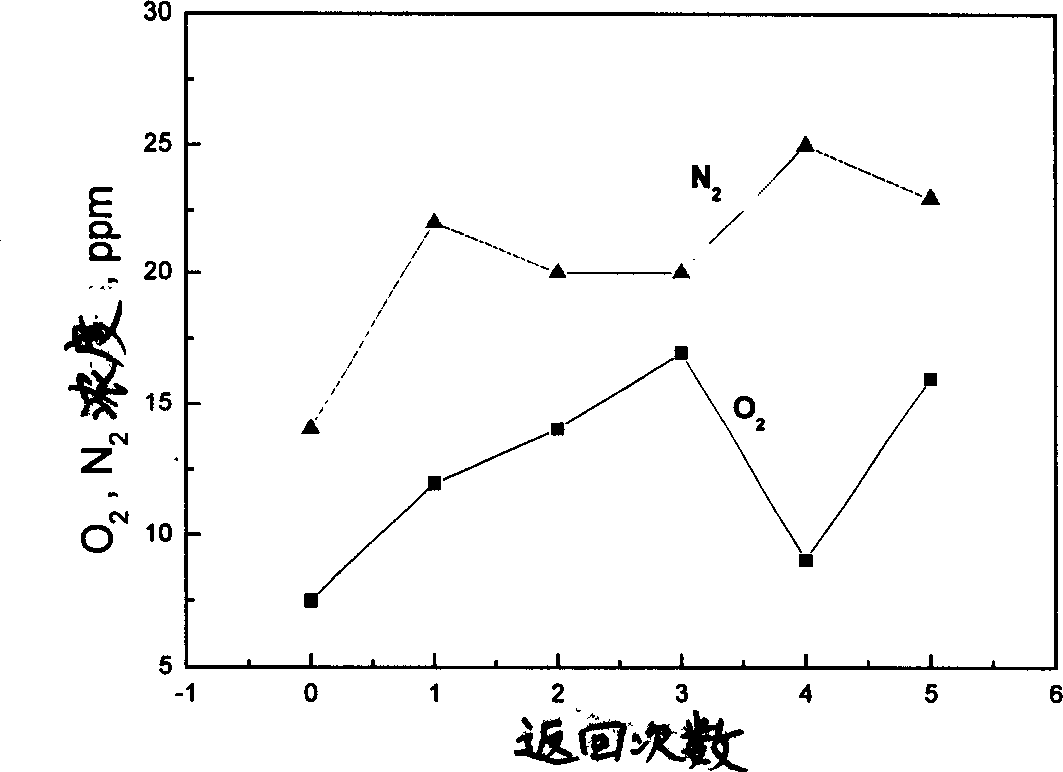

Vacuum smelting technology of hafnium containing nickel base casting high temperature alloy K488 reverse material alloy

InactiveCN1786228ADecreased tensile strength at room temperatureLower yield strengthRare-earth elementChemical composition

The invention relates to hafnium containing nickel base casting high temperature alloy K488 reverts alloy vacuum melting technique. It includes the following steps: melting reverts; pouring after melting, fining, cooling; using alumina ceramics filter screen to do the first filtration for alloy solution while pouring; adjusting the alloy solution component; mixing in proportion of 50% reverts and 50% fresh material; doing the first alloying treatment after melting, fining, cooling; adding dope material C, Cr-B inter-alloy, Al, Ti, Zr; doing the second alloying treatment after cooling; adding Ce, Y, Hf; and using alumina ceramics filter screen to do the second filtration for alloy solution while pouring to gain product. The technique adopts adding rare earth element method to purify reverting alloy. After many times returning melting, all of the alloy capability, chemical component, and impurity content can reach technical condition demand Q / 3B 1376-2005. The N content is far lower than 100ppm.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Method for producing basalt fibre reinforcing composite material and application in producing boat hull

The invention provides a method for making a basalt fiber enhanced composite material and the application of the method on making ship bodies. The formula of the method comprises vinyl ester resin or unsaturated polyester resin, a peroxide initiator and a promoter; the resin is injected and solidified and molded under the condition of vacuum aid resin transfer molding by raw material mixing. The method for making the basalt fiber enhanced composite material is characterized in that the raw material contains 30 to 70 percent mass of the basalt fiber as the enhancing material. The technique is used for making the ship bodies of army auxiliary ship and high speed ships, the ship bodies have outstanding aging resistant property, creep resistant property and anti-explosion impact property in addition to excellent mechanical property, ocean environment resistant property and high temperature resistance property, meanwhile, the method for making the basalt fiber enhanced composite material can lower the building cost of ship bodies and prolong the service life of ships.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

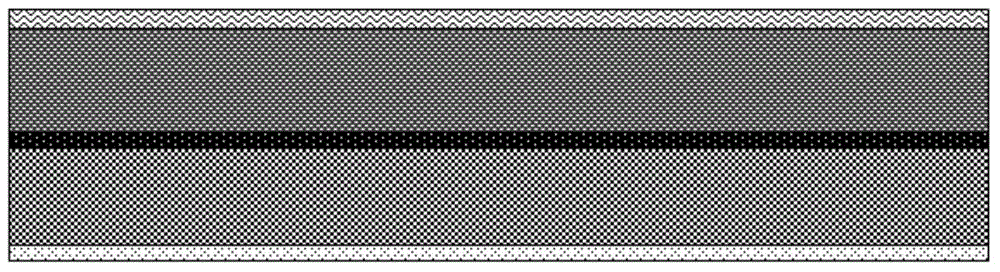

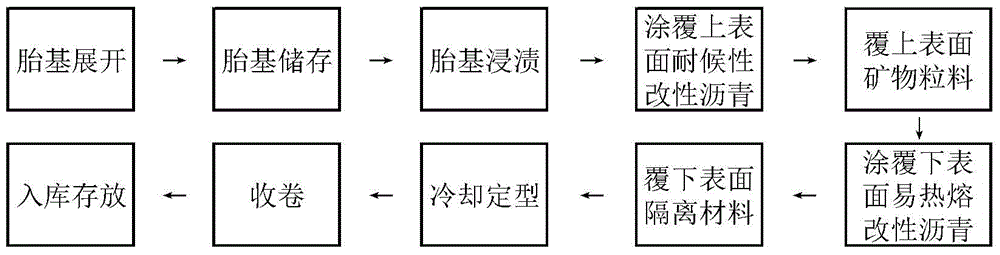

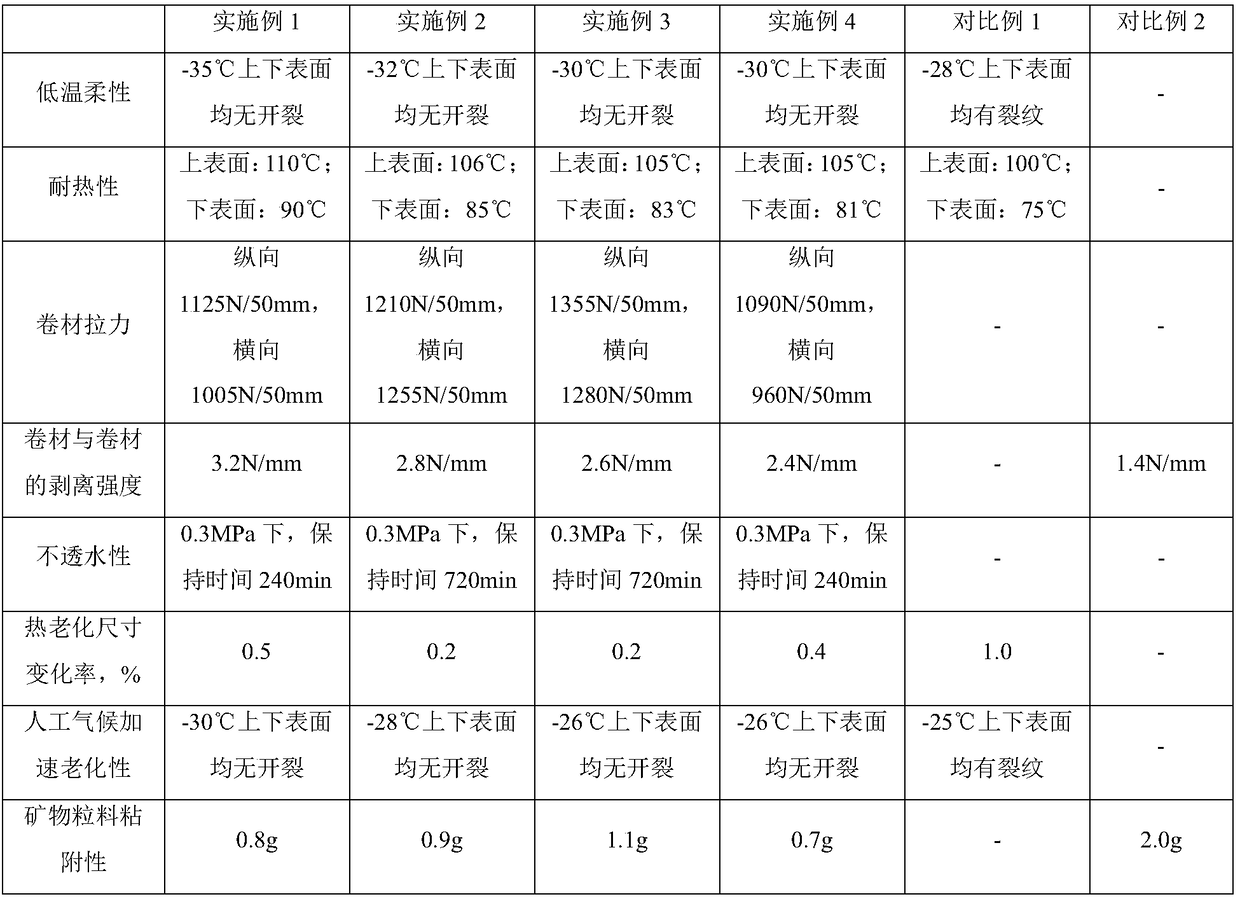

Weathering resistance modified asphalt waterproof coiled material

ActiveCN104369445AHigh nitrogen contentHigh molecular weightSynthetic resin layered productsConstructions elementsPolyesterGlass fiber

The present invention discloses a weathering resistance modified asphalt waterproof coiled material, wherein a glass fiber felt or polyester felt is adopted as a reinforcement, a weathering resistance modified asphalt layer is coated on the upper surface of the reinforcement, a modified asphalt layer with the characteristic of easy hot melting is coated on the lower surface of the reinforcement, a mineral particle layer is covered on the upper surface of the weathering resistance modified asphalt layer, and a polyethylene film is covered on the lower surface of the modified asphalt layer with the characteristic of easy hot melting. According to the present invention, the weathering resistance modified asphalt waterproof coiled material has characteristics of long service life, high waterproof performance, low construction temperature, reduction of aging of the modified asphalt at the high temperature, and reduction of environment pollution, and can be used for industrial and civil building roofing waterproof projects at different temperatures in different regions.

Owner:JINZHOU DONGFANG YUHONG BUILDING MATERIALS

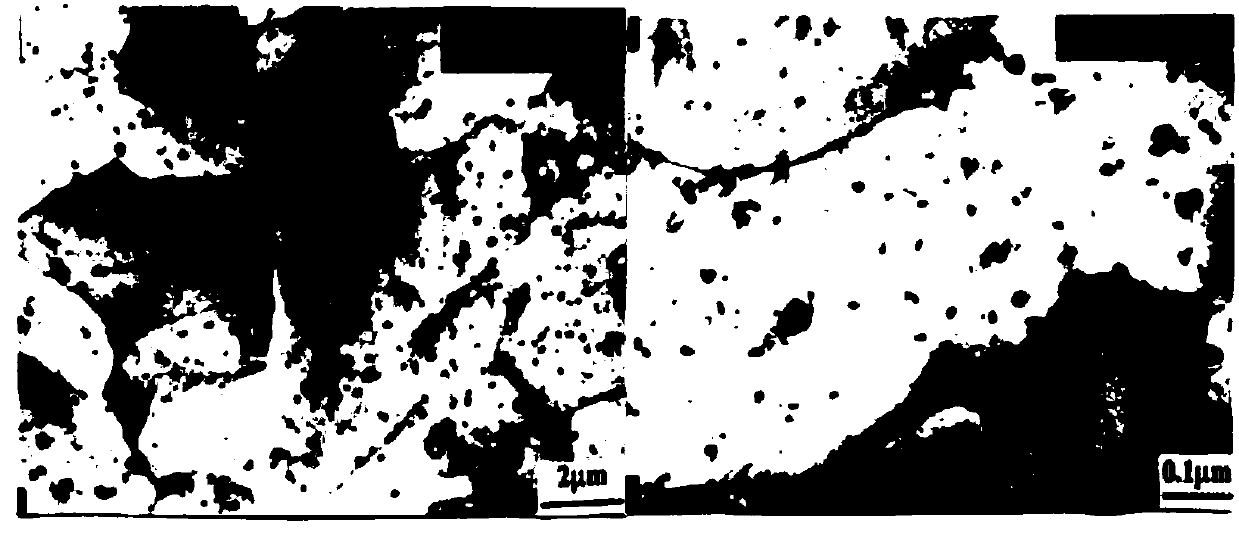

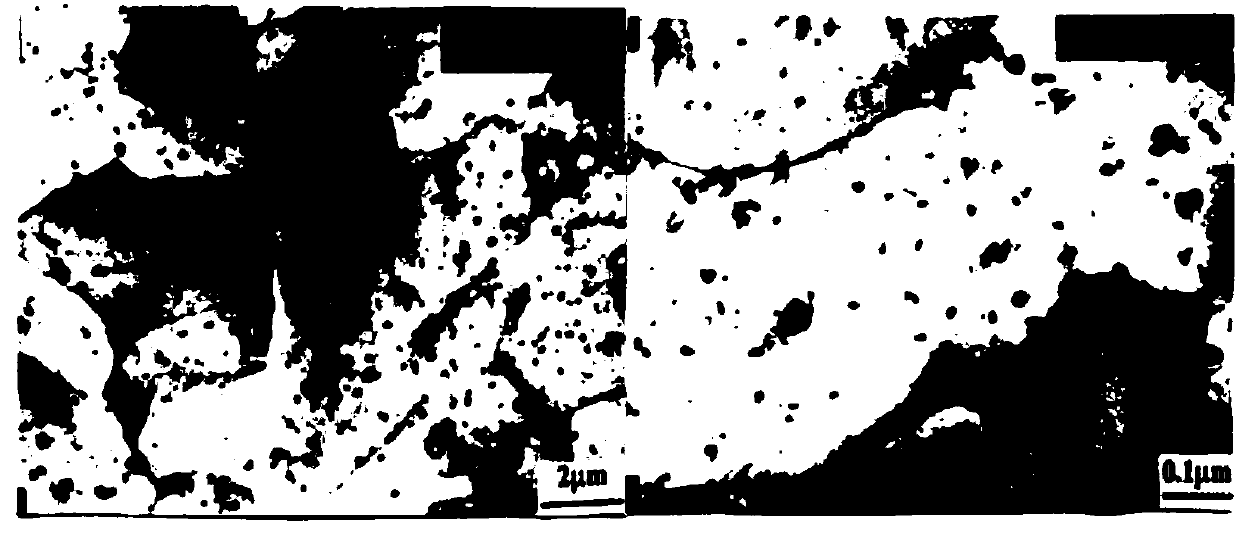

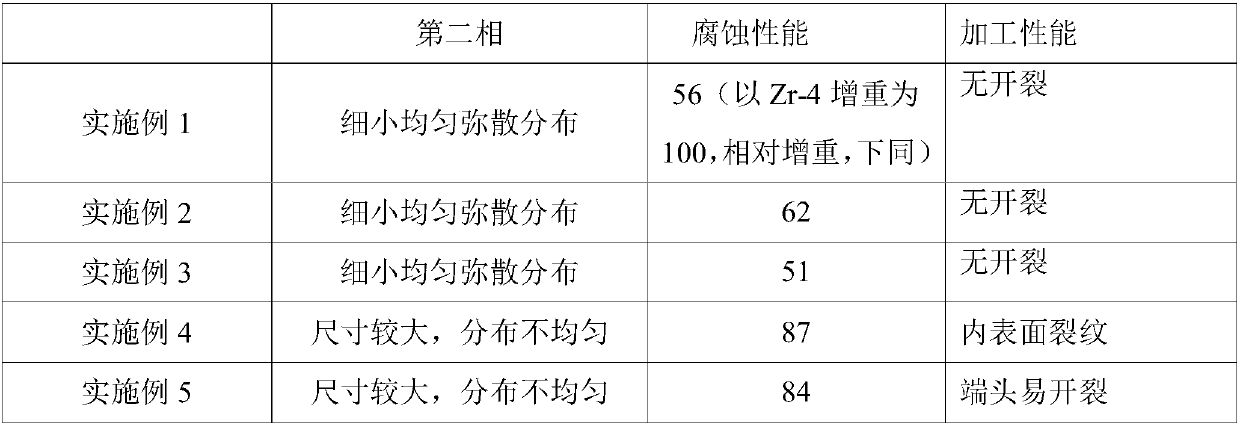

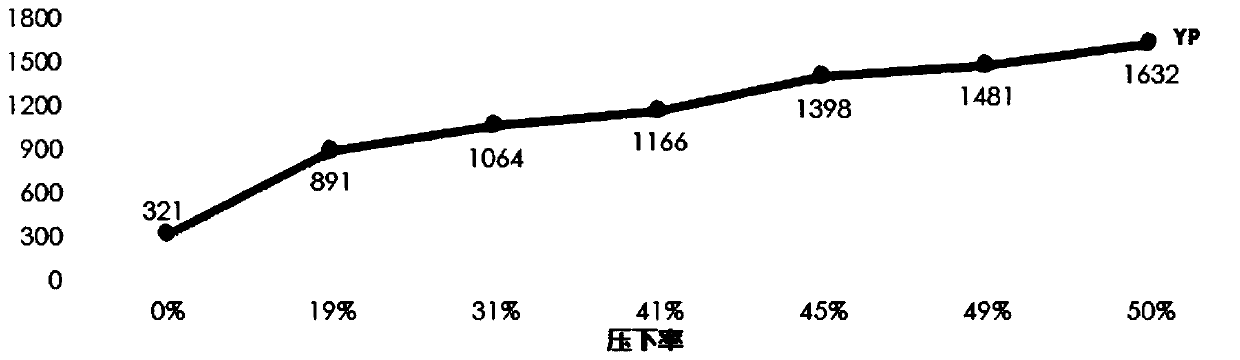

Manufacturing technology of zirconium alloy cladding tubular product

ActiveCN107116339AImprove performanceImprove processing stabilityManufacturing technologyStress relief

The invention discloses a manufacturing technology of a zirconium alloy cladding tubular product. The manufacturing technology of the zirconium alloy cladding tubular product solves the problem that in the prior art, a manufacturing technology suitable for an N36 zirconium alloy finished-product cladding tubular product is not provided. The manufacturing technology of the zirconium alloy cladding tubular product comprises the steps that (1) N36 zirconium alloy is made into an extrusion ingot after smelting, forging and quenching; (2) the extrusion ingot is made into a tube blank with the outer diameter being 71-79 mm and the inner diameter being 40-50 mm through thermal extrusion; (3) the tube blank is rolled into a tube blank with the outer diameter being 50-60 mm and the wall thickness being 10-11.5 mm through the first pass, and annealing is conducted after rolling; (4) cold rolling is conducted for 3-4 passes, finally the cladding tubular product is manufactured, and intermediate annealing is conducted between two adjacent passes of cold rolling; and (5) after final stress relief annealing or final recrystallization annealing is conducted, the cladding tubular product is made into the finished-product tubular product. The manufacturing technology of the zirconium alloy cladding tubular product has the advantages of being stable in technology, high in finished product rate and the like. Besides, the manufactured tubular product has the advantages of being quite excellent in corrosion resistance, tensile property, bursting property, texture, CSR and the like.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

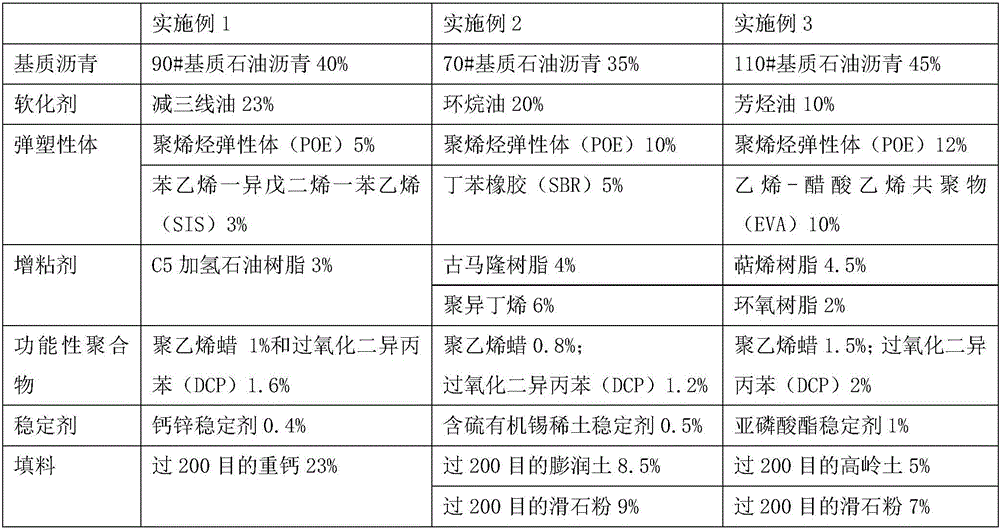

Non-cured rubber asphalt waterproof paint and preparation method thereof

InactiveCN106634602ANot affected by adhesive propertiesImprove thermal stabilityBituminous coatingsBituminous waterproofingPolymer science

The invention discloses a non-cured rubber asphalt waterproof paint and a preparation method thereof. The preparation method comprises the following steps: 1) weighing a matrix asphalt, a softener, an elastic plastic body, an adhesion agent, a functional polymer, a stabilizing agent and a filling material; 2)injecting the matrix asphalt to a reaction vessel, heating the materials, stirring the materials, adding the softener, and stirring the materials; 3) adding the obtained mixture and the elastic plastic body in a colloid grinder, growing the materials, opening the colloid grinder, grinding the materials, and continuously growing the materials; 4) adding an adhesion agent and a functional polymer, continuously stirring the materials; 5) adding a filling material and stirring the materials; and 6) adding a stabilizing agent, and stirring the material. The paint has high heat resistance, good construction property, good thermostability, chemical stability and anti-ultraviolet aging capability, bond property is not influenced due to extraneous environment, the paint has construction property for a wet basic layer, can increase the interfacial affinity interaction with the wet basic layer, and construction quality and progress can be effectively guaranteed, and the paint is environmentally friendly.

Owner:LOGISTICS UNIV OF CAPF

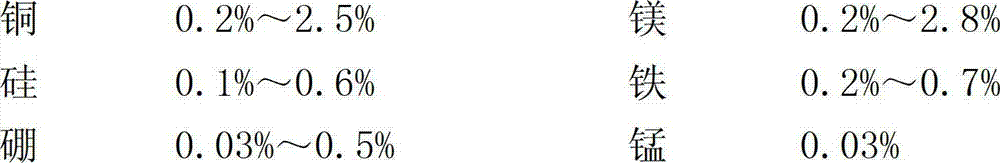

Aluminum-copper-magnesium alloy wire rod and manufacturing technique thereof

The invention relates to an aluminum-copper-magnesium alloy wire rod and a manufacturing technique of the aluminum-copper-magnesium alloy wire rod. The aluminum-copper-magnesium alloy wire rod is formed by the following raw materials in percentage by weight: 0.2-2.5% of copper, 0.2-2.8% of magnesium, 0.1-0.6% of silicon, 0.2-0.7% of iron, 0.03-0.5% of boron, 0.03% of manganese, 0.03% of zinc, 0.03% of chrome, 0.01% of titanium, and 96%-98% of aluminum. The manufacturing technique comprises the following steps: (1), smelting of aluminum alloy, (2), online treatment of aluminum alloy, (3), casting of aluminum alloy, (4), rolling of aluminum alloy wire rod, and (5), carrying out online aging treatment on the rolled aluminum alloy wire rod to obtain the wire rod, wherein the drawing out temperature is not higher than 60 DEG C. The aluminum-copper-magnesium alloy wire rod meets the performance requirements on the raw material aluminum alloy wire rod in copper clad aluminum alloy in the cable industry field, in particular the requirements on the performances in the aspects of tensile strength, percentage elongation and compressive creep, and the like.

Owner:庆毅 +1

Microporous oil-containing self-lubricating polytetrafluoroethylene (PTFE) material for sealing and preparation method and application thereof

ActiveCN102585406AImproved creep propertiesGood flexibilityOther chemical processesOil and greaseTetrafluoroethylene

The invention discloses a microporous oil-containing self-lubricating polytetrafluoroethylene (PTFE) material for sealing and a preparation method and application thereof. The PTFE material consists of the following components in percentage by mass: 50 to 98 percent of PTFE resin, 1 to 30 percent of naphthalene and 1 to 20 percent of oil. The method comprises the following steps of: mixing the PTFE resin and the naphthalene, performing die pressing, and sintering to prepare a porous PTFE semi-finished product; and soaking the porous PTFE semi-finished product in the oil, putting into a vacuum box, and keeping in vacuum for at least 2 hours to obtain the microporous oil-containing self-lubricating PTFE material for sealing. The microporous oil-containing self-lubricating PTFE material for sealing has high self-sealing property, lubricating property and elasticity, a good self-lubricating effect can be achieved even if the oil is not changed for a long time when the material is used as a sealing material, and a long-acting sealing effect is achieved; and if an anti-rusting agent permeates pores, machine equipment can be protected, and the service life of a machine is prolonged.

Owner:GUANGZHOU MECHANICAL ENG RES INST

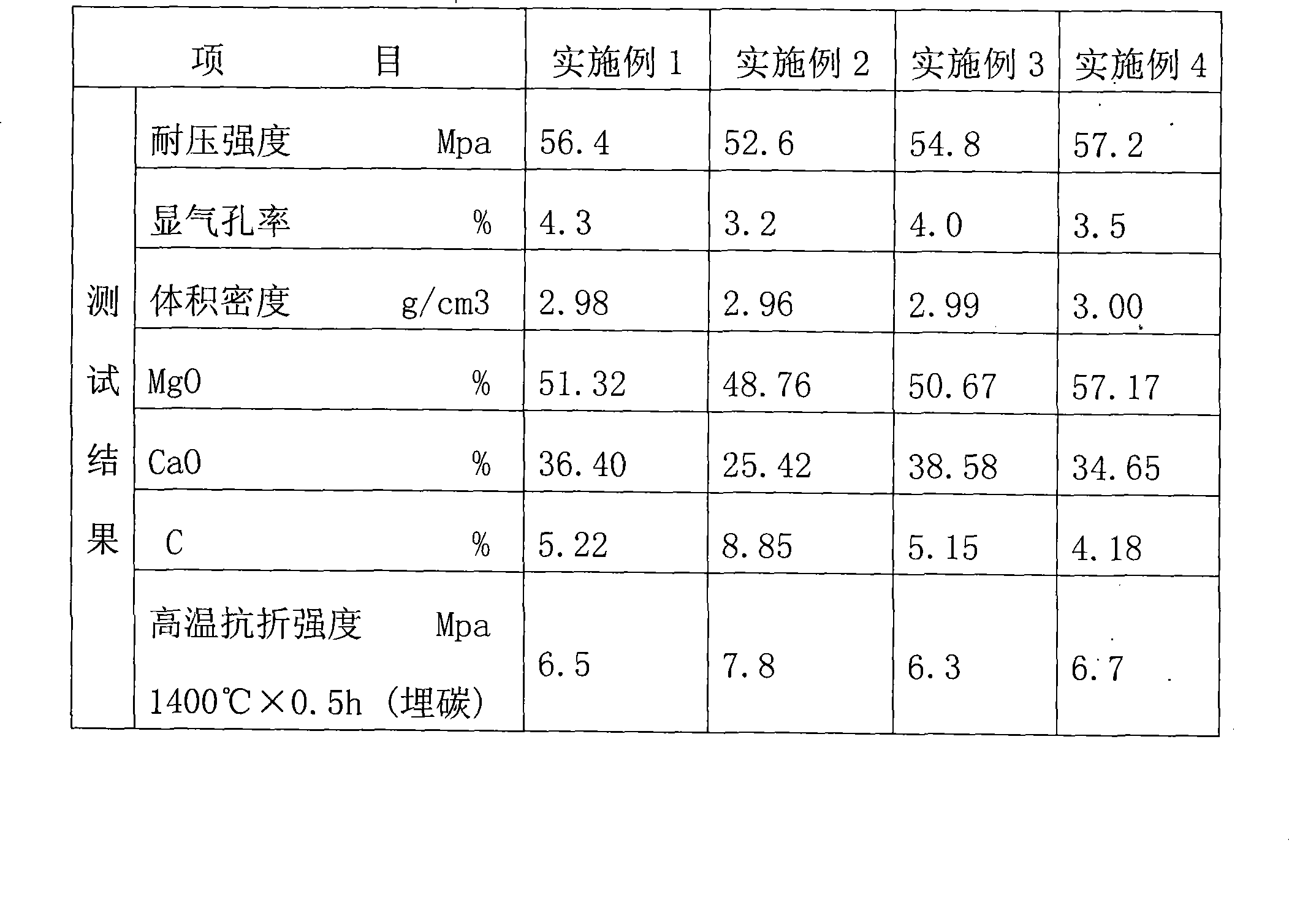

High-calcium magnesia-calcium-carbon brick and manufacturing method thereof

The invention relates to a high-calcium magnesite-dolomite carbon brick and a method for making the same. The invention adopts a technical proposal that the high-calcium magnesite-dolomite carbon brick is made from the following raw materials by weight percentage: 40 to 60 percent of 1 to 5mm calcium magnesite clinker, 5 to 15 percent of less than or equal to 1mm calcium magnesite clinker, 1 to 15 percent of less than or equal to 1mm magnesite clinker, 20 to 30 percent of less than or equal to 0.088mm magnesite powder, 2 to 8 percent of graphite, 0.5 to 3 percent of less than or equal to 0.088mm aluminum powder, 0.5 to 3 percent of less than or equal to 0.088mm silicon powder, 0.5 to 3 percent of less than or equal to 0.088mm silicon carbide powder and 3 to 6 percent of phenolic resin. The method comprises: mixing the raw materials uniformly according to a mixture ratio and pressing the well mixed raw materials into green bricks; keeping the green bricks at 220 DEG C for 4 to 7 hours and drying the green bricks for more than 20 hours totally; and performing hydration-proof treatment to the green bricks after the green bricks are moved out of a drying kiln. The brick is alkaline and can overcome the defects of molten steel pollution and unstable service life.

Owner:DASHIQIAO JINLONG REFRACTORY MATERIAL

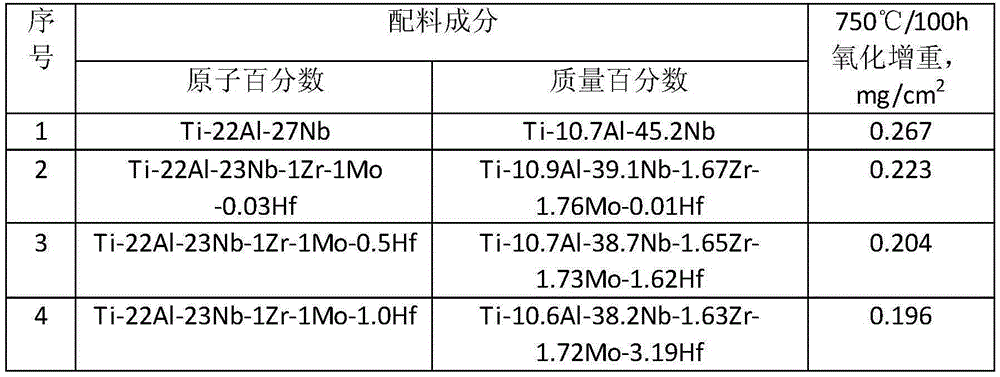

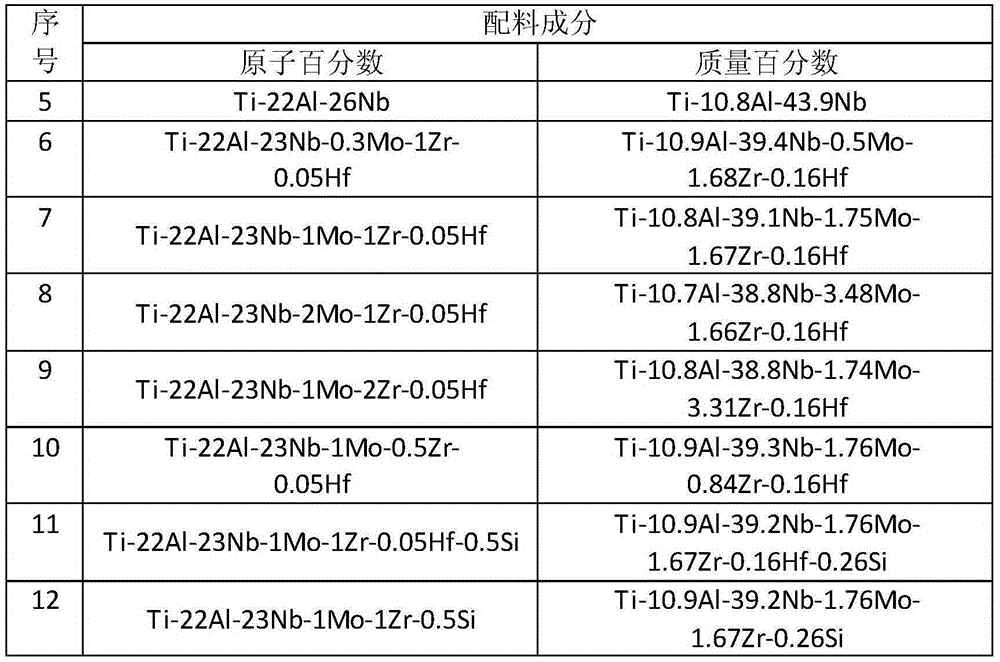

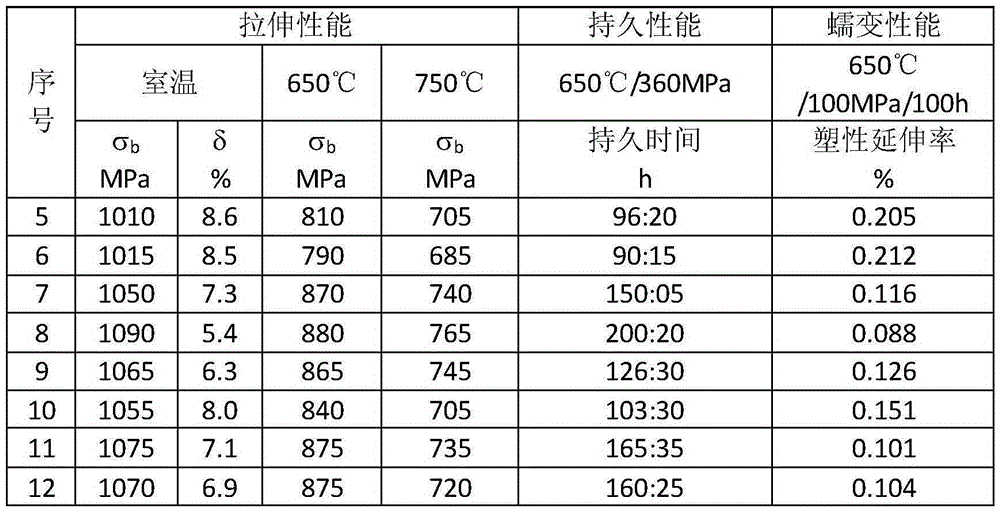

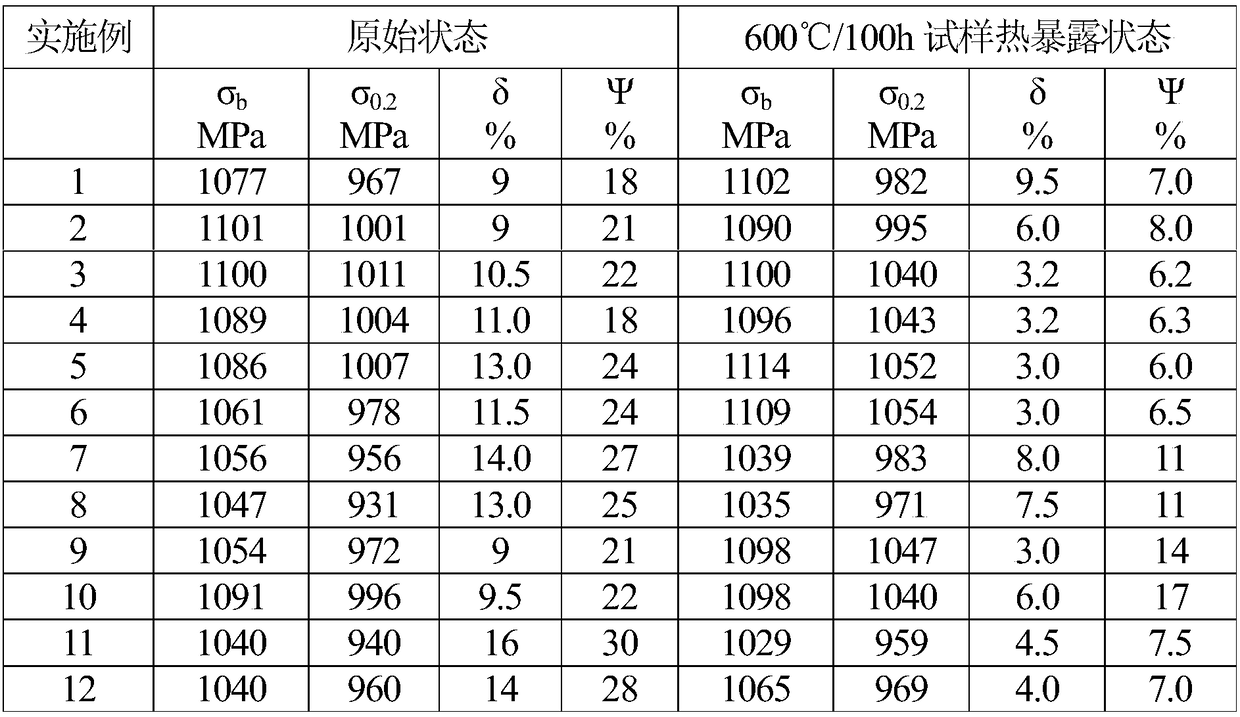

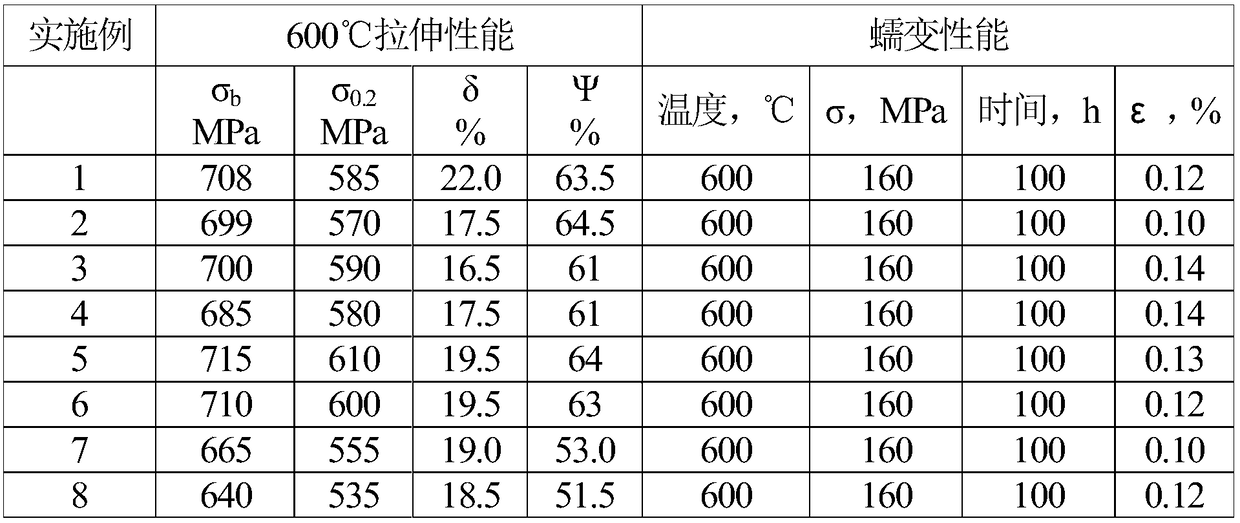

Ti2AlNb base alloy

ActiveCN105331849AImprove antioxidant capacityLong lasting at high temperatureAlloyOxidation resistance

The invention provides Ti2AlNb base alloy. The Ti2AlNb base alloy is characterized by comprising, by atomic percent, 20%-25% of Al, 20%-24% of Nb, 0.3%-2% of Mo, 0.5%-2% of Zr, 0.01%-0.5% of Hf, 0-0.8% of Si and the balance Ti and inevitable impurities; and the sum of Mo, Zr, Hf and Si is larger than or equal to 1.0%. The Ti2AlNb base alloy has good high-temperature oxidation resistance, room temperature plasticity, high-temperature tensile strength and endurance performance.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Epoxy non-cured rubber asphalt waterproof coating and preparation method thereof

InactiveCN107739575ASolve the problem of heating to constructionEnsure safetyFireproof paintsOther rubber coatingsSelf-healingEpoxy

The invention discloses an epoxy non-cured rubber asphalt waterproof coating and a preparation method thereof and belongs to the field of coatings. The coating comprises a component A and a componentB, wherein the component A is prepared from asphalt, plasticizers, polymer modifiers and epoxy resin; the component B is prepared from epoxy curing agents. The problem that the non-cured rubber asphalt waterproof coating can be constructed after the coating is heated can be solved; the coating is energy-saving and environmentally friendly; the safety of constructors is ensured; the construction operation is simplified; the application range of the product is expanded; the coating is excellent in construction performance, does not need to be heated in the whole construction process, is excellent in high-temperature performance, can achieve obstacle-free construction under high temperature and low temperature, and is high in flexibility, high in elongation rate, excellent in creep property,high in self-healing capability, high in water channeling resistance and high in adhesion performance.

Owner:SICHUAN SHUYANG WATERPROOF MATERIAL

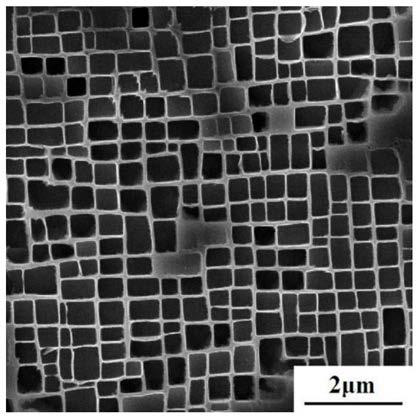

Third-generation nickle base monocrystal high temperature alloy with stable texture and preparation method

ActiveCN111455220AImproved creep propertiesEnsure organizational stabilityPolycrystalline material growthAfter-treatment detailsSingle crystal superalloyDirectional solidification

The invention discloses third-generation nickle base monocrystal high temperature alloy with a stable texture and a preparation method thereof. The third-generation nickle base monocrystal high temperature alloy is composed of Al, Ta, W, Re, Mo, Cr, Co, Hf and Ni; and W and Ni are added in the form of Ni-W intermediate alloy. Directional solidification is adopted to prepare monocrystal alloy; through multistep high temperature long-time solid solution homogenization treatment, high temperature aging treatment and low temperature aging treatment, the third-generation nickle base monocrystal high temperature alloy is free of incipient melting and precipitation of TCP phase to lower the TCP precipitation tendency, so that alloy reducing Re content reaches the performance level of the third-generation nickle base monocrystal high temperature alloy, and the obtained nickle base monocrystal high temperature alloy has higher intermediate and high temperature strength, excellent instant tensile property and creep property and high texture stability.

Owner:苏州高晶新材料科技有限公司

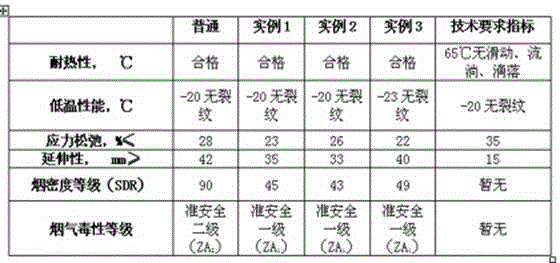

Environment-friendly smoke-suppression-type non-cured rubber-asphalt waterproof coating material and preparation method thereof

InactiveCN104789127AReduce asphalt fumeGood creepConjugated diene hydrocarbon coatingsBituminous coatingsRubberized asphaltPolymer chemistry

The invention relates to an environment-friendly smoke-suppression-type non-cured rubber-asphalt waterproof coating material and a preparation method thereof. An environment-friendly waterproof material with a smoke suppression effect is achieved through adding smoke suppressants of certain fractions based on a non-cured rubber-asphalt waterproof coating material. The waterproof coating material contains the ingredients in percentage by weight: 35-45% of modified asphalt, 25-35% of dispersant, 5-12% of tackifier, 0.5-1.5% of physical smoke suppressant, 3-5% of polymer smoke suppressant and 20-30% of heavy calcium carbonate. The waterproof coating material has good creep property and bond strength and is outstandingly characterized by having smoke suppression characteristic. According to the waterproof coating material, a large volume of harmful smoke generated during the high-temperature melting of the non-cured rubber-asphalt waterproof coating material can be effectively suppressed. The waterproof coating material disclosed by the invention has the characteristics of never curing, low-temperature resistance, no high-temperature flow, good waterproof performance, environmental friendliness, smoke suppression and the like, and can be extensively applied to waterproof projects of various building structures.

Owner:TANGSHAN DESHENG WATERPROOF

Extruding and forming method of polyethylene pipe for water supply

ActiveCN103568240AGood tensile strength and creepGood toughness and cold resistanceTubular articlesHigh-density polyethyleneMoisture

The invention discloses an extruding and forming method of a polyethylene pipe for water supply. The extruding and forming method of the polyethylene pipe for water supply comprises the following steps: (1) vacuumizing high-density polyethylene resin and black master batch, and stirring and mixing at high speed uniformly by a high-speed mixing machine after vacuumizing treatment, wherein the moisture content of uniformly mixed materials is below 0.4%; (2) adding the uniformly mixed materials into a material cylinder of a screw extruder, conveying the materials to a material feeding section forward through the friction and shearing effects of the inner wall of the material cylinder and the surface of a screw under the screw rotation effect, changing the materials from the powdery solid into high-viscosity elastomers gradually through the compression, fusion and homogenization processes, extruding the high-viscosity elastomers through an opening die on a head of the screw extruder so as to acquire a pipe consistent with the opening die in shape at the extruding temperature of 110-130 DEG C; (3) cooling, and dragging; and (4) spraying a code, cutting, polishing and detecting, wherein the product up to the standard after checking is the polyethylene pipe for water supply. The extruding and forming method of the polyethylene pipe for water supply, which is provided by the invention, is rapid in extruding speed and is high in production efficiency; the prepared pipe is improved in abrasion resistance, is good in aging resistance, prolonged in the service life, and low in production cost.

Owner:扬州巨业耐磨复合材料有限责任公司

Novel aluminum alloy wire rod for cable, and preparation method and application thereof

InactiveCN103352145ANo adverse effect on electrical propertiesReduce peelingNon-insulated conductorsMetal/alloy conductorsRare-earth elementImpurity

The invention relates to the field of non-ferrous metal wire rods, especially to a novel aluminum alloy wire rod for a cable and a preparation method thereof. The aluminum alloy wire rod for the cable comprises, by weight, 0.05 to 0.15% of silicon, 0.5 to 0.9% of iron, 0.1 to 0.3% of copper, 0.05 to 0.08% of zinc, 0.05 to 0.2% of boron, 0.01 to 0.04% of antimony, 0.05 to 0.08% of nickel, 0.05 to 0.09% of zirconium and 0.05 to 0.08% of rare earth, with the balance being aluminum and unavoidable impurities. According to the aluminum alloy wire rod for the cable provided by the invention, through adjustment of the content of the rare earth element in the wire rod and introduction of other doping elements, the prepared aluminum alloy wire rod has conductivity of more than 62% IACS, maximum tensile strength of 135 MPa and elongation of about 30%, and particularly, the aluminum alloy wire rod has an obviously improved anti-creeping property and substantially enhanced comprehensive electrical properties.

Owner:CHAOHU JINYE ELECTRIC MACHINERY

301 stainless steel production method, and 301 stainless steel and application thereof

ActiveCN110218852AImprove hardenabilityHigh strengthProcess efficiency improvementSteelmakingSmelting process

The invention discloses a 301 stainless steel production method, and 301 stainless steel and an application thereof. The 301 stainless steel production method is characterized by including following steps: smelting a steel blank; heating a plate blank; rolling the plate blank; performing solid dissolution treatment; performing acid pickling and levelling; rolling; performing solid dissolution andacid pickling operation on sheet material 1.0-1.5mm in thickness through a cold annealing and acid pickling furnace at temperature of 1207-1216 DEG C and at speed L / S of 80-97.5mpm so as to fully dissolve the sheet material, and finally obtaining a 2B surface cold-rolled stainless steel product 9-10 grade in grain size and 1100-1120Mpa in product tensile strength. The 301 stainless steel production method has the beneficial effect of obtaining 301Si and 301SiMo stainless steel new products by adjusting product compositions and increasing content of Si and Mo, and meanwhile controlling harmfulelements such as S and P in steelmaking, implementing a clean steel smelting process, controlling inclusions, enabling the 301 stainless steel to have high strength, endowing the 301 stainless steel with certain corrosion resistance, and enabling the 301 stainless steel to meet use requirements.

Owner:ZHANGJIAGANG POHANG STAINLESS STEEL

Linear object, bolt, nut and washer each comprising magnesium alloy

InactiveUS20120070248A1Improve plastic formabilitySpecific compositionWashersNutsHeat resistanceCreep strain

There is provided a linear object comprising magnesium-alloy having not only excellent heat resistance but also excellent plastic formability. The linear object comprising magnesium-alloy contains, on a mass percent basis, 0.1% to 6% Y, one or more elements selected from the group consisting of 0.1% to 6% Al, 0.01% to 2% Zn, 0.01% to 2% Mn, 0.1% to 6% Sn, 0.01% to 2% Ca, 0.01% to 2% Si, 0.01% to 2% Zr, and 0.01% to 2% Nd, and the balance being Mg and incidental impurities, in which the linear object comprising magnesium-alloy has a creep strain of 1.0% or less, the creep strain being determined by a creep test at a temperature of 150° C. and a stress of 75 MPa for 100 hours.

Owner:SUMITOMO ELECTRIC IND LTD

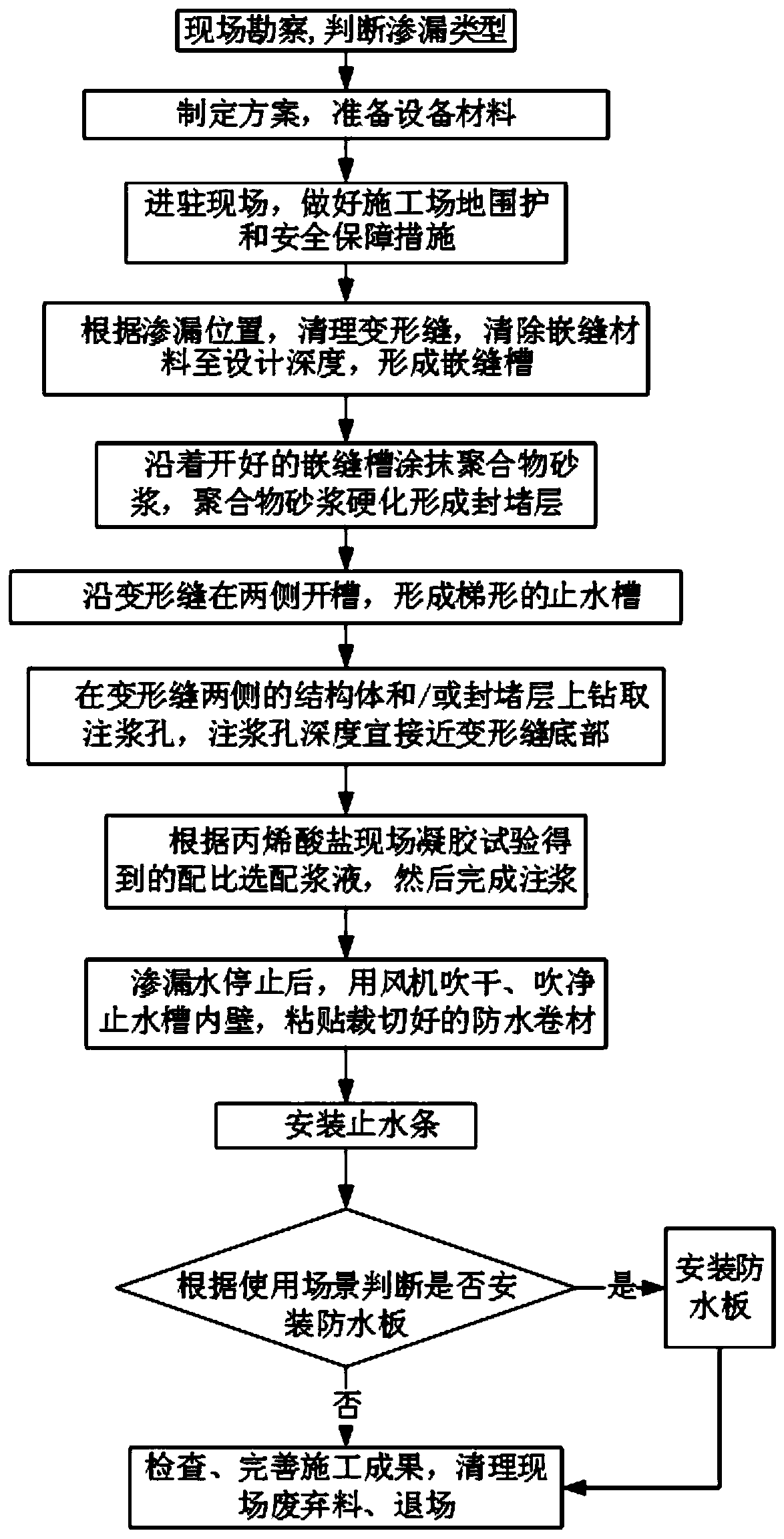

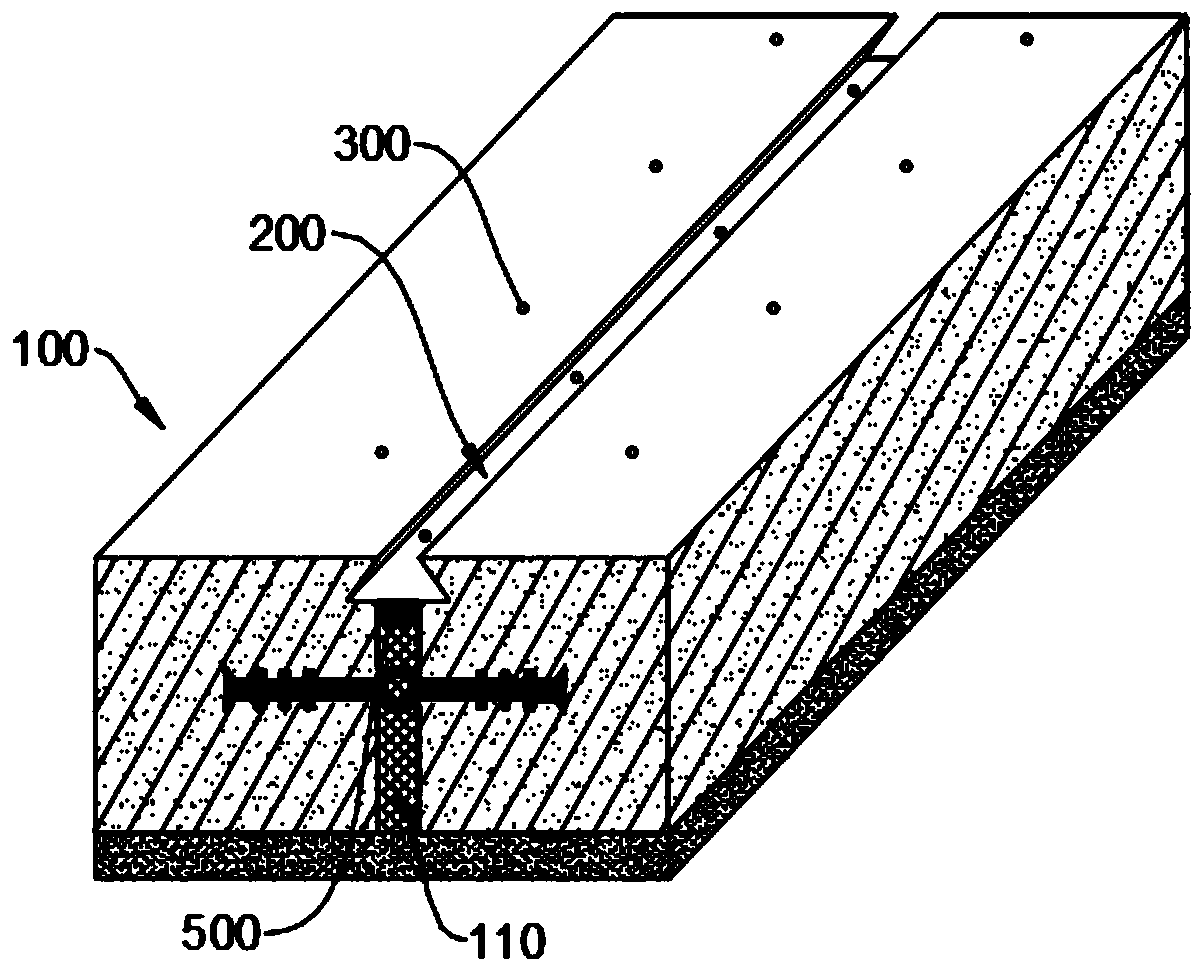

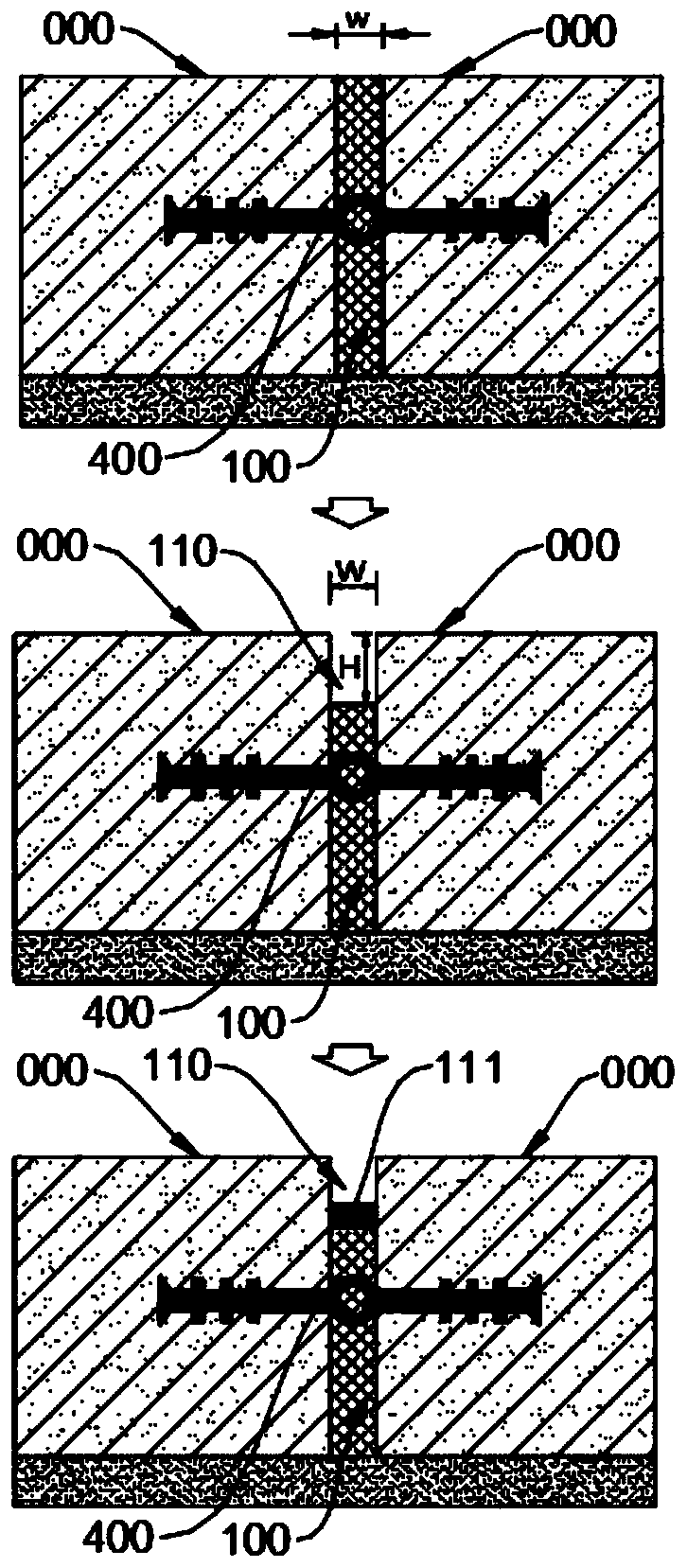

Deformation joint treatment method and deformation joint waterproof structure

InactiveCN110629800AEasy to manageBroaden applicationArtificial islandsProtective foundationWater leakageWater seepage

The invention relates to the field of water leakage treatment of building joints, in particular to a deformation joint treatment method and a deformation joint waterproof structure. The deformation joint treatment method comprises the steps that 1, on-site survey is conducted; 2, the type of deformation joint leakage is determined based on the result of the on-site survey; and 3, a construction plan is made based on the type of the deformation joint leakage. According to the deformation joint treatment method, the on-site survey is firstly conducted, information of the deformation joint is collected, the width and length of the deformation joint, the location and cause of water seepage, the number of water seepage points, the amount of water seepage, and the damage condition of a water stop are obtained; the type of the deformation joint leakage is determined based on the location and cause of water seepage, the number of water seepage, the amount of water seepage, and the damage condition of the water stop; according to the determined type of the deformation joint leakage, a targeted construction plan is made to better treat the leakage. According to the deformation joint treatment method, a flexible waterproof structure is formed, in the process of water blocking, a water blocking material can passively adapt to the deformation of the structure, and the problem of water leakage caused by the material damage due to the deformation of the structure is alleviated.

Owner:SUBWAY OPERATION TECH R & D CENT BEIJING SUBWAY OPERATION CO LTD +1

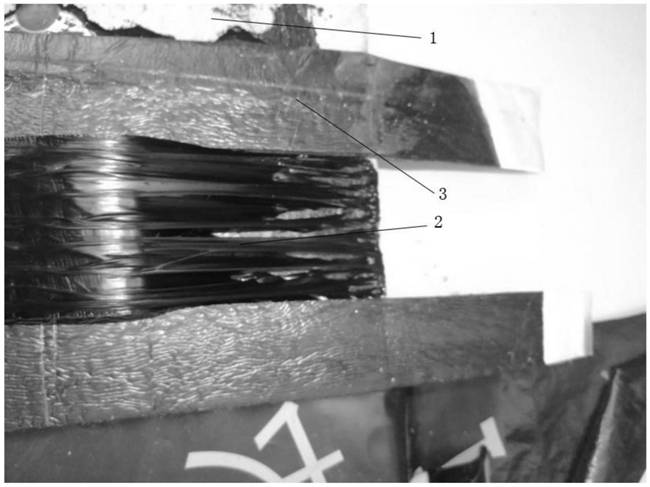

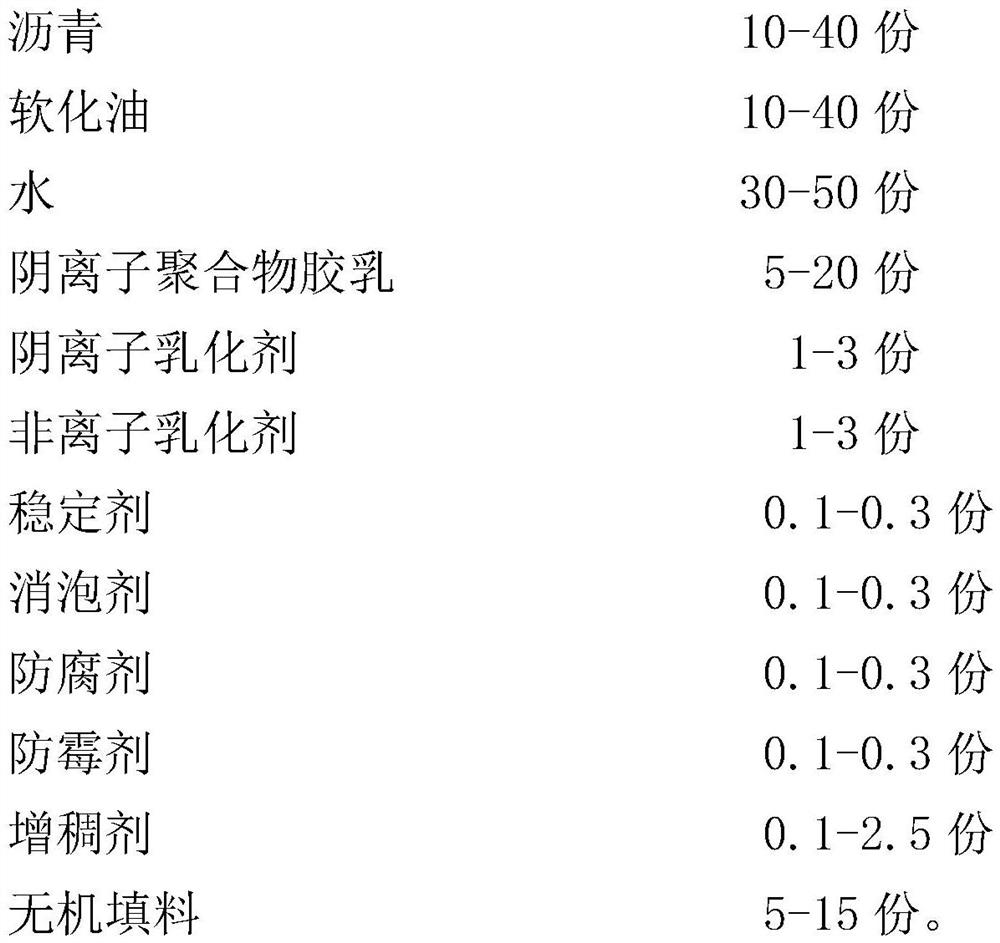

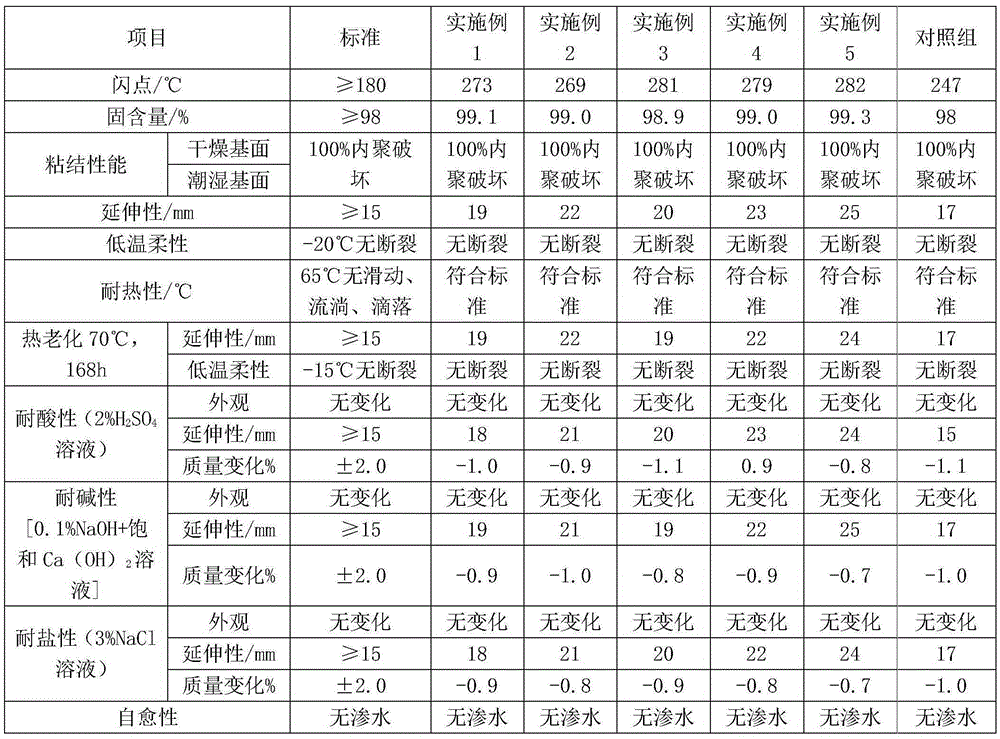

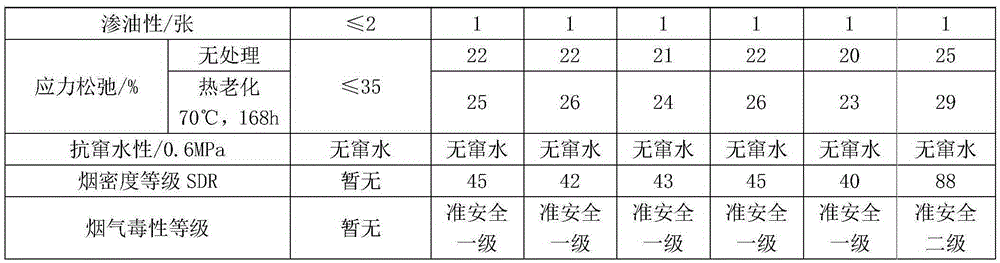

Single-component asphalt-based water-based non-cured rubber asphalt waterproof coating and preparation method thereof

InactiveCN111793436AImproved creep propertiesImprove adhesionConjugated diene hydrocarbon coatingsChloropene polymer coatingsPolymer scienceAnionic polymers

The invention relates to a single-component asphalt-based water-based non-cured rubber asphalt waterproof coating and a preparation method thereof. The coating is mainly prepared from the following components in parts by weight: 10-40 parts of asphalt, 10 to 40 parts of softening oil, 30-50 parts of water, 5-20 parts of anionic polymer latex, 1-3 parts of an anionic emulsifier, 1-3 parts of a nonionic emulsifier, 0.1-0.3 part of a stabilizer, 0.1-0.3 part of a defoaming agent, 0.1-0.3 part of a preservative, 0.1-0.3 part of a mildew preventive, 0.1-2.5 parts of a thickener and 5-15 parts of aninorganic filler. According to the invention, the waterproof coating overcomes the problems that existing oily non-cured rubber asphalt waterproof coatings contain harmful volatile substances and areharmful to human health and the problems that existing water-based non-cured rubber asphalt waterproof coatings have common performance or are double-component formulas and complex in construction process, and has the advantages of excellent bonding performance with waterproof coiled materials and various construction base layers (base surfaces) and favorable construction performance.

Owner:上海三棵树防水技术有限公司

Smoke-suppression non-cured rubber bitumen waterproof coating material

InactiveCN105238271ARich pore structureImprove adsorption capacityFireproof paintsWax coatingsEpoxyBituminous waterproofing

The present invention discloses a smoke-suppression non-cured rubber bitumen waterproof coating material, wherein the raw materials comprise, by weight, 20-28 parts of bitumen, 3-7 parts of a styrene-butadiene-styrene block copolymer, 2.5-3.5 parts of styrene butadiene rubber, 15-20 parts of paraffin oil, 1-3 parts of solvent oil, 5-15 parts of recycled rubber powder, 20-25 parts of heavy calcium carbonate, 3-7 parts of asbestos wool, 4-8 parts of fly ash, 3-6 parts of a terpene resin, 0.5-2 parts of an epoxy resin, 1-3 parts of epoxy soybean oil, 0.5-1.5 parts of an antioxidant 1076, 0.1-0.3 part of a light stabilizer 292, 0.3-0.5 part of 2,4-dihydroxydiphenyl benzophenone, 0.5-1 part of ABS-g-MAH, 0.3-0.7 parts of dicumyl peroxide, 0.3-0.5 part of vinyltriethoxysilane, 4-6 parts of microencapsulated red phosphorus, 1-2 parts of a modified smoke suppressant, and 0.5-1 part of a C9 petroleum resin. The smoke-suppression non-cured rubber bitumen waterproof coating material of the present invention has characteristics of good smoke suppression performance and good water resistance.

Owner:天长市金牛防水防腐材料有限公司

Flexible leak-stopping agent, and preparation method and application thereof

ActiveCN106566501AImprove thixotropyEffective residencyDrilling compositionSealing/packingOrganic acidTemperature conditioning

The invention relates to a flexible leak-stopping agent and a preparation method thereof. The flexible leak-stopping agent comprises a structure forming agent, an active nanometer reinforcing agent, an active nano-material, a cementing curing cross-linking agent, an organic high-molecular polymer and a temperature conditioning agent, wherein the structure forming agent comprises, by mass, 20 to 60% of unsaturated organic acid, 20 to 60% of an alkaline earth oxide, 0.05 to 0.1% of a catalyst and 0.01 to 0.2% of a coupling agent, and the active nanometer reinforcing agent comprises, by mass, 30 to 60% of formaldehyde or acetaldehyde, 20 to 40% of urea and 0.5 to 1% of a stabilizing agent. Flexible chemical leak stopping for damage of a sleeve pipe of an oil-water well and selective water plugging for an oil well via the flexible leak-stopping agent are carried out in oil fields in China for the first time and have good application prospects.

Owner:盘锦鸿鼎油气技术服务有限公司

Reactive SBS (styrene-butadiene-styrene) modified asphalt and self-adhesive waterproof coiled material prepared from same

InactiveCN102115607AImprove overall strengthImprove high and low temperature performance and aging resistanceRoof covering using flexible materialsBuilding insulationsMaleic anhydrideCalcium carbonate

The invention relates to a reactive SBS (styrene-butadiene-styrene) modified asphalt and a self-adhesive waterproof coiled material prepared from the same, belonging to the field of waterproof materials. The scheme is as follows: the reactive SBS modified asphalt is prepared from the following components in parts by weight: 45-60 parts of petroleum asphalt, 10-15 parts of maleated SBS rubber, 3-6parts of ethylene propylene diene monomer, 3-6 parts of coumarone indene resin, 2-4 parts of terpene resin and 20-35 parts of activated calcium carbonate. The maleic-anhydride-grafted SBS rubber can react with active groups in the asphalt to form a powerful three-dimensional network, thereby enhancing the integral strength of the asphalt and improving the high / low-temperature properties and ageing resistance of the asphalt. The self-adhesive waterproof coiled material prepared from the reactive SBS modified asphalt comprises a waterproof layer and a release film layer coated on one side of the waterproof layer, wherein the waterproof layer is a tyre base dipped with the reactive SBS modified asphalt. The waterproof coiled material has high adhesive force with the base layer to be laid, and the coiled materials self-adhere to each other at the overlap joint through the modified asphalt instead of adding adhesive or heating.

Owner:河南省天地建筑防水工程有限公司

Composite self-adhesive shale surface modified asphalt waterproof roll and preparation method thereof

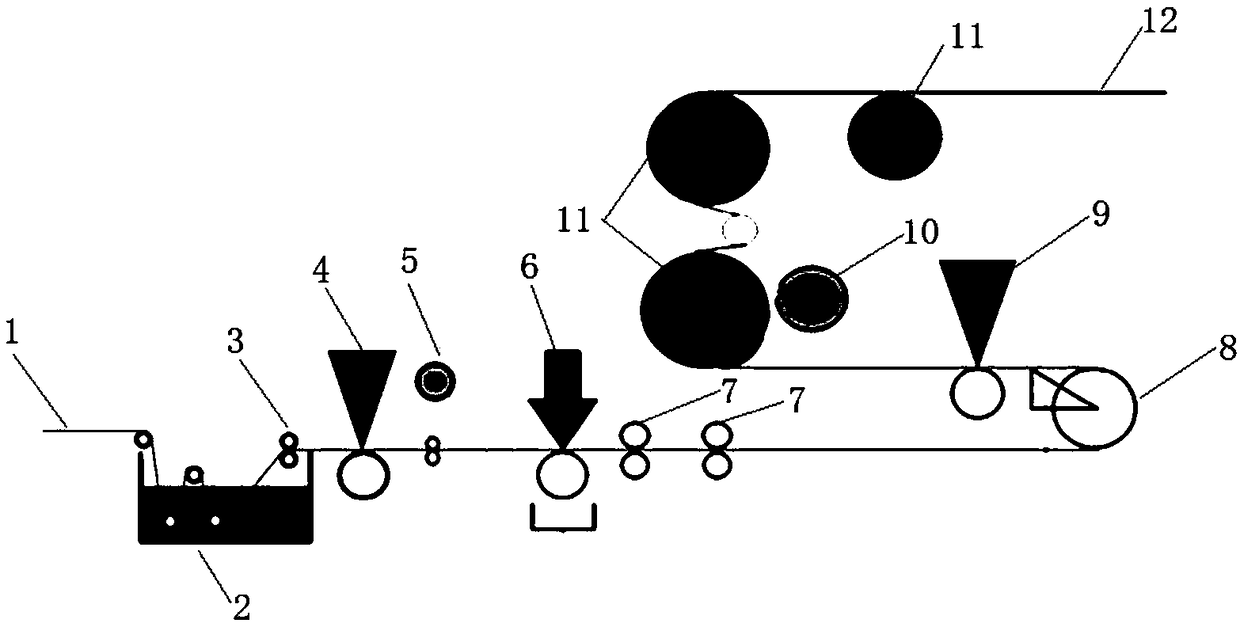

ActiveCN109130440AReduce energy consumptionGood exposed usabilitySynthetic resin layered productsLaminationProduction linePolyester

The invention discloses a composite self-adhesive shale surface modified asphalt waterproof roll and a preparation method thereof. The preparation method comprises the steps that a polyester base is sequentially subjected to preimpregnation and squeezing, the upper surface of the polyester base is coated with a modified asphalt masking material by a first scraping-coating box, side membranes are applied, sand application is performed, rolling compaction is performed, a turning roller turns, the lower surface of the polyester base is coated with a self-adhered modified asphalt masking materialby a second scraping-coating box, an isolating membrane is applied, roller cooling is performed for formation, and the composite self-adhesive shale surface modified asphalt waterproof roll is obtained. The polyester base modified asphalt waterproof roll is produced by adopting a scraping-coating process through process innovation, and modified asphalt waterproof rolls with upper and lower surfaces made of different asphalt masking materials can be produced. In addition, the links such as discharging from an oil bath, roller heating and water cooling are omitted, and the energy consumption ofa production line is effectively reduced by 20% or above.

Owner:苏州东方雨虹建筑材料有限公司

Preparation method of high-temperature titanium alloy bar

The invention belongs to the field of titanium-base alloys and particularly relates to a preparation method of a high-temperature titanium alloy bar. The preparation method comprises the following steps: heating a prepared Ti60 titanium alloy cast ingot to 1150-1200 DEG C, and carrying out blank-opening forging in a beta phase region by virtue of a rapid forging machine or a hydraulic press; heating to 1080-1150 DEG C, carrying out repeated upsetting and swaging forging by virtue of the rapid forging machine or the hydraulic press, heating the forged blank to Tbeta-120 DEG C to Tbeta-30 DEG C(Tbeta is a Ti60 titanium alloy alpha+beta / beta phase inversion temperature), and carrying out repeated upsetting and swaging forging by virtue of the rapid forging machine or the hydraulic press until the blank is in a required size, so as to obtain the titanium alloy bar, wherein the macrostructure of the titanium alloy bar is a fuzzy crystal, and the microstructure of the titanium alloy bar isuniform. After the prepared Ti60 titanium alloy bar is subjected to solid dissolving and ageing thermal treatment, the matching degree of the obdurability of the bar is relatively good, and the matching degrees of the durability, creeping strength and thermal stability are relatively good. The preparation method is convenient in operation and relatively strong in process controllability, and the batch stability of the prepared Ti60 titanium alloy bars is good.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com