Composite self-adhesive shale surface modified asphalt waterproof roll and preparation method thereof

A technology of modified asphalt and waterproof membranes, which is applied in chemical instruments and methods, building insulation materials, synthetic resin layered products, etc. It can solve problems such as air pollution, difficulty in controlling lap joints and low surface temperature, etc. Achieve the effect of solving technical problems of shedding, good exposed usability, and enhancing adhesive adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

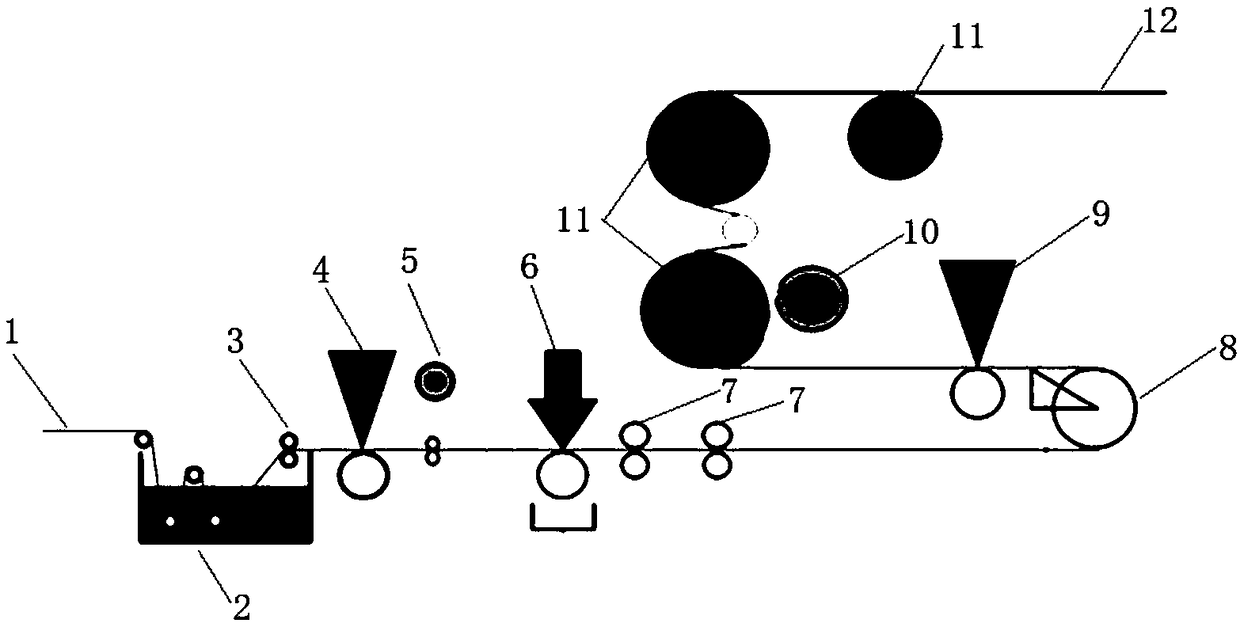

[0017] One aspect of the present invention provides a method for preparing a composite self-adhesive shale surface modified asphalt waterproof membrane, the preparation method comprising:

[0018] The polyester tire is pre-impregnated, squeezed, coated with surface modified asphalt coating material, edge covering film, cloth sand, roller compaction, turning roll turning, and coated with the second knife coating box in the first knife coating box. The self-adhesive modified asphalt coating material on the lower surface, the isolation film, and the roll are cooled and shaped to obtain the composite self-adhesive shale surface modified asphalt waterproofing membrane.

[0019] The production of modified asphalt waterproofing membranes in the prior art mainly adopts the dipping-oiling process. Based on the problems existing in the existing dipping-oiling process, the present invention realizes scraping-coating of asphalt on the upper and lower surfaces of the polyester base by scrap...

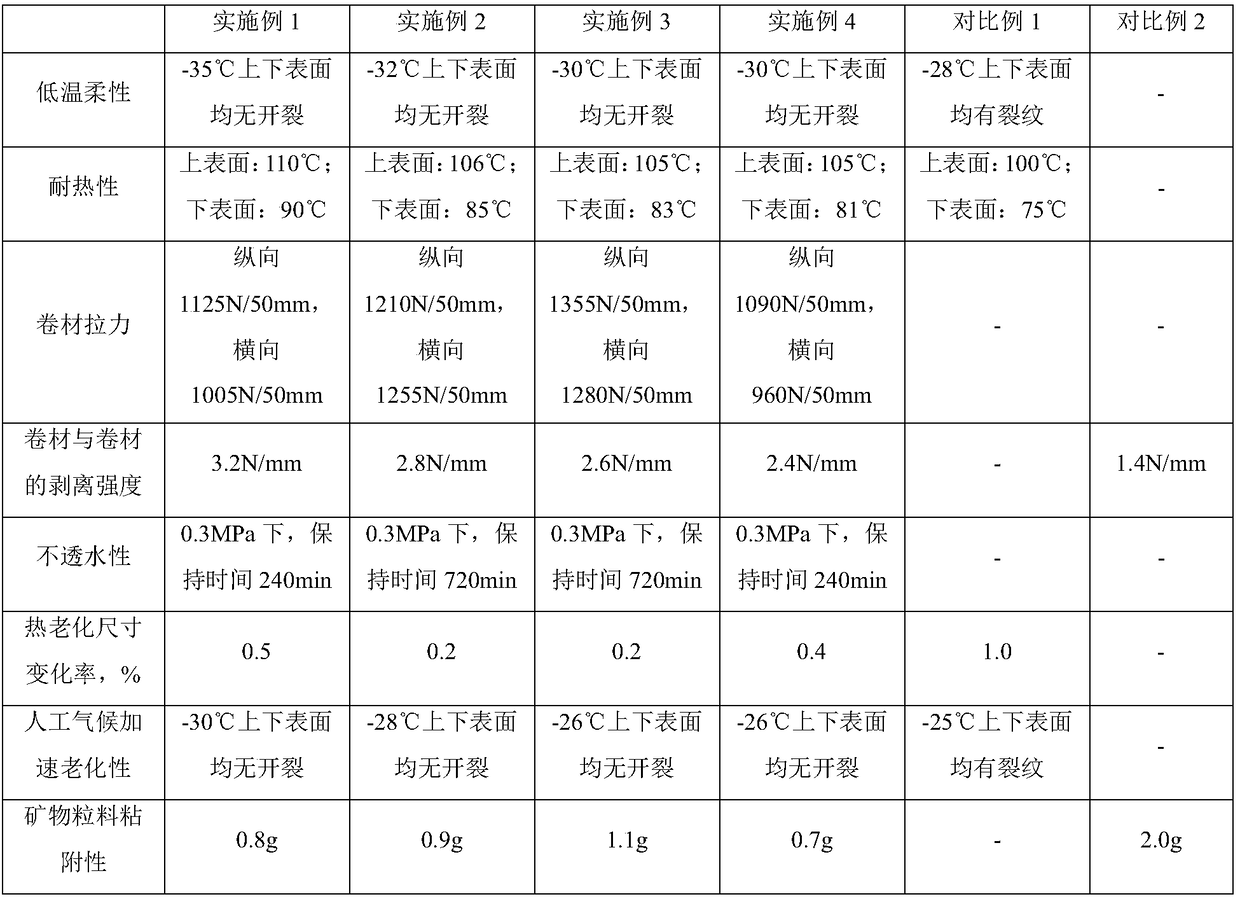

Embodiment 1

[0043] This example provides a composite self-adhesive shale surface modified asphalt waterproof membrane, the specific preparation method is as follows:

[0044] (1) In terms of the total weight of the SBS modified asphalt coating material on the above surface, 48wt% of petroleum asphalt, 11wt% of second-line oil, 14wt% of SBS modifier, 3wt% of APAO modifier, 4wt% of C5 petroleum resin, Mongolian Mix 3wt% of desoil, 3wt% of tris(2,4-di-tert-butyl)phenyl phosphite and 14wt% of 200 mesh talc powder evenly, then heat up to 180°C for shear blending, and stir for 5.5 hours to obtain the upper surface SBS modified asphalt coating material;

[0045] (2) In terms of the total weight of the following surface self-adhesive modified asphalt coating materials, petroleum asphalt 45wt%, second line oil 14wt%, SBR modifier 10wt%, SBS modifier 9wt%, C5 petroleum resin 4wt%, 3 wt% of montmorillonite, 15 wt% of 200-mesh talc powder were heated to 180°C for shear blending, and stirred for 5.5 ...

Embodiment 2

[0048] This example provides a composite self-adhesive shale surface modified asphalt waterproof membrane, the specific preparation method is as follows:

[0049] (1) In terms of the total weight of the SBS modified asphalt coating material on the above surface, 50wt% of petroleum asphalt, 9wt% of second-line oil, 12wt% of SBS modifier, 3wt% of APAO modifier, 4wt% of C5 petroleum resin, Mongolian 4wt% desoiling, 2wt% tris(2,4-di-tert-butyl)phenyl phosphite, 16wt% 200 mesh talcum powder, heated to 180°C for shear blending, and stirred for 5-6 hours to obtain the SBS modification on the upper surface. permanent asphalt coating material;

[0050] (2) In terms of the total weight of the following surface self-adhesive modified asphalt coating materials, petroleum asphalt 46wt%, second line oil 12wt%, SBR modifier 11wt%, SBS modifier 7wt%, C5 petroleum resin 4wt%, 3wt% of montmorillonite, 16wt% of 200 mesh talcum powder are heated to 180°C for shear blending, and stirred for 5-6 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com